Kubota u15-3 Workshop Manual

WORKSHOP MANUAL

KUBOTA EXCAVATOR

U15-3

Code No.97899-61270

Record of Revisions

Symbol Date Main Revised Points & Corrective Measures Person-in-charge

1

2

3

4

ss

CONTENTS

I Product engineering section

II Service engineering section

WSM U15-3

I Product engineering section

A.Developing concept and feature . . . . . . . . . . . . . . . . . . . . . .I-3

a. Objective and Concept of Development . . . . . . . . . . . . . . . . . . . . . . . I-3

b. Main Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

c. Major Selling Points and Improvements . . . . . . . . . . . . . . . . . . . . . . . I-4

d. Evaluation of Competitive Power with Competitors . . . . . . . . . . . . . .I-8

e. Actual performance comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-11

B.Machine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-12

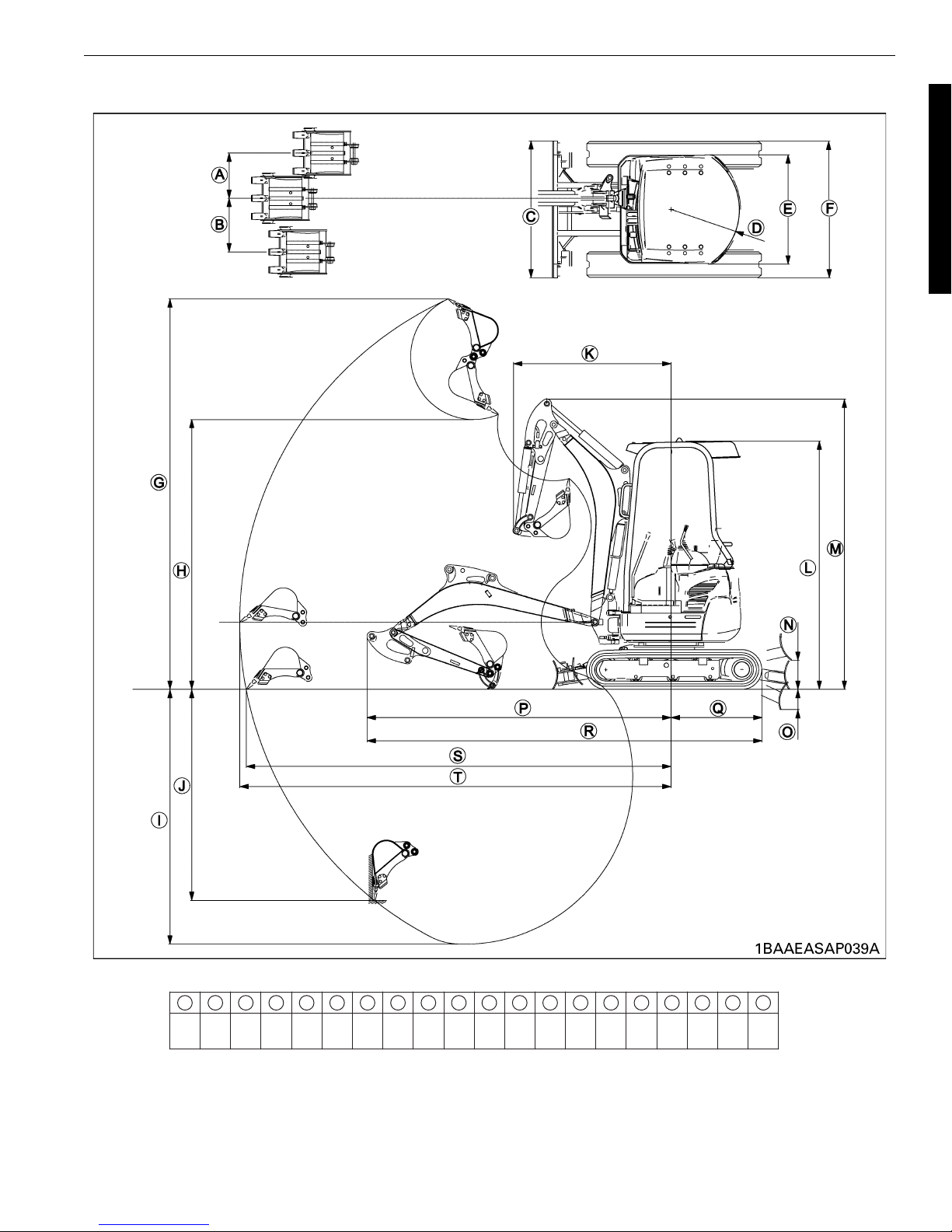

a. Major dimensions and working range (with rubber crawler) . . . . . . . I-12

b. Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-13

c. Performance and lifting capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-14

I-1

WSM U15-3

I-2

WSM U15-3

A.Developing concept and feature

a. Objective and Concept of Development

1 Objective of Development

Development of products which go ahead of competitive companies in terms of reduced manufacturing

costs while reinforcing the performance in horizontal operability, workability, durability, comfort and

safety.

2 Product Concept

Integration of the world's best actual performance of backhoe and the spirit of innovation.

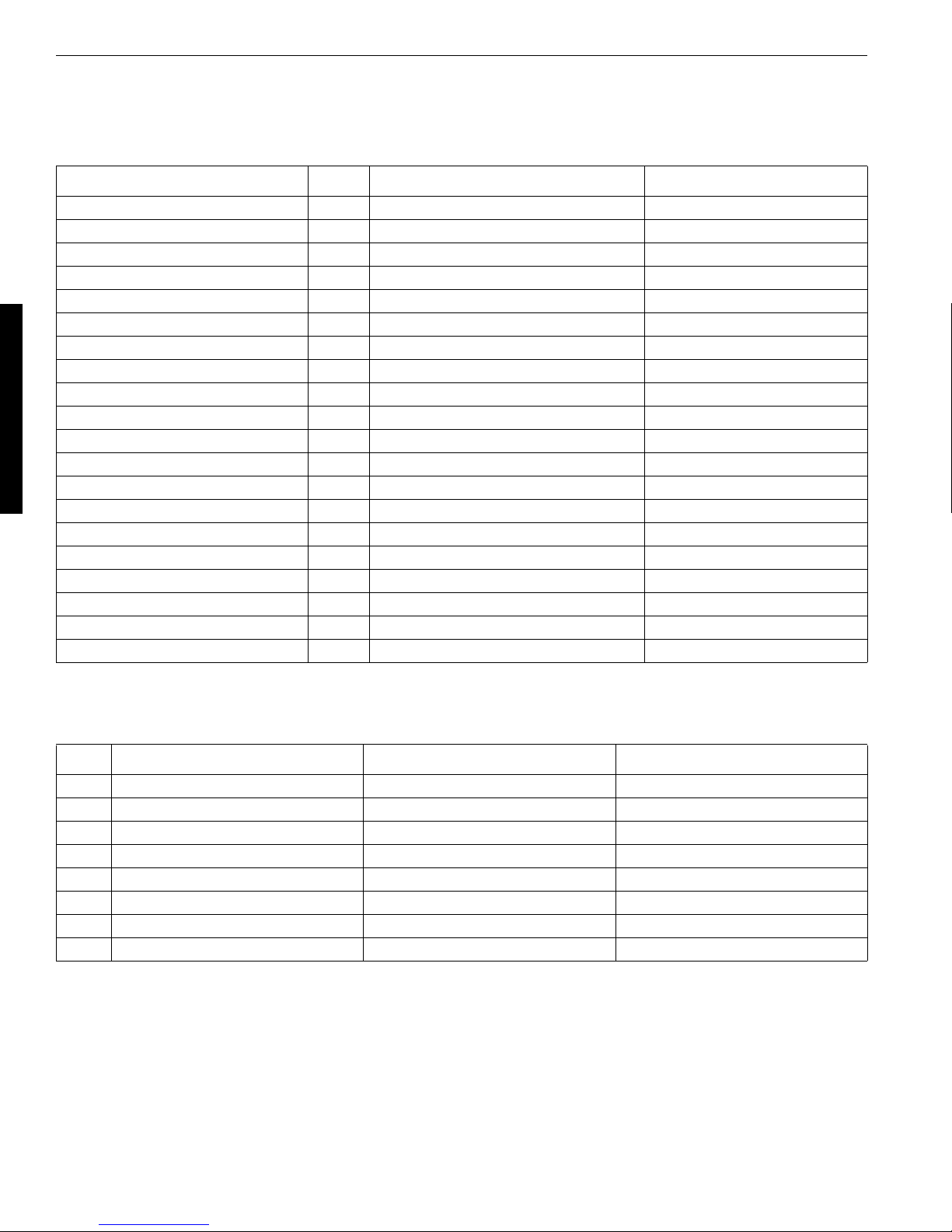

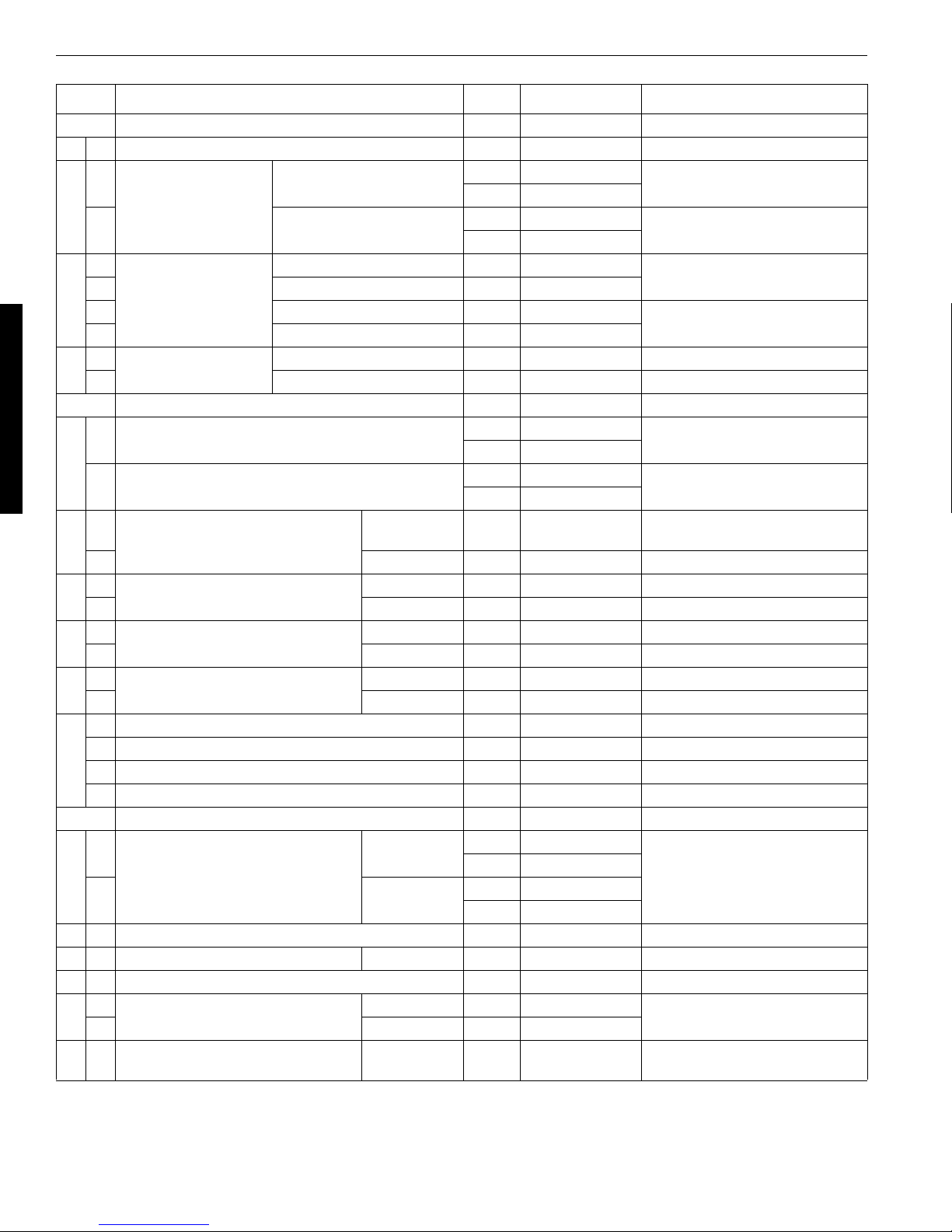

b. Main Specifications

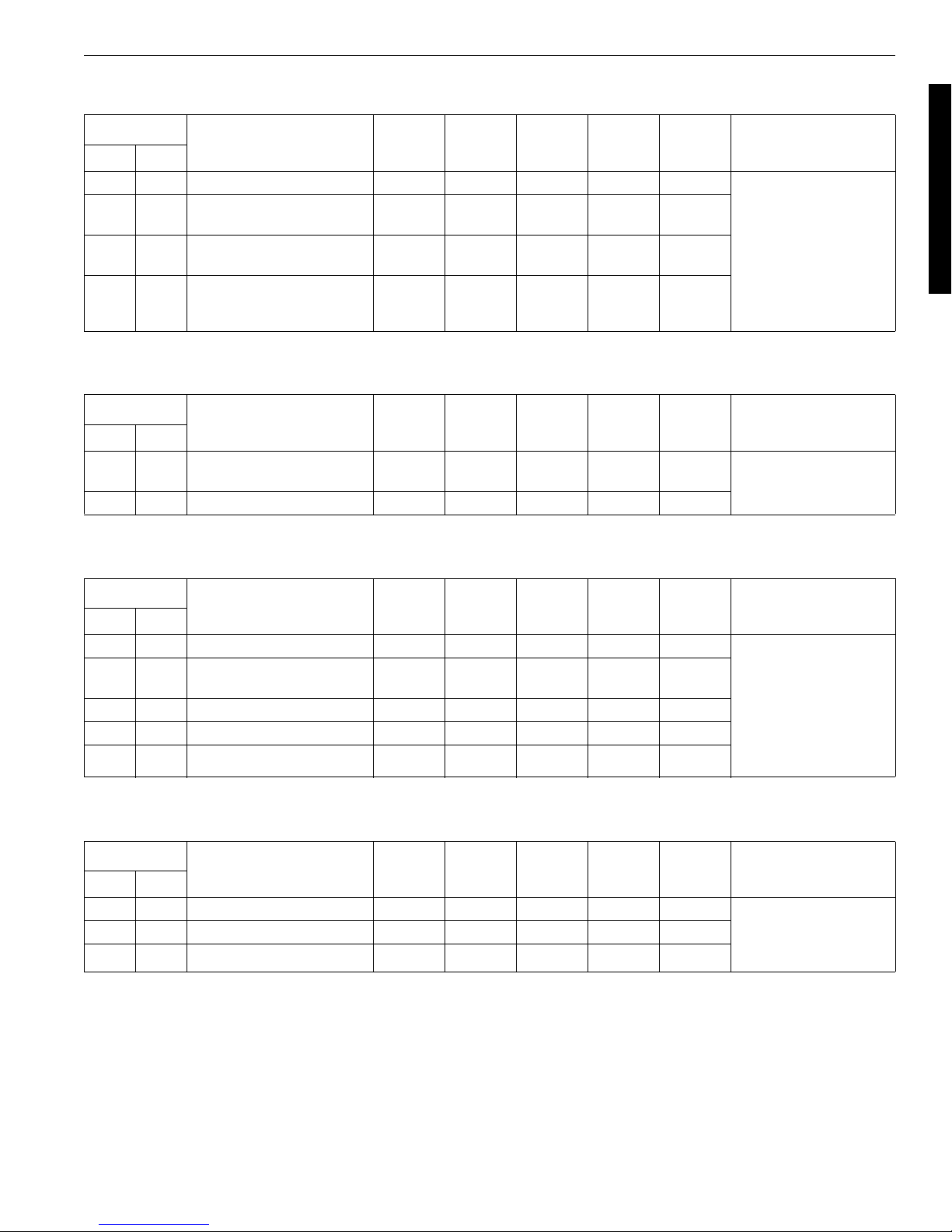

model U15-3 U-15

Brand KUBOTA KUBOTA

Type D782-EBH-4 D782-BH

Engine

Machine weight kg 1600 1450

Excavating capacity

Hydraulic pump

P1, P2

Output

Displacement

Bucket kN (kgf) 15.2 (1550) 12.5

Arm kN (kgf) 8.8 (900) 8.5

Relief pressure

Pump discharge rate L/min 16.6 15.1

Relief pressure

P3

Pump discharge rate L/min 10.4 9.5

PS/rpm 13/2300 12/2100

kW/rpm 9.6/2300 8.8/2100

3

cm

kg/cm

kg/cm

2

2

778 778

220 210

190 210

I-3

WSM U15-3

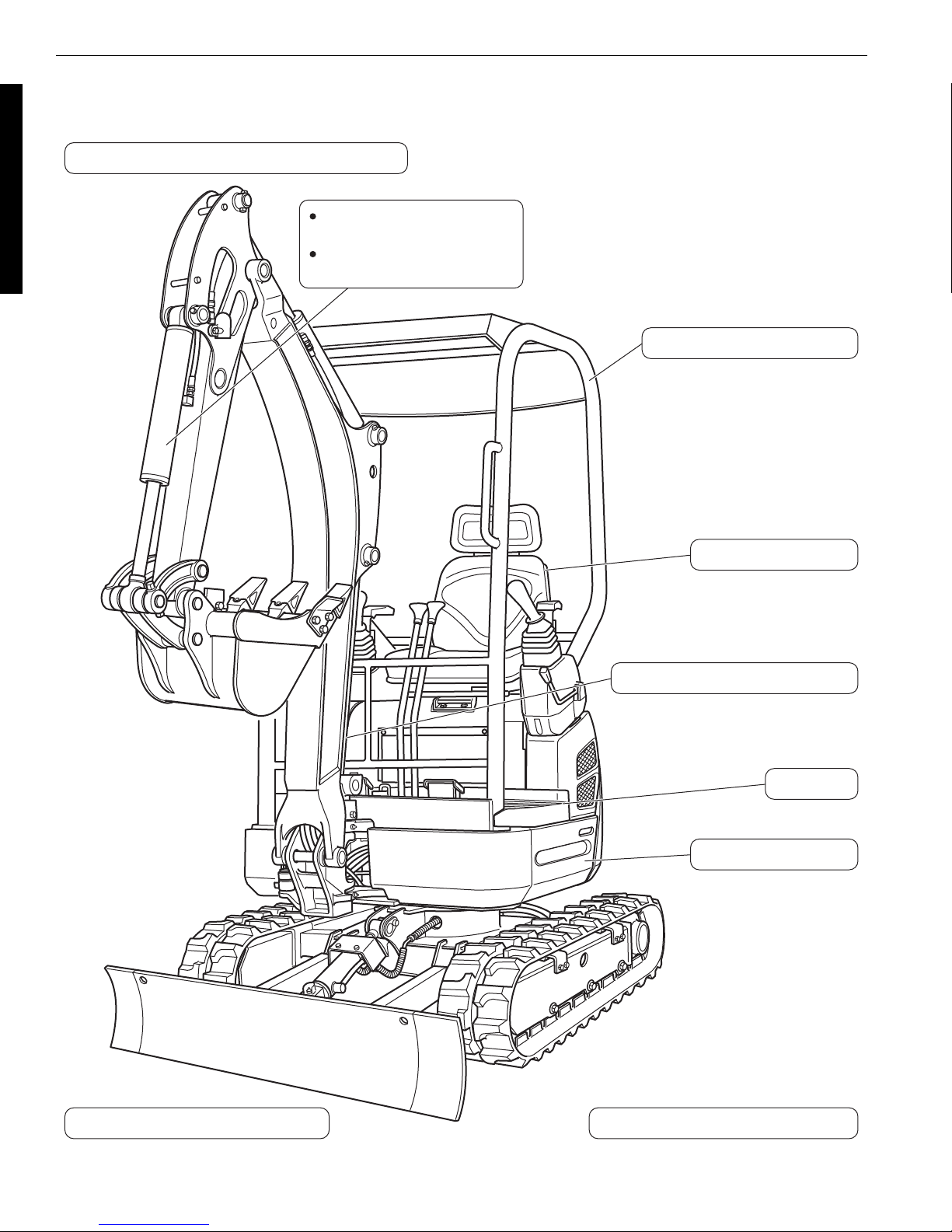

c. Major Selling Points and Improvements

1. Quick chart

Inner package of hoses for all attachments

Max. excavation capacity

increased by 22%

Max. excavation depth

increased by 10%

4-port ROPS specification

Engine start control

High-positioned boom cylinder

Flat steps

Travel lock function

Theft-proof version (EU - option)

Standard equipped with SC valve

I-4

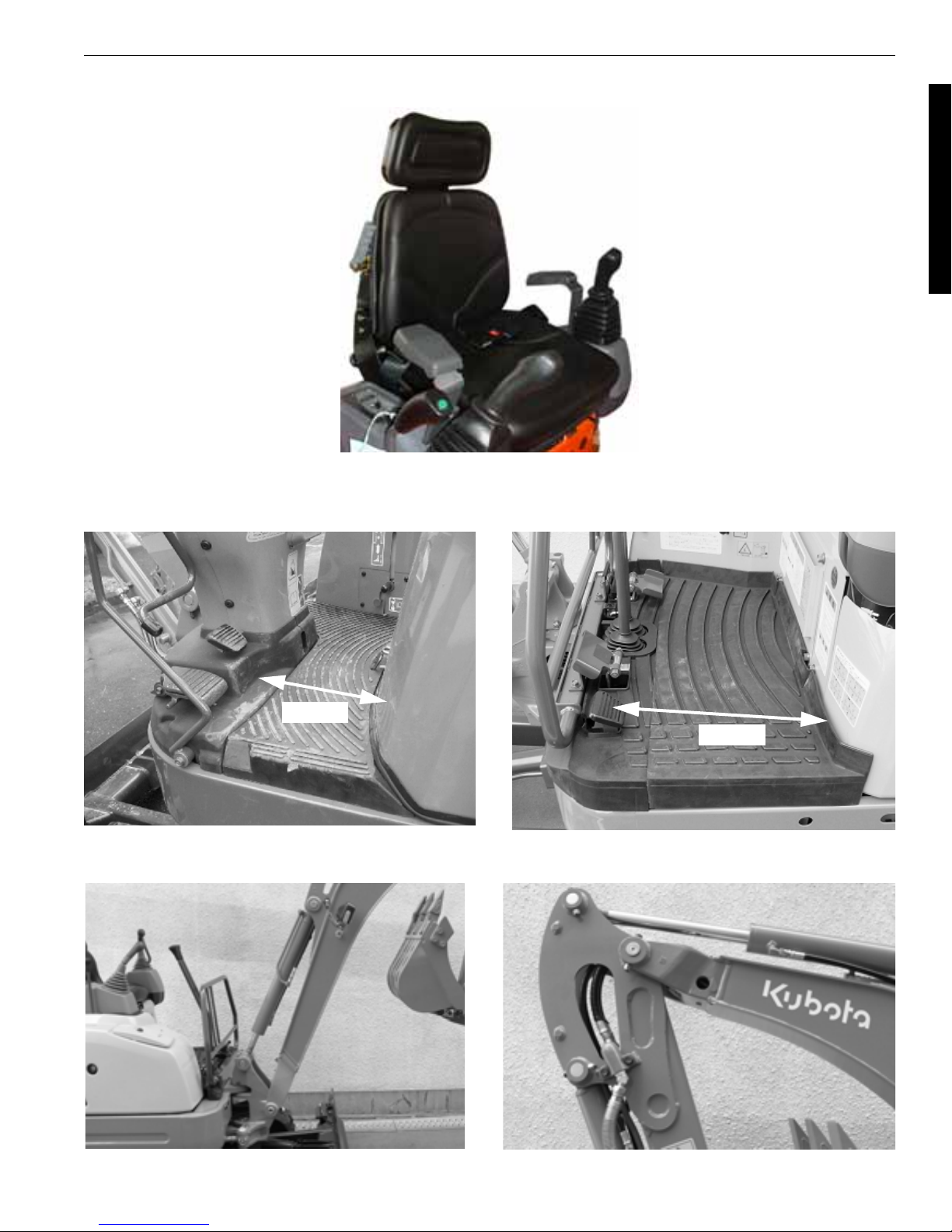

2. Wrist arm control lever

s

3. Enlarged foot space

U-15 (Previous model)

WSM U15-3

U15-3 (New model)

330mm

4. Upper positioned boom cylinder 5.

460mm

Inner package of hoses for front attachment

I-5

WSM U15-3

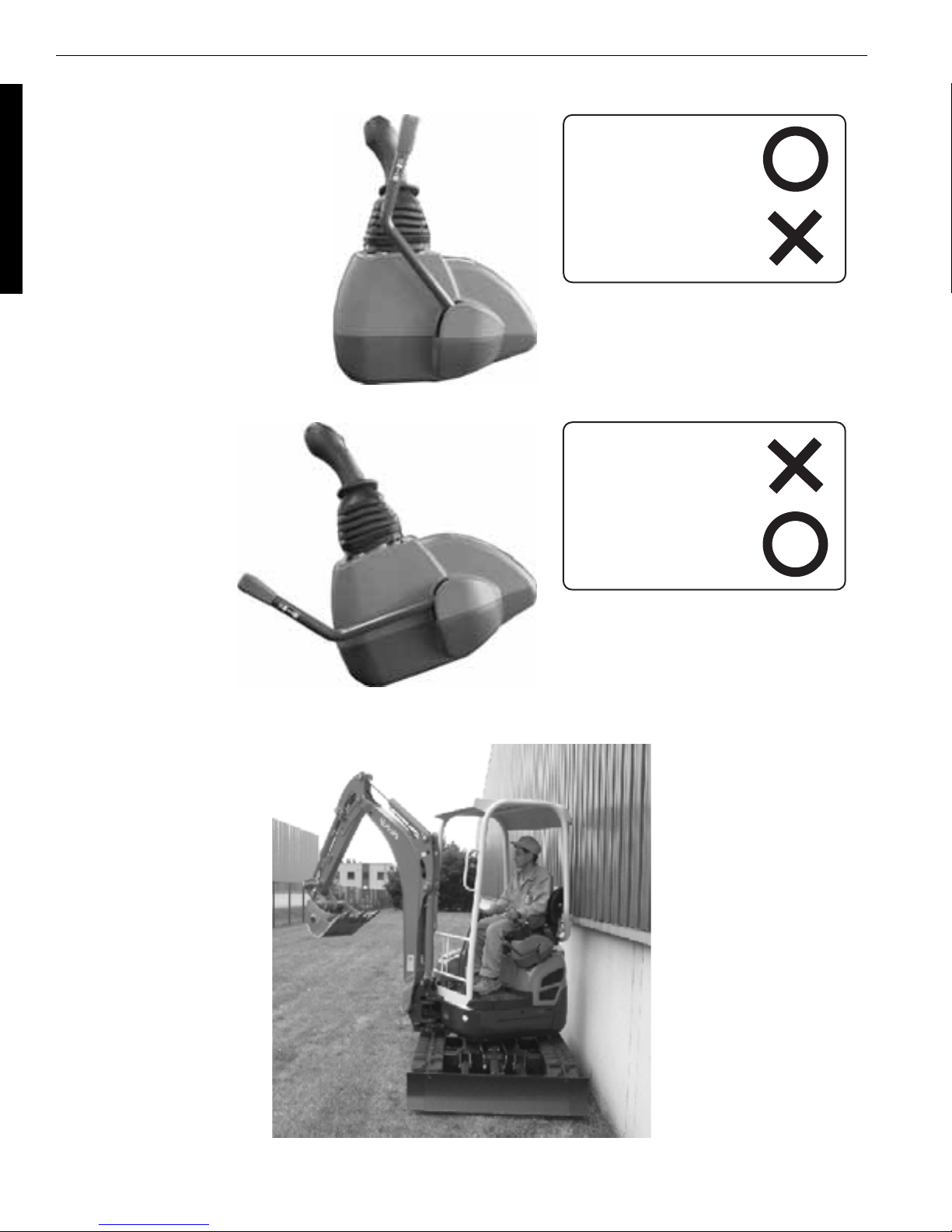

6. Engine start control, Travel lock function

Unloading lever : UP

Unloading lever : DOWN

Engine start :

Front attachment,

traveling :

Engine start :

7. 4-post ROPS

Front attachment,

traveling :

The equipment is of European specifications.

I-6

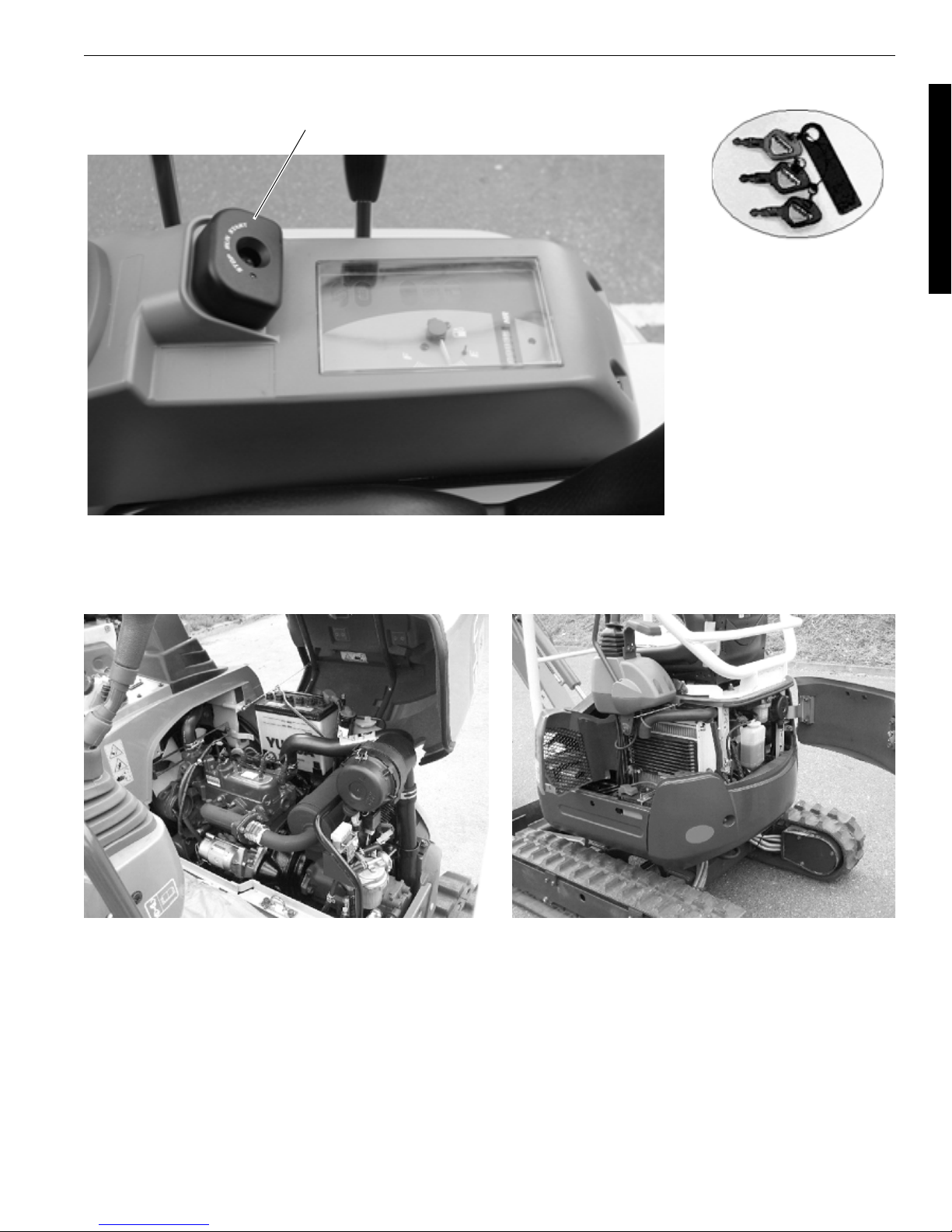

8. Machine equipped with theft-proof device (Future EU option)

Antenna unit

WSM U15-3

Starter key set

9. Side-opening type full-open hood

U-15 (Previous model) U15-3 (New model)

Paint color and equipment are of European specifications.

I-7

WSM U15-3

{

{

{

{

{

{

{

{

{

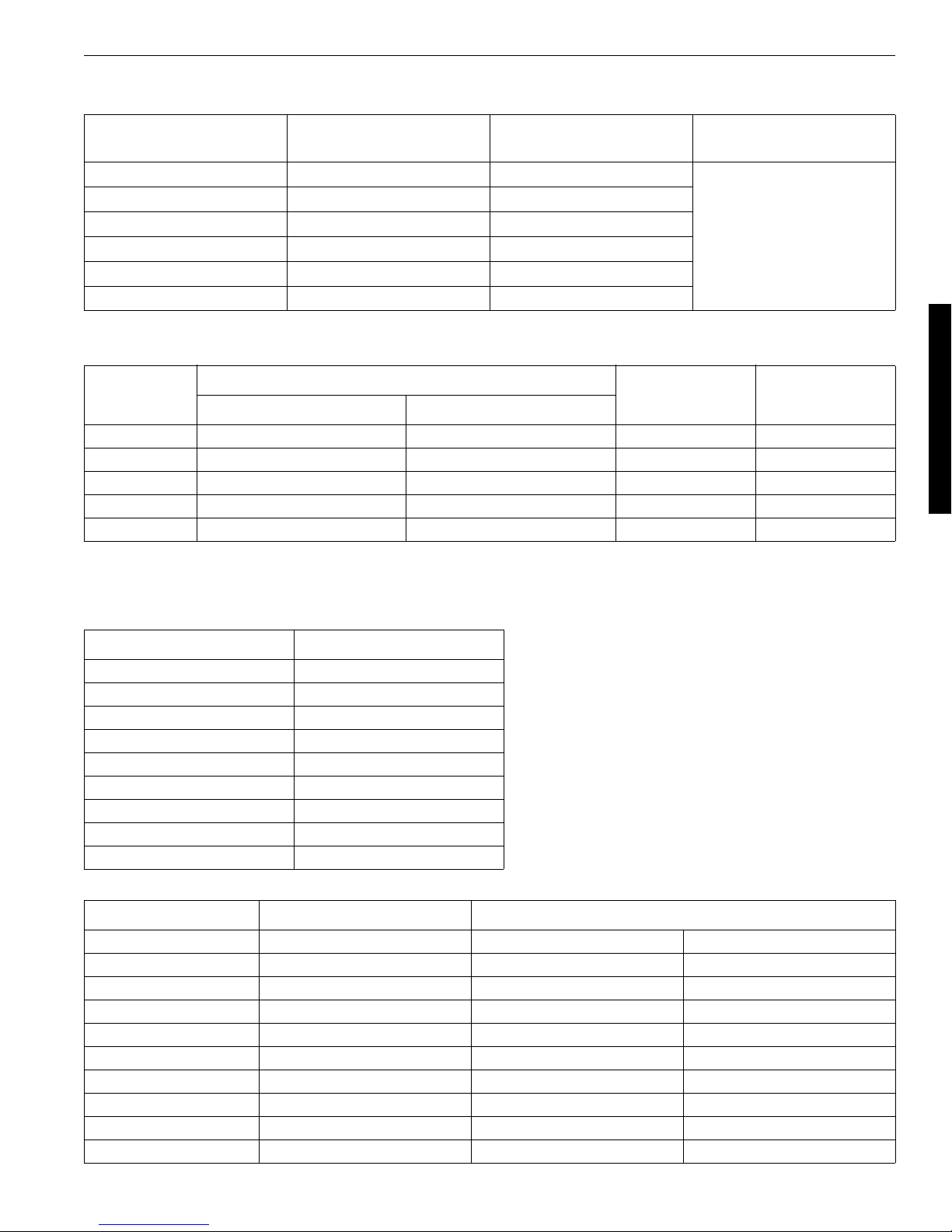

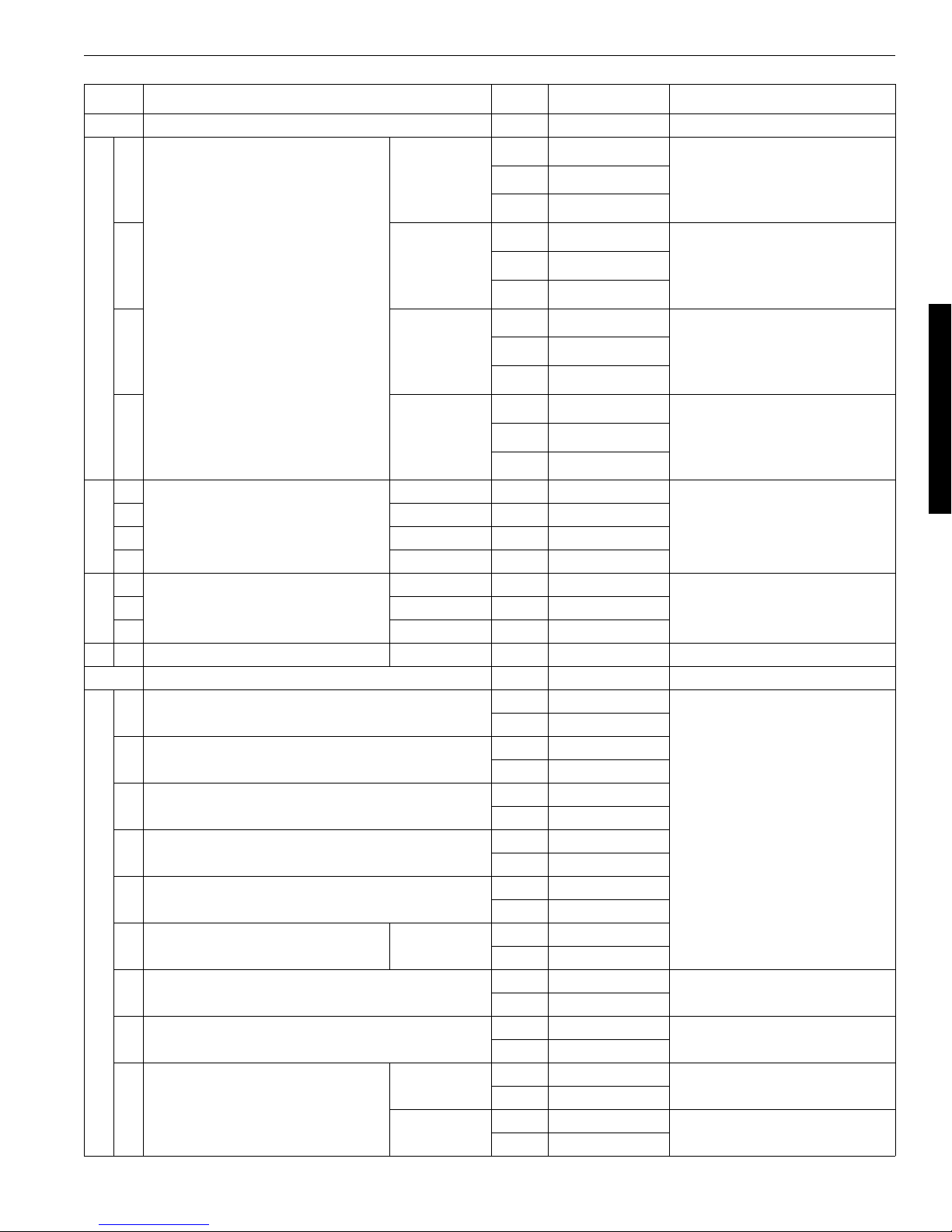

d. Evaluation of Competitive Power with Competitors

1. Workability

Offence Defense

{ Increase in engine output 9.6 8.8 11.2 8.5 11.3

{

{

{

{

{

{

{

2. Durability

Offence Defense

{

{

{

{

{

{

{

{ Boom cast steel members

{ High-tensile brass bush

Item U15-3

Max. excavation capacity

increased by 22%

Max. excavation depth

increased by 10%

Max. vertical depth

increased by 11%

Max. excavation radius

increased by 5%

Travel 2-speed traction force

increased by 5%

Travel 2-speed speed

increased by 8%

Swiveling force increased by

12%

Item U15-3

Boom cylinder Protection of

cylinder by high-positioning

Protection by inner package

of hoses for all attachments

Standard equipped with tension spring

Double-grouser type iron

crawler <For domestic market only>

Introduction of high-back

and integrated seat

Prevention of water entry by

enclosed hydraulic oil tank

Equipped with starter automatic release function

Current

U-15

15.2 12.5 14.2 13.7 14.4

2310 2100 2155 2100 2170

1900 1720 1870 1750 1720

3900 3720 3900 3720 3800

2.2/4.3 2.0/4.0 2.3/4.3 2.1/4.3 2.3/4.0

Current

U-15

KOMATSU

PC15MR

----

----

KOMATSU

PC15MR

xxxx

''xx

x {{{

x--{

x {{{

x---

x---

x { xx

x { --

YAN MAR

Vio15

YAN MAR

Vio15

SCM

301.5CR

SCM

301.5CR

Appealing point in sales

We will appeal such a

point that the max. excavation capacity and max.

excavation depth which

are the basic performances of excavating

machine take a lead over

those of our existing

machines as well as

competitive companies'

machines.

Appealing point in sales

As the greatest differentiation from competitive

companies' products, we

will appeal such a point

that loading work can be

performed without hassle. This is because the

machine can be brought

close to a 2-ton dump

truck without damage to

the boom cylinder during

loading work. Such job is

found often with

machines of this class.

We will also appeal such

a point that the machine

is equipped with the

inner package of hoses

for all attachments which

gives no damage to cylinder.

I-8

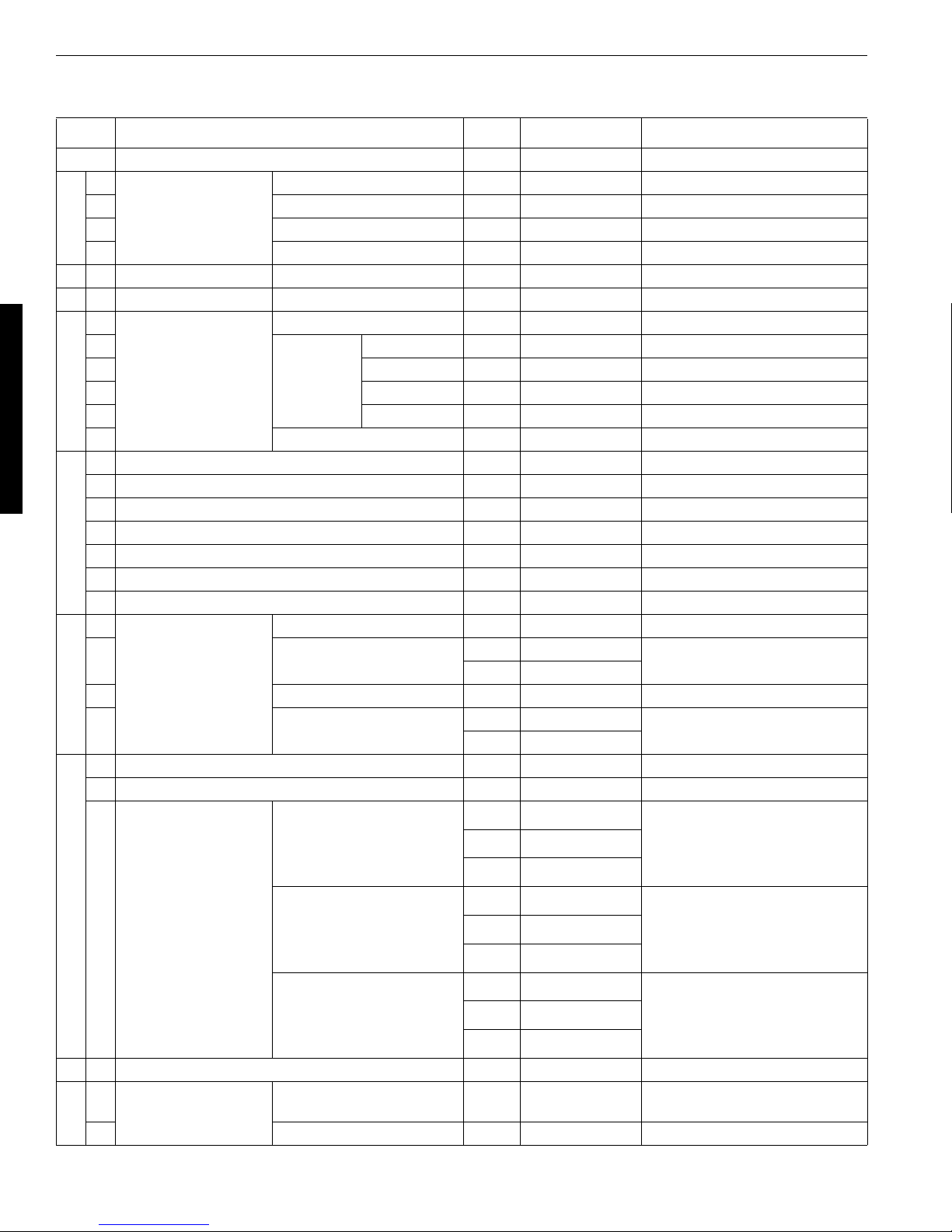

3. Operability

{

{

{

{

{

{

{

{

{

{

{

{

{

{

WSM U15-3

Offence Defense

{ Horizontal operation

Starter key used also for

{

higher-ranked models

Equipped with auto-glow

{

indicator

Right and left pedaling for

{

swing

4. Comfort

Offence Defense

{ Ample getting-on/off space

{ Flat steps

5. Maintainability

Item U15-3

Item U15-3

Current

U-15

Current

U-15

Front

operation

KOMATSU

PC15MR

x {{{We will appeal the com-

x---

x---

x {{{

KOMATSU

PC15MR

x {{{

YAN MAR

Vio15

YAN MAR

Vio15

'''

SCM

301.5CR

SCM

301.5CR

Appealing point in sales

fort and operability of

horizontal operation to

users of current U-15.

We will also appeal to

rental users that the

starter key can be used

also for higher-ranked

models.

Appealing point in sales

We will appeal the

ampleness of getting-on/

off space.

Offence Defense

{ Theft-proof specification

{

Standard equipped with SC

valve

{ Rotary joint O-ring

{ Side-opening full-open hood

{ Split-type dozer hose

Item U15-3

6. Safety

Offence Defense

{ Travel lock function, Unlock

{ Engine start control

{ Compatible with ROPS

Item U15-3

Current

U-15

Current

U-15

KOMATSU

PC15MR

x x x x We will appeal to rental

' --

x---

xxxx

{ x { x

KOMATSU

PC15MR

xxx{ We will appeal such a

xxx{

xxxx

YAN MAR

Vio15

YAN MAR

Vio15

SCM

301.5CR

SCM

301.5CR

Appealing point in sales

uses that the machine

can be equipped with a

new system theft-proof

device as well as the

improved operability of

SC valve and 4P multivalve.

Appealing point in sales

point that the machine

assures the Japan's topclass safety.

I-9

WSM U15-3

7. Working Range

U15-3 U-15 Difference

Max. excavation depth 2310 2100 +210

Max. vertical excavation depth 1900 1720 +180

Max. excavation radius 3900 3720 +180

Max. excavation height 3540 3740 -200

Max. dumping height 2440 2600 -160

Max. floor excavation radius 3840 3610 +230

1200 1270 -70

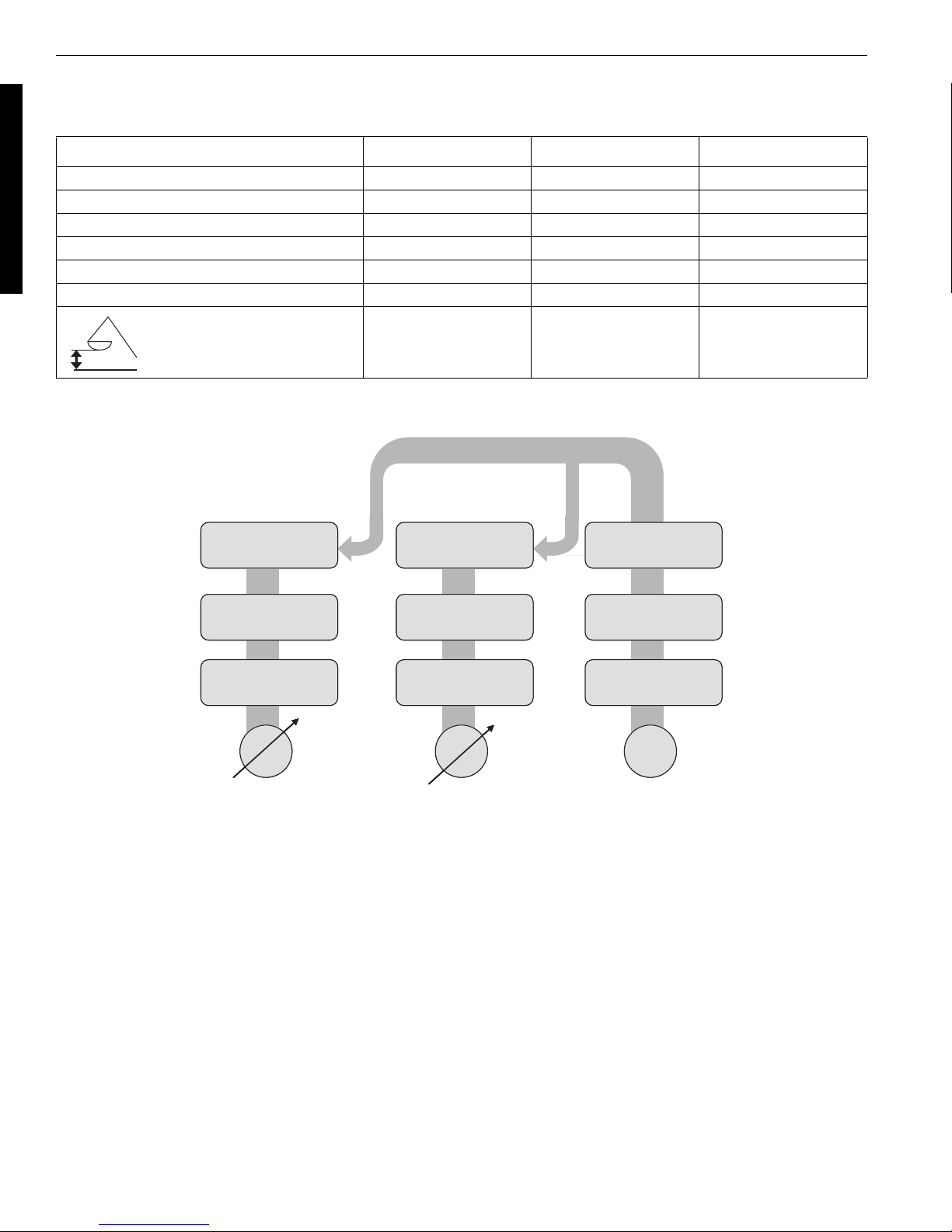

8. Outline of Hydraulic System (Travel straight function)

mm

䉰䊷䊎䉴

䊑䊷䊛

Boom

Bucket

䊋䉬䉾䊃

Travel Left

ⴕᏀ

䌐

䋱

P

1

21.6 MPa

16.6 L/min

Travel straight function is possible only together with boom operation.

Service

䉝䊷䊛

Arm

ⴕฝ

Travel Right

䌐

䋲

P

2

21.6 MPa

16.6 L/min

ᣓ࿁

Swivel

䊄䊷䉱

Dozer

䉴䉟䊮䉫

Swing

䌐

䋳

P

3

18.6 MPa

10.4 L/min

I-10

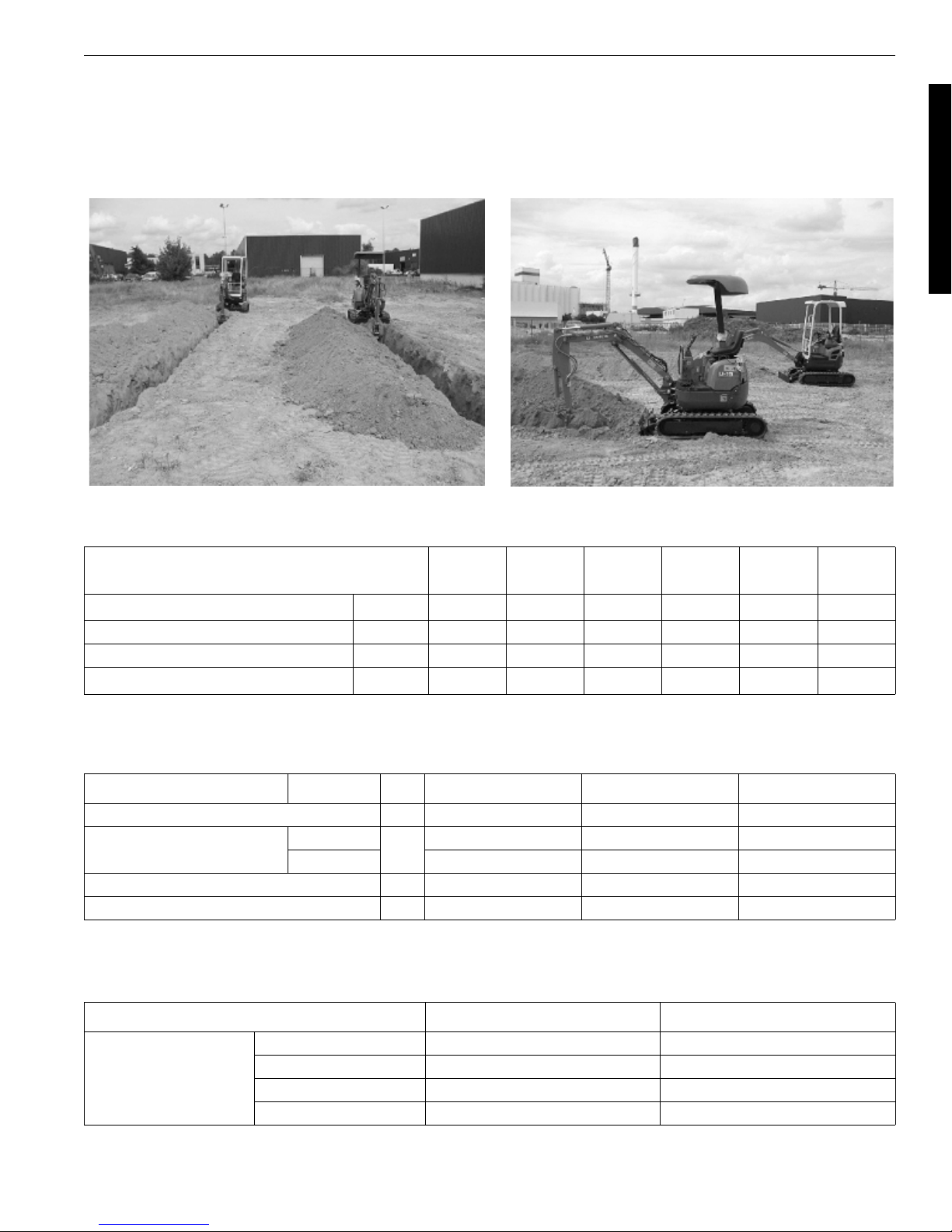

e. Actual performance comparison

1. On-site Excavation Test

-Test Conditions1 m trench excavation, 45-deg. discharge of soil

Excavation work for 10 min., (5-min. rotation)

WSM U15-3

The equipment is of European specifications.

U15-3 U-15

Volume of soil discharged per hour

Cycle time sec 8.3 9.8 +15%

Fuel consumption cc/10min 400 390

Volume of soil discharged per liter of fuel

3

/h

m

3

/L

m

31.4 25.0 +26% *24.3 *26.3 *25.9

13.1 10.7 +22%

Increasin

g rate

PC15MR-1

Vio15-2 301.5CR

* Actual measurement

2. Comparison of Operating Speed

U15-3 U-15 difference

1. Attachment operated 3 times sec 47.3 48.9 +3.4%

2. Boom

(Ground level to top)

3. Swiveling speed rpm 9.0 7.8 +13.3%

4. Combined operation sec 29.7 29.9 -0.20

UP

DOWN 2.5 2.4 -4.0%

sec

2.3 2.9 +26.1%

* Actual measurement

3. Comparison of Stability

Dynamic Front *148 *148

Tipping load

Dynamic Side *138 *127

Static Front *194 *213

Static Side *181 *177

U15-3 U-15

* Actual measurement

I-11

WSM U15-3

B.

Machine specifications

a. Major dimensions and working range (with rubber crawler)

Unit U15-3 Remarks

1 Overall length (at transport) mm 3570

2 Overall height (at transport) mm 2250

3 Overall width mm 1240/990

4 Minimum road clearance mm 145

5 Dozer outer width x height mm 1240/990 x 261

6 Tumbler-to-tumbler distance mm 1230

7 Crawler center distance mm 1010/760

8 Crawler shoe width mm 230

9 Crawler height mm 360

10 Swivel structure rear end height mm 422

11 Overall crawler length mm 1587

12 Approach angle deg. 30.1

13 Maximum digging height mm 3540

14 Maximum digging radius mm 3900

15 Maximum digging depth mm 2310

16 Maximum dumping height mm 2440

17 Maximum vertical digging depth mm 1910

18 Minimum front turning radius mm 1430/1207 Front/swing

19 Minimum tail turning radius mm 620

20 Ground contact pressure

21 Swing angle left/right deg. 63/58

22 Bucket lift angle deg. 180

23 Maximum ground digging radius mm 3840

24 Minimum ground finishing radius mm 1320

25 Radius at maximum digging height mm 2015

26 Radius at maximum dumping height mm 2012

Maximum bucket bottom height with

27

arm vertical

Overall height with arm crowded and

28

minimum front swivel radius

kPa

2

(kgf/cm

)

mm 1200 Arm vertical or fully crowded

mm 1430

25 (0.25)

from operator’s manual

I-12

b. Dimensional drawings

WSM U15-3

A B C D E F G H I J K L M N O P Q R S T

410 485

990

1240

620

980

990

3540 2440 2310 1910 1430 2250 2630 265 180 2750 825 3570 3840 3900

1240

I-13

from operator’s manual

(mm)

WSM U15-3

c. Performance and lifting capacity

1. Performance

Unit U15-3 Remarks

Standard bucket capacity

Maximum digging force, arm KN(kgf) 8.8 (900) Teeth bottom

Maximum digging force, bucket KN(kgf) 15.2 (1550) Teeth bottom

Cycle time sec/cycle 10.8

Digging performance

Dozer capacity

heaped

Digging performance, cycle time conditions:Dig 1m depth with Standard bucket and dump soil on the

3

m

3

/h

m

3

m

ground after 45° swivel.

0.04 CECE

33.4

0.067 without extention blade

I-14

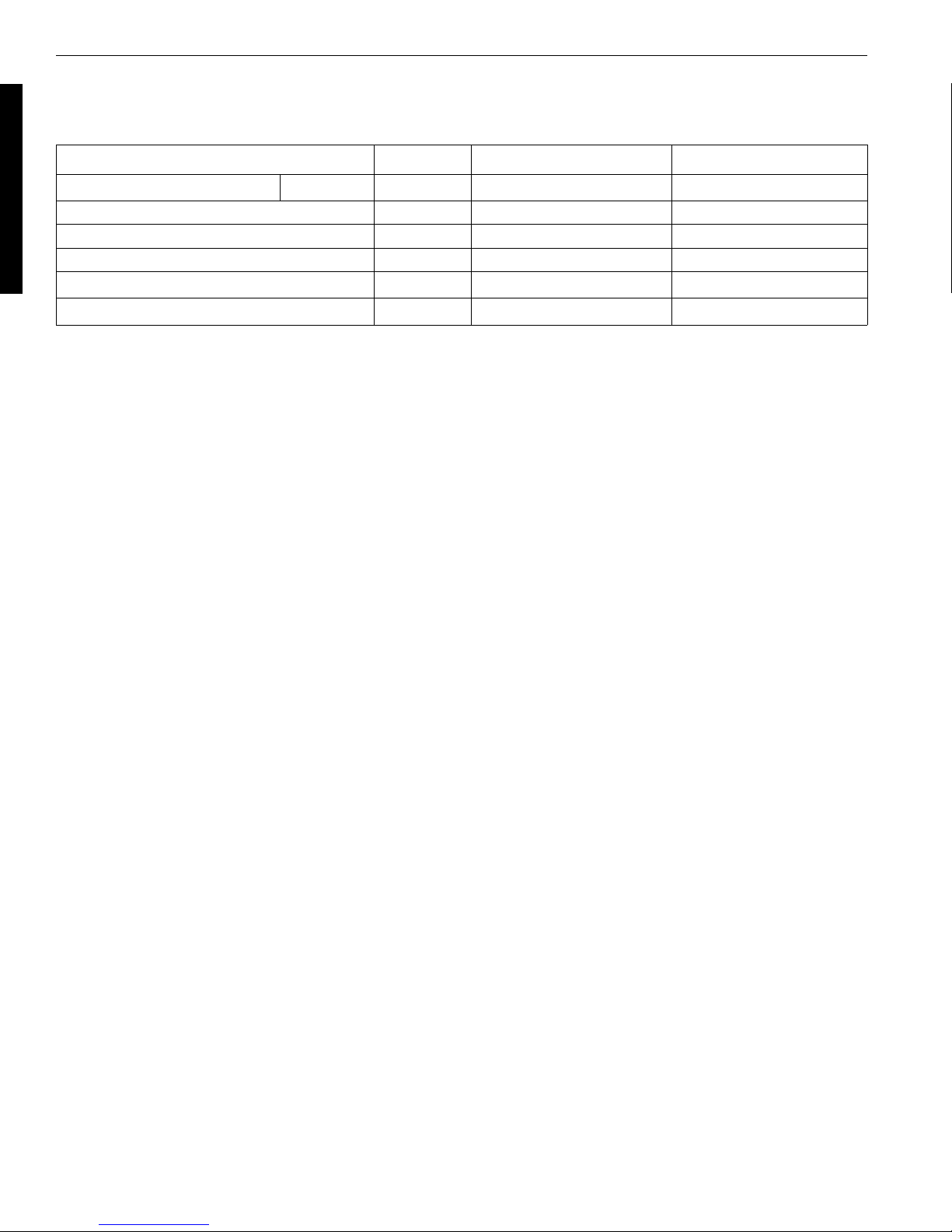

2. Lifting capacity

Lifting posture Dozer Unit U15-3 Remarks

Maximum lifting capacity

(standard arm)

(kgf)

Up kgf 215 (T) 215 (T)

Down kgf 280 (R) 280 (R)

Up kgf 100 (T) 185 (T)

Down kgf 135 (T) 195 (T)

Up kgf 475 (R) 475 (R)

Crawler extended crawler retracted

60

WSM U15-3

Down kgf 475 (R) 475 (R)

Up kgf 275 (T) 475 (R)

Down kgf 315 (T) 475 (R)

Lifting capacity

The machine can lift the loads listed above when the hydraulic pressure is as specified. But the actual measurements are based on "n = 1", which means some fluctuations are expected.

Measuring conditions:

(1) Hydraulic oil temperature: 50 ± 5 °C, riding operator (about 60 kg), engine at maximum rpm.

(2) The boom is inched until the other end of the machine comes off the ground or the boom circuit gets

relieved. Then the loads are measured.

Note:The loads also vary depending on the ground surface condition, dozer's ground-contact status,

operator's weight, remaining fuel and other factors.

(3) The boom swing position is set at the center.

(The machine may turn over if it is set off the center.)

*The above figures show the machine that is about to life a load.

In the above table, (T) means that the machine may turn over if the load is heavier. And (R) means that the

boom circuit gets relieved if the load is heavier.

I-15

WSM U15-3

I-16

WSM U15-3

II Service engineering section

A.Maintenance specifications. . . . . . . . . . . . . . . . . . . . . . . . . II-3

a. List of oil and water quantities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-3

b. Tightening torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-4

c. Quality specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-6

d. Operating noise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-11

B.Machine body structure and function . . . . . . . . . . . . . . . . II-13

a. Overall Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-13

b. Front attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-23

c. Control levers and linkage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-28

d. Under carriage components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-34

C.Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-44

a. Main specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-44

b. Performance curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-45

c. Engine electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-46

d. Engine servicing data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-47

e. Engine Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-48

f. Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-49

g. Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-52

h. Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-54

D.Hydraulic system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-55

a. Main pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-55

b. Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-61

c. Swivel motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-69

d. Travel motor (Wheel motor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-73

e. Pilot valve (Remote control valve). . . . . . . . . . . . . . . . . . . . . . . . . . II-83

f. Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-87

g. Swivel Joint (Rotary joint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-92

h. Unload valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-96

i. Selector valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-98

j. Accessaries of hydraulic compornents . . . . . . . . . . . . . . . . . . . . . . II-99

h. Hydraulic system flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-103

l. Service port system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-108

m. Hydraulic components layout : U15-3 . . . . . . . . . . . . . . . . . . . . . . II-111

n. Hydraulic circuit diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-112

II-1

WSM U15-3

E.Electrical system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-113

a. New Functions of Electric System . . . . . . . . . . . . . . . . . . . . . . . . . II-113

b. Battery circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-114

c. Key switch (Engine starter switch). . . . . . . . . . . . . . . . . . . . . . . . . II-115

d. Safty lever lock switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-116

e. Solenoid valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-118

f. Travel hi-speed control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-120

g. Meter panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-127

h. Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-133

i. Auto glow circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-134

j. Auto release control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-144

k. Water temp. sensor & gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-151

l. Fuel control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-153

m. Engine stop solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-154

n. coil commander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-156

o. Fuel sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-158

p. Engine oil pressure sensor circuit . . . . . . . . . . . . . . . . . . . . . . . . . II-161

q. Engine electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-162

r. Horn circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-164

s. Charging system (Alternator). . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-167

t. Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-171

u. Route of Electric Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-174

v. Electrical component layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-181

w. Electric Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-182

x. Electrical Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-187

II-2

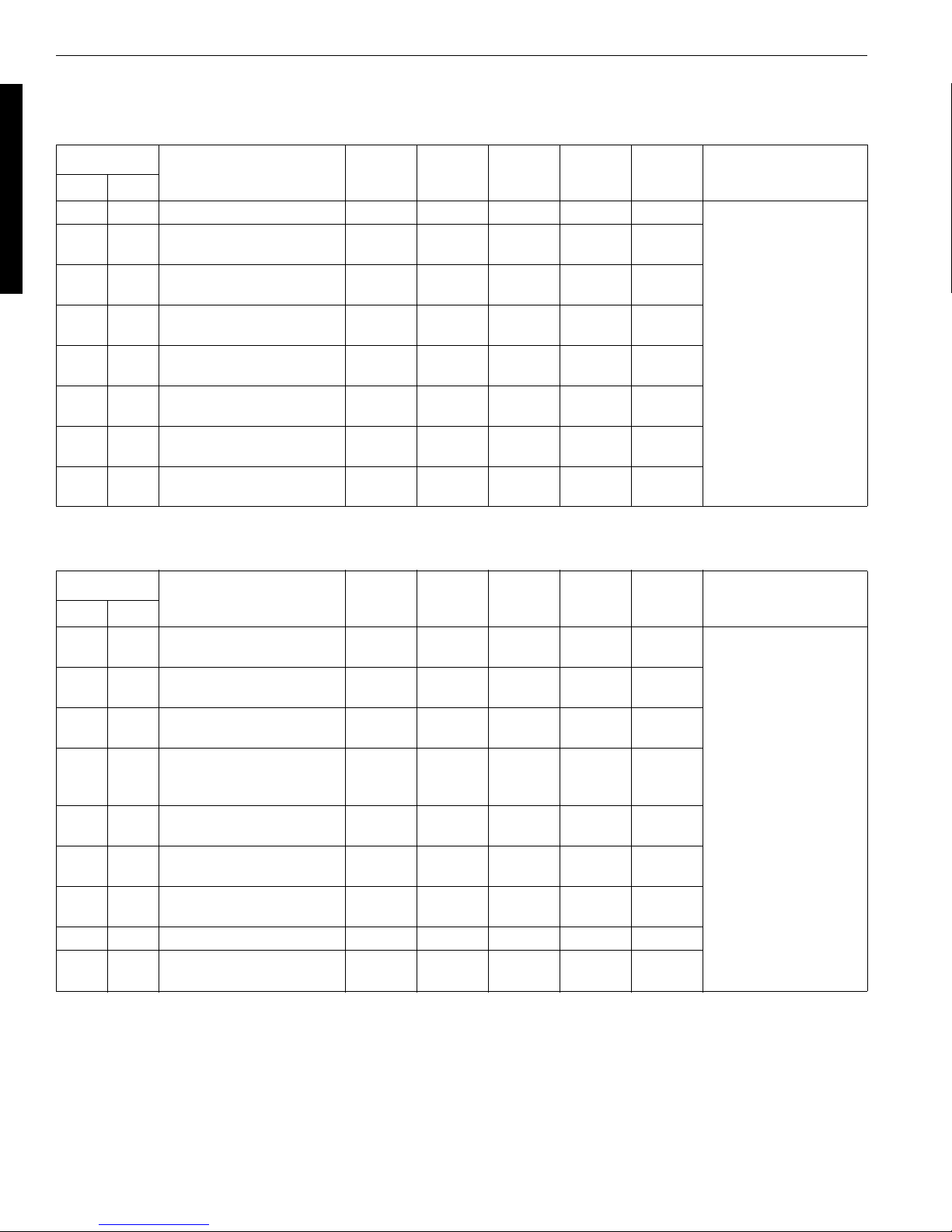

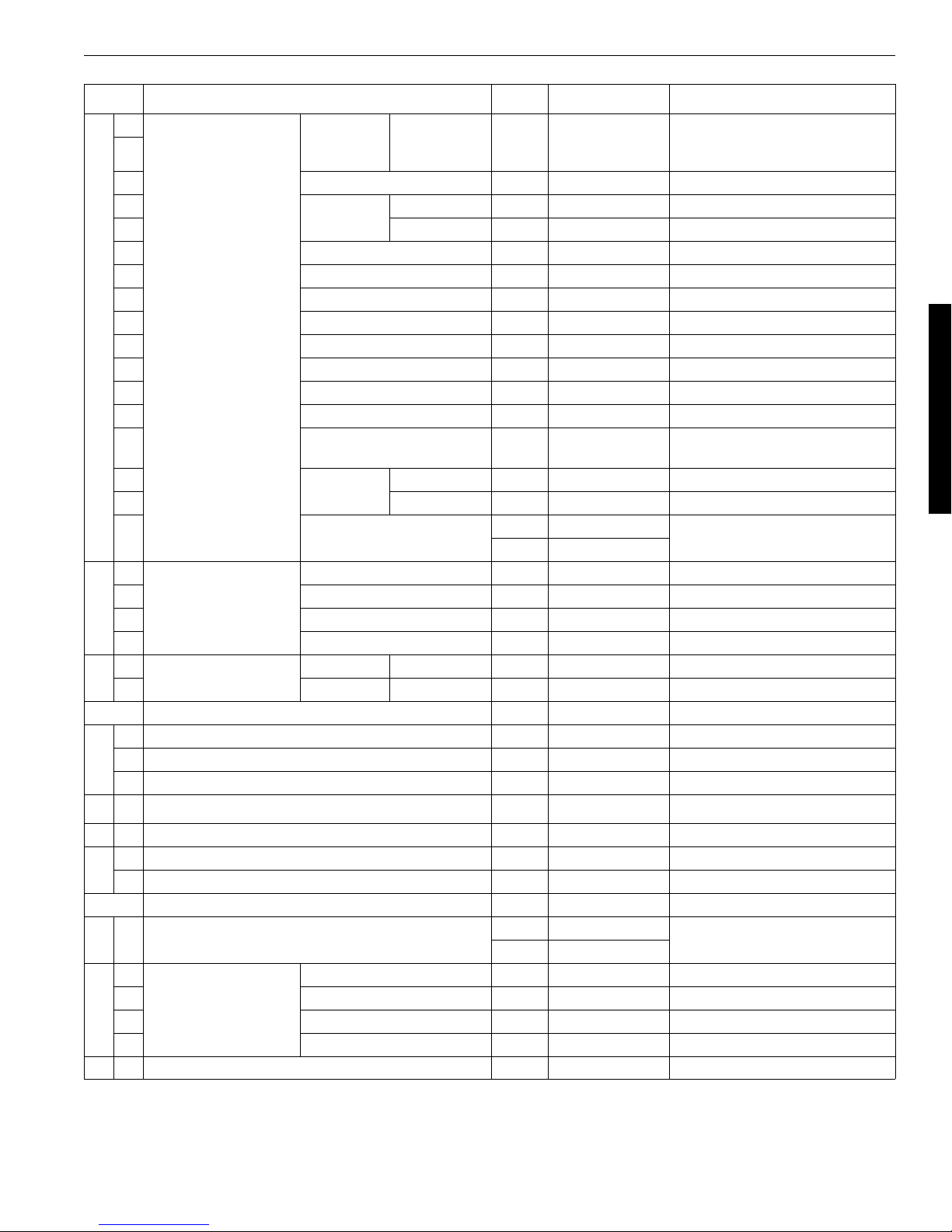

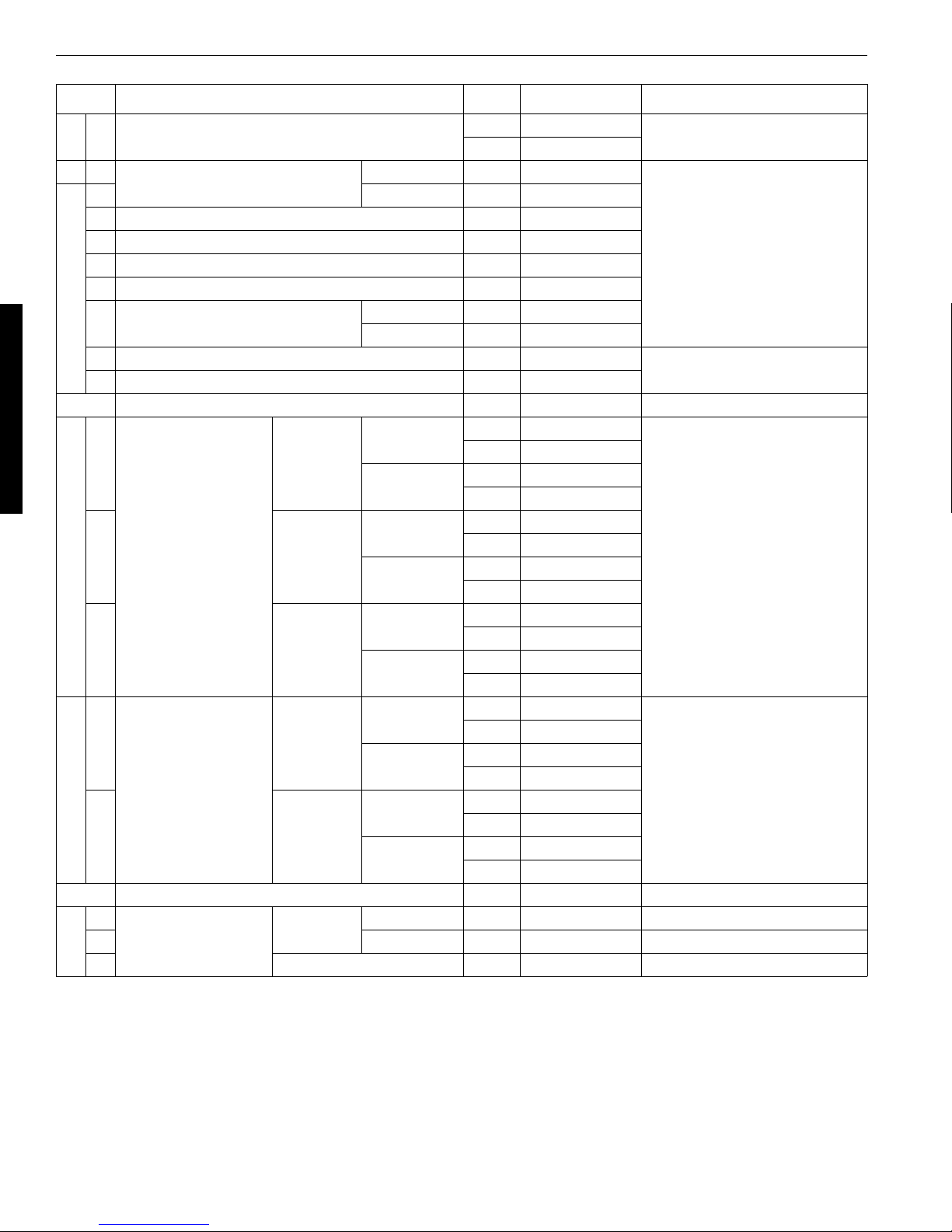

A.Maintenance specifications

a. List of oil and water quantities

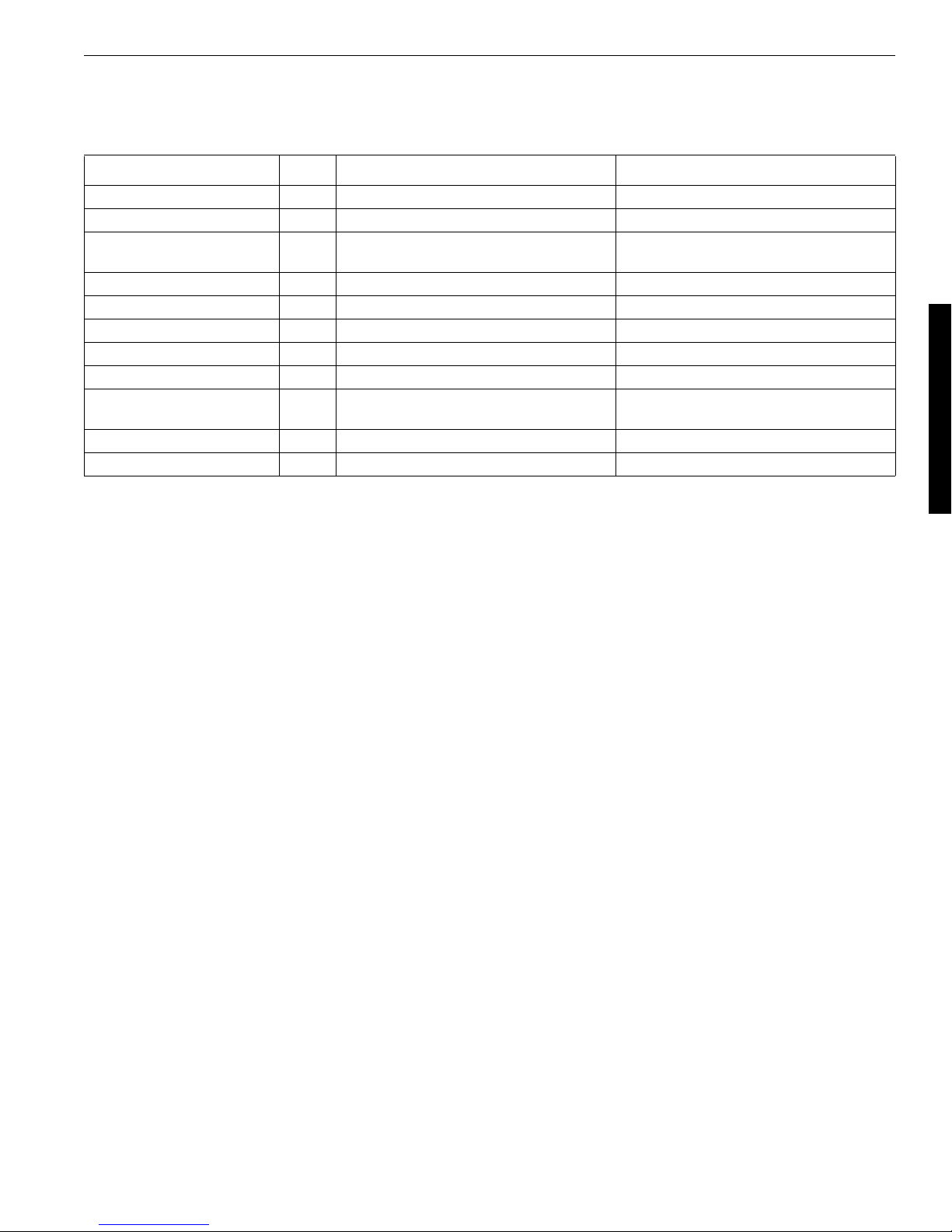

Unit U15-3 Remarks

Radiator soft water L 2.7 Kubota LLC-N-50F

Reserve tank soft water L 0.6

Crankcase engine oil

(at filter replacement)

Hydraulic tank oil L 13 ISO 46

Total hydraulic oil L 22 ISO 46

Wheel motor gear oil L 0.25 SAE 90 (API, GL-4)

Swivel reducer gear oil L -

Track roller gear oil cc 40 Engine Oil SAE 30 Class CD

Carrier roller

(upper track roller)

Front idler cc 30 Engine Oil SAE 30 Class CD

Fuel tank light oil (full) L 18 Diesel light oil No. 3

L3.5

cc - Grease EP2

Class CC

10W30

WSM U15-3

II-3

WSM U15-3

b. Tightening torque

1. Machine

Loctite U15-3 Remarks

Travel wheel motor { 60.8 ~ 70.6 (6.2 ~ 7.2)

Control valve {

Sprocket { 60.8 ~ 70.6 (6.2 ~ 7.2)

Track roller { 103 ~ 117.7 (10.5 ~ 12)

Carrier roller 48.1 ~ 55.9 (4.9 ~ 5.7) Slide plate

Plate (idler) 77.5 ~ 90.2 (7.9 ~ 9.2)

Grease cylinder nipple 98.0 ~ 108.0 (9.0 ~ 11.0)

Swivel bearing { 103 ~ 117.7 (10.5 ~ 12)

Swivel motor { 367.7 ~ 431.5 (37.5 ~ 44.0)

Return filter 19.6 ~ 29.4 (2.0 ~ 3.0)

Engine bracket/engine support {

Engine anti-vibration rubber { 39.2 ~ 45.1 (4.0 ~ 4.6) Nut

Engine anti-vibration rubber 39.2 ~ 45.1 (4.0 ~ 4.6)

Counterweight { 107.9 ~ 125.5 (11.0 ~ 12.8) Oil tank

Coupling 48.1 ~ 55.9 (4.9 ~ 5.7)

Main pump 77.5 ~ 90.2 (7.9 ~ 9.2)

Rotary joint 48.1 ~ 55.9 (4.9 ~ 5.7)

Rotary joint stopper { 48.1 ~ 55.9 (4.9 ~ 5.7)

Muffler flange 23.5 ~ 27.5 (2.4 ~ 2.8)

Control valve through bolt 13.7 ~ 14.7 (1.4 ~ 1.5)

Unit: N·m (kgf·m)

2. General bolt/nut tightening torque

Unit: N·m (kgf·m)

4T 7T 9T

M6 7.8 ~ 9.3 (0.8 ~ 0.95) 9.8 ~ 11.3 (1.0 ~ 1.15) 12.3 ~ 14.2 (1.25 ~ 1.45)

M8 17.7 ~ 20.6 (1.8 ~ 2.1) 23.5 ~ 27.5 (2.4 ~ 2.8) 29.4 ~ 34.3 (3.0 ~ 3.5)

M10 39.2 ~ 45.1 (4.0 ~ 4.6) 48.1 ~ 55.9 (4.9 ~ 5.7) 60.8 ~ 70.6 (6.2 ~ 7.2)

M12 62.8 ~ 72.6 (6.4 ~ 7.4) 77.5 ~ 90.2 (7.9 ~ 9.2) 103.0 ~ 117.7 (10.5 ~ 12.0)

M14 107.9 ~ 125.5 (11.0 ~ 12.8) 123.6 ~ 147.1 (12.6 ~ 15.0) 166.7 ~ 196.1 (17.0 ~ 20.0)

M16 166.7 ~ 191.2 (17.0 ~ 19.5) 196.1 ~ 225.4 (20.0 ~ 23.0) 259.7 ~ 304 (26.5 ~ 31.0)

M18 245.2 ~ 284.4 (25.0 ~ 29.0) 274.6 ~ 318.7 (28.0 ~ 32.5) 343.2 ~ 402.1 (35.0 ~ 41.0)

M20 333.4 ~ 392.3 (34.0 ~ 40.0) 367.7 ~ 431.5 (37.5 ~ 44.0) 519.8 ~ 568.8 (53.0 ~ 58.0)

II-4

3. Hydraulic pipe tightening torque

WSM U15-3

Steel pipe size (mm)

(O.D. x I.D. x Thickness)

I8 x 6 x t1

I10 x 7 x t1.5

I12 x 9 x t1.5

I16 x 12 x t2

I18 x 14 x t2

I27.2 x 21.6 x t2.8

Tightening torque

N·m (kgf·m)

29.4 ~ 39.2 (3.0 ~ 4.0) *17

39.2 ~ 44.1 (4.0 ~ 4.5) *19

53.9 ~ 63.7 (5.5 ~ 6.5) *21

88.3 ~ 98.1 (9.0 ~ 10.0) *29

127.5 ~ 137.3(13.0 ~ 14.0) *32

235.4 ~ 255.0(24.0 ~ 26.0) *41

Wrench width (mm)

[Reference]

Remarks

* Ihara-made sleeve nuts

4. Hydraulic hose tightening torque

Thread size

(piping thread)

1/8” 7.8 ~ 11.8 (0.8 ~ 1.2) 19.6 ~ 29.4 (2.0 ~ 3.0) *17

1/4” 24.5 ~ 29.4 (2.5 ~ 3.0) 36.3 ~ 44.1 (3.7 ~ 4.5) *19

3/8” 37.2 ~ 42.1 (3.8 ~ 4.3) 68.6 ~ 73.5 (7.0 ~ 7.5) *22

1/2” 58.8 ~ 63.7 (6.0 ~ 6.5) 83.4 ~ 88.3 (8.5 ~ 9.0) *27

3/4” 117.7 ~ 127.5 (12.0 ~ 13.0) 166.6 ~ 181.3 (17.0 ~ 18.5) *36

Note: * Wrench width may vary depending on the manufacturer, thread diameter and other factors.

Tightening torque N·m (kgf·m)

Union nut Taper thread

Wrench width

[Reference]

Remarks

5. Engine

N·m (kgf·m)

Engine model D782

Cylinder head cover 4.9 (0.5)

Nozzle holder 58.8 (6.0)

Rocker arm bracket nut 10.8 (1.1)

Cylinder head cover 40.2 (4.1)

Connecting rod bolt 28.4 (2.9)

Flywheel 56.9 (5.8)

Bg case bolt 1 14.7 (1.5)

Bg case bolt 2 28.4 (2.9)

Bearing case cover bolt 10.8 (1.1)

Hose clamp (threaded type) N·m (kgf·cm)

Part code Applicable diameter (mm) Tightening torque

09318-89016 12 ~ 16 2.5 ~ 3.4 (25 ~ 35)

09318-89039 31 ~ 40 2.5 ~ 3.4 (25 ~ 35)

09318-89045 36 ~ 46 2.5 ~ 3.4 (25 ~ 35)

RB101-63631 13 ~ 20 3.4 ~ 4.4 (35 ~ 45)

RC101-64581 15 ~ 25 4.9 ~ 5.9 (50 ~ 60)

68311-72821 26 ~ 38 4.9 ~ 5.9 (50 ~ 60)

RC411-63181 40 ~ 55 4.9 ~ 5.9 (50 ~ 60)

RC401-63191 50 ~ 60 4.9 ~ 5.9 (50 ~ 60)

69284-63171 77 ~ 95 4.9 ~ 5.9 (50 ~ 60)

RD411-63821 32 ~ 44 4.9 ~ 5.9 (50 ~ 60)

II-5

WSM U15-3

c. Quality specifications

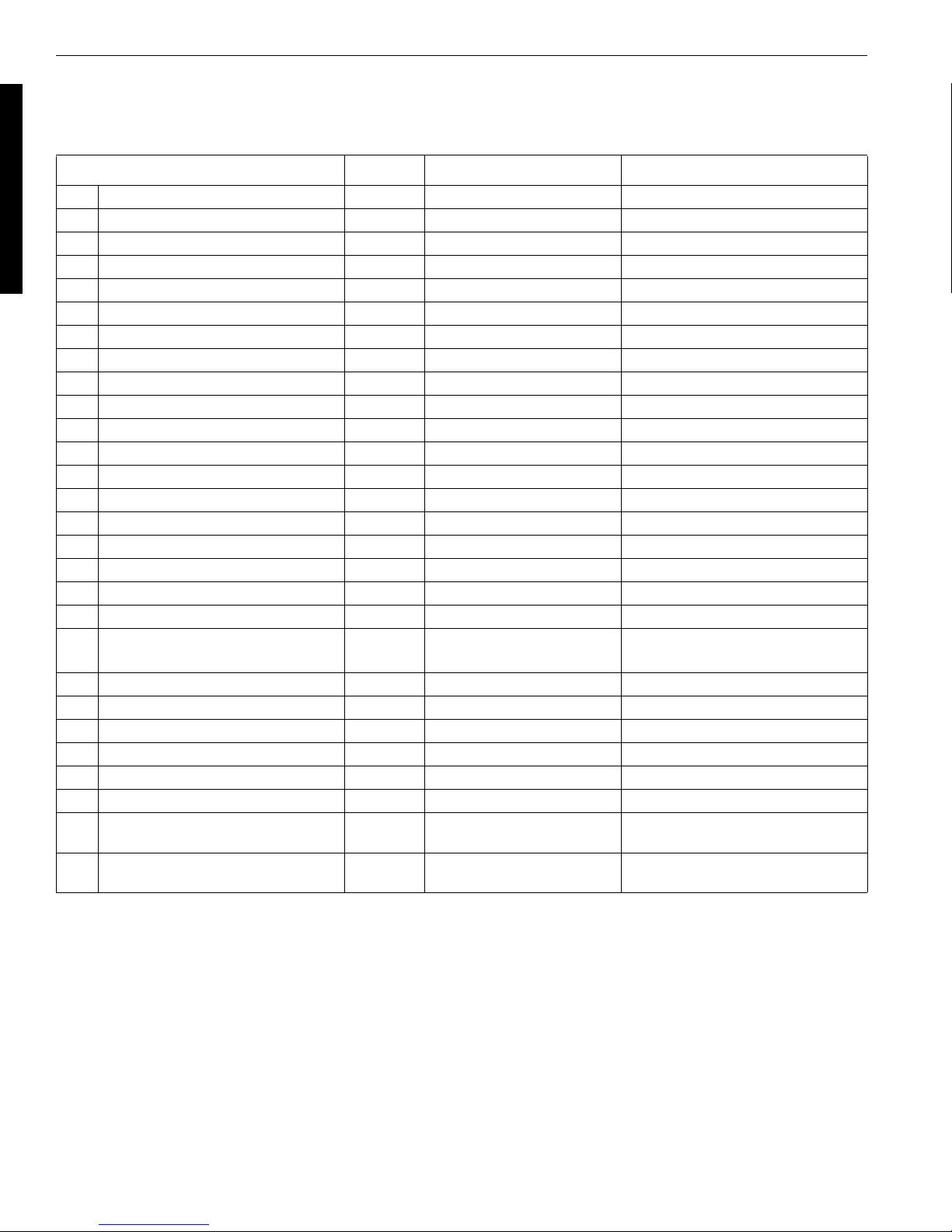

No Specificatios Items Unit U15-3 Remarks

Q1 Main Speed JIS A8404

1 1 Machine size Total length (Transport) mm 3575 ± 71

2 Total width mm 1240/990 ± 12

3 Total height (Canopy) mm 2300 ± 23

4 Total height (Cabin) mm -

2 1 Weight Machine weight (Canopy) kg 1600 ± 32 Fuel tank

2 Machine weight (Cabin) kg -

3 1 Performance Swivel speed rpm 8.7 ± 0.9 Rated engine RPM, K=100%

2 Travel speed F1 km/h 2.2 ± 0.2

3F2km/h4.0 ± 0.4

4 R1 km/h 2.2 ± 0.2

5 R2 km/h 4.0 ± 0.4

6 Gradeability deg 30 <

4 1 Rear end min. turning radius mm 620 ± 12

2 Swivel frame rear ground clearance mm 422 ± 8

3 Tambler center distance mm 1230 ± 37

4 Crawler total length mm 1587 ± 48

5 Crawler total width mm 1240/990 ± 26

6 Crawler shoe width mm 230 ± 5

7 Min. ground clearance mm 145 ± 4

5 1 Engine, Model name D782-BH-4

2 Rated output DIN 70020 kw 9.6 ± 0.2

ps 13.0 ± 0.3

3 Rated speed rpm 2300

4 Displacement L 0.778

cc 778

6 1 Hydraulic pump type Variable x2 +gear

2 Pump delivery L 16.6 x 2, 10.4, 6.2

3 Main relief pressure

(Bench set)

P1,P2 Mpa

kgf/cm

2

Bar

P3 Mpa

2

kgf/cm

Bar

P4 Mpa

2

kgf/cm

Bar

7 1 Swivel motor type

8 1 Under carrage Travel motor type Variable displace-

3 Crawler shoe type Rubber

+1.0

21.6

-

0.5

+10

220

-

5

+9.8

216

-

4.9

+1.0

18.6

-

0.5

+10

190

-

5

+9.8

186

-

4.9

+1.0

3.9

-

0.5

+10

40

-

5

+9.8

39

-

4.9

ment pump

II-6

WSM U15-3

No Specificatios Items Unit U15-3 Remarks

9 1 Front attachment Bucket

2

heaped

capacity

CECE

3 Bucket width mm 456 ± 10 Without side cutter

4 Swing angle L deg 63 ± 2

5 R deg 58 ± 2

6 Max. digging radius mm 3901 ± 59

7

Ground level Max. digging radius

8 Ground level Min. finish radius mm 1320 ± 26 Bucket bottom horizontal

9 Max. digging depth mm 2306 ± 46

10 Max. vertical digging depth mm 1911 ± 38

11 Max. digging height mm 3536 ± 71

12 Max. dump height mm 2443 ± 49

14 Mini. turning radius mm 1426 ± 43

15 Mini. turning radius

(Left swing)

16 Off-set

17 R mm 385 ± 12

amount

Lmm510 ± 15

18 Max. digging force kgf 1.55

10 1 Dozer Width mm 1244/990 ± 5

2 Height mm 261 ± 5

4 Max. lift above GL mm 263 ± 13

5 Max. below GL mm 182 ± 9

11 4 Water & oil Fuel Tank L 17.5 ± 0.9

5 Hydraulic oil Tank L 13 ± 0.7

Q2 Main Specs JIS A8404

1 1 Bucket tooth slaggish mm 73 ± 93

2 Decline of front attachment mm 0 ± 10

3 Dozer's declination mm 0 ± 10

3 3 Min. clearance of bucket teeth to boom cylinder protector mm

4 1 Approach angle deg 30.1 ± 3.0

5 1 Crawler height mm 360 ± 7 Include grouser on the sprocket

2 Max. crawler height mm 360 ± 7

Q3 Engine performance

1 1 Max. engine torque

2 1 Max, engine rpm no load rpm 2600 >

2 1 pump relief rpm

3 2 pump relief rpm 2300 <

4 3 pump relief rpm 2300 <

3 1 Idling rpm rpm 1200 + 150/-0

3

m

0.04 ± 0.002

mm 3843 ± 58

mm 1207 ± 36

N15.2

+34

37

-

16

kgf•m/rpm

N•m/rpm

4.52/1750

44.3/1750

II-7

WSM U15-3

No Specificatios Items Unit U15-3 Remarks

Q4 Travelling performance

1 1 Travel motor block performance, L/R mm 300 > 20 deg, 10 min

2 1 Max, Traction force F1 kgf•m 1255 ± 126 K=65%

kN•m 12.8 ± 1.3

2 F2 kgf•m 637 ± 64

kN•m 6.5 ± 0.7

3 1 Travel straightness F1 mm 600 > 10m distance

2 F2 mm 600 >

3 Dozer F1 mm 600 > Dozer up & down 10m distance

4 Dozer R1 mm 600 >

4 1 Track shoe sag distance Iron mm 25 ~ 30

2 Rubber mm 10 ~ 15

Q5 Work performance

4 2 Arm digging force kgf 824< Bucket tooth root

kN 8.4<

3 Bucket digging force kgf 1412< Machine stance to JIS bucket tooth

kN 14.4<

5 1 Boom speed up sec 2.2 ± 0.3 Oil temp. 50 ± 5°C

3 down sec 2.5 ± 0.3 Oil temp. 50 ± 5°C

6 1 Arm speed crowd sec 3.5 ± 0.3 Oil temp. 50 ± 5°C

2 extend sec 2.4 ± 0.3 Oil temp. 50 ± 5°C

7 1 Bucket speed crowd sec 2.8 ± 0.3 Oil temp. 50 ± 5°C

2 dump sec 1.9 ± 0.3 Oil temp. 50 ± 5°C

8 1 Dozer speed up sec 1.4 ± 0.3 Max. down to max. up

2 down sec 1.9 ± 0.3 Max. up to max. down

13 1 Max. digging height radius mm 2015 ± 202

2 Max. dump height radius mm 2012 ± 121 at bucket pin

4 Bucket bottom height at arm vertical mm 1200 ± 36 Bucket horizontal

5 Bucket wrist angle degree 180 ± 3

Q6 Swivel, swing performance

1 1 Swivel torque L kgf•m 217 < Arm extend,show/Quick

kN•m 2.1 <

2Rkgf•m217 <

kN•m 2.1 <

2 1 Swivel capable angle at slope deg 18 < Bucket load=JIS heaped x 1.8

3 1 Swivel block performance L/R deg 30 >

5 1 Swivel start-up speed sec 2.1 ± 0.2 0 ~ 90 deg swivel

7 1 Swing speed Left sec 4.6 ± 0.3

2 Right sec 3.7 ± 0.3

8 1 Swing Lock Swivel R&L mm 6 > 90 deg-swivel, 100 times actual

root

Max. heiht to ground

digging cylinder dislocation

II-8

WSM U15-3

No Specificatios Items Unit U15-3 Remarks

Q7 Hydraulic performance

1 1 Relief pressure setting P1

kgf/cm

2

MPa

bar

2P2

kgf/cm

2

MPa

bar

3P3

kgf/cm

2

MPa

bar

4P4

kgf/cm

2

MPa

bar

5 1 Cylinder block performance Boom mm 25 > Arm extend, bucket

2 Arm mm 15 >

3 Bucket mm 10 >

4 Dozer mm 25 >

6 1 Boom cushioning performance 30°C sec 3 >

2 50°C sec 0.5 to 1.5

3 80°C sec 0.3 <

8 1 Service port flow No load/load L 27

Q8 Lever operating force & stroke

1 1 Boom lever operating force kgf 1.4 ± 0.5 Measured 20 mm below the grip

kN 13.7 ± 4.9

4 Arm lever kgf 1.4 ± 0.5

N 13.7 ± 4.9

5 Bucket lever kgf 1.4 ± 0.5

N 13.7 ± 4.9

6 Swivel (Swing) lever kgf 1.4 ± 0.5

N 13.7 ± 4.9

7 Dozer lever kgf 3.1 ± 0.5

N 30.0 ± 4.9

8 Travel lever L/R kgf 1.5 ± 0.5

N 15.0 ± 4.9

9 Accelerator lever (up/down) kgf 3.4 ± 1.5 Measured 30 mm below the grip

N 35.0 ± 14.7

10 Swing pedal kgf 10.0 ± 1.0 Measured Step end.

N 98.0 ± 9.8

11 Safety lock lever, L&R up kgf 2.0 ± 1.0

N 20.0 ± 9.8

down kgf 3.0 ± 1.0

N 30.0 ± 9.8

220

21.6

215.8

220

21.6

215.8

190

18.6

186.3

40

3.9

39.2

+10

-

+10

-

+1.0

-

+10

-

+1.0

-

+10

-

+1.0

-

5

+1.0

-

+9.8

-

5

5

5

0.5

0.5

+9.8

-

0.5

+9.8

-

0.5

+9.8

-

4.9

4.9

4.9

4.9

Hydraulic oil temp. 50 ± 5°C

height 1m, 10 min.

Bucket load : Heaped

Soil gravity : 1.8

end.

end.

II-9

WSM U15-3

No Specificatios Items Unit U15-3 Remarks

1 13 Service port pedal kgf 5.0 ± 1.0 L / R

N 51.0 ± 10

2 1 Boom lever stroke up mm 72 ± 10 Measured grip end

2 down mm 72 ± 10

3 Arm lever stroke (crowd/dump) mm 72 ± 10

4 Bucket lever stroke (crowd/dump) mm 74 ± 10

5 Swivel lever stroke mm 74 ± 10

6 Dozer lever up & down mm 80 ± 10

7 Travel lever, L & R, F & R L mm 75 ± 10

R mm 75 ± 10

9 Swing pedal stroke mm 6 ± 10 Measured Step end

10 Service port pedal stroke (LH & RH) mm 12 ± 10

Q9 Stability

1 1 Standard arm, Dynamic

operation load limit

2 Bucket load

3 Bucket load

2 1 Standard arm, Static

operation load limit

2 Bucket load

Q10 Comfortability

11Noise level At operator’s

2 Cab db(A) - Cab door close

3 Noise source; LWA db(A) 92 >

Bucket load

to 10 degrees

tipping

to tipping,

track frame

extended

to tipping,

track frame

retracked

Bucket load

to tipping,

track frame

extended

to tipping,

track frame

retracked

ear LPA

Side, dozer up kgf - arm extended, bucket crowd, swing

N-

Over end,

dozer up

Side, dozer up kgf 121 <

Over end,

dozer up

Side, dozer up kgf 63 <

Over end,

dozer up

Side, dozer up kgf 162 < front level crowd, swing 0 degree,

Over end,

dozer up

Side, dozer up kgf 95 <

Over end,

dozer up

Canopy db(A) 78 >

kgf -

N-

N1187 <

kgf 130 <

N1275 <

N 618 <

kgf 130 <

N1275 <

N1589 <

kgf 175 <

N1716 <

N932 <

kgf 175 <

N1716 <

0 degree, exclude bucket weight

37Kg.

exclude bucket weight 37Kg.

Load is added at the top of arm.

II-10

Loading...

Loading...