KONICA MINOLTA QMS magicolor 6100 Service Manual

magicolor 6100 Series Service Manual

1750039-001C

The essentials of imaging

www.minolta-qms.com

Safety and Revision Information

magicolor 6100 Series Service Manual Page i

Page ii magicolor 6100 Series Service Manual

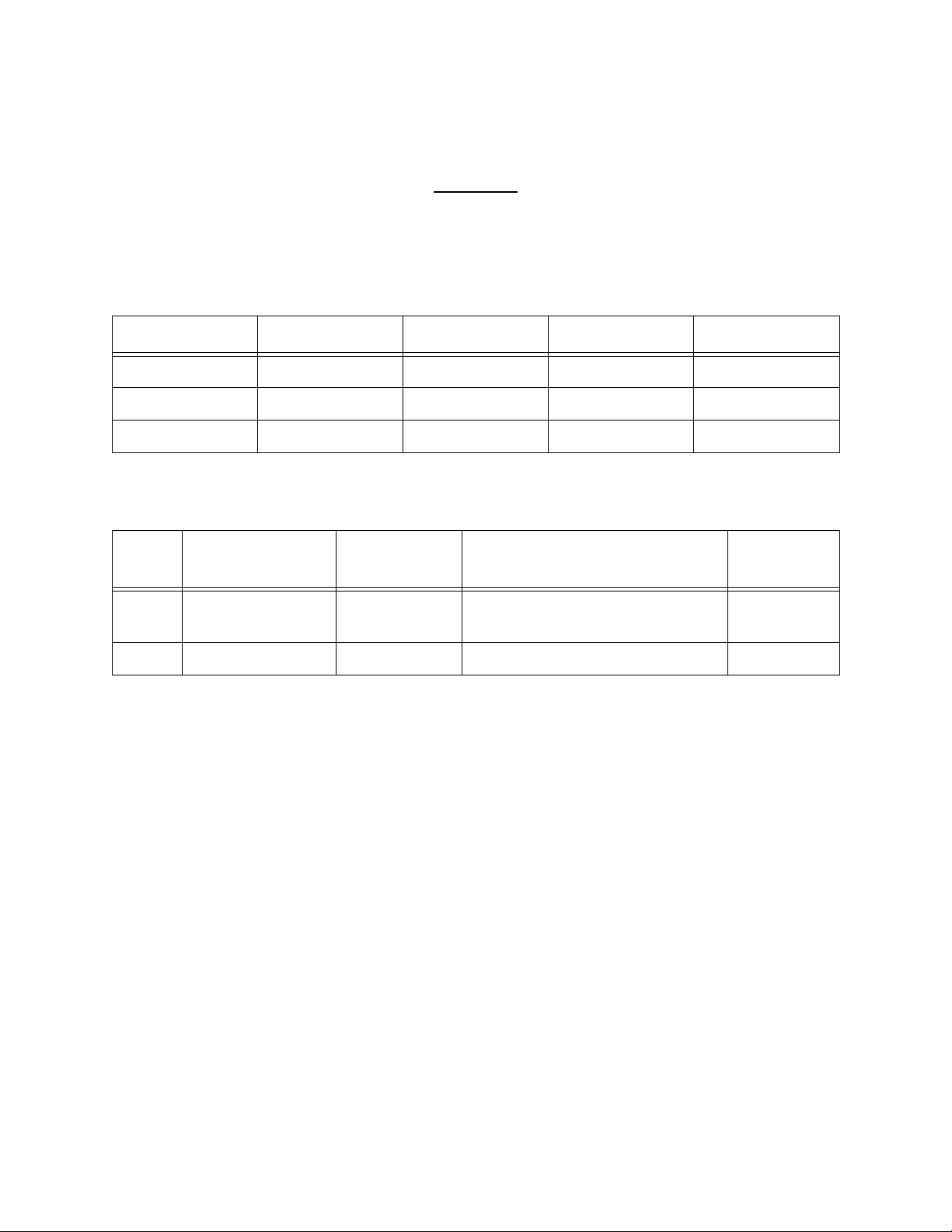

Revision Control Table

No. Date of Revision Revision Code Description of Revision

1 July, 1999 First Edition First edition.

2 August, 1999 “A” Edition Reviewed to cover the mass-production

unit.

3 October, 1999 “A” Edition Reviewed following pages:

3-3, 7-34, 7-42, 7-60, 9-1 and 9-5

4 October, 1999 QMS REV. 001 Internal manual revision. Duplexer and

LFU information added.

5 March 2000 QMS REV. 001A Final OEM information included. Format

revision.

6 July 2000 Minolta-QMS

Rev. 001B

7 June 2001 Minolta-QMS

Added LFU wiring diagram. Error message corrections included

New OEM information included.

Rev. 001C

Note:Some pages found within this manual are 11” x 17”. If you print out the Acrobat files, please note

these pages should be printed seperately.

FCC NOTICE

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his/her own expense.

A shielded cable is required to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules.

Caution: Any modifications or changes to this product not expressly approved in writing by the manufacturer responsible for compliance to Federal Regulations could void the user's authority to operate this product within the Laws and Regulations of the Federal Communications Commission.

Canadian Compliance

magicolor 6100 Series Service Manual Page iii

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus

set out in the Radio Interference Regulations of the Canadian Department of Communications.

"Le presnt appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux

appareils numeriques (de la Class A) prescrites dans le Reglement sur le brouillage radioelectrique edicte

par le ministere des Communications du Canada."

Product Safety

WARNING

WARNING

Laser Product

This engine is certified as a Class 1 laser product and complies with

CDRH Laser-Radiation Standards, 21 CFR Chapter 1, Subchapter J.

Use of controls, adjustments or performances of procedures other than

those specified in this manual may result in hazardous radiation exposure.

Ozone Gas

This engine is provided with the ozone filter in order to reduce exhaust

ozone in compliance with Product Safety Standards. The ozone filter

must be replaced yearly; otherwise, it may cause a strong odor, which will

likely have ill effects on bronchial tubes.

Page iv magicolor 6100 Series Service Manual

Documentation Disclaimer

QMS MAKES NO REPRESENTATION OR WARRANTIES OF ANY

KIND WHATSOEVER WITH RESPECT TO THE CONTENTS

HEREOF AND SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

i Safety Instructions

i.i Safety Principles

i.i.i Before starting any procedure, read this manual thoroughly. Read and understand

i.i.ii When handling any P.W.B. use all necessary ESD precautions.

i.i.iii Perform all the operations by following the procedures described in this manual.

the safety instructions found in this section.

Follow all the cautions and warnings set out in the procedures and on safety labels

affixed to the machine. Failure to do so may result in personal injuries or equipment

damage.

i.i.iv Perform only the procedures explained in this manual. Refrain from opening or

touching any portions that are not related with your operation.

i.i.v Repair and replacement of parts should be performed by trained and qualified ser-

vice personnel only. Operators should not attempt to do such repair or replacement.

i.i.vi It must be understood that the above-mentioned cautions and warnings do not cover

everything, because it is impossible to guess at or evaluate all the circumstances

beforehand.

i.ii Special Safety Information

i.ii.i Introductory Information

The warnings and cautions are made clear by “Signal Words” such as DANGER,

WARNING and CAUTION.

i.ii.i.i Definition of Signal Words

magicolor 6100 Series Service Manual Page v

DANGER

is used to indicate the presence of a hazard which will cause

severe human injuries or a fatal accident if ignored.

WARNING

is used to indicate the presence of a hazard or unsafe practices which may cause severe human injuries or a fatal accident if

ignored.

CAUTION

is used to indicate the presence of a hazard or unsafe practices which may cause minor human injuries if ignored. CAUTION also

calls attention to safety messages in this manual.

i.ii.i.ii Follow Safety Instructions

Carefully read all the safety messages set out in this manual and also in

the safety signs placed on your equipment. Do not remove safety labels

from products. Replace the safety labels if they become smeared or damaged. Learn how to operate the equipment and how to use the controls

properly. Do not let anyone operate the equipment without reading the

instructions. Keep the equipment in proper working condition. Unauthorized modification to the equipment may impair product function and

safety, and affect the life of equipment.

The following are the various kinds of “

manual.

WARNINGs

” contained in this

WARNING

HAZARDOUS VOLTAGE

It may cause serious injuries or fatal accidents. Voltage is now applied

from the power supply of printer. There is the danger of electric shock if

you touch the active area inside the printer.

Make sure to turn the power supply switch OFF and pull out the plug

from the outlet before starting the maintenance work on the printer.

WARNING

HARMFUL OZONE GAS

Inhalation of an excessive amount of ozone gas may adversely affect the

respiratory organs.

The ozone filter is provided in this printer to reduce the exhaust ozone.

This filter must be replaced with a new filter periodically in accordance

with the manual for this printer.

Page vi magicolor 6100 Series Service Manual

CAUTION

HOT SURFACE

Can cause serious burns.

The fusing unit is approximately 150°C, therefore, the areas around the

fuser are also very hot.

When you need to change the cleaning pad or remove jammed paper, wait

about 20 minutes after opening up the paper exit unit and confirm that the

unit is well cooled down.

CAUTION

ROTATING PARTS

Be aware of the danger of getting your fingers or hand caught in the

printer or associated rollers causing serious injuries. Note that the exit

roller is rotating while printing.

Be careful not to get your hair, fingers, hands, sleeves or neckties caught

in the printer while operating the machine.

The following are the various kinds of “

Manual.

CAUTIONs

” contained in this

CAUTION

HAZARDOUS POWDER

Toner is a fine powder known to cause a powder explosion if dumped into

open fire. Strictly refrain from dumping toner into the fire for disposal.

Toner is a fine powder known to cause problems with eyes, and problems

with respiratory organs if inhaled.

Handle the toner cartridge, waste toner pack, and developing unit carefully.

CAUTION

POWER CORD AND PLUG

This printer is equipped with a 3-wire power cord and 3-pronged plug (bipolar plug with grounding) for user safety.

magicolor 6100 Series Service Manual Page vii

Connect the power cord to a properly grounded electrical receptacle to

avoid an electric shock.

CAUTION

SAFETY INTERLOCK

Cover and paper delivery unit of this printer have electric safety interlocks to turn the power off whenever they are opened. Do not attempt to

circumvent these safety interlocks.

CAUTION

Do not step on or lean against the paper cassette. Failure to follow this

guideline may cause the printer to tip over. This may cause injuries or it

may damage the printer.

Do not step on or lean against the printer door. Failure to follow this

guideline may cause the printer to tip over. This may cause injuries or it

may damage the printer.

Page viii magicolor 6100 Series Service Manual

magicolor 6100 Series Service Manual Page ix

Page x magicolor 6100 Series Service Manual

i Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

i.i Safety Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

i.ii Special Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1.0 Outline of Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1 Name and Function of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Name and Function of Duplexer Components . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 Name and Function of LFU Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Internal Structure of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Internal Structure of the Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 Description of The Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.0 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1 Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1 Conditions for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4.0 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1 Basic Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Print System and Transfer/Transport System . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3 Optical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.4 Paper Transportation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.5 Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.6 Structure of the Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

5.0 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Cleaning for Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Periodic Maintenance Cycles and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

6.0 Operation of and Adjustments through the Operator Panel. . . . . . . . . . . . . . . . . . . . . . 6-3

6.1 Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2 Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 Operation of Normal Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4 Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.5 Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

7.0 Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.1 Replacement of Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.2 Replacement of Printed Wire Boards (P.W.B) . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

magicolor 6100 Series Service Manual

7.3 Replacement of Motor Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

7.4 Replacement of Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

7.5 Replacement of Switches and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

7.6 Replacement of Rollers, Drums, and Other Components. . . . . . . . . . . . . . . . . 7-69

7.7 Replacement of the Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-80

7.8 Duplexer Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-83

7.9 Replacement of Lower Feed Unit Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-107

8.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.1 Troubleshooting Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2 Operator Call Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.3 Paper Transport Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8.4 Printer Errors (non-Operator Call Errors). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

8.5 Imaging Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-72

9.0 Spare Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

magicolor 6100 Series Service Manual

Section 1:

Outline of Product

magicolor 6100 Series Service Manual Page 1-1

Page 1-2 magicolor 6100 Series Service Manual

1.0 Outline of Product

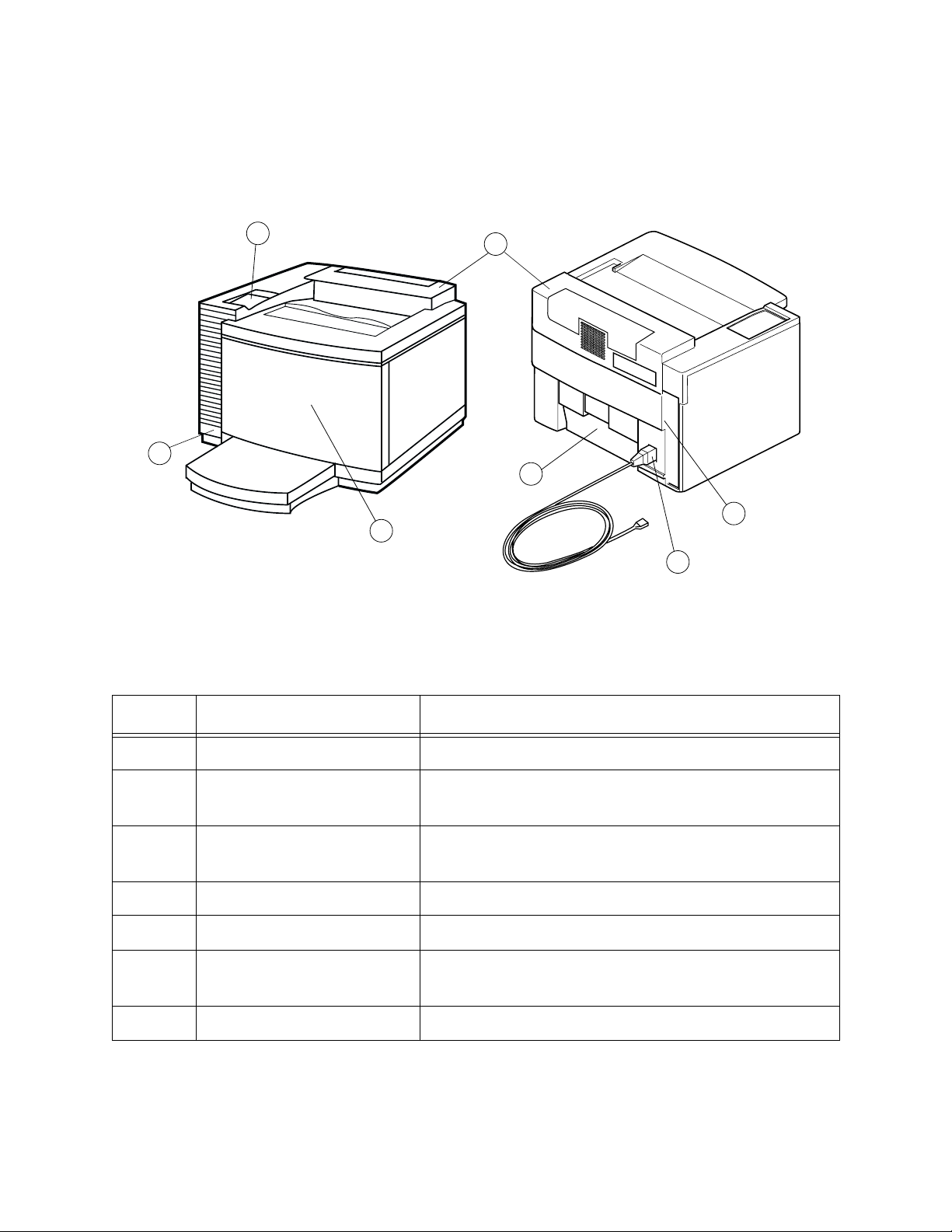

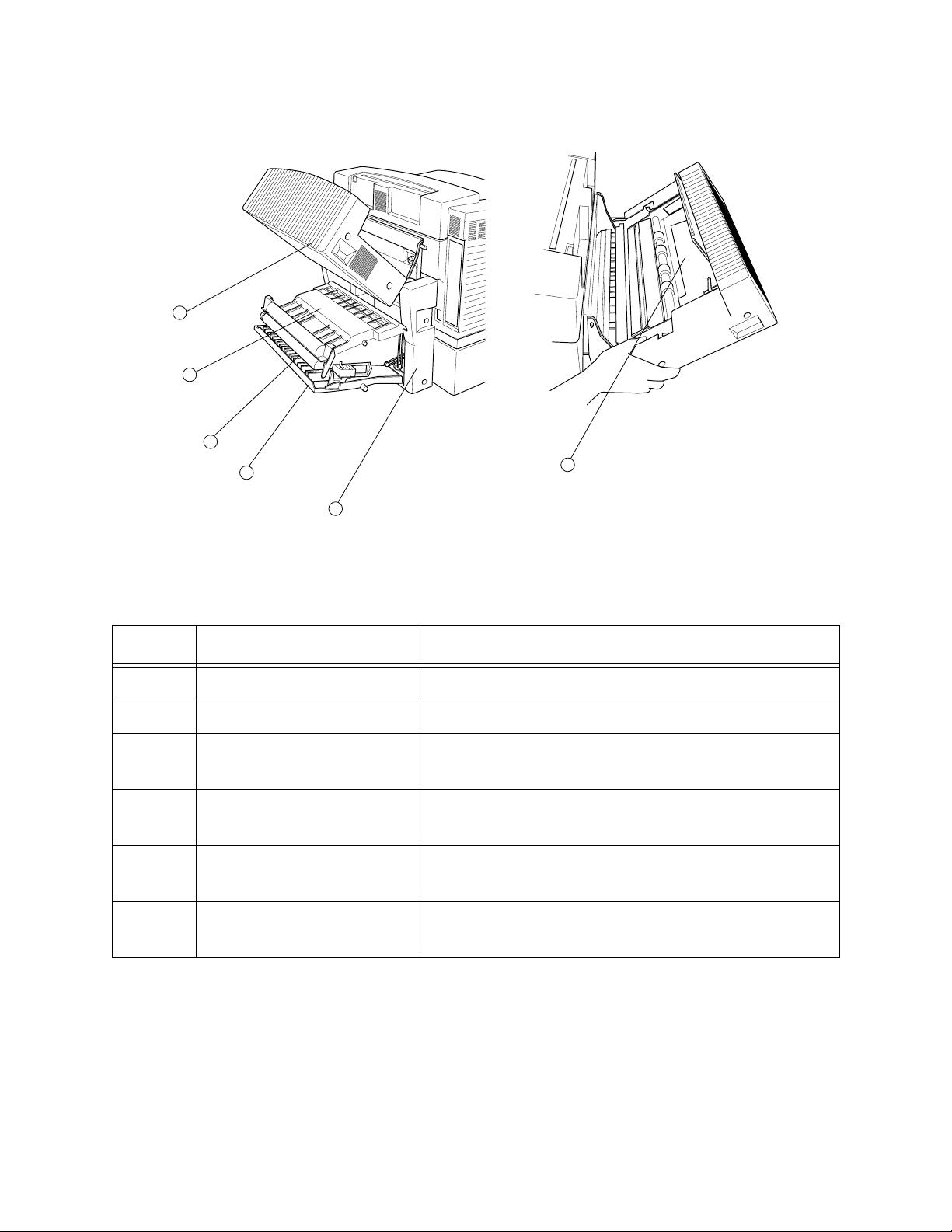

1.1 Name and Function of Components

1

3

4

6

7

2

5

Fig. 1-1

Number Name of Part Function of Part

1 Operator Panel Displays a status of printer operation.

2 Front Door Acts as a front enclosure. Open when replacing toner

cartridges or waste toner packs.

3 Paper Exit Unit Acts as an enclosure for the paper exit and output

paper tray.

4 Main Switch Powers On/Off the printer.

5 Power Connection Connects to a power supply cable.

6 Transfer Unit Door Acts as a rear enclosure. Open when clearing an inter-

nal jam or performing maintenance.

7 Interface Connector Panel Video controller PWB installation location.

magicolor 6100 Series Service Manual Page 1-3

1.2 Name and Function of Duplexer Components

1

5

4

3

2

Fig. 1-2

6

Number Name of Part Function of Part

1 Top Unit Transports the front side of the page to the duplexer.

2 Lower Unit Reverses the front page for printing on the back page.

3 Lower-rear Cover Open for clearing an inner jam or performing mainte-

nance. Rear enclosure.

4 Reverse Paper Guide Unit Open for clearing inner jams or performing mainte-

nance. Paper reverse and transport unit.

5 Reverse Input Paper Guide Open for clearing inner jams or performing mainte-

nance. Paper reverse and transport guide.

6 Paper Guide FU Open for clearing “DUPLEX JAM.” Paper transpor-

tation guide in D-top unit.

Page 1-4 magicolor 6100 Series Service Manual

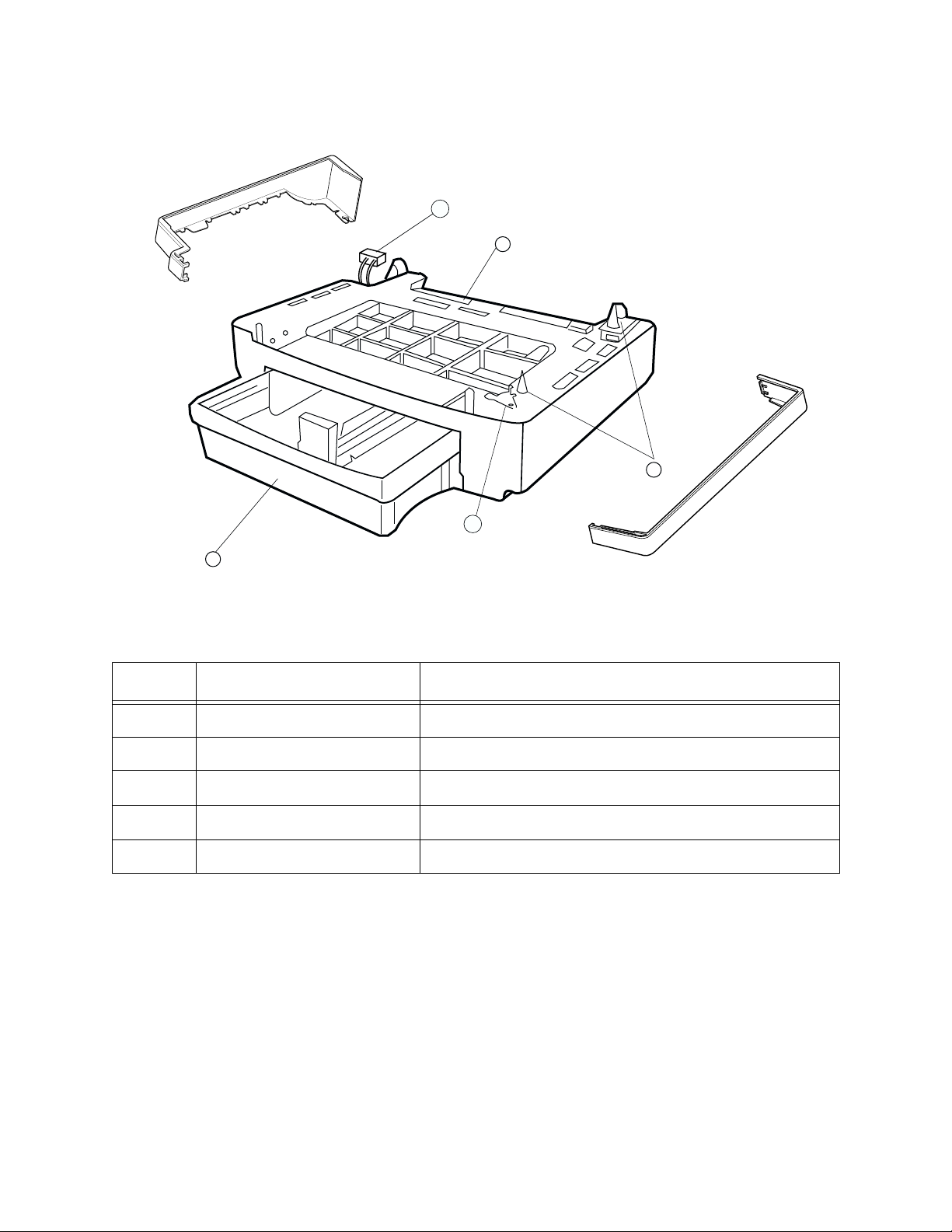

1.3 Name and Function of LFU Components

5

3

1

Fig. 1-3

2

4

Number Name of Component Function of Component

1 Paper Cassette Holds paper.

2 Paper Guide Guides paper from paper cassette to printer.

3 Tray Latch Secures LFU to printer.

4 Connector Pin Aligns the printer engine with the lower feeder unit.

5 Signal Connector Activates lower feeder unit through electrical signal.

magicolor 6100 Series Service Manual Page 1-5

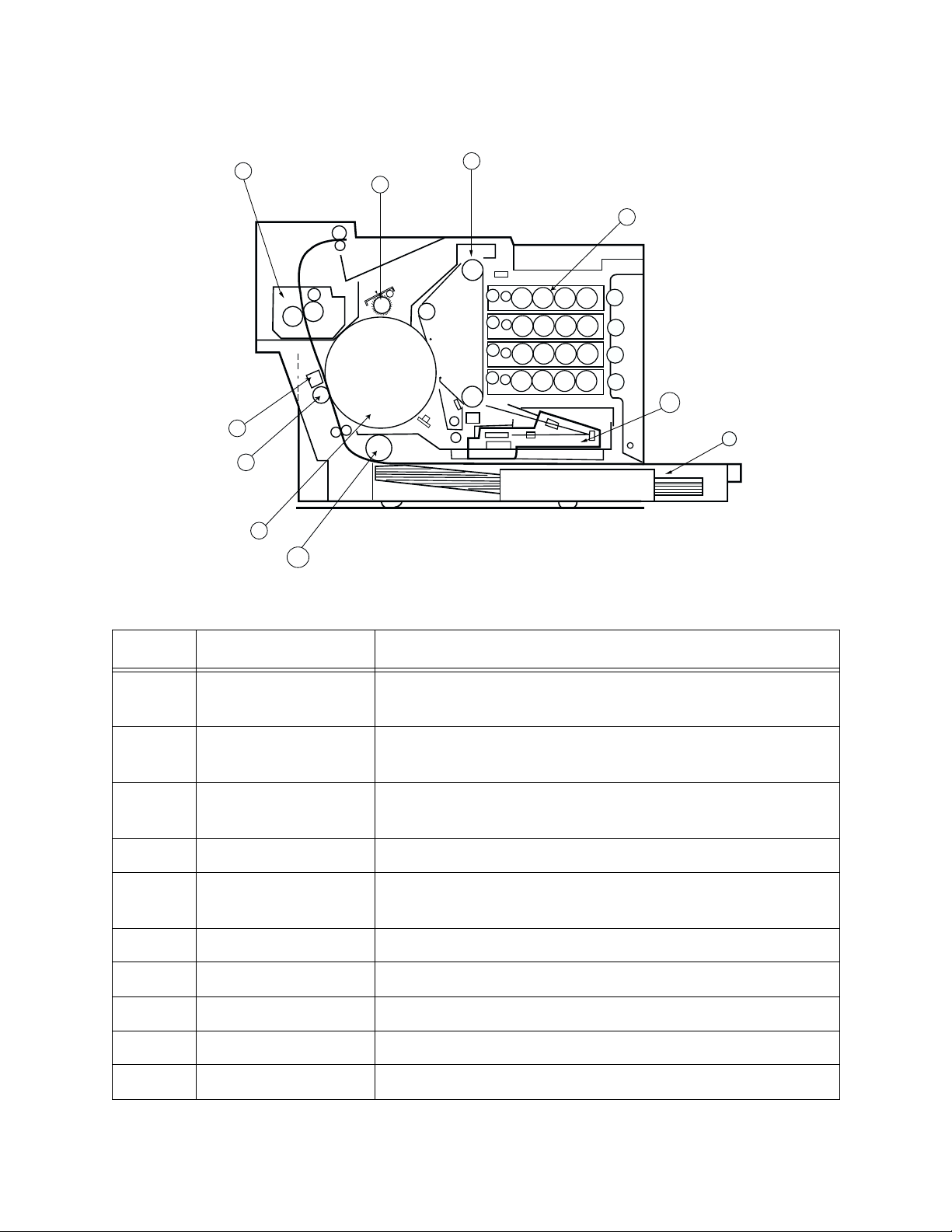

1.4 Internal Structure of the Printer

4

3

6

7

5

9

2

1

K

Y

M

C

10

8

Fig. 1-4

Number Name of Component Function of Component

1 Toner Cartridge Contains the independent toner cartridges (K, Y, M, C) used

during the development process.

2 OPC Belt Cartridge Holds the latent image for development. After development

of each color layer, the image is transferred to the drum.

3 Drum Cleaner Cleans and collects waste toner left adhering to the transfer

drum.

4 Fuser Fuses toner images on the paper using heat and pressure.

5 Transfer Drum Receives each color layer from the OPC.Holds the com-

pleted image to be transfered to the paper.

6 Paper Discharger Separates a sheet of paper from the transfer drum.

7 Transfer Roller Transfers the toner image from the transfer drum to paper.

8 Paper Cassette Holds paper to be fed into the printer.

9 Pick-up Roller Feeds paper automatically from the paper cassette.

10 Optical Unit Creates a latent image on the OPC belt.

Page 1-6 magicolor 6100 Series Service Manual

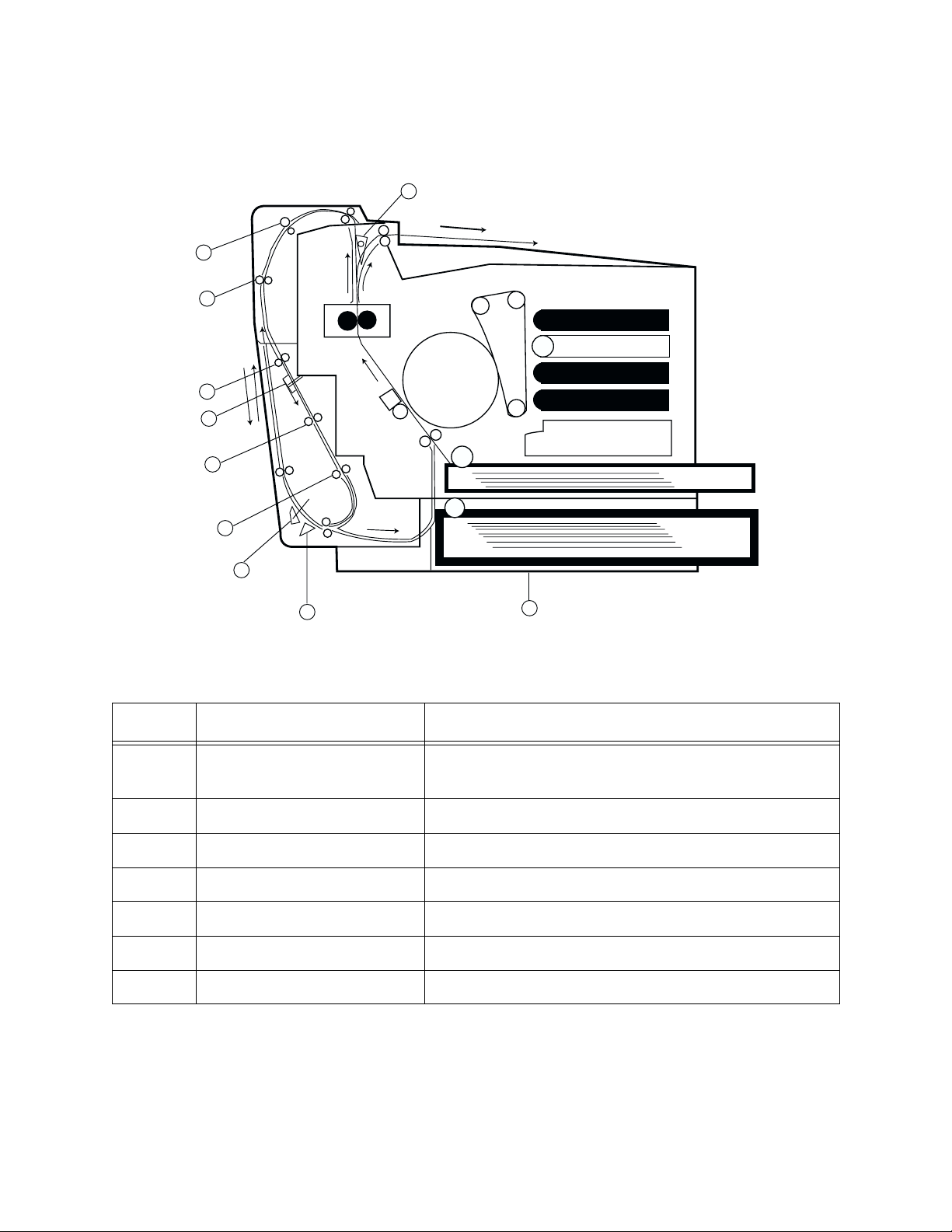

1.5 Internal Structure of the Duplexer

4

D1

2

D2

2

D3

2

7

D4

2

3

6

5

1

Fig. 1-5

Number Name of Component Function of Component

1 Lower Feed Unit (LFU) Feeds paper to printer. Required for duplex opera-

tion.

2 Transport Rollers (D1 - D4) Transports paper.

3 Registration Roller Performs registration for back side of paper.

4 Shutter AS (U) Switches paper to the duplexer.

5 Shutter AS (L) Switches paper from the duplexer.

6 Sensor PT4 Senses paper.

7 Sensor PT5 Senses paper.

magicolor 6100 Series Service Manual Page 1-7

1.6 Description of The Operator Panel

'a b c d e f g h i j k l m n o

P Q R S T U V W X Y Z 1

2

5

7

8

10

MESSAGE

DATA

MENU

SELECT

ONLINE

ONLINE

MEDIA

READY

CANCEL

Number Description

1 LCD: 16 characters by 2 lines

1

3

4

6

9

11

12

2 Message LED

3 Online LED

4 Ready LED

5 Online Key

6Cancel Key

7 Data LED (Red)

8 Menu Key

9Media Key

10 Select Key

11 Scroll Key (Left)

12 Scroll Key (Right)

Page 1-8 magicolor 6100 Series Service Manual

Section 2:

Product Specifications

magicolor 6100 Series Service Manual Page 2-1

Page 2-2 magicolor 6100 Series Service Manual

2.0 Specifications

2.1 Rating

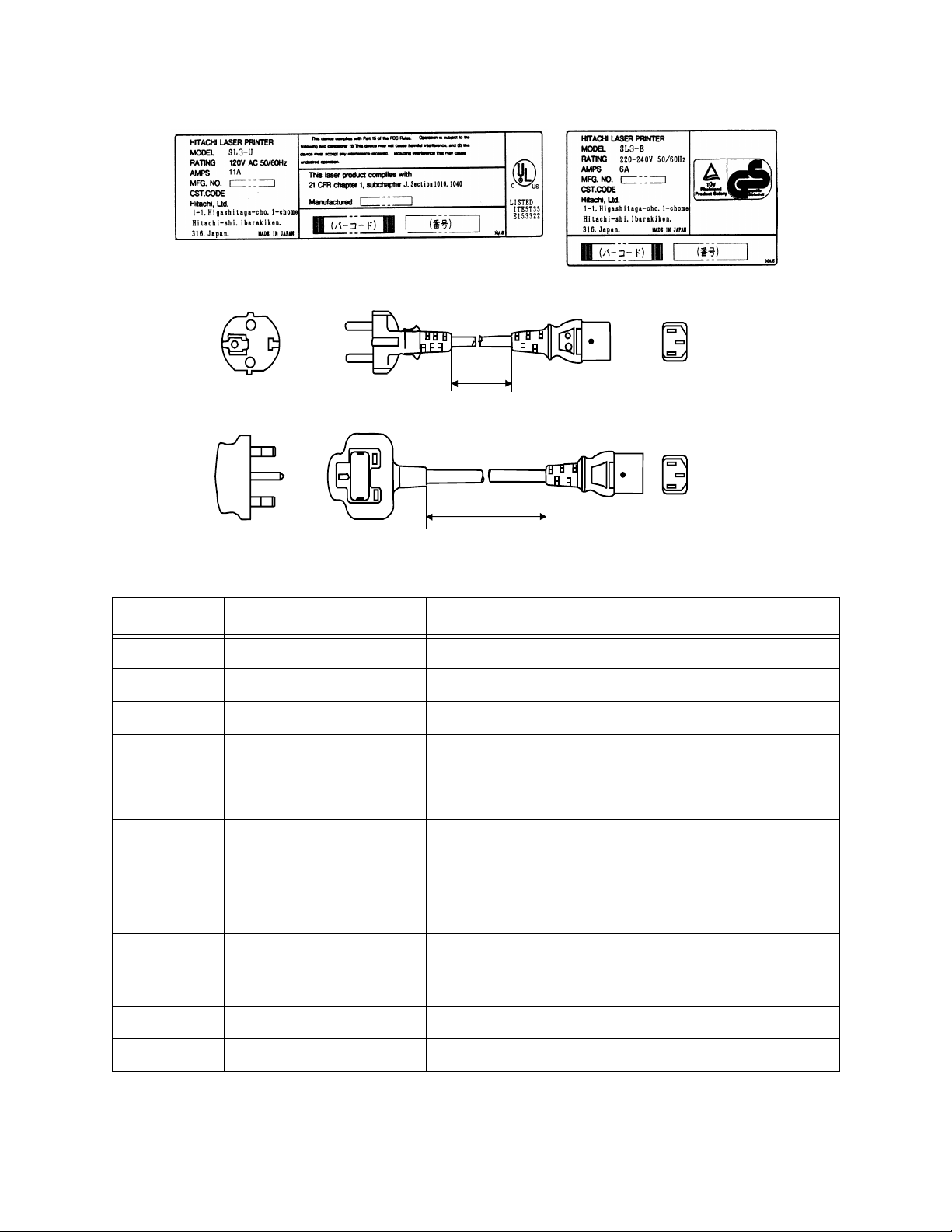

WARNING

Use the power supply cord provided, or a similar cord complying with

following specifications: 3-wire power cord with grounding. Using a cord

that does not adhere to these specifications may result in an electric

shock.

Printer Version Voltage (V) Frequency (Hz) Input Current (A) Power Cord

United States 120 50/60 11 1 (Standard)

Europe 220 - 240 50/60 6 Not included. *1

Japan 100 50/60 13 1 (Standard)

*1:European customers must purchase and use a power cord complying

with the following specifications.

Figure Model Name Rating Approval Agency

A H05VV-F3G0.75 250VAC, 6A VDE, OVE, SEMKO, CEBEC,

Applicable

Europe (Con-

NEMKO, DEMKO, FIMKO

B H05VV-F3-0.75 250VAC, 6A BS UK

Area

tinent)

magicolor 6100 Series Service Manual Page 2-3

Fig. A: Power Cord for Europe

2.5m

Fig. B: Power Cord for UK

2.5m

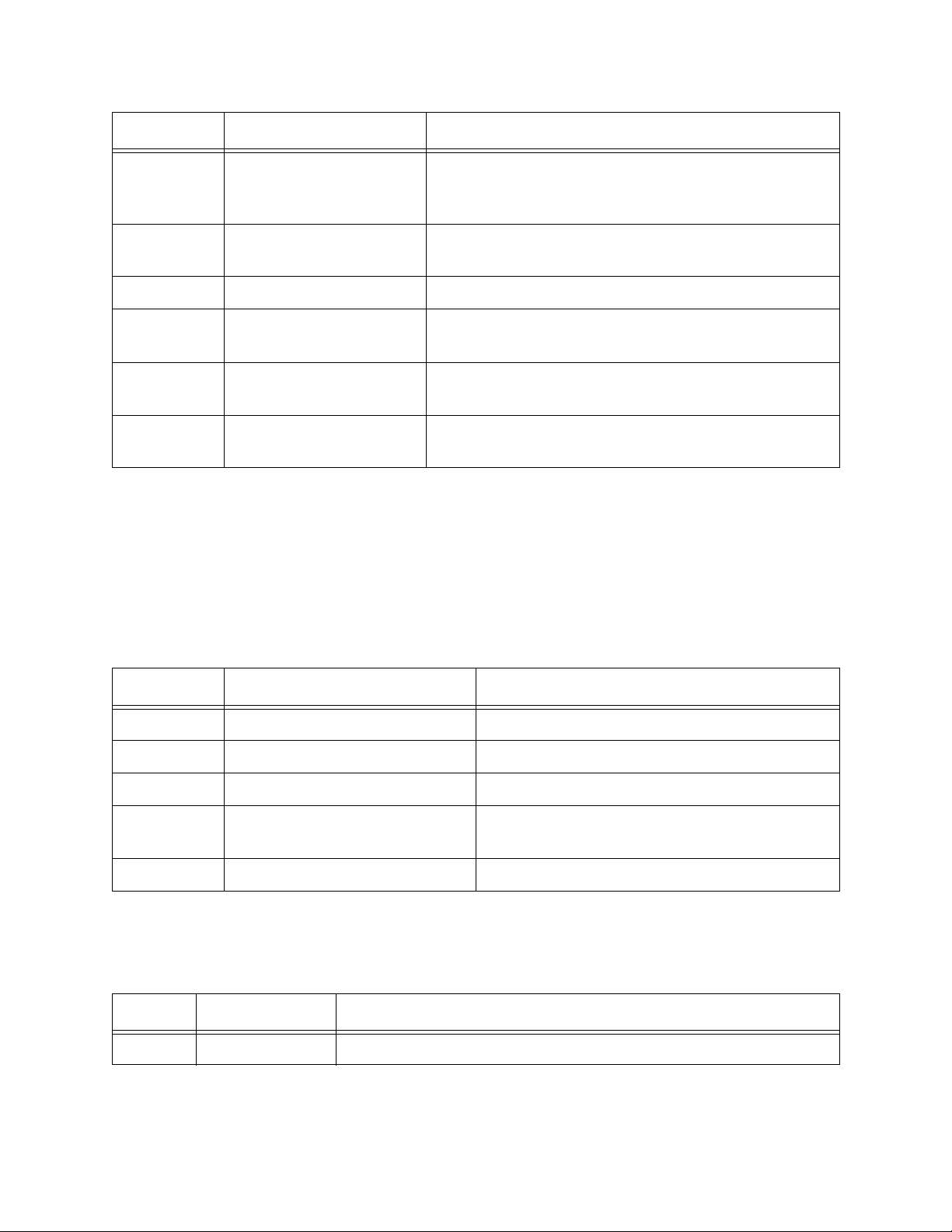

2.2 Printer Specifications

Number Item Description/Specification

1 Printing Method Semiconductor laser and electrophotographic print.

2 Scanning Method Semiconductor laser with rotating mirror.

3 Recording Method Black writing electrophotographic.

4 Processing Method Cyan, Magenta, Yellow, and Black toner image transfer to

print media.

5 Fusing Method Heated rollers.

6 Print Speed

a). Monochrome

b). Two-Color

c). Three-Color

d). Four-Color

37 Warm-Up Time (Ambient

a). 24 Letter/A4; 12 Tabloid/A3

b). 12 Letter/A4; 6 Tabloid/A3

c). 8 Letter/A4; 4 Tabloid/A3

d). 6 Letter/A4; 3 Tabloid/A3

210 seconds maximum

Temperature 68° F or 20°

C)

84 Resolution 600 dpi (base unit)

9 Feeding Method Cassette Feed

Page 2-4 magicolor 6100 Series Service Manual

Number Item Description/Specification

10 Cassette Capacity Standard Paper: 250 sheets, OHP: 50 sheets,

Envelope: 30 envelopes (15 envelopes under humid con-

ditions), Post Card: 50

11 Media Letter, Legal, Executive (A4), OHP, Label, Envelope, A3

Nobi, A3

12 Paper Exit Face Down, 250 sheets

13 External Dimension 24.2” (W) x 21.3” (D) x 16.5” (H)

615 mm (W) x 540 mm (D) x 420 mm (H)

14 Acoustic Noise Standby: 48dB (A)

Printing: 55dB (A), 60dB (A) at maximum

15 Weight of Printer Without Consumables: Approx. 101 lbs/46kg

With Consumables: Approx. 119 lbs/54kg

2.2.1 Lower Feed Unit Specifications

Number Item Description/Specification

1 Lower Feed Unit Option for printer

2 Cassette Capacity Paper: 500 sheets

3 Media Sizes Letter, Legal, A4, Executive, B5, Label, Ledger

4 Dimensions 19.5” (W) x 19” (D) x 4.5” (H)

500mm (W) x 484mm (D) x 116mm (H)

5 Weight Approximately 17.6 lbs (11kg)

2.2.2 Duplexer Specifications

Number Item Description/Specification

1 Duplexer Option for printer

magicolor 6100 Series Service Manual Page 2-5

Number Item Description/Specification

2Mandatory

Lower Feeder Unit

Option

3 Media Sizes Letter, Legal, A3 Nobi, A3, A4

4 Cassette

Capacity

Face-Down Output Tray: 250 sheets

Lower Feed Unit: 500 sheets

5 Rated Voltage 24VDC to be supplied from Printer

6 Dimensions Duplexer: 19.1” (W) x 7.8” (D) x 23.1” (H)

485mm (W) x 198mm (D) x 588mm (H).

Printer with Duplexer: 24.2” (W) x 24.4” (D) x 24” (H)

615mm (W) x 620mm (D) x 610mm (H)

7 Weight Duplexer: Approx. 26.5 lbs. (12kg)

Printer with Duplexer and Lower Feed Unit: Approx. 169.9 lbs. (77kg)

Page 2-6 magicolor 6100 Series Service Manual

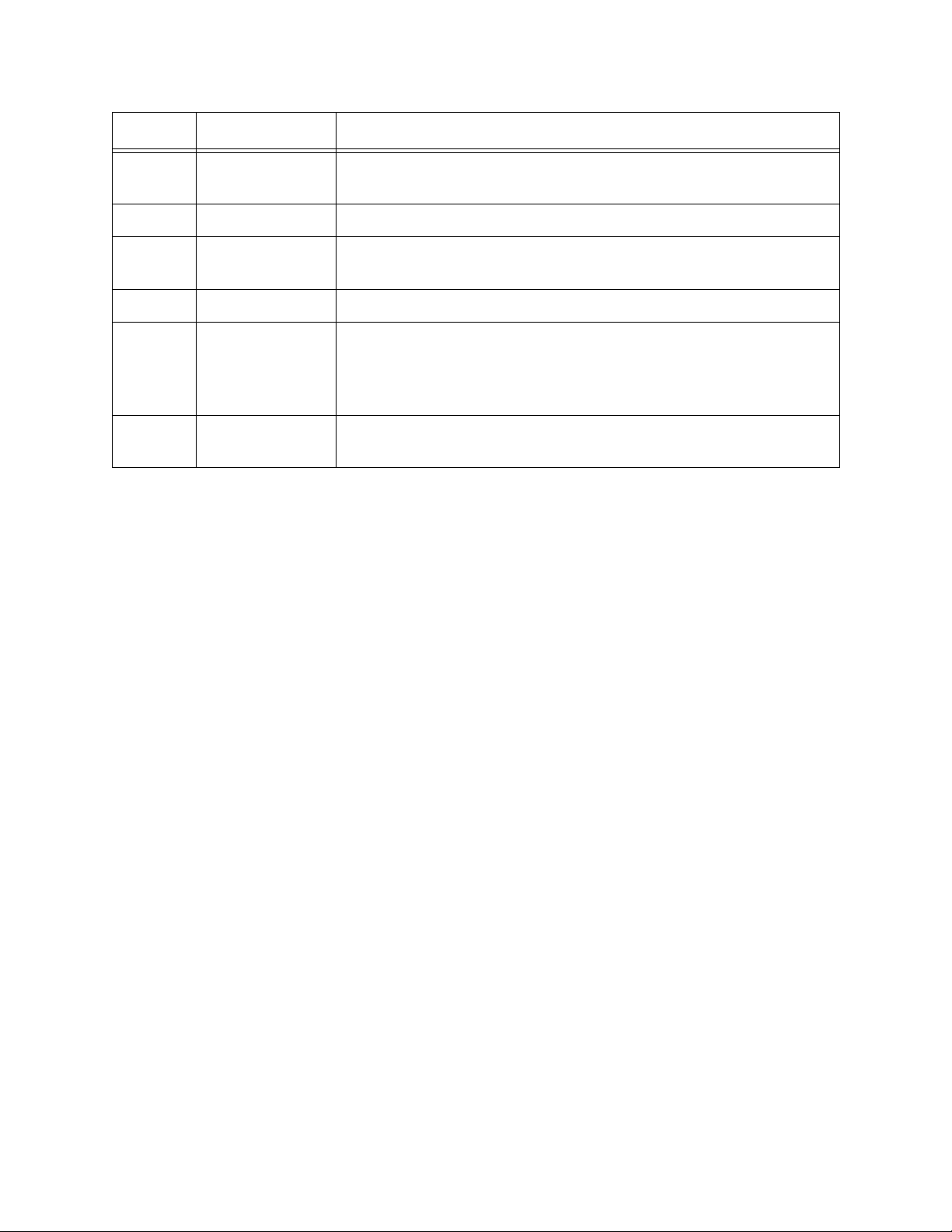

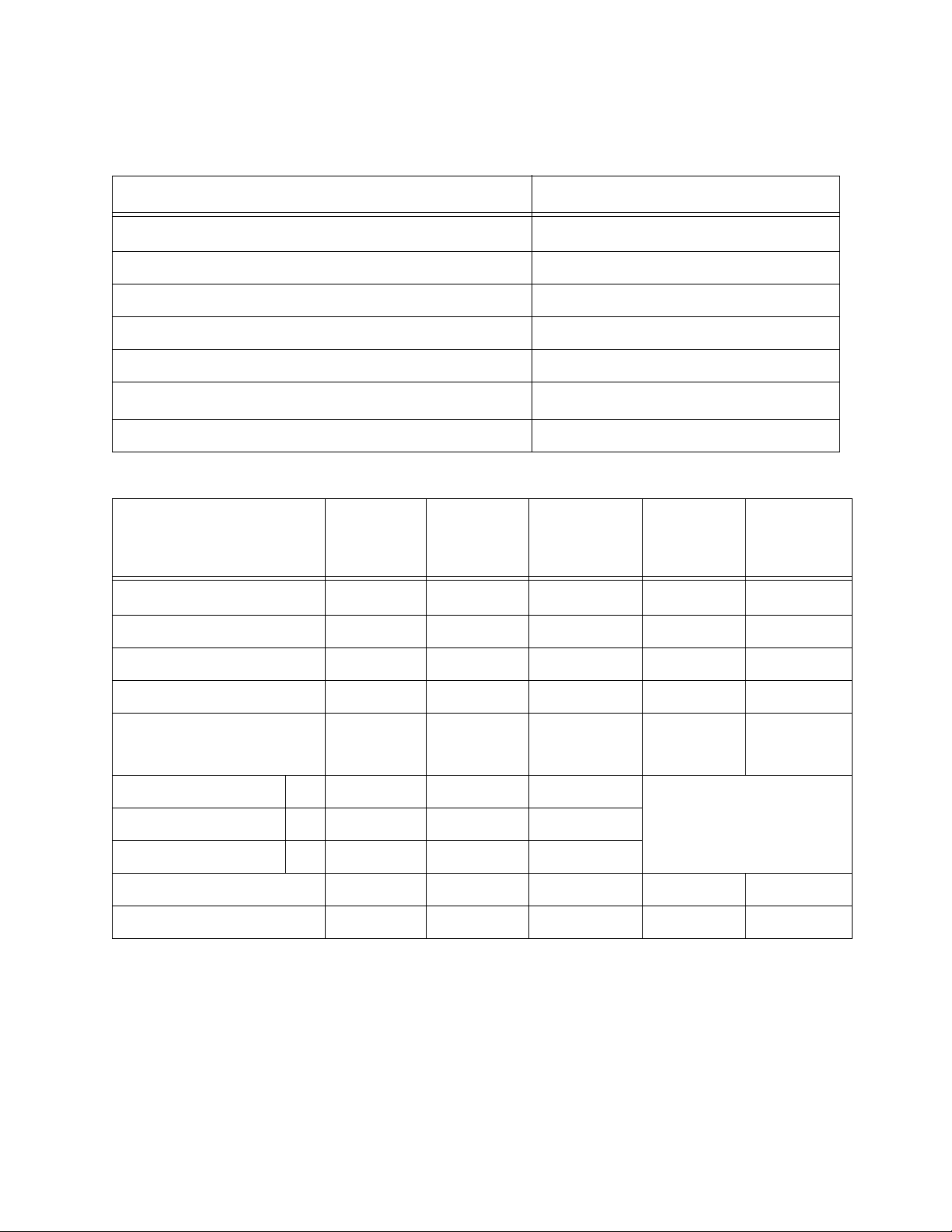

Table 2-1: Characteristics of OEM Paper

Item Description

Basis Weight (g/m

2

)

82 ± 5

Thickness (µm) 95 ± 6

Smoothness (Bekk) 90 ± 20

Stiffness (Clark) 100 ± 15

Brightness (%) 85 ± 2

Surface Resistance (¾)

10

10

~ 10

11

Grain Direction Long

Table 2-2: Characteristics of OEM Recommended Paper and Other Media

Paper

Hammermil

l Laserprint

Label

Avery 5260

OHP Sheet

Paper Weight (g/m

Paper

Xerox 4024

2

)

75 ± 4 90 ± 4 163 ± 7 142 ± 4 90 ± 4

Thickness (µ/m) 102 ± 6 105 ± 6 184 ± 7 110 ± 6 125 ± 10

Smoothness (Bekk) 35 ± 4 120 ± 20 20 ± 6 500 ± 100 22 ± 10

SPHINX

Auto Fil

#1914

Stiffness (Clark) 100 ± 15 90 ± 15 65 ± 15 56 ± 15 70 ± 20

Surface Resistance x 10

(¾)

9

10 ~ 100 10 ~ 100 1 ~ 100

10 ~ 1000

10 ~ 1000

a

b

1 ~ 100

CIE L* 94 ± 2 94 ± 2 94 ± 2

Š 80%

LAB a* 0.4 ± 1 -0.5 ± 1 -0.2 ± 1

(Transmittance)

L*a*b* b* 1.6 ± 1 2.2 ±1 4.5 ±1

Brightness (%) 80 ± 2 85 ± 2 77 ± 3 --- 82 ± 5

Grain Direction Long Long Long --- ---

a. Printed side.

b. Back side.

Measurement Conditions: 63.5 to 81°F (17.5 ~ 27.0°C) and 50 ~ 70% RH

Note: Keep the paper sealed. Do not open the paper until using it.

magicolor 6100 Series Service Manual Page 2-7

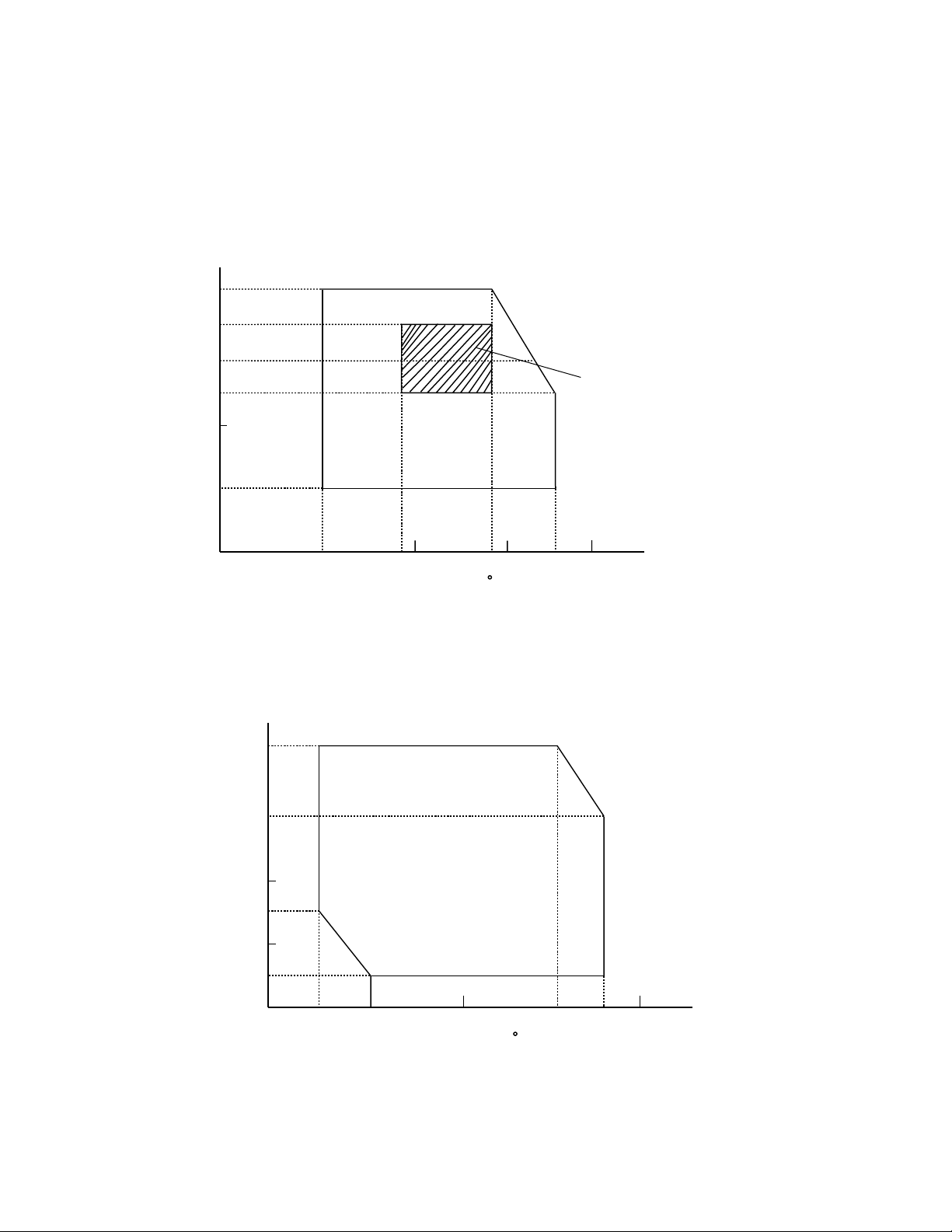

2.3 Environmental Conditions

100 17.5 20 27 30 32.5 40

Recommended Conditions

63.5 ~ 81° F (17.5 ~ 27.0°

50 ~ 70% RH

20

60

70

80

40

Ambient Humidity (%RH)

Ambient Temperature ( )

C

50

2.3.1 Ambient Temperature / Humidity / Altitude:

2.3.1.1 Operating: 10.0 ~ 32.5°C, 20 ~ 80% RH

(See the figure below.)

2.3.1.2 Idle: 41~95°F (5.0~35.0°C), 10 ~ 80% RH

(See the figure below.)

80

60

40

30

Ambient Humidity (%RH)

20

10

5

10020303540

Ambient Temperature( )

C

Page 2-8 magicolor 6100 Series Service Manual

Loading...

Loading...