Kymco MO BW250 Service Manual - chap11 (albero motore)

11. CRANKCASE/CRANKSHAFT

11-0

Bet & Win 2 50

11

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CRANKCASE/CRANKSHAFT

__________________________________________________________________________________

SCHEMATIC DRAWING ---------------------------------------------- 11-1

SERVICE INFORMATION -------------------------------------------- 11-2

TROUBLESHOOTING ------------------------------------------------- 11-2

CRANKCASE SEPARATION ----------------------------------------- 11-3

CRANKSHAFT INSPECTION----------------------------------------- 11-4

CRANKCASE ASSEMBLY -------------------------------------------- 11-5

11

11. CRANKCASE/CRANKSHAFT

11-1

Bet & Win 2 50

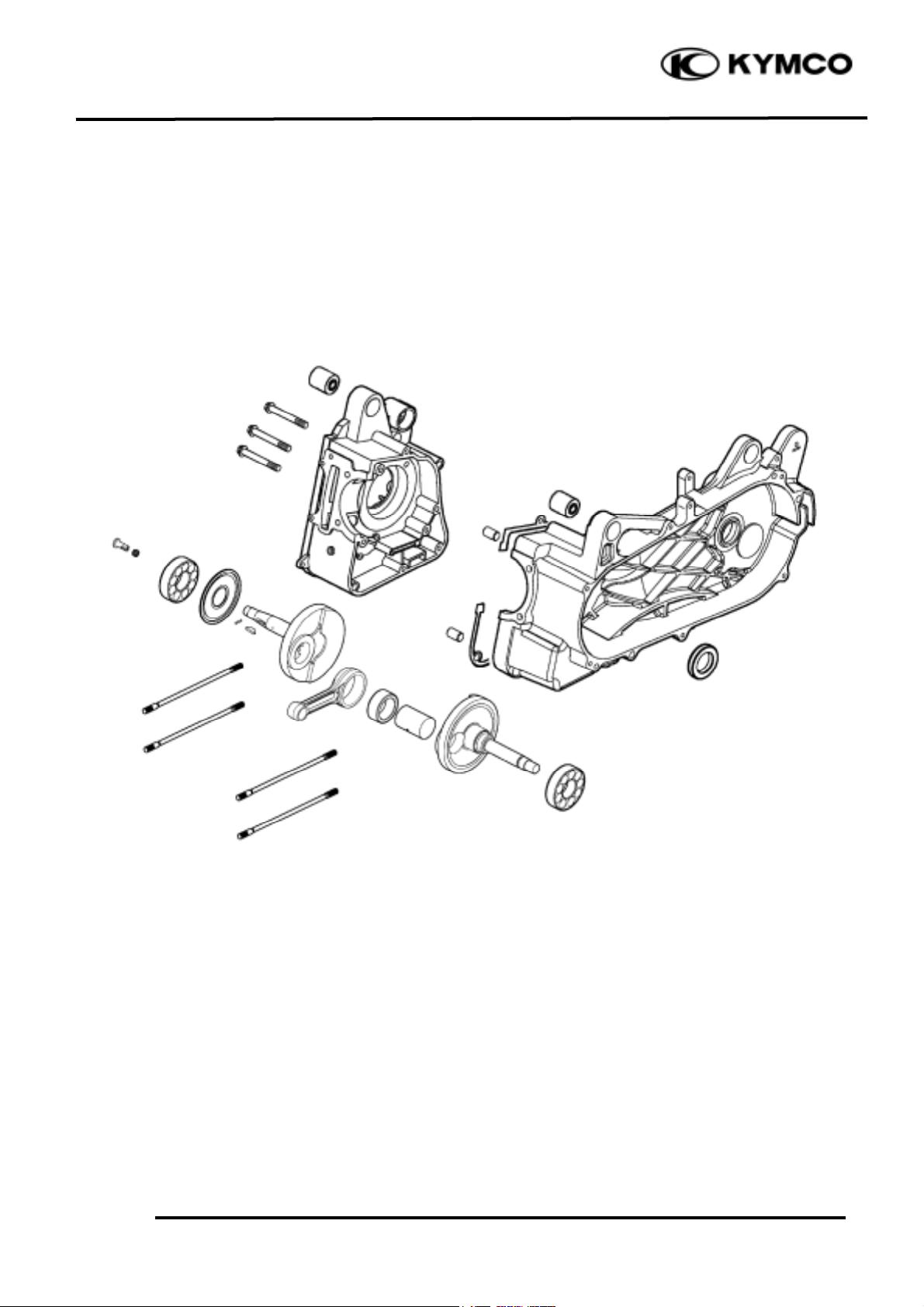

SCHEMATIC DRAWING

11. CRANKCASE/CRANKSHAFT

11-2

Bet & Win 2 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• This section covers crankcase separation to service the crankshaft. The engine must be removed

for this operation.

• When separating the crankcase, never use a driver to pry the crankcase mating surfaces apart

forcedly to prevent damaging the mating surfaces.

• When installing the crankcase, do not use an iron hammer to tap it.

• The following parts must be removed before separating the crankcase.

Cylinder head (!6-4)

Cylinder/piston (!7-3)

Right crankcase cover/drive and driven pulley (!8-3)

A.C. generator/starter clutch (!10-3)

Rear wheel/rear shock absorber (!15-4)

Starter motor (!19-3)

Oil pump (!4-4)

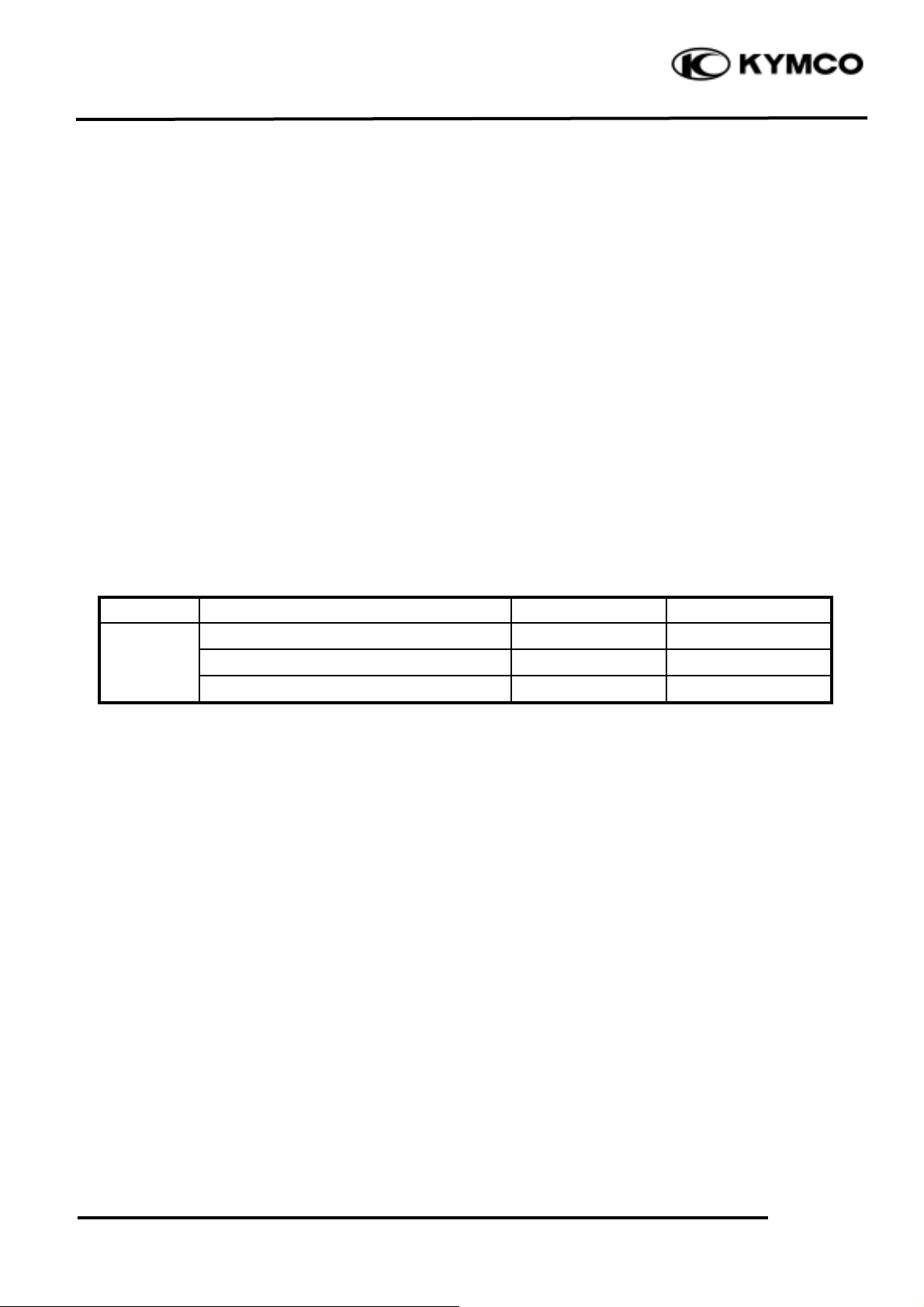

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Connecting rod big end side clearance

0.15_ 0.35

0.6

Crankshaft

Connecting rod big end radial clearance

0._ 0.008

0.05

Runoutæ0.10

TORQUE VALUES

Crankcase bolt 7.8_ 10.8N-m

Cam chain tensioner slipper bolt 7.8_ 11.8N-m

SPECIAL TOOL

Gear remover

TROUBLESHOOTING

Excessive engine noise

• Excessive bearing play

• Excessive crankpin bearing play

• Worn piston pin and piston pin hole

Loading...

Loading...