Kubota Tractors Shop Manual

WORKSHOP MANUAL

KiSC issued 06, 2006 A

TRACTOR

MECHANISM

KiSC issued 06, 2006 A

TO THE READER

KiSC issued 06, 2006 A

The main purpose of this manual is to train the servicin g pers onnel s o that he / sh e

can understand and service Kubota machines with speed.

This manual is also a n excellent reference for the trained mechanic who wan ts to

refresh his memory on Kubota machines.

All information and illustrations contained in this manual are based on the latest

product information available at the time of publication.

The right is reserved to make changes in all information at any time without notice.

NOTE: The chapter of the engi ne is not included in this manu al. Refer to workshop

manual of diesel en gine me chani sm (C ode No. 9Y 021- 01873 or 97 897-6 0812

CD-ROM Version).

The peculiar one to the s pecified model such as transmis sion cross section,

schematic of hydraulic circuit and electrical circuit are not described in this

manual. Please refer to each workshop manual according to the tractor model.

October 2001

© KUBOTA Corporation 2001

KiSC issued 06, 2006 A

1 ENGINE

KiSC issued 06, 2006 A

2 CLUTCH

KiSC issued 06, 2006 A

MECHANISM

KiSC issued 06, 2006 A

CONTENTS

1. DRY TYPE, SINGLE PLATE CLUTCH......................................................2-M1

2. DRY TYPE, DUAL STAGE CLUTCH.........................................................2-M2

3. HYDRAULIC MULTIPLE DISC CLUTCH....................................................2-M4

[1] TYPE 1 (For Travelling) ......................................................................... 2-M4

[2] TYPE 2 (For PTO)..................................................................................2-M5

TRACTOR, WSM

KiSC issued 06, 2006 A

1. DRY TYPE, SINGLE PLATE CLUTCH

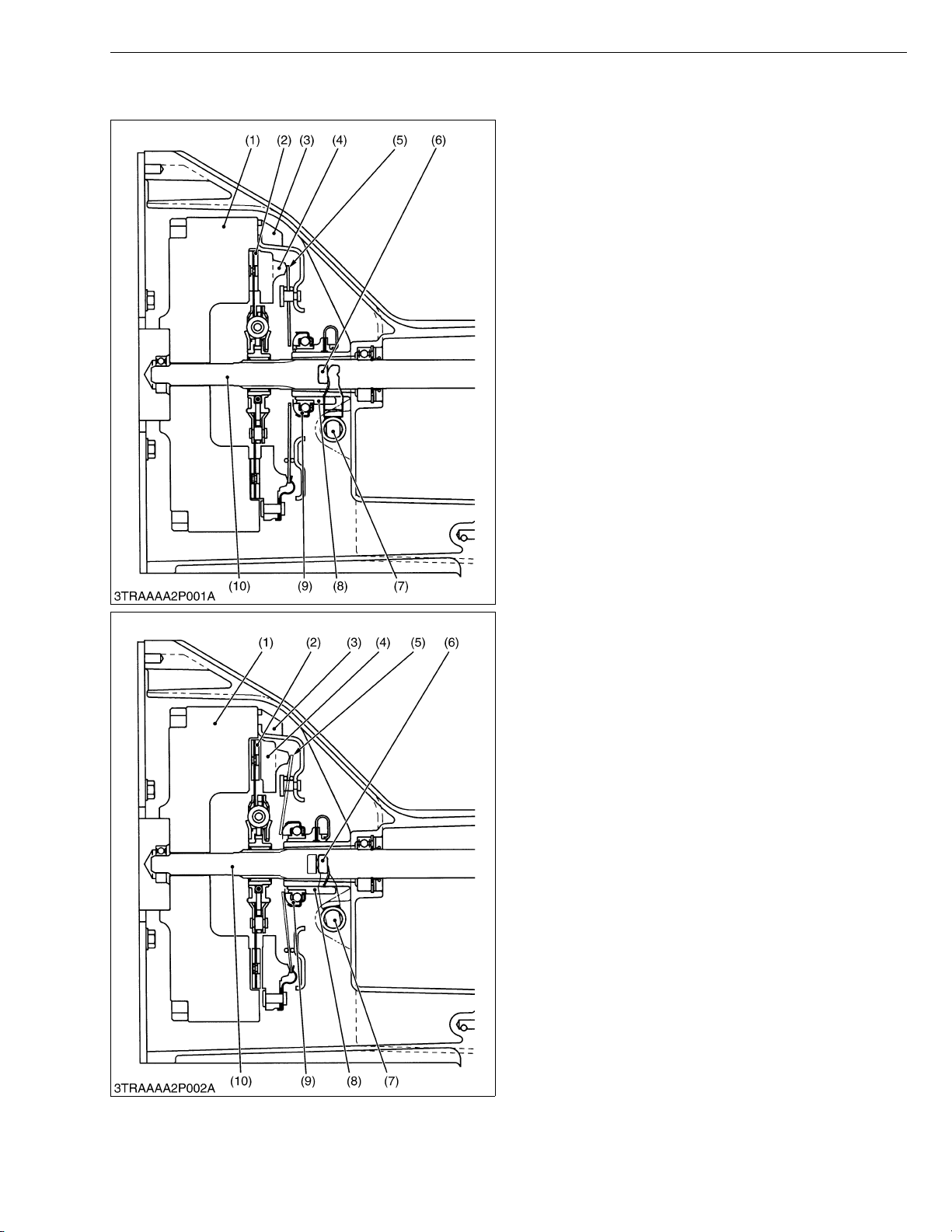

■ Clutch “Engaged”

When the clutch peda l is not depressed, the clutch

release bearing (9) a nd the finger s of diaphragm spring

(5) are not connected to each other.

Accordingly, the pressure plate (4) is tightly pressed

against the flywheel (1) by the diaphragm spring (5). As

a result, rotation of the fly wheel (1) is trans mitted to the

transmission through the clutch shaft (10) due to the

frictional force among the flywheel (1), clutch disc (2) and

pressure plate (4).

(1) Flywheel

(2) Clutch Disc

(3) Clutch Cover

(4) Pressure Plate

(5) Diaphragm Spring

CLUTCH

(6) Release Fork

(7) Clutch Rod

(8) Release Hub

(9) Release Bearing

(10) Clutch Shaft

W10126980

■ Clutch “Disengaged”

When the clutch pedal is depressed, the clutch pedal

rod is pulled to move the clutch rod (7). Then, the

release fork (6) push es the release hub (8) and release

bearing (9) toward the flywheel. Simultaneously, the

release bearing (9) pushes the diaphragm spring (5).

As the pressure plate (4) is pulled by the diaphragm

spring (5), the frictional force among the flywheel (1),

clutch disc (2) and pressure plate (4) disappears.

Therefore, rotation of the flywheel (1) is not

transmitted to the clutch disc (2), and then the rotation of

the clutch shaft (10) stops.

(1) Flywheel

(2) Clutch Disc

(3) Clutch Cover

(4) Pressure Plate

(5) Diaphragm Spring

(6) Release Fork

(7) Clutch Rod

(8) Release Hub

(9) Release Bearing

(10) Clutch Shaft

W10129450

2-M1

TRACTOR, WSM

KiSC issued 06, 2006 A

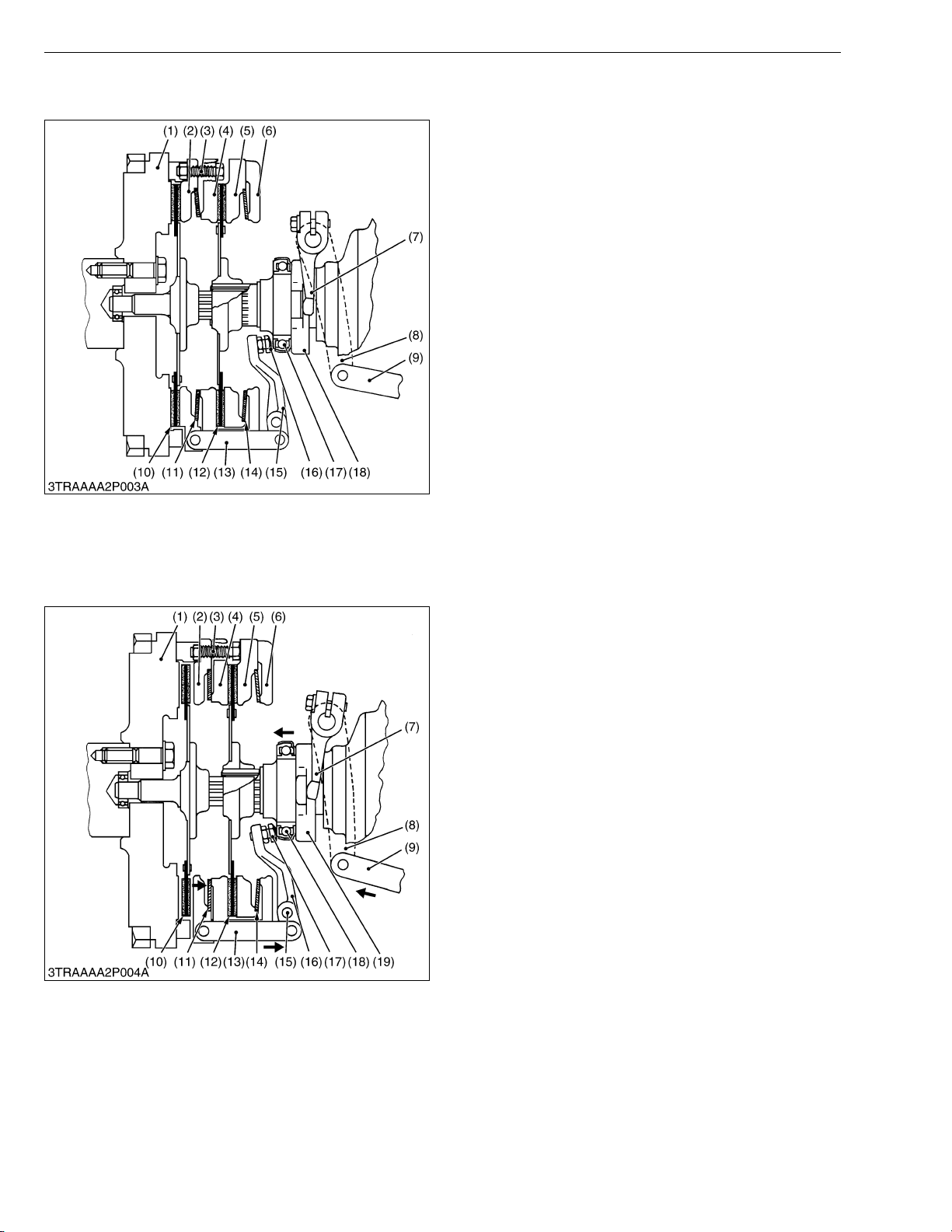

2. DRY TYPE, DUAL STAGE CLUTCH

A dual stage clutch is a combination of two single

plate clutches. One clutch controls power transmitted to

travelling, and the other to the PTO.

■ Travelling Clutch “Engaged”

■ PTO Clutch “Engaged”

When the clutch p edal is not depressed, there is a

certain amount of clearance between the release bearing

(17) and the adjusting screw (16) mounted on the release

lever (15). Under the conditions above;

• The travelling clutch disc (10) is pressed between the

flywheel (1) and the pressur e plate 1 (2) by the forc e

of the belleville spring (11).

• The PTO clutch disc (12) is pressed between the

clutch cover 1 ( 4) an d th e pr ess ur e p late 2 ( 5 ) b y the

force of the belleville spring (14).

Thus, the rotation of flywhe el is transmitted to both

the travelling and PTO systems.

(1) Flywheel

(2) Pressure Plate 1 (Travelling)

(3) Adjusting Screw

(4) Clutch Cover 1

(5) Pressure Plate 2 (PTO)

(6) Clutch Cover 2

(7) Release Fork

(8) Clutch Lever

(9) Clutch Rod

■ Travelling Clutch “Disengaged”

■ PTO Clutch “Engaged”

When the clutch ped al is depressed t o the middle of

the stroke, the clutch rod (9) is pushed to move the clutch

lever (8). Then, the release for k (7) push es the releas e

hub (19) and release bearing (18) toward the flywhee l.

Simultaneously, the release bearing (18) pushes the

adjusting screw (17) attached to the release lever (16).

The release lever pulls the pressure plate 1 (2) by

means of the releas e rod (13) as the lever t urns at the

clevis pin (15) as a fulcrum.

When the pressure plate 1 is pulled, friction force

among the clutch cover 1 (4), cl utch disc (10) and the

pressure plate 1 (2) is lost. The rotation of flywheel is not

transmitted to travelling system.

At this time, the pressure plate 2 (5) is in contact with

the head of the adju sting screw (3) which serves as a

stopper.

(1) Flywheel

(2) Pressure Plate 1 (Travelling)

(3) Adjusting Screw

(4) Clutch Cover 1

(5) Pressure Plate 2 (PTO)

(6) Clutch Cover 2

(7) Release Fork

(8) Clutch Lever

(9) Clutch Rod

(10) Clutch Disc (Travelling)

CLUTCH

(10) Clutch Disc (Travelling)

(11) Belleville Spring

(12) Clutch Disc (PTO)

(13) Release Rod

(14) Belleville Spring

(15) Release Lever

(16) Adjusting Screw

(17) Release Bearing

(18) Release Hub

W10128590

(11) Belleville Spring

(12) Clutch Disc (PTO)

(13) Release Rod

(14) Belleville Spring

(15) Clevis Pin

(16) Release Lever

(17) Adjusting Screw

(18) Release Bearing

(19) Release Hub

W10133220

2-M2

TRACTOR, WSM

KiSC issued 06, 2006 A

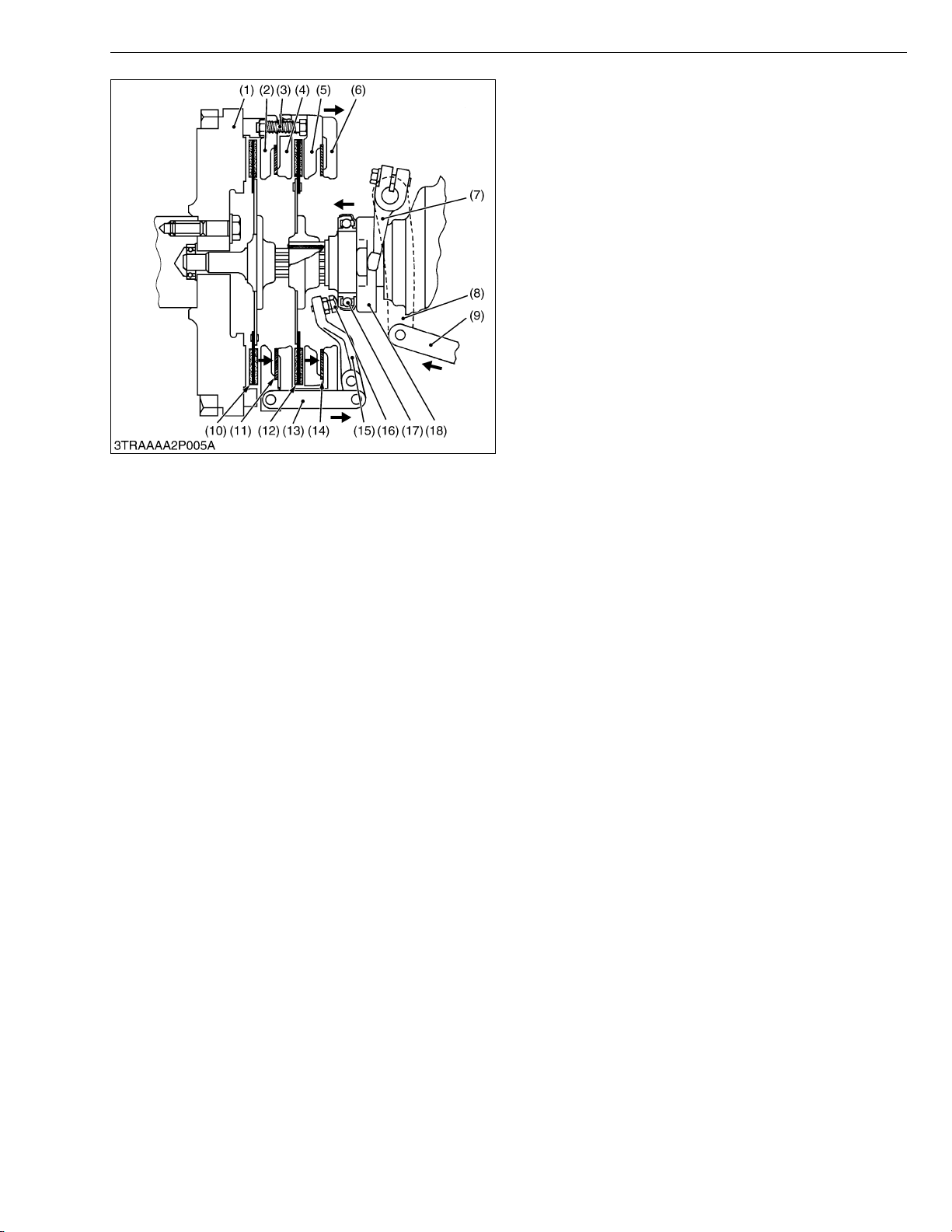

CLUTCH

■ Travelling Clutch “Disengaged”

■ PTO Clutch “Disengaged”

When the clutch pedal is depressed to the full stroke,

the pressure plate 2 (5) is pushed to the right by the

adjusting screw (3).

This results in no friction among the flywheel (1),

clutch disc (12) and pressure plate 2 (5).

The rotation of flywheel is not transmitted to PTO

system and travelling system.

(1) Flywheel

(2) Pressure Plate 1 (Travelling)

(3) Adjusting Screw

(4) Clutch Cover 1

(5) Pressure Plate 2 (PTO)

(6) Clutch Cover 2

(7) Release Fork

(8) Clutch Lever

(9) Clutch Rod

(10) Clutch Disc (Travelling)

(11) Belleville Spring

(12) Clutch Disc (PTO)

(13) Release Rod

(14) Belleville Spring

(15) Release Lever

(16) Adjusting Screw

(17) Release Bearing

(18) Release Hub

W10139990

2-M3

TRACTOR, WSM

KiSC issued 06, 2006 A

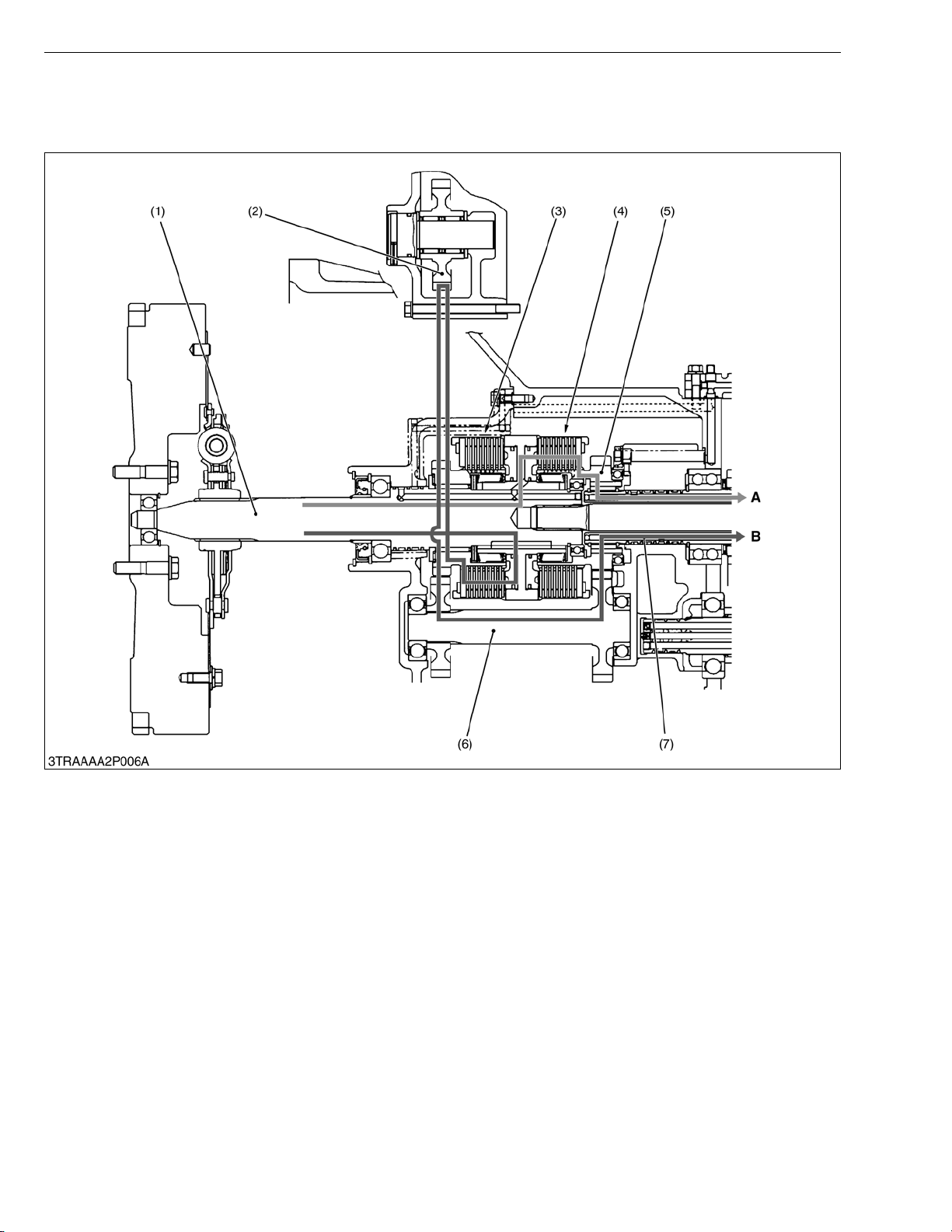

3. HYDRAULIC MULTIPLE DISC CLUTCH

[1] TYPE 1 (For Travelling)

CLUTCH

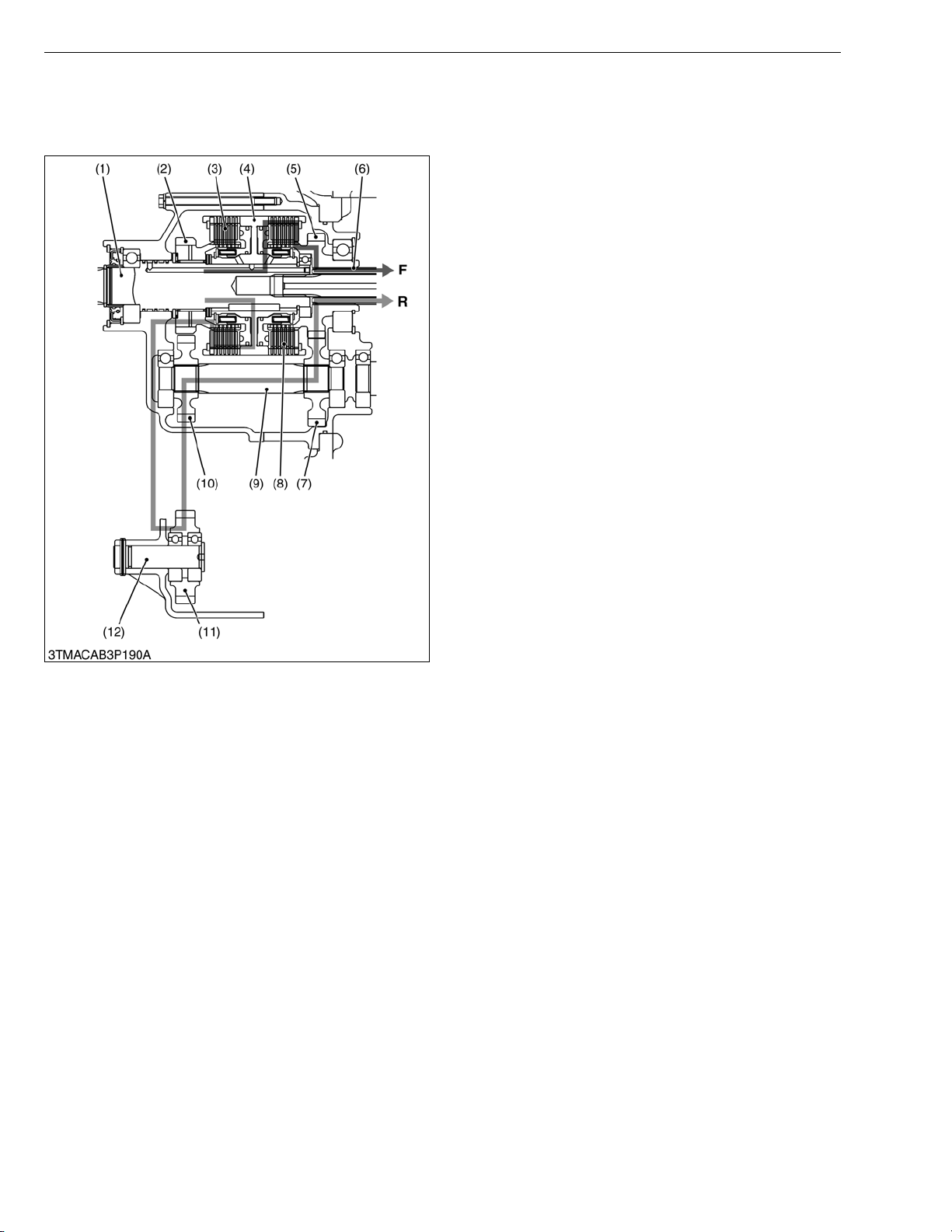

(1) Input Shaft

(2) Idle Gear

(3) Clutch Pack (Reverse)

(4) Clutch Pack (Forward)

(5) Reverse Gear

(6) Reverse Gear Shaft

(7) Output Shaft

A : Forward

B : Reverse

When the clutch contr ol valve is a t “Neutral” position, the oi l from hydraulic pump does not flow t o clutch pac k.

Therefore the power from input shaft (1) is not transmitted to output shaft (7).

When the clutch control v alve is set at “Forward” position, the oil from hydra ulic pu mp fl ows to the f orward side

of the clutch pack (4). As a result, power is transmitted from input shaft (1) to output shaft (7) through clutch pack (4).

When the clutch control valve is set at “Reverse” position, the oil from hydraulic pump flows to the reverse side of

the clutch pack (3). As a result, power is transmitted from input shaft (1) to output shaft (7).

2-M4

TRACTOR, WSM

KiSC issued 06, 2006 A

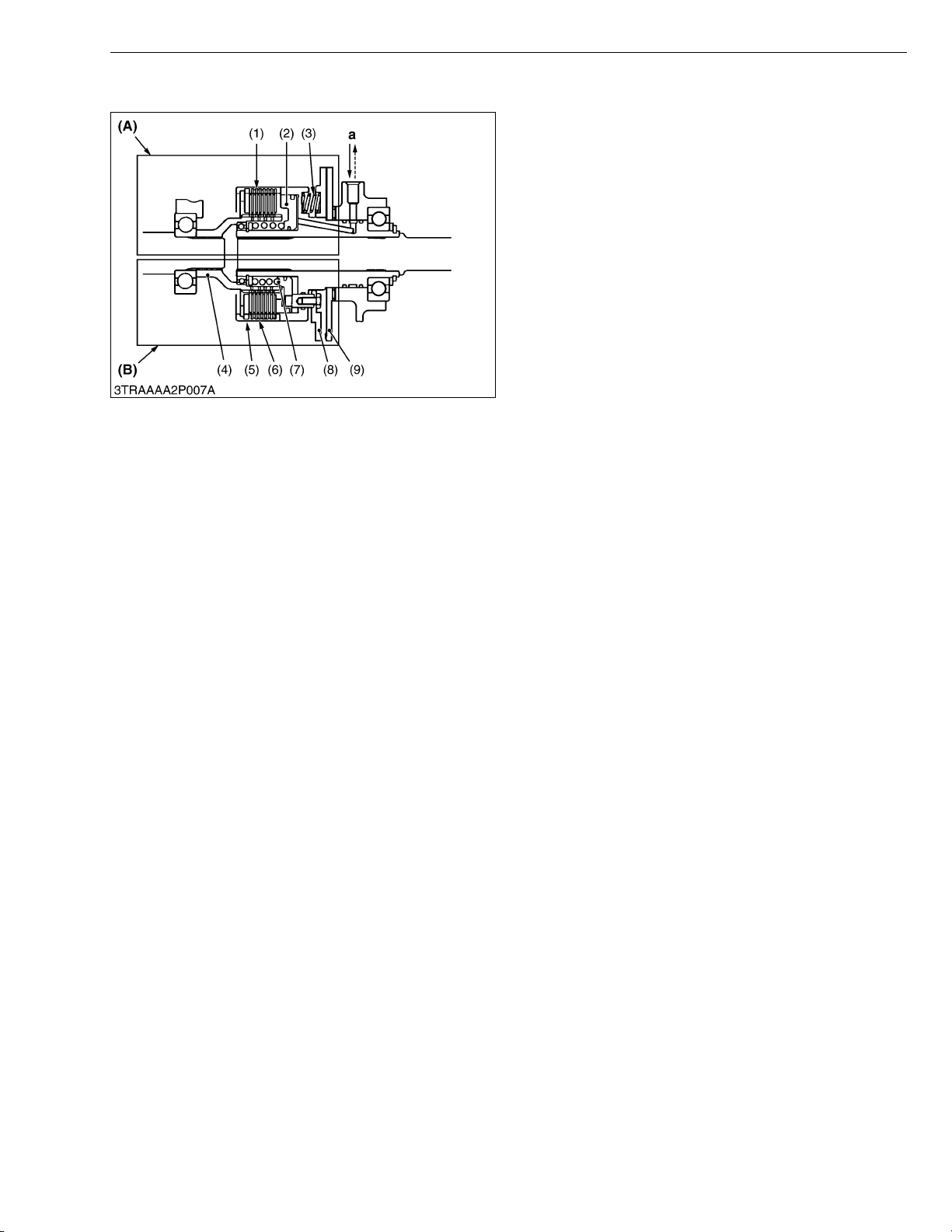

[2] TYPE 2 (For PTO)

CLUTCH

When the clutch control valve is set at the

“ENGAGED” position, the oil from hydraulic pump flows

to clutch valve. Oil entering the clutc h pack pushes the

piston (2) to engage the clutch pack.

When the clutch control valve is set at the

“DISENGAGED” position, the oil from hydrau lic pump

stopped and the o il in th e c lu tc h p ack is drai ne d i nto the

transmission case. Thus the piston (2) is pushed back by

the return spring (7). When the piston (2) is pushed

back, the brake pl ate (8) is also moved to contact the

brake disc (9) so as to stop the rotati on and drag of the

PTO shaft.

(1) Plate

(2) Piston

(3) Brake Spring

(4) Clutch Hub

(5) Back Plate

(6) Clutch Disc

(7) Return Spring

(8) Brake Plate

(9) Brake Disc

a : From or To Clutch Control

Valve

(A) DISENGAGED

(B) ENGAGED

W10151580

2-M5

3 TRANSMISSION

KiSC issued 06, 2006 A

MECHANISM

KiSC issued 06, 2006 A

CONTENTS

1. TRANSMISSION GEARS .............................................................................3-M1

[1] SLIDING MESH TYPE........................................................................... 3-M1

[2] CONSTANT MESH TYPE......................................................................3-M2

[3] SYNCHRONOUS MESH TYPE.............................................................3-M3

2. HYDRAULIC SHUTTLE SHIFT....................................................................3-M4

[1] HYDRAULIC SHUTTLE SHIFT..............................................................3-M4

[2] HYDRAULIC SHUTTLE VALVE (TYPE 1)

(Code No. 3A691-23800, 3A051-23803) .................................................3-M5

(1) Operation...........................................................................................3-M6

[3] HYDRAULIC SHUTTLE VALVE (TYPE 2)

(Code No. YW119-0103)........................................................................3-M16

(1) Structure ..........................................................................................3-M16

(2) Operation.........................................................................................3-M18

3. SWING SHIFT.............................................................................................3-M28

4. DUAL SPEED ............................................................................................. 3-M31

[1] DUAL SPEED SECTION ..................................................................... 3-M32

[2] DUAL SPEED VALVE (Code No. YW217-00100) ..............................3-M33

5. HYDROSTATIC TRANSMISSION (TYPE 1) (Code No. 6C150-11603)..3-M34

[1] STRUCTURE......................................................................................... 3-M34

[2] OIL FLOW AND VALVES ...................................................................3-M36

[3] OPERATION..........................................................................................3-M40

[4] CONTROL LINKAGE............................................................................ 3-M43

6. HYDROSTATIC TRANSMISSION (TYPE 2) (Code No. TA240-58004)..3-M44

[1] STRUCTURE......................................................................................... 3-M44

[2] FUNCTION OF EACH COMPONENTS..............................................3-M46

[3] OIL FLOW.............................................................................................3-M49

[4] OPERATION..........................................................................................3-M50

[5] CONTROL LINKAGE............................................................................ 3-M56

7. HYDROSTATIC TRANSMISSION (TYPE 3) (Code No. 6C200-11604)..3-M57

[1] STRUCTURE......................................................................................... 3-M57

[2] PUMP AND MOTOR............................................................................ 3-M59

[3] OIL FLOW AND VALVES ...................................................................3-M60

[4] CONTROL LINKAGE............................................................................ 3-M68

[5] CRUISE CONTROL LINKAGE ............................................................3-M69

(1) Cruise Control..................................................................................3-M69

(2) Cruise Control Release....................................................................3-M70

8. HYDROSTATIC TRANSMISSION (TYPE 4)

(Code No. TD020-59992, TD060-59994).....................................................3-M71

[1] STRUCTURE......................................................................................... 3-M71

[2] OIL FLOW.............................................................................................3-M73

[3] FUNCTION OF COMPONENTS.......................................................... 3-M74

[4] OPERATION..........................................................................................3-M75

[5] CONTROL LINKAGE............................................................................ 3-M78

[6] CRUISE CONTROL.............................................................................. 3-M79

9. HYDROSTATIC TRANSMISSION (TYPE 5) (Code No. TC220-59990)..3-M81

KiSC issued 06, 2006 A

[1] STRUCTURE .........................................................................................3-M81

[2] OIL FLOW ................. ....... ...... ....... ...................................... ....... ...... .....3-M83

[3] OPERATION ..........................................................................................3-M84

[4] CONTROL LINKAGE ....................................... ...... ....... ...... ....... ...... .....3-M87

(1) HST Pedal Linkage .........................................................................3-M87

(2) Cruise Control ..................................................................................3-M88

10. GLIDE SHIFT TRANSMISSION (TYPE 1)

(GST Valve Code No. TA040-65015, TA040-99034).................................3-M89

[1] CHARACTERISTIC AND OUTLINE............................. ...... ....... ...... .....3-M89

[2] HYDRAULIC CIRCUIT..................................... .....................................3-M90

[3] STRUCTURE .........................................................................................3-M91

[4] CONSTRUCTION PARTS ....................................................................3-M92

(1) Regulator Valve................................................................................3-M92

(2) GST Valve Assembly .......................................................................3-M93

(3) Rotary Valve.....................................................................................3-M94

(4) Shift Pistons .....................................................................................3-M95

(5) Shift Check Valves ...........................................................................3-M96

(6) Low-pass Valve................................................................................3-M97

(7) Modulating Valve..............................................................................3-M98

(8) Modulating Check Valve...................................................................3-M99

(9) Accumulator ...................................................................................3-M100

(10)Clutch Valve...................................................................................3-M101

(11)Clutch Pack....................................................................................3-M102

11. GLIDE SHIFT TRANSMISSION (TYPE 2)

(GST Valve Code No. T1063-65004).........................................................3-M103

[1] CHARACTERISTIC AND SYSTEM OUTLINE..................................3-M103

[2] POWER TRAIN...................................................................................3-M104

[3] ELECTRICAL CONTROL SYSTEM...................................................3-M105

(1) Construc ti on and Functio n of Compon ents........................... ...... ...3- M10 5

(2) Electrical Control............................................................................3-M108

[4] HYDRAULIC CONTROL SYSTEM ....................................................3-M109

(1) Hydraulic Circuit and System Outline.............................................3-M109

(2) Construc ti on and Functio n of Compon ents........................... ...... ...3- M11 1

12. POWER SHIFT SYSTEM.........................................................................3-M118

[1] CONSTRUCTION AND FUNCTION OF COMPONENTS................3-M118

(1) Electric Components......................................................................3-M118

(2) Hydraulic Components...................................................................3-M122

[2] ELECTRIC CONTROL SYSTEM .......................................................3-M124

(1) Control System...............................................................................3-M124

(2) Power Shift Control ........................................................................3-M125

[3] AUTO SPEED CONTROL..................................................................3-M126

(1) Travel Mode ...................................................................................3-M126

(2) Field Mod e ...... ...... ....... ...... ....................................... ...... ....... ...... ...3-M128

MECHANISM

KiSC issued 06, 2006 A

[4] OTHER CONTROL.............................................................................3-M130

(1) Down-hill Control............................................................................ 3-M130

(2) Clutch Pedal Control......................................................................3-M130

(3) Shuttle Control ...............................................................................3-M130

(4) Auxiliary Control.............................................................................3-M131

[5] HYDRAULIC CONTROL SYSTEM.................................................... 3-M132

(1) Hydraulic Circuit.............................................................................3-M132

[6] POWER SHIFT VALVE......................................................................3-M133

13. DIFFERENTIAL GEAR SYSTEM.............................................................3-M136

[1] STRUCTURE....................................................................................... 3-M136

[2] OPERATION........................................................................................3-M136

[3] DIFFERENTIAL LOCK........................................................................ 3-M137

(1) Dog Clutch Type ............................................................................3-M137

(2) Pin Type......................................................................................... 3-M138

(3) Hydraulic Actuated Type................................................................3-M139

14. FINAL REDUCTION SYSTEM.................................................................3-M140

15. PTO SYSTEM...........................................................................................3-M141

[1] REAR AND MID PTO SYSTEM....................................................... 3-M141

[2] LIVE PTO AND GROUND PTO.......................................................3-M142

[3] INDEPENDENT PTO SYSTEM .........................................................3-M143

[4] REAR PTO SHAFT............................................................................3-M144

(1) Fixed PTO Shaft Type ...................................................................3-M144

(2) Interchangeable PTO Shaft Type ..................................................3-M145

[5] ONE-WAY CLUTCH SYSTEM...........................................................3-M146

TRACTOR, WSM

KiSC issued 06, 2006 A

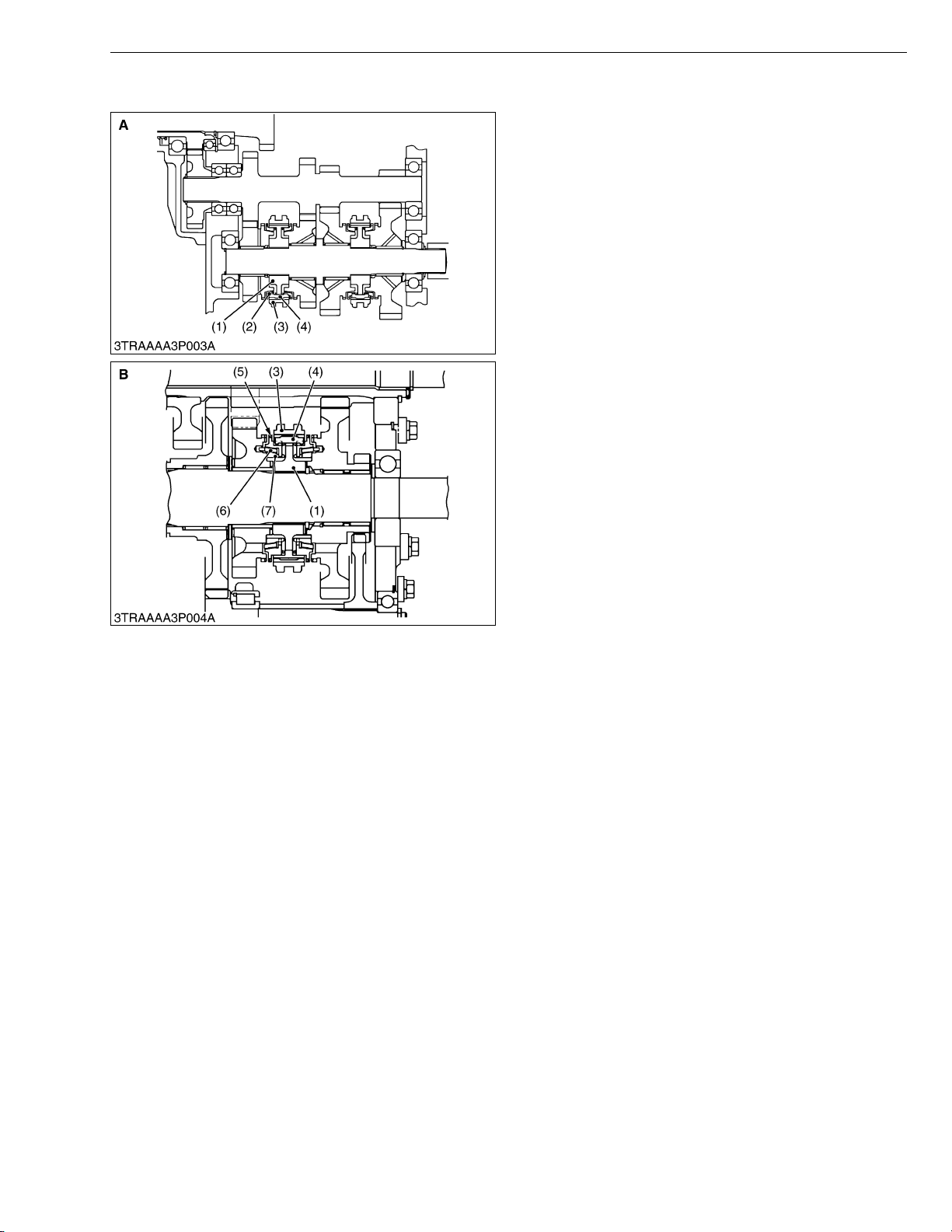

1. TRANSMISSION GEARS

[1] SLIDING MESH TYPE

TRANSMISSION

In sliding mesh type, when the speed is selected, the

sliding gear is sl ide on the shaft and engaging gears to

enable the transmission of power.

(1) Shifter Gear 1

(2) Shifter Gear 2

(3) Shifter Gear 3

(4) Shifter Gear 4

W10126510

3-M1

TRACTOR, WSM

KiSC issued 06, 2006 A

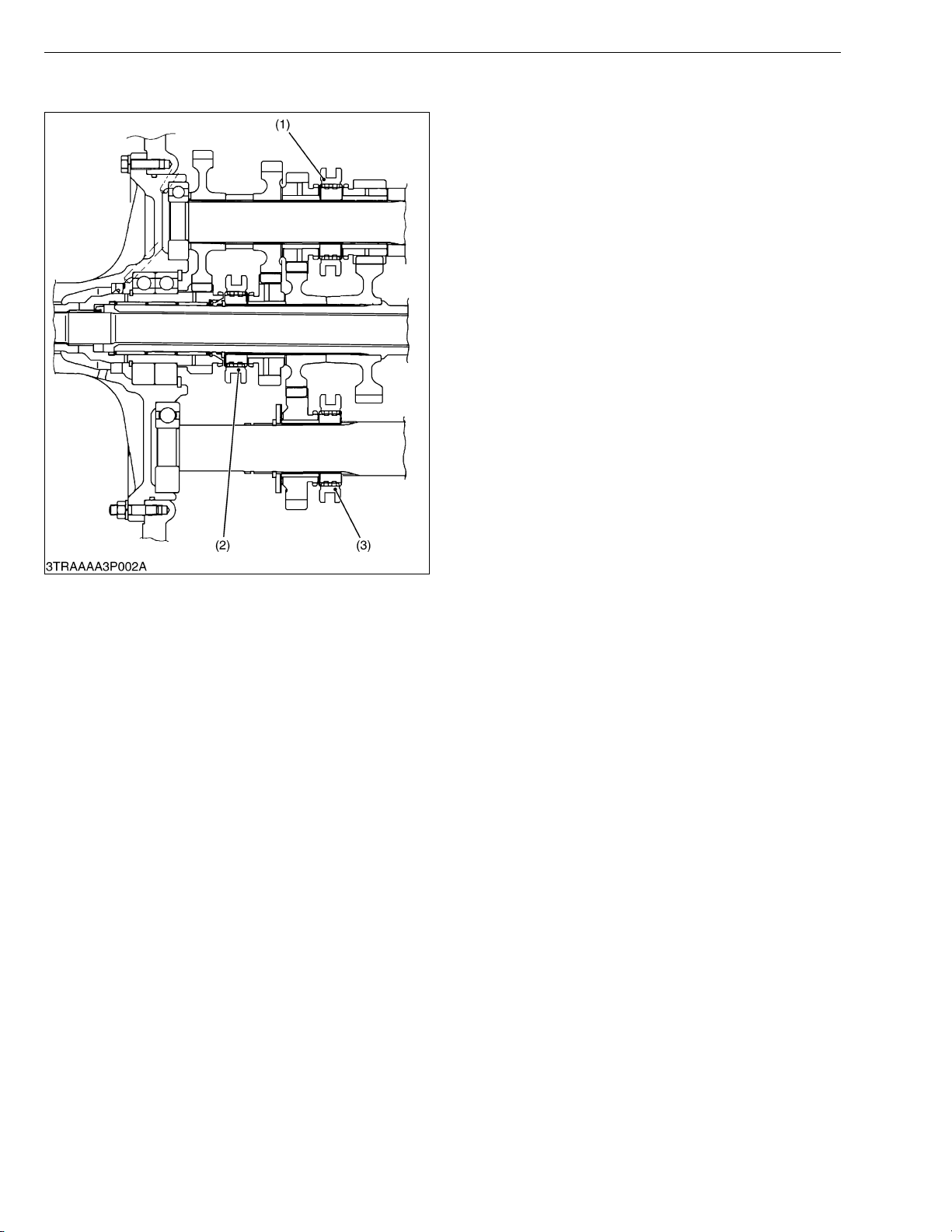

[2] CONSTANT MESH TYPE

TRANSMISSION

In constant mesh type, each gear always engaged

with its opponent gear. When the speed is selected by

this type, shifter on the shaft slides to eng age the gear

and shaft. As a result, the transmission of power

becomes possible.

The constant mesh type have the advantage of much

less frequency in gear breakage compared to sliding

mesh type.

(1) Shifter 1

(2) Shifter 2

(3) Shifter 3

W10127640

3-M2

TRACTOR, WSM

KiSC issued 06, 2006 A

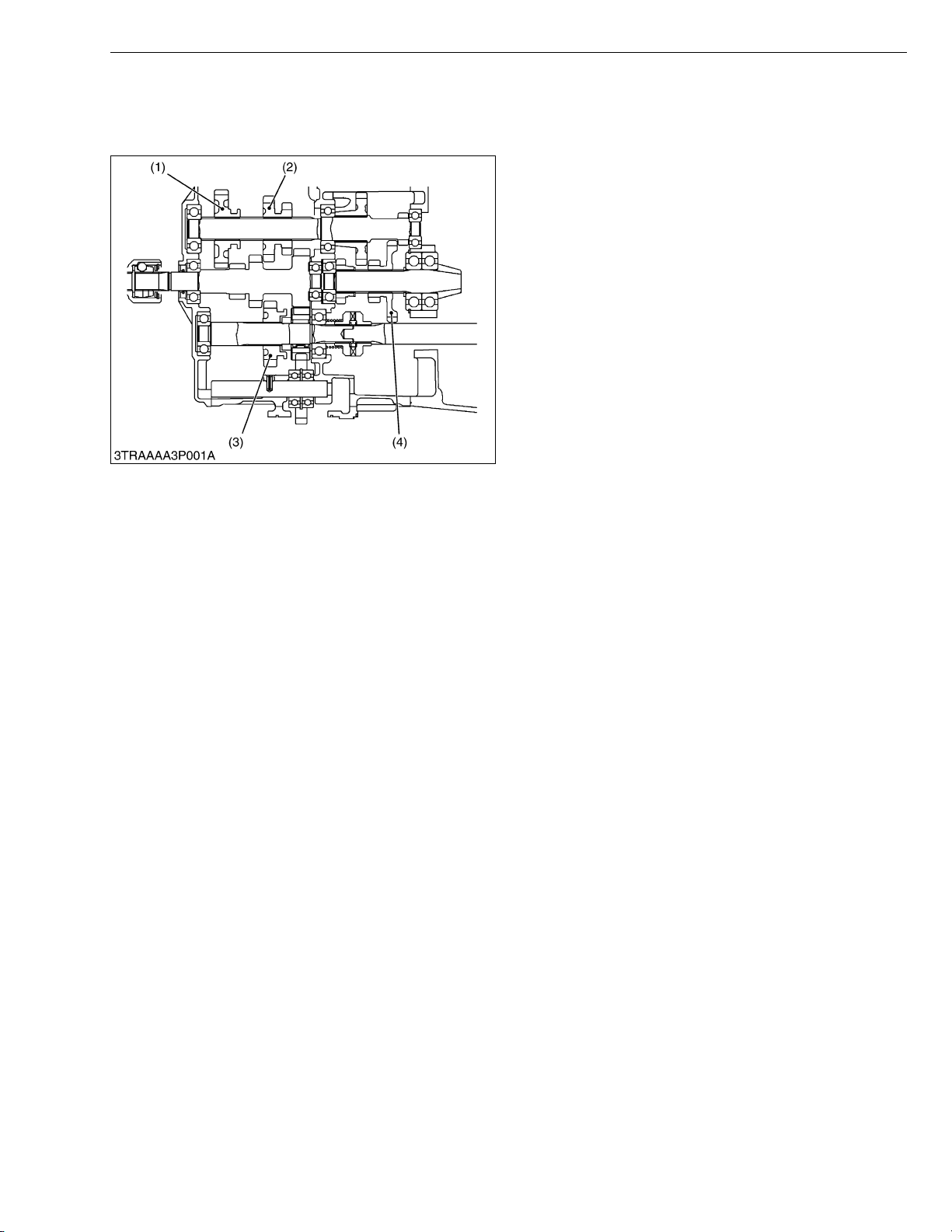

[3] SYNCHRONOUS MESH TYPE

TRANSMISSION

Synchronous mesh type transmits power by sliding

the shifter as well as constant mesh type.

However, the rotation of driving side parts and driven

side parts is sy nc hr on iz ed wit h s y nc hrono us me sh type,

and to facilitate changing the speed, synchronizer is

installed.

Therefore, it is poss ible to change the speed in this

type while the tractor even is moving.

(1) Hub

(2) Synchronizer Ring

(3) Shifter

(4) Synchronizer Key

(5) Outer Synchronizer Ring

(6) Center Ring

(7) Inner Synchronizer Ring

A : Type 1 (Single Cone Type)

B : Type 2 (Double Cone Type)

W10128140

3-M3

TRACTOR, WSM

■

KiSC issued 06, 2006 A

2. HYDRAULIC SHUTTLE SHIFT

[1] HYDRAULIC SHUTTLE SHIFT

The hydraulic shuttle shift allows the operators to

change forward and reverse with a shuttle lever.

When the shuttle lever is move to the “Forward” or

“Reverse” position, each side of th e hydraulic c lutch is

engaged. The power is transmitted as follows

■ Forward

Input Shaft (1) → Shuttle Clutc h Body (4) → Clutch

Disc and Plate (8) → 28T Gear (5) → 1st Shaft (6)

■ Reverse

Input Shaft (1) → Shuttle Clutc h Body (4) → Clutch

Disc and Plate (3) → 26T Gear (2) → 25T Idle Gear (11)

→ 23T Gear (10) → Shaft 1 (9) → 25T Gear (7) → 28T

Gear (5) → 1st Shaft (6)

NOTE

• When the clutch pedal is depressed, neither

“Forward” side or “Reverse” side is engaged and

the power is not transmitted.

(1) Input Shaft

(2) 26T Gear

(3) Clutch Disc and Plate

(4) Shuttle Clutch Body

(5) 28T Gear

(6) 1st Shaft

TRANSMISSION

(7) 25T Gear

(8) Clutch Disc and Plate

(9) Shaft 1

(10) 23T Gear

(11) 25T Idle Gear

(12) Idle Shaft

W1012816

3-M4

TRACTOR, WSM

KiSC issued 06, 2006 A

TRANSMISSION

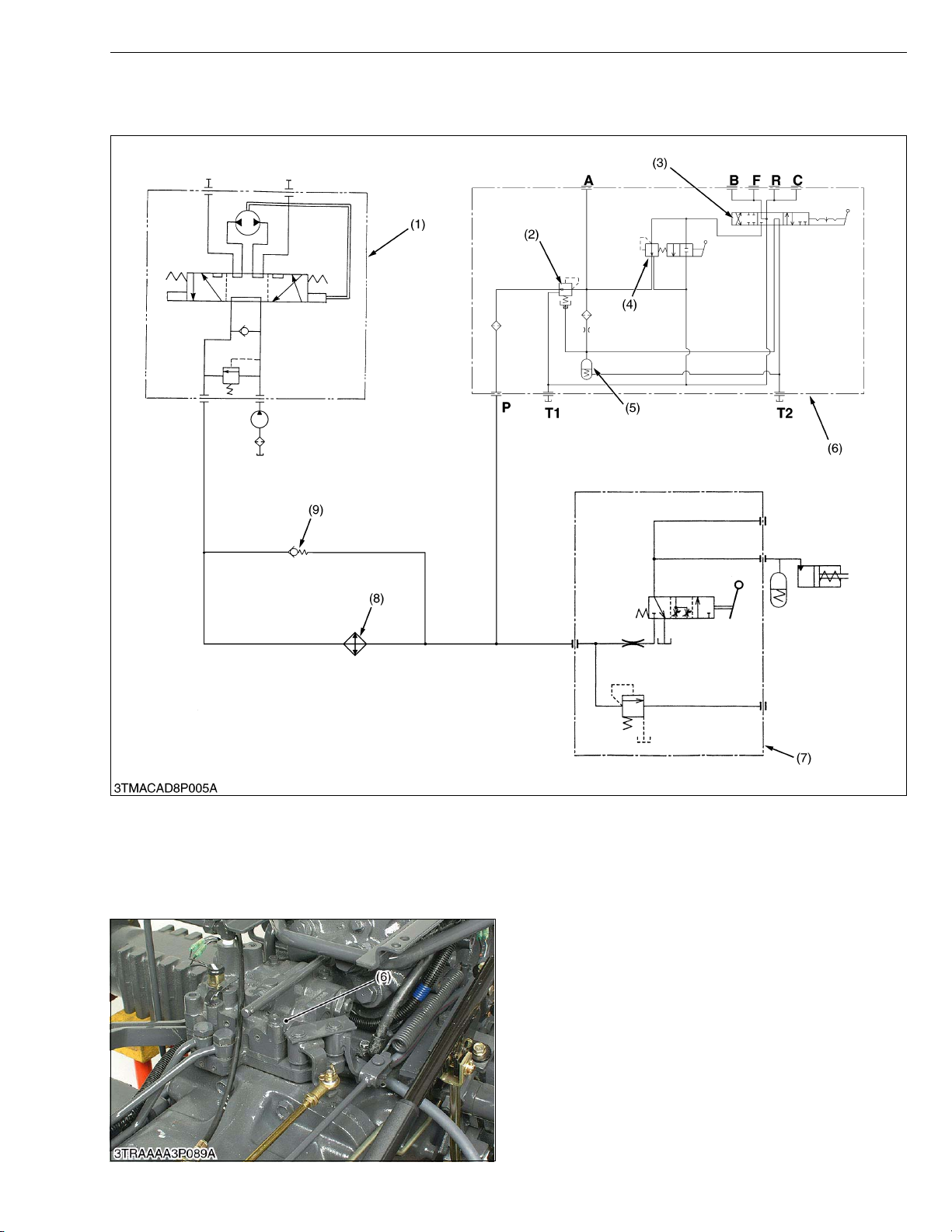

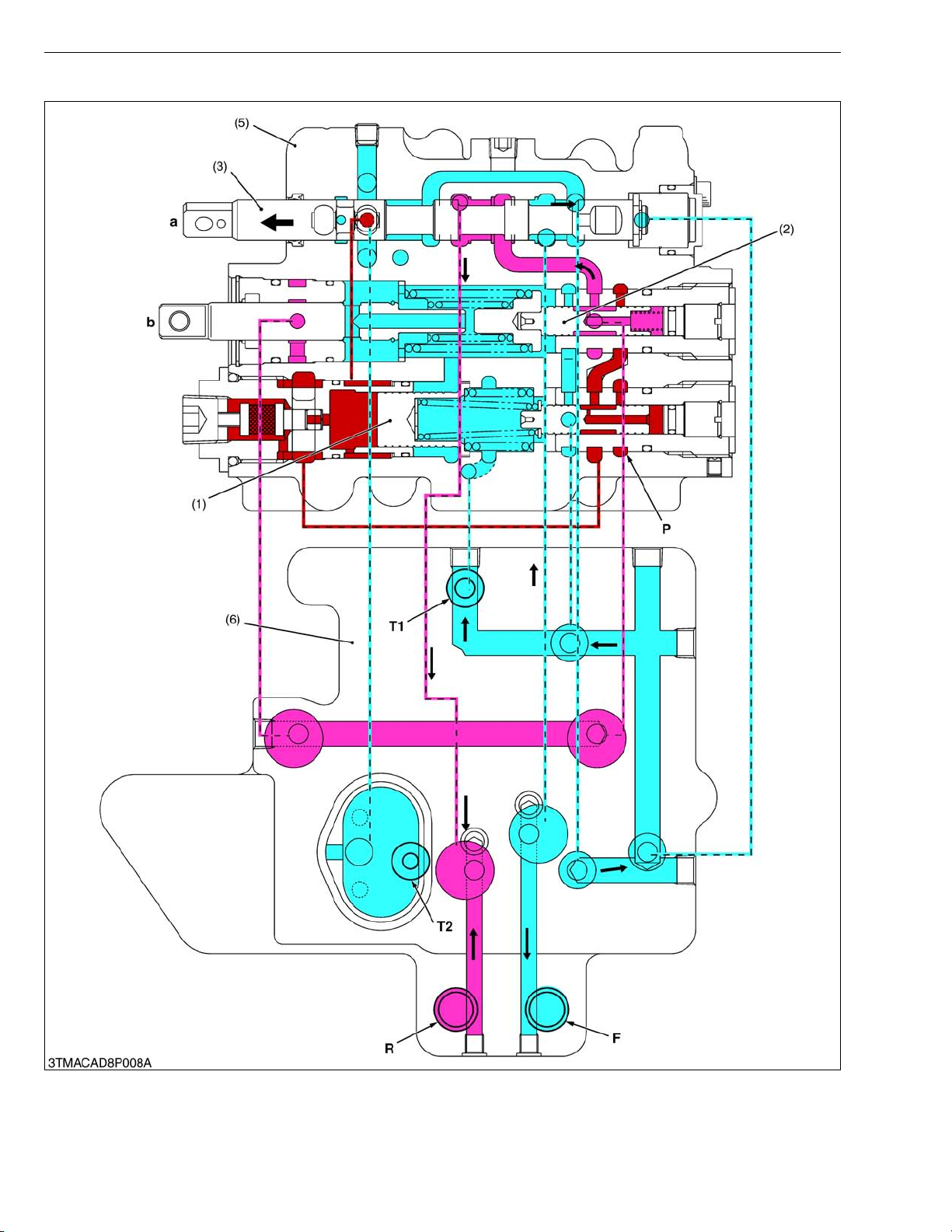

[2] HYDRAULIC SHUTTLE VALVE (TYPE 1) (Code No. 3A691-23800, 3A051-

23803)

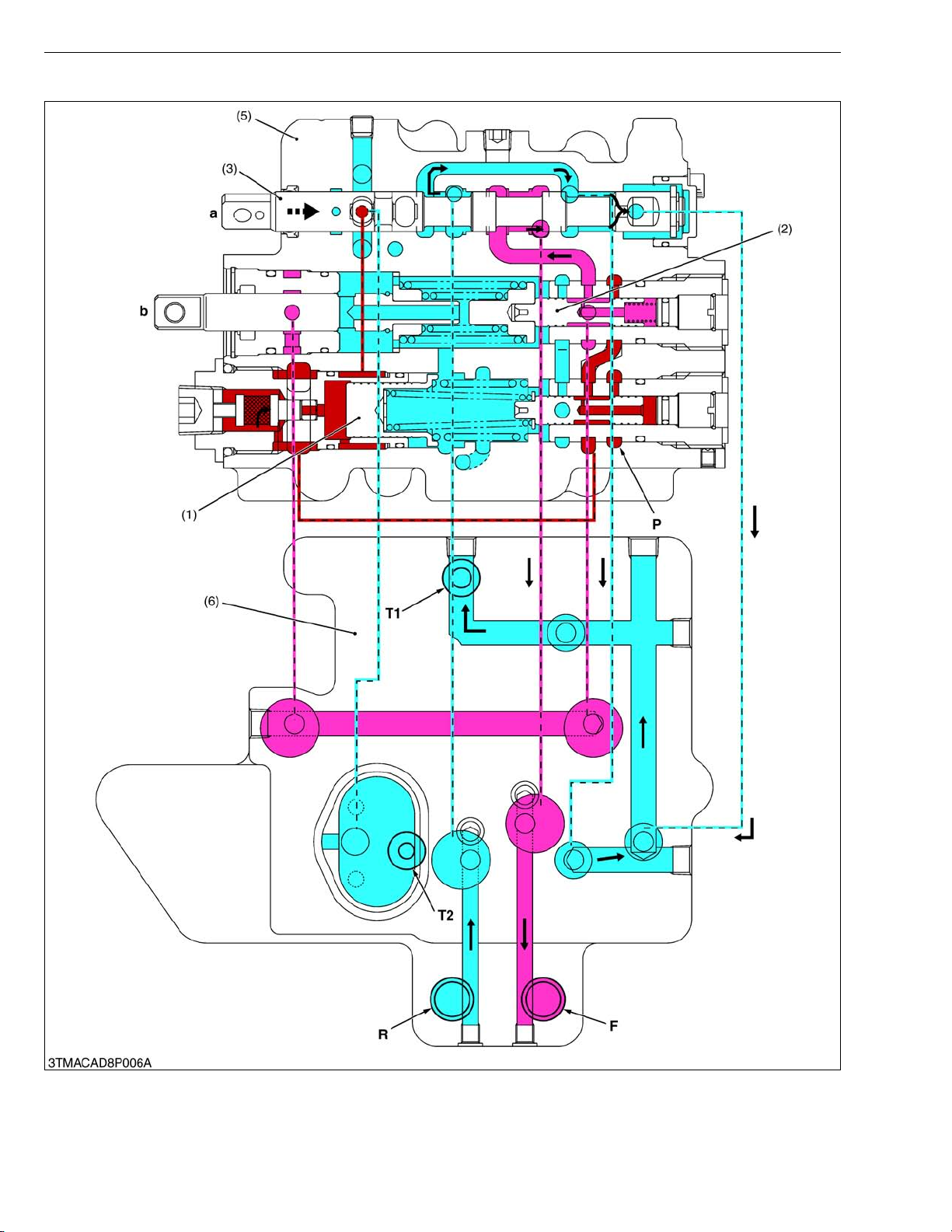

(1) Power Steering Controller

(2) Modulating Valve

(3) Shuttle Shift Spool

(4) Proportionally Reducing Valve

(Forward, Reverse)

(5) Accumulate Valve

(6) Shuttle Valve

(7) PTO Control Valve

(8) Oil Cooler

(9) Oil Cooler Relief Valve

P : From Power Steering

Controller

A : Pressure Check Port

(Modulation)

B : Pressure Check Port

(Forward)

F : To Clutch Body (Forward)

R : To Clutch Body (Reverse)

C : Pressure Check Port

(Reverse)

1, T2 : Tank Port

T

Hydraulic shuttle valve is composed of modulating

valve (2), proportio nally reducing valve (4) , shuttle shift

spool (3), accumulate valve (5) and other component

parts.

3-M5

W1023055

TRACTOR, WSM

KiSC issued 06, 2006 A

(1) Operation

■ Shuttle Lever at Neutral Position

TRANSMISSION

3-M6

TRACTOR, WSM

KiSC issued 06, 2006 A

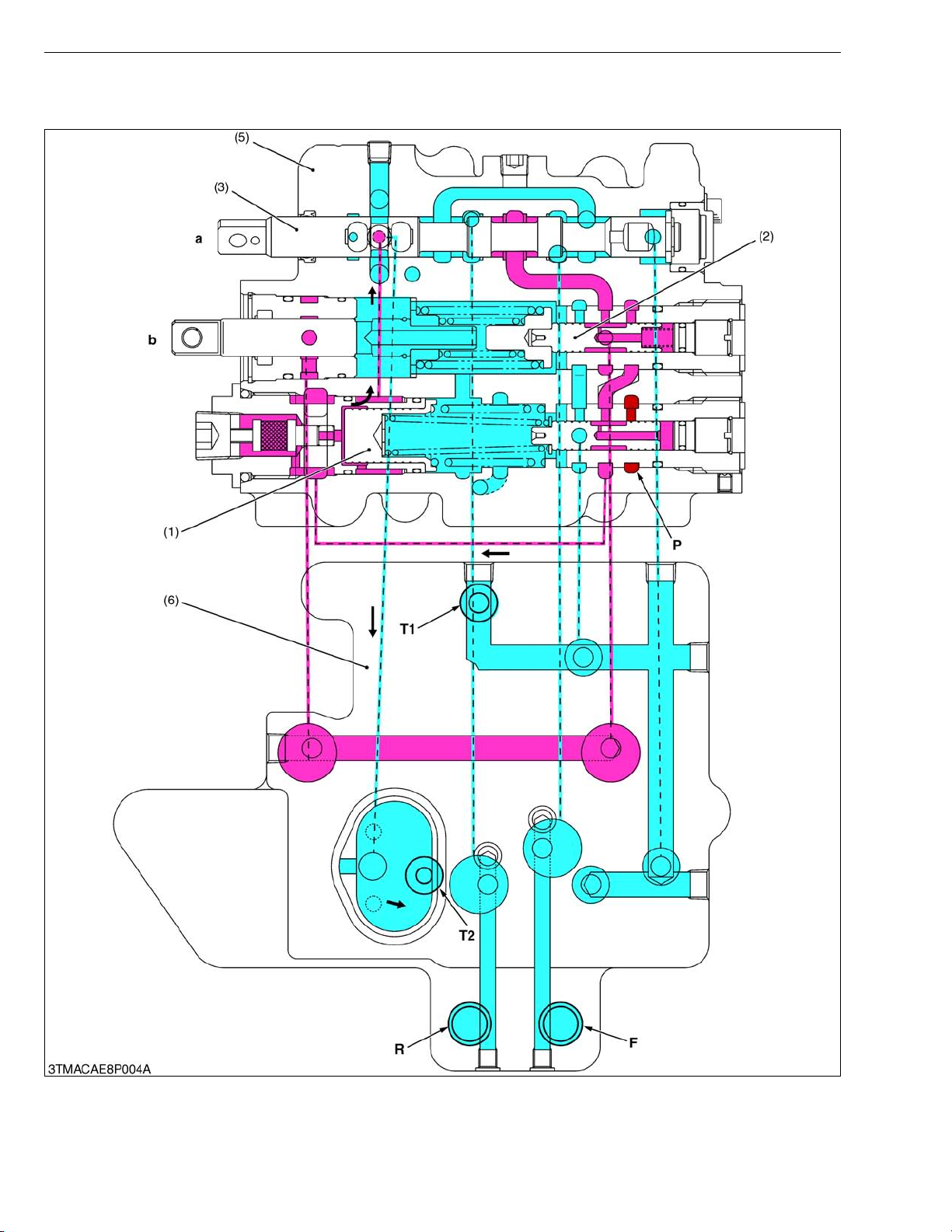

TRANSMISSION

(1) Modulating Valve

(2) Proportionally Reducing Valve

(3) Spool (Forward, Reverse)

(4) Accumulate Valve

(5) Shuttle Valve Case 1

(6) Shuttle Valve Case 2

(7) Shuttle Lever

(8) Clutch Pedal

A : Check Port (Modulation)

B : Check Port (Forward)

C : Check Port (Reverse)

P : From Pump

F : To Clutch Body (Forward)

R : To Clutch Body (Reverse)

1 : To Transmission Case

T

2 : To Transmission Case

T

a : Connect to Shuttle Lever

b : Connect to Clutch Pedal

When the sh ut t le l ev e r a t Neutral position, as the oil passage between P port to F or R port is closed by spool (3),

pressure- fed oil from P port flows to the T

2 port. Thus the shuttle clutch is not engage.

3-M7

TRACTOR, WSM

KiSC issued 06, 2006 A

TRANSMISSION

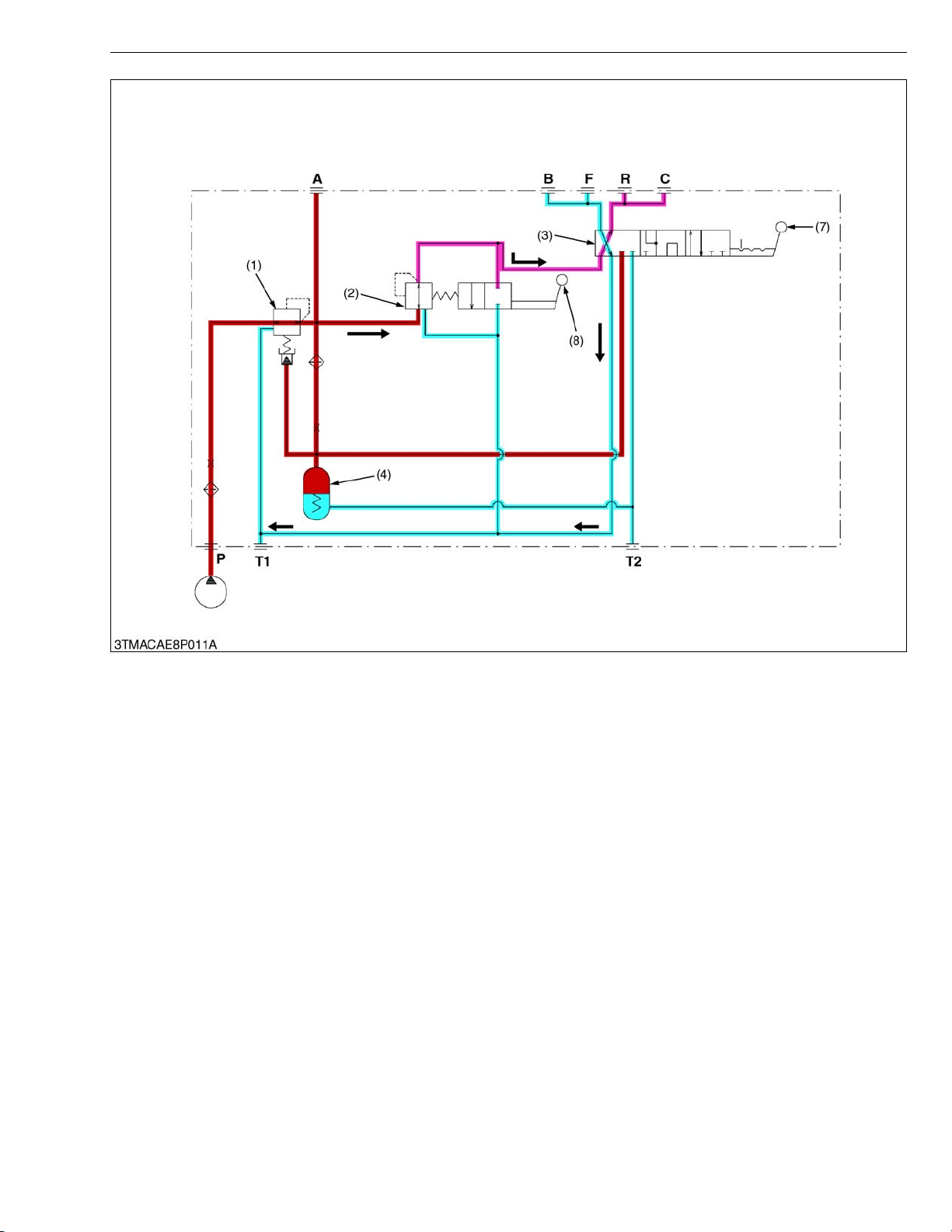

■ When Shuttle Lever is Shifting Neutral to Forward or Reverse Position (Clutch Pedal is Released)

a : Connect to Shuttle Lever b : Connect to Clutch Pedal

3-M8

TRACTOR, WSM

KiSC issued 06, 2006 A

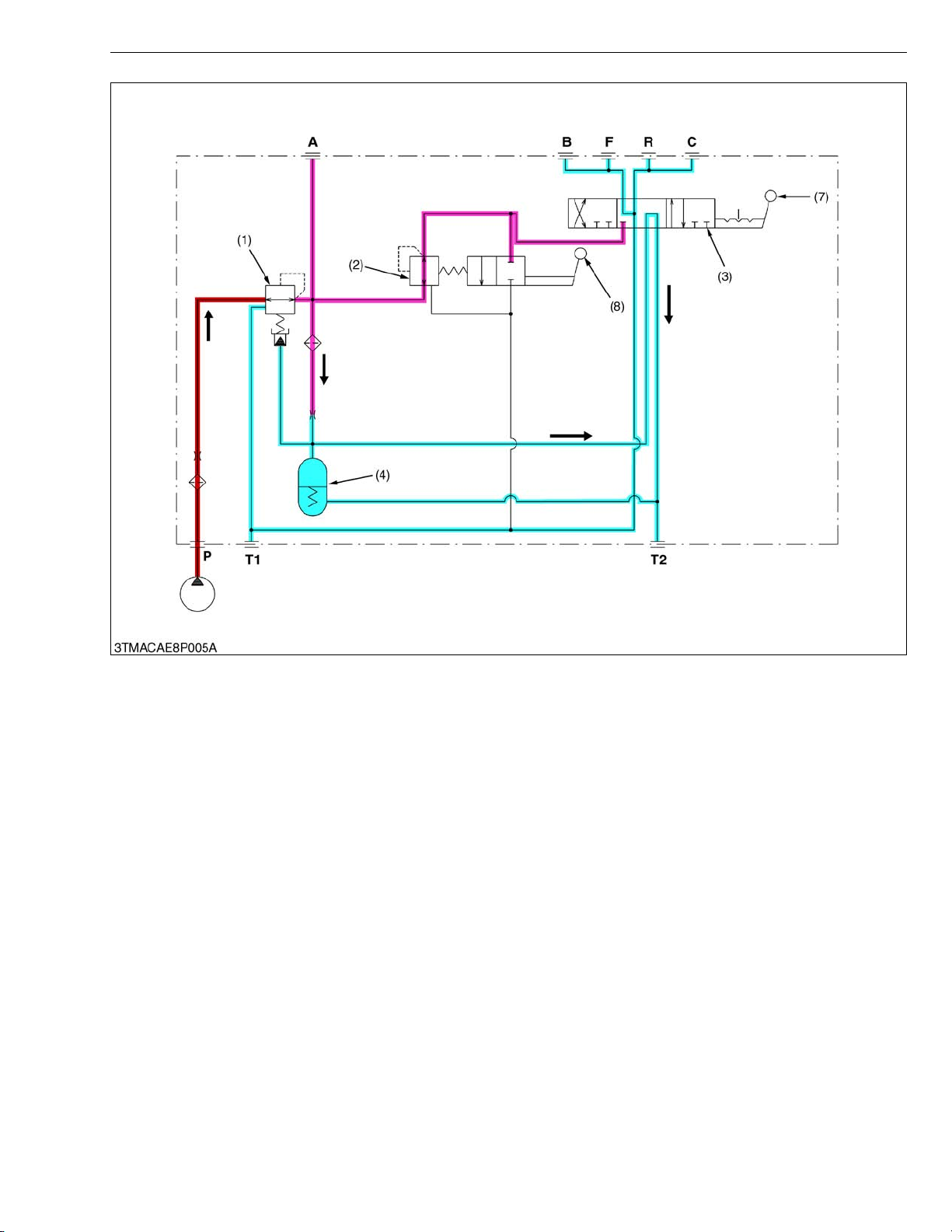

TRANSMISSION

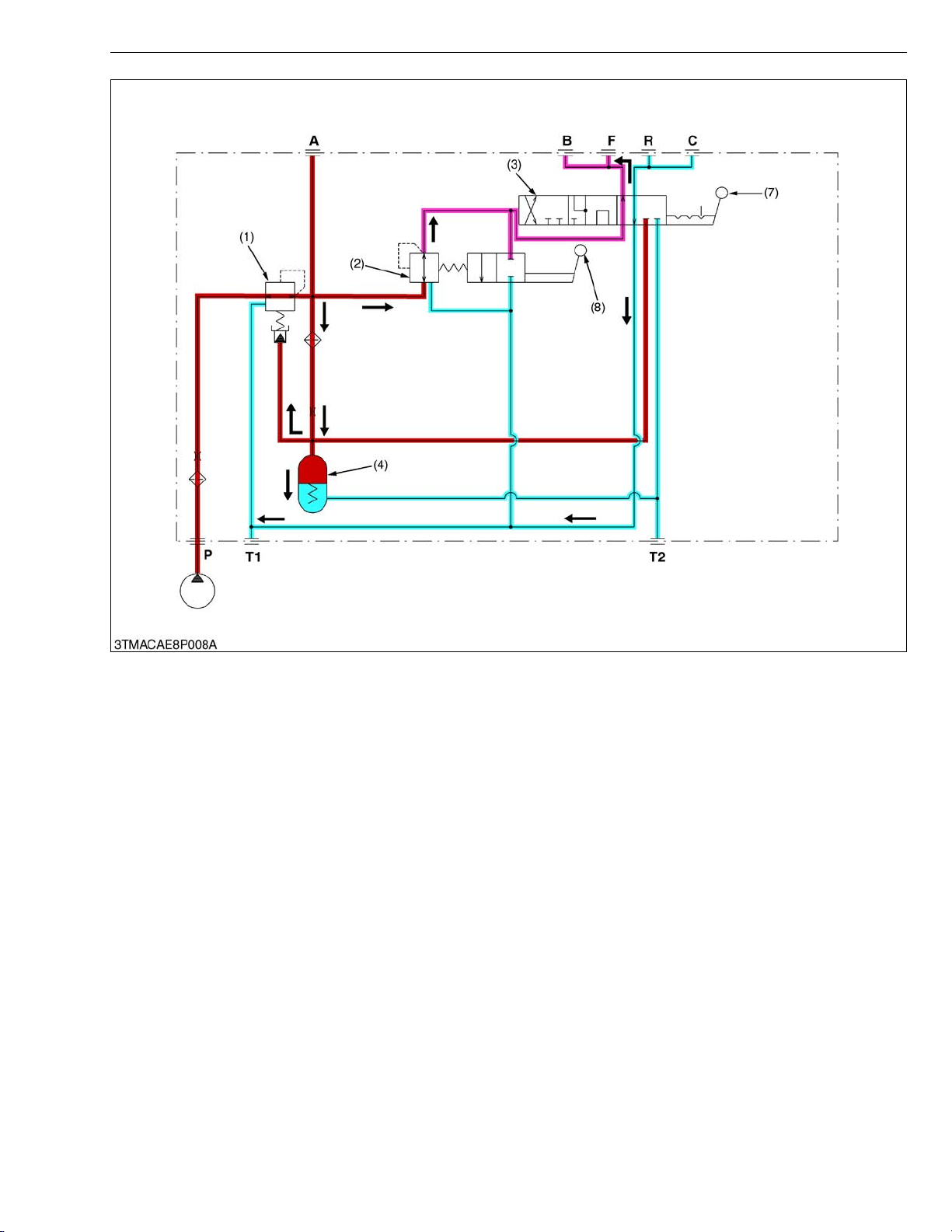

(1) Modulating Valve

(2) Proportionally Reducing Valve

(3) Spool (Forward, Reverse)

(4) Accumulate Valve

(5) Shuttle Valve Case 1

(6) Shuttle Valve Case 2

(7) Shuttle Lever

(8) Clutch Pedal

A : Check Port (Modulation)

B : Check Port (Forward)

C : Check Port (Reverse)

P : From Pump

F : To Clutch Body (Forward)

R : To Clutch Body (Reverse)

1 : To Transmission Case

T

2 : To Transmission Case

T

When the shuttle lever is moved to “FORWARD” or “REVERSE”, pressure-fed oil from P port flows into shuttle

clutch via F or R port. At this time, the pressure of F or R port is increased gradually by modulating valve (1).

When the shuttl e clutch is engaging, the accumulate valve ( 4) assists the operatio n of modulating valve (1) to

reduce a shock.

3-M9

TRACTOR, WSM

KiSC issued 06, 2006 A

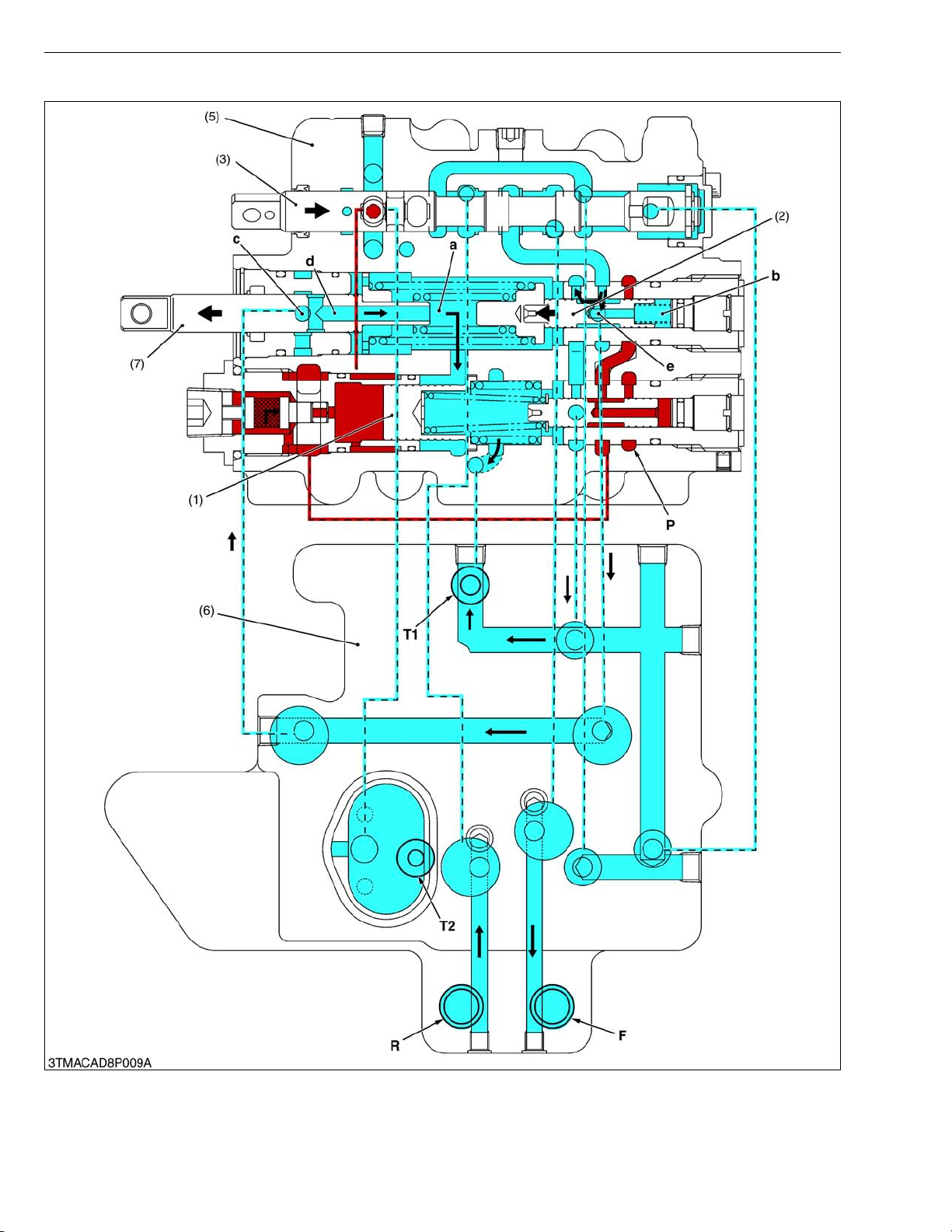

■ Shuttle Lever at Forward Position (Clutch Pedal is Released)

TRANSMISSION

a : Connect to Shuttle Lever b : Connect to Clutch Pedal

3-M10

TRACTOR, WSM

KiSC issued 06, 2006 A

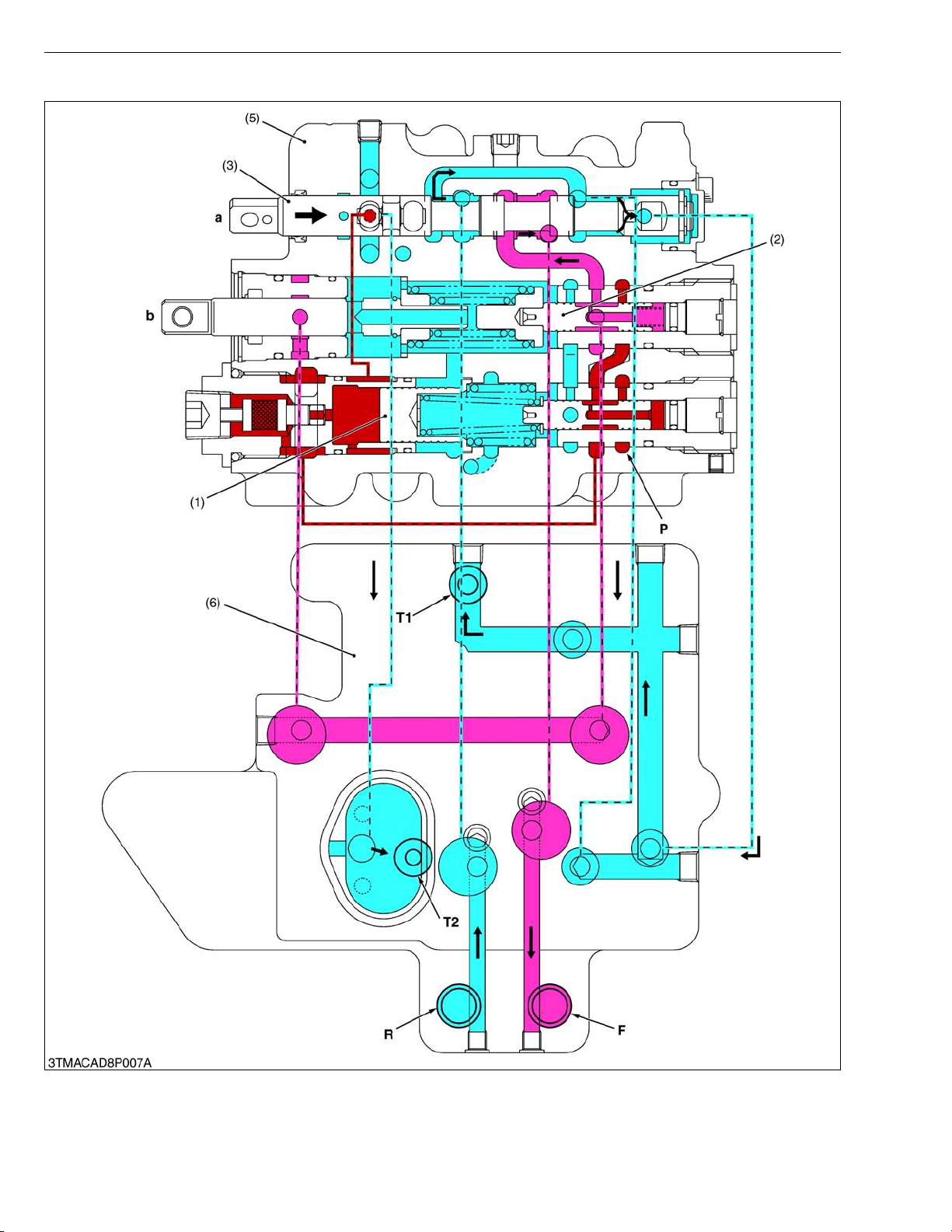

TRANSMISSION

(1) Modulating Valve

(2) Proportionally Reducing Valve

(3) Spool (Forward, Reverse)

(4) Accumulate Valve

(5) Shuttle Valve Case 1

(6) Shuttle Valve Case 2

(7) Shuttle Lever

(8) Clutch Pedal

A : Check Port (Modulation)

B : Check Port (Forward)

C : Check Port (Reverse)

P : From Pump

F : To Clutch Body (Forward)

R : To Clutch Body (Reverse)

1 : To Transmission Case

T

2 : To Transmission Case

T

When the shuttle lever hav e been setting on the F side, the oil pressure on F port i s constantly controlled by

proportionally reducing valve (2).

On the other hand, the oil in the R side of shuttle clutch returns to T

1 port through R port and spool (3).

3-M11

TRACTOR, WSM

KiSC issued 06, 2006 A

■ Shuttle Lever at Reverse Position (Clutch Pedal is Released)

TRANSMISSION

a : Connect to Shuttle Lever b : Connect to Clutch Pedal

3-M12

TRACTOR, WSM

KiSC issued 06, 2006 A

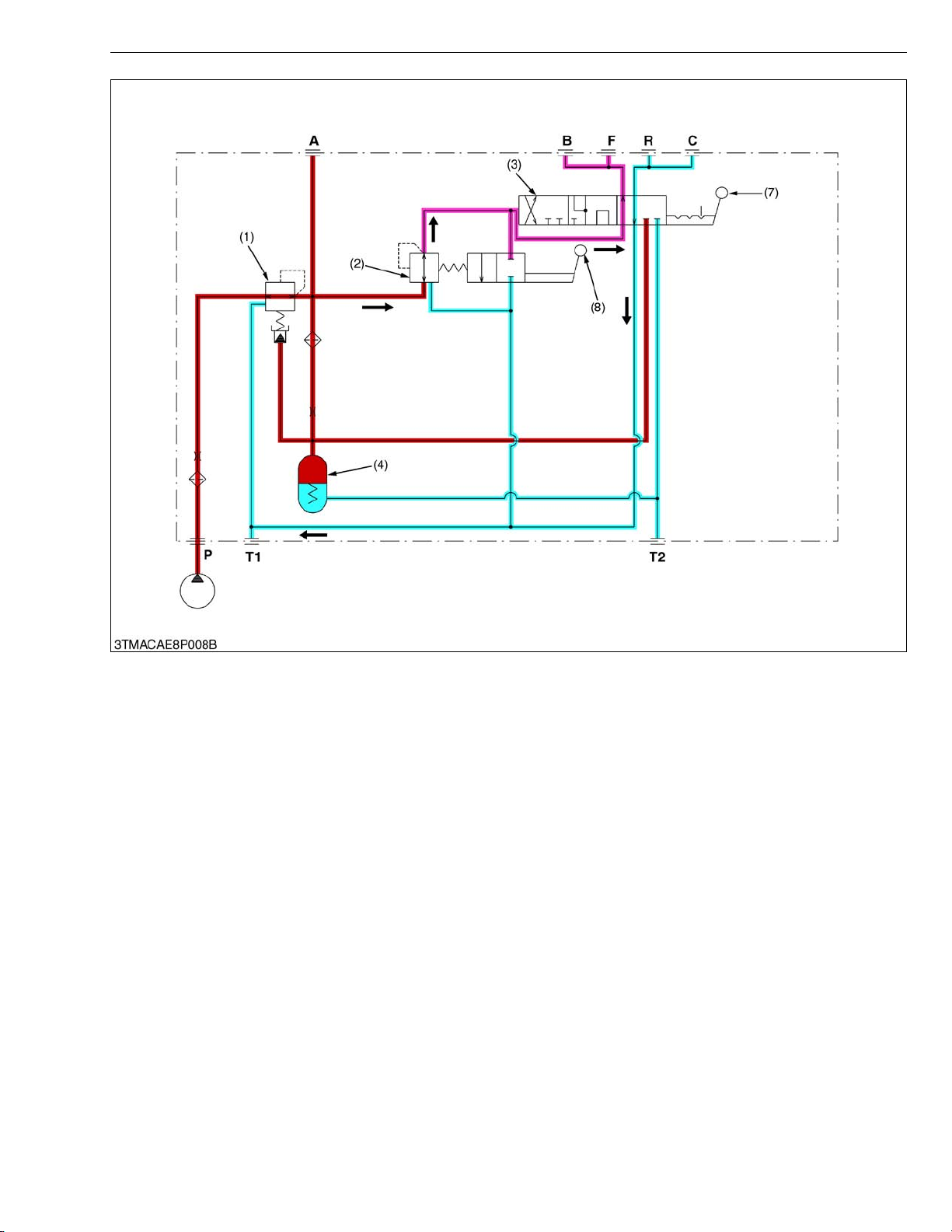

TRANSMISSION

(1) Modulating Valve

(2) Proportionally Reducing Valve

(3) Spool (Forward, Reverse)

(4) Accumulate Valve

(5) Shuttle Valve Case 1

(6) Shuttle Valve Case 2

(7) Shuttle Lever

(8) Clutch Pedal

A : Check Port (Modulation)

B : Check Port (Forward)

C : Check Port (Reverse)

P : From Pump

F : To Clutch Body (Forward)

R : To Clutch Body (Reverse)

1 : To Transmission Case

T

2 : To Transmission Case

T

When the shuttle lever have been setting on the R side, the oil pressure on R port is constantly controlled by

proportionally reducing valve (2).

On the other hand, the oil in the F side of shuttle clutch returns to T

1 port through F port and spool (3).

3-M13

TRACTOR, WSM

KiSC issued 06, 2006 A

■ When Clutch Pedal is Depressed (with Shuttle Lever at Forward or Reverse Position)

TRANSMISSION

a : Connect to Shuttle Lever b : Connect to Clutch Pedal

3-M14

Loading...

Loading...