Page 1

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

DB-431

SERVICE MANUAL

10794

Page 2

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

CONTENTS

GENERAL,

MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ...........................................................................................M-1

2. PARTS IDENTIFICATION ........................ ........................... ............................M-1

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM ..............................................................................................M-2

5. ELECTRICAL COMPONENTS LAYOUT ........................................................M-3

6. MECHANISM AND CONTROL ............................... ............................ .............M-4

6-1. Vertical Transport Drive Mechanism ........................................................M-4

6-2. Paper Take-Up Mechanism .....................................................................M-4

6-3. Paper Take-Up Mechanism .....................................................................M-5

6-4. Paper Take-Up Operations ......................................................................M-6

(1) Lift 1 Paper Take-Up Operations .....................................................M-6

(2) Lift 2 Paper Take-Up Operations .....................................................M-8

6-5. Paper Separating Mechanism .................................................................M-11

6-6. Paper Pressure Releasing Mechanism ...................................................M-11

6-7. Paper Take-Up Roll Retracting Mechanism ............................................M-12

6-8. LCC-in-Position Detection ..................................... ..................................M- 1 2

6-9. Edge Guides and Trailing Edge Stop ......................................................M-13

6-10.Paper Size Setting ...................................................................................M-13

6-11.Lifting Mechanism ....................................................................................M-14

(1) Lift 1 and 2 Ascent Conditions . ........................................................M-15

(2) Lift 1 and 2 Stop Conditions ................. ............................ ...............M-15

(3) LCC Lift-Up Motor EMOT Control ........................ ............... .............M-15

(4) Descent Motion ....................... ........................... ..............................M-16

6-12.Paper Near Empty Detection ...................................................................M-16

6-13.Paper Empty Detection ............................................................................M-17

6-14.Panel Display ...........................................................................................M-17

6-15.Paper Dehumidifying Heaters (Option) ................................................... .M-18

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

1-1. Maintenance Schedule ............................................................................D-1

1-2. Removal of Exterior Parts ........................................................................ D-2

1-3. Removal of the Paper Take-Up Unit ........................................................D-3

1-4. Removal of the Paper Take-Up Rolls ......................................................D-4

1-5. Removal of the Feed Roll, Separator Roll and Torque Limiter Assy .......D-6

1-6. Cleaning of the Paper Take-Up Roll ........................................................D-6

1-7. Cleaning of the Feed Roll and Separator Roll .........................................D-6

1-8. Cleaning of the Vertical Transport Roller/Ro lls ................ ........................D-7

1-9. Cleaning of the Roll with a Torque Limiter ............................................ .. .D-7

2. ADJUSTMENT .................................................................................................D-8

2-1. Reference Position Adjustment ............................... ........................... .....D-8

MISFEED/MALFUNCTION DETECTION

1. MISFEED DETECTION .................................... ........................... ....................T- 1

i

Page 3

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-1. Location of Misfeed Detecting Sensors ...................................................T-1

1-2. Misfeed Detection Timing .......... ............. .... ...... ............. ...... ........... ...... ...T-2

2. MALFUNCTION DETECTION .............................................................. ...........T-2

ii

Page 4

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

GENERAL,

MECHANICAL/ELECTRICAL

Page 5

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1. SPECIFICATIONS

Type : Front Loading Type LCC

Type of Paper : Plain paper

Paper Size : B5C, A4C, Letter C

Paper Weight :

Registration : Center

Paper Capacity : 2,500 sheets (1250 × 2)

Power Requirements : DC24 V ± 10 %, DC5.1 V ± 5 % (supplied from copier)

Dimensions : Width ... 535 mm or 21 in

Weight : 17 kg or 37-1/2 lbs.

64 to 90 g/m

Depth ... 568 mm or 22-1/4 in

Height ... 284 mm or 11-1/4 in

2

or 17 to 24 lbs.

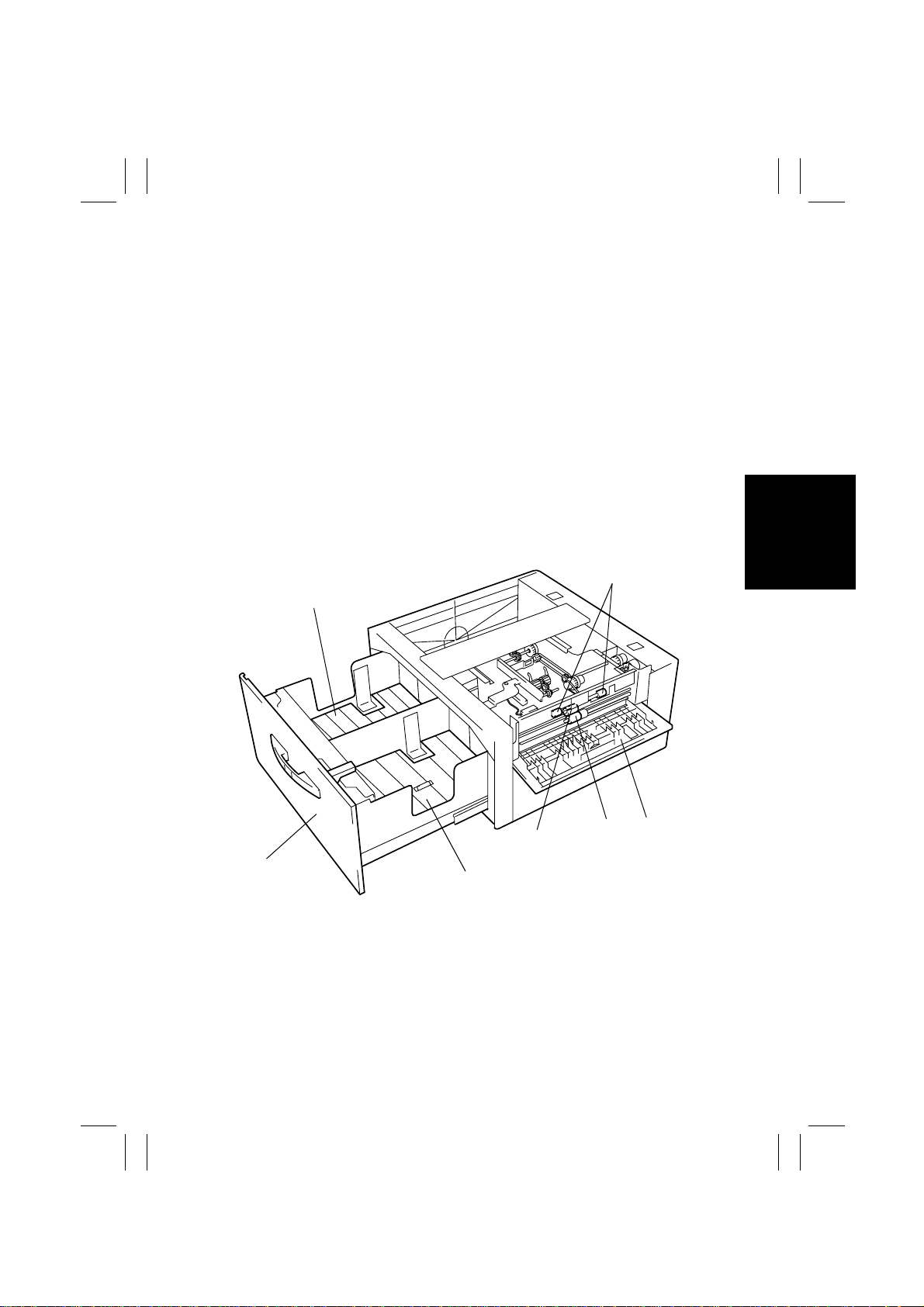

2. PARTS IDENTIFICATION

2

1

7

1. Lift 2

2. Vertical Transport Rolls

3. Right Side Door

4. Separator Roll

6

5. Feed Roll

6. Lift 1

7. Front Cover

M-1

4

5

3

4659M001AA

Page 6

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

3. CROSS-SECTIONAL VIEW

1

1. Lift 2

2. Paper Take-Up Roll 2

3. Lift 1

4. Paper Take-Up Roll 1

4. DRIVE SYSTEM

Paper Take-Up Drive Mechanism

2345 6

7

8

4659M007AA

5. Vertical Transport Roller

6. Vertical Transport Roll

7. Feed Roll

8. Separator Roll

Vertical Transport Drive Mechanism

Lift Drive Mechanism

4659M002AB

M-2

Page 7

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

5. ELECTRICAL COMPONENTS LAYOUT

SIDE

RCL

PWB-A

RS1

BCL

FRONT

P1CL

RSEN

LS1

S1

HMOT

RS2

EMOT

Symbol Name Symbol Name

PWB-A

LCC Control Board

HMOT

LCC Transport Motor

EMOT

LCC Lift-Up Motor

P1CL

Paper Take-Up Clutch 1

P2CL

Paper Take-Up Clutch 2

BCL

Separator Clutch

RCL

Registration Clutch

PPS0

LCC Paper Take-Up Sensor

PPS1

Paper Empty Sensor 1

P2CL

FRONT

LS2

PPS1

EMP

S1

Paper Standby Position Sensor

RSEN

Registration Sensor

EMP

Paper Empty Sensor 2

SIDE

Side Cover Set Sensor

LCC Set Sensor

RS1

Paper Near Empty Sensor 1

RS2

Paper Near Empty Sensor 2

LS1

Lift-Up Sensor 1

LS2

Lift-Up Sensor 2

PPS0

4659M003AA

M-3

Page 8

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6. MECHANISM AND CONTROL

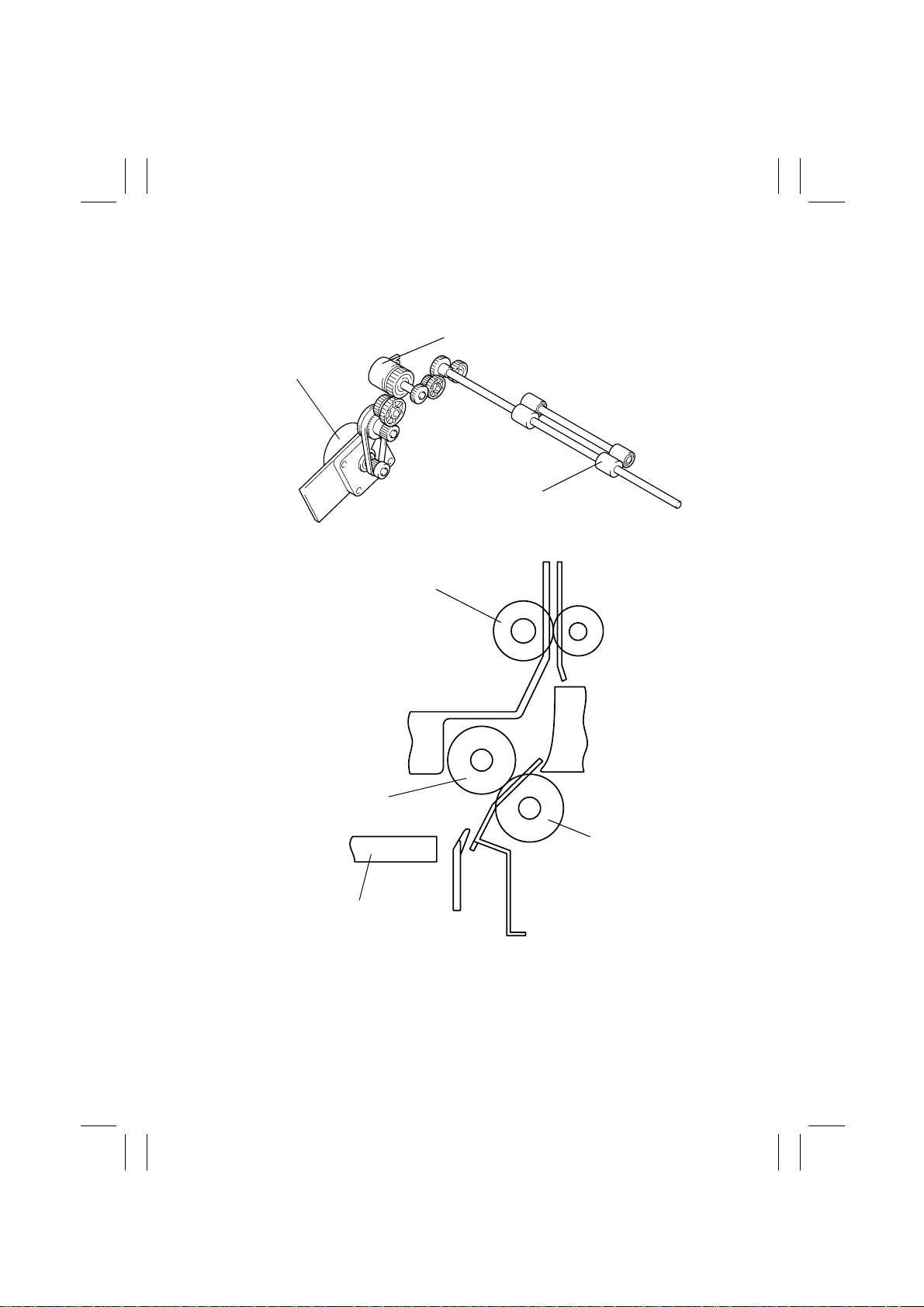

6-1. Vertical Transport Drive Mechanism

• The LCC Transport Motor provides the drive for the Vertical Transport Roller.

Registration Clutch RCL

LCC Transport Motor

HMOT

Vertical Transport Roller

Vertical Transport Roller

4659M004AB

Feed Roll

Separator Roll

Lift 1

4659M506AA

6-2. Paper Take-Up Mechanism

• The LCC Transport Motor is energized and deenergized by the signals output from pins

1 to 6 of CN6A on the LCC Control Board.

M-4

Page 9

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-3. Paper Take-Up Mechanism

• Paper take-up drive is provided by the LCC Transport Motor.

Separator Clutch BCL

LCC Transport Motor

HMOT

Paper Take-Up Clutch 2

P2CL

Paper Empty Sensor 1

PPS1

Paper Take-Up

Roll 2

Paper Take-Up Clutch 1

P1CL

4659M005AB

LCC Paper Take-Up Sensor

PPS0

Paper Take-Up

Roll 1

Separator Roll

Roll with a Torque Limiter

M-5

Paper Standby Position

Sensor S1

4496M021AB

Page 10

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-4. Paper Take-Up Operations

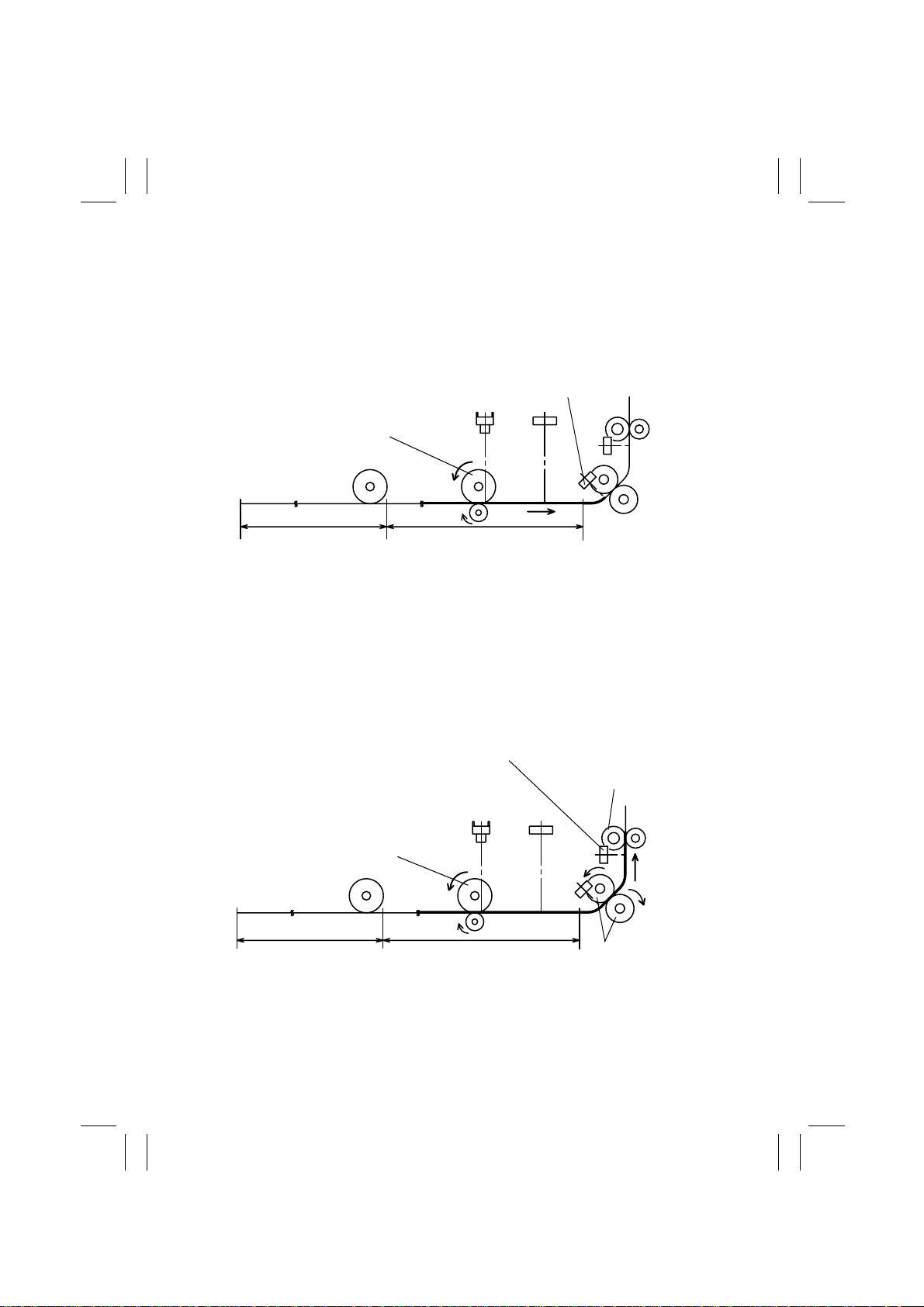

(1) Lift 1 Paper Take-Up Operations

Operation 1

• After Lift 1 has completed its ascent motion, Paper Take-Up Roll 1 is driven.

• Paper is transported until its leading edge activates the Paper Standby Position Sensor

(this position serves as the standby position for paper take-up).

Paper Standby Position Sensor S1

Paper Take-Up Roll 1

Lift 2 Lift 1

Operation 2

• A Paper Take-Up signal is sent from the copier.

• The Separator and Feed Rolls, and Paper Take-Up Roll 1 work together to transport the

paper to the Registration Sensor.

• When the Registration Sensor is activated, the paper is further transported over the distance between the Registration Sensor and Vertical Transport Roller, plus a registration

loop length.

• Paper Take-Up Roll 1 is stopped.

Registration Sensor RSEN

Vertical Transport Roller

Paper Take-Up Roll 1

Lift 2 Lift 1

4659M524AA

Separator/Feed

Roll

4659M525AA

M-6

Page 11

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

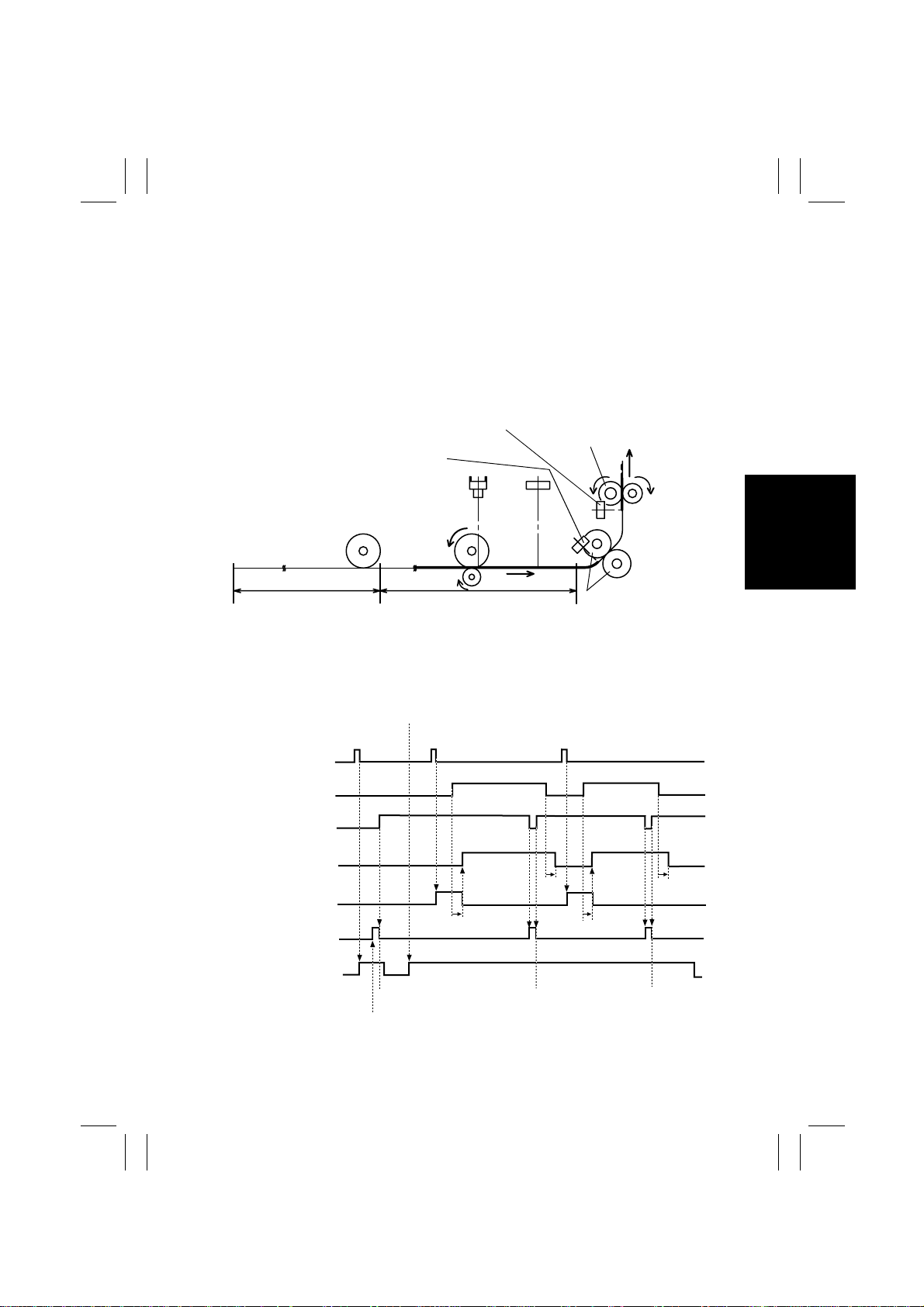

Operation 3

• The Vertical Transport Roller is driven to feed the paper toward the copier.

• When the trailing edge of the paper deactivates the Paper Standby Position Sensor, the

subsequent paper is transported up to the standby position.

• Separator and Feed Rolls are brought to a stop after the lapse of a given period of time

after the Registration Sensor has been deactivated by the tr ailing edge of the paper

being taken up and fed in.

• The next Paper Take-Up signal is issued after the lapse of a given period time after the

Vertical Transport Roller has started turning for the transport of the preceding sheet of

paper.

Registration Sensor RSEN

Vertical Transport Roller

Paper Standby Position Sensor S1

Lift 2 Lift 1

✽

These operations 1 to 3 are repeated to transport paper from Lift 1.

Taking up and feeding two sheets of paper from Lift 1

Start Key ON

Operation

Copier Signal

Registration

Sensor RSEN

Paper Standby

Position S1

Registrator

Clutch RCL

Separator

Clutch BCL

Take-Up

Clutch 1 P1CL

LCC T ransport

Motor HMOT

ON

OFF

H

L

H

L

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Enable Signal

Standby PositionStandby Position

After Lift 1 Has Completed Liffting Motion

Paper Take-Up SignalPaper Take-Up Signal

Separator/Feed

Roll

4659M526AA

Standby Position

4659M521CA

M-7

Page 12

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

(2) Lift 2 Paper Take-Up Operations

Operation 1

• When Lift 1 runs out of paper, it is placed into its upper limit position (to establish a paper

path into the copier from Lift 2).

• When the trailing edge of the last sheet of paper from Lift 1 deactivates Paper Empty

Sensor 1, Paper Take-Up Roll 1 and Paper Take-Up Roll 2 are started to turn.

• Paper is transported until its leading edge activates the LCC Paper Take-Up Sensor.

Paper Empty Sensor 1 PPS1

LCC Paper Take-Up Sensor PPS0

Paper Take-Up

Roll 2

Paper Take-Up

Roll 1

Lift 2 Lift 1

4659M527AA

Operation 2

• Paper Take-Up Roll 1 is driven.

• Paper is transported from the position of the LCC Paper Take-Up Sensor to a point at

which the Paper Standby Position Sensor is activated (this position serves as the

standby position for paper take-up).

Paper Standby Position Sensor S1

LCC Paper Take-Up Sensor PPS0

Paper Take-Up Roll 1

Lift 2 Lift 1

M-8

4659M524AA

Page 13

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

Operation 3

• A Paper Take-Up signal is sent from the copier.

• The Separator and Feed Rolls, and Paper Take-Up Roll 1 work together to transport the

paper to the Registration Sensor.

• When the Registration Sensor is activated, the paper is further transported over the distance between the Registration Sensor and Vertical Transport Roller, plus a registration

loop length.

• Paper Take-Up Roll 1 is stopped.

• The Vertical Transport Roller is driven to feed the paper toward the copier.

• When the trailing edge of the paper being transported deactivates Paper Empty Sensor

1, Paper Take-Up Roll 1 and Paper Take-Up Roll 2 are driven.

• The subsequent sheet of paper is transported until it activates Paper Empty Sensor 1.

Registrator Sensor RSEN

Paper Standby Position Sensor S1

Paper Empty Sensor 1

PPS1

Vertical Transport Roller

Paper Take-Up

Roll 2

Lift 2 Lift 1

Paper Take-Up

Roll 1

Separator/Feed

Roll

4659M529AA

M-9

Page 14

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

Operation 4

• After the lapse of a given period of time after the trailing edge of the preceding sheet of

paper has deactivated the LCC Paper Take-Up Sensor, the subsequent sheet of paper

located at Paper Empty Sensor 1 is transported to the standby position.

• Separator and Feed Rolls are brought to a stop after the lapse of a given period of time

after the Registration Sensor has been deactivated by the tr ailing edge of the paper

being taken up and fed in.

• The next Paper Take-Up signal is issued after the lapse of a given period time after the

Vertical Transport Roller has started turning for the transport of the preceding sheet of

paper.

Paper Standby Position Sensor S1

LCC Paper Take-Up Sensor PPS0

Registrator Sensor RSEN

Vertical Transport Roller

Paper Empty Sensor 1

PPS1

Separator/Feed

Roll

Lift 2 Lift 1

✽

These operations 1 to 4 are repeated to transport paper from Lift 2.

Taking up and feeding two sheets of paper from Lift 2

Start Key ON

Copier Signal

Registration Sensor

RSEN

Paper Standby

Position Sensor S1

LCC Paper Take-Up

Sensor PPS0

Paper Empty

Sensor 1 PPS1

Registration

Sensor RSEN

Separator Clutch

BCL

Paper Tak e-Up

Clutch 1 P1CL

Paper Tak e-Up

Clutch 2 P2CL

LCC T ransport

Motor HMOT

ON

OFF

H

L

H

L

H

L

H

L

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Standby Position Standby Position Standby Position

Paper Take-Up Signal Paper Take-Up Signal

4659M530AA

4659M522CA

M-10

Page 15

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-5. Paper Separating Mechanism

• The difference in friction coefficient between the Feed Roll and Separator Roll is used to

stop the rotation of the Separator Roll for the prevention of double feed.

<Normal Feeding>

• When only one sheet of paper is taken up, the friction

Feed Roll

Paper

Separator Roll

Driven or stationary

4425M012AA

<Double Feeding>

Feed Roll

1st Sheet of Paper

2nd Sheet of Paper

Separator Roll

4425M013AA

Stationary

coefficient on the top side of the paper is equal to that

on the underside. The Separator Roll is driven by the

Feed Roll, which results in the paper being fed on.

• Since the friction coefficient between the second

sheet of paper and the Separator Roll is greater than

that between the first and second sheets of paper,

the Separator Roll remains stationary, allowing the

Feed Roll to feed only the first sheet of paper.

6-6. Paper Pressure Releasing Mechanism

• When the LCC is slid out, the Pressure Release Rail pushes the Separator Roll assy

downward so that it is released from the Feed Roll.

Feed Roll

Separator Roll

Assy

Pressure Release Rail

4659M509AA 4659M510AA

M-11

Page 16

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-7. Paper Take-Up Roll Retracting Mechanism

• When the LCC is slid out, the Pressure Release Lever pushes the Paper Take-Up Roll

upward so that it is released from the paper stack.

Paper Take-Up Roll 2

Paper Take-Up Roll 1

Pressure Release Lever

4659M009AA

6-8. LCC-in-Position Detection

• When the LCC is slid into the copier, the light blocking plate blocks the LCC Set Sensor

and the copier determines that the LCC has been slid into it.

LCC Set Sensor

FRONT

Bloking Plate

4659M512AA

M-12

Page 17

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-9. Edge Guides and Trailing Edge Stop

• The Trailing Edge Stop is secured to the specified size position with a screw. (It is not

installed when Letter Crosswise paper is to be loaded.)

• The Edge Guides can be slid to the specified size positions and secured with screws.

• The Slides of the drawer must be slid all the way in the directions of the arrows.

• When the positions of the Edge Guides and Trailing Edge Stop have been changed, the

corresponding paper size must be set (according to the “Paper Size Setting” procedures

that follow).

Edge Guides

Trailing Edge Stop

4659M006AA

Slides

4659M008AA

6-10. Paper Size Setting

• Paper sizes that can be set: B5C, A4C, Letter C

• After the Edge Guides and Trailing Edge Stop have been repositioned, flip keys of the

DIP switch on the LCC Control Board to the positions corresponding to the paper size as

detailed below.

SW1

ON

OFF

1234

PWB-A

4659M508AA

SW1 1 2 3 4

B5 Crosswise OFF ON OFF OFF

A4 Crosswise ON OFF OFF OFF

Letter Crosswise OFF OFF OFF OFF

M-13

Page 18

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-11. Lifting Mechanism

• The lifting mechanism controls the ascent motion of Lift 1 and Lift 2 using the LCC Lift-Up

Motor that is turned forward or backward as necessary to ensure reliable paper take-up

and feeding.

One-Way Gears

Couplings

LCC Lift-Up Motor

EMOT

Lift 1

Lift 2

When LCC is Slid in:

4659M514AA

4659M010AA

LCC Set Sensor FRONT is blocked.

LCC Lift-Up Motor EMOT turns forward to raise Lift 1.

The paper stack causes the light blocking plate of the

Paper Take-Up Roll 1 Assy to block Lift-Up Sensor 1 LS1.

EMOT is deenergized and then energized to start turning

backward, thereby raising Lift 2.

The paper stack causes the light blocking plate of the

Paper Take-Up Roll 2 Assy to block Lift-Up Sensor 2 LS2.

EMOT is deenergized.

M-14

Page 19

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

During a Copy Cycle:

Paper is consumed as copy cycles are run.

The Paper Take-Up Roll gradually lowers,

unblocking the Lift-Up Sensor.

EMOT is energized and the Lift is raised. This lifts

4659M515AA

4659M514AA

the paper stack to block the Lift-Up Sensor.

(1) Lift 1 and 2 Ascent Conditions

• The LCC is slid into position.

• The Lift-Up Sensor is unblocked while a paper take-up sequence is being carried out

with paper present on the Lift.

(2) Lift 1 and 2 Stop Conditions

• The Lift-Up Sensor is bl ocked.

• The Lift-Up Sensor is blocked while the paper stack top level position is being corrected.

When LCC Slid in:

ON

OFF

H

L

Forward

Rotation

H

L

H

L

Backward

Rotation

4659M523CA

LCC Set Sensor

FRONT

LCC Lift-Up Motor

EMOT

Lift-Up Sensor 1

LS1

Lift-Up Sensor 2

LS2

(3) LCC Lift-Up Motor EMOT Control

• Rotation of the LCC Lift-Up Motor is controlled by the signals output from pins 1 and 2 of

CN5A on the LCC Control Board.

EMOT Lift 1 Lift 2

Energized

(Forward Rotation)

Energized

(Backward Rotation)

Ascent Stop H L

Stop Ascent L H

CN5A

12

Deenergized Stop Stop L L

M-15

Page 20

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

(4) Descent Motion

• When the LCC is slid out the copier, Lift 1 and 2 are lowered. To absorb shocks that

would otherwise be applied during the descent motion, springs are loaded in the rear

side of the LCC.

Lift 1

Lift 2

Springs

4659M517AA

6-12. Paper Near Empty Detection

• The Paper-Near-Empty Sensor detects a paper-near-empty condition in the drawer.

• A given number of sheets of paper has been determined as the basis for detection of a

paper-near-empty condition.

Predetermined No. of Sheets (Paper Level)

Paper-Near-Empty Detected 100 ± 50 sheets

Paper Near Empty Sensor 1/2

RS1/RS2

4659M518AA

M-16

Page 21

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-13. Paper Empty Detection

• The Paper Empty Sensor detects a paper-empty condition in the drawer.

• When Paper is Loaded

Light emitted by the LED of Paper Empty Sensor 1/2

is reflected off the paper stack, causing the copier to

determine that there is paper loaded in the LCC.

4659M519AA

• When Paper is not Loaded

Light emitted by the LED of Paper Empty Sensor 1/2

is not reflected, causing the copier to determine that

there is no paper loaded in the LCC.

4659M520AA

6-14. Panel Display

• Paper-near-empty and paper-empty conditions are detected in Lift 1 and Lift 2.

• The paper-near-empty and paper-empty conditions are displayed on the Touch Panel.

Lift 1

Paper-near-empty Paper-empty

Lift 2

❍

: Paper-near-empty display ●: Paper-empty display

Paper-near-empty

Paper-empty

❍❍

❍●

M-17

Page 22

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

6-15. Paper Dehumidifying Heaters (Option)

• The Paper Dehumidifying Heater prevents an image transfer failure from occurring,

caused by paper that gets damp under changing environmental conditions (temperature

and humidity).

Condition

Power cord plugged in ON

Power Switch OFF ON

Sleep ON

Copy cycle OFF

Predrive

(Imaging Unit Motor energized)

Paper Dehumidifying Heater

(Heater Switch ON)

OFF

M-18

Page 23

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

DIS/REASSEMBLY,

ADJUSTMENT

Page 24

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1. DISASSEMBLY

1-1. Maintenance Schedule

• To ensure good copies and an extended service life of the this LCC, it is recommended

that the maintenance jobs described in this schedule be carried out.

Maintenance

PM Parts

Paper Take-Up

Roll 1

Paper Take-Up

Roll 2

Feed Roll

Separator Roll

Vertical

Transport

Roller

Vertical

Transport Roll

Roll with torque

limiter

Torque Limiter

Assy

K=1,000 sheets

✽

The above maintenance schedule is to be based on the value of Counter/Life.

✽

Cleaning (indicated by “❍” in the above schedule) should be performed when a paper

transport failure occurs.

✽

The above information is subject to change without notice.

✽

The Feed Roll, Separator Roll, and Torque Limiter Assy should be replaced at the same

time.

Schedule Cycle (K)

Clean Replace

❍

❍

❍

❍

❍

❍

❍

– 200 – 112E-4110 1

300

300 112E51 230 2

200 112E51 240 1

200 112E51 250 1

––1

––2

––1

Tools

Used for

Cleaning

Cloth,

alcohol

Parts No. QTY

112E51220 1

Counter/

Life

LCC

Parts 1

LCC

Parts 2

Reference

Page

☞

☞

☞

☞

☞

☞

☞

☞

D-4

D-4

D-6

D-6

D-7

D-7

D-7

D-6

D-1

Page 25

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-2. Removal of Exterior Parts

1

2

4659D001AA 4496D002AA

No. Part Name Removal Steps

1 Left Cover Remove tw o screws and take off the cover.

2 Front Cover

3 Right Side Door Open this door and take it off.

4 Maintenance Cover Remove one screw and take off the cover.

5 Rear Cover

6 Right Cover Remove two screws and take off the cover.

Slide out the drawer, remove three screws, and take off the

cover.

After the Maintenance Cover has been removed, remove four

screws and take off the cover.

3

6

4

5

D-2

Page 26

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-3. Removal of the Paper Take-Up Unit

1. Slide out the LCC.

2. Remove two screws and the Left Cover.

3. Remove one screw and the Maintenance Cover.

4659D003AA

4. Remove four screws and the Rear Cover.

5. Unplug three connectors and remove the harness

from four cord clamps.

4659D004AA

6. Remove two screws and the Right Cover.

4659D011AA

4496D006AB

7. Open the Right Side Door.

8. Remove two screws and the Paper Take-Up Unit.

D-3

Page 27

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-4. Removal of the Paper Take-Up Rolls

1. Remove the Paper Take-Up Unit.

2. Unplug one connector of Lift-Up Sensor 1 and one

connector of Paper Take-Up Clutch 1 on the Paper

Take-Up Roll 1 Assy.

3. Unhook two springs.

4496D007AC

4. Remove one screw and, while taking off the timing

belt in the direction of the clutch, remove the Paper

Take-Up Roll 1 Assy.

4496D008AC

NOTE

• When reinstalling the Paper Take-Up Roll 1 Assy,

make sure that the edges of the assy are positioned

correctly as illustrated.

4659D005AA

4496D009AD

4659D006AA

5. Unplug one connector of Lift-Up Sensor 2 and one

connector of Paper Take-Up Clutch 2 on the Paper

Take-Up Roll 2 Assy.

6. Unhook two springs.

7. Remove one screw and the Paper Take-Up Roll 2

Assy.

D-4

Page 28

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

NOTE

• When reinstalling the Paper Take-Up Roll 2 Assy,

make sure that the edges of the assy are positioned

correctly as illustrated.

4659D007AA

NOTE

• When reinstalling each Paper Take-Up Roll assy,

make sure that the Paper Take-Up Clutch is positioned correctly as illustrated.

4496D012AB

8. Snap off one C-clip from the Paper Take-Up Roll 1

shaft.

9. Remove the shaft and Paper Take-Up Roll 1.

4659D008AA

4659D009AA

4659D010AB

NOTE

• When reinstalling Paper Take-Up Roll 1, make sure

that the C-clip faces in the direction shown.

10. Snap off two C-clips and take off Paper Take-Up

Roll 2.

D-5

Page 29

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-5. Removal of the Feed Roll, Separator Roll and Torque Limiter

Assy

1. Open the Right Side Door.

2. Snap off one C-clip from the Separator Roll shaft

and remove the Separator Roll and Torque Limiter

Assy.

4496D023AA

3. Snap off one C-clip from the Feed Roll shaft and

remove the Feed Roll.

4496D016AB

1-6. Cleaning of the Paper Take-Up Roll

1. Remove the Paper Take-Up Unit.

2. Using a soft cloth dampened with alcohol, wipe the

surface of Paper Take-Up Roll 1/2.

4496D017AC

1-7. Cleaning of the Feed Roll and Separator Roll

1. Open the Right Side Door.

2. Using a soft cloth dampened with alcohol, wipe the

surface of the Feed/Separator Roll.

4496D018AA

D-6

Page 30

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-8. Cleaning of the Vertical Transport Roller/Rolls

1. Remove the Paper Take-Up Unit.

2. Using a soft cloth dampened with alcohol, wipe the

surface of the Vertical Transport Roller/Rolls.

4659D501AA

1-9. Cleaning of the Roll with a Torque Limiter

1. Slide out the LCC.

2. Using a soft cloth dampened with alcohol, wipe the

surface of the roll with a torque limiter.

4496D022AA

D-7

Page 31

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

2. ADJUSTMENT

2-1. Reference Position Adjustment

1. Press the Utility key and touch “Meter Count.”

2. Press the following keys in this order to show the

Tech. Rep. mode screen: Stop → 0 → 0 → Stop →

0 → 1.

3. Touch “Machine Adjust.”

4658D507CA

4. Touch “PRT Area.”

4658D508CA

Feeding

Direction

5. Touch “Left Margin.”

4658D509CA

6. Touch “3rd.”

4659D503CA

7. Press the Start key to produce a test print.

8. Measure dimension A to determine if it falls within

A

the specified range.

✽

Specifications: 3.0 ± 1.0 mm

9. Using or key, input the difference

between the measured value of dimension A and

the specifications.

4658D505AA

10. Produce another test print and make a check

again.

D-8

Page 32

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

MISFEED/MALFUNCTION

DETECTION

Page 33

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1. MISFEED DETECTION

1-1. Location of Misfeed Detecting Sensors

LCC Paper Take-Up Sensor

PPS0

Paper Empty Sensor 1

PPS1

Paper Take-Up Sensor of the 2nd Drawer

PC101

Registration Sensor RSEN

Paper Standby Position

Sensor S1

T-1

4659T501AA

Page 34

FrameMaker Ver.5.5(PC) DB-431 OPTION FOR 7915/7920

01.02.09

1-2. Misfeed Detection Timing

• The following lists the types of misfeed detection and detection timings for different misfeed locations.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the paper detected by the sensor.

Type Detection Start Detection

Paper left

Lift 1 paper take-up

failure

Lift 2 paper take-up

failure

Registration Sensor’s

failure to detect leading

edge

Registration Sensor’s

failure to detect trailing

edge

Paper take-up failure

Misfeed in the vertical

transport section

Misfeed caused by a size

error

✽

1: Only when a misfeed condition is reset (when power is turned ON, LCC Drawer is slid

into position, and the door is closed)

Power Switch ON

Misfeed reset

Paper Take-Up Clutch 1 ON

Paper Take-Up Clutch 2 ON

Paper Take-Up Clutch 1 ON

Separator Clutch ON Registration Sensor (L)

Registration Clutch ON Registration Sensor (T)

LCC Paper Take-Up Request

signal

Registration Clutch energized

Paper Take-Up Sensor of the

2nd Drawer (L)

Registration Sensor ON

Paper Standby Position

Sensor (L)

Paper Empty Sensor 1 (L)

LCC Paper Take-Up Sensor

(L) ✽1

Paper Standby Position

Sensor (L)

Registration Clutch energized

Paper Take-Up Sensor of the

2nd Drawer (L)

Paper Take-Up Sensor of the

2nd Drawer (T)

2. MALFUNCTION DETECTION

Code Description Detection Timing

C0990 LCC Lift-Up Motor

EMOT failure to turn

C0991 Lift 1 ascent motion

failure

C0995 LCC Transport Motor

HMOT failure to turn

C0999 Lift 2 ascent motion

failure

The overcurrent detection circuit detects an overcurrent

condition that lasts for a given period of time while EMOT

remains energized.

Lift-Up Sensor 1 LS1 is not blocked (H) within a given

period of time after EMOT has been energized (Lift 1 has

started moving up).

The HMOT Lock signal is not input for a given period of

time.

Lift-Up Sensor 2 LS2 is not blocked (H) within a given

period of time after EMOT has been energized (Lift 2 has

started moving up).

T-2

Loading...

Loading...