Page 1

KORG POLYSIX

A MIDI Retrofit Kit for the KORG POLYSIX

Owner’s Manual

"Korg USA proudly announces the PS6-MRK MIDI Retrofit Kit for the Korg Poly-6 Synthesizer.

Thanks to modern software/hardware technology, a gr eat classic analog synthesizer, the Kor g Poly-6, has now

been upgraded with one of the most advanced and comprehensive MIDI Retrofits ever devised for a pre-MIDI

synthesizer.

With MIDI, your Poly-6 can now join the MIDI revolution, easily connecting with other MIDI synthesizers,

expander modules, sequencers, drum machines , personal computers and more ... " - so far the original tex t of the

MIDI retrofit kit produced by Korg in 1986. This has now com e true once m ore with the present retr ofit k it designed

by Ricard Wolf (Sweden) and Johannes Hausensteiner (Austria).

Polysix M - MIDI-upgrade for the Korg Polysix:

• Comprehensive MIDI implementation:

Note number, bend and mod wheels, pedals, arpeggio clock, program change and program dumps.

• Memory expansion to 128 programs

• Individual parameter update in realtime via MIDI

• A number of other enhancements such as sustain pedal, edit recall and arpeggiator MIDI sync.

Page 2

2

Features

MIDI IN functionality: note on, note off, all notes off, bend wheel, mod wheel, program change, sustain pedal,

chord memory pedal, arpeggio switch, MIDI clock , start and stop (for the arpeggiator), sysex pr ogram dump,

mode messages, active sensing.

MIDI OUT functionality: note on, note off, all notes off , bend wheel, mod wheel, program change, sustain pedal,

chord memory pedal, arpeggio switch, sysex program dump, active sensing.

Individually selectable MIDI in and out channels 1..16.

Omni on/off, local on/off, and poly/mono mode messages received.

Arpeggiator can sync to MIDI clock at one of eight different clock rates.

Arpeggiated notes are sent over MIDI OUT.

Expands memory to 128 programs, grouped in 4 groups (1..4) of 4 banks (A..D) of 8 programs (1..8).

Edit recall functionality.

Individual parameter update in realtime via MIDI.

Chord memory pedal can now function as sustain pedal (switchable) with automatic pedal polarity detection.

Sysex dumps in banks of 32 or 128 programs can be sent and received.

128 program tape dump available, as well as 32 program format compatible with the original Polysix.

8 selectable key assign modes; dual and triple voic e capability: up to three voices can be layered on the sam e note

for fatter polyphonic sound.

Programmable noise generator.

Programmable bend wheel (VCO/VCF).

Programmable mod wheel (VCO/VCF/VCA).

Page 3

3

Connections

Rear panel MIDI jacks:

1) MIDI IN

Connect to MIDI Out of other synthesizer, computer, etc.

2) MIDI OUT

Connect to MIDI In of other synthesizer, computer, etc.

3) MIDI THRU

MIDI Thru delivers a copy of the signal received at MIDI In.

4) VCF fcM IN

The VCF fcM IN jack can act as a m odulation pedal. It applies the s ame ef fect as the m od wheel without taking

the hands off the keyboard.

5) CHORD MEMORY

The Chord Memory footswitch input can act as a HOLD foots witch now. Switch polarity is detected automatically

during power on. So be sure to connect the footswitch before powering on. Can be set to Chord Memory operation.

Page 4

4

Features and Functions

1) INTRODUCTION

An important goal for the Polysix M has been to retain the original character of the ins trument while at the sam e

time expanding its functionality. The machine is operated in the same way as the original Polysix with the sole

exception of the new functions, in order for all users to feel at hom e. All sound parameters (VCO, VCF, VCF, MG,

EG, EFFECTS, BEND, TUNE and OUT PUT) operate exactly as before, and these will not be discussed f urther in

this manual. The arpeggiator works in exactly the same way as before, apart f rom the f act that it is now poss ible to

synchronize it to a MIDI clock (e.g. from a drum machine or sequencer).

2) NEW CONNECTORS

On the rear panel of the Polysix M there are three DIN connectors on the left hand side of the panel (rear view).

From left to right these are MIDI THRU, MIDI OUT, and MIDI IN. (This order is employed by most manufacturers.)

All data sent to the synthesizer is received via MIDI IN and all MIDI data that the synthesizer transmits is sent via

MIDI OUT. MIDI THRU delivers a carbon copy of the received data at MIDI IN and is used for daisy-chaining

several instruments from a single MIDI source.

3) MEMORY

The original Polysix had 32 memory locations (progr am s) or ganized in 4 banks of 8 programs each (4 x 8 = 32).

This organization has been retained in the Polysix M but in order to increase the m emory to 128 programs, the

memory has been subdivided into four groups . In this way one obtains 4 groups x 4 banks x 8 program s = 128

programs total.

The memory group currently selected is indicated by one of the LEDs 1..4 flashing. T o select another memory

group:

(1)Press MANUAL and hold it.

(2)At the same time press one of the buttons 1..4. T he c orresponding LED will star t flas hing indicating the cur rently

selected group.

Example:

The currently selected program is group 3, program B4. T his is indicated by LED 3 flashing with B and 4 being

constantly illuminated. To change to, let’s say, group 3, program C7 it is only necessary to press C and 7 as usual

since group 3 is already selected.

In order to, say, select group 1, program A5:

(1)Press and hold MANUAL.

(2)Press 1. "1" starts to flash indicating memory group 1.

(3)Release MANUAL and press A and 5 as usual.

To store a program at a memory location press WRITE as usual and then the program num ber (m ake sur e that

the WRITE switch is in the WRITE ENABLE position).

Example:

The currently selected program is group 2, program D3. To store this program at location D6 instead:

(1)Press WRITE. WRITE starts to flash.

(2)Press 6. WRITE stops flashing and the program has been stored.

Page 5

5

To store the program in group 1, program A1 instead:

(1)Press WRITE. WRITE starts flashing.

(2)Select memory group 1 by holding MANUAL and pressing 1. 1 starts to flash indicating memory group 1.

(3)Release MANUAL.

(4)Press A to select bank A.

(5)Finally press 1 to store the program. The WRITE LED will go out.

If the wrong group or bank is selected, simply move the WRITE switch to the WRITE DISABLE position and then

back to the WRITE ENABLE position, causing the WRITE LED to go out. Then restart the operation.

In this manual program num bers will be referred to as, for instance, 3C4 m eaning "memory group 3, bank C,

program 4".

4) EDIT RECALL

Imagine the following situation:

You have created wondrous new sound by editing program 1A4. By mistake you press 5 causing the synthesizer

to immediately call up program 1A5 and erasing your hard worked edit.

In order to avoid this type of frustration the latest edit is saved in a s pecial mem ory location in the m achine, the

edit recall buffer. This is indicated by the MANUAL LED flashing. In order to recall the latest edit at any time:

(1)Press and hold MANUAL.

(2)Press 8. MANUAL will start flashing and the edited sound will be fetched for continued editing.

Example:

Assume program 2B4 is a string patch. Upon selecting this patch you notice that the release time is a bit too

short. Adjust this using the RELEASE knob. By doing this the sound is also copied into the EDIT RECALL buffer,

this is indicated by MANUAL flashing. You now want to save your new patch to another program location, but do not

know which locations are free. Thanks to the EDIT RECALL function it is now possible to examine the other

programs while the edit is kept safe in the edit recall buf fer. Eventually you find that 4D5 is available. In order to

fetch the edit hold MANUAL and press 8. The edited str ing patch is now fetched from the edit rec all buffer and

MANUAL begins to flash to indicate that an edit sound is being heard. After this the patch can be stored at the

memory location as usual.

To sum up:

- As soon as a patch is edited it is saved in an edit recall buffer.

- The contents of the buffer can be retrieved at any time using MANUAL-8.

However, note that if you press MANUAL (on its own) in order to mak e the front panel ’live’ (the MANUAL LED

lights up), changes are not saved in the edit recall buffer. There is no need since the patch is available on the panel

itself and can be retrieved simply by pressing MANUAL.

Additionally, please note that only changes made to the VCO, VCF, VCA, MG, EG, and EFFECTS param eters

are saved in the edit recall buffer since the settings of the other knobs and switches are not part of a program patch.

Page 6

6

5) KEY ASSIGN FEATURES

No need to worry - POLY, UNISON, and CHORD MEMORY work just as before - with, however, som e new

optional functionality.

This section is a bit in-depth technic al; if you do not understand what is going on, just skip to the next sect ion.

Upon powering up these settings are the same as for the original Polysix.

First of all, what is a synthesizer voice? It is not a little dwarf squashed away in a corner of the machine! Ins tead,

we can imagine a choir of 6 people. Let’s assum e we are dealing with super-vocalists who can cover the whole

tonal range of bass to soprano. This choir could sing in several different ’modes’. They could sing six separate

parts. Or they could all sing the same part. Or they could sing a three-part song, with two choir m embers singing

each part. Or they could...

As long as they limit themselves to the physical limit of six notes at once, they could sing anything in any

combination.

The Polysix operates in much the same manner. W e can play at the most six notes at once since we have six

voices in the machine. How these voices are handled is selected by the key assign mode.

The key assign mode describes how the synthesizer will react to the keys played. Are all notes to be heard

individually (POLY), or should only one be heard but with all six voices at once (UNISON), or...

Even in the POLY mode there area few variants. What happens, for instance, if more than 6 keys are

depressed? Should the last keys pressed be ignored so that none of the first notes heard will be lost, should the last

6 keys to be pressed always be heard so as not to ’lose’ any notes?

In many cases this is set by the manufacturer of the ins trum ent and cannot be c hanged. T he Polysix M however

offers the possibility of adjusting the key assign mode to suit the style of music and playing.

This is done in the following manner:

When pressing POLY, UNISON, or CHORD MEMORY hold it down, which will allow the key assign mode to be

adjusted by pressing A..D and 1..6.

The following functionality is available:

(*) indicates that this is a power-up default setting. T hese are the same as the key assign modes in the original

Polysix.

A) POLY MODE:

Button LED off LED on

A When a new key is press ed the nex t voice in tur n is

assigned (cyclic mode). (*)

The synthesizer always selects the lowestnumbered non-sounding voice (reset-to-zero).

B No voice memory. (*) If the same key is pressed several times, the

same voice is used (memory).

C If more than six keys are depressed, only the oldest

are heard.

If more than six k eys are depressed, only the last

are heard. (*)

D The MG delay is retriggered only when all keys

have been released (and a new one depressed). (*)

The MG delay is retriggered as soon as a new key

is depressed.

These functions can be enabled/disabled by pressing the corresponding button (while POLY is depressed).

In addition to this LEDs 1..3 show how many voices are played for each key depressed:

1: SINGLE - only one voice per key (*)

2: DUAL - two voices per key.

3: TRIPLE - three voices per key.

These are selected by pressing 1, 2, or 3 (while POLY is depressed).

Note that the polyphony of the instrument decreases in the DUAL and TRIPLE modes (three-note polyphony in

DUAL and two-note polyphony in TRIPLE).

Page 7

7

B) UNISON MODE:

Button LED off LED on

A Single trig. The voices are retriggered only when all

keys have been released (and a new one is

depressed).

Multi trig. The voices are retriggered as soon as a

new key is depressed. (*)

B See C. Last key priority. The last key pressed is heard. (*)

( Only if B is off )

C Lowest note priority. The lowest key pressed is

heard.

Highest note priority. The highest key pressed is

heard.

D ( See POLY MODE D )

These modes are selected in the same way as the poly modes.

In addition to this the number of voices to be played can be selected by holding UNISON and pr es sing 1, 2, 3, 4,

5, or 6.

C) CHORD MEMORY MODE:

This is actually a monophonic mode even though a whole chord can be programm ed. T his is due to the f act that

it is ONE sole key that sets the root note for the chord when playing in this mode.

A..D thus work in the same way as in UNISON MODE. (In order to change the k ey assign mode hold CHORD

MEMORY while pressing A..D .)

In this mode it is not possible to set the number of voices to be played using 1..6, however, it is possible to select

whether the pedal connected to the CHORD MEMORY input on the rear of the instrument will function as a sustain

pedal or chord memory pedal - see below.

5) SUSTAIN PEDAL

The greatest omiss ion from the original Polysix is without doubt the lack of a s ustain pedal input. This has been

corrected in the Polysix M. The pedal connected to the CHORD MEMORY input on the rear of the instrument can

function either as a sustain pedal or as a chord memory pedal.

When the m achine is switched on, the pedal will be set to s ustain pedal m ode (contrar y to the original Polysix).

By holding the CHORD MEMORY button and pressing 1 chord memory pedal mode can be selected. In order to

switch back to sustain pedal functionality repeat the same procedure.

When the CHORD MEMORY button is depres sed, LED 1 shows the s elected m ode: LED 1 of f m eans the pedal

operates as a sustain pedal. LED 1 on means the pedal operates as a chord memory pedal.

Note that the Polysix M will accept both pedals with opening and closing (make or break) contacts. Upon power

up the machine assum es the pedal is in the ’up’ (not depressed) position, no matter which elec trical state (open or

closed) this represents. The other position of the pedal will then be the ’down’ (depressed) position. Therefore,

remember to k eep the pedal released and plugged in to the synthesizer when it is turned on, or else it is poss ible

that the pedal will seem to be inverted when used.

6) THE ARPEGGIATOR

The arpeggiator works as before with the additional functionality of being able to synchronize to MIDI, for

instance from a MIDI drum machine. See the section on arpeggio parameters below for information on MIDI

synchronization.

Please note that when the arpeggiator is on it operates on the notes pressed on the k eyboard and sends the

resulting arpeggiation out via MIDI. Incoming MIDI data is received as usual, even when the arpeggiator is

operating. It is thus not possible to arpeggiate over incoming MIDI notes; however it is possible for the ar peggiator

to play an external synthesizer connected to MIDI OUT.

Also note that it is now possible to have HOLD selected while the arpeggiator is operating.

Page 8

8

7) MIDI and TAPE ENABLE

In order to select MIDI channels etc. the machine is switched into TAPE ENABLE mode.

In contrast to the original Polysix it is possible to play the machine and edit sounds even in TAPE ENABLE

mode. It is not possible to select (or write) programs or c hange the key assign m ode. The arpeggiator and HOLD

functions operate however.

Additionally the TAPE ENABLE mode is of course used when saving/loading programs to/from tape. This is

done in much the same way as before, so only changes from the original Polysix are described here.

8) SAVE/LOAD PROGRAMS TO/FROM TAPE

Switch the machine to TAPE ENABLE mode. Make sure that the PO LY, UNISON, and CHO RD MEMORY LEDs

are off. If not, press the corresponding button.

If the TO TAPE, FRO M TAPE, or VERIFY buttons are pressed, the corresponding operation will be perform ed.

Note however that the whole memory of 128 programs is s aved. (Note: it is not possible to load a 128-program

dump made this way into a original 32-program Polysix). For transf erring programs in groups of 32, for ins tance in

order to load sound data from an original Polysix dump, memory group 1..4 must be selected first.

Example 1:

In order to load a 32-program dump into memory group 3:

(1)Switch the machine to tape enable mode.

(2)Press 3. 3 lights up and indicates that memory group 3 has been selected.

(3)Press FROM TAPE as usual and start playing the program tape. The 32 program s on tape are now loaded into

memory group 3. This is indicated by FOUND and LOADING lighting up when the data has been found on the

tape. 1..8 will then light up as usual while loading.

Example 2:

To save all 128 programs on tape.

(1)Switch the machine to tape enable mode.

(2)Start the tape recorder in record mode.

(3)Press TO TAPE. 1..8 will now light sequentially four times in a r ow to show that the data is being sent to the tape

recorder.

(4)Stop the tape recorder.

Just as before it is advisable to verify that the data has been recorded correctly using the VERIFY function as

usual.

It is also possible to dump program s via MIDI to a MIDI sequencer or MIDI data filer. In order to do this press

MANUAL instead of TO TAPE to start the dump.

In order to load back program data via MIDI it is only required to transmit the data via MIDI to the Polysix M.

Upon receiving the data it will be automatically stored in the internal memory.

Example:

To send memory group 2 to a computer via MIDI for further storage to disk for instance:

(1)Connect the Polysix M MIDI OUT connector to MIDI IN on the computer.

(2)Prepare the computer for data reception.

(3)Switch the Polysix M to tape enable mode.

(4)Press 2. Memory bank 2 is now selected, indicated by LED 2 lighting up.

(5)Press MANUAL. Data for the 32 program s in m emory group 2 are now sent to the com puter. MANUAL rem ains

lit for the duration of the dump.

If 2 were not pressed in stage 4, the whole memory of 128 programs would have been sent.

To store a program dump in the Polysix M simply send the data to the synthesizer. The dum p will be written to

memory automatically, provided that the write switch is in the WRITE ENABLE position.

See the Polysix M MIDI implementation for the data for mat. MIDI commands ar e also available to request the

synthesizer to dump its programs.

Page 9

9

9) MIDI OUT PARAMETERS

To set the MIDI OUT param eters press POLY in tape enable mode. PO LY will light up indicating that the MIDI

OUT parameter mode has been selected.

The following parameters are available:

A) MIDI FILTER

LEDs A..D indicate MIDI filters. MIDI filters inhibit certain MIDI data fr om being transm itted. The following filters

are available:

A - note data (note on/note off/all notes off)

B - wheel data (bend and mod wheels)

C - program change

D - pedal (sustain pedal and chord memory pedal)

When the res pective LED is illuminated the corresponding inform ation is transmitted, otherwise not. Press the

corresponding button to toggle the filter on/off.

B) MIDI OUT CHANNEL

The MIDI OUT channel is indicated on 1..8 . Channel numbers above 8 are indicated by the corresponding LED

flashing. To obtain the selected channel num ber in this cas e add 8 to the LED flashing. T o c hange channels s im ply

press the corresponding button. For channel numbers above 8 press the same button twice.

Example:

Channel 9 is selected. This is indicated by LED 1 flashing (1 + 8 = 9). In order to change to channel 13:

(1)Press 5 (13 - 8 = 5). 5 lights up indicating channel 5.

(2)Press 5 again. 5 starts flashing indicating channel 13.

10) MIDI IN PARAMETERS

To set the MIDI IN parameters press UNISON in tape enable mode. UNISON will light up indicating that the MIDI

IN parameter mode has been selected.

The following parameters are available:

A) MIDI FILTERS

These work as the corres ponding MIDI OUT parameters but of cours e select what should be received by the

machine.

Example:

To turn off reception of program change messages:

(1)Switch to tape enable mode and press UNISON. UNISON lights up indicating MIDI IN parameter mode.

(2)The program change r eception filter s tatus is shown on LED C. If this LED is not lit, program change mess ages

are not received.

(3)Otherwise press C to turn the LED off.

B) LOCAL

Local mode is indicated on MANUAL. If the MANUAL LED is on, the synthesizer operates "as usual", i.e. the

keyboard, wheels, and pedal control the machine. By turning local mode off (by pressing MANUAL in MIDI IN

parameter mode, turning off the LED), all key depressions, bend and mod wheel changes, and pedals will only be

sent via MIDI (the corresponding MIDI OUT filters permitting) and not to the sound generating circuits in the

synthesizer. This can be useful in sequencing and master keyboard applications.

Note: The synthesizer will always respond to incoming MIDI data no matter whether LOCAL is on or off.

Page 10

10

C) OMNI

The W RITE LED indicates om ni mode. When the W RIT E LED is on om ni m ode is s elected (’omni on’) and the

synthesizer disregards the channel number of incom ing MIDI data resulting in data being received from all MIDI

channels. When omni mode is off (WRITE LED is off) MIDI data is only received on the channel indicated by 1..8.

Note that local and omni modes c an be controlled via MIDI using the LOCAL and OMNI MIDI com mands (see the

Polysix M MIDI implementation).

D) MIDI IN CHANNEL

The MIDI IN channel is indicated and selected in the same manner as the MIDI OUT channel.

11) ARPEGGIATOR PARAMETERS

To set the arpeggiator parameters pres s the CHORD MEMO RY button in tape enable m ode. CHORD MEMO RY

lights up to indicate that arpeggiator parameter mode has been selected.

The following parameters are available:

A) NORMAL/MIDI CLOCK

This is indicated on the MANUAL LED. W hen MANUAL is lit, this m eans that the ar peggiator is controlled using

the ARPEGGIATOR SPEED knob on the f ront panel (or the ARPEGGIO TRIG IN connector on the rear panel if

something is connected to this c onnector). If MANUAL is not lit, clock pulses are der ived from the inc oming MIDI

clock.

Note that when the machine is in MIDI clock mode (MANUAL not lit) and the arpeggiator is on, it will not start

until a START (250) or CONTINUE (251) MIDI m essage has been received. In the same way the arpeggiator will

stop when a STOP (252) message is received. Sequencers and drum machines usually send these messages

when they are started and stopped.

B) STEP SPEED

LEDs 1..8 indicate how fast the arpeggiator runs when synched to MIDI:

LED one step is equivalent to

1 32nd note triplet

2 32nd note (demisemiquaver)

3 16th note triplet

4 16th note (semiquaver)

5 8th note triplet

6 8th note (quaver)

7 quarter note triplet

8 quarter note (crotchet)

The step speed is selected by pressing the corresponding button.

C) HOLDOFF TIME

A..D indicate the holdoff time. T his is, to put it precisely, the time after the ar peggiator has been retriggered by

pressing a new key (after all keys have been released) that it will not respond to an external clock pulse.

Simple, isn’t it! For those interest ed in arpeggiator details there is a furt her explanation below; otherwise simply

disregard this parameter!

The full story is as follows: Normally when all keys have been released and a new key (or several keys) is

pressed the new note to be arpeggiated should be triggered immediately without waiting for a clock pulse.

Otherwise there would be the risk of missing the first arpeggiated note if the key was pressed the millisecond after a

clock pulse was received. The arpeggiator would seem to m iss a step. On the other hand, another poss ibility is that

a key is depressed a few millisec onds before a clock pulse is r ec eived. In this cas e a double tr ig would be the resu lt

- one trigger caused by the key pressed and another by the clock pulse. The result of the double trig would be that

the arpeggiator would advance an extra step for no apparent reason. (This problem does not arise when the

arpeggiator is clocked internally as the internal clock generator is r eset every time a new key is depressed - try for

yourself by setting a slow arpeggio rate and retriggering the arpeggiator clock generator by pressing a k ey on the

keyboard!) In order to avoid double triggering when keys are pressed just bef ore a c loc k is r ec eived a holdof f per iod

has been implemented which disables clock pulse reception for a cert ain length of time after the arpeggiator has

been triggered by a key depression. The holdoff time can be s et using A..D, from about 10ms at setting A up to

about 35ms at setting D. The power-on default is D.

In practice the holdoff value should m ak e little dif ferenc e but if you experience s trange triggering when using the

arpeggiator with MIDI sync, experiment with other holdoff settings.

Page 11

11

12) PROGRAMMABLE NOISE GENERATOR

A WHITE NO ISE noise generator is built on the MIDI pcb. Contr ol is f ully mem orized with patches. It is switched

on when waveform sawtooth or pulse is selec ted and PW M SPEED is greater than "1". PWM SPEED acts also as

NOISE VOLUME control. The noise signal is AC coupled and fed to the VCO saw/pulse/sub osc. summ ing node of

each voice on KLM-366 via a 33k resistor. The noise is generated digitally by means of a looped shift register.

13) PROGRAMMABLE BEND WHEEL (optional, see modifications section)

When doing this modif ication, the BEND wheel can be switched to either bend the VCO (as with the original

Polysix) or to bend the VCF. This setting is stored along with each patch. T he BEND INTENSITY pot is only active

in VCO mode. VCF bending mode is always full range.

14) PROGRAMMABLE MOD WHEEL

The MOD W heel (and als o MIDI Modulation IN) will follow the program m ed LFO MODE switch. This m eans you

can select LFO MODE ’VCA’ and MG LEVEL ’0’. You then may add tremolo manually with the MOD wheel.

15) MODULATION PEDAL IN

You may modify the VCF fcM IN for an input for a modulation pedal (10k log):

• tip is -5V (via 1k safety resistor)

• ring is CV input

• sleeve is GND

Note: - The modulation pedal follows - like the modulation wheel - the programmed LFO MODE.

- The effect achieved by the mod pedal is available only locally; there is no control change command sent via

MIDI.

16) TEST MODE

(ONLY FOR SERVICE TECHNICIANS OR THE TECHNICALLY INTERESTED)

In the original Polysix there are two different test modes.

One is started by setting the switch on the KLM-367 circuit board in the TEST position and s witching the front

panel TAPE ENABLE switch to the ENABLE position and then back to the DISABLE pos ition. This is used to adjust

the programmer DAC.

The other test mode is started by jumpering pins DB7 and P17 using a diode (cathode towards DB7) on the

8049 processor on the KLM-366 circuit board (this can be done on the keyboard connector CN04). In this mode the

CV DAC is set to generate 0V, 2.5V, or 5V depending on the position of the OCTAVE switch (16’ results in 0V, etc.).

This mode is used to check the CV DAC and is not described in the service manual.

In the Polysix M both these modes have been merged into one which perf orms both tasks. The test m ode is

started in the following manner:

(1)Enter tape mode by switching the TAPE switch to the ENABLE position.

(2)Press 5, 6, 7, and 8 at the same time.

(3)Hold these four buttons and exit tape mode (TAPE DISABLE).

(4)The machine is now in the test mode and cannot be operated in the normal manner.

To adjust the programmer DAC it is still necessary to switch the KLM-367 switch to the TEST position.

To exit the test mode press A (or cycle power).

Page 12

12

17) Individual Parameter Update

Newly recognized MIDI commands allow for individual parameter update in realtime:

MIDI Controller CC06 (DATA entry)

MIDI Controller CC96 (DATA increment)

MIDI Controller CC97 (DATA decrement)

MIDI Controller CC98 (Non Registered Parameter Number, fine)

MIDI Controller CC99 (Non Registered Parameter Number, coarse)

A) Use of NRPN

Paramter selecting is done by MIDI controller CC98/99 (NPRN) . There is a c onversion table used f or param eter

seletcion:

62h (CC98) 63h (CC99) PolySix parameter name

0 0..5 OCTAVE

1 6..11 WAVEFORM

2 12..17 PW/PWM

3 18..23 PWM SPEED

4 24..29 SUB OSC

5 30..35 FILTER CUTOFF

6 36..41 FILTER RESONANCE

7 42..47 EG INTENSITY

8 48..53 KBD TRACKING

9 54..59 VCA EG MODE

10 60..65 ATTENUATOR

11 66..71 BEND MODE

12 72..77 MG SPEED

13 78..83 MG DELAY

14 84..89 MG LEVEL

15 90..95 MG MODE

16 96..101 ATTACK

17 102..107 DECAY

18 108..113 SUSTAIN

19 114..119 RELEASE

20 120..125 EFFECT MODE

21..127 126..127 EFFECT SPEED

B) Editing a parameter

(1)Send NRPN (CC98, CC99) message to select corresponding parameter.

(2)Send either Data Entry (CC06) message with new value of param eter. The received Data Entry value (range

0..127) is multiplied by two to achieve the whole byte range (0..254) .

OR (alternatively or additionally) send Data In/Decrement message to do UP/DOWN editing.

Note: - Only the highest bits of a Data Entry message will be significant for a switch parameter.

- No fiddling with bits or similar is necessary.

Page 13

13

PolySixM PC based editor

There is also an editor for PolySixM. It runs on any PC under DOS. For MIDI connection to PolySixM you need a

MPU-401 (UART mode) compatible card. To invoke the editor simply type:

P6 [o] ... with no option the editor defaults to MPU-401 card

with option ’o’ the editor works in offline mode (no PolySixM connected)

1) Tasks:

In conjunction with the editor PolySix performes the following tasks:

- Downloading edit buffer (currently produced sound)

- Downloading complete patch set

- Uploading edit buffer

- Uploading complete patch set

- Edited-to-original-sound compare function

- Naming a patch (on disk)

- Saving and loading complete patch set to/from disk

- Playing a note from within the editor

- Working offline with the editor (rearranging patches etc.)

2) How to edit:

Patch editing with the PolySix editor is done the following way:

(1)Select the desired parameter with cursor keys.

(2)Up/down editing is done via PGUP/PGDN keys.

(3)You may also enter a value directly (analog parameters only):

press SPACE and enter the desired value followed by ENTER.

(4)Some functions are executed via a command line which appears in the upper left of the screen. ESC leaves the

command line without any action. Backspace is supported, cursor keys are not.

3) Supported Functions:

Following functions are available within P6.EXE:

<F1> .. displays short online help.

<F2> .. selects new patch on PolySixM and downloads edit buffer from PolySixM.

<F3> .. Edits patch name. Each patc h can be given a name. This name is s aved to disk; it has no effec t on

PolySixM itself.

<F4> .. Compare. If this function is selected during sound editing, the original sound will be uploaded to

PolySixM temporarily. Further editing is not possible while in com pare mode. A message "CO MPARE

- press F4" is displayed in the command line area. Press <F4> to switch back to edit mode.

If ESC is depressed compare mode is cancelled. The edited sound is discarded and the original

sound is kept.

<F5> .. Current edited sound is saved (under same patch number).

<F6> .. Current edited sound is saved under different patch number.You will be prompted for new patch number.

<F7> .. The whole patch memory of PolySixM (128 patches) will be downloaded from PolySixM.

<F8> .. Plays the selected MIDI note for 500msec.

<F9> .. Switches the selected MIDI note on.

<F10> .. Switches the selected MIDI note off.

<sF1> .. Redraw the screen.

<sF2> .. Edits the patch number displayed in the upper right of the screen. This does NOT send a PGM

CHANGE message to PolySixM.

By this function it is possible to change patches within the memory of the PC e.g. when working in

offline mode (rearranging patch numbers etc.).

<sF3> .. Displays all patch names of currently loaded patch set.

<sF4> .. Recalls the backup edit buffer to the current patch which contains the last edited sound.

<sF5> .. Downloads the edit buffer (= currently produced sound) from PolySixM.

<sF6> .. Changes the MIDI channel for communication with PolySixM.

When P6.EXE is started CH #1 is automatically selected.

<sF7> .. Uploads the current COMPLET E patch set to PolySixM. Be careful as all 128 patches in PolySixM will

be overwritten (if Write Enable is ON).

<sF8> .. Changes the MIDI note number for playing sounds on PolySixM.

When P6.EXE is started note number #60 (C5) is automatically selected. You may enter the note

number as a (decimal) number or as a key (e.g. G#7).

<sF9> .. This loads a previously stored PolySixM sysex file to memory.

<sF10> .. This stores the current patch set to disk.

Page 14

14

4) FileFormats:

The PolySix editor program supports several different file formats:

- raw sysex dump file format (includes sysex header; *.SYX)

- extended PolySix editor file format (incl. patch names; *.P6)

- PolySix Patch Chart file format (ASCII text; *.TXT)

- Patch Names File (ASCII test; *.NAM)

For a detailed description of these formats see below. When exec uting <sF9> or <sF10> you get a menu from

where you can choose different options. When pressing <x> or <ENTER> you leave the menu and nothing

happens. When entering a string of more than one character this is interpreted as file name for Load/Save

operation. Note that the file name extension (.SYX, .P6, .TXT, .NAM) is added automatically when the entered string

contains no dot (’.’). The default file format af ter s tarting PolySixM editor is raw SysEx dump. It is further possible to

select a specific group of patches (group 1..4), 32 patches eac h (A1..D8) to load/save from/to disk . This mak es it

possible to combine legacy (32 patch) tape dumps to full 128 patch sets. There are also functions provided for

viewing directory contents or even a complete temporary DOS session.

A) Raw SysEx file format (default extension .SYX):

- sysex header:

F0 Start of Exclusive

42 Manufacturer ID Korg

0n n .. MIDI channel number

0g g .. patch group: (0 .. all groups)

- patch data:

16 bytes patch data * 32 (one group only); each byte saved as two bytes with high nibble 0

or:

16 bytes patch data * 128 (no group selected); each byte saved as two bytes with high nibble 0

- checksum:

cc checksum byte (0 .. 7F)

- sysex trailer:

F7 End of Exclusive

The resulting file size is:

4 + 16 * 32 * 2 + 1 + 1 = 1030 bytes (single patch group)

4 + 16 * 128 * 2 + 1 + 1 = 4102 bytes (all groups)

B) Extended PolySix Editor file format (default extension .P6):

16 bytes patch name

16 bytes patch data (as described above)

This is repeated 32 times for 32 patches (one group) or 128 times (all groups). The resulting file size is

32 * 32 bytes = 1024 bytes (one group)

128 * 32 bytes = 4096 bytes (all groups)

C) PolySix Patch Chart file format (default extension .TXT):

This is a plain text file which repr oduces the setting charts in ASCII text. The form at is the sam e as displayed

within the editor. Example:

Patch name: Brass Patch #: A1

+----+----+----+----+----+----+----+----+----+----+----+----+

| | 16’ SAW 10 0 OFF| 4 2 +1.2 7 | GAT 0 |

| | OCT WAVE PW/M SPD SUB| CUT RES INT KBD|MODE ATT|

|TUNE| V C O | V C F | V C A |

+----+----+----+----+----+----+----+----+----+----+----+----+

| VCO| o 6 2 2 VCO| 4 5 7 10 | OFF 0 |

| | FREQ DEL LVL MODE| ATT DEC SUS REL|MODE SPD|

|BEND| M G | E G | E F F |

+----+----+----+----+----+----+----+----+----+----+----+----+

When you print this file you get pages with 4 patch charts each.

D) Patch names file format (default extension .NAM):

This is a plain text file, too. You find there the names of your PolySix patches.

Page 15

15

5) Edit buffer:

The edit buffer consists of 16 bytes with the following layout:

Fourteen bytes analog parameters:

offset Parameter

00 Effects Speed/Intensity

01 VCF Cutpff Frequency

02 VCF Envelope Intensity

03 VCF Resonance

04 EG Attack

05 EG Decay

06 EG Sustain

07 EG Release

08 VCF Keyboard Tracking

09 Pulsse Width / PWM Depth

10 PWM Speed

11 MG Frequency

12 MG Delay

13 MG Level

Two bytes of switch parameters:

offset b7 b6 b5 b4 b3 b2 b1 b0

14 MG Mode Sub Oscillator Waveform Octave

15 Programmable Attenuator

B.Mode

Effects Mode

VCA Md

Page 16

16

6) Switch parameter values:

As the values of the switch parameters are not always what you would expect the values are given here for

reference:

Parameter b7 b6 b5 b4 b3 b2 b1 b0 Value

VCO Octave 0 0 16’

01 8’

10 4’

11 2’ *

VCO Waveform 0 0 PW

0 1 SAW+PW **

1 0 PWM

11

SAW+PW+PWM *

Sub Oscillator 0 0 OFF

0 1 1 Oct dn

1 0 2 Oct dn

1 1 2Oct dn *

MG Mode 0 0 VCA

0 1 VCF

1 0 VCO

1 1 VCO+VCF *

VCA Mode 0 GATE

1EG

Effects Mode 0 0 OFF

0 1 Chorus

1 0 Phaser

1 1 Ensemble

Bend Mode 0 VCO Bend

1 VCF Bend

Attenuator 0 0 0 0 -10 dB

0 0 0 1 -8 dB

0 0 1 0 -6 dB

0 0 1 1 -4 dB

0 1 0 0 -2 dB

0101 0 dB

0 1 1 0 +2 dB

0 1 1 1 +4 dB

1 0 0 0 +6 dB

1 0 0 1 +8 dB

1 0 1 0 +10 dB

1 0 1 1 +12 dB ***

1 1 0 0 +14 dB ***

1 1 0 1 +16 dB ***

1 1 1 0 +18 dB ***

1 1 1 1 +20 dB ***

Notes: * These settings are not used.

** If D1 on KLM-366 is removed. You can shut off the pulse wave by setting the PW control to '10'.

*** These settings are not used during program ming. W hen sending a MIDI Volume com mand (CC07)

all 16 values are taken advantage of (4bit resolution).

Page 17

17

Modifications

1) GENERAL

In order to make the MIDI retr ofit work some m odifications have to be done to several modules of the Polysix.

There are additional modifications which ar e not related to MIDI. Some of them are mandatory, some of them are

optional. So please read this whole section carefully and decide then what you want to implement.

There are some things to do on the c ontrol panel pcbs. Although it seems to be a lot of work I recom mend to

unmount all modules f rom the contr ol panel lid. This is m uc h saf er when drilling the holes f or the MIDI j ack s. At this

occasion you can thoroughly clean the lid, knobs, and buttons.

There are basic solder skills necessary to do the following.

Additionally you need appropriate tools:

• small solder iron (max. 25Watts)

• solder

• desolder vacuum pump or solder wick

• pair of pliers

• pair of pincers

• pair of tweezers

• knife (cutter)

• various screwdrivers

• multimeter is helpful

For mounting the MIDI jacks you will need:

• hammer

• hard pointed tool

• drilling machine with 3.5mm, 6.5mm, and 14mm drills

• round file

• black permanent marker

All parts, wires, etc. are included in the kit. Check the contents of the kit against the packing list.

You will have to cut pcb traces. Be sure that they are really interrupted and there is no chance of coming

together again. A good way of doing this is to cut twice, 1mm apart and remove the remaining pcb trace in between.

Connecting two points to each other means to solder a wire from here to there (use the thin green wire supplied).

Be careful not to make any shorts to neighboring pins, etc.

If you are not sure whether you will be able to carry out the necessary steps, find someone who is experienced in

this kind of stuff.

Before you start working save all your patches to tape. Otherwise they will get lost. It is also a good idea to

thoroughly check the whole instrument. Turn every knob, press every button, etc. and make a note of any

anomalies. When you finished installation and some functions seem not working you will be glad if you know

whether they worked before or not.

When I speak of "upper" or "lower" end of a component I mean when viewing the Polysix in normal playing

position facing the keyboard ("upper" is side towards back, "lower" is side towards keyboard).

OK, here we go:

Page 18

18

2) MANDATORY MODIFICATIONS

A) On KLM-366:

Enable voice gates in tape interface mode:

• Cut pcb trace IC4/pin1 to via (component side).

• Connect IC4/pin1 to IC4/pin16.

Separate UNISON LED from unison detune function:

• Remove R118 (10k).

• Connect IC5/pin13 to IC2/pin14.

• Connect IC2/pin15 to IC30/pin6.

Separate CHORD MEMORY pushbutton from footswitch input:

• Cut pcb trace to D3/anode (component side).

• Connect D3/anode to IC6/pin33.

B) On KLM-367:

Remove the backup battery. There is a lithium battery on the new MIDI pcb you received.

Disable mute circuit during tape interface mode:

• Cut pcb trace to IC5/pin3 directly at IC5/pin3 (solder side). Be sure not to damage the passing by pcb trace.

• Connect IC5/pin3 to IC5/pin7.

Connection cable to MIDI pcb:

• Solder the open ends of the supplied 10 way cable (drawing no. PS 6M 00 05 004) to the respective target

points on KLM-367 (refer to picture and drawing).

Page 19

19

C) On KLM-369:

Feed the control voltages from the wheels into the multiplexer for A/D converting:

• Remove R16 (430k) and J4 (0 Ohm).

• Cut pcb trace to IC2/pin2 directly at pin2 (solder side).

• Cut pcb trace to IC2/pin4 directly at pin4 (solder side).

• Connect CN09/pin5 to IC2/pin4.

• Connect CN09/pin6 to IC2/pin2.

Note: These two connections require rather long wires. Route them on the component side of the pcb where you

can fix them below other components (e.g. a potentiometer).

D) On wheel assembly:

• Swap brown and orange wires of BEND pot.

• Disconnect two yellow wires from MOD pot. Leave them together and insulate the mending point with

shrinking tube.

• Disconnect red wire from BEND pot and connect to r ed wire of cable to J7 of MIDI pcb. Insulate with a piece

of shrinking tube.

• Disconnect blue wire from MOD pot and connect to middle pin of BEND pot. This blue wire will be quite short;

lengthen it with supplied piece of blue wire (40mm) and insulate with shrinking tube.

• Connect "upper" end of BEND pot to "upper" end of MOD pot. Use orange wire (140mm).

• Connect "lower" end of BEND pot to "lower" end of MOD pot. Use brown wire (140mm).

Refer to drawing no. PS 6M 00 05 005.

E) Mounting MIDI jacks:

These three DIN jacks are what you have waited for. Now you got them. The only thing you have to do is to drill

some holes into the back of your Polysix ...

To make this tas k easier I created a template which is part of the kit. Once m ore I recommend to unm ount

everything from the top/back lid of the Polysix. Work is much safer then. Be sure that no filings are left in the

instrument!

(1)Unmount the control panel, knobs , rear jack as sembly, power switch assembly, power supply pcb, power cable

hooks and take off the lid. Make notes or a sketch about connections and locations of components.

(2)Take off the cable clip on the inside of the lid. It is right on the sam e position where the MIDI jacks are going to

be.

(3)Take the template and fold it along the line.

(4)Hold the template against the lid: folded side on top of lid, MIDI jacks drawings on back side.

• Align left edge of template with edge of lid.

• Fix template in this position with adhesive tape.

• Take hammer and pointed tool and mark center points of holes to be drilled.

(5)Take off the template and drill the holes (good luck!).

• The big holes probably need some finish with the round file. Check size and shape with DIN jack and MIDI

cable.

• When you are satisfied with the shape of the holes paint the edges with black permanent marker.

(6)Before assembling the c ontrol panel with all the knobs, etc. mak e all modifications to KLM-369, KLM-370, and

KLM-371.

(7)Reassemble control panel.

Page 20

20

3) OPTIONAL MODIFICATIONS

Besides MIDI there are following features on the MIDI pcb:

A) White Noise generator (programmable level):

• Solder the free ends of cable drawing no. PS 6M 00 05 003 to the "upper" end of R150 of each unit on KLM366 (refer to drawing). It is possible that noise is enabled in your patches. It is disabled when waveform PW M

is selected or when PWM SPEED setting at ’0’.

B) Waveforms Sawtooth and Pulse appearing simultaneously:

• Remove D1 from KLM-366.

Note: When Saw is selec ted the pulse wave is generated, too. To switch off the pulse wave turn the PW knob

fully clockwise (’10’). You have to check and reprogram your patches after this modification.

C) Programmable BEND wheel (selectable VCO or VCF bending).

On KLM-370 the EFFECTS MODE switch (OFF/CH/PH/EN) has to be coded onto two data bits:

• Remove D3.

• Mount two diodes (1N4148, supplied):

• D3A: anode to D1/anode; cathode to former D3/cathode

• D3B: anode to D2/anode; cathode to former D3/cathode

(cathode side is marked with a black ring).

Obtain signals from KLM-367 for decoding EFFECTS MODE:

• Desolder IC34 (4042) an replace with supplied DIL16 IC socket. Desoldering in best done by cutting each leg

of the IC and then removing each leg separately.

• On the wheel panel (e.g. above BEND Wheel) mount BEND Mode switch:

• Drill a hole (6.5mm / 1/2") and mount switch connected to cable PS 6M 00 05 005.

On the jack panel (at the rear):

• Disconnect orange wire from f cM In j ac k (you will loose this input in this case; it can be used for a modulation

pedal input, see below). Solder a single pin onto the end of this wire and put a piece of shr inking tube over it.

This single pin will be used to connect to the orange wire of c able PS 6M 00 05 005, which has a single

receptacle on its orange wire.

On KLM-366:

• Remove R50 (100k), R51 (150k), and C58 (0.01u).

• Cut pcb trace IC10/pin1 to (former) R50.

• Connect former R50/"upper" pin to former R51/"upper" pin.

Note: If you want to keep the fcM input, you have to connect the orange wire of cable PS 6M 00 05 005 via an

additional 33k resistor to KLM-366/IC13/pin2 instead (this is the sum ming node of the VCF cutof f frequency

control voltages). Additionally do not remove R50, R51, and C58 from KLM-366.

You will have to check and maybe reprogram the EFFECTS MODE setting of your patches.

If you do not want the BEND Wheel be programmable and leave the EFFECTS MODE as it is, do not

perform any of these modifications. Instead you have to remove the c onnec tion pins labeled J 6 f r om the MIDI

pcb (solder side).

D) Modulation Pedal In jack:

On jack panel assembly:

• Replace the fcM In jack ( see above) with supplied stereo j ack c onnected to cable PS 6M 00 05 006 ( you will

loose the fcM In function).

• Connect GND wire to neighboring jack (Arpeggio Trig In).

E) Make the BANK LEDs A-D equally bright when more than one LED is on:

On KLM-371:

• Remove R14 (470 Ohm), J12, J13, J16 (0 Ohm)

• Mount 0 Ohm or wire bridge into R14 location.

• Mount 470 Ohm into J12 location.

• Mount 470 Ohm into J13 location.

• Mount 470 Ohm into J16 location.

F) If you experienced the headphones being too loud you may replace KLM-368/R4 and R8 (1k) by 3k3.

Page 21

21

4) MOUNT THE PS6M MIDI PCB INTO THE POLYSIX

When you have finished all m odifications it is time to r eassem ble your Polysix and mount the heart of your MIDI

retrofit kit: the PS6M MIDI pcb.

(1)Reassemble the control panel ( jack panel assem bly, KLM-376, KLM-369, KLM-370, KLM-371, power cord), put

the lid in its place and connect all cables.

(2)Mount the wheel panel and connect to KLM-369/CN09.

(3)Mount KLM-366 board. Connect all cables with exception of CN05 (cable to KLM-367, green wires).

(4)Bring KLM-367 board in its position (do not screw it at this stage).

(5)Take the four 3x10mm standoffs and the insulation plate.

(6)Put the standoffs onto the 4 mounting holes of KLM-367.

(7) Lay the insulation plate onto the stand-off. This can be a bit tricky. You can make it easier if you glue the

standoffs to the insulation plate.

(8)Take the PS6M MIDI pcb and plug it onto KLM367/IC22 (Programm er CPU) s ocket and IC34 ( 4042) sock et. Be

sure to have all pins correctly aligned!

(9)Screw the PS6M MIDI pcb together with KLM-367 be means of supplied 3x35mm screws to the chassis.

(10) Make all connections to KLM-367 first (also the cable to KLM366/CN05), then to MIDI pcb (refer to picture):

• Cable from KLM-366/IC6 (Key Assignor CPU) socket has to be connected to J2. Be sure to fit all pins c orrectly

into KLM-366/IC6 socket.

• Cable from MIDI jacks has to be connected to J3.

• Cable from KLM-366/R150(unit 0-5) has to be connected to J4.

• Cable coming up from KLM-367 has to be connected to J5.

• Cable from wheel panel has to be connected to J7.

• Cable from Mod Pedal In jack has to be connected to J8.

(11) You may have noticed that there are two trimpots on the MIDI pcb. Normally you would not have to adjust them

as this is done at testing the board before shipping. For reference the functions are given here:

• P1 sets the modulation intensity applied by MOD wheel, MOD pedal, and MIDI modulation.

• P2 sets the white noise source to VCO balance.

Page 22

22

POLYSIX-M V2.1 MIDI IMPLEMENTATION (18.Mar.2000)

1) TRANSMITTED DATA

(A), (B), (C), or (D) means that the messages are only transmitted when the respective output filters are enabled:

(A) - note data

(B) - wheel data

(C) - program change

(D) - sustain pedal / chord memory pedal

nnnn is the midi output channel;

x is don’t care

A) Voice Messages:

1001 nnnn 0kkk kkkk 0vvv vvvv Note on/off (A) Note number (36..96) Velocity (64=on;0=off)

1100 nnnn 0ppp pppp Program change (C) Pgm. number

(0..127)

Note: The programs are arranged in the following order:

Pgm. chg. no 0 - 7: Group 1:Bank A:Programs 1..8

Pgm. chg. no 8 - 15: Group 1:Bank B:Programs 1..8

..

Pgm. chg. no 24 - 31: Group 1:Bank D:Programs 1..8

Pgm. chg. no 32 - 39: Group 2:Bank A:Programs 1..8

..

Pgm. chg. no112 - 127: Group 4:Bank D:Programs 1..8

1011 nnnn 0000 0001 0vvv vvvv Control change Mod wheel; no 1 (B) Value (0..127)

1011 nnnn 0100 0000 0vvv vvvv Control change Sustain pedl;no 64(D) Value (0=off; 127=on)

1011 nnnn 0100 0100 0vvv vvvv Control change ChMem pedl;no70(D) Value (0=off; 127=on)

Note: Only one of sustain pedal/ch mem pedal will be transmitted,

depending on the setting of the CH MEM Pedal parameter.

1011 nnnn 0111 1011 0000 0000 Control change All notes off (A)

Note: All notes off is transmitted:

A) When arpeggiator is stopped or started

B) When output channel is changed and (A) is enabled

C) When output filter (A) is turned off

1110 nnnn 0LLL LLLL 0hhh hhhh Pitch bend (B) LSB MSB

Note: LSB is 0 if MSB<65, LSB=2*(MSB-64) if MSB>64

Page 23

23

B) System Exclusive:

1111 0000 System Exclusive F0

0100 0010 Korg ID 42

0000 nnnn Device ID (MIDI channel) 0n

0ccc cccc Command Code (see below) cc

0ddd dddd <data> dd

.. ..

1111 0111 End of Exclusive F7

Note: The only system exclusive messages transmitted are program dumps. These may be initiated by:

A) Pressing MANUAL in TAPE MODE when neither POLY, UNISON, CH MEM is lit.

B) Upon reception of a valid dump request command (see received data).

The following command codes may be sent:

C=0 sending all 128 programs

C=1, 2, 3, 4 sending memory group 1, 2, 3, or 4 respectively

The data format is as follows:

Each program consists of 16 data bytes. However, since these are in the range 0..255, they cannot be

transmitted in this form via MIDI. Theref ore, each byte is broken down into two nibbles, and is sent low nibble first.

Each program therefore consists of 32 MIDI bytes in the range 0..15. The programs are sent in program number

order (see above: program changes). At the end of a dump a checksum is sent. This checksum is generated by

adding all the program data bytes (not MIDI bytes) in the dump and keeping only the 7 lowest bits. The check s um is

transmitted directly after the last program nibble. Thus all 128 programs constitute 128*16*2+1=4097 MIDI bytes

(the <data> segment above), whereas a single memory group (32 programs) is 32*16*2+1=1025 MIDI bytes

(including the checksum byte).

Example: 128 program dump:

1111 0000 Sysex

0100 0010 Korg ID

0000 nnnn MIDI ch

0000 0000 Command code 0; 128 programs

0000 LLLL Group 1, Bank A, Program 1, low nibble of 1. byte

0000 hhhh Group 1, Bank A, Program 1, high nibble of 1. byte

0000 LLLL Group 1, Bank A, Program 1, low nibble of 2. byte

0000 hhhh Group 1, Bank A, Program 1, high nibble of 2. byte

..

0000 hhhh Group 4, Bank D, Program 8, high nibble of 16. byte

0ccc cccc Checksum of the preceding 128*16=2048 program data bytes

1111 0111 EOX

C) System Realtime:

1111 1110 Active sensing

Note: Active sensing is transmitted every 150ms

except during MIDI dump and tape operations.

2) RECEIVED DATA

(A), (B), (C) or (D) means that the messages are only recognized hen the respective input filters are enabled:

(A) - note data

(B) - wheel data

(C) - program change

(D) - sustain pedal / chord memory pedal

The mode mes s ages ( Contr ol 122..127) will only be recognized on the set midi in c hannel, regar dles s of omni on or

off. This is noted in the tables below as (*).

nnnn is the midi input channel

x is don’t care

Page 24

24

A) Voice Messages:

1000 nnnn 0kkk kkkk 0xxx xxxx Note off (A) Note number Rel. velocity (ignored)

1001 nnnn 0kkk kkkk 0vvv vvvv Note on/off (A) Note number Vel.(0=off,all othr=on)

Note: The Polysix-M will respond to the entire MIDI key range 0..127;

however notes generating higher pitches than 4’ key number 96 will be

reduced by octaves until they are within playable range.

1100 nnnn 0ppp pppp Program change (C) Pgm. number (0..127)

Note: See ’Transmitted Data’ section for program order.

1011 nnnn 0000 0001 0vvv vvvv Control change Mod wheel; no 1 (B) Value (0..127)

1011 nnnn 0000 0110 0vvv vvvv Control change Data Entry; no 6 Value (0..127)

1011 nnnn 0000 0111 0vvv vxxx Control change Volume; no 7 Val.(0..127); 4bit reso

1011 nnnn 0100 0000 0vvv vvvv Control change Sustain pedl;no 64(D) Val (0=off,all othr=on)

1011 nnnn 0100 0100 0vvv vvvv Control change Ch mem pedl;no70(D) Val (0=off,all othr=on)

1011 nnnn 0100 0101 0vvv vvvv Control change Arpeggiator sw; no 71 Val (0=off,all othr=on)

Note: The arpeggiator switch command has the sam e function as the

front panel ARPEGGIATOR button. Do not confuse it with the MIDI

start/stop commands.

1011 nnnn 0110 0000 0xxx xxxx Control change Data Increment; no96 Value ignored

1011 nnnn 0110 0001 0xxx xxxx Control change Data Decrement;no97 Value ignored

1011 nnnn 0110 0010 0vvv vvvv Control change NRPN fine; no 98 Value (0..127)

Note: Parameters are mapped via table (see ‘Individual Parameter

Update’ above)

1011 nnnn 0110 0011 0vvv vvvv Control change NRPN coarse; no 99 Value (0..127)

Note: Parameters are mapped via table (see ‘Individual Parameter

Update’ above)

1011 nnnn 0111 1010 0vvv vvvv Control change LOCAL command (*) Val (0=off,all othr=on)

1011 nnnn 0111 1011 0xxx xxxx Control change All notes off (A) (*) don't care

1011 nnnn 0111 1100 0xxx xxxx Control change OMNI OFF cmd (*) don't care

Note: OMNI OFF also functions as all notes off.

1011 nnnn 0111 1101 0xxx xxxx Control change OMNI ON cmd (*) don't care

1011 nnnn 0111 1110 0000 0001 Control change MONO ON cmd (*) Only mono-1 recogniz

Note: MONO ON will set the Polysix-M in UNISON m ode and turn all

notes off.

1011 nnnn 0111 1111 0xxx xxxx Control change POLY ON cmd (*) don't care

Note: POLY ON will set the Polysix-M in POLY mode and turn all notes

off.

1110 nnnn 0Lxx xxxx 0hhh hhhh Pitch bend (B) LSB MSB

Note: Pitch Bend has 8 bit resolution

Page 25

25

B) System Exclusive:

1111 0000 System Exclusive F0

0100 0010 Korg ID 42

0000 nnnn Device ID (MIDI channel) 0n

0ccc cccc Command Code (see below) cc

0ddd dddd

<data> (commands 10h..14h have no data)

dd

.. ..

1111 0111 End of Exclusive F7

The following command codes are recognized:

Code Meaning Action

00h 128-program dump follows Loads data into memory if WRITE is enabled

01h Memory group 1 dump follows - " 02h Memory group 2 dump follows - " 03h Memory group 3 dump follows - " 04h Memory group 4 dump follows - " 10h Request 128 program dump Sends 128-program dump (see ’Transmitted Data’ section)

11h Request memory group 1 dump Sends 32 programs of memory group 1 ( - " - )

12h Request memory group 2 dump Sends 32 programs of memory group 2 ( - " - )

13h Request memory group 3 dump Sends 32 programs of memory group 3 ( - " - )

14h Request memory group 4 dump Sends 32 programs of memory group 4 ( - " - )

20h Request edit buffer dump Sends the currently produced sound (edit buffer)

21h Upload edit buffer Receives currently produced sound (edit buffer)

22h Write patch Writes currently produced sound to patch memory

See the ’Transmitted Data’ section for information on the dump formats.

Data format of edit buffer dump (both receive and transmit):

1111 0000 Sysex

0100 0010 Korg ID

0000 nnnn MIDI ch

0010 0000 Command code 20h; (dump edit buffer) or 21h (load edit buffer)

0000 LLLL low nibble of 1. byte of edit buffer

0000 hhhh high nibble of 1. byte

..

0000 LLLL low nibble of 16. byte

0000 hhhh high nibble of 16. byte

1111 0111 EOX

Details of Write Patch command (receive):

1111 0000 Sysex

0100 0010 Korg ID

0000 nnnn MIDI ch

0010 0010 Command code 22h; (write patch)

0ppp pppp Patch number where to write the currently produced sound

1111 0111 EOX

PolysixM answers with a single byte: 00h for OK

55h for write error (e.g. Write is Disabled)

Page 26

26

C) System Realtime

1111 1000 MIDI timing clock

Note: The timing clock is for the arpeggiator. The ar peggiator trigger is generated by dividing the

midi clock by the required clock division ratio. T he m idi cloc k divider oper ates even when m idi sync

is not enabled, allowing the arpeggiator to synchronize properly even if midi sync has not been

enabled since the reception of the last START comm and. The midi timing clock is recognized for

midi clock divider counting purposes only after a START or CONTINUE command. Midi clocks after

a STOP command will not be recognized.

The following clock division ratios are employed:

Ratio Arpeggiator step length Clock division parameter

2 32nd note triplet 1

3 32nd note 2

4 16th note triplet 3

6 16th note 4

8 8th note triplet 5

12 8th note 6

16 quarter note triplet 7

24 quarter note 8

1111 1010 START command

1111 1011 CONTINUE command

1111 1100 STOP command

Note: The operation of the START, CONTINUE, and STOP commands is as follows:

When a ST ART command is r ece ived the internal midi clock divider is r ese t and enabled. If midi sync is enabled

and the arpeggiator is on, the next midi clock will trigger the arpeggiator.

The CONTINUE command functions in the same way as the START command except that the midi clock divider

is not reset. Thus it enables the midi clock divider allowing the arpeggiator to operate if midi sync is enabled.

The STOP com mand halts the midi clock divider. Subsequent m idi clock bytes will neither be counted by the

midi clock divider nor trigger the arpeggiator until a START or CONTINUE command is received.

Note that the START, CONTINUE, and STOP commands do not actually turn the arpeggiator on or off!

1111 1110 Active sensing

Note: If active sensing is not repeated within

300ms of being received, the Polysix-M will turn all

notes off.

Page 27

27

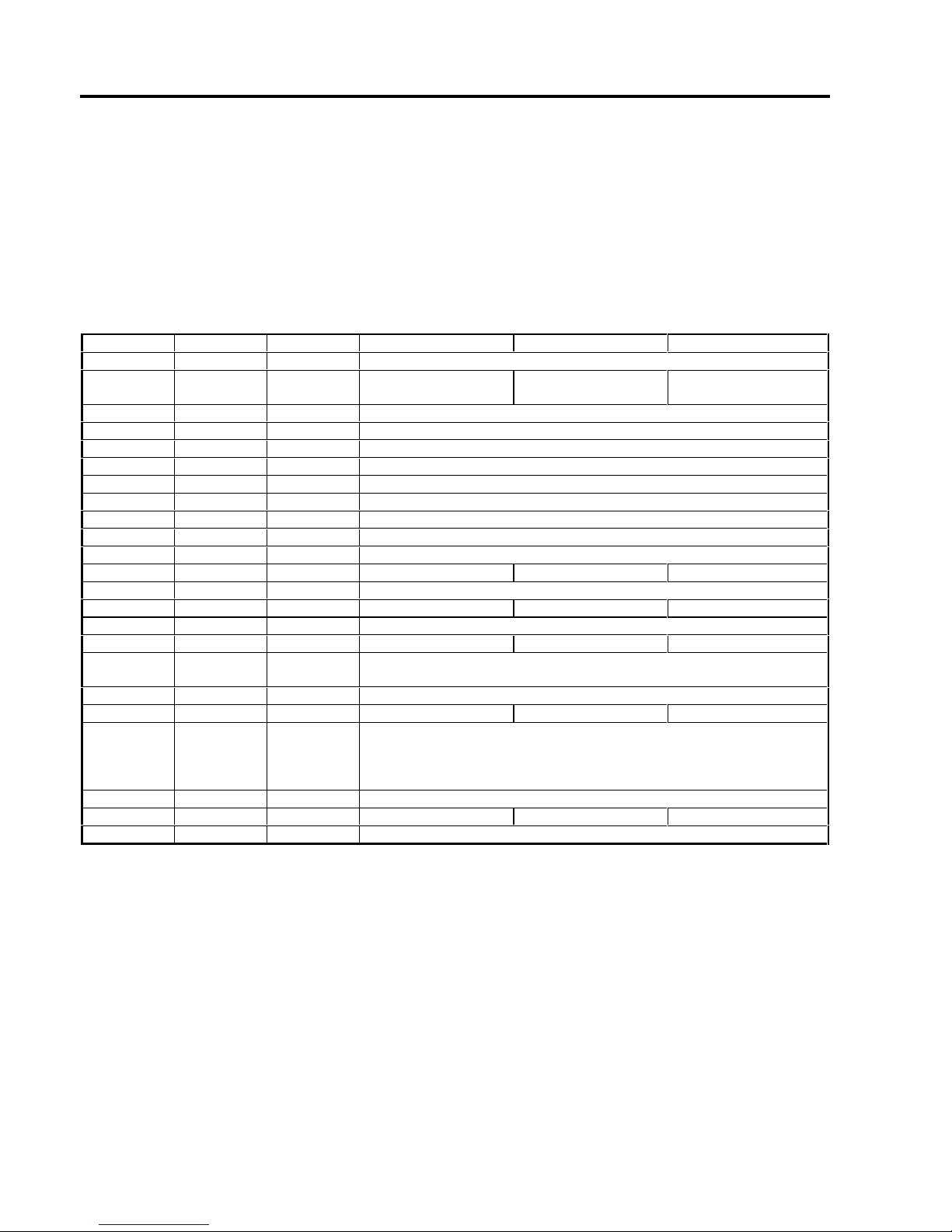

3) MIDI IMPLEMENTATION CHART

[ 6 voice polyphonic synthesizer ] Date : 18.Mar.2000

Model PS-6M MIDI Implementation Chart Version : RW/JH2.1

+----------------------------------------------------------------------+

| | Transmitted | Recognized | Remarks |

| Function ... | | | |

|-------------------+----------------+----------------+----------------|

|Basic Default | 1-16 | 1-16 | memorized |

|Channel Changed | 1-16 | 1-16, all ch | |

|-------------------+----------------+----------------+----------------|

| Default | x | 3 | |

|Mode Messages | x | OMNI ON/OFF, | |

| | | POLY, MONO | |

| Altered | ************** | x | MONO ignored |

|-------------------+----------------+----------------+----------------|

|Note | 36-96 | 0 - 127 | * |

|Number | True voice| ************** | 21 - 108 | |

|-------------------+----------------+----------------+----------------|

|Velocity Note ON | x v=64 | x | |

| Note OFF | x v=0 | x | |

|-------------------+----------------+----------------+----------------|

|After Key’s | x | x | |

|Touch Ch’s | x | x | |

|-------------------+----------------+----------------+----------------|

|Pitch Bender | o (B) | o (B) | 8 bit reso |

|-------------------+----------------+----------------+----------------|

| 1 | o (B) | o (B) | Modulation |

| 6 | x | o | Data Entry |

| 7 | x | o | Volume 4bit res|

| 64 | o (D) | o (D) | Hold |

|Control 70 | o (D) | o (D) | Chord Memory |

|Change 71 | x | o | Arpeggiator |

| 96 | x | o | Data Increment |

| 97 | x | o | Data Decrement |

| 98 | x | o | NRPN Fine |

| 99 | x | o | NRPN Coarse |

|-------------------+----------------+----------------+----------------|

|Prog | o (C) | o (C) 0 - 127 | |

|Change | True # | ************** | 0 - 127 | |

|-------------------+----------------+----------------+----------------|

|System Exclusive | o | o | Pgm/edit dump |

|-------------------+----------------+----------------+----------------|

|System | Song Pos | x | x | |

| | Song Sel | x | x | |

|Common | Tune | x | x | |

|-------------------+----------------+----------------+----------------|

|System |Clock | x | o | for arpeggiator|

|Real Time |Commands| x | o | |

|-------------------+----------------+----------------+----------------|

| |Local ON/OFF | x | o 122 | |

| |All Notes OFF| o (A) 123 | o (A) 123 | |

|Aux |OMNI OFF | x | o 124 | |

|Mes- |OMNI ON | x | o 125 | |

|sages|MONO | x | o 126 | only MONO-1 rec|

| |POLY | x | o 127 | |

| |Active Sense | o | o | |

| |Reset | x | x | |

|-------------------+----------------+----------------+----------------|

|Notes | (A),(B),(C),(D) refer to the input and output |

| | midi filters. |

| | |

+----------------------------------------------------------------------+

Mode 1 : OMNI ON, POLY Mode 2 : OMNI ON, MONO o : Yes

Mode 3 : OMNI OFF, POLY Mode 4 : OMNI OFF, MONO x : No

Page 28

28

Revision History

1) CREDITS

I want to thank Ricard W olf from Sweden f or doing excellent work in both hardware and software and m aking the

results available for others.

2) REVISIONS

30.Oct.1999 Firmware: RW1.1 10.Sep.1989

Hardware: PS6M.0A 17.Oct.1999.

25.May 2000 PolySixM ROM RW/JH V2.1: 18-Mar-2000

- MIDI control over single parameters

- Reception of MIDI controller #$07 (Volume)

#$06 (Data Entry)

#$60 (Data Increment)

#$61 (Data Decrement)

#$62 (NRPN Fine)

#$63 (NRPN Coarse)

- Works with PolySixM editor P6.EXE V1.1

PolySixM editor P6.EXE V1.1: 18-Mar-2000:

- First revision.

- Needs PolySixM ROM revision RW/JH V2.1

3) MISCELLANEOUS

There are future enhancements planned; such as: keyboard split, key window function, memorized key assign

mode.

If anything is unclear to you or you encounter any difficulties with modifications or have any questions or

suggestions, please let me know:

My email address is:

jo.synth

@crossnet.at

Loading...

Loading...