Page 1

AFR-12/AF-5

SERVICE MANUAL

Page 2

GENERAL/MECHANICAL/

ELECTRICAL

Table Of Contents-1 AFR-12/AF-5Rev. 1.0/05.99

Page 3

1GENERAL/MECHANICAL/ELECTRICAL

1.1 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

1.2 Components Identification- - - - - - - - - - - - - - - - - - - - 4

1.3 Cross-sectional View- - - - - - - - - - - - - - - - - - - - - - - - 6

1.4 Driv e System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

1.5 Electrical Component Layout- - - - - - - - - - - - - - - - - - 9

1.6 Description Of Modes - - - - - - - - - - - - - - - - - - - - - - 1 0

1.6.1 Mixed Original Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

1.6.2 1-Sided Original Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

1.6.3 2-Sided Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

1.6.4 2-in-1 Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

1.6.5 S-ADF (Single Feed) Mode - - - - - - - - - - - - - - - - - - - - - - - - 10

1.6.6 Thin Mode (As set by "Ori ginal Thickness" of User’s Mode) - 11

1.7 Document Take-up/feeding Mechanism - - - - - - - - - 12

1.7.1 Construction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

1.7.2 Document Pick-Up Mechanism - - - - - - - - - - - - - - - - - - - - -13

1.7.3 Document Tak e- U p Mec hanism- - - - - - - - - - - - - - - - - - - - - 14

1.7.4 Separating Mechanism - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

1.7.5 Single Feed Mechanism - - - - - - - - - - - - - - - - - - - - - - - - - - 17

1.8 Document Transport Mechanism- - - - - - - - - - - - - - 18

1.8.1 Construction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

1.8.2 Document Transpo rt Mechanism - - - - - - - - - - - - - - - - - - - - 18

1.8.3 Original Width Scale Retraction Mechanism - - - - - - - - - - - - 19

1.9 Turnover/Exit Mechanism - - - - - - - - - - - - - - - - - - - 20

1.9.1 Construction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

1.9.2 Turnover/Exit Document Transport Mechanism- - - - - - - - - - 21

1.9.3 Turnover/Exit Switching Mechanism (AFR-12) - - - - - - - - - - 23

1.9.4 Exit Mechanism (AF-5) - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Table Of Contents-2EP1052 Rev. 1.0/05. 99

Page 4

1.10 Miscell an eous - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

1.10.1 Document Size Detection Mechanism - - - - - - - - - - - - - - - - 25

1.10.2 Raised/Lowered Position Detecting Mechanism - - - - - - - - - 25

Table Of Contents-3 AFR-12/AF-5Rev. 1.0/05.99

Page 5

1GENERAL/MECHANICAL/ELECTRICAL

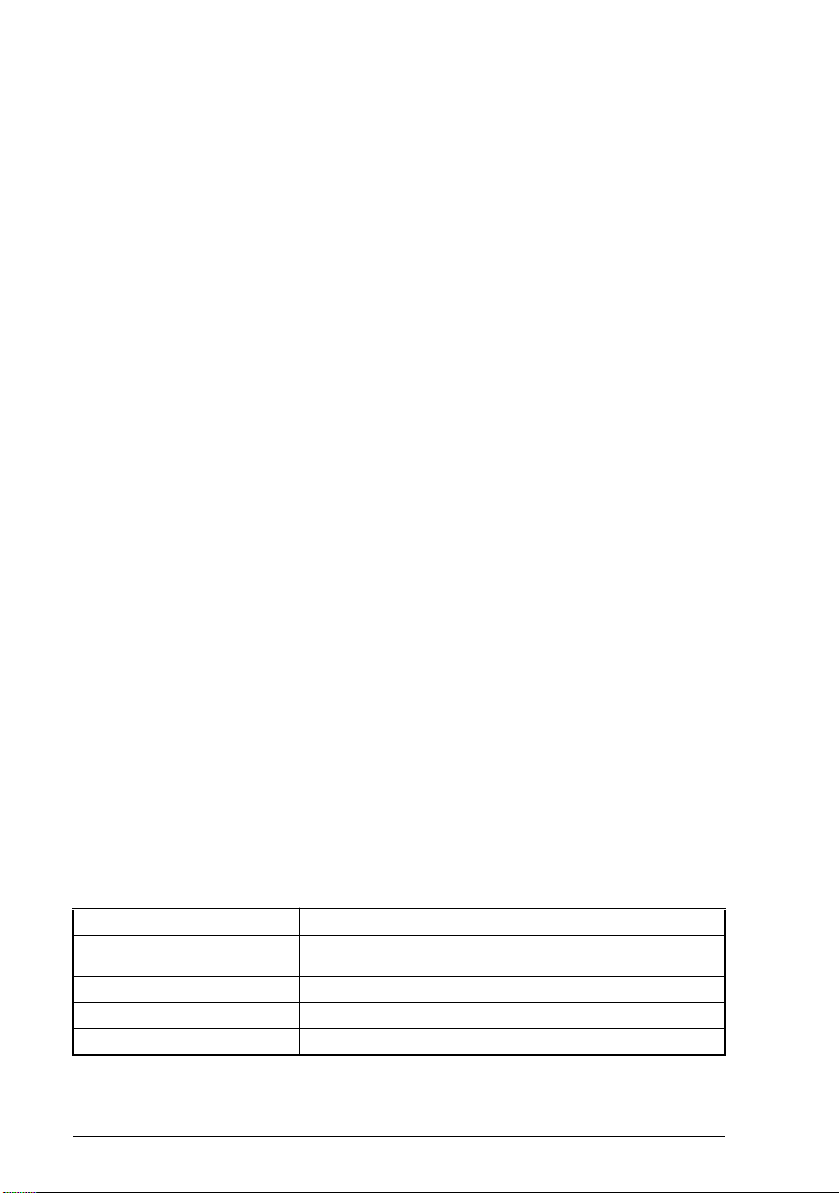

1.1 Specifications

NAME Duplexing Document Feed er AFR-12

Document Feeder AF-5

Electrical

General/Mechanical

TYPE

● Paper Take-Up: Take-up from top of stack,

U-turn feeding

● Transpor t: Automatic single-belt trans port system

● Turnover: Loop turnover system (AFR-12)

● Ejection: U-turn ejection

INST ALLAT ION Mounted onto the copier

TYPE OF DOCUMENT

● Plain paper

● 1-Sided and Dual Original

● Scanning (2-in-1) Modes: 50 to 100 g/m²

● 2-Sided Mode: 60 to 90 g/m²

● Mixed Original Mode: 60 to 90 g/m²

● Single Feed Mode: AFR-12 · 35 to 200 g/m²,

AF-5 · 35 to 157 g/m²

DETECT ABLE

DOCUMENT SIZES

CAP ACITY

A3L, B4L, A4LC, B5LC, A5L, 11" x 17"L, 8-1/2 " x 14" L,

8-1/2" x 11"LC, 11" x 15"L, 8-1/4" x 13"L

● Document Feed Table:

A4 or smaller 50 sheets (of paper weighing 80 g/m²)

B4 or larger 30 sheets (of paper weighing 80 g/m²)

● Document Exit Table:

A4 or smaller 50 sheets (of paper weighing 80 g/m²)

B4 or larger 30 sheets (of paper weighing 80 g/m²)

ALIGNMENT Aligned along the rear Document Edge Guide

DOCUMENT LOADING Face up (Single Feed Mode-Face down)

M-1 AFR-12/AF-5Rev. 1.0/05.99

Page 6

MODES ● 1-Sided Original

● 2-Sided Original

● 2-in-1

● Mixed Original

● Single Feed Mode

The "Original Thickness" function of User ’s Choice

permits selection between the plain paper and thi n

paper mode.

POWER SOURCE 24 VDC, supplied from the copier

POWER

CONSUMPTION

DIMENSIONS

<AFR-12>

WEIGHT

<AFR-12>

DIMENSIONS

<AF-5>

WEIGHT

<AF-5>

OPERA TING

ENVIRONMENT

DOCUMENTS WHICH

CANNOT BE USED

AFR-12 · 60W or less/2.5A AF-5 · 48W or less/2A

Width 627 mm

Depth 515 mm

Height 125 mm

13.0 kg

Width 604 mm

Depth 515 mm

Height 125 mm

12.0 kg or less

Same as copier

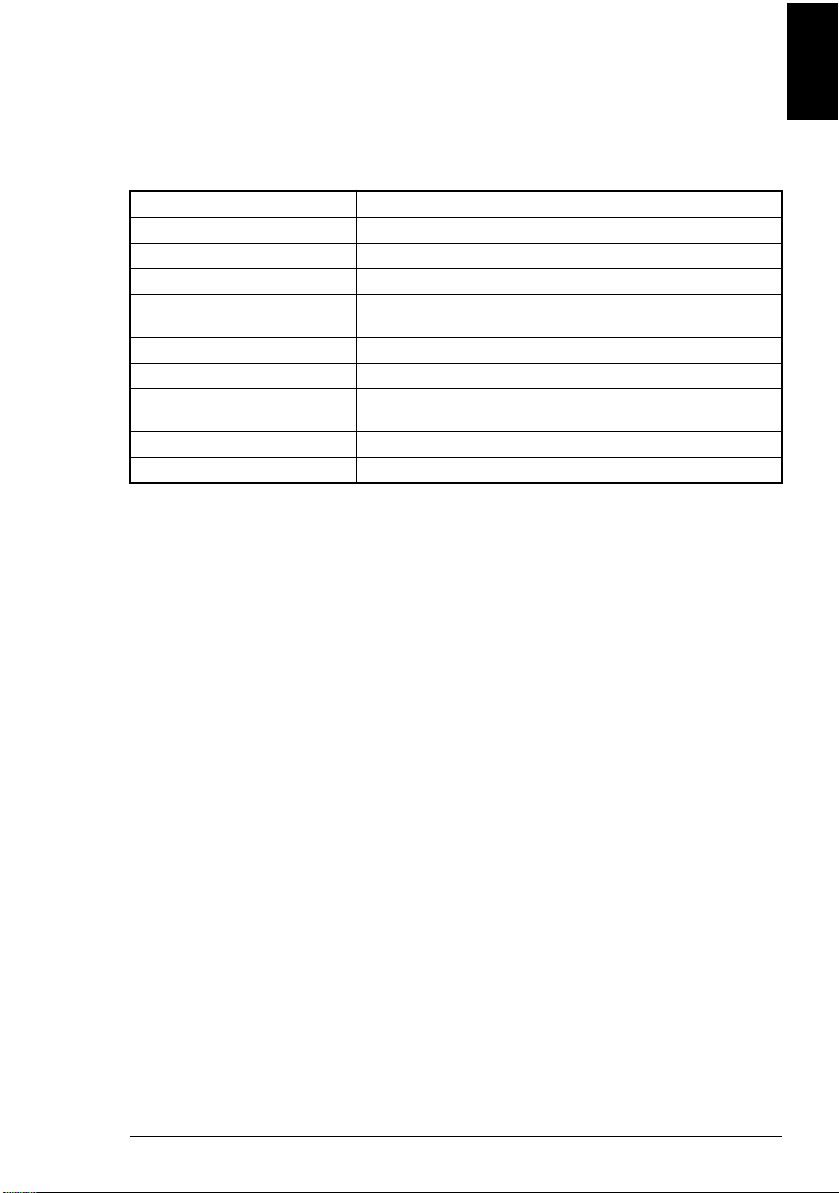

The following docum ents, if used in the AFR-12/AF-5,

are very likely to cause trouble.

Type of Document Possible Trouble

Documents stapled or clipped

together

Documents glued together Take-up failure, damaged document

Documents folded, torn, or wrinkled Take-up failure, damaged document

Documents severely curled Documents mis-fed due to being dog-eared

Take-up failure, damaged document, defective drive train due to

jammed staples or clips.

M-2AFR-12/AF-5 Rev. 1.0/05. 99

Page 7

DOCUMENTS FOR

WHICH

The following documents, if used in the

AFR-12/AF-5, may or may not cause trouble.

FEEDING CANNOT BE

GUARANTEED.

Type of Document Possible Trouble

Slightly curled documents Dog-eared pages, ejection failure

Heat-sensitive paper for facsimile Crease, ejection failure

Coated documents Take-up failure

Documents with uneven surface

(letter head etc.)

Translucent paper Take-up failure, transport failure

Paper just ejected from the ADF Take-up failure, transport failure

Perforated documents (loose

leafed etc.)

Documents weighing 40 to 50 g/m² Folded leading edge, transport failure

Folded documents Transport failure, distorted image

Take-up failure

Take-up failure, transport failure

Electrical

General/Mechanical

M-3 AFR-12/AF-5Rev. 1.0/05.99

Page 8

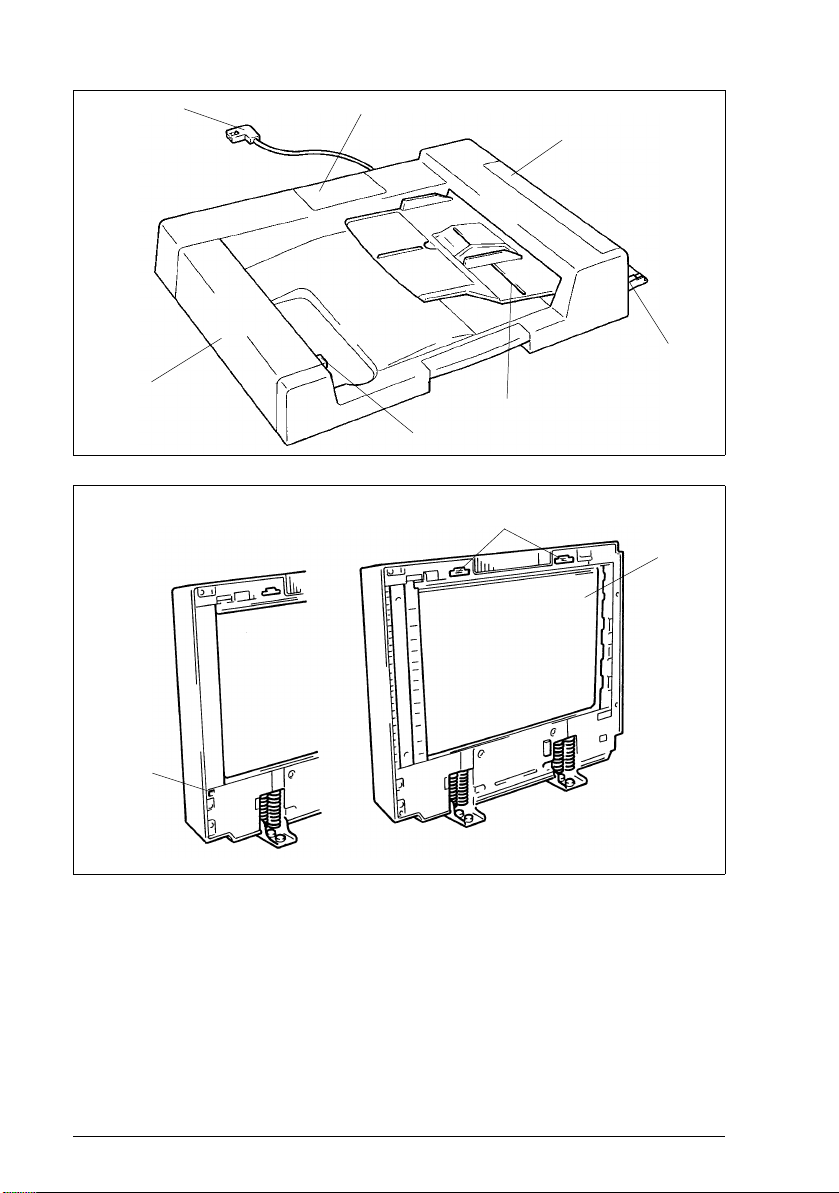

1.2 Components Identification

1

7

<AF-5> <AFR-12>

2

3

4

5

6

9

8

10

M-4AFR-12/AF-5 Rev. 1.0/05. 99

Page 9

1. Hookup Cord

2. Maintenance Cover

3. T a ke -Up Co ve r

4. Single Feed Tray

5. Document Feed Table

6. Turnover Cover Release Swit ch (AFR-12)

7. Turnover Cover (AFR- 12)

8. Transport Belt

9. Magnet Catches

10.Guide Plate Release Lever (AF-5)

Electrical

General/Mechanical

M-5 AFR-12/AF-5Rev. 1.0/05.99

Page 10

1.3 Cross-sectional View

19

18

<AFR-12>

1

2

3

4

5

17

16 15

21

20

22

14

13

12

<AF-5>

11

10

6

9

7

8

M-6AFR-12/AF-5 Rev. 1.0/05. 99

Page 11

1. Document Detecting Sensor (S1)

2. Document Take-Up Roller

3. Document Separator Roll er

4. Registration Sensor

5. Single Feed Transpor t Roller

6. Manual Feed Take-up Sensor (PWB-D)

7. Single Feed Transpor t Roll

8. Registration Driven Roller

9. Registration Drive Roller

10.Size Sensor

11.Transport Belt Drive Roller

12.Transport Rolls

13.Transport Belt Guide Roller

14.Transport Belt Driven Roller

15. Exit Ro lle r

16.Turnover Roller

17.Turnover/Exit Sensor

18.Turnover/Exit Switching Plate

19.Exit Roll

20.Exit Transport Roll

21.Exit Sensor (S3)

22.Exit Transport Roller

Electrical

General/Mechanical

M-7 AFR-12/AF-5Rev. 1.0/05.99

Page 12

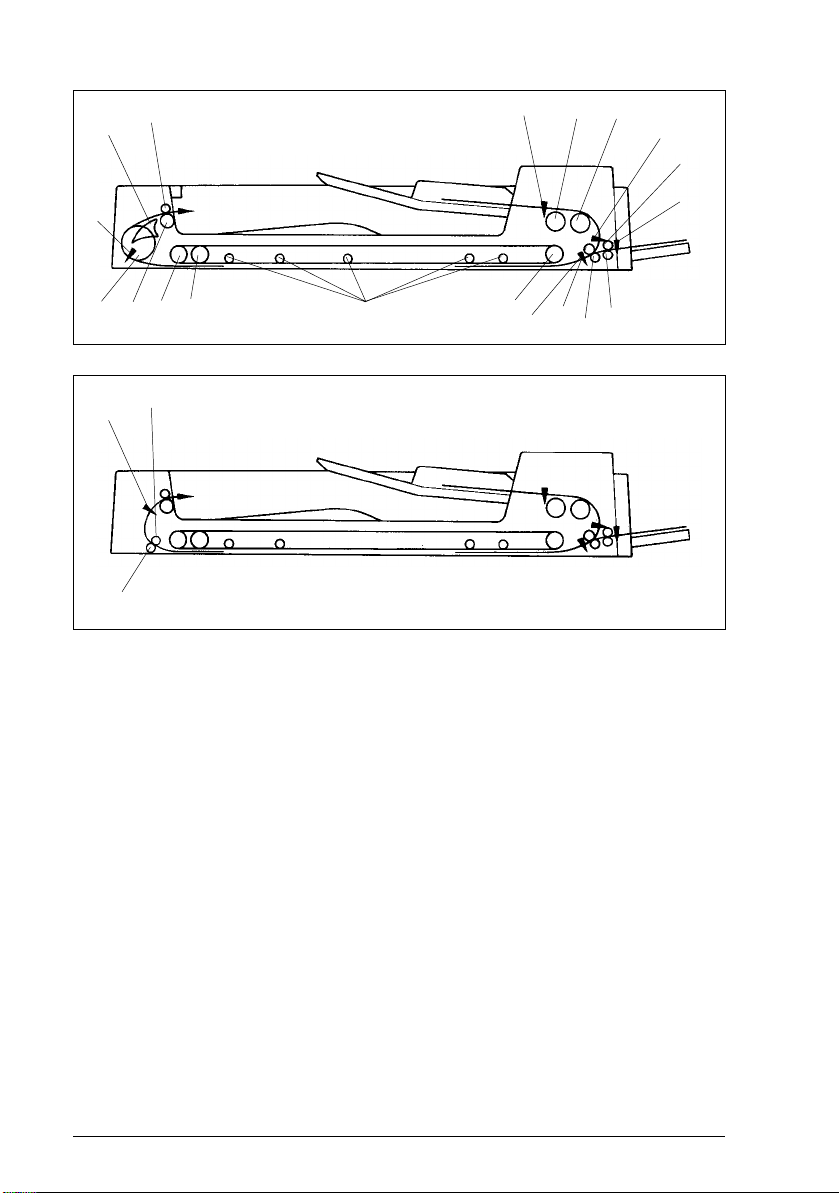

1.4 Drive System

Exit Mechanism

<AF-5>

Exit Motor (M3)

Turnover/

Exit Mechanism

<AFR-12>

Turnover/Exit Motor (M3)

Take-Up/

Transport Mechanism

Take-Up Motor (M1)

Transport Motor ( M2 )

Transport Belt Drive Mech anism

M-8AFR-12/AF-5 Rev. 1.0/05. 99

Page 13

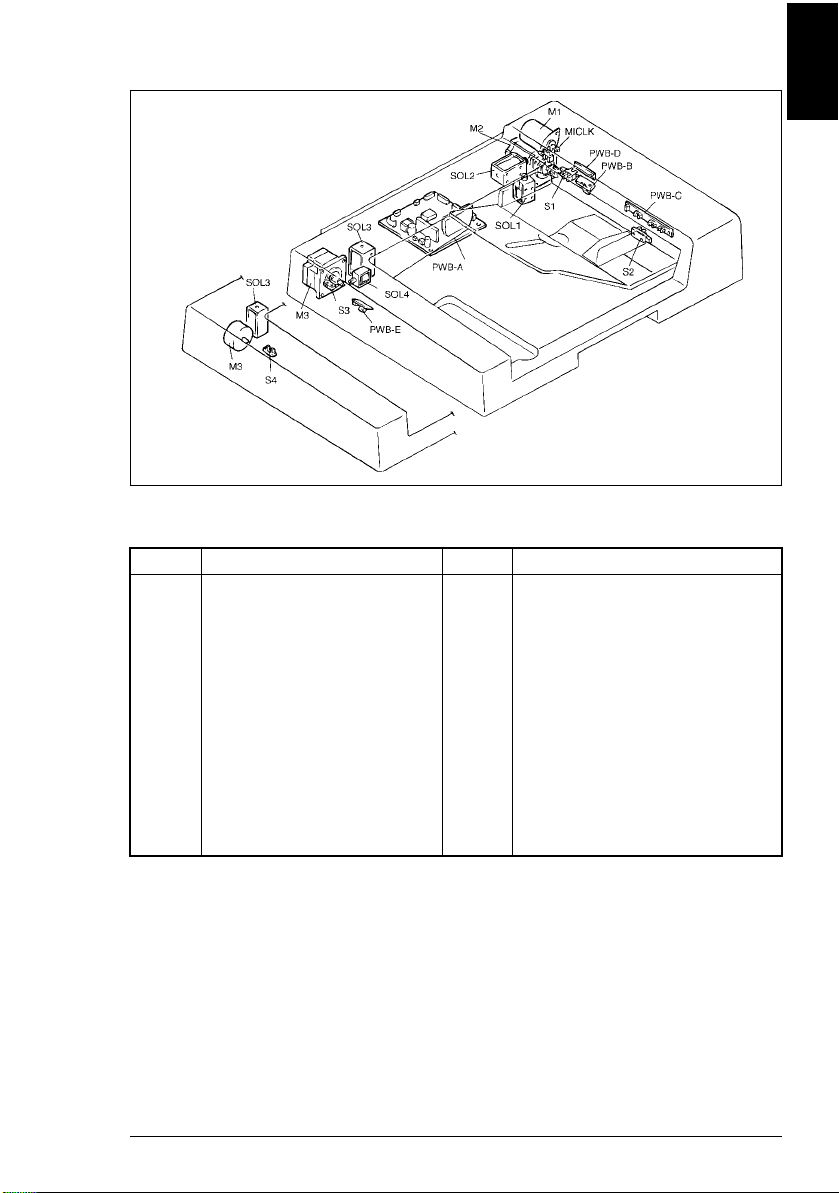

1.5 Electrical Component Layout

<AFR-12>

<AF-5>

Code Name Code Name

PWB-A

PWB-B

PWB-C

PWB-D

PWB-E

M1

M2

M3

M3

Main Control Board

Registration Sensor

Size Sensor

Manual Feed Take-up Sensor

Turnover/Exit Sensor

Take-Up Mot o r

Transport Motor

Turnover/Exit Motor (AFR-12)

Exit Motor (AF-5)

SOL1

SOL2

SOL3

SOL4

S1

S2

S3

S4

MICLK

Document Stopper Solenoid

Document Pressure Solenoid

Scale Solenoid

Turnover/Exit Switching Solenoid

Document Detecting Sensor

Feed Cover Set Switch

Turnover Cover Set Switch

Exit Sensor

Document Feed Motor Pulse Sensor

Electrical

General/Mechanical

M-9 AFR-12/AF-5Rev. 1.0/05.99

Page 14

1.6 Description Of Modes

1.6.1 Mixed Original Mode

● If the Mixed Orig key on the control panel is pressed when the copier is set

in 1- or 2-sided mode, or 2-in-1 mode, the copier detects the size of the

document each time a document is taken up and fed in. The copier feeds

the copy paper of a size selected from among the available paper sources

according to the document size detected.

1.6.2 1-Sided Original Mode

● When in this mode, the copier detects the size of the document which is

taken up and fed in first .

● The copier therefore needs to determine the size of the copy paper only

once based on the detec ted document size and the copying se tting made on

the control pane l. This makes for faster paper feed timing on the part of the

copier.

NOTE

If a set of documents of varying sizes are used in this mode, image trouble could

result including missing copy image. (The system does not force a misfeed

condition.)

1.6.3 2-Sided Mode

● The copier automatically turns over the 2-sided document for a speedy

copying operation (copies are made in the order of the first and second

pages).

1.6.4 2-in-1 Mode

● When in this mode, the copier positions two different documents on the

Original Glass side-by-side for making a copy of the two documents onto

one side of a single sheet of paper in a single copy run.

● If this mode is to be used for a set of documents of different widths, the

Mixed Orig key must first be pressed.

1.6.5 S-ADF (Single Feed) Mode

● When a single document is placed in the Single Feed Tray, the ADF

automatically takes it up and feeds it in to let the copier run a single copy

cycle.

NOTE

The ADF automatically takes up and feeds in documents even when two or more

documents are placed on the Single Feed Tray ; However, it could resul t in a double

feed or other faulty condition. Only one document should therefore be lo aded.

M-10AFR-12/AF-5 Rev. 1.0/05. 99

Page 15

1.6.6 Thin Mode (As set by "Original Thickness" of User’s M ode)

● When in this mode, the ADF transports the document at a low speed and

stops it without l etting it hit against the Original Width Scale.

Electrical

General/Mechanical

M-11 AFR-12/AF-5Rev. 1.0/05.99

Page 16

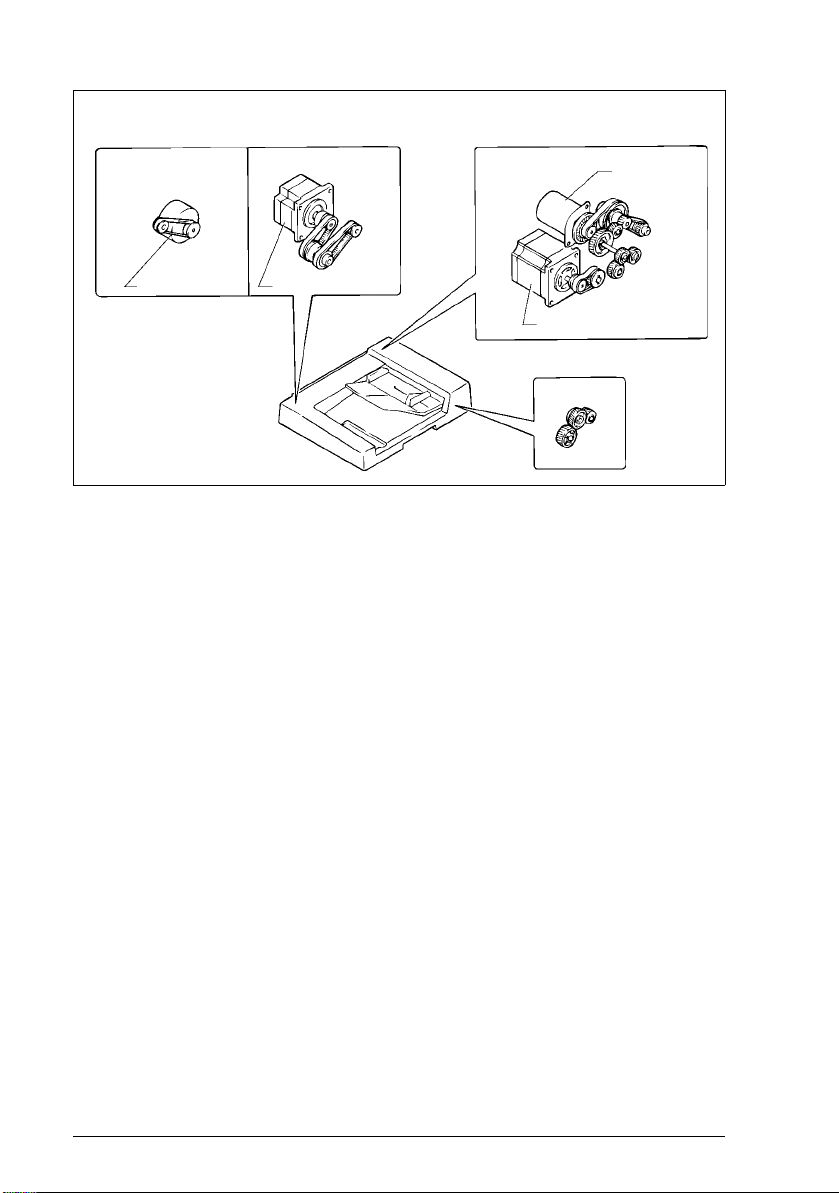

1.7 Document Take-up/feeding Mechanism

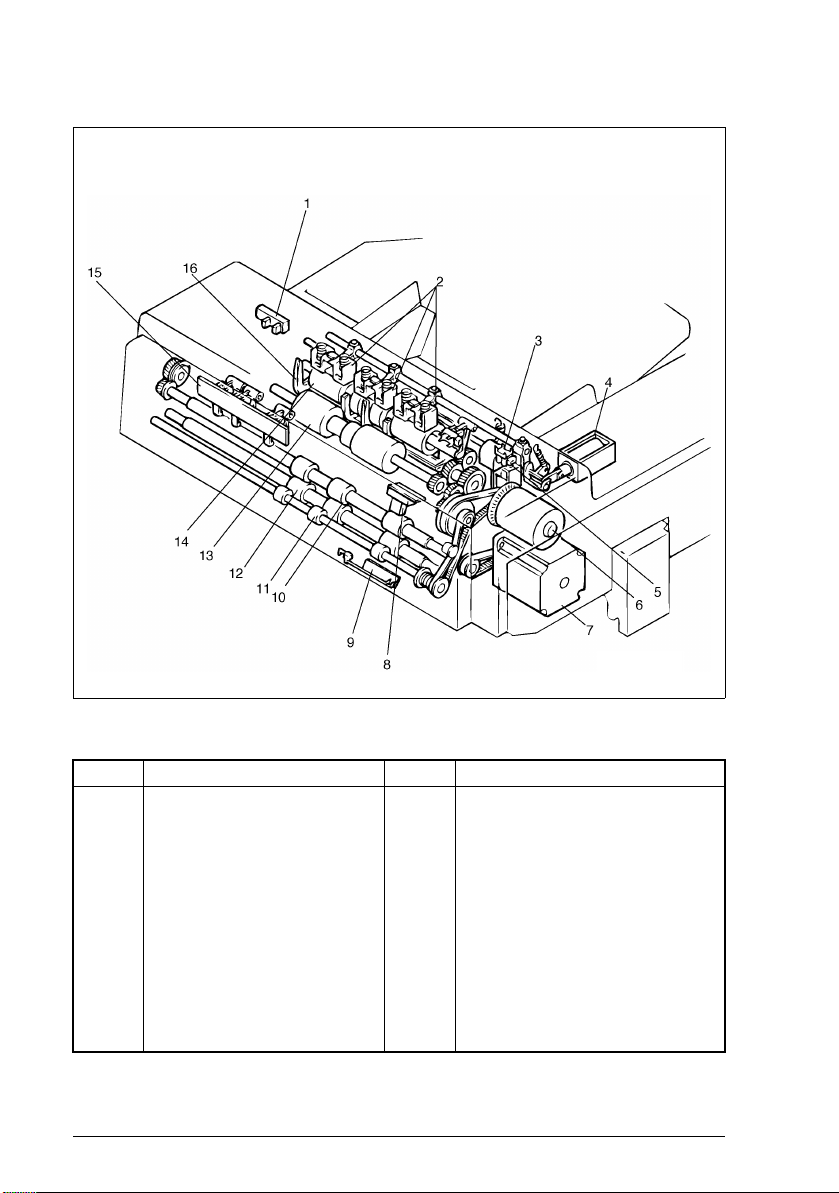

1.7.1 Construction

No. Name No. Name

1

Feed Cover Set Sensor (S2)

2

Document Pressure Pad

3

Document Feed Motor Pulse Sensor

(M1CLK)

4

Document Pressure Solenoid (SOL2)

5

Document Stopper Solenoid (SOL1)

6

Take-Up Motor (M1)

7

Transport Motor

8

Registration Sensor (PWB-B)

9

Manual Feed Take-up Sensor

(PWB-D)

10

Registration Drive Roller

11

Single Feed Transport Roller

12

Registration Driven Roller

13

Document Separator Roller

14

Document Take-Up Roller

15

Size Sens or (PWB-C)

16

Document Stopper Guide Plate

M-12AFR-12/AF-5 Rev. 1.0/05. 99

Page 17

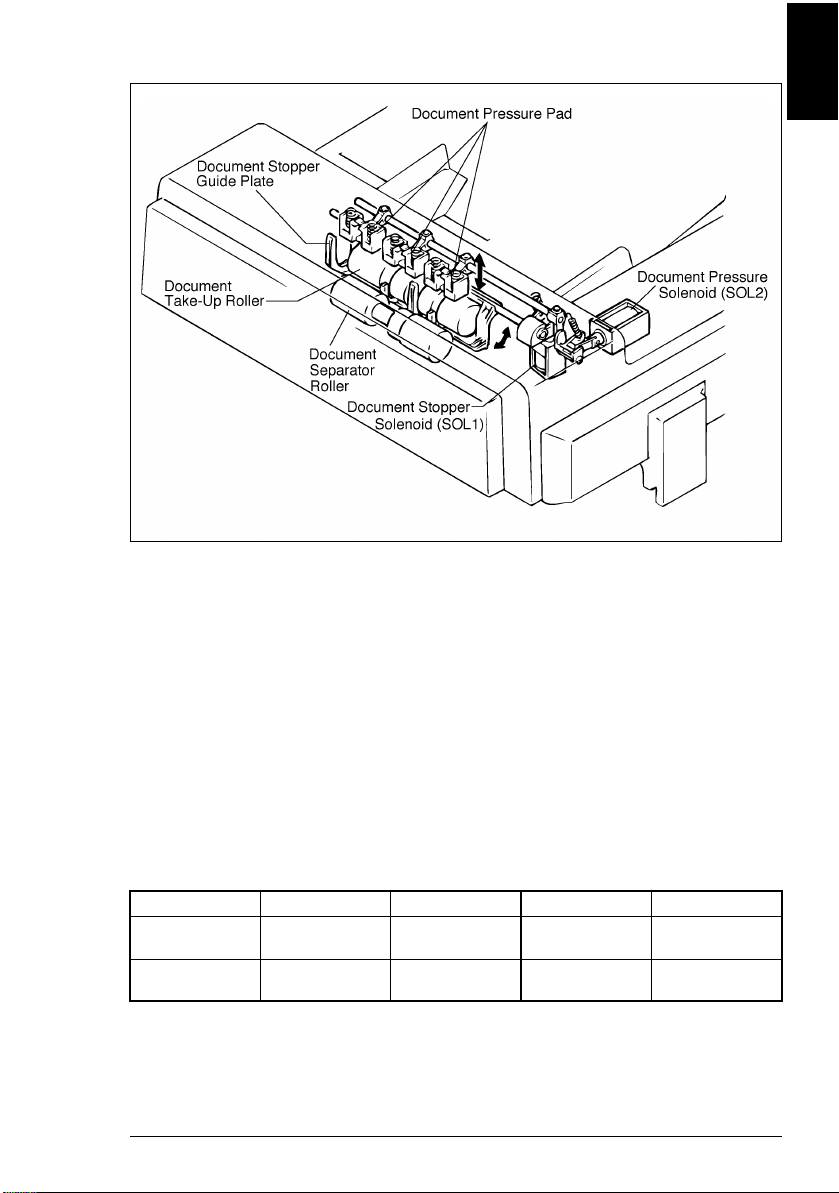

1.7.2 Document Pick-Up Mechanism

● The document pick-up mechanism consists of the Document Pressure

Pads, Document Stopper Guide Plate and Document Take-Up Roller.

● When documents are loaded on the document feed table, they are pressed

against the Document Take-Up Roller by the Document Pressure Pads,

then they are taken up by the Document Take-Up Roller one by one,

commencing with the one from the bottom of the stack.

● The Document Stopper Gu ide Pl ate det ermines t he leadi ng edge posi tio n of

the documents loaded in the ADF. It is normally in the raised position, and

is lowered at the star t of pi ck-up motion.

Electrical

General/Mechanical

SOL1/2 Control

SOL 1 and 2 are energized and de-energized by the signal output from IC3A on

PWB-A.

SOL1 IC3A-20 IC3A-21 SOL2 IC3A- 16

ON

(Stopper UP)

OFF

(Stopper DOWN)

HLONH

LHOFFL

M-13 AFR-12/AF-5Rev. 1.0/05.99

Page 18

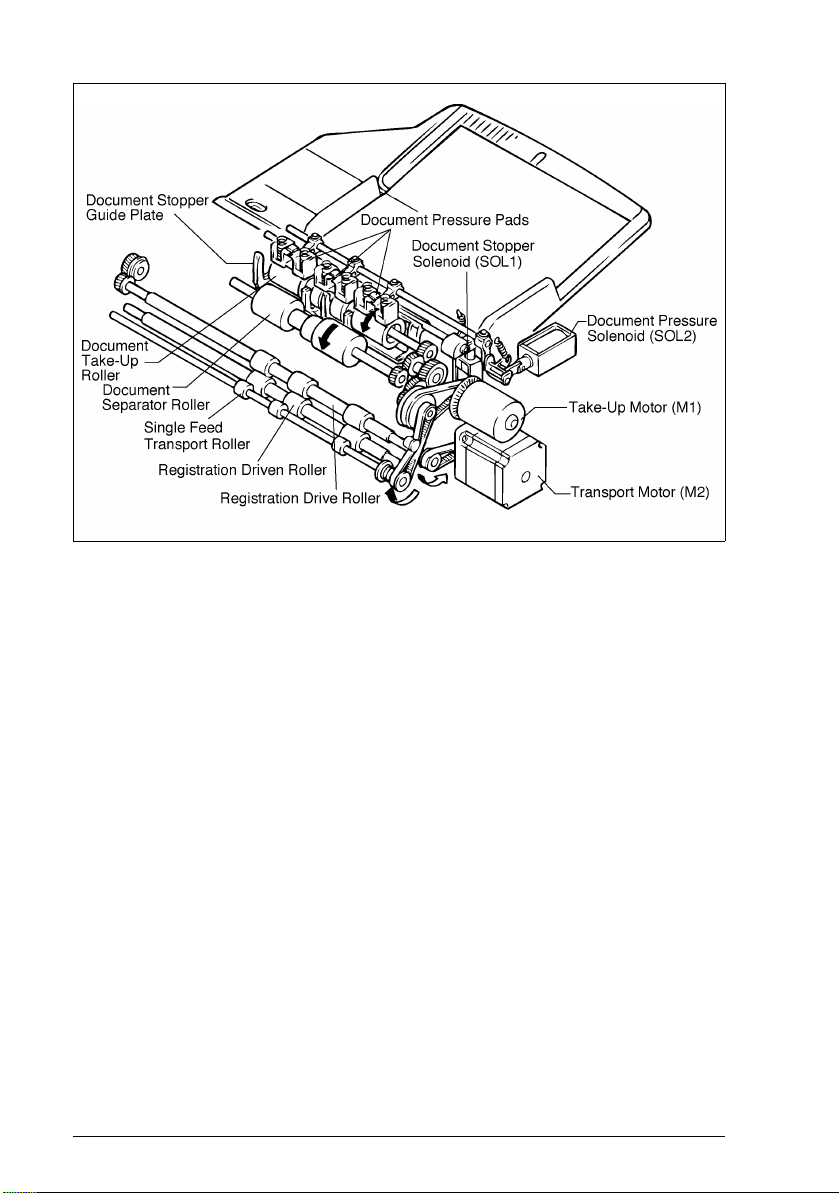

1.7.3 Document Take-Up Mechanism

● The document take-up m echanism takes up a document from the bottom of

a set of documents loaded on the Single Feed Tray and feeds it up to the

registration roller. It is drive n by the Take-Up Motor.

● The Take-Up motor (M1) rotates the Document Take-Up Roller, Document

Separator Roller and Single Feed Transport Roller via Gears, Pulleys and

Timing Belt.

M-14AFR-12/AF-5 Rev. 1.0/05. 99

Page 19

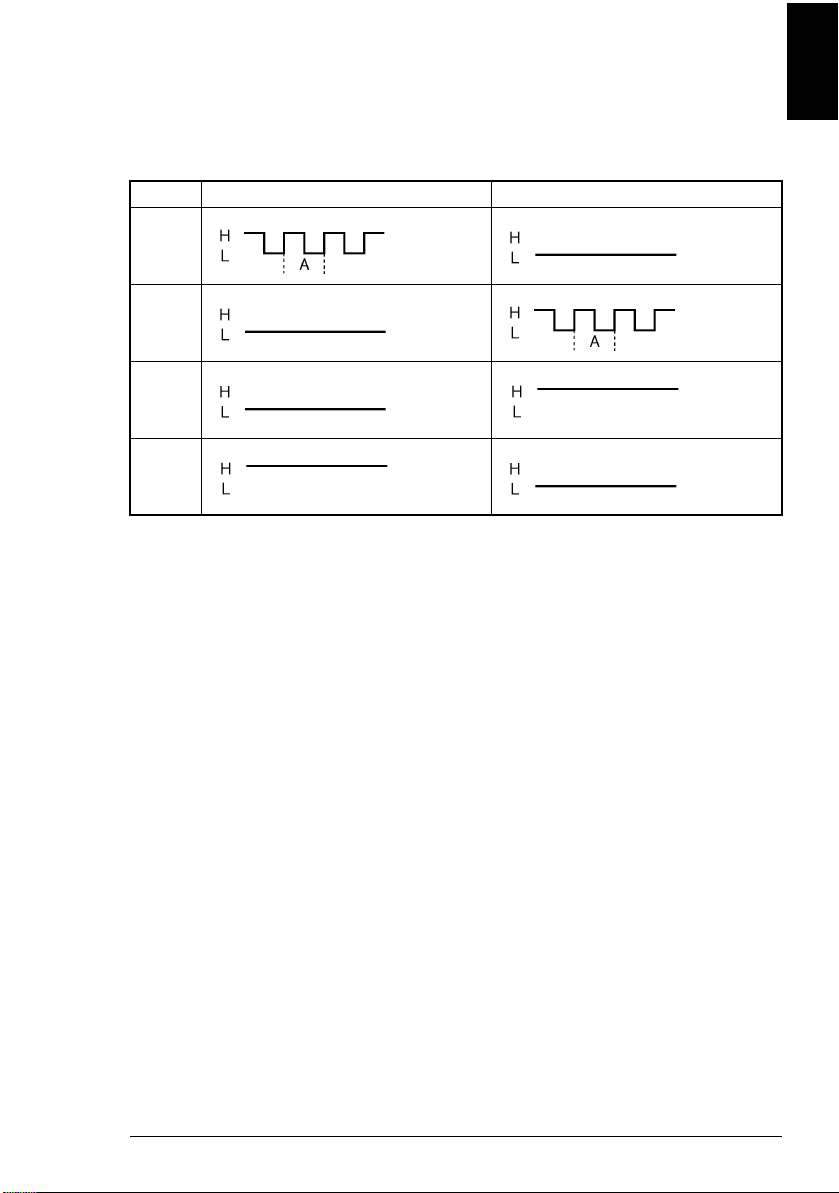

M1 Control

M1 is controlled by the following output signals. M1 speed is detected by the pulse

disk mounted on the motor output shaft and Document Feed Motor Pulse Sensor

(M1 CLK). M1 pulses are applied to IC1A-74, and period A is maintained at the

same length so that the motor rotates at a constant speed.

IC3 Forward Backward

Pin 65

(MIL1)

Pin 66

(MUL2)

Pin 67

(MIHI)

Pin 68

(MIL2)

Electrical

General/Mechanical

M-15 AFR-12/AF-5Rev. 1.0/05.99

Page 20

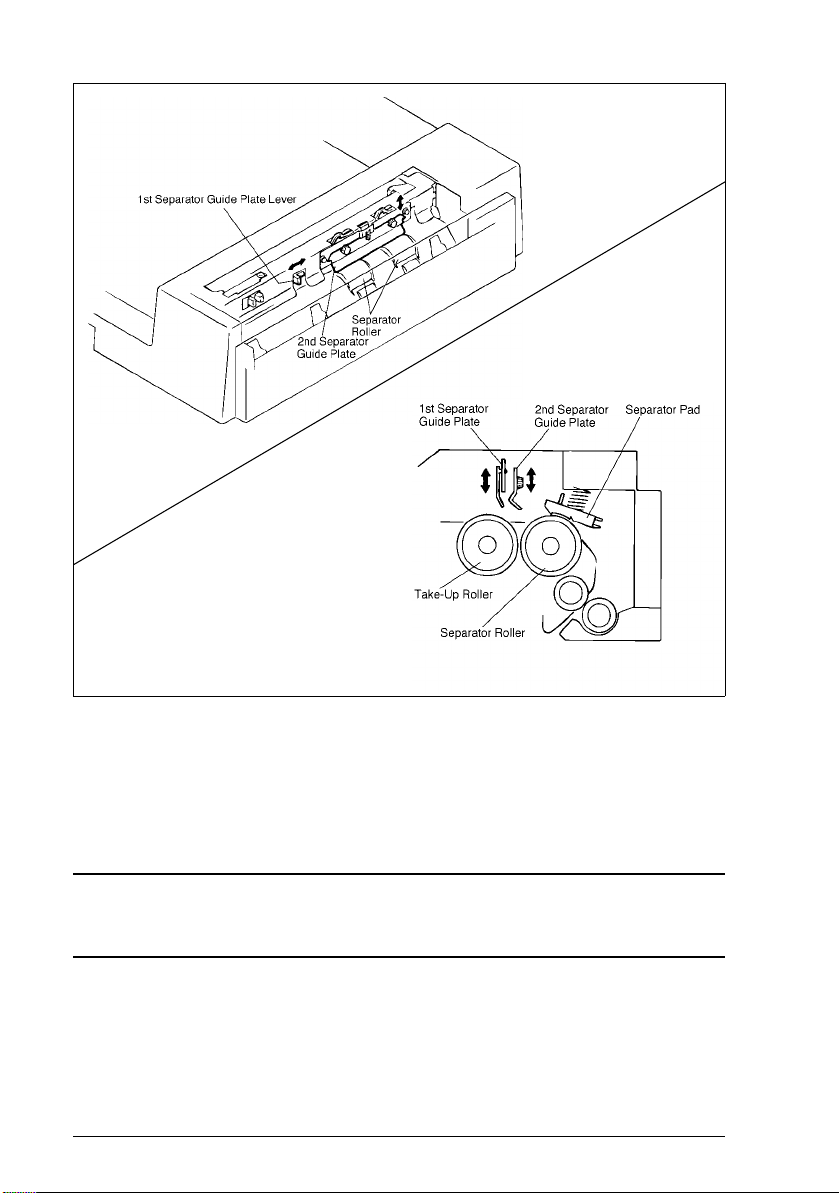

1.7.4 Separating Mechanism

● Movable Separator Guide Plates are used in the Document Separating

Mechanism. The height of the 1st and 2nd Separator Guide Plates can be

adjusted by a lever or screws, respectively.

● Lowering the Guide Plates can reduce the occurrence of Smudging on the

back of documents and smearing of the document image by reducing the

number of documents delivered of the Separator Roller.

NOTE

Both 1st an d 2n d Sep arator Guide Pla tes ha ve b een set i n the rais ed p ositi on at the

time of shipment from the factory.

● The Separator Pad is design ed t o be pr esse d aga inst the Sepa rator Rolle rs.

This ensures t hat documents ar e transport ed one by one even i f two or more

documents are fed fr om the Take-Up Roller.

M-16AFR-12/AF-5 Rev. 1.0/05. 99

Page 21

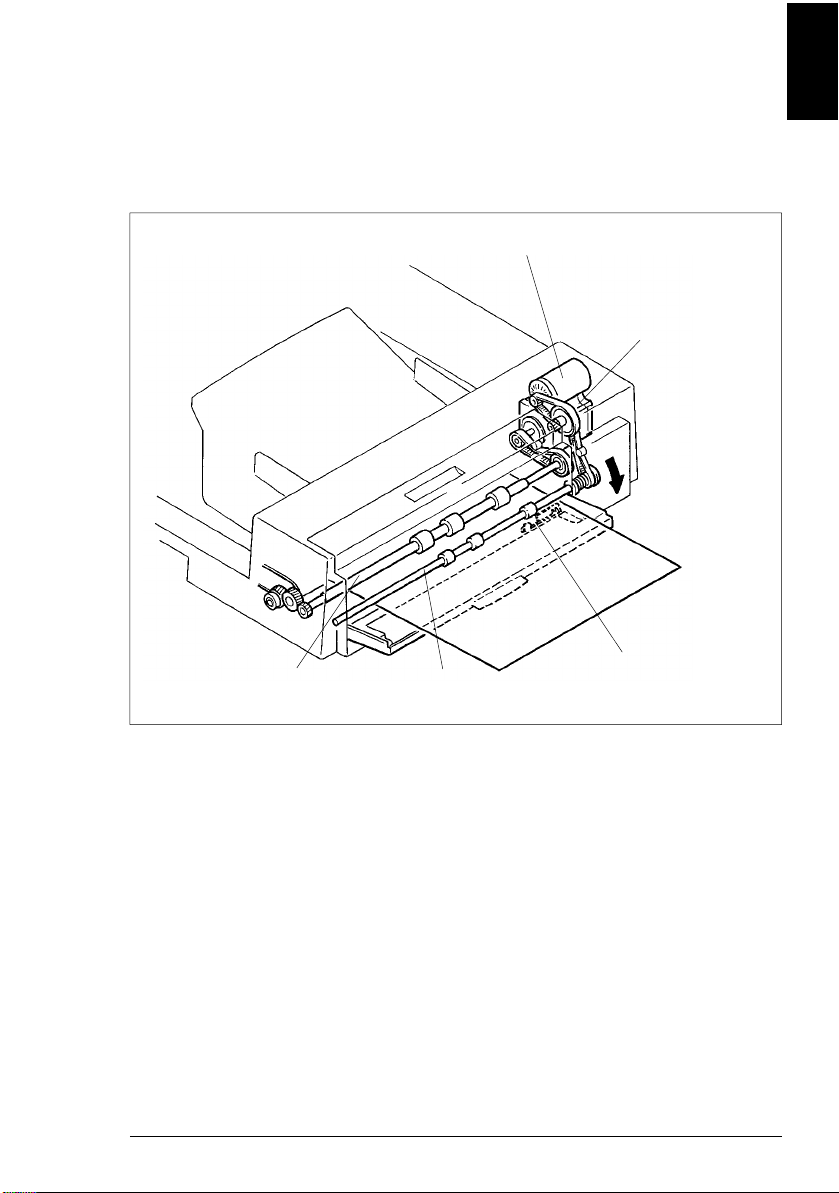

1.7.5 Sing le Feed M e chanis m

● The single feed mechanism is used to copy docum ents one at a time only.

● Open the Single Feed Tray and set a doc um ent in place. The Manual Feed

Take-up Sensor (PWB-D) will detect the document and the Single Feed

Transport Roller/Registration Roller begins to rotate to take up the

document automatically even if the Start key i s not pressed.

Take-Up Motor (M1)

Transport Motor (M2)

Electrical

General/Mechanical

Registration Drive

Roller

Single Feed

Transport Roller

M-17 AFR-12/AF-5Rev. 1.0/05.99

Manual Feed

Take - up Sens o r (P WB-D)

Page 22

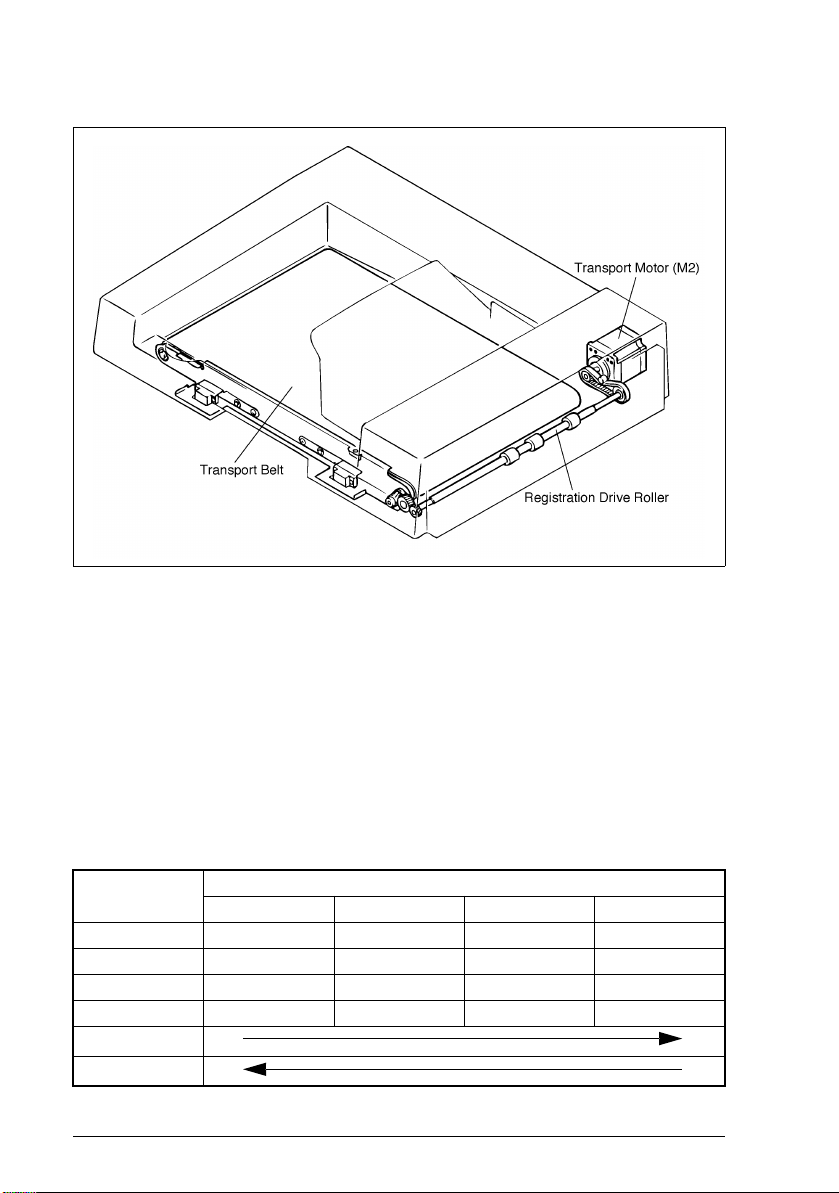

1.8 Document Transport Mechanism

1.8.1 Construction

1.8.2 Document Transport Mec hanism

● The document transport mechanism transport the document, which has

been fed up to the Registration Roller from the document take-up

mechanism, up to the Original Width Scale by means of the Document

Transport Belt.

● During the turnover motion, the Document Transport Belt is turned to

transport the docum ent toward the take-up end.

M2 Control

Whether M2 is turned f orward or bac kward is det ermined by the combinat i on of the

following signals output from IC4 on PWB-A.

IC4

Pin 2 H H L L

Pin 3 L L H H

Pin 6 L H H L

Pin 7 H L L H

Forward Rotation

Backward Rotation

Step1 Step2 Step3 Step4

Procedure

M-18AFR-12/AF-5 Rev. 1.0/05. 99

Page 23

1.8.3 Original Width Scal e Retraction Mechanism

● When the document is positioned on the Original Glass by the ADF, the

leading edge o f the d ocument is p res sed agai nst th e Ori ginal Width Scale t o

improve positioning accuracy. During turnover and ejection motion,

however, the document must move over the Original Width Scale. For this

reason, the Orig inal Width Scale retraction mechanism is employed.

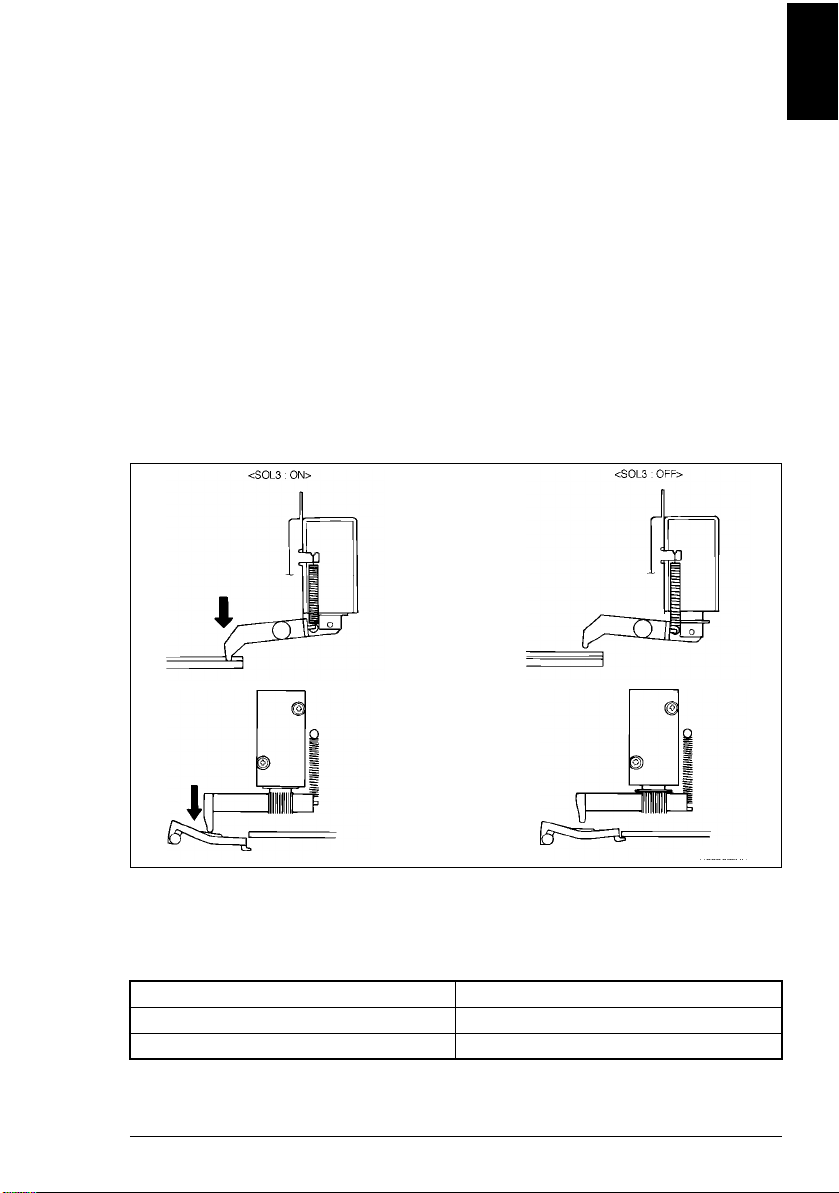

● Scale Solenoid SOL3 is used to drive the retraction mechanism.

<Operation>

When the document is positioned: SOL3 is de-energized and the Original

Width Scale i s rai sed by t he t ensio n of t he

Original Width Scal e Spring.

While the document is being

transported and during a copy cycle:

SOL3 is en ergi zed and the Original Width

Scale is pressed downward by the

Original Width Scale Drive Lever and

spring.

Electrical

General/Mechanical

SOL3 Control

The SOL3 is energized and de- energized by the signal output from IC3A on

PWB-A.

SOL3 IC3A-14

ON H

OFF L

M-19 AFR-12/AF-5Rev. 1.0/05.99

Page 24

1.9 Turnover/Exit Mechanism

1.9.1 Construction

<AF-5>

Exit

Transport Roller

Exit Motor (M3)

Exit

Roller

Scale Solenoid (SOL3)

Exit Sensor (S4)

M-20AFR-12/AF-5 Rev. 1.0/05. 99

Page 25

1.9.2 Turnover/Exit Docu men t Transport Mechanism

● The turnover/exit document transport mechanism turns over and ejects the

document which has been transported by the document transport

mechanism. It is driven by the Turnover/ Exit Motor (M3).

● M3 turns both the Turnover Roller and Exit Roller. These rollers are turned

in the same direction regardless of whether a document is turned over or

ejected from the ADF.

Electrical

General/Mechanical

M-21 AFR-12/AF-5Rev. 1.0/05.99

Page 26

M3 Control

Whether M3 is turned f orward or bac kward is det ermined by the combinat ion of t he

following signals output from IC13 or PWB-A.

<AFR-12>

IC13

Pin 2 HHHLLLLL

Pin 3 L L L L H H H L

Pin 6 LLHHHLLL

Pin 7 HLLLLLHH

Forward Rotation

IC13

Pin 2 H H L L

Pin 3 L L H H

Pin 6 L H H L

Pin 7 H L L H

Forward Rotation

Step1 Step2 Step3 Step4 Step5 Step6 Step7 Step8

Step1 Step2 Step3 Step4

Procedur

<AF-5>

Procedure

M-22AFR-12/AF-5 Rev. 1.0/05. 99

Page 27

1.9.3 Turnover/Exit Switchi ng M echanism (AFR-12)

● The turnover/exit switching mechanism uses the Turnover/Exit Switching

Plate which is swung downward or upward to change the document path,

thereby allowing the document to be turned over or ejected from the ADF.

This plate is actuat ed by the Turnover/Exit Swit ching Solenoid (SOL4).

SOL4 Control

The SOL4 is energized and de- energized by the signal output from IC3A on

PWB-A.

SOL4 IC3A-17

ON H

OFF L

Electrical

General/Mechanical

M-23 AFR-12/AF-5Rev. 1.0/05.99

Page 28

1.9.4 Exit Mechanism (AF-5)

● If a document misfeed occurs in the document path of the exit mechanism,

the Guide Plate Release Leve r may be pres sed downward usi ng the ti p of a

screwdriver or similar device, thereby raising the Guide Plate to allow the

user or Tech. Rep. to clear a document.

M-24AFR-12/AF-5 Rev. 1.0/05. 99

Page 29

1.10 Miscellaneous

1.10.1 Document Size Detection Mechanism

1. Width Detectio n

● The width of the document is detected by the sensor located on the Size

Sensor (PWB-C).

● The sensor is turned ON and OFF by actuator locat ed at point s approx. 268

mm respectively, from the Rear Document Guide.

2. Length Detection

● The length of the document is detected by the number of pulses generated

by the Transport Motor (M2) for the period in which the Registration Roller

starts turning and the tra il ing edge of the document passes the Registration

Sensor (PWB-B).

1.10.2 Raised/Lowered Position Detecting Mechanism

● DF Set Switch is located at the front left corner of the copier and a magnet

catch is mounted on the front left of the ADF. The position of the ADF,

whether rai sed or lowered, can be detected as the reed swi tch is turned ON

and OFF by the magnet catch.

● Opening/closing the ADF serves to reset a misfeed condition and allows

selection of a Test Mode operation.

Electrical

General/Mechanical

1.10.3

M-25 AFR-12/AF-5Rev. 1.0/05.99

Page 30

TEST MODES

Table Of Contents-1 AFR-12/AF-5Rev. 1.0/05.99

Page 31

2TEST MODES

2.1 Test Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.1.1 Paper Passage Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

2.1.2 Unit Check- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

2.1.3 Sensor Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

2.1.4 Sensor Adjustment Check- - - - - - - - - - - - - - - - - - - - - - - - - - 9

Table Of Contents-2AFR-12/AF-5 Rev. 1.0/05. 99

Page 32

2TEST MODES

2.1 Test Modes

Test Modes

PSW1

SW1

ON

LED5

LED4

LED3

LED2

LED1

<Test Mode Setting Pr ocedure>

1. The test mode is initiated when the DIP switch (AW1-6) is set to ON with the

Main Switch of the copier set to OFF and then Main Switch is ON.

SW1-6

ON Test Mode

OFF Normal Mode

2. Various test modes are availa ble. They can be se lected by a combi nation of DIP

switches (SW1-1 to 1-6).

S-1 AFR-12/AF-5Rev. 1.0/05.99

Page 33

2.1.1 Paper Passage Check

1. With the Main Switch set to OFF, select the desir ed test mode as shown below.

Transport Speed

High-speed Mode OFF OFF –––ON

Medium-speed Mode ON OFF – – – ON

Low-speed Mode OFF ON – – – ON

123456

SW1

2. Select whether docum ents are to be fed continuously or intermittently.

Continuous Feed After the desired test mode is selected, turn the Main Switch ON.

Intermittent Feed While holding down PSW1, turn the Main Switch ON.

3. Select the plain paper mode or thin paper mode.

Test Mode SW1-3

Plain Paper OFF

Thin Paper ON

4. Select th e d esired test mod e fr om t he ta ble be lo w, the n o pen and cl ose t he ADF

to confirm the selection.

Tes t Mode

1-sided Non-mixed Mode (high-speed) OF F OFF – – – ON

1-sided Mixed Mode (normal) ON OFF – – – ON

2-sided Mode (AFR-12) OFF ON – – – ON

2-in-1 Mode OFF ON – – – ON

123456

SW1

* The following two modes are available to allow the user to check the actual

paper stop position by stopping the paper without allowing it to contact the

Original Width Scale and then raising the Scale. These modes are available

only when the plain paper mode is selected.

● 1-sided document

<Setting Method>

❍ Turn PSW1 ON with the ADF open, then close the ADF and carry out the

test.

● 2-sided document

<Setting Method>

❍ Turn PSW1 ON with the turnover cover open, then close the cover and

carry out the test.

S-2AFR-12/AF-5 Rev. 1.0/ 05.99

Page 34

(1) Flow of Paper Passage Test

Select the desired test mode.

Load a required number of sheets of paper on the Single

feed Tray, then turn PSW1 ON.

The selected test mode starts.

● Tu rning PS W1 ON d uring a test will interrup t the tes t.

Turning it ON agai n will ejec t all the she ets of paper and

terminate the test.

● In the case of the intermittent mode, the test is carried

out each time the PSW1 is turned ON.

(2) LED Status when the Copier is in Standby for Paper Passage Test

● Faulty sections are indicated as follows while the copier is in standby for a

paper passage test. If no fault is present, all the LEDs (LED1 to 4) will be

OFF.

Test Modes

LED

12345

◆❍❍❍●

❍◆❍❍●

❍❍◆❍●Turnover (AFR-12) cover set is faulty.

● : For monotoring ❍ : Not lit ◆ : Lit up

Take-up cover set is faulty.

ADF set is faulty.

Discription

NOTE

LED5 blinks at all ti m es.

S-3 AFR-12/AF-5Rev. 1.0/05.99

Page 35

2.1.2 Unit Check

1. Set SW1-6 to ON with the Main Switch set to OFF.

2. Turn the Main Switch ON, select the desir ed mode from the foll owing table, th en

open and close the ADF to conf ir m the sel ection.

Tes t Mode

Take-Up Motor Check OFF OFF ON OFF OFF OFF

Transport Motor Check ON OFF ON OFF OFF OFF

Exit Motor Check OFF ON ON OFF OFF OFF

Solenoid Check ON ON ON OFF OFF OFF

123456

SW1

3. Turn PSW1 ON to start the test.

–Take-Up Motor Check–

LED

12345

❍❍❍❍●

◆❍❍❍●

❍◆❍❍●

◆◆❍❍● 3 Backward rotation

● : For monotoring ❍ : Not lit ◆ : Lit up

Number of

Times PSW1

is Turned ON

0Stop

1 Forward rotation

2Stop

Operation

S-4AFR-12/AF-5 Rev. 1.0/ 05.99

Page 36

–Transport Motor Check–

LED

12345

❍❍❍❍●

◆❍❍❍●

❍◆❍❍●

◆◆❍❍●

❍❍◆❍●

◆❍◆❍●

❍◆◆❍●

◆◆◆❍●

❍❍❍◆●

◆❍❍◆●

❍◆❍◆●

◆◆❍◆●

● : For monotoring ❍ : Not lit ◆ : Lit up

Number of

Times PSW1

is Turned ON

0Stop

1

Forward rotation

2Stop

3

Backward rotation

4Stop

5

Medium-speed/

Forward rotation

6Stop

7

Medium-speed/

Backward rotation

8Stop

9

Forward rotation

10 Stop

11

Backward rotation

Operation

High-speed/

High-speed/

Low-speed/

Low-speed/

Test Modes

–Exit Motor Check–

LED

12345

❍❍❍❍●

◆❍❍❍●

❍◆❍❍● 2Stop

◆◆❍❍● 3

❍❍◆❍● 4Stop

◆❍◆❍● 5

❍◆◆❍● 6Stop

◆◆◆❍●

● : For monotoring ❍ : Not lit ◆ : Lit up

Number of

Times PSW1

Operation

is Turned ON

0Stop

1

High-speed/

Rotation

Medium-speed/

Rotation

Low-speed/

Rotation

7 Eject-speed

S-5 AFR-12/AF-5Rev. 1.0/05.99

Page 37

–Solenoid Check–

LED

12345

❍❍❍❍●

◆❍❍❍●

❍◆❍❍●

◆◆❍❍●

❍❍◆❍●

◆❍◆❍●

❍◆◆❍●

◆◆◆❍●

● : For monotoring ❍ : Not lit ◆ : Lit up

Number of

Times PSW1

is Turned ON

0Stop

1

2Stop

3

Medium-speed/

4Stop

5

6Stop

7 Eject-speed

Operation

High-speed/

Rotation

Rotation

Low-speed/

Rotation

S-6AFR-12/AF-5 Rev. 1.0/ 05.99

Page 38

2.1.3 Sensor Check

1. Set the SW1-6 to ON with the Main Switch set to OFF.

2. Turn the Main Switch ON, select the desire d mode from the foll owing table, the n

open and close the ADF to confirm the selection.

Te st M od e

Paper Passage Sensor OFF OFF OFF OFF OFF OFF

Cover Sensor ON OFF OFF OFF OFF OFF

Other Sensors OFF ON OFF OFF OFF OFF

123456

SW1

3. Block each sensor with a piece of paper etc. to check whether the

corresponding LED lights up.

NOTE

LED Status

Paper is present: Lit

No paper present: Not lit

– Paper Passage Sensor Check –

LD1: Document Detecting Sensor (S1)

LD2: Manual Feed Take-up Sensor (PWB-D)

LD3: Registrat ion Sensor (PWB-B)

LD4: Exit Sensor (S4): AF-5

Turnover/Exi t Sensor (PWB-E): AFR-12

Test Modes

– Cover Sensor Check –

LD1: Feed Cover Set Sensor (S2)

LD2: Size Reset Switch (S108)

LD3: Turnover Cover Set Swit ch (S3): AFR-12

S-7 AFR-12/AF-5Rev. 1.0/05.99

Page 39

– Other Sensors Check –

LD1: Size Sensor (Rear)

LD2: Size Sensor (Center)

LD3: Size Sensor (Front)

LD4: Document Feed Motor Pulse Sensor

(M1CLK)

NOTE

PWB-C

LD1, LD3 Japan Only

LD4 (Document Feed Motor Pulse Sensor) lights up when the sensor is blocked,

and goes out when the sensor is unblocked.

S-8AFR-12/AF-5 Rev. 1.0/ 05.99

Page 40

2.1.4 Sensor Adjustment Check

1. Set the SW1-6 to ON with the Main Switch set to OFF.

2. Turn the Main Switch ON, select the sensor adjustment mode as shown in the

following table, then open and close the ADF to confirm the selection.

Te st M od e

Sensor Adjustment

123456

ON OFF OFF ON OFF OFF

SW1

3. Turn the PSW1 ON to start the test.

NOTE

An error will oc cur if adjust ment is carr ied out with t he take- up/tur nover co ver open.

So make sure that the cover is closed before st arting adjustment.

– Registration Sensor Adjustment –

LED1 LED2 Sensor Status

❍❍

❍◆

◆❍

◆◆Adjustment complete

Initialized

Upper-limit error

Lower-limit error

– Exit Sensor Adjustm ent –

LED3 LED4 Sensor Status

❍❍

❍◆

◆❍

◆◆Adjustment complete

❍: Not lit

◆: Lit up

Initialized

Upper-limit error

Lower-limit error

Test Modes

2.1.5

S-9 AFR-12/AF-5Rev. 1.0/05.99

Page 41

DIS/REASSEMBLY/ADJUSTMENT

Table Of Contents-1 AFR-12/AF-5Rev. 1.0/05.99

Page 42

For the Utmost Safety

Warning

● For replacement parts, use the genuine parts with their part numbers

specified in the parts manual. Use of a wrong part could cause an overload

or dielectric breakdown, resulting in an electric shock or fire.

● Replace a blown fuse or thermal fuse with the corresponding genuine part

with its part number specified in the parts manual. Use of a fuse with a

different rating or one with the same rating but of a different type can result

in a fire. Especially when a thermal fuse blows frequently, the thermal

control system is probably faulty. Be sure to take necessary action.

● Before attempting to disassemble the machine, be sure to unplug its power

cord. The machine contains a high voltage unit and a circuit with a large

current capac ity that may cause an electri c shock or bur n from s parking. T he

machine also contains quick moving parts, which could injure a person. If

the machine uses a laser, a person can lose his/her eyesight by a laser

beam leak.

● Wherever feasible, keep the c over s and par ts m ounted when ener gizi ng the

machine. If it is absolutely necessary to energize the machine with its cover

removed, do not touch an exposed part that is being charged and use care

not to allow your clothing to be caught by a timing belt, gear, or other moving

part.

● Do not leave the machine unattended while it is being energized.

CAUTION

● To actuate an interlock switch with a cover removed or opened, be sure to

use the interlock switch actuating jig. Use of folded paper can damage the

interlock sw itch mechanism.

Table Of Contents-2AFR-12/AF-5 Rev. 1.0/05. 99

Page 43

CAUTION

● A high voltage is being a ppl ied to the par t marked wit h the sy mbol shown on

the right. Touching it can cause an electric shock. Be sure to unplug the

power cord when servic ing this part or other parts near it.

● When the machine is energized with any of its co ver s removed, ne ver use a

flammable spray near it, as a fire can result.

● Make sure that correct screws (diameter and length of the screw, binding/

tapping screws) are used in the correct places when assembling parts. If a

wrong screw is used, a short insulating distance could result. It could also

result in collapsed threads, which provides only a poor grounding

connection, resulting in an electr ic shock.

● A toothed washer and spring wash er, if used originally, must be reinstall ed.

If they are left out, a contact failure results, causing an electric shoc k or fire.

● Replace a lithium cell only with one having the part number specified in the

parts manual. An explosion could result if the cell is installed with wrong

polarity or a wrong cell is in stalled. Dispose of a used lithiu m cell according

to the appli cable local regulat ions. Never throw it away or abandon i t on the

user’s premises.

Other Precautions

● While the machine is being energized, do not unplug or plug in a connec tor

on a PWB or relay harness.

● Since the Magnet Roller of the Imaging Unit generates a strong magnetic

force, do not bring a CRT, watc h, floppy disk, or magnetic card near it.

● Use of an air gun or v acuu m generat es s tati c elect ricit y which can cause the

ATDC Sensor and associa ted pa rts to brea k down. Be sure the refor e to use

a blower brush or c loth to clean th ese parts. I f a unit is to be c leaned, be sur e

to remove the sens ors in advance.

● MOS lCs are susceptible to static electricity. When handling a PWB loaded

with MOS ICs, follow precautions given in “1-2. INSTRUCTIONS FOR

HANDLING THE PWBs WITH MOS ICs.”

● The PC Drum is highly delicate. When handling the PC Drum, follow the

precautions given in “1-3. HANDLING OF THE PC DRUM.”

● To reassemble, reverse the order of disassembly unless otherwise

specified.

● Note that replacement of a PWB may call for readjustments or resetting of

particula r it em s.

Table Of Contents-3 AFR-12/AF-5Rev. 1.0/05.99

Page 44

CAUTION

DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED

BY THE MANUFACTURER. DISPOSE OF USED BATTERIES ACCORDING TO

THE MANUFACTURER’S INSTRUCTIONS.

ADVARSEL

LITHIUMBATTERI - EKSPLOSIONSFARE VED FEJLAGTIG HÅNDTERING.

UDSKIFTNING MÅ KUN SKE MED BATTERI AF SAMME FABRIKAT OG TYPE.

LEVÅR DET BRUGLE BAFFERI TILBAGE TIL LEVERANDOREN.

Table Of Contents-4AFR-12/AF-5 Rev. 1.0/05. 99

Page 45

3DIS/REASSEMBLY, ADJUSTMENT

3.1 Disassembly

3.1.1 Removal of the Document Transport Belt

● Push the lever to the left,, then snap of f the C clip to release the Belt assy.

● Hold the top of the Transport Belt Assy and tilt the Assy towards you to

remove it.

Adjustment

Dis/Reassembly

D-1 AFR-12/AF-5Rev. 1.0/05.99

Page 46

● Remove two screws as shown in the figure, then bend the Exit Roller side

toremove the Transport Belt.

3.1.2 Removal of the Document Take-Up Roller Assy

● Remove the Transport Belt , then remove the Cover and Document Stopper

Guide Plate to remove the Take-Up Roller Assy.

D-2AFR-12/AF-5 Rev. 1.0/05.99

Page 47

3.1.3 Removal of the Document Take-Up and Separator Rollers

● Snap off the four C clips, then remove the rollers one by one.

NOTE

Take care not to lose the two pins attached to the Document Take-Up Roller.

Adjustment

Dis/Reassembly

D-3 AFR-12/AF-5Rev. 1.0/05.99

Page 48

3.1.4 Removal of the Separator Pad

● Open the Single Feed Single Feed Tray and Feed Cover, then remove four

screws to remove the Feed Cover.

● Push each Separator Pad to slide it upwards and remove it.

D-4AFR-12/AF-5 Rev. 1.0/05.99

Page 49

3.1.5 Removal of the Document Take-Up Unit Assy

● Remove the Transport Belt.

● Remove the Maintenanc e Cover a nd un plug t he connec tor s fr om PWB-A a s

shown in the figure. Remove the Single Feed Tray.

● Remove the ADF from the copier, and place it on a table upside down.

● Remove the Cover.

● Remove five screws, open the Feed Cover and lift out the Document Take-

Up Unit Assy.

Adjustment

Dis/Reassembly

NOTE

When reinstalling the Document Take-Up Unit Assy, make sure that the Feed

Cover is open. Tighten the five screws lightly by hand, then tighten securely after

the ADF is reinstall ed on the copier.

D-5 AFR-12/AF-5Rev. 1.0/05.99

Page 50

3.1.6 Removal of the Turnover/E xit Assy (AFR-12)

● Remove the Transport Belt, Maintenance Cover and unplug the connectors

from PWB-A as shown in the figure.

● Open the Turnover/Exit Cover and remove the screw.

● Remove the Cover and grounding wire (black).

● Remove five screws, ope n the Tur nover/Ex it Cover an d l ift out th e Turnov er/

Exit Unit A ss y .

NOTE

When reinstalling the Turnover/Exit Unit Assy, make sure that the Turnover/Exit

Cover is open.

D-6AFR-12/AF-5 Rev. 1.0/05.99

Page 51

3.1.7 Removal of the Take-Up Moto r/Transport Motor Unit (AF- 5)

● Remove the Transport Belt.

● Remove the Cover and grounding wire (black).

● Remove five screws, unplug the connectors as shown in the figure, then

remove the Exit Unit Assy.

3.1.8 Removal of the Take-Up Moto r/Transport Motor Unit

● Remove the Take-Up Unit Assy.

● Remove three screws, unplug from connectors, take out two wire saddles

and a spring to remove the Motor Unit.

Adjustment

Dis/Reassembly

D-7 AFR-12/AF-5Rev. 1.0/05.99

Page 52

3.2 Adjustments

3.2.1 Adjustment of Magnet Height NOTE

Requirement

The clearance between the Magnetic Catch and Original Glass should be

0 to 0.5 mm.

1. Remove the Transport Belt and two Screw Covers. (Push up from inside)

2. Set the Transp ort Bel t and, close the ADF, loo sen the Magn etic Catc h adjust ing

screws, check the clearance of the Magnet Catch, then tighten the adjusting

screws.

D-8AFR-12/AF-5 Rev. 1.0/05.99

Page 53

3.2.2 Adjustment of the Document Feed Table NOTE

Requirement

The document Feed Table s hould be positioned within 0 +/- 1 mm fr om the edge of

the Document Positi oning Plate.

1. Slide the Document Positioning Plate towards t he rear and secure it with tape.

2. Affix a piece of tape to each of the Magnet Catch Plates.

3. Place a document on the Document Feed Table and select 1-sided mode.

4. Press the Start key , th en press the Stop key immediately.

5. Open the ADF gently and remove the tape from the Document Positioning

Plate, taking care not to allow the document to move.

6. Check whether the document is aligned with the edge of the Document

Positioning Plat e.

7. If the document is off in direction "a", move the Document Feed Table towards

you. If the document is off in direction "b", move the Document Feed Table

towards the rear.

Adjustment

Dis/Reassembly

D-9 AFR-12/AF-5Rev. 1.0/05.99

Page 54

3.2.3 Adjustment of the Singl e Feed Tray NOTE

Requirement

The document Feed Table should be positioned within +/- 1 mm from the edge of

the Document Positi oning Plate.

1. Slide the Document Positioning Plate towards the rear and secure it with tape.

2. Affix a piece of tape to each of the Magnet Catch Plates.

1. Place a document on the Docum ent Feed Table and select 1-side d mode .

2. Press the Start key, t hen press the Stop key immediately.

3. Open the ADF gently and remove the tape from the Document Positioning

Plate, taking care not to allow the document to move.

4. Check whether the document is aligned with the edge of the Document

Positioning Plate.

5. If the document is off in direction "a", move the Single Feed Tray towards you.

If the document is off in direction "b", move the Single Feed Tray towards the

rear.

a

b

D-10AFR-12/AF-5 Rev. 1.0/05.99

Page 55

3.2.4 Adjustment of Document Stop Position in the 1-Sided Mode NOTE

Requirement

The document should be 0 to 1 mm in the direction of b from the end face of the

Original Widt h Scale.

1. Set "U-4" (Lightweight Original) of User’s Choice to "1." (Make the adjustment

in the Lightweight Original mode.)

NOTE: Metric areas only

2. Slide the Document Positioning Plate towards t he rear and secure it with tape.

3. Affix a piece of tape to each of the Magnet Catch Plates.

Adjustment

Dis/Reassembly

4. Place a document on the Document Feed Table, and select

1-sided original/1-sided copy mode.

5. Press the Start key , th en press the Stop key immediately.

6. Open the ADF gently and check whether t he documen t is aligne d with the edg e

of the Original Glass.

7. Set the service cho ice mode "c-31".

8. Referring to page D-17, adjust the document stop position.

a b

D-11 AFR-12/AF-5Rev. 1.0/05.99

Page 56

3.2.5 Adjustment of Document Stop Position in the 2-Sided Mode NOTE

Requirement

The document should be 0 to 1 mm in the direction of b from the end face of the

Original Widt h Scale.

1. Set "U-4" (Lightweight Original) of User’s Choice to "1." (Make the adjustment

in the Lightweight Original mode.)

NOTE: Metric areas only

2. Slide the Document Positioning Plate towards the rear and secure it with tape.

3. Affix a piece of tape to each of the Magnet Catch Plates.

4. Place a document on the Document Feed Table, and select 2-sided original/1-

sided copy mode.

5. Press the Start key, t hen press the Stop key immediately.

6. Open the ADF gently and chec k whether t he documen t is aligne d with the edge

of the Original Glass.

7. Set the service choice mode "c-32".

8. Referring to page D-17, adjust the document stop position.

a

b

D-12AFR-12/AF-5 Rev. 1.0/05.99

Page 57

3.2.6 Adjustment of Document Stop Position in the 2-in-1 Mode NOTE

Requirement

The document should be 0 to 1 mm in the direction of b from the end face of the

Original Widt h Scale.

1. Set "U-4" (Lightweight Original) of User’s Choice to "1." (Make the adjustment

in the Lightweight Original mode.)

NOTE: Metric areas only

2. Slide the Document Positioning Plate towards t he rear and secure it with tape.

3. Affix a piece of tape to each of the Magnet Catch Plates.

Adjustment

Dis/Reassembly

4. Place two A4Y documents on the Document Feed Table, and select

1-sided original/1-sided 2-in- 1 copy m ode.

5. Press the Start key , th en press the Stop key immediately.

6. Open the ADF gently and check whether t he documen t is aligne d with the edg e

of the Original Glass.

7. Set the service cho ice mode "c-33".

8. Referring to page D-17, adjust the document stop position.

ba

D-13 AFR-12/AF-5Rev. 1.0/05.99

Page 58

3.2.7 Adjustment of Distance Between Documents in the 2-in-1 Mode NOTE

Requirement

The second document should be 0 to 1 mm in the direction of b from the trailing

edge of the first document.

1. Set "U-4" (Lightweight Original) of User’s Choice to "1." (Make the adjustment

in the Lightweight Original mode.)

NOTE: Metric areas only

2. Slide the Document Positioning Plate towards the rear and secure it with tape.

3. Affix a piece of tape to each of the Magnet Catch Plates.

4. Place two A4Y documents on the Document Feed Table, and select

1-sided orig inal/1-sided 2-in-1 copy m ode.

5. Press the Start key, t hen press the Stop key immediately.

6. Open the ADF gently and check whether the 2nd document is positioned

correctly in relation with the 1st document.

7. Set the service choice mode "c-34".

8. Referring to page D-17, adjust the document stop position.

ab

D-14AFR-12/AF-5 Rev. 1.0/05.99

Page 59

3.2.8 Adjustment of Document Stop Position in the Single Feed Mode NOTE

Requirement

The document should be 0 to 1 mm in the direction of b from the end face of the

Original Widt h Scale.

1. Set "U-4" (Lightweight Original) of User’s Choice to "1." (Make the adjustment

in the Lightweight Original mode.)

NOTE: Metric areas only

2. Slide the Document Positioning Plate towards t he rear and secure it with tape.

3. Affix a piece of tape to each of the Magnet Catch Plates.

Adjustment

Dis/Reassembly

4. Place a document into the Manual Feed Port, and press the Stop key

immediately.

5. Open the ADF gently and check whether t he documen t is aligne d with the edg e

of the Original Glass.

6. Set the service cho ice mode "c-37".

7. Referring to page D-17, adjust the document stop position.

ba

D-15 AFR-12/AF-5Rev. 1.0/05.99

Page 60

3.2.9 Adjustment of ADF Registrati on Loop

1. Place a document on the Docum ent Feed Table and press the Start key .

2. Change the setting for service choice "c-38", rem ove the document and place it

on the Document Feed Table agai n, then press the Start key.

3. Referring to the table below, repeat steps 1 and 2 until the document is

positioned so that it can be transported by the Transport Belt.

Setting Method

1. Press the “Stop” , “0 ”, “Stop”, “1”, “2” keys in tha t order.

2. Select the desi red mode, then press the Start key.

3. Press the Clear key to clear the currently selected value.

4. Referring to the table below, enter a setting equi valent to the deviation .

5. Press the Start key to conf irm the entry.

6. Press the Reset key twi ce to return to the main screen.

Stop Position Adjustment Table

Setting

Deviatio

n (mm)

43 7

44 6 52 2

45 5 53 3

46 4 54 4

47 3 55 5

48 2 56 6

49 1 57 7

50 0 Default 58 8

Direction Setting

Moves in direction "a"

(towards the Original Width

Scale )

51 1

Deviatio

n (mm)

Direction

Moves in direction "b"

(towards the Take-Up

Mechanism)

D-16AFR-12/AF-5 Rev. 1.0/05.99

Page 61

3.2.10 Adjustment of Document Stopper Solenoid SOL1

1. Remove the Document Tak e-Up Unit Ass y and place i t on a table upsi de down.

2. Loosen two screws and bring the brush (marked "A" in the figure) of the

Document Stopper Guide Plate into contact with the Take-Up Roller.

3. While pressing the Document Stopper Guide Plate against the Take-Up Roller

gently, lift the solenoid by holding the two screws until it comes to a stop, then

tighten the scr ews.

Adjustment

Dis/Reassembly

NOTE

After comple tion o f adju st ment, l ift the Docu ment Stopper Guid e Plate to che ck t hat

the Guide Plate is supported smoothly by the retaining force of the solenoid.

D-17 AFR-12/AF-5Rev. 1.0/05.99

Page 62

3.2.11 Adjustment of Document Pressu re Solenoid SOL2 NOTE

Requirement

The clearanc e be tween t he Gui de Pla te and Weigh t Lever s hould be app roximat ely

2 ± 1 mm.

1. Remove the Document Take -Up Unit Assy, and place it on a table.

2. Loosen two screws.

3. While pushing t he Plunger towards the Soleno id (up to the posi tion at which t he

Plunger stops), move the Solenoid so that the clearance between the Guide

Plate and Weight Lever is within the specified range.

NOTE

When moving the Solenoid, make sure that the Plunger is pushed towards the

Solenoid and that there is no play between the Plunger and Weight Lever.

D-18AFR-12/AF-5 Rev. 1.0/05.99

Page 63

3.2.12 Adjustment of Scale Solenoid SOL3 NOTE

Requirement

The exposed end of the Stopper Lever is positioned within approximately

8.7 ± 0.2 mm in length.

1. Remove the Turnover/Exit Unit Assy and place it on a table upside down.

2. Loosen two screws.

3. Move the Solenoid up and down so that the exposed end of the Stopper Lever

is within the speci fied length.

4. Tighten the two scr ews.

Adjustment

Dis/Reassembly

D-19 AFR-12/AF-5Rev. 1.0/05.99

Page 64

3.2.13 Adjustment of Turnover/Exit Switching Solenoid SOL4 (AFR-12)

1. Remove the Turnover/Exit Unit Assy and place it on a table.

2. With sponge fitted to the Turnover/Exit Cover in contact with the Turnover/Exit

Switching Plate, move t he solen oid to t he right and lef t to obt ain a cl earance " 0"

at part A shown in the figure, move the solenoid to the right or left so that the

gap indicated by "A" in the figure is eliminat ed.

3. Tighten the two scr ews.

Sponge

A

D-20AFR-12/AF-5 Rev. 1.0/05.99

Page 65

3.2.14 Adjustment of the Separat ing Pressure of Document Separ ator Pad

1. Remove the Take-Up Unit Cover.

2. Loosen each screw and tig hten it to an appropriate level.

NOTE

Make sure that the separating pressure of bot h pads is the same.

Adjustment

Dis/Reassembly

D-21 AFR-12/AF-5Rev. 1.0/05.99

Page 66

3.2.15 Adjustment of the Distance bet w een Separator Rollers

1. Open the Take-Up Cover and loosen the four screws of the Separator Guide

Plate.

2. Cut out a piece of paper of approx. 150 mm by 50 mm and place it between the

Guide Plate and Roller.

3. While gently holding down the Separator Guide Mount Plate (press the Guide

as strongly as th e spri ng pressure), tighten the two screws to the Mount Plate.

4. Tighten the two screws that secure 2nd Separator Guide Plate in position.

5. Loosen the two screws on the 2nd Separator Guide Plate Mount Plate. Raise

the mount plate as far a s it will go and, keeping the m ount plate in that position,

tighten the two screws.

6. Loosen the two scr ews that secur e 2nd Separator Gui de Plate in po sition. Rais e

the guide plate as far as it will go and, keeping the plate in that position, tighten

the two screws.

3.2.16

Separator Guide Plate

2nd Separator Guid e Plat e

D-22AFR-12/AF-5 Rev. 1.0/05.99

Page 67

TROUBLESHOOTING

Table Of Contents-1 AFR-12/AF-5Rev. 1.0/05.99

Page 68

4TROUBLESHOOTING

4.1 Misfeed Detec ti o n - - - - - - - - - - - - - - - - - - - - - - - - - - 1

4.2 Troubleshooting Procedure- - - - - - - - - - - - - - - - - - - 2

Table Of Contents-2AFR-12/AF-5 Rev. 1.0/05. 99

Page 69

4TROUBLESHOOTING

4.1 Misfeed Detec ti o n

Misfeed at the ADF Take-Up/Single Feed Section

Description Detection Timing

Document not reaching

Registration Sensor (PWB-B)

Take-Up Motor (M1) malfunction Document Feed Pulse Sensor (M1CLK) is not activated within

PWB-B is not activated within approx. 1 sec. after Take-Up Motor

(M1) is energized.

approx. 0.2 sec. after M1 is energized.

Misfeed at the Transport Section

Description Detection Timing

Document staying at Registration

Sensor (PWB-B)

Document staying on Glass (before

operation)

Document staying on Glass (after

operation)

Misfeed at the Turnover/Exit Section (AFR-12 only)

Description Detection Timing

Document not reaching Exit Sensor

(PWB-E) (during ejection/turnover)

Document staying at PWB-E

(during ejection)

Document staying at PWB-E

(during turnover)

Description Detection Timing

Document not reaching Exit Sensor

(S4)

Document staying at S4 S4 is not deactivated within approx. 3 sec. after S4 is activated.

PWB-B is not activated even if the next document has reached the

scan position.

A sensor indicates that there is still a document in the document

path when the next document is placed on the Document Feed

Table and all covers are closed.

Exit Sensor (PWB-E: AFR/12, S4: AF-5) is activated when a 1st

document is taken up and fed in.

S4 is not activated within approx. 0.5 sec. after Turnover/Exit Motor

(M3) is energized.

PWB-E S4 is not deactivated within approx. 2 sec. after PWB-E is

activated.

PWB-E S4 is not deactivated within approx. 2 sec. after PWB-E is

activated.

Misfeed at Exit Section (AF-5 only)

S4 is not activated within approx. 0.7 sec. after Turnover/Exit Motor

(M3) is energized.

Troubleshooting

T-1 AFR-12/AF-5Rev. 1.0/05.99

Page 70

4.2 Troubleshooting Procedure

T-2AFR-12/AF-5 Rev. 1.0/05. 99

Page 71

Mis-feed at the ADF Take-Up Section

Symptom Step No. Check Item Result Action

● The document is

not taken up at all.

1 Does the document used

meet the specifications for

reliable feeding?

2 Has the capacity of the

Document Feed Table been

exceeded?

3 A re any of the Document

Take-Up Rollers, Document

Separator Rollers and

Document Separator Pads

deformed, worn or dirty with

paper dust?

Carry out the unit test for the

4

Document Pressure

Solen oid (S OL2) to check

whether it functions

properly.

5 Does the voltage across

CN9-2 on PWB-A and GND

change from 24 VDC when

the Start key is pressed?

6 Carry out the unit test for the

Document Stopper Solenoid

(SOL1) to check whether it

functions properly.

7 Does the voltage across

CN12-3 on PWB-A and

GND change from 24 VDC

to 0 VDC

instantaneously and then

return to 24 VDC when the

Start key is pressed?

Carry out the unit test for the

8

Document Feed Motor

Pulse Sensor (M1CLK) to

check whether it functions

properly.

9 Does the voltage across

CN5-3 on PWB-A and GND

change to "H" when M1CLK

is blocked and change to "L"

when M1CLK is unblocked,

when the pulse disk is

turned by hand?

10 Carry out the unit test for the

Take-Up Motor (M1) to

check whether it functions

properly.

11 Does the voltage across

CN6-1 on PWB-A and GND

change from 24 VDC when

the Start key is pressed?

NO Instruct the user to use

documents that meet the

specifications for reliable

feeding.

YES Instruct the user not to exceed

the capacity.

YES Clean or replace them.

YES Carry out step 6.

YES Replace SOL2.

NO Replace PWB-A.

YES Carry out step 8.

YES Replace SOL1.

NO Replace PWB-A.

YES Carry out step 10.

YES Replace PWB-A.

NO Rep lace.

YES Check each gear for damage.

YES Replace M1.

NO Replace PWB-A.

Troubleshooting

T-3 AFR-12/AF-5Rev. 1.0/05.99

Page 72

Mis-feed at the ADF Take-Up Section

Symptom Step No. Check Item Result Action

● The panel

indicates a

misfeed in the

ADF when the

Start key is

pressed, though

no documents are

placed on the

Document Feed

Table.

● The document is

not taken up in

single feed mode.

1

Does the actuator of the

Document Detecting Sensor

(S1) function properly?

2 Carry out the unit test for S1

to check whether it functions

properly.

3 Does the voltage across

CN3-12 on PWB-A and

GND change from 5 VDC to

0 VDC when the actuator is

lifted by hand?

1 Does the actuator of the

Manual Document Detecting

Sensor (PWB-D) function

properly?

2 Carry out the unit test for

PWB-D to check whether it

functions properly.

3 Does the voltage across

CN5-9 on PWB-A and GND

change from 5 VDC to 0

VDC when the light is

blocked with a piece of

paper?

4 Is the tension of the Timing

Belt correct and the Manual

Feed Transport Roller

clean?

NO Repair or replace the actuator.

YES Check the copier.

YES Replace PWB-A.

NO Replace S1.

NO Repair or replace the actuator.

YES Go to step 4.

YES Replace PWB-A.

NO Replace PWB-D.

YES Adjust the tension and clean or

replace the Roller.

T-4AFR-12/AF-5 Rev. 1.0/05. 99

Page 73

Mis-feed at the ADF Transport Section

Symptom Step No. Check Item Result Action

● The document has

stopped near the

Registration

Roller.

1 Does the document used

meet the specifications for

reliable feeding?

2 Is the Registration Roller

deformed, worn or dirty?

3 Are there any problems

along the document path

between the Registration

Roller and Transport Belt?

4 Is the Transport Belt

installed properly?

5 Is the Transport Belt

deformed, worn or dirty?

6 Carry out the unit test for the

Registration Sensor (PWBD) to check whether it

functions properly.

7 Does the voltage across

CN5-5 on PWB-A and GND

change from "H" to "L" when

the light is blocked with a

piece of paper?

8 Is the tension of the Timing

Belt correct?

NO Instruct the user to use

documents that meet the

specifications for reliable

feeding.

YES Clean the Registration Roller.

YES Clean, repair or replace the

transport path.

NO Install it properly.

YES Clean or repair the Belt.

YES Go to step 8.

YES Replace PWB-A.

NO Replace PWB-B.

NO Adjust the tension of the

Timing Belt.

Troubleshooting

T-5 AFR-12/AF-5Rev. 1.0/05.99

Page 74

Mis-feed at the ADF Transport Section

Symptom Step No. Check Item Result Action

● The document is

caught by the

Original Width

Scale.

● The document has

slipped between

the Original Glass

and Original Width

Scale.

● The document

gets caught

behind the

Transport Belt (2sided mode).

1 Does the document used

meet the specifications for

reliable feeding?

2

When the Original Width

Scale is pushed and

released by hand, does it

return to the correct position

by the force of the spring?

3 Carry out the unit test for the

Scale Solenoid (SOL3) to

check whether it functions

properly.

4 After start of transport, does

the voltage across CN4-2 of

PWB-A and GND change

from "H" to "L"?

5 Is the Transport Belt

NO Instruct the user to use

documents that meet the

specifications for reliable

feeding.

NO Check the mount position of

the spring at the bottom of the

Original Width

Scale. Replace the spring.

YES Go to step 5.

YES Replace SOL3.

NO Replace PWB-A.

YES Clean or replace it.

deformed, worn or dirty?

● The document has

stopped near the

Exit Sensor (S4).

● The document has

stopped near the

Turnover/Exit

Sensor (PWB-D).

(AFR-12)

1 Carry out the unit test for S4

to check whether it functions

properly.

2 Does the voltage across

CN4-5 on PWB-A and GND

change from 5 VDC to 0

VDC when S4 is blocked

with a piece of paper?

3 Is the Exit Roller deformed,

worn or dirty?

1 Carry out the unit test for

PWB-D to check whether it

functions properly.

2 Does the voltage across

CN11-6 on PWB-A and

GND change from "H" to "L"

when PWB-D is blocked

YES Go to step 3.

YES Replace PWB-A.

NO Replace S4.

YES Clean or replace it.

YES Go to step 3.

YES Replace PWB-A.

NO Replace PWB-D.

with a piece of paper?

3 Is the Turnover/Exit Roller

deformed, worn or dirty?

YES Clean.

T-6AFR-12/AF-5 Rev. 1.0/05. 99

Page 75

Misfeed Detected When Documents are Loaded

Symptom Step No. Check Item Result Action

● The panel

indicates a

misfeed in the

ADF when a

document is

placedon the

Document Feed

Table.

1 Is there still a document in

the ADF?

2 Carry out the unit test for the

Registration Sensor (PWBB) to check whether it

functions properly.

3 Does the voltage across

CN5-5 on PWB-A and GND

change from "H" to "L" when

the light is blocked with a

piece of paper?

4 Carry out the unit test for the

Size Sensor (PWB-C) to

check whether it functions

properly.

5 Does the voltage across

CN3-3, 3-4 and 3-5 on

PWB-A and GND change

from 5 VDC to 0 VDC when

the light is blocked with a

piece of paper?

6 Does the actuator of PWB-C

operate properly?

YES Remove the document.

YES Go to step 4.

YES Replace PWB-A.

NO Replace PWB-B.

YES Go to step 6.

YES Replace PWB-A.

NO Replace PWB-C.

YES Repair or replace the actuator.

4.3

Troubleshooting

T-7 AFR-12/AF-5Rev. 1.0/05.99

Loading...

Loading...