Page 1

PF-730

SERVICE

MANUAL

Published in February 2011

843NJ110

3NJSM060

First Edition

Page 2

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE

OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your

local solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE

DE TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES

INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les

fonctionnaires municipaux de votre région pour les détails concernant des déchets solides

et une mise au rebut appropriée.

Page 3

Revision history

Revision Date Replaced pages Remarks

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect com-

pliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point of attention is

shown inside the symbol.

General warning. Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action. Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required. Remove the power plug from the wall outlet.

Always ground the copier.

Page 7

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check that

it is adequate for the rated current. .....................................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper

authorities. ..........................................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .........

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. .................

• Do not install the copier near a radiator, heater, other heat source or near flammable material. This

may cause fire. ...................................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ............

• Always handle the machine by the correct locations when moving it. .................................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ..............................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally

ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately.

If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. .....................................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .........................................................................................................................

Page 8

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ................

• Always follow the procedures for maintenance described in the service manual and other related

brochures. ..........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. ........................................................................................................................

• Always use parts having the correct specifications. ............................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure

when replacing them. Using a piece of wire, for example, could lead to fire or other serious acci-

dent. ...................................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ..................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ...............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. .................................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ...............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely

secured so they will not be caught in rotating sections. ......................................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ..........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ...........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ......................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ........................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ................................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ..........

• Remove toner completely from electronic components. .....................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ......................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. .......................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. .......................................

• Handle greases and solvents with care by following the instructions below: ......................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet immedi-

ately. ...................................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. ........................................................................................

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an electric shock

might occur. ........................................................................................................................................

Page 10

This page is intentionally left blank.

Page 11

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................ 1-1-1

1-1-2 Parts names .......................................................................................................................... 1-1-2

1-1-3 Machine cross section ........................................................................................................... 1-1-3

1-2 Installation

1-2-1 Installation environment......................................................................................................... 1-2-1

1-2-2 Unpacking.............................................................................................................................. 1-2-2

(1) Precaution for unpacking.................................................................................................. 1-2-2

1-2-3 Unpacking.............................................................................................................................. 1-2-3

(1) Unpacking......................................................................................................................... 1-2-3

(2) Remove the tapes and pad .............................................................................................. 1-2-4

1-2-4 Installing the cassette heater (Option) ................................................................................... 1-2-6

1-3 Maintenance Mode

1-3-1 Maintenance mode ................................................................................................................ 1-3-1

(1) Executing a maintenance item ......................................................................................... 1-3-1

(2) Maintenance modes item list ............................................................................................ 1-3-2

(3) Contents of the maintenance mode items ........................................................................ 1-3-3

3NJ

1-4 Troubleshooting

1-4-1 Paper mis feed detection ....................................................................................................... 1-4-1

(1) Paper mis feed indication ................................................................................................. 1-4-1

(2) Paper mis feed detection condition .................................................................................. 1-4-1

1-4-2 Self-diagnostic function ......................................................................................................... 1-4-5

(1) Self-diagnostic function .................................................................................................... 1-4-5

(2) Self diagnostic codes........................................................................................................ 1-4-5

1-4-3 Electric problems ................................................................................................................... 1-4-8

1-4-4 Mechanical problems........................................................................................................... 1-4-10

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly........................................................................... 1-5-1

(1) Precautions....................................................................................................................... 1-5-1

1-5-2 Paper feed section................................................................................................................. 1-5-2

(1) Detaching and refitting the PF forwarding, PF paper feed and PF separation pulleys..... 1-5-2

1-5-3 PWBs..................................................................................................................................... 1-5-7

(1) Detaching and refitting the PF main PWB ........................................................................ 1-5-7

1-5-4 Driving section ....................................................................................................................... 1-5-9

(1) Detaching and refitting the PF Driving unit ....................................................................... 1-5-9

(2) Detaching and refitting the PF lift motors ....................................................................... 1-5-10

2-1 Mechanical Construction

2-1-1 Mechanical construction ........................................................................................................ 2-1-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................ 2-2-1

(1) PWB and sensors............................................................................................................. 2-2-1

(2) Motors and others............................................................................................................. 2-2-3

Page 12

2-3 Operation of the PWBs

2-3-1 PF main PWB ........................................................................................................................ 2-3-1

2-4 Appendixes

2-4-1 Appendixes ............................................................................................................................ 2-4-7

(1) Wiring diagram ................................................................................................................. 2-4-7

3NJ

Page 13

1-1 Specifications

1-1-1 Specifications

Item Specifications

Paper weight 64 to 256g/m

Paper types Plain (80g/m2 or less), Thick (256g/m2 or less), recycled

3NJ

2

Paper size

A3, B4, A4, A4R, B5, B5R, A5R, Folio, Ledger, Legal, OficioII, 8.5 × 13.5",

Letter, LetterR, Excutive, StatementR, 8K, 16K, 16KR

Paper capacity 1000 sheets (500 sheets x 2) (80g/m

Dimensions

598 (W) x 315 (H) x 699.6 (D) mm

23

9/19” (W) x 12 3/8” (H) x 27 9/16” (D)

Weight Approx. 30kg / Approx. 66.1 lbs

Power source Electrically connected to the machine. (3.3 V DC, 24 V DC)

NOTE: These specifications are subject to change without notice.

2

)

1-1-1

Page 14

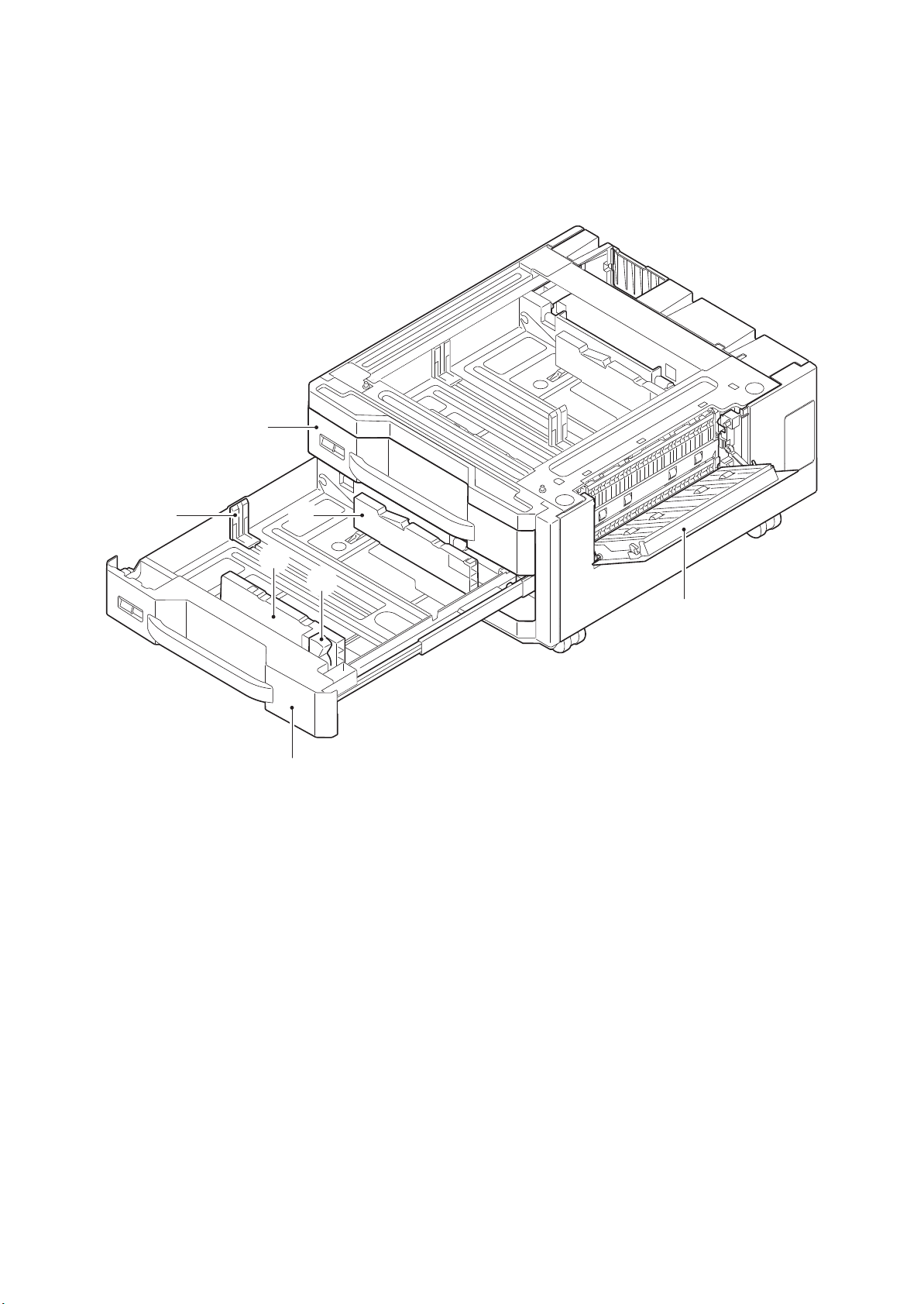

1-1-2 Parts names

1. PF paper conveying guide

2. Cassette 3

3. Cassette 4

4. PF paper size width guides

5. PF paper size width adjusting tab

6. PF paper size length guide

2

3NJ

6

4

4

5

1

3

Figure 1-1-1

1-1-2

Page 15

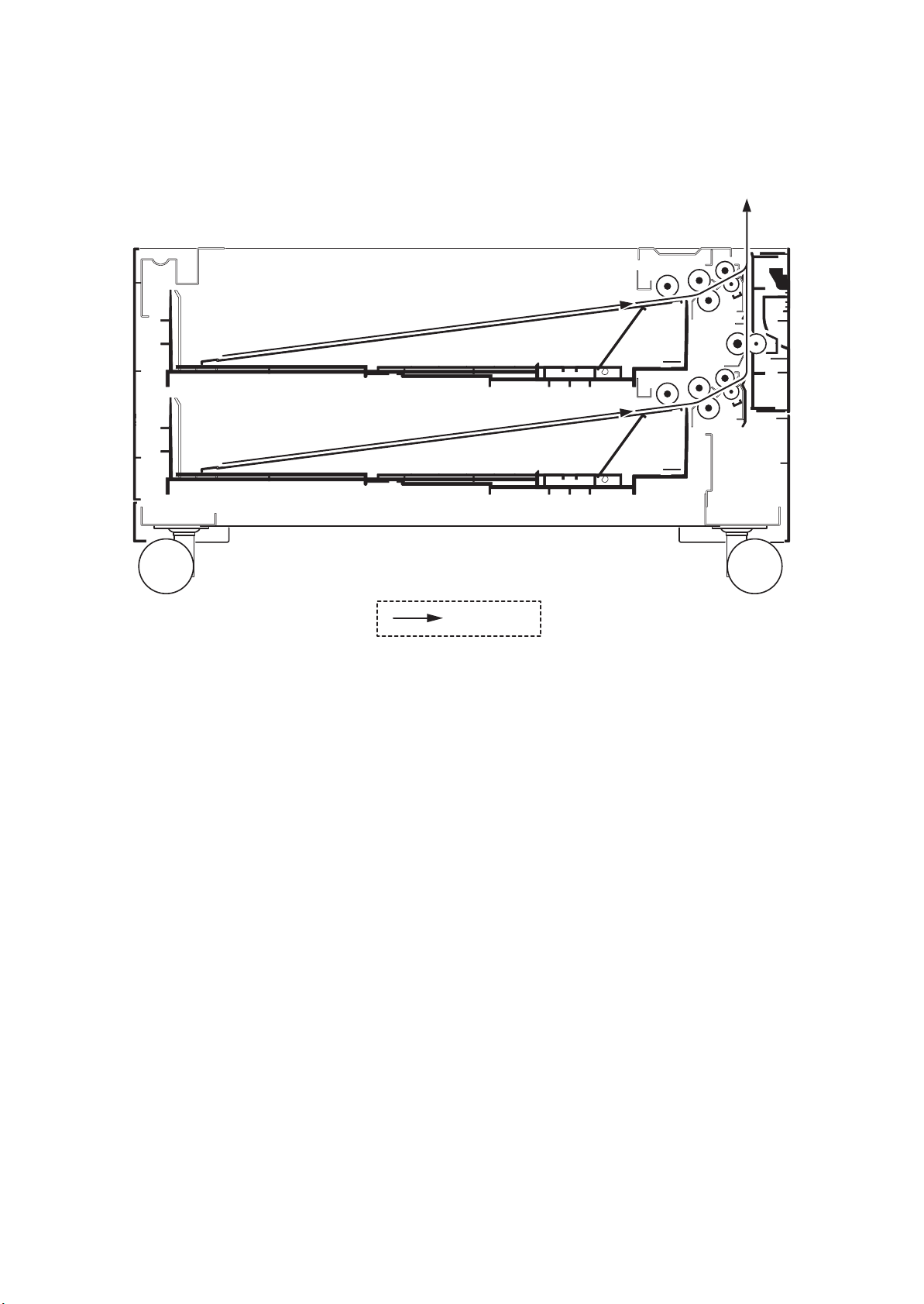

1-1-3 Machine cross section

3NJ

Paper path

Figure 1-1-2

1-1-3

Page 16

3NJ

This page is intentionally left blank.

1-1-4

Page 17

3NJ

1-2 Installation

1-2-1 Installation environment

Installation location (Be based on the machine establishment place.)

Avoid direct sunlight or bright lighting. Ensure that the photo conductor will not be exposed to direct sunlight or

other strong light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an abrupt

change in the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1°).

Avoid air-borne substances that may adversely affect the machine or degrade the photo conductor, such as

mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

1-2-1

Page 18

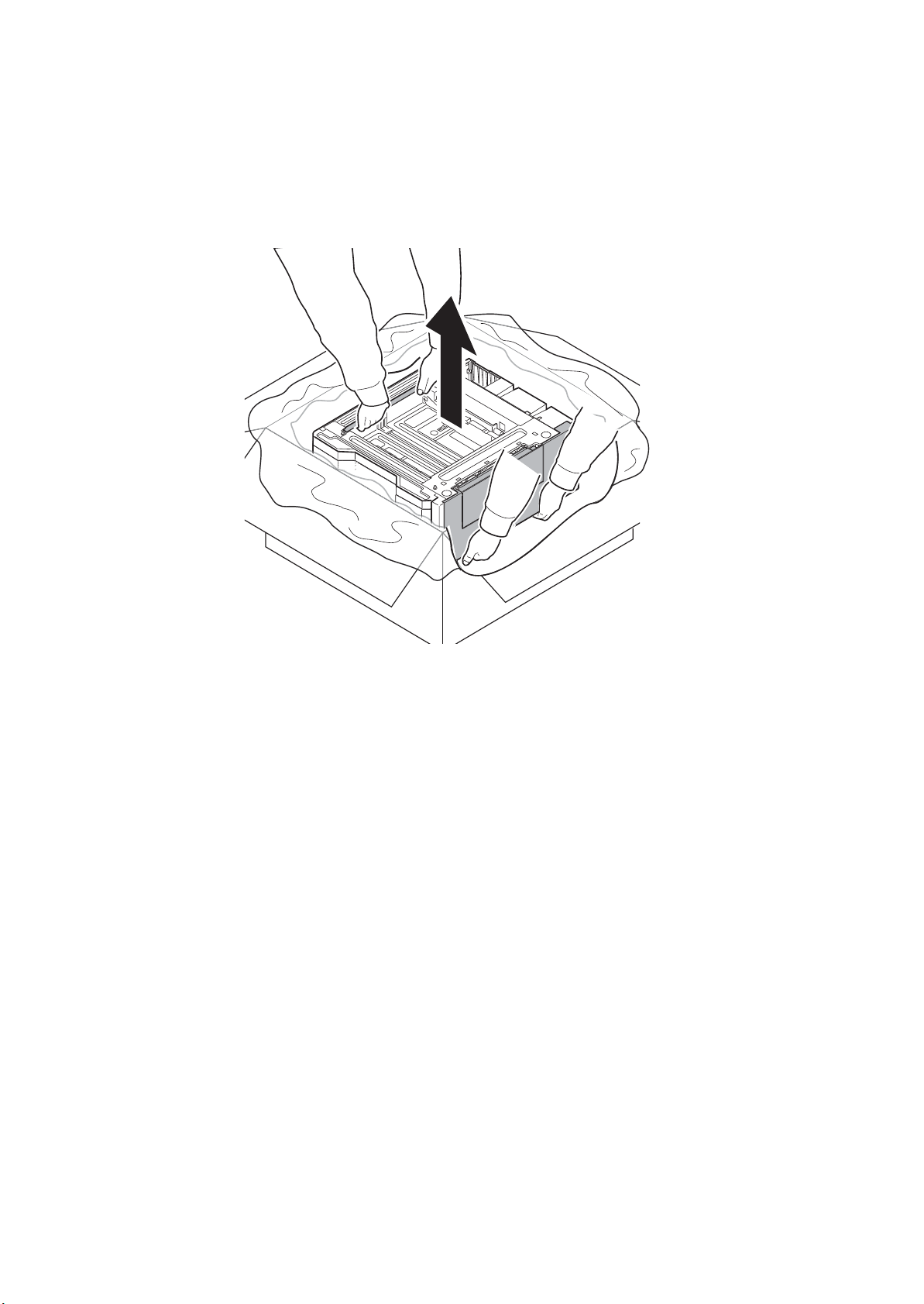

1-2-2 Unpacking

(1) Precaution for unpacking

Hold the positions shown in the figure and remove the paper feeder from the outer case.

3NJ

Figure 1-2-1

1-2-2

Page 19

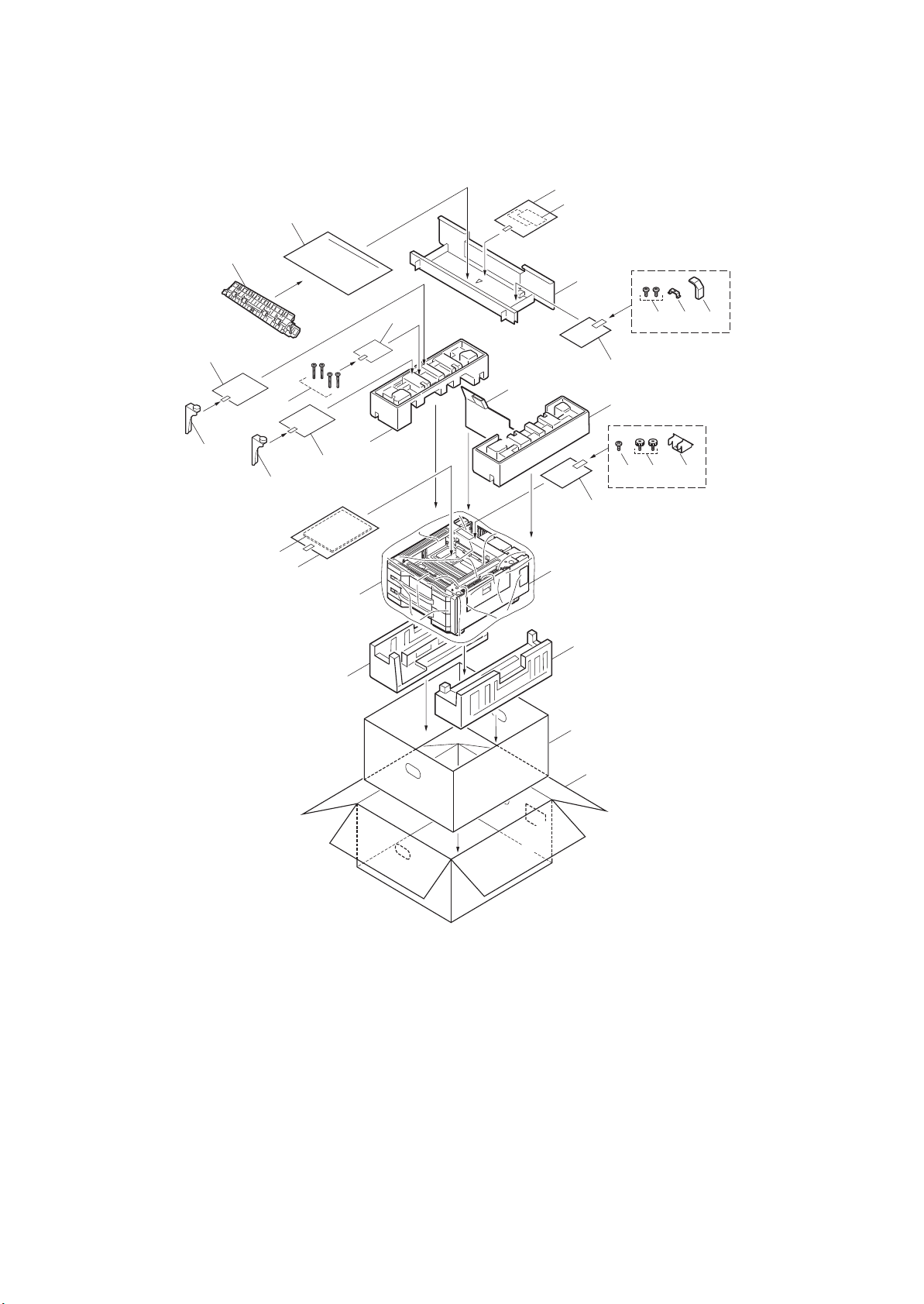

1-2-3 Unpacking

1. Paper feeder

2. Outer case

3. Inner case

4. Bottom left pad

5. Bottom right pad

6. Upper left pad

7. Upper right pad

8. Rear pad

9. Machine cover

10. Plastic bag

11. Installation guide

12. Accessory box

13. Plastic bag

14. Paper size plates

15. Plastic bag

16. Middle roller unit

17. Plastic bag

18. S tight screw M4 x 8B

19. Clamp

20. Wire cover

21. Plastic bag

22. S tight screws M4 x 8B

23. Pins

24. Retainer

25. Plastic bag

26. Supporting plate

27. Plastic bag

28. S tight screws M4 x 20B

(1) Unpacking

15

16

3NJ

13

14

12

25

26

11

28

26

10

25

27

18 19 20

17

8

7

6

6

22 23 24

21

1

9

5

4

3

Caution: Place the machine on a level surface. See the Installation Guide for installation.

Figure 1-2-2 Unpacking

1-2-3

2

Page 20

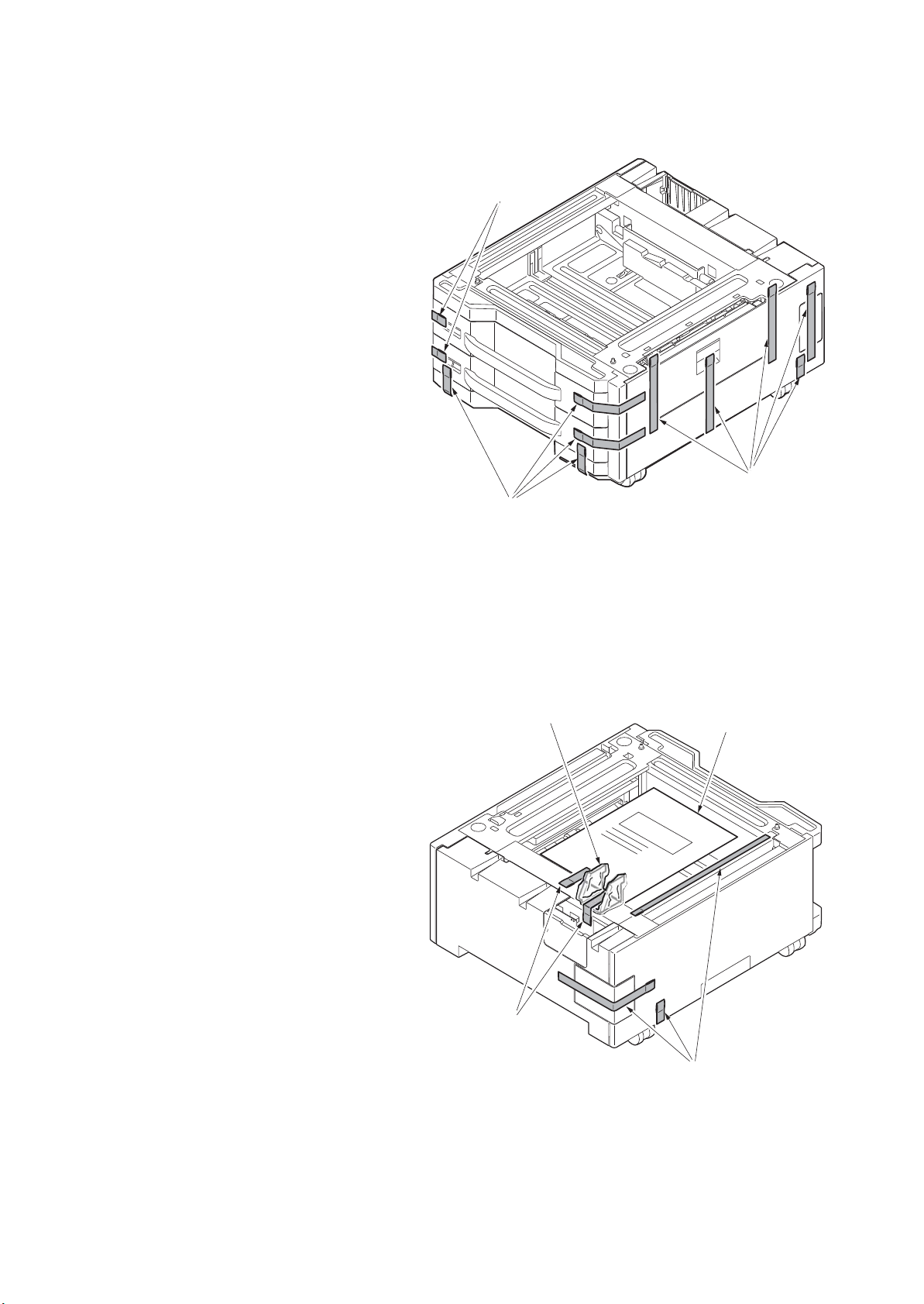

(2) Remove the tapes and pad

Procedure

1. Remove eleven tapes.

3NJ

Ta pe s

Ta pe s

Ta pe s

2. Remove five tapes and then remove the

retainer and the leaflet.

Retainer

Ta pe s

Figure 1-2-3

Leaflet

1-2-4

Ta pe s

Figure 1-2-4

Page 21

3NJ

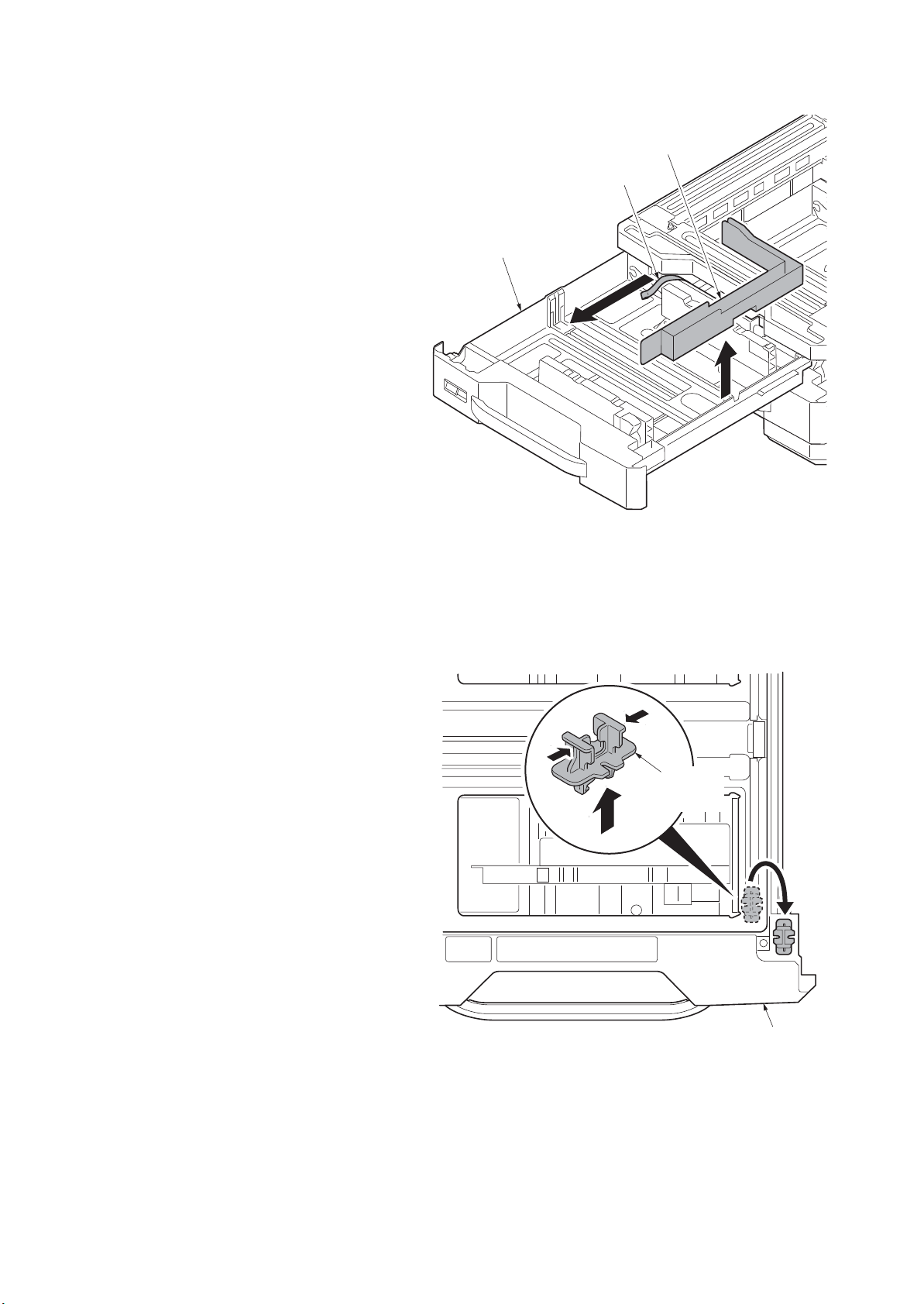

3. Pull the upper cassette forward.

4. Remove the tape.

5. Remove the pad from cassette.

Pad

Ta pe

Cassette

Figure 1-2-5

6. Remove the lift plate stopper from

cassette and attach it to the storage

location.

* : When moveing the machine,attach the

lift plate in original position.

7. Gently push cassette back in.

8. Repeat steps 3 to 7 similarly for lower

cassette.

Lift plate

stopper

Cassette

Figure 1-2-6

1-2-5

Page 22

1-2-4 Installing the cassette heater (Option)

Procedure

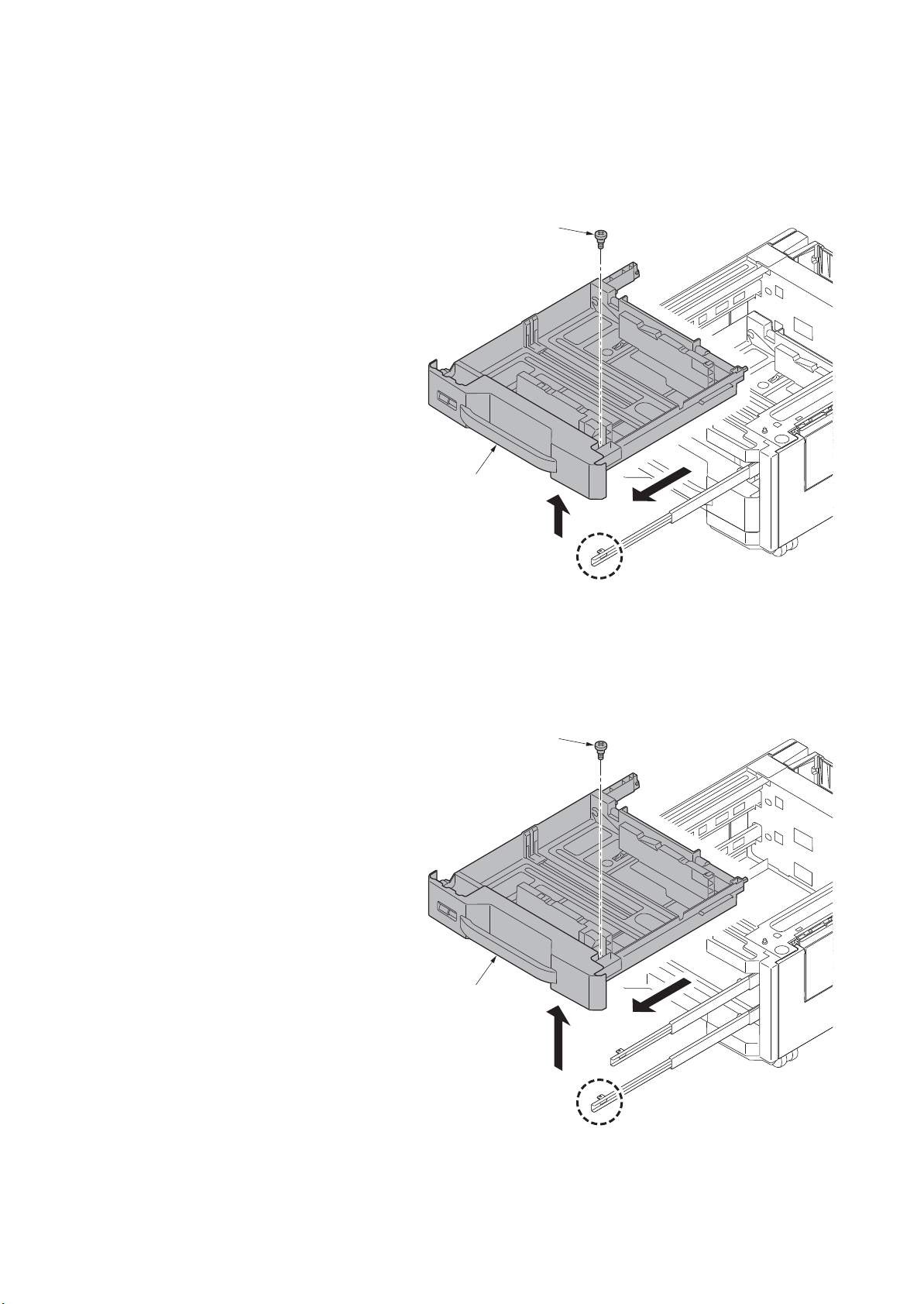

1. Pull the cassette 3 forward.

2. Remove the pin and then remove the

cassette 3.

Cassette 3

Pin

3NJ

3. Pull the cassette 4 forward.

4. Remove the pin and then remove the

cassette 4.

Figure 1-2-7

Pin

Cassette 4

1-2-6

Figure 1-2-8

Page 23

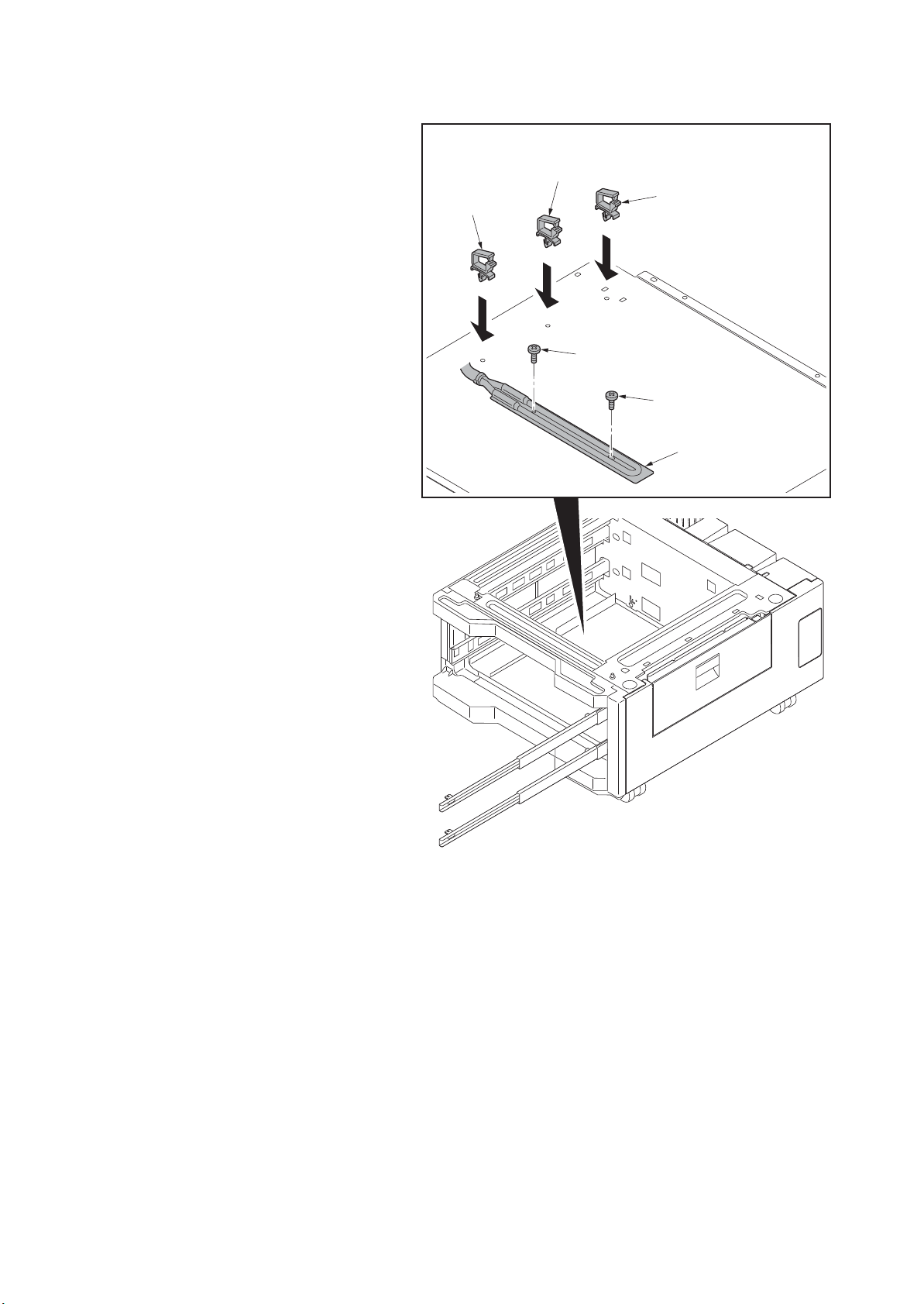

5. Install three wire saddles on the bottom

frame of the paper feeder.

6. Install the cassette heater by using two

screws.

Wire saddle

3NJ

Wire saddle

Wire saddle

Screw

Screw

Cassette heater

1-2-7

Figure 1-2-9

Page 24

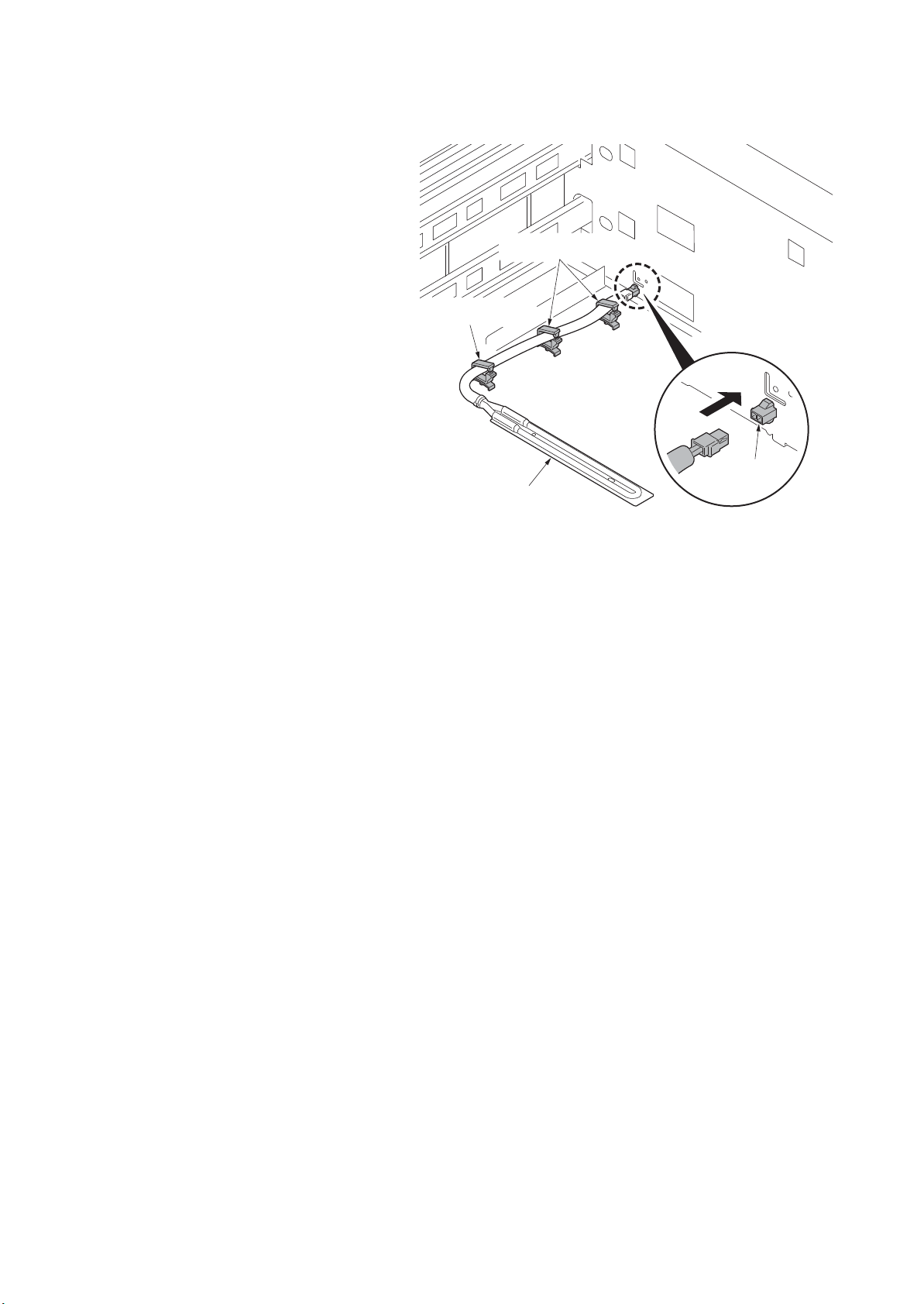

7. Connect the connector of the cassette

heater to the connector in the rear

frame of the paper feeder.

8. Pass through the wire of the cassette

heater to three wire saddles.

3NJ

Wire saddles

Wire saddle

Connector

Cassette heater

Figure 1-2-10

1-2-8

Page 25

1-3 Maintenance Mode

1-3-1 Maintenance mode

The machine is equipped with a maintenance function which can be used to maintain and service the

machine.

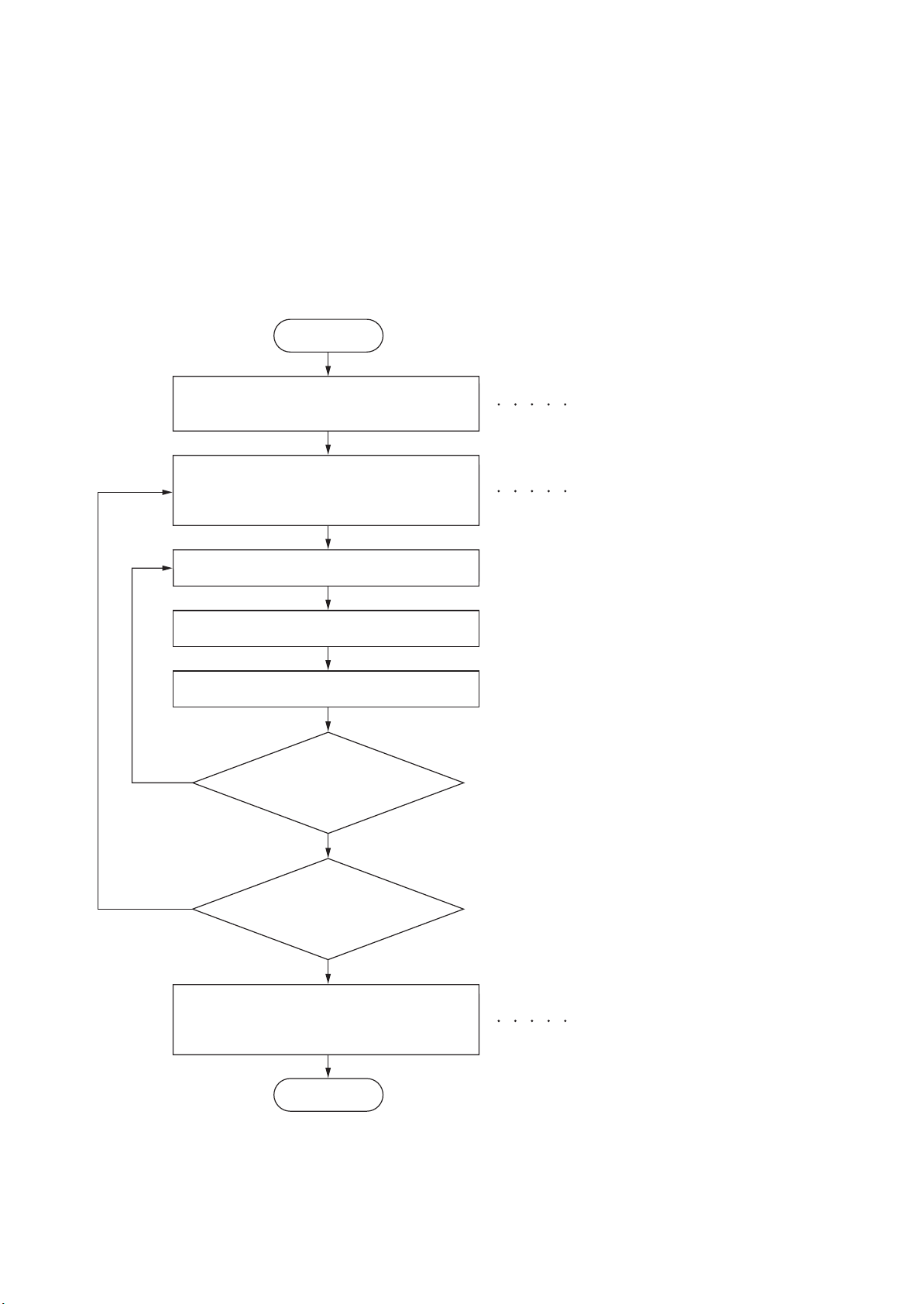

(1) Executing a maintenance item

Start

3NJ

Enter “10871087” using

the numeric keys.

Enter the maintenance item

number using the cursor

or numeric keys.

Press the start key.

The selected maintenance item is run.

Press the stop key.

Yes

Repeat the same

maintenance item?

up/down

keys

Maintenance mode is entered.

The maintenance item is selected.

Yes

No

Run another maintenance

item?

No

Enter 001 using the cursor

up/down keys or numeric keys

and press the start key.

End

Maintenance mode is exited.

1-3-1

Page 26

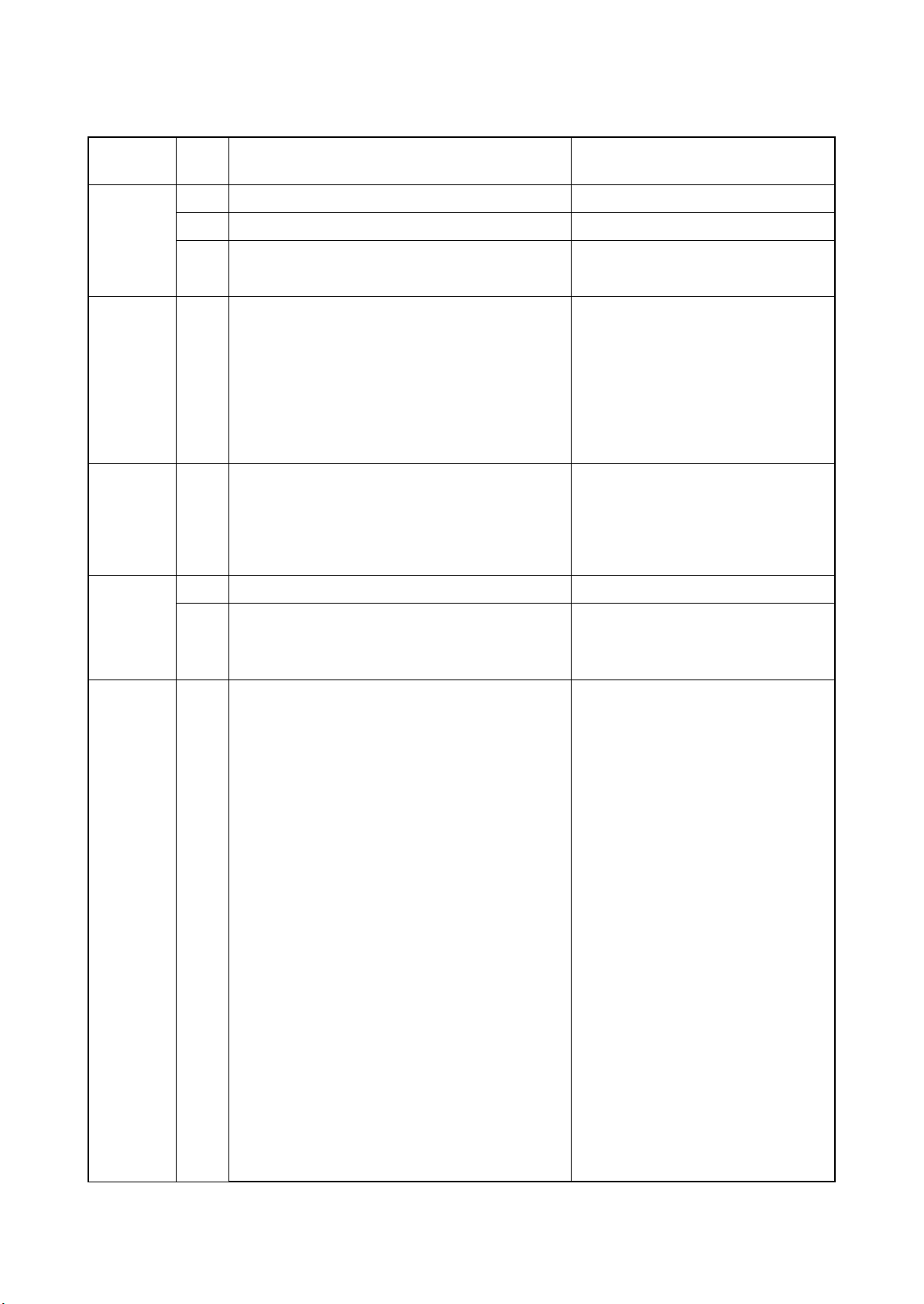

(2) Maintenance modes item list

3NJ

Section Item

No.

General U000 Outputting an own-status report -

U001 Exiting the maintenance mode -

U019 Displaying the ROM version -

Drive,

paper feed

and paper

conveying

system

Operation

panel and

support

equipment

Mode

setting

U034 Adjusting the print start timing

LSU Out Top 0/0/0/0/0/0/0/0/0/0/0/0

LSU Out Left 0/0/0/0/0/0/0/0/0

LSU Out Top B/W 0/0/0/0/0/0

LSU Out Top 3/4 0/0/0/0/0/0

U247 Setting the paper feed device -

U327 Setting the cassette heater control Off

U341 Specific paper feed location setting for printing

function

Content of maintenance item Initial setting

-

Others U901 Checking copy counts by paper feed locations -

1-3-2

Page 27

(3) Contents of the maintenance mode items

Display Output list

Maintenance List of the current settings of the maintenance modes

User Status Outputs the user status page

Service Status Outputs the service status page

Event Outputs the event log

Network Status Outputs the network status page

All Outputs the all reports

Display Description

Ready List of the current settings of the maintenance modes

Active Outputs the user status page

Complete Outputs the service status page

Error Outputs the event log

Item No. Description

U000 Outputting an own-status report

Description

Outputs lists of the current settings of the maintenance items, and paper jam and service call

occurrences. Outputs the event log or service status page. Also sends output data to the USB

memory.

Purpose

To check the current setting of the maintenance items, or paper jam or service call occurrences.

Before initializing or replacing the backup RAM, output a list of the current settings of the maintenance items to reenter the settings after initialization or replacement.

Method

1. Press the start key.

2. Select the item to be output using the cursor up/down keys.

3NJ

3. Press the start key. A list is output.

4. Press the start key. The interrupt print mode is entered and a list is output.

When A4/Letter paper is available, a report of this size is output. If not, specify the paper feed

location.

The output status is displayed.

1-3-3

Page 28

Item No. Description

Display Output list

Print Outputs the report

USB (Text) Sends output data to the USB memory (text type)

USB (HTML) Sends output data to the USB memory (HTML type)

U000 Method: Send to the USB memory

1. Press the power key on the operation panel, and after verifying the main power indicator has

gone off, switch off the main power switch.

2. Insert USB memory in USB memory slot.

3. Turn the main power switch on.

4. Enter the maintenance item.

5. Press the start key.

6. Select the item to be send.

7. Select [Text] or [HTML].

8. Press the start key.

Output will be sent to the USB memory.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

3NJ

1-3-4

Page 29

Item No. Description

No. Items Description

(1) System version

(2) System date

(3) Engine soft version

(4) Engine boot version

U000 Event log

Event Log

MFP

(1)

Firmware version 2LC_2000.000.000 2010.10.27

(12)(8)

Paper Jam Log

#

Count.

16

9999999

15

8888888

14

7777777

13

6666666

12

5555555

11

4444444

10

3333333

9

2222222

8

1111111

7

999999

6

888888

5

777777

0501.01.08.01.01

4

666666

3

555555

2

444444

1

(9)

Service Call Log

#

Count.

8

1111111

7

999999

6

888888

5

777777

4

666666

3

555555

2

444444

1

(10)

Maintenance Log

# Count.

Log Data Nothing...

Unknown toner Log

(11)

#

Count.

5

1111111

4

999999

3

888888

2

777777

1

666666

Event Descriprions

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

4002.01.08.01.01

0501.01.08.01.01

(a) (b) (c) (d) (e)

4002.01.08.01.01

0501.01.08.01.01

1

4002.01.08.01.01

Service Code

01.6000

01.2100

01.4000

01.6000

01.2100

01.4000

01.6000

1

01.2100

Item

Item

01.00

01.00

01.00

01.00

01.00

Counter Log

J0000:

(f) (g) (h)

J0001:

J0002:

J0003:

222

J0004:

J0005:

J0006:

J0007:

J0008:

J0009:

J0010:

J0012:

999

J0013:

J0014:

J0015:

J0016:

J0017:

J0018:

J0019:

J0020:

J0021:

J0022:

J0023:

J0024:

J0025:

J0026:

J0027:

J0028:

J0029:

J0030:

J0031:

J0032:

J0033:

J0034:

J0035:

J0036:

J0037:

J0038:

J0039:

J0040:

3NJ

(2)

27/Oct/2010 08:40

(6)(5)(4)(3)

[XXXXXXXX][XXXXXXXX][XXXXXXXX][XXXXXXXX]

J0041:

0

J0042:

1

J0043:

11

J0044:

J0045:

1

J0046:

1

J0047:

1

J0048:

1

J0049:

1

J0050:

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

C0000:

1

C0001:

1

C0002:

1

C0003:

1

C0004:

1

C0005:

1

C0006:

1

C0007:

1

C0008:

1

C0009:

C0010:

C0011:

C0012:

C0013:

C0014:

C0015:

C0016:

C0017:

C0018:

C0019:

C0020:

C0021:

C0022:

C0023:

10

11

12

13

14

15

16

17

18

19

20

21

22

23

0

T00:

T01:

T02:

T03:

T04:

T05:

10

20

30

40

50

999

1

2

3

4

5

6

7

8

9

Detail of event log

Figure 1-3-1

1-3-5

(7)

[XXXXXXXXXXXXXXXX]

Page 30

Item No. Description

No. Items Description

(5) Controller BROM version

(6) Operation panel mask version

(7) Machine serial number

(8) Paper Jam

Log

# Count. Event

Remembers 1 to 16 of

occurrence. If the occurrence of the previous

paper jam is less than

16, all of the paper jams

are logged. When the

occurrence excesseds

16, the oldest occurrence is removed.

The total page count

at the time of the

paper jam.

Log code (hexadecimal, 5 categories)

(a) Cause of a paper

jam

(b) Paper source

(c) Paper size

(d) Paper type

(e) Paper eject

(a) Cause of paper jam (Hexadecimal)

For details on the case of paper jam, refer to Paper Mis feed Detection.

(P.1-4-1)

(b) Detail of paper source (Hexadecimal)

00: MP tray

01: Cassette 1

02: Cassette 2

03: Cassette 3 (paper feeder/large capacity feeder)

04: Cassette 4 (paper feeder/large capacity feeder)

05: Cassette 5 (side feeder/SMT paper feeder)

06: Cassette 6 (side paper feeder/side large capacity feeder)

07: Cassette 7 (side paper feeder/side large capacity feeder)

08 to 09: Reserved

(c) Detail of paper size (Hexadecimal)

00: (Not specified)

01: Monarch

02: Business

03: International DL

04: International C5

05: Executive

06: Letter-R

86: Letter-E

07: Legal

08: A4R

88: A4E

09: B5R

89: B5E

0A: A3

0B: B4

0C: Ledger

0D: A5R

0E: A6

0F: B6

10: Commercial #9

11: Commercial #6

12: ISO B5

13: Custom size

1E: C4

1F: Postcard

20: Reply-paid post-

card

21: Oficio II

22: Special 1

23: Special 2

24: A3 wide

25: Ledger wide

26: Full bleed paper

(12 x 8)

27: 8K

28: 16K-R

A8: 16K-E

32: Statement-R

B2: Statement-E

33: Folio

34: Western type 2

35: Western type 4

U000 Detail of event log

3NJ

1-3-6

Page 31

Item No. Description

No. Items Description

(8)

cont.

Paper Jam

Log

(d) Detail of paper type (Hexadecimal)

01: Plain

02: Transparency

03: Preprinted

04: Labels

05: Bond

06: Recycled

07: Vellum

08: Rough

09: Letterhead

0A: Color

0B: Prepunched

0C: Envelope

0D: Cardstock

0E: Coated

0F: 2nd side

10: Media 16

11: High quality

15: Custom 1

16: Custom 2

17: Custom 3

18: Custom 4

19: Custom 5

1A: Custom 6

1B: Custom 7

1C: Custom 8

(e) Detail of paper eject location (Hexadecimal)

01: Face down (FD)

02: Face up (FU)/1000-sheet finisher face up (FU)/

4000-sheet finisher left sub tray (FU)

03: 1000-sheet finisher face down (FD)

4000-sheet finisher main tray (FD)

05: Job separator tray

06: 4000-sheet finisher right sub tray (FU)

07: 4000-sheet finisher left sub tray (FD)

09: 4000-sheet finisher right sub tray (FD)

0A: Center-folding unit tray

0B: Mailbox tray 1 (FD)

0C: Mailbox tray 1 (FU)

15: Mailbox tray 2 (FD)

16: Mailbox tray 2 (FU)

1F: Mailbox tray 3 (FD)

20: Mailbox tray 3 (FU)

29: Mailbox tray 4 (FD)

2A: Mailbox tray 4 (FU)

33: Mailbox tray 5 (FD)

34: Mailbox tray 5 (FU)

3D: Mailbox tray 6 (FD)

3E: Mailbox tray 6 (FU)

47: Mailbox tray 7 (FD)

48: Mailbox tray 7 (FU)

04/0D/0E: Reserved

U000

3NJ

1-3-7

Page 32

Item No. Description

No. Items Description

(9) Service Call

Log

# Count. Service Code

Remembers 1 to 8

of occurrence of self

diagnostics error. If

the occurrence of

the previous diagnostics error is less

than 8, all of the

diagnostics errors

are logged.

The total page

count at the time of

the self diagnostics

error.

Self diagnostic error code

(See page 1-4-5)

Example:

01.6000

01: Self diagnostic error

6000: Self diagnostic error

code number

(10) Maintenance

Log

# Count. Item

Remembers 1 to 8

of occurrence of

replacement. If the

occurrence of the

previous replacement of toner container is less than 8,

all of the occurrences of replacement are logged.

The total page

count at the time of

the replacement of

the toner container.

Code of maintenance

replacing item

(1 byte, 2 categories)

First byte (Replacing item)

01: Toner container

Second byte

(Type of replacing item)

00: Black

01: Cyan

02: Magenta

03: Yellow

First byte (Replacing item)

02: Maintenance kit

Second byte

(Type of replacing item)

01: MK-8305A/8505A

02: MK-8305B/8505B

03: MK-8305C/8505C

(11) Unknown

Toner Log

# Count. Item

Remembers 1 to 5

of occurrence of

unknown toner

detection. If the

occurrence of the

previous unknown

toner detection is

less than 5, all of the

unknown toner

detection are

logged.

The total page

count at the time of

the toner empty

error with using an

unknown toner

container.

Unknown toner log code

(1 byte, 2 categories)

First byte

01: Toner container (Fixed)

Second byte

00: Black

01: Cyan

02: Magenta

03: Yellow

U000

3NJ

1-3-8

Page 33

Item No. Description

No. Items Description

(12) Counter Log

Comprised of

three log counters including

paper jams, self

diagnostics

errors, and

replacement of

the toner container.

(f) Paper jam (g) Self diagnostic

error

(h) Maintenance item

replacing

Indicates the log

counter of paper

jams depending on

location.

Refer to Paper Jam

Log.

All instances including those are not

occurred are displayed.

Indicates the log

counter of self diagnostics errors

depending on

cause.

Example:

C6000: 4

Self diagnostics

error 6000 has happened four times.

Indicates the log counter depending on the

maintenance item for

maintenance.

T: Toner container

00: Black

01: Cyan

02: Magenta

03: Yellow

M: Maintenance kit

01: MK-8305A/8505A

02: MK-8305B/8505B

03: MK-8305C/8505C

Example:

T00: 1

The toner container has

been replaced once.

U000

3NJ

1-3-9

Page 34

Item No. Description

U000 Service status page (1)

3NJ

Service Status Page

MFP

(1)

Firmware version 2LC_2000.000.000 2010.10.27

Controller Information

Memory status

(7)

Total Size

Time

(8)

Local Time Zone

(9)

Date and Time

(10)

Time Server

Installed Options

Document Processor

(11)

Paper feeder

(12)

Finisher

(13)

Job Separator

(14)

Document Guaed (A)

(15)

Card Authentication Kit (B)

(16)

Internet FAX Kit (A)

(17)

Security Kit (E)

(18)

Data Security Kit (E) Software Type I

UG-34

(19)

Print Coverage

(20)

Average(%)

(21)

To ta l

K: 1.10

C: 2.20

M: 3.30

Y: 4.40

(22)

Copy

K: 1.10

C: 2.20

M: 3.30

Y: 4.40

(23)

Printer

K: 1.10

C: 2.20

M: 3.30

Y: 4.40

(24)

FAX

K: 1.10

(25)

Period

(26)

Last Page K/C/M/Y(%)

/ Usage Page(A4/Letter Conversion)

/ 1111111 . 11

/ 2222222.22

/ 3333333.33

/ 4444444.44

/ 1111111 . 11

/ 2222222.22

/ 3333333.33

/ 4444444.44

/ 1111111 . 11

/ 2222222.22

/ 3333333.33

/ 4444444.44

/ 1111111 . 11

(27/10/2010 - 03/11/2010 08:40)

1.00 / 2.22 / 3.33 / 4.44

2.0 GB

+01:00 Amsterdam

27/10/2010 12:00

10.183.53.13

Installed

Cassette

1000-Finisher

Installed

Installed

Installed

Installed

Installed

Installed

(32)

FRPO Status

Default Pattern Switch

Default Font Number

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

e-MPS error control

(2)

27/10/2010 12:00

(3) (4) (5)

[XXXXXXXX] [XXXXXXXX] [XXXXXXXX]

B8

C5*1000+C2*100+C3

Y6

0

00000

0

(27)

FAX Information Slot1/Slot2

(28)

Rings (Normal)

(29)

Rings (FAX/TEL)

(30)

Rings (TAD)

(31)

Option DIMM Size

3

3

3

16 MB

1

Figure 1-3-2

1-3-10

(6)

[XXXXXXXXXXXXXXXX]

Page 35

Item No. Description

U000 Service status page (2)

Service Status Page

MFP

3NJ

27/10/2010 12:00

Firmware version 2LC_2000.000.000 2010.10.27

Engine Information

(33)

NVRAM Version

(34)

Scanner Version

(35)

FAX Slot1

FAX BOOT Version

FAX APL Version

FAX IPL Version

(36)

MAC Address

1/2

(41)

(42)

(43)

(44)

(58)

(59)

(64)

(65)

(66)

(67)

(68)

(69)

(70)

(71)

(72)

(73)

(39) (40)

100/100

0/0/0/0/0/0/0/0

0000000/0000000/0000000/0000000/0000000/0000000/0000000/

0000000/0000000/0000000/0000000/0000000/0000000/0000000/0000000/0000000/0000000/0000000/

F00/U00/0/0/0/0/30/30/70/70/abcde/1/0

0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/

0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/

0000/0100/0500/1000/0000/0100/0500/1000/0000/0100/0500/1000/0000/0100/0500/1000/

0000/0100/0500/1000/0000/0100/0500/1000/0000/0100/0500/1000/0000/0100/0500/1000/

00000000000000000000000000000000/0000000000000000000000000000000000000000/0000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

0000000000000000/0000000000000000/0000000000000000/0000000000000000/0000000000000000/

12345678/11223344/00001234abcd567800001234abcd5678/01234567890123456789012345678901/0008/00/07

12345678/11223344/00001234abcd567800001234abcd5678/01234567890123456789012345678901/0008/00/07

12345678/11223344/00001234abcd567800001234abcd5678/01234567890123456789012345678901/0008/00/07

12345678/11223344/00001234abcd567800001234abcd5678/01234567890123456789012345678901/0008/00/07

XXXXXXXX

[ABCDEFGHIJ][ABCDEFGHIJ]

00070107FE/0700FE00FE/00FE000100/0000000000/0000000000/0000000000/00000A010A/0A0A0A3200/

0008000000/080000001D/0096009B00/9B009BFFFB/0082000000/000000001F/0000002C00/0000000000/

0000000000/0000000000/0000000000/0000000000/0000000000/0000000000/0000000000/0000010105/

010A000000/0000000000/003C4C0100/0000000087/A28000363C/8000676B83/0000000000/0000000000/

0000000000/0000000000/0000000000/0000000000/0000000000/0000000000/0000000000/0000000005/

0000000000/0000000000/0000000000/0000000000/0000000000/000000024E/

ABCDEFGHIJ/ABCDEFGHIJ/ABCDEFGHIJ/ABCDEFGHIJ/

_1F31225_1F31225

2LC_1200.001.089

2LC_5000.001.001

2LC_5100.001.001

2LC_5200.001.001

00:C0:EE:D0:01:0D

(45) (46) (47) (48) (49) (50) (51) (52) (53) (54) (55) (56) (57)

[XXXXXXXX] [XXXXXXXX] [XXXXXXXX]

Send Information

(37)

Date and Time

(38)

Address

10/10/27

(60) (61) (62)

2

Figure 1-3-3

1-3-11

[XXXXXXXXXXXXXXXX]

Page 36

Item No. Description

No. Description Supplement

(1) Firmware version -

(2) System date -

(3) Engine soft version -

(4) Engine boot version -

(5) Operation panel mask version -

(6) Machine serial number -

(7) Total memory size -

(8) Local time zone -

(9) Report output date Day/Month/Year hour:minute

(10) NTP server name -

(11) Presence or absence of the

document processor

Installed/Not Installed

(12) Presence or absence of the

paper feeder

Paper feeder/Large capacity feeder/Not Installed

(13) Presence or absence of the

finisher

1000-sheet finisher/4000-sheet finisher/

Not Installed

(14) Presence or absence of the

job separator

Installed/Not Installed

(15) Presence or absence of the

printed document guard kit

Installed/Not Installed

(16) Presence or absence of the IC

card authentication kit

Installed/Not Installed/Trial

(17) Presence or absence of the

internet fax kit

Installed/Not Installed

(18) Presence or absence of the

data security kit

Installed/Not Installed

(19) Presence or absence of the

UG-34

Installed/Not Installed

(20) Page of relation to the A4/Letter -

(21) Average coverage for total Black/Cyan/Magenta/Yellow

(22) Average coverage for copy Black/Cyan/Magenta/Yellow

(23) Average coverage for printer Black/Cyan/Magenta/Yellow

(24) Average coverage for fax Black/Cyan/Magenta/Yellow

(25) Cleared date and output date -

(26) Coverage on the final output

page

-

U000 Detail of service status page

3NJ

1-3-12

Page 37

Item No. Description

No. Description Supplement

(27) Fax kit information This item is printed only when the fax kit is

installed.

(28) Number of rings 0 to 15

(29) Number of rings before auto-

matic switching

0 to 15

(30) Number of rings before connect-

ing to answering machine

0 to 15

(31) Optional DIMM size -

(32) FRPO setting -

(33) NV RAM version _ 1F3 1225 _ 1F3 1225

(a) (b) (c) (d) (e) (f)

(a) Consistency of the present software version

and the database

_ (underscore): OK

* (Asterisk): NG

(b) Database version

(c) The oldest time stamp of database version

(d) Consistency of the present software version

and the ME firmware version

_ (underscore): OK

* (Asterisk): NG

(e) ME firmware version

(f) The oldest time stamp of the ME database ver-

sion

Normal if (a) and (d) are underscored, and (b) and

(e) are identical with (c) and (f).

(34) Scanner firmware version -

(35) Fax firmware version This item is printed only when the fax kit is

installed.

(36) Mac address -

(37) The last sent date and time -

(38) Transmission address -

(39) Destination information -

(40) Area information -

(41) Margin settings Top margin/Left margin

(42) Margin/Page length/Page width

settings

Top margin integer part/Top margin decimal part/

Left margin integer part/Left margin decimal part/

Page length integer part/Page length decimal part/

Page width integer part/Page width decimal part

U000

3NJ

1-3-13

Page 38

Item No. Description

No. Description Supplement

(43) Life counter (The first line) Machine life/MP tray/Cassette 1/Cassette 2/

Cassette 3/Cassette 4/Duplex

(44)

Life counter (The second line) Drum unit K/Drum unit C/Drum unit M/Drum unit Y/

Transfer belt unit/Developer unit K/

Developer unit C/Developer unit M/

Developer unit Y/Maintenance kit A/

Maintenance kit B

(45) Panel lock information 0: OFF/1: Partial lock/2: Full lock

(46) USB information U00: Not installed/U01: Full speed/U02: Hi speed

(47) Paper handling information 0: Paper source unit select/1: Paper source unit

(48) Color printing double count

mode

0: All single counts

1: A3, Single count, Less than 420 mm (length)

2: Legal, Single count, 356 mm or less (length)

3: Folio, Single count, Less than 330 mm (length)

(49) Black and white printing double

count mode

0: All single counts

1: A3, Single count, Less than 420 mm (length)

2: Legal, Single count, 356 mm or less (length)

3: Folio, Single count, Less than 330 mm (length)

(50) Billing counting timing -

(51) Temperature (machine inside) -

(52) Temperature (machine outside) -

(53) Relative temperature

(machine outside)

-

(54) Absolute temperature

(machine outside)

-

(55) Fixed assets number -

(56) Job end judgment time-out time -

(57) Job end detection mode -

(58) Media type attributes

1 to 28 (Not used: 18, 19, 20)

Weight settings Fuser settings

0: Light 0: High

1: Normal 1 1: Middle

2: Normal 2 2: Low

3: Normal 3 3: Vellum

4: Heavy 1 Duplex settings

5: Heavy 2 0: Disable

6: Heavy 3 1: Enable

7: Extra Heavy

U000

3NJ

1-3-14

Page 39

Item No. Description

No. Description Supplement

(59) Calibration information Black/Cyan/Magenta/Yellow

(60) Calibration information -

(61) Calibration information -

(62) Calibration information -

(63) Calibration information -

(64) Calibration information -

(65) Calibration information -

(66) Calibration information -

(67) Calibration information -

(68) Calibration information -

(69) RFID information -

(70) RFID reader/writer version infor-

mation

-

(71) Color table version -

(72) Color table 2 version -

(73) Maintenance information -

Code conversion

ABCDEFGH I J

0123456789

U000

3NJ

U001 Exiting the maintenance mode

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

Description

Exits the maintenance mode and returns to the normal copy mode.

Purpose

To exit the maintenance mode.

Method

1. Press the start key. The normal copy mode is entered.

1-3-15

Page 40

Item No. Description

Display Description

Main Main ROM

MMI Operation ROM

Browser Browser ROM

Engine Engine ROM

Engine Boot Engine booting

Scanner Scanner ROM

Scanner Boot Scanner booting

RFID RFID ROM

IH CPU IH CPU ROM

IH CPU Boot IH CPU booting

Motor CPU Motor CPU ROM

Motor CPU Boot Motor CPU booting

Dictionary -

Option Language Optional language ROM

PDF1.7 Resource PDF1.7 resource ROM

Solution Framework Framework ROM

FMU FMU ROM

Weekly Timer Weekly Timer ROM

Color Table1(Copy) Color table 1 (copy) ROM

Color Table2(Copy) Color table 2 (copy) ROM

Color Table1(Prn) Color table 1 (printer) ROM

Color Table2(Prn) Color table 2 (printer) ROM

DP Document processor ROM

DP Boot Document processor booting

PF1 Paper feeder / Large capacity feeder ROM

PF1 Boot Paper feeder / Large capacity feeder booting

Side PF SMT paper feeder /Side feeder ROM

Side PF Boot SMT paper feeder /Side feeder booting

U019 Displaying the ROM version

Description

Displays the part number of the ROM fitted to each PWB.

Purpose

To check the part number or to decide, if the newest version of ROM is installed.

Method

1. Press the start key. The ROM version are displayed.

2. Change the screen using the cursor up/down keys.

3NJ

1-3-16

Page 41

Item No. Description

Display Description

PF2 Side paper feeder / Side large capacity feeder ROM

PF2 Boot Side paper feeder / Side large capacity feeder booting

DF 1000-sheet finisher / 4000-sheet finisher ROM

DF Boot 1000-sheet finisher / 4000-sheet finisher booting

PH Punch unit ROM

PH Boot Punch unit booting

MT Mailbox ROM

MT Boot Mailbox booting

BF Center-folding unit ROM

BF Boot Center-folding unit booting

Fax APL1 Fax APL 1

Fax Boot1 Fax booting 1

Fax IPL1 Fax IPL 1

Fax APL2 Fax APL 2 (dual Fax)

Fax Boot2 Fax booting 2 (dual Fax)

Fax IPL2 Fax IPL 2 (dual Fax)

U019

3NJ

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

1-3-17

Page 42

Item No. Description

Display Description

LSU Out Top Leading edge registration adjustment

LSU Out Left Center line adjustment

LSU Out Top B/W Leading edge registration adjustment in black/white mode

LSU Out Top 3/4 Leading edge registration adjustment at 3/4 times of line speed

U034 Adjusting the print start timing

Description

Adjusts the leading edge registration or center line.

Purpose

Make the adjustment if there is a regular error between the leading edges of the copy image and

original.

Make the adjustment if there is a regular error between the center lines of the copy image and

original.

Method

1. Press the start key.

2. Select the item to be adjusted.

3NJ

1-3-18

Page 43

Item No. Description

Display Description

Setting

range

Initial

setting

Change in

value per step

MPT(L) Paper feed from MP tray

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

MPT Half(L) Paper feed from MP tray

(when large size thick paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette(L) Paper feed from cassette

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette

Half(L)

Paper feed from cassette

(when large size thick paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex(L) Duplex mode (second)

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex

Half(L)

Duplex mode (second)

(when large size thick paper is used)

-3.0 to 3.0 0 0.1 mm

MPT(S) Paper feed from MP tray

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

MPT

Half(S)

Paper feed from MP tray

(when small size thick paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette(S) Paper feed from cassette

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette

Half(S)

Paper feed from cassette

(when small size thick paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex(S) Duplex mode (second)

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex

Half(S)

Duplex mode (second)

(when small size thick paper is used)

-3.0 to 3.0 0 0.1 mm

U034 Adjustment: Leading edge registration adjustment

1. Press the system menu key.

2. Press the start key to output a test pattern.

3. Press the system menu key.

4. Select the item to be adjusted.

[LSU Out Top]

3NJ

Large size: 218 mm or more in width of paper.

1-3-19

Page 44

Item No. Description

Display Description

Setting

range

Initial

setting

Change in

value per step

MPT(L) Paper feed from MP tray

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette(L) Paper feed from cassette

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex(L) Duplex mode (second)

(when large size paper is used)

-3.0 to 3.0 0 0.1 mm

MPT(S) Paper feed from MP tray

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

Cassette(S) Paper feed from cassette

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

Duplex(S) Duplex mode (second)

(when small size paper is used)

-3.0 to 3.0 0 0.1 mm

U034

U066 U071

U034 [LSU Out Top B/W] [LSU Out Top 3/4]

Large size: 218 mm or more in width of paper.

3NJ

5. Change the setting value using the cursor +/- or numeric keys.

For output example 1, increase the value. For output example 2, decrease the value.

Leading edge

registration

(20 ± 1.0 mm)

6. Press the start key. The value is set.

Remark

When changing the setting value of [Large] each item is modified, equal to amount of the value

which is changed adds also the value of [Small] each item and is pulled.

Caution

Check the copy image after the adjustment. If the image is still incorrect, perform the following

adjustments in maintenance mode.

Correct image

Output

example 1

Figure 1-3-4

Output

example 2

1-3-20

Page 45

Item No. Description

Display Description

Setting

range

Initial

setting

Change in

value per step

MPT Paper feed from MP tray -3.0 to 3.0 0 0.1 mm

Cassette1 Paper feed from cassette 1 -3.0 to 3.0 0 0.1 mm

Cassette2 Paper feed from cassette 2 -3.0 to 3.0 0 0.1 mm

Cassette3 Paper feed from optional cassette 3 -3.0 to 3.0 0 0.1 mm

Cassette4 Paper feed from optional cassette 4 -3.0 to 3.0 0 0.1 mm

Cassette5 Paper feed from optional cassette 5 -3.0 to 3.0 0 0.1 mm

Cassette6 Paper feed from optional cassette 6

*

-3.0 to 3.0 0 0.1 mm

Cassette7 Paper feed from optional cassette 7

*

-3.0 to 3.0 0 0.1 mm

Duplex Duplex mode (second) -3.0 to 3.0 0 0.1 mm

U034

U067 U072

U034 Adjustment: Center line adjustment

1. Press the system menu key.

2. Press the start key to output a test pattern.

3. Press the system menu key.

4. Select the item to be adjusted.

3NJ

*: 45 ppm/55 ppm model only.

5. Change the setting value using the +/- keys or numeric keys.

For output example 1, increase the value. For output example 2, decrease the value.

6. Press the start key. The value is set.

Caution

Check the copy image after the adjustment. If the image is still incorrect, perform the following

adjustments in maintenance mode.

Center line of printing

(within ± 2.0 mm)

Correct image

Output

example 1

Figure 1-3-5

Output

example 2

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

1-3-21

Page 46

Item No. Description

Display Description

2PF Paper feeder

LCF Large capacity feeder

Side Deck Side feeder

SMT SMT paper feeder

Side 2PF Side paper feeder

Side LCF Side large capacity feeder

Display Description

Motor Off PF paper feed motor (PFPFM) is turned off

On PF paper feed motor (PFPFM) is turned on

Clutch C1 PF paper conveying clutch 1 (PFPCCL1) is turned on

C2 PF paper conveying clutch 2 (PFPCCL2) is turned on

V Feed(H) PF paper feed clutch 1 (PFPFCL1) is turned on

V Feed(L) PF paper feed clutch 2 (PFPFCL2) is turned on

Solenoid Cassette1 PF pickup solenoid 1 (PFPUSOL1) is turned on

Cassette2 PF pickup solenoid 2 (PFPUSOL2) is turned on

U247 Setting the paper feed device

Description

Turns on motor and clutches of paper feeder device.

Purpose

To check the operation of motor and clutches of paper feed device.

Method

1. Press the start key.

2. Select the paper feed device.

3NJ

Method: [2PF/Side 2PF]

1. Press [Motor], [Clutch] or [Solenoid] and select the item.

2. Select [Execute].

3. Press the start key. The operation starts.

4. To stop operation, press the stop key.

1-3-22

Page 47

Item No. Description

Display Description

Motor Off PF paper feed motor (PFPFM) is turned off

On PF paper feed motor (PFPFM) is turned on

Clutch C1 PF paper conveying clutch 1 (PFPCCL1) is turned on

C2 PF paper conveying clutch 2 (PFPCCL2) is turned on

V Feed PF paper conveying clutch 3 (PFPCCL3) is turned on

H Feed1 PF paper feed clutch 1 (PFPFCL1) is turned on

H Feed2 PF paper feed clutch 2 (PFPFCL2) is turned on

Solenoid Cassette1 PF pickup solenoid 1 (PFPUSOL1) is turned on

Cassette2 PF pickup solenoid 2 (PFPUSOL2) is turned on

Display Description

Motor Off SF paper feed motor (SFPFM) is turned off

On SF paper feed motor (SFPFM) is turned on

Clutch C1 SF paper conveying clutch (SFPCCL) is turned on

Solenoid Cassette1 SF pickup solenoid (PFPUSOL) is turned on

Display Description

Motor Off SMT paper feed motor (SMTPFM) is turned off

On SMT paper feed motor (SMTPFM) is turned on

Clutch C1 SMT paper conveying clutch 1 (SMTPCCL1) is turned on

C2 SMT paper conveying clutch 2 (SMTPCCL2) is turned on

H Feed SMT paper feed clutch (SMTPFCL) is turned on

Solenoid Cassette1 SMT pickup solenoid (SMTPUSOL) is turned on

Retard SMT feedshift solenoid (SMTFSSOL) is turned on

U247 Method: [LCF/Side LCF]

1. Press [Motor], [Clutch] or [Solenoid] and select the item.

2. Select [Execute].

3. Press the start key. The operation starts.

4. To stop operation, press the stop key.

3NJ

Method: [Side Deck]

1. Press [Motor], [Clutch] or [Solenoid] and select the item.

2. Select [Execute].

3. Press the start key. The operation starts.

4. To stop operation, press the stop key.

Method: [SMT]

1. Press [Motor], [Clutch] or [Solenoid] and select the item.

2. Select [Execute].

3. Press the start key. The operation starts.

4. To stop operation, press the stop key.

1-3-23

Page 48

Item No. Description

Display Description

On Cassette heater ON

Off Cassette heater OFF

U247 Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

U327 Setting the cassette heater control

Description

Sets the cassette heater control.

Purpose

To change the setting according to the machine installation environment.

Setting

1. Press the start key.

2. Select On or Off.

3NJ

Initial setting: Off

3. Press the start key. The setting is set.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

1-3-24

Page 49

Item No. Description

Display Description

Cassette1 Cassette 1

Cassette2 Cassette 2

Cassette3 Cassette 3 (paper feeder/large capacity feeder)

Cassette4 Cassette 4 (paper feeder/large capacity feeder)

Cassette5 Cassette 5 (SMT paper feeder/side feeder)

Cassette6 Cassette 6 (side paper feeder/side large capacity feeder)

Cassette7 Cassette 7 (side paper feeder/side large capacity feeder)

U341 Specific paper feed location setting for printing function

Description

Sets a paper feed location specified for printer output (only if a printer kit is installed).

Purpose

To use a paper feed location only for printer output.

A paper feed location specified for printer output cannot be used for copy output.

Method

1. Press the start key.

2. Select the paper feed location for the printer.

Two or more cassette can be selected.

3NJ

When an optional paper feed device is not installed, the corresponding count is not displayed.

3. Press the start key. The setting is set.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

1-3-25

Page 50

Item No. Description

Display Description

MPT MP tray

Cassette1 Cassette 1

Cassette2 Cassette 2

Cassette3 Cassette 3 (paper feeder/large capacity feeder)

Cassette4 Cassette 4 (paper feeder/large capacity feeder)

Cassette5 Cassette 5 (SMT paper feeder/side feeder)

Cassette6 Cassette 6 (side paper feeder/side large capacity feeder)

Cassette7 Cassette 7 (side paper feeder/side large capacity feeder)

Duplex Duplex unit

U901 Checking copy counts by paper feed locations

Description

Displays or clears paper feed counts by paper feed locations.

Purpose

To check the time to replace consumable parts. Also to clear the counts after replacing the consumable parts.

Method

1. Press the start key. The counts by paper feed locations are displayed.

3NJ

* : When an optional paper feed device is not installed, the corresponding count is not dis-

played.

Clearing

1. Select the counts to be cleared.

[Cassette3], [Cassette4], [Cassette5], [Cassette6] and [Cassette7] cannot be cleared.

2. Select the counts for all and press [Clear].

3. Press the start key. The counts is cleared.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

1-3-26

Page 51

3NJ

C. Mis feed in cassette 3 or 4

E. Mis feed in PF paper conveying cover

L. Mis feed in cassette 5

M. Mis feed in cassette 6 or 7

PFPS1

PFFS1

PFPS2

PFFS2

PFPCS2

PFPCS1

1-4 Troubleshooting

1-4-1 Paper mis feed detection

(1) Paper mis feed indication

When a paper mis feed occurs, the machine immediately stops printing and displays the paper mis feed message on the operation panel. To remove paper mis feed in the machine, pull out the cassette, open the paper

conveying unit or paper conveying cover.

D

L

C

E

C

M

M

M

Figure 1-4-1 Paper mis feed indication

(2) Paper mis feed detection condition

Figure 1-4-2 Paper jam location

1-4-1

Page 52

3NJ

Code Contents Conditions

0000 Initial jam The power is turned on when a sensor in the con-

veying system is on.

0210 PF paper conveying cover

open

0503 No paper feed from cassette 3 PF feed sensor 1 (PFFS1) does not turn on dur-

0504 No paper feed from cassette 4 PF feed sensor 2 (PFFS2) does not turn on dur-

0506 No paper feed from cassette 6 PF feed sensor 1 (PFFS1) does not turn on dur-

0507 No paper feed from cassette 7 PF feed sensor 2 (PFFS2) does not turn on dur-

0513 Multiple sheets in cassette 3 PF feed sensor 1 (PFFS1) does not turn off dur-

0514 Multiple sheets in cassette 4 PF feed sensor 2 (PFFS2) does not turn off dur-

0516 Multiple sheets in cassette 6 PF feed sensor 1 (PFFS1) does not turn off dur-

The PF paper conveying cover is opened during

printing.

ing paper feed from cassette 3.

ing paper feed from cassette 4.

ing paper feed from cassette 6.

ing paper feed from cassette 7.

ing paper feed from cassette 3.

ing paper feed from cassette 4.

ing paper feed from cassette 6.

Jam

location*

-

E

C

C

M

M

C

C

M

0517 Multiple sheets in cassette 7 PF feed sensor 2 (PFFS2) does not turn off dur-

ing paper feed from cassette 7.

1303 Middle sensor non arrival jam Middle sensor (MS) does not turn on during paper

feed from cassette 3.

1304 Middle sensor (MS) does not turn on during paper

feed from cassette 4.

1306 Middle sensor (MS) does not turn on during paper

feed from cassette 6.

1307 Middle sensor (MS) does not turn on during paper

feed from cassette 7.

1313 Middle sensor stay jam Middle sensor (MS) does not turn off during paper

feed from cassette 3.

1314 Middle sensor (MS) does not turn off during paper

feed from cassette 4.

1316 Middle sensor (MS) does not turn off during paper

feed from cassette 6.

1317 Middle sensor (MS) does not turn off during paper

feed from cassette 7.

1503 Paper conveying sensor non

arrival jam

Paper conveying sensor (PCS) does not turn on

during paper feed from cassette 3 .

M

C

C

C

C

E

E

E

E

C

1504 Paper conveying sensor (PCS) does not turn on

during paper feed from cassette 4.

*: Refer to figure 1-4-1 for paper mis feed indication (see page 1-4-1).

1-4-2

C

Page 53

3NJ

Code Contents Conditions

1513 Paper conveying sensor stay

jam

1514 Paper conveying sensor (PCS) does not turn off

1703 PF paper conveying sensor 1

non arrival jam

1704 PF paper conveying sensor 1 (PFPCS1) does not

1713 PF paper conveying sensor 1

stay jam

1714 PF paper conveying sensor 1 (PFPCS1) does not

1904 PF paper conveying sensor 2

non arrival jam

1914 PF paper conveying sensor 2

stay jam

2106 PF paper conveying sensor 1

non arrival jam

Paper conveying sensor (PCS) does not turn off

during paper feed from cassette 3.

during paper feed from cassette 4.

PF paper conveying sensor 1 (PFPCS1) does not

turn on during paper feed from cassette 3.

turn on during paper feed from cassette 4.

PF paper conveying sensor 1 (PFPCS1) does not

turn off during paper feed from cassette 3.

turn off during paper feed from cassette 4.

PF paper conveying sensor 2 (PFPCS2) does not

turn on during paper feed from cassette 4.

PF paper conveying sensor 2 (PFPCS2) does not

turn off during paper feed from cassette 4.

PF paper conveying sensor 1 (PFPCS1) does not

turn on during paper feed from cassette 6.

Jam

location*

E

E

C

C

E

E

C

E

M

2107 PF paper conveying sensor 1 (PFPCS1) does not

turn on during paper feed from cassette 7.

2116 PF paper conveying sensor 1

stay jam

2117 PF paper conveying sensor 1 (PFPCS1) does not

2307 PF paper conveying sensor 2

non arrival jam

2317 PF paper conveying sensor 2

stay jam

3406 SMT paper conveying sensor

1 non arrival jam

3407 SMT paper conveying sensor 1 (SMTPCS1) does

3416

3417 SMT paper conveying sensor 1 (SMTPCS1) does

3506 SMT paper conveying sensor

SMT paper conveying sensor

1 stay jam

2 non arrival jam

PF paper conveying sensor 1 (PFPCS1) does not

turn off during paper feed from cassette 6.

turn off during paper feed from cassette 7.

PF paper conveying sensor 2 (PFPCS2) does not

turn on during paper feed from cassette 7.

PF paper conveying sensor 2 (PFPCS2) does not

turn off during paper feed from cassette 7.

SMT paper conveying sensor 1 (SMTPCS1) does

not turn on during paper feed from cassette 6.

not turn on during paper feed from cassette 7.

SMT paper conveying sensor 1 (SMTPCS1) does

not turn off during paper feed from cassette 6.

not turn off during paper feed from cassette 7.

SMT paper conveying sensor 2 (SMTPCS2) does

not turn on during paper feed from cassette 6.

M

L

L

M

M

M

M

L

L

M

3507 SMT paper conveying sensor 2 (SMTPCS2) does

not turn on during paper feed from cassette 7.

*: Refer to figure 1-4-1 for paper mis feed indication (see page 1-4-1).

1-4-3

M

Page 54

3NJ

Code Contents Conditions

3516 SMT paper conveying sensor

2 stay jam

3517 SMT paper conveying sensor 2 (SMTPCS2) does

3606 SMT paper conveying sensor

3 non arrival jam

3607 SMT paper conveying sensor 3 (SMTPCS3) does

3616 SMT paper conveying sensor

3 stay jam

3617 SMT paper conveying sensor 3 (SMTPCS3) does

3706 SMT paper conveying sensor

4 non arrival jam

3707 SMT paper conveying sensor 4 (SMTPCS4) does

3716 SMT paper conveying sensor

4 stay jam

SMT paper conveying sensor 2 (SMTPCS2) does

not turn off during paper feed from cassette 6.

not turn off during paper feed from cassette 7.

SMT paper conveying sensor 3 (SMTPCS3) does

not turn on during paper feed from cassette 6.

not turn on during paper feed from cassette 7.

SMT paper conveying sensor 3 (SMTPCS3) does

not turn off during paper feed from cassette 6.

not turn off during paper feed from cassette 7.

SMT paper conveying sensor 4 (SMTPCS4) does

not turn on during paper feed from cassette 6.

not turn on during paper feed from cassette 7.

SMT paper conveying sensor 4 (SMTPCS4) does

not turn off during paper feed from cassette 6.

Jam

location*

L

L

M

M

L

M

M

M

L

3717 SMT paper conveying sensor 4 (SMTPCS4) does

not turn off during paper feed from cassette 7.

L

*: Refer to figure 1-4-1 for paper mis feed indication (see page 1-4-1).

1-4-4

Page 55

3NJ

1-4-2 Self-diagnostic function

(1) Self-diagnostic function

This machine is equipped with self-diagnostic function. When a problem is detected, the machine stops printing and display an error message on the operation panel. An error message consists of a message prompting

a contact to service personnel and a four-digit error code indicating the type of the error.

Machine failure.

Call service.

C####

Error occurred.

Turn the main power

switch off and on.

C####

Figure 1-4-3

(2) Self diagnostic codes

If the part causing the problem was not supplied, use the unit including the part for replacement.

Code Contents Causes

1030 PF lift motor 1 error

After cassette 3 is inserted,

PF lift sensor 1 does not turn

on within 12 s. This error is

detected 2 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1s or more 2 times successively. However, the first 1 s

after PF lift motor 1 is turned

on is excluded from detection.

Defective bottom

plate elevation

mechanism in the

cassette.

Defective connector cable or poor

contact in the connector.

Defective drive

transmission system of motor.

Defective PF lift

motor 1.

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Reinsert the connector. Also check for continuity within the connector cable. If none,

replace the cable.

PF lift motor 1 and PF main PWB (YC7)

Check if the gears rotate smoothly. If not,

grease the bushes and gears. Check for

broken gears and replace if any.

Replace the PF lift motor 1.

Check procedures/

corrective measures

Defective PF main

PWB.

1-4-5

Replace the PF main PWB and check for

correct operation (see page 1-5-7).

Page 56

3NJ

Code Contents Causes

1040 PF lift motor 2 error

After cassette 4 is inserted,

PF lift sensor 2 does not turn

on within 12 s. This error is

detected 2 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1s or more 2 times successively. However, the first 1 s

after PF lift motor 2 is turned

on is excluded from detection.

1060 PF lift motor 1 error

After cassette 6 is inserted,

PF lift sensor 1 does not turn

on within 12 s. This error is

detected 2 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1s or more 2 times successively. However, the first 1 s

after PF lift motor 1 is turned

on is excluded from detection.

Defective bottom

plate elevation

mechanism in the

cassette.

Defective connector cable or poor

contact in the connector.

Defective drive

transmission system of motor.

Defective PF lift

motor 2.

Defective PF main

PWB.

Defective bottom

plate elevation

mechanism in the

cassette.

Defective connector cable or poor

contact in the connector.

Defective drive

transmission system of motor.

Defective PF lift

motor 1.

Check procedures/

corrective measures

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Reinsert the connector. Also check for continuity within the connector cable. If none,

replace the cable.

PF lift motor 2 and PF main PWB (YC7)

Check if the gears rotate smoothly. If not,

grease the bushes and gears. Check for

broken gears and replace if any.

Replace the PF lift motor 2.

Replace the PF main PWB and check for

correct operation (see page 1-5-7).

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Reinsert the connector. Also check for continuity within the connector cable. If none,

replace the cable.

PF lift motor 1 and PF main PWB (YC7)

Check if the gears rotate smoothly. If not,

grease the bushes and gears. Check for

broken gears and replace if any.

Replace the PF lift motor 1.

1070 PF lift motor 2 error

After cassette 4 is inserted,

PF lift sensor 2 does not turn

on within 12 s. This error is

detected 2 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1s or more 2 times successively. However, the first 1 s

after PF lift motor 2 is turned

on is excluded from detection.

Defective PF main

PWB.

Defective bottom

plate elevation

mechanism in the

cassette.

Defective connector cable or poor

contact in the connector.

Defective drive

transmission system of motor.

Defective PF lift

motor 2.

Defective PF main

PWB.

1-4-6

Replace the PF main PWB and check for