Page 1

Kontron CG1200 Carrier Grade Server

Document Revision 1.1

Page 2

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide i

» Table of Contents «

1

Introduction ...................................................................................... 1

1.1 About this Manual..................................................................................................................... 1

1.2 Manual Organization ................................................................................................................ 1

1.3 What Your Server Includes ....................................................................................................... 2

1.4 Product Accessories ................................................................................................................. 2

1.5 Additional Information and Software ......................................................................................... 3

2

Features .......................................................................................... 4

2.1 Server Components ................................................................................................................. 6

2.2 CG1200 Server Front Panel ..................................................................................................... 7

2.3 CG1200 Server Back Panel ...................................................................................................... 9

2.4 Front Panel Board .................................................................................................................. 10

2.5 LED/Switch Board .................................................................................................................. 10

2.6 Telco Alarm Module (TAM) Board ........................................................................................... 11

2.7 Hard Disk Drives .................................................................................................................... 11

2.8 Software and Hardware RAID ................................................................................................. 11

2.9 SD Flash Module .................................................................................................................... 11

2.10 Server Board (Baseboard) ...................................................................................................... 12

2.11 Riser Card Assembly .............................................................................................................. 13

2.12 Ethernet NIC Ports ................................................................................................................. 13

2.13 Remote Management Module 4 .............................................................................................. 13

2.14 I/O Module ............................................................................................................................. 14

2.15 Power Supply Subsystem ....................................................................................................... 14

2.16 System Cooling ...................................................................................................................... 14

2.17 Processors and Memory DIMMs ............................................................................................. 15

2.17.1 Processors ......................................................................................................... 15

2.17.2 Memory ............................................................................................................. 15

3

Standard Component Installations and Upgrades .......................... 16

3.1 Before You Begin ................................................................................................................... 16

3.1.1 Tools and Supplies Needed ..................................................................................... 16

3.1.2 System References ................................................................................................. 16

3.2 General Installation Procedures .............................................................................................. 16

3.2.1 Removing the Chassis Cover ................................................................................... 16

www.kontron.com

www.kontron.com

Page 3

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide ii

3.2.2 Re-installing the Chassis Cover ............................................................................... 17

3.2.3 Removing the Front Bezel ....................................................................................... 17

3.2.4 Re-Installing the Front Bezel .................................................................................... 18

3.2.5 Removing the Riser Card Assembly......................................................................... 18

3.2.6 Re-Installing the Riser Card Assembly ..................................................................... 19

3.3 Internal System Components Configuration and Installation Procedures ................................. 20

3.3.1 Configuring Memory DIMMs .................................................................................... 20

3.3.2 Supported Memory .................................................................................................. 20

3.3.3 Installing Memory DIMMs ........................................................................................ 21

3.3.4 Replacing or Removing Memory DIMMs .................................................................. 22

3.3.5 Adding or Replacing a Processor ............................................................................. 23

3.3.6 Installing the Heat Sink ............................................................................................ 30

3.3.7 Configuring Jumpers on the Server Board ............................................................... 31

4

Optional Component Installation Procedures ................................. 34

4.1 Before You Begin ................................................................................................................... 34

4.1.1 Tools and Supplies Needed ..................................................................................... 34

4.1.2 System References ................................................................................................. 34

4.1.3 Cable Routing Reference......................................................................................... 34

4.2 Installing or Replacing Hard Disk Drives ................................................................................. 37

4.2.1 Removing an HDD Carrier from the Chassis ............................................................ 37

4.2.2 Installing a Hard Drive in a Carrier ........................................................................... 38

4.3 Installing a Hardware RAID Controller .................................................................................... 40

4.3.1 Installing the ROC Module ....................................................................................... 40

4.3.2 Installing the SuperCap Module ............................................................................... 44

4.4 Adding or Replacing a Power Supply Module ......................................................................... 48

4.4.1 Adding a Second Power Supply Module .................................................................. 48

4.4.2 Replacing a Power Supply ....................................................................................... 49

4.5 Replacing a PCI Riser Card .................................................................................................... 49

4.5.1 Removing the Old Riser Card .................................................................................. 50

4.5.2 Installing a new Riser Card ...................................................................................... 50

4.6 Installing a PCI Add-in Card ................................................................................................... 50

4.7 Installing a Remote Management Module 4 ............................................................................ 52

4.8 Installing an I/O Module .......................................................................................................... 56

4.9 Installing an eUSB Flash Drive ............................................................................................... 58

4.10 Installing the Server into a Rack ............................................................................................. 59

4.10.1 Connecting the Power Cord ............................................................................... 59

www.kontron.com

www.kontron.com

Page 4

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide iii

4.10.2 Tools and Supplies Needed ............................................................................... 59

4.10.3 Equipment Rack Precautions ............................................................................. 60

5

Server Component Replacements ................................................. 61

5.1 Before You Begin ................................................................................................................... 61

5.1.1 System References ................................................................................................. 61

5.1.2 Cable Routing Reference......................................................................................... 61

5.2 Replacing Fans ...................................................................................................................... 61

5.3 Replacing the Front Panel Board ............................................................................................ 63

5.3.1 Removing the Old Front Panel Board ....................................................................... 65

5.3.2 Installing the New Front Panel Board ....................................................................... 66

5.4 Replacing the LED/Switch Board ............................................................................................ 67

5.4.1 Removing the Old LED/Switch Board ....................................................................... 67

5.4.2 Installing the New LED/Switch Board ....................................................................... 68

5.4.3 Replacing the LED/Switch Light Pipe Assembly ....................................................... 68

5.5 Replacing the Telco Alarms Module (TAM) ............................................................................. 68

5.5.1 Removing the Old Telco Alarms Module .................................................................. 69

5.5.2 Installing the New Telco Alarms Module................................................................... 70

5.6 Replacing the SAS Backplane Board ...................................................................................... 70

5.6.1 Removing the Old SAS Backplane Board ................................................................ 71

5.6.2 Installing the New SAS Backplane Board ................................................................. 73

5.7 Replacing the Power Distribution Board .................................................................................. 74

5.7.1 Removing the Old Power Distribution Board ............................................................ 74

5.7.2 Installing the New Power Distribution Board ............................................................. 77

5.8 Replacing the S2400EP4 Server Board .................................................................................. 79

5.8.1 Removing the Old Server Board from the Chassis ................................................... 79

5.8.2 Installing the New Server Board ............................................................................... 81

6

Server Utilities ............................................................................... 83

6.1 Using the BIOS Setup Utility ................................................................................................... 83

6.1.1 Using BIOS Setup ................................................................................................... 83

6.1.2 Starting Setup.......................................................................................................... 83

6.1.3 If You Cannot Access Setup .................................................................................... 83

6.1.4 Setup Menus ........................................................................................................... 83

6.2 Upgrading the BIOS ............................................................................................................... 85

6.2.1 Preparing for the Upgrade ....................................................................................... 85

6.2.2 Updating the System Firmware ................................................................................ 85

www.kontron.com

www.kontron.com

Page 5

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide iv

6.3 Restoring BIOS Default Settings ............................................................................................. 85

6.4 Clearing the Password ........................................................................................................... 86

6.5 BMC Force Update Procedure ................................................................................................ 86

6.6 ME Force Update Procedure .................................................................................................. 87

7

Troubleshooting ............................................................................. 88

7.1 Resetting the System ............................................................................................................. 88

7.2 Problems Following Initial System Installation ......................................................................... 88

7.2.1 First Steps Checklist ................................................................................................ 88

7.3 Hardware Diagnostic Testing .................................................................................................. 89

7.3.1 Verifying Proper Operation of Key System Lights ..................................................... 89

7.3.2 Confirming the Operating System Load ................................................................... 89

7.4 Specific Problems and Corrective Actions ............................................................................... 89

7.4.1 Power Light does not Light ...................................................................................... 89

7.4.2 No Characters Appear on Screen ............................................................................ 90

7.4.3 Characters are Distorted or Incorrect ....................................................................... 90

7.4.4 System Cooling Fans do not Rotate Properly ........................................................... 90

7.4.5 Cannot Connect to a Server .................................................................................... 91

7.4.6 Diagnostics Pass but the Connection Fails .............................................................. 91

7.4.7 The (NIC) Controller Stopped Working When an Add-in Adapter was Installed ......... 91

7.4.8 The Add-in Adapter Stopped Working without Apparent Cause ................................ 91

7.4.9 System Boots When Installing a PCI Card ............................................................... 92

7.4.10 Problems with Newly Installed Application Software ........................................... 92

7.4.11 Problems with Application Software that Ran Correctly Earlier ............................ 92

7.4.12 Devices are not Recognized under Device Manager (Windows*OS) ................... 92

7.4.13 Hard Drive(s) are not Recognized ...................................................................... 92

7.5 Light-Guided Diagnostics........................................................................................................ 93

7.5.1 5 Volt Stand-by LED ................................................................................................ 93

7.5.2 DIMM Fault LEDs .................................................................................................... 93

7.5.3 System ID LED, System Status LED, and POST Code Diagnostic LED ................... 93

7.5.4 POST Error Beep Codes ......................................................................................... 95

8

Warranty ........................................................................................ 97

9

Appendix A: Safety Information ..................................................... 98

9.1 Emissions Disclaimer ............................................................................................................. 98

9.2 Intended Uses ........................................................................................................................ 98

9.2.1 If AC power supplies are installed: ........................................................................... 98

www.kontron.com

www.kontron.com

Page 6

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide v

9.2.2 If DC power supplies are installed: ........................................................................... 99

9.2.3 DC Power Supply 48V Input Power Mating Connector ............................................. 99

9.2.4 DC Power Supply Earth Grounding Studs on Chassis ............................................ 100

9.2.5 Overcurrent protection ........................................................................................... 100

9.2.6 Temperature and Ventilation .................................................................................. 100

9.3 Safety Cautions .................................................................................................................... 100

9.3.1 Wichtige Sicherheitshinweise ................................................................................. 102

9.3.2 Consignes de sécurité ........................................................................................... 104

9.3.3 Instrucciones de seguridad importantes ................................................................. 105

10 Appendix B: Regulatory and Certification Information .................. 110

10.1 Product Regulatory Compliance ........................................................................................... 110

10.1.1 Product Safety Compliance .............................................................................. 110

10.1.2 Product EMC Compliance - Class A Compliance .............................................. 110

10.1.3 Certifications/Registrations/Declarations .......................................................... 110

10.2 Electromagnetic Compatibility Notices .................................................................................. 111

10.2.1 FCC (USA) ...................................................................................................... 111

10.2.2 Industry Canada (ICES-003) ............................................................................ 111

10.2.3 Europe (CE Declaration of Conformity)............................................................. 111

10.2.4 VCCI (Japan) ................................................................................................... 112

10.2.5 BSMI (Taiwan) ................................................................................................. 112

10.2.6 Regulated Specified Components .................................................................... 112

11 Appendix C: NEBS Considerations .............................................. 113

12 Appendix D: Getting Help ............................................................ 114

12.1 World Wide Web .................................................................................................................. 114

12.2 Telephone ............................................................................................................................ 114

12.3 Email .................................................................................................................................... 114

www.kontron.com

www.kontron.com

Page 7

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 1

1 Introduction

1.1 About this Manual

Thank you for purchasing and using the Kontron CG1200 Carrier Grade Server.

This manual is for trained system technicians who are responsible for troubleshooting, upgrading, and

maintaining this server. This document provides a brief overview of the features of the system followed by

a list of accessories or other components you may need or want to purchase, instructions for how to add

or replace components in the CG1200 server, and troubleshooting information.

NOTE: Always be sure to search for CG1200 on the Support website at http://us.kontron.com/support/for

the latest version of this manual with possible updates since this version was published.

1.2 Manual Organization

Chapter 2 Features

provides a brief overview of the CG1200 server. In this chapter, you will find a list of the server board

features, chassis features, illustrations of the product, and product diagrams to help you identify

components and their locations

Chapter 3 Standard Component Installations and Upgrades

provides instructions for adding and replacing standard components such as processors and memory

DIMMs. Use this chapter for step-by-step instructions and diagrams for installing or replacing

components.

Chapter 4 Optional Component Installation Procedures

provides instructions for adding optional components such as PCI add-in cards, hardware RAID5

components, and an SD flash module. Use this chapter for step-by-step instructions and diagrams for

installing components.

Chapter 5 Server Component Replacements

provides instructions for replacing components such as boards and fans. Use this chapter for step-bystep instructions and diagrams for replacing components.

Chapter 6 Server Utilities

provides instructions for using the utilities that are shipped with the board or that may be required to

update the system. This includes how to navigate through the BIOS (Basic Input/Output System) setup

screens, how to perform a BIOS update, and how to reset the password or CMOS (Complementary Metal

Oxide Semiconductor). Information about the specific BIOS settings and screens is available in the Intel®

Server Board S2400EP4 Family Technical Product Specification.

Chapter 7 Troubleshooting

provides troubleshooting information. In this chapter, you will find BIOS error messages and POST

(Power-on Self Test) code messages. You will also find suggestions for performing troubleshooting

activities to identify the source of a problem.

Chapter 8 Warranty

provides the warranty information

Appendix A: Safety Information

provides the emissions disclaimer, power supply information, temperature and ventilation guidelines, and

safety cautions in multiple languages.

Appendix B: Regulatory and Certification Information

presents the regulatory and safety compliances and electromagnetic compatibility notices

1

Page 8

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 2

Appendix D: Getting Help

1.3 What Your Server Includes

Your CG1200 server includes the following components:

• One 1U chassis

• One Intel® Server Board S2400EP4 with DDR3 memory slots (memory not included)

• Four removable hard drive carriers

• One DC or AC power subsystem: one hot-swappable power supply module and a power distribution

board. (The other power supply bay has a filler panel in it. For redundancy another separately

orderable power supply module must be added.)

• Five dual-rotor fan assemblies for cooling the processor(s), DIMM(s), PCI slot, and other internal

components in two cooling zones.

• A front panel board ,LED/switch board, telco alarms module (TAM) board, and PCIe riser assembly

(for one FH/FL card)

• Internal cables and connectors

See Chapter 3 for initial installation and configuration instructions.

1.4 Product Accessories

The following list shows the separately orderable components and optional accessories available for

inclusion in the initial order or to have as spares. Refer to the CG1200 Carrier Grade Server Configuration

Guide for a complete list of orderable spares and options. The Configuration Guide can be found on the

Kontron Support Website at http://us.kontron.com/support/ (search for CG1200, click on Product

Downloads, then Ordering Guide).

• LGA 2011 (socket R) support for Intel® Xeon® E5-2400 and E5-2400 v2 processors series

• Registered DDR3 Memory (RDIMM), LV-RDIMM, Unbuffered DDR3 Memory (UDIMM) with ECC and

Load Reduced DDR3 Memory (LR-DIMM)

• Up to four hot-swappable 2.5” SAS HDDs or SATA SSDs

• Hard disk drive carriers (four already shipped with the server)

• Optional Intel HW RAID on chip (ROC) or SW RAID IOC available.

• Optional I/O module

• Intel® Remote Management Module 4 (RMM4) or RMM4Lite options

• One front-access SD media flash module

• Internal flash storage supported (eUSB)

• Power cord

• AC or DC power supply module (650W) for redundancy

• Rack mount kits available for purchase directly from Kontron – see Configuration Guide

For information about the accessories, memory, processors, and ordering information, refer to the

CG1200 Carrier Grade Server Configuration Guide on http://us.kontron.com/support/(search for CG1200,

click on Product Downloads, then Ordering Guide).

For information about third-party hardware that has been tested and can be used with your system, refer

to the CG1200 Carrier Grade Server Tested Hardware and Operating System List (THOL) on

http://us.kontron.com/support/ (search for CG1200, click on Product Downloads, then Compatibility

Matrix).

2

Page 9

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 3

1.5 Additional Information and Software

If you need more technical information or information about the accessories that can be used with this

CG1200 server, refer to the Technical Product Specifications (TPS) for the system and the server board.

The TPS documents are located on the Kontron support website at http://us.kontron.com/support. The

system TPS provides in-depth technical information about the server. The server board TPS provides indepth technical information about the server board, including BIOS settings and chipset information.

3

Page 10

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 4

2 Features

This chapter briefly describes the main features of the Kontron CG1200 Carrier Grade Server. It provides

a diagram of the product, a list of the server features, and a diagram showing the location of important

components and connections on the server system.

Figure 1 shows the CG1200 server.

Figure 1: Kontron CG1200 Carrier Grade Server

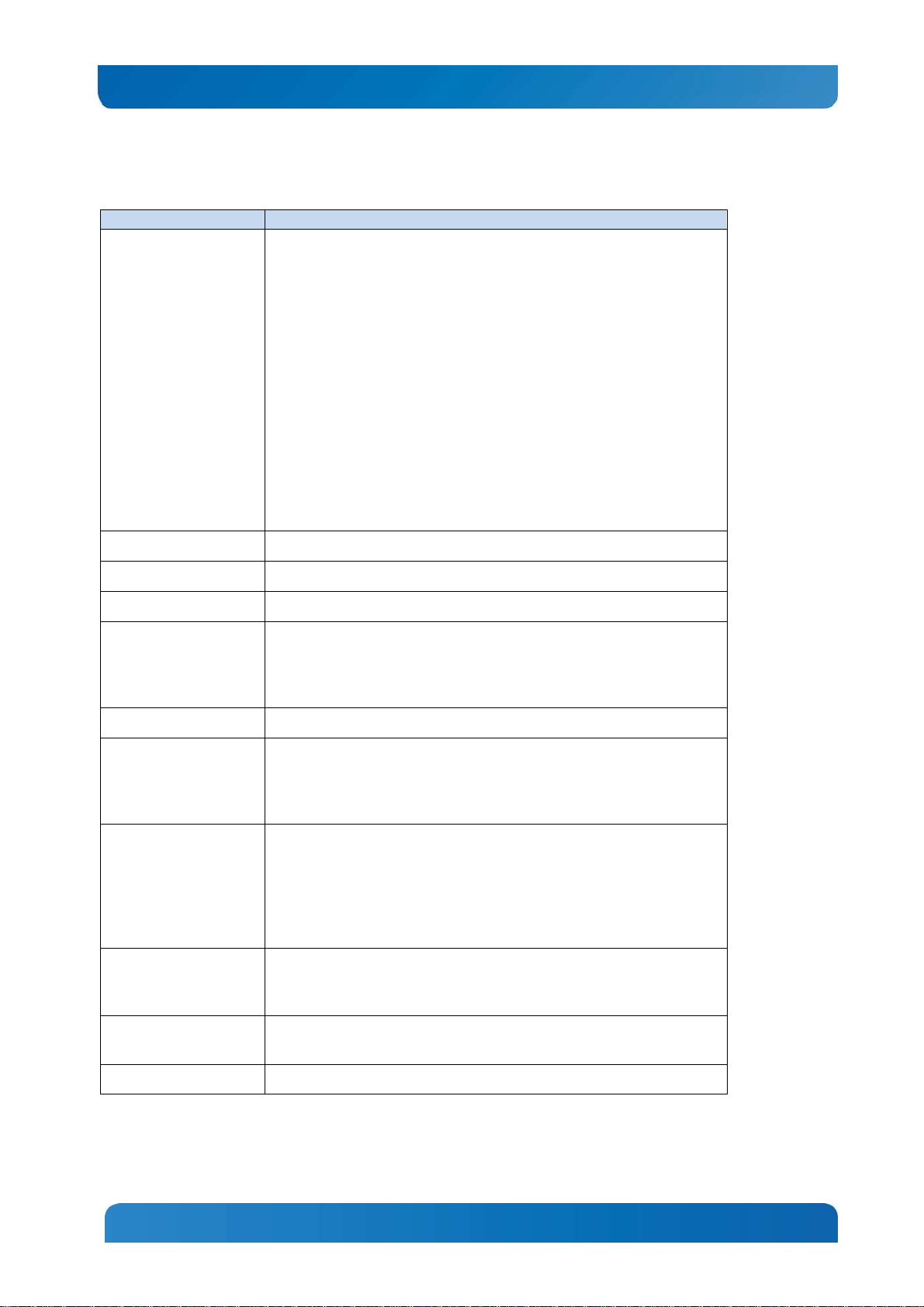

Table 1 summarizes the major features of the server system.

4

Page 11

Feature

Description

Peripheral Interfaces

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 5

Table 1: CG1200 Server Features

External connections:

One DE-15 video VGA connector (rear)

One DB-15 TAM dry relay connector (rear)

Four RJ45 10/100/1000 Mbps network connections (rear)

Two USB 2.0 connectors (rear)

Two USB 2.0 connectors (front)

One RJ-45 serial connector (rear)

One dedicated management NIC port, (optional Intel® RMM4) or

personality module connector

Internal connections:

One internal USB header for embedded flash drives

One Intel® RAID C600 upgrade key connector with RKSAS54 preinstalled

One RMM4 connector for an optional Intel® Remote Management Module

4 module

Video Integrated graphics core with 2D hardware accelerator

LAN Four RJ-45 10/100/1000 Mbps connectors

Expansion Capabilities One PCIe x16 Gen 3 riser slot

Up to four 2.5-inch SAS HDD or SATA SDD hard drives

Hard Drive Options

Peripherals One SD media flash module (front panel access)

Front Panel Buttons

Front Panel LEDs

Power Supply

Onboard SAS SW RAID with Intel® ESRT2 RAID 0/1/10 or RSTe RAID

0/1/10

Intel® RAID on Chip (ROC) and I/O controller (IOC) support optional

Power on/off

System reset

Chassis ID

NMI

Power status

Chassis identification

System status

HDD activity/fault

NIC activity

Alarms (critical, major, minor, power)

Up to two 650W power supply modules (AC or DC)

PMBus 1.2 specification support

Auxiliary I/O power dongle

Fans

System Management Integrated BMC (iBMC) with advanced options

Five 40x56mm dual rotor fans

Redundant cooling

5

Page 12

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 6

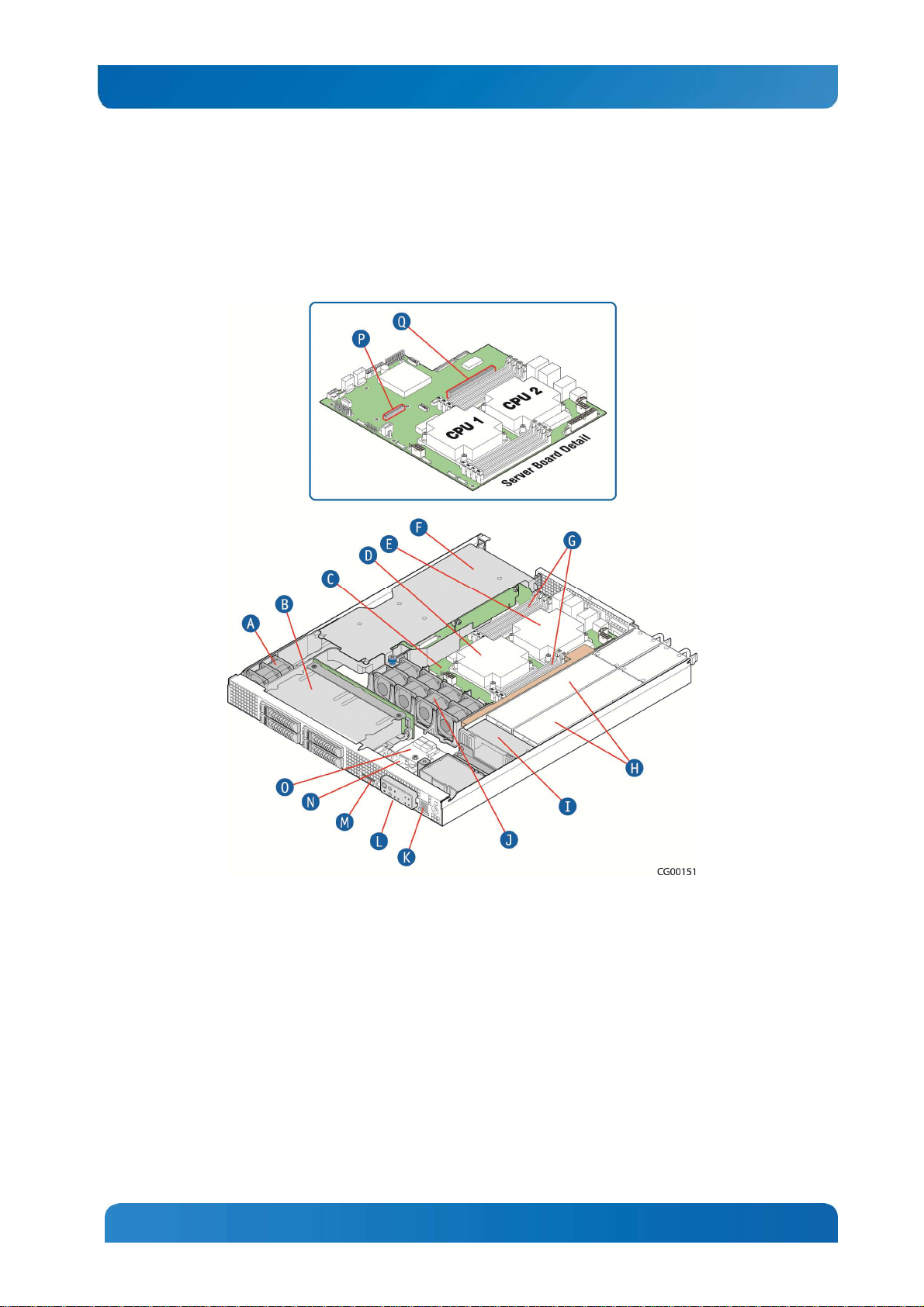

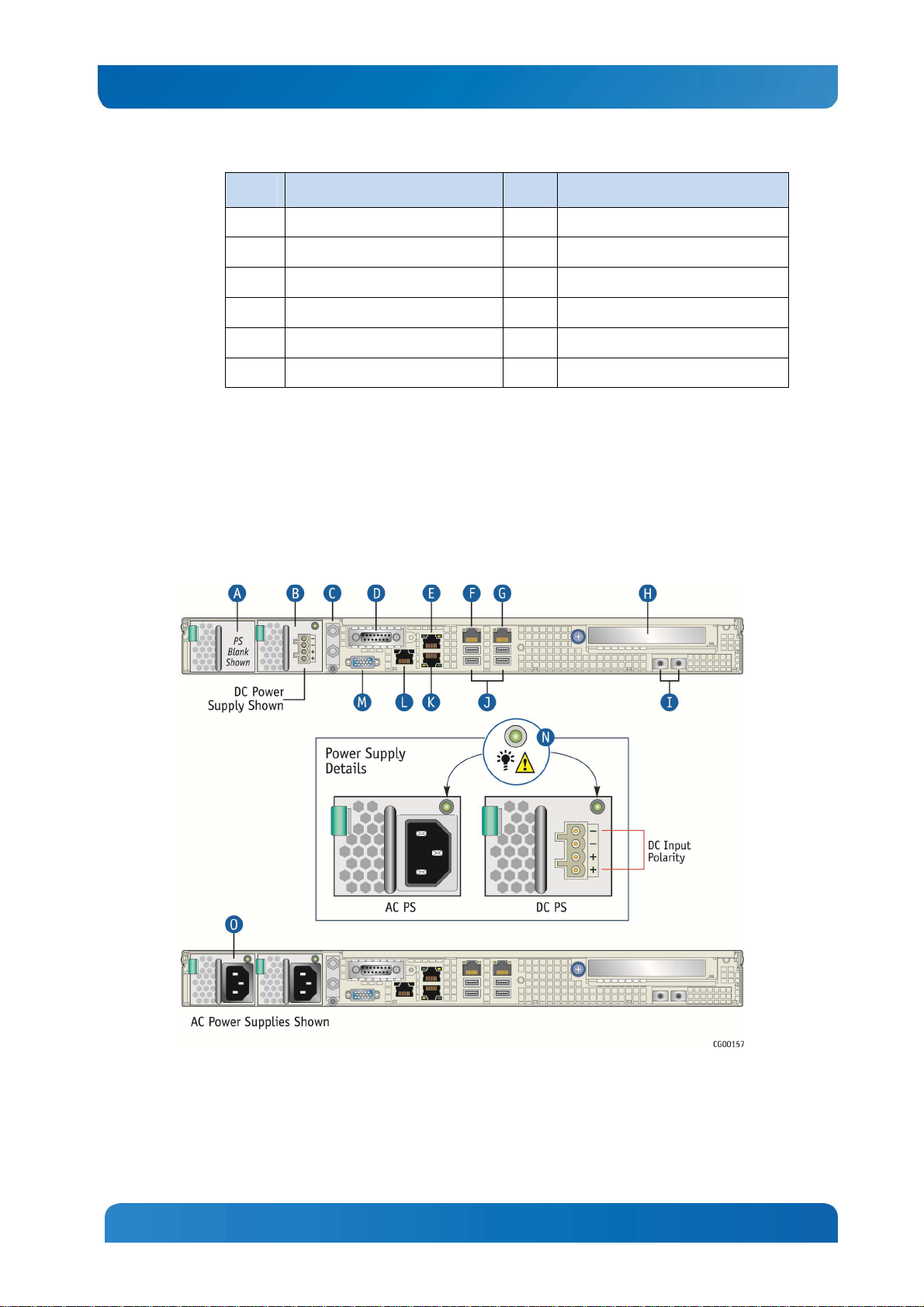

2.1 Server Components

Figure 2 shows the CG1200 server with the top cover removed to show the internal components.

Figure 2: CG1200 Server Components

6

Page 13

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 7

Table 2: CG1200 Server Components

Item Description Item Description

A

B

C

D

E

F

G

H

I

PCI fan (one pair)

SAS hard drive bay

Intel® S2400EP4 Server Board

CPU 1

CPU 2

PCIe FH/FL riser card assembly

Eight DDR3 memory DIMM slots, two banks of

four DIMMs for each processor

Redundant, hot-swappable AC or DC power

supply modules

Power distribution board (PDB)

J

K

L

M

N

O

P

Q

CPU/memory fans (four pairs)

USB ports (two)

Front panel switches and indicators

SD media slot

Front panel board

Telco alarm module (TAM) board

RAID module connector

PCIe slot

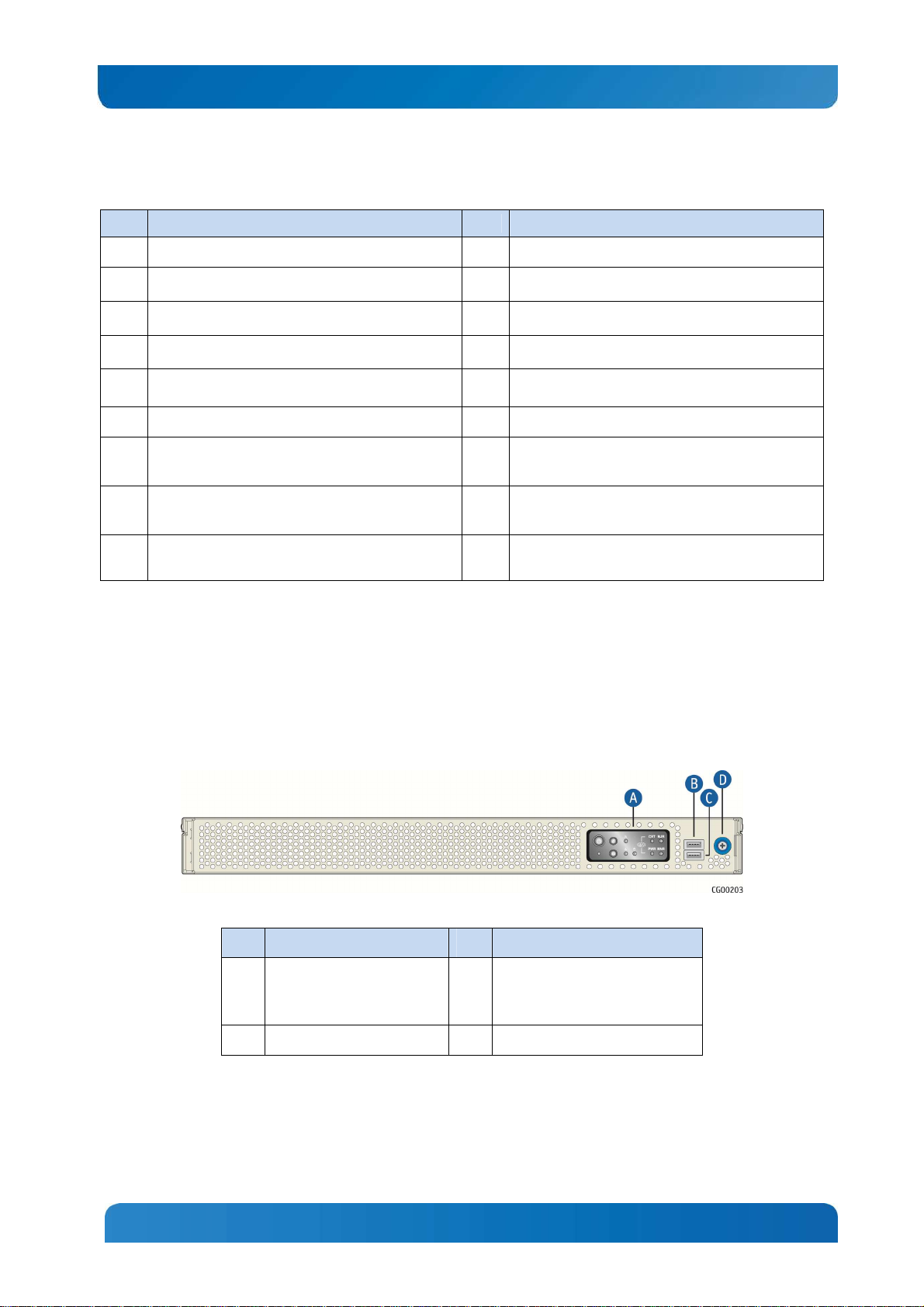

2.2 CG1200 Server Front Panel

Figure 3 shows the front panel of the CG1200 server with the bezel installed.

Figure 3: CG1200 Server Front View (Bezel Installed)

Item Description Item Description

A

Front panel control buttons

and status indicator and

telco alarm LEDs

B

USB port

Figure 4 shows the front panel of the CG1200 server with the bezel removed.

7

C

USB port

D

Bezel captive screw

Page 14

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 8

Figure 4: CG1200 Server Front View (Bezel Removed)

Item Description Item Description

A

B

C

D

E

Hard disk drive slot 3

Hard disk drive slot 2

Mini-bezel control buttons, status

indicator and telco alarm LEDs

USB port

USB port

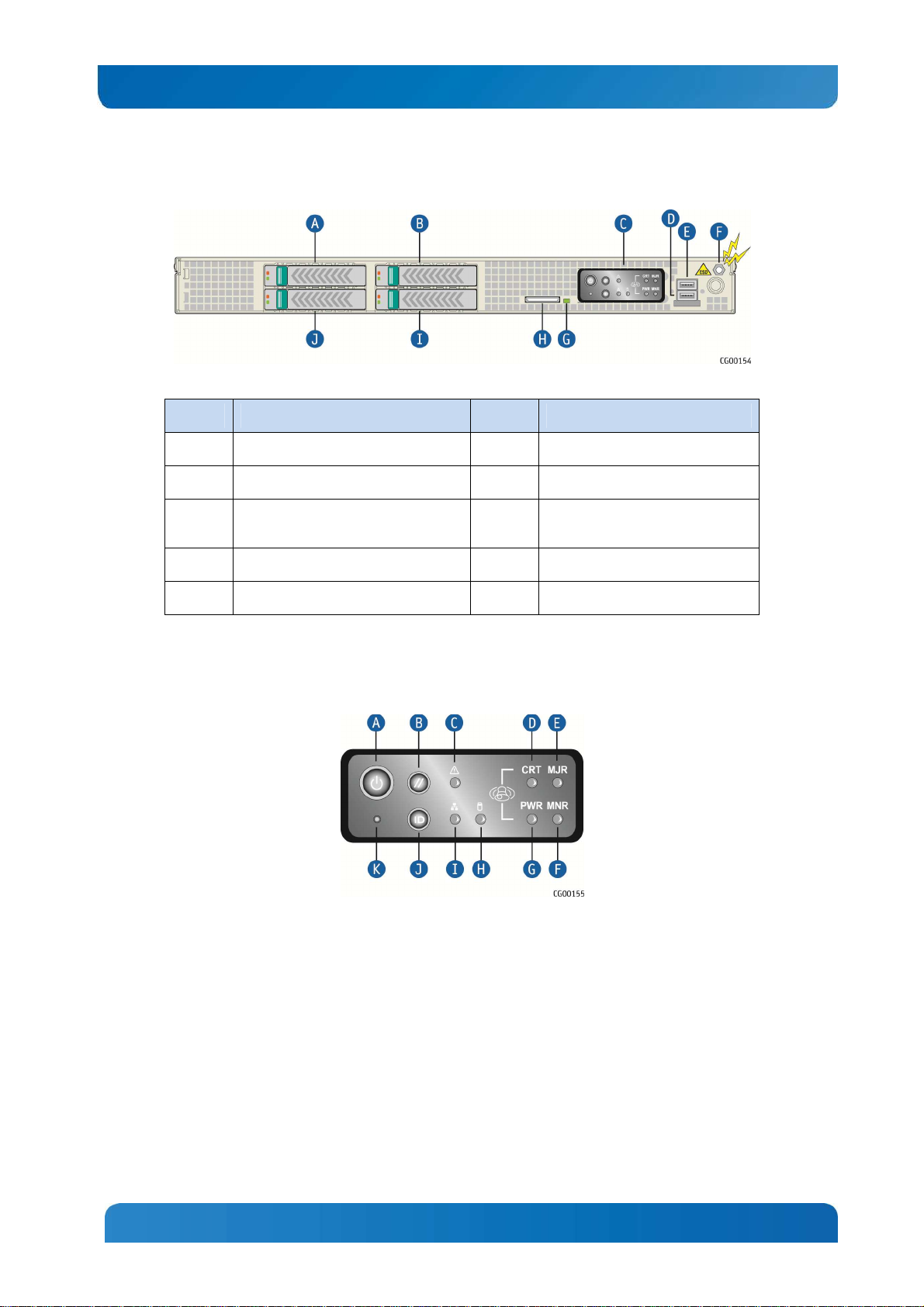

Figure 5 shows the CG1200 server control panel.

Figure 5: CG1200 Server Control Panel

F

G

H

I

J

ESD ground strap attachment

SD flash card LED

SD flash card slot

Hard disk drive slot 0

Hard disk drive slot 1

8

Page 15

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 9

Item Description Item Description

A

B

C

D

E

F

† Critical and Major alarm indicators are bi-color LEDs that can be configured to be yellow or

red by means of an SDR TAM setting. Yellow is the default color.

Power button

System reset button

System status indicator LED

Critical alarm (amber or red†)

Major alarm (amber or red†)

Minor alarm (amber)

2.3 CG1200 Server Back Panel

Figure 6 shows the back panel of the CG1200 server.

Figure 6: CG1200 Server Rear View

G

H

I

J

K

Power alarm (amber)

HDD activity LED

NIC activity LED

Chassis ID button

NMI button

9

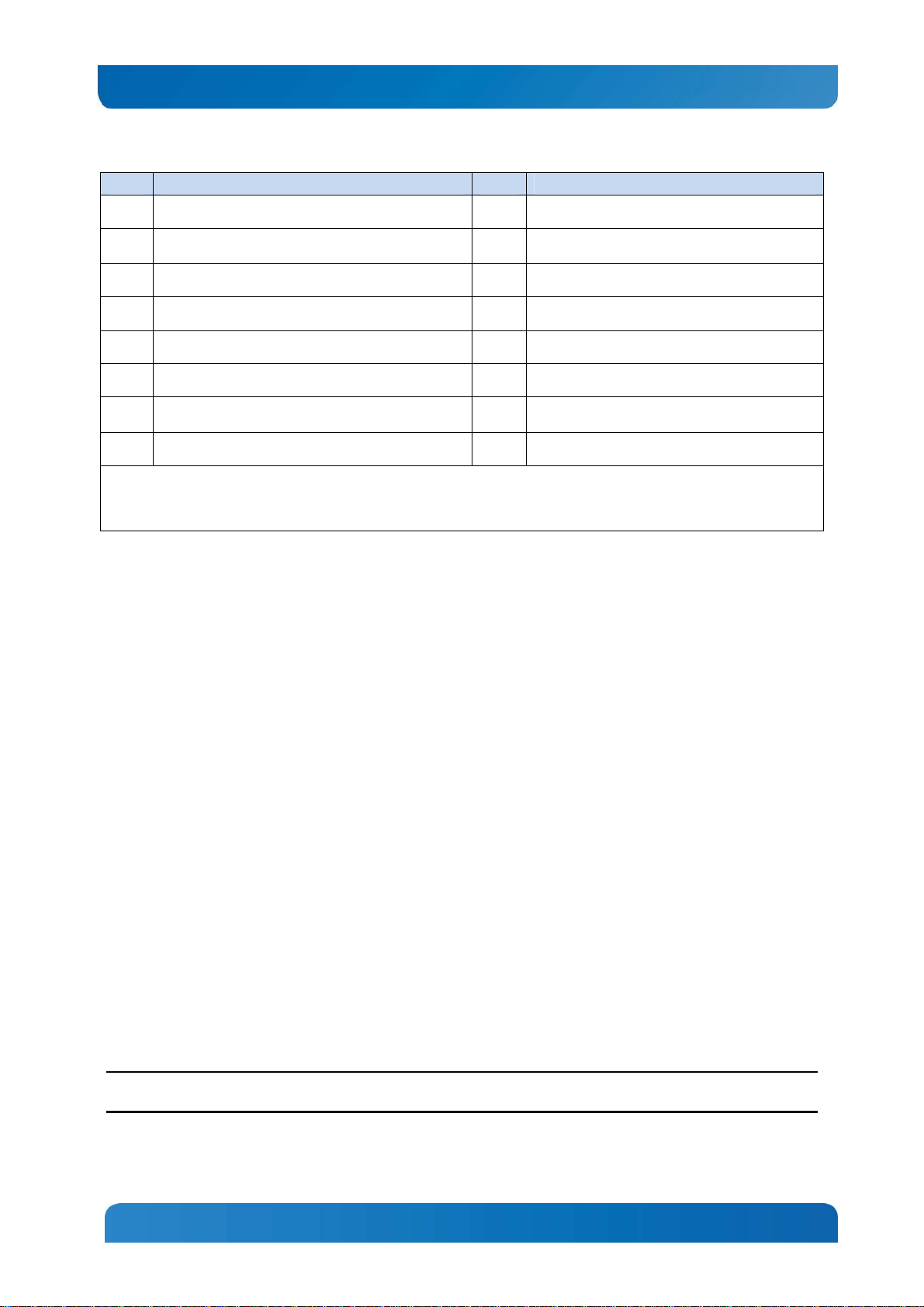

Page 16

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 10

2. If RMM4 NIC is not used, a filler panel occupies this space

Item Description Item Description

A

B

C

D

E

F

G

H

NOTES:

1. In non-redundant configurations, power supply slot 2 must have a filler panel installed.

Optional power supply slot 2 (filler panel shown)1

Power supply slot 1 (shown with DC power supply

installed)

DC power grounding studs

Telco alarms connector

NIC port 1

NIC port 3

NIC port 4

PCIe slot

I

J

K

L

M

N

O

I/O module (filler panel shown)2

USB ports

NIC port 2

Serial port A

Video port

Power supply LEDs

Power supply 2 (shown with AC power supply

installed)

2.4 Front Panel Board

The front panel (FP) board is located behind the front bezel and in front of the fans. The FP board

provides the following feature set:

• Two USB ports: one to drive the USB ports on the front panel USB connector and one to drive the SD

flash module controller.

• Control circuitry for driving the NIC activity LED, the system status LED, the power LED, and the disk

activity LED, which are all located on the LED/switch board

• On-board LED that indicates USB flash drive activity

• System power state and status indicators -- power, reset, and NMI switches

NOTE: There may be features (for future use) in addition to those in this list.

2.5 LED/Switch Board

The LED/switch board provides input selection switches and LED status indicators for the server system.

The LED/switch board is connected to the FP board and receives status and alarm signals from it. The

LED/switch board has the following features:

• Connects the front panel board signals to the front panel. There are four switches and five LEDs. The

power status LED and the chassis ID LED are embedded in the switch and the other three LEDs are

on the control panel. (See Figure 5.)

• On board switches for power, reset, chassis ID, and NMI

• On board LEDs to indicate power status, chassis ID, system status, HDD activity/fault and NIC

activity

NOTE: For information about the telco alarm LEDs that are also on the front panel, see Section 7.5, LightGuided Diagnostics

10

Page 17

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 11

2.6 Telco Alarm Module (TAM) Board

The CG1200 server Telco Alarms Module (TAM) board provides the connector interface and supporting

logic for the telco alarms function. The TAM board also provides an alarms function with fault relays and

access by cable to the fault relay contacts at the back of the system. A ribbon cable connects the TAM

board to the front panel board.

For detailed information about the telco alarms and fault relays, see the “Telco Alarms (TAM)” chapter in

the CG1200 Carrier Grade Server Technical Product Specification on the Kontron support website at

http://us.kontron.com/support.

2.7 Hard Disk Drives

The CG1200 Carrier Grade Server chassis supports up to four hard disk drives that are accessible from

the front of the chassis when the bezel is removed. The hard disk drives are mounted in removable drive

carriers that latch into the drive bay sub-assembly. Up to four 2.5-inch hot-swappable drives, either serial

attached SCSI (SAS) rotating hard drives or SATA solid state drives (SSDs), can be mounted in the drive

bay.

Each drives can consume up to 12W of power. Drives used in this server must be specified to run at a

maximum ambient temperature of 40°C.

NOTES:

1) SATA rotating HDDs are not recommended for use in this system because they are sensitive to

rotational vibration from system fan blades and other HDDs.

2) The CG1200 server does not support all SAS or SATA drive models. For a list of validated hard drive

manufacturers and hard drive types, refer to the Tested Hardware and Operating System List (THOL) on

the Kontron website at http://us.kontron.com/support/ (search for CG1200, click on Product Downloads,

then Compatibility Matrix).

2.8 Software and Hardware RAID

Software RAID 0/1/10 is provided for all four SAS drives or SATA SSDs. If additional levels of software

and/or HW RAID are needed, see the Configuration Guide for all orderable options.

Hardware RAID (Intel ROC) is available as a separately-orderable module and an additional separatelyorderable CG1200 RAID cable kit that provides the cables and brackets required for installation.

For more information about these options, refer to the Configuration Guide located on the support website

at http://us.kontron.com/support/, (Search for CG1200, click on Product Downloads, then Ordering

Guide).

2.9 SD Flash Module

There is one front-accessible USB SD flash module. For a list of validated SD cards to use with this

module, see the Tested Hardware and Operating System List (THOL) on the Kontron website at

http://us.kontron.com/support/ (search for CG1200, click on Product Downloads, and then Compatibility

Matrix).

11

Page 18

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 12

2.10 Server Board (Baseboard)

The CG1200 server uses the Intel® S2400EP4 server board for the baseboard. The processors and

memory DIMMs are on the server board and support for several optional accessories, such a PCI riser

slot, the platform management subsystem, and RMM4or I/O module connectors.

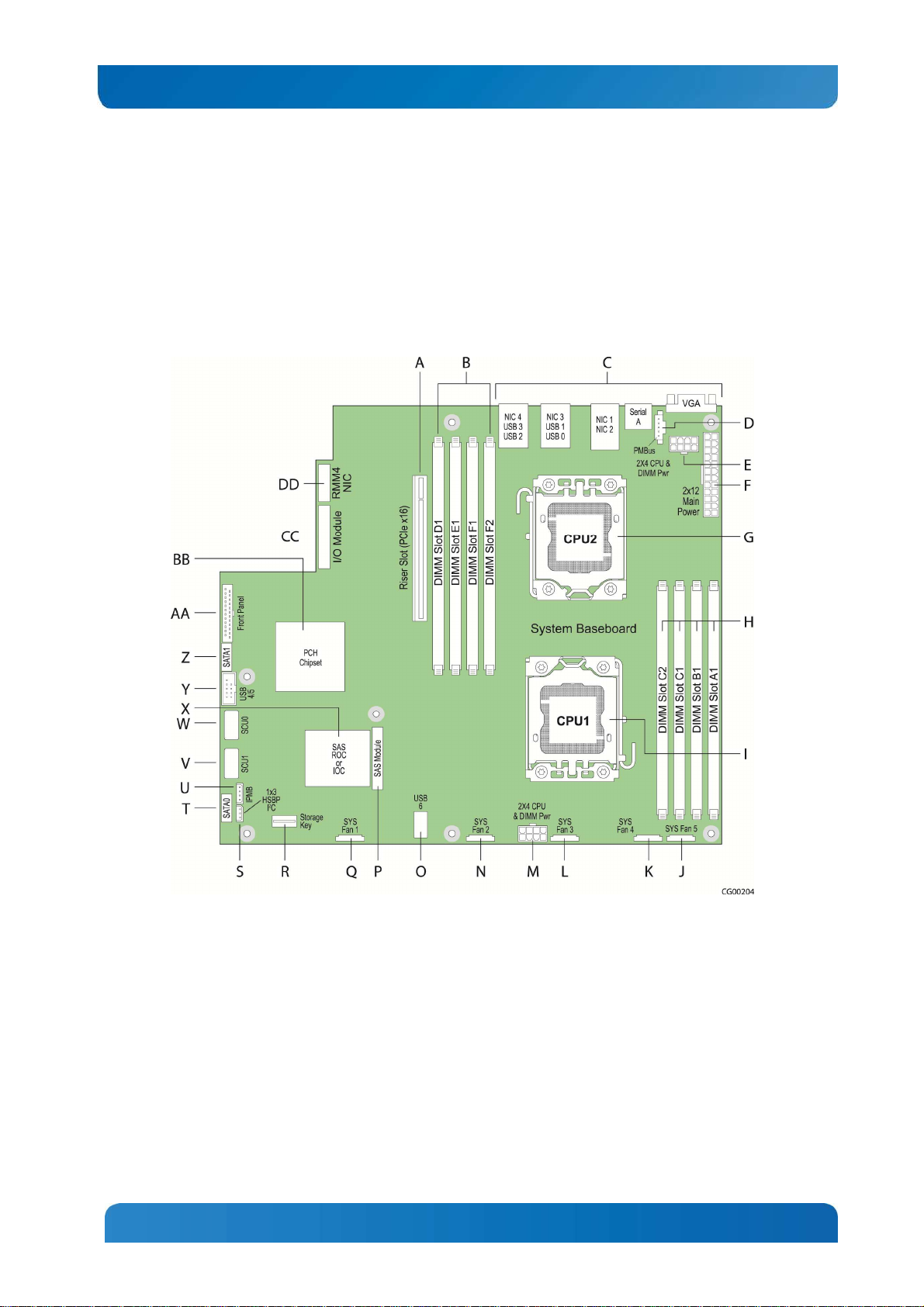

Figure 7 shows the key components and connectors on the S2400EP4 server board.

Figure 7: Baseboard Components and Connectors

12

Page 19

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 13

Item Description Item Description

A PCIe x16 riser slot P SAS module

B CPU 2 DIMM slots Q Fan 1 power connector

C Rear panel I/O connectors R RKSAS4 storage key (pre-installed)

D PMBus connector S HSBP I2C connector

E CPU2 processor and DIMMs power

connector

F Baseboard main power connector U IPMB connector

G CPU processor socket V SAS HDD connector SCU1

H CPU1 DIMM slots W SAS HDD connector SCU0

I CPU1 processor socket X SAS RAID module (ROC or IOC)

J Fan 5 power connector Y Front panel USB connector

K Fan 4 power connector Z SATA 1 connector

L Fan 3 power connector AA Front panel connector

M CPU1 processor and DIMMs power

connector

N Fan 2 power connector CC I/O module connector

O Internal USB 6 connector DD RMM4 NIC or I/O module connector

T SATA 0 connector

BB Controller hub (PCH) chipset

2.11 Riser Card Assembly

The Intel® Server Board S2400EP4 has one riser slot capable of supporting a full-height, full-length PCIe

x16 riser card.

Once a PCI add-in card is installed and the riser card assembly is remounted in the chassis, the card is

accessible from the server back panel.

2.12 Ethernet NIC Ports

The S2400EP4 server board (baseboard) provides four network interface controller (NIC) RJ-45

connectors on the chassis back panel. Additional rear-accessible GbE NIC ports can be added to the

system by using a PCIe add-in card or installed as an I/O module.

2.13 Remote Management Module 4

RMM4 is a supported option on the S2400EP4 server board iBMC. To use this feature, a separatelyorderable RMM4 kit must be installed. Another option is an RMM4Lite kit that enables advanced features

in the iBMC without using a dedicated management NIC.

13

Page 20

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 14

2.14 I/O Module

Space on the chassis floor with support standoffs is provided for adding an optional I/O module at the rear

of the server. An I/O module connector (and use of a smaller connector also used for RMM4 support) is

how the I/O module is connected to communicate with the server board.

2.15 Power Supply Subsystem

The power supply subsystem consists of up to two AC or DC hot-swappable power supply modules (two

needed for redundancy) and a power distribution board (PDB). The server comes with one power supply

module and a filler panel in the second power supply slot. The second redundant power supply is

separately-orderable.

The power supply module is rated for 650W output capability in full AC or DC input voltage range. The

minimum steady-state DC input voltage at which the equipment remains fully operational is -38 VDC. The

nominal operating voltage of the DC system is -48 VDC.

The server also includes an auxiliary power dongle from the power distribution board for use with

optional, additional cards.

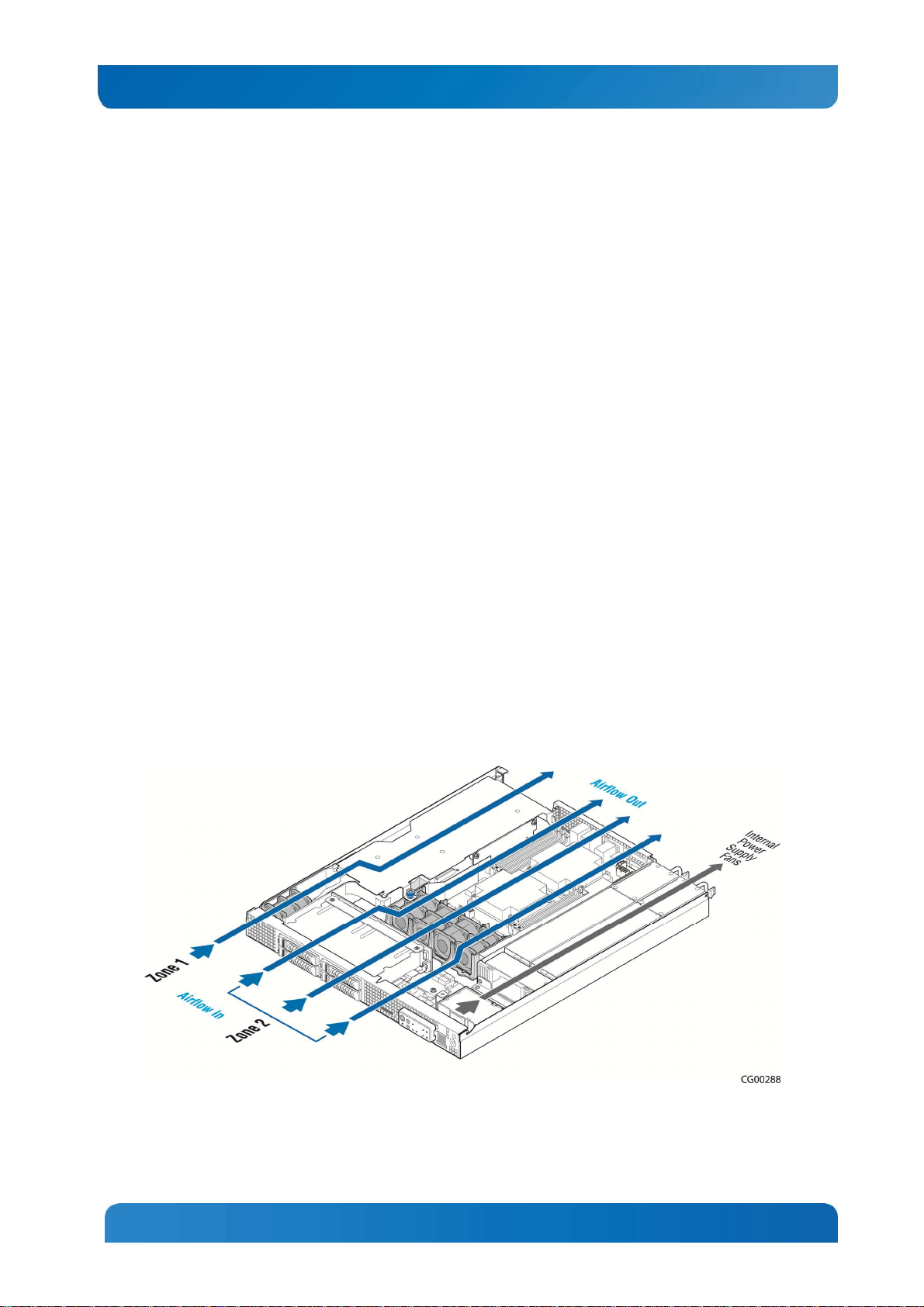

2.16 System Cooling

There are two cooling areas in the CG1200 server as illustrated in

Figure 8. All system components except the PCI riser card assembly and components under it are

cooled by a set of four CPU/DIMM dual rotor fans mounted near the front of the chassis behind the SAS

HDD bay. The PCI riser card assembly is cooled by a separate fan located in front of the riser assembly

on the left side of the chassis

Internal power supply fans cool the power distribution board (PDB) and power supply modules.

Figure 8: CG1200 Server Cooling Areas

The five-fan cooling subsystem is sized to provide cooling for:

14

Page 21

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 15

• Up to two 70W server board processors

• Up to 256 GBytes of DDR3 memory

• Up to four hard disk drives

• One PCIe adapter

The cooling subsystem meets acoustic and thermal requirements at the lower fan speed settings. At the

higher fan speed settings, thermal requirements are met for the maximum ambient temperatures, but

acoustic requirements are not specified above 23 C+/-2 C.

2.17 Processors and Memory DIMMs

NOTE: To avoid integration difficulties and possible board damage, your server must meet the

requirements outlined below. For a list of qualified processors refer to the CG1200 Carrier Grade Server

Configuration Guide located on the support website at

click on Product Downloads, then Ordering Guide). For a list of qualified DIMMs refer to the Tested

Memory List at

http://us.kontron.com/support/

(search for CG1200, click on Product Downloads, then

Compatibility Matrix).

2.17.1 Processors

http://us.kontron.com/support/

(search for CG1200,

The S2400EP4server board accommodates FC-LGA 1356 Socket B2 support for two Intel® Xeon® E524XXL or E5-24XXL v2 processors. These processors can be ordered from Intel or an authorized

distributor using the Kontron part numbers listed in the CG1200 Carrier Grade Server Configuration

Guide.

2.17.2 Memory

The S2400EP4 server board supports 8 DIMM slots – one DIMM slots/channel for channels A,B,D,E and

two DIMM slots/channel for channels C and F. The server board supports registered DDR3 Memory

(RDIMM), Low-Voltage DDR3 memory (LVDDR3), load-reduced DIMMs (LRDIMMs), or unbuffered DDR3

memory (UDIMM) with data transfer rates of 800, 1066, 1333, and 1600 MT/s).

For detailed information about configuring memory on the server board, see the Intel® Server Board

S2400EP4 Family TPS.

15

Page 22

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 16

3 Standard Component Installations and Upgrades

3.1 Before You Begin

Before working with your server product, pay close attention to the safety instructions provided in this

manual. See Appendix A, “Appendix A: Safety Information”

Warning: Electrostatic discharge (ESD) and ESD protection: ESD can damage disk drives, boards, and

other parts. We recommend that you perform all procedures in this chapter only at an ESD workstation. If

one is not available, provide some ESD protection by wearing an antistatic wrist strap attached to chassis

ground (any unpainted metal surface) on your server when handling parts.

3.1.1 Tools and Supplies Needed

• #1 and #2 Phillips (cross-point) screwdrivers (or interchangeable tip screwdriver with #1 and #2

Phillips bits)

• Personal grounding device such as an anti-static wrist strap and a grounded conductive pad

3.1.2 System References

All references to left, right, front, rear, top, and bottom assume that you are facing the front of the server,

as it would be positioned for normal operation.

3.2 General Installation Procedures

The following sections present general installation and removal procedures that are required before

removing or installing internal components that are not hot-swappable.

3.2.1 Removing the Chassis Cover

The CG1200 server must be operated with the top cover in place to ensure proper cooling. You will need

to remove the top cover to add or replace components inside the chassis that are not hot-swappable.

CAUTION: 5V standby power is present inside the chassis whenever the power supply module(s) are

connected to a power source. Before removing the top cover, always power down the server and unplug

all peripheral devices and the power cable.

A non-skid surface or a stop behind the server may be needed to prevent the server from sliding on your

work surface.

1. Observe the safety and ESD precautions in Appendix A, “Appendix A: Safety Information”.

2. Turn off all external devices connected to the server.

Turn off the server.

3. Disconnect the power cord(s).

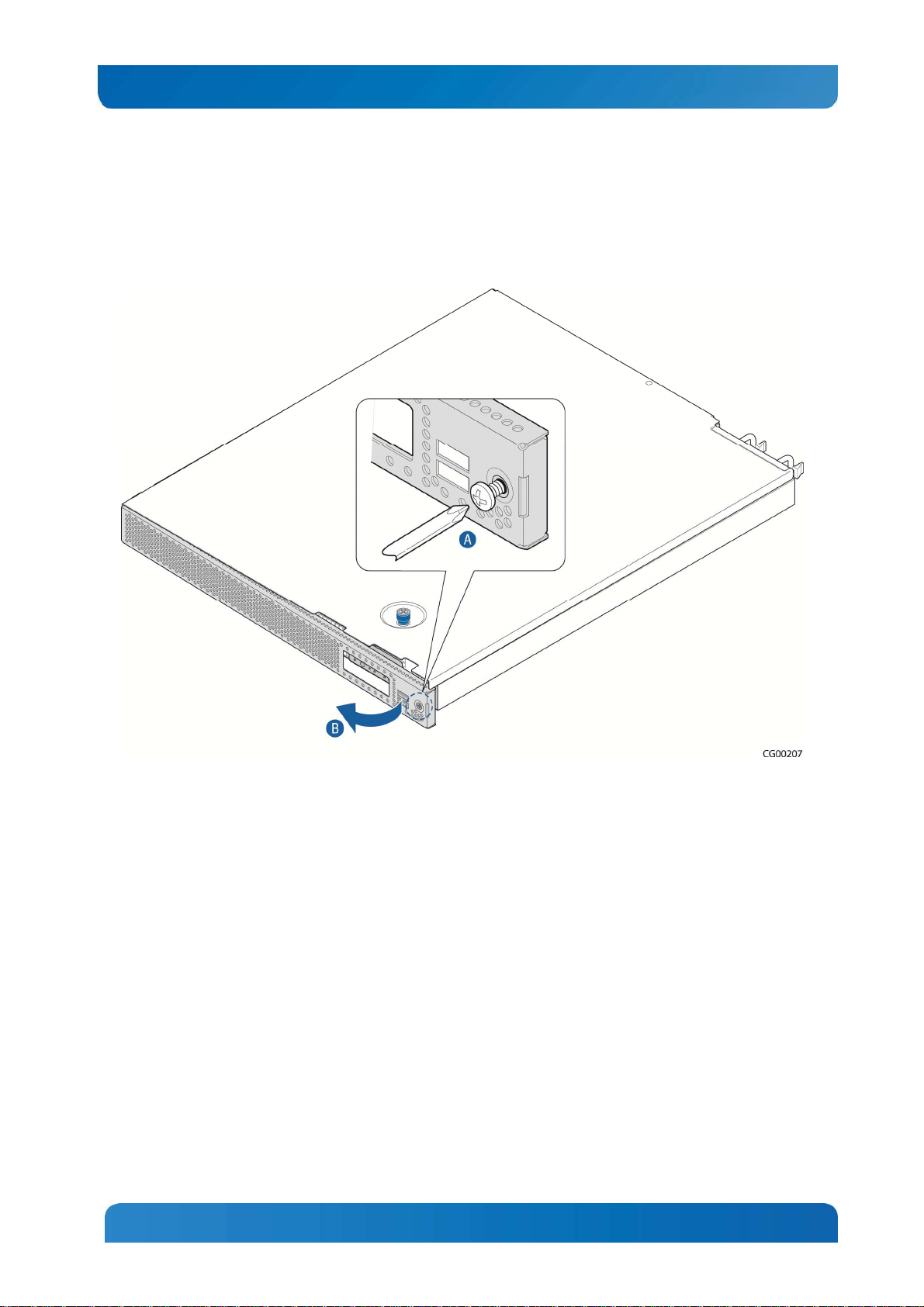

Figure 9 shows the top cover and how it is removed.

Removing the Cover

1. Loosen the captive thumb screw at the front of the cover (“A”).

2. Using the blue contact points on each side of the top cover (“B”), slide the cover backwards.

16

Page 23

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 17

3. Lift the cover straight up to remove it from the chassis (“C”).

Figure 9: Removing the Cover

3.2.2 Re-installing the Chassis Cover

When you are finished working inside the chassis, you must put the cover back on before turning the

server back on. This step is required to ensure proper cooling.

Re-Installing the Cover

1. Starting from the rear of the chassis, place the cover down over the chassis with the side edges

outside the chassis walls.

2. Slide the cover forward until it is flush with the front panel.

3. Tighten the blue thumbscrew at the front of the top cover.

4. Reconnect any external devices and the power cord(s).

CAUTION: This unit must have the cover installed when it is running to ensure proper cooling.

3.2.3 Removing the Front Bezel

You need to remove the front bezel for tasks such as:

• Installing or removing hard disk drives

• Observing the individual hard disk drive activity/fault indicators on the drive carriers

• Replacing the control panel LED/switch board

• Accessing SD card slot

17

Page 24

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 18

NOTE: The server does not have to be powered down just to remove the front bezel.

1. Loosen the captive bezel retention screw on the right side of the bezel (Figure 10, “A”).

2. Rotate the bezel to the left to free it from the pins on the front panel, (“B”) and remove it.

Figure 10: Removing the Front Bezel

3.2.4 Re-Installing the Front Bezel

1. Insert the tabs on the left side of the bezel into the slots on the front panel of the chassis.

2. Move the bezel toward the right and align it around the control panel and the USB ports.

3. Tighten the retention screw to secure the bezel. (Torque to 8lbf*in)

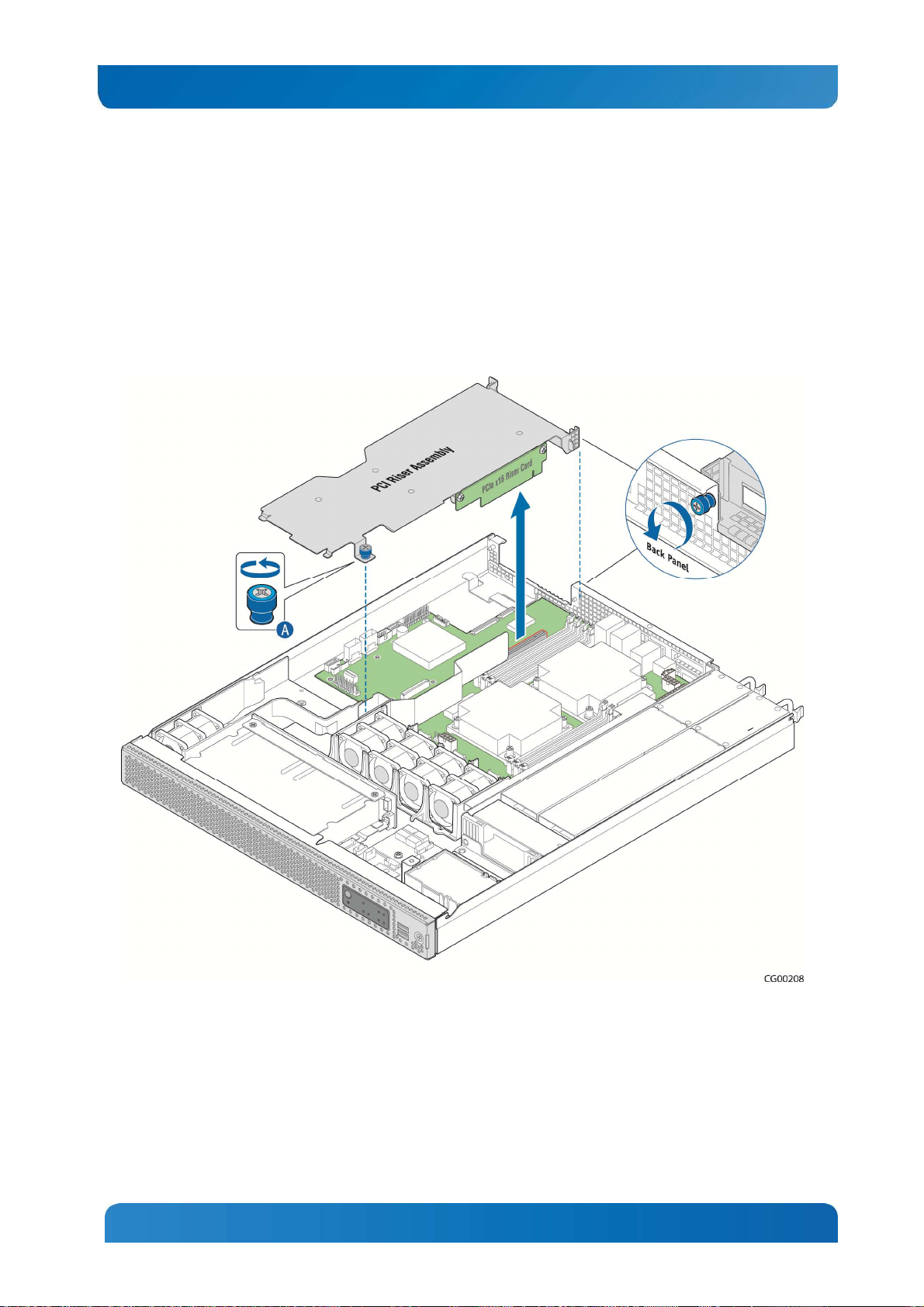

3.2.5 Removing the Riser Card Assembly

The riser card assembly has to be removed from the chassis to perform tasks such as:

• Replacing a riser card

• Installing or replacing a PCI add-in card

• Installing or replacing a hardware RAID controller

• Working with any components on the server board that are near the riser card assembly, such as the

CPU2 DIMMs, an I/O module, or an RMM4 card

• Replacing the server board

To remove the riser card assembly:

1. Power down the server and remove all external devices and the power cord(s)

18

Page 25

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 19

2. Remove the chassis cover. For instructions, see Section 3.2.1 “Removing the Chassis Cover”.

3. Loosen the blue captive retention screw (

4. Figure 11, “A”) at the front of the riser assembly and the blue captive screw at the back panel of the

chassis.

5. Unhook the rear of the assembly from the guide pin on the back panel and lift the riser card assembly

out of the chassis.

Figure 11: Removing the Riser Card Assembly

3.2.6 Re-Installing the Riser Card Assembly

To re-install the riser card assembly:

1. Align the riser card with the card slot on the server board.

2. Position the riser front tab/captive screw over the stand-off on the chassis floor.

Make sure the tab at the rear of the assembly hooks over the guide pin on the chassis back panel.

19

Page 26

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 20

3. Press down to mate the riser card with the slot on the server board.

NOTE: To avoid damaging the card edge, be sure that the card is lined up straight with the header, not on

an angle.

4. Tighten the blue captive retention screws at the front of the assembly and on the back panel.

5. Replace the chassis cover. For instructions see Section 3.2.2“Re-Installing the Cover”.

3.3 Internal System Components Configuration and Installation

Procedures

This section covers separately-orderable components that must be installed for your server to operate. It

also covers replacing these components and where relevant, such as with memory DIMMs, how to

configure them.

You install your separately-orderable DIMMs and processors on the Intel® Server Board S2400EP4,

which is the baseboard for this server.

NOTE: Be sure to read the information about the configuration rules and memory feature options in the

Intel® Server Board S2400EP4 Family Technical Product Specification e before you begin.

3.3.1 Configuring Memory DIMMs

The memory DIMM slots are located in two separate banks on the S2400EP4 server board. Detailed

information about the memory subsystem in the CG1200 server can be found in the Intel® Server Board

S2400EP4 Family Technical Product Specification located on the Kontron support website

http://us.kontron.com/support

(search for CG1200, click on Product Downloads, then Technical Info).

3.3.2 Supported Memory

The Intel® Server Board S2400EP4 supports eight DIMM slots with three memory channels for each

processor. There is one DIMM slot per channel for channels A, B, D, and E and two DIMM slots per

channel for channels C and F. Up to eight DIMMs can be used with dual-processor sockets giving a

maximum memory capacity of 256 GB.

The server board supports DDR3 800, DDR3 1066, DDR3 1333, and DDR3 1600 memory transfer rates.

Memory modules of mixed speed are supported by automatic selection of the highest common frequency

of all memory modules.

For detailed information about UDIMM, RDIMM and LRDIMM support guidelines, see Section 3.2.2.1,

“Supported Memory” in the Intel® Server Board S2400EP4 Family TPS.

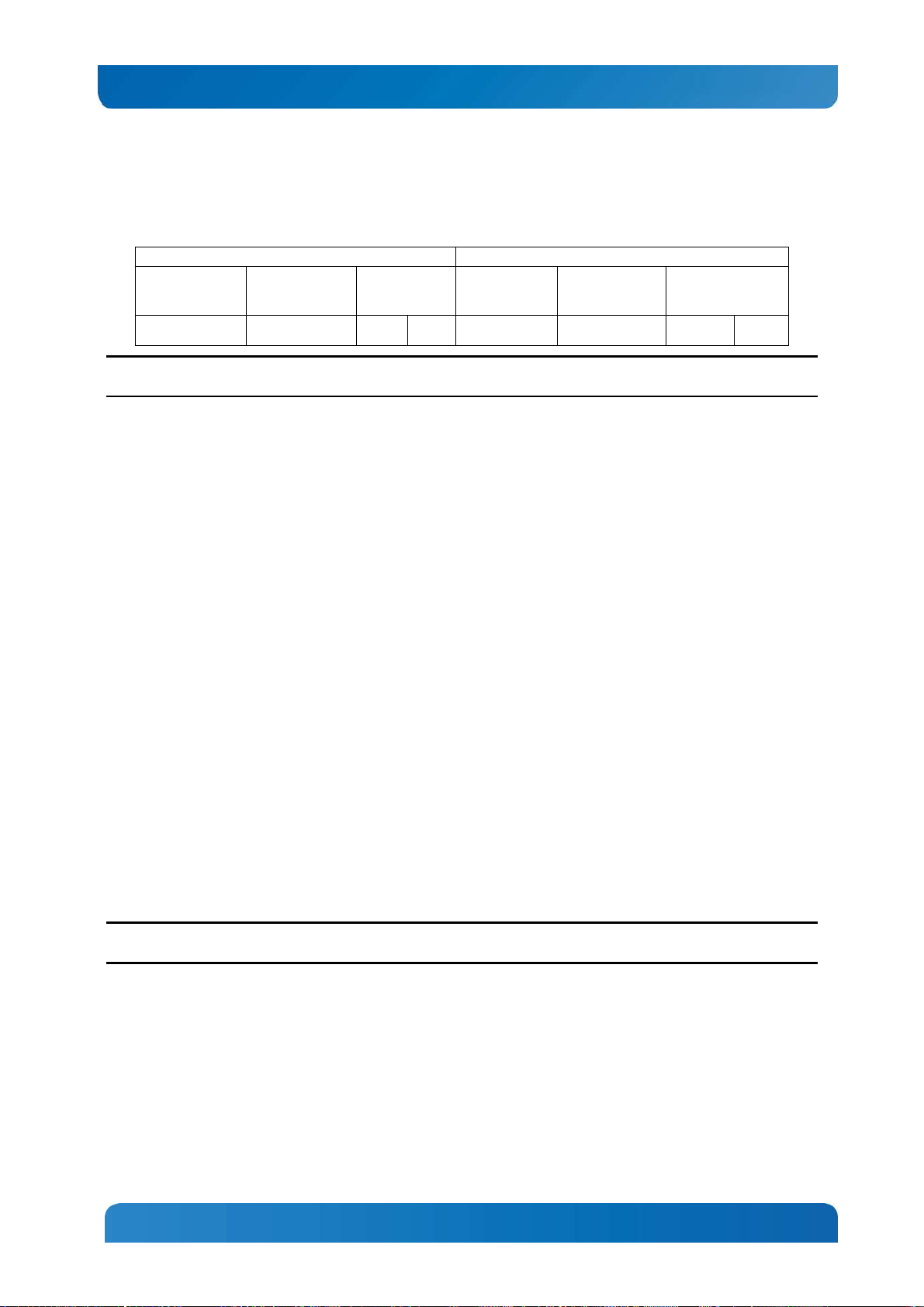

Memory Map and Population Rules

The nomenclature for DIMM sockets implemented on the Intel® Server Board S2400EP4 is shown in

Table 4.

20

Page 27

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 21

Processor Socket 1

Processor Socket 2

Table 3: Memory Map

(0) Channel A (1) Channel B

A1 B1 C1 C2 D1 E1 F1 F2

(2) Channel

C

(0) Channel D (1) Channel E

(2) Channel F

NOTE: Although mixed DIMM configurations may be functional, platform validations are performed only

on systems configured with identical DIMMs.

The S2400EP4 server board memory is implemented according to the following rules

• DIMMs are organized into physical slots on DDR3 memory channels that belong to processor

sockets.

• The memory channels from processor socket 1 are identified as Channel A, B, C.

The memory channels from processor socket 2 are identified as Channel E, F.

• Each memory slot on the server board is identified by channel and slot number within the channel.

For example, DIMM_A1 is the first slot on Channel A on processor 1; DIMM_D1 is the first DIMM

socket on Channel E on processor 2.

• The memory slots associated with a given processor are unavailable if the given processor socket is

not populated.

• A processor can be installed without populating the associated memory slots, provided the other

processor is installed with associated memory. In this case, the memory is shared by the processors.

However, the platform suffers performance degradation and latency because of the remote memory

accesses.

• Processor sockets are self-contained and autonomous. However, all memory subsystem support (i.e.,

Memory RAS, Error Management, etc.) in the BIOS setup is applied commonly across processor

sockets.

• The blue memory slots on the server board identify the first memory slot for each memory channel.

• For more information about population considerations, see Section 3.2.2.2 “Memory Slot Identification

and Population Rules” in the Intel® Server Board S2400EP4 Family TPS.

For information about what memory has been tested on the CG1200 server, see CG1200 Tested Memory

List on the Kontron website at http://us.kontron.com/support/ (Search for CG1200, click on Product

Downloads, then Tested Memory.)

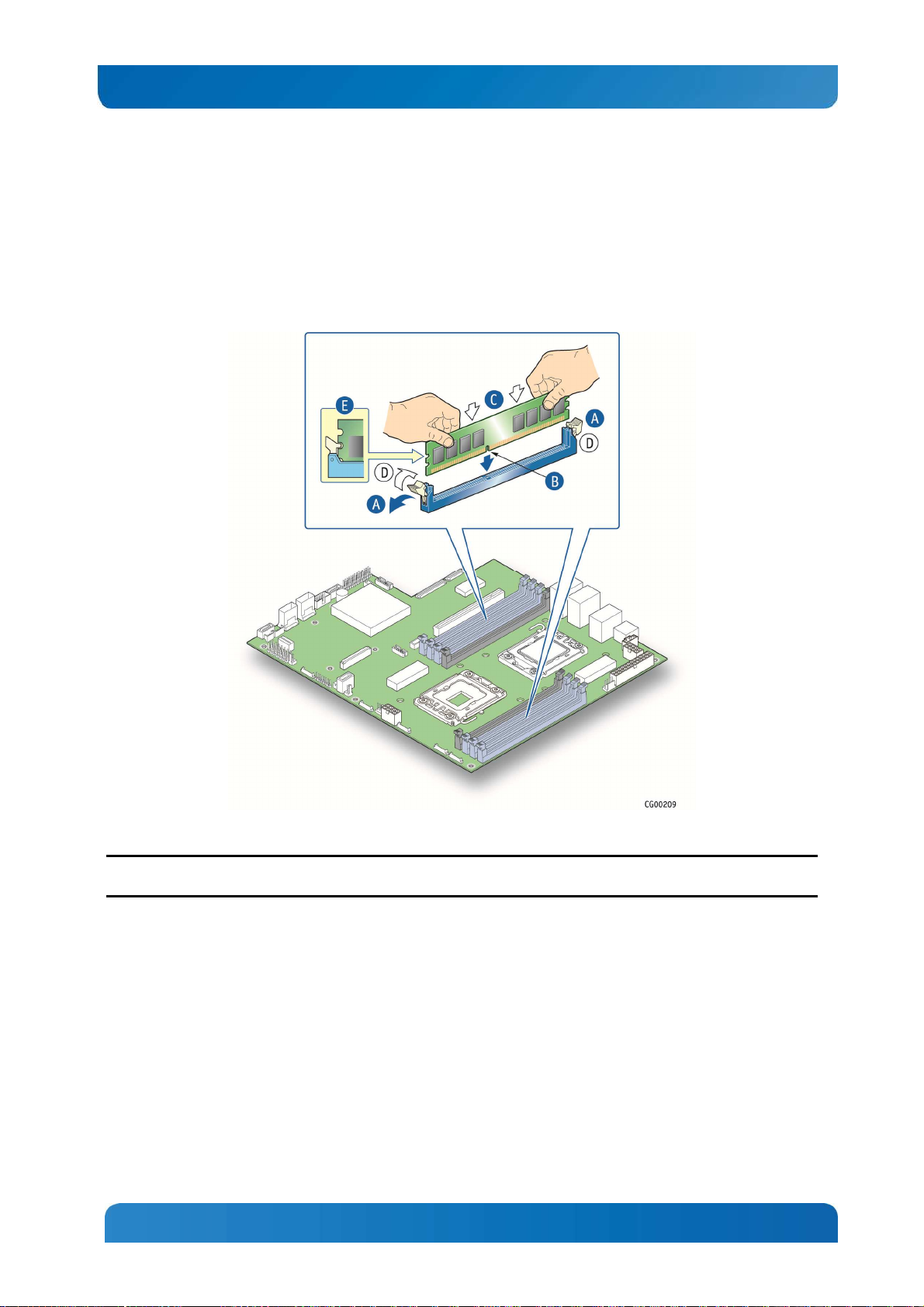

3.3.3 Installing Memory DIMMs

NOTE: To reduce the risk of electrostatic discharge (ESD) damage to the processor or the DIMM, be sure

to use a ground strap attached to the front panel (with the bezel removed).

To install DIMMs in the S2400EP4 server board slots:

1.

Power down the server and remove all peripheral devices and the power cord(s)

2.

Remove the chassis cover. For instructions, see Section 3.2.1 “Removing the Chassis Cover”.

3.

Note the location of the alignment notch. ( Figure 12, “B”)

4.

Insert the DIMM, making sure the connector edge of the DIMM aligns correctly with slot. (“E”)

21

Page 28

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 22

5.

Using both hands, push down firmly and evenly on both sides of the DIMM until it snaps into place and

the levers close.(“C”)

IMPORTANT: Visually check that each latch is fully closed and correctly engaged with the notch on

the DIMM edge. (“D”)

6.

Replace the riser card assembly and the chassis cover if you have completed all work inside of the

server.

Figure 12: Memory DIMM Installation

3.3.4 Replacing or Removing Memory DIMMs

NOTE: To reduce the risk of electrostatic discharge (ESD) damage to the processor or the DIMM, use a

ground strap attached to the front panel (with the bezel removed).

To remove a DIMM from the S2400EP4 server board, follow these steps:

1.

Power down the server and remove all peripheral devices and the power cord(s)

2.

Remove the chassis cover. For instructions, see Section 3.2.1, “Removing the Cover”.

3.

Open the DIMM slot levers for the DIMM you want to remove. ()

4.

Using both hands, hold the DIMM by the edges and lift it up from the slot. Store the DIMM in an anti-

static package.

5.

If you are installing a replacement DIMM in this slot, return to Step 5 in “ Installing Memory DIMMs”.

Otherwise, replace the chassis cover if you have completed all work inside the server. See Section

3.2.2, “Re-installing the Chassis Cover” for instructions.

22

Page 29

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 23

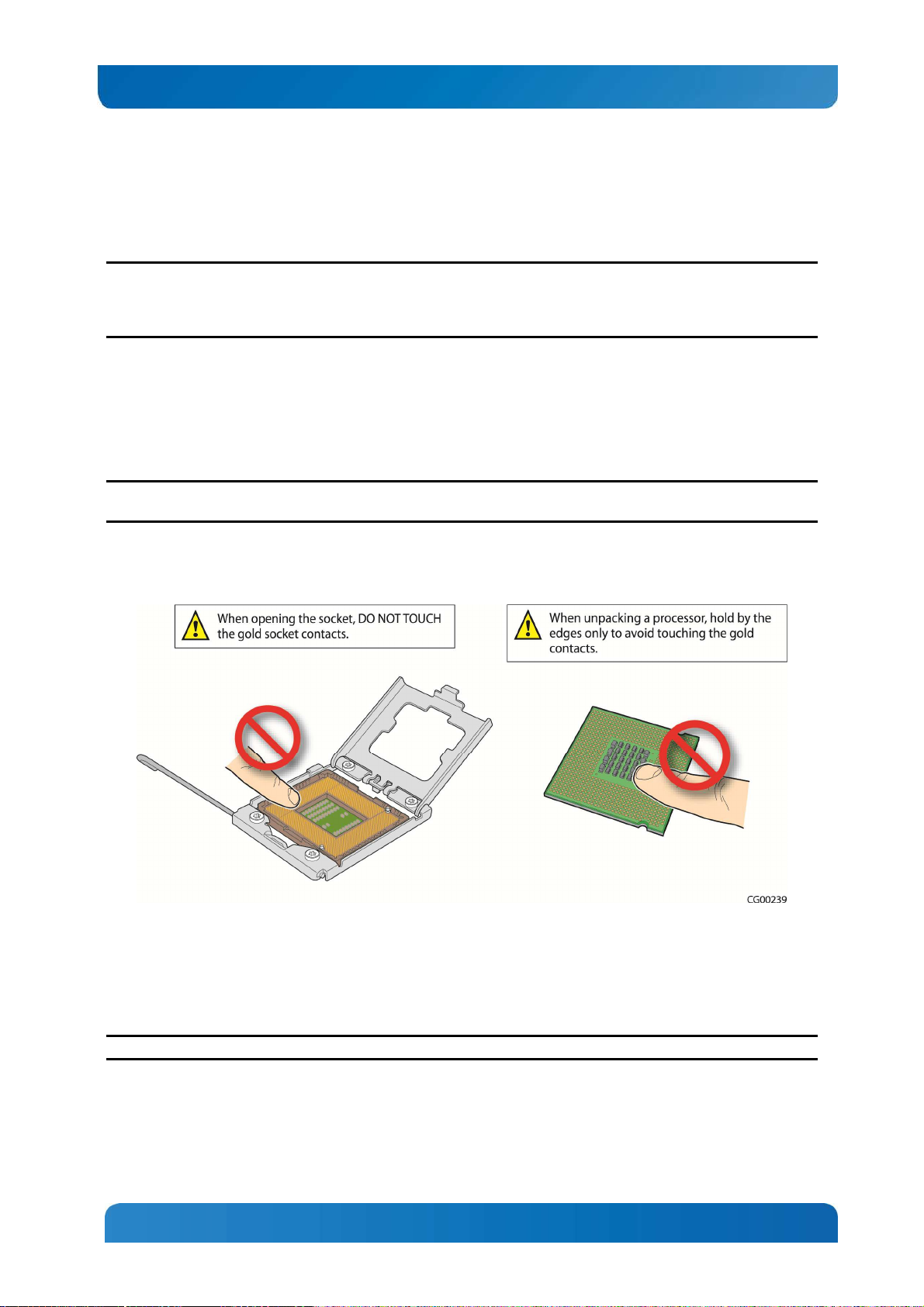

3.3.5 Adding or Replacing a Processor

CAUTION: The processor must be appropriate: You could damage the server board if you install a

processor that is inappropriate for your server. Refer to the Configuration Guide located on the support

web page

Ordering Guide) for a list of compatible processors for the CG1200 server.

Use the instructions provided below to add or replace a processor instead of using the instructions that

came with the processor.

Follow the instructions below to remove and then install a processor, referring to Figure 13 through Figure

22.

ESD and Processor Handling Precautions

NOTE: When handling the processors and sockets, to reduce the risk of electrostatic discharge (ESD)

damage to the processor use a ground strap attached to the front panel (with the bezel removed.)

http://us.kontron.com/support/

(search for CG1200, click on Product Downloads, and then

Figure 13: Cautions for Handling Processors

Removing a Processor

1. Loosen the four captive screws on the corners of the heat sink with a #2 Phillips screwdriver. (Figure

14, “A”)

2. Twist the heat sink slightly to break the seal between the heat sink and the processor. (“B”)

3. Lift the heat sink from the processor. If it does not pull up easily, twist the heat sink again.

NOTE: Do not force the heat sink from the processor. Doing so could damage the processor.

23

Page 30

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 24

Figure 14: Removing the Heat Sink

4. Open the socket by pushing the lever handle down and away from the socket to release it. (Figure

16)

24

Page 31

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 25

Figure 15: Using the Socket Lever

5. Lift the load plate up off the processor. (Figure 16)

25

Page 32

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 26

Figure 16.Opening the Load Plate

6. Remove the protective cover in the socket (Figure 17 ) or the processor if you are replacing an

existing one.

26

Page 33

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 27

Figure 17 Removing the Socket Protective Cover

Installing a New Processor

NOTE: Follow the ESD precautions covered in “ESD and Processor Handling Precautions”.

To install a processor, follow these instructions:

1. Take the processor out of its packaging and remove the protective shipping cover by grasping the

cover tab and pulling it away from the load plate. Store the protective cover for future use (

2. Figure 18).

Figure 18: Removing the Shipping Cover

27

Page 34

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 28

CAUTION: The underside of the processor has components that may damage the socket pins if installed

improperly. The processor must align correctly with the socket opening before installation. Gently place

the processor onto the socket surface. Do not drop the processor into the socket!

3. Orient the processor with the socket so that the processor cutouts match the socket notches (

4. Figure 19).

5. Gently place the processor in the socket.

Figure 19: Installing the Processor in the Processor Socket

6. Carefully close the load plate (Figure 20).

7. Close the socket lever and ensure that the load plate tab engages under the socket lever when fully

closed.

28

Page 35

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 29

Figure 20: Closing the Processor Load Plate

6. When the load plate comes down and the lever is latched, the socket cover pops off. Save it for future

use if the processor is removed from the socket (

7. Figure 21).

29

Page 36

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 30

Figure 21: Closing the Socket Lever

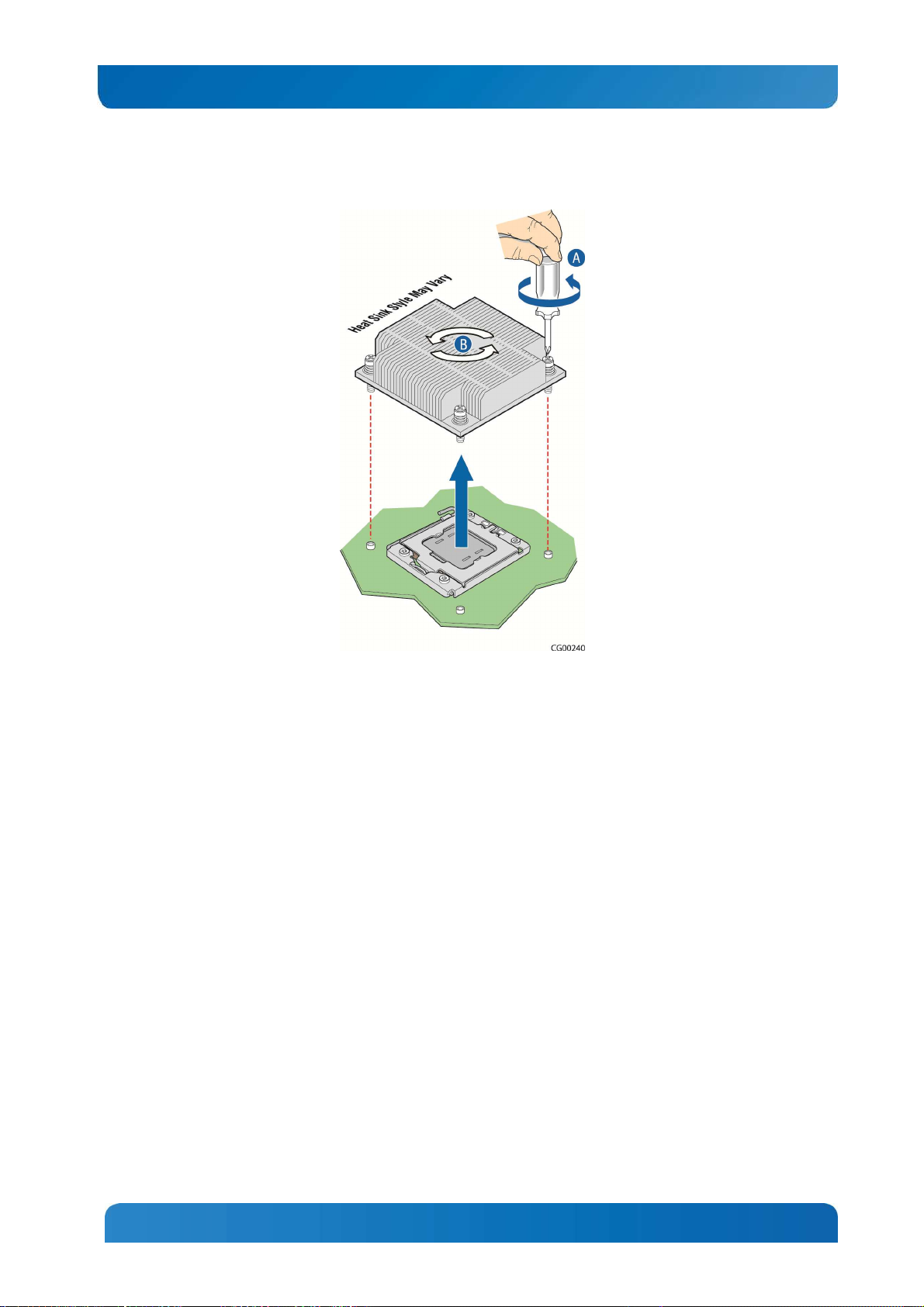

3.3.6 Installing the Heat Sink

1. If this is a new heat sink (not the one you removed above), remove the protective film, if present, on

the Thermal Interface Material (TIM) located on the bottom of the heat sink (Figure 22, “A”).

2. Set the heat sink over the processor, lining up the four captive screws with the four posts surrounding

the processor. Align the heat sink fins to the front and back of the chassis for correct airflow (front to

back). Use caution and make sure that no cables are pinched beneath the heat sink.

3. Loosely screw in the captive screws on the heat sink corners and then tighten one, then the one

diagonally opposite, and so on until each one is firmly tightened (“B”).

CAUTION: the torque spec for these screws is 8 inch pounds. Be careful not to exceed it.

30

Page 37

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 31

Figure 22: Installing a Heat Sink

3.3.7 Configuring Jumpers on the Server Board

The jumpers are located on the S2400EP4 server board. The system comes with the baseboard jumpers

configured in the default position for normal system operation. Only change the jumper position for

performing the desired recovery procedures outlined in this section. To work with the jumpers defined in

this section, you must first power down the chassis, remove the cover, remove riser card assembly as

described in Section 3.2 “General Installation Procedures”, and any optional modules or cables that might

be in the way. The other components on the server board can remain in place.

These 3-pin jumper blocks can be used to configure, protect, or recover specific features of the server

board. This section shows the jumper blocks available and what they do. For detailed information about

using these jumpers, see the Intel® Server Board S2400EP4 Family Technical Product Specification,

Chapter 9, “Reset and Recovery Jumpers”.

Pin 1 on each jumper block is identified by this symbol on the silkscreen: ▼

Figure 23 shows the jumper blocks.

31

Page 38

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 32

Figure 23: Jumper Blocks (J1L4, J1L6, J1L7, J2L4, J2L5)

32

Page 39

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 33

Table 4: Server Board Jumpers (J1L4, J1L6, J1L7, J2L4, J2L5)

Jumper Name Pins System Results

J1L4: BIOS

Default

J1L6: BIOS

Recovery

J1L7: BMC Force

Update

J2L4: ME Force

Update

J2L5: Password

Clear

1 - 2 These pins should be jumpered for normal system operation (Default)

2 - 3 If pins 2 – 3 are jumpered when AC power is unplugged, the CMOS

settings are cleared within five seconds.

Pins 2 - 3 should not be jumpered for normal operation.

1 - 2 These pins should be jumpered for normal system operation (Default)

2 - 3 The main system BIOS does not boot with pins 2 – 3 connected. The

system only boots from EFI-bootable recovery media with the recovery

BIOS image.

1 - 2 BMC Firmware Force Update Mode – Disabled (Default)

2 - 3 BMC Firmware Force Update Mode – Enabled

1 - 2 ME Firmware Force Update Mode – Disabled (Default)

2 - 3 ME Firmware Force Update Mode – Enabled

1 - 2 These pins should be jumpered for normal system operation (Default)

2 - 3 To clear administrator and user passwords, power on the system with

pins 2 – 3 connected. The administrator and user passwords clear in 5 –

10 seconds after power on.

Pins 2 – 3 should not be connected for normal system operation.

See Chapter 9, “Jumper Blocks” in the Intel® Server Board S400EP4 Family TPS on the Kontron Support

website for more information about the recovery features.

33

Page 40

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 34

4 Optional Component Installation Procedures

This chapter covers separately-orderable components that you may want to add or replace in your

Kontron CG1200 Carrier Grade Server. Most of these components can be ordered as accessories from

Kontron and some are from third party vendors. For more information about what is available from

Kontron, see the CG1200 Carrier Grade Server Configuration Guide. For a list of qualified third party

vendors, see the Tested Hardware and Operating System List (THOL). The latest version of the

Configuration Guide is located on the Kontron support website at http://us.kontron.com/support/ (search

for CG1200, click on Product Downloads, then Ordering Guide). The latest version of the THOL is

located on the support website at http://us.kontron.com/support (search for CG1200, click on Product

Downloads, then Compatibility Matrix).

4.1 Before You Begin

Before working with your server product, pay close attention to the safety instructions provided in this

manual. See Appendix A: Safety Information”.

WARNING: Electrostatic discharge (ESD) and ESD protection: ESD can damage disk drives, boards, and

other parts. We recommend that you perform all procedures in this chapter only at an ESD workstation. If

one is not available, provide some ESD protection by wearing an antistatic wrist strap attached to chassis

ground (any unpainted metal surface) on your server when handling parts.

4.1.1 Tools and Supplies Needed

• #1 and #2 Phillips (cross-point) screwdrivers (or interchangeable tip screwdriver with #1 and #2

Phillips bits)

• Personal grounding device such as an anti-static wrist strap and a grounded conductive pad

4.1.2 System References

All references to left, right, front, top, and bottom assume that you are facing the front of the server, as it

would be positioned for normal operation.

4.1.3 Cable Routing Reference

It is important for cables to be connected correctly. See Figure 24 and Table 5 for cable routing and for

more detailed information, see the Kontron CG1200 Carrier Grade Server Technical Product

Specification.

34

Page 41

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 35

Figure 24: Cable Routing

35

Page 42

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 36

End #1 Connection

End #3 Connection

Table 5: System Cables

Interconnect #: Name:

1. Baseboard SSI Main

Power

2. CPU 1 and DIMM Power

3. CPU 2 and DIMM Power

4. SAS HDD Backplane

Board Power

5. SSI Front Panel Board

Power

6. Auxiliary I/O Power

Dongle

Baseboard SSI Power

Control Signal

7. PMBus Signal

8. HSBP I2C / HDD LED

End #2 Connection

End #1: Power Distribution

Board

End #2: Baseboard

End #1:Power Distribution

Board

End #2: Baseboard

End #1:Power Distribution

Board

End #2: Baseboard

End #1:Power Distribution

Board

End #2: SAS HDD Backplane

End #1:Power Distribution

Board

End #2: Front Panel Board

End #1:Power Distribution

Board

End #2: Cable to Cable

connector Baseboard

End #1: Power Distribution

Board Front Panel Board

End #2: Baseboard

End #1:SAS HDD Backplane

Board

End #2: Baseboard HSBP I2C

End #4 Connection

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: N/A

End #4: N/A

End #3: C-2-C (HDD-LED)

End #4:

9. Front Panel Signal

10. Front Panel Board USB

11. LED/Switch Board Power

and Signal

12. TAM Signal

End #1: Baseboard

End #2: Front Panel Board

End #1: Baseboard

End #2: Front Panel Board

End #1:Front Panel Board

End #2: LED/Switch Board

End #1:Front Panel Board

End #2: TAM Module

End #1:TAM Module

13. Alarms

End #2: System Rear Panel

Alarms Connector

14. Fan Power and Signal

(Fans 5A–5B)

15. Fan Power and Signal

(Fans 4A-4B)

End #1: Baseboard

End #2: Fan Pair (5A–5B)

End #1: Baseboard

End #2: Fan Pair (4A-4B)

36

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

Page 43

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 37

End #1 Connection

End #3 Connection

Interconnect #: Name:

16. Fan Power and Signal

(Fans 3A-3B)

17. Fan Power and Signal

(Fans 2A-2B)

18. Fan Power and Signal

(Fans 1A-1B)

End #2 Connection

End #1:Baseboard

End #2: Fan Pair (3A-3B)

End #1:Baseboard

End #2: Fan Pair (2A-2B)

End #1:Baseboard

End #2: Fan Pair (1A-1B)

End #4 Connection

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #3: NA

End #4: NA

End #1:SAS HDD Backplane

19. Mini-SAS Signal

(HDD 0-1 /SCU0 )

Board

End #2: Baseboard SAS 0-3

End #3: N/A

End #4: NA

SCU0 Connector

4.2 Installing or Replacing Hard Disk Drives

Up to four hot-swappable SAS hard disk drives can be installed in your CG1200 server. The drives go

into carriers that connect to the SAS backplane board once the carriers with drives attached are inserted

back into the drive bay slots. The CG1200 server ships with four drive carriers.

CAUTION: If you install fewer than four hard disk drives, the unused drive slots must contain the empty

carriers with filler panels that ship with the server to maintain proper cooling.

The CG1200 server does not support all SAS HDD or SATA SDD disk drives. To see a list of validated

manufacturers and drive models, refer to the THOL. The latest version of the THOL is located on the

Kontron support website at

http://us.kontron.com/support/

. (Search for CG1200, click on Product Downloads,

then Compatibility Matrix).

NOTE: SATA rotating HDDs are not recommended for use in this system because they are sensitive to

rotational vibration from system fan blades and other HDDs.

You must remove the front bezel to add or replace a hard drive in one of the drive slots. It is not

necessary to remove the chassis cover or to power down the system. The hard drives are hot-swappable.

4.2.1 Removing an HDD Carrier from the Chassis

1. Remove the front bezel. For instructions, see 3.2.3, “Removing the Front Bezel”.

2. Select the drive slot where you want to install/replace the drive.

Drive slot 0 must be used first, then drive slot 1 and so on.

(Drive slot numbers are printed on the front panel to identify the drive slots.)

3. Remove the drive carrier from the drive bay by pressing the green button to open the lever that

engages the drive to the backplane (Figure 25, “A”).

4. Pull the drive carrier out of the chassis (“B”).

37

Page 44

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 38

Figure 25: Removing the Drive Carrier

4.2.2 Installing a Hard Drive in a Carrier

1. If the drive carrier is empty (that is, if you are installing a drive in it for the first time), remove the black

plastic filler panel by unfastening the four screws that attach it to the carrier (Figure 26, “A”).

Set the screws aside for use with the new drive.

2. If a drive is already installed (that is, if you are replacing the drive), remove it by unfastening the four

screws that attach the drive to the drive carrier (Figure 26, “A”).

Set the screws aside for use with the new drive.

3. Lift the drive (or filler panel) out of the carrier (“B”).

38

Page 45

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 39

Figure 26: Removing a Hard Drive

4. Install the new drive in the drive carrier (Figure 27, “A”) and secure the drive with the four screws that

come with the carrier (“B”).

Figure 27: Installing a Hard Drive

5. With the drive carrier locking lever fully open, push the hard drive carrier into the drive slot in the

chassis until it stops (Figure 28 “A”).

6. Press the locking lever until it snaps shut and secures the drive in the slot (“B”).

Replace the front bezel. For instructions, see 3.2.4, “

39

Page 46

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 40

7. Re-Installing the Front Bezel”.

Figure 28: Inserting a New Hard Drive into the Chassis

4.3 Installing a Hardware RAID Controller

The CG1200 server supports the use of a RAID-on-chip (ROC) hardware RAID controller. This option is

separately orderable. The ROC module can be used with or without a SuperCap maintenance-free

backup module. If you are using the SuperCap module, the ROC module must be installed first, then the

SuperCap module.

Before you can install the ROC you must first remove the chassis cover, the front bezel, the PCIe fan

duct, and the riser card assembly.

4.3.1 Installing the ROC Module

1. Power down the server and remove all external devices and the power cord(s).

2. Remove the chassis cover. For instructions, see Section 3.2.1 “Removing the Chassis Cover”.

3. Remove the front bezel if you will be using the ESD ground attachment on the server for your anti-

static wrist strap grounding. For instructions, see section 3.2.3, “Removing the Front Bezel”.

4. Remove the riser card assembly. For instructions, see section 3.2.5, “Removing the Riser Card

Assembly”.

5. Remove the black plastic PCIe fan duct assembly:

NOTE: The fan does not need to be removed from the duct.

a. Disconnect the fan power/signal cable from the server board. (Figure 29, “A”)

40

Page 47

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 41

b. Unfasten the screw at the back of the duct assembly (“B”) and slide the assembly up and

away from the chassis retention bracket (“C”).

Figure 29: Removing the PCIe Fan Duct

6. Disconnect the mini-SAS cable from both the SAS HDD backplane (“A”) and the SCU0 connector

on the server board (“B”). The ROC module uses a different cable that comes in the cable kit.

41

Page 48

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 42

Figure 30: Removing the Mini-SAS Cable

7. Install the ROC module:

a. Firmly fasten the connector on the new SAS cable provided in the cable kit to the ROC

module. (Figure 31)

Figure 31: Connecting the SAS Cable to the ROC Module

42

Page 49

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 43

b. Snap the four plastic standoffs from the RAID kit into the holes on the server board

(Figure 32, “B”).

c. Align the ROC module with the four standoffs and press down on the module to secure it

in place (“A”).

d. Install the four plastic compression pins through the holes on the ROC card and into the

standoffs. Press and tighten each pin in the standoffs to firmly secure the module to the

server board (“C”).

Figure 32: Installing the ROC Module on the Server Board

e. Firmly fasten the other end of the SAS cable to the connector on the SAS HDD

backplane.

Make sure the cable routes under the small air baffle to the right of the fan duct assembly

location.

43

Page 50

Kontron CG1200 Carrier Grade Server Installation and Maintenance Guide 44

Figure 33: Connecting the Mini-SAS Cable to the Backplane