Page 1

PF-70

Page 2

CONTENTS

1-1 Specifications

1-1-1 Specifications ....................................................................................................................................... 1-1-1

1-1-2 Parts names ......................................................................................................................................... 1-1-2

1-1-3 Machine cross section.......................................................................................................................... 1-1-3

1-1-4 Drive system ........................................................................................................................................ 1-1-4

1-2 Installation

1-2-1 Unpacking ............................................................................................................................................ 1-2-1

1-2-2 Installing the desk dehumidifier (service part) ...................................................................................... 1-2-2

1-3 Troubleshooting

1-3-1 Paper misfeed detection ...................................................................................................................... 1-3-1

(1) Paper misfeed indication ................................................................................................................ 1-3-1

(2) Paper misfeed detection conditions................................................................................................ 1-3-1

(3) Paper misfeeds............................................................................................................................... 1-3-3

1-3-2 Self-diagnosis....................................................................................................................................... 1-3-5

(1) Self-diagnostic function .................................................................................................................. 1-3-5

(2) Self-diagnostic codes ..................................................................................................................... 1-3-5

1-3-3 Electrical problems ............................................................................................................................... 1-3-7

(1) The paper feed desk does not operate when the copier print key is pressed. ............................... 1-3-7

(2) The desk drive motor does not operate. ......................................................................................... 1-3-7

(3) The desk upper paper feed clutch does not operate. ..................................................................... 1-3-7

(4) The desk lower paper feed clutch does not operate....................................................................... 1-3-7

(5) The desk feed clutch does not operate. ......................................................................................... 1-3-7

(6) The desk upper lift motor does not operate. ................................................................................... 1-3-8

(7) The desk lower lift motor does not operate. ................................................................................... 1-3-8

(8) The bypass paper feed clutch does not operate. ........................................................................... 1-3-8

(9) The size of paper in the lower drawer is not displayed correctly. ................................................... 1-3-8

(10) The message requesting covers to be closed is displayed when the desk left cover is closed. .... 1-3-9

(11) Others. ............................................................................................................................................ 1-3-9

1-3-4 Mechanical problems ......................................................................................................................... 1-3-10

(1) No paper feed. .............................................................................................................................. 1-3-10

(2) Skewed paper feed....................................................................................................................... 1-3-10

(3) Multiple sheets of paper are fed at one time. ............................................................................... 1-3-10

(4) Paper jams. .................................................................................................................................. 1-3-10

(5) Abnormal noise is heard. .............................................................................................................. 1-3-10

3CC

1-4 Assembly and Disassembly

1-4-1 Precautions for assembly and disassembly ......................................................................................... 1-4-1

(1) Precautions..................................................................................................................................... 1-4-1

1-4-2 Paper feed section ............................................................................................................................... 1-4-2

(1) Detaching and refitting the forwarding, paper feed and separation pulleys.................................... 1-4-2

(2) Replacing the desk upper or lower paper width switches............................................................... 1-4-4

(3) Replacing the desk feed, upper and lower paper feed clutches ..................................................... 1-4-5

(4) Adjusting the position of the rack adjuster ...................................................................................... 1-4-7

(5) Adjusting the amount of slack......................................................................................................... 1-4-8

2-1 Mechanical construction

2-1-1 Mechanical construction....................................................................................................................... 2-1-1

1-1-1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ........................................................................................................................... 2-2-1

2-3 Operation of the PCBs

2-3-1 Desk main PCB .................................................................................................................................... 2-3-1

Page 3

3CC

2-4 Appendixes

Timing chart No. 1 .......................................................................................................................................... 2-4-1

Timing chart No. 2 .......................................................................................................................................... 2-4-2

Wiring diagram ............................................................................................................................................... 2-4-3

1-1-2

Page 4

1-1-1 Specifications

3CC

Paper..............................................Plain paper (75 – 80 g/m2)

Paper size ......................................A3 – A5R, folio, 11" × 17" – 5

1

/2" × 81/2"

Capacity .........................................550 sheets

Power source .................................Electrically connected to the copier.

Dimensions .................................... 585 (W) × 590 (D) × 315 (H) mm

1

/16" (W) × 231/4" (D) × 123/8" (H)

23

Weight............................................ 25 kg/55 lbs

1-1-1

Page 5

3CC

1-1-2 Parts names

1

2

3

Figure 1-1-1

1 Upper drawer

2 Lower drawer

3 Desk left cover

1-1-2

Page 6

1-1-3 Machine cross section

3CC

Paper path

Figure 1-1-2 Machine cross section

1-1-3

Page 7

3CC

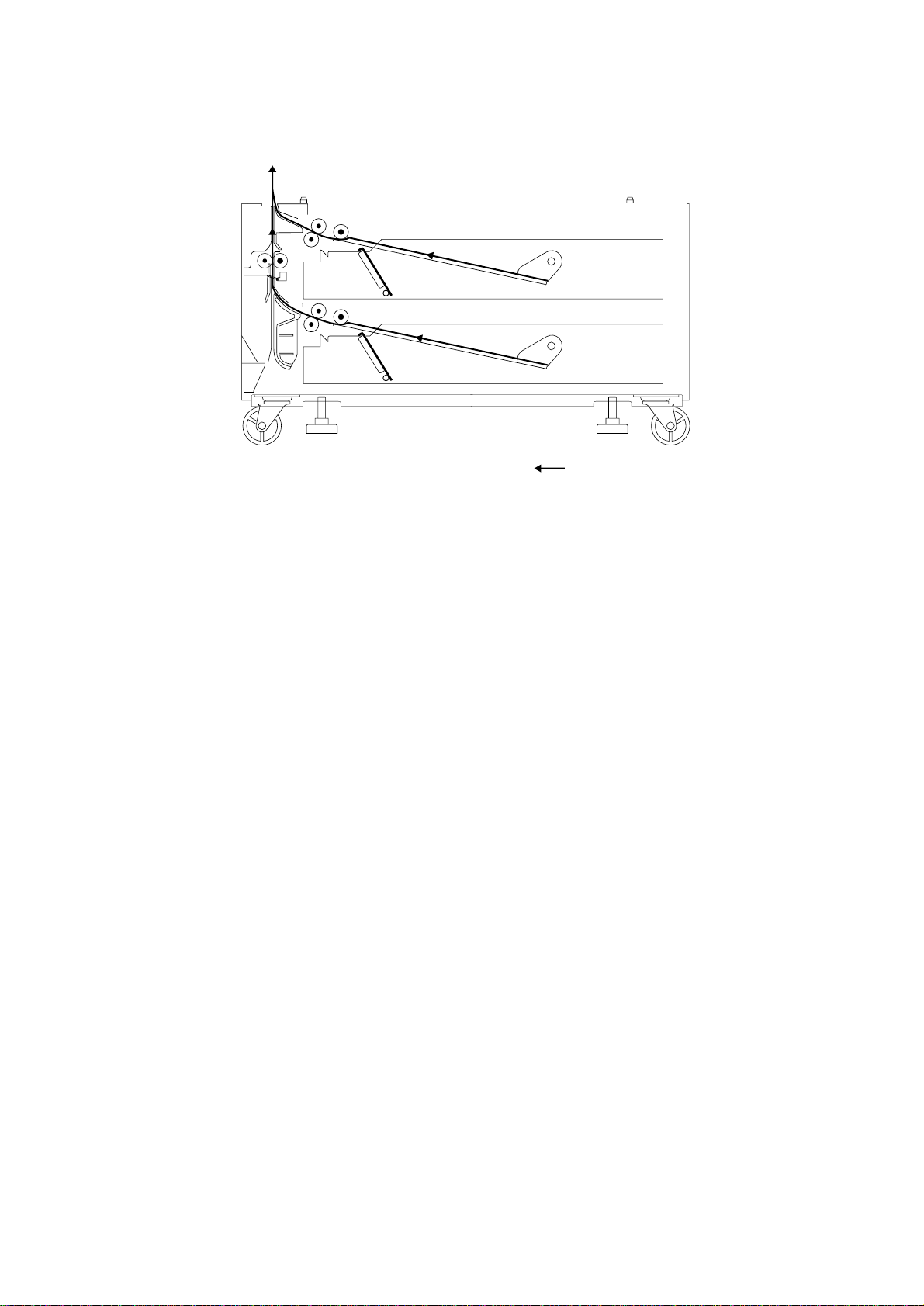

1-1-4 Drive system

84

9

7

6

3

2

1

5

Figure 1-1-3 Drive system

1 Desk drive motor gear

2 Idle gear 67/34

3 Gear 41

4 Desk upper paper feed clutch gear

5 Gear 41

As viewed from machine front

6 Desk lower paper feed clutch gear

7 Gear 20

8 Gear 26

9 Desk feed clutch gear

1-1-4

Page 8

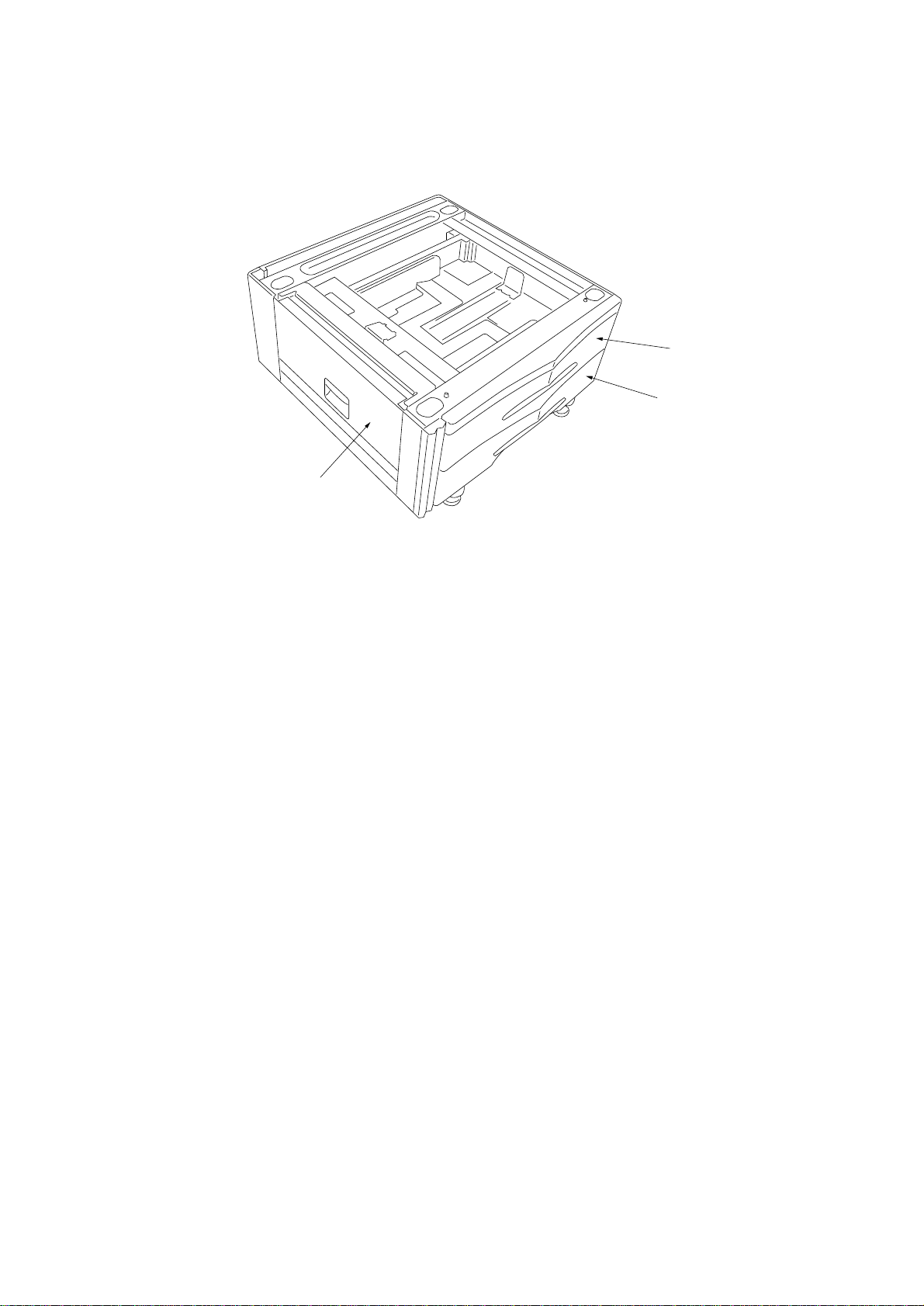

1-2-1 Unpacking

3CC

#

0

8

9

234

56

%

@

0

^

8

!

1

0

Figure 1-2-1

1 Paper feed desk

2 Retainer

3 Cross-head chromate binding screws,

CVM4 × 06

4 Pins

5 Stays

6 Chrome TP screws, M4 × 10

7 Outer case

8 Bottom pads

$

7

9 Upper pad

0 Stays

! Machine cover

@ Rear spacer

# Plastic bag

$ Bar code label

% Plastic bag

^ Installation guide

1-2-1

Page 9

3CC

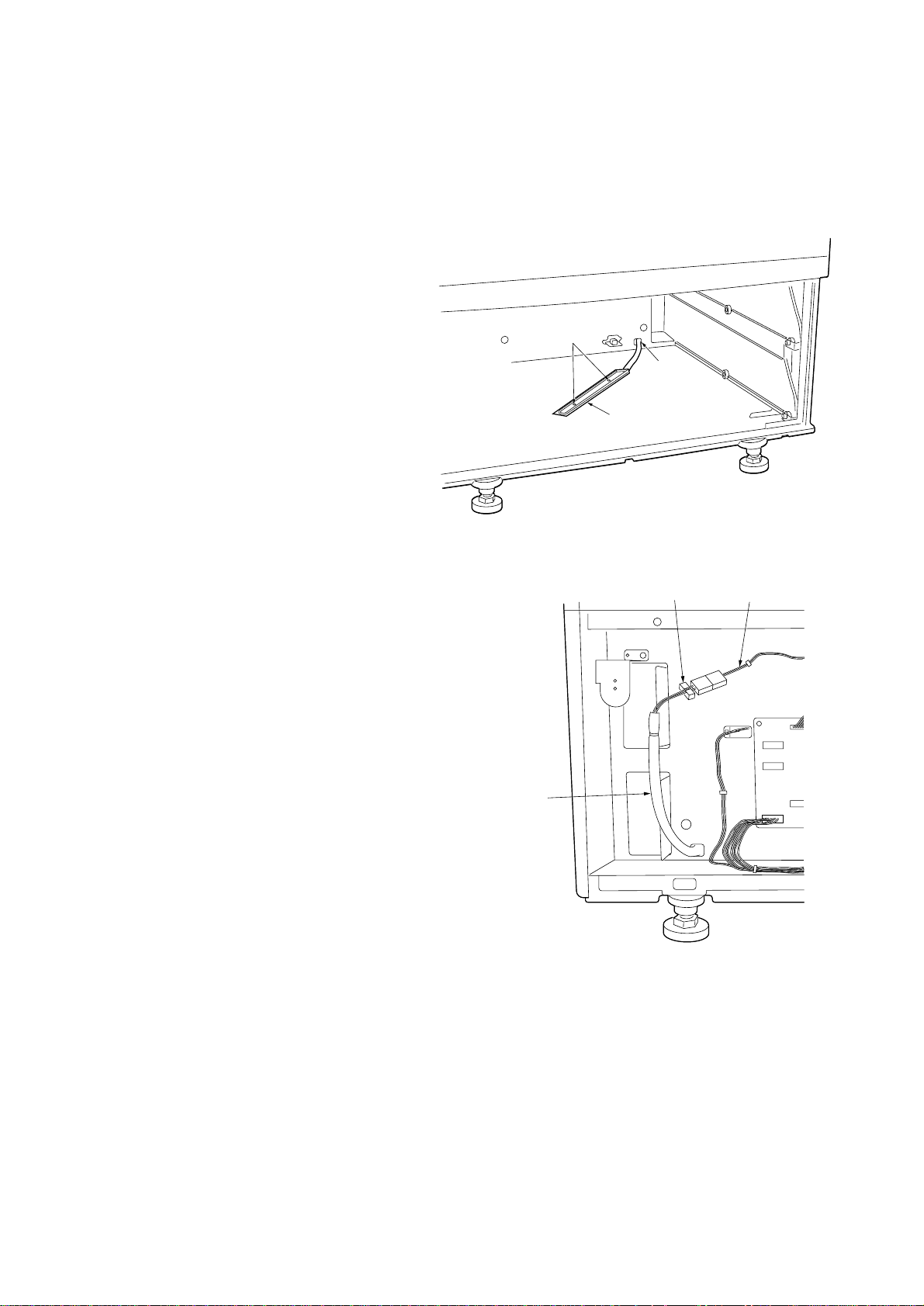

1-2-2 Installing the desk dehumidifier (service part)

Desk dehumidifier installation requires the following parts:

Desk dehumidifier (P/N 33960020): for 220 – 240 V specifications only

Desk dehumidifier (P/N 34860030): for 120 V specifications only

Two (2) M4 × 8 S tight screws (P/N B3324080)

Procedure

1. Remove the upper and lower drawers.

2. Remove the three screws holding the desk

rear cover and then the cover.

3. Pass the desk dehumidifier cable to the

machine rear through the cable hole in the

machine right.

4. Attach the desk dehumidifier using the two M4

× 8 S tight screws.

M4 × 8 S

tight screws

Cable hole

Desk dehumidifier

5. Insert the desk dehumidifier connector into the

connector of the main harness.

6. Tidy up the desk dehumidifier cable using the

wire saddle and route the cable while clipping

the wire saddles into the holes in the rear

frame.

7. Refit all removed parts.

Figure 1-2-2

Wire saddle Main harness

Desk dehumidifier

cable

Figure 1-2-3

1-2-2

Page 10

3CC

1-3-1 Paper misfeed detection

(1) Paper misfeed indication

When a paper jam occurs, the machine immediately stops operation. The operation unit of the copier shows a jam message

and the jam location.

To reset the paper misfeed detection, open and close the desk left cover to turn the desk safety switch off and on.

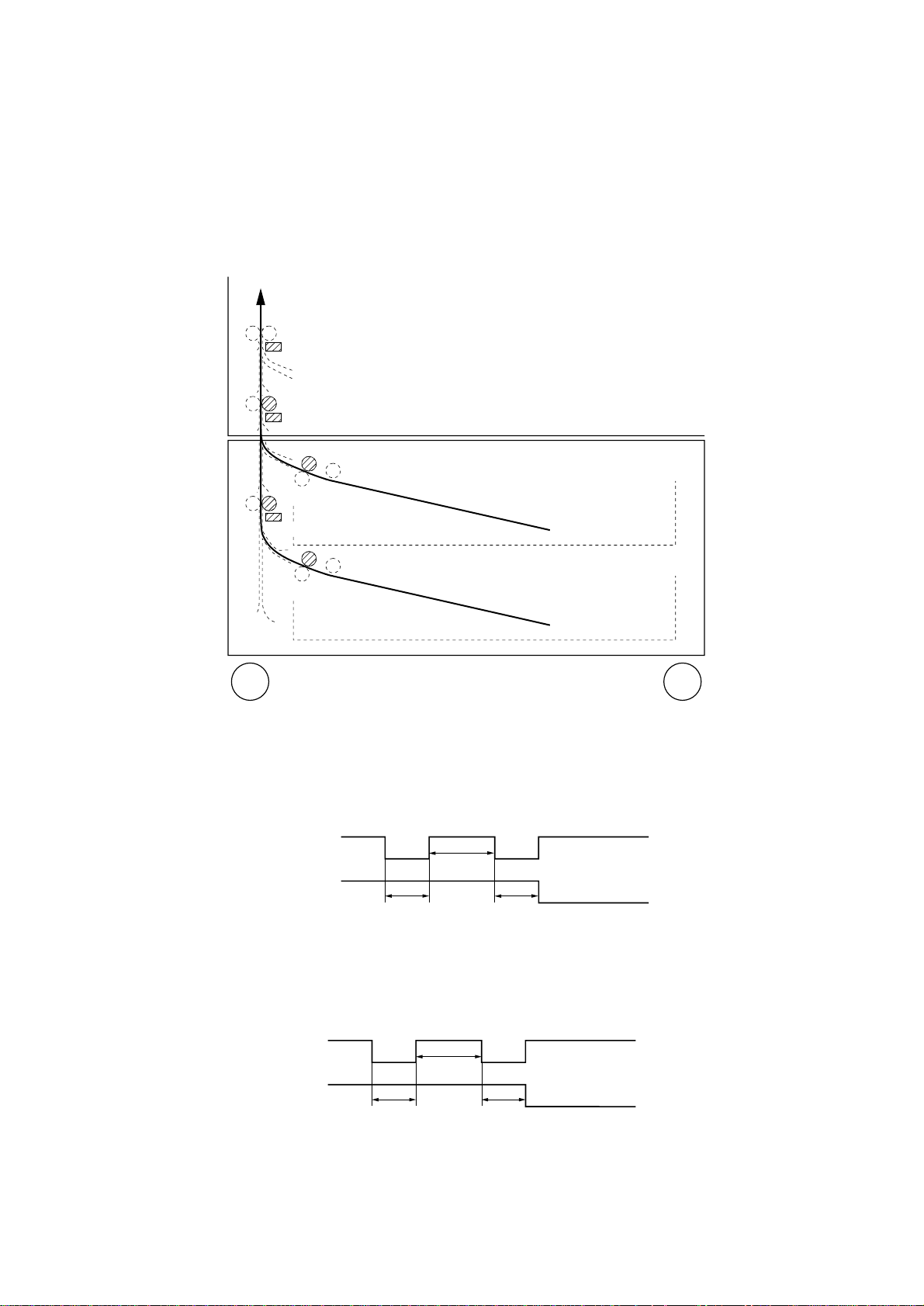

(2) Paper misfeed detection conditions

FSW2

FCL3

FSW3

DPFCL-U

DFCL

DFSW

DPFCL-L

Figure 1-3-1 Paper feed desk

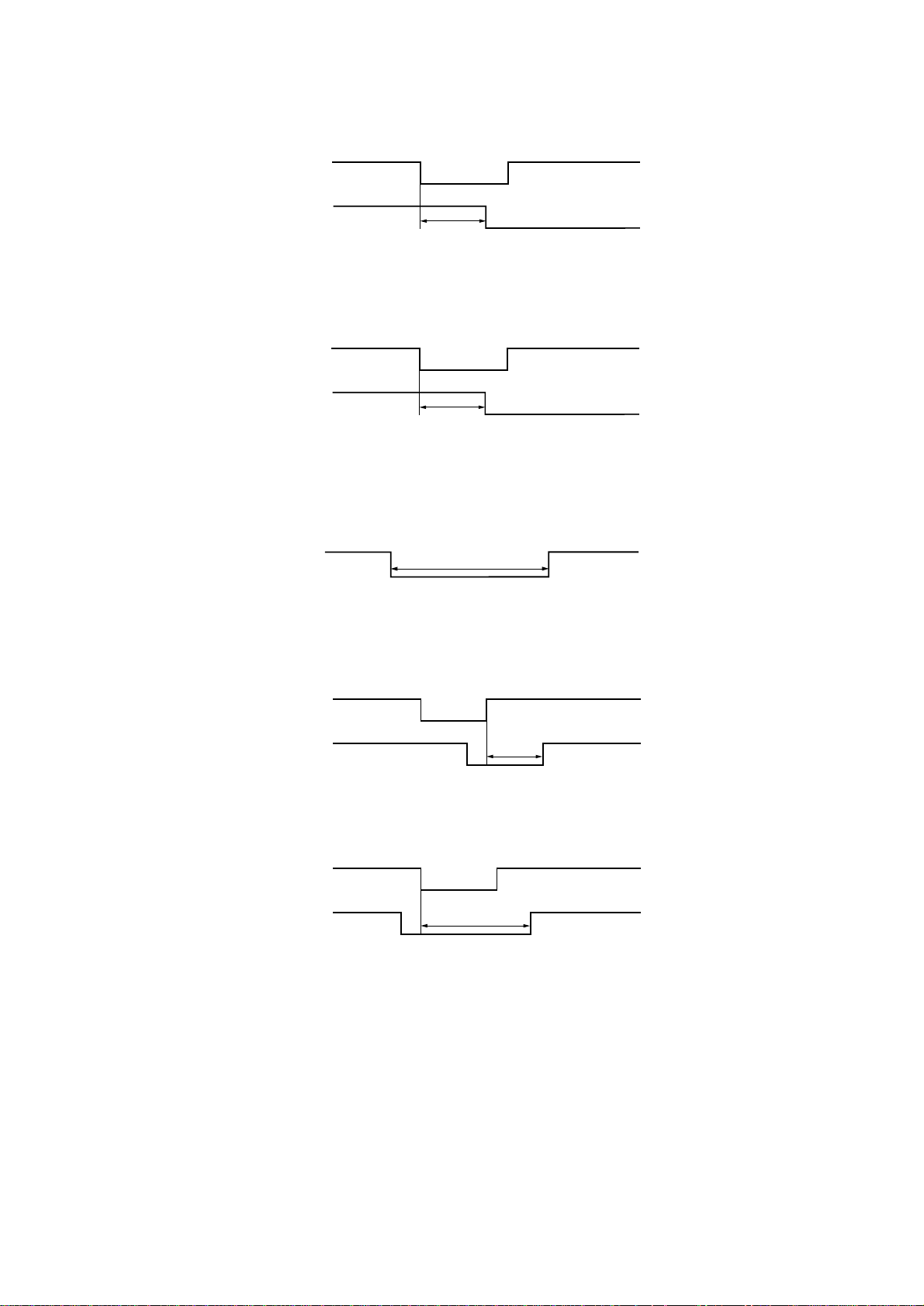

• No paper feed from desk upper drawer (jam code 12)

Feed switch 3 (FSW3) of the copier does not turn on within 880 ms of the desk upper paper feed clutch (DPFCL-U) turning

on; the clutch is then held off for 1 s and turned back on, but the switch again fails to turn on within 880 ms of the retry.

DPFCL-U

FSW3 (copier)

880 ms

1 s

880 ms

Off

On

Off

On

Timing chart 1-3-1

• No paper feed from desk lower drawer (jam code 13)

The desk feed switch (DFSW) does not turn on within 880 ms of the desk lower paper feed clutch (DPFCL-L) turning on; the

clutch is then held off for 1 s and turned back on, but the switch again fails to turn on within 880 ms of the retry.

DPFCL-L

DFSW

880 ms

1 s

880 ms

Off

On

Off

On

Timing chart 1-3-2

1-3-1

Page 11

3CC

• Jam in copier vertical paper conveying section (jam code 18)

Feed switch 2 (FSW2) of the copier does not turn on within 1203 ms of feed switch 3 (FSW3) of the copier turning on.

FSW3 (copier)

FSW2 (copier)

1203 ms

Off

On

Off

On

Timing chart 1-3-3

• Jam in paper feed desk vertical paper conveying section (jam code 19)

Feed switch 3 (FSW3) of the copier does not turn on within 888 ms of the desk feed switch (DFSW) turning on.

DFSW

FSW3 (copier)

888 ms

Off

On

Off

On

Timing chart 1-3-4

• Multiple sheets in paper feed section (jam code 21)

Feed switch 3 (FSW3) of the copier and the desk f eed switch (DFSW) do not turn off within the time required to convey the

length of the used paper size plus 635 ms of turning on.

FSW3 (copier)

DFSW

Paper size + 635 ms

Off

On

Timing chart 1-3-5

• Multiple sheets in vertical paper conveying section (jam code 22)

Feed switch 2 (FSW2) of the copier does not turn off within 1203 ms of feed switch 3 (FSW3) of the copier turning off.

FSW3 (copier)

FSW2 (copier)

1203 ms

Off

On

Off

On

Timing chart 1-3-6

Feed switch 2 (FSW2) of the copier does not turn off within 1203 ms of feed switch 3 (FSW3) of the copier turning on.

FSW3 (copier)

FSW2 (copier)

1203 ms

Off

On

Off

On

Timing chart 1-3-7

1-3-2

Page 12

(3) Paper misfeeds

3CC

Problem

(1)

A paper jam in the

paper feed section

is indicated during

copying (no paper

feed from desk

upper drawer).

Jam code 12

(2)

A paper jam in the

paper feed section

is indicated during

copying (no paper

feed from desk

lower drawer).

Jam code 13

Causes/check procedures

Paper in the desk upper

drawer is extremely curled.

Check if the paper feed

pulley, separation pulley or

forwarding pulley of the

desk upper drawer is

deformed.

Broken copier feed switch 3

actuator.

Defective copier feed switch

3.

Check if the desk upper

paper feed clutch

malfunctions.

Electrical problem with the

desk upper paper feed

clutch.

Paper in the desk lower

drawer is extremely curled.

Check if the paper feed

pulley, separation pulley or

forwarding pulley of the

desk lower drawer is

deformed.

Corrective measures

Change the paper.

Check visually and replace any deformed pulleys.

Check visually and replace feed switch 3 if the actuator is

broken.

Run maintenance item U031 and turn feed switch 3 on and off

manually. Replace feed switch 3 if indication of the corresponding switch on the operation panel is not displayed in reverse.

Run maintenance item U247 and select the desk upper paper

feed clutch on the operation panel to be turned on and off.

Check the status and remedy if necessary.

Check (see page 1-3-7).

Change the paper.

Check visually and replace any deformed pulleys.

(3)

A paper jam in the

paper feed section

is indicated during

copying (jam in

copier vertical paper

conveying section).

Jam code 18

Broken desk feed switch

actuator.

Defective desk feed switch.

Check if the desk lower

paper feed clutch

malfunctions.

Electrical problem with the

desk lower paper feed

clutch.

Broken copier feed switch 2

actuator.

Defective copier feed switch

2.

Check visually and replace the desk feed switch if the actuator

is broken.

With 5 V DC present at CN2-8 on the desk main PCB, check if

CN2-7 on the desk main PCB goes low when the desk feed

switch is turned on. If not, replace the desk feed switch.

Run maintenance item U247 and select the desk lower paper

feed clutch on the operation panel to be turned on and off.

Check the status and remedy if necessary.

Check (see page 1-3-7).

Check visually and replace feed switch 2 if the actuator is

broken.

Run maintenance item U031 and turn feed switch 2 on and off

manually. Replace feed switch 2 if indication of the corresponding switch on the operation panel is not displayed in reverse.

1-3-3

Page 13

3CC

Problem

(4)

A paper jam in the

paper feed section

is indicated during

copying (jam in

paper desk vertical

paper conveying

section).

Jam code 19

(5)

A paper jam in the

paper feed section

is indicated during

copying (multiple

sheets in paper feed

section).

Jam code 21

Causes/check procedures

Broken copier feed switch 3

actuator.

Defective copier feed switch

3.

Check if the desk lower

paper feed clutch

malfunctions.

Electrical problem with the

desk lower paper feed

clutch.

Check if the desk feed

clutch malfunctions.

Electrical problem with the

desk feed clutch.

Check if the desk feed

rollers or pulleys are soiled

with paper powder.

Check if the desk feed

rollers or pulleys are soiled

with paper powder.

Corrective measures

Check visually and replace feed switch 3 if the actuator is

broken.

Run maintenance item U031 and turn feed switch 3 on and off

manually. Replace feed switch 3 if indication of the corresponding switch on the operation panel is not displayed in reverse.

Run maintenance item U247 and select the desk lower paper

feed clutch on the operation panel to be turned on and off.

Check the status and remedy if necessary.

Check (see page 1-3-7).

Run maintenance item U247 and select the desk feed clutch

on the operation panel to be turned on and off. Check the

status and remedy if necessary.

Check (see page 1-3-7).

Check and clean with isopropyl alcohol if soiled.

Check and clean with isopropyl alcohol if soiled.

(6)

A paper jam in the

paper feed section

is indicated during

copying (multiple

sheets in copier

vertical conveying

section).

Jam code 22

Check if the copier feed

rollers or pulleys are soiled

with paper powder.

Check and clean with isopropyl alcohol if soiled.

1-3-4

Page 14

3CC

1-3-2 Self-diagnosis

(1) Self-diagnostic function

When a problem is detected in the paper feed desk, copying is disabled and the problem displayed on the operation unit of

the copier as a code consisting of “C” followed by a number between 0420 and 2600, indicating the nature of the problem.

After removing the problem, the self-diagnostic function can be reset by turning the desk safety switch off and back on.

(2) Self diagnostic codes

Code

C0420

C1030

Contents

Communication problem

An error code from the paper feed desk

is detected eight times in succession.

No communication: there is no reply

after 3 retries.

Abnormal communication: a

communication error (parity or

checksum error) is detected five times

in succession.

Desk upper lift motor problem

When the upper drawer of the paper

feed desk is inserted, the desk upper lift

limit switch does not turn on within 6 s

of the desk upper lift motor turning on

and the desk upper lift limit switch does

not turn on by turning off the desk

upper lift motor for 200 ms and retrying

twice.

During copying, the desk upper lift limit

switch does not turn on within 200 ms

of the desk upper lift motor turning on.

Causes

Poor contact of

the connector

terminals.

Defective copier

main PCB.

Defective desk

main PCB.

Broken gears or

couplings of the

desk upper lift

motor.

Defective desk

upper lift motor.

Poor contact of

the desk upper lift

motor connector

terminals.

Defective desk

upper lift limit

switch.

Remarks

Check procedures/corrective measures

Check the connection of connectors CN3

on the copier main PCB and CN5 on the

desk main PCB, and the continuity across

the connector terminals. Remedy or

replace if necessary.

Replace the copier main PCB and check

for correct operation.

Replace the desk main PCB and check for

correct operation.

Replace the desk upper lift motor.

Check for continuity across the coil. If

none, replace the desk upper lift motor.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Check if CN1-5 on the desk main PCB

goes low when the desk upper lift limit

switch is turned off. If not, replace the desk

upper lift limit switch.

Poor contact of

the desk upper lift

limit switch

connector

terminals.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

1-3-5

Page 15

3CC

Code

C1040

C1170

Contents

Desk lower lift motor problem

When the lower drawer of the paper

feed desk is inserted, the desk lower lift

limit switch does not turn on within 6 s

of the desk lower lift motor turning on

and the desk lower lift limit switch does

not turn on by turning off the desk lower

lift motor for 200 ms and retrying twice.

During copying, the desk lower lift limit

switch does not turn on within 200 ms

of the desk lower lift motor turning on.

Paper feed desk incorrect type

problem

Causes

Broken gears of

couplings of the

desk lower lift

motor.

Defective desk

lower lift motor.

Poor contact of

the desk lower lift

motor connector

terminals.

Defective desk

lower lift limit

switch.

Poor contact of

the desk lower lift

limit switch

connector

terminals.

Desk for the

printer is installed.

Remarks

Check procedures/corrective measures

Replace the desk lower lift motor.

Check for continuity across the coil. If

none, replace the desk lower lift motor.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Check if CN1-7 on the desk main PCB

goes low when the desk lower lift limit

switch is turned off. If not, replace the desk

lower lift limit switch.

Reinsert the connector. Also check for

continuity within the connector cable. If

none, repair or replace the cable.

Replace the desk fot the copier.

C2600

Desk drive motor problem

No pulse is input within 500 ms of the

start-up.

No pulse is input within 100 ms of the

previous pulse input.

Defective desk

drive motor PCB.

Desk drive motor

does not rotate

correctly (the

motor is overloaded).

Poor contact in

the desk drive

motor connector

terminals.

Replace the desk drive motor PCB and

check for correct operation.

Check the gears and remedy if necessary.

Reinsert the connector. Also check for continuity within the connector cable. If none,

remedy or replace the cable.

1-3-6

Page 16

1-3-3 Electrical problems

3CC

Problem

(1)

The paper feed

desk does not

operate when the

copier print key is

pressed.

(2)

The desk drive

motor does not

operate.

(3)

The desk upper

paper feed clutch

does not operate.

Causes

Poor contact of the signal

cable connector terminals

between the paper feed

desk and the copier.

Defective desk safety

switch.

Poor contact of the desk

drive motor connector

terminals.

Broken desk drive motor

gear.

Defective desk drive motor.

Defective desk main PCB.

Broken desk upper paper

feed clutch coil.

Poor contact of the desk

upper paper feed clutch

connector terminals.

Check procedures/corrective measures

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check for continuity across the contacts. If none, replace the

desk safety switch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check visually and replace the desk drive motor if necessary.

Check if the desk drive motor operates when CN4-6 on the

desk main PCB goes low. If not, replace the desk drive motor.

Check if CN4-6 on the desk main PCB goes low when the desk

drive motor is operated in maintenance item U247. If not,

replace the desk main PCB.

Check for continuity across the coil. If none, replace the desk

upper paper feed clutch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

(4)

The desk lower

paper feed clutch

does not operate.

(5)

The desk feed

clutch does not

operate.

Defective desk main PCB.

Broken desk lower paper

feed clutch coil.

Poor contact of the desk

lower paper feed clutch

connector terminals.

Defective desk main PCB.

Broken desk feed clutch

coil.

Poor contact of the desk

feed clutch connector

terminals.

Defective desk main PCB.

Check if CN1-14 on the desk main PCB goes low when the

desk upper paper feed clutch is operated in maintenance item

U247. If not, replace the desk main PCB.

Check for continuity across the coil. If none, replace the desk

lower paper feed clutch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check if CN1-13 on the desk main PCB goes low when the

desk lower paper feed clutch is operated in maintenance item

U247. If not, replace the desk main PCB.

Check for continuity across the coil. If none, replace the desk

feed clutch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check if CN2-1 on the desk main PCB goes low when the desk

feed clutch is operated in maintenance item U247. If not,

replace the desk main PCB.

1-3-7

Page 17

3CC

Problem

(6)

The desk upper lift

motor does not

operate.

(7)

The desk lower lift

motor does not

operate.

(8)

The size of paper in

the upper drawer is

not displayed

correctly.

Causes

Broken desk upper lift motor

coil.

Poor contact of the desk

upper lift motor connector

terminals.

Defective desk main PCB.

Broken desk lower lift motor

coil.

Poor contact of the desk

lower lift motor connector

terminals.

Defective desk main PCB.

Poor contact of the desk

upper paper length switch

connector terminals.

Poor contact of the desk

upper paper width switch

connector terminals.

Check procedures/corrective measures

Check for continuity across the coil. If none, replace the desk

upper lift motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check if 24 V DC is output across CN2-5 (–) and CN2-6 (+) on

the desk main PCB right after the desk upper drawer is

installed. If not, replace the desk main PCB.

Check for continuity across the coil. If none, replace the desk

lower lift motor.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check if 24 V DC is output across CN2-3 (–) and CN2-4 (+) on

the desk main PCB right after the desk lower drawer is

installed. If not, replace the desk main PCB.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

(9)

The size of paper in

the lower drawer is

not displayed

correctly.

Defective desk upper paper

length switch.

Defective desk upper paper

width switch.

Poor contact of the desk

lower paper length switch

connector terminals.

Poor contact of the desk

lower paper width switch

connector terminals.

Defective desk lower paper

length switch.

Defective desk lower paper

width switch.

Check if CN3-7 on the desk main PCB goes low when the desk

upper paper length switch is turned on. If not, replace the desk

upper paper length switch.

Check for continuity between CN3-9 and CN3-1, CN3-2, and

CN3-3 on the desk main PCB. If the continuity is unaffected by

movement of the width guides in the upper drawer (i.e. either

remains present or remains absent), then replace the desk

upper paper width switch.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check if CN3-8 on the desk main PCB goes low when the desk

lower paper length switch is turned on. If not, replace the desk

lower paper length switch.

Check for continuity between CN3-10 and CN3-4, CN3-5, and

CN3-6 on the desk main PCB. If the continuity is unaffected by

movement of the width guides in the lower drawer (i.e. either

remains present or remains absent), then replace the desk

lower paper width switch.

1-3-8

Page 18

3CC

Problem

(10)

The message

requesting covers to

be closed is

displayed when the

desk left cover is

closed.

(11)

Others.

Causes

Poor contact of the desk

safety switch connector

terminals.

Defective desk safety

switch.

Wiring is broken, shorted or

makes poor contact.

Noise.

Check procedures/corrective measures

Reinsert the connector. Also check for continuity within the

connector cable. If none, repair or replace the cable.

Check for continuity across the contacts. If there is no

continuity when the desk safety switch is on, replace it.

Check for continuity. If none, repair.

Locate the source of noise and remove.

1-3-9

Page 19

3CC

1-3-4 Mechanical problems

Problem

(1)

No paper feed.

(2)

Skewed paper feed.

(3)

Multiple sheets of paper

are fed at one time.

(4)

Paper jams.

Causes/check procedures

Check if the surfaces of the following rollers

and pulleys are soiled with paper powder:

forwarding pulley, paper feed pulley,

separation pulley, desk feed roller and desk

feed pulley.

Check if the paper feed pulley or separation

pulley is deformed.

Check if the forwarding pulley is deformed.

Electrical problem with the following

electromagnetic clutches: desk upper/lower

paper feed clutches and desk feed clutch.

Width guide in the drawer installed

incorrectly.

Deformed width guide in the drawer.

Check if the separation pulley is deformed.

Check if the paper is curled.

Check if the paper is excessively curled.

Deformed guides along the paper conveying

path.

Corrective measures

Clean with isopropyl alcohol.

Replace (see page 1-4-2).

Replace (see page 1-4-2).

See pages 1-3-7.

Check the width guide visually and remedy

or replace if necessary.

Check the width guide visually and remedy

or replace if it is deformed.

Replace the separation pulley if it is worn

(see page 1-4-2).

Change the paper.

Change the paper.

Check visually and remedy or replace any

deformed guides.

(5)

Abnormal noise is

heard.

Check if the pulleys, rollers and gears

operate smoothly.

Check if the desk upper and lower paper

feed clutches and the desk feed clutch are

installed correctly.

Grease the bearings and gears.

Remedy.

1-3-10

Page 20

1-4-1 Precautions for assembly and disassembly

(1) Precautions

• Be sure to turn the main switch off and disconnect the power plug before starting disassembly.

• When handling PCBs, do not touch connectors with bare hands or damage the board.

• Do not touch PCBs containing ICs with bare hands or any object prone to static charge.

• Use the following testers when measuring voltages:

Hioki 3200

Sanwa MD-180C

Sanwa YX-360TR

Beckman TECH300

Beckman DM45

Beckman 330 (capable of measuring RMS values)

Beckman 3030 (capable of measuring RMS values)

Beckman DM850 (capable of measuring RMS values)

Fluke 8060A (capable of measuring RMS values)

Arlec DMM1050

Arlec YF1030C

3CC

1-4-1

Page 21

3CC

1-4-2 Paper feed section

(1) Detaching and refitting the forwarding, paper feed and separation pulleys

Replace the forwarding, paper feed and separation pulleys as follows.

Procedure

• Removing the primary paper feed units

1. Remove the upper and lower drawers.

2. Remove the two screws holding the lower

front cover and then the cover.

3. Remove the one screw from each of the

primary paper feed units and then the units.

Screws

Primary paper

feed units

• Removing the forwarding pulley

4. Remove the stopper.

5. Raise the forwarding pulley retainer in the

direction of the arrow, and remove from the

primary paper feed unit.

6. Remove the stop ring, pull the forwarding

pulley shaft in the direction of the arrow, and

remove the forwarding pulley.

Figure 1-4-1 Detaching the primary paper feed units

Forwarding pulley retainer

Stopper

Figure 1-4-2 Detaching the forwarding pulley retainer

Forwarding pulley

Stop ring

Forwarding pulley shaft

1-4-2

Figure 1-4-3 Detaching the forwarding pulley

Page 22

• Removing the paper feed pulley

7. Remove the two stop rings.

8. Pull the paper feed shaft toward the rear of

the primary paper feed unit (in the direction of

the arrow) and remove the paper feed pulley

and gear.

• Removing the separation pulley

9. Remove the stop ring from the rear of the

primary paper feed unit.

10. Pull the separation shaft toward the rear of

the machine (in the direction of the arrow)

and remove the separation pulley.

11. Replace the forwarding, paper feed and

separation pulleys.

12. Refit all removed parts.

Stop rings

Paper feed shaft Gear Paper feed pulley

Figure 1-4-4 Detaching the paper feed pulley

Stop ring

Separation shaft

Separation pulley

3CC

Cautions:

• When fitting the forwarding pulley, orient it

correctly as shown in Figure 1-4-6.

• When fitting the paper feed pulley and gear , keep

the blue end of the paper feed pulley and the

black end of the gear toward the machine rear.

Figure 1-4-5 Detaching the separation pulley

Machine front Machine rear

Forwarding pulley

Figure 1-4-6

1-4-3

Page 23

3CC

(2) Replacing the desk upper or lower paper width switches

Replace the desk upper or lower paper width switches as follows.

Caution:

After replacing a desk paper width switch, be sure to perform (4) Adjusting the position of the rack adjuster.

Procedure

1. Remove the drawer.

Screws

2. Remove the two screws and 8-pin socket

from the rear of the drawer.

3. Detach the 8-pin desk paper width switch

connector from the 8-pin socket.

4. Remove the three screws holding the rack

adjuster.

5. While raising the drawer lift in the direction of

8-pin socket

the arrow, remove the rack adjuster.

Screws

8-pin connector

Figure 1-4-7 Detaching the rack adjuster

Rack adjuster

Drawer lift

6. Remove the two screws from the back of the

rack adjuster and then the desk paper width

switch.

7. Apply the specified grease to the printed

surface of the new desk paper width switch

(shaded area in the diagram) and fit the

switch to the rack adjuster.

8. Refit all removed parts.

Screws

Desk paper width switch

Figure 1-4-8 Detaching the desk paper width switch

Apply the specified grease.

1-4-4

Figure 1-4-9 Desk paper width switch

Page 24

(3) Replacing the desk feed, upper and lower paper feed clutches

Replace the desk feed, upper and lower paper feed clutches as follows.

Procedure

1. Remove the three screws holding the desk

Clamp

rear cover and then the cover.

2. Remove the cable from the retainer clamp.

3. Remove the three screws holding the retainer

and then the retainer.

4. Remove the two screws holding the rear

cover left retainer and then the retainer.

Screws

Retainer

Figure 1-4-10

3CC

Screws

Rear cover

left retainer

5. Remove the upper and lower stop rings and

bearings from the desk upper and lower

paper feed clutches.

6. Remove the stop ring from the desk feed

clutch.

7. Remove the three screws holding the desk

drive motor retainer and then the retainer.

Desk upper paper feed clutch

Stop ring and bearing

Desk feed clutch

Stop ring

Desk lower paper

feed clutch

Stop ring and bearing

Figure 1-4-11

Desk drive motor retainer

Screws

Figure 1-4-12 Detaching the desk drive motor retainer

1-4-5

Page 25

3CC

8. Remove the connectors of the desk feed,

upper and lower paper feed clutches and

then the clutches.

9. Replace the clutches.

10. Refit all removed parts.

Caution:

When fitting the clutches, be sure to refit the whirl-stops.

Desk upper paper feed clutch

Connector

Desk feed clutch

Connector

Desk lower paper

feed clutch

Connector

Figure 1-4-13 Detaching the desk feed, upper and lower

paper feed clutches

1-4-6

Page 26

3CC

(4) Adjusting the position of the rack adjuster

Perform the following adjustment if there is a regular error between the center lines of the copy image and the original on the

paper fed from the drawer.

Procedure

Start

Enter maintenance mode.

Run maintenance item U993.

Select “VTC PG1” and output

a test pattern.

Is the image correct?

Yes

Exit maintenance mode.

End

No

Correct image Output

Loosen the three screws holding

the rack adjuster and change the

position of the adjuster so that

the centers of the original and

the copy image are aligned.

• For output example 1, move

toward the machine front ( ).

• For output example 2, move

toward the machine rear ( ).

Screws

example 1

Figure 1-4-14

Output

example 2

Rack adjuster

Figure 1-4-15 Adjusting the position of the rack adjuster

1-4-7

Page 27

3CC

(5) Adjusting the amount of slack

Perform the f ollowing adjustment if the leading edge of the cop y image is missing or v aries randomly, or if the copy paper is

Z-folded.

Procedure

Start

Enter maintenance mode.

Enter “051” using the numeric keys.

Press the start key.

Select “FEED DATA.”

Select the drawer to be adjusted.

Press the interrupt key.

Press the start key

to make a test copy.

Is the leading edge

of the image missing or varying randomly

(copy example 1)?

No

Is the copy paper

Z-folded (copy example 2)?

Yes

Yes

Original Copy

Press the start key.

The new setting is stored.

Increase the value using

the cursor upper key.

Decrease the value using

the cursor lower key.

example 1

Figure 1-4-16

Copy

example 2

1-4-8

No

Press the stop/clear key.

Exit maintenance mode.

End

Setting range: 0 – 255

Changing the value by 1 changes

the amount of slack by 0.67 mm

Reference: 0

The greater the value, the larger

the amount of slack;

The smaller the value, the smaller

the amount of slack.

Page 28

3CC

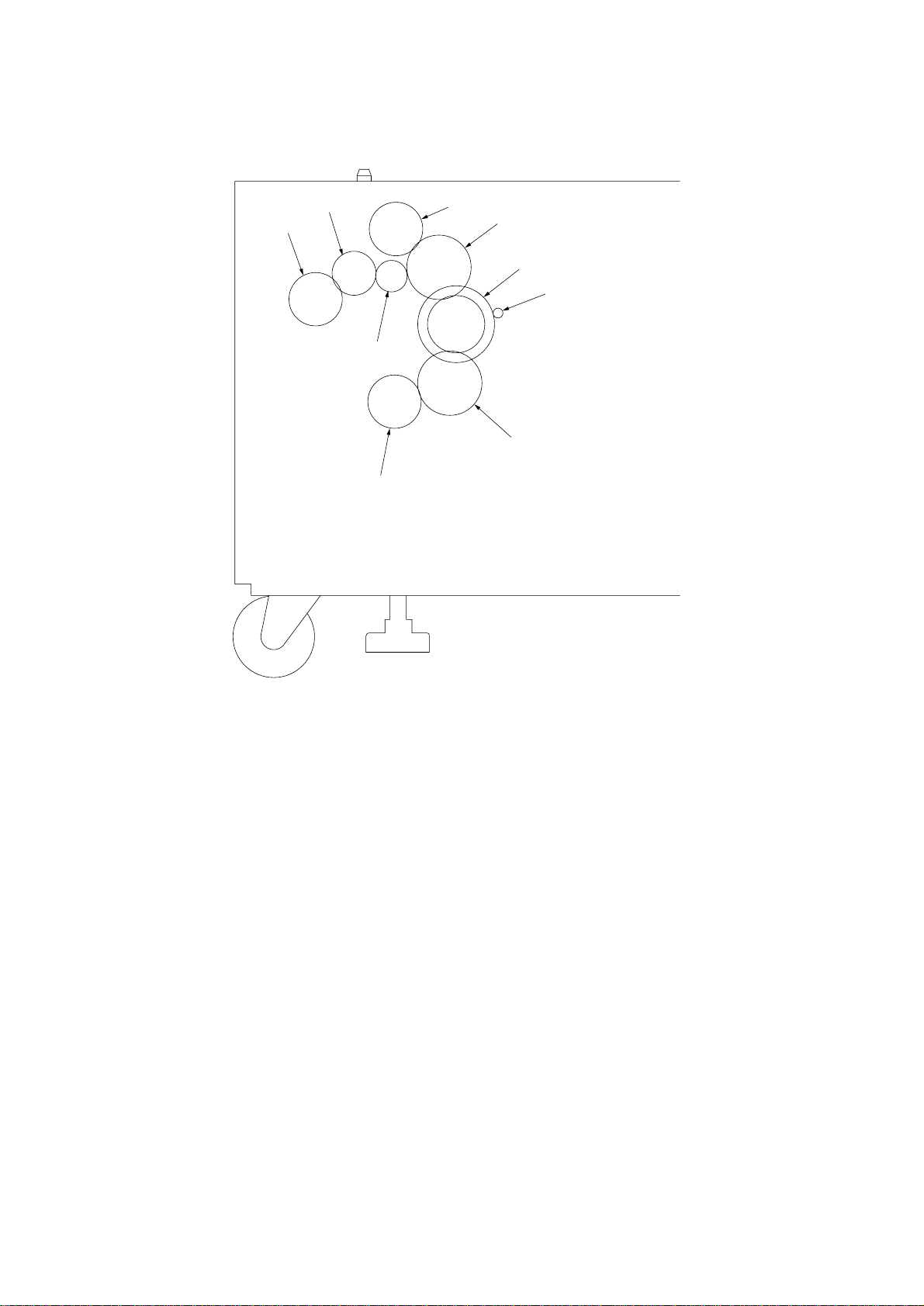

2-1-1 Mechanical construction

The paper feed desk feeds paper from either of its two drawers to the copier main body. When paper is fed from the lower

drawer of the paper feed desk, the desk feed clutch (DFCL) is operated to rotate the desk feed roller and pulley to carry the

paper into the copier main body.

82@

$

4

5

&

!

9

2

#

3

^

3

0

Figure 2-1-1 Paper feed desk

1 Forwarding pulley

2 Paper feed pulley

3 Separation pulley

4 Desk feed roller

5 Desk feed pulley

6 Drawer lift

7 Lift operating plate

8 Desk upper feed guide

9 Desk middle feed guide

0 Desk lower feed guide

! Desk feed guide

@ Desk upper paper feed clutch (DPFCL-U)

(

%

1

*

1

6

7

¤

6

7

‹

# Desk lower paper feed clutch (DPFCL-L)

$ Desk feed clutch (DFCL)

% Desk upper paper switch (DPSW-U)

^ Desk lower paper switch (DPSW-L)

& Desk feed switch (DFSW)

* Desk upper lift limit switch (DLICSW-U)

( Desk lower lift limit switch (DLICSW-L)

) Desk upper paper length switch (DPLSW-U)

⁄ Desk lower paper length switch (DPLSW-L)

¤ Desk upper paper width switch (DPWSW-U)

‹ Desk lower paper width switch (DPWSW-L)

)

⁄

DPSW-U

DPFCL-U

DFCL

DFSW

Figure 2-1-2 Paper feed desk block diagram

DPFCL-L

DPSW-L DLICSW-L

DLICSW-U

DMPCB

CN1-5

CN1-6

CN1-14

CN2-1

CN1-7

CN1-8

CN1-13

CN2-7

2-1-1

Page 29

3CC

• Paper feed from the desk upper drawer

Start key

DDM

FCL3 (copier)

100 ms

a

d

17 ms

c

b

DPFCL-U

RSW (copier)

FSW3 (copier)

DM (copier)

Timing chart 2-1-1 Paper feed from the desk upper drawer

a 100 ms after the start key is pressed, the desk drive motor (DDM) turns on at the same time as the drive motor (DM) turns

on, starting the drive for the paper feed desk. The desk upper paper feed clutch (DPFCL-U) turns on to start rotating the

forwarding pulley and paper feed pulley to start paper feed from the upper drawer.

b 1379 ms after the leading edge of the paper turns the feed switch 3 (FSW3) on, the desk upper paper feed clutch (DPFCL-

U) turns off.

c 17 ms after the leading edge of the paper turns the registration switch (RSW) on, feed clutch 3 (FCL3) turns off.

d The desk drive motor (DDM) turns off at the same time as the drive motor (DM) turns off to stop the drive for the paper feed

desk.

1379 ms

Automatic copy density control;

A3/11" × 17" paper; magnification of 100%

2-1-2

Page 30

• Paper feed from the desk lower drawer

Start key

100 ms

DDM

FCL3 (copier)

DFCL

DPFCL-L

FSW3 (copier)

DFSW

DM (copier)

a

b

c

123 ms

344 ms

123 ms

d

A4/11" × 8

f

e

Manual copy density control;

1

/2" paper; magnification of 100%

3CC

Timing chart 2-1-2 Paper feed from the desk lower drawer

a 100 ms after the start key is pressed, the desk drive motor (DDM) turns on at the same time as the drive motor (DM) turns

on, starting the drive for the paper feed desk. The desk lower paper feed clutch (DPFCL-L) turns on to start rotating the

forwarding pulley and paper feed pulley to start paper feed from the lower drawer.

b At the same time as the leading edge of the paper turns the desk feed switch (DFSW) on, the desk feed clutch (DFCL) turns

on to rotate the desk feed roller to convey the paper to the copier.

c 344 ms after the desk feed switch (DFSW) turns on, the desk lower paper feed clutch (DPFCL-L) turns off.

d 123 ms after the trailing edge of the paper turns the desk feed switch (DFSW) off, the desk feed clutch (DFCL) turns off.

e 123 ms after the trailing edge of the paper turns feed switch 3 (FSW3) off, feed clutch 3 (FCL3) turns off.

f The desk drive motor (DDM) turns off at the same time as the drive motor (DM) turns off to stop the drive for the paper feed

desk.

2-1-3

Page 31

2-2-1 Electrical parts layout

35

15

3CC

16

12

13

9

46

14

10

18

Machine front Machine inside Machine rear

1

7

8

17

2

11

Figure 2-2-1 Layout of electrical parts

1. Desk main PCB (DMPCB) ........................... Controls electrical parts.

2. Desk safety switch (DSSW) ......................... Breaks the safety circuit when the desk left cover is opened, and resets

paper jam detection.

3. Desk upper paper switch (DPSW-U) ........... Detects the presence of paper in the desk upper drawer.

4. Desk lower paper switch (DPSW-L)............. Detects the presence of paper in the desk lower drawer.

5. Desk upper lift limit switch (DLICSW-U) ...... Detects the desk upper drawer lift reaching the upper limit.

6. Desk lower lift limit switch (DLICSW-L)........ Detects the desk lower drawer lift reaching the upper limit.

7. Desk upper paper length switch (DPLSW-U)Detects the length of paper in the desk upper drawer.

8. Desk lower paper length switch (DPLSW-L) Detects the length of paper in the desk lower drawer.

9. Desk upper paper width switch (DPWSW-U)Detects the width of paper in the desk upper drawer.

10. Desk lower paper width switch (DPWSW-L) Detects the width of paper in the desk lower drawer.

11. Desk feed switch (DFSW) ............................ Controls the desk lower paper feed clutch.

12. Desk drive motor (DDM) .............................. Drives the paper feed desk.

13. Desk upper lift motor (DCLM-U) .................. Drives the desk upper drawer lift.

14. Desk lower lift motor (DCLM-L) ................... Drives the desk lower drawer lift.

15. Desk upper paper feed clutch (DPFCL-U) ... Primary paper feed from the desk upper drawer.

16. Desk lower paper feed clutch (DPFCL-L) .... Primary paper feed from the desk lower drawer.

17. Desk feed clutch (DFCL) ............................. Conveys paper to the copier.

18.Desk dehumidifier* (DDH)............................. Dehumidifies paper.

* Service part.

2-2-1

Page 32

2-3-1 Desk main PCB

3CC

DMPCB

DDM

DCLM-U

DCLM-L

DPFCL-U

DPFCL-L

DFCL

DPSW-U

DPSW-L

DLICSW-U

DLICSW-L

DPLSW-U

DPLSW-L

DPWSW-U

DPWSW-L

Motor

driver

(IC8)

CPU

(IC5)

DESK RXD

DESK TXD

FSW SIG

DSSW

DFSW

Copier

main PCB

(MPCB)

Figure 2-3-1 Desk main PCB block diagram

The desk main PCB (DMPCB) is controlled from the copier main PCB (MPCB) which controls the inputs from and outputs

to the motors, clutches and switches on the paper feed desk through the CPU IC5 serially via two-way serial/parallel 8-bit

data conversion.

2-3-1

Page 33

J10

1

J32

J26

J47

J75

J9

J77

J76

J78

J106

J28

J43

J45

J48

J49

J46

L25

J83

J87

J88

J84

J89

J90

J85

J86

CN2

L9

J30

J29

J51

J108

J31

J50

J110

L23

C20

J52

J53

17

18

+

J54

J109

CN4

CN6

L13

11

1

12

2

J111

3

1

7

1

CN3

L14

J55

J91

J92

Figure 2-3-2

J68

J69

C40

J98

J17

J8

L7

J6

C4

J7

J18

J21

J19

IC5

J72

J71

J73

IC7

11

J102

J100 J101J99

12

1

J22

IC8

X1

IC3

22

8

J103

IC1

J24

J40

J104 J74

+

J23

C16

J42

J80

J81

J82

J41

J44

C42

9

L24

8

J25

J27

+

J79

J107

1

J105

CN5

110

J1

J4

D1

IC2

1

IC4

J33

J61

J56

J93

CN1

1

2

J59

J94

J35

J95

8

J58

J57

J2

J13

J12J11

15

16

J36

J60

J3

J34

J62

J96

J38

IC6

J97

J5

J15

J37

J65

J66

L22

J63

J67

J14

J70

J20

J64

L5D2

+

J16

J39

8

+

3CC

2-3-2

Page 34

Terminals (CN) V olta ge Remarks

1-1 1-9 5 V DC 5 V DC supply for DLICSW-U, output

1-2 1-10 5 V DC 5 V DC supply for DPSW-U, output

1-3 1-11 5 V DC 5 V DC supply for DLICSW-L, output

1-4 1-12 5 V DC 5 V DC supply for DPSW-L, output

1-5 1-9 5/0 V DC DLICSW-U on/off, input

1-6 1-10 0/5 V DC DPSW-U on/off, input

1-7 1-11 5/0 V DC DLICSW-L on/off, input

1-8 1-12 0/5 V DC DPSW-L on/off, input

1-13 5-8 0/24 V DC DPFCL-L on/off, input

1-14 5-8 24 V DC 24 V DC supply for DPFCL-L, output

1-15 5-8 0/24 V DC DPFCL-U on/off, input

1-16 5-8 24 V DC 24 V DC supply for DPFCL-U, output

2-1 5-8 0/24 V DC DFCL on/off, input

2-2 5-8 24 V DC 24 V DC supply for DFCL, output

2-3 5-8 0/24 V DC DCLM-L on/off, input

2-4 5-8 24 V DC 24 V DC supply for DCLM-L, output

2-5 5-8 0/24 V DC DCLM-U on/off, input

2-6 5-8 24 V DC 24 V DC supply for DCLM-U, output

2-7 2-9 0/5 V DC DFSW on/off, output

2-8 2-9 5 V DC 5 V DC supply for DFSW, output

2-15 2-13 0/5 V DC Paper level detection switch on/off, input

2-16 2-14 0/5 V DC Paper level detection switch on/off, input

2-17 2-13 0/5 V DC Paper level detection switch on/off, input

2-18 2-14 0/5 V DC Paper level detection switch on/off, input

3-1 3-9 0/5 V DC DPWSW-U (DIG0) on/off, input

3-2 3-9 0/5 V DC DPWSW-U (DIG1) on/off, input

3-3 3-9 0/5 V DC DPWSW-U (DIG2) on/off, input

3-4 3-10 0/5 V DC DPWSW-L (DIG0) on/off, input

3-5 3-10 0/5 V DC DPWSW-L (DIG1) on/off, input

3-6 3-10 0/5 V DC DPWSW-L (DIG2) on/off, input

3-7 3-11 0/5 V DC DPLSW-U on/off, input

3-8 3-12 0/5 V DC DPLSW-L on/off, input

4-1 4-2 24 V DC 24 V DC supply for DDM, output

4-4 4-3 5 V DC 5 V DC supply for DDM, output

4-5 4-2 0/5 V DC (pulse) Clock signal to DDM, output

4-6 4-2 0/5 V DC DDM on/off, output

4-7 4-2 0/5 V DC LOCK signal to DDM, input

5-1 5-2 0/5 V DC FSW3 on/off from the copier, input

5-3 5-2 0/5 V DC (pulse) Serial communication signal to the copier, output

5-5 5-4 0/5 V DC (pulse) Serial communication signal to the copier, input

5-6 5-7 5 V DC 5 V DC supply, input

5-10 5-8 24 V DC 24 V DC supply, input

6-1 5-8 24/0 V DC DSSW on/off, input

6-3 5-8 24 V DC 24 V DC supply for DSSW, output

3CC

2-3-3

Page 35

Start key

DM CN11-A3

DDM CN4-6

RCL CN10-A5

FCL1 CN10-A7

FCL2 CN10-A9

FCL3 CN10-A11

DPFCL-UCN1-14

MC REM CN9-14

FSM CN2-7, 8, 9, 10

CL CN13-4

RSW CN8-25

ESW CN2-15

FSW1 CN15-5

FSW2 CN15-8

FSW3 CN15-11

TC REMCN9-9

DB REMCN9-11

17 ms

78 ms

124 ms

124 ms

48 ms

Min 78 ms

100 ms

30 ms

30 ms

100 ms

190 ms

190 ms

1055 ms

1379 ms

323 ms

323 ms

350 ms

500 ms

518 ms

300 ms

200 ms

Image ready

215 ms

17 ms

1379 ms

3CC

Timing chart No. 1 Continuous copying an A3/11" × 17" original onto two sheets of A3/11" × 17" copy paper from the paper feed

desk upper drawer, magnification ratio 100%, auto copy density control

2-4-1

Page 36

3CC

Start key

DM CN11-A3

DDM CN4-6

RCL CN10-A5

FCL1 CN10-A7

FCL2 CN10-A9

FCL3 CN10-A11

DFCL CN2-1

DPFCL-L CN1-13

MC REMCN9-14

FSM CN2-7, 8, 9, 10

CL CN13-4

RSW CN8-25

ESW CN2-15

FSW1 CN15-5

FSW2 CN15-8

FSW3 CN15-11

DFSW CN2-7

TC REM CN9-9

DB REM CN9-11

100 ms

123 ms

123 ms

17 ms

30 ms

48 ms

Min 78 ms

124 ms

100 ms

344 ms

323 ms

518 ms

500 ms

200 ms

300 ms

350 ms

190 ms

Image ready

215 ms

" copy paper from the paper feed desk lower drawer,

2

/

1

" original onto an A4/11" × 8

2

/

1

magnification ratio 100%, manual copy density control

Timing chart No. 2 Copying an A4/11" × 8

2-4-2

Page 37

Wiring diagram

A B C D E F G H IJ

1

2

C113

RD:C101-15

RD:C121-1

BE:C103-10

GN:C103-4

PE:C103-5

PK:C103-6

14325678

C311

RD:C311-3

RD:C311-4

BE:C312-1

YW:C312-2

LB:C312-3

PK:C312-4

76583412

BE:C311-8

YW:C311-5

LB:C311-6

PK:C311-7

LOWER DRAWER

C312

1

GND

2

DPWSW-U DIG0

3

DPWSW-U DIG1

4

DPWSW-U DIG2

5

DPWSW-U

C112

RD:C101-16

RD:C117-1

BE:C103-9

GN:C103-1

PE:C103-2

PK:C103-3

C116

OE:C101-4

LB:C101-8

BE:C101-12

OE:C101-3

YW:C101-7

BE:C101-11

14325678

14325678

C301

RD:C301-3

RD:C301-4

BE:C302-1

YW:C302-2

LB:C302-3

PK:C302-4

76583412

C211

GY:C213-1

GY:C213-2

GY:C213-3

GY:C212-1

GY:C212-2

GY:C212-3

78563412

BE:C301-8

YW:C301-5

LB:C301-6

PK:C301-7

GY:C211-4

GY:C211-3

GY:C211-6

GY:C211-5

GY:C211-8

GY:C211-7

UPPER DRAWER

C302

1

GND

2

DPWSW-L DIG0

3

DPWSW-L DIG1

4

DPWSW-L DIG2

5

LOWER DRAWER

PAPER FEED UNIT

C213

1

5 V

2

DPSW-L

3

GND

1

5 V

2

DLICSW-L

3

GND

C212

DPWSW-L

DPSW-L

DLICSW-L

C115

OE:C101-2

LB:C101-6

BE:C101-10

OE:C101-1

YW:C101-5

BE:C101-9

12345678

C201

GY:C203-1

GY:C203-2

GY:C203-3

GY:C202-1

GY:C202-2

GY:C202-3

78563412

GY:C201-4

GY:C201-3

GY:C201-6

GY:C201-5

GY:C201-8

GY:C201-7

UPPER DRAWER

PAPER FEED UNIT

C203

1

5 V

2

DPSW-U

3

GND

1

5 V

2

DLICSW-U

3

GND

C202

3CC

1

2

DPSW-U

DLICSW-U

3

DDM

4

RD:C104-1

BE:C104-2

DPLSW-U

DPLSW-L

BE:C104-3

OE:C104-4

YW:C104-5

YW:C104-6

GN:C104-7

DDH

RD:C102-4

5

GN:C102-3

LB:C102-15

BE:C102-13

PE:C102-17

6

C110

1

24 V

2

DCLM-U REM

3

DCLM-U SIG1

4

COM

5

DCLM-U SIG2

YW:C103-7

BE:C103-11

YW:C103-8

BE:C103-12

CN107

1

GND

2

DPLSW-U

CN106

1

GND

2

DPLSW-L

DCLM-U

C114

1

24 V

2

GND

3

GND

4

5 V

5

DDM CLOCK

6

DDM REM

7

DDM LOCK

RD:C102-6

GN:C102-5

LB:C102-16

BE:C102-14

PE:C102-18

YW:C101-13

RD:C113-5

C108

1

24 V

2

DCLM-L REM

3

DCLM-L SIG1

4

COM

5

DCLM-L SIG2

C124C121

1

DPFCL-L REM

3

2

2

24 V

3

1

DPFCL-L

DCLM-L

C119 C401 C402

BE:C102-9

OE:C102-8

LB:C102-7

RD:C105-1

BN:C105-3

YW:C102-1

RD:C102-2

1

2

3

C118

1

2

3

3

2

1

BE:C402-1

1

OE:C402-2

2

LB:C402-3

3

24 V

DSSW

C123C120

1

DFCL REM

2

3

24 V

DSSW

DFCL

BE:C401-1

OE:C401-2

LB:C401-3

YW:C101-14

RD:C112-5

1

2

3

GND

5 V

DFSW

3

2

1

C124C121

1

2

3

DPFCL-U REM

24 V

DFSW

DPFCL-U

3

4

5

6

DDH COM

DDH LIVE

1

2

7

8

Copier

WE

12

BK

6

PE

11

BE

10

YW

9

BE

8

PK

7

OE

4

BE

3

BE

2

RD

1

1

2

3

4

5

6

7

8

9

10

FSW3 SIG

GND

RXD

GND

TXD

5.1 V

GND

GND

24 V

OE:C115-3

OE:C115-6

OE:C116-3

OE:C116-6

YW:C115-2

LB:C115-5

YW:C116-2

LB:C116-5

BE:C115-1

BE:C115-4

BE:C116-1

BE:C116-4

YW:C121-3

123456789101112131415

5 V

5 V

5 V

5 V

DLICSW-U

DPSW-U

DLICSW-L

DPSW-L

GND

GND

GND

CN1:C101

GND

YW:C117-3

RD:C113-6

DPFCL-L

DPFCL-U

24 V

RD:C112-6

YW:C120-3

RD:C120-1

GN:C110-2

RD:C110-1

GN:C108-2

RD:C108-1

LB:C119-3

OE:C119-2

BE:C119-1

16

1234567891011121314151617

24 V

DFCL REM

24 V

DCLM-U REM

24 V

DCLM-L REM

24 V

DFSW

5 V

CN2:C102

GND

GND

GND

DCLM-U SIG1

MPCB

18

DCLM-L SIG1

DCLM-U SIG2

DCLM-L SIG2

GN:C112-3

PE:C112-4

PK:C112-1

GN:C113-3

PE:C113-4

PK:C113-1

YW:C107-2

YW:C106-2

BE:C112-2

1234567891011

DPWSW-L DIG0

DPWSW-L DIG1

DPWSW-L DIG2

DPWSW-U DIG0

DPWSW-U DIG1

DPWSW-U DIG2

DPLSW-U

CN3:C103

DPLSW-L

BE:C113-2

GND

GND

BE:C107-1

BE:C106-1

12

GND

GND

RD:C114-1

BE:C114-2

BE:C114-3

OE:C114-4

1234567

24 V

GND

GND

5 V

CN4:C104

YW:C114-5

YW:C114-6

GN:C114-7

DDM CLOCK

DDM REM

DDM LOCK

RD:C118-1

123

24 V

CN6:C105

BN:C118-2

DSSW

Wire color Mark

Brown

Yellow

Blue

White

Red

Orange

Light blue

Gray

Black

Purple

Green

Pink

BN

YW

BE

WE

RD

OE

LB

GY

BK

PE

GN

PK

7

8

A B C D E F G H IJ

2-4-3

Loading...

Loading...