Page 1

Installation and Operation Instructions Document 2140A

Installation and Operation

Instructions for

Mighty Therm

Lo-NOx

Hydronic Boilers and

Volume Water Heaters

Models PH and PW

Sizes 500-1825

These instructions are to be stored in the pocket provided on the boiler.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

W ARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0256700A

Page 2

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction................................................... 3

1.2 Heater Identification...................................... 3

1.3 General Flow Requirement........................... 3

SECTION 2.

Installation

2.1 Heater Placement......................................... 4

2.2 Installation of Indoor Heaters ........................ 4

2.2.1 Combustion Air Supply..................................4

2.2.1.a Conventional Ventilation ...............................4

2.2.1.b Forced-Air V entilation ................................... 5

2.2.2 Venting..........................................................5

2.2.3 Removal of Existing Heater .......................... 6

2.3 Installation of Outdoor Heaters ..................... 6

2.4 Gas Supply and Piping ................................. 6

2.5 Electrical Wiring............................................7

SECTION 3.

Water Piping Instruction

3.1 General Piping Practice ................................ 8

3.2 Heating Boiler (PH Model) ............................ 8

3.2.1 Variable Water Flow System......................... 8

3.2.2 System Pressure Requirements ...................8

3.2.3 Hot/Chilled Water Systems...........................8

3.2.4 Combined Sp ace Heating/Potable

Water Heating Systems................................ 9

3.2.5 Piping System Requirements...................... 10

3.2.6 Filling the System ....................................... 10

3.3 Water Heater (PW Model) .......................... 10

3.3.1 Water Chemistry.........................................10

3.3.2 Piping System Requirements...................... 11

3.3.3 Water Expansion ........................................ 11

3.3.4 Pump Requirements................................... 11

3.3.5 Water Pressure........................................... 13

3.3.6 Tank Installation..........................................14

3.3.7 Two-Temperature........................................ 14

SECTION 4.

Operating Instructions

4.1 Controls - General ...................................... 15

4.1.1 Electronic Ignition Control ...........................15

4.1.2 Hot Surface Igniter......................................15

4.1.3 Combustion Air Pressure Switch.................15

4.1.4 Operating Controls...................................... 15

4.1.5 High Limit Control ....................................... 15

4.1.6 Flow Switch ................................................ 16

4.1.7 Low Water Cut Off...................................... 16

4.2 S tart-Up Requirement s ............................... 16

4.3 Normal Operating Sequence ...................... 17

4.4 Hi-Limit Checkout ....................................... 17

4.5 Start-Up Procedure..................................... 17

4.5.1 Lighting Instructions.................................... 18

4.5.2 To Turn Off Gas to Appliance...................... 18

4.6 Setting the Temperature Controls ............... 18

4.6.1 Hydronic Boilers.......................................... 18

4.6.2 Water Heaters ............................................ 18

SECTION 5.

Maintenance

5.1 General Instructions.................................... 18

5.2 Combustion Air Blower ............................... 19

5.3 Heat Exchanger.......................................... 19

5.3.1 External Cleaning of Heat Exchanger .........19

5.3.2 Internal Cleaning of Heat Exchanger .......... 20

5.4 Gas and Electric Controls ........................... 20

5.5 Burner Removal and Cleaning.................... 20

SECTION 6.

Troubleshooting

6.1 Sequence of Operation............................... 20

6.2 Electrical Components................................21

6.2.1 General Troubleshooting ............................ 21

6.2.2 Electrical Troubleshooting...........................21

6.3 Mechanical Components ............................ 23

6.3.1 Pressure Relief Valves Leaking

Intermittently or S teadily..............................23

6.3.2 Heater is Pounding, Knocking or

Emitting Steam from Relief Valves..............23

6.3.3 Soot in Flueways or in Tubes, or Noxious

Fumes Indicative of Bad Combustion ......... 23

6.3.4 Water Dripping in Firebox ........................... 23

SECTION 7.

Parts Descriptions and

Order Numbers

7.1 Jack and Combustion Chamber

Components ............................................... 25

7.2 Water System ............................................. 25

7.3 Electrical Components................................26

7.4 Gas Train....................................................26

7.5 Burner Tray.................................................26

7.6 Outdoor Jacket ...........................................33

Page 3

Mighty Therm Lo-NOx

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides information for the

installation and operation of Laars gas-fired hydronic

boilers and water heaters. It is strongly recommended

that all application and installation procedures be

reviewed completely before proceeding with the

installation. Consult the Laars factory, or local factory

representative with any problems or questions

regarding this equipment. Experience has shown that

most problems are caused by improper installation,

not system design.

Some accessory items are shipped in separate

packages. Verify receipt of all items listed on the

package slip. Inspect everything for possible damage

upon delivery, and inform the carrier of any shortages

or impairments. Any such claims should be filed with

the carrier. The carrier, not the shipper, is responsible

for shortages and damage to the shipment whether

visible or concealed.

IMPORTANT WARNING

The Laars heaters must be installed in

accordance with the procedures outlined in this

manual. The warranty does not apply to boilers not

installed or operated in accordance with these

procedures. Consult local building and safety codes

before proceeding with work. The installation must

conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to

the latest edition of the National Fuel Gas Code;

ANSI Z223.1, National Electrical Code ANSI/NFPA

70 and/ or in Canada CAN 1 -13149 requirements.

When required by the authority having

jurisdiction, the installation must conform to

American Society of Mechanical Engineers safety

codes for controls and safety devices for automatically

fired boilers No. CSD-1, and in Canada CGA 3.3. Any

modification to the boiler, its gas controls, gas

orifices, wiring or draft diverter may void the Laars

warranty. If field conditions require such

modifications, consult factory.

1.2 Heater Identification

Consult rating plate on the boiler. The following

example simplifies the boiler identification.

1 2 3456

PH 1200 I N 21 K

(1) Basic heater model (see descriptions below).

(2) Input rate x 1000 BTU/h.

(3) Indoor (I) or Outdoor (E) installation.

(4) Gas type: Natural (N).

(5) Ignition system: (21) Hot surface (proved igniter)

ignition system.

(6) Firing modes:

On/Off (C)

2-stage (K)

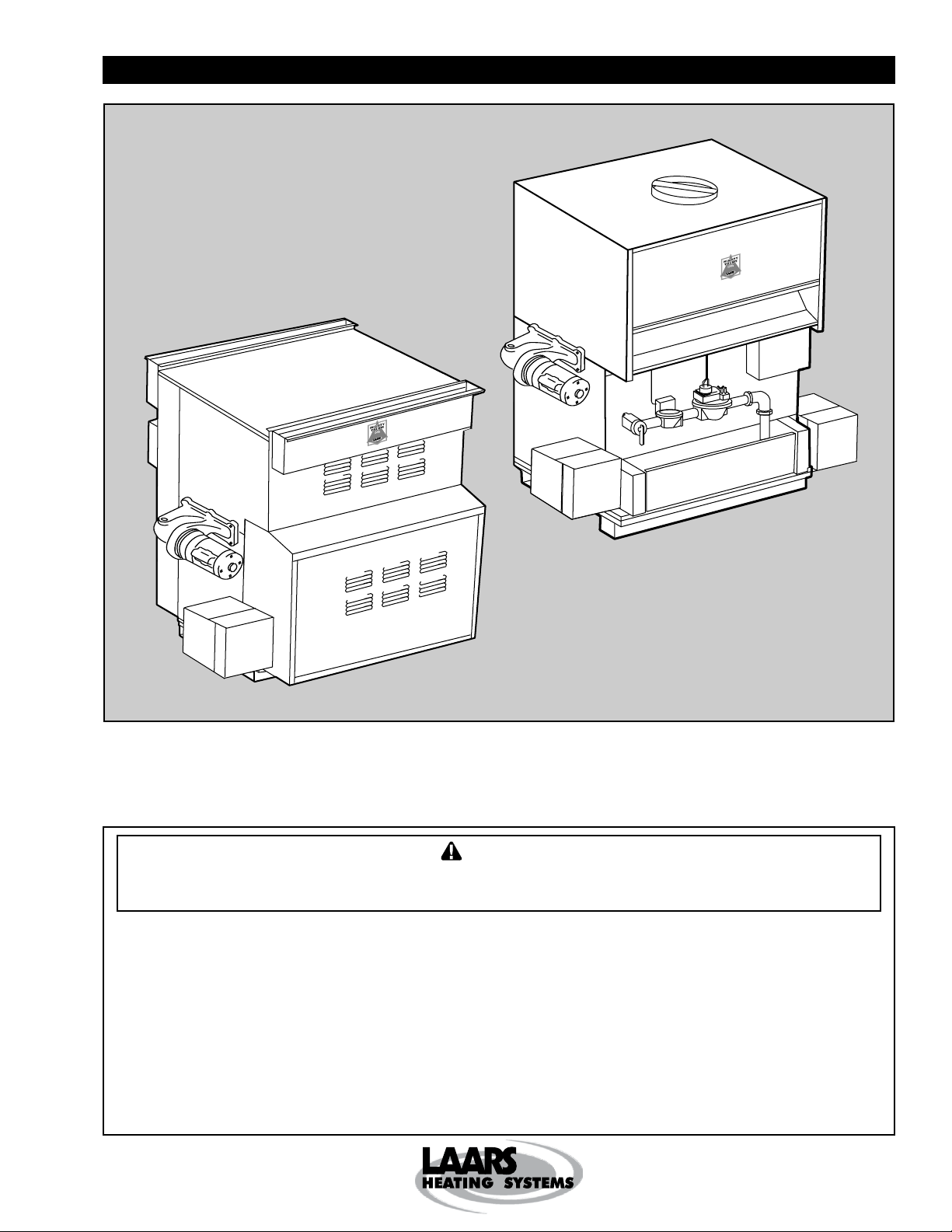

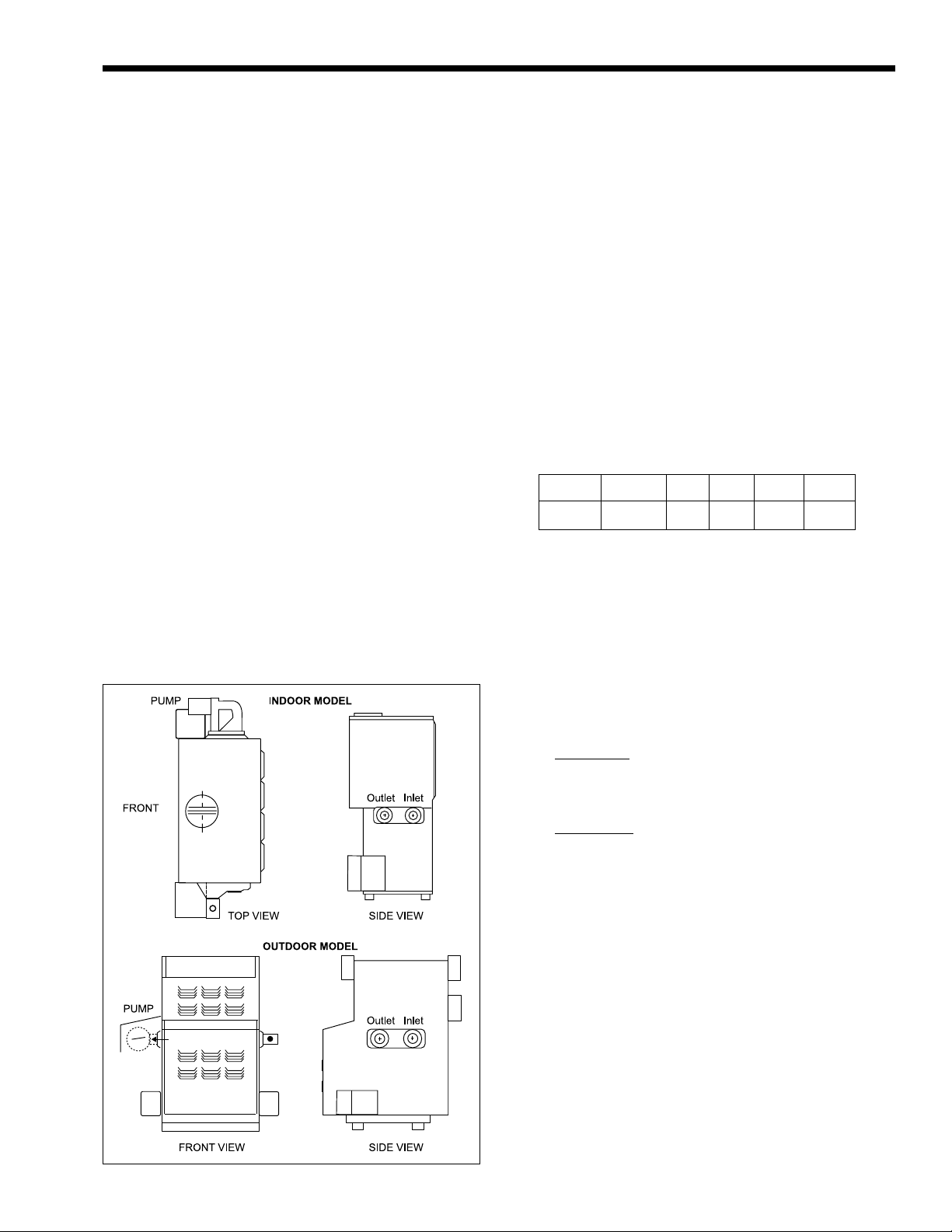

Figure 1. Boiler Configuration.

Model PH hydronic heating boilers come with

integrally mount pumps. Pumps are sized for pressure

drop through the heat exchanger only.

Model PW water heaters for use with separate

storage tank come with integrally mount pumps.

Pumps are sized for pressure drop through the heat

exchanger plus 30 feet (9.1m) of pipes and normal

fitting.

Laars heaters are available in two

configurations: an indoor version and an outdoor

version. Both are available from the factory (see

Figure 1).

1.3 General Water Flow Requirement

For proper operation, all low volume hot water

heaters must have continuous flow through the heat

exchanger when firing. The system pump must be

capable of developing sufficient pressure to overcome

the resistance of the heater plus the entire circulating

system at the designed flow rate.

Page 4

Page 4

LAARS HEATING SYSTEMS

SECTION 2.

Installation

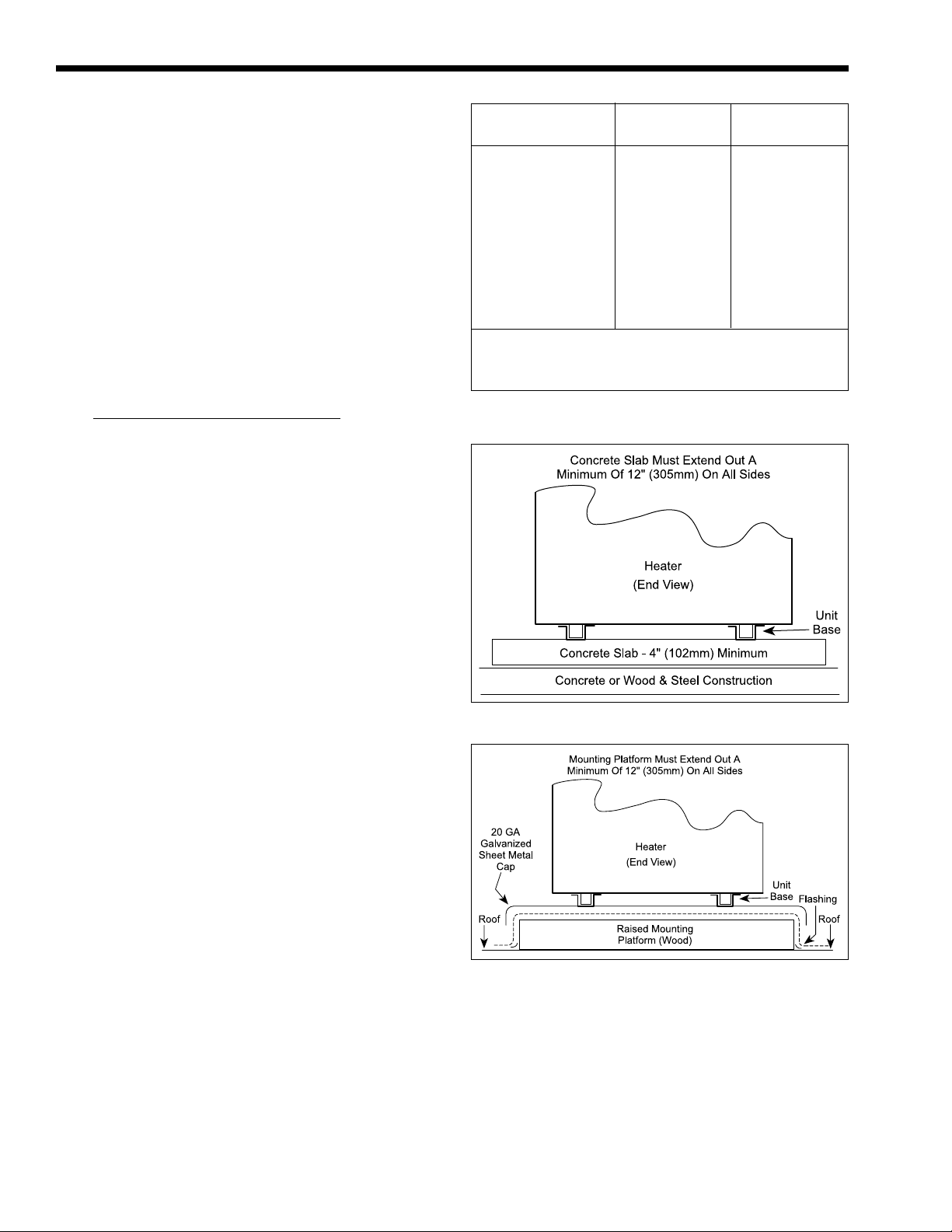

2.1 Heater Placement

The heater must be placed to provide specific

clearances on all sides for maintenance and

inspections. There must also be minimum distances

maintained from combustible surfaces. These

clearances also apply to noncombustible materials

because the heater requires air circulation for proper

operation.

The heater should be mounted on a level surface.

An integral base for an installation on combustible

flooring is provided as standard equipment on all

models.

Do not install a heater on carpeting.

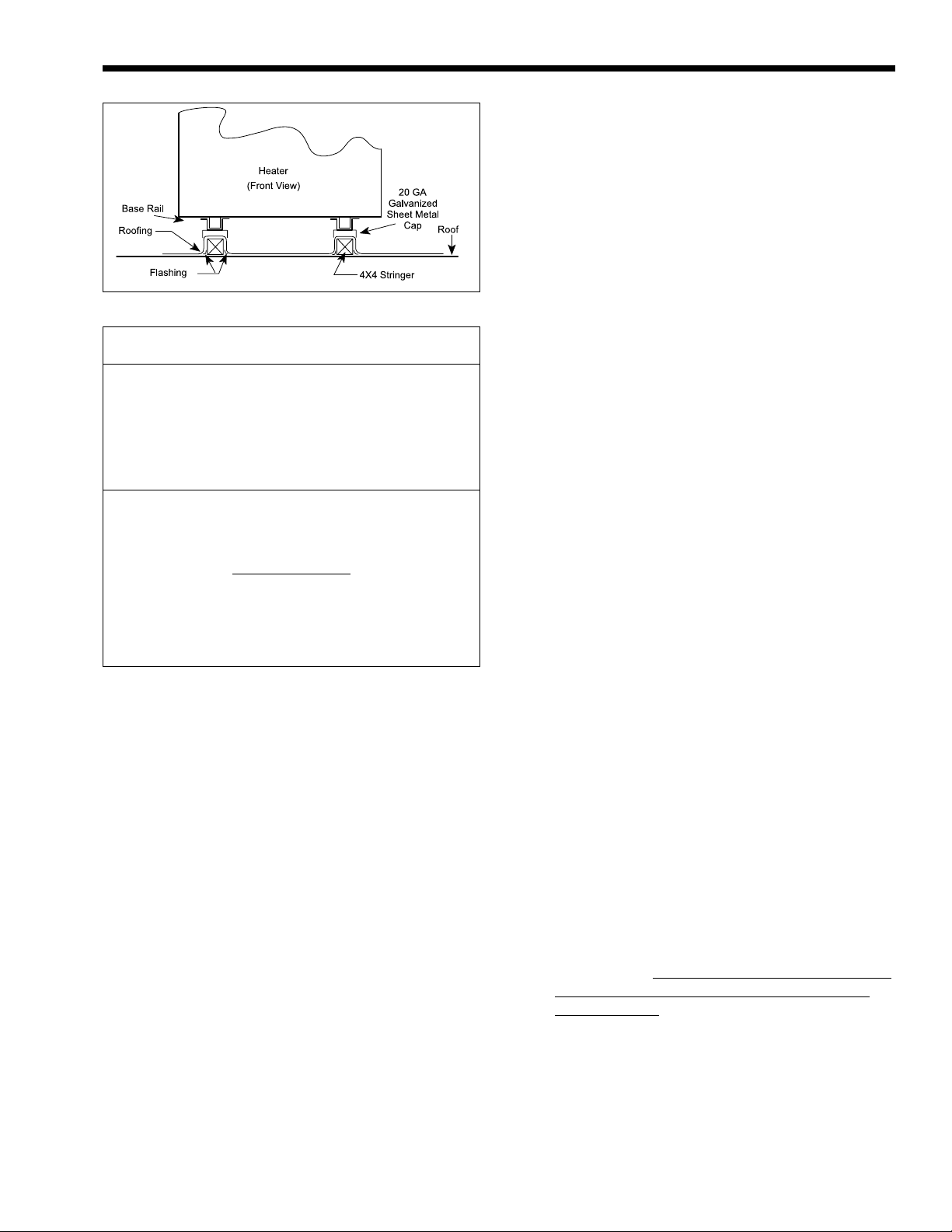

Under the national Fuel Gas Code, ANSI

Z223.1, it is permissible to place the heater on floors

other than noncombustible when the installation

complies with the American Insurance Code. Figures

2, 3, and 4 show common installation on combustible

flooring.

Clearance Indoor Outdoor

from in. mm in. mm

Top 30 762 unobstructed

Water Conn. side 12* 305 24 610

Pump side 6* 152 24 610

Front Alcove* unobstructed

Rear 8 203 24 610

Vent pipe** 6 152 - - -

Hot water pipes per code per code

* Water connection and pump side clearances of 24" (610mm)

and front clearances of 48" (1219mm) will allow easier

service access.

** One inch using type B vent (refer to Manufacturer's Instructions).

Table 1. Minimum Heater Clearances From

Adjacent Surfaces.

2.2 Installation of Indoor Heaters

Locate the heater to provide adequate clearance

for inspection and service on all sides. See Table 1.

Install indoor heaters on a waterproof floor with

an adequate floor drain and a 6" (152mm) minimum

curb on all four sides to protect the building if heater

repairs are required. The manufacturer will not be

held liable for any water damage in connection

with this heater.

2.2.1 Combustion Air Supply

The heater location must provide sufficient air

supply for proper combustion and ventilation of the

surrounding area as outlined in the latest edition of

ANSI standard Z223.1, and any local codes that may

be applicable. Inadequate combustion air supply may

result in incomplete combustion, sooting of the heat

exchanger, and unsafe operation of the boiler.

2.2.1.a Conventional Ventilation

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1: Two permanent openings, one

commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of

the bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts, with

the outdoors or spaces that freely communicate with

the outdoors.. When directly communicating with the

Figure 2. Typical Heater Installation on Concrete Slab.

Figure 3. Typical Heater Installation on Roof Using

Raised Platform (wood).

outdoors, or when communicating to the outdoors

through vertical ducts, each opening shall have a

minimum free area of 1 square inch per 4000 BTU/h

(550 square mm/kW) of the total input rating of all

equipment in the enclosure. When communicating to

the outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than 1

square inch per 2000 BTU/h (1100 square mm/Kw) of

the total input rating of all equipment in the enclosure.

Page 5

Mighty Therm Lo-NOx

Figure 4. Typical Heater Installation on Concrete Slab.

Heater Each Opening*

Size square inches square cm

500 125 807

715 179 1155

999 250 1613

1010 253 1632

1200 300 1936

1430 358 2310

1825 457 2950

* Net Free Area.

Check with louver manufacturers for net free area of louvers.

Correct for screen resistance to the net free area if a screen is

installed. Check all local codes applicable to combustion air.

Area indicated is for

and one at the ceiling, so the total net free area could be

double the figures indicated. For special conditions refer to the

latest edition of ANSI Z223.1.

Consult factory if openings do not communicate directly

through the walls with the outdoors.

Table 2. Minimum Recommended Air Supply to Heater,

one of two openings: one at floor level

Per Method 1.

See Table 2 for recommended opening sizes

pertaining to Method 1.

Method 2: One permanent opening, commencing

within 12 inches (300 mm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors, or shall communicate

through a vertical or horizontal duct to the outdoors or

spaces that directly communicate with the outdoors,

and shall have a minimum free area of 1 square inch

per 3000 BTU/h (700 square mm/kW) of the total input

rating of all equipment located in the enclosure. This

opening must not be less than the sum of the areas of all

vent connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, provided they conform

to the requirements in the applicable codes.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CAN/CGA B149.

An improperly ventilated equipment room can

get excessively hot and cause accelerated

deterioration of controls and electrical components.

In Canada, Table 2 does not apply. Consult local

building codes or, in the absence of such requirements,

follow CGA requirements and/or CAN/CGA B-149

standard.

Page 5

2.2.1.b Forced-Air Ventilation

In the United States: any equipment which

exhausts air from the heater room can deplete the

combustion air supply or reverse the natural draft

action of the venting system. This could cause flue

products to accumulate in the heater room. Additional

air must be supplied to compensate for such exhaust.

The information in Table 2 is not applicable in

installations where exhaust fans or blowers of any

type are used. Such installations must be designed by

qualified engineers.

In Canada: follow Canadian standard, CAN/

CGA B-149 or local codes.

If a blower or fan is used to supply air to the

heater room, the installer should make sure it does not

create drafts which could cause nuisance shutdowns.

If a blower is necessary to provide adequate

combustion air to the heater, a suitable switch or

interlock must be wired into the heater control circuit

to prevent the heater from firing unless the blower is

operating.

The heater must be completely isolated and

protected from any source of corrosive chemical fumes

such as trichlorethylene, perchloroethylene, chlorine, etc.

2.2.2 Venting

IMPORTANT NOTE: Mighty Therm LO-NOx

units are not fan-assisted. They are natural draft

appliances. The fans on the Mighty Therm LO-NOx

units are for combustion assistance only. Venting

systems must be sized as natural draft, atmospheric

vent, and not as fan-assisted vent systems.

1. Laars heaters have built-in draft diverters for

natural draft operation and must not be

connected to any portion of a mechanical draft

system under positive pressure. The flue outlet

must be connected to a clear, unobstructed vent

of adequate capacity ending above the highest

point of the building with an approved vent cap.

The venting system should be installed

according to Category 1, Natural Draft per the

latest edition of ANSI Z223.1 and/or, in Canada,

CAN/CGA B-149 and any local codes having

jurisdiction.

2. Do not weld or fasten the vent pipe to the boiler

drafthood. The weight of the stack must not rest

on the heater.

The drafthood and heater top must

be easily removable for normal heater service

and inspection.

IMPORTANT NOTE: Do not use sheet metal

screws at the snap lock joints of Type B gas vents.

3. Avoid using long horizontal runs of the vent

pipe, and too many 90° elbows, reductions or

restrictions. Horizontal runs should have at least

a 1/4" (6mm) rise per foot in the direction of

flow. A vent connector should be supported for

the design and weight of the material used to

maintain clearances and prevent physical

damage and separation of joints.

Page 6

Page 6

LAARS HEATING SYSTEMS

4. Avoid terminating heater vents near air

conditioning or air supply fans. The fans can

pick up exhausted flue products from the heater

and return them inside the building creating a

possible health hazard. A minimum of 4 feet

(1.2m) horizontal distance must be maintained

from electrical meters, gas meters, and relief

equipment.

5. Always use double-wall or insulated vent pipe

(Type B or equivalent). In cold weather,

uninsulated outside vents can chill the rising flue

products blocking the natural draft action of the

venting systems. This can create a health hazard

by spilling flue products in the heater room.

6. Avoid oversized vent piping or extremely long

runs of pipe which may cause excessive cooling

and condensation. Rule of Thumb: the total

length of the vent, including the connector and

any offset, should not exceed 15 feet (4.6m) for

every inch (25mm) of vent diameter. Longer

total lengths shown in venting tables are based

on maximum capacity, not condensation factors.

7. When the installation of a draft fan is necessary

in connecting a venting system to a Laars heater,

the installation should be engineered by

competent personnel following good engineering

practices. The draft fan supplier should be

consulted for correct size. The installation

should be in accordance with the latest edition of

ANSI Z223.1 and/or, in Canada, CAN/CGA B149 and any local codes having jurisdiction.

When a draft fan is installed, a suitable draft

switch must be wired into the boiler control

circuit at terminal designated "Field Interlock"

to prevent firing of the boiler unless a positive

draft has been established.

2.2.3 Removal of Existing Heater

At the time of removal of an existing heater, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine that

there is no blockage or restriction, leakage,

corrosion or other deficiencies which could

cause an unsafe condition.

3. Insofar as is practical, close all building doors

and windows, as well as all doors between the

space in which the appliances remaining

connected to the common venting system are

located and other spaces of the building. Turn on

clothes dryers and any appliance not connected

to the common venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts so they will operate at maximum speed.

Do not operate a summer exhaust fan. Close

fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust

thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

(if the appliance is equipped with a drafthood),

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return door, windows, exhaust fans,

fireplace dampers and any other gas-burning

appliances to their previous condition of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code,

ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the

minimum size as determined using the

appropriate Tables in Appendix G in the

National Fuel Gas Code, ANSI Z223.1.

In Canada, at the time the boiler is removed from

common venting system, the common venting system

should be resized so the installation conforms to CAN/

CGA B149.1 or .2.

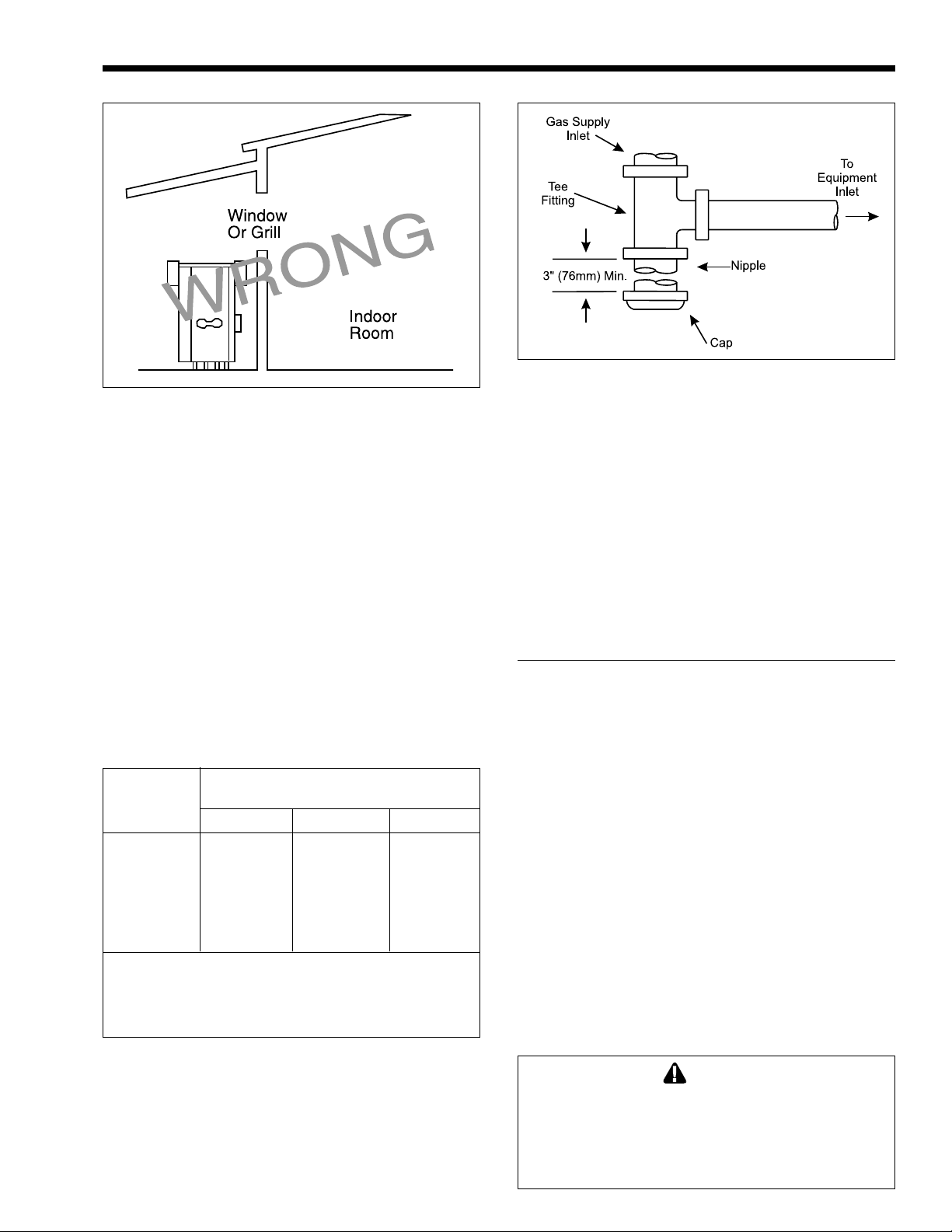

2.3 Installation of Outdoor Heaters

(Not available in Canada)

1. Locate the heater to provide the clearances as

listed in Table 1, “Minimum Heater Clearances.”

2. Do not place the heater in an enclosure or wall

recess. Avoid locations where wind deflection

off structures might cause downdraft. When such

wind conditions are possible, place the heater at

least 3 feet (0.9m) from the structures.

3. Never install the heater under any kind of roof

overhang. Do not place the heater below or

adjacent to any doors, windows, louvers, grills,

etc., which connect in any way with an inhabited

area of a building. This includes other structures

such as garages or utility rooms (see Figure 5).

4. Although the Laars models are CSA designed

certified for outdoor installations, such

installations are not recommended in areas where

the danger of freezing exists unless proper

precautions are taken for freeze protection.

Outdoor installations are not recommended in

areas where the danger of snow blockage exists.

Page 7

Mighty Therm Lo-NOx

Figure 5. Incorrect Outdoor Installation.

The heater should be located a safe distance

from Propane gas storage and filling equipment.

Consult local codes and fire protection authorities for

advice on specific installation restrictions.

2.4 Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1. Verify that the heater is fitted for the proper type

of gas by checking the rating plate. Laars heaters

are normally equipped to operate below a

2000 foot (609.6m) altitude. Heaters equipped to

operate at higher altitudes have appropriate

stickers or tags attached, also printed

information on rating plate.

2. Use the figures in Table 3 to provide adequate

gas piping from the gas meter to the heater.

Distance from Gas Meter

or Last Stage Regulator

Size 0-100' 100-200' 200-300'

500 1½" 2" 2"

715 2" 2" 2½"

999 2" 2½" 3"

1010 2" 2½" 3"

1200 2½" 3" 3"

1430 2½" 3" 3"

1825 2½" 3" 3½"

NOTE: These figures are for Natural Gas (.65 Sp. Gr.), and are

based on 1/2" water column pressure drop. Check supply

pressure with a manometer, and local code requirements for

variations. An average number of tees and elbows have been

taken into account.

Table 3. Gas Piping Sizes.

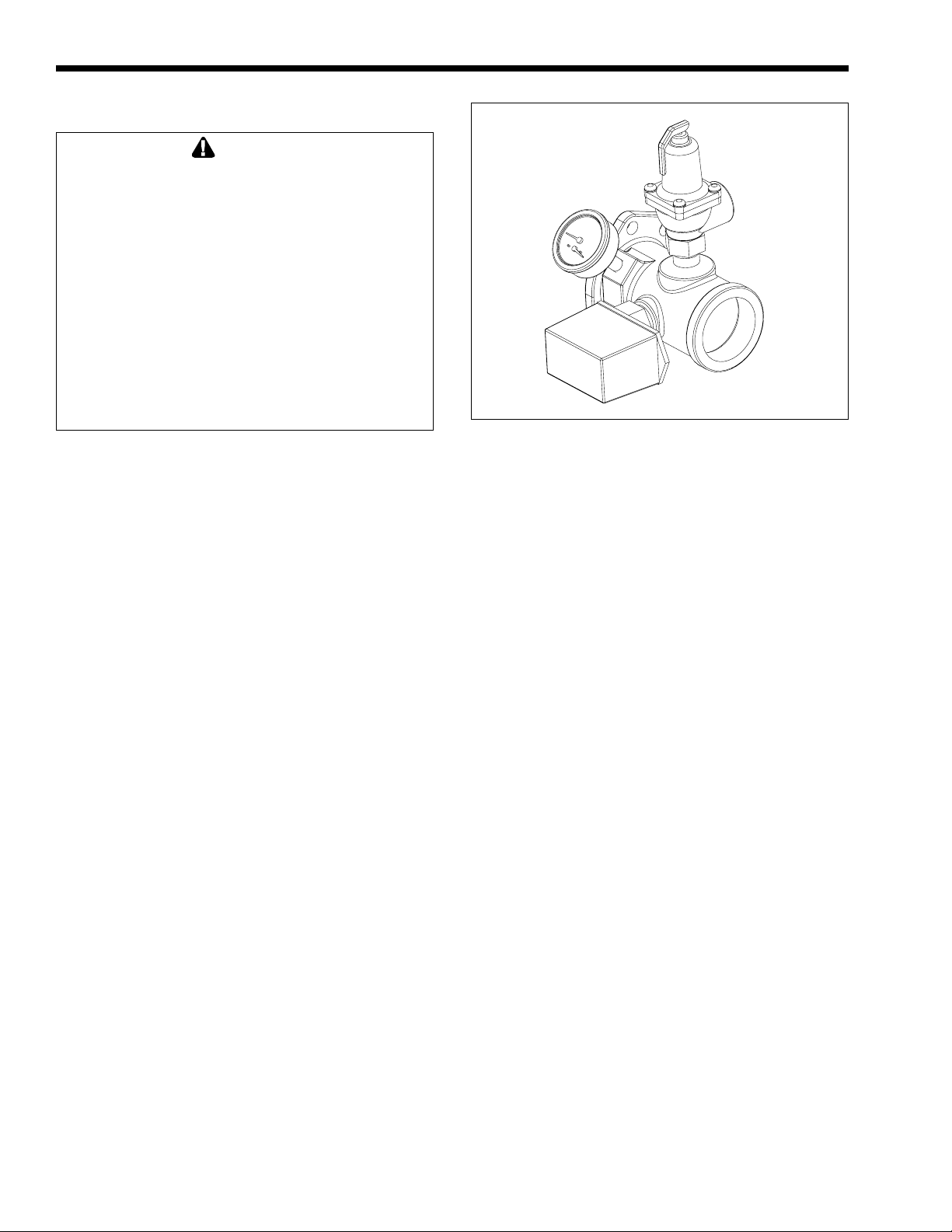

3. A sediment trap (drip leg) must be provided

ahead of the gas controls (see Figure 6). A

manual gas shutoff valve must also be provided

for service convenience and safety. A cap must

be provided for cleaning purposes. Check the

local codes.

Page 7

Figure 6. Sediment Trap Installation.

4. The heater and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 psig. The heater

must be isolated from the gas supply piping

system by closing its individual manual gas

shutoff valve during any pressure testing of the

piping system at test pressures equal to or less

than 1/2 psig.

5. Provide gas supply pressure to the heater as

follows:

Natural

Gas

Max. (inches water column) 10

Min. (inches water column) 6.5

NOTE: the heater and all other gas appliances sharing

the boiler gas supply line must be firing at maximum

capacity to properly measure the inlet supply pressure.

Low gas pressure could be an indication of an

undersized gas meter and /or obstructed gas supply

line.

6. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator is

preset at the factory and normally requires no

further adjustment.

7. The gas manifold and control assembly is

factory tested and conforms to the safe lighting

and other performance criteria specified in the

latest editions of ANSI Z21.13 and CGA 3.3

Low Pressure Boiler Standard.

8. Before operating the heater, test the complete

gas supply system and all connections for leaks

using a soap solution. Do not use raw flame.

Caution

Since some leak test solutions (including soap

and water) may cause corrosion or stress

cracking, the piping must be rinsed with water

after testing, unless it has been determined

that the leak test solution is noncorrosive.

Page 8

Page 8

2.5 Electrical Wiring

WARNING

The heater must be electrically grounded in

accordance with the most recent edition of the

National Electrical Code, ANSI/NFPA 70. In

Canada, all electrical wiring to the boiler should

be in accordance with the latest edition of CSA

C22.1 Canadian Electrical Code, Part 1. Do not

rely on the gas or water piping to ground the

metal parts of the boiler. Plastic pipe or

dielectric unions often isolate the heater

electrically. Service and maintenance

personnel who work on or around the heater

may be standing on wet floors and could be

electrocuted by an ungrounded heater.

Wiring diagrams are included in the information

packet provided with each unit.

1. All Laars heaters need 115V 60Hz supply

voltage unless specifically ordered otherwise.

Check heater wiring and pump for correct

voltage, frequency and phase. Consult the

National Electrical Code or the Canadian

Electrical Code regarding branch circuit

requirements for equipment with these motors.

2. The heater should be wired exactly as shown in

the wiring diagram.

3. All field installed electrical safety devices and

all field installed controllers (valve end switches,

draft switches, relays, timers) can be connected

to the heater control to the terminals shown in

the wiring diagram designated “Field Interlock.”

4. Where the heater is installed with a draft fan

refer to the fan manufacturer's wiring diagram.

The draft switch should be wired across the field

interlock terminals in the heater control panel.

SECTION 3.

Water Piping Instruction

3.1 General Piping Practice

1. Be sure to provide valves at the inlet and outlet

of the heater so it can be readily isolated for

service. A butterfly, ball type or similar type of

valve is recommended.

2. The pressure relief valve installed in the tapped

opening provided in the outlet header (see Figure

7), must be piped, but not fastened, to a drain or

floor sink. The drain pipe must be the same size

as the valve outlet and must pitch downward

from the valve. Pay special attention to relief

valve settings in installations where the heater is

located on the ground floor of a tall building, or

where the operating temperature of the heater is

LAARS HEATING SYSTEMS

Figure 7. Pressure Relief Valve Location.

above 210°F (99°C). In both instances, the static

pressure of the system is elevated and could

cause the relief valve to leak and bring

considerable raw water into the system.

3. Where no special setting of the relief valve is

ordered, the factory will furnish a 75 psi setting

for heating boilers (PH models), and 125 psi for

water heaters (PW models).

4. The pressure relief valve lever must be tripped at

least once a year to insure that waterways are

clean. When manually operating lever, water

will discharge through the drain line. Precautions

must be taken to avoid contact with hot water

and water damage.

3.2 Heating Boiler (PH Model)

3.2.1 Variable Water Flow System

Heating systems using zone valves, zone pumps

or 3-way valves can experience reduced water flow

through the boiler. This can result in an excessive

water temperature rise and unstable boiler operation.

If the system water flow is variable, the boiler's

temperature sensor must be installed in the outlet

water. Laars recommends primary-secondary pumping

for all variable flow systems (see Figure 9). Primarysecondary pumping is mandatory for variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler

even though the system flow is variable. In a primarysecondary system the pressure drop of the boiler is not

added to the system.

3.2.2 System Pressure Requirements

The boilers are designed to operate on closed,

pressurized systems. Maintain a minimum of 12 psi

(81.8 kPa) on the system where boiler supply water

temperature is 200°F (93°C) or less. If higher

temperatures are required, the minimum system

Page 9

Mighty Therm Lo-NOx

Page 9

pressure should be at least 15 psi (102.2 kPa) above

the water vapor pressure corresponding to the elevated

water temperature.

Heating boilers are not suitable for open systems

unless the supply water temperatures are kept below

180°F (82°C), and a minimum of 5 psi (34.1 kPa)

static head is maintained at the boiler.

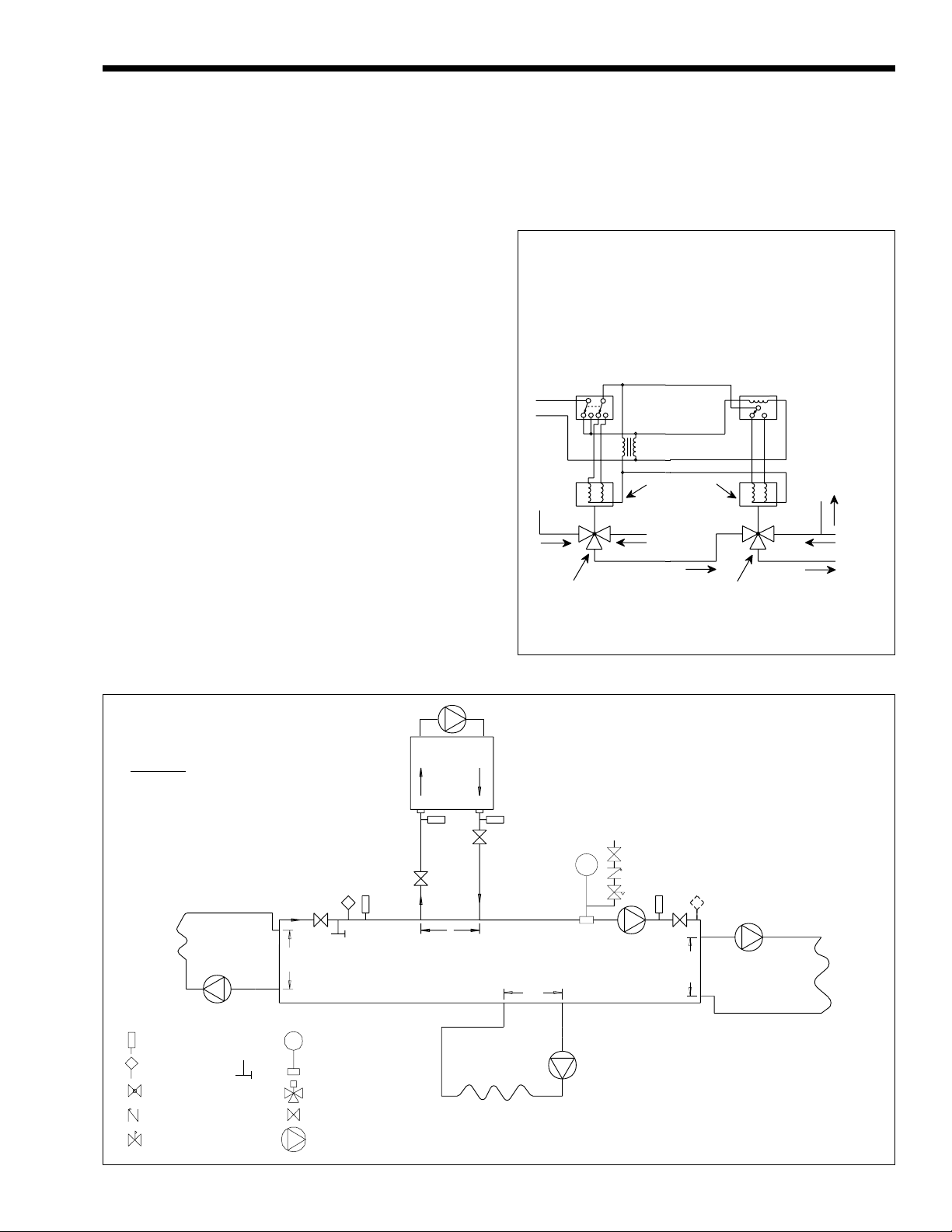

3.2.3 Hot/Chilled Water Systems

When a boiler is connected to an air

conditioning system where the same water is used for

heating and cooling, you must prevent chilled water

from entering the boiler When changing such a system

from cooling to heating, allow the chilled water to

circulate through the building, after the chiller has

been turned off, for a period long enough for the water

to warm up to at least 105°F (41°C) before the water

flows into the boiler. It is equally important to prevent

hot water from entering the chiller. The system shown

in Figure 8 is suggested to make sure the system water

is neither too hot nor too cold when a changeover

takes place. When a boiler is connected to heating

coils located in air handling units (where they may be

exposed to refrigerated air circulation), install a flow

control valve or other automatic means to prevent

gravity circulation of chilled water through the boiler.

Chilled water in the boiler will create condensate on

the boiler tubes. Boilers installed in violation of the

foregoing may void the warranty.

3.2.4 Combined Space Heating/Potable

Water Heating Systems

When using the Laars boiler as a source of heat

for a combined space heating/potable water heating

system, be sure to follow the instructions of the space

heating system.

Suggested Wiring Diagram For

Tempering System Water at

Changeover From Heating To Cooling

DPDT Manual or Automatic

Change-Over Switch

DPDT - Set at Change-Over

Temperature

115/24V

Transformer

From

Chiller

3-Way Valve No. 1

Change-Over

(Heating and Cooling)

Valve Motors

2-Pos

3-Wire - 24V

From

Boiler

3-Way Valve No. 2

To By-Pass

Both Heater and

Chiller

Clock Timer

Auto-Resetting

Set at 15 Minute SPDT

To Boiler

and

Chiller

By-Pass

From

System

To

System

WARNING: This drawing shows suggested

piping configuration and valving. Check with

local codes and ordinances for additional

requirements.

12"

Max.

LEGEND:

Thermometer

Temperature

Sensor

Globe Valve

Check V alve

Pressure Reducing Valve

w/Fast Fill Bypass

Purge

Valve

Expansion T ank

with Air Scoop and

Auto Air Vent

3-Wa y Valve

Valve

Pump

12"

Max.

Figure 8. Boiler-Chiller Installation.

Boiler Circulation

Pump

Cold Water

Make-Up

System Pump

12"

12"

Max.

Boiler circuit piping must be equal to or larger than

boiler water connection size.

Boiler circulation pump sized for flow through

boiler.

Dotted devices indicate alternate locations.

Max.

Figure 9. Primary-Secondary Plumbing.

Page 10

Page 10

LAARS HEATING SYSTEMS

Do not use water piping, fittings, valves, pumps,

and any other components which are not compatible

with potable water.

Do not connect the heater, which will be used to

supply potable water, to any heating system or

components previously used with a nonpotable water

heating system.

Do not add boiler treatment or any chemicals to

the heating system piping, since the piping contains

water for potable use.

Do not use solder containing lead in the potable

water lines.

Some jurisdictions may require a backflow

preventer in the cold water line. In such cases,

pressure relief valve may discharge water due to

expansion. An expansion tank approved for potable

water will eliminate this condition. Follow the

manufacturer's instructions for installation of the

expansion tank.

3.2.5 Piping System Requirements

1. Provide a boiler installed above radiation level

with a low water cutoff device either as part of

the boiler or at the time of boiler installation.

2. Install manual and/or automatic bleeding devices

at high points in the system to eliminate air.

Install a correctly sized expansion or

compression tank with suitable air charger and

tank drainer, as appropriate.

3. Support the weight of all water and gas piping by

suitable hangers or floor stands.

4. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

3.2.6 Filling The System

1. Ensure the system is fully connected. Close all

bleeding devices and open make-up water valve.

Allow system to fill slowly.

2. If make-up water pump is employed, adjust

pressure switch on pumping system to provide a

minimum of 12 psi (81.8 kPa) at the highest

point in the heating loop.

3. If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the

highest point in the heating loop.

4. Open bleeding devices on all radiation units at

the high points in the piping throughout the

system, unless automatic air bleeders are

provided at such points.

5. Run system circulating pump and boiler pump

for a minimum of 30 minutes with the boiler gas

shut off.

6. Open all strainers in the circulating system,

check flow switch operation, and check for

debris.

7. Recheck all air bleeders as described in Step 4

above.

8. Check liquid level in expansion tank. With the

system full of water and under normal operating

pressure, the level of water in the expansion tank

should not exceed 1/4 of the total, with the

balance filled with air.

9. Start up boiler according to procedure described

in Section 4. Operate the entire system,

including the pump, boiler, and radiation units

for one (1) hour.

10. Recheck the water level in the expansion tank. If

the water level exceeds 1/4 of the volume of the

expansion tank, open the tank drainer and drain

to that level.

11. Shut down the entire system and vent all

radiation units and high points in the system

piping as described in Step 4 above.

12. Close make-up water valve and check strainer in

pressure reducing valve for sediment or debris

from the make-up water line. Reopen make-up

water valve.

13. Check gauge for correct water pressure and also

check water level in system. If the height

indicated above the boiler insures that water is at

the highest point in the circulating loop, then the

system is ready for operation.

14. Within three (3) days of start-up, recheck all air

bleeders and expansion tank as described in

Steps 4 and 8 above.

3.3 Water Heater (PW Model)

3.3.1 Water Chemistry

Laars equipment is designed for use in a wide

variety of water conditions. The water velocity

maintained in the heat exchanger tubes is kept high

enough to prevent scaling from hard water and low

enough to avoid corrosion from soft water. Ninetyfive percent of the urban areas in the country have

water that is compatible with this equipment, but in

some areas a water supply will contain a large

quantity of scaling chemicals or the water may be

extremely soft and corrosive. In rare situations the

water will contain both scaling chemicals and

corrosive chemicals such as calcium or sodium

chloride. These conditions may be the result of a

nearby well or pumping station and the particular

condition may not be characteristic of the entire city

water system.

If an installer observes damage from these

conditions to any water handling equipment in the

area, a factory representative should be contacted

immediately for assistance in minimizing maintenance

costs. If erosion is present, the pump impeller can be

replaced to reduce water velocity. If scaling

conditions are bad, tube cleaning maintenance

schedules can be established to prevent tube burn-out

and cracking. Neglecting the problem could mean

serious damage to the heater and water system.

Scaling can be recognized as a layer deposited

Page 11

Mighty Therm Lo-NOx

Page 11

on the inner walls of the tube which reduces the inner

diameter of the tube. Scale can be any color or

texture; smooth or rough, granular or amorphous.

Signs of erosion are generally pitting, cavitation,

ridges and “islands” on the inner walls of the tubes.

Since this condition results from extremely soft water

sources, or as a result of a water softening program,

the internal copper surfaces will be extremely shiny.

Other chemicals, such as chlorine or chlorides in the

water, will cause dark surfaces of erosion.

In areas where the water supply is extremely

corrosive, it is advisable to order the heater with

cupro-nickel tubes in the exchanger.

Damage From Scaling, Corrosion, or Erosion

is Not Covered by the Warranty.

3.3.2 Piping System Requirements

1. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

2. All two-temperature systems using temperature

valves must have forced recirculation in the low

temperature building loop.

3. A check valve installed at the hot water inlet to

the tempering valve will prevent cold water from

being drawn in reverse through the tempering

valve into the hot water.

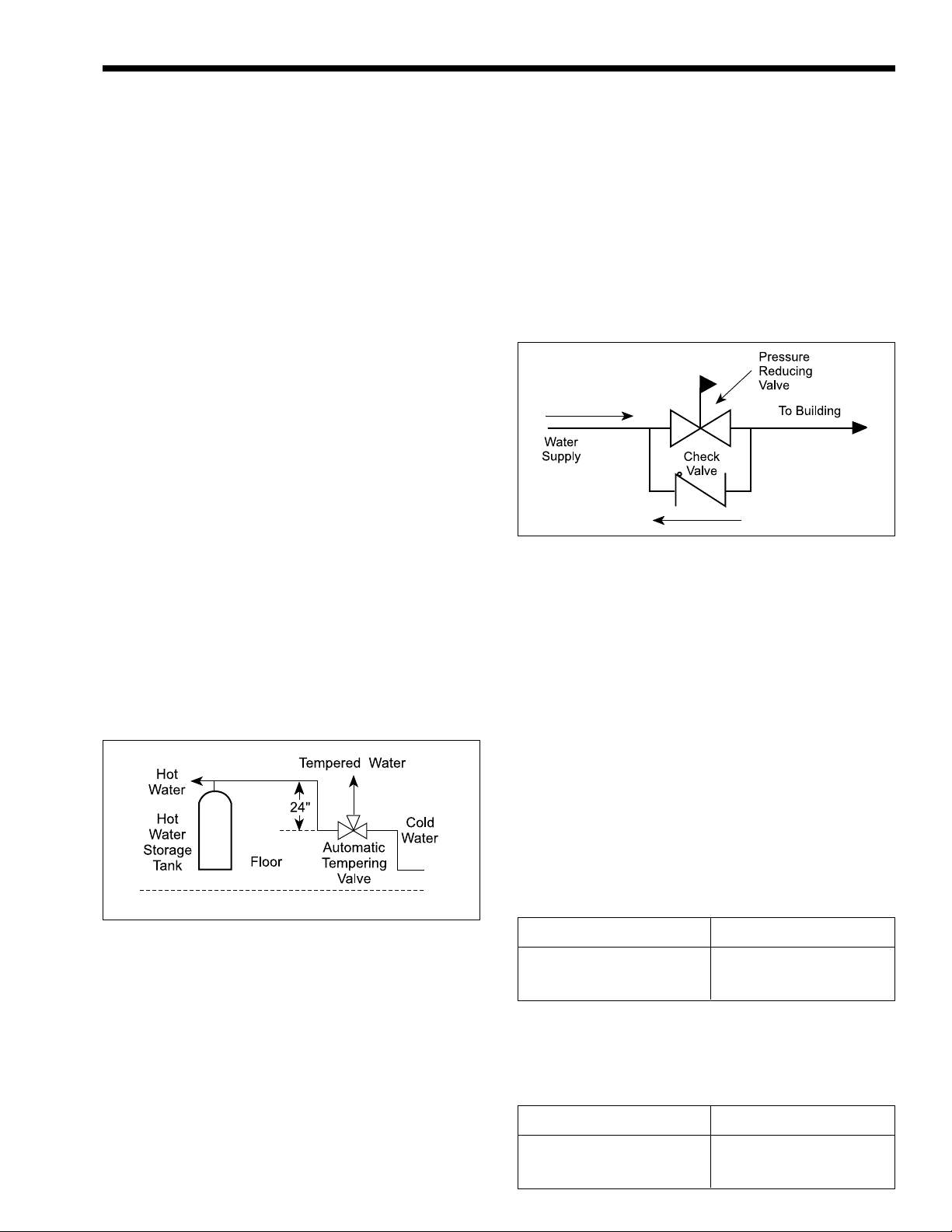

4. When installing a tempering valve, place at

bottom of antithermosyphon loop at least 24"

high to prevent excessive hot water from

entering mixed water supply. Bring the cold

water supply up from the floor to the valve (see

Figure 10).

The following suggestions may solve the

problem:

1. Replace the installed water pressure reducing

valve with a suitable valve having a back flow

port. These valves have a back flow port which

allows water to flow backwards when the

pressure in the system exceeds the pressure in

the mains.

2. Install a check valve around the pressure

reducing valve to permit reverse flow. This will

allow the expanded water to back flow into the

mains (see Figure 11).

Figure 11. Check Valve/Pressure Reducing Valve

Installation.

3. Install an auxiliary small relief valve set at 25 psi

less than the main relief valve. The valve must

be piped to a drain and may require occasional

cleaning. It will bleed off the expanded water

and protect the main pressure relief valve from

becoming fouled.

4. Install a properly sized expansion tank.

Figure 10. Tempering Valve Installation.

3.3.3 Water Expansion

When cold water is heated the water expands. If

no water is being used during the heat-up period the

expanded water will normally back up into the city

mains.

A water pressure reducing valve installed in the

incoming cold water line may act as a check valve and

prevent the expanded water from moving backward.

This will cause pressure to rise in the heater, which

will be relieved by the pressure relief valve.

If the relief valve pops frequently a mineral

deposit may build up on the valve seat, causing it to

leak.

3.3.4 Pump Requirements

1. The factory provided pump on PW heaters are

sized to provide proper circulation through the

heater and heater-to-tank circulation loop (see

Figures 12, 13 and 14). If the heater-to-tank

circulation loop does not contain more than 6

elbows and 30 feet of pipe, use pipe fittings in

the loop no smaller than the following:

Model Pipe Size

500 through 715 2"

999 through 1825 2-1/2"

If the heater-to-tank circulating loop contains

more than 6 elbows and 30 feet of pipe, use

pipe or fittings in the loop no smaller than the

following:

Model Pipe Size

500 through 715 2-1/2"

999 through 1825 3"

Page 12

Page 12

LAARS HEATING SYSTEMS

Figure 12. Hot Water Supply System with Vertical Tank.

NOTES:

Heavy line indicates Heater to Tank Circulating Loop.

Figure 13. Hot Water Supply System with Horizontal Tank.

NOTES:

Heavy line indicates Heater to Tank Circulating Loop.

Page 13

Mighty Therm Lo-NOx

Page 13

Figure 14. Hot Water Supply System Using Dual Tanks.

2. Model PW heater is not suitable for heating

swimming pools or any other application where

temperature of the water flowing through the

heater remains below the dew point (110°F).

In applications requiring the rapid use of

measured volumes of water, the recovery of the

heater between the time intervals of use must

equal the volume used. See the recovery table in

the current Document 2129 (Submittal Data).

3. Pump Sizing: the heater circulating pump is

sized to provide enough flow to prevent damage

to the heat exchanger. Specifications in Table 4

include allowance for 30 feet of piping and 6

elbows between heater and tank.

IMPORTANT: Check oil level in pump before

starting. Oil pump every three (3) months. Fill

bearing assembly to lower level of overflow

vent. Add five (5) or six (6) drops of oil to front

and rear of motor. Use 20W non-detergent oil.

Pumps located in excessively hot or dusty

locations should be oiled once a month. Self

lubricating pumps do not require oiling.

4. The pump should be accessible for lubrication,

inspection and service.

NOTES:

1. Heavy line indicates Heater to Tank Circulating Loop.

2. When a very large volume of water is circulated in the building

loop with the use of a separate pump, tee building loop into cold

water supply and return to storage tank.

Flow Head* Temp. Rise

Water Rate Loss Across

Model Category (GPM) (ft.) Heater, (°F)

500 Normal 68 9.9 11

715 Normal 68 11.0 16

999 Soft 45 3.9 35

and Normal 68 7.5 23

1010 Hard 90 11.7 18

1200 Normal 68 7.8 27

1430 Normal 68 8.1 32

1825 Normal** 90 13.5 30

Water Category Grain Hardness per Gal.

Soft 1 through 7.5

Normal 7.6 through 17

Hard Over 17

* Pressure drop includes loss through 30 feet of pipe and normal fittings when

heater is installed with storage tank. Pipe and fittings are assumed to be 2" on

Models (500-715) and 2 1/2" on Models (1010-1825)

** To prevent erosion, these models must be ordered with cupro-nickel heat

exchanger tubes.

Soft 45 5.0 17

Hard 90 15.7 8

Soft 45 5.3 24

Hard 90 17.8 12

Soft 68 7.8 27

Hard 90 12.2 21

Soft** 68 8 . 1 32

Hard 90 12.6 24

Soft** 90 13.5 30

Hard 90 13.5 30

Table 4. Pump Performance Requirements.

Page 14

Page 14

LAARS HEATING SYSTEMS

3.3.5 Water Pressure

It is very important that water pressure in the

system be maintained above 30 psi. If the system

pressure should drop below this, the vapor pressure of

water in the suction side of the pump can cause

hammer and cavitation in the pump and damage the

heater through lack of water circulation.

For protection against excessive pressure the

water heater is equipped with a pressure relief valve.

When the water heater is connected to a separate

storage vessel, a temperature and pressure relief valve

must be installed on the storage vessel. The

temperature and pressure relief valve must be designcertified in accordance with the requirements for

Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, ANSI Z21.22. (in Canada,

in accordance with the requirements for the Standard

for Temperature and Pressure Relief Valves and

Vacuum Relief Valves, CAN1-4.4).

The temperature and pressure relief valve must

have a BTU/h (kW/h) capacity rating that is greater

than the BTU/h (kW/h) input of the water heater. The

temperature and pressure relief valve must be marked

with a maximum working pressure not to exceed the

maximum working pressure shown on the rating plate

of the water heater, or the maximum working pressure

of the separate storage vessel, whichever is the lower

pressure. The temperature and pressure relief valve

must have a maximum working temperature not to

exceed 210°F (99°C).

Do not place any shutoff valves between the

temperature and pressure relief valve and the storage

vessel.

The relief valves discharge water in large

quantities should circumstances demand.

3.3.6 Tank Installation

1. Be sure the floor is waterproof and structurally

capable of supporting the tank when it is filled

with water.

2. The tank should be placed so that manholes,

inspection covers, nameplates and drain valves

are accessible.

3. Be sure the tank is suitable for the water in the

system. Some water is corrosive and requires a

protected tank with a special lining.

4. If the tank is glass-lined, it should be equipped

with a suitable magnesium anode. It is good

practice to replace the anode when it is

approximately 50% used. The factory warranty

on a glass-lined tank, if provided, will be void if

a satisfactory anode is not in place at the time of

a failure or if it is consumed by cathodic action.

5. Make sure the tank connections in the heatertank circulating loop are the proper size as listed

in Section 3.3.4. If tappings are smaller than the

recommended pipe size, a larger pump may be

required. Consult the factory if in doubt.

6. Install a pipe in the tank drain fitting that goes to

a floor sink, and install a drain valve. If a floor

sink is not available, install a hose bib.

3.3.7 Two-Temperature System

See Figures 15 and 16 for piping schematics.

This system is designed to maintain the tempered

water circulating loop at the desired temperature

Figure 15. Two Temperature Hot Water Supply system with Horizontal Tank.

Legend

Check V alve

T empering Valve

Venturi (Suction) Te e

Throttling Valves / Service Valves

Page 15

Mighty Therm Lo-NOx

Page 15

Legend

Check Valve

T empering Valve

Venturi (Suction) Te e

Throttling Valves / Service Valves

Figure 16. Two Temperature Hot Water Supply System with Vertical Tank.

during idle periods as well as when there is a demand

for hot water. It is recommended for general purpose

water supply including shower and bathing

applications. Water at 180°F is available directly from

the tank.

WARNING

Hot water can scald! Hot water can produce

third degree burns in 6 seconds at 140°F

(60°C) and in 30 seconds at 130°F (54°C).

VAC establishing the flame at the burner(s). The

control then switches to the sensing mode to monitor

the flame presence. The unit performs its own safety

check during trial for ignition period and if the flame

is not established, the control interrupts the power to

the main gas valve(s) and goes into lockout.

4.1.2 Hot Surface Igniter

This is a 120 VAC, silicon carbide igniter.

During ignition cycle the igniter will glow for a few

seconds until reaching the proper ignition temperature

to ignite the gas at the burner ports.

SECTION 4.

Operating Instructions

4.1.3 Combustion Air Pressure Switch

The diaphragm type air pressure switch is

provided to prove the combustion air flow required for

proper combustion. Tube connection is attached to the

4.1 Controls - General

positive barbed end.

(See Figures 17 and 18)

4.1.1 Electronic Ignition Control

This is a proved hot surface ignition control. It

combines a hot surface igniter and a flame sensor.

Upon a call for heat, the igniter is energized from a

nominal 120 VAC and is proven to be capable of

ignition. The gas valve(s) is then powered with 24

4.1.4 Operating Controls

Single or two-stage aquastats are provided in

models PH and PW heaters to control the desired

service water temperature. The temperature sensing

bulb is located either in the boiler inlet or outlet

header.

Page 16

Page 16

LAARS HEATING SYSTEMS

NOTE: Indoor unit shown. Outdoor unit, door must be removed to access controls.

Figure 17. Controls Location.

Figure 18. Operating and Safety Components.

4.1.5 High Limit Control

The manual reset high limit switches are

provided as standard equipment on all heaters.

Automatic reset switches are optionally provided. The

4.1.7 Low Water Cut Off

The low water cut off automatically shuts off the

heater whenever water level drops below probe. The

probe is located at the heater water inlet header.

temperature sensing bulb of the switch is always

located in the heater outlet. Burners will automatically

4.2 Start-Up Requirements

shut down whenever overheating of water occurs

(exceeding the temperature set point of the switch).

Do not use this appliance if any part has been

4.1.6 Flow Switch

Standard on all models: The switch is mounted

in the outlet “tee” connection. The flow switch shuts

down all burners in case of pump failure and/or

reduced water flow.

under water. Immediately call a qualified

service technician to inspect the heater. The

possible damage to a flooded appliance can be

extensive and present numerous safety

hazards. Any appliance that has been under

water must be replaced.

WARNING

Page 17

Mighty Therm Lo-NOx

Page 17

NOTE: Safe lighting and other performance

criteria were met with the gas manifold and control

assembly provided on the heater when it underwent

tests specified in ANSI Z21.13 and CAN1-4.3-M85.

Before placing the heater in operation, check the

automatic safety shutoff devices. Once the heater is

connected to the gas piping and after all of the

requirements in Sections 2 and 3 have been met,

follow these procedures:

1. Before beginning the tests, make sure the main

manual gas valve, and any other heater firing

valves, are in the OFF position. The heater's gas

valve is turned OFF as follows:

a. Sizes 500 and 715: Turn the gas control

knob clockwise to OFF.

b. Sizes 1010 through 1825: Manual gas valve

is OFF when handle is at right angle to the

gas pipe (see Figure 19).

2. The ignition control turns on the combustion

blower. After about a 15 second pre-ignition

purge, while the blower clears the combustion

chamber, the igniter is turned on. The igniter

takes about 25 seconds to heat up. A glow can be

seen through the view port (see Figure 17).

3. The manual gas valve must be ON for the burner

to ignite. This valve is turned ON as follows:

a. Size 500 and 715: Turn counterclockwise

to ON (see Figure 19).

b. Sizes 1010 through 1825: Valve is ON

when handle is parallel to the gas pipe (see

Figure 19).

4.4 Hi-Limit Checkout

After running the boiler for a long enough period

to bring the water temperature within the range of the

hi-limit, slowly back off the high limit setting until the

boiler shuts off. The main burners should re-ignite

when the hi-limit is turned back up to its original

setting and the hi-limit is reset.

4.5 Start-Up Procedure

(See Section 4.2 for Startup

Requirements)

Figure 19. Handle Position of Gas Valves.

2. Before placing the heater in operation, be certain

that the heater is filled with water and all air is

purged from the system.

3. Make sure the power switch on the heater is in

the ON position. Reset all safety devices (hilimit, switch, low water cutoff, etc.).

4.3 Normal Operating Sequence

When the circulation pump is running, the heater

will turn itself on and off via the temperature control.

When the water temperature drops below the

differential setting, below the set point, the following

sequence happens:

1. The temperature control (aquastat) powers the

ignition control.

WARNING

If you do not follow these instructions exactly, a

fire or explosion may result causing property

damage, personal injury or loss of life.

1. This appliance does not have a pilot. It is

equipped with an ignition device which

automatically lights the burner. Do

light the burner by hand.

2. BEFORE OPERATING, smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS

a. Do not try to light any appliance.

b. Do not touch any electric switch; do not

use any phone in your building.

c. Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

d. If you cannot reach your gas supplier, call

the fire department.

3. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, don't try to repair it,

call a qualified service technician. Force or

attempted repair may result in a fire or

explosion.

not try to

Page 18

Page 18

LAARS HEATING SYSTEMS

4. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

the heater.

4.5.1 Lighting Instructions

1. STOP! Read the safety information (1 through 4)

above.

2. Turn off all electric power to the appliance.

3. Remove control access panel.

4. Set the thermostat or aquastat to lowest setting.

5. This appliance is equipped with an ignition

device which automatically lights the burner. Do

not try to light the burner by hand.

6. Turn off manual gas valve. Valve is off when

valve handle is at right angle to the gas pipe. On

combination valves (size 500 and 715) turn gas

control knob clockwise

Figure 19).

7. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow the safety information

titled “Before Operating”. If you don't smell gas,

go to next step.

8. Turn gas control knob counterclockwise

to ON.

9. Set thermostat or aquastat to desired setting.

10. Replace control access panel.

11. Turn on all electric power to the appliance.

12. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance”

and call your service technician or gas supplier.

4.5.2 To Turn Off Gas to Appliance

1. Turn off all electric power to the appliance if

service is to be performed.

2. Remove control access panel.

3. Set the thermostat or aquastat to lowest setting.

4. Turn the gas control knob clockwise

Do not force.

5. Replace control access panel.

to OFF position (see

to OFF.

4.6 Setting the Temperature Controls

4.6.1 Hydronic Boilers

To set the temperature and high-limit controls:

1. Set the temperature controller at the system

design temperature.

2. Set the high-limit 40°F to 50°F above

temperature controller setting.

4.6.2 Water Heaters

The hi-limit switch is factory set and should not

be adjusted.

WARNING

Adjusting the temperature control past the

recommended setting can result in a scalding

injury. Hot water can produce third degree

burns in 6 seconds at 140°F (60°C) and in 30

seconds at 130°F (54°C).

Water temperature can be adjusted at the

temperature control. The temperature control is

adjusted to its lowest setting when it is shipped from

the factory. The 130°F (54°C) setting is the

recommended starting point for setting the

temperature control. Make sure that the hi-limit switch

is set 30°F (17°C) higher than the temperature control.

The recommended setting will result in

satisfactory energy savings. Lowering the temperature

may result in reduced energy costs. Connecting the

heater to a separate storage vessel and lowering the

temperature setting, may reduce energy losses during

standby periods when hot water is not being used, and

may meet normal hot water needs. For increased hot

water usage, a higher temperature setting may be

necessary to meet increased demand. Reset the

temperature setting to a lower level after periods of

increased usage are over.

SECTION 5.

Maintenance

Caution

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

5.1 General Instructions

1. Oil the water circulating pump in accordance

with the manufacturer's instructions.

2. Oil the combustion air blower motor bearings

every 6 months.

3. If a strainer is used in a pressure reducing valve

or in the piping, clean it every 6 months in

accordance with the manufacturer's instructions.

Page 19

Mighty Therm Lo-NOx

4. At startup and every 6 months after, using the

burners view port, look at the burner flame for

proper performance. The burner should not

require maintenance in normal operation. If any

malfunction indicates that the burner needs

service (e.g., a flame that is yellow, or entire

burner surface glowing red), call a professional

service technician. The flame should be checked

for the following:

a. Normal Flame: Blue flame color, with

slight yellow tips, with a well-defined inner

cone.

b. Yellow Flames: Can be caused by blockage

of primary air flow to the burner(s) or

excessive gas input. This condition MUST

be corrected immediately.

c. Lifting Flames: Lifting flames can be

caused by over firing the burner(s) or

excessive primary air.

5. Inspect the venting system for blockage, leakage,

and corrosion at least once a year.

6. Keep the heater area clear of combustible

material, gasoline, and other flammable liquids

and vapors.

7. Be sure all combustion air and ventilation

openings are not blocked.

5.2 Combustion Air Blower

This heater uses a fan assisted combustion

process. For proper operation of the burners, inspect

the air blower for contamination one week after startup and every three (3) months thereafter. Blower

housing inlet must be completely isolated and

protected from any source of corrosive chemical

fumes, and from exhaust vents of cleaning equipment

or laundry establishments.

1. To inspect and service the blower, shut off all

electrical and gas supply to the heater.

2. Remove the screws holding the blower housing

cover to expose the blower (see Figure 20).

3. Remove filter and clean any contamination or

debris (see Figure 20).

4. Remove the air orifice off the blower inlet to

inspect the blower wheel. Clean the blower

housing and its wheel from any contamination or

debris.

5. Remove manifold compartment cover, inspect

the compartment and around the gas manifold

for lint or any other form of debris. If required,

vacuum out all contamination.

6. Replace all parts securely in place.

Page 19

Figure 20. Blower-Housing.

5.3 Heat Exchanger

Check for fouling on the external surfaces of the

heat exchanger every six months. (NOTE: After

installation and first start-up, check the heat

exchanger for fouling after the following periods of

operation: 24 hours, 7 days, 30 days, 90 days, and

once every six months thereafter).

WARNING

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide in flue gases which could result in

severe injury, property damage, or death.

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion and is

a sign of combustion air and/or venting problems. As

soon as any fouling is observed, the cause of the

fouling should be corrected. The heat exchanger can

be checked by removing the venting and top panel as

necessary to inspect from above. Also check the vent

system for defects at this time.

5.3.1 External Cleaning of Heat

Exchanger

1. If cleaning is required, disconnect electrical

supply to the heater and remove wires and

conduit from the heater’s pump.

2. Turn off the gas supply by closing the manual

gas valve on the heater.

3. Isolate the heat exchanger from water supply.

4. Remove the vent pipe (for outdoor units remove

vent top assembly), top panel, upper jacket

assembly and flue collector (see Figures 22 and

28).

5. Drain the heat exchanger.

Page 20

Page 20

LAARS HEATING SYSTEMS

6. Disconnect the flange and the adapter tee from

the heat exchanger inlet and outlet.

7. Remove temperature-sensing probes from inlet

and outlet header.

8. Remove the heat exchanger from the heater. The

heat exchangers are heavy and require

minimum two people to remove to avoid

personal injury

9. Remove the tube’s baffles from the heat

exchanger.

Caution

Black carbon soot buildup on a dirty heat

exchanger can be ignited by a random spark or

flame. To prevent this from happening, dampen

the soot deposits with a wet brush or fine water

spray before servicing the heat exchanger.

10. Clean the heat exchanger: A light accumulation

of soot or corrosion on the outside of the heat

exchanger can be easily removed after the heat

baffles are removed. Use a wire brush to remove

loose soot and scale from the heat exchanger. Do

not use water or compressed air for cleaning.

NOTE: While the heat exchanger is out of the

heater, inspect the firewall refractory blocks for

cracks, wear and breakage. Replace if necessary.

11. Reassemble in reverse order and be sure the heat

exchanger baffles are replaced.

3. Air pressure proving switch(es).

4. Automatic electric and manual gas valve(s).

5. Water flow sensing safety device.

6. Low water cutoffs (every six months).

5.5 Burner Removal and Cleaning

1. Disconnect electrical supply to the heater.

2. Turn off main manual gas valve on the heater.

3. Remove the cover of air mixture plenum.

4. Disconnect air tube(s) from air mixture plenum

barb(s), and remove wires from igniter and flame

sensor.

5. Disconnect gas valve train from the gas manifold.

6. Remove screws from manifold mounting

brackets. Pull manifold/orifice assembly away

from the burner panel.

7. Remove screws attaching air mixture plenum to

the side air duct(s) and to the burner panel, and

then slide away the mixture plenum.

8. Remove burner panel off the front lower jacket.

9. Disconnect burners from panel by removing

mounting screws from each burner. Use caution

to prevent damage to burner gaskets, insulation

blanket, hot surface igniter or flame sensor.

10. Clean soot and any debris from burners with a

stiff bristle brush. Damaged burners or burner

gaskets must be replaced.

5.3.2 Internal Cleaning of Heat Exchanger

1. To remove the heat exchanger, follow the

procedure detailed in 5.3.2 (1 through 8).

2. Remove the inlet/outlet header of the heat

exchanger.

3. Remove the return cover of the heat exchanger.

4. Clean the internal surface. (Laars offers a tube

cleaning kit part no. R00100000.)

5. Reassemble in the reverse order.

5.4 Gas and Electric Controls

The gas and electric controls on the heaters are

designed for both dependable operation and long life.

Safe operation of the heater depends on their proper

functioning. A professional service technician should

check the following basic items every year, and

replace when necessary.

NOTE: the warranty does not cover damage

caused by lack of required maintenance or improper

operating practices.

1. Water temperature controls.

2. Ignition control system.

SECTION 6.

Troubleshooting

6.1 Sequence of Operation

To troubleshoot the heater properly you must first

understand the sequence of operation of the heater:

1. Upon a call for heat a 24 VAC signal is sent

through fusible links and high limit(s) to the

ignition control “H” terminal.

2. The “IND” terminal of the ignition control is

energized with 115 VAC for a (15) second preignition purge period during which the combustion blower purges the combustion chamber.

3. After the purge period, terminal “S1” is

energized with 115 VAC for (20 to 35) second

igniter heat up period. The glow of the igniter

can be seen through the heater view port.

4. Then there is a seven second trial for ignition.

During this time the gas valves are energized

with 24 VAC, and the main burner ignites. The

gas valves will remain energized throughout the

call for heat as long as the ignition control flame

sensor senses a stable flame.

Page 21

Mighty Therm Lo-NOx

Page 21

5. After the call for heat is satisfied the ignition

control closes the gas valves and operates the

blower for a thirty (30) second post purge cycle.

This clears the combustion chamber of

combustion products.

The ignition is attempted one time. If ignition is

not successful, the control shuts down and “locks

out.” It remains in the lockout condition until the

lockout reset button on the ignition control is reset.

6.2 Electrical Components

This section describes guidelines for checking

the operation of electrical components installed on the

heater. Refer to the wiring diagram for correct

connection locations.

6.2.1 General Troubleshooting

This section describes guidelines for checking

the electrical components of the heater. Experience

has shown that most complaints about heaters failing

to fire have nothing to do with the heater itself.

Usually, one of the protective switches in the heater

system has shut down operation.

Any of the following can prevent proper

operation. Check these items first:

1. Be sure the heater has been properly installed

(see Section 2 and 3).

2. Make sure the pump is not airlocked, clogged or

otherwise inoperative.

3. Make sure the gas valve is on and there is

sufficient gas pressure in the line. All external

gas valves must be open.

Caution

The ignition control and igniter operate on

115VAC power. Keep this in mind while

servicing the heater, and take care to avoid

electrical shock.

4. Verify that the electrical circuit serving the

heater is ON.

5. Make sure the toggle switch on the right side of

the heater is ON.

6. Check the fuse inside the black, twist-lock fuse

holder. If it is burned, replace it.

7. With the power off inspect all electrical connections and wiring. Finding a loose connection or

charred wire can save a lot of time and money.

8. Make sure the temperature controller is set high

enough to call for heat.

9. Make sure none of the manual reset controls, i.e.,

low water cutoff, high limit, etc., have tripped.

Reset any tripped switches.

If the pump is circulating water and the

foregoing items check out okay, the trouble may be in

the heater control system.

IMPORTANT: Disconnect power to the heater

before removing or replacing any component or wire

connection. If the power is not disconnected, “jumping”

the gas valve or accidentally grounding the wire harness

or component terminals to the heater frame or jacket

could cause the ignition control fuse to blow.

6.2.2 Electrical Troubleshooting

Troubleshooting procedures should only be

performed by professional service technicians

qualified in heater maintenance.

Some electrical components are wired in

parallel, so it is necessary to troubleshoot in the order

that they appear on the wiring diagram or the

troubleshooting flow chart (see Figure 21).

The following steps should be used when

troubleshooting the heater:

1. Remove the control panel cover of heater.

2. Turn the manual gas valve on the heater off.

3. If the heater has locked out turn the toggle

switch off for 5 seconds then back on to reset the

heater.

4. Use the troubleshooting flow chart (see Figure

21) to determine what components and wiring

should be tested first.

5. Test each component by checking for 24 VAC or

115 VAC entering and exiting the device. If

there is voltage entering the safety device, but

none leaving then there is an open circuit and it

must be determined why it is open. When testing

components between “MV ” of the ignition

control and the gas valve install a meter and let

the heater cycle through one complete sequence

of operation. During the sequence of operation

these safeties will only be energized for the

seven second trial for ignition.

6. Turn the manual gas valve of the heater on and

fire the heater.

Caution

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

Page 22

Page 22

LAARS HEATING SYSTEMS

Figure 21. Troubleshooting Chart.

Page 23

Mighty Therm Lo-NOx

Page 23

6.3 Mechanical Components

6.3.1 Pressure Relief Valves Leaking Intermittently or Steadily

Possible Cause Remedy

A. Static pressure in system exceeds A. Calculate height of water in system above heater. Install

setting of relief valve. new valve with psi setting 25% above required static system

working pressure. Do not exceed 160 psi.

B. Expansion tank is waterlogged B. Drain expansion tank, then reopen it to the system. Look

(if installed). for leaks in expansion tank or fittings. Calculate required

volume of expansion tank in relation to system to

determine that tank is adequate.

6.3.2 Heater is Pounding, Knocking or Emitting Steam from Relief Valves

A. Low or no water flow. A. This condition is usually caused by lack of adequate water

flow through heater. Check the following:

1. Is the heater wired into the pump circuit so that the heater

cannot fire unless the pump is running?

2. Check to see that all valves in system are open to be sure

that water can circulate through the heater and the system.

3. If the system has automatic water valves (2-way or 3-way)

that can cut off the water flow through the heater, check to

see that they are equipped with end-switches which shut the

heater down when the water flow through the heater is

reduced by 70% from full flow

4. Examine pump for clogged impeller.

B. Low or no system pressure. B. Clean strainer in pressure reducing valve. Look for closed

valve water line or a leak in the system.

C. Clogged “Y” strainer. C. Remove strainer element and clean screen.

D. Debris from system piping is D. Remove header covers. Examine all tubes and waterways.

blocking tubes. Use new gaskets when reassembling. Clean out tubes.

E. Scale has formed in tubes. E. PH - Check for inflow of raw water (is due to system leak).

See Section 3.2.

PW - Water chemistry or flow problems, see Section 3.3.