Page 1

» User’s Guide «

KBox C-101

User’s Guide (Version 2.00)

1055-6575

www.kontron.com

Page 2

This page is intentionally left blank.

www.kontron.com

Page 3

1. Table of Contents KBox C-101 – User’s Guide (Version 2.00)

1. Table of Contents

1. Table of Contents ..................................................................................................................................... 1

1.1. Table of Figures...................................................................................................................................... 4

2. Introduction ........................................................................................................................................... 6

2.1. Symbols used in this Manual ..................................................................................................................... 7

3. Important Instructions............................................................................................................................. 8

3.1. Obligation of Diligence............................................................................................................................ 8

3.2. Personnel ............................................................................................................................................. 8

3.3. Appropriate Use, Field of Application ......................................................................................................... 8

3.4. Warranty Note ....................................................................................................................................... 8

3.5. Exclusion of Accident Liability Obligation.................................................................................................... 8

3.6. Liability Limitation / Exemption from the Warranty Obligation ........................................................................ 8

4. General Safety Instructions for IT Equipment............................................................................................... 9

4.1. Electrostatic Discharge (ESD) ..................................................................................................................10

4.1.1. Grounding Methods......................................................................................................................... 10

5. Electromagnetic Compatibility (Class B Device) ..........................................................................................11

5.1. Electromagnetic Compatibility (EU) ..........................................................................................................11

5.2. FCC Statement (USA).............................................................................................................................. 11

5.3. EMC-Compliance (Canada) ......................................................................................................................11

6. Shipment and Unpacking .........................................................................................................................12

6.1. Unpacking ........................................................................................................................................... 12

6.2. Scope of Delivery...................................................................................................................................12

6.2.1. Standard....................................................................................................................................... 12

6.2.2. Optional Parts ................................................................................................................................12

6.2.3. Optional System Extension ............................................................................................................... 12

6.3. Spare Parts ..........................................................................................................................................12

6.4. Type Label and Product Identification ....................................................................................................... 13

7. System Overview.....................................................................................................................................14

7.1. RTC..................................................................................................................................................... 15

7.1.1. RTC Buffer Time ..............................................................................................................................15

7.1.2. Setting the RTC...............................................................................................................................16

7.2. System Expansion Capabilities .................................................................................................................16

7.2.1. Mini PCI Express® Interfaces............................................................................................................. 16

7.2.2. Standard PCI Express® Interfaces ......................................................................................................16

7.2.3. SATA Interfaces ..............................................................................................................................16

7.2.4. mSATA (MO-300) ............................................................................................................................16

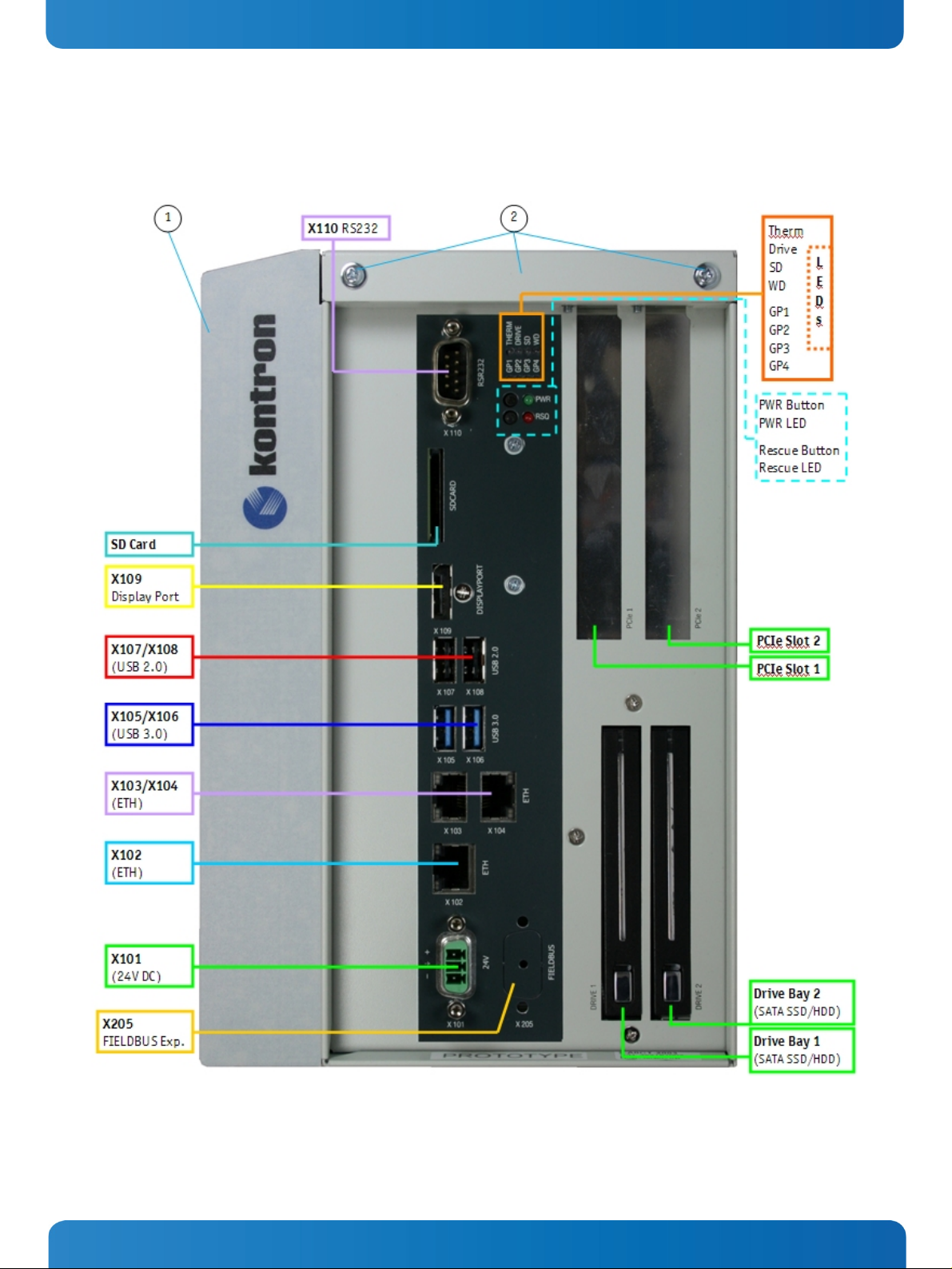

7.3. Front Side ............................................................................................................................................18

7.3.1. X101 - Power Input Connector........................................................................................................... 20

7.3.2. X102/X103/X104 - Ethernet Connectors (ETH) ..................................................................................... 20

7.3.3. X105/X106 - USB 3.0.......................................................................................................................20

7.3.4. X107/X108 - USB 2.0.......................................................................................................................20

7.3.5. X109 - DisplayPort ..........................................................................................................................20

7.3.6. SDCARD Slot ..................................................................................................................................21

7.3.7. X110 - RS232 .................................................................................................................................21

www.kontron.com 1

Page 4

1. Table of Contents KBox C-101 – User’s Guide (Version 2.00)

7.3.8. POWER Button and PWR LED ............................................................................................................. 22

7.3.9. RESCUE Button and RSQ LED............................................................................................................. 22

7.3.10. Status and General Purpose LEDs ..................................................................................................... 23

7.3.11. X205 - Optional FIELDBUS Interface ................................................................................................. 23

7.3.12. PCIe Expansion Slots 1 and 2 .......................................................................................................... 23

7.3.13. SATA Drive Bays............................................................................................................................ 24

7.4. Left and Right Side View......................................................................................................................... 25

7.5. Top and Bottom Side View ...................................................................................................................... 25

7.6. Rear Side View...................................................................................................................................... 26

7.6.1. Functional Earth Stud ..................................................................................................................... 26

7.7. Internal View ....................................................................................................................................... 27

7.7.1. Integrated COMe Module ................................................................................................................. 28

7.7.2. mSATA Socket................................................................................................................................ 28

7.7.3. Expansion Slots for PCIe Mini Cards.................................................................................................... 29

7.7.4. Expansion Slots for PCIe x4 Cards ...................................................................................................... 29

8. Thermal Considerations........................................................................................................................... 30

8.1. Available Processors.............................................................................................................................. 30

8.2. Convection Cooling ............................................................................................................................... 30

8.3. Active Cooling via the optional Fan Tray .................................................................................................... 30

8.4. Minimum System Clearance..................................................................................................................... 30

8.5. Maximum Temperatures ......................................................................................................................... 30

8.6. Third Party Components ......................................................................................................................... 31

8.7. Processor Thermal Monitoring ................................................................................................................. 31

8.8. Processor Thermal Trip Feature ................................................................................................................ 31

9. Installation Instructions......................................................................................................................... 32

9.1. Instructions for Control Cabinet Mount Installation..................................................................................... 32

10. Accessing Internal Components.............................................................................................................. 33

10.1. Top Cover .......................................................................................................................................... 34

10.2. Opening and Closing the KBox C-101 ...................................................................................................... 35

10.2.1. Installing/Removing the PCIe Expansion Cards................................................................................... 37

10.2.2. Installing/Removing the PCIe Mini Card ............................................................................................ 37

10.2.3. Installing an mSATA SSD ................................................................................................................ 38

11. Control Cabinet Mounting...................................................................................................................... 39

11.1. DC Power Connection ........................................................................................................................... 40

11.1.1. Cabling....................................................................................................................................... 40

12. Starting Up.......................................................................................................................................... 41

12.1. Connecting to DC Main Power Supply....................................................................................................... 41

12.2. Power OFF/ON Procedure ...................................................................................................................... 42

12.3. Operating System and Hardware Component Drivers .................................................................................. 43

13. Maintenance and Cleaning..................................................................................................................... 44

14. System Extensions................................................................................................................................ 45

14.1. Serial Port RS232/RS422 ...................................................................................................................... 46

14.2. CAN Port............................................................................................................................................ 46

14.3. DVI-D Interface Connector .................................................................................................................... 46

14.4. UPS Battery (Uninterruptable Power Supply) TBD ...................................................................................... 46

14.5. Optional KBox C-101 Version with Fan Tray............................................................................................... 47

2 www.kontron.com

Page 5

1. Table of Contents KBox C-101 – User’s Guide (Version 2.00)

14.6. Fan Tray............................................................................................................................................. 48

14.6.1. Replacing the Fan Tray ...................................................................................................................48

14.6.2. Cleaning the Air Filter ....................................................................................................................49

15. uEFI BIOS.............................................................................................................................................51

15.1. uEFI Shell Introduction, Basic Operation..................................................................................................51

15.1.1. Entering the uEFI Shell...................................................................................................................51

15.1.2. Exiting the uEFI Shell.....................................................................................................................51

15.1.3. Kontron-Specific uEFI Shell Commands .............................................................................................52

15.2. uEFI Shell Scripting..............................................................................................................................52

15.2.1. Startup Scripting ..........................................................................................................................52

15.2.2. Create a Startup Script ...................................................................................................................53

15.2.3. Examples of Startup Scripts.............................................................................................................53

15.3. Updating the uEFI BIOS ........................................................................................................................54

15.3.1. uEFI BIOS Recovery .......................................................................................................................54

15.3.2. Determining the Active Flash........................................................................................................... 54

16. Technical Specification ..........................................................................................................................55

16.1. Mechanical Specifications of the KBox C-101............................................................................................. 56

16.2. Mechanical Specifications of the KBox C-101 with Fan Tray Option ................................................................57

16.3. Environmental Specifications................................................................................................................. 58

16.4. CE-Directives and Standards .................................................................................................................. 59

17. KBox C-101 CPLD Specific Registers.........................................................................................................60

17.1. Reset Status Register (RSTAT) ................................................................................................................60

17.2. Interrupt Status Register (INTSTAT) ........................................................................................................61

17.3. Shutdown Control Register (SHDN_CTRL) .................................................................................................61

17.4. SPI Flash Control Registers (SPIFCTRL).....................................................................................................62

17.5. LED Control / Status Register (LCTRLSR)...................................................................................................62

18. Standard Interfaces – Pin Assignments....................................................................................................63

18.1.1. (X 101) Power Input Connector........................................................................................................63

18.1.2. (X 110) Serial Interface RS232.........................................................................................................63

18.1.3. DisplayPort ..................................................................................................................................64

18.1.4. (X 107, X 108) USB 2.0 Port ............................................................................................................64

18.1.5. (X 105, X 105) USB3.0 Port .............................................................................................................64

18.1.6. (X 102, X 103, X 104) Ethernet Connectors......................................................................................... 65

18.2. Optional Interfaces via Adapter Modules ..................................................................................................66

18.2.1. DVI-D (Single Link)........................................................................................................................66

18.2.2. Serial Port RS232/RS422 ................................................................................................................67

18.2.3. CAN Bus Port ................................................................................................................................68

18.2.4. UPS Connector (TBD) .....................................................................................................................68

19. Technical Support .................................................................................................................................69

19.1. Returning Defective Merchandise............................................................................................................69

www.kontron.com 3

Page 6

1. Table of Contents KBox C-101 – User’s Guide (Version 2.00)

1.1. Table of Figures

Fig. 1: Type label.........................................................................................................................................13

Fig. 2: RTC buffer time depending on temperature .............................................................................................15

Fig. 3: Bottom side view ...............................................................................................................................17

Fig. 4: Right side view ..................................................................................................................................17

Fig. 5: Front side view config. with removable drives..........................................................................................17

Fig. 6: Front side view config. without removable drives .....................................................................................17

Fig. 7: Left side view ....................................................................................................................................17

Fig. 8: Top side view ....................................................................................................................................17

Fig. 9: Rear side view ...................................................................................................................................17

Fig. 10: KBox C-101 - front view (shown with removable drive bays) .....................................................................18

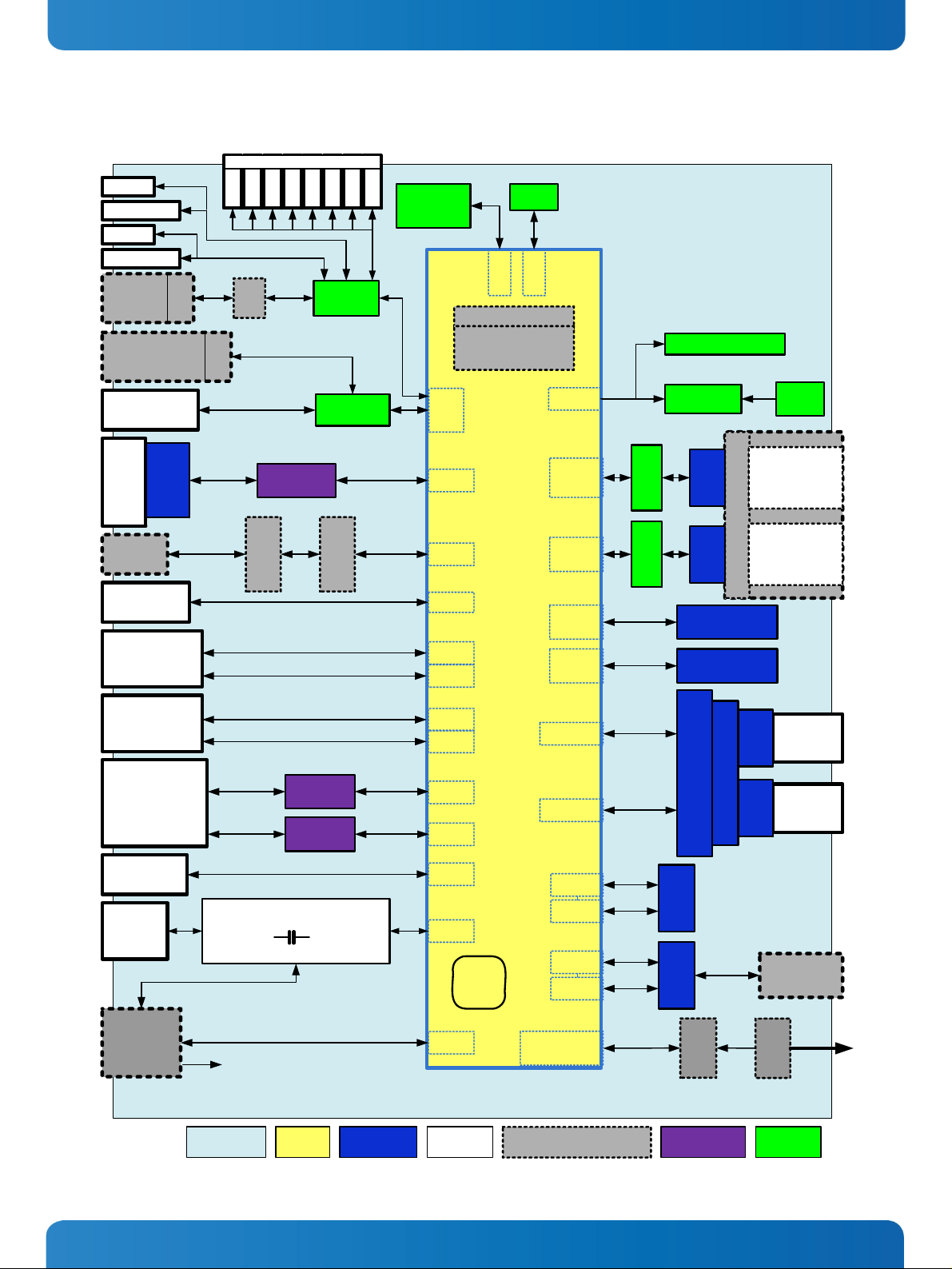

Fig. 11: Block Diagram - KBox C-101 ...............................................................................................................19

Fig. 12: X101 - 24VDC power input connector ...................................................................................................20

Fig. 13: SDCARD slot ....................................................................................................................................21

Fig. 14: SD card (not included) ......................................................................................................................21

Fig. 15:Detail - Power button and PWR LED/Rescue button and RSQ LED ................................................................22

Fig. 16: Detail - Status and General Purpose LEDs ..............................................................................................23

Fig. 17: X205 - Optional FIELDBUS interface.....................................................................................................23

Fig. 18: PCIe 1 and PCIe 2 slots ......................................................................................................................23

Fig. 19: Drive 1 and Drive 2 for removable 2.5" SATA HDD/SSD (option); closed drive bays........................................24

Fig. 20: Drive bay 1 with opened drive bay cover ...............................................................................................24

Fig. 21: Inserting/removing a 2.5" removable SSD ............................................................................................24

Fig. 22: Right side of the KBox C-101 system ....................................................................................................25

Fig. 23: Left side of the KBox C-101 system ......................................................................................................25

Fig. 24:Top side of the KBox C-101 system .......................................................................................................25

Fig. 25: Bottom side of the KBox C-101 system .................................................................................................25

Fig. 26: Rear side of the KBox C-101 system .....................................................................................................26

Fig. 27: KBox C-101 - internal view.................................................................................................................27

Fig. 28: KBox C-101 - internal view with COM Express module ..............................................................................28

Fig. 29: Inside of the top cover with fixing brackets ...........................................................................................34

Fig. 30: This movment allow you to remove the centring and fixing bracket of the top cover (detail of the KBox C-101) ..35

Fig. 31: Removing the cover (detail of the KBox C-101) ......................................................................................35

Fig. 32: KBox C-101 without top cover - removing the rihgt side cover...................................................................36

Fig. 33: KBox C-101 without top and right side cover .........................................................................................36

Fig. 34: Detail inside of the KBox C-101 with PCIe Riser card for 2x PCIe x4 slots......................................................37

4 www.kontron.com

Page 7

1. Table of Contents KBox C-101 – User’s Guide (Version 2.00)

Fig. 35: Keep out area for mounting around KBox C-101 (front side view).............................................................. 39

Fig. 36: Phoenix power plug terminal ............................................................................................................. 40

Fig. 37: KBox C-101 with removable drive bays and optional interfaces .................................................................45

Fig. 38: KBox C-101 with optional interfaces and without removable drive bays and ................................................ 45

Fig. 39: KBox C-101 equipped with the optional fan tray .................................................................................... 47

Fig. 40: Fan tray of the KBox C-101 (cable connection between fan and fan connector are included in this assembly).... 48

Fig. 41: Detail KBox C-101 with fan tray extension: air filter holder on the bottom side ............................................49

Fig. 42: KBox c-101 with removed fan tray and removed air filter .........................................................................50

Fig. 43: Holder without air filter .................................................................................................................... 50

Fig. 44: Holder with air filter......................................................................................................................... 50

Fig. 45: Air filter......................................................................................................................................... 50

Fig. 46:Dimensions: right side ...................................................................................................................... 56

Fig. 47: Dimensions: front side with key holes ..................................................................................................56

Fig. 48:Dimensions: detail key hole................................................................................................................ 56

Fig. 49: Dimensions: top side ........................................................................................................................ 56

Fig. 50:Dimensions: right side (with fan tray option)......................................................................................... 57

Fig. 51: Dimensions: front side with key holes (with fan tray option) .................................................................... 57

Fig. 52:Dimensions: detail key hole................................................................................................................ 57

Fig. 53: Dimensions: top side (with fan trayoption)........................................................................................... 57

www.kontron.com 5

Page 8

2. Introduction KBox C-101 – User’s Guide (Version 2.00)

2. Introduction

Kontron would like to point out that the information contained in this manual may be subject to technical alteration,

particularly as a result of the constant upgrading of Kontron products. The attached documentation does not entail any

guarantee on the part of Kontron with respect to technical processes described in the manual or any product

characteristics set out in the manual. Kontron does not accept any liability for any printing errors or other inaccuracies in

the manual unless it can be proven that Kontron is aware of such errors or inaccuracies or that Kontron is unaware of

these as a result of gross negligence and Kontron has failed to eliminate these errors or inaccuracies for this reason.

Kontron expressly informs the user that this manual only contains a general description of technical processes and

instructions which may not be applicable in every individual case. In cases of doubt, please contact Kontron.

This manual is protected by copyright. All rights are reserved by Kontron. Copies of all or part of this manual or

translations into a different language may only be made with the prior written consent of Kontron. Kontron points out

that the information contained in this manual is constantly being updated in line with the technical alterations and

improvements made by Kontron to the products and thus this manual only reflects the technical status of the products by

Kontron at the time of printing.

© 2014 by Kontron Europe

Printing and duplication, even of sections, is only permissible with the express approval of

Kontron Europe GmbH

Lise-Meitner-Str. 3-5

86156 Augsburg

Germany

6 www.kontron.com

Page 9

2. Introduction KBox C-101 – User’s Guide (Version 2.00)

2.1. Symbols used in this Manual

Symbol Meaning

This symbol indicates the danger of injury to the user or the risk of damage to the product if the

corresponding warning notices are not observed.

This symbol indicates that the product or parts thereof may be damaged if the corresponding warning

notices are not observed.

This symbol indicates general information about the product and the user manual.

This symbol indicates detail information about the specific product configuration.

This symbol precedes helpful hints and tips for daily use.

www.kontron.com 7

Page 10

3. Important Instructions KBox C-101 – User’s Guide (Version 2.00)

3. Important Instructions

Prior performing any installation or commissioning work with the device, this manual must be read carefully to become

familiar with the device. The general safety instructions and information apply to all Kontron equipment for industrial

control applications.

This manual provides important information required for the proper operation of the KBox C-101!

This chapter contains instructions which must be observed when working with the KBox C-101.

3.1. Obligation of Diligence

The operator must ensure that industrial PCs of the KBox Series are only used in control cabinet environments, the

operation manual is understood and the personnel has the necessary authorization and regularly training about relevant

standards, regulations and instructions.

Further the operator must ensure that the industrial PC is mounted, operated and maintained according to the instruction

of this manual.

Depending on the target application the operator must observe the current applicable national and international

regulations and standards.

3.2. Personnel

Only personnel with appropriate qualifications, trainings and authorization are permitted to install and work with the

Kontron KBox C-101 industrial PC.

All applicable technical standards, regulations and guidelines for the installation and usage of the device must be

understood and followed. Further accident prevention regulations and directives must be observed.

Every user of this system must be familiar with the instructions described in this manual.

3.3. Appropriate Use, Field of Application

The KBox C-101 is to be used in control cabinet applications only. Necessary fire enclosures and similar safety measures

are to be provided by the control cabinet. The operator must ensure that the place of installation complies with applicable

national and international standards and regulations.

3.4. Warranty Note

Due to their limited service life, parts which by their nature are subject to a particularly high degree of wear (wearing

parts) are excluded from the warranty beyond that provided by law. This applies e.g., to buffer battery storage media like

SD cards.

3.5. Exclusion of Accident Liability Obligation

Kontron shall be exempted from the statutory accident liability obligation if the user fails to observe the included

document: “General Safety Instructions for IT Equipment” the hints in this manual or eventually the warning signs label

on the device.

3.6. Liability Limitation / Exemption from the Warranty Obligation

In the event of damage to the device caused by failure to observe the included document “General Safety Instructions for

IT Equipment” in this manual or eventually the warning signs label on the device, Kontron shall not be required to honor

the warranty even during the warranty period and shall be exempted from the statutory accident liability obligation.

8 www.kontron.com

Page 11

4. General Safety Instructions for IT Equipment KBox C-101 – User’s Guide (Version 2.00)

4. General Safety Instructions for IT Equipment

Please read this chapter carefully and take careful note of the instructions, which have been compiled for

your safety and to ensure to apply in accordance with intended regulations. If the following general

safety instructions are not observed, it could lead to injuries to the operator and/or damage of the

product; in cases of nonobservance of the instructions Kontron is exempt from accident liability, this

also applies during the warranty period.

The product has been built and tested according to the basic safety requirements for low voltage (LVD) applications and

has left the manufacturer in safety-related, flawless condition. To maintain this condition and to also ensure safe

operation, the operator must not only observe the correct operating conditions for the product but also the following

general safety instructions:

❏ The product must be used as specified in the product documentation, in which the instructions for safety for the

product and for the operator are described. These contain guidelines for setting up, installation and assembly,

maintenance, transport or storage.

❏ The on-site electrical installation must meet the requirements of the country's specific local regulations.

❏ If a power cable comes with the product, only this cable should be used. Do not use an extension cable to connect the

product.

❏ To guarantee that sufficient air circulation is available to cool the product, please ensure that the ventilation

openings are not covered or blocked. If an air filter is provided, this should be cleaned regularly. Do not place the

system close to heat sources or damp places. Make sure the system is well ventilated.

❏ Only devices or parts which fulfill the requirements of SELV circuits (Safety Extra Low Voltage) as stipulated by

IEC 60950-1 may be connected to the available interfaces.

❏ Before opening the device, make sure that the device is disconnected from the mains.

❏ Switching off the device by its power button does not disconnect it from the mains. Complete disconnection is only

possible if the power cable is removed from the wall plug or from the device. Ensure that there is free and easy access

to enable disconnection.

❏ The device may only be opened for the insertion or removal of add-on cards (depending on the configuration of the

system). This may only be carried out by qualified operators.

❏ If extensions are being carried out, the following must be observed:

• all effective legal regulations and all technical data are adhered to

• the power consumption of any add-on card does not exceed the specified limitations

• the current consumption of the system does not exceed the value stated on the product label.

❏ Only original accessories that have been approved by Kontron can be used.

❏ Please note: safe operation is no longer possible when any of the following applies:

• the device has visible damages or

• the device is no longer functioning

In this case the device must be switched off and it must be ensured that the device can no longer be operated.

www.kontron.com 9

Page 12

4. General Safety Instructions for IT Equipment KBox C-101 – User’s Guide (Version 2.00)

Additional safety instructions for DC power supply circuits

❏ To guarantee safe operation of devices with DC power supply voltages larger than 60 volts DC or a power consumption

larger than 240 VA, please observe that:

• the device is set up, installed and operated in a room or enclosure marked with “RESTRICTED ACCESS”, if there are no

safety messages on product as safety signs and labels on the device itself.

• no cables or parts without insulation in electrical circuits with dangerous voltage or power should be touched

directly or indirectly

• a reliable protective earthing connection is provided

• a suitable, easily accessible disconnecting device is used in the application (e.g. overcurrent protective device,), if

the device itself is not disconnectable

• a disconnect device, if provided in or as part of the equipment, shall disconnect both poles simultaneously

• interconnecting power circuits of different devices cause no electrical hazards

❏ A sufficient dimensioning of the power cable wires must be selected – according to the maximum electrical

specifications on the product label – as stipulated by EN60950-1 or VDE0100 or EN60204 or UL508 regulations.

❏ The devices do not generally fulfill the requirements for "centralized DC power systems“ (UL 60950-1, Annex NAB; D2)

and therefore may not be connected to such devices!

4.1. Electrostatic Discharge (ESD)

A sudden discharge of electrostatic electricity can destroy static-sensitive devices or micro-circuitry. Proper packaging

and grounding techniques are necessary precautions to prevent damage. Always take the following precautions:

1. Transport boards in static-safe containers such as boxes or bags.

2. Keep electrostatic sensitive parts in their containers until they arrive at the ESD-safe workplace.

3. Always be properly grounded when touching a sensitive board, component, or assembly.

4. Store electrostatic-sensitive boards in protective packaging or on antistatic mats.

4.1.1. Grounding Methods

The following measures help to avoid electrostatic damages to the device:

1. Cover workstations with approved antistatic material. Always wear a wrist strap connected to workplace as well as

properly grounded tools and equipment.

2. Use anti-static mats, heel straps, or air ionizes to give added protection.

3. Always handle electrostatic sensitive components by their edge or by their casing.

4. Avoid contact with pins, leads, or circuitry.

5. Turn off power and input signals before inserting and removing connectors or connecting test equipment.

6. Keep work area free of non-conductive materials such as ordinary plastic assembly aids and styrofoam.

7. Use field service tools such as cutters, screwdrivers, and vacuum cleaners which are conductive.

8. Always place drives and boards PCB-assembly-side down on the foam.

10 www.kontron.com

Page 13

5. Electromagnetic Compatibility (Class B Device) KBox C-101 – User’s Guide (Version 2.00)

5. Electromagnetic Compatibility (Class B Device)

5.1. Electromagnetic Compatibility (EU)

This product complies with the European Council Directive on the approximation of the laws of the member states relating

to electromagnetic compatibility (2004/108/EC), Class B limits for Information Technology Equipment according to

European Standard EN 55022.

5.2. FCC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

❏ Reorient or relocate the receiving antenna.

❏ Increase the separation between the equipment and receiver.

❏ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

❏ Consult the dealer or an experienced radio/TV technician for help.

5.3. EMC-Compliance (Canada)

The method of compliance is self-declaration to Canadian ICES-003:

(English): This Class B digital apparatus complies with the Canadian ICES-003.

(French) : Cet appareil numérique de la class B est conforme à la norme NMB-003 du Canada.

www.kontron.com 11

Page 14

6. Shipment and Unpacking KBox C-101 – User’s Guide (Version 2.00)

6. Shipment and Unpacking

6.1. Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the contents and your order, please contact Kontron

for help and information.

6.2. Scope of Delivery

6.2.1. Standard

KBox C-101 (corresponding to the ordered system configuration)

POWER-SUBCON PSC 1,5/ 3-F, 3-pin plug

General Safety Instructions for IT Equipment

6.2.2. Optional Parts

Front accessible drive bays for 2.5" HDD/SSDs

Mini-PCIe cards

mSATA cards (MO-300)

PCIe cards

6.2.3. Optional System Extension

RS232/RS422 Port: via internal factory mounted and configured RS232/RS422 adapter module

CAN Port: via internal factory mounted CAN adapter module

DVI-D (single Link) Port: via internal factory mounted DVI-D adapter module

External UPS (Uninterruptable Power Supply): via internal factory mounted UPS adapter module

Optional system expansion with fan tray

6.3. Spare Parts

The following spare parts are available for field replacement:

Spare Part Part Number

Fan tray 1055-4009

Air filter 1055-4670

12 www.kontron.com

Page 15

6. Shipment and Unpacking KBox C-101 – User’s Guide (Version 2.00)

6.4. Type Label and Product Identification

The type label (product name, serial number) and the inspection status label of your KBox C-101 system are located on

the right side of the device (refer to

Fig. 1 and Fig. 22, pos. 9).

Fig. 1: Type label

www.kontron.com 13

Page 16

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7. System Overview

The KBox C-101 System is a highly scalable and flexible industrial automation process monitor and control system. As

such, it is designed to provide application process visualization and supervisory interaction capability. Performance

scalability is achieved through the use of various Kontron COM Express® CPU modules (form factor: basic and type 6

pinout).

KBox C-101 offers maintenance free ("Wartungsfrei") operation. That means it operates without battery, fans and

rotating media (HDD's). The system flexibility is a result of the basic design concept of the KBox C-101:

❏ use of a prime carrier board which provides COM Express® and a set of standard IO interfacing

❏ a comprehensive set of optionally available IOs and devices.

The following interfaces are available with the KBox C-101:

Standard front panel:

❏ 24VDC input power (X101)

❏ 3x Gigabit Ethernet (X102, X103, X104)

❏ 2x USB 3.0 (X105, X106)

❏ 2x USB 2.0 (X107, X108)

❏ DisplayPort (X109)

❏ SD Card slot (without X numbered slot)

❏ RS232 serial (X110)

❏ Switches with integrated LEDs:

• RSQ (rescue)

• PWR (power)

❏ LEDs:

• GP1 to GP4 (general purpose LEDs)

• THERM (thermal status)

• DRIVE (SSD/HDD drive status)

• SD (SDHC/SDXC status)

• WD (Watchdog status)

❏ Standard carrier onboard and system expansion capabilities

• 2x SATA plus device power

• 2x mSATA (MO-300 sites)

• 2x Mini PCIe x1 slots (one slot is on the top side, the second one on the bottom side of the baseboard

• 2x PCIe x4 slots on Riser card

14 www.kontron.com

Page 17

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

The KBox C-101 is a fanless system with a compact aluminum chassis with cooling fins.

The rated voltage of the mains can be found on the type label. The type label is located at the right side of the device.

The device is designed be operated wall mounted inside a control cabinet, in vertical position, except

with the top side facing down.

When switching on the KBox C-101, make sure that the air exhaust openings on the top side

pos. 12), the air intake openings on the bottom side (

chassis (

To provide sufficient heat dissipation by the cooling of the device, do not cover the cooling fins of the

KBox C-101. Do not place any objects on the device. When installing the system, please note the

clearance recommendation in the section

Fig. 23, Fig. 24 and Fig. 25, pos. 6) are not obstructed (covered) by any objects.

16.1 “Mechanical Specifications”.

Fig. 25, pos. 11) and the cooling fins of the

Fig. 24,

7.1. RTC

The KBox C-101 comprises a chipset external RTC. This RTC is connected to the SMBus of the processor module. A RTC of

type RV-8564 or compatible is used. To provide a valid date and time when no power is connected to the KBox C-101, the

RTC is equipped with a goldcap buffer.

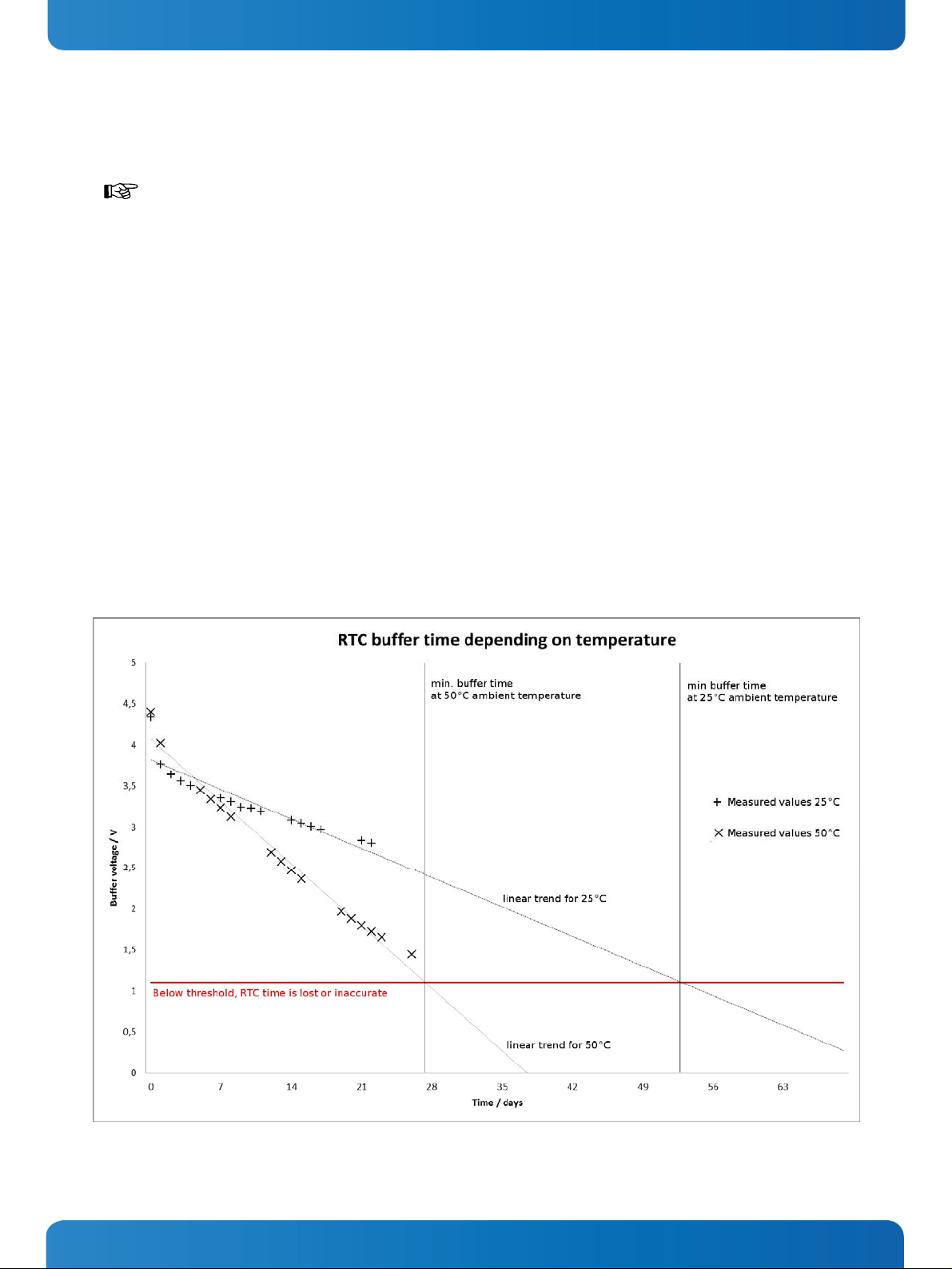

7.1.1. RTC Buffer Time

The RTC buffer time is depending of the ambient temperature. To better understand the different behavior of the goldcap

buffer of your system refer to the diagram below:

Fig. 2: RTC buffer time depending on temperature

www.kontron.com 15

Page 18

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

If the time is not valid this is indicated by a status bit in the RTC registers. For details see the RV-8564 application manual.

To get the maximum buffer time it is necessary to have the system a certain time powered on. This ensures

that the buffer capacitors are fully loaded.

The buffer time depends on the ambient temperature and on how long the box is connected to its power

supply.

7.1.2. Setting the RTC

During startup, the uEFI performs a comparison of chipset clock and external RTC and sets the chipset clock accordingly if

the RTC time is valid. Further it is possible to set the time manually by accessing the RTC over the SMBus.

7.2. System Expansion Capabilities

For the configuration of your KBox C-101 please follow the ordering options specified in:

“Configuration Guides – KBox C-101“ on our web site

www.kontron.com.

7.2.1. Mini PCI Express® Interfaces

There are two Mini PCIe interfaces on the KBox C-101 baseboard. One Mini PCIe interface connector is accessible from the

top of the KBox C-101 when the top panel is removed. The other Mini PCIe interface connector is located on the bottom

site of the baseboard and is not accessible in the field. This interface connector is intended to be used for the Fieldbus

expansion. If a customer requires this system expansion, it must be so stipulated when ordering, as the device must be

installed at the factory.

7.2.2. Standard PCI Express® Interfaces

The KBox C-101 provides two half-length standard height PCIe slots which are accessible when the top cover is removed.

7.2.3. SATA Interfaces

The KBox C-101 offers two SATA interfaces for. These are either connected to two internal drive bays or optional to front

accessible drive bays for 2.5" HDDs or SSDs (refer to the subsection

7.2.4. mSATA (MO-300)

The KBox C-101 has two mSATA interfaces which are accessible when the top panel is removed.

7.3.13 “SATA Drive Bays”.

16 www.kontron.com

Page 19

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

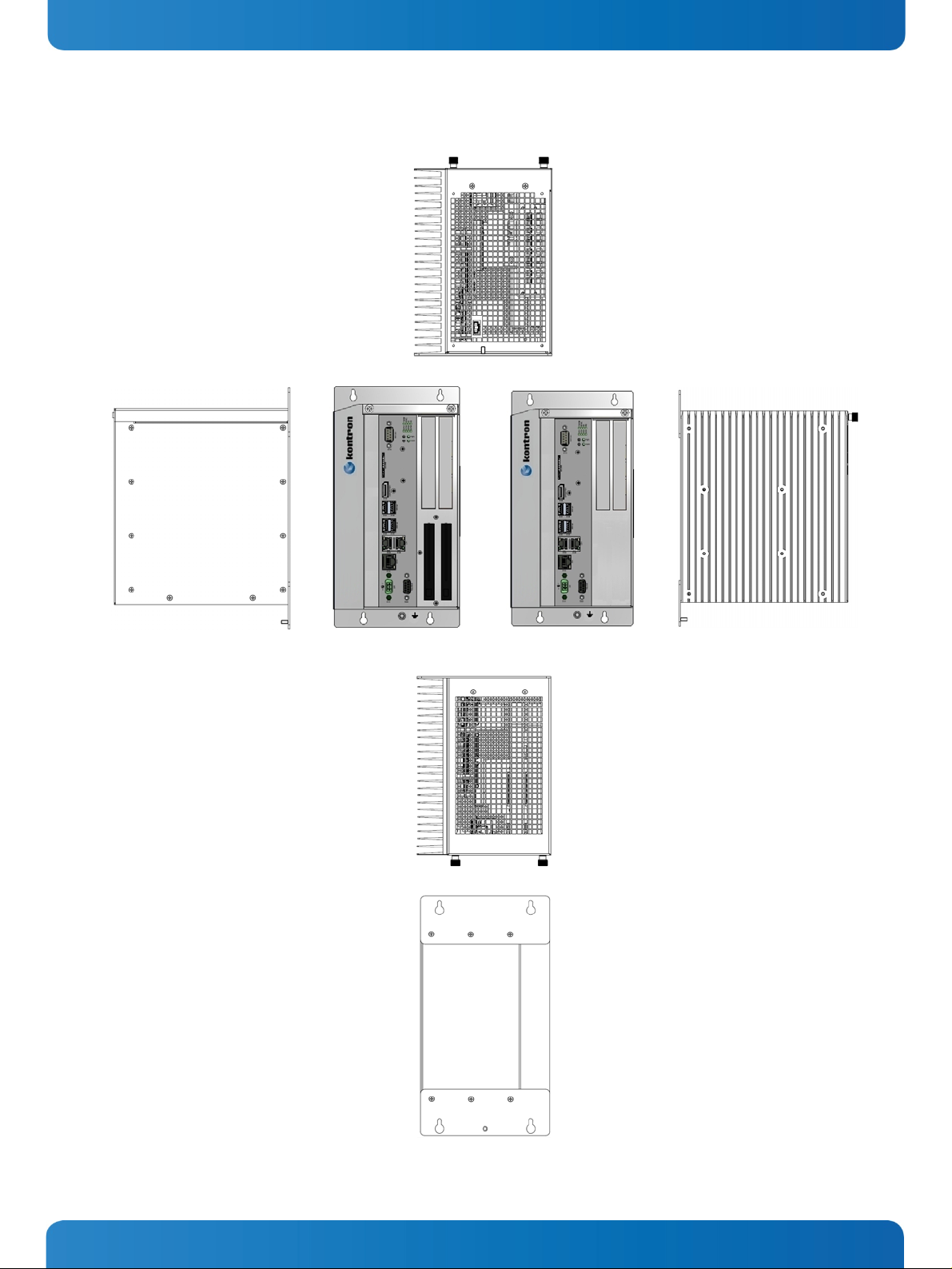

Fig. 3: Bottom side view

Fig. 4: Right side view Fig. 5: Front side view config.

with removable drives

Fig. 6: Front side view config.

without removable drives

Fig. 7: Left side view

Fig. 8: Top side view

Fig. 9: Rear side view

www.kontron.com 17

Page 20

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.3. Front Side

Fig. 10: KBox C-101 - front view (shown with removable drive bays)

1 Side of KBox C-101 with cooling fins

2 Top side cover with knurled screws

18 www.kontron.com

Page 21

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

LEDs

PWR LED

Power Button

RSQ LED

RESCUE Button

CAN

X 203

galvanic

RS232/RS422

X 204

Serial RS232

X 110

THERM

SJA

isolation

1000

via Adapter Module

galvanic

isolation

CPLD

Super I/O

SPI Flash

RESCUE BIOS

LPC

GP4

GP3

GP2

GP1

WD

SD

DRIVE

System

EPROM

C

2

I

SPI

CPU Options

i5 / i7 / Celeron®

SMBUS

KBox C-101

Temperatur Sensor

RTC

Ultra low power

Gold

CAP

Slot

Connector

SD Card

SD Card

DVI Port

X 202

DisplayPort

X 109

2x USB (2.0)

X 107

X 108

2x USB (3.0)

X 105

X 106

2x ETH (RJ45)

X 103

X 104

ETH (RJ45)

X 102

PWR IN

24 VDC

X 101

UPS

Uninterruptible

Power Supply

X 201

SD Card

Controller

DVI

DVI

Redriver

Gb LAN

Gb LAN

Controller

Gb LAN

Gb LAN

Controller

Gb LAN

Power Supply

and Power Monitor

10 ms Hold-Up

to CPLD

2.5" HDD/SSD

2.5" HDD/SSD

Internal or Removable

Connector

PCIe x4

Riser Card

Connector

PCIe x4

FIELDBUS

Drive 1

for

Drive 2

for

PCIe 1

Slot

PCIe 2

Slot

X 205

to external

Fan Tray

FAN

(Option)

Connector

USB2

Display PortDVI

Converter

DP to DVI

DDI2

DDI1

USB6

USB7

USB1

USB0

PCIe x1

PCIe x1

PCIe3

PCIe4

COM Express® - Basic

GBE

VCC

BIOS

Flash

USB8

SATA0

6 Gb/s

SATA1

3 Gb/s

SATA2

6 Gb/s

SATA3

6 Gb/s

Type 6 Module

PEG8-11

PEG12-15

PCIe1

USB4

PCIe2

USB5

FAN_TACHIN

/PWMOUT

PCIe x4

PCIe x4

PCIe x1

USB 2.0

PCIe x1

USB 2.0

SATA

Repeater

SATA

Repeater

onnector

SATA0C

SATA1

Connector

mSATA1

Connector (MO-300)

mSATA2

Connector (MO-300)

PCIe x8 Connector

Connector

Mini PCIe

via Adapter

Module

Connector

Mini PCIe

TachoFAN_CTRL

FAN

Control

Baseboard

Legend

Baseboard

COMe

Module

www.kontron.com 19

Onboard

connectord

External

interfaces

Optional ext. interfaces and

Fig. 11: Block Diagram - KBox C-101

onboard components

Onboard

controller

Complex

function

Page 22

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

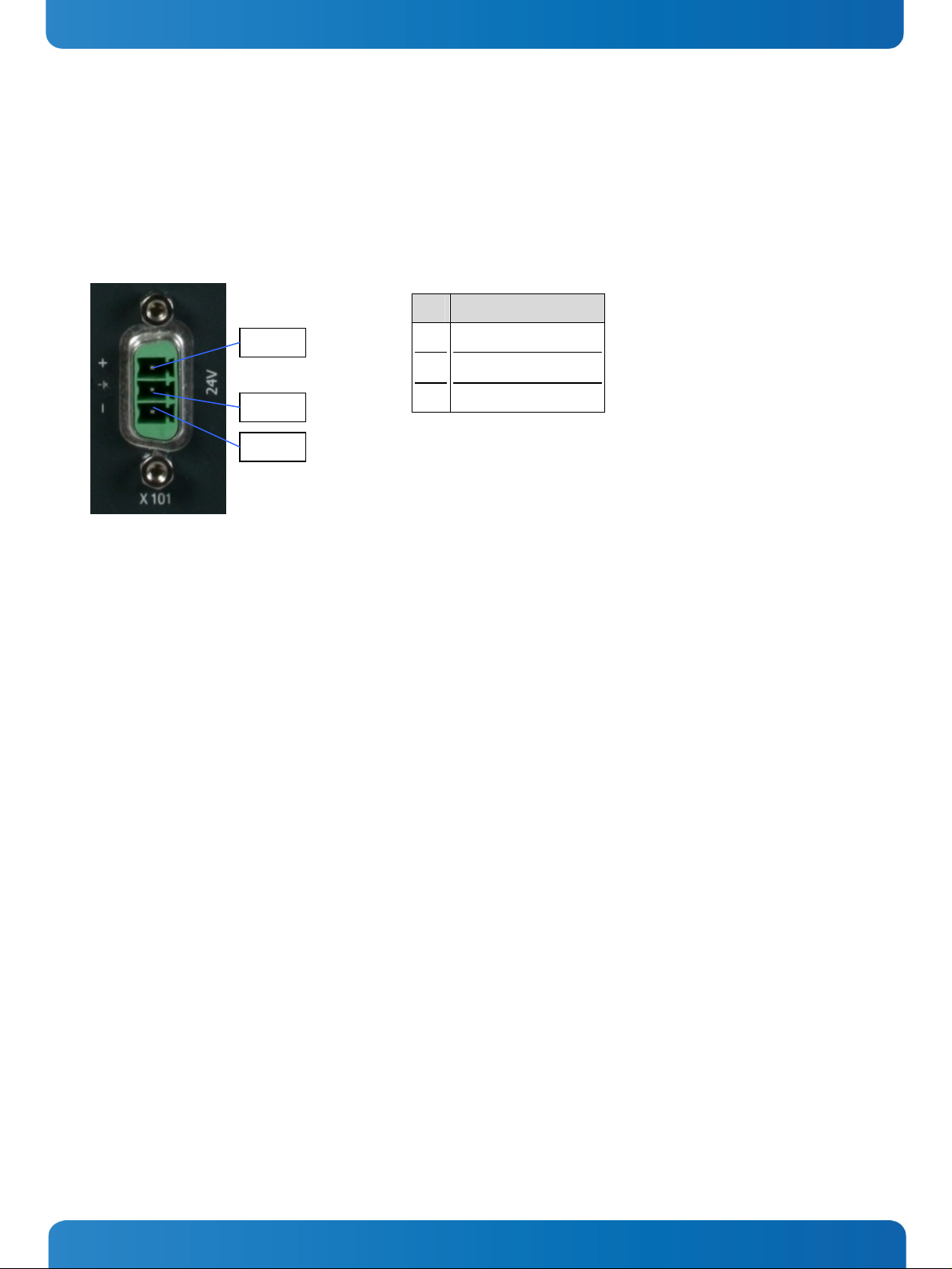

7.3.1. X101 - Power Input Connector

The 3-pin connector (X101,

supply. For pin assignments refer to the subsection

Fig. 10) provides the power connection of the KBox C-101 to the appropriate DC main power

18.1.1.

The external cable connector is a Phoenix PSC 1,5/ 3-M, 3-pin plug with an SCT-D-SUB 9-KG housing. This power plug is

delivered along with the KBox C-101. Please observe the section

12.1 “Connecting to DC Main Power Supply”. The mating

connector is a Phoenix PSC 1,5/ 3-F connector.

Pin Signal Name

1

Pin 1

Pin 2

+24 VDC (input)

2

Functional Earth

3

0V (input)

Pin 3

Fig. 12: X101 - 24VDC power input connector

7.3.2. X102/X103/X104 - Ethernet Connectors (ETH)

These connectors (X102/X103/X104, Fig. 10) are Gigabit Ethernet 10/100/1000 Mbit/s, IEEE 1588 capable interfaces.

The connectors are standard 8-pin RJ45 type connectors with status LEDs:

Activity/link: green = link up; green blinking = activity.

Speed: off, green, yellow (10/100/1000 MBit/s).

For pin assignment refer to subsection

18.1.6.

7.3.3. X105/X106 - USB 3.0

The KBox C-101 provides two USB 3.0/2.0 interfaces. These connectors (X105/X106,

or USB 2.0 compatible devices to the system. For pin assignment refer to subsection

Fig. 10) allow connection of USB 3.0

18.1.5.

7.3.4. X107/X108 - USB 2.0

The KBox C-101 provides two USB 2.0/1.1 interfaces. These connectors (X107/X108,

compatible devices to the system. For pin assignment refer to subsection

18.1.4.

Fig. 10) allow connection of USB-

7.3.5. X109 - DisplayPort

This is a DisplayPort compliant interface realized using a standard DisplayPort connector. An external (digital) display can

be connected to the DisplayPort connector (X109,

Fig. 10). For pin assignment refer to subsection 18.1.3.

20 www.kontron.com

Page 23

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.3.6. SDCARD Slot

This slot, marked “SDCARD” is an SDHC/SDXC compliant interface realized using a standard SD card connector. It is

accessible at the front side of the KBox C-101 (

Fig. 10) and is located between the serial interface (RS232/X110) and

DISPLAYPORT.

• This SD card reader supports SD, SDHC and SDXC cards.

• SD card activity is indicated by the SD LED on the KBox C-101 front side.

• This interface permits hot-plugging of SD card. The system can also be booted from this interface.

Fig. 13: SDCARD slot Fig. 14: SD card (not included)

This interfaces support hot-swapping.

To prevent data loss when removing the SD or SDHC or SDXC card, it may not be removed during a read

or write access [while the green SD LED (

Fig. 16) of the drives is green flashing].

To install a card please perform following steps:

1. Insert the SD/SDHC/SDXC card into the SDCARD slot marked “SDCARD” (see

Fig. 10. and Fig. 13) on the front side of

the KBox C-101.

2. Gently push the card into the open slot until it snaps (clicks) into place. When the card was inserted correctly, the

green SD LED (

Fig. 16) of the multi card reader lights up (provided that the computer is switched on and booted up).

Do not act with force when inserting the memory card. If this seems to be necessary, the card is not

inserted properly in the guide of the slot. Remove the card from the slot and re-insert it with care.

3. The card is ready for use.

To remove a card, proceed as follow described:

1. Push the SD/SDHC/SDXC card in all the way and then let it “push” itself out (there is a spring loaded mechanism in the

holder which does this).

2. Once the card is released, grasp the protruding part of the card and remove the card from the holder.

7.3.7. X110 - RS232

This interface (X110,

a serial peripheral. For pin assignment refer to subsection

Fig. 10) is provided as a 9-pin D-SUB connector; it is RS232 configured and allows the connection of

18.1.2.

www.kontron.com 21

Page 24

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.3.8. POWER Button and PWR LED

1

2

1 Power button (PWR)

2 Power LED (PWR)

3 Rescue button (RSQ)

3

Fig. 15:Detail - Power button and PWR LED/Rescue button and RSQ LED

4

4 Rescue LED (RSQ)

This power button (PWR, Fig. 10, Fig. 15, pos. 1) is used to initiate a system power shut down or power start up after a

power shut down. A forced system shutdown can be initiated by pressing the power button for longer than four seconds.

The power LED (marked PWR,

Fig. 10, Fig. 15, pos. 2) is on green steady when power is applied to the system.

Prerequisite:

The KBox C-101 has to be connected to an appropriate main power supply (DC).

Even when the system is turned off via the power button there is still a standby voltage on the

baseboard. The unit is only completely disconnected from the DC mains, when the power is removed

As soon as external power is applied to the main input power connector, X101, the KBox C-101 begins to operate (boots

up and then starts the operating system and application where available).

To perform an orderly shutdown of the system, press the PWR button and the system shuts down under the control of the

operating system.

To perform an immediate forced shutdown of the system, press the PWR button for more than four seconds and the system

power is buttoned off (no matter what the state of the application or operating system is). Performing a forced shutdown

can lead to loss of data or other undesirable effects.

Once the system has been shutdown, it can restarted by pressing the PWR button (assuming that power is still applied to

the main input power connector, X101).

7.3.9. RESCUE Button and RSQ LED

The rescue function is not intended for use with a system in an application environment. It is designed

for a maintenance environment (where the standard BIOS flash is corrupted) to attempt to get the

system to boot in a defined and safe state for further failure resolution.

Please refer to the chapter

17 “KBox C-101 CPLD Specific Registers”.

The RESCUE button (RSQ,

LED (RSQ,

Fig. 10, Fig. 15, pos. 4) blinks red when the backup flash is selected for booting. The backup flash contains a

Fig. 10, Fig. 15, pos. 3) is used to force using the backup flash for system booting. The RESCUE

cloned BIOS (uEFI) version. In the event the system does not properly start-up or gets hung-up and restarting (cold

booting) the system does not help, it is possible to switch to the backup boot flash and then restart the system. To do

this, press the RSQ button for more than five seconds, whether or not the system is running it will now start-up using the

backup flash for booting.

To revert to using the standard boot flash, the system must be cold started using the PWR button or remove power

completely from the system and then reapply.

22 www.kontron.com

Page 25

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.3.10. Status and General Purpose LEDs

After power is applied and the KBox C-101 performs the boot procedure the LEDs show the POST code. In case of a boot

failure within the uEFI the last post code is displayed. When the boot phase is passed without errors, the LEDs change to

their status and general purpose function.

The following table provides information concerning these LEDs (

Fig. 10 and Fig. 16).

Status and General Purpose LEDs

Designator Function Color Description

THERM Thermal Red blinking

The system turns off due to

over temperature

DRIVE Drives (SSD/HDD) Green SSD/HDD active

SD SD Card Green SD card active

WD Watchdog Red blinking Watchdog timeout occurred

GP1 General Purpose 1

GP2 General Purpose 2

GP3 General Purpose 3

GP4 General Purpose 4

Fig. 16: Detail - Status and General Purpose LEDs

Red/Green/Orange

Red/Green/Orange

Red/Green/Orange

Red/Green/Orange

User general purpose 1

User general purpose 2

User general purpose 3

User general purpose 4

7.3.11. X205 - Optional FIELDBUS Interface

The optional interface (FIELDBUS) on the front side of the KBox C-101 must

be ordered separately. To add a FIELDBUS interface to the KBox C-101 the

second mPCIe slot, on the bottom of the baseboard, will be used. This

connection can be implemented at factory only.

Fig. 17: X205 - Optional FIELDBUS interface

7.3.12. PCIe Expansion Slots 1 and 2

The KBox C-101 provides two PCIe x4 slots for half-length PCIe add-on cards. The two PCIe x4 expansions utilize a subset

of the connections from the processor chipset PEG port. To access these slots (

Fig. 10, PCIe 1 and PCIe 2) in order to

install or remove PCIe x4 expansion cards you have to remove the top side access cover. For better accessibility of the

expansion slots you should to remove the right side access cover (

For installation/removing of the mSATA SSD refer to the subsection

1

2

Fig. 24 and Fig. 22, pos 1 and 3) also.

10.2.3, “Installing an mSATA SSD”.

1 PCIe 1 slot

2 PCIe 2 slot

Fig. 18: PCIe 1 and PCIe 2 slots

www.kontron.com 23

Page 26

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.3.13. SATA Drive Bays

Depending on the ordered system configuration, your KBox C-101 can be equipped with up to two removable drive bays

(refer to

Fig. 10 and Fig. 19) or two internal 2.5" SATA HDD. The internal HDDs/SSDs are not accessible from the outside.

The two 2.5” removable drive bays (DRIVE 1 and DRIVE 2) are accessible from the front side (

Fig. 10) of the KBox C-101.

Both drive bays are designed for removable 2.5” SATA SSD/HDDs (without mounting frames).

The drives support following dive speeds:

DRIVE 1: up to SATA 6 Gb/s.

DRIVE 2: up to SATA 3 Gb/s.

If the KBox C-101 configuration with internal SATA HDD/SSD was chosen, the Drive 1 and Drive 2 for

removable SATA HDD/SSD are not available (refer to

Fig. 6).

If the KBox C-101 configuration with removable SATA HDD/SSD was chosen, no installation of an internal

SATA HDD (with mounting frame) is possible.

4

3

1

2

Fig. 19: Drive 1 and Drive 2 for removable 2.5" SATA HDD/SSD

(option); closed drive bays

Fig. 20: Drive bay 1 with opened drive bay cover

5

Fig. 21: Inserting/removing a 2.5" removable SSD

Legend for

1 Slide button to release the drive bay cover

2 Cover of the drive bay

Fig. 19, Fig. 20 and Fig. 21:

4 Opened drive bay cover

5 Inserting or removing a 2.5" removable SATA HDD/SSD

3 Drive bay for 2.5" removable SATA HDD/SSD

To install/remove a drive, please perform the following steps:

1. Slide the drive cover release button to the right (

Fig. 19, pos. 1). The drive cover will spring up.

2. Pull the drive cover up.

3. Insert/remove the drive into /out from the bay receptacle.

4. Close the cover.

The drive is now ready for operation.

These interfaces support hot-swapping.

To prevent data loss when removing the

removable HDD/SSD, it may not be removed

during a read or write access [while the green

DRIVE LED (

Fig. 16) of the drives is green

flashing].

24 www.kontron.com

Page 27

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.4. Left and Right Side View

1

2

3

2

Fig. 22: Right side of the KBox C-101 system

Legend for Fig. 22, Fig. 23, Fig. 24 and Fig. 25:

1 Top side access cover with knurled screws

2 10x screws that secure the right side access cover

3 Right side access cover

4 Upper mounting plate with key holes

5 Lower mounting plate with M4 ground stud and key holes

6 Cooling fins of the chassis

4

6

9

7

5

Fig. 23: Left side of the KBox C-101 system

7 Screws that secure the COMExpress module

8 Screws that secure the cooling fins to the chassis

9 Type label

10 Hole for further system fan try extension

11 Air intake openings on the bottom cover

12 Air exhaust openings on the top cover

1

8

7

8

7.5. Top and Bottom Side View

4

6

6

12

10

Fig. 24:Top side of the KBox C-101 system

1

Fig. 25: Bottom side of the KBox C-101 system

When powering on the KBox C-101, make sure that the air intake and exhaust openings are not

obstructed. To provide sufficient heat dissipation for the cooling of the KBox C-101 platform, never cover

the cooling fins of the chassis. Do not place any objects onto the device.

www.kontron.com 25

1

11

5

Page 28

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.6. Rear Side View

The KBox C-101 is designed for wall mounting, in vertical position inside of a control cabinet.

Please observe the mounting instructions included in the section 9.1 “Instructions for Control Cabinet Mount

Installation

KBox C-101 version with the optional fan expansion refer to the subsection

C-101 with Fan Tray

Please do not remove the screws marked with red (

”, and the outline dimensions in the subsection 16.1 “Mechanical Specifications”. For the dimension of the

”

1

4

5

Fig. 26, pos. 2 and 4).

16.2 “Mechanical Specifications of the KBox

1 Key holes on the upper mounting

plate

2 Screws that secures the upper

mounting plate of the KBox C-101

3 Key holes on the lower mounting

plate

4 Screws that secures the lower

mounting plate of the KBox C-101

5 Chassis bottom

6 Functional Earth stud

4

3

Fig. 26: Rear side of the KBox C-101 system

7.6.1. Functional Earth Stud

There is an M4 functional earth terminal on the lower mounting plate of the KBox C-101 (Fig. 26, pos. 6). This terminal

may be connected as required.

The KBox C-101 with the stud marked with a “Functional Earth” symbol (

an appropriate “common earth” connection point.

6

Fig. 26) has to be grounded to

26 www.kontron.com

Page 29

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.7. Internal View

15

1

2

3

4

5

6

7

Fig. 27: KBox C-101 - internal view

14

13

12

11

10

9

8

1 Cover retaining bracket on the front side

2 LED indicators circuit

3 Screws that secure the PCIe slot brackets

4 1x Mini PCIe slot for PCIe Mini card (please observe

the note below)

5 PCI x8 slot

6 Riser card with 2x PCIe x4 slots

7 Mounting frame for removable 2.5" drive bays

8 Lower mounting bracket with key holes

The KBox C-101 provides two internal Mini PCIe slots. One of them you can see in

The second Mini PCIe slot is on the bottom of the baseboard and can be only at the factory fitted with an

expansion card.

9 SATA cable connections (power and data)

10 Baseboard

11 2x mSATA slots

12 Mechanical fixing assemblies for:

2x 2.5" mSATA SSD and 1x PCIe Mini card (two fixing

bolts for each mSATA SSD and PCIe Mini card) (please

observe the note below)

13 Cover retaining bracket on the rear side

14 Cooling fins

15 Upper mounting bracket with key holes

Fig. 27, pos. 4.

www.kontron.com 27

Page 30

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.7.1. Integrated COMe Module

Depending on the ordered system configuration, your KBox C-101 accommodates a baseboard with either a COMe-bHL6

i5-4402E or a COMe-bHL6 i7-4700EQ module.

9

8

1

2

3

4

5

Fig. 28: KBox C-101 - internal view with COM Express module

1 COM Express module

2 Baseboard

3 Mechanical fixing assemblies for 1x PCIe Mini card;

(two fixing bolts for each PCIe Mini card)

4 Screws that secure the PCIe slot brackets

5 Riser card with 2x PCIe x4 slots

Refer to the information and technical data in the user manual of the installed COMe-bHL6 i5-4402E / i74700EQ Module.

7

6

6 Cover retaining plate on the rear side

7 Mechanical fixing assemblies for 2x 2.5" mSATA SSD

(two fixing bolts for each mSATA SSD)

8 Upper mounting bracket with key holes

9 Cooling fins

The user’s manual of the installed COMe Module can be downloaded from our web page

www.kontron.com .

Search for the name of the installed board.

7.7.2. mSATA Socket

Depending on the system configuration ordered your KBox C-101 can be extended with up to two mSATA SSD.

For installation/removing of the mSATA SSD refer to the subsection

10.2.3, “Installing an mSATA SSD”.

28 www.kontron.com

Page 31

7. System Overview KBox C-101 – User’s Guide (Version 2.00)

7.7.3. Expansion Slots for PCIe Mini Cards

Depending on the system configuration ordered your KBox C-101 can be extended with up to two PCIe Mini cards.

The KBox C-101 provides two internal Mini PCIe slots for PCIe Mini cards.

One of them you can see it in

baseboard and can be only at the factory fitted with an expansion card.

Fig. 27, pos. 4). The second Mini PCIe slot is on the bottom side of the

For installation/removing of the PCIe Mini card (

Installing/Removing the PCIe Mini Card”.

“

Fig. 27, pos. 4), please refer to the subsection 10.2.2

7.7.4. Expansion Slots for PCIe x4 Cards

Depending on the system configuration ordered your KBox C-101 can be extended with up to two PCIe x4 cards (fullheight, half-length form factor).

For installation/removing of the PCIe x4cards (

Installing/Removing the PCIe Expansion Cards”.

“

Fig. 27, pos. 6), please refer to the subsection 10.2.1

To expand your system with additional cards, please observe the power consumption specified in the

chapter

16 “Technical Specification”. The power consumption of each additional card does not exceed

15 W.

www.kontron.com 29

Page 32

8. Thermal Considerations KBox C-101 – User’s Guide (Version 2.00)

8. Thermal Considerations

8.1. Available Processors

Please refer to the chapter 16 “Technical Specification”.

The list of processors is not complete and may be extended over the product lifetime.

8.2. Convection Cooling

The KBox C-101 is designed for ambient air convection cooling within the specified ambient air temperature ranges.

Therefore it is imperative that air flow to and from the unit is guaranteed.

In addition, implementers must empirically verify the cooling concept for the KBox C-101 including optionally installed

devices prior implementing the unit in the intended application.

8.3. Active Cooling via the optional Fan Tray

For applications where convection cooling is not sufficient, there is the possibility to use the optional fan tray (externally

mounted to the KBox C-101). The optional fan tray extension allows the KBox C-101 to operate at higher ambient

temperature conditions and provides a higher airflow through the chassis providing better cooling of the system internal

components.

8.4. Minimum System Clearance

To provide a maximum of airflow through and around the box, minimum distances to surrounding parts must be observed

(please refer to the chapter

11 “Control Cabinet Mounting” and Fig. 35).

8.5. Maximum Temperatures

As the Intel® processors provide only certain settings for maximal power consumption, some typically are used for the

following table. This table can be seen as a guideline.

KBox C-101 without Fan Tray KBox C-101 with Fan Tray

Processor Power

Consumption

25W 65 5 70 2

37W 59 5 65 2

47W 50 5 55 2

Max. ambient

Temperature [°C]

The maximum system ambient temperature depends mostly on the power consumption of the processor

and the chipset.

Approx. System internal

Temp. Rise [°C]

Max. ambient

Temperature [°C]

Approx. System internal

Temp. Rise [°C]

30 www.kontron.com

Page 33

8. Thermal Considerations KBox C-101 – User’s Guide (Version 2.00)

For the temperature evaluation a specialised tool from Intel

Depending on the power consumption one or more cores were set to 75% workload. This includes the graphics core. The

tool also handles the usage of the "Turbo Mode" of certain processor types.

The processor utilisation depends highly on the software used. Software using multicore feature will run

on several cores whereas standard software will only utilise one core. In this case the processor will use

the "Turbo Mode" to increase the clock for the core with the highest workload, as long as the

temperature is within limits.

®

was used to set the processor to a defined workload.

8.6. Third Party Components

When the KBox C-101 is extended and configured with third party components like PCIe extension cards and hard drives

(HDD or SSD), it has to be taken into account that the air temperature inside the system is higher than the ambient

temperature. An approximately internal temperature rise is given for assistance.

8.7. Processor Thermal Monitoring

The processor used with the KBox C-101 system provides internal thermal monitoring. Every core of the processor

comprises a temperature sensor.

To allow an optimal operation and long-term reliability, the processor must operate in the specified temperature range.

To avoid overheating the processor performs an automatic thermal management, which intends to keep the processor

temperature below the highest value of the temperature range. This behavior is a CPU standard feature.

8.8. Processor Thermal Trip Feature

The Processor Thermal Trip feature protects the processor from catastrophic overheating. The Thermal Trip Tensor

threshold is set well above the normal operating temperature to ensure that there are no false trips. The processor will

stop all executions when the junction temperature exceeds approximately 125°C. This event will be indicated by the red

blinking "Thermal" LED on the front panel. This behavior cannot be altered. Once activated, the event remains latched

until power is cycled.

www.kontron.com 31

Page 34

9. Installation Instructions KBox C-101 – User’s Guide (Version 2.00)

9. Installation Instructions

9.1. Instructions for Control Cabinet Mount Installation

The KBox C-101 comes with attached wall mount brackets. The available mounting key holes of the wall mount brackets

allow the unit attaching to a wall of a fire resistant enclosure.

Expansion card installation should be performed before installing the KBox C-101 into the control

cabinet.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where a safe work

station is not guaranteed, it is important for the user to be electrically discharged before touching the

product with his/her hands or tools. This is most easily done by touching a metal part of the system

chassis.

Do not handle this product out of its protective enclosure while it is not used for operational purposes

unless it is otherwise protected.

Prior any installation work ensure that there are no live wires on the installation site

Do not handle the device if there is any damage visible.

Do not operate the KBox C-101 with foreign objects inside the chassis.

Further do not insert any retrieval device into the device while it is connected to power.

Kontron rejects all liability for any and all damages resulting from operation of the unit with foreign

objects inside the chassis.

The KBox C-101 has to be installed and operated only by trained and qualified personnel.

The KBox C-101 system is designed for usage within control cabinets only.

Only personnel with appropriate qualifications, trainings and authorization are permitted to install and