Page 1

User’s Manual Document 1239A

User’s Information for

®

MASCOT

II

Wall Mounted,

Modulating Boiler

Model LMH

125 MBTU/h

Combination

Boiler and Water Heater

Model LMC

125 MBTU/h

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dansle bâtiment où vous êtes.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2338600A

Page 2

Page 2

LAARS Heating Systems

CONTENTS

Familiarizing yourself to the Laars Mascot II ................2

1. Caring For Your Mascot II

2. Filling, Shut Down and Restart

3. Digital Display and Control ....................................5-7

......................................... 3

...............................3-4

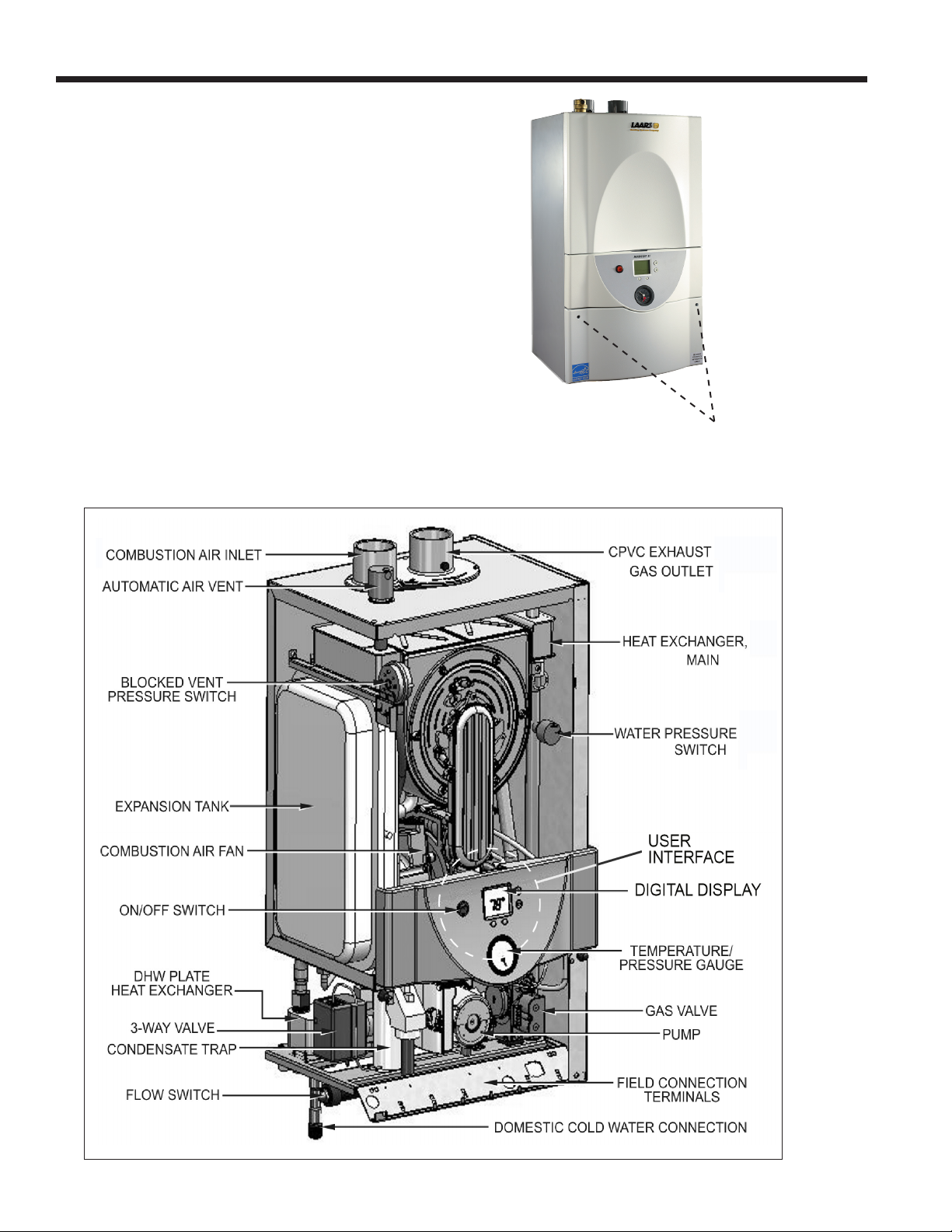

FAMILIARIZING YOURSELF TO THE

MASCOT

®

II

To open the front panels. Remove these two phillips screws, and

fold lower door down. The middle panel will then also fold down.

This will reveal the two screws that hold the upper panel in place.

Figure 2. Location of Components.

Page 3

User’s Manual - Mascot II Boilers and Water Heaters

Page 3

1. Caring For Your Mascot II

Your Mascot II will require very little

maintenance. However, as with any ne appliance

there are certain steps that should be taken to ensure

continuing optimum performance.

1.1 General Care

Keep the area around the Mascot II clean and

free from combustible materials, gasoline and other

ammable liquids and vapors.

The Mascot II must be completely isolated and

protected from any source of corrosive chemical fumes

such as trichlorethylene, perchlorethylene, chlorine,

etc.

Keep bottom and top openings on the boiler free

for proper ventilation of interior components.

Do not obstruct or block a free ow of air to the

boiler to ensure proper ventilation.

If desired, clean the jacket surfaces with a damp

cloth and mild detergent. Do not use ammable

cleaning materials.

If sidewall vented, keep the vent terminal clear

of obstructions — do not pile snow against the vent

terminal. Clean the intake screen often, and then

develop an appropriate maintenance schedule.

1.2 Annual Inspection of Flue and Vents

Visually inspect the vent pipe once a year. Should

any deterioration exist, have the affected parts replaced

by a qualied service person.

2. Filling, Shut Down and Restart

2.1 Filling the Boiler System

1. Ensure the system is fully connected. Close all

bleeding devices and open make-up water valve.

Allow system to ll slowly.

2. Move manual lever on 3-way valve actuator to

“open” position, allowing air to purge from boiler

loop. Valve is normally in DHW position until

there is a call for Central Heat via “T-T” contacts.

3. If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the highest

point in the heating loop.

4. Open bleeding devices on all radiation units at the

high points in the piping throughout the system,

unless automatic air bleeders are provided at such

points.

Note that there is an air bleed located on the left

side of Mascot II, on top of the jacket.

5. Cycle the boiler pump on and off 10 times, 10

seconds on and 10 seconds off to remove all air

from the heat exchanger. Then run system and

appliance pump for a minimum of 30 minutes with

the gas shut off.

6. Using manual lever located on left side of 3-way

valve actuator, move from “open” position back to

closed position repeatedly. This process forces air

out of the internal DHW loop.

1.3 In the Event of a Power Failure

The Mascot II can not be operated during

an electrical power outage. If there is an extended

power outage with danger from freezing, then the

Mascot II (and all other water systems) should be

drained completely. When draining the boiler, turn

off main electrical disconnect switch. When placing

back in service, refer to Section 2 of this Manual for

instruction. All draining and lling must only be done

by a qualied service person.

1.4 Full Service Every Three (3) Years

In addition to the annual visual inspections, a

qualied service agency should conduct a detailed

inspection of all ue product carrying areas of the

boiler and its venting system.

WARNING

Failure to remove all air from the heat exchanger could

lead to property damage, severe injury or death.

7. Recheck all air bleeders as described in Step 4.

8. Shut down the entire system and vent all radiation

units and high points in the system piping, as

described in Step 4.

9. Close make-up water valve and check strainer in

pressure reducing valve for sediment or debris from

the make-up water line. Reopen make-up water

valve.

10. Check gauge for correct water pressure and then

the system is ready for operation.

11. Refer to local codes and the make-up water valve

manufacturer’s instructions as to whether the

make-up water valve should be left open or closed.

12. After placing the unit in operation, the ignition

system safety shutoff device must be tested.

Page 4

Page 4

LAARS Heating Systems

Shut off the manual gas valve, and call the unit for

heat. Main gas valve will be energized, attempting

to light, for four (4) seconds, and then will deenergize. The unit will go into lockout after the

required number of trial for ignition periods.

Press the manual reset button on the boiler control,

or the user display, open the manual gas valve and

allow the unit to light. While the unit is operating,

close the manual gas valve and ensure that power to

the main gas valve has been cut.

13. Within three (3) days of start-up, recheck all air

bleeders and the expansion tank as described in

Steps 4 and 8 above.

WARNING

Improper adjustment may lead to poor combustion

quality, increasing the amount of carbon monoxide

produced. Excessive carbon monoxide levels may

lead to personal injury or death.

WARNING

Do not use this boiler if any part has been under

water. Immediately call a qualied service technician

to inspect the boiler and to replace any part of the

control system and any gas control which has been

under water.

2.2 Shutting Down Mascot II

1. Turn off the main electrical disconnect switch.

2. Close all manual gas valves.

3. If freezing is anticipated, drain Mascot II and be

sure to also protect building piping from freezing.

All water must be removed from heat exchanger

and condensate trap or else damage from freezing

may occur.

This step to be performed by a qualied service person.

2.3 To Restart Mascot II

If drained, please refer back to section 2.1 of

this manual before restarting.

1. Turn off the main electrical disconnect switch.

2. Close all manual gas valves.

3. WAIT FIVE (5) MINUTES.

4. Set the aquastat or thermostat to its lowest setting.

5. Open all manual gas valves.

6. Reset all safety switches (pressure switch, manual

reset high limit, etc.).

7. Switch on electrical power.

8. Burner will go through a prepurge period and

ignitor warm-up period, followed by ignition.

WARNING

Should overheating occur or the gas supply fail to

shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply

at a location external to the boiler.

FOR SERVICE

Contact your installing contractor, gas utility, Laars

dealer, or call Laars for the nearest authorized

representative in your area.

Page 5

User’s Manual - Mascot II Boilers and Water Heaters

MENU ITEM FUNCTION RANGE DEFAULT

3. Digital Display and Control

Figure 3. The User Interface.

Outlet water Displays the current outlet 55-180°F 120°F

temperature water temperature & allows

the setpoint to be adjusted

Inlet water Displays the current inlet — —

temperature water temperature

Delta T Displays the current — —

temperature rise across

the heat exchanger

DHW Domestic Hot Water

Stack Displays the current stack — —

temperature temperature

Outdoor Displays the current outdoor — —

temperature air temperature

Firing Rate Displays an indicator of the — —

current ring rate based

upon fan RPM. The actual

ring rate may vary.

The Mascot II has an integrated electronic control

that replaces many of the individual component controls

found on older appliances. The control acts as the

ignition control, pump control, high limit and cascading/

lead lag control and more. All of these functions and

setups are managed through the Digital Display.

3.1 Digital Display Navigation

The Digital Display is centered in the middle

of the User Interface and has 3 seperate modes of

control. They are USER, SETUP and DIAGNOSTIC.

Scalding Risk: Laars recommends

the use of a thermostatic mixing

valve at domestic hot water

outlet (boiler location) to

reduce potential for scalding.

The following thermostatic mixing

valve model has been tested and

approved for Mascot II application: Honeywell AM100US-1. Contact Laars for additional recommended models.

The names of these modes gives you an idea of the

levels of control. A USER might be the homeowner or

a service technician. SETUP displays all the controls

needed when setting up or expanding the boiler. And

DIAGNOSTIC is intended for a Mascot ll trained

technician. Please view Table 1, Table 2, and Table 3.

USER Mode is the home screen shown on the

control. If the display is not in USER Mode wait for the

display timeout period to be reached or press the Done

button to return to the USER Mode.

SETUP Mode is accessed by holding the up and

down arrow keys simultaneously for 3 seconds.

DIAGNOSTIC Mode can be activated by a trained

Mascot II technician.

Once in a particular menu structure, navigation

consists of pressing the next button to scroll from item

MENU ITEM DEFINITION

F or C Selects temperature units

LBTHODLOD Outdoor reset enable/disable -

enables menu items

LBT Low boiler setpoint during outdoor reset

HOD High outdoor temperature setpoint

LOD Low outdoor temperature setpoint

RMT Add Used for Lead/Lag (follow menus)

LL Lead/Lag enable/disable - enables menu items

HS Hysteresis - temp range between on/off cycles

bL Base Load % - input rate before next boiler res

Sd Warm weather shut-down temperature

ASC Anti short cycle - minutes of delay between

startup

bAC Future use - Press DONE to exit menu.

PAS Future use - Press DONE to exit menu.

NOTE: When enabling/disabling functions, select "Done" and wait 30

seconds before scrolling.

to item and then pressing the up and down arrows to

change values. Once the value is adjusted, the NEXT or

DONE button can be pressed.

MENU ITEM DESCRIPTION

Please view your Install/Operating Manual

Page 5

Caution

Table 1. USER Mode Menu.

Caution

Table 2. SETUP Mode Parameters.

Table 3. DIAGNOSTIC Mode Menu.

Page 6

Page 6

LAARS Heating Systems

3.2 Ignition Control- Sequence of Events

1. Call for heat

2. Safety chain check

3. Fan starts.

4. Prepurge timer is started.

5. Pre ignition time of 2 seconds to check the ame

sensor operation and status.

6. Trial for ignition period, 4 seconds. The direct

spark ignition switches to constant spark for three

seconds, during which time the gas valve is open.

For the last second of the ignition period direct

spark is de-energized and the ame sensor checks

for established ame. If ame is sensed the control

enters “Run” to satisfy the demand. If ame is

not established the control enters a retry, starting

from step 2. If ame has not been established in

the appropriate number of retries the control will

lockout with a 109 error code.

7. Call for heat complete

8. Gas valve off

9. Fan and pump over run times active to purge the

system

The sequence is the same for DHW or Central

Heat modes. Upon a call for Central Heat, the 3-way

valve will shift position, allowing boiler water to enter

the building’s heating loop. Only after the value shifts

position will the ring sequence begin.

3.3 Modulation Control

The control uses a PID algorithm to adjust

the ring rate of the boiler as the control point is

approached. The goal of the control is to operate

at a minimum ring rate to match the load on the

appliance. The burner modulates to achieve the setpoint

temperature, away from the actual off point.

3.5 High Limit

The control uses a dual thermistor sensor to

monitor the Mascot II’s maximum temperature. The

high limit sensor is installed in the outlet water. A dual

thermistor sensor is used, so that the two temperatures

can be monitored and compared to conrm accuracy.

The control will automatically reduce the ring of the

Mascot II to prevent the high limit from tripping. The

high limit setpoint is not adjustable.

3.6 Stack Temperature

The stack temperature is a dual thermistor sensor

and is limit rated. The control compares each of the

temperature readings to determine accuracy. The stack

sensor is used as a limiting feature to avoid excessive

temperatures in the venting.

3.7 Domestic Hot Water Temperature

The domestic hot water temperature sensor is used

to control DHW temperature. The DHW setpoint can be

adjusted through the USER menu structure.

DHW setpoint is displayed during DHW mode. For

LMH model, an aquastat will be used in lieu of a sensor

to control temperature of an indirect tank.

Caution

Scalding Risk: Laars recommends the use of a

thermostatic mixing valve at domestic hot water

outlet (boiler location) to reduce potential for

scalding.

The following thermostatic mixing valve model has been

tested and approved for Mascot II application: Honeywell

AM100-US-1. Contact Laars for additional recommended

models.

3.4 Pump Control

The boiler pump is active anytime there is a call

for heat applied to the control. When there is a central

heat call supplied the system pump relay is active. If

there is a DHW call supplied while the central heat

call is active the system pump turns off. This happens

because of domestic hot water priority, which forces

the control to satisfy the domestic water demand prior

to the hydronic demand. When the last heat demand is

satised the boiler pump enters an overrun time.

Page 7

User’s Manual - Mascot II Boilers and Water Heaters

3.8 Lead Lag / Cascading

Lead Lag/Cascading allows multiple boilers

to be connected together and controlled from

one common sensor input. Up to 8 boilers can be

connected together in a single system. To setup Lead/

Lag or cascading operation there are several settings

in the “setup” menu structure that must be adjusted

for the specic installation, each is covered in the

following sections.

3.8.1 Lead Lag Setpoint

The lead lag setpoint is set from the “user”

menu using the “LL” variable. This is the temperature

the boiler is attempting to maintain at the system

sensor. This setting doesn’t control the boiler

outlet temperature, so the water temperature at the

boiler outlet may be much hotter than the system

temperature setpoint. Adjust the LL setpoint to the

desired operating temperature of the system.

3.8.2 Lead Lag Master/Slave Selection

In the SETUP menu structure, the “LL” menu

allows the lead lag system to be turned on and the

boiler to be congured as a master or slave control.

In each lead lag system there can only be one master

control, so proper selection is important to avoid

operating issues. To set the boiler to lead lag “master”

operation the LL menu should be set to “LDR”. To set

the boiler to slave, “SLA” should be selected.

3.8.3 Lead Lag Address

The Lead Lag address must be set for each boiler

connected to the lead lag system. Each boiler must

have a unique address selected for the system to work

properly. Typically, the lead or master boiler should be

set to address one and the remaining boilers should be

set to values 2–8 depending upon how many boilers

are installed in the system.

3.8.4 Lead Lag Hysteresis

The lead lag system uses a hysteresis value set

in the setup menu, called, “HS”. The hysteresis and

setpoint values control the on and off points of the

boiler. If the lead lag setpoint is adjusted to 120°F

with a hysteresis value of 5°F the boiler will turn off

when the water temperature reaches 125°F and will

turn back on when the water temperature reaches

115°F. Set the hysteresis values to match the boiler to

the system operating characteristics. Setting this value

correctly will help reduce the chance of short cycling.

3.8.5 Lead Lag Base Load Setting

The lead lag system uses a base load setting that

is set through the “setup” menu called “bL”. The base

load setting identies the ring rate that the operating

boiler must achieve before the next boiler in the

system is allowed to operate. The default setting is

50% to avoid short cycling and operating the boilers at

higher, less efcient, ring rates.

Page 7

Page 8

Page 8

LAARS Heating Systems

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 1212 Document 1239A

H2338600A

Loading...

Loading...