Page 1

Installation, Operation and Maintenance Instructions Document 1106D

Installation,

Operation and

Maintenance

Instructions for

MAX

Residential

Oil-Fired Boiler

Models MAX 75 (DV)

MAX 100 (DV)

MAX 120 (DV)

MAX 140 (DV)

MAX 165 (DV)

FOR YOUR SAFETY : This product must be installed and serviced by a professional service technician,

qualified in boiler installation and maintenance. Improper installation and/or operation could create

carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

W ARNING

If the information in this manual is not followed exactly , a fire or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

Installation and service must be performed by a qualified installer , service agency , or fuel oil

supplier.

READ AND SAVE THESE INSTRUCTIONS FOR REFERENCE

70-196D

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction...................................................3

SECTION 2.

Technical Specifications

2A. Boiler Outputs ............................................... 5

SECTION 3.

Installation

3A. Freight Claims............................................... 6

3B. Regulations ...................................................6

3C. Sizing the System ......................................... 6

3D. Location ........................................................6

3E. Clearance ..................................................... 6

3F. Combustion Air (other than direct vent) ......... 6

3G. Ventilation Air (conventional chimney

and direct vent) ............................................. 7

3H. Chimney Connection ..................................... 7

3I. Direct Vent Balanced Flue System................ 8

3J. Installation of Balanced Flue System ............ 9

3K. Boiler Piping..................................................9

3L. Freeze Protection ......................................... 9

3M. Indirect Hot Water Tank.............................. 10

3N. Burner Controls ........................................... 10

3O. Fuel System................................................ 10

3P. Gravity Head System .................................. 10

3Q. Suction Lift System ..................................... 10

3R. Oil Filter ...................................................... 10

3S. Wiring .........................................................10

SECTION 4.

Operation

4A. Preliminary Burner Settings......................... 19

4B. Burner Adjustments..................................... 19

4C. Sequence of Operation ............................... 19

SECTION 5.

Maintenance and Service

5A. Boiler .......................................................... 22

5B. Oil Burners.................................................. 22

5C. Oil Filter ...................................................... 22

5D. Cold Oil ....................................................... 22

SECTION 6.

Homeowner Information

6A. Living With Your Boiler ................................ 22

6B. General Information .................................... 23

SECTION 7.

Part Numbers

................................................................... 23

Page 3

MAX Oil-Fired Boiler

SECTION 1.

General Information

1A. Introduction

The MAX Boiler has been constructed to meet

the stringent requirements of the ASME Boiler Codes

and designed to provide a rapid response to hot water

and heating demands at a very high thermal efficiency.

This is a low mass boiler. To take advantage of

this feature, and prevent short cycling, always select

the lowest firing rate satisfactory for the load

requirement.

The boiler is supplied either for connection to a

conventional chimney or comes complete with a

balanced flue system for direct venting through the

wall.

With the balanced flue system, air for

combustion is drawn from outside through a terminal

and ducted directly to the burner, making the boiler

virtually room sealed. Flue gases are discharged

through the same terminal so that wind pressures are

applied equally to inlet and outlet, making it a true

balanced flue system. A silencer is also incorporated

in the terminal to reduce the flue gas discharge noise.

This is a particularly useful feature if the terminal is

located near a bedroom window or adjacent to

neighboring properties.

The boiler is constructed with two concentric

water jackets, the inner one forming the furnace tube

and the outer the flue gas annulus. Flue gas retarders

fitted around the annulus are specifically designed to

extract the maximum heat from the gases with

minimum pressure loss.

Page 3

The simple annular design also makes it possible

to keep the water content to a minimum (only 3.2 gals.

[12L] for the MAX (DV) 75, 100, 120 and 5.1 gals.

[19L] for the MAX (DV) 140, 165). Because of this

low mass, water is rapidly heated to the temperature

demands. Another benefit of the low thermal mass is

the insignificant level of standby loss when the burner

shuts down.

To achieve the best possible heat transfer, the

boiler is designed on the “Series Flow” principle

whereby the return water is preheated by first passing

through the outer water annulus before coming into

contact with the furnace tube. This arrangement also

provides a counter flow of flue gases and water so that

the coolest gases come into contact with the coolest

water for the most efficient heat transfer.

Heavily insulated doors at front and back of

boiler, provide easy access for cleaning and

inspection, with the burner being swung on the front

door either left or right as required.

Accurate sensing of temperature and pressure is

assured by grouping all controls and safety devices on

a common supply manifold.

The use of the latest flame retention head burner

allows the boiler to operate under a slight positive

pressure which ensures stable combustion under

virtually all operating conditions.

MAX (DV) GPH Nozzle Pump Input AFUE Heating Water Shipping

Model Rate Size Pressure MBTH/hr Rating Capacity Content Weight

75 0.72 0.65 140 101 87.0 85,900 3.0 12 324 147

100 1.00 0.85 140 140 86.5 121,200 3.2 12 324 147

120 1.20 1.00 140 168 86.0 141,600 3.2 12 324 147

140 1.40 1.20 150 196 85.6 166,000 5.1 19 431 196

165 1.65 1.35 150 231 85.0 192,400 5.1 19 431 196

GPH P.S.I. % BTU/h gal. L lbs. kg

Table 1. Boiler Specifications.

Page 4

Page 4

LAARS Heating Systems

(127mm)

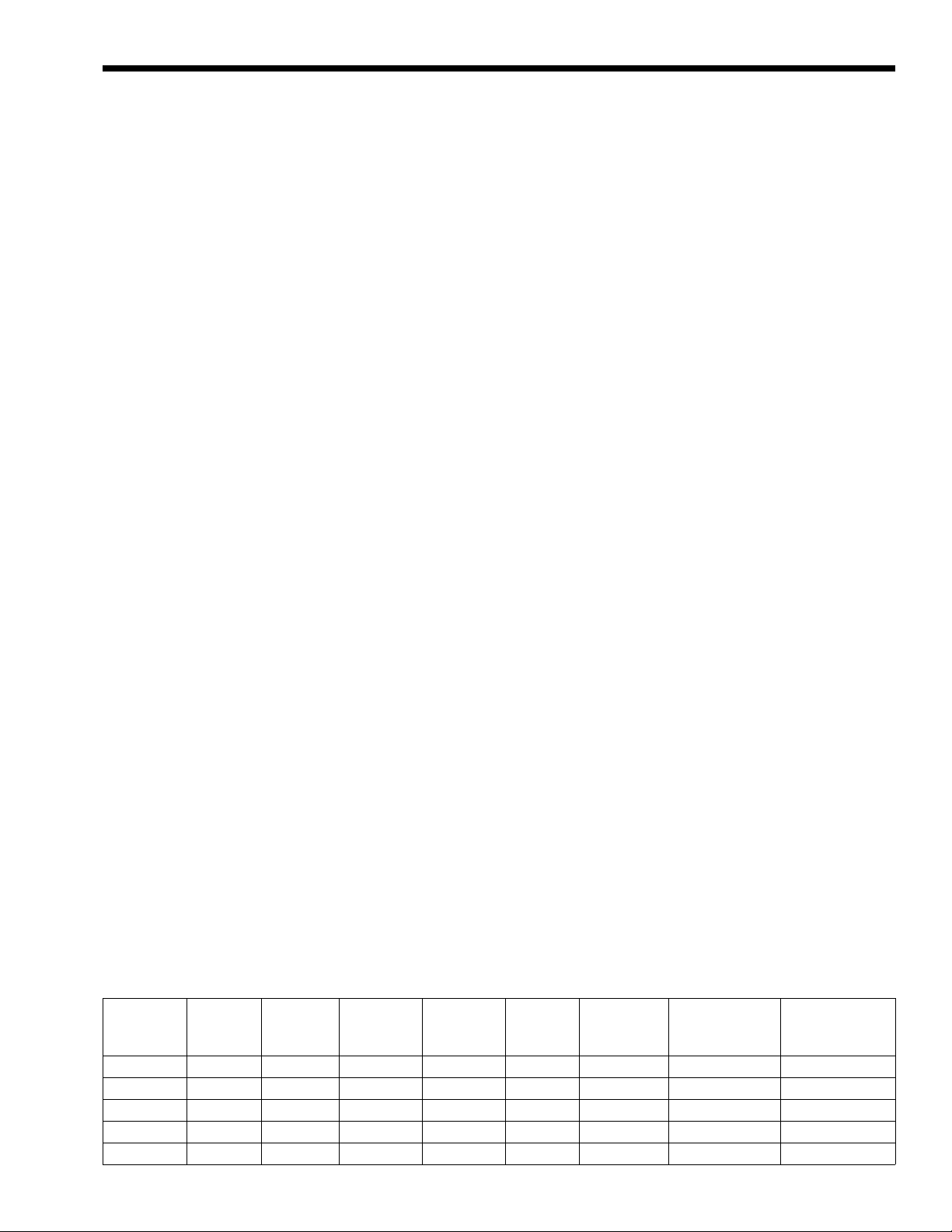

Side Front

Figure 1. Boiler Dimensions (refer to Table 2).

Table 2. Boiler Dimensions.

Page 5

MAX Oil-Fired Boiler

Page 5

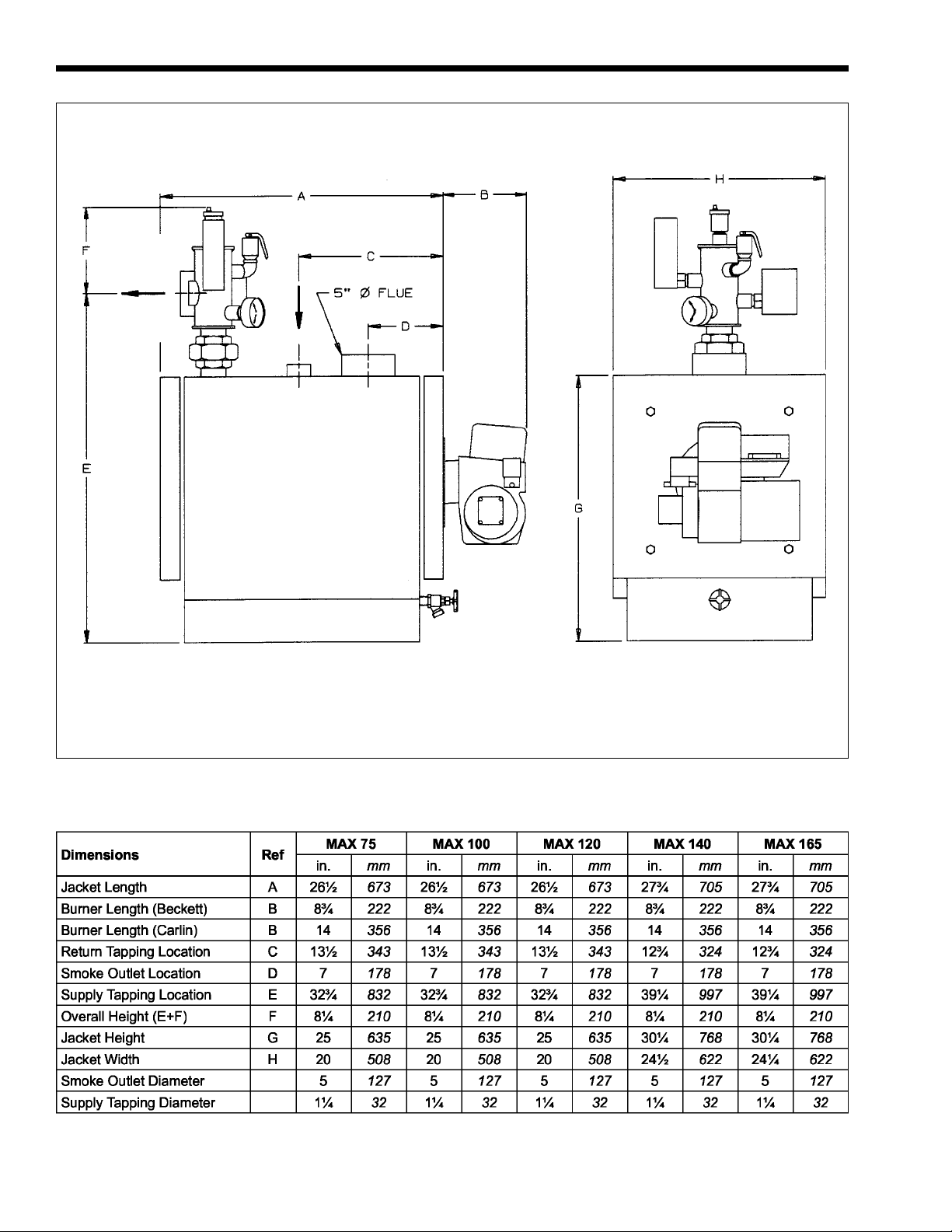

Auto Air Vent

Honeywell L4006E High Limit Aquastat

(Manual Reset)

1¼" Supply

¾" Relief Valve

Honeywell L8148 Aquastat

Temperature / Pressure Gauge

1¼" Return

Flue Gas

Sampling Plug

Figure 2. Controls Layout.

SECTION 2.

Technical Specifications

2A. Boiler Outputs

Boiler constructed and hydrostatically tested in

accordance with ASME Boiler code Section IV.

Beckett / Carlin / Riello (model varies) Oil

Burner complete with flame retention head,

Honeywell control and cad. cell. or equivalent

(A post purge timer and oil solenoid valve is

fitted to direct vent burners)

Honeywell L8148A Aquastat Relay.

Honeywell L4006E High Limit Aquastat

(manual reset - direct vent boilers only)

Temperature and pressure gauge.

Pressure relief valve 3/4"

Automatic air vent

Air eliminator built into supply manifold

Boiler drain valve 1/2"

• 2500-004: 15-foot vent kit contains 15-feet of 5"

stainless steel pipe (for vent) and 15-feet of 4"

aluminum (for ducted air), with clamps, adapters,

heatshield and silicone.

•

2500-009: Direct vent terminal (Univent

terminal) to be used with either 10-foot or 15foot vent kits, for all MAX DV boiler sizes.

In addition, the following vent terminal extensions

can be used to bring the terminal above grade level to

meet code requirements:

•

2500-010: Vent terminal extension for 75, 100 and

120

•

2500-011: Vent terminal extension for 140 and 165

Balanced Flue System Kits

(direct vent boilers only)

For direct venting, vent pipe kits and vent

terminals are available.

•

2500-002: 10-foot vent kit contains 10-feet of 5"

stainless steel pipe (for vent) and 10-feet of 4"

aluminum (for ducted air), with clamps, adapters,

heatshield and silicone.

Page 6

Page 6

LAARS Heating Systems

SECTION 3.

Installation

3A. Freight Claims

The boiler and it's components should be

inspected for damage upon arrival and any claim filed

immediately against the carrier by the consignee. The

carrier is responsible for taking prompt action on all

claims.

3B. Regulations

THE BOILER INSTALLATION MUST BE

CARRIED OUT BY A QUALIFIED INSTALLER

IN ACCORDANCE WITH THE REGULATIONS

OF AUTHORITIES HAVING JURISDICTION

AND CSA STANDARD B139 or ANSI / NFPA 31

Installation of Oil Burning Equipment - latest edition,

the

National Electrical Code ANSI / NFPA 70 - latest

edition and local codes and authorities having

jurisdiction. Such applicable requirements take

precedence over the general requirements contained

herein.

The installer must also be properly licensed and

experienced in all the codes and ordinances.

WARNING

In the interest of safety, gasoline or other flammable

fluids or vapors must not be stored or used in the

vicinity of the boiler.

3C. Sizing the System

Over sizing the boiler will cause short cycling

and reduce its operational efficiency, so it is

recommended that a building heat loss calculation is

made to ensure that the correct size boiler is used

(see Table 1).

3D. Location

The boiler should be mounted on a solid level

floor and located as close as possible to the chimney

or the position chosen for the direct vent terminal.

The boiler can be mounted on a combustible floor due

to its wet base construction, however, a check should

be made to ensure the floor is capable of supporting

the installed weight of the boiler including its water

content.

A closet may be used to enclose the boiler,

providing the enclosure is properly vented to ensure

the controls do not become overheated (see

Ventilation Air section). The boiler must also have the

correct amount of air available for combustion when

using a conventional chimney (see Combustion Air

section).

When installed,

necessary use metal shims under the base to level the

the boiler must be level. If

unit particularly front to back otherwise air could be

trapped inside the boiler.

3E. Clearance

Adequate clearance should be allowed around

the boiler for cleaning and servicing. The following

minimum clearances are recommended:

Front - 24" (610mm) (for hinging door)

Rear - 6" (152mm)

Sides - 6" (152mm)

Clearance from combustible materials should be in

accordance with local and national codes. Guidance is

given in the National Fire Protection Bulletin NFPA,

Installation of Oil Burning Equipment. All other

applicable codes should also be followed.

3F. Combustion Air

(other than direct vent)

WARNING

As an additional measure of safety, Laars strongly

recommends installation of suitable Carbon

Monoxide detectors in the vicinity of this appliance

and in any adjacent occupied spaces.

AVERTISSEMENT

Laars recommande fortement, comme mesure de

sécurité supplémentaire, l'installation de détecteurs

de monoxyde de carbone adaptés dans le voisinage

de l'appareil et dans chacune des pièces habitées

adjacentes.

Chimney Vent: For boilers installed in

basements, infiltration may be adequate to provide

combustion air. For buildings of exceptionally tight

construction, the boiler must be installed in an

unconfined space, or in an area which directly

communicates with an unconfined space. An

unconfined space is a space whose volume is 50 cubic

ft. (1.4m3) or more per 1,000 BTU (293kW) of the

aggregate input of all appliances in that space. Two

openings to the space, one 6" (152mm) from the floor

and one 6" (152mm) from the ceiling of the enclosure

must be provided. Each opening must have at least

168 square inches (1084 sq.cm) of free area.

Chimney Vent with outside air duct connected

directly to burner: In an installation of exceptionally

tight construction, intake air may be ducted directly to

the burner from the outdoors. On an AF2 burner

remove the black air intake shroud to connect the 4"

(102mm) aluminium duct (up to 15 equivalent ft.

[4.6m] maximum). Terminate the duct on the outside

of the building with a suitable protective cover. This

cover must be located at least 16" (406mm) above

grade or above an anticipated snow line.

Page 7

MAX Oil-Fired Boiler

Page 7

On Carlin EZ-1 burners install model # 97406

combustion air intake system.

3G. Ventilation Air

(conventional chimney and

direct vent)

Where the boiler is installed in a basement there

is normally sufficient air infiltration to provide

adequate ventilation.

Where the boiler is installed in a closet or

otherwise confined space ventilation must be provided

to keep the controls from overheating. This is

accomplished by providing two openings to the space,

one 6" (152mm) from the floor and one 6" (152mm)

from the ceiling.

3H. Chimney Connection

Caution

An oil-fired unit shall be connected to a vent having

sufficient draft at all times to ensure sfe and proper

operation of the unit.

The chimney must be inspected and thoroughly

cleaned before connecting boiler. Most local codes

require the chimney to be lined when using an oil fired

boiler in order to protect the bricks and mortar from the

condensation produced by modern high efficient boilers.

The chimney must terminate at least 3 ft. (0.9m)

above the point where it passes through the roof and

be in a position free from down draft.

The boiler should be connected to the chimney

with the shortest possible run of 5 in. flue pipe and be

located above the chimney base to allow a drop leg for

scale accumulation to avoid blocking flue pipe

entrance.

Horizontal runs should be pitched up towards

chimney at approximately 1/4 inch per foot.

Install balanced damper on chimneys higher than

20 feet (6.1m).

Install "Blocked Vent Switch" provided in

accordance with attached instructions. Follow all

Warnings, Cautions and Maintenance Instructions for

safe, trouble free operation.

IMPORTANT: Max 75-140 may condense

when vented into an outside chimney. To minimize

potential for condensing, install either thermostatic

union or recirc bypass, shown in Figures 12 and 13.

As the boiler and flue pipe are under slight

positive pressure on start-up, it is necessary to seal all

pipe joints with high temperature tape or silicone

sealant to avoid any flue gas leakage into room.

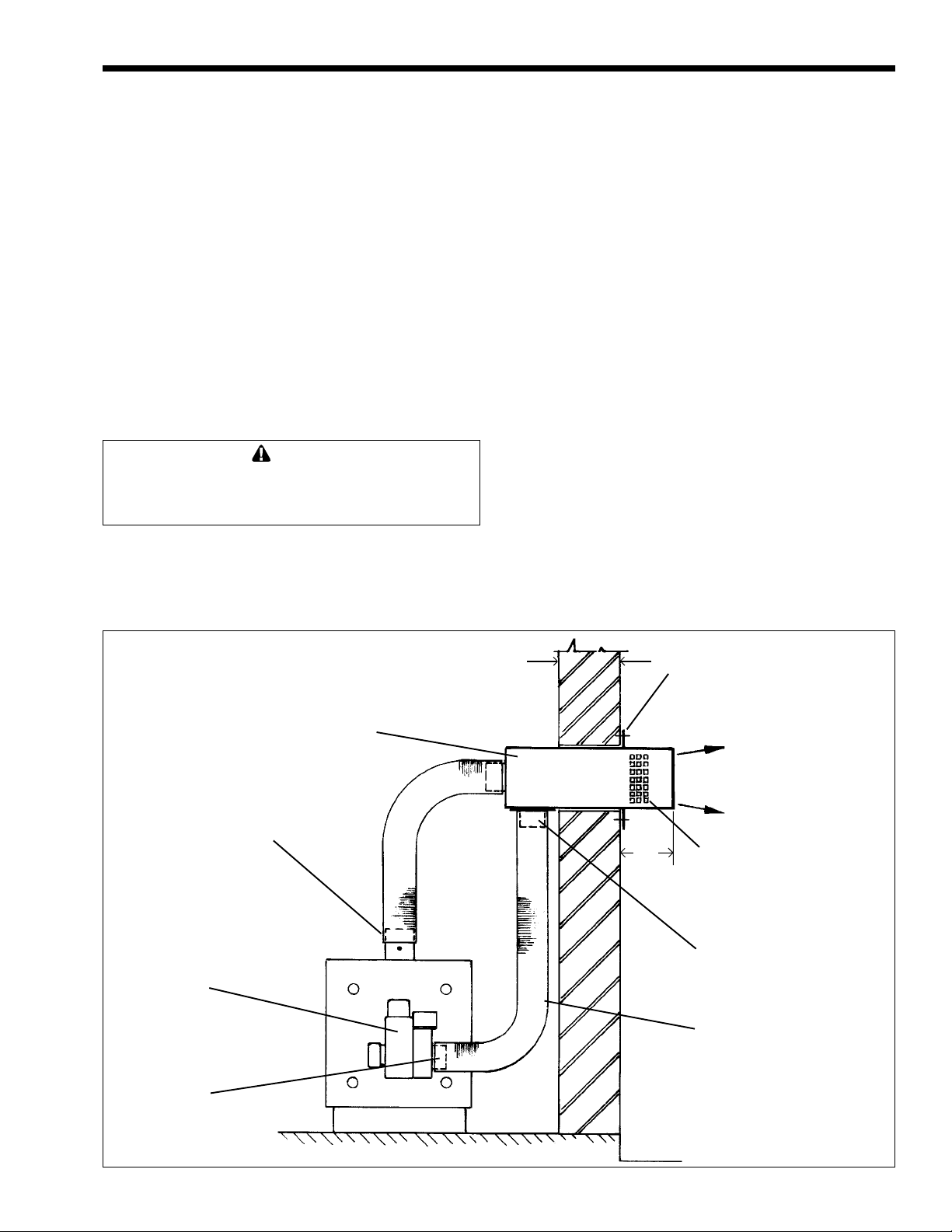

5" diameter flue pipe secure both ends of

pipe with clamps and

seal with silicone

Oil Burner

Burner Intake Air

& Adaptor

Balanced Flue T erminal

10" max.

Flange Fix to Wall

Ð

Ï

6½"

Gas Flue Discharge

Air Intake Screen

4" pipe adapter

4" diameter air pipe - secure

both ends

with clamps

Figure 3. Direct Vent Balanced Flue System.

Page 8

Page 8

³

Minimum 1.5

(0.5)

LAARS Heating Systems

3

³

4

(1.2)

(0.9)

³

³

7

(2.1)

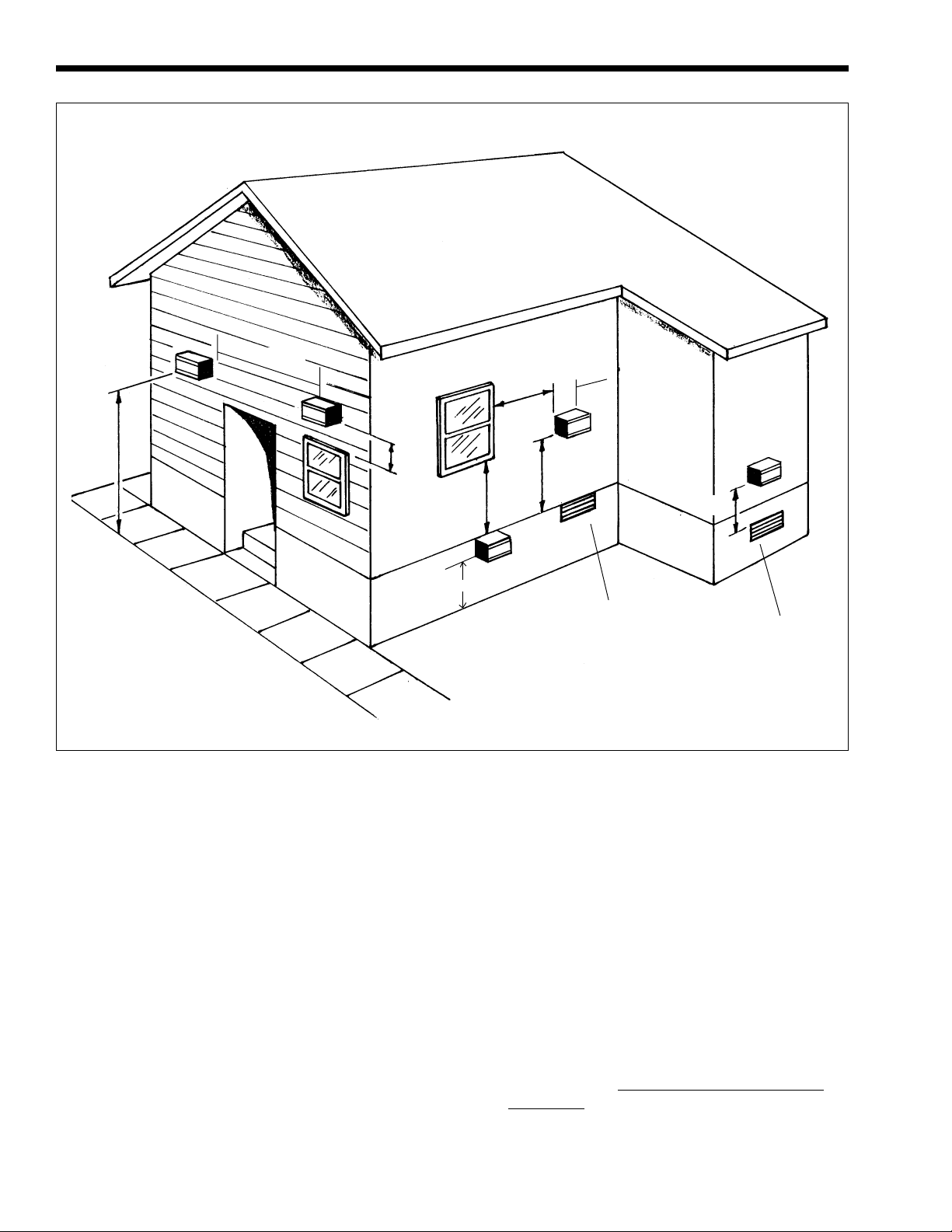

Figure 4. Terminal Locations - Minimum Distances.

1

(0.3)

3I. Direct Vent Balanced Flue System

With this system flue gases are vented directly

through the wall and fresh air for combustion is drawn

in through the same terminal, thus ensuring wind

pressures are equal to the intake and flue gas

discharge to create a balanced flue condition.

The terminal also incorporates a silencer to

reduce the flue gas discharge noise and a specially

designed end cap which throws the flue gases clear of

the wall to avoid surface discoloration.

NOTE: If the burner is not correctly adjusted it

is possible that surface discoloration may occur. Laars

will not accept any responsibility for such

discoloration.

The position chosen for the Balanced Flue

Terminal must conform to the following guidelines:

1. The terminal shall not be less than 3 ft. (0.9m)

above or 10 ft. (3m) horizontally from any forced

air inlet into the building.

1.5

(0.5)

1

(0.3)

Gravity Air Inlet

1 (0.3)

4

(1.2)

3

(0.9)

Forced Air Inlet

Dimensions shown in feet (m).

2. The terminal shall not be less than 4 ft. (1.2m)

below, 4 ft. (1.2m) horizontally or 1 ft. (0.3m)

above any door, window, or gravity air inlet into

the building.

3. The terminal shall not be less than 3 ft. (0.9m)

from an inside corner of an L shaped building.

4. The terminal shall not be less than 7 ft. (2.1m)

above grade when located adjacent to public

walkways.

5. The terminal shall not be less than 2 ft. (0.6m)

from an adjacent building.

6. IMPORTANT: The terminal shall be located at

a height not liable to blockage from leaves, snow

or other debris,

at least one foot (0.3m) above

grade level.

7. The terminal shall be positioned so that flue gases

are not directed where they can jeopardize people,

overheat combustible structures, or enter buildings.

Page 9

MAX Oil-Fired Boiler

Page 9

8. As the balanced flue vent system operates under

a slight positive pressure it is essential to seal all

flue joints to prevent leakage of flue gases into

the building.

certified pressure venting.

9. Vent terminal should be well away from

shrubbery or other obstructions that would

prevent free air flow to and from vent terminal.

Do not terminate vent under decks, stairways, or

car ports. When ever possible, locations under

windows should be avoided.

10. Vent termination should not be mounted

directly above or within 3' horizontally from

an oil tank vent.

Vent exhaust piping must be

3J. Installation of Balanced Flue System

1. Having decided the location for the terminal, cut

a hole in wall 7.5" high x 10.5" wide (191 x

267mm).

2. Insert terminal through the hole from outside and

screw to wall at the fixing flange, after applying a

bead of silicone sealant on the back face of the

flange.

3. Fit the 5 in. flexible pipe between end of

terminal and boiler flue outlet, cutting pipe to

suit installation. Secure both ends of pipe with

clamps and seal with silicone sealant to prevent

any flue gas leakage.

The pipe should rise from the boiler to terminal

and be supported at regular intervals dependent upon

length of pipe used.

Terminal must be installed pitching down to outside

¼" per foot to prevent rain entering vent piping.

Notes: (a) The “Univent” terminal is certified

for use with zero clearance from combustible

materials. The connection between the flue pipe and

the balanced flue terminal must be provided with a 6"

(152mm) clearance from combustibles or any reduced

clearance acceptable to NFPA 31. P/N 70-330

(included with all direct vent kits) may be installed on

the balanced flue terminal to reduce the required

clearance to 2" in accordance with NFPA 31.

(b) The terminal is packed with insulation and is

also air cooled thus making it suitable for installation

through combustible walls.

4. Fit the 4 inch pipe adapter to the underside of

terminal and connect the 4 inch flexible pipe

between adapter and air intake ring on burner

after first removing the black shroud. Cut the

pipe to suit installation and securely fasten to

burner and terminal with three fixing screws.

Support pipe at regular intervals dependent upon

length.

5. Finally, seal all around terminal on inside of wall

with silicone sealant.

Note:

“Univent” suitable for wall thickness up

to 10" (229mm).

3K. Boiler Piping

The supply manifold (control center) provided

with the boiler comes equipped with an air eliminator

provided through an automatic float vent. This will

provide system air elimination. Unit may be piped into

a non diaphragm expansion tank utilizing this

connection.

The pressure relief valve should be piped to a

safe place of discharge.

The piping and related connections should

follow good practice using approved joint sealants and

conform with all state and local codes. When the

boiler is connected to applications where standby

temperatures may drop below 60°F (16°C) or to a

large volume of water (e.g. radiant floors) then an anticondensing means must be provided. This may be

accomplished utilizing a by-pass loop (see Figure 12)

or optional thermostatic union (see Figure 13) p/n

2400-030.

Note: This is a low mass boiler. Follow

suggested piping diagrams to minimize the chance of

short-cycling.

3L. Freeze Protection

Proper precautions for freeze protection are

recommended for boiler installations in areas where

the danger of freezing exists.

Power outage, interruption of oil supply, failure

of system components, activation of safety devices,

etc., may prevent a boiler from firing. Any time a

boiler is subjected to freezing conditions, and the

boiler is not able to fire, and/or the water is not

able to circulate, there is a risk of freezing in the

boiler or in the pipes in the system. When water

freezes, it expands. This can result in bursting of

pipes in the system, or damage to the boiler, which

could result in leaking or flooding conditions.

Freeze protection additives may be used. Do not

use automotive anti-freeze. Maintaining a mixture of

minimum 65% water and maximum 35% properly

inhibited HVAC glycol, which contains an antifoamant, is the preferred method of freeze protection

for Max boilers. Percentage of glycol used in the

Max boiler must not exceed 35%. Typically, this

mixture will serve as freeze protection for

temperatures down to approximately 0°F (-18°C), and

will serve as burst protection for temperatures down to

approximately –35°F (-30°C).

IMPORTANT NOTES: Different glycol

products may provide varying degrees of protection.

Glycol products must be maintained properly in a

heating system, or they may become ineffective.

Consult the glycol specifications, or the glycol

manufacturer, for information about specific products,

maintenance of solutions, and set up according to your

Page 10

Page 10

LAARS Heating Systems

particular conditions

3M. Indirect Hot Water Tank

Install the tank in accordance with the

manufacturers instructions using recommended pipe

sizes, location of temperature / pressure relief valve

and any other special requirement for correct

installation.

A thermal expansion tank may be required on

hot water tanks equipped with check valves or back

flow preventors on the cold water supply.

3N. Burner Controls

The burner is fitted with a fully automatic

control system which incorporates a cad cell to

monitor the flame and shut down the burner in the

event of flame failure. A push button is provided to

restart the burner, but this must never be pressed more

than once following a flame failure.

Pre-purge (direct vent only) provides an air

supply prior to oil flow to ensure clean combustion

under all conditions.

Post purge is also fitted to direct vent burners to

completely clear all residual gases from the boiler and flue

system. This is necessary with direct vent flues because of

the lack of draft prevailing after the burner shuts down. The

post purge time is factory set at 30 seconds.

3S. Wiring

Wiring connections between burner and aquastat

on supply manifold should be made in accordance with

wiring diagrams in this manual (see Figures 5 through

11). External wiring must be in accordance with local

codes and regulations.

For convenience of servicing, a fuse disconnect

switch should be fitted near the boiler. Field

connections should be protected with a 15 amp fuse.

If an indirect hot water tank is used, the aquastat

on tank should be wired so as to have preference over

heating of the building. This requires the use of a

Honeywell L6006A-1145 or equivalent aquastat on

the tank working in conjunction with a zone valve or

circulator relay. See wiring diagrams in this manual.

On boilers piped direct (no zones) set anticipator

on thermostat to 0.8 amps.

3O. Fuel System (oil supply no heavier

than #2 fuel oil)

The oil supply should be run in heavy walled

copper tubing, without any joints, using flared fittings

only. It is important that the oil feed line to the burner

is air tight otherwise firing problems could result.

3P. Gravity Head System

Where the fuel supply is level with or above the

burner only a single pipe is required.

3Q. Suction Lift System

Where the burner is above the fuel supply a

return line must be provided in addition to the supply

line. The arrangement requires the fitting of the

bypass plug (provided) in the return port of the fuel

unit. Air is automatically purged from the fuel unit

and returned to the storage tank with this arrangement.

NOTE: If the suction lift exceeds 10 feet (3m),

a two stage fuel unit should be used. For Riello

burners obtain C700 kit for respective burners.

3R. Oil Filter

An in-line oil filter should be fitted in the supply

line and located inside the building between the tank

shut-off valve and as near to the burner as possible. A

shut-off valve should also be located close to the

burner for ease of servicing.

Page 11

MAX Oil-Fired Boiler

Page 11

Figure 5. Internal Wiring with Beckett AF II, AFG and CF375 with Honeywell R7184P Control.

Page 12

Page 12

LAARS Heating Systems

Figure 6. Internal Wiring with Carlin EZ-1.

Page 13

MAX Oil-Fired Boiler

Page 13

Figure 7. Internal Wiring with Riello BF5 (direct vent).

Page 14

Page 14

LAARS Heating Systems

Figure 8. Wiring Diagram. Boiler Only. Zoning with Zone Valves.

Figure 9. Wiring Diagram. Boiler Only. Zoning with Circulators.

Page 15

MAX Oil-Fired Boiler

Page 15

Figure 10. Wiring Diagram. Boiler with Indirect Water Heater. Zoning with Zone Valves.

Figure 11. Wiring Diagram. Boiler with Indirect Water Heater. Zoning with Circulators.

Page 16

Page 16

LAARS Heating Systems

Figure 12. Piping Diagram. “MAX” Boiler with Indirect Water Heater. Zoning with Zone Valves.

Figure 13. Piping Diagram. “MAX” Boiler with Indirect Water Heater. Zoning with Circulators.

Page 17

MAX Oil-Fired Boiler

Page 17

Figure 14. Piping and Wiring Diagrams. MAX Boiler in a Radiant Application.

Page 18

Page 18

Figure 15. Piping Diagram. MAX Boiler with Buffer Tank for Multi-Zone Application.

LAARS Heating Systems

Page 19

MAX Oil-Fired Boiler

Page 19

SECTION 4.

Operation

1. Check the boiler service switch is in the off

position.

2. Check the boiler is filled with water and the

complete system is purged of air.

3. Check the “cold fill” pressure is correct - usually

12 p.s.i.

4. Check there is ample oil in the storage tank and

all manual shut-off valves in the fuel system are

OPEN.

5. Set limit switch located in L8148A aquastat at

200º F (93°C).

6. Set manual reset limit switch at 220º F (104°C)

(Direct Vent Boilers Only).

7. Carry out burner settings, see “Preliminary

Burner Settings” (Table 3).

8. Push the safety reset button on burner control and

release. Adjust room thermostat or tank aquastat

to call for heat, switch ON boiler service switch

and burner should start.

Caution

When using a direct vent system -

If smoke is seen coming from the vent terminal,

switch off burner immediately. Otherwise the outside

wall could be discolored. Check “Preliminary Burner

Settings” again.

9. On one pipe systems the pump should be bled as

soon as the burner motor starts. Bleed oil into a

container for at least 15 seconds until it is seen

to be free of air bubbles.

With two pipe suction systems, the air is returned

to the oil storage tank where it is dissipated.

10. Adjust burner to achieve the reading shown under

4B “Burner Adjustments.”

11. If burner fails to start, check “Trouble Shooting

Guide” (Table 4).

4A. Preliminary Burner Settings

1. Fit the nozzle to suit firing rate required

2. Set air dial to the appropriate setting

3. Fit correct number stop pin or positioning bar to

burner.

4. Fit a pressure gauge to the fuel pump.

4B. Burner Adjustments

Test equipment required:

CO

analyzer Stack thermometer

2

Draft gauge Smoke tester

Fuel pressure gauge

Test readings should be taken from the plug in

the flue collar. Over the fire sampling is not

necessary on pressure fired boilers.

NOTE: Do not drill into the flexible vent pipe.

After firing the burner for about 5 minutes, make

the following checks and adjustments:

1. Check the pump pressure and if necessary adjust

pressure to obtain 140 / 150 p.s.i.

2. Gradually close air dial until a slight smoke trace

is measured, then take a flue gas sample and

check CO

3. Open air dial to reduce CO

reading which should be about 13%.

2

by ½%, then lock

2

dial in this position.

NOTE: The slight increase in excess air

provides a built in margin to ensure clean combustion

throughout the heating season.

(4) The vent pressure of the MAX DV will vary

dependent upon length of vent pipe used and the

firing rate chosen.

If pressure exceeds 0.13" W.C. recheck burner

setup for excess air / low CO

reading.

2

NOTE: With conventional chimneys the

pressure loss will be less because of the higher draft

normally generated.

5. Flue gas temperature will vary according to the

firing rate. The following typical net

temperatures should be obtained after

approximately 15 minutes of burner operation.

Note that the temperatures listed are net

temperatures. The net temperature listed should

be compared to the measured (actual)

temperature minus the temperature of the

combustion air. (i.e. use the outside temperature

when the combustion air is ducted, and use the

room temperature when room air is used for

combustion:

320°F @ 0.75 GPH (160°C @ .75mL/s)

350°F @ 1.00 GPH (177°C @ 1mL/s)

420°F @ 1.20 GPH (216°C @ 1.20mL/s)

330°F @ 1.40 GPH (166°C @ 1.40mL/s)

410°F @ 1.65 GPH (210°C @ 1.65mL/s)

4C. Sequence of Operation

When the room thermostat or hot water tank

aquastat calls for heat the burner and circulating pump

start. The burner and pump continue to run until the

heat demand is satisfied - the hot water tank being

satisfied before the room heating requirements.

If the boiler water reaches the high limit setting of

200º F (93°C) the burner will shut off but the pump

will continue to operate to clear the residual heat.

When the boiler temperature falls the burner will

restart if there is still a demand for heat.

A manual reset high limit aquastat (set at 220ºF)

(104°C) is provided on Direct Vent Boilers to shut off

the burner in the event of a failure of the high limit

control.

The burner features a post purge timer on Direct

Vent Boilers which provides a timed overrun of the fan

to clear residual flue gases from the boiler and flue

system after combustion is shut off.

Page 20

Page 20

0.75

MAX DV

LAARS Heating Systems

1.00

MAX DV

1.20

MAX DV

1.40

MAX DV

1.65

MAX DV

Refer to Rating Label for draft settings.

Table 3. Preliminary Burner Settings.

The minimum and Maximum flue outlet

pressures, measured at the flue gas sampling plug,

shall be –0.15 in. W.C. and -0.01 in. W.C.

Page 21

MAX Oil-Fired Boiler

Page 21

FAULT

BURNER

DOES NOT

START

BURNER RUNS

BUT FLAME NOT

ESTABLISHED

POSSIBLE CAUSE ACTION

Primary safety control tripped

High limit thermostat or blocked vent switch

tripped (MAX only)

Thermostat satisfied Turn thermostat to a higher setting.

Fuse blown or breaker tripped

Check voltage at burner between orange If voltage confirmed replace primary control.

and white wires If no voltage check t-stat and wiring connects.

Motor or fuel pump seized

Cad. cell dirty or faulty Clean face or replace cell.

No oil supply Check oil level in tank and oil supply to burner.

Water in oil tank Drain water from tank and bleed line to burner.

Nozzle plugged Replace with nozzle specified in manual.

Ignition transformer faulty

Electrodes carboned or shorting Clean electrode and check settings.

MAX-DV blocked vent or air intake Clear debris from around vent terminal.

Press reset button on control.

Note: ONLY PRESS ONCE.

Press reset button on both controls.

Fit new fuse or reset breaker. If it blows again,

check for short circuit.

Turn off power to burner and rotate by hand.

Replace if necessary.

Check quality of spark and replace transformer

if necessary.

FLAME

ESTABLISHED

THEN BURNER

LOCKS OUT

BURNER

PULSATES

Faulty oil valve Replace valve.

Too much combustion air Reduce air setting to obtain 11 to 12% CO2.

Low oil pressure Check pump pressure and adjust to 140 psi.

Water in oil tank Drain water from tank and bleed line to burner.

Oil filter or pump strainer plugged Replace filter cartridge and clean strainer.

Too much or too little combustion air Adjust air control to obtain 11 to 12% CO2.

Air trapped in fuel pump Bleed off air from pressure gauge port.

Low oil pressure Check pump pressure and adjust to 140 psi.

Lack of combustion air Check terminal for block at air intake screens.

Terminal fouled with debris at flue gas outlet Remove end cap and clean outlet.

Incorrect air setting Adjust air control to obtain 11 to 12% CO2.

Air leakage into fuel system Bleed pump and seal air leaks.

Water in oil tank Drain water from tank oil at burner.

Incorrect pump pressure Check oil pressure and adjust to 140 psi.

Pump coupling worn or broken Replace coupling.

Nozzle partially pluggeD Replace with nozzle specified in manual.

Boiler flue ways fouled Brush out all flue deposits.

Table 4. Troubleshooting.

Page 22

Page 22

LAARS Heating Systems

SECTION 5.

Maintenance and Service

To maintain the boilers high thermal efficiency

and reliable operation, it should be serviced and the

vent system inspected every year by a qualified

service person.

The service should preferably be carried out

directly after the heating season so as to avoid any

unnecessary corrosion.

5A. Boiler

The boiler flue ways may be cleaned by

swinging open front door after disconnecting flexible

air pipe and oil line from burner.

Remove the baffles from the flue gas annulus,

brush out scale deposits with a flexible brush and

remove with a vacuum cleaner. The rear door can

also be taken off if required to gain access for a

complete inspection of the internal flue ways. When

replacing doors ensure that they are fully tightened to

make a gas tight seal.

5B. Oil Burners

Clean combustion head assembly and all air

handling parts. Inspect condition of nozzle and

replace if necessary with a nozzle of the same make

and specification.

Check the electrode settings are in accordance

with the oil burner instructions. Also ensure the high

voltage leads are firmly secured to the ignition

electrodes. Clean all deposits from blower wheel

blades. Clean screen in fuel pump.

5C. Oil Filter

Replace the oil filter cartridge with one of the

same specifications.

SECTION 6.

Homeowner Information

WARNING

Never use gasoline, waste oil or garbage in your

boiler.

Never try to ignite oil by tossing burning paper or

other material into your boiler.

Never leave combustible materials around

your boiler.

Never tamper with the boiler controls or

burner settings.

6A. Living With Your Boiler

1. Shut down Instructions

a. Switch OFF boiler service switch.

b. Close all manual fuel shutoff valves.

c. If the boiler is going to be off for an extended

period of time and the threat of freezing

exists, drain water from boiler and heating

system.

Caution

Always keep the oil supply valve shut off, if the

burner is shut down for an extended period of

time.

2. Care of shut down boiler and restarting after an

extended shut down

a. Keep area around boiler clean and free of

litter during shut down.

b. Restarting should be done by a qualified

Service Person after inspecting the vent

system and ensuring that the oil supply is not

contaminated or degraded.

5D. Cold Oil

If the oil tank is outside, or a situation exists that

may cause very cold oil to be pumped to the burner, a

nozzle line heater and tiger loop are recommended.

Caution

Do not start the burner unless all cleanout doors

are secured in place.

Caution

Never burn garbage or paper in the unit, and

never leave combustible material around it.

3. Boiler Blow-down after draining to prevent

freezing.

a. Open all zone valves or flow checks in the

heating system and ensure that boiler is not

isolated from the heating system.

b. After water has stopped flowing remove the

air vent from the control center at the top of

the boiler and attach an air hose to the open

fitting. Start the flow of air and leave open

until all water stops flowing. Disconnect air

hose.

Page 23

MAX Oil-Fired Boiler

Page 23

c. Blow down domestic water piping and heater

using the same principle to prevent damage

to it by freezing.

4. Contact service personnel before remodeling, for

annual servicing/maintenance, before extended

periods of shutdown, and before start-up.

SERVICE PERSONNEL

Name______________________________________

Address____________________________________

__________________________________________

Telephone __________________________________

Caution

Do not tamper with the unit or controls - call

Service Personnel.

6B. General

1. To avoid unnecessary expense and inconvenience,

your boiler should be serviced at least once a

year by a qualified service person.

2. Always keep the fuel tank full, especially in

summer to prevent moisture condensing on the

inside surface of the tank.

3. The oil burner motor is permanently lubricated no oiling is necessary.

4. Keep a regular check on the direct vent terminal

for any blockage by leaves or other debris. Your

boiler relies on an adequate supply of air for

clean combustion and any obstruction of the air

inlet could result in poor combustion and fuel

odors.

5. If you experience problems with your boiler

check the following points before calling the

service person:

a. Check that there is fuel in the tank.

b. Check the room thermostat is set high

enough.

c. Check the service switch near the boiler is in

the ON position.

d. Check that the burner control reset button, if

open (popped) reset by pushing button in. If

burner does not complete a proper start and

heat sequence DO NOT RESET SWITCH A

SECOND TIME until a qualified service

person has inspected the burner.

e. Check that the manual reset control has not

opened (popped). Do not reset more than one

time without having the boiler inspected by a

qualified service person.

SECTION 7.

Part Numbers

Part Number Description

70-002 Boiler Body 75/100/120

71-002 Boiler Body 140/165

70-160 Control Center (manifold only)

70-184 Beckett AF2 (for direct vent MAX DV)

72-184 Beckett AF2 (for chimney vent MAX only

70-185 Carlin EZ-1 Elite Burner

(for direct vent MAX DV)

72-185 Carlin EZ-1 Elite Burner

(for chimney vent MAX only)

70-552 Riello BF-5 (for direct vent MAX DV)

70-375 Beckett AFG (MAX 140)

70-376 Beckett AFG (MAX DV 140)

70-377 Beckett CF375 (MAX 165)

70-378 Beckett CF375 (MAX DV 165)

70-202 Z-Flex, stainless steel, 5" x 15'

70-204 Z-Flex, aluminum, steel, 4" x 15'

70-212 Z-Flex, stainless steel, 5" x 10'

70-214 Z-Flex, aluminum, 4" x 10'

70-274 MAX DV Control Center (boxed)

72-274 MAX Control Center (boxed)

70-306 Left Side, Jacket 75/100/120

71-306 Left Side, Jacket 140/165

70-314 Right Side, Jacket 75/100/120

71-314 Right Side, Jacket 140/165

70-318 Top Panel, Jacket 75/100/120

71-318 Top Panel, Jacket 140/165

70-322 Top Cover, Jacket 75/100/120

71-322 Top Cover, Jacket 140/165

70-326 Rear Plate, Jacket 75/100/120

71-326 Rear Plate, Jacket 140/165

70-122 Front Panel, Jacket 75/100/120

71-122 Front Panel, Jacket 140/165

Page 24

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way , Rochester , NH 03867 • 603.335.6300 • Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0910 Document 1106D

70-196D

Loading...

Loading...