LAARS Mighty Therm AP Installation Manual

Installation and Operation Instructions Document 3006T

Installation and Operation

Instructions for

Mighty Therm

Pool Heating Boiler

Model AP

Sizes 500 - 1825

These instructions are to be stored in the

pocket provided on the heater.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualifi ed in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in fl ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a fi re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fi re department.

Installation and service must be performed

by a qualifi ed installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute blessure

ou la mort.

Ne pas entreposer ni utiliser d’essence ni d’autres

vapeurs ou liquides infl ammables dans le voisinage

de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par un

installateur ou un service d’entretien qualifi é ou par le

fournisseur de gaz.

AVERTISSEMENT

H0067300T

Page 2

LAARS Heating Systems

Table of Contents

Section 1

General Information

1.1 Introduction ....................................................3

1.2 Heater Identifi cation .......................................3

1.3 Primary/Secondary Pump and Piping ............3

1.4 Certifi cations ..................................................3

1.5 Engineering Assistance ................................. 3

Section 2

Installation

2.1 Heater Placement ..........................................4

2.2 Installation of Indoor Heaters ......................... 4

2.2.1 Combustion Air Supply ..................................4

2.2.2 Venting ...........................................................5

2.2.3 Common Venting System

Test Procedure ..............................................6

2.2.3 Instructions Relatives au Test des

Systèmes à Évent Commun ..........................6

2.3 Installation of Outdoor Heaters ......................7

2.4 Gas Supply and Piping ..................................7

2.5 Electrical Wiring .............................................8

2.6 General Piping Instructions ...........................9

2.7 Heater By-Pass Piping ..................................9

2.8 Temperature Sensor Placement

and Installation ..............................................9

2.9 Automatic Chlorinators ................................10

Section 3

Operation

3.1 Controls - General .......................................10

3.2 Initial Start-Up .............................................. 11

3.3 Safety Shutoff Component Checkout .......... 12

3.4 Inlet Temperature and

Temperature Rise Adjustment .....................13

3.5 Heater Shut Down ....................................... 13

3.6 Spring and Fall Operation

Stand-by Service .........................................13

3.7 Winter Operation Complete Shutdown ........ 14

3.8 Time Clock Operation ..................................14

3.9 Therapeutic Pools (Spas) ............................ 14

Section 4

Maintenance ..................................................... 15

Section 5

Troubleshooting

.............................................16

Section 6

Parts Description and Order Numbers ..18

Mighty Therm Commercial Pool Heating Boiler

Page 3

Section 1

General Information

1.1 Introduction

This manual provides information for the installation

and operation of Laars Model AP pool heating boilers.

It is strongly recommended that all application and

installation procedures be reviewed completely before

proceeding with the installation. Consult the Laars

factory, or local factory representative, with any problems

or questions regarding this equipment. Experience has

shown that most problems are caused by improper

installation, not system design.

Some accessory items are shipped in separate packages.

Verify receipt of all packages listed on the packing slip.

Inspect everything for possible damage upon delivery,

and inform the carrier of any shortages or impairments.

Any such claims should be fi led with the carrier. The

carrier, not the shipper, is responsible for shortages and

damage to the shipment whether visible or concealed.

WARNING

The model AP commercial pool heater must

be used on potable water only. For heating

pools containing salt water, a specially

equipped heater must be used; consult your

distributor or factory representative. The

pool heater must be installed in accordance

with the procedures outlined in this manual.

The warranty does not apply to heaters not installed or

operated in accordance with these procedures. Consult

local building and safety codes before proceeding with

work. The installation must conform to the requirements

of the authority having jurisdiction or, in the absence of

such requirements, to the latest edition of the National

Fuel Gas Code; ANSI Z223.1, National Electrical Code

ANSI/NFPA 70. In Canada, the installation must conform

with the latest edition of CSA B149 requirements.

When required by the authority having jurisdiction,

the installation must conform to American Society of

Mechanical Engineers safety codes for controls and

safety devices for automatically fi red heaters No. CSD-1,

and in Canada CSA 3.3. Any modifi cation of the heater,

its gas controls, gas orifi ces, wiring or drafter diverter

may void the Laars warranty. If fi eld conditions require

such modifi cations, consult the factory.

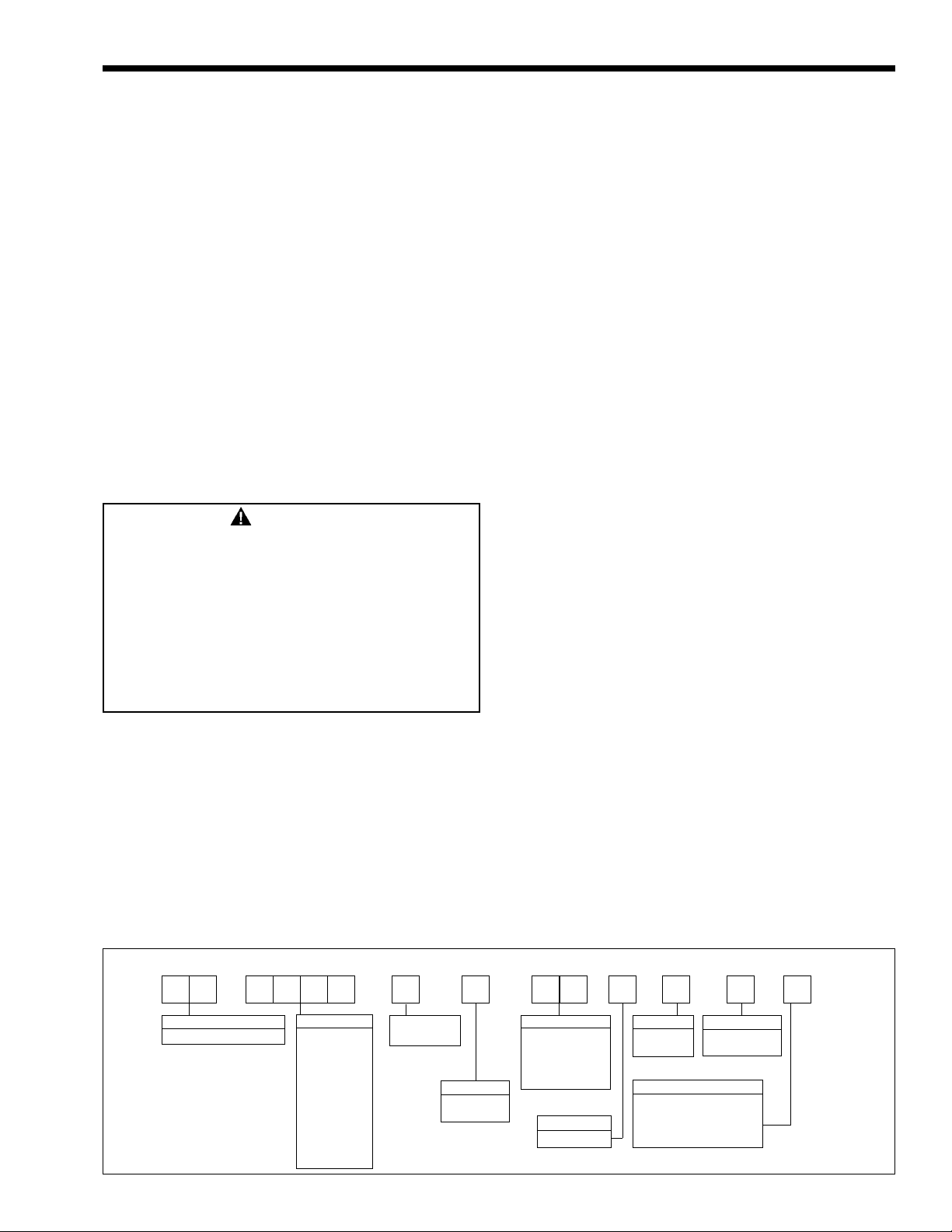

1.2 Heater Identifi cation

Consult rating plate on the heater. Shown below is a

breakdown of the model nomenclature. Laars commercial

pool heating boilers are available in two confi gurations:

an indoor version and an outdoor version. Outdoor

models are not available in Canada.

1.3 Primary/Secondary Pump and Piping

All models are supplied with integrally mounted pumps.

The 1825 models use a 3/4 HP pump and all other models

are supplied with 1/2 HP pumps. These pumps are sized

for the pressure drop through the heat exchanger and

through the bypass piping as shown in Figure 10.

Any deviations from the arrangement shown may

increase the head on the pump, reduce fl ow and hinder

performance (see Section 2.7). For spas see Section 3.9.

This piping arrangement and the integral pump allow hot

water to be recirculated to the heater inlet, thus raising

the inlet temperature and greatly reducing condensation.

1.4 Certifi cations

All models are design-certifi ed by CSA for natural or

propane gas and conform to ASME Code requirement for

160 PSI water pressure.

1.5 Engineering Assistance

Consult the factory or distributor regarding any questions

or problems which arise in the specifi cation, installation

or operation of Laars equipment. An experienced

engineering staff is ready to assist in assuring the proper

performance and application of Laars products.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

MODEL

AP-POOL

Figure 1. Heater Identifi cation (Model Nomenclature)

SIZE

BTU/HR X 1000

0500

0600

0715

0850

0999

1010

1200

1430

1670

1825

I-INDOOR

E-OUTDOOR

FUEL

N-NATURAL

P-PROPANE

IGNITION

04-SPARK 110V

09-SPARK 24V

11-SPARK 24V

16-STND. PILOT

FIRING MODE

ON/OFF

C

VERSION

1 - 8 TUBE

B-10 TUBE

HEAT EXCHANGER

C-GLASS LINED/COPPER

N-GLASS LINES/CU-NI

K-BRONZE/COPPER

S-BRONZE/CU-NI

REVISION

P-PUMP (U.S.)

Q-PUMP (CAN)

Page 4

LAARS Heating Systems

Section 2

Installation

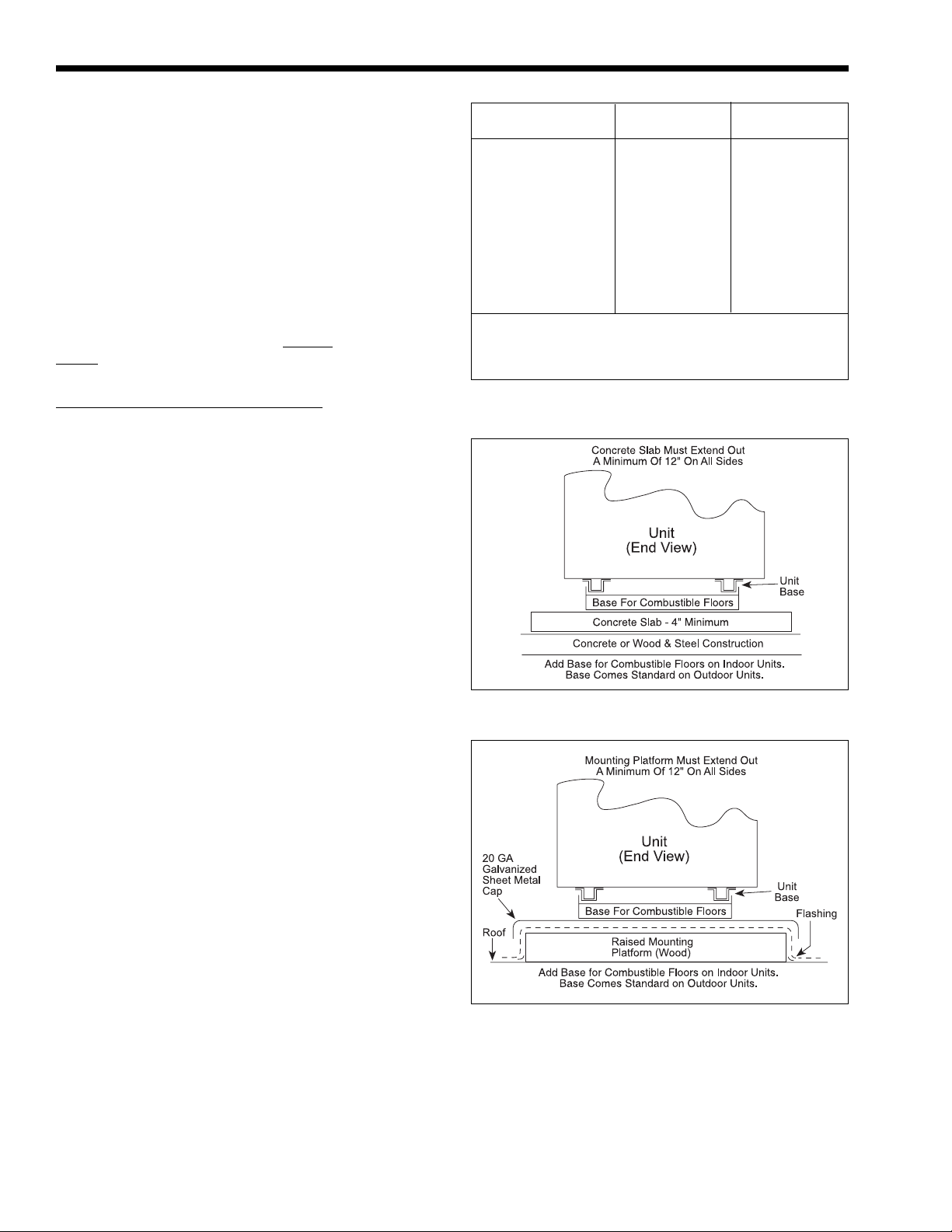

2.1 Heater Placement

The pool heater must be placed to provide specifi c

clearances on all sides for maintenance and inspections.

There must also be minimum distances maintained from

combustible surfaces. These clearances also apply to

noncombustible materials because the pool heater requires

air circulation for proper operation.

The pool heater should be mounted on a level surface. An

integral base for an installation on combustible fl ooring is

provided as standard equipment on outdoor models. For

indoor models, special base rails part number 10539000

must be used for combustible fl ooring.

Do not install a pool heater on carpeting.

Under the national Fuel Gas Code, ANSI Z223.1, it

is permissible to place the heater on fl oors other than

noncombustible when the installation complies with the

American Insurance Code. Figures 2, 3, 4 and 5 show

common installation on combustible fl ooring.

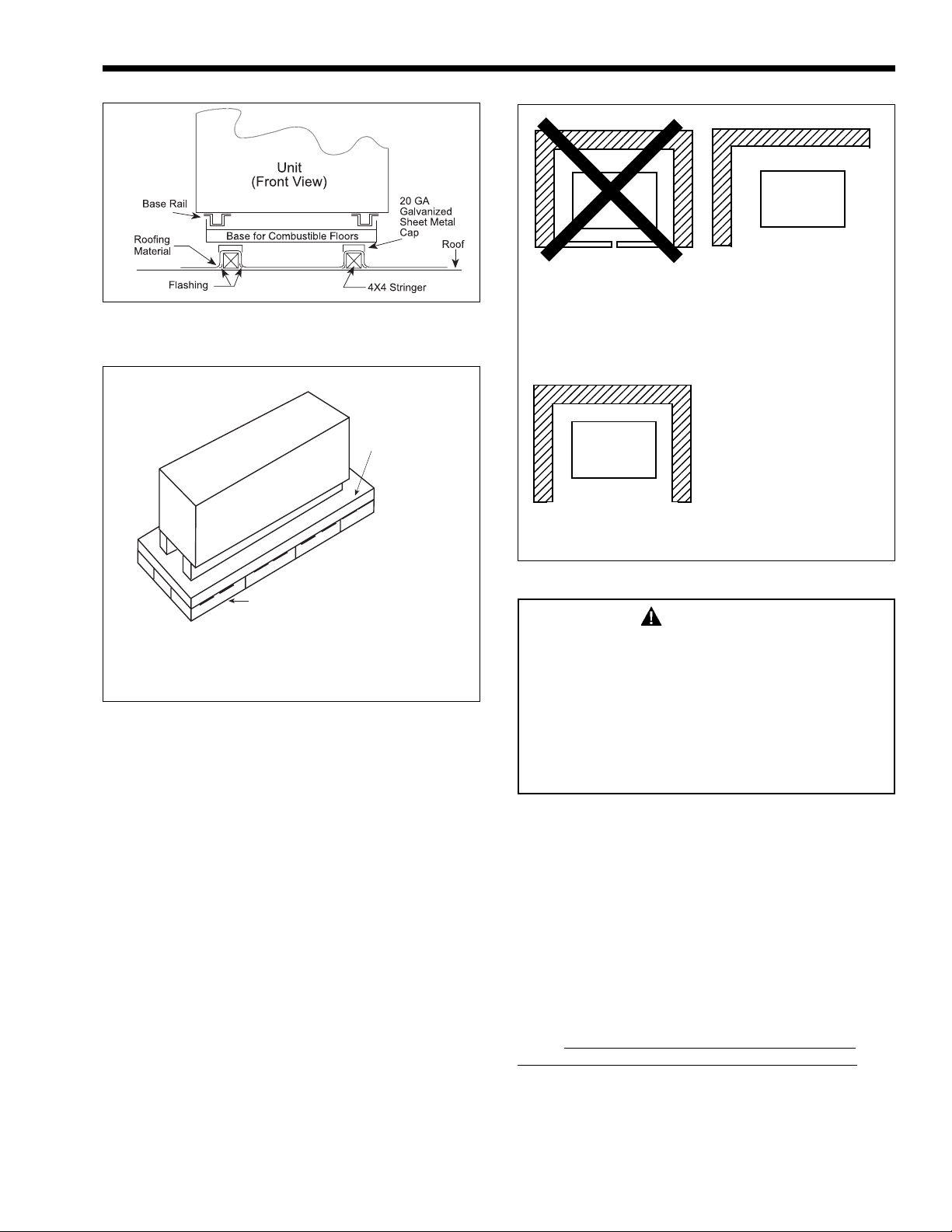

2.2 Installation of Indoor Heaters

Locate the pool heater to provide adequate clearance

for inspection and service on all sides. See Table 1. For

alcove installation, see Figure 6.

Install indoor heaters on a waterproof fl oor with an

adequate fl oor drain and a 6" (152mm) minimum curb on

all four sides to protect the building if heater repairs are

required. The manufacturer will not be held liable for

any water damage in connection with this heater.

2.2.1 Combustion Air Supply

The heater location must provide suffi cient air supply

for proper combustion and ventilation of the surrounding

area as outlined in the latest edition of ANSI standard

Z223.1, and any local codes that may be applicable. Inadequate combustion air supply may result in incomplete

combustion, sooting of the heat exchanger, and unsafe

operation of the heater.

Clearance Indoor Outdoor

from in. mm in. mm

Top 30 762 unobstructed

Water Conn. side 12* 305 24 610

Pump side 6* 152 24 610

Front Alcove* unobstructed

Rear 8 203 24 610

Vent pipe** 6 152 - - -

Hot water pipes per code per code

* Water connection and pump side clearances of 24"

(610mm) and front clearances of 48" (1219mm) will allow

easier service access.

** Using type B vent (refer to Manufacturer's Instructions).

Table 1 - Minimum Heater Clearances

from Adjacent Surfaces

Figure 2 - Typical Heater Installation on Concrete Slab

a. Conventional Ventilation

In the United States, the most common of these requirements specify that boiler rooms should be provided with

two permanent air supply openings communicating directly through the wall to outside air one within 12 inches

(305mm) of the ceiling, and the other within 12 inches

(305mm) of the fl oor. Each opening should have a minimum free area of one square inch (6.5 sq. cm) per 4,000

BTU/hr input of the total input rating of all appliances in

the enclosed area. See Table 2 for recommended air supply

for each model. An improperly ventilated equipment room

can get excessively hot and cause accelerated deterioration

of controls and electrical components.

Pool heaters installed in vaults (“pits”) must have

combustion air ducted to bottom of the vault, even if the top

is unobstructed. Ducting should be sized for a minimum of

one square inch (6.5 sq. cm) per 2,000 BTU/hr input of the

Figure 3 - Typical Heater Installation on Roof

Using Raised Platform (Wood)

total input rating of all appliances in the vault. Contact the

Service Department for more information.

In Canada, Table 2 does not apply. Consult local building

codes or, in the absence of such requirements, follow

CSA B149 standard.

Mighty Therm Commercial Pool Heating Boiler

Page 5

Water

Heater

Figure 4 - Typical Heater Installation on Roof

Using 4x4 Stringer

Base must extend out

min. 12" (305mm) on

all sides of

heater frame.

Concrete blocks or tile min. 7" (178mm)

high with 3" (76mm) min. air openings.

Blocks must provide solid base and be braced so they

cannot slip out of place. Air openings in blocks must be

arranged to provide unobstructed opening through entire

width or length of base.

Figure 5 - Installation on Concrete Blocks or Tile

20 ga. min.

galvanized sheet

metal

under entire

heater.

b. Forced-Air Ventilation

In the United States: any equipment which exhausts air

from the boiler room can deplete the combustion air

supply or reverse the natural draft action of the venting

system. This could cause fl ue products to accumulate

in the boiler room. Additional air must be supplied to

compensate for such exhaust. The information in Table

2 is not applicable in installations where exhaust fans or

blowers of any type are used. Such installations must be

designed by qualifi ed engineers.

In Canada: follow Canadian standard, CSA B149 or local

codes.

If a blower or fan is used to supply air to the boiler room,

the installer should make sure it does not create drafts

which could cause nuisance shutdowns of the pilot. If a

blower is necessary to provide adequate combustion air

to the heater, a suitable switch or interlock must be wired

into the heater control circuit to prevent the heater from

fi ring unless the blower is operating.

The heater must be completely isolated and protected

from any source of corrosive chemical fumes such as

trichlorethylene, perchloroethylene, chlorine, etc.

CLOSET INSTALLATION

(UNACCEPTABLE)

A closet is any 4 sided enclosure

which is less than 16* times the total

volume of all the gas fired appliances

within the enclosure.

Water

Heater

* When the ceiling height exceeds 8 feet, you are only allowed to consider 8

feet when calculating the total volume of the enclosure.

Figure 6 - Alcove Installation

ROOM INSTALLATION

(ACCEPTABLE)

A room is any enclosure which is at

least 16* times greater than the total

volume of all the gas fired appliances

within the enclosure.

ALCOVE INSTALLATION

(ACCEPTABLE)

An alcove suitable for the installation

of a water heater is a restricted section

of a room not separated from the

room by a door or partition and which

meets the minimum clearances for

the specific model water heater listed

below.

WARNING

Chemicals stored in the equipment room may

cause corrosion. Sodium hypochlorite feeders,

vented tablet containers, pellet salt and other

chemicals may off-gas into the air in the room

and be drawn into the combustion and dilution

air, corroding the pool heater's metallic parts.

Corrosion damage is not covered under the

limited warranty.

2.2.2 Venting

Laars heaters have built-in draft diverters for natural draft

operation and must not be connected to any portion of a

mechanical draft system under positive pressure. The fl ue

outlet must be connected to a clear, unobstructed vent of

adequate capacity ending above the highest point of the

building with an approved vent cap. The venting system

should be installed according to the latest edition of

ANSI Z223.1 and/or, in Canada, CSA B149 and any local

codes having jurisdiction.

Do not weld or fasten the vent pipe to the heater

drafthood. The weight of the stack must not rest on the

heater. The drafthood and heater top must be easily

removable for normal heater service and inspection.

IMPORTANT NOTE: Do not use sheet metal screws at

the snap lock joints of Type B gas vents.

Avoid using long horizontal runs of the vent pipe, and too

many 90° elbows, reductions or restrictions. Horizontal

runs should have at least a 1/4" (6mm) rise per foot in the

Page 6

LAARS Heating Systems

direction of fl ow. A vent connector should be supported

for the design and weight of the material used to maintain

clearances and prevent physical damage and separation

of joints.

Avoid terminating heater vents near air conditioning

or air supply fans. The fans can pick up exhausted fl ue

products from the heater and return them inside the

building creating a possible health hazard. A minimum

of 4 feet (1.2m), in Canada 6 feet (1.8m), horizontal

distance must be maintained from electrical meters, gas

meters, and relief equipment.

Always use double-wall or insulated vent pipe (Type B

or equivalent). In cold weather, uninsulated outside vents

can chill the rising fl ue products blocking the natural

draft action of the venting systems. This can create a

health hazard by spilling fl ue products in the boiler room.

When the installation of a draft fan is necessary

in connecting a venting system to a Laars heater,

the installation should be engineered by competent

personnel following good engineering practices. The

draft fan supplier should be consulted for correct size.

The installation should be in accordance with the latest

edition of ANSI Z223.1 and/or, in Canada, CSA B149

and any local codes having jurisdiction. When a draft

fan is installed, a suitable draft switch must be wired into

the heater control circuit at terminal designated "Field

Interlock" to prevent fi ring of the heater unless a positive

draft has been established.

2.2.3 Common Venting System

Test Procedure

At the time of the removal of an existing heater, the

following steps shall be followed with each appliance

remaining connected to the common venting system.

During the testing of each unit, the other appliances

remaining connected to the common venting system

should not be operated.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch. Determine that there is no

blockage or restriction, leakage, corrosion, or other

defi ciencies which could cause an unsafe condition.

3. Insofar as it is practical, close all building doors and

windows. Also close all doors between the space

in which the appliances remaining connected to the

common venting system are located and the other

spaces of the building. Turn on any clothes dryer

and any appliance not connected to the common

venting system. Turn on any exhaust fans, in clud ing

range hoods and bath room ex hausts, so they will

operate at maximum speed. Do not operate a

summer exhaust fan. Close all fi replace dampers.

4. Place in operation the appliance being in spect ed.

Follow the lighting instructions for the unit.

Adjust the thermostat so the appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use

the fl ame of a match or candle, or smoke from a

cigarette, cigar, or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fi replace dampers and

any other gas-burning appliance to their previous

condition of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1 and/or CSA B149, Installation Codes. When

resizing any portion of the common venting system,

the common venting system should be resized to

approach the minimum size as determined using the

appropriate tables in Appendix G in the National

Fuel Gas Code, ANSI Z223.1 and/or CSA B149

Installation Codes.

2.2.3 Instructions Relatives au Test des Systèmes à

Évent Commun

Au moment du restrait dʼune chaudière existante, les

mesures suivantes doivent être prises pour chaque

appareil toujours reccordé au système dʼévacuation ne

fonctionnet pas:

1. Sceller toutes les ouvertures non utilisées du

systèmes dʼévacuation.

2. Inspecter de façon visuelle le système dʼévacuation

pour déterminer la grosseur et lʼinclinaison

horizontale qui conviennent et sʼassurer que le

système est exempt dʼobstruction, dʼétranglement,

de fuite, de corrosion et autres défaillances qui

pourraient présenter des risques.

3. Dans la mesure du possible, fermer toutes les portes

et les fenêtres du bâtiment et toutes les portes entre

lʼespace où les appareils toujours raccordés au

système dʼévacuation sont installés et les autres

espaces du bâtiment. Mettre en marche les sécheuses, tous les appareils non raccordés au système

dʼévacuation common et tous les ventilateurs

dʼextraction comme les hottes de cuisinière et les

ventilateurs des salles de bain. Sʼassurer que ces

ventilateurs fonctionnent à la vitesse maximale. Ne

pas faire fonctionner les ventilateurs dʼété. Fermer

les registres des cheminées.

4. Mettre lʼappareil inspecté en marche. Suivre les

instructions dʼallumage. Régler le thermostat de

façon que lʼappareil fonctionne de façon continue.

5. Faire fonctionner le brûleur principal pendant 5 min

ensuite, déterminer si le coupe-tirage déborde à louverture

de décharge. Utiliser la fl amme dʼune chandelle ou la

fumée dʼune cigarette, dʼune cigare ou dʼune pipe.

6. Une fois quʼil a été déterminé, selon la méthode

indiquée ci-dessus, que chaque appareil raccordé

au systéme dʼévacuation est mis à lʼair libre de

façon adéquate. Remettre les portes et les fenêtres,

les ventilateurs, les registres de cheminées et les

appareils au gaz à leur position originale.

Mighty Therm Commercial Pool Heating Boiler

Page 7

7. Tout mauvais fonctionnement du systéme

dʼévacuation commun devrait être corrigé de façon

que lʼinstallation soit conforme au National Fuel Gas

Code, ANSI.Z223.1 et (ou) aux Codes dʼInstallation

CSA B149. Si la grosseur dʼune section du système

dʼévacuation doit être modifi ée, le système devrait

être modifi é pour respecter les valeurs minimales des

tableaux pertinents de lʼappendice G du National

Fuel Gas Code, ANSI Z2231.1 et (ou) des Codes

dʼInstallation CSA B149.

2.3 Installation of Outdoor Heaters

1. Locate the heater to provide the clearances as listed

in Table 1, “Minimum Heater Clearances.”

2. Do not place the heater in an enclosure or wall

recess. Avoid locations where wind defl ection off

structures might cause downdraft. When such wind

conditions are possible, place the heater at least 3

feet (0.9m) from the structures.

3. If the heater must be installed in a four sided

enclosure with an open top, such as when

equipment is surrounded by block walls, provision

for combustion air at the bottom of the enclosure

must be provided even if the enclosure is large.

Openings with a minimum of 1 square inch (6.5

sq. cm) per 4,000 BTU/hr input of all appliances

contained in the enclosure must be located in the

walls within 12” of the fl oor to provide enough

combustion air for the pool heater.

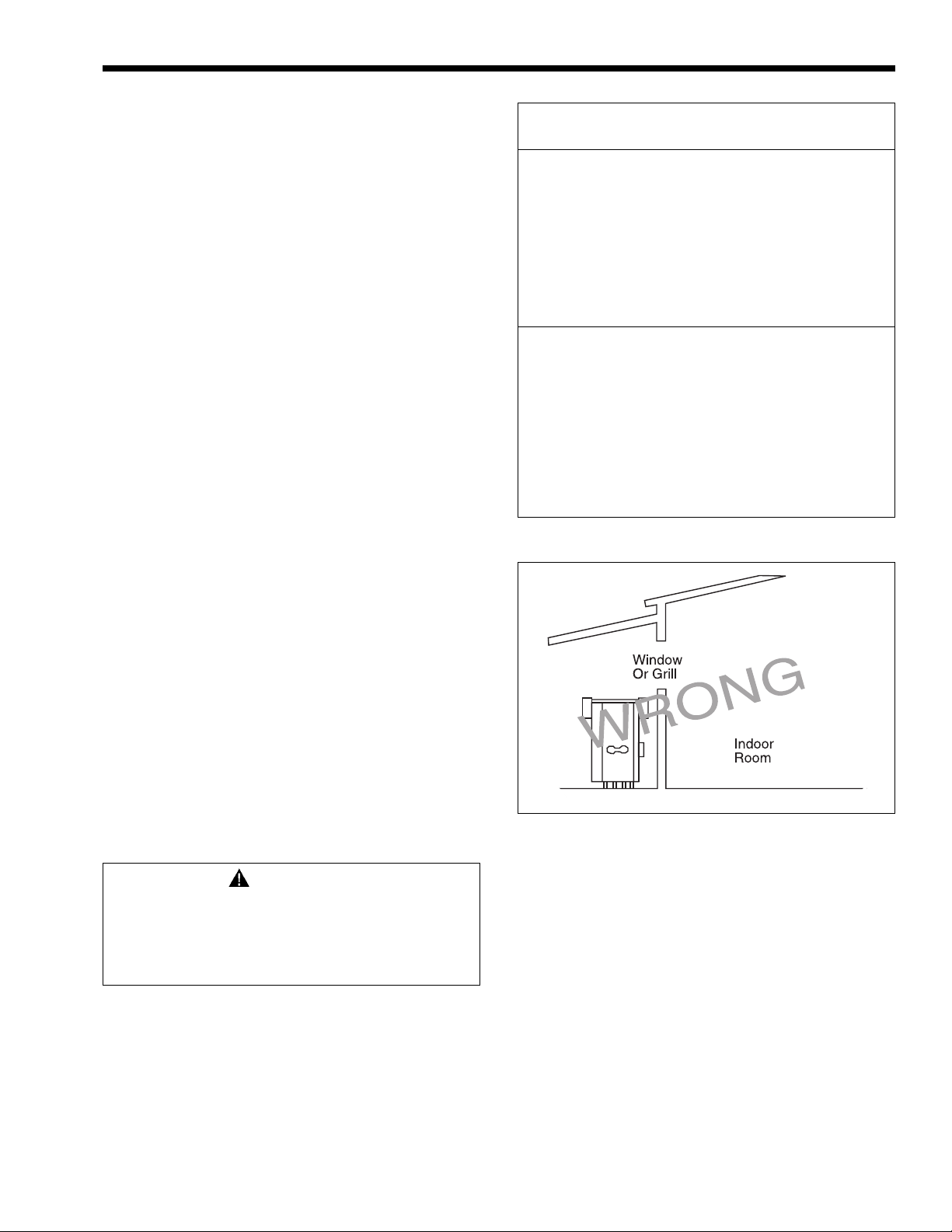

4. Never install the heater under any kind of roof

overhang. Do not place the heater below or adjacent

to any doors, windows, louvers, grills, etc., which

connect in any way with an inhabited area of a

building. This includes other structures such as

garages or utility rooms (see Figure 7).

5. Although these models are CSA design certifi ed

for outdoor installations, such installations are not

recommended in areas where the danger of freezing

exists unless proper precautions are taken for freeze

protection.

Outdoor installations are not recommended in areas

where the danger of snow blockage exists.

WARNING

Liquefi ed petroleum gas is heavier than air.

Therefore, the pool heater should not be

installed in pits or other locations where gas

could accumulate.

The heater should be located a safe distance from

Propane gas storage and fi lling equipment. Consult local

codes and fi re protection authorities for advice on specifi c

installation restrictions.

2.4 Gas Supply and Piping

Review the following instructions before proceeding with

the installation.

1. Verify that the heater is fi tted for the proper type of gas

by checking the rating plate. Laars heaters are normally

Heater Each Opening*

Size square inches square cm

500 125 806.5

600 150 967.8

715 179 1154.9

850 213 1374.3

1010 253 1632.4

1200 300 1935.6

1430 358 2309.8

1670 418 2696.9

1825 457 2948.6

Net Free Area.

*

Check with louver manufacturers for net free area of louvers.

Correct for screen resistance to the net free area if a screen is

installed. Check all local codes applicable to combustion air.

Area indicated is for one of two openings: one at fl oor level and

one at the ceiling, so the total net free area could be double the

fi gures indicated. For special conditions refer to the latest edition

of ANSI Z223.1.

Consult factory if openings do not communicate directly through

the walls with the outdoors.

Table 2 - Minimum Recommended Air Supply to Heater

Figure 7 - Incorrect Outdoor Installation

equipped to operate below a 2000 foot (609.6m)

altitude. Heaters equipped to operate at higher altitudes

have appropriate stickers or tags attached, also printed

information on rating plate.

2. Use the fi gures in Table 3 to provide adequate gas

piping from the gas meter to the heater.

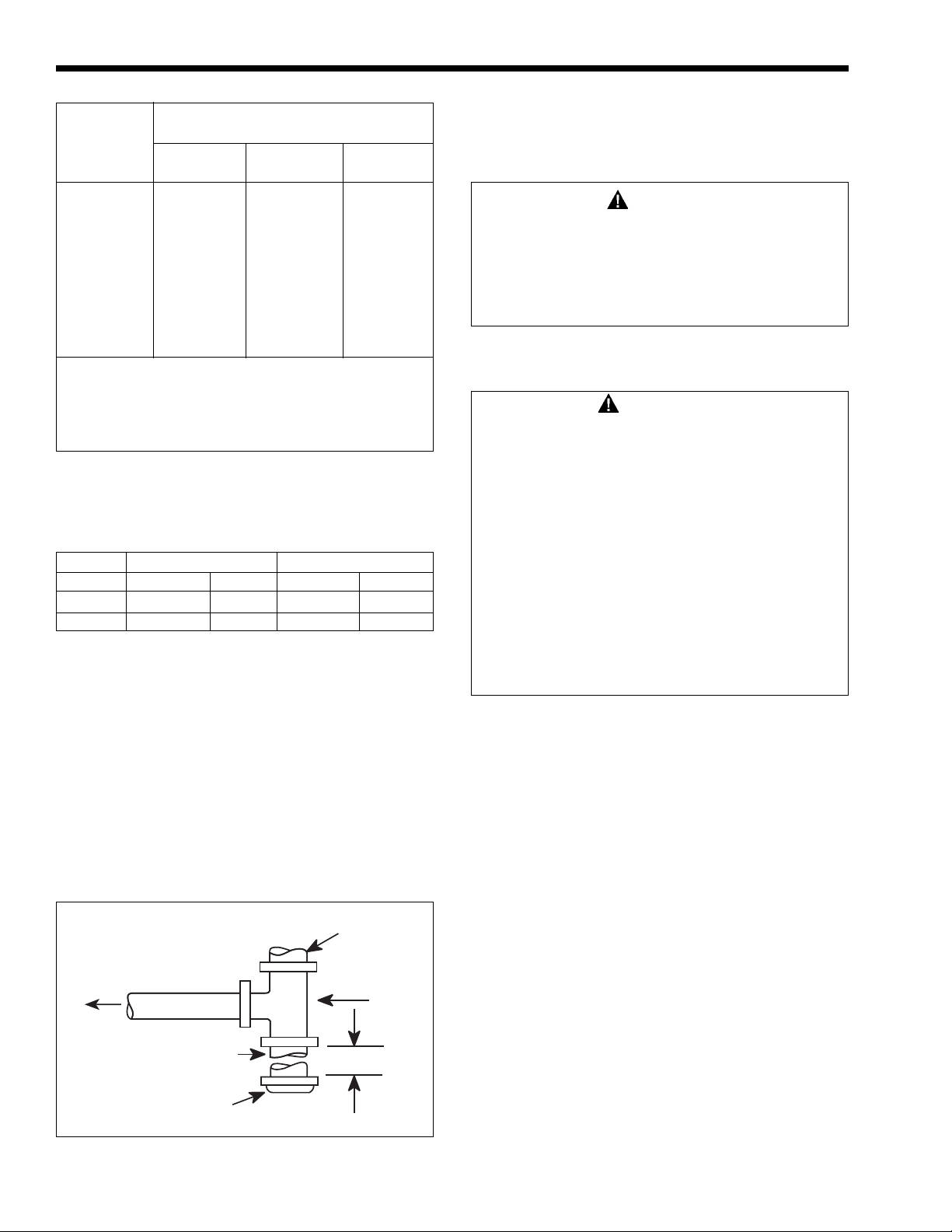

3. A sediment trap (drip leg) must be provided ahead

of the gas controls (see Figure 8). A manual gas

shutoff valve must also be provided for service

convenience and safety. Check the local codes.

4. The heater and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa). The heater

must be isolated from the gas supply piping system

by closing its individual manual gas shutoff valve

during any pressure testing of the piping system at

test pressures equal to or less than 1/2 psig (3.5kPa).

Page 8

LAARS Heating Systems

Distance from Gas Meter

Heater or Last Stage Regulator

Size

0-30.5m 30.5-61m 61-91.4m

500 1½" 2" 2"

600 1½" 2" 2½"

715 2" 2" 2½"

850 2" 2½" 2½"

1010 2" 2½" 3"

1200 2½" 3" 3"

1430 2½" 3" 3"

1670 2½" 3" 3

1825 2½" 3" 3½"

NOTE: These fi gures are for Natural Gas (.65 Sp. Gr.), and are

based on 1/2" water column pressure drop. Check supply pressure

with a manometer, and local code requirements for variations. For

Propane Gas, reduce pipe diameter one size. An average number

of tees and elbows have been taken into account.

Table 3 - Gas Piping Sizes

0-100' 100-200' 200-300'

5. Provide gas supply pressure to the heater as

follows:

Natural Gas Propane Gas

In. W.C. kPa In. W.C. kPa

Max. 10 2.5 13 3.4

Min. 6.5 1.6 11 2.7

NOTE: the heater and all other gas appliances sharing

the heater gas supply line must be fi ring at maximum

capacity to properly measure the inlet supply pressure.

Low gas pressure could be an indication of an undersized

gas meter and /or obstructed gas supply line.

6. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator is preset

at the factory and normally requires no further

adjustment.

The gas manifold and control assembly is

factory tested and conforms to the safe lighting and other

performance criteria specifi ed in the latest editions of

ANSI Z21.13.CSA4.9, Low Pressure Boiler Standard.

Gas Supply

To

Equipment

Inlet

Nipple

Cap

Figure 8 - Sediment Trap Installation

Inlet

Te e

Fitting

3" (76mm) Min.

Before operating the heater, the complete gas supply

system and all connections must be tested for leaks using

a soap solution. Do not use raw fl ame.

Caution

Since some leak test solutions (including soap

and water) may cause corrosion or stress

cracking, the piping must be rinsed with water

after testing, unless it has been determined

that the leak test solution is noncorrosive.

2.5 Electrical Wiring

WARNING

The heater must be electrically grounded in

accordance with the most recent edition of

the National Electrical Code, ANSI/NFPA 70.

In Canada, all electrical wiring to the heater

should be in accordance with the latest edition

of CSA C22.1 Canadian Electrical Code, Part

1. Do not rely on the gas or water piping to

ground the metal parts of the heater. Plastic

pipe or dielectric unions often isolate the

heater electrically. Service and maintenance

personnel who work on or around the heater

may be standing on wet fl oors and could be

electrocuted by an ungrounded heater.

Wiring diagrams are included in the information packet

provided with each unit.

1. All Model AP pool heating heaters need 115V

60Hz supply voltage unless specifi cally ordered

otherwise.

2. The 1825 models are supplied with 3/4 HP pump

motors. All other models are supplied with 1/2 HP

pump motors. Consult the National Electrical Code

or the Canadian Electrical Code regarding branch

circuit requirements for equipment with these

motors.

3. The heaters should be wired exactly as shown in the

wiring diagram.

IMPORTANT NOTE: The pool fi lter pump and heater

must be electrically interlocked so the heater cannot

come on unless the pump is running and there is full

fl ow in the fi lter piping where the heater is connected. If

the pool fi lter pump operation is intermittent the heater

must be shut off prior to pump shutdown. See paragraph

heading Auxiliary Time Clock Wiring on the next page.

If the backwash operation is manual the heater must be

shut off manually during backwashing.

Mighty Therm Commercial Pool Heating Boiler

Figure 9 - Pressure Relief Valve Location

Auxiliary Time Clock Wiring:

If a time clock is used to control the fi lter pump

operation, a separate switch or relay must be used to

shut off the heater at least 15 minutes before the fi lter

pump is shut off. Wire the switch or relay (often called

the Fireman Switch) to the terminals shown in the wiring

diagram as “Field Interlock.”

4. All fi eld installed electrical safety devices and all

fi eld installed controllers (valve end switches, draft

switches, relays, timers) can be connected to the

heater control to the terminals shown in the wiring

diagram designated “Field Interlock.”

5. Field location of the temperature sensor is

described in Section 2.8.

Where the heater is installed with a draft fan refer to

the fan manufacturer's wiring diagram. The draft switch

should be wired across the fi eld interlock terminals in the

heater control panel.

Page 9

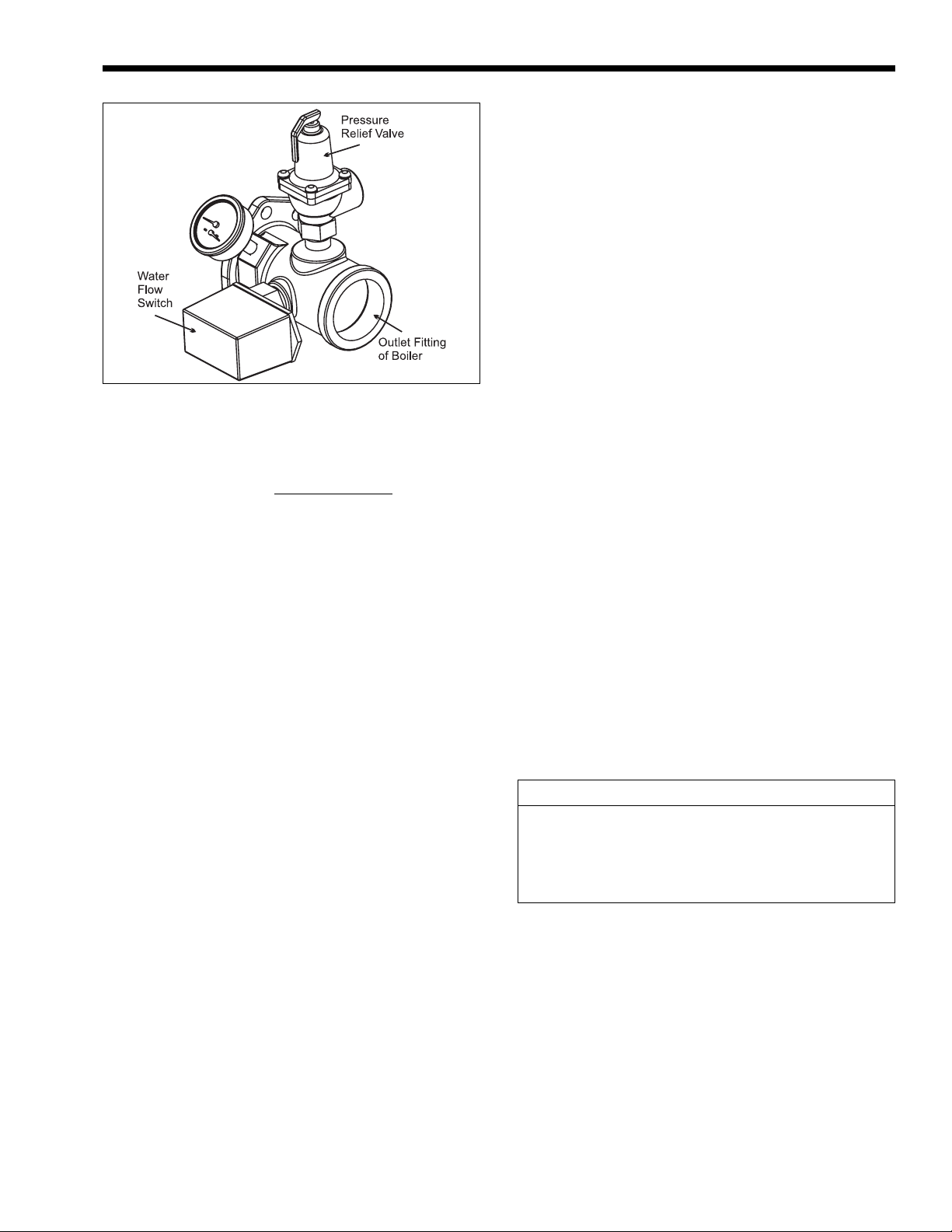

The pressure relief valve lever must be tripped at least

once a year to ensure that waterways are clean. When

manually operating lever, water will discharge through

the drain line. Precautions must be taken to avoid contact

with hot water and water damage.

2.7 Heater By-Pass Piping

All AP series heaters, 500-1825 models, must be installed

with bypass piping. Please use Figure 10 as your guide to

plumb the bypass. For spas see Section 3.9.

All models are supplied with integral pumps. These

pumps are sized for the pressure drop through the heat

exchanger, 30' of piping, and through the bypass piping

as shown in Figure 10.

If the distance from the pool heater to the pool loop

piping is greater than 15' please contact the Service

Department for assistance (see back page for phone and

fax numbers).

Any deviations from the arrangement shown may reduce

fl ow, hinder performance, and will void the warranty.

2½ inch NPT piping is shown, however, models 500I1430I and models 500E-1010E may be installed using 2

inch NPT piping.

All models must be installed in the primary/secondary

arrangement shown. The heater loop piping must tee into the

fi lter loop piping with the inlet and outlet connection spaced

a maximum of 4 pipe diameters apart (see Figure 10).

The integral pump will provide the right amount of fl ow

for the pool heater, and the return water to the pool will

be maintained below 104°F, provided the piping diagram

is followed correctly and the fi lter pump fl ow rate is at

least the “Minimum Filter Pump Flow Rate” in Table 4.

The outlet valve “B” and the bypass valve “A” must have

a provision for locking the handles in place (or removing

them) after the temperature rise and inlet temperature

adjustments have been made.

2.6 General Piping Instructions

In addition to the bypass valve “A” and outlet valve

“B” shown in Figure 10, an inlet valve “C” should be

provided so that the heater can be readily isolated for

service. Butterfl y and globe valves are recommended for

this application to allow for precise adjustment of water

fl ows. For spa applications see Section 3.9.

Since heater outlet temperatures can reach 150°F (66°C)

in some cases, copper or CPVC are recommended

materials for heater connection piping. PVC material may

be used for the inlet valve and the piping upstream of it.

When pipe, fi ttings, grids or any other element of the

fi lter system are made of plastic materials, they may be

damaged by the momentary "back siphoning" of hot

water from the heater when the fi lter pump stops running.

The pressure relief valve installed in the tapped opening

provided in the outlet header (see Figure 9), must be

piped, but not connected, to a drain or fl oor sink. The

drain pipe must be the same size as the valve outlet and

must pitch downward from the valve. Where no special

setting of the relief valve is ordered, the factory will

furnish a 75 psi setting.

Heater Model Minimum Filter Pump Flow Rate

500-850 90 GPM

1010-1200 110 GPM

1430 140 GPM

1670-1825 180 GPM

Table 4 - Minimum Flow to Supply Heater Loop

2.8 Temperature Sensor Placement

and Installation

Two temperature sensing devices are installed on the

heater that require sensing bulbs be fi eld installed

according to Figure 10.

1. Install the thermistor based sensor's immersion

well on the underside of the pool loop piping. The

well should be installed just upstream of the heater

inlet tee. DO NOT INSTALL the bulb in the

heater loop piping or down stream of the heater

outlet tee.

Loading...

Loading...