Page 1

Installation, Operation and Maintenance Instructions Document 1162A

OUT OF

PRODUCTION

Installation, Operation

and Maintenance

Instructions for

Mighty Therm

™

LO-NOx

Hydronic Boiler

Models HH-PH

Sizes 250/400

For Natural Gas Only

U.S. Reg. 1,483,289

Canada Reg. 333,796

FOR YOUR SAFETY : This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0251300A

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction.................................................... 3

1.2 Warranty........................................................ 3

SECTION 2.

Installation Instructions

2.1 General Information....................................... 5

2.2 Field Assembly .............................................. 5

2.3 Site Location.................................................. 7

2.3.1 Installation Information .................................. 7

2.3.2 Outdoor Installation .......................................8

2.3.3 Flooring - Typical Installation......................... 8

2.4 Combustion and Ventilation Air Supply .........8

2.4.1 Outdoor Air Supply ........................................ 9

2.4.2 Indoor Air Supply...........................................9

2.4.3 Exhaust Fans or Vents .................................. 9

2.5 Venting (Category I) ......................................9

2.5.1 General Information....................................... 9

2.5.2 Common Venting System2

Venting Multiple Appliances ........................ 10

2.5.3 Inspection of Commonly Vented

Appliances................................................... 11

2.6 Water Flow System ..................................... 12

2.6.1 Freeze Protection ........................................ 12

2.6.2 Pump Requirements.................................... 12

2.6.3 Variable Water Flow Systems ..................... 13

2.6.4 System Pressure Requirements.................. 13

2.6.5 Chilled Water Systems ................................ 15

2.6.6 System to Boiler Piping ............................... 14

2.6.7 Filling the System ........................................ 15

2.6.8 Minimum Boiler Temperature ...................... 15

2.7 Gas Supply and Piping

(Natural Gas Only) ...................................... 15

2.7.1 General Instructions ....................................15

2.8 Electrical Wiring........................................... 16

PRODUCTION

OUT OF

SECTION 3.

Operating Instructions

3.1 Start-Up Procedure ..................................... 17

3.2. Setting the Temperature Controls ............... 17

3.3 Hi-Limit Switch Checkout ............................ 17

3.4 Shut-Down Procedure ................................. 17

SECTION 4.

Maintenance

4.1 General Instructions ....................................24

4.2 Heat Exchanger........................................... 24

4.2.1 Inspecting the Heat Exchanger ................... 24

4.2.2 Cleaning the Heat Exchanger ..................... 24

SECTION 5.

Troubleshooting and Service

5.1 Gas Pressure Tests..................................... 25

5.1.1 Checking the Main Line Gas Pressure ........ 25

5.1.2 Checking the Manifold

Regulated Gas Pressure ............................. 26

5.2 Electrical Troubleshooting ........................... 26

5.2.1 Boiler Does Not Come On........................... 26

5.2.2 Testing the Transformer .............................. 27

5.2.3 Testing the Electrical Power Supply ............ 27

5.2.4 Testing the Manual Reset

Hi-Limit Switch............................................. 27

5.2.5 Testing the Flow Switch............................... 27

5.2.6 Testing the Fusible Link

(flame roll-out switch) .................................. 28

5.2.7 Testing the Fuse.......................................... 28

5.2.8 Testing the Ignition Control..........................28

5.2.9 Combustion Air Blower................................28

5.2.10 Boiler Will Not Shut Off................................ 29

SECTION 6.

Replacement Parts

6.1 Ordering Information ................................... 29

6.2 Parts List ..................................................... 29

Page 3

Mighty Therm LO-NOx Hydronic Boiler

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides installation, operating, and

maintenance instructions for Model HH, PH Hydronic

Boilers, Sizes 250 and 400. Review all application and

installation procedures completely before proceeding

with the installation. Experience has shown that most

operating problems are caused by improper

installation.

The boilers are offered in a basic configuration

(see Figure 1). On PH boilers the pump is factory

installed.

WARNING

Mighty Therm hydronic boilers must be installed in

accordance with the procedures detailed in this

manual, or the Laars Heating Systems warranty will

be voided. The installation must conform to the

requirements of the local jurisdiction having

authority, and, in the United States, to the latest

edition of the National Fuel Gas Code, ANSI Z223.

In Canada, the installation must conform to the

latest edition of CSA B149.1 Natural Gas

Installation Code and/or local codes. Any

modifications to the boiler, its gas controls, or wiring

may void the warranty. If field conditions require

modifications consult the factory representative

before initiating such modifications. Improper

installation could result in property damage, injury,

or even death.

PRODUCTION

OUT OF

1.2 Warranty

Laars Heating Systems Mighty Therm boilers are

covered by a limited warranty . The owner should fill

out the warranty registration card and return it to Laars

Heating Systems.

All warranty claims must be made to an

authorized Laars Heating Systems representative or

directly to the factory . Claims must include the serial

number and model (this information can be found on

the rating plate), installation date, and name of the

installer. For specific warranty conditions refer to your

Limited W arranty.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on the

packing slip. Inspect everything for damage

immediately upon delivery , and advise the carrier of

any shortages or damage. Any such claims should be

filed with the carrier. The carrier, not the shipper , is

responsible for shortages and damage to the shipment

whether visible or concealed.

MISE EN GARDE

Les appareils de chauffage à eau chaude Mighty

Therm doivent être installés dans le respect des

directives détaillées contenues dans ce manuel, à

défaut de quoi la garantie fournie par Laars Heating

Systems sera annulée. L’installation doit être

conforme à la réglementation locale ou, en

l’absence de réglementation locale, avec le

National Fuel Gas Code, ANSI Z223. Au Canada,

l’installation doit respecter les exigences de la plus

récente édition du Code d’installation du gaz naturel

CSA B149.1, et/ou des codes de la construction

locaux. Toute modification apportée à la chaudière,

aux régulateurs de gaz ou au câblage peut

compromettre la garantie. Si certaines conditions

particulières rendent des adaptations nécessaires,

consulter un représentant du fabricant avant

d’entreprendre ces modifications. Une mauvaise

installation peut entraîner des dommages matériels,

des blessures ou même la mort.

Page 4

Page 4

LAARS Heating Systems

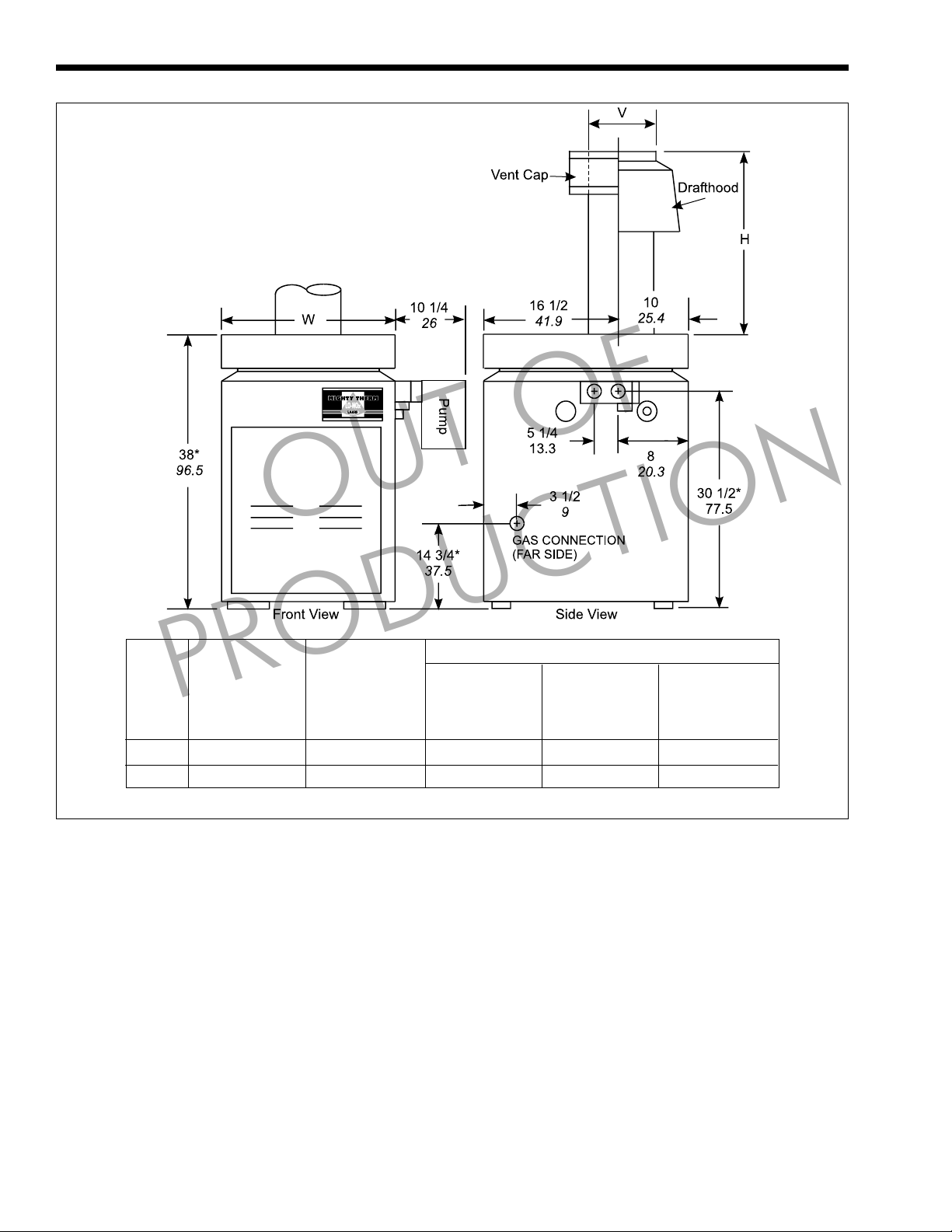

NOTE:* For outdoor models, add 6 inches (15.2cm) for

outdoor base.

Dimensions shown in inches

(centimeters)

OUT OF

Venting Dimensions

Model Firing Heater

Size Rate Width

PRODUCTION

MBtu/h kW in cm in cm in cm in cm

250 250 73.3 22 1/2 57.2 7 17.8 18 1/4 46.4 25 1/4 64.1

400 399 117.0 31 3/4 80.6 9 22.9 21 1/2 54.6 27 1/2 69.9

All dimensions are nominal.

“W” “V” “H” “H”

Drafthood Vent Outdoor Indoor

Vent Cap Diameter Dim Dim

Figure 1. General Configuration.

Page 5

Mighty Therm LO-NOx Hydronic Boiler

Page 5

SECTION 2.

Installation Instructions

2.1 General Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in severe injury,

property damage or death. Follow the

manufacturer’s maintenance schedule for the

appliance. Follow local regulations with respect to

installation of carbon monoxide (CO) detectors.

MISE EN GARDE

Une mauvaise installation ou un entretien inadéquat

peut être la cause de nausées ou d’asphyxie en

raison de la présence de niveaux dangereux de

monoxyde de carbone dans les résidus de

combustion et peut entraîner des dommages

matériels, des blessures ou même la mort. Suivre

les directives du fabricant au sujet du programme

d’entretien de l’appareil. Suivre les règlements

locaux touchant l’installation de détecteurs de

monoxyde de carbone (CO).

All gas-fired products require correct installation

to assure safe operation. The requirements for boilers

include the following:

1. Field assembly of drafthood or vent cap (see

2. Appropriate site location clearances and flooring.

3. Suf ficient combustion and ventilation air.

4. Adequate venting of combustion products.

5. Adequate water flow.

6. Properly sized gas meter and piping.

7. Proper electrical wiring.

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

2.2 Field Assembly

with the top assembly in the low-profile configuration

for outdoor installations.

indoor installation when equipped with a special

drafthood, which must be installed without

modification. The part number for the drafthood is on

the boiler rating plate. Follow this procedure to make

the conversion:

PRODUCTION

Section 2.2).

This manual provides the information needed to

The HH, PH boilers are shipped from the factory

The HH, PH boilers are design certified for

OUT OF

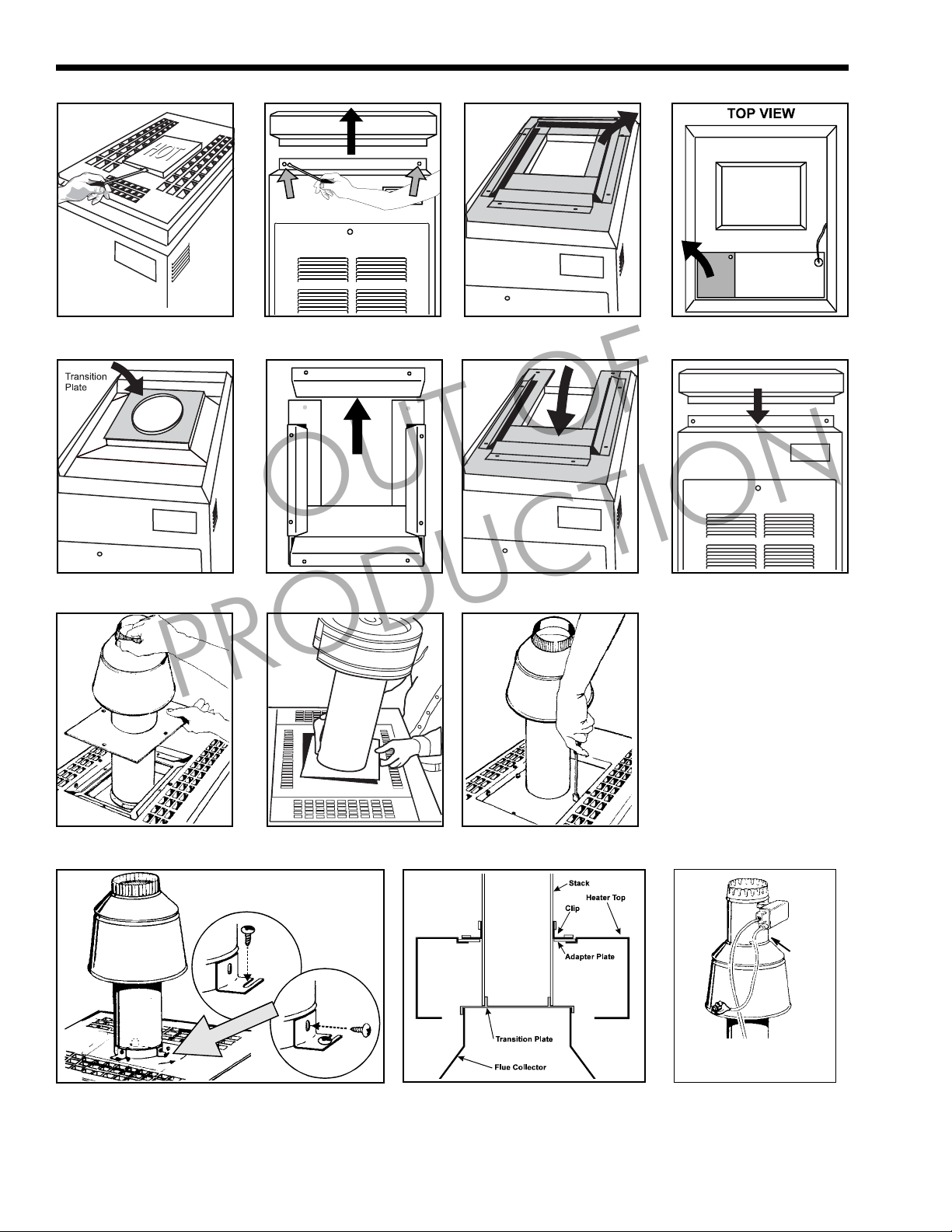

1. Remove the top plate, stamped "HOT", by

slipping a fine-blade screwdriver into the slot and

prying it up (see Figure 2).

2. Remove the top by removing all eight screws

connecting it to the jacket (see Figure 3).

3. Remove the rainguard assembly (see Figure 4).

4. Remove the two screws securing the left

vestibule cover (see Figure 5). The cover can be

discarded.

5. Remove the vent cap or drafthood and

accessories from the carton.

NOTE: Vent cap is for outdoor installation, when

required.

6. Place transition plate (with 14" long side)

securely on top of flue collector so flue gases will

not leak (see Figure 6).

7. Remove back portion of rainguard (see Figure 7).

8. Re-install the rainguard (see Figure 8).

9. Replace boiler top and all eight screws (see

Figure 9).

10. Slide the adapter plate up over the bottom of the

stack extension. Fit the stack extension, of the

drafthood or the vent cap, on top of the collar of

the flue transition plate (see Figures 10 and 11).

11. Seat the adapter plate on the top assembly , and

secure it with screws supplied in the kit (see

Figure 12).

12. Attach the clips to the adapter plate by securing

the slotted side of the clips with the screws in the

kit (see Figure 13).

13. Use the holes in the clips as guides to drill three

1/8" dia. holes in the stack.

14. Secure the stack to the clips with the screws

supplied in the kit (see Figure 13).

15. Figure 14 shows a cross-section of the finished

installation.

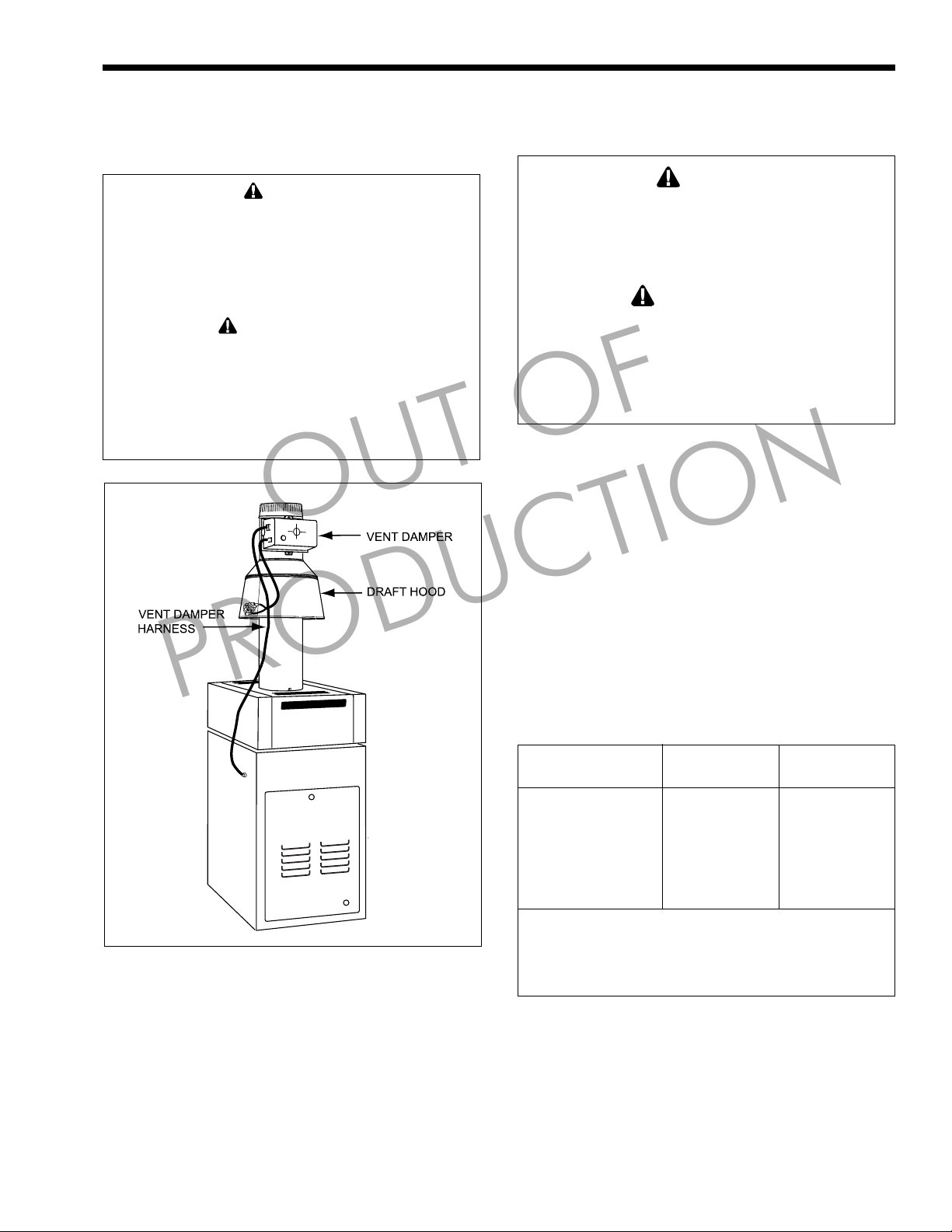

16. Find the vent damper box which is located in the

boiler package (boiler model 250 only).

17. Install the vent damper directly to the top of the

draft hood outlet. The damper operator should

face to the front of the boiler, and the flow

direction arrow should point upward. Use the

vent damper wire harness to connect the vent

damper to the boiler. The bracket end of the

harness should be connected to the vent damper

actuator (see Figure 16).

18. Plug the wiring for the drafthood switch into the

receptacle on the left side of the vent damper box

(see Figure 15).

19. Do not modify the automatic vent damper device.

The venting system must be arranged so that only

the boiler is served by the vent damper device

supplied with the boiler. Provide at least six

Page 6

Page 6

LAARS Heating Systems

Figure 2. Figure 3.

Figure 4. Figure 5.

OUT OF

Figure 6. Figure 7. Figure 8. Figure 9.

PRODUCTION

Figure 10. Figure 11.

Figure 13. Figure 14.

Figure 12.

Figure 15. Drafthood

Switch Receptacle.

Page 7

Mighty Therm LO-NOx Hydronic Boiler

Page 7

inches clearance between the automatic vent

damper and combustible construction, and be

sure to allow access for servicing the damper.

WARNING

Do not force the damper to open or close by moving

the damper blade, turning the shaft, or turning the

position indicator. Doing so can cause an unsafe

condition, leading to property damage, injury or

death.

MISE EN GARDE

Ne pas forcer l’ouverture ou la fermeture du registre

en faisant bouger le volet du registre, en tournant la

tige ou en tournant l’indicateur de pression. Cela

peut engendrer une situation non sécuritaire

susceptible de provoquer des dégâts matériels, des

blessures ou la mort.

OUT OF

PRODUCTION

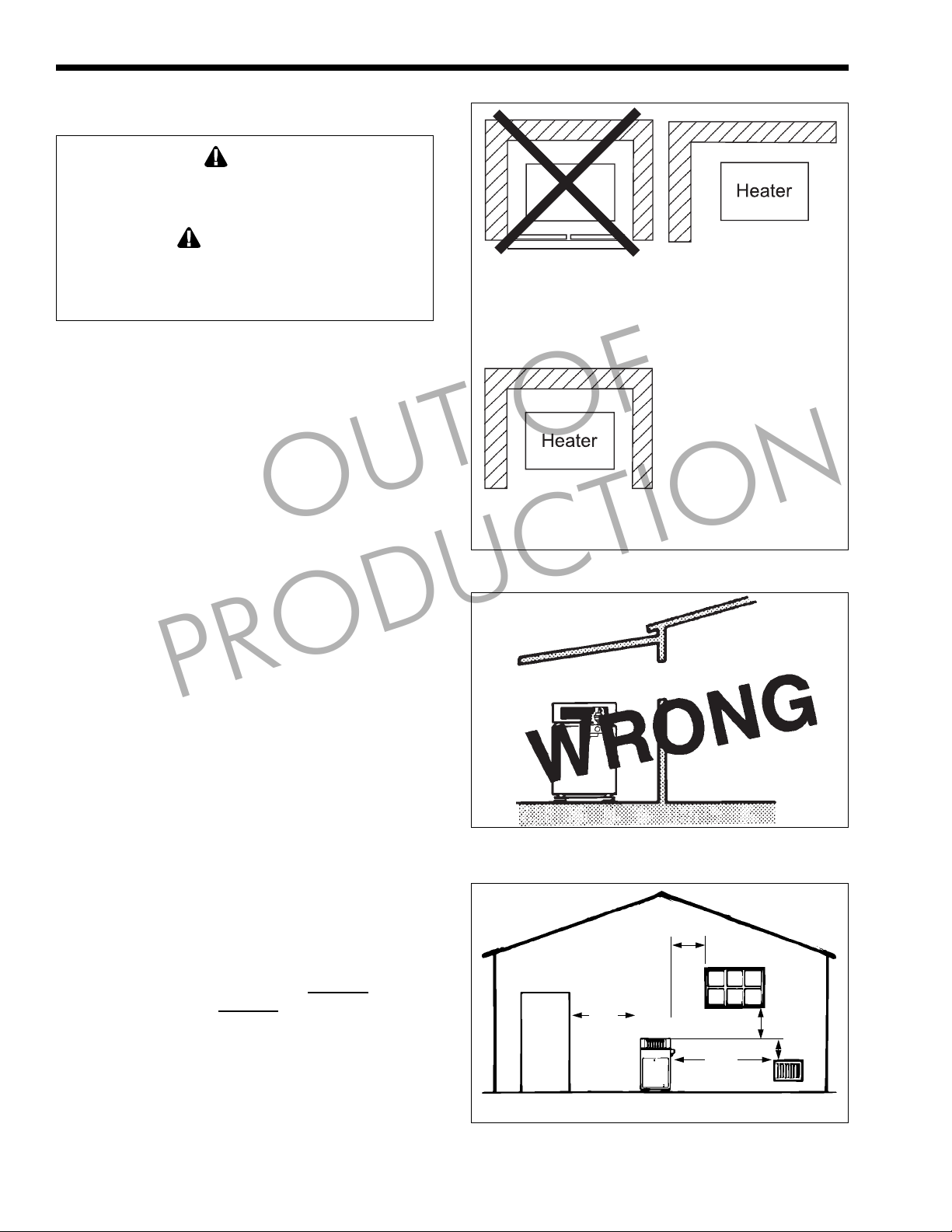

2.3 Site Location

2.3.1 Installation Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in property damage,

severe injury, or death.

MISE EN GARDE

Une mauvaise installation ou un entretien inadéquat

peut provoquer la nausée ou l’asphyxie en raison

de la présence de niveaux dangereux de monoxyde

de carbone dans les résidus de combustion et peut

entraîner des dommages matériels, des blessures

ou même la mort.

Avoid placing the boiler in locations where it can

cause damage by water or condensate leakage. If this is

not possible, provide a suitable drain pan under the

boiler to catch and divert any leakage. The pan must

not restrict air flow around the boiler.

Locate the boiler to provide adequate clearance

on all sides for inspection, service and to provide

adequate air circulation for proper operation.

Locate the boiler so the clearances from

combustible surfaces shown in Table 1 and Figure 17

are met.

Locate the boiler on a waterproof floor with a

floor drain and a 6 inch (15.2 cm) minimum curb on all

four sides to protect the building if boiler repairs are

needed.

Figure 16. Vent Damper Installation (Model 250 only).

Indoors Outdoors

Clearance from: inch cm inch cm

Top 37 94 Unobstructed

Water conn. side 12 30.5 Unobstructed

Opposite side 6 15.2 6 15.2

Front Alcove Unobstructed

Rear 6 15.2 6 15.2

Vent* 6 15.2 —

Flooring: Combustible

Service clearance = 36 inches (91.4cm) at front of boiler,

and 18 inches (46cm) at water connection side.

*1" (2.5cm) if double wall vent is used.

6" base for outdoor boiler is required.

Table 1. Minimum Boiler Clearances

from Combustible Surfaces.

Page 8

Page 8

2.3.2 Outdoor Installation

Caution

Outdoor installations are not recommended in areas

where the danger of snow blockage exists.

Avertissement

L’installation à l’extérieur n’est pas recommandée

dans les zones où il y a des risques d’obstruction

par la neige.

1. Locate the boiler in an open, unroofed area. Do

not locate the boiler below or adjacent to any

doors, windows, louvers, grills, etc., which

connect in any way with an inhabited area of a

building, even though the access might be

through another structure such as a garage or

utility room (see Figure 18 and Table 1).

2. There must be a minimum of 4 feet (1.22 m)

horizontally and vertically between the boiler and

any door, window, or gravity inlet to a building

OUT OF

(see Figure 19).

3. Minimum clearance of 4 feet (1.22m) [6 feet

(1.83m) in Canada] horizontally from, and in no

case above or below , unless the minimum

horizontal distance is maintained, from electric

meters, gas meters, regulators and relief

equipment.

4. If the boiler is installed close to a structure,

protect it from rain water runoff with rain gutters

PRODUCTION

on the roof or other measures. Do not locate the

boiler near sprinkler systems that could spray

water on it.

5. Avoid locations where wind deflection off nearby

structures might cause wind loading and

downdraft conditions. Where downdraft

conditions exist, locate the boiler at least 3 feet

(0.91 m) from the structure.

LAARS Heating Systems

Closet Installation

(unacceptable)

A closet is any 4 sided enclosure

which is less than 16* times the

total volume of all the gas fired

appliances within the enclosure.

REAR

FRONT

* When the ceiling height exceeds 8 feet, you are only allowed to

consider 8 feet when calculating the total volume of the enclosure.

Figure 17. Alcove Installation.

WINDOW

OR GRILL

Figure 18. Incorrect Outdoor Installation.

Room Installation

(acceptable)

A room is any enclosure which is

at least 16* times greater than the

total volume of all the gas fired

appliances within the enclosure

Alcove Installation

(acceptable)

An alcove suitable for the

installation of a heater is a

restricted section of a room not

separated from the room by a door

or partition and which meets the

minimum clearances specified in

this manual.

INDOOR

ROOM

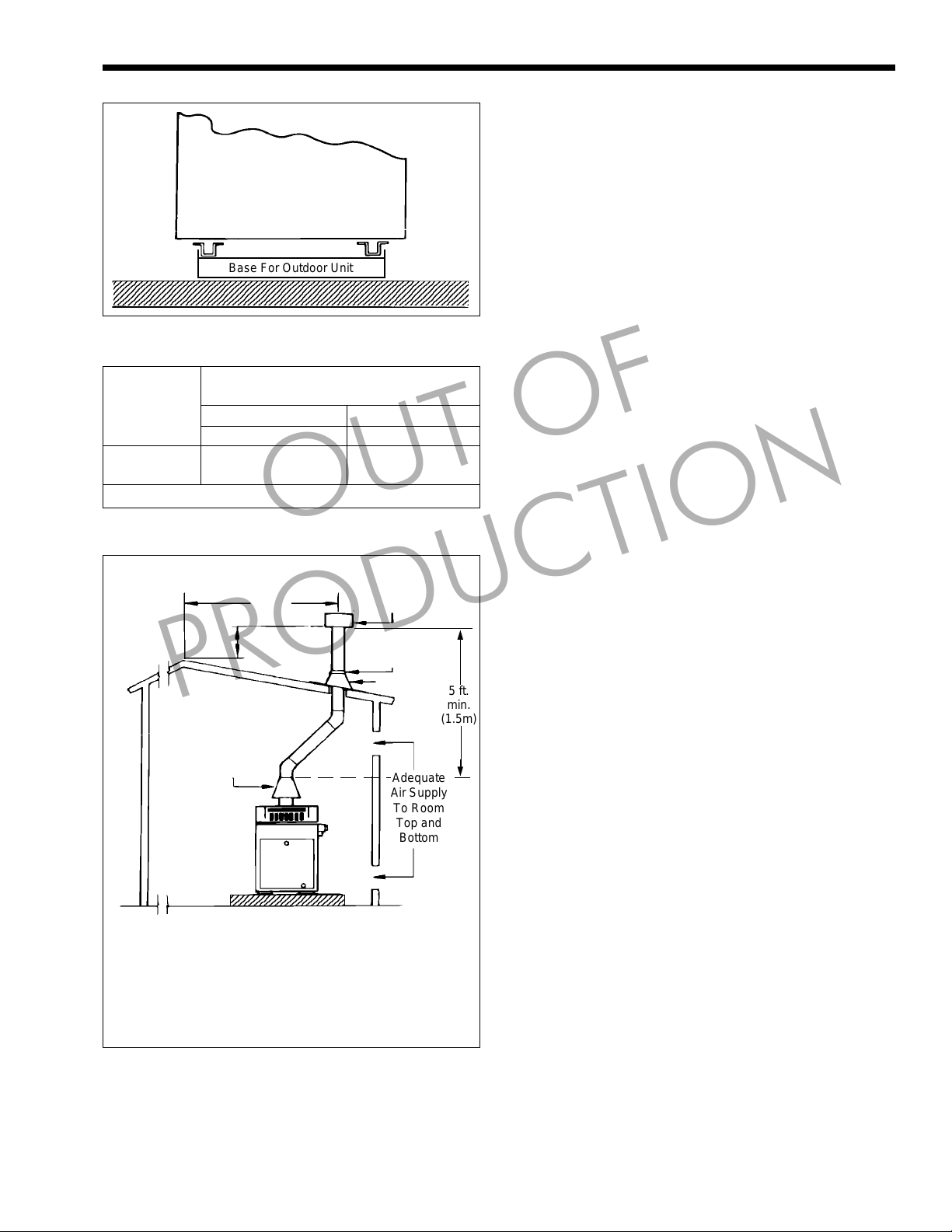

2.3.3 Flooring - T ypical Installation

All outdoor boilers must be installed with the

special base, as a standard part of the boiler. The base,

part number R0368900, is provided in a separate

package. The boiler is designed and certified for

installation on combustible flooring.

the boiler on carpeting.

NEVER store objects on or

NEVER install

around the base of the boiler. For outdoor base

installation, see Figure 20.

2.4 Combustion and Ventilation

Air Supply

All indoor installations must have openings to

outside air for combustion, ventilation and dilution of

flue gases from inside the building (see Figure 21 and

4 ft.

(1.2m)

4 ft.

(1.2m)

10 ft.

(3.0m)

Minimum Clearances

Figure 19. Outdoor Location Installation.

4 ft.

(1.2m)

3 ft.

(0.9m)

Forced Air Inlet

Page 9

Mighty Therm LO-NOx Hydronic Boiler

5

5

5

12345678901234567890123

1

3

12345678901234567890123

LAARS

UNIT

(Side View)

2345678901234567890123456789012123456789012345678901234567890121234

2345678901234567890123456789012123456789012345678901234567890121234

2345678901234567890123456789012123456789012345678901234567890121234

Figure 20. Base for Outdoor Installation.

Base For Outdoor Unit

Page 9

T able 2 ). Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

Boiler rooms which are confined spaces require

two permanent air supply openings: one within 12

inches (30.5 cm) of the ceiling, the other within 12

inches (30.5 cm) of the floor.

NOTE: Check with louver manufacturers for net free

area of louvers. If screens or louvers are installed, add

50 percent for each screen/louver to the net free area.

Check the latest edition of ANSI Z223.1 or in Canada

CSA B149 and all local codes applicable to

combustion air.

Required Net Free Opening Area

Directly from Outside

At Top At Bottom

Model in.

250 63 406 63 406

400 100 645 100 645

Note: For screens or louvers, add 50%.

Table 2. Air Openings to Outside.

Vent terminated at

least 2 ft. (61cm)

above any

object within

10 ft. (3.0m)

PRODUCTION

1/4 in. (0.6cm)

Minimum Pitch

Per Foot of

Horizontal Pipe

Notes:

1. The drafthood must sit directly on top of the heater

as shown and must not be altered in any manner.

2. An Underwriters' Laboratories listed vent cap is required to eliminate downdraft and allow the heater

to function properly.

3. Use approved roof fitting.

Figure 21. Indoor Installation and Venting.

2

10 ft.

(3.0m)

2 ft. (61cm)

Drafthood

234567890123456789012

cm

2

in.

2

cm

OUT OF

Listed Vent

Cap

Storm Collar

Roof Jack

Adequate

Air Supply

To Room

Top and

Bottom

2

5 ft.

min.

(1.5m)

2.4.1 Outdoor Air Supply

When combustion air comes directly through an

outside wall, each opening must have a minimum free

area of at least one square inch for each 4,000 BTU/h

input of the total input rating of all appliances in the

enclosed area. (In Canada, refer to CSA B149.1)

2.4.2 Indoor Air Supply

Confined and non-confined areas have different

requirements for installation. Check the latest edition

of ANSI Z223.1 or in Canada CSA B149 and all local

codes applicable to combustion air.

2.4.3 Exhaust Fans or Vents

Any equipment which uses air or removes air

from the boiler room can use up the combustion air

supply or reverse the natural draft action of the venting

system. This could cause flue products to build up in

the boiler room. More air must be supplied to make up

for the decrease.

2.5 V enting (Category I)

2.5.1 General Information

When installed indoors, the drafthood must be

connected to a venting system. The venting system

must be installed by a qualified installer and in

accordance with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance with

CSA B149.1, and any local codes that apply.

The vent pipe must have a listed vent cap, and

extend at least 2 feet (0.6 m) above any object within a

10 foot (3.0 m) radius.

NOTE: Do not use sheet metal screws at the snap

lock joints of Type B double-wall gas vents.

Do not weld or bolt the vent pipe to the boiler

drafthood. The weight of the stack must not rest on the

boiler. The drafthood and boiler top must be easily

removable for normal boiler service and inspection.

Page 10

Page 10

LAARS Heating Systems

WARNING

Avoid ending boiler vents near air conditioning or air

supply fans. The fans can pick up exhaust flue

products from the boiler and return them inside the

building, creating a possible health hazard, resulting

in serious injury or death.

MISE EN GARDE

Éviter de placer les sorties d’évent près des

appareils de climatisation ou les ventilateurs des

prises d’air. Ces prises d’air peuvent aspirer les

résidus de combustion et les faire pénétrer à

l’intérieur de l’immeuble, ce qui peut représenter

une menace pour la santé et occasionner des

blessures corporelles sérieuses ou même la mort.

Locate unit as close as practical to a chimney or

vent termination. Have horizontal runs sloping

upwards not less than 1/4 inch per foot (21mm/m)

from the boiler to the vent terminal. Support a vent

connector for the design and weight of the material

used to maintain clearances and prevent physical

damage and separate of joints.

Doivent présenter des tronçons horzontaux dont

la pente montante est d’au moins 1/4 po par pied

21mm/m) entre la chaudière et l’évent. Doivent

préciser que les sections horizontales doivent être

supportées pour prévenir le fléchissement.

Always use double-wall or insulated vent pipe

(Type B or equivalent).

In cold weather, uninsulated outside vents can chill

the rising flue products, blocking the natural draft

action of the venting system. This can create a

serious health hazard which can ultimately cause

death by spilling flue products into the boiler room.

Dans les régions froides, les évents non isolés

peuvent occasionner la condensation des résidus

de combustion qui y circulent, ce qui a pour effet de

réduire le tirage naturel du système d’évacuation

des résidus. Cela peut représenter une sérieuse

menace pour la santé, pouvant même provoquer la

mort en causant le refoulement des résidus de

combustion dans la chaufferie.

Avoid oversize vent piping or extremely long

runs of the pipe which may cause too much cooling

and condensation of flue gases.

When the installation of a power vent or draft fan

in the venting system is necessary , qualified personnel

should design the installation following good

PRODUCTION

WARNING

MISE EN GARDE

OUT OF

engineering practices and all applicable codes. A

suitable draft switch must be wired into the boiler

control circuit at the terminal designated Field

Interlock to keep the boiler from firing unless there is a

positive draft.

2.5.2 Common Venting Systems

Venting Multiple Appliances

When installing venting for a Mighty Therm LoNOx boiler or water heater installed as a Category I

fan-assisted appliance with other Category I appliances

through one shared duct called a “common vent”,

special care must be taken by the installer to ensure

safe operation. In the event that the common vent is

blocked, it is possible, especially for fan-assisted

devices, to vent backwards through non-operating

appliances sharing the vent, allowing combustion

products to infiltrate occupied spaces. If the

appliances are allowed to operate in this condition,

serious injury or death may occur.

WARNING

Operation of appliances with a blocked common

vent may lead to serious injury or death. Safety

devices must be implemented to prevent blocked

common vent operation. If safe operation of all

appliances connected to a common vent cannot be

assured, including prevention of spillage of flue

gasses into living spaces, common venting should

not be applied, and appliances should each be

vented separately.

AVERTISSEMENT

Le fonctionnement des appareils avec un système

d’évacuation bloqué peut provoquer des blessures

graves, voire la mort. Des dispositifs de sécurité

doivent être installés pour éviter le blocage des

systèmes d’évacuation. Si le fonctionnement de

tous les appareils connectés à un système

d’évacuation commun ne peut pas être assuré, y

compris la prévention de la dispersion des gaz

toxiques dans les espaces habités, on ne devrait

pas installer un système d’évacuation commun et

chaque appareil devrait être ventilé séparément.

It is for this reason that, in addition to following

proper vent sizing, construction and safety

requirements from the National Fuel Gas Code, ANSI

Z223.1 or in Canada, from CSA B149.1 as well as all

applicable local codes, it is required that installers

provide some means to prevent operation with a

blocked common vent. It is suggested that a blocked

vent safety system be employed such that if the switch

from one appliance trips due to excessive stack spill or

backpressure indicating a blocked vent condition, that

all appliances attached to the vent be locked out and

prevented from operating. As an additional precaution,

it is recommended that a Carbon Monoxide (CO)

Page 11

Mighty Therm LO-NOx Hydronic Boiler

Page 11

alarm be installed in all enclosed spaces containing

combustion appliances. If assistance is required in

determining how a blocked vent safety system should

be connected to a LAARS product, please call

Applications Engineering at (603) 335-6300.

Refer to the installation and operating

instructions on all appliances to be common vented for

instructions, warnings, restrictions and safety

requirements. If safe operation of all appliances

connected to a common vent cannot be assured,

including prevention of spillage of flue gasses into

living spaces, common venting should not be applied,

and appliances should each be vented separately .

2.5.3 Inspection of Commonly Vented

Appliances

If the instrumentation of this boiler replaces an

older boiler in a common vent system with other

appliances, or if you remove additional appliances

from the common vent, all the appliances must be

checked for proper venting.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

Sceller toutes les ouvertures non utilisées du

système d’évacuation.

2. Visually inspect the venting system for proper

3. Insofar as it is practical, close all building doors

PRODUCTION

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

Inspecter de façon visuelle le système

d’évacuation pour déterminer la grosseur et

l’inclinaison horizontale qui conviennent et

s’assurer que le système est exampt

d’obstruction, d’étranglement, de fuite, de

corrosion et autres défaillances qui pourraient

présenter des risques.

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers and

any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l’espace où les appareils toujours

OUT OF

raccordés au système d’évacuation sont installés

et les autres espaces du bùtiment. Mettre en

marche les sécheuses, tous les appareils non

raccordés au systéme d’évacuation commun et

tous les ventilateurs d’extraction comme les

hottes de cuisinière et les ventilateurs des salles

de bain. S’assurer que ces ventilateurs

fonctionnent à la vitesse maximale. Ne pas faire

fonctionner les ventilateurs d’été. Fermer les

registres des cheminées.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust

thermostat so appliance will operate

continuously.

Mettre l’appareil inspecté en marche. Suivre les

instructions d’allumage. Régler le thermostat de

façon que l’appareil fonctionne de façon

continue.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

Faire fonctionner le brûleur principal pendant 5

min ensuite, déterminer si le coupe-tirage

déborde à l’ouverture de décharge. Utiliser la

flamme d’une allumette ou d’une chandelle ou la

fumée d’une cigarette, d’une cigare ou d’une

pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning

appliance to their previous conditions of use.

Une fois qu’il a été déterminé, selon la méthode

inidquée ci-dessus, que chaque appareil raccordé

au système d’évacuation est mis à l’air libre de

façon adéquate. Remettre les portes et les

fenêtres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position

originale.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the

minimum size as determined using the

appropriate tables in Appendix G in the National

Fuel Gas Code, ANSI Z223.1.

T out mauvais fonctionnement du système

d’évacuation commun devrait être corrigé de

façon que l’installation soit conforme au national

Fuel Gas Code, ANSI Z223.1 et (ou) aux codes

d}installation CSA-B149.1. Si la grosseur d’une

Page 12

Page 12

LAARS Heating Systems

section du système d’évacuation doit être

modifiée, le système devrait être modifié pour

respecter les valeurs minimales des tableaux

pertinents de l’appendices F du National Fuel

Gas Code, ANSI Z2231.1 et (ou) des codes

d}installation CSA-B149.1.

2.6 Water Flow System

2.6.1 Freeze Protection

Proper precautions for freeze protection are

recommended for boiler installations in areas where

the danger of freezing exists.

Power outage, interruption of gas supply , failure

of system components, activation of safety devices,

etc., may prevent a boiler from firing. Any time a

boiler is subjected to freezing conditions, and the

boiler is not able to fire, and/or the water is not able

to circulate, there is a risk of freezing in the boiler

or in the pipes in the system. When water freezes, it

expands. This can result in bursting of pipes in the

system, or damage to the boiler, which could result in

leaking or flooding conditions.

Do not use automotive anti-freeze. Maintaining a

mixture of minimum 50% water and maximum 50%

properly inhibited HVAC glycol, which contains an

antifoamant, is the preferred method of freeze

protection for Mighty Therm boilers. Percentage of

glycol used in the Mighty Therm boiler must not

exceed 50%. Typically, this mixture will serve as burst

protection for temperatures down to approximately

-35°F (-30°C). To get the desired temperature rise

OUT OF

PRODUCTION

across the boiler when the is mixture is used, increase

the water flow by 15% above the original

recommendation. Increase the head loss requirement

by 20%.

IMPORTANT NOTES: Different glycol products may

provide varying degrees of protection. Glycol products

must be maintained properly in a heating system, or

they may become ineffective. Consult the glycol

specifications, or the glycol manufacturer, for

information about specific products, maintenance of

solutions, and set up according to your particular

conditions.

2.6.2 Pump Requirements

High recovery , low volume water boilers need

enough water flow for efficient operation. The system

pump must develop enough pressure to overcome the

pressure drop of the boiler plus the pressure drop of

the entire circulation system at the flow rates selected

from T able 3.

The correct flow rate can be verified by checking

the temperature rise of water as it passes through the

boiler. T o check the temperature rise, measure the

difference in water temperature between the boiler

inlet and outlet to determine flow . For example: If a

Size 250 boiler is installed; the inlet water temperature

is 160°F (71°C); and the outlet water temperature is

185°F (85°C); then there is a 25°F (14°C) temperature

rise. Per Table 3 this equals a flow rate of 16 GPM

(1.0L/s) and a head loss (pressure drop) of 1.2 feet of

water. If a higher temperature rise is measured, flow

Figure 22. Multiple Boilers, Primary Secondary Sytem.

Page 13

Mighty Therm LO-NOx Hydronic Boiler

Page 13

OUT OF

Figure 23. Multiple Boilers, Low Temperature System.

Temperature Rise in °F °C

PRODUCTION

Size GPM H/L* L/s GPM H/L* L/s GPM H/L* L/s GPM H/L* L/s

250 20 2.1 1.26 0.6 16 1.00 1.2 0.4 13 0.82 0.8 0.2 11 0.69 0.6 0.2

400 31 1.96 5.2 1.6 25 1.58 3.4 1.0 21 1.32 2.3 0.7 18 1.13 1.7 0.5

Water Flow - GPM or L/s: Gallons per minute or Liters per second.

*Pressure drop (head loss) through the boiler, expressed in feet or meters of water (H

must be increased by changing the piping or pump

size.

2.6.3 Variable Water Flow Systems

There can be reduced water flow through the

boiler in heating systems using zone valves, zone

pumps or 3-way valves. This can result in a high

temperature rise across the boiler. Laars recommends

primary-secondary pumping for all variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler even

though the system flow is variable. In a primarysecondary system the pressure drop of the boiler is not

added to the system (see Figures 22, 23 and 24).

20°F 11°C 25°F 14°C 30°F 17°C 35°F 19°C

ft m ft m ft m ft m

0).

2

Table 3. Temperature Rise.

2.6.4 System Pressure Requirements

The HH, PH boilers are designed to operate on

closed, pressurized systems. A minimum of 12 psi

(82.7kPa) should be maintained on the system where

boiler supply water temperatures are 200°F (93°C) or

less. If higher temperatures are required, the minimum

system pressure should be at least 15 psi (103.4 kPa)

above the water vapor pressure corresponding to the

elevated water temperature.

Do not use the HH, PH boilers to operate on

open, pressurized systems unless the supply water

temperatures are kept below 180°F (82°C), and a

minimum of 5 psi (34.5 kPa) static head is maintained

at the boiler.

Page 14

Page 14

LAARS Heating Systems

OUT OF

Figure 24. One Boiler, Multi-Temperature System.

2.6.5 Chilled Water Systems

If the boiler is part of a refrigeration system,

include the proper valves to isolate the boiler from the

refrigeration system during times when the boiler is

not operating.

When the boiler piping is connected to heating

coils, which are close to refrigerated air circulation,

install flow control valves or other automatic methods

to prevent gravity circulation of the boiler water during

the cooling cycle.

2.6.6 System to Boiler Piping

1. Install gate valves at the inlet and outlet to the

boiler so it can be isolated for service.

2. Make sure the pressure relief valve (see Figure

25) has its outlet piped to a drain or floor sink.

Pay special attention to relief valve settings in

installations where the boiler is located on the

ground floor of a tall building, or where the

operating temperature of the boiler is above

210°F (99°C). In both cases, the static pressure of

the system is raised. This would bring raw water

into the system. The factory will furnish a 75 psi

(516.8 kPa) setting unless a special setting is

ordered.

PRODUCTION

Pressure

Flow

Switch

Figure 25. Pressure Relief Valve.

3. Install a low water cutoff device if the boiler is

installed above radiation level.

4. Install manual and/or automatic air venting

devices at high points in the system to get rid

of air.

5. Install a correctly sized expansion or

compression tank in accordance with the

manufacturer's instructions.

Relief Valve

High-Limit

Dry Well

Page 15

Mighty Therm LO-NOx Hydronic Boiler

Page 15

6. Support the weight of all water and gas piping

with suitable hangers or floor stands.

7. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

2.6.7 Filling the System

1. Close all air vents and open the makeup water

valve. Let the system fill slowly .

2. If a makeup water pump is used, adjust the

pressure switch on the pumping system to

maintain at least 12 psi (82.7 kPa) at the highest

point in the heating loop.

3. If a water pressure regulator is installed on the

makeup water line, adjust the pressure regulator

to provide at least 12 psi (82.7 kPa) at the highest

point in the heating loop.

4. Open air vents on all radiation units at the high

points in the piping throughout the system, unless

automatic air vents are installed at those points.

5. Run the system circulating pump for at least 30

minutes with the boiler shut off.

6. Recheck all air vents as described in S tep 4 above.

7. With the system full of water and under normal

operating pressure, the air pressure in the expansion

tank should be at least 12 psi (82.7 kPa).

8. Start up the boiler following the instructions

found on the inside of the boiler.

9. Operate the whole system, including the pump,

boiler, and radiation units for 1 hour.

PRODUCTION

10. Shut down the entire system and vent all

radiation units and high points in the system

piping as described in Step 4 above.

11. Close the makeup water valve and check the

strainer in the pressure reducing valve for sediment or debris. Reopen the makeup water valve.

12. Check the gauge to make sure the water pressure

is right, and check water level in the system. If

the water level indicated above the boiler shows

that water is at the highest point in the circulating

loop, then the system is ready for operation.

13. Within 3 days of start-up, recheck all air vents

and expansion tank as described in Steps 4 and 8

above.

2.6.8 Minimum Boiler T emperature

The boiler inlet water temperature must be

minimum 110°F (43°C) when the system has come up

to normal operating conditions. Lower temperature

inlet water may allow the production of condensation

on the outside of the copper finned tubes, which can

block the flue gases and/or cause improper

combustion, leading to heat exchanger sooting.

OUT OF

For systems with lower than 110°F (43°C)

temperature, boiler must be protected from low

temperature return water. There are many methods of

achieving low temperature protection. Figure 23

shows an example of such a system. Damage caused

by condensation is not covered under the terms of the

limited warranty .

2.7 Gas Supply and Piping

(Natural Gas Only)

2.7.1 General Instructions

Review the following instructions before

continuing the installation.

1. Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance

with CSA-B149.1 and all loc a l c od e s t ha t a p pl y.

2. Check the rating plate to make sure the boiler is

fitted for the type of gas being used. Laars LO-

NOx boilers are normally equipped to operate

with natural gas below a 2000 foot (609 m)

altitude.

3. If a gas pressure regulator is required, the

installation must be in accordance with the latest

edition of ANSI Z223.1. In Canada, the

installation must be in accordance with CSA-

B149.1 and all local codes that apply .

4. The figures in Table 5 should be used to size the

gas piping from the gas meter to the boiler.

5. Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 26). Fit the trap with a

threaded cap which can be removed for cleaning.

6. Install a non-restrictive manual gas shutoff valve

for service and safety . Check the local codes.

7. Disconnect the boiler and its individual shutoff

valve from the supply gas system during pressure

Distance from Gas Meter or Last Stage Regulator

0-100 feet 100-200 feet 200-300 feet

0-30 m 30-60 m 60-90 m

Boiler Nat. Nat. Nat.

Size in. (NPT) in. (NPT) in. (NPT)

250 1¼ 1¼ 1½

400 1¼ 1½ 2

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and

are based on ½ inch (13mm) water column pressure

drop. Check supply pressure with a manometer, and

local code requirements for variations.

2. Check supply pressure and local code requirements

before preceding with work.

3. Pipe fittings must be considered when determining gas

pipe sizing.

Table 5. Pipe Size Requirements (natural gas).

Page 16

Page 16

G

S

I

O

R

T

LAARS Heating Systems

MANUAL SHUT-OFF

VALVE

CAP

NIPPLE

UNION

T

BOILE

INLE

AS

UPPLY

NLET

Figure 26. T-Fitting and Sediment Trap.

T-FITTING

3" (76 mm)

MIN.

testing of the system at pressures higher than 1/2

pounds per square inch (psi) (3.4 kilopacals

[kPa]). If the test pressure is equal to or less than

1/2 psi (3.45 kPa), close the manual shutoff valve

on the boiler during the piping pressure test.

8. Gas supply pressures to the boiler are listed in

T able 6.

OUT OF

Supply Pressure Natural Gas

Water Column in. mm

Minimum 6 152

See Rating Plate

Maximum 10.5 267

Table 6. Gas Supply Pressure Requirements.

PRODUCTION

NOTE: The boiler and all other gas appliances sharing

the boiler gas supply line must be firing at maximum

capacity to properly measure the inlet supply

pressure. Low gas pressure could indicate an undersized gas meter and/or obstructed gas supply line.

9. Do not exceed the maximum inlet gas pressures

specified. Excessive pressure will result in

damage to the boiler's gas controls. The minimum

pressure specified is for gas input adjustment.

10. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator on the

gas valve is preset at the factory, and does not

normally need adjustment.

11. Before operating the boiler, test the complete gas

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking,

rinse the piping with water after testing.

Étant donné que certaines solutions utilisées pour

vérifier les fuites (dont le savon et l’eau) peuvent

causer la corrosion ou la fissuration, rincer les

canalisations avec de l’eau après avoir effectué les

essais.

2.8 Electrical Wiring

Electrically ground the boiler in accordance with the

latest edition of the National Electrical Code, ANSI/

NFPA 70. In Canada, use C22.1. Do not rely on the

gas or water piping to ground the metal parts of the

boiler. Often, plastic pipe or dielectric unions isolate

the boiler electrically. Service and maintenance

personnel who work on or around the boiler may be

standing on wet floors and could be electrocuted by

an ungrounded boiler. Electrocution can cause

serious injury or death. The electric circuit to which

the unit will be connected should be “OFF” during

installation and wiring of the unit.

La chaudière doit être reliée à la terre en respectant

les exigences de la plus récente édition du National

Electrical Code ANSI/NFPA 70.Au Canada, utiliser

le C22.1. Ne pas avoir recours aux canalisations de

gaz ou d’eau pour relier à la terre les pièces

métalliques de la chaudière. Les tuyaux de

plastique ou raccordements diélectriques servent

souvent à isoler la chaudière au point de vue

électrique. Les employés qui sont appelés à

travailler sur la chaudière ou autour pour effectuer

l’entretien et les réparations peuvent se retrouver

sur un plancher mouillé et risquer l’électrocution si

l’appareil n’est pas adéquatement mis à la terre.

L’électrocution peut occasionner des blessures

graves ou la mort. Le circuit électrique auquel

l’appareil est branché doit être en position d’arrêt

« OFF » durant l’installation et le câblage de

l’appareil.

Caution

Avertissement

WARNING

MISE EN GARDE

supply system and all connections for leaks using

a soap solution.

1. Check boiler wiring and pump for correct

voltage, frequency , and phase. Check to make

sure boiler is wired for 120 volts alternating

current (VAC). If 240 VAC, contact local factory

representative or Laars.

2. Wire the boiler and pump exactly as shown in the

wiring diagram supplied with the boiler. See

Figures 30 through 33 for a typical example of a

wiring diagram.

Page 17

Mighty Therm LO-NOx Hydronic Boiler

Page 17

3. Electrically interlock the pump and boiler so the

boiler cannot come on unless the pump is

running.

4. Connect all field-installed devices (draft

switches, relays, timers, outdoor temperature

reset devices, etc.) to the boiler wiring at points

labeled Field Interlock.

SECTION 3.

Operating Instructions

NOTE: Safe lighting and other performance criteria

were met with the gas manifold and control assembly

installed on the boiler during tests specified in ANSI

Z21.13.

WARNING

For your safety, when starting the boiler, keep your

head and face well away from the lower firebox

opening to prevent any risk of personal injury.

Vent pipes, drafthoods, and boiler tops get hot!

These surfaces can cause serious burns. Do not

touch these surfaces while the boiler is in operation.

Pour assurer sa sécurité, la personne qui allume la

chaudière devrait garder la tête le plus éloignée

possible de l’ouverture inférieure de la chambre de

combustion afin de prévenir tout risque de blessure

au moment de l’allumage.

Les tuyaux d’évent, les coupe-tirage et la surface

supérieure des chaudières deviennent très chauds !

Toucher à ces surfaces peut occasionner des

blessures sérieuses. Ne pas toucher à ces surfaces

alors que la chaudière fonctionne.

3.1 Start-Up Procedure

1. Make sure the system pump is running and there

2. Follow the lighting and shutdown procedure in

3.2 Setting the Temperature Controls

PRODUCTION

is water flow .

Figure 28 or 29.

OUT OF

MISE EN GARDE

Temperature Controller

Manual Reset Hi-Limit

Figure 27. Temperature Controls.

T o set the temperature and high-limit controls:

1. Set the temperature controller at the system

design temperature.

2. For boilers with the temperature controller bulb

at the boiler inlet, set the high-limit 40°F to 50°F

above temperature controller setting.

3. For boilers with the temperature controller bulb

at the boiler outlet, set the high-limit 15°F to

25°F above temperature controller setting.

3.3 Hi-Limit Switch Checkout

After running the boiler for a long enough period,

bring the water temperature within the range of the hilimit switch and slowly back off the high limit setting

until the boiler shuts off. The main burners should

reignite (following the normal ignition cycle) when the

hi-limit switch is reset and turned back up to its

original setting. The boiler should now run until it

shuts off automatically on operating control.

Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to the

boiler (refer to troubleshooting section).

Caution

On a boiler equipped with the vent damper device,

the damper must be in the open position when the

main burners are operating.

Avertissement

Le registre des chaudières munies d’un dispositif

de volet motorisé doit être en position ouverte lors

que les brûleurs principaux fonctionnent.

3.4 Shut-Down Procedure

Shut down the boiler following the instructions in

Figures 28 and 29.

Where there is a danger of freezing, shut off the

water supply and remove the drain plugs on both sides

of the boiler jacket. Drain every part of the system

subject to damage from freezing temperatures.

Page 18

Page 18

LAARS Heating Systems

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

A. This appliance does not have a pilot light. It is

equipped with an ignition device which

automatically lights the heater. Do NOT try to

light the burners by hand.

B. BEFORE OPERATING, smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas

supplier's instructions.

OUT OF

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on

this label.

2. Turn appliance switch to “OFF” and remove

the heater door.

3. Turn off all electric power to the appliance.

4. Set the thermostat to lowest setting.

5. This appliance is equipped with an ignition

device which automatically lights the heater.

Do not try to light the burners by hand.

6. Turn gas control knob clockwise to

“OFF”.

7. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor. If

you smell gas, STOP! Follow “B” in the safety

information above on this label. If you don't

smell gas, go to next step.

8. Turn gas control knob counterclockwise

to “ON”.

PRODUCTION

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the

knob will not push in or turn by hand, don't

try to repair it, call a qualified service

technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

9. Set thermostat to desired setting. Replace

heater door.

10. Turn on all electric power to appliance.

11. Turn applicance switch from “OFF” to “ON”.

12. If the appliance will not operate, check that

the pump is on, and all of the safety switches

are reset. Otherwise, follow the instructions

“To Turn Off Gas To Appliance” and call your

service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Turn appliance switch to “OFF”.

2. Remove the heater door.

3. Set the thermostat to lowest setting.

Figure 28. Lighting and Shutdown Instructions.

4. Turn off all electric power to the appliance if

service is to be performed.

5. Turn gas control knob clockwise to “OFF”.

6. Replace heater door.

Page 19

Mighty Therm LO-NOx Hydronic Boiler

POUR VOTRE SÉCURITÉ LISEZ AVANT DE METTRE EN MARCHE

AVERTISSEMENT: Quiconque ne respecte pas à la lettre les instructions dans

la présente notice risque de déclencher un incendie ou une explosion entraînant

des dommages, des blessures ou la mort.

Page 19

A. Cet appareil ne comporte pas de veilleuse. Il est

muni d’un dispositif d’allumage qui allume

automatiquement le brûleur. ne tentez pas

d’allumer le brûleur manuellement.

B. AVANT DE FAIRE FOCTIONNER, reniflez tout

autour de l’appareil pour déceler une odeur de

gaz. Reniflez près du plancher, car certains gaz

sont plus lourds que l’air et peuvent s’accumuler

au niveau du sol.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareil

• Ne touchez à aucun interrupteur; ne pas

vous servir des téléphones se trouvant dans

le bâtiment.

OUT OF

INSTRUCTIONS DE MISE EN MARCHE

1. ARRÊTEZ! Lisez les instructions de sécurité sur la

portion supéerieure de cette étiquette.

2. Mettre le bouton de commande à “OFF”. Enlevez la

portière du chauffe-eau.

3. Coupez l’alimentation électrique de l’appareil.

4. Réglez le thermostat à la température la plus

5. Cet appareil est muni d’un dispositif d’allumage qui

6. Tournez le bouton de la commande de gaz dans le

7. Attendre cinq (5) minutes pour laisser échapper

PRODUCTION

basse.

met le chauffe-eau en marche automatiquement. Ne

pas essayer d’allumer les brûleurs à main.

sens des aiguilles d’une montre jusqu’à la

position “OFF”.

tout le gaz. Reniflez tout autour de l’appareil, y

compris près du plancher, pour déceler une odeur

de gaz. Si vous sentez une odeur de gaz,

ARRÊTEZ! Passez à l’étape B des instructions de

sécurité sur la portion supérieure de cette

étiquette. S’il n’y a pas d’odeur de gaz, passez à

l’étape suivante.

• Appelez immédiatement votre fournisseur

de gaz depuis un voisin. Suivez les

instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

C. Ne poussez ou tournez la manette

d’admission du gaz qu’à la main; ne jamais

utiliser d’outil. si la manette reste coincée, ne

pas tenter de la réparer; appelez un

technicien qualifié. Le fait de forcer la

manette ou de la réparer peut déclencher une

explosion ou un incendie.

D. N’utilisez pas cet appareil s’il a été plongé

dans l’eau, même partiellement. Faites

inspecter l’appareil par un technicien qualifié

et remplacez toute partie du système de

contrôle et toute commande qui ont été

plongés dans l’eau

8. Tournez le bouton de commande de gaz dans le

sense contraire des aiguilles d’une montre

jusqu’à la position “ON”.

9. Replacez le panneau d’accès aux commandes.

10. Mettez l’appareil sous tension.

11. Réglez le thermostat comme désiré et tournez le

bouton de commande de la position “OFF” à la

position “ON”.

12. Si l’appareil ne se met pas en marche, suivez

les instructions intitulées “Comment couper

l’admission de gaz de l’appareil” et appelez un

technicien qualifié ou le fournisseur de

gaz.

COMMENT COUPER L’ADMISSION DE GAZ DE L’APPAREIL

1. Mettre le bouton de commande à “OFF”. Enlevez la

portiére du chauffe-eau.

2. Réglez le thermostat à la température la plus basse.

3. Couplez l’alimentation électrique de l’appareil s’il

faut procéder à l’entretien.

Figure 29. Instructions D’allumage et de Fermeture.

4. Tournez le bouton de contrôl de gaz dans le sens

des aiguilles d’une montre jusqu’à la position

“OFF”.

5. Replacez le panneau d’accès aux commandes.

Page 20

Page 20

LAARS Heating Systems

OUT OF

PRODUCTION

Figure 30. Mighty Therm LO-NOx, PH250.

Page 21

Mighty Therm LO-NOx Hydronic Boiler

Page 21

OUT OF

PRODUCTION

Figure 31. Mighty Therm LO-NOx, HH250.

Page 22

Page 22

LAARS Heating Systems

OUT OF

PRODUCTION

Figure 32. Mighty Therm LO-NOx, PH 400.

Page 23

Mighty Therm LO-NOx Hydronic Boiler

Page 23

OUT OF

PRODUCTION

Figure 33. Mighty Therm LO-NOx, HH 400.

Page 24

Page 24

SECTION 4.

Maintenance

4.1 General Instructions

1. Oil the water circulating pump in accordance

with the manufacturer's instructions.

2. If a strainer is used in a pressure reducing valve

or in the piping, clean it every 6 months in

accordance with the manufacturer's instructions.

3. At startup and every 6 months after, check the

main burner flame. If the flame has the

appearance of sooting tips, check for debris near

orifices. Call service technician.

LAARS Heating Systems

Plug

Figure 35. Scale Inspection.

(see Figure 35). Perform this inspection after 60

days of and after 120 days of operation. This will

establish a regular inspection routine.

3. Reinstall both plugs after inspection.

OUT OF

Figure 34. Flame Patterns.

4. Inspect the venting system for blockage, leakage,

and corrosion at least once a year.

5. Keep the boiler area clear of combustible

material, gasoline, and other flammable liquids

and vapors.

6. Be sure all combustion air and ventilation

openings are not blocked.

7. Check for black carbon soot buildup on the

external surfaces of the heat exchanger every 6

months.

8. Do not use the boiler if any part has been under

water. Replace anypart of the control system and

any gas control which has been under water.

NOTE: After installation and first startup, check the

heat exchanger for black carbon soot buildup after the

following periods of operation: 24 hours, 7 days, 30

days, 90 days, and once every 6 months thereafter.

PRODUCTION

4.2.2 Cleaning the Heat Exchanger

An inspection and cleaning of the complete heat

exchanger can only be done by removing it from the

boiler.

1. Remove the heat exchanger.

WARNING

Black carbon soot buildup on a dirty heat exchanger

can be ignited by a random spark or flame. To

prevent this happening, dampen the soot deposits

with a wet brush or fine water spray before

servicing the heat exchanger. Ignition of soot can

possibly cause serious injury or burns, and in

extreme cases, death.

MISE EN GARDE

L’accumulation de suie noire ou de saleté sur

l’échangeur thermique peut s’enflammer par le

contact d’une étincelle ou d’une flamme. Humidifier

les dépôts de suie à l’aide d’une brosse mouillée ou

d’une vaporisation d’eau avant d’effectuer

l’entretien de l’échangeur thermique afin

d’empêcher que cela se produise. L’embrasement

de la suie peut occasionner des blessures graves,

de brûlures et même, dans les cas extrêmes, la

mort.

4.2 HEAT EXCHANGER

4.2.1 Inspecting the Heat Exchanger

T o check the scale buildup, periodically inspect

the tube having the highest temperature as follows:

1. Remove the ¼ inch, NPT plug located on the left

side of the boiler.

2. Remove the lar ge, hex-head plug located on the

right side of the boiler under the in/out header

2. Remove the heat baffles and check for a light

accumulation of soot or corrosion on the outside

of the heat exchanger tubes.

NOTE: While the heat exchanger is out of the boiler,

inspect the firewall insulation blankets for wear and

tear. Replace if necessary.

3. Use a wire brush to remove soot and loose scale

from the heat exchanger. Do not use water or

compressed air for cleaning.

Page 25

Mighty Therm LO-NOx Hydronic Boiler

City

Water

Supply

Notes:

1. When pressure relief valve is used, it must be removed and the hole plugged, as shown.

2. Remove the plug before reinstalling the heat exchanger.

Figure 36. Heat Exchanger Tube Cleaning.

400-500 RPM

Drill Motor

Page 25

NOTE: Use only the correct carbide tipped reamers

which are available from Laars.

4. Ream the insides of the tubes (see Figure 36).

5. Pull the reamer out frequently to remove lime

powder and prevent the drill from binding in the

tube.

6. Install new gaskets. Do not reuse the old ones.

7. Tighten the header bolts progressively , starting

with the two center bolts. Maximum torque is 20

inch pounds (27 Nm). Do not over-torque.

8. Pressure test the heat exchanger for leaks with

city water supply before re-installing.

9. When placing the heat exchanger back in the

10. If a header bolt is stripped, drive it out of the

11. Reinstall the heat exchanger.

PRODUCTION

boiler, carefully hold the refractory insulation

blocks apart and lower the heat exchanger into

place. Be sure the sheet metal covers, which

protect the insulation blocks, are replaced

carefully.

header plate and replace it (see Section 6, Parts

List).

OUT OF

SECTION 5.

Troubleshooting and Service

5.1 Gas Pressure Tests

Use the following procedures to check the main

gas supply and manifold gas pressures. A manometer

kit is available from Laars and instructions for its use

are included in the kit. A dry gas pressure gauge may

also be used for either test.

Suggested

Manometer

Position

Main

Shutoff Valve

(Field

Supplied)

Figure 37. Gas Manifold Pressure Test.

5.1.1 Checking the Main Line

Gas Pressure

1. Attach a manometer (or a dry gas pressure gauge)

to boiler jacket (see Figure 37).

2. Open both columns on the manometer.

3. Use shutoff valve outside the boiler jacket to shut

off all gas supply to the boiler.

4. Remove the 1/8 inch NPT test plug in the inlet

side of the gas valve and replace it with the 1/8

inch NPT fitting from the manometer kit.

5. Attach one end of the manometer hose to the

fitting on the gas valve and the other end to the

manometer.

6. Open gas supply shutoff valve outside the boiler

and follow the lighting instructions in Figures 28

and 29 to turn on the boiler.

7. With the main burners firing, the manometer

reading should be between 6 and 10.5 inches

(15.2 and 26.7 cm) W.C.

Page 26

Page 26

LAARS Heating Systems

5.1.2 Checking the Manifold

Regulated Gas Pressure

1. Attach a manometer (or a dry gas pressure gauge)

to boiler jacket (see Figure 37).

2. Open both columns on the manometer.

3. Use shutoff valve, on outside of boiler jacket, to

shut off all gas supply to the boiler.

4. Remove the 1/8 inch NPT test plug on the outlet

side of the gas valve, and replace it with the 1/8

inch NPT fitting from the manometer kit.

5. Attach one end of the manometer hose to the

fitting on the gas valve and the other end to the

manometer.

6. Turn on gas supply to the boiler, and follow the

lighting instructions in Figures 28 or 29 to turn

on the boiler.

7. With the main burner firing, the manometer

reading should be 4 inches (10cm) W.C. for

natural gas.

8. Turn the toggle switch to OFF.

9. Shut the system down following the shutdown

instructions in Figures 28 or 29.

11. Disconnect the manometer tubing from the gas

valve and replace the 1/8 inch NPT fitting with

the original plug.

OUT OF

5.2 Electrical Troubleshooting

This section describes procedures for checking

the electrical power and control components of the

boiler. Read all of these procedures before starting

repairs.

Problems with boilers not firing are usually

caused by something reducing water flow through the

boiler, causing the protective switches in the boiler

system to shut down the boiler.

The following tools are required for proper

service and problem diagnosis of the boiler and

heating system.

1. Gas pressure test kit with range from 0 to 14

inches (0 to 35.6 cm) W.C.

2. Electric meter(s) with the following ranges:

a. 0 to 500 volts VAC

b. 0 to 2000 ohms (:)

c. 0 to 20 microamps (PA)

3. Tube cleaning kit with a reamer, stainless steel

brush, speed handle, and handle extensions.

4. A pressure gauge and a thermometer with proper

ranges for boiler operation.

5.2.1 Boiler Does Not Come On

Important: Disconnect power to the boiler before

removing or replacing any component or wire

connection.

PRODUCTION

WARNING

If power is not disconnected, jumpering gas valve or

accidental grounding of the wire harness, or

component terminals to the boiler frame or jacket

could cause the ignition control fuse to blow or may

cause the boiler to fire, resulting in injury or property

damage.

MISE EN GARDE

Si l’alimentation électrique n’est pas coupée, un

contact avec la soupape de gaz, la mise à la terre

accidentelle du faisceau de câbles ou des bornes

des composants au cadre ou à la paroi de la

chaudière peut faire sauter les fusibles ou

provoquer l’allumage de la chaudière, occasionnant

des blessures des dégâts matériels.

1. Make sure the boiler has been properly installed.

2. Make sure the pump is not airlocked, clogged or

otherwise inoperative.

3. Make sure the gas valve is on and there is gas

pressure in the line.

4. Check all electrical connections and wiring.

Finding a loose connection or a charred wire can

save a lot of time and money .

5. Check the fuse inside the twist-lock fuse holder.

If it is burned, replace it with a 2-amp fuse (Part

No. E0084400). If there is a short, the cause of

the short must be found and repaired. Do not

jumper or bypass the fuse.

6. Make sure the electrical circuit to the boiler is on.

7. Make sure the toggle switch on the right side of

the boiler is on.

8. Make sure the temperature control is set high

enough to call for heat.

9. Make sure the manual reset on the safety controls

(e.g., low water cutoff, hi-limit switch, etc.) has

not tripped. If it has, reset it.

If the pump is circulating water, and the rest of

these items check out all right, the trouble could be in

the boiler control system.

Caution

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

Attention

Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher. Les

erreurs de câblage peuvent nuire au bon

fonctionnement et être dangereuses. S’assurer que

l’appareil fonctionne adéquatement une fois

l’entretien terminé.

Page 27

Mighty Therm LO-NOx Hydronic Boiler

Figure 38. Testing the Transformer.

5.2.2 Testing the Transformer

NOTE: Keep the pump running.

T esting the transformer requires an AC voltmeter

with a 50 volt (V) range. Test the transformer using the

following procedures:

1. Clip a lead from the voltmeter to the yellow wire

2. Touch the other lead to the red wire terminal (see

3. If the voltmeter does not show voltage, check the

4. If the voltage is less than 20VAC, the electrical

PRODUCTION

terminal on the transformer (this lead stays

connected to this terminal for all tests).

Figure 37). The voltmeter should read 20 to 28VAC.

electrical power supply .

circuit to the boiler may be supplying less than

103VAC. This could be due to high pump load or

air conditioners or other appliances on the circuit.

OUT OF

Page 27

5.2.4 Testing the Manual Reset

Hi-Limit Switch

T o test the manual reset hi-limit switch (see

Figure 39):

1. Touch the other lead of the voltmeter to both

terminals of the manual reset hi-limit switch. The

voltmeter should read 20 to 28VAC at both

terminals.

2. If no voltage is detected at one terminal, reset the

manual reset hi-limit switch by pressing the reset

button. Check the temperature setting.

3. If after pressing the reset button there is still no

voltage indicated at one terminal, replace the

manual reset hi-limit switch. An open switch may

indicate excessive water temperatures or

improper setting.

5.2.5 Testing the Flow Switch

The flow switch is a safety device that senses

water flow through the boiler. When the switch senses

adequate water flow , it closes, allowing the boiler to

fire. If the water flow is too low , the switch remains

open and prevents the boiler from firing regardless of

the temperature control setting.

The flow switch is factory mounted and wired.

Never attempt to repair the flow switch. If the flow

switch is found to be defective, replace the flow

switch. To test the flow switch:

1. Remove cap from flow switch (see Figure 25).

2. Touch a voltmeter lead to each terminal of the

flow switch.

3. If the voltmeter reads voltage at each of the

terminals, the switch is good.

5.2.3 Testing the Electrical Power Supply

The electrical components of the HH and PH

boilers operate with supply voltage ranging from 103

to 126VAC at 60 Hertz (Hz). To test the electrical

power supply:

1. Measure the voltage at the hot and neutral

connections inside the boiler electrical junction

box.

2. Voltage outside of the required range may be due

to poor wiring connections, to other loads (e.g.,

air conditioners, compressors) on the circuit, to

high pump load, or to an electrical utility

company problem.

Figure 39. Testing the Manual Reset Hi-limit Switch.

Page 28

Page 28

OUT OF

PRODUCTION

LAARS Heating Systems

4. If there is no voltage at one terminal, it indicates

an open switch. Replace the flow switch.

5.2.6 Testing the Fusible Link

(flame roll-out switch)

The fusible link is a thermally fusible element

which shuts down the boiler if it detects excessive

temperatures inside the heat exchanger compartment.

T o test the fusible link (flame roll-out switch):

1. Remove the electrical wiring from the fuses and

check across each fuse's terminals with a

continuity or ohm meter.