KONICA MINOLTA EP1085 Service Manual

FrameMaker Ver.5.5E(PC) COVER [FIELD SERVICE] FOR EP1054/EP1085/EP2030

98.09.11

FrameMaker Ver.5.5E(PC) COVER [FIELD SERVICE] FOR EP1054/EP1085/EP2030

98.09.11

EP1054/EP1085/EP2030 SERVICE MANUAL

EP1054/EP1085/EP2030

SERVICE MANUAL

Copyright

1998 MINOLTA CO., Ltd.

Printed in Japan

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

MINOLTA CO., LTD.

1174-7991-11 98114400

[

FIELD SERVICE

]

FIELD SERVICE

[

]

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the following precautions to

prevent accidents and ensure utmost safety.

✽

Depending on the model, some of the precautions given in the following do not apply.

Different markings are used to denote specific meanings as detailed below.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

The following graphic symbols are used to give instructions that need to be observed.

Used to call the service engineer attention to what is graphically represented

inside the marking (including a warning).

Used to prohibit the service engineer from doing what is graphically represented

inside the marking.

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Used to instruct the service engineer to do what is graphically represented inside

the marking.

WARNING

1. Always observe precautions.

•

Parts requiring special attention in this product will include a label containing the

mark shown on the left plus precautionary notes. Be sure to observe the precautions.

•

Be sure to observe the “Safety Information” given in Operator’s Manual.

2. Before starting the procedures, be sure to unplug the power cord.

•

This product contains a high-voltage unit and a circuit with a large current

capacity that may cause an electric shock or burn.

•

The product also contains parts that can jerk suddenly and cause injure.

•

If this product uses a laser, laser beam leakage may cause eye damage or

blindness.

3. Use the specified parts.

•

For replacement parts, always use the genuine parts specified in the manufacturer’s Parts Manual. Installing a wrong or unauthorized part could cause

dielectric breakdown, overload, or undermine safety devices resulting in possible electric shock or fire.

•

Replace a blown electrical fuse or thermal fuse with its corresponding genuine

part specified in the manufacturer’s P arts Manual. Installing a f use of a different

make or rating could lead to a possible fire. If a thermal fuse blows frequently,

the temperature control system is probably of a problem and action must be

taken to eliminate the cause of the problem.

P-1

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

4. Handle the power cord with care and never use a multiple socket.

•

Do not brake, crush or otherwise damage the power cord. Placing a heavy

object on the power cord, or pulling or bending it may damage it, resulting in a

possible fire or electric shock.

•

Do not use a multiple outlet to which any other appliances or machines is connected.

•

Be sure the power outlet meets or exceeds the specified capacity.

5. Be careful about the high-voltage parts.

•

A part marked with the symbol shown on the left carries a high voltage. Touching it could result in an electric shock or burn. Be sure to unplug the power cord

before servicing this part or the parts near it.

6. Do not keep your hands wet when performing the procedures.

•

Do not unplug or plug in the power cord, or perform any kind of service or

inspection with wet hands. Doing so could result in an electric shock.

7. Do not touch a high-temperature part.

•

A part marked with the symbol shown on the left and other parts such as the

exposure lamp and fusing roller can be very hot while the machine is energized.

Touching them may result in a burn.

•

Wait until these parts have cooled down before replacing them or any surrounding parts.

8. Make a ground connection at all times (This item may not be effected in USA).

•

Be sure to connect a ground wire to the ground terminal even when performing

an inspection or repair. Without proper grounding, electrical leakage could

result in an electric shock or fire.

•

Never connect the ground wire to a gas pipe, water pipe, telephone ground wire,

or a lightning conductor.

9. Do not remodel the product.

•

Modifying this product in a manner not authorized by the manufacturer may

result in a fire or electric shock. If this product uses a laser, laser beam leakage

may cause eye damage or blindness.

10. Restore all parts and harnesses to their original positions.

•

To promote safety and prevent product damage, make sure the harnesses are

returned to their original positions and properly secured in their clamps and saddles in order to avoid hot parts, high-voltage parts, and sharp edges, or being

crushed.

•

To promote safety, make sure that all tubing and other insulating materials are

returned to their original positions. Make sure that floating components mounted

on the circuit boards are at their correct distance and position off the boards.

P-2

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

CAUTION

1. Precautions for Service Jobs

•

A toothed washer and spring washer, if used originally, must be reinstalled.

Omitting them may result in contact failure which could cause an electric shock

or fire.

•

When reassembling parts, make sure that the correct screws (size, type) are

used in the correct places. Using the wrong screw could lead to stripped

threads, poorly secured parts, poor insulating or grounding, and result in a malfunction, electric shock or injury.

•

Take great care to avoid personal injury from possible burrs and sharp edges on

the parts, frames and chassis of the product.

•

When moving the product or removing an option, use care not to injure your

back or allow your hands to be caught in mechanisms.

2. Precautions for Servicing with Covers and Parts Removed

•

Wherever feasible, keep all parts and covers mounted when energizing the

product.

•

If energizing the product with a cover removed is absolutely unavoidable, do not

touch any exposed live parts and use care not to allow your clothing to be

caught in the moving parts. Never leave a product in this condition unattended.

•

Never place disassembled parts or a container of liquid on the product parts falling into, or the liquid spilling inside, the mechanism could result in an electric

shock or fire.

•

Never use a flammable spray near the product. This could result in a fire.

•

Make sure the power cord is unplugged before removing or installing circuit

boards or plugging in or unplugging connectors.

•

Always use the interlock switch actuating jig to actuate an interlock switch when

a cover is opened or removed. The use of folded paper or some other object

may damage the interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

3. Precautions for Working Environment

•

The product must be placed on a flat, level surface that is stable and secure.

•

Never place this product or its parts on an unsteady or tilting workbench when

servicing.

•

Provide good ventilation at regular intervals if a service job must be done in a

confined space for a long period time.

•

Avoid dusty locations and places exposed to oil mist or steam.

•

Avoid working positions that may block the ventilation port of the product.

4. Precautions for Handling Batteries (Lithium, Nickel-Cadmium, etc.)

•

Replace a rundown battery with the same type as specified in the manufacturer’s parts manual.

•

Before installing a new battery, make sure of the correct polarity of the installation or the battery could burst.

•

Dispose of used batteries according to the local regulations. Nev er dispose of

them at the user’s premises or attempt to try to discharge one.

P-3

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

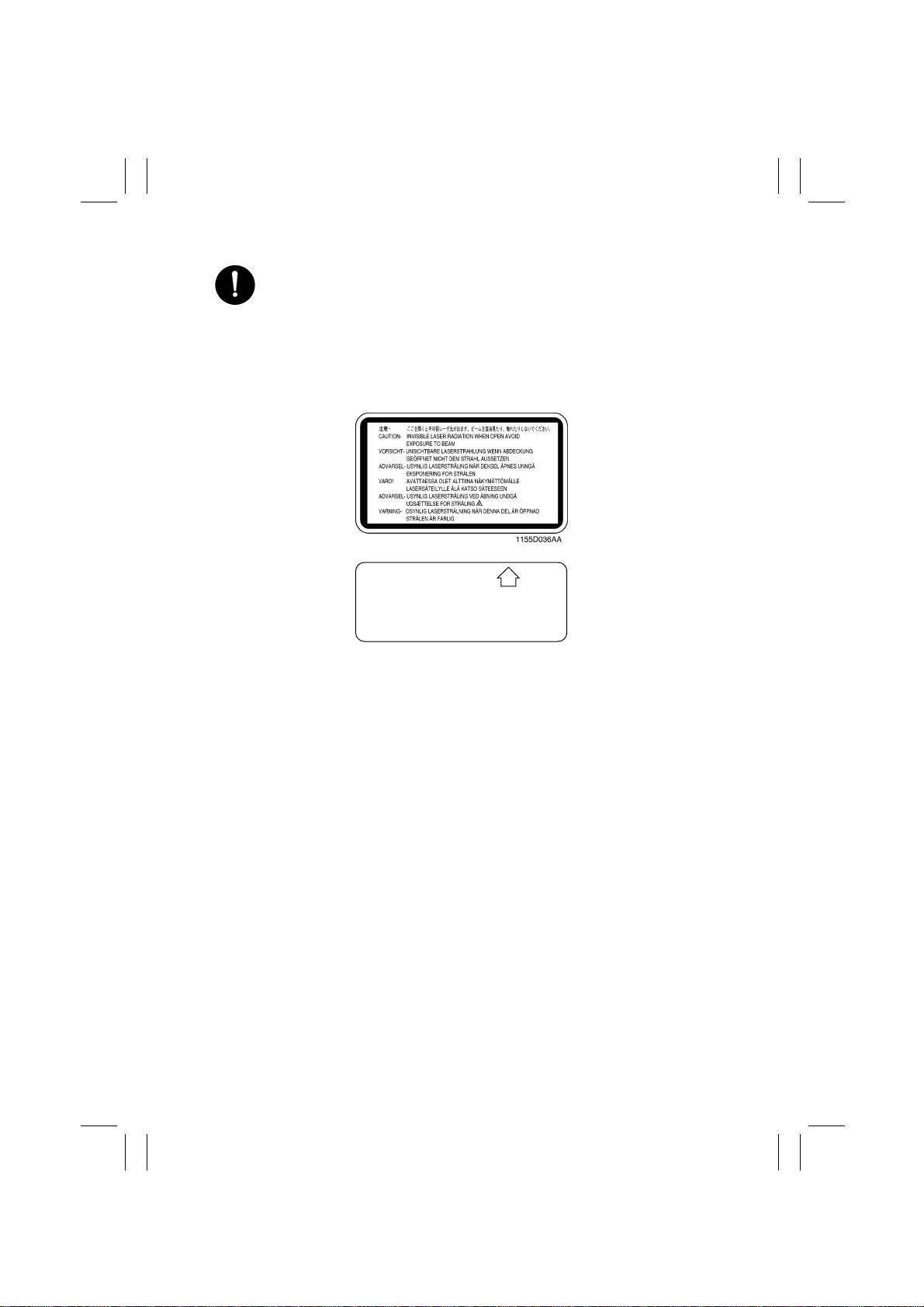

5. Precautions for Laser Beam (Products Employing Laser Only)

•

Removing the cover marked with the follo wing caution label could lead to possible exposure to the laser beam, resulting in eye damage or blindness. Be sure

to unplug the power cord before removing this cover.

•

If removing this cover while the power is ON is una voidable, be sure to wear protective laser goggles that meet specifications.

•

Make sure that no one enters the room when the machine is in this condition.

•

When handling the laser unit, observe the “Precautions for Handling Laser

Equipment.”

.

DANGER

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE

TO BEAM

0947-7127-01

1144D270AA

P-4

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

Other Precautions

•

To reassemble the product, reverse the order of disassembly unless otherwise specified.

•

While the product is energized, do not unplug or plug connectors into the circuit boards

or harnesses.

•

The magnet roller generates a strong magnetic field. Do not bring it near a watch, floppy

disk, magnetic card, or CRT tube.

•

An air gun and vacuum cleaner generates a strong electrostatic charge that can destroy

the ATDC sensor and other sensors. Before cleaning a component with one of these

devices, be sure to remove all the sensors. Otherwise, use a blower brush and cloth

when cleaning parts.

•

When handling circuit boards with MOS ICs, observe the “INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs” (applicable only to the products using MOS ICs).

•

The PC Drum is a very delicate component. Observe the precautions given in “HANDLING OF THE PC DRUM” because mishandling may result in serious image problems.

•

Note that replacement of a circuit board may call for readjustments or resetting of particular items, or software installation.

•

After completing a service job, perform a safety check. Make sure that all parts, wiring

and screws are returned to their original positions.

•

Check the area surrounding the service site for any signs of damage, wear or need of

repair.

•

Do not pull out the toner hopper while the toner bottle is turning. This could result in a

damaged hopper motor or locking mechanism.

•

If the product is to be run with the front door open, make sure that the toner hopper is in

the locked position.

P-5

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.01

98.10.02

Used Batteries Precautions

(ALL Areas)

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

(Germany only)

Explosinsgefahr bei unsachgemäßen austausch der batterie.

Ersatz nur durch denselben oder einen vom hersteller empfohlenen ähnlichen typ.

Entsorgung gebrauchter batterien nach angaben des herstellers.

(France)

Ily a danger d’explosion s’ily a remplacement incorrec de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un type équivalent recommande par le constructueur.

Mettre au rebut les batteries usageés conformément aux instructions du fabricant.

(Denmark only)

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

(Norway only)

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

CAUTION

VORSICHT!

ATTENTION

ADVA RSEL!

ADVARSEL

(Sweden only)

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

(Finland only)

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä Käytetty paristo

valmistajan ohjeiden mukaisesti.

VARNING

VAROlTUS

P-6

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030

98.10.07

INDEX (FIELD SERVICE)

DIS/REASSEMBLY,

ADJUSTMENT

SWITCHES ON PWBs,

TECH. REP. SETTINGS

TROUBLESHOOTING

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

EP1054/EP1085/EP2030

DIS/REASSEMBLY,

ADJUSTMENT

18605

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

CONTENTS

1. SERVICE INSTRUCTIONS .............................................................................D-1

1-1. INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs .............D-1

1-2. HANDLING OF THE PC DRUM ......... ...................................... ...............D-1

1-3. PARTS WHICH MUST NOT BE TOUCHED ...........................................D-4

(1) Screws .............................................................................................D-4

(2) Variable Resistors on Board .......................................... ..................D-4

(3) Other Screws ...................................................................................D-4

2. DISASSEMBLY/REASSEMBLY ...................................................................... D-5

2-1. DOORS, COVERS, AND EXTERIOR PARTS: IDENTIFICATION AND

REMOVAL PROCEDURES .....................................................................D-5

2-2. REMOVAL OF PWBs ..............................................................................D-8

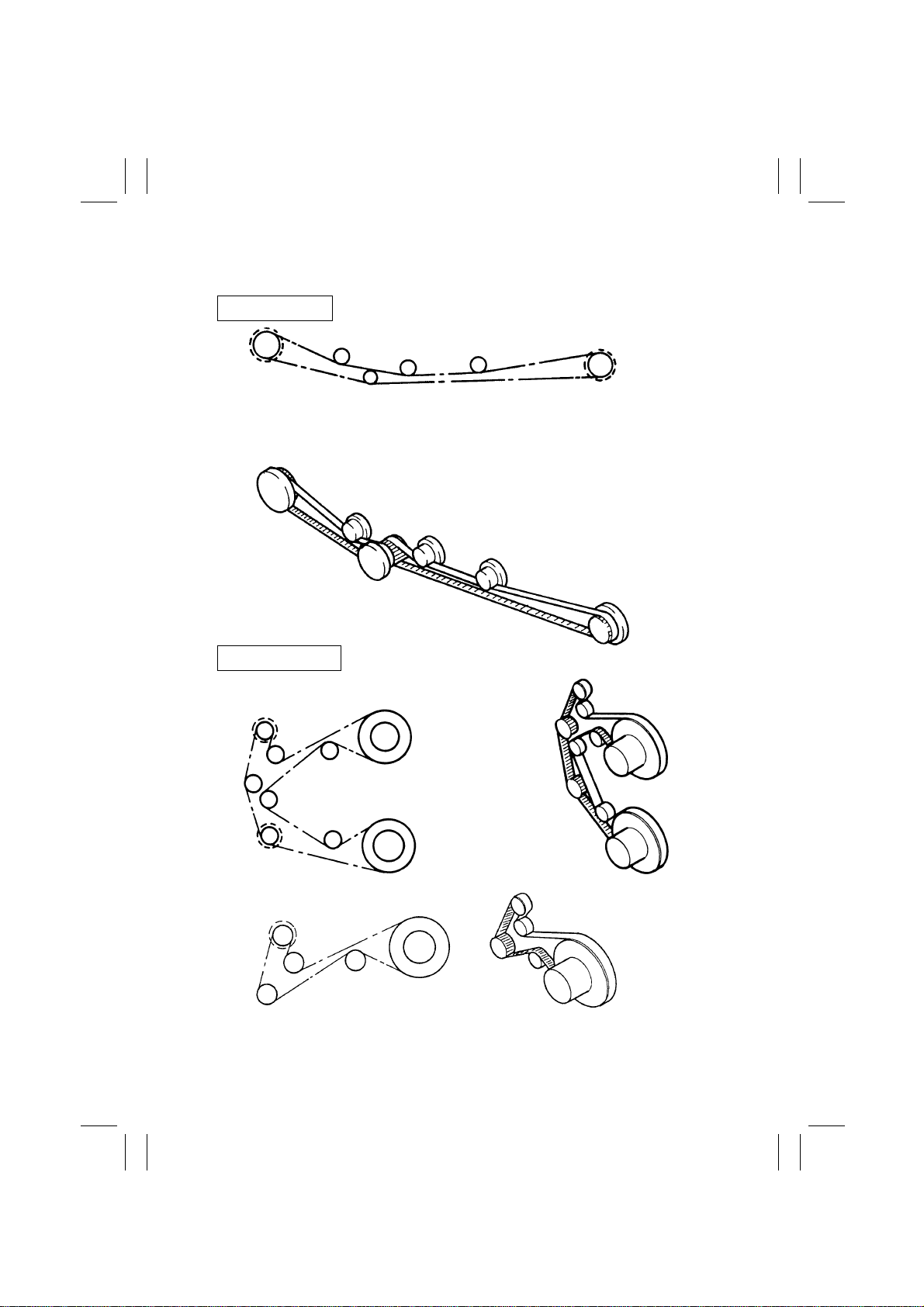

2-3. BELT INSTALLATIONS ...........................................................................D-10

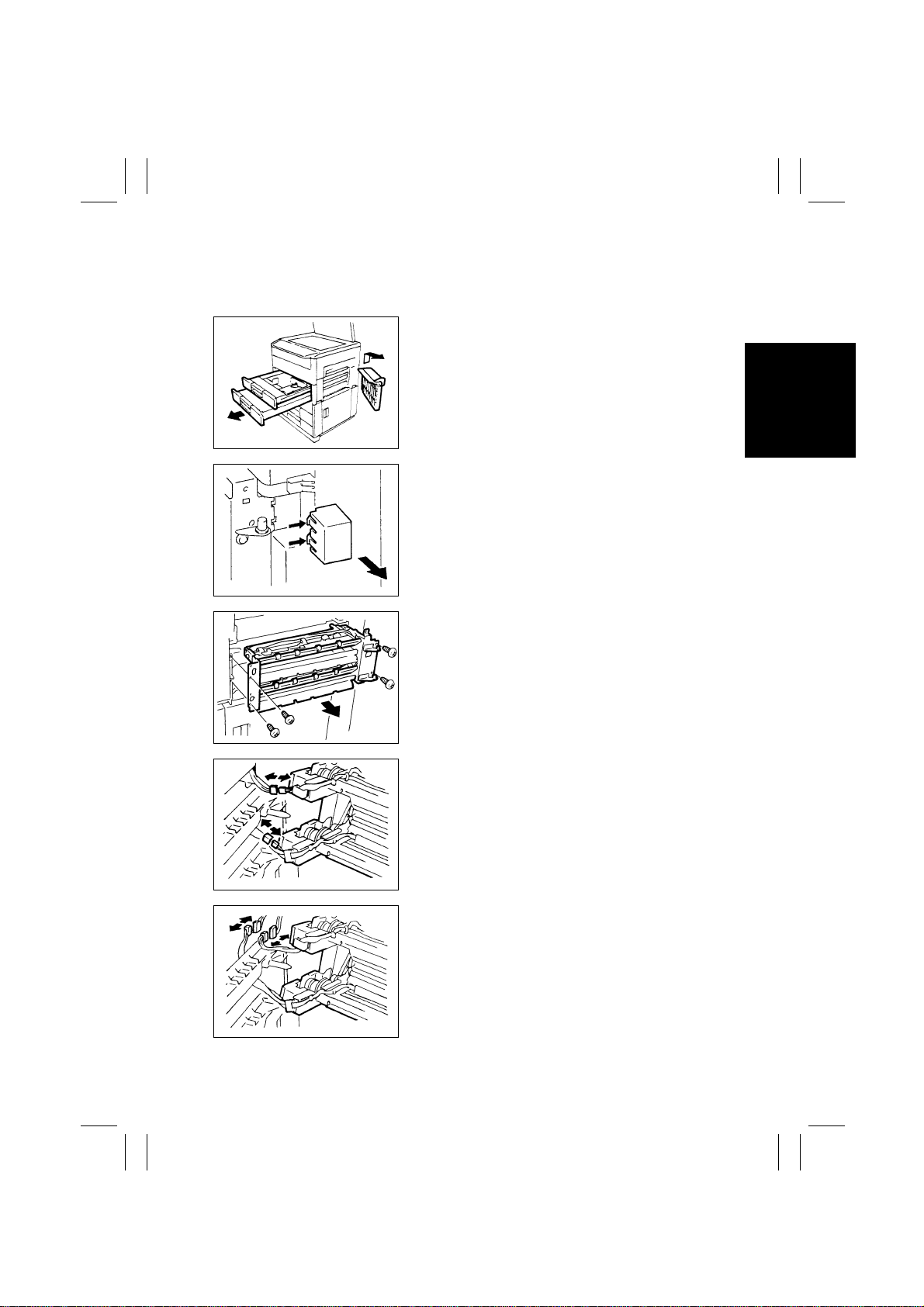

2-4. PAPER TAKE-UP/TRANSPORT SECTIONS .........................................D-11

(1) Removal of the Paper Take-Up Unit .............. ..................... .............D-11

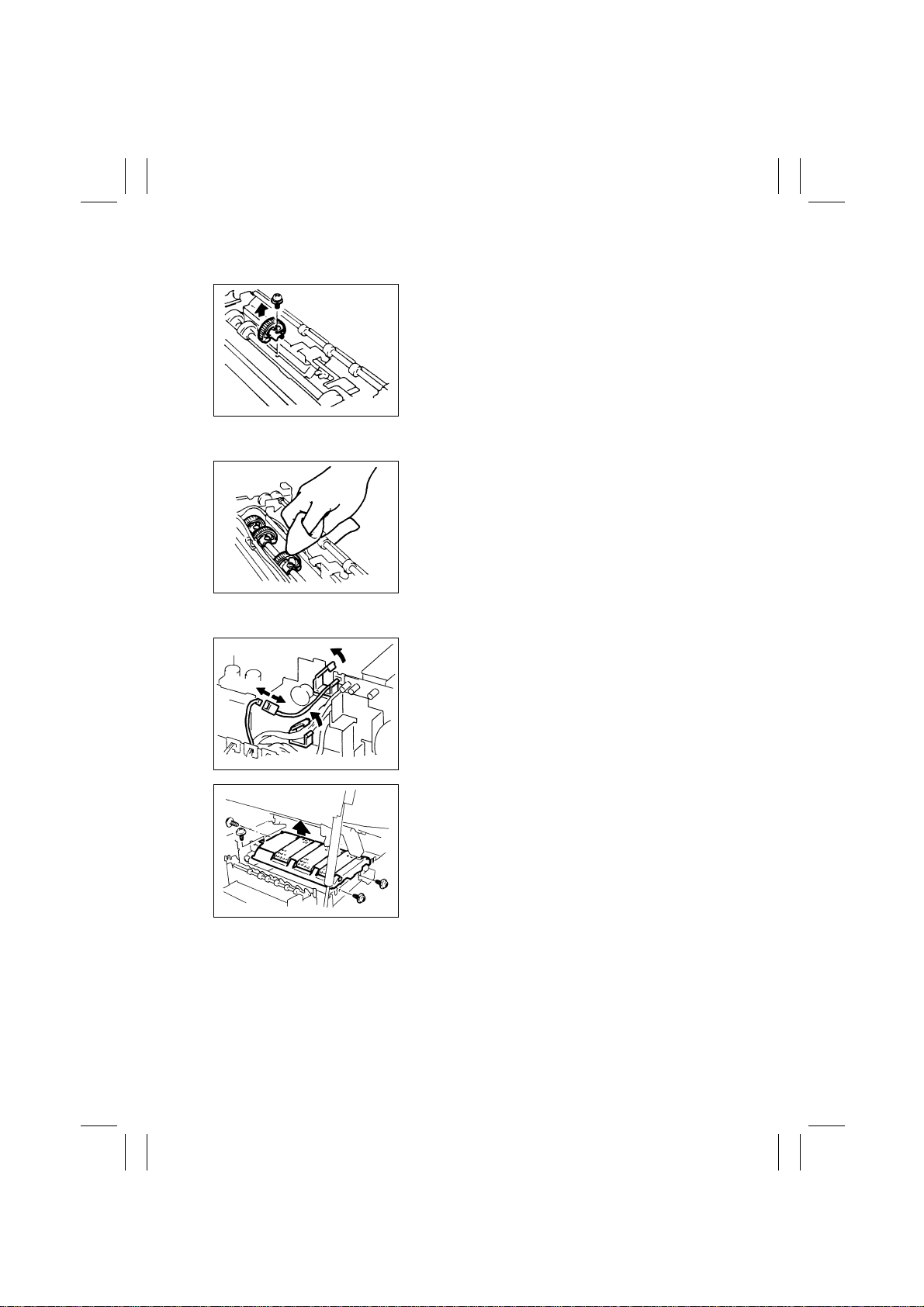

(2) Removal of the Paper Take-Up Rolls ............................ ..................D-12

(3) Cleaning of the Paper Take-Up Rolls ........................................... ...D-12

(4) Removal of the Suction Unit ............................................................D-12

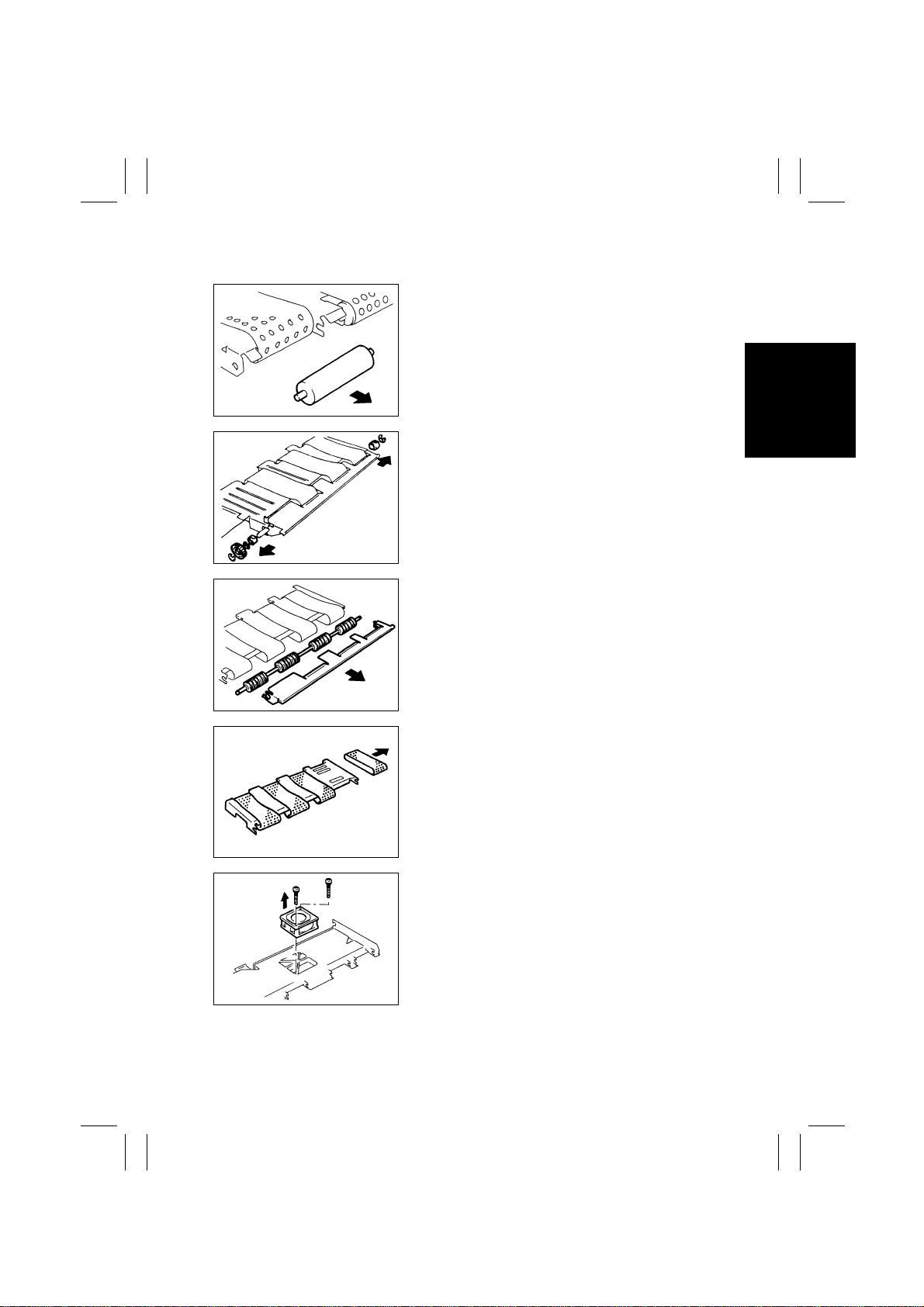

(5) Disassembly of the Suction Unit ......................................................D-13

(6) Replacement of the Paper Lifting Springs (2nd Drawer):

23 cpm copier only ................... ................... .................. ..................D-14

(7) Disassembly of the Multi Bypass Table

(15/18 cpm copier: OPTION) ...........................................................D-15

2-5. OPTICAL SECTION ......................................... .......................................D-20

(1) Removal of the Lens Drive Cable ....................................................D-20

(2) Winding of the Lens Drive Cable .....................................................D-21

(3) Removal of the Scanner Drive Cable ..............................................D-22

(4) Winding of the Scanner Drive Cable ...............................................D-25

(5) Removal of the Scanner ..................................................................D-29

(6) Cleaning of the Exposure Lamp ......................................................D-29

(7) Cleaning of the 1st/2nd/3rd Mirrors ............................. ....................D-30

(8) Cleaning of the Lens and 4th Mirror .................. ..............................D-30

(9) Cleaning of the Optical Section Cooling Fan Filter

(15/18 cpm copier only) ...................... ...................................... .......D-30

2-6. IMAGING UNIT ........................................................................................D-31

(1) Disassembly, Cleaning, Replacement and Starter Changing of

the Imaging Unit ..............................................................................D-31

(2) Cleaning of the Main Erase Lamp .................................... ...............D-35

(3) Cleaning of the Image Erase Lamp ........................... ..................... .D-35

2-7. PC DRUM CHARGE CORONA/IMAGE TRANSFER CORONA UNIT ....D-37

(1) Cleaning of the PC Drum Charge Corona Housing .........................D-37

(2) Cleaning of the PC Drum Charge Corona Grid Mesh .....................D-38

(3) Cleaning of the Comb Electrode .......................... ............................D-38

(4) Cleaning of the Image Transfer/Paper Separator Coronas Wires ...D-38

(5) Cleaning of the Image Transfer/Paper Separator Coronas

Housing ...........................................................................................D-39

(6) Cleaning of the Lower Pre-Image Transfer Guide Plate ..................D-39

i

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

(7) Replacement of the Ozone Filter ..................................................... D-39

2-8. FUSING UNIT ..........................................................................................D-40

(1) Removal of the Fusing Unit .............................................................D-40

(2) Cleaning of the Pre-Fusing Guide Plate ..........................................D-41

(3) Removal of the Upper Fusing Roller ...............................................D-41

(4) Cleaning of the Upper Fusing Roller ..................... ..................... .....D-43

(5) Cleaning of the Upper Paper Separator Fingers .............................D-43

(6) Cleaning of the Fusing Thermistor ........................ ..........................D-43

(7) Removal of the Lower Fusing Roller ...............................................D-43

(8) Cleaning of the Lower Fusing Roller ..................... ..................... .....D-44

(9) Cleaning of the Lower Paper Separator Fingers .............................D-44

(10) Disassembly of the Exit/Duplex Switching Unit (Option) .................D-45

3. ADJUSTMENT ................................................................................................. D-49

3-1. JIGS AND TOOLS USED ............... .........................................................D-49

3-2. ADJUSTMENT REQUIREMENTS LIST ..................................................D-50

3-3. ADJUSTMENT OF SWITCHES ...............................................................D-51

(1) Adjustment of Front Door Interlock Switch S21 .............................. .D-51

3-4. ELECTRICAL/IMAGE ADJUST MENTS ..................................................D-52

(1) Adjustment of the Maximum Exposure Lamp Voltage for

the Manual Mode .............................................................................D-52

(2) Adjustment of the Optimum Exposure Setting in the Manual Mode D-55

(3) Adjustment of the Optimum Exposure Setting in the Auto Mode ....D-56

(4) Adjustment of the ATDC Sensor ......................... ............................D-57

(5) Adjustment of the Aperture Blades ............................................. .....D-58

(6) Adjustment of the Multi Bypass Table Reference Position ..............D-59

(7) Adjustment of the 1st/2nd (23 cpm copier only)

Drawer Reference Position ..............................................................D-60

(8) Adjustment of the Paper Lifting Plate Springs (2nd Drawer):

23 cpm copier only ................... ................... .................. ..................D-61

(9) Adjustment of the Leading Edge Registration .................................D-62

(10) Adjustment of the Image Leading Edge Erase Width ......................D-66

(11) Adjustment of the Image Erase Lamp Position ...............................D-68

3-5. OTHER ADJUSTMENTS .........................................................................D-69

(1) Adjustment of the Scanner/Mirrors Carriage Position .....................D-69

(2) Adjustment of the Gap Between the Doctor Blade and

Sleeve Roller ...................................................................................D-70

(3) Adjustment of the Original Size Detecting Board ............................D-71

4. MISCELLANEOUS ..........................................................................................D-72

4-1. INSTALLATION OF THE PLUG-IN COUNTER MOUNTING BRACKET

(OPTION) .................................................................................................D-72

ii

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

1 SERVICE INSTRUCTIONS

1-1. INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs

The following precautions must be observed when handling P.W. Boards with MOS

(Metal Oxide Semiconductor) ICs.

During Transportation/Storage:

•

During transportation or when in storage, new P.W. Boards must not be indiscriminately

removed from their protective conductive bags.

•

Do not store or place P.W. Boards in a location exposed to direct sunlight.

•

When it becomes absolutely necessary to remove a Board from its conductive bag or

case, always place it on its conductive mat in an area as free as possible from static electricity.

•

Do not touch the pins of the ICs with your bare hands.

During Replacement:

•

Before unplugging connectors from the P.W. Boards, make sure that the power cord has

been unplugged from the outlet.

•

When removing a Board from its conductive bag or conductive case, do not touch the

pins of the ICs or the printed pattern. Place it in position by holding only the edges of the

Board.

•

Before plugging connectors into the Board, make sure that the power cord has been

unplugged from the power outlet.

During Inspection:

•

Avoid checking the IC directly with a multimeter; use connectors on the Board.

•

Never create a closed circuit across IC pins with a metal tool.

•

When it is absolutely necessary to touch the ICs and other electrical components on the

Board, be sure to ground your body.

1-2. HANDLING OF THE PC DRUM

During Transportation/Storage:

•

Use the specified carton whenever moving or storing the PC Drum.

•

The storage temperature is in the range between –20°C and +40°C.

•

In summer, avoid leaving the PC Drum in a car for a long time.

Handling:

•

Ensure that the correct PC Drum is used.

•

Whenever the PC Drum has been removed from the copier, store it in its container or protect it with a Drum Cloth.

•

The PC Drum exhibits greatest light fatigue after being exposed to strong light over an

extended period of time. Never, therefore, expose it to direct sunlight.

•

Use care not to contaminate the surface of the PC Drum with oil-base solvent, fingerprints, and other foreign matter.

•

Do not scratch the surface of the PC Drum.

•

Do not apply chemicals to the surface of the PC Drum.

•

Do not attempt to wipe clean the surface of the PC Drum.

D-1

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

If, however, the surface is contaminated with fingerprints, clean it using the following procedure.

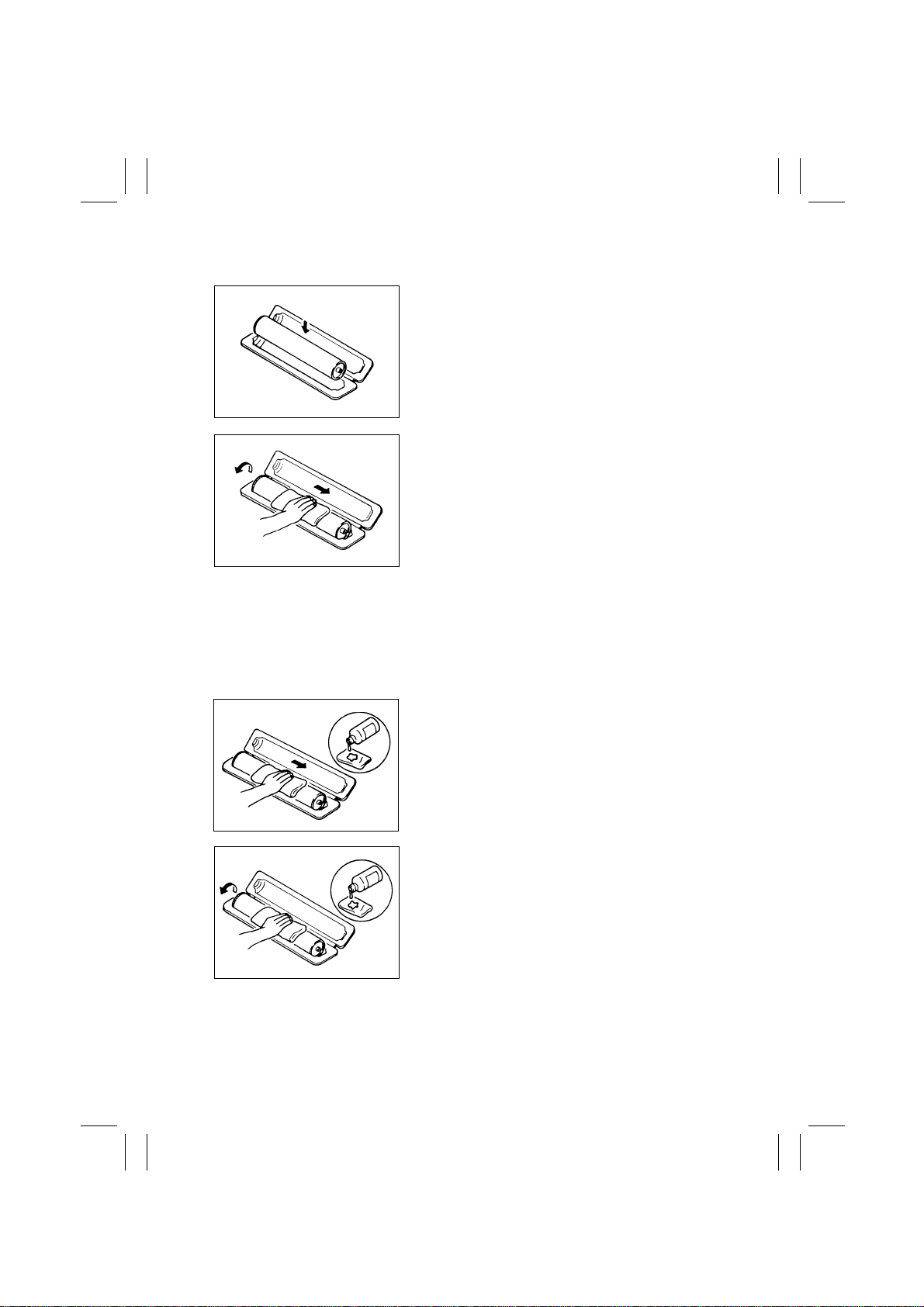

1. Place the PC Drum into one half of its container.

1076D001

2. Gently wipe the residual toner off the surface of the

PC Drum with a dry, Dust-Free Cotton Pad.

A. Rotate the PC Drum so that the area of its surface

on which the line of toner left by the Cleaning

Blade is present is facing straight up. Wipe the surface in one continuous movement from the rear

edge of the PC Drum to the front edge and off the

1076D002

surface of the PC Drum.

B. Rotate the PC Drum slightly and wipe the newly

exposed surface area with a CLEAN face of the

Dust-Free Cotton Pad. Repeat this procedure until

the entire surface of the PC Drum has been thoroughly cleaned.

✽

At this time, always use a CLEAN face of the dry

Dust-Free Cotton P ad until no toner is e vident on the

face of the Pad after wiping.

1076D003

1076D004

3. Soak a small amount of either ethyl alcohol or isopropyl alcohol into a clean, unused Dust-Free Cotton Pad which has been folded over into quarters.

Now, wipe the surface of the PC Drum in one continuous movement from its rear edge to its front

edge and off its surface one to two times.

✽

Never move the Pad back and forth.

4. Using the SAME face of the Pad, repeat the procedure explained in the latter half of step 3 until the

entire surface of the PC Drum has been wiped.

Always OVERLAP the areas when wiping. Two

complete turns of the PC Drum would be appropriate for cleaning.

D-2

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

NOTES

•

The Organic Photoconductor Drum is softer than CdS and Selenium Drums and is therefore susceptible to scratches.

•

Even when the PC Drum is only locally dirtied, wipe the entire surface.

•

Do not expose the PC Drum to direct sunlight. Clean it as quickly as possible even under

interior illumination.

•

If dirt remains after cleaning, repeat the entire procedure from the beginning one more

time.

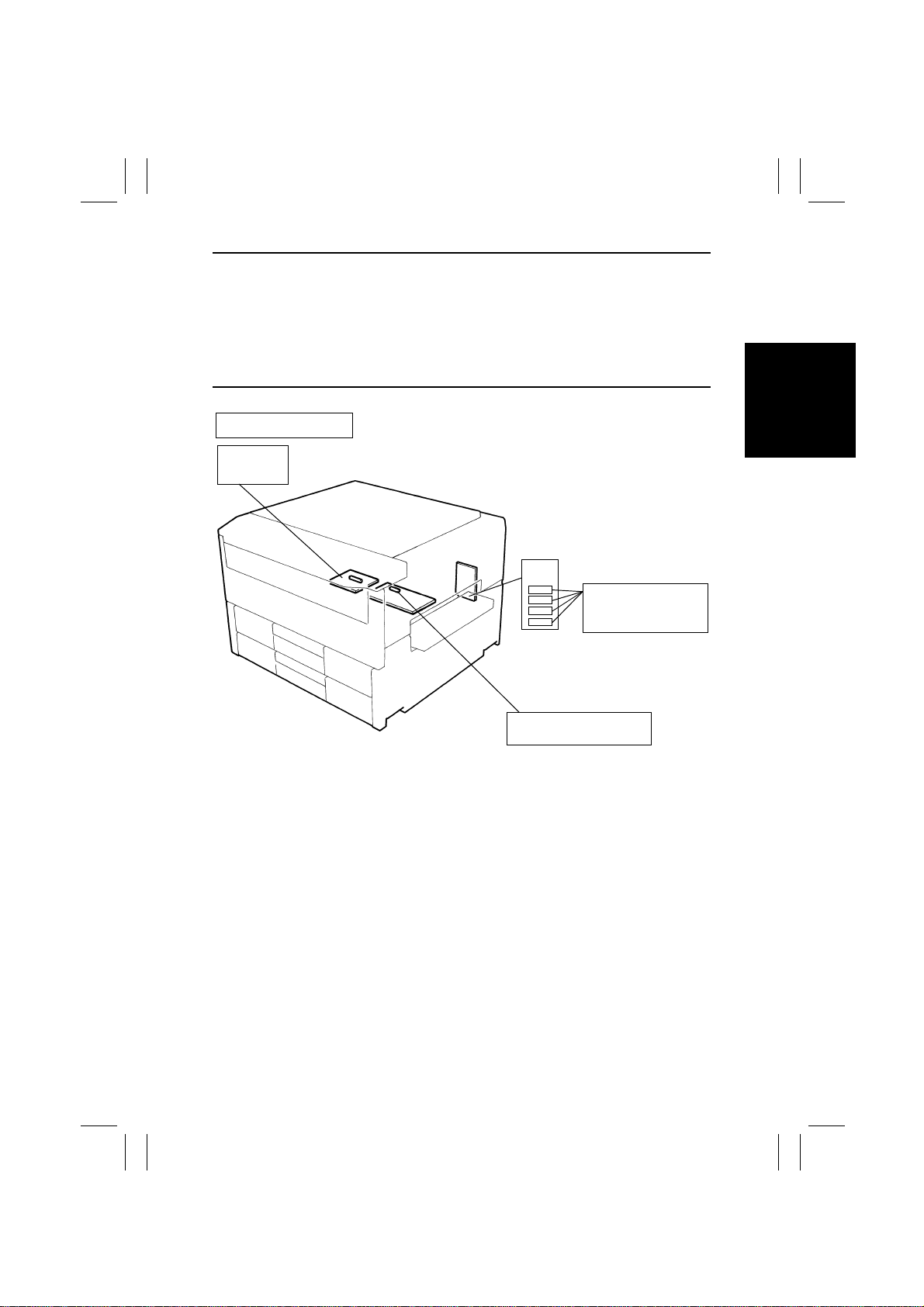

Identification of Fuses

PWB-D

250V 15A

Power Supply Board

PWB-C

250V 3A

1171D001AA

D-3

Power Supply Unit PU2

125V 10A

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

1151D042AA

98.04.13

1-3. PARTS WHICH MUST NOT BE TOUCHED

(1) S crews

Purpose of Application of Red Paint

Red paint is applied to the screws which cannot be readjusted, set, or reinstalled in he field.

The basic rule is not to remove or loosen the screws to which red paint is applied. In addition, be advised that, if two or more screws are designated as those which must not be

touched on a single part, only one representative screw may be marked with red paint.

(2) Variable Resistors on Board

Do not turn the variable resistors on boards for which no adjusting instructions are given in

“ADJUSTMENT.”

(3) Other Screws

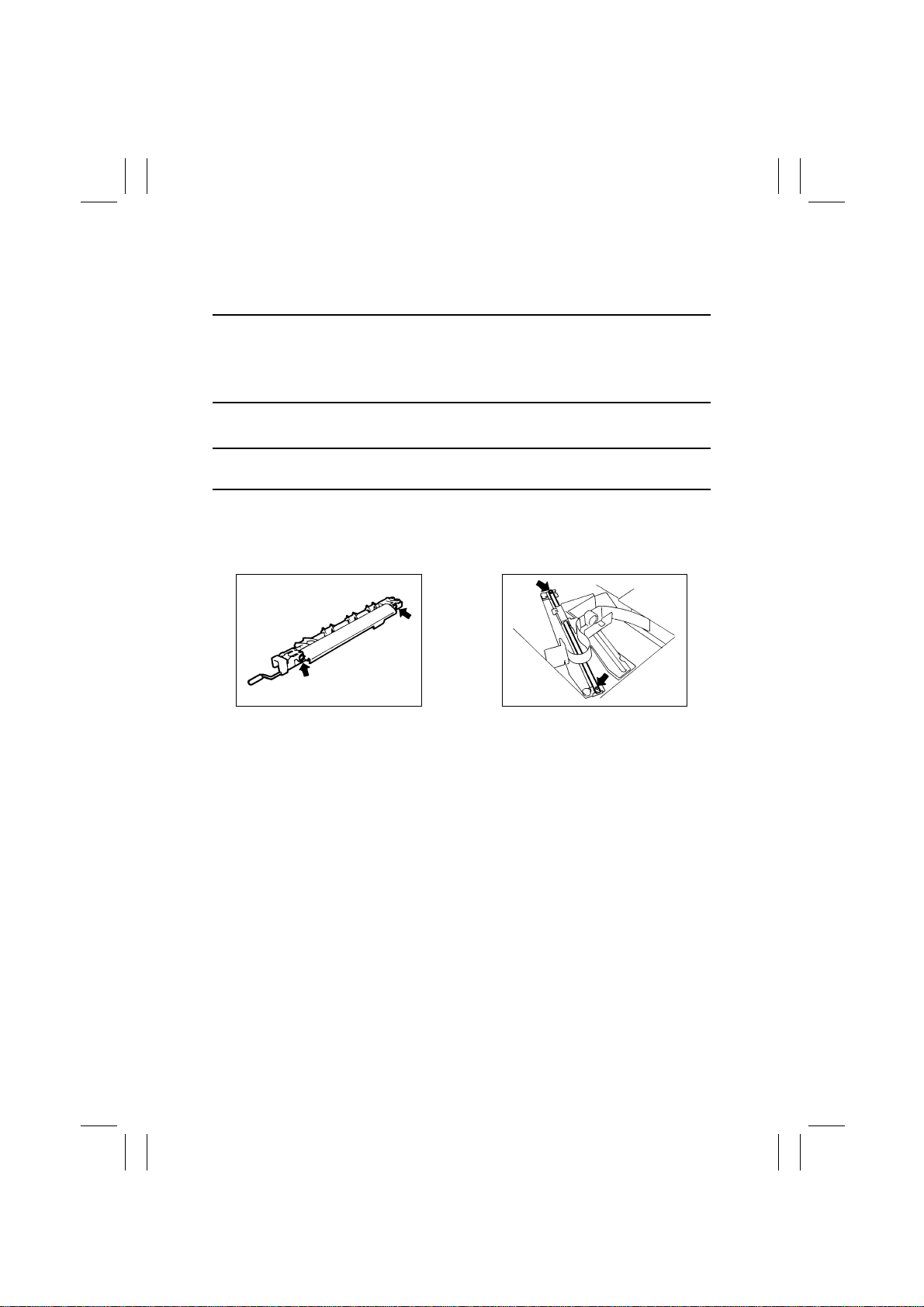

Lower Pre-Image Transfer

Guide Plate (2 screws)

1139D078AA

Lens Rail height

setting screws (2)

D-4

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

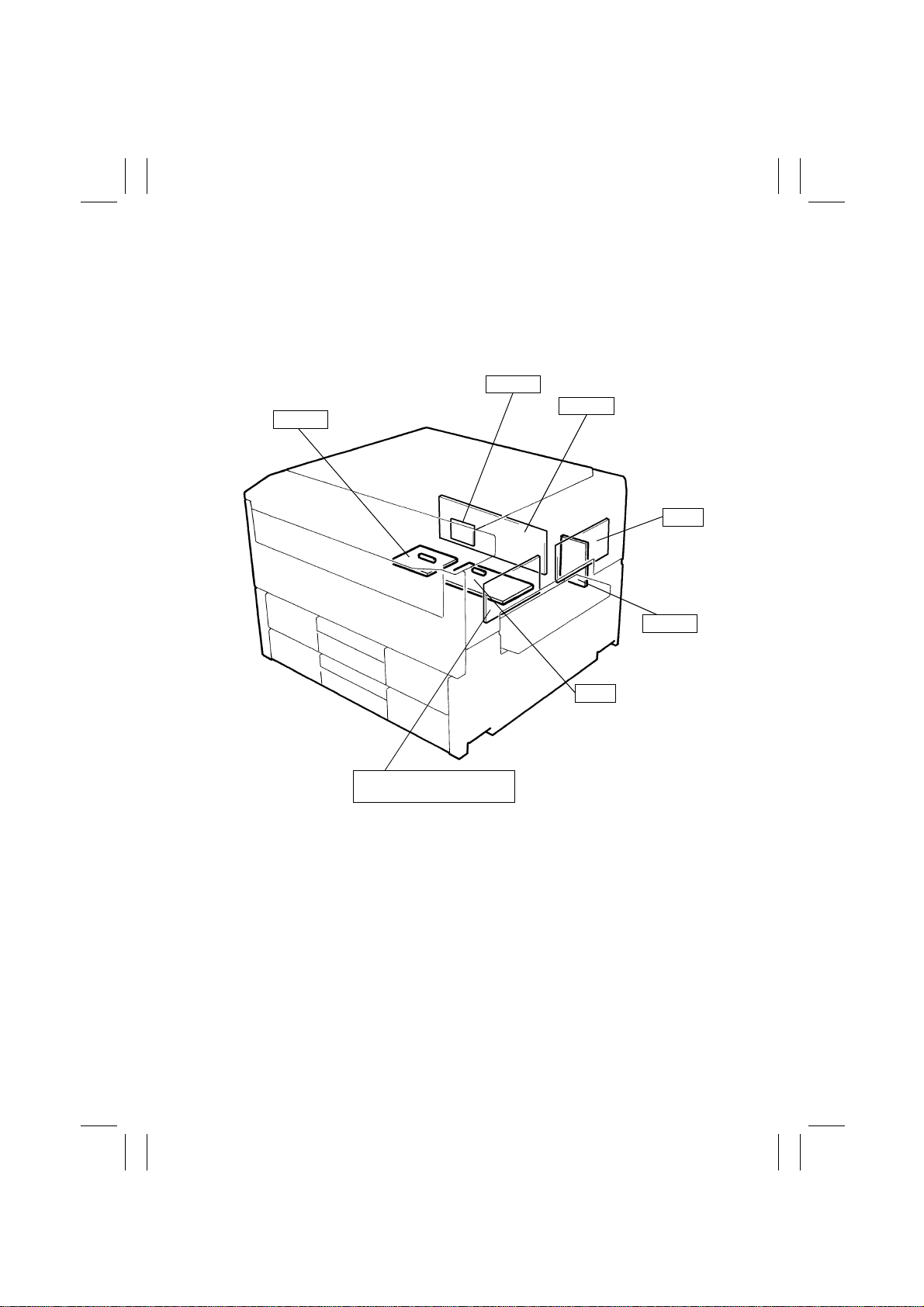

2 DISASSEMBLY/REASSEMBLY

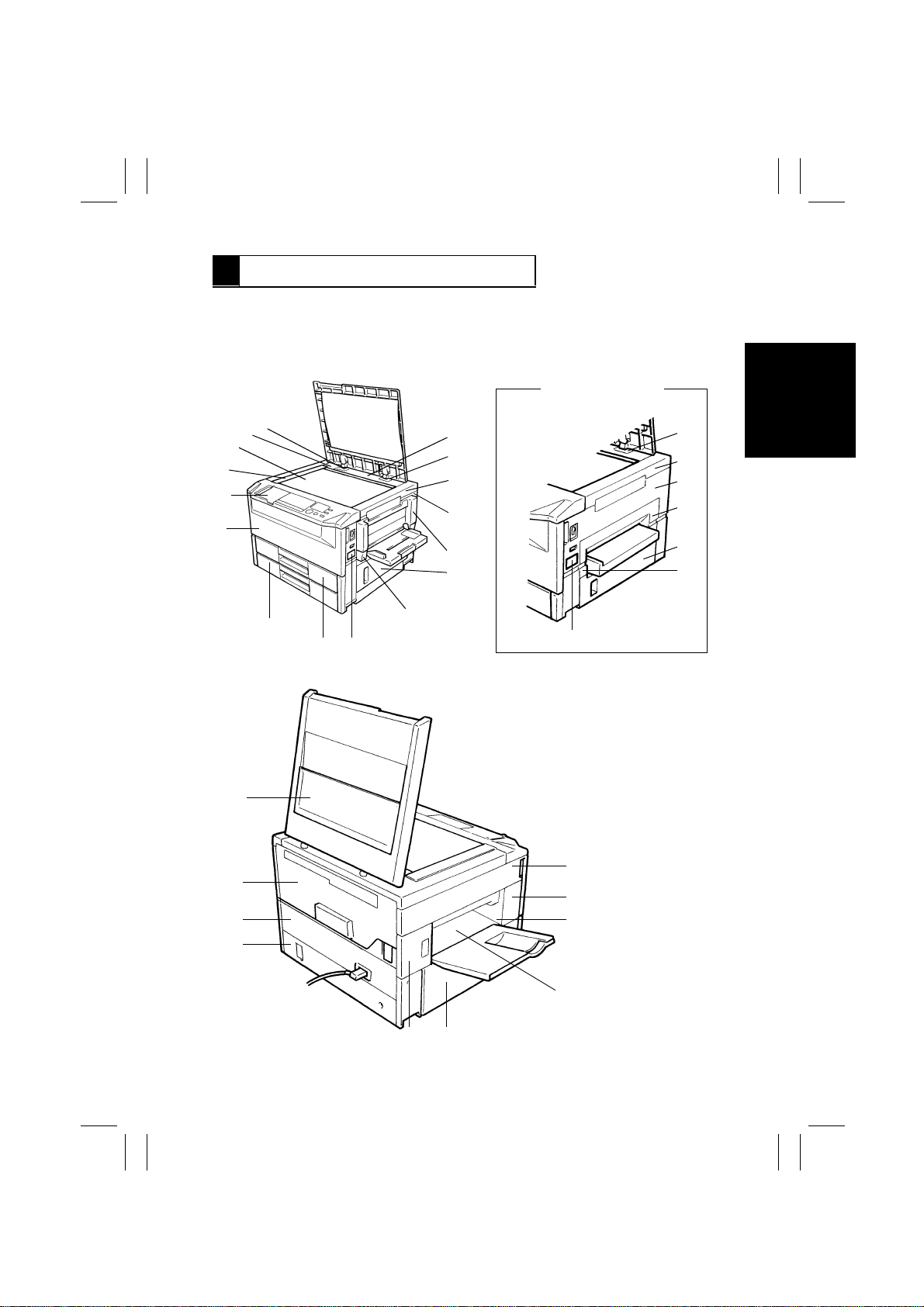

2-1. DOORS, COVERS, AND EXTERIOR PARTS: IDENTIFICA TION

AND REMOVAL PROCEDURES

<23 cpm copier>

<15/18 cpm copier>

6

5

4

3

2

1

13

1151D001AA

19

18

17

20

16 (

✽

1)

15

14

(✽1: 23 cpm copier only)

7

8

9

10

11 (

12

✽

1)

14

21

22

23

8

9

10

11

12

13

1151D027AA

2526

D-5

24

1151D028AA

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

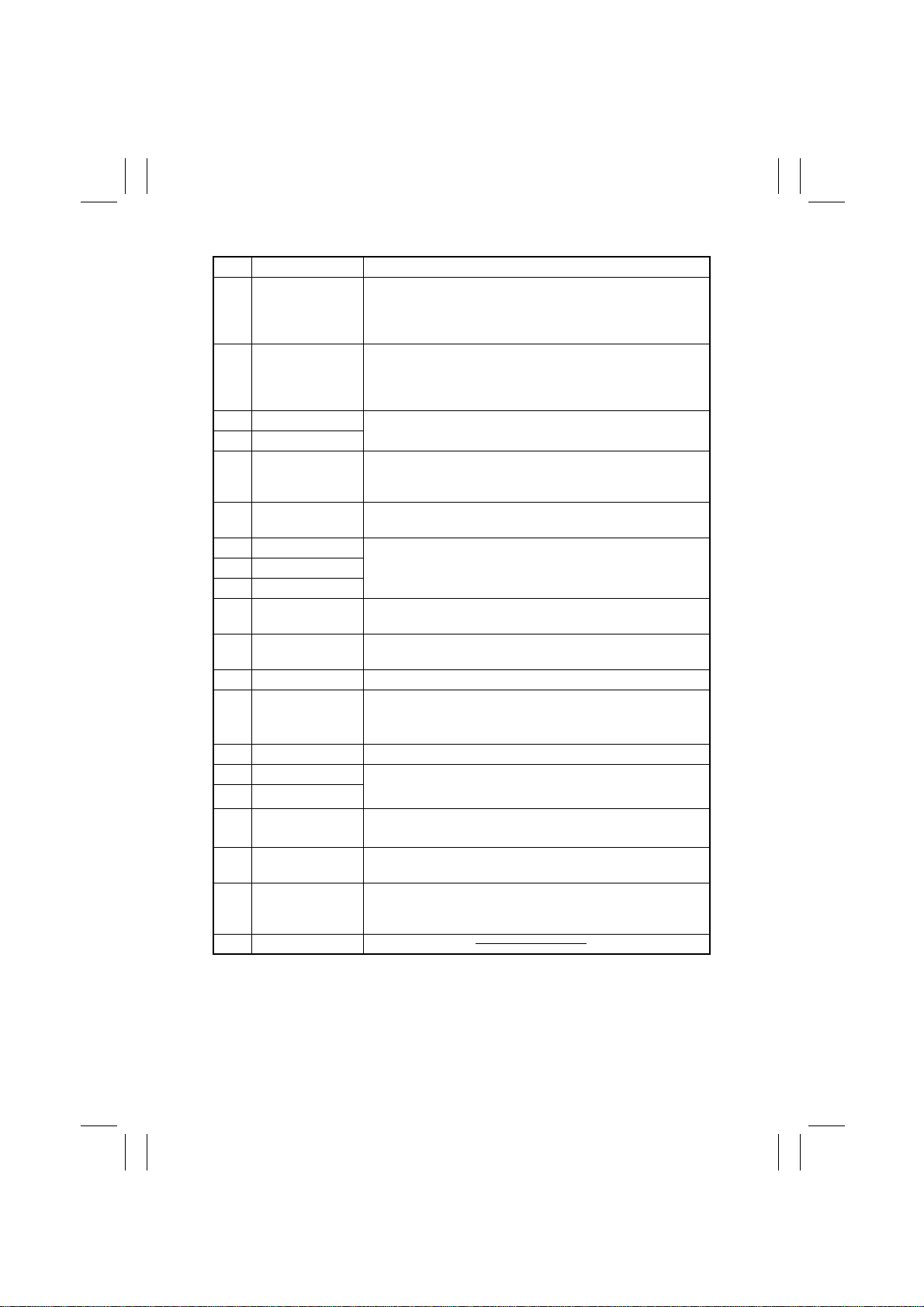

No. Part Name Removal Procedure

1 Front Door Swing down No.1. → Remove one screw that secures the Belt.

2 Control Panel Swing down No.1. → Remove No.9. → Release and swing up

3 Original Scales Remove two screws that secure the Scales.

4 Original Glass

5 Rear Upper Cover

(Small)

6 Left Hinge Cover Remove the Original Cover. → Remove one screw that

7 Rear Upper Cover Remove the Original Cover. → Remove No.6, 8 and 9. →

8 Right Hinge Cover

9 Upper Right Cover

10 Right Cover Remove No.11. → Remove No. 9. → Remove two screws that

11 Middle Right Cover Remove screws that secure No.11. (23 cpm copier: three/

12 Right Door Open No.12 and remove it by lifting it up.

13 Multi Bypass Table

Mounting Bracket

✽

1

14 Counter Cover Remove No.14 by snapping if off.

15 1st Drawer Slide out the Drawer and remove one screw that secures the

16

2nd Drawer

17 Lower Rear Cover

✽

2

18 Rear Cover Swing down No.1. → Release and swing up the Upper Half of

19 Upper Rear Cover Swing down No.1. → Release and swing up the Upper Half of

20 Original Cover

Remove the Original Cover by pulling it up.

→

Remove two screws that secure the Front Door (only on

one side). → Slide the Door to the side from which the screws

have been removed.

the Upper Half of the copier. → Remove No.21. → Remove

two screws that secure the control panel and loosen another

five screws that secure the control panel.

Remove the Original Cover. → Release and swing up the

Upper Half of the copier . → Remove the Screw Co v er and one

mounting screw of No.5.

secures the Left Hinge Cover.

Remove one screw that secures No.7.

secure No.10.

15/18 cpm copier: four).

Remove two screws that secure the Multi Bypass Table

Mounting Bracket.

Stopper at the rear left corner.

✽

2

Remove two screws that secure the Lower Rear Cover.

the copier. → Remove two screws that secure the Rear Cover.

the copier. → Remove three screws that secure the Upper

Rear Cover.

D-6

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

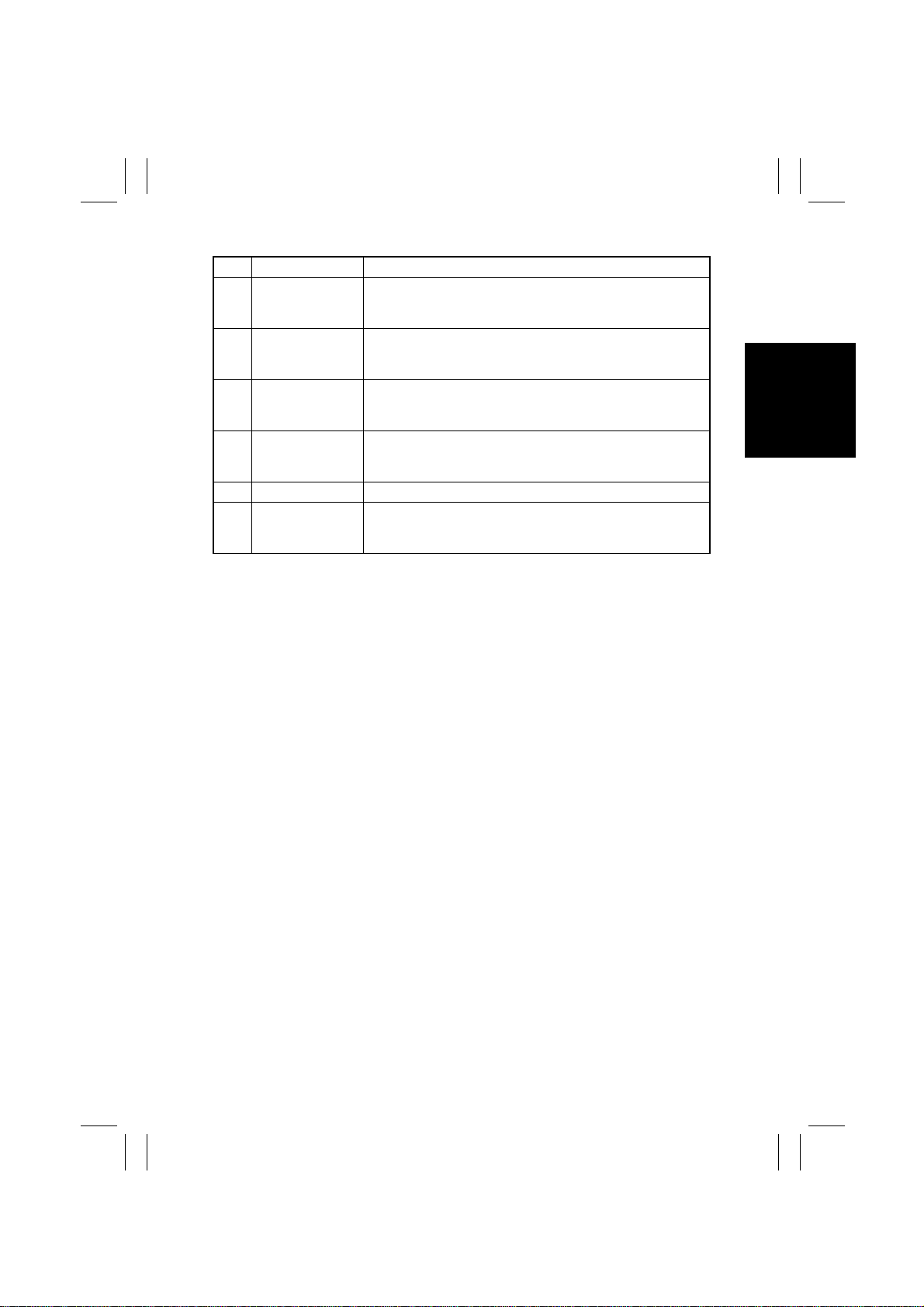

No. Part Name Removal Procedure

21 Upper Left Cover Swing down No.1. → Release and swing up the Upper Half of

22 Middle Front Left

Cover

23 Front Exit Cover Swing down No.1. → Release and swing up the Upper Half of

24 Rear Exit Cover Swing down No.1. → Release and swing up the Upper Half of

25 Lower Left Cover Remove four screws that secure the Lower Left Cover.

26 Middle Rear Left

Cover

✽

1: Multi Bypass Section: 15/18 cpm copier option

✽

2: 18/23 cpm copier only

the copier. → Remove four screws that secure the Upper Left

Cover.

Swing down No.1. → Release and swing up the Upper Half of

the copier. → Remove one screw that secures the Middle

Front Left Cover.

the copier. → Remove No.22. → Remove one screw that

secures the Front Exit Cover.

the copier. → Remove No.26. → Remove one screw that

secures the Rear Exit Cover.

Swing down No.1. → Release and swing up the Upper Half of

the copier. → Remove one screw that secures the Middle Rear

Left Cover.

D-7

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

2-2. REMOVAL OF PWBs

•

When removing a PWB, first go over “PRECAUTIONS FOR HANDLING THE PWBs”

contained in SWITCHES ON PWBs and use the removal procedures given on the next

page.

•

Replacement of a PWB may call for readjustments or resetting of particular items.

•

The removal procedures given on the ne xt page omit the steps to unplug connectors and

remove the PWB from the PWB support.

PWB-Y

PWB-D

PWB-A

PU1

PWB-E (15/18 cpm copier)

PWB-F (23 cpm copier)

PWB-C

PU2

1174D001AA

D-8

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

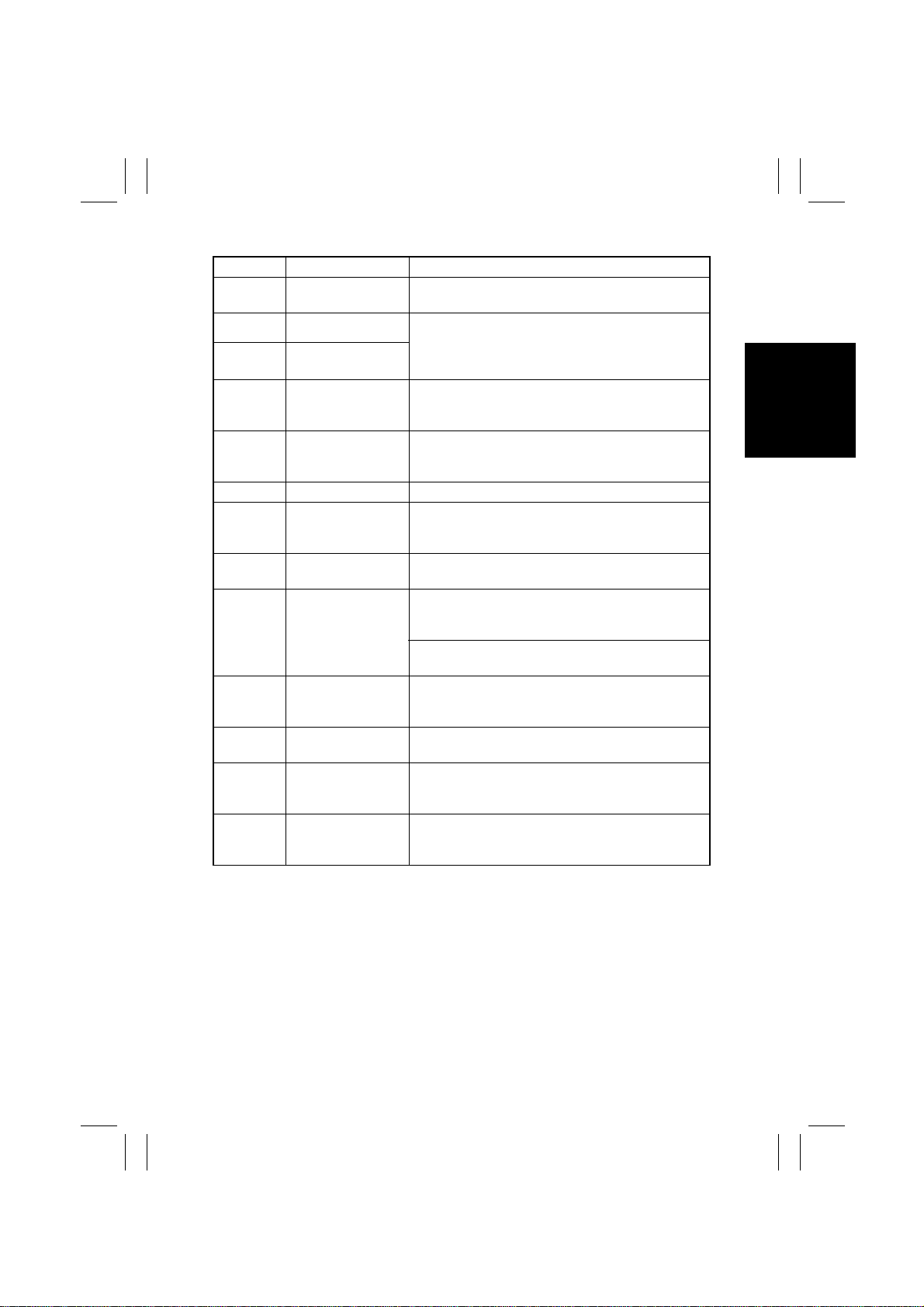

Symbol Part Name Removal Procedure

PWB-A Master Board Open 1. → Release and swing up the Upper Half of

PWB-C Power Supply Board Open 1. → Release and swing up the Upper Half of

PWB-D Noise Filter Board

PWB-E

(15/18 cpm

copier)

PWB-F

(23 cpm

copier)

PWB-H AE Sensor Board Remove 3 and 4. → Remove the optical cover.

PWB-P Control Panel Open 1. → Remove 9. → Release and swing up the

PWB-Y RAM Board Open 1. → Release and swing up the Upper Half of

PU1 Power Supply Unit <18/23 cpm copier>

PU2 DC Power Supply

HV1 High Voltage Unit Open 1. → Release and swing up the Upper Half of

UN2

(18/23 cpm

copier only)

UN3 ATDC Sensor Open 1. → Release and swing up the Upper Half of

✽

Details of Readjustments/Resetting Involved In Replacement of PWB-Y, UN2 and UN3.

•

When PWB-Y is replaced:

Carry out Memory Clear and then make the Tech. Rep. Program, User's Choice, and

Adjust settings again.

•

When UN2 is replaced: (18/23 cpm copier only)

Adjust the Original Size Detecting Board.

•

When UN3 is replaced:

Discard the developer which had been used until UN3 was replaced, charge the Developing Unit with fresh starter, and adjust ATDC.

Motor Drive Board Open 1 and 12. → Remove 9, 10, and 11.

Motor Drive Board Open 1. → Remove 11. → Remove 9 and 10. →

Unit

Original Size Detecting Board

the copier. → Remove 19.

the copier. → Remove 17 (18/23 cpm copier only), 18,

and 19. → Remove four screws that secure the Power

Supply Unit Cover.

Remove the Multi Bypass Unit.

Upper Half of the copier. → Remove 21. → Remove

seven screws that secure Control Panel.

the copier. → Remove 19.

Open 1. → Remove 11. → Remove 9 and 10. →

Remove the Multi Bypass Unit.

<15 cpm copier>

Open 1 and 12. → Remove 9, 10, and 11.

Open 1. → Release and swing up the Upper Half of

the copier. → Remove 17 (18/23 cpm copier only) and

18.

the copier. → Remove 19.

Remove 3 and 4. → Remove the optical cover.

the copier. → Take out the I/U. → Remove two screws

that secure the Synchronizing Roller Guide Unit.

→

Remove PWB-A.

D-9

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

2-3. BELT INSTALLATIONS

•

Rear View

Drive/Suction Unit

Paper Take-Up Unit

<18/23 cpm copier>

<15 cpm copier>

1151D052AB

1151D050AA

1142D005AA

D-10

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

2-4. PAPER TAKE-UP/TRANSPORT SECTIONS

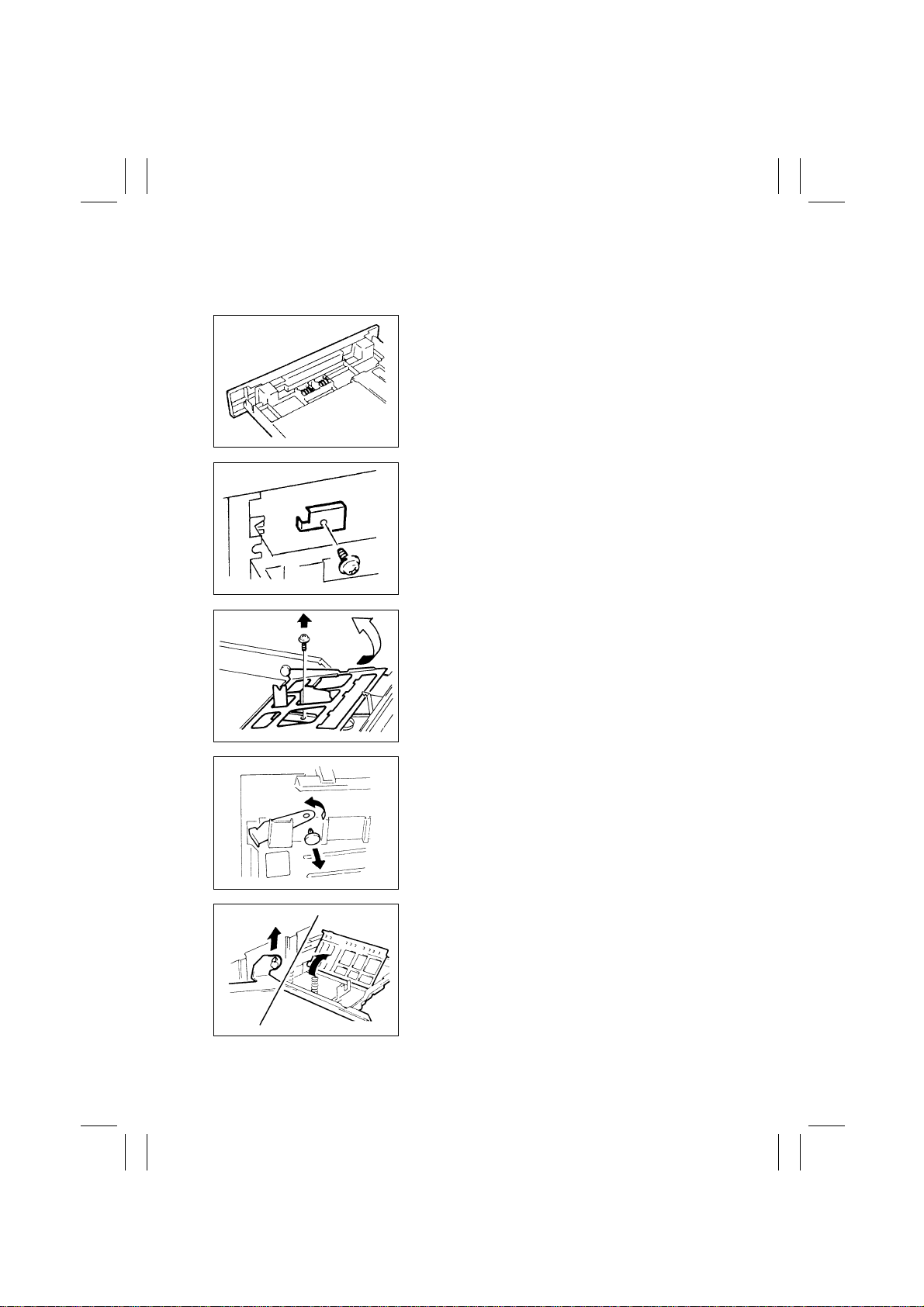

(1) Removal of the Paper Take-Up Unit

1. Remove the Multi Bypass Table. (15/18 cpm

copier: OPTION) See p. D-15. (NO 1 ~ 7)

2. Slide out the 1st and 2nd (23 cpm copier only)

Drawers.

1139D084AA

3. Press the tabs at the two places indicated by the

arrow and, at the same time, remove the cover.

(15/18 cpm copier only)

1142D007AA

1151D020AA

1139D086AA

1139D238AA

4. Remove screws and the Paper Take-Up Unit. (23

cpm copier: four screws/15/18 cpm copier: five

screws)

5. Unplug the connectors from the solenoids on the

Paper Take-Up Unit. (23 cpm copier: two connectors/15/18 cpm copier: one connector)

6. Remove the Rear and Rear Upper covers.

7. Remove the DC Power Supply Unit.

8. Remove the harness from the wiring saddle.

9. Unplug the connectors (23 cpm copier: two connectors/15/18 cpm copier: one connector).

D-11

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

(2) Removal of the Paper Take-Up Rolls

1. Remove one screw to remove the Paper Take-Up

Roll.

1139D088AA

(3) Cleaning of the Paper Take-Up Rolls

1. Remove the Paper Take-Up Unit from the copier.

2. Using a soft cloth dampened with alcohol, wipe

clean the Paper Take-Up Rolls.

1139D089AA

(4) Rem oval of the Suction Unit

1151D029AA

1151D030AA

1. Remove the Fusing Unit. (See p. D-40.)

2. Unplug the Suction Fan connector and remove the

wire from the clamp.

3. Remove four screws to remove the Suction Unit.

D-12

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

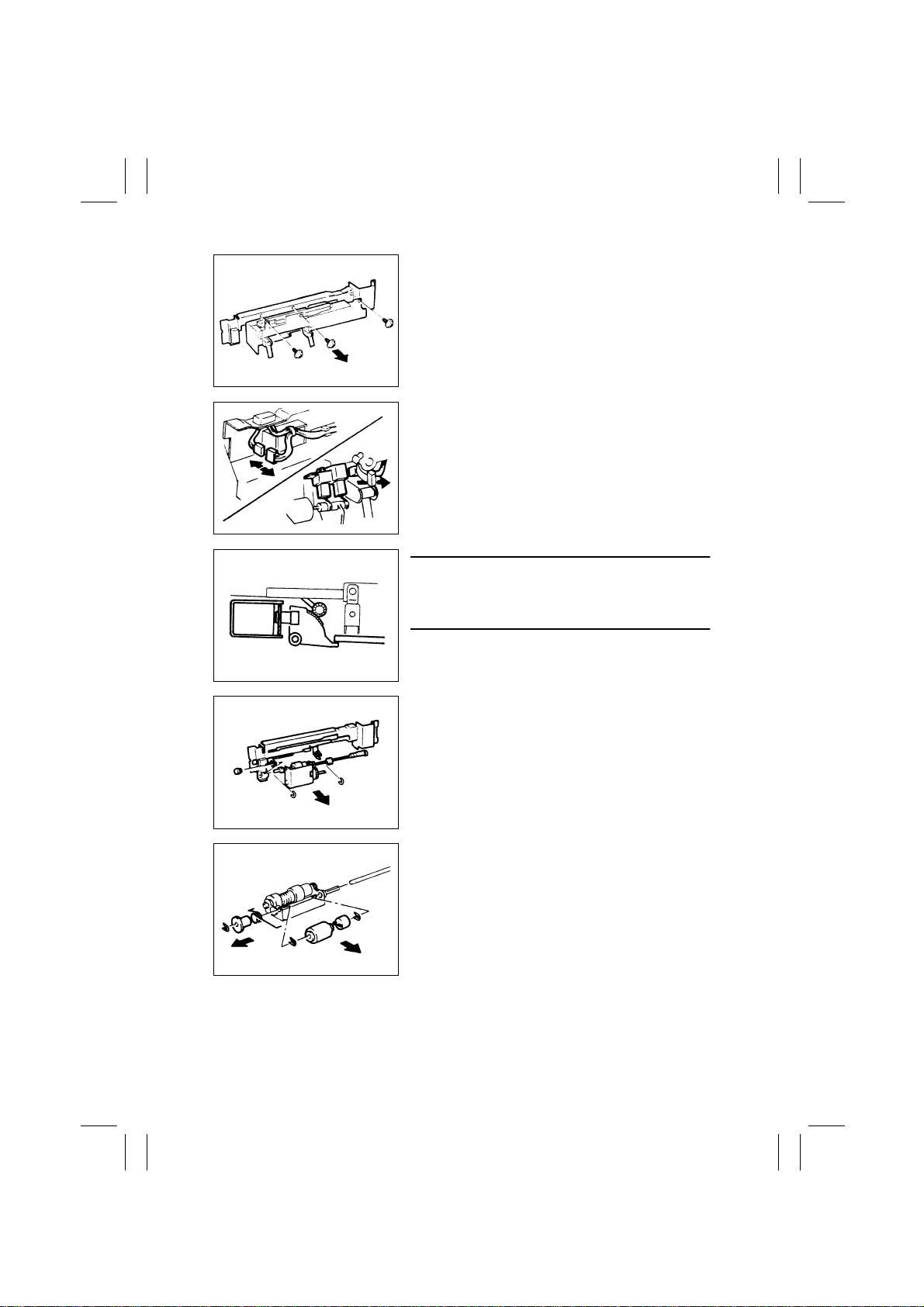

(5) Disassembly of the Suction Unit

1. Remove the four Suction Drive Rolls and six bushings by pulling them in the direction of the arrow.

1151D004AA

2. Snap off the three E-rings from the Suction Drive

Unit.

3. Remove the gear and bushings.

1139D094AA

4. Remove the Pre-Fusing Guide Plate.

5. Remove the Suction Drive Unit.

1151D005AA

1151D006AA

1151D009AA

6. Remove the four belts.

7. Remove the Suction Fan.

D-13

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

(6) Replacement of the Paper Lifting Springs (2nd Drawer): 23 cpm copier only

Remark

•

The replacement springs are installed on the underside of the 2nd Drawer.

1139U044AA

1. Remove the Stoppers of the 2nd Drawer and the

2nd Drawer.

1136P243AA

1151D043AA

1139U045AA

1139U047AA

2. Remove one screw and the Edge Guide Unit.

3. Remove the F ront Separator Finger by remo ving its

pin.

4. Raise the Paper Lifting Plate Unit and replace the

Paper Lifting Springs. See p. D-61.

D-14

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

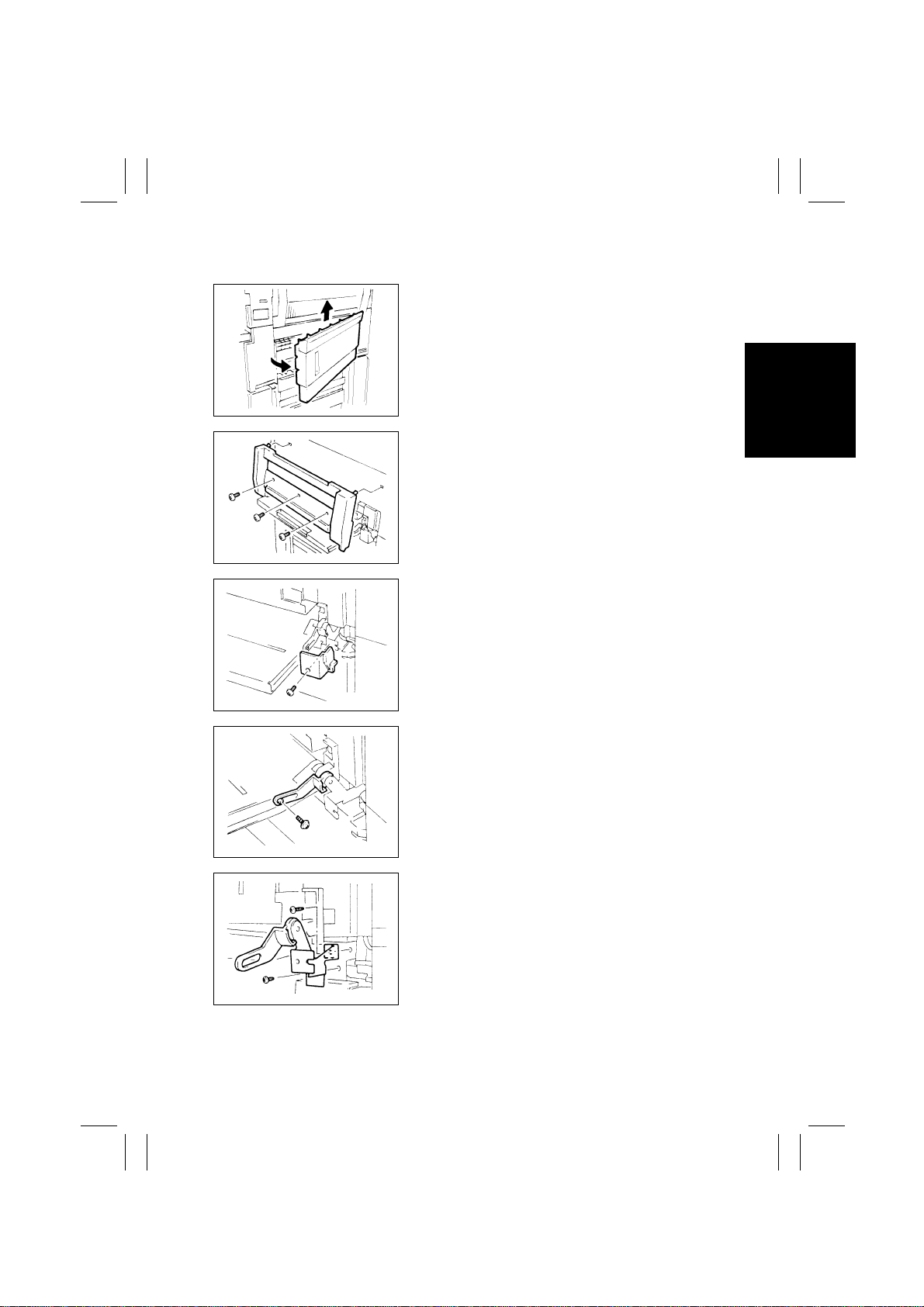

(7) Disassembly of the Multi Bypass Table (15/18 cpm copier: OPTION)

1. Remove the Right Door.

1139D099AA

2. Remove three screws and the Large Cover.

4425U408AA

3. Remove one screw and the Small Cover.

1139D227AA

1139D222AA

1139D223AA

4. Remove three screws and the Guide Lever Unit.

D-15

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

5. Remove four screws and the Multi Bypass Table.

6. Unplug the Multi Bypass Table connector.

1139D240AA

7. Remove one screw and the Multi Bypass Table.

1139D225AA

8. Unplug one connector.

9. Remove the Tension Unit.

1151D018AA

1139D101AA

1139D102AA

10. Remove two screws and the Clutch Mounting

Bracket.

11. Remove two screws and the Lower Guide.

D-16

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

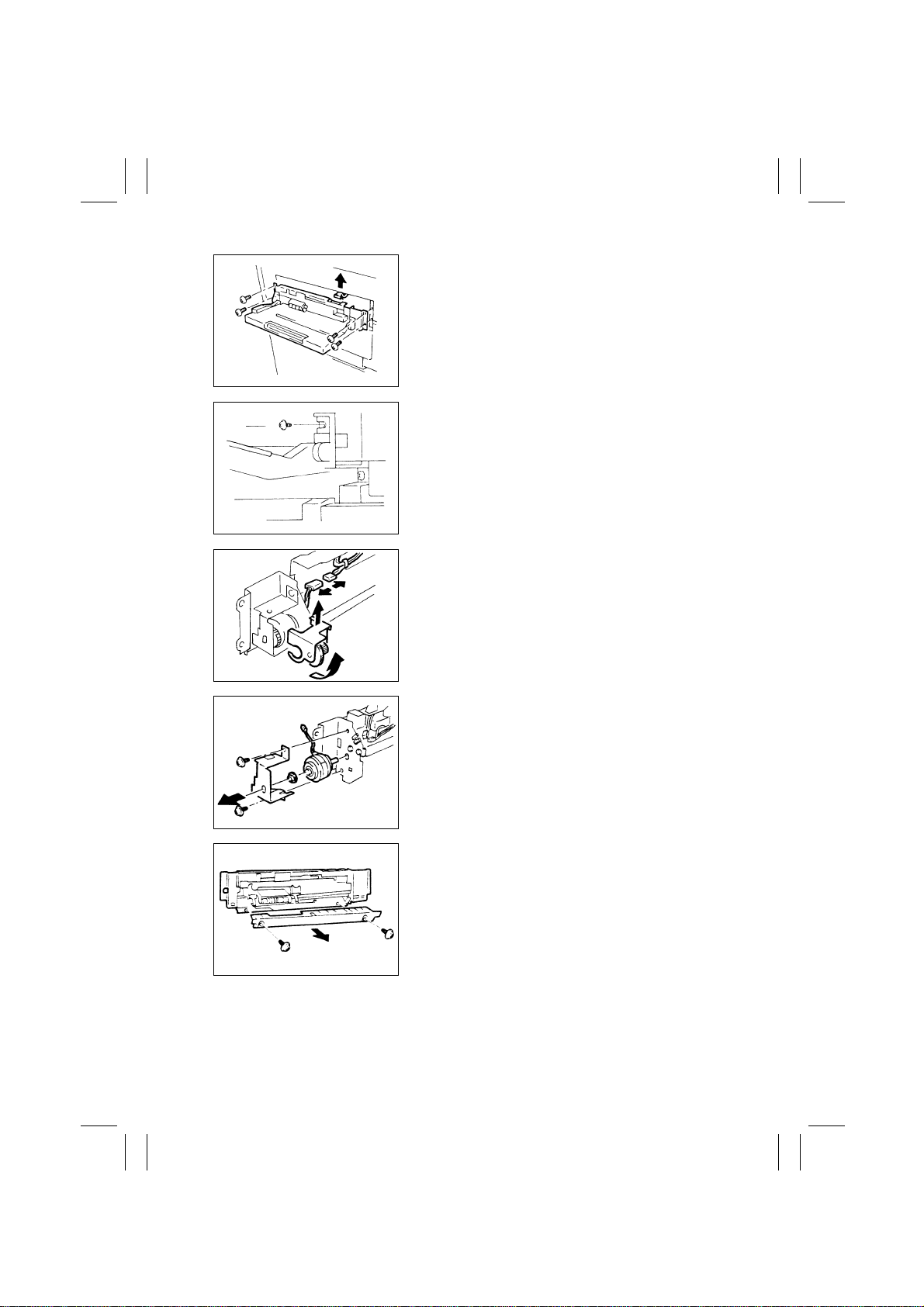

12. Remove four screws and the Separator Guide

Plate Unit.

1139D103AA

NOTE

When reinstalling the Separator Guide Plate Unit,

press the parts shown on the left up against the copier

frame (both at front and rear).

1139D104AA

13. Remove two screws and the Lev er.

1139D105AA

1139D106AA

1139D107AA

14. Snap off one C-clip and remove the Separator Unit.

NOTE

•

Please use tweezers when reinstalling the C-clip.

15. Snap off one C-clip and remove the Separator Roll

Assy .

D-17

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

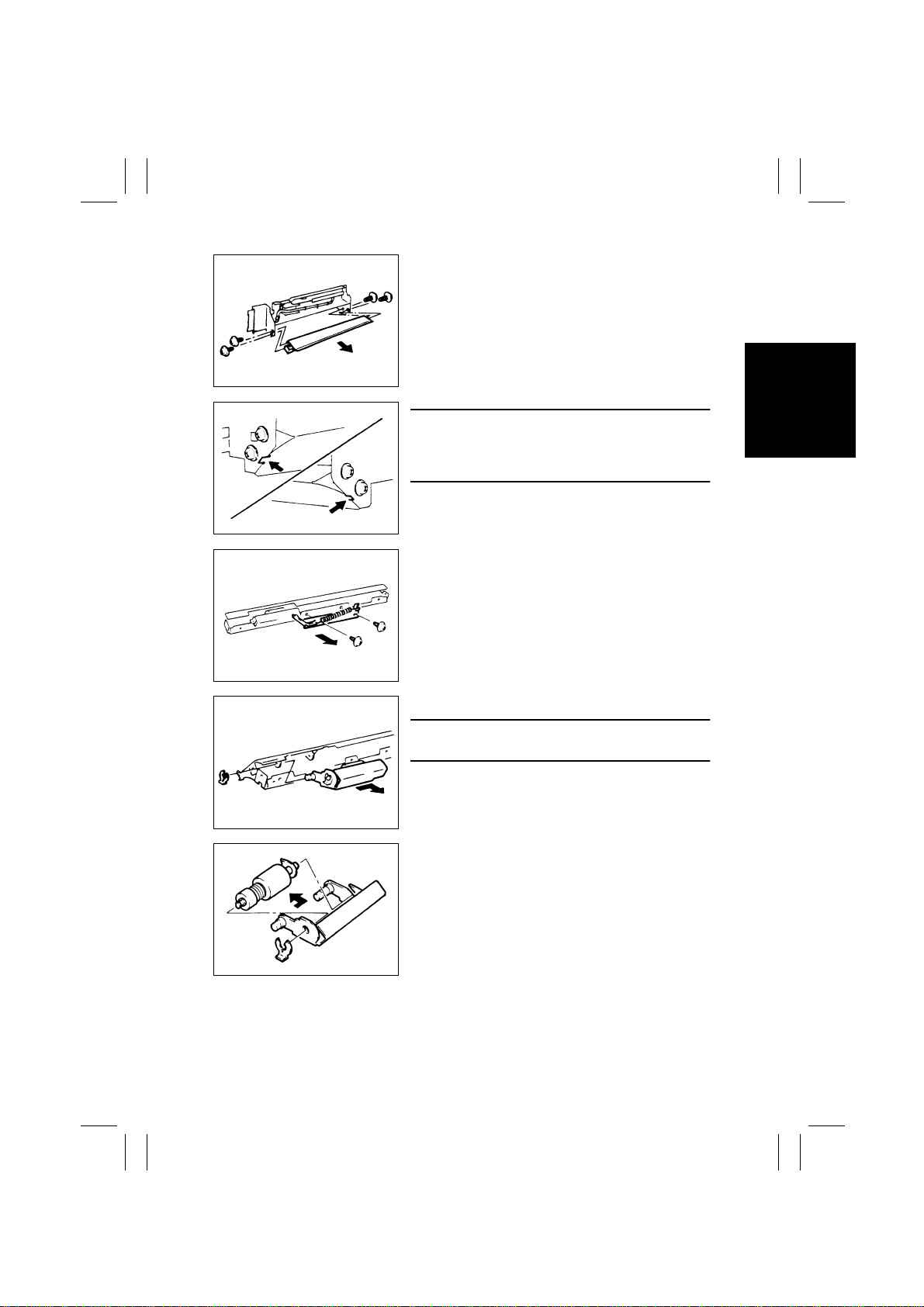

16. Remove three screws and the Solenoid Mounting

Bracket.

1139D108AA

17. Unplug one solenoid connector.

18. Unplug one photosensor connector and remove

the harness from the clamp.

1139D109AA

NOTE

When reinstalling the Solenoid Mounting Bracket,

make sure that the Solenoid is in the deenergized

position.

1139D110AA

1139D111AA

1139D112AA

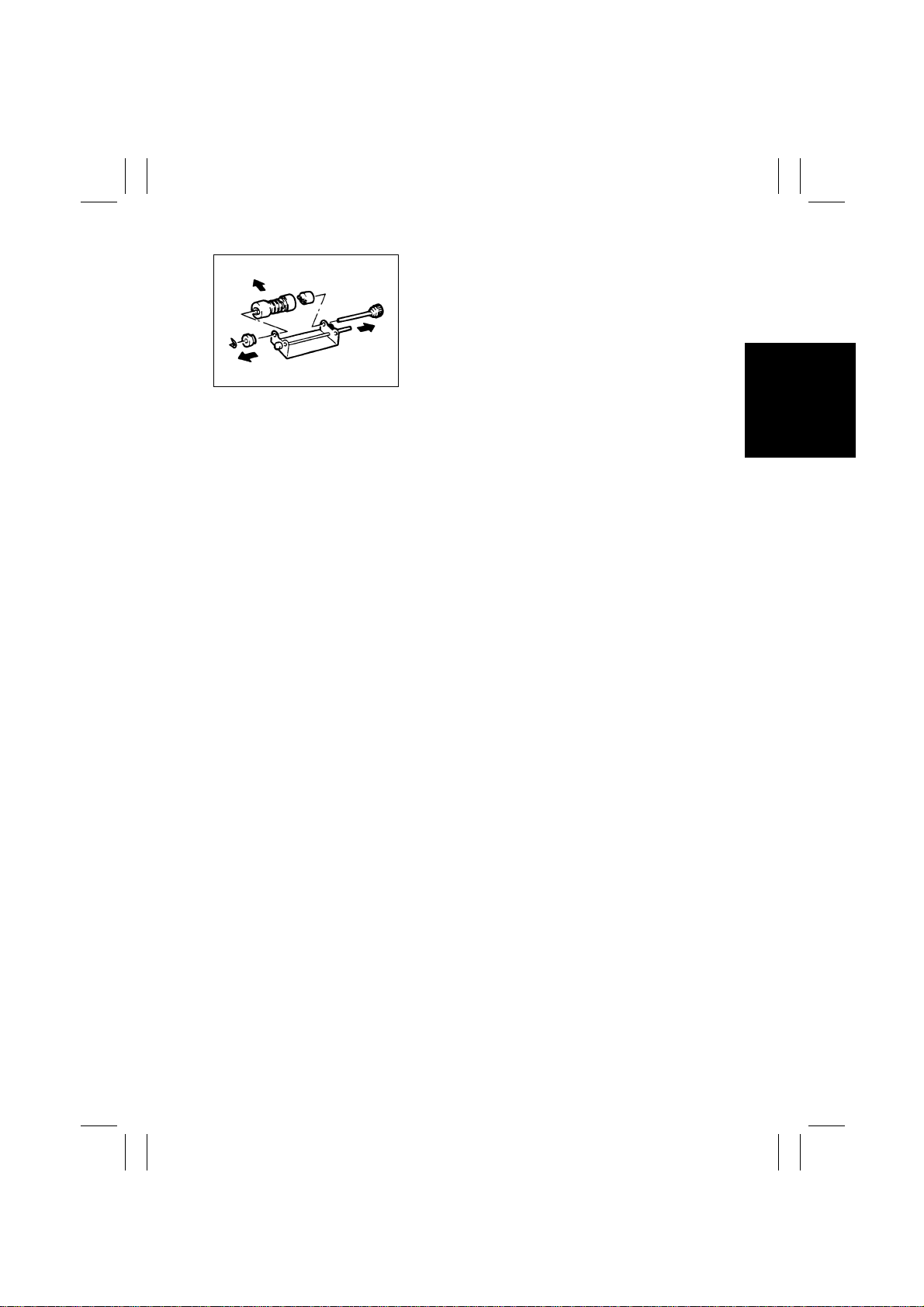

19. Snap off the two C-clips to remove the Paper TakeUp Roll Unit.

20. Snap off the three C-clips to remove the Paper

Feed Roll.

D-18

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 DIS/REASSEMBLY, ADJUSTMENT

98.04.13

21. Snap off one C-clip and remove the Paper Take-Up

Roll.

1139D113AA

D-19

Loading...

Loading...