LAARS Mighty Therm LO-NOx VW User Manual

Installation, Operation and Maintenance Instructions Document 2137A

OUT OF

PRODUCTION

Installation, Operation

and Maintenance

Instructions for

TM

Mighty Therm

LO-NOx

Volume Water Heater

Model VW-PW

Sizes 250/400

For Natural Gas Only

U.S. Reg. 1,483,289

Canada Reg. 333,796

FOR YOUR SAFETY : This product must be installed and serviced by a professional service technician,

qualified in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0250000A

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction.................................................... 3

1.2 Warranty........................................................ 4

SECTION 2.

Installation Instructions

2.1 General Information....................................... 4

2.2 Field Assembly .............................................. 4

2.3 Site Location.................................................. 6

2.3.1 Installation Information .................................. 6

2.3.2 Outdoor Installation (U.S. only) ..................... 6

2.3.3 Flooring - Typical Installation......................... 6

2.4 Combustion and Ventilation Air Supply .........7

2.4.1 Outdoor Air Supply ........................................ 8

2.4.2 Indoor Air Supply...........................................8

2.4.3 Exhaust Fans or Vents .................................. 8

2.5 Venting (Category I) ......................................8

2.5.1 General Information....................................... 8

2.5.2 Common Venting System.............................. 8

2.5.3 Inspection of Commonly Vented

Appliances..................................................... 9

2.6 Water Flow ..................................................10

2.6.1 Water Chemistry.......................................... 10

2.6.2 Water Hardness .......................................... 10

2.6.3 Freeze Protection ........................................ 10

2.6.4 Pump Requirements.................................... 10

2.6.5 Pressure Buildup in Water System.............. 11

2.6.6 Pressure Relief Valve.................................. 13

2.6.7 Water Pressure ........................................... 13

2.6.8 Storage Tank Installation............................. 13

2.6.9 Thermal Circulation of Hot Water

in Cold Water Supply Lines ......................... 13

2.7 Gas Supply and Piping

(Natural Gas Only) ...................................... 13

2.7.1 General Instructions ....................................13

2.8 Electrical Wiring........................................... 14

PRODUCTION

OUT OF

SECTION 3.

Operating Instructions

3.1 Start-Up Procedure ..................................... 15

3.2. Setting the Temperature Controls ............... 15

3.2.1 Remote Water Heater Temperature

Control......................................................... 15

3.2.2 Internal Water Heater

Temperature Control ...................................15

3.3 Hi-Limit Switch Checkout ............................ 22

3.4 Shut-Down Procedure ................................. 22

SECTION 4.

Maintenance

4.1 General Instructions ....................................22

4.2 Heat Exchanger........................................... 22

4.2.1 Inspecting the Heat Exchanger ................... 22

4.2.2 Cleaning the Heat Exchanger ..................... 23

SECTION 5.

Troubleshooting and Service

5.1 Gas Pressure Tests..................................... 23

5.1.1 Checking the Main Line Gas Pressure ........ 23

5.1.2 Checking the Manifold

Regulated Gas Pressure ............................. 24

5.2 Electrical Troubleshooting ........................... 24

5.2.1 Heater Does Not Come On ......................... 24

5.2.2 Testing the Transformer .............................. 25

5.2.3 Testing the Electrical Power Supply ............ 25

5.2.4 Testing the Manual Reset

Hi-Limit Switch............................................. 25

5.2.5 Testing the Flow Switch............................... 26

5.2.6 Testing the Fusible Link

(flame roll-out switch) .................................. 26

5.2.7 Testing the Fuse.......................................... 26

5.2.8 Testing the Ignition Control..........................26

5.2.9 Combustion Air Blower................................26

5.2.10 Heater Will Not Shut Off .............................. 27

SECTION 6.

Replacement Parts

6.1 Ordering Information ................................... 27

6.2 Parts List ..................................................... 27

Mighty Therm LO-NOx Volume Water Heater

MIGHTY

THERM

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides installation, operating, and

maintenance instructions for Model VW-PW Volume

Water Heaters, Sizes 250 and 400. Review all

application and installation procedures completely

before proceeding with the installation. Experience has

shown that most operating problems are caused by

improper installation.

The heaters are offered in a basic configuration

(see Figure 1). On PW heaters, a factory-supplied

pump is mounted on the unit. PW models are not

available for hard water applications. There is no pump

mounted on VW units. Pump for VW units is to be

field-supplied.

NOTE:* For outdoor models, add 6 inches (15.2cm) for

outdoor base.

OUT OF

WARNING

Mighty Therm water heaters must be installed in

accordance with the procedures detailed in this

manual, or the Laars Heating Systems warranty will

be voided. The installation must conform to the

requirements of the local jurisdiction having

authority, and, in the United States, to the latest

edition of the National Fuel Gas Code, ANSI

Z223.1. In Canada, the installation must conform to

the latest edition of CAN/CGA-B149.1 Natural Gas

Installation Code and/or local codes. Any

modifications to the boiler, its gas controls, or wiring

may void the warranty. If field conditions require

modifications consult the factory representative

before initiating such modifications.

V

Vent Cap

Drafthood

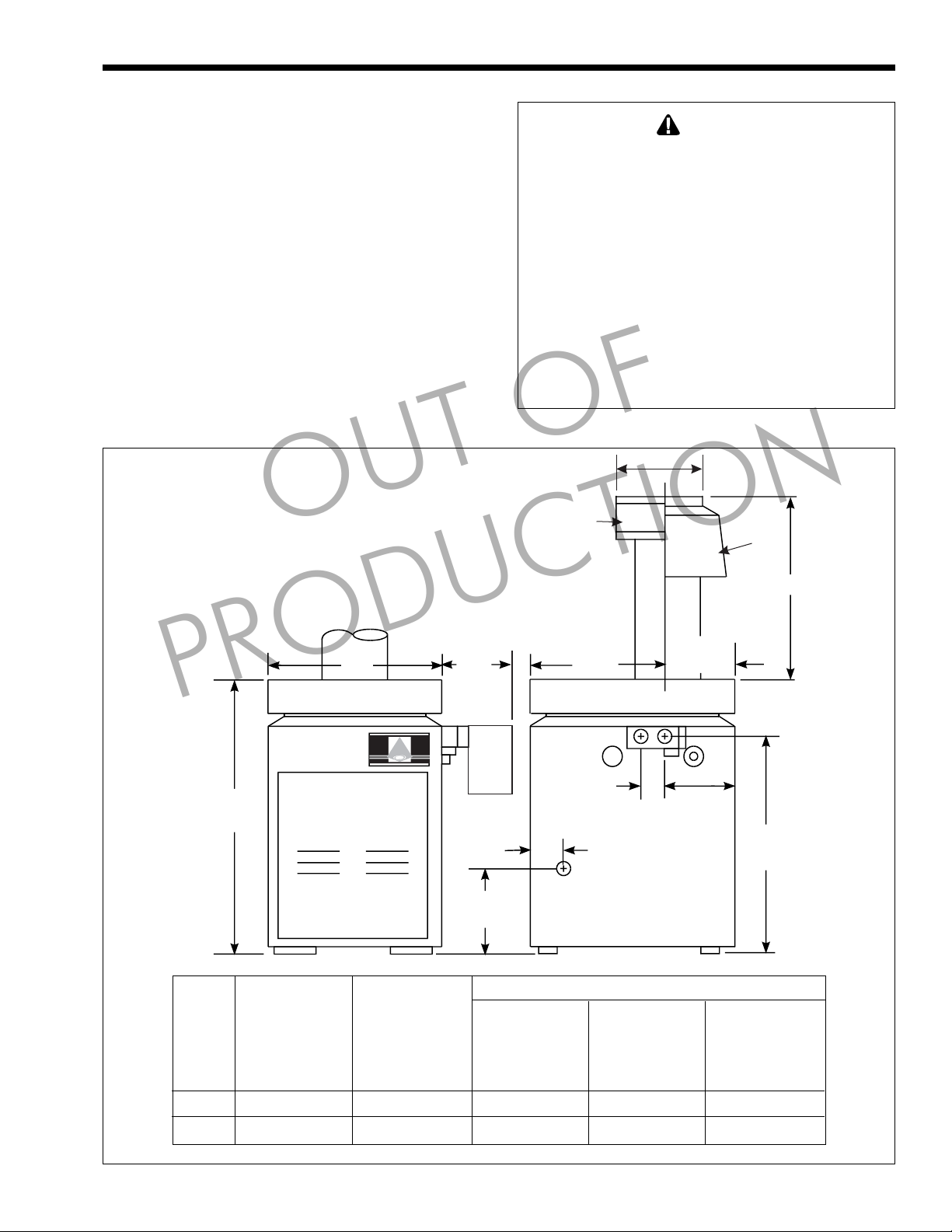

Dimensions shown in

inches centimeters

W

10 1/4

26

16 1/2

41.9

10

25.4

H

PRODUCTION

MIGHTY THERM

LO-NOx

LAARS

38*

96.5

Front View Side View

Model Firing Heater

Size Rate Width

Btu/hr

(1000's)

250 250 73.3 22 1/2 57.2 7 17.8 18 1/4 46.4 25 1/4 64.1

400 399 117.0 31 3/4 80.6 9 22.9 21 1/2 54.6 27 1/2 69.9

kW in cm in cm in cm in cm

“W” “V” “H” “H”

Pump

5 1/4

13.3

3 1/2

9

GAS CONNECTION

14 3/4*

37.5

Drafthood Vent Outdoor Indoor

Vent Cap Diameter Dim Dim

FAR SIDE

Venting Dimensions

8

20.3

30 1/2*

77.5

All dimensions are nominal.

Figure 1. General Configuration.

Page 4

LAARS Heating Systems

1.2 Warranty

Laars Heating Systems Mighty Therm heaters are

covered by a limited warranty . The owner should fill

out the warranty registration card and return it to Laars

Heating Systems.

All warranty claims must be made to an

authorized Laars Heating Systems representative or

directly to the factory . Claims must include the serial

number and model (this information can be found on

the rating plate), installation date, and name of the

installer. For specific warranty conditions refer to your

Limited W arranty.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on the

packing slip. Inspect everything for damage

immediately upon delivery, and advise the carrier of

any shortages or damage. Any such claims should be

filed with the carrier. The carrier, not the shipper, is

responsible for shortages and damage to the shipment

whether visible or concealed.

SECTION 2.

OUT OF

Installation Instructions

for outdoor installations. In special circumstances an

outdoor vent cap may be required. Check the part

number on the rating plate.

The VW, PW heaters are design certified for

indoor installation when equipped with a special

drafthood, which must be installed without

modification. The part number for the drafthood is on

the heater rating plate. Follow this procedure to make

the conversion:

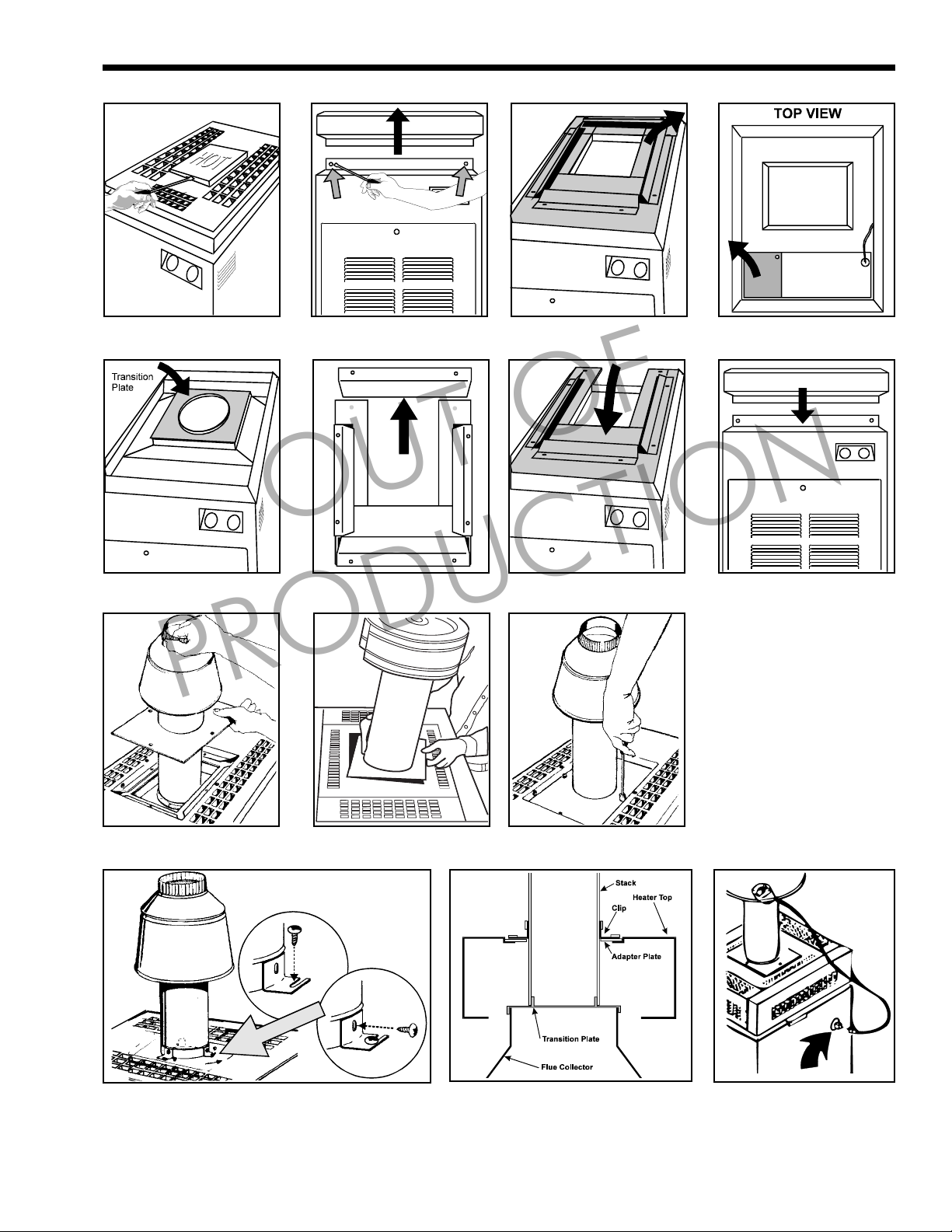

1. Remove the top plate, stamped "HOT", by

slipping a fine-blade screwdriver into the slot and

prying it up (see Figure 2).

2. Remove the top by removing all eight screws

connecting it to the jacket (see Figure 3).

3. Remove the rainguard assembly (see Figure 4).

4. Remove the two screws securing the left

vestibule cover (see Figure 5). The cover can be

discarded.

5. Remove the vent cap or drafthood and

accessories from the carton.

6. Place transition plate (with 14" long side)

securely on top of flue collector so flue gases will

not leak (see Figure 6).

2.1 General Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in sever injury,

property damage or death. Follow the manufacturer’s maintenance schedule for the appliance. Follow

local regulations with respect to installation of

carbon monoxide (CO) detectors.

All gas-fired products require correct installation

to assure safe operation. The requirements for heaters

include the following:

1. Field assembly of drafthood or vent cap (see

Section 2.2).

2. Appropriate site location clearances and flooring.

3. Sufficient combustion and ventilation air.

4. Adequate venting of combustion products.

5. Adequate water flow .

6. Properly sized gas meter and piping.

7. Proper electrical wiring.

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

2.2 Field Assembly

The VW-PW heaters are shipped from the factory

with the top assembly in the low-profile configuration

PRODUCTION

7. Remove back portion of rainguard (see Figure 7).

8. Re-install the rainguard (see Figure 8).

9. Replace heater top and all eight screws (see

Figure 9).

10. Slide the adapter plate up over the bottom of the

stack extension. Fit the stack extension, of the

drafthood or the vent cap, on top of the collar of

the flue transition plate (see Figures 10 and 11).

11. Seat the adapter plate on the top assembly , and

secure it with screws supplied in the kit (see

Figure 12).

12. Attach the clips to the adapter plate by securing

the slotted side of the clips with the screws in the

kit (see Figure 13).

13. Use the holes in the clips as guides to drill three

1/8" dia. holes in the stack.

14. Secure the stack to the clips with the screws

supplied in the kit (see Figure 13).

15. Figure 14 shows a cross-section of the finished

installation.

16. Indoor models, size 250 only , require an adapter

cable (included with product). The cable connects

the blocked vent safety switch (BVSS) on the

bell of the external draft hood to the 6-position

Molex plug on the side of the unit (see Figure

15). Refer to instruction sheet included with

cable.

Mighty Therm LO-NOx Volume Water Heater

Page 5

Figure 2. Figure 3.

Figure 4. Figure 5.

OUT OF

Figure 6. Figure 7. Figure 8. Figure 9.

PRODUCTION

Figure 10. Figure 11.

Figure 13. Figure 14.

Figure 12.

Figure 15. Drafthood

Switch Receptacle.

Page 6

2.3 Site Location

2.3.1 Installation Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in severe injury,

property damage, or death.

A void placing the heater in locations where it can

cause damage by water or condensate leakage. If this is

not possible, provide a suitable drain pan under the

heater to catch and divert any leakage. The pan must

not restrict air flow around the heater.

Locate the heater to provide adequate clearance

on all sides for inspection, service and to provide

adequate air circulation for proper operation.

Locate the heater so the clearances from

combustible surfaces shown in Table 1 and Figure 16

are met.

Locate the heater on a waterproof floor with a

floor drain and a 6 inch (152 mm) minimum curb on

all four sides to protect the building if heater repairs

are needed.

Clearance from: inch cm inch cm

Top 37 94 Unobstructed

Water conn. side 12 30.5 Unobstructed

Opposite side 6 15.2 6 15.2

Front Alcove Unobstructed

Rear 6 15.2 6 15.2

Vent* 6 15.2 —

Flooring: Combustible

Service clearance = 36 inches (91.4cm) at front of heater,

and 18 inches (46cm) at water connection side.

*1" (2.5cm) if double wall vent is used.

6" base for outdoor boiler is required.

Table 1. Minimum Boiler Clearances

PRODUCTION

from Combustible Surfaces.

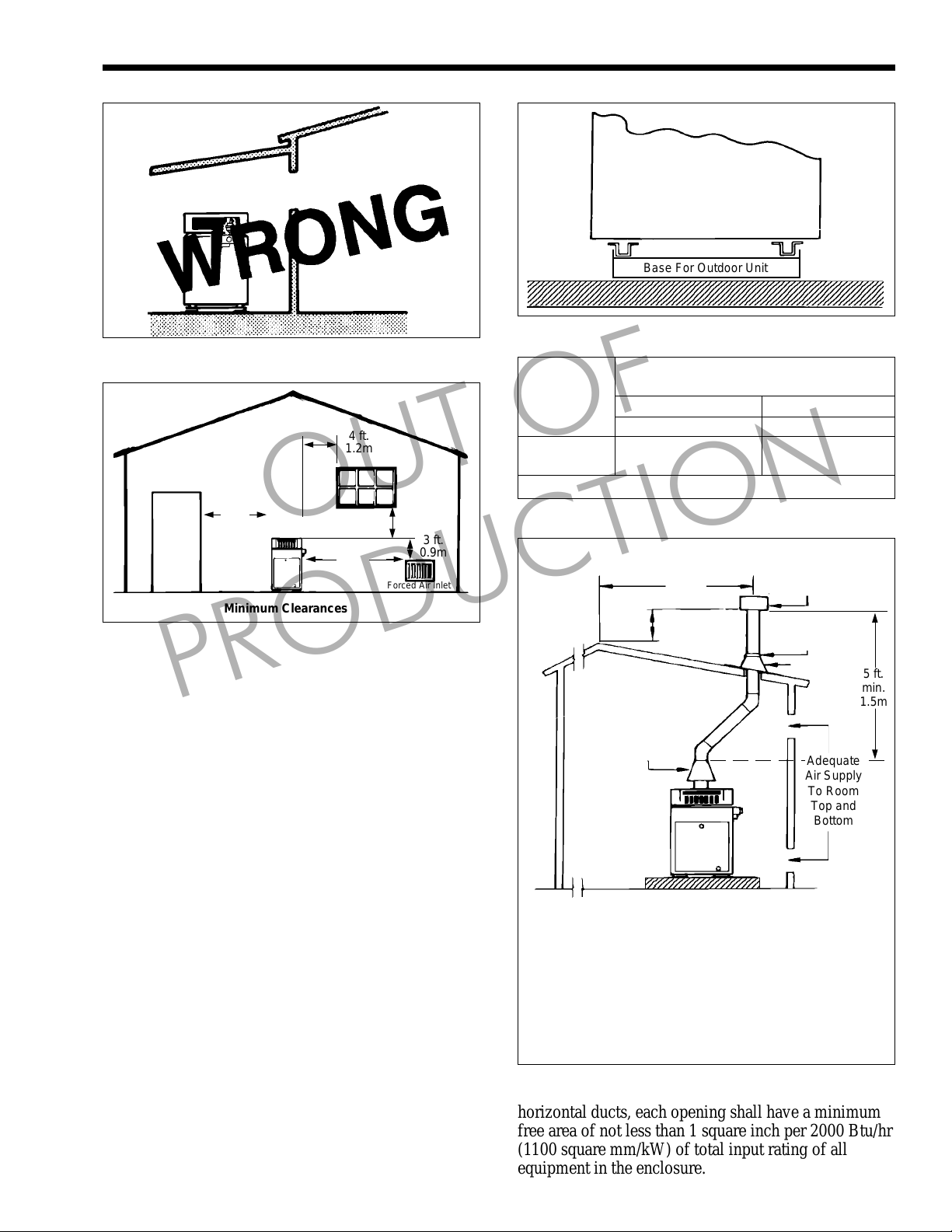

2.3.2 Outdoor Installation

Outdoor installations are not recommended in areas

where the danger of snow blockage exists.

a. Locate the heater in an open, unroofed area. Do

not locate the heater below or adjacent to any

doors, windows, louvers, grills, etc., which

connect in any way with an inhabited area of a

building, even though the access might be

through another structure such as a garage or

utility room (see Figure 17 and Table 1).

OUT OF

Indoors Outdoors

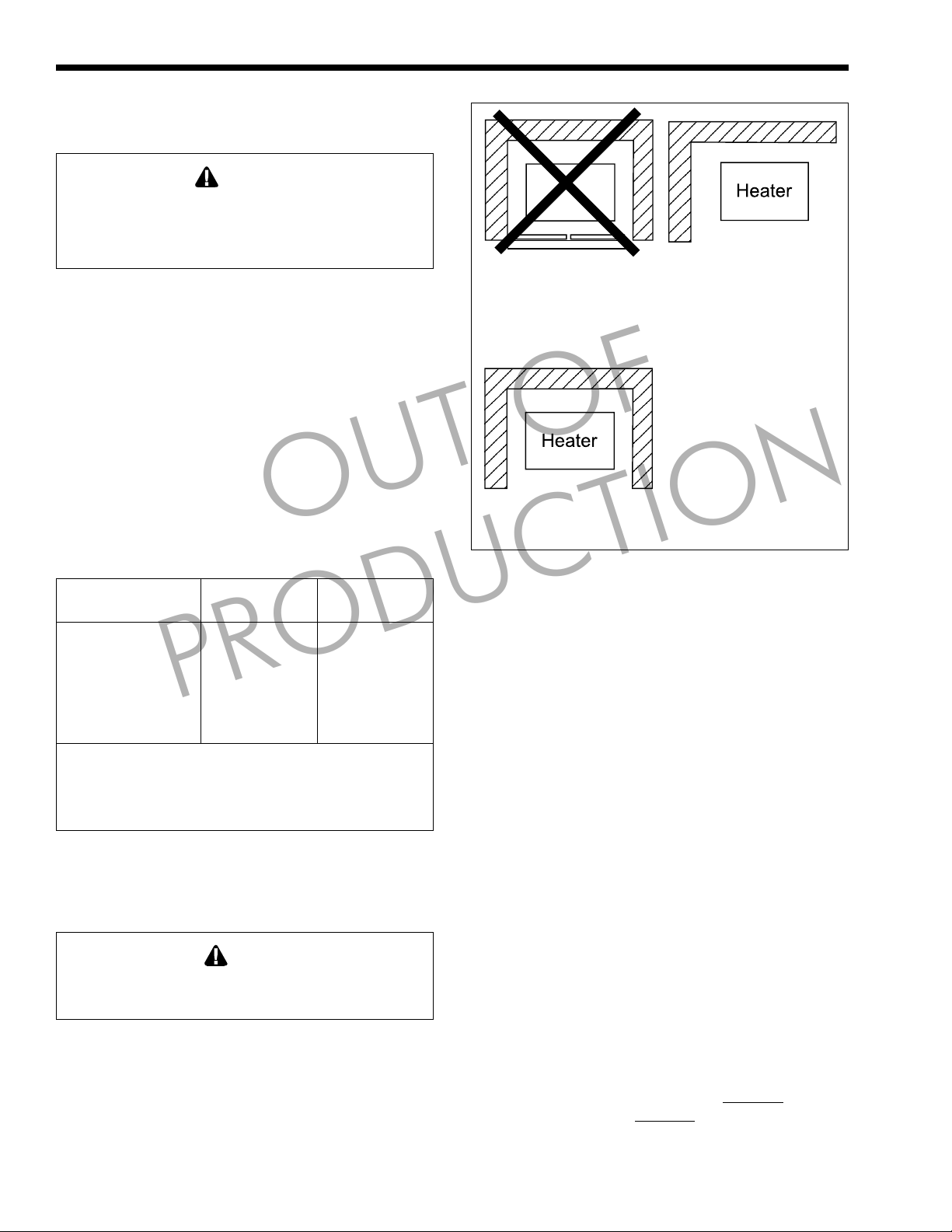

Caution

LAARS Heating Systems

Closet Installation

(unacceptable)

A closet is any 4 sided enclosure

which is less than 16* times the

total volume of all the gas fired

appliances within the enclosure.

REAR

FRONT

* When the ceiling height exceeds 8 feet, you are only allowed to

consider 8 feet when calculating the total volume of the enclosure.

Figure 16. Alcove Installation.

Room Installation

(acceptable)

A room is any enclosure which is

at least 16* times greater than the

total volume of all the gas fired

appliances within the enclosure

Alcove Installation

(acceptable)

An alcove suitable for the

installation of a heater is a

restricted section of a room not

separated from the room by a door

or partition and which meets the

minimum clearances specified in

this manual.

b. There must be a minimum of 4 feet (1.22 m)

horizontally and vertically between the heater

and any door, window, or gravity inlet to a

building (see Figure 18).

c. Minimum clearance of 4 feet (1.22m) [6 feet

(1.83m) in Canada] horizontally from, and in no

case above or below , unless the minimum

horizontal distance is maintained, from electric

meters, gas meters, regulators and relief

equipment.

d. If the heater is installed close to a structure,

protect it from rain water runoff with rain gutters

on the roof or other measures. Do not locate the

heater near sprinkler systems that could spray

water on it.

e. Avoid locations where wind deflection off nearby

structures might cause wind loading and

downdraft conditions. Where downdraft

conditions exist, locate the heater at least 3 feet

(0.91 m) from the structure.

2.3.3 Flooring - T ypical Installation

All outdoor boilers must be installed with the

special base, as a standard part of the heater. The base,

part number R0368900, is provided in a separate

package. The heater is designed and certified for

installation on combustible flooring.

the heater on carpeting.

NEVER store objects on or

NEVER install

around the base of the heater. For outdoor base

installation, see Figure 18.

Mighty Therm LO-NOx Volume Water Heater

123456789012345678901234567890121234567890123456789012345678901212345

1

5

1

5

1

5

123456789012345678901234567890121234567890123456789012345678901212345

3

Page 7

WINDOW

OR GRILL

INDOOR

ROOM

Figure 17. Incorrect Outdoor Installation.

4 ft.

1.2m

4 ft.

1.2m

Minimum Clearances

Figure 18. Outdoor Location Installation.

OUT OF

10 ft.

3.0m

4 ft.

1.2m

3 ft.

0.9m

Forced Air Inlet

2.4 Combustion and Ventilation

Air Supply

PRODUCTION

All indoor installations must have openings to

outside air for combustion, ventilation and dilution of

flue gases from inside the building (see Figure 20 and

T able 2 ). Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

In the United States, the most common

requirements specify that the space (enclosure) shall

communicate with the outdoors in accordance with

method 1 or 2, which follow . Where ducts are used,

they shall be of the same cross-sectional area as the

free area of the openings to which they connect.

Method 1:

T wo permanent openings, one commencing

within 12" (30 cm) of the top and one commencing

within 12" (30 cm) of the bottom of the enclosure shall

be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces that

freely communicate with the outdoors. When directly

communicating with the outdoors, or through vertical

ducts, each opening shall have a minimum free area of

1 square inch per 4000 Btu/hr (550 square mm/kW) of

total input rating of all equipment in the enclosure.

When communicating to the outdoors through

LAARS

UNIT

(Side View)

2345678901234567890123456789012123456789012345678901234567890121234

2345678901234567890123456789012123456789012345678901234567890121234

2345678901234567890123456789012123456789012345678901234567890121234

Figure 19. Base for Outdoor Installation.

Model in.

250 63 406 63 406

400 100 645 100 645

Note: For screens or louvers, add 50%.

Table 2. Air Openings to Outside.

Vent terminated at

least 2 ft. (61cm)

above any

object within

10 ft. (3.0m)

Notes:

1. The drafthood must sit directly on top of the heater

as shown and must not be altered in any manner.

2. A vent cap listed or certified for the application by a

Nationally Recognized Testing Laboratory (NRTL)

such as Underwriter’s Laboratories (UL) is required to

eliminate downdraft and to allow the heater to function

properly.

3. Use approved roof fitting.

Figure 20. Indoor Installation and Venting.

Base For Outdoor Unit

Required Net Free Opening Area

2

10 ft.

3.0m

2 ft. 61cm

1/4 in. 0.6cm

Minimum Pitch

Per Foot of

Horizontal Pipe

Drafthood

234567890123456789012

Directly from Outside

At Top At Bottom

cm

2

2

in.

Listed Vent

Cap

Storm Collar

Roof Jack

Adequate

Air Supply

To Room

Top and

Bottom

cm

2

5 ft.

min.

1.5m

horizontal ducts, each opening shall have a minimum

free area of not less than 1 square inch per 2000 Btu/hr

(1100 square mm/kW) of total input rating of all

equipment in the enclosure.

Page 8

LAARS Heating Systems

Method 2:

One permanent opening, commencing within 12"

(30 cm) of the top of the enclosure shall be permitted.

The opening shall directly communicate with the

outdoors or shall communicate through a vertical or

horizontal duct to the outdoors or spaces that directly

communicate with the outdoors, and shall have a

minimum free area of 1 square inch per 3000 Btu/hr

(734 square mm/kW) of the total input rating of all

equipment located in the enclosure. This opening must

not be less than the sum of the areas of all vent

connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in ANSI Z223.1, or other

applicable codes.

In Canada, Table 2 does not apply. Consult local

building and safety codes or, in absence of such

requirements, follow CSA B149.1.

NOTE: Check with louver manufacturers for net free

area of louvers. If screens or louvers are installed,

add 50 percent for each screen/louver to the net free

area.

2.4.1 Outdoor Air Supply

When combustion air comes directly through an

outside wall, each opening must have a minimum free

area of at least one square inch for each 4,000 BTU/h

input of the total input rating of all appliances in the

enclosed area. (In Canada, refer to CSA-B149.1.)

OUT OF

PRODUCTION

2.4.2 Indoor Air Supply

Confined and non-confined areas have different

requirements for installation. Check the latest edition

of ANSI Z223.1 or in Canada CSA-B149.1 and all

local codes applicable to combustion air.

2.4.3 Exhaust Fans or Vents

Any equipment which uses air or removes air

from the heater room can use up the combustion air

supply or reverse the natural draft action of the venting

system. This could cause flue products to build up in

the heater room. More air must be supplied to make up

for the decrease.

2.5 V enting (Category I)

2.5.1 General Information

When installed indoors, the drafthood must be

connected to a venting system. The venting system

must be installed by a qualified installer and in

accordance with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance with

CSA-B149.1, and any local codes that apply .

The vent pipe must have a listed vent cap, and

extend at least 2 feet (0.6 m) above any object within a

10 foot (3.0 m) radius.

NOTE: Do not use sheet metal screws at the snap

lock joints of Type B double-wall gas vents.

Do not weld or bolt the vent pipe to the heater

drafthood. The weight of the stack must not rest on the

heater. The drafthood and heater top must be easily

removable for normal heater service and inspection.

WARNING

Avoid ending heater vents near air conditioning or

air supply fans. The fans can pick up exhaust flue

products from the heater and return them inside the

building, creating a possible health hazard.

Locate unit as close as practical to a chimney or

vent termination. Have horizontal runs sloping

upwards not less than 1/4 inch per foot (21mm/m)

from the boiler to the vent terminal. Support a vent

connector for the design and weight of the material

used to maintain clearances and prevent physical

damage and separate of joints.

Doivent présenter des tronçons horzontaux dont

la pente montante est d’au moins 1/4 po par pied

21mm/m) entre la chaudière et l’évent. Doivent

préciser que les sections horizontales doivent être

supportées pour prévenir le fléchissement.

Always use double-wall or insulated vent pipe

(Type B or equivalent).

WARNING

In cold weather, uninsulated outside vents can chill

the rising flue products, blocking the natural draft

action of the venting system. This can create a

health hazard by spilling flue products into the

heater room.

A void oversize vent piping or extremely long

runs of the pipe which may cause too much cooling

and condensation of flue gases.

When the installation of a power vent or draft fan

in the venting system is necessary , qualified personnel

should design the installation following good

engineering practices and all applicable codes. A

suitable draft switch must be wired into the heater

control circuit at the terminal designated Field

Interlock to keep the heater from firing unless there is

a positive draft.

2.5.2 Common Venting Systems

Venting Multiple Appliances

When installing venting for a Mighty Therm LoNOx boiler or water heater installed as a Category I

fan-assisted appliance with other Category I appliances

through one shared duct called a “common vent”,

special care must be taken by the installer to ensure

safe operation. In the event that the common vent is

Mighty Therm LO-NOx Volume Water Heater

Page 9

blocked, it is possible, especially for fan-assisted

devices, to vent backwards through non-operating

appliances sharing the vent, allowing combustion

products to infiltrate occupied spaces. If the

appliances are allowed to operate in this condition,

serious injury or death may occur.

WARNING

Operation of appliances with a blocked common

vent may lead to serious injury or death. Safety

devices must be implemented to prevent blocked

common vent operation. If safe operation of all

appliances connected to a common vent cannot be

assured, including prevention of spillage of flue

gasses into living spaces, common venting should

not be applied, and appliances should each be

vented separately.

AVERTISSEMENT

Le fonctionnement des appareils avec un système

d’évacuation bloqué peut provoquer des blessures

graves, voire la mort. Des dispositifs de sécurité

doivent être installés pour éviter le blocage des

systèmes d’évacuation. Si le fonctionnement de

tous les appareils connectés à un système

d’évacuation commun ne peut pas être assuré, y

compris la prévention de la dispersion des gaz

toxiques dans les espaces habités, on ne devrait

pas installer un système d’évacuation commun et

chaque appareil devrait être ventilé séparément.

It is for this reason that, in addition to following

proper vent sizing, construction and safety

requirements from the National Fuel Gas Code, ANSI

Z223.1 or in Canada, from CSA B149.1 as well as all

applicable local codes, it is required that installers

provide some means to prevent operation with a

blocked common vent. It is suggested that a blocked

vent safety system be employed such that if the switch

from one appliance trips due to excessive stack spill or

backpressure indicating a blocked vent condition, that

all appliances attached to the vent be locked out and

prevented from operating. As an additional precaution,

it is recommended that a Carbon Monoxide (CO)

alarm be installed in all enclosed spaces containing

combustion appliances. If assistance is required in

determining how a blocked vent safety system should

be connected to a LAARS product, please call

Applications Engineering at (603) 335-6300.

instructions on all appliances to be common vented for

instructions, warnings, restrictions and safety

requirements. If safe operation of all appliances

connected to a common vent cannot be assured,

including prevention of spillage of flue gasses into

living spaces, common venting should not be applied,

and appliances should each be vented separately .

PRODUCTION

Refer to the installation and operating

OUT OF

2.5.3 Inspection of Commonly Vented

Appliances

If the instrumentation of this heater replaces an

older heater in a common vent system with other

appliances, or if you remove additional appliances

from the common vent, all the appliances must be

checked for proper venting.

At the time of removal of an existing heater, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

Sceller toutes les ouvertures non utilisées du

système d’évacuation.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

Inspecter de façon visuelle le système

d’évacuation pour déterminer la grosseur et

l’inclinaison horizontale qui conviennent et

s’assurer que le système est exampt

d’obstruction, d’étranglement, de fuite, de

corrosion et autres défaillances qui pourraient

présenter des risques.

3. Insofar as it is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers and

any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l’espace où les appareils toujours

raccordés au système d’évacuation sont installés

et les autres espaces du bùtiment. Mettre en

marche les sécheuses, tous les appareils non

raccordés au systéme d’évacuation commun et

tous les ventilateurs d’extraction comme les

hottes de cuisinière et les ventilateurs des salles

de bain. S’assurer que ces ventilateurs

fonctionnent à la vitesse maximale. Ne pas faire

fonctionner les ventilateurs d’été. Fermer les

registres des cheminées.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust

thermostat so appliance will operate

continuously.

Page 10

LAARS Heating Systems

Mettre l’appareil inspecté en marche. Suivre les

instructions d’allumage. Régler le thermostat de

façon que l’appareil fonctionne de façon

continue.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

Faire fonctionner le brûleur principal pendant 5

min ensuite, déterminer si le coupe-tirage

déborde à l’ouverture de décharge. Utiliser la

flamme d’une allumette ou d’une chandelle ou la

fumée d’une cigarette, d’une cigare ou d’une

pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning

appliance to their previous conditions of use.

Une fois qu’il a été déterminé, selon la méthode

inidquée ci-dessus, que chaque appareil raccordé

au système d’évacuation est mis à l’air libre de

façon adéquate. Remettre les portes et les

fenêtres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position

originale.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the

minimum size as determined using the

appropriate tables in Appendix G in the National

Fuel Gas Code, ANSI Z223.1.

T out mauvais fonctionnement du système

d’évacuation commun devrait être corrigé de

façon que l’installation soit conforme au national

Fuel Gas Code, ANSI Z223.1 et (ou) aux codes

d}installation CSA-B149.1. Si la grosseur d’une

section du système d’évacuation doit être

modifiée, le système devrait être modifié pour

respecter les valeurs minimales des tableaux

pertinents de l’appendices F du National Fuel

Gas Code, ANSI Z2231.1 et (ou) des codes

d}installation CSA-B149.1.

PRODUCTION

OUT OF

2.6 Water Flow

2.6.1 Water Chemistry

Laars equipment is designed to be used in a

variety of water conditions. With the proper pump, the

water velocity in the heat exchanger tubes is kept high

enough to prevent scaling from hard water, yet low

enough to avoid erosion by soft water.

NOTE: It is possible to have hard and soft water in the

same city. Check with the local water companies.

If an installer sees damage to any water handling

equipment at the installation site, it should be repaired

as soon as possible to help reduce maintenance costs.

If there is erosion, resize the pump to reduce water

velocity before the tube ruptures. If scaling is bad, set

up a heat exchanger tube-cleaning maintenance

schedule to prevent heat exchanger tube cracking and

wear. Not fixing the condition will mean serious

damage to the heater and the water system.

NOTES: In areas where the water supply is soft or

corrosive, the heater must have cupronickel tubes in

the heat exchanger. Laars does not warrant heat

exchangers damaged by scaling, corrosion, or

erosion.

2.6.2 Water Hardness

Consider the water hardness when selecting a

pump for the heater (see Table 3). Hard water needs a

pump which can provide high flow to prevent scaling,

while soft water needs low flow to prevent erosion.

Hardness Grains per Parts

Category Gallon per Million

Soft 1 through 7.5 17 through 128

Normal 7.6 through 17 129 through 291

Hard Over 17 Over 291

Table 3. Water Hardness.

2.6.3 Freeze Protection

Although VW, PW heaters are design-certified

for outdoor installations, such installations are not

recommended in areas subject to freezing temperatures

unless proper precautions are taken.

Power outage, interruption of gas supply , failure

of system components, activation of safety devices,

etc., may prevent a heater from firing. Any time a

heater is subjected to freezing conditions, and the

heater is not able to fire, and/or the water is not

able to circulate, there is a risk of freezing in the

heater or in the pipes in the system. When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the heater, which could

result in leaking or flooding conditions.

2.6.4 Pump Requirements

PW heaters are equipped with factory-mounted

and wired pumps. The pump is for heater-to-tank

circulation only . See Table 4 for pump performance.

PW heaters are not available for hard water applications.

VW and PW heaters are not designed for applications where the temperature of the water flowing

through the heater remains below the dew point, 110°F

(43°C).

Loading...

Loading...