Page 1

6. CYLINDER HEAD/CYLINDER/PISTON

6-0

BET & WIN 5 0

6

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CYLINDER HEAD/CYLINDER/PISTON

__________________________________________________________________________________

SERVICE INFORMATION........................................................ 6-1

TROUBLESHOOTING.............................................................. 6-1

CYLINDER HEAD.................................................................... 6-2

CYLINDER/PISTON................................................................. 6-4

6

Page 2

6. CYLINDER HEAD/CYLINDER/PISTON

6-1

BET & WIN 5 0

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder head, cylinder and piston can be serviced with the engine installed in the frame.

• Before disassembly, clean the engine to prevent dust from entering the engine.

• Remove all gasket material from the mating surfaces.

• Do not use a driver to pry between the cylinder and cylinder head, cylinder and crankcase.

• Do not damage the cylinder inside and the piston surface.

• After disassembly, clean the removed parts before inspection. When assembling, apply the

specified engine oil to movable parts.

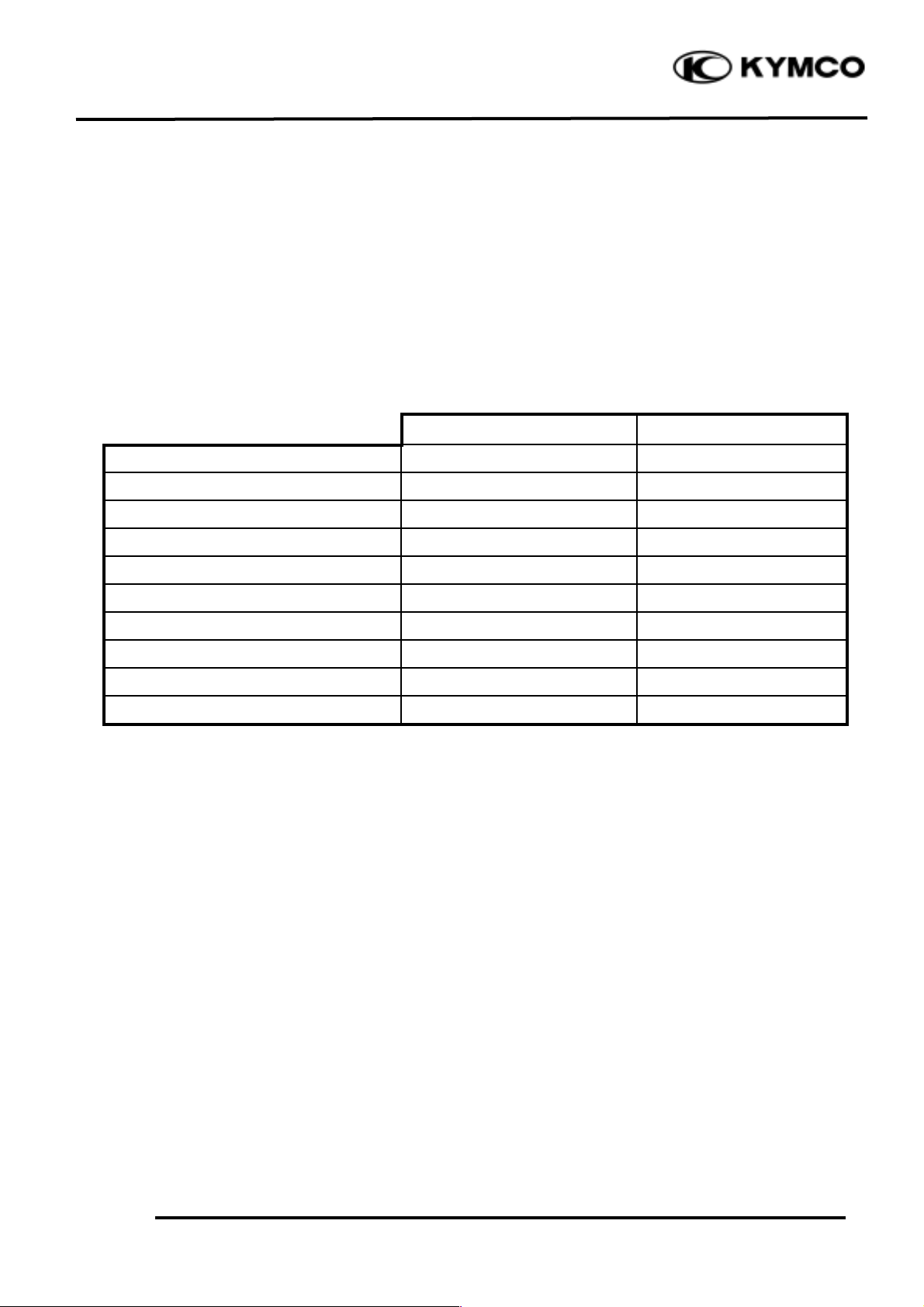

SPECIFICATIONS

Standard (mm)

Service Limit (mm)

Item

B&W50

B&W50

Cylinder head warpage

0.10

Piston O.D.(5mm from bottom of piston

38.970_ 38.955

38.90

Cylinder-to- piston clearance

0.03_ 0.07

0.10

Piston pin hole I.D.

12.002_ 12.008

12.03

Piston pin O.D.

11.994_ 12.0

11.98

Piston-to-piston pin clearance

0.002_ 0.014

0.03

Piston ring end gap (top/second)

0.10_ 0.25

0.40

Connecting rod small end I.D.

17.005_ 17.017

17.03

Cylinder bore

39.0_ 39.025

39.05

TORQUE VALUES

Cylinder head bolt 14.7_ 16.66N-m

Exhaust muffler joint lock nut 9.8_ 13.72N-m

Exhaust muffler lock bolt 29.4_ 35.28N-m

Spark plug 10.78_ 16.66N-m

TROUBLESHOOTING

Compression too low, hard starting

or poor performance at low speed Abnormal noisy piston

• Leaking cylinder head gasket • Worn cylinder and piston

• Loose spark plug • Worn piston pin or piston pin hole

• Worn, stuck or broken piston and piston rings • Worn connecting rod small end bearing

• Worn or damaged cylinder and piston

Compression too high, overheating

or knocking Abnormal noisy piston rings

• Excessive carbon build-up in cylinder head • Worn, stuck or broken piston rings

or on piston head • Worn or damaged cylinder

Page 3

6. CYLINDER HEAD/CYLINDER/PISTON

6-2

BET & WIN 5 0

CYLINDER HEAD

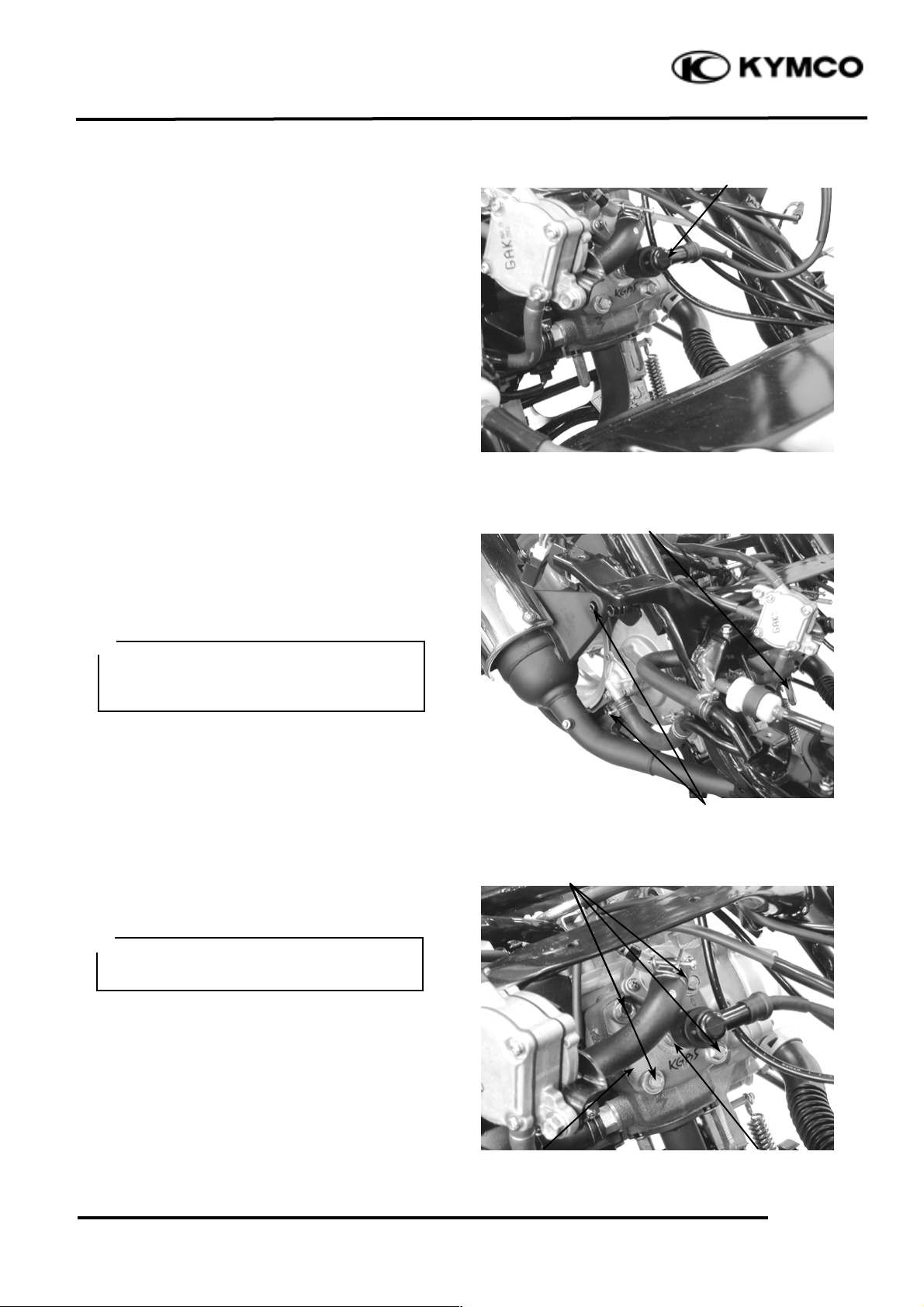

REMOVAL

Remove the rear carrier.

Remove the frame body cover. (2-2)

Drain the coolant.

Disconnect the thermosensor wire from the

thermosensor.

Disconnect the water hose from the

thermostat housing.

Remove the spark plug cap.

Remove the two joint lock nuts on the front

of the exhaust muffler and then remove the

two exhaust muffler lock bolts.

The installation sequence is the reverse of

removal.

Remove the spark plug.

Remove the cylinder head bolts and the

cylinder head.

Remove the cylinder head gasket.

Cylinder head Bolts

Exhaust muffler joint lock nut

Bolts

Cylinder Head

Spark Plug

Spark Plug Cap

When installing the exhaust muffler,

first tighten the two nuts on the front

and then tighten the two bolts.

°Ø

Loosen the bolts diagonally in 2 or 3

times.

°Ø

Page 4

6. CYLINDER HEAD/CYLINDER/PISTON

6-3

BET & WIN 5 0

COMBUSTION CHAMBER

DECABONIZING

Remove the carbon deposits from the

combustion chamber

CYLINDER HEAD INSPECTION

Check the cylinder head for warpage with a

straight edge and feeler gauge.

Service Limit: 0.10mm replace if over

CYLINDER HEAD INSTALLATION

Install the cylinder head on the cylinder

properly.

Install a new cylinder head gasket onto the

cylinder.

Avoid damaging the combustion

chamber wall and cylinder mating

surface.

°Ø

Cylinder head Gasket

Combustion Chamber

Mating Surface

Be careful not to damage the mating

surfaces.

°Ø

Page 5

6. CYLINDER HEAD/CYLINDER/PISTON

6-4

BET & WIN 5 0

Cylinder Head Bolts Installation

Install and tighten the cylinder head bolts

diagonally in 2 or 3 times.

Torque: 14.7_ 16.66N-m

Install the spark plug.

Torque: 10.78_ 16.66N-m

CYLINDER/PISTON

CYLINDER REMOVAL

Remove the met-in box and seat.

Remove the frame body cover.

Remove the cylinder head. (6-3)

Remove the two exhaust muffler joint lock

nuts and two exhaust muffler lock bolts.

Remove the exhaust muffler.

Remove the cylinder.

Remove the cylinder gasket.

PISTON REMOVAL

Remove the piston pin clip to remove the

piston pin and piston.

Cylinder head Bolts

Piston Pin Clip

Exhaust Muffler Lock

Cylinder Head

Joint Lock Nuts

Piston

Spark Plug

Piston Pin

Do not pry between the cylinder and

crankcase or strike the fins.

°Ø

• Do not damage or scratch the piston.

• Do not apply side force to the

connect-ing rod when removing the

piston pin.

• Place clean shop towels in the crank-

case to keep the piston pin clip from

falling into the crankcase.

°Ø

Page 6

6. CYLINDER HEAD/CYLINDER/PISTON

6-5

BET & WIN 5 0

Spread each piston ring and remove by

lifting it up at a point just opposite the gap.

Remove the expander.

CYLINDER/PISTON INSPECTION

Check the cylinder and piston for wear or

damage.

Clean carbon deposits from the exhaust

port area.

Measure the cylinder bore at three levels of

A, B and C in both X and Y directions.

Avoid the port area. Take the maximum

figure measured to determine the cylinder

bore.

Service Limit: 39.05mm replace if over

Be careful not to damage the cylinder

inside wall.

°Ø

Page 7

6. CYLINDER HEAD/CYLINDER/PISTON

6-6

BET & WIN 5 0

Inspect the top of the cylinder for warpage.

Service Limit: 0.10mm replace if over

Measure the piston O.D. at a point 5mm

from the bottom of the piston skirt.

Service Limit: 38.90mm replace if below

Measure the piston-to-cylinder clearance.

Service Limit: 0.10mm replace if over

A Mark

The cylinder has an A mark or no mark

on it. When replacing the cylinder with

a new one, use a cylinder having the

same mark as the old one.

°Ø

Page 8

6. CYLINDER HEAD/CYLINDER/PISTON

6-7

BET & WIN 5 0

Measure the piston pin hole I.D.

Service Limit: 12.03mm replace if over

Measure the piston pin O.D.

Service Limit: 11.98mm replace if below

Measure the piston-to-piston pin clearance.

Service Limit: 0.03mm replace if over

PISTON RING INSPECTION

Measure each piston ring end gap.

Service Limits: Top/Second

0.40mm replace if over

CONNECTING ROD SMALL END

INSPECTION

Install the piston pin and bearing in the

connecting rod small end and check for

excessive play.

Measure the connecting road small end I.D.

Service Limit: 17.03mm replace if over

Piston Ring

Feeler Gauge

Set each piston ring squarely into the

cylinder using the piston and measure

the end gap.

°Ø

Page 9

6. CYLINDER HEAD/CYLINDER/PISTON

6-8

BET & WIN 5 0

PISTON/CYLINDER INSTALLATION

First install the expander in the second ring

groove.

Then install the top and second rings in

their respective ring grooves.

The piston rings should be pressed into the

grooves with even force.

After installation, check and make sure that

each ring is flush with the piston at several

points around the ring.

A ring that will not compress means that

the ring groove has carbon deposits in it and

should be cleaned.

Install a new cylinder gasket on the mating

surface between the cylinder and crankcase.

Make sure that the ring end gaps are aligned

with the piston ring pins in the ring

grooves.

Lubricate the cylinder inside and piston

rings with engine oil and install the piston

into the cylinder while compressing the

piston rings.

Install the cylinder head.

Torque: 14.7_ 16.66N-m

Install the exhaust muffler and tighten the

exhaust muffler joint lock nuts.

Torque: 9.8_ 13.72N-m

Tighten the exhaust muffler lock bolts.

Torque: 29.4_ 35.28N-m

Install the frame covers.

Expander

Top Ring (1st Ring)

Cylinder Gasket

Piston

Ring Pins

Second Ring

Be careful not to damage the piston.

°Ø

Page 10

6. CYLINDER HEAD/CYLINDER/PISTON

6-9

BET & WIN 5 0

Loading...

Loading...