LAARS Mighty Therm HH-PH Installation Manual

Installation, Operation and Maintenance Instructions Document 1064E

Installation,

Operation and

Maintenance

Instructions for

Mighty Therm

Hydronic Boilers

Model HH-PH

Sizes 175-400

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0147400E

A subsidiary of BRADFORD WHITE Corporation

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction ................................................... 3

1B. Warranty ....................................................... 3

1C. Technical Assistance.................................... 3

SECTION 2.

Installation Instructions

2A. General Information ...................................... 4

2B. Field Assembly ............................................. 4

2C. Site Location................................................. 5

2C-1. Installation Information ................................. 5

2C-2. Outdoor Installation (U.S. Only) .................... 6

2C-3. Flooring - Typical Installation ........................ 6

2D. Combustion and Ventilation

Air Supply ..................................................... 7

2D-1. Outdoor Air Supply ....................................... 7

2D-2. Indoor Air Supply .......................................... 7

2D-3. Exhaust Fans or Vents ................................. 7

2E. Venting of Combustion Products .................. 7

2E-1. General Information ...................................... 7

2E-2. Replacement of Existing Boiler ..................... 8

2F. Water Flow System ...................................... 8

2F-1. Reversible Water Connections ..................... 8

2F-2. Freeze Protection ....................................... 11

2F-3. Pump Requirements ................................... 11

2F-4. Variable Water Flow Systems .................... 13

2F-5. System Pressure Requirements ................. 13

2F-6. Chilled Water Systems ............................... 15

2F-7. System to Boiler Piping .............................. 15

2F-8. Filling the System ....................................... 15

SF-9. Minimum Boiler Temperature ..................... 15

2G. Gas Supply and Piping ............................... 16

2G-1. General Instructions ................................... 16

2G-2. Special Precautions for Propane Gas ........ 16

2H. Electrical Wiring .......................................... 19

SECTION 3.

Operating Instructions

3A. Setting the Temperature Controls .............. 19

3B. Start-Up Procedure .................................... 20

3C. Adjustment for Minimum Input Rate

(Models with Modulating Gas Valve) .......... 20

3D. Hi-Limit Switch Checkout ........................... 20

3E. Shut-Down Procedure ................................ 21

SECTION 4.

Service Instructions

4A. Regular Inspection ..................................... 21

4B. Replacement of Gas Controls .................... 21

SECTION 5.

Parts List for HH and PH Boilers

5A. General Information .................................... 22

5B. Parts List .................................................... 22

Mighty Therm HH-PH Hydronic Boilers

Page 3

SECTION 1.

General Information

1A. Introduction

This manual provides installation and operation

instructions for the Model HH and PH Hydronic

Boilers, Sizes 175 through 400. Review all application

and installation procedures completely before

proceeding with the installation. Experience has

shown that most operating problems are caused by

improper installation.

The HH-PH boilers are offered in a basic

configuration (see Figure 1). On PH boilers the pump

is factory installed. On HH boilers the pump is field

installed.

1B. Warranty

The HH-PH boilers are sold with a limited

factory warranty.

Make all warranty claims to an authorized Laars

representative or directly to the factory. Claims must

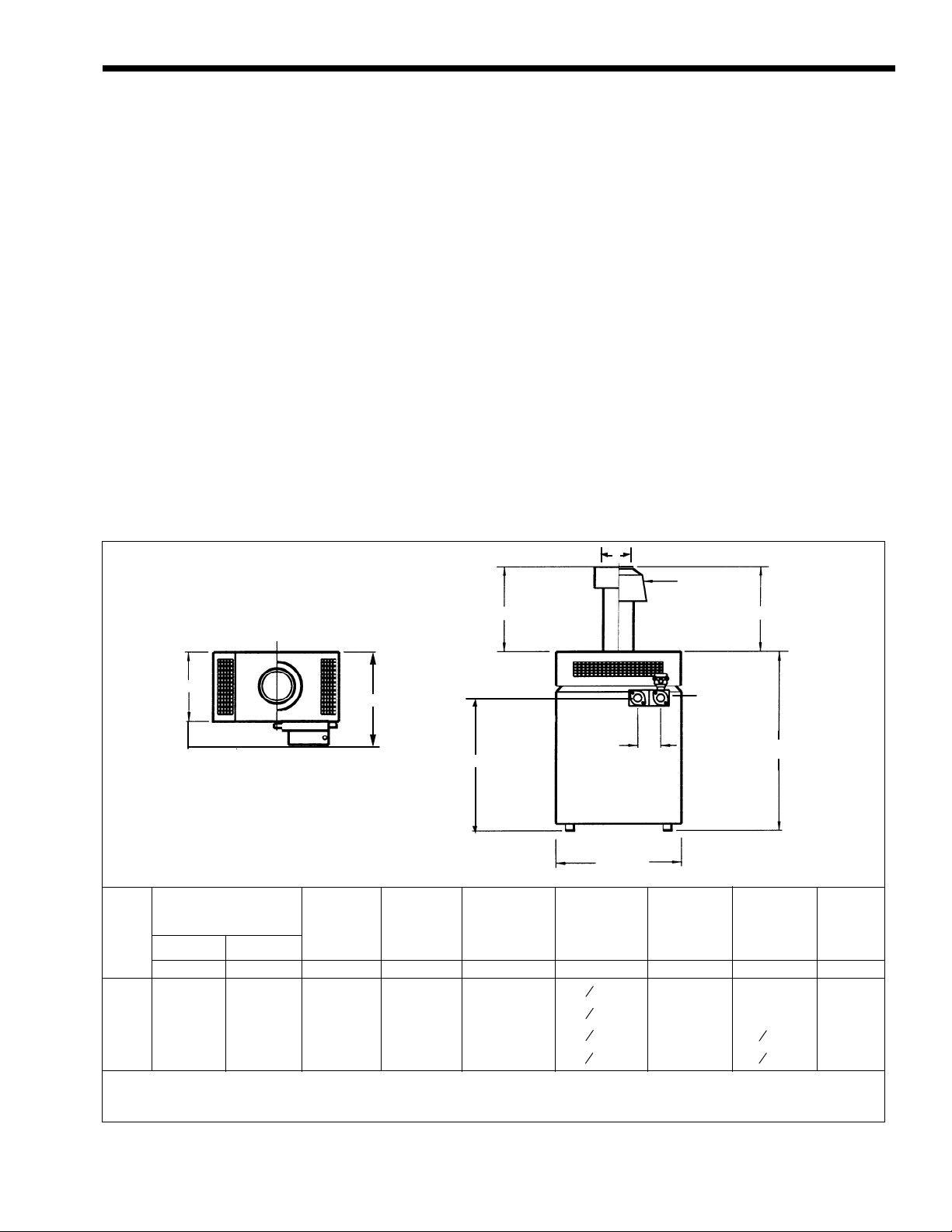

TOP VIEW

include the boiler serial number and model (this

information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

Some accessory items are shipped in separate

packages. Inspect everything for damage immediately

upon delivery, and advise the transporter of any

shortages or damage. Any such claims should be filed

with the transporter. The transporter will not accept a

claim from the shipper, Laars.

The warranty does not cover damage caused by

improper installation, operation, or field modification.

1C. Technical Assistance

Consult Laars or your local company

representative with any questions or problems

involving the specification, installation and operation

of Laars equipment. An experienced technical support

staff is ready to assist in assuring the proper

performance and application of Laars products.

V

OPTIONAL

VENT CAP FOR

OUTDOOR USE

CC

DRAFTHOOD

DRAFTHOOD MUST

BE INSTALLED IN

THE FIELD

SIDE VIEW

30-3/16 in. (767mm)

INLET

5-1/2 in.

(140mm)

26-1/2 in.

(673mm)

HEADER

LOCATION

OUTLET

40-9/16 in. (1030mm)

8-1/2 in.

(216mm)

A

INLET OUTLET

B

Gas Connection C* C

Size Water C (Indoor (Indoor V

Connect. U.S. Only w/ Vent w/o Vent Vent

Nat. Propane Size A B (Outdoor) Damper) Damper) Dia.

Size in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

1

175 ¾ 19 ½ 13 1½ 38 18 457 26½ 673 14

250 ¾ 19 ½ 13 1½ 38 22½ 572 31 787 18

325 ¾ 19 ½ 13 1½ 38 26¾ 679 35¾ 908 19

400 ¾ 19 ½ 13 1½ 38 31¾ 806 40¼ 1022 22

/16357 28½ 724 23½ 597 6 152

1

/16473 30½ 775 24¾ 629 7 178

3

/16488 —— 257/8657 8 203

5

/8575 —— 267/8683 9 229

*Vent damper only required on indoor installations, sizes 175 and 250.

Note: Dimensions may vary.

Figure 1. General Configuration.

Page 4

SECTION 2.

Installation Instructions

2A. General Information

LAARS HEATING SYSTEMS

Follow local regulations with respect to installation

WARNING

of carbon monoxide (CO) detectors and

manufacturer's maintenance schedule of the boiler.

Install the HH-PH boilers in accordance with the

procedures in this manual (or the Laars warranty may

be voided), local codes and ordinances. In the absence

of such codes, install the boilers in accordance with

the latest edition of the National Fuel Gas Code, ANSI

Z223.1. In Canada, the installation must be in

accordance with CAN1-B149.1 or .2 and local codes.

The authority having jurisdiction may require the

installation conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1. Any changes to the boiler, gas

controls, gas orifices, wiring or draft hood may void

the warranty. If field conditions require change,

consult the factory.

All gas-fired products require correct installation

to assure safe operation. The requirements for boilers

include the following:

1. Field assembly of draft hood and vent cap

(if required – see Section 2B)

2. Appropriate site location (clearances) and

flooring

3. Sufficient combustion and ventilation air

4. Adequate venting of combustion products

5. Adequate water flow

6. Properly sized gas meter and piping

7. Proper electrical wiring

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

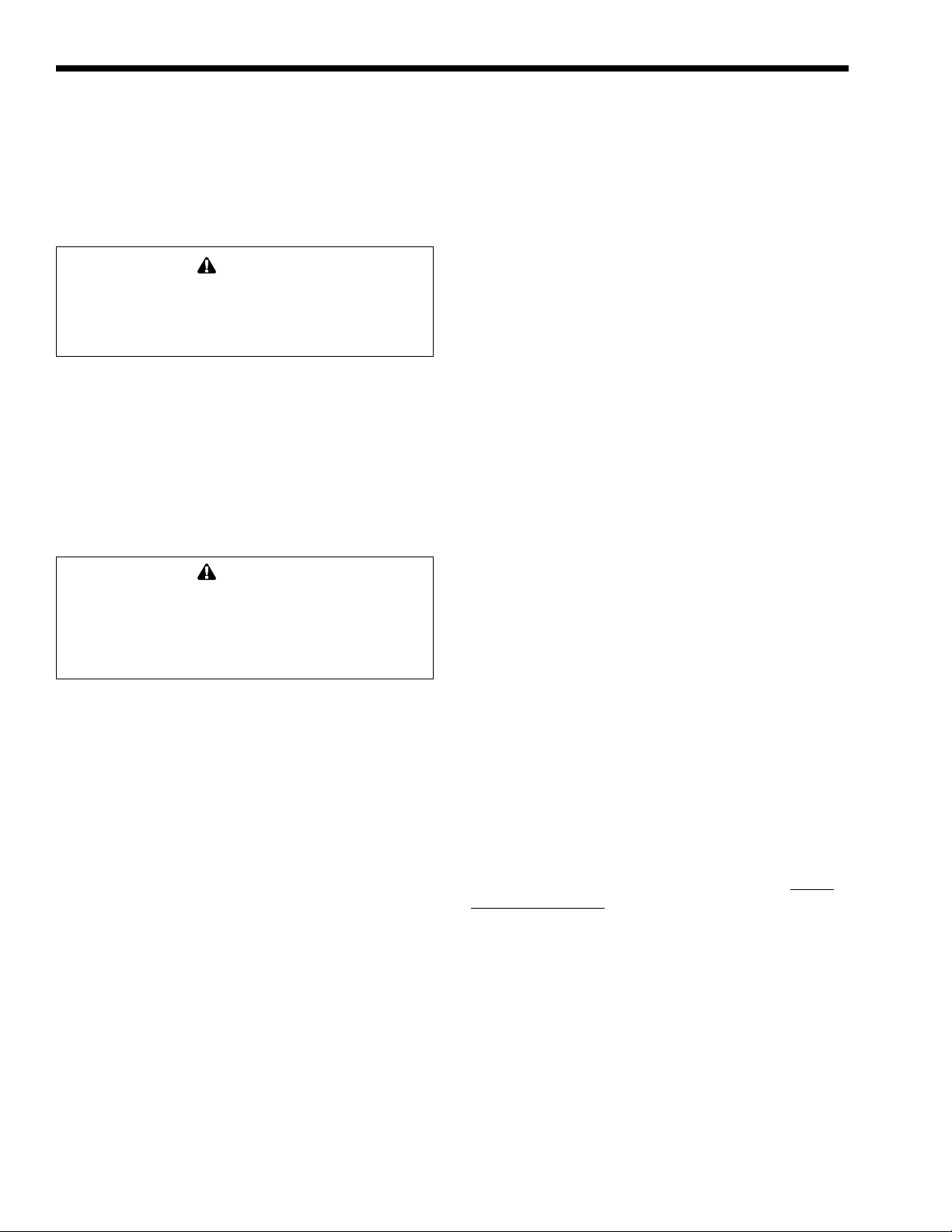

2B. Field Assembly

The HH-PH boiler is shipped from the factory

with the top assembly in the low-profile configuration

for outdoor installations.

The HH-PH boiler is design certified for indoor

installation when equipped with a drafthood, which

must be installed without modification. Check the

rating plate on the boiler for the correct Laars part

number.

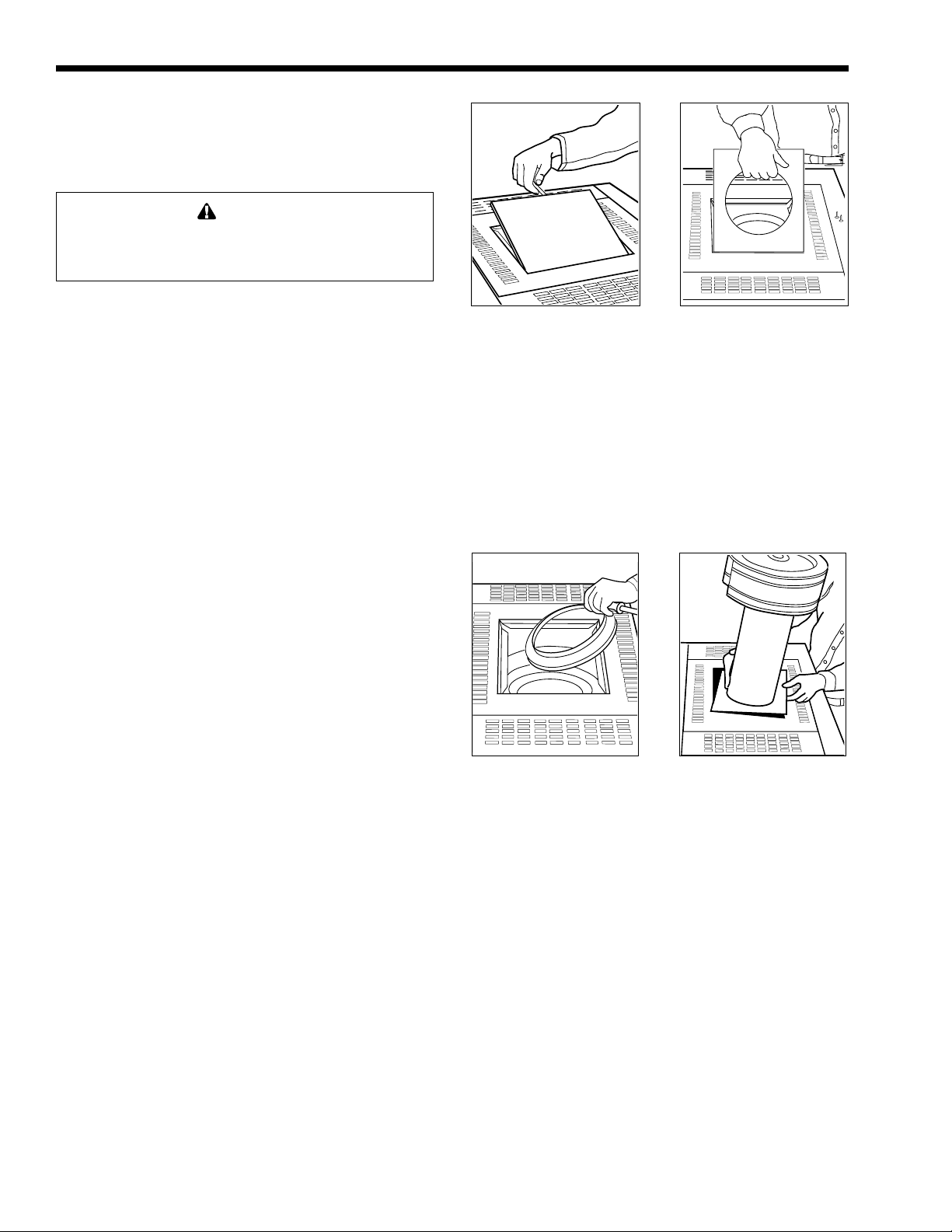

Follow this procedure to make the conversion:

a. Remove the top filler plate, stamped “HOT,” by

slipping a fine-blade screw driver into the slot at

HOT

HOT

Figure 2. Top Filler Plate.

Figure 3. Adapter Plate.

the rear of the plate and gently prying it up (see

Figure 2).

b. Remove the two screws attaching the adapter

plate to the top assembly and lift it out (see

Figure 3).

c. Remove the vent cap or drafthood from its

package.

d. Disengage the flue transition ring from the stack

extension and place it on top of the collector

assembly as shown in Figure 4.

Figure 4. Flue Transition

Ring.

Figure 5. Vent Cap with

Adapter Plate

e. Slide the adapter plate over the bottom of the

stack extension as shown in Figure 5. Fit the

stack extension down over the flue transition

ring. Seat the adapter plate on the top assembly

and secure it with two screws (see Figure 6).

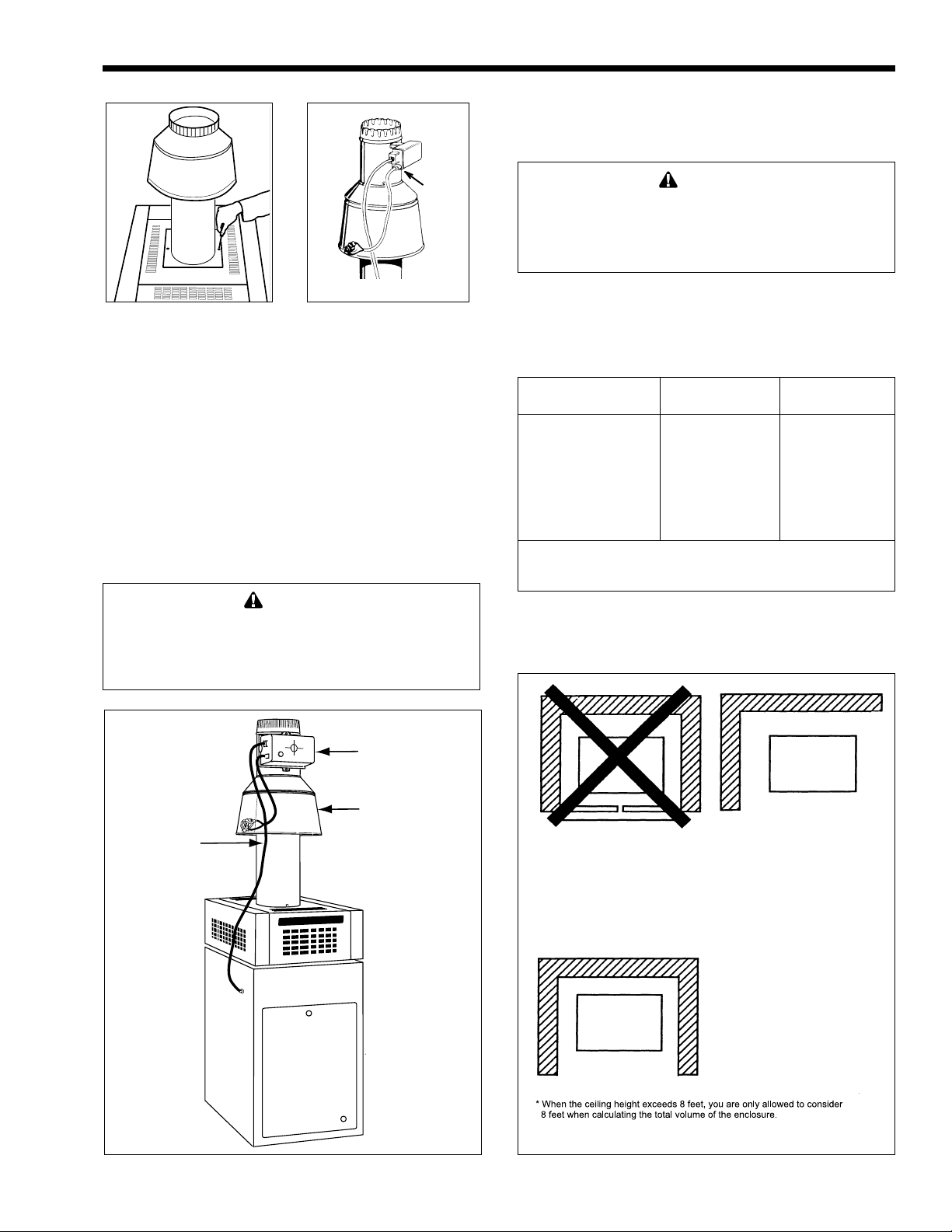

f. Find the vent damper box which is located in the

boiler package (boiler models 175 to 250 only)

(see Figure 8).

g. Install the vent damper directly to the top of the

draft hood outlet. The damper operator should

face to the front of the boiler, and the flow

direction arrow should point upward. Use the

vent damper wire harness to connect the vent

damper to the boiler. The bracket end of the

harness should be connected to the vent damper

actuator.

Mighty Therm HH-PH Hydronic Boilers

r

Figure 6. Drafthood with

Adapter Plate.

Figure 7. Drafthood Switch

Receptacle.

Page 5

2C. Site Location

2C-1. Installation Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in severe injury,

property damage, or death.

Locate the boiler to provide clearances on all

sides for maintenance and inspection. There must also

be minimum distances maintained from combustible

surfaces (see Table 1 and Figure 9).

h. Plug the wiring for the drafthood switch into the

receptacle on the left side of the vent damper box

(see Figure 7).

i. Do not modify the automatic vent damper

device. The venting system must be arranged so

that only the boiler is served by the vent damper

device supplied with the boiler. Provide at least

six inches clearance between the automatic vent

damper and combustible construction, and be

sure to allow access for servicing the damper.

WARNING

Do not force motor operation when the operator is

fastened to the damper by moving the damper

blade, turning the shaft, or turning the position

indicator.

VENT DAMPER

DRAFT HOOD

VENT DAMPER

HARNESS

Indoors Outdoors

Clearance from: inch mm inch mm

Top 37 940 Unobstructed

Water conn. side 12 305 Unobstructed

Opposite side 6 152 6 152

Front Alcove Unobstructed

Rear 6 152 6 152

Vent* 6 152 —

Flooring Combustible Combustible

Service clearance = 36 inches (914mm) at front of heater,

and 18 inches (457mm) at water connection side.

*1" (25mm) if double wall vent is used.

Table 1. Minimum Boiler Clearances

From Combustible Surfaces.

Heater

Closet Installation

(unacceptable)

A closet is any 4 sided enclosure

which is less than 16* times the

total volume of all the gas fired

appliances within the enclosure.

Room Installation

(acceptable)

A room is any enclosure which is

at least 16* times greater than the

total volume of all the gas fired

appliances within the enclosure.

Figure 8. Vent Damper Installation (Models 175 and

250 only).

Alcove Installation

(acceptable)

Heater

* When the cieling height exceeds 8 feet, you are only allowed to consider 8

feet when calculating the total volume of the enclosure.

An alcove suitable for the

installation of a heater is a

restricted section of a room not

separated from the room by a doo

or partition and which meets the

minimum clearances specified in

this manual.

Figure 9. Alcove Installation.

Page 6

LAARS HEATING SYSTEMS

The boiler must be isolated or otherwise

protected from any source of corrosive chemical

fumes, such as trichlorethylene, perchlorethylene,

chlorine, etc. Install the boiler so that the gas ignition

system components are protected from water

(drippings, spraying, rain, etc.) during operation and

service. Locate the boiler on a waterproof floor with a

floor drain and a 6 inch (152 mm) minimum curb on

all four sides to protect the building if boiler repairs

are needed.

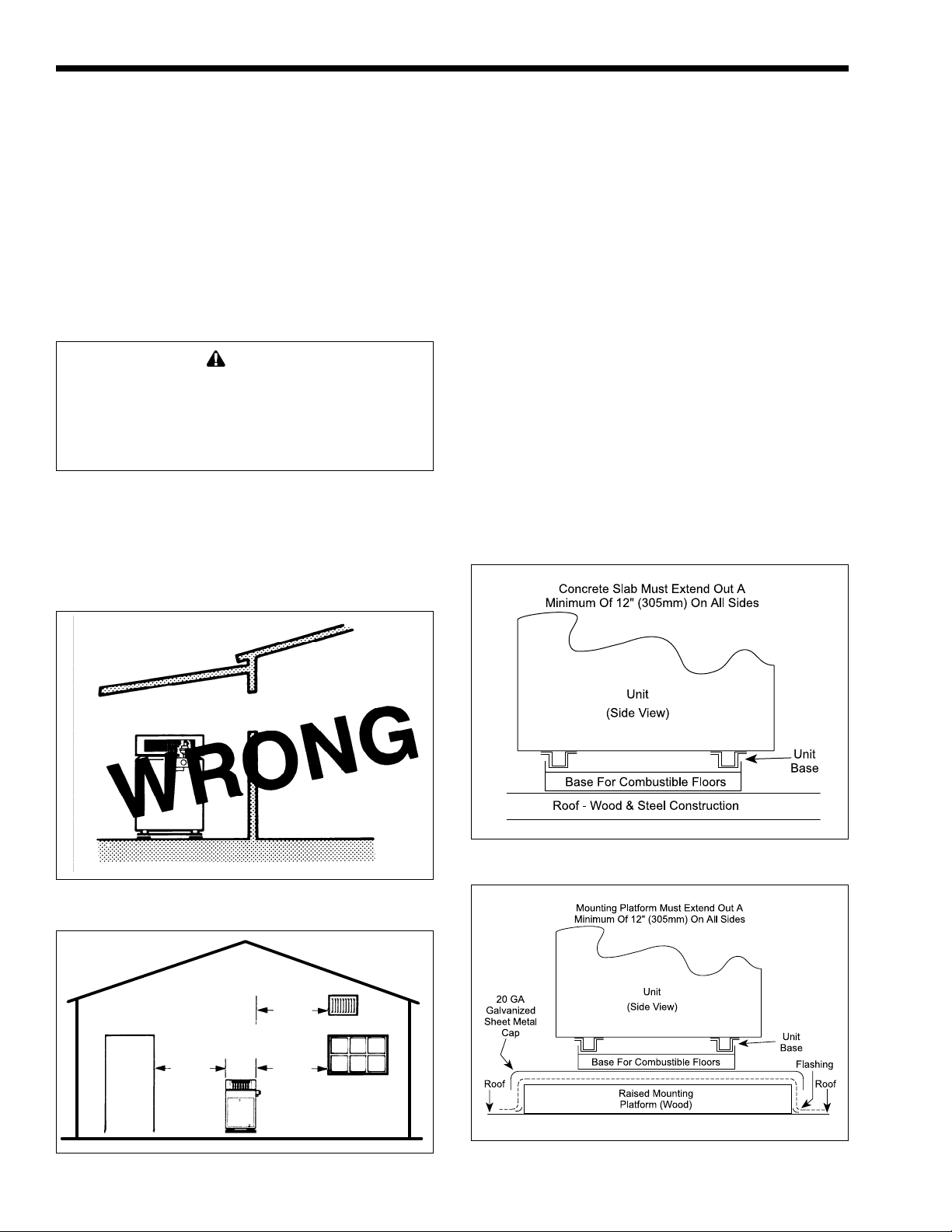

2C-2. Outdoor Installation (U.S. Only)

Caution

Outdoor installations are not recommended in

areas where the danger of snow blockage exists.

HH-PH boilers can be installed in the “low-profile,”

grate top configuration as received from the factory,

or with an optional vent cap/stack.

Locate the boiler in an open, unroofed area. Do

not locate the boiler below or adjacent to any doors,

windows, louvers, grills, etc., which connect in any

way with an inhabited area of a building, even though

the access might be through another structure such as

a garage or utility room (see Figure 10 and Table 1).

There must be a minimum of 4 feet (1.2 m)

horizontally between the boiler and any door, window,

or gravity inlet to a building (see Figure 11). Also, the

horizontal clearance should be maintained from any

electric meters, gas meters, regulators, or relief

equipment.

If the boiler is installed close to a structure,

protect it from rain water runoff with rain gutters on

the roof or other measures. Do not locate the boiler

near sprinkler systems that could spray water on it.

Avoid locations where wind deflection off

nearby structures might cause wind loading and

downdraft conditions. Where downdraft conditions

exist, locate the boiler at least 3 feet (0.9 m) from the

structure.

2C-3. Flooring - Typical Installation

All boilers are equipped with a special base, as a

standard part of the boiler. The unit is designed and

certified for installation on combustible flooring.

Never install the boiler on carpeting. Never store

objects on or around the base of the boiler.

For rooftop installation, see Figure 12 through

Figure 14.

WINDOW

OR GRILL

INDOOR

ROOM

Figure 10. Incorrect Outdoor Installation.

4 ft.

(1.2 m)

4 ft.

(1.2 m)

4 ft.

(1.2 m)

Figure 12. Standard Base for Combustible Floor.

Figure 11. Outdoor Location.

Figure 13. Typical Roof Mounting with Standard

Combustible Mount Base.

Mighty Therm HH-PH Hydronic Boilers

Page 7

Required Net Free Opening Area

Directly from Outside

At Top At Bottom

Model in.

175 44 284 44 284

250 63 406 63 406

325 82 529 82 529

400 100 645 100 645

Note: For screens or louvers, add 50%.

Table 2. Air Openings to Outside.

2

cm

2

in.

2

cm

2

Figure 14. Typical Roof Mounting.

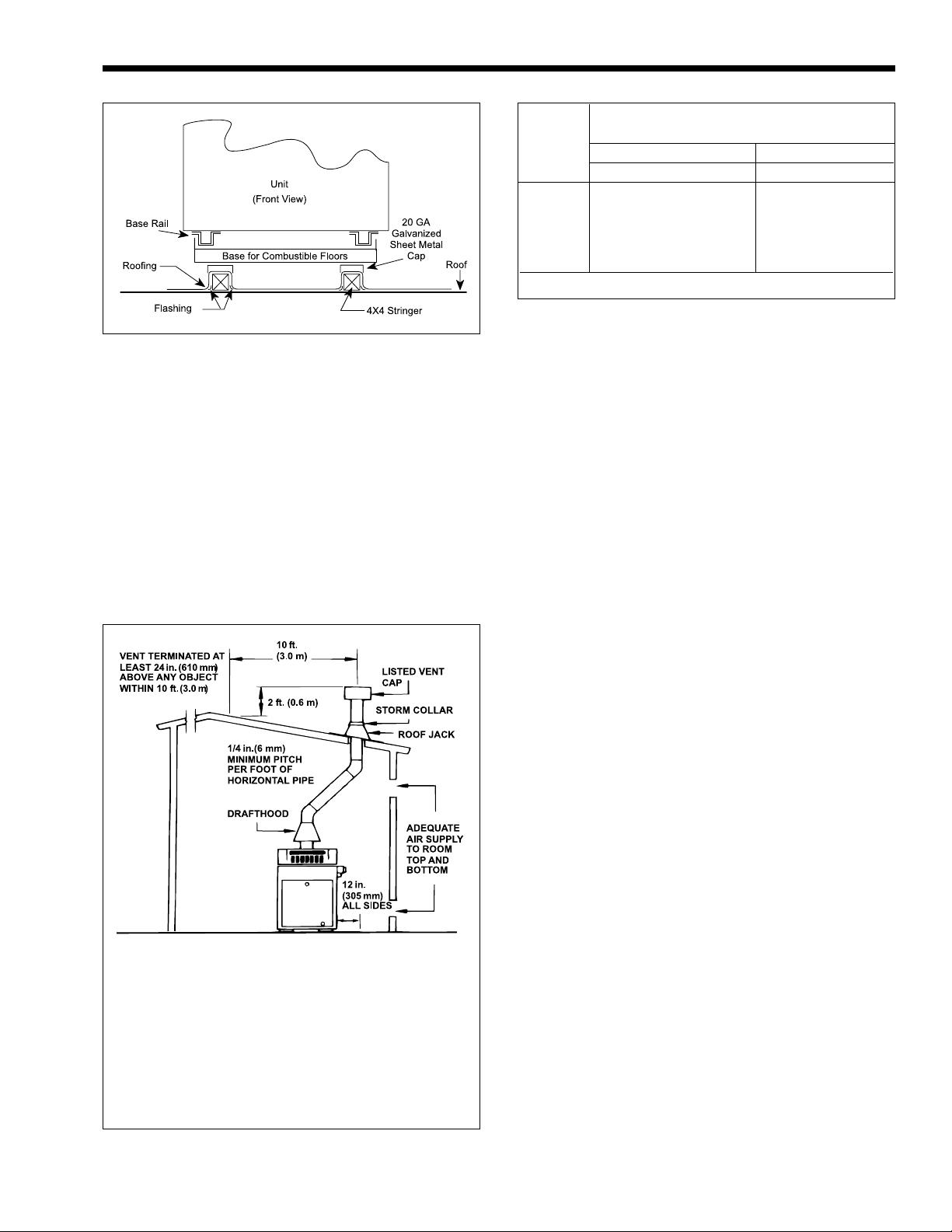

2D. Combustion and Ventilation

Air Supply

All indoor installations must have openings to

outside air for combustion, ventilation and dilution of

flue gases from inside the building (see Figure 15 and

Table 2). Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

Boiler rooms which are confined spaces require

two permanent air supply openings: one within

12 inches (305 mm) of the ceiling, the other within 12

inches (305 mm) of the floor.

NOTE: Check with louver manufacturers for net

free area of louvers. If not available, add 50 percent

for each screen/louver to the net free area. Check all

local codes applicable to combustion air.

2D-1. Outdoor Air Supply

When combustion air comes directly through an

outside wall, each opening must have a minimum free

area of at least one square inch for each 4,000 BTU/h

input of the total input rating of all appliances in the

enclosed area. (In Canada, refer to CGA B149.1

and .2.)

2D-2. Indoor Air Supply

Confined and non-confined areas have different

requirements for installation. Consult the latest edition

of the National Gas Code for installation requirements.

2D-3. Exhaust Fans or Vents

Any equipment which uses air or removes air

from the boiler room can use up the combustion air

supply or reverse the natural draft action of the

venting system. This could cause flue products to

build up in the boiler room. More air must be supplied

to make up for the decrease. This must be designed by

a qualified engineer.

Notes:

1. The drafthood must sit directly on top of the boiler

as shown and must not be altered in any manner.

2. An Underwriters' Laboratories listed vent cap is

required to eliminate downdraft and allow the

boiler to function properly.

3. Use approved roof fitting.

4. Vent damper is required on models 175 and 250.

Figure 15. Indoor Installation Venting.

2E. Venting of Combustion Products

2E-1. General Information

When installed indoors, the drafthood and the

vent damper device (models 175 and 250) must be

connected to a venting system without alteration. The

venting system must be installed by a qualified

installer and in accordance with the latest edition of

ANSI Z223.1. In Canada, the installation must be in

accordance with CAN1-B149.1 or .2, and any local

codes that apply.

The vent pipe must have a listed vent cap and

extend at least 2 feet (0.6 m) above any object within a

10 foot (3.0 m) radius (see Figure 15).

Page 8

LAARS HEATING SYSTEMS

NOTE: Do not use sheet metal screws at the

snap lock joints of Type B gas vents.

Do not weld or bolt the vent pipe to the boiler

drafthood or the vent damper if one is installed. The

weight of the stack must not rest on the boiler. The

drafthood and boiler top must be easily removable for

normal boiler service and inspection.

WARNING

Avoid ending boiler vents near air conditioning or air

supply fans. The fans can pick up exhaust flue

products from the boiler and return them inside the

building, creating a possible health hazard.

Avoid horizontal runs of the vent pipe, and 90

degree elbows, reductions and restrictions. Horizontal

runs should have at least a ¼ inch (6 mm) rise per foot

in the direction of flow. Support a vent connector for

the design and weight of the material used to maintain

clearances and prevent physical damage and

separation of joints.

Always use double-wall or insulated vent pipe

(Type B or equivalent).

WARNING

In cold weather, uninsulated outside vents can chill

the rising flue products, blocking the natural draft

action of the venting system. This can create a

health hazard by spilling flue products into the boiler

room.

fans, including range hoods and bathroom

exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan.

Close all fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the lighting instructions for the unit.

Adjust the thermostat so the appliance will

operate continuously.

5. After 5 minutes of main burner operation, test for

spillage at the draft hood relief opening. Use the

flame of a match or candle, or smoke from a

cigarette, cigar, or pipe.

6. The tests should show that each appliance

connected to the common venting system vents

properly. Return all doors, windows, exhaust

fans, fireplace dampers and any other gas-burning

appliances to their previous condition of use.

7. Any improper operation of the common venting

system should be corrected. The installation

should conform with the National Fuel Gas

Code, ANSI Z223.1. When resizing any portion

of the common venting system, the system

should be sized to approach the minimum

practical size. Refer to the tables in Appendix G

in the National Fuel Gas Code, ANSI Z223.1. (In

Canada, at the time the boiler is removed from

the common venting system, the common

venting system should be resized. The

installation should conform to CAN/CGA

B149.1 or .2.)

Avoid oversize vent piping or extremely long

runs of the pipe which may cause too much cooling

and condensation of flue gasses.

2E-2. Replacement of Existing Boiler

At the time of the removal of an existing boiler,

the following steps shall be followed with each

appliance remaining connected to the common venting

system. During the testing of each unit, the other

appliances remaining connected to the common

venting system should not be operated.

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch. Determine that there is

no blockage or restriction, leakage, corrosion, or

other deficiencies which could cause an unsafe

condition.

3. As far as possible, close all building doors and

windows. Also close all doors between the space

in which the appliances remaining connected to

the common venting system are located and the

other spaces of the building. Turn on any clothes

dryer and any appliance not connected to the

common venting system. Turn on any exhaust

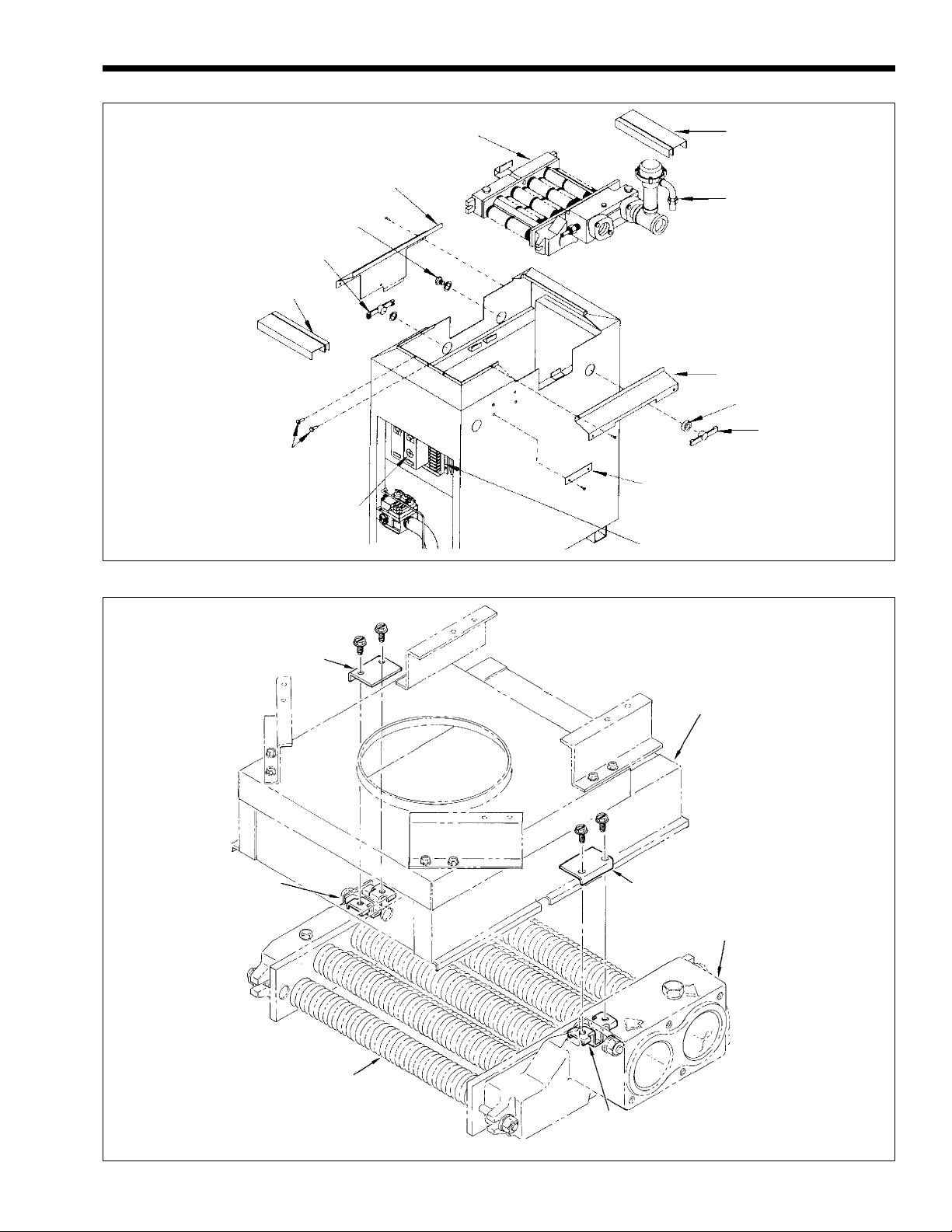

2F. Water Flow System

2F-1. Reversible Water Connections

NOTE: This procedure is not recommended for

the PH pump-mounted models.

Laars ships the HH boiler with the water

connections on the right side. The HH boiler can be

installed with the water connections on either side. It

could be necessary, or helpful, to switch the

connections to the left side to improve access for

installation service. Perform this modification

installing the boiler using the following procedures:

1. Remove the front door.

2. If there is a vent cap or drafthood installed, it

must be removed before removing the grate top

assembly. On indoor installations (models 175-

250), the drafthood switch must be disconnected

at the vent damper receptacle on the left side of

the boiler.

3. If the unit is in the low-profile outdoor

configuration, remove the hex-head screws (see

Figure 16) and lift the top assembly straight up.

4. Remove the screws that fastens the flue collector

hold-down clamps and remove the clamps (see

Figure 17).

before

Mighty Therm HH-PH Hydronic Boilers

Page 9

REAR TILE COVER

HEAT EXCHANGER

ASSEMBLY

DRAIN PLUG

DRAIN VALVE

REAR TILE

COVER

HEX HEAD

SCREWS

MANUAL RESET

HIGH LIMIT

SWITCH BOX

Figure 16. Heat Exchanger Removal.

FLOW SWITCH

CONDUIT

GAP CLOSURE

GROMMET

DRAIN

VALVE

METAL CHANNEL

(FOR CAPILLARY TUBE)

TERMINAL STRIP

Bracket

Clamp

Flue Collector

Clamp

In/Out Header

Heat Exchanger

Figure 17. Flue Collector Holddown Clamps.

Bracket

Loading...

Loading...