Page 1

Installation, Operation and Maintenance Instructions Document 2060D

Installation,

Operation and

Maintenance

Instructions for

Mighty Max

Hydronic Boilers

Model HH

Sizes 320M - 1000M

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

If the information in this manual is not

WARNING

followed exactly , a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by a

qualified installer , service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’inst allation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2090800D

Page 2

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction.................................................... 3

1B. Warranty........................................................3

1C. Technical Assistance.....................................3

SECTION 2.

Installation Instructions

2A. General Information....................................... 4

2B. Boiler Placement ........................................... 4

2C. Installation of Outdoor Boilers........................4

2D. Freeze Protection .......................................... 4

2E. Installation of Indoor Boilers...........................5

2E-1. Combustion Air Supply and Ventilation ..........5

2E-2. Removal of Existing Boiler............................. 5

2F. Gas Supply and Piping .................................. 6

2G. Water System Requirements.........................8

2G-1. Flow Requirements........................................8

2G-2. Variable Water Flow Systems........................8

2G-3. System Pressure Requirements ....................9

2G-4. Hot/Chilled Water Systems............................ 9

2G-5. Combined Space Heating/Potable

Water Heating Systems................................. 9

2H. Piping of System to Boiler .............................. 9

2I. Filling the System ........................................ 10

2J. Venting and Combustion Air Information ..... 10

2K. Top-to-Rear Vent Collar Conversion............12

2L. Venting ........................................................ 13

2L-1. Vertical Venting - Category I ........................ 13

2L-2. Vertical Venting - Non Category I.................13

2L-3. Vertical Venting - Non Category 1................13

2L-4. Side Wall Vent Terminal ..............................14

2M. Air for Combustion and Ventilation............... 14

2M-1. Air From Room ............................................ 15

2M-2. Ducted Combustion Air................................15

2M-3. Conversion for Ducted

Combustion Air ............................................ 15

2M-4. Combustion Air Piping ................................. 16

2N. Electrical Wiring ........................................... 16

SECTION 3.

Operating Instructions

3A. Start Up Requirements ................................ 16

3B. Hi-Limit checkout ......................................... 18

3C. Venturi and Gas Pressure

Regulator System ........................................ 18

3C-1. Overall Operation......................................... 18

3C-2. Venturi Adjustment ...................................... 18

3D. To Start Up System ..................................... 19

3D-1. Setting Temperature Controls...................... 20

3E. To Shut Down System ................................. 20

3F. Venturi Combustion Flow System ................ 20

3F-1. Pressure Measurement Ports ...................... 20

3F-2. Venturi Adjustment ...................................... 20

3F-3. Venturi Setup Procedure..............................22

SECTION 4.

Maintenance

4A. General Instructions..................................... 22

4B. Heat Exchanger........................................... 22

4B-1. Inspection of the Heat Exchanger................ 23

4B-1a. External heat Exchanger Inspection ............ 23

4B-1b. Internal Heat Exchanger Inspection ............. 23

4B-2. Cleaning the Heat Exchanger ...................... 23

4B-2a. Cleaning the Heat Exchanger - External...... 23

4B-2b. Cleaning the Heat Exchanger - Internal ....... 23

4C. Gas and Electric Controls ............................ 23

4D. Filter ............................................................ 24

4D-1. Filter Function .............................................. 24

4D-2. Filter Service................................................ 24

SECTION 5.

Troubleshooting

5A. Sequence of Operation................................ 24

5B. Venturi and Gas Pressure

Regulator System ........................................ 26

5B-1. Field Checkout............................................. 26

5C. Electrical Components ................................. 26

5C-1. General Troubleshooting ............................. 26

5C-2. Electrical Troubleshooting ........................... 26

SECTION 6.

Parts List for Mighty Max HH Boiler

6A. General Information..................................... 27

Page 3

Mighty Max Hydronic Boiler

Page 3

SECTION 1.

General Information

1A. Introduction

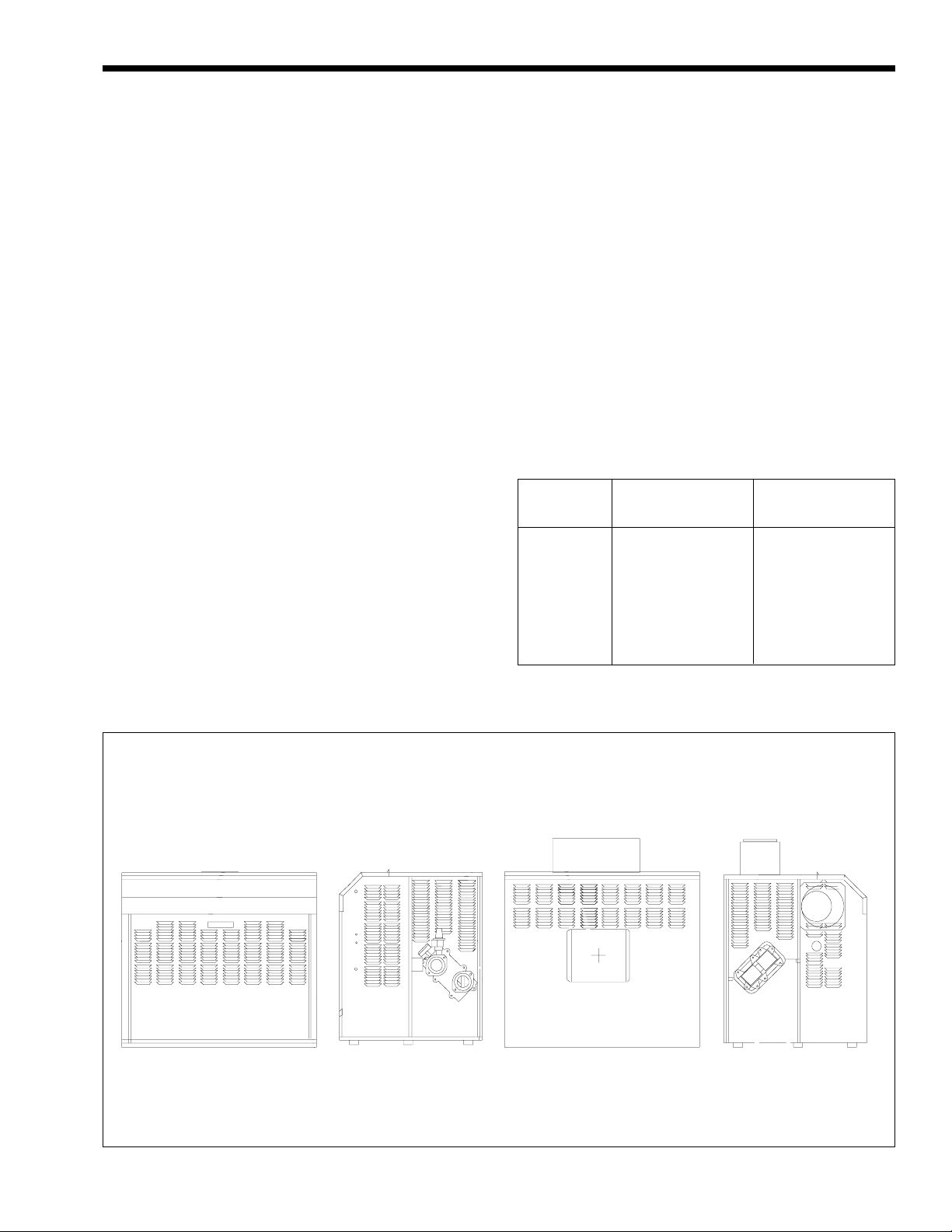

This manual contains installation, operation and

maintenance instruction for the Mighty Max hydronic

boiler, Model HH, sizes 320M, 400M, 520M, 625M,

775M and 1000M. Review all application and

installation procedures completely before proceeding

with the installation. Consult the local factory

representative or Laars factory with any questions

regarding this equipment. Experience has shown that

most operating problems are caused by improper

installation. The HH boilers are offered in an indoor

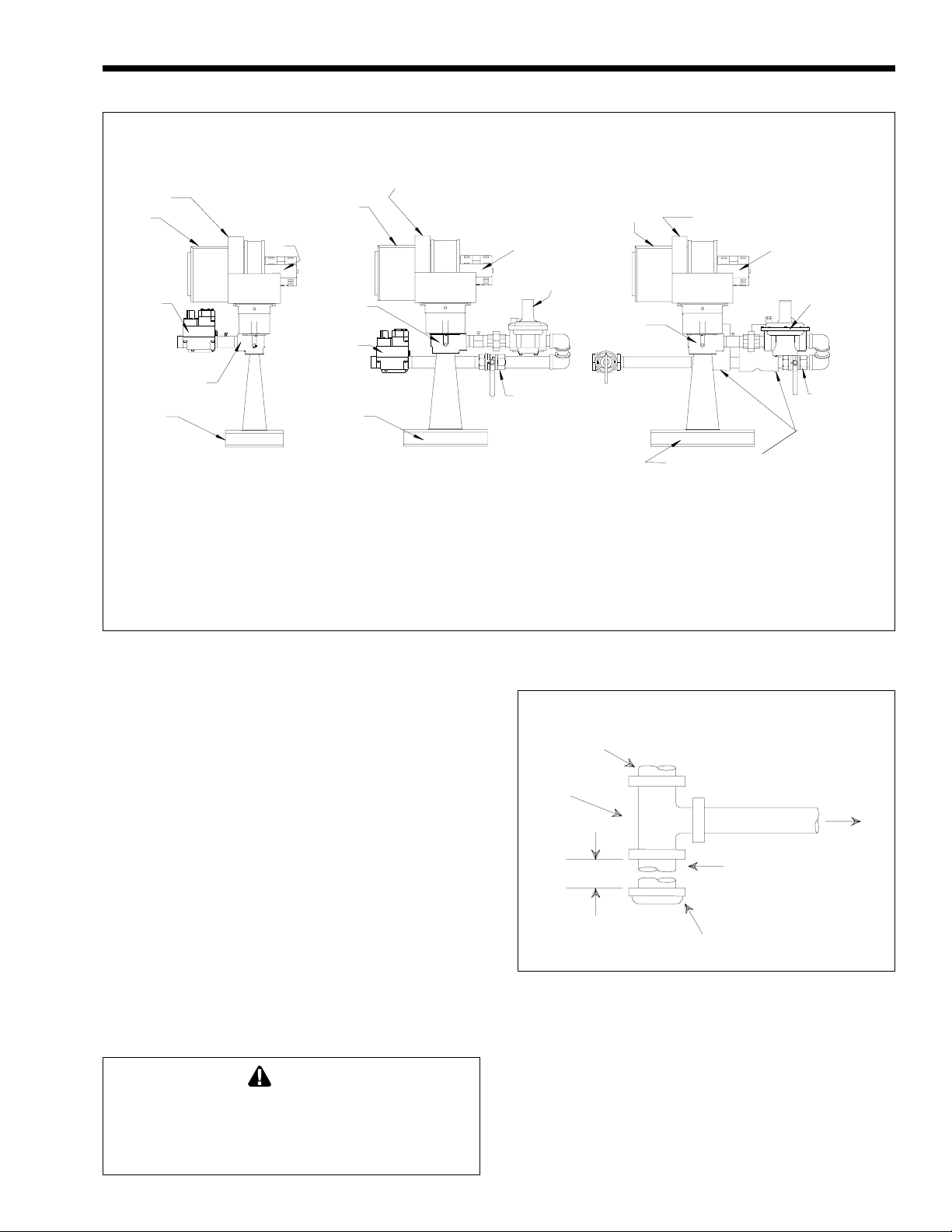

version and an outdoor version (see Figure 1). Table 1

lists the input/output ratings for each boiler size.

The indoor version is convertible for outdoor use

with the installation of a conversion kit. See Section 6,

Parts List, for part number.

1B. Warranty

The Mighty Max HH boilers are sold with a

limited factory warranty. Details are specified on the

back cover of this manual.

Make all warranty claims to an authorized Laars

representative or directly to the factory. Claims must

include the heater serial number and model number

(this information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

Some accessory items are shipped in separate

packages. Inspect everything for damage immediately

upon delivery, and advise the transporter of any

shortages or damage. Any such claims should be filed

with the transporter. The transporter will not accept a

claim from the shipper, Laars.

The warranty does not cover damage caused by

improper installation, operation, or field modification.

1C. Technical Assistance

Consult the local factory representative or Laars

factory with any questions regarding the specification,

installation, and operation of Laars equipment. An

experienced technical support staff is ready to assist in

assuring the proper performance and application of

Laars products.

Boiler Input Output

Size BTU/h kW BTU/h kW

320M 320,000 94 272,000 80

400M 399,000 17 339,150 99

520M 520,000 152 442,000 130

625M 625,000 183 531,250 156

775M 775,000 227 658,750 193

1000M 1,000,000 293 850,000 249

Table 1. Input/Output Ratings.

INDOOR OUTDOOR

Front Side

(Water Connections)

Figure 1. Mighty Max HH Boiler Configuration.

Rear Side

(Opposite Water

Connections)

Page 4

Page 4

LAARS HEATING SYSTEMS

SECTION 2.

Installation Instructions

2A. General Information

Install the Mighty Max HH boiler in accordance

with the procedures in this manual (or the Laars

warranty may be voided), local codes, and ordinances.

In the absence of such codes, install the heaters in

accordance with the latest edition of the National Fuel

Gas Code, ANSI Z223.1/National Fire Protection

Association (NFPA) 54. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2 and

local codes. The authority having jurisdiction may

require the installation be in accordance with the

American Society of Mechanical Engineers (ASME)

Safety Codes for Controls and Safety Devices for

Automatically Fired Heaters, CSD-1, and in Canada,

Canadian Gas Association (CGA) 3.3. Any changes to

the boiler, its gas controls, gas orifices or wiring may

void the warranty. If field conditions require change,

consult the factory.

The Mighty Max HH boiler is designed-certified

for installation on a combustible floor. Do not install

the boiler directly on carpeting.

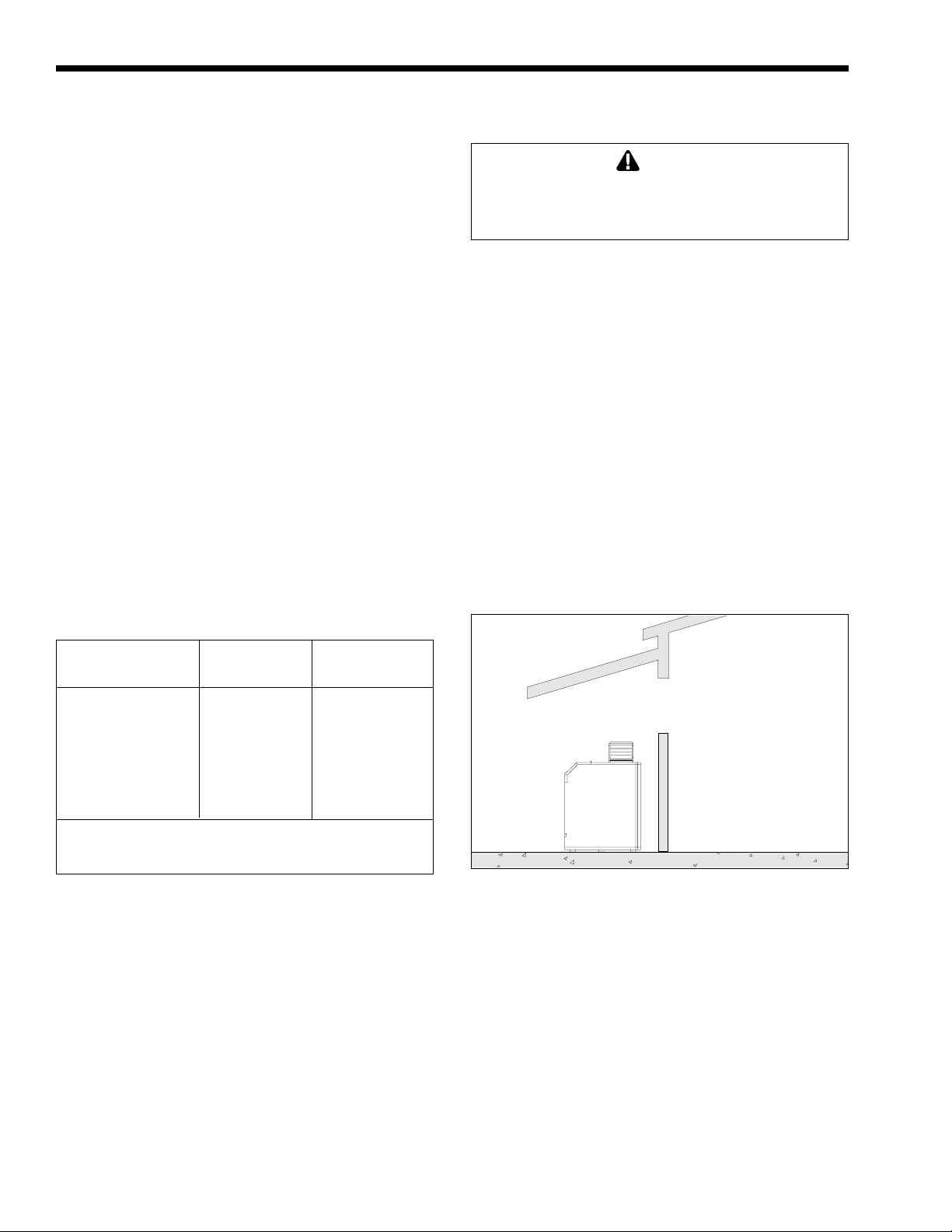

2B. Boiler Placement

2C. Installation of Outdoor Boilers

Caution

Outdoor installations are not recommended in

areas where the danger of snow blockage

exists.

1. Locate the boiler to provide at least the

minimum clearances as listed in Section 2B,

“Boiler Placement.” HH boilers require an

outdoor terminal kit when installed outdoors (see

Section 6, Parts List).

2. Do not locate the boiler in an enclosure or

through-wall recess. Avoid locations where wind

deflection off structures might cause down-draft.

When such wind conditions are possible, locate

the boiler at least 3 feet (.9m) from structures.

3. Never install the boiler under any kind of roof

overhang. Do not locate the boiler below or

adjacent to any doors, windows, louvers, grills,

etc. which communicate in any way with an

inhabited area of a building, even though such

communication might be through another

structure such as a garage or utility room (see

Figure 2).

Clearance From Indoor Outdoor

Combustibles Inches mm Inches mm

Top 18 457 Unobstructed

Water Conn. Side 12 305 12 305

Opposite Side 6 152 6 152

Front Alcove Unobstructed

Rear 6 152 6 152

Vent *6* 152 —

Flooring Combustible Combustible

Service clearance = 24 in. (610mm) at front of boiler.

*1 in. (25mm) if double wall vent is used.

Table 2. Minimum Boiler Clearances

from Combustible Surfaces.

Locate the boiler to provide adequate clearances

on all sides for maintenance and inspection. There

must also be minimum distances maintained from

combustible surfaces (See Table 2).

The boiler must be isolated or otherwise

protected from any source of corrosive chemical

fumes, such as trichlorethylene, perchlorethylene,

chlorine, etc. Install the boiler so that the gas ignition

system components are protected from water

(drippings, spraying, rain, etc.) during operation and

service.

WINDOW

OR GRILL

WRONG

Figure 2. Incorrect Installation of Boiler.

INDOOR

ROOM

2D. Freeze Protection

Boiler installations are not recommended in

areas where the danger of freezing exists unless

proper precautions are made for freeze protection.

Maintaining a mixture of 50% water and 50%

properly inhibited HVAC glycol is the preferred

method of freeze protection for hydronic systems. (Do

not use automotive antifreeze.) This mixture will

protect the boiler to temperatures of about -35°F

(-37°C). To get the desired temperature rise across the

boiler when this mixture is used, increase the water

flow recommendation by 15%. Increase the head loss

requirement by 20%. Note: If your application does

Page 5

Mighty Max Hydronic Boiler

Page 5

not require the full freeze protection of a 50%/50%

mixture, it is beneficial to use a maximum 30% glycol

solution. This mixture will protect the boiler to

temperatures of about 5°F (-15°C), and will serve as

burst protection for boilers that are not in use.

2E. Installation of Indoor Boilers

2E-1. Combustion Air Supply and

Ventilation

There are a variety of options available to the

installer when it comes to venting and combustion air;

venting can be vertical or horizontal, it can originate

at the top of the boiler or the back, and combustion air

can be obtained from the room where the boiler is

installed or ducted directly to the boiler from

outdoors. See Sections 2J through 2M for details.

2E-2. Removal of Existing Boiler

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion

and other deficiencies which could cause an

unsafe condition.

3. Insofar as is practical, close all building doors

and windows, and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers

and any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust

thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

if the appliance is equipped with a drafthood,

after 5 minutes of main burner operation. Use

the flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return door, windows, exhaust fans,

fireplace dampers and any other gas-burning

appliances to their previous condition of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code,

ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the

minimum size as determined using the

appropriate Tables in Appendix G in the

National Fuel Gas Code, ANSI Z223.1.

In Canada, at the time the boiler is removed from

common venting system, the common venting system

should be resized so the installation conforms to

CAN/CGA B149.1 or .2.

2E-2. Removal of Existing Boiler

Au moment du retrait d’une chaudière existante,

les mesures suivantes doivent être prises pour chaque

appareil toujours raccordé au système d’evacuation

commun et qui fonctionne alors que d’autres appareils

toujours raccordés au système d’évacuation ne

fonctionnent pas:

1. Sceller toutes les ouvertures non utilisées du

système d’évacuation.

2. Inspecter de façon visuelle le système

d’évacuation pour déterminer la grosseur et

l’inclinaison horiztonale qui conviennent et

s’assurer que le système est exempt

d’obstruction, d’étranglement, de fuite, de

corrosion et autres défaillances qui pourraient

présenter des risques.

3. Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l’espace, où les appareils tojours

raccordés et les autres espaces du bâtiment.

Mettre en marche les sécheuses, tous les

appareils non raccordés au système d’évacuation

commun et tous les ventilateurs d’extraction

comme les hottes de cuisinère et les ventilateurs

des salles de bain. S’assurer que ces ventilateurs

fonctionnent à la vitesse maximale, Ne pas faire

fonctionner les ventilateurs d’été. Fermer les

registres des cheminées.

4. Mettre l’appareil inspecté en marche. Suivre les

instructions d’allumage. Régler le thermostat de

façon continue.

5. Faire fonctionner le brûleur principal pendant 5

min ensuite déterminer si le coupe-tirage

déborde à l’ouverture de décharge. Utiliser la

flamme d’une allumette ou d’une chandelle ou la

afumée d’une cigarette, d’une cigare ou d’une

pipe.

6. Une fois qu’il a été déterminé, selon la méthode

indiquée ci-dessus, que chaque appareil raccordé

Page 6

Page 6

LAARS HEATING SYSTEMS

Distance from Gas Meter or Last Stage Regulator

0-100 feet 100-200 feet 200-300 feet

0-30m 30-60m 60-90m

Natural Propane Natural Propane Natural Propane

Size in.

320M

400M

520M

625M

775M

1000M

Notes: 1. These numbers are based on 1/2 inch (13mm) water column pressure drop.

1.25

1.25

1.50

1.50

2.00

2.00

2. Check supply pressure and local code requirements before proceeding with work.

3. Pipe fittings must be considered when determining gas pipe sizing.

mm

32

32

38

38

51

51

in.

1.25

1.25

1.25

1.25

1.50

1.50

Table 3. Natural Gas and Propane, Pipe Size Requirements.

au systéme d’évacuation est mis à l’air libre de

façon adéquate. Remettre les portes et les

fenêres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position

originale.

7. Tout mauvais fonctionnement du systéme

d’évacuation commun devrait êvacuation

commun devrait être corrigé de façon que

l’installation soit conforme au National Fuel

Gas Code, ANSI Z223.1/NFPA 54 et (ou) aux

codes d’installation CAN/CGA-B149. Si la

grosseur d’une section du systéme devrait être

modifié ppour respecter les valeurs minimales

des tableaux pertinents de l’appendice F du

National Fuel Gas Code, ANSI Z223.1/NFPA 54

et (ou) des codes d’installation CAN/CGA-B149.

mm

32

32

32

32

38

38

in.

1.50

1.50

2.00

2.00

2.00

2.50

mm

38

38

51

51

51

64

in.

1.25

1.25

1.50

1.50

1.50

2.00

mm

32

32

38

38

38

51

operate at high altitudes have appropriate

stickers or tags attached.

3. The figures in Table 3 should be used to size the

gas piping from the gas meter to the boiler.

Check local codes for BTU/h capacity required.

4. Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 4). Fit the trap with a

threaded cap which can be removed for cleaning.

5. When required by code, install a second manual

gas shutoff valve. Do not remove manual shutoff

valve supplied with the boiler.

6. Disconnect the boiler and its individual shutoff

valve from the gas supply piping system during

pressure testing of the system at pressures higher

than 1/2 psi (3.5 kPa). Isolate the boiler from the

gas supply piping system by closing its

2F. Gas Supply and Piping

Review the following instructions before

continuing the installation.

1. Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1/NFPA 54.

In Canada, the installation must be in accordance

with CAN1-B149.1 or .2 and all local codes that

apply. See Figure 3 for boiler gas valve

individual manual gas shutoff valve during any

pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psi

(3.5 kPa).

7. Gas supply pressures to the boiler are listed in

Table 4.

Supply Pressure

Water Column

arrangement.

2. Check the rating plate to make sure the boiler is

Minimum 5

fitted for the type of gas being used. Laars

boilers are normally equipped to operate below a

2000 foot (610m) altitude. Boilers equipped to

Maximum 9

Table 4. Gas Supply Pressure Requirements.

in.

1.50

2.00

2.00

2.00

2.50

3.00

mm

38

51

51

51

64

76

Natural Gas Propane Gas

in.

mm

127

229

in.

1.50

1.50

1.50

2.00

2.00

2.50

in.

9

14

mm

38

38

38

51

51

64

mm

229

356

Page 7

Mighty Max Hydronic Boiler

Air Shutter

Enclosure

Filter

Housing

Automatic,

Regulator

and

Redundant

Gas Valve

Mixture

Plenum

Venturi

Blower

Motor

Filter

Housing

Venturi

Automatic

and

Redundant

Gas Valve

Mixture

Plenum

Air Shutter

Enclosure

Blower

Motor

Regulator

Manual Gas

Valves When

Used On

Canadian Unit

or U.S.Unit

Requiring

CSD-1 Code

Filter

Housing

Venturi

Air Shutter

Enclosure

Mixture

Plenum

Blower

Motor

Automatic

Main

Gas Valves

Page 7

Regulator

Manual Gas

Valves When

Used On

Canadian Unit

or U.S.Unit

Requiring

CSD-1 Code

SIZES:

320M, 400M

SIZES:

520M, 625M

SIZES:

775M, 1000M

Note: The above diagram is a representation. Actual venturi assembly may vary depending on boiler size.

Figure 3. Boiler Gas Valve Arrangement.

NOTE: The boiler and all other gas appliances

sharing the boiler gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could be an

Gas Supply

Inlet

indication of an undersize gas meter and/or obstructed

gas supply line.

8. Do not exceed the maximum inlet gas pressures

Tee

Fitting

specified. Excessive pressure will result in

damage to the heater's gas controls. The

minimum pressures specified are for gas input

3 In.

(76mm) Min.

Nipple

adjustment.

9. The correct differential gas pressure is stamped

on the rating plate. The regulator is preset at the

Cap

factory, but may need adjustment for altitude per

Section 3.

10. Before operating the heater, test the complete

Figure 4. T-Fitting Sediment Trap Installation.

gas supply system and all connections for leaks

using a soap solution.

To Equipment

Inlet

Caution

Since some leak test solutions (including soap

and water) may cause corrosion or stress

cracking, rinse the piping with water after

testing.

Page 8

Page 8

LAARS HEATING SYSTEMS

2G. Water System Requirements

2G-1. Flow Requirements

The Model HH boilers must have continuous

flow through the heat exchanger when firing for

proper operation. The system pump must be capable

of developing sufficient pressure to overcome the

resistance of the boiler plus the entire circulating

system at the designated flow (see Table 5). The

temperature rise across the boiler should never exceed

40°F (22°C).

2G-2. Variable Water Flow Systems

There can be reduced water flow through the

boiler in heating systems using zone valves, zone

pumps or 3-way valves. This can result in a high

temperature rise across the boiler. Laars recommends

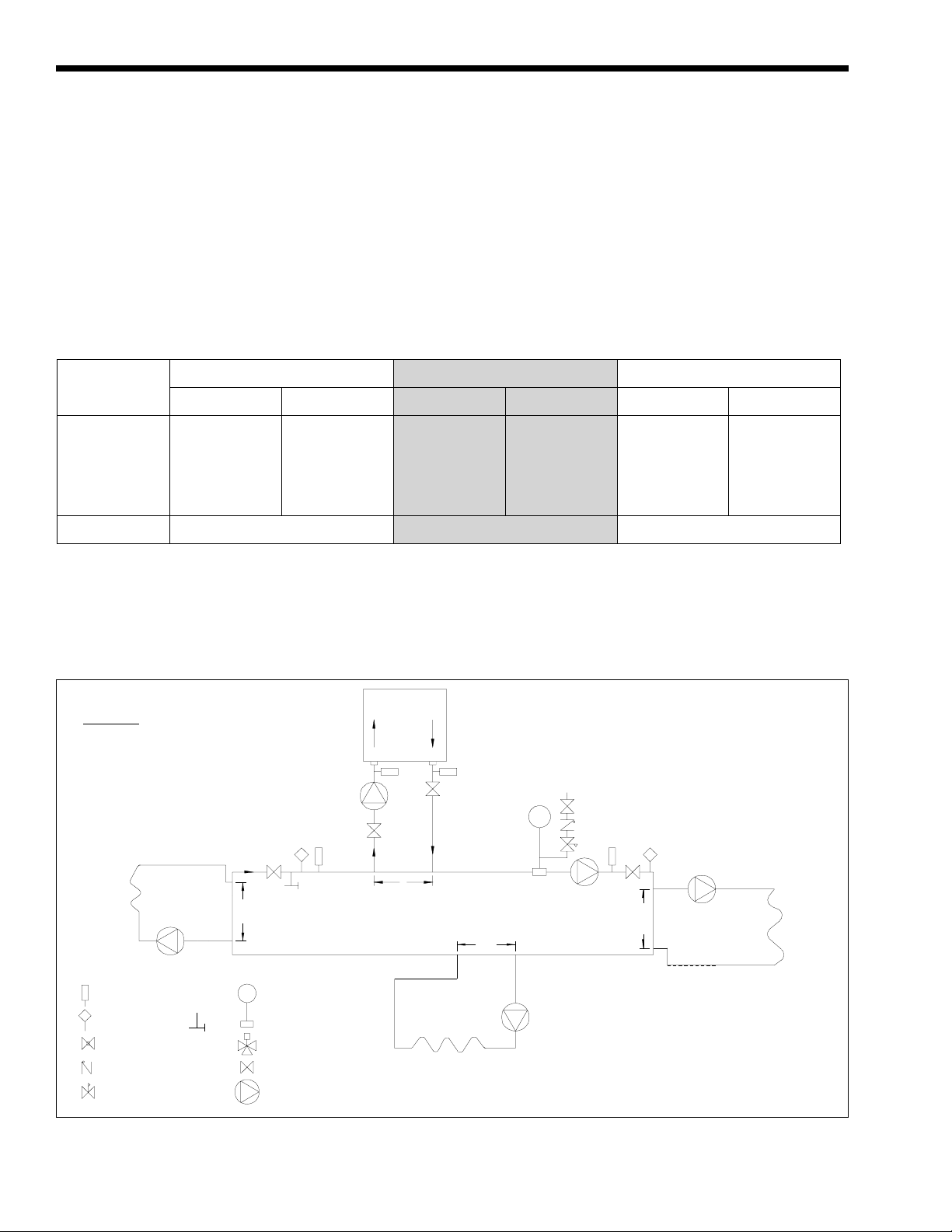

primary-secondary pumping for all variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler

even though the system flow is variable. In a primarysecondary system the pressure drop of the boiler is not

added to the system (see Figure 5).

TEMPERA TURE RISE IN DEGREES (°F / °C )

10°F

6°C

15°F

MODEL

LPS H/L m

3.41

4.29

5.55

6.69

8.33

10.73

3.4

8.0

2.7

3.7

6.9

11.4

GPM H/L ft.

36

45

58

70

87

113

5.0

11.5

4.0

5.7

9.4

16.5

HH0320M

HH0400M

HH0520M

HH0625M

HH0775M

HH1000M

GPM H/L ft.

54

68

88

106

132

170

11.2

26.2

8.9

12.2

22.5

37.3

Flow High Normal Low

NOTES: Sizes 320M and 400M use 4-pass heat exchangers; 520M, 625M and 775M use 2-pass heat exchangers.

*Pressure drop (head loss) through the boiler, expressed in ft. of H2O.

Shaded area is the recommended flow and temperature rise. Minimum inlet temperature is 105°F.

8°C

LPS H/L m

2.27

2.84

3.66

4.42

5.49

7.13

1.5

3.5

1.2

1.7

2.9

5.0

20°F

GPM H/L ft.

27

34

44

53

65

85

2.8

6.6

2.6

3.3

5.2

9.4

11°C

LPS H/L m

1.70

2.15

2.78

3.34

4.10

5.36

0.9

2.0

0.8

1.0

1.6

2.9

WARNING: This drawing shows suggested

piping configuraiton and valving. Check with

local codes and ordinances for additional

requirements.

Boiler Circulation

12"

Max.

LEGEND:

Thermometer

Temperature

Sensor

Globe Valve

Check Valve

Pressure Reducing Valve

w/Fast Fill Bypass

Purge

Valve

Expansion T ank

with Air Scoop and

Auto Air Vent

3-Way Valve

Valve

Pump

Pump

Table 5. Temperature Rise.

12"

Max.

12"

Max.

Cold Water

Make-Up

System Pump

12"

Max.

Boiler circuit piping must be equal to or larger than

boiler water connection size.

Boiler circulation pump sized for flow through

boiler.

Dotted devices indicate alternate locations.

Figure 5. Primary-Secondary Plumbing.

Page 9

Mighty Max Hydronic Boiler

Page 9

2G-3. System Pressure Requirements

The Model HH boilers are designed to operate

on closed, pressurized systems. Maintain a minimum

of 12 psi (81.8 kPa) on the system where boiler supply

water temperature is 200°F (93°C) or less. If higher

temperatures are required, the minimum system

pressure should be at least 15 psi (102.2 kPa) above

the water vapor pressure corresponding to the elevated

water temperature.

The Model HH boilers are not suitable for open

systems unless the supply water temperatures are

kept below 180°F (82°C), and a minimum of 5 psi

(34.1 kPa) static head is maintained at the boiler.

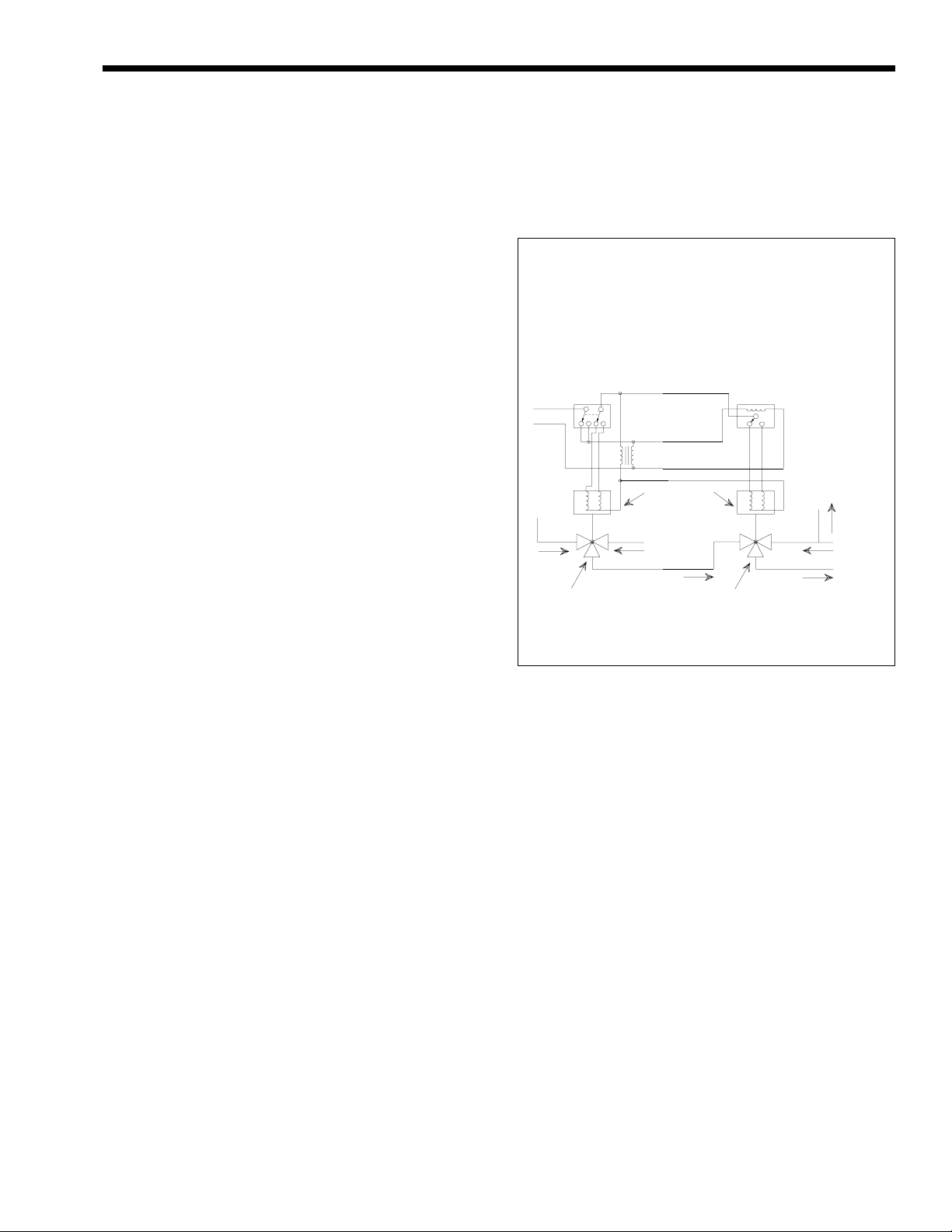

2G-4. Hot/Chilled Water Systems

When a boiler is connected to an air

conditioning system where the same water is used for

heating and cooling, you must prevent chilled water

from entering the boiler. When changing such a

system from cooling to heating, allow the chilled

water to circulate through the building, after the

chiller has been turned off, for a period long enough

for the water to warm up to at least 105°F (41°C)

before the water flows into the boiler. It is equally

important to prevent hot water from entering the

chiller. The system shown in Figure 6 is suggested to

make sure the system water is neither too hot nor too

cold when a changeover takes place. When a boiler is

connected to heating coils located in air handling units

(where they may be exposed to refrigerated air

circulation), install a flow control valve or other

automatic means to prevent gravity circulation of

chilled water through the boiler. Chilled water in the

boiler will create condensate on the boiler tubes.

Boilers installed in violation of the foregoing may

void the warranty.

2G-5. Combined Space Heating/Potable

Water Heating Systems

When using the Mighty Max boiler as a source

of heat for a combined space heating/potable water

heating system, be sure to follow the instructions of

the space heating system.

Do not use water piping, fittings, valves, pumps,

and any other components which are not compatible

with potable water.

Do not connect the heater, which will be used to

supply potable water, to any heating system or

components previously used with a nonpotable water

heating system.

Do not add boiler treatment or any chemicals to

the heating system piping, since the piping contains

water for potable use.

Do not use solder containing lead in the potable

water lines.

Some jurisdictions may require a backflow

preventer in the cold water line. In such cases,

pressure relief valve may discharge water due to

expansion. An expansion tank approved for potable

water will eliminate this condition. Follow the

manufacturer's instructions for installation of the

expansion tank.

Suggested Wiring Diagram For

Tempering System Water at

Changeover From Heating To Cooling

DPDT Manual or Automatic

Change-Over Switch

DPDT - Set at Change-Over

Temperature

115/24V

Transformer

From

Chiller

3-Way Valve No. 1

Change-Over

(Heating and Cooling)

Figure 6. Boiler-Chiller Installation.

Valve Motors

2-Pos

3-Wire - 24V

From

Boiler

3-Way Valve No. 2

To By-Pass

Both Heater and

Chiller

Clock Timer

Auto-Resetting

Set at 15 Minute SPDT

To Boiler

and

Chiller

By-Pass

From

System

To

System

2H. Piping of System to Boiler

1. Be sure to provide gate valves at the inlet and

outlet to the boiler so it can be readily isolated

for service.

2. The pressure relief valve installed in the tapped

opening provided in the outlet header must be

piped, but not fastened, to a drain or floor sink.

The drain pipe must be the same size as the valve

outlet and must pitch downward from the valve. If

the PRV supplied with the boiler is not factory

installed, install it in the front header consistent

with the ANSI/ASME Boiler and Pressure Vessel

Code, Section IV. Pay special attention to relief

valve settings in installations where the boiler is

located on the ground floor of a tall building, or

where the operating temperature of the boiler is

above 210°F (99°C). In both instances, the static

pressure of the system is elevated and could cause

the relief valve to leak and bring considerable raw

water into the system. Where no special setting of

the relief valve is ordered, the factory will furnish

a 75 psi (511.5 kPa) setting. Never reduce the

relief valve opening. If necessary, install the relief

valve in a Tee immediately past the boiler outlet.

Page 10

Page 10

LAARS HEATING SYSTEMS

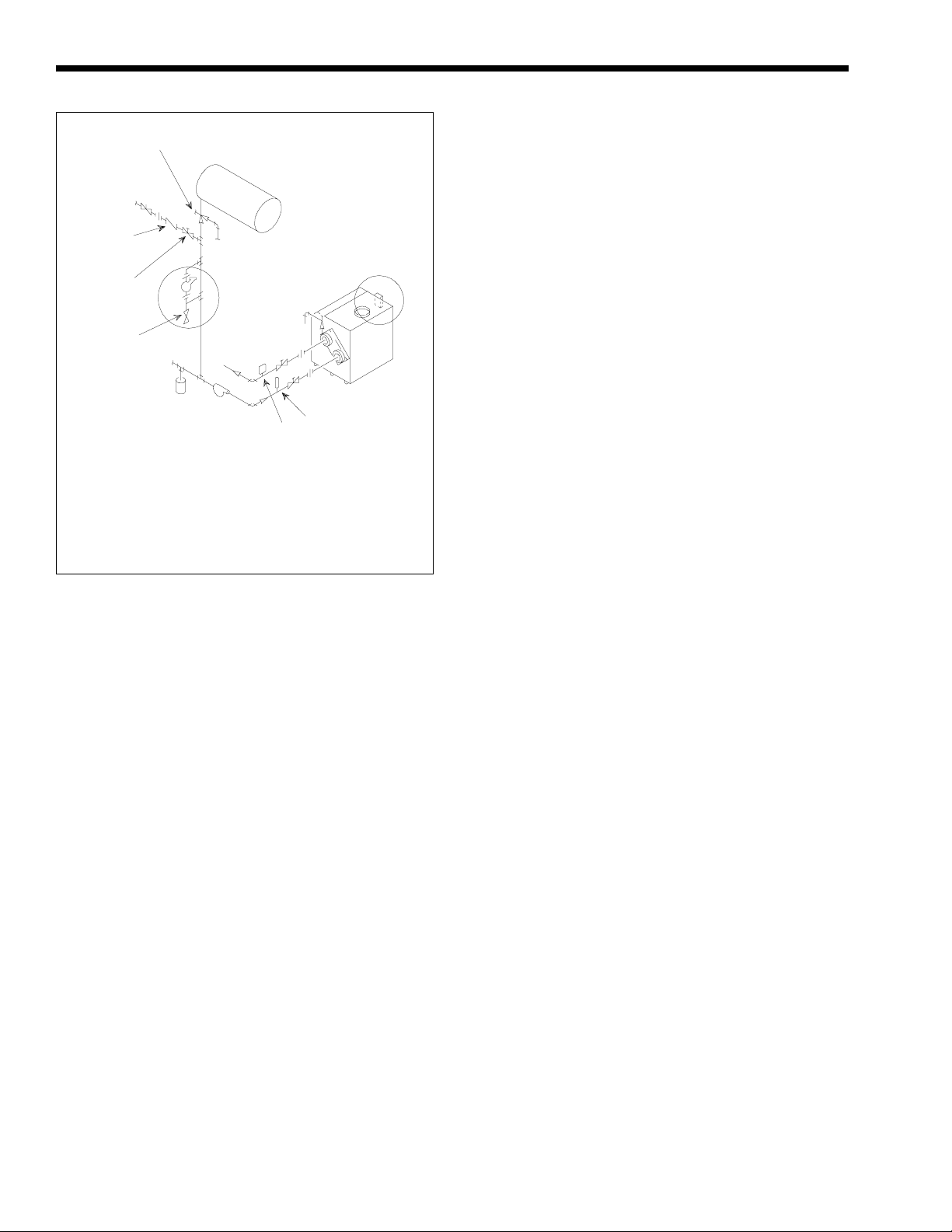

Air Changer

and Tank

Drainer

Make-Up

Water

Supply

Check

Valve

Pressure

Reducing

Valve

Blow Down

Valve

Strainer

NOTES: Select Method 1 or 2 when using low water cutoff accessory:

1. Under Method 1, the low water cutoff is furnished by Laars and shipped

as a separate item for fieldinstallation.

2. Under Method 2, electronic low water cutoff isinstalled, wired and tested

on boiler in Laars factory.

3. Preferred locaiton of system pump is shown. Compression tank must

always be on suction side of pump.

Figure 7. Boiler Piping.

To Drain

Method 1

To

System

Pump

Expansion

Tank

Method 2

To

Drain

Thermometer

Temperature

and Pressure

Gauge

3. Provide a boiler installed above radiation level

with a low water cutoff device either as part of

the boiler or at the time of boiler installation (see

Figure 7).

4. Install manual and/or automatic bleeding devices

at high points in the system to eliminate air.

Install a correctly sized expansion or

compression tank with suitable air charger and

tank drainer, as appropriate.

5. Support the weight of all water and gas piping by

suitable hangers or floor stands.

6. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

2I. Filling The System

1. Ensure the system is fully connected. Close all

bleeding devices and open make-up water valve.

Allow system to fill slowly.

2. If make-up water pump is employed, adjust

pressure switch on pumping system to provide a

minimum of 12 psi (81.8 kPa) at the highest

point in the heating loop.

3. If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the

highest point in the heating loop.

4. Open bleeding devices on all radiation units at

the high points in the piping throughout the

system, unless automatic air bleeders are

provided at such points.

5. Run system circulating pump for a minimum of

30 minutes with the boiler shut off.

6. Open all strainers in the circulating system,

check flow switch operation, and check for

debris.

7. Recheck all air bleeders as described in Step 4

above.

8. Check liquid level in expansion tank. With the

system full of water and under normal operating

pressure, the level of water in the expansion tank

should not exceed 1/4 of the total, with the

balance filled with air.

9. Start up boiler according to procedure described

in Section 3A. Operate the entire system,

including the pump, boiler, and radiation units

for one (1) hour.

10. Recheck the water level in the expansion tank. If

the water level exceeds 1/4 of the volume of the

expansion tank, open the tank drainer and drain

to that level.

11. Shut down the entire system and vent all

radiation units and high points in the system

piping as described in Step 4 above.

12. Close make-up water valve and check strainer in

pressure reducing valve for sediment or debris

from the make-up water line. Reopen make-up

water valve.

13. Check gauge for correct water pressure and also

check water level in the system. If the height

indicated above the boiler insures that water is at

the highest point in the circulating loop, then the

system is ready for operation.

14. Within three (3) days of start-up, recheck all air

bleeders and the expansion tank as described in

Steps 4 and 8 above.

IMPORTANT:

The installer is responsible for identifying to the

owner/operator the location of all emergency

shutoff devices.

2J. Venting and Combustion Air

Information

Provisions for venting and supply of air for

venting and combustion must be done in accordance

with these instructions and applicable requirements of

the latest edition of ANSI Z223.1/NFPA 54. In

Canada, installation must be in accordance with CAN/

CGA B149.1 or .2, and applicable local codes.

There are a variety of ways to provide venting

and combustion air for the boiler (see Figure 8).

Page 11

Mighty Max Hydronic Boiler

Screen Provided

On Vertical Intake

Air Terminal

Category I

Vertical Venting (Category I)

Combustion Air In

Through Louvers

Page 11

For vertically ducted combustion air:

• Combustion air intake must

terminate at least 3 feet (0.91m)

lower than vent termination, if it is

located within a 10 foot (3.05m)

radius.

• Combustion air intake must be at

least 1 foot (0.3m) above roof top

and normal snow levels.

Vertical Venting

with Ducted

Combustion Air

Non-Category I

Horizontal Venting

Any Vent Which Does Not Meet

Category I Combustion Air

Through Louvers

Exhaust Terminal Detail

Wall

Side View

Horizontal

Intake Terminal Detail

(Combustion Air)

Horizontal Venting

Ducted Combustion Air

(Certified As Direct Vent)

NOTE:All views are shown

from rear of heater

Figure 8. Venting and Combustion Air Options.

Wall

Side View

Page 12

Page 12

LAARS HEATING SYSTEMS

Vent

Collar/Stack

Blank Plate

(Boiler

Jacket)

Adapter Plate

Top Panel

1. Removal of Blank Plate and Adapter

Plate From Boiler

Blank Plate On

Boiler Jacket

Top Panel

Blank Plate On

Flue Collector

3. Blank Plate Placement

Over Stack Top Opening

Blank Plate

(Flue

Collector)

2. Removal of Blank Plate From

Rear of Flue Collector

Figure 9. Top-To-Rear Vent Collar.

The Mighty Max HH boiler is certified as a true

direct vent unit when installed according to the

instructions for horizontal venting and ducted

combustion air. This can be done even if the runs are

vertical.

2K. Top-to-Rear Vent Collar Conversion

The Mighty Max HH boiler is shipped with the

vent collar on top of the heater. Follow this procedure

to convert it for rear connection (see Figure 9).

1. Remove the adapter plate from the top panel.

2. On the boiler jacket, remove the top panel and

ease its lip from under the edge of the bonnet to

gain access to the flue collector.

Vent

Collar/Stack

4. Connecting Vent Collar/Stack

to Flue Collector

3. Remove the vent collar/stack from the flue

collector. Do not damage the vent collar/stack

during removal.

4. Remove the blank plate from the rear of the

jacket.

5. Remove the blank plate from the rear section of

the flue collector. Be careful not to lose the

insulation attached to the plate.

6. Apply high temperature sealant and install the

blank plate (previously removed from the rear

section of the flue collector) on top of the flue

collector.

7. Install the blank plate (previously removed from

the rear of the boiler jacket) over the stack

opening on the top panel of the boiler.

Page 13

Mighty Max Hydronic Boiler

r

Page 13

8. Apply high temperature sealant (see Table 6) to

vent collar/stack and install on the rear of the

flue collector.

Term Description

Pipe Type 304, Type 316, or 29-4C

stainless steel, 24 gauge minimum

Joint Sealing 3M Type 433 sealing tape with 400°F

(204°C) rating or high temperature

silicone sealer with 500°F (260°C)

rating, Dow No. 736

Insulation R5 minimum with protective cover

Table 6. Required Horizontal Venting Material.

9. Slip the adapter plate over the vent collar/stack

and install it onto the rear boiler jacket (see

Figure 9).

2L. Venting

Venting must be in accordance with these

instructions and applicable requirements of the latest

edition of ANSI Z223.1/NFPA 54. In Canada,

installation must be in accordance with the latest

edition of CAN/CGA B149.1 or .2, and applicable

local codes.

2L-1. Vertical Venting - Category I

The Mighty Max boiler has a fan-assisted

combustion system, so vertical vents must be installed

in accordance with the special code requirements for

Category I - Fan-Assisted Appliances. These

requirements can be found in the latest edition of

ANSI Z223.1/NFPA 54, Appendix G, Table 1, and in

Canada, CAN/CGA B149.1 or .2, Amendment No. 1.

These codes permit installation as a single appliance

or in combination with other Category I appliances.

However, there are very important requirements for

minimum and maximum vent diameter and length.

Make sure vertically-vented installations comply with

these codes.

NOTE: If a vent cannot be installed in

accordance with the requirements of these codes, it

must be installed as a horizontal vent, even if it is

mainly vertical.

2L-2. Vertical Venting - Non-Category I

When venting does not meet the code

requirements for Category I - Fan-Assisted Vertical

Vents, it can develop positive pressure. Such venting

must be installed in accordance with this section or

Section 2L-3.

The following requirements must be used for

Non-Category I venting:

1. Laars specified vent pipe material (Table 6) and

sizes (Table 7).

2. Pipe insulation and sealing tape.

3. Routing vent pipe through spaces which, except

for the terminal, remain above 60°F (16°C)

during heater operation.

2L-3. Horizontal Venting - Non-Category I

When venting is horizontal, or cannot meet the

code requirements for Category I - Fan-Assisted

Vertical Vents, it can develop positive pressure and

must be installed in accordance with this section.

The following requirements must be used for

Horizontal Venting - Non-Category I:

1. Laars specified vent pipe material (Table 6) and

sizes (Table 7).

2. Laars side wall vent hood.

3. Pipe insulation and sealing tape.

4. Routing vent pipe through spaces which, except

for the terminal, remain above 60°F (16°C)

during heater operation.

Heater

Size

320M

400M

520M

625M

775M

1000M

IMPORTANT: Maximum pipe length allowed is 50 feet (15m), regardless of the number of elbows. Maximum number of elbows allowed is 5.

Vent pipe minimum clearance from combustible surfaces is 6 inches (152mm).

Pipe Diameter M ax Pipe Length

in.

6

7

8

8

9

10

mm

152

178

203

203

229

254

Table 7. Vent Piping Specifications (Combustion Air Exhaust).

ft.

50

50

50

50

50

50

m

15

15

15

15

15

15

Max No.

of Elbows

5

5

5

5

5

5

Side Wall

Vent Terminal

Part Number

D2004500

D2004600

D2004700

D2004700

D2004800

D2006200

Side Wall

Combustion Air

Terminal Part Numbe

20260701

20260702

20260703

20260704

20260705

20526906

Page 14

Page 14

LAARS HEATING SYSTEMS

Vent Hood

3 (0.9m) Minimum

Vent

Hood

Vent Hood

7 (2.1) Minimum

Above Public

Walkway

Figure 10. Building Exterior.

6 (1.8) Above Any

Outside Air Intake

Within 10 (3.0)

Vent Hood

Vent Hood

1 (0.3) Above Grade

2L-4. Side Wall Vent Terminal

The side wall vent hood must be used when the

heater is vented through a side wall. It provides a

means of installing vent piping through the building

wall, and must be located in accordance with ANSI

Z223.1/NFPA 54 and applicable local codes. In

Canada the installation must be in accordance with

CAN/CGA B149.1 or .2 and local applicable codes

(see Figure 10). Consider the following when

installing the terminal:

1. Locate the vent terminal so that it will not be

damaged by pedestrians and other traffic, and so

the discharge is not objectionable. The National

Fuel Gas Code requires a through-wall vent

terminal be at least 7 feet (2.1m) above grade if

located at a public walkway.

2. Locate the vent terminal so that vent gases

cannot be drawn into air conditioning system

inlets. The National Fuel Gas Code requires that

it be at least 6 feet (1.8m) above any such inlet

that is within 10 feet (3.0m).

3. Locate the vent terminal so that vent gases

cannot enter the building through doors,

windows, gravity inlets or other openings. The

National Fuel Gas Code requires that it be

located at least 4 feet (1.2m) below, 4 feet

4 (1.2)

Minimum

Vent Hood Must Be

Mounted 4 (1.2)

Minimum Below Windows

Dimensions shown in feet (m).

(1.2m) horizontally from, or 3 feet (0.9m) above

such openings.

4. Locate the vent terminal so that it cannot be

blocked by snow. The National Fuel Gas code

requires that it be at least 12 inches (305mm)

above grade, but the installer may determine it

should be higher depending on local conditions.

5. Locate the terminal so the vent exhaust does not

settle on building surfaces and other nearby

objects. Vent products may damage such

surfaces or objects. But the actual construction

of the vent terminal and the flow of vent

products must not be altered.

6. Locate the terminal at least 6 feet (1.8m)

horizontally from any gas or electric metering,

regulating, or relief equipment, or building

opening.

2M. Air for Combustion and Ventilation

The boiler requires air for combustion and the

space around the boiler requires ventilation.

Combustion air can be provided by standard practices

as specified in the installation codes (ANSI Z223.1/

NFPA 54, in Canada, CAN/CGA B149.1 or .2 and

local applicable codes), or ducted directly to the

boiler. Ventilation air must be provided in either case.

4 (1.2)

Minimum

Page 15

Mighty Max Hydronic Boiler

Page 15

2M-1. Air From Room

Standard requirements for providing air for

combustion and ventilation are provided by ANSI

Z223.1/NFPA 54 and in Canada by CAN/CGA

B149.1 or .2. These codes require passages be

provided for air flow into the space where the boiler is

installed. The size of these passages is based on the

firing rate of the boiler and the path of air flow into

the space. In general, installations which take air from

inside the building require larger passages than those

which take air directly through an outside wall.

Failure to provide adequate combustion and

ventilation air can cause the boiler, and other

appliances occupying the same space, to operate with

dangerous and inefficient combustion, and can cause

overheating of the space. Be sure to provide air

passages in accordance with ANSI Z223.1/NFPA 54,

in Canada, CAN/CGA B149.1 or .2 and local

applicable codes, and do not permit any other

condition, such as an exhaust blower, to affect the air

supply for combustion and ventilation.

2M-2.Ducted Combustion Air

Combustion air can be brought directly to the

boiler through a duct of suitable size and length (see

Table 7). Consult Laars about installations not

covered by Table 7.

Combustion air must be taken from out-of-doors

by means of the Laars side wall terminal.

Locate the terminal within 10 feet (3.0m) of the boiler

vent exhaust terminal, but no closer than 3 feet (0.9m)

(centerline distance).

Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning fluid,

chlorine compounds, etc.). Locate it so that it will not

be subject to damage by accident or vandalism. It

must be at least 7 feet (2.1m) above a public walkway.

Use single-wall galvanized pipe for the

combustion air duct. Route the duct to the heater as

directly as possible. Seal all joints with tape. Provide

adequate hangers. The heater must not support the

weight of the combustion air duct.

When combustion air is ducted to the boiler,

other provisions must be made for boiler room

ventilation. HH boilers lose less than 1 percent of

their input rating to the room, but other heat sources

may be present. Provide enough ventilation air to meet

comfort specifications. Make sure the ventilation air is

not directed at the boiler, water piping or other

equipment which could be damaged by freezing.

Boiler Size Assembly Number

320 20258101

400 20258102

520 20258103

625 20258104

775 20258105

1000 20258106

Table 8. Combustion Air Assembly.

Louvered

Plate

Inlet

Adapter

Plate

Pipe

2M-3.Conversion for Ducted

Combustion Air

The conversion to ducted combustion air

requires the parts listed in Table 8. Follow these

procedures to convert the heater (see Figure 11):

Ducted Combustion

Air Pipe

Figure 11. Ducted Combustion Air Conversion.

Page 16

Page 16

LAARS HEATING SYSTEMS

1. Remove the louvered plate from the left side of

the boiler.

2. Remove the adapter plate from the shipping

container.

3. Install the blower motor housing collar in gasket.

4. Slip one end of the inlet pipe over the collar on

the adapter plate.

5. Slide the inlet pipe and adapter plate into the

boiler opening until the pipe is aligned with the

blower motor.

6. Slip the end of the inlet pipe over the blower

motor housing collar.

7. Secure the adapter plate to the side of the boiler

with the 4 screws.

2M-4.Combustion Air Piping

Run piping of the appropriate size between the

air intake terminal and the boiler (see Table 7). Table

9 lists the materials for piping the boiler.

Term Description

Pipe Single-wall galvanized steel pipe,

24 gauge minimum.

Joint Sealing Permanent duct tape or aluminum

tape

Insulation Not required, but recommend R5

insulation for cold installations

(consult American Society of

Heating, Refrigerating, and

Air Condditioning Engineers

(ASHRAE) handbook

Table 9. Required Combustion Air Piping Material.

2N. Electrical Wiring

WARNING

Electrically ground the heater in accordance

with the latest edition of ANSI/NFPA 70. In

Canada, use CSA C22.1. Do not rely on the

gas or water piping to ground the metal parts

of the heater. Often, plastic pipe or dielectric

unions isolate the boiler electrically. Service

and maintenance personnel who work on or

around the boiler may be standing on wet

floors and could be electrocuted by an

ungrounded boiler.

1. Check boiler wiring and pump for correct

voltage, frequency, and phase.

2. Wire the boiler and pump exactly as shown in

the wiring diagram supplied with the boiler (see

Figure 12).

3. Electrically interlock the pump and boiler so the

boiler cannot come on unless the pump is

running.

4. Connect all field-installed devices (relays,

timers, temperature devices, etc.) to the boiler

wiring at points labeled “Field Interlock” (see

Figure 12).

SECTION 3.

Operation

WARNING

Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to replace the appliance.

3A. Start Up Requirements

Lighting: Safe lighting and other performance

criteria were met with the gas manifold and control

assembly provided on the boiler when it underwent

tests specified in ANSI Z21.13 Standard.

Before placing the boiler in operation, check the

automatic safety shutoff devices. Once the boiler is

connected to the gas piping and after all of the

requirements in Section 2 have been met, follow this

procedure:

1. Before beginning the tests, make sure the main

manual gas valve, and any other boiler firing

valves, are in the OFF position.

NOTE: The gas valve is turned off as follows:

• Size 775/1000 Valve is OFF when handle is at

right angle to gas pipe.

• Sizes 520/625 Turn clockwise to OFF and

• Sizes 320/400 Press in gas control knob

slightly and turn clockwise to

OFF. Knob cannot be turned

unless it is pushed in slightly.

Do not force it.

2. Make sure the power switch on the boiler is in

the ON position. Reset all safety devices (high

limit, pressure switch, Low-Water-Cutoff, etc.).

3. Normal Operating Sequence

When the circulation pump is running, the boiler

will turn itself on and off in response to the

water temperature. When the water cools below

the set temperature, the following sequence

occurs:

a. The aquastat powers the ignition control.

b. The ignition control turns on the

combustion fan. After about a 15 second

Page 17

Mighty Max Hydronic Boiler

Page 17

ATTENTION

IGNITION SYSTEM 20 ON/OFF

SIZES 320-1000, NA TURAL OR PROPANE

Au moment de l’entretien des commandes, étiquetez tous les fils

avant de les débrancher. Les erreurs de câblage peuvent nuire au

bon fonctionnement et être dangereuses.

S’assurer que l’appareil fonctionne adéquatement une fois

l’entretien terminé.

Caution

Figure 12. Wiring Diagram.

Label all wires prior to disconnection when servicing controls.

wiring errors can cause improper and dangerous operation.

Verify proper operation after operation servicing.

Page 18

Page 18

LAARS HEATING SYSTEMS

Front View of Boiler

Igniter

Junction

Box

NOTE: Sight glass

location may vary.

Figure 13. Periodic Flame Observation.

Sight Glass

For Flame Observation

pre-ignition purge, while the fan clears the

combustion chamber, the igniter is turned

on. The igniter takes about 25 seconds to

heat up. You can see a glow through the

view port (see Figure 13).

NOTE: The manual gas valve must be ON for the

burner to ignite. This valve is turned ON as follows:

• Size 775/1000 Valve is ON when handle is

parallel to as pipe.

• Sizes 320/400 Turn counterclockwise 520/625

to ON.

c. When the igniter is hot, the ignition control

turns on the gas valve and the burner

ignites. You can see the burner flame

through the view port (see Figure 13).

d. The boiler operates until the aquastat

senses that the water is hot enough, and the

burner shuts off. The combustion fan runs

for about one minute to blow all

combustion products out of the boiler.

If the igniter fails to ignite the burner in step 3

(for example, if there is air in the gas line), the

ignition control shuts off the gas valve after a few

seconds of operation. The purge and ignition sequence

is automatically repeated. If there is no ignition in

three tries, the ignition control “locks out” until the

problem is corrected. Contact a qualified service

technician.

3B. Hi-Limit Checkout

After running the boiler for a long enough period

to bring the water temperature within the range of the

hi-limit, slowly back off the high limit setting until the

boiler shuts off. The main burners should re-ignite

when the hi-limit is turned back up to its original

setting and the hi-limit is reset.

3C. Venturi and Gas Pressure Regulator

System

3C-1. Overall Operation

The gas control system of the Mighty Max boiler

is similar to that of a carburetor of a gasoline engine: a

venturi pulls the gas into the combustion air stream

(see Figure 14). In this system, changes in combustion

air flow automatically change the gas flow.

Air

Gas

Orifice

Air/Gas

Mixture

Figure 14. Typical Venturi System.

The flow of air through the venturi creates a

pressure difference. At the narrowest point of the

venturi, the throat, high velocity creates a low

pressure condition which pulls gas in through an

orifice.

For a correct gas/air ratio, the gas pressure must

be the same as the air pressure, but with a slight

negative offset. A special gas regulator (called a

“negative pressure regulator”) which has an equalizer

tube connected to the venturi inlet, maintains the

required gas pressure.

When the system is operating, a combustion fan

forces air into the venturi, creating pressure at the

inlet. The gas regulator sets gas pressure, and gas is

pulled through the orifice. The sizes of the venturi

throat and gas orifice are factory set to provide the

correct air/gas ratio.

3C-2. Venturi Adjustment

The field checkout involves measuring gas and

venturi pressures, and observing the flame through the

sight glass. If necessary, the gas input rate can be

measured by timing the gas meter.

Equalizer

Tube

Negative

Pressure Regulator

Gas

Overall

Operation

Page 19

Mighty Max Hydronic Boiler

Page 19

Use a single, inclined manometer or digital

manometer with a 4.0 inch water column range. Install

shutoff valves at the gas orifice (regulator outlet) tap

(red), at the venturi inlet tap (blue) and at the venturi

throat tap (yellow). After installing the shutoff valves,

be certain they are closed.

1. With the heater off, connect the positive side of

the manometer to the shutoff valve on the

venturi inlet tap (blue). Open the shutoff valve.

2. Loosen the nut on the blower damper to allow

for adjustment. Turn the boiler on so that the

blower is running and the boiler is not firing. In

this unfired condition, adjust the damper until

the venturi inlet pressure (blue tap) is 1.2 inches

water column.

3. Approximately 40 seconds after the blower starts

the gas valves will open. The boiler is now

firing. If the heater is not running, check all

manual gas valves and heater safety devices.

Ensure proper gas supply pressures according to

the table in Section 2.

4. Now that the boiler is firing, use the blower

damper to readjust the venturi inlet pressure

according to the installation’s altitude in Table

10 (+1.6" w.c. at sea level).

6. Using the toggle switch, turn the heater off. Turn

the heater back on and check the gas pressure

offset after the heater has fired. If the gas offset

pressure is not according to Table 10, adjust the

regulator as needed.

7. While the heater is still running, close the

shutoff valve on the gas orifice tap (red), then

remove the manometer hose from the shutoff

valve. Connect the negative side of the

manometer to the shutoff valve on the venturi

throat tap (yellow). This reading is called the

venturi throat differential pressure and should

appear according to altitude in Table 10 (+2.6"

w.c. at sea level). If it does not appear according

to Table 10, contact a qualified service

technician.

Venturi Inlet

“Low” Side of

Manometer

“High” Side of

Manometer

Tap (Blue)

Elevation Venturi Inlet Gas Throat

Ft. Pressure Pressure Differential

(Blue Tap) Offset Pressure

“WC H20” “WC H20” “WC H20”

SEA LEVEL +1.6 +0.4 +2.6

1000 +1.5 +0.4 +2.5

2000 +1.5 +0.4 +2.4

3000 +1.4 +0.4 +2.3

4000 +1.4 +0.3 +2.2

5000 +1.3 +0.3 +2.2

6000 +1.3 +0.3 +2.1

7000 +1.2 +0.3 +2.0

8000 +1.2 +0.3 +1.9

9000 +1.1 +0.3 +1.9

10000 +1.1 +0.3 +1.8

Table 10. Venturi Pressure Settings.

5. Leaving the positive side of the manometer

connected to the venturi inlet tap (blue), connect

the negative side of the manometer to the shutoff

valve on the gas orifice tap (red). Open the

shutoff valve to take a pressure reading. This

reading is called the gas pressure offset. Using

the regulator only, adjust the gas pressure offset

according to the installation's altitude in Table 5

(+0.4" w.c. at sea level). REPLACE THE

REGULATOR CAP BEFORE TAKING GAS

PRESSURE READINGS. Turn the regulator

screw clockwise to decrease the gas pressure

offset, turn the regulator screw counterclockwise to increase the offset.

Venturi Throat

Tap (Yellow)

Gas Orifice

Tap (Red)

Figure 15. Measurement of Venturi Throat Pressure

Differential.

After setting all pressures, turn the heater off and

replace each shutoff valve with the factory installed

threaded plugs. The venturi has now been adjusted for

proper operation.

3D. To Start Up System

(See Section 3A for Startup Requirements)

1. Be certain the system pump is running.

2. Set the thermostat or aquastat to its lowest

setting.

3. Turn off electric power to the appliance.

4. Remove the control access panel.

5. Turn off the manual gas valve.

6. Wait five (5) minutes to clear out any gas, then

smell for gas, including near the floor. Be sure to

smell next to the floor because some gas is

heavier than air and will settle on the floor.

Page 20

Page 20

Caution

This appliance is equipped with an ignition

device which automatically lights the burner.

Do not try to light the burner by hand.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you don't smell gas, go to the next step.

7. Turn on manual gas valves.

8. Rest all safety devices (manual resets on high

limit, low water cutoff, etc.).

9. Replace control access panel.

10. Turn on all electric power to the boiler.

11. Set thermostat to desired setting.

12. If the boiler will not operate, follow the

instructions to turn off gas to boiler and call your

service technician or gas supplier.

a. Turn off main electrical switch.

b. Close all manual gas valves.

3D-1. Setting Temperature Controls

The temperature control differential is factory

set at 15°F. This setting can be adjusted from 1 to

30°F to suit your application. Adjustment is made by

taking the cover off the temperature controller and

turning the potentiometer marked “DIFF”, which is

located just below and to the left of the controller’s

setpoint dial.

To set the temperature and high-limit controls:

a. Set the temperature controller at the system

design temperature.

b. For boilers with the temperature controller bulb

at the boiler inlet, set the high-limit 40°F to 50°F

above temperature controller setting.

c. For boilers with the temperature controller bulb

at the boiler outlet, set the high-limit 15°F to

25°F above temperature controller setting.

3E. To Shut Down System

To shut down the boiler, turn off all manual gas

valves and electrical disconnect switch.

NOTE: There is a filter which needs to be cleaned

prior to setting pressures. See Section 4D-2 “Filter

Service” before proceeding.

3F. Venturi Combustion Flow System

Verifying proper operation of the combustion

flow system has two aspects - air flow and gas flow.

Air flow is checked by measuring pressures at service

LAARS HEATING SYSTEMS

taps on the venturi. Gas flow is checked by evaluating

venturi pressures and the regulator offset pressure.

In a venturi flow system the difference between

various pressures is far more important than their

“gauge” value relative to the room. The gas pressure

offset and the gas orifice pressure differential are

especially important concepts. The following section

describes this setup procedure.

3F-1. Pressure Measurement Ports

Air flow enters the venturi through the filter box

and blower assembly. It is pushed through a

converging section and into the throat, where pressure

is reduced substantially. Gas flow is pulled into the

throat through an orifice. The orifice is located

between the throat and the regulator. Air and gas are

combined in the throat and mix thoroughly as they

proceed through the venturi tailpipe to the burner.

Service taps are provided at three places. One is

located on the chamber with the gas connection, this

tap is called the gas plenum tap. The other is located

above the gas plenum tap, this port is called the

venturi inlet tap. The third tap, gas orifice tap, is

located on the red orifice holder directly before the

gas connects to the venturi. These taps have service

plugs in them. Do not remove any of the plastic

fittings or plastic tubing. To evaluate system operation

requires accurate measurement at these taps. An

inclined manometer with a zero to 6 inches water

column range is ideal. Other instruments may be used,

but the “positive/negative” nature of the readings must

be well understood. Gas pressure offset measurements

are at very low levels (0.4" WC), the instrumentation

must be capable of determining it accurately.

3F-2. Venturi Adjustment

Note that an equalizer tube is connected from a

port on the side of the venturi inlet to the port of the

regulator. This is a very important component which

allows the regulator to track air pressure even when

abnormal conditions occur, such as blockage of the

combustion air. Before firing, confirm that this tube

and the venturi pressure switch tubes are in place and

firmly connected.

The field checkout involves measuring gas and

venturi pressures, and observing the flame through the

sight glass. If necessary, the gas input rate can be

measured by timing the gas meter.

Install shutoff valves at the gas orifice (regulator

outlet) tap (red), at the venturi inlet tap and at the gas

plenum tap. Do not remove any of the plastic fittings

or plastic tubing. After installing the shutoff valves,

be certain they are closed.

a. Unfired Venturi Differential Pressure

NOTE: Turn off the main manual gas valve.

Page 21

Mighty Max Hydronic Boiler

The difference in pressure between the venturi

inlet tap and the gas plenum tap (see Figure 16). This

measurement is taken by connecting the positive side

of the manometer to the venturi inlet tap and

connecting the negative side of the manometer to the

gas plenum tap. This measurement is taken with the

boiler not firing. It is a temporary setting used to start

the boiler and check for air flow problems.

Page 21

Figure 16. Unfired Venturi Differential Pressure.

b. Gas Offset Pressure

The difference in pressure between the venturi

inlet tap and the outlet of the gas regulator (see

Figure 17). This measurement is taken by connecting

the positive side of the manometer to the venturi inlet

tap and connecting the negative side of the manometer

to the gas orifice tap. This measurement is an

indication of the gas to air ratio and must be

performed while the unit is firing.

c. Gas Orifice Differential Pressure

This measurement is the pressure drop across the

gas orifice. This measurement is taken by connecting

the positive side of the manometer to the gas orifice

tap and the negative side of the manometer to the gas

plenum tap (see Figure 18). This measurement in

conjunction with the gas orifice size is an indication

of the gas firing rate and must be performed while the

unit is firing.

Figure 17. Gas Offset Pressure.

Figure 18. Gas Orifice Differential Pressure.

Page 22

Page 22

LAARS HEATING SYSTEMS

By setting the gas offset pressure and gas orifice

differential pressure according to Table 11, the correct

input rate and gas to air ratio is achieved.

GAS GAS ORIFICE UNFIRED

ELEVATION, OFFSET DIFFERENTIAL VENTURI

FT PRESSURE PRESSURE DIFFERENTIAL

inch W.C. inch W.C. inch W.C.

SEA LEVEL +0.4 +4.0 +5.8

2000 +0.4 +3.7 +5.3

4000 +0.4 +3.4 +4.9

6000 +0.4 +3.2 +4.6

8000 +0.4 +2.9 +4.2

10000 +0.4 +2.7 +3.9

Table 11. Venturi Pressure Settings.

3F-3. Venturi Setup Procedure

1. Loosen the nut on the blower shutter to allow for

adjustment. Turn the heater on so that the blower

is running and the heater is not firing. Measure

the unfired venturi differential pressure. In this

unfired condition, adjust the shutter until the

unfired venturi differential pressure is according

to Table 1, “Unfired Venturi Differential” (5.8 ±

.3 inches wc at sea level). If this pressure range

can not be achieved, check for blockage in the

combustion air inlet, boiler and venting system.

If there is no obvious cause contact a qualified

Laars service technician.

2. Approximately 40 seconds after the blower starts

the gas valves will open. The heater is now

firing. If the heater is not running, check all

manual gas valves and heater safety devices.

Ensure proper gas supply pressures according to

Table 4 in Section 2.

3. Measure the gas offset pressure. Using the

regulator only, adjust the gas offset pressure

according to the installation’s altitude in Table

11 (+0.4 inches wc. at sea level). REPLACE

THE REGULATOR CAP BEFORE TAKING

GAS PRESSURE READINGS. Turn the

regulator screw clockwise to decrease the gas

offset pressure, turn the regulator screw

counterclockwise to increase the offset.

4. Using the toggle switch, turn the heater off. Turn

the heater back on and check the gas offset

pressure while the heater is firing. If the gas

offset pressure is not according to Table 11,

adjust the regulator as needed.

5. Measure the gas orifice differential pressure.

This pressure must be adjusted according to

Table 1 (4.0 ± .2 inches wc at sea level). Use the

blower shutter to adjust the gas orifice

differential.

6. By adjusting the gas orifice differential, the gas

offset pressure will change. Therefore you must

repeat steps 3-5 until the gas offset and gas

orifice differential pressures are according to

Table 11.

7. After setting all pressures, turn the heater off and

replace each shutoff valve with the factory

installed threaded plugs. The venturi has now

been adjusted for proper operation.

SECTION 4.

Maintenance

4A. General Instructions

1. Oil the water circulating pump in accordance

with the manufacturer's instructions.

2. Oil the blower motor bearings every 6 months.

3. If a strainer is used in a pressure reducing valve

or in the piping, clean it every 6 months in

accordance with the manufacturer's instructions.

4. At startup and every 6 months after, look at the

main burner flame for proper performance. The

burner should not require maintenance in normal

operation. If any malfunction indicates that the

burner needs service (e.g., a flame that is yellow,

or entire burner surface glowing red), call a

professional service technician. Flame

characteristics may be inspected during the first

30 seconds after ignition. Characteristics of a

good flame are:

a. Blue flame color.

b. Dark-colored burner surface with

occasional glowing fibers on surface.

NOTE: After 30 seconds of operation the

combustion chamber will heat up and prevent reliable

flame observation.

5. Inspect the venting system for blockage, leakage,

and corrosion at least once a year.

6. Keep the heater area clear of combustible

material, gasoline, and other flammable liquids

and vapors.

7. Be sure all combustion air and ventilation

openings are not blocked.

8. After installation and first startup, check the heat

exchanger for black carbon soot buildup after the

following periods of operation: 24 hours, 7 days,

30 days, 90 days, and once every 6 months

thereafter.

4B. Heat Exchanger

Black carbon soot buildup on the external

surfaces of the heat exchanger is caused by one or

more of the following: incomplete combustion,

combustion air problems, venting problems and heater

short cycling. As soon as any buildup is seen, correct

the cause of the buildup. Scale can build up on the

Page 23

Mighty Max Hydronic Boiler

Page 23

inner surface of the heat exchanger tubes and

restrict the water flow. Inspect the heat exchanger in

accordance with Section 4B-1.

If the heat exchanger needs cleaning, see

Section 4B-2.

4B-1. Inspection of the Heat Exchanger

WARNING

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide in flue gases which could result in

severe injury, property damage, or death.

4B-1a. External Heat Exchanger

Inspection

1. Disconnect electrical supply to the heater.

2. Turn off the gas supply by closing the manual

gas valve on the heater.

3. On indoor models, remove the vent pipe, top

jacket section, flue collector.

4. On outdoor models, remove outdoor vent

terminal, top jacket section, flue collector.

5. After removing the flue collector, inspect the

finned copper tubing using a flashlight.

6. If there is a buildup of black carbon soot or other

debris on the heat exchanger tubes which may

restrict flue gas passage, refer to Section 4B-2a.

7. If there is no buildup of black carbon soot or other

debris which may restrict flue gas passage

through the heat exchanger, reassemble the heater.

4B-1b. Internal Heat Exchanger Inspection

1. Remove the inlet/outlet header of the heat

exchanger.

2. Remove the return cover of the heat exchanger.

3. Inspect the internal surface of the copper tubes

for signs of scale buildup and erosion.

4. If build-up exists, clean per 4B-2b.