Page 1

WORKSHOP MANUAL

KUBOTA EXCAVATOR

KX91-3S

KX121-3S

U35S,U35-3S

·D

·D

·D

, 101-3

D

,161-3S

, U45-3S

Minor change Chapter

·D

·D

Code No.97899-61260

Page 2

Record of Revisions

Symbol Date Main Revised Points & Corrective Measures Person-in-charge

1

2

3

4

Page 3

CONTENTS

I Sales Engineering Section............................................... I-1

A. Quick feature chart ................................................................................. I-2

B. Feature discriptions ................................................................................ I-4

C. New innovations ..................................................................................... I-6

D. Specifications: Super series (KTC, KCL, KTA-version).......................... I-7

II Service Engineering Section........................................... II-1

A. General outline ...................................................................................... II-2

B. Finger control service port system....................................................... II-22

C. Hydraulic system modification ............................................................. II-57

D. Hydraulic circuit diagram ..................................................................... II-91

E. Engine upgrade ................................................................................. II-109

F. Electrical system................................................................................ II-114

EU-version

KX91-3D, KX101-3D,KX121-3D, KX161-3D

U35-3D, U45-3D

PP-version

KX91-3S, KX121-3S, KX161-3S

U35S, U35-3S, U45-3S

Note: EU-version is for KE, KUK, and KBM. PP-version is for KTC, KCL, and KTA.

This WSM minor change edition has been compiled to explain the main contents of the

minor change, such as new service port system, new auto-idle system, some hydraulic

system change, engine upgrade for KX161-3S, etc.

As for the service information which are identical to the machines before minor change,

please refer to the correspondent WSM.

Page 4

WSM Minor Change I Sales Engineering Section

I Sales Engineering Section

A. Quick feature chart..............................................................I-2

B. Feature discriptions.............................................................I-4

C. New innovations..................................................................I-6

D. Specifications: Super series (KTC, KCL, KTA-version) ......I-7

I - 1

Page 5

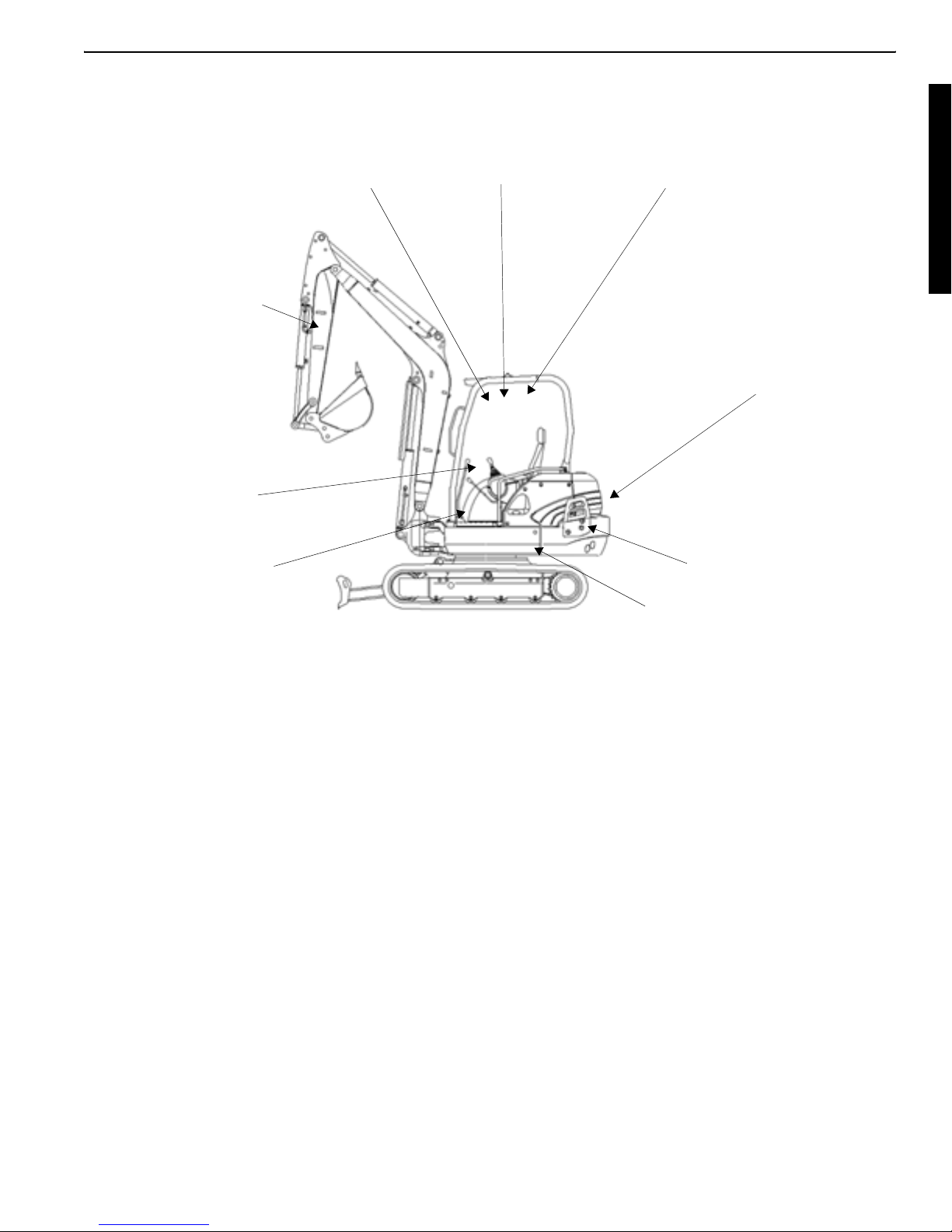

WSM Minor Change I Sales Engineering Section

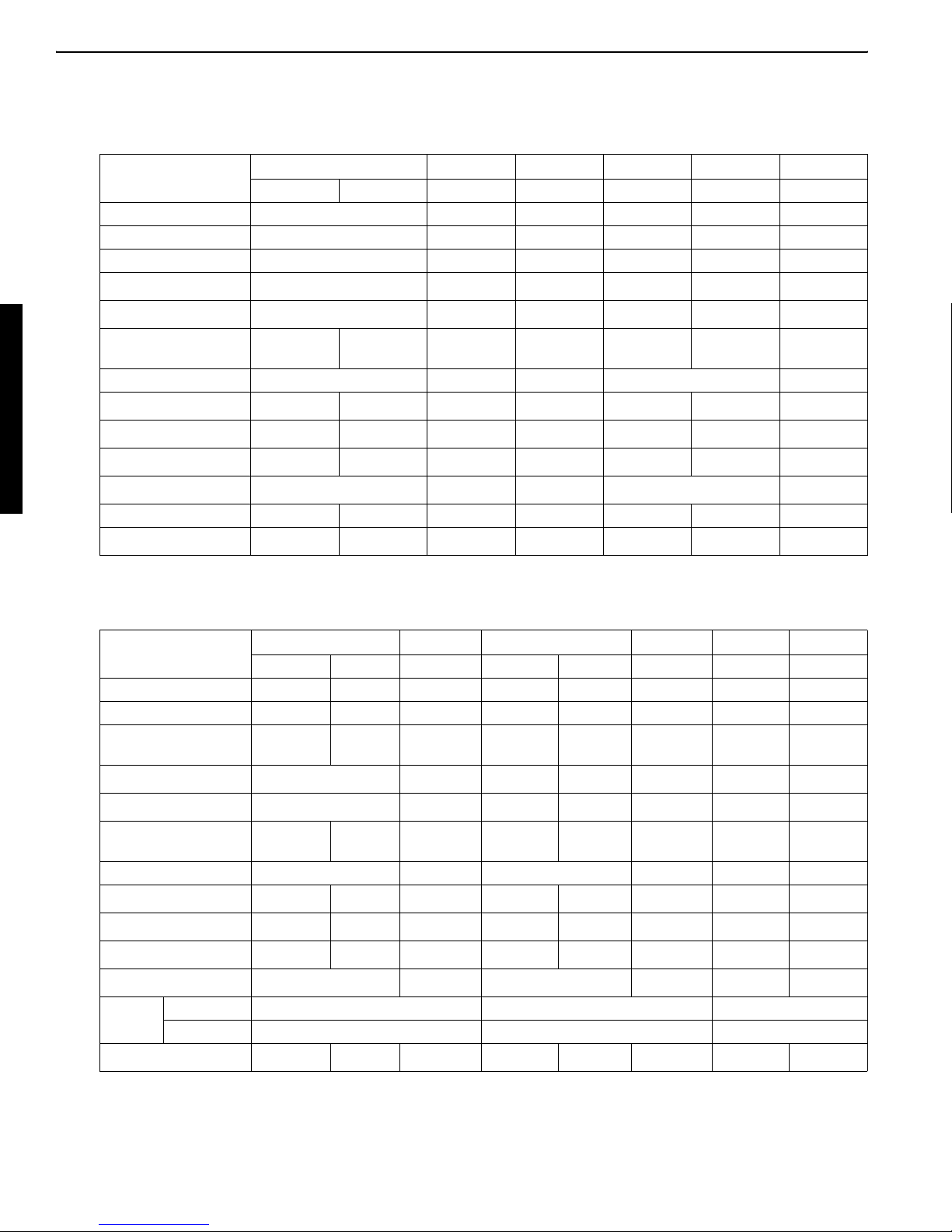

A. Quick feature chart

a. KX91-3S, KX91-3D, KX101-3D, U35S, U35-3S, U35-3D

Basic performance improved (new)

Greater working range of this class

(1) Maximum digging and dumping heights

(2) Maximum digging depth

Safeness upgraded

(1) Full-scale 4-post ROPS/FOPS

canopy

(3) Standard equipped with ROPS/

FOPS cabin (cab type)(with

steel-framed skylight)

(4) Engine neutral start

(5) Travel lock

(6) Master key-compatible immo-

bilizer (option)

Operator’s comfort

enhanced

(1) Digital navigation system

(2) Heater with outside-air inlet

defroster

(standard on cab type)

(3) Cup holder

(standard on cab type)

(4) Optional headlights

(option on cab type)

Maintainability

(1) Hydraulic components collectively located

on the right machine side

(2) Right hood fully opened

(3) Sectional dozer hose, etc.

Better maneuverability

(1) Service port local control (wrist rest type)

(2) Travel bi-speed button (dozer lever)

(3) Independent swing pedal on the left side (hydraulic pilot)

I - 2

Page 6

WSM Minor Change I Sales Engineering Section

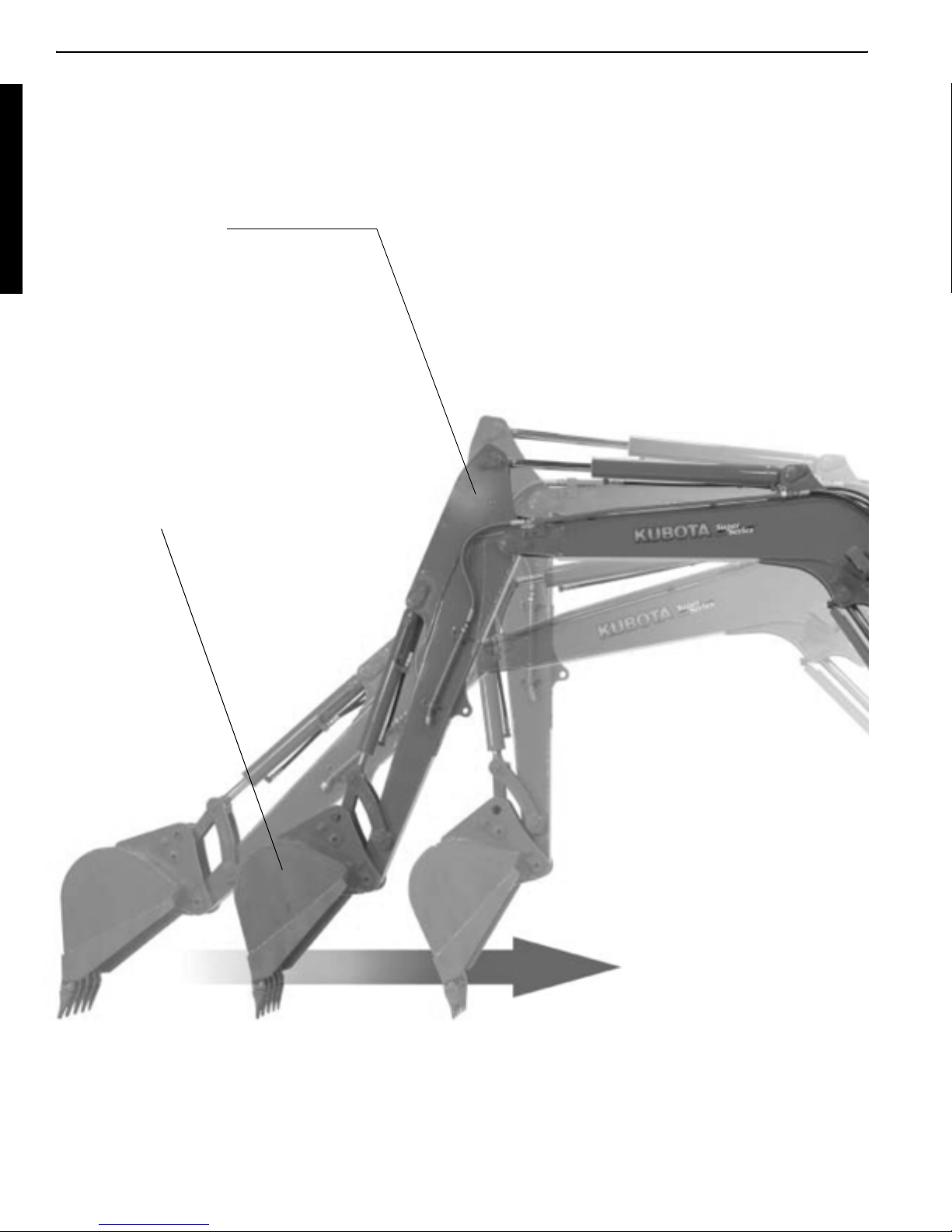

b. KX121-3S, KX121-3D, KX161-3S, KX161-3D, U45-3S, U45-3D

New immobilizer system introduced

Thumb bracket adopted

(North America)

Travel bi-speed switch

(Dozer lever)

Independent swing pedal

on the right side

(Europe)

Service port knob control

Digital navigation system adopted

Greater engine output (KX161-3S)

Sedimenter separately located

Larger fuel tank capacity

(KX91-3S, KX161-3S)

North America, Australia, Europe

I - 3

Page 7

WSM Minor Change I Sales Engineering Section

B. Feature discriptions

(Super series)

Boom operation

Kubota's Hydraulic Matching System allows easy,

simultaneous and smooth operations of the boom,

arm, bucket and house swing. Perfectly matched

speed, power and cylinder timing deliver extraordinary responsiveness, even with the slightest operator movements or in the toughest conditions (The

KX121-3 and KX161-3 feature the Load Sensing

Hydraulic System).

Strongest bucket breakout force in its class

Kubota's Hydraulic Matching system is unmatched for power or

ease of use. Load sensing hydraulics, which automatically regulate

and distribute optimum oil amounts to each cylinder, make it ideal

for your toughest trenching projects or your lightest dozing tasks. In

any situation, you can always rely on the KX-3 Super Series for

complete work efficiency.

Safety

With our Engine Start Lockout System, the engine cranks only

when the safety levers are raised. Our safety Lever Lockout

System helps prevent unexpected excavator and attachment

movement when entering or exiting the unit. An Auto House

Parking Brake automatically locks the house in the position it

was in when the engine was shut off. This means that a swing

lock pin is no longer required, making the excavator more compact during transport and secure when parked on an incline. And

an OSHA certified ROPS/FOPS canopy and cab protects

against rollovers or falling objects.

Wide Working Range

The KX-3 Super Series' powerful and responsive front working

group is perfect for all your digging, lifting and loading jobs.

Plus, with increases and improvements to our bucket

capacities, reach and digging depths, the Super Series exceed

many of the latest construction site requirements.

I - 4

Page 8

WSM Minor Change I Sales Engineering Section

Operator comfort

Get total comfort from a spacious operating area that features ultra

quietness, deluxe climate control and a high back suspensionengineered seat with adjustable wrist rests. Well-placed controls

and levers provide an increase in deck space and foot room. A

lowsound-level cab design reduces engine vibration to a minimum.

Our ergonomic seat and wrist supports adjust to your individual

posture. And with T.P.S.S. technology, change quickly between

ISO and SAE operating patterns without tools or leaving your seat,

and with only the flick of a switch. Combined, these advantages

reduce fatigue while helping to maintain your peak performance

(A/C available only on KX121-3 and KX161-3 models).

Easy maintenance

The KX-3 Super Series not only make

daily maintenance a breeze, but also

make more-detailed periodic maintenance hassle-free as well. Wide opening

side and rear covers, as well as centrally

located components, give you quick and

easy access for the servicing of vital

areas like the engine, the fuel/water separator, the radiator, coolant, air filter, control valve and hydraulic tank.

KUBOTA engine

The ultra powerful, incredibly dependable

Kubota diesel engines deliver unmatched

horsepower while minimizing emissions

to meet EPA standards. They produce

quick starts in temperatures as low as 4qF, low sound as well as low vibration.

They even then follow through with superior fuel-efficiency.

Extraordinary stability and lifting capacity

The KX-3 Series is equipped with innovative and superior counter balancing technology for

increased excavator stability. Long tumbler distance, a lower center of gravity and Double Outer

Flanged Lower Track Rollers combine to deliver safe and effective performance when working

over the side, with hydraulic attachments mounted or when lifting a broad range of heavy objects.

I - 5

Page 9

WSM Minor Change I Sales Engineering Section

C. New innovations

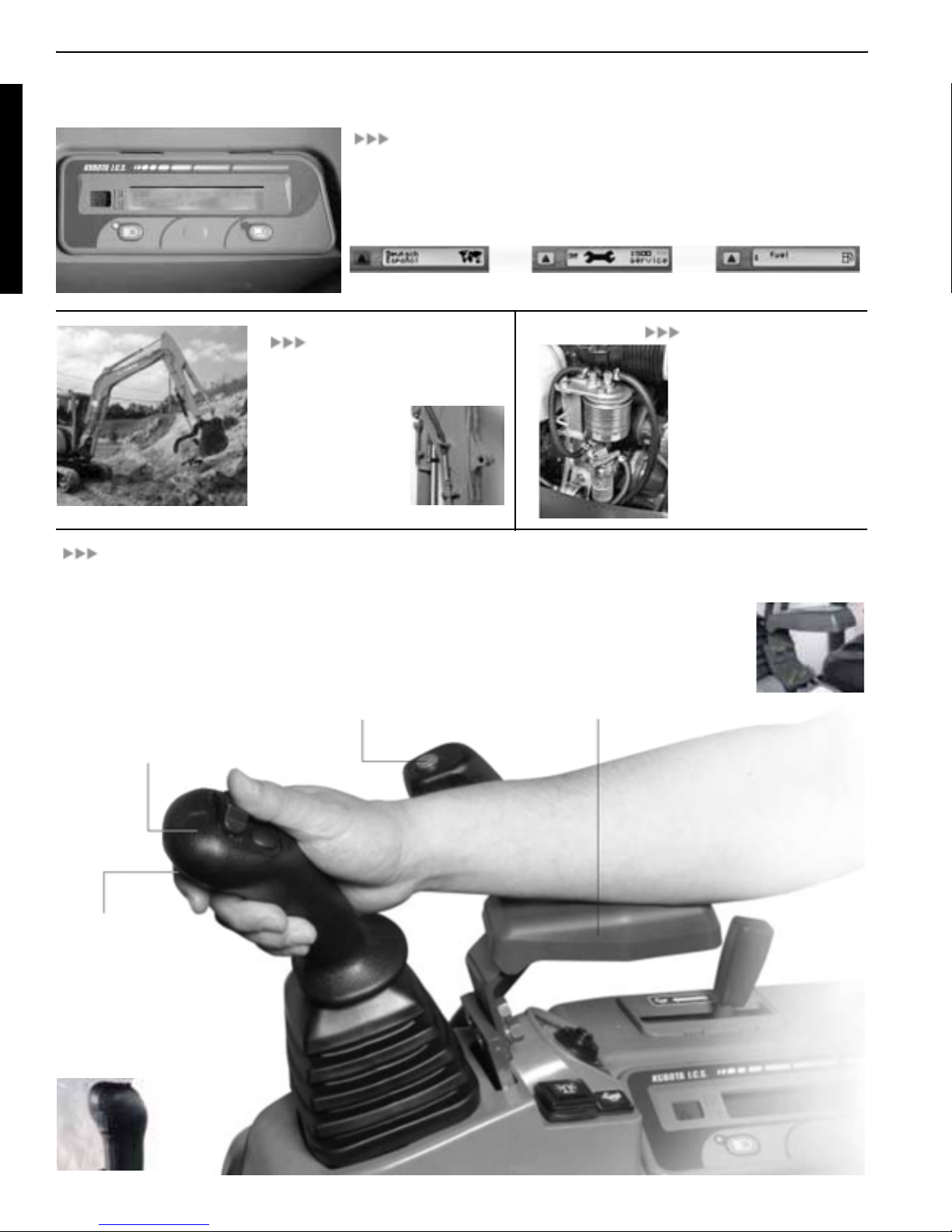

DIGITAL PANEL

Informative, interactive and functional. Kubota's all-new liquid crystal display (LCD) panel

accurately shows easy-to-understand diagnostics and digital readings. The Kubota Intelligent Control System (KICS) will even alert the operator to when routine maintenance is

due. Plus, when filling-up with fuel, the KICS informs the operator that the tank is nearly full.

The panel reduces excavator downtime and repair fees for a decrease in total operating

costs.

Language selection display Information when service time comes Low fuel display

USER-FRIENDLY OPERABILITY

SHORT STROKE

OPERATING LEVER

The new operating levers require less

effort and shorter movement, increasing control, responsiveness and comfort. With only the slightest flick of the

wrist, smooth excavator operation and

reduced operator fatigue are assured.

THUMB BRACKET

The optional hydraulic thumb opens up

opportunities for loading and material

handling tasks. It allows

you to pinch material

between the thumb and

bucket, retracting for

normal excavation.

Installation time is significantly reduced with

the factory installed

2 SPEED SWITCH

The new 2-Speed Travel Switch is

conveniently mounted on the dozer

lever for easier operation and control. It allows increased floor space

as well as advanced user-friendly

travel speed changes.

FUEL-WATER

SEPARATOR

The Water Separator has

been relocated to an easy to

reach position under the

improved Fuel Filter. This

gives the Super Series Models

with enhanced fuel and water

filtration, increased durability

and greater overall excavator

performance.

NEW WRIST RESTS

Set the new, custom adjustable

armrests to your favorite position, or

just move them out of the way.

Either way, they help reduce arm

movement and operator fatigue for

increased job efficiency.

BREAKER SWITCH

The breaker switch lets you manage the hydraulic breaker attachment quickly, easily and without

having to reach for the control.

Repositioned from the floor, simple forefinger activation as well as

convenient thumb operation of the

hydraulic breaker is possible.

I - 6

Page 10

WSM Minor Change I Sales Engineering Section

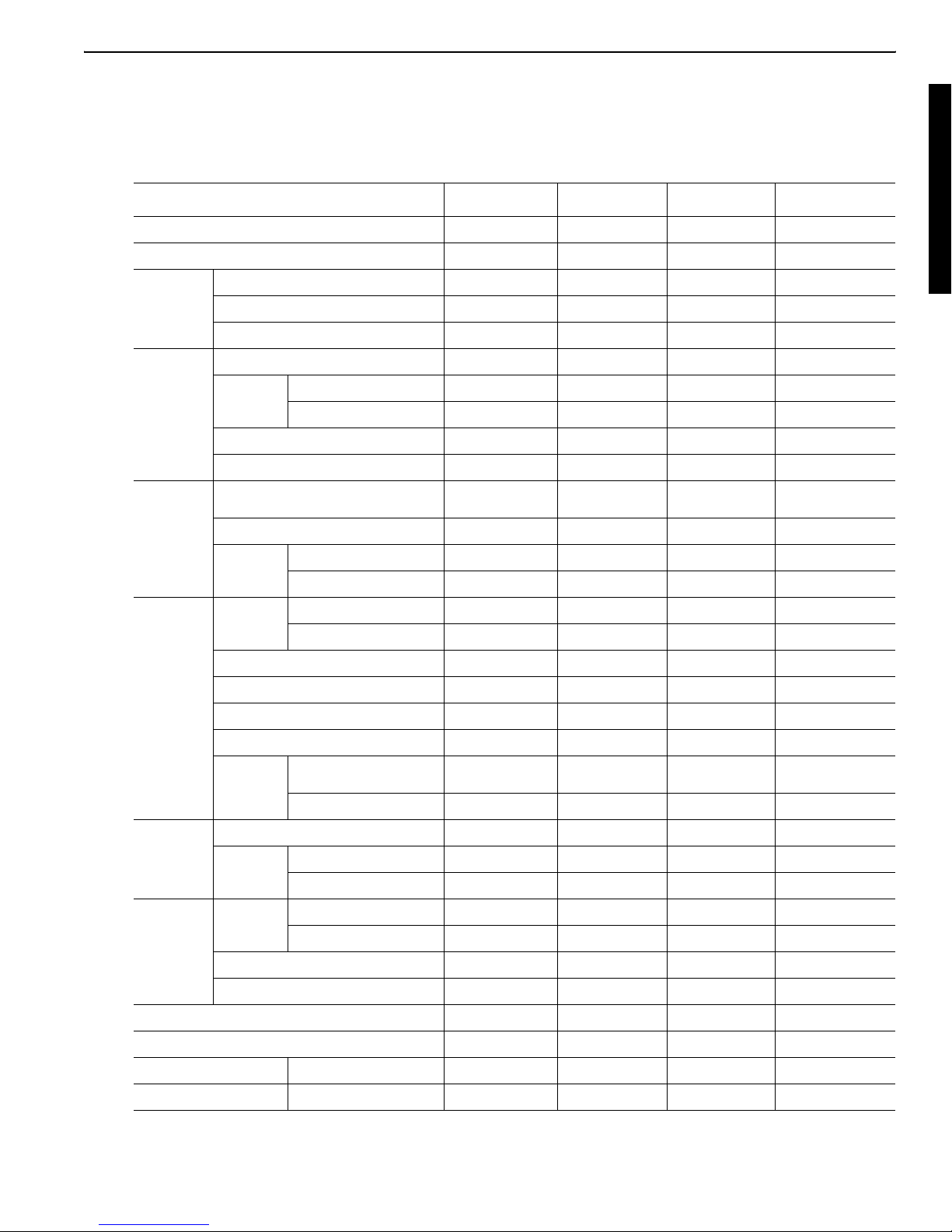

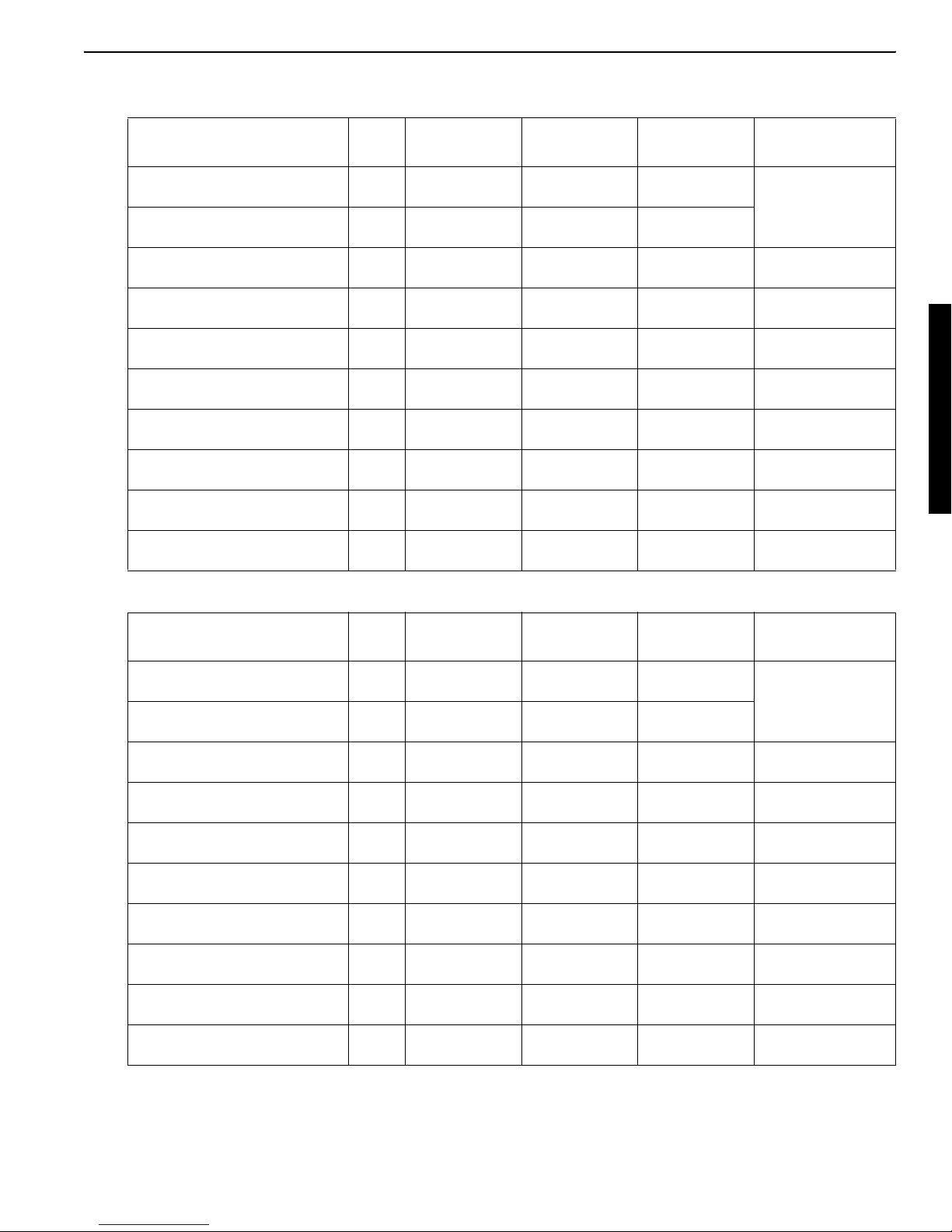

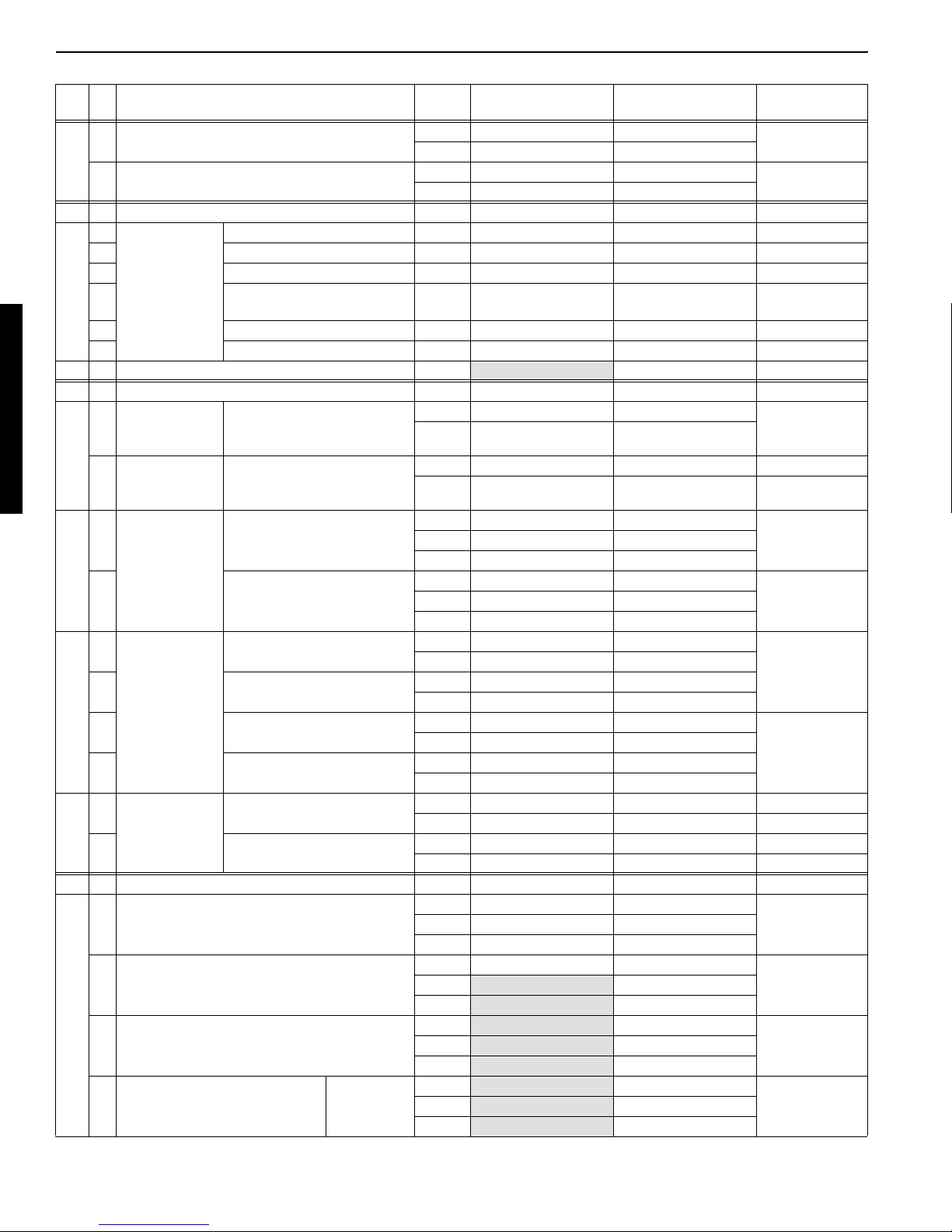

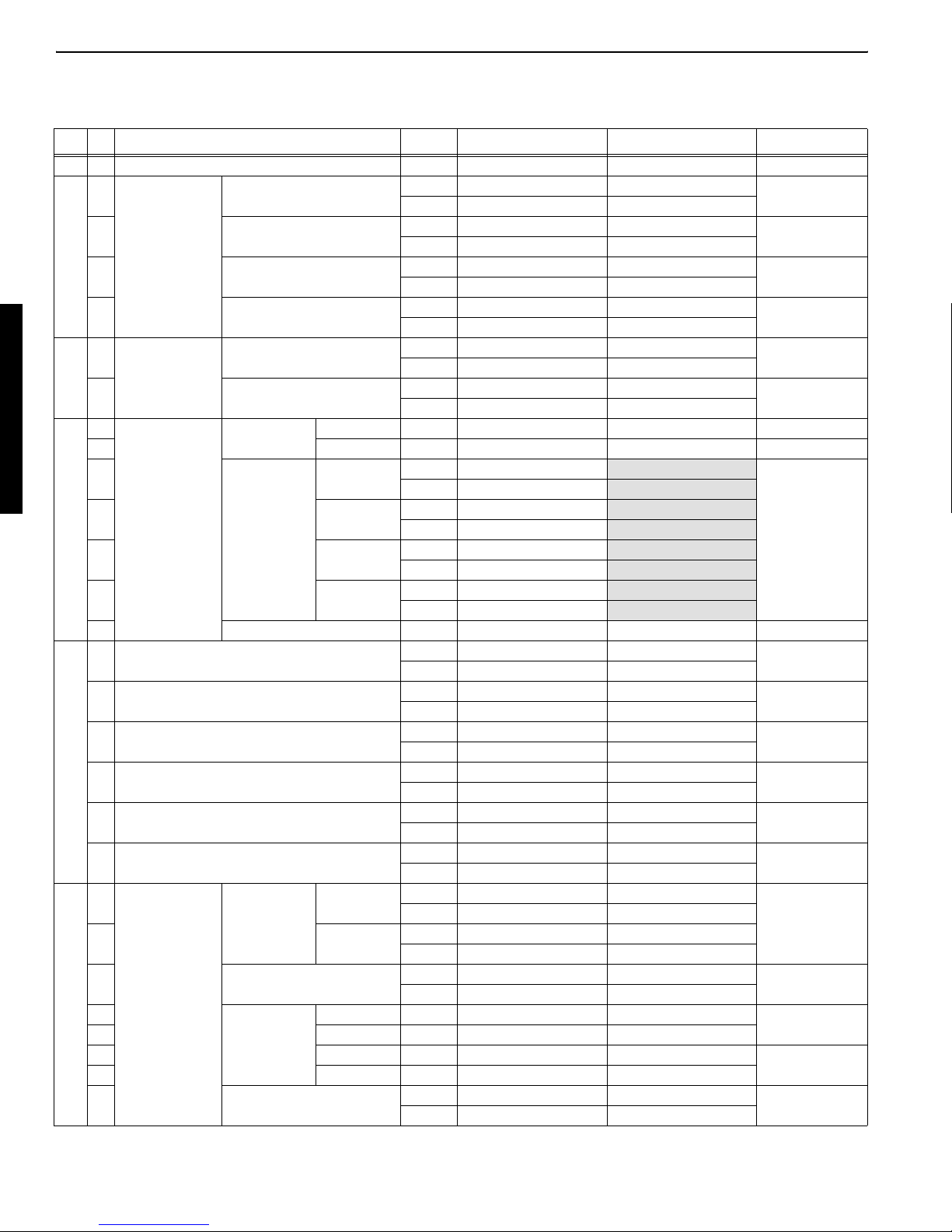

D. Specifications: Super series (KTC, KCL, KTA-version)

1.Main machine specifications

Model KX91-3S U35S / U35-3S KX121-3S KX161-3S

Type of ROPS/FOPS Canopy / Cab Canopy / Cab Canopy / Cab Canopy / Cab

Type of tracks Steel / Rubber Steel / Rubber Steel / Rubber Steel / Rubber

Engine Model Kubota D1503-M Kubota D1503-M Kubota V2203-M Kubota V2403-M

Output (SAE 1349 gross) HP(kW)/rpm 28.0 (20.9) / 2300 28.0 (20.9) / 2300 42.0 (30.7) / 2250 47.0 (34.6) / 2200

Displacement cu.in. (cc) 91.5" (1499) 91.5" (1499) 134.1" (2197) 148.5" (2434)

Dimensions Overall length ft.in. (mm) 15'7" (4760) 15'5" (4695) 16'9" (5090) 18'8" (5540)

Overall height

Overall width ft.in. (mm) 5'1" (1550) 5'7" (1700) 5'7" (1700) 6'5" (1960)

Min. ground clearance in. (mm) 11.6" (295) 11.4" (290) 13.0" (330) 12.6" (320)

Hydraulic system Pump capacity GPM (l/min) 10.9 (41.4) variable u 2

Auxiliary hydraulic flow GPM (l/min) 10.9 (41.4) 10.3 (39.1) 15.9 (60.0) 19.3 (73)

Max. breakout

force

Drive system

Swing system Unit swing speed rpm 9.4 8.9 9.4 9.3

Travel Speed

Max. traction force lbs.(kgf) 5600 (2540) 6098 (2766) 9697 (4398) 12861 (5833)

Tumbler distance ft.in. (mm) 5'1" (1560) 5'6" (1665) 5'8" (1710) 6'6" (1990)

Crawler length ft.in. (mm) 6'7" (2000) 6'11" (2100) 7'2" (2175) 8'2" (2500)

Shoe width in. (mm) 11.8" (300) 11.8" (300) 13.8" (350) 15.7" (400)

Ground contact

pressure

Boom swing

angle

canopy ft.in. (mm) 8'0" (2440) 8'0" (2440) 8'3" (2495) 8'4" (2540)

cab ft.in. (mm) 8'0" (2440) 8'0" (2440) 8'2" (2480) 8'4" (2540)

5.5 (20.9) Gear u 1

Bucket lbs.(kgf) 8059 (3655) 8397 (3809) 8754 (3970) 11118 (5043)

Arm lbs.(kgf) 3592 (1629) 4222 (1915) 3947 (1790) 4967 (2253)

Low mph (km/h) 1.9 (3.1) 1.9 (3.0) 1.7 (2.7) 1.6 (2.5)

High mph (km/h) 2.9 (4.8) 2.9 (4.6) 3.1 (5.0) 2.9 (4.6)

Canopy Cab Rubber/

Steel

Rubber/Steel psi (kgf/cm2) 4.70 (0.33) / 4.56 (0.32) 4.8 (0.34) / 5.0 (0.35) 4.41 (0.31) / 4.41 (0.31) 3.27 (0.23) / 3.41 (0.24)

Left degree 80 70 80 80

Right degree 50 50 50 50

psi (kgf/cm2) 4.64 (0.33) / 4.70 (0.33) 4.7 (0.33) / 4.8 (0.34) 4.41 (0.31) / 4.55 (0.32) 4.27 (0.30) / 4.41 (0.31)

10.3 (39.1) u 2

5.5 (20.7) u 1

25.0 (94.5) 31.4 (118.8)

Blade

Dimensions

Max.lift above ground in. (mm) 14.6" (370) 14.6" (370) 15.7" (400) 17.9" (455)

Max.drop below ground in. (mm) 14.6" (370) 14.6" (370) 15.9" (405) 14.8" (375)

Hydraulic oil (reservoir/system) gal (l) 9.5 (36) / 14.5 (55) 9.5 (36) / 14.5 (55) 11.6 (44) / 17.7 (67) 11.6 (44) / 17.7 (67)

Fuel reservoir gal (l) 13.2 (50) 10.6 (40) 16.9 (64) 18.5 (70)

Operating weight Including Canopy Rubber/Steel lbs.(kgf) 7110 (3225) / 7319 (3320) 8025 (3640) / 8234 (3735) 9063 (4110) / 9283 (4210) 11532 (5230) / 12348 (5600)

operator's weight 175lbs. Cab Rubber/Steel lbs.(kgf) 7330 (3325) / 7540 (3420) 8267 (3750) / 8477 (3845) 9261 (4200) / 9371 (4250) 11698 (5305) / 12513 (5675)

Width ft.in. (mm) 5'1" (1550) 5'7" (1700) 5'7" (1700) 6'5" (1960)

Height in. (mm) 13.2" (335) 13.2" (335) 13.8" (350) 15.4" (390)

I - 7

Page 11

WSM Minor Change I Sales Engineering Section

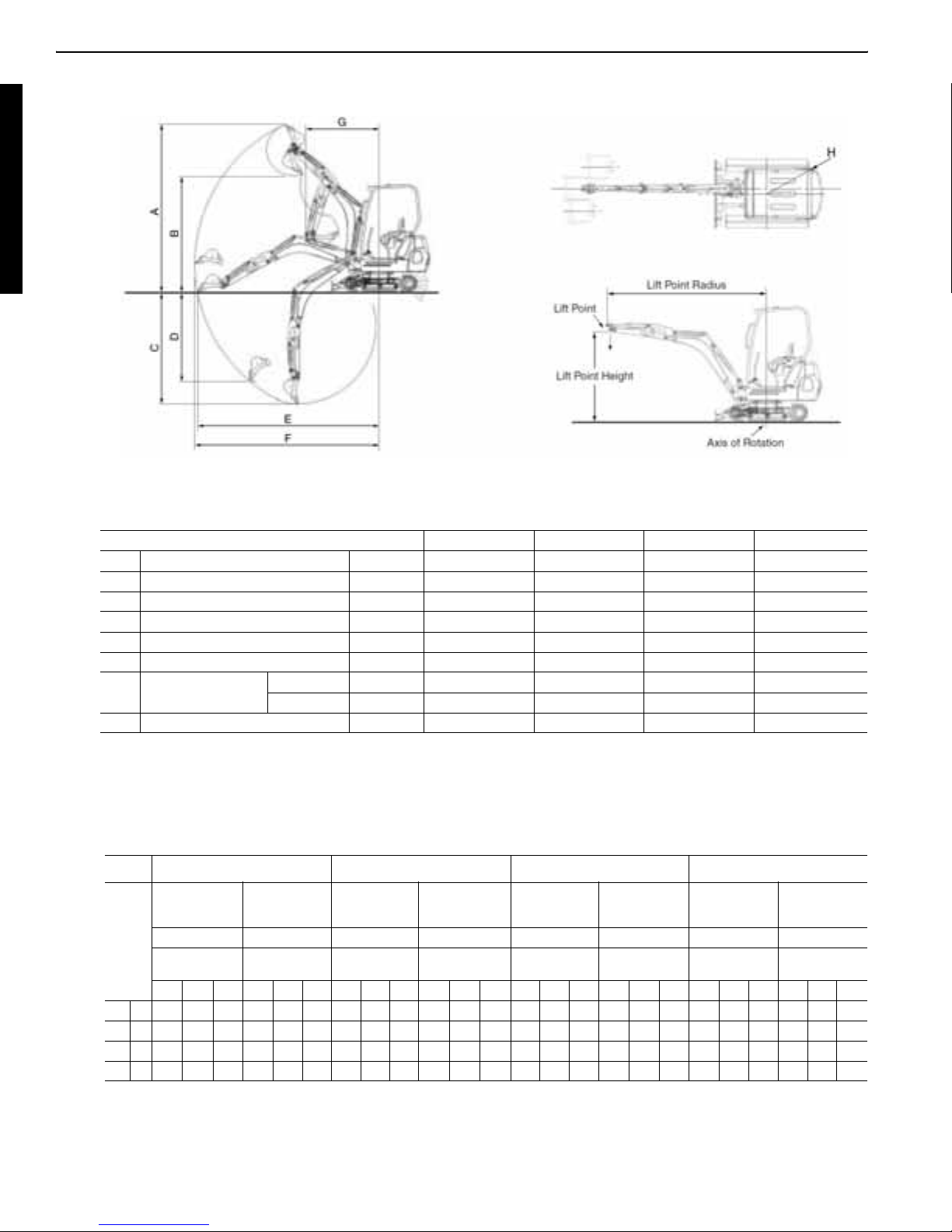

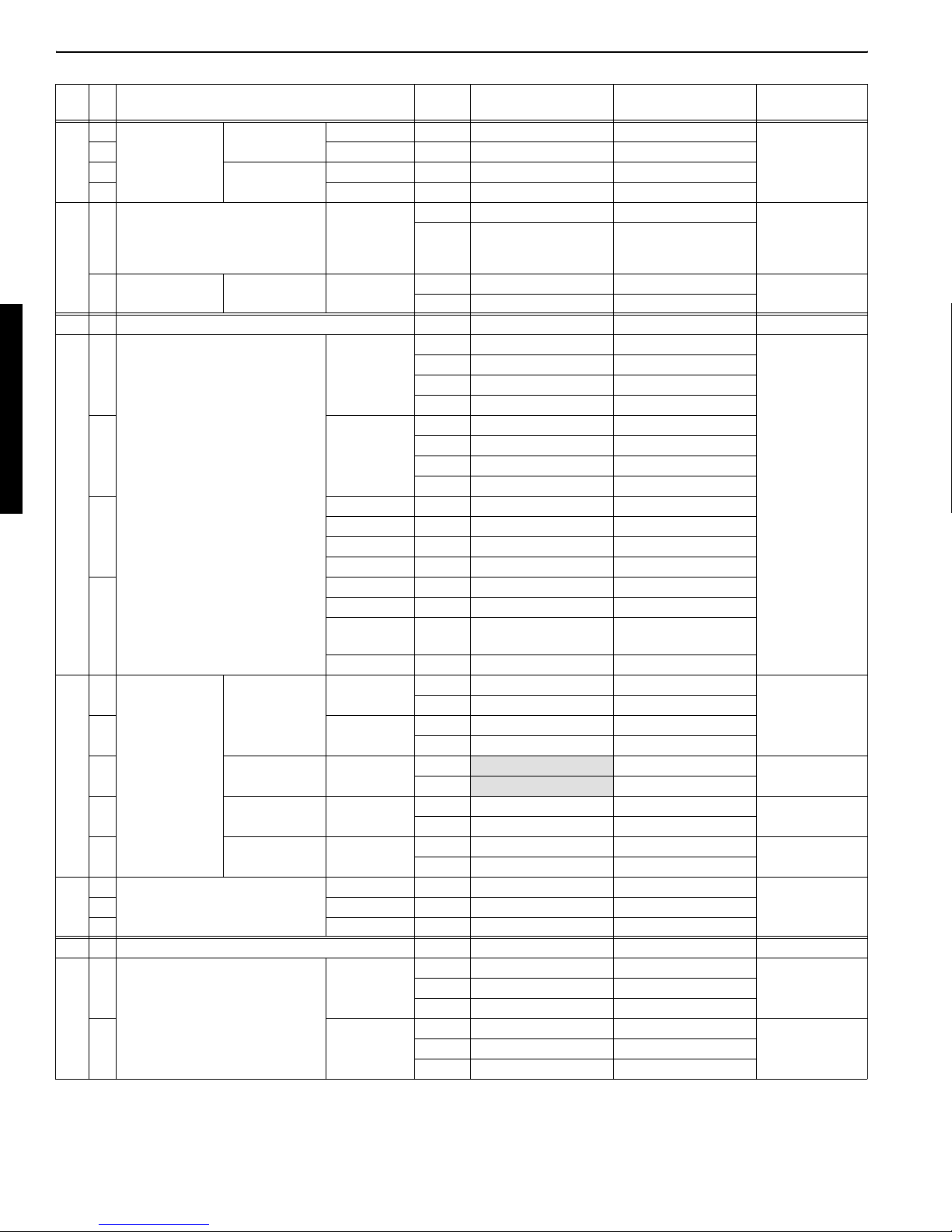

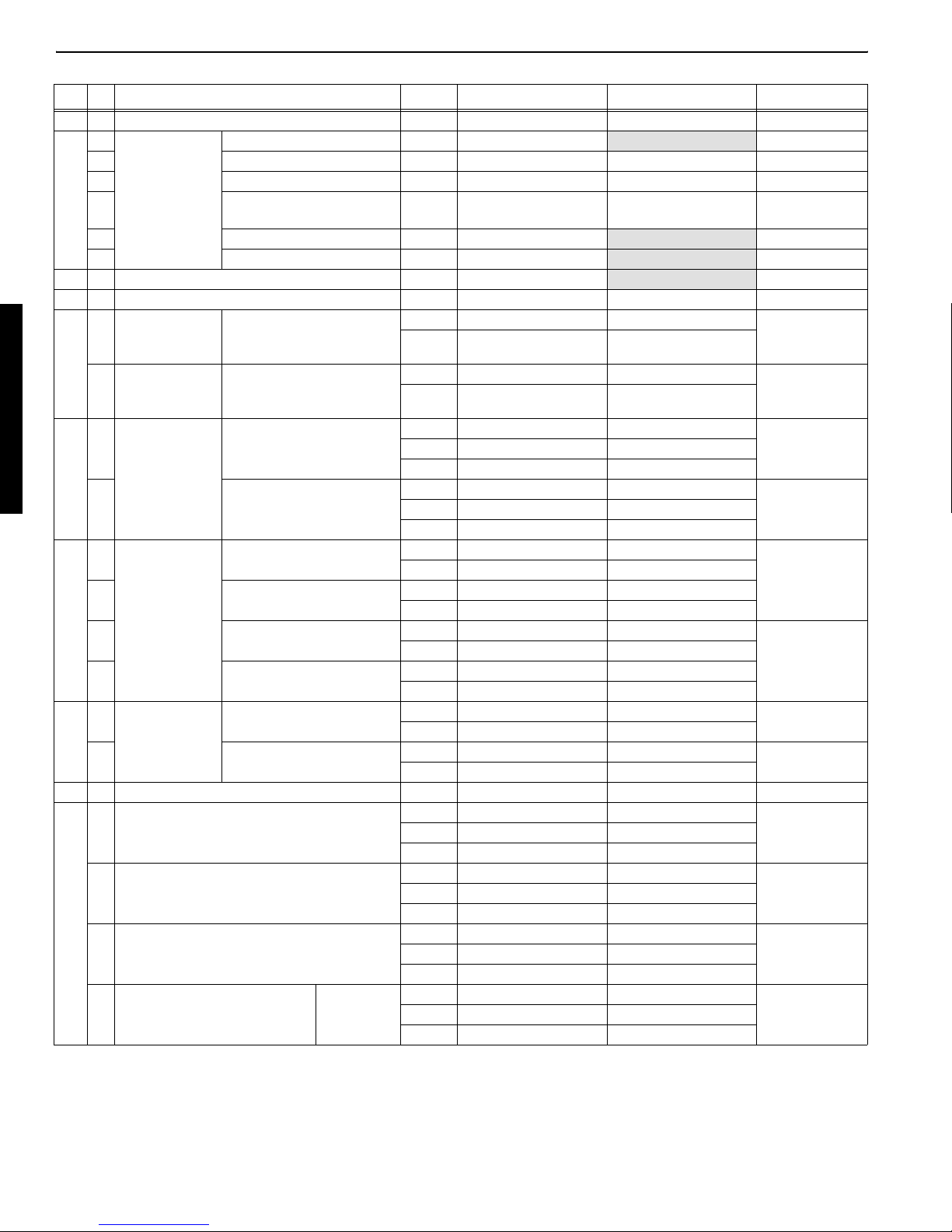

2.DIMENSIONS

3.WORKING RANGE

Model KX91-3S U35S KX121-3S KX161-3S

A Max. digging height ft.in. (mm) 16'3" (4940) 16'3" (4945) 17'10" (5420) 18'9" (5715)

B Max. dumping height ft.in. (mm) 11'7" (3530) 11'7" (3525) 12'9" (3890) 13'8" (4155)

C Max. digging depth ft.in. (mm) 10'5" (3185) 10'4" (3140) 11'6" (3505) 12'7" (3830)

D Max. vertical digging depth ft.in. (mm) 7'10" (2390) 7'4" (2230) 8'2" (2480) 8'6" (2585)

E Max. digging radius @ ground ft.in. (mm) 16'10" (5135) 16'11" (5145) 18'0" (5475) 20'1" (6130)

F Max. digging radius ft.in. (mm) 17'3" (5245) 17'3" (5260) 18'5" (5600) 20'6" (6260)

G Min. turning radius

H Min. tail turning radius ft.in. (mm) 4'4" (1310) 33.5" (850) 4'3" (1300) 3'7" (1090)

W/O ft.in. (mm) 6'2" (1870) 6'7" (2015) 6'9" (2060) 7'11" (2420)

W swing ft.in. (mm) 4'9" (1440) 5'3" (1603) 5'6" (1665) 6'5" (1955)

The company reserves the right to change the above specifications without notice. This brochure is for descriptive purpose only.

Please contact your local Kubota dealer for warranty infomation. For your safety, KUBOTA strongly recommends the use of a Rollover Protective structure (ROPS) and seat belt almost all applications.

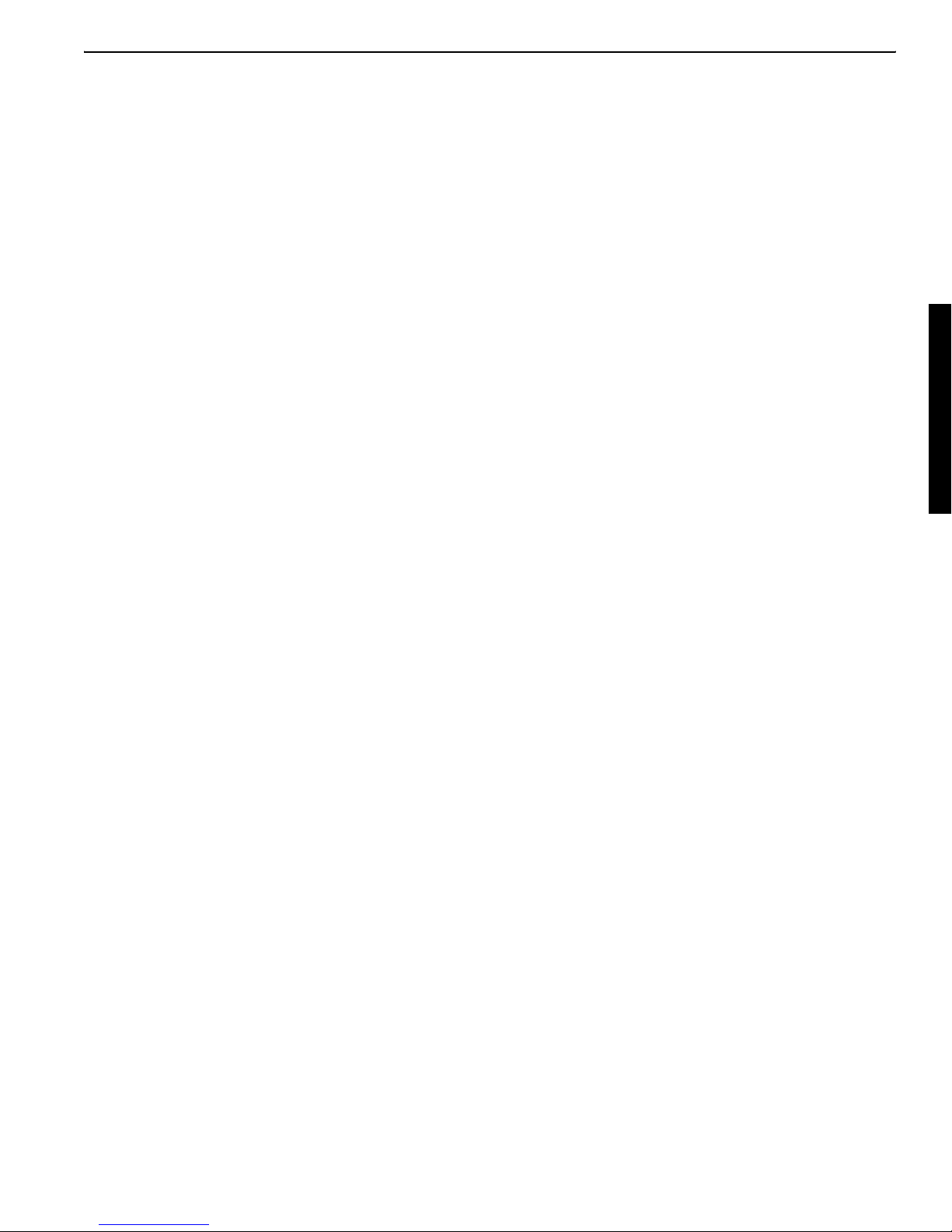

4.LIFTING CAPACITY

U35S KX91-3S KX121-3S KX161-3S

LIFTING CAPACITY

OVER-FRONT

LIFT

POINT

HEIGHT

GL 6 2.13 1.61 - 2.13 1.42 - 1.78 1.42 1.36 1.78 1.30 1.03 3.09 2.19 2.01 3.09 1.83 1.46 4.29 2.6 2.12 4.29 2.59 1.66

BLADE DOWN

unit=1000lba unit=1000lba unit=1000lba unit=1000lba unit=1000lba unit=1000lba unit=1000lba unit=1000lba

LIFT POINT RADIUS

(ft)

4 2.79 1.76 1.58 2.52 1.39 1.10 2.42 1.58 1.43 2.29 1.27 1.01 4.03 2.44 2.15 3.15 1.78 1.43 - 3 2.25 - 2.49 1.63

2 3.28 1.91 1.63 2.42 1.35 1.08 2.95 1.74 1.50 2.18 1.23 0.99 4.66 2.67 2.27 3.02 1.73 1.41 3.9 3.33 2.36 3.9 2.4 1.59

0 3.46 1.99 - 2.37 1.33 - 3.22 1.84 1.53 2.11 1.20 0.97 4.89 2.81 2.34 2.96 1.70 1.38 4.73 3.33 2.43 4.3 2.34 1.57

(ft)

8 12 MAX 8 12 MAX 8 12 MAX 8 12 MAX 8 12 MAX 8 12 MAX 8 12 MAX 8 12 MAX

LIFTING CAPACITY

OVER-SIDE

LIFT POINT

RADIUS (ft)

LIFTING CAPAC-

ITY OVER-FRONT

BLADE DOWN

LIFT POINT

RADIUS (ft)

LIFTING CAPACITY

OVER-SIDE

LIFT POINT RADIUS

(ft)

LIFTING CAPACITY

OVER-FRONT

BLADE DOWN

LIFT POINT

RADIUS (ft)

LIFTING CAPACITY

OVER-SIDE

LIFT POINT RADIUS

(ft)

LIFTING CAPACITY

OVER-FRONT

BLADE DOWN

LIFT POINT

RADIUS (ft)

LIFTING CAPACITY

OVER-SIDE

LIFT POINT

RADIUS (ft)

Machine with ROPS canopy and rubber crawler, without bucket

I - 8

Page 12

WSM Minor Change II Service Engineering Section

II Service Engineering Section

A. General outline...................................................................II-2

a. New engineering points........................................................................ II-2

b. Photos of main modified parts.............................................................. II-3

c. Major specifications incorporated......................................................... II-4

d. Quantity water and oil........................................................................... II-5

e. Quality specifications............................................................................ II-6

B. Finger control service port system ...................................II-22

a. Feature and purpose.......................................................................... II-22

b. Outline of control system.................................................................... II-23

c. Hydraulic circuit diagram .................................................................... II-25

d. Knob structure and function ............................................................... II-26

e. Initial settings of the knob................................................................... II-32

f. S/P valve start point setting................................................................ II-34

g. Manual feeling setting ........................................................................ II-40

h. Panel display operation flow chart...................................................... II-42

i. Proportional control solenoid valve (S/P valve).................................. II-51

j. Other controls..................................................................................... II-55

k. Troubleshooting.................................................................................. II-56

C. Hydraulic system modification .........................................II-57

a. Outline................................................................................................ II-57

b. Hydraulic pump: KX161-3s, KX161-3D ............................................. II-58

c. Control valve ...................................................................................... II-63

d. Accumulator ....................................................................................... II-68

e. Hydraulic system line ......................................................................... II-73

f. Service port (S/P) solenoid valve ....................................................... II-82

g. Travel motor: KX91-3S: PP-version ................................................... II-85

h. Travel motor minor change: KX121-3SD, 161-3SD, U45-3SD......... II-89

D. Hydraulic circuit diagram..................................................II-91

E. Engine upgrade..............................................................II-109

a. General............................................................................................. II-109

b. Engine specifications........................................................................ II-109

c. Engine performance curve ............................................................... II-111

F. Electrical system............................................................II-114

II - 1

Page 13

WSM Minor Change II Service Engineering Section

A. General outline

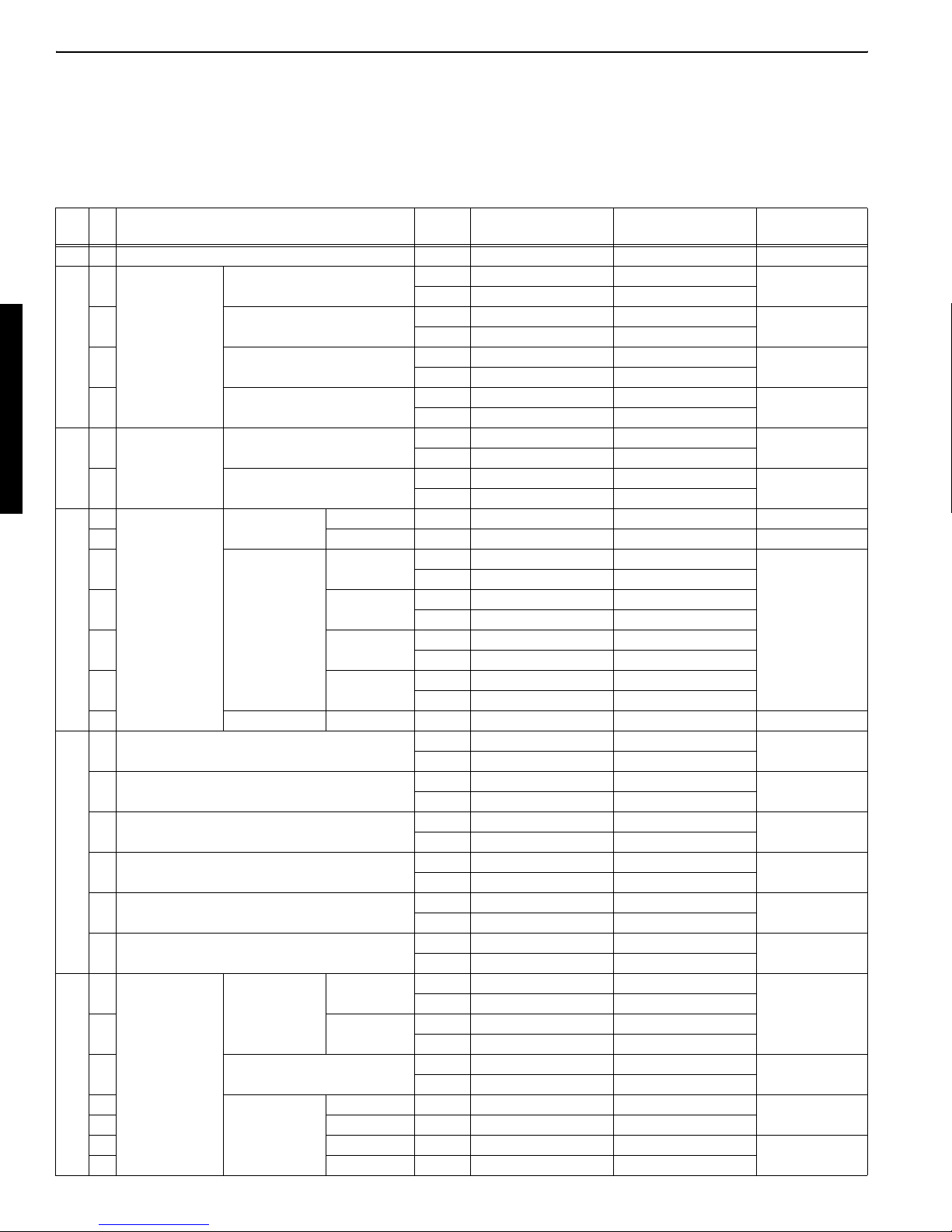

a. New engineering points

PP-version (KTC, KCL, KTA) EU-version

No New contents

8 Digital panel

4 Arm with thumb

bracket, option

Finger control ser-

vice port

3 Breaker switch

7 Two speed switch

6 Fuel-water separa-

tor

9 Anti-theft system - 5 Accumulator in pilot

control line

2 Proportional control

solenoid valve

10 Upgraded engine

V2403-M -

KX91-3S,

U35S, U35-3S

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

٤ ٤ ٤٤٤٤

KX121-3S,

KX161-3S,

U45-3S

KX161-3S PP-

version only

٤

KX91-3D,

KX101-3D

٤٤٤٤

----

U35-3D KX121-3D,

KX161-3D

U45-3D

II - 2

Page 14

WSM Minor Change II Service Engineering Section

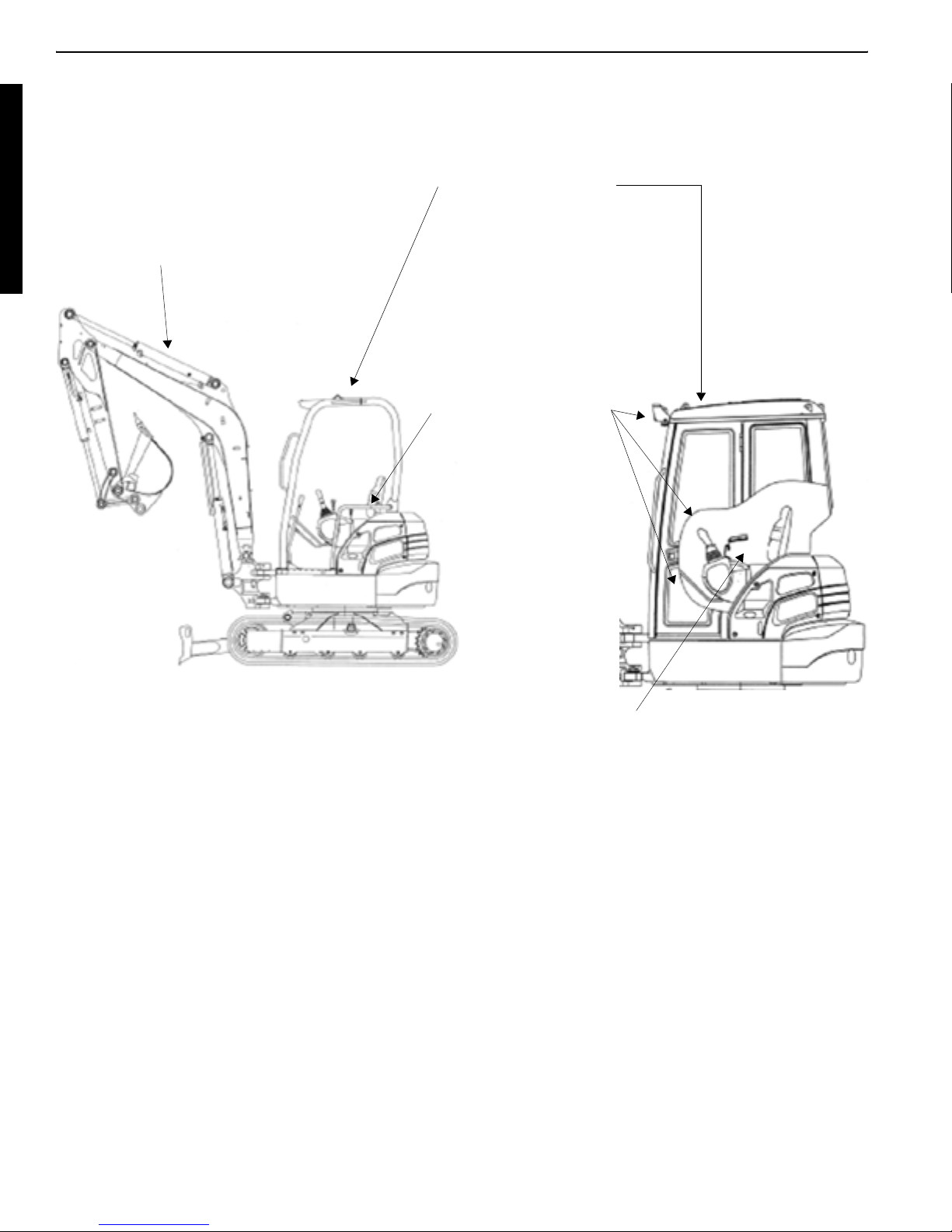

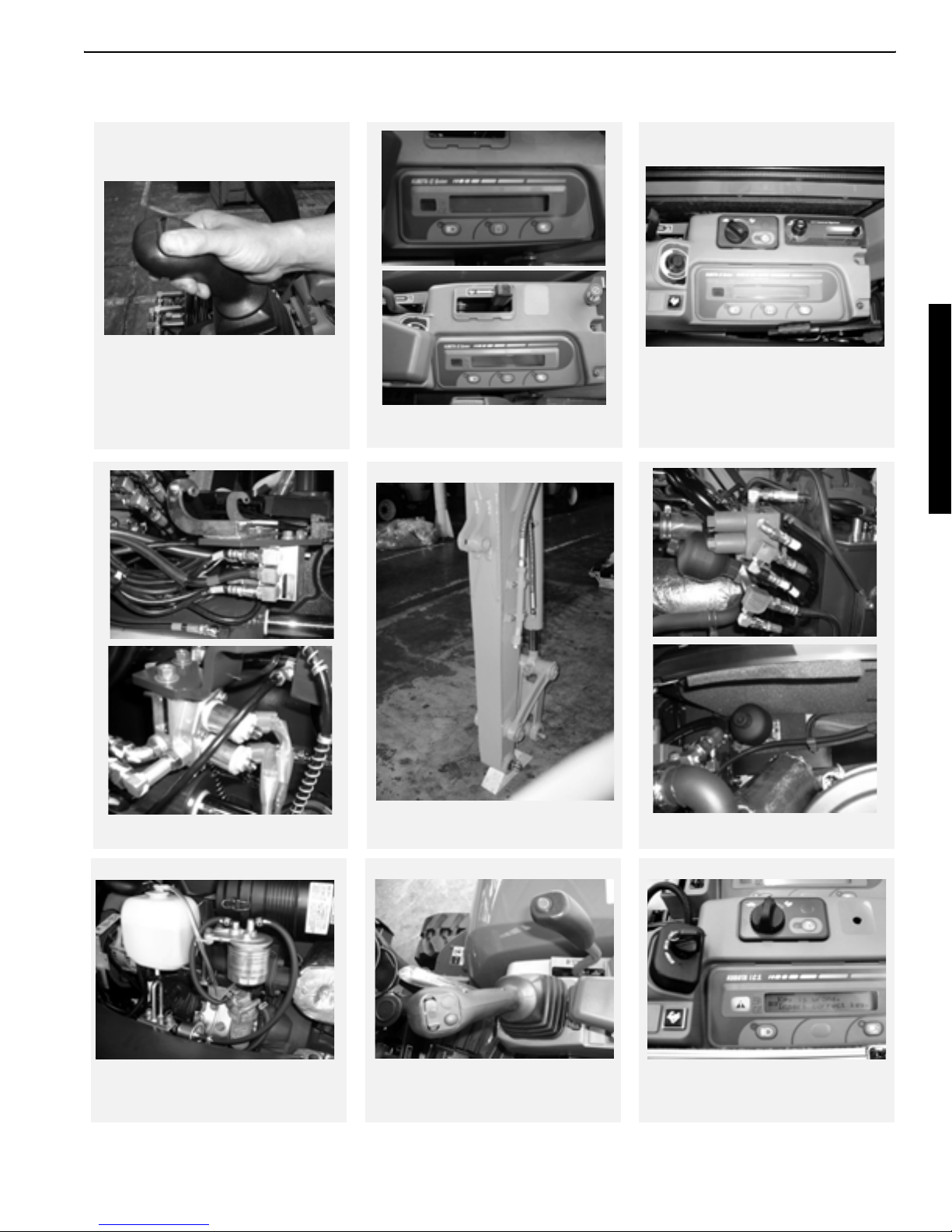

b. Photos of main modified parts

No.1 Knob switch

No.2 S/P solenoid valve

No.8 Digital meter panel

No.4 Arm with thumb bracket

No.8 Digital meter panel, AI-version

No.5 Accumulator in pilot line

No.6 Fuel-water separator

No.7 Two speed switch

II - 3

No.9 Anti-theft system

(EU-version)

Page 15

WSM Minor Change II Service Engineering Section

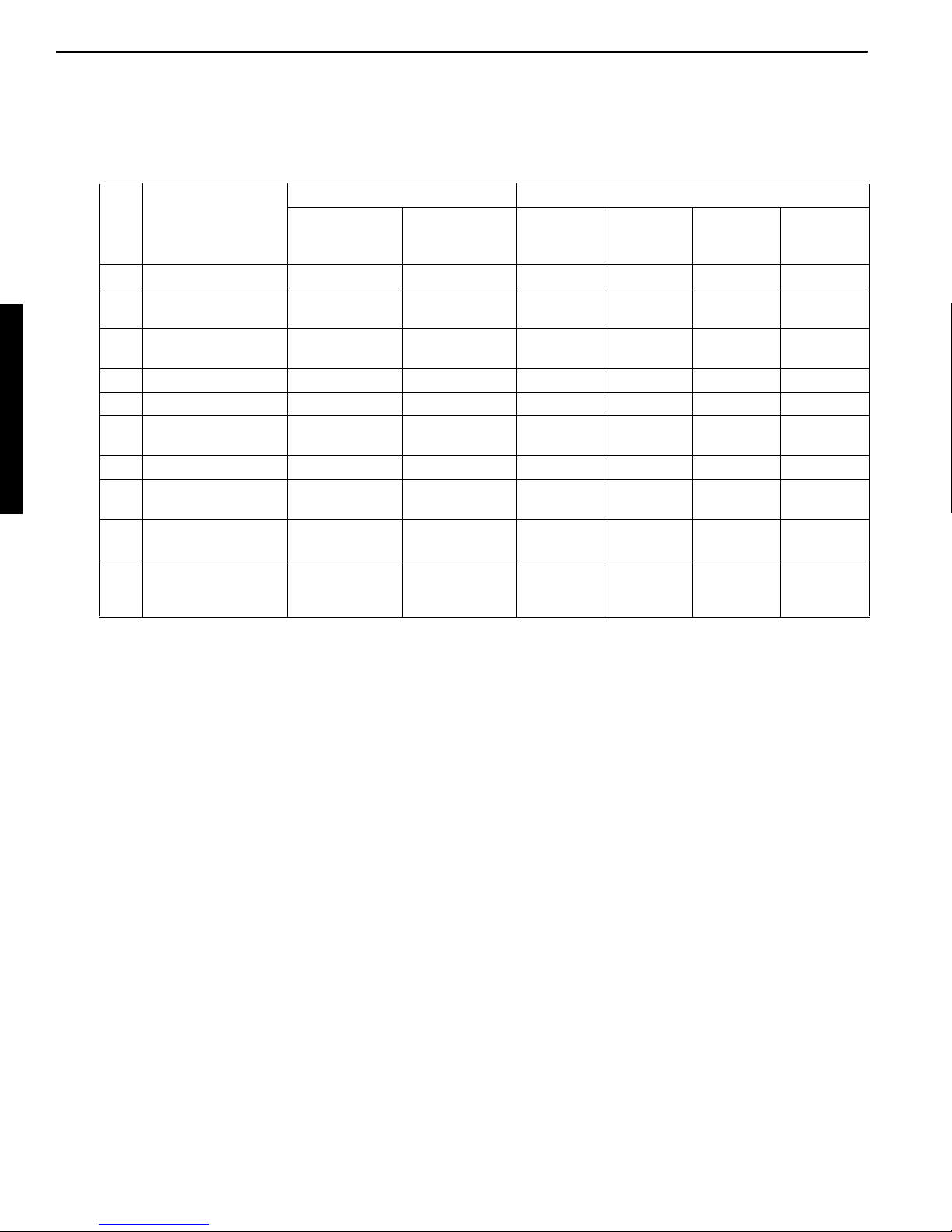

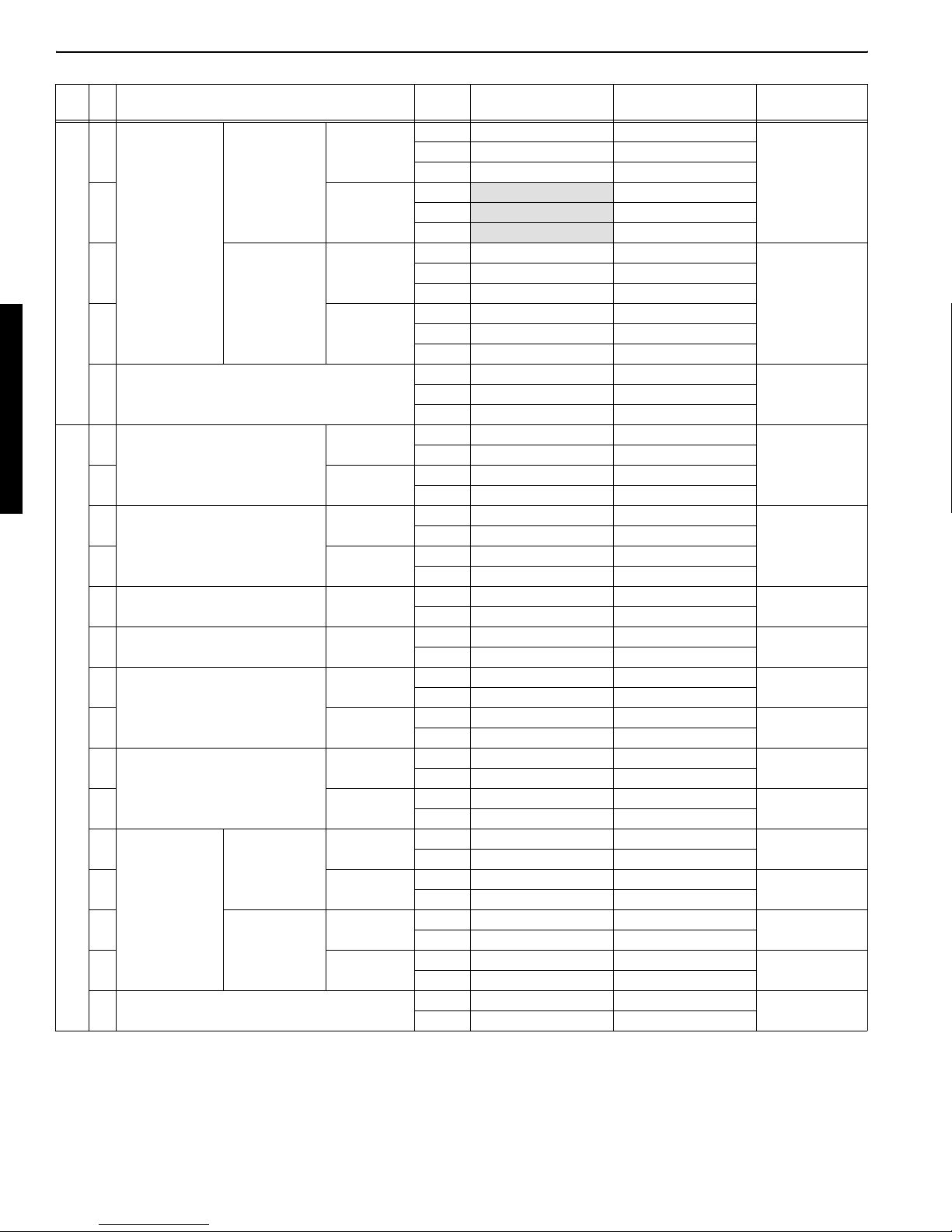

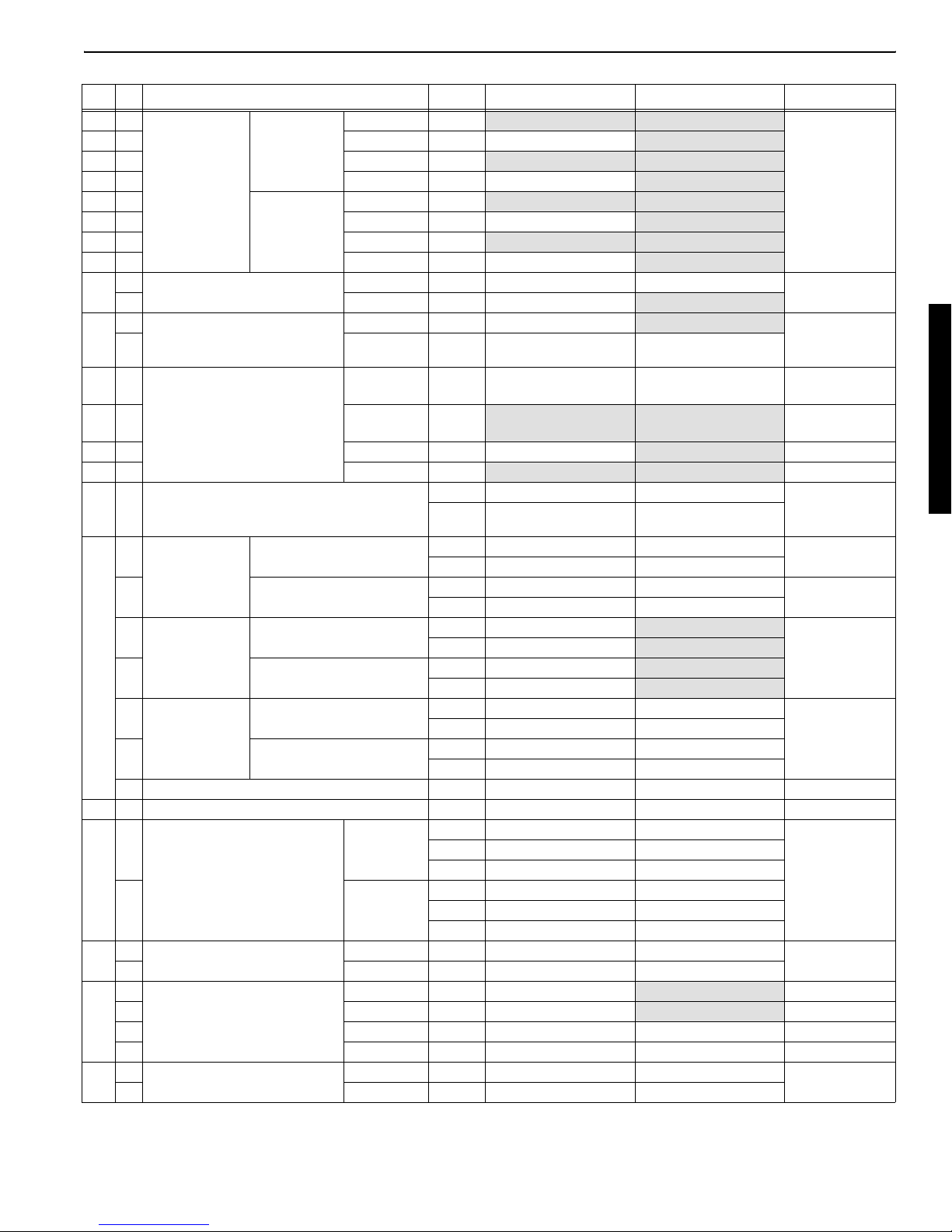

c. Major specifications incorporated

- KX91-3S, KX91-3D, KX101-3D, U35S, U35-3S, U35-3D -

Specs.

STD arm 1550mm 1275mm 1350mm 1350mm 1350mm 1350mm

Rubber track 300mm mm300mm mm

Iron track 300mm mm300mm mm

Cab (Rops / Fops)

Canopy (Rops / Fops)

Telescopic arm

(1246 - 2046)

Bucket Local content mm Local content m

Travel alarm

Canopy light

Arm rest Wrist rest

TPSS

Engines type D1503-M mmmmmm

Third line valve

KTC, KCL KTA EU EU KTC, KCL KTA EU

KX91-3S

{

{

{ ² {{²²²

² { ²²²{ ²

² { ²²²{ ²

{

{ ²² { ²

²²{{²²{

D KX101-3D

KX91-3

mm

mm

Wrist rest mm

U35S U35-3S

U35-3

{{

{{

{

D

m

m

Wrist rest

- KX121-3S, KX121-3D, KX161-3S, KX161-3D, U45-3S, U45-3D -

Specs.

STD arm 1600mm m 1300mm 1780mm m 1480mm 1360mm m

Rubber track 350mm mm400mm mm400mm m

Iron track 350mm mm

Cab (Rops / Fops)

Canopy (Rops / Fops)

Telescopic arm

(1246 - 2046)

Bucket Local content m Local content mmm

Travel alarm

Canopy light

Arm rest

TPSS

Engine

type

Third line valve

STD V2203-M-E2BH-2-N V2403-M-E2BH-1 V2203-M-E2BH-2-N

Air con. V2203-M-E2BH-3-N V2403-M-E2BH-2 V2203-M-E2BH-3-N

KX121-3S

KTC, KCL KTA EU KTC, KCL KTA EU KTA EU

{

{

²²² ²² ² ² ²

² { ²²{ ² { ²

² { ²²{ ² { ²

Wrist rest

{

{ ² { ² { ²

{{

KX121-3

Wrist rest m

D

m

m

KX161-3S

400mm /

550mm

mm

{{

{{

{

KX161-3D

mmm

mmm

Wrist rest

U45-3S

400mm /

550mm

{

U45-3D

m

Wrist rest

II - 4

Page 16

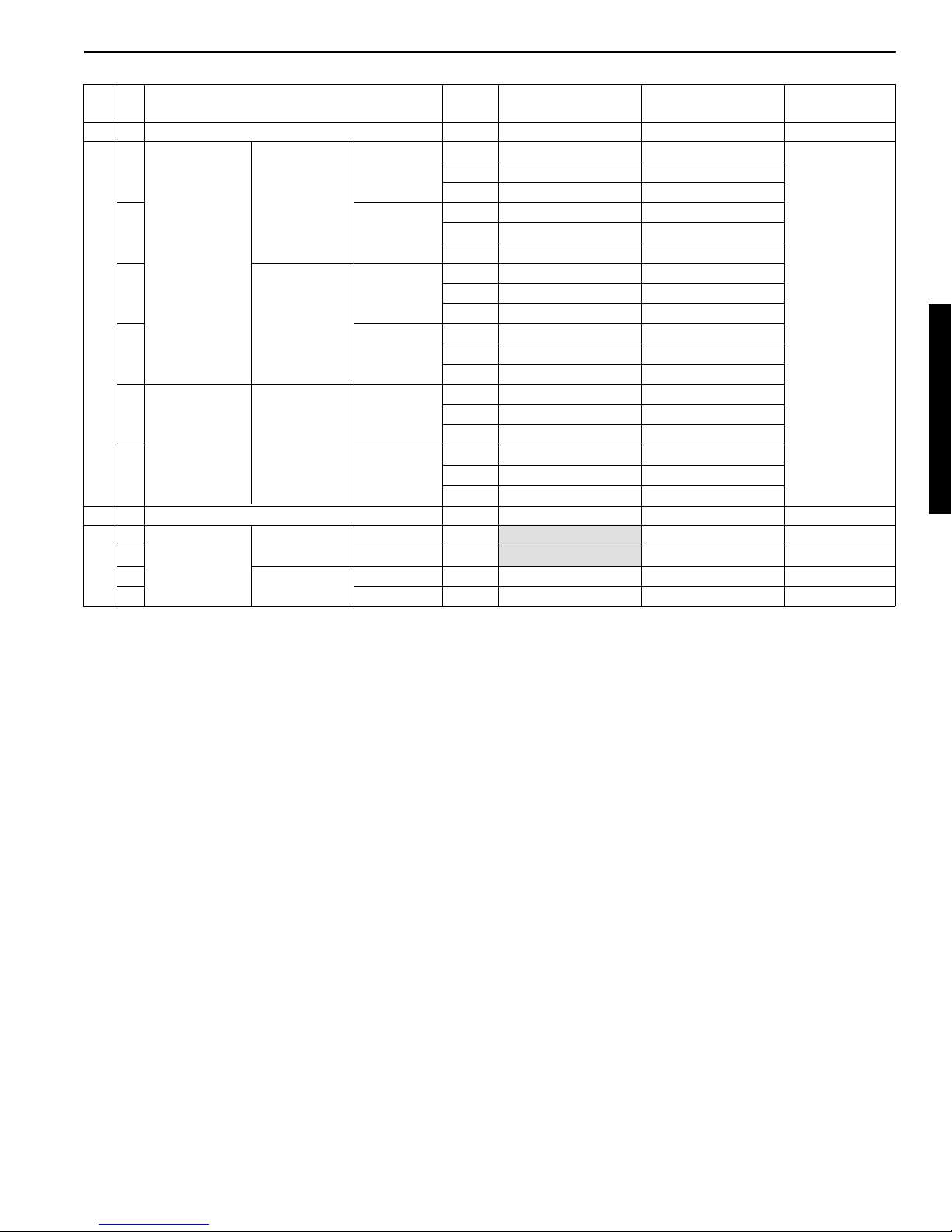

WSM Minor Change II Service Engineering Section

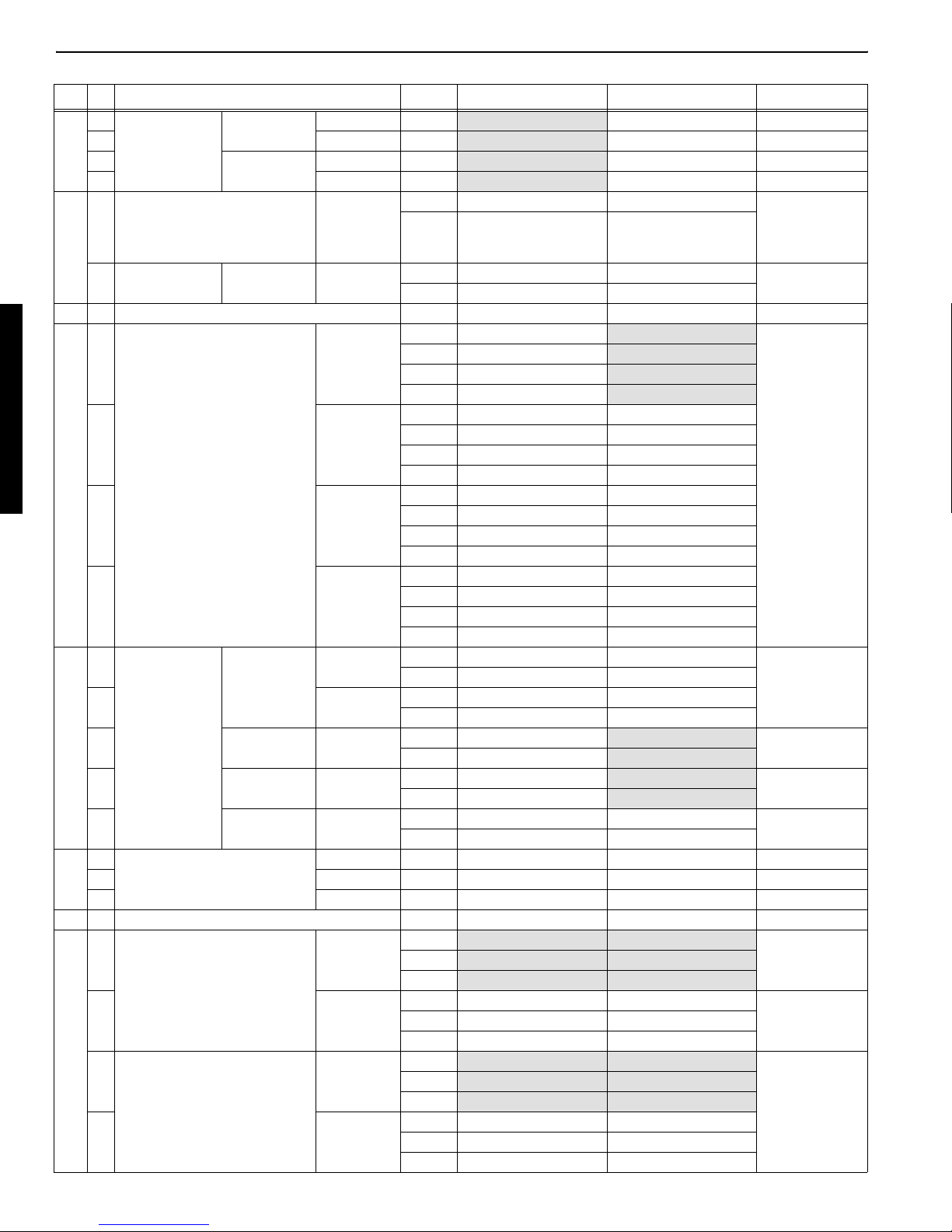

d. Quantity water and oil

Radiator

Reserve tank

Engine Crank case

Hydraulic oil Full

Hydraulic oil Tank

Wheel motor

Track roller

Upper roller

Front idler

Fuel tank

Unit

L

gal

L

gal

L

gal

L

gal

L

gal

L

gal

cc

gal

cc

gal

cc

gal

L

gal

KX91-3S

KX91-3

7.3

1.93

1.6

0.42

5.3

1.40

55.0

14.53

36.0

9.51

0.5

0.13

70

0.018

60

0.016

80

0.02

46.5

12.30

D

KX101-3D

U35S, U35-3S

U35-3D

Remarks

mm

L.L.C

mm

mm

mm

mm

mm

mm

mm

mm

m

40.6

10.6

SAE10W30(CD)

ISO 46

ISO 46

SAE90 (API GL-4)

SAE30(CD)

SAE30(CD)

SAE30(CD)

Radiator

Reserve tank

Engine Crank case

Hydraulic oil Full

Hydraulic oil Tank

Wheel motor

Track roller

Upper roller

Front idler

Fuel tank

Unit

L

gal

L

gal

L

gal

L

gal

L

gal

L

gal

cc

gal

cc

gal

cc

gal

L

gal

KX121-3S

KX121-3

7.4 (7.7)

1.96 (2.04)

1.1

0.29

8.5

2.25

75

19.8

46

12.2

0.5

0.13

80

0.021

60

0.016

80

0.021

64

16.9

U45-3S

D

U45-3

D

KX161-3S

KX161-3

D

Remarks

mm

m

0.5

0.13

mm

mm

mm

m

0.9

0.24

mm

mm

m

50

0.013

L.L.C

SAE10W30(CD)

ISO 46

ISO 46

SAE90 (API GL-4)

SAE30(CD)

SAE30(CD)

SAE30(CD)

mm

NOTE: In the super series, coolant amount has been increased due to the warming line of the service

port value.

II - 5

Page 17

WSM Minor Change II Service Engineering Section

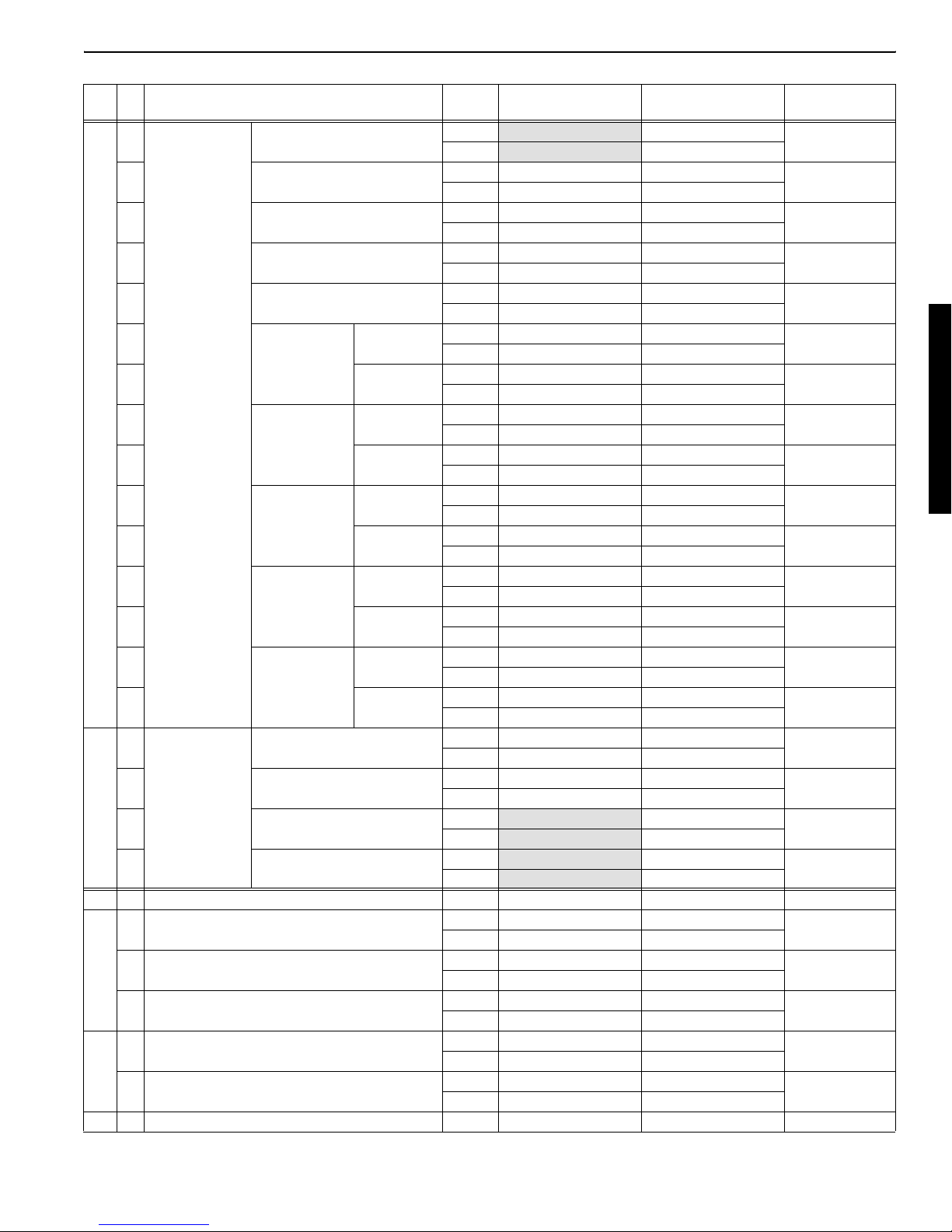

e. Quality specifications

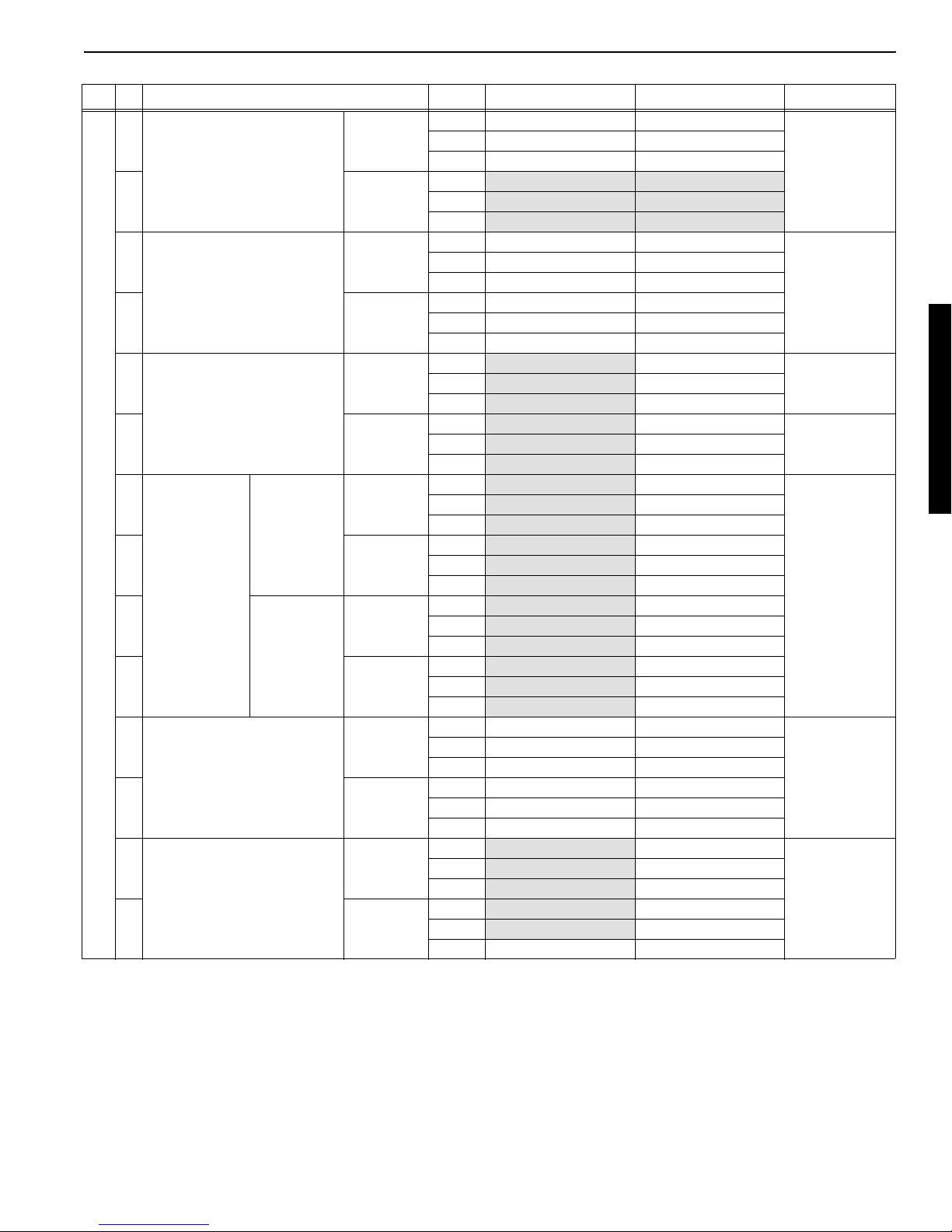

Note: 1. Only those data with bold letter and with shadow are different from those of the previous models before modification.

2. EU-version will be announced later.

U35S ( KTC, KCL ), U35-3S ( KTA ), KX91-3S(KTC,KCL,KTA)

Machine specification : Service port, Wrist rest, STD-arm, KBT-cab, KBT-bucket.

No Specificatios Items Unit

Q1 Main Speed JIS A8404

1 1 Machine size

2

3

4

2 1 Weight

2

3 1 Performance

2Rrpm9r 0.9 9.4 r 0.9

3

4

5

6

7 Gradeability deg 30 30

4 1 Rear end min. turning radius mm 850 r 17 1310 r 26

2 Swivel frame rear ground clearance mm 525 r 11 530 r 11

3 Tambler center distance mm 1670 r 50 1560 r 47

4 Crawler total length mm 2100 r 63 2000 r 60

5 Crawler total width mm 1700 r 34 1550 r 31

6 Min. ground clearance mm 285 r 9290r 9

5 1 Front attach-

ment

2 SAE, JIS m3 0.1 0.1

3 Bucket width mm 555 r 12 555 r 11 Without side cut-

4 Swing angle Canopy L deg 70 r 280r 2

5 Canopy R deg 50 r 248r 2

6 Cabin L deg r 80 r 2

7 Cabin R deg r 48 r 2

Total length (Transport)

Total w i dth

Total height (Canopy)

Total height (Cabin)

Machine weight (Canopy)

Machine weight (Cabin)

Swivel speed

Travel speed

Bucket heaped

capacity

Lrpm9r 0.9 9.4 r 0.9

Lubber F1

Lubber F2

Iron F1

Iron F2

CECE m3 0.077

mm 4695 r 94 4760 r 95

inch 184.8 r 3.7 187.4 r 3.7

mm 1700 r 17 1550 r 16

inch 66.9 r 0.7 61.0 r 0.6

mm 2440 r 24

inch 96.1 r 0.9

mm 2440 r 24

inch 96.1 r 0.9

kg 3560 r 71 3225 r 65 Fuel tank

lbs 7848.4 r 156.5 7109.8 r 143.3

kg 3660 r 73 3225 r 67

lbs 8068.8 r 160.9 7109.8 r 147.7

km/h 3.0 r 0.3 3.1 r 0.3

mph 1.86 r 0.19 1.93 r 0.19

km/h 4.6 r 0.5 4.8

mph 2.86 r 0.31 2.98 r 0.31

km/h 2.9 r 0.3 3.0 r 0.3

mph 1.80 r 0.19 1.86 r 0.19

km/h 4.6 r 0.5 4.8 r 0.5

mph 2.86 r 0.31 2.98 r 0.31

inch 33.5 r 0.7 51.6 r 1.0

inch 20.7 r 0.4 20.9 r 0.4

inch 65.7 r 2.0 61.4 r 1.9

inch 82.7 r 2.5 78.7 r 2.4

inch 66.9 r 1.3 61.0 r 1.2

inch 11.2 r 0.4 11.4 r 0.4

yd3

yd3 0.13 0.13

inch 21.9 r 0.5 21.9 r 0.4

U35S (KTC, KCL)

U35-3S (KTA)

KX91-3S

(KTC, KCL, KTA)

r 0.5

0.01

ter

Remarks

II - 6

Page 18

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

5 8 Front attach-

ment

9 Ground level Max. digging

10 Ground level Min. finish

11 Max. digging depth mm 3115 r 62 3185 r 64

12 Max. vertical digging depth mm 2185 r 44 2390 r 48

13 Max. digging

14 Cabin mm 4660 r 93

15 Max. dump

16 Cabin mm 3265 r 65

17 Max. dump

18 Cabin mm 1125 r 34

19 Mini. turning

20 Cabin mm 2190 r 66

21 Mini. turning

22 Cabin mm -

6 1 Dozer Width mm 1700 r 5 1550 r 5

2 Height mm 335 r 25 355 r 10

3 Max. lift above GL mm

4 Max. below GL mm

Q2 Main Specs JIS A8404

1 1 Bucket tooth slaggish mm 70 >

2 Tilt amount of front attachment mm 10 >

3 Dozer's declination mm 10 >

2 1 Eccentric amount from swing center mm From swivel cen-

2 Distance to swing center mm 72 r 25.0 135 r 25.0

3 1 Approach angle deg 31.4 r 3.5 30 r 3

Max. digging radius mm 5255 r 79 5245 r 79

inch

radius

radius

Conopy mm 4890 r 98 4875 r 98

height

Conopy mm 3470 r 69

height

Conopy mm 1230 r 37 965 r 29

height (Arm

vertical)

Conopy mm 2065 r 62 1940 r 116

radius

Conopy mm radius (Left

swing)

mm 5140 r 77 5135 r 77

inch 202.4 r 3.0 202.2 r 3.0

mm 1755 r 35 1410 r 28 Bucket bottom

inch 69.1 r 1.4 55.5 r 1.1

inch 122.6 r 2.4 125.4 r 2.5

inch 86.0 r 1.7 94.1 r 1.9

inch 192.5 r 3.9 191.9 r 3.9

inch 183.5 r 3.7

inch 136.6 r 2.7

inch 128.5 r 2.6

inch 48.4 r 1.5 38.0 r 1.1

inch 44.3 r 1.3

inch 81.3 r 2.4 76.4 r 4.6

inch 86.2 r 2.6

inch -

inch -

inch 66.9 r 0.2 61.0 r 0.2

inch 13.2 r 1.0 14.0 r 0.4

inch

inch

inch 2.76 >

inch 0.39 >

inch 0.39 >

inch

inch 2.83 r 1.0 5.31 r 1.0

U35S (KTC, KCL)

U35-3S (KTA)

206.9 r 3.1 206.5 r 3.1

370 r 26 375 r 26

14.6 r 1.0 14.8 r 1.0

370 r 26 365 r 26

14.6 r 1.0 14.4 r 1.0

KX91-3S

(KTC, KCL, KTA)

Remarks

horizontal

ter

II - 7

Page 19

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

4 1 Crawler height mm 420 r 8 430 r 9 Include grouser

inch 16.54 r 0.31 16.93 r 0.35

2 Max. crawler height mm 450 r 9455r 14

inch 17.72 r 0.35 17.91 r 0.55

Q3 Engine performance

1 1 "Max, engine

rpm"

2 1 pump relief rpm - 3 2 pump relief rpm - 4 3 pump relief rpm - - Boom, arm,

5 2 pump relief rpm 2300 <

6 Dozer+2 pump relief rpm 2100 <

2 1 Idler rpm

Q4 Travelling performance

1 1 Travel motor

block performance

2 Travel motor

block performance

2 1 Max, Traction

force

2 F2 kgf 1546 1485

3 1 Travel straight-

ness

2F2 mm600>

3 Dozer F1 mm 600 > Dozer up &

4 Dozer R1 mm 600 >

4 1 Track shoe sag

distance

2 Rubber mm 10 to 15

Q5 Work performance

1 1 Boom lifting capacity kgf 575 434 Front end, Arm

2 Arm digging force kgf 1888 1629 Bucket tooth

3 Bucket digging force kgf

4 Dozer force down kgf

no load rpm 2550 >

L mm 300 > 20 deg, 10 min

inch 11.81 >

Rubber mm 300 >

inch 11.81 >

F1 kgf 2766 2655 On the center

kN 27.1 26.0

lbs 6098 5853

kN 15.2 14.6

lbs 3408 3274

F1 mm 600 > 10m distance

inch 23.62 >

inch 23.62 >

inch 23.62 >

inch 23.62 >

Iron mm 75 to 80

inch 2.95 to 3.15

inch 0.39 to 0.59

kN 5.6 4.3

lbw 1268 957

kN

lbw

kN

lbw

kN

lbw

U35S (KTC, KCL)

U35-3S (KTA)

1050 r 50

18.5 16.0

4162 3591

2882 / 3810 3655 Machine stance

28.3 / 37.4 35.8

6354 / 8400 8058

2652 2841 Cutting edge

26.0 27.9

5847 6263

KX91-3S

(KTC, KCL, KTA)

Remarks

on the spocket

swivel

down 10m distance

extend bucket

crowd, at tooth

root

to JIS bucket

tooth root

down force at

ground level

II - 8

Page 20

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

2 1 Boom speed Canopy up 1st sec 2.4 r 0.3 2.1 r 0.3 Oil temp.

2 up 2nd sec 3 down sec 3.0 r 0.3 2.9 r 0.3

4 down sec 5 Cabine up (GoT) sec -

6 up (LoT) sec -

7 down (ToG) sec -

8 down (ToL) sec -

3 1 Arm speed crowd sec 3.1 r 0.3

2 extend sec 2.7 r 0.3 3 r 0.3

4 1 Bucket speed crowd sec 2.6 r 0.3 2.7 r 0.3 Oil temp.

2 dump sec 1.7 r 0.3 1.9 r 0.3

5 1 Dozer speed up (GoT) sec - Max. down to

2 up (LoT) sec 2.2 r 0.3 2.1 r 0.3 Max. up to max.

3 down (ToG) sec -

4 down (ToL) sec 2.9 r 0.3 2.8 r 0.3

6 1 Arm cylinder cavitation mm 5 > Oil temp.

inch 0.20 >

7 1 Max. digging

height radius

2 Cabine mm 3215 r 322

3 Max. dump

height radius

4Cabine mm

5 Bucket bottom

height at arm

vertical

6 Cabine mm 1415 r 42

7 Bucket wrist angle degree - 190 r 3

Q6 Swivel, swing performance

1 1 Swivel torque L kgfm 738 627 Arm

2R

2 1 Swivel angle L deg 15 < 20 , 19< Bucket load=JIS

2 R deg 15 < 20 , 19<

3 1 Swivel block performance L deg 5 > 6 >

2Rdeg5>6>

3Ldeg30>

4Rdeg30>

4 1 Swivel start-up speed L sec 2.5 r 0.3 3 r 0.3 0~90 deg swivel

2Rsec2.5r 0.3 3 r 0.3

Canopy mm 2800 2920

inch 110.24 114.96 r 11.50

inch 126.57 r 12.68

Canopy mm

inch 103.19 r 6.18 109.84 r 6.57

inch

Canopy mm 1525 r 46 1265 r 48 Bucket horizon-

inch 60.04 r 1.81 49.80 r 1.89

inch 55.71 r 1.65

kN.m 7.2 6.1

lbs

ft

kgf

kN.m 7.2 6.1

ftlbs

U35S (KTC, KCL)

U35-3S (KTA)

2621 r 157 2790 r 167 at bucket pin

2961 r 178

116.57 r 7.01

5338 4535

m

5338 4535

738 627

KX91-3S

(KTC, KCL, KTA)

292

r

Remarks

50r5qC

(122r41qF )

Ground to max.

height (exculude cushioning)

50r5qC

(122r41qF)

max. up

down

95r5qC

(203r41qF)

tal

extend,show/

Quick

heapedu1.8

II - 9

Page 21

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

5 1 Swing speed Canopy L sec 5.8 r 0.3 5.9 r 0.5

2Rsec4.6r 0.3 4.5 r 0.5

3 Cabine L sec

4Rsec

6 1 Swing Lock Swivel R&L mm 10 > 90 deg-swivel,

inch 0.39 >

2 Reciprocating

motion

Q7 Hydraulic performance

1 1 Relief pressure setting P1 kgf/cm2 255 r 5 245 At pump delivery

2 P2 kgf/cm2 255 r 5 245

3 P3 kgf/cm2 207 r 5 210

4 P4 kgf/cm2 40 +3, -0

2 1 Cylinder oil

sealing capacity

295r5qC

3Arm50r5qC

4 Bucket 50r5qC

5 Dozer 50r5qC

3 1 Boom cushioning performance 30qC(86qF) sec 3 >

250qC(122qF) sec 0.4 to 1.3

380qC(176qF) sec 0.3 <

Q8 Lever operating force & stroke

1 1 Boom lever operating force up kgf 1.7 r 1.0 1.7 r 0.5

2 down kgf 1.4 r 1.0 1.4 r 0.5

L / R Swing mm 90 deg-swivel,

inch

MPa 25.0 r 0.5 24.0

bar 24.5 r 24.5 24.5

psi 3627 r 71 3485

MPa 25.0 r 0.5 24.0

bar 24.5 r 24.5 24.5

psi 3627 r 71 3485

MPa 20.3 r 0.5 20.6

bar 24.5 r 24.5 24.5

psi 2944 r 71 2987

MPa 3.9 +0.3, -0

bar 3.9 +0.03, -

psi 569 +43, -0

Boom 50r5qC

(122r41qF)

(203r41qF)

(122r41qF)

(122r41qF)

(122r41qF)

mm 6 > 20 > Arm extend,

inch 0.24 > 0.79 >

mm 6 > 20 >

inch 0.24 > 0.79 >

mm

inch

mm 25 > Bucket load=JIS

inch 0.98 >

mm 20

inch 0.79

N16.67r 9.81 16.67 r 4.90

lbs 3.7 r 2.2 3.7 r 1.1

N13.73r 9.81 13.73 r 4.90

lbs 3.1 r 2.2 3.1 r 1.1

U35S (KTC, KCL)

U35-3S (KTA)

0

20 > 15 > height 1m, 10

0.79 > 0.59 >

KX91-3S

(KTC, KCL, KTA)

Remarks

100 times actual

digging cylinder

dislocation

100 times

50r5qC

bucket

min.

heapedu1.8

II - 10

Page 22

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

1 3 Arm lever crowd kgf 1.7 r 1.0 1.7 r 0.5 Extend & crowd

N16.67r 9.81 16.67 r 4.90

lbs 3.7 r 2.2 3.7 r 1.1

4 extend kgf 1.4 r 1.0 1.4 r 0.5

N13.73r 9.81 13.73 r 4.90

lbs 3.1 r 2.2 3.1 r 1.1

5 Bucket lever crowd kgf 1.2 r 1.0 1.2 r 0.5 Dump & crowd

N 11.77 r 9.81 11.77 r 4.90

lbs 2.6 r 2.2 2.6 r 1.1

6 extend kgf 1.2 r 1.0 1.2 r 0.5

N 11.77 r 9.81 11.77 r 4.90

lbs 2.6 r 2.2 2.6 r 1.1

7 Swivel (Swing) lever R kgf 1.2 r 1.0 1.2 r 0.5 Left & right

N11.77r 9.81 11.77 r 4.90

lbs 2.6 r 2.2 2.6 r 1.1

8Lkgf1.2r 1.0 1.2 r 0.5

N11.77r 9.81 11.77 r 4.90

lbs 2.6 r 2.2 2.6 r 1.1

9 Dozer lever up kgf 2.0 r 0.5 Up & down

N 19.61 r 4.90

lbs 4.4 r 1.1

10 down kgf 2.0 r

N19.61r 4.90

lbs 4.4 r 1.1

11 Travel lever L Forward kgf 1.8 r 0.5

N 17.65 r 4.90

lbs 4.0 r 1.1

12 Back kgf 1.8 r 0.5

N17.65r 4.90

lbs 4.0 r 1.1

13 R Forward kgf 1.8 r 0.5

N 17.65 r 4.90

lbs 4.0 r 1.1

14 Back kgf 1.8 r 0.5

N17.65r 4.90

lbs 4.0 r 1.1

15 Accelerator lever up kgf 5.0 r 1.0 AI-version has

N 49.03 r 9.81

lbs 11.0 r 2.2

16 down kgf

N

lbs

17 Swing pedal R kgf 5.0 r 1.0

N49.03r 9.81

lbs 11.0 r 2.2

18 L kgf 5.0 r 1.0

N 49.03 r 9.81

lbs 11.0 r 2.2

U35S (KTC, KCL)

U35-3S (KTA)

0.5

3.5 r 1.0

34.32 r 9.81

7.7 r 2.2

KX91-3S

(KTC, KCL, KTA)

Remarks

accel.

II - 11

Page 23

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

1 19 Safety lock

lever

20 down kgf

21 L up kgf 2.7 r 1.0 Up & down

22 down kgf 6.0 r 1.0 5.0 r 1.0

23 Travel Hi-Lo change kgf 1.5 r 0.5 3.1 r 1.0

2 1 Boom lever stroke up mm 110 r 10

2 down mm 110 r 10

3 Arm lever stroke crowd mm 110 r 10

4 extend mm 110 r 10

5 Bucket lever stroke crowd mm 85 r 10

6 Bucket lever stroke extend mm 85 r 10

7 Swivel, swing lever stroke R mm 85 r 10

8Lmm85r 10

9 Dozer lever stroke up mm 55 r 10

10 down mm 55 r 10

11 Tra vel lever

stroke

12 Back mm 73 r 10 75 r 10

13 R Forward mm 73 r 10 75 r 10

14 Back mm 73 r 10 75 r 10

15 Accel. Lever mm 55 r 10 65 r 10

Rupkgf0.8r 0.2 Up & down

N7.85r 1.96

lbs 1.8 r 0.4

N

lbs

N26r 10

lbs 19.5 r 7.4

N49r 10 49.03 r 9.81

lbs 43.4 r 7.4 11.0 r 2.2

N39r 10 30.40 r 9.81

lbs 10.8 r 3.6 6.8 r 2.2

inch 4.33 r 0.39

inch 4.33 r 0.39

inch 4.33 r 0.39

inch 4.33 r 0.39

inch 3.35 r 0.39

inch 3.35 r 0.39

inch 3.35 r 0.39

inch 3.35 r 0.39

inch 55.00 r 0.39

inch 2.17 r 0.39

L Forward mm 73 r 10 75 r 10

inch 2.87 r 0.39 2.95 r 0.39

inch 2.87 r 0.39 2.95 r 0.39

inch 2.87 r 0.39 2.95 r 0.39

inch 2.87 r 0.39 2.95 r 0.39

inch 2.17 r 0.39 2.56 r 0.39

U35S (KTC, KCL)

U35-3S (KTA)

0.4 r 0.2

3.92 r 1.96

0.9 r 0.4

KX91-3S

(KTC, KCL, KTA)

Remarks

II - 12

Page 24

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit

Q9 Stability

1 1 Standard arm,

Dynamic operation load limit

2 Front, dozer upkgf -

3 Bucket load to

4 Front, dozer upkgf - 294

5 Standard arm,

static limited

load

6 Front kgf 450 428

Q10 Comfortability

1 1 Noise level At operator's

2Cabdb(A)81 > Cab door close

3 Noise

4db(A)95>

Bucket load to

10 degrees tipping

tip fully

Bucket load to

tip fully

ear LPA

source;LWA

Side,

dozer up

Side,

dozer up

Side kgf 430 393

Canopy db(A)

7m db(A)

kgf - Arm extend,

N-

lbs -

Nlbs kgf - 276

N - 2706.64

lbs - 608.5

N - 2883.16

lbs - 648.2

N 4216.86 3854.01

lbs 948.0 866.4

N 4412.99 4197.25

lbs 992.1 943.6

U35S (KTC, KCL)

U35-3S (KTA)

81 > 80 >

KX91-3S

(KTC, KCL, KTA)

b u c k e t c r o w d

oil temp.50r5qC

(122r41qF)

Remarks

II - 13

Page 25

WSM Minor Change II Service Engineering Section

KX121-3S, 161-3S : KTC, KCL, KTA Version

Machine specification : Service port, TPSS, Arm rest, Long arm, 4 POSTcanopy, KTC-bucket

No Specificatios Items Unit KX121-3S KX161-3S Remarks

Q1 Main Speed JIS A8404

1 1 Machine size Total length (Transport) mm 5090 r 102 5540 r 111

inch 200.4 r 4.0 218.1 r 4.4

2 Total width mm 1700 r 17 1960 r 20

inch 66.9 r 0.7 77.2 r 0.8

3 Total height (Canopy) mm 2495 r 25

inch 98.2 r 1.0

4 Total height (Cabin) mm 2480 r 25 2540 r 25

inch 97.6 r 1.0 100.0 r 1.0

2 1 Weight Machine weight (Canopy) kg 4030 r 81 5065 r 101 Fuel tank

lbs 8884.5 r 178.6 11166.3 r 222.7

2 Machine weight (Cabin) kg 4095 r 82 5140 r 103

lbs 9027.8 r 180.8 11331.6 r 227.1

3 1 Performance Swivel speed L rpm 9.2 r 0.9 9.3 r 0.9

2Rrpm9.2r 0.9 9.3 r 0.9

3 Travel speed Lubber F1 km/h 3.0 r 0.3

mph 1.86 r 0.19

4 Lubber F2 km/h 5.0 r 5 4.6 r 0.5

mph 3.11 r 3.11

5 Iron F1 km/h 2.9 r 0.3

mph 1.80 r 0.19 1.43 r 0.12

6 Iron F2 km/h 4.7 r 0.5

mph 2.92 r 0.31

7 Gradeability deg 30 30

4 1 Rear end min. turning radius mm 1300 r 26 1090 r 22

inch 51.2 r 1.0 42.9 r 0.9

2 Swivel frame rear ground clearance mm 574 r 11 620 r 12

inch 22.6 r 0.4 24.4 r 0.5

3 Tambler center distance mm 1710 r 51 1990 r 60

inch 67.3 r 2.0 78.3 r 2.4

4 Crawler total length mm 2175 r 65 2500 r 75

inch 85.6 r 2.6 98.4 r 3.0

5 Crawler total width mm 1700 r 34 1960 r 39

inch 66.9 r 1.3 77.2 r 1.5

6 Min. ground clearance mm 330 r 10 320 r 10

inch 13.0 r 0.4 12.6 r 0.4

5 1 Front attach-

ment

2 SAE, JIS m3 0.12 0.14

3 Bucket width mm 600 r 12 Without side cut-

4 Swing angle Canopy L deg 75 r 2

5 Canopy R deg 48 r 2

6 Cabin L deg 75 r 2

7 Cabin R deg 48 r 2

8 Max. digging radius mm 5600 r 16 6260 r 94

Bucket

heaped

capacity

CECE m3

yd3

yd3 0.16 0.18

inch 23.6 r 0.5

inch 220.5 r 0.6 246.5 r 3.7

2.5 r 0.2

1.55 r 0.12

2.86 r 0.31

2.3 r 0.2

4.2 r 0.4

2.61 r 0.25

ter

II - 14

Page 26

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

5 9 Front attach-

ment

10 Ground level Min. finish

11 Max. digging depth mm 3505 r 70 3830 r 77

12 Max. vertical digging depth mm 2480 r 74 2585 r 78

13 Max. digging

14 Cabin mm 5420 r 108 5715 r 14

15 Max. dump

16 Cabin mm 3890 r 78 4155 r 83

17 Max. dump

18 Cabin mm 1250 r 37 1285 r 39

19 Front attach-

ment

20 Cabin mm 2060 r 62 2420 r 73

21 Mini. turning

22 Cabin mm 1665 r 50 1995 r 59

6 1 Dozer Width mm 1700 r 51960r 5

2 Height mm 350 r 20 360 r 10

3 Max. lift above GL mm 395 r 50 455 r 50

4 Max. below GL mm 410 r 50 370 r 50

Q2 Main Specs JIS A8404

1 1 Bucket tooth slaggish mm 50

2mm0

3 Dozer's declination mm 3

2 1 Eccentric amount from swing center mm 195 170 From swivel cen-

2 Distance to swing center mm

3 1 Approach angle deg 30 r 3

4 1 Crawler height mm 470 r 9 520 r 10 Include grouser

2 Max. crawler height mm 490 r 10 550 r 11

Ground level Max. digging

radius

radius

Conopy mm 5420 r 108 5715 r 14

height

Conopy mm 3890 r 78 4155 r 83

height

Conopy mm 1250 r 37 1285 r 39

height (Arm

vertical)

Mini. turning

radius

radius (Left

swing)

Conopy mm 2060 r 62 2420 r 73

Conopy mm 1665 r 50 1955 r 59

mm 5475 r 82 6130 r 92

inch 215.6 r 3.2 241.3 r 3.6

mm 1805 r 36 1940 r 39 Bucket bottom

inch 71.1 r 1.4 76.4 r 1.5

inch 138.0 r 2.8 150.8 r 3.0

inch 97.6 r 2.9 101.8 r 3.1

inch 213.4 r 4.3 225.0 r 0.6

inch 213.4 r 4.3 225.0 r 0.6

inch 153.1 r 3.1 163.6 r 3.3

inch 153.1 r 3.1 163.6 r 3.3

inch 49.2 r

inch 49.2 r 1.5 50.6 r 1.5

inch 81.1 r 2.4 95.3 r 2.9

inch 81.1 r 2.4 95.3 r 2.9

inch 65.6 r 2.0 77.0 r 2.3

inch 65.6 r 2.0 78.5 r 2.3

inch 66.9 r 0.2 77.2 r 0.2

inch 13.8 r 0.8 14.2 r 0.4

inch 15.6 r 2.0 17.9 r 2.0

inch 16.1 r 2.0 14.6 r 2.0

inch 1.97

inch 0

inch 0.12

inch 7.68 6.69

inch

inch 18.50 r 0.35 20.47 r 0.39

inch 19.29 r 0.39 21.65 r 0.43

1.5 50.6 r 1.5

horizontal

ter

on the spocket

II - 15

Page 27

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

Q3 Engine performance

1 1 Max, engine

rpm

2 1 pump relief rpm - 3 2 pump relief rpm - 4 3 pump relief rpm - - Boom, arm,

5 2 pump relief rpm 2250 2150d

6 Dozer+2 pump relief rpm 2250

2 1 Idler rpm 1100 +50, -150

Q4 Travelling performance

1 1 Travel motor

block performance

2 Travel motor

block performance

2 1 Max, Traction

force

2 F2 kgf 1455 1972

3 1 Travel straight-

ness

2F2 mm600

3 Dozer F1 mm 600 Dozer up &

4 Dozer R1 mm 600

4 1 Track shoe sag

distance

2 Rubber mm 10 r 5

Q5 Work performance

1 1 Boom lifting capacity kgf 734 790 Front end, Arm

2 Arm digging force kgf 1790 2253 Bucket tooth

3 Bucket digging force kgf 3005 5043 Machine stance

4 Dozer force down kgf 3160 4170 Cutting edge

no load rpm 2450 d

Lmm272 300t 261 , 300t 20 deg, 10 min

inch 10.71 11.8t 10.28 , 11.8t

Rubber mm 272 300t 261 , 300t

inch 10.71 11.8t 10.28 , 11.8t

F1 kgf 3081 4083 On the center

kN 30.2 40.0

lbs 6792 9001

kN 14.3 19.3

lbs 3208 4348

F1 mm 600 10m distance

inch 23.62

inch 23.62

inch 23.62

inch 23.62

Iron mm 40 r 5

inch 1.57 r 0.20

inch 0.39 r 0.20

kN 7.2 7.7

lbw 1618 1742

kN 17.6 22.1

lbw 3946 4967

kN 29.5 49.5

lbw 6625 11118

kN 31.0 40.9

lbw 6967 9193

2400 d

swivel

2200 , 2100d

2200 , 2100d

1200 +50, -150

down 10m distance

extend bucket

crowd, at tooth

root

to JIS bucket

tooth root

down force at

ground level

II - 16

Page 28

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

2 1 Boom speed Canopy up (GoT) sec 2.7 r 0.3 Oil temp.

2 up (LoT) sec 4.9 r 0.3

3 down(ToG) sec

4 down sec 5.1 r 0.3 4.6 r 0.3

5 Cabine up 1st sec

6 up 2nd sec 4.9 r 0.3 4.7 r 0.3

7 down sec

8 down sec 5.1 r 0.3 4.6 r 0.3

3 1 Arm speed crowd sec 3.2 r 0.3 3.1 r 0.3

2 extend sec 2.8 r 0.3

4 1 Bucket speed crowd sec 2.7 r 0.3 2.9 r 0.3 Oil temp.

2 dump sec 2.2 r 0.3 2 r 0.3

5 1 Dozer speed up (GoT) sec 1.2 r 0.3 1.5 r 0.3 Max. down to

2 up (LoT) sec

3 down(ToG) sec 1.4 r 0.3

4 down (ToL) sec 3.0 r 0.3 3.8 r 0.3

6 1 Arm cylinder cavitation mm 0, 5 t 0, 0.5 t Oil temp.

inch 0 0

7 1 Max. digging

height radius

2 Cabine mm 2825 r 282 3640 r 364

3 Max. dump

height radius

4 Cabine mm 2790 r 167 3325

5 Bucket bottom

height at arm

vertical

6 Cabine mm 1585 r 415 1600

7 Bucket wrist angle degree 197 r 3 168.5 r 3

Q6 Swivel, swing performance

1 1 Swivel torque L kgfm 840 1265 Arm

2Rkgfm 840 1265

2 1 Swivel angle L deg 20 17 Bucket load=JIS

2Rdeg2017

3 1 Swivel block performance L deg 0

2 R deg 0 5 >

3 L deg 30 30 >

4 R deg 30 30 >

4 1 Swivel start-up speed L sec 2.1 r 0.3 2.5 r 0.3 0~90 deg swivel

2Rsec2.1r 0.3 2.5 r 0.3

Canopy mm 2825 r 282 3640 r 364

inch 111.22 r 11.10 143.31 r 14.33

inch 111.22 r 11.10 143.31 r 14.33

Canopy mm 2790 r 167

inch 109.84 r 6.57

inch 109.84 r 6.57 130.91

Canopy mm 1585 r 415 1600 Bucket horizon-

inch 62.40 r 16.34 62.99

inch 62.40 r 16.34 62.99

kN.m 8.2 12.4

ftlbs 6075 9149

kN.m 8.2 12.4

ftlbs 6075 9149

2.7 r 0.3

2.7 r 0.3

2.7 r 0.3

2.3 r 0.3 2.5 r 0.3 Max. up to max.

4.7 r 0.3

3.1 r 0.3

1.9 r 0.3

3325 at bucket pin

130.91

5 >

50r5qC(122r41q

F)

Ground to max.

height (exculude cushioning)

50r5qC(122r41q

F)

max. up

down

95r5qC(203r41q

F)

tal

extend,show/

Quick

u1.8

heaped

II - 17

Page 29

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

5 1 Swing speed Canopy L sec 6.7 r 0.7 6.7 r 0.5

2Rsec

3 Cabine L sec

4Rsec6.5 r 0.7 7.7 r 0.5

6 1 Swing Lock Swivel R&L mm 2 2, 10 > 90 deg-swivel,

inch 0.08

2 Reciprocating

motion

Q7 Hydraulic performance

1 1 Relief pressure setting P1 kgf/cm2 250 +10, -5

2P2kgf/cm2-

3P3kgf/cm2-

4P4kgf/cm240r 5.1

2 1 Cylinder oil

sealing capacity

295r5qC

3Arm50r5qC

4Bucket50r5qC

5 Dozer 50r5qC

3 1 Boom cushioning performance 30qC(86qF) sec 3

250qC(122qF) sec 0.4 to 1.3

380qC(176qF) sec 0.3

Q8 Lever operating force & stroke

1 1 Boom lever operating force up kgf

2 down kgf 1.5 r 0.5

3 Arm lever crowd kgf

4 extend kgf 1.5 r 0.5

L / R Swing mm 90 deg-swivel,

inch

MPa 24.5 +1.0, -0.5

bar 24.5 +10, -5 24.5 +10, -5

psi 3556 +140, -70

MPa -

bar -

psi -

MPa -

bar -

psi -

MPa 3.9 r 5.0

bar 3.9 r 5.0

psi 569 r 73

Boom 50r5qC

(122r41qF)

(203r41qF)

(122r41qF)

(122r41qF)

(122r41qF)

mm 20 Arm extend,

inch 0.79

mm 20

inch 0.79

mm 20

inch 0.79

mm 10 Bucket load=JIS

inch 0.39

mm 20 3

inch 0.79 0.12

N 17.65 r 4.90

lbs 4.0 r 1.1

N 14.71 r 4.90

lbs 3.3 r 1.1

N

lbs 4.0 r 1.1

N 14.71 r 4.90

lbs 3.3 r 1.1

6.5 r 0.7 7.7 r 0.5

6.7 r 0.7 6.7 r 0.5

100 times actual

digging cylinder

dislocation

100 times

245 +10, -5 At pump deliv-

24.0 +1.0, -0.5

3485 +140, -70

1.8 r 0.5

1.8 r 0.5 Extend & crowd

17.65 r 4.90

ery 50r5qC

bucket

height 1m, 10

min.

heaped

u1.8

II - 18

Page 30

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

1 5 Bucket lever crowd kgf 1.5 r 0.5 Dump & crowd

N 14.71 r 4.90

lbs 3.3 r 1.1

6 extend kgf

N 17.65 r 4.90

lbs 4.0 r 1.1

7 Swivel (Swing) lever R kgf 1.5 r 0.5 Left & right

N 14.71 r 4.90

lbs 3.3 r 1.1

8Lkgf1.5r 0.5

N 14.71 r 4.90

lbs 3.3 r 1.1

9 Dozer lever up kgf

N 9.81 r 4.90 23.54 r 4.90

lbs

10 down kgf

N 14.71 r 4.90 23.54 r 4.90

lbs

11 Travel lever L Forward kgf

N 11 .77 r 4.90 14.71 r 4.90

lbs

12 Back kgf

N 11 .77 r 4.90 14.71 r 4.90

lbs

13 R Forward kgf

N 11 .77 r 4.90 14.71 r 4.90

lbs

14 Back kgf

N 11 .77 r 4.90 14.71 r 4.90

lbs

15 Accelerator lever up kgf 5 r 1.0 r AI-version has

N 49.03 r 9.81 -

lbs 11.0 r 2.2 -

16 down kgf 3.5 r 1.0 -

N 34.32 r 9.81 -

lbs 7.7 r 2.2 -

17 Swing pedal R kgf

N

lbs

18 L kgf

N

lbs 9.0 r 2.2

1.8 r 0.5

1.0 r 0.5 2.4 r 0.5 Up & down

2.2 r 1.1 5.3 r 1.1

1.5 r 0.5 2.4 r 0.5

3.3 r 1.1 5.3 r 1.1

1.2 r 0.5 1.5 r 0.5

2.6 r 1.1 3.3 r 1.1

1.2 r 0.5 1.5 r 0.5

2.6 r 1.1 3.3 r 1.1

1.2 r 0.5 1.5 r 0.5

2.6 r 1.1 3.3 r 1.1

1.2 r 0.5 1.5 r 0.5

2.6 r 1.1 3.3 r 1.1

accel dial not a

lever.

3.4 r 1.0

33.34 r 9.81

7.5 r 2.2

4.1 r 1.0

40.21 r 9.81

II - 19

Page 31

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

1 19 Safety lock

lever

20 down kgf 0.4 r 0.2

21 L up kgf 2.7 r 1.0 Up & down

22 down kgf

23 Travel Hi-Lo change kgf 4.0 r 1.0 3.5 r 1.0 Super servier

2 1 Boom lever stroke up mm

2 down mm 72 r 10

3 Arm lever stroke crowd mm 72 r 10

4extendmm72 r 10

5 Bucket lever stroke crowd mm 72 r 10

6 Bucket lever stroke extend mm 95 r 10

7 Swivel, swing lever stroke R mm

8Lmm72 r 10

9 Dozer lever stroke up mm 60 r 10

10 down mm 60 r 10

11 Travel lever

stroke

12 Back mm 70 r 10

13 R Forward mm 70 r 10

14 Back mm 70 r 10

R up kgf 0.8 r 0.2 Up & down

N7.85r 1.96

lbs 1.8 r 0.4

N3.92r 1.96

lbs 0.9 r 0.4

N 26.48 r 9.81

lbs 6.0 r 2.2

4.5 r 1.0

N 44.13 r 9.81

lbs

N 39.23 r 9.81 34.32 r 9.81

lbs 8.8 r 2.2 7.7 r 2.2

inch 2.83 r 0.39

inch 2.83 r 0.39

inch 2.83 r 0.39

inch 2.83 r 0.39

inch 2.83 r 0.39

inch 3.74 r 0.39

inch 2.83 r 0.39

inch 2.83 r 0.39

inch 2.36 r 0.39

inch 2.36 r 0.39

L Forward mm

inch 2.76 r 0.39

inch 2.76 r 0.39

inch 2.76 r 0.39

inch 2.76 r 0.39

9.9 r 2.2

have a switch

72 r 10

72 r 10

70 r 10

II - 20

Page 32

WSM Minor Change II Service Engineering Section

No Specificatios Items Unit KX121-3S KX161-3S Remarks

Q9 Stability

1 1 Standard arm,

Dynamic operation load limit

2 Front, dozer upkgf

3 Bucket load to

4 Front, dozer upkgf

5 Standard arm,

static limited

load

6 Front kgf

2 1 Standard arm,

Dynamic operation load limit

2 Front, dozer upkgf

3 Bucket load to

4 Front, dozer upkgf

5 Standard arm,

static limited

load

6 Front kgf

Q10 Comfortability

1 1 Noise level At operator's

2 Cab db(A) Cab door close

3 Noise

4 db(A)

Bucket load to

10 degrees

tipping

tip fully

Bucket load to

tip fully

Bucket load to

10 degrees

tipping

tip fully

Bucket load to

tip fully

ear LPA

source;LWA

Side,

dozer up

Side,

dozer up

Side kgf

Side,

dozer up

Side,

dozer up

Side kgf

Canopy db(A)

7m db(A)

kgf Arm extend,

N

lbs

N

lbs

kgf

N

lbs

N

lbs

N

lbs

N

lbs

kgf Arm extend,

N

lbs

N

lbs

kgf

N

lbs

N

lbs

N

lbs

N

lbs

b u c k e t c r o w d

oil temp. 50r5qC

(122r41qF)

b u c k e t c r o w d

oil temp. 50r5qC

(122r41qF)

II - 21

Page 33

WSM Minor Change II Service Engineering Section

B. Finger control service port system

a. Feature and purpose

1 The service port pedal has been replaced by a lever-top knob switch: Feather-touch finger control

realized.

2 The breaker can easily be operated with a button switch.

3 Optimum control feeling adjustments can be made for maneuvering various attachments efficiently.

4 Safe attachment handling is ensured through fool proof control.

Thumb

Breaker Auger

When a thumb (and tilt bucket) attached, the foot pedal has been used to operate. It has not been

easy for fine control in this way. Such operation can now be finely controlled with your hand (thumb)

and you can ensure more space around your feet.

Service port functions have been tremendously upgraded.

Tilt bucket

II - 22

Page 34

WSM Minor Change II Service Engineering Section

b. Outline of control system

1. Aux. port finger operation

Fine control by finger operation

c Proportionality operation of AUX. port.

d Full open output hold Switch at the time of breaker operation.

e Hand operation ON-OFF Switch. (secure safety priority)

2. Control layout

AUX port hand operation

Breaker Lock sw

Option sw

Travel Hi-Low lamp

Option lamp

Travel Hi-Hold sw

Work lamp sw

Display change sw

Anti Theft Antenna

(EU-version only)

Option: KX91-3S,D or above

Accel

Option: KX41-3SV or above

Hand operation ON-OFF sw

AI-sw

Controller

Knob position signal Right proportional control valve output

Input

Breaker mode select signal

signal

Service mode select signal

CPU

II - 23

Out-

put

Left proportional control valve output

Page 35

WSM Minor Change II Service Engineering Section

3. Service port system components

Meter panel

Main key

ON

Safety lever

lock switch

Knob switch

o start

Breaker switch

Input

Work

switch

lamp

CPU

EEPROM

S/P

switch

Proportional solenoid valve

Output

Main control valve

Panel

selector

switch

Thumb cylinder

II - 24

Page 36

WSM Minor Change II Service Engineering Section

2

Main pump, P

Cylinder rod,

thumb release

Thumb cylinder

Main controle valve,

service port section

Cylinder bottom,

thumb crowd

p

Pilot pump, P

c. Hydraulic circuit diagram

PWM current

PWM current

II - 25

Page 37

WSM Minor Change II Service Engineering Section

d. Knob structure and function

The knob has a built-in IC chip that is different from that for potentiometers.

1)Service mode:Press the center switch of the meter panel to call the service mode.

2)Knob control: Shift the knob to L or R direction to call two way PTO operation.

3)Breaker operation:Press the back button of the knob to call the breaker mode.

1. Structure of knob switch

+5 V

PROPORTIONAL OUTPUT

GND

Horn SW

Breaker SW

ELECTRIC CIRCUIT

4

3

2

1

8

7

6

5

RED

WHITE

BLACK

BLUE

GREEN

YELLOW

GRAY

1

3

2

4

7

6

5

(1)

(2)

(1) Knob switch (2) Horn switch

(3)

(3) Breaker switch

II - 26

Page 38

WSM Minor Change II Service Engineering Section

2. Basic operation of the knob

1) With the key on

When the key is on, the system gets started out of

the service mode OFF-position.

In other words, the knob is not operative. (This is for

safety.)

2) Service mode

Press the center switch of the meter panel, and the

center LED indicator lights up and the system gets in

the service mode. Now the knob is operative. Move

the knob to the left for the thumb to grasp an object.

Move it to the right for the thumb to release it.

3) Breaker mode

The breaker mode is enabled while in the service

mode. Press the breaker switch on the back of the

knob to activate the breaker. The main pump fully

feeds the fluid to the breaker. If the thumb is

attached in place, the main pump feeds the full

amount of fluid from the service port to the thumb

cylinder.

<Breaker switch function>

(1) Push the S/P switch on.

(2) Press the breaker switch.

(3) Breaker starts pounding.

(4) Press the breaker switch again.

(5) Breaker stops.

4) Releasing the breaker

There are three methods to release the breaker operation.

(1) Press the breaker switch again to stop the breaker.

(2) Press the service port switch to off position. (The center LED indication goes off.)

(3) Or, move the knob for over 0.2 second.

(4) Or, lift up the safety lock lever.

(5) Turn the main key to off position.

II - 27

Page 39

WSM Minor Change II Service Engineering Section

3. Flow chart; Service port operation

Key

ON

No

No

Is safety lock lever

down position?

Yes

Service port switch

ON

Service port switch lamp

lights up

Is breaker switch ON?

Yes

Breaker starts.

OFF

No service port operation

Yes

Is knob switch shifted?

Yes

Thumb cylinder

starts moving.

1) Press breaker switch on again?

2) Move the knob switch?

3) Raise the safety lock lever?

4) Main key off?

One of above operations?

Breaker stops

While breaker is working;

Release the knob switch

to neutral.

Thumb cylinder stops.

Yes

II - 28

Page 40

WSM Minor Change II Service Engineering Section

4. S/P switch (service port switch)

<Function chart>

(1) Main key

(2) S/P switch

(3) Service port

function

(4) Safety lock

lever

(5) Warning lamp

buzzer

ON

OFF

Push

Effective

Non-effective

Up

Down

(5 ~ 6 sec.)

Service port switch (S/P sw) in the middle bottom

on the meter panel controls the service port functions, such as thumb switch and breaker switch.

In order to get the service port function, first push

this switch and then control the two switches on

the knob lever.

(1) Service port switch

II - 29

Page 41

WSM Minor Change II Service Engineering Section

5. How the knob switch works

1) Let's suppose that the breaker has been released. To call the breaker mode again, it is necessary to press the back button (breaker switch) of the knob. (This is for safety.)

2) To release the breaker, just move the knob. This is highly convenient.

3) Let's say that you have forcefully moved the lever to operate the other functions, such as boom

up or down or etc. The knob may be momentarily shaken, which may fluctuate the voltage and

unnecessarily release the breaker. To avoid this, the knob must be moved for over 0.2 second

to release the breaker operation. Just for reference, the knob does not tilt for over 0.2 second

under usual lever control conditions.

6. Breaker operation

(1) Main key

(2) Safety lock lever

ON

o start

down

(3) Meter panel controller

ON

(4) Server port switch pushed

(8) Knob switch

ON

(6) Breaker switch

(7) Breaker

(5) Proportional control

solenoid valve

Note: When the safety lock lever is up position, all switches of service port switch, breaker switch and

knob switch don’t function at all. This is also for safety purpose.

Therefore, once the safety lock lever is shifted up while service port operation, breaker or

thumb cylinder stops.

When to start the breaker again, first shift down the safety lock lever, press ON the service port

switch and press the breaker switch. Safety lock switch has the priority for the safety.

II - 30

Page 42

WSM Minor Change II Service Engineering Section

7. Interrelation among current, pressure and flow

6DPSOHGDWD7KXPEFODPS%RWWRPVLGH$SRUWOHIW

0,1USP$

0$;USP$

@

Â

3LORWVHFRQGDU\SUHVVXUH>NJ IFP

&XUUHQWP$

2LOIORZDPRXQWOPLQ2LOIORZDPRXQWOPLQ

3LORWVHFRQGDU\SUHVVXUH>NJÂIFP@

&XUUHQWP$

Note: Above charts are just the sample figures to illustrate the interrelation among the three

parameters.

1. Current: PWM current provided from the panel controller.

2. Pressure: Secondary pilot pressure delivered from S/P solenoid valve.

3. Flow: Oil flow amount supplied to the thumb cylinder.

II - 31

Page 43

WSM Minor Change II Service Engineering Section

e. Initial settings of the knob

1. Set-up and adjustment of service port

This new finger control service port system requires three types of set-up and adjustment procedures.

Items to set-up When

Knob initial set-up 1. Knob change

2. S/P valve change

3. Meter panel change

S/P valve start-point set-up 1. S/P valve change

2. Main control valve change

3. Pilot pump change

4. Hydraulic actuator change

Manual feeling adjustment 1. Hydraulic actuator change

2. Operator change and feeling change

2. Purpose

Three settings (right and left ends, and neutral) of the knob are kept in the meter controller’s memory. Note that there are fluctuations from knob to knob.

The knob has been factory-set at Hirakata Factory or KBM. When the meter, the knob or the proportional control solenoid valve has been replaced, the knob settings must be manually reprogrammed. If not reprogrammed, the thumb may get activated even in neutral or slowly move even

at the right end.

The meter memory keeps the following data in the EEPROM addresses

u 8 = 8184 then 5 V.

1023

But actual data varies as follows.

Address 45: Left end

Address 46: Neutral

Address 47: Right end

o

o

o

0.4 a 0.8 V

2.4 a 2.8 V

4.40 a 4.80 V

<Knob shift amount and output voltage>

Voltage

4.5 V (Address 47)

2.5 V (Address 46)

0.5 V (Address 45)

Left end Right end

Neutral

Knob shift amount

(Knob shift angle)

II - 32

Page 44

WSM Minor Change II Service Engineering Section

3. Background and meaning of knob initial set-up

1) The output voltages at the neutral, rightmost and leftmost positions of a knob are entered as initial settings. Accordingly, correlation between the knob's right-left shift and the output voltage is

stored in microcomputer memory.

2) The voltage generated by the knob's movement is converted by the microcomputer to a PWM

control current. In this way, ordinary operations can be carried on under proportional control.

3) Also the voltages at the neutral, rightmost and leftmost positions of a new control knob are

entered as initial settings in microcomputer memory. Such data serves to control the output

voltage in proportion to the knob's movement.

4) Suppose that you have replaced a control knob but forgotten to make its initial settings. The

previous knob's data, still in microcomputer memory, may be slightly different from new entries.

This may cause different operating feelings.

5) These settings can be made with the key on. Thanks to the built-in temperature compensation

function, there is no problem with ambient temperatures in making the settings.

FYI (For Your Information)

1. Knob switch and Hall element (IC chip)

The knob switch has a temperature-compensated Hall element incorporated. The Hall element consists of a magnet and a coil as shown below. A kind of sensor, this switch has the tilt angle Éý,

which changes the quantity of magnetism. This quantity is converted to voltage. The input voltage is

set at 5 V maximum. With the knob switch at neutral position, the output is about 2.5 V.

2. Hall effect

Let's suppose, as shown in Fig. 1,

that a current is applied to a rectan-

Magnetic flux B [T]

gular solid and a magnetic field is

added perpendicular to the direction

of current. There will be a voltage

that is perpendicular to the direction

Length

T [m]

Voltage

of current as well as to the direction

of magnetic field. This phenomenon

is called the Hall effect, and the voltage thus generated is called the Hall

voltage.

Current I [A]

This effect was discovered by American physicist Edwin H. Hall in 1879.

The effect has the nature of taking

place very frequently with semicon-

Fig. 1 Hall effect

ductors, but rarely with conductors.

3. Hall element

The Hall effect is discussed above. The Hall element includes semiconductors that produce the Hall

effect. Given that the effect takes place very frequently with semiconductors, but rarely with conductors, semiconductors are used to make the Hall element.

Here are the materials to make the Hall element.

- Silicon (Si)

- Germanium (Ge)

- Gallium arsenide (GaAs)

- Indium arsenide (InAs)

- Indium antimonide (InSb)

V [V]

II - 33

Page 45

WSM Minor Change II Service Engineering Section

f. S/P valve start point setting

1. Performance characteristics profile: Knob shift amount vs Output current

Current

Proportional control valve BProportional control valve A

Right end

Knob

Left end

950 mA

450 mA

Neutral

1) A dead zone is provided to keep the thumb intact in neutral. Some margins are also given to

start the thumb at each end.

2) The right-end, neutral, and left-end settings of the knob are presupposed to be in memory.

3) The profile is flexibly modifiable even for maximum engine rpm and idling speed. When the

engine runs at middle speed, for example, the average is determined from the idling map and

maximum map and finally outputted.

4) Suppose that the thumb starts moving at the current of 500 mA. The knob's operating map must

begin with 450 mA because it is necessary to provide an inching zone and give better feeling.

5) At the 500mA level, however, there could be fluctuations due to the control valve, proportional

control valve, hoses and other factors. The meter keeps the initial map and performs as well,

but the inching zone might be longer or shorter depending on the machine.

6) The starting point setting is made to cope with such problem. In the setting mode, the meter

shows the current gradually higher from 450 mA. When the thumb starts moving, the operator is

supposed to press and release the button twice for releasing and grasping of the thumb. The

meter memorizes the then setting.

Address 48:

Address 49:

o

o

Release R Deviation

Grasp L Deviation

The following correction is made for control.

Current

950 mA

450 + (The value in the address 49) 450 + (The value in the address 48)

Left end

Neutral

Proportional control valve BProportional control valve A

Right end

Knob

II - 34

Page 46

WSM Minor Change II Service Engineering Section

7) Service engineers do not notice, but at Hirakata

Factory and KBM, the starting point has been

measured at the service port (red pressure measuring port for North America and Europe) and

fluctuations have been put in the meter memory.

At the manufacturing plants, however, the

machine is not equipped with any thumb attachment. Actually, the starting point is expected to

be measured locally. It would take dealers trouble.

At the manufacturing level, therefore, a pressure

take-out plug is prepared. Although a thumb is

not attached, a current flows to the proportional

control valve and the pressure level changes at a

certain point. This pressure level is detected and

put into memory.

Note: 450 mA and 950 mA are default values

before setting in the factory.

Actual value may differ model by model

(1) Pressure port

and machine by machine after the factory

setting up.

8) Fortunately, the dealers are expected to do just the following in the field

(1) Usually Just install the attachment (Thumb) and

connect the service port hoses.

(2) When the meter is replaced Make the knob initial setting

and the starting point setting.

(3) When the knob is replaced Make the knob initial setting.

(4) When the proportional

control valve replaced

Make the starting point setting,

knob initial setting

The above knob initial setting and starting point setting are required. Otherwise the performance may be unstable depending on finish accuracies of

the component parts.

II - 35

Page 47

WSM Minor Change II Service Engineering Section

2. Background and meaning of start-point setting

1) The purpose of this setting is to keep the knob's operating force of starting the attachment

(thumb cylinder) constant whether the engine runs idle or at maximum speed.

2) The proportional control valve's start-point is activated when you have slowly moved the knob

to start the attachment that is connected with the service port circuit.

3) The knob's action point is referred to in some different factors: knob's movement, output voltage, controller's output PWM current, proportional control valve's hydraulic pressure, pilot secondary pressure of service port main control valve, and hydraulic pressure of attachment

(thumb cylinder, for example).

4) The start-point setting works as follows. When a component of the service port system line has

been replaced, the component with its slightly different individual behavior pattern may delicately affect the line's final output. To compensate such deviation, the initial setting (star-point

setting) must be entered in the controller.

5) The following factors are important in affecting the start-point.

(1) Oil temperature

(2) Engine rpm

(3) Proportional control valve

(4) Main control valve, service port section

(5) Service port load fluctuations

6) These factors are therefore considered for the start-point setting.

(1) Oil temperature

(2) Engine rpm

(3) Proportional control valve

(4) Main control valve,

o

50 qC

o

Idling, Maximum

o

At each replacement

o

At each replacement

service port section

(5) Service port load fluctuations

o

Basically it is preferable to make the setting for

each attachment. If it does not feel unusual,

however, it can be up to the user's judgment.

II - 36

Page 48

WSM Minor Change II Service Engineering Section

3. Illustration of the start-point setting

Voltage fluctuation signal

according to the knob's

PWM current

Pilot secondary pressure signal

S/P section

Main hydraulic line

movement

Move the knob, and you will find the point where the thumb cylinder starts moving. Just when the

cylinder gets activated, press the selector switch. Do this for the right and left movements of the

knob.

Does control start when the start-point has been reached?

]

2

Ps [kgf/cm

[mA]

Pilot secondary pressure

when the thumb cylinder

starts moving.

[mA]

Input current when

the thumb cylinder

starts moving.

Knob movement [T]

II - 37

Page 49

WSM Minor Change II Service Engineering Section

4. Concrete behavior at the start-point setting

PWM input

to the solenoid valve

(mA)

Pilot secondary pressure

l

R,

full stroke

Machine B

Standard

Machine A

Ps

Pilot Secondary pressure current

]

difference a

i

T

. As

s

difference b

L,

full stroke

T

:standard knob angle to start S/P

s

T

:Machine A knob angle to start S/P before set-up.

a

T

:Machine B knob angle to start S/P before set-up.

b

i

l

θbθsθ

a