Page 1

KWANG YANG MOTOR CO.,LTD.

Page 2

Page 3

Dear KYMCO UXV 500 Users:

Thank you for purchasing this KYMCO UXV 500 and welcome to the family

of KYMCO UXV500 riders. To enjoy safety and more pleasant riding, become

thoroughly familiar with this owner manual before you ride the UXV 500.

You safety depends not only on your own alertness and familiarity with the

UXV 500 but also the UXV mechanical condition.

A pre-ride inspection before every outing and regular maintenance are

essential. The quality of each KYMCO UXV 500 is guaranteed.

Note: 1. The information and specifications stated in this manual are for

reference only and subject to change without notice.

2.When starting the engine, the battery must be installed to facilitate

starting and increase the engine performance.

Page 4

INDEX

AD

Auxiliary Outlet 32 39

Air Cleaner 62 Daily Safet y Checks 47

B

Batter y r emove 65 Driving Downhill 51

Brake Fluid Inspection 61 Driving Uphill 52

Brake Pedal 40 Driving Reverse 54

Differential Lock Lever And Indictor

Driving Safety 48

CE

Cargo Bed 42-44 Emission Contr ol System 55-56

Choke Knob 32 Engine Oil 57-59

Crossing Water 53

Cooling System Inspection 67 Fuel Lever I nspection/Refilling 23

F

Fuse Replacement 66

Fuel Cap Key 6

Page 5

r

INDEX

GO

Gear Selector 35 26-31

Operation Instruction for Multi-Mete

P

I

Indicator Lights 24-25 Pillows Aduust 34

Ignition Switch 36 Parking Brake Release 41

Ignition Switch Key 6 Packing 51

PERIODIC MAINTENANCE/L UBRICATI O N

77-79

LR

Light Sw it ch 37 Right Glove Compartment Key 6

Location Of Part s 7-10

S

Serial Number Locat ions 4-5

Start The Engine 49- 50

Spark Arrestor 56

Spark Plug I nspection 70

Specifications

72-76

Page 6

INDEX

T

Throttle Pedal 40

Tool Kit 71

U

Under-Hood 45-46

W

2WD/4WD Swit ch 38

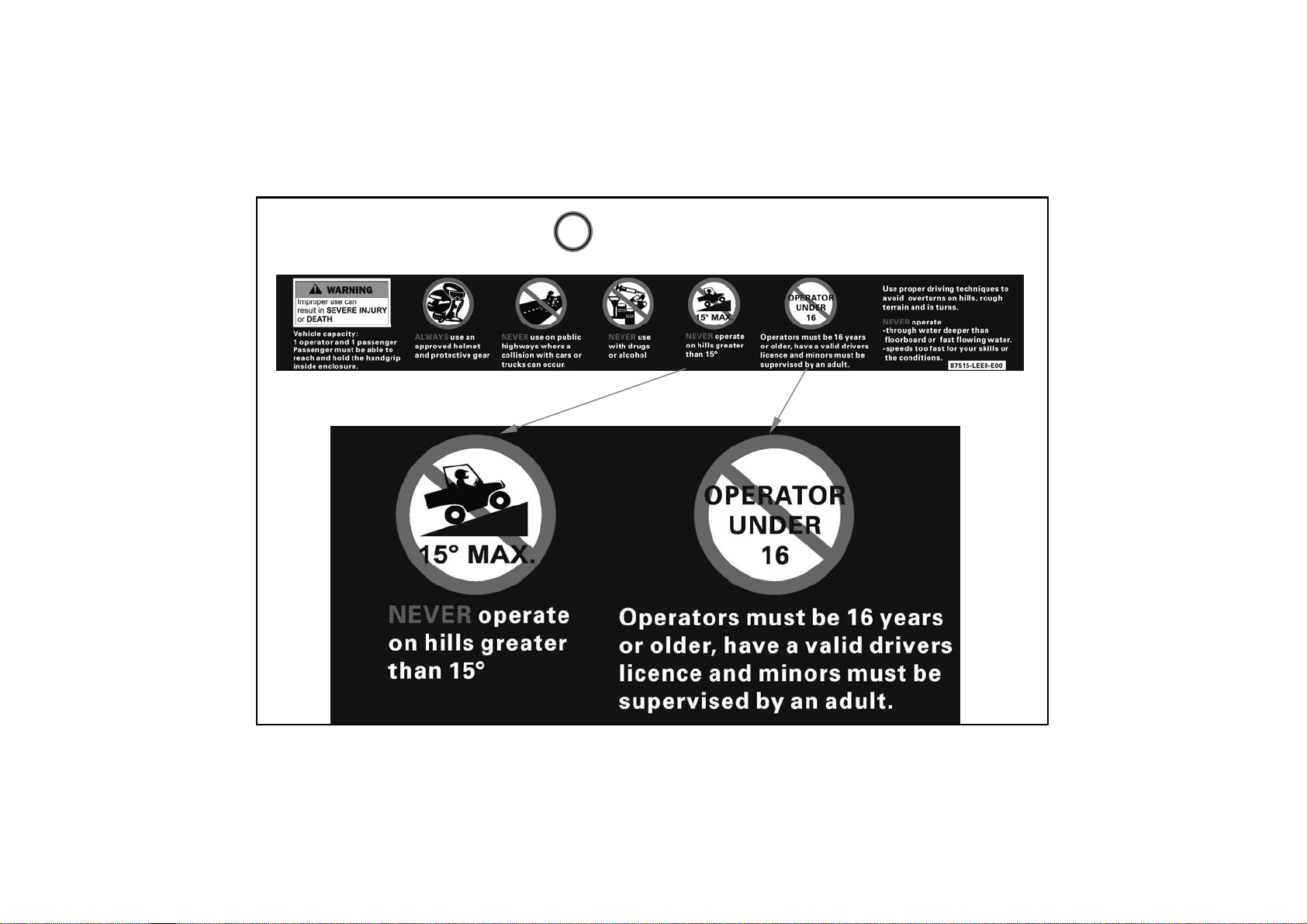

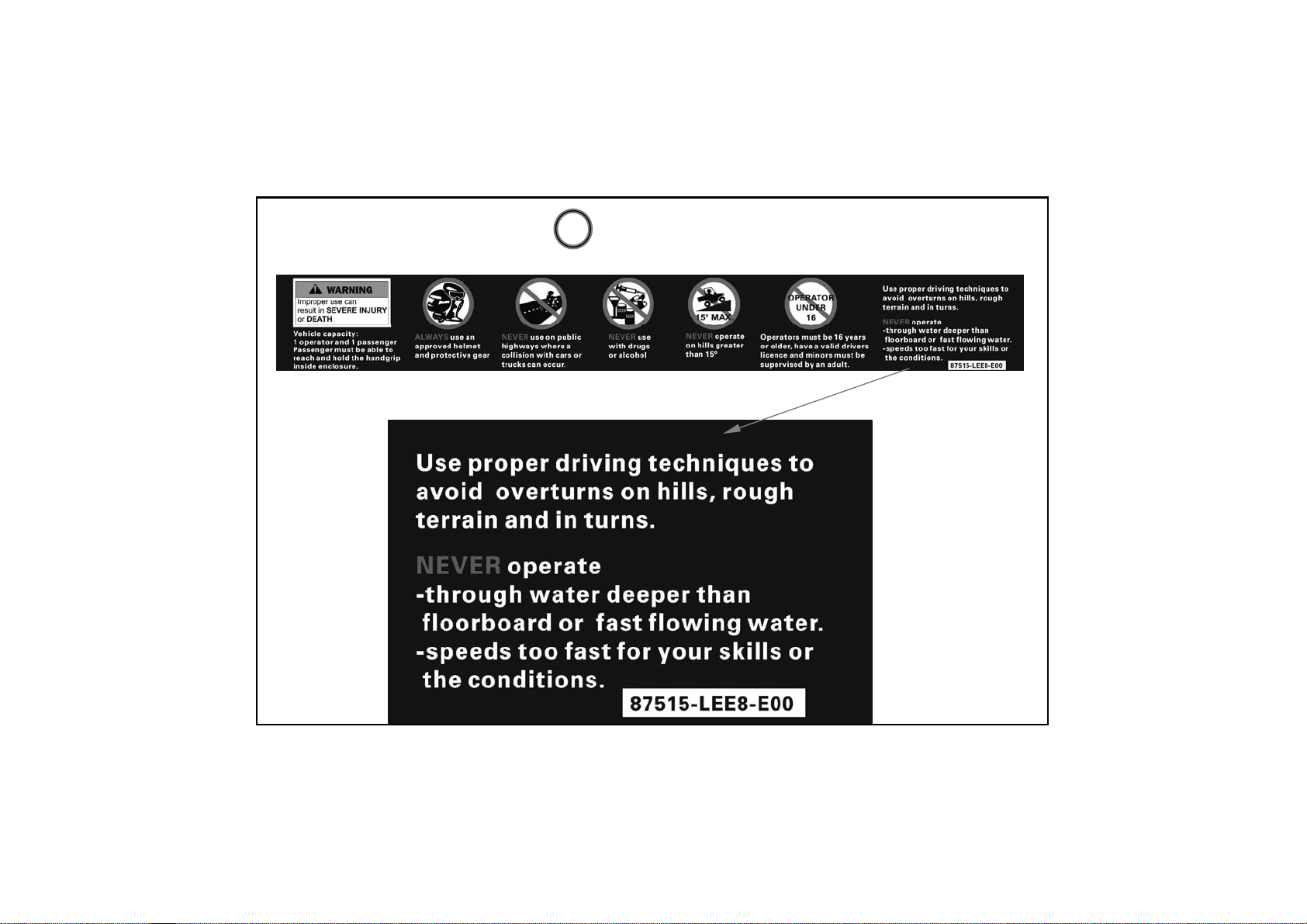

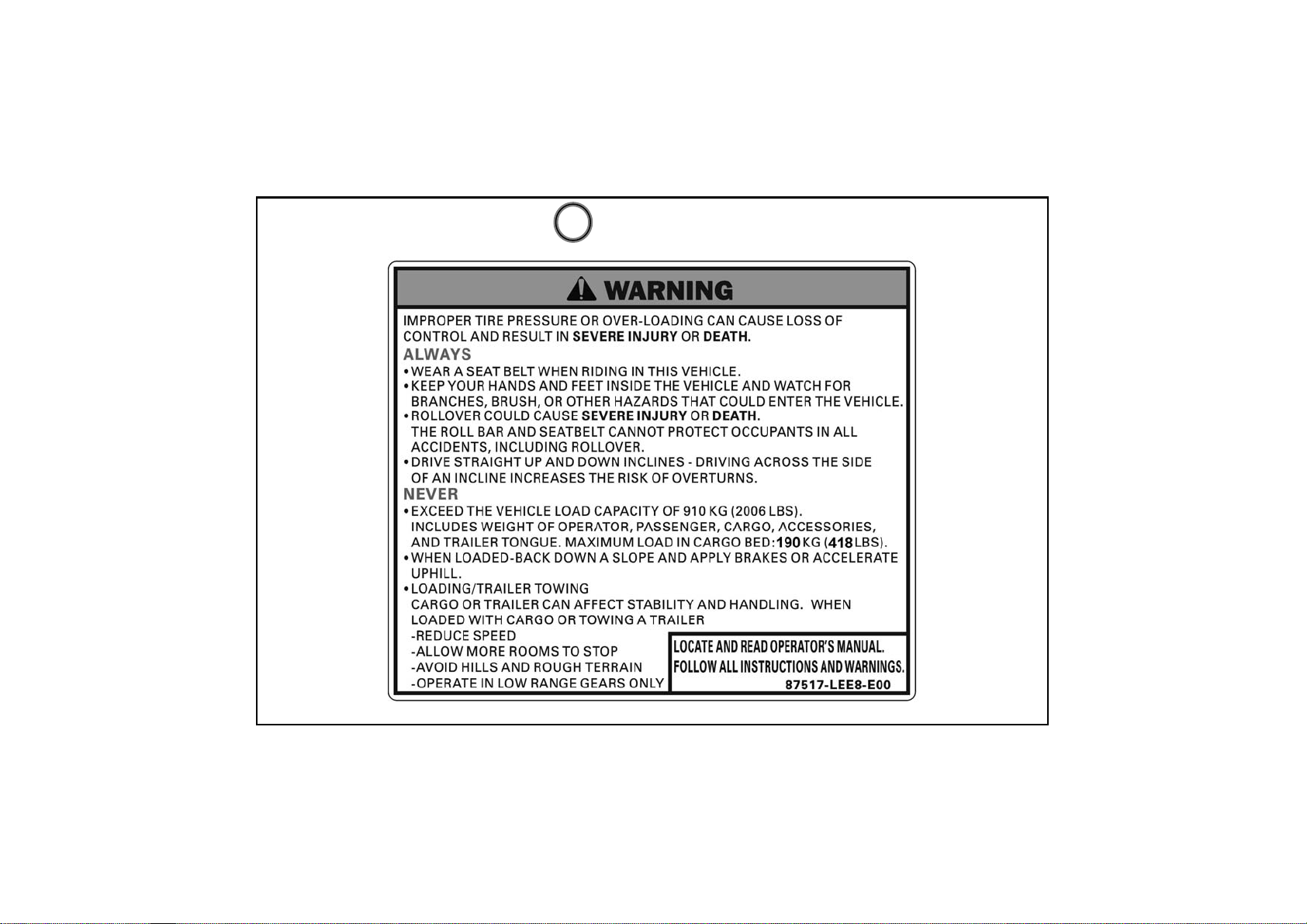

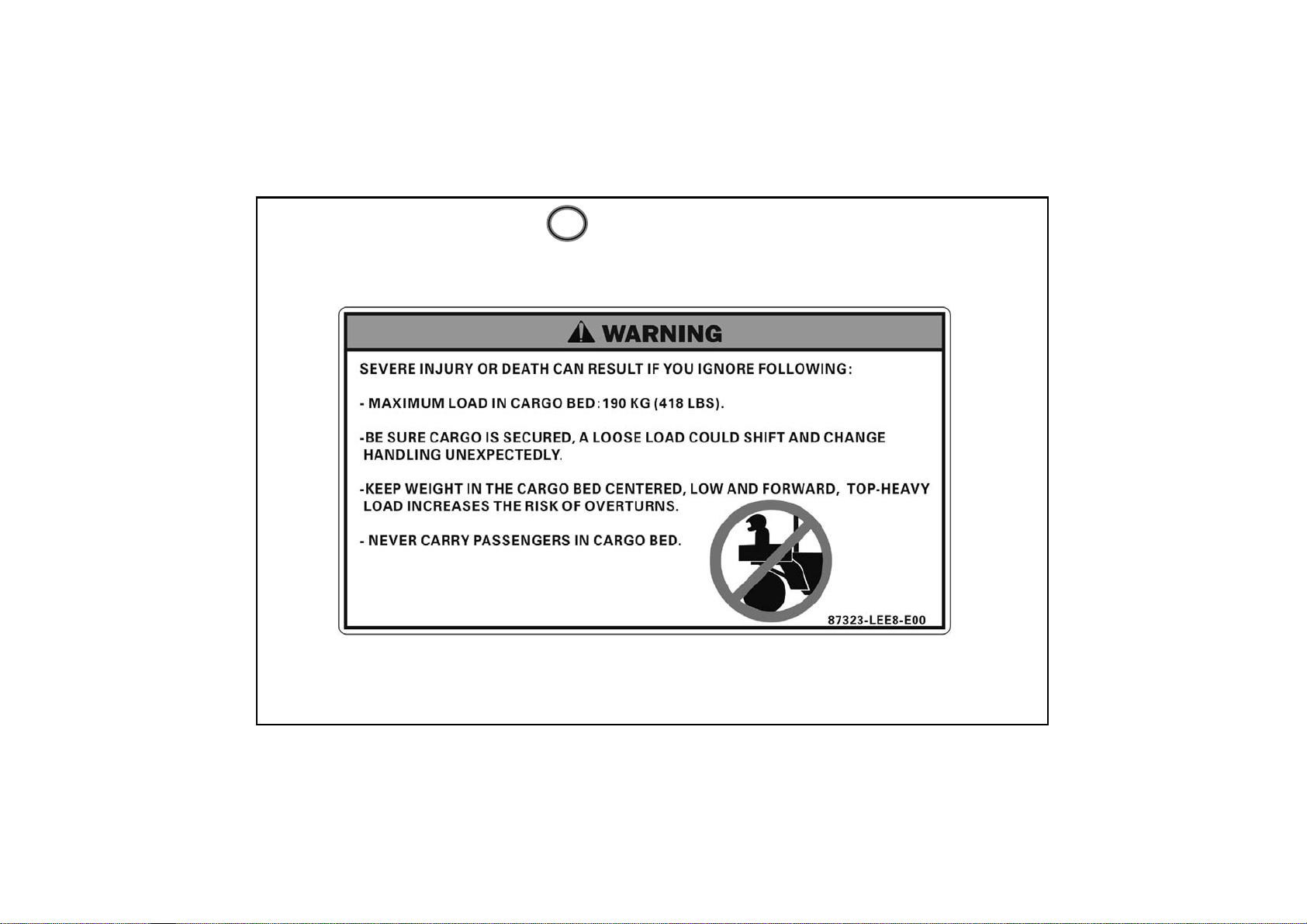

Warning Labels Locat on 11-13

Warning Labels 14-22

Page 7

This vehicle can be dangerous to operate.

A impact or rollover can occur quickly. even during routine maneuvers such

as turning and driving on hills or over obstacles, if you fail to take proper

precautions.

For your safety, understand and follow all the warnings contained in this

Owner’s Manual and labels on this vehicle.

Keep this Owner’s Manual with this vehicle at all times.

Failure to follow the warnings contained in this manual

can result in serious injury or death.

Particularly important information is distinguished in this manual by the

Following notations:

Indicates a strong possibility that serious injury or death may

WARNING

!

Result if instructions are not followed.

Indicates a possibility that equipment or property damage

CAUTION

!

could result if instructions are not followed.

●Note: Gives helpful information

1

Page 8

This vehicle is not a toy and can be dangerous to operate.

●Always go slowly and be extra careful when operating on unfamiliar terrain.

Always be alert to changing terrain conditions when operating this vehicle.

●Never operate on too rough, slippery, or loose terrain.

●Always follow proper procedures for turning as represent in this manual.

Institution turning at slow speeds before attempting to turn at faster speeds.

Do not turn at intemperate speed.

●Never operate on hills too steep for your abilities and cross the side of a hill,

Practice on smaller hills before attempting larger hills .

●Always use proper procedures if you stall or roll backward when climbing a hill.

To avoid maintain a steady speed when climbing a hill. IN case of you stall or

roll return,follow the procedure for braking described in this manual.

●Operation of this vehicle is restricted to people 16 years of age and older who

possess a valid operator’s license. Usually, no person under the age Of 6

may ride as a passenger on this vehicle.

WARNING

2

Page 9

Safety Watchful

●Always read the owner’s manual carefully and follow the operating

procedures described. Pay special attention to the warnings contained

In the manual and on all labels.

●

Never operate this vehicle with the canopy frame removed.

Always wear the seat belt when driving.

●

Never operate this vehicle on a public road. even a dirt or gravel one

●

WARNING

,because you may not be able to avoid colliding with other vehicles .

Always avoid paved surfaces. This vehicle isn’t designed to be used on

●

paved surfaces and may seriously affect handling and control.

Always follow this age prescription:

●

Operation of this vehicle is restricted to people 16 years of age and older who

possess a valid operator’s license. Usually, no person under the age

Of 6 may ride as a passenger on this vehicle.

3

Page 10

Serial Number Locations

This vehicle has 2 serial numbers:The frame number and Engine serial number.

The frame number is located on the frame near right front wheel place.

Frame Number

4

Page 11

Serial Number Locations

The engine serial number is located on the right side of the engine crankcase.

Engine Serial Number

5

Page 12

Ignition Switch Key/Fuel Cap Key

Right Glove Compartment Key

Fore keys come with this vehicle. Keep the spare in the safe place.

Fuel Cap Key

Right Glove Compartment

Ignition Switch Key→2PCS

Key →2PCS

6

Page 13

Location Of Parts (1)

4

5

6

1.Right Head Pillow 2.Right Seat 3.Right Tail /Brake Light

4.Left Head Pillow 5. Left Seat 6.Left Tail /Brake Light

1

2

3

7

Page 14

Location Of Parts (2)

11

10

12

13

14

9

8

15

7

8

07.Seat Belts

08.Cargo Bed

09.Headlights

10.Battery

11.Steering Wheel

12.Cab Frame

13.hands Bars

14.Bumper

15.Tool or Parts Box

Page 15

Location Of Parts (3)

21

16

16.Under-Hood

17.Hands Bars

18.Seat Belts

17

19.Fuel Tank Cap

20.Muffler&

Spark Arrester

21. Latch Handles

18

19

20

9

Page 16

Location Of Parts(4)

25

26

20

21

22

27

28

29

20.Right Glove Compartment 21. Auxiliary Outlet 22.Speedometer

23. Center Glove Compartment 24.Shifting The Automatic Transaxle

25. Choke Knob 26.Ignition Switch 27.Steering Wheel 28.Brake Pedal

29.Throttle Pedal

10

23

24

Page 17

Warning Labels Location

1

4

2

3

5

6

11

Page 18

Warning Labels Location

8

7

12

Page 19

Warning Labels Location

10

9

13

Page 20

Warning Labels

1

14

Page 21

Warning Labels

1

15

Page 22

Warning Labels

1

16

Page 23

Warning Labels

1

17

Page 24

Warning Labels

2

18

Page 25

Warning Labels

3

4 9

5

10

19

Page 26

Warning Labels

6

20

Page 27

Warning Labels

7

21

Page 28

Warning Labels

8

11

22

Page 29

Features And Controls

Fuel Lever Inspection/Refilling

Check if fuel is sufficient.

If the fuel gauge pointer is E(flash).refill

nonleaded gasoline as soon as possible.

(Refilling Method)

1.Turn the tank cap counterclockwise with

hand to open the cap.

2.Use only nonleaded gasoline.

3.Turn the fuel tank cap clockwise to tighten

it.

4.Close the fuel tank cap in the reverse

order of opening.

CAUTION

!

OPEN CLOSE

Be sure to stop the engine before refilling.The gasoline level shall not exceed

the reference plate;otherwise the fuel will penetrate out.

23

Page 30

Features And Controls

Indicator Lights

The indicator lights on the console display:

1. Lower Gear 2. High Gear 3.Neutral Gear 4.Reverse Gear 5. Parking Brake

6. High Temperature Indicator Light 7.High Beam Indicator Light

7.Lock:( Differential Lock Indicator Light )

7

8

6

5

2134

24

Page 31

Features And Controls

Instruments and Indicators

1.Speedometer 2. Km/h or Mph 3. Clock 4.2WD OR 4WD 5.Fuel Gauge

6.ODO meter7. Adjust button

4

5

6

1

2

3

7

25

Page 32

Features And Controls

Operation Instruction for Multi-meter

Button A(MODE)

Button B(SET)

26

Page 33

Features And Controls

Operation Instruction for Multi-meter

(1)Press and hold button A until 2

seconds.

Shift the unit mph or km/h

Button A(MODE)

27

Page 34

Features And Controls

Operation Instruction for Multi-meter

(1)Press and hold button B until 2

seconds.

Shift function to ODO or TRIP(A)

Once again Press and hold button

B until 2 seconds change TRIP(B)

Button B(SET)

28

Page 35

Features And Controls

Operation Instruction for Multi-meter

(1)Press and hold button A&B

until 2 seconds.

Simultaneously to reset to zero

when at TRIP(A)or TRIP(B)

function.

Button A(MODE)

Button B(SET)

29

Page 36

Features And Controls

Operation Instruction for Multi-meter

(1)Press and hold button A&B

until 2 seconds . when at ODO

function.

than you can see clock position

is flash word .

Button A(MODE)

Button B(SET)

30

Page 37

Features And Controls

Operation Instruction for Multi-meter

When you seeing clock position is

flash word . You can start setting

hour item. Press button B adjust

Correct hours than Press button A

you can see the minute

flash. adjust correct minute.

Waiting for 2second .finish times

setting.

position is

Button A(MODE)

Button B(SET)

31

Page 38

Features And Controls

Auxiliary Outlet

The 12-volt receptacle has spade

connections on the back that may be used to

power an auxiliary light or other optional

accessories or lights. The connections are

behind the console,under the hood.

Choke Knob

The choke knob located on the dashboard

,to the left of the steering shaft,provides a

rich mixture for cold staring.

Pull the choke knob all the way out until it

stops and hold it to start the engine.Warm

the engine up using the choke and throttle

until the idle speed is stable,and then release

the choke knob.

Choke Knob

Auxiliary Outlet

32

Page 39

Features And Controls

Seat Removal

Pull up on front of seat it toward the front of

vehicle.

Install the seat by sliding the tabs into the

rear of the seat base.Push down firmly on

the front of the pins are fully seated into the

grommets.

Seat Belts

The UXV500 is equipped with lap-shoulder

seat belts for the operator and passenger.

33

Page 40

Features And Controls

Pillows adjust

If you want adjusting your pillows.remove the 3 screws then adjusting

you need pillow position install the 3 screws.

34

Page 41

Features And Controls

Gear Selector

1.Lower Gear

2.High Gear

3.Neutral Gear

4.Reverse Gear

To change gears,stop the vehicle and

with the engine idling, move the lever

to the desired gear. Do not attempt to

shift gears with engine speed above

idle or while the vehicle is moving.

Always place the transmission in gear

with the parking brake locked

whenever the vehicle is left

unattended.

Maintaining shift linkage adjustment is

important to assure proper

transmission function .See your dealer

if you experience any shifting

problems.

.

35

Page 42

Features And Controls

Switches

Ignition Switch

The ignition switch is a 3-position,keyoperated switch, The key can be removed

from the switch when it is in the OFF

position.

ON: Electrical circuits are on

Electrical equipment can be used.

OFF: Engine off .All electrical circuits are.

off except Acc.12V

START: Electrical starter is engaged by

holding ignition switch key in this

position. Upon release ,the key will

return to the ON position.

36

Page 43

Features And Controls

Switches

Light Switch

The ignition switch key must be in the ON

position to operate the headlights.

The switch has 4 positions.

1:Light off -At this position , light is turn off.

2: Position light - At this position , light is

turn off

3.LO Headlight Beam- When you select

this position .the low beam will illuminate.

4.Hi Headlight Beam- When you select this

position .the high beam will illuminate

.High Beam Indicator Light will turn on.

37

2

1

3

4

Page 44

Features And Controls

Switches

2WD/4WD Switch

Pushing the switch to the 4WD position or to

the 2WD position

1:2WD-At this position , LED speedometer

will show 2wd word.

2:4WD-At this position , LED speedometer

will show 4wd word.

.

38

Page 45

Features And Controls

Differential Lock lever and indicator

The front axle is equipped with a lockable

differential that allows the operator to choose

between an open differential or

a closed differential in low traction situations.

Pulling the lock lever up.

To lock the differential on the 4WD, move the 4WD

differential Button.

39

Page 46

Features And Controls

Brake Pedal(1)

Depress the brake pedal to slow or stop or

stop the vehicle.

Throttle Pedal(2)

Push the pedal down to increase engine

speed .Spring pressure returns the pedal to

the rest position when released.

Always check that the throttle pedal returns

normally before starting the engine. Make

sure there’s adequate throttle pedal free

play.

(2)

(1)

40

Page 47

Features And Controls

Parking Brake Release(3)

To release the parking brake, pull the

release handle Spring pressure helps return

the lever to the released position .make sure

the parking brake lever is functioning

properly before each operation.

41

(3)

Page 48

Features And Controls

Cargo Bed (Lift and lower the cargo bed)

Push the cargo bed release

lever to right side, then

slowly lift up cargo bed until

it stop.

Lower the cargo bed slowly

to its original position and

be sure the it is locked into

place.

To lift

To lower

Cargo Bed Lever

Maximum load in cargo bed:n

42

190 KG

Page 49

Features And Controls

Cargo Bed(Open and close the tailgate 1)

To open---(1)

Unlock the latches,and then lower

the tailgate.

(1)

Latch(x2)

43

PULL

Page 50

Features And Controls

Cargo Bed(Open and close the tailgate 2)

To close

Please the tailgate in the

original position ,and then

hook the latches.

44

Page 51

Features And Controls

Under-Hood (To Open)

Unhook the hood latches and 3PU-screws,and then slowly tilt the hood up

until it stops.

PU- Screws x3

Latch x2

45

Page 52

Features And Controls

Under-Hood (To Close)

Lower the hood slowly to its original position ,and then hook the hood

latches and Screws.

PU- Screws x3

Latch x2

46

Page 53

How to operate

Daily Safety Checks

Check the following items each day before operation.

1.Fuel→→→→→→→Enough fuel in tank,no leaks.

2.Engine Oil →→→→Oil lever between lever holes(when engine is cold),no

leaks.

3.Air Cleaner→→→→Check the restriction gauge.

4.Tires →→→→→→→Air pressure(when cold)and check tires cracks, damage

or abnormal wear.Check for any imbedded stones or other

foreign particles in tread.

Front wheel Air pressure :0.7kgf/cm²;10psi

Rear wheel Air pressure :0.98kgf/cm²;14psi

Headlight & other indicate light →→ Check the operate is normal.

Brake/Brake oil lever →→ Check the operate and oil lever is normal.

Coolant →→Coolant lever between lever lines(when engine is cold),no leaks.

Front final gear case & transmission case →→No oil leaks

47

Page 54

How to operate

Driving Safely(Driving procedures)

1.Sit in the driver’s seat and fasten the seat belt.:

2.After staring the engine and allowing it to warm up,shift the transmission

into gear.

3.Check your surroundings and determine your path of travel.

4.Release the parking brake.

5.Keeping both hands on the steering wheel, slowly depress the throttle with

your right foot and begin driving.Vehicle speed is controlled by the amount of

throttle opening & transmission shifting is automatic.

6.Drive slowly . Practice maneuvering and using the throttle and brakes on

level surfaces.

48

Page 55

How to operate

Start the engine

Note:

!

Never run the vehicle in a closed area, such as a

garage Exhaust gases contain carbon monoxide,

a colorless, odorless, poisonous gas.

Breathing exhaust gas leads to carbon monoxide

poisoning, asphyxiation, and death.

1.Wear the seat belts.

2.Set the parking brake.

3.Put the gear shift lever in the “N(neutral) position.

4.Turn the ignition switch clock wise to the START position; then when the engine

starts, release to the RUN position.

WARNING

When the engine is

already warm or the

weather is hot.

(35°C,95°F or more), do

not use the choke.

5.When the engine is cold(same as outside temperature), cannot start engine, you

will pulling the choke knob the way out until it stops and hold it.

49

Page 56

How to operate

Start the engine

!

Do not run the starting attempt. The starter motor may

overheat causing severe starter motor damage. Allow

15 seconds between starting attempts to allow the

starter motor to cool.

Braking/Stopping

Always allow plenty of room and time to stop smoothly. Sometimes quick stops

are inevitable’ so always be prepared.Whether you’re stopping quickly’ do

this:

1.Release the accelerator;then press the foot brake pedal to apply the brake.

2.If the wheels lock,release them for a second;then apply them again .On

surfaces such as ice,mud or loose gravel’ pump the brake pedal rapidly.

3.Never ride the brake .Even maintaining minimal pressure on the brake pedal

will cause the brake pads drag on the disc and may overheat the brake fluid.

CAUTION

50

Page 57

How to operate

Parking

Parking involves flowing the previous rules for braking;then :

1.After the vehicle stops,shift into neutral gear.

2.Set the parking brake.

3.Turn off the ignition key.

4.If you have to park on the hill,shift to low range,set the parking brake,and

block the wheel on the downhill side.

Driving downhill

Always drive straight down the hill and always avoid hills sleeper than 15°

1.Keep both hands on the wheel.

2.Prior to descending the hill,shift into range and release the accelerator to

allow maximum engine brake.Do not use 4 wheel drive when descending a

hill.Engine braking can cause the front wheels to slide reducing steering control.

51

Page 58

How to operate

Driving uphill

whenever travel straight uphill, follow these precautions:

1.Always travel straight uphill.

2.Avoid steep hills(15° maximum)

3.Keep both feet on the floor.

4.Proceed at a steady rate of speed and throttle opening.

NEVER OPERATE UP OR

DOWN HILLS STEEPER

THAN 15°

52

15° maximum

Page 59

How to operate

Crossing water

UXV500 can only operate in water up to its floorboard.Stay away from fast

moving rivers. This vehicle’s tires can be buoyant.In deep water,the vehicle

may lose traction due to floating.

1.Physically check the depth and current of the water, especially if you can not

see the bottom.Also,check for boulders,logs,or any other hidden obstacles.

2.Keep speed slow while maintaining momentum.

3.Make sure you have a way out on the other side of the water.

4.Once you have cleared the water,briefly apply the brakes to make sure they

work.

53

Page 60

How to operate

Driving in reverse

Follow these guidelines when operating in reverse:

1.Back slowly.

2.Apply the brakes lightly for stopping.

3.Avoid turning at sharp angles.

4.Always avoid backing downhill.

5.Never open the throttle suddenly while backing.

6. Always inspect left and right fields of vision before backing.

54

Page 61

Emission Control System

Crankcase Emission Control System

This engine is equipped with a closed crankcase system .

Blow-by gases forced back to the comb7ustion chamber by the intake s7ystem.

The system does not allow the blow-b7y gases to enter the atmosphere.

Exhaust Emission Control System

The emissions from the exhaust of this vehicle are controlled by engine

design,including factory-set fuel delivery and ignition.KYMCO Exhaust

Emission Control System including

second air supply system & catalyzer

any kymco

design.

convert system.please do not change

Noise Exhaust Emission Control System

Do not modify the engine ,intake or exhaust components, as doing so may

affect compliance with state and local noise level requirements.

55

Page 62

Emission Control System

Spark Arrestor

Your UXV 500 has a spark arrestor.

The spark arrestor be installed and functional when the vehicle operated on

public lands.

Remove method

remove 3 screws

56

Clean method

Use the iron brush cleaning

carbon on the spark arrestor

Page 63

Maintenance And Lubrication

Engine Oil

Always check and change the oil at the OWNER MANUAL standard intervals.

The oil tank is located under the seat.

1.Position the vehicle on the surface.

2.Start the engine and let it idle for 20~30seconds.

3.Stop the engine and remove the seat.

4.Add fresh oil into the oil tank .

Make sure the engine oil at the specified level.

Add oil as ne cessary. Check for leaks.

Oil quantity:

Engine oil:

Periodic oil change:

3 L (2.64 Imp qt, 3.18 US qt)

Total amount:

3.6 L (3.17 Imp qt, 3.82 US qt)

Recom me n ded engine o il classification: API

Service SJ typ e or higher

57

0

1 0

SAE 5W

0

-1 0

30

0

50

0

SAE 10W 30

SAE 10W 40

0

0

10

0

0

70

90

-

-

SAE 20W 40

SAE 20W 50

20

-

-

0

30

0

0

0

110 F

0

40 C

Page 64

Maintenance And Lubrication

ENGINE OIL

1.Engine oil level measurement

A. Place the machine on a level place.

B. Warm up the engine for several minutes and stop it.

C. Check the oil level through the inspection window.

D. The oil level should be between the maximum (H) and minimum (L) marks.

If the level is low, add oil to raise it to the proper level.

NOTE:

Wait a few minutes until the oil level settles

before checking.

H

L

58

Page 65

Maintenance And Lubrication

Engine oil replacement and oil filter cleaning

1. Place the machine on a level place.

2. Warm up the engine for several minutes and stop it.

3. Place a container under the engine.

4. Remove the oil fill cap (1) and oil fill cap

(2) to drain the oil.

CAUTION:

Be sure no foreign material enters the

crankcase.

CAUTION:

When removing the oil filter cap, the

compression spring, oil strainer and O-ring

will fall out. Take care not to lose these

parts.

(2) oil filter cap

59

(1) oil fill cap

Page 66

Maintenance And Lubrication

NOTE:

Skip steps E to I if the oil filter cartridge is not

being replaced.

Remove the oil filter cartridge with an oil cartridge wrench.

oil filter

remove lock

60

Page 67

Maintenance And Lubrication

BRA KE FLUID INSPECTIO N

Check if the fluid level is below the lower level

mark through the inspection window.

W ARNING

POTENTIAL HAZARD

Brake fluid contacting the skink or eyes.

WH AT CAN HAPPEN

May cause irritation.

HOW TO AVOID THE HAZARD

Avoid contacting brake fluid with the skin

or eyes. In case of contact, flush thoroughly

with water and call a doctor if your eyes

were exposed.

61

(1) Lower level mark

(2) Upper level mark

Page 68

Maintenance And Lubrication

Air Cleaner

Remove the center cover screws and center cover

Remove

Shifting The Automatic Transaxle bolt.

62

Page 69

Maintenance And Lubrication

Air Cleaner

Remove air cleaner cover screws.

Remove air cleaner filter

63

Page 70

Maintenance And Lubrication

Air Cleaner

Clean the air cleaner filter

64

Page 71

Maintenance And Lubrication

Battery remove

1. Make sure the ignition switch is OFF.

2. Remove the under-hood hook& pu bolts.

3. Remove the battery cover screws.

4. Disconnect the negative (-) terminal lead (1)

from the battery first, then disconnect the

positive (+) terminal lead (2).

5. Remove the battery.

Battery installation

1. Install in the reverse order of removal.

2. After installing the battery, check to see if

the battery cables are routed correctly.

NOTE:

First connect the positive (+) cable and then

negati ve (-) cable to avoi d short circu it.

(1)(2)

65

Page 72

Maintenance And Lubrication

Fuse Replacement

The fuse box stored in the battery compartment.

To replace a fuse:

1. Make sure the ignition switch is OFF.

2. Remove the under-hood hook& pu bolts

3. Open the fuse box cap.

4. Pull the old fuse out of the fuse holder.

5. Push the new fuse in to the fuse holder.

6. Close the fuse box cap and install seat.

CAUTION:

To prevent accidental short-circuiting, turn

off the main switch when checking or

replacing a fuse.

(1) (2) (3) (4) (5) (6)

(6)FAN MOTER---------15A

(5)IGNITION--------------15A

(4)LIGHT------------------15A

(3)DC12VPOWER------15A

(2)SPARE-----------------15A

(1)SPARE-----------------30A

66

Page 73

Maintenance And Lubrication

Cooling System Inspection

1. Remove the under-hood hook& pu

bolts

2. Check the coolant level in the

coolant reservoir when the engine is

cold as the coolant level will vary with

engine temperature. The coolant level

should be between the maximum and

minimum marks.

3. If the level is low, remove the coolant

reservoir cap, and then add coolant or

distilled water to raise it to the

specified level.

CAUTION:

Hard water or salt water is harmful to the

engine. You may use distilled water if rou

can n ot get so ft wa ter.

NOTE:

1. If water is added, have a KYMCO dealer

check the antifreeze content of the coolant

as soon as possible.

2. The radiator fan operation is completely

automatic. It is switched on or off according

to the coolant temperature in the radiator.

FULL

LOW

67

Page 74

Maintenance And Lubrication

WHEEL REMOVEL

1.Elevate the wheel by placing a suitable

stand under the frame.

2.Remove the nuts from the wheel.

3. Remove the wheel assembly.

(1)

WHEEL INSTALLATION

When reinstalling a wheel, tighten the wheel

nuts in a crisscross(rather than a

circular)pattern.Be sure the tapered a side of the

wheel nuts(1)face the wheel rim(2).

Wheel nut torque:

Front:55 N-m(5.5 kgf-m,40 lbf-ft)

Rear:55 N-m(5.5 kgf-m, 40 lbf -ft)

Be sure the tapered side of the wheel nuts(1)

face the wheel rim(2).

OK

(2)

(1)

68

(1) Wh eel nut (2) Wheel rim

Page 75

Maintenance And Lubrication

NOTE:

The arrow mark on the tire must point

toward the rotating direction of the wheel.

(1)

(1) A rrow mark

POTENTIAL HAZARD

Installing wheels improperly.

WHAT CAN HAPPEN

A wheel may come loose, possibly leading

to an accident.

HOW TO AVOID THE HAZARD

Car efully follow the in structions in t his

Owner's Manual when installing.

W ARNING

69

Page 76

Maintenance And Lubrication

n

e

e

Before installing the spark plug, measure the

SPARK PLUG INSPECTION

The spark plug is an important engine

component and is easy to inspect. The conditio

of the spark plug can indicate the condition of

the engine.

For example, a very white center el ectrode

porcelain color could indicate an intake air leak

or carburetion problem for that cylinder. Do not

attempt to diagnose such problems yourself.

Instead, take the machine to a KYMCO dealer.

You should periodically remove and inspect the

spark plug because heat and dep osits wil l caus

the spark plug to slowly break down and erode.

If electrode erosion becomes excessive, you

should replace the spark plug with one of the

proper type.

electro de gap with a feeler gauge and adjust to

specification.

Spark plug gap:

0.9 mm ( 0 .0 2 4 ~0 .0 2 8 i n )

(A)

(A) Spark plug gap

W h e n in s ta l l i n g th e sp a rk pl u g , al w a y s cle a n th

ga s ke t s u rfa c e a n d us e a ne w ga s ke t. Wip e o ff

an y gr i me fro m th e th re a d s an d ti g h te n to the

specified torque.

Standard spark plug (NGK): CR7E

Tighten ing torque:

Spark plug:

17 .2 N - m (1.7 2 kg f- m, 1 3 l b f- ft)

70

Page 77

Maintenance And Lubrication

Tool kit

The tool kit put down location at

The tool kit includes the following items:

(1) Hexagon wrench

(2) Spark plug wrench

(3) 8/12;10/14;17/19 mm wrench

(4) Screwdriver

(5) Screwdriver handle

(6) Tool bag

(7)Air pressure gauge

Right Glove Compartment .

71

(6)

(7)

(4)

(1) (2)(3) (5)

Page 78

Specifications

MO DEL UXV500(OFF RO AD)

DIMENSIONS:

OVERAL L L ENGTH

OVERAL L W IDTH

OVERAL L HEIG HT

SEAT HEIG HT

WHEELBASE

GRO UND CLEARANCE

MINMUN. TURNING RADIUS

BASIC WEIGHT:

WITH OIL AND FULL FUEL TANK

MAX. CARGO BED LOAD

DRY W EIGHT

MAX. W EIG HT CAPACITY

ENGINE:

ENGINE TYPE

CY LINDER ARRANGEMENT

BOREx STROKE

ACTUAL DISPL ACEM ENT

COMPRES SIO N RATI O

STARING SYSTEM

LUBRICATI ON SYSTEM

2870MM

1500MM

1850MM

805MM

1910MM

310MM

4060MM

560KG

190KG

525KG

350KG

4 -STRO KE,DO HC

SINGL E CYLINDER

92x 75MM

498.5CC

10.5:1

ELECTRIC STARTER

WET SUMP

72

Page 79

Specifications

MO DEL UXV500(OFF RO AD)

ENGINE G EAR BOX:

CAPICITY/EXCHANGE/TYPE

FRONT GEAR BOX:

CAPICITY/EXCHANGE/TYPE

REAR GE AR BOX

CAPICITY/EXCHANGE/TYPE

AIR FILTER:

FUEL:

TYPE

FUEL TANK CAPACITY

CA RBURETOR:

TYPE/MAN UFACTURER

SPARK PLUG:

TYPE/MAN UFACTURER

SPARK PLUG

CLUTH TYPE:

3.6L,5W-30

275ML,(SAE80#)

250ML,(SAE80#)

SPONGE ELEMENT

UNLEADED G ASOLI NE

32L

LEE8/ KYM CO

CR7E-NGK

0.9MM

WET CENTRI FUGA L AUTO M A TIC

73

Page 80

Specifications

MO DEL UXV500(OFF RO AD)

TRANSMISSION:

PRIMARY REDUCTION SYSTEM

SECONDARY REDUCTION SYSTEM

TRANSMI SSIO N TYPE:

TIRE:

TYPE

SIZE(FRONT)

SIZE(REAR)

WHEEL MATERIAL

PRESSURE FR/RR

BRA KES:

SYSTEM FRONT AND REAR UNIFI ED

TYPE(FRO NT) DUAL DISC BRAKE

TYPE(REAR) SINGLE DISC BRAKE

OPERATI ON FOOT O PERATION

SUSPENSION:

FRONT SUSPENSIO N DOUBLE WI SHBONE

REAR SUSPENSION DOUBLE WISHBONE

SHOCK ABSORBER: COI L SPRI NG/ OI L DAM PER

V-BELT

SHAFT DRIVE

V-BELT AUTOM ATI C

TUBELESS

25x8-12

25x10-12

STEEL

0.7/0. 98( k gf / cm2) O R 10/14 psi

74

Page 81

Specifications

MO DEL UXV500(OFF RO AD)

WHEEL T RAVEL:

FRONT WHEEL TRAVEL

REAR WHEEL TRAVEL

ELETRICAL:

IG NITI O N SYSTEM

GENERATO R S YSTE M

BATTERY TYPE

BATTERY CAPACI TY

HAEDLIGHT TYPE:

BULB VOLT AGE

WATTAGE X QUANTITY:

HAEDLIGHT: 12V35/35W*2

NO. PLATE LIGHT NONE

REAR LIGHT 12V21/5W * 2

INDICAT ORS FR /RR DI RE CT IO N NONE

BRAKE LIG HT 12V21/ 5 W * 2

POSITI O N LIGHT 12V21/5W* 2

190MM

190MM

DC, CDI

A.C.MAGNETO

MF-VTX20L

12V18AH

HS1

75

Page 82

Specifications

MO DEL UXV500(ON ROAD)

SPECIFIED FUSES:

MAIN FUSE 30A

FAN MOTER

IGNITION

LIGHT

DC12VPOWER

SPARE

SPARE

15A

15A

15A

15A

15A

30A

76

Page 83

PERIODIC MAINTENANCE/LUBRICATION

ITEM

ROUTINE

!

Engine oil

*Oil strainer

Engine oil filter cartridge

Final gear oil

Differential gear oil

Air filter element

(for engine and *V-belt

compartment)

*Carburetor

*Cylinder head cover

breather system

Spark plug

*Fuel line

*Valves

Replace (Warm engine before draining).

!

Clean.

!

Replace if necessary.

!

Replace

!

Check oil level/oil leakage

!

Replace every 12 months.

!

Check oil level/oil leakage

!

Replace every 12 months.

!

Clean. (More often in wet or dusty areas.)

!

Replace if necessary.

!

Check idle speed/starter operation.

!

Adjust if necessary.

!

Check breather hose for cracks or damage.

!

Replace if necessary.

!

Check condition.

!

Adjust gap and clean.

!

Replace if necessary.

!

Check fuel hose for cracks or damage.

!

Replace if necessary.

!

Check valve clearance.

!

Adjust if necessary.

WHICHEVER COMES FIRST

mi

Km

MONTH

INITIAL EVERY

100

150

600

1200

1000

2000

1612

(Cont’d)

77

Page 84

ITEM

*Brake

*Coolant

*V-belt

*Exhaust system

Spark arrester

*Wheels

*Wheel bearings

*Steering system

*Drive shaft boots

*Suspension

WHICHEVER COMES FIRST

ROUTINE

!

Check operation and brake fluid.

!

Replace brake pad if necessary.

!

Check coolant leakage.

!

Replace if necessary.

!

Replace coolant every 24 months.

!

Check operation.

!

Replace if damage or excessive wear.

!

Check leakage.

!

Retighten if necessary.

!

Replace gasket if necessary.

!

Clean

!

Check balance/damage/runout.

!

Replace if necessary.

!

Check bearing assembly for looseness/damage.

!

Replace if damaged.

!

Check operation.

!

Replace if damaged.

!

Check toe-in.

!

Adjust if necessary.

!

Check operation.

!

Replace if damaged.

!

Check operation.

!

Correct if necessary.

mi

Km

MONTH

INITIAL EVERY

100

150

600

1200

1000

2000

1

6

12

78

(Cont’d)

Page 85

ITEM

WHICHEVER COMES FIRST

ROUTINE

*Knuckle shafts/

Steering shaft

*Fittings and Fasteners

* : It is recommended that these items be serviced by a KYMCO dealer.

** : Lithium soap base grease.

!

Lubricate every 6 months.

!

Check all chassis fittings and fasteners.

!

Correct if necessary.

mi

Km

MONTH

INITIAL EVERY

100

150

600

1200

1000

2000

1

6

12

79

Page 86

Maintenance Record

Page 87

Maintenance Record

Page 88

Maintenance Record

Page 89

Maintenance Record

Page 90

Maintenance Record

Page 91

Maintenance Record

Page 92

By KWANG YANG Motor Co., Ltd.

Frist Edition, Oct 2007

All rights reserved. Any reproduction or

unauthorized use without the written permission of

KWANG YANG Motor Co., Ltd.

is expressly prohibited.

T200-UAA0AA-US

Page 93

KWANG YANG MOTER CO .,LTD

NO.35 Wan Hsing Street,San Min District

Kaohsiung, Taiwan, Republic Of China

Telephone : 886-7-3822526

Fax : 886-7-3950021

Printed in Taiwan

Loading...

Loading...