Konica Minolta QMS magicolor2 Service Manual

MANUAL NO. :

MAINTENANCE MANUAL

FOR

HITACHI COLOR LASER PRINTER

MODEL SL1

Hitachi, Ltd.

Tokyo, Japan

February, 27 , 1998

Read & Keep This Manual

• Read the safety instructions carefully, and understand the contents before starting the

maintenance Work.

• Keep this manual always available for reference.

No, Date of Revision Revision Code Description of Revision

1 July 14, 1997 First Edition First Edition (Original)

2 October 13, 1997 Revision “A” First revision made and issued as Rev.”A”

3 February 27, 1998 Revision “B” First revision made and issued as Rev.”B”

Revision Control Table

This equipment has been tested and found to comply with the limits for a Class B digital

device pursuant to Part 15 of FCC Rules. These limits are specified to provide the

reasonable protection against harmful interference in a residential installation.

Since this equipment generates, uses, and radiates the radio frequency, it may cause

harmful interference to the radio communications if not installed or used in accordance

with the instructions set out hereunder. However, there is no guarantee that such

interference will not occur in a particular installation.

If this equipment causes harmful interference to the radio or television reception, which

can be checked and confirmed by powering the equipment off and on, the users are

encouraged to correct the interference by taking one or more of the following countermeasures:

. Reorient or relocate the receiving antenna.

. Give more clearance between the equipment and receiver.

. Connect the equipment into the outlet of other circuit which is different from the

one being used for the receiver.

. Consult the dealer or experienced radio/television technician for help.

FCC Notice

WARNING

Canadian Compliance

This digital apparatus does not exceed the Class B limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

"Le presnt appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques (de la Class B) prescrites dans le Reglement

sur le brouillage radioelectrique edicte par le ministere des Communications du

Canada."

( i )

1

2

3

4

Product Safety

Laser Product

SL1 is certified as a Class 1 laser product and complies with DHHS Laser-Radiation

Standards, 21 CFR Chapter 1, Subchapter J.

Caution

Use of controls, adjustments or performances of procedures other than those specified

in this Manual may result in hazardous radiation exposure.

SL1 is provided with the ozone filter in order to reduce exhausted ozone in compliance

with Product Safety Standards. Ozone filter must be replaced with new filter yearly,

otherwise, it may cause strong odor which will likely have ill effects to bronchial tubes.

Therefore, this periodical replacement with new filter must be strictly respected.

HITACHI, LTD. MAKES NO REPRESENTATION OR WARRANTIES OF ANY KIND

WHATSOEVER WITH RESPECT TO THE CONTENTS HEREOF AND SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE.

Ozone Gas

Caution

Documentation Disclaimer

(ii)

SAFETY INSTRUCTIONS

1. Safety Instructions

1.1 Safety Principle

(1). Before starting your operation, read this Manual thoroughly. Especially, read

the safety instructions of this section carefully and understand the contents.

(2). Perform all the operations by following the procedures described in this

Manual. Follow all the cautions and warnings set out in the procedures and

on safety labels affixed on the machine. Failure to do so may result in the

human injuries or equipment damages.

(3). Perform only the procedures explained in this Manual. Refrain from opening

or touching any portions that are not related with your operation.

(4). Repair and replacement of parts should be performed by trained and qualified

persons only. Operator should not attempt to do such repair or replacement

works.

(5). It must be appreciated that above-mentioned cautions and warnings do not

cover everything, because it is impossible to guess or evaluate all the

circumstances beforehand.

1.2 Special Safety Information

(1). Introductory Information

The cautions and warnings are made clear by following the "Safety Alert

Symbol" or "Signal Words" such as DANGER, WARNING and CAUTION.

. Safety Alert Symbol

This is the safety alert symbol. When you find this symbol placed on

your equipments or marked in this Manual, be alert for the potential of

human injuries. Follow the recommended precautions and safety

operation practices.

1

(iii)

(1). Introductory Information (..... continue)

. Understanding Signal Words

DANGER is used to indicate the presence of a hazard which will cause

severe human injuries or fatal accident if the warning is ignored.

WARNING is used to indicate the presence of a hazard or unsafe practices

which may cause severe human injuries or fatal accident if the warning is

ignored.

CAUTION is used to indicate the presence of a hazard or unsafe practices

which may cause minor human injuries if the warning is ignored.

CAUTION also calls attention to safety messages in this Manual.

. Follow Safety Instructions

Carefully read all the safety messages set out in this Manual and also in the

safety signs placed on your equipments. In this Manual, the safety

instructions (safety alert symbols and signal words) are bracketed by

rectangular enclosure to call for attention. Keep the safety signs in good

condition without missing or damage. Replace the safety signs if smeared

or damaged. Learn how to operate the equipment and how to use the

control properly. Do not let anyone operate without acknowledging the

instructions. Keep the equipments in proper working condition.

Unauthorized modification to equipments may impair the function & safety,

and affect the life of equipments.

Listed below is the various kind of "WARNING" contained in this Manual.

WARNING

HAZARDOUS VOLTAGE

It may cause serious injuries or fatal accidents. Voltage is now applied

from the power supply of printer. There is the danger of electrical shock if

you touch the active area inside the printer.

Make sure to turn the power supply switch OFF and pull out the plug from

the outlet before starting maintenance work to printer.

2

3

(iv)

. Follow Safety Instructions (.... continue)

HARMFUL OZONE GAS

Inhalation of excessive amount of ozone gas may adversely affect the

respiratory organs.

Ozone Filter is provided to this printer to reduce the exhausted ozone.

This filter must be replaced with new filter periodically in accordance with

the Manual attached to this printer.

Listed below are the various kinds of "CAUTION" contained in this Manual.

HOT SURFACE

Can cause a burn.

Fusing Unit is approx.160 hot , so that perimeter is also very hot.

When you need to change the cleaning pad or remove jammed papers,

wait about 20 minutes after opening up the paper exit unit and confirm the

unit to be well cooled down.

ROTATING PARTS

Be cautioned about the potential danger of various rollers to get your

fingers or hand caught into the machine and cause serious injuries.

Note that the exit roller ejecting printed papers is rotating while printing.

Be careful not to get your hairs, fingers, hands, and sleeve or necktie

caught in the machine while operating the machine.

3

WARNING

CAUTION

C

(v)

. Follow Safety Instructions (.... continue)

HAZARDOUS POWDER

Toner is fine powder to cause powder explosion if dumped into the fire.

Strictly refrain from dumping toner into the fire for disposal.

Toner is fine powder to cause troubles to eyes and respiratory organs if

inhaled.

Handle carefully toner cartridge, waste toner pack and developing unit not

to spread the toner.

HAZARDOUS POWDER

POWER CORDS & PLUGS

This printer is equipped with 3-wire power cords and 3-pronged plugs

(bi-polar plug with grounding) for the user's safety.

Use these power cords in conjunction with properly grounded electrical

receptacles to avoid an electrical shock.

SAFETY INTERLOCK

Cover and Paper Delivery Unit of this printer have electrical safety interlocks

to turn the power off whenever they are opened. Do not attempt to

circumvent these safety interlocks.

CAUTION

3

CAUTION

CAUTION

CAUTION

(vi)

CONTENTS

PREFACE and SAFETY INSTRUCTIONS

1. OUTLINE OF PRODUCT

2. SPECIFICATIONS OF PRODUCT

3. INSTALLATION

4. STRUCTURE OF EACH COMPONENT SYSTEMS

5. PERIODIC MAINTENANCE

6. OPERATION AND ADJUSTMENT OF OPERATOR PANEL

7. REPLACEMENT OF MAINTENANCE PARTS

8. TROBLESHOOTING

9. PARTS LIST

1. Outline of Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 Name & Function of Each Parts . . . . . . . . . . . . . . . .1-1

1.2 Internal Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Description of Operator Panel . . . . . . . . . . . . . . . . .1-4

1. Outline of Product

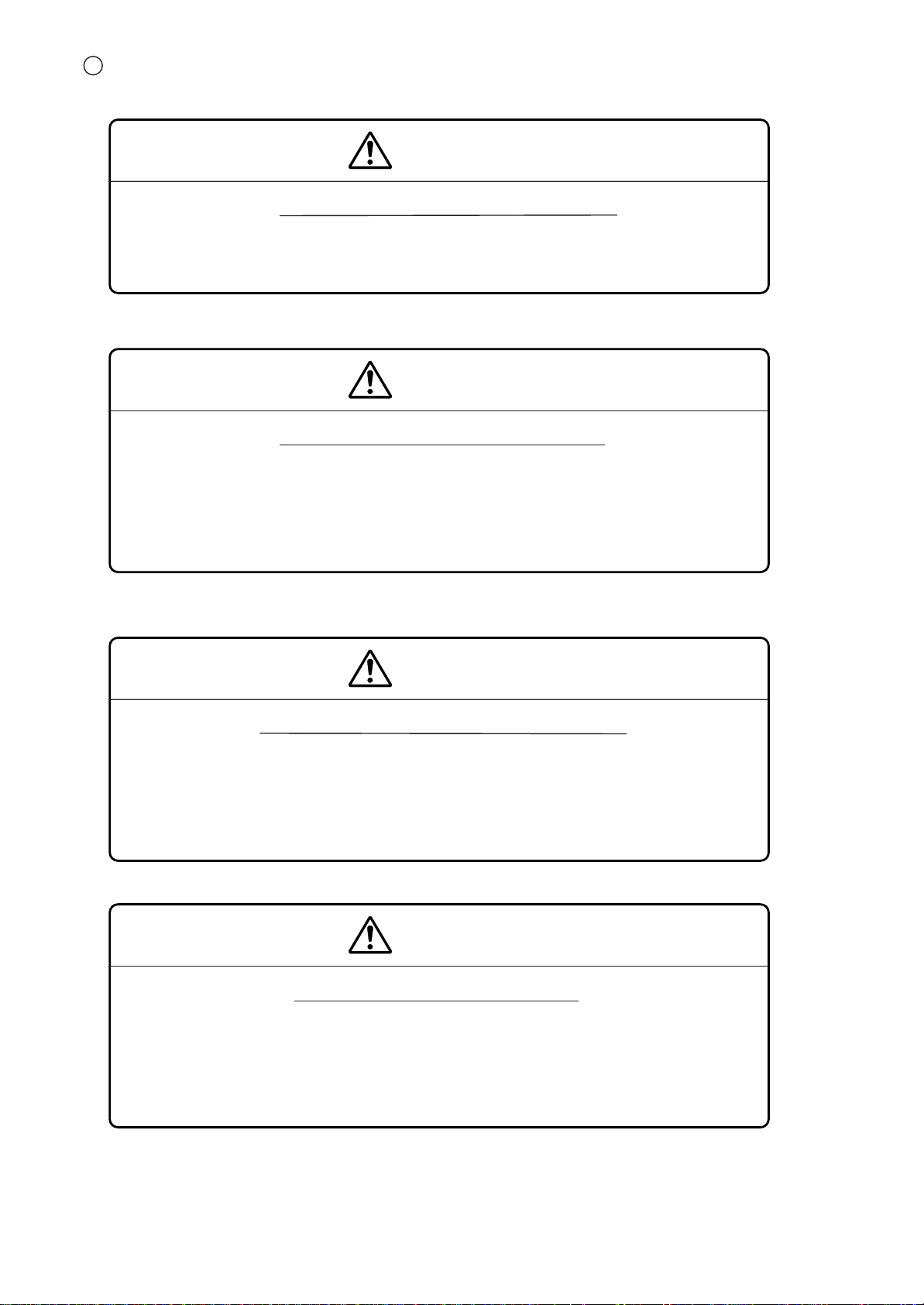

1.1 Name & Function of Each Parts

Operator Panel

Top Cover

Paper Exit Cover

Front Cover

Main Switch

Paper Cassette

Paper Exit Unit

Interface Connector Box

AC Input Inlet

Back Cover(L)

[Back Face]

[Front Face]

1-1

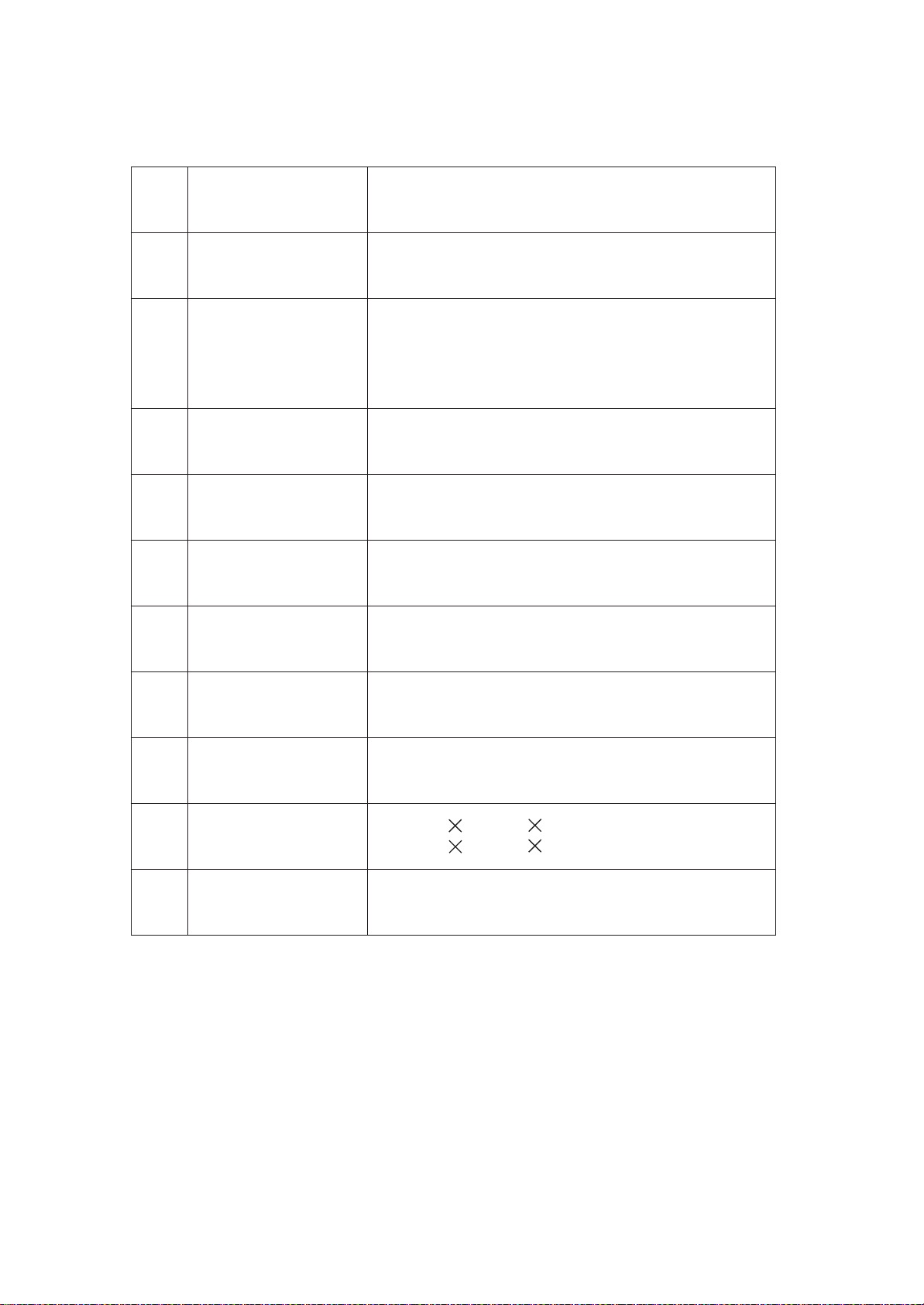

No. Name of Parts Outline of Functions

1 Top Cover

To act as an upper enclosure and also a paper tray

for printed papers.

2 Operator Panel

To display a status of printer operation and

motion.

3 Front Cover

To act as a front enclosure, and to be opened

when replacing a toner cartridge or waste

toner pack.

4 Paper Exit Cover

To exit a printed paper onto a top cover,

acting also as paper tray for printed paper.

To be opened when replacing an OPC belt

cartridge.

5 Main Switch

To operate power-on and off of printer.

(Pushing for On/Off operation)

6 AC Input Inlet

To connect a power supply cable.

7 Back Cover (L)

To act as a rear enclosure, and to be opened

when clearing an internal jam or doing a

maintenance work.

8 Interface Connector Box Space where a controller PWB to be installed.

1-2

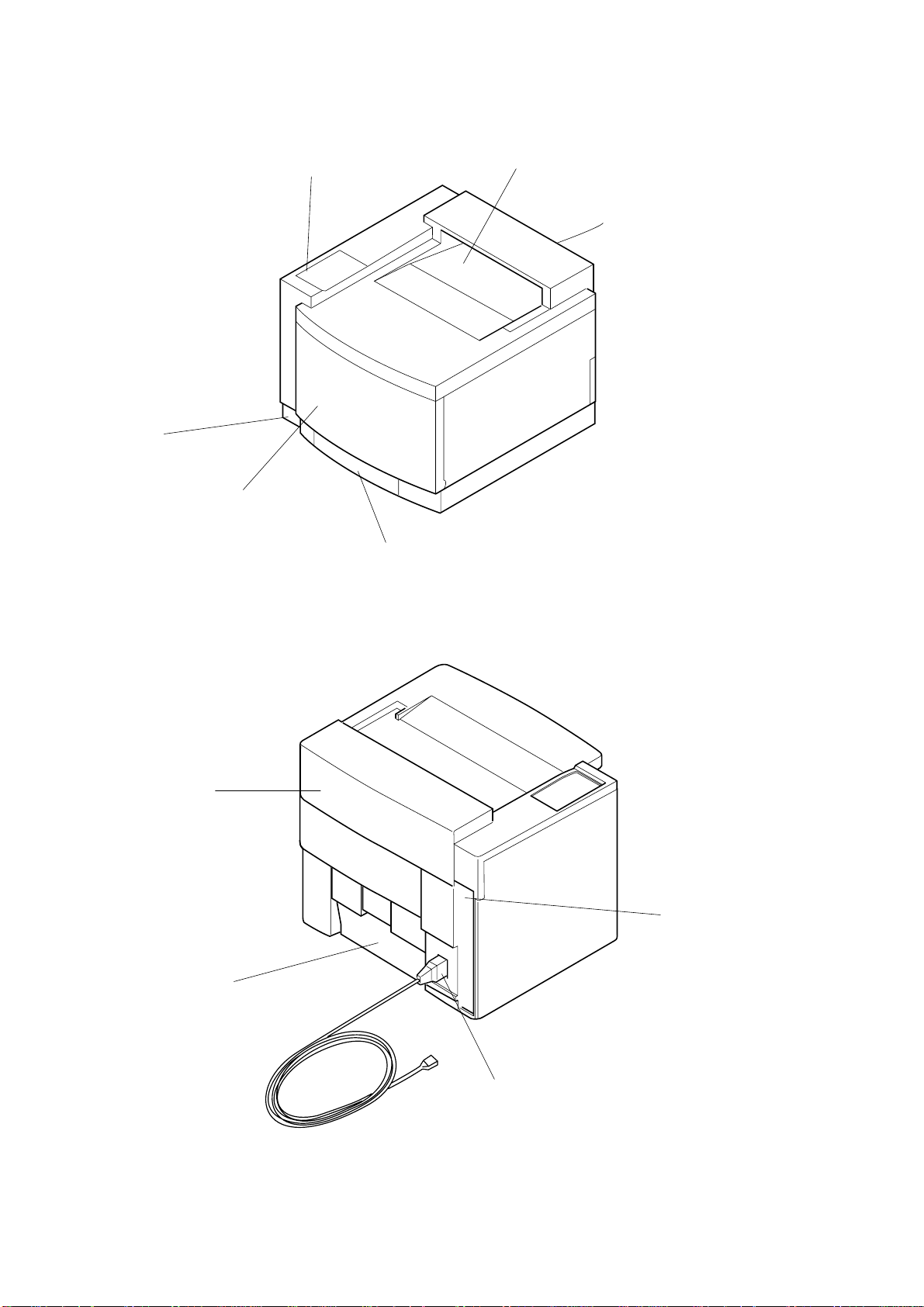

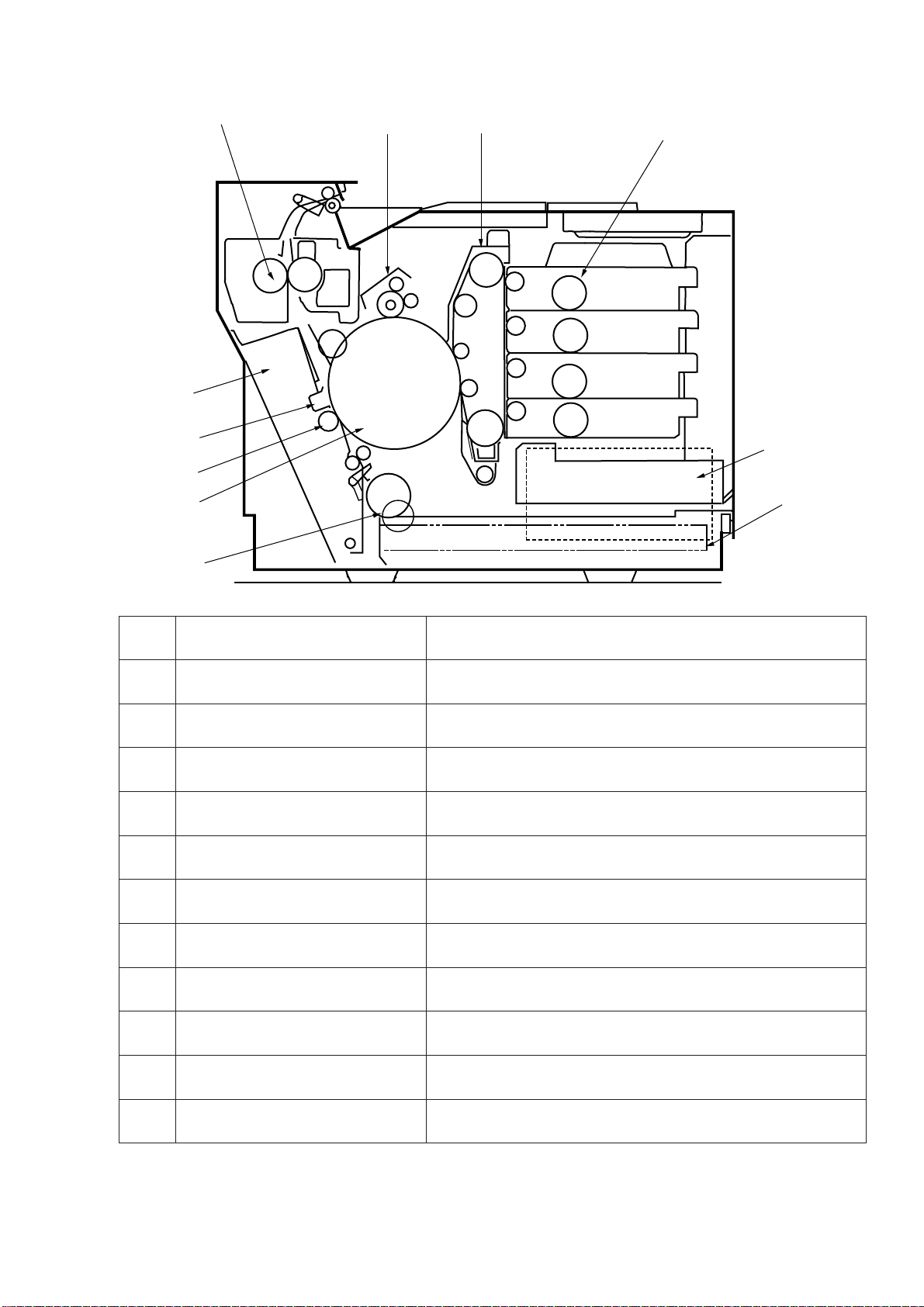

1.2 Internal Structure

1-3

K

Y

M

C

Fusing Unit

Transfer Unit

Paper Discharger

Transfer Roller

Transfer Drum

Paper Pick Up Roller

Drum Cleaner

Belt Cartridge

Toner Cartridge

@(K,Y,M,C)

Paper Cassette

Optical Unit

No. Name of Components Outline of Functions

1 Toner Cartridge

2 Belt Cartridge

3 Drum Cleaner

4 Fusing Unit

5 Transfer Unit

6 Transfer Drum

7 Paper Discharger

8 Transfer Roller

9 Paper Cassette

10 Paper Pick Up Roller

11 Optical Unit

To contain the toners (K, Y, M, C) for developing.

Each toner cartridge of K,Y, M, C is independent.

To form images, including the OPC belt.

To clean and collect waste toner adhering to the

transfer drum.

To fuse by heat the toner images on the paper.

To transfer toner images from the transfer drum to

the paper.

To form color images, maintaining the toner

images of OPC belt on the drum.

To emit the corona for separating a paper from

transfer drum.

To transfer the toner image of transfer drum to

a paper.

To feed papers automatically.

To feed papers automatically from the paper

cassette.

To generate a laser beam and scan over the OPC

belt.

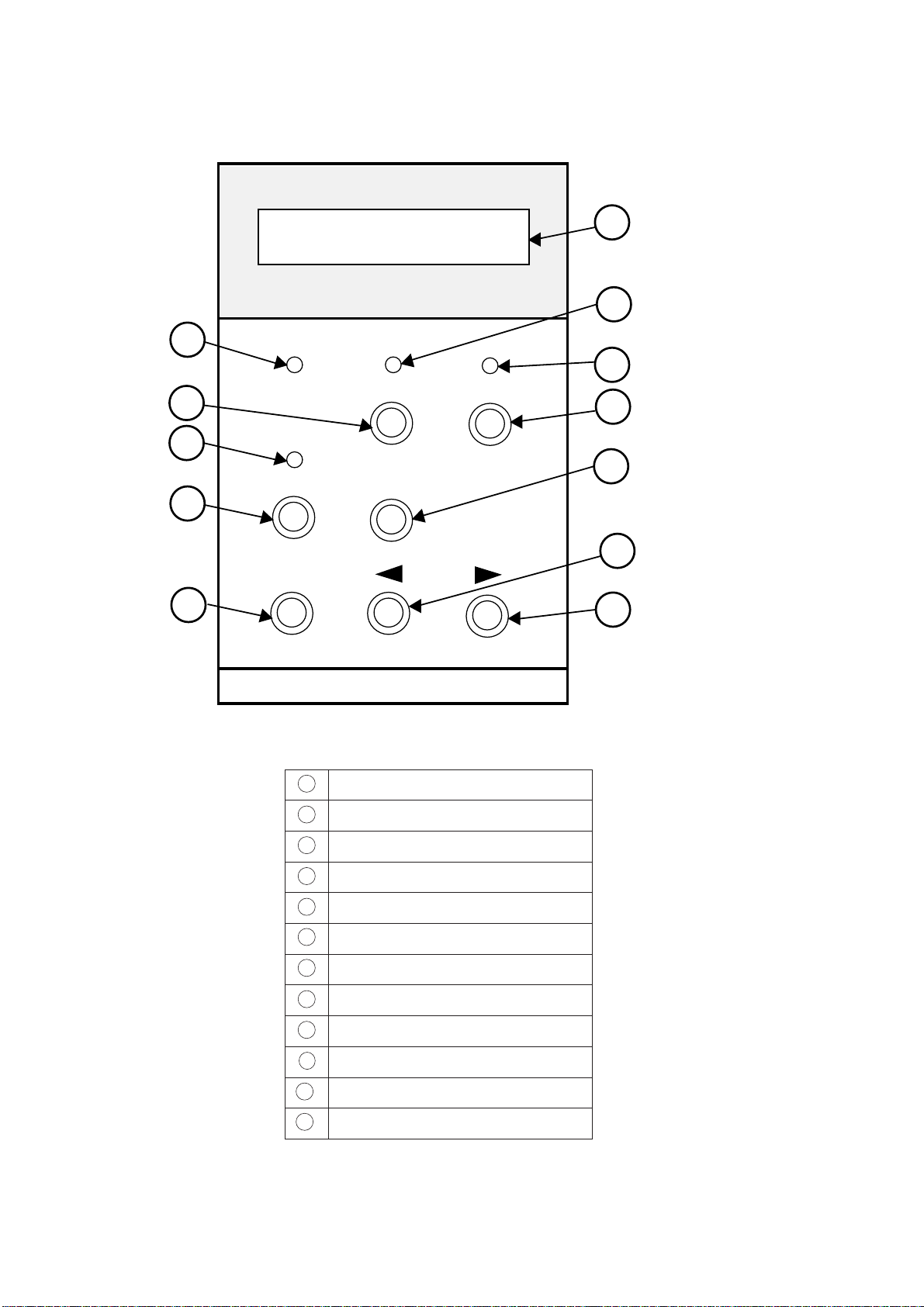

1.3 Description of Operator Panel

(1) Standard

‘abcdefghijklmno

PQRSTUVWXOPQRSTU

1

3

4

6

9

11

12

10

8

7

5

2

MESSAGE ONLINE MEDIA

FREE SIZE CLEAR

SELECT

LCD:16 characters by 2 lines

Message LED

Online LED

Media LED

Online Key

Media Select Key

Free Size LED (Red)

Free Size Key

Clear Key

Select Key

Scroll Key (Left)

Scroll Key (Right)

1

2

4

3

5

6

7

8

9

10

11

12

Description:

1-4

2. Specifications of Product . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 General Specification . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Environmental Condition . . . . . . . . . . . . . . . . . . . . . 2-5

2. Specifications of Product

2.1 Rating

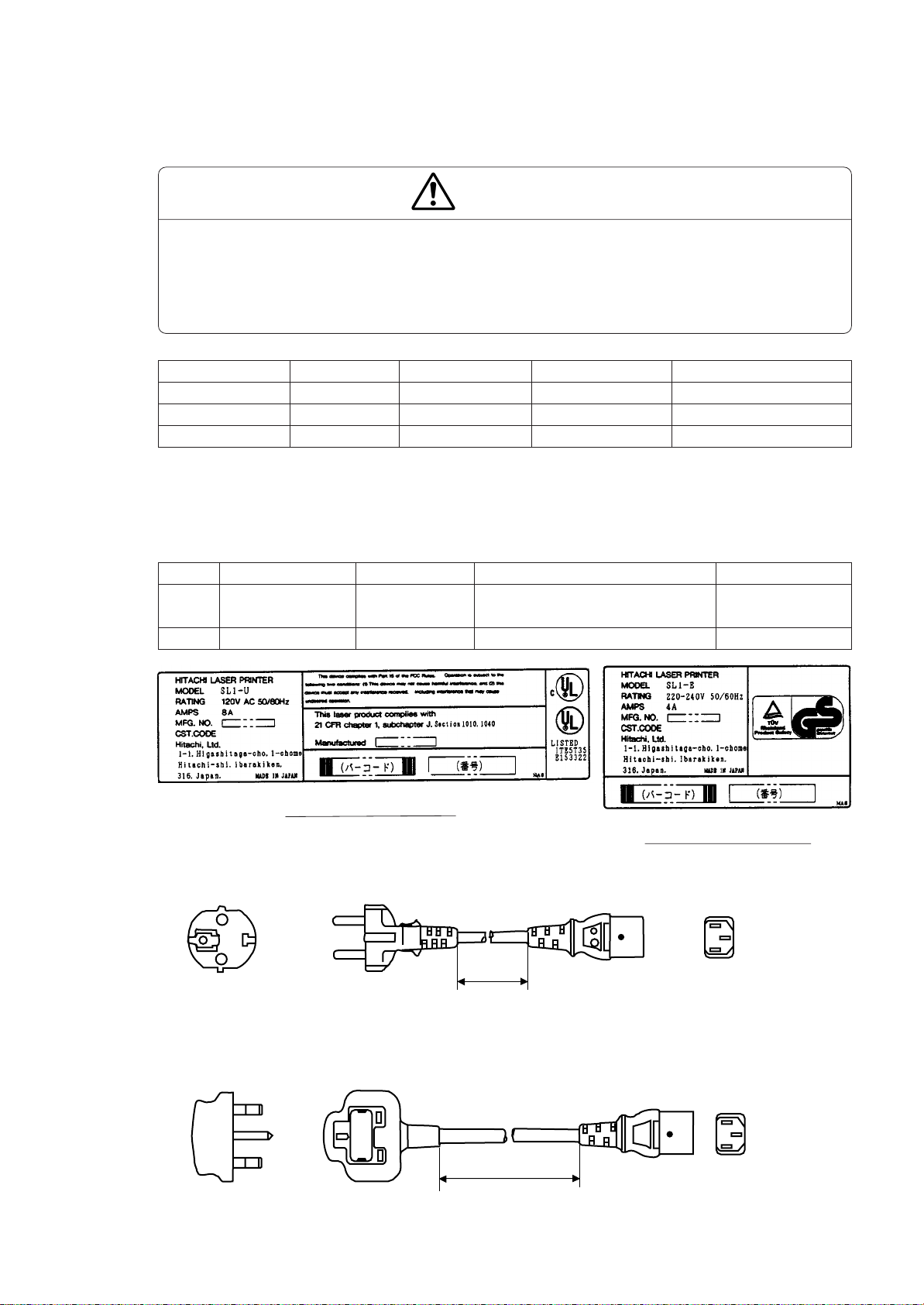

WARNING

Use the power supply cord provided as an accessory, or the similar cord

complying with following specification (3-wire power cord with grounding).

Use of the "out of specification" cord may result in the electric shock.

Name of Model Voltage (V) Frequency (Hz) Input Current (A) Power Cord (Piece)

SL1-U 120 50/60 8 1 (Standard)

SL1-E 220 - 240 50/60 4 Not included. *1

SL1-J 100 50/60 10 1 (Standard)

*1: As to SL1-E, customers are requested to purchase and use the power

cord complying with the following specifications.

Figure Name of Model Rating Approval Agency Applicable Area

A H05VV-F3G0.75 250VAC, 6A

VDE, OVE, SEMKO, CEBEC, Europe

NEMKO, DEMKO, FIMKO (Continent)

B H05VV-F3-0.75 250VAC, 6A BS UK

Fig.A: Power Cord for Europe

2.5m

Fig.A: Power Cord for Europe

2.5m

2-1

Rating label of SL1-E

Rating label of SL1-U

2.2 General Specification

No. Item Description

1 Printing Method Semiconductor Laser and Electrophotography

Print Speed Cassette Feed and Continuous Print:

a). Monochrome a). 16 sheets per minutes (Letter size)

2 b). 2 (two) Color b). 8 sheets per minutes (Letter size)

c). 3 (three) Color c). 5.3 sheets per minutes (Letter size)

d). 4 (four) Color d). 4 sheets per minutes (Letter size)

3 Warming-Up Time 210 seconds (max.), 180 seconds (Normal)

4 Resolution 600dpi

5 Feeding Method Cassette Feed

6 Cassette Capacity

7 Printable Media

8 Paper Exit System Face Down, 250 sheets (capacity)

9 External Dimension

10 Weight of Printer Approximately 36kg (79 pounds)

Ordinary Paper: 250 sheets, OHP: 50 sheets

Envelope: 30 envelopes, Post Card: 50 cards

500 (W) 490 (D) 388 (H) (unit: mm)

19.7 (W) 19.3 (D) 15.3 (H) (unit: inch)

2-2

Letter, Legal, Executive (A4, B5), OHP, Label,

SPHINX

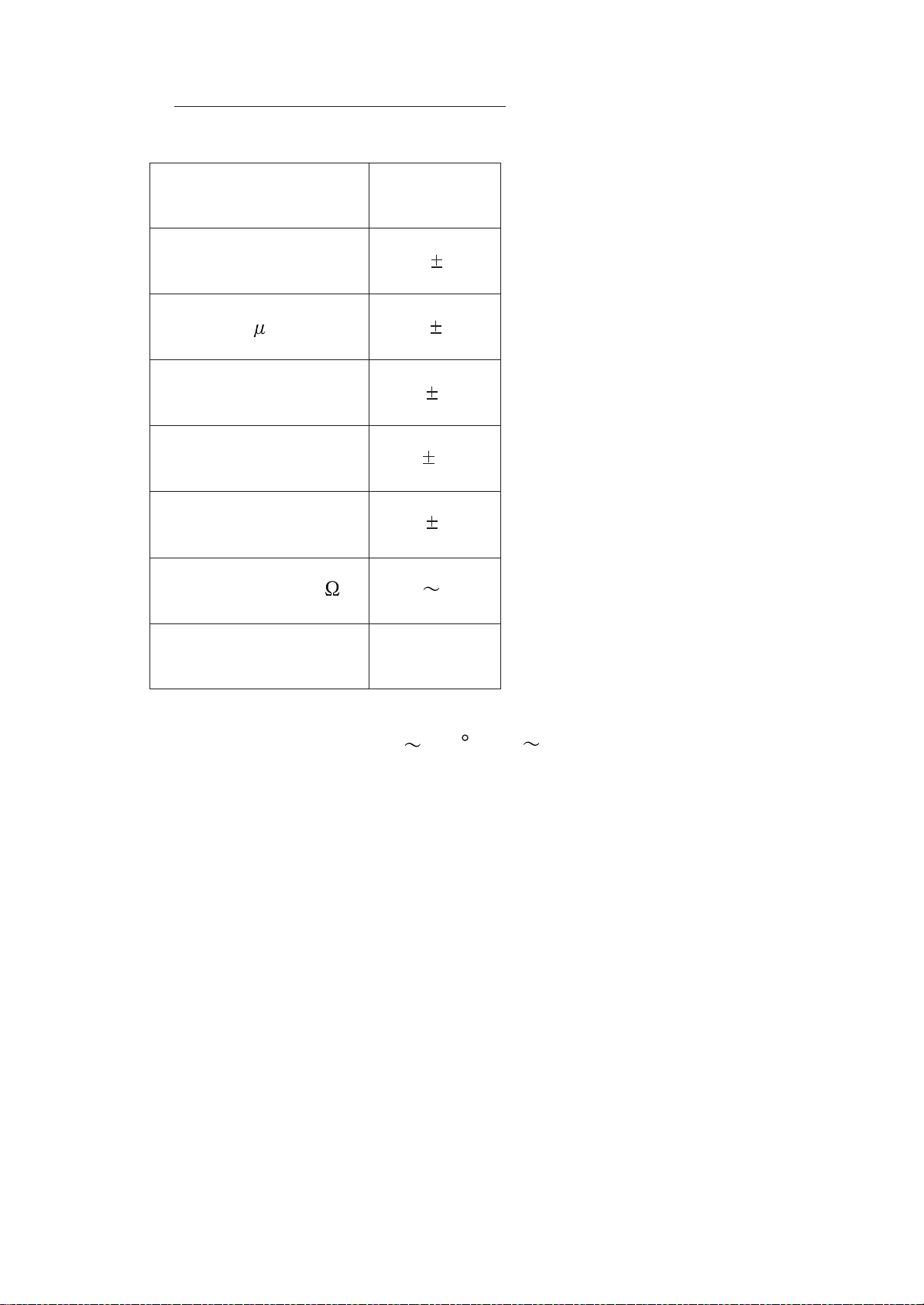

Table 2-1: Characteristics of Hitachi Paper

Item Description

Basis Weight (g/m

2

) 82 5

Thickness ( m) 95 6

Smoothness (Bekk) 90 20

(seconds)

Stiffness (Clark) 100 15

Brightness (%) 85 2

Surface Resistance ( ) 10

10

10

11

Grain Direction Long

Measurement Condition: 17.5 27.0 , 50 70%RH

[Note]: Keep the paper sealed, and do not open the paper bag until using the

papers.

C

2-3

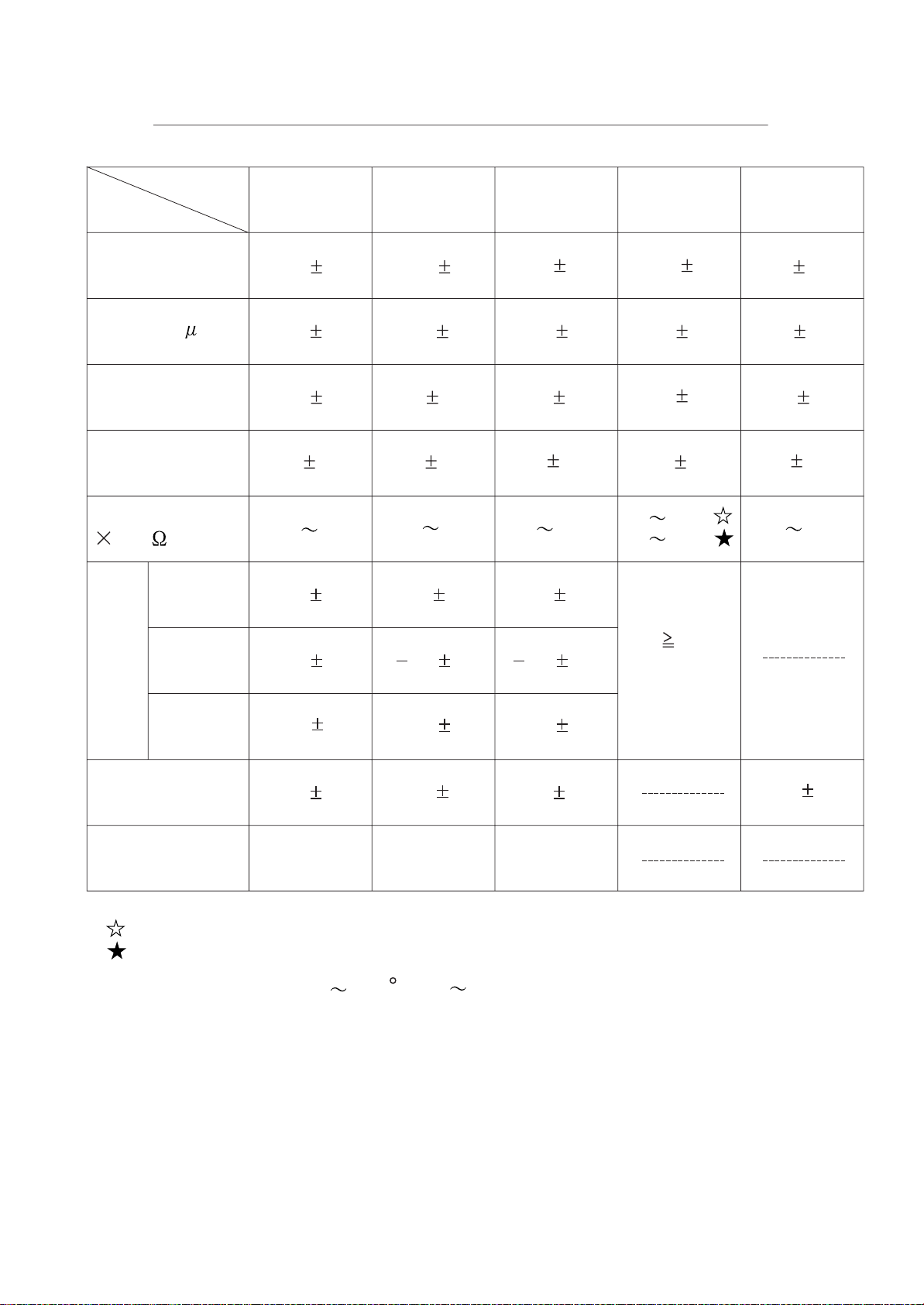

Table 2-2: Characteristics of Hitachi Recommend Paper, OHP Sheet, and Label

Media

Item

Paper

Paper Hammermill

Label

Xerox 4024

Laserprint (white)

Avery 5260

OHP Sheet

SPHINX

Auto Fil #1914

Basis Weight (g/m

2

) 75 4 90 4 163 7 142 4 90 4

Thickness ( /m) 102 6 105 6 184 7 110 6 125 10

Smoothness(Bekk) 35 4 120 20 20 6 500 100 22 10

Stiffness (Clark) 100 15 90 15 65 15 56 15 70 20

Surface Resistance

10

9

( )

10 100 10 100 1 100

10 1000

10 1000

1 100

CIE

LAB

L*a*b*

L* 94 2 94 2 93 2

a* 0.4 1 0.5 1 0.2 1

b* 1.6 1 2.2 1 4.5 1

80%

(Transmittance)

Brightness (%) 80 2 85 2 77 3

Grain Direction Long Long Long

82 5

: Printed Side

: Back Side

Measurement Condition: 17.5 27.0 , 50 70%RH

C

2-4

2.3 Environmental Condition

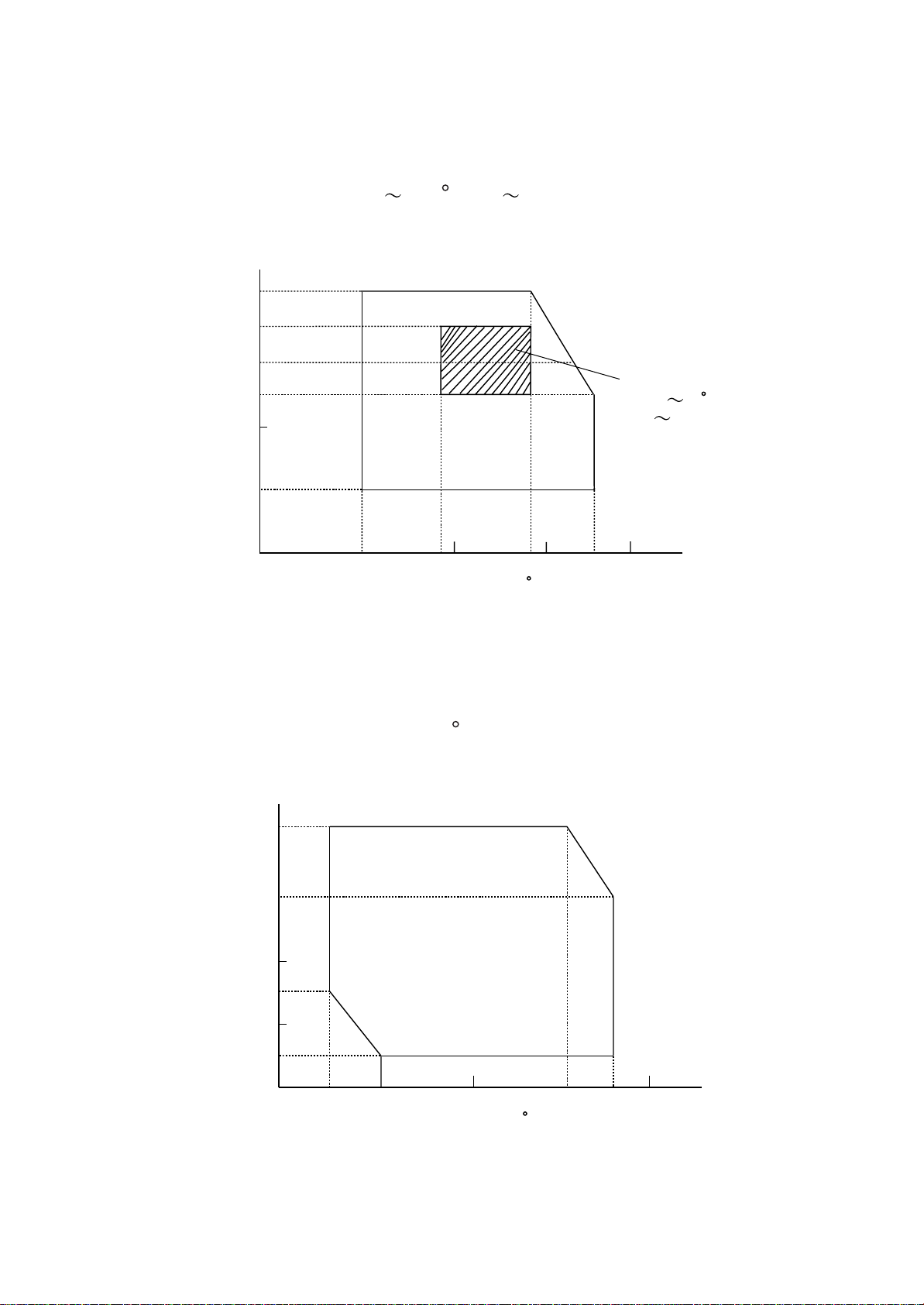

(1). Ambient Temperature / Humidity / Altitude:

(a). Under Operation: 10.0 32.5 , 20 80%RH

(See the figure below.)

C

(b). Under No Operation: 5.0 ~ 35.0 , 10 ~ 80%RH

(See the figure below.)

C

2-5

80

70

60

50

40

20

Ambien Humidity (%RH)

100 17.5 20 27 30 32.5 40

Ambient Temperature ( )

C

Recommended Condition;

17.5 27

50 70%RH

C

80

60

40

30

Ambient Humidity (%RH)

20

10

5

10020303540

Ambient Temperature( )

C

Temperature

Normal

Condition

(c). Storage and Transportation Environment of Printer

The following defines the storage and transportation environment of the printers that

have been packed according to Hitachi specification. However, this section

does not cover the belt cartridges, toner cartridges and developer cartridges.

In particular, since consumables such as toner etc. are packaged, the following

environmental conditions should be respected. During transportation, strictly refrain

from leaving the goods on the ground or under the blazing sun.

Humidity 10% ~ 90%RH

Period of Storage One Year

Other No Condensation

Atmosphere 613 ~ 1,067hpa (460 ~ 800mmHg)

Severe

Condition

0 ~ 35 (32 ~ 95 )

High Temperature: 35 ~ 40 (95 ~104 )

Low Temperature: 10 ~ 0 (14 ~ 32 )

C

C

F F

C

C

F F

C C

F F

The period under the severe condition should not be continuous, but assumed as

accumulation of intermittent time. However, the accumulation of intermittent time

should not by any means exceed 48 hours at maximum.

[Note]: Normal condition should occupy more than 90% of total storage period.

Sever condition should be less than 10% of total storage period.

2-6

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Conditions for Installation . . . . . . . . . . . . . . . . . . . .3-1

3.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2.1 Unpacking of Printer . . . . . . . . . . . . . . . . . . . . .3-2

3.2.2 Unpacking of Starter Kit . . . . . . . . . . . . . . . . . .3-4

3.3 Installation Work . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Installation of toner cartridge to the printer . . . . .3-5

3.3.2 Installation of OPC Belt Cartridge . . . . . . . . . . .3-6

3.3.3 Installation of Cleaning Roller and Oil Bottle . . .3-7

3.3.4 Test Run and Test Print . . . . . . . . . . . . . . . . . . .3-8

3. Installation

3.1 Conditions for Installation

Laser beam printer is likely influenced by the environment of set-up location.

IF Printer was set up at the inappropriate location, the printer may not perform

the characteristic functions as expected. Therefore, the following factors

should be taken into consideration prior to deciding where to set.

(1). Environmental Conditions

Printer should not be set up at the locations referred to by the following

items (a) through (d) specifying the inappropriate locations for set-up.

(a). Likely to receive the direct sunbeam or similar light.

(For example, window side)

(b). Likely to cause the big difference in temperature and humidity between

the maximum and minimum level. (Normal operation environment is

within 10 ~ 35 , 20 ~ 80%RH and without any condensation.)

(c). Likely to receive cold wind from air-conditioner or worm wind from

heater, or to receive direct radiant heat.

(d). Likely to cause much dust or have corrosive gas like ammonia.

(e). Users to select the location of good ventilation and set a printer on the

flat surface.

(f). Users to check the maximum tilt of set-up location to be within 1 .

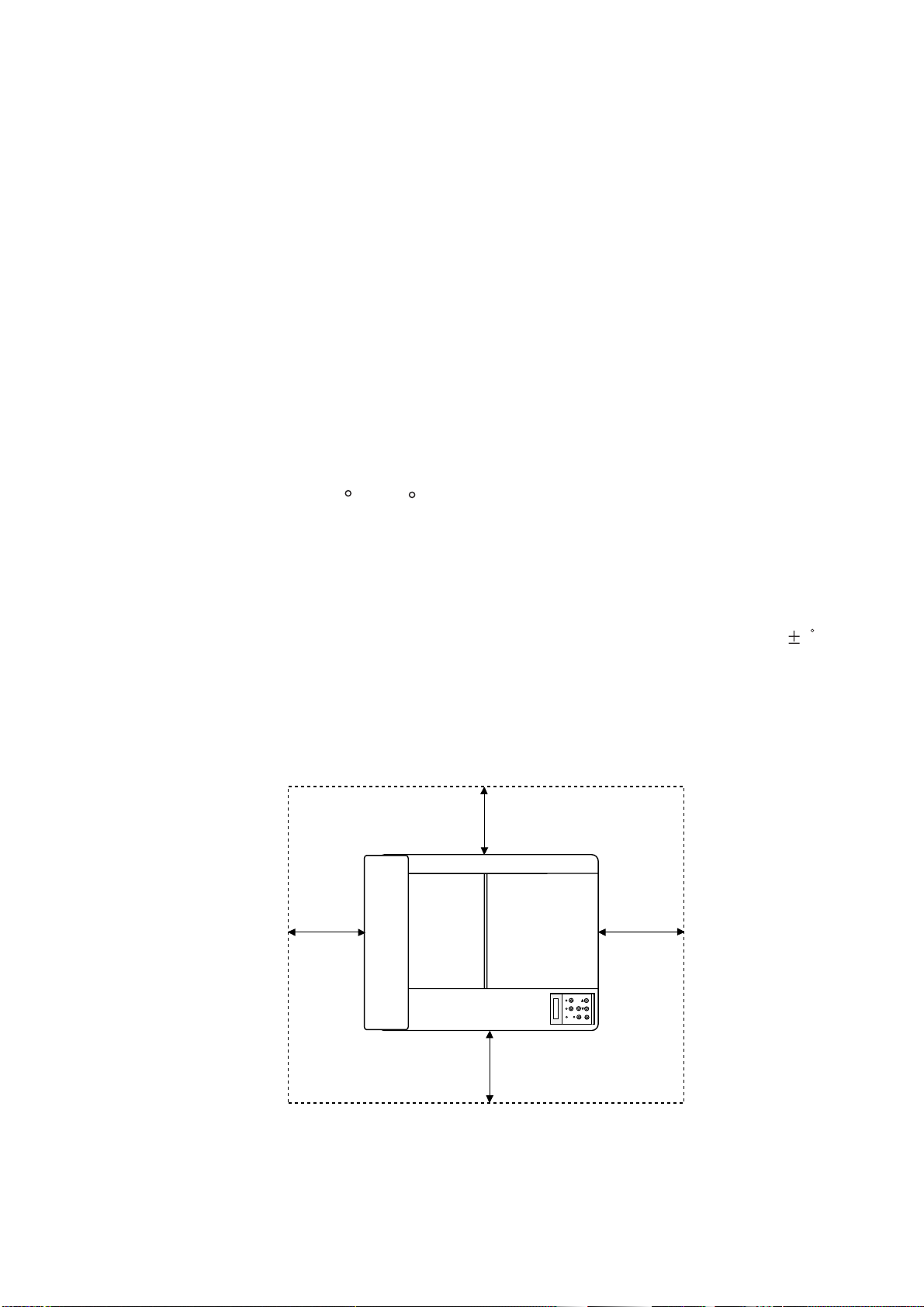

(2). Basic Layout of Printer Set-Up Location

Fig.3-1 shows the basic layout of printer set-up location suitable for the

smooth operation and maintenance of printer.

C

C

[Fig.3-1]

3-1

10cm(4")

40cm(16") 70cm(28")

Paper Exit Side

10cm(4")

Front Side

3.2 Unpacking

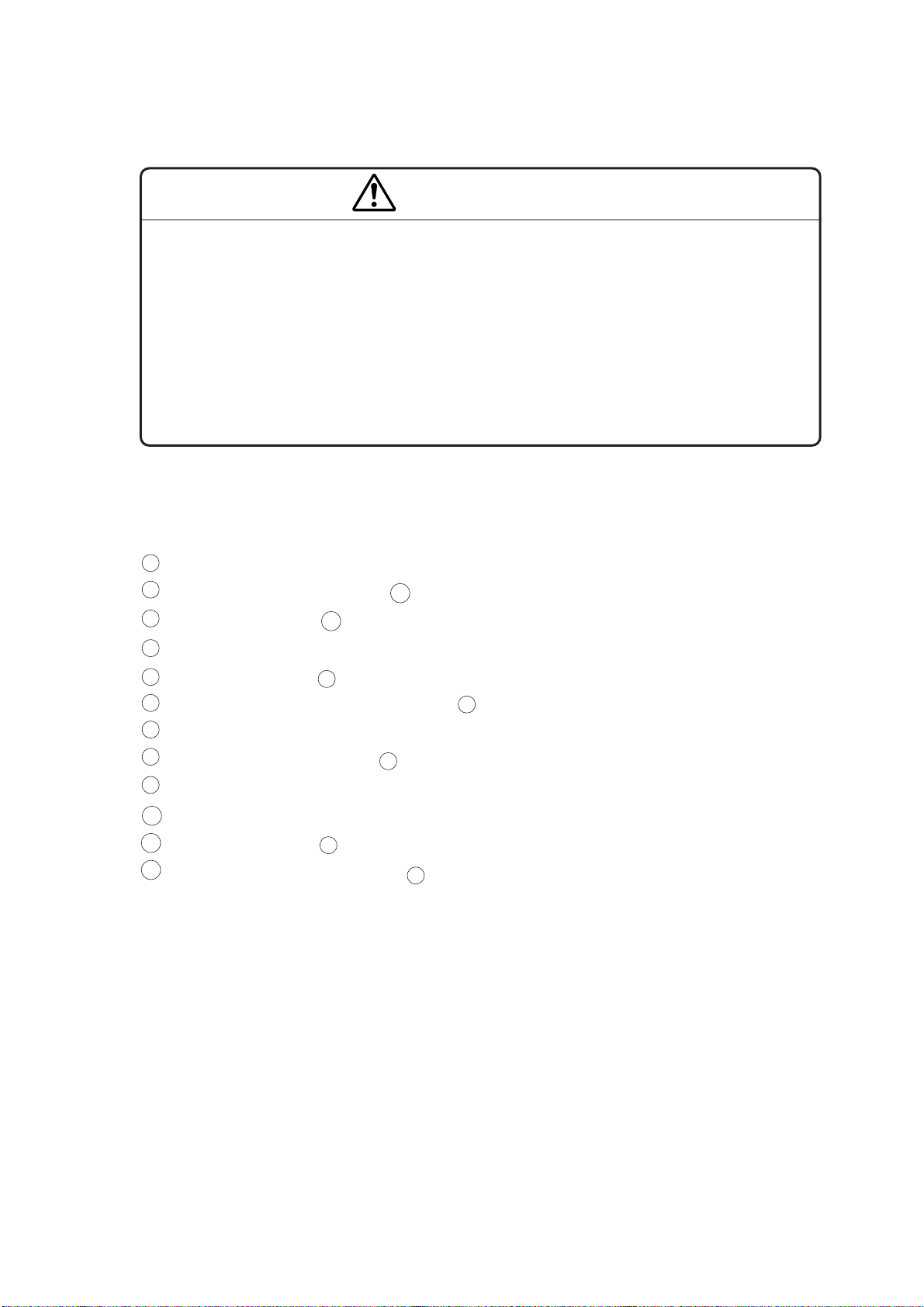

WARNING

•The package containing a printer weighs approximately 40kg, so that it is

too heavy for one person to carry. It needs more than two adults to move

the printer. Since this printer is a precision machine, ensure to carry it

slowly with good care so that no impact shall be given to the printer while

moving.

•Do not attempt to hold a printer as covered by vinyl sheet, because it is

slippery and results in damage and injury if dropped from your hand.

3-2-1 Unpacking of Printer (Fig.3-2)

. Cut the bands (2 pcs.) binding the package.

. Remove the plastic joints (4 locations).

. Remove the tape binding the top of package.

. Open up the top of package to take the starter kit out.

. Lift the outer box up for removal.

. Remove the top partition packing .

. Take the power cable out.

. Open up the vinyl sheet covering the printer body.

. Lift up the printer body with another person's help, and lay it on the floor.

. Set up the printer on the suitable location.

. Remove the tape fixing the paper cassette.

. Remove the protective tape (1 location).

1

2

4

3

5

6

7

8

9

10

3-2

18

3

17

1

8

9

5

11

12

9

8

oh

Band

14

X^[^Lbg

d„P[u

x[X

3-3

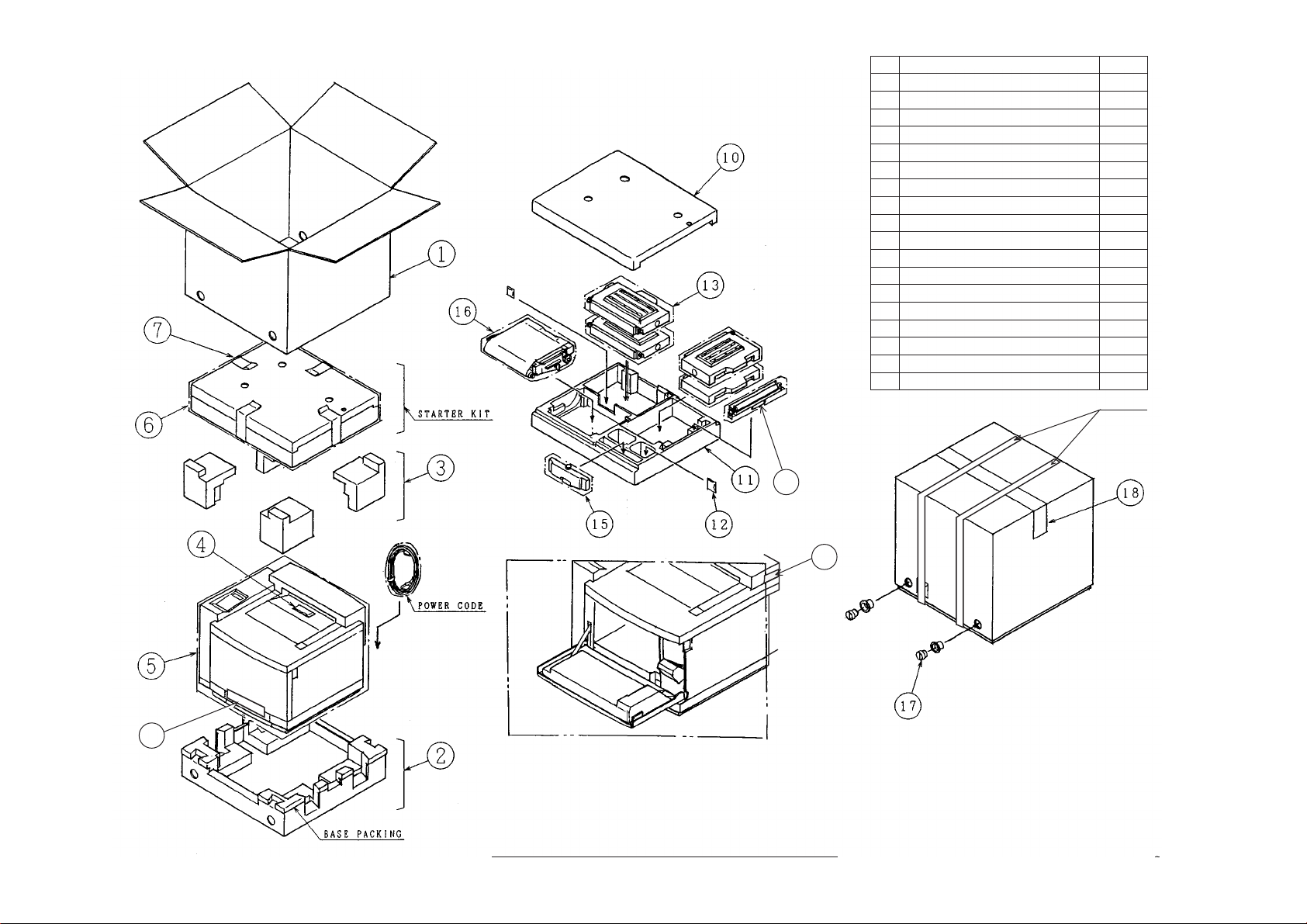

No. NANE OF PARTS Q’TY

1 OUTER BOX 1

2 BASE 1

3 UPPER PACKING 1

4 SILICA GEL (EN) 1

5 POLYETHYLENE BAG (EN) 1

6 POLYETHYLENE BAG (ST) 1

7 ST KIT TAPE 4

8 TAPE 1

9 PR TAPE 1

10 STARTER KIT PACKING (U) 1

11 STARTER KIT PACKING (L) 1

12 SILICA GEL (ST) 2

13 POLYETHYLENE BAG (T) 4

14 POLYETHYLENE BAG (CL) 1

15 POLYETHYLENE BAG (OIL) 1

16 POLYETHYLENE BAG (OPC) 1

17 JOINT 4

18 OUTER BOX TAPE 1

Fig.3-2:Unpacking of Printer Package

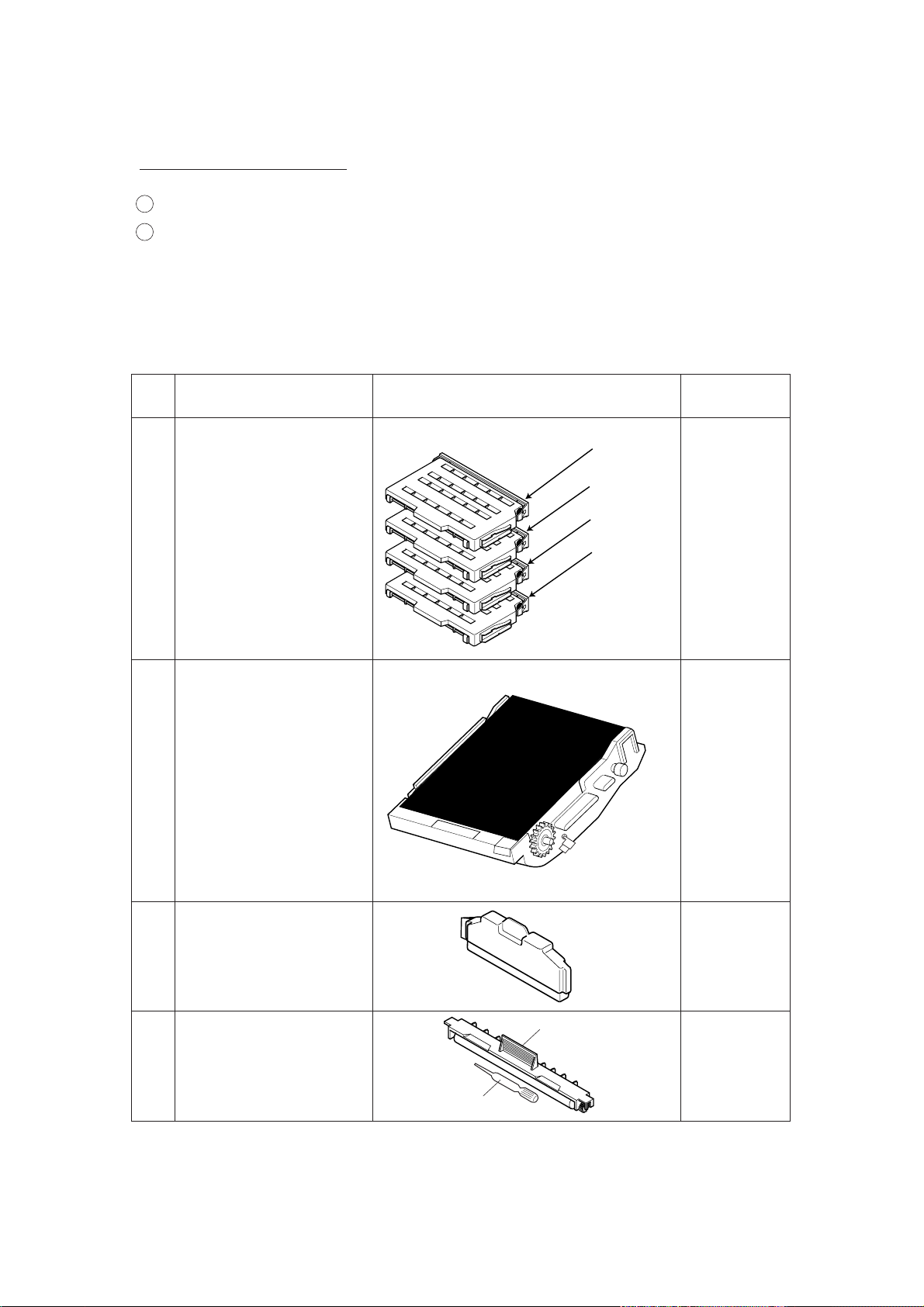

3-2-2 Unpacking of Starter Kit

Procedure of Unpacking

. Open up the vinyl sheet covering the starter kit.

. Confirm all of the following kits to be inside the starter kit's packing box.

1

2

No. Name of Kit Appearance Quantity

1

2

3

4

Toner Cartridge

(Y.M.C.K)

OPC Belt Cartridge

Oil Bottle

Cleaning Roller

Y (Yellow)

M (Magenta)

C (Cyan)

K (Black)

4

1

1 set.

1

3-4

Cleaning Roller

Spuit

3.3 Installation Work

Install the unit parts of starter kit to the printer according to the following procedures:

3.3.1 Installation of OPC Belt Cartridge: (Fig.3-3 ~ 3-6)

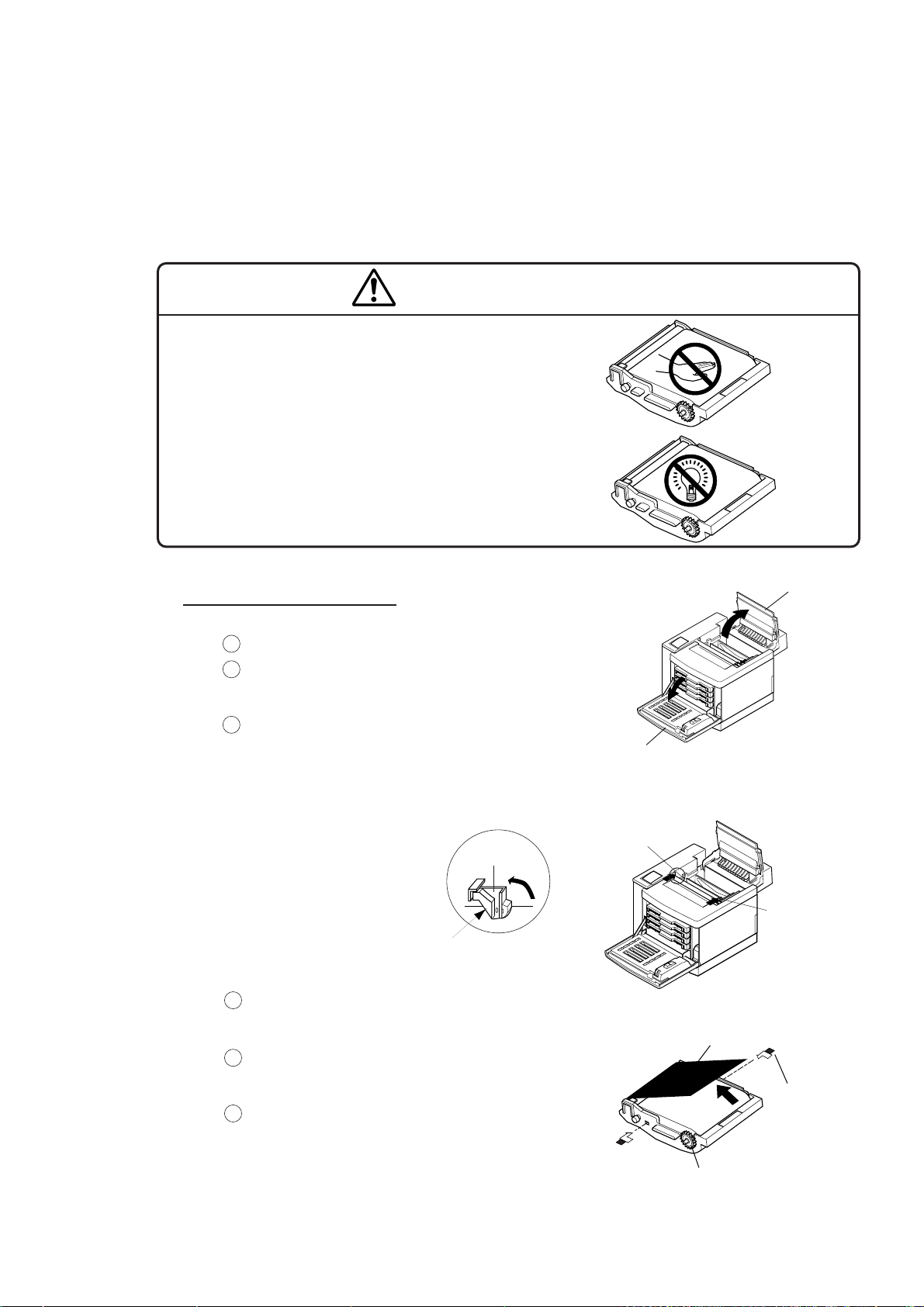

PRECAUTION

Do not directly touch the OPC belt

surface with bare hands or gloves.

If OPC belt is exposed for more

than two minutes under the light

of 800 lux, the belt may be defective.

Procedures of Installation

. Open the front cover.

. Open the paper exit cover.

. Erect the lock lever BC provided

at both sides (left and right).

. Pull and remove the tension release

pins of both sides (left & right).

. Remove the protective sheet

from a new belt cartridge.

. Push the new belt cartridge into the

printer, along the guide of lock lever

BC provided at both sides.

Paper Exit Cover

Front Cover

Lock Lever BC

(Right)

Lock Lever BC

(Left)

Guide

Lock Lever BC

[Fig.3-3]

[Fig.3-4]

1

2

3

3-5

4

5

g

[Fig.3-5]

6

Protective Sheet

Tension

Release Pins

Belt Cartrid

e

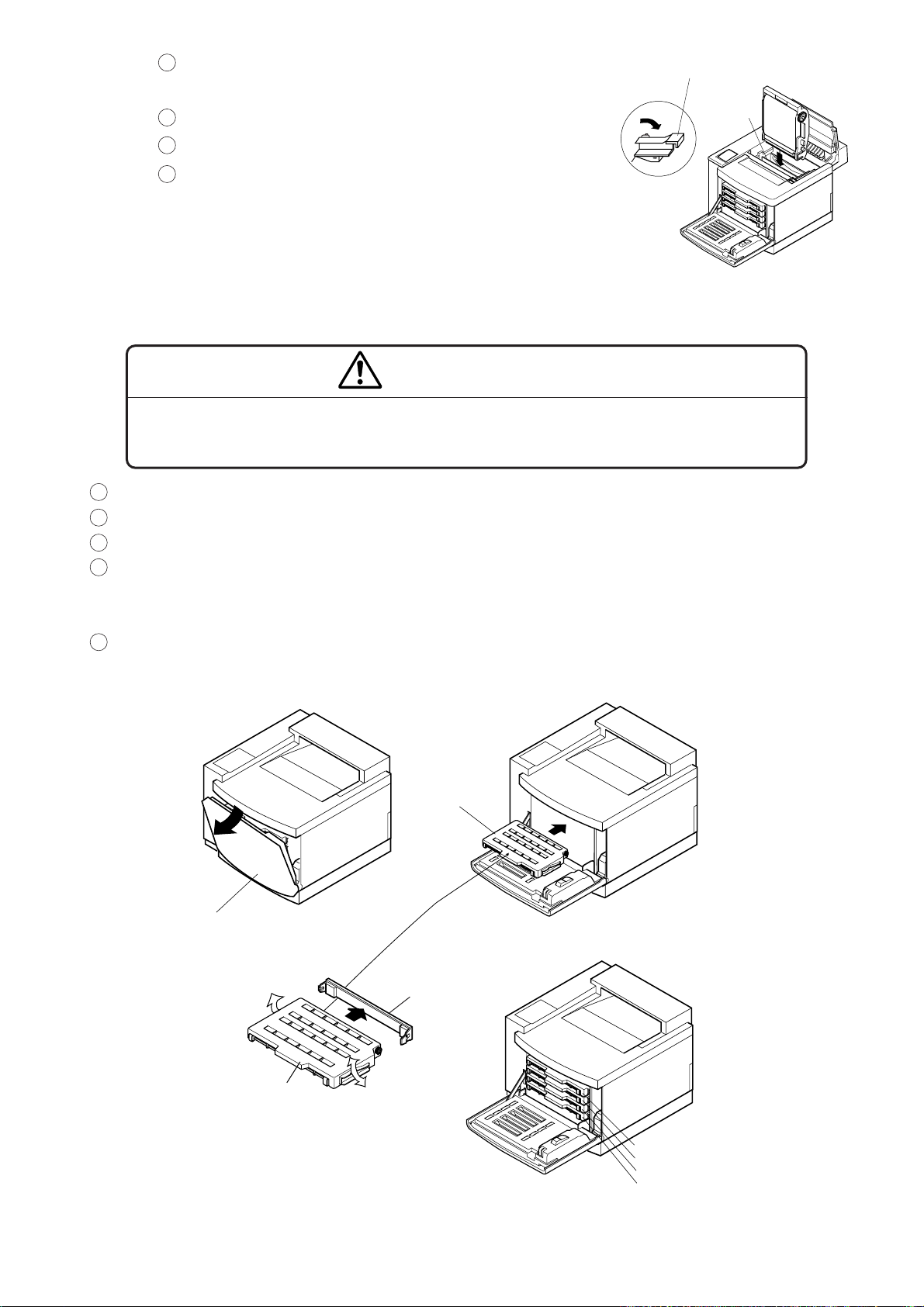

. Push new belt cartridge along the

guide of both sides into the printer.

. Set the lock lever BC.

. Close the paper exit cover.

. Close the front cover.

Guide

Lock Lever BC

[Fig.3-6]

6

7

8

9

. Open the front cover unit.

. Holding a toner cartridge horizontally, shake it to left and right for three to four times.

. Remove a protective cover of toner cartridge.

. Push the new toner cartridge along the guide into the printer.

Installation order of toner cartridge in terms of color shall be Cyan (C), Magenta (M),

Yellow (Y), and Black (K).

. Close the front cover unit.

1

2

4

3

5

Front Cover

[Fig.3-7]

Toner Cartridge

[Fig.3-8]

Toner Cartridge

Protect Cover

K

Y

M

C

[Fig.3-9]

3-6

3.3.2 Installation of toner cartridge to the printer: (Fig.3-7~3-9)

Caution

Refrain from holding a toner cartridge vertically, otherwise, it may adversely

affect the print quality.

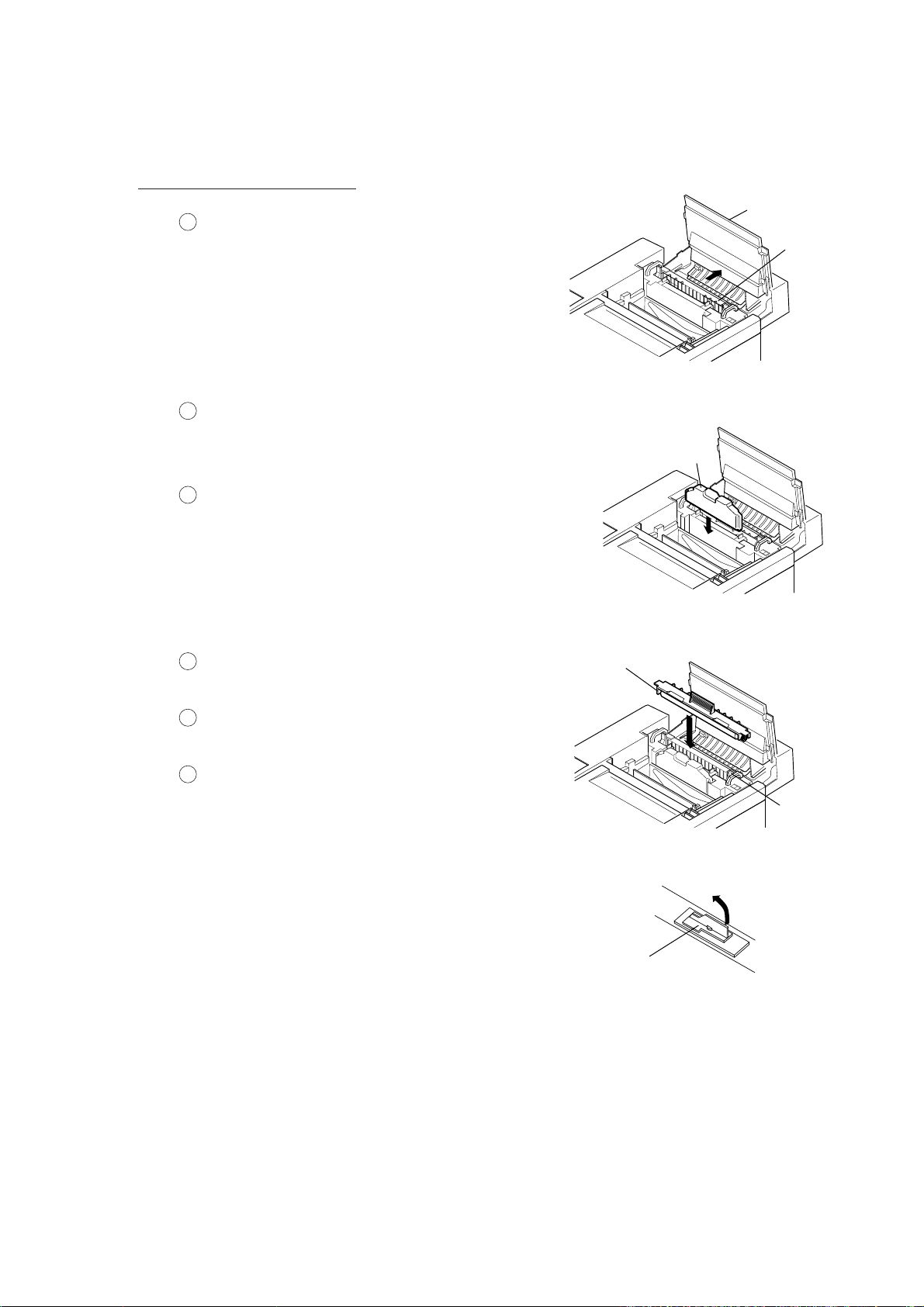

3.3.3 Installation of Cleaning Roller and Oil Bottle:(Fig.3-10 ~ 3-13)

Procedures of Installation

. Open the paper exit unit.

. Open the retainer lock lever

of oil bottle and the cleaning

roller.

. Install the oil bottle to the

fusing unit.

. Install the cleaning roller to

the fusing unit.

. Hold the cleaning roller with

the retainer lock lever.

. Close the paper exit cover.

Paper Exit Cover

Fusing Unit

Fusing Oil Bottle

Cleaning Roller

Lock Lever

[Fig.3-10]

[Fig.3-11]

[Fig.3-12]

1

2

4

3

5

6

3-7

Lock Lever

4

5

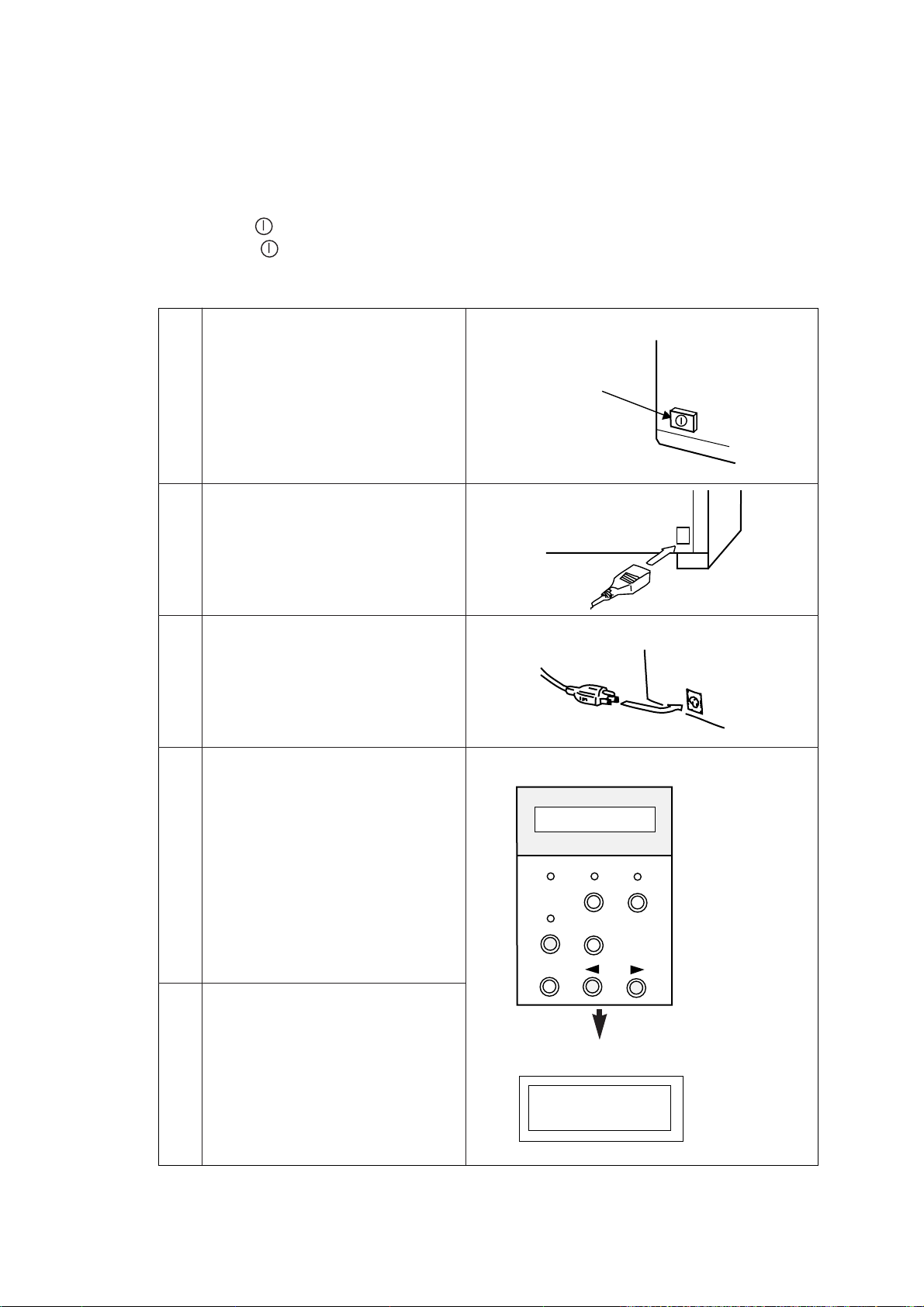

3.3.4 Test Run & Test Print

(1). Power-On & Off

( i ). Power-On:

There is mark on the power supply switch located on the side panel of the

printer. represents the power supply switch with push-on/push-off function.

1

2

3

Prior to connecting a power

cable, confirm that the push

button top of power supply

switch located at the lower

left front of printer projects

from the cover surface.

This means that the printer is in

the power-off status.

Connect a connector of power

supply cable to the printer.

Insert a plug of the power

supply cable to the inlet.

Pressing the scroll keys (left &

right) and Free Size key, push

the push button top of power

supply switch. Next, press the

ONLINE key. Then, the display

of operator panel turns to be the

status of (a), and "MESSAGE"

LED lamp starts to blink.

This blinking means

that the printer is in the

warming-up process.

"MESSAGE" LED lamp

changes to be lit within 210

seconds at max., when screen

(b) appears on the operator

panel display.

Power Supply Switch

(a). Indication at Warming-UP

01 WAIT /UPP

U:LT L:[ ] [

MESSAGE ONLINE MEDIA

FREE SIZE CLEAR

SELECT

(a). Indication at Warming-UP

00 READY /UPP

U:LT

3-8

Loading...

Loading...