Kubota D1803-CR-E4, D1803-CR-TE4, D1803-CR-TIE4, V2403-CR-TE4, V2403-CR-TE4BG Workshop Manual

...Page 1

WORKSHOP MANUAL

KiSC issued 12, 2018 A

DIESEL ENGINE

D1803-CR-E4,D1803-CR-TE4,

D1803-CR-TIE4,V2403-CR-E4,

V2403-CR-TE4,

V2403-CR-TE4BG,

V2403-CR-TIE4

Page 2

TO THE READER

KiSC issued 12, 2018 A

This workshop manual provides safety information for service activity, general information such as specifications and

dimensions of the machine, mechanisms and structure descriptions of the machine, and service procedures.

Safety

This section contains safety service descriptions and safety label information.

General

This section contains general instructions, tightening torques, general machine information and special tools.

Maintenance

This section contains information for the recommended oil and general maintenance procedures.

Each section basically consists of mechanism and servicing.

Mechanism

part

Mechanism

or component parts. This part should become prehended before proceeding with troubleshooting, disassembling,

assembling, and servicing works.

Servicing

Servicing part contains information and procedures for maintenance, troubleshooting and repair works. The reader

should follow these instructions in order to satisfy any servicing work safely, correctly and quickly.

In this WSM, service specifications and service limits are defined as followings.

Service specifications:

Specification which corresponds to new machine's ex-factory. It is based on quality standard, drawings, or actual

measurements conducted by Kubota. This value is used to determine whether there is a problem with the machine in

the event of a troubleshooting. However, it is necessary to consider degradation due to wear, based on the operating

time of the machine, application or maintenance condition.

Service limits:

Service limit is a value corresponding to the recommended performance limit by taking long term-use wear into

account. When the service limit is reached, the machine is required to have proper repair, overhaul or replacement in

order to keep safe and adequate performance.

All of the illustrations, photographs, specifications, and other information in this manual were created based on the

latest model at the time of publication.

The parts names used in this manual are unified into names representing the functions of the parts. Therefore, it does

not necessarily correspond to the names used in other materials (parts list, operators manual etc.) and the name on

the label / identification plates on the product.

Kubota reserves the right to change all information at any time without notice.

contains information and explanations for the structure, functions, and specifications of the machine

© KUBOTA Corporation

February 2013

Page 3

RECORD OF REVISIONS

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

i

KiSC issued 12, 2018 A

Main revised contents and corrective measures are described in a table.

Find the main revised point and corrective measure through the reference page.

Last digit

of the Code

No.

1 2013.07 Rail pressure sensor

2 2013.12 Thermostat

3 2014.06 Oil separator

4 2014.09 Oil separator

5 2014.11 D1803-CR-TIE4

6 2017.04 SCV Added the information about disassembling and assembling. 4-124

Month of

Revision

Part name Main revised point and corrective measure

EGR valve lift sensor

Common rail and injection

pipes

alve guide

V

Rail

Diesel particulate filter

(DPF)

Air cleaner and others

Crankshaft position sensor

Fuel camshaft

Pistons

Flywheel

Main bearing case assembly

Positive crankcase ventilation (PCV) valve

Starter

Alternator

Glow plug

Pressure limiter valve

V2403-CR-TE4BG

V2403-CR-TIE4

Correction point

• 2. SPECIFICA

• 3. PERFORMANCE CURVES

• 4. MAINTENANCE CHECK LIST

– Cleaning water jacket and radiator interior

– Changing radiator coolant (L.L.C.)

• Mechanism

– Rail pressure sensor

– EGR valve lift sensor

• Servicing

– Adjusting valve clearance

– Common rail and injection pipes

– Replacing valve guide

– Measuring angular deviation between crankshaft TDC

and crankshaft position sensor detected TDC

Correction point

• 2. SPECIFICATIONS

• Model name and engine serial number

• Checking valve clearance

• Judging reuse of DPF filter comp after cleaning (Cleaning

contractor)

• Checking DPF differential pressure pipes and hoses

• Thermostat

• Rail

• Function of diesel particulate filter (DPF)

• TROUBLESHOOTING

• Adjusting valve clearance

• Disassembling and assembling

– Air cleaner and others

– Filter comp (DPF) (If necessary)

– Crankshaft position sensor

– Fuel camshaft

– Pistons

– Flywheel

– Main bearing case assembly

Correction point

• MAINTENANCE CHECK LIST

•

Check and maintenance

– Replacing oil separator element

– Checking positive crankcase ventilation (PCV) valve

• Checking and servicing

– Checking starter motor

– Checking magnetic switch of starter

– Checking magnetic switch continuity

– Checking alternator on unit

– Checking glow plug continuity

Correction the picture

Correction the information

Added the information of V2403-CR-TE4BG

Added the model about D1803-CR-TIE4 and V2403-CR-TIE4

These models are equipped DOC only instead of DPF.

TIONS

Reference

page

2-10

2-14

3-1

3-13

3-28

4-24

4-98

4-112

2-10

3-16

3-23

4-87

3-1

3-19

3-19

4-103

4-104

4-105

4-105

4-106

4-6

-

4-148

(Continued)

Page 4

Last digit

ii

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

KiSC issued 12, 2018 A

of the Code

No.

7 2018.12 Mechanism

Month of

Revision

Part name Main revised point and corrective measure

Servicing

Added the information about all mechanism section.

Added the follow information about checking and adjusting.

• Checking injector

•

Checking suction control valve (SCV)

• Checking sensors

• Adjusting air gap between crank/camshaft position sensor

and flywheel/pulsar gear

Separate disassembling and assembling

Added follow servicing information.

• Replacing injector

• Replacing engine ECU

• Replacing DPF

Change notification about fan drive pulley mounting nut tightening

torque

Reference

page

4-96

4-107

4-107

4-114

4-115

4-191

4-193

4-196

Page 5

CONTENTS

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

iii

KiSC issued 12, 2018 A

1. SAFETY

SAFETY FIRST

1.

Working precautions.................................................................................................................................1-1

2. Preparing for emergencies .......................................................................................................................1-1

3. Working cautions ...................................................................................................................................... 1-2

4. Starting the machine safely ......................................................................................................................1-3

5. Preventing fires......................................................................................................................................... 1-3

6. Preventing acid burns...............................................................................................................................1-4

7. Avoiding high pressure fluid......................................................................................................................1-4

8. Avoiding hot exhaust ................................................................................................................................1-4

9. Cleaning exhaust filter .............................................................................................................................. 1-4

2. GENERAL

GENERAL WORKING PRECAUTIONS ............................................................................................................2-1

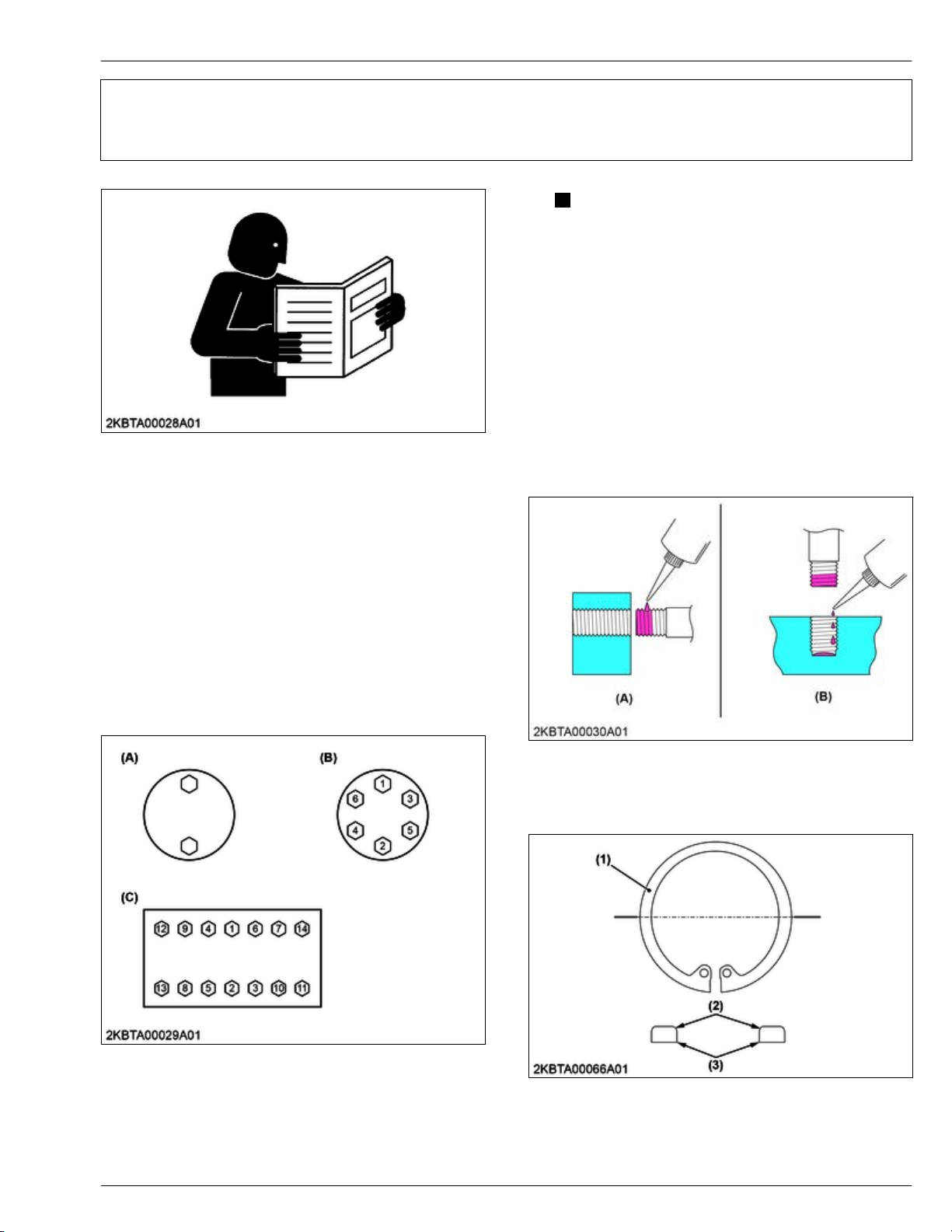

1. Tightening bolts and nuts..........................................................................................................................2-1

2. Applying thread-locking fluid..................................................................................................................... 2-1

3. Installing circlips .......................................................................................................................................2-1

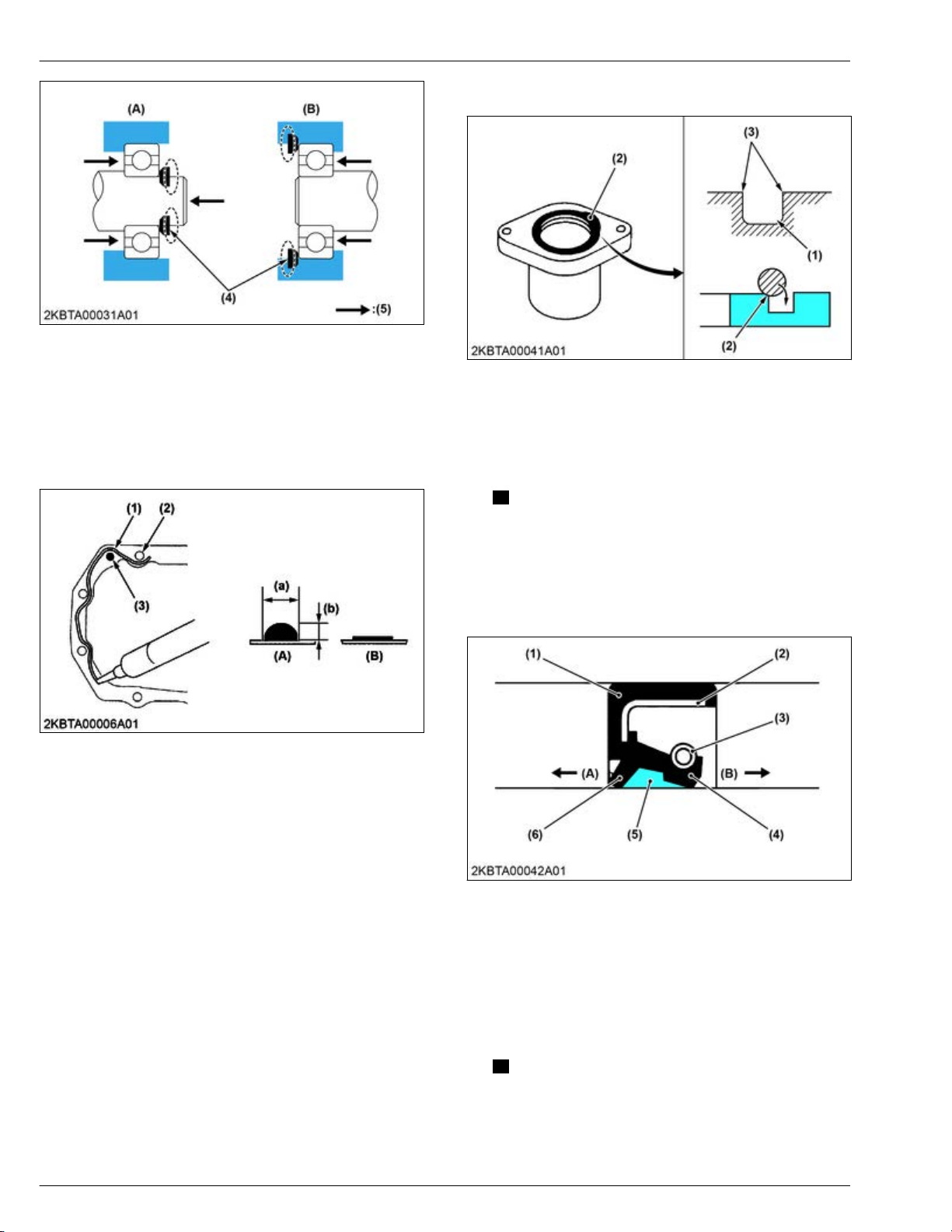

4. Handling liquid gasket ..............................................................................................................................2-2

5. Replacing O-rings.....................................................................................................................................2-2

6. Replacing oil seals.................................................................................................................................... 2-2

7. Handling the battery .................................................................................................................................2-3

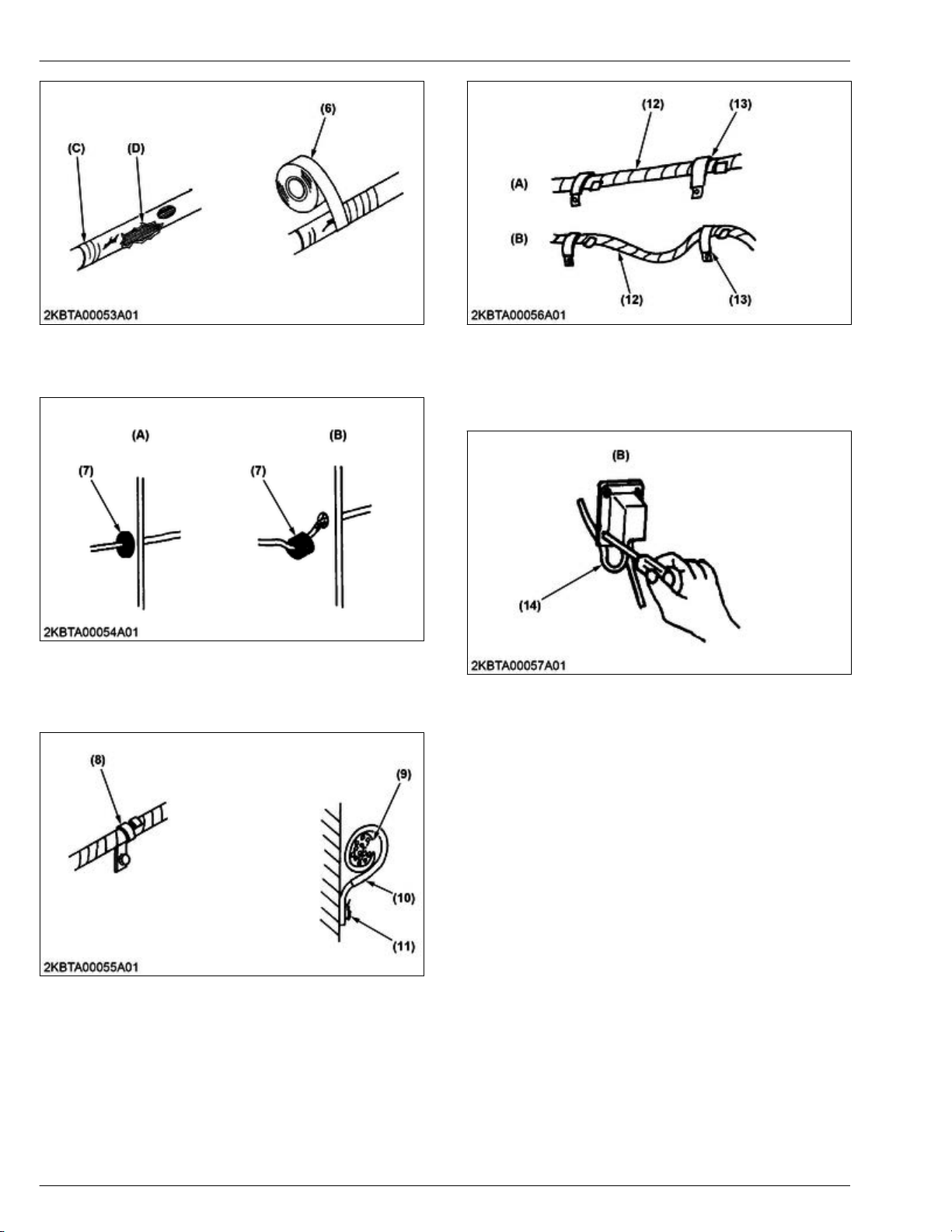

8. Handling electrical wiring..........................................................................................................................2-3

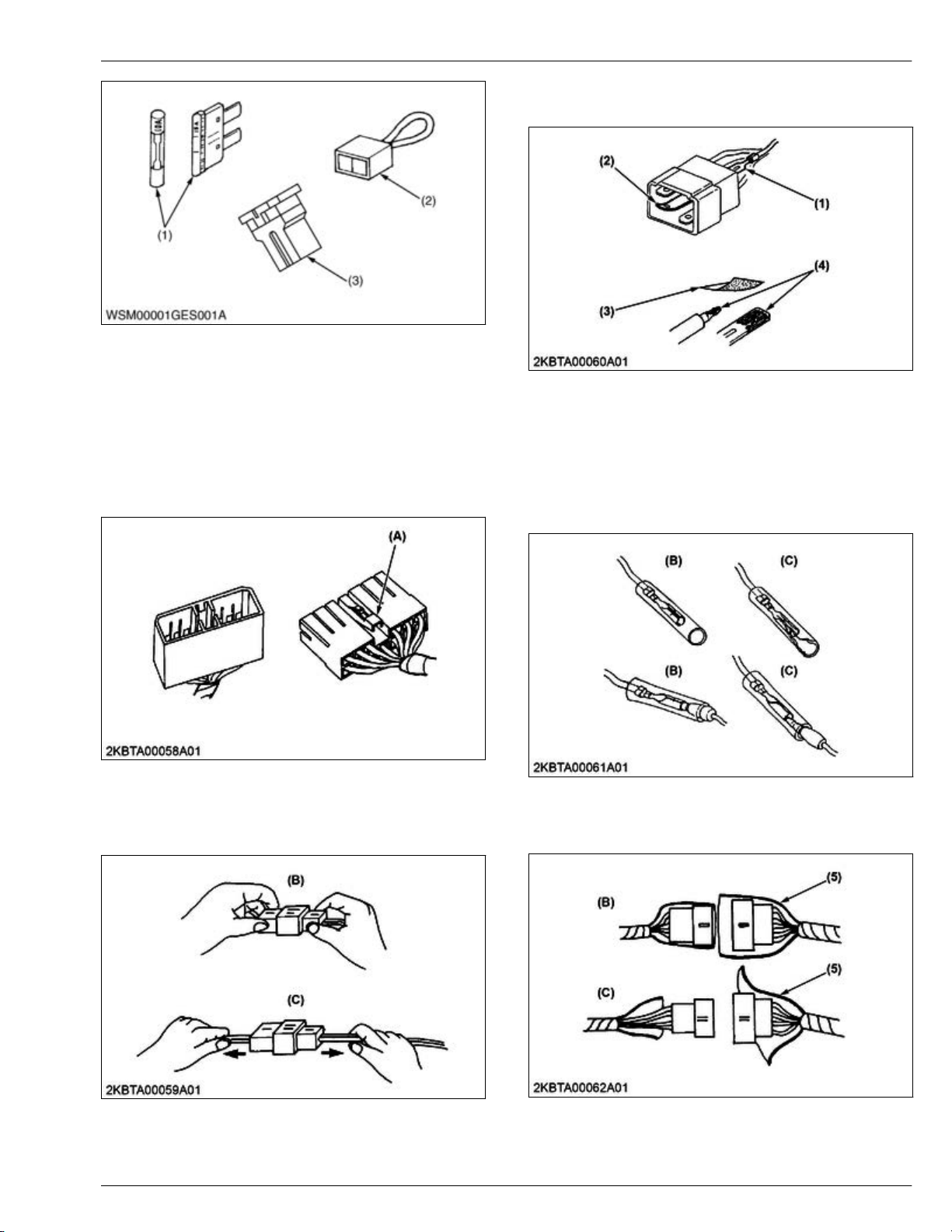

9. Handling fuses..........................................................................................................................................2-4

10. Handling connectors...............................................................................................................................2-5

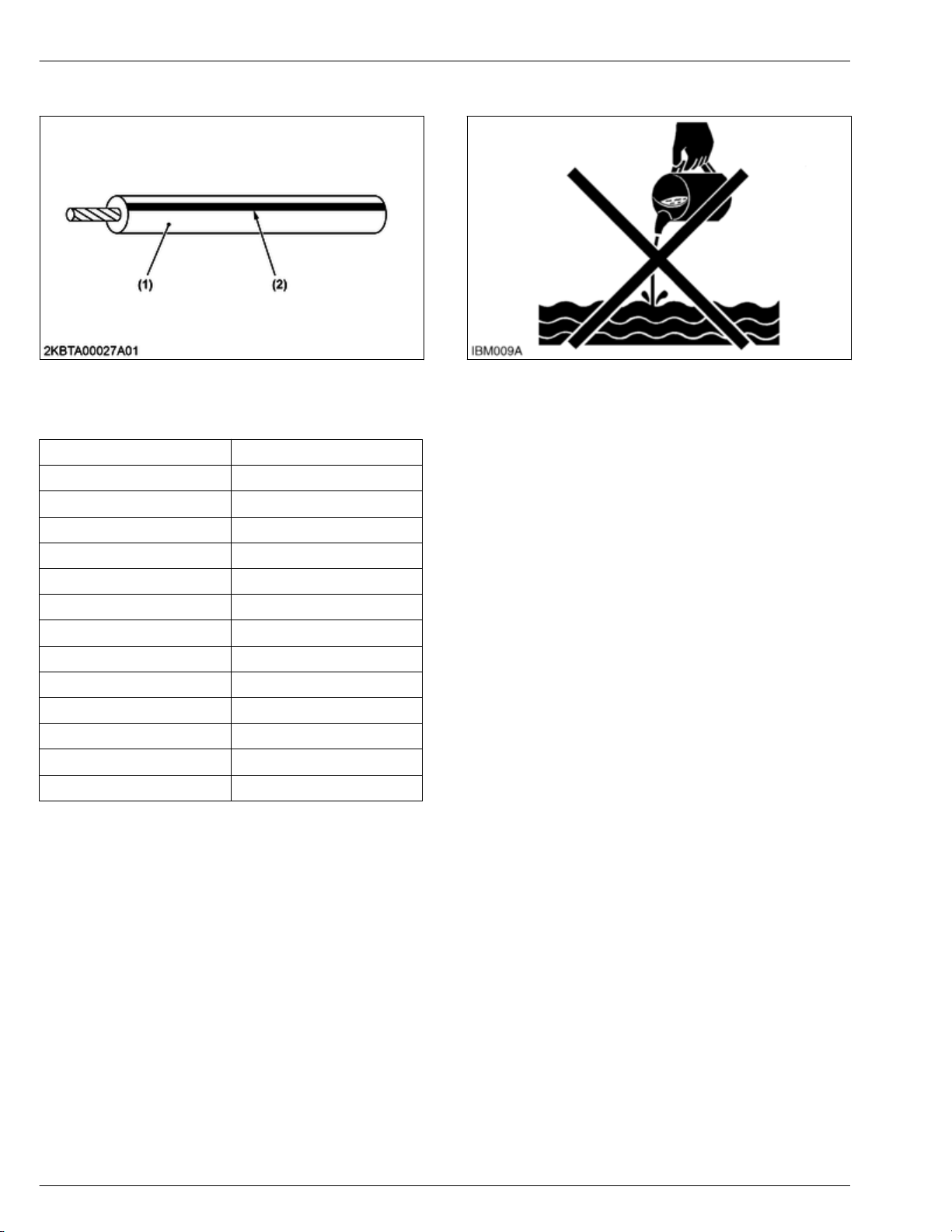

11. Wiring color ............................................................................................................................................. 2-6

12. Dispose fluids correctly........................................................................................................................... 2-6

GENERAL MACHINE INFORMATION ..............................................................................................................2-7

1. Engine identification .................................................................................................................................2-7

1.1 Engine model name and engine serial number................................................................................. 2-7

1.2 E4B engine........................................................................................................................................ 2-8

1.3 Cylinder number................................................................................................................................2-9

2. Muffler full assembly identification............................................................................................................2-9

2.1 Part number and serial number (DPF) .............................................................................................. 2-9

3. Specifications .........................................................................................................................................2-10

3.1 Specification for D1803-CR-E4, TE4 ..............................................................................................2-10

3.2 Specification for V2403-CR-E4, TE4............................................................................................... 2-11

3.3 Specification for D1803-CR-TIE4, V2403-CR-TIE4 ........................................................................2-12

3.4 Specification for V2403-CR-TE4BG................................................................................................2-13

4. Performance curves ...............................................................................................................................2-14

4.1 Performance curve for D1803-CR-E4 ............................................................................................. 2-14

4.2 Performance curve for D1803-CR-TE4...........................................................................................2-15

4.3 Performance curve for D1803-CR-TIE4..........................................................................................2-16

4.4 Performance curve for V2403-CR-E4 .............................................................................................2-17

4.5 Performance curve for V2403-CR-TE4 ........................................................................................... 2-18

4.6 Performance curve for V2403-CR-TIE4 .......................................................................................... 2-19

5. Dimensions.............................................................................................................................................2-20

5.1 Dimensions .....................................................................................................................................2-20

6. Wiring diagram .......................................................................................................................................2-21

6.1 Engine intermediate harness (Engine side harness) ......................................................................2-21

6.2 Injector intermediate harness (Engine side harness)......................................................................2-23

6.3 Engine ECU intermediate harness (OEM side harness).................................................................2-24

6.4 System wiring diagram for D1803-CR-E4, D1803-CR-TE4, V2403-CR-E4, V2403-CR-TE4,

6.5 System wiring diagram for D1803-CR-TIE4, V2403-CR-TIE4 ........................................................2-31

..................................................................................................................................................1-1

V2403-CR-TE4BG ..........................................................................................................................2-29

Page 6

SPECIAL TOOLS............................................................................................................................................. 2-33

iv

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

KiSC issued 12, 2018 A

1. Diesel engine compression tester

2. Compression tester adapter K

..........................................................................................................2-33

................................................................................................................2-34

3. Oil pressure tester ..................................................................................................................................2-35

4. Valve guide replacing tool.......................................................................................................................2-35

5. Bushing replacing tools ..........................................................................................................................2-35

6. Flywheel stopper ....................................................................................................................................2-36

7. Crankshaft bearing 1 replacing tool........................................................................................................2-36

8. Auxiliary socket for fixing crankshaft sleeve ........................................................................................... 2-37

9. Injection top correction jig.......................................................................................................................2-38

10. Bearing case cover oil seal replacing tool ............................................................................................2-40

3. MAINTENANCE

MAINTENANCE CHECK LIST........................................................................................................................... 3-1

CHECK AND MAINTENANCE........................................................................................................................... 3-5

1. Daily check points..................................................................................................................................... 3-5

1.1 Checking engine oil level ..................................................................................................................3-5

1.2 Checking fuel level ............................................................................................................................ 3-6

1.3 Checking coolant level ......................................................................................................................3-6

1.4 Checking fan belt ..............................................................................................................................3-7

2. Check points of initial 50 hours................................................................................................................. 3-7

2.1 Changing engine oil ..........................................................................................................................3-7

2.2 Replacing oil filter cartridge...............................................................................................................3-8

3. Check point of every 50 hours..................................................................................................................3-8

3.1 Checking fuel hoses and clamp bands .............................................................................................3-8

3.2 Checking and draining water separator (Type 1) .............................................................................. 3-9

4. Check points of every 250 hours .............................................................................................................. 3-9

4.1 Cleaning air cleaner primary element ...............................................................................................3-9

4.2 Adjusting fan belt tension ................................................................................................................ 3-10

4.3 Checking radiator hose and clamp bands.......................................................................................3-10

4.4 Checking intake air line ................................................................................................................... 3-11

5. Check points of every 400 hours ............................................................................................................ 3-11

5.1 Changing engine oil ........................................................................................................................ 3-11

5.2 Replacing oil filter cartridge.............................................................................................................3-12

6. Check points of every 500 hours ............................................................................................................ 3-12

6.1 Replacing fuel filter cartridge........................................................................................................... 3-12

6.2 Cleaning water separator (Type 1).................................................................................................. 3-13

6.3 Replacing water separator filter (Type 2) ........................................................................................ 3-13

6.4 Cleaning water jacket and radiator interior...................................................................................... 3-13

6.5 Replacing fan belt ...........................................................................................................................3-15

7. Check point of every 1000 hours............................................................................................................3-16

7.1 Checking valve clearance ...............................................................................................................3-16

8. Check points of every 1500 hours .......................................................................................................... 3-17

8.1 Checking injector (with Diagmaster) ...............................................................................................3-17

8.2 Checking EGR cooler...................................................................................................................... 3-18

8.3 Replacing oil separator element...................................................................................................... 3-19

8.4 Checking positive crankcase ventilation (PCV) valve .....................................................................3-19

9. Check points of every 3000 hours .......................................................................................................... 3-20

9.1 Checking turbocharger....................................................................................................................3-20

9.2 Cleaning DPF..................................................................................................................................3-20

9.3 Judging reuse of DPF filter comp before cleaning (Service dealer)................................................3-22

9.4 Judging reuse of DPF filter comp after cleaning (Cleaning contractor)........................................... 3-23

9.5 Checking EGR system (with Diagmaster).......................................................................................3-24

10. Check points of every 1 year ................................................................................................................ 3-25

10.1 Replacing air cleaner element....................................................................................................... 3-25

10.2 Checking DPF differential pressure pipes and hoses ...................................................................3-25

10.3 Checking EGR piping....................................................................................................................3-26

10.4 Checking intake air line ................................................................................................................. 3-26

Page 7

10.5 Checking exhaust manifold ........................................................................................................... 3-27

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

v

KiSC issued 12, 2018 A

10.6 Replacing water separator filter (T

......................................................................................3-27

ype 2)

11. Check points of every 2 years............................................................................................................... 3-27

11.1 Replacing fan belt..........................................................................................................................3-27

11.2 Replacing oil separator rubber hose.............................................................................................. 3-27

11.3 Replacing rubber hose of differential pressure sensor .................................................................. 3-28

11.4 Replacing intake hose (after air flow sensor) and intercooler hose...............................................3-28

11.5 Replacing EGR cooler hose ..........................................................................................................3-28

11.6 Replacing water hose .................................................................................................................... 3-28

11.7 Replacing lubricant hose ...............................................................................................................3-28

11.8 Changing radiator coolant .............................................................................................................3-28

11.9 Replacing radiator hose and clamp bands ....................................................................................3-30

11.10 Replacing fuel hose and clamps.................................................................................................. 3-31

11.11 Replacing intake air line............................................................................................................... 3-31

4. ENGINE

MECHANISM ..................................................................................................................................................... 4-1

1. General (Introduction)............................................................................................................................... 4-1

1.1 Feature of combustion (E-CDIS).......................................................................................................4-1

1.2 Structure of combustion (Center direct injection system (E-CDIS)) .................................................. 4-1

1.3 Flow of combustion (E-CDIS)............................................................................................................ 4-1

1.4 Control of combustion (E-CDIS)........................................................................................................ 4-2

2. Engine body.............................................................................................................................................. 4-3

2.1 Structure of engine body ................................................................................................................... 4-3

2.2 Feature of engine body .....................................................................................................................4-4

2.3 Crankcase ......................................................................................................................................... 4-4

2.3.1 Outline of crankcase ................................................................................................................. 4-4

2.3.2 Structure of crankcase..............................................................................................................4-4

2.3.3 Function of crankcase............................................................................................................... 4-4

2.3.4 Specification of crankcase ........................................................................................................ 4-4

2.4 Cylinder head .................................................................................................................................... 4-4

2.4.1 Outline of cylinder head ............................................................................................................ 4-4

2.4.2 Structure of cylinder head.........................................................................................................4-4

2.4.3 Function of cylinder head.......................................................................................................... 4-4

2.5 Cylinder head cover ..........................................................................................................................4-5

2.5.1 Outline of cylinder head cover ..................................................................................................4-5

2.5.2 Structure of cylinder head cover ............................................................................................... 4-5

2.5.3 Function of cylinder head cover................................................................................................4-5

2.6 Breather ............................................................................................................................................4-5

2.6.1 Outline of breather .................................................................................................................... 4-5

2.6.2 Structure of breather.................................................................................................................4-5

2.6.3 Function of breather.................................................................................................................. 4-5

2.7 Oil separator...................................................................................................................................... 4-5

2.7.1 Outline of oil separator.............................................................................................................. 4-5

2.7.2 Structure of oil separator ..........................................................................................................4-6

2.7.3 Function of oil separator ...........................................................................................................4-6

2.8 Piston ................................................................................................................................................4-6

2.8.1 Outline of piston........................................................................................................................4-6

2.8.2 Structure of piston..................................................................................................................... 4-6

2.8.3 Function of piston .....................................................................................................................4-6

2.8.4 Specification of piston...............................................................................................................4-6

2.9 Piston ring .........................................................................................................................................4-7

2.9.1 Outline of piston ring.................................................................................................................4-7

2.9.2 Structure of piston ring.............................................................................................................. 4-7

2.9.3 Function of piston ring ..............................................................................................................4-7

2.9.4 Specification of piston ring........................................................................................................4-7

2.10 Connecting rod................................................................................................................................4-7

2.10.1 Outline of connecting rod........................................................................................................4-7

Page 8

2.10.2 Structure of connecting rod..................................................................................................... 4-7

vi

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

KiSC issued 12, 2018 A

2.10.3 Function of connecting rod

1 Crankshaft .......................................................................................................................................4-8

2.1

.....................................................................................................4-8

2.11.1 Outline of crankshaft ...............................................................................................................4-8

2.11.2 Structure of crankshaft ............................................................................................................ 4-8

2.11.3 Function of crankshaft.............................................................................................................4-8

2.11.4 Specification of crankshaft ......................................................................................................4-8

2.12 Main bearing case...........................................................................................................................4-8

2.12.1 Outline of main bearing case .................................................................................................. 4-8

2.12.2 Structure of main bearing case...............................................................................................4-8

2.12.3 Function of main bearing case................................................................................................ 4-8

2.13 Flywheel .......................................................................................................................................... 4-9

2.13.1 Outline of flywheel ..................................................................................................................4-9

2.13.2 Structure of flywheel ...............................................................................................................4-9

2.13.3 Function of flywheel ................................................................................................................ 4-9

2.13.4 Specification of flywheel .........................................................................................................4-9

2.14 Rocker arm...................................................................................................................................... 4-9

2.14.1 Outline of rocker arm ..............................................................................................................4-9

2.14.2 Structure of rocker arm ........................................................................................................... 4-9

2.14.3 Function of rocker arm..........................................................................................................4-10

2.15 Camshaft.......................................................................................................................................4-10

2.15.1 Outline of camshaft...............................................................................................................4-10

2.15.2 Structure of camshaft............................................................................................................ 4-10

2.15.3 Function of camshaft ............................................................................................................4-10

2.15.4 Specification of camshaft......................................................................................................4-10

2.16 Valve..............................................................................................................................................4-10

2.16.1 Outline of valve ..................................................................................................................... 4-10

2.16.2 Structure of valve..................................................................................................................4-10

2.16.3 Function of valve................................................................................................................... 4-10

2.16.4 Specification of valve ............................................................................................................ 4-10

2.17 Tappet ........................................................................................................................................... 4-11

2.17.1 Outline of tappet ................................................................................................................... 4-11

2.17.2 Structure of tappet ................................................................................................................4-11

2.17.3 Function of tappet ................................................................................................................. 4-11

2.18 Push rod........................................................................................................................................ 4-11

2.18.1 Outline of push rod ............................................................................................................... 4-11

2.18.2 Structure of push rod ............................................................................................................ 4-11

2.18.3 Function of push rod ............................................................................................................. 4-12

2.19 Timing gears..................................................................................................................................4-12

2.19.1 Outline of timing gears..........................................................................................................4-12

2.19.2 Structure of timing gears....................................................................................................... 4-12

2.19.3 Function of timing gears .......................................................................................................4-12

3. Fuel system ............................................................................................................................................4-13

3.1 Structure of common rail system (CRS) engine..............................................................................4-13

3.2 Feature of common rail system (CRS) engine ................................................................................ 4-14

3.3 Flow of common rail system (CRS) engine.....................................................................................4-15

3.4 Control of common rail system (CRS) engine.................................................................................4-17

3.5 Fuel tank .........................................................................................................................................4-17

3.5.1 Outline of fuel tank..................................................................................................................4-17

3.5.2 Structure of fuel tank............................................................................................................... 4-17

3.5.3 Function of fuel tank ...............................................................................................................4-17

3.5.4 Specification of fuel tank.........................................................................................................4-17

3.6 Water separator...............................................................................................................................4-17

3.6.1 Outline of water separator ......................................................................................................4-17

3.6.2 Structure of water separator (Type1)......................................................................................4-17

3.6.3 Structure of water separator (Type2)......................................................................................4-17

3.6.4 Function of water separator .................................................................................................... 4-18

3.6.5 Specification of water separator (Type2) ................................................................................ 4-18

Page 9

3.7 Electromagnetic fuel feed pump...................................................................................................... 4-18

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

vii

KiSC issued 12, 2018 A

3.7.1 Outline of electromagnetic fuel feed pump

3.7.2 Structure of electromagnetic fuel feed pump

.............................................................................4-18

..........................................................................4-18

3.7.3 Function of electromagnetic fuel feed pump...........................................................................4-18

3.7.4 Specification of electromagnetic fuel feed pump ....................................................................4-18

3.8 Fuel feed pump ...............................................................................................................................4-19

3.8.1 Outline of fuel feed pump........................................................................................................ 4-19

3.8.2 Structure of fuel feed pump ....................................................................................................4-19

3.8.3 Function of fuel feed pump .....................................................................................................4-19

3.8.4 Specification of fuel feed pump............................................................................................... 4-19

3.9 Fuel filter .........................................................................................................................................4-20

3.9.1 Outline of fuel filter..................................................................................................................4-20

3.9.2 Structure of fuel filter............................................................................................................... 4-20

3.9.3 Function of fuel filter ...............................................................................................................4-20

3.9.4 Specification of fuel filter.........................................................................................................4-20

3.10 Supply pump .................................................................................................................................4-20

3.10.1 Outline of supply pump ......................................................................................................... 4-20

3.10.2 Structure of supply pump......................................................................................................4-20

3.10.3 Function of supply pump....................................................................................................... 4-21

3.10.4 Specification of supply pump ................................................................................................ 4-23

3.11 Injection pipe .................................................................................................................................4-23

3.11.1 Outline of injection pipe.........................................................................................................4-23

3.11.2 Structure of injection pipe...................................................................................................... 4-23

3.11.3 Function of injection pipe ......................................................................................................4-24

3.12 Rail assembly................................................................................................................................4-24

3.12.1 Outline of rail assembly ........................................................................................................4-24

3.12.2 Structure of rail assembly .....................................................................................................4-24

3.12.3 Function of rail assembly ...................................................................................................... 4-24

3.12.4 Specification of rail assembly ...............................................................................................4-25

3.13 Injector ..........................................................................................................................................4-26

3.13.1 Outline of injector..................................................................................................................4-26

3.13.2 Structure of injector............................................................................................................... 4-26

3.13.3 Function of injector ...............................................................................................................4-27

3.13.4 Specification of injector.........................................................................................................4-29

3.14 Overflow pipe ................................................................................................................................4-29

3.14.1 Outline of overflow pipe ........................................................................................................4-29

3.14.2 Structure of overflow pipe ..................................................................................................... 4-29

3.14.3 Function of overflow pipe......................................................................................................4-29

3.15 Check valve................................................................................................................................... 4-29

3.15.1 Outline of check valve........................................................................................................... 4-29

3.15.2 Structure of check valve .......................................................................................................4-29

3.15.3 Function of check valve ........................................................................................................4-29

3.15.4 Specification of check valve.................................................................................................. 4-29

3.16 Fuel cooler ....................................................................................................................................4-29

3.16.1 Outline of fuel cooler.............................................................................................................4-29

3.16.2 Structure of fuel cooler.......................................................................................................... 4-30

3.16.3 Function of fuel cooler ..........................................................................................................4-30

3.17 Engine ECU ..................................................................................................................................4-30

3.17.1 Outline of engine ECU .......................................................................................................... 4-30

3.17.2 Structure of engine ECU.......................................................................................................4-30

3.17.3 Function of engine ECU........................................................................................................ 4-30

3.17.4 Specification of engine ECU ................................................................................................. 4-30

3.18 Crankshaft position sensor............................................................................................................ 4-31

3.18.1 Outline of crankshaft position sensor.................................................................................... 4-31

3.18.2 Structure of crankshaft position sensor ................................................................................4-31

3.18.3 Function of crankshaft position sensor .................................................................................4-31

3.18.4 Specification of crankshaft position sensor........................................................................... 4-31

3.19 Camshaft position sensor.............................................................................................................. 4-32

Page 10

3.19.1 Outline of camshaft position sensor...................................................................................... 4-32

viii

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

KiSC issued 12, 2018 A

3.19.2 Structure of camshaft position sensor

3.19.3 Function of camshaft position sensor

..................................................................................4-32

...................................................................................4-32

3.19.4 Specification of camshaft position sensor............................................................................. 4-32

3.20 Coolant temperature sensor.......................................................................................................... 4-33

3.20.1 Outline of coolant temperature sensor.................................................................................. 4-33

3.20.2 Structure of coolant temperature sensor ..............................................................................4-33

3.20.3 Function of coolant temperature sensor ...............................................................................4-33

3.20.4 Specification of coolant temperature sensor......................................................................... 4-33

3.21 Boost pressure sensor ..................................................................................................................4-34

3.21.1 Outline of boost pressure sensor..........................................................................................4-34

3.21.2 Structure of boost pressure sensor....................................................................................... 4-34

3.21.3 Function of boost pressure sensor .......................................................................................4-34

3.21.4 Specification of boost pressure sensor.................................................................................4-34

3.22 Atmosphere pressure sensor ........................................................................................................ 4-34

3.22.1 Outline of atmosphere pressure sensor................................................................................ 4-34

3.22.2 Structure of atmosphere pressure sensor ............................................................................4-34

3.22.3 Function of atmosphere pressure sensor .............................................................................4-34

3.23 Fuel camshaft................................................................................................................................ 4-35

3.23.1 Outline of fuel camshaft ........................................................................................................ 4-35

3.23.2 Structure of fuel camshaft.....................................................................................................4-35

3.23.3 Function of fuel camshaft...................................................................................................... 4-35

4. Intake and exhaust system.....................................................................................................................4-36

4.1 Structure of intake and exhaust system .......................................................................................... 4-36

4.2 Feature of intake and exhaust system ............................................................................................4-37

4.3 Flow of intake and exhaust system ................................................................................................. 4-38

4.4 Control of intake and exhaust system ............................................................................................. 4-40

4.5 Pre-cleaner...................................................................................................................................... 4-40

4.5.1 Outline of pre-cleaner .............................................................................................................4-40

4.5.2 Structure of pre-cleaner .......................................................................................................... 4-40

4.5.3 Function of pre-cleaner...........................................................................................................4-40

4.5.4 Specification of pre-cleaner ....................................................................................................4-40

4.6 Air cleaner ....................................................................................................................................... 4-40

4.6.1 Outline of air cleaner............................................................................................................... 4-40

4.6.2 Structure of air cleaner ...........................................................................................................4-40

4.6.3 Function of air cleaner ............................................................................................................4-40

4.6.4 Specification of air cleaner...................................................................................................... 4-40

4.7 Turbocharger................................................................................................................................... 4-40

4.7.1 Outline of turbocharger ........................................................................................................... 4-40

4.7.2 Structure of turbocharger........................................................................................................4-41

4.7.3 Function of turbocharger......................................................................................................... 4-41

4.7.4 Specification of turbocharger .................................................................................................. 4-41

4.8 Intercooler .......................................................................................................................................4-41

4.8.1 Outline of intercooler............................................................................................................... 4-41

4.8.2 Structure of intercooler ...........................................................................................................4-41

4.8.3 Function of intercooler ............................................................................................................4-41

4.8.4 Specification of intercooler...................................................................................................... 4-41

4.9 Glow plug ........................................................................................................................................4-42

4.9.1 Outline of glow plug ................................................................................................................4-42

4.9.2 Structure of glow plug ............................................................................................................. 4-42

4.9.3 Function of glow plug..............................................................................................................4-42

4.9.4 Specification of glow plug .......................................................................................................4-42

4.10 Intake manifold..............................................................................................................................4-42

4.10.1 Outline of intake manifold .....................................................................................................4-42

4.10.2 Structure of intake manifold .................................................................................................. 4-42

4.10.3 Function of intake manifold...................................................................................................4-42

4.11 Exhaust manifold ........................................................................................................................... 4-42

4.11.1 Outline of exhaust manifold................................................................................................... 4-42

Page 11

4.11.2 Structure of exhaust manifold ...............................................................................................4-42

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

ix

KiSC issued 12, 2018 A

4.1

1.3 Function of exhaust manifold

................................................................................................4-43

5. Exhaust gas recirculation (EGR) system................................................................................................4-44

5.1 Structure of EGR system ................................................................................................................4-44

5.2 Feature of EGR system................................................................................................................... 4-45

5.3 Flow of EGR system........................................................................................................................4-46

5.4 Control of EGR system ...................................................................................................................4-47

5.5 EGR cooler...................................................................................................................................... 4-47

5.5.1 Outline of EGR cooler.............................................................................................................4-47

5.5.2 Structure of EGR cooler.......................................................................................................... 4-47

5.5.3 Function of EGR cooler ..........................................................................................................4-47

5.5.4 Specification of EGR cooler....................................................................................................4-47

5.6 EGR valve ....................................................................................................................................... 4-47

5.6.1 Outline of EGR valve ..............................................................................................................4-47

5.6.2 Structure of EGR valve ........................................................................................................... 4-48

5.6.3 Function of EGR valve............................................................................................................4-50

5.6.4 Specification of EGR valve .....................................................................................................4-50

5.7 Reed valve ......................................................................................................................................4-50

5.7.1 Outline of reed valve...............................................................................................................4-50

5.7.2 Structure of reed valve............................................................................................................ 4-50

5.7.3 Function of reed valve ............................................................................................................4-50

6. Lubricating system.................................................................................................................................. 4-51

6.1 Structure of lubricating system........................................................................................................4-51

6.2 Feature of lubricating system .......................................................................................................... 4-52

6.3 Flow of lubricating system...............................................................................................................4-53

6.4 Oil pan.............................................................................................................................................4-55

6.4.1 Outline of oil pan.....................................................................................................................4-55

6.4.2 Structure of oil pan.................................................................................................................. 4-55

6.4.3 Function of oil pan ..................................................................................................................4-55

6.4.4 Specification of oil pan............................................................................................................4-55

6.5 Oil strainer.......................................................................................................................................4-55

6.5.1 Outline of oil strainer...............................................................................................................4-55

6.5.2 Structure of oil strainer............................................................................................................ 4-55

6.5.3 Function of oil strainer ............................................................................................................4-55

6.5.4 Specification of oil strainer......................................................................................................4-55

6.6 Oil pump..........................................................................................................................................4-56

6.6.1 Outline of oil pump..................................................................................................................4-56

6.6.2 Structure of oil pump............................................................................................................... 4-56

6.6.3 Function of oil pump ...............................................................................................................4-56

6.6.4 Specification of oil pump.........................................................................................................4-56

6.7 Relief valve...................................................................................................................................... 4-56

6.7.1 Outline of relief valve ..............................................................................................................4-56

6.7.2 Structure of relief valve ........................................................................................................... 4-56

6.7.3 Function of relief valve............................................................................................................4-57

6.8 Oil filter ............................................................................................................................................ 4-57

6.8.1 Outline of oil filter .................................................................................................................... 4-57

6.8.2 Structure of oil filter.................................................................................................................4-57

6.8.3 Function of oil filter.................................................................................................................. 4-57

6.8.4 Specification of oil filter ........................................................................................................... 4-57

6.9 Oil cooler ......................................................................................................................................... 4-57

6.9.1 Outline of oil cooler ................................................................................................................. 4-57

6.9.2 Structure of oil cooler..............................................................................................................4-57

6.9.3 Function of oil cooler............................................................................................................... 4-58

6.9.4 Specification of oil cooler ........................................................................................................ 4-58

6.10 Oil pressure switch........................................................................................................................4-58

6.10.1 Outline of oil pressure switch................................................................................................4-58

6.10.2 Structure of oil pressure switch............................................................................................. 4-58

6.10.3 Function of oil pressure switch .............................................................................................4-58

Page 12

6.10.4 Specification of oil pressure switch.......................................................................................4-59

x

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

KiSC issued 12, 2018 A

7. Cooling system

7.1 Structure of cooling system

.......................................................................................................................................4-60

.............................................................................................................4-60

7.2 Feature of cooling system ............................................................................................................... 4-61

7.3 Flow of cooling system (Bottom by-pass system) ........................................................................... 4-61

7.4 Control of cooling system (Bottom by-pass system) ....................................................................... 4-61

7.5 Water pump..................................................................................................................................... 4-61

7.5.1 Outline of water pump............................................................................................................. 4-61

7.5.2 Structure of water pump .........................................................................................................4-61

7.5.3 Function of water pump ..........................................................................................................4-62

7.6 Thermostat ...................................................................................................................................... 4-62

7.6.1 Outline of thermostat ..............................................................................................................4-62

7.6.2 Structure of thermostat ...........................................................................................................4-62

7.6.3 Function of thermostat ............................................................................................................ 4-62

7.6.4 Specification of thermostat .....................................................................................................4-62

7.7 Radiator........................................................................................................................................... 4-63

7.7.1 Outline of radiator ...................................................................................................................4-63

7.7.2 Structure of radiator ................................................................................................................ 4-63

7.7.3 Function of radiator.................................................................................................................4-63

7.7.4 Specification of radiator ..........................................................................................................4-63

7.8 Radiator cap....................................................................................................................................4-63

7.8.1 Outline of radiator cap ............................................................................................................4-63

7.8.2 Structure of radiator cap .........................................................................................................4-63

7.8.3 Function of radiator cap .......................................................................................................... 4-64

7.8.4 Specification of radiator cap ...................................................................................................4-64

7.9 Cooling fan ...................................................................................................................................... 4-64

7.9.1 Outline of cooling fan .............................................................................................................. 4-64

7.9.2 Structure of cooling fan...........................................................................................................4-64

7.9.3 Function of cooling fan............................................................................................................ 4-64

7.9.4 Specification of cooling fan ..................................................................................................... 4-64

7.10 Reserve tank ................................................................................................................................. 4-65

7.10.1 Outline of reserve tank.......................................................................................................... 4-65

7.10.2 Structure of reserve tank ......................................................................................................4-65

7.10.3 Function of reserve tank .......................................................................................................4-65

7.11 Fan belt..........................................................................................................................................4-65

7.11.1 Outline of fan belt .................................................................................................................. 4-65

7.11.2 Structure of fan belt...............................................................................................................4-65

7.11.3 Function of fan belt................................................................................................................4-65

8. Electrical system..................................................................................................................................... 4-66

8.1 Structure of electrical system .......................................................................................................... 4-66

8.2 Feature of electrical system ............................................................................................................4-67

8.3 Flow of electrical system ................................................................................................................. 4-68

8.4 Control of electrical system ............................................................................................................. 4-70

8.5 Battery.............................................................................................................................................4-70

8.5.1 Outline of battery ....................................................................................................................4-70

8.5.2 Structure of battery .................................................................................................................4-70

8.5.3 Function of battery .................................................................................................................. 4-70

8.5.4 Specification of battery ...........................................................................................................4-70

8.6 Key switch ....................................................................................................................................... 4-70

8.6.1 Outline of key switch...............................................................................................................4-70

8.6.2 Structure of key switch............................................................................................................ 4-70

8.6.3 Function of key switch ............................................................................................................4-71

8.6.4 Specification of key switch......................................................................................................4-71

8.7 Starter (Planetary gear reduction type) ........................................................................................... 4-71

8.7.1 Outline of starter (planetary gear reduction type) ...................................................................4-71

8.7.2 Structure of starter (planetary gear reduction type) ................................................................ 4-71

8.7.3 Function of starter (planetary gear reduction type).................................................................4-71

8.7.4 Specification of starter (planetary gear reduction type) ..........................................................4-72

Page 13

8.8 Alternator......................................................................................................................................... 4-72

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

xi

KiSC issued 12, 2018 A

8.8.1 Outline of alternator

8.8.2 Structure of alternator

................................................................................................................4-72

.............................................................................................................4-72

8.8.3 Function of alternator..............................................................................................................4-72

8.8.4 Specification of alternator .......................................................................................................4-74

9. Aftertreatment system ............................................................................................................................4-75

9.1 Structure of diesel particulate filter (DPF) system...........................................................................4-75

9.2 Feature of diesel particulate filter (DPF) system ............................................................................. 4-75

9.3 Flow of diesel particulate filter (DPF) system..................................................................................4-75

9.4 Control of diesel particulate filter (DPF) system..............................................................................4-76

9.5 Structure of diesel oxidation catalyst (DOC) system.......................................................................4-78

9.6 Feature of diesel oxidation catalyst (DOC) system ......................................................................... 4-78

9.7 Flow of diesel oxidation catalyst (DOC) system..............................................................................4-78

9.8 Diesel oxidation catalyst (DOC) ......................................................................................................4-79

9.8.1 Outline of diesel oxidation catalyst (DOC) .............................................................................. 4-79

9.8.2 Structure of diesel oxidation catalyst (DOC)...........................................................................4-79

9.8.3 Function of diesel oxidation catalyst (DOC)............................................................................ 4-79

9.9 Diesel particulate filter (DPF) ..........................................................................................................4-79

9.9.1 Outline of diesel particulate filter (DPF) .................................................................................. 4-79

9.9.2 Structure of diesel particulate filter (DPF)...............................................................................4-79

9.9.3 Function of diesel particulate filter (DPF)................................................................................ 4-80