Kyocera 13600, 9600, 11100 Adjustment Manual

ADJUSTMENT GUIDE

TABLE OF CONTENTS

Introduction......................................................................................................................................................... 3

How to Read This Manual................................................................................................................................. 4

Symbols Used in the Manuals.......................................................................................................................4

Disclaimer........................................................................................................................................................4

Notes...............................................................................................................................................................4

Machine Types............................................................................................................................................... 5

Manuals for This Machine................................................................................................................................. 6

About Printing Surfaces...................................................................................................................................... 7

1. Adjustment Settings for Skilled Operators

Displaying the [Adjustment Settings for Skilled Operators] Button.................................................................9

Accessing Adjustment Settings for Skilled Operators....................................................................................12

Layout of Adjustment Settings for Skilled Operators..................................................................................... 14

Features of the Displayed Items and Setting Operations..............................................................................15

Notes on How Adjustment Settings are Applied to Printed Copies............................................................. 17

2. Details of Menu Items in Adjustment Settings for Skilled Operators

Menu Items and Functions...............................................................................................................................19

Setting Values................................................................................................................................................... 27

[Machine: Image Position].......................................................................................................................... 27

[Machine: Image Quality]...........................................................................................................................34

[Machine: Paper Feed/ Output]................................................................................................................ 39

[Machine: Maintenance]............................................................................................................................ 47

[Finishing: Finisher].......................................................................................................................................54

[Finishing: Fold]............................................................................................................................................ 76

[Finishing: Stacker].......................................................................................................................................84

3. Custom Paper Settings for Administrators

Accessing Advanced Settings......................................................................................................................... 91

Access Using the Control Panel.................................................................................................................. 91

Access Using Web Image Monitor............................................................................................................ 93

Description of Paper Icons...............................................................................................................................94

Deleting Saved Custom Paper Profiles........................................................................................................... 95

Backing up and Restoring Custom Paper Profiles..........................................................................................97

Backing up Custom Paper Profiles Saved in the Saved Paper Library.................................................... 97

Backing up Custom Paper Profiles Registered Under the [Edit Custom Paper] Setting..........................98

1

Paper Presets in "Advanced Settings".............................................................................................................99

Displaying the Paper Profile Version.......................................................................................................... 99

4. Details of Menu Items in Advanced Settings

Menu Items and Functions............................................................................................................................ 101

Setting Values.................................................................................................................................................108

Paper Feed Adjustment............................................................................................................................. 108

Paper Delivery Adjustment........................................................................................................................109

Image Position/Scaling Adjustment.........................................................................................................110

Line Speed Adjustment..............................................................................................................................116

Toner Adhesion Adjustment......................................................................................................................119

Transfer Adjustment................................................................................................................................... 119

Paper Feed Adjustment: Two-tray wide LCT........................................................................................... 122

Fuser Adjustment........................................................................................................................................124

Decurler Adjustment.................................................................................................................................. 129

Finishing Position Adjustment....................................................................................................................130

2

Introduction

This manual contains detailed instructions and notes on the operation and use of this machine. For your

safety and benefit, read this manual carefully before using the machine. Keep this manual in a handy

place for quick reference.

3

How to Read This Manual

Symbols Used in the Manuals

This manual uses the following symbols:

Indicates points to pay attention to when using the machine, and explanations of likely causes of paper

misfeeds, damage to originals, or loss of data. Be sure to read these explanations.

Indicates supplementary explanations of the machine’s functions, and instructions on resolving user

errors.

This symbol is located at the end of sections. It indicates where you can find further relevant information.

[ ]

Indicates the names of keys on the machine's display or control panels.

Disclaimer

To the maximum extent permitted by applicable laws, in no event will the manufacturer be liable for any

damages whatsoever arising out of failures of this product, losses of documents or data, or the use or

non-use of this product and operation manuals provided with it.

Contents of this manual are subject to change without prior notice.

Make sure that you always copy or have backups of the data registered in this machine. Documents or

data might be erased due to your operational errors or malfunctions of the machine.

In no event will the company be liable for direct, indirect, special, incidental, or consequential damages

as a result of handling or operating the machine.

Notes

Contents of this manual are subject to change without prior notice.

The manufacturer shall not be responsible for any damage or expense that might result from the use of

parts other than genuine parts from the manufacturer with your office products.

For good output quality, the manufacturer recommends that you use genuine toner from the

manufacturer.

4

Some illustrations in this manual might be slightly different from the machine.

Two kinds of size notation are employed in this manual.

Machine Types

Check the type of your machine before reading the manuals.

• Type 1: 9600

• Type 2: 11100

• Type 3: 13600

Certain types might not be available in some countries. For details, please contact your local dealer.

Certain options might not be available in some countries. For details, please contact your local dealer.

5

Manuals for This Machine

The following manuals are for skilled operators only.

Adjustment Item Menu Guide

This manual explains the items in [Adjustment Settings for Skilled Operators] and the advanced

settings for custom paper adjustment in "Advanced Settings".

Replacement Guide

This manual explains how to replace the machine's components.

Troubleshooting

This manual explains how to troubleshoot problems related to image quality, paper delivery, and

other aspects of machine operation.

6

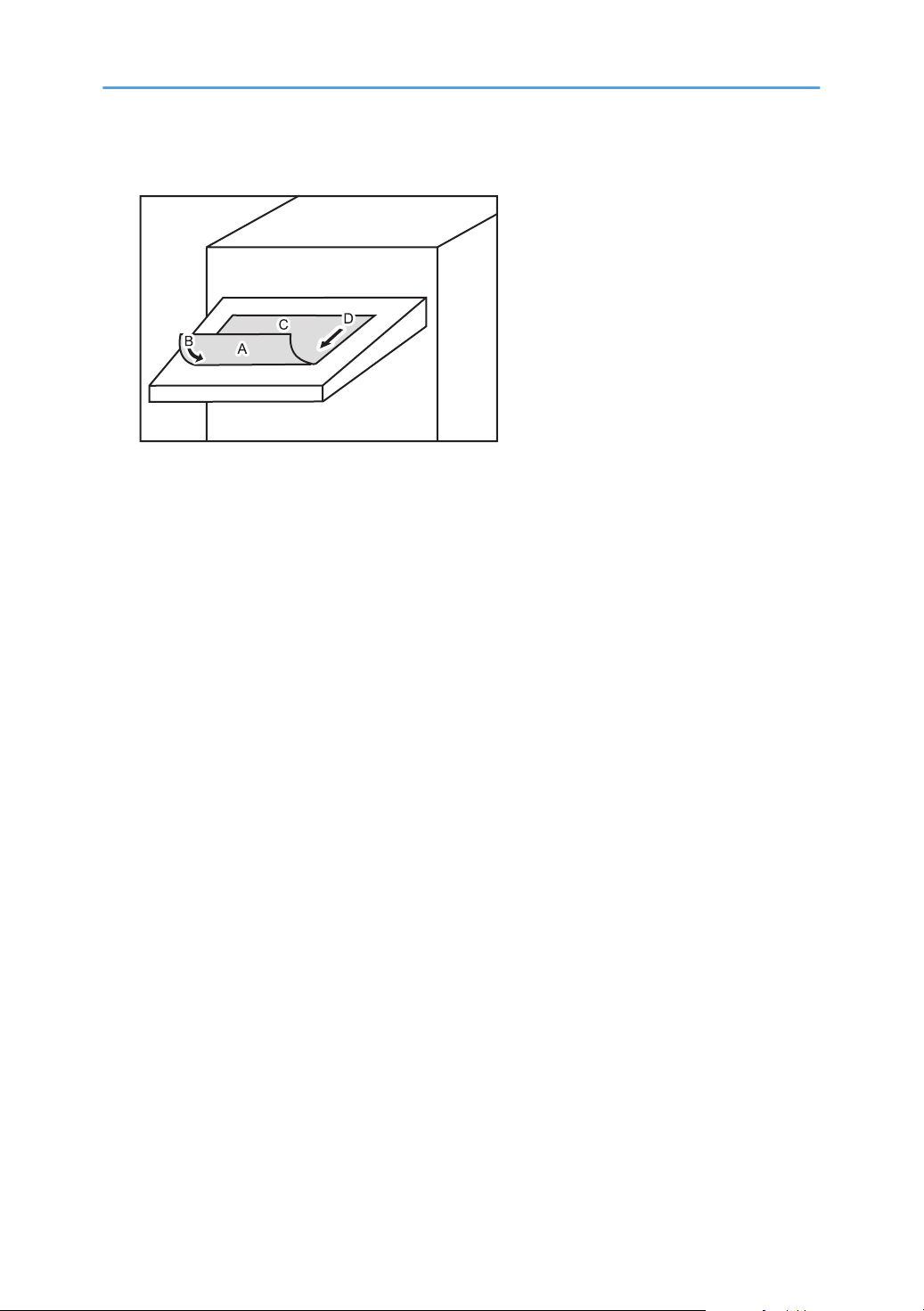

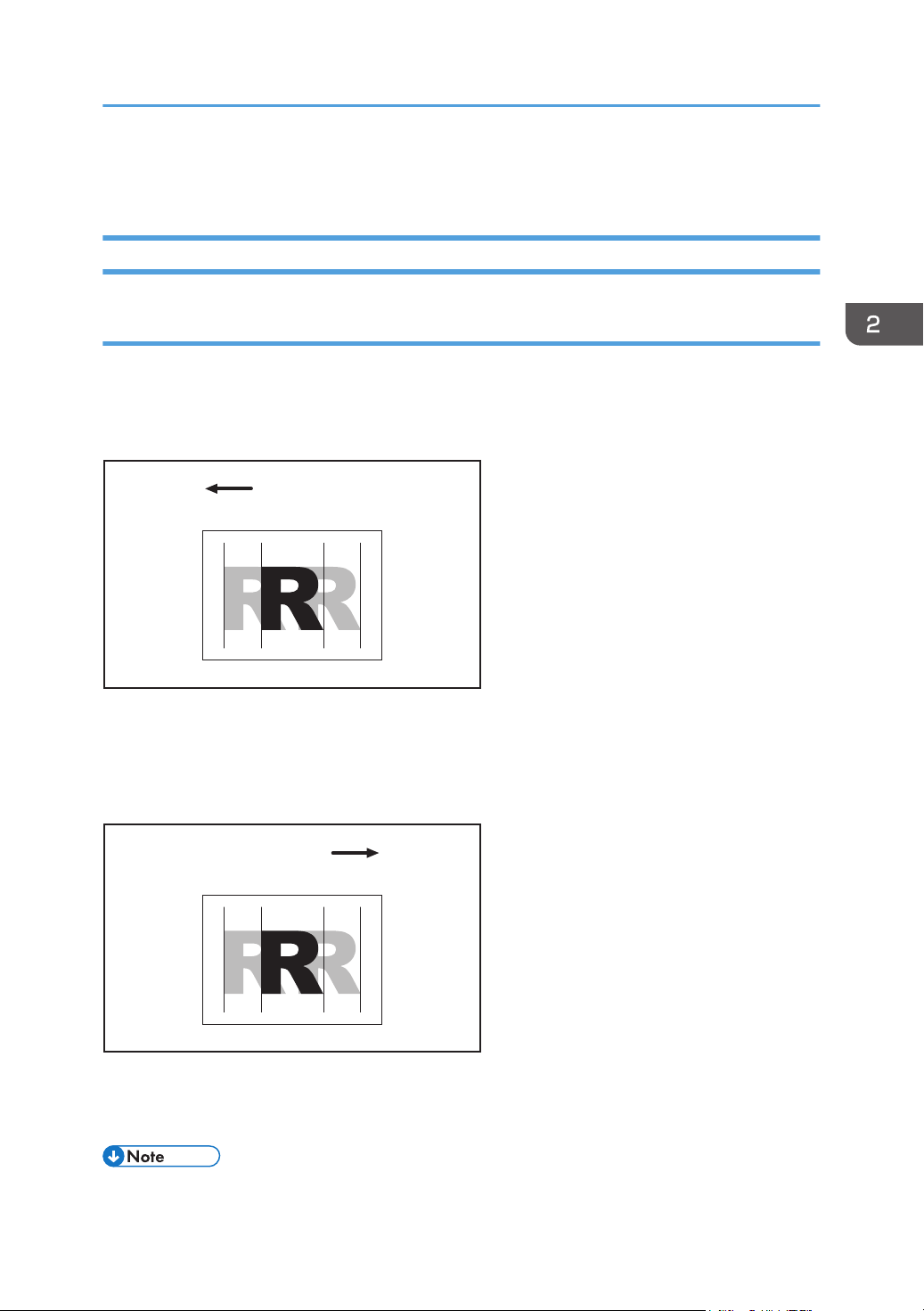

About Printing Surfaces

DSM008

DSM009

Depending on the setting, printed copies are fed as follows:

Side 1 is the surface of the paper printed during one-sided printing, or the surface of the first print during

duplex printing.

Side 2 is the surface of the paper printed on the back side of Side 1 during duplex printing.

Single-sided printing: Printed side face down

A. Side 1

B. Paper feed direction of Side 1

Single-sided printing: Printed side face up

A. Side 1

B. Paper feed direction of Side 1

7

Duplex printing

DSM010

A. Side 1

B. Paper feed direction of Side 1

C. Side 2

D. Paper feed direction of Side 2

8

1. Adjustment Settings for Skilled

CWW222

Operators

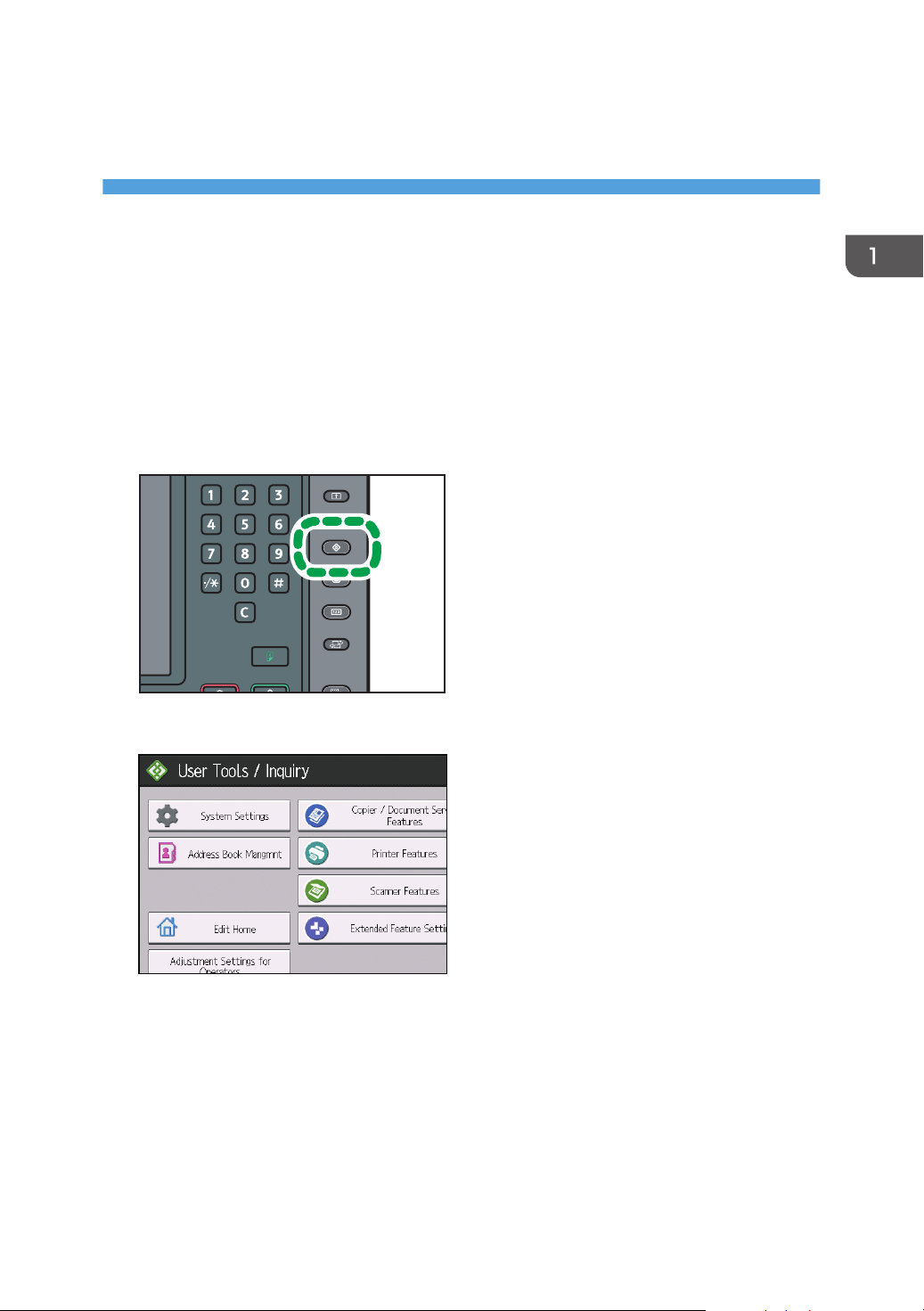

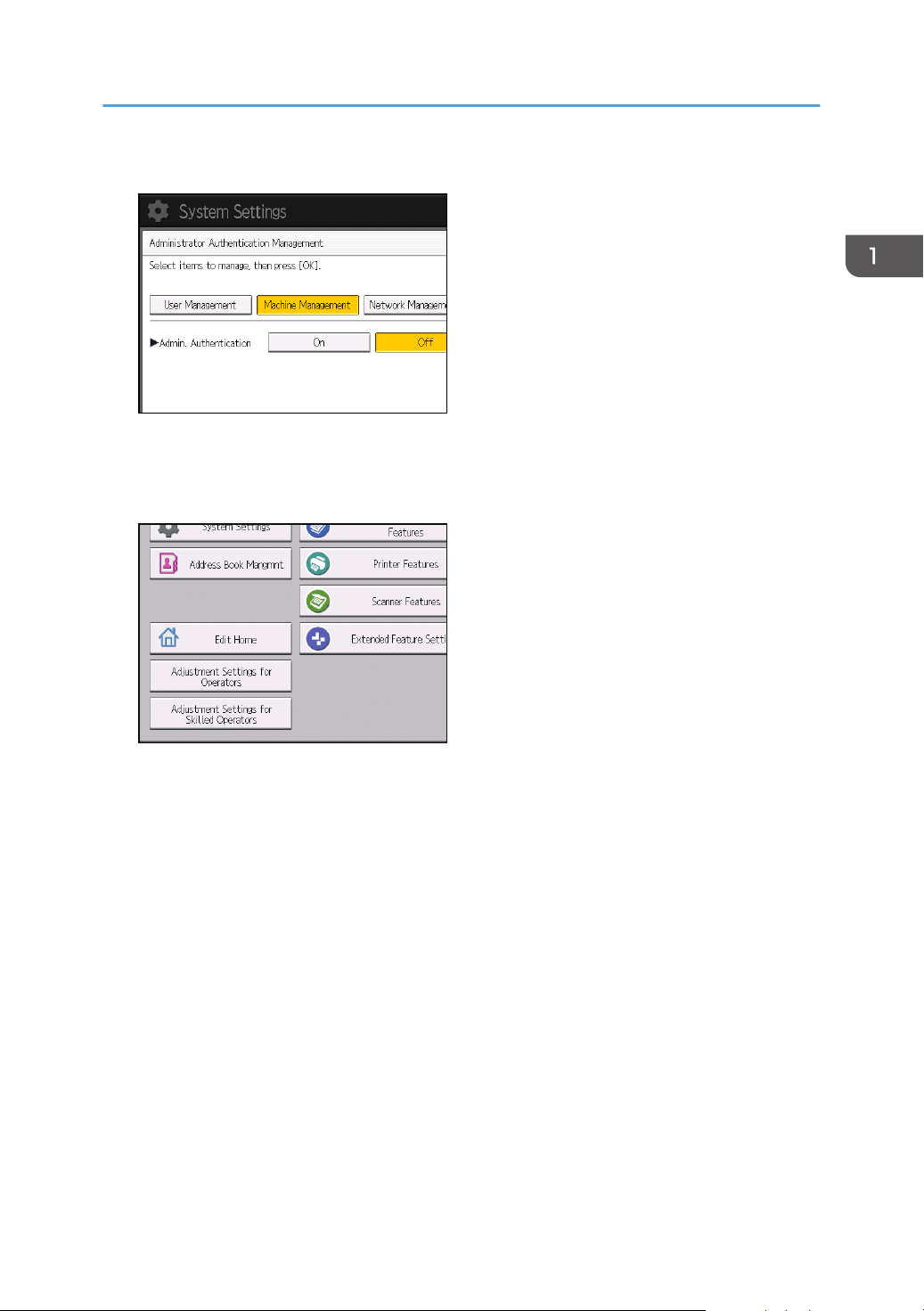

Displaying the [Adjustment Settings for Skilled Operators] Button

To use the Adjustment Settings for Skilled Operators, you must first configure your machine's

Administrator Authentication Management setting.

1. Press the [User Tools] key on the control panel.

2. Press [System Settings] on the display.

9

1. Adjustment Settings for Skilled Operators

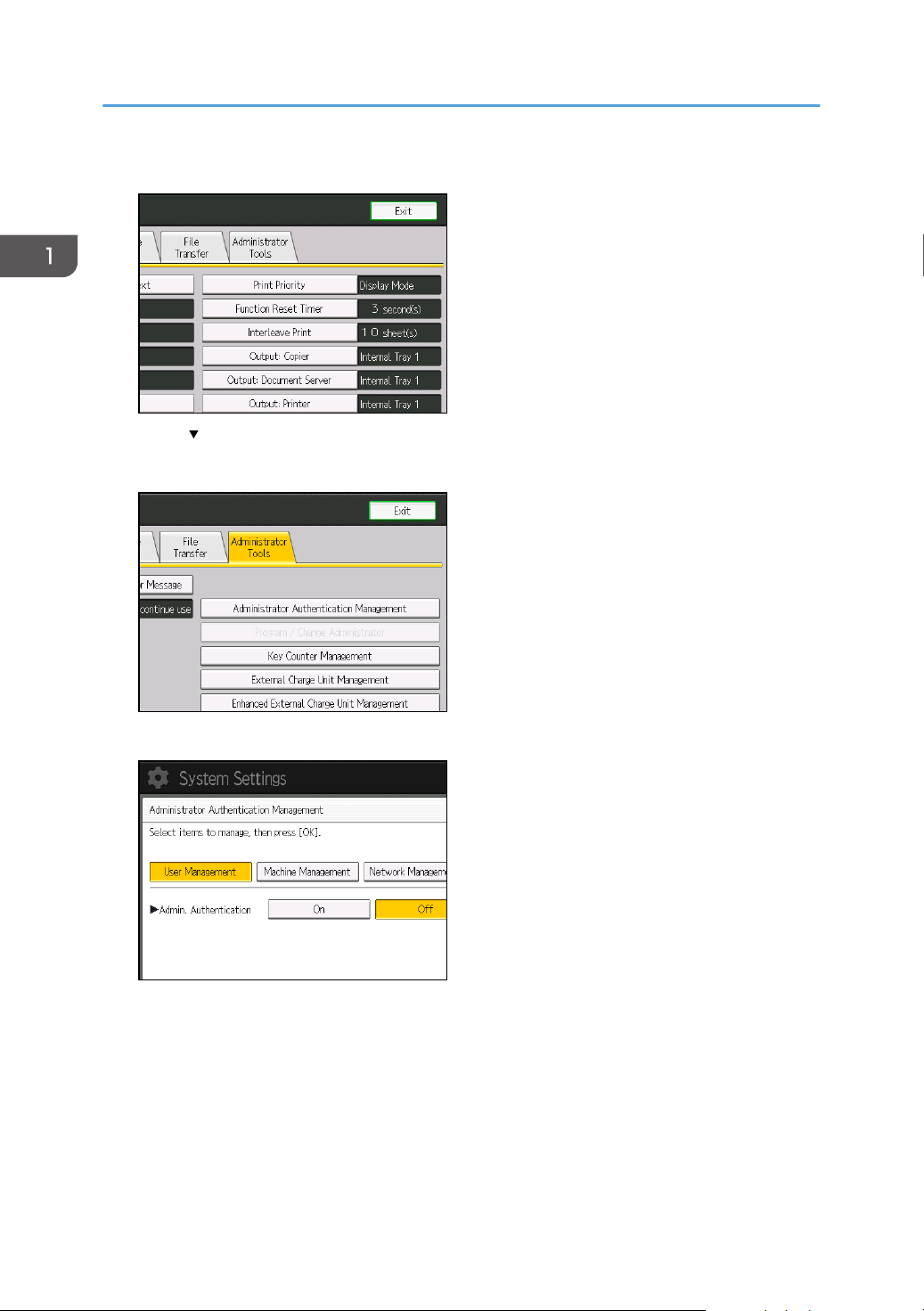

3. Press [Administrator Tools].

4. Press [ Next].

5. Press [Administrator Authentication Management].

10

6. Press [Machine Management].

Displaying the [Adjustment Settings for Skilled Operators] Button

7. Select [On] for "Admin. Authentication".

8. Press [OK].

9. Press [Exit].

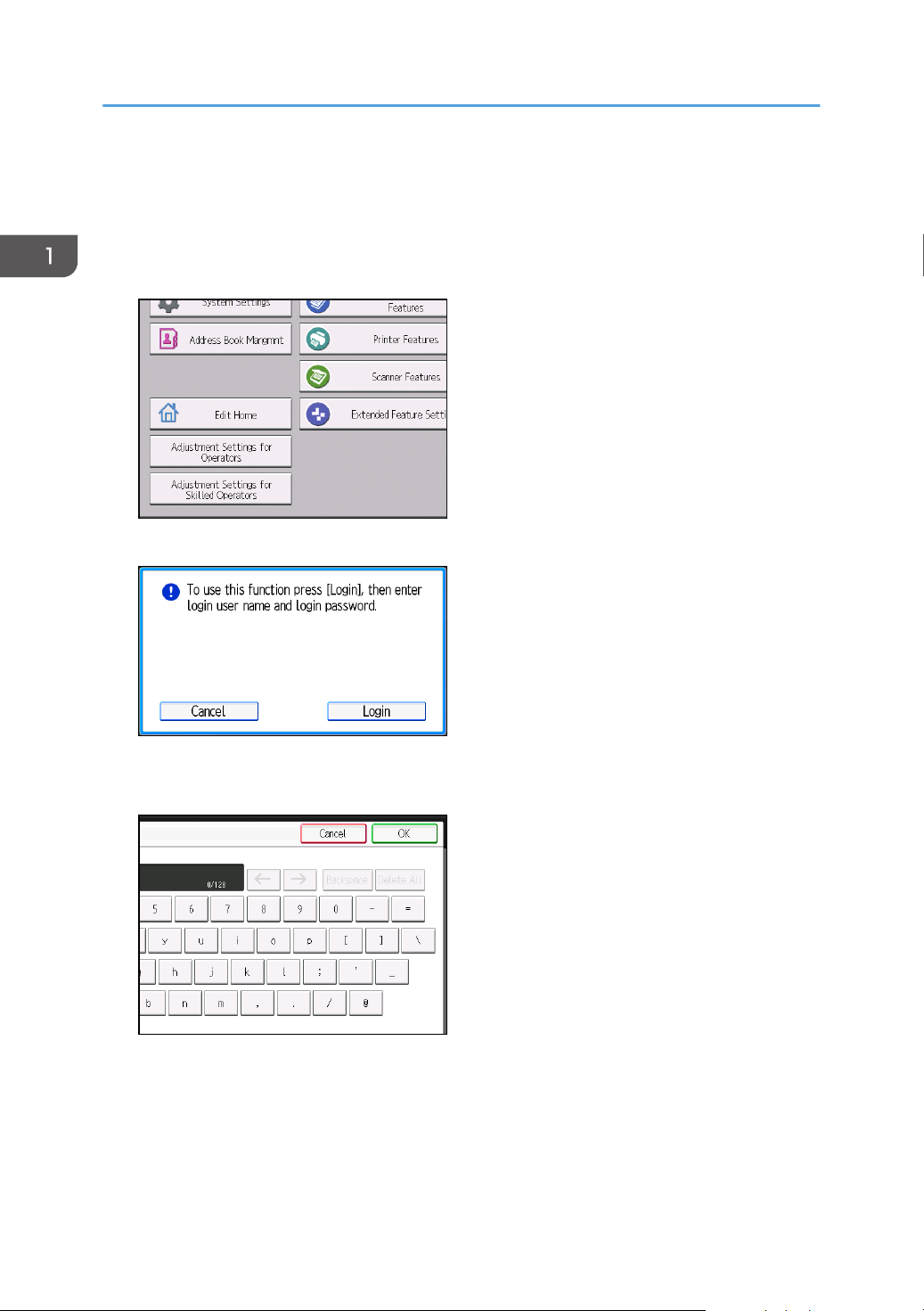

The [Adjustment Settings for Skilled Operators] button appears.

11

1. Adjustment Settings for Skilled Operators

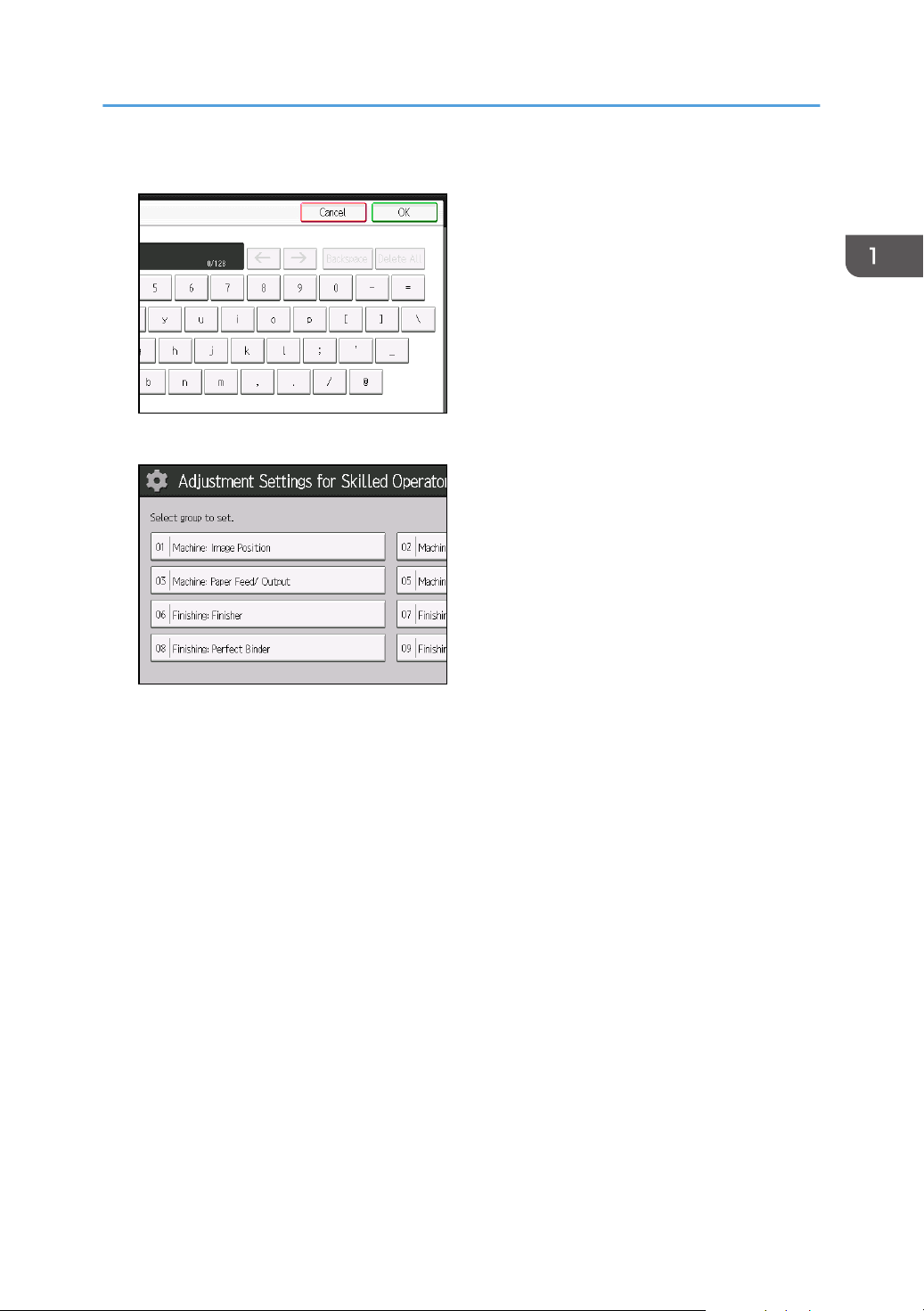

Accessing Adjustment Settings for Skilled Operators

1. Press [Adjustment Settings for Skilled Operators].

2. Press [Login].

12

3. Enter your login user name, and then press [OK].

If you are logging on as the administrator for the first time, enter "admin".

4. Enter your login password, and then press [OK].

The Adjustment Settings for Skilled Operators appears.

Accessing Adjustment Settings for Skilled Operators

13

321

DTJ001

1. Adjustment Settings for Skilled Operators

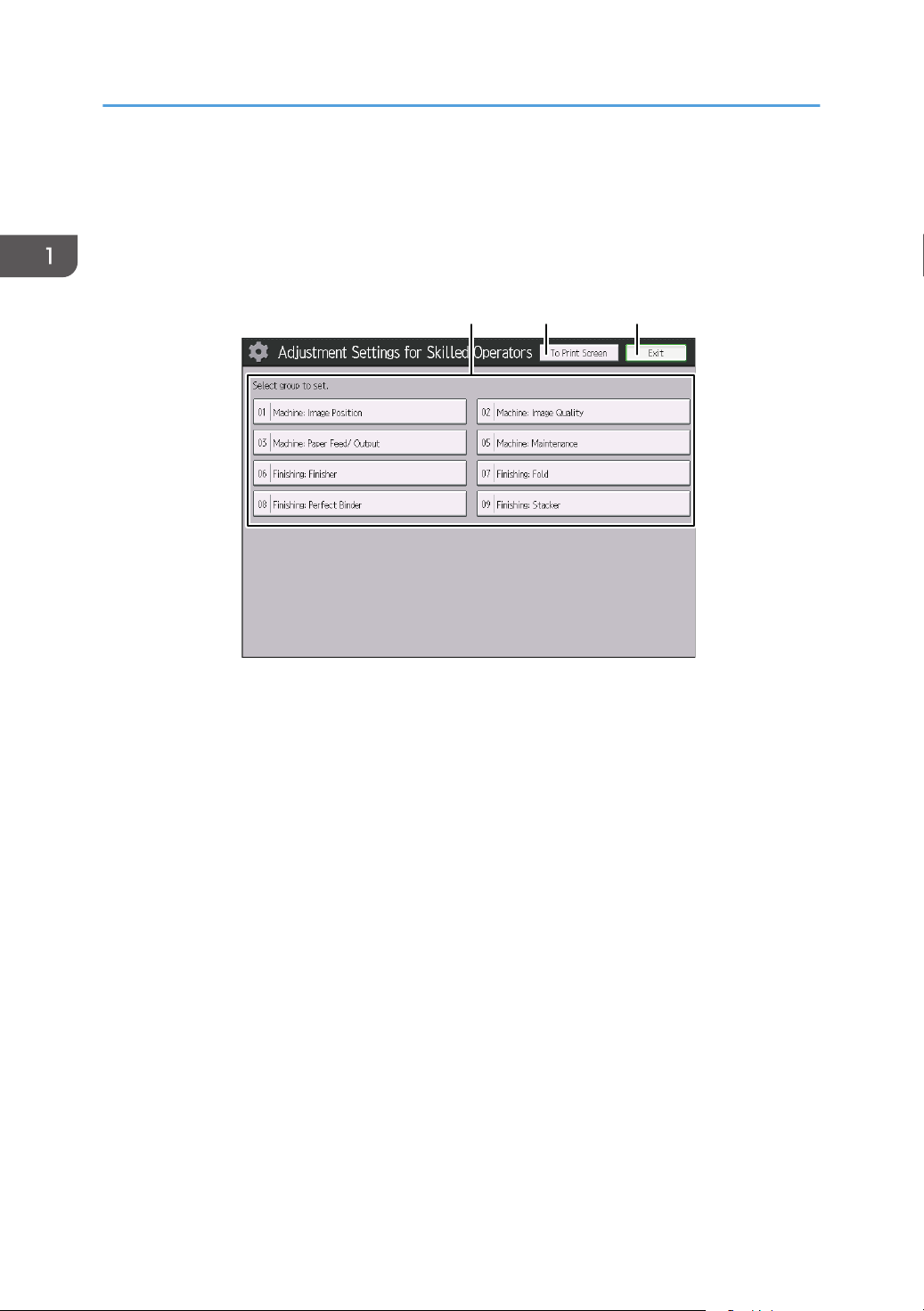

Layout of Adjustment Settings for Skilled Operators

This section explains how to use Adjustment Settings for Skilled Operators.

1. Adjustment items are displayed in this area. Select the setting you want to specify or change.

2. Press this button to display the print screen. You can use this screen to view the changes you have

made.

3. Press this button to close Adjustment Settings for Skilled Operators.

14

Features of the Displayed Items and Setting Operations

Features of the Displayed Items and Setting

Operations

The following operations are available for each adjustment item:

• Value setting

• Item setting

• Executing

• Display only

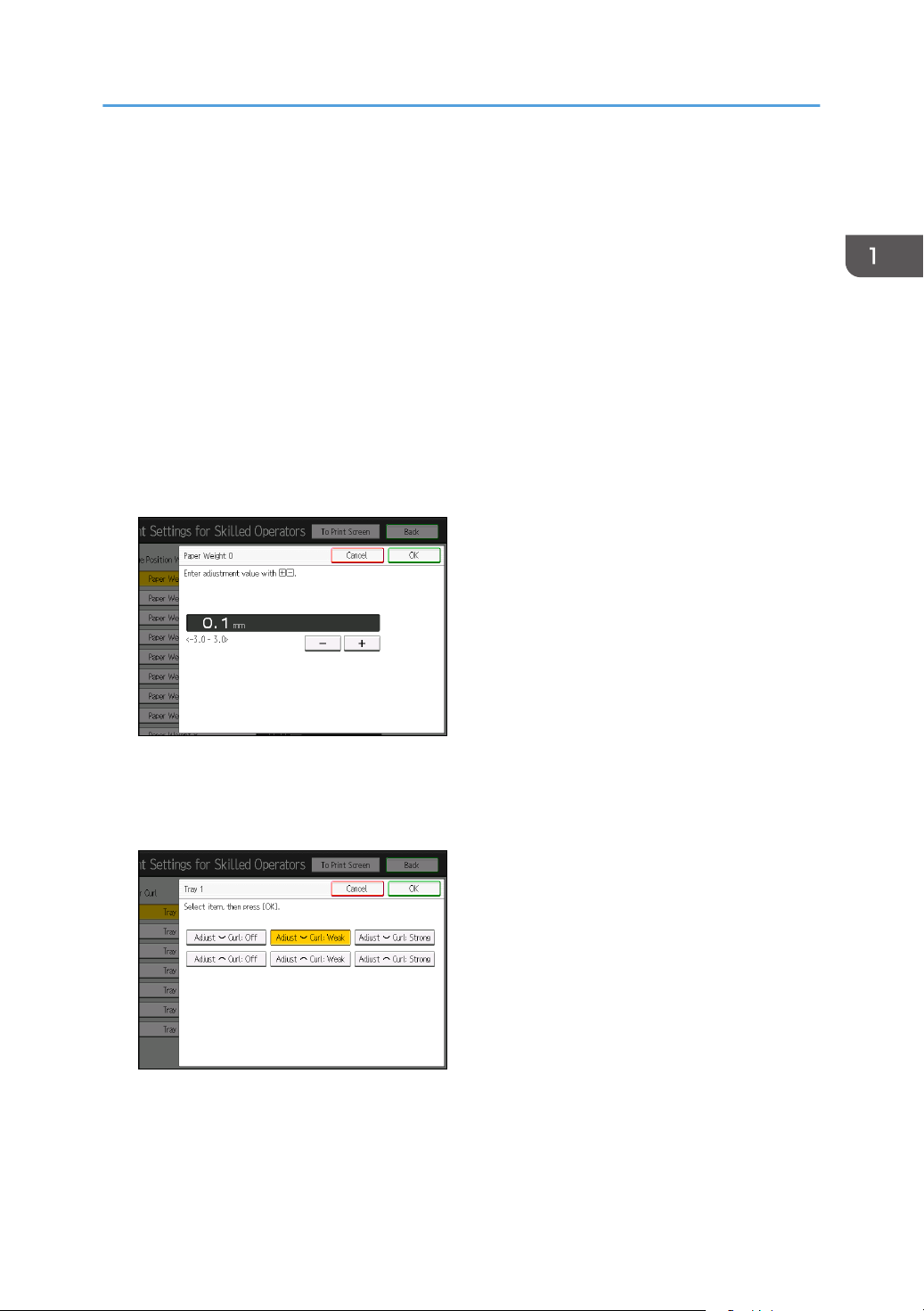

Value setting

Press [+] to increase the value, or [-] to decrease.

Select [OK] to apply the new setting.

Item setting

Select the item you require.

Select [OK] to apply the new setting.

Executing

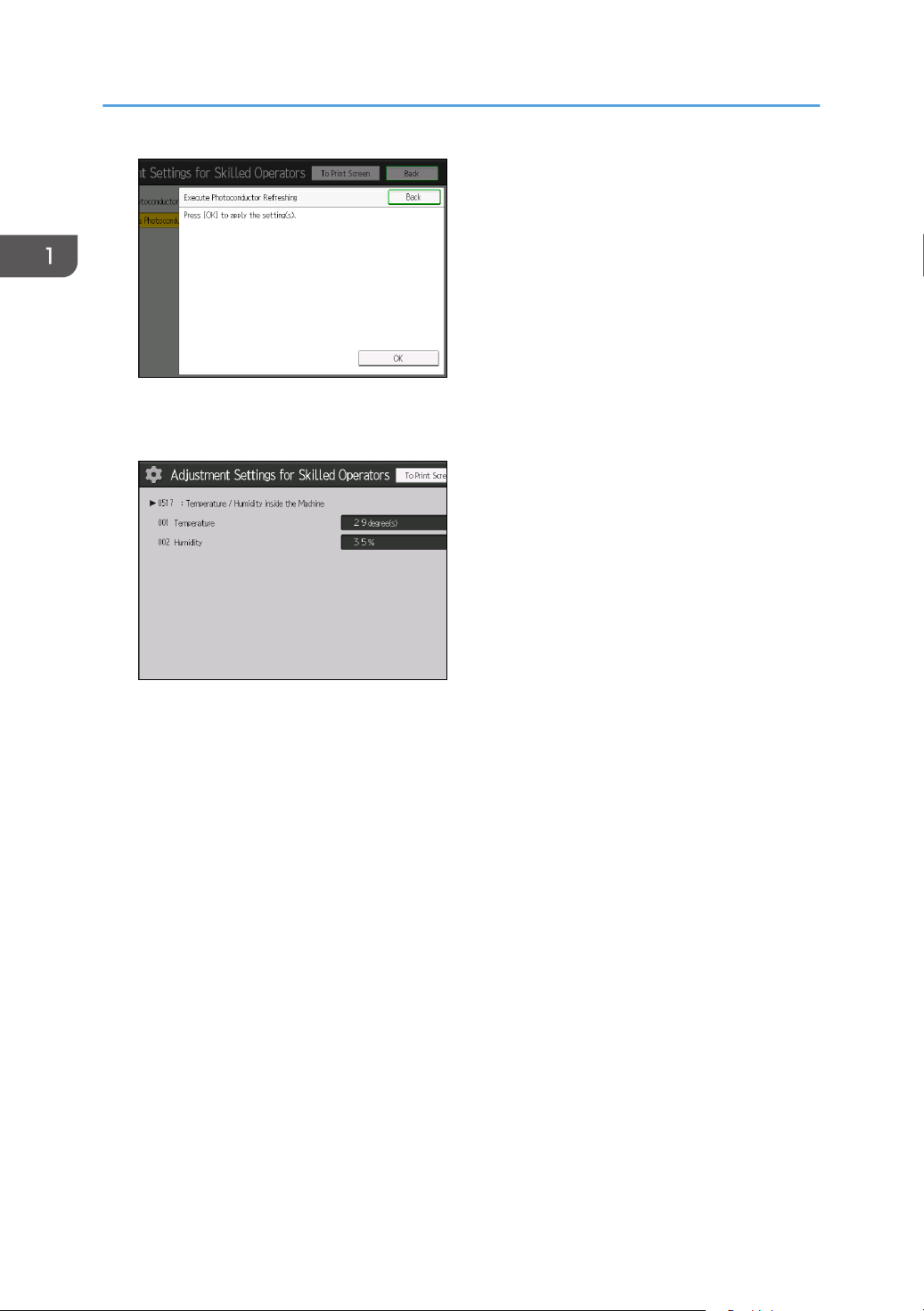

Press [OK] to perform a selected function.

15

1. Adjustment Settings for Skilled Operators

Display only

You can check the setting for the selected item.

16

Notes on How Adjustment Settings are Applied to Printed Copies

Notes on How Adjustment Settings are Applied

to Printed Copies

The adjustment settings are applied to printed copies according to the settings specified for each paper

tray, paper size, and paper weight.

Depending on the adjustment setting, the same settings specified under different categories may be

applied to printed copies concurrently.

• Settings for each paper tray

• Settings for each paper weight

• Settings for each paper size

Settings for each paper tray

These adjustment settings can be specified for each paper tray.

The settings are applied only to printed copies fed from each paper tray.

Settings for each paper weight

These adjustment settings can be specified for each paper weight.

The settings are applied only to printed copies of each paper weight*1.

This appears as [Paper Thickness] in "Tray Paper Settings".

*1

17

1. Adjustment Settings for Skilled Operators

Settings for each paper size

These adjustment settings can be specified for each paper size.

The settings are applied only to printed copies of each paper size.

• For information about the paper tray, paper thickness, and tray paper size settings that can be

specified for a particular function, see the manual for the relevant function.

18

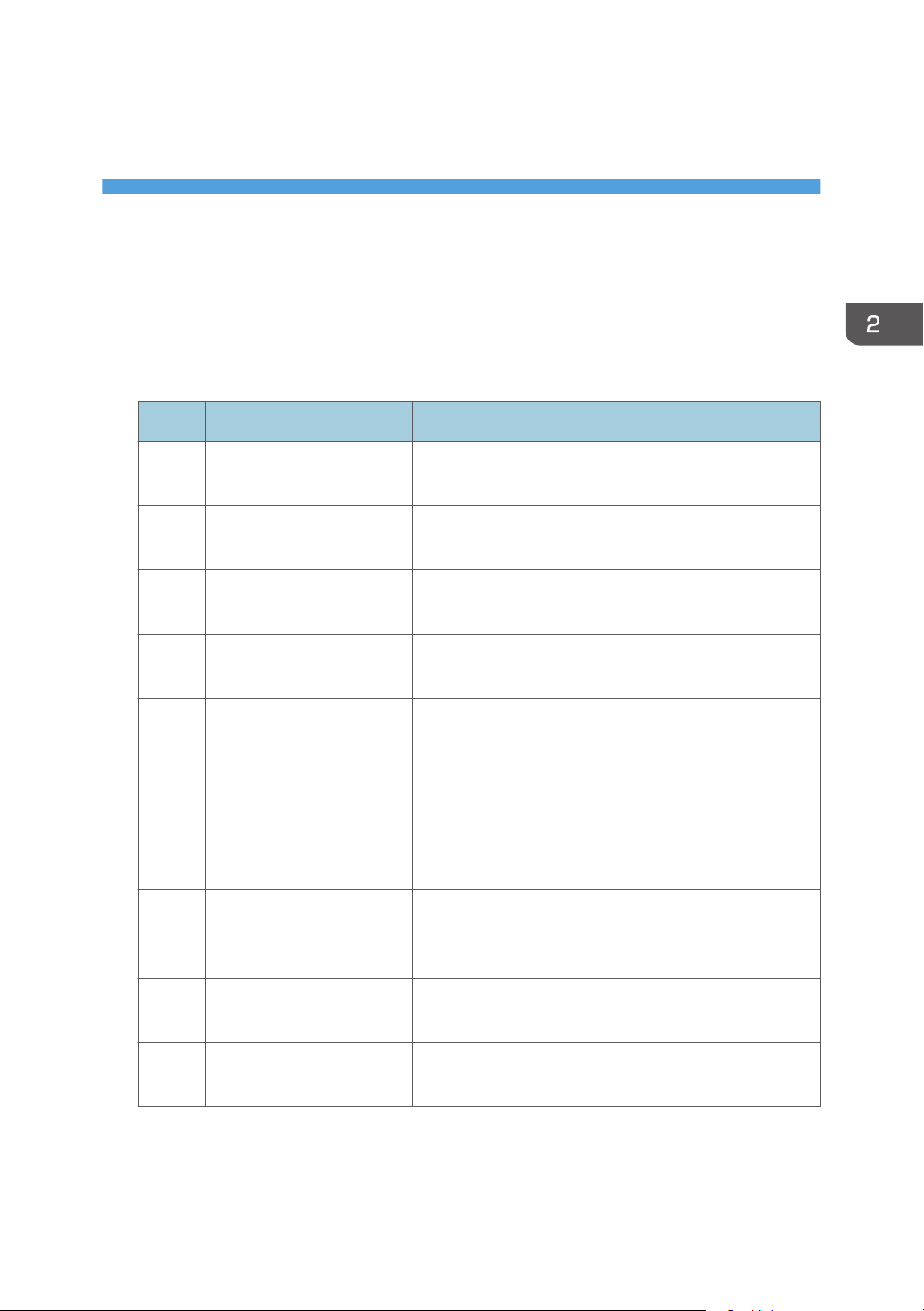

2. Details of Menu Items in Adjustment Settings for Skilled Operators

Menu Items and Functions

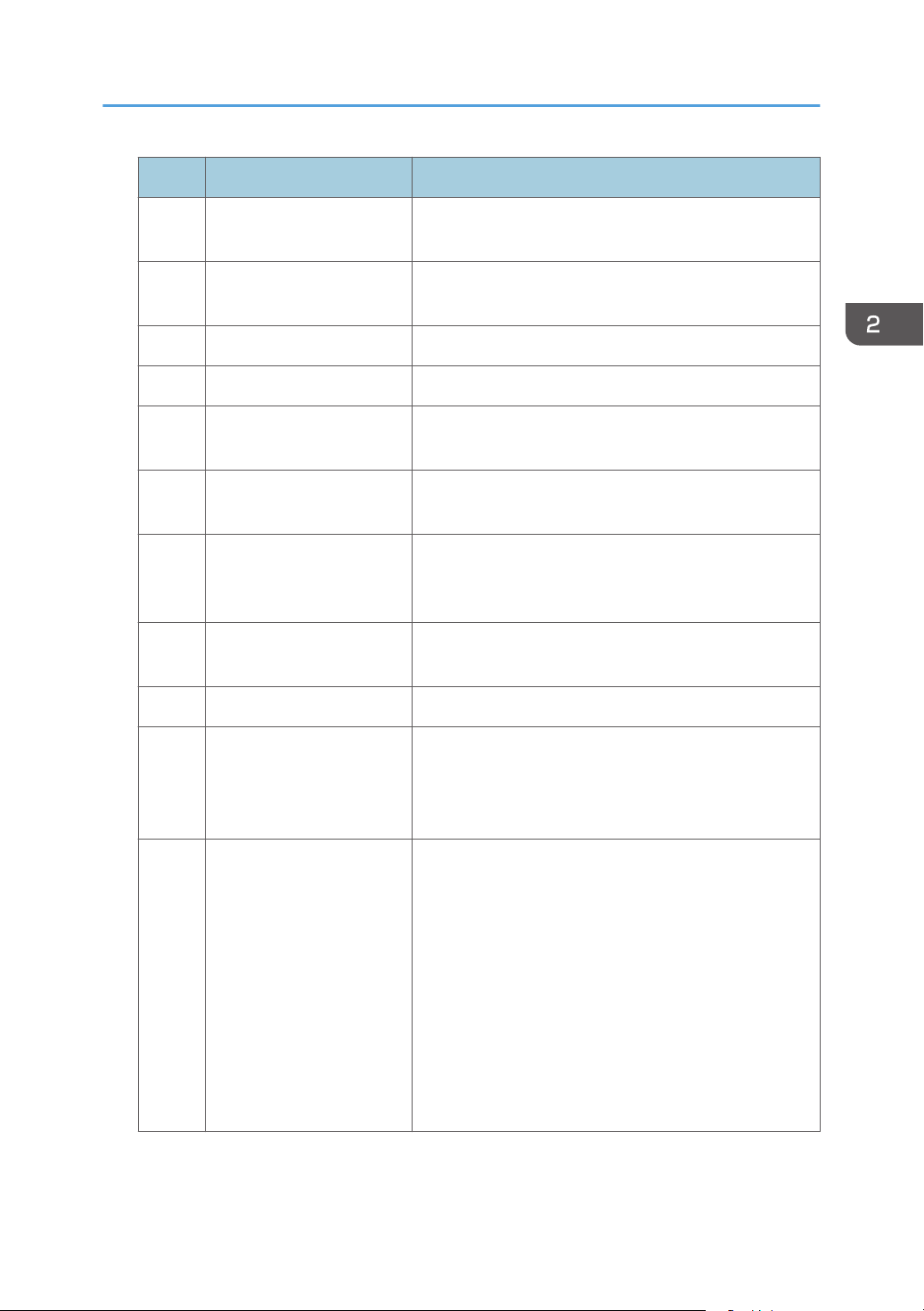

[Machine: Image Position]

For details about the following items, see page 27 "[Machine: Image Position]".

No. Item Description

0101 [Adjust Image Position With

Feed Direction]

0102 [Adjust Image Position

Across Feed Direction]

0103 [Adjust Registration Paper

Buckle]

0104 [Adjust Registration Paper

Buckle (Thick Paper)]

0105 [Deactivate Image Position

Adjustment Across Feed

Dir]

0106 [Select Test Pattern for

Image Position Adjustment]

*2

Adjust the horizontal position of the print image.

Adjust the vertical position of the print image.

Adjust the degree of paper arching at the registration

gate*1.

Adjust the degree of paper arching at the registration

gate*1 when using paper of Paper Weight 5 to 8.

Specify whether or not the machine automatically detects

paper pathway deviations during the paper feeding

process and adjusts the vertical position of the print

image accordingly.

Also specify whether or not to stop printing when the

vertical position has deviated exceeding the adjustable

range (3 mm/0.1 inch) when feeding.

Select the test image for adjusting the image position.

*2

*2

Adjust the position and scaling applied to scanned

images when using the Auto Document Feeder (ADF).

Specify whether or not to detect multiple feeding of

originals loaded in the Auto Document Feeder (ADF).

0107 [ADF Adjustment]

0108 [ADF Double Feed

Detection]

This is an internal function for adjusting skew correction and transfer timing.

*1

This function is available for 11100 and 13600.

*2

19

2. Details of Menu Items in Adjustment Settings for Skilled Operators

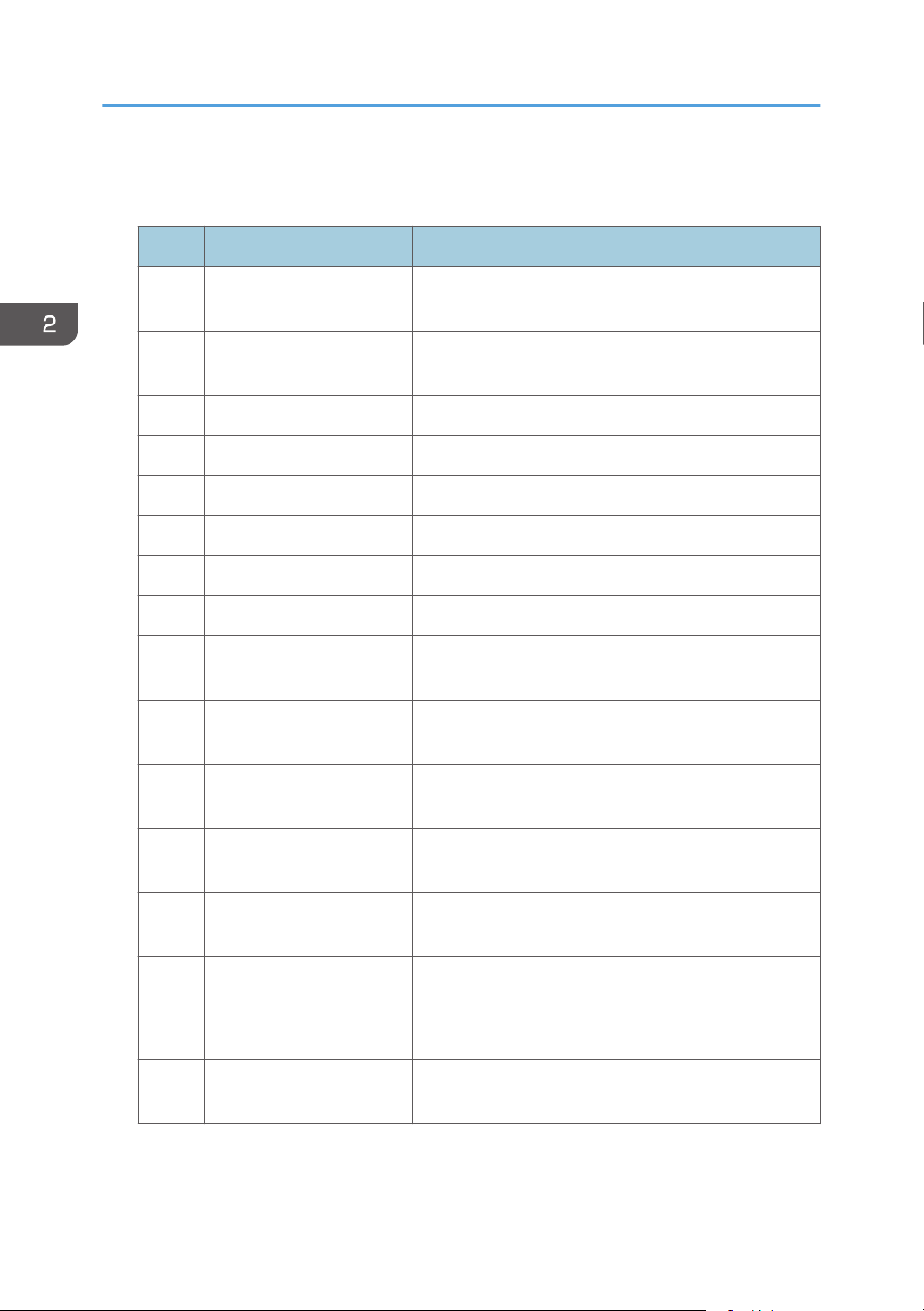

[Machine: Image Quality]

For details about the following items, see page 34 "[Machine: Image Quality]".

No. Item Description

0201 [Adjust Erase Margin With

Feed Direction]

Adjust the mask width at the leading edge or trailing

edge of the image.

0202 [Adjust Image Density] Execute image density control manually.

0203 [Image Density Adjustment

Execute Interval]

0204 [Adjust Maximum Image

Density]

Specify the number of sheets the machine prints before it

automatically adjusts image density.

Specify the adhesion of toner to the drum surface and

intermediate transfer belt when image density adjustment

is executed.

0205 [Adjust Line Width] Adjust the intensity of the laser for transferring image

data to the drum.

0206 [Adjust Density Difference

Across Feed Direction]

0207 [Adjust Fusing Temperature

on Standby]

0208 [Avoid Ppr Trnsf Shock

Jitter: Feed Interval Adj]

Adjust the image density difference between the top and

bottom of the image.

Adjust the set fusing temperature according to the

machine status.

Specify whether or not to enable the mode to reduce the

jitter*1 produced when paper enters the paper transfer

roller.

0211 [Toner Refreshing Mode] Specify the threshold for the average image area ratio at

0212 [Productivity Priority Mode] Specify whether or not to increase throughput on a job

0213 [Continuous Slip Sheet

Feed Mode]

A shock that occurs as the leading or trailing end of paper passes through the transfer unit. When this

*1

shock is transmitted to the drum via the intermediate transfer belt, banding occurs.

[Machine: Paper Feed/ Output]

For details about the following items, see page 39 "[Machine: Paper Feed/ Output]".

20

which toner refreshing mode is enabled.

that involves printing on thick and then on thin paper.

Specify whether or not to temporarily stop the imaging

unit in order to avoid reductions in image quality that

may occur in continuous slip sheet feed mode.

Menu Items and Functions

No. Item Description

0301 [Double Feed Detection] Specify whether or not to detect double feeding of

paper.

0302 [When Double Feed is

Detected]

Specify how the machine behaves when it detects a

double feed.

0304 [Skew Detection] Specify whether or not to detect paper skew.

0305 [Skew Detection Level] Adjust the permissible range of skew.

0306 [Adjust Wide LCT Fan

Level]

0307 [Adjust Wide LCT Fan

Timer]

Adjust the airflow of the three-tray wide LCT (LCIT

RT5080) for fanning the sheets.

Adjust the duration of the airflow of the three-tray wide

LCT (LCIT RT5080) for fanning the sheets.

0308 [Pickup Assist Setting] Specify the paper feed roller movement when using

three-tray wide LCT (LCIT RT5080), LCT (LCIT RT5070),

and multi bypass tray.

0309 [Adjust Paper Separation

Time]

To prevent multi-feeding, adjust the paper separation

time when feeding paper.

0310 [Adjust Paper Curl] Specify the method for straightening curled sheets.

0311 [Registration Jam Detection

with Feed Direction]

Specify whether or not to stop printing when the

deviation in the feed direction exceeds the adjustable

range (3 mm/0.1 inch) when feeding paper in the

paper tray or duplex unit.

0312 [Lower Jam Detection

Strictness]

Disables the following jam detection functions:

• Skew Detection (J49)

• Registration Detection with Feed Direction out of

range(J050) (correction control to be performed)

• Registration Detection across Feed Direction out of

range(J080) (correction control to be performed)

In addition, fix the CIS light intensity in Color Paper

Correction setting to Color Paper 2.

The setting is applied to all the paper types and trays at

a time.

21

2. Details of Menu Items in Adjustment Settings for Skilled Operators

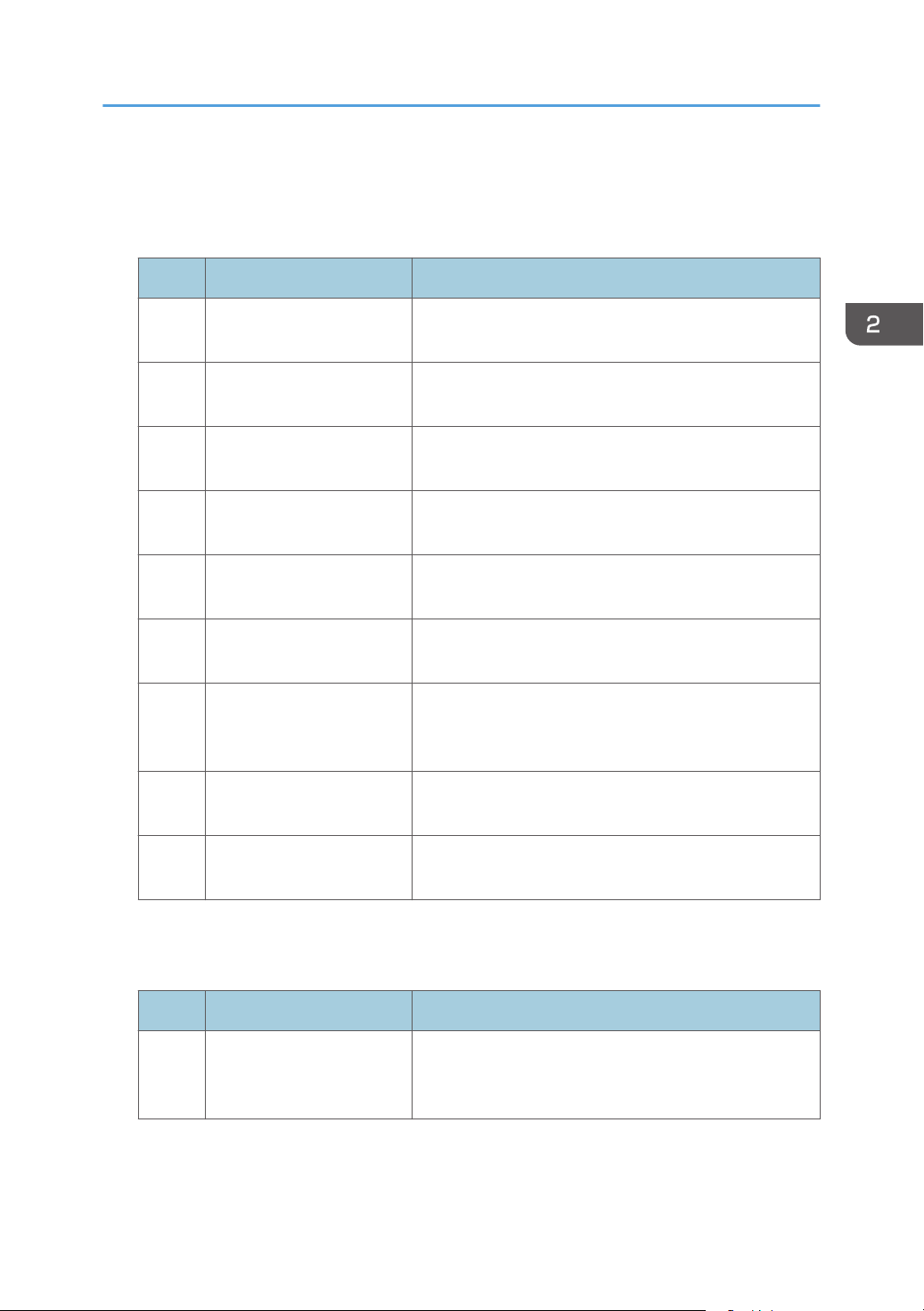

[Machine: Maintenance]

For details about the following items, see page 47 "[Machine: Maintenance]".

No. Item Description

0502 [Execute Photoconductor

Remove dust on the drum surface.

Refreshing]

0503 [Unscrew/Screw-on Cap

Screw on or unscrew the toner bottle cap.

to Replace Toner Bottle]

0504 [Developer Fill] Fill the developer unit with fresh developer.

0505 [Developer Fill: Result] Display the result of filling developer.

0506 [Developer Exhaust] Discharge used developer into the developer bottle.

0507 [Developer Exhaust: Result] Display the result of discharging developer.

0509 [Developer Setup: Result] Display the result of developer setup.

0512 [ITB Manual Lubrication] Lubricate the intermediate transfer belt.

0515 [Reset Replaceable Parts

Counter Reset the counter for replaceable parts.

Counter]

0516 [Estimated Life Already

Display the duty cycle counters of replaceable parts.

Used]

0517 [Temperature / Humidity

Display the internal temperature and humidity.

inside the Machine]

[Finishing: Finisher]

22

0518 [Temperature / Humidity

Display the external temperature and humidity.

outside the Machine]

0520 [Back Up / Restore Custom

Back up and restore custom paper profiles.

Paper Data]

0521 [Counter Settings for Fusing

Unit Replacement]

This setting can be used with multiple fuser units.

Up to four fuser units can be recorded.

Displays the counter of each part of the fuser unit.

0522 [Execute Charger

Clean the charge unit.

Cleaning]

For details about the following items, see page 54 "[Finishing: Finisher]".

No. Item Description

Menu Items and Functions

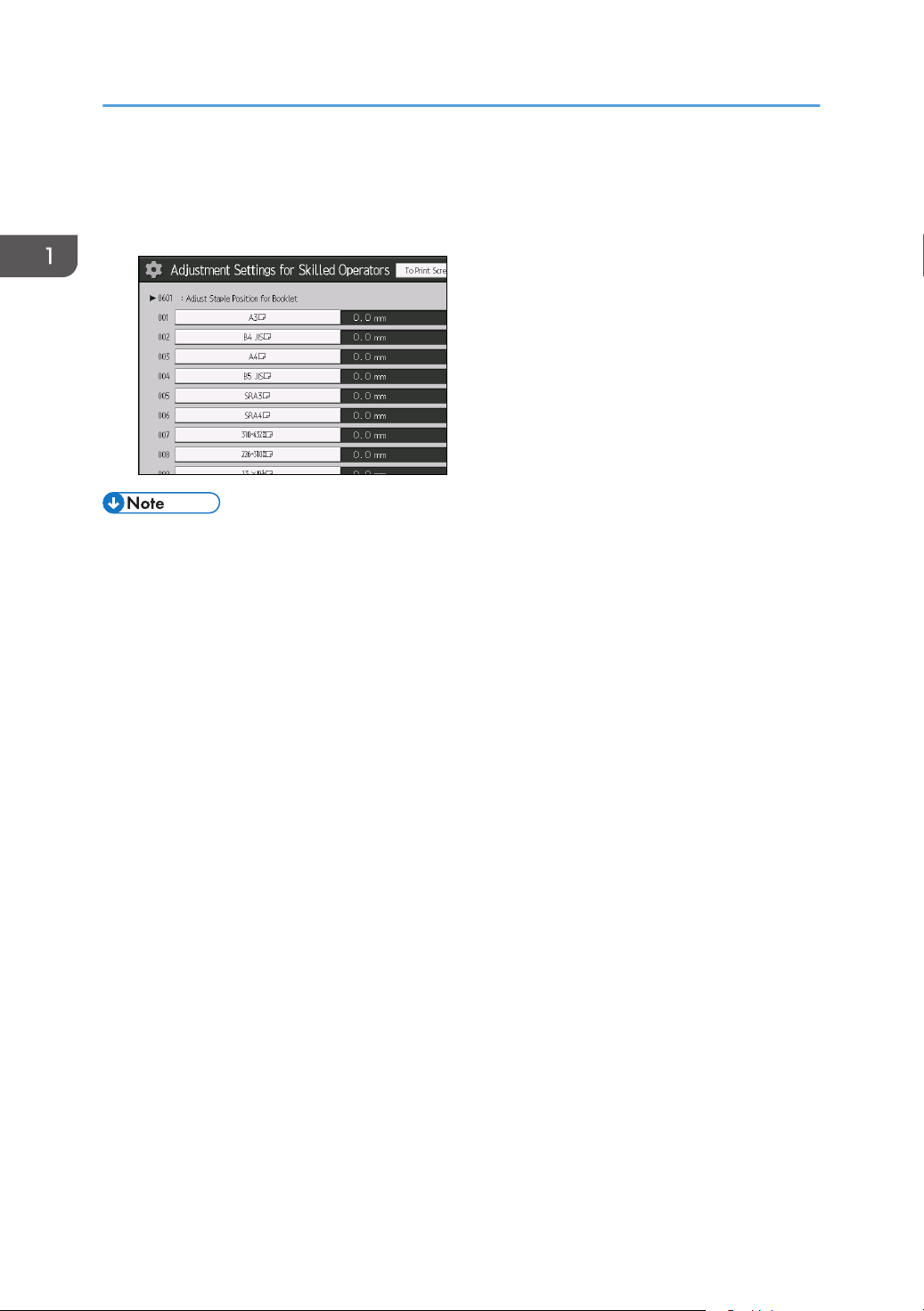

0601 [Adjust Staple Position for

Booklet]

0602 [Adjust Folding Position for

Booklet]

0603 [Adjust Staple Position

Across Feed Direction 1]

0604 [Adjust Staple Position

Across Feed Direction 2]

0605 [Adjust Staple Position With

Feed Direction]

0606 [Adjust Punch Position

Across Feed Direction]

0607 [Adjust Punch Position With

Feed Direction]

0608 [Paper Alignment for

Booklet Across Feed Dir.]

Adjust the horizontal position of the booklet staples when

using Booklet Finisher SR5060.

Adjust the horizontal position of the folding when using

Booklet Finisher SR5060.

Adjust the vertical position of the staple (applied at an

edge) when using the Finisher SR5050 or Booklet

Finisher SR5060.

Adjust the vertical position of the staples (dual) when

using the Finisher SR5050 or Booklet Finisher SR5060.

Adjust the horizontal position of the staples when using

Finisher SR5050 or Booklet Finisher SR5060.

Adjust the vertical position of the punch holes when using

Finisher SR5050 or Booklet Finisher SR5060.

Adjust the horizontal position of the punch holes when

using Finisher SR5050 or Booklet Finisher SR5060.

Adjust the width of the staple jogger*1 for booklets when

using Booklet Finisher SR5060.

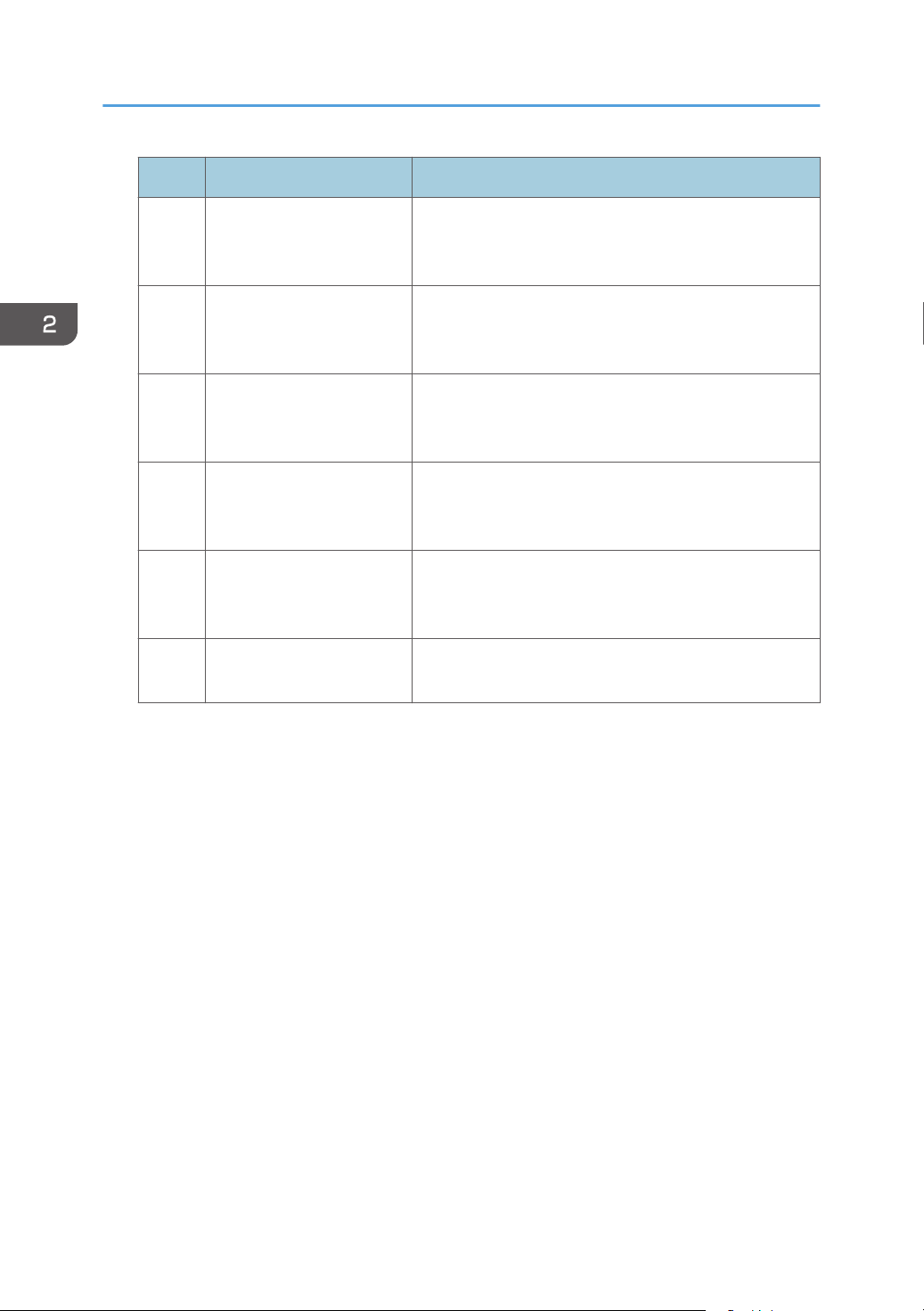

0609 [Set Number of Folds for

Booklet]

0610 [Paper Alignment for

Booklet With Feed Dir.]

0611 [Paper Alignment for

Stapling Across Feed

Direction]

0612 [Paper Alignment in Shift

Tray Across Feed Direction]

0613 [Paper Alignment for

Stapling With Feed

Direction]

Specify the number of additional booklet folds when

using the Booklet Finisher SR5060.

Adjust the travel distance of the paper edge stopper for

booklets when using Booklet Finisher SR5060.

Adjust the width of the staple jogger*1 for edge stapling

when using Finisher SR5050 or Booklet Finisher

SR5060.

Adjust the width of the paper alignment jogger*1 in the

shift tray when using Finisher SR5050 or Booklet Finisher

SR5060.

Adjust the travel distance of the paper edge stopper for

edge stapling when using Finisher SR5050 or Booklet

Finisher SR5060.

23

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0614 [Punch Skew Correction] Disable punch skew correction if jams or edge-folding

problems occur particularly when punching lightweight

paper using Finisher SR5050 or Booklet Finisher

SR5060.

0615 [Z-fold Skew Correction] Specify how to correct skew (occurring during paper

transport) when Z-folding with the folding unit.

0616 [Correct Z-fold Skew] Adjust the length of sheets moved for Z-fold skew

correction.

0617 [Correct Z-fold Skew

(Reverse)]

Adjust how much the registration roller rotates in reverse

for Z-fold skew correction.

0618 [Correct Punch Skew] Adjust the amount of skew correction for punching when

using Finisher SR5050 or Booklet Finisher SR5060.

0619 [Paper Alignment in Shift

Tray Setting]

Specify the accuracy of printed paper alignment when

applying shift-sorting with the Finisher SR5050 or

Booklet Finisher SR5060.

0620 [Number of Sheet Align for

Stapling]

0621 [Adjust Output Tray

Descending Position]

Specify the number of sheets the staple unit aligns at a

time for stapling.

Specify the descending position for the finisher shift tray

when paper is delivered to it using Finisher SR5050 or

Booklet Finisher SR5060.

0622 [Adjust Exit Guide Close

Timing (Booklet Fin)]

Specify when to close the exit guide after paper is

delivered to the finisher shift tray of Finisher SR5050 or

Booklet Finisher SR5060.

0623 [Output Trail Edge Press

Setting]

Specify whether or not to press down the trailing edge of

the paper when it is delivered to the finisher shift tray of

Finisher SR5050 or Booklet Finisher SR5060.

24

0624 [Output Fan Setting] Specify how the shift tray fan moves when using Finisher

SR5050 or Booklet Finisher SR5060.

0625 [Adjust Output Fan Level] Adjust the airflow of the shift tray for fanning the sheets

when using Finisher SR5050 or Booklet Finisher

SR5060.

0626 [Maximum No. Stacked

Sheets in Output Tray]

Specify the amount of paper stacked in Finisher SR5050

or Booklet Finisher SR5060.

Guide for alignment of printed paper. Printed paper is centered by the right and left guides.

*1

[Finishing: Fold]

For details about the following items, see page 76 "[Finishing: Fold]".

No. Item Description

Menu Items and Functions

0701 [Half Fold Position (Multi-

sheet Fold)]

0702 [Letter Fold-out Position 1

(Multi-sheet Fold)]

0703 [Letter Fold-out Position 2

(Multi-sheet Fold)]

0704 [Letter Fold-in Position 1

(Multi-sheet Fold)]

0705 [Letter Fold-in Position 2

(Multi-sheet Fold)]

0706 [Folding Unit Tray Full

Detection]

0707 [Number of Sheets Folded

after Full Detection]

Adjust the fold position of half folded sheets when using

the multi-folding unit.

Adjust the fold position for the bottom segment of letter

fold-out sheets when using the multi-folding unit.

Adjust the overall fold size of letters fold-out sheets when

using the multi-folding unit.

Adjust the fold position of the bottom segment of letter

fold-in sheets when using the multi-folding unit.

Adjust the fold position of letters fold-in sheets when

using the multi-folding unit.

Specify whether or not to automatically detect when the

folding unit tray becomes full.

Specify the number of sheets the machine prints when it

detects that the folding unit tray is full before displaying a

warning message.

0708 [Adjust Z-fold Position 1] Adjust the width of the bottom end segment of Z-folded

sheets when using the multi-folding unit.

0709 [Adjust Z-fold Position 2] Adjust the overall fold size of Z-fold sheets when using

the multi-folding unit.

[Finishing: Stacker]

For details about the following items, see page 84 "[Finishing: Stacker]".

No. Item Description

0901 [Paper Alignment in

Stacker Tray Across Feed

Adjust the width of the main jogger*1 when the high

capacity stacker is installed.

Direction 1]

25

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0902 [Paper Alignment in

Stacker Tray Across Feed

Adjust the width of the sub jogger*1 when the high

capacity stacker is installed.

Direction 2]

0903 [Paper Alignment in

Stacker Tray With Feed

Adjust the travel distance of the paper edge stopper

when the high capacity stacker is installed.

Direction]

0904 [Paper Alignment in 2nd

Stacker Tray Across Feed

Adjust the width of the main jogger*1 when the second

high capacity stacker is installed.

Dir. 1]

0905 [Paper Alignment in 2nd

Stacker Tray Across Feed

Adjust the width of the sub jogger*1 when the second

high capacity stacker is installed.

Dir. 2]

0906 [Paper Alignment in 2nd

Stacker Tray With Feed

Adjust the travel distance of the paper edge stopper

when the second high capacity stacker is installed.

Direction]

0907 [Maximum Stack Quantity

Set the maximum number of sheets for the stacker tray.

in Stacker Tray]

Guide for alignment of printed paper. Printed paper is centered by the right and left guides.

*1

26

Setting Values

(Leading Edge) (Trailing Edge)

Left

To p

Bottom

Right

Paper feed direction

(+)(-)

Default

CEZ012

(Leading edge)(Trailing edge)

Left Right

Paper feed direction

(+)

(-)

Default

CEZ013

To p

Bottom

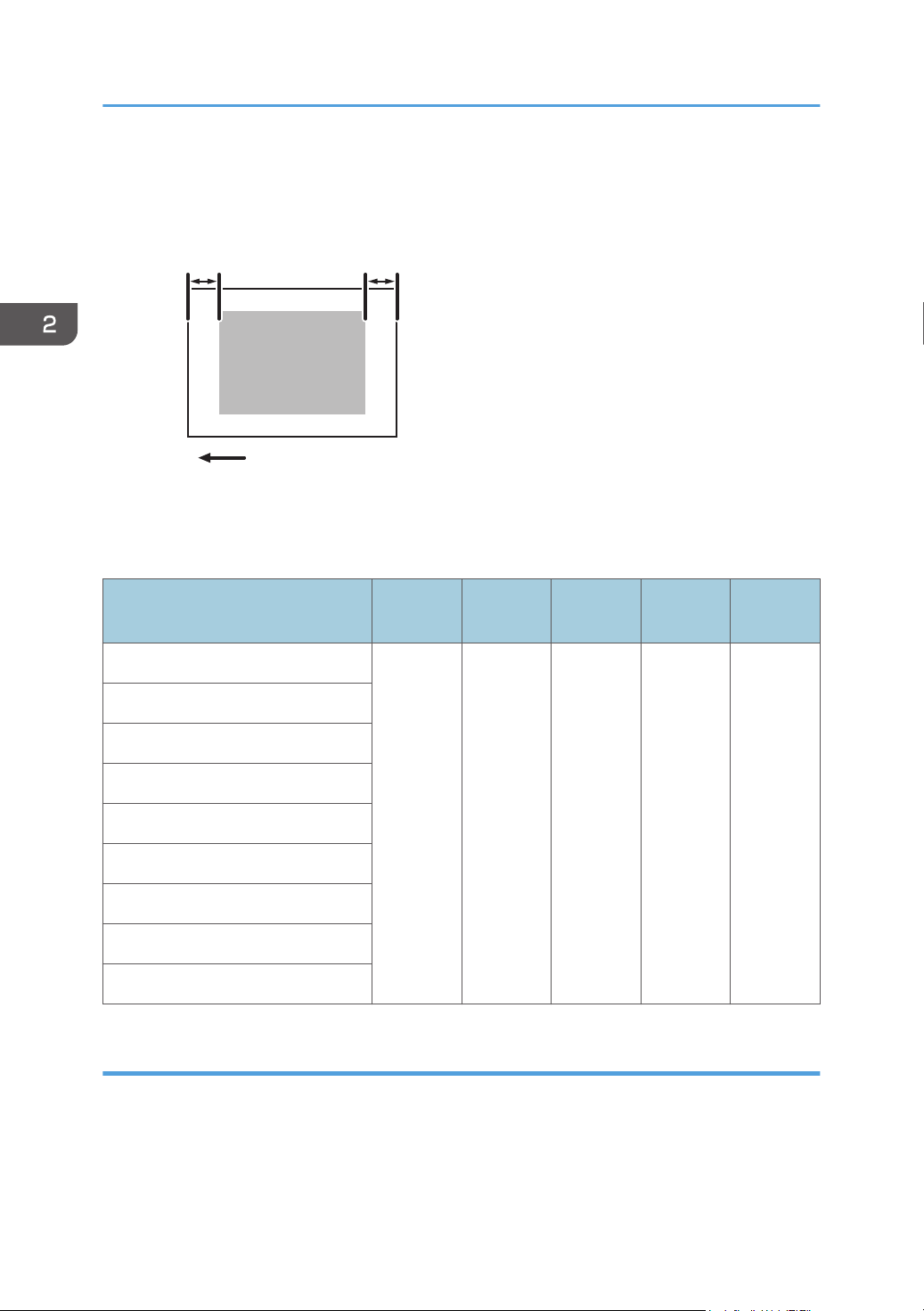

[Machine: Image Position]

0101: [Adjust Image Position With Feed Direction]

Adjust the horizontal position of the print image.

You cannot individually adjust the image position on sides 1 and 2.

Side 1

Setting Values

Press [+] to shift the image to the right (trailing edge).

Press [−] to shift the image the left (leading edge).

Side 2

Press [+] to shift the image to the left (trailing edge).

Press [−] to shift the image to the right (leading edge).

• If sheets are delivered face down, turn them over horizontally and check the image position.

27

Paper feed direction

Leading-edge margin Trailing-edge margin

CEZ586

2. Details of Menu Items in Adjustment Settings for Skilled Operators

• If the leading-edge margin on Side 1 of the paper is too narrow, paper jams may occur.

• If the trailing-edge margin on Side 1 of the paper is too narrow, paper jams may occur when

printing on the back side of paper during duplex printing.

• This setting is not effective for paper fed from paper trays with custom paper presets. For such

paper, the value specified in 08: [Adj Image Position of Side1 With Feed], 09: [Adj Image Position

of Side2 With Feed] in "Advanced Settings" takes precedence.

Setting Items

[Paper Weight 0] 0.0 3.0 -3.0 0.1 mm

[Paper Weight 1]

[Paper Weight 2]

[Paper Weight 3]

[Paper Weight 4]

[Paper Weight 5]

[Paper Weight 6]

[Paper Weight 7]

[Paper Weight 8]

0102: [Adjust Image Position Across Feed Direction]

Adjust the vertical position of the print image.

Default

Value

Max.

Value

Min.

Value

Step Unit

28

Loading...

Loading...