Page 1

DE 4002

5.959-343 (2005-04-06)

Page 2

English

Operating Instructions Page 3

Spare Parts List Page 30

Français

Español

Notice d’instructions Page 12

Liste des pièces de rechange Page 30

Instrucciones de servicio Página 21

Liste des pièces de rechange Página 30

Page 3

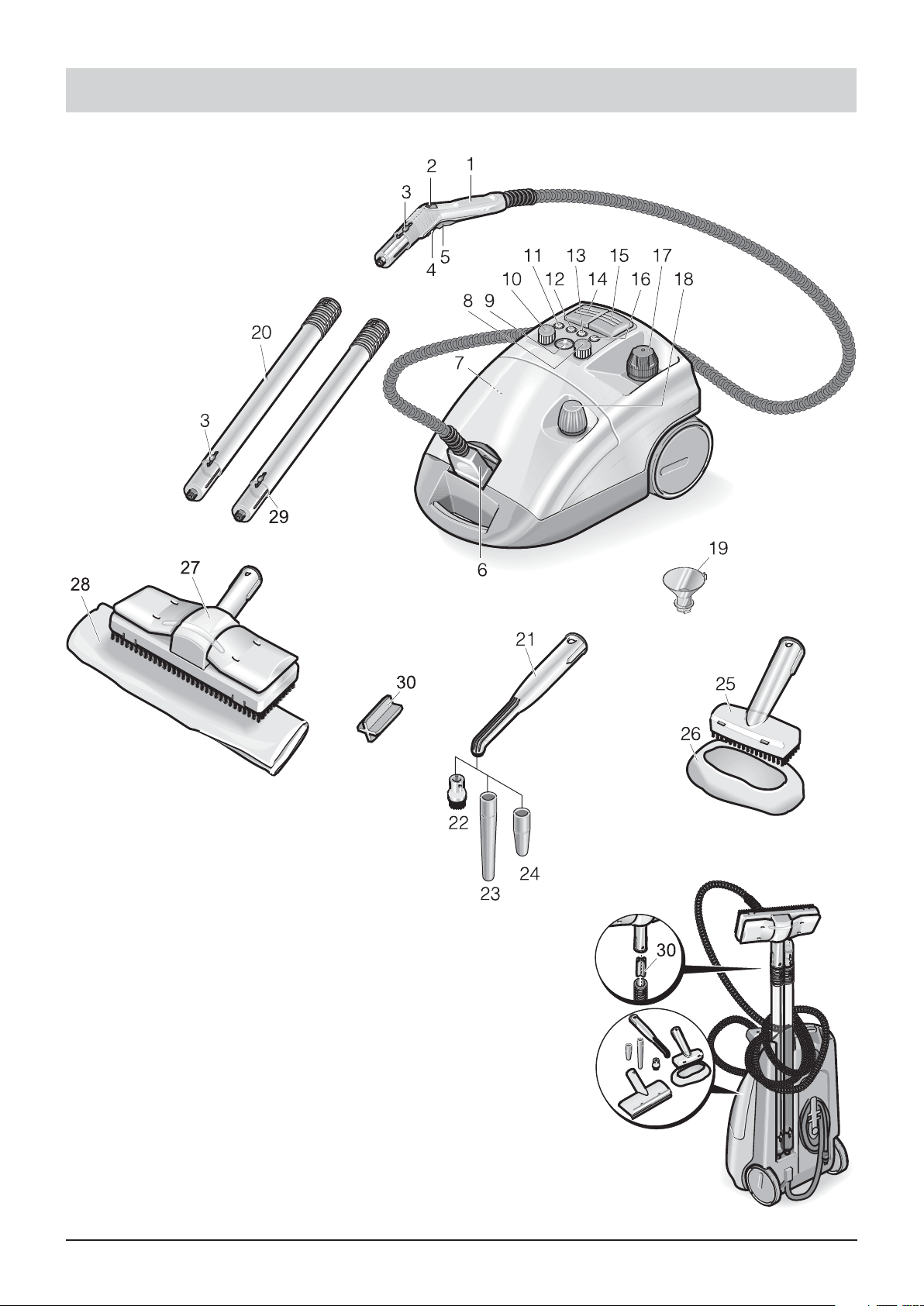

1. Starting the unit

English

3

Page 4

DE 4002

1. Starting the unit

1 Steam pistol

2 Handwheel for steam control

3 Release button

4 Locking mechanism (child lock)

5 Steam switch

6 Modular accessory plug

7 Reset button – Descaling completed

8 VAPOHYDRO control knob

9 Temperature indicator

10 Steam control knob

11 Indicator light – Descaling due (white)

12 Indicator lamp –

Low water warning, additional tank (red)

13 Indicator lamp – Heater (yellow)

14 Heater ON/OFF switch

15 Steam supply switch

16 Indicator lamp –

Low water warning, boiler (red)

17 Boiler cap with safety valve

18 Tank cap

19 Funnel for filling tank

20 Extension tubes

21 Spot nozzle

22 Circular brush

23 Extension

24 Power nozzle (red)

25 Hand nozzle

26 Terry-towelling slip-on

27 Floor nozzle

28 Large wiping cloth

29 Retaining bracket

30 Floor Nozzle Storage Fitment

For the sake of the environment

The packaging material can be recycled.

Please do not place the packaging into the

ordinary refuse for disposal, but arrange for

the proper recycling.

Old appliances contain valuable materials

that can be recycled. Please arrange for the

proper recycling of old appliances. Batteries,

oil, and similar substances must not enter the

environment. Please dispose of your old appliances

using appropriate collec-tion systems.

1.1 Unpacking the unit

• If you notice any transport damage while

unpacking the unit, please report it to your dealer

immediately.

1.2 Attaching the accessories

• Connect the modular accessory plug to the main

unit. The lugs on the plug must lock into place on

the cover of the main unit socket.

• Attach the required accessory (floor, hand or spot

nozzle) to the steam gun. Push both parts

together until the lock button on the steam gun

snaps into place.

• If required, use the extension tubes. Assemble the

tube sections by pushing one into the other until

the button snaps into place.

• Press the release button to separate the accessories from each other.

1.3 Filling the boiler with water

• Remove the safety cap from the main unit.

• Using the funnel, pour a maximum of 2 litres of

tap water into the boiler. Hot water shortens the

heating-up time.

Note: With the unit standing on a level surface, the

boiler can be filled up to 2 cm below the top of the

filler neck.

• Do not use any detergents.

• Refit the safety cap onto the main unit, and ensure

that it is properly tightened.

4

Page 5

1. Starting the unit

English

Additional tank

Fill the additional tank in order to prolong the time

that the cleaner can be used before it requires

refilling.

• Unscrew the cap on the additional tank.

• Using the funnel, pour a maximum of 2 litres of

tap water into the tank.

• Screw the cap back onto the tank.

1.4 Switching the unit ON

• Plug the unit into a mains socket, and switch it on

by means of the steam supply switch and the

heater switch. Indicator lamps should be

illuminated.

Note: The full heat rating will only be available if the

modular accessory plug is connected to the main

unit while it is heating up.

• When the heater indicator lamp extinguishes, the

system is ready for use.

Note: Do not place the unit in an upright position

while it is switched ON. Otherwise the heater will

automatically switch OFF after a short interval, and

the red indicator lamp (low water warning) will light

up.

• For transporting the unit, switch the heater OFF

by means of the heater switch.

WATER WARNING lamp for the additional tank

illuminates.

• Fill the tank with a maximum of 2 litres of tap

water.

• Using the funnel, fill the additional tank with a

maximum of 2 litres of tap water.

Note: If the pump does not deliver any water,

although the additional tank is full, it is a sign that

the boiler requires descaling – see 3.1 Descaling

the boiler.

1.6 Switching the unit OFF

• Switch the unit OFF by means of switches.

• Remove the modular plug from the main unit, while

lifting up the socket cover at the same time.

• Remove the plug from the mains socket.

• Any remaining water can be left inside the unit.

1.7 Transporting the unit

• If you have been working with the extension tubes

and the floor nozzle, it is quite easy to transport

the unit.

• Turn the heater OFF with switch, stand the unit

upright, and attach the extension tube to the

retaining bracket on the underside of the main unit.

• When you press the steam switch, steam is

expelled from the steam gun. Always direct the

steam gun at a piece of cloth until the steam flows

evenly out of the nozzle.

• The heater is switched on continually while the

unit is in use (indicator lamp lights up), so that the

pressure inside the boiler is maintained at a

constant level.

• If you have switched the unit on and there is no

water in the boiler, heater indicator lamp will light

up initially before the low-water thermostat

switches the heater off. The low-water indicator

lamp will then light up.

1.5 Refilling the boiler with water

Note:When there is no water left in the additional

tank, a warning signal is sounded and the LOW

1.8 Storing the unit

• Place the hand and spot nozzles, together with

the smaller items, in the accessory compartment.

• Wind the cable around the holder on the base of

the main unit. Attach the floor nozzle to one of the

extension tubes, and insert both tubes into the

recesses in the base of the unit.

• Ensure that the brushes are allowed to cool down

without the bristles becoming deformed in the

process.

5

Page 6

DE 4002

2. Directions for use

2.1 Important fundamental information

To achieve satisfactory results with a steam

cleaner, it is most important that the initial cleaning

stage is performed thoroughly. This means that

where detergents and other cleaning products

have been used for many years, the immediate

objective must be to strip away the layer that will

have built up. By using a steam cleaner, dirt is lifted

off, as described previously, and picked up by the

cloth. Depending upon the amount to be cleaned

off, the dirt will have been completely removed after

the cleaner has been applied 1 - 2 times. The result

is a floor surface that is free of streaks. The same

applies when cleaning windows. The steam

cleaner cannot remove large amounts of limescale

directly. A description of the procedure for

successfully removing these types of deposits is

contained in the section concerning the cleaning

of bathroom fittings.

2.2 Special notes on cleaning

Fabrics

Before steam-cleaning fabrics or textiles, we

recommend that first of all you carry out a test on

an inconspicuous part of the material. Apply plenty

of steam to the test area, and then allow the

material to dry out so that you can determine

whether any changes in colour or shape occur.

Coated or painted surfaces

When steam-cleaning kitchen cabinets or other

items of furniture, doors, parquet flooring, painted

or plastic-coated surfaces, please take into account

that waxes, furniture polish, plastic coatings or

paint may be dissolved or lifted off if they are

subjected to prolonged exposure to the steam jet.

Apply only small amounts of steam directly to these

types of surface, or clean them with a cloth to which

the steam has been applied first.

2.3 Steam volume control with rotary knob

• If you are working with the standard accessories

or the iron, you can control the volume of steam

by adjusting the rotary knob on the main unit.

2.4 VAPOHYDRO rotary control knob

• In washrooms or tiled areas, for example, you

can also flush the dirt away instead of wiping it

off with the cloth. This is achieved by varying the

moisture content of the steam by adjusting rotary

knob on the main unit. The greater the amount of

moisture in the steam, i.e. the more water there

is in the steam jet, the better the washing results

will be.

If you turn the rotary knob all the way round to

“+”, a jet of hot water is discharged from the

nozzle giving the greatest flushing effect.

• Use the VAPOHYDRO feature together with the

spot nozzle, for example, for cleaning the

bathroom.

• If you are working with cloths (floor nozzle, hand

nozzle), set the VAPOHYDRO rotary control

knob to “–”, so that the steam jet contains as little

moisture as possible. This improves the ability of

the steam to loosen and dissolve the dirt.

Note:

If you turn the VAPOHYDRO rotary control knob

to “+”, the boiler will empty more quickly.

2.5 Temperature indicator

• This indicator shows you whether you are

working within the proper temperature range

(green area).

2.6 Steam gun

Glass surfaces / window panes

Glass surfaces may break if they are subjected to

uneven heating. Especially in the case of low

exterior temperatures, you should first of all spray

steam lightly over the whole glass surface in order

to even out any differences in temperature and to

avoid the build-up of tension on the surface of the

glass. Do not apply the steam jet directly to the

sealed parts of the window.

6

• The steam can be used without accessories for

the following cleaning jobs:

– Deodorising clothing and removing creases

from garments;

– Dusting houseplants (maintain a distance of

approx. 30 cm);

– Damp dusting: apply small amount of steam to

surface and then wipe dry with a clean cloth.

Page 7

2. Directions for use

English

2.7 Spot nozzle

• The spot nozzle can be attached either directly to

the steam gun or via the extension tubes.

• Because the steam temperature and pressure

are at their highest immediately the steam leaves

the nozzle, the closer you hold the steam jet to

the object to be cleaned, the better the cleaning

results will be.

• The spot nozzle can be used for cleaning:

– locations that are difficult to reach, such as in

corners, joints, etc.

– curtains, radiators

– lavatories

– stainless steel

– taps and similar fittings

– coated or enamelled surfaces

– and for lifting off stains.

• Use the extension tube for locations that are

particularly difficult to reach.

• If required, the circular brush can be pushed onto

the front of the spot nozzle.

Note:The circular brush is not suitable for cleaning

sensitive surfaces.

2.8 Floor nozzle

• Depending upon the actual cleaning task, the floor

nozzle can be used with the extension tubes. You

can use this nozzle for all large washable wall

and floor surfaces. Place the floor nozzle onto

the folded large cloth, and then pull the cloth

under the retaining clips on each side.

• The best results for wiping up dirt are achieved

when you turn the cloth over, or replace it,

frequently.

• For more effective cleaning of heavily soiled

surfaces, slow down your working speed to allow

the steam more time to penetrate the grime.

2.9 Hand nozzle

• Depending upon the actual cleaning task, use

the hand nozzle with the extension tubes.

• You can use the hand nozzle with the cloth for

cleaning:

– small washable surfaces

– upholstery

– sensitive surfaces.

2.10 Optional accessories

Only accessories approved by the manufacturer

may be used with this unit.

Household iron (Order no. 6.959-262)

• Connect the modular plug on the household iron

to the main unit.

Steam-ironing

– For ironing all types of fabrics the temperature

control should be set at least to the

In this setting the steam discharged from the

iron prevents the fabric from being overheated.

– The higher the selected temperature, the dryer

and less visible is the steam; the volume of

steam remains the same however.

– As soon as the lamp on the iron extinguishes, it

is ready for use.

– As soon as you press the switch, a solenoid

valve in the main unit opens and steam flows

out of the base of the iron. If you push the

switch forwards, steam is expelled

continuously; if you push the switch towards the

rear, shots of steam are discharged.

– Begin by directing the steam onto a piece of

cloth until water no longer comes out of the iron.

– Turn the steam volume control on the main unit

to obtain the desired amount of steam.

– You can hold the iron vertically for steaming

curtains, clothes, etc.

...

stage.

• Any traces of detergents left on the floor surface

to be cleaned may form streaks. As a rule these

streaks will disappear after the steam cleaner has

been applied several times.

7

Page 8

DE 4002

2. Directions for use

Dry-ironing

– If you wish to iron without using steam, switch

the steam supply switch on the main unit to ON,

and the heater switch to OFF.

– Set the temperature dial for the desired fabric

type.

Synthetic fibres Wool Linen

Window nozzle (Order no. 6.962-007)

• Attach the window nozzle directly to the steam

gun. Use the extension tubes if required.

• Apply steam evenly to the glass surface from a

distance of approx. 20 cm. Switch off the steam

supply and squeegee the glass surface in straight

passes from top to bottom. Wipe the rubber lip

and the bottom edge of the window dry after each

pass.

Biological Descaler RM 511

(Order no. 6.290-239)

– 3 x 100 g powder for cleaning the boiler

– See Section 3.

Window wiper, 230 mm 6.962-007

Hand nozzle with wire bristles 6.962-014

Spot nozzle, long, 400 mm 6.962-015

Spot nozzle, short, 140 mm 6.962-016

Circular brush Ø 60 mm 6.962-017

Triangular brush, small, 90 mm 6.962-018

Circular brush, small, qty 5 6.962-019

Triangular brush, large, 130 mm 6.962-024

Cloth set, qty 10 6.962-025

Circular brush, small, qty 5 6.962-139

Extension tube, 250 mm 6.962-144

Caddy 6.962-239

Wallpaper remover (Order no. 6.962-013)

With the wallpaper remover you can use the steam

cleaner for stripping wallpaper.

• Procedure:

– Place the wallpaper remover with its entire

surface on the edge of a sheet of wallpaper.

Allow the steam to penetrate until the wallpaper

is soaked through (approx. 10 sec.).

– Without switching it off, move the wallpaper

remover to a new location. Use a putty knife to

lift the loosened wallpaper, and pull it off

completely.

– The steam may not be able to readily penetrate

woodchip wallpaper that has been painted

several times. In this case we recommend that

you go over the wallpaper with a spiked roller

before steam is applied.

8

Page 9

3. Care, Maintenance & Troubleshooting

English

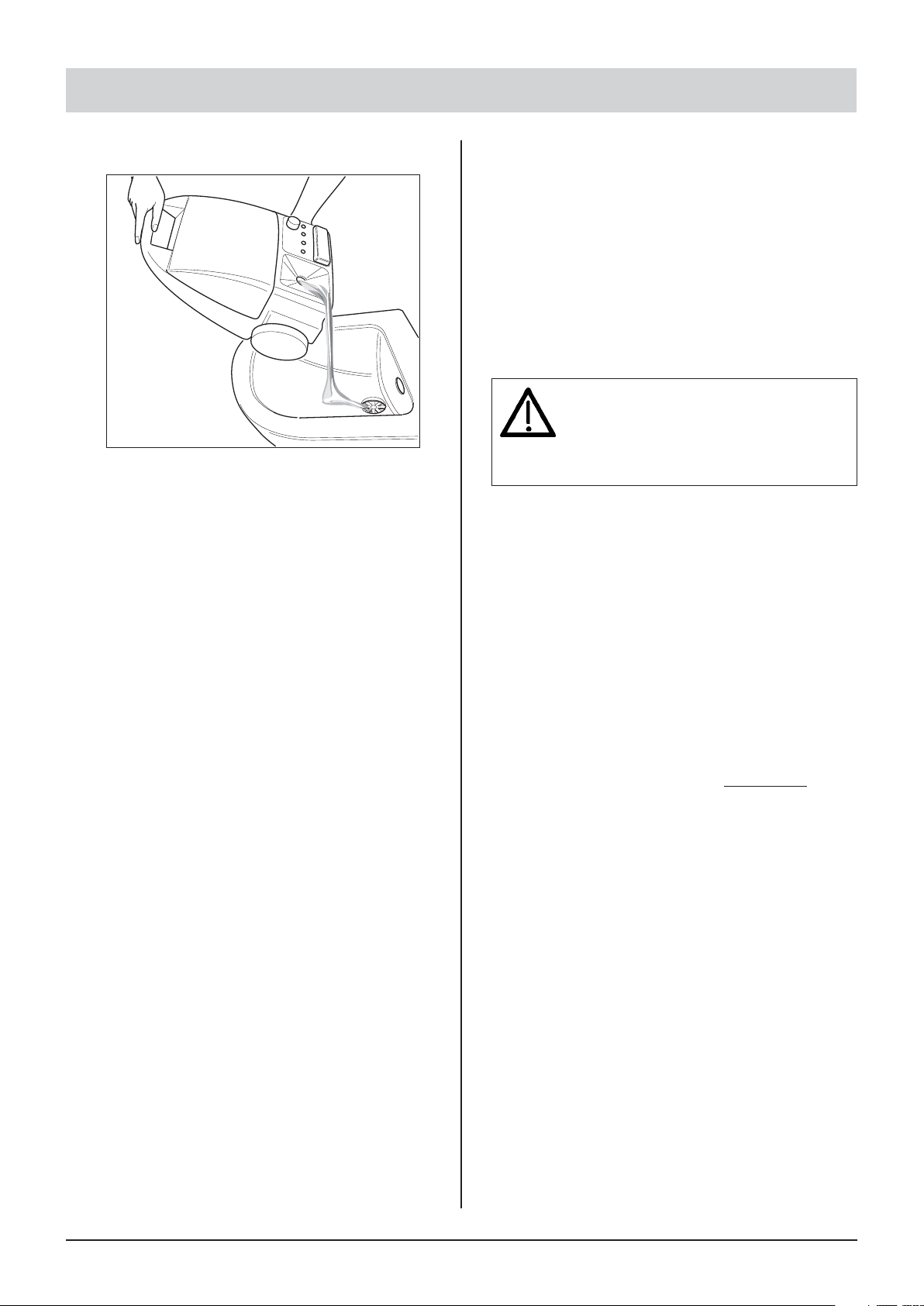

3.1 Cleaning the boiler

Rinsing out the boiler

• To clean the boiler, we recommend that you fill it

with water and shake it vigorously. This should

loosen any scale that has settled at the bottom

of the boiler. If you now pour the water out of the

boiler, the scale will be flushed out at the same

time (see ill.).

Procedure

• Unplug the steam cleaner from the mains

electricity.

• Empty the boiler entirely of any remaining water.

• Dissolve the contents of two bags in 2 litre of

warm water while continuously stirring the liquid

at the same time.

• Pour the solution into the boiler, and allow to

stand for approx. 8 hours.

The safety cap must not be attached

to the boiler while descaling is being

carried out. Make sure that the cleaner

can not be used while there is any

descaling solution left in the boiler.

• Pour the contents of the boiler out at the side

(see ill.), and rinse out the boiler at least twice

with cold water to ensure that no descaling

solution or deposits are left inside.

• Switch on the cleaner.

• For soft water (up to 1.8 mmol/L) the boiler should

be flushed out after it has been refilled 15 times,

for harder water after every fifth time.

Descaling the boiler

• We recommend that you descale the appliance

as soon as the “Descaling due” indicator light

illuminates.

• In order to remove any scale that has built up on

the walls of the boiler, we recommend that you

clean the boiler with KÄRCHER Biological

Decalcifying Liquid RM 511.

• KÄRCHER Biological Decalcifying Liquid RM 511

is based on citric acid and is therefore entirely

biodegradable.

• In order to avoid damaging your steam cleaner,

use only products for descaling that have been

officially approved by KÄRCHER.

• Press the reset button until the “Descaling due”

light extinguishes.

• Your steam cleaner is now ready for use again.

After approx. 50 operating hours, the “Descaling

due” light will illuminate to show that it is time to

descale the appliance once more.

Note: If you use distilled water exclusively, it will

not be necessary to descale the cleaner.

When the “Descaling due” indicator light illuminates, just press the reset button until the light goes

out.

Filter replacement

• When using polluted water the filter can become

blocked. This makes itself apparent either by

extraordinarily long running times of the pump or

a total functional failure. In this case the filter

should be replaced.

3.2 What to do if there is a problem

• If the low-water warning lamp lights up because

the unit has been stood upright although it still

operating, follow the procedure described in the

section “Refilling the boiler with water”.

• If you encounter any other problems with the

cleaner, you should contact your local authorised

customer service agent.

9

Page 10

DE 4002

4. Safety devices

This steam cleaner has been fitted with various

safety devices to provide multiple protection

measures. The most important safety components

are described below.

4.1 Pressure controller

The pressure controller maintains the boiler

pressure at as constant a level as is possible while

the cleaner is in use. The heater is switched off

when the operating pressure inside the boiler

reaches its maximum of 3.2 bar, and switched on

again when the pressure drops as a result of steam

being drawn off.

4.2 Low-water thermostat

As the water inside the boiler is consumed, the

temperature around the heater rises. The low-water

thermostat switches the heater off, and the red lowwater warning lamp lights up. The heater is

prevented from switching on again until the boiler

has cooled down, or it has been refilled with water.

4.3 Safety thermostat

If the low-water thermostat fails and the cleaner

overheats, then the safety thermostat switches the

whole unit off. Contact your authorised KÄRCHER

Customer Service agent so that the safety

thermostat can be reset.

4.4 Safety cap

The safety cap seals off the boiler and keeps the

steam pressure inside. If the pressure controller

becomes defective, and the pressure inside the

boiler rises above 5.5 bar, an overpressure valve

opens inside the safety cap, and steam escapes

into the open. Contact your authorised KÄRCHER

Customer Service agent before using the cleaner

again.

5. General information

5.1 Warranty

The applicable warranty conditions in different

countries are issued by the respective national

distributor of KÄRCHER products. During the

warranty period, any malfunctions of the unit

caused by a material or manufacturing defect will

be repaired free of charge.

In the event of a warranty claim, please take the

cleaner, with accessories and proof of purchase, to

your original dealer or to the nearest authorised

customer service centre.

We will not be held liable for damages occurring as

a consequence of improper handling of the cleaner,

or of failure to observe the Operating Instructions.

5.2 Recycling information

This appliance has been constructed in compliance

with the Directive on Recycling, No. 2243, issued

by the German Association of Engineers.

10

Page 11

English

6. Technical specifications

Electrical connection

Voltage 120 V

Current type 1~50/60 Hz

Voltage at handgun 24 V

Mains connection cable, Order no. * CDN 6.647-791

Performance data

Heater power consumption 1800 W

Pump 50 W

Max. operating pressure 32 bar

Permissible operating pressure 50 bar

Heating time ca. 5.5 min/L water

Max. steam volume 75 g/min

Dimensions

Weight without accessories 80 kg

Water capacity 40 L

Tank capacity 20 L

Boiler capacity 24 L

Width 305 mm

Lenght 480 mm

Height 265 mm

Circuit diagram 0.087-983

S1 Heater switch

S2 Steam supply switch

S3 Pressure switch

S4 Safety thermostat

S5 Low-water thermostat

S6 Reset button – Descaling completed

S7 Steam switch, steam gun

S8 Steam switch, iron

H1 Indicator lamp, heater

H2 Indicator lamp, low water warning

H3 Indicator lamp, fresh-water tank

H4 Indicator light – Descaling due

H5 Buzzer

E1 Heating element, 1500 W

E2 Heating element, 750 W

E3 Heating element, iron, 750 W

MV1 Solenoid valve

M1 Pump

N1 Electronics

T1 Transformer

F1 Fuse

C1 Capacitor

X1 Mains plug

X2 Plug, coupling

X3 Plug, steam supply

11

Page 12

DE 4002

1. Mise en service

12

Page 13

1. Mise en service

Français

1 Pistolet à vapeur

2 Manette de régulation du débit de vapeur

3 Touche de déverrouillage

4 Verrouillage (sécurité-enfants)

5 Commutateur de vapeur

6 Bloc connecteur

7 Bouton-poussoir à réarmement: détartrage

8 Bouton rotatif de régulation VAPOHYDRO

9 Thermomètre

10 Bouton rotatif régulant le débit de vapeur

11 Témoin de contrôle – Détartrage (blanc)

12 Témoin de contrôle (rouge) de manque d’eau dans

le réservoir supplémentaire

13 Témoin de contrôle (jaune) du chauffage

14 Commutateur de chauffage (Marche/Arrêt)

15 Commutateur d’alimentation en vapeur

16 Témoin de contrôle (rouge) de manque d’eau dans

la chaudière à vapeur

17 Bouchon de sécurité

18 Bouchon du réservoir

19 Entonnoir de remplissage

20 Tuyau-rallonge

21 Buse à jet crayon

22 Brosse ronde

23 Rallonge

24 Buse de puissance (rouge)

25 Buse manuelle

26 Revêtement en tissu éponge

27 Buse de sol

28 Grand chiffon de nettoyage

29 Support

30 Adaptateur pour buse sols

Respect de l’environnement

Les matériaux constitutifs de l’emballage

sont recyclables. Ne pas jeter les

emballages dans les ordures ménagères,

mais les rendre à un système de recyclage.

Les appareils usés contiennent des

matériaux précieux recyclables lesquels

doivent être rendus à un système de

recyclage. Des batteries, de l’huile et

d’autres substances semblables ne doivent jamais

être tout simplement jetées. Pour cette raison,

utiliser des systèmes adéquats de collecte pour

éliminer les appareils usés.

1.1 Déballage de l’appareil

• Si lors du déballage vous constatez des dégâts

dus au transport, veuillez en informer votre

transporteur par lettre recommandée avec

accusé de réception dans les 3 jours. Faites les

réserves nécessaires sur le bon de livraison

(article 105 du Code de Commerce).

1.2 Montage des accessoires

• Reliez le bloc connecteur avec l’appareil. Les

saillies nez du bloc connecteur doivent encocher

contre le couvercle de la prise du Vaporapid.

• Montez l’accessoire désiré contre la poignée

(buse de sol, buse manuelle ou buse à jet crayon).

Pour ce faire, emboîtez les pièces les unes dans

les autres jusqu’à ce que le cran de verrouillage

situé contre la poignée encoche.

• Utilisez si nécessaire les tuyaux-rallonges. Pour

ce faire, emmanchez les pièces les unes dans

les autres jusqu’à ce que la touche correspondante encoche.

• Pour déboîter les accessoires, appuyez sur la

touche de déverrouillage.

1.3 Remplissage de l’eau

• Dévissez la fermeture de sécurité de l’appareil.

• Avec l’entonnoir, versez au maximum 2 litres

d’eau du robinet dans la chaudière. De l’eau

chaude raccourcit le délai de chauffage.

Remarque: chaudière à l’horizontal, l’eau peut

arriver dedans 2 cm en-dessous du bord de l’orifice

de remplissage.

• N’utilisez pas de détergent.

• Revissez bien fermement la fermeture de sécurité

sur l’appareil.

Réservoir supplémentaire

Pour obtenir une plus longue autonomie de travail,

vous pouvez également remplir le réservoir

supplémentaire.

• Dévissez le couvercle obturant le réservoir

supplémentaire.

13

Page 14

DE 4002

1. Mise en service

• Avec l’entonnoir, versez au maximum 2 litres

d’eau du robinet dans ce réservoir.

• Revissez le couvercle sur le réservoir supplémentaire.

1.4 Mise en service de l’appareil

• Branchez la fiche mâle dans une prise de courant

et enclenchez l’appareil par le commutateur

d’alimentation en vapeur et par le commutateur

de chauffage. Les témoins de contrôle doivent

s’allumer.

Remarque: la puissance totale de chauffage n’est

disponible que si le bloc connecteur est branché

sur l’appareil pendant la phase d’échauffement.

• Une fois que le témoin de contrôle du chauffage

s’éteint, l’appareil est prêt à fonctionner.

Remarque: appareil enclenché, ne le posez jamais à la verticale. Le chauffage s’éteint sinon

automatiquement au bout d’un temps bref et le

témoin de contrôle rouge s’allume.

• Pour transporter l’appareil, éteignez le chauffage

par le commutateur.

• Lorsque vous actionnez le commutateur de

vapeur, cette dernière jaillit. Commencez toujours

par diriger le pistolet à vapeur sur un chiffon

jusqu’à ce que le jet de vapeur devienne régulier.

• L’appareil est prêt à fonctionner dès que le témoin

de contrôle du chauffage s’éteint.

Remarque: si la pompe ne refoule pas l’eau bien

que le réservoir supplémentaire soit plein, c’est le

signe qu’il faut détartrer la chaudière. Voir à la

section 3.1 la rubrique intitulée «Détartrage de la

chaudière».

1.6 Arrêt de l’appareil

• Eteignez l’appareil par les commutateurs.

• Débranchez le bloc connecteur de l’appareil. Pour

ce faire, soulevez le couvercle de la prise femelle

de l’appareil.

• Débranchez la fiche mâle de la prise de courant.

• L’eau non utilisée peut rester dans l’appareil.

1.7 Déplacement de l’appareil

• L’appareil est très facile à déplacer si vous vous

en servez avec les tuyaux-rallonges et la buse

de sol.

• Pour ce faire, éteignez le chauffage par le

commutateur, posez l’appareil à la verticale puis

emboîtez le tuyau-rallonge dans son support sous

l’appareil.

• Pendant l’utilisation, le chauffage se rallume

périodiquement (le témoin de contrôle s’allume)

pour maintenir la chaudière sous pression.

• Si vous avez allumé l’appareil alors qu’il ne

contenait plus d’eau, le témoin de contrôle du

chauffage s’allume le premier jusqu’à ce que le

thermostat de sécurité coupe le chauffage.

Ensuite s’allume le témoin de contrôle de manque

d’eau.

1.5 Rajouter de l’eau

Remarque: une fois l’eau consommée dans le

réservoir supplémentaire, un signal sonore retentit

et le témoin de contrôle de manque d’eau dans le

réservoir supplémentaire s’allume.

• Avec l’entonnoir, versez au maximum 2 litres d’eau

du robinet dans le réservoir supplémentaire.

1.8 Rangement de l’appareil

• Rangez la buse manuelle, la buse à jet crayon et

la quincaillerie dans le casier à accessoires.

• Enroulez le câble autour de son logement situé

sous l’appareil. Adaptez la buse de sol à un des

tuyaux puis faites encocher les tuyaux dans les

évidements ménagés contre le fond de l’appareil.

• Laissez toujours refroidir les soies des brosses

de sorte qu’elles ne puissent pas se déformer.

14

Page 15

2. Conseils d’utilisation

Français

2.1 Consignes fondamentales

L’opération la plus importante dans le nettoyage à

la vapeur, c’est un prénettoyage à fond.

Explication: là où l’on a nettoyé pendant des

années avec des détergents, il s’est formé une

couche qu’il faudra décoller au cours d’un

nettoyage de base. Pendant le nettoyage au

nettoyeur à vapeur, ce dernier, suivant la

description ci-dessous, décolle les souillures qui

viennent adhérer à la toile. Suivant le degré

d’encrassement, ces souillures disparaissent

complètement au bout de 1 à 2 nettoyages. Le

résultat: un sol exempt de stries. Même chose pour

le nettoyage des fenêtres. Le nettoyeur ne peut

pas décoller directement les dépôts de tartre épais.

A la rubrique sur le nettoyage des sanitaires, nous

avons décrit comment nettoyer efficacement ces

derniers.

2.2 Consignes particulières

Nettoyage des textiles

Avant de traiter les textiles, effectuez toujours

d’abord un essai à un endroit occulté. Pour ce faire,

passez la surface intensément au jet de vapeur

puis laissez-la sécher pour vérifier si des

modifications de couleur ou de forme se sont

produites.

Nettoyage de surfaces à revêtement ou peintes

Si vous voulez nettoyer à la vapeur du mobilier de

cuisine ou de séjour, des portes, surfaces peintes

ou recouvertes d’un revêtement en plastique,

rappelez-vous que, sous l’effet prolongé de la

vapeur, la cire, le brillant pour meuble, le

revêtement plastique ou la peinture peuvent se

décoller. Pour cette raison, ne passez la vapeur

que brièvement dessus ou nettoyez avec un

chiffon préalablement échauffé à la vapeur.

Nettoyage des vitres

Des surfaces vitrées inégalement chauffées

peuvent se rompre. Surtout lorsqu’il fait assez froid

dehors, passez légèrement d’abord toute la

surface vitrée à la vapeur pour compenser les

différences de température, et pour éviter

l’apparition de tensions mécaniques à la surface

de la vitre. Ne dirigez pas le jet de vapeur

directement sur les parties scellées de la fenêtre.

2.3 Régulation du débit de vapeur par le

bouton rotatif

• Si vous travaillez avec des accessoires standard

ou avec le fer à repasser, vous pouvez réguler le

débit de vapeur par le biais du bouton rotatif

équipant le nettoyeur.

2.4 Régulation VAPOHYDRO par le bouton

rotatif

• Dans les locaux humides, au lieu d’enlever les

souillures avec un chiffon, vous pouvez les

enlever à la vapeur saturée d’eau. Pour ce faire,

réglez l’humidité de la vapeur par le bouton rotatif

situé sur l’appareil. Plus la vapeur est humide,

plus la quantité d’eau dans le jet de vapeur est

importante et plus le nettoyage est efficace.

Lorsque vous tournez le bouton rotatif

complètement sur «+», un jet d’eau chaude jaillit.

C’est sur cette position que l’effet nettoyant est

maximal.

• Pour nettoyer la salle de bains, utilisez la

VAPOHYDRO avec par ex. la buse à jet crayon.

• Si vous utilisez des textiles (buse de sol, buse

manuelle), amenez le bouton rotatif de régulation

VAPOHYDRO sur «–» afin que le jet de vapeur

contienne le moins d’humidité possible. Vous

améliorez de cette façon le pouvoir nettoyant de

la vapeur.

Remarque: Si vous positionnez le bouton rotatif

de régulation VAPOHYDRO sur «+», la chaudière

se vide plus vite.

2.5 Indicateur de température

• Il indique si vous travaillez dans la bonne plage

de températures (zone verte).

2.6 Le pistolet à vapeur

• Vous pouvez utiliser le pistolet à vapeur sans

accessoire pour

– Supprimer les mauvaises odeurs des

vêtements et les déplisser;

– Dépoussiérer les plantes (distance entre la

buse et la plante: 30 cm env.);

– Essuyer la poussière par voie humide. Pour ce

faire, passez un jet de vapeur léger puis

essuyez et séchez avec un chiffon propre.

15

Page 16

DE 4002

2. Conseils d’utilisation

2.7 Buse à jet crayon

• Suivant besoins, vous pouvez poser la buse à

jet crayon directement sur le pistolet à vapeur ou

intercaler entre eux les tuyaux-rallonges.

• Plus la buse est proche de l’objet à nettoyer et

plus l’effet nettoyant est puissant étant donné

que la pression et la chaleur de la vapeur sont

maximum au sortir de la buse.

• Vous pouvez utiliser la buse à jet crayon par ex.

pour nettoyer les surfaces suivantes:

– Zones difficilement accessibles tels que les

(re)coins et les joints, etc.

– Persiennes, radiateurs de chauffage central.

–WC

– Acier inoxydable

– Robinetteries

– Surfaces à revêtement et émaillées

– Et pour dissoudre les taches.

• Utilisez la rallonge pour atteindre les zones

inaccessibles.

• Si nécessaire, vous pouvez emmancher la

broche ronde sur la buse à jet crayon.

Remarque: la brosse ronde ne convient pas pour

nettoyer les surfaces sensibles.

2.8 Buse de sol

• Utilisez la buse de sol avec les tuyaux-rallonges

si nécessaire. Utilisez cette buse sur tous les

grands revêtements muraux et de sol lavables.

Posez la buse de sol sur le grand chiffon plié et

tirez-le latéralement sous les agrafes.

• Si vous retournez régulièrement le chiffon et le

changez, ceci améliore l’absorption des souillures.

• Nettoyez les surfaces fortement encrassées en

travaillant plus lentement. Ceci permet à la

vapeur d’agir plus longtemps.

• Si des résidus de détergent se trouvent encore

sur le sol à nettoyer, des stries risquent de se

former. Elles disparaissent en général après

plusieurs passages au nettoyeur à vapeur.

2.9 Buse manuelle

• Utilisez la buse manuelle avec les tuyaux-

rallonges si nécessaire.

• Vous pouvez combiner la buse manuelle et le

chiffon de nettoyage par ex. pour nettoyer:

– Les petites surfaces lavables

– Les étoffes décoratives sur meubles

– Les surfaces sensibles.

2.10 Accessoires spéciaux

N’utilisez que des accessoires autorisés par le

fabricant.

Fer à repasser (N° de réf. 6.959-262)

• Accessoire spécial en vente dans le commerce.

Repassage à la vapeur

– Tournez le thermostat jusqu’au degré

que soit le tissu à repasser. La vapeur

jaillissante empêche le tissu de surchauffer.

– Plus la température sélectionnée est élevée,

plus la vapeur est sèche et transparente, la

quantité de vapeur expulsée restant

inchangée.

– Le fer est prêt à servir une fois que la lampe du

fer s’éteint.

– Lorsque vous actionnez le commutateur, une

électrovanne s’ouvre dans l’appareil et la

vapeur afflue vers la semelle du fer. Si vous

poussez le commutateur vers l’avant, la vapeur

s’échappe en permanence. Si vous poussez le

commutateur vers l’arrière, vous donnez un

coup de vapeur.

– Dirigez d’abord la vapeur sur un chiffon jusqu’à

ce qu’il ne sorte plus d’eau avec la vapeur.

– Tournez le bouton régulateur de débit de

vapeur sur le débit désiré.

– Vous pouvez également utiliser le fer

verticalement pour passer les rideaux, les

vêtements, etc., à la vapeur.

...

quel

16

Page 17

2. Conseils d’utilisation

Français

Repassage à sec

– Si vous voulez repasser sans vapeur,

enclenchez le commutateur d’arrivée de vapeur

et éteignez le commutateur de chauffage.

– Sur le fer à repasser, réglez le thermostat du

fer sur le type de tissu désiré.

Fibre synthétique Laine Lin

Buse pour fenêtre (N° de réf. 6.962-007)

• Utilisez la buse pour fenêtre directement avec le

pistolet à vapeur. Si nécessaire, utilisez les

tuyaux rallonges.

• Pulvérisez la vapeur uniformément sur les vitres

à une distance de 20 cm environ. Ensuite,

coupez l’arrivée de la vapeur et passez la vitre à

la râclette en caoutchouc en décrivant des laies

régulières de haut en bas. Au bas de chaque laie,

essuyez et séchez la raclette ainsi que le bas de

la fenêtre.

Décolleur de tapisserie (N° de réf. 6.962-013)

Le décolleur de tapisserie vous permet d’utiliser le

nettoyeur à vapeur pour enlever les vieilles

tapisseries.

Biodétartrant RM 511 (n° de réf. 6.290-239)

– 3 x 100 g de poudre pour détartrer la chaudière.

– Utilisation: voir au chapitre 3.

Raclette pour fenêtre,

longueur 230 mm 6.962-007

Buse manuelle à crins

en fil métallique 6.962-014

Buse à jet crayon

longueur, 400 mm 6.962-015

Buse à jet crayon courte, 140 mm 6.962-016

Brosse-couronne, Ø 60 mm 6.962-017

Brosse triangulaire

petit format, 90 mm 6.962-018

Brosse ronde petit format,

Ø 25 mm, 5 unités 6.962-019

Brosse triangulaire

grand format, 130 mm 6.962-024

Toiles de nettoyage en kit, 10 unités 6.962-025

Brosse ronde petit format,

Ø 25 mm, 5 unités 6.962-139

Tuyau-rallonge, 250 mm 6.962-144

Chariot «Caddy» 6.962-239

• Procédure:

– Appliquez le décolleur de tapisserie sur toute

sa surface au bord d’une laie de tapisserie et

laissez agir la vapeur jusqu’à ce que la

tapisserie soit complètement ramollie (10

secondes env.).

– Déplacez le décolleur de tapisserie sans

couper l’alimentation en vapeur. Avec une

spatule, soulevez la surface de tapisserie

décollée et arrachez-la du mur.

– Si les tapisseries Ingrain ont été recouvertes

de plusieurs couches de peinture, la vapeur

risque de ne pas atteindre le support-papier.

Dans ce cas, nous recommandons de passer

pré-alablement un rouleau à aiguilles sur la

tapisserie.

17

Page 18

DE 4002

3. Nettoyage, entretien, dérangements et remèdes

3.1 Nettoyage de la chaudière

Rinçage de la chaudière

• Pour nettoyer la chaudière, nous recommandons

de la remplir d’eau et ensuite de la secouer

vigoureusement. Ceci décolle les résidus de

calcaire qui se sont déposés au fond de la

chaudière. Ensuite, videz de nouveau l’eau. Les

résidus de calcaire sont emportés par l’eau (voir

la figure).

Procédure

• Débranchez le nettoyeur à vapeur de la prise de

courant.

• Videz complètement l’eau non inutilisée se

trouvant encore dans la chaudière.

• Dans 2 litre d’eau chaude, dissolvez entièrement le

contenu du sachet en remuant continuellement.

• Versez la solution dans la chaudière et laissez-la

agir 8 heures env.

Pendant la procédure de détartrage, la

fermeture de sécurité ne doit pas être

vissée. Assurez-vous que personne

n’utilise l’appareil tant que la solution

détartrante se trouve dans la

chaudière.

• Videz la chaudière comme indiqué sur la figure

puis rincez-la au moins deux fois à l’eau froide

pour vous assurer qu’aucun résidu de calcaire ne

soit resté dans l’appareil.

• Mettez l’appareil en service.

• Si l’eau de votre région n’est pas dure (jusqu’à

10 °dH), rincez la chaudière tous les 15 pleins de

chaudière. Si sa dureté dépasse 15 °dH, rincezla tous les 5 pleins.

Détartrage de la chaudière

• Nous vous recommandons de détartrer l’appareil

dès que le témoin de contrôle „Détartrage“

s’allume.

• Pour enlever les résidus de calcaire tenaces qui

se sont déposés sur les parois de la chaudière,

nous recommandons de la nettoyer avec le

détartrant biologique Kärcher RM 511.

• Le détartrant biologique Kärcher RM 511 est un

produit à base d’acide de citron entièrement

biodégradable.

• Pour effectuer le détartrage de votre nettoyeur à

vapeur, utilisez exclusivement des produits

Kärcher autorisés afin de ne pas endommager

l’appareil.

• Appuyez sur le bouton-poussoir à réarmement

jusqu’à ce que le témoin de contrôle „Détartrage“

s’éteigne.

• Maintenant, votre nettoyeur à vapeur est prêt à

servir. Au bout de 50 heures de service environ,

le témoin de contrôle „Détartrage“ s’allume pour

signaler qu’il faut détartrer l’appareil.

Remarque: aucun détartrage nécessaire si

l’appareil fonctionne exclusivement à l’eau

déminéralisée (eau de batterie).

Lorsque le témoin de contrôle „Détartrage“

s’allume, appuyez seulement sur le boutonpoussoir à réarmement jusqu’à ce que le témoin de

contrôle s’éteigne.

• Si vous utilisez de l’eau salie, le filtre risque de se

boucher. Vous vous en rendrez compte par un

allongement inhabituel de la durée de marche de

la pompe ou par une panne de fonctionnement

complète. Dans ce cas, changez le filtre.

3.2 Que faire en cas de dérangement?

18

• Si le témoin de contrôle de manque d’eau s’allume

parce que vous avez placé l’appareil à la verticale

pendant le service, procédez comme l’indique la

section «Rajouter de l’eau».

Page 19

4. Eléments de sécurité

Français

• En présence de dérangements d’une autre nature,

ne confiez la réparation qu’au service après-vente

(SAV) agréé.

Ce nettoyeur à vapeur est équipé de plusieurs

dispositifs de sécurité et donc protégé de plusieurs

façons. Les sections suivantes indiquent les

éléments de sécurité les plus importants.

4.1 Régulateur de pression

Pendant le fonctionnement de l’appareil, le

régulateur de pression maintient dans la chaudière

une pression aussi constante que possible. Le

chauffage s’éteint lorsque la pression de service

maximale dépasse 3,2 bars dans la chaudière. Il

se remet en marche lorsque la consommation de

vapeur a provoqué une chute de la pression.

4.2 Thermostat de manque d’eau

Lorsque très peu d’eau reste dans la chaudière, la

chaleur produite par le chauffage augmente. Le

thermostat de manque d’eau coupe le chauffage et

le témoin rouge de manque d’eau s’allume. Le

chauffage se remet en marche lorsque la chaudière

a refroidi ou après l’avoir à nouveau remplie.

4.3 Thermostat de sécurité

Si le thermostat de manque d’eau tombe en panne

et que l’appareil surchauffe, le thermostat de

sécurité éteint l’appareil. Pour réarmer le thermostat

de sécurité, adressez-vous au SAV Kärcher

compétent.

4.4 Fermeture de sécurité

La fermeture de sécurité verrouille la chaudière afin

de contenir la pression de la vapeur restante. Si le

régulateur de pression tombe en panne et que la

pression à l’intérieur de la chaudière dépasse

5,5 bars, une vanne de surpression s’ouvre dans

la fermeture de sécurité et la vapeur s’échappe par

la fermeture. Adressez-vous au SAV Kärcher compétent avant de remettre l’appareil en service.

5. Consignes générales

5.1 Garantie

Dans chaque pays, les conditions de garantie en

vigueur sont celles publiées par notre société de

distribution autorisée. Si pendant la durée de la

garantie votre appareil présente des vices de

matière ou de fabrication, la réparation est gratuite.

En cas de garantie, veuillez vous adresser avec

les accessoires et la preuve d’achat à votre

revendeur ou à votre bureau du service aprèsvente autorisé le plus proche de chez vous.

Nous déclinons toute responsabilité des dommage

imputables à des manipulations inexpertes de

l’appareil ou à un irrespect du contenu de la notice

d’emploi.

5.2 Remarque concernant l’élimination future

Cet appareil a été construit selon la directive de

recyclage VDI 2243.

19

Page 20

DE 4002

6. Données techniques

Branchement électrique

Tension 120 V

Type de courant 60 Hz

Tension dans la poignée 24 V

Cordon de branchement au secteur, n° de réf. *CDN 6.647-791

Performances

Puissance de chauffe 1800 W

Pompe 50 W

Pression de service maxi. 3,2 bar

Pression de service admissible 5,0 bar

Durée de chauffage env. 5,5 min/1 l d’eau

Quantité de vapeur maxi. 75 g/min.

Dimensions

Poids sans les accessoires 8,0 kg

Quantité d’eau remplissable 4,0 l

Contenance du réservoir 2,0 l

Contenance de la chaudière 2,4 l

Largeur 305 mm

Longueur 480 mm

Hauteur 265 mm

Schéma des circuits électriques 0.087-983

S1 Commutateur du chauffage

S2 Commutateur d’alimentation en vapeur

S3 Pressostat

S4 Thermostat de sécurité

S5 Thermostat de manque d’eau

S6 Bouton-poussoir à réarmement: détartrage

S7 Commutateur de vapeur sur la poignée

S8 Commutateur de vapeur sur le fer à repasser

H1 Témoin de contrôle du chauffage

H2 Témoin de contrôle du manque d’eau

H3 Témoin de contrôle du réservoir d’eau propre

H4 Témoin de contrôle - Détartrage

H5 Générateur de signaux

E1 Chauffage, 1500 W

E2 Chauffage, 750 W

E3 Chauffage du fer à repasser, 750 W

MV1 Electrovanne

M1 Pompe

N1 Carte électronique

T1 Transformateur

F1 Fusible

C1 Condensateur

X1 Connecteur

X2 Connecteur de raccordement

X3 Connecteur de la conduite de vapeur

20

Page 21

1. Puesta en marcha del aparato

Español

21

Page 22

DE 4002

1. Puesta en marcha del aparato

1 Pistola para aplicación del vapor

2 Ruedecilla para regular el caudal del vapor

3 Pulsador de desenclavamiento

4 Enclavamiento (seguro para niños)

5 Interruptor de alimentación de vapor en la

pistola

6 Toma de vapor (acoplamiento monobloque de

la manguera de vapor)

7 Pulsador de reposición de la función de

desincrustación

8 Mando giratorio para la regulación de la

humedad del vapor «VAPOHYDRO»

9 Indicador de temperatura

10 Mando giratorio para la alimentación de vapor

11 Piloto de aviso «Desincrustación de la caldera»

(blanco)

12 Piloto de aviso para la falta de agua en el

depósito adicional (rojo)

13 Piloto de aviso del interruptor de la calefacción

(amarillo)

14 Interruptor de la calefacción

15 Interruptor para la alimentación de vapor

16 Piloto de aviso para la falta de agua en la

caldera (rojo)

17 Cierre de seguridad

18 Cierre (tapón roscado) del depósito adicional

19 Embudo de llenado

20 Tubos de prolongación

21 Boquilla de chorro concentrado

22 Cepillo circular

23 Elemento de prolongación

24 Boquilla superpotente (roja)

25 Boquilla para tapicerías (limpieza manual)

26 Funda de tejido de rizo

27 Boquilla barredora de suelos

28 Paño de limpieza grande, para la boquilla

barredora de suelos

29 Soporte

30 Soporte para el ensamblaje de la tobera de

suelos

1.1 Desembalar el aparato

• Si al desembalar el aparato comprobara Vd. algún

daño o desperfecto en el mismo, rogamos se dirija

inmediatamente al Distribuidor en donde adquirió

el aparato.

1.2 Montar los accesorios

• Introducir el acoplamiento monobloque de la

manguera de vapor en la correspondiente toma de

vapor del aparato. Prestar atención a que el saliente

del acoplamiento monobloque encaje en la tapa de

la toma de vapor del aparato.

• Acoplar el accesorio específico que vaya a

utilizarse (boquilla barredora de suelos, boquilla

para limpieza manual o boquilla de chorro

concentrado) a la pistola de aplicación de vapor.

• En caso necesario pueden acoplarse los tubos de

prolongación. Para ello se han de empalmar éstos,

haciendo enclavar el pulsador de enclavamiento y

desenclavamiento.

• Para desacoplar los diferentes accesorios,

presionar el pulsador de enclavamiento y

desenclavamiento.

1.3 Rellenar agua en el aparato

• Retirar el cierre de seguridad del aparato.

• Llenar un máximo de 2 litros de agua de red en la

caldera con ayuda del embudo. En caso de

agregar agua caliente, se acorta la duración del

período de calentamiento del agua.

Advertencia: La caldera puede llenarse, estando

colocado el aparato en posición horizontal, hasta

2 cm debajo del borde la boca de llenado.

Respete el medio ambiente

Los materiales de embalaje son reciclables.

Po favor, no tire el embalaje a la basura

doméstica; en vez de ello, entréguelo en los

puntos oficiales de recogida para su reciclaje

o recuperación.

Los aparatos viejos contienen ma-teriales

valiosos reciclables que deberían ser

entregados para su aprovechamiento

posterior. Evite el contacto de baterías,

aceites y materias semejantes con el

me-dioambiente. Por este motivo, entregue los

aparatos usados en los puntos de recogida previstos

para su reciclaje.

22

• No agregar ningún tipo de detergente.

• Volver a montar el cierre de seguridad en el

aparato y apretarlo.

Depósito de agua adicional

Para lograr unos intervalos de trabajo activo más

prolongados puede llenarse el depósito de agua

adicional.

• Soltar y retirar el tapón roscado del depósito.

• Llenar un máximo de 2 litros de agua de red en el

depósito adicional con ayuda del embudo.

• Colocar el tapón roscado en su sitio y fijarlo.

Page 23

1. Puesta en marcha del aparato

Español

1.4 Puesta en marcha del aparato

• Conectar el aparato accionando el interruptor para

la alimentación de vapor y el interruptor de la

calefacción. Los pilotos de aviso tienen que

iluminarse.

Atención: El aparato sólo llega a desarrollar su

máxima potencia de calentamiento si el

acoplamiento monobloque de la manguera de vapor

(6) se encuentra acoplado al aparato en el momento

de iniciarse el ciclo de calentamiento.

• Una vez que el piloto de aviso de la calefacción

naranja se apaga, el sistema está en disposición

de funcionamiento.

Advertencia: En caso de desplazar el

enclavamiento (seguro para niños) hacia atrás, el

interruptor de aplicación del vapor no se puede

accionar. En caso de desplazar el enclavamiento

hacia adelante, el interruptor de aplicación del vapor

queda libre y se puede accionar.

• Desconectar el interruptor de la calefacción al

transportar el aparato.

• Al accionar el interruptor de aplicación del vapor

en la empuñadura de la pistola, sale vapor por la

pistola. Proyectar primero el vapor sobre un paño,

hasta sea proyectado de modo regular.

• El piloto de aviso naranja de la calefacción se

ilumina y apaga durante el servicio del aparato en

función del consumo de vapor, a fin de mantener

constante la presión en el interior de la caldera.

• Al conectar la limpiadora sin haber agua en la

caldera, se ilumina primero el piloto de aviso de la

calefacción, hasta que el termostato de seguridad

la desconecte. A continuación se ilumina el piloto

de aviso para la falta de agua.

1.5 Rellenar agua

Advertencia: En caso de agotarse el agua del

depósito adicional se escucha una señal acústica

de aviso y se ilumina el piloto de aviso para la falta

de agua en el depósito adicional.

• Llenar un máximo de 2 litros de agua de red en el

depósito adicional con ayuda del embudo.

que desincrustar la caldera (véase al respecto el

capítulo 3.1, apartado «Desincrustación de la

caldera»).

1.6 Desconexión del aparato

• Desconectar el aparato a través de los

interruptores.

• Extraer el acoplamiento monobloque de la

manguera de vapor del aparato, levantando para

ello la tapa de la toma de vapor del aparato.

• Extraer el enchufe de conexión del aparato, de la

toma de corriente.

• El agua residual que pudiera encontrarse en la

caldera puede dejarse en la misma.

1.7 Desplazamiento del aparato

• Si se está trabajando con los tubos de prolongación

y la boquilla barredora de suelos, el aparato

también se puede desplazar y transportar fácilmente

por encima de peldaños o escaleras.

• Para ello se desconecta la calefacción a través del

interruptor y se coloca el aparato en posición

vertical, encajando el tubo de prolongación con el

soporte que se encuentra en la parte inferior del

cuerpo de la limpiadora.

1.8 Guardar el aparato

• Colocar la boquilla de limpieza manual, la boquilla

de chorro concentrado y las restantes piezas

pequeñas en el compartimento específico para los

accesorios.

• Enrollar el cable de conexión del aparato en torno al

soporte que se encuentra en el fondo del mismo.

Montar la boquilla barredora de suelos sobre uno de

los tubos de prolongación e introducir los dos tubos

en los alojamientos correspondientes que figuran en

el fondo del aparato.

• Antes de guardar los cepillos o boquillas con

cepillos, dejar enfriar primero las cerdas de éstos,

a fin de evitar las posibles deformaciones de las

cerdas.

• Tan pronto como se apaga el piloto de aviso del

interruptor de la calefacción el aparato está en

disposición de funcionamiento.

Advertencia: En caso de la bomba no transportara

agua a pesar de estar lleno el depósito adicional, hay

23

Page 24

DE 4002

2. Advertencias para la aplicación práctica del aparato

2.1 Observaciones de carácter general

Una limpieza previa a fondo de las superficies antes

de limpiarlas con la limpiadora de vapor es el punto

más importante a observar en la limpieza con vapor.

Es decir: En las zonas o superficies que se han

limpiado durante años de un modo convencional

aplicando detergentes, los restos de éstos han

formado unos depósitos que se han de eliminar

primero mediante una limpieza básica. Con la

limpiadora de vapor se desprenden las capas de

suciedad acumuladas tal como se describe más abajo,

recogiéndolas con un paño. Según el grado de

suciedad se necesitarán uno o dos ciclos de limpieza

hasta eliminar completamente la suciedad. El

resultado será un suelo limpio, sin franjas. Los mismo

ocurre con las ventanas o superficies acristaladas. La

limpiadora de vapor no puede eliminar directamente

los depósitos calcáreos muy gruesos. En el apartado

correspondiente a la limpieza de las zonas húmedas

y sanitarias, sin embargo, se describe de qué modo

se pueden eliminar también estas capas con la

limpiadora de vapor.

2.2 Advertencias y consejos especiales

Limpieza de materiales textiles

Antes de proceder a la eliminación de manchas y a

la limpieza de materiales textiles, deberá hacerse

primero una prueba en un lugar poco visible del

objeto a limpiar, a fin de evitar posibles daños del

mismo. Para ello se aplica intensamente vapor sobre

dicho lugar, dejándolo secar a continuación. De este

modo se puede comprobar si se producen

decoloraciones o deformaciones en el tejido.

Limpieza de superficies recubiertas de capas

protectoras o barnizadas

En caso de limpiar con vapor superficies u objetos de

madera tratada (muebles de cocina o comedor, puertas,

etc.), así como superficies pintadas, barnizadas o

recubiertas de capas de plástico con vapor, deberá

tenerse muy en cuenta que la exposición prolongada a

la acción del vapor de estos objetos, puede conducir a

la disolución o desprendimiento de las capas de cera,

lustre para muebles, revestimiento o pintura. Por ello

aconsejamos proyectar el vapor sólo muy brevemente

sobre estas superficies y materiales, o bien limpiarlas

con un paño sobre el que se ha proyectado previamente

el vapor.

exteriores, deberá aplicarse primero una fina capa de

vapor sobre los cristales a limpiar, con objeto de

compensar las diferencias de temperatura y evitar

tensiones en la superficie de los cristales. No aplicar

el vapor sobre las zonas selladas de las ventanas.

2.3 Regulación del caudal de vapor a través del

mando giratorio

• En caso de trabajar con el accesorio estándar o una

plancha, el caudal del vapor se puede regular a

través del mando giratorio del aparato.

2.4 Regulación de la humedad del vapor

«VAPOHYDRO»

• La suciedad acumulada en las zonas húmedas

(cuarto de baño, inodoro,..) también se puede

desprender y eliminar con el chorro de vapor en

lugar de recogerla con un paño. Para ello se ajusta

el grado de humedad del vapor a través del mando

giratorio. Cuanto mayor sea el grado de humedad

del vapor, más agua contiene el chorro de vapor,

lográndose así un mayor efecto de enjuague.

Girando el mando completamente hasta la posición

«+», se logra el máximo efecto de enjuague al

producirse un chorro de agua caliente.

• Para la limpieza del cuarto de baño aconsejamos

aplicar la opción «Vapohydro» en combinación, por

ejemplo, con la boquilla de chorro concentrado.

• En caso de trabajar con paños colocados en las

boquillas barredora de suelos o para tapicerías,

girar el mando completamente a la posición «–», a

fin de trabajar con un mínimo grado de humedad en

el chorro de vapor. De este manera se mejora la

fuerza de desprendimiento de la suciedad, del

chorro de vapor.

Advertencia: Colocando el mando de la regulación

de la humedad del vapor «Vapohydro» en la posición

de máximo ajuste «+», el depósito del agua del

aparato se vacía con mayor rapidez.

2.5 Indicador de temperatura

• Este indicador señala si se está trabajando en el

margen de temperatura correcto (zona verde).

Limpieza de ventanas y superficies acristaladas

Las superficies acristaladas expuestas a diferentes

temperaturas, pueden saltar. Por ello,

particularmente al registrarse bajas temperaturas

24

Page 25

2. Advertencias para la aplicación práctica del aparato

Español

2.6 Pistola de vapor

• La pistola de vapor, sin boquillas acopladas, puede

utilizarse para

– la eliminación de malos olores y arrugas en las

prendas de vestir;

– la eliminación del polvo acumulado sobre plantas

(¡distancia de trabajo aproximadamente 30 cm!);

– limpieza en húmedo del polvo acumulado sobre

objetos y superficies. Para ello se proyecta una

ligera capa de vapor sobre la superficie a limpiar,

secándola a continuación con un paño seco y

limpio.

2.7 Boquilla de chorro concentrado

• La boquilla de chorro concentrado se puede acoplar,

según el caso, directamente sobre la pistola de

aplicación del vapor o sobre los tubos de

prolongación empalmados a la pistola de vapor.

• La potencia limpiadora aumenta cuanto más

próxima esté la boquilla del objeto a limpiar, dado

que la temperatura y la presión alcanzan su máximo

grado de eficacia inmediatamente después de

abandonar el aparato.

2.8 Boquilla barredora de suelos

• Utilizar la boquilla barredora acoplada a los tubos

de prolongación en caso necesario. La boquilla se

emplea en la limpieza de todas las grandes

superficies de material susceptible de ser lavado.

Para ello se coloca la boquilla sobre un paño grande,

limpio y seco, que se fija a ésta con ayuda de las

pinzas de sujeción laterales de la boquilla.

• El grado de absorción de la suciedad del paño se

puede mejorar volviéndolo regularmente.

• Para la limpieza de superficies con elevado grado

de suciedad, deberá trabajarse lentamente a fin de

prolongar el tiempo de actuación del vapor.

• Si en el suelo a limpiar se encontraran restos de

detergentes de anteriores limpiezas, pueden

producirse franjas. Las franjas, sin embargo,

desaparecen por regla general tras varias

aplicaciones de la limpiadora de vapor.

2.9 Boquilla para tapicerías

• La boquilla puede acoplarse, en caso de necesidad,

a los tubos de prolongación.

• La boquilla de chorro concentrado puede utilizarse

para la limpieza de

– zonas y puntos de difícil acceso, como por

ejemplo esquinas y rincones, juntas, etc.

– persianas, radiadores de calefacción

– inodoros

– objetos de acero inoxidable

– llaves y grifos

– superficies provistas de revestimientos de capas

protectoras o esmaltadas

– separación y eliminación de manchas

• Utilizar el elemento de prolongación para limpiar

zonas particularmente inaccesibles como ranuras,

juntas, etc.

• El cepillo circular puede montarse en caso de

necesidad sobre la boquilla de chorro concentrado.

Atención: El cepillo circular no es apropiado para la

limpieza de superficies sensibles.

• Esta boquilla, con la funda de tejido de rizo montada,

es apropiada para la limpieza de

– pequeñas superficies lavables

– revestimientos textiles de los muebles de tapicería

– superficies sensibles

2.10 Accesorios opcionales

Sólo deberán usarse accesorios y repuestos

homologados por el Fabricante.

Plancha (Nº de pedido 6.959-262)

• Introducir el acoplamiento monobloque de la

manguera de vapor de la plancha en la

correspondiente toma de vapor del aparato.

Planchado con vapor

– Ajustar la temperatura, para el planchado general

de prendas, con ayuda del regulador de

temperatura giratorio a la posición mínima

vapor proyectado por la plancha impide el

sobrecalentamiento del tejido.

– Cuanto más elevada sea la temperatura ajustada

en el regulador, más seco sale el vapor, aunque el

caudal del mismo no se modifica.

– Una vez que el piloto de aviso de la plancha se ha

apagado, la plancha está en disposición de

funcionamiento.

...

. El

25

Page 26

DE 4002

2. Advertencias para la aplicación práctica del aparato

– Al pulsar el interruptor para aplicación de vapor,

abre una electroválvula y el vapor es proyectado

a través de la planta de la plancha. En caso de

desplazar el interruptor hacia adelante, se produce

la salida continua del vapor. Si se desplaza el

interruptor hacia atrás, se producen ráfagas de

vapor.

– Proyectar el vapor primero contra un paño hasta

que no salga agua por la boquilla.

– Ajustar en el regulador del caudal de vapor el

caudal de vapor deseado.

– Para proyectar vapor y planchar cortinas, vestidos

y objetos semejantes, la plancha se puede colocar

y emplear en posición vertical.

Planchado en seco

– Para planchar en seco, sin vapor, se conecta el

interruptor de alimentación de vapor del aparato y

se desconecta el interruptor de la calefacción.

– Ajustar la temperatura apropiada, en función del

tipo de tejido, con ayuda del regulador de

temperatura giratorio de la plancha.

Fibra sintética Lana Lienzo

• Modo de proceder:

– Colocar la boquilla sobre el borde de una tira de

papel y dejar actuar el vapor hasta que el papel

esté ablandado (aprox. 10 segundos).

– Desplazar la boquilla, sin dejar de aplicar vapor.

Desprender la tira de papel ablandado con una

espátula y retirarla de la pared.

– En los papeles de fibra gruesa con varias capas

de pintura, puede ser que el vapor no llegue a

traspasar las capas de pintura para despegar el

papel. En este caso deberá desbastarse la

superficie del papel aplicando un rodillo de púas

sobre el mismo.

Desincrustante biológico RM 511

(Nº de pedido 6.290-239)

– En polvo, 3 x 100 g, para la limpieza y

desincrustación de la caldera.

– Aplicación: Véase capítulo 3.

Boquilla para la limpieza

de ventanas, 230 mm 6.962-007

Boquilla de limpieza manual con

cerdas de alambre 6.962-014

Boquilla para la limpieza de ventanas

(Nº de pedido 6.962-007)

• Acoplar la boquilla para la limpieza de ventanas

directamente sobre la pistola de aplicación de vapor.

En caso necesario, acoplarla a los tubos de

prolongación.

• Aplicar uniformemente el vapor sobre la superficie

acristalada a limpiar desde una distancia de 20 cm.

Desconectar a continuación la alimentación de

vapor y limpiar el cristal, trabajando por tramos y

desde arriba hacia abajo, con el borde de goma.

Secar el borde de goma de la boquilla y el borde

inferior del marco de la ventana tras cada tramo

limpio.

Boquilla para despegar papeles pintados

(Nº de pedido 6.962-013)

Combinando la boquilla para despegar papeles

pintados con la limpiadora de vapor, se despegan con

toda eficacia y facilidad prácticamente todos los tipos

de papeles pintados.

Boquilla de chorro concentrado,

larga, 400 mm 6.962-015

Boquilla de chorro concentrado,

corta, 140 mm 6.962-016

Cepillo circular, diámetro 60 mm 6.962-017

Boquilla para tapicerías,

pequeña, 90 mm 6.962-018

Cepillo circular, pequeño,

diámetro 25 mm, 5 unidades 6.962-019

Boquilla para tapicerías,

grande, 130 mm 6.962-024

Juego de paños de limpieza 6.962-025

Cepillo circular, pequeño,

diámetro 25 mm, 5 unidades 6.962-139

Tubo de prolongación, 250 mm 6.962-144

Carro de transporte 6.962-239

26

Page 27

Español

3. Trabajos de cuidado y mantenimiento, localización de averías

3.1 Limpieza de la caldera

Enjuagar la caldera

• Para limpiar la caldera aconsejamos llenarla de

agua y agitarla fuertemente. De este modo se

desprenden las incrustaciones de cal que pudieran

haberse acumulado en el fondo de la misma. Al

vaciar la caldera, se eliminan las incrustaciones de

cal desprendidas. (Véase la ilustración correspondiente).

• Enjuagar la caldera, en zonas de agua de red blanda

(hasta 10° de dureza alemana), como mínimo tras

cada 15 llenados de la caldera. En zonas de agua de

agua de red dura, hacer lo propio como mínimo tras

cada 5 llenados de la caldera.

Desincrustación de la caldera

• Se aconseja desincrustar el aparato cuando se

ilumine el piloto de aviso «Desincrustación de la

caldera»

• Para eliminar las incrustaciones y sedimentaciones

de cal en las paredes de la caldera, aconsejamos

limpiarla con el agente desincrustante biológico RM

511 de Kärcher.

• El agente desincrustante biológico RM 511 es un

producto sobre la base de ácido cítrico,

completamente biodegradable.

• Con objeto de evitar daños en el aparato sólo

deberán emplearse para la desincrustación de la

caldera los productos y agentes homologados o

autorizados por el Fabricante.

Modo de proceder

• Extraer el cable de conexión del aparato de la red

eléctrica.

• Vaciar completamente el agua residual que

pudiera haber en la caldera .

• Disolver el contenido de la bolsa 2 litro de agua

templada, sin dejar de remover la mezcla.

• llenar la solución desincrustante en la caldera y

dejarla actuar durante 8 horas.

Durante el proceso de desincrustación

no se deberá montar en ningún caso el

cierre de seguridad en la limpiadora.

Cerciórese de que el aparato no sea

usado mientras haya agente desincrustante en la caldera.

• Vaciar la caldera volcándola por una de sus

esquinas. Enjuagarla con agua fría como mínimo

dos veces, hasta asegurar que no queden

residuos en la caldera.

• Poner el aparato en funcionamiento.

• Oprimir el pulsador para reposición de la función

de desincrustación hasta que el piloto de aviso

«Desincrustación de la caldera» se apague.

• Su limpiadora de vapor está en disposición de

funcionamiento. Al cabo de unas 50 horas de

funcionamiento, el piloto de aviso

«Desincrustación de la caldera» vuelve a señalar

la necesidad de efectuar una desincrustación.

Advertencia: En caso de usar exclusivamente

agua desmineralizada (agua para baterías), no es

necesario efectuar la desincrustación de la caldera.

En este caso, al iluminarse el piloto de aviso

«Desincrustación de la caldera», sólo hay que

oprimir el pulsador para reposición de la función

«Desincrustación de la caldera» hasta que el piloto

de aviso se apague.

Cambio de filtro

• En caso de haber utilizado agua con impurezas, el

filtro puede quedar resultar obstruido. Esto se

manifiesta en forma de unos prolongados ciclos

de trabajo de la bomba o su avería. En este caso

hay que sustituir el filtro.

27

Page 28

DE 4002

4. Elementos y equipos de seguridad

3.2 ¿Qué hacer en caso de avería?

• En caso de iluminarse el piloto de aviso para la

falta de agua por haber colocado el aparato en

posición vertical durante su funcionamiento,

deberá procederse del mismo modo que se señala

en el punto «Rellenar agua en la caldera».

• En caso de producirse otras averías o perturbaciones, avisar al Servicio Técnico Postventa.

Esta limpiadora de vapor está equipada con varios

sistemas de seguridad. A continuación pasamos a

detallar las características y funcionamiento de los

más importantes.

4.1 Regulador de presión

El regulador de presión permite mantener la presión

de la caldera al nivel más constante posible durante

el funcionamiento del aparato. La calefacción se

desconecta al alcanzarse la máxima presión de

servicio admisible de 3,2 bares, volviéndose a

conectar al registrarse descensos de la presión a

causa del consumo de vapor que se produce.

4.2 Termostato para la falta de agua

Al estar a punto de consumirse el agua de la caldera,

aumenta la temperatura de la pared de ésta. El

termostato para la falta de agua desconecta la

calefacción y el piloto de aviso contra la falta de agua

rojo se ilumina.

4.3 Termostato de seguridad

En caso de que el termostato para la falta de agua

estuviera defectuoso se sobrecalentara el aparato,

el termostato de seguridad desconecta la

limpiadora. Consulte con el Servicio Técnico

Postventa de Kärcher antes de volver a poner el

aparato en marcha.

4.4 Cierre de seguridad

Este aparato está equipado con un cierre de

seguridad especial. Por esta razón no es posible

abrirlo mientras exista aún vapor a presión en el

interior del aparato. En caso de que el regulador de

presión estuviera defectuoso y la presión de la

caldera fuera superior a los 5,5 bares, se abre una

válvula de seguridad integrada en el cierre,

evacuándose a través de la misma una parte del

vapor. Consulte con el Servicio Técnico Postventa

de Kärcher antes de volver a poner el aparato en

marcha.

5. Advertencias de carácter general

5.1 Garantía

En cada país rigen las condiciones de garantía

establecidas por las correspondientes Sociedades

Distribuidoras. Las perturbaciones y averías de su

aparato serán subsanadas de modo gratuito en la

medida en que las causas de las mismas sean

debidas a defectos de material o de fabricación.

En un caso de garantía rogamos se dirija con el

aparato y sus accesorios, así como el comprobante/

factura de la compra, al Distribuidor en donde

adquirió el aparato o a la Delegación Oficial del

Servicio Postventa más próxima.

No asumimos ninguna responsabilidad por los daños

que pudieran resultar del uso o manipulación

indebidos del aparato, o del incumplimiento de las

instrucciones de servicio.

5.2 Advertencia sobre el reciclaje de los

aparatos

El aparato ha sido fabricado según la norma de la

Asociación de Ingenieros Alemanes 2243 relativa al

reciclaje o la recuperación de materiales.

28

Page 29

6. Características Técnicas

Conexión a la red eléctrica

Tensión 120 V

Tipo de corriente 60 Hz

Tensión en la empuñadura 24 V

Cable de conexión a la red eléctrica, Nº de pedido *CDN 6.647-791

Potencia y rendimientos

Potencia de calefacción 1800 W

Bomba 50 W

Máxima presión de la caldera 3,2 bares

Máxima presión de servicio admisible 5,0 bares

Duración del ciclo de calefacción aprox. 5,5 min./1 litro de

agua

Máximo caudal del vapor 75 g/min.

Medidas

Peso (sin accesorios) 8,0 kg

Máxima capacidad del recipiente 4,0 l

Capacidad del depósito de agua 2,0 l

Máxima capacidad de la caldera 2,4 l

Anchura 305 mm

Longitud 480 mm

Altura 265 mm

Español

Esquema de circuitos eléctricos Nº 0.087-983

S1 Interruptor de la calefacción

S2 Interruptor de la alimentación de vapor

S3 Presostato

S4 Termostato de seguridad

S5 Termostato para la falta de agua

S6 Pulsador de reposición de la función de

desincrustación

S7 Interruptor para la alimentación

de vapor en la pistola

S8 Interruptor para la alimentación

de vapor en la plancha

H1 Piloto de aviso para el funcionamiento de la

calefacción

H2 Piloto de aviso para la falta de agua

H3 Piloto de aviso del depósito de agua limpia

H4 Piloto de aviso «Desincrustación de la caldera»

H5 Transmisor de señales

E1 Calefacción 1.500 W

E2 Calefacción 750 W

E3 Calefacción de la plancha 750 W

MV1 Electroválvula

M1 Bomba

N1 Sistema electrónico

T1 Transformador

F1 Fusible

C1 Condensador

X1 Enchufe

X2 Acoplamiento del enchufe

X3 Enchufe de la línea de alimentación de vapor

29

Page 30

Page 31

Loading...

Loading...