Kubota u27-4 Service Manual

OPERATOR'S MANUAL

U.S.A. :KUBOTATRACTORCORPORATION

Canada :KUBOTACANADALTD.

France :KUBOTAEUROPES.A.S

Italy :KUBOTAEUROPES.A.SItalyBranch

Germany :KUBOTABAUMASCHINENGmbH

U.K. :KUBOTA(U.K.)LTD.

Australia :KUBOTATRACTORAUSTRALIAPTYLTD.

Malaysia :SIMEKUBOTASDN.BHD.

Philippines :KUBOTAPHILIPPINES,INC.

Taiwan :SHINTAIWANAGRICULTURALMACHINERYCO.,LTD.

Thailand :SIAMKUBOTACORPORATIONCO.,LTD.

1000

KubotaDrive,Grapevine,TX

Telephone:

590014

Telephone:(

19-25

Telephone:(

ViaGrandi,

Telephone:(

Steinhauserstr,

Telephone:(

DormerRoad,Thame,Oxfordshire,OX

Telephone:(

25-29

Telephone:(

3

No.

Seksyen

Telephone:(

232

QuirinoHi㷅hway,Baesa,QuezonCity

Telephone:(

16

,Fen㷅pin㷅2ndRd,TaliaoShian㷅Kaohsiun㷅

Telephone:(

101/19-24

Pathumthani

Telephone:(

888-4

KUBOTA

thAvenue,Markham,Ontario,L3S4K4,Canada

905)294-7477

,RueJulesVercruysse,Z.I.BP88,

33)1-3426-3434

2920068

PermasWay,Tru㷅anina,VIC

JalanSepadu25/

25,40400

Moo20,NavanakornIndustrialEstate,TambonKhlon㷅nuen㷅,AmphurKhlon㷅luan㷅,

PeschieraBorrome(MI)Italy

39)02-51650377

100,66482

49)6332-4870100

44)1844-214500

61)-3-9394-4400

123

ShahAlam,Selan㷅orDarulEhsanMalaysia

60)3-736-1388

63)2-422-3500

886)7-702-2333

12120

,THAILAND

66)2-909-0300

76051

95101

ZweibruckenRheinlandpfalzGermany

93

3029

,Australia

TamanPerindustrianAxis,

Ar㷅enteuilCedex,France

UN,U.K.

1106

,Philippines

83107

,TaiwanR.O.C.

KUBOTA

EXCAVATOR

MODEL

U

27-4

AV. I. 1-1. -. K

Japan :KUBOTACorporation

Farm&IndustrialMachineryInternationalOperationsHeadquarters

2-47

,Shikitsuhi㷅ashi1-chome,Naniwa-ku,Osaka,Japan

556-8601

English (U.S.A.)

Code No. RH418-8193-1

KUBOTA Corporation 2017

©

U

2

7

4

1BAAEAPAP0010 1BAAEABAP0280

READ AND SAVE THIS MANUAL

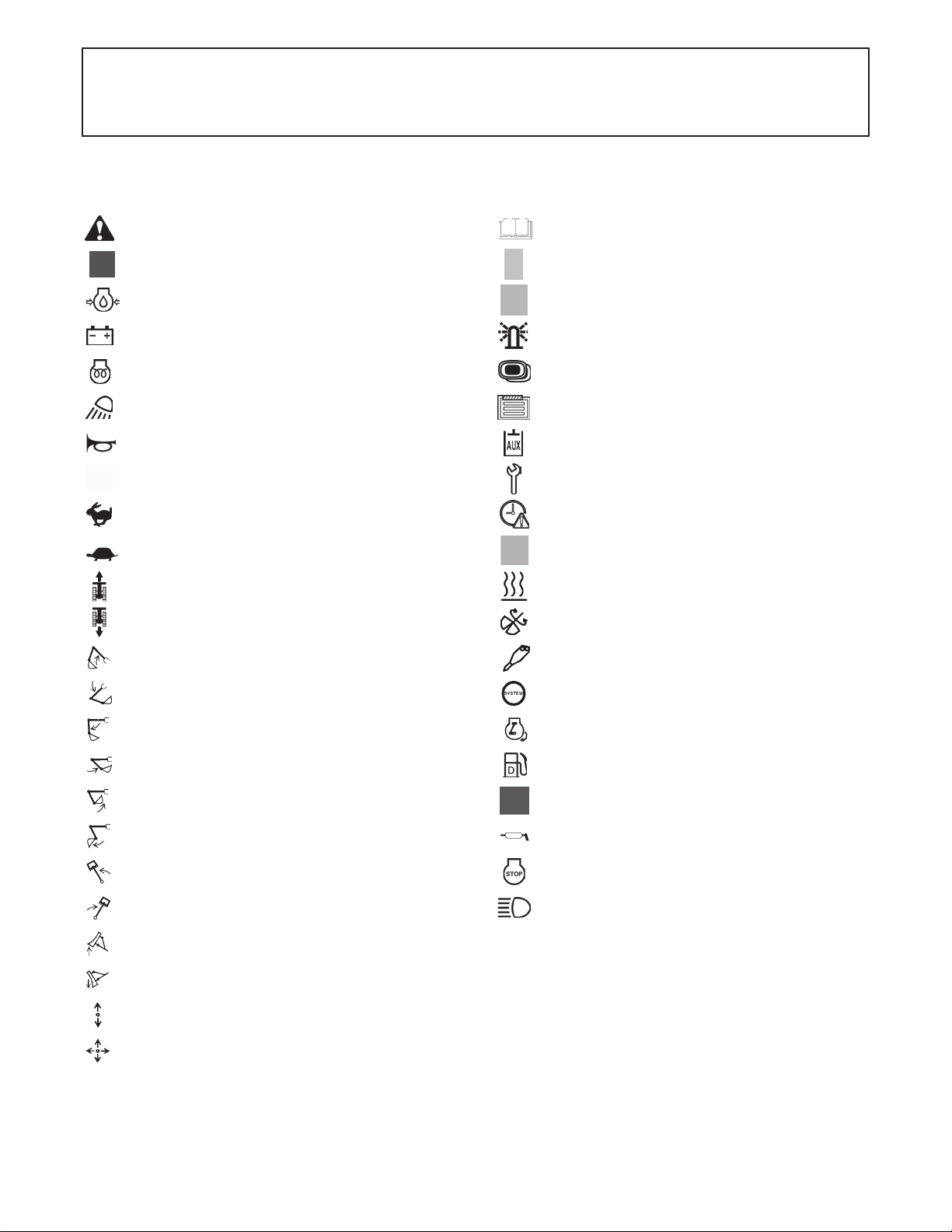

ABBREVIATION LIST

Abbreviations Definitions

AI

API

ASTM

CECE

DIN

EN

FRONT

Hi

ISO

JIS

L

L/min

Lo

MIL

OPG

OSHA

Auto Idle

American Petroleum Institute

American Society for Testing and Materials, USA

Committee for European Construction Equipment

Deutsches Institut für Normung, GERMANY

(German Institute for Standardization)

European Standard

"Front" means the direction towards the boom and dozer

High speed

International Organization for Standardization

Japanese Industry Standard

Volume (Liter)

Liter per minute

Low speed

Military Standard

Operator Protective Guards

Occupational Safety and Health Administration

ROPS

rpm

SAE

TPSS

Roll-Over Protective Structure

Revolutions Per Minute

Society of Automotive Engineers, USA

Two Pattern Selection System

California Proposition 65

WARNING

Engine exhaust, some of its constituents,

certain vehicle components and fluids,

contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

IMPORTANT

The engine in this machine is not equipped by the manufacturer

with a standard spark arrester.

It is a violation of California Public Resource Code Section 4442 to

Use or operate this engine on or near any forest-covered, brushcovered land, or grass-covered land unless the exhaust system is

equipped with a working spark arrester meeting state laws. Other

states or federal areas may have similar laws.

U27-4

English (U.S.A.)

GENERAL SYMBOLS

The instruments and operation elements have been marked with a series of symbols in order to simplify the operation of

your excavator. These symbols are listed below with the respective descriptions.

Warning light

Fuel indicator

Engine oil indicator

Charge indicator

Glow indicator

Working lights

Horn

Hydraulic oil

Travel speed

Low speed

Forward travel

Backward travel

Raise boom

Read operator’s manual

Bolted

Released

Rotary beacon

Display selector switch

Menu button

Auxiliary port indicator

Service interval indicator

Set clock indicator

Indicator coolant temperature

Fan

Indirect return flow

Direct return flow

Lower boom

Arm crowd

Arm dump

Bucket crowd

Bucket dump

Swivel boom (left)

Swivel boom (right)

Dozer up

Dozer down

Lever direction

Control lever direction

System lamp

Warning lamp “Auto Idle (AI) Lamp”

Diesel

Gear oil

Grease

Engine stop control lamp

Working light switch

FOREWORD

You are now the proud owner of a KUBOTA Excavator. This excavator is a product

of KUBOTA quality engineering and manufacturing. It is made of fine materials and

under a rigid quality control system. It will give you long, satisfactory service. To

obtain the best use of your excavator, please read this manual carefully. It will help

you become familiar with the operation of the excavator and contains many helpful

hints about excavator maintenance. It is KUBOTA's policy to utilize as quickly as

possible every advance in our research. The immediate use of new techniques in

the manufacture of products may cause some small parts of this manual to be

outdated. KUBOTA distributors and dealers will have the most up-to-date

information. Please do not hesitate to consult with them.

SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used throughout this manual

and on labels on the machine itself to warn of the possibility of personal injury.

Read these instructions carefully. It is essential that you read the instructions and

safety regulations before you attempt to assemble or use this unit.

DANGER :

WARNING :

CAUTION :

IMPORTANT :

NOTE : Gives helpful information.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Indicates that equipment or property damage could result if

instructions are not followed.

CONTENTS

SAFE OPERATION ............................................................................................ -1

DEALER SERVICE...................................................................................................... 1

TECHNICAL DATA...................................................................................................... 3

DESCRIPTION OF MACHINE PARTS........................................................................ 4

INSTRUMENT PANEL AND CONTROL ELEMENTS................................................. 5

CHECKS BEFORE START ......................................................................................... 8

DAILY CHECKS....................................................................................................... 8

CAB TYPE MACHINES ........................................................................................... 8

Wiper/Washer Switch .......................................................................................................8

Interior Lamp..................................................................................................................... 8

Working Light Switch ........................................................................................................9

Heater Switch ...................................................................................................................9

Opening/Closing of CAB Door........................................................................................ 10

Opening/Closing of Front CAB Window..........................................................................10

Opening/Closing of Side CAB Window........................................................................... 11

Emergency Hammer....................................................................................................... 11

HANDLING THE SAFETY DEVICES..................................................................... 11

Pilot Control Lock Lever.................................................................................................. 11

OPERATION OF THE ENGINE................................................................................. 12

STARTING THE ENGINE ...................................................................................... 12

Display Selector Switch .................................................................................................. 13

Battery Charge Lamp...................................................................................................... 15

Engine Oil Pressure Warning Lamp ...............................................................................15

Glow Lamp......................................................................................................................15

LCD for Normal Operation.............................................................................................. 16

LCD for Warning............................................................................................................. 17

Warning Lamp ................................................................................................................17

Checkpoints after Starting the Engine ............................................................................18

STARTING THE ENGINE UNDER COLD CONDITIONS...................................... 18

Precautions in case of Overheat.....................................................................................18

STOPPING THE ENGINE...................................................................................... 19

Engine Stop Button.........................................................................................................19

STARTING WITH AN AUXILIARY BATTERY ....................................................... 19

Observe Following Guidelines when Starting with an Auxiliary Battery..........................19

EXCAVATOR OPERATION ...................................................................................... 21

RUNNING-IN OF THE NEW EXCAVATOR........................................................... 21

Do not Work with Full Engine Rpm's or Full Loads during the First 50 Working Hours.. 21

Oil Change in the Run-in Stage...................................................................................... 21

Seat Belt .........................................................................................................................21

STARTING ............................................................................................................. 21

Operator's Seat...............................................................................................................21

Pilot Control Lock Lever.................................................................................................. 22

Working Light Switch ......................................................................................................22

CONTENTS

Travel Buzzer.................................................................................................................. 22

Beacon Light Switch ....................................................................................................... 22

TWO PATTERN SELECTION SYSTEM (TPSS) ................................................... 23

Pattern Change............................................................................................................... 23

OPERATION OF THE BOOM................................................................................ 24

OPERATION OF THE ARM................................................................................... 24

OPERATION OF THE BUCKET ............................................................................ 25

SWIVEL(UNIT SWING)OPERATION .................................................................... 25

BOOM SWING OPERATION................................................................................. 25

OPERATION OF THE DOZER .............................................................................. 26

AUX PORT OPERATION....................................................................................... 26

One-way Hold Switch .....................................................................................................27

DRIVING ................................................................................................................ 28

Drive Levers (Right, Left)................................................................................................29

Throttle Lever..................................................................................................................29

Travel Speed Switch.......................................................................................................30

TURNS................................................................................................................... 30

Pivot Turn ....................................................................................................................... 30

Spin Turn ........................................................................................................................31

UP AND DOWNHILL TRAVELLING ...................................................................... 32

PARKING ON A SLOPE ........................................................................................ 32

PARKING ............................................................................................................... 32

1-way or 2-way CIRCUIT SELECTION VALVE OPERATION ............................... 33

IMPORTANT INFORMATION ON EXCAVATOR OPERATION ............................ 34

HOW TO RELEASE PRESSURE TRAPPED IN THE HYDRAULIC SYSTEM...... 34

TRANSPORTING THE EXCAVATOR ON A TRUCK................................................ 35

LIFTING OF THE EXCAVATOR................................................................................ 37

MAINTENANCE......................................................................................................... 39

MAINTENANCE INTERVALS ................................................................................ 39

OPENING AND CLOSING OF PARTS.................................................................. 41

Opening and Closing of the Fuel Tank Cap....................................................................41

Opening/Closing of the Engine Hood .............................................................................41

Opening/Closing of the Side Cover ................................................................................42

Opening/Closing of the Radiator Cover..........................................................................42

Opening/Closing of the Swivel Frame Cover.................................................................. 42

Where to store the Grease Gun......................................................................................42

Where to keep Operator's Manual..................................................................................43

Cup Holder......................................................................................................................43

DAILY CHECKS..................................................................................................... 43

Checking Coolant Level..................................................................................................43

Checking Fuel Level .......................................................................................................44

Checking Engine Oil Level.............................................................................................. 44

Checking Hydraulic Oil Level.......................................................................................... 45

Lubrication Points ........................................................................................................... 46

Check Fan Belt ...............................................................................................................47

Checking Radiator and Oil Cooler ..................................................................................47

Checking Washer Liquid (only for CAB type) .................................................................48

Checking and Cleaning Engine and Electrical Wiring.....................................................48

Washing Whole Machine................................................................................................ 48

CONTENTS

REGULAR CHECKS AND MAINTENANCE WORK ................................................. 49

EVERY 50 SERVICE HOURS ............................................................................... 49

Draining the Water from the Fuel Tank...........................................................................49

Draining Water Separator............................................................................................... 49

Battery ............................................................................................................................ 50

Battery Charging.............................................................................................................50

Greasing of Swing Bearing Teeth...................................................................................51

EVERY 200 SERVICE HOURS ............................................................................. 51

Checking Fan Belt Tension.............................................................................................51

Checking Radiator Hoses and Clamps...........................................................................52

Inspection and Cleaning Air Filter Element.....................................................................52

Air Filter Maintenance..................................................................................................... 53

Greasing Swing Bearing................................................................................................. 53

Checking Fuel Line and Intake Air Line ..........................................................................53

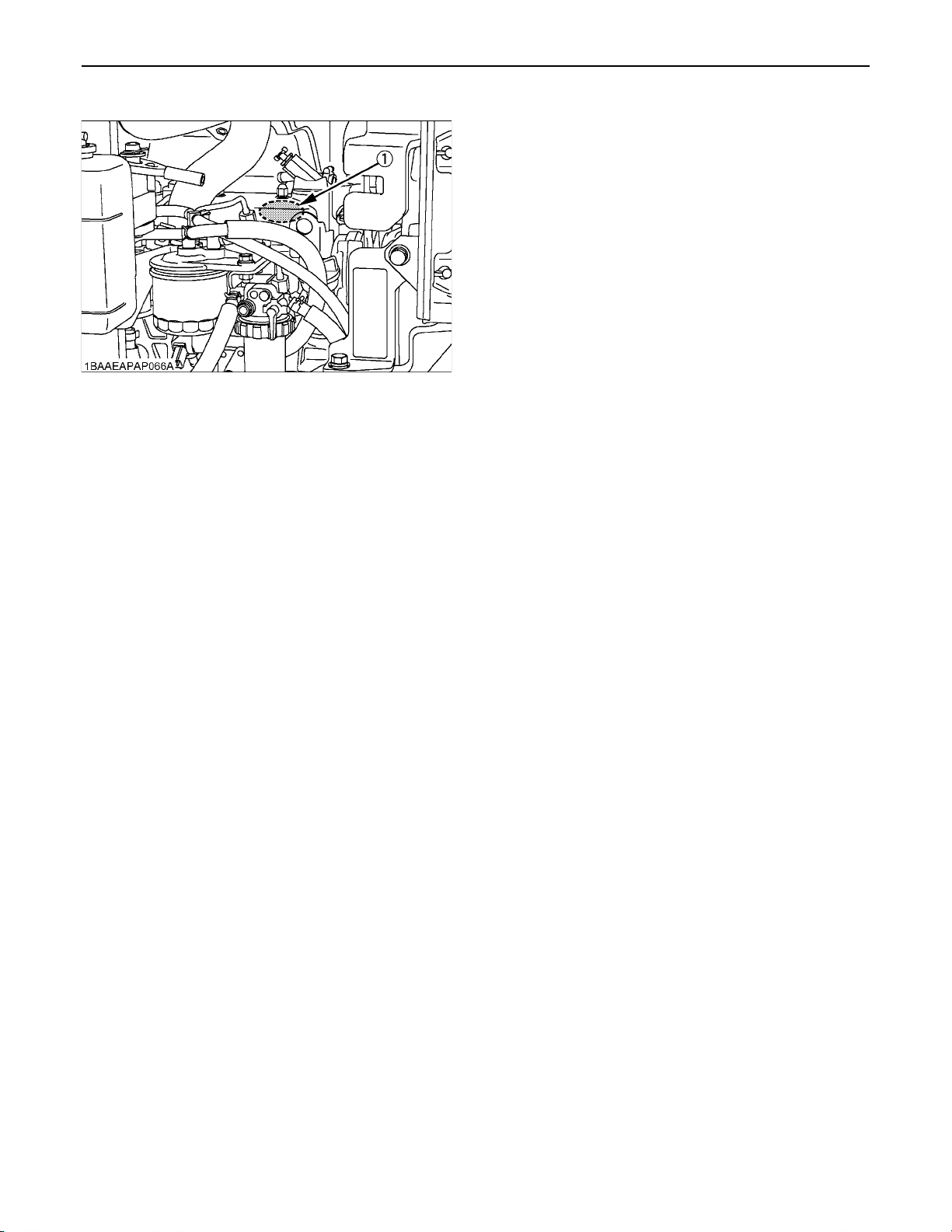

EVERY 250 SERVICE HOURS ............................................................................. 54

Lubrication of the Pilot Valve .......................................................................................... 54

EVERY 500 SERVICE HOURS ............................................................................. 54

Changing Engine Oil (Change the engine oil every 500 hours, or every 1 year in the case

that service hour is less than 500 hours)........................................................................54

Replacing Engine Oil Filter Cartridge (Replace the engine oil filter cartridge every 500

hours,or every 1 year in the case that service hour is less than 500 hours)...................55

Drive unit Oil Change(First Oil Change of the 50 hours) ................................................ 56

Replacing Fuel Filter Cartridge....................................................................................... 56

Replacing Hydraulic Return Filter Element..................................................................... 57

EVERY 1000 SERVICE HOURS ........................................................................... 57

Replacing the Hydraulic Pilot Filter Element...................................................................57

Hydraulic Oil Change (Including Replacing of the Suction Filter in the Hydraulic Tank) 58

Hydraulic Oil Check with Hydraulic Breakers .................................................................59

EVERY 1000 SERVICE HOURS OR ONCE A YEAR ........................................... 59

Replacing Air Filter Element ...........................................................................................59

EVERY 1500 SERVICE HOURS ........................................................................... 59

Checking Fuel Injection Nozzle (Injection Pressure) ...................................................... 59

EVERY 2000 SERVICE HOURS ........................................................................... 59

Changing Front Idler and Track Roller Oil ......................................................................59

Checking the Alternator and Starter Motor .....................................................................59

EVERY 3000 SERVICE HOURS ........................................................................... 60

Checking Injection Pump................................................................................................60

ANNUAL SERVICING............................................................................................ 60

Electrical Wiring and Fuses ............................................................................................60

Checking the Electrical Circuit ........................................................................................60

BIENNIAL SERVICING .......................................................................................... 60

Replacement of Radiator Hoses and Hose Clamps ....................................................... 60

Changing Radiator Coolant ............................................................................................60

Replacing Fuel Hoses and Hose Clamps.......................................................................61

Replacing Intake Air line.................................................................................................61

OTHER ADJUSTMENTS AND REPLACEMENTS.................................................... 62

PURGING OF THE FUEL SYSTEM ...................................................................... 62

ADJUSTMENT OF TRACKS ................................................................................. 62

Special Information when Using Rubber Tracks.............................................................63

CHANGING THE BUCKET .................................................................................... 64

FUSES ................................................................................................................... 64

CONTENTS

Replacing Fuses............................................................................................................. 64

Fuse Capacities and Circuits.......................................................................................... 64

Slow Blow Fuse ..............................................................................................................64

TROUBLESHOOTING............................................................................................... 65

KUBOTA I.C.S. NAVIGATION LIST OF MESSAGES ........................................... 66

OPERATION UNDER COLD WEATHER CONDITIONS .......................................... 71

PREPARATION FOR OPERATION IN COLD WEATHER .................................... 71

PROCEDURE AFTER COMPLETING WORK ...................................................... 71

LONG STORAGE ...................................................................................................... 72

RECOMMENDED OILS............................................................................................. 74

MAIN DIMENSIONS .................................................................................................. 76

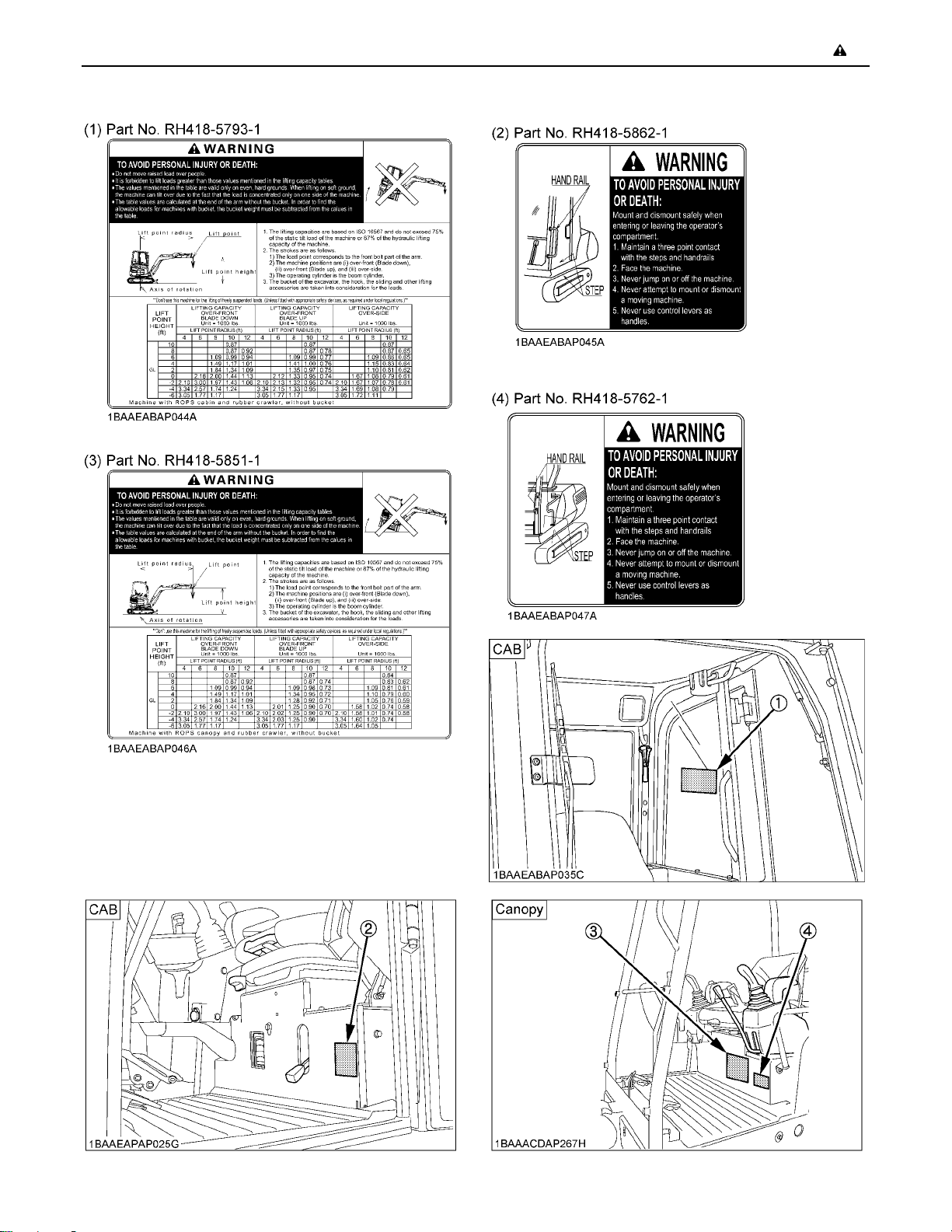

LIFTING CAPACITY .................................................................................................. 78

SAFE OPERATION

-1SAFE OPERATION

Careful operation is your best insurance against an

accident.

Read and understand this manual carefully, before

operating the excavator.

Every user, however experienced, should carefully read

and understand this manual and those of the attachments

and accessories before operating the excavator. The

owner is obliged to inform all operators of these

instructions in detail.

Keep this manual in the storage location. (See "Where to

keep Operator's Manual" in "MAINTENANCE" section.)

1. BEFORE OPERATION

1. Know your equipment and its limitations. Read and

understand this entire manual before attempting to

start and operate the excavator.

2. Pay special attention to and obey the danger, warning

and caution labels on the machine.

3. For your safety, a ROPS/OPG (Top Guard Level I)

with a seat belt is installed by KUBOTA.

A ROPS: Roll-Over Protective Structure

A OPG (Top Guard Level I): Operator Protective

Guards of Top Guard Level I

OPG (Top Guard Level I) in accordance with

ISO10262 is equivalent in definition to FOPS (Falling

Object Protective Structure).

Always use the seat belt when the machine is

equipped with a ROPS/OPG (Top Guard Level I) as

this combination will reduce the risk of serious injury or

death, should the excavator be upset or falling objects

occur.

Do not modify any structural members of the ROPS/

OPG (Top Guard Level I) by welding, drilling, bending,

grinding or cutting, as this may weaken the structure.

If any component is damaged, replace it. Do not

attempt repairs. If the ROPS/OPG (Top Guard Level I)

is loosened or removed for any reason, make sure all

parts are reinstalled correctly. Tighten mounting bolts

to proper torque.

4. ROPS meets requirements of ISO 3471.

OPG (Top Guard Level I) meets requirements of

OSHA 1926 1003/ISO 10262.

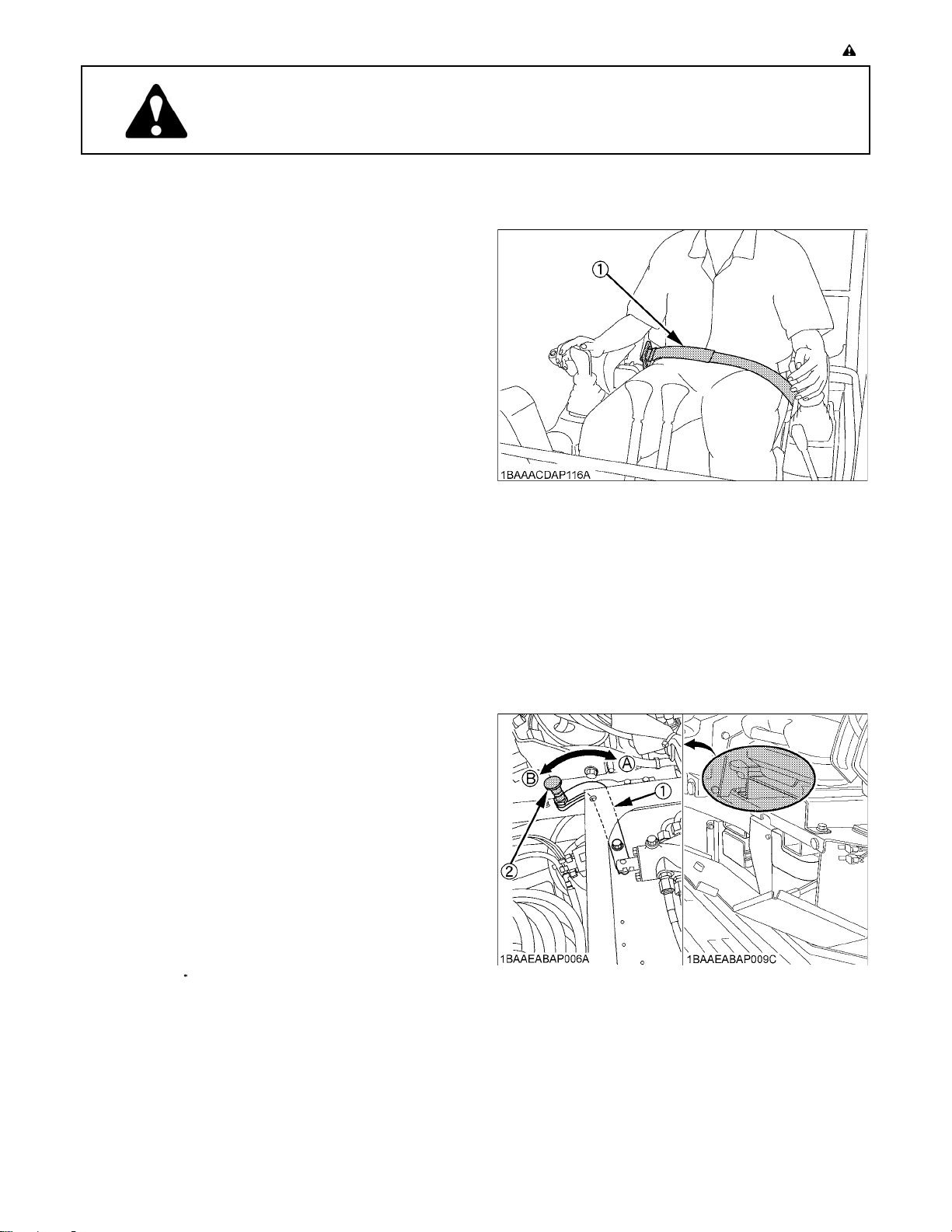

5. The seat belt must be inspected regularly and

replaced if frayed or damaged.

(1) Seat belt

6. Always sit in the operator's seat when starting engine

or operating levers or controls.

7. Study control lever pattern A and pattern B. Then

choose the one which is most familiar.

Familiarize yourself with the pattern selected by

operating the unit slowly and at low engine speed.

A The lever and red knob will be locked automatically

when the new pattern position is reached.

A Do not operate the excavator unless the lever and red

knob have been locked into a pattern position.

(1) Pattern selector lever

(Two Pattern Selection System: TPSS)

(2) Red knob

(A) "Pattern A"

(B) "Pattern B"

SAFE OPERATION-2

8. Do not operate the excavator while under the influence

of alcohol, medication, controlled substances or while

fatigued.

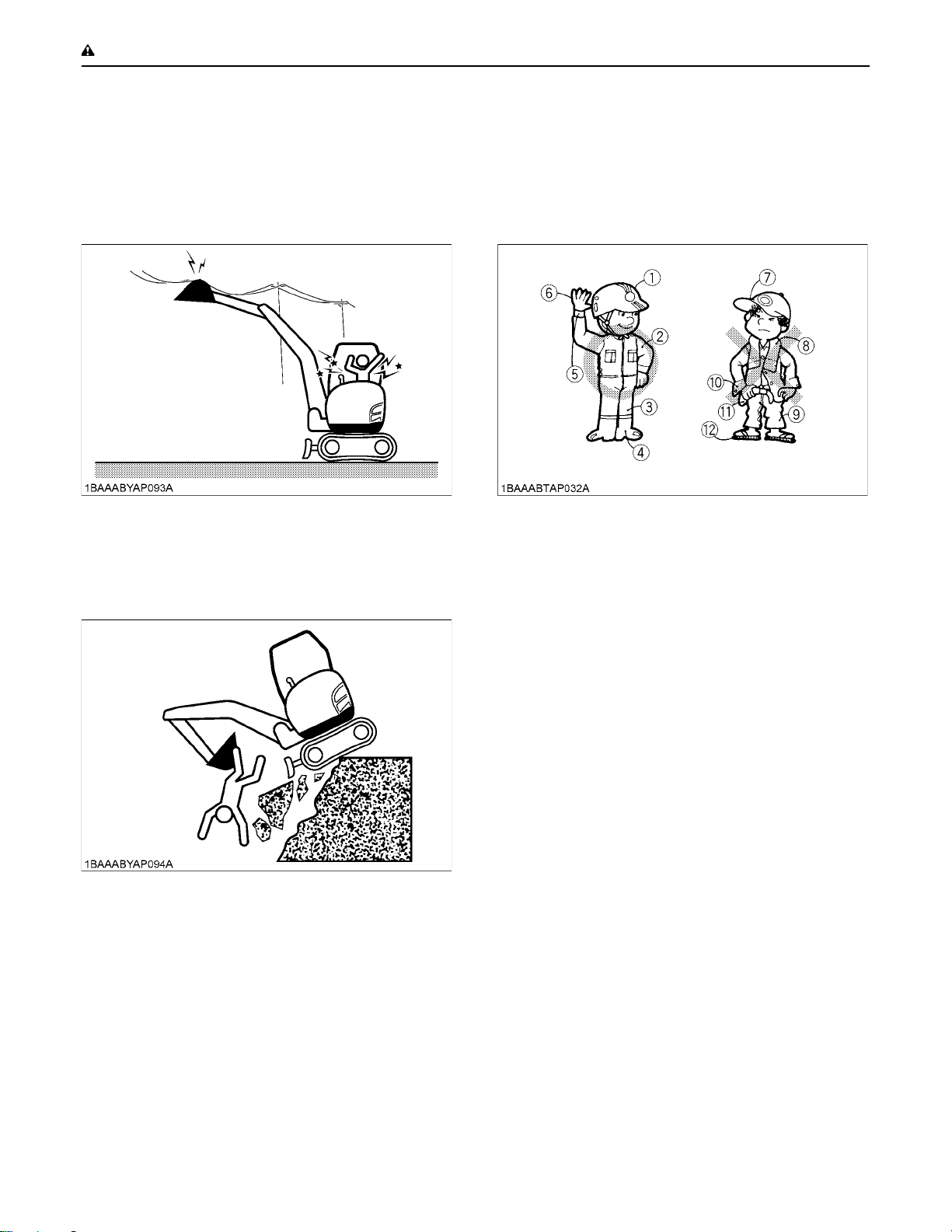

9. Check the surroundings carefully before using the

excavator or when attachments are being attached.

A Pay attention to the overhead clearance with electric

wires.

A Check for pipes and buried cables before digging. Use

your local utility service to check for such items (if

available).

A Check for hidden holes, hindrances, soft underground,

and overhangs.

11.Do not wear baggy, torn or oversized clothing when

working with the excavator as such clothing can get

caught in rotating parts or control elements which can

cause accidents or injuries. Wear adequate safety

clothing, e.g. safety helmet, safety shoes, eye

protection, ear protection, working gloves, etc., as

necessary and as prescribed by law or statutes.

(1) Helmet

(2) Clothing fit for work

(3) Tight seams

(4) Good grip footwear

(5) Well fitting cuffs

(6) Working gloves

(7) Soft hat

(8) Towel

(9) Baggy trousers

(10) Loose cuffs of the shirt

(11) Baggy shirt

(12) Sandals or open-toed shoes

A Do not allow any persons within the working range of

the excavator during operation.

10.Do not allow anyone to use the excavator until they

have been advised of the work to be performed and

they have indicated that they have read and

understood the operator's manual.

12.Do not allow passengers to ride on any part of the

excavator at any time. The operator must remain in the

excavator seat during operation.

13.Check levers, pedals and all mechanical parts for

correct adjustment and wear. Replace worn or

damaged parts immediately. Check nuts and bolts

regularly for correct torque.

14.Keep your excavator clean. Heavy soiling, grease,

dust and grass can cause fires, accidents or injuries.

15.Use only KUBOTA authorized attachments.

16.Before starting the excavator, be absolutely sure that

the excavator has been filled with fuel, lubricated,

greased and undergone all necessary maintenance.

17.Do not modify the excavator, as such could lead to

unforeseen safety problems.

18.Do not operate a hydraulic hammer on anything that is

above the operator's seat level as objects may fall into

the operator station.

19.Make sure attachments, particularly those utilizing

quick attach systems, are securely mounted.

20.Install protective guards on the excavator when

working in areas where objects may fall or be thrown.

2. OPERATING THE EXCAVATOR

Operator safety is a priority. Safe operation, specifically

with respect to overturning hazards, entails understanding

the equipment and environmental conditions at the time of

use. Some prohibited uses which can affect overturning

hazards include traveling and turning with implements

and loads carried too high etc. This manual sets forth

some of the obvious risks, but the list is not, and cannot

be, exhaustive. It is the operator's responsibility to be alert

for any equipment or environmental condition that could

compromise safe operation.

C Starting

1. Mount and dismount the machine safely. Always face

the machine. Always use handrails and available

steps and keep yourself well balanced. Do not grab or

hold any of the control levers and switches. Do not

jump on or off the machine, whether stationary or in

motion.

2. Start and control the excavator only from the

operator's seat. The driver should not lean out of his

seat when the engine is running.

3. Before starting the engine, make sure that the lock

levers are in the "LOCKED" position and all control

levers and pedals are in their neutral positions and the

seat belt is fastened correctly.

Before starting the engine, make sure that the control

levers, travel lever, pedals and other control elements

are not stuck and can be moved smoothly.

If stuck, for example, a lever may fail to return, possibly

putting you in danger.

If anything wrong is found, immediately pinpoint the

cause and correct it.

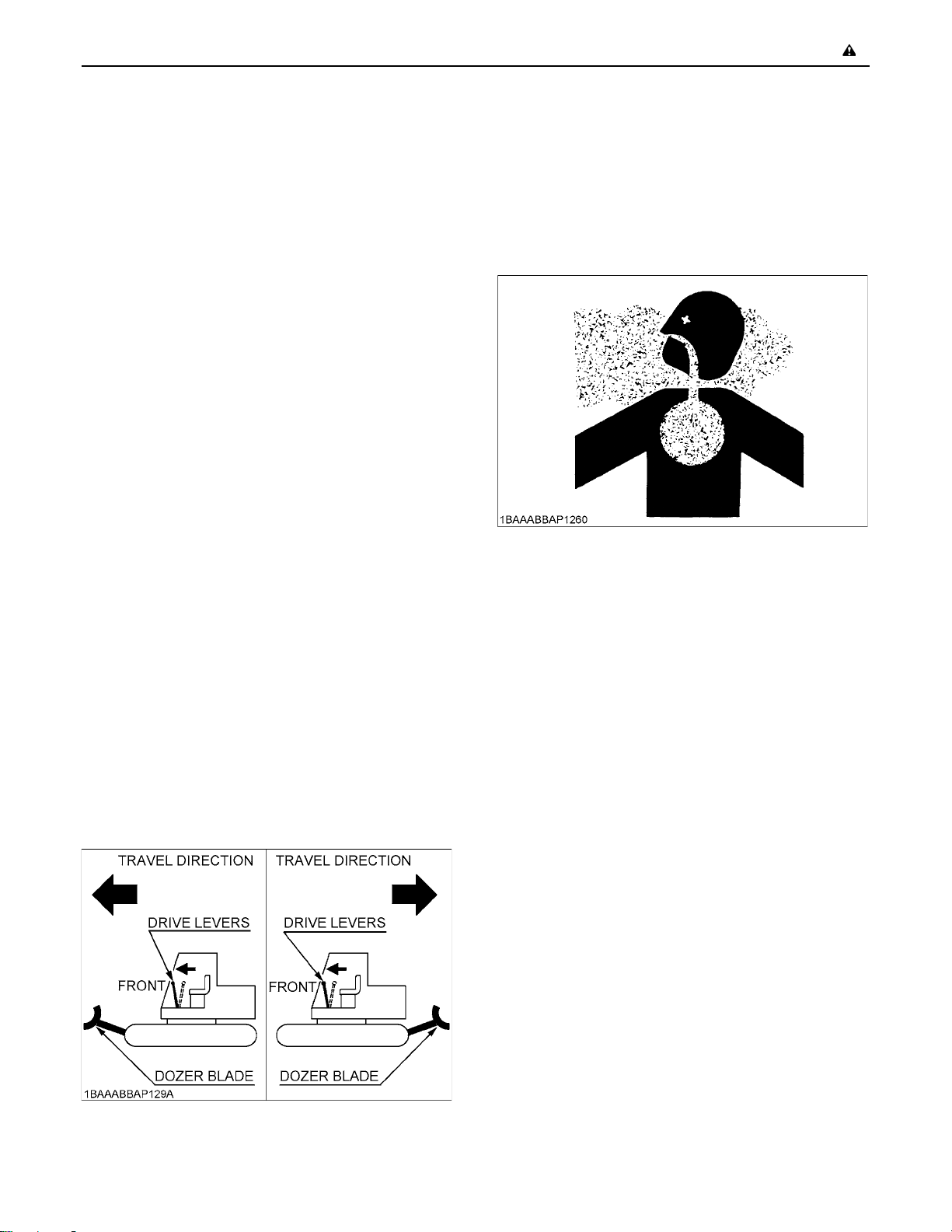

4. Before operating the excavator, make sure that the

dozer blade is in front of you. If the levers are activated

with the dozer blade at the rear, the tracks will move in

the opposite direction of the drive levers.

-3SAFE OPERATION

C Working

1. Do not operate or idle engine in a non-ventilated area.

Carbon monoxide gas is colorless, odorless, and

deadly. If you experience the initial symptoms of low to

moderate co poisoning, which include the following,

stop operation, seek medical attention and contact

your local dealer. These symptoms are: headache,

fatigue, shortness of breath, nausea, or dizziness.

2. Keep all safety equipment and covers in place.

Replace damaged or missing safety devices.

3. When operating, keep hands and body inside of the

ROPS / OPG (Top Guard Level I) protective envelope.

4. Take precautions against tipping over. Stay away from

steep slopes and embankments. Do not swing the

bucket downhill. Lower the dozer blade when digging.

Keep the bucket as low as possible while driving uphill.

Turn slowly on slopes (at reduced speed). Do not

place the excavator near the edges of trenches and

banks, as the earth can give way due to the weight of

the excavator.

Never cross an incline horizontally or at an angle,

which can cause the machine to rollover. Approach

inclines vertically to avoid loss of control.

Avoid performing any work with the machine when it is

on an incline, which could cause it to become

unbalanced and rollover. Always take care when

moving the machine on an incline.

5. Watch where you are going at all times.

Watch for and avoid obstacles. Remain alert for trees,

wires and other obstructions.

6. Do not change direction on steep slopes, or the

excavator could tip over.

Before changing direction, beware of people in the

work area.

7. When the working light alone do not provide sufficient

visibility, prepare additional stationary artificial lighting

and observe safety rules for night work.

8. When towing the excavator or pulling a load, the load

must be less than the strength of the towing line

attached to excavator.

SAFE OPERATION-4

Max. drawbar pull at

coupling hook

Max. vertical load at

coupling hook

9. The towing eye should not be used for tie down or

lifting of the machine.

10.When the excavator is parked or left unattended on a

slope, be sure to put the bucket on the ground and

place all control levers in neutral position, then brace

the tracks with chocks.

A When working in groups, always let the others

know what you are going to do before you do it.

Keep others away from the machine working area.

Be sure to lock the boom swing pedal when the

boom swing function is not used.

11.For details of operating the excavator, see the

"EXCAVATOR OPERATION" section.

C Safety for children

Tragedy can occur if the operator is not alert to the

presence of children. Children generally are attracted to

machines and the work they do.

1. Never assume that children will remain where you last

saw them.

2. Keep children out of the work area and under the

watchful eye of another responsible adult.

3. Be alert and shut your machine down if children enter

the work area.

4. Never carry children on your machine. There is not a

safe place for them to ride. They may fall off and be run

over or interfere with your control of the machine.

5. Never allow children to operate the machine even

under adult supervision.

6. Never allow children to play on the machine or on the

attachments.

7. Use extra caution when backing up. Look behind and

down to make sure the area clear before moving.

70.4 kN (7184 kgf) [15838 lbf]

7.2 kN (735 kgf) [1621 lbf]

3. AFTER OPERATION

Before leaving the machine,

A Park the excavator on a firm, flat and level surface. If

this is not possible, park across the slope.

A Lower the attachments and the dozer blade to the

ground.

A Stop the engine.

A Release pressure in the hydraulic system.

A Lock all control levers.

A Remove the key.

A Lock the CAB door (if equipped).

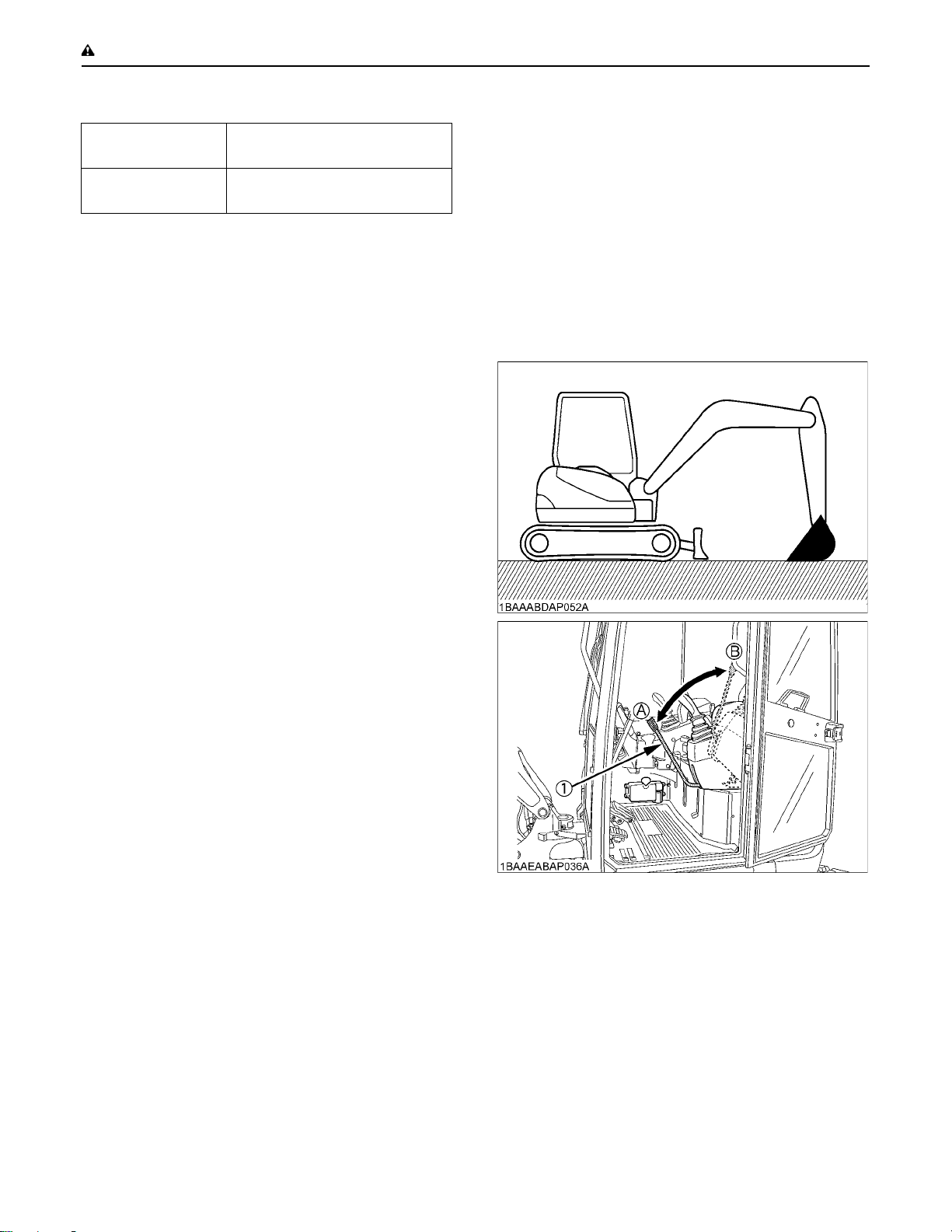

(1) Pilot control lock lever (A) "UNLOCK"

(B) "LOCKED"

-5SAFE OPERATION

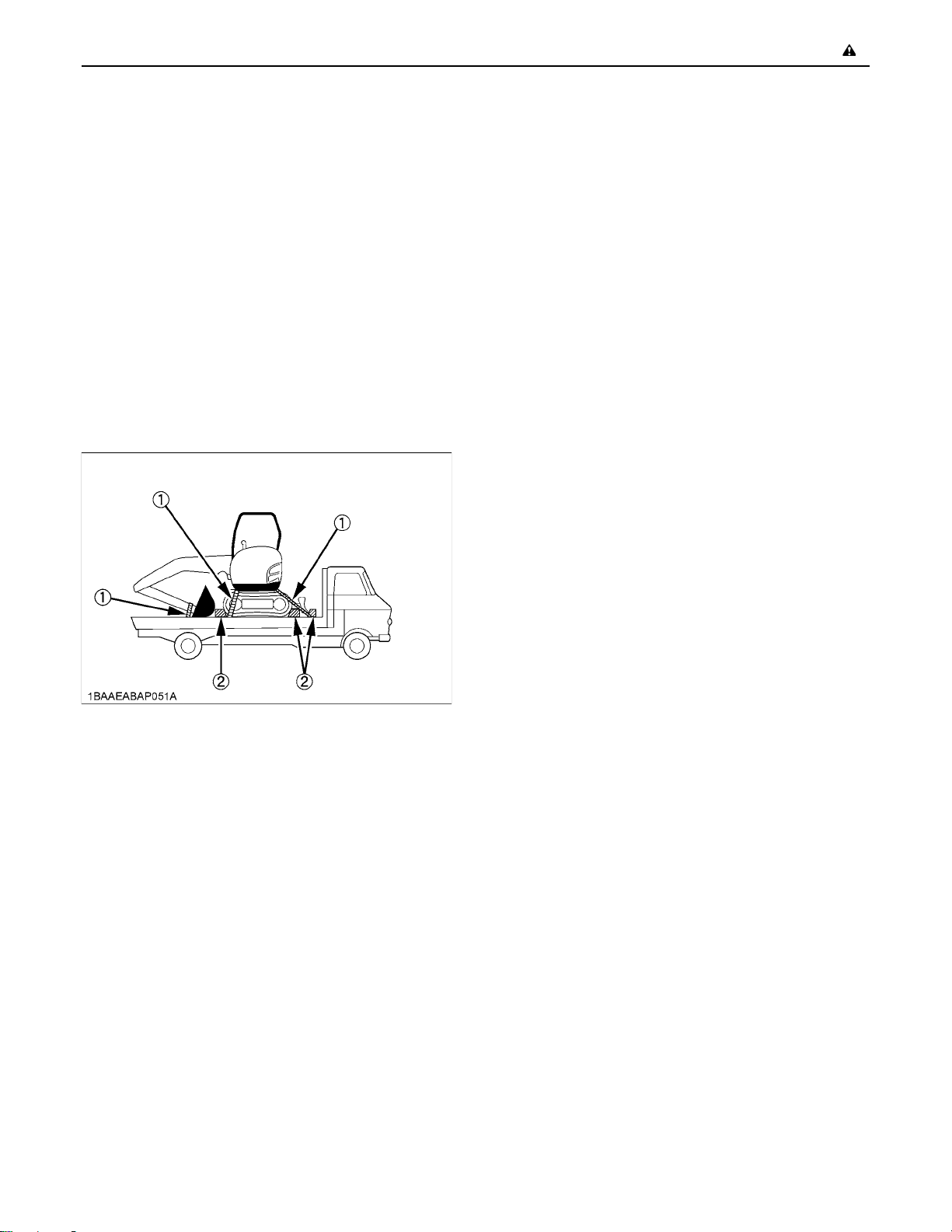

4. SAFE LOADING AND TRANSPORT OF

THE EXCAVATOR

1. Observe all regulations concerning the transport of

excavators on public roads.

2. Use adequately long and robust ramps when loading

on the machine. (for details see "TRANSPORTING

THE EXCAVATOR ON A VEHICLE")

3. Do not change the running direction and to avoid

tipping over, do not try to swing the attachment

crosswise to the loading ramps.

4. Lower the attachment on the loading bed and release

the pressure from the hydraulic system.

Stop the engine then remove the key.

After loading the excavator on the truck, block the

tracks with blocks and tie down the excavator at the

appropriate locations.

(1) Chain

(2) Block

5. MAINTENANCE

Before doing maintenance work on the excavator, place

the machine on a firm, flat and level surface, lower the

attachments to the ground, stop the engine, release

pressure trapped in the hydraulic system, lock all control

levers and remove the key. When dismantling hydraulic

parts, make sure that the hydraulic oil has cooled down

sufficiently to avoid burns.

Start maintenance work carefully, e.g. loosen plug slowly

so that oil will not squirt out.

1. Before doing work on the engine, the exhaust system,

the radiator and the hydraulics, let the excavator cool

down sufficiently.

2. Always turn off the engine when filling the fuel tank.

Avoid spilling and over-filling of fuel.

3. Smoking is prohibited while refueling or handling the

battery. Keep sparks and fire away from the fuel tank

and battery. Flammable gases escape from the

battery, especially during charging.

4. Do not use or charge a refillable type battery if the fluid

level is below the LOWER (lower limit level) mark.

Otherwise, the battery component parts may

prematurely deteriorate, which may shorten the

battery's service life or cause an explosion. Check the

fluid level regularly and add distilled water as required

so that the fluid level is between the UPPER and

LOWER levels.

5. Read and follow the directions "STARTING WITH AN

AUXILIARY BATTERY" in "OPERATION OF THE

ENGINE", when starting with an auxiliary battery.

6. Keep a first-aid box and a fire extinguisher at hand at

all times.

5. Avoid abrupt braking of the vehicle with the excavator

loaded. Sudden braking cause the excavator to move

and may cause a serious accident.

6. Do not use the hooks on the roof of cab or canopy for

lifting the excavator.

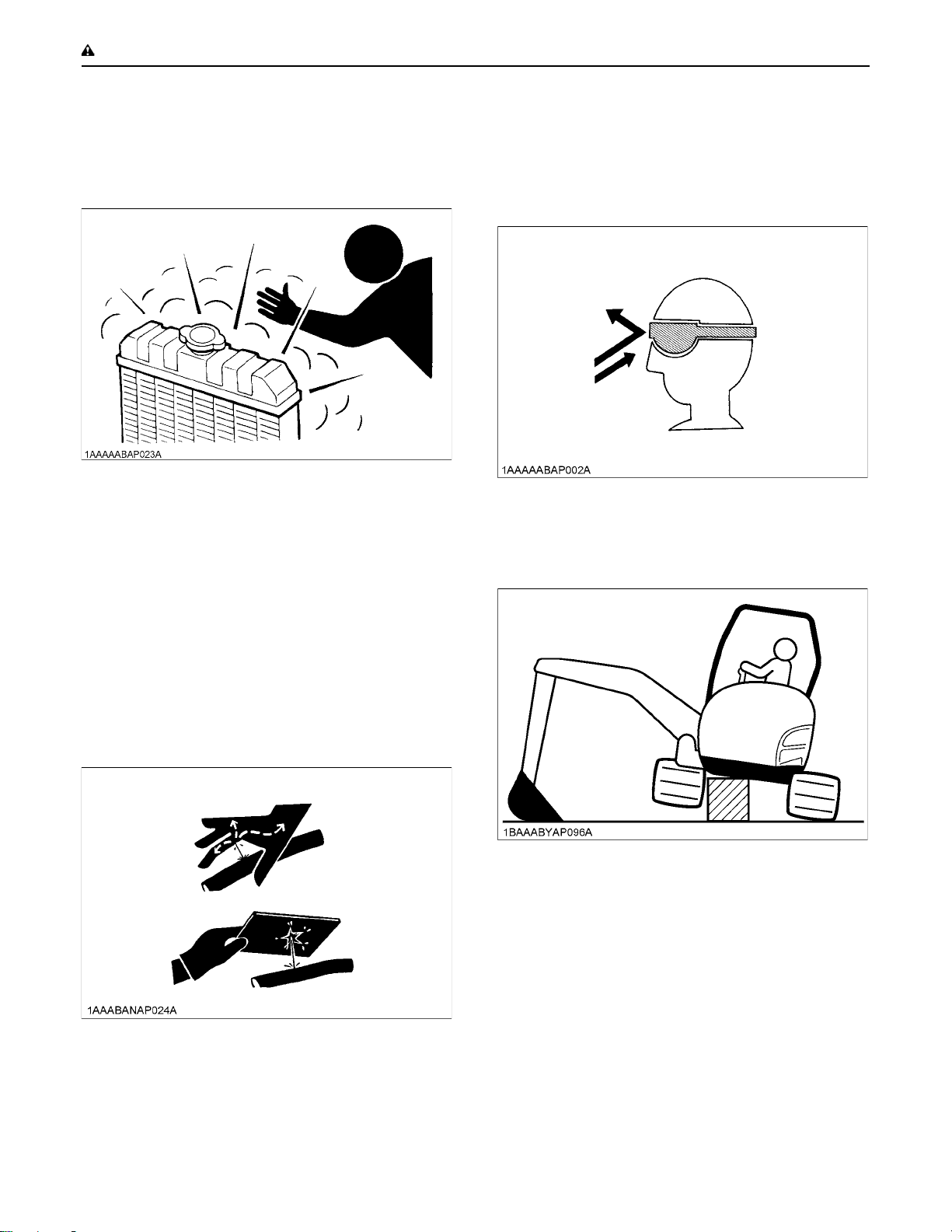

SAFE OPERATION-6

7. Do not open the radiator cap before the radiator has

cooled down sufficiently.

First loosen the cap to the first stop and allow the

system enough time to release the remaining

pressure. Then loosen the cap completely.

8. To avoid short-circuiting the battery, always remove

the ground cable first and attach the positive cable

first.

9. Oil under high pressure can penetrate the skin and

may be harmful to your health if not treated

immediately.

10.Leaking hydraulic fluid has enough pressure to

penetrate the skin and cause serious injuries.

Leakages from pin holes can be totally invisible. Do

not use hands for checking for leaks. Always use a

piece of wood or cardboard. It is strongly

recommended that you use a face mask or eye

protection.

Should injuries occur with leaking hydraulic fluid,

contact a doctor immediately. This fluid can cause

gangrene or serious allergic reactions.

13.To avoid fire, do not heat the hydraulic components

(tanks, pipes, hoses, cylinders) before they have been

drained and washed.

14.Use eye protection or a face mask to protect the eyes

and respiratory system against dust and other foreign

particles.

15.Securely support excavator with stands or suitable

blocking before working underneath. For your safety,

do not work under any hydraulically supported

devices. They can settle, suddenly leak down, or be

accidentally lowered.

11.To avoid environmental damage from acid and heavy

metals, dispose of the battery appropriately.

12.Observe all laws and regulations concerning the

disposal of used oil, coolants, solvents, hydraulic

fluids, battery acids and batteries.

16.Do not dismantle the spring of the track tensioner. If

dismantling is necessary, contact your KUBOTA

dealer where the machine was purchased, or

competent service shop. The assembly must be done

according to the KUBOTA work shop manual (W.S.M.)

for the product involved.

17.When lifting the machine itself with an attachment,

place a safety block or safety post to prevent the

machine from rolling over. Keep the pilot control lock

lever in the "LOCKED" position.

18.Inspect ROPS / OPG (Top Guard Level I) for damage

and if damage is found contact your KUBOTA dealer

for repair.

19.KUBOTA does not use asbestos containing

components and recommends against the use of such

components. Components containing asbestos

should be handled in accordance with applicable

regulations and industry practice.

20.Do not open a high-pressure fuel system. Highpressure fluid remaining in fuel lines can cause

serious injury. Do not disconnect nor attempt to repair

fuel lines, sensors, or any other components between

the high- pressure fuel pump and injectors on engines

with high-pressure common rail fuel system.

21.To avoid hazardous high voltage, turn the key switch

to the "STOP" position and disconnect the battery

ground cable if it is necessary to check to repair the

computer, harness or connectors.

22.Fire prevention

Excavator and some attachments have components

that are at high temperatures under normal operating

conditions. The primary source of high temperatures is

the engine and exhaust system. The electrical system,

if damaged or incorrectly maintained, can be a source

of arcing or sparks.

The following fire prevention guidelines will help to

keep your equipment up and running efficiently and

keep the risk of fire to a minimum.

A Blow off all accumulated debris near hot engine

exhaust components such as turbocharger and

exhaust manifold as well as exhaust pipes and muffler

more frequently when working in severe conditions.

A Clean out all accumulated flammable debris such as

leaves, straw, pine needles, branches, bark, small

wood chips and any other combustible materials from

inside the machine belly pans or lower unit structures

as well as from area in proximity to the engine.

A Inspect all fuel lines and hydraulic hoses for wear or for

deterioration. Replace them immediately if they begin

to leak.

A Examine electrical wiring and connectors frequently

for damage. Repair any wires that are loose or frayed

before operating the machine. Clean all electrical

connections and tighten all electrical connections as

necessary.

A Inspect the exhaust system daily for any signs of

leakage. Check for broken pipes and muffler and also

for loose or missing bolts, nuts and clamps. If any

exhaust leaks or fractured parts are found, repairs

must be completed prior to operation.

A Always keep a multipurpose fire extinguisher on or

near the machine. Be familiar with the operation of the

fire extinguisher.

-7SAFE OPERATION

SAFE OPERATION-8

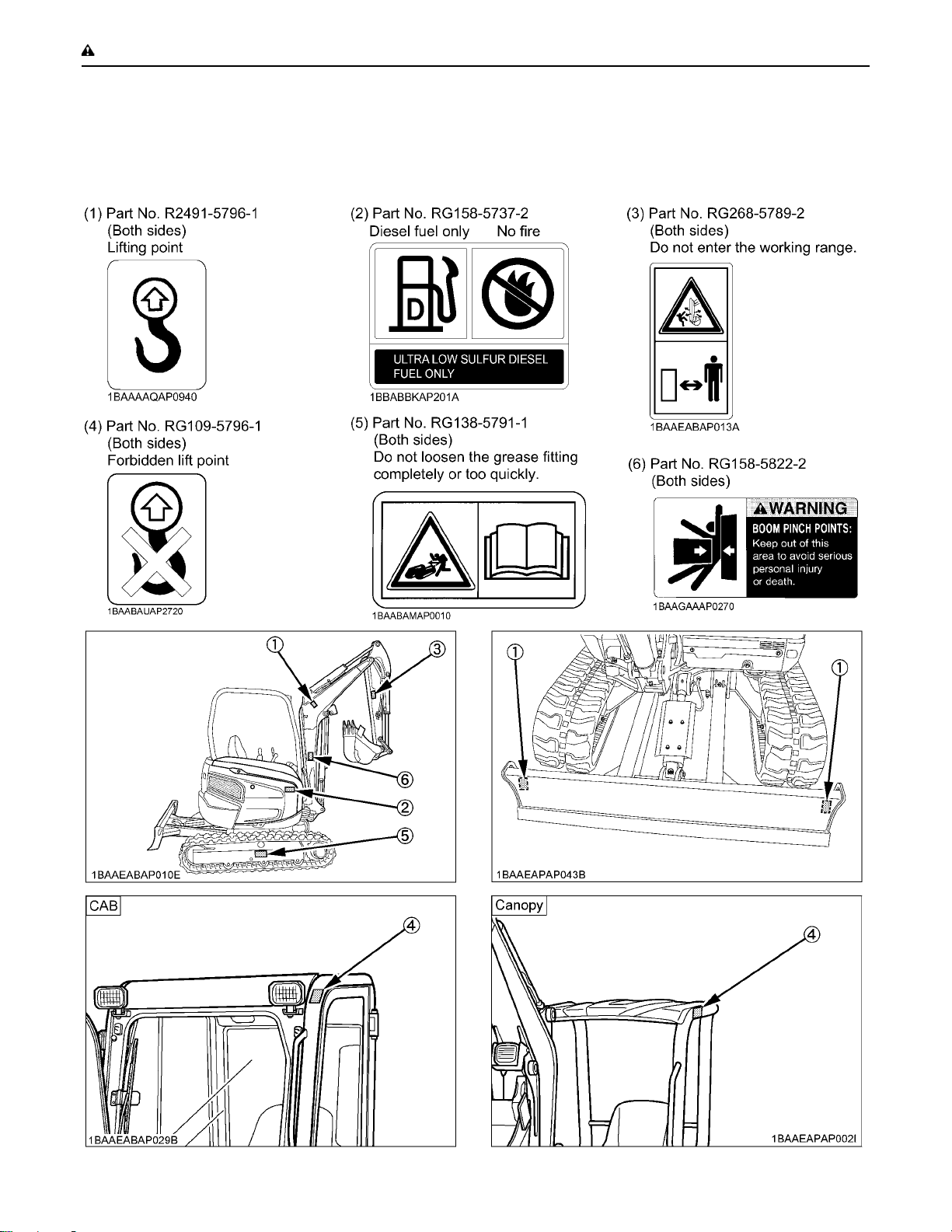

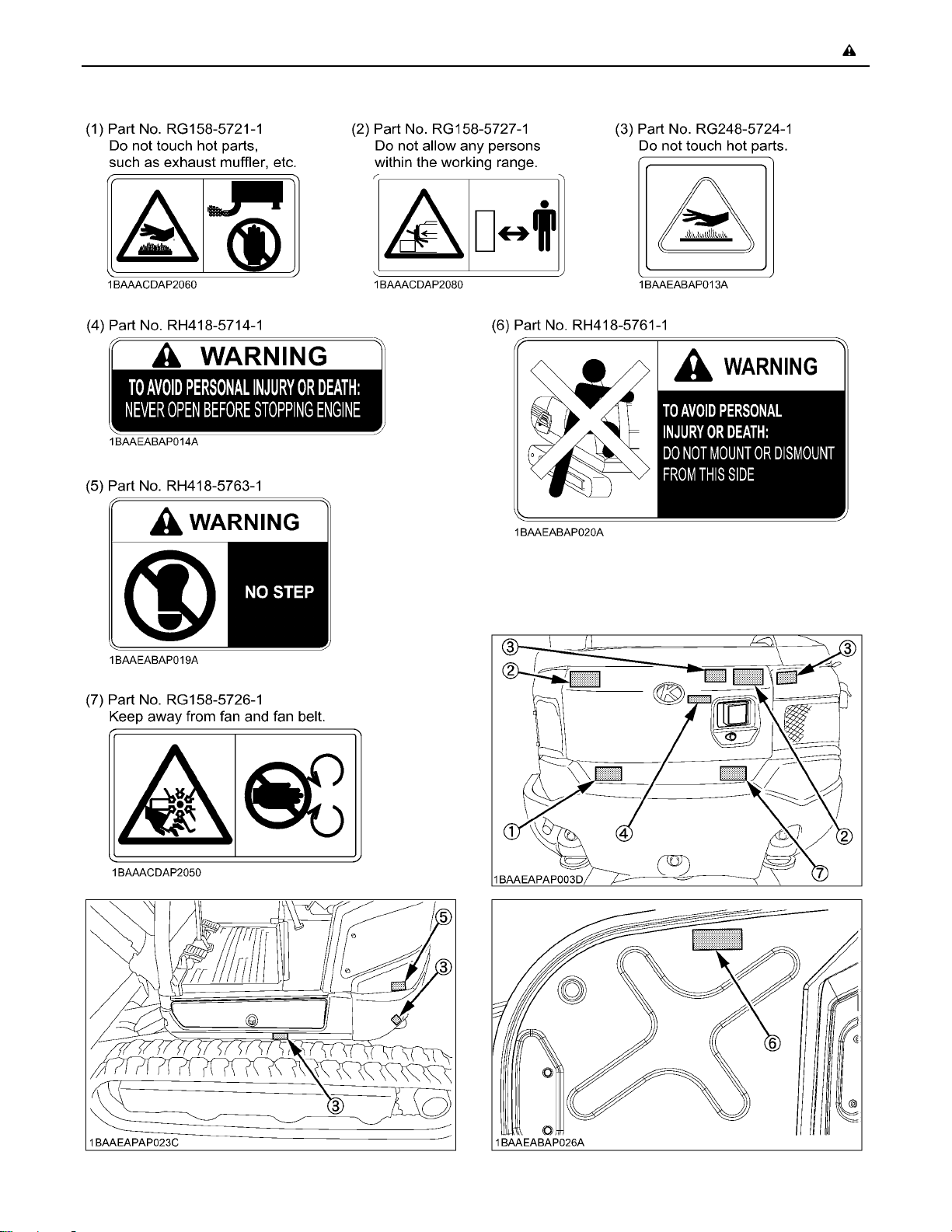

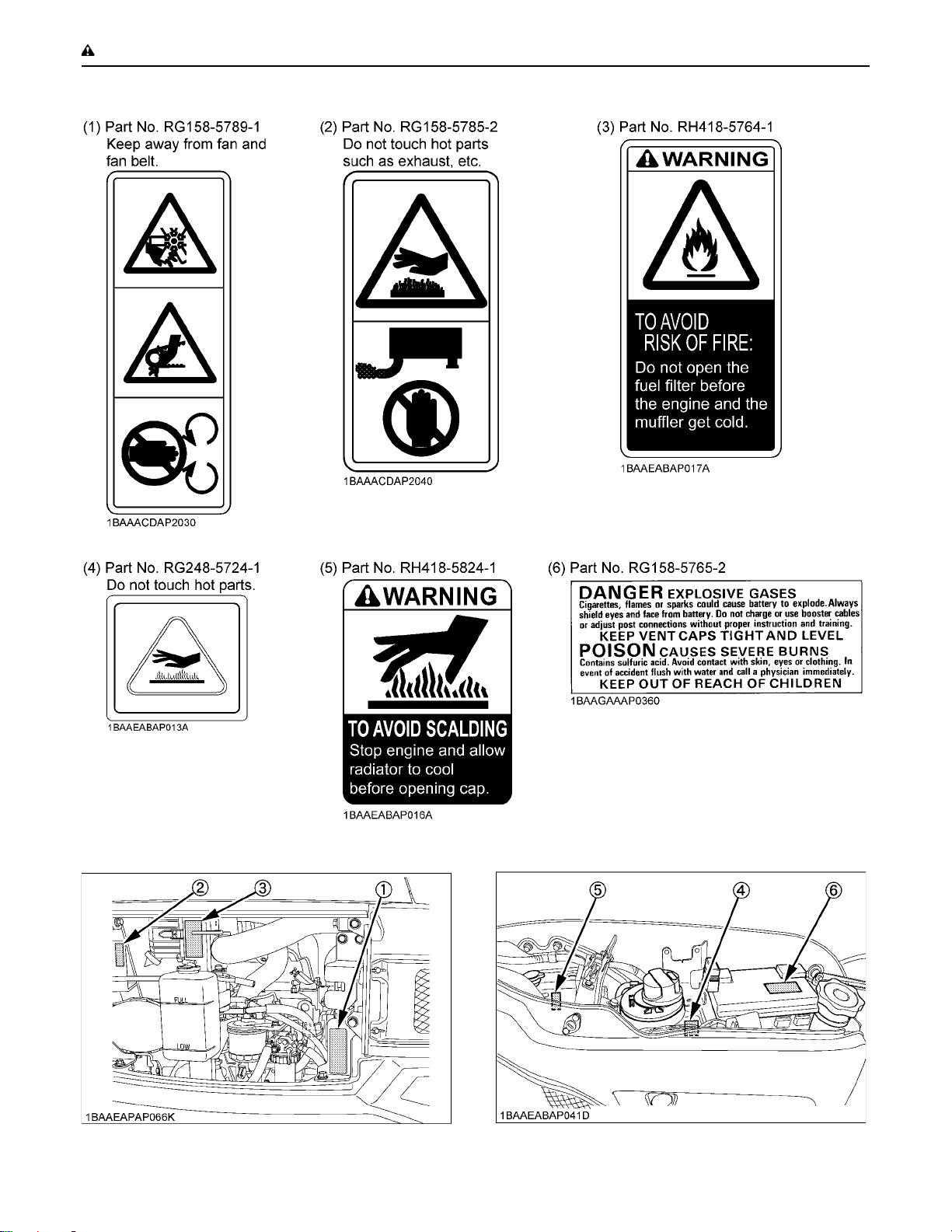

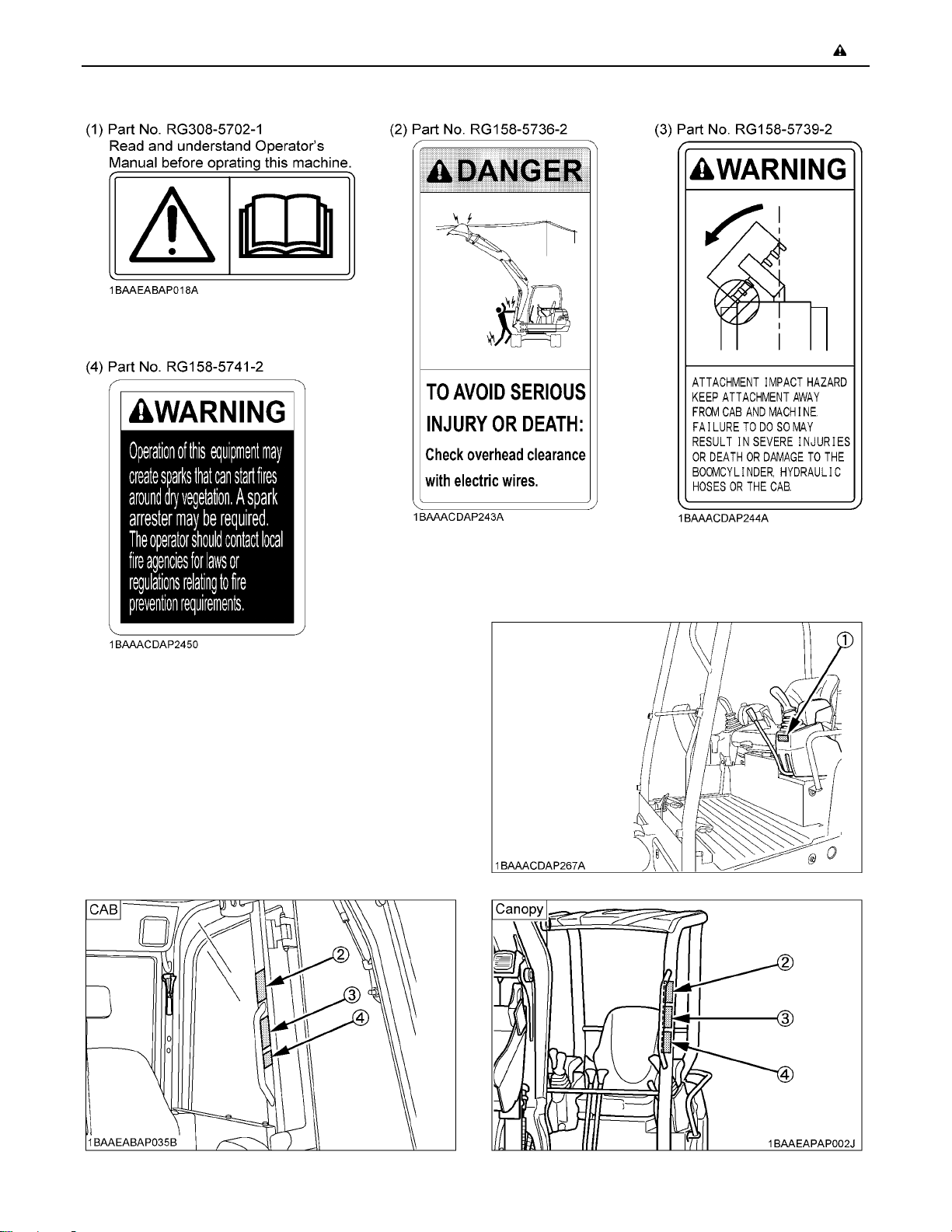

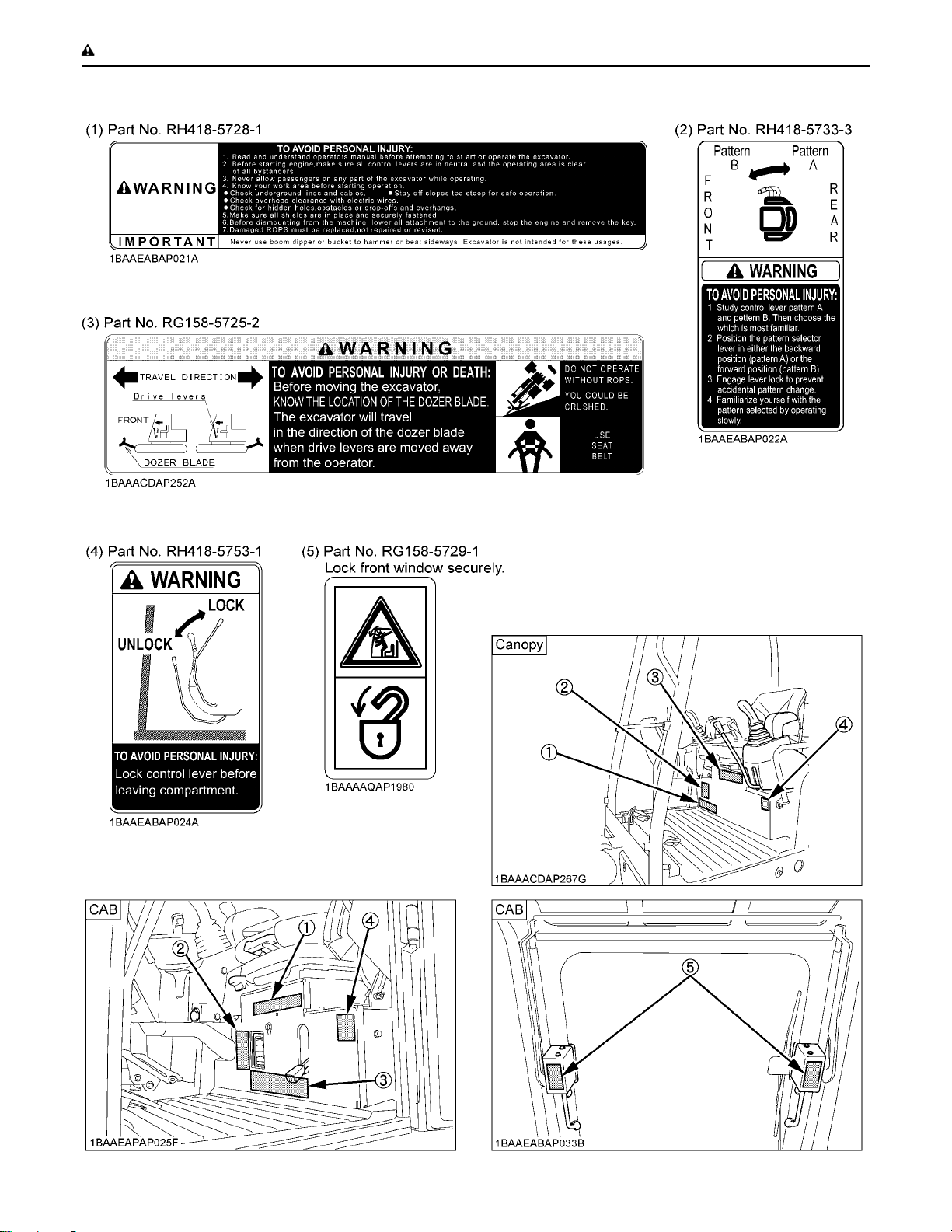

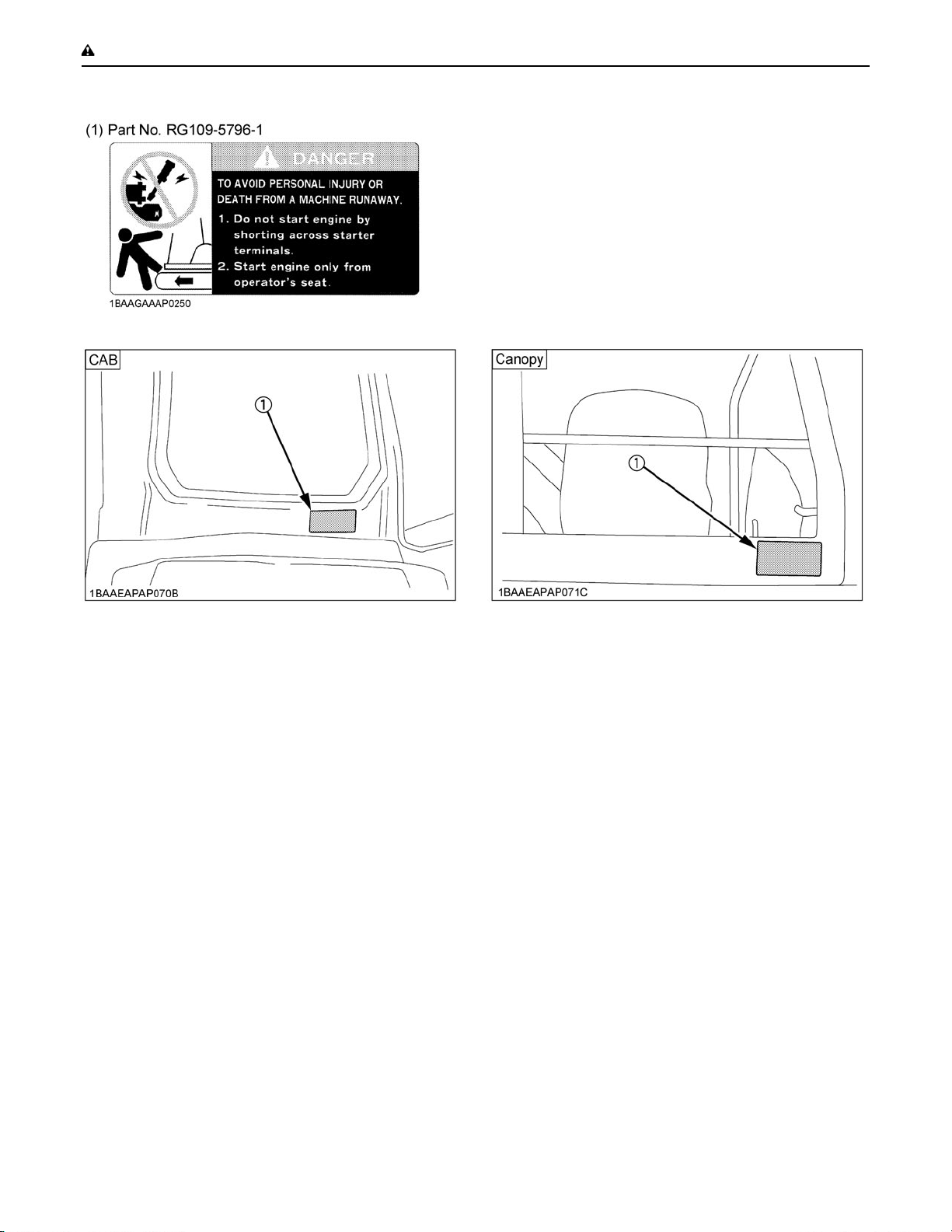

6. DANGER, WARNING AND CAUTION LABELS

Keep the safety and warning symbols (labels ) on the excavator clean and legible, replacing them if necessary.

The positioning of the safety symbols is illustrated in the following figures.

-9SAFE OPERATION

SAFE OPERATION-10

-11SAFE OPERATION

SAFE OPERATION-12

-13SAFE OPERATION

SAFE OPERATION-14

7. CARE OF DANGER, WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, and dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels from your KUBOTA dealer.

4. If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new label(s) is

(are) attached in the same location(s) as the replaced component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to outside

edge.

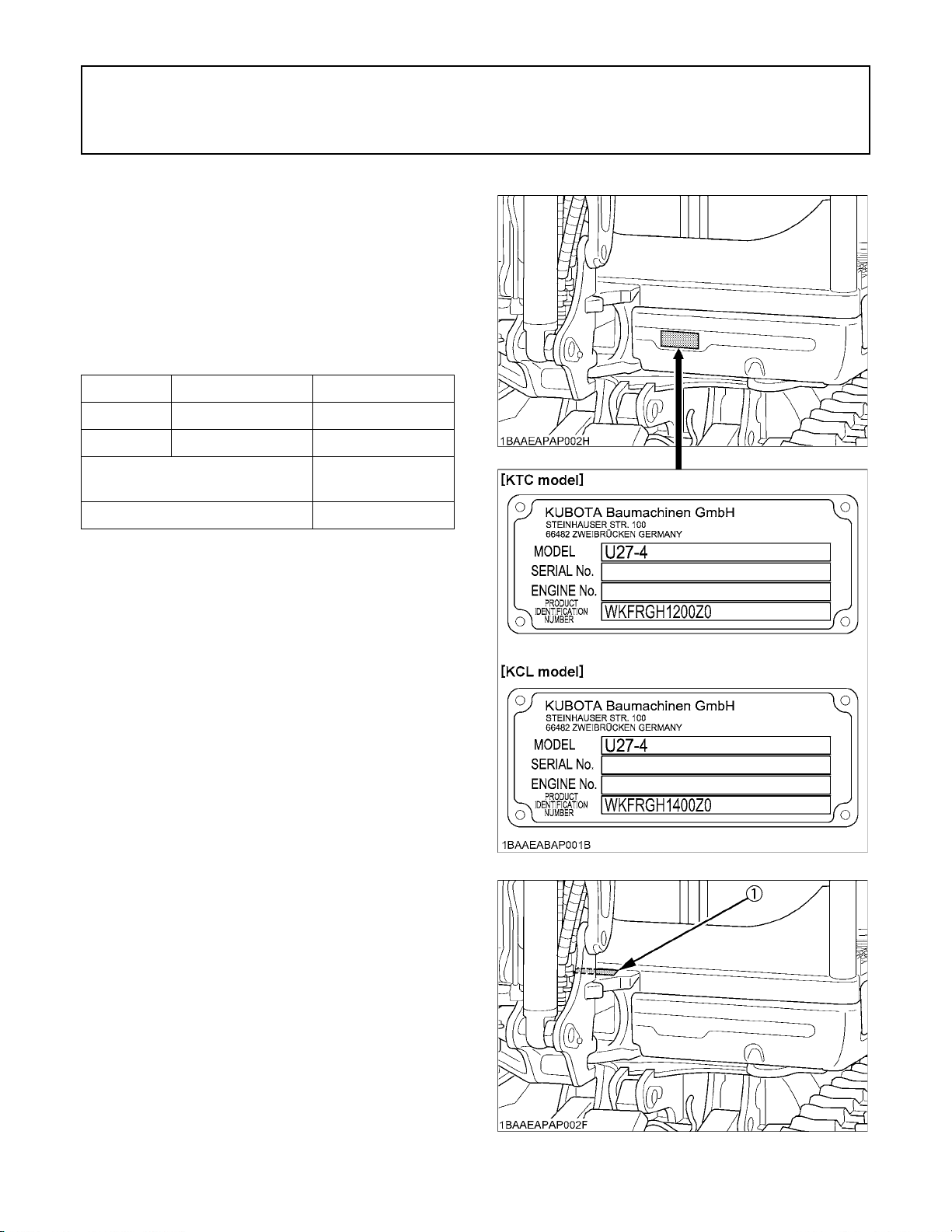

DEALER SERVICE

Your KUBOTA dealer is always ready to help so that your

excavator offers the best performance. After having

carefully read these instructions, you will realize that

much of the routine maintenance can be done by yourself.

For service, contact the KUBOTA Dealer shop from which

you purchased your product, or your local KUBOTA

dealer. When ordering spare parts from your KUBOTA

dealer, always mention the serial number of the excavator

and the engine.

Note these numbers right away in the supplied lines.

Model Serial No.

Excavator

Engine

Dealer's name

(To be filled in through the owner)

1DEALER SERVICE

Date of purchase

C Warranty policy

This product is warranted under the KUBOTA Limited

Express Warranty, a copy of which may be obtained from

your selling dealer. No warranty shall, however, apply if

the product has not been handled according to the

instruction given in the Operator's Manual even it is within

the warranty period.

The Product(s) described in this Operator’s Manual are

designed and manufactured only for the country in which

they are initially wholesaled by KUBOTA or one of its

affiliated companies. Neither KUBOTA Corporation nor its

affiliated companies provide warranty for any Product

which is re-sold or retailed in any country other than the

country for which the Product(s) were designed or

manufactured.

C Scrapping the product and its procedure

To put the product out of service, correctly follow the local

rules and regulations of the country or territory where you

reside. If you have questions, consult your local KUBOTA

Dealer.

(1) Serial No.

DEALER SERVICE2

(1) Engine serial No.

TECHNICAL DATA

KUBOTA EXCAVATOR

Model name U27-4

Type canopy cabin

Mass (without operator) kg (lbs.) 2490 (5490) 2590 (5711)

Volume (CECE) m (cu.in.) 0.054 (3295)

Standard

bucket

Width [with side cutter] mm (in.) 450 [475] (17.7 [18.7])

Weight kg (lbs.) 55 (121)

3TECHNICAL DATA

Type

(water cooled 4 cycle Diesel)

Model name KUBOTA D1105-E4-BH-5

Engine

Performance

Dozer (width & height) mm (in.) 1500 x300 (59 x 12)

Boom swing angle

Total displacement cm (cu.in.) 1123 (68.5)

Output

Rated speed rpm 2400

Swing speed rpm 9.9

Travel

speed

Ground pressure kPa

(kgf/cm )

[psi]

Climbing angle % (deg) 27 (15)

Max. lateral sway % (deg) 18 (10)

SAE gross kW (HP) 15.6 (20.9)

SAE Net kW (HP) 14.8 (19.8)

fast km/h (mph) 4.5 (2.8)

slow km/h (mph) 2.5 (1.6)

Left rad (deg) 1.31 (75)

Right rad (deg) 0.96 (55)

3 cylinder - diesel engine water cooled

23.7

(0.24)

[3.44]

24.7

(0.25)

[3.58]

Max. displacement

Pressure

connection

for attachments

Fuel tank capacity L (US gal) 33 (8.72)

A Above dimensions are based on the machine with JPN bucket.

JPN = made in Japan

A Above dimensions are based on the machine with rubber crawlers.

A Specifications subject to change without notice.

L (US gal) / min

Max. pressure MPa

(kgf/cm )

[psi]

48.0 (12.7)

21.6

(220)

[3133]

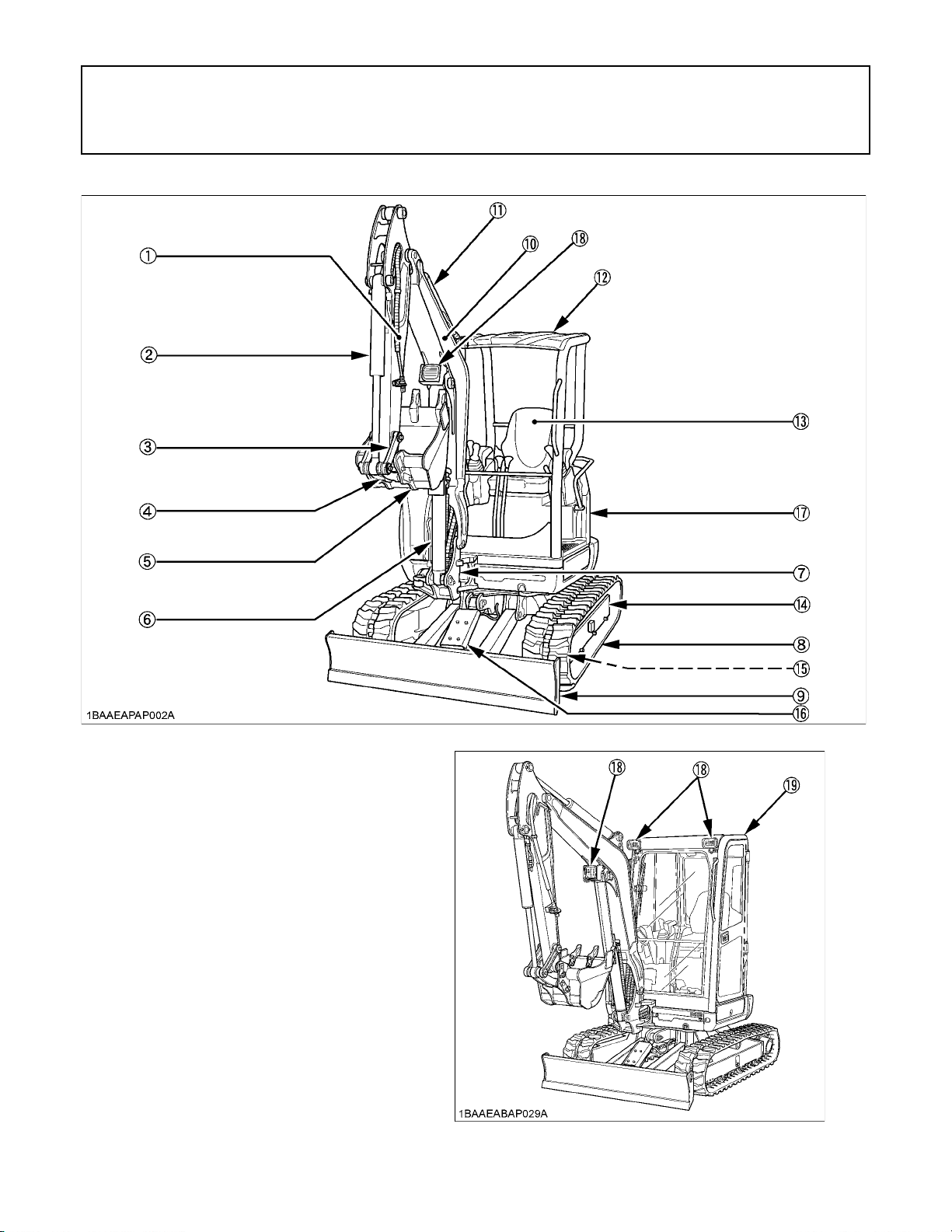

4 DESCRIPTION OF MACHINE PARTS

DESCRIPTION OF MACHINE PARTS

[Canopy]

DEPICTED CONTENTS

(1) Arm

(2) Bucket cylinder

(3) Bucket link 2

(4) Bucket link 1

(5) Bucket

(6) Boom cylinder

(7) Swing bracket

(8) Crawler

(9) Dozer

(10) Boom

(11) Arm cylinder

(12) ROPS

(13) Operator's seat

(14) Drive sprocket

(15) Front idler

(16) Dozer cylinder

(17) Engine hood

(18) Working light

(19) Cabin

[Cabin]

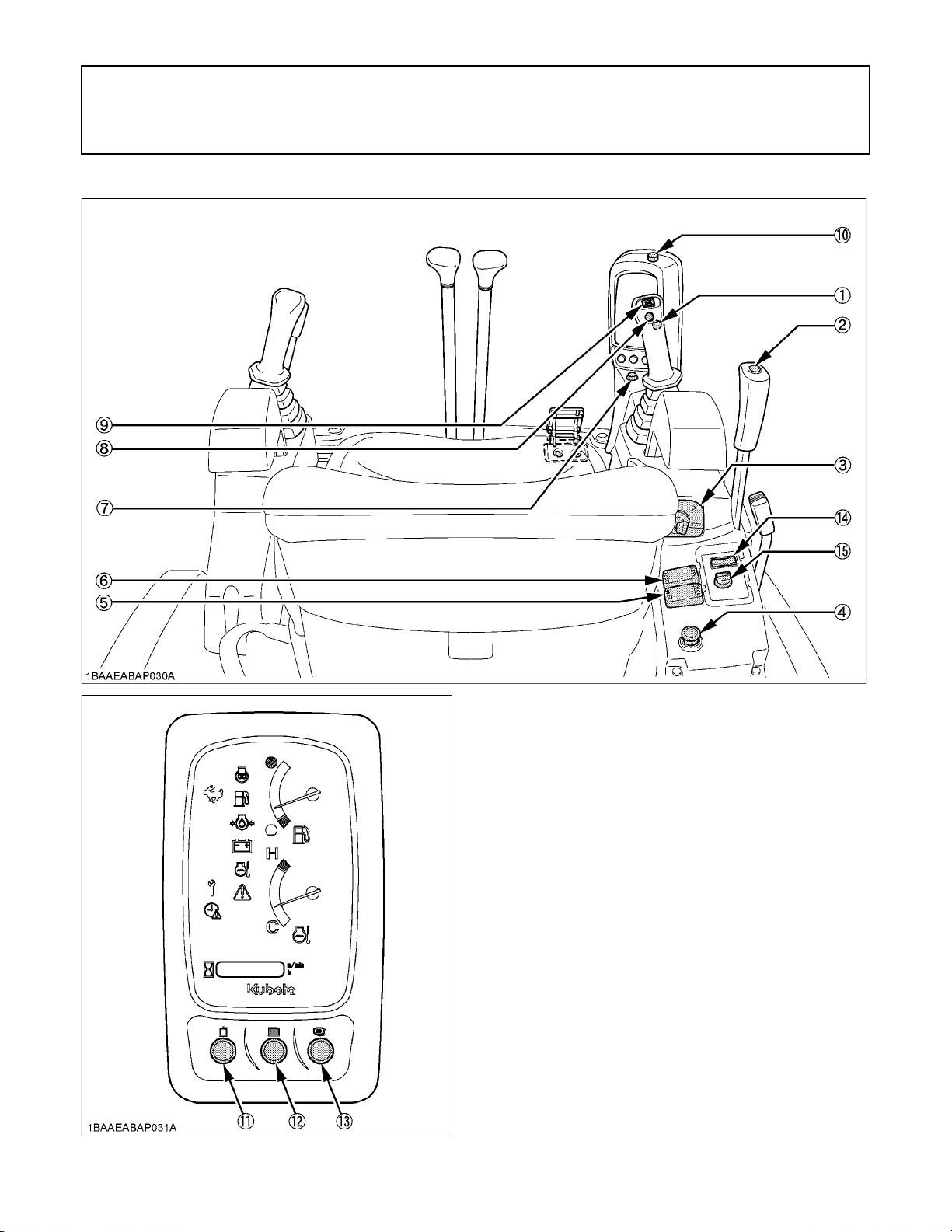

5INSTRUMENT PANEL AND CONTROL ELEMENTS

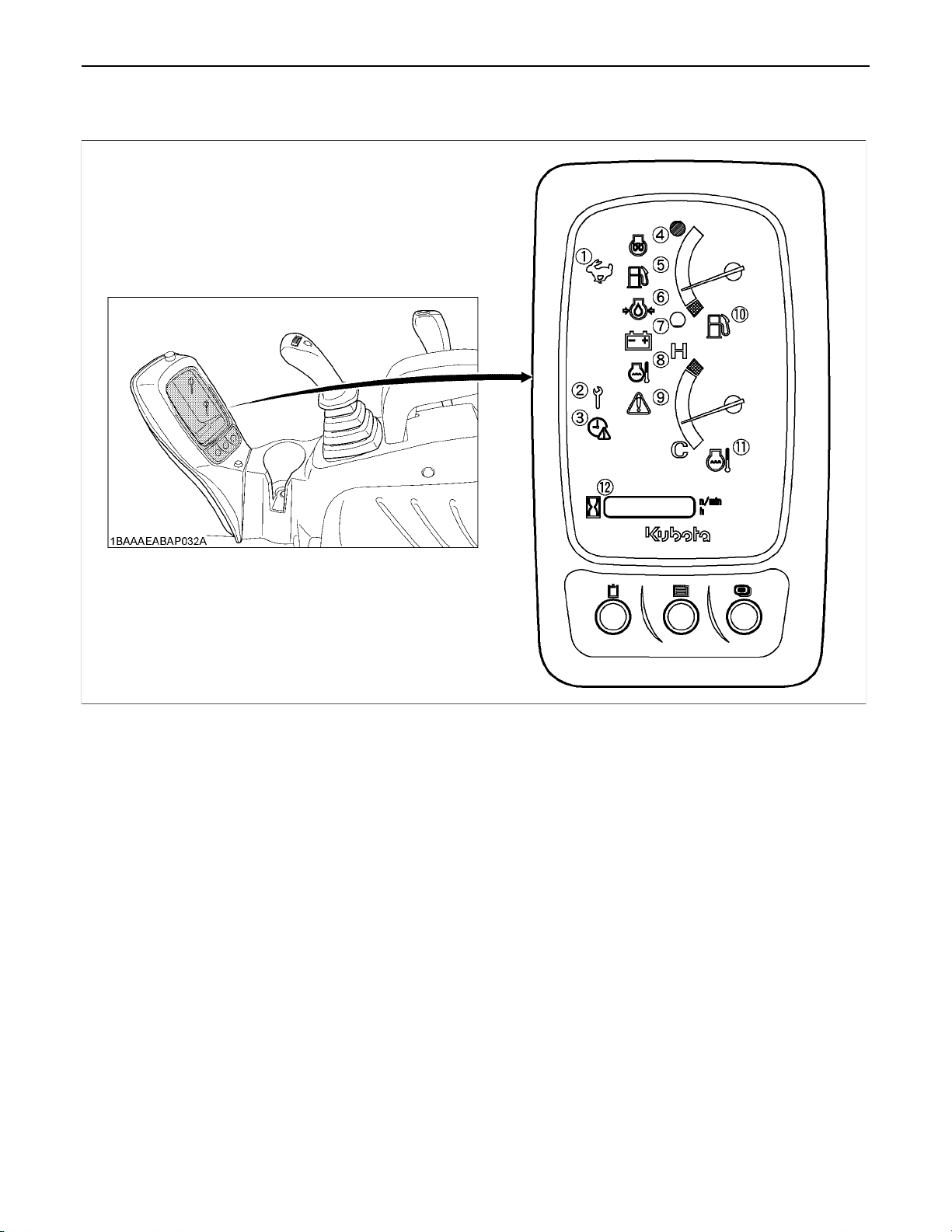

INSTRUMENT PANEL AND CONTROL ELEMENTS

B Switches

DEPICTED CONTENTS

(1) One way hold switch............................................

(2) Travel speed switch.............................................

(3) Starter switch.......................................................

(4) Engine stop button...............................................

(5) Beacon light switch..............................................

(6) Working light switch.............................................

(7) Indicator for auxiliary port.....................................

(8) Horn switch..........................................................

(9) Rocker switch for auxiliary port............................

(10) Potentiometer for auxiliary port..........................

(11) Enable switch for auxiliary port (switch 1)..........

(12) User setting switch (switch 2)............................

(13) Display selector switch (switch 3)......................

[Cab model]

(14) Wiper / washer switch........................................

(15) Heater switch.....................................................

Ref. page

27

30

12

19

22

9, 22

26

12

26

34

26

13

13

8

9

6 INSTRUMENT PANEL AND CONTROL ELEMENTS

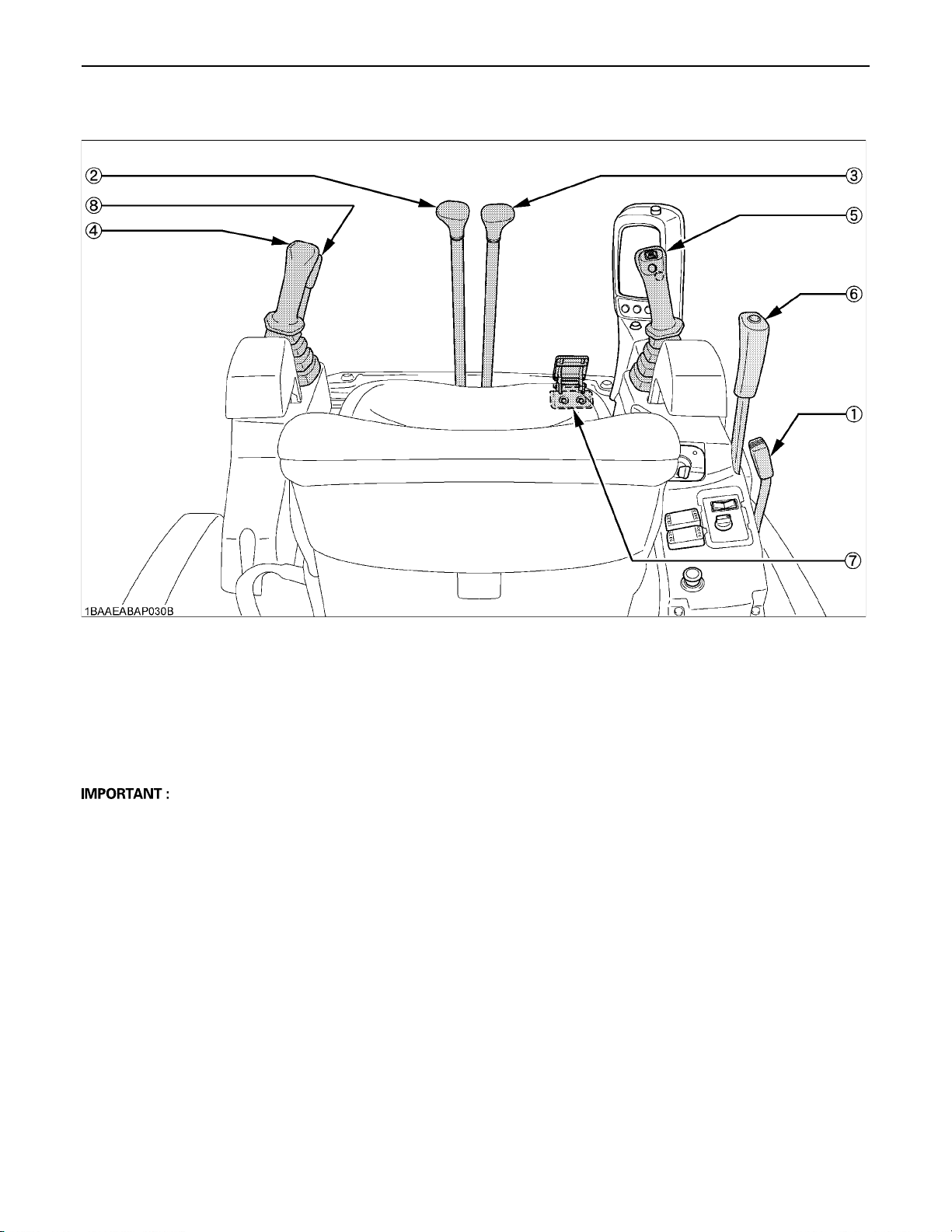

B Control Pedals and Levers

DEPICTED CONTENTS

(1) Throttle lever........................................................

(2) Drive lever (left)....................................................

(3) Drive lever (right)..................................................

(4) Control lever for front attachments (left)...............

(5) Control lever for front attachments (right).............

(6) Dozer control lever................................................

(7) Boom swing pedal.................................................

(8) Pilot control lock lever *.........................................

Ref. page

29

29

29

24, 24, 25

24, 24, 25

26

25

11

D Pulling up the pilot control lock lever prevents inadvertent machine movement.

B Instrument Panel

7INSTRUMENT PANEL AND CONTROL ELEMENTS

DEPICTED CONTENTS

(1) Travel speed indicator lamp.................................

(2) Periodic check lamp.............................................

(3) Clock setting request lamp...................................

(4) Glow lamp.............................................................

(5) Remaining fuel warning lamp................................

(6) Engine oil pressure warning lamp.........................

Ref. page

30

66

13

15

16

15

(7) Battery charge lamp..............................................

(8) Coolant temperature warning lamp.......................

(9) Warning lamp........................................................

(10) Fuel gauge..........................................................

(11) Coolant temperature gauge................................

(12) LCD....................................................................

Ref. page

15

16

17

16

16

16

8 CHECKS BEFORE START

CHECKS BEFORE START

DAILY CHECKS

In order to avoid damage, it is important to check the

condition of the excavator before starting.

To avoid personal injury or death:

A Do maintenance work on the excavator only on

even ground with the engine off and the pilot

control lock lever in the "LOCKED" position.

Checks

Go around the excavator and check for visual damage

and wear.

Check coolant level. (See "DAILY CHECKS" in

"MAINTENANCE" section.)

Check fuel level.

Check engine oil level.

Check hydraulic fluid level.

Check air filter for clogging.

Check all greasing points.

Check all control lamps, indicators, revolution counter and

hour meter.

Confirm all controls move freely and do not stick.

Check the light system.

Check the seat belt and the ROPS/OPG (Top Guard Level

I) safety device.

Check the condition of the safety and warning labels. (See

"DANGER, WARNING AND CAUTION LABELS" in

"SAFE OPERATION" section.)

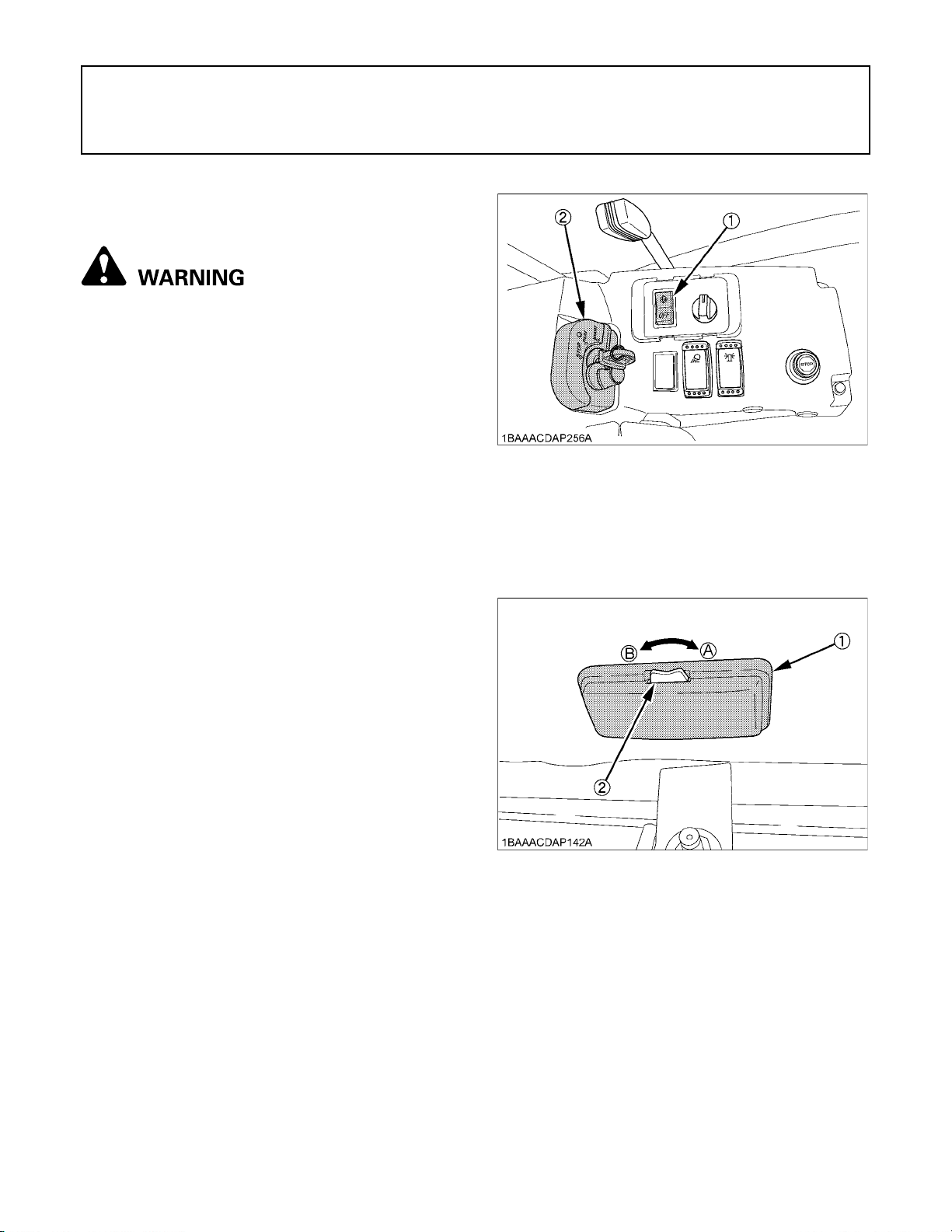

(1) Wiper / Washer switch

(2) Starter switch

BInterior Lamp

To turn on the interior lamp, set the interior lamp switch to

the "ON" position.

CAB TYPE MACHINES

BWiper/Washer Switch

To move the wiper, turn on the switch for the wiper when

the starter switch in position "RUN". A further push on the

switch will activate the washer system. Even when the

wiper switch is in position "OFF", the washer switch

functions if it is pressed.

A Do not activate the washer switch if the tank for the

cleaning fluid is empty; the pump can be damaged.

A Do not activate the wiper switch if the window is dry. In

this case, make sure that cleaning fluid is applied to

the pane before activating the wiper.

A In frosty conditions, make sure that the wiper blade is

not frozen to the glass before switching-on. The motor

can be damaged if the wiper system is used under

such conditions.

(1) Interior lamp

(2) Interior lamp switch

(A) "ON"

(B) "OFF"

Loading...

Loading...