Kyocera TASKalfa 2550ci, FS-C8020MFP, FS-C8520, FS-8025MFP, FS-8525MFP SERVICEBULLETINS 2MV 0013 D069 CSSD 1

Page 1

(Revised Issue 1) (Page.1/5)

Subject

Notes When Refitting the Drive Unit (Prevention of the

Abnormal Noise from the Intermediate Transfer Belt Unit)

Model l:

TASKalfa 2550ci, FS-C8525MFP, FS-C8520MFP,

FS-C8025MFP, FS-C8020MFP

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measure: No particular problems are expected.

Serial Nos. of Affected Machine:

- Shape change of the BASE TERMINAL (No-supplied parts): Please refer to the table on the page 5.

- Shape change of the shaft (No.1): From the production in July, 2013.*

* The above is the plan at the present moment. Please note that there is a possibility of change after giving this information.

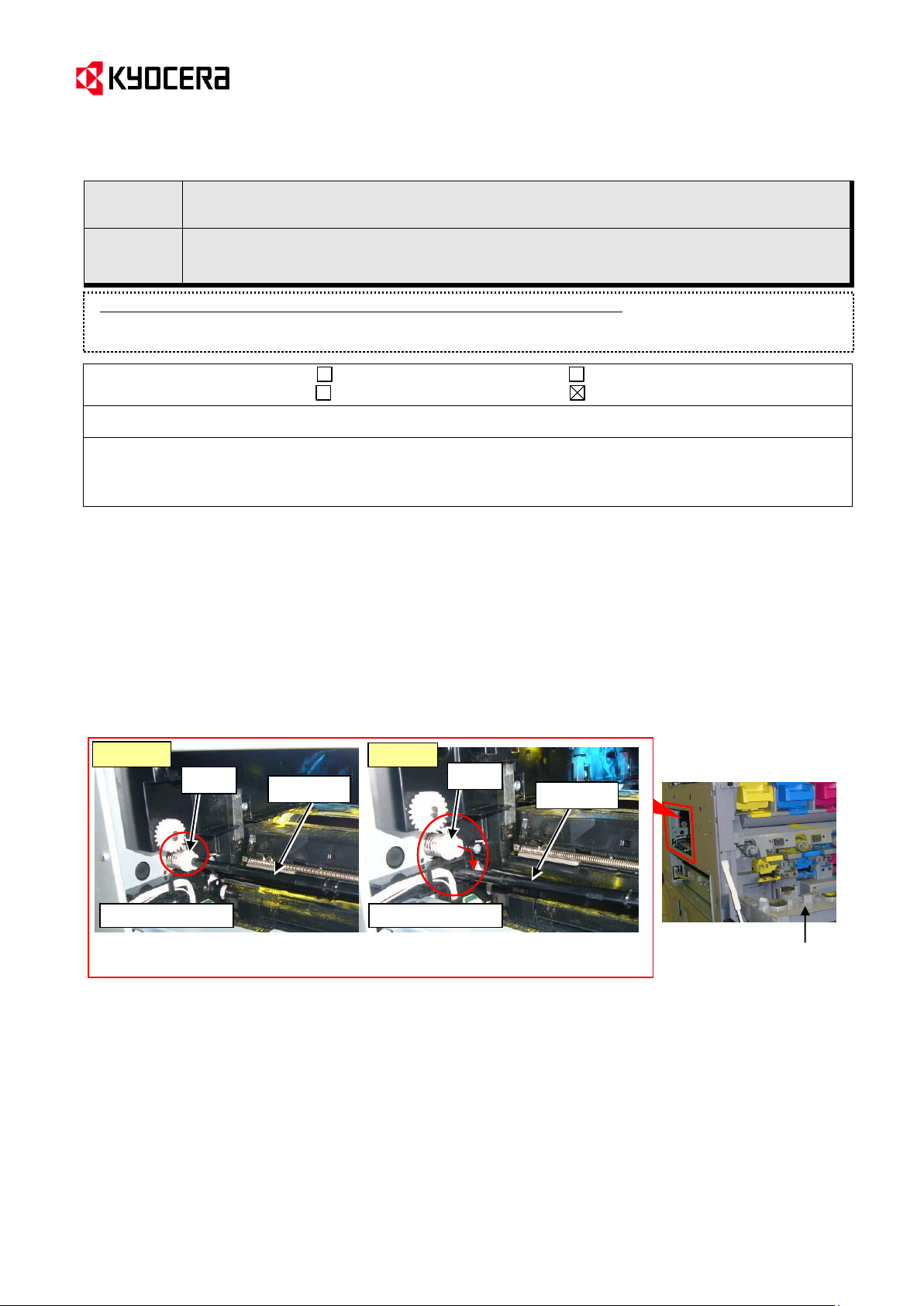

Correct

Wrong

The shaft (X) is inserted in the (-->)

joint of the drive unit.

Machine rear side

The shaft (X) comes off from the (-->)

joint of the drive unit.

Shaft (X)

Retainer section

Joint

Joint

Shaft (X)

Machine rear side

Service Bulletin Ref. No. 2MV-0013 (D069)

[Service Information] <Date> July 2, 2013

This time, the description with (-->) was revised from the previous information.

<Number of changes: 9> The part name was corrected from cam to joint.

The permanent measures were added to the pages 3 and 4.

[Notes]

When refitting the drive unit, please make sure to insert the following shaft (X in the figure) into the (-->)

joint of the drive unit, and then fix the drive unit.

Afterwards, please check if the (-->) joint (X) is inserted in the gear on the machine front side.

[Phenomenon when the shaft (X) comes off]

If the shaft (X) comes off, some abnormal noise from the intermediate transfer unit might be recognized or toner

might leak from the retainer section. (Please refer to the next page for more details on the mechanism.)

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 2

(Revised Issue 1) (Page.2/5)

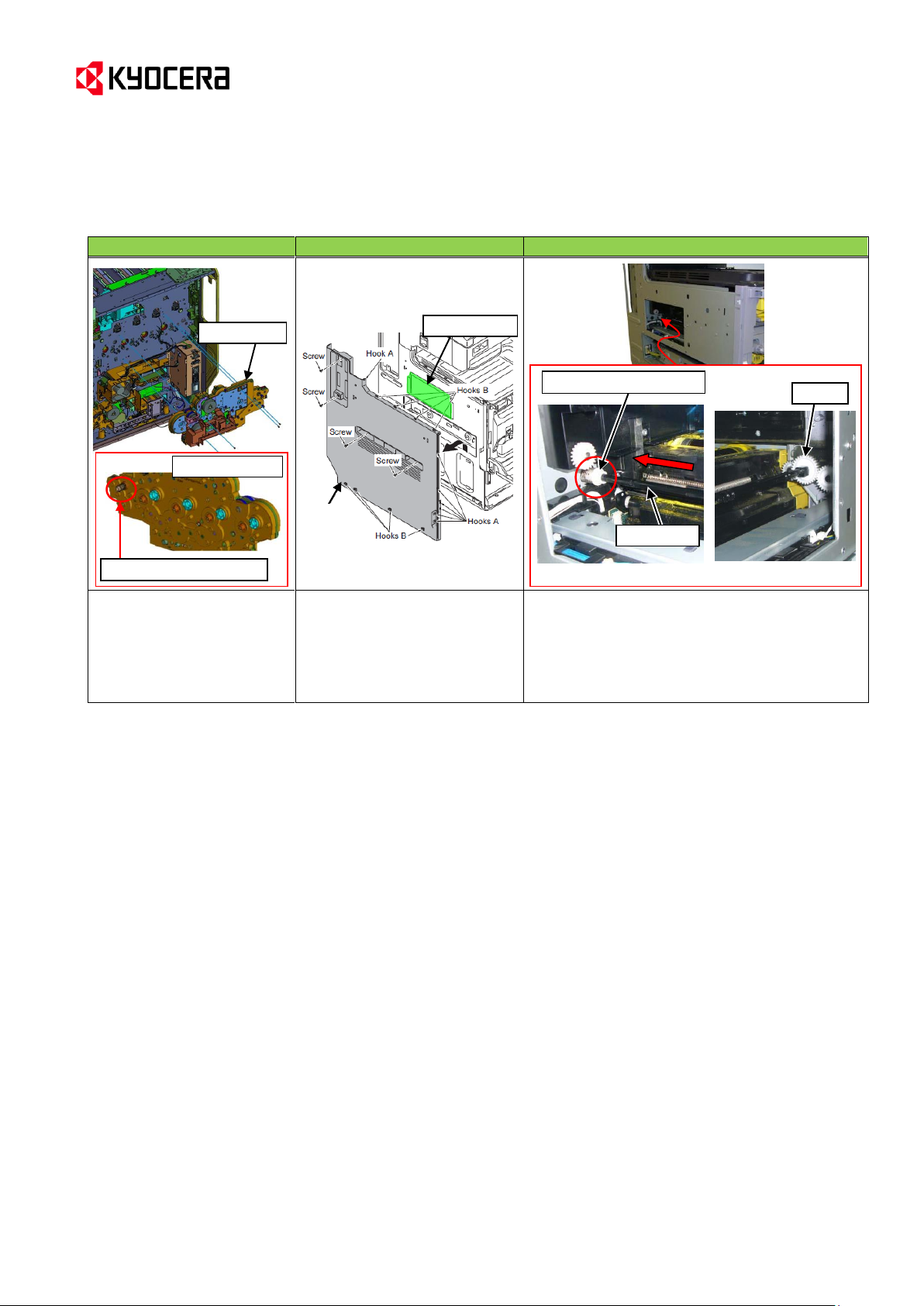

1

2

3

Refit the drive unit (*).

* DR-895 (302K09312_)

Remove the left lower cover, the

main PWB and the intermediate

transfer unit to insert the shaft (X)

into the (-->) joint of the drive unit

from the aperture of the metal plate

behind the main PWB.

Insert the shaft (X) into the (-->) joint of the drive

unit.

(Note) At this time, check if the front end of the shaft

(X) is inserted in the gear on the machine

front side.

Machine inside

Joint part with the shaft

Cam of the drive unit

Shaft (X)

(Machine front side)

(Machine rear side)

Gear

Drive unit

Left

lower

cover

Main PWB

Service Bulletin Ref. No. 2MV-0013 (D069)

[Service Information] <Date> July 2, 2013

[Procedures how to refit the drive unit]

<Mechanism of the phenomenon when the shaft (X) comes off>

1) The spiral (A) to convey the waste toner collected from the intermediate transfer unit to the retainer section

does not rotate. Therefore, waste toner accumulates in the cleaning screw section inside of the intermediate

transfer unit. As a result, some abnormal noise might be generated by skipping of the teeth of the machine

side gear to drive the cleaning screw.

2) The drive transmission part (B) to the spiral inside of the retainer section does not drive. Therefore, the spiral

is not rorated to convery the waste toner collected from the intermediate transfer unit and the drum unit to the

waste toner bottle. As a result, the waste toner excessively accumulated inside of the retainer section might

leak.

Customer Services & Support Division (CSSD)

KYOCERA Document Solutions Europe

Page 3

(Revised Issue 1) (Page.3/5)

Gear skipping the teeth

(Driven by the machine side)

Shaft (X)

Drive unit

Cleaning screw

To retainer section

Drive transmission section (B) to

the spiral inside the retainer section

B

B’

The spiral inside of the retainer

section is rotated by the drive

transmitted from B to B’.

Spiral (A) transfering

the waste toner to the

retainer section

Spiral inside the

retainer section

- The shaft (X) transmits the drive to A and B in the figure above.

- The red arrow ( ) in the figure above indicates the flowing direction of the waste toner.

Service Bulletin Ref. No. 2MV-0013 (D069)

[Service Information] <Date> July 2, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 4

(Revised Issue 1) (Page.4/5)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

302K031710

2K031710

302MV21110

2MV21110

SHAFT TRANSFER CLEANING

DRIVE

1

1

O

O

(Old)

(New)

Ribs added to

BASE TERMINAL

Shape change of the

shaft (No.1)

Drive unit

Joint

Shaft (No.1)

Rear frame

Front frame

<Shape change of the shaft (No.1)>

BASE TERMINAL

Shape changed

Ribs added

<Shape change of the BASE TERMINAL

(Not supplied)>

<Cross section>

The shaft will not fall off by being held by the ribs

of the BASE TERMINAL when detaching the drive

unit.

BASE TERMINAL

(Old)

(New)

(Machine left side)

BASE TERMINAL

No.1

No.1

Service Bulletin Ref. No. 2MV-0013 (D069)

[Service Information] <Date> July 2, 2013

(-->)

Permanent measures

The shape of the shaft (No.1) and the BASE TERMINAL (Not supplied) was changed so that the shaft removed

from the joint of the drive unit will not fall off when detaching the drive unit and the shaft can be smoothly inserted

into the joint of the drive unit when reattaching the drive unit.

Customer Services & Support Division (CSSD)

KYOCERA Document Solutions Europe

Page 5

(Revised Issue 1) (Page.5/5)

KDE

1102MV3NL0

NUZ3714494

KDE

1102MZ3NL0

NXE3703694

KDE

1102MY3NL0

NXA3702191

Service Bulletin Ref. No. 2MV-0013 (D069)

[Service Information] <Date> July 2, 2013

Serial Nos. of the Affected Machines

<Shape change of the base terminal (not supplied)>

TASKalfa 2550ci

TASKalfa 206ci

TASKalfa 256ci

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Loading...

Loading...