®®

QMS magicolor 2 Print System Operation

1800482-001B

Trademarks

The following are trademarks or registered trademarks of their respective owners. Other

product names mentioned in this manual may also be trademarks or registered

trademarks of their respective owners. Registered trademarks are registered in the

United States Patent and Trademark Office; some trademarks may also be registered in

other countries. QMS, Crown, CrownAdmin, CrownCopy, CrownNet, magicolor, the

QMS logo, and the Crown seal are registered trademarks of QMS, Inc., and CrownView,

ImageServer, Multi-Res, PS Executive Series, Q

QMS, Inc. PostScript is a trademark of Adobe Systems Incorporated for a page

description language and may be registered in certain jurisdictions. Throughout this

manual, “PostScript Level 2” is used to refer to a set of capabilities defined by Adobe

Systems for its PostScript Level 2 page description language. These capabilities,

among others, are implemented in this product through a QMS-developed emulation

that is compatible with Adobe's PostScript Level 2 language. Adobe, Acrobat, the

Acrobat logo/Adobe Systems Incorporated. 3Com, 3+Open/3Com Corporation. Aldus,

Aldus PageMaker, Aldus FreeHand/Aldus Corporation. Apple, AppleTalk, EtherTalk,

LaserWriter, LocalTalk, Macintosh, TrueType/Apple Computer, Inc. VINES/Banyan.

Centronics/Centronics. Color Solutions, ColorBlind/Color Solutions. DEC, DECnet,

LN03, LN03 Plus, VMS/Digital Equipment Corporation. PhoneNET/Farallon Computing,

Inc. CompuServe /H & R Block. Hewlett-Packard, HP, PCL, HP-GL, LaserJet/HewlettPackard Co. IBM, OS/2, Token-Ring/International Business Machines Corporation.

Intel/Intel Corporation. Iomega, Jaz, Zip/Iomega. Microsoft, MS-DOS/Microsoft

Corporation. NEC, V

Pantone. PANTONE is Pantone, Inc.’s check-standard trademark for color reproduction and

color reproduction materials. QuarkXPress/Quark, Inc. TOPS/Sun Microsystems, Inc.

UNIX/UNIX Systems Laboratories. SIMM/Wang Laboratories. Ethernet/Xerox. All other

trademarks are the property of their respective owners.

R4300/NEC. Novell and NetWare/Novell, Inc. Pantone, PANTONE/

COLOR, and QFORM are trademarks of

Proprietary Statement

The digitally encoded software included with your QMS magicolor 2 Print System is

Copyrighted © 1998 by QMS, Inc. All Rights Reserved. This software may not be

reproduced, modified, displayed, transferred, or copied in any form or in any manner or

on any media, in whole or in part, without the express written permission of QMS, Inc.

Copyright Notice

This manual is Copyrighted © 1998 by QMS, Inc., One Magnum Pass, Mobile, AL

36618. All Rights Reserved. This manual may not be copied in whole or in part, nor

transferred to any other media or language, without the express written permission of

QMS, Inc.

Contents

1 Introduction

Introduction .................................................................................. 1-2

About This Manual .......................................................................1-2

Typographic Conventions 1-4

2 Consumables

Introduction .................................................................................. 2-2

Loading the Media Cassette ........................................................2-2

Prepare the Paper 2-2

Load the Cassette 2-2

Using Media Other than Paper ....................................................2-4

Using Envelopes 2-4

Using Labels 2-7

Using Letterhead and Memo Media 2-7

Using Transparencies 2-8

Using Toner Cartridges ............................................................... 2-9

Toner Cartridge Life 2-9

Refilled Toner Cartridges 2-9

Toner Cartridge Storage 2-10

Replacing a Toner Cartridge .................................................... 2-11

3 Advanced Printing Features

Introduction ................................... ...... ............. ............. ............. .. 3-2

High-Resolution Printing ........................................................... 3-2

How Much Memory Do You Need? 3-3

Setting the Default Resolution 3-4

Cassette Chaining ....................................................................... 3-5

Enabling/Disabling Cassette Chaining 3-5

Collating Output .................................................... ..................... 3-6

Enabling/Disabling Collation 3-6

Working with Chunk Collation 3-7

Improving Collation Performance 3-8

2-Sided Printing ........................................................................... 3-9

Printing on Standard and Custom Media Sizes ........................ 3-9

Working with Status Pages ..................................................... 3-10

Identifying a Status Page Type 3-10

Printing a Status Page 3-11

Cancelling/Ending Print Jobs ............ ....................................... 3-11

Cancelling a Print Job 3-12

Cancelling all Print Jobs 3-12

Ending a Print Job 3-13

4 Color Printing

Introduction ................................... ...... ............. ............. ............. .. 4-2

QCOLOR Color Control ............................................................... 4-2

Accessing QCOLOR for Windows 95 4-2

QMS magicolor 2 Operationii

Other Methods of Color Control .................................................4-4

Color Matching 4-4

About Printer Halftones and CRDs 4-7

Color Density ................................................................................4-9

Adjusting the Color Density 4-9

5 Printer Care

Introduction .................................................................................. 5-2

Handling the Printer .....................................................................5-2

Cleaning the Printer .....................................................................5-3

Guidelines for Cleaning Inside the Printer 5-4

Cleaning the Transfer Unit 5-4

Cleaning the Paper Exit Rollers 5-7

Cleaning the OPC Belt Cartridge 5-8

Cleaning the Laser Lens 5-10

Cleaning the Exterior of The Printer 5-11

Maintenance Schedule ..............................................................5-12

Replacing the Fuser Oil Bottle and Cleaning Roller ...............5-14

Replacing the OPC Belt Cartridge ............................................5-17

Replacing the Ozone Filter ........................................................5-20

Replacing the Waste Toner Pack .............................................5-21

6 CrownView Printer Web

Page

Introduction .................................................................................. 6-2

Setting up the Printer Web Page ................................................6-3

Assigning a Printer Name 6-3

Setting Up Your Browser Software 6-4

Printer Home Page .......................................................................6-8

Home 6-10

Operator Control 6-11

Contents iii

General Settings 6-13

Printer Jobs 6-21

Consumable Status 6-23

Accounting 6-25

System Support Page 6-26

QMS, Inc. Page 6-28

Online Help Page 6-28

7 Media Jams

Introduction ................................... ...... ............. ............. ............. .. 7-2

Automatic Jam Recovery ............................................................ 7-2

Preventing Media Jams .............................................................. 7-2

Understanding the Media Path ....................... ....... ...... ....... ........ 7-3

Understanding Media Jam Status Messages ....... ...... ....... ........ 7-4

Removing Media Jams ....................... ....... ...... ....... ..................... 7-5

Misfeed Jams 7-5

Inner Jams, Outer and Drum Jams 7-6

8 Troubleshooting Printer

Problems

Introduction ................................... ...... ............. ............. ............. .. 8-3

Status and Service Messages .................................................... 8-3

Status Messages 8-3

Service Mess ages 8-11

HP-GL Error Codes and PCL Error Codes .............................. 8-13

Testing PC-Printer Communication ........................................ 8-14

Creating the Test File 8-14

Sending the Test File 8-14

Testing Macintosh-Printer Communication ............... ............. 8-18

Testing Macintosh Communication 8-18

Printer Problem Checklist ........................................................ 8-19

QMS magicolor 2 Operationiv

OPC Belt Cartridge Problems ...................................................8-21

Control Panel Problems ............................................................8-22

Data Indicator Stays Lit 8-22

No Advanced Status Page’ 8-22

No Start-up Page 8-22

Paper Jam Message Stays On 8-23

Printer Resets 8-23

PostScript Errors 8-23

Windows Driver Problems .........................................................8-24

Printer Description Files 8-24

CrownNet Problems ...................................................................8-24

Output Problems ........................................................................8-25

1200x600, 2400x600 dpi Printing Unavailable 8-25

Blank Pages 8-26

Not All Pages Print 8-26

Kanji Option Kit Problems .........................................................8-27

Can't Download Kanji Fonts 8-27

Can't Access Kanji Fonts 8-28

Can't Access the Kanji File Through Your Application 8-28

Print Quality Problems .............................................................8-29

Color Density Problems ............................................................8-30

Engine ROM 8-30

Image Defects ..... ....... ...... ....... ...... ....... .......................................8-32

General 8-32

Specific 8-32

Placing a Service Call ...............................................................8-38

9 Repacking the Printer

Introduction .................................................................................. 9-2

What's Involved? 9-2

Remove Cables and Cassette(s) .................................................9-3

Remove the Toner Cartridges .....................................................9-3

Remove the OPC Belt Cartridge ................................................9-3

Contents v

Prepare the Fuser Unit ............................................................... 9-5

Change the Waste Toner Pack ................................................... 9-9

Remove the Lower Input Feeder .............................................. 9-11

Repack the Printer ..................................................................... 9-13

A QMS Customer Support

Sources of Support ......... ...... ....... ...... ....... ...... ....... ...... ....... ...... ..A-2

Your QMS Vendor A-2

Your Application Vendor A-2

Q-FAX A-2

CompuServe A-3

Internet A-3

QMS Customer Response Center (CRC) A-4

QMS World-wide Offices .............................................................A-5

B Configuration Menu

Introduction ................................... ...... ............. ............. ............. ..B-2

Menu Chart Conventions ............................................................B-2

Administration Menu ................................. ...... ....... ...... ....... ...... ..B-3

Installation Menu ............. ............................................................B-9

Operator Control Menu .............................................................B-10

Index

v

Administration/Communications/Network2/CrownNet

Menu B-4

QMS magicolor 2 Operationvi

1

Introduction

In This Chapter . . .

n “Introduction” on page 1-2

n “About This Manual” on page 1-2

Introduction

Introduction

This manual pro vid es information on insta lling co nsum ables such as

media and toner cartridges. You’ll also find i nformation on advanced

printing f eat ure s , print er care, print quality, and troublesho oti ng. Us e th is

guide in conjunction with y our ot her QMS

About This Manual

magicolor

2 documentation.

Introduction

1

Consumables

2

Advanced

3

Printing Features

Color Printing

4

Printer Care

5

CrownView

6

Printer Web Page

Media Jams

7

Provides an overview of this guide.

Describes the media that’s best

suited for your printer; how to load

paper, labels, transparencies,

envelopes; and how to replace the

toner cartridges, OPC belt cartridge,

fuser oil bottle, cleaning roller, and

waste toner pack.

Explains how to collate output, print a

status page, cancel a print job, and

end a print job.

Describes how to print documents in

color.

Describes how to handle and clean

the printer.

Contains information on how to access

and use the printer’s web page.

Explains how to locate and clear

media jams.

QMS magicolor 2 Op

eration1-2

About This

Manual

Troubleshooting

8

Printer Problems

Repacking the

9

Printer

QMS Customer

A

Support

Configuration

B

Menu

Lists printer status messages, outlines

printer and print quality problems and

solutions, and describes how to place

a service call.

Explains how to repack the printer in

case you need to relocate or ship your

printer after it’s been installed.

Provides product sales and support

telephone numbers, and describes

how to communicate with QMS

through CompuServe, the Internet,

and Q-FAX

Provides a view of the printer’s

configuration menu.

.

1-3Introduction

About This

Manual

Typographic Conventions

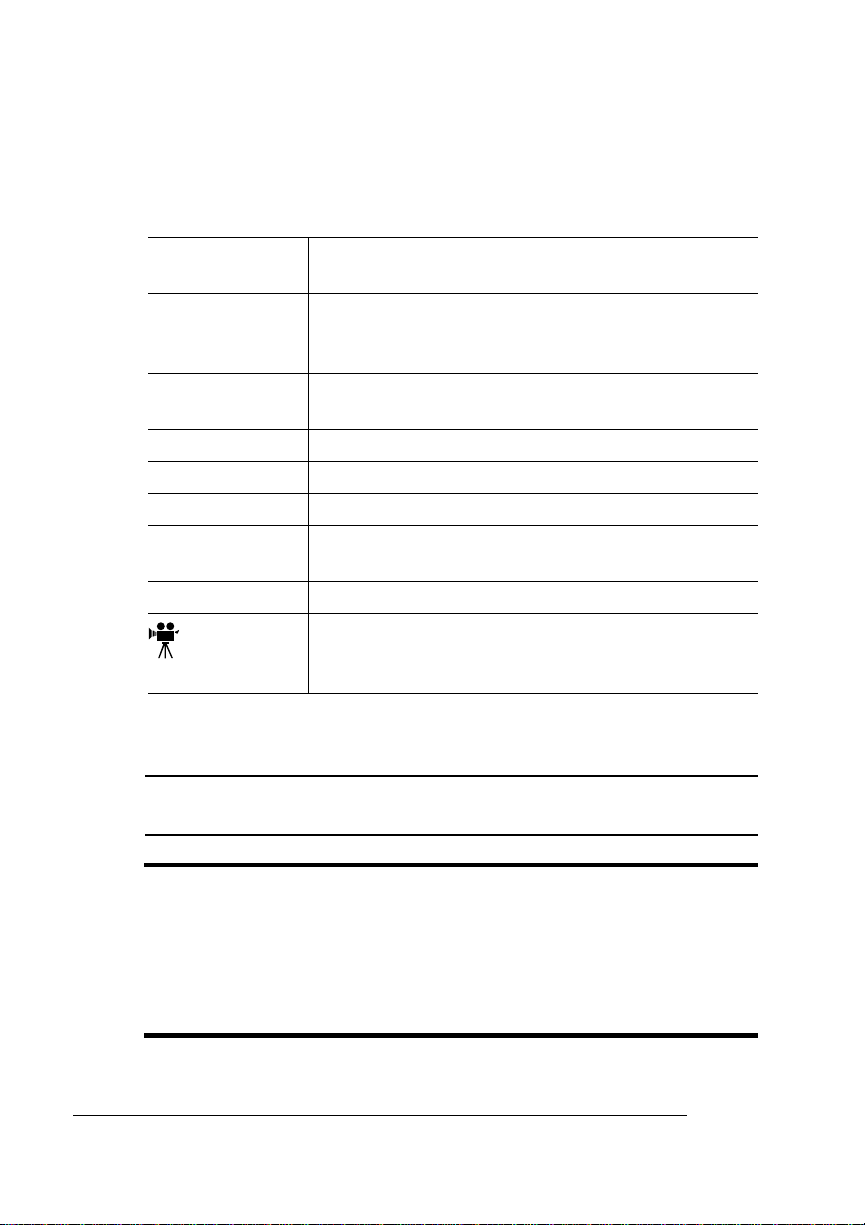

The following typographic conventions are used in this manual:

Mixed-Case

Courier

Mixed-Case

Italic

Courier

UPPERCASE

COURIER

lowercase bold PostScript operators and DOS commands

lowercase italic

UPPERCASE File and utility names

↵ Press the Enter key (PC) or Return key

^ Press and hold down the Ctrl key (PC)

» Note:

Notes contain tips, extra information, or important information

Text you type, and messages and information

displayed on the screen

Variable text you type; replace the italicized

word(s) with information specific to your printer or

computer

Information displayed in the printer message

window

Variable information in text.

(Macintosh)

In Adobe Acrobat PDF versions of the manual,

click to play a QuickTime video clip of the

procedure described in the text.

that deserves emphasis or reiteration.

s Caution:

Cautions present information that you need to know to avoid

equipment damage, process failure, or extreme annoyance.

M WARNING!

Warnings indicate the possibility of personal injury if a

specific procedure is not performed exactly as described in the

manual.

ACHTUNG!

Bitte halten Sie sich exakt an die im Handbuch

beschriebene Vorgehensweise, da sonst Verletzungsgefahr

bestehen könnte.

v

QMS magicolor 2 Op

eration1-4

2

Consumables

In This Chapter . . .

n “Introduction” on page 2-2

n “Loading the Media Cassette” on page 2-2

n “Using Media Other than Paper” on page 2-4

n “Using Toner Cartridges” on page 2-9

n “Replacing a Toner Cartridge” on page 2-11

Introduction

Introduction

This chapter covers basic printer operation, such as loading paper,

transparencies, labels, and envelopes; and replacing toner cartridges.

Loading the Media Cassette

Prepare the Paper

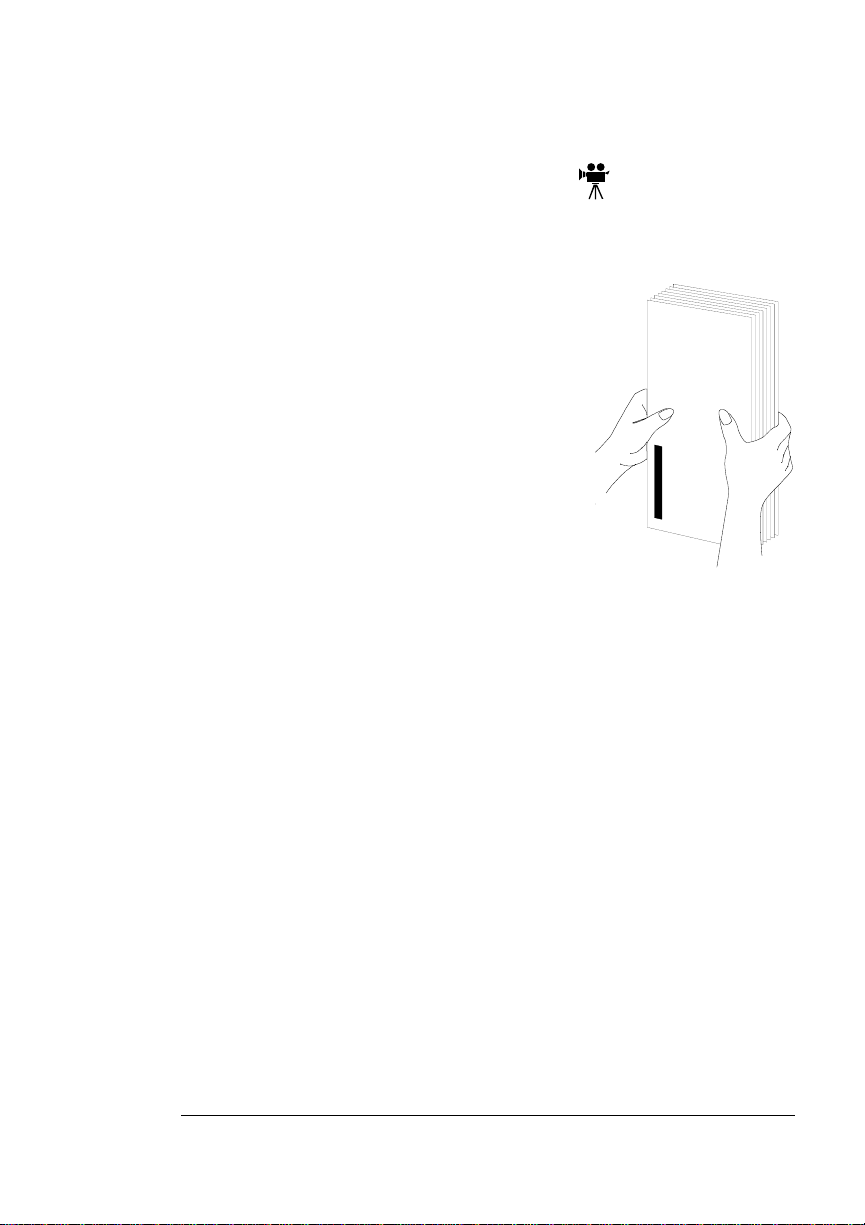

1 Take a stack of about 250 sheets (

» Note:

2 Holding the stack with one hand, fan the paper with the other.

3 Take off the top and bottom sheets.

Don’t unwrap the paper above the printer as this might

cause paper particles to fall into the printer.

This gets air through the sheets and prevents static buildup.

Residual glue buildup on these sheets may cause media jams.

½ ream).

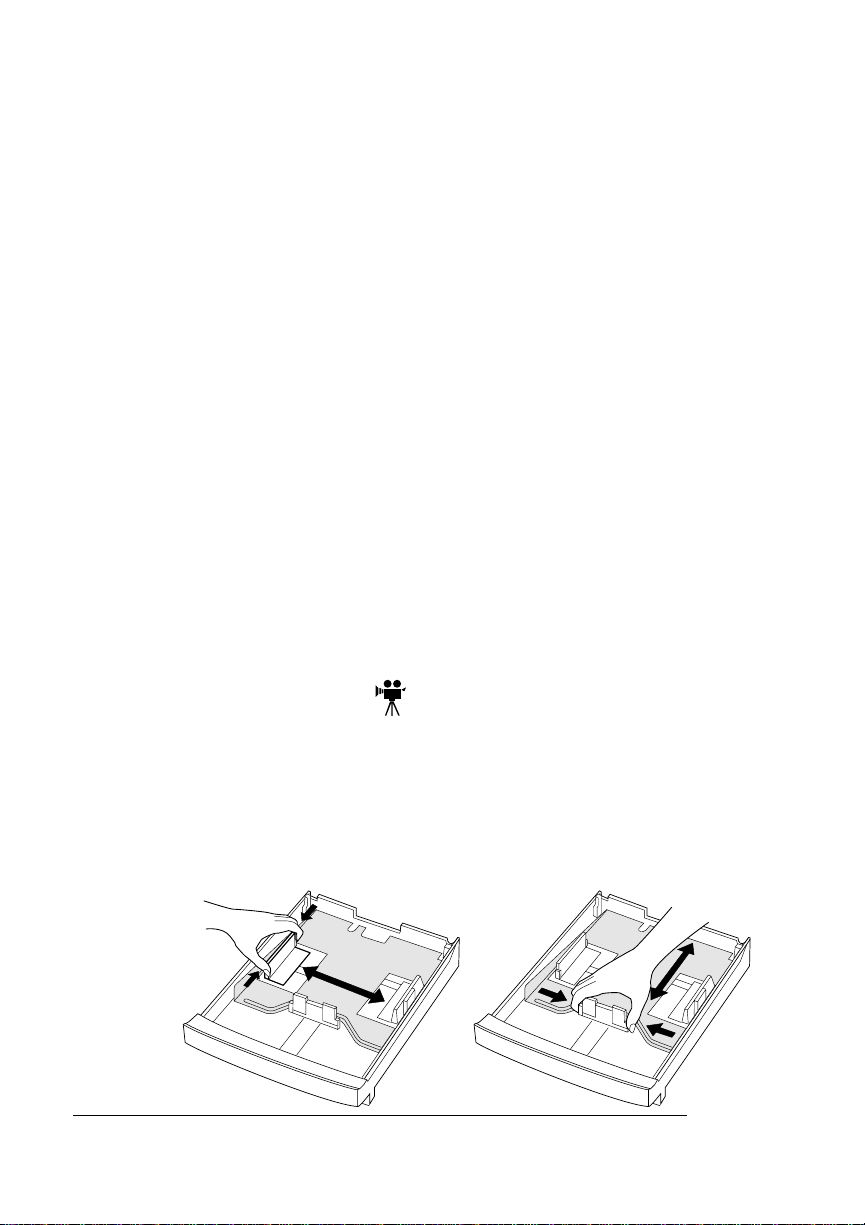

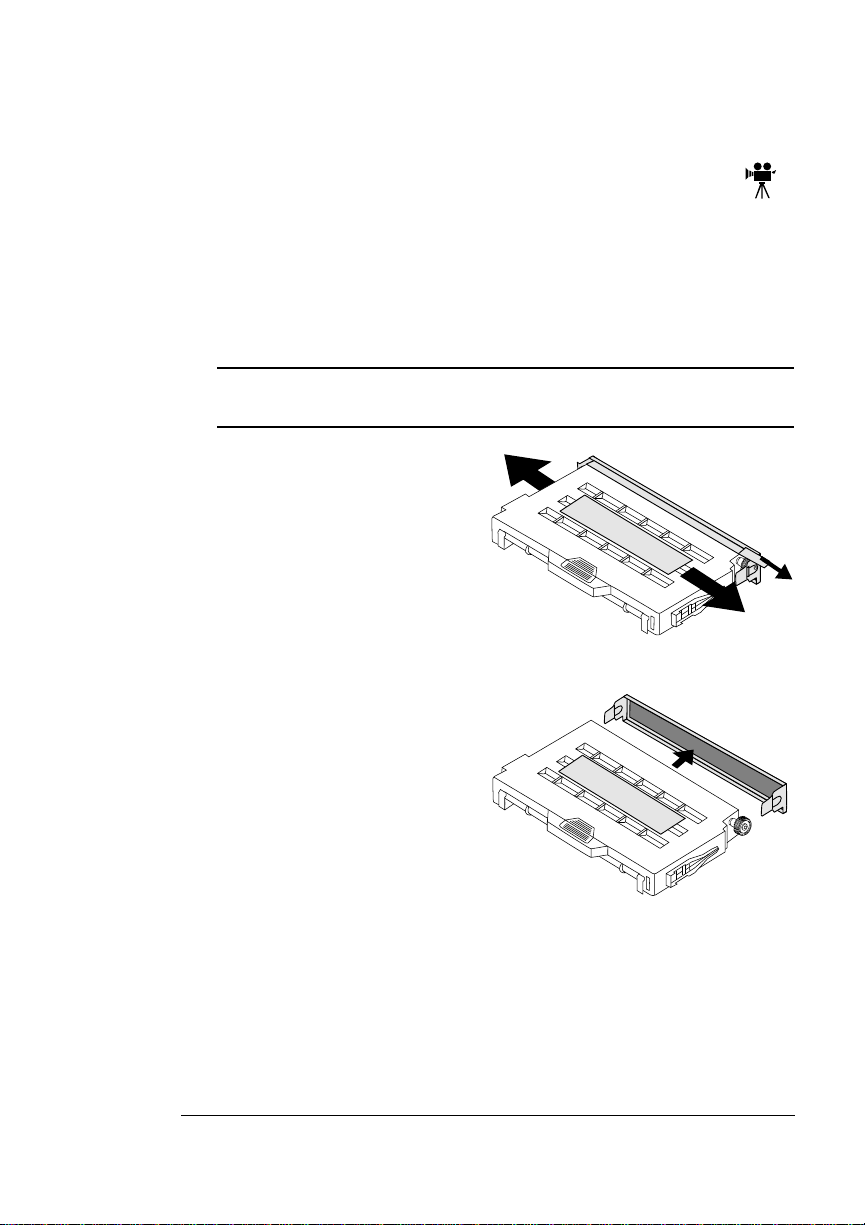

Load the Cassette

1 Remove the media cassette from the printer.

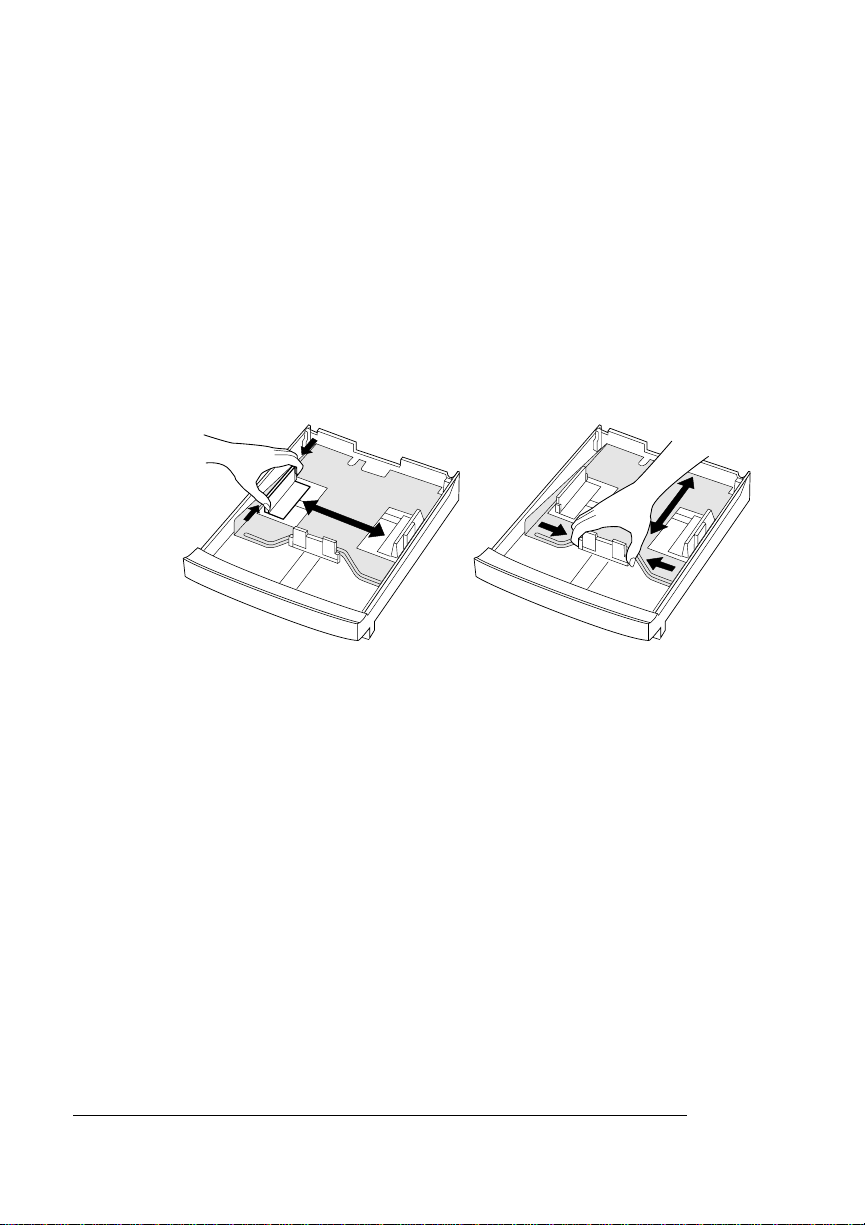

2 Adjust the media guides to fit the size paper you’re loading.

Squeeze the retainers at the ends of the left width guide and/or

the length guide, move the guide to the appropriate lo cation

(media sizes are listed on the cassette) , and r eleas e the ret ainers.

QMS magicolor 2 Op

eration2-2

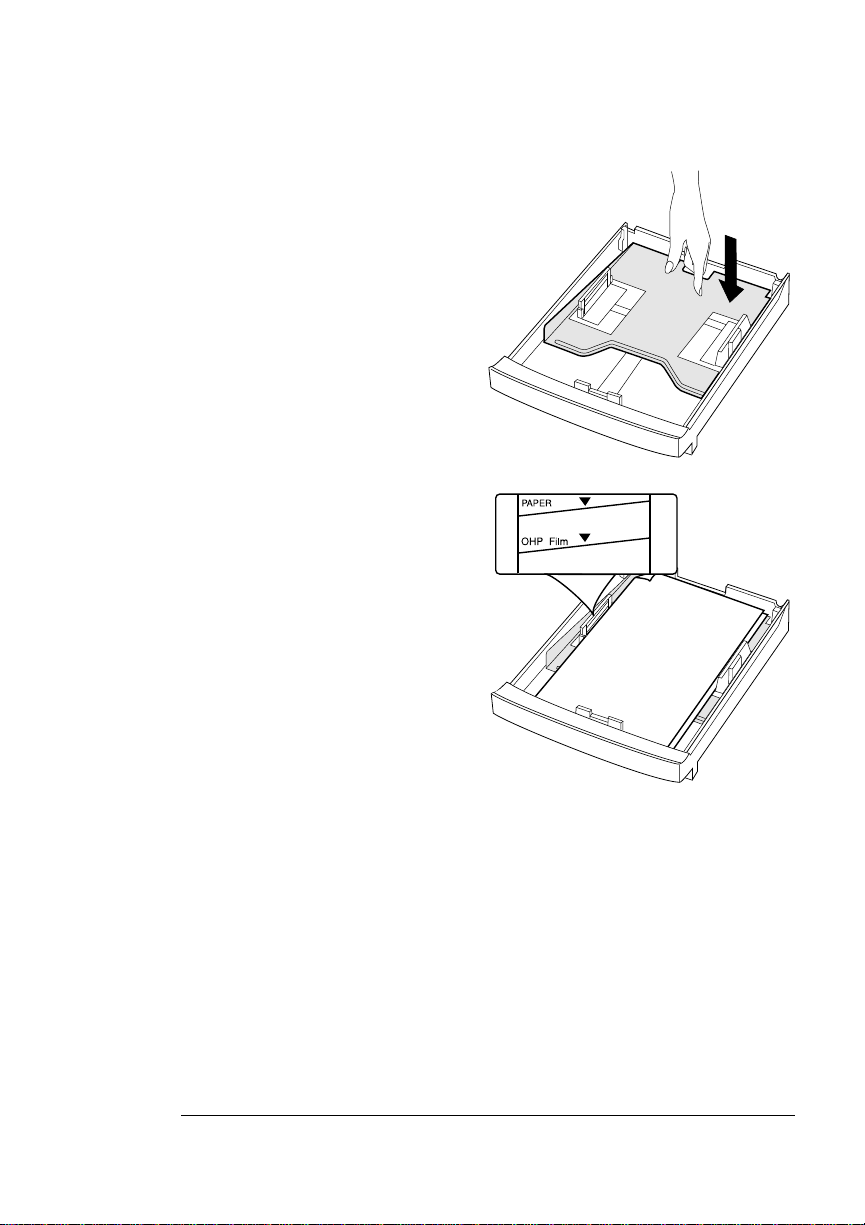

3 Push the media pressure

plate down to lock it in

position.

4 Load the paper.

n A fill limit mark is provided

on the inside left side of

the cassette. The media

cassette holds 250 sheets

2

of 20 lb (75g/m

) paper.

(Paper is packed in reams

of 500 sheets.) Do not

overfill the cassette.

Loading the

Media Cassette

n The printing side of the

paper should face up. An

arrow on the paper package label indicates the

face-up side of the paper.

5 Slide the media cassette back into the printer.

2-3Consumables

Using Media Other than Paper

Using Media Other than Paper

s Caution:

Although the QMS magicolor 2 was designed for occasional

printing on a wide range of media types, it is not intended to print

exclusively on a single media type except plain paper. Continuous

printing on media other than plain paper (such as transparencies,

labels, or thick stock) may adversely affect print quality or reduce

engine life.

Using Envelopes

Formatting Your printer receives the instructions to print on envelopes

from your applic ati on.

n When formatting data for envelopes, leave at least a 0.16"

(4.06 mm) margin from the edges of the envelope.

n Print on the front side only. Some parts of the envelope

consist of three layers of paper—the front, back, and flap.

Anything printed in these layered regions may be lost or

faded.

n See your ap plicatio n docume ntation f or spec ific inf ormatio n

on printing envelopes.

Input Source Upper slot; universal cassette

Capacity Up to 15, depending on the thickness of the

envelopes

Type Refer to the specifications in chapter 2, “Print Media,” in the

Reference

Notes n Use envelopes with a smooth exterior surface. Envelopes

with a rough surface may jam in the media cassette.

n You can print only on the address side of the en velope.

n You can print envelopes from either cassette, but only in

the upper position, not from the optional lower input feeder.

QMS magicolor 2 Op

eration2-4

Using Media

Other than

Paper

Loading and Printing Envelopes

1 Place the envelopes on a flat surface, and flatten them by

pressing down the corners.

2 Flex the envelope stack (including the

edges) to remove any stiffness.

3 Correct any dog-eared corners, and

then tap the envelopes on a flat surface

to align them

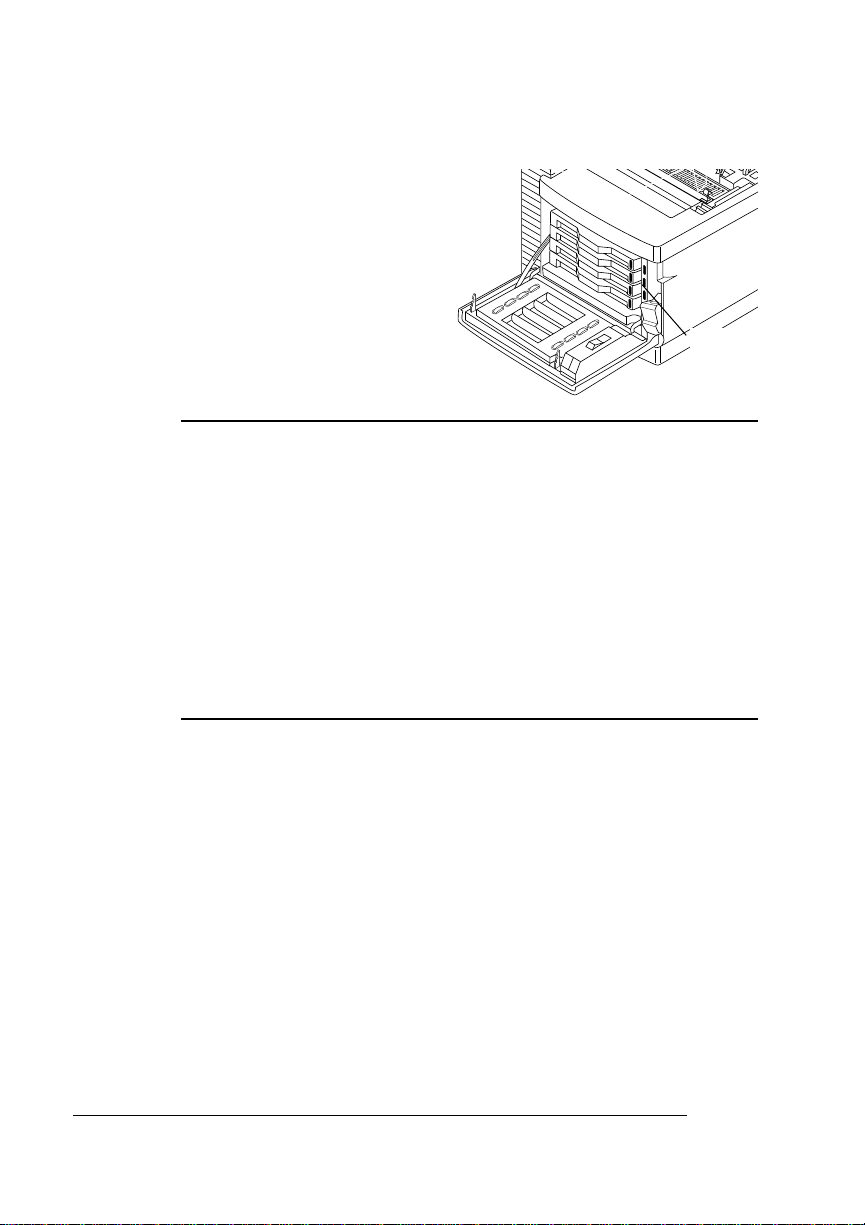

4 Remove the media cassette from the printer (and remove an y

media in the cassette).

The media cassette must be located in the upper position, not in

the optional lower input feeder.

2-5Consumables

Using Media

Other than

Paper

5 Adjust the media guides to the length and width of the enve-

lopes.

Squeeze the retainers at the ends of the left width guide and/or

the length guide, move the guide to the appropriate lo cation

(media sizes are listed on the cassette) , and r eleas e the ret ainers.

» Note:

Make sure the guides are snug enough to keep the

envelopes straight, but not so tight that they buckle the

envelopes.

6 Place the envelope stack into the cassette with the printing-

side up.

» Note:

Check your application documentation to determine if the flap

should be placed on the left or on the right. Y ou can also print a single

envelope to check the orientation before printing multiple copies.

7 Insert the cassette into the printer.

The media cassette must be located in the upper position, not in

the optional lower input feeder.

8 Open the flap of each envelope immediately (before it cools)

after the envelope is delivered to the output tray.

» Note:

gummed area on the flaps may seal. Using envelopes with

emulsion-based glue avoids this problem.

Because the envelopes pass through heated rollers, the

QMS magicolor 2 Op

eration2-6

Using Media

Other than

Paper

Using Labels

Formatting Format lab el data wi thin y our a pplicati on. Try printing your data

on a plain sheet of paper first to check placement.

Input Source Upper cassette

Capacity Up to 50, depending on the thickness of the labels

Type Refer to the specifications in chapter 2, “Print Media,” in the

Reference

Notes n Av oid usin g labels with exposed adhesive; it ma y stick to

the toner cartridge o r the f ixing roller, caus ing l abels to p eel

off and media jams to occur.

n Check your ap plicatio n documentation for other i nformation

on printing labels.

Loading and Printing Labels

1 Load labels the same way you load paper.

» Note:

If your label stock has a top-of-page, place the top-of-page

toward the rear of the printer.

2 In the Operator Control/Media/For Upper Bin menu, select

Thick Stock.

Using Letterhead and Memo Media

Formatting Format letterhead or memo data within your application. Try print-

ing your data on a plain sheet of paper first to check placement.

Input Source Upper cassette

Capacity Up to 250 sheets, depending on the thickness of

the media

Type Refer to the specifications in chapter 2, “Print Media,” in the

Reference

Notes n Check your ap plicatio n documentation for other i nformation

about printing on letterhead and memo media.

2-7Consumables

Using Media

Other than

Paper

Loading and Printing Letterhead and Memo Media

n Load letterhead and memo media the

same way you would load paper.

» Note:

Load the media printing-side up with

the top of the media (the letterhead or

memo information) toward the back of the

cassette.

Using Transparencies

Formatting Format the information to be printed on the transparencies

within your application. Try printing your data on a plain sheet

of paper first to check placement.

Input Source Upper cassette

Capacity Up to 50 sheets, depen ding on the thickness of the

transparencies

» Note:

Type Refer to the specifications in chapter 2, “Print Media,” in the

Reference

Notes n Keep the media path clean. Transparencies are especially

sensitive to a dirty media path. If there are shadows on

either the top or the bottom of the sheets, ref er to chapter 5,

“Printer Care,” for instructions on how to clean the printer.

If you hav e problems feed in g 50 sheets ,

try loading only 5– 10 sheets at a time . Loading a

large number of transparencies at a time may

cause static buildup, thus causing feeding

problems.

n Check your appli cation do cumentation f or other inf ormation

about printing on transparencies.

Loading and Printing Transparencies

n Load transparencies the same way you would load paper.

QMS magicolor 2 Op

eration2-8

Using Toner Cartridges

Toner Cartridge Life

A toner cartridge contains enough toner to print the following number

of letter/A4-size pages:

Color Rated life @ normal 5% page co verage

Black 10,000 pages

Yellow 6,000 pages

Magenta 6,000 pages

Cyan 6,000 pages

x

When toner runs low in a cartridge,

message window. It’s your option whether to continue printing;

usually, parts of the page print lighter.

When toner is low, it’s sometimes helpful to take the cartridge out of

the printer and redistribute the toner by gently rocking the cartridge

side to side. Then reinstall the cartridge. If the TONER LOW message

remains in the message window after you redistribute the toner,

replace the cartridge.

TONER LOW displays in the

Using Toner

Cartridges

The printer stops 330 pages after detecting that toner in a cartridge is

low. TONER OUT displays in the message window.

Refilled Toner Cartridges

Refilled toner cartridges may produce variations in toner quality and

reliability and may reduce the print quality of your documents. In addition, toner leaks affect your warranty.

2-9Consumables

Using Toner

Cartridges

Toner Cartridge Storage

n Keep toner cartridges in their packaging until you’re ready to

install them.

n Store toner cartridges in a cool, dry location away from sunlight

(due to heat). The maximum storage temperature is 95

and the maximum storage humidity is 80% without condensation.

n Keep toner cartridges level during storage. Do not stand or store

cartridge on their ends or turn upside down; the toner inside the

cartridges may become caked or unequally distributed.

n Keep toner cartridges away from salty air environments and cor-

rosive gases such as aerosols.

n Keep toner cartridges away from disk drives and floppy disks. The

magnets in the cartridge can damage stored data.

° F (35° C)

QMS magicolor 2 Op

eration2-10

Replacing a Toner Cartridge

Replacing a Toner Cartridge

Your printer uses four toner cartridges: black, yellow, magenta, and

cyan.

1 Open the printer’s front cover.

2 Remove and discard the empty toner cartridge.

s Caution:

dispose of it by burning

3 Remove the toner cartridge

from its shipping carton.

4 Distribute the toner in the

cartridge.

Holding the cartridge with both

hands, gently rock it from sideto-side five or six times.

5 Pull the tab.

6 Remove the orange protec-

tive cover from the cartridge.

Put the old toner cartridge in a trash receptacle. Do not

PullPull

TabTab

2-11Consumables

Replacing a

Toner Cartridge

7 Install the toner cartridge.

Align the toner cartridge with

the cartridge guides, and gently push the cartridge into the

printer until it’s firmly seated.

Colored

labels

s Caution:

Each toner cartridge has a colored label that

corresponds to a colored label to the right of the cartr i dge slots.

Always install the toner cartridge in the slot with a label of the

same color.

If a toner cartridge doesn’t slide in easily, don’t force it. In

addition, don’t push it in until you hear a click. If you hear a click,

you’ve locked it into place against the OPC belt cartr id ge and

your prints may be smudged. Pull the toner cartridge out so that

it’s firmly seated but not locked into place. While the cartridges

may appear not to be fully inserted, closing the front cover will

guide them to their final position.

8 Close the printer’s front cover.

9 In the Operator Control/Consumables/Item Replaced/

menu choose Yes to reset the consumables usage monitoring system.

» Note:

When you replace a toner cartridge after an x TONER

EMPTY message displays in the message window, the engine

automatically recovers. However, you must manually reset the

consumables usage monitoring system to ensure accurate

consumables monitoring.

To access consumables usage information, use the Operator

Control/Consumables/Print Statistics menu or the CrownView

printer web page.

x

T oner

v

QMS magicolor 2 Op

eration2-12

3

Advanced Printing Features

In This Chapter . . .

n “Introduction” on page 3-2

n “High-Resolution Printing” on page 3-2

n “Cassette Chaining” on page 3-5

n “Collating Output” on page 3-6

n “2-Sided Printing” on page 3-8

n “Printing on Standard and Custom Media Sizes” on page 3-9

n “Working with Status Pages” on page 3-10

n “Cancelling/Ending Pri nt Jo b s” on page 3-11

Introduction

Introduction

This chapter describes changing print resolution, chaining paper cassettes, collating output, printing a status page, cancelling a print job,

and ending a print job.

High-Resolution Printing

QMS Multi-Res technology provides a print resolution for almost

every application or budget. The QMS

magicolor

the following resolutions at up to rated engine speed:

2 supports each of

300x300 dpi Built into al l

the fastest processing time for producing draft-quality

output. 300x300 dpi resolution is also required by some

printer emulations.

600x600 dpi The standard r esolution in the base

the standard resoluti on for busines s doc uments. 600x600

dpi resolution provides excellent print quality for most

business applications, such as letters, propo sals, and

presentations. With 600 dpi in both horizontal and ve rtical

directions, it also provides the best quality line drawings

for engineering applications.

1200x600 dpi For improved halftone quality in graphics and images,

1200x600 dpi re so lut ion is avai lable for all media sizes on

the base

capable of pro ducin g 120 0x600 dp i reso lu tion throu gh the

installation of additional memory.

2400x600 dpi For graphic arts and desktop publishing applications,

where the best quality g raphics and photo realistic images

are required, the

standard with 2400x600 dpi resolution for many media

sizes. The magic olo r 2 CX Print Sy ste m is als o ca pa bl e of

producing 2400 x600 dpi resolu tion thr ough th e insta llatio n

of additional memory.

magicolor

magicolor

2 Print Systems, thi s re soluti on has

2 EX. The

magicolor

magicolor

magicolor

2 EX Print System comes

2 CX is also

2 CX is also

QMS magicolor 2 Op

eration3-2

How Much Memory Do You Need?

HighResolution

Printing

» Note:

If a certain resolution is chosen and the minimum amount of

memory is not installed in the printer, the file is printed using the next

lower resolution that can handle the job. For example, if you attempt

to print a 4-color image at 2400x600 dpi resolution on legal media,

but the printer has only 24 MB of RAM instead of the required 88 MB

minimum, the file prints at 600x600 dpi.

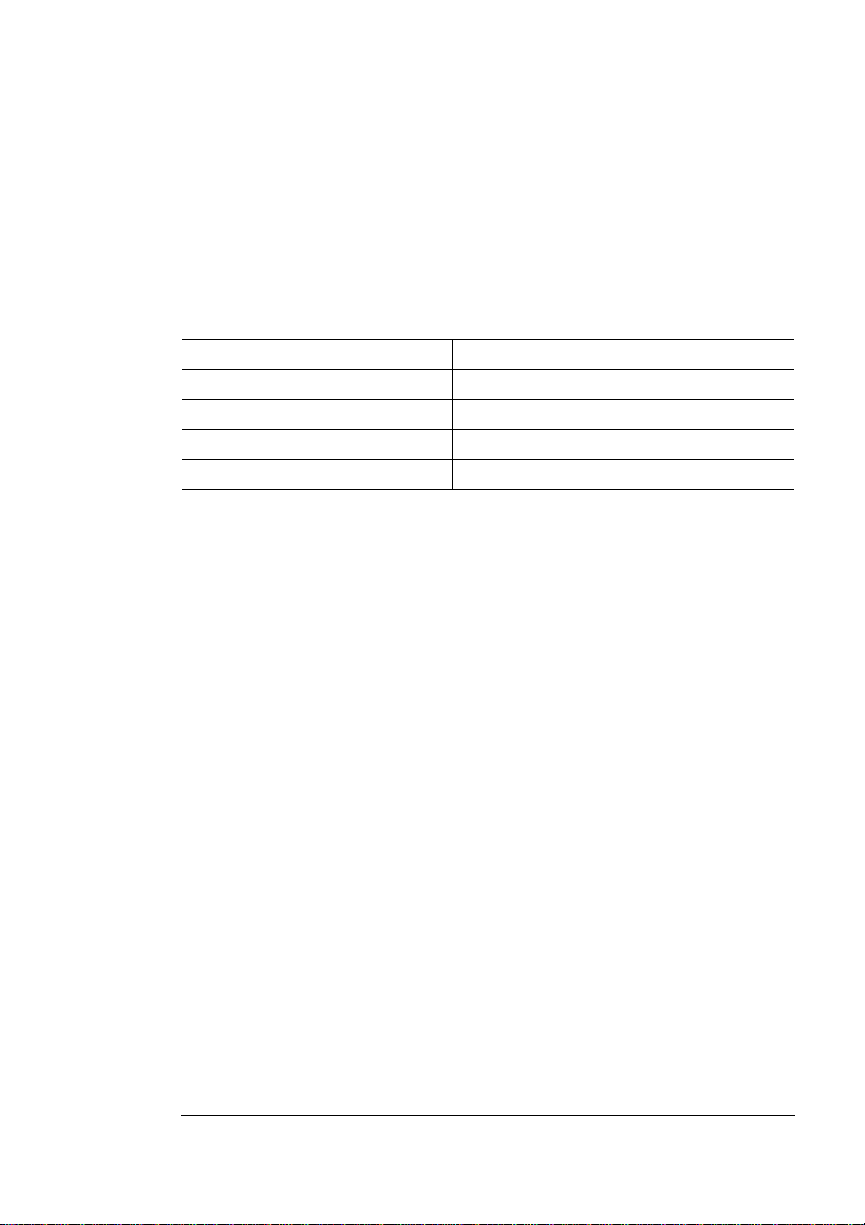

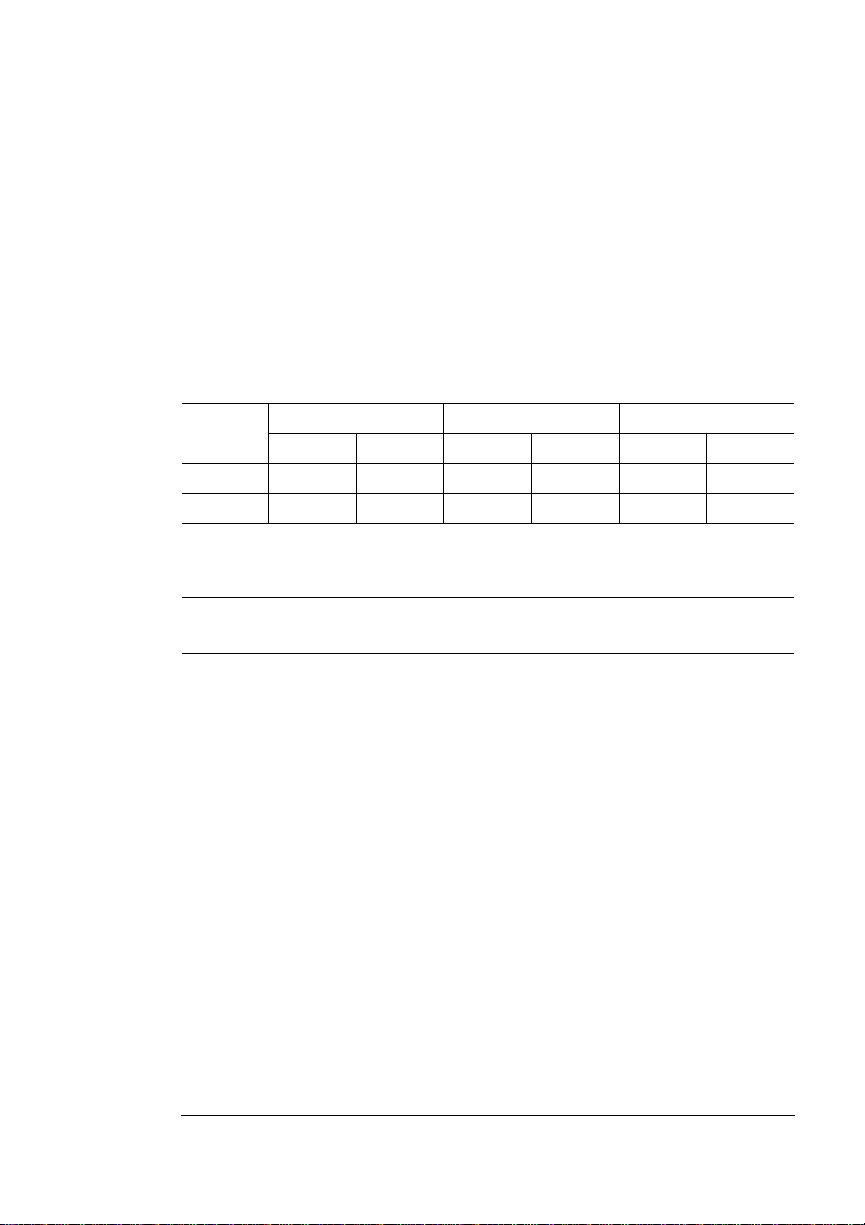

Minimum System Memory Requirements

Media

Size

Letter/A4 24 MB 24 MB 24 MB 40 MB* 24 MB 72 MB*

Legal 24 MB 24 MB 24 MB 48 MB* 24 MB 88 MB**

» Note:

a hard disk installed and disk swapping enabled, add an additional 4 MB

of RAM for each media size.

* Additional memory required on a

** Additional memory required on a

You may also need additional memory (SIMMs) for the following:

n To print complex graphics or complex PostScript documents

n For increased collation performance

300x300/600x600 1200x600 2400x600

Mono 4-Color Mono 4-Color Mono 4-Color

These values are f or a printer with out a ha rd disk . F or a printer wi th

magicolor

magicolor

2 CX

2 CX and

magicolor

2 EX

n For increased spooling performance

3-3Advanced Printing Features

HighResolution

Printing

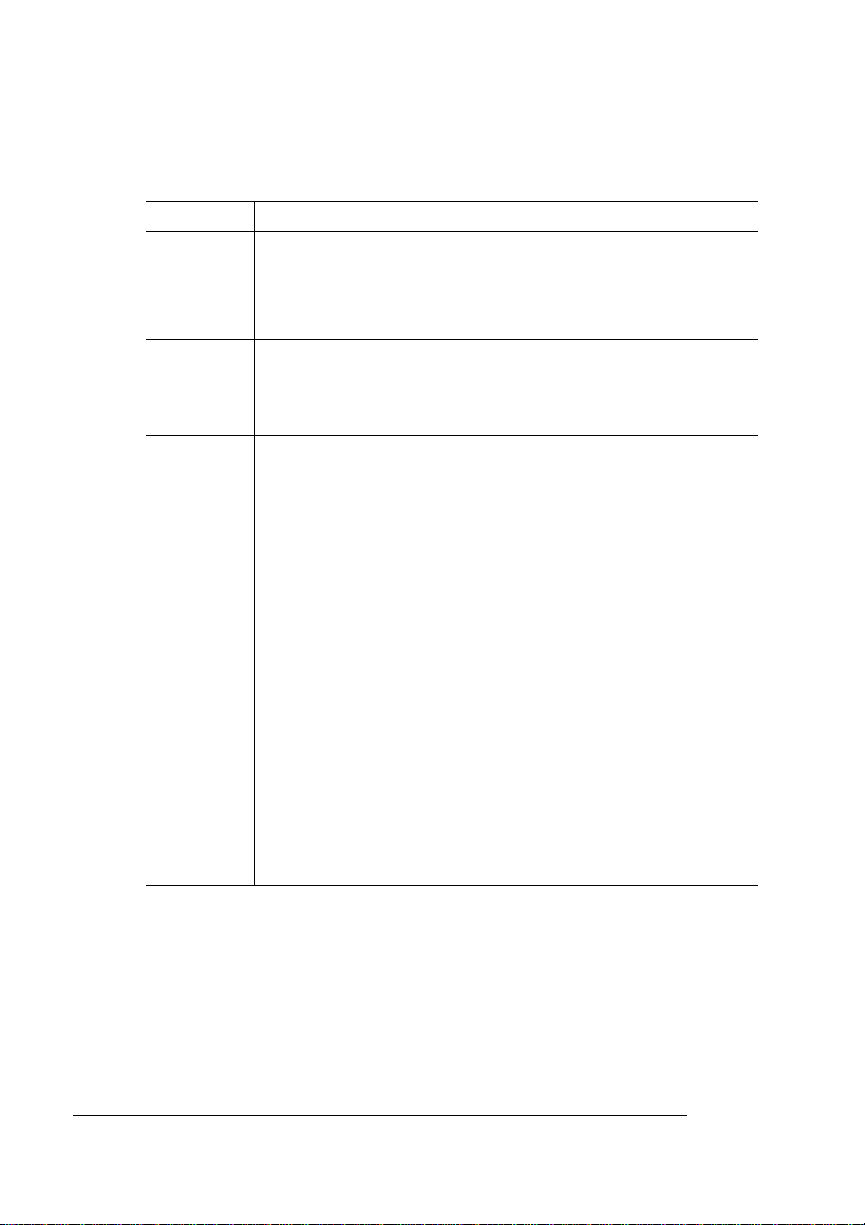

Setting the Default Resolution

Menu Administration/Engine/Def Resolution

Choices 300 dpi—300x300 dpi resolution

600 dpi—600x600 dpi resolution

1200 dpi—1200x600 dpi resolution

2400 dpi—2400x600 dpi resolution

Default 600 dpi, 1200 dpi, or 2400 dpi—your printer’s default is the

highest resolution available for the amount of RAM installed in

the printer (see “Minimum System Memory Requirements” on

page 3-3 for more information)

Notes Whenever possible, set the print resolution through your

application. If the print resolution can’t be set through the

application, you can set it through the configuration menu, the

printer driver, or QMS Document Option Commands (DOCs).

If you want the printer to use a lower default resolution when

you restore defaults, set this option to your choice (and make

any other necessary configuration settings), and then use the

Administration/Miscellaneous/Save Defaults menu to save

your custom defaults. See “Working with Custom

Configurations” in chapter 4, “Printer Configuration,” of the

Reference

In addition, after you lower the default resolution, you should

reconfigure the printer me mo ry (Administr a tio n/Memory/Quick

Config menu) to distrib ute it better f or tha t particular resolu tion.

For example, if you set the default resolution to 600 dpi when

your printer has enoug h memory to print at 2400 dpi, the frame

buffer remains configured fo r 2400 dpi , whi ch means that

printer memory that could be better used somewhere else is

being wasted.

for more information.

QMS magicolor 2 Op

eration3-4

Cassette Chaining

If you have an optional lower input feeder, you may choose to have

the printer automatically draw media from the other cassette (inputbin) when the current cassette empties. This is called cassette chaining, and it provides a total media input capacity of 500 sheets.

Enabling/Disabling Cassette Chaining

There are four ways to enable/disable cassette chaining:

n Use your application. (Check the documentation to see if your

application includes a specific procedure for using a dualcassette printer.)

n Select an alternate cassette for chaining in the QMS Level 2

Windows printer driver.

n On a network, use CrownAdmin 3 to select the media cassettes

and/or the media source.

n Configure the printer through the configuration menu.

Cassette

Chaining

Using the Configuration Menu

Menu Operator Control/Chain Inputbins

Choices On—Switches to the next cassette with the same size and

type of media when the default cassette is empty.

Off—Doesn’t switch cassettes; uses only the default cassette.

On Any—Switc hes to the ne x t cassette , regardl ess of the size

and type of media installed, when the default input bin is

empty.

Default On

Notes Use the Operato r Control/Inputbin menu to set the default

inputbin.

3-5Advanced Printing Features

Collating Output

Collating Output

You can print multiple copies of documents either as complete sets in

numeric order (collated) or as separate sheets. The following figure

shows collated and uncollated stacking for two copies of a f our-page file.

Collated

4

3

2

1

4

3

2

1

Uncollated

1

2

2

1

4

3

3

The main advantage of collation is convenience and the time savings

derived from not having to separate and sort individual copies of a

document. Each copy of the document exists as a whole unless

chunk collation has occurred.

Enabling/Disabling Collation

There are three ways to enable/disable collation:

n Use your application. (Check the documentation to see if your

application includes a specific procedure for collating pages.)

n Select collation in the QMS Level 2 Windows printer driver.

4

n On a network, use CrownAdmin 3 to select collation.

n Configure the printer through the configuration menu.

QMS magicolor 2 Op

eration3-6

Collating

Output

Using the Configuration Menu

Menu Operator Control/Collation

Choices On, Off

Default Off

Working with Chunk Collation

For a multiple copy document with collation On, there must be

enough display list memory to hold the display list blocks for all pages

in the collation range. (For more information on Display List blocks,

see “Display List” in chapter 5, “Additional Technical Information,” in

Reference

the

boundary is forced after the last compiled page of the collation range.

Chunk Collation

This mechanism of introducing a forced boundary—or breaking a

document down into several smaller, more manageable sets—is

known as chunk collation. For example, in the following illustration,

copies “a” and “b” of each set must be manually combined to create

one collated document. The order of printing is copy 1(a), copy 2(a),

copy 3(a), copy 4(a), copy 1(b), copy 2(b), copy 3(b), and copy 4(b).

manual.) If there’s not enough memory , then a collation

» Note:

If chunk collation occurs, you may want to enable header and

trailer pages to help you determine the beginning and end of each

collated sequence.

3-7Advanced Printing Features

Collating

Output

Improving Collation Performance

To avoid chunk collation, your printer must have sufficient memory to

store an entire document before printing begins. Of course, this

always depends on the size of your print job versus the amount of

available memory in your printer. The QMS

more of memory can fully collate most print jobs.

To impro ve collation perf ormance, which allows y ou to collate longer and

more complex print jobs on y ou r printer, you can do o ne of the following:

n Add more printer memory, which automatically increases the dis-

play list client’s memory settings.

n Take any memory not being used by other clients, and add it to

the Administration/Memory/K Mem Display memory setting.

magicolor

2 with 24 MB or

s Caution:

Use this option only if y ou’re familiar with adjusting memory clients’ values. (Refer to chapter 4, “Printer Configuration,” in

the Reference man ual f or inf ormation.) Inc orr ect use of this option

could cause your s ystem to operate incorrectly.

n If your printer has an optional hard disk, set the Administration/

Memory/Enable Disk Swap menu to On. This distributes any

extra memory to all clients.

n Collate through your application.

» Note:

Collating through your application is more time consuming

than collating through the printer. The application sends the

complete job the requested number of times rather than sending

it once and holding data in printer memory.

QMS magicolor 2 Op

eration3-8

2-Sided Printing

2-Sided

Printing

While the QMS

duplex print manually: Print on one side of the paper, reinsert the

printed sheet( s ) i nt o t he med ia cas s et t e (blank side up and th e t op of

the page to w ard the bac k of t he p rinte r), a nd t hen print t he secon d sid e .

» Note:

Media jams may occur if the printed sheet(s) reinserted in the

media cassette are not entirely flat.

magicolor

2 doesn’t have a duplexing option, you can

Printing on Standard and Custom Media Sizes

The QMS

ever, the way you identify the size to the printer varies:

n Standard “sensed” media sizes—The printer automatically

n Standard “non-sensed” media sizes—The printer can print on

magicolor

senses six media sizes—A4, B5 JIS, Com 10*, Executive,

Foolscap, Legal, and Letter. To print on these medi a sizes, you

need to do no more than load the media in the cassette.

five media sizes—A5*, B5 ISO, DL Envelope*, Folio, SP Folio,

Statement*, UK Quarto—that it can’t automatically sense. To print

on these media sizes, you must load the media in the cassette

and then choose the appropriate size from either the Operator

Control/Custom Bin/Upper or Operator Control/Custom Bin/

Optional menu.

2 prints on a wide variety of media sizes. How-

n Non-standard “non-sensed” media sizes—The printer can

also print on non-standard media sizes up to 8.5"x13.8"

(215.9x350.5 mm). To print on these media sizes, you must load

the media in the cassette, choose Universal from the Operator

Control/Custom Bin/Upper or Operator Control/Custom Bin/

*This media size can be printed only from a cassette installed in the upper/standard position.

3-9Advanced Printing Features

Working with Status Pages

Optional menu, and then identify the media size in your

application.

» Note:

If you preview your file in your application, the dimensions

of the Universal media size rather than your custom size will be

shown in the preview window, and your document will be imaged

in the lower-left corner of this media size. You must manually

move the margins in from the left and right as well as up from the

bottom to define the correct imageable area for your custom

media size.

Working with Status Pages

Identifying a Status Page Type

Menu Administration/Special Pages/Status Page Type

Choices Standard, Advanced

Default Standard

Standard

This one-page document provides

n Printer identification (the printer’s name, firmware information,

and number of sheets/faces printed during the life of the printer)

» Note:

n Printer settings (printer set-up options for paper handling)

n Current memory configuration (pri nte r memory settings)

n Timeouts (printer timeout settings)

The number of sheets/faces statistics differ from the

number of sheets printed statistics in CrownView and the

consumables statistics page (Operator Control/Consumables/

Print Statistics), which refer to the number of sheets/faces printed

to date during the current consumables tracking period

(Administration/Consumables/Start Period menu).

QMS magicolor 2 Op

eration3-10

Cancelling/ Ending Print Jobs

n Communication settings and input buffer sizes (host-printer com-

munication settings, including spooling memory sizes)

n Tickmarks in the lower-left corner for image alignment

Advanced

This multi-page document provides

n All the information from the standard status page

n The configuration menu settings

n A full list of fonts and downloaded emulations

Printing a Status Page

Menu Administration/Special Pages/Print Status

Choices No, Yes

Default Yes

Cancelling/Ending Print Jobs

The Cancel key has three functions:

n It cancels the oldest print job in the system.

n It cancels all jobs with a printing, interpreting, terminating, or

spooled status.

n It allows you to send an end-of-job indicator to a currently compil-

ing print job waiting on incoming data.

You don’t have to press the Online key before using the Cancel key.

3-11Advanced Printing Features

Cancelling/

Ending Print

Jobs

Cancelling a Print Job

Press this key... to... The message window

Cancel Access the Job Cancel menu. JOB CANCEL

Cancel or Select Cancel the oldest job in the

queue.

Cancelling all Print Jobs

Press this key... to... The message window

Cancel Access the Job Cancel menu. JOB CANCEL

Next (twice) Advances to the Cancel All

Jobs mode.

Cancel or

Select

Cancel all jobs with a printing,

interpreting, spooled, or

terminating status. The

CANCEL ALL JOBS

message displays until all

print jobs are completely

removed.

reads...

CANCEL JOB

CANCEL JOB

IS SELECTED

reads...

CANCEL JOB

JOB CANCEL

CANCEL ALL JOBS

CANCEL ALL JOBS

IS SELECTED

QMS magicolor 2 Op

eration3-12

Ending a Print Job

Use this procedure when the message window displays

WAITING ON INPUT

END JOB?

Cancelling/

Ending Print

Jobs

» Note:

This procedure does not end print jobs that are still receiving

data. Its only purpose is to provide an end-of-job indicator for a print

job that does not have one. You can identify an end-of-job indicator in

the Administration/Communications/Parallel and Administration/

Communications/Serial menu. (Refer to chapter 5, “Additional

Technical Information,” in the Reference Manual for a complete

discussion of End J ob Mode.

Press this key... to... The message window

reads...

Cancel Access the Job Cancel menu. JOB CANCEL

CANCEL JOB

Next (twice) Adv an ce to the End Job

mode.

Cancel or Select Select End Job. END JOB

JOB CANCEL

END JOB

IS SELECTED

v

3-13Advanced Printing Features

4

Color Printing

In This Chapter . . .

n “Introduction” on page 4-2

n “QCOLOR Color Control” on page 4-2

n “Other Methods of Color Control” on page 4-4

n “Color Density” on page 4-9

Introduction

Introduction

Your QMS

technology that produces inexpensive and durable color prints at

300x300, 600x600, 1200 x6 00, and 240 0 x600 dpi on plain paper,

envelopes, labels, and transparencies.

magicolor

2 Print System features advanced color laser

QCOLOR Color Control

To help you optimize color output, QMS developed QCOLOR, which

provides automatic or custom color control. Q

configures the QMS

the contents of the document and the media on which it will be

printed. Q

matching, P ANT ONE

2.1 support by means of ICC 3.2-compliant printer profiles. Q

automatic color control is accessed through the QMS Level 2

Windows 95 printer driver.

COLOR matching capabilities include CIE-based color

magicolor

®*

Color simulation, and ICM 2.0 and ColorSync

Accessing QCOLOR for Windows 95

1 If you haven’t already, install the QMS Level 2 Windows

driver.

2 Open or create the file you want to print.

2 for the best output quality based on

COLOR dynamically

COLOR

3 From the File menu, choose Print Setup.

Some applications may call this option something else, such as

Page Setup.

4 In the Print Setup dialog box, make sure the QMS

2 is selected, then choose the Options or Properties button.

The QMS Level 2 Windows driver dialog box appears.

*

Pantone, Inc.’s check-standard trademark for color reproduction and color reproduction

materials.

QMS magicolor 2 Op

magicolor

eration4-2

QCOLOR Color

Control

5 On the Job tab (Windows 95 driver) or Paper tab (Windows

3.1/Windows 95 driver), select a Quick Color Setup setting:

n Automatic Color Control (if you’re printing a combination of

document types)

Automatic Color Control is the best option for most jobs,

because it's designed to provide the best color output for a

large variety of documents. However, if the Automatic setting

doesn’t provide satisfactory color output for a particular page

element or document type, then select a more specific

COLOR setting (for example, Photographic for scanned pho-

Q

tographic images).

n Graphics (if you’re printing color graphics)

n Grayscale (if you’re printing images with gray shades)

n Photographic (if you’re printing photographic images)

n Text and Spot Color (if you’re printing text or spot colors)

n Third Party Color Management (if you want to allow your

application to control color settings)

n Color All Black (if you want to print monochrome)

n Customize (if you want to customize the color settings by

using the options on the Color tab)

» Note:

Because Q

COLOR

automatically adjusts the settings on the

Color tab (Windows 95 driver) or Color Setup tab (Windows 3.1/

Windows 95 driver), you don’t have to adjust them manually.

However, if you want to customize them, you can get information

about them and other options in the driver by choosing the Help

button. Also, some applications (like PageMaker and V entura

Publisher) specify color outside the Windows driver, in which

case the color settings in the QMS Level 2 Windows driver are

ignored.

6 Choose the media type you’re using.

Use either the Windows 95 printer driver’s Paper tab or the

printer’s Operator Control/Media/For Upper Bin or Operator

Control/Media/For Optional Bin menu.

4-3Color Printing

Other Methods of Color Control

7 Choose any other printing options you want.

Choose the Help button in the printer driver for detailed descriptions of the options.

8 Choose OK until you return to the application.

9 From the File menu, choose Print.

10 In the Print dialog box, select any other options you want

and then choose OK.

Other Methods of Color

Control

Color Matching

A major concern in the color publishing industry today is color consistency across devices with different color models. For example, when

you scan a color photograph, the scanner sends the image data to

the computer in an RGB (Red-Blue-Green) format. The computer

then converts the data into another RGB format to display it on the

monitor. When the image data is sent to the printer, it is converted

into CMYK (Cyan-Magenta-Yellow-blacK) format by the printer driver

or application. Because of these conversions, a color output device

(like your printer) may produce colors dramatically different from

those seen on the computer screen, or in the original image.

To keep colors more consistent, you can use color matching, which

uses software to describe colors for different devices in a common

language to make sure that color is produced in the same shade on

all devices.

Color Matching with a Color Management System

Color management systems (CMSs) work by translating color information from different devices into a common language. A CMS first

gets information about the way these devices create color and the

QMS magicolor 2 Op

eration4-4

Other Methods

of Color

Control

range of colors they can produce. (This information is contained in

device

device's color descriptions to the CIE model, which is an international,

device-independent standard for color.

For example, to make a printer’s color output look the same as the

colors on your computer monitor, a CMS translates the monitor’s RGB

colors into device-independent CIE color, and then translates from

the CIE color into the printer's CMYK colors. A CMS can warn you (or

automatically adjust color) when the colors you specify are outside

the output device’s range, and they can show you on screen how the

printed output will look.

The advantages of using a CMS are that you get consistent color

across all devices, and an on-screen preview of output. However,

CMSs are not portable across platforms, they can be expensive, and

they do consume processing time and power at the host.

A few well-known color management systems include Kodak ColorFlow, Agfa ColorTune, Pantone POCE, Apple ColorSync, Microsoft

ICM, Color Solutions ColorBlind, and Linotype-Hell LinoColor. The following are shipped with your printer:

profiles

.) Then, using this information, the CMS maps each

n An Apple ColorSync/ICC (International Color Consortium) device

profile

n A Windows ICM device profile

Instructions for installation and use are included on the

ware Utilities

with the printer.

Color Matching with PostScript Level 2

Your printer's PostScript Level 2 allows it to accept device-independent CIE color specification directly (in addition to CMYK or RGB

color specifications). This means that if you have an application that

supports PostScript Level 2 printing (such as Adobe PhotoShop) or if

you use the QMS-developed driver for Windows or Macintosh, your

printer will perform color matching automatically. These drivers work

with the printer-resident color rendering dictionaries to match colors.

See control panel for more information on CRDs.

CD-ROM or on the supplemental color disk provided

QMS Soft-

4-5Color Printing

Other Methods

of Color

Control

The advantages of Level 2 color matching are that it is portable, it is

application- and printer-resident (there’s nothing else to buy), and it is

performed at the printer level (so it doesn’t tie up your host). However ,

no on-screen preview of output is provided, and you are not warned if

a color is out of printer’s gamut (color range).

Color Matching with PANTONE

Your printer has been approved by Pantone, Inc. to simulate PANTONE Colors. Pantone specifies hundreds of spot colors, each identified by a unique number. Each of these spot colors can be simulated

on the printer with the appropriate combination of process (CMYK)

colors.

Within a Pantone-licensed application (such as Aldus FreeHand or

Adobe Illustrator), you can choose a P ANT ONE Color number and the

corresponding CMYK simulation is printed. Pantone tables for supporting applications are shipped on the

ROM or on a supplemental color disk with the printer, including the

following:

n Adobe Illustrator (Macintosh and Windows)

*

QMS Software Utilities

CD-

n CorelDRAW (Windows only)

n Macromedia FreeHand (Macintosh and Windows)

n QuarkXPress (Macintosh only)

Instructions for installation and use of these files are included on the

Pantone disk shipped with your printer.

The formulas in the P ANTONE Color look-up charts result in Pantoneapproved color only under the following conditions:

n A Pantone-licensed application (such as Adobe Illustrator,

QuarkXPress, and Macromedia FreeHand) is used to create the

color.

n The colors are printed with QMS-supplied toner.

*

Pantone, Inc.’s check-standard trademark for color reproduction and color reproduction

materials.

QMS magicolor 2 Op

eration4-6

Other Methods

of Color

Control

n The colors are printed on Hammermill Laser Print white paper.

The formulas listed in the Pantone charts are only for the

*

CX printer. Also , the PANTONE

Colors generated by this printer are

magicolor

four-color process simulations and may not exactly match Pantoneidentified solid color standards. Use current PANTONE Color Reference Manuals (available from Pantone, Inc.) for accurate color.

The advantages of using PANT ONE Color matching are that it is easy

to use, it is widely supported, and that it is good for spot color. However, it is not as accurate as other methods of color matching, it can’t

be used for photographs, and it is only supported by applications.

About Printer Halftones and CRDs

The printer’s default CRD (Color Rendering Dictionary) can be

changed through the QMS-developed Macintosh and Windows

drivers or, if your application requires you to use a non-QMS driver,

you can change the CRD at the printer’s control panel

(Administration/Emulations/PostScript/Color Rendering menu). See

chapter 4, “Printer Configuration,” of the

Reference

information on using the control panel.

Halftones

The enhanced halftone uses amplitude-modulation (AM) screening.

Some applications may be set up to ignore the printer’s color settings.

See chapter 3, “Connecting to a PC,” and chapter 5, “Connecting to a

Macintosh,” in the Getting Started manual.

manual for

2

Color Rendering Dictionaries (CRDs)

Since the printer has a different range of colors than other color

devices (such as your monitor), a color rendering dictionary is necessary to tell the printer how to print colors that are out of its range. The

printer has three default CRD settings:

*

Pantone, Inc.’s check-standard trademark for color reproduction and color reproduction

materials.

4-7Color Printing

Other Methods

of Color

Control

Colorimetric—The Colorimetric CRD is designed f o r very basic color

matching and one-to-one conversion from CIE color to CMYK color.

With Colorimet ric cho se n as t he prin te r de fault CRD, all colors are

reproduced exactly unless a specified color is “out of gamut” (out of the

printer's ra nge). Fo r ou t o f g am u t co lo r s , th e C ol orim et ric C R D su bs t itutes the cl osest “ in-gam ut” co lor . The resul t is t hat e xact color match es

between the two devices are maint ained wherever possible, but the

printed image may ha ve a smaller range of colors than the original

image (since several image colors may be mapped to a single printer

color). We recommend that you use this CRD for printing spot colors.

Business—The Business CRD matches the images on a monitor as

closely as possible (WYSIWYG). Use the Business CRD for computer-generated graphics.

Photographic—QMS developed the Photographic CRD to optimize

the quality of photographic images and other images with many subtle color shifts. Like the Colorimetric CRD, the Photographic CRD

substitutes out-of-gamut colors with in-gamut colors, but it also

adjusts (compresses) all other colors (whether in-gamut or out-ofgamut) as necessary to maintain the proportional relationship

between the colors.

QMS magicolor 2 Op

eration4-8

Color Density

Adjusting the Color Density

Use the following procedure to check and adjust the color density.

Color Density

▲ Caution

print the calibration page described in step 3 on good quality paper,

such as Hammermill LaserPrint Radiant White or Weyerhauser First

Choice premium paper. Otherwise, the color of the paper could affect

the results.

1 Set the density of each color to 0.

2 Access the printer’s Administration/Special Pages/Calibra-

3 Press Select to print a calibration

: For best results when checking the printer’s color density,

a Access the printer’s Administration/Engine/Density/Cyan menu.

b Set the cyan color density to 0.

Press the Previous key to decrease the density setting or the

Next key to increase the setting.

c Repeat steps a and b for the magenta, yellow , and blac k color

densities.

d Save your changes.

tion Page menu.

page.

This page provides a density range

for each of the printer’s colors—

cyan, magenta, yellow, and black.

4-9Color Printing

Color Density

4 Compare the calibration page to

the four calibration cards that

were provided with your printer.

Each card features a single color—

cyan, magenta, yellow, or black.

a Place the calibration page on a sheet of clean white paper in

b Align the cutout in the cyan color

a well-lighted area.

calibration card over the cyan

column on the calibration page.

c Decide which block on the calibration page most closely

matches the cyan color calibration card.

» Note:

It may be easier to decide which colors match if you

view the output at a distance (3–4 feet) and squint.

d Make a note of the value (-4 to +4) associated with that block,

or simply mark the pane through the cutout in the card.

You wil l need this value in step 6.

e Repeat steps b–d with the magenta, yellow, and bl ack

calibration ca rds.

5 Access the printer’s Administration/Engine/Density/Cyan

menu.

QMS magicolor 2 Op

eration4-10

Color Density

6 Adjust the cyan color density according to the number you

recorded in step 4.

Press the Previous key to decrease the density setting or the

Next key to increase the setting.

7 Repeat steps 5 and 6 for the magenta, yellow, and black color

densities.

8 Save your changes.

9 Print a new calibration page (Administration/Special Pages/

Calibration Page menu).

10 Compare the new calibration page to the four calibration

cards again.

11 Make any additional adjustments necessary.

If none are necessary, you’re done and ready to print.

v

4-11Color Printing

5

Printer Care

In This Chapter . . .

n “Introduction” on page 5-2

n “Handling the Printer” on page 5-2

n “Cleaning the Printer” on page 5-3

n “Maintenance Schedule” on page 5-12

n “Replacing the Fuser Oil Bottle and Cleaning Roller” on

page 5-14

n “Replacing the OPC Belt Cartridge” on page 5-17

n “Replacing the Ozone Filter” on page 5-20

n “Replacing the Waste Toner Pack” on page 5-21

Introduction

Introduction

This chapter describes how to handle and clean the printer.

Blurred or splotchy prints and paper jams can result from dusty printer

parts. Regular cleaning takes only a few minutes and helps ensure

print quality. Printer parts that require cleaning are the paper pick-up

rollers and the outside surface of the printer.

Handling the Printer

Handle the printer with care to preserve its life. Abuse may cause

damage. Keep the following guidelines in mind:

n Do not place anything on the top of the printer.

n Avoid spraying cleaning solution dire ct ly on the printer’s surface;

the spray could penetrate through the air vents of the printer and

damage the internal circuits.

n Be careful when cleaning the inside or removing paper jams, as

the fuser assembly and other internal parts become very hot.

Open the printer cover, and let the interior of the printer cool

before handling the inside of the printer.

n Always close the printer covers gently. Never expose the printer

to vibrations.

n Do not cover the printer immediately after using it. Turn it off and

wait until it cools down.

n Do not leave the printer open for any length of time, especially in

well-lit places; light may damage the OPC belt cartridge.

n Do not open the printer during printing and do not tap paper

stacks on the printer.

n Do not tilt, lubricate, or disassemble the printer.

QMS magicolor 2 Op

eration5-2

Cleaning the Printer

n Do not touch the electrical contacts, gears, or laser beam

devices. Doing so may damage the printer and cause the print

quality to deteriorate.

n Keep media in the output tray at minimum level. If the media

stacks too high, your printer may experience media jams and

excessive media curl.

n Lift the printer from the bottom only, using the carrying grips

under each side corner. Make sure two people are available to lift

the printer when moving it.

n Keep the following in mind when storing the printer for an

extended period:

— Unplug the printer.

— Rem ove the toner and OPC belt cartridges from inside the

printer. After removing the cartridges, return them to their

original packaging. If the original packaging is not available,

protect the toner cartridges from spilling toner, and protect

the OPC belt cartridge from damage and light.

— See appendix B, “Technical Specifications,” in the

manual for storage specifications.

Cleaning the Printer

Paper dust may accumulate inside the printer. This could affect the

printer’s performance. To prevent any potential problems associated

with this, you should clean your printer on a regular basis. You need

to clean both the inside and outside of the printer.

M WARNING!

disconnect all interface cables before cleaning.

ACHTUNG!

Sie den Drucker reinigen.

Turn off the printer, unplug the power cord, and

Ziehen Sie den Netzstecker aus der Steckdose bevor

Reference

5-3Printer Care

Cleaning the

Printer

Guidelines for Cleaning Inside the Printer

n Either clean the printer before use, or allow a few minutes after

unplugging it to allow the fusing unit to cool down.

n Turn off the printer, unplug the power cord, and disconnect all

interface cables before cleaning inside the printer.

n Read all caution and warning labels carefully, making sure to fol-

low any instructions contained in them. These labels are located

on the inside of the printer’s covers and the interior of the printer

body.

n Use only dry, lint-free cotton cloths or swabs.

n Make sure any parts removed during cleaning are replaced

before you plug in the power cord, reconnect the interf ace cabl es,

and turn on the printer.

Cleaning the Transfer Unit

These items in the transfer unit require cleaning:

n Registration rollers

n Transfer roller

n Paper discharge

» Note:

A dry cotton cloth and dry cotton swab are required for this

procedure.

1 Turn off and unplug the printer.

QMS magicolor 2 Op

eration5-4

Cleaning the

Printer

2 Open the printer’s rear cover.

3 Using a dry cotton cloth, clean any paper dust and toner

buildup from the registration rollers.

You can manually rotate the rollers while cleaning them by turning

the white gear on the left end of the roller shaft.

White gear

Registration

Rollers

5-5Printer Care

Cleaning the

Printer

4 Clean the transfer roller.

a Remove the transfer roller

unit by lifting the lock lever at

the right end of the transfer

roller unit until the unit is

freed, and then lifting the

unit out.

» Note:

Because you cannot

see when the unit is

released, it’s best to lift the

unit and the lock lever at the

same time.

b Using a dry cotton cloth, clean any paper dust and toner

buildup from the transfer roller.

» Note:

c Reinstall the transfer roller in the transfer unit.

5 Clean the paper discharger.

a Remove the paper

Manually rotate the roller while cleaning it.

discharger by pushing it to

the right and then lifting it up

and out of the transfer unit.

(It comes out after the tabs

on the charger have cleared

their retainers.)

Lock Lever

Transfer Roller

b Using a dry cotton cloth,

clean any paper dust and

toner buildup from the

outside of the paper

discharger.

c Using a dry cotton swab, clean any paper dust and toner

buildup from the interior of the paper discharger.

QMS magicolor 2 Op

eration5-6

Cleaning the

Printer

d Using a dry cotton swab,

clean the paper discharger

wire.

e Reinstall the paper

discharger in the transfer

unit, and then push it down

and to the left to lock it in

place.

6 Clean any paper dust and

toner buildup found on the

transfer unit itself.

7 Close the printer’s rear cover.

Cleaning the Paper Exit Rollers

» Note:

A dry cotton cloth is required for this procedure.

1 Turn off and unplug the printer.

2 Open the printer’s top cover.

3 Using a dry cotton cloth, clean

the paper exit rollers.

Wire inside

While manually rotating each

paper exit roller, clean each

roller.

4 Close the printer’s top cover.

5-7Printer Care

Cleaning the

h

Printer

Cleaning the OPC Belt Cartridge

s Caution:

The OPC belt is extremely sensitive to touch. Always handle

the cartridge so you don’t touch the surface of the belt. Any body oil

left on the surface of the belt will prevent toner from adhering to the

belt which results in poor image quality . Also , k eep the cartridge away

from anything that may scratch the surface of the belt. Any scratches

will show in the image produced.

The OPC belt is also extremely sensitive to bright light and direct

sunlight. Always leave it in its protective bag until you are ready to

install it. Any exposure to light should be limited to two minutes. If you

suspect the belt is damaged due to exposure to light, put the belt in a

dark place to recover. Depending on the amount of exposure,

recovery may take up to two hours. Recovery time is dependent on

the amount of exposure sustained. Recovery is not guaranteed.

» Note:

A dry cotton cloth is required for this procedure.

1 Turn off and unplug the printer.

2 Open the printer’s fr o nt and t op covers, release the OPC belt

cartridge lock levers, and remove the OPC belt cartridge.

3 Using a dry cotton cloth, clean

any toner buildup fr om around

the cleaning blade.

Cleaning blade

s Caution:

Don’t touch the edge

of the cleaning blade.

4 Clean any paper dust and

toner buildup found on the

OPC belt cartridge itself.

s Caution:

Handle the cartridge carefully . The belt is very sensitive

to hand oils and scratches, both of which reduce print quality.

QMS magicolor 2 Op

Dont touc

here.

eration5-8

Cleaning the

Printer

5 Remove the corona-wire cleaning brush from inside the fr ont

of the printer.

6 Turn the OPC belt cartridge so that the handle is facing away

from you.

7 Use the brush to clean the corona wire inside end of the OPC

belt cartridge.

s Caution: The corona wire is very delicate. Do not press hard on

the wire.

8 Reinstall the OPC belt cartridge, and secure its lock levers.

9 Return the corona-wire cleaning brush to its holder, and then

close the printer’s front and top covers.

5-9Printer Care

Cleaning the

Printer

Cleaning the Laser Lens

It’s necessary to clean the laser lens only when you find vertical white

or light-color streaking in all primary colors on your printouts.

» Note:

A dry cotton cloth or dry cotton swab is required for this

procedure.

1 Open the printer’s front cover.

2 Remove the four toner cartridges.

3 Remove the laser lens.

Use the two tabs on top of the

lens.

4 Using a dry cotton cloth, wipe

the lens.

5 Reinstall the laser lens.

It slides in at a 45° angle.

6 Reinstall the four toner car-

tridges.

7 Close the printer’s front cover.

QMS magicolor 2 Op

eration5-10

Cleaning the

Printer

Cleaning the Exterior of The Printer

M WARNING!

Turn off the printer, unplug the power cord, and

disconnect all interface cables before cleaning. Do not spill water or

detergent into the printer; otherwise the printer will be damaged and

an electric shock may occur.

ACHTUNG!

Sie den Drucker reinigen. Versch

ü

ssigkeiten auf dem Drucker, da das Gerät sonst beschädigt wird

Fl

Ziehen Sie den Netzstecker aus der Steckdose bevor

ü

tten Sie kein Wasser oder andere

oder die Gefahr eines elektrischen Schlages besteht.

To protect your printer and maintain its appearance, clean the exterior

regularly. Use the following guidelines:

n Use only a dry or slightly damp, lint-free, soft cloth moistened only

with water or mild detergent.

n Never use cleaning solutions that contain solvents, such as alco-

hol and benzene. Solvents may damage the printer’s finish.

n Always test any cleaning solution on a small area of your printer

to check the solution's performance.

n Never use sharp or rough implements, such as wire or plastic

cleaning pads.

n Never spray a cleaning solution directly on the printer as the

cleaning solution will penetrate to the interior of the printer and

cause damage.

5-11Printer Care

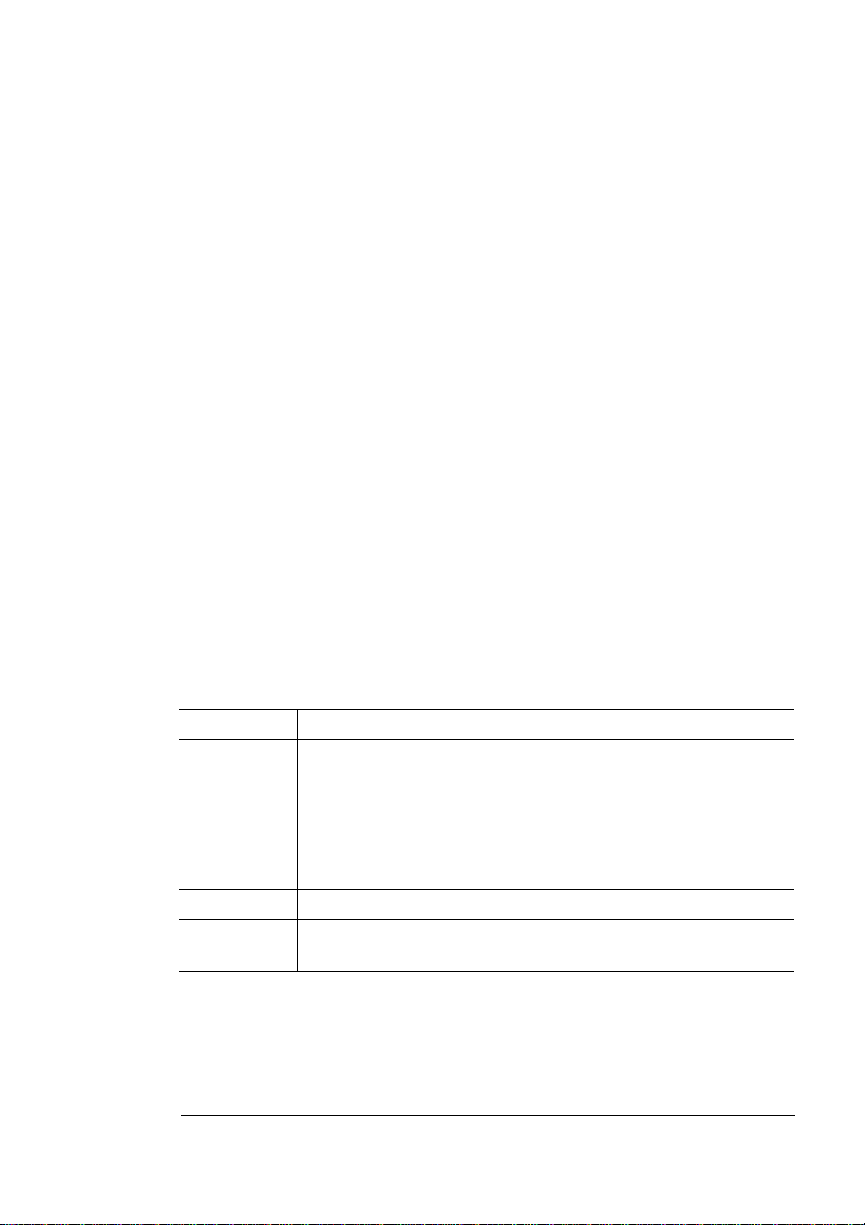

Maintenance Schedule

Maintenance Schedule

The stated life expectancy of each consumable is based on printing

under specific operating conditions, such as media type, number of

color planes, page size, and page coverage (usually 5% coverage of

letter/A4-size media). The actual life expectancy will vary depending

on these and other printing variables, including continuous or intermittent printing, ambient temperature, and humidity.

This item needs

replacing...

20,000-page preventive maintenance

120,000-page preventive maintenance

AC paper discharger 120,000 pages** QMS Nat ional Service

Cleaning roller CHECK CLEANING ROLLER

Drum cleaner 120,000 planes* QMS National Service

Fuser oil bottle FUSER OIL LOW or FUSER

Fuser unit 60,000 pages** maximum

After... By...

20,000 pages** QMS National Service

120,000 pages** QMS National Service

User

displays in the message

window (after 12,000

pages** at 5% coverage of

each color)

OIL EMPTY displays in the

message window (fuser oil

bottle life is media

dependent: coarse r pa per

requires more oil)

(at an equal mix of b lack and

4-color pages, all with 5%

coverage of each color)

See “Replacing the

Fuser Oil Bottle and

Cleaning Roller” on

page 5-14.

User

See “Replacing the

Fuser Oil Bottle and

Cleaning Roller” on

page 5-14.

QMS National Service

QMS magicolor 2 Op

eration5-12

Maintenance

Schedule

This item needs

After... By...

replacing...

OPC belt cartridge REPLACE BELT displays in

the message window

(maximum lif e—5 0,000

planes*, usually occurs with

User

See“Replacing the OPC

Belt Cartridge” on page

5-17.

continuous use; minimum

life—20 ,000 planes*, us ually

occurs with intermittent use

although other factors also

affect cartridge life)

Ozone filter 12 months User

See “Replacing the

Ozone Filter” on page

5-20.

Tra ns fer roller 120,000 pages** QMS Nat ional Service

Waste toner pack WASTE TONER FULL

displays in the message

window (after 12,000

pages** at 5% coverage of

User

See “Replacing the

Waste Toner Pack” on

page 5-21.

each color)

*A plane is a single pass of the OPC belt (one toner color). For example, a one-color

print job makes one pass (one plane), and a two-color print job makes two passes

(two planes).

**A single-sided page (also called a face) usually consists of four passes of the OPC

belt, since most color print jobs use all four toner colors.

5-13Printer Care

Replacing the Fuser Oil Bottle and Cleaning Roller

Replacing the Fuser Oil Bottle

and Cleaning Roller

s Caution:

is also expensive to replace. Fuser life will be shortened (or the fuser

permanently damaged) if the oil bottle and cleaning roller are not

changed when needed and installed properly. This type of damage is

not covered under warranty or service contract.

M WARNING!

severe burns. Make sure the unit is cool before handling it.

ACHTUNG!

Verbrennungsgefahr besteht. Bitte lassen Sie die Fixiereinheit einige

Zeit abkühlen, bevor Sie diese berühren.

1 Turn off the printer.

2 Open the printer’s top cover .

3 Open the two cleaning r oller

The fuser unit is an integral part of the imaging process and

The fuser unit can become extremely hot and cause

Die Fixiereinheit kann sehr heiß werden, so daß

lock levers.

QMS magicolor 2 Op

eration5-14

4 Remove the old oil bottle.

Replacing the

Fuser Oil Bottle

and Cleaning

Roller

s Caution:

Hold a sheet of

paper under the oil bottle while

removing it, so oil doesn’t drip

into the printer.

5 Remove the old cleaning

roller.

6 Lower the new oil bottle into

its slot.

The tab on the side of the bottle must be on the right.

5-15Printer Care

Replacing the

Fuser Oil Bottle

and Cleaning

Roller

7 Install the cleaning roller in

its slot.

The tab on the top of the

cleaning roller must be on the

left.

8 Close the two lock levers.

9 Close the printer’s top

cover.

10 Turn on the printer.

11 Reset the consumables