Page 1

1156SBT000AA

EP5000/EP4000

TROUBLESHOOTING

Page 2

1139SBT0100A

INTRODUCTION1

1139SBT0101A

1-1. General Precautions

1. When servicing thecopier with its covers removed, use utmost care to prevent your hands, clothing, and

tools from being caught in revolving parts including the chains and gears. When servicing the copier with

the Lower Rear Cover removed, be sure to install the jig.

2. Before attempting to replace parts and unplugging connectors, make sure that the power cord of the copier has been unplugged from the wall outlet.

3. Never create a closed circuit across connector pins except those specified in the text and on the printed

circuit.

4. When creating a closed circuit and measuring a voltage across connector pins specified in the text, be

sure to use the green wire (GND).

5. When the user is using a word processor or personal computer from the wall outlet of the same line, take

necessary steps to prevent the circuit breaker from opening due to overloads.

6. Keep all disassembled parts in good order and keep tools under control so that none will be lost or damaged.

1139SBT0102A

1-2. How to Use This Book

1. If a component on a PWB or any other functional unit including a motor is defective, the text only instructs

you to replace the whole PWB or functional unit and does not give troubleshooting procedures applicable

within the defective unit.

2. All troubleshooting procedures contained herein assume that there are no breaks in the harnesses and

cords and all connectors are plugged into the right positions.

3. For the removal procedures of covers and parts, see DIS/REASSEMBLY, ADJUSTMENT.

4. The troubleshooting procedures are given in the order of greater frequency of trouble or order of operation.

5. The procedures preclude possible malfunctions due to noise and other external causes.

1139SBT0103A

1-3. Reading the Text

1. The paper transport failure troubleshooting procedures are given according to the symptom. First identify

the location where the paper is present and start the procedure for that particular location. For malfunction

troubleshooting, start with step 1 and onward.

2. Make checks in numerical order of steps and, if an item is checked okay, go to the next step.

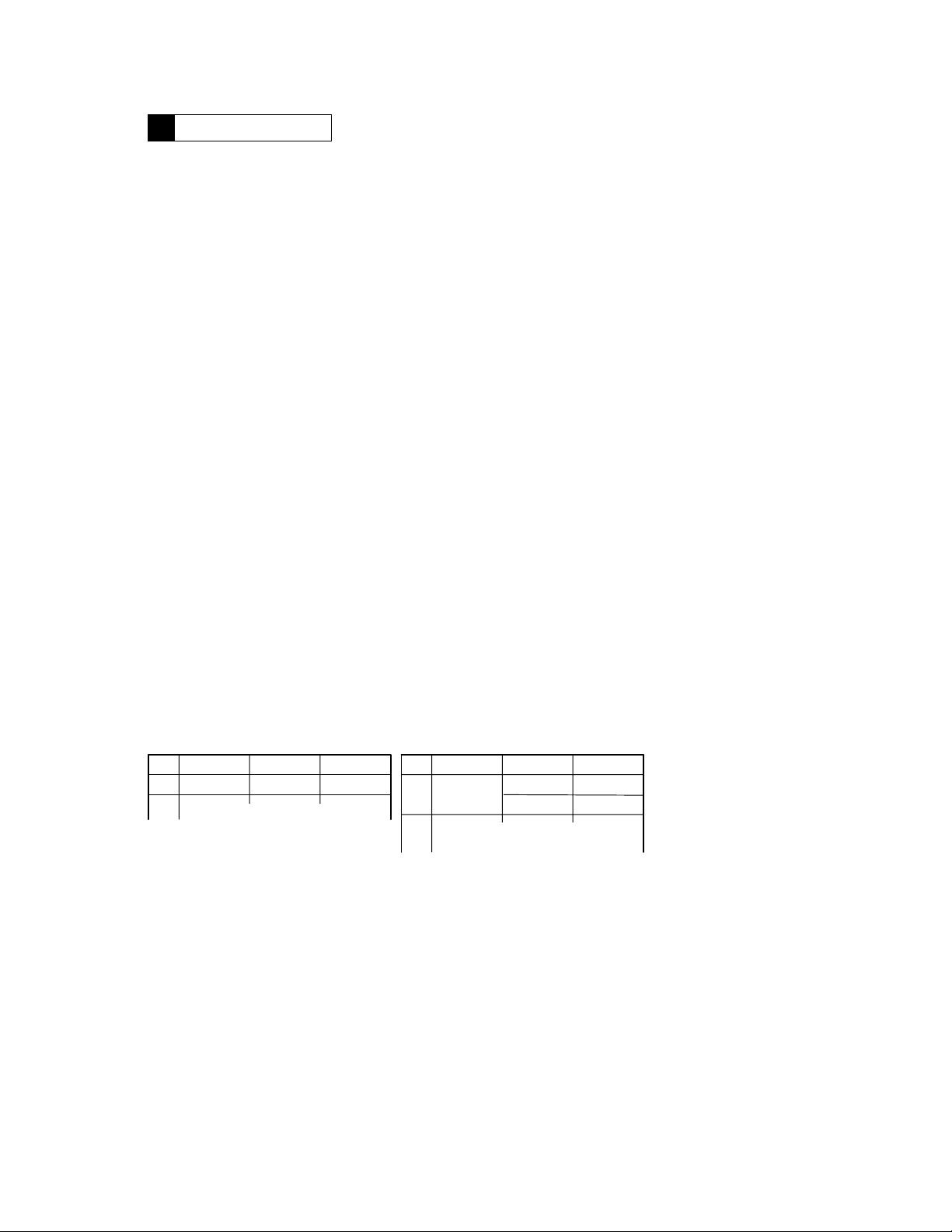

Pattern 1 Pattern 2

Check ItemStep Result Action

12Is...? YES Do this.

↑↑↑↑

Go to step 2 if you answered NO.

1

2

T-1

Check ItemStep Result Action

Is...? YES

Go to step 2 if it checks okay.

Do this.

NO Check that.

↑↑↑↑

Page 3

1151SBT0200A

I/O PORT CHECK2

1156SBT0201A

2-1. Controlled Parts Check Procedure

To allow the Tech. Rep. to easily and safely determine whether a particular controlled part is fully operational, this copier provides the following provision: checking the data of the I/O port of the board IC with

the copier in the standby state (including a misfeed, malfunction, and closure failure condition) allows the

Tech. Rep. to determine whether a signal is properly input to, and output from, a controlled part.

<Procedure>

1) On the circuit diagram accompanying the text, locate the I/O port of the controlled part which is probably

defective when a misfeed or malfunction occurs.

2) Select the “IC Port Data Check” function of “I/O Check” in the Tech. Rep. mode and access the screen

which contains the port identified in step 1 above. (See SWITCHES ON PWBs/TECH. REP. MODE.)

3) Change or check the input or output port data to determine whether the controlled part is operational

and signals are properly input and output.

4) If the controlled part does not operate properly after changing the output port data, select “Controller

Board Check” of “I/O Check” in the Tech. Rep. mode and determine whether the board is responsible

for that malfunction or not.

Note: Only the output ports given on pages T-37 and 38 may be checked by “Controller Board Check”

of “I/O Check” in the Tech. Rep. mode.

T-2

Page 4

<Controlled Part Check Procedure by Changing Input Port Data>

Example: When a paper misfeed occurs in the paper take-up section of the copier,1st Drawer Pa-

<Procedure>

1) Remove the sheet of paper misfed and reset the misfeed.

2) From the I/O port check list, it is found that the H/L input signal to PC56 is supplied from PWB-A

3) Select “IC Port Check” from the I/O Check function in the Tech. Rep. mode and access the

4) Check that the input port data of PWB-A (IC3A) APB3 on the screen is “H” (sensor being un-

5) Move the PC56 actuator to block the sensor.

6) Return to the “I/O Check” basic screen once, select “IC Port Check” again, choose the screen

per Take-Up Sensor PC56 is considered to be responsible for it.

(IC3A) APB3.

screen which includes the input ports of PWB-A (IC3A) APB3.

blocked).

which includes the APB3 input port data, and make sure that the data has changed from “H”

to “L”.

L: PC56 is operational. H: PC56 is faulty.

T-3

Page 5

<Controlled Part Check Procedure by Changing Output Port Data>

Example: When a manual paper misfeed occurs, Manual Feed Paper Take-Up Clutch CL3 is con-

<Procedure>

1) Remove the sheet of paper misfed and reset the misfeed.

2) From the I/O port check list, it is found that the ON/OFF output signal of CL3 is supplied from

3) Select “IC Port Check” from the I/O Check function in the Tech. Rep. mode and access the

4) Check that the output port data of PWB-A (IC5A) BPA1 on the screen is “1” (CL3 is deener-

5) Touch the “CHANGE” key on the screen to change the data from “1” to “0”, causing CL3 to be

6) If CL3 was not energized, make the “Controller Board Check” in the same mode (for some elec-

7) If the “ON” signal of CL51 is not output from PWB-A, the corresponding malfunction code is

sidered to be responsible for it.

PWB-A (IC5A) BPA1.

screen which includes the output ports of PWB-A (IC5A) BPA1.

gized).

energized for approx. 5 seconds. This allows you to determine whether the Clutch is “operational or faulty” by checking for the Clutch sound.

Operational: Sound produced. Faulty: No sound produced.

trical parts only).

displayed.

* For CL3, “C0337” is displayed.

T-4

Page 6

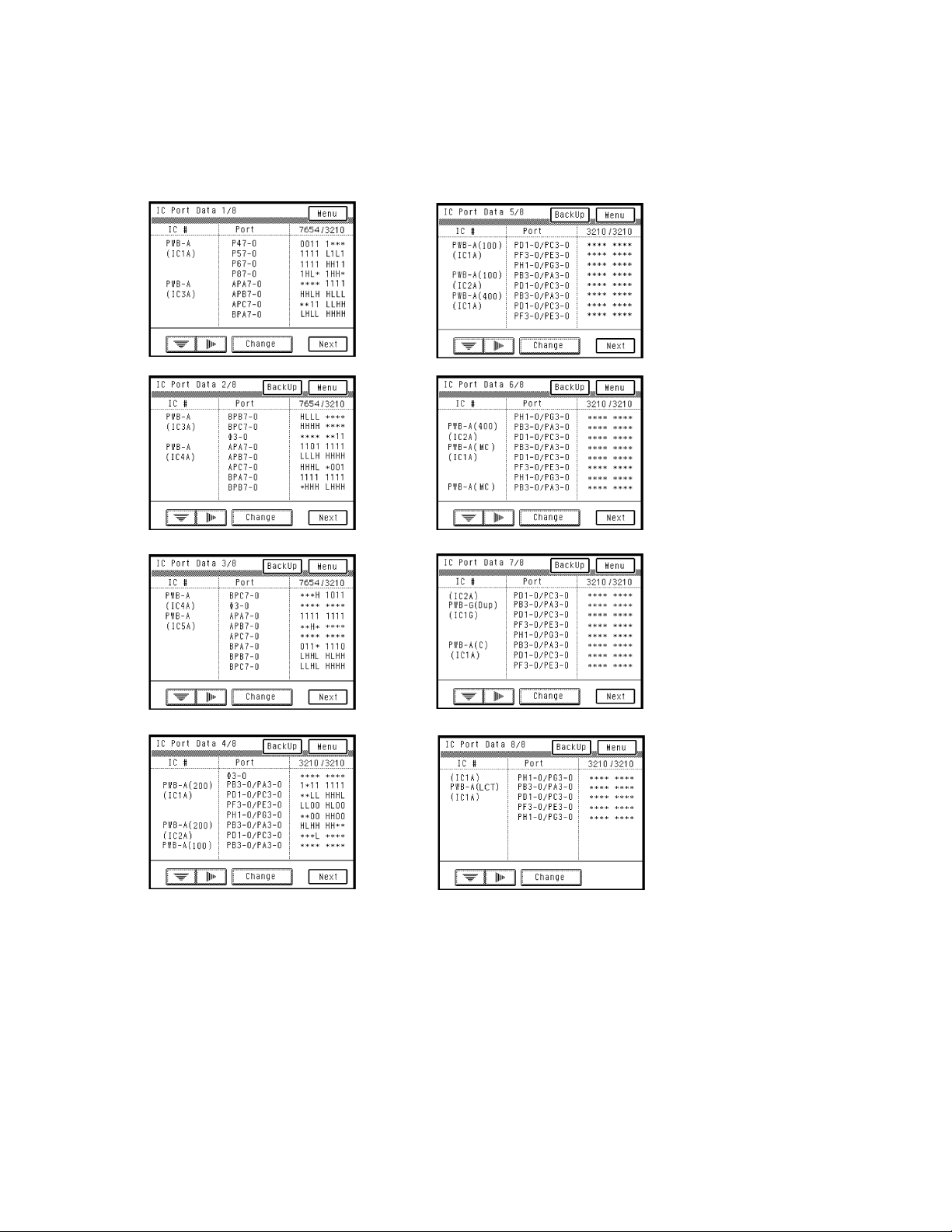

1156SBT0202A

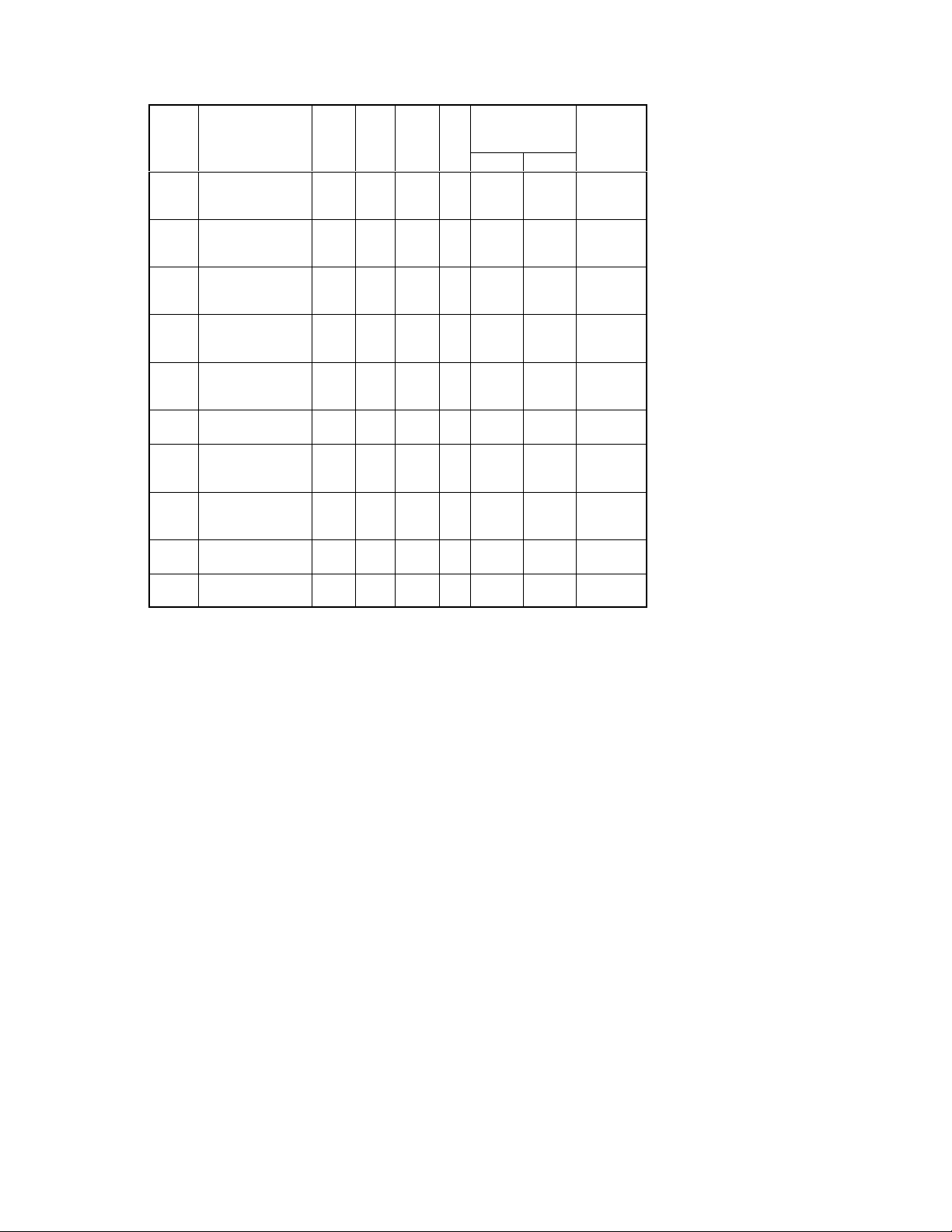

2-2. I/O Port Check List

<Port Check Screens>

The following screens are displayed in the standby mode but may not always be as shown below

D

because some port data are undefined. (Copier+PF-205)

1156T016CA

1156T017CA

1156T018CA

1156T020CA

1156T021CA

1156T022CA

1156T019CA

1156T023CA

T-5

Page 7

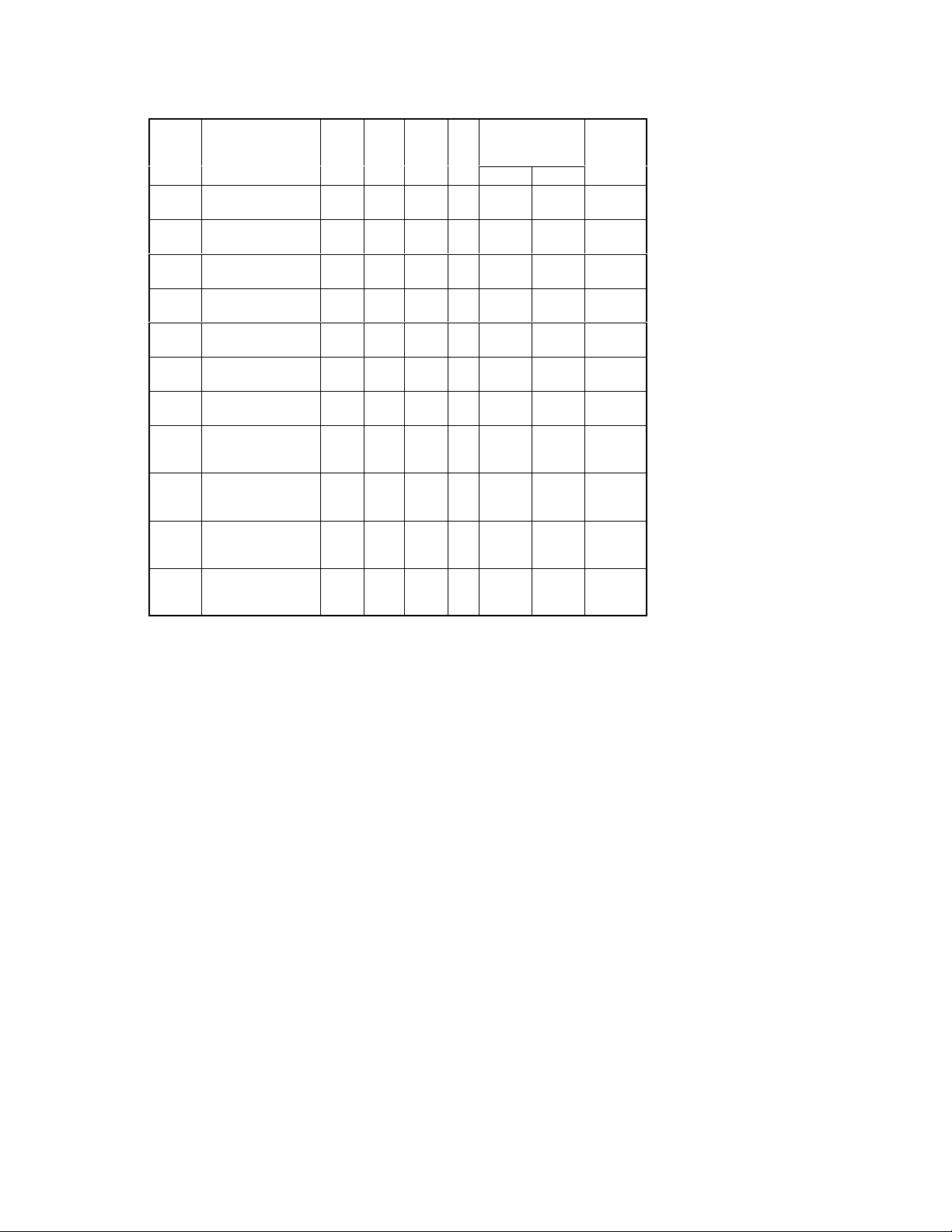

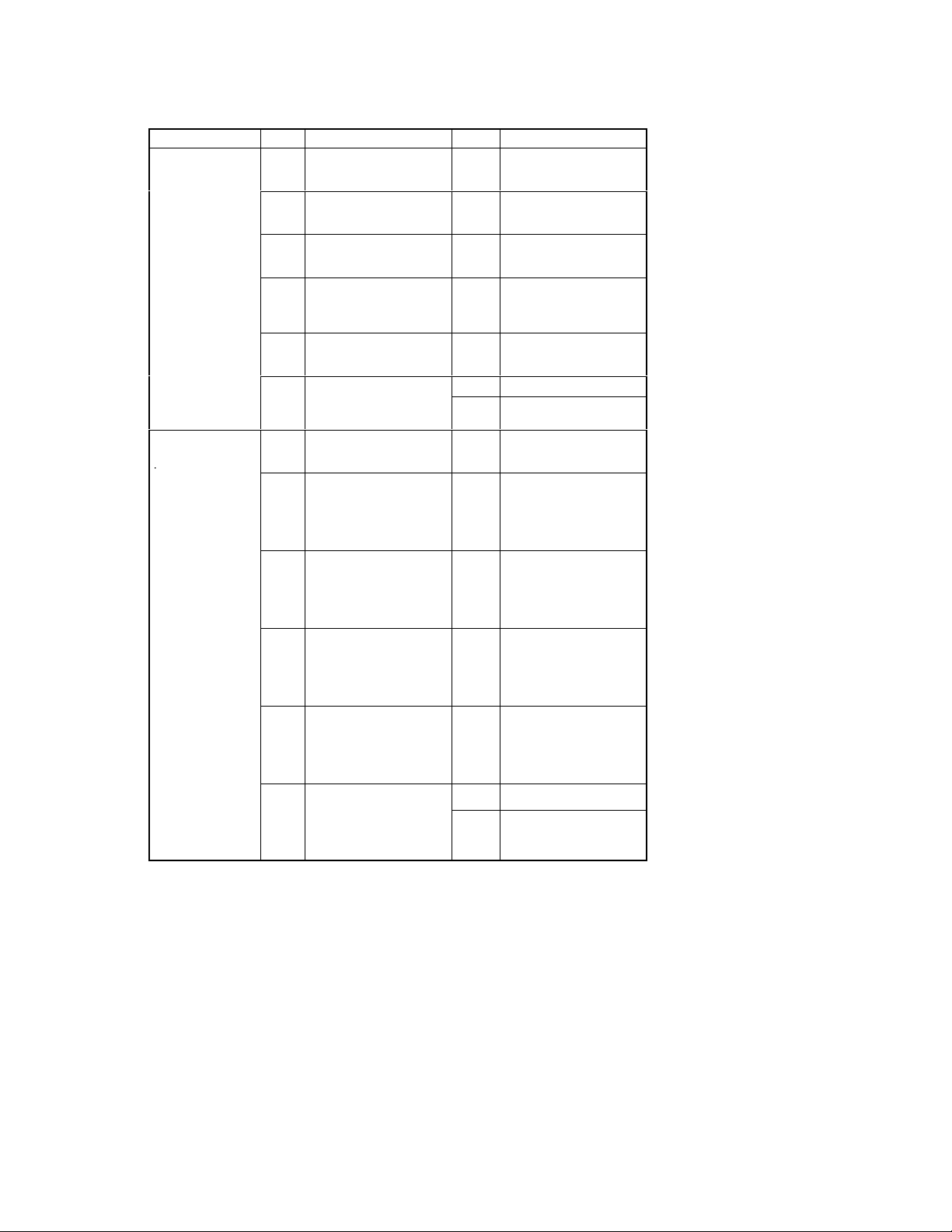

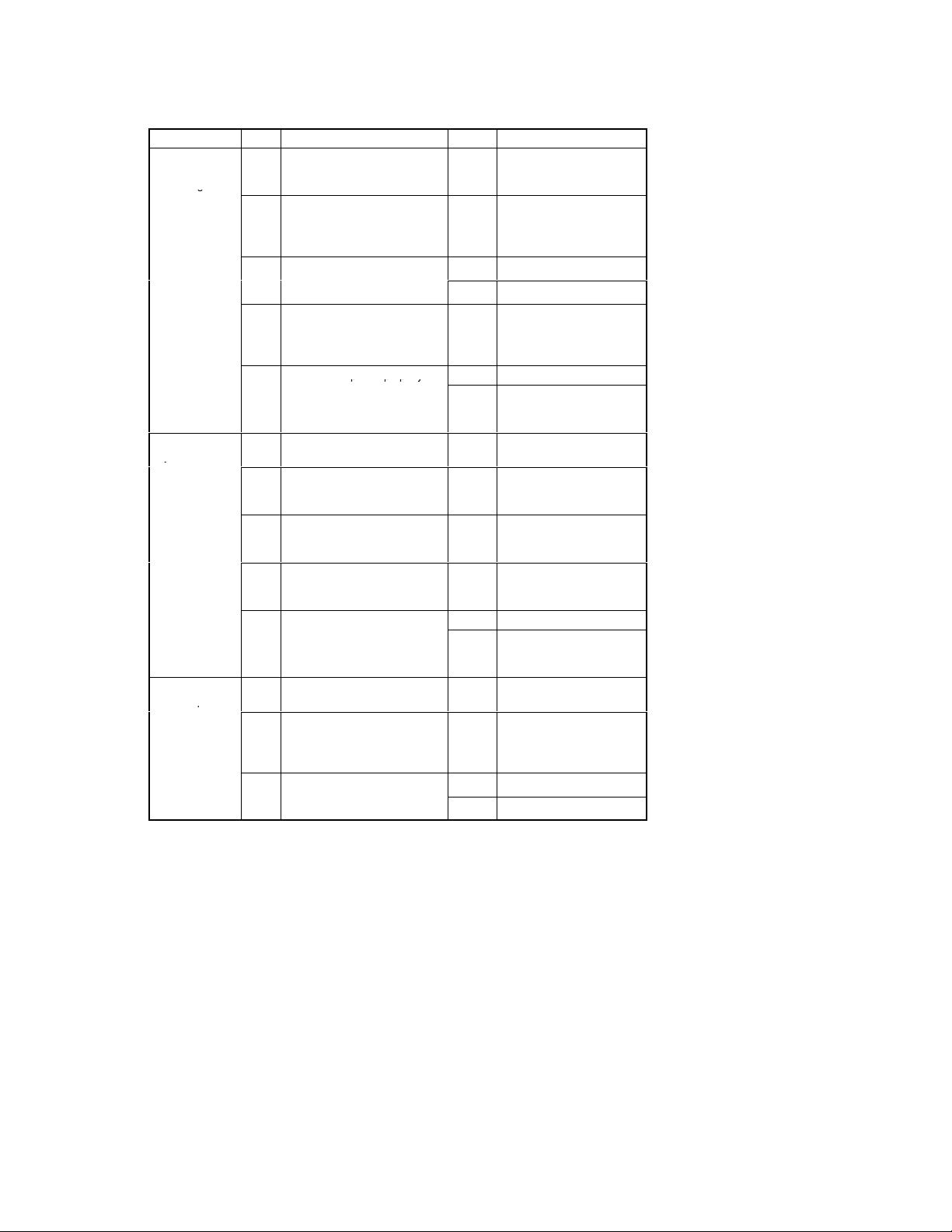

<I/O Port Check List>

bol

No.No

No

Copier *The shaded areas of the following table indicate that the output check cannot be made by

touching the Change key.

Sym-

M11

M12

M13

M14

M15

Parts/Signal Name

bol

M1 Main Drive Motor/REM 2/8 IC4A BPA2

Main Drive Motor/lock

↑↑↑↑

signal

M2 Scanner Motor/SCAN 3/8 IC4A APC0

Ventilation Fan Motor/

M3

REM

Ventilation Fan Motor/

↑↑↑↑

lock signal

Suction Fan Motor/se-

M4

lect signal

Suction Fan Motor/lock

↑↑↑↑

signal

Original Glass Cooling

M5

Fan Motor/REM

Original Glass Cooling

↑↑↑↑

Fan Motor/lock signal

Main Hopper Toner Re-

M8

plenishing Motor/REM

Sub Hopper Toner Re-

M9

plenishing Motor/REM

1st Drawer Paper TakeUp Motor

2nd Drawer Paper TakeUp Motor

1st Drawer Paper Lift-Up

Motor (UP)

1st Drawer Paper Lift-Up

↑↑↑↑

Motor (DOWN)

2nd Drawer Paper

Lift-Up Motor (UP)

2nd Drawer Paper

↑↑↑↑

Lift-Up Motor (DOWN)

Fusing Section Cooling

Fan Motor/REM

Dis-

IC

play

Page

2/8 IC4A BPB1

3/8 IC4A BPC1

2/8 IC4A BPB6

3/8 IC4A BPC2

3/8 IC4A BPC7

3/8 IC4A BPC0

2/8 IC4A BPB5

3/8 IC4A BPC3

3/8 IC5A APA2

3/8 IC5A APA0

3/8 IC5A APA1

3/8 IC5A APA4

3/8 IC5A APA5

3/8 IC5A APA6

3/8 IC5A APA7

3/8 IC4A APC2

Port

No.

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

f

f

f

f

f

f

f

f

Display

Hor1 Lor0

OFF ON PJ18A-9

When

locked

Stop

OFF ON PJ34A-1

When

locked

Turned

at high

speed

When

locked

OFF ON PJ15A-5

When

locked

OFF ON PJ11A-4A

OFF ON PJ11A-2A

Turn in-

hibited

Turn in-

hibited

OFF ON (up) PJ18A-5

OFF

OFF ON (up) PJ8A-7

OFF

OFF ON PJ10A-1

When

turned

Scan

cycle

When

turned

Turned

at low

speed

When

turned

When

turned

Turn

per-

mitted

Turn

per-

mitted

ON

(down)

ON

(down)

CN/PJ

No.

PJ18A-10

PJ8A-5

PJ34A-3

PJ15A-4

PJ15A-3

PJ15A-7

PJ18A-1

PJ18A-2

PJ18A-6

PJ18A-8

.

T-6

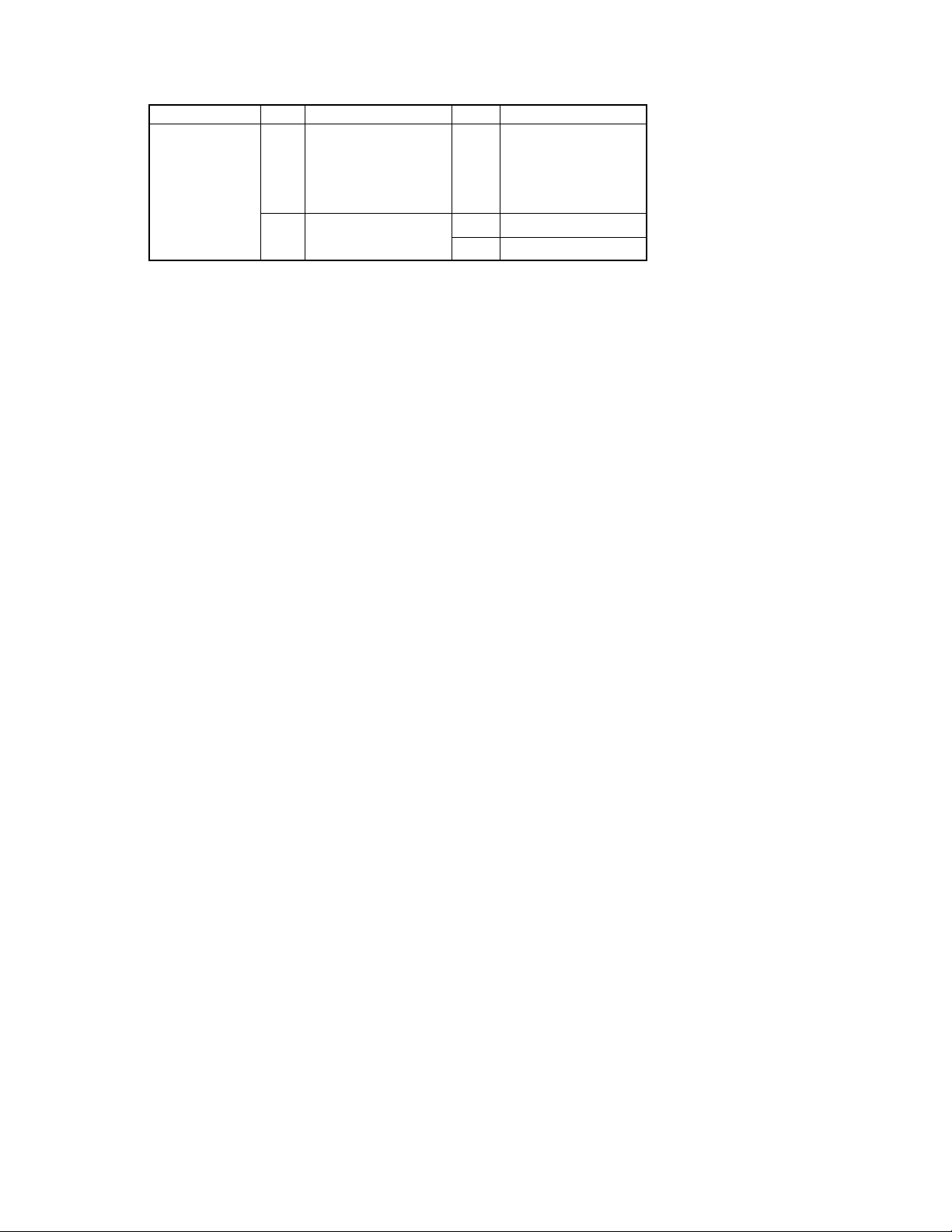

Page 8

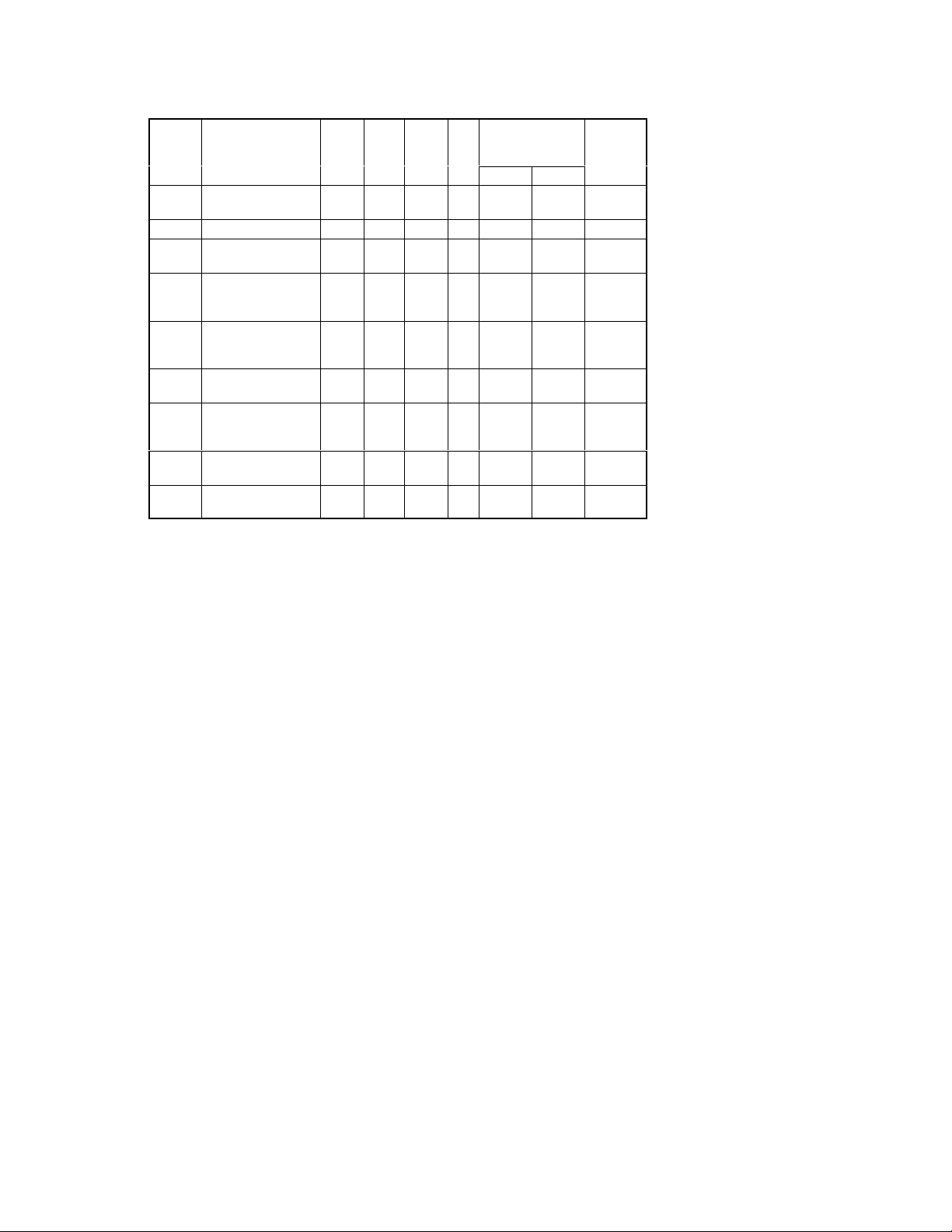

Dis-

No.No

No

Symbol Parts/Signal Name

Fusing Section Cooling Fan Motor/lock

↑↑↑↑

signal

SL1 Separator Solenoid 2/8 IC4A BPA0

Exit/Duplex Switching

SL5

Solenoid

Manual Feed Paper

Take-Up Solenoid

SL51

(UP)

Manual Feed Paper

Take-Up Solenoid

↑↑↑↑

(DOWN)

Paper Transport

CL1

Clutch

Synchronizing Roller

CL2

Clutch

Manual Feed Paper

CL3

Take-Up Clutch

Duplex Unit Vertical

PC12

Transport Sensor

Toner Bottle Home

PC35

Position Sensor

Manual Feed Paper

PC51

Empty Sensor

Transport Roller Sen-

PC54

sor

Paper Leading Edge

PC55

Detecting Sensor

1st Drawer Paper

PC56

Take-Up Sensor

2nd Drawer Paper

PC57

Take-Up Sensor

1st Drawer Set Sen-

PC61

sor

2nd Drawer Set Sen-

PC62

sor

Page

IC

play

No.

3/8 IC4A APB6

2/8 IC4A BPA5

3/8 IC5A BPA2

3/8 IC5A BPA3

2/8 IC4A BPA3

2/8 IC4A BPA4

3/8 IC5A BPA1

3/8 IC5A BPB0

3/8 IC4A BPC5

3/8 IC5A BPB1

3/8 IC5A BPB6

3/8 IC5A BPB5

1/8 IC3A APB3

1/8 IC3A APB4

1/8 IC3A BPA5

1/8 IC3A APB5

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

f

Display

Hor1 Lor0

When

locked

OFF ON PJ11A-6A

OFF ON PJ14A-6

OFF

OFF

OFF ON PJ14A-2

OFF ON PJ14A-4

OFF ON PJ15A-12

Paper

present

Un-

blocked

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Out of

positionInposition

Out of

positionInposition

(down)

not

present

Blocked PJ11A-9

not

present

not

present

not

present

not

present

not

present

When

turned

ON

(up)

ON

Paper

Paper

Paper

Paper

Paper

Paper

CN/PJ

No.

.

PJ10A-3

PJ15A-10

PJ15A-9

PJ17A-8

PJ15A-14

PJ19A-5

PJ19A-2

PJ21A-5A

PJ21A-5B

PJ22A-2

PJ22A-6

T-7

Page 9

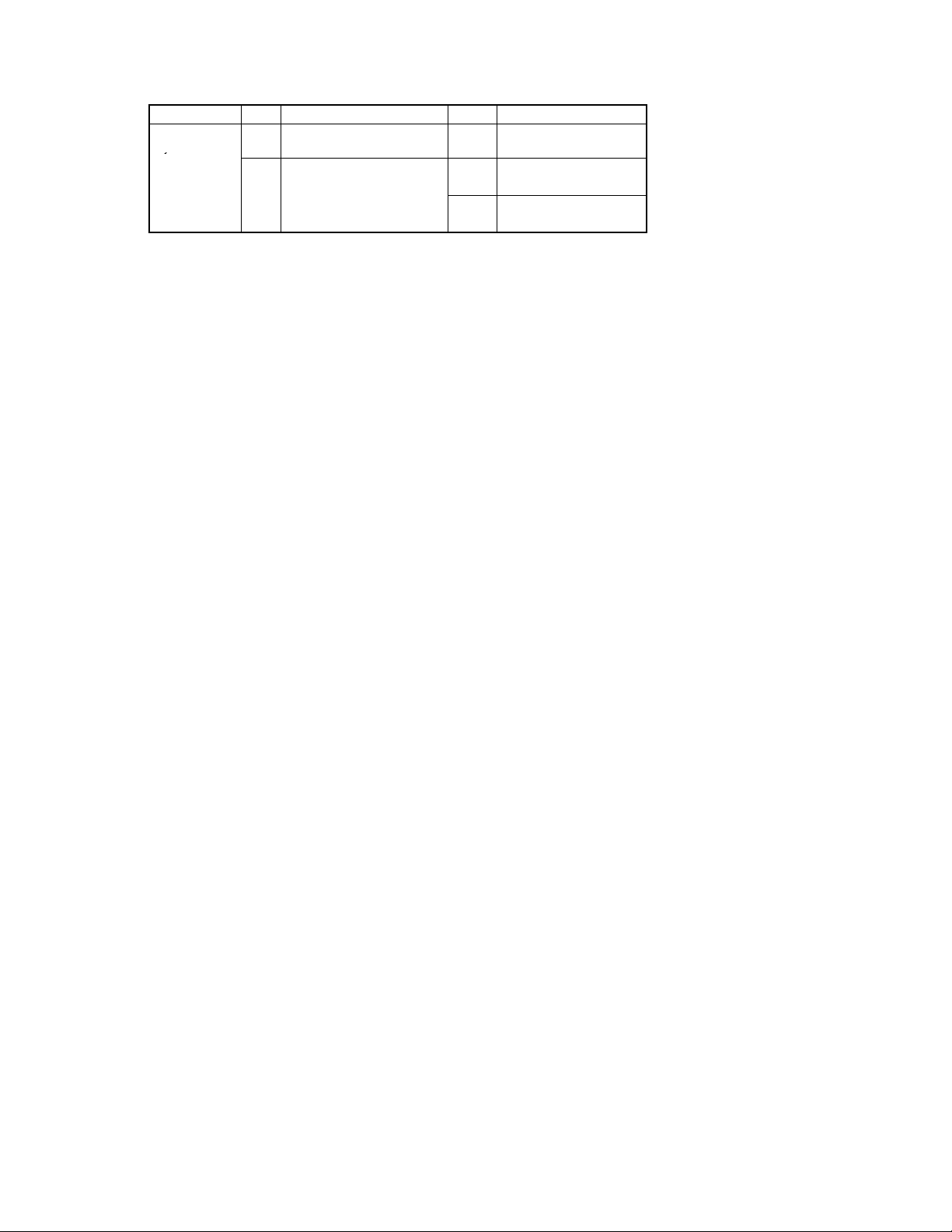

Sym-

bol

No.No

No

Parts/Signal Name

bol

1st Drawer Vertical

PC63

Transport Sensor

2nd Drawer Vertical

PC64

Transport Sensor

1st Drawer Lift-Up

PC65

Sensor

2nd Drawer Lift-Up

PC66

Sensor

1st Drawer Lift-Up

PC67

Motor Pulse Sensor

2nd Drawer Lift-Up

PC68

Motor Pulse Sensor

1stDrawer Lower

Limit Position Sen-

PC69

sor

2ndDrawer Lower

Limit Position Sen-

PC70

sor

Paper Size Detect-

PC72

ing Sensor 5

Paper Size Detect-

PC73

ing Sensor 6

Scanner Reference

PC81

Position Sensor

PC101

PC102

PC111

PC112

1st Drawer Paper

Empty Sensor

2nd Drawer Paper

Empty Sensor

Original Cover

Detecting Sensor

Toner Hopper Home

Position Sensor

CNT1 Total Counter/REM 1/8 IC1A P55

Total Counter/Set 2/8 IC4A APB7

↑↑↑↑

Dis-

IC

play

Page

1/8 IC3A APB6

1/8 IC3A APB7

1/8 IC3A APB1

1/8 IC3A APB2

1/8 IC3A APC0

1/8 IC3A APC1

1/8 IC3A BPA2

1/8 IC3A BPA3

2/8 IC3A BPB6

2/8 IC3A BPB7

2/8 IC4A APC4

1/8 IC3A APC2

1/8 IC3A APC3

2/8 IC4A APB5

3/8 IC5A BPB7

Port

No.

No.

Operation Charac-

teristics/Panel Dis-

I/O

.

f

play

Hor1 Lor0

Paper

not

present

Paper

not

present

Not at

upper

limit

Not at

upper

limit

Un-

blocked

Un-

blocked

Not at

lower

limit

Not at

lower

limit

Size not

detected

Size not

detected

Not at

home

Paper

not

present

Paper

not

present

Raised Lowered PJ12A-1

Not at

home

Normally

Out of

position

Paper

present

Paper

present

At up-

per limit

At up-

per limit

Blocked PJ23A-2

Blocked PJ23A-5

At lower

limit

At lower

limit

Size de-

tected

Size de-

tected

At home PJ8A-4

Paper

present

Paper

present

At home PJ11A-9B

When

counting

In posi-

tion

CN/PJ

No.

.

PJ21A-8A

PJ21A-8B

PJ21A-2A

PJ21A-2B

PJ24A-5

PJ24A-6

PJ25A-2

PJ25A-5

PJ23A-9

PJ23A-12

PJ13A-6

−

T-8

Page 10

Sym-

bol

No.No

No

CNT2 Plug-In Counter/REM 1/8 IC1A P44

RY1 Main Relay 1/8 IC1A P46

LA1

LA2

LA2

S21

S22

S23

S53 Paper Exit Switch 3/8 IC4A BPB2

S61

S62

S63

S64

S106

Parts/Signal Name

bol

Plug-In Counter/Set 3/8 IC5A BPC3

↑↑↑↑

H1 Fusing Heater Lamp 1/8 IC1A P57

Paper Dehumidifying

H3

Heater

Exposure Lamp/AVR

REM

Main Erase Lamp/

REM

Main Erase Lamp/

failure detection

S1 Power Switch 1/8 IC1A P53

Front Door Interlock

Switch

Right Upper Door

Interlock Switch

Left Upper Door

Interlock Switch

Paper Size Detecting

Switch 1

Paper Size Detecting

Switch 2

Paper Size Detecting

Switch 3

Paper Size Detecting

Switch 4

Toner Empty

Detecting Switch

Dis-

IC

No.

Port

No.

play

Page

1/8 IC1A P45

1/8 IC1A P61

2/8 IC4A BPA1

2/8 IC4A APC7

1/8 IC1A P51

3/8 IC5A BPB2

3/8 IC5A BPC6

1/8 IC3A BPA6

1/8 IC3A BPA7

2/8 IC3A BPB4

2/8 IC3A BPB5

3/8 IC1A BPC6

Operation Charac-

teristics/Panel Dis-

I/O

.

f

f

f

f

f

f

play

Hor1 Lor0

When

Normally

Out of

positionInposition

OFF ON PJ33A-2

ON OFF PJ4A-5

ON OFF PJ4A-3

OFF ON PJ8A-13

OFF ON PJ12A-3

OFF ON PJ12A-5

OFF ON PJ4A-1

OFF ON PJ4A-4

OFF ON PJ16A-2

OFF ON PJ16A-4

Paper

present

Size yet

to be de-

tected

Size yet

to be de-

tected

Size yet

to be de-

tected

Size yet

to be de-

tected

Toner

still avail-

able

count-

ing

Paper

not

present

Size de-

tected

Size de-

tected

Size de-

tected

Size de-

tected

Toner

empty

CN/PJ

No.

.

PJ28A-9

PJ28A-7

PJ20A-12

PJ26A-2

PJ26A-4

PJ26A-7

PJ26A-9

PJ11A-8B

T-9

Page 11

Sym-

bol

No.No

No

bol

UN5

↑↑↑↑

UN6

↑↑↑↑

PWB-G

Parts/Signal Name

1st Drawer Paper

Descent Key

Manual Down

Display 1

2ndDrawer Paper

Descent Key

Manual Down

Display 2

AIDC Sensor Board/

AIDC REM

Dis-

IC

No.

Port

No.

play

Page

1/8 IC3A BPA0

1/8 IC3A APC4

1/8 IC3A BPA1

1/8 IC3A APC5

2/8 IC4A APA4

Operation Charac-

teristics/Panel Dis-

I/O

.

f

f

f

play

Hor1 Lor0

OFF ON PJ24A-3

OFF ON PJ24A-1

OFF ON PJ24A-4

OFF ON PJ24A-2

OFF ON −

CN/PJ

No.

.

T-10

Page 12

PF-205

No.No

No

Symbol

M21

M22

M23

M24

M25

PC11

PC13

PC17

PC18

PC19

PC20

PC21

PC22

PC23

Parts/Signal Name

Vertical Transport

Drive Motor

3rd Drawer Paper

Take-Up Motor

4th Drawer Paper

Take-Up Motor

3rd Drawer Paper

Lift-Up Motor

3rd Drawer Paper

↑↑↑↑

Lift-Up Motor

4th Drawer Paper LiftUp Motor

4th Drawer Paper Lift-

↑↑↑↑

Up Motor

Lower Left Door

Sensor

Duplex Unit Turnover

Path Sensor

Vertical Transport

Sensor 3

Lower Right Door

Sensor

3rd Drawer Paper

Lift-Up Sensor

3rd Drawer Paper

Empty Sensor

3rd Drawer Paper

Take-Up Sensor

Vertical Transport

Sensor 4

4th Drawer Paper LiftUp Sensor

Dis-

IC

play

No.

Page

4/8 IC1A PB3

4/8 IC1A PB1

4/8 IC1A PB0

4/8 IC1A PA0

4/8 IC1A PA1

4/8 IC1A PA2

4/8 IC1A PA3

4/8 IC2A PB1

4/8 IC2A PB0

4/8 IC1A PC3

4/8 IC1A PE2

4/8 IC1A PG3

4/8 IC1A PC0

4/8 IC1A PE3

4/8 IC1A PC2

4/8 IC1A PF3

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

f

Display

Hor1 Lor0

Turn in-

hibited

Turn in-

hibited

Turn in-

hibited

OFF

OFF

Out of

positionInposition

Paper

not

present

Paper

not

present

Out of

positionInposition

Not at

upper

limit

Paper

not

present

Paper

not

present

Paper

not

present

Not at

upper

limit

Turn

per-

mitted

Turn

per-

mitted

Turn

per-

mitted

− ON (up) PJ9A-8B

ON

(down)

− ON (up) PJ9A-2A

ON

(down)

Paper

present

Paper

present

At up-

per limit

Paper

present

Paper

present

Paper

present

At up-

per limit

CN/PJ

No.

.

PJ12A-1~

4

PJ11A-1~

4

PJ10A-1~

4

PJ9A-7B

PJ9A-1A

PJ3A-2

PJ3A-5

PJ7A-5

PJ7A-2

PJ6A-12

PJ6A-2

PJ6A-9

PJ6A-5

PJ8A-8

T-11

Page 13

Symbol Parts/Signal Name

No.No

No

4th Drawer Paper

PC24

Empty Sensor

3rd Drawer Set

PC25

Sensor

4th Drawer Set

PC26

Sensor

3rd Drawer Paper

Lift-Up Motor Pulse

PC27

Sensor

4th Drawer Paper LiftUp Motor Pulse

PC28

Sensor

4th Drawer Paper

PC29

Take-Up Sensor

Large Capacity Toner

Collecting Box Set

PC31

Sensor

Dis-

IC

play

No.

Page

4/8 IC1A PD0

4/8 IC1A PG2

4/8 IC1A PF2

4/8 IC1A PC1

4/8 IC1A PD1

4/8 IC2A PB3

4/8 IC2A PC3

Port

No.

Operation Char-

acteristics/Panel

I/O

.

Display

Hor1 Lor0

Paper

present

Out of

positionInposition

Out of

positionInposition

blocked

blocked

Paper

present

Paper

present

not

Un-

Un-

not

not

Paper

present

Blocked

Blocked

Paper

present

Paper

present

CN/PJ

No.

.

PJ8A-2

PJ9A-2B

PJ9A-7A

PJ9A-5B

PJ9A-4A

PJ8A-5

PJ2A-2

T-12

Page 14

PF-105

bol

No.No

No

Sym-

PC11

PC13

PC17

PC18

Parts/Signal Name

bol

Vertical Transport

M21

Drive Motor

3rd Drawer Paper

M22

Take-Up Motor

Main Tray Elevator

M26

Motor

Main Tray Elevator

↑↑↑↑

Motor

M27 Paper Shift Motor 5/8 IC1A PA 0

Paper Shift Motor 5/8 IC1A PA 1

↑↑↑↑

M28 Shift Gate Motor 5/8 IC1A PB2

Shift Tray Paper

PC1

Empty Sensor

Main Tray Lower

PC2

Position Sensor

Shifter Home

PC3

Position Sensor

Shifter Return

PC4

Position Sensor

Elevator Motor

PC5

Pulse Sensor

Shift Motor Pulse

PC6

Sensor

3rd Drawer Set

PC7

Sensor

Lower Left Door

Sensor

Duplex Unit Turnover Path Sensor

Vertical Transport

Sensor 3

Lower Right Door

Sensor

Dis-

IC

play

No.

Page

5/8 IC1A PB3

5/8 IC1A PB1

5/8 IC1A PA2

5/8 IC1A PA3

5/8 IC1A PD1

6/8 IC2A PC1

6/8 IC2A PC0

6/8 IC2A PD1

5/8 IC1A PF2

5/8 IC1A PD0

6/8 IC1A PG2

6/8 IC2A PB1

6/8 IC2A PB0

5/8 IC1A PC3

5/8 IC1A PE2

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

f

Display

Hor1 Lor0

Turn in-

hibited

Turn in-

hibited

Up/stop Down PJ4A-6B

Down/

stop

Trans-

fer/stop

Return/

stop

OFF ON PJ4A-2B

Paper

not

present

Not at

lower

limit

Not at

home

Not at

returned

position

Un-

blocked

Un-

blocked

Out of

positionInposition

Out of

positionInposition

Paper

not

present

Paper

not

present

Out of

positionInposition

Turn

per-

mitted

Turn

per-

mitted

Up PJ4A-7B

Return PJ4A-4B

Transfer PJ4A-5B

Paper

present

At

lower

limit

At home PJ4A-8A

At

returned

position

Blocked

Blocked

Paper

present

Paper

present

CN/PJ

No.

.

PJ12A-1~4

PJ11A-1~4

PJ4A-4A

PJ4A-9A

PJ4A-7A

PJ4A-5A

PJ4A-3A

PJ5A-2

PJ3A-2

PJ3A-5

PJ7A-5

PJ7A-2

T-13

Page 15

Sym-

bol

No.No

No

bol

PC19

PC20

PC21

PC22

PC31

PC34

PC35

PWB-E

UN21

SL41

Parts/Signal Name

3rd Drawer Paper

Lift-Up Sensor

3rd Drawer Paper

Empty Sensor

3rd Drawer Paper

Take-Up Sensor

Vertical Transport

Sensor 4

Large Capacity

Toner Collecting Box

Set Sensor

Shift Gate Position

Sensor

Lower Position

Sensor

Main Tray Paper

Empty Board

Drawer Paper

Descent Key

3rd Drawer Lock

Solenoid

Dis-

IC

play

No.

Page

6/8 IC1A PG3

5/8 IC1A PC0

5/8 IC1A PE3

5/8 IC1A PC2

4/8 IC2A PC3

5/8 IC1A PC1

6/8 IC2A PB3

5/8 IC1A PF3

6/8 IC2A PC2

6/8 IC2A PA1

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

Display

Hor1 Lor0

Not at

upper

limit

Paper

not

present

Paper

not

present

Paper

not

present

Out of

positionInposition

Un-

blocked

Not at

lower

limit

Paper

not

present

OFF ON PJ4A-10A

OFF ON PJ5A-5

At

upper

limit

Paper

present

Paper

present

Paper

present

Blocked

At lower

limit

Paper

present

CN/PJ

No.

.

PJ6A-12

PJ6A-2

PJ6A-9

PJ6A-5

PJ2A-2

PJ4A-1B

PJ4A-2A

PJ4A-6A

T-14

Page 16

AD-9

No.No

No

Symbol

M31

CL31

SL31

SL32

SL33

PC8

PC9

PC14

PC15

PC16

Parts/Signal Name

Duplex Unit Drive

Motor

Duplex Unit Drive

↑↑↑↑

Motor/lock signal

Duplex Unit Paper

Take-Up Clutch

Duplex Unit Gate

Switching Solenoid

Duplex Unit Rear

Finger Solenoid

Duplex Unit Pick-Up

Solenoid

Duplex Gate Home

Position Sensor

Front/Rear Edge

Guide Plate Home

Position Sensor

Duplex Unit Paper

Entry Sensor

Duplex Unit Paper

Empty Sensor

Duplex Unit Paper

Take-Up Sensor

Dis-

IC

play

No.

Page

7/8 IC1G PB3

7/8 IC1G PE1

7/8 IC1G PA3

7/8 IC1G PH1

7/8 IC1G PH0

7/8 IC1G PB2

7/8 IC1G PE0

7/8 IC1G PC3

7/8 IC1G PC1

7/8 IC1G PC2

7/8 IC1G PC0

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

Display

Hor1 Lor0

OFF ON PJ6G-2

When

locked

present

present

present

When

turned

OFF ON PJ2G-7

OFF ON PJ3G-5

OFF ON PJ3G-7

OFF ON PJ2G-12

Not at

Not at

Paper

Paper

Paper

home

home

not

not

not

At home PJ7G-2

At home PJ7G-5

Paper

present

Paper

present

Paper

present

CN/PJ

No.

PJ6G-1

PJ3G-2

PJ2A-4

PJ2G-9

.

T-15

Page 17

C-301

No.No

No

Dis-

Symbol

HMOT Elevator Motor 8/8 IC1A PH0

PWB-B

EMP-

SEN

KSEN Paper Feed Sensor 8/8 IC1A PG0

LEV-

SEN

LOW-

SEN

DSEN

SET-

SEN

Parts/Signal Name

Elevator Motor 8/8 IC1A PH1

↑↑↑↑

Paper Plate Descent

Switch Board

Paper Empty Sensor 8/8 IC1A PC1

Paper Plate Raised

Position Sensor

Paper Plate Lowered

Position Sensor

Cassette Door

Sensor

Set Sensor 8/8 IC1A PC2

Page

IC

play

No.

8/8 IC1A PG1

8/8 IC1A PC0

8/8 IC1A PG3

8/8 IC1A PG2

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

Display

Hor1 Lor0

Down/

stop

Up/stop Down CN5A-1

OFF ON CN2A-2

Paper

present

Paper

present

Not upper limit

Not at

lower

limit

Out of

position

Out of

positionInposition

Up CN5A-2

Paper

not

present

Paper

not

present

At up-

per limit

At lower

limit

In posi-

tion

CN/PJ

No.

.

CN2A-5

CN2A-3

CN2A-6

CN3A-5

CN3A-2

CN2A-4

T-16

Page 18

PF205 : MC

No.No

No

Symbol

M21

M22

M23

M24

↑↑↑↑

M25

↑↑↑↑

PC11

PC13

PC17

PC18

PC19

PC21

PC22

PC23

PC25

PC26

Parts/Signal Name

Vertical Transport

Drive Motor

3rd Drawer Paper

Take-Up Motor

4th Drawer Paper

Take-Up Motor

3rd Drawer Paper

Lift-Up Motor

3rd Drawer Paper

Lift-Up Motor

4th Drawer Paper

Lift-Up Motor

4th Drawer Paper

Lift-Up Motor

Lower Left Door

Sensor

Duplex Unit Turnover Path Sensor

Vertical Transport

Sensor 3

Lower Right Door

Sensor

3rd Drawer Paper

Lift-Up Sensor

3rd Drawer Paper

Take-Up Sensor

Vertical Transport

Sensor 4

4th Drawer Paper

Lift-Up Sensor

3rd Drawer Set

Sensor

4th Drawer Set

Sensor

Dis-

IC

play

No.

Page

6/8 IC1A PB3

6/8 IC1A PB1

6/8 IC1A PB0

6/8 IC1A PA0

6/8 IC1A PA1

6/8 IC1A PA2

6/8 IC1A PA3

6/8 IC2A PB1

6/8 IC2A PB0

6/8 IC1A PC3

6/8 IC1A PE2

6/8 IC1A PG3

6/8 IC1A PE3

6/8 IC1A PC2

6/8 IC1A PF3

6/8 IC1A PG2

6/8 IC1A PF2

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

f

Display

Hor1 Lor0

Turn in-

hibited

Turn in-

hibited

Turn in-

hibited

OFF ON (up) PJ9A-8B

OFF ON (up) PJ9A-7B

OFF ON (up) PJ9A-2A

OFF ON (up) PJ9A-1A

Out of

positionInposition

Paper

not

present

Paper

not

present

Out of

positionInposition

Not at

upper

limit

Paper

not

present

Paper

not

present

Not at

upper

limit

Out of

positionInposition

Out of

positionInposition

Turn

per-

mitted

Turn

per-

mitted

Turn

per-

mitted

Paper

present

Paper

present

upper

limit

Paper

present

Paper

present

upper

limit

CN/PJ

No.

.

PJ12A-1~

4

PJ11A-1~

4

PJ10A-1~

4

PJ3A-2

PJ3A-5

PJ7A-5

PJ7A-2

At

PJ6A-12

PJ6A-9

PJ6A-5

At

PJ8A-8

PJ9A-2B

PJ9A-7A

T-17

Page 19

Symbol Parts/Signal Name

No.No

No

PC29

PC31

PC67

PC68

PC69

PC70

PWB-E1

PWB-E2

UN5

UN6

4th Drawer Paper

Take-Up Sensor

Large Capacity Toner Collecting Box Set

Sensor

3rd Drawer Paper

Lift-Up Motor Pulse

Sensor

4th Drawer Paper

Lift-Up Motor Pulse

Sensor

3rd Drawer Lower

Position Sensor

4th Drawer Lower

Position Sensor

3rd Drawer Paper

Empty Board

4th Drawer Paper

Empty Board

3rdDrawer Paper

Descent Key

4thDrawer Paper

Descent Key

Dis-

IC

play

No.

Page

6/8 IC2A PB3

6/8 IC2A PC3

6/8 IC1A PC1

6/8 IC1A PD1

7/8 IC2A PD1

7/8 IC2A PC0

6/8 IC1A PC0

6/8 IC1A PD0

7/8 IC2A PC1

7/8 IC2A PC2

Port

No.

Operation Char-

acteristics/Panel

I/O

.

Display

Hor1 Lor0

Paper

present

Out of

positionInposition

blocked

blocked

Not at

lower

Not at

lower

Paper

present

Paper

present

OFF ON PJ4A-9A

OFF ON PJ4A-10A

not

present

Un-

Blocked

Un-

Blocked PJ9A-4A

limit

limit

not

present

not

present

Paper

lower

limit

lower

limit

Paper

Paper

CN/PJ

No.

.

PJ8A-5

PJ2A-2

PJ9A-5B

At

PJ4A-7A

At

PJ4A-8A

PJ4A-4A

PJ4A-3A

T-18

Page 20

PF-5D/AD-8

No.No

No

Symbol

M21

M31

↑↑↑↑

CL31

SL31

SL32

SL33

PC8

PC9

PC11

PC13

PC14

PC15

PC16

PC17

PC18

PC31

Parts/Signal Name

Vertical Transport

Drive Motor

Duplex Unit Drive

Motor

Duplex Unit Drive

Motor/lock signal

Duplex Unit Paper

Take-Up Clutch

Duplex Unit Gate

Switching Solenoid

Duplex Unit Rear

Finger Solenoid

Duplex Unit Pick-Up

Solenoid

Duplex Gate Home

Position Sensor

Front/Rear Edge

Guide Plate Home

Position Sensor

Lower Left Door

Sensor

Duplex Unit Turnover

Path Sensor

Duplex Unit Paper

Entry Sensor

Duplex Unit Paper

Empty Sensor

Duplex Unit Paper

Take-Up Sensor

Vertical Transport

Sensor 3

Lower Right Door

Sensor

Large Capacity Toner

Collecting Box Set

Sensor

Dis-

IC

play

No.

Page

4/8 IC1A PB3

7/8 IC1G PB3

7/8 IC1G PE1

7/8 IC1G PA3

7/8 IC1G PH1

7/8 IC1G PH0

7/8 IC1G FB2

7/8 IC1G PE0

7/8 IC1G PC3

5/8 IC2A PB1

5/8 IC2A PB0

7/8 IC1G PC1

7/8 IC1G PC2

7/8 IC1G PC0

5/8 IC1A PC3

5/8 IC1A PE2

5/8 IC2A PC3

Port

No.

Operation Char-

acteristics/Panel

I/O

.

f

f

f

f

f

f

Display

Hor1 Lor0

Turn in-

hibited

OFF ON PJ5G-2

When

locked

OFF ON PJ2G-7

OFF ON PJ3G-5

OFF ON PJ3G-7

OFF ON PJ2G-12

Not at

home

Not at

home

Out of

positionInposition

Paper

not

present

Paper

not

present

Paper

not

present

Paper

not

present

Paper

not

present

Out of

positionInposition

Out of

positionInposition

Turn

per-

mitted

When

turned

At home PJ7G-2

At home PJ7G-5

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

CN/PJ

No.

.

PJ12A-1~

4

PJ5G-1

PJ3A-2

PJ3A-5

PJ3G-2

PJ2G-4

PJ2G-9

PJ7A-5

PJ7A-2

PJ2A-2

T-19

Page 21

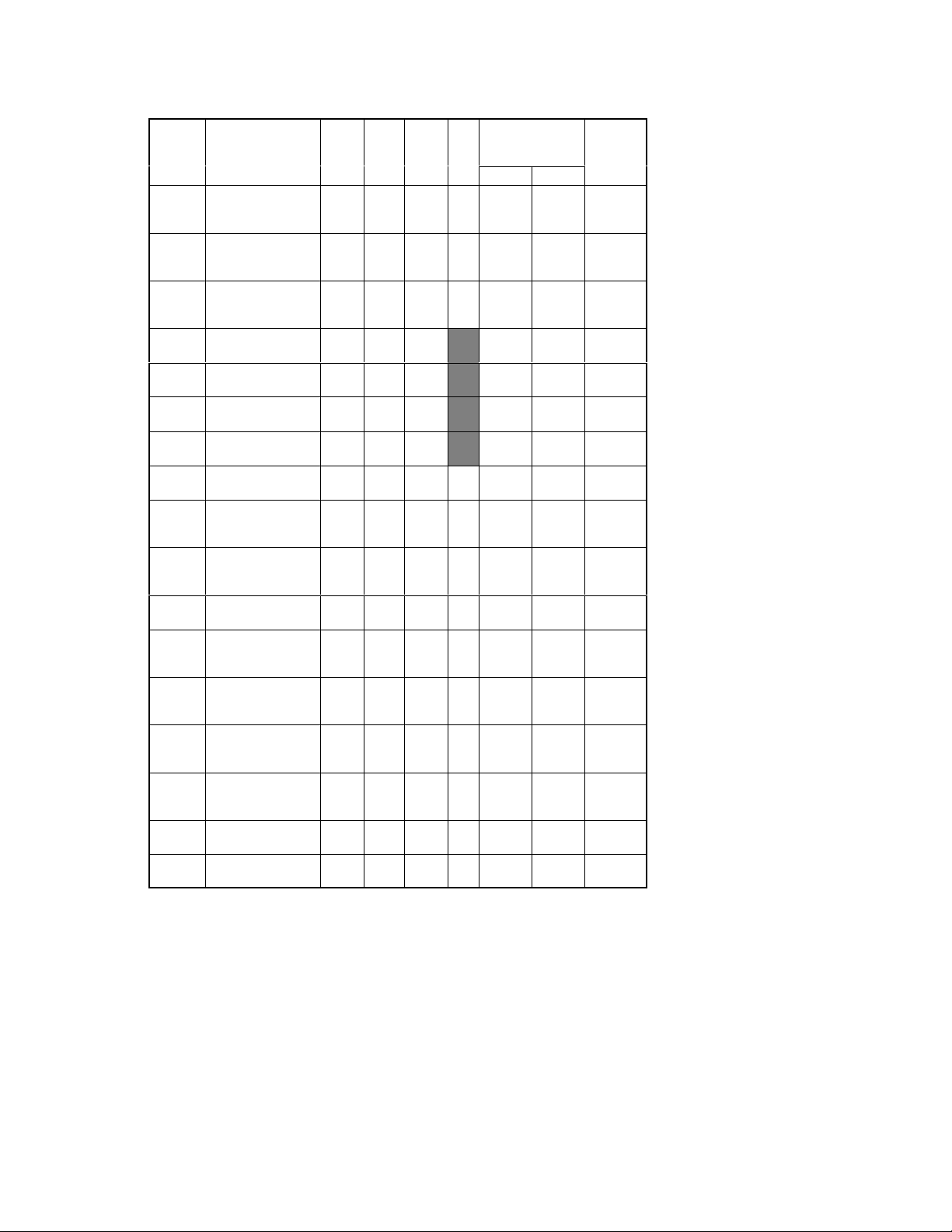

1151SBT0300A

PAPER TRANSPORT FAILURE3

1156SBT0301A

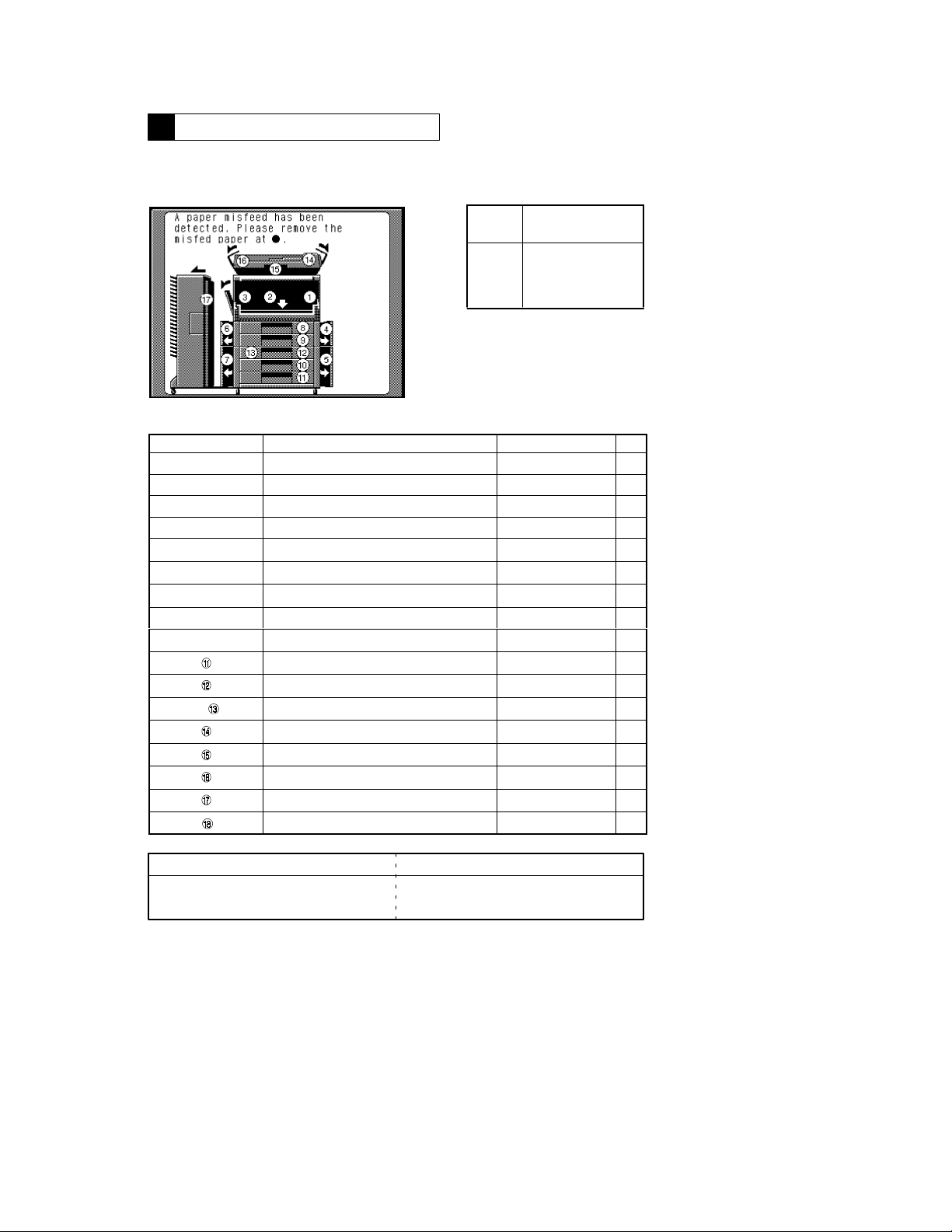

3-1. Paper Misfeed

When a paper misfeed occurs, the Touch Panel shows the corresponding message, misfeed location and

paper location.

Blinking

Light

Steady

Light

There is a misfeed at

that location.

There might be a

sheet of paper

stopped at that

location.

1149T002CA

Blinking/Steady LED

➀

➁

➂

➃

➃,➄

➅,➆

➇

➈

➉

,

➆

Multi Bypass take-up and transport T-22

Transport/separator T-20

Fusing/exit T-24

Copier take-up/vertical transport T-17,18

Paper Feed Cabinet take-up/vertical transport T-25 to 28

Duplex Unit vertical transport T-30

1st Drawer take-up T-17

2nd Drawer take-up T-17

3rd Drawer take-up T-25 to 28

4th Drawer take-up T-26

Duplex Unit take-up T-32,33

Duplex Unit storage T-31

ADF take-up −

ADF transport −

ADF turnover/exit −

Sorter −

LCC −

Misfeed/Paper Location Ref. Page

<Display Resetting Method>

When misfeed occurs in the copier Open and close the Front Door.

When misfeed occurs in the option (except Duplex Unit)

Raise and lower the option, or slide the option

away from, and back up against, the copier.

*When option is installed

*

*

*

*

*

*

*

*

*

*

*

T-20

Page 22

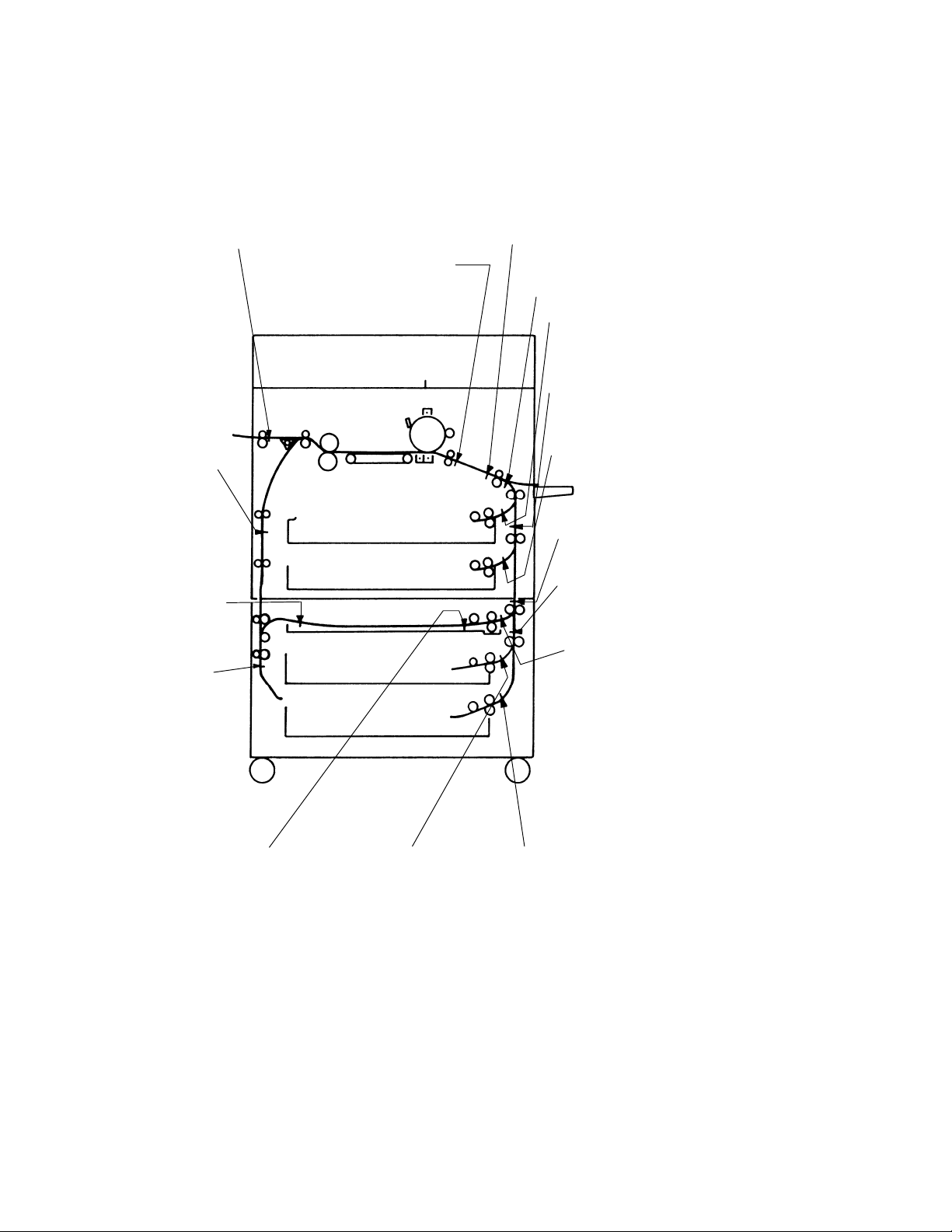

<Misfeed Detecting Sensor Layout>

*When options (PF-205+AD-9)

are installed

Paper Exit Sensor (S53)

*Duplex Unit

Vertical Transport

Sensor (PC12)

*Duplex Unit

Paper Entry

Sensor (PC14)

*Duplex Unit

Turnover Path

Sensor (PC13)

Paper Leading Edge Detecting

Sensor (PC54)

Transport Roller Sensor (PC54)

1st Drawer

Vertical Transport

Sensor (PC63)

1st Drawer Paper

Take-Up Sensor

(PC56)

2nd Drawer

Vertical Transport

Sensor (PC64)

2nd Drawer Paper

Take-Up Sensor

(PC57)

*Vertical Transport Detection

Sensor 3 (PC17)

*Vertical Transport Detection

Sensor 4 (PC22)

*Duplex Unit

Paper T ake-up

Sensor (PC16)

*Duplex Unit Paper

Empty Sensor

(PC15)

*3rd Drawer

Paper T ake-up

Sensor (PC21)

T-21

1156T001AB

*4th Drawer

Paper T ake-up

Sensor (PC29)

Page 23

1156SBT0302A

g

g

p

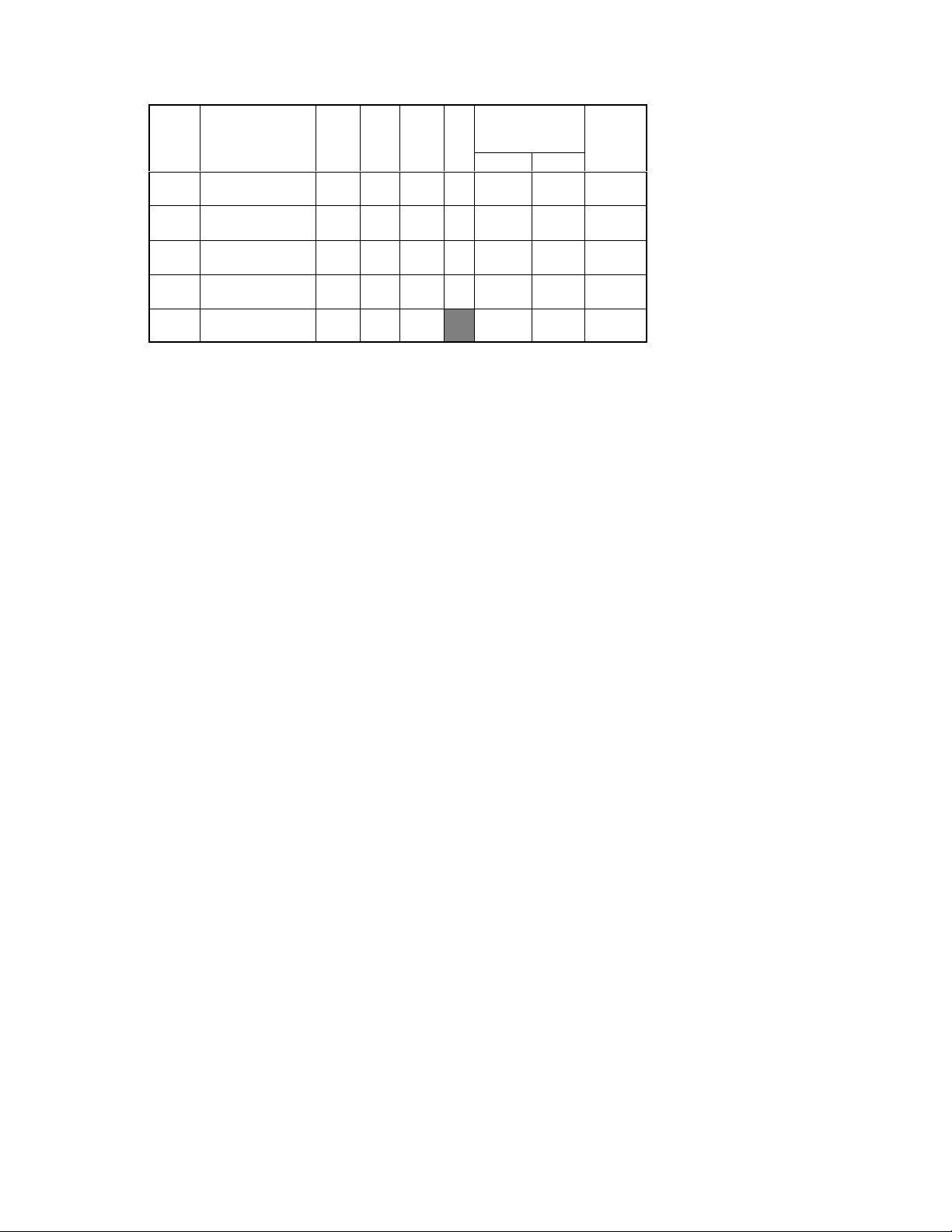

3-2. Misfeed Detection Types and Detection Timings

The following table lists the types of misfeed detection classified by the misfeed locations and their corre-

D

sponding detection timings.

Note: For the misfeed detection types and detection timings in the options, see the Service Manual for

the options.

<Copier Paper Take-up Misfeed>

Type Detection Timing

Paper take-up failure

detection

Paper take-up trailing

edge detection

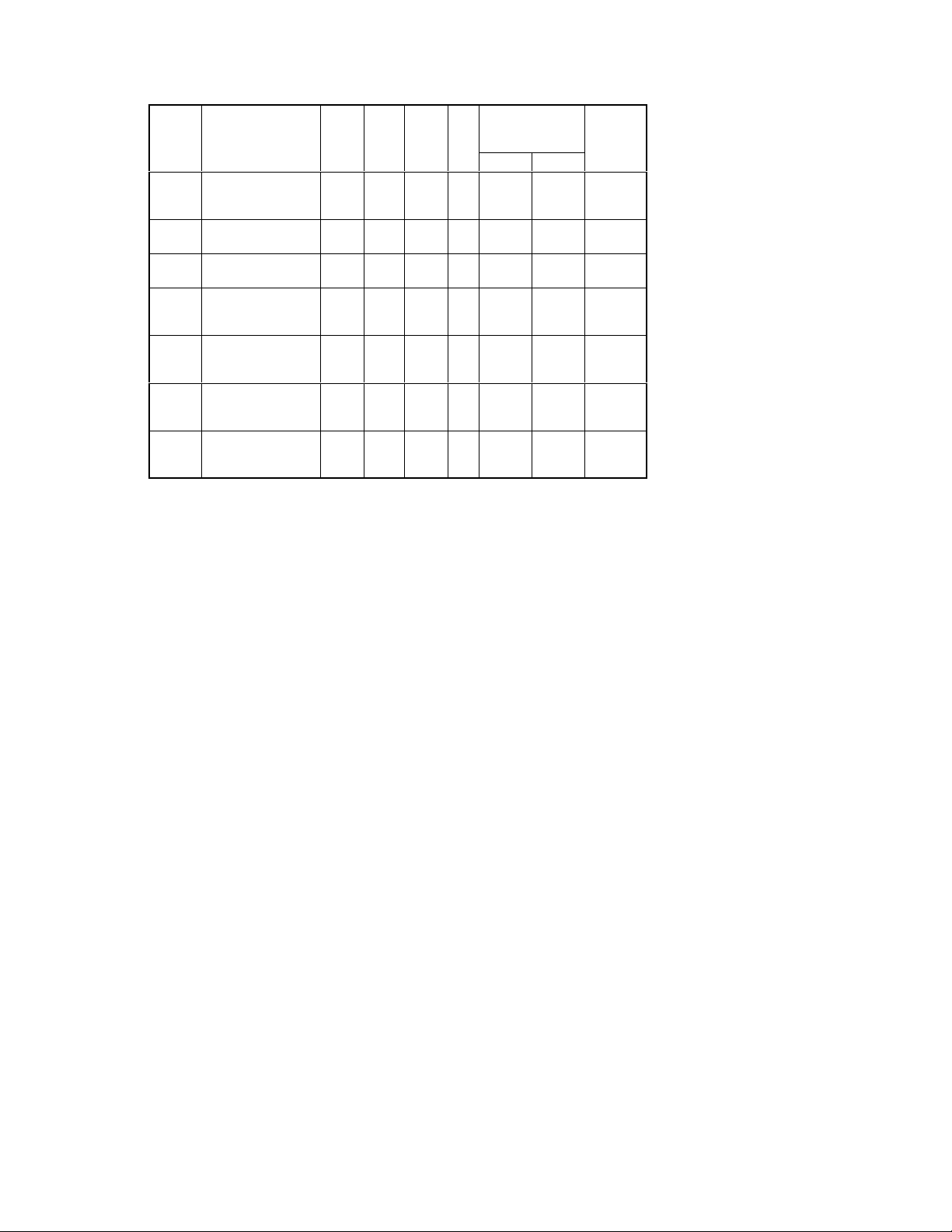

Paper take-up leading

edge detection

Leading edge detection by

Transport Roller Sensor

PC54

1st Drawer Paper Take-Up Sensor PC56 is not blocked (L) even after

the lapse of approx. 2.2 sec. after 1st Drawer Paper Take-Up Motor M11

has been energized.

2nd Drawer Paper Take-Up Sensor PC57 is not blocked (L) even after

the lapse of approx. 2.2 sec. after 2nd Drawer Paper Take-Up Motor

M12 has been energized.

PC56 is not unblocked (H) even after the lapse of T (which varies for

paper sizes) after it has been blocked (L).

PC57 is not unblocked (H) even after the lapse of T (which varies for

paper sizes) after it has been blocked (L).

1st Drawer Vertical Transport Sensor PC63 is not blocked (L) even after

the lapse of approx. 2 sec. after PC56 has been blocked (L).

2nd Drawer Vertical Transport Sensor PC64 is not blocked (L) even

after the lapse of approx. 2 sec. after PC57 has been blocked (L).

PC54 is not blocked (L) even after the lapse of approx. 1.3 sec. after

PC63 has been blocked (L).

PC54 is not blocked (L) even after the lapse of approx. 1.7 sec. after

PC64 has been blocked (L).

<Multi-Bypass Misfeed>

Type Detection Timing

Paper take-up failure

detection

PC54 is not blocked (L) even after the lapse of approx. 2.5 sec. after

Manual Feed Paper Take-Up Clutch CL3 has been energized.

<Transport/Separator Misfeed>

Type Detection Timing

Trailing edge detection by

Transport Roller Sensor

PC54

Leading edge detection by

Paper Leading Edge Detecting Sensor PC55

Trailing edge detection by

PC55

PC54 is not unblocked (H) even after the lapse of T (which varies for

paper sizes) after the TRON signal has been input.

PC55 is not blocked (L) even after the lapse of approx. 1.2 sec. after

PC54 has been blocked (L).

PC55 is not unblocked (H) even after the lapse of approx. 1.2 sec. after

PC54 has been unblocked (H).

T-22

Page 24

<Fusing/Exit Misfeed>

Type Detection Timing

Leading edge detection by

Paper Exit Switch S53

Trailing edge detection by

S53

S53 is not deactuated even after the lapse of approx. 2 sec. after the

TRON signal has been input.

S53 is not actuated even after the lapse of approx. 2.5 sec. after PC55

has been unblocked (H).

T-23

Page 25

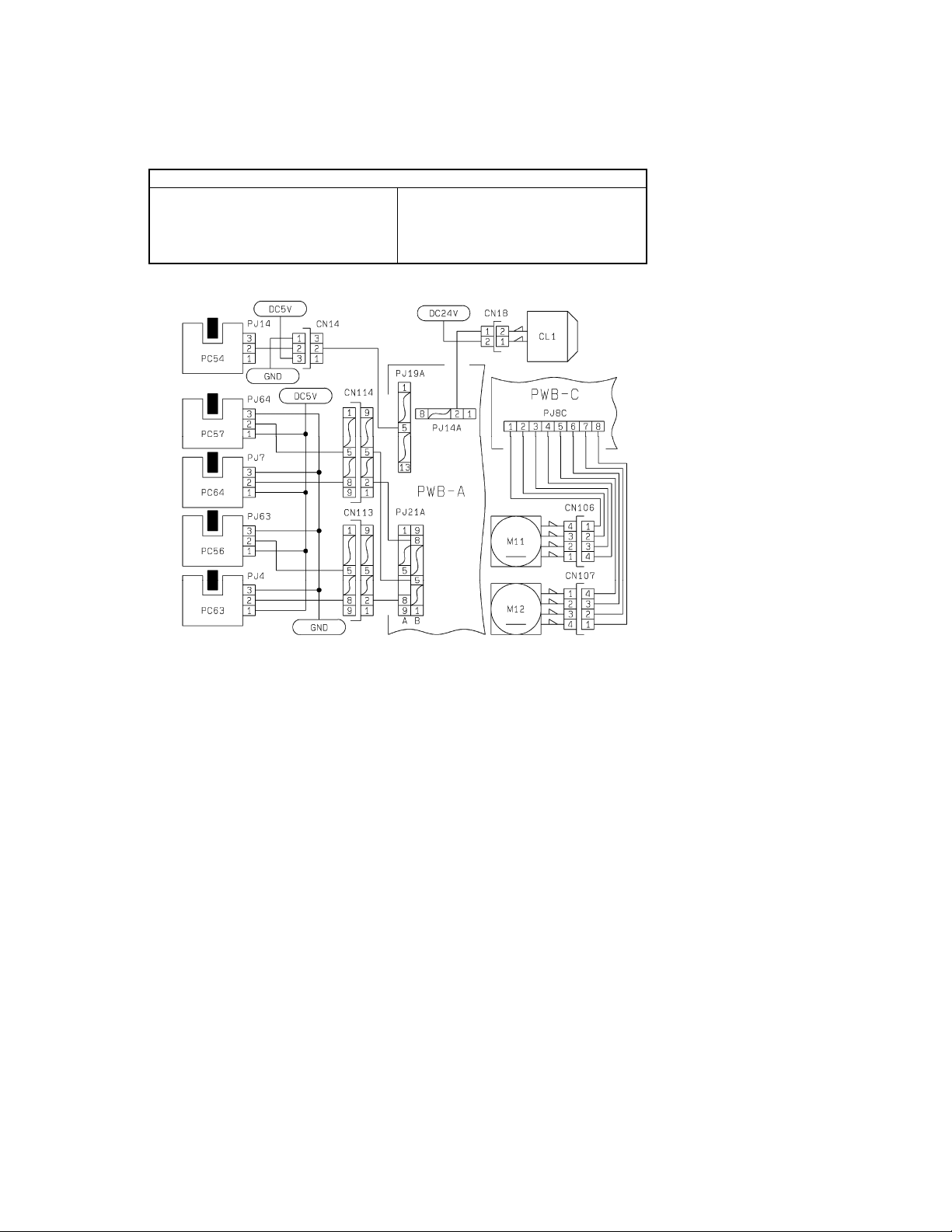

1156SBT0303A

3-3. Misfeed Clearing Procedures

1156SBT030301A

1) Copier Paper Take-Up Misfeed

Relevant Electrical Parts

2nd Drawer Paper Take-Up Sensor PC57

D

1st Drawer Vertical Transport Sensor PC63

D

2nd Drawer Vertical Transport Sector PC64

D

Transport Roller Sensor PC54

D

1st Drawer Paper Take-Up Motor M11

D

2nd Drawer Paper Take-Up Motor M12

D

Paper Transport Clutch CL1

D

Power Supply Board PWB−C

D

Master Board PWB-A

D

T-24

1156C01TAA

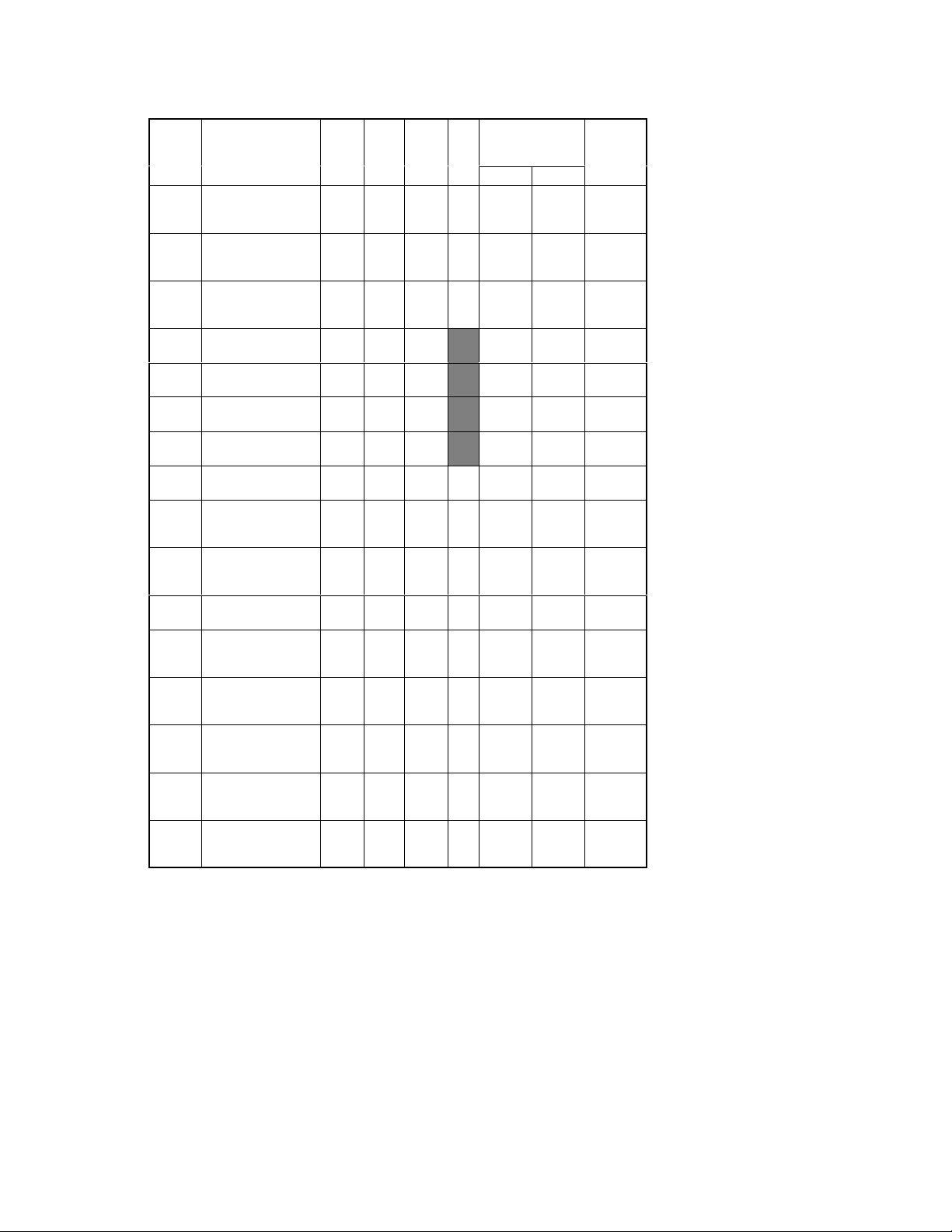

Page 26

!Copier Paper Take-Up Misfeed Clearing Procedure

T

ake Up

Sensor

p

y

ly?

Symptom Step Check Item Result Action

Paper is not taken

D

up at all.

Paper is stationary

D

before the Paper

Take-Up Sensor.

Paper is stationary

at the Vertical Transport Section.

.

Does the paper being used

meet product specifica-

1

tions?

Is the paper curled, waved,

or damp?

2

Is the Trailing Edge Stop or

Edge Guide in good posi-

3

tion?

Are the Paper Take-Up Roll

and Separator Roll de-

4

formed, worn, or dirty with

paper dust?

Is the Paper Take-Up Motor

(M11, M12) turning when

5

the Start key is pressed?

Run the “Controller/Board

Check.” Is either of the

6

malfunction codes C032A

and C032B displayed?

Are the Vertical Transport

Rollers deformed, worn, or

1

dirty with paper dust?

Does PC63 operate properly?

Using the IC Port Data

2

Check function, make an input port check on PWB-A

(IC3A) APB6.

Does PC64 operate properly?

Using the IC Port Data

3

Check function, make an input port check on PWB-A

(IC3A) APB7.

Does PC56 operate properly?

Using the IC Port Data

4

Check function, make an input port check on PWB-A

(IC3A) APB3.

Does PC57 operate properly?

Using the IC Port Data

5

Check function, make an input port check on PWB-A

(IC3A) APB4.

Does PC54 operate properl

?

Using the IC Port Data

6

Check function, make an input port check on PWB-A

(IC5A) BPB6.

Instruct the user to use the

paper that meets product

NO

specifications.

Change the paper. Instruct

the user in how to store the

YES

paper.

Position the edge stop and

guide to meet the paper

NO

size.

Clean or change the Paper

Take-Up Roll and/or Sepa-

YES

rator Roll.

Check the motor for overload.

NO

Change PWB-A.

YES

Change M11, M12, or

NO

PWB-C.

Clean or change the Vertical Transport Rollers.

YES

Check the PC63 actuator

for operation and, if it

checks okay, change PC63.

NO

Check the PC64 actuator

for operation and, if it

checks okay, change PC64.

NO

Check the PC56 actuator

for operation and, if it

checks okay, change PC56.

NO

Check the PC57 actuator

for operation and, if it

checks okay, change PC57.

NO

Change PWB-A.

YES

Check the PC54 actuator

for operation and, if it

NO

checks okay, change PC54.

T-25

Page 27

Symptom Step Check Item Result Action

Paper is stationary

at the Vertical Transport Section

Does CL1 operate properly?

Using the IC Port Data

7

Check function, set the data

of PWB-A (IC4A) BPA3 to

“0.”

Run the “Controller Board

”

Check.” Is the malfunction

8

code “C0321” displayed?

Check the drive transmission path.

YES

Change PWB-A.

YES

Change CL1.

NO

T-26

Page 28

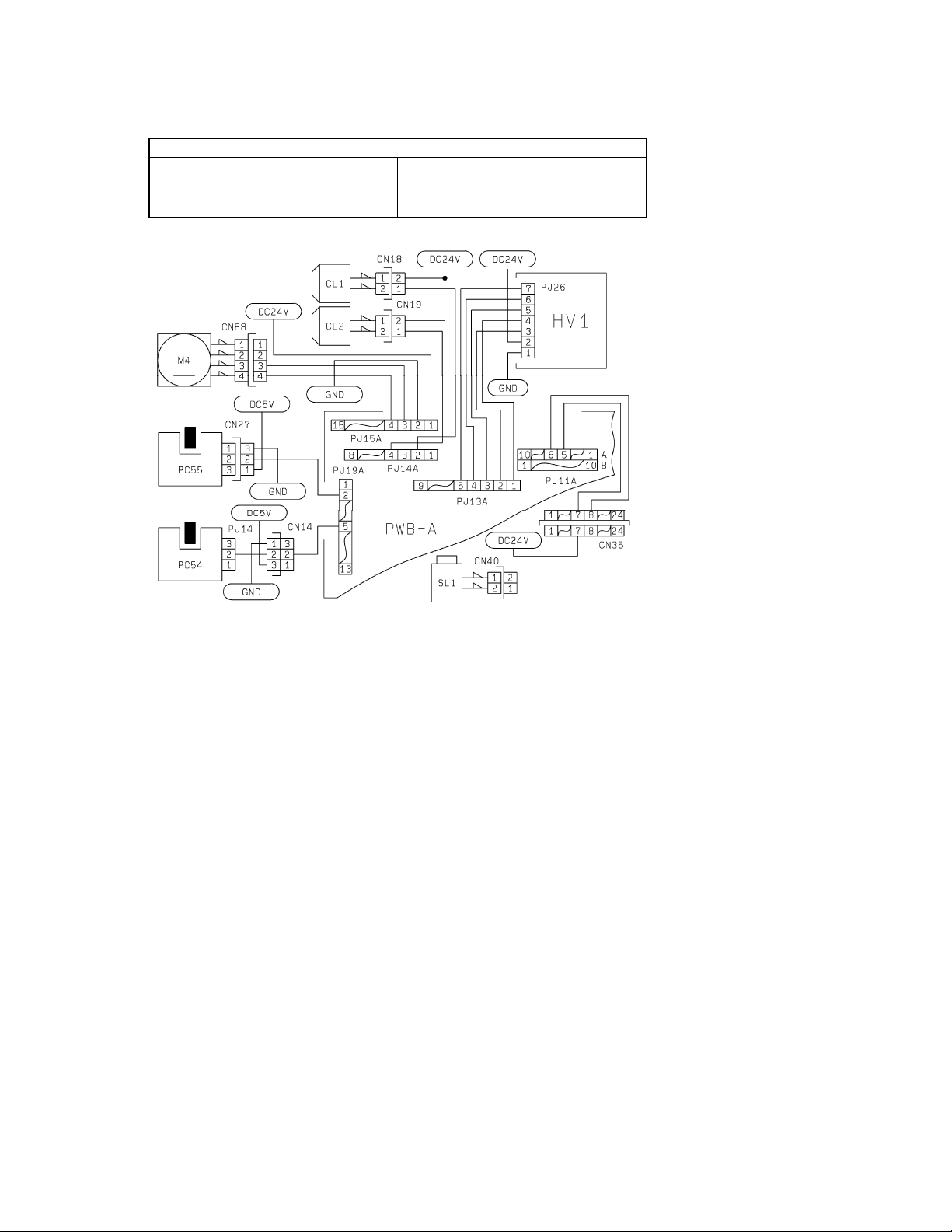

1156SBT030302A

2) Transport/Separator Misfeed

Transport Roller Sensor PC54

D

Paper Leading Edge Detecting Sensor PC55

D

Paper Transport Clutch CL1

D

Synchronizing Roller Clutch CL2

D

Relevant Electrical Parts

Separator Solenoid SL1

D

Suction Fan Motor M4

D

High Voltage Unit HV1

D

Master Board PWB-A

D

T-27

1156C02TAA

Page 29

!Transport/Separator Misfeed Clearing Procedure

g

p

pp y

y

p

Symptom Step Check Item Result Action

Paper is stationary at the Synchronizing Roller.

Paper is stationary near the PC

Drum.

Paper is wedged

at the Paper

Separator Fingers.

Is the paper curled, waved or

damp?

1

Does CL2 operate properly?

Using the IC Port Data Check

2

function, set the data of PWB-A

(IC4A) BPA4 to “0.”

Run the “Controller Board

”

Check.” Is the malfunction code

3

“C0320” displayed?

Is an adequate length of loop

formed before the Synchroniz-

4

ing Roller?

Does PC55 operate properly? YES Change PWB-A.

Using the IC Port Data Check

5

function, make an input port

check on PWB-A (IC5A) BPB5.

Is the Pre-Image Transfer Guide

1

Plate deformed or dirty?

Are the Image Transfer/Paper

Separator Corona wires deterio-

2

rated or dirty?

Is the paper guide at the Paper

Separator Corona deformed or

3

dirty?

Are the Synchronizing Rollers

deformed, worn, or dirty with pa-

4

per dust?

Run the “Controller Board YES Change PWB-A.

Check.” Is the malfunction code

5

“C031D” or ”C031E” displayed?

Are the Paper Separator Fin-

1

gers deformed or dirty?

Does SL1 operate properly?

Using the IC Port Data Check

2

function, set the data of PWB-A

(IC4A) BPA0 to “0.”

Run the “Controller Board

”

Check.” Is the malfunction code

3

“C0324” displayed?

Change the paper. Instruct

the user in how to store the

YES

paper.

Check the drive transmission path.

YES

Change PWB-A.

YES

Change CL2.

NO

Adjust the loop length using

the “Loop Adjust (Drawer)”

NO

function of “Tech. Rep.

Choice.”

Check the PC55 actuator for

operation and, if it checks

NO

okay, change PC55.

Correct, clean, or change

YES

the guide plate.

Clean or change the wires.

YES

Clean or change the paper

guide.

YES

Clean or change the Synchronizing Rollers.

YES

Change the Image Transfer/

Paper Separator Coronas

NO

Assy or HV1.

Clean or change the Paper

YES

Separator Fingers.

Check the drive transmission path.

YES

Change PWB-A.

YES

Change SL1.

NO

T-28

Page 30

Symptom Step Check Item Result Action

y

Paper is stationary on the Suction Belts.

Do the Suction Belts turn when

1

the Main Drive Motor runs?

Does M4 operate properly?

Using the IC Port Data Check

function, set the data of PWB-A

2

(IC4A) BPC2 to “0.” Does M4

then run at full speed?

Check the drive gears and

NO

timing belt.

Check the Suction Belts.

YES

Change M4 or PWB-A.

NO

T-29

Page 31

1156SBT030303A

3) Multi Bypass Misfeed

Manual Feed Paper Empty Sensor PC51

D

Manual Feed Paper Take-Up Solenoid SL51

D

Manual Feed Paper Take-Up Clutch CL3

D

Relevant Electrical Parts

Master Board PWB-A

D

T-30

1156C03TAA

Page 32

!Multi Bypass Misfeed Clearing Procedure

y

tected

ly?

Symptom Step Check Item Result Action

Paper is not detected.

.

Paper is not taken

up at all.

Does PC51 operate properl

?

Using the IC Port Data

1

Check function, make an input port check on PWB-A

(IC5A) BPB1.

Does the paper being used

meet product specifica-

1

tions?

Is the paper curled, waved,

or damp?

2

Is the Manual Bypass Paper Take-Up Roll deformed,

3

worn, or dirty with paper

dust?

Does SL51 operate properly?

Using the IC Port Data

4

Check function, set the data

of PWB-A (IC5A) BPA3 to

“0.” Does the roll then go

down?

Run the “Controller/Board

”

Check.” Is the malfunction

5

code ”C0336” displayed?

Does CL3 operate properly?

Using the IC Port Data

6

Check function, set the data

of PWB-A (IC5A) BPA1 to

“0.”

Run the “Controller/Board

”

Check.” Is the malfunction

7

code “C0337” displayed?

Change PWB-A.

YES

Check the PC51 actuator

for operation and, if it

NO

checks okay, change PC51.

Instruct the user to use the

paper that meets product

NO

specifications.

Change the paper. Instruct

the user in how to store the

YES

paper.

Clean or change the Manual Bypass Paper Take-Up

YES

Roll.

Check the drive transmission path.

YES

Change PWB-A.

YES

Change SL51.

NO

Check the drive transmission path.

YES

Change PWB-A.

YES

Change CL3.

NO

T-31

Page 33

1156SBT030304A

4) Fusing/Exit Misfeed

Paper Exit Switch S53

D

Relevant Electrical Parts

Suction Fan Motor M4

D

Master Board PWB-A

D

1156C04TAA

T-32

Page 34

!Fusing/Exit Misfeed Clearing Procedure

Check

function

set

the

data

g

y

at

the

Exit

Roller

ly?

Symptom Step Check Item Result Action

Paper is stationary

before the Fusing

Roller.

Paper is stationary

at the Fusing Roller.

Paper is stationary

at the Exit Roller.

.

Is the paper curled, waved,

or damp?

1

Is the Fusing Guide Plate

2

deformed or dirty?

Does M4 operate properly?

Using the IC Port Data

Check function, set the data

3

of PWB-A (IC4A) BPC2 to

“0.” Does M4 then turn at

full speed?

Are the Fusing Rollers dirty

1

or scratched?

Are the Fusing Roller Paper

Separator Fingers de-

2

formed, worn, or dirty?

3 Is the Cleaning Roller dirty

or scratched?

Does S53 operate properl

?

Using the IC Port Data

1

Check function, make an input port check of PWB-A

(IC5A) BPB3.

,

Change the paper. Instruct

the user in how to store the

YES

paper.

Clean, correct, or change

YES

the Fusing Guide Plate.

Check the Suction Belts.

YES

Change M4 or PWB-A.

NO

Clean or change the Fusing

YES

Rollers.

Clean, correct, or change

the defective separator fin-

YES

gers.

Clean or change the Clean-

YES

ing Roller.

Change PWB-A.

YES

Check the S53 actuator for

operation and, if it checks

NO

okay, change S53.

T-33

Page 35

1156SBT030305A

5) PF-205 Paper Take-Up Misfeed

Relevant Electrical Parts

3rd Drawer Paper Take-Up Sensor PC21

D

4th Drawer Paper Take-Up Sensor PC29

D

Vertical Transport Sensor 3 PC17

D

Vertical Transport Sensor 4 PC22

D

3rd Drawer Paper Take-Up Motor M22

D

4th Drawer Paper Take-Up Motor M23

D

Vertical Transport Drive Motor M21

D

PF-205 Master Board PWB-A

D

EP5000/EP4000 Master Board PWB-A

D

T-34

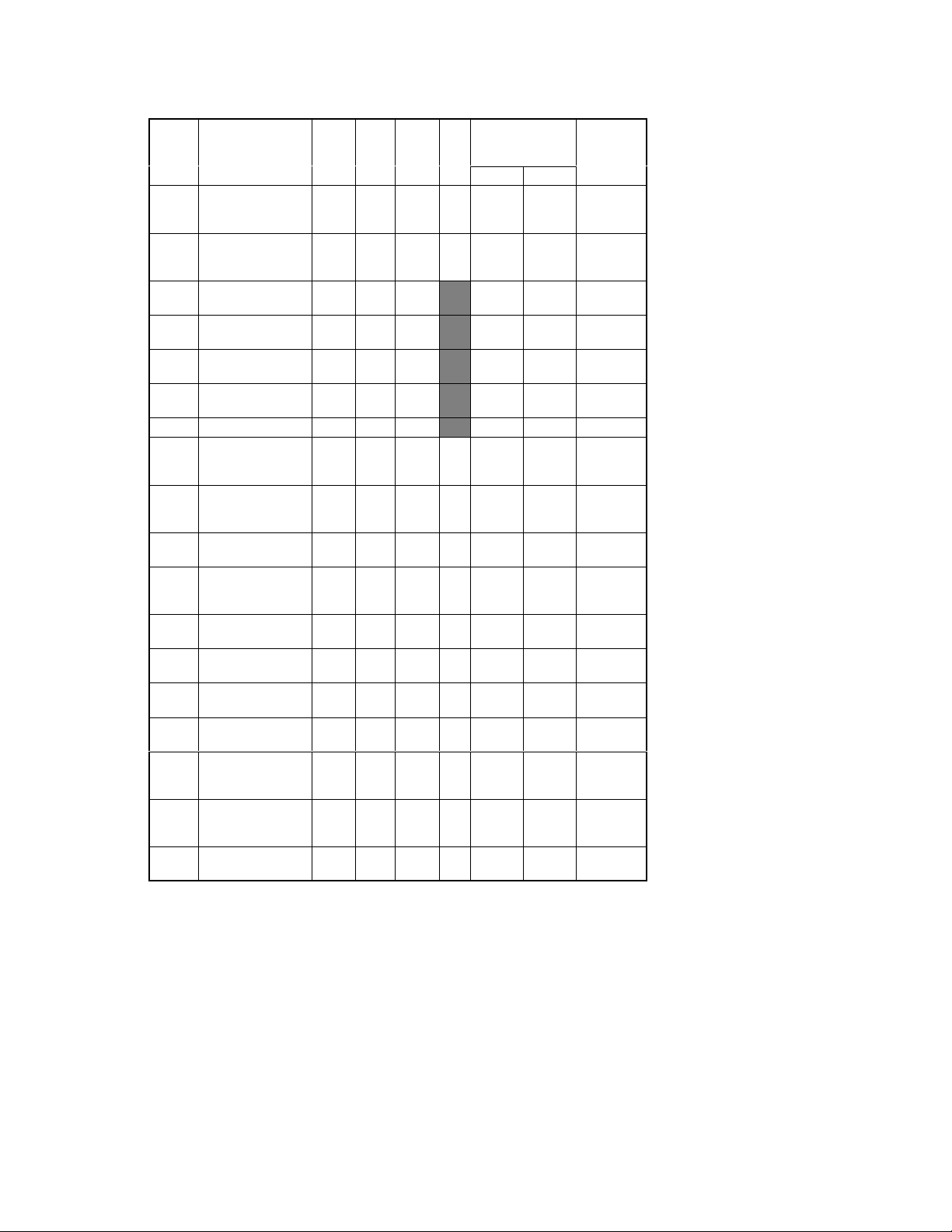

1156C24TAA

Page 36

Symptom Step Check Item Result Action

S

Start

keyispressed?

D

Change

PWB A

T

ransport

Section

is

pressed?

D

Change

PWB A

g

Paper is not tak-

D

en up at all.

Paper is station-

D

ary before the

Paper Take-Up

ensor.

Paper is stationary

at the Vertical

Transport Section.

Does the paper being used

meet product specifications?

1

Is the paper curled, waved, or

damp?

2

Are the Paper Take-Up Roll and

Separator Roll deformed, worn,

4

or dirty with paper dust?

Is the Paper Take-Up Motor

(M22, M23) turning when the

Start key is pressed?

5

Is Vertical Transport Drive Motor

M21 turning when the Start key

.

is pressed?

1

Are the Vertical Transport Rollers deformed, worn, or dirty with

2

paper dust?

Does PC17 operate properly?

Using the IC Port Data Check

3

function, make an input port

check on PWB-A (200) IC1A

PC3 (metric areas) or PWB-A

(MC) IC1A PC3 (inch areas).

Does PC22 operate properly?

Using the IC Port Data Check

function, make an input port

4

check on PWB-A (200) IC1A

PC2 (metric areas) or PWB-A

(MC) IC1A PC2 (inch areas).

Does PC21 operate properly?

Using the IC Port Data Check

function, make an input port

5

check on PWB-A (200) IC1A

PE3 (metric areas) or PWB-A

(MC) IC1A PE3 (inch areas).

Does PC29 operate properly?

Using the IC Port Data Check

function, make an input port

6

check on PWB-A (200) IC1A

PB3 (metric areas) or PWB-A

(MC) IC1A PB3 (inch areas).

Instruct the user to use

the paper that meets

NO

product specifications.

Change the paper.

Instruct the user in how

YES

to store the paper.

Clean or change the Paper Take-Up Roll and/or

YES

Separator Roll.

Check the motor for

D

overload.

Change PWB-A

D

NO

NO

YES

NO

NO

NO

YES

NO

(PF-205) or

PWB-A (copier).

Change M22 or M23.

Check the motor for

D

overload.

Change PWB-A

D

(PF-205) or

PWB-A (copier).

Change M21.

Clean or change the Vertical Transport Rollers.

Check the PC17 actuator

for operation and, if it operates properly, change

PC17.

Check the PC22 actuator

for operation and, if it operates properly, change

PC22.

Check the PC21 actuator

for operation and, if it operates properly, change

PC21.

Change PWB-A (PF-205)

or PWB-A (copier).

Check the PC29 actuator

for operation and, if it operates properly, change

PC29.

T-35

Page 37

1156SBT030306A

6) PF-105 Paper Take-Up Misfeed

Relevant Electrical Parts

3rd Drawer Paper Take-Up Sensor PC21

D

Vertical Transport Sensor 3 PC17

D

Vertical Transport Sensor 4 PC22

D

3rd Drawer Paper Take-Up Motor M22

D

Vertical Transport Drive Motor M21

D

PF-105 Master Board PWB-A

D

EP5000/EP4000 Master Board PWB-A

D

T-36

1156C26TAA

Page 38

Symptom Step Check Item Result Action

g

Paper is not taken

D

up at all.

Paper is stationary

D

before the Paper

Take-Up Sensor.

Paper is stationary

at the Vertical Transport Section.

Does the paper being used

meet product specifica-

1

tions?

Is the paper curled, waved,

or damp?

2

Are the Paper Take-Up Roll

and Separator Roll de-

4

formed, worn, or dirty with

paper dust?

Is 3rd Drawer Paper TakeUp Motor M22 turning when

the Start key is pressed?

5

Is Vertical Transport Drive

Motor M21 turning when the

Start key is pressed?

1

Are the Vertical Transport

Rollers deformed, worn, or

2

dirty with paper dust?

Does PC17 operate properly?

3

Using the IC Port Data

Check function, make an input port check on PWB-A

(400) (IC1A) PC3.

Does PC22 operate properly?

Using the IC Port Data

4

Check function, make an input port check on PWB-A

(400) (IC1A) PC2.

Does PC21 operate properly?

Using the IC Port Data

Check function, make an in-

5

put port check on PWB-A

(400) (IC1A) PE3.

Instruct the user to use the

paper that meets product

NO

specifications.

Change the paper. Instruct

the user in how to store the

YES

paper.

Clean or change the Paper

Take-up Roll and/or Sepa-

YES

rator Roll.

Check the motor for over-

D

load.

Change PWB-A (PF-105)

D

NO

or PWB-A (copier).

Change M22.

Check the motor for over-

D

load.

Change PWB-A (PF-105)

D

NO

or PWB-A (copier).

Change M21.

Clean or change the Vertical Transport Rollers.

YES

Check the PC17 actuator

for operation and, if it operates properly, change

NO

PC17.

Check the PC22 actuator

for operation and, if it operates properly, change

NO

PC22.

Change PWB-A (PF-105)

or PWB-A (copier).

YES

Change M21.

Check the PC21 actuator

for operation and, if it oper-

NO

ates properly, change

PC21.

T-37

Page 39

1156SBT030307A

7) AD-9 Vertical Transport/Storage Misfeed

Relevant Electrical Parts

Vertical Transport Sensor 3 PC17

D

Duplex Unit Vertical Transport Sensor PC12

D

Duplex Unit Turnover Path Sensor PC13

D

Duplex Unit Paper Entry Sensor PC14

D

Duplex Unit Paper Empty Sensor PC15

D

Vertical Transport Sensor 3 PC17

D

D

D

D

D

D

D

Exit/Duplex Switching Solenoid SL5

Duplex Unit Gate Switching Solenoid SL31

Duplex Unit Drive Motor M31

Duplex Unit Master Board PWB-G

PF-205/105 Master Board PWB-A

EP5000/EP4000 Master Board PWB-A

T-38

1156C30TAA

Page 40

!AD-9 Vertical Transport Misfeed Clearing Procedure

y

Symptom Step Check Item Result Action

Paper is stationary

at the copier exit

section.

Paper is stationary

at the Duplex Unit

Vertical Transport

Section.

Paper is stationary

at the Duplex Unit

Turnover Section.

Does SL5 operate properly?

Using the IC Port Data

1

Check function, set the data

of PWB-A (IC4A) BPA5 to

“0.”

Run the “Controller Board

”

Check.” Is the malfunction

2

code “C0324” displayed?

Do the Vertical Transport

Roller and drive coupling

operate properly when M31

is running?

1

Using the IC Port Data

Check function, set the data

of PWB-G (Dup) (IC1G)

PB3 to “0.”

Does PC12 operate properly?

Using the IC Port Data

2

Check function, make an input port check of PWB-A

(IC5A) BPB0.

Do the Paddle Roller, Slip

Roller, and drive coupling

operate properly when M31

is running?

1

Using the IC Port Data

Check function, set the data

of PWB-G (Dup) (IC1G)

PB3 to “0.”

Does PC13 operate properly?

Using the IC Port Data

2

Check function, make an input port check of PWB-A

(200/400) (IC2A) PB0.

Check the drive transmission path.

YES

Change PWB-A.

YES

Change SL51.

NO

Check the gears, belts, and

rollers.

NO

Change PWB-A.

YES

Check the PC12 actuator

for operation and, if it oper-

NO

ates properly, change

PC12.

Check the gears, belts, and

rollers.

NO

Change PWB-A (copier) or

YES

PWB-A (PF-205/105).

Check the PC13 actuator

for operation and, if it oper-

NO

ates properly, change

PC13.

T-39

Page 41

!AD-9 Storage Misfeed Clearing Procedure

pp

,

y

g

Symptom Step Check Item Result Action

The leading edge of

the paper is stationary inside the Duplex Unit.

Paper is stationary

at the storage section.

Is the Paper Guide Mylar

1

dirty or deformed?

Does PC14 operate properly? Using the IC Port Data

Check function, make an input port check on PWB-A

2

(Dup) (IC1G) PC1.

Does SL31 operate properly?

Using the IC Port Data

3

Check function, set the data

of PWB-A (Dup) (IC1G)

PH1 to “0.”

Does PC15 operate properly?

Using the IC Port Data

Check function, make an in-

1

put port check of PWB-A

(Dup) (IC1G) C2.

Clean or change the mylar.

YES

Change PWB-G, PWB-A

(copier), or PWB-A

YES

(PF-205/105).

Check the PC14 actuator

for operation and, if it oper-

NO

ates properly, change

PC14.

Check the Gate Switching

YES

Lever for operation.

Change PWB-G, PWB-A

(copier), or PWB-A

NO

(PF-205/105). Change

SL31.

Change PWB-G, PWB-A

(copier), or PWB-A

YES

(PF-205/105).

Check the PC15 actuator

for operation and, if it oper-

NO

ates properly, change

PC15.

T-40

Page 42

1156SBT030308A

8) AD-9 Paper Take-Up Misfeed

Relevant Electrical Parts

Duplex Unit Paper Take-Up Sensor PC16

D

Vertical Transport Sensor 3 PC17

D

Vertical Transport Drive Motor M21

D

Duplex Unit Paper Take-Up Clutch CL31

D

Duplex Unit Pick-Up Solenoid SL33

D

Duplex Unit Master Board PWB-G

D

PF-205/105 Master Board PWB-A

D

EP5000/EP4000 Master Board PWB-A

D

T-41

1156C31TAA

Page 43

!AD-9 Paper Take-Up Misfeed Clearing Procedure

p1y

y

g

y

y

Symptom Step Check Item Result Action

Paper is not taken

up at all.

Paper is stationary

at the Vertical Transport Section.

Does SL33 operate properly?

Using the IC Port Data

Check function, set the data

of PWB-A (Dup) (IC1G)

PB2 to “0.”

Does CL33 operate properly?

Using the IC Port Data

2

Check function, set the data

of PWB-A (Dup) (IC1G)

PA3 to “0.”

Are the Take-Up Roll, Feed

Roll, and Separator Roll de-

3

formed, worn, or dirty with

paper dust?

Is Vertical Transport Drive

Motor M21 turning when a

copy is taken up and fed

1

into the copier from the Duplex Unit?

Are the Vertical Transport

Rollers deformed, worn, or

2

dirty with paper dust?

Does PC17 operate properly?

Using the IC Port Data

3

Check function, make an input port check of PWB-A

(200, 400) (IC1A) PC3.

Does PC16 operate properly?

Using the IC Port Data

4

Check function, make an input port check of PWB-A

(Dup) (IC1G) PC0.

Check the pick-up mecha-

YES

nism.

Change PWB-G, PWB-A

(copier), or PWB-A

NO

(PF-205/105). Change

SL33.

Check the drive transmis-

YES

sion path.

Change PWB-G, PWB-A

(copier), or PWB-A

NO

(PF-205/105). Change

CL31.

Clean or change the defective roll.

YES

Check the motor for over-

YES

load.

Change PWB-A (copier) or

PWB-A (PF-205/105).

NO

Change M21.

Clean or change the defective roller.

YES

Change PWB-A (copier) or

YES

PWB-A (PF-205/105).

Check the PC17 actuator

for operation and, if it oper-

NO

ates properly, change

PC17.

Change PWB-A (copier) or

YES

PWB-A (PF-205/105).

Check the PC16 actuator

for operation and, if it oper-

NO

ates properly, change

PC16.

T-42

Page 44

1151SBT0400A

MALFUNCTIONS4

1156SBT0401A

4-1. Detection Timings Classified by Malfunction Codes

The codes marked with an asterisk (*) are the candidates for isolated malfunctions.

D

C00## Drive Malfunctions

* Code Description Detection Timing

Main Drive Motor M1’s failure to turn The lock signal remains HIGH for a continu-

C0000

Main Drive Motor M1 turning at abnormal timing

C0001

Suction Fan Motor M4’s failure to turn The lock signal remains HIGH for a continu-

C0040

Fusing Section Cooling Fan Motor

M15’s failure to turn

C0046

Fusing Section Cooling Fan Motor

* C0047

* C004b

* C004d

M15 turning at abnormal timing

Original Glass Cooling Fan Motor

M5’s failure to turn

C004A

Original Glass Cooling Fan Motor M5

turning at abnormal timing

Ventilation Fan Motor M3’s failure to

turn

C004c

Ventilation Fan Motor M3 turning at

abnormal timing

Main Hopper Toner Replenishing Motor M8’s failure to turn

C0070

Main Hopper Toner Replenishing Mo-

C0071

tor M8 turning at abnormal timing

Sub Hopper Toner Replenishing Motor

M9’s failure to turn

C0072

1156SBT040101A

ous 2.0-sec. or more period while M1 is energized.

The lock signal remains LOW for a continuous 1.5-sec. or more period while M1 is deenergized.

ous 1.0-sec. or more period while M4 is energized.

The lock signal remains HIGH for a continuous 2.0-sec. or more period while M15 is energized.

The lock signal remains LOW for a continuous 2.0-sec. or more period while M15 is

deenergized.

The lock signal remains HIGH for a continuous 2.0-sec. or more period while M5 is energized.

The lock signal remains LOW for a continuous 2.0-sec. or more period while M5 is deenergized.

The lock signal remains HIGH for a continuous 2.0-sec. or more period while M3 is energized.

The lock signal remains LOW for a continuous 2.0-sec. or more period while M3 is deenergized.

Toner Bottle Home Position Sensor PC35

D

does not go from HIGH to LOW within 12 sec.

after M8 has been energized.

PC35 does not go LOW within 12 sec. after

D

M8 has been energized and PC35 gone

HIGH.

PC35 is HIGH 2 sec. after M8 has been deenergized.

When the current toner-to-carrier ratio is 2%

lower than the SCH-90 setting and the Add

Toner Indicator is not lit on the control panel, a

toner replenishing sequence is carried out

(M9 is turned); the toner-to-carrier ratio does

not increase by 1% within 140 seconds or by

2% within 220 seconds.

T-43

Page 45

C02## Corona Malfunction

* Code Description Detection Timing

PC Drum Charge, Image Transfer, Paper Separator Corona malfunction

C0200

1156SBT040102A

The leak signal (SCD) turns ON after the PC

Drum Charge and Image Transfer/Paper Separator Corona output has been turned ON.

C03## Master Board/Harness Malfunctions

The copier performs a self-diagnostic sequence to determine if the microprocessor outputs a signal to

D

each of the IC ports on Master Board PWB-A properly. It is intended for detecting the following malfunctions (C03##).

Any malfunction is detected when “Controller Board Check” available from the “I/O Check” function of the

D

Tech. Rep. mode is executed.

If the microprocessor fails to output any of these signals or if any of the electronic components on the board

D

(driver IC, etc.) is faulty,the copier determines that there is a faulty condition existing and shows the corresponding malfunction code on the Touch Panel.

C0350, C0351, C0352, C0353, or C0357 is displayed when there is a communication fault between the

D

copier and paper feeder option or Duplex Unit, and detected as an isolated malfunction when the Power

Switch is turned ON.

Code Description Master Board Port

*

C0300 Port diagnosis cannot be started. —

C0310 Drum Dehumidifying Heater H2 REM signal IC1A P45

C0311 Fusing Heater Lamp H1 REM signal IC1A P57

C0312 Exposure Lamp Regulator PWB-J REM signal IC1A P61

C0313 AE Sensor Board PWB-H PWM signal IC1A P60

C0314 Image Erase Lamp LA3 DATA IC1A P64

C0315 Image Erase Lamp LA3 MODE IC1A P65

C0316 Image Erase Lamp LA3 CLOCK IC1A P66

C0317 Image Erase Lamp LA3 STROBE IC1A P67

C0318 Copy vendor count (during copy cycle) IC3A APA1

C0319 Copy vendor count (size) IC3A APA0

C031A 2nd Drawer Paper Take-Up Motor M12 energization IC3Aφ1

C031B 1st Drawer Paper Take-Up Motor M11 energization IC3AφO

C031C Original size detection IC4A APA7

C031D Original size detection, marketing area 2 IC4A APA6

C031E Original size detection, marketing area 1 IC4A APA5

C031F Scanner Motor M2 SCAN signal IC4A APC0

C0320 Scanner Motor M2 ENABLE signal IC4A APC1

C0321 Fusing Section Cooling Fan Motor M15 REM signal IC4A APC2

C0322 Separator/Developing Bias output REM signal IC4A BPA7

C0323 PC Drum Charge/Image Transfer output REM signal IC4A BPA6

C0324 Exit/Duplex Switching Solenoid SL5 IC4A BPA5

C0325 Synchronizing Roller Clutch CL2 IC4A BPA4

C0326 Paper Transport Clutch CL1 IC4A BPA3

C0327 Main Drive Motor M1 REM signal IC4A BPA2

C0328 Main Erase Lamp LA2 REM signal IC4A BPA1

C0329 Separator Solenoid SL1 REM signal IC4A BPA0

1156SBT040103A

T-44

Page 46

* Code Description Master Board Port

g

py

/

C032A Main Hopper Toner Replenishing Motor M8 IC4A BPC3

C032B Suction Fan Motor M4 33/ Ventilation Fan Motor M3 IC4A BPC2

C032C Ventilation Fan Motor M3 IC4A BPC1

C032D 2nd Drawer Paper Lift-Up Motor M14 DOWN IC5A APA7

C032E 2nd Drawer Paper Lift-Up Motor M14 UP IC5A APA6

C032F 1st Drawer Paper Lift-Up Motor M13 DOWN IC5A APA5

C0330 1st Drawer Paper Lift-Up Motor M13 UP IC5A APA4

C0331 Separator bias switching IC5A APA3

C0332 Sub Hopper Toner Replenishing Motor M9 IC5A APA2

C0333 2nd Drawer Paper Take-Up Motor M12 ENABLE IC5A APA1

C0334 1st Drawer Paper Take-Up Motor M11 ENABLE IC5A APA0

C0335 Manual Feed Paper Take-Up Solenoid SL4 UP IC5A BPA2

C0336 Manual Feed Paper Take-Up Solenoid SL4 DOWN IC5A BPA3

C0337 Manual Feed Paper Take-Up Clutch CL3 IC5A BPA1

C0338 Warming-up completion signal IC5A BPA7

C0339 During copy cycle IC5A BPA6

C033A SSR2 REM signal (MH only) IC5A BPA5

C033B Exposure Lamp Regulator PWB-J PWM signal IC4A TOUT

C033C Grid PWM signal IC5A TOUT

C0350 Paper Feed Cabinet S/P-0 IC3 SO0

C0351 Paper Feed Cabinet S/P-1 IC3 SO1

C0352 Duplex Unit S/P-2 IC3 SO2

C0353 Large Capacity Cassette S/P-3 IC3 SO3

C0357

IC3 S13

T-45

Page 47

1156SBT040104A

C04## Exposure Lamp Malfunctions

* Code Description Detection Timing

C0400 Exposure Lamp LA1’s failure to turnONThe output from AE Sensor Board PWB-H

C0410 Exposure Lamp LA1 turning ON at ab-

normal timing

1156SBT040105A

does not become 4.0V or more for the period

between when LA1 turns ON and the Scanner

starts a scan motion and when the Image

Leading Edge signal (BASE) turns ON.

With LA1 OFF, the output from PWB-H remains 3.9V or less for a continuous 3-sec.

period at any timing while the Scanner is at

the home position or the Original Cover is

lowered.

C05## Fusing Malfunctions

* Code Description Detection Timing

C0500 Warming-up failure

(Fusing Heater Lamp failure)

C0510 Abnormally low fusing temperature

(Fusing Heater Lamp failure)

C0520 Abnormally high fusing temperature

(Fusing Heater Lamp turning ON at

abnormal timing)

The surface temperature of the Upper Fusing

Roller does not reach a given level even after the

lapse of a given period of time during warming-up

as detailed below:

If the temperature is 165_C or less when the Pow-

D

er Switch is turned ON:

EP4051 EP3051

From room temperature 105S 60S

to 65_C

65_C~140_C 210S 110S

140_C~170_C 220S 120S

*170_C~200_C 145S 100S

*170_C~190_C 145S 100S

If the temperature is more than 165_C when the

D

Power Switch is turned ON:

*~200_C 200S 120S

*~190_C 200S 120S

*A 200_C temperature control is provided for the

first 1 hour after the Power Switch has been

turned ON and 190_C temperature control is

provided thereafter.

The surface temperature of the Upper Fusing

Roller remains 135

5-sec. period or more after the copier has completed warming up.

The surface temperature of the Upper Fusing

Roller remains 230

5-sec. period or more after the copier has completed warming up.

°°°°

°°°°

EP4051 EP3051

C or less for a continuous

C or more for a continuous

T-46

Page 48

1156SBT040106A

C06## Optical Malfunctions

* Code Description Detection Timing

C0600 Scanner Motor M2 malfunction

C0610 Lens Motor M6 malfunction The output from Lens Reference Position Sensor

C0620 Mirror Motor M7 malfunction

C06F0 SHOME signal failure (Signal does

not go LOW)

C06F1 SHOME signal failure (Signal does

not go HIGH)

C06F2 BASE signal failure (Signal does

not go LOW)

C06F3 BASE signal failure (Signal does

not go HIGH)

C06F4 TRON signal failure (Signal does

not go LOW)

C06F5 TRON signal failure (Signal does

not go HIGH)

C06F6 SCEND signal failure (Signal does

not go LOW)

C06F7 SCEND signal failure (Signal does

not go HIGH)

When the Scanner is at a position other than

D

home, Scanner Reference Position Sensor

PC81 does not go from HIGH to LOW even after

the lapse of 20 sec. after the Power Switch has

been turned ON.

When the Scanner is at the home position, PC81

D

does not go from LOW to HIGH even after the

lapse of 5 sec. after the Scanner has started a

scan motion.

PC81 does not go from HIGH to LOW even after

D

the lapse of 20 sec. after the Scanner has started

a scan motion.

PC90 does not go from HIGH to LOW, or vice

versa, even after the lapse of 15 sec. after M6

has started turning.

The output from Mirror Reference Position Sen-

D

sor PC86 does not go from HIGH to LOW even

after the lapse of 10 sec. after M7 has started

turning.

The output from PC86 does not go from LOW to

D

HIGH even after the lapse of 3 sec. after M7 has

started turning.

When the Scanner is at a position other than

D

home, the SHOME signal does not go HIGH

even after the lapse of 7 sec. after the SCAN signal has gone LOW.

The SHOME signal is HIGH even after the lapse

D

of 5 sec. after the BASE signal has gone from

LOW to HIGH.

The SHOME signal remains LOW even after the

lapse of 7 sec. after it has gone LOW.

The BASE signal does not go LOW even after

the lapse of 5 sec. after the SHOME signal has

gone HIGH.