Kymco MO BW250 Service Manual - chap13 (alimentazione)

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-0

Bet & Win 2 50

13

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FUEL SYSTEM/CARBURETOR/FUEL PUMP

__________________________________________________________________________________

FUEL SYSTEM --------------------------------------------------------- 13- 1

SCHEMATIC DRAWING ---------------------------------------------- 13- 2

OPERATION OF CARBURETOR JETS------------------------------ 13- 3

SERVICE INFORMATION -------------------------------------------- 13- 5

CARBURETOR REMOVAL ------------------------------------------- 13- 7

VACUUM CHAMBER DISASSEMBLY------------------------------ 13- 7

FLOAT CHAMBER DISASSEMBLY--------------------------------- 13- 9

AUTO BYSTARTER INSPECTION/REMOVAL-------------------- 13-11

AIR CUT-OFF VALVE (A.C.V.)-------------------------------------- 13-12

AUTO BYSTARTER INSTALLATION ------------------------------ 13-14

FLOAT CHAMBER ASSEMBLY ------------------------------------- 13-15

FLOAT LEVEL INSPECTION ---------------------------------------- 13-16

VACUUM CHAMBER ASSEMBLY ---------------------------------- 13-16

CARBURETOR INSTALLATION ------------------------------------ 13-17

FUEL PUMP REMOVAL/DISASSEMBLY -------------------------- 13-18

FUEL PUMP INSPECTION-------------------------------------------- 13-19

FUEL PUMP ASSEMBLY --------------------------------------------- 13-19

FUEL PUMP INSTALLATION --------------------------------------- 13-20

FUEL TANK REMOVAL ---------------------------------------------- 13-20

13

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-1

Bet & Win 2 50

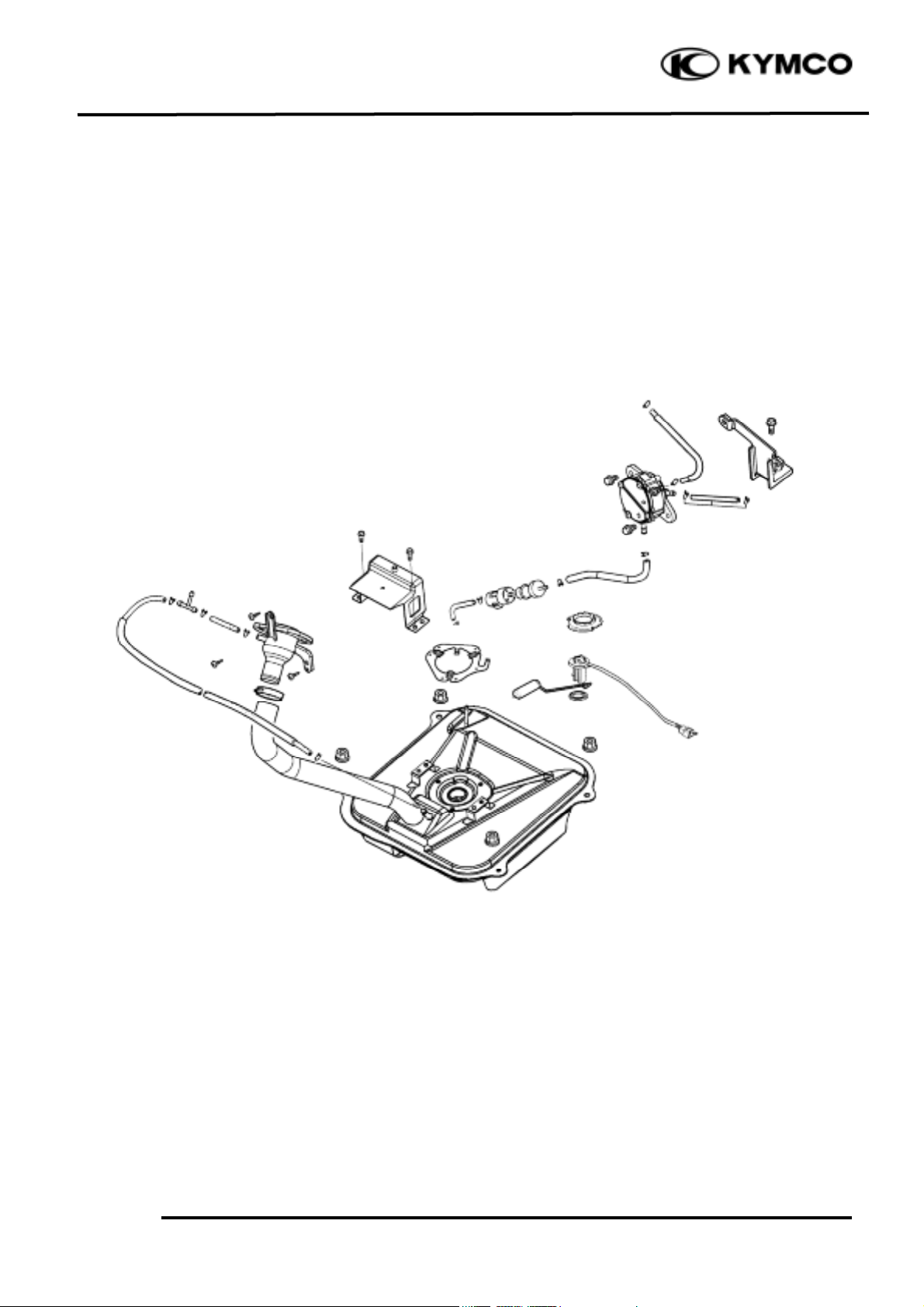

FUEL SYSTEM

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-2

Bet & Win 2 50

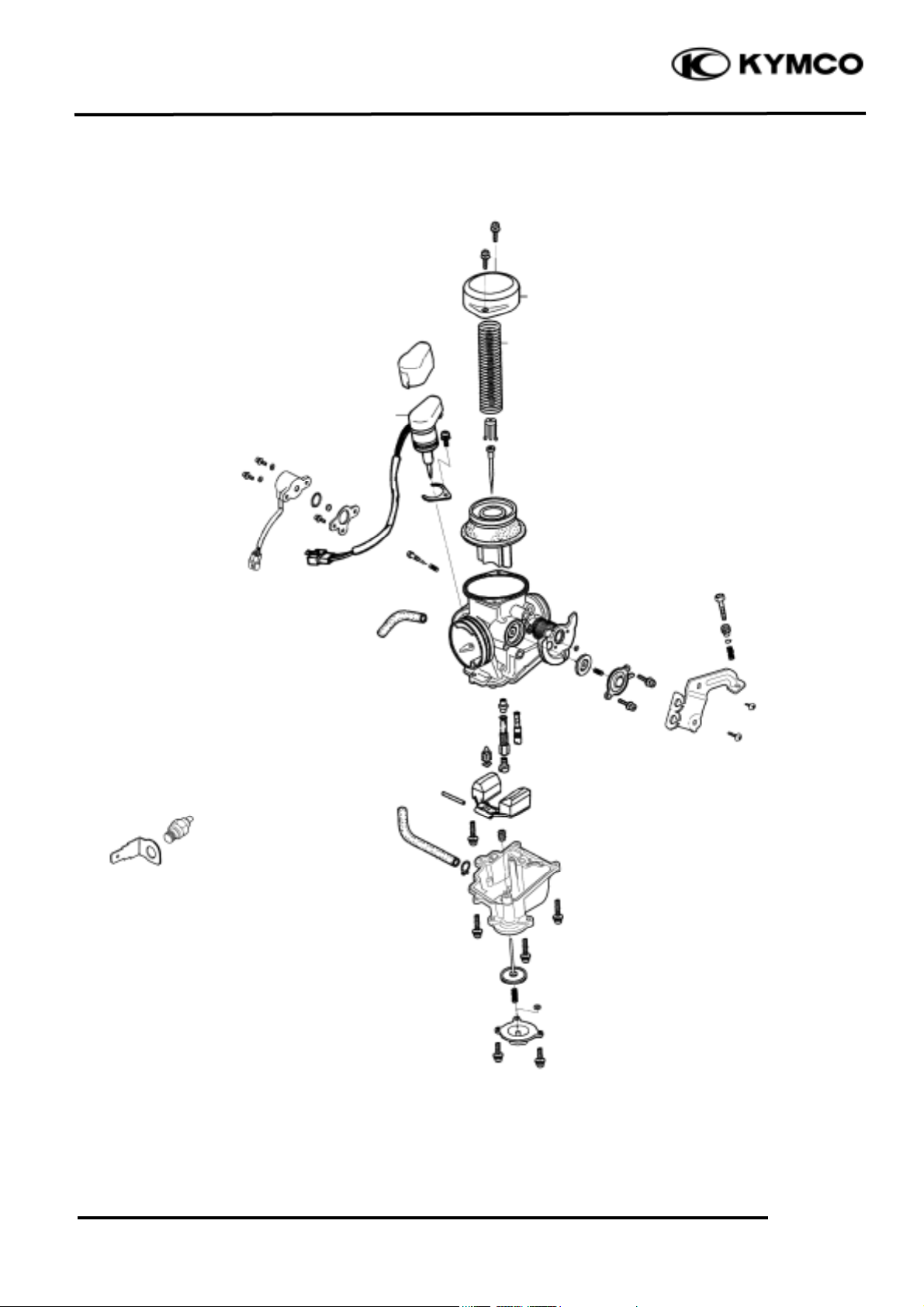

SCHEMATIC DRAWING

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-3

Bet & Win 2 50

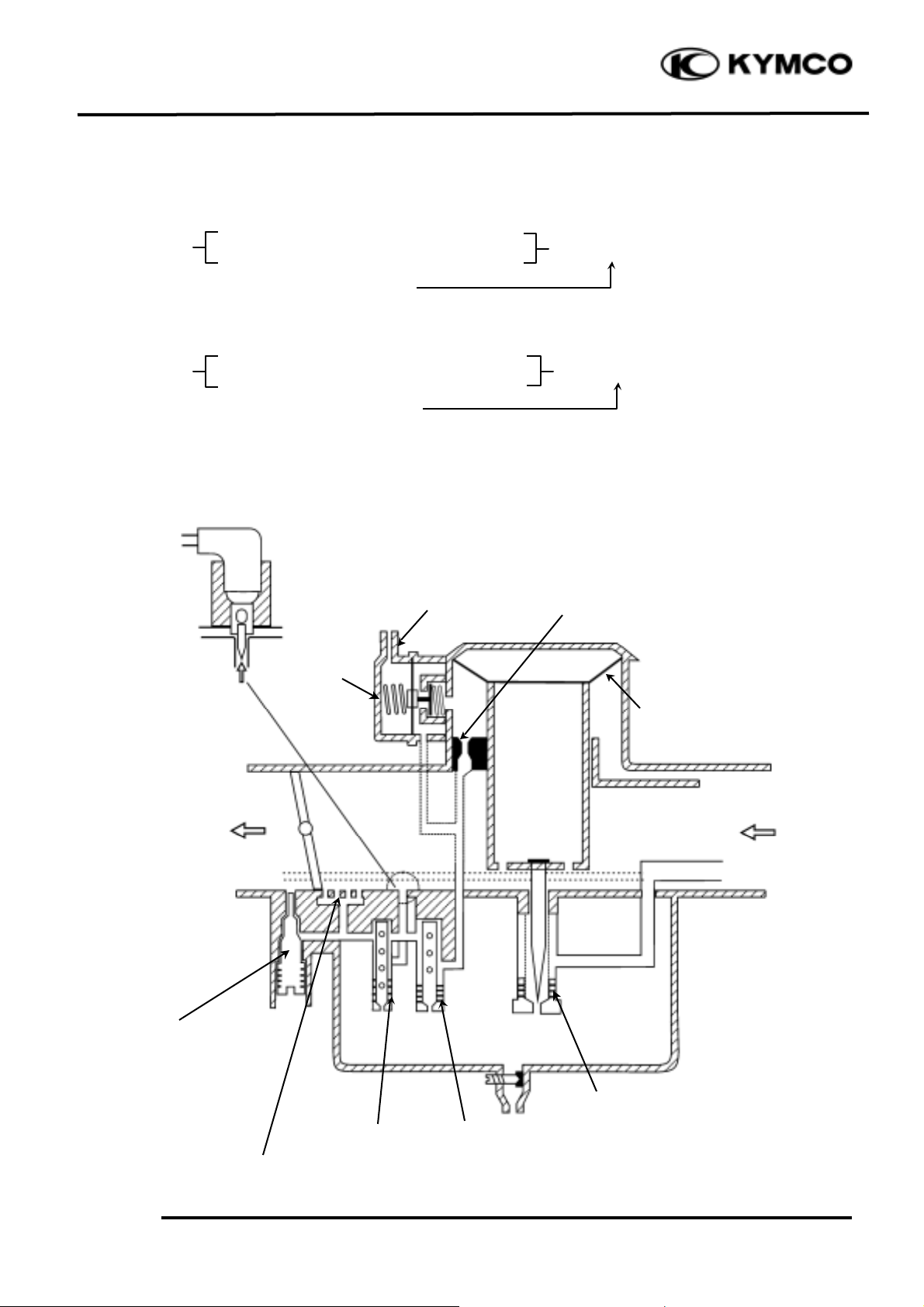

OPERATION OF CARBURETOR JETS

1. LOW SPEED

Venturi (slightly opened throttle valve)

Low Speed Air Inlet

※ Fuel in Float Chamber‡ Slow Jet

-------------------- Low Speed Small Jet Holes

2.MIDDLE SPEED

Venturi (halfway opened throttle valve)

High Speed Air Jet

※ Fuel in Float Chamber‡ Main Jet

Main Jet (The slow jet also works.)

Low & Middle Speed Supplementary Device:

Vacuum Tube

Low Speed Air Jet

Main Jet

Vacuum Diaphragm

Throttle

Valve

Low & Middle Speed Supplementary Fuel Inlets

Slow Jet

Bypass Jet

Pilot Screw

ACV

Air

※ Air

※ Air

Air Bleed Holes‡ Mixture…….

Air Bleed Holes‡ Mixture…….

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-4

Bet & Win 2 50

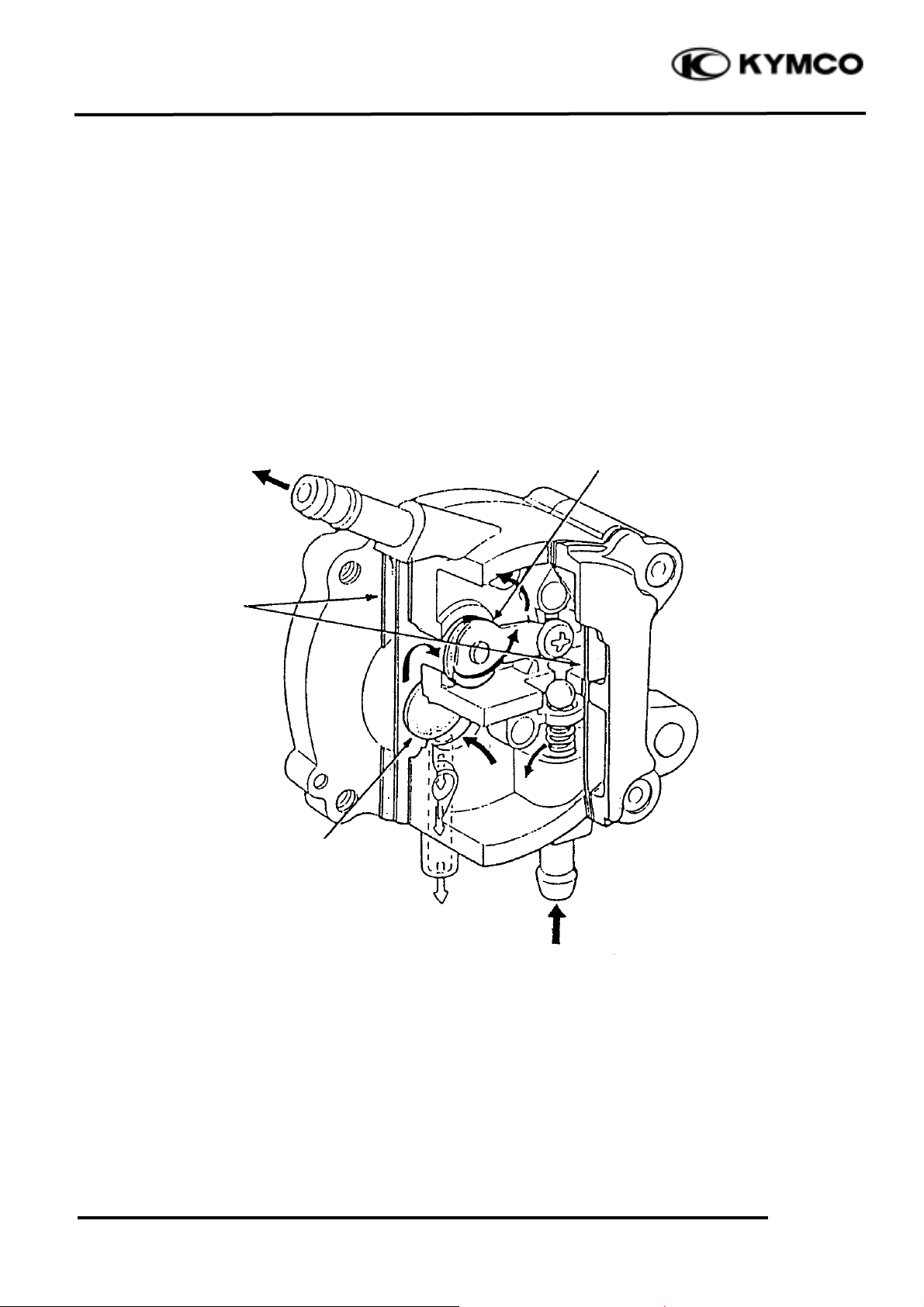

FUEL PUMP

CONSTRUCTION:

The fuel pump adopted for this model is a vacuum-type fuel pump which utilizes the positive and

negative pulsating pressures produced by the engine crankcase to control the oil pump diaphragms

and deliver fuel from the fuel tank to the carburetor through the suction valve and outlet valve.

FUEL PUMP CONSTRUCTION

Diaphragms

Inlet

Outlet

Suction Valve

Outlet Valve

Pulsating Pressure

from Crankcase

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-5

Bet & Win 2 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When working with gasoline, keep away from sparks and flames.

• Note the locations of O-rings when disassembling and replace them with new ones during

assembly.

• Before float chamber disassembly, drain the residual gasoline from the float chamber.

• Do not try to disassemble the auto bystarter.

• When assembling the vacuum chamber and air cut-off valve, be careful not to damage the

diaphragms.

• All cables, fuel lines and wires must be routed and secured at correct locations.

• When removing the fuel tank, keep sparks and flames away from the working area.

• When removing the fuel tank, the remaining fuel in the tank must be lower than _ of the fuel tank

capacity to avoid gasoline overflowing.

• Fuel tank capacity: 10.5 liters

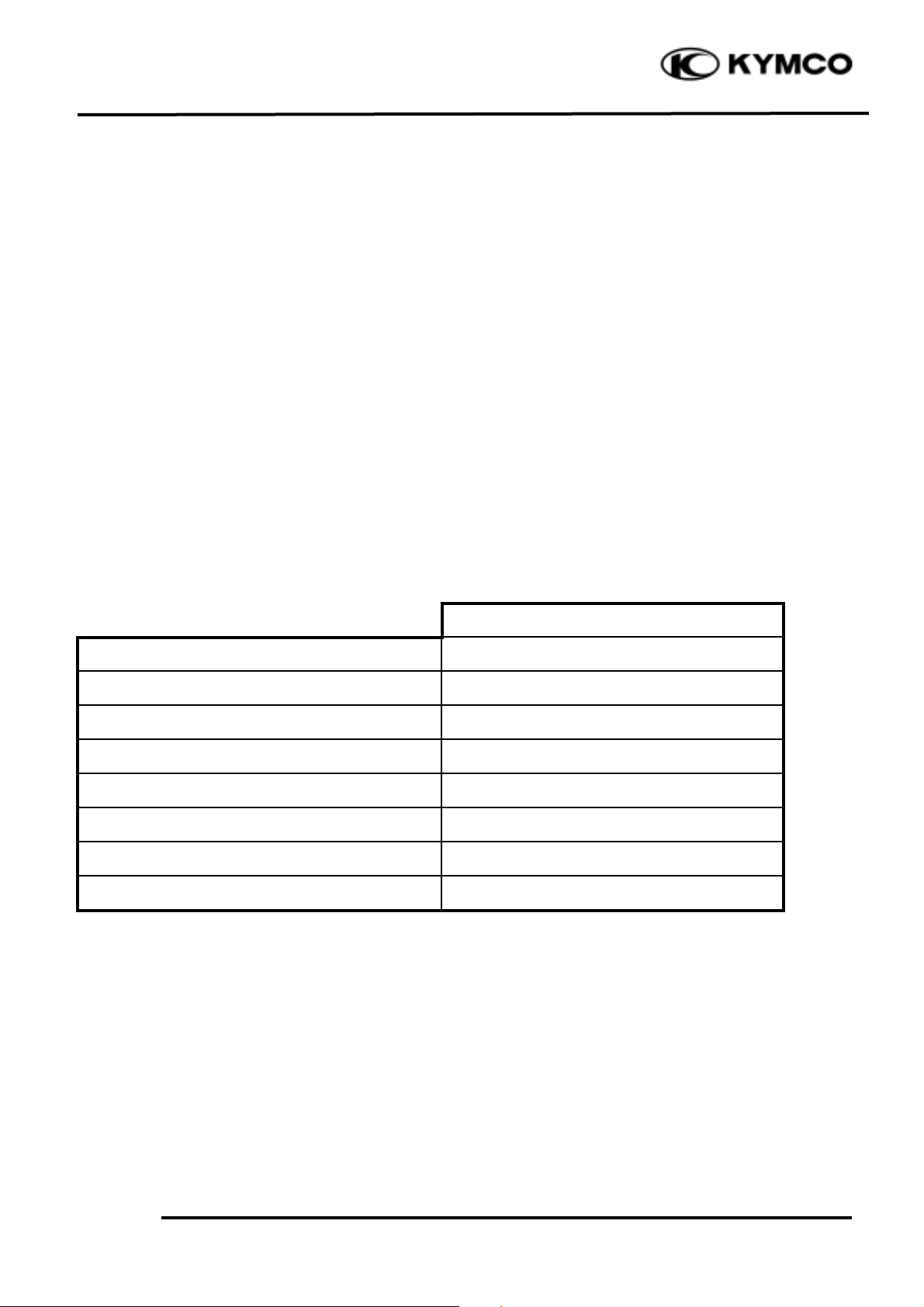

SPECIFICATIONS

SH50CA

Venturi dia. (mm)

CVK30

Identification number

CVK038B

Float level (mm)

18.5

Pilot screw opening

1/2~4

Main jet

108#

Slow jet

38#

Idle speed

1450

Fuel pump output

17L/Hr/7000rpm

SPECIAL TOOLS

Float level gauge

Fuel unit remover

13. FUEL SYSTEM/CARBURETOR/

FUEL PUMP/ FUEL TANK

13-6

Bet & Win 2 50

TROUBLESHOOTING

Engine does not start Engine idles roughly, stalls or runs poorly

• No fuel in tank • Incorrect idle speed

• Restricted fuel line • Rich mixture

• Too much fuel getting to cylinder • Lean mixture

• Clogged air cleaner • Clogged air cleaner

• Contaminated fuel • Intake air leak

• Faulty fuel pump • Contaminated fuel

• Faulty air-cut off valve

• Damaged vacuum tube and connectors

• Damaged carburetor insulator

Throttle does not open fully, so engine stalls Rich mixture

• Damaged vacuum piston diaphragm • Auto bystarter valve opens excessively

• Clogged diaphragm hole • Faulty float valve

• Float level too high

Lean mixture • Clogged air jets

• Clogged fuel jets • Auto bystarter valve set plate installed in

• Clogged fuel tank cap breather hole

the wrong groove

• Clogged fuel filter •Clogged air cleaner

• Bent, kinked or restricted fuel line

• Faulty float valve

• Float level too low

• Faulty fuel pump or insufficient output

Engine is hard to start

• No fuel in tank

• Restricted fuel line

• Clogged fuel strainer

• Faulty fuel pump

• Broken or clogged vacuum tube

• Faulty or clogged charcoal canister

Lean mixture

• Clogged charcoal canister

• Bent, kinked or restricted fuel line

• Clogged fuel strainer

• Float level too low

Loading...

Loading...