Page 1

MODEL U17

PRINTED IN JAPAN

English (U.S.A.)

Code No. RA238-8150-7

KUBOTA Corporation 2008

©

U

17

1BAABBKAP0850

Page 2

LIST OF ABBREVIATION

Abbreviations

API

ASTM

CECE

DIN

EN

Front

Hi

ISO

JIS

L

Lo

L/min

MIL

OPG

(Top Guard Level I)

ROPS

rpm

SAE

TPSS

Description

American Petroleum Institute

American Society for Testing and Materials, USA

Commitee for European Construction Machinery

German Institute for Standards, Federal Republic of

Germany

European Standard

“Front” means the front view towards the boom and

dozer

High speed

International Organization for Standardization

Japanese Industrial Standard

Volume (Liter)

Low speed

Liter per minute

Military Standards

Operator Protective Guards of Top Guard Level I

Roll-over Protective Structures

Revolutions Per minute

Society of Automotive Engineering

Two Pattern Selection System

California Proposition 65

33

WA RN IN G

Engine exhaust, some of its constituents,

certain vehicle components and fluids,

contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

IMPORTANT

The engine in this machine is not equipped by the manufacturer

with a standard spark arrester.

It is a violation of California Public Resource Code Section 4442 to

use or operate this engine on or near any forest-covered, brushcovered land, or grass- covered land unless the exhaust system is

equipped with a working spark arrester meeting state laws. Other

states or federal areas may have similar laws.

U17

English (U.S.A.)

AT . K . 12 - 19 . 2 . AK

Page 3

GENERAL SYMBOLS

The instruments and operation elements have been marked with a series of symbols in order

to simplify the operation of your excavator. These symbols are listed below with the respective

descriptions.

Bucket dump

Safety alert Symbol

3

Warning lamp “Fuel level too low”

T

System lamp

Warning lamp “Engine Oil pressure”

l

Warning lamp “Battery charge”

g

Warning lamp “Auto Idle (AI) Lamp”

Indicator lamp “Glow”

“

Boom swing (left)

”

Boom swing (Right)

’

Dozer raise

Dozer lower

Operation direction of control lever

Operation direction of control lever

Working light switch

7

Horn

5

Wiper/Washer switch

Z

Diesel

R

Hydraulic fl uid

E

Gear oil

W

Grease

Fast

j

Slow

k

Excavator - Overhead movement toward

the front

Excavator - Overhead movement toward

the rear

Boom up

æ

Boom down

…

Read operator’s manual

V

Engine stop control lamp

c

Lock

Unlock

Reducing / Increasing track width

Arm up

≥

Arm crowd

≤

Bucket crowd

‘

Page 4

FOREWORD

You are now the proud owner of a KUBOTA excavator. This excavator

is a product of KUBOTA quality engineering and manufacturing. It is

made of the fi ne materials and under rigid quality control systems. It

will give you long, satisfactory service. To obtain the best use of your

excavator, please read this manual carefully. It will help you become

familiar with the operation of the excavator and contains many helpful

hints about excavator maintenance. It is KUBOTA’s policy to utilize as

quick as possible every advance in our research. The immediate use of

new techniques in the manufacture of products may cause some small

parts of this manual to be outdated. KUBOTA distributors and dealers

will have the most up-to-date information. Please do not hesitate to

consult with them.

Page 5

3

This symbol, the industry’s “Safety Alert Symbol”, is used throughout

this manual and on labels on the machine itself to warn of the

possibility of personal injury. Read these instructions carefully. It is

essential that you read the instructions and safety regulations before

you attempt to assemble or use this unit.

SAFETY FIRST

3

3

3

IMPORTANT : Indicates that equipment or property damage

NOTE : Gives helpful information.

DANGER : Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING : Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION : Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury.

could result if instructions are not followed.

Page 6

Page 7

CONTENTS

SAFE OPERATION ..................... 1

3

DEALER SERVICE ...........................13

TECHNICAL DATA ...........................14

Operating Instructions

DESCRIPTION OF

MACHINE PARTS .........................15

INSTRUMENT PANEL AND

CONTROL ELEMENTS ...................16

BEFORE START ...............................19

DAILY CHECKS ............................19

Tilting The Seat ........................... 19

OPENING AND

CLOSING OF PARTS ..............19

HANDLING THE SAFETY

DEVICES .................................22

OPERATION

STARTING THE ENGINE .............23

STARTING THE ENGINE

UNDER COLD CONDITIONS ...31

STOPPING THE ENGINE .............31

STARTING WITH

AN AUXILIARY BATTERY ......32

EXCAVATOR OPERATION ...............33

CONTROL OBSERVATIONS

DURING OPERATION .............33

RUNNING-IN OF

THE NEW EXCAVATOR ........33

STARTING ..................................33

OF

THE ENGINE .........23

TWO PATTERN SELECTION

SYSTEM (TPSS) ......................35

OPERATION OF THE BOOM .......36

OPERATION OF THE ARM ..........36

OPERATION OF BUCKET ...........37

SWIVEL (UNIT SWING)

OPERATION ............................37

BOOM SWING OPERATION ......38

BOOM SWING PEDAL ................38

OPERATION OF

TRACK WIDTH CHANGE

AND DOZER ...........................39

SERVICE PORT OPERATION ......41

DRIVING ......................................41

TURNS .......................................43

UP AND DOWNHILL

TRAVELLING ..........................45

PARKING ON A SLOPE ...............45

IMPORTANT INFORMATION ON

EXCAVATOR OPERATION .....46

TRANSPORTING THE EXCAVATOR

ON A TRUCK ................................47

LIFTING OF THE EXCAVATOR .........49

Care and Maintenance

MAINTENANCE ...............................51

MAINTENANCE INTERVALS ......51

DAILY CHECKS ............................53

REGULAR CHECKS AND

MAINTENANCE WORK ...............58

EVERY 50 SERVICE HOURS ......58

EVERY 200 SERVICE HOURS ....60

EVERY 250 SERVICE HOURS .....60

Page 8

EVERY 500 SERVICE HOURS .....61

EVERY 1000 SERVICE HOURS ...66

EVERY 1000 SERVICE HOURS OR

ONCE A YEAR .........................67

EVERY 2000 SERVICE HOURS ....67

ANNUAL SERVICING ................68

BIENNIAL SERVICING ...............68

OTHER SERVICING .....................69

OTHER ADJUSTMENTS AND

REPLACEMENTS ........................70

PURGING OF THE FUEL

SYSTEM .................................70

ADJUSTMENT OF TRACKS ........70

EXCHANGE OF BUCKET TEETH

AND SIDE CUTTERS

[JPN BUCKET VERSION] ........72

FUSES .........................................74

TROUBLESHOOTING ......................75

OPERATION UNDER COLD

WEATHER CONDITIONS ................82

PREPARATION FOR OPERATION

IN COLD WEATHER ................82

PROCEDURE AFTER

DONE WORK ...........................82

LONG STORAGE .............................83

RECOMMENDED OILS ...................85

MAIN DIMENSIONS .......................87

LIFTING CAPACITY .........................88

Page 9

1

3

The best insurance against accidents is to

abide by the safety regulations.

Read and understand this section carefully,

before operating the excavator.

Every user, however experienced, should

carefully read and understand this section

and those of the attachments and accessories

before taking the excavator into operation.

The owner is obliged to inform the operators

of these instruction in detail.

Keep this manual in the storage place. (See

"Keeping the Operator's Manual" in the

BEFORE START section.)

SAFE OPERATION

1. BEFORE OPERATION

1. Make yourself acquainted with the

excavator and be aware of its limits.

Read this operator’s manual carefully

before starting the excavator.

2. Obey the danger, warning and caution

labels on the machine.

3. For your safety, a ROPS/OPG (Top Guard

Level I) with a seat belt is installed by

KUBOTA.

A ROPS: Roll-Over Protective Structure

A OPG (Top Guard Level I): Operator

Protective Guards of Top Guard Level I

OPG (Top Guard Level I) in accordance

with ISO10262 is equivalent in defi nition

to FOPS (Falling Object Protective

Structure).

Always use the seat belt when the

machine is equipped with a ROPS/OPG

(Top Guard Level I) as this combination

will reduce the risk of serious injury or

death, should the excavator be upset or

falling objects occur.

Do not modify any structural members

of the ROPS/OPG (Top Guard Level I)

by welding, drilling, bending, grinding

or cutting, as this may weaken the

structure.

If any component is damaged, replace

it. Do not attempt repairs. If the ROPS/

OPG (Top Guard Level I) is loosened or

removed for any reason, make sure all

parts are reinstalled correctly. Tighten

mounting bolts to proper torque.

4. ROPS meets requirements of ISO 3471.

OPG (Top Guard Level I) meets

requirements of OSHA 1926·1003/ISO

10262.

5. The seat belt must be inspected regularly

and replaced if frayed or damaged.

(1) Seat belt

Page 10

2

6. Track can be set at the narrow width 39in.

(990mm) and the standard width 49in.

(1240mm).

(for details see “OPERATION OF TRACK

WIDTH CHANGE AND DOZER”)

Do not operate in narrow track width

39in. (990mm), it makes risk of the

excavator tipping over, operate always

in standard track width 49in. (1240mm),

except to pass through narrow space on

a even ground.

7. Do not use the excavator under the

infl uence of alcohol, medication as well

as other substances. Fatigue is also

dangerous.

8. Check the surroundings carefully before

using the excavator or when attachments

are being attached.

Pay attention to the overhead clearance

with electric wires.

During excavator use do not allow any

persons within the working range.

9. Do not allow other persons to use

the machine before having informed

him on the exact operation and work

instructions, and be assured that the

operator’s manual has been read and

understood.

10. Do not wear baggy, torn or too large

clothing when working with the

excavator. Clothing can get caught in

rotating parts or control elements which

can cause accidents or injuries. Wear

adequate safety clothing, e.g. safety

helmet, safety shoes, eye protection,

ear protection, working gloves, etc., as

necessary and as prescribed by law or

statutes.

Check for pipes and buried cables.

Check for hidden holes, hindrances, soft

underground and overhangs.

(1) Helmet

(2) Clothing fi t for work

(3) Tight seams

(4) Good grip shoewear

(5) Well fi tting cuffs

(6) Working gloves

(7) Straw hat

(8) Towel

(9) Baggy trousers

(10) Loose cuffs of the shirt

(11) Baggy shirt

(12) Rubber sandals

Page 11

3

11. Do not allow passengers to get on any

part of the excavator seat throughout

operation.

12. Check mechanical parts for correct

adjustments and wear. Exchange worn

or damaged parts immediately.

13. Keep your excavator clean. Heavy

soiling, grease, dust and grass can

infl ame and cause accidents or injuries.

14. Use only KUBOTA authorized

attachments.

15. Before starting the excavator, be

absolutely sure that the excavator has

been fi lled with fuel, lubricated, greased

and undergone other maintenance

work.

16. Do not modify the excavator, otherwise

it could lead to unforeseen safety

problems.

17. Make sure attachments, particulary

those utilizing quick attach systems, are

securely mounted.

2. STARTING OF THE EXCAVATOR

1. Get into and out of the machine safely.

Always face the machine. Always use

handrails and available steps and keep

yourself well balanced. Do not hold any

of the control Ievers and switches. Do

not jump on or off the machine, whether

stationary or in motion.

2. Start and control the excavator only from

the operator’s seat. The driver should not

lean out of his seat when the engine is

running.

3. Before starting the engine, make sure

that all control levers (including auxiliary

control levers) are in their neutral

positions.

Before starting the engine, make sure

that the control levers, travel lever,

pedals and other control elements are

not stuck and can be moved smoothly.

If stuck, for example, a lever may fail to

return, possibly putting you in danger.

If anything wrong is found, immediately

pinpoint the cause and correct it.

4. Do not start the engine by jumping

the starter connections. Do not try to

circumvent using the starter switch,

otherwise the engine could start suddenly

and the excavator could move.

Page 12

4

5. Make sure that the dozer is on the front

side. (The dozer must be raised.) If the

levers are activated with the dozer on the

rear end, the driving direction is in the

opposite direction of the drive levers.

6. Do not run the engine in closed or badly

ventilated rooms. Carbon monoxide is

colourless, odourless and deadly.

Safety for children

Tragedy can occur if the operator is not

alert to the presence of children. Children

generally are attached to machines and the

work they do.

1. Never assume that children will remain

where you last saw them.

2. Keep children out of the work area

and under the watchful eye of another

responsible adult.

3. Be alert and shut your machine down if

children enter the work area.

4. Never carry children on your machine.

There is no safe place for them to

ride. They may fall off and be run over

or interfere with your control of the

machine.

5. Never allow children to operate the

machine even under adult supervision.

6. Never allow children to play on the

machine or on the attachments.

7. Use extra caution when backing up. Look

behind and down to make sure the area

clear before moving.

8. When parking your machine, if at all

possible, park on a fi rm, fl at and level

surface; if not, park across a slope. Lower

the bucket and dozer to the ground,

remove the key place the control lock

levers in the locked position from the

ignition before you leave.

7. Keep all safety equipment and covers

in place. Replace damaged or missing

safety device.

8. Precautions against tipping over. In order

to secure safe operation, keep away from

steep slopes and embankments. Do not

swing the bucket downwards. Lower the

dozer during digging. Keep the bucket as

low as possible while driving upwards.

Turn slowly on slopes (do not fast). Do

not keep the excavator near the edges

of trenches and banks, as the earth

can give away due to the weight of the

excavator.

9. Watch out at all times where the

excavator is being moved to. Keep an

eye out for hindrances.

10. Keep enough distance from trench and

bank edges.

Page 13

5

3. AFTER OPERATION

Before leaving the machine,

Bring the excavater on a fi rm, fl at and

level surface.

Lower the attachments and the dozer

blade on the ground.

Stop the engine.

Lock all control levers.

Remove the key.

4. SAFE LOADING AND TRANSPORT

OF THE EXCAVATOR

1. Observe all regulations concerning the

transport of excavators on public roads.

2. Use adequately long and robust ramps

when loading on a truck. (for details see

“TRANSPORTING THE EXCAVATOR ON

A TRUCK”)

3. Do not change the running direction

and to avoid a tipping over, do not try to

swing the attachment crosswise to the

loading ramps.

4. After loading of the excavator on a truck,

engage the swing lock pin.

Lower the attachment on the loading

plane and release the pressure from the

hydraulic system.

Block the tracks with blocks and wire

down the excavator. After loading the

excavator on a truck, tie down the

undercarriage of the excavator with a

strong steel wire on the truck.

(1) lock lever for control lever (A) “Lock”

(Left side) (B) “Unlock”

(1) Swing lock pin (A)”Unlock”

(B)”Lock”

Page 14

6

5. Do not brake abruptly with the excavator

loaded. Mortal accidents could happen.

6. If the excavator is used to tow another

machine, the load must be smaller than

the strength of the hook.

7. Do not use hooks on the roof of canopy

for lifting the excavator.

Max. drawbar pull at

coupling hook

Max. vertical load at

coupling hook

32.3 kN

2.7 kN

5. MAINTENANCE

Before doing maintenance work on the

excavator, place the machine on a fi rm, fl at

and level surface, Iower the attachments on

the ground, stop the engine then remove

the key and release the cylinder pressure

by actuating the levers. When dismantling

hydraulic parts, make sure that the hydraulic

oil has cooled down suffi ciently to avoid

burns.

Start maintenance work carefully, e.g. loosen

screws slowly so that oil will not squirt out.

1. Before doing work on the engine, the

exhaust system, the radiator and the

hydraulics, let the excavator cool down

suffi ciently.

2. Turn off the engine at all times when

fi lling with fuel. Avoid spilling and overfi lling of fuel.

3. Smoking is prohibited while tanking

and handling the battery! Keep sparks

and fi re away from the fuel tank and

battery. Flammable gases escape from

the battery, especially during charging.

4. Do not use or charge the refi llable

type battery if the fl uid level is below

the LOWER (lower limit level) mark.

Otherwise, the battery component parts

may prematurely deteriorate, which

may shorten the battery's service life

or cause an explosion. Check the fl uid

level regularly and add distilled water as

required so that the fl uid level is between

the UPPER and LOWER levels.

5. Read and follow “STARTING WITH AN

AUXILIARY BATTERY” in “OPERATION

OF THE ENGINE”, when starting with an

auxiliary battery.

6. To avoid short-circuiting the battery,

always remove the earth cable fi rst and

attach the plus cable fi rst.

7. Keep a fi r st-aid box and a fi re extinguisher

at hand at all times.

8. Do not open the radiator cap before the

radiator has cooled down suffi ciently.

First loosen the cap to the fi rst stop and

allow the system enough time to release

the remaining pressure. Then loosen the

cap completely.

9. Leaking hydraulic fl uid has enough

pressure to penetrate the skin and cause

serious injuries. Leakages from pin

holes can be totally invisible. Do not use

the bare hand for checking on possible

leakages. Always use a piece of wood or

cardboard. It is strongly recommended

to use a face mask or eye protection.

Should injuries occur with leaking

hydraulic fl uid, contact a doctor

immediately. This fl uid can cause

gangrene or serious allergic reactions.

10. To avoid leakage of battery acid which

contains heavy metals, do not throw the

battery away.

11. Observe all laws and regulations

concerning the disposal of used oil,

coolants, solvents, hydraulic fl uids,

battery acids and batteries.

12. To avoid fi re, do not heat the hydraulic

components (tanks, pipes, hoses,

cylinders) before they are drained and

washed.

Page 15

7

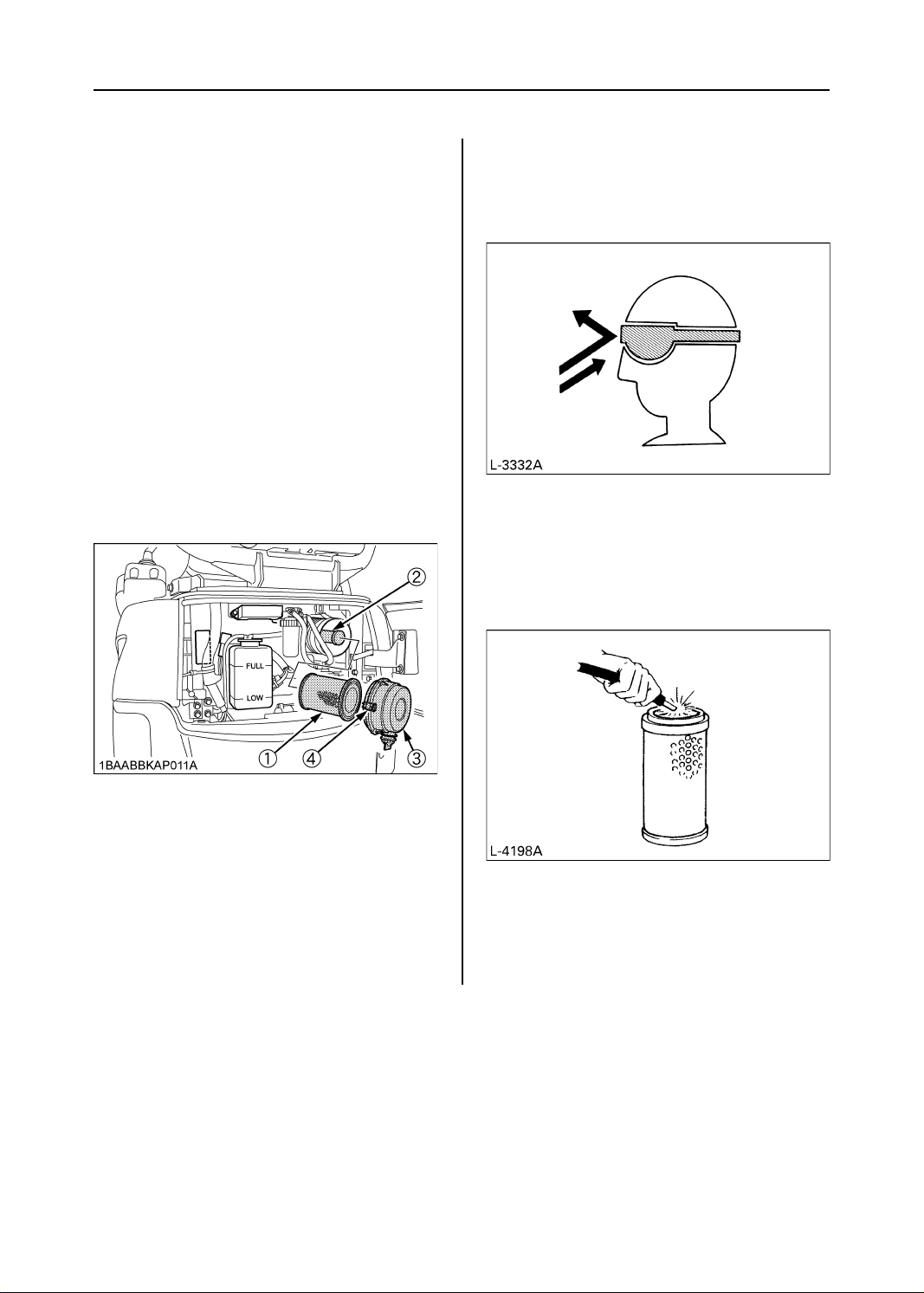

13. Use a face mask or eye protection to

protect the eyes and respiratory system

against dust and other foreign particles.

14. Securely support excavator with stands

or suitable blocking before working

underneath. For your safety, do not

work under any hydraulically supported

devices. They can settle, suddenly leak

down, or be accidentally lowered.

15. Do not crawl under the excavator if the

excavator is only supported by the boom

and arm or the dozer. The excavator can

tip over or lower itself due to hydraulic

pressure loss. Always use safety struts

or other appropriate supports.

16. KUBOTA uses no parts which are lined

with asbestos. Do not use these kind of

parts even if they can be installed.

17. Fire prevention

Excavator and some attachments

have components that are at high

temperatures under normal operating

conditions. The primary source of

high temperatures is the engine and

exhaust system. The electrical system, if

damaged or incorrectly maintained, can

be a source of arcing or sparks.

The following fi re prevention guidelines

will help to keep your equipment up and

running effi ciently and keep the risk of

fi re to a minimum.

Blow off all accumulated debris near

hot engine exhaust components such

as turbocharger and exhaust manifold

as well as exhaust pipes and muffl er

more frequently when working in severe

conditions.

Clean out all accumulated fl ammable

debris such as leaves, straw, pine

needles, branches, bark, small wood

chips and any other combustible

materials from inside the machine belly

pans or lower unit structures as well as

from area in proximity to the engine.

Inspect all fuel lines and hydraulic hoses

for wear or for deterioration. Replace

them immediately if they begin to leak.

Examine electrical wiring and connectors

frequently for damage. Repair any wires

that are loose or frayed before operating

the machine. Clean all electrical

connections and tighten all electrical

connections as necessary.

Inspect the exhaust system daily for any

signs of leakage. Check for broken pipes

and muffl er and also for loose or missing

bolts, nuts and clamps. If any exhaust

leaks or fractured parts are found, repairs

must be completed prior to operation.

Always keep a multipurpose fi re

extinguisher on or near the machine.

Be familiar with the operation of the fi re

extinguisher.

Page 16

8

6. DANGER, WARNING AND CAUTION LABELS

(1) Code No. RA238-5747-1 (2) Code No. RA228-5733-1

Page 17

9

(1) Code No. RC418-5753-1

(3) Code No. RD517-5795-2

[Both sides]

(2) Code No. RA228-5762-1

Page 18

10

(1) Code No. RC418-5728-4

(2) Code No. RC418-5727-4

(3) Code No. RC418-5733-5

(5) Code No. RA228-5751-2

(4) Code No. RD809-5738-2 (6) Code No. 6C300-4744-1

1BAAAARAP1000

Page 19

11

(1) Code No. RC108-5718-1

(3) Code No. RD358-5736-1

Diesel fuel only No fi re

(2) Code No. RA228-5728-2

(4) Code No. RA228-5776-1

[Both sides]

(6) Code No. RC108-5796-1

[Both sides]

(5) Code No. 68328-5735-1 [Both sides]

(7) Code No. RB419-5796-2

[Both sides]

Page 20

12

(1) Code No. RB238-5737-1 (2) Code No. RC418-5737-2

(3) Code No. TC030-4958-1

(4) Code No. RC108-5754-1

1BAAAAQAP0860

7. CARE OF DANGER, WARNING AND CAUTION LABELS

(1) Keep danger, warning and caution labels, clean and free from obstructing material.

(2) Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

(3) Replace damaged or missing danger, warning and caution labels with new labels from your

KUBOTA dealer.

(4) If a component with danger, warning and caution label (s) affi xed is replaced with new

part, make sure new label (s) is (are) attached in the same location (s) as the replaced

component.

(5) Mount new danger, warning and caution labels by applying on a clean dry surface and

pressing any bubbles to outside edge.

Page 21

DEALER SERVICE

Your KUBOTA dealer is always ready to

help so that your excavator offers the best

performance. After having carefully read

this manual, you will realize that much of

the routine maintenance can be done by

yourself. Your KUBOTA dealer is responsible

for servicing and the delivery of spare

parts. When ordering spare parts from your

KUBOTA dealer, always mention the serial

number of the excavator and the engine.

Note these numbers right away in the

supplied lines.

Model Serial No.

Excavator

Engine

Dealer's name

(To be fi lled in through the owner)

13

(1) Serial No.

(1) Engine serial No.

Page 22

14

TECHNICAL DATA

Model name

Type

Operating weight

(including operator's)

Type

Model name

Total displacement

cc (cu.in)

Engine

Performance

Dozer

Boom swing angle

Pressure

connection

for

attachments

Fuel tank capacity

Engine

power

Rated speed

Low idle speed

Unit swing speed

Travel

speed

Ground

pressure

(With operator)

Climbing angle

Width X Height

Max. displacement

(Theoretical)

Max. pressure

SAE gross

SAE NET

Fast

Slow

Left

Right

US gal (L)/min

mph (km/h)

mph (km/h)

US gal (L)

lbs.(kg)

kW(HP)

kW(HP)

rpm

rpm

rpm

psi

(kPa)

[kgf/cm

%(deg)

in.(mm)

deg (rad)

deg (rad)

psi

(MPa)

[kgf/cm

KUBOTA EXCAVATOR

U17

Canopy

3704 (1680)

Water cooled 4 cycle diesel engine with 3 cylinder

KUBOTA D902

898 (54.8)

12.0 (16.1)

11.3 (15.1)

2300

1300 ~ 1400

9.1

2.6 (4.1)

1.4 (2.1)

3.7

2

]

39.0/48.8 X 10.2 (990/1240 X 260)

2

]

26

[0.26]

58 (30)

65 (1.13)

58 (1.01)

7.32 (27.7)

2702

(18.6)

[190]

5.0 (19)

NOTE:

Above dimensions are based on the machine with rubber trucks and JPN bucket.

JPN = made in Japan

Specifi cations subject to change without notice.

∗ With unloaded digging bucket.

∗ Firm compacted soil.

∗ Operators must exercise extra caution and follow instructions in the operator's manual.

∗ Worse condition or heavier attachment to the above will decrease climbing angle.

Page 23

15

DESCRIPTION OF MACHINE PARTS

DEPICTED CONTENTS

(1) Arm

(2) Bucket cylinder

(3) Bucket link

(4) Bucket

(5) Swing bracket

(6) Dozer cylinder

(7) Dozer

(8) Arm cylinder

(9) Boom

(10) Canopy (Rops / OPG (Top Guard Level I))

(11) Operator’s seat

(12) Boom cylinder

(13) Drive sprocket

(14) Track roller

(15) Front idler

Page 24

16

INSTRUMENT PANEL AND CONTROL ELEMENTS

Instrument Panel, Switches

DEPICTED CONTENTS

(1) Horn switch

(2) LCD display

(3) Starter switch

(4) Working light switch

(5) Working light

(6) Working light (Option)

Page 25

Instrument Panel

17

DEPICTED CONTENTS

(1) Speed indicator lamp

(2) AUX operation lamp

(3) Periodic check lamp

(4) Clock setting request lamp

(5) Glow lamp

(6) Remaining fuel warning lamp

(7) Engine oil pressure warning lamp

(8) Battery charge lamp

(9) Coolant temperature warning lamp

(10) Warning lamp

(11) Fuel gauge

(12) Coolant temperature gauge

(13) LCD display

(14) User setting switch (switch 2)

(15) Display selector switch (switch 3)

Page 26

18

Control Pedals and Levers

DEPICTED CONTENTS

(1) Drive lever (left)

(2) Control lever for front attachments (left)

(3) Lock lever for attachment control

(4) Service port pedal

(5) Drive lever (right)

(6) Control lever for front attachments (right)

(7) Two travel speed switch

(8) Control lever for dozer or track width

(9) Throttle lever

(10) Boom swing pedal

(11) Track width change / dozer select lever

Page 27

BEFORE START

19

DAILY CHECKS

In order to avoid damage, it is important to

check the condition of the excavator before

starting.

CAUTION

3

Checks

Walk around the excavator and check for

visual damage and wear.

Check coolant level. (See regular checkpoints

in “MAINTENANCE”.)

Check fuel level.

Check engine oil level.

Check hydraulic fl uid level.

Check air fi lter for clogging.

Check all control lamps, indicators, engine

rpm's counter and hour meter.

Check the light system.

Check the seat belt and the Rops/OPG (Top

Guard Level I) safety device.

Check the condition of the danger, warning

and caution labels. (See "DANGER,

WARNING AND CAUTION LABELS" in "SAFE

OPERATION" .)

To avoid personal injury:

Do maintenance work on the

excavator only on even ground

with the engine off and the

safety devices in the “Lock”

position.

TILTING THE SEAT

CAUTION

3

To tilt the seat forward, pull the seat tilting

lock lever and tilt the seat forward.

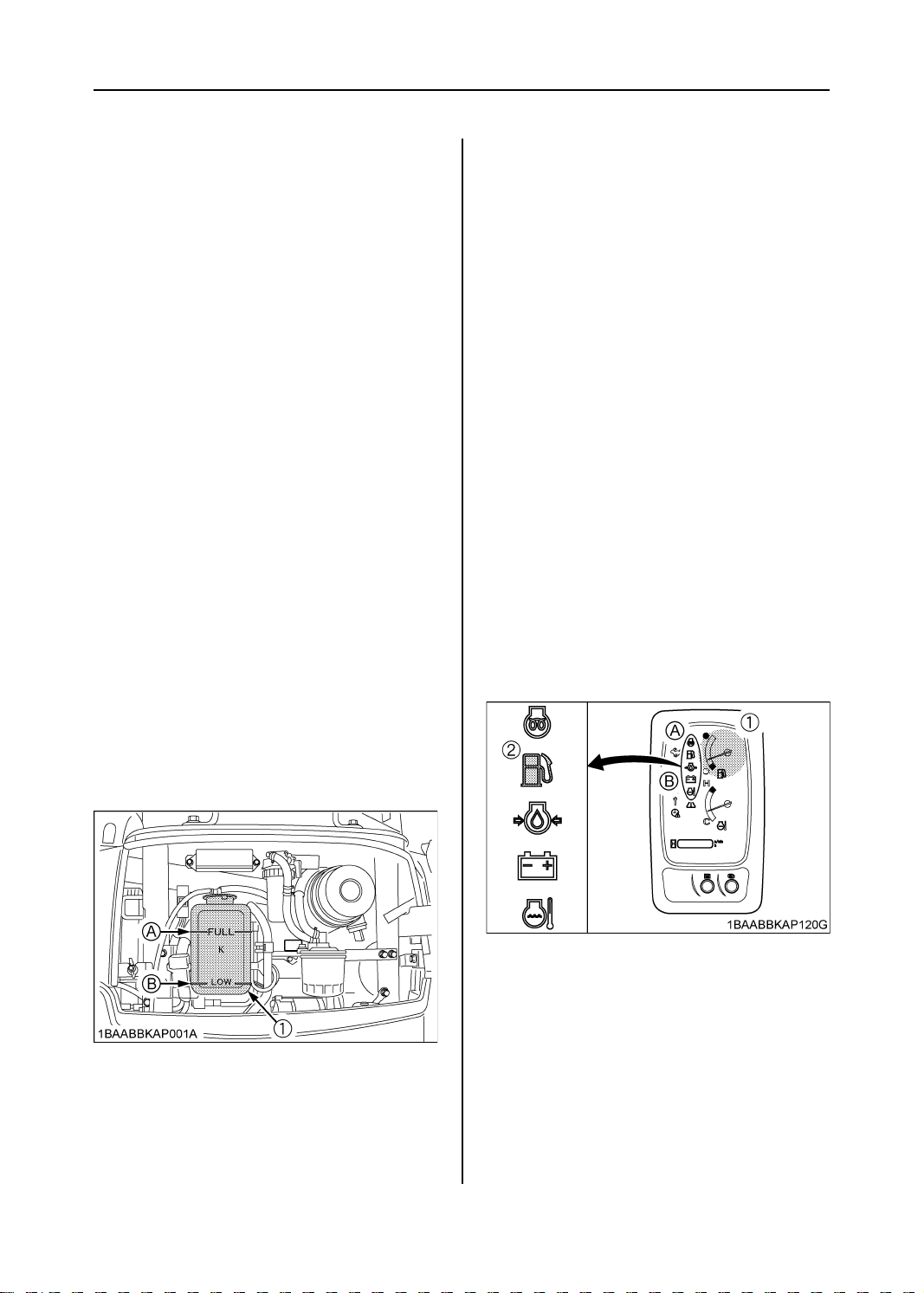

(1) Seat tilting lock lever (A) “Tilting forward”

(2) Lock lever for (B) “Lock”

attachment control

To avoid personal injury:

Lock the lever for attachment

control when tilting the seat.

OPENING AND CLOSING OF

PARTS

Opening / Closing the Rear

Bonnet

CAUTION

3

1. Put the starter key in the key slot and

When the rear bonnet is opened, the rear

To avoid personal injury:

Do not touch the exhaust

muffl er or the exhaust pipe;

serious burns can occur.

turn it clockwise to the vertical position.

The rear bonnet will be unlocked. Press

the button, and the rear bonnet can be

opened sideways.

bonnet will be locked with the lock lever.

Page 28

20

2. To close the rear bonnet, make sure the

left bonnet is locked, unlock the lock

lever and push the rear bonnet until it

clicks into position. To lock the bonnet,

turn the starter key counterclockwise to

the horizontal position.

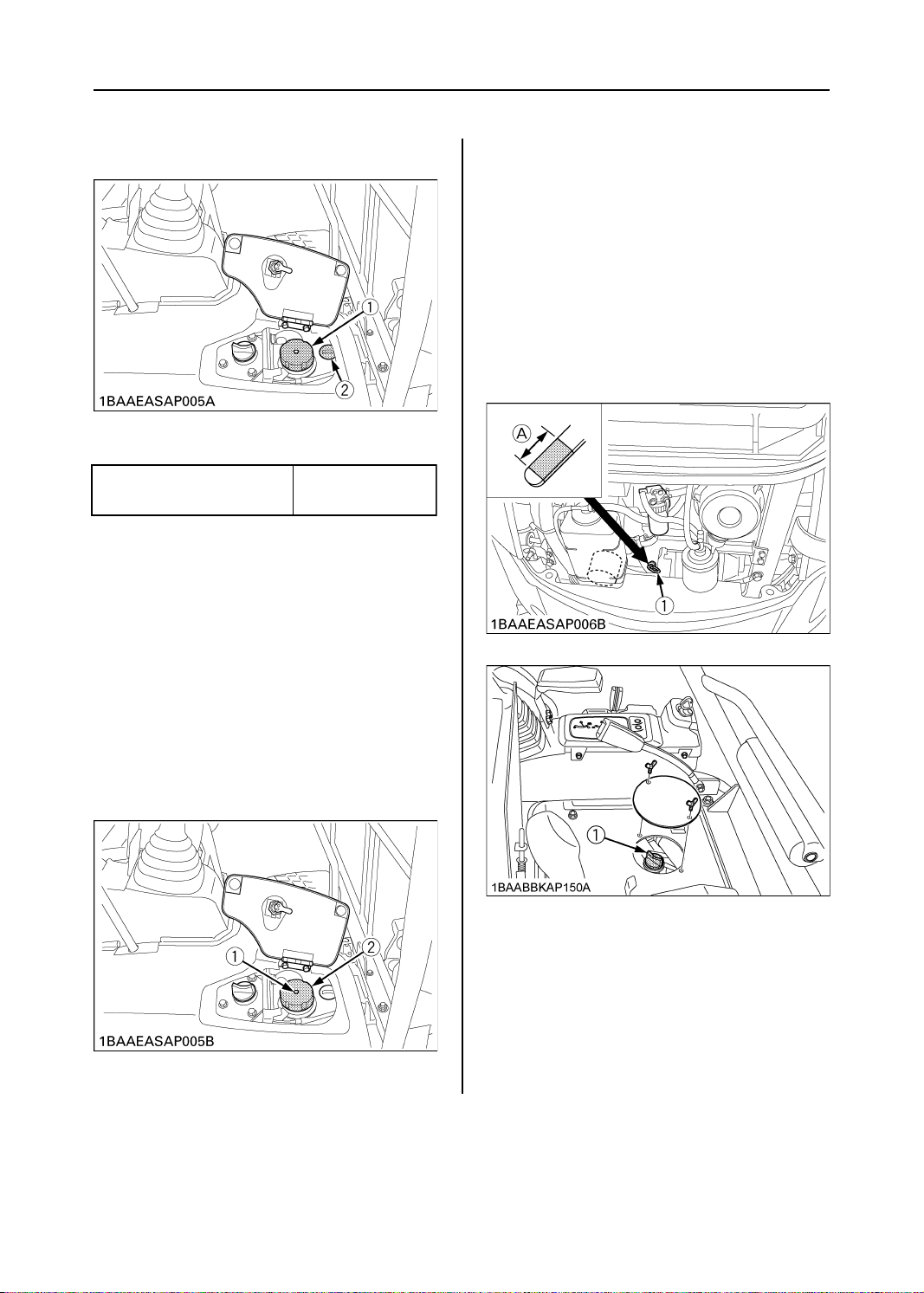

(1) Key (A) “Lock”

(2) Rear bonnet (B) “Unlock”

(3) Button

Opening/closing the left bonnet

1. Remove the rubber mat off the left

bonnet side. Then undo the step fi xture.

(1) Rubber mat

(2) Left bonnet

2. To open the left bonnet, do this: open the

rear bonnet fi rst and then turn the wing

nut, located as shown below, to unlock

the left bonnet.

(1) Lock lever (A) “Lock”

(B) “Unlock”

IMPORTANT:

Do not run the machine with the bonnet

open. The bonnet may get damaged.

(1) Left bonnet

(2) Rear bonnet

(3) Wing nut

3. To close the left bonnet, do this: push it

back into position, apply the lock fi xture

in place and hand-tighten the wing nut.

4. Spread the rubber mat back in its original

place.

Page 29

21

Opening and Closing of the Fuel

Tank Cover

To open the tank cover, fi rst insert the key

into the key slot and turn it counterclockwise

to unlock, then open the tank cover upward.

For closing, return the tank cover to original

position and turn the key clockwise to lock,

then remove the key.

(1) Key (A) “Unlock”

(2) Tank cover (B) “Lock”

Keeping the Tools

(1) Tool Box

Operator's Manual Storage

Keeping the operator's manual in the tool

box.

(1) Air vent

(2) Fuel tank cap

Page 30

22

HANDLING THE SAFETY DEVICES

Control lever lock

CAUTION

3

The attachment control lever lock is located

on the left side.

When the excavator is not used

or left unattended, be sure to

place the lock lever in "Lock"

position .

(1) Lock lever for attachment (A) “Lock”

control (B) “Unlock”

Swing lock pin

This pin is used to lock the swing frame. Set

the lock pin to the “Lock” position and the

swing frame gets locked to the track frame.

IMPORTANT:

Before locking the lock pin, be sure to

place the swing frame and the track frame

in parallel with each other.

(1) Swing lock pin (A) “Unlock”

(B) “Lock”

Page 31

OPERATION OF THE ENGINE

23

CAUTION

3

IMPORTANT:

Do not use start help spray or similar

In order not to overload the battery and

When the engine does not start in 10 sec.,

To avoid personal injury:

Read “SAFE OPERATION” at

the beginning of this operator's

manual.

Obey the danger, warning and

caution labels on the excavator.

Exhaust gases are poisonous. Do

not let the engine run in closed

quarters without suffi cient and

adequate ventilation.

Always start the engine from

the operator's seat. Do not start

the engine while standing next

to the excavator. Before starting

the engine, sound the horn to

get the attention of persons

standing nearby.

fl uids.

starter, avoid start-ups of more than 10

sec.

please set the interval of 20 sec. or more,

and restart.

Horn Switch

When the key in "RUN" position, the horn

sounds by pushing the switch.

STARTING THE ENGINE

CAUTION

3

Start the engine in the following manner:

1. Make sure that the fuel shutoff-valve is in

(1) Fuel shutoff-valve (A)”Open”

2. Before starting the engine, make sure

To avoid personal injury:

The operator should not

depend solely on the alarm

lamps, but should always

conduct the routine checks (see

“MAINTENANCE”).

the “Open” position.

that all control levers are in the neutral

positions.

(1) Horn switch

(1) Drive lever (left)

(2) Drive lever (right)

(3) Attachment control lever (left)

(4) Attachment control lever (right)

(5) Lock lever

Page 32

24

3. Pull the lock lever all the way back. (lock

position).

4. Insert the key into the starter switch and

turn it to the "RUN" position.

(1) Starter Switch (A) “STOP”

(B) “RUN”

(C) “START”

5. Turn the key to "START" position and

release after the engine has started; it will

automatically return to the "RUN" position.

6. Check if all warning lamps have gone

out. Should a warning lamp still be lit up,

stop the engine then remove the key and

check for the cause.

Display Selector Switch

Press the display selector switch while the

engine is running. The electronic meter’s

LCD display will change from one indication

mode to the other.

Change the three-mode display according

to your jobs.

NOTE:

When the lock levers are in "UNLOCK"

position, the engine dose not start.

(1) Display selector switch

(2) LCD display

NOTE:

With the starter key at the ”STOP”

position, press the electronic meter’s

display selector switch, and the LCD

display shows the hour meter for 10

seconds.

Page 33

25

Setting the clock

[

Selecting the clock setting mode

]

1. Insert the key into the starter switch and

turn it to the "RUN" position.

(1) Starter Switch (A) “STOP”

(B) “RUN”

(C) “START”

2. Press the user setting switch (switch 2

(1)).

3. Select the clock setting mode by pressing

the display selector switch (switch 3 (2))

and the clock setting request lamp “

”

on the instrument panel lights up.

[

Setting the year

]

Press switch 2 (1) and the numeric setting

will be smaller.

Press switch 3 (2) and the numeric setting

will be larger.

Switch 2 Switch 3

2015

2014

2013

2017

2016

2015

NOTE:

While setting the clock, the clock setting

request lamp on the instrument panel is

blinking.

[

Setting the month

]

(1) User setting switch (switch 2)

(2) Display selector switch (switch 3)

(3) Clock setting request lamp

NOTE:

Press switch 3 (2) for a long time and the

year, month, day, hour and minute will

be selected in this order.

Press switch 2 and the numeric setting will

be smaller.

Press switch 3 and the numeric setting will

be larger.

Switch 2 Switch 3

10

9

8

12

11

10

Page 34

26

[

Setting the day

]

Press switch 2 and the numeric setting will

be smaller.

Press switch 3 and the numeric setting will

be larger.

Switch 2 Switch 3

09

08

07

[

Changing the AM/PM system to the 24-hour

system

]

11

10

09

Select the AM/PM system or 24-hour system

by pressing switch 3.

[

Setting the hour

]

Press switch 2 and the numeric setting will

be smaller.

Press switch 3 and the numeric setting will

be larger.

Switch 2 Switch 3

11

10

9

[

Setting the minute

]

13 (or 01)

12

11

Press switch 2 and the numeric setting will

be smaller.

Press switch 3 and the numeric setting will

be larger.

Switch 2 Switch 3

50

49

48

52

51

50

If switch 3 is pressed for a long time, the new

settings will be made.

NOTE:

If the battery is disconnected, the clock

setting request lamp ”

” (yellow) will

blink for requesting the setting the clock.

Page 35

LCD Display for Normal Operation

Fuel gauge

CAUTION

3

To avoid personal injury:

Before adding fuel, be sure to

stop the engine.

Be sure to keep open fl ame away

from the machine. Otherwise a

fi re may result.

Coolant Temperature Gauge

CAUTION

3

To avoid personal injury:

Do not open the radiator cap

during or just after operation.

Hot coolant may gush out and

scald you. Wait for the coolant

to cool down before opening

the cap.

27

If the fuel in the tank goes below the

prescribed level, the warning lamp will

fl ash.

If this should happen during operation,

refuel as soon as possible.

(1) Fuel gauge (A) ”FULL”

(2) Remaining fuel warning lamp (B) ”EMPTY”

IMPORTANT:

If the fuel gauge indicator is near the

”

”, add fuel as soon as possible. If the

indicator is near ”

operates on a slope, the engine may

run out of fuel.

” and the machine

With the starter key at the

the cooling water temperature is indicated.

(1) Coolant temperature gauge (A) ”HOT”

(B) ”COOL”

Hour-meter

Indicates the total operating hours of the

machine.

How the indicator works

The meter advances one hour after

an hour of operation regardless of the

engine rpm.

”RUN”

position,

NOTE:

To open the fuel cap, keep the starter key

inserted.

Engine tachometer

Indicates the current rpm of the engine.

NOTE:

The LCD display may be illegible when

viewed from a certain angle. This is not a

display failure.

Page 36

28

LCD Display for Warning

Engine oil pressure warning lamp

The engine oil pressure warning lamp lights

up due to failure of the lubricating system

with the engine running.

When the starter key is turned to ”RUN”

position with the engine off, this engine

oil pressure lamp lights up, warning lamp

blinks and when the engine starts, the

lamps go out.

If the lamp stays on with the engine

running, stop the engine and check the

engine oil level.

(1) Engine oil pressure lamp

(2) Warning lamp (red)

(3) Error code

Warning Lamp

The warning lamp is used to indicate broken

wire, short-circuit, fuel shortage and other

problems.

IMPORTANT:

Do not just look at the meter, but also

carry out the inspection and correction

accordingly.

NOTE:

The warning lamp starts fl ashing in red if

a serious problem occurs. If the system

gets in warning signal, the warning lamp

starts fl ashing in yellow.

Warnings and errors are displayed and

an alarm buzzer beeps.

Let your KUBOTA dealer inform you of

details concerning care and maintenance.

Battery charge lamp

This battery charge lamp lights up if the

charging system fails with the engine running.

When the starter key is turned to ”RUN”

position with the engine off, the battery

charge lamp lights up, warning lamp blinks

and when the engine starts, the lamps go out.

If the lamp stays on with the engine running,

stop the engine and check the V-belt.

(1) Battery charge lamp

(2) Warning lamp (red)

(3) Error code

(1) Warning lamp

(2) Error code

Overheat warning

If the water temperature has risen too high,

the water temperature warning lamp lights

up and the following error code (E:015) gets

displayed.

(1) Water temperature warning lamp

(2) Error code

Page 37

29

With the error code displayed, take the

procedure below.

1. Bring the machine to a stop on a safe

place. (Get the engine unloaded.)

2. Do not yet stop the engine, but allow it

to run idle unloaded for 5 minutes or so.

Then stop the engine.

3. Keep yourself away enough from the

machine for another 10 minutes or while

the engine is emitting steam.

4. Make sure there is no risk of getting

burned.

Then remove the cause of overheat,

referring to “TROUBLESHOOTING”.

Finally get the engine restarted.

Checkpoints after Starting the

Engine

After starting the engine, but before starting

operation, check the following points:

1. Put the throttle lever down and let the

engine idle for approx. fi ve minutes. This

allows the engine lubricant to warm up

and penetrate every part of the engine.

2. Once the engine has warmed up, check:

the warning lamp ”Engine oil

pressure” has gone out.

the warning lamp ”Battery charge”

goes out when engine speed is

increased.

the color of the exhaust is normal

and no abnormal noises or

vibrations are heard or felt.

no fl uid is leaking from pipes or

hoses.

Glow Lamp

With the starter key at the ”RUN” position,

the engine’s preheat status is indicated.

NOTE:

When the starter switch is turned to

the ”RUN” position, the engine will be

preheated for a given period of time and

the indicator will turn on.

The above indication appears momentarily

when the engine is started, but it does

not indicate trouble. (This is because the

oil charge sensor output fl uctuates when

the engine is started.)

The following symbol appears momentarily

as the engine starts. This is not an error.

(1) Glow lamp

Battery Charge Lamp

This warning lamp lights up if the charging

system fails while the engine is running.

When the starter switch is turned ”ON” with

the engine off, the lamp lights up, and when

the engine gets started, the lamp goes out.

Should any following conditions occur,

stop the engine immediately.

The engine rpm’s increases or

decreases suddenly.

Sudden abnormal noises are heard.

Exhaust is black.

Warning lamp for engine oil lights up

during operation.

IMPORTANT:

In these cases, the excavator must be

checked and serviced by your local the

KUBOTA dealer.

NOTE:

If there is disconnection or failure in the

charging system when the key is turned to

”RUN”, the following symbol will appear.

(1) Battery charge lamp

Page 38

30

Engine Oil Pressure Warning Lamp

The engine oil pressure warning lamp lights

up due to failure of the lubricating system

with the engine running. When the starter

switch is turned ”ON” with the engine off,

this lamp lights up, and when the engine

starts, the lamp goes out. If the lamp stays

on with the engine running, stop the engine

and check the engine oil level.

NOTE:

If there is disconnection, failure or

breakdown in the lubricating system

when the key is turned to ”RUN”, the

following symbol will appear.

(1) Engine oil pressure warning lamp

Checkpoints after Starting the

Engine

After starting the engine, but before starting

operation, check two following points:

1. Put the throttle lever in "LOW" position

and let the engine idle for approx. 5

minutes. This allows the engine lubricant

to warm up and penetrate every part of

the engine.

Note:

This idling is usually called "Warm-

up".

2. Once the engine has warmed up, check:

the warning lamp "Engine oil

pressure" has gone out.

the warning lamp "Battery charge"

goes out when engine speed is

increased.

the colour of the exhaust is normal

and no abnormal noises or vibrations

are heard or felt.

no fl uid is leaking from pipes or

hoses.

Should any following conditions occur,

stop the engine immediately.

The engine rpm's increases or decreases

suddenly.

Sudden abnormal noises are heard.

Exhaust is black.

Alarm lamp for engine oil lights up

during operation.

IMPORTANT:

In these cases, the excavator must be

checked and serviced by your local

KUBOTA dealer.

Precautions in case of overheat

CAUTION

3

If by any chance cooling water gets heated

up to the boiling point or over (overheated),

the whistle at the reserve tank drain hose

end blows. In such case, take the following

steps.

1. Stop operation in a safe condition.

2. Do not stop the engine suddenly. Keep

3. Keep yourself enough away from the

4. Make sure there is no hazard of

Do not open the radiator cap

during and just after operation.

Hot water may gush out and

get you burned. Wait long

enough until the radiator cools

down.

(Disconnect the engine’s load.)

the engine idling under no load for about

5 minutes and turn it off.

machine for another 10 minutes or while

steam is given off.

getting burned. Pinpoint and remove

the cause of overheat, referring to

“TROUBLESHOOTING”. Then get the

engine restarted.

Page 39

31

STARTING THE ENGINE UNDER

COLD CONDITIONS

CAUTION

3

Start the engine in the following manner;

1. Pull the lock levers all the way back (lock

2. Turn the starter switch to the "RUN"

3. Move the starter switch to the "START"

4. Release the starter switch after the

IMPORTANT:

Let the engine warm up after start-

Do not operate the excavator under full

To avoid personal injury:

Make sure that the lock lever

is in the lock position during

warm up.

position).

position (glow position) and keep until

the indicator lamp has gone out.

position; to crank and start the engine.

engine has started; it will automatically

return to the "RUN" position.

up for approx. 10 minutes under no

load conditions. If the hydraulic fl uid

temperature is too low, the operations

will be affected.

load before the engine has warmed up

enough.

STOPPING THE ENGINE

WARNING

3

1. After slowing the engine to idle, turn the

key to "STOP".

2. Remove the key.

Emergency Engine Stop Fuse

3

The engine will stop when the cap is

removed and the fuse inside is pulled out.

The engine can be restarted when the fuse is

pushed back into its original position.

To avoid personal injury or death:

Do not keep the bucket or

dozer in the lifted position, as a

person could accidently touch

the levers and cause serious

accidents.

CAUTION

To avoid personal injury:

Do not open engine hood

before stopping engine. Only

when engine does not stop by

key, open engine hood and pull

out the fuse.

(1)

Emergency engine stop fuse

(B) “PULL OUT”

NOTE:

If the engine does not stop with the key,

contact your KUBOTA dealer.

(A) “OPEN”

Page 40

32

STARTING WITH AN AUXILIARY

BATTERY

CAUTION

3

Observe Following Guidelines

1. Bring the helping machine with the same

THE MACHINES MUST NOT COME IN

2. Bring the levers and pedal of both

3. Wear eye protection and rubber gloves.

4. Remove the battery caps from both

5. Connect the terminal of the red jumper

6. Connect the black negative cable to

7. Connect the other end of the black cable

8. Start the engine of the helping machine

9. Disconnect the jumper cables in the

To avoid personal injury:

Battery gases can explode.

Do not smoke and keep sparks

and fl ames away.

Do not start the engine with

an auxiliary battery if excavator

battery is frozen.

Do not connect the black

jumper cable to the negative

(—) terminal of the excavator

battery.

when Starting with an Auxiliary

Battery

battery voltage as near as possible to the

machine.

CONTACT WITH EACH OTHER.

machines in the neutral position.

batteries. (If present)

cable with the plus (

low battery and connect the other end of

the cable to the plus (

auxiliary battery.

the minus (—) terminal of the auxiliary

battery.

(coming from the auxiliary battery) to the

machine frame as far away as possible

from the low battery.

and let it run for a while. Start the

machine with the low battery.

reverse sequence.

+

) terminal of the

+

) terminal of the

(1) Low battery

(2) Auxiliary battery

(3) Jumper cables

IMPORTANT:

This excavator has a negative (—) earthed

12 Volt starting system.

Only use the same voltage when using an

auxiliary battery.

Using a higher voltage will cause

serious damage to the electrical system.

When using an auxiliary battery, only

the compatible (same) voltage is

permissible.

Page 41

EXCAVATOR OPERATION

33

CONTROL OBSERVATIONS DURING

OPERATION

Stop the Engine immediately if:

Sudden increase or decrease in engine

rpm's occurs.

Sudden abnormal noises occur.

Exhaust gases turn suddenly very dark.

Make following control observations during

operation to be sure that everything

functions normally.

Oil Change in the Run-in Stage

The lubrication oil plays a specifi c and

important role during the run-in phase of the

excavator. The numerous movable parts are

not yet run-in, so many fi ne metal particles

are generated and cause damage and

shorten the lifetime of many components.

Pay attention to the oil-change intervals

and complete them sooner than later.

See the subject "REGULAR CHECKS AND

MAINTENANCE WORK" for more details on

the oil-change intervals.

Seat Belt

RUNNING-IN OF THE NEW

EXCAVATOR

The operation and care of the new excavator

infl uences its life span. Your new excavator

has been carefully checked and tested

before leaving the factory. In spite of this,

all movable components must run-in during

the fi rst 50 work hours. Do not work with

full engine rpm's and full loads during this

period. It is most important to run-in your

excavator properly in order to achieve its

full performance and longevity. During the

running-in, the following points should be

adhered to in all cases.

3

WARNING

To avoid personal injury or death:

Always use the seat belt with a

ROPS/OPG (Top Guard Level I)

protection structure. Adjust the

seat to the optimal position and

buckle up.

Do not Work with Full Engine

Rpm's or Full Loads during the

First 50 Working Hours

Let the engine warm up suffi ciently in

the cold season.

Do not let the engine rev-up more than

necessary.

(1) Seat belt

STARTING

CAUTION

3

To avoid personal injury:

No persons, other than those

familiar with the excavator, are

allowed to use the excavator.

Do not allow any person other

than the operator to ride on the

excavator.

Page 42

34

1. Adjusting the Operator’s Seat

Operator's Seat

CAUTION

3

To avoid personal injury:

Make sure that the seat is

completely secured after each

adjustment.

Do not allow any person other

than the driver to ride on the

excavator.

Move up the lever (2) toward G from the

center (free state), and the spring force

gets stronger. Move it down toward F,

and the spring force gets weaker.

Travel adjustment (Horizontal) : (4)

Pull up and unlock the travel adjust lever

(horizontal) (4). Slide the seat back and

forth to an optimum position.

Make sure the seat has got locked in the

desired position.

Armrest angle adjustment : (5)

Turn up or down the armrest angle

adjust knob (5) to position the armrests

to an appropriate angle.

Turn up the knob (5) toward (d) to tilt

up the armrests toward E. Turn it down

toward (e) to tilt them down toward D.

2. Bring the lock lever into the

"Unlock" position.

CAUTION

3

To avoid personal injury:

Check safety features all around

the excavator.

(1) Knob for tilt (A) "FORWARD"

(2) Suspension adjustment (B) "BACK"

lever (C) "UNLOCK"

(3) Travel adjust lever

Backrest angle adjust knob : (1)

Pull up and unlock the backrest angle

adjust knob (1). Reposition the backrest

in Direction A or B to an optimum angle.

Driver's weight adjustment : (2)

Sit on the seat and swing the weight

adjust lever (2) 90º in Direction (c).

Move up or down the lever (2) several

times until the arrow mark comes to the

center of the weight indicator (3).

(1) Lock lever for (A) “Lock”

attachment control (B) “Unlock”

Page 43

35

Working Light Switch

If the key in “RUN” position, the lights can be

switched on by pressing the switch.

(1) Working light switch

Night operation

CAUTION

3

To avoid personal injury:

Visibility is reduced in darkness,

so that the working light

alone is not enough. Prepare

additional lighting, observe

safety rules as well as special

regulations for night work.

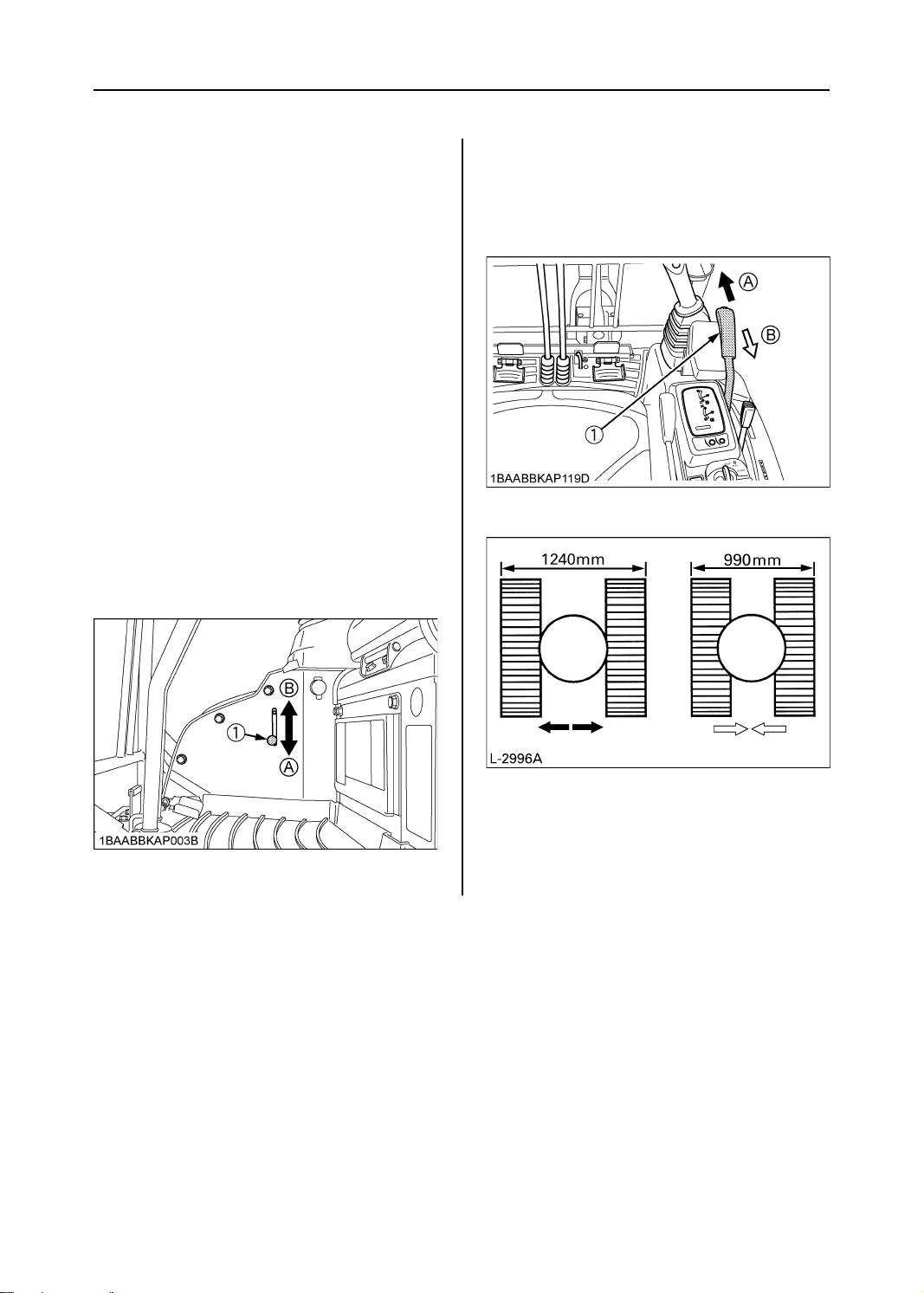

TWO PATTERN SELECTION

SYSTEM (TPSS)

CAUTION

3

Pattern Change

Position the pattern selector lever to the

desired position.

To avoid personal injury:

Study control lever pattern A

and pattern B.

Then choose the one which is

most familiar

Position the pattern selector

lever in either the left side

position of the machine (pattern

A) or the right side position

(pattern B).

Familiarize yourself with the

pattern selected by operating

slowly.

Travel Buzzer (OPTION)

When you handle the drive levers, the buzzer

sounds at the same time or before the

excavator starts to run.

(1) Pattern selector lever (A) Pattern A

(Two Pattern Selection (B) Pattern B

System: TPSS)

Page 44

36

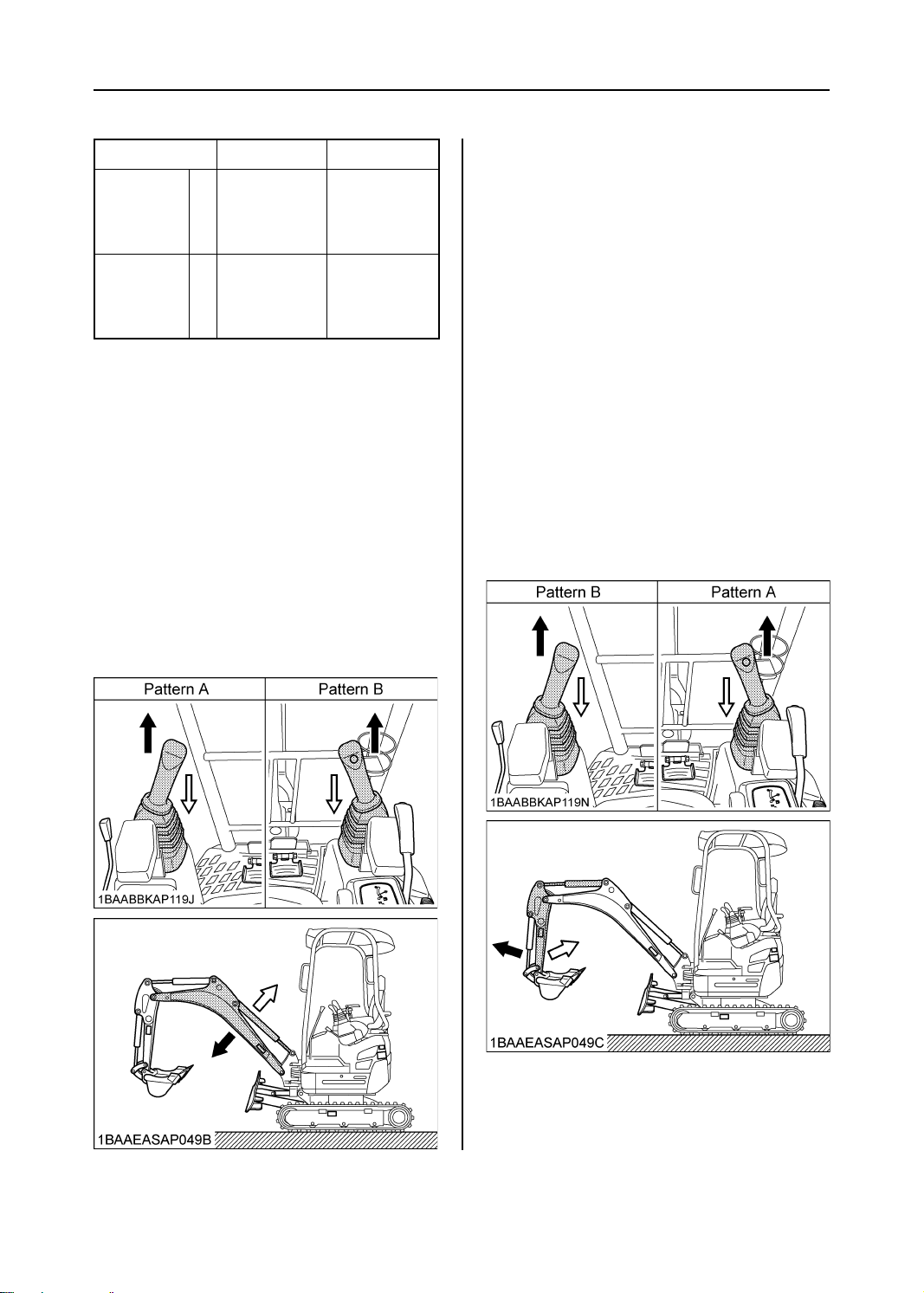

Lever Position

Attachment

Control Lever

(Left)

Attachment

Control Lever

(Right)

Boom down

A

Boom up

B

Swing left

C

Swing right

D

Arm up

1

Arm crowd

2

Bucket crowd

3

Bucket dump

4

Pattern BPattern A

Arm up

Arm crowd

Swing left

Swing right

Boom down

Boom up

Bucket crowd

Bucket dump

OPERATION OF THE BOOM

To raise the boom, pull the attachment

control lever back.

The boom is equipped with a cushion

cylinder which helps prevents excavated

material in the bucket from falling out. Low

hydraulic oil temperature, (e.g. after starting

the engine in cold weather) the cushioning

function will be effected for a short period of

time (approx. 3 to 5 seconds). This condition

results from the viscosity of the hydraulic oil

and is not a sign of malfunction.

The cushion cylinder will operate normally

as the oil warms up.

IMPORTANT:

When lowering the boom, make sure

that it does not hit the dozer and that the

bucket teeth do not touch the dozer.

OPERATION OF THE ARM

Pull back the attachment control lever and the

arm will be pulled in. To move the arm out,

push the control lever towards the front.

NOTE:

When pulling in the arm, the movement

may stop for a short moment when the

arm is in its vertical position. This is

caused by the combined load of the arm

and bucket moving the cylinder piston

away from the hydraulic fl ow causing a

short delay in the cylinder action, until the

fl ow catches up with cylinder piston. This

is a characteristic of the hydraulic system

and is no sign of a malfunction.

Page 45

37

OPERATION OF BUCKET

To dig using the bucket, move the right

attachment control lever from the neutral

position left. Moving the control lever right,

moves the bucket outwards and dumps its

contents.

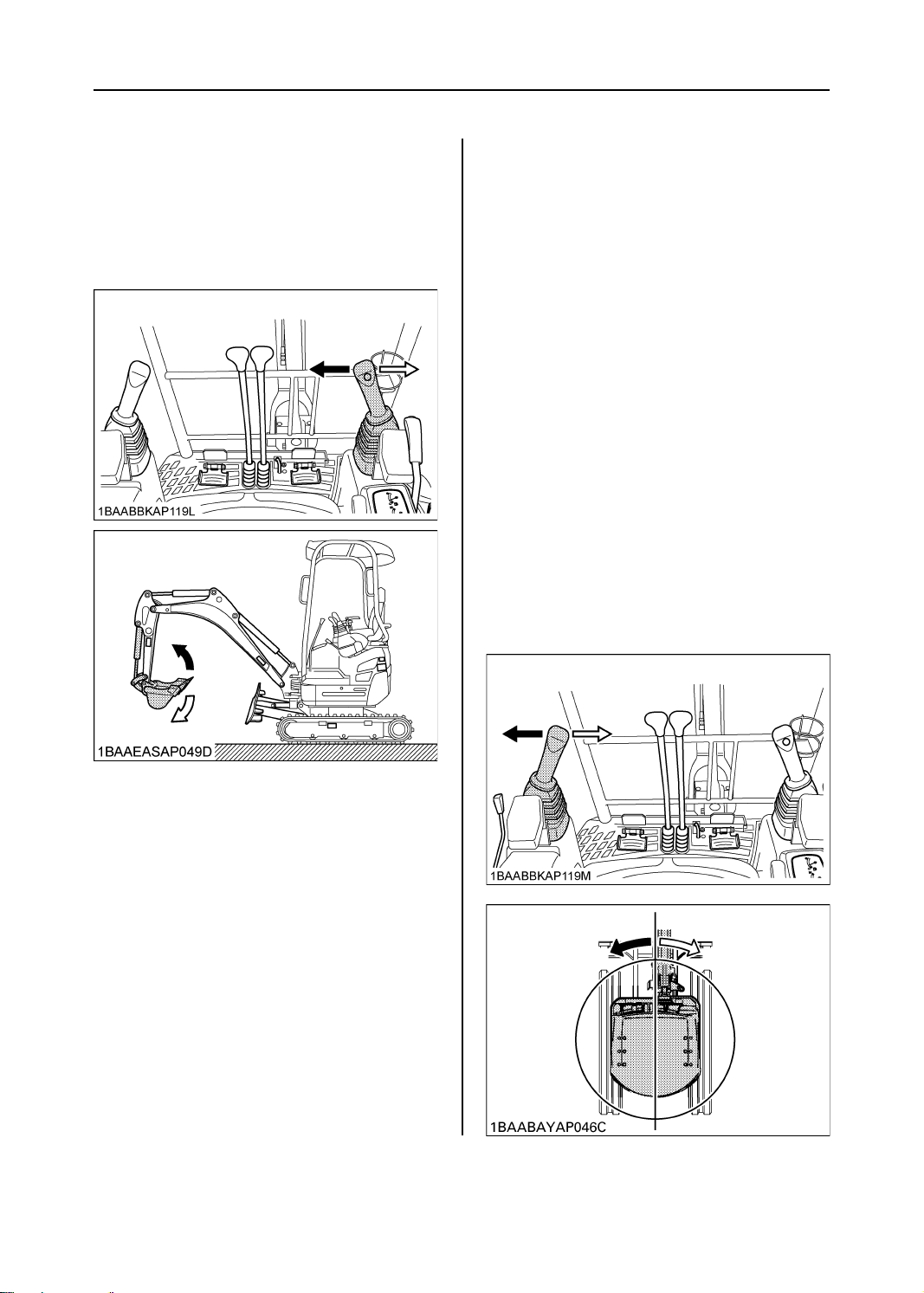

SWIVEL (UNIT SWING) OPERATION

CAUTION

3

IMPORTANT:

Do not operate the left attachment control

Unlock the swing lock pin before doing

1. Move the control lever to the left and the

2. Move the control lever to the right and

To avoid personal injury:

When working in groups,

always let the others know

what you are going to do before

you do it.

Keep away from the working

area.

lever abruptly from right to left (or vice

versa). Because of the law of inertia, this

causes an impact load on the swing gear

and the swing motor. Additionally, the life

of the excavator will be shortened.

swivel operations.

upper structure will turn to the left.

the upper structure will turn to the right.

Page 46

38

BOOM SWING OPERATION

1. Step on the left side of the pedal to swing

the boom to the left.

2. Step on the right side of the pedal to

swing the boom to the right.

BOOM SWING PEDAL

WARNING

3

3

To avoid personal injury or death:

Always keep your toes within

the edge of foot step; otherwise

there is a possibility that your

toes will be caught between

swing frame and boom or

boom cylinder.

CAUTION

To avoid personal injury:

When boom swing operation is

not in use, fold the boom swing

pedal forward to fi x the pedal

from unexpected move.

(1) Boom swing pedal (A) Swing to left

(B) Swing to right

(A) “Fix”

Page 47

39

OPERATION OF TRACK WIDTH

CHANGE AND DOZER

CAUTION

3

Operation of the Track Width

1. Set the track width change/dozer select

To avoid personal injury:

Do not operate in narrow track

width [39in. (990mm)], it makes

risk of the excavator tipping

over, operate always in standard

track width [49in. (1240mm)],

except to pass through narrow

space on a even ground.

For changing the track width

or using the dozer, set

the track width change/

dozer select lever fully.

If not, the excavator may

unintentionaly move.

lever to the “Track width change”

position (B).

2. Push the control lever forward.

... The track width increases [from 39in.

to 49in. (990 mm to 1240 mm)].

Pull the control lever backward.

... The track width reduces [from 49in. to

39in. (1240 mm to 990 mm)].

(1) Control lever (A) “Increase”

(B) “Reduce”

(1) Track width change / (A) ”Dozer”

dozer select lever (B) ”Track width change”

3. After track width change, be sure to set

the track width change/dozer select lever

to the “Dozer” position (A).

Page 48

40

Adjustment of the Dozer Width

For changing from standard width to narrow

width:

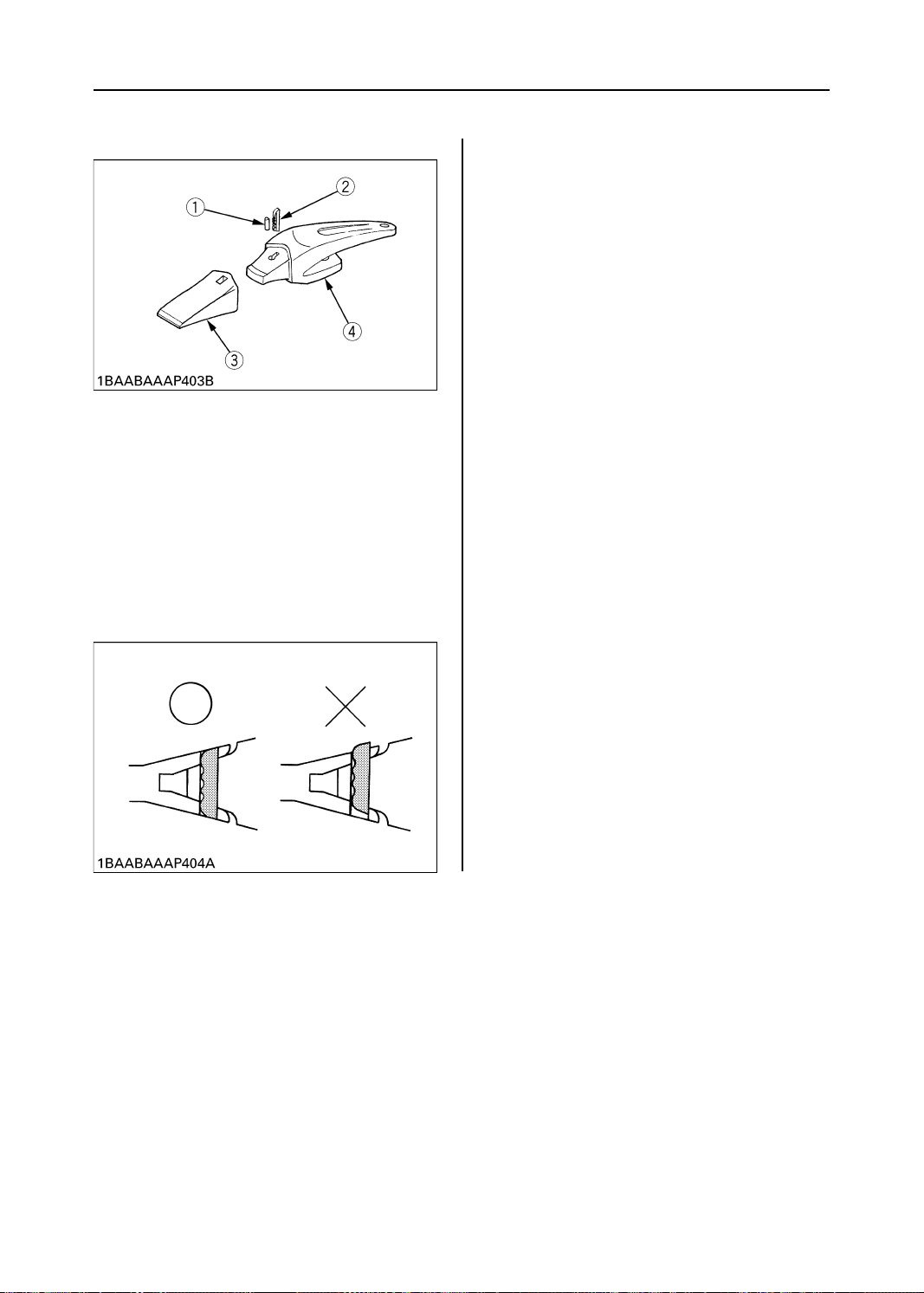

1. Pull out the fi xing pin (2) and remove the

extension dozer (1).

2. Set as under illustration the extension

dozer (1), insert fi xing pin (2).

3. It is the same operations for opposite

side (left or right), and also for changing

from standard width to wide width.

Operation of the Dozer

NOTE:

While operating the dozer, the track width

change / dozer select lever must be set

position (A).

(1) Track width change / (A) “Dozer”

dozer select lever

1. To raise the dozer, pull back the control

lever. Pushing the control lever forwards,

lowers the dozer.

(1) Extension dozer

(2) Fixing pin

(1) Control lever (A) “Lower”

(B) “Raise”

2. While undertaking earth moving work,

control both drive levers with the left

hand and the control lever with the right

hand.

Page 49

41

SERVICE PORT OPERATION

This pedal is used to operate attachments

such as breakers.

(1) Service port (A) Sends oil to the port (A)

pedal (B) Sends oil to the port (B)

NOTE:

When the service port is not in use, fold

the service port pedal forward. The pedal

gets fi xed and can be used as footrest.

(1) Service port pedal (A) “Fix”

DRIVING

WARNING

3

To avoid personal injury or death:

Before starting the engine,

make sure that no one is near

the excavator.

Before operating the excavator,

check the track direction. (Idler

and dozer to the front of the

excavator).

(1) Port (A)

(2) Port (B)

Push the right of the pedal () to send oil

to the port (A).

Push the left of the pedal () to send oil

to the port (B).

Max. Flow Volume

Theoretical US gal (L)/min.

Max. Pressure psi

[MPa (kgf/cm

IMPORTANT:

When the service port is not used for a

long period, dirt particles can settle in the

lower part of the service port lines.

When the plugs on the service port lines

are removed to connect attachments,

drain approx. 100 cc of oil per side.

For breaker choices, contact your dealer.

2

)]

7.32 (27.7)

2697

[18.6 (190)]

(A) ”Front”

Avoid travelling across a slope

or working sideways on a

slope.

Page 50

42

1. To lock the swing frame with the track

frame, engage the swing lock pin.

2. Adjust the engine speed from idling to

an intermediate speed.

3. Unlock the lock lever for attachment

control.

4. Raise the dozer and hold the bucket

about 8 to 16 in. (20 to 40 cm) over the

ground.

(A) 8 to 16 in. (20 to 40 cm)

Throttle Lever

At the operator’s seat,

1. Move the throttle lever to the

“FAST” position, and the engine speed

increases.

2. To stop the engine, push the throttle

lever fully to the “SLOW” position and

turn the starter switch to the “STOP”

position.

Drive Levers (Right, Left)

WARNING

3

Pushing the drive lever forward, moves the

excavator forward, and vice-versa. The front

of the excavator is the direction where the

dozer is present.

(1) Drive lever (left) (A) “Forward”

(2) Drive lever (right) (B) “Backward”

To avoid personal injury or death:

If the swing frame has

been turned 180º, i.e. the

dozer is, seen from the

operator, “behind”, then the

travel direction is opposite to

the drive direction of the levers

(when activating the drive lever

forwards, the excavator, seen

from the operator, will move

backwards).

(1)Throttle lever (A) ”FAST”

(B) ”SLOW”

IMPORTANT:

If the track are clogged with sand or

gravel while working on soft ground, lift

up one track with the help of the boom,

arm and bucket and let the track rotate to

shake off the sand and gravel.

(A) “Rotate to shake off sand and gravel”

Page 51

43

Travel Speed Switch

CAUTION

3

Travel speed will increase when the switch is

pushed down.

1. Press the travel speed switch. The travel

2. Press the travel speed switch again, and

To avoid personal injury:

When activating the travel

speed switch, it must be

pushed down completely.

speed changes from fi rst speed to

second. The

the travel speed changes from second to

fi rst. The

j symbol lights up.

j symbol light goes out.

TURNS

CAUTION

3

Pivot Turn

NOTE:

Movement as illustrated shows the

When the dozer is in the back, the steering

direction is reversed.

(For example, push the left drive lever

forward and the excavator turns right; the

left track, seen from the operator, will move

backward from the operator.)

Change of Direction while Stationary

1. Push the left drive lever forward; the

To avoid personal injury:

Do not change direction on

steep slopes, or the excavator

could tip over.

Before changing direction,

beware of people in the working

area.

turning directions with the dozer in the

front.

excavator will turn to the right.

(1) Travel speed switch

(2)

j symbol

NOTE:

Each time the travel speed switch is

pressed, the travel speed is switched

between fi rst and second.

IMPORTANT:

Do not activate the travel speed switch

when there is increased drive resistance

(e. g. driving on inclines or on uneven

grounds).

2. Pull the left drive lever backward; the

excavator will turn to the left.

Page 52

44

Change of Direction while Travelling

1. While travelling forwards, bring the left

(right) drive lever in the neutral position;

the excavator will turn to the left (right).

(A) ”Travelling forward”

(C) ”Neutral position”

2. While travelling backwords, bring the left

(right) drive lever in the neutral position;

the excavator will turn to the right (left).

Spin Turn

When both drive levers are activated in

the opposite directions, both track will

rotate with the same speed but in opposite

directions. Center of rotation is the center of

the excavator.

(A) “Left spin turn”

(B) “Travelling backward”

(C) ”Neutral position”

(B) “Right spin turn”

Page 53

45

UP AND DOWNHILL TRAVELLING

CAUTION

3

While travelling uphill, keep the lower edge

of the bucket approx. 8 to 16in. (20 to 40cm)

above the ground. Although the KUBOTA

excavator will not slip easily because of the

tracks, it is safer to let the bucket slide over

the ground while travelling downhill. Always

choose slow speed for uphill and downhill

travelling.

[

UPHILL TRAVELLING

To avoid personal injury:

Before travelling up and

downhill, be sure to be in

standard track width [49in.

(1240mm)].

When travelling up or down a

slope for long periods of time,

be sure to engage the swing

lock pin. Also engage the swing

lock pin when standing on a

slope for a long time or the

excavator is being transported.

]

PARKING ON A SLOPE

WARNING

3

(1) Drag

To avoid personal injury or death:

When the excavator is parked

or left unattended on a slope,

be sure to put the bucket on

the ground and place all control

levers in neutral position, then

brace the tracks with drags.

(A) 8 to 16 in. (20 to 40 cm)

[

DOWNHILL TRAVELLING

]

Page 54

46

IMPORTANT INFORMATION ON

If the water or mud level reaches higher

EXCAVATOR OPERATION

Do not try to crush concrete or boulders

using side swings with the bucket. Also

avoid using side sweeps of the bucket to

move earth piles.

Under all circumstances avoid the

following operations:

Excavation using the gravitational

impact of the machine.

Compacting of gravel or soil using

the dropping action of the bucket.

Excavation using the travelling power

of the machine.

Do not try to drop or shake off soil

adhering to the bucket in the manner

given in the points below. This can cause

damage to the machine.

Adhered soil can be shaken off when

the bucket is being emptied by moving

the bucket out to the maximum stroke

of the cylinder. Should this not suffi ce,

swing out the arm as far as possible and

operate the bucket back and forth.

Do not hit the dozer with the boom

cylinder!

Make sure that the boom cylinder does

not hit the dozer when doing deep

excavation. If necessary swing around

so that the dozer is in the back of the

machine.

Pay attention when pulling in the

bucket!

When pulling in the bucket (for driving or

transportation) avoid hitting the dozer.

Avoid collisions!

When moving the excavator, pay

attention that the dozer does not collide

with obstructions such as boulders etc..

Such collisions shorten the life of the

dozer and the cylinder substantially.

Support the machine correctly!

When stabilizing the machine with the

dozer, Iower the dozer to engage the full

width on the ground.

The excavator must be properly pressure

than the top of the tracks, the swivel

bearing, swivel motor gear and ring gear

may be exposed to mud, water and other

foreign objects.

washed after each use.

Thoroughly clean the area around

the swivel bearing, swivel motor

gear and ring gear to remove foreign

objects.

Inspect the swivel motor oil sump (if

equipped) for water contamination. If

water is present, refer to operator's

manual for lubricant replacement

procedure.

Refer to operator's manual for proper

swivel bearing, swivel motor gear

and ring gear lubrication procedures.

Reinstall any protective covering if

removed earier.

Page 55

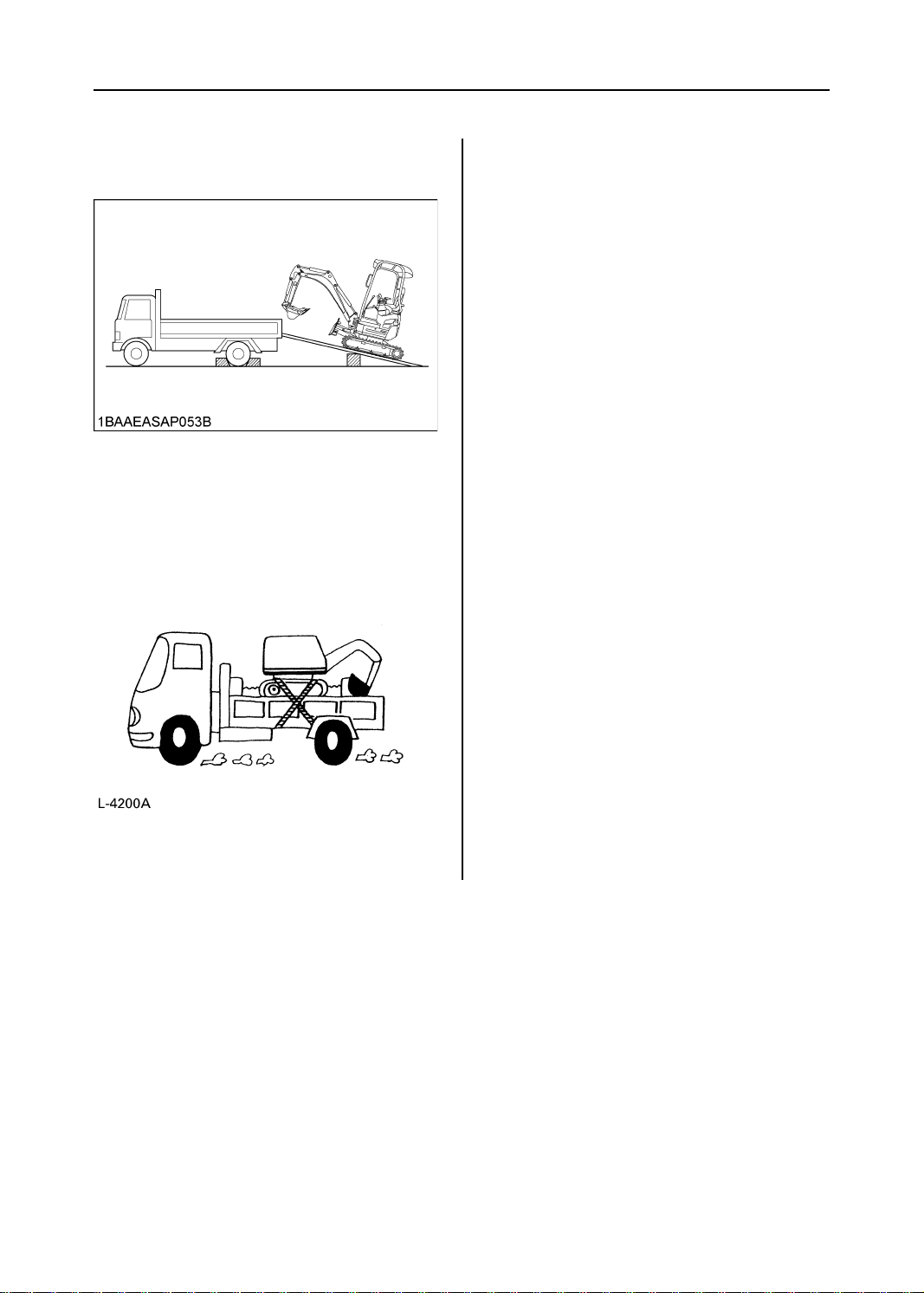

47

TRANSPORTING THE EXCAVATOR ON A TRUCK

3

DANGER

To avoid personal injury or death:

No directional changes should

be made when the excavator is

on the ramp. Should a change

of direction be necessary, drive

off the ramp completely and

make the turn.

When driving forwards or

backwards onto the truck, or

when swinging the upper body,

make sure that neither the

cabin or the gates of the truck

will be damaged.

Transporting on a Truck

WARNING

3

Prepare a platform to load or unload the

excavator. Take following steps when using

ramps.

1. Apply the parking brakes of the truck,

To avoid personal injury or death:

After loading the machine on

the truck, lower the bucket and

dozer onto the truck bed. Lock

the swing frame with the swing

lock pin.

and block the drive wheels from both

sides.

When the excavator reaches

the point between the ramps

and the truck bed, halt and

then move very slowly until

the excavator reaches the

horizontal position.

Move the excavator onto

the truck only with the

arm completely pulled in.

Otherwise the truck cabin could

be damaged when swinging

around the upper body.

Do not jack up the machine

using its boom to load or

unload the excavator from

the truck. Dangerous situation

could arise.

2. Use mounting brackets to secure the

ramp properly. Connect the ramps

directly to the truck bed.

Page 56

48

3. For additional safety, use blocks or

supports under the ramps and the truck

bed.

4. Align the ramps and the tracks and

then drive the excavator slowly up the

ramps. After ensuring that the tracks are

completely on the truck bed, swivel the

upper body around to the back of the

truck.

5. Block the tracks and wire down the

excavator.

6. Before unloading, remove the swing lock

pin and then raise the dozer and bucket

from the truck bed.

Page 57

LIFTING OF THE EXCAVATOR

49

DANGER

3

To avoid personal injury or death:

The correct instructions for

safe handling are described

here. Read these instructions

carefully before moving the

machine. Make sure that the

operating personnel read the

operator's manual carefully.

Basics when Lifting with Cables

or Straps

1. The lifting and crane operation is to be

undertaken according to the guidelines

described.

2. The equipment for lifting mentioned

in these instructions are only given as

reference, the standards concerning

strength, control and other details are

based on the respective applicable

guidelines.

Safety Aspects when Lifting with

Cables or Straps

Abide by following steps when lifting:

1. Do not lift loads that exceed the

maximum load capacity of the crane.

2. Choose correct equipment suitable to