Page 1

Installation and Operation Instructions Document 4206

Installation and Operation

Instructions for

MC Extension Box

Providing up to 12 Stages of Full Modulation Control

The MC Extension Box (MCX) increases the

number of stages a Laars Modulating Control (MC)

can control from 4 to 12. All logic, memory, and

control algorithms reside in the MC panel. The MC

panel directly controls four built-in stages. When an

MCX is connected to the MC, the MC will

automatically recognize eight additional stages. Any

of the twelve stages can be the lead stage and

automatic rotation provides even wear among all

active stages.

The MCX can be equipped with up to four

output cards, each of which controls a pair of stages.

There are two types of output cards: 135Ω cards

control up to two fully modulating 135Ω stages, and

Current/Voltage cards can be programmed to control

two 0-5V, 1-5V, 0-10V, 2-10V, or 4-20mA stages. To

select the type of output for Current/Voltage cards,

follow the directions in the MC I/O Manual (System

Startup, Selecting the Output Type).

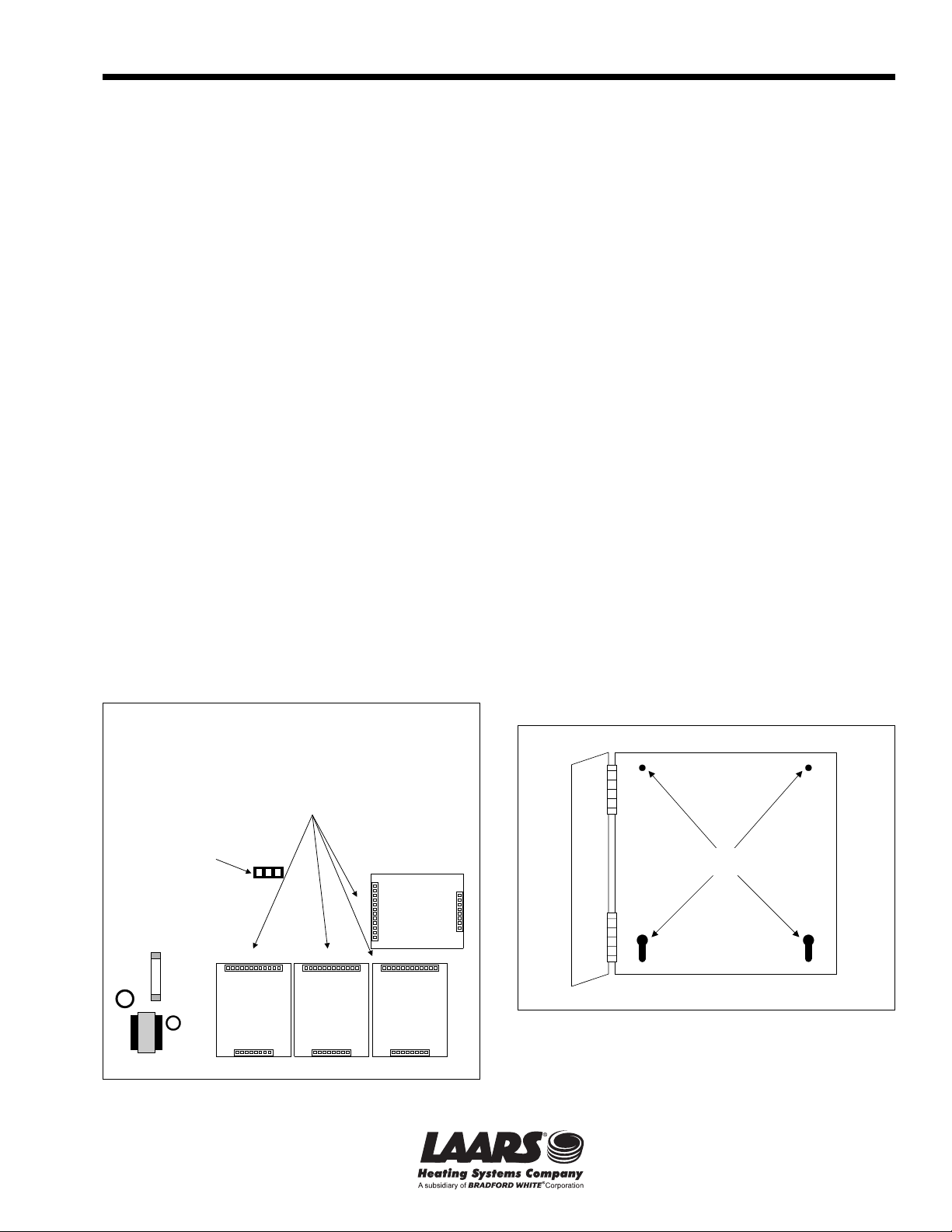

EXTENSION MODULE

REAR VIEW

Each new stage must also be configured for its

Mode (Auto, Manual, Standby, On, and Off), Ignition

Start Point, and Modulation Start Point as described in

the MC I/O manual (Stage Settings). All other steps

and procedures to configure the MC presented in its I/

O manual must be completed to insure smooth

operation of a MC/MCX system.

SECTION 1.

Installation

1.1 Mounting the EXM

Select a location adjacent to the MC control and

within the reach of the provided Panel-to-Panel cable.

Remove the MCX panel from the metal

enclosure by removing the top center screw and

loosening the two bottom screws. Lift the panel out.

Screw the enclosure to the surface through the

mounting holes in the back of the enclosure.

Output Cards are ordered

separately as required

Connection to

MC

Card 4 Card 3 Card 2

Fuse

Figure 1. MCX Rear View.

Mount Output

Card 4 here to

control Stages

K and L

J12

Mount Output

Card 3 here to

control Stages

IandJ

Card 1

Mount Output

Mount Output

Card 2 here to

control Stages

GandH

Mounting Holes

EandF

Card here to

control Stages

Figure 2. Mounting Holes.

Page 2

Page 2

LAARS HEATING SYSTEMS

1.2 Mounting the Output Cards

The Output Cards are mounted on the rear of the

MCX (see Figure 1).

Each Output Card controls two stages. The two

stages connected to one Output Card must have the

same type of output (135Ω, 0-5V, 1-5V, 0-10V, 210V, or 4-20mA). However, different types of Output

Cards can be combined on the MCX, and each Output

Card can be programmed differently.

Align the Output Card with the pins on the back

of the panel and gently press them on until the top of

the pins appear through the Output Card connector.

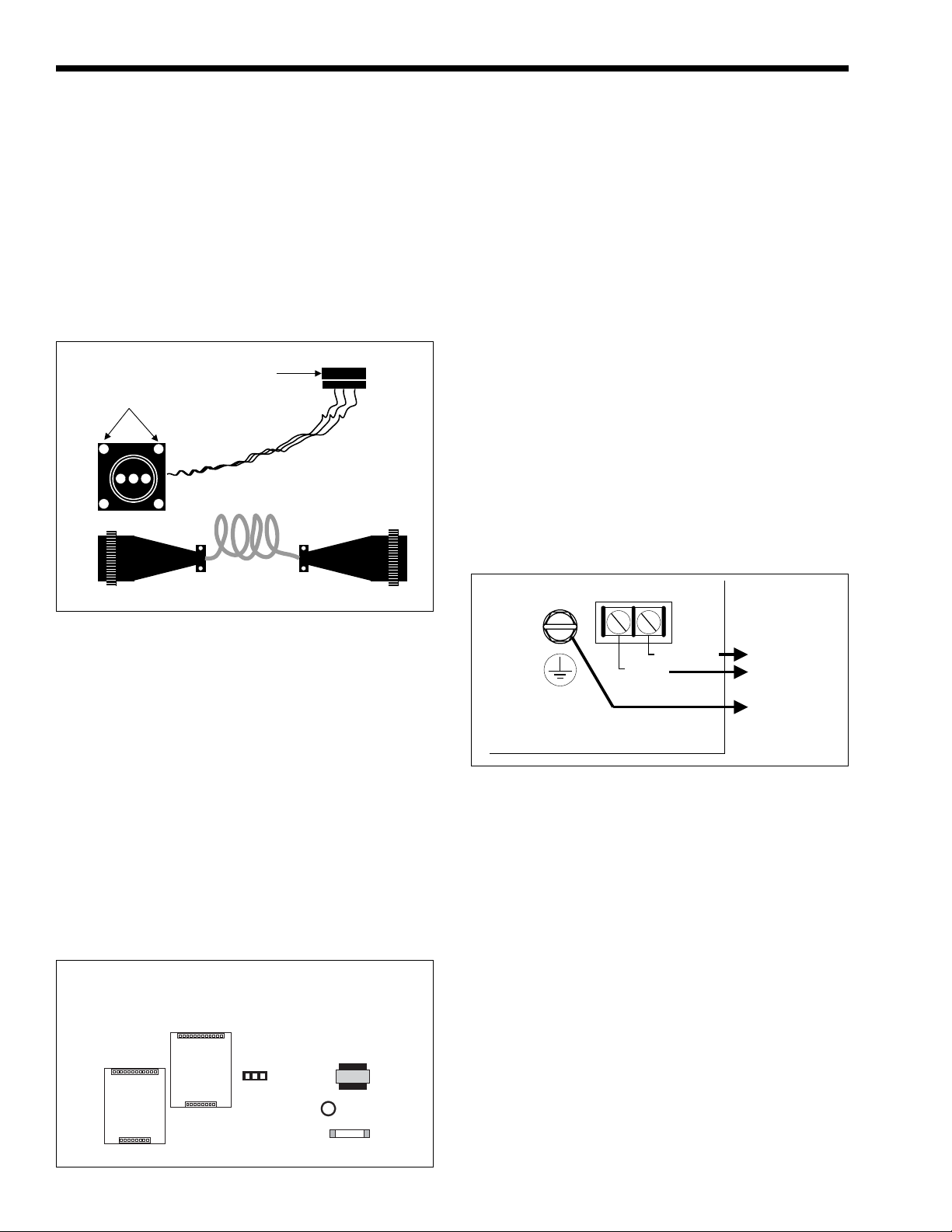

Mounting

holes

To header

MCX

J12

or

MCX

JP4

Header Cable

1.4 Attaching the Connecting Cable

to the MC

Remove the MC from its enclosure.

Secure the remaining Header cable to the

enclosure as described above.

On the rear of the MC, locate JP4 and attach the

three screw terminal connector.

Return the panel to its enclosure, replace the top

screw, and tighten the bottom two screws.

Reattach the Panel-to-Panel cable to the Header

cables.

1.5 Wiring the Power

Bring the 120VAC 60Hz power wires through a

bottom Knockout of the enclosure. The right front

Knockout is preferred.

Class 1 voltages must enter the enclosure

through a different opening from any Class 2 voltage

wiring.

Connect the hot line to terminal marked LINE.

Connect the neutral line to the terminal marked

NEUT.

The green ground screw MUST be connected to

earth ground (see Figure 5).

Panel-to-Panel Cable

Figure 3. Cable Connections.

1.3 Attaching the Connecting Cable

to the MCX

Disconnect the Panel-to-Panel cable from the

two Header cables (see Figure 3).

Remove a Knockout from the enclosure.

Insert the end of the Header cable with three

screw terminals through the Knockout into the interior

of the enclosure.

Use the mounting holes to secure the square end

of the Header cable to the enclosure.

Connect the three screw connector to the black

header on the rear of the MCX marked J12 (see

Figure 1).

Return the panel to its enclosure, replace the top

screw, and tighten the bottom two screws.

MC REAR VIEW

Output A&B

Output C&D

JP4

Fuse

Figure 4. MC Rear View.

Neutral

Line

SAFETY

GROUND

MUST BE

CONNECTED

Figure 5. Power Wiring.

120VAC

60 Hz

Earth

Ground

1.6 Installing the Output Relays

Each output stage (E through L) which is to be

used must have a relay installed in the socket. These

relays are ordered separately (p/n CA002300).

To install a relay, orient the pins and then press it

gently into the appropriate socket.

Any stage output which does not have a relay

must have its Mode set to Off (see MC I/O manual,

Stage Settings).

1.7 Wiring the Stage Outputs

Each Stage output (E through L) has one

Normally Open (N.O.) relay contact.

The N.O. contacts are dry contacts only. They do

not source any voltage.

Each N.O. contact is capable of switching 6A

resistive at 120VAC.

Total output of all stages must not exceed 15A.

Wire the N.O. relay contacts in series with the

unit’s limit circuit (see Figure 6).

Page 3

MC Extension Box

Page 3

Limit Circuit

1

E

2

3

F

4

Figure 6. Stage Wiring.

Class 1 voltages must enter the enclosure

through a different opening from any Class 2 voltage

wiring.

1.8 Wiring to 135

The MCX can be equipped to operate up to eight

135 Ω modulating motors.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

Wire as shown in Figure 7 and Table 1.

1.9 Wiring to Current Controlled

Modulating Motors

The MCX can be equipped to operate up to eight

4-20 mA modulating motors.

To program the control for 4-20 mA output, see

the MC I/O manual (MC I/O Manual, System Startup

settings).

Apply the supplied label marked 4-20 mA below

the output terminals.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

The MCX sources 24VDC excitation voltage for

the 4-20mA signal.

Wire as shown in Figure 7 and Table 1.

1.10Wiring to Voltage Controlled

Modulating Motors

The EXM can be equipped to operate up to eight

0-5 V, 0-10V, 1-5V, or 2-10V modulating motors.

To select the range, 0-5V, 0-10V, 1-5V or 210V, see the MC I/O manual (MC I/O Manual,

System Startup settings).

Apply the supplied label marked Voltage below

the output terminals.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

Wire as shown in Figure 7 and Table 1.

1.11Wiring the Lockout Inputs

A closure across the pair of MCX LOCKOUT

INPUT terminals informs the MC that the particular

stages's boiler, chiller, etc. has encountered a safety

limit and can not be restarted without a manual reset.

The MC will not activate or modulate a Stage in

Lockout.

ΩΩ

Ω Modulating Motors

ΩΩ

Typical for

each stage

C1

C2 C3

B

RW

135W

E

RWB

135 W

Motor

C1

C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

+

-

GND

24

Current

E

-+

4 - 20mA

Motor

C1

C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12

GND

Voltage

E

V+

GND

Voltage

Motor

C5 C6 C7 C8 C9 C10 C11 C12

C4

B RW

135W

B RW

135W

F

BRW

-

NC

GND

135 W

Motor

24

Current

+

BRW

-

NC

GND

135 W

Motor

Current

F

4 - 20mA

GND

V+NC

-+

Motor

Voltage

4 - 20mA

V+NC

-+

Motor

GND

Voltage

NC

F

V+

GND

Voltage

Motor

Voltage

Motor

G

+

24

G

G

B RW

BRW

NC

GND

4 - 20mA

Motor

GND

V+

V+

GND

135W

H

135 W

Motor

+

24

Current

H

-+

Voltage

H

Voltage

Motor

NC

V+NC

V+GND

Figure 7. Control Voltage Wiring.

A pair of LOCKOUT INPUT terminals is

provided for each stage.

The Lockout signal must be a dry contact closure

from the boiler, chiller, etc. controlled by that stage's

output.

The LOCKOUT INPUTS are dry contacts only.

No voltage can be placed across the terminals.

Wire the Lockout signals to their respective

STAGE terminals (see Figure 8):

- STAGE E to Lockout Input terminals B1&B2

- STAGE F to Lockout Input terminals B3&B4

- STAGE G to Lockout Input terminals B5&B6

- STAGE H to Lockout Input terminals B7&B8

- STAGE I to Lockout Input terminals B9&B10

- STAGE J to Lockout Input terminals B11&B12

- STAGE K to Lockout Input terminals B13&B14

- STAGE L to Lockout Input terminals B15&B16

Page 4

135W Current Voltage

Stage E

Stage F

Stage G

Stage H

Stage I

Stage J

Stage K

Stage L

Common

C2

C5

C8

C11

C14

C17

C20

C23

Increase

Mod

C3

C6

C9

C12

C15

C18

C21

C24

Decrease

Mod

C1

C4

C7

C10

C13

C16

C19

C22

SECTION 2.

Operation

2.1 EXM Status Lights

Whenever the MCX is powered, the red LED

marked POWER, located in the upper left of the panel,

should be lit. If it is not, check the 120VAC power

source.

If the MCX is correctly connected to a powered

MC, the green LED marked COMM ERROR will blink

on and off, approximately once a second. If the light is

does not blink, check the connecting cables.

If the N.O. contacts of a Stage relay are

energized, the red LED immediately to the left of the

relay will be on. If the relay is not energized, the red

LED will be off.

2.2 Display Stage Status

The percent modulation and Mode of each stage

is displayed on the main screen of the MC control (see

Figure 9). Stages in the Automatic mode which are not

active show ---.

The default screen shows Stages A through D.

Simply rotate the ADJUST knob clockwise (without

pressing) to see the remaining Stages, E through L.

Rotate the ADJUST knob counterclockwise to go

back in the Stage order.

Stages A through D correspond to the Stages

marked A through D on the MC panel.

Stages E through L correspond to Stages of the

MCX.

2.3 Stage Settings

All Stage setting are made at the MC panel.

If the COMM ERROR LED is flashing, the MC

recognizes the MCX panel and all its Stages.

Signal

Sink (GND)

C1

C4

C7

C10

C13

C16

C19

C22

Table 1.

24V

Source (+)

C2

C5

C8

C11

C14

C17

C20

C23

C3

C6

C9

C12

C15

C18

C21

C24

Carefully follow all the steps in the MC I/O

manual (Stage Settings) to set up Stages E through L.

WARNING

Each Stage, A through L MUST be setup properly.

Failure to do so will result in erratic set point control

and may cause system damage.

Dry Contact

B1

Lockout

Signal

Figure 8. Dry Contact Wiring.

140°F

<A> B C D

100% 100% 100% 100%

140°F

EFGH

100% 61% --- ---

140°F

IJKL

Off Off Off Off

Figure 9. Main Screen Display and Operation.

B2

B3

B4

B5

B6

ADJUST

PRESS TO SELECT

ADJUST

PRESS TO SELECT

GNDV+

C1

C4

C7

C10

C13

C16

C19

C22

Lockout

E

Lockout

F

Lockout

G

Rotate

Clockwise

Rotate

Clockwise

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0806 Document 4206

Loading...

Loading...