Konica Minolta QMS 2560 Service Manual

CONTENTS

1 CONFIGURATION OF THE PRINTER

1-1. General Description of Each Section ................................................ C-2

(1) Paper Feed Section ..................................................... ...... ..... ...C-2

(2) Print Head Unit (Exposure Section) ........................ ..... .............. C-2

(3) Imaging Cartridge ....................................................................... C-2

(4) Transfer Section ............................... ...... ..... ...... .........................C-2

(5) Fusing Section ........................................................ ..... ...... ..... ...C-2

(6) Paper Exit Section ................................................... ..... ...... ........ C-2

1-2. General Flow for Printing Process .................................................... C-3

2 PAPER FEED SECTION

2-1. Tray 1 (1st Paper Cassette) .............................................................. C-4

(1) 1st Cassette Set Sensor (PC6) .................................................. C-5

(2) 1st Cassette Paper Empty Sensor (PC4) ...................................C-5

(3) 1st Cassette Paper Near Empty Sensor (PC5) ..........................C-6

(4) Double Feed Sensor .................................................................. C-6

(5) Synchronizing Roller Sensor (PC2) ...........................................C-7

(6) 1st Cassette Paper Size Detection ............................................C-7

2-2. Tray 2 (2nd Paper Cassette) ............................................................ C-8

(1) 2nd Cassette Set Switch (SW3) ................................................. C-9

(2) 2nd Cassette Paper Empty Sensor (PC22) ............................... C-9

(3) 2nd Cassette Paper Near Empty Sensor (PC25) ....................... C-9

(4) 2nd Cassette Side Door Detecting Sensor (PC23) .................... C-10

(5) 2nd Cassette Paper Size Detection ........................................... C-10

2-3. Paper Feed .......................................................................................C-11

(1) Registration Compensation ........................................................C-11

(2) Paper Feeding ................................................... ...... ...................C-11

........................................................................... C-4

......................................................C-1

3 PRINT HEAD UNIT (EXPOSURE SECTION)

4 MAGING CARTRIDGE

4-1. Parts Names and Functions of the Imaging Cartridge ...................... C-13

4-2. Charging Section .............................................................................. C-14

4-3. Developm ent Sec tion ........................ ...... ...... ....................................C-14

5 TRANSFER SECTION

6 FUSING SECTION

7 PAPER EXIT SECTION

8 DETECTION OF A NEW IMAGING CARTRIDGE

9 RIGHT DOOR INTERLOCK SWITCH (S2)

10 PRINT SEQUENCE

11 PARALLEL INTERFACE

.............................................................................. C-13

.............................................................................. C-15

.................................................................................... C-16

............................................................................. C-18

................................................................................... C-20

............................................................................ C-22

........................................... C-12

.................................... C-19

............................................... C-19

i

11-1.Connector pin assignments

(Standard Centronics and IEEE1284-Type B)...................................C-22

11-2.Compatibility mode handshake timing values ...................................C-22

ii

FrameMaker Ver.5.1(PC) SP-411 A: PRODUCT INSTALLATION

98.07.17

A: PRODUCT

INSTALLATION

FrameMaker Ver.5.1(PC) SP-411 A: PRODUCT INSTALLATION

98.07.17

1 PRECAUTIONS FOR INSTALLATION

1-1. Installation Site

When installing the printer, please avoid the types of locations listed below, both for safety

conditions and to breakdowns.

•

Which is exposed to direct sunlight.

•

Which is damp or dusty.

•

Where it may be splashed with water.

•

Which is tilted or subject to undue vibration.

•

Where it will be subject to extremely high or low temperature or humidity.

•

Where it will be subject to sudden fluctuations in either temperature or humidity.

•

Which is near volatile flammables or corrosive gas.

•

Which is in the direct air stream of an air conditioner, heater, or ventilator.

•

Which is near a TV set or radio.

1-2. Environmental Requirements

In order to make sure the printer function s in good condition, please make sure ambient

environment satisfies the following requirements:

Temperature : 10 to 35°C Temperature fluctuation : ±10°C per hour or less

Humidity : 15 to 85% RH Humidity fluctuation : ±20% RH per hour or less

Altitude : 0 to 2500m Atmospheric pressure : 760 hPa or more

1-3. Pow er Requirements

Do not plug the Pow er cord into a pow er outlet via an e xtension cord supplyi ng electricity to

more than one unit.

Power source 120-127V, 50-60Hz 220-240V, 50-60Hz

Voltage fluctuation +6%, -10% ±10%

Frequency fluctuation ±3Hz

When any other electric appliance is sourced from the same power outlet, make sure that

the current capacity of the outlet is not exceeded.

•

Ensure that the power outlet is not hidden behind any object, allowing the user to immediately unplug the power cord when necessary.

•

The power-outlet shall be installed near the equipment and easily accessible.

•

The power cord should not be cracked or scratched.

A-1

FrameMaker Ver.5.1(PC) SP-411 A: PRODUCT INSTALLATION

98.07.17

2 INSTALLATION

2-1. Connection

The following items should be connected before use.

•

Connect the Parallel Interface Cable.

•

Connect the Power Cord.

2-2. Moving

Caution:

The printer weighs approximately 30kg (2 pounds) without the Imaging Cartridge, paper

and Options. Don’t lift the printer by yourself. Have at least on other person assist you.

A-2

FrameMaker Ver.5.1(PC) SP-411 A: PRODUCT INSTALLATION

98.07.17

2-3. Space Requirement

Note:

The minimum space requirements for install of the printer are enclosed in a . To ensure

easy operation, replacement of consumable, and maintenance service jobs, provide the following space for the installation of the printer.

A-3

PagePro25

B: GENERAL INFORMATION

PagePro25

1 SPECIFICA-

TIONS

Type :Desktop Laser Beam Printer

Printing system :Electrostatic dry powdered imaging system + Imaging Cartridge

Exposure system :Laser Diode + Polygon Mirror scanning

Print resolution :600 dpi, smoothing (Fine-ART), photo tone mode

Print image :Single print within 4 mm of paper edge

Printing time :Single print 10.5 sec./Letter C (C: crosswise)

Multi printing time :Multi print 25 sheets/min/Letter C

Paper

Paper size

PCL built-in fonts :35 Agfa Intellifonts, 10 TrueType fonts

Paper feeding system :6 way system

Paper exit system :Face down (500 sheets maximum/A4 C/Letter C)

Warm-up time :Within 60 seconds (when power supplied at 23°C )

System speed :114.84 mm/second

Fusing system :Heat Roller fusing system

Charging system :Rotating Charge Brush system

Development :Fine Micro Toning system

Separating system :Paper separator (+ comb electrode????)

Cleaning system :Blade system

Dimensions :535 mm(W) x 543 mm(D) x 428 mm(H)

Weight :Approximately 30 kg (without Imaging Cartridge (TBD) kg)

Power supply :AC 120V 60Hz , AC 230V 50/60Hz

Power consumption: :1050W or less (rated operation??)

Atmosphere :Temperature 10 - 35°C

Acoustic noise :55 dB (A) or less (printing)

Printer life :500,000 prints (converted to A4 C or Letter C) or 5 years

Recommended prints

per month??

Imaging Cartridge life : 15,000 prints or more/A4 C/Letter C (when the black-to-white ratio is 5% on multi prints)

Duplex print (option) within (TBD) mm of paper edge

Duplex print (option) 18.6 sec./Letter C

Duplex print (option) 17.4 sheets/min/Letter C

Tray 1/ Manual Unit (option)

: •

Ordinary plain paper (60 - 90 g/m

Label, Thick paper (91 - 163 g/m

Tray 2 : Ordinary plain paper (60 - 90 g/m

Tray 3 - 5 (option)/2500 Sheet LCC (option) :

Ordinary plain paper (60 - 90 g/m

Tray 1/Manual Unit (option)

: •

A3, JIS B4, A4, JIS B5, A5, Letter, Legal 14, Ledger, Ex ecutive, Envelop (DL, Com-10,

C5, B5), Custom size (92 - 297 mm (width), 140 - 432 mm (length))

Tray 2/ Tray 3 - 5 (option)

A3, JIS B4, A4, JIS B5, A5, Letter, Legal 14, Ledger, Executive

Tray 1 (multi-purpose) (250 sheets)

Tray 2 (500 Sheet Cassette) (No 250 Sheet Universal Cassette???)

Options included: 590 mm(W) x 543 mm(D) x 808 mm(H)

(TBD)W or less on the average (printing)

(TBD)W or less on the average (standby)

45W or less (low power)

Humidity 15 - 85% RH (without condensation)

38 dB (A) or less (standby)

:6,000 prints on the average

2

)/Recycled paper (6 0 - 90 g/m2), OHP, L etterhead,

2

), Envelop

2

)/ Recycled paper (60 - 90 g/m2)

2

)/Recycled paper (60 - 90 g/m2)

B-1

Controller

CPU :PowerPC603e 90MHz

Memory :DRAM 4MB, ROM 4MB, NVRAM 4KB

Interface :IEEE1284 (Compatible, Nibble, ECP) Connector type B (36 pin Centronics)

Display Panel :LCD 16 characters x 2 lines , 3 LEDs, 8 keys

Accessories

Options

(Automatic interface selection upon data reception if an optional Network Board is used.)

Supporti ng 8 langu ages

:Power Cord (only North America??)

:Imaging Cartridge

:CD-ROM or FDs(s??)

Printer driver

•

Windows3.1/Windows95/WindowsNT4.0 (PCL5e + XL)

Status monitor

•

Windows95/WindowsNT4.0

Fonts

•

Agfa Font Manager with 96 fonts

:Manual?? (for printer and driver, one copy each)

:Manual Unit

:Duplex Unit

:Tray 3 - 5

250 Sheet Universal Cassette/500 Sheet Fixed Cassette

:2500 Sheet LCC (Large Capacity Cassette)

:5 Bin Main Bin (500 sheets)

:Hard Disk Unit (2.5” EIDE??, 2.1GB)

:Extend memory DRAM 96MB (SIMM x 3)

:PostScript 3

ROM-SIMM board x 1, 4MB

•

PostScript 136 fonts

•

MacOS system Ver. 7.5 or greater, PPD file

•

PS printer dri ver f or Windows3.1

•

PS printer driver Windows95

•

:Network Boar d 1 slot

Interface

•

Ethernet 100/10 Base T, 10 Base2, TokenRing

Protocol TCP/IP, IPX/SPX, AppleTalk

•

Managing function?? Buil t-in Web server function which i s possible to manage with

•

Web browser, SNMP (IPX, IP) + printer MIB

Attached software

•

IPX browser (Windows95), supporting Windows95 peer to peer

PagePro25

Mac, AppleTalk, and TrueType are trademarks of Apple, Inc. Windows 3.1, Windows95, and WindowsNT are registered

trademarks of M icro soft C o rporation. IPX/SPX i s a reg i ster ed t radem ark of Novel Corporat ion. PostScript is a registered

trademark of Adob e System, Inc. Othe r company names or bran d names are regist ered trademarks o r trademarks of

respective corporations.

B-2

2 PA RTS IDENTIFI CA -

TIONS

PagePro25

B-3

PagePro25

B-4

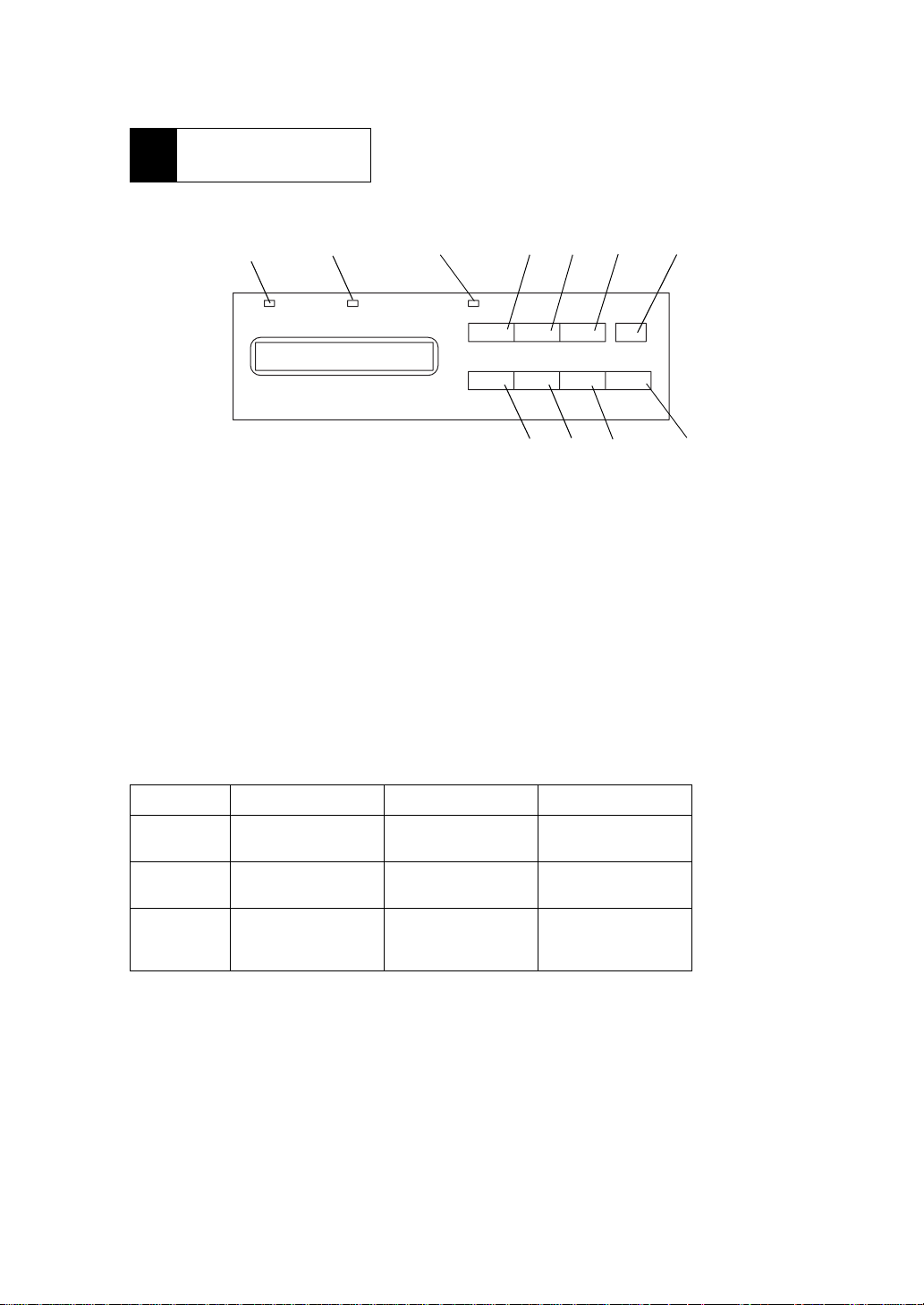

3 CONTROL

PANEL

3-1. Control panel

PagePro25

(1) LED

1

2

Data Message

1. Data LED 8. Enter/Job Cancel key

2. Mess age LED 9. Select ke y

3. On Line LED 10. Item key

4. On Line key 11. Menu key

5. Proceed key

6. Tray1 Paper key

7. Shift key

3 4

On Line Proceed Tray 1 Paper Shift

Menu Item Select Enter

▲▲▲

▼▼▼

5

6

∗

Job Cancel

91011

7

8

LED On Off Flashing

On Line

(Green??)

Data

(Green??)

Message

(Amber??)

On-line (ready) Off-line Being off-line

Print data in memory No data in memory

Fatal error

(Engine error, etc.)

(Service call)

No problem Restorable error

Receiving data

•

Processing data

•

(Paper empty, Memory

error, etc.)

B-5

(2) Function of Keys

PagePro25

Key

On Line :Changes the on-line/off-line condition. Acts as a stop key during in on-line.

Proceed

Tray1 P ape r

Menu

Item

Select

Enter/Job Cancel

Shift

NOTE

For the Service Mode for a serviceman, see E “Adjustment”.

Commands the printer to continue printing for forcibly ejecting the paper when the

: •

printer goes to off-line because of occurrence of an error.

Commands the printer to print the data in memory in off-line if the Data LED is lit. (If On

•

Line is pressed while the Data LED is lit, the LED stays lit in off-line.)

Enters the Tray1 Paper Menu mode while in off-line.

: •

Selects a Menu from the Tray1 Paper menu.

•

Enters the Menu mode while in off-line.

: •

Selects a Menu from the Menu mode.

•

Selects an Item from the selected Menu.

: •

Selects an Option from the selected Item.

: •

Selects an Option from the selected Tray1 Paper Menu.

•

Pressing the key continuously will cause the printer to move quickly through the

•

Options.

Sets up the Option being select ed.

: •

In off-line, pressing Enter/Job Can cel + Shift cancels a job being processed. Also, it

•

clears the print data in memory if any.

Pressing Shift + Menu selects a Menu in the Menu mode in the reverse order.

: •

Pressing Shift + Item selects an Item in the Menu in the reverse order.

•

Pressing Shift + Select selects an Option in the reverse order.

•

Function

------------------------------

X-X.Service Mode

(This should be moved to E “Adjustment”, if this is not written in E yet.)

The service mode is prepared for a serviceman.

(1) How To Enter the Service Mode

While pressing and ho lding On Li ne + Menu + Select, tu rn on the power of th e printe r. Keep press these keys for more

than three seconds, then the following “SERVICE MENU” appears on the LCD.

SERVICE MENU

TOTAL COUNT

Item

(2) How To Exit the Service Mode

Press the On Line to exit the Service mode. The initialization seque nce is performed and the pr inter return s to normal

condition.

B-6

(3) Service Mode Tree

PagePro25

Menu

SERVICE MENU TOTAL COUNT 0000000 - 9999999

LARGE SIZE COUNT 0000000 - 9999999

STAPLE COUNT 000000 - 999999

I/C COUNT 000000 - 999999 (??What display for “Limit”??)

LOOP ADJUST T2-5 -4.9, -4.2, -2.8, -2.1, -0.7, 0*, +0.7, +2.1, +2.8, +4.2, +4.9 mm

LOOP ADJUST T1 -4.9, -4.2, -2.8, -2.1, -0.7, 0*, +0.7, +2.1, +2.8, +4.2, +4.9 mm

[LOOP ADJUST DUP] -4.9, -4.2, -2.8, -2.1, -0.7, 0*, +0.7, +2.1, +2.8, +4.2, +4.9 mm

SERVICE MESSAG E PERMANENT OFF, ON*

*: Default setting

[ ]: Displayed when the option is installed.

Item Option

RESET COUNT

RESET COUNT

(4) Explanations for Items in the Service Mode

In the Service m ode, you can d isplay counte r value s or rese t the cou nte rs. The cou nte r value for I/C COUNT is stored in

the EEPROM in the engine. Other counter values are stored in the EEPROM in the controller (controller board).

TOTAL COUNT:

The total number o f printed sheets after deliver y from the factory is displayed in 7 dig its. You cannot clear this

counter.

LARGE SIZE COUNT:

The total number of printed sheets for A3 and ledger after delivery from the factory is displayed in 7 digits. Y ou cannot

clear this counter.

STAPLE COUNT:

The number of times an optional stapler has been used is displayed in 6 digits.

To reset the counter, select “RESET COUNT” with the Select key and press the Enter key. “RESET OK?” will be d isplayed on the LCD. Press the Enter key again to clear the counter.

I/C COUNT:

The number of times the PC drum in the imaging cartridge has been turned is displayed in 6 digits.

To reset the counter, select “RESET COUNT” with the Select key and press the Enter key. “RESET OK?” will be d isplayed on the LCD. Press the Enter key again to clear the counter.

LOOP ADJUST T2-5, LOOP ADJUST T1, [LOOP ADJUST DUP]:

The loop value for tray 2 - 5, tray 1, and optional manual unit and duplex unit can be adjusted. The loop value set here

will affect the registration compensation for paper (paper skew compensation). If registration is not correctly made,

the loop value should be adjusted to correct it. (For registration compensation, see 2-3 “Paper Feed” in C “MECHANICAL/ELECTRICAL”.)

SERVICE MESSAGE:

In the default setting (“ON ”), the Maintenance Menu will b e displayed normally. If “PERMANENT OFF” is set, no

items and no “MAINTENANCE REQ#” will be displayed even if the Maintenance Menu is selected.

B-7

3-2. Condition Messages

Message

READY

TRAY1EMPTY

Warning message

PagePro25

Messages

READY :Awaiting data

OFF LINE :Off-line

PROCESSING :Image processing for data received through the par allel port

PRINTING :Printi ng dat a

COPYING :Feeding paper with the engine

CANCELING JOB :Canceling job

After canceling, the printer goes to on-line.

Menu modes

TRAY1 PAPER MENU

PRINT MENU

PCL MENU

SYSTEM MENU

MAINTENANCE MENU

ADJUST MENU

PARALLEL MENU

[NETWORK MENU]

TEST PRINT MENU

WARMING UP :Printer warming up

SELF TEST :Power-on self-check

FORMA TTING HDD :Formatting the hard disk (option)

CLEANING :Engine cleani ng

POWER SAVE :Power saving mode

CONTEXT SAVE :Context saving

[ ]: Displayed when the option is installed.

Warning message s

(Please see the instruction manual?)

B-8

3-3. Caution Messages

DATA COM PRESSION

Caution message

(Please see the instruction manual?)

3-4. Auto-continuabl e Messages

MEMORY OVERFLOW

Auto-continuable message

(Please see the instruction manual?)

3-5. Operator Call Messages

NO PAPER

Operator call message

(Please see the instruction manual?)

PagePro25

3-6. Serviceman Call Messages

FATAL ERROR1 ROM

Serviceman call message

(Please see the instruction manual?)

B-9

3-7. Key Condition Diagram

PagePro25

B-10

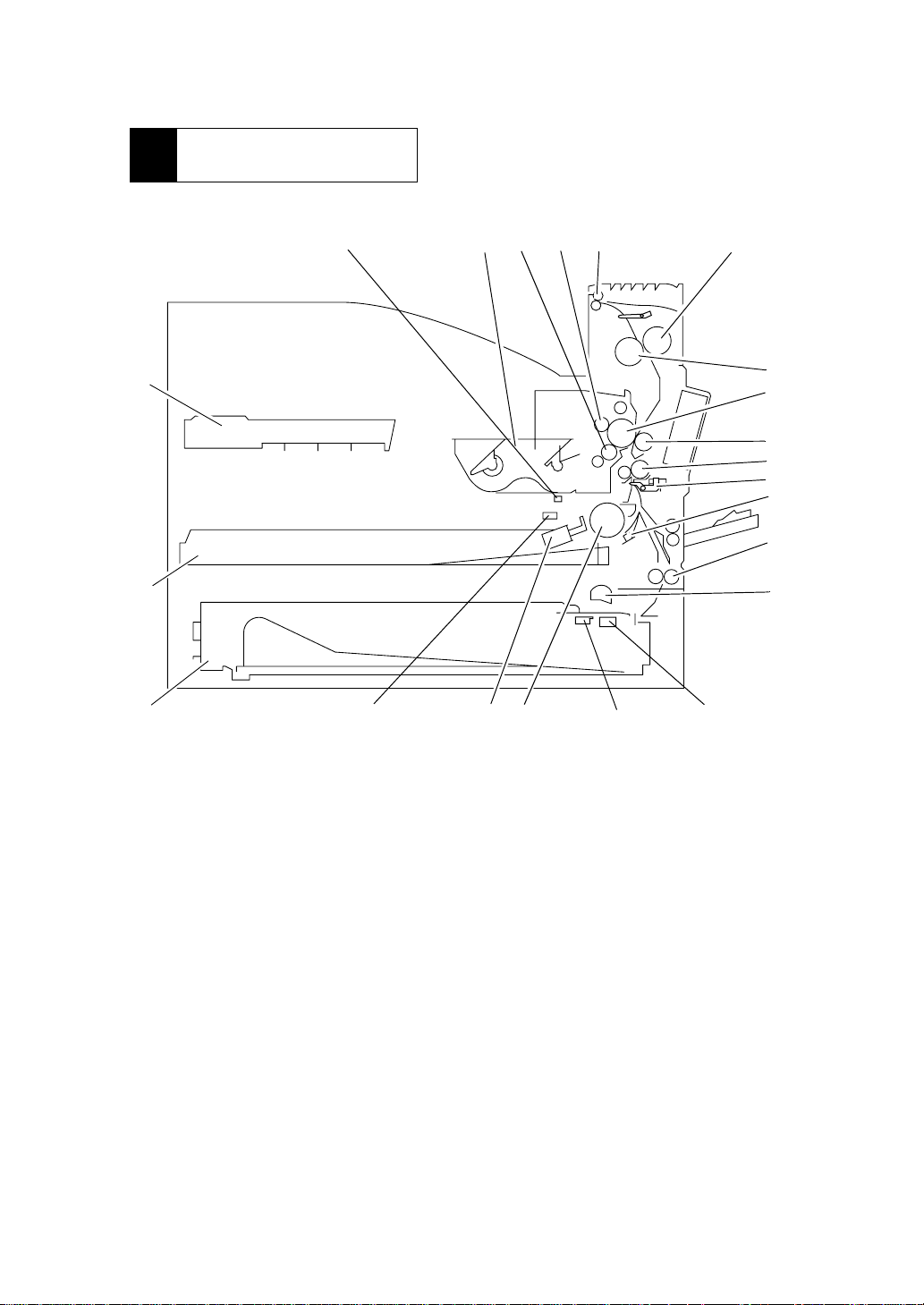

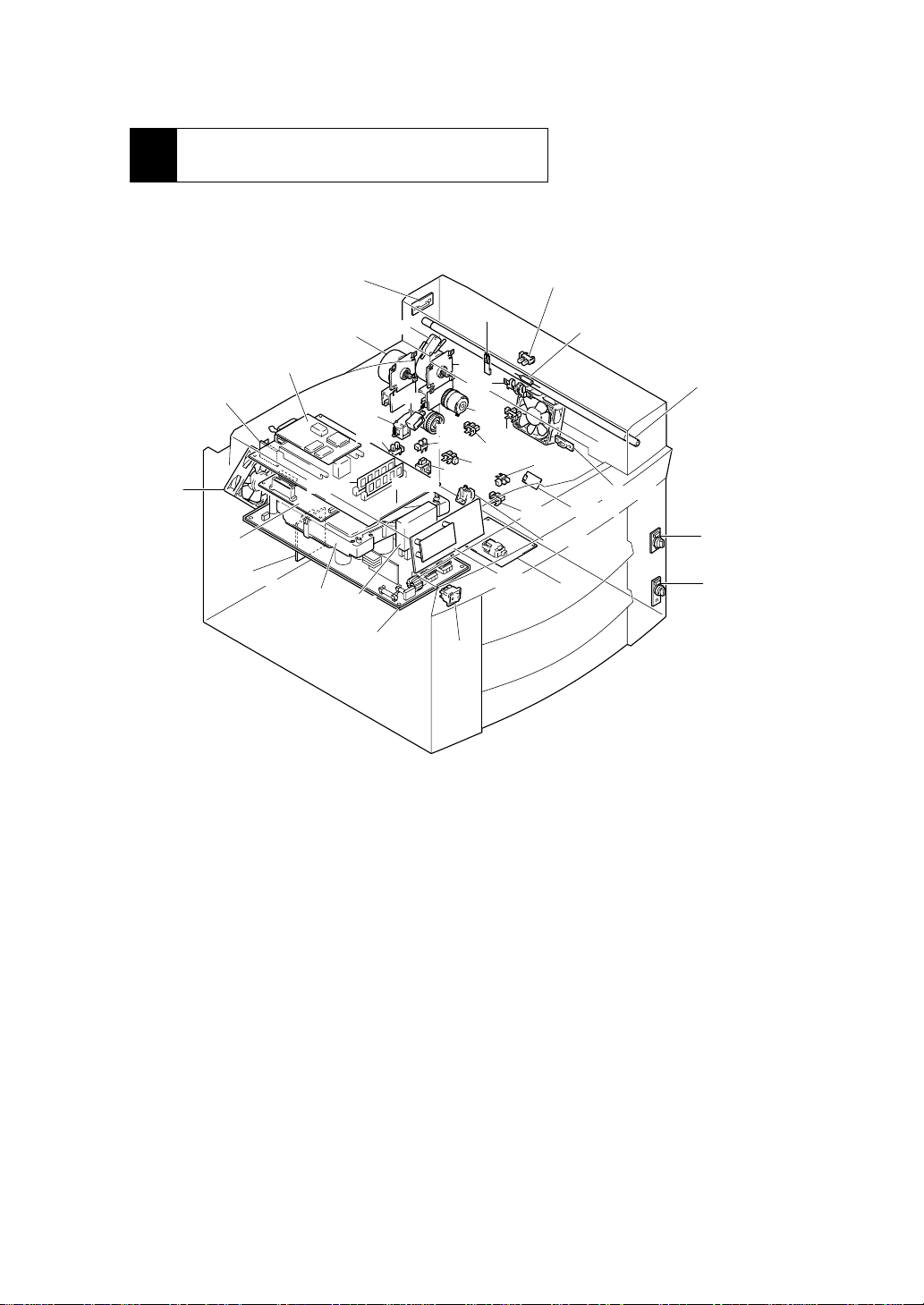

4 COMPONENT LAY-

OUT

PagePro25

23

22

2

3

5

4

6

8

9

1

10

11

12

13

14

15

16

21

20 19

1718

1. Print Head Unit (PU)

2. Toner Empty Detecting Board (PWB-G)

3. Imaging Cartridge

4. Sleev e Rolle r

5. Charge Brush

6. Paper Exit Roller

7. Paper Exit Sensor (PC3)

8. Lower Fusing Roller

9. Upper Fusing Roller (Fusing Roller Heater Lamp (H1) is incorporated.)

10. PC Drum

11. Transfer Roller

12. Synchronizing Roller

13. Synchronizing Roller Sensor (PC2)

14. Double Feed Detecting Sensor Board (PWB-H)

15. 2nd Cassette Transport Roller

16. 2nd Cassette Paper T a ke-up Roller

17. 2nd Cassette Paper Empty Sensor (PC22)

18. 2nd Cassette Paper Take-up Solenoid (SL21)

19. 1st Cassette Paper Take-up Roller

20. 1st Cassette Paper Take-up Solenoid (SL1)

21. 1st Cassette Paper Empty Sensor (PC4)

22. 2nd Paper Cassette

23. 1st Paper Cassette

B-11

PagePro25

T

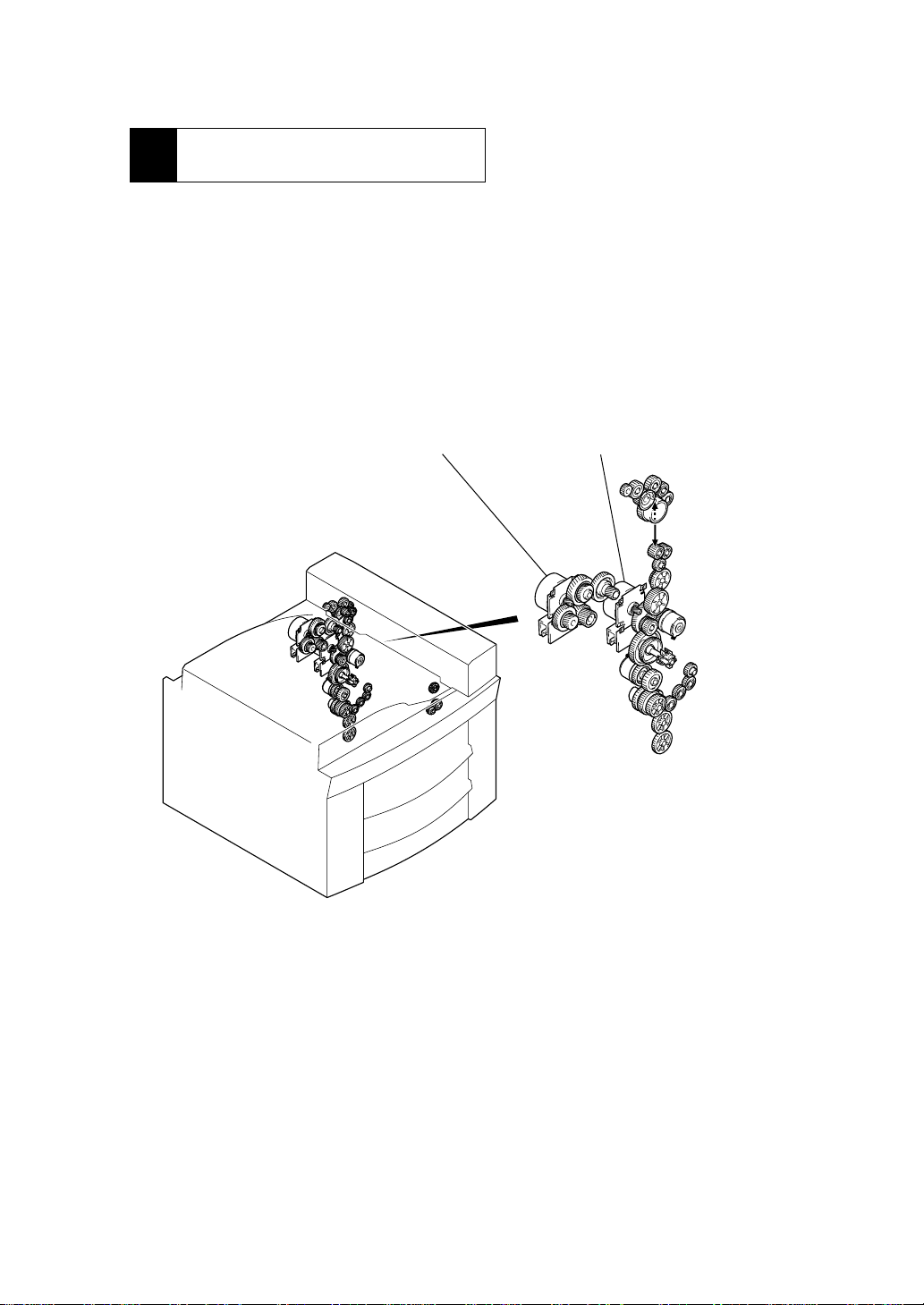

5 GEAR/ROLLER ASSIGN-

MENT

The locations of the gears and rol lers in the printe r is shown below. The transpor t motor (M2) transm its the power to the

paper driving p arts for feeding paper. Meanwhile, th e I/C dr ive m oto r ( M1 ) tran smits th e power to the driving parts in the

imaging cartridge.

I/C Drive Motor (M1)

Transport Motor (M2)

4108 (SP411) KUDOUBUHIN LAYOU

B-12

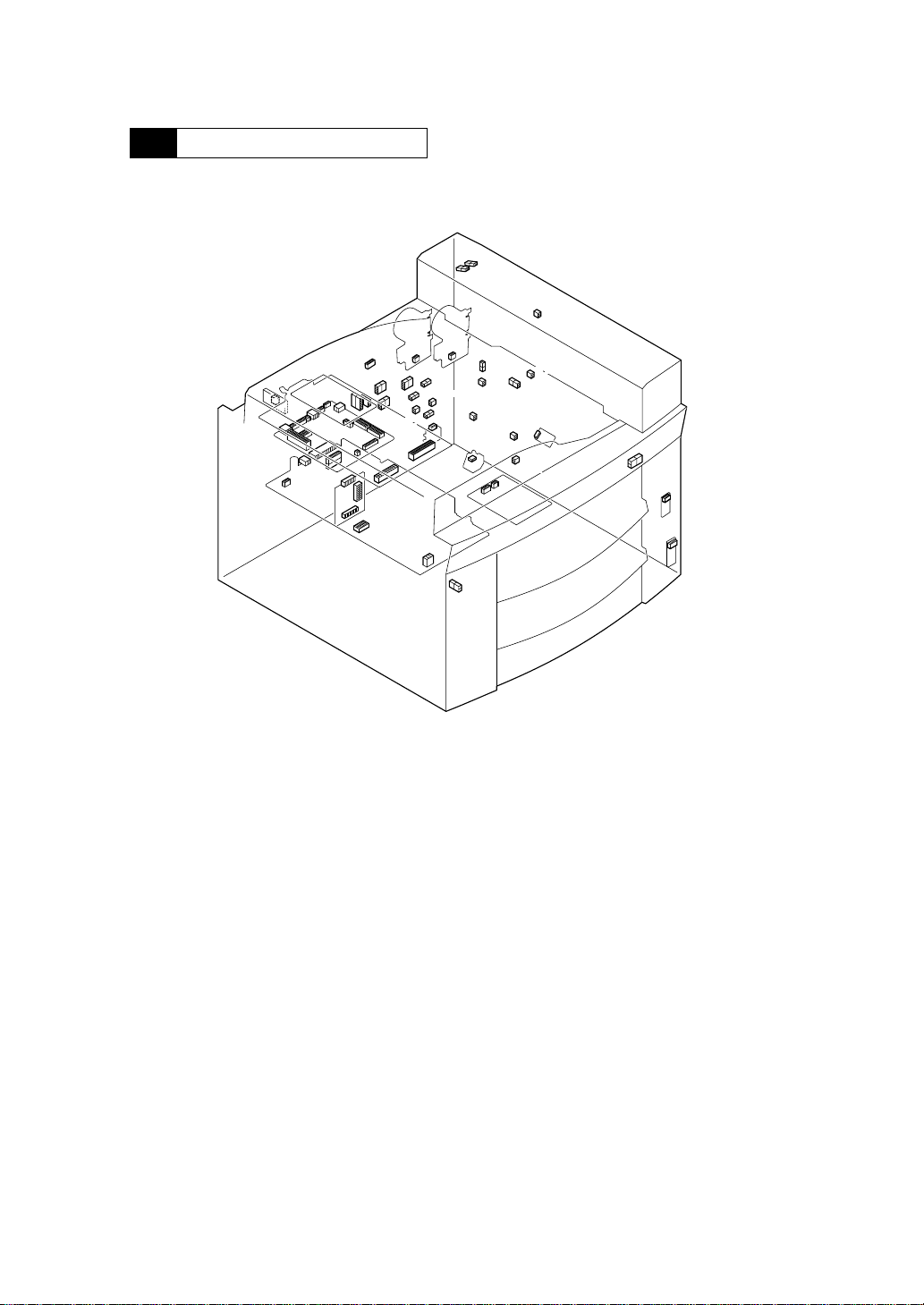

6 ELECTRICAL COMPONENT LAY-

O

OUT

PagePro25

M4

PWB-L

PWB-A

PWB-NT

PWB-A1

PWB-R1

*

SIMM

PH

M1

SL21

*

HDD

PC5

PU1

*

S2

SL1

PWB-P

CL1

PC6

SW3

S1

M2

TS1

PC23

TH1

CL2

PC2

PC25

PWB-OP

PC4

PC22

PC3

PWB-G

HV1

TF1

H1

M3

PWB-R2

PWB-H

PWB-S1

PWB-S2

4108 (SP411) ELECTORICAL LAY

PU :Print Head Unit SL21 :2nd Cassette Paper Take-up Solenoid

PU1 :Power Supply Unit CL1 :Synchronizing Clutch

HV1 :High Voltage Unit CL2 :Transport Clutch

PWB-A : Main Board S1 :Power Switch

PWB-A2 : 2nd Cassette Main Board S2 :Right Door Interlock Switch

PWB-G :Toner Empty Detecting Board SW3 :2nd Cassette Set Switch

PWB-H :Double Feed Detecting Sensor Board PC2 : Synchronizing Roller Sensor

PWB-L :PPM Switching Board PC3 :Paper Exit Sensor

PWB-OP :Control Panel PC4 :1st Cassette Paper Empty Sensor

PWB-P :Controller Board PC5 :1st Cassette Paper Near Empty Sensor

PWB-R1 :Fuser Frame Resistor Board PC6 :1st Cassette Set Sensor

PWB-R2 :Pre-Transfer Guide Plate Resistor Board PC22 :2nd Cassette Paper Empty Sensor

PWB-S1 :1st Cassette Paper Size detecting Board PC23 : 2nd Cassette Side Door Detecting Sensor

PWB-S2 :2nd Cassette Paper Size detecting Board PC25 :2nd Cassette Paper Near Empty Sensor

M1 :I/C Drive Motor H1 :Fusing Roller Heater Lamp

M2 :Transport Motor TF1 :Fusing Roller Heater Lamp Fuse

M3 :Cooling Fan Motor TH1 : Fusing Roller Thermistor

M4 :Power Unit Cooling Fan Motor TS1 :Fusing Roller Thermostat

SL1 :1st Cassette Paper Take-up Solenoid

B-13

7 CONNECTOR LAYOUT

9p

4p

13p

PagePro25

3p

4p

3p

(PC)

2p

(CL)

3p

(fan)

3p

(PC)

3p

(PC)

(CL)

2p

10p

6p

2p

(SL)

3p

(PC)

3p

(PC)

(PC)

3p

2p

3p

(PC)

(PC)

14p

14p

3p

2p

2p

4108 (SP411) CONNECTOR LAYOUT

B-14

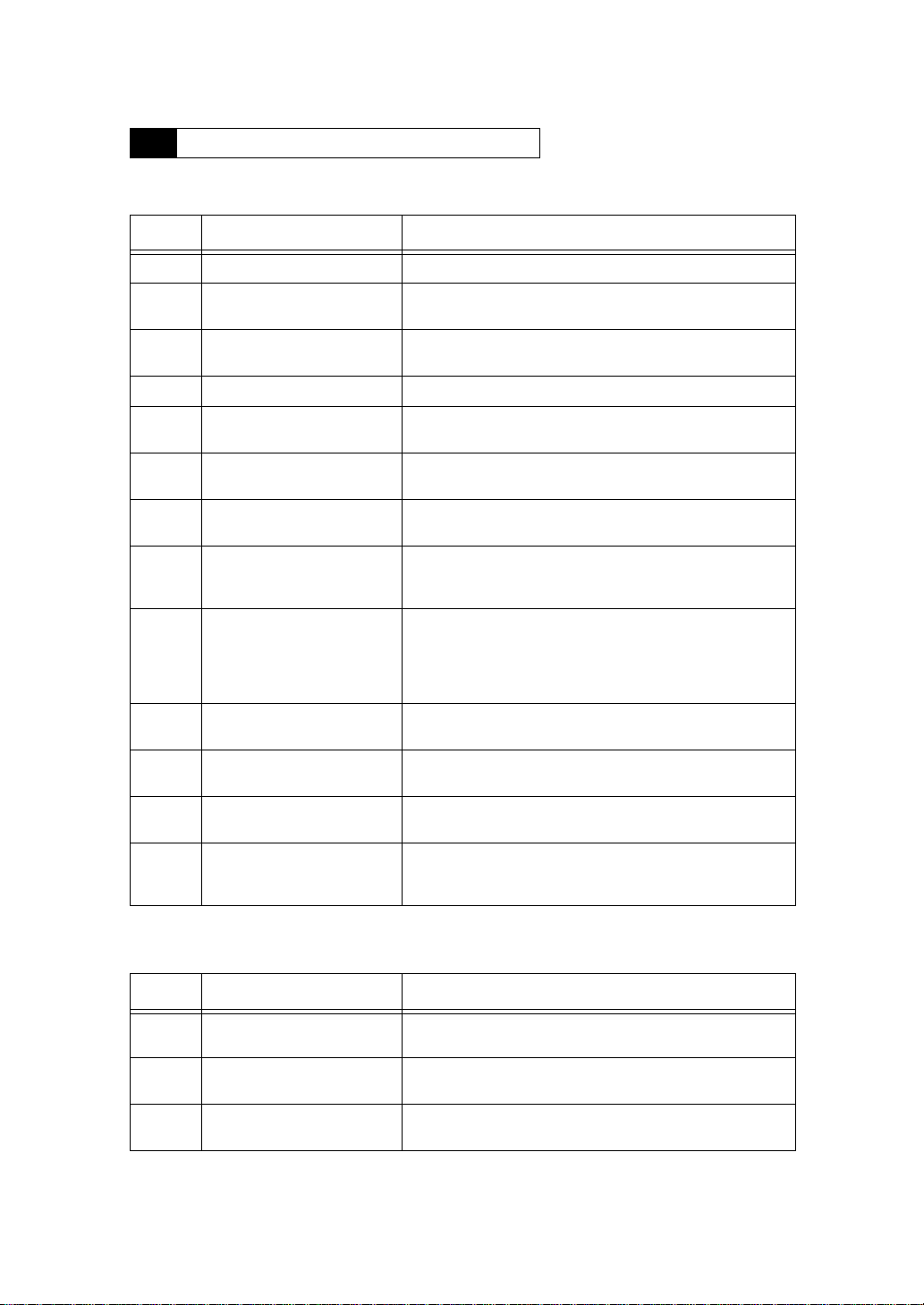

8 SWITCH/SENSOR IDENTIFICATION

Printer main body

Symbol Name Function

S1 Power Switch Turns power on and off.

S2 Right Door Interlock

Switch

Detects open/close condition of the right door.

When it is closed, the switch is ON.

PagePro25

PC2 Synchronizing Roller

PC3 Paper Exit Sensor Detects paper ejection from the printer. Active: “L”

PC4 1st Cassette Paper

PC5 1st Cassette Paper Near

PC6 1st Cassette Set Sensor Detects that the 1st paper cassette is installed in the tray 1. Active:

SW3 2nd Cassette Set Switch Detects that the 2nd paper cassette is installed in the tray 2. Switch

TH1 Fusing Roller

TS1 Fusing Roller

TF1 Fusing Roller Heater

Sensor

Empty Sensor

Empty Sensor

Double Feed Sensor Detects the possibility of double feeding on the 1st paper cassette.

−

Toner Empty Sensor Detects toner empty condition. Active: “L”

−

Thermistor

Thermostat

Lamp Fuse

Detects the paper fed from the tray . Activ e : “L”.

Detects paper empty condition of the 1st paper cassette.

Active: “H”

Detects paper near empty condition of the 1st paper cassette.

Active: “L”

“H”

is turned ON when the cassette is installed. Also detects the type of

cassette; 250 sheet universal cassette or 500 sheet fixed cassette.

Active: “L”

(Detects whether the leading edge of the paper to be t aken up next

runs 10 mm o r mor e from the nip point.) Th e senso r is on th e dou ble feed sensor board (PWB-H)

The sensor is on the toner empty detecting board (PWB-G).

Detects the temperature of the upper fusing roller.

Shuts off the applicatio n voltage to the fusing roller heater lamp

(H1) when temperature becomes abnormal.

Blows own fuse immedi ately to shut off the application voltage to

the fusing roller he ater lamp (H1) when tempe rature rises abnormally.

2nd Paper Cassette

Symbol Name Function

PC22 2nd Cassette Paper

Empty Sensor

PC25 2nd Cassette Paper

Near Empty Sensor

PC23 2nd Cassette Side

Door Detecting Sensor

Detects paper empty condition of the 2nd paper cassette.

Active: “L”

Detects paper near empty condition of the 2nd paper cassette.

Active: “L”

Detects open/close condition of the 2nd cassette side door.

When it is opened, the sensor output is “H”.

B-15

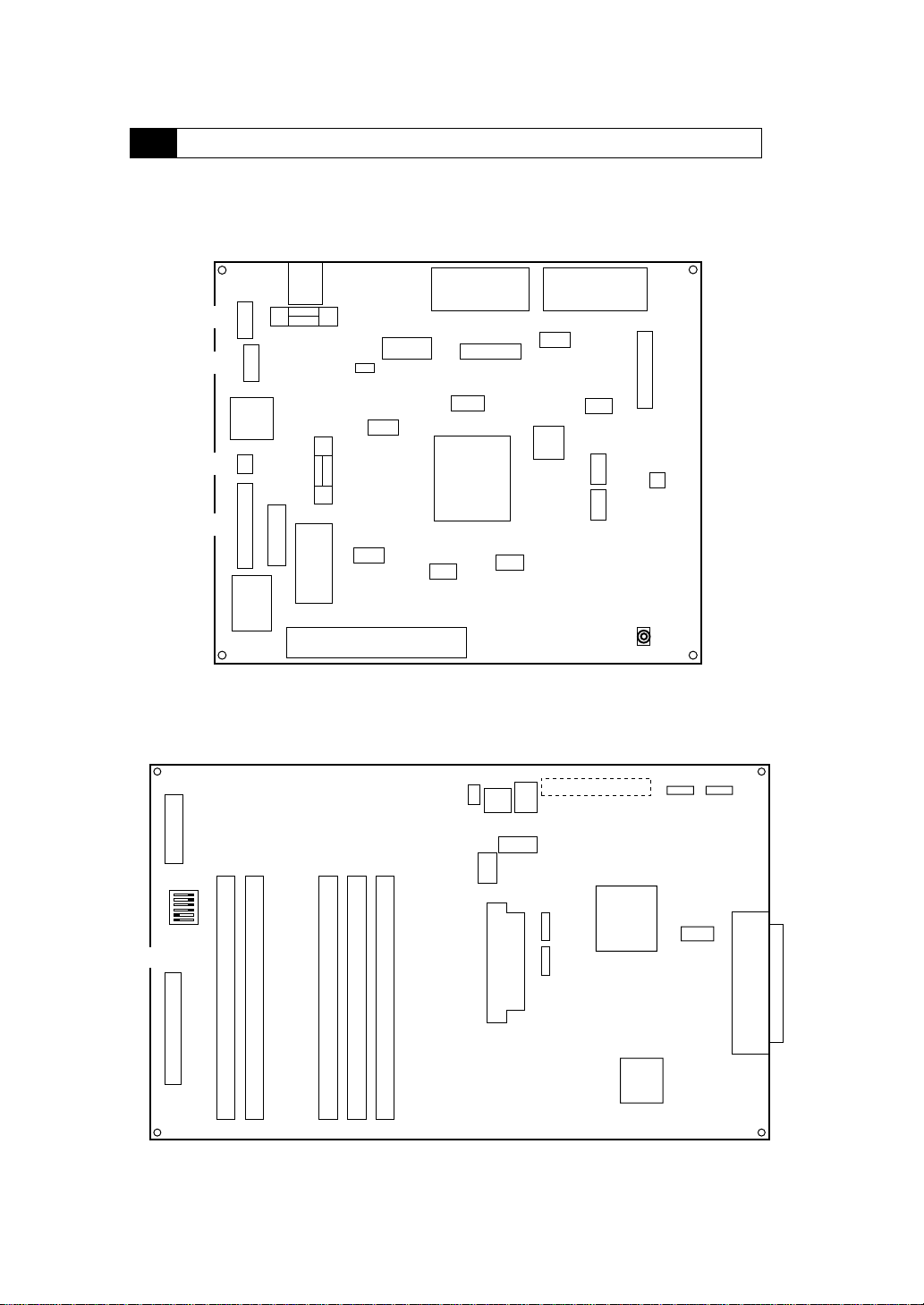

9 ELECTRICAL SERVICE PARTS ON P.W. BOARDS

PWB-A

PagePro25

PJ9 (6P)

PJ8 (5P)

PJ6 (2P)

PJ3 (13P)

PWB-P

PJ7

(3P)

PJ2

(4P)

F2

PJ5

(9P)

PJ10

(2P)

PJ4

(20P)

F1

PJ12 (7P)

IC9

IC18

IC13

PJ1 (32P)

PJ13 (26P)

IC20

IC1

IC6

IC19

IC7

IC16

IC3

PJ14 (28P)

IC10

IC15

IC14

CN1 (32P)

PJ16

(12P)

PJ21 (3P)

VR1

CN2 (20P)

SIMM1, 2 (ROM)

CN3 (44P)

SIMM3, 4, 5 (RAM)

B-16

CN4

(50P)

CN5

(36P)

Loading...

Loading...