Page 1

Quick Guide

Before Getting Started

1

Let's Make Prints

2

Installing Software

3

Basic Operations

4

Maintaining the Finishing Quality

5

Troubleshooting

6

Fiery Color Server

Appendix

7

Page 2

Welcome

W

G

Thi

.

CAUTIO

T

dli

o

g

.

N

D

[ ]

Th

comp

old

Thi

Thank you for purchasing this machine.

This Quick Guide describes basic operations, maintenance, troubleshooting for this machine.

This information will be useful to enable the full capabilities of this machine and to utilize such

functionality efficiently.

Notations and symbols used in this manual

ARNIN

s symbol indicates that negligence of the instructions may lead to death or serious injury

N

his symbol indicates that negligence of the instructions may lead to mishan

r property damage.

NOTICE

This symbol indicates a risk that may result in damage to this machine or originals.

Follow the instructions to avoid property dama

e.

Tips

This symbol indicates information that complements the topic or optional devices required to use a certain function.

Reference

This symbol indicates a function or functions that are related to the topic

The meaning of other notations and symbols are as follows.

ng that may cause injury

otation/Symbol

B

escription

ese brackets indicate the name of a key on the touch panel or of a button on a

uter screen.

Words in bold type indicate the name of a key on the control panel

ption, or of User's Guide.

s check mark indicates a prere

uisite of a procedural step.

of a part, of an

Page 3

bizhub PRESS C1100/C1085

Configuration and Usage of this Guide

There are two types of User's Guides for this machine: booklet manuals and User's Guide CD.

When you want to learn about detailed functions or operation procedures, refer to the HTML User's Guide included

in the User's Guide CD.

For information about how to use the HTML User's Guide, refer to Section 7.1 "Good Use of the HTML User's Guide"

in this guide.

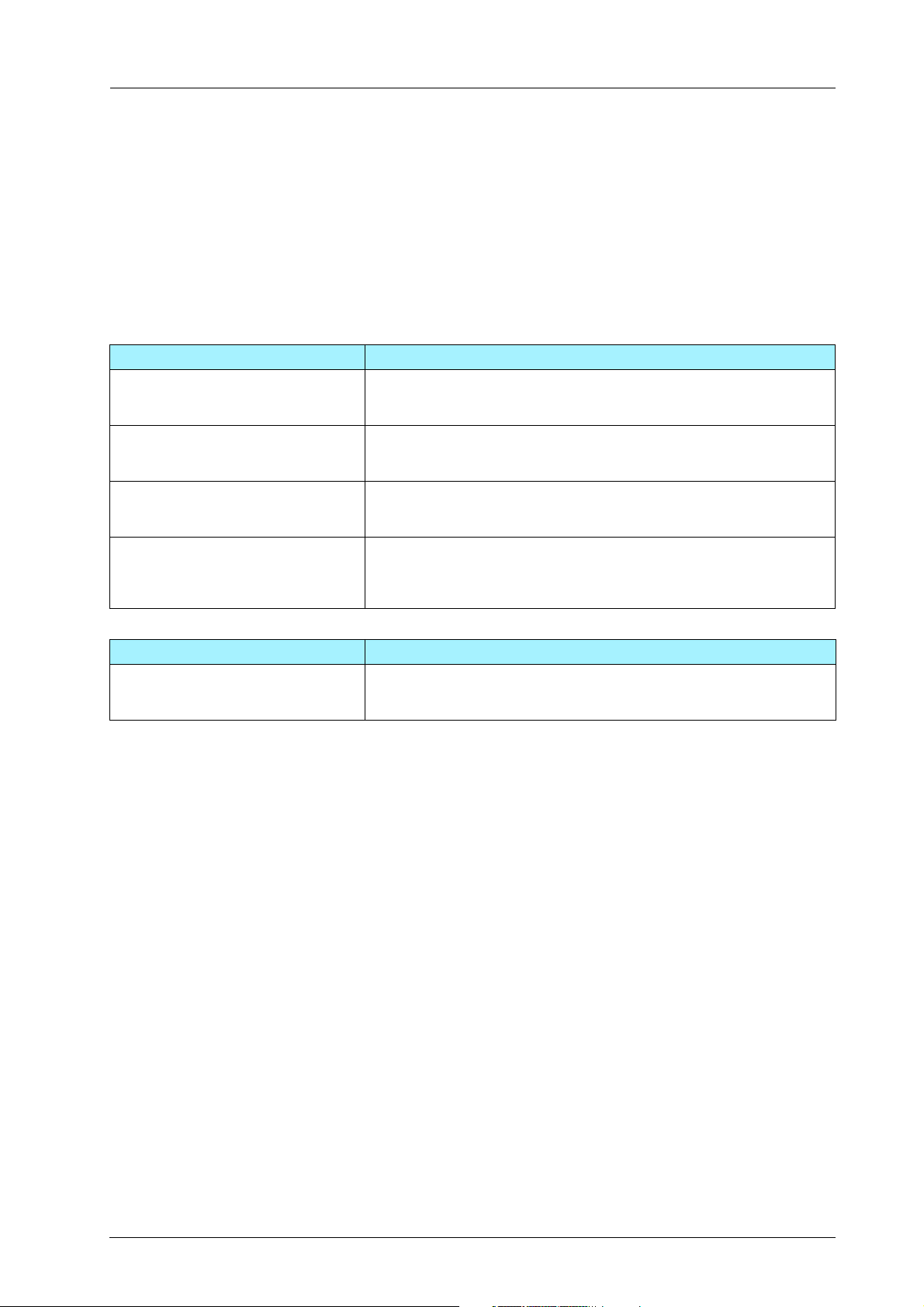

Title of booklet manual Overview

Quick Guide IC-602 This guide describes basic operations of this machine, how to install the

printer driver and applications required to use the Image Controller IC602, and how to replace consumables.

Quick Guide Fiery Color Server (This

guide)

Safety Information This guide provides precautions and requests that should be followed to

User's Guide - Security This guide describes the security functions.

This guide describes basic operations of this machine, how to install the

printer driver and applications required to use the Image Controller IC-

310 or Image Controller IC-308, and how to replace consumables.

ensure safe usage of this machine.

Be sure to read this guide before using the machine.

This guide is available when you want to know how to use the Enhanced

Security mode or how to operate this machine when using the Enhanced

Security function.

Title of manual in User's Guide CD Overview

HTML User's Guide This guide describes basic operations, functions that enable more con-

venient operations, how to carry out maintenance, simple troubleshooting, and various settings of this machine.

For details about the main body of the Fiery Color Server, the related printer drivers, and applications, refer to the

User's Guide supplied with the Fiery Color Server.

Note that a basic technical knowledge about the product is required to enable users to perform maintenance work or

troubleshooting operations. Maintenance and troubleshooting operations should be carried out as instructed in this

guide, the HTML User's Guide included in the User's Guide CD supplied with this machine, or the User's Guide

supplied with the Fiery Color Server.

Should you experience any problems, contact your service representative.

x-i

Page 4

Configuration and Usage of this Guide

Tips

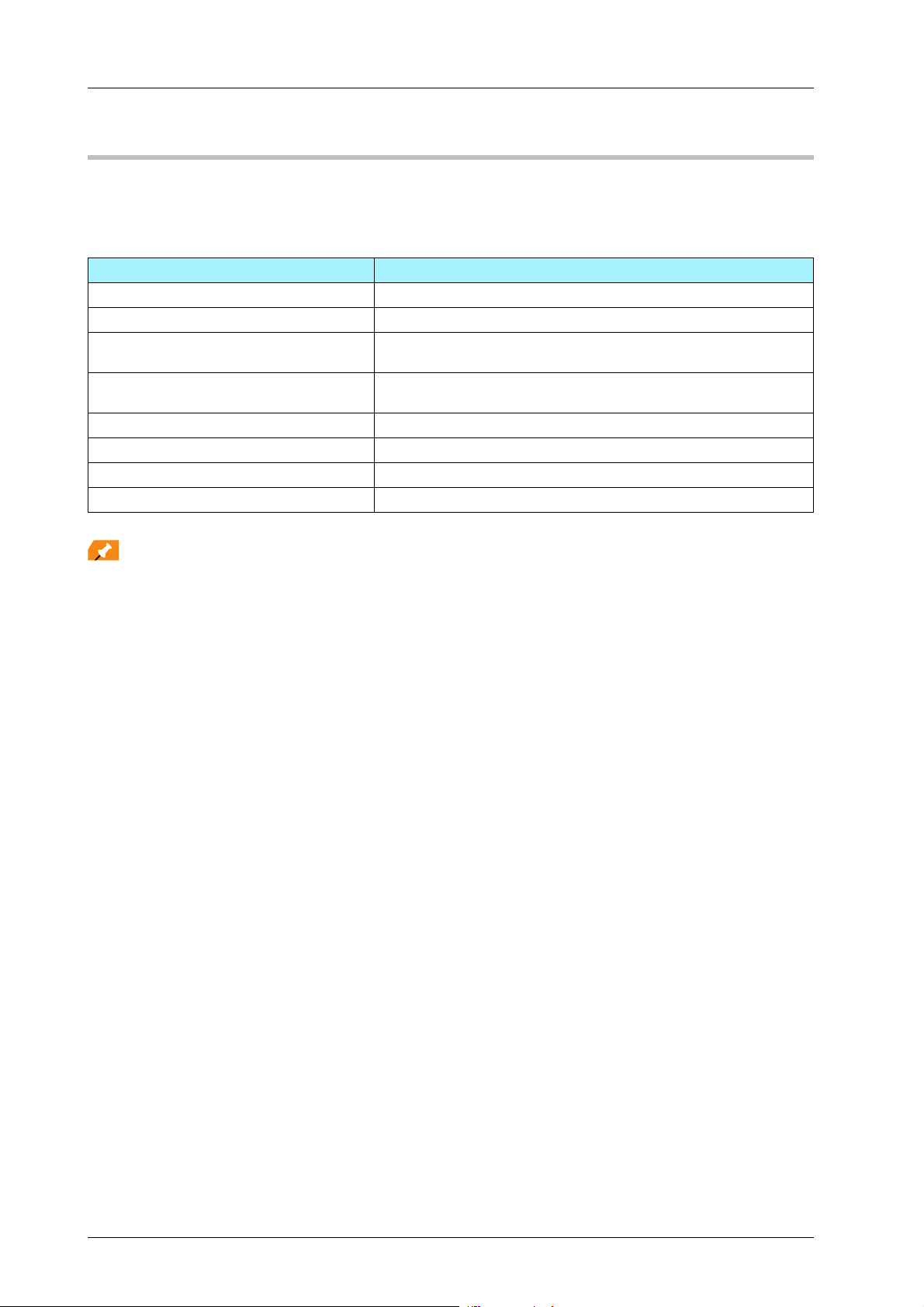

HTML User's Guide operating environment

)Supported Operating Systems/Browsers

This guide describes the operation verification in the operating systems and browsers shown below.

Operating system Web browser

Microsoft Windows XP (Service Pack 3) Internet Explorer 8.x

Windows Vista (Service Pack 2) Internet Explorer 9.x

Windows 7 (Service Pack 1) Internet Explorer 9.x

Firefox 26.x

Windows 8 Internet Explorer 10.x

Firefox 26.x

Mac OS X 10.5 Safari 4.x

Mac OS X 10.6 Safari 5.x

Mac OS X 10.7 Safari 5.x

Mac OS X 10.8 Safari 6.x

- Check that [JavaScript] of your Web browser is enabled. The HTML User's Guide uses [JavaScript] for the page

display or search function.

- Note that some of the functions may not work normally depending on your system environment. Please be

forewarned.

- Problems may be able to be solved by using the latest Web browser.

)Display resolution

1024 e 768 pixels or more

x-ii

Page 5

bizhub PRESS C1100/C1085

NOTICE

How to display the top page of the HTML User's Guide

)In a Windows environment

In Windows XP, when the User's Guide CD is inserted into the CD-ROM drive of your computer, the Web browser

starts up automatically, and the top page is displayed.

In Windows Vista/7/8, when the User's Guide CD is inserted into the CD-ROM drive of your computer, an auto play

message is displayed. If you click [rundll32.exe], the top page is displayed.

If the top page is not displayed, open [My Computer] or [Computer], right-click the [Users_Guide_CD] icon, then click

[Open]. Double-click [index.html] in the folder to open the top page.

In Windows Vista or Windows 7, [Computer] is displayed on the desktop or on the [Start] menu. In Windows 8, rightclick in the Start window and click [All apps] to display it in the list.

)In a Macintosh environment

Open the CD icon on the desktop, then double-click [index.html] to display the top page.

NOTICE

In Mac OS X 10.7 or later, the CD icon may not be displayed on the desktop even when the User's Guide CD is

inserted into the drive. In this case, the mount setting may be disabled. Check whether or not the mount setting is

disabled in "Preferences" of Finder.

Conventions used in this guide

This guide describes product names and system configurations as follows.

Product name Conventions used in this guide

bizhub PRESS C1100/C1085 This machine: Indicates the entire system including options and

functions.

The main body: Indicates a main unit that covers printing functions.

The machine: Indicates a mechanical part related to the structure or

mechanism.

Microsoft Windows Windows

Optional products are described with no model number added as follows unless otherwise specified.

Product name Conventions used in this guide

Image Controller IC-602

Image Controller IC-310

Image Controller IC-308

Finisher FS-532 Finisher

Saddle Stitcher SD-506

Saddle Stitcher SD-510

The convention above is also applied to other optional devices.

Image Controller

Saddle Stitcher

x-iii

Page 6

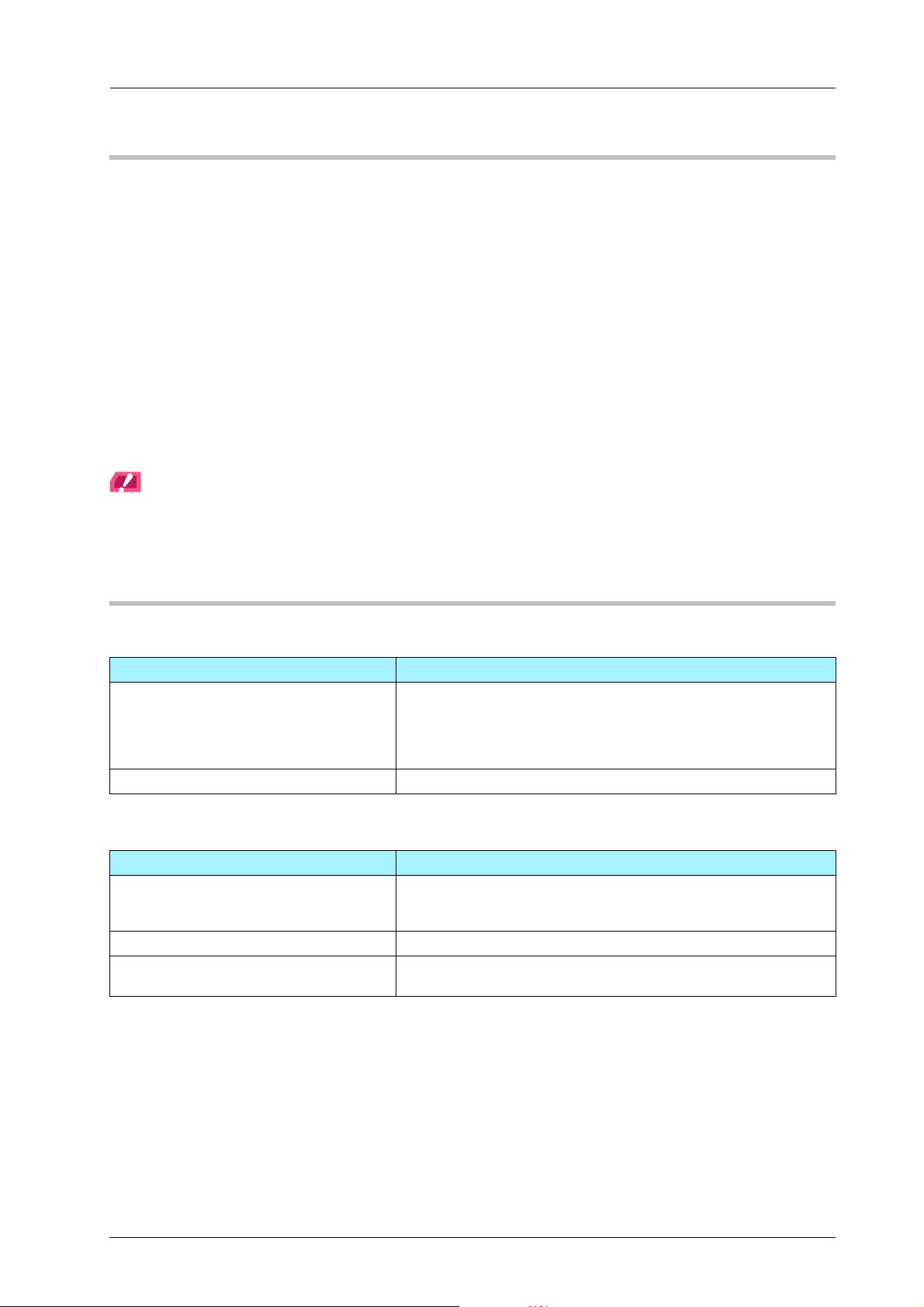

Make a Note about This Machine Information

Make a Note about This Machine Information

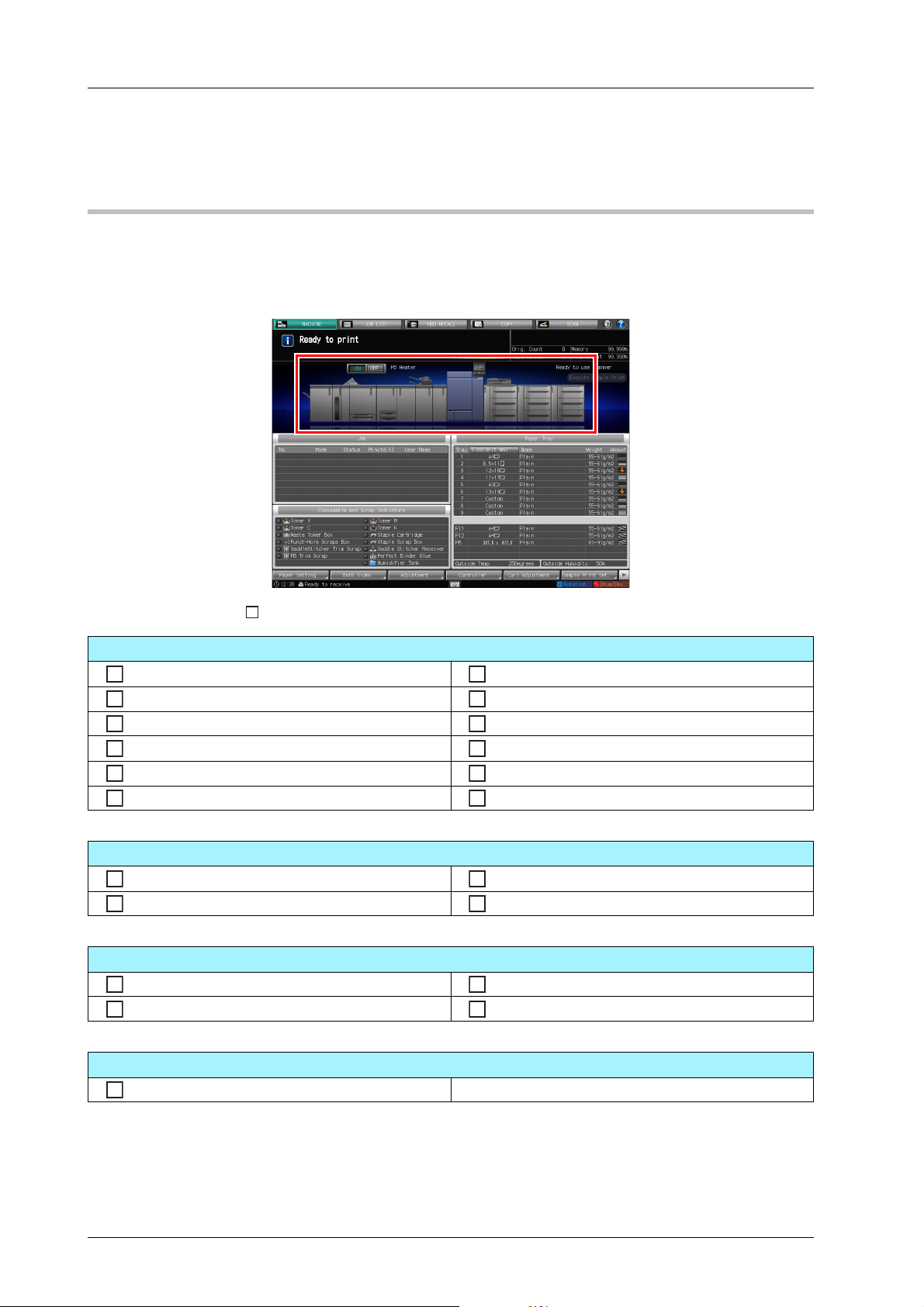

Checking the mounted optional devices

Get to know the optional devices mounted on this machine.

You can check a part of the mounted optional devices on the [MACHINE] screen of the touch panel.

Select the check boxes ( ) of the installed optional devices; this is convenient to manage optional devices.

Output-related optional devices

Finisher FS-532 Folding Unit FD-503

Perfect Binder PB-503 Punch Kit PK-522

Saddle Stitcher SD-506 Multi Puncher GP-501

Saddle Stitcher SD-510 Auto Ring Binder GP-502

Large Capacity Stacker Handcart LC-501 Relay Unit RU-510

Large Capacity Stacker LS-506 Relay Unit RU-511

Feeding-related optional devices

Paper Feeder Unit PF-707 Feed Adjuster FA-502

Paper Feeder Unit PF-708 Post Inserter PI-502

Electronic optional devices

Image Controller IC-602 Image Controller IC-310

Image Controller IC-308 Authentication Unit AU-201

Original-related optional device

Working Table WT-512

The available optional devices vary depending on your model.

x-iv

Page 7

bizhub PRESS C1100/C1085

Tips

NOTICE

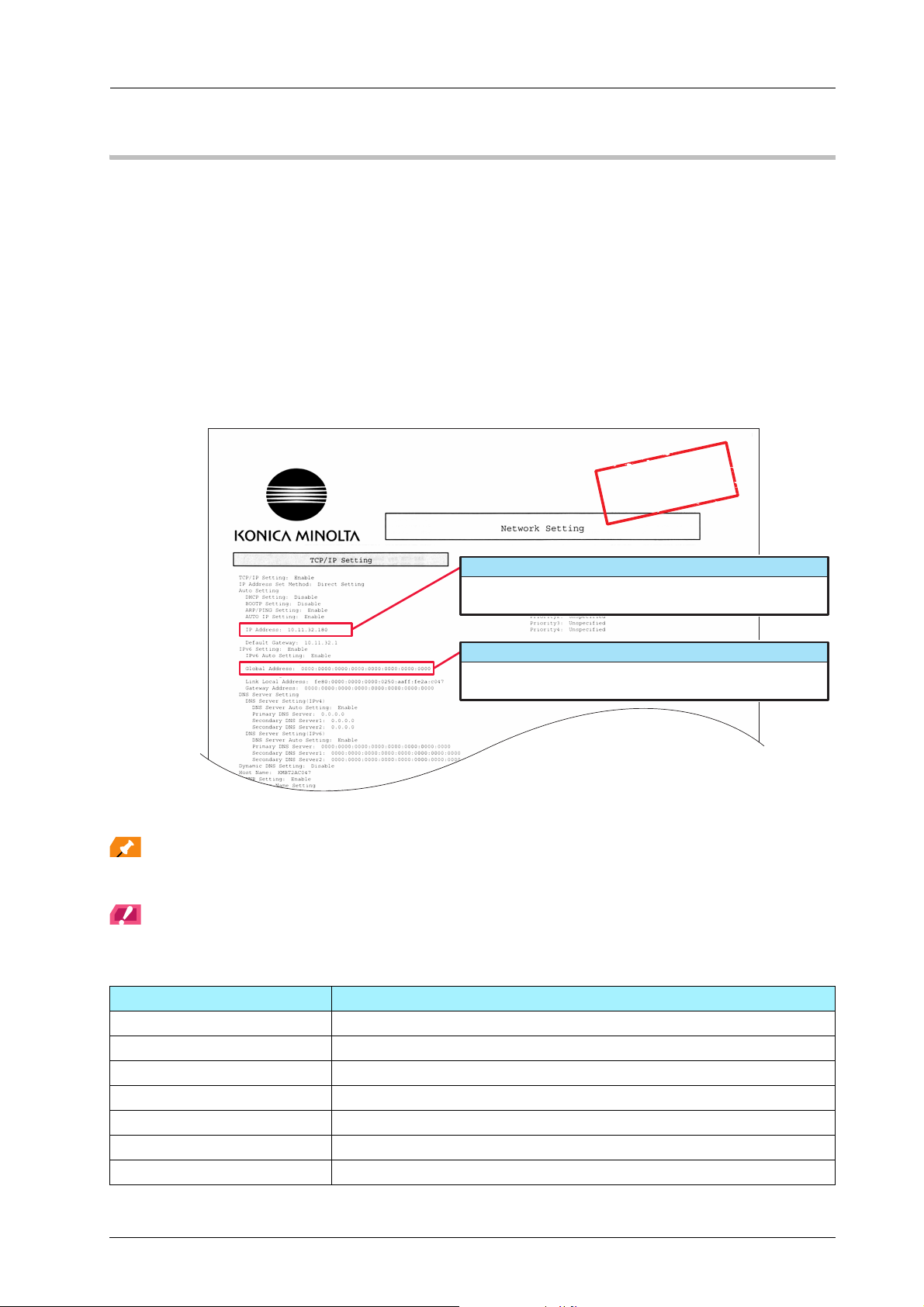

IP address (IPv4 address) entry field

Global address (IPv6 address) entry field

Checking network information

Make a note about network information required to use functions of this machine such as printer functions and various

applications.

To check network information, print out the Configuration Page Print.

)Printing out the Configuration Page Print

A From the [MACHINE] screen on the touch panel, select [Controller] - [Tools] tab -

[Configuration], then press [Yes].

Note down the IP address printed on the Configuration Page Print in the entry field according to your

environment.

Sample

- If necessary, note down other network information in the following table.

- To check network information, the administrator privilege may be required. Contact your machine administrator.

NOTICE

Some notes may include confidential information. Handle this guide with great care.

In particular, do not enter information such as the password.

Item Entry field

Example: JSP port number Example: 30081

x-v

Page 8

Contents

Contents

Configuration and Usage of this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-i

HTML User's Guide operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-ii

Supported Operating Systems/Browsers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-ii

Display resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-ii

How to display the top page of the HTML User's Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iii

In a Windows environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iii

In a Macintosh environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iii

Conventions used in this guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iii

Make a Note about This Machine Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iv

Checking the mounted optional devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-iv

Checking network information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-v

Printing out the Configuration Page Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-v

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x-vi

1 Before Getting Started

1.1 Turning the Power ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Available Operations in this Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Turning the power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Turning the power off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Power saving function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Major functions of this machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Print functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Copy functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Scan functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hold function of print jobs using the HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Device control function (WebTools) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Application functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Fiery Command WorkStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Printer Delete Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Fiery Remote Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Fiery Hot Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2 Let's Make Prints

2.1 Printing Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Step 1: Prepare the printer driver and applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Step 2: Load paper into a tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Step 3: Configure information of the paper loaded into a tray in this machine . . . . . . . . . . . 2-2

Step 4: Use the printer driver to print data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Step 5: Check the finishing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3 Installing Software

3.1 Installing the Printer Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

In a Windows environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

In a Macintosh environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Characteristics of printer driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

In a Windows environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Default setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

In a Macintosh environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Default setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

x-vi

Page 9

bizhub PRESS C1100/C1085

3.2 Installing Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Fiery Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Fiery Utility setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Function overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

In a Windows environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

In a Macintosh environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Starting applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Starting Fiery Command WorkStation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Starting Fiery Remote Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Starting Fiery Hot Folders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4 Basic Operations

4.1 Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Loading paper into the Paper Feeder Unit PF-708. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Loading Paper in Post Inserter of Folding Unit FD-503 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Paper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Specifying paper information for a tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Printer Driver Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Printer driver functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

[Color Mode]: Select an output color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

[Color Mode]: General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

[Color Mode]: Expert Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5 Maintaining the Finishing Quality

5.1 Both Sides Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Both Sides Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Adjustment flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Making the Both Sides Adjustment for each tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chart Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Zoom and Image Shift Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.2 Image Quality Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Image Quality adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Daily image quality management (Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Calibration timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Executing calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Color Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Auto setting of Color Density Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Manual setting of Color Density Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Executing calibration using the image controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Specifying the reference image quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Particular adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.3 Adjusting the Finisher and Saddle Stitcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Opening the screen to be adjusted. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Adjustable settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

6 Troubleshooting

6.1 Replenish and Replace Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Replacing a toner bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Replacing a staple cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Replacing a waste toner box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

x-vii

Page 10

Contents

6.2 Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

How to view the animation guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

[JAM Position] screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Illustration screen for Jam handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3 If the Specified Paper is not Found . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4 If an Error has been Displayed during Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

HDD space insufficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.5 Hue Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

When calibration is executed for daily management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

When calibration is not executed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.6 Image Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

7Appendix

7.1 Good Use of the HTML User's Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(1) Let's master the search function! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(2) Confirm the setting required for the target finishing in an operation example! . . . . . . . 7-1

7.2 Name of each Component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

External components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Internal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Control Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.3 Convenient Use of Scan Function (Scan to SMB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Step 1: Prepare the destination computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

In a Windows environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

In a Macintosh environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Step 2: Connect this machine to the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Step 3: Prepare the operating environment for SMB transmission . . . . . . . . . . . . . . . . . . . 7-10

Step 4: Configure settings according to your environment . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Step 5: Send scan data to a public folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.4 Major Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Feeding-related optional devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Paper Feeder Unit PF-707 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Paper Feeder Unit PF-708 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Post Inserter (Folding Unit FD-503) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Post Inserter PI-502 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Output-related optional devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Relay Unit RU-511 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Relay Unit RU-510 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Folding Unit FD-503 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Large Capacity Stacker LS-506 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Saddle Stitcher SD-506 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Perfect Binder PB-503 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Finisher FS-532 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Multi Puncher GP-501 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Auto Ring Binder GP-502. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Electronic optional devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Image Controller IC-602. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Image Controller IC-308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Image Controller IC-310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Authentication Unit AU-201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Original-related optional devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Reverse Automatic Document Feeder (ADF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.5 Weight for each size and copying speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Weight for each size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.6 Maximum paper size and printing area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

x-viii

Page 11

bizhub PRESS C1100/C1085

NOTICE

OFF ON

ONOFF

1 Before Getting Started

1.1 Turning the Power ON/OFF

)Power supply

This machine has two power switches: main power switch and sub power switch.

NOTICE

The main power switch is normally kept turned on.

The main power switch must be turned on or off only when you start this machine for the first time or when you restart

this machine.

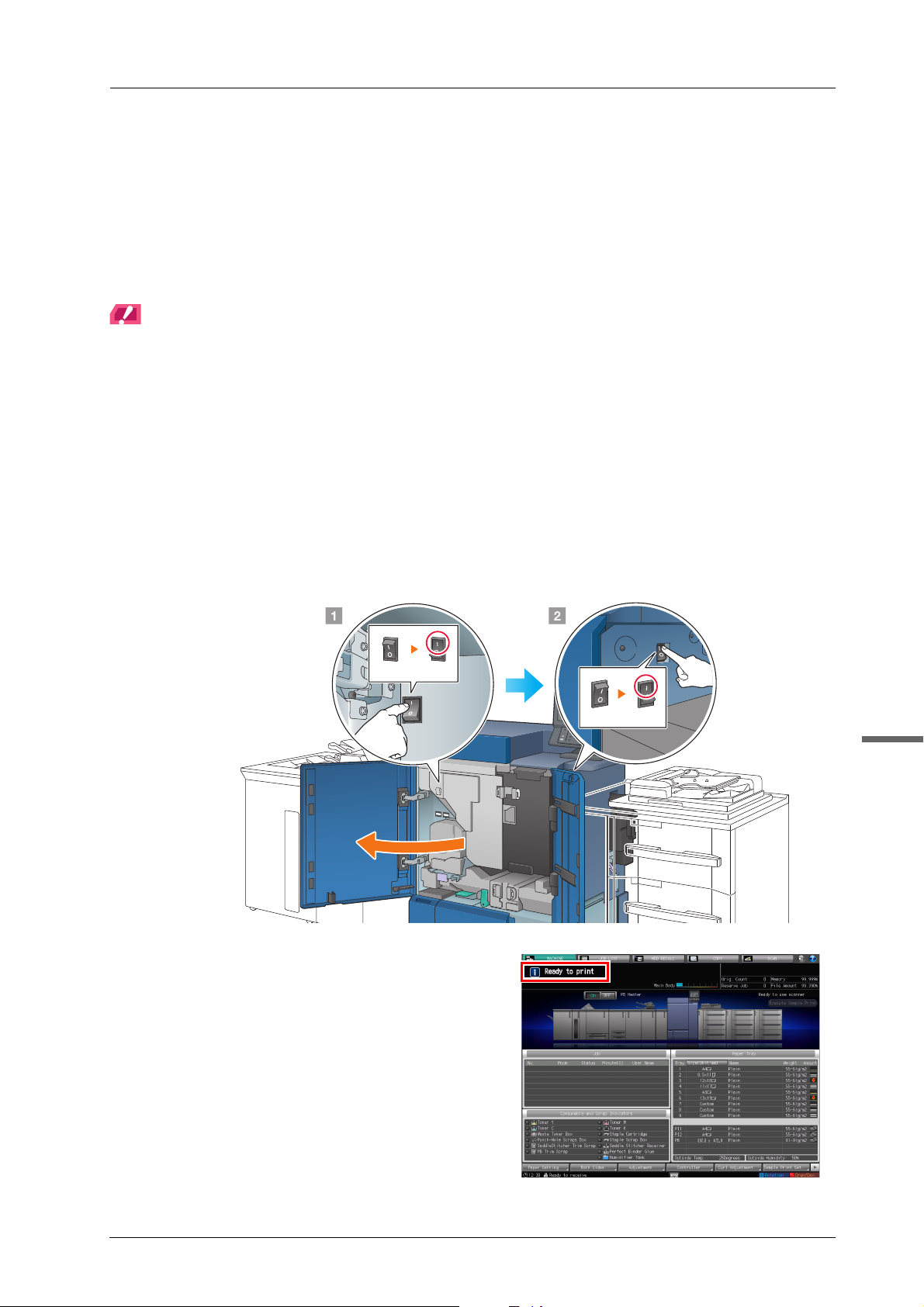

)Turning the power on

A Open the right side door and left side door of the main body, then turn the main

power switch on.

When the main power switch is turned on, the Power LED on the control panel lights up red.

B Turn on the sub power switch on the right-hand side of the main body.

When the sub power switch is turned on, the Power LED on the control panel lights up in green.

After the start screen has been displayed, the

default screen is displayed.

The default screen can be selected from

Utility/Counter. For details, refer to the HTML

User's Guide.

When [Ready to print] is displayed on the

[MACHINE] screen, you can use this machine.

1

1-1

Page 12

1.1 Turning the Power ON/OFF

NOTICE

Tips

ON

OFF

C Turn the power switch on the rear side on ( ), then

press the power button on the front side ( ).

NOTICE

After this machine has completely started, turn the image controller on.

If [Machine is warming up] is displayed on the [MACHINE] screen, it indicates that this machine is in the warm-up state.

Warm-up processing takes approximately eight minutes.

1-2

Page 13

)Turning the power off

NOTICE

NOTICE

ON OFF

ON OFF

A Turn off the sub power switch.

The touch panel display is cleared, and the Power LED on the

control panel is changed from green to red.

NOTICE

While the following message is displayed, do not turn off the main

power switch. Otherwise, a problem such as a toner fixation in the

machine may occur.

[Cooling in progress / Power is turned off automatically]

[Power off in progress / Please do not turn the main power switch off]

B Turn off the main power switch.

NOTICE

When turning the main power switch off then on, b e sur e to w ait f or 10

seconds or longer before turning the main power switch on a gai n. I f th e

main power switch is turned on again within 10 seconds, the machine

may not function normally.

bizhub PRESS C1100/C1085

1

1-3

Page 14

1.1 Turning the Power ON/OFF

NOTICE

Tips

ON

OFF

C Press the Menu button on the control panel ( ),

press row selection button 4, then select [Shut Down

System] ( ).

NOTICE

After this machine has exited completely, turn the Image Controller IC310 or Image Controller IC-308 system off.

D When the system has quit, turn the power switch on the rear side off ( ).

The Image Controller IC-310 or Image Controller IC-308 can reset Fiery software or restart the entire system as

necessary.

- To reset only the Fiery software, press the Menu button on the control panel, then use the row selection button

to select [Restart Server] - [Restart Server] in sequence. In this case, do not reboot the Windows operating

system.

- To reboot the entire system including the Windows operating system, press the Menu button on the control

panel, then use the row selection button to select [Restart Server] - [Reboot System] in sequence.

- You can set the Image Controller IC-308 to turn on or off at the same time when the power of the main body is

turned on or off. For details, refer to the User's Guide supplied with the Fiery Color Server.

1-4

Page 15

bizhub PRESS C1100/C1085

Tips

Reference

NOTICE

)Power saving function

Using the following functions can reduce the power consumption of this machine and provide greater power saving

effects.

Function Description

Power Save function

ErP Setting Turns the main power off after the Auto Low Power mode, Auto Shut

Weekly Timer Automatically turns the power of this machine on or off based on the

Auto Low Power Turns off the touch panel display to reduce the power consumption

of this machine. This machine is placed into the Auto Low Power

mode when:

• The specified period of time has elapsed with no print jobs executed in the printable state

• Power Save on the control panel has been pressed for a second or more

This mode is available when [Auto Low Power] is selected by selecting Utility/Counter - [Administrator Setting] - [System Setting] [Power Save Setting] - [Power Save Function Setting].

There are eight power saving time periods available: 5 min., 10 min.,

15 min., 30 min., 60 min., 90 min., 120 min. and 240 min., from which

you can select the desired one.

Auto Shut OFF Turns off all LEDs except Power Save and Power LED on the con-

trol panel, to reduce the power consumption of this machine. This

machine is placed into the Auto Shut OFF mode when:

• The specified period of time has elapsed with no print jobs executed in the printable state

• Power Save on the control panel has been pressed for a second or more

If the Auto S hut O FF mo de is kept for a long time , it may take a while

to warm up this machine upon restart.

This mode is available when [Auto Shut OFF] is selected by selecting

Utility/Counter - [Administrator Setting] - [System Setting] - [Power

Save Setting] - [Power Save Function Setting].

There are seven power saving time periods available: 0 min., 1 min.,

30 min., 60 min., 90 min., 120 min. and 240 min., from which you can

select the desired one.

OFF mode, or the sub power switch is kept in the off state for the

specified period of time.

There are seven power-saving time periods available: Do Not

Switch, 12 Hours, 24 Hours, 36 Hours, 48 Hours, 60 Hours and 72

Hours, from which you can select the desired one.

If the Weekly Timer is set to [Weekly Timer ON], [ErP Setting] appears dimmed and you will not be able to configure this setting.

specified time or day of the week.

1

- Since Utility/Counter - [Administrator Setting] - [System Setting] - [Power Save Setting] - [Power Save Function

Setting] is the same as Utility/Counter - [User Setting] - [System Setting] - [Power Save Setting] - [Power Save

Function Setting], use either of the methods to configure a setting.

- If Power Save on the control panel is pressed for one second or more, either of Auto Low Power or Auto Shut

OFF is enabled. To enable either function, select [Administrator Setting] - [System Setting] - [Power Save Setting]

- [Power Save Function Setting].

For details about how to configure and use the above functions, refer to the HTML User's Guide.

NOTICE

In the Auto Shut OFF mode, only jobs from [PageScope Direct Print (PSDP)] can be printed out. To use other jobs,

check that this machine can be used normally.

If this machine is turned off because the Weekly Timer has started, job data is not received even if it is sent. While this

machine can be used normally, send job data again.

1-5

Page 16

1.2 Available Operations in this Machine

1.2 Available Operations in this Machine

Major functions of this machine

)Print functions

This machine can be used as a printing system by installing an optional Image Controller.

You can print data on this machine via the printer driver using the application software installed on your computer.

You can configure a layout or finish setting by implementing a simple action when printing data.

)Copy functions

If an optional Paper Feeder Unit PF-708 is mounted, you can specify copy conditions such as the original scan

setting, paper size, or the finish setting to copy data.

1-6

Page 17

bizhub PRESS C1100/C1085

)Scan functions

If an optional Paper Feeder Unit PF-708 and Image Controller are mounted, you can send the scan data as an email attachment, or send it to the shared computer (SMB server) or FTP server.

In addition, you can give a scan instruction from a computer on the network to import the scan data to your computer.

)Hold function of print jobs using the HDD

You can temporarily save an executed print or copy job to reprint it from the job list or save it on the HDD of this

machine.

)Device control function (WebTools)

WebTools is a device control utility program provided by the HTTP server built in to the image controller.

You can access an image controller via the network using the Web browser of the computer to check the status of this

machine or configure various settings from WebTools.

1

1-7

Page 18

1.2 Available Operations in this Machine

Application functions

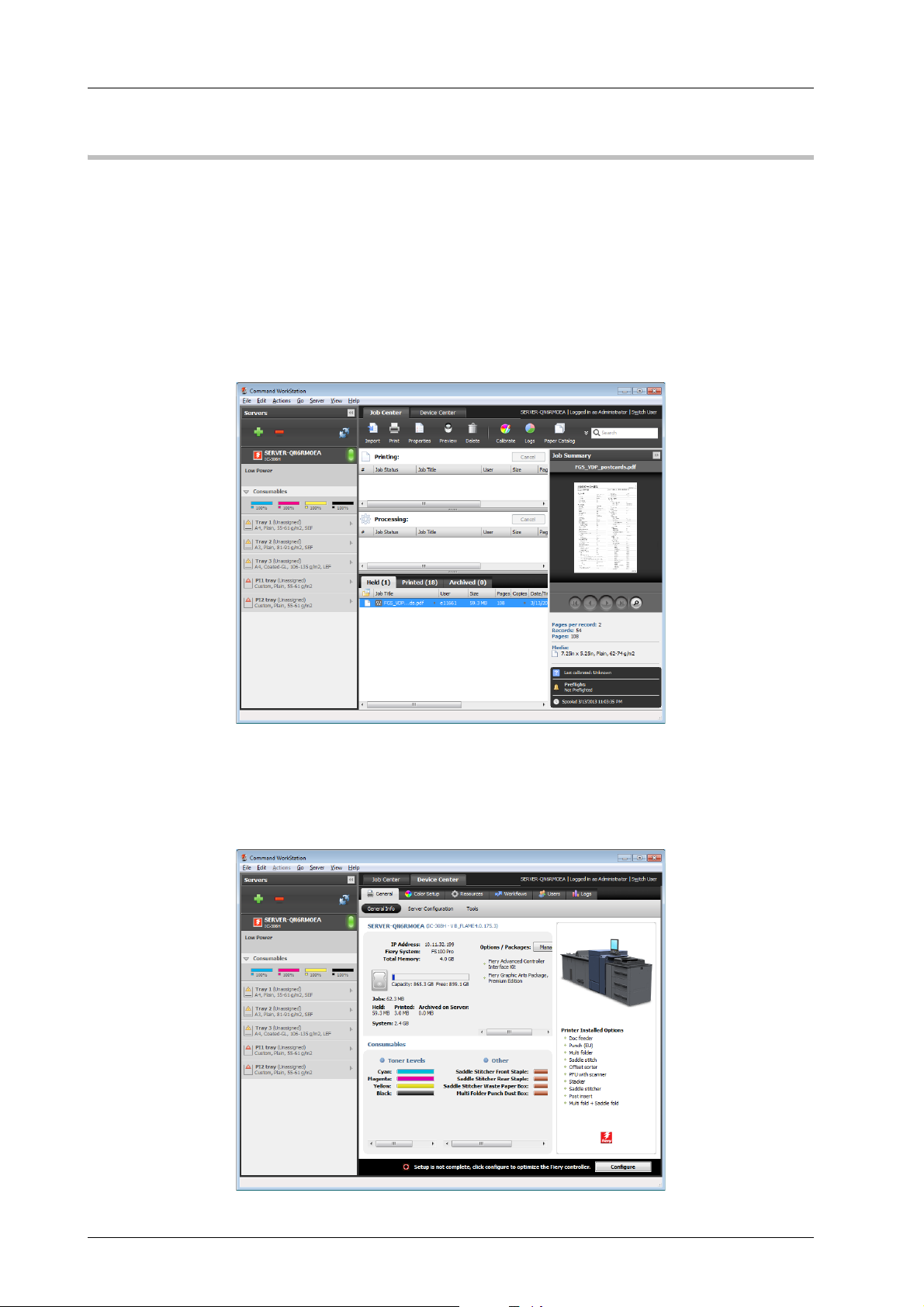

)Fiery Command WorkStation

Fiery Command WorkStation is an application that manages jobs and image controller via the network.

Job management function

The [Job Center] tab provides the functions for job operator. You can check the job status that is being processed by

the controller or that is being printed, and check an overview of the processed job. You can also search or print a job,

calibrate the controller for stable color reproduction, or check the log data.

Device control function

The [Device Center] tab provides the functions for the administrator. You can check or set the settings of the image

controller, set up the color, adjust the tray, define the paper or view the job log.

1-8

Page 19

bizhub PRESS C1100/C1085

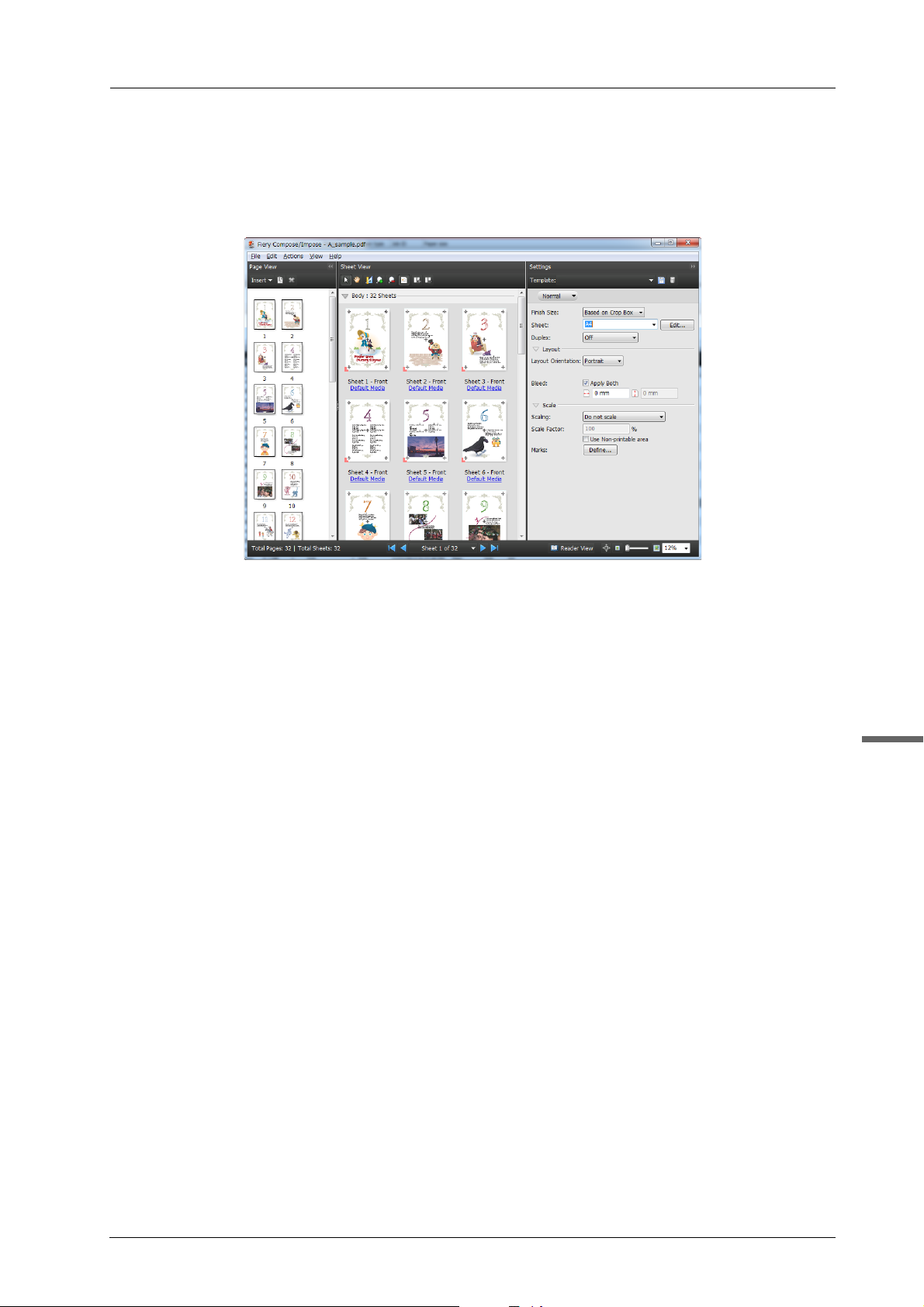

Imposition function

Using Fiery Impose (option), you can impose each page on Fiery Command WorkStation.

)Printer Delete Utility

Printer Delete Utility is an application that is used to completely delete the Fiery printer driver from the computer. For

details about how to use this application, refer to the User's Guide supplied with the Fiery Color Server.

)Fiery Remote Scan

Fiery Remote Scan is an application that is used to perform remote scanning, to import a file from the E-mail box and

save it on the computer, or to import scanned data into the application to edit it. For details about how to use this

application, refer to the User's Guide supplied with the Fiery Color Server.

)Fiery Hot Folders

Fiery Hot Folders is an application that is used to set attributes to any folder on the computer and automatically send

data that has been dragged and dropped in the folder to the image controller. For details about how to use this

application, refer to the User's Guide supplied with the Fiery Color Server.

1

1-9

Page 20

2.1 Printing Flow

Reference

Tips

2 Let's Make Prints

This chapter describes a basic print workflow using this machine.

First confirm the basic flow to print data, then add detailed settings and adjustment to meet your requirements.

For information about application settings of this machine and adjustment procedures, refer to the HTML User's

Guide.

2.1 Printing Flow

First check that your original data is printed in the following flow.

The detailed operations or setting procedures are described in the reference page for each step.

The User's Guide CD supplied with this machine includes a sample PDF file for printing. This file is helpful if you have

no original data.

Step 1: Prepare the printer driver and applications

Install the printer driver and applications in your computer.

After installation is completed, configure information of the mounted devices

using the printer driver in order to use optional functions.

For details, refer to the following pages.

- To install the printer driver: Refer to page 3-1.

- To install applications: Refer to page 3-11.

Step 2: Load paper into a tray

Load paper into the paper tray.

For details, refer to the following pages.

- To load paper into Paper Feeder Unit: Refer to page 4-1.

- To load paper into another optional device: Refer to page 4-2.

2-1

Page 21

bizhub PRESS C1100/C1085

Step 3: Configure information of the paper loaded into a tray in this machine

Specify the type, size, weight, and other values of paper.

For details, refer to page 4-3.

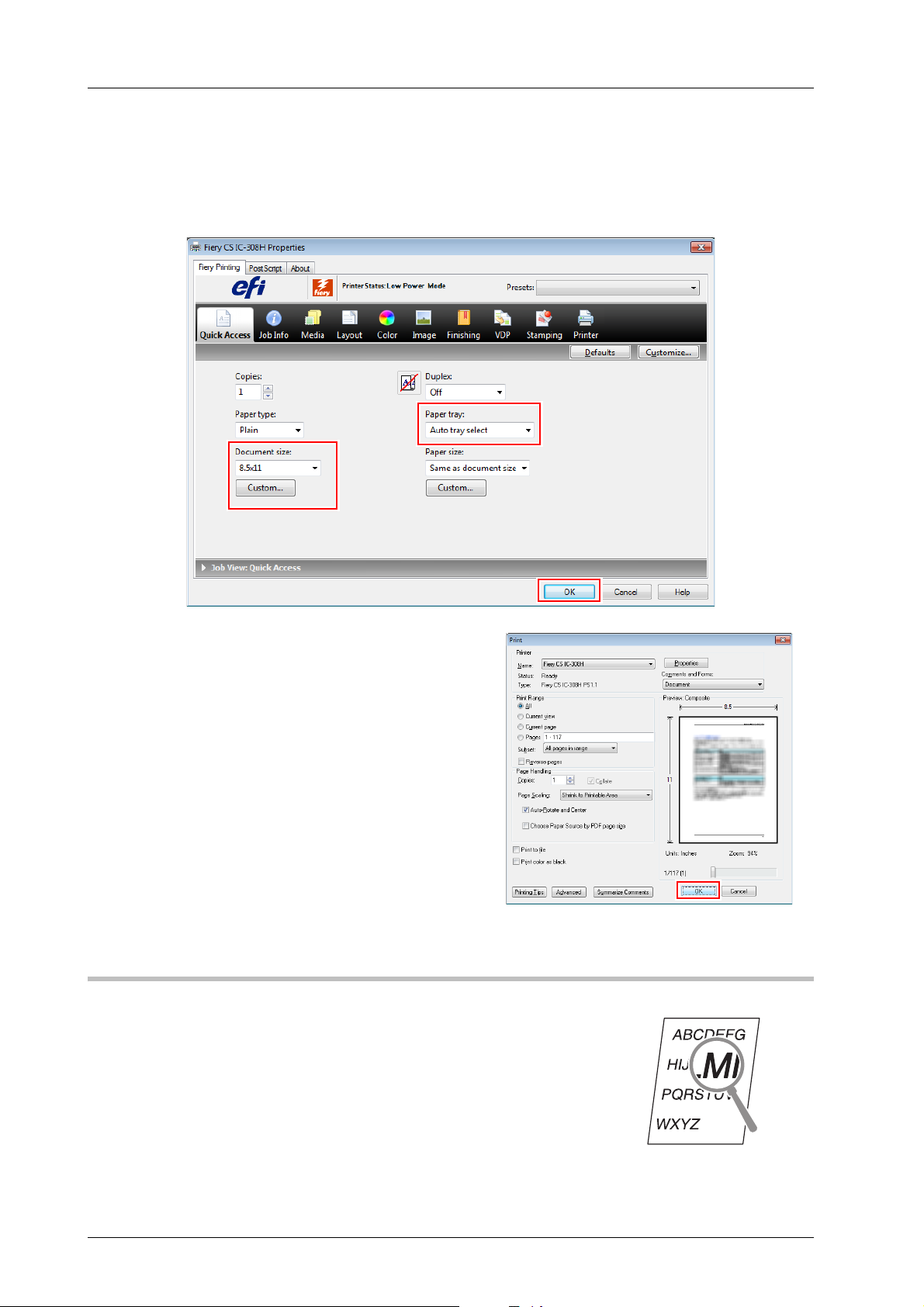

Step 4: Use the printer driver to print data

Print original data through your computer.

0 Check the application environment of original data in advance. This guide shows a procedure example of how

to use Adobe Reader XI in a Windows 7 environment.

A Click [Print] in the file menu of the application software to display the Print window.

B Select the installed printer driver from [Printer Name], then click [Properties].

2

2-2

Page 22

2.1 Printing Flow

C Click the [Quick Access] tab on the setting screen of the printer driver, then select the

paper size of the original data in [Original Size].

Check the setting, then click [OK].

- In [Paper Tray], you can select a tray to load paper to be printed into.

- For information about other functions of the printer driver, refer to page 4-8.

D Click [OK].

Original data is printed, and printed sheets are

output to the Output Tray of this machine.

- You can save print jobs on the HDD of the

controller (Hold job).

If print jobs are saved on the HDD, you can

make prints without reconfiguring settings

the next time you print; which makes simple

reprinting jobs easier.

The items you can configure or adjust vary

depending on where print jobs are saved on

the HDD. For details, refer to the User's

Guide supplied with the Fiery Color Server.

- For information about how to take an action

when data is printed with an incorrect paper

size, refer to page 6-10.

Step 5: Check the finishing

Check the image quality reproducibility, printing position misalignment, fold or

staple position, and other items after printing data.

For information about finishing checkpoints and adjustment procedures, refer to

the HTML User's Guide.

2-3

Page 23

bizhub PRESS C1100/C1085

3 Installing Software

3.1 Installing the Printer Driver

Operating environment

)In a Windows environment

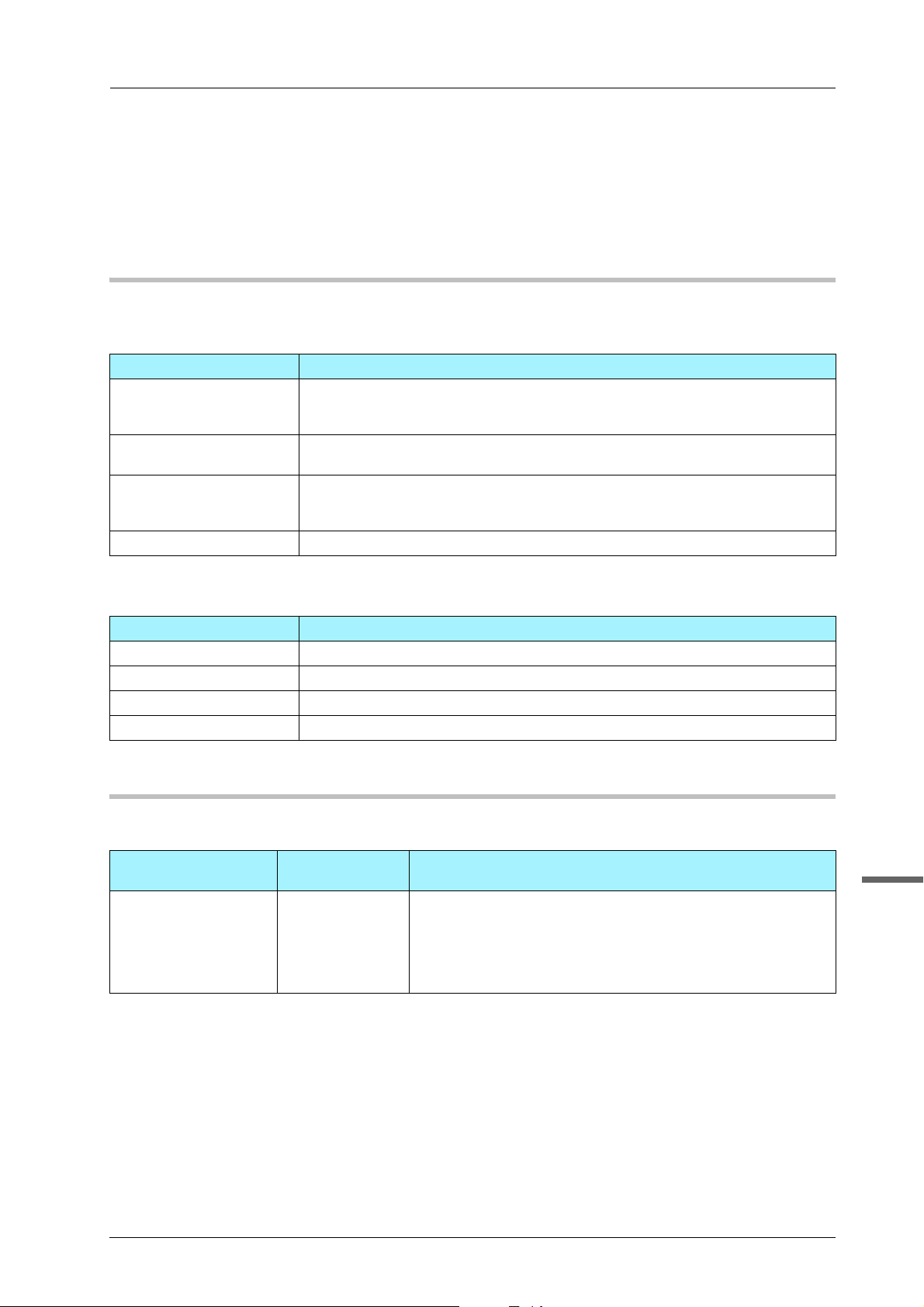

Item Specifications

Operating System Windows XP, Windows Server 2003, Windows Vista (32 bits/64 bits), Windows Serv-

er 2008 (32 bits/64 bits), Windows Server 2008 R2 (64bit), Windows 7 (32 bits/64

bits), Windows 8 (32bit/64bit) , Windows Server 2012

CPU Any processor of the same or higher specifications as recommended for your oper-

ating system

Memory Memory capacity as recommended for your operating system

The memory must have a sufficient free space to support the operating system and

required applications.

Drive DVD drive

)In a Macintosh environment

Item Specifications

Operating System Mac OS 9.x, Mac OS X 10.4 (Japanese and PPD only) /10.5/10.6/10.7/10.8

CPU PowerPC, Intel Processor

Memory Memory capacity as recommended for your operating system

Drive DVD drive

Characteristics of printer driver

There are the following types of printer drivers that can be installed on this machine.

Printer driver Page descrip-

tion language

PostScript 3 driver CPSI3019 Available when exactly printing data that is created using the ap-

The PostScript 3 driver is also compatible with Adobe PDF Print Engine (APPE) 2.5 and PCL interpreter.

Description

plication software compatible with PS such as Adobe.

This driver is commonly used in applications where good color reproducibility is important.

This driver provides various configurable functions compared with

the PostScript PPD driver (PS-PPD).

3

3-1

Page 24

3.1 Installing the Printer Driver

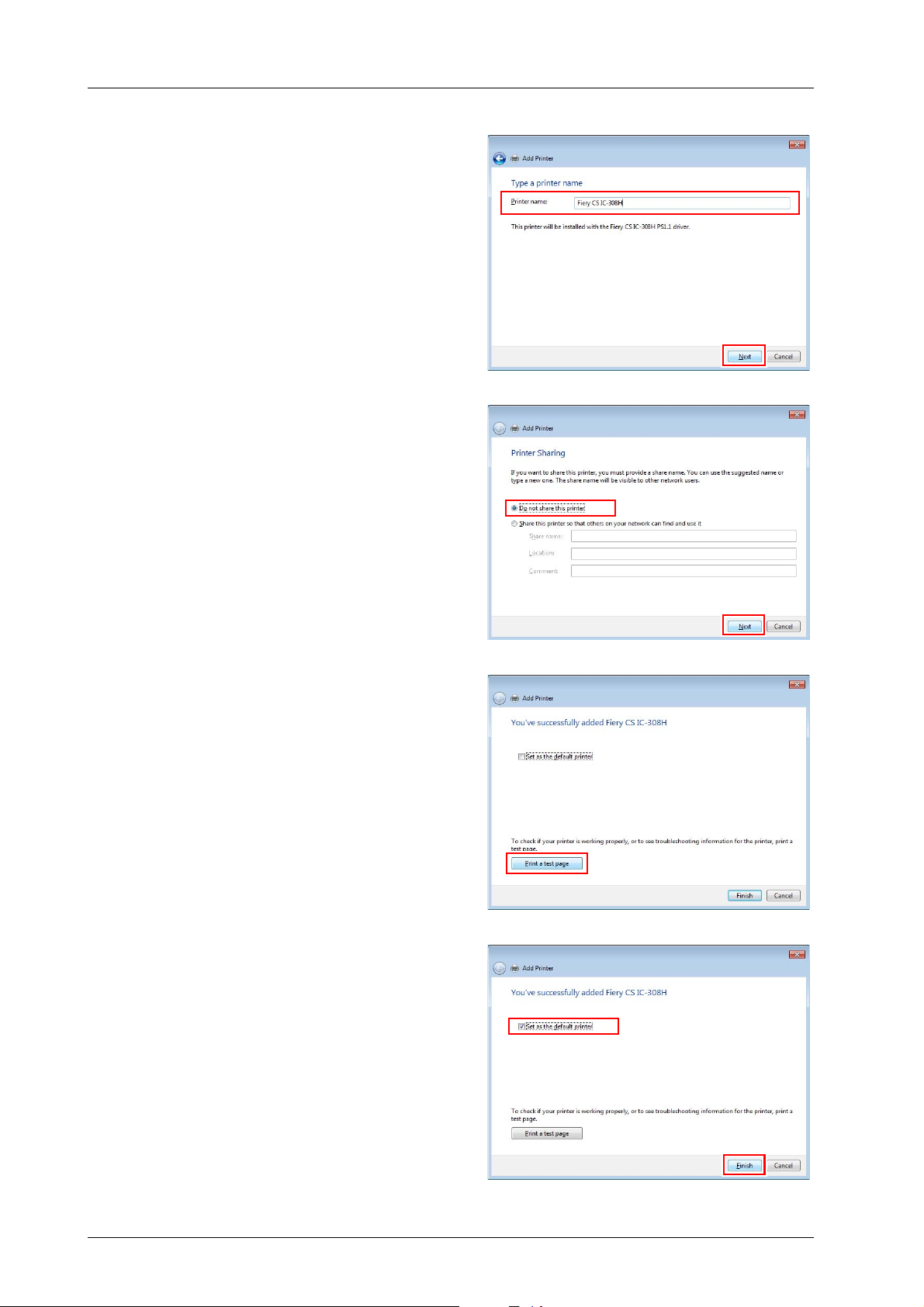

In a Windows environment

)Installation

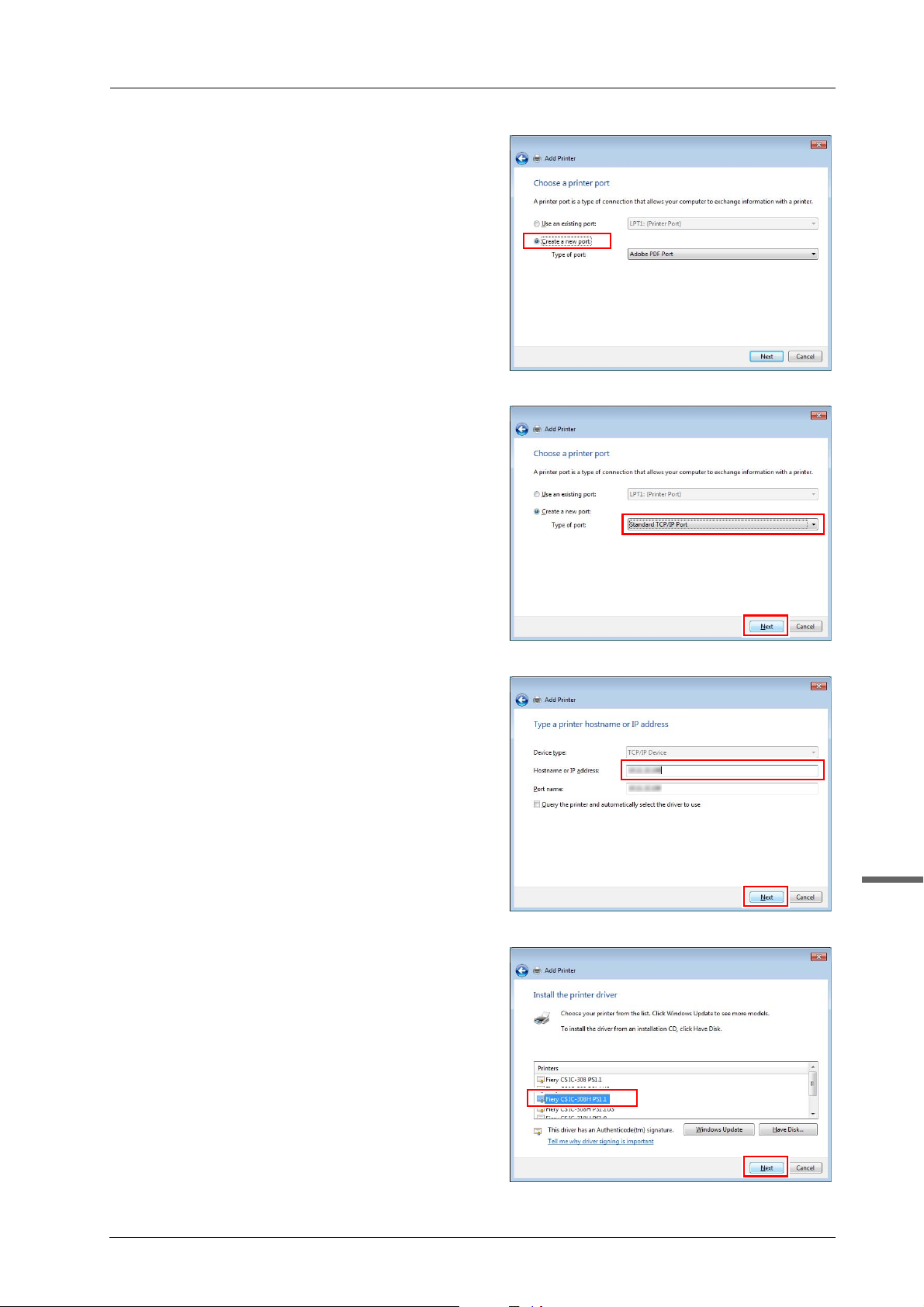

Use the Add Printer Wizard to install the printer driver on your computer.

This guide describes how to install the driver in a Windows 7 environment.

0 A network setting must be configured on this machine before beginning the installation procedure. For details,

refer to the HTML User's Guide.

0 To carry out this task, the computer's administrator privilege is required.

0 You can also install the printer driver using the installer.

A Insert the User Software DVD into the DVD drive of the computer.

B Double-click [setup.exe] in the DVD.

The installer starts.

C Select [English], then click [Next].

D Click [Next].

E Check the license agreement, click [I accept the terms of the license agreement], then

click [Next].

If the [Windows Security] window is displayed, click [Install].

F Click [Add a local printer].

- In Windows 8, select [The printer that I want

isn't listed] - [Add a local printer or network

printer with manual settings], then click

[Next].

- In Windows Vista/Windows Server 2008,

click [Add a local printer].

- In Windows XP/Windows Server 2003, select

[Local printer attached to this computer],

then click [Next].

3-2

Page 25

G Select [Create a new port].

H In [Type of port], select [Standard

TCP/IP Port], then click [Next].

bizhub PRESS C1100/C1085

I Enter the host name or IP address, then

click [Next].

J Select the name of the printer to be

installed, then click [Next].

3

3-3

Page 26

3.1 Installing the Printer Driver

K Enter the printer name, then click [Next].

If the installation confirmation message is

displayed, click [Install].

L Select [Do not share this printer], then

click [Next].

When using Windows Server 2008/Windows

Server 2003 as a printer server, click [Share this

printer so that others on your network can find

and use it], then enter the share name.

M When printing a test page, click [Print a

test page].

Check the test page printing result.

Then, click [Close].

N Select whether to set to a daily-used

printer, then click [Finish].

The printer driver is installed.

3-4

Page 27

bizhub PRESS C1100/C1085

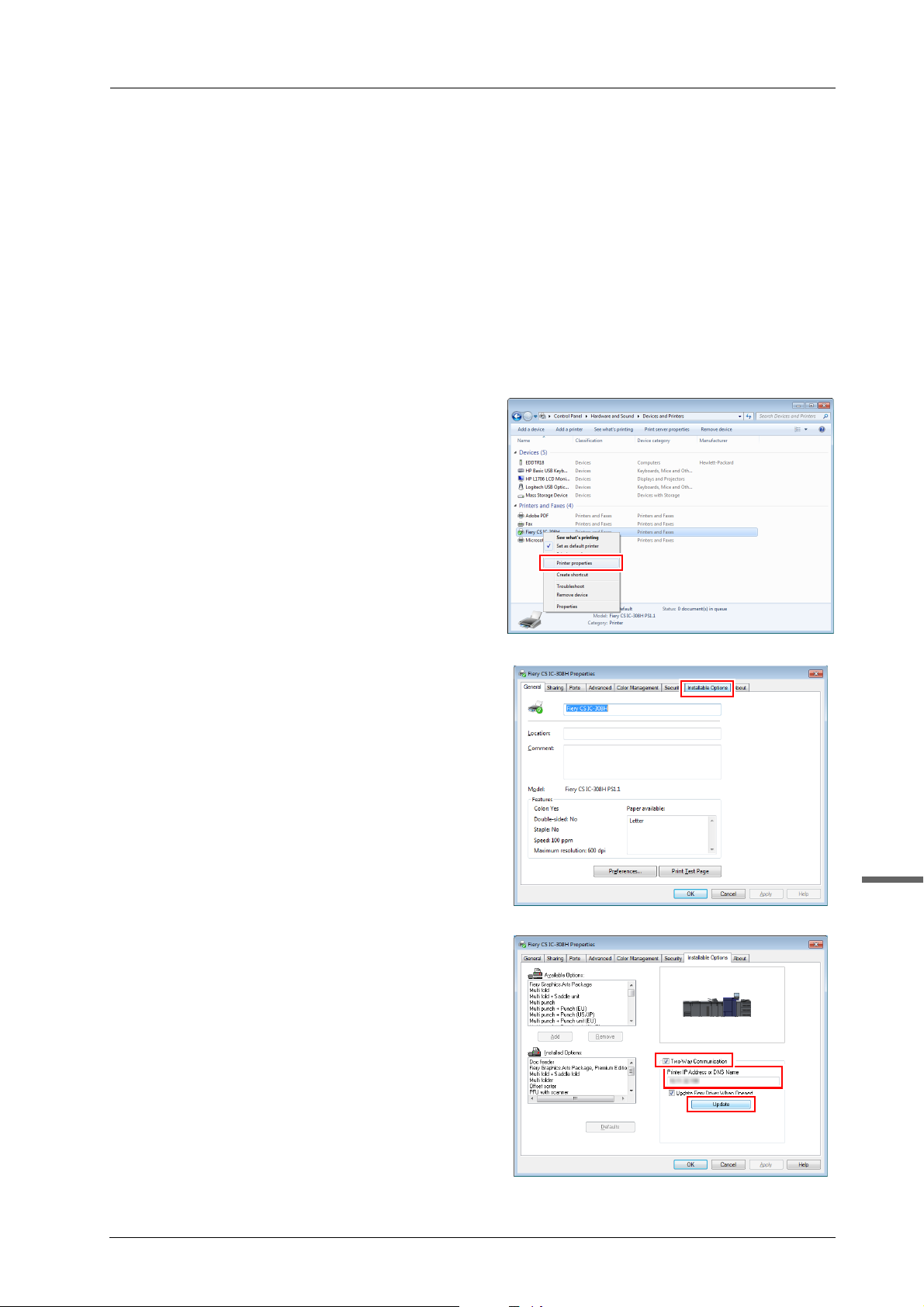

)Default setting

Check that optional information of this machine is configured correctly on the printer driver.

0 If optional information of this machine is not configured correctly on the printer driver, you cannot use optional

functions. If any optional function is mounted, be sure to configure a setting.

A Display the printer window.

- In Windows 7/Server 2008 R2, open the Start menu, then click [Devices and Printers].

- In Windows 8/Server 2012, right-click on the Start screen, click [All Apps], then select [Control Panel]

- [Hardware and Sound] - [View devices and printers].

- In Windows Vista/Server 2008, open the Start menu, select [Control Panel] - [Hardware and Sound],

then click [Printers].

- In Windows XP/Server 2003, open the Start menu, then click [Printers and Faxes].

B Open [Properties].

Right-click the icon of the installed printer, and

click [Printer Properties].

C Click the [Installable Options] tab.

D Select the [Two-Way Communication]

check box, enter the IP address or DNS

name of the printer, then click [Update].

Acquire optional information from the main body,

then apply it to the setting of [Installed Options].

If you have failed to acquire optional information,

check the network setting.

3

3-5

Page 28

3.1 Installing the Printer Driver

NOTICE

E Click [OK].

The optional information setting of the machine is then completed.

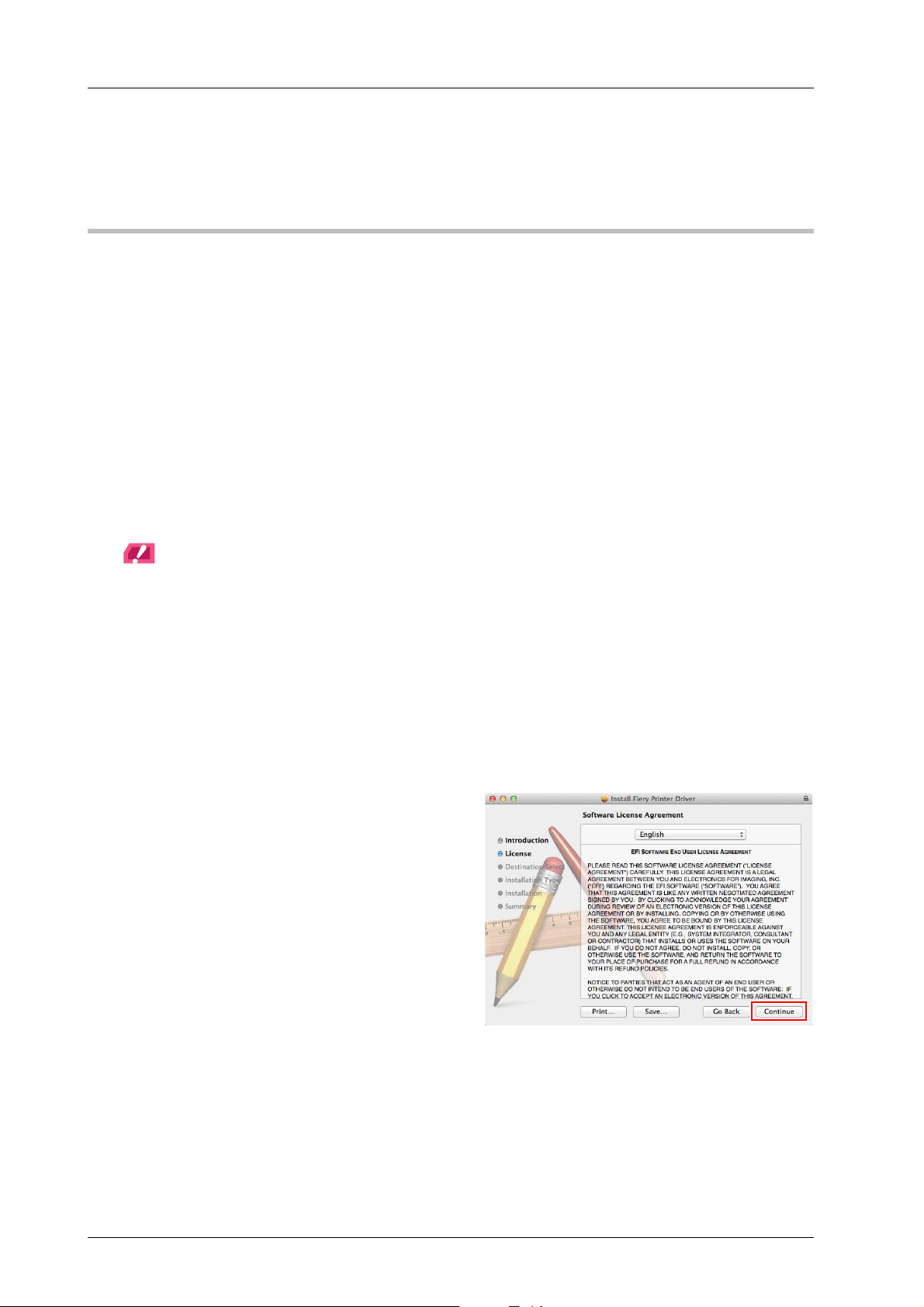

In a Macintosh environment

)Installation

Install the printer driver on your computer from the User Software DVD supplied with this machine, then add the

desired printer to the computer.

This guide describes how to install the PostScript3 driver in a Mac OS X 10.8 environment and add a Bonjourconnected printer.

0 For information about how to add a printer using another connection method (LPR or IPP), refer to the HTML

User's Guide.

0 A network setting must be configured on this machine before beginning the installation procedure. For details,

refer to the HTML User's Guide.

0 To carry out this task, the computer's administrator privilege is required.

0 Exit all applications before starting this task.

A Insert the User Software DVD into the DVD drive of the computer.

NOTICE

In OS X 1 0.7 or la ter , even if t he User Software DVD is inserted into the drive, the DVD icon may not be displayed

on the desktop. In this case, the mount setting may be disabled. Check whether or not the mount setting is

disabled in "Preferences" of Finder.

B Open the folder that contains the desired printer driver in the DVD.

Select the appropriate folder to fit the printer driver, operating system, and language.

C Copy the [Fiery Printer Driver Installer.app] file to the desktop, then double-click it.

The installer starts.

D Follow the on-screen instructions to click [Continue].

E Check the license agreement, then click

[Continue].

F Click [Agree].

3-6

Page 29

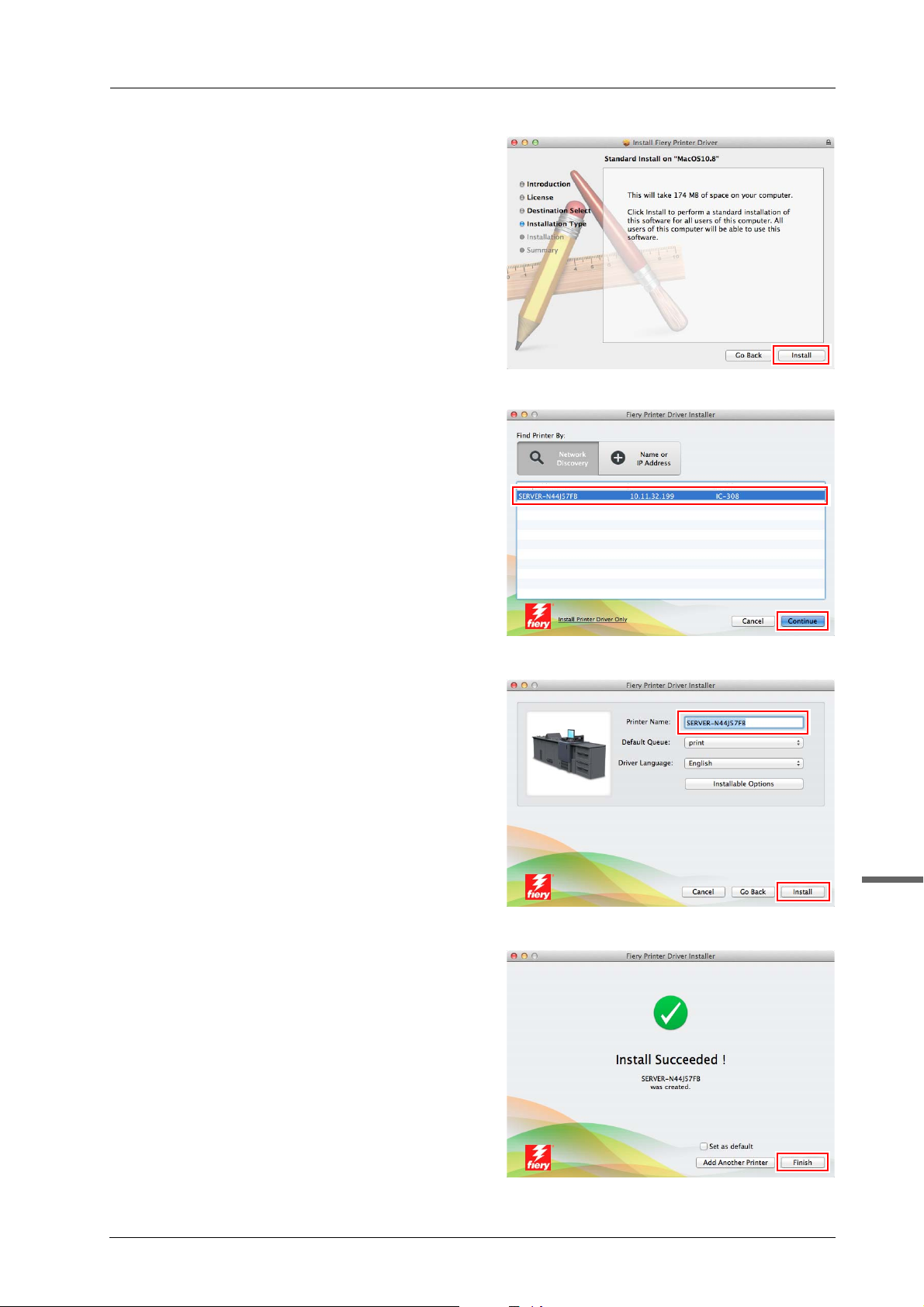

G Click [Install].

When the screen for entering [Name] and

[Password] is displayed, enter the computer

administrator's name and password into the

respective fields, then click [Install Software].

H Select the name of the printer to be

installed, then click [Continue].

bizhub PRESS C1100/C1085

I Enter the printer name, then click

[Install].

J When the installation is completed, click

[Finish].

To set to a daily-used printer, select the [Set as

default] check box.

3

3-7

Page 30

3.1 Installing the Printer Driver

K Click [Close].

Then, add a Bonjour-connected printer to your

computer.

L In the Apple Menu, select [System Preferences], then click the [Print & Scan] ([Print &

Fax] in OS X 10.5/10.6) icon.

M Click [+].

If the menu appears, select [Add Printer or

Scanner].

N Click [Default].

Connected printers are detected. If no printer is

detected, restart this machine.

3-8

Page 31

O Specify the Bonjour-connected printer

to be added in the [Name] list.

- Specifying a printer displays the appropriate

printer driver in the [Use] field. If the printer

driver is not displayed correctly, select

[Select Printer Software...], then directly

specify the desired printer driver.

- To check the printer name of this machine,

select [Administrator Setting] - [Network

Setting] - [NIC Setting] - [Bonjour Setting].

P Click [Add].

- In OS X 10.7/10.8, option information is configured automatically.

- In OS X 10.5/10.6, proceed to Step 17.

Q Configure optional information of this

machine, then click [OK] or [Continue].

Then, configure the default setting for the printer

driver. For details, refer to page 3-10.

bizhub PRESS C1100/C1085

3-9

3

Page 32

3.1 Installing the Printer Driver

)Default setting

Check that optional information of this machine is configured correctly on the printer driver.

0 If optional information of this machine is not configured correctly on the printer driver, you cannot use optional

functions. If any optional function is mounted, be sure to configure a setting.

A Select [System Preferences] in the Apple Menu, then click the [Print & Scan] ([Print &

Fax] in OS X 10.5/10.6) icon.

B Select the name of the installed printer, then click [Options & Supplies] - [Driver].

C Configure optional information of this

machine.

D Click [OK].

The optional information setting of the machine is then completed.

3-10

Page 33

bizhub PRESS C1100/C1085

Reference

3.2 Installing Applications

Operating environment

)Fiery Utility

Item Specifications

Operating System Windows XP, Windows Server 2003, Windows Vista, Windows Server 2008, Win-

CPU Windows: Pentium4 1GHz or higher

HDD 3GB or more

Memory 1GB or more / Memory capacity as recommended for your operating system

Display 1024 e 768 pixels or more

Drive DVD drive

Network environment The TCP/IP protocol setting must be configured correctly.

dows Server 2008 R2, Windows 7, Windows 8 , Windows Server 2012

Mac OS X 10.5/10.6/10.7/10.8

®

Macintosh: PowerPC

The memory must have sufficient free space to support the operating system and

applications.

G5 or multi-core Intel® processor

Fiery Utility setup

)Function overview

/ Job management

Fiery Utility is an application that is used to operate print jobs or scanned data on a computer.

The following four types of Fiery Utility are available.

Fiery Utility Description

Fiery Command WorkStation

Fiery Printer Delete Utility Completely deletes the printer driver from the computer.

Fiery Remote Scan Initiate scanning remotely, retrieve the scanned files from the mailbox and save them

Fiery Hot Folders Sets attributes to any folder on the computer, and automatically sends data that has

Manages jobs and image controller via the network.

to the computer, and open the scanned file in a host application for editing purposes.

been dragged and dropped in the folder to the image controller.

Because the print attributes frequently used are stored in a folder in advance, you

do not need to specify attributes for each printing, enabling to work in an efficient

manner.

3

For details, refer to the User's Guide supplied with the Fiery Color Server.

3-11

Page 34

3.2 Installing Applications

In a Windows environment

)Installation

Start the installer from the User Software DVD supplied with this machine, then install Fiery Utility on your computer.

0 To carry out this task, the computer's administrator privilege is required.

A Insert the User Software DVD into the DVD drive of the computer.

- If the installer does not start, double-click [setup.exe] on the DVD, then proceed to Step 2.

- When the [User Account Control] window is displayed, click [Continue] or [Yes].

B Click [Next].

C Check the license agreement, click [I accept the terms of the license agreement], then

click [Next].

D Check the destination folder.

To change the destination folder, click [Browse]

to specify the desired folder.

E Select a language, then click [Next].

F Select the check box of the software to

be installed, then click [Next].

3-12

Page 35

bizhub PRESS C1100/C1085

NOTICE

G Confirm the program folder name, then

click [Next].

H To automatically start Fiery Command WorkStation when logging on to the

computer, click [Yes]; otherwise, click [No].

I Select the total size of the software to be

installed, then click [Next].

If the [Windows Security] window is displayed,

click [Install].

J Click [Yes, I want to restart my computer now.], then click [Finish].

When the computer restarts, installation is completed.

In a Macintosh environment

)Installation

Start the installer from the User Software DVD supplied with this machine, then install Fiery Utility on your computer.

This guide describes how to install Fiery Command WorkStation.

A Insert the User Software DVD into the DVD drive of the computer.

NOTICE

In OS X 10.7 or later, even if the User Software DVD is inserted into the drive, the DVD icon may not be displayed

on the desktop. In this case, the mount setting may be disabled. Check whether or not the mount setting is

disabled in "Preferences" of Finder.

B Copy the [CWS5.mpkg] file in the DVD to the desktop, then double-click it.

- For Fiery Remote Scan, copy [Fiery Remote Scan.mpkg].

- For Fiery Hot Folders, copy [EFI Hot Folders.mpkg].

3

3-13

Page 36

3.2 Installing Applications

C Select the [I agree to the EFI Terms Of

Service] check box.

D Click [Install].

The screen for entering [Name] and [Password] is

displayed during processing. Enter the computer

administrator's name and password into the

respective fields.

E When the installation is completed, click

[Close].

Installation is completed.

3-14

Page 37

Starting applications

)Starting Fiery Command WorkStation

To start Fiery Command WorkStation, first perform the login procedure.

A Start Fiery Command WorkStation.

- In Windows 7/Windows Vista/Windows Server 2008 R2/Windows Server 2008/Windows

XP/Windows Server 2003, open the Start menu, then click [All Programs] - [Fiery] - [Fiery Command

WorkStation 5].

- In Windows 8/Server 2012, click [Fiery Command WorkStation 5] on the Start screen.

- In Macintosh, select [Go] menu - [Applications] - [Fiery] - [Command WorkStation 5], then double-

click [Command WorkStation].

B Select a Fiery Color Server to be

connected, then click [Add].

You can also specify any subnetwork or the IP

address range to search for the desired Fiery

Color Server. For details, refer to the User's

Guide supplied with the Fiery Color Server.

bizhub PRESS C1100/C1085

C Click [Connect].

D Select the user privileges, then enter the

password.

- For user privileges, you can select the

following items.

Administrator: Can perform all operations.

Operator: Can only perform job operations.

Guest: Can view information only.

- The default password is "Fiery.1".

If [Operator] or [Guest] is selected for user

privileges, you do not need to enter the

password.

3

3-15

Page 38

3.2 Installing Applications

E Click [Login].

Fiery Command WorkStation starts.

)Starting Fiery Remote Scan

To start Fiery Remote Scan, first select a Fiery Color Server to be connected.

A Start Fiery Remote Scan.

- In Windows 7/Windows Vista/Windows Server 2008 R2/Windows Server 2008/Windows

XP/Windows Server 2003, open the Start menu, then click [All Programs] - [Fiery] - [Fiery Remote

Scan 6].

- In Windows 8/Server 2012, click [Fiery Remote Scan 6] on the Start screen.

- In Macintosh, select [Go] menu - [Applications] - [Fiery] - [Fiery], then double-click [Fiery Remote

Scan].

B Select a Fiery Color Server to be

connected, then click [Add].

You can also specify any subnetwork or the IP

address range to search for the desired Fiery

Color Server. For details, refer to the User's

Guide supplied with the Fiery Color Server.

C Click [Connect].

Fiery Remote Scan starts, and you can import a

scan file.

)Starting Fiery Hot Folders

% Start Fiery Hot Folders.

Fiery Hot Folders starts, and you can configure hot folders.

- In Windows 7/Windows Vista/Windows Server 2008 R2/Windows Server 2008/Windows

XP/Windows Server 2003, open the Start menu, then click [All Programs] - [Fiery] - [Fiery Hot

Folders].

- In Windows 8/Server 2012, click [Fiery Hot Folders] on the Start screen.

- In Macintosh, select [Go] menu - [Applications] - [Fiery] - [Hot Folders], then double-click [Fiery Hot

Folders Console].

3-16

Page 39

bizhub PRESS C1100/C1085

NOTICE

NOTICE

NOTICE

4 Basic Operations

4.1 Loading Paper

Loading paper into the Paper Feeder Unit PF-708

The following describes how to load paper into an optional Paper Feeder Unit PF-708. The same paper loading

procedure is used for Paper Feeder Units PF-707 and Paper Feeder Units PF-708. The same paper loading

procedure is used for each tray.

A Pull out the tray to load paper into.

NOTICE

Trays can be pulled out only when this machine is turned on. Before

pulling out the target tray, check that the sub power switch is turned

on.

In order to prevent the machine from falling down, only one tray can

be pulled out at a time.

B Turn the side guide lock knobs (2 pieces)

counterclockwise to loosen them.

C While pressing the side guide lock release lever

( ), slide the side guide plates to any positions

().

Determine their locations based on the size indicator of the

bottom plate of the tray.

NOTICE

To slide the side guide plates, be sure to hold both side guide

plates together. If you move it by holding only either of the side guide

plate, the side guide plate that is held may become displaced.

D While pressing the rear guide lock release lever,

slide the rear guide plate to any positions.

Determine their locations based on the size indicator of the

bottom plate of the tray.

4

E To fix the side guide plates at the correct locations, load an appropriate amount of

paper into the tray while aligning it to the left-hand side of the tray.

NOTICE

Load paper with the print side facing up.

4-1

Page 40

4.1 Loading Paper

NOTICE

NOTICE

NOTICE

F Press the side guide plates against the paper, then turn the side guide lock knobs

(2 pieces) clockwise to fix them.

G Load the remaining paper into the tray, then press

the rear guide plate against the paper.

NOTICE

Be careful not to load paper above the , mark that indicates the

height limit on the side guide plate. Otherwise, a paper jam may

occur.

To load paper with a width less than 139.7 mm/5.5", use the small

size guides built in to the side guide plates. For information about

how to use the small size guides, refer to the HTML User's Guide.

Be sure that the rear guide plate is securely pressed against the

paper. If there is any gap between the rear guide plate and the

paper, this machine will not be able to detect the correct paper size.

It may cause a paper feeder machine error.

Load paper with the print side facing up.

H Close the tray.

Push the tray in until it locks into place.

The amount indicator changes from to in the tray information display area of the

[MACHINE] or [COPY] screen.

NOTICE

Carefully close the tray. Otherwise, the machine may be subjected to an unexpected impact due to the tray or

paper weight, which may lead to a machine error.

Loading Paper in Post Inserter of Folding Unit FD-503

Select [Paper Setting] on the [MACHINE] screen or the [COPY] screen, then change the paper setting of the upper tray

or lower tray of the post inserter.

A Load paper into the upper tray or lower tray of the

post inserter.

The Amount indicator changes from to on the

[MACHINE] screen or the [COPY] screen.

B Press the tray guide plates against the paper.

NOTICE

Do not load more than 500 sheets (80 g/m2 / 21 lb Bond) for each of the upper and lower trays. Also, do not load

above the limit line indicated on the tray guide plates.

4-2

Page 41

bizhub PRESS C1100/C1085

4.2 Paper Setting

Specifying paper information for a tray

Specify the required information (size, type, weight, and other values) for the paper loaded into a paper tray.

If standard-size paper is loaded, its size is recognized automatically. To load custom-size paper, specify the required

size.

A Press [Paper Setting] on the [MACHINE]

screen.

You can also press [Paper Setting] on the [COPY]

screen to specify the required size.

B Select the tray with paper loaded, then

press [Change Set].

C Press [Paper Type] to select the desired

paper type.

4

4-3

Page 42

4.2 Paper Setting

D Press [Paper Size].

E Select one of the options under Size

Setting to fit the paper loaded into the

tray.

4-4

Page 43

F Specify the size.

[Standard]: Recognized automatically.

In [Detect Size Setting], you can select the size to be detected.

There is, however, a group of sizes having subtle distinctions, so that the machine cannot distinguish in

the operation of size detection. To identify these sizes as one size so that they can be judged by the

machine, you can select the size to be detected in [Detect Size Setting].

bizhub PRESS C1100/C1085

[Custom]: Specify the value in items (1) to (3).

- You can name and register the size specified in [Size Registration].

- To recall the registered size, select [Size Recall].

- Item (3) is not displayed depending on the mounted optional device.

4

4-5

Page 44

4.2 Paper Setting

[Tab Paper]: Specify the paper size and the number of tabs.

G If you select [Detect Size Setting] in

[Standard], press [OK].

This returns to the [Size Setting] screen.

This step is not required if you select [Custom] or

[Tab Paper].

H Press [OK].

This returns to the [Change Individual Set] screen.

4-6

Page 45

I Specify other items, if necessary.

Tips

Tips

J Press [OK].

This returns to the [Paper Setting] screen.

bizhub PRESS C1100/C1085

K Press [Close].

This returns to the [MACHINE] screen.

If you press [Paper Setting] on the [COPY] screen

to specify the paper size, the screen returns to the

[COPY] screen.

Paper setting is then completed.

For details about setting items, refer to the HTML User's Guide.

To register paper conditions in a paper profile, press [Register]. For details about how to register a paper profile, refer

to the HTML User's Guide.

4

4-7

Page 46

4.3 Printer Driver Setting

Reference

4.3 Printer Driver Setting

Printer driver functions

This section describes how to specify the color mode using the printer driver.

)[Color Mode]: Select an output color

Open [Color] in the Print Setting screen of the printer driver, then select [Color Mode] from [CMYK] or [Gray Scale].

Before selecting the color mode, execute calibration. For details, refer to page 5-19.

The color mode can also be specified in [Color Setup] of Fiery Command WorkStation. For details, refer to the User's

Guide supplied with the Fiery Color Server.

4-8

Page 47

bizhub PRESS C1100/C1085

Reference

)[Color Mode]: General

To specify the basic defaults for color processing, open [Color] in the Printing Preferences window, then click [Basic

Settings]. You can also change the setting for each print job.

You also select [Color Setup] of Fiery Command WorkStation to configure [Basic Settings] in the color mode. For

details, refer to the User's Guide supplied with the Fiery Color Server.

4

4-9

Page 48

4.3 Printer Driver Setting

Reference

)[Color Mode]: Expert Setting

To set defaults to all items for color processing, open [Color] in the Printing Preferences window, then click [Expert

Settings].

You can also change the setting for each print job.

You can also select [Color Setup] of Fiery Command WorkStation to configure [Expert Settings] in the color mode.

For details, refer to the User's Guide supplied with the Fiery Color Server.

4-10

Page 49

bizhub PRESS C1100/C1085

Tips

Reference

Reference

NOTICE

5 Maintaining the Finishing Quality

5.1 Both Sides Adjustment

Both Sides Adjustment

When performing the duplex printing, you can adjust a misalignment between the front and back sides to align the

printing positions on the front and back sides. This task is referred to as Both Sides Adjustment.

A heat impact of the fixing unit may cause a slight enlargement or reduction of paper during printing. The impact level

varies depending on the type or weight of paper, therefore, if you have changed paper to be loaded into a tray, be sure

to carry out the Both Sides Adjustment.

Two methods are available to carry out the Both Sides Adjustment: entering from [Paper Setting] and from [Both Sides]

on the [MACHINE] screen. This guide describes how to enter from [Paper Setting] for adjustment.

For information about how to enter from [Both Sides], refer to the HTML User's Guide.

Adjustment flow

Follow the procedure below to proceed the Both Sides Adjustment.

A Check the reference position of the print side

To judge whether a print position is misaligned, the required reference position adjustment must be

completed on this machine.

Before starting the Both Sides Adjustment, check the adjustment value of the reference position. If

necessary, adjust it.

There are the following adjustment items to be checked. To check them, on the [MACHINE] screen, select

[Adjustment] - [Machine Adjustment] - [Printer Adjustment].

- [01 Restart Timing Adjustment]

- [02 Centering Adjustment]

- [03 FD-Mag. Adjustment]

- [04 CD-Mag. Adjustment]

First adjust the front side in the order of 03 -> 04 -> 01 -> 02, then adjust the back side in the same order.

For information about how to check or readjust the adjustment value, refer to the HTML User's Guide.

B Making the Both Sides Adjustment for each tray

The following two adjustment methods are available.

- Chart Adjustment: Available when an unclear misalignment is found between the front and back

sides. (page 5-2)

- Zoom, Image Shift: Available when the fine adjustment is required after the chart adjustment or when

a misalignment between the front and back sides is clear. (page 5-9)

If skewing or wrinkling occur during printing, adjust the registration loop amount before making the chart adjustment

or the zoom and image shift adjustment. For details, refer to the HTML User's Guide.

5

NOTICE

A high technical skill is required to adjust the reference position on the print side. Before carrying out this adjustment,

contact your service representative.

5-1

Page 50

5.1 Both Sides Adjustment

Tips

Making the Both Sides Adjustment for each tray

Adjust a misalignment between the front and back sides, which is caused during the duplex printing, for each tray.

The following two methods are available to carry out the Both Sides Adjustment.

- Chart Adjustment

- Zoom and Image Shift Adjustment

You can register Both Sides Adjustment values in a paper profile with paper conditions specified. If paper conditions

are registered, you can carry out printing under the previous conditions even when you have changed a tray to load

paper into. For information about how to edit or register a paper profile, refer to the HTML User's Guide.

)Chart Adjustment

You can print out a Both Sides Adjustment chart, measure measurement points using a scale, and enter measurement

values in order to carry out the adjustment.

Using this function, you can only enter measurement values to carry out the both-side adjustment. This is convenient

when an unclear misalignment is detected between the front and back sides to perform the duplex printing with a new

type of paper or to change paper in a tray.

A Press [Paper Setting] on the [MACHINE]

screen.

B Select the tray with the target paper

loaded, then press [Change Set].

5-2

Page 51

C Press [Both Sides Adj.].

D Select [Front], then press [Chart

Adjustment].

bizhub PRESS C1100/C1085

E Press [Print Mode].

F When the [PRINT MODE] screen is

displayed, press Start on the control

panel.

A test chart is printed out.

5

5-3

Page 52

5.1 Both Sides Adjustment

[1]

[5] [7]

[6] [8]

[2]

[3] [4]

[1]

[5]

G Press [Exit Print Mode].

H Measure the line length at each of points

[1] to [8] on the printed-out chart using a

scale.

- The figure on the right illustrates an example

to measure points [1] and [5]. As illustrated in

this example, measure the line length at each

printed point.

- The measurement value can be entered in

units of up to 0.1 mm.

- Write down the measured lengths so that you

do not forget them.

5-4

Page 53

bizhub PRESS C1100/C1085

I Press each point number, then enter the measured length using either the keypad on

the screen, [,], or [+].

- To reset a value, press [Clear].

J When entry processing is completed,

press [Adjustment Start].

In the next step, adjust the back side.

K Select [Back], then press [Chart

Adjustment].

5

5-5

Page 54

5.1 Both Sides Adjustment

L Press [Print Mode].

M When the [PRINT MODE] screen is

displayed, press Start on the control

panel.

A test chart is printed out.

N Press [Exit Print Mode].

5-6

Page 55

O Measure a misalignment between the

marks of [1] to [4] printed on the

[back] side of the output chart and the

marks on the [front] side.

- In this figure, the black mark indicates

the front side and the blue mark indicates

the back side.

- Measure a misalignment between printing

positions in the horizontal direction (X axis)

and vertical direction (Y axis).

- The measurement value can be entered in

units of up to 0.1 mm.

- For example, as illustrated in this figure, if the

mark of [1] printed on the back side is

misaligned 0.5 mm rightward and 0.3 mm

downward compared with the mark printed

on the front side, adjust the printing position

0.5 mm in the X direction and 0.3 mm in the

Y direction.

- Write down the measured values so that you

do not forget them.

bizhub PRESS C1100/C1085

[1]

back

x

y

P Press [X] or [Y] at each point, then enter the measured value using either the keypad

on the screen, [,], or [+].

- If the printing position is misaligned leftward or upward, enter the value with a negative sign (-). If the

printing position is misaligned rightward or downward, enter the value with a positive sign (+).

- To reset a value, press [Clear].

- To switch the positive sign (+) and negative sign (-), press [+/-].

5-7

5

Page 56

5.1 Both Sides Adjustment

Q When entry processing is completed,

press [Adjustment Start].

R After the adjustment is completed, press

[OK].

To finely adjust the adjustment value,

continuously proceed to step 4 in "Zoom and

Image Shift Adjustment" (page 5-9).

S Press [Close] to exit the adjustment.

Chart Adjustment is then completed.

- To register adjustment values in a paper

profile, press [Register].

- For details about how to register a paper

profile, refer to the HTML User's Guide.

5-8

Page 57

bizhub PRESS C1100/C1085

)Zoom and Image Shift Adjustment

You can finely adjust the zoom ratio of the print side and the top, bottom, left, and right positions on the front and back

sides.

Using this function can directly enter the adjustment value in percentage or with the required value. This is convenient

when you want to carry out fine adjustment after the chart adjustment or you have the duplex printing result.