Page 1

L

OUTLAW

0

NEW

STATE-OF-THE-ART

SUSPENSION

TAMES

THE

TOUGHEST

TRACKS.

0

THE

EXTREMELY

LIGHT

AND

EFFICIENT

SUPER

SPRINT

TRANSMISSION

WITH

'SLIPPER

'

CLUTCH

TRANSMITS

THE

POWER

TO

THE

WHEELS,

MINIMIZING

POWER

LOSS.

NEW

TRANSMISSION

ALSO

ALLOWS

EASY

AD.JUSTMENT

OF

THE

BALL

DIFFERENTIAL

AND

SLIPPER.

0

ADJUSTABLE

OIL-FILLED

SHOCKS

ABSORB

THE

BUMPS,

KEEPING

THE

TRUCK

UNDER

CONTROL.

® KYOC0521 No. 31324

Sport

KYOC0522 No. 31324 H

Sport

W/O.S

. •

12

CZ·R

KYOC0523

No.

31326 H

Team

Entire

Conte

nts@Copyright

1994

lq#IJSHIJ

Page 2

IMPORTANT: PLEASE READ THROUGH THE ENTIRE

INSTRUCTION MANUAL BEFORE BUILD

ING

THE OUTLAW

RAMPA

GE

PRO

.

We want your experience of building th

is

mode

l to be a

su

ccess.

So

before

you r

emo

ve

any

parts

from the

ir

pac

kages and begin assembly:

• Read through the entire manual carefully to make

sure

that you are thoroughly acquainted with the model.

• This instruction manual

is

for both the Outlaw Rampage

Pro Sport and Team Trucks . Differences in assembly

or

parts will be

not

ed as: (Team Tr

uck

Only).

• If for any reason you think this model may not

be

for you,

return

It

Immediately. Please N

ote

: Your hobby

dealer

cannot accept a m

ode

l kit f

or

return after assembly has

begun.

• The Kyosho Outlaw Rampage Pro

is

a sophisticated, high

per1ormance,

gas

powered off-road truck. Gas powered

RIC

trucl<s

are no more diffiCult to build and operate than

electric

RIC

trucks.

They

do

require a few

different

building

procedures

than

electrics.

If

you

follow

the

directions closely, the Kyosho Outlaw Rampage Pro will

provide many years

of

competitive RIC truck racing.

Key

Number~art

Name \

Quantity Used

I

(§)

" @

Dri:'washer

(t I

Note

: Some parts are Identified with a key number@ .

The

'E'

stands f

or

parts tree

'E'.

The 4

is

the part number

on the tree.

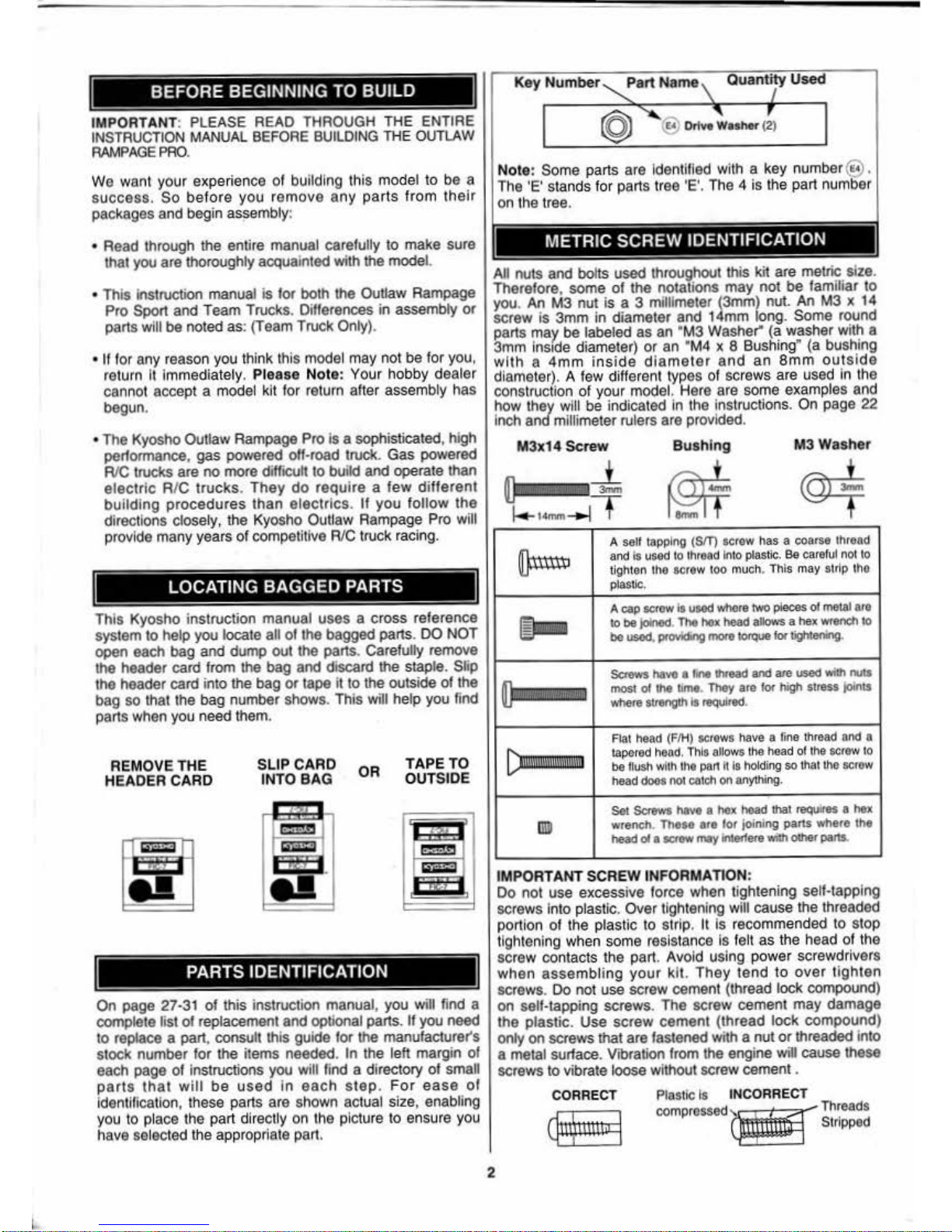

METRIC SCREW IDENTIFICATION

All nuts

and

bolts used throughout this kit

are

metric size.

Therefore, some

of

the notations

may

not

be

familiar to

you.

An

M3 nut

is

a 3 millimeter (3mm) nut. An M3 x 14

screw

is

3mm

in diameter

and

14mm long. Some round

parts may

be labeled as an 'M3 Washer" {a washer with a

3mm

lns

1de

diameter)

or

an '

M4

x 8 Bushing" (a

bus~ing

with a 4m

m insi

de diame

ter

and

an

8mm

outs1d e

diameter). A few different types of screws are used

In the

construction

of

your model. Here are some examples and

how they will be indicated In the instructions.

On

page 22

Inch and millimeter rulers are provided.

M3x14

Sc

'rew

Bushing

M3

Washer

~

A self tapping (SIT) screw has a coarse lhread

and

is

used

to

thread into

plastic

..

86 careful

not

to

tight

en the

screw too

much

. l his

may

strip tho

pla

stic.

This Kyosho instruction manual

uses a cross

reference

'=--

system

to

help you locate all

of

the bagged parts.

DO

NO

T

~

A

cap

scrow Is usod wllcre two pieces ol molal

are

to

be

jo!nod. Tho

l>ox

head

allows a hex

wrench

to

be

usod,

Pfovldong

more

10<q0e

fa<

tightening.

open each bag and dump out the parts. Carefully remove

the header card from the bag and

discard the staple. Slip

the header card into the

babeg

ohr

tape T

itht?

the11ohuts1 ide of0thed

ft'luMI!MM

bag

so

that the bag num r s ows. IS

w1

e p you

1n

~-

Screws

haw

a

fono

thread

and

are used wilt! nutS

most of tn.

umo

.

Thoy

are

lor high slress joll1ts

where

strength

IS

required.

parts when you need them.

RE

MOVE THE

HEADER CARD

SLIP CARD

INTO BAG

OR

TA

PE TO

OUTSIDE

On

page 27·31 of this instruction manual, you will find a

complete list of replacement and

optional parts.

If

you need

to replace a part. consult this guide for

the manufacturer's

stock number for the items needed.

In the left margin

of

each page of instructions you will find a directory

of

small

parts

that

will

be

used

In

each

step.

For

ease

of

identification, these parts are shown actua l size, enabling

you

to

place the part directly

on

the picture to ensure you

have

se

lected the appropriate part.

2

Aal

head (FIH)

acrows

have a

fine

tf1read

and a

1apered

head.

This

allows tho

head

ol the

acrow

10

be

!lush wllh lhe pan h

Is

holding so lllat lhe

acrow

head doos no1

C4tch

on

anything.

llJJ)

Set

Sc<ews

have a nex

head

that

requ

ires a

heX

wrench.

TheM

are

for

joining parts where the

head

o1

a SCtttW

may

intorf""' wilh other paru.

IMPORTANT SCREW INFORMATION:

Do

not

use

excess

ive

force when tightening self·tapping

screws into plastic. Over tightening will cause the threaded

portion

of

the plastic to strip . It

is

recommended to stop

tighteni

ng

when some res istance Is felt as the head of the

screw contacts the part . Avoid using power screwdrivers

when

assembling

your kit.

They

tend

to

over

tighten

screws.

Do

not use screw cement (thre

ad

lock compound)

on

self-tapping screws. The screw oement may damage

the plastic.

Use

screw

cement (thread lock

compound)

only

on

scre

ws

that are fastened with a

nut

or

threaded into

a metal

sur1ace

. Vibration from the engine will cause these

screws to vib rate loose

wijhout screw cement .

CORRECT

INCORRECT

l:jtt\ittltii""J

Page 3

•

I

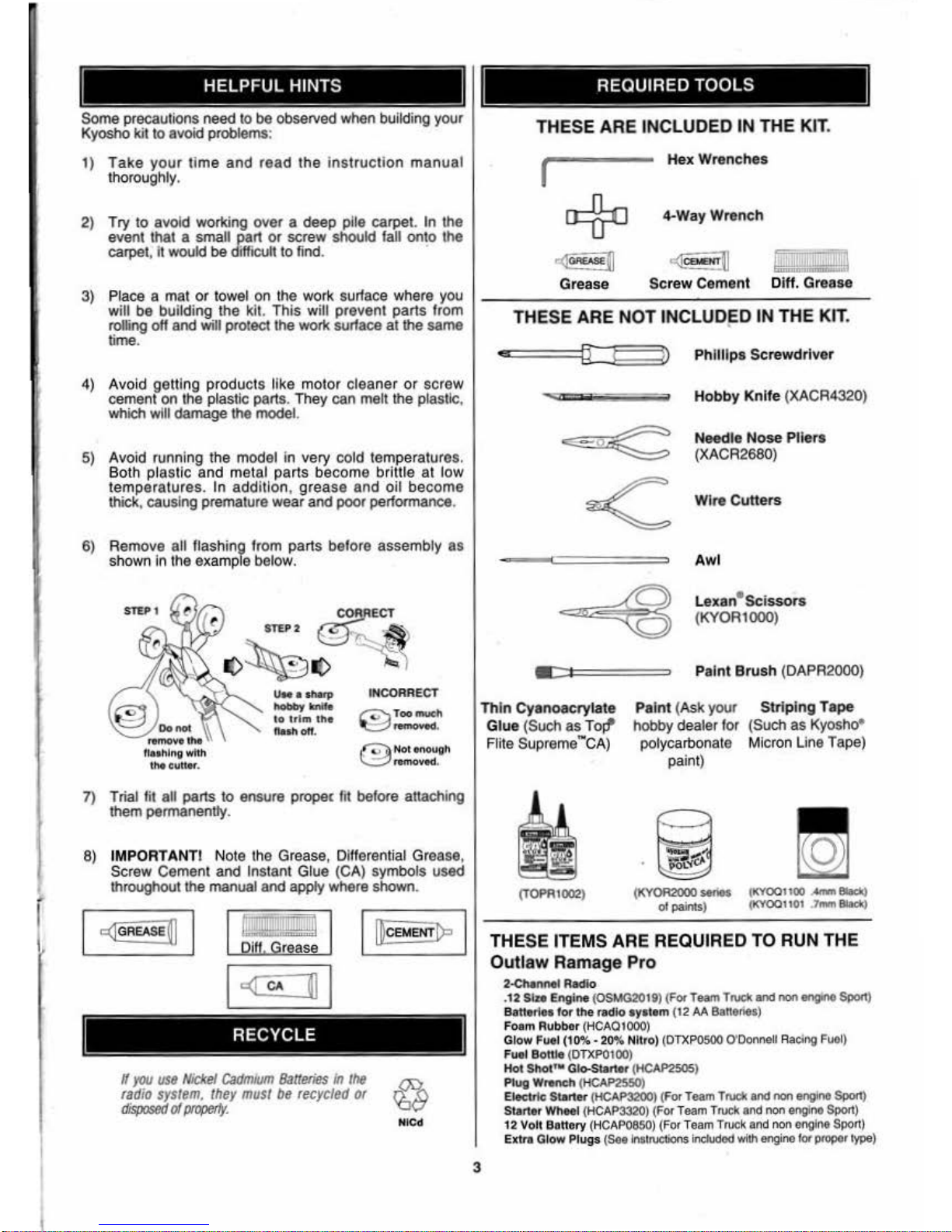

Some precautions need to be obseiVed when building your

Kyosho kit to avoid problems:

1)

Take

your

lim

e and

read

the instrucllon

manua

l

thorough

ly

.

2) Try to avoid working over a deep

pile carpet. tn the

event that a small part or screw should fall onto the

carpet,

it

would be difficult to find. ·

3)

Place a mat

or

towel on the work surface where you

will be building

the kit. This will prevent parts from

rolling off and

will protect the work surface at the same

time.

4) Avoid gening products like motor cleaner or screw

cement

on

the plastic parts . They can melt the plastic,

which

will damage the model.

5)

Avoid running the model in very cold temperatures.

Both plastic and

met

al

parts become brittle at low

temperatures. In add i

ti

on, grease and

oil

beco

me

thick, causing premature wear and poor performance.

6) Remove all flashing from parts before assembly as

shown

in

the example below.

~

Donot

~

removeUM

tl

u hlng wfth

tMCUHet.

STEP2

UM•Wrp

hobbykrifo

to lrlm

the

RashoH.

INCO

RRE

CT

7) Trial fit all parts

to

ensure propec fit before anachi

ng

them permanently.

8) IMPORTANT! Note the Grease, Differential Grease,

Screw Cement and Instant Glue (CA) symbols used

throughout the manual and apply where shown.

Diff. Grease

If

Y<HJ

use

N

idcel

CadmiUm

Batteries

In

the

Cli:!.

radio

system,

they

must

be recycled

or

r>

-:-o

d

isposed

of

property.

'ClO

NICd

...

THESE ARE INCLUDED IN THE KIT.

r

..:r

G-

u

Grease

Hex Wrenches

4·Way Wrench

c([

caoEHT

~

I!!!JiJillB

Screw

Cement Diff. Grease

THESE ARE N

OT

INCLUDED IN THE KIT.

••

'

[ l

~

Phil

lips

Screwdriver

Hobby K

ni

fe (XACR4320)

Need

le

Nose Pliers

(XACR2680)

Wire Cutte

rs

Awl

Lexan•

scissors

(KYOR1000)

Paint

Brush

(DAPR2000)

Thin

Cyanoacrylate

G

lue

(Such as Toll"

Flite Supreme - CA)

Paint (Ask your

hobby dealer for

polycarbonate

Striping

Tape

(Such as Kyosho•

Micron Line Tape)

3

paint)

=

...

-

90L'i(J'

(TOf'Rt002)

(

KYOR2000

series (KY00

1100

.....,. 8laciQ

of paints) t

KY0011

0t

7mm

8laciQ

THESE ITEMS ARE REQUIRED

TO

RUN THE

Outlaw Ramage Pro

2-<:

hannet Radio

.

12

Stu

Engine (OSMG20t9) (For Te

am

TNCI<

and non

engtnO

Sport)

Ba

Horiot

for

the redlo ayatem

(12

AA

Banolies)

Foom Rubber (HCAQfOOO)

Glow Fuel (1

0%.

20% Nitro)

(DTXPOSOO O'Donne

ll Racing

Fuo

l)

Fu

el BoHle (

DTXP0100

)

Hoi

Shot'

M Glo-Start

•r

(HCAP2505)

Plug Wreneh

(

HCAP2550

)

Elect

ric

Starter (

HCAP3200

) (For

Team TNCI<

end

non engino Sport)

Starter Wheel (H

CAP3320)

(For

Tea

m T

ruc

k and non engine

Sport)

12 Volt Banory (

HCAP

0850)

(For Team Truck and non

et1lJ

ine Sport)

Extn1

Glow Plugs (Soolnslruetions included with

engine

for propor

type)

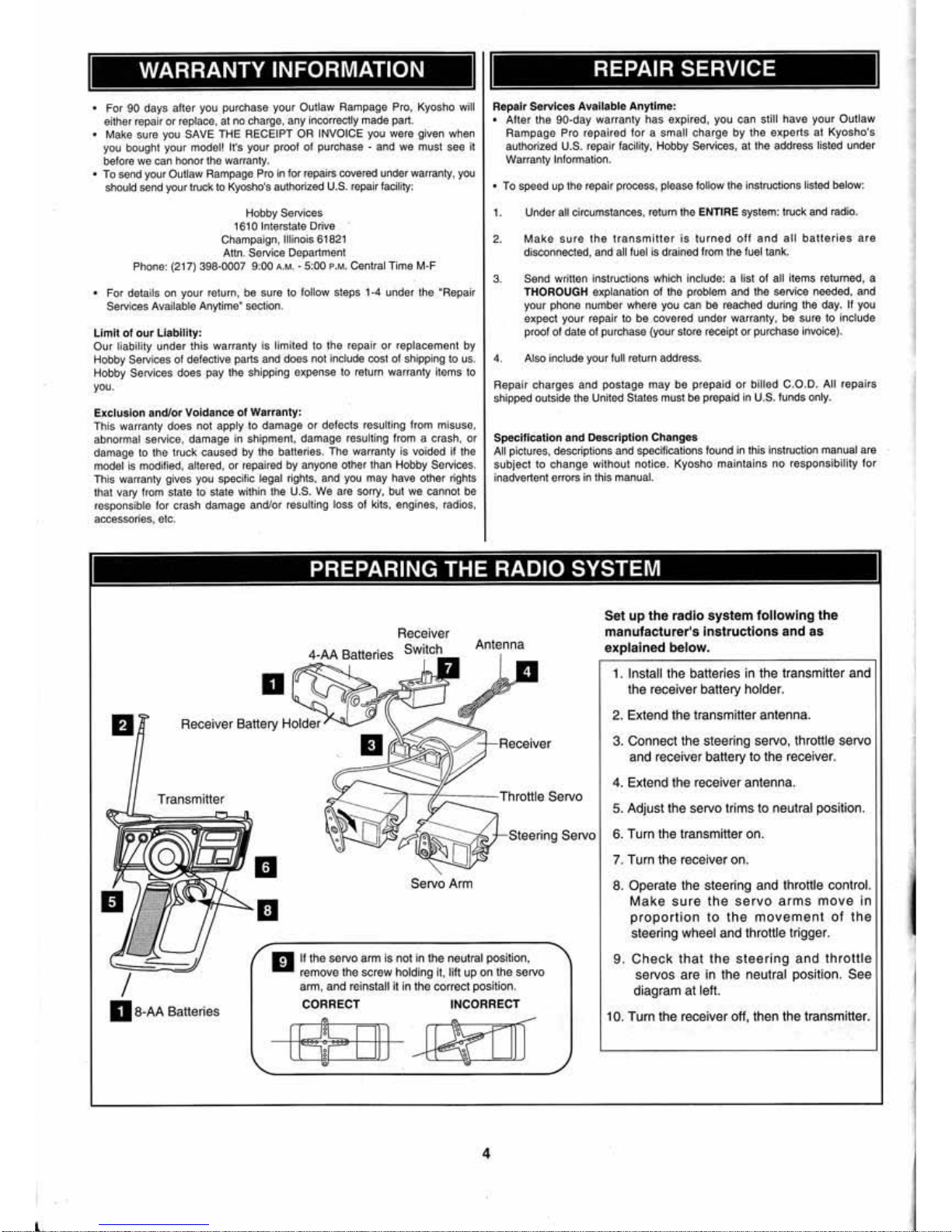

Page 4

l

•

for

90

daY$

after you pur

Chase

your Outlaw Rampage Pro, Kyosho will

eittleJ repair

or replace,

at

no

charge. any inoor rectly made part.

•

Make

sure you SAVE

THE

AECE

IPT

OR INVOICE

you were given

when

you

bought your model! It's

your proof

oJ

purchase •

and

we most

see

11

befoce

we

c-an

honc)tthe warranty.

•

To send yout Outlaw

Rampage

Pro In for tepairs

covered

under warranty,

you

shou

ld

send

your truck to K

yoshO's

avtllorized U.S. tepair f

acility:

Hobby Services

1610 Interstate Drive

Champaign,

Illinois

61821

Attn. Service

Oepa

.rtment

Phone: (217) 398·0007 9;00 A,u,

·5:00P.M

. Central Time M·F

• For

deta

ils

on

your return,

be

sure

to

follow steps

HI

under the •Repair

Serv

ices Available

Anytime•

seclion.

Limit

of

our Liability:

Ou

r tiability under this warranty

ls

limited to the repair

or

rep

lacement by

Hobby

Services of defective

parts

and docs notlnclode

cost

of

shipping

to

us.

Hobby SetVices does pay the shipping

oxs>ense

to retum warranty Ite

ms

to

yoo

.

Exclusion and/or Voidance

of

Watranty:

This

wa1ranty

ooes not apply to damage

or

dofcc.

ts

cosui1J~

trom mi

suse

.

abtlormal service, damage in &hipment, damage resulting

from

a crash,

or

da

mage

to

tho truck caused

by

the batteries. The warranty Is

V¢kjecf

If the

model

Is

mOdified.

altered. or

repWred

by

anyone

otheJ

than Hobby

SetVIces

.

This

warranty gives

you

specific legal rights. and

you

may

have

other rights

thai

va.JY

!tom

sta

te

to

s.14ite within t

he

U.S.

We

ate sotry, but

we

cannot

be

respons

libte

fot

crash damage and/or resulting

sass

of kit

s,

engines, mdios.

accessories.

otc

,

Ropalt

SOrvlcos

Avallt~ble

Anytime:

After

the 90·day watranty has expired, you can still have your Outlaw

Rampago

Pro tepalro<l

lor

a small

cha

rge

by

1.he

ex;perts a.t

Kyosho't>

authorized

U.S

. topair

facil

ity, Hobby Services, at the

address

listed unde r

Warranty I

nformation

.

•

To

speoo

up tho repair process,

please

tolklw the lnsltuctlons list

ed below:

1.

Und~

all circ

umstancGs. r01

um

the

ENTIRE

system: truck

and

radio.

2.

Make

sure

the trans

mitter

is

turned

off

and

all

batteries

are

diSCOnnected.

and all

fuel

is drained f

rom

ltle fuel tank.

3.

Send

written instructions which include: a O

st

of all It

ems

retvmed. e

THOROUGH

explanation of tM problem and tho service

nee<led.

and

your

phone

nu

mbEH

whe1e

you can

be

reachod during the

day

.

If

you

expect

your repair

to

be

covered

ur"'dor

warranty.

be

su

re

to

Include

proof of date of purc

hase (your stote receipt

or

pur~aso

Invoice).

4.

AlSo Include your lull ret

urn

addr

ess.

Aepalr ch

cuges

and postage may

be

ptepaid

or bill

ed

C.O.D. All repairs.

shipped outside the

UnitGd

States must

be

prepaid In U.S.

funcls only.

SpeeiftcaUon end

De

scription Changes

All

pictures. descrip tions and

speci.ticatlons

found

in

chis

1nstructlon manual are

subj~t

to change without nolice. Kyosho maintains

no

responsibility for

inadvertent errors in this manual.

PREPARING THE RADIO SYSTEM

B

Transmitter

8-

AA Batteries

D

Receiver

Batteries Switch

~'

Set

up

the

radio

system

following

the

manufacturer

's

Instructions

and

as

explained below.

1.

Install the batteries in the transmitter and

lhe

receiver battery holder.

2. Extend the

transmi«er antenna.

3. Connect the

steering servo, throttle servo

a

nd

receiver battery to the recei

ver

.

4. Extend the receiver antenna.

5. Adjustlhe servo trims to neutral position.

-}-Stole ring Servo 6. Turn the transmi«er on.

Servo Arm

au the servo arm Is not in

the

neutral position,

remove the scr

ew holdi

ng

it, lift

vp

on the sorvo

arm, and

roinstalf 1t

In

lhe correct position.

CORRECT INCORRECT

rFfF

I

Ill

JPifiiT

4

7. Turn the

recei

ver

on

.

8. Operate the steering and throttle control.

Make sure

the

servo

arms

move

In

proportion

to

the

movement

of

the

steering wheel and throttle trigger.

9. Ch

eck

that

the

steer

ing

and

throttle

servos are

In

lhe

neutral position.

See

diagram at lett.

10.

Tum the receiv

er

ott, then the transmitter.

Page 5

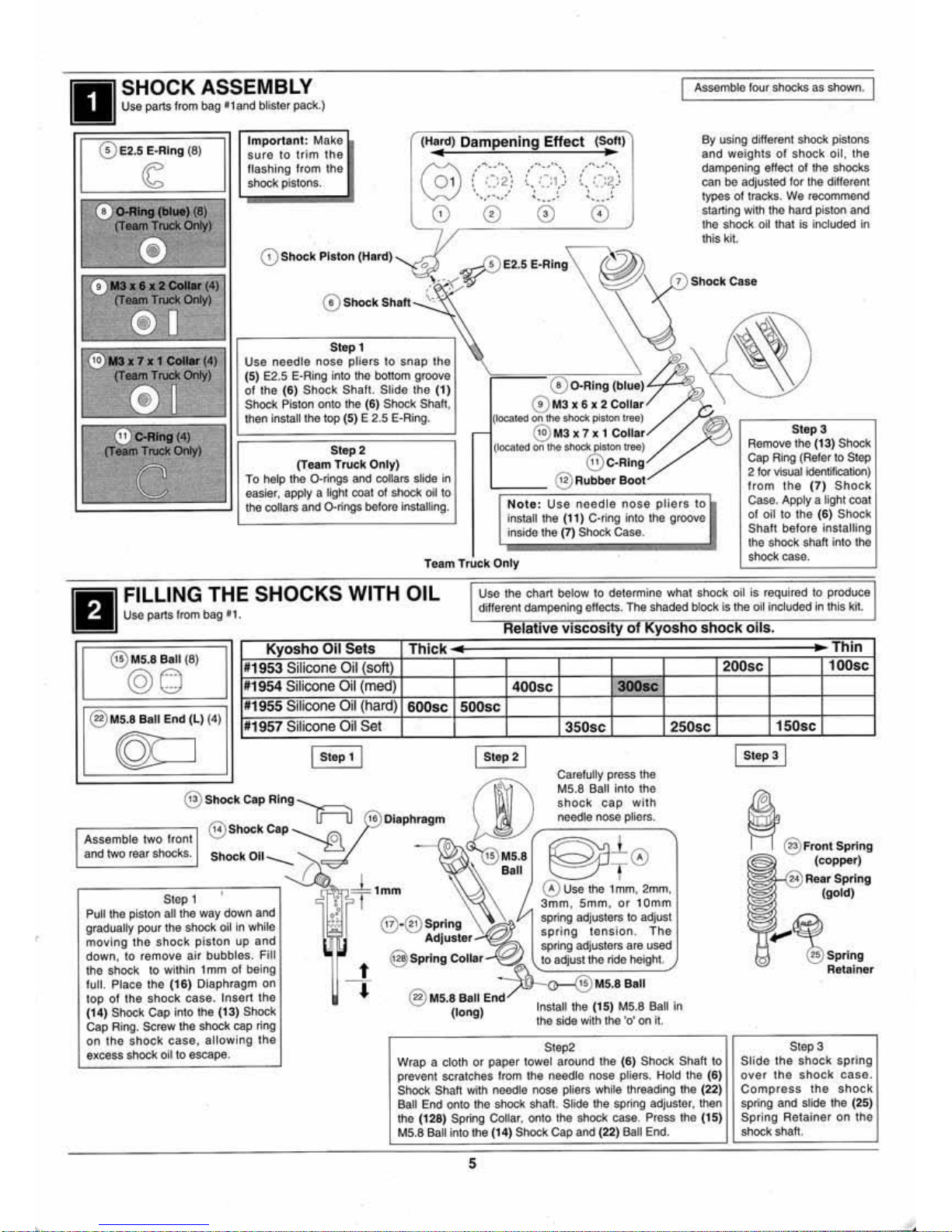

Assemble four shocks as shown.

0 E2.5

E·Ring

(8)

Important:

Make

(Hard)

Dampening

Effect

(Soft)

By

usi

ng

different

shock

pistons

suro

to trim

the

and wei

ghts

of

shock

oil

, the

~

flashing f

rom

the

@

,

...

_

.....

.-..

.....

.

..

-

.....

dampeni

ng

effect

ol

t

he

shocks

. '

. . . .

shock pistons.

: : .. ~ 2

~

\ :

..

~1

J

:

.-.2

'

can

be

adjusted for the different

. ·-.

. . . .

..

·

..

.

-·

'

•

' ' ' '

tYJ)eS

ot ttaeks. We recomroond

0

0411ng

(blue)

(8)

· ... -

...

'·

.,..,.·

..

...

-·

0 0 0 0

starting wl

111111o

!lard piston and

(T

~

Only)

the

shock oil that is included

in

111is

klt.

0 s

E2

.5 -

'"9

~~X

llllZ

coa.r

(4)

0

shOckPiston(Ha

rd)

~

~

ER

'

,

..

<

. ,

(~

1

Shock

Case

. .

cr...,

Trude

OnfY)

0

Shock

Shalt

'~

.

®rt

~

~

~

118x7

x 1

coa.r

(4)

Step

1

~

Use

needle

nose pli

ers

to

snap

the

(T~rude

Only)

(5) E2.5 E·Ring Into t

oo

bottom groove

0 O·A

ing

(blue~/

*

TI

of

tho

(6)

Shock

Shalt

. Slide

tho

(1)

Shock Piston onto

111e

(6)

Shock Shall,

{!)

M3

x 6 x 2

Collar

tnen Install the top (5) E 2.5 E·Aing. (l

oe&

tod on the shock piston t

ree

)

~

Cofllng

(4)

- @

M3

x 7 x 1

Collar

Step

3

(T...,

Trude

enly)

Step

2

(located on t

he

shOC:k

piston

uee

)

Remove the (13) Shock

c

(Team

Truck

Only)

@

C·Ring

Cap Ring (Refer to Step

To help t

he

0 -rings

e.nd

ooflars slide in

@)

Rubber

Boot

2tor

Visua

l ldentiflcallon)

easier,

apply a llghl ooat of

Shoe!<

otl to

lrom lhe

(7)

Shock

Case. Apply a

Jighl coa

t

lhe collars and O.rings b&loro Installing.

Note

: U

se

need

le

nose

pli

ers

to

install the (

11

) C-ring

ln1o

tho groove

ol

oil to

the

(6)

Shock

inside

111e

(7) Shock

Case

.

Shal1 before installing

t

he

shOck

shaft into the

Team

Truck

Only

$hOek casa.

1

•·•1

~.~L!.~~

o

~~~

t

~

SHO

C K S

WITH

OIL

Use the chart betow to

detem

'li

ne

what shock oil

is

required to produce

different

da.mpen

il)9

elfeC1s.

The

shaded block ls the oil included in this kit.

Relative VIscosity

of

Kyosho

shock

oils.

@)

M5.8

Ball

(8)

Kyosho

Oil

Seta

Thick

Thin

@6)

N1

953 Silicone Oil (soft)

200sc

100sc

N1954 Sil

icone Oil (med)

400sc

300sc

@)

M5.8 Ball

End (L) {4)

N1955 Silicone Oil (hard)

soosc

500sc

N1957

Silicone Oil Set

©0

l

step1

1

@ Shock Cop

Ring

"[r=:u

.-------:-

--,

11.\

shock

Cap

Assemb

le two hont v.;;

and two

rear shOCks

.

I

Step2

1

I

.....

350sc

Carefully press the

M5

.8 Ball

1nto

the

shock

cap

with

needle

oose

pilo

ts .

250sc

,---

-,...---

--;--

--,

"'--~

ID=*=1mm

Sl

ep

1

\O

}>,

.Gv

.,.,

eall

@PT

0

0

Use

the 1 mm, 2mm,

3mm

, Smm.

or

10mm

Pull the piston all the

way

down and

gradually pour t

he

shock oil in

whUc

moving

the

shock

piston

up

and

down. to remo

ve

air

bubb

les. F

ill

the

sha<:k

to wlthln 1

mm

ol

being

lull. Place the

(16)

Diaphragm

on

top of

lhe

shock

case. lnsen lhe

(14)

Sllock Cap into the (13) Shock

Cap

Ring. SCrew

the

shoclc cap ring

on

the

shock

caso

, a

llo

wing

the

excess shock oil to escape.

t

--.

Adjuster

spnng

tsnston

. T

he

sptlng adjusters a

re

used

@ spring

Collar

to adjust the ride height.

~~

M5.8Boll

@ Ms.8 Boll

End

~

(long) Install

lho

(15) M5.8 Ball in

the

side with t

he

•a•

on

it.

Step2

Wrap a

clo

th

or

paptH towel aroun<f the (6) Shock Shaft

to

prevent sctatches

hom

the neodle nose pliers. Hold the (

6)

Shock

Slla

ft wilh noodle nose pliers whi

le

threading

111e

(22)

Ball End

onto

the shock shaft. Slide the

SP•ing

adjuster. then

lho

(128) Spring Coll

ar.

onto lhe

Shock case. Press tho (15)

M5

.8 Ball into the (14) Shock Cap and

(22)

Ball End.

5

150sc

I

Steps

I

~

@

Fron

t

Spring

(copper)

Step3

Slide

the

shock

spring

o

ver

tho

shock

caso

.

Compress

the

shock

spring

and slide tho (25)

Spring

Retainer

on

the

shock

slla~

.

Page 6

L .

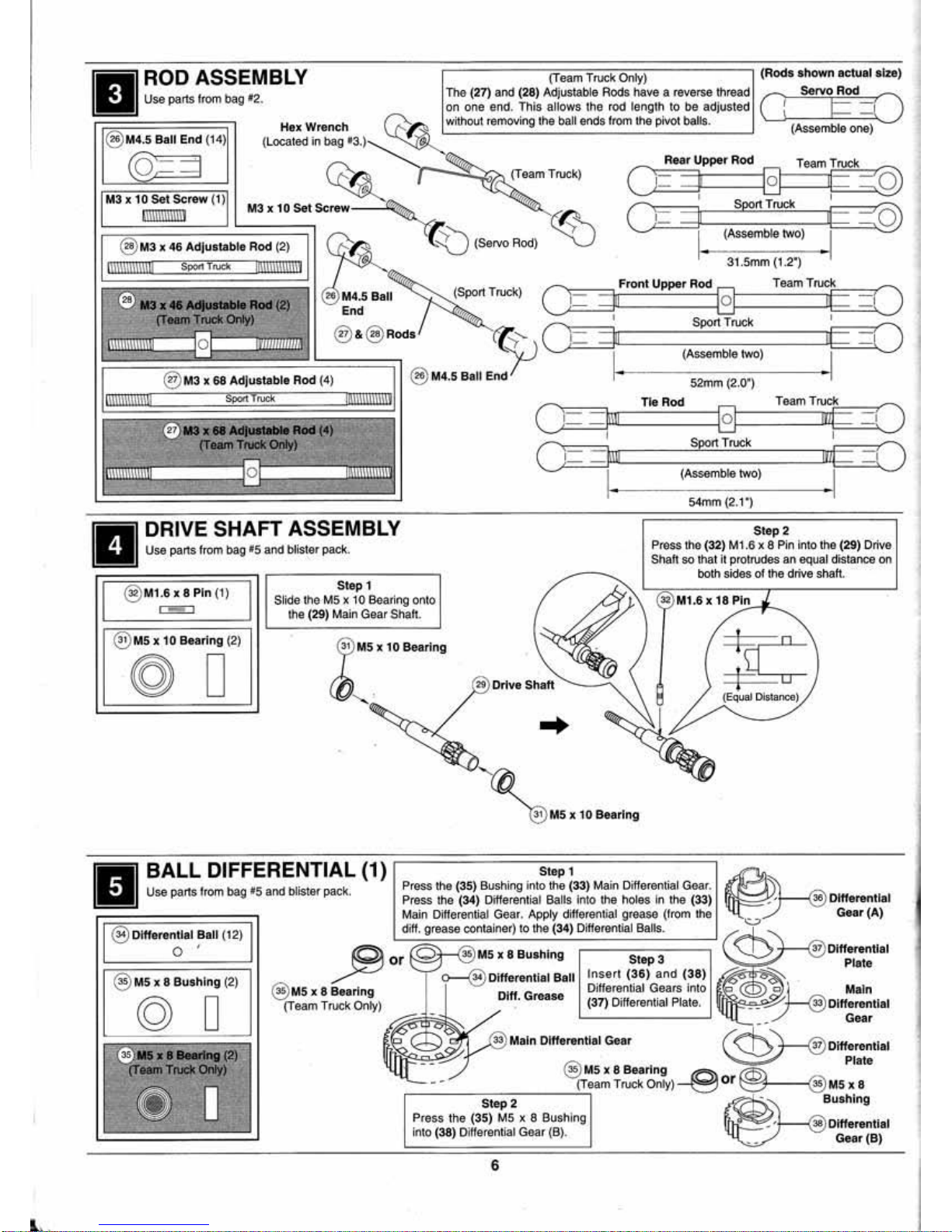

ROD ASSEMBLY

U

se

parts trom

bag

12.

54mm (2.1·1

DRIVE SHAFT ASSEMBLY

Step 2

Use pans

from

bag

il5 and blister pack.

Press the (32)

M1.6

x 8 Pin Into the (29) Drive

Shah

so that

it

protrudes

an

equal distance

on

both sides

of

the drive shatt.

@ M1.6 X 8 Pin (

1)

I - I

® MS X 1 0 Bearing (2)

@ D

@

MS

X 8 Bushing (2)

© D

Step 1

Slide

t,.,e

M5 x tO

Bea

ring onto

the

(29) Main Gear

Shah

.

@)

Msx

10

Bear

ing

..

\31l•MSx 10 Bearing

Step 1

Press the (35) Bushing into

the

(33) Main Differential Gear.

Press the

(34)

Differential Balls into the holes In the (33)

Ma

in OifferentiaJ

Gear.

App

ly differential grease (f

rom

the

ditf.

grease

container)

to

the (34) DifferootiaiBalls.

)9or

@

M5

x 8 Beari

ng

(Team T

ruc

k Oflly)

Dfff. Grease

6

Step3

l

nsen

(36)

and

(38)

Differential Gears Into

(37) Differential Plate.

~~·1--

--<'0)

Ditferentla

l

Gear (A)

Plate

Ma

in

Gear

Plate

Gear (B)

Page 7

II

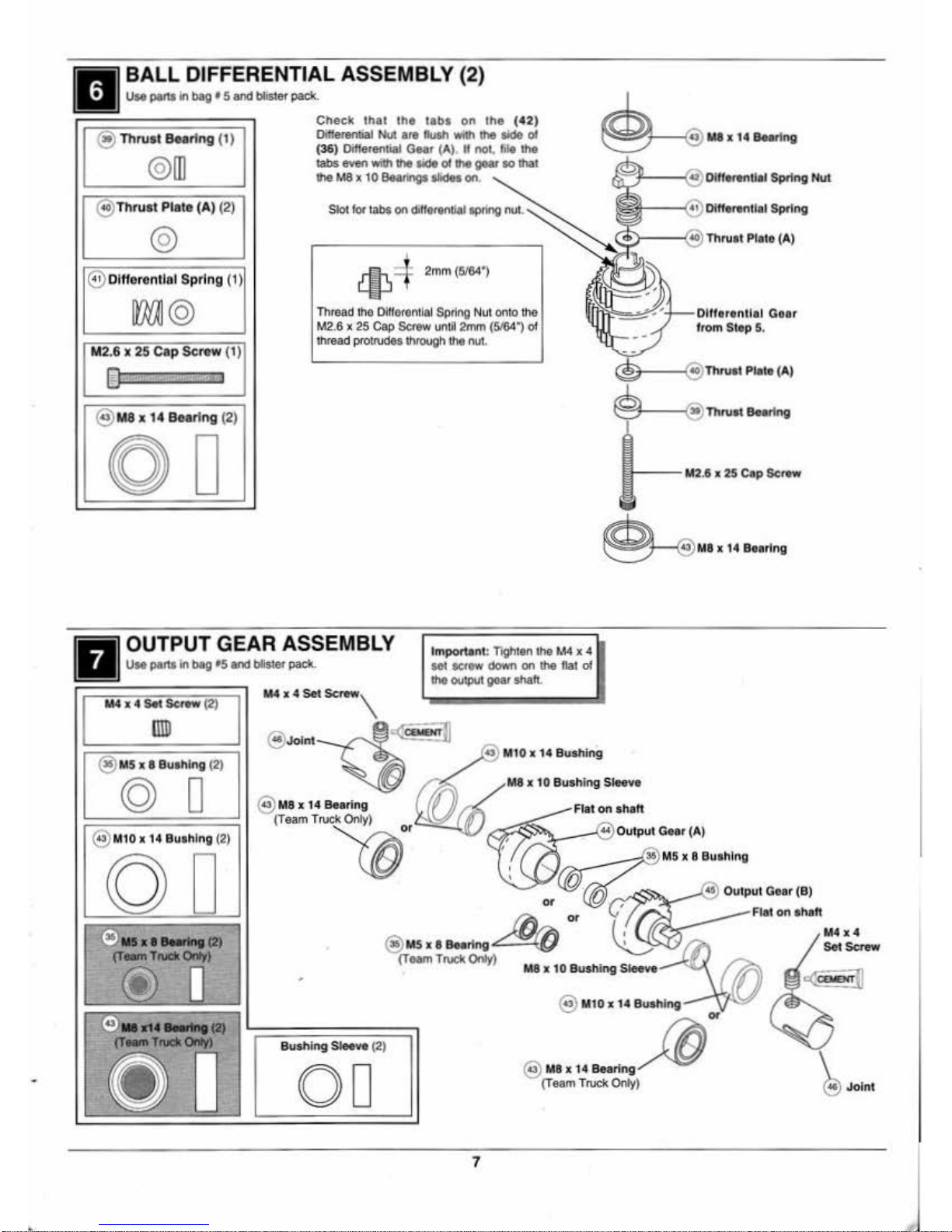

BALL DIFFERENTIAL ASSEMBLY (2)

use pans In

bag

• 5

and

blister

pack.

@)

Thrust

Bearing

(t)

@

Ill

@ Thrust Plate (A) (2)

@

@ Differentia l Spring (1)

m©

M2.6 x 25 Cap Serew (

1)

@

I I

@)

M8 x 14 Bea

ri

ng

(2)

0

D

Cheek

that

the

tabs

on

the (42

)

Differen1181

Nut

are

1\Jsh

"'"'

tho

-

o4

(36)

Oiffere<~tial

Gear (A).

If

not. file

the

tab5

oven

"''h

tho

- of

tho

gear

so

that

tho

M8

x 10

BeaMgs-

on

.

~

4

2mm (5184")

Thread the

Dltlor

entlal Spring Nut onto

tho

M2.6 x

25

Cap

Screw

un~l2mm

(5184")

o4

thread

protrudes

througl\

the

nut

.

~~

~1'-.:J'-

Dlftor

enllo

l Goar

from

Stop

5.

ci!ii+--

--1.40\

'rllnuot Plato (A)

~

ThruotBearlng

>--

- M2.6 X

25

Cap

Screw

~

M

B

x

14

Be

aring

OUTPUT GEAR ASSEMBLY

Important: Tighten

tho

M4

x 4

sot

SCfOW

down

on

tho

flat

of

tho

OUtput

gear

slla.ft.

Use

pans

In

bag •5

and

blister

paek.

M4 x 4

Set

Screw

(2)

ll1D

@>

Ms x 8

Bushing (2)

© D

@)

MtO

X

14 Bua

hlng

(2)

OD

..

.....

-.

(2)

(T-

TNd<

Orfy)

M4

x 4

Set

Scnow,

@

Me x 14

Bearing

(T

earn

Truek Only)

"0

0'

Bushing

Sleeve (2)

OD

7

MB

x 10 Bushing Sleeve

@)

M

10 r 14 Bushing

@)

MB x

t4

Bea

ring

~

(Team Truek Only)

Ot

Joint

Page 8

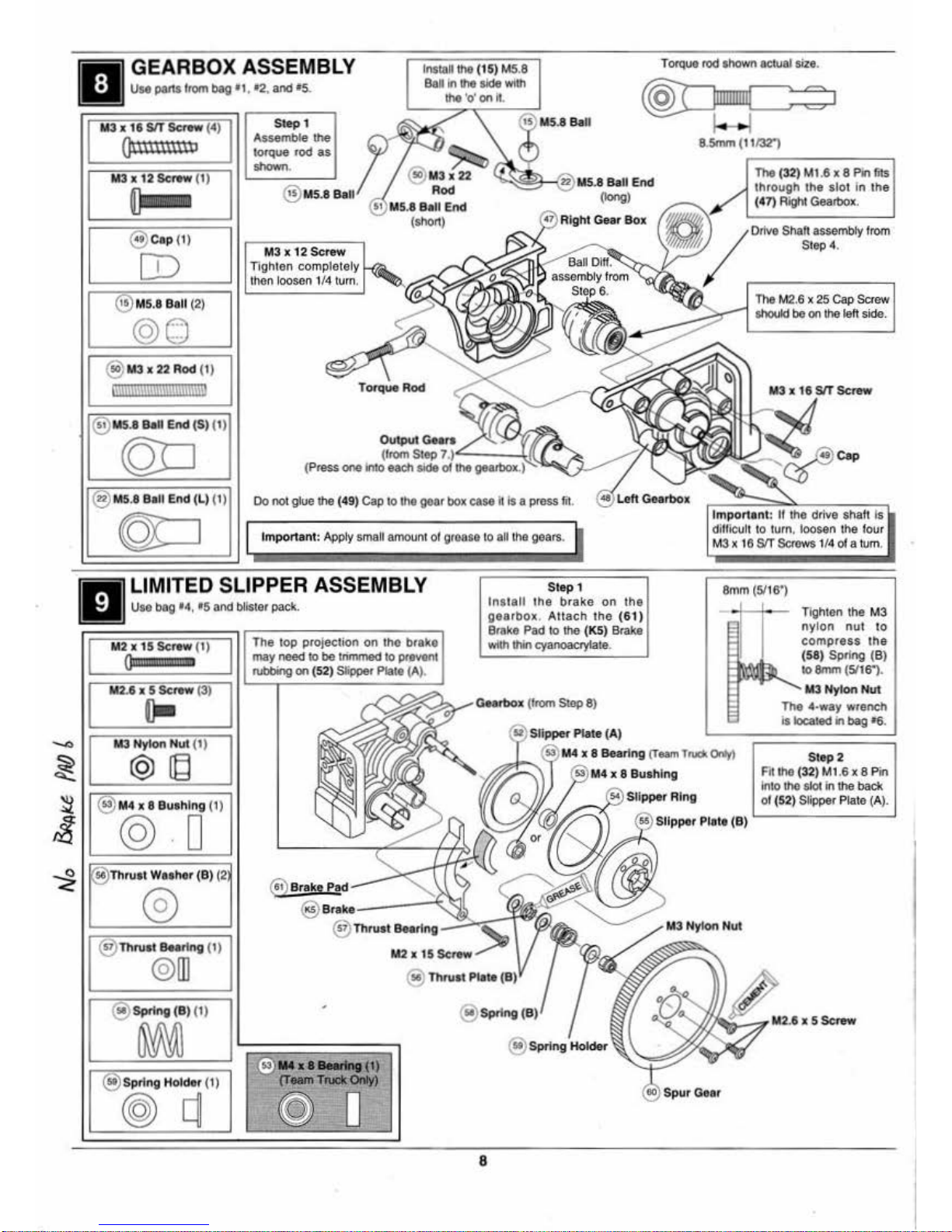

GEARBOX ASSEMBLY

IM18111h8

( 1 5) M5.8

Ball

In

111e

aide with

the

'o'

on

11

.

Torquo rod shown

&c:tual

size.

Use

pans

from

bag

•1,

t2

, and

•s..

@]C:::Jm

llllllHIIII

~IIII=~:

~=~I

~

M3 x 12 Screw

(1)

~

@

cap

(1)

[D

@)Ms.e

Ball

(2)

@Q

@)

M3x

22 Rod (1)

6\11\i\lmlllllll\\\\lmm

@ M5.8

BaU

End

(S) (

1)

(QO

@ M5.8

Boll

End

(L

) (1)

©D

Step

1

Assemble

the

torque

rod

as

shown.

~~--{i22

M5.8

BaU

End

M3 x 12

Screw

Tighte

n c

ompletely

then loosen 114 tum.

T<><queRod

Do

no

t glue lhe (49) Cap

to

the

goer

box case k Is a press

fit

Important:

App

ly

small amount of groase to all t

he

gears.

(long)

8.5mm

(11/32")

The

(32) M1.6 X 8

Pin

fils

through

the

slot

in the

( 4 7) Righi Geart>ox.

Important

: II

the dri

ve

sha

h Is

ditficull to t

urn

. loosen

the

four

M3 x

16

SIT

Screws 1/4

of

a tum.

LIMITED SLIPPER ASSEMBLY

Step

1

8mm

(5116')

Uso bag

•4,

•s

and

blister pack.

Install the

bra

ke

on the

gearbo

x.

Attach the

(61)

Brake Pad to lhe (KS) Brake

with lllin cyanoaaylate.

M2

x 15 Screw

(I)

Qllillill§!i!§iJ!I*

M2.6 x s

Sc

rew

(3)

o-

.._,.

MJ

Nylon

Nul

(1)

~

@

ltd

~

@

M4

x 8

Buahlng

(1)

i © '0

..

Thrust

Was

her

(B)

(2

@

@

Thruat Baorl

ng

(1)

©

rn

@ Spring (B

)(

I)

~

@)

Spring

Holder

(! )

(@)q

The

lop

projection

on

tho

brako

may

need

to

be

lrimmed

to

pr.GVGnt

rubbing

on

(52

)

Sipper

Plate

(A)

,

®

~;Iipper

Plat

e (A)

x 8

Bearing

(Team

T-

Onl1)

@

Brake

Pad

@

Brak••

---4.~

@

Thru•t

Baoring

~~....:-t

•

..

........

lng(1)

(TMRI

TIUCirOnly)

~

(]

M2x15Scnow

•~

@ Th

rv

tt

Pllta

@ Spring

@

sprtng

Holder

8

(eo)

SD

'"' Goer

Tighten

the

M3

nylon nut

10

compress

the

(58)

Spring

(Bl

to

8mm (5116").

M3NylonNut

The

4-way

wrench

1s

loca1ed in

1>a9

•s

.

Step 2

Fit the (32) M1.6 X 8 P

in

Into t

he

slol in

lhe

back

of (52) Slippar Pl

at

o (A).

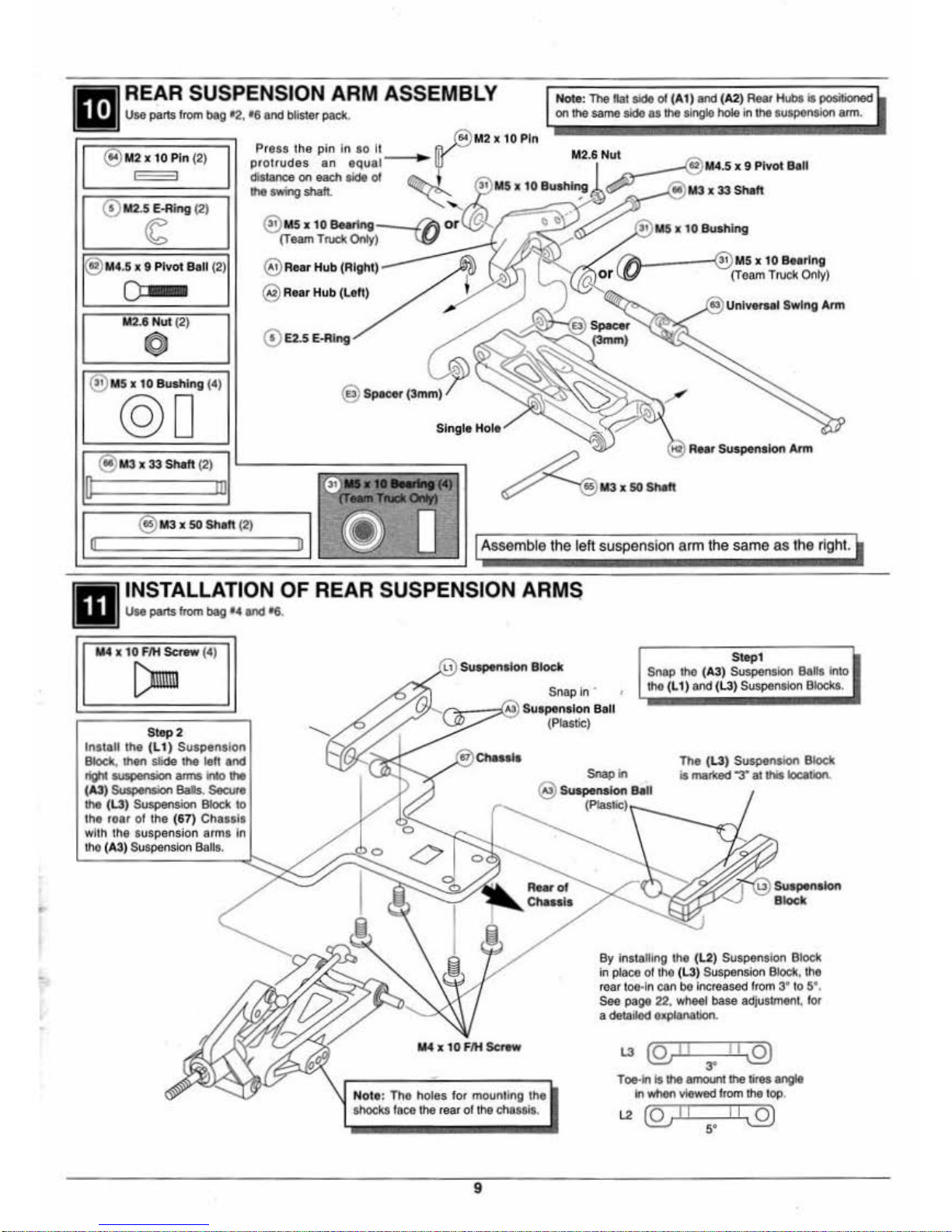

Page 9

..

REAR SUSPENSION ARM ASSEMBLY

U

se

pallS

from bag

02,

•6 and bllsler pact<.

@

1112 X 10 Pin

(2)

0

111

2.5 E-Ri

ng

(2)

<6

®

M4

.5 x 9 Pivot

Ball

(2)

0

M

UNut

(2)

0

@ Ms x

10

Bushing

(4)

@0

@)

Roar

Hub

(Right)

@ Rear

Hub

(Left)

0 E2.S E-Ri

ng

@)

Specor

(3mm)

~

Single Hole

@)

111

3x

33

Shalt

(2)

'---

-~~

~~~~~~

n

rn

~

••IIateM

u

---01111

Note:

The

Pat

side

of

(A

1)

and

(A2)

Rear HubS

Is

positioned

on

the

sa

me side

as

the

single

hole

in l

ha

susponsJon

arm

.

IA----(ii)

Ms x

10

Beorlng

~

r

w-

- (Te

am

Trucl<

0011

y)

e3

Universal Swi

ng

Arm

to

Rear

Suspension

Atm

I O @

M3xSOShah

(2) I @ 0

Assemb

le the left suspension

arm

the

same

as

the

right.

INSTALLATION

OF

REAR SUSPENSION ARMS

Use

pallS

from

bag

••

end •6.

1114

x 10

F/H

Screw

(4)

[)mm

Step2

Insta

ll

the

(L1)

Suspension

Bloc

k,

llw>n

Slide

the leh

~t

_..;on

arms

Into

(A3) Suspension Bals. SeouroJ

tile

(L3)

Suspension Block

to

t

ho

roar

of the

(67)

Chassis

wilt\ t

he suspension arms

1n

1110 (A3

) Suspension Balls .

Suspension

Block

512p1

Sn

ap

in ·

;>'' (7!;

--:

;::::'\el

Suspension

Ball

(Plastic)

Snap

t

ho (A3

) Suspension Balls into

tllo

(L

1)

end

(L3)

Suspension Blocks.

Snap

in

The (L3)

Suspension

Block

Is marked -:r

8l

INs location.

@)

Suspension Ball

Note: The hol

es for

mounl1ng the

shocks faoo

lhe

rear of the c

hassis

.

9

By installing

tho

(L2) Sus

pension

Bloc

k

in plaoo of tho (L3) Suspension Bl

ocl<.

the

rear toe-In

can

be

lncr

eased

fro

m 3' to 5

'.

Sao page 22, wheel base adjustmen t. l

or

a detailod explanation.

L3

(QJII

11

\2)

3'

T oe-ln Is tile amount

lhe

liras angle

Ill

when

viewed from lhe

top

.

L2

(QJ

II

s•

II

J2)

Page 10

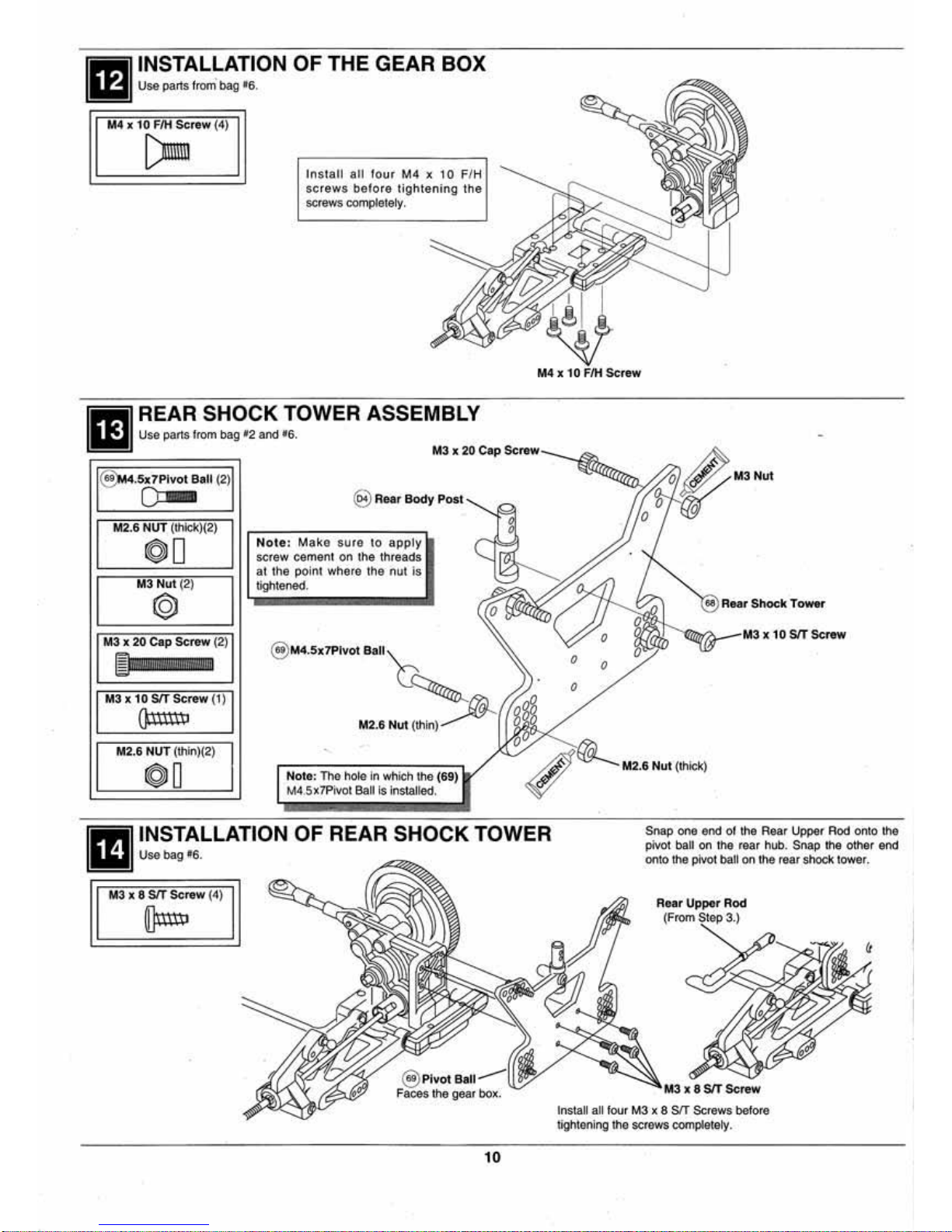

INSTALLATION OF THE GEAR BOX

Use

parts from' bag •6.

M4 x

10

F/H

Screw

(4)

[)mnn

Ins fall

all

four

M4

x

10

F/H

screws

befo

re

tightening

the

screws completely.

fttl

~~!~

r

!~?.~~J.O

WER

ASSEMBLY

~

M3 X

20

Cap

Sc"'w

@)14.Sx7Pivot

Boll

(2)

~

@)

ReorBody

Post

M

2.6

NUT

(1111ck)(2)

©l

D

N

ote:

Make

sure

to

apply

screw cement on lhe threads

I

M3

Nut

(2)

@

I

at the point whe(e the nut

is

tightened.

M3 x

20

Cap

Screw

(2)

@M4.

Sx7Pivot

Ball

't?

~I!MIIMII!

!

M3 x 10 SIT

Screw (1)

O;llm~

M2

.6 N

ut

(l/1in)

M2.6 NUT (l/1in)(2)

.

©lO

Note:

Tho

hole

In which the

M4

.5x7Pivot Ball Is Installed.

(69)

INSTALLATION OF REAR SHOCK TOWER

Use

bag

•s.

M3 x 8 SIT Scr

ew

(4)

ijJn®

@ Pivot Ball

Faces the gear box.

10

0

0

es

Rear

Shock

Tower

Snap one end of the Rear U

pper

Rod onto the

plvoo

ball

on

l

he

rear hub. Snap the other end

onto

the

pivot

batt on the

rear

shock tower.

Rear Upper

Rod

(From Step 3.)

M3

X 8 SIT

Screw

Install all four

M3

x 8 SIT Screws before

ligh

tening

oho

screws completely.

Page 11

lil!!l

FRONT HUB ASSEMBLY

~

Use parts lrom

bag

"2 and blister pack.

R

ight

Knuckle

@)

M4.5 X 7 Plvo1

8<1

11

(2)

Arm

0:-

i

_j_

·-

@

1114

.5

X 9

Pivot

8<1

11

(2)

Step\

T - ·

Tm1

il'e-

~

0

area

lrom

(12)

Threa.d

lhe

M2.6 Nul on untU

1

mm (3/64")

ol

1hroad

sho

ws

above

the nut

....

' • x 7

Plvol

Ball

(

~

"'!9

1114•

Step2

Instal

the

(70

) Front

AXle

in

the

(12) Ri

ght

Knuckle

Arm. The

Right

Knuc:lde

@)

E3

.0

E-Alng

(2)

Aim

as

shaNn.

M2

.6

~

""'

=

1114

.5

,.

I

8<111

x9Pivo

Nut

hole through

(70)

Front Axle Is

dril

led

at an angle.

line

up

the

ho

le In the axle and knuckle

~

l

A

~

./

\!9

1114

X

'Z7

Shaft

(2)

Step3

Sllde

tho

Rigl\t Knuckle Arm aOMmbty Into

the

(11)

Right Front

Hub

and

secure

it with

m

tho

(71)

M4

X

'Z7

Shalt.

Nola

tho angje

ol

tho

lront axle shown in the diagram below.

~

@>

Front

@~

~

M2

.6

Nut

(4)

@ Ri

ght

Knuckle

~~

-

Ri

ghi

Front

Hu

b

Step

4

©l

(

Marl<

od

with

an

'A')

'ft

E·Ring

\

·

·-~-

·----------------

--------

---------

------

-----------

-------

------

Step\

Left Knuck

le

@ MAx27Sha Trim tho

(1

3) Left

Knuckl<l

Aim

Arm

tho aamo

as

the

(1

2) Ri

ght

It

Knuclclo

Aim

as

shown

above

.

@ M4.5 X 9

Pivot

Ball

~

Step2

lnstaQ

tho (70) Front

AxlO

in

tho

(13)

Lon Knuckle Arm.

M2

.6

Nut

Step3

Slide the left knuckle arm

@

Left

Front

Hub

usembly

into

the

(14

J

LO~

F rent

Hub

and

secure ~ will

the

(71)

M4 x27 Shalt. Note

the

anglo ol

Step4

tho (70) Front

AXle

shOWn

In tho lns·lall the pivot balls In the

Insta

ll

tho pivot balls In the

knuckle

arm

assomb

ly.

~

M4.5

X 7

Pivot Boll

li~:ll.----

M2

.6

Nut

I

u

a Lett

KnuckJe

Arm

~

FrontAx

.

le

0

diagram at tho

righ

t knoolde

arm

assembly.

--

r

@)

E3

.0 E·

Ring

The

axle anglas down.

1M

INSTALLATION

OF

FRO

NT SHOC

K TO

WER

111!11

Usa

pat~Sircm

bag "2.

Step

1

I@>

M4.5 x 7

Pivot

Bell

(2)

0

M3 x

20

Cap

Screw

(2)

~

M3

X 8

f/H

SIT

Sc.-

(4)

~

M2.6

Nut

(thin) (2)

0 0

M2

.6

Nut

(thick) (2)

00

I

M3

Nut

(2

)

I

@

lnslal

al

lout

M3

x 8 FIH-SIT screws

before tighterWig

them

down.

@

Fron

t

Bulkhe

ad

Instal tho M3 x

20

cap

Screw

in

this

hole

..

11

Snap

the Iron!

upper

rods, lrorn Step

3. onto

tho

M4.5 x 1

piVot

belli.

Stop2

Install

the

M3 x

20

cap screws

and

the (

69) M4

.5 • 7

PM><

Bals

.

lmportont Instal

the

M3

X 8

F/H-s!T

acrews from the side wl

th

the

countersink

for

tne

he

ad

of

the

screw

to set ln.

l

Page 12

..

INSTALLATION

OF

FRONT ARMS

Use parts

11om

bag

02.

{D

E2.5 E·Ri

ng

(6)

(6

@ M3 x 27 Shott (2)

0 Dl

@ M3 X 44 Shalt

(2)

[U

Note: Chec

k that

the

suspension arms move

freely.

rr

they

do

not

locate

v.ilere they

are binding

and

hghtly

trwn

lhe

.....

Slep

1

Al!aCh

lhe

right

la>uclde

ann

8.-.bly

10

lhe

(H1)

FIOOI

S<_...aon

Ann

R;glll

KntJCkte

Ann

Assemllly

m

Step2

Attath tho (H1)

Front~

Arm to the (73) Front Bulkhead

with

the (75

) M3 x

44

Shalt

.

Secure

the

shall

with

the

(5)

E2.5 E-Rings.

Step3

Snap

lhe

front upper rods

onto

lhe pivot

bal

on

lhe

la>uclde ann assombly.

@)

11

3 x «

Shall

'

Assemble

lhe

left

side

""'

same

as

the

right

Bulkhead

1 E2.5 E·Ring

fMl INSTALLING

THE

FRONT

SUSPENSION TO

FRONT

CHASSIS PLATE

~

Use

parts from

bag

"2.

M4 x 10

Fill

Screw

(4)

[)um

Note: Install ell four M4 x

10 F/H

screws beforo tighleolng

them

.

Front

Cl\aulo

Plaia

Front

BumP«

1M

SERVO SAVER ASSEMBLY

~

U

so

parts

from

bag •3.

Slide

the (87) Servo Saver Spring over the

sorvo

savor

oseomb

ly

after installi

ng

servo

saver(C).

Use a Uat bladed scr

ewdriver

10

pry open (83) Sorvo Saver (A)

during

essom

bly.

12

Sorvo Saver (B)

Romove

111e

shadod portion of

(62)

Servo Saver (B).

Use

(84)

for

all

Futaba SOM>S.

®

@l

®

Use (85)

fOf

Ainronics.

(i)

KO and JR standard @

servos

.

&.

®

Use (86) for Alnronlcs

G)

and

KO

mini servos. O

Ss

----

--------------------------

7.

12

~------

------------

-----------

l

Page 13

1M]

INSTALLATION

OF

THE

SERVO SAVER AND MOUNTS

ON

THE SERVO

~

Use

pans

from b

ag

•a.

@ M4.5 x 7

Pillow

Ball (1)

o::-

M2

.6 Nut (2)

0

M2.6 x

12

srr

serew

(1)

On

uunh

M3

x 10 srr

serew

(2)

or

(3)

it

~

Thread

the

M2.6 n

ut

on

unfit

lmm

(31641

of thread shows

above

the

nut.

(3164")

@)

M 4.5 X 7 Pi

vot

Ba

ll

(3)

o::-

~

@:

~~

40mm

(1

.5)

II the servo you are

usi

ng

is 40mm

(1.5•)

,

u

se

the

(F2) Servo

Mounts (A).

0

Note

: Do not Install t

he

rubber

grommets and

eyelets

on

the

servo

.

M3Washer

~

M3

x 10

srr

serow

M Servo Saver Collar

M3 x 10 srr

serew

'-'

,c (For AlrtronieS Servos)

~~

Importan

t:

With the

servo

centered,

install

the

servo saver

90

° to the

side

of the

servo

.

M2

.6 x 12 SIT Screw

(For Futuba and

KO

Servos}

go

•

Steering

Arm

(

C)

N

ote

the dir

ection

of

(C3)

Steering Arm (C) when anached

to (C2)

Steering

Arm

(B).

Stee

ri

ng

Arm

(B)

M 2.6 Nut (3)

@ M4.5 x 7

Pivot

Ball Thread lhe M2.6 nul on the

(69)

M4

.5 x 7 Pivot Ball until

,

1

1

mm

(3/64

")

ot thr

ead

-'--

1

mm

shows

above

the

nut

on

all

M2.6 Nut T (3/&4") three pivot balls.

0

@ E4.0 E·Ring (2)

~

@

Ms

x 10 Bus

hing

(4)

@0

@ M2

Stoppe

r (2)

@IQJ

M3

x 3

Set sere

w (2)

I11J)

@M4.S

x 7

Pivot

Ball

---l;(

M2.6

Nut

.._,

,.,

@ E4.0 E-Ri

ng

~~---

1

@>

Steering

Link

age Brace- -,

@

MS

x 1 o

_But•hfng

'-..!1

~

or

@

MSx

10

Bearing

(Team Truck Only)

@)

M4.Sx7

Pivot

Ball

@>

Ms x 10

Bualhlng

~

or

@>Ms x 10 Bearing

(Team

Truck Only)

E4.0

Ring

:t-®

1

MS

x 10

Bushing

or

@

M5

x 10

Bearing

(Team

Truck Only)

(0)-.-{!09)

M4

.5 x 7

Pivot

Ball

M2.6Nul

#

@ M2Stopper -

~

0

Screw

Steering

Arm

(B) 81 M2

Stopper

T\'@;IM5

x 10 Bu.

shfng

or

t!)

Msx

10 Bea

rin

g

(T

eam

Truck Only)

~'----,@>steering

Post

Snap

the

Tie

Rods from

Step 3

onto

the (69) Pivot

Balls.

13

Page 14

ltSI

~~!!~~

m

L!

~!O

N

OF FRONT SUSPENSION ASSEMBLY TO MAIN CHASSIS

.

M3 x 10

F/H

Screw

(2)

r:-

M3 X 14

F/H·SIT

Screw

(2)

~·w"·

~t

....

Ut~~

M4

X 8 FIH

Screw

(2)

.

[)nn

If

using

Mount, in

@ Hold-Down

'111

(F3) Servo

~

stall

the

(F4) . '

hold~dow

n In the back '

of

(F3).

Step2

Install

th

e steering servo as

showt1

•

Make

suro

the

centerline

of

the

steering

servo

and

the

centerline

of

the

left

steering

lin

kag

e

are

parallel

.

St0<1rlng Servo

-v

1

1

Trv

' '

In

stall the screws

Into

the

front

holes.

Step 1

Install the front sus-

pension

assembly, the

IWO

M3

x 10 F/H and

M4

x 8

F/H

screws.

and

the s1eeri

ng

servo

before

lightening

the

screws

down

.

Use

screw

cement

on

lhe

M3

x 10

F/H

screws.

M3 x 14

F/H-SIT

Screw

(Anaclles servo)

M4

x 8 F/H

Screw

(Anaclles front cllassls)

W

caoENT

]P

M3

x 1 o F/H

Scrow

(Anaclles servo saver)

CLUTCH ASSEMBLY

hold

the

drive

washe

r

U

se

parts from bag

•7

and

bl

ister pack.

a

hex

wrench

In

the

hole

while tightening

M3 x 6 Washer (1)

@

M3

x 6 Cap

Screw

(1)

~

M3 x 16

Cap Screw (4)

~

M3

Nylon

Nut

(4)

©~

@ E7.0 E·Ring (1)

n

@

Ms

x a

Bea

ring

(2)

0 D

Note

: L

ay

the 1.5

mm

hex

wrench in

the

two

slots

in

the

top of

(100)

Pinion

Gear.

Hold onto

the

clutch bell and tighlen

1he pinion

gear

with

the

hex

wrench

.

The

0.

$ . . 12 CZ·R

do&s

not

require

the

flywhee

l spacer.

II

Install

ing

the O.S. 10FP with

recoil

starter

or

Enya

engine,

use a KYOC3538

1963

10

Flywheel Spacer (not lncfu<led).

i:;;;;~n•

M3

Nylon

Nuotl<:::ii

•

use

the

KYOC4723

*

·aA.'>.·

5

Pilot

Shaft (not included).

@

Clutch

@ Pinion Gear 48P/25T

@

MS

X 8

Be•orln~l,

M3

X 6

Wa1Sh<>r

--.:

14

To allow for

adjuslment.

do

not tighlen the

M3 Nylon Nuts

until Step

24.

If

an Enya Engine is goi

ng

to

be

installed

use

the

KYOC3455

'92309

Engine Mount (not inclu<led).

Pinon

Page 15

ENGINE INSTALLATION

Use parts from bag t4, t7.

M3 Washer

(4)

@

M3

x a

screw

(4

)

[pumm

M2.6

x25

Cap

SCrew (2)

~

rr

f/llfl.flill !l·l

l!.'il

ft

I

9

Exhaust

Adapter

St

ep 4

Install

lhe

muffler

as

shown

,

I

mportant:

Before installing the engine on

the chassis. check that

lhe

thro«le

cum

on

t

he

carburetor is

on

the l

eft side

, opposite

the

muffler.

U

it

is not.

cheek

the

inslructions

lnctuded with the engine

oo

removal

of

tho

carburetor. Reinstall t

he

carburetor with

tOO

t

hronte

arm

on

Lh&

lett side.

x

2S

Step

1

Install aJI four

M3

x 8 scrows and

washers.

Do

not

tighten completely

to anow for adiustment.

Washer

1M

FUEL

TANK

INSTALLATION

l'lil!l

Use

parts from bag •7,

M3

x

10

FIH·SIT

SCI'1!w

(2)

~

To

hole

in

Important: A more

secure

f

uel

line

fitt

ing

can

bo

achieved

by

using

a phillips

screwdriver

to

flare

the

pr

essure

i

nle

t

and

fuel

outlet hOles.

I

~

c

:::J

I

15

Step

2

Adjust

the

engine

so

that the (60)

Spur

Gear

is

centered on

the

(1

00)

Pinion

Gear

.

Ti

ghten

the

M3

x 16

cap

screws so

the

engine

cannot move

back and forth.

St

op

3

Place a piece

of

notebook

paper

between

tM

(60)

Spur

Gear

and (100)

Pinion

Geaf.

t

Slide the engine

over

to squeeze the

paper

between

the

gears. Tighten the four

M3

x 8

screws. Remove

the

pape

r. Th9 gears should

spin freely

with

no blnding.

Remove. one

at

a

time.

the

M3

x 8 screws. Place screw cement

on

tho threads

and

reinstall the screw.

The

other

three

M3

x 8

screws

will

prevent the

engi

ne

from moving

out

of

adjustment

The

screw

cement

must

be

us.ecf

or

the engine

will

Vibrate the screws loose.

t

ho

fuel

li

ne

under the

fuel tank.

Page 16

ltfJI

!~~

rts

~;!~;.

~~

STALLATION

Step2

M4

x 12

Screw

M3

x10 SIT

Screw

(2)

~

M4

x12

Screw

(4)

ijnuam

M4 x10 FIH

Screw

(2)

[)mnn

M3

x

10

SIT

Screw

(4)

~

Step 2

Plug the ser'los and receiver

switch Into

the

recetver.

Tum

tho

transmitter

and

receiver on

and

check that the servos are plugged

into the proper

receiver sockets.

Tu

rn

the receiver, I han tha

transmllter off. Bund le the servo

loads

toge

the

r with a (1 03)

ne

Strap and

cut

off the excess strap.

Step 3

Important: SeaJ

the

receiver In a

plastic

bag

or

use a Kyosho

Receiver Protector

i923

02KY

,

KG

or KP.

Then

sandwich the

rece

iver

between

a

piece

at

1/4 •

foam

rubber

to

protect

it

from vibration.

II'\StaU

the receiver

battery under tho radio plate.

Step 1

Tempora

rily

insta

ll

lhls

screw. It will

be

permanently

Installed

in

Step 28.

Install the (03) Front Body Post,

so lhal the holes

race

each other.

Top

Plate

M4 x

12

Screw

t"'-'

/

Slide

the

(1

08)

Top

Plate through

the

(72)

Front

ShOck

Tower.

M3

x 10 SIT

Screw

Front

Body

Post

Mount

~--======::;::-

M4

X

10

FIH

Screw

M3 x

10

SIT

Screw

Swhch Plate

Sc-rews

(In

cluded

with

Radio

System)

Switch

Plate

Step

1

Install the

Throttl~

Servo and Receiver

Switch.

•

Throttle

Servo

(Item

induded

with

radio

system.)

(Included

with

Rad

io

System)

,~'.Js.

·

Nota:

Do

not

............

_

gronvnets and

eyelets on

the

""""'

@>

Servo

Mount

---...,

I

nsta

ll a (K3)

Servo

Mount on the opposite

end at

the

seiVO

also.

Reulve

r

Switch

(Included

with

radio system)

Receiver B

attery

(Included

w~h

radio system)

16

~~

,.p-

.d>

"'~

'~

o'""

~

~'<-r:}'

Step4

Aftec

securing

tne

reoeiver

and reoofver battery to the

(L4) Radio Plate with the

(109) Large Strap,

C\11

off

the excess strap.

Note: Do

no

t crush

the

loam rubbe

r.

It

must

be

able to isolate the receive!'

from vibration.

Large

Strap

Page 17

RADIO PLATE INSTALLATION

Use parts lrom

bag

13, 14

and

16

.

M3 xtO

SIT Screw (1)

~

M3 xto

Screw (1)

~

M3

x10 F

IH

screw

(2)

l)mm

M3 x15

FIH

SCrew (1)

Dnnlll\lllllDIIm

Torque rod attached

to

gear

box

In 8.

M3 x10

SC<ew

1

screw,

befor

e

the

radio

plate.

Then

x 12

screw

--

M3 x

10

SIT

Screw

1M]

FRONT

AND REAR

SHOCK

INSTALLATION

~

Use

parts lrom bag 11.

M3

x12 FIH

Screw

(2)

[)11\\)!!UU!U

jj!

l

M3

x14

Screw (2)

&--

@

Shock

Collar

(4)

©

([]

@

M3

Plastic

Nut

(4)

{9)

§}

__..

-,

M3

x 14 Screw

17

/Note the

direction ol

the

/

(117)

Shock Collar.

The

~

largor end 1s against lhe

11

~

M3Nut.

Shock

Collar

Ci

L--

F

ront

Shock

(Copper

SP<Ing)

Page 18

IE!·JI

J!'p~

rts

~r!:'"~~

4.

~!

.

NKAG

E

ADJUSTMENT

Trim a servo arm (included with the

M3

x3

Set

S<:rew (2)

lDD

radio system)

to

the shape shown

below.

@

M2

Stopper

(2)

@§

M3

x 3

Set

Screw

16mm

@

M2Stopper

Step2

lnslall l

he

(112) Throtlle Rod in

lhe

top hole

of

the thronle

arm

if

using the O.S . . 1

2CZ

·R.

II

using

an

Enya

0<

O.S.

10FP

engine

, Install it in

lhe hole approximately 1

3mm

(

33164

')

from the center

of

lhelhrolllo

arm

.

14mm

(9116")

F

ull

Speed

Idle Speed

Cut

off the

end

of

the

(111)

Brake Rod

if

it

hils

the

(68)

Rear

Shock

Tower

.

Idle st

op

sctew

M2

Stopper

0

0

0

0

00~

Step

7

Warni

ng:

To preven t dirt fr

om

damaging your engine,

saturate

the

loam

fitter

material with

leftover

shock

oil

rrom this kit or use the special Kyosho Air Filter

Oil that is

sold separately, KYOC2032 .

Air

Fitter

Cap

Foam

Alter

A

ft

Filler

Case

Slide this end through

the Brake

and

secure

it

with

an

(81)

M2

Stopper.

throtUe

arm

.

Install the throttle

rod

in the hOle

16mm (41/64")

from

the

center

.

Move

the lhro"Je arm so that the carburetor is

open 1 mm

(3164"

),

as

shown

at Idle

speed

belOw. Wrlh

lhe

seNO centered. install !he S8NO

arm 9oo

to

the

servo

as

shown

. Make a 90°

bend In the Ulrollle

rod

at

the hole 1

6mm

(518")

outlrom

the

center

. Install the throtlle rod in lhe

hOle

of

the servo arm

and

s"""'"

ft

with

an

(81)

M2

Stopper. Cut-off

the

excess thrott

le

rod

above

!he

(81)

M2 Slopper.

------------------------------------

-

I

step

&I

Br

ake Adjustment

With

the

transrniuer

and

receiver turned on,

squeete

the throttle trigger to full speed. The

cal'buretor

bar

rel should be

fuUy

open. It the servo

arm

moves too

far

. the

throttJe

rod

will

benc

l. Move

the throttle

rod

in

1owards

the center.

one

hole on

ths

servo arm . If

your

ltansmitter

has

end poi

nt

adjustment, reduce the amount

of

servo

arm

movement. If the carburetor barrel does not open

far enough,

move

the throttle rod one hole closer

to

the

center

on

the

thrott

le

arm

.

Release the thronle tri9gcf.

The

carburetor should Push the throttle trigger forward.

The

throttle rod

be

open only 1mm

(3164")

. Adjust the idle

stop

shou

ld bend slightly and the

brake

should

move

screw

to limit the amount the barrel closes. The: against the (52) SUpper Plate (A).

Try

to rotate !he

brake shoukf have

no

pressure

on

it

a.t

idle. Adjust:

rear lites

. T

hey

should

bo

difficult to rotate.

By

1he

M2

Stopper,

so

it

is

touching the brl!ke lever. : adjusling the (81)

M2

Stopper

on

lhe

(111) Brake

:

Rod

. the amount

of

btaking

force

can

be

adjusted.

18

Page 19

1!11J

WHEEL ASSEMBLY

Iiiii

The

wlleel$

ate

under

lhe leXlll'l" body ~ lhe

box.

@ RN rT1re

Hint

: Drill two 118. brealhor holes

toward the Inside of

each

Whool

.

m

:~:

~

~

~~~~~~~:!!

t

?.~

~

M4

Fla~

Nylon

N

ut

(4)

@[§

@ Me X tO Bu5hl

ng

(4)

©0

M2 X 5

SIT

Screw (6)

{Jml>

Aea.r

Wheel

Small hole

In

rear

whea

l disk Ia

lor the

rearwhooL

M4

F

langed

Nylon

Nut

A$$ernble

owo

rronc

and

IWO

rear-

-

Hint: Drill

two

118"

breather holes

Iowan! t

ho lnsi<Ja

of each wlleel.

Re

ar

Wheel Dil

k

After Installing

the

lires

on the

wne.ts.

gtue

lho

~

res

lo the

_,

wllh

lhin

CA.

inslant type

grue.

F'rt

the (

64

) M2 x tO Pin Into t

ho

slo4

In

the back

c4

lhe (E4)

Drive

W

ashe

r.

or

Front

Wheel

®-B

M6

x10 Bearing

(T

eam

Trucl<

Only)

~

M6 x10

Bearing

(Team

Truc

k Only)

M4

Fla

nged

Nylon

Nut

19

Page 20

IEtcil

TRIMMING THE BODY

Orilla 6mm

(114

" hole)

N

umber

Plata

(on both sides)

IFill

PAINTING THE BODY

Firs1 wash

the

body with

soap

and water to remove

any dirt

and

oil

. Ri

nse

and

dry

thoroughly.

Ask

your hobby shop

dea

ler

for polyca rbonate paint

made

tor

Lexan• bodies.

Apply

the

paine

to

the

underside

of

lhe

body.

Th

is

w!11

help prevent the

paint from becoming

scratched and provi

de

a

hi

gh

gloss shi

ne

on

!he

outs

ide

of the body.

1M

MOUNTING THE BODY

~

U

se

parts

from

bag, 14.

@

Body

Pin (

5)

~

Carefully remove tho shaded areas

of

the

body with Lexan• Scissors

or

e sharp

l>ot>by

kn~e.

I

mportant:

The number plates are located

in th& rear wheel wells and the rear spoiler

is bel

ow

the tailgate.

Drill two 6mm

(114

1

ho

les.

Body

II painting the body in more

than

one

ooJor

, use masking tape or l

lqiJid

mask

to mask the design. Always paint the darkest

cok>r

first If you don't, the

darker color

may

show through the light

COSor

paint. Ovorspray and paint

runs under masking tape

may

be

removed with pai

nt

remover made for

plastic.

Oo

not use standard paint remover. It may damage the Lexan•.

Note: The body

com~

with a protective film on

the

outside,

to

prevent paint overspray. Remove the film before applying decals.

\

Install a (127) Body Pin under tho

(126)

body

to

adjust

lhe

heigh!

and

one

on

top

to

secure

lllebody.

@

Body

Pin

20

Page 21

1. Adjust the

M3

Nylon Nut on the slipper

so

that

the

spring

is

compressed to 7mm

(9132").

2. Hold the left wheel and spur gear

tightly.

3. Rotate

the

right

wheel.

If

the ball

differential

is

set

correctly, the M3 nylon

nut on the slipper will rotate the same

direction as the right

wheel.

- ·

+-

+--

7mm

(9/32")

M3

Nylon

Nut

1

S

p1ur

Gear

4.

II

the M3

nylOn

nut does not rotate, remove the

red

cap

from

the

left side

or the gearbox, to

tighten

the ball differential.

5. Insert a 2mm hex wrench into the adjustment hole the

red

cap

was

covering

. Loosen

the

ball differential.

Make

sure

the

hex

t

rotatawheetcfocl<wlse

)

wrench

fits

into

the

.,......

...

2mm hex

M2.6 x 25 cap screw in

the

ball differential.

6.

While

holding

the

left

rear

wheel

and

Tight

en

the

the

2mm hex

wrench

, ball dlfferenUal.

rotate

the right

wheel

(

rotate-

•.

counterclockwise,

one

red

cap

countorctodcWiSe

)

revolution. This will tighten the ball differential.

7. Remove the

2mm hex wrench

and

rep

eat

Steps 2

and 3. Continue adjusting the

ball differential until the

M3

nylOn

nut

rotates with the right wheel.

If

the ball differential

is

set too

tigh~

the truck

will

under-steer. Under-steer (

or

'push'

is when the truck wants to continue going straight

when

the

front wheels are turned. If the ball

cfiff.

is

set to loose, it

wiD

slip rather than

the slipper, causing excessive dill. wear.

8. After the ball differential

is

adjusted properl

y,

re-install

the

red

cap

on the gearbox.

9. Re-adjust the M3 nyton nut on the slipper

so

that the

spring

is

compressed to

Bmm

(5/16').

1. The

slippe

r will need

to

be adj

usted

to

match the

surface on which

the

truck

is being

run on .

To

set the

slipper, mark off a distance

of

1 meter (40') on the track.

Set the truck

at

one end, and from a dead stop the slipper

should slip

for the 1 meter (40i distance.

2.

If the ball differential and slipper are not adjusted properly,

runrtina

the

truck will heat and damage parts.

By

Inserting different spacers E1, E2,

E3

into

the

rear

hubs, 7 different wheel bases can be achieved. A shorter

wheel base (the distance from the frant axle ta the rear

axle) will provide quicker turning response , but less high

speed straightaway

stability. The short wheel base

is

good

lor

small, tight-cornered tracks.

21

A longer wheel

base

provides better high

speed

, straightaway

stability.

but

reduces the steering response. This set

up

is

good

for

tracks with

wide

turns

and

lOng

straightaways. This

kit comes

with 1 mm, 2mm and 3mm

spacers.

Front

of

Truck

~

E3

(3mm)

--J.l

E1

(1

mm)

----.(;/

/

~

E2(2mm)

Tae-in is when the front

of

the wheels angle toward each

other, when viewed from the top.

By

incorporating 1• to 2•

of toe-in

in

each wheel, the truck will track straighter down

the straightaways. The reason

for

this Is,

if

there

is

any

play in the steering linkage. the wheels will move left

and

right

slightly

without

any

servo

arm

movement.

By

providing

toe-

in,

both

wheels

try

to

move

outward

eliminating any play In the steering linkag

e.

The f

ron

t toe-

In

can be adjusted by shortening or lengthening the tie-

rods. Front

of

Truck

i----

- -

VIe

wed

from

the top

(sketch is exaggerated)

To

adjust the rear toe-in use the L2 5• suspension block

or the L3 3' suspension block. On most tracks the L3 3 •

will work well, providi

ng

good steering response with

good straightaway tracking. The

L2 5• should be used

on

tracks requiring good straightaway tracking, but less

steering response.

Caster

is

the angling

of

the front

hub

backwards. The

stock caster angle on

the Outlaw Ramage Pro truck

is

ao

•.

Optional front hubs are available from Kyosho. The

XRW-0 1 (· 10) will provide 20" of caster. The XRW-02

(·15) will

provide 15" of caster.

'

Fr

ont

of

Truck

_....-,(';

~

'-'

"

Front

Hub

i--

r.,.:-.

Knuckle

A

rm

Caster

affec

ts

the

straight

line handling

of

the

truck.

Caster causes the front wheels to return

to

the center

when turned.

Too

much

caster can reduce the turning

response. The stock

ao

• front

hub

will work well on most

tracks.

If

you are racing on a very tightly curved track,

reducing the caster may improve the corning, but

re

duce

the straightaway

stability.

Page 22

Fr

ont Cambe

r

Camber is

the angle of the wheel

in

relation to the chassis.

Negative

camber

is when the

top

of

the wheel leans In

toward the chassis. Positive camber is when the top

of

the

wheel leans away from the chassis. o• camber

is

when the

wheel

Is 90° to the chassis

or

ground.

By

attaching the

upper rod

towards arr

ow 'A', ther

e will

be

less

camber

when the wheel

is dell

ected upward. This Is good for flat,

straight tracks with wi

de

turns. By attaching t

he

upper rod

towards arrow

'B',

there will

be

more camb

er

when t

he

wheel

is

deflected upward. This

is goo

d for tight curved

tracks. The reason is, as the truck turn

s, the

chassis leans

toward the outside of the turn. de

pr

essing the suspension

arm

and raising the wheel. By having more camber. the

wheel stays more perpendicular to the ground. providing

better tracti

on

.

Fr

ont

0

oo

*B''·C''A'

'A'

Shock

ooo

\

Tower

0

'C'

'B'

Standard

Pos

itio

n

0

90•

The truck should

be

set

up

with the upper rod In position '

C'

and

o• to 2• of negative camber with the chassis level. If

the camber needs to

be

changed

to

match the track, make

sure you adjust the upper rod length after relocati

ng

the

mounting positi

on

. Set·up both sides

of

the truck identically.

Rear Camber

By

attaching the upper rod towards arrow 'A' there will

be

l

ess

camber when the wheel deflects upward in turns. This

will provide more maneuverability, but more likely the truck

may spin out.

By attaching tho upper rod towards arrow 'B' there

will

be

more camber when the wheel dell

ecls upward In turns. This

will provide less maneuver

ab

ility but it will be less likely that

the truck

will spin out.

As

on t

he

front, set the rear wheels

at

o• to 2" negative camber with the chassis level.

'B' 'C' 'A'

0

'C'

0

90•

000

000

*A' 0

0

i'i'r

- 'B'

S

tandard

Pos

iti

on

22

1. Always tum your transmitter

on

first, then your receive

r.

When finished running the truck, tum your receiver off first,

then your transmitter.

2. Check that no

one

else is

on

your frequency. II they are.

do

not

turn

your

radio

system on.

Wait

until

they