®

magicolor 6100

Series

Maintenance

Guide

1800646-001A

Dear magicolor 6100 Series Printer User:

Thank you for purchasing a magicolor 6100 Series printer. Place this

near the printer for quick information.

Guide

For technical support:

click on 24-Hour On-line Help. The Answer Base (the dancing sun icon) helps you

locate the information you need by asking you questions. You can also refer to the

Installation Guide

= Dispose of used consumables properly according to your local

regulations. Do not dispose of them by burning.

= Keep dry

= The fuser can become extremely hot and cause severe burns. Make sure the unit

is cool before handling it.

Point your web browser to www.minolta-qms.com, and then

and the

User’s Guide

for further information.

Maintenance

Trademarks

The following are registered trademarks of MINOLTA-QMS, Inc.: QMS, the

MINOLTA-QMS logo, Crown, and magicolor.

Minolta is a trademark of Minolta Co., Ltd. Other product names mentioned in this

guide may also be trademarks or registered trademarks of their respective owners.

Proprietary Statement

The digitally encoded software included with your printer is Copyrighted © 2001 by

MINOLTA-QMS, Inc. All Rights Reserved. This software may not be reproduced,

modified, displayed, transferred, or copied in any form or in any manner or on any

media, in whole or in part, without the express written permission of MINOLTAQMS, Inc.

Copyright Notice

This guide is Copyrighted © 2001 by MINOLTA-QMS, Inc., One Magnum Pass,

Mobile, AL 36618. All Rights Reserved. This document may not be copied, in whole

or part, nor transferred to any other media or language, without written permission

of MINOLTA-QMS, Inc.

Notice

MINOLTA-QMS, Inc. reserves the right to make changes to this guide and to the

equipment described herein without notice. Considerable effort has been made to

ensure that this guide is free of inaccuracies and omissions. However, MINOLTAQMS, Inc. makes no warranty of any kind including, but not limited to, any implied

warranties of merchantability and fitness for a particular purpose with regard to this

guide. MINOLTA-QMS, Inc. assumes no responsibility for, or liability for, errors

contained in this guide or for incidental, special, or consequential damages arising

out of the furnishing of this guide, or the use of this guide in operating the

equipment, or in connection with the performance of the equipment when so

operated.

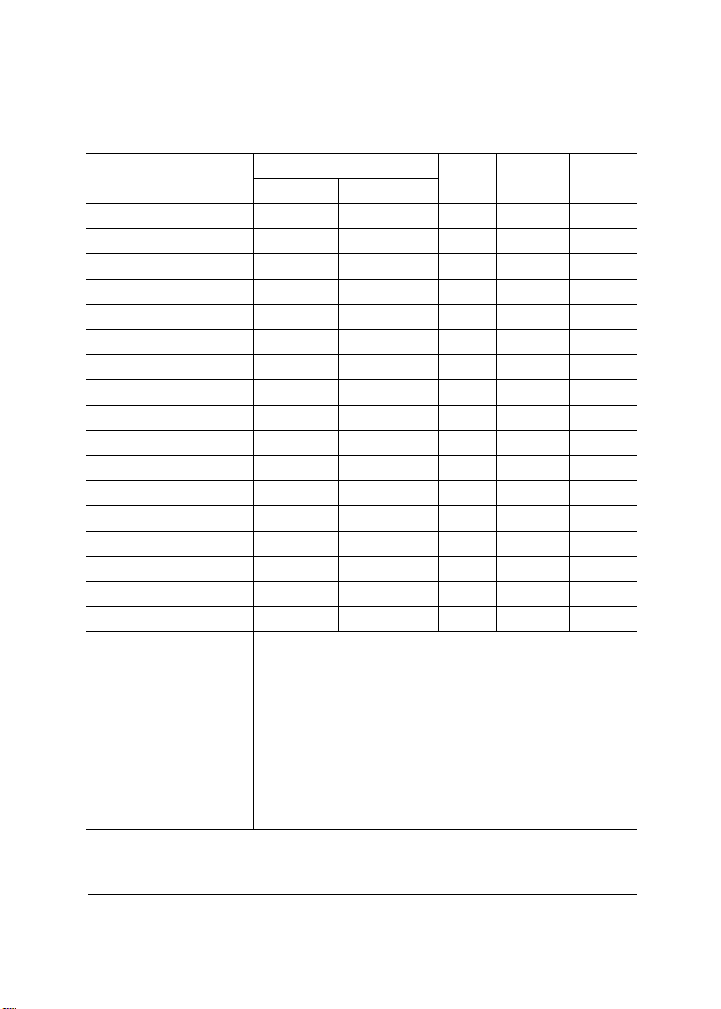

Media Specifications

Media Type Media Size Printer

Inches Millimeters

Mode

A3 11.7 x 16.5 297.0 x 420.0 Auto.

Input

Source

(3)

U/L Yes

(1)

Autoduplex

A4 8.2 x 11.7 210.0 x 297.0 Auto. U/A/L Yes

A4 Transparency 8.2 x 11.7 210.0 x 297.0 Auto. U/A No

B4 10.1 x 14.3 257.0 x 364.0 Auto. U/L No

B5 (ISO) Envelope 6.9 x 9.8 176.0 x 250.0 Thick F No

B5 (JIS) 7.2 x 10.1 182.0 x 257.0 Auto. U/A No

Commercial #10 Envelope 4.1 x 9.5 105.0 x 241.3 Thick F No

International DL Envelope 4.3 x 8.7 110.0 x 220.0 Thick F No

Executive 7.3 x 10.5 184.0 x 267.0 Auto. U Yes

Japanese Postcard 3.9 x 5.8 100.0 x 148.0 Thick F No

Ledger 11.0 x 17.0 279.4 x 432.0 Auto. U/L Yes

Legal 8.5 x 14.0 215.9 x 355.6 Auto. U/L Yes

Letter 8.5 x 11.0 215.9 x 279.4 Auto. U/A/L Yes

Letter Transparency 8.5 x 11.0 215.9 x 279.4 Auto. U/A No

Oversize 13 x 19 330.2 x 482.6 Auto. U No

(4)

Oversize

Oversize

Notes

(4)

13 x 18 330.2 x 457.2 Auto. U No

12 x 18 304.8 x 457.2 Auto. U No

(1) U = Upper universal media tray (250 sheet)

A = Upper letter/A4 (optional) media tray (250 sheet)

F = Media tray with optional envelope or postcard feeder

L = Lower feeder unit (optional) media tray (500 sheet)

(2) An optional duplex unit can be added to all models that have a

lower feeder unit attached. Only plain paper can be autoduplexed.

(3) Transparencies and plain paper up to 24 lb bond [90 g/m

the Automatic (Auto.) mode to print; other media types/weights use

the Thick Stock mode.

(4) Not available on magicolor 6100 DeskLaser.

The single face-down output bin has a capacity of 250 sheets of

20 lb (75 g/m

2

) bond paper.

2

] use

(2)

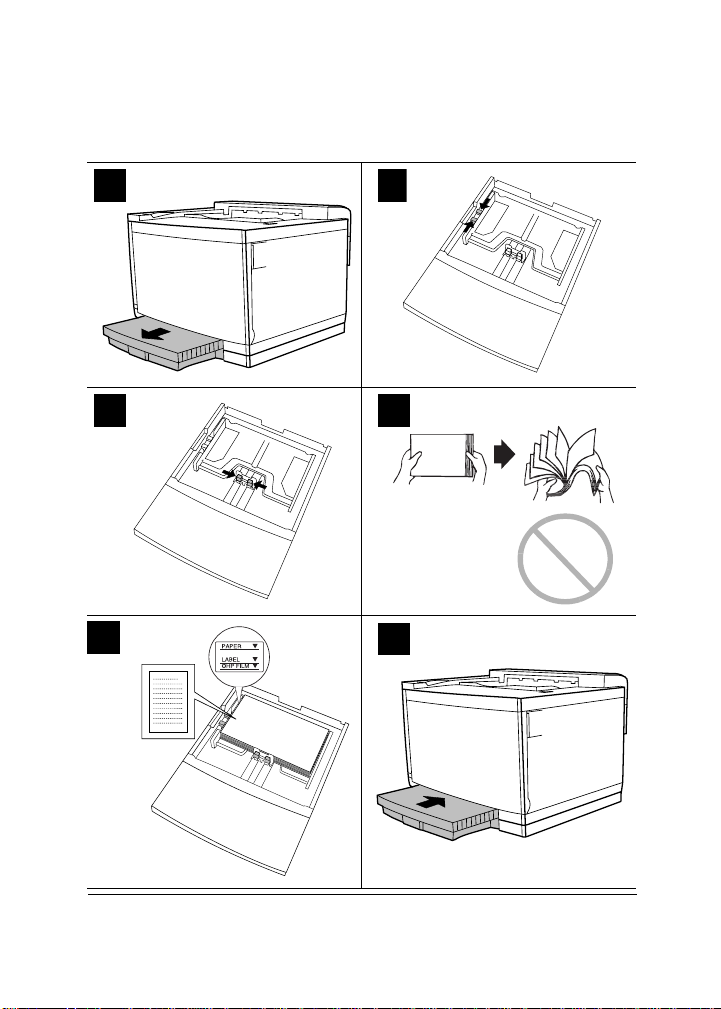

1

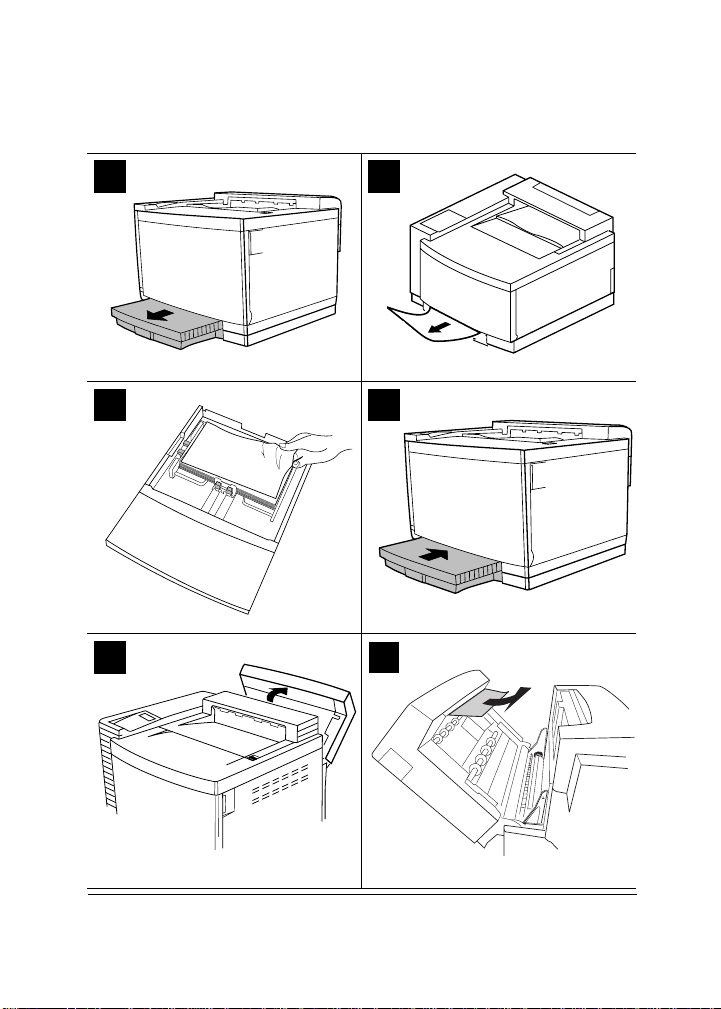

Loading Media

2

154dv

1

3

4

OHP

5

6

2

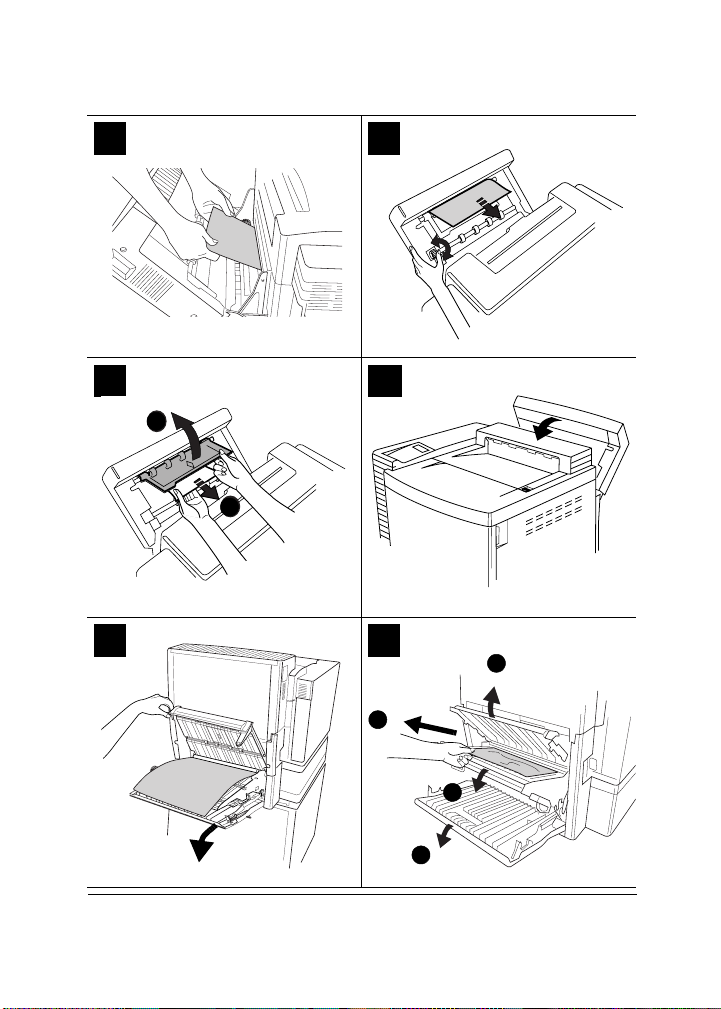

Clearing Media Jams

1 2

3 4

5 6

3

7 8

2

1

9

a

b

11

10

12

c

d

b

a

4

13

a

b

c

14

15 16

17 18

1

2b

2a

5

20 21

22

b

b

a

a

Preventive Maintenance Schedule

30K MAINTENANCE

240K MAINTENANCE

Preventive maintenance is needed after 30,000

pages have been printed.

Preventive maintenance is needed after 240,000

pages have been printed.

6

Maintenance Schedule

Attention

Consumable life is expressed in simplex letter/A4 pages at

normal 5% coverage in continuous printing. A duplex page is

equivalent to two simplex pages. The stated life expectancy of

each consumable is based on printing under specific operating

conditions, such as ratio of color to monochrome, and media

type and size. The actual life expectancy will vary (or be

reduced) depending on these and other printing variables,

including continuous (optimal consumable life) or intermittent

(for example, one-page jobs) printing, ambient temperature,

and humidity.

User replaces... After...

Cleaning roller 20,000 pages.

Fuser oil bottle Up to 12,000 pages.

OPC belt cartridge Up to 120,000 pages.

Toner cartridge Approximately 14,000 planes per black cartridge

Waste toner bottle 18,000 color planes.

Ozone filter Every 12 months.

Notes

Fuser oil life is media dependent. Heavy coverage,

intermittent printing, and different media types can

use up oil at an accelerated rate, reducing fuser oil

bottle life.

Other factors also affect cartridge life.

and 8,500 planes per yellow, magenta, and cyan

cartridge).

The printer ships with an initial starter toner kit—

this means the black toner cartridge has a life of

7,000 planes, while cyan, magenta, and yellow

initial starter cartridges each have a life of 4,250

planes—at 5% coverage of each color.

The fusing unit, transfer drum, paper pickup roller,

and paper separation pad must be replaced by a

MINOLTA-QMS authorized service provider. Refer

to the

Service & Support Guide

.

.

7

Error Messages

5"

Frequent jams in any area indicate that the area should be

checked, repaired, cleaned, and/or replaced. Repeated jams

will also occur if you’re using the wrong weight print media

or if the media does not match the specifications noted in the

User’s Guide

Error Message Problem Solution

CALL FOR

SERVICE <

<

COLOR

LOW

<

COLOR

EMPTY

ENERGY SAVER

MEDIA MISMATCH

OUTPUT BIN FULL

PUT <X> IN

<Y> BIN

REPLACE <X>

<X> DOOR OPEN

<X> EMPTY

X>

> TONER

> TONER

.

A service call is needed for

<X

> (the service number

reference).

The indicated toner cartridge

is low. There is still enough

toner for approximately 100

letter/A4 planes (at 5% coverage) before the printer stops.

The indicated toner cartridge

is empty.

Energy Saver has been

activated.

The media detected in the tray

doesn’t match the media size

setting.

The media has exceeded

the limit in the output bin.

Refill the specified input tray

with the specified media size.

The specified item needs to

be replaced.

The specified door (cover) is

not closed properly.

The specified item is empty ,

such as the fuser oil.

Place a service call for the

service number reference.

Refer to the

port Guide

qms.com for further

information

If print quality is reduced,

redistribute the toner in

the cartridge, or replace the

cartridge.

Replace the toner cartridge.

No action needed.

Change the media in the tray

or change the media size

setting

Remove the media from the

specified output bin.

Refill the specified input tray

with the specified media size.

Replace the specified item.

Close the door(s).

Replace the specified item.

Service & Sup-

or www.minolta-

.

.

8

Error Message Problem Solution

<X> JAM

<X> LOW

<X> MISINSTALLED

Misfeed jams occur between

the upper or optional tray and

the print engine. A misfeed

jam may be as simple as a

sheet of media not being

picked, or it may be that the

media was picked but not fed

properly.

Duplex jams occur in the

duplex area or duplex refeed

area on the models with

duplex units installed.

Fuser jams occur in the fuser

area.

Drum jams occur in the transfer drum area.

Transfer jams occur in the

transfer roller area. This type

of jam means that the media

did not make it to the paper

exit area.

Input bin jams occur in the

input bin.

Output bin jams occur in the

output bin.

The specified item is near end

of life, such as the fuser oil.

The indicated item is not

installed correctly.

Locate and remove the jam.

Replace the specified item.

Reinstall the specified item.

9

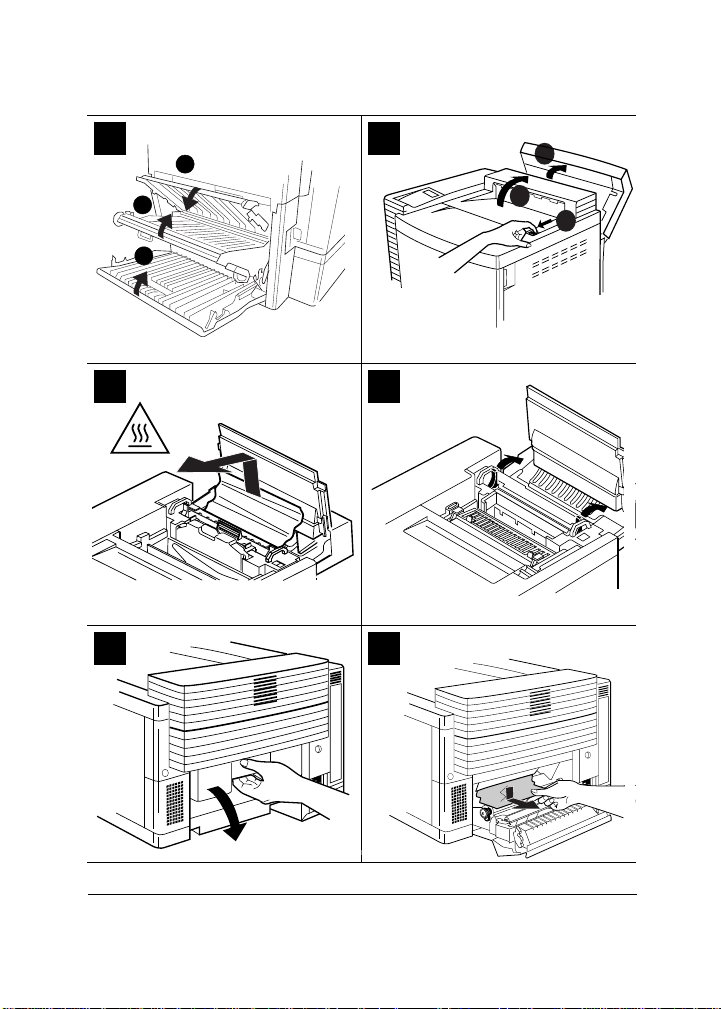

Replacing a Toner Cartridge

1 2

3

5

4

b

a

6

K

Y

M

C

7

10

Replacing the OPC Belt Cartridge

4

1

1

2b

2a

2

ð

3

5

6

a

b

007mati.eps

a

11

7

8

12

9

c

c

b

b

a

a

Replacing the Waste Toner Bottle

1 2

3 4

a

b

73z.eps

5 6

13

Replacing the Fuser Oil Bottle/Cleaning Roller

1 2

1

2b

2a

3 4

5 6

14

7

8

9 10

11

15

12

b

b

a

a

Replacing the Ozone Filter

b

a

1

2

a

b

Cleaning Schedule

a

a

This item needs thorough

cleaning...

„ Printer exterior As needed

„ Duplex unit paper guides

or rollers

„ Laser lens

„ OPC corona wire

„ Paper exit rollers

„ Printer interior

„ Transfer unit (transfer roller,

registration rollers, paper

discharger/wire)

16

After...

Every 30,000 single-sided pages,

every 12 months, or as needed,

whichever comes earlier

Cleaning

Use Avoid

A soft

control panel

A soft

the printer

Mild neutral detergent to clean

the printer

cloth to clean the

dry

cloth to clean

damp

Printer Exterior

MESSAGE

Sharp or rough implements

(such as wire or plastic cleaning

pads); any liquid

Sharp or rough implements (such

as wire or plastic cleaning pads)

Abrasive or corrosive solutions

that contain solvents (such as

alcohol or benzine); aerosol or

pump-sprayed cleaners

17

Cleaning the Transfer Unit

1 2

3 4

18

5 6

7 8

19

Cleaning the Laser Lens

1

3 4

a

b

5 6

2

4X

4X

20

Cleaning the OPC Corona Wire

1

1

2b

2a

3 4

5

2

ð

21

6

7

22

8

b

b

a

a

c

c

Cleaning the Paper Exit Rollers

1 2

3

5 6

23

4

b

b

a

a

Loading...

Loading...