Kyocera PF-75 Service Manual

PF-75

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Parts names ......................................................................................................................................... 1-1-2

1-1-3 Machine cross section.......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

1-2-2 Installing the dehumidifier heaters (service part) ................................................................................. 1-2-2

1-3 Troubleshooting

1-3-1 Paper misfeed detection ...................................................................................................................... 1-3-1

(1) Paper misfeed indication ................................................................................................................ 1-3-1

(2) Paper misfeed detection conditions................................................................................................ 1-3-1

(3) Paper misfeeds............................................................................................................................... 1-3-3

1-3-2 Self-diagnosis....................................................................................................................................... 1-3-5

(1) Self-diagnostic function .................................................................................................................. 1-3-5

(2) Self-diagnostic codes ..................................................................................................................... 1-3-6

1-3-3 Electrical problems ............................................................................................................................... 1-3-8

(1) The large paper deck does not operate when the copier main switch is turned on........................ 1-3-8

(2) The deck paper conveying motor does not operate. ...................................................................... 1-3-8

(3) Paper deck motor 1 does not operate. ........................................................................................... 1-3-8

(4) Paper deck motor 2 does not operate. ........................................................................................... 1-3-8

(5) Paper feed clutch 1 does not operate............................................................................................. 1-3-8

(6) Paper feed clutch 2 does not operate............................................................................................. 1-3-9

(7) The paper conveying clutch does not operate................................................................................ 1-3-9

1-3-4 Mechanical problems ......................................................................................................................... 1-3-10

(1) No primary paper feed. ................................................................................................................. 1-3-10

(2) Paper is fed askew. ...................................................................................................................... 1-3-10

(3) Multiple sheets of paper are fed at one time. ............................................................................... 1-3-10

(4) Paper jams. .................................................................................................................................. 1-3-10

(5) Abnormal noise is heard. .............................................................................................................. 1-3-10

5FF

1-4 Assembly and Disassembly

1-4-1 Precautions for assembly and disassembly ......................................................................................... 1-4-1

(1) Precautions..................................................................................................................................... 1-4-1

1-4-2 Paper feed section ............................................................................................................................... 1-4-2

(1) Detaching and refitting the upper and lower deck separation rollers.............................................. 1-4-2

(2) Detaching and refitting the deck paper conveying unit assembly................................................... 1-4-3

(3) Detaching and refitting deck paper feed rollers 1 and 2 ................................................................. 1-4-3

(4) Adjusting the position of the center adjuster (center line alignment) .............................................. 1-4-4

(5) Adjusting the amount of slack......................................................................................................... 1-4-5

2-1 Mechanical construction

2-1-1 Mechanical construction....................................................................................................................... 2-1-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

1-1-1

2-3 Operation of the PCBs

2-3-1 Deck main PCB .................................................................................................................................... 2-3-1

(1) Paper deck motor drive circuits ...................................................................................................... 1-4-2

(2) Operating principle of reflective photosensors

PPSENS1, PPSENS2, PPSENS3 and PESENS ........................................................................... 1-4-3

5FF

2-4 Appendixes

Timing chart No. 1 .......................................................................................................................................... 2-4-1

Timing chart No. 2 .......................................................................................................................................... 2-4-2

Wiring diagram ............................................................................................................................................... 2-4-3

1-1-2

1-1-1 Specifications

5FF

Paper..............................................Plain paper (75 – 80 g/m2)

Paper size ......................................A4, B5, 11" × 8

1

/2"

Capacity .........................................3000 sheets (1500 sheets × 2)

Power source .................................Electrically connected to the copier

Dimensions .................................... 585 (W) × 590 (D) × 315 (H) mm

1

/16" (W) × 231/4" (D) × 123/8" (H)

23

Weight ............................................ 35 kg/77.2 lbs

1-1-1

5FF

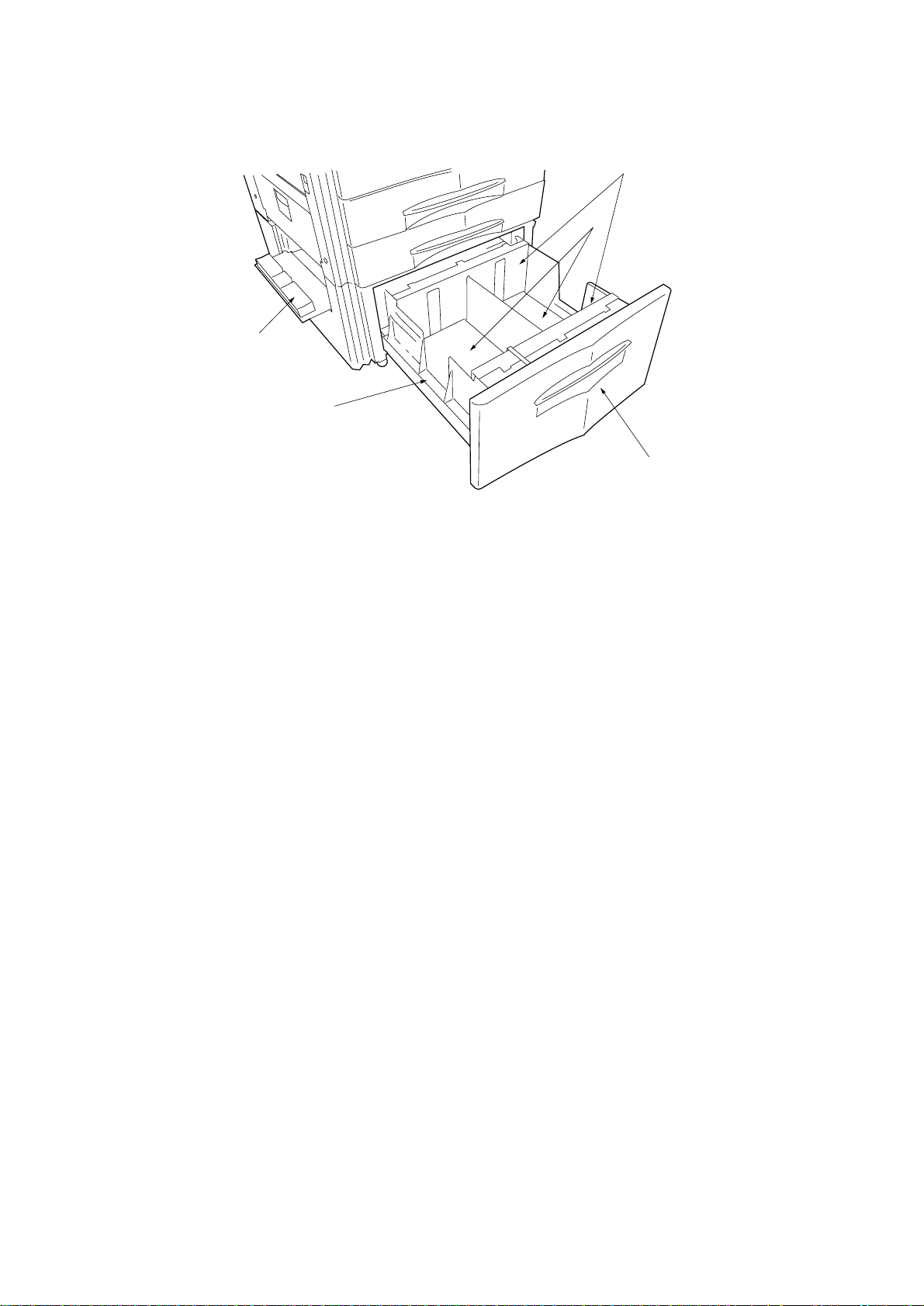

1-1-2 Parts names

5

1

2

3

4

Figure 1-1-2 Parts names

1 Lifts

2 Deck side cover

3 Drawer

4 Deck front cover

5 Paper side guides

1-1-2

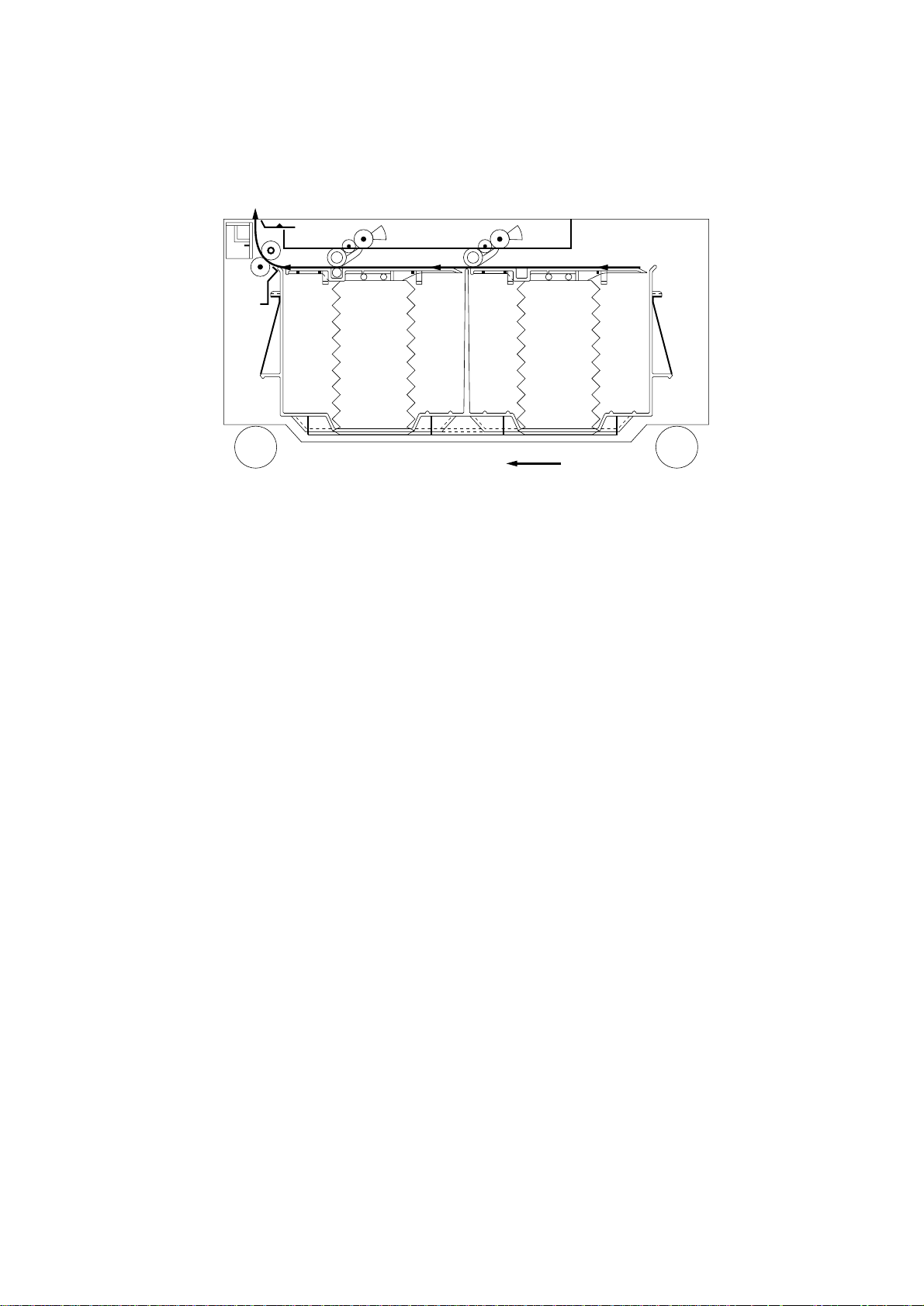

1-1-3 Machine cross section

5FF

Paper path

Figure 1-1-3 Machine cross section

1-1-3

5FF

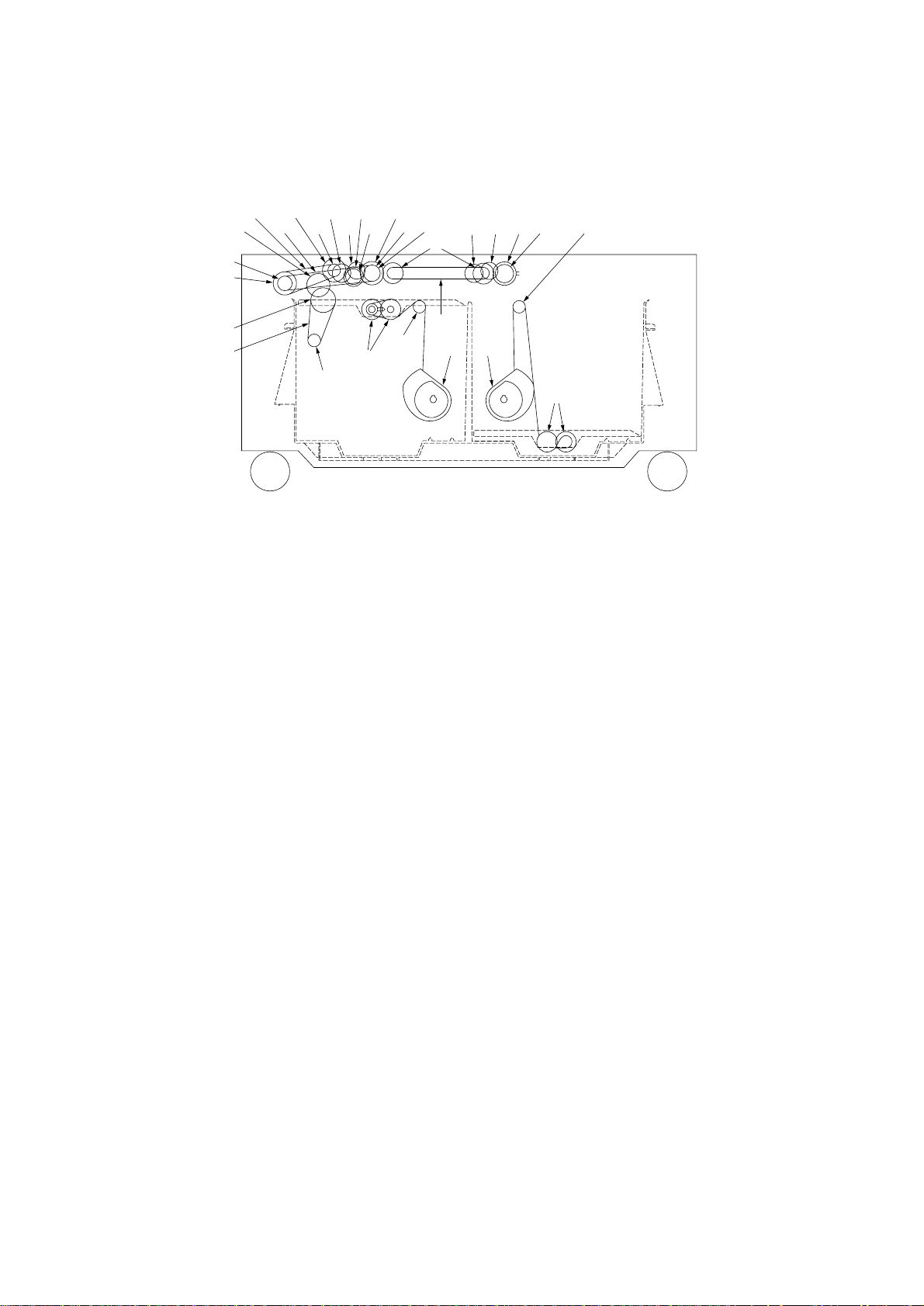

1-1-4 Drive system

3(6805@!7845 ^

4)794

2

1

%

⁄

#

^

(

&*

$

#

As viewed from machine front

Figure 1-1-4

1 Pulley 2M-40

2 Pulley S3M-16

3 Gear 0.8-35/1-20

4 Gear 2.6

5 Gear 0.8-23

6 Pulley 2M-18

7 Pickup roller gear 0.8-23

8 Gear 0.9-26

9 Gear 30

0 Gear 0.8-24

! Pulley 3M-18

@ Pulley 14, gear 0.8-32

# Gear 1.0-24

$ Pulley S2M-18

% Pulley 43, gear 20

^ Lift pulley

& Left lift belt assembly

* Right lift belt assembly

( Belt S3M276

) Belt 2M0950

⁄ Belt 2M0840

1-1-4

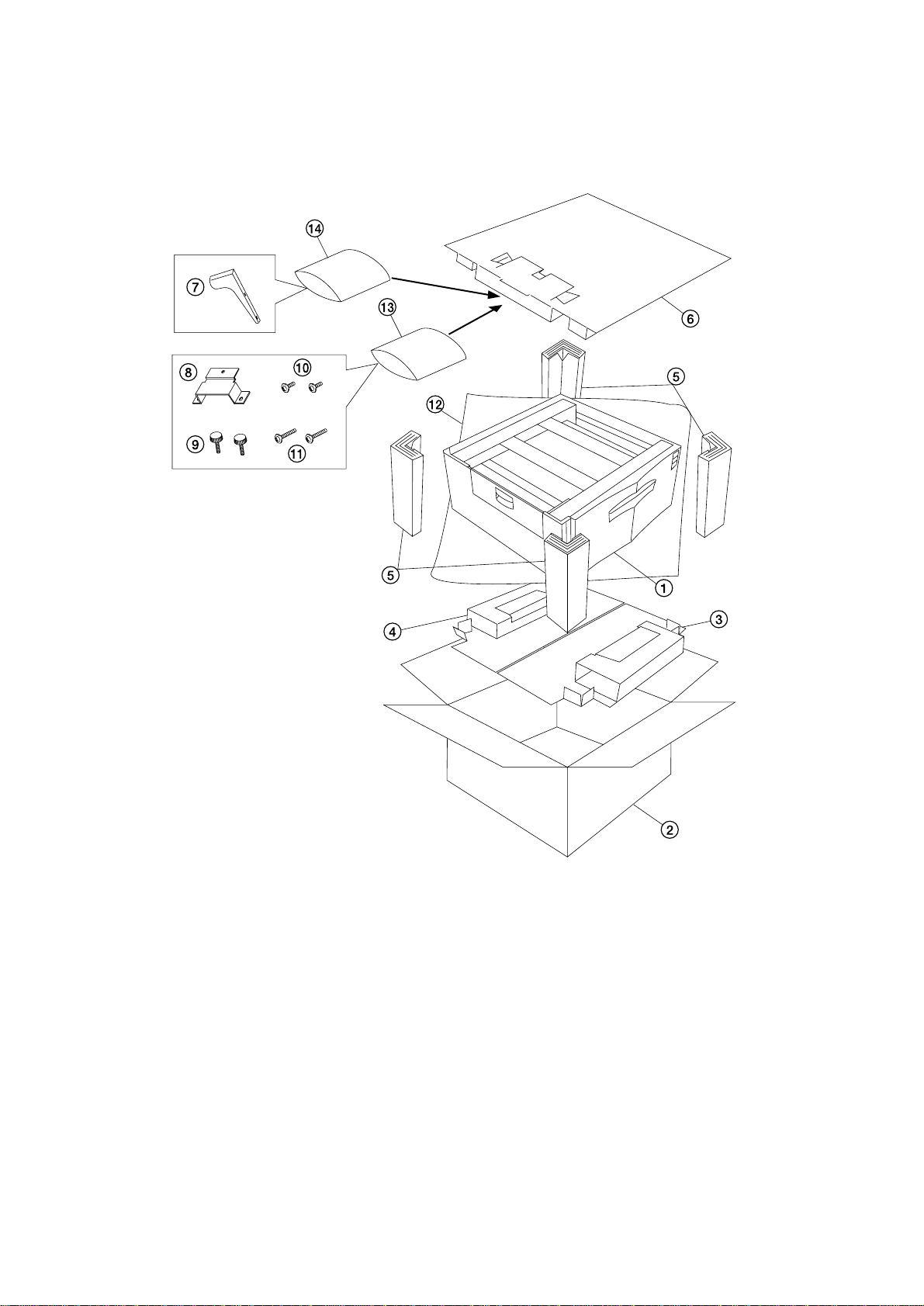

1-2-1 Unpacking

5FF

1 Large paper deck

2 Outer case

3 Lower front pad

4 Lower rear pad

5 Support

6 Upper pad

7 Stay

Figure 1-2-1

8 Retainer

9 Pins

0 Cross-head chromate binding screws,

CVM4 × 06

! Chrome TP screws, M4 × 16

@ Machine cover

# Plastic bag

$ Plastic bag

1-2-1

5FF

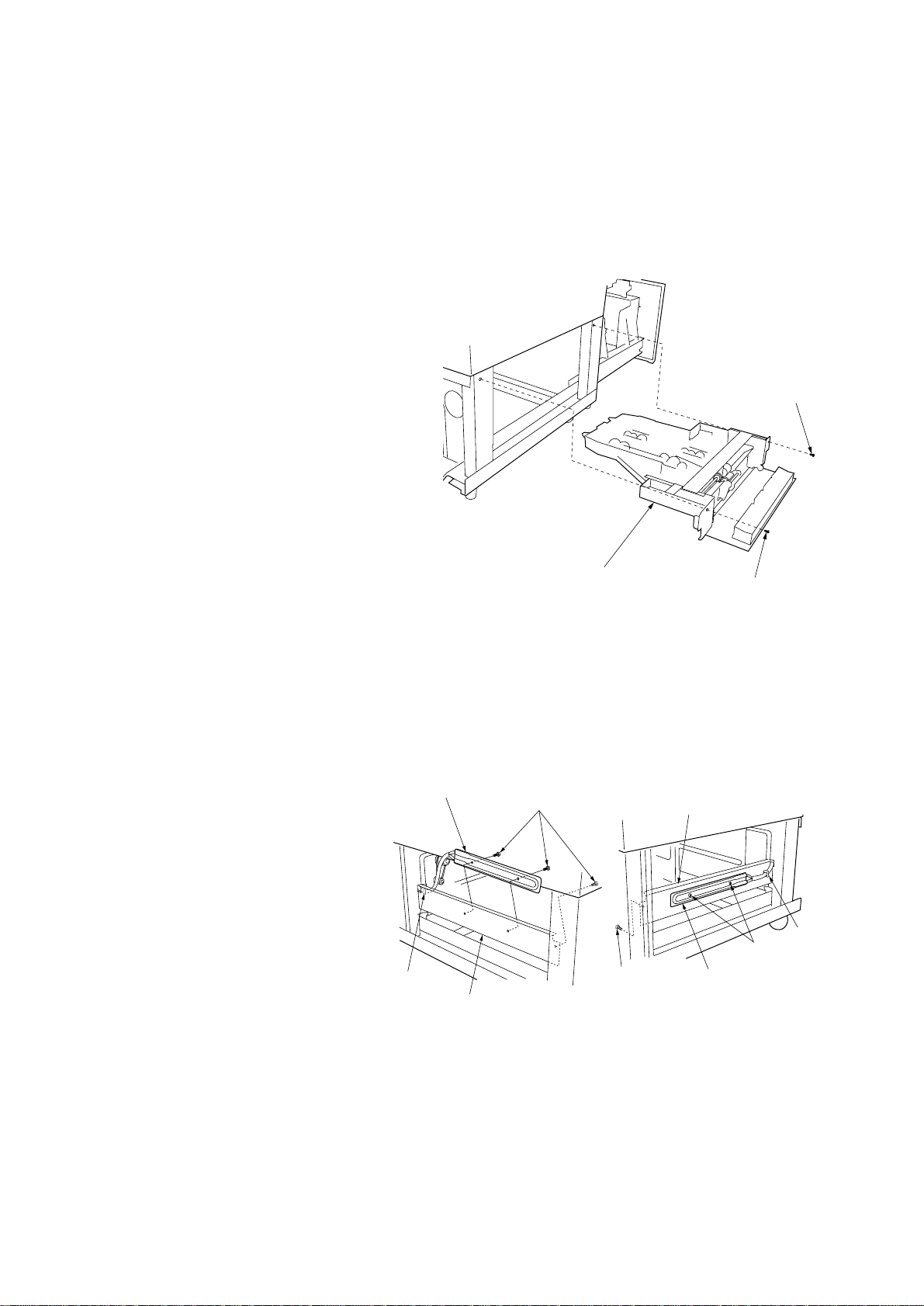

1-2-2 Installing the dehumidifier heaters (service part)

Dehumidifier heater installation requires the following parts:

Two (2) dehumidifier heaters (P/N 33960020): for 220 – 240 V specifications only

Two (2) dehumidifier heaters (P/N 34860030): for 120 V specifications only

Two (2) dehumidifier heater retainers (P/N 5A707690)

Six (6) M4 × 6 IT tap-tight (S-tight) screws (P/N 37611570)

Relay wire (P/N 5A707890)

Ten (10) wire saddles (P/N M2109000)

Procedure

1. Remove the two screws from each of the deck

right cover and deck left cover and then the

covers.

2. Remove the three screws holding the deck

rear cover and then the cover.

3. Open the large paper deck.

4. Remove the two screws holding the deck

paper conveying unit assembly and then the

assembly.

Screw

5. Fit the dehumidifier heaters to the dehumidifier

heater retainers using the two screws and wire

saddle for each.

6. Fit the dehumidifier heater retainers to the left

and right of the large paper deck using one

screw for each.

Dehumidifier heater

Wire saddle

Dehumidifier heater retainer

Deck paper conveying

unit assembly

Figure 1-2-2

Screws

Screw

Screw

Dehumidifier heater retainer

Wire

saddle

Screws

Dehumidifier heater

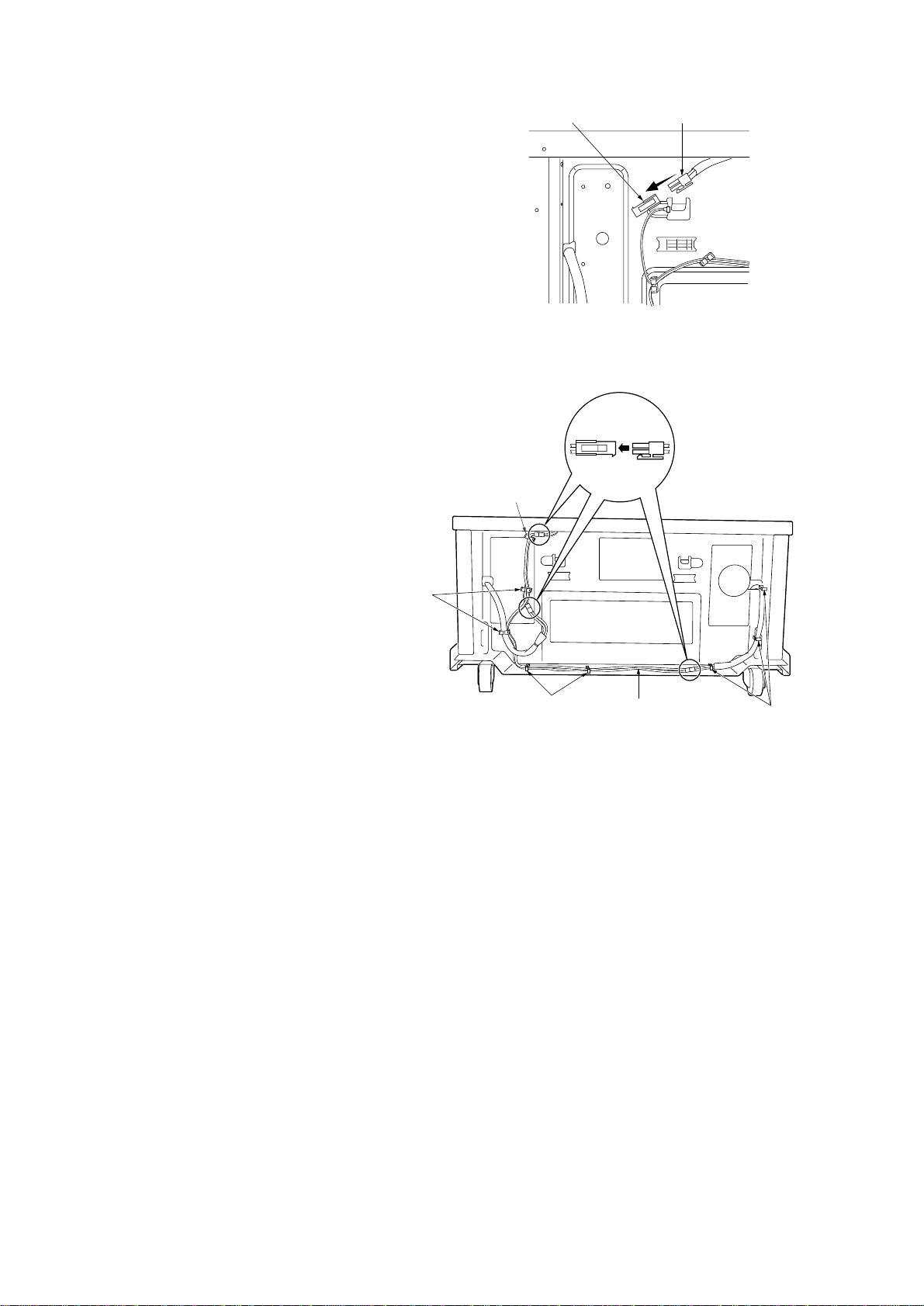

7. Pull the dehumidifier heater cable out to the

machine rear through the cable hole.

1-2-2

Machine rightMachine left

Figure 1-2-3

5FF

8. Detach the open connector from the connector

of the main harness on the machine rear.

9. Insert the dehumidifier heater connectors into

the relay wire connectors.

10. Insert the main harness connector into the

relay wire connector.

11. Tidy up the dehumidifier heater cable and relay

wire using the eight wire saddles and route the

cable and wire while clipping the wire saddles

into the holes in the rear frame.

12. Refit all removed parts.

Main harnessOpen connector

Figure 1-2-4

Wire saddle

Wire

saddles

Wire saddles

Relay wire

Figure 1-2-5

Wire saddles

1-2-3

5FF

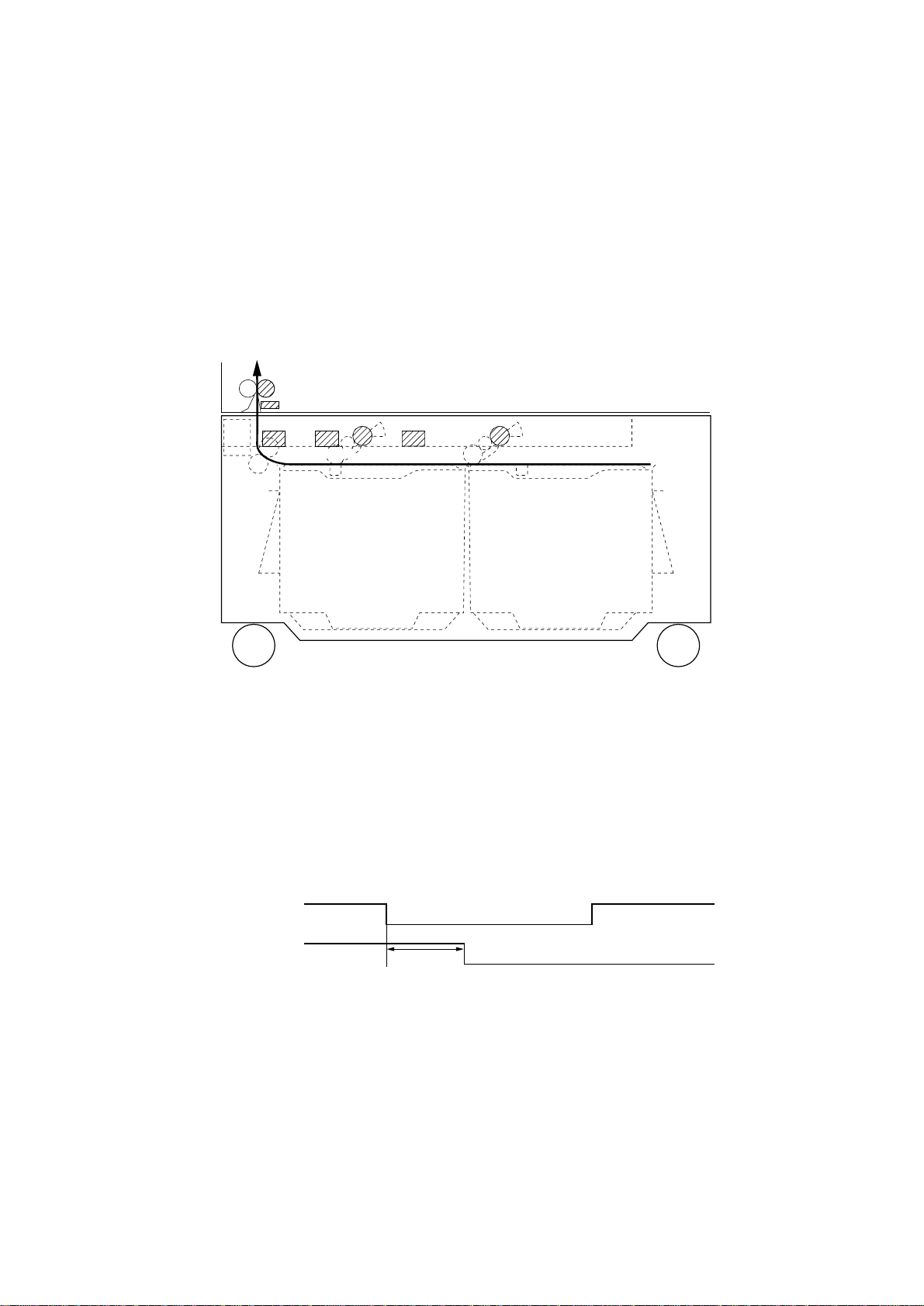

1-3-1 Paper misfeed detection

(1) Paper misfeed indication

When a paper jam occurs, the machine immediately stops operation. The operation unit of the copier shows a jam message

and the jam location.

To reset the paper misfeed detection, open and close the deck side cover or the large paper deck to turn the side cover

switch or the deck open/closed safety switch off and on.

(2) Paper misfeed detection conditions

FCL3

FSW3

PPSENS1

PPSENS3

PPSENS2

PFCL1 PFCL2

Figure 1-3-1 Large paper deck

• No paper feed from large paper deck (jam code 12)

Feed switch 3 (FSW3) of the copier does not turn on within 650 ms of paper feed clutch 1 (PFCL1) turning on.

PFCL1

FSW3 (Copier)

650 ms

Timing chart 1-3-1

1-3-1

5FF

• Jam in large paper deck horizontal paper conveying section (jam code 15)

Paper path sensor 3 (PPSENS3) does not turn on within 290 ms of paper feed clutch 2 (PFCL2) turning on.

PFCL2

PPSENS3

290 ms

Timing chart 1-3-2

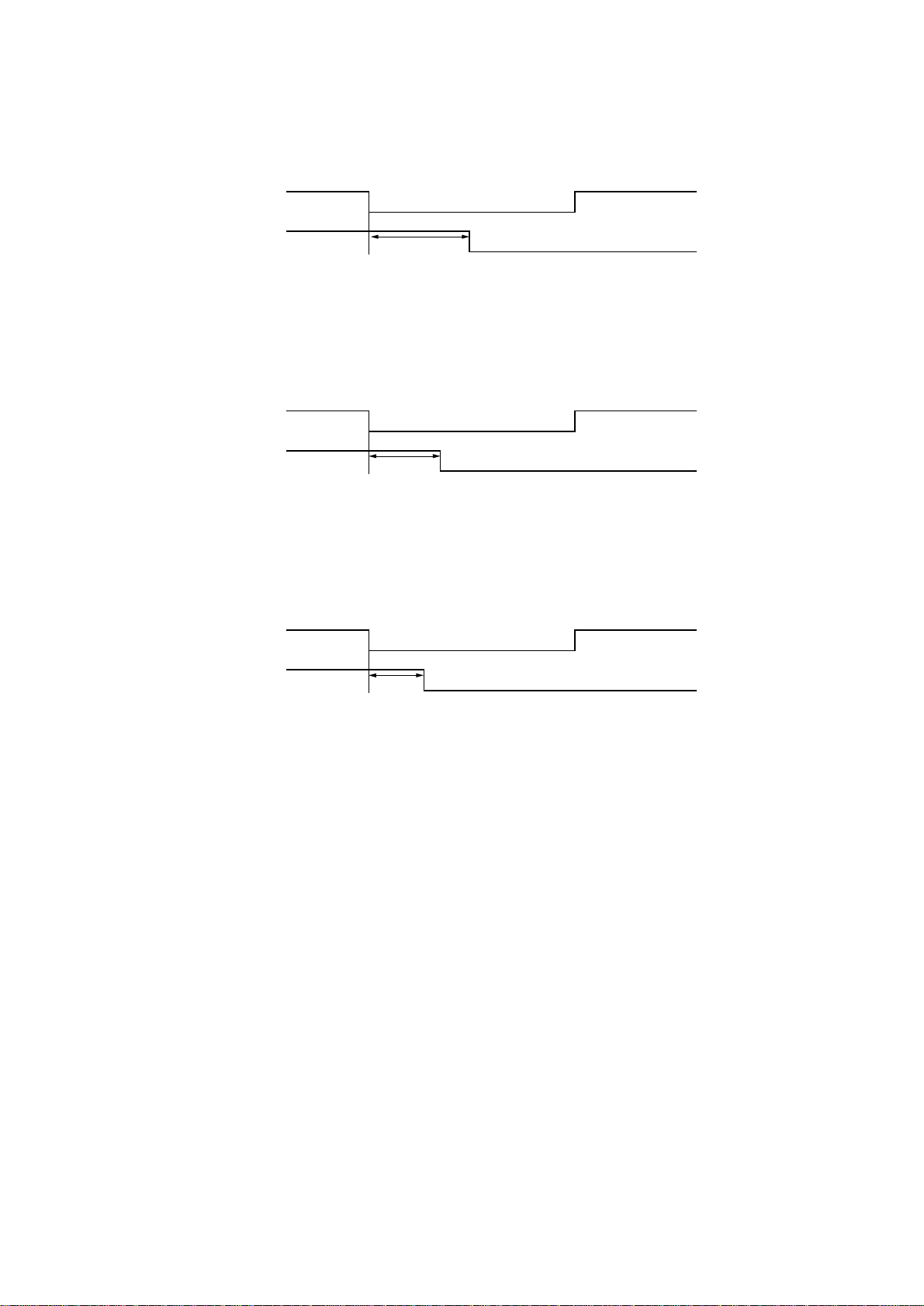

• Jam in large paper deck horizontal paper conveying section (jam code 16)

Paper path sensor 2 (PPSENS2) does not turn on within 310 ms of paper path sensor 3 (PPSENS3) turning on.

PPSENS3

PPSENS2

310 ms

Timing chart 1-3-3

• Jam in large paper deck horizontal paper conveying section (jam code 17)

Paper path sensor 1 (PPSENS1) does not turn on within 190 ms of paper path sensor 2 (PPSENS2) turning on.

PPSENS2

PPSENS1

190 ms

Timing chart 1-3-4

1-3-2

Loading...

Loading...