Page 1

AD-7

SERVICE MANUAL

Page 2

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIO N S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1

2. PARTS IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-2

3. CROSS-SECTIONAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3

4. DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-4

5. ELECTRICAL COMPONENTS LAYOUT . . . . . . . . . . . . . . . . . . . . M-5

6. DESCRIPTION OF EACH MECHANISM AND CONTROL

6-1. Exit/Turnover Switching Mechanism . . . . . . . . . . . . . . . . . . . M-6

6-2. Fuser Oil Cleaning Mechanism. . . . . . . . . . . . . . . . . . . . . . . . M-6

6-3. Paper Standby Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-6

6-4. Switchback Operation (Turnover). . . . . . . . . . . . . . . . . . . . . . M-7

7. OPERATION AND CONTROL

7-1. No. of Multiple 2-Sided Copies . . . . . . . . . . . . . . . . . . . . . . . . M-8

7-2. Sensor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-8

7-3. 2-Sided Copying Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . M-10

DIS/RE ASSE MBL Y, ADJ USTM EN T

1. DISASSEMBLY

1-1. Removal of the Exterior Covers and Guides . . . . . . . . . . . . . D-1

1-2. Removal of Vertical Transport Clutch CL1. . . . . . . . . . . . . . . D-2

1-3. Removal of the Vertical Transport Roller (Metallic One) . . . D-3

1-4. Removal of the Vertical Transport Roller (Rubber One). . . . D-3

1-5. Removal of the Turnover Entrance Guide . . . . . . . . . . . . . . . D-4

2. ADJUSTMENTS

2-1. Adjustment of Dup. Left-Margin . . . . . . . . . . . . . . . . . . . . . . . D-4

2-2. Adjustment of Exit/Turnover Switching Solenoid SL1. . . . . . D-5

TROUBLESHOOTING

1. MISFEED DETECTION

1-1. Misfeed Detection Conditions . . . . . . . . . . . . . . . . . . . . . . . . . T-1

1-2. Misfeed Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . T-2

APPENDED DIAGRAMS

◆

ELECTRICAL WIRING DIAGRAM / ELECTRICAL CIRCUIT DIAGRAM

i

Page 3

GENERAL,

MECHANICAL/

ELECTRICAL

Page 4

SPECIFICATIONS

1

Type : Sheet turnover device for making automatic

2-sided copies

Instal la t i on : Mounte d to t he co pi e r

Modes : Exit mode

Duplex mode (single- and two-sheet paper

attraction)

Max. Storage

Capacity

Exit Tray Capacity : 250 sheets of 90-g/m

Registration : Center

Power Source : DC24V ( supplied from copier)

Power Consumption : 30W or le ss

Dimensions : Width .....121 mm or 4-3/4"

Weight : 8.9 kg or 19-1/2 lbs. (including the mount)

Environmental

Requirements

Paper Requirements

- Exit mode Type of Paper : Recommended paper weighing 60 to 90 g/m

Paper Si ze : A5 lengt h w ise to A3 lengt hwi s e and A3 Wide or

- Duplex mode Type of Paper : Recommended paper weighing 60 to 90 g/m

Paper Size : A5 lengthwise to A3 lengthwise or 5-1/2" × 8-1/2"

: 2 (A4 crosswise or s mal l e r, tw o-sheet pape r

attraction mode)

Depth .....536 mm or 21"

Height .. .. 345 mm or 13-1/2"

: Same as copier

16 to 24 lbs., OHP transparencies, thick paper

weighi ng 15 7 g/ m

5-1/2" × 8-1/2" lengthwise to 11" × 17" lengthwise

and Full Bleed

16 to 24 lbs.

lengthwise to 11" × 17" lengthwise

2

or 24-lb. paper

2

or 42 lbs. max.

2

or

2

or

M-1

Page 5

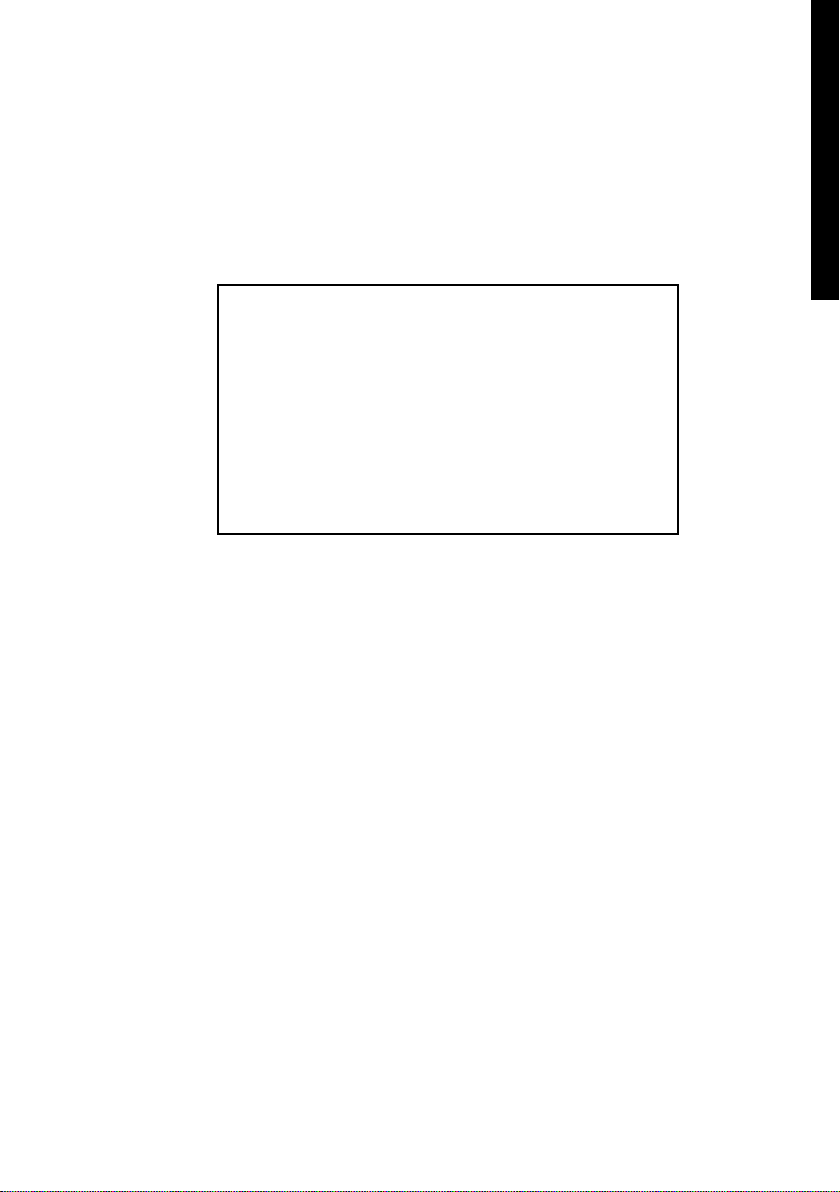

PARTS IDENTIFICATION

2

3

2

1

7

8

4

5

6

4458M001AA

10

9

4458M002AA

No. Name No. Name

1 Exit Tray 6 Exit Section Lower Cover

2 Exit Section Cover 7 Turnover Tray

3 Rear Cover 8 Exit/Turnover Sw itching Finger

4 Top Cover 9 Vertical Transport Guide

5 Front Cover 10 Hookup Cord

M-2

Page 6

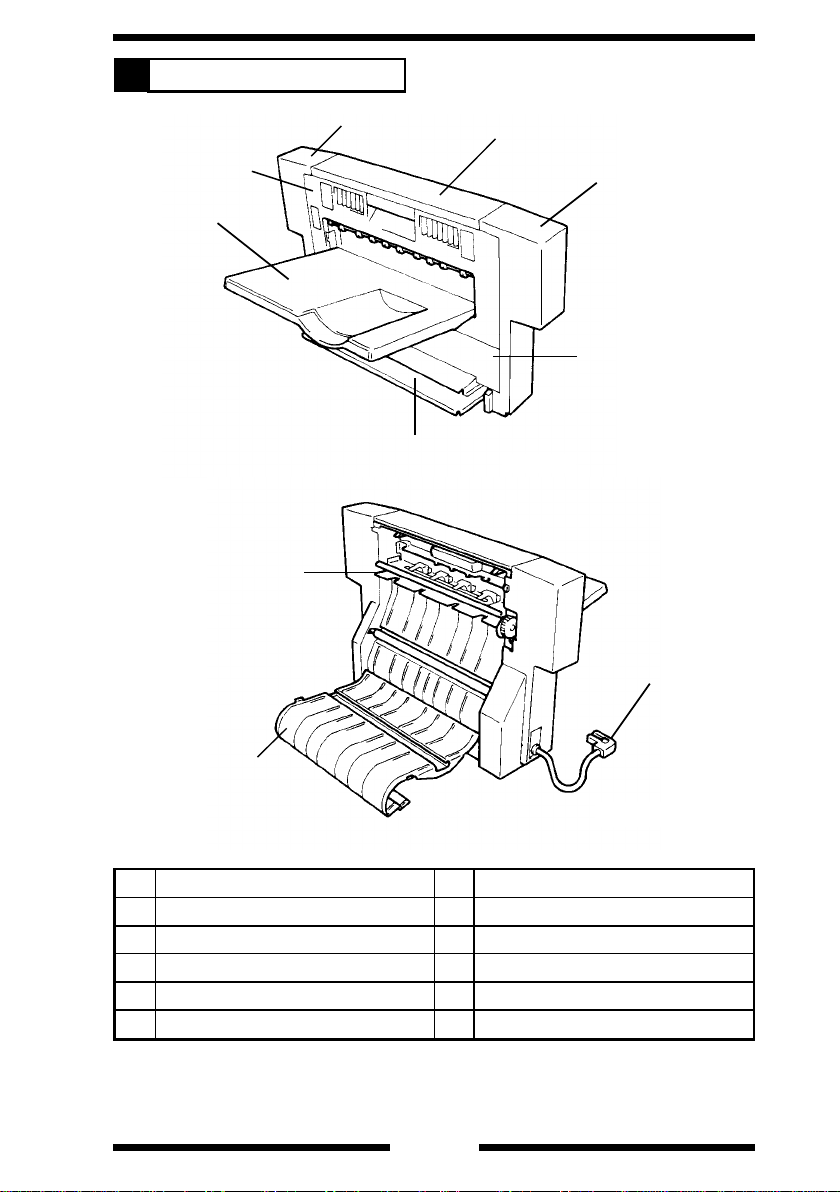

CROSS-SECTIONAL VIEW

3

1

9

8

7

No. Name Function

1 Exit Rollers Feed the copy out onto the Exit Tra y.

Exit/Turnover

2

Switching Finger

Vertical Transpor t

3

Guide

Vertical Transpor t

4

Rollers

Vertical Transpor t

5

Sensor PC3

Duplex Paper

6

Take-Up Port

7 Turnover Tray

8 Turnover Rollers

Switchback

9

Sensor PC1

Directs a copy for exit or turnover depending on the

operating mode.

Serves as a guide for the copy for turnover. Used also for

clearing a misfeed.

Transports the copy for turnover. Also removes the fuser

oil from the copy.

Detects a copy to be later turned over. Serves also as a

misfeed sensor.

The port through which the copy which has been turned

over is taken up and fed into the copier for the second

copy cycle.

Prevents the portion of the copy out of the Duplex Unit for

turnover from drooping down.

Reverse the copy fed fro m the ver tical t ransport section

(switchback motion) so that it can be taken up and fed

again into the copier.

Detects the reference t iming for the switchback mot ion of

the copy fed from the vertical transport section.

2

3

4

5

6

4458M003AA

M-3

Page 7

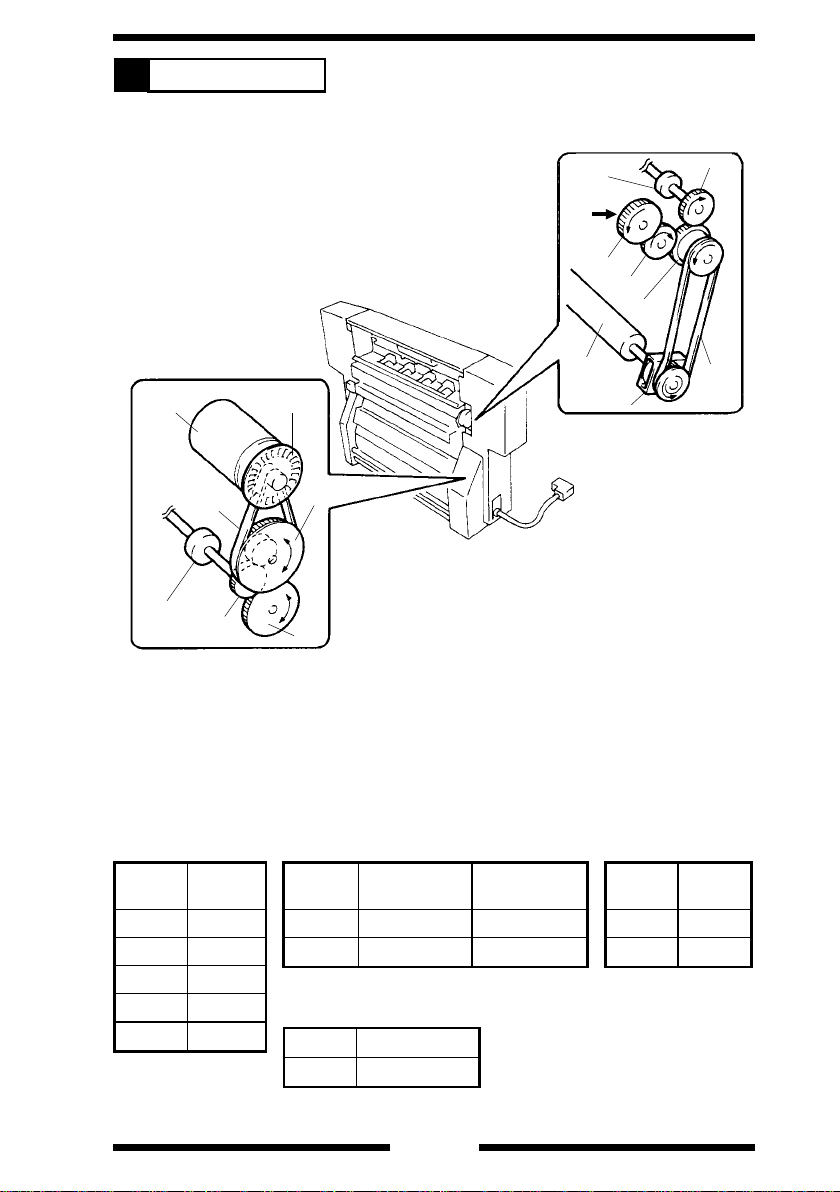

DRIVE SYSTEM

4

M1

Turnover

Roller

B2

G4

P1

PG2

G5

Exit Roller

Drive from

Copier

G1

Vertical

Transport

Roller

G3

G2

PG1

B1

CL1

4458M004AA

Gear

Symbol

G1 30

G2 24

G3 24

G4 19

G5 33

No. of

Teeth

Pulley

Symbol

PG1 31 28

PG2 15 64

No. of

Teeth, Gear

Pulley

Symbol No. of Teeth

P1 16

M-4

No. of

Teeth, Pulley

Belt

Symbol

B1 288

B2 191.01

Length

(mm)

Page 8

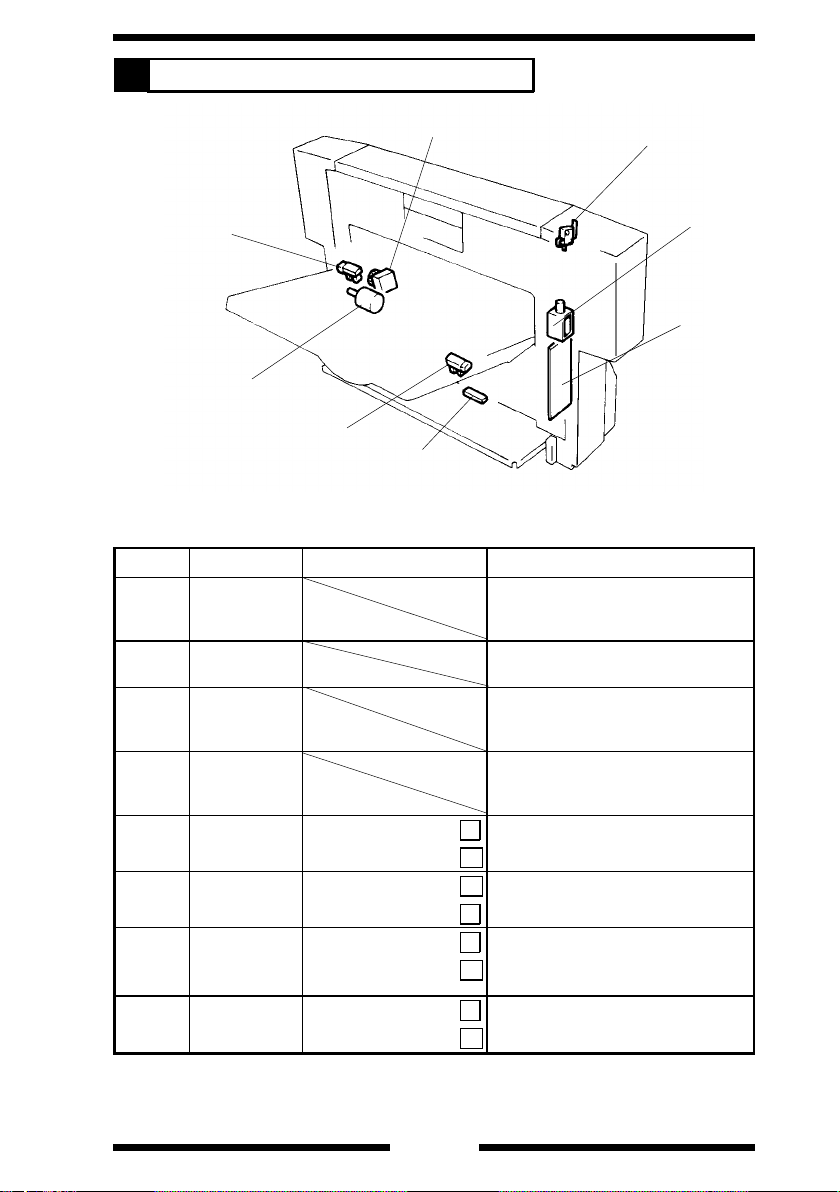

ELECTRICAL COMPONENTS LAYOUT

5

CL1

PC2

M1

PC3

PC1

◆

Functi on of Each Component

Symbol Name Input Signals (∗) Function

PWB-A Drive Board

M1

SL1

CL1

PC1

(PJ2A-8)

PC2

(PJ3A-2)

PC3

(PJ2A-9)

S1

(PJ2A-6)

Turnover

Motor

Exit/Turnover

Switching

Solenoid

Vertical

Transport

Clutch

Switchback

Sensor

Motor Pulse

Sensor

Vertical

Transport

Sensor

Duplex Unit

Set Switch

Paper present:

Paper not present:

Unblocked:

Blocked:

Paper present:

Paper not present:

Unit in position:

Unit out of position:

Performs commu nica tio n wi th the

copier and controls the elec trical

components of the Duplex Unit.

Drives the Turnove r Rollers to

effect a switchback motion.

Moves the Exit/Turnover

Switching Finger to chan ge the

paper path.

Controls the start and stop of the

Vertical Transpor t Ro llers to keep

the copy in the standby state.

L

Detects the reference tim i ng for a

switchback motion .

H

H

Detects the speed of M1.

L

L

Detects the copy present at th e

vertical transport section.

H

L

Detects whether or not the Duplex

Unit is installed in position.

H

S1

SL1

PWB-A

4458M005AA

∗

Signals at th e p r int jack on PW B-A.

M-5

Page 9

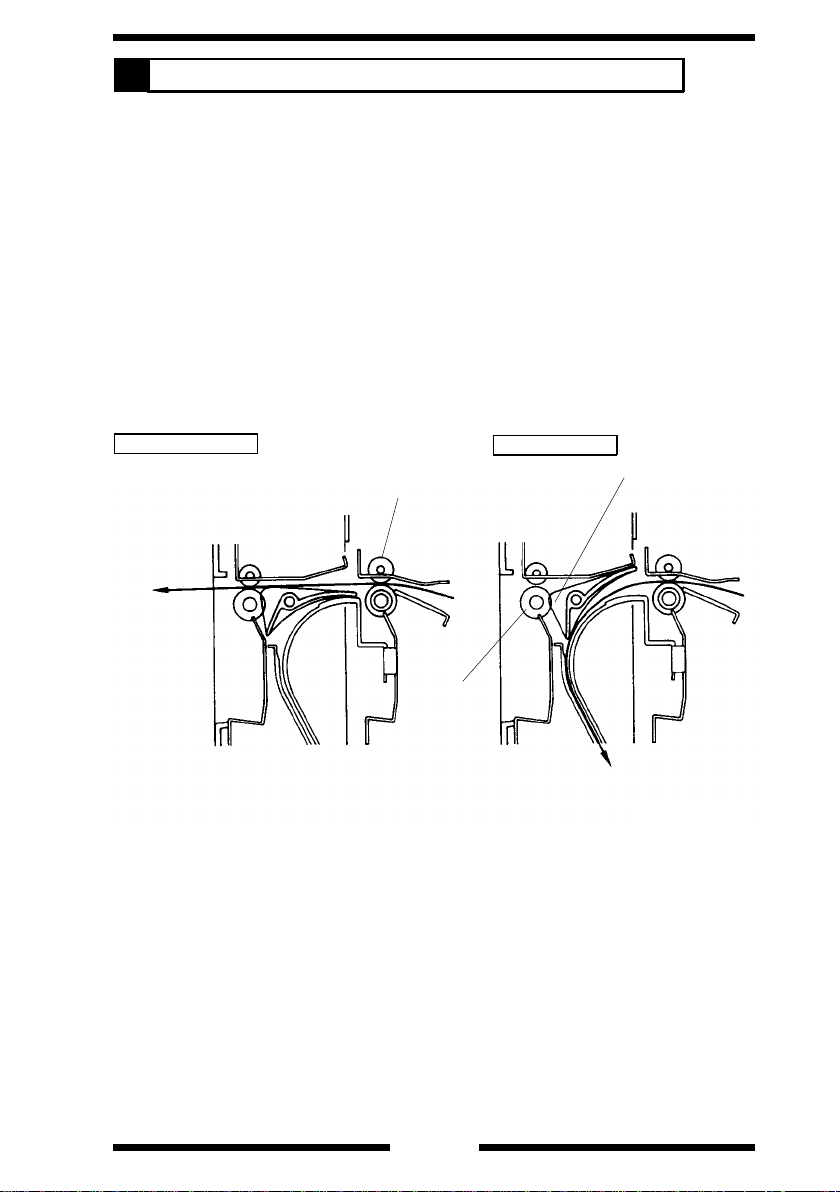

DESCRIPTION OF EACH MECHANISM AND CONTROL

6

6-1. Exit/Turnover Switching Mechanism

•

The exit/turnover switching mechanism uses the Exit/Turnover Switching

Finger that is moved to change the paper path either for exit or turnover.

•

When in the E xi t mo de or when the co py i s to be fed out in the Dupl ex

mode, Exit/Turnover Switching Solenoid SL1 remains deenergized and the

copy moves above the Exit/Turnover Switching Finger and is fed out of the

copier by the Exit Rollers.

•

When the copy is to be turned over in the Duplex mode, SL1 is ener gized

and the copy moves beneath and along the Exit/Turnover Switching Finger

and is fed by t he Ve rt ical Tran sp or t Rol l er s of the Du pl e x Uni t down

towards the turnover section.

•

As noted above, S L 1 moves the Exit/Turnover Switching Finger to change

the pa per path. I t is energized when a L O W si gnal fr om t he copier is input

to PJ2A-1 on PWB-A.

SL1: Deenergized

Exit

Paper Exit

Roller of Copier

Exit Roller

SL1: Energized

Exit/Turnover

Switching Finger

To Turnover Section

4458M006AA

M-6

Page 10

6-2. Fuser Oil Cleaning Mechanism

•

Since fuser oil is on the front side of the paper after the fusing process, it is

transferred onto the surface of the PC Drum via the Transfer Film during

the seco nd co py pr o ce ss of 2- s i de d cop yin g, whi c h res ul t s i n ima ge

problems. Silicone rubber rollers are used as the Vertical Transport

Rollers of the Duplex Unit. They function to recover fuser oil from the

surface of the paper.

6-3. Paper Standby Control

•

In a Duplex mode making two or more c op y sets of an original set (which

involves two-sheet paper attraction), two sheets of paper are present in the

Duplex Unit, one waiting for take-up from the Duplex Unit following the

turnover cycle and the other remaining stationary at the vertical transport

section. (See "7. OPERATION AND CONTROL" that follows.)

•

There is no problem with the paper waiting for take-up from the Duplex Unit

as it i s d r iven independen t ly of the copier drive. The paper at th e v ertical

transport section is, however, being transported and the drive from the

copier must be cut off. To accomplish this, Vertical Transport Clutch CL1

is mounted on the sh aft of the Ve r ti c al Tr an sp ort Roller and it c ou pl e s or

cuts off the copier drive to the roller.

•

CL1 is energized to stop the Vertical Transport Roller rotation when a LOW

signal from the copier is input to PJ2A-4 on PWB-A.

M-7

Page 11

6-4. Switchback Operation (Turnover)

•

The Turnover Roller turns forward to transport the copy to the turnover

section and, as soon as the trailing edge of the copy moves past

Switchback Sensor PC1, it stops turning. The Turnover Roller then turns

backward to turn over the copy and feed it back into the copier.

•

The drive for the Turnover Roller comes from Turnover Motor M1 wh ich is

turned forward , ba ck wa rd , or st op pe d by th e si gn al s fed from the co pier as

follows.

PJ2A-2 PJ2A-3 Copy Motion

Turning forward Transported towards Turnover Tray

Turning backward

Stopped Stationary

L

H

H

H

Transported tow ar ds D uplex paper

L

take-up side

H

Copy Transported Towards Turnover

Tray

Copy

Turnover Tray

Standby Position

Horizontal Tra nspo rt

Sensor of Cop ier

Turnover Position (Copy is temporarily

stationary)

Switchback

Sensor PC1

4458M007AB

M-8

Page 12

OPERATION AND CONTR OL

7

7-1. No. of Multiple 2-Sided Copies

•

The Duple x Uni t c an st o re only up to two co pi e s in i t an d th e cop i er do es

not sto r e in memo r y the i m age data it scan ned. For these reasons, the

number of multiple 2-sided copies that can be made varies depending on

the paper size, copying mode, and whether the Duplexing Document

Feeder is used or not . Her e are t he de t ai l s .

Copy Paper Size A5, A4C (∗1) A4L, B4L, A3L

Original Placement ADF Glass ADF Glass

1-sided → 2-sided 99 sets (*2) 2 sets (*3) 2 sets (*4) 1 set

2-sided → 2-sided 2 sets (*4)

Book → 2-sided

Copyin g Mo de

*L: Lengthwise; C: Crosswise; ADF: Duplexing Document Feeder

*1: Only when two shee ts of paper ar e to b e attra cted to the Transfer D ru m. I f a

particular copy cycle does not involve attraction of two sheets of paper, the

same control is provided as that for the paper size of B5L or larger.

*2: The originals are fed by the 2-in-1 mode and a book copy cycle is repeated in

which four 2-sided copies are made.

*3: Only when Auto Color Se lect is disabled.

*4: Only when Auto Expos ure, Aut o Co lor Select , and A uto P aper/S ize are disabled.

*5: A cycle is repeated in which four 2-sided copies are made.

99 sets (*5)

2 sets (*4)

7-2. Sensor Locations

•

The illustration below locates different sensors that provide reference for

paper move ment t h roughout t he Dup le x Un i t.

PC3

PC1

Duplex Unit Side

• PC1: Switchback Sensor

• PC3: Vertical Transport

Sensor

S10

PC24

Copier Side

• PC18: Paper Leading Edg e De tecting S enso r

• PC19: Transport Rolle r Sensor

• PC21: Separating Failure D et ecting Sensor

• PC24: Horizontal Tr an spor t Sensor

• S10: Paper Exit Switch

PC18

PC21

PC19

Transfer Drum

PC Drum

4458M009AA

M-9

Page 13

7-3. 2-Sided Copying Operation

1) Making 2-Sided Copies from 2-Sided Original Using ADF (One A4C

original, one copy set)

Paper Position Operation Sequence

The copy is separated from the Transfer Drum after

the image transfer process.

Separating Failure D etect ing Sen sor PC21 is

activated.

The copy reaches Paper Exit Switch S10.

4458M101AA

Exit/Turnover Switching Solenoid SL1 is energized.

The copy is transpor ted t o the vert ical tra nspo rt

section to reach Vert ical Transport Sensor PC3.

Turnover Mo tor M1 turns forward.

4458M010AA

4458M011AA

4458M012AA

4458M013AA

The copy reaches Switchback Sensor PC1.

Turnover Motor M1 turns forward to tra nspo rt t he

copy onto the Turnover Tray.

The trailing edge of the copy moves past PC1.

M1 is temporar ily deenergized and then start s tur ning

backward. (Th e copy is turned over, and the n taken

up and fed into the copier.)

The copy reaches Horizontal Transport Sensor PC24.

As Horizontal Transport Drive Clutch CL23 is

energized, the copy is fed onto t he Synchro n izing

Rollers.

The image tran sfer to the se cond fac e of the copy is

completed a n d then the copy undergoes s ep aration

and fusing befor e being fed out of the c opie r.

4458M014AA

M-10

Page 14

2) Making 2-Sided Copies from 1-Sided Originals Using ADF (Two A4C

originals, two copy sets)

Paper Position Operation Sequence

Two sheets of pape r for the first or iginal are

separated from the Transfer Drum after the image

transfer process.

The first copy activates Separating Failure Detecting

Sensor PC21.

4458M015AA

The first copy reaches Paper Exit Switch S10.

Exit/Turnover Switching Solenoid SL1 is energized.

The first copy is tran sported t o the ver tical t ransport

section to reach Vert ical Transport Sensor PC3.

Turnover Mo tor M1 turns forward.

4458M016AA

4458M017AA

4458M018AA

4458M019AA

The first copy re aches Switchback Sensor PC 1.

Turnover Motor M1 turns forward to transport the first

copy onto the Turnover Tray.

As Vertical Transpo rt Clut ch C L1 is ene rg ized, the

second copy is stationary at the vertical transport

section.

The trailing edge of the first copy move s past PC1.

M1 is temporar ily deenergized and then start s tur ning

backward. (Th e first cop y is turned ov er, a n d then

taken up and fed into the copier.)

The first copy reaches Horizontal Transport Sensor

PC24.

As Horizontal Transport Drive Clutch CL23 is

energized, the first copy is fed onto the Synchronizing

Rollers.

The first copy reaches Paper Leading E dge D etect ing

Sensor PC18 and stops at the Synchronizing Rollers.

➀➁

M-11

Page 15

Paper Position Operation Sequence

➀

➁

As CL1 is deenergiz ed and M17 is energized, the

second copy is transpor ted t o the turn over sec tio n.

The second copy reaches PC1.

M1 turns forwa rd to transport the second copy to the

Turnover Tr ay.

4458M020AA

The trailing edge of the second cop y moves past PC1.

M1 is temporar ily deenergized and then start s tur ning

backward. (Th e second copy is turned ov er, and

then taken up and fed into the copier.) At the same

time, the first copy is again attracted to the Transfer

Drum.

4458M021AA

4458M015AA

4458M022AA

The first and secon d copies are attracted to the

Transfer Drum. When the image transfer to the

second faces of the copies is completed, the copies

undergo separation and fusing before being fed out

of the copier.

M-12

Page 16

DIS/REASSEMBLY,

ADJUSTMENT

Precautions for Disassembly, Reassembly and Adjustment

1. Before attempting to disassemble the unit, always make sure that no power is

being supplied f rom the copier .

2. While power is being supplied to the unit, do not attempt to remove/install the

print jacks from/to the PWBs or unplug/plug in the connectors.

3. If th e u ni t is run with its covers rem oved, use care not t o allo w your clot hing t o

be caught in revolving parts such as th e timing belt.

4. The ba sic rule i s do not r un the un i t any ti me du r i ng dis/reas se m bl y .

5. A toothed washer is used with the screw that secures the ground wire to

ensure positive conduction. Do not forget to insert this washer at reassembly.

6. To reasse mbl e t he un i t, re ve rse t he order of di sa ss emb l y unl e ss ot h er wi s e

specified.

7. Do not attempt to loosen or remove the screw to which red paint has been

applied.

8. The screw to which blue paint has been applied may be removed, but needs to

be adjusted whenever it has been removed.

Purpose of Applying Red Paint

Red paint is applied to those screws that cannot be readjusted or reinstalled in

the field.

Page 17

DISASSEMBLY

1

1-1. Removal of the Exterior Covers and Guides

1

6

4

4458M008AA

3

No. Cover/Gu i de Na me No. of Scr e ws Steps Requi re d Befo re Re mov al

1 Rear C ov er 4 None

2 Front Cover 4 None

3 E xi t S ec t i on Lower Cove r 4 Removal of th e Fron t and Rear Co ver s

4 Exit Section Cover 2 Removal of two ornamental covers

5 Turnover Low er Guide 2 Remov al of th e Fro nt and Rear Co vers

6 V ertica l T r a ns port G uide 2 R emoval of the F ront and Rear Co ve r s

5

4458M008AA

2

D-1

Page 18

1-2. Removal of Vertical Transport Clutch CL1

1. Remove the Front and Rear Covers.

2. Remove t he Exit Sec t i on Lower Co ver .

3. Unplug the connector of CL1.

4458D001AA

4. Loosen the screw shown to release the belt tension.

*

Do not forget to tighten this screw at reinstallation.

4458D005AA

5. Snap off one plastic ring and remove the flange and

belt.

4458D002AA

Frame

Collar

0

4458D003AA

CL1

4458D004AA

6. Loosen one screw with an Allen wrench to remove

CL1 and the collar.

*

When reinstalling CL1, press it against the collar

and, a t the same tim e, t ig hten the screw.

Hook the l oc k of the c lutch onto the frame.

D-2

Page 19

1-3. Removal of the Vertical Transport Roller (Metallic One)

1. Remove the Front and Rear Covers.

2. Unhook two te ns io n c oi l spri n gs .

4458D006AA

3. Remove the plastic ri ngs and bushings from the front

and rear ends and then remove the Vertical Transport

Roller.

4458D007AA

1-4. Removal of the Vertical Transport Roller (Rubber One)

1. Remove the Front and Rear Covers.

2. Remove t he Exit Sec t i on Lower Co ver .

3. Remove V er t i cal Tr a nsp or t C l ut c h CL 1 an d c ol la r .

4. Remove the plastic ring and bearing from the rear end.

4458D008AA

4458D009AA

5. Remove the plastic ri ngs and bushings from the front

end.

6. Remove t he Vert ic al Transport Rolle r.

D-3

Page 20

1-5. Removal of the Turnover Entrance Guide

1. Remove t he Front and Re ar Co ver s.

2. Remove the Turnover Lower Guide.

3. Remove f our scre ws at the fro nt and rear and the

Turno ver Entrance Gui de.

4458D014AA

*

Try to pre ss the T urn o ver Entr an c e G u ide up as

shown at reins t al l a tio n.

0

ADJUSTMENTS

2

Vertical

Transport

Frame

Turnover Entrance

Guide

4458D015AA

2-1. Adjustment of Dup. Left-Margin

Requir e m en ts : The di s t an ce be tween the fr o nt e dg e of th e p ap er and the f ront edg e of t he t est

pattern should be 3 ±1.5mm.

1. Set the copier into the Service mode and select the

following functions in that order:

"Machine Adjust," "PRT Area," and "Dup. Left-Margin."

4458D016AA

2. Select the drawer to be adj usted and press the Start

key.

3. M ea sur e d i me ns io n " A" o n th e te s t p rint fed out of the

copier.

*: No adjustments are necessary if the measurement

A

4458D017AA

is 3 ±1.5mm.

4. If the measurement taken in step 3 falls outside the

speci f i ed ra ng e, a dj u s t usin g th e ▲ or ▼ key.

D-4

Page 21

2-2. Adjustment of Exit/Turnover Switching Solenoid SL1

1. R em ov e t he Front Cover .

2. R em ov e t he ha r ness of Du p le x Uni t Set S wi t c h S1

from t he edge cov er.

SL1

3. Unplug the connector from Drive Board PWB-A.

SL1

PWB-A

4458D010AA

4458D011AA

4458D012AA

Upper Guide Plate

Exit/

Turnover

Switching

Finger

4. Remove one screw and the solenoid assy.

5. Unhook the tension coil spring.

6. R em ov e t wo s cr e ws an d th e sol e no i d.

*

When securing the solenoid at reinstallation, slide it

downward as far as it will go.

*

When sec u ri ng t he s o l en oi d assy, en sur e that the

Exit/Turnover Switching Finger is in contact with the

sponge of th e Upper Gui de Plate with the solenoid i n

the energized position.

After reinsta llati on, check that the switching finger

operates smoothly.

4458D013AA

D-5

Page 22

TROUBLESHOOTING

Genera l Precautions

1. When servicing the unit with its covers removed, use utmost care to prevent

your hands, c l othing, and tools fro m being caught in revol ving parts.

2. Befor e att e m pti n g to rep l ac e parts and un pl u gg i ng co nn ectors, mak e sure that

no power is being supplied from the copier.

3. Never cre at e a clos ed cir cuit acr oss conne ctor pi ns exce pt those a ut horized in

the text and on the PWB.

4. When creating a closed circuit and measuring a voltage across connector pins

speci fi e d in the text, be su re to us e th e gre en wi re (GND).

5. Keep all disassembled parts in good order and keep tools under control so that

none will be lost or damaged.

Reading the Text

1. If a component on a PWB or any other functional part including a motor is

defective, the text only instructs you to replace the whole PWB or functional

part and does not give troubleshooting procedure applicable within the

defective part.

2. The text assumes that there are no breaks in the harnesses and cords and all

connectors are plugged into the right positions.

Page 23

MISFEED DETECTION

1

1-1. Misfeed Detection Conditions

A misfeed in the Duplex Unit is detected under any of the following conditions and a misfeed

•

indication is given on the control panel of the copier. A misfeed can be reset by unlocking and

locking the Duplex Unit.

A mis fe ed a t th e ve r t i cal transp o r t s ection

•

Type Detection Timing

Paper left Vertical Transport Sensor PC3 is unblocked ( L ) when the Power

Leading edge of paper PC3 is not unblocke d ( L ) even after t he la ps e of appr ox. 3.3 se c . af te r

Trailing edge o f paper PC3 is not blocke d ( H ) even after t he lapse of appro x. 3.3 sec . after

A misfeed at the turnover section

•

Type Detection Timing

Paper left Switchback Sensor PC1 is activated ( L ) when the Power Switch is

Leading edge of pape r PC1 is not a c tiv a te d ( H ) even after t he l a pse of appr o x. 1.2 sec . af te r

Trailing edge o f paper PC1 is ac ti va ted ( L ) even afte r the l a ps e of appro x. 4.8 se c . af te r PC 1

Paper which has been

turned over

Switch i s tu rned ON, a m i sf eed is res et , or the F ron t Door is ope ne d an d

closed.

Paper Ex i t S wi t ch S 10 of the c opier h a s detected the leading edge of the

paper.

S10 of the copier has detected the trailing edg e of the pa per.

turned ON, a misfeed is reset, or the Front Door is opened and closed.

PC3 has d et ec t ed t he l e ad i ng edge of the paper.

has det ec t ed t he l e ad i ng edge of the pa p er.

PC1 dete cts no paper at a timing when it should have detected paper

after it has been turned over (e.g., when the paper which has been turned

over i s pulled out).

A mis fe ed a t the Dup l e x pap er tak e-u p section

•

Type Detection Timing

Paper lef t Horiz on ta l Tra ns p ort S e ns o r PC2 4 of th e c op i e r i s blo cke d ( L ) when

Leading edge of pape r PC24 of th e c opie r is no t bl ocked ( L ) even af ter the la p se o f ap prox.

Trailing edge o f paper PC24 is no t unblo c k ed ( H ) e v en af ter t he lapse of a pprox. 1.8 se c.

the Power Switch is turned ON, a misfeed is reset, or the Front Door is

opened a n d cl o se d.

1.8 sec. a ft er PC1 ha s d et ec t ed t he l e ad i ng edge of the pap e r whi ch was

turned over.

after PC1 has detected the trailing edg e of the pape r which was turned

over.

T-1

Page 24

1-2. Mi sf e ed Trouble s h oo t ing Procedures

A Misfeed at the Vertical Transport Section

•

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

A misfeed

occurs before

paper

reaches the

vertical

transport

section.

A misfeed

occurs before

paper

reache s PC3.

Step

No.

1 Is Vertic al T r ansport Sens or

PC3 unblocked by a sheet of

paper present at the vertical

trans po rt sec t ion of the Dup l ex

Unit?

2 Doe s the a ctuator of PC 3

operate properly?

3 Is the voltage across PJ2A-9 on

PWB-A an d G ND DC 5 V? D oe s

that voltage change to DC0V

when PC3 is unblocked?

1 Is Exit/Turnover Switching

Solenoid SL1 energized during

the Duplex mode?

2 Does the voltage across PJ2A-1

on PWB-A and GND change

from DC5V to DC0V when SL1

is ener gized?

3 Has the Exit /Turnover Swit ching

Finge r been adjusted properly?

1 Do th e Ve rti c a l T r an s po rt

Rollers turn when drive is

trans mitted fro m t he c o pi e r?

2 Is the voltage across PJ2A-4 on

PWB-A and GND DC5V

normally?

3 Are th e V ert i c al Tr an s po rt

Rollers dirty or scratched?

Check It e m Re sult Action

YES Remove the paper from the

vertical transport section.

NO C h eck th e ins t al le d positio n of

PC3 and check the actuator for

deform at i on a n d foreig n matter.

YES Make checks on the copier side.

NO C h eck the w ir i n g be tw ee n

PWB-A an d PC 3 an d, i f i t i s

intact, replace PC3 or PWB-A.

YES G o to st ep 3.

YES Ch ec k th e wi ri n g be tw ee n

PWB-A an d SL 1 an d, i f i t i s

intact, replace SL1 or PWB-A.

NO Make checks on the copier side.

YES Clean the Exit/Turnover

Switc hi n g Fi ng er and gu i de

plate.

NO Adjust SL1.

YES G o to st ep 3.

YES Ch ec k th e wi ri n g be tw ee n

PWB-A and Vertic al Tr an s port

Clutch CL1 and, if it is intact,

replace CL1 or PWB-A.

NO Make checks on the copier side.

YES Cl e an o r re p l ace the de fect i ve

Vertical Transport Roller.

NO Clean the Vertical Transport

Guide an d c he ck it fo r

deformation.

T-2

Page 25

A Misfeed at the Vertical Transport Section

•

Symptom

A misfeed

occurs after

paper has

reached

Vertical

Transport

Sensor PC3.

Step

No.

1 Does Turnover Motor M1 turn

when pa pe r is fe d int o th e

Duplex Unit?

2 Does the voltage across PJ2A-2

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

3 Doe s the a ctuator of PC 3

operate properly?

4 Is the voltage across PJ2A-9 on

PWB-A an d G ND DC 5 V? D oe s

that voltage change to DC0V

when PC3 is unblocked?

Check It e m Re sult Action

YES G o to st ep 3.

YES Ch ec k th e wi ri n g be tw ee n

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

NO C h eck th e ins t al le d positio n of

PC3 and check the actuator for

deform at i on a n d foreig n matter.

YES Make checks on the copier side.

NO C h eck the w ir i n g be tw ee n

PWB-A an d PC 3 an d, i f i t i s

intact, replace PC3 or PWB-A.

T-3

Page 26

A Misfeed at the Turnover Section

•

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

Paper is yet

to reac h P C 1.

Paper is

stationary at

the Tur no ver

Rollers.

Paper is not

transported to

the Dupl e x

paper take-up

side.

Step

No.

1 Is Switchback Sensor PC1

activ a te d by a sheet of pape r

present at the turnover section

of the Duplex Unit (or dust on

the underside of the sensor)?

2 Is P C1 i n sta l l ed correct ly ? NO C o rr ect th e i n st a lled pos i ti on of

3 Is the voltage across PJ2A-8 on

PWB-A an d G ND DC 5 V? D oe s

that voltage change to DC0V

when a sheet of paper is

inserted to activate PC1?

1 Is the Turnover Entrance Guide

deformed or dirty?

1 Does Turnover Motor M1 turn

when pa pe r is fe d int o th e

Duplex Unit?

2 Does the voltage across PJ2A-2

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

1 Doe s M1 tu r n ba ck wa r d af te r

paper has been fed out onto the

Turnover Tray?

2 Does the voltage across PJ2A-3

on PWB-A and GND change

from DC5V to DC0V when M1 is

energized?

Check It e m Re sult Action

YES Remove the paper from the

turnover section. Or clean the

unders i de o f th e senso r .

PC1.

YES Make checks on the copier side.

NO C h eck the w ir i n g be tw ee n

PWB-A an d PC 1 an d, i f i t i s

intact, replace PC1 or PWB-A.

YES Clean or replace the Turnover

Entran c e Gui d e.

NO C heck the Vertic al T r ansport

Guide an d V ert i c al Tran s po rt

Rollers for dirt and deformation.

YES Clean the Turnover Rollers and

Turno ver Guide.

YES Ch ec k th e wi ri n g be tw ee n

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

YES Clean the Turnover Rollers and

Turno ver Guide.

YES Ch ec k th e wi ri n g be tw ee n

PWB-A and M1 and, if it is

intact, replace M1 or PWB-A.

NO Make checks on the copier side.

T-4

Page 27

A Mis fe ed a t the Dup l e x Pa p e r T ake-U p S e c ti on

•

Symptom

A misfeed

occurs

immediately

after the

Power Switch

has been

turned ON.

A misfeed

occurs before

paper

reaches

Horizontal

Transport

Sensor PC24.

A misfeed

occurs after

paper has

reached

PC24 of th e

copier.

Step

No.

1 See TROUBLESHOOTING of

the copier.

1 Is the Turnover Entrance Guide

or Turnover Lower Guide

deformed or dirty?

2 Is the Turnover Roller or the

Duplex Paper Take-Up Guide of

the copier deformed or dirty?

1 See TROUBLESHOOTING of

the copier.

Check It e m Re sult Action

YES Clean or replace the Turnover

Entran c e Gui d e or Turn ov e r

Lower Guide.

YES Clean or replace the Turnover

Roller or the Dupl ex Pa per

Take-U p G ui d e of th e c op i e r.

NO Check Horizontal Transport

Drive C l ut c h CL 23 o f th e c opi e r.

T-5

Page 28

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

Loading...

Loading...