Page 1

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

DIS/REASSEMBLY,

ADJUSTMENT

18605

Page 2

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

CONTENTS

1. SERVICE INSTRUCTIONS ............................................................................. D-1

1-1. IDENTIFICATION OF FUSES ............................................... ............. .....D-1

1-2. PARTS WHICH MUST NOT BE TOUCHED ...........................................D-2

(1) Red Painted Screws ............................................ ......................... ...D-2

(2) Variable Resistors on Board ....... ............ .......................... ...............D-2

2. DISASSEMBLY/REASSEMBLY ......................................................................D-3

2-1. DOORS, COVERS, AND EXTERIOR PARTS:

IDENTIFICATION AND REMOVAL PROCEDURES ...............................D-3

2-2. REMOVAL OF CIRCUIT BOARDS AND OTHER

ELECTRICAL COMPONENTS ................................................................D-5

(1) Removal of the CCD Unit ................................................................ D-6

(2) Removal of the Image Processing Board ........................................D-6

(3) Removal of the IR PRIF Board ........................................................D-9

(4) Removal of the Scanner Motor Drive Board ....................................D-10

(5) Removal of the Flat Cable ............................................................... D-10

(6) Removal of DC Power Supply 2 ......................................................D-11

(7) Removal of the Paper Size Detecting Board ...................................D-13

(8) Removal of the LED Board and ATDC Sensors Y, M, and C ..........D-13

2-3. MAINTENANCE SCHEDULE .................................................................. D-16

2-4. Guidelines for Life Specifications Values by Unit ....................................D-18

2-5. Removal of Units .....................................................................................D-20

(1) Removal of the Toner Hopper Unit ..................................................D-21

(2) Removal of the LED Unit .................................................................D-22

2-6. Cleaning and Disassembly of the IR Unit ................................................D-25

(1) Cleaning of the Scanner Rails ........................................................ .D-25

(2) Cleaning of the Mirrors (1st/2nd/3rd) ...............................................D-25

(3) Cleaning of the Lens ........................... .... .. ....... .. .. .... .. .. ....... .. .... .. .. ...D-25

(4) Cleaning of the Original Glass ................ .......................... ...............D-26

(5) Removal of the Original Glass Cooling Fan Motor ......................... .D-26

(6) Removal of the Scanner Motor ........................................................D-26

(7) Removal of IR Cooling Fan Motor 2 ................................................D-27

(8) Removal of IR Cooling Fan Motor 1 ................................................D-28

(9) Removal of the Scanner Home Sensor ...........................................D-28

(10) Removal of the Or igin a l Co ver Detecting Sensor ............................D-29

(11) Removal of Original Size Detecting Sensors FD1 and FD2 ............D-29

(12) Removal of Origina l S i ze De tecting Sensor CD1 ............................D-30

(13) Removal of the Size Reset Switch ..................................................D-30

(14) Removal of the Scanner Assy .........................................................D-30

(15) Removal of the Exposure Lamp ......................................................D-31

(16) Removal of the Temperature Fuse .................................................. D-31

(17) Removal of the Scanner Drive Cables ............................................D-32

(18) Winding of the Scanner Drive Cables ..............................................D-33

2-7. CLEANING AND DISASSEMBLY OF THE ENGINE PARTS ................. D-38

(1) Cleaning of the Paper Take-Up Roll ................................................D-38

(2) Cleaning of the Paper Separator Roll ..............................................D-38

(3) Cleaning of the Synchroni zin g Ro lle rs ................... ..........................D-38

i

Page 3

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(4) Cleaning of the Paper Dust Remover ..............................................D-39

(5) Cleaning of the Transfer Belt Un it ............................................ .......D-39

(6) Cleaning of the LED ................................................ ........................D-40

(7) Cleaning of the Area around the Waste Toner Collecting Port ........D-40

(8) Cleaning of the Fusing Entrance Guide Plate .................................D-41

(9) Removal of the Imaging Unit Motor C/M/Y/Bk .................................D-41

(10) Removal of the Main Motor .............................................................D-43

(11) Removal of the Ozone Ventilation Fan Motor ..................................D-43

(12) Removal of the Fusing Drive Motor .................................................D-43

(13) Removal of the Fusing Pressure/Retraction Motor ..........................D-44

(14) Removal of the 1st Image Transfer Pressure/Retraction Motor ......D-45

(15) Removal of Toner Replenishing Motor C/Bk ...................................D-46

(16) Removal of Toner Replenishing Motor Y/M .....................................D-46

(17) Removal of the Cleaning Web Drive Motor .....................................D-46

(18) Removal of the Power Supply Cooling Fan Motor ...........................D-47

(19) Removal of Fusing Cooling Fan Motor 2 ......................................... D-48

(20) Removal of Fusing Cooling Fan Motor 1 ......................................... D-48

(21) Removal of the 2nd Image Transfer Pressure/Retraction Clutch ....D-50

(22) Remov a l o f the Synchronizing Roller Clutch .... ................. .. ............D-50

(23) Removal of the Manual Feed Paper Take-Up Clutch ......................D-51

(24) Removal of the Paper Take-Up Clutch ............................................D-52

(25) Removal of AIDC/Registration Sensor 1/2 ......................................D-53

(26) Removal of the Temperature/Humidity Sensor ...............................D-54

(27) Removal of the Toner Supply Door Sensor .....................................D-54

(28) Removal of the Manual Feed Paper Take-Up Sensor .....................D-54

(29) Removal of the 1st Image Transfer Retraction Position Sensor ......D-55

(30) Removal of the Double Feed Sensor ..............................................D-55

(31) Removal of the Drawer Set Sensor and Drawer Paper

Near-Empty Sensor ................ ......................... ............ ....................D-56

(32) Removal of the Left Door Switch ..................................................... D-57

(33) Removal of the Righ t Do o r Switch ...................................................D-57

(34) Removal of the Fr o n t Do o r Switch ............................. ......................D-58

(35) Removal of the Fusing Roller Rotation Detecting Sensor ...............D-58

(36) Removal of the Fusing Retraction Position Sensor .........................D -58

(37) Removal of the Exit Sensor .............................................................D-58

(38) Removal of the 2nd Image Transfer Pressure Position Sensor ......D-59

(39) Removal of the Synchronizing Roller Sensor ..................................D-59

(40) Removal of the OHP Detecting Sensor ...........................................D-59

(41) Removal of the CD Paper Size Detecting Sensor Assy ..................D-60

(42) Removal of the Paper Take-Up Roll ................................................D-60

(43) Removal of the Paper Separator Roll ..............................................D-61

(44) Removal of High Voltage Unit 1 ...................................................... D -61

(45) Removal of High Voltage Unit 2/3 ...................................................D-61

(46) Removal of DC Power Supply 1 ......................................................D-61

(47) Removal of the Charge Neutralizing Relay ..................................... D-62

(48) Removal of the Waste Toner Full Detecting Sensor .......................D-62

(49) Removal of the Waste Toner Bottle Set Sensor ..............................D-62

ii

Page 4

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(50) Removal of the Toner Empty Switch (Y/M/C/Bk) ............. ................D-63

3. ADJUSTMENTS ..............................................................................................D-64

3-1. ADJUSTMENT JIGS AND TOOLS USED (SPECIAL TOOLS) ...............D-64

3-2. OTHER TOOLS USED (ACCESSORY PARTS OF MACHINE) .............D-64

3-3. ADJUSTMENT REQUIREMENTS LIST .................................................. D-65

3-4. ADJUSTMENT OF SWITCHES ...............................................................D-66

(1) Microswitches .................................................................................. D-66

3-5. ADJUSTMENT OF BELT TENSION ........................................................ D-67

(1) Adjustment of the Scanner Motor Timing Belt .................................D-67

3-6. ELECTRICAL/IMAGE ADJUSTMENT .............................................. .......D-68

(1) Accessing the Tech. Rep. Mode ......................................................D-68

(2) Producing a Test Print .....................................................................D-68

(3) Touch Panel Adj. ......................................................... ....... .. .... .. .. ...D-69

(4) Top Margin ......................................................................................D-70

(5) Left Margin ............................................................................ ...........D-72

(6) Dup. Left Margin ..............................................................................D-73

(7) Paper Loop ......................................................................................D-74

(8) Color Shift Correctio n ............. ............ ............. ......................... .......D-75

(9) Fuser Nip ......................... ...................................... ..........................D-78

(10) Fuser Temp. .......... ............ .......................... ......................... ...........D-80

(11) Fuser Speed ....................................................................................D-81

(12) Left Image ..................................................................................... .. .D-82

(13) Top Image .......................................................................................D-83

(14) CD-Mag. ..........................................................................................D-84

(15) FD-Mag. ........................................................................................... D-85

(16) Org. Detect Sensor ..........................................................................D-86

(17) Gradation Adjust ..............................................................................D-87

(18) PRT Max Density ........................................... ..................................D-88

(19) PRT Highlight .................... .......................... ......................... ...........D-88

(20) Background Voltage Margin ............................................................D-89

4. OTHER ADJUSTMENTS .......................... ......................... ............ ..................D-90

4-1. Adjustment of the Position of the Scanner and 2nd/3rd

Mirrors Carriage .......................................................................................D-90

(1) Adjustment of the 2nd/3rd Mirrors Carriage Assy

for Parallel Alignment ......................................................................D-91

5. MISCELLANEOUS ..........................................................................................D-93

5-1. INSTALLATION OF THE MECHANICAL COUNTER (OPTION) ............ D-93

5-2. MO U N T IN G O F THE ORIGINAL SIZE DETECTING SENSORS

(OPTION) ................................................................................................. D-94

5-3. FLASH MEMORY ....................................................................................D-95

5-4. REMOUNTING RAM IC (IC5) ..................................................................D-97

iii

Page 5

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

1. SERVICE INSTRUCTIONS

1-1. IDENTIFICATION OF FUSES

DC Power Supply 2 PU2

250 V 3 A (F1)

4004D100AB

DC Power Supply 1 PU1

125 V 15 A (F1)

120 V 10 A (F2)

125 V 15 A (F3)

125 V 15 A (F4)

4004D101AB

D-1

Page 6

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

1-2. PARTS WHICH MUST NOT BE TOUCHED

(1) Red Painted Screws

Purpose of Application of Red Paint

• Red painted screws show that the assembly or unit secured can only be adjusted or set

at the factory and should not be adjusted, set, or removed in the field.

• Note that when two or more screws are used on the part in questions, only one representative screw may be marked with red paint.

(2) Variable Resistors on Board

Do not turn the variable resistors on boards for which no adjusting instructions are given in

ADJUSTMENT.

D-2

Page 7

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

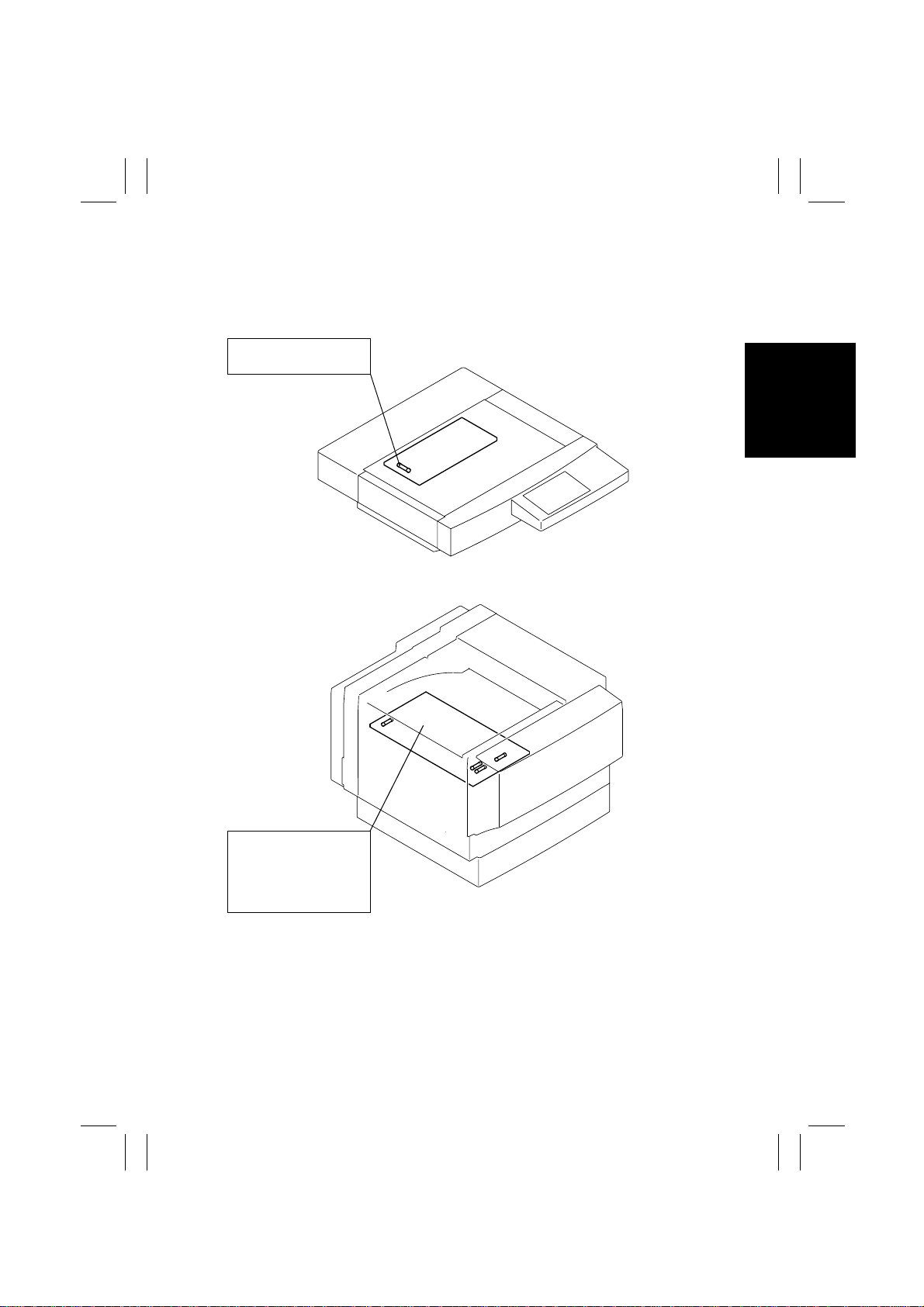

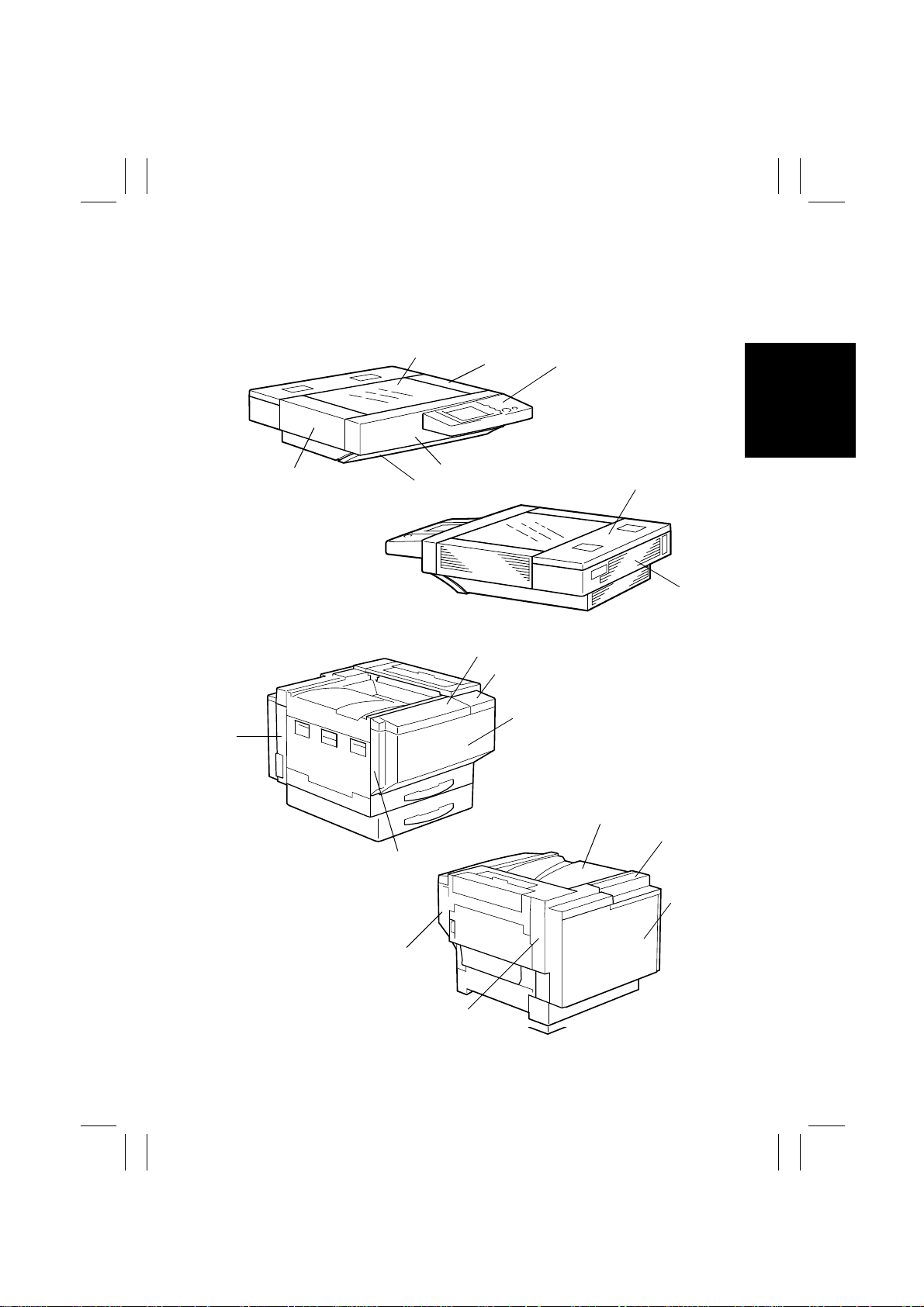

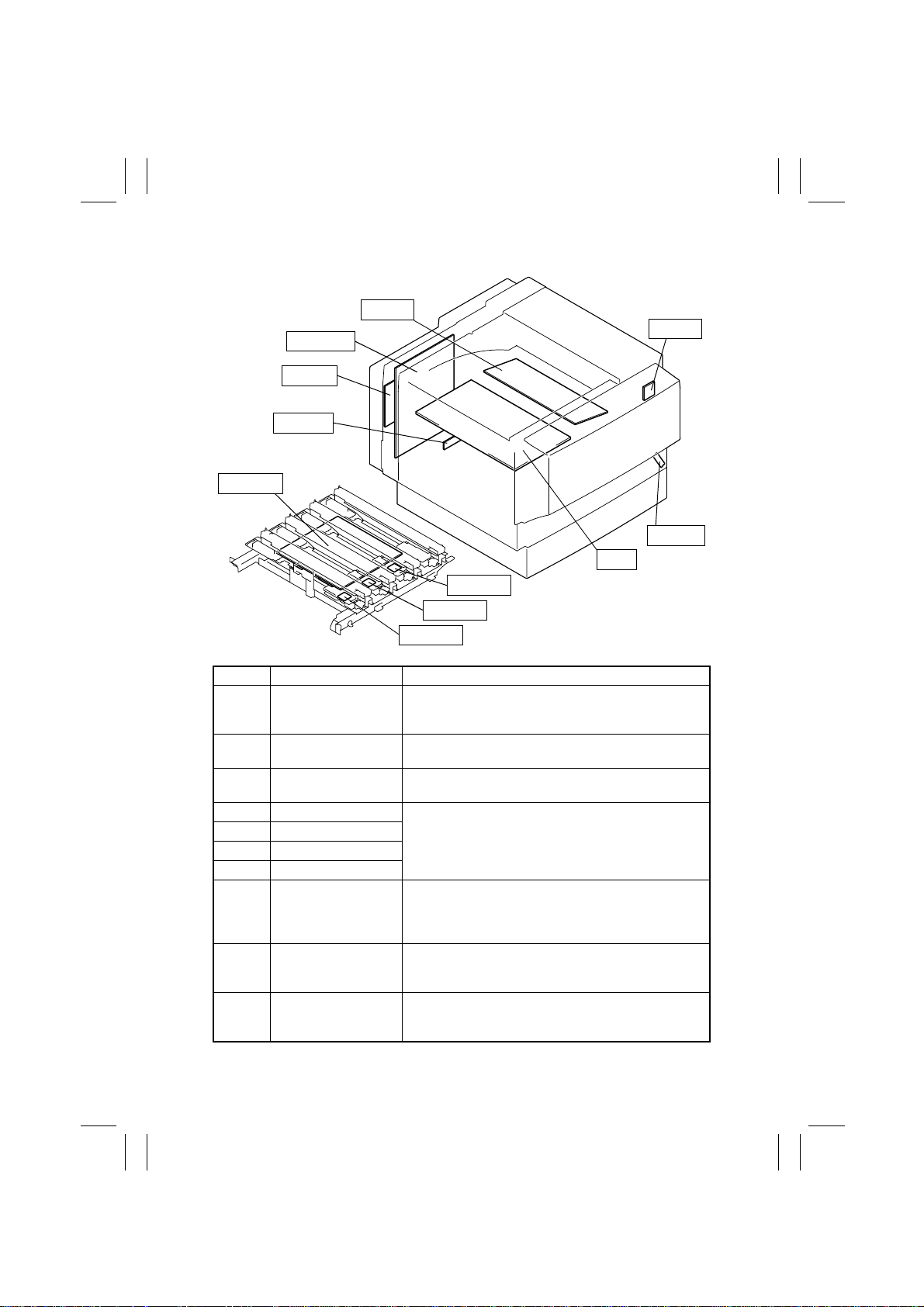

2. DISASSEMBLY/REASSEMBLY

2-1. DOORS, COVERS, AND EXTERIOR PARTS:

IDENTIFICATION AND REMOVAL PROCEDURES

IR

Printer

1

1

8

5

2

4

2

3

3

4004D102AA

6

7

4004D103AA

4

4004D104AA

6

7

5

8

10

9

4004D105AA

D-3

Page 8

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

IR

No. Name Removal Procedure

1 Original Glass Remove the IR Right Cover. → Remove the IR Rear Cover. →

2 IR Right Cover Remove two screws and the IR Right Cover.

3 Control Panel Remove two covers below the Control Panel. → Remove two

4 IR Front Cover Remove the Control Panel. → Remove one screw and two Control

5 IR Lower Front

Cover

6 IR Rear Upper

Cover

7 IR Rear Cover Disconnect the power cable and IR hookup cable. → Remove four

8 IR Left Cover Remove the IR Front Cover. → Remove the IR Rear Upper Cover. →

Remove one screw and the Original Glass fixing brackets (front and

rear). → Remove the Original Glass.

screws, unplug one connector, and remove the Control Panel.

Panel fixing brackets. → Remove one screw and the Scanner Home

Sensor Assy. → Remove the two upper joints from the Copier Stand.

→

Loosen two screws and remove the IR Front Cover. → Loosen

two lower screws and remove two upper screws and the IR Front

Cover.

Remove the Control Panel. → Demount the IR Unit from the Copier

Stand. → Remove two screws and the IR Lower Front Cover.

Remove the Original Cover. → Remove three screws and the Rear

Upper Cover.

screws and the IR Rear Cover.

Remove three screws and the IR Left Cover.

Printer

No. Name Removal Procedure

1 Rear Left

Cover

2 Hopper Door Open the Right Door. → Open the Upper Right Door. → Remove the

3 Panel Door Open the Front Door. → Open the Hopper Door. → Remove one

4 Front Door Open the Front Door. → Lift the Front Door off the copier.

5 Hopper Left

Cover

6 Paper Output

Cover

7 Rear Upper

Cover

8 Rear Cover Remove seven screws and the Rear Cover.

9 Rear Right

Cover

10 Front Right

Cover

Open the Left Door. → Remove the Waste Toner Bottle. → Remove

the Ozone Filter. → Remove two screws and the Rear Left Cover.

actuator of the Toner Supply Door Sensor. → Snap off one retaining

ring E type from the left hinge of the Hopper Door and slide the Hopper Door in closed position to the right to take it off.

screw and the Panel Door.

Open the Front Door. → Open the Hopper Door. → Remove one

screw and lift the Hopper Left Cover upward to take it off.

Open the Right Door. → Open the Upper Right Door. → Remove two

screws and the Paper Output Cover.

Remove the Paper Output Cover. → Remove the Rear Cover. →

Remove three screws and the Rear Upper Cover.

Open the Right Door. → Remove one screw and the Rear Right

Cover.

Remove the Panel Door. → Remove one screw and the Front Right

Cover.

D-4

Page 9

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

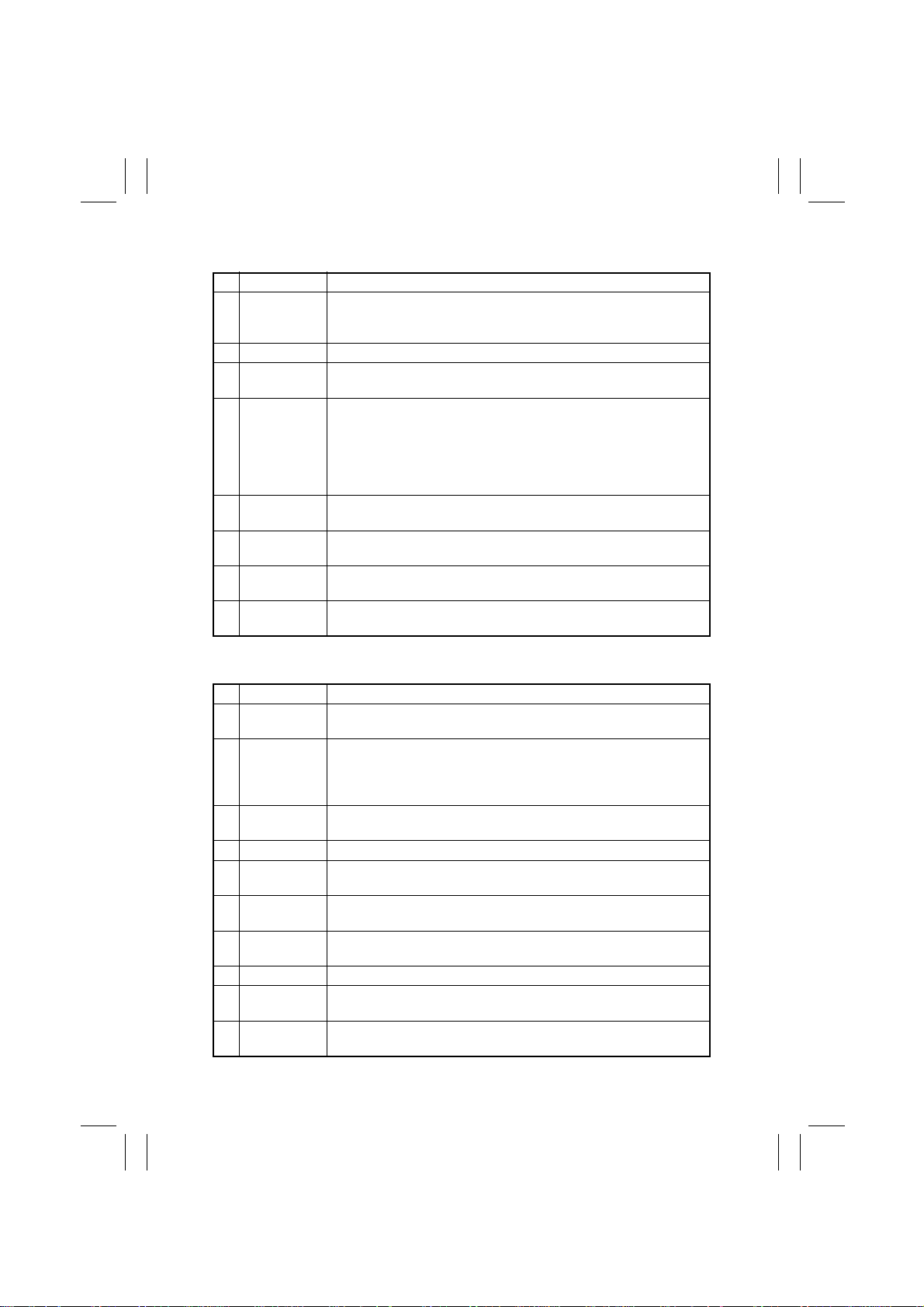

2-2. REMOVAL OF CIRCUIT BOARDS AND OTHER

ELECTRICAL COMPONENTS

• When removing a circuit board or other electrical component, refer to “Handling of

PWBs” and follow the corresponding removal procedures.

• The removal procedures given in the following omit the removal of connectors and

screws securing the circuit board support or circuit board.

• Where it is absolutely necessary to touch the ICs and other electrical components on the

board, be sure to ground your body.

IR

PWB-IC

PWB-Z

PWB-D

Symbol Name Removal Procedures

PWB-A CCD Sensor Board

PWB-C

PWB-D IR PRIF Board

PWB-IC

PWB-Z Flat Cable

PU2 DC Power Supply 2

Image Processing

Board

Scanner Motor Drive

Board

☞

☞

☞

☞

☞

☞

D-6

D-6

D-9

D-10

D-10

D-11

PU2

PWB-A

PWB-C

4004D106AC

D-5

Page 10

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

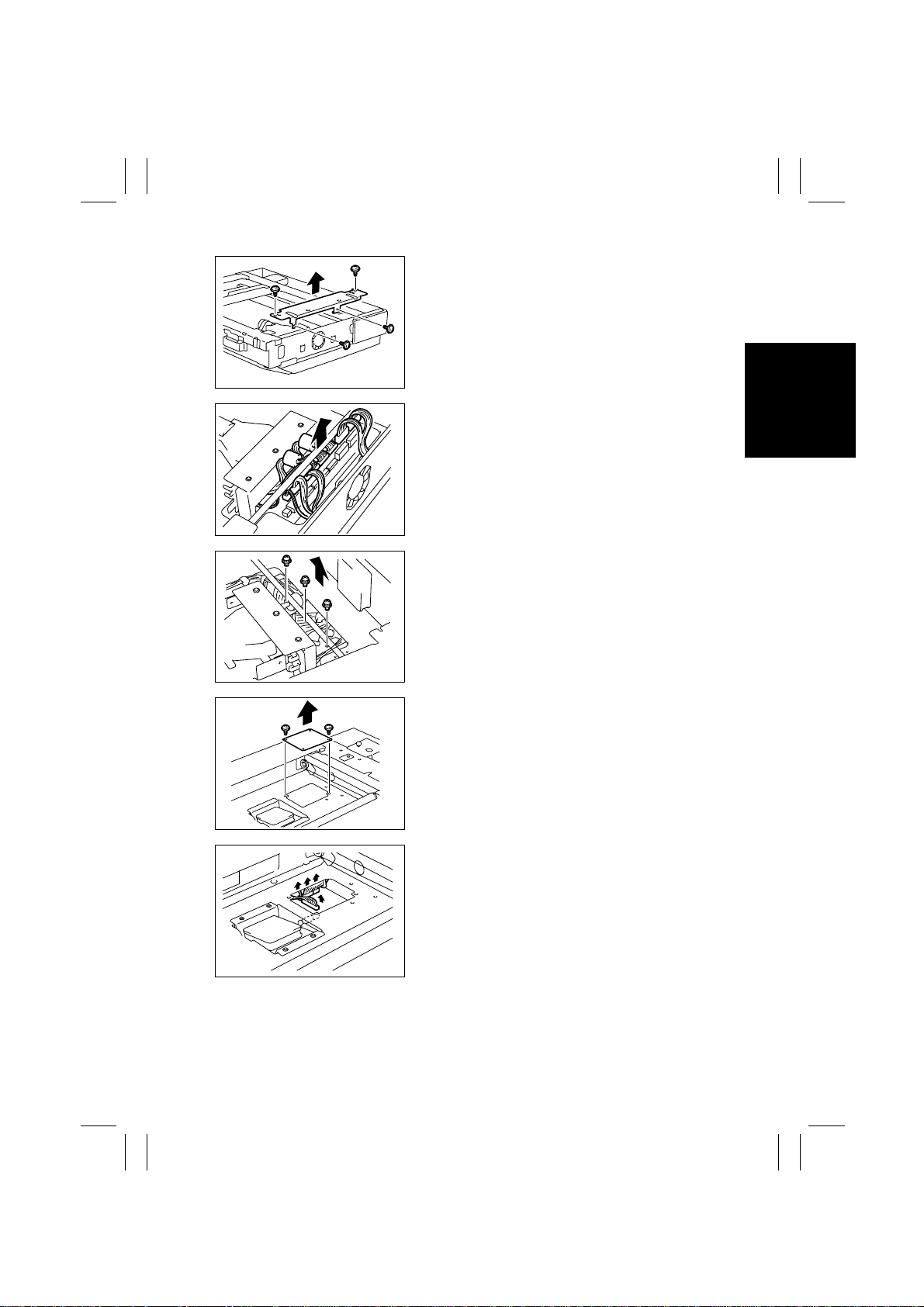

(1) Removal of the CCD Unit

1. Remove the IR Right Cover and Original Glass.

2. Remove eight screws and the optical cover.

4004D001AC

3. Remove three screws and the imaging processing lid on the right inside the IR.

4004D002AB

4. Unplug three connectors.

5. Remove three screws and the CCD Unit.

4004D003AA

(2) Removal of the Image Processing Board

1. Remove the IR Right Cover, IR Front Cover, IR

Lower Front Cover, and IR Rear Upper Cover.

2. Remove the Original Glass.

3. Remove eight screws and the optical cover.

4004D001AC

4. Remove three screws and the imaging processing lid on the right inside the IR.

4004D002AB

D-6

Page 11

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

5. Remove four screws and the metal bracket on

the upper right of the IR.

4004D004AA

6. Unplug eight connectors on the Image Processing Board.

4004D005AA

7. Remove three screws that secure the Image Processing Unit on the right.

4004D006AA

4004D007AA

4004D008AA

8. Remove two screws and the image processing lid

on the left inside the IR.

9. Unplug four connectors on the Image Processing

Board.

D-7

Page 12

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

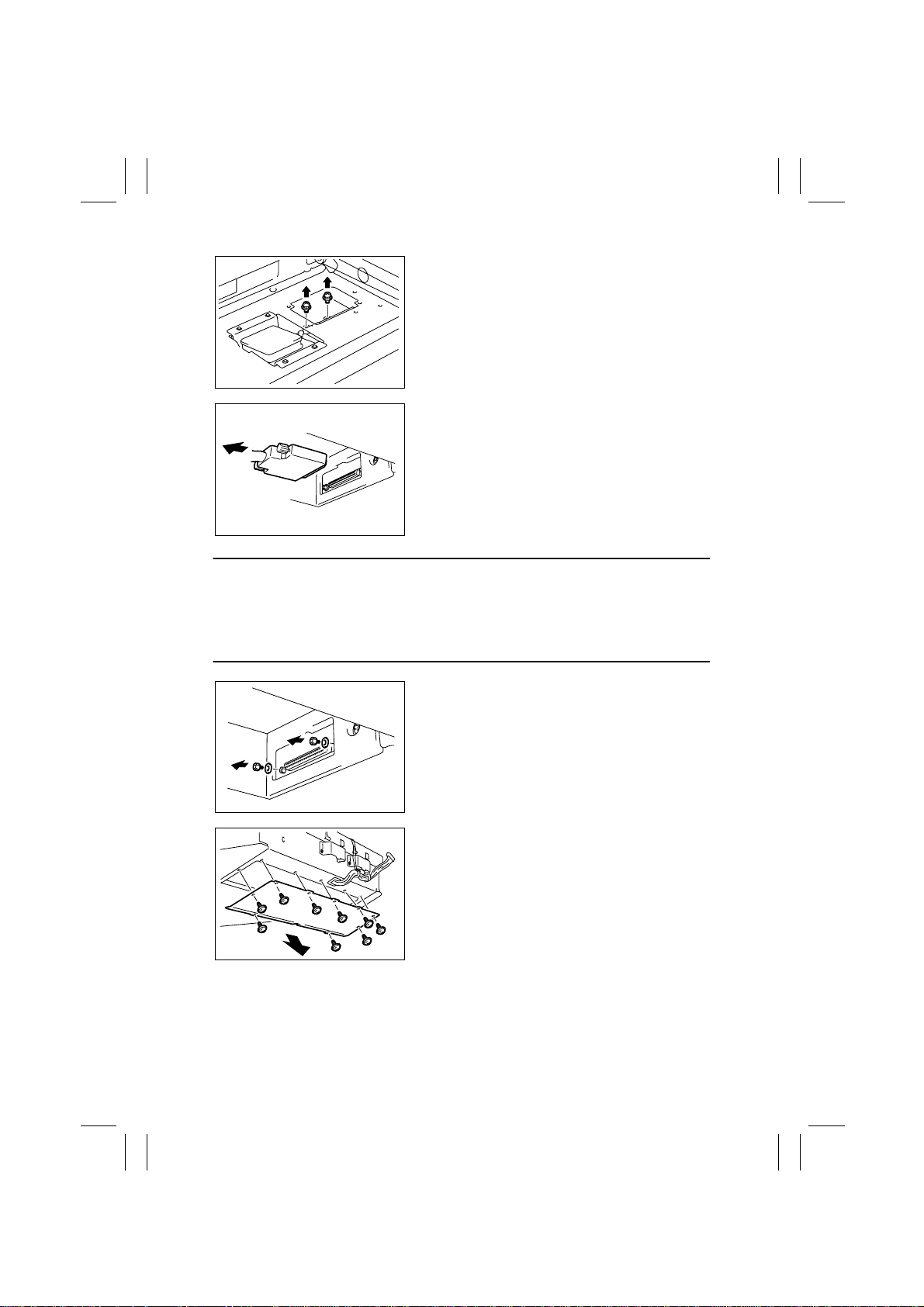

10. Remove two screws that secure the Image Processing Unit on the left.

4004D009AA

11. Remove the IR hookup cable.

4004D010AA

Precautions for Removal/Reinstallation of the IR Hookup Cable

• Be sure to hold onto the connector of the cable when removing or reinstalling the cable.

NEVER pull on the cable.

• At reinstallation, make sure that the connector is not tilt.

• When securing the connector, use a flat-blade screwdriver and tighten the connector

firmly.

4004D011AA

4004D012AC

12. Remove two screws and two washers.

13. Remove nine screws and the Image Processing

Unit protective guide.

D-8

Page 13

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

14. Pull out the Image Processing Unit.

4004D013AA

15. Remove 11 screws and the Image Processing

Board.

4004D014AA

NOTE

• At reinstallation, make sure that the Image Pro-

cessing Board is properly connected to the IR

PRIF Board.

4004D194AA

(3) Removal of the IR PRIF Board

4004D195AA

4004D196AA

1. Pull out the Image Processing Board Unit.

☞

D-6 (steps 1 through 14)

2. Remove five screws and the IR PRIF Board.

NOTE

• At reinstallation, make sure that the IR PRIF Board

is properly connected to the Image Processing

Board.

D-9

Page 14

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(4) Removal of the Scanner Motor Drive Board

1. Remove the IR Right Cover, IR Rear Right

Cover, IR Rear Upper Cover, and IR Rear Cover.

2. Remove two screws and the reinforcement

frame.

4004D015AA

3. Unplug three connectors.

4. Remove one screw. Then, remove the Scanner

Motor Drive Board from the PWB support.

4004D016AB

(5) Removal of the Flat Cable

1. Remove the IR Rear Upper Cover and IR Rear Cover.

2. Remove the Original Glass.

3. Remove the Scanner Assy.

4. Remove two screws, unplug one connector, and

remove the Scanner Assy Flat Cable.

4004D025AA

4004D018AB

5. Unplug one connector and remove the harness

from one wiring saddle.

6. Remove two screws and the Original Glass Cooling Fan Motor.

D-10

Page 15

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

7. Remove one screw, unplug one connector, and

remove the Flat Cable.

4004D019AA

(6) Removal of DC Power Supply 2

1. Remove the IR Rear Cover.

2. Remove two screws that secure the IR power

receptacle.

4004D020AB

3. Remove six screws, two harness holders, and

the DC Power Supply 2 cover.

4004D021AA

4004D022AA

4004D023AA

4. Remove one screw that secures DC Power Supply 2 in position.

5. Unplug six connectors.

6. Take off DC Power Supply 2 by sliding it to the

right.

D-11

Page 16

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

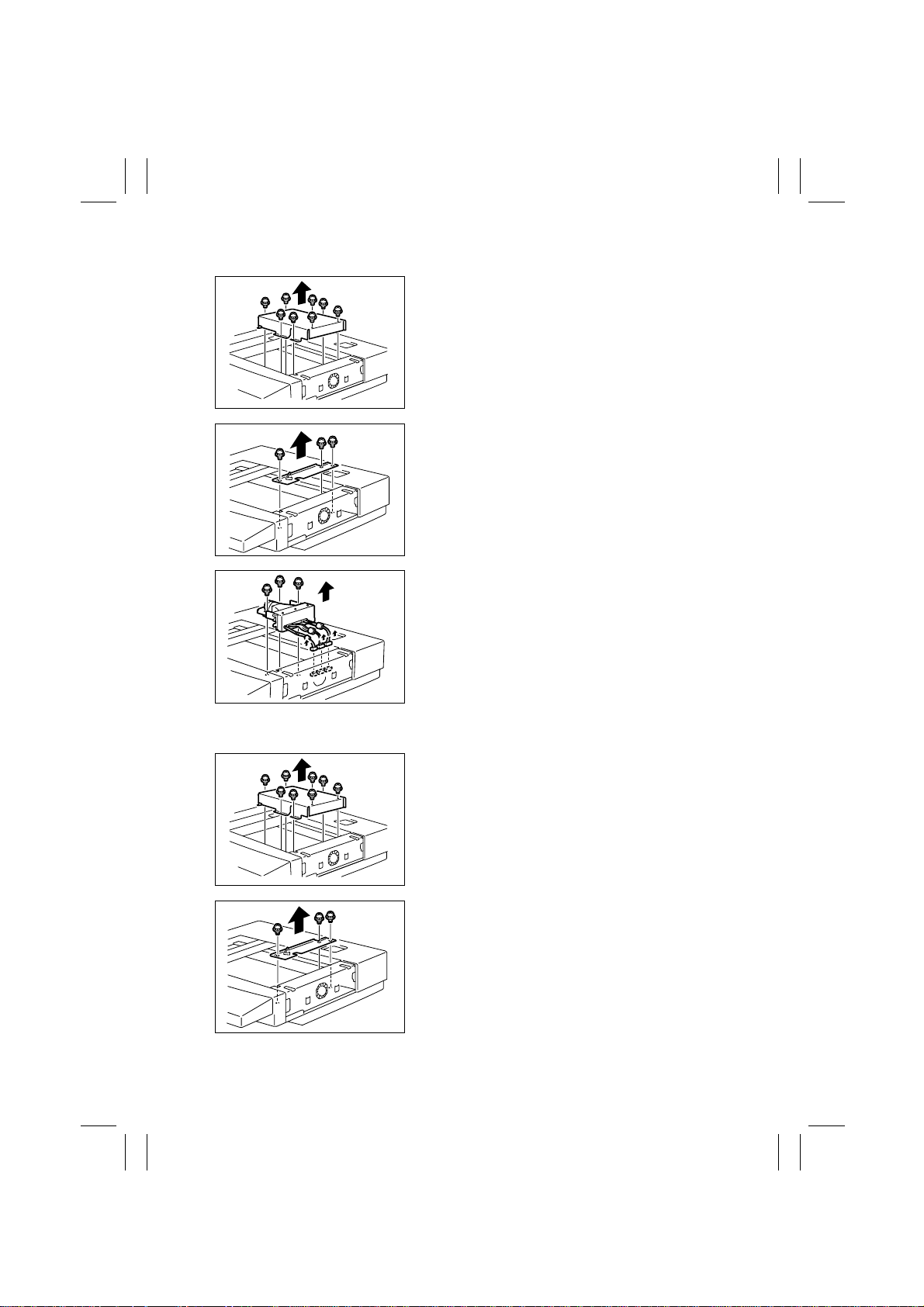

Printer

PWB-I

PWB-PIC

PWB-H

PWB-I1

PWB-LK

PWB-N3

PWB-N2

PWB-N1

PWB-T

PWB-S

PU1

4004D183AA

Symbol Name Removal Procedures

PWB-H MSC Board Remove the Rear Cover. → Remove the Rear Left Co ve r.

PWB-I Master Board Remove the Paper O utput Cover. → Unplug 21 connectors

PWB-I1 Paper Size Detecting

Board

PWB-LK LED Board

PWB-N1 ATDC Sensor Y

PWB-N2 ATDC Sensor M

PWB-N3 ATDC Sensor C

PWB-PIC PIC Board Remove the Rear Cover. → Remove the Rear Left Co ve r.

PWB-S Paper Type Detection

Board

PWB-T Tech. Rep. Setting

Switches Board

Remove the PWB Shield Cover. → Unplug two connec-

→

tors and remove four screws and th e MSC Board.

and remove six screws and the Master Board.

D-13

☞

D-13

☞

Remove the PWB Shield Cover. → Remove the MSC

→

Board. → Unplug two connectors and remove 12 screws

and the PIC Board.

Open the Front Door. → Remove one screw and the P aper

Type Detection Board cover. → Unplug one connector and

remove one screw and the Paper Type Detection Board.

Open the Front Door. → Remove the Right Front Cover. →

Unplug one connector and remov e one screw and the

Tech. Rep. Setting Switches Board.

D-12

Page 17

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

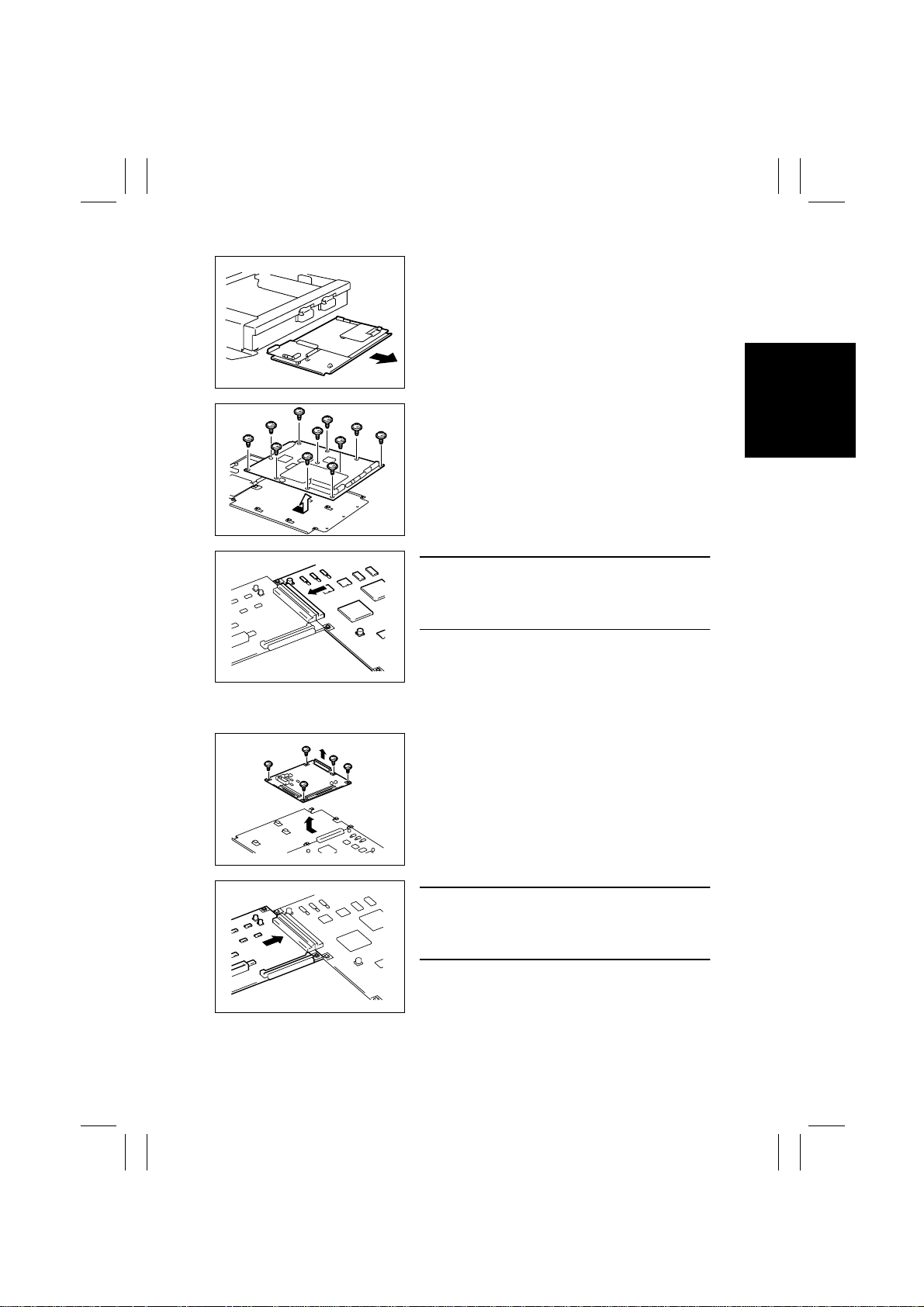

(7) Removal of the Paper Size Detecting Board

1. Remove High Voltage Unit 1 and 2.

☞

D-56 (steps 1 through 8)

2. Remove two screws, unplug one connector, and

remove the Paper Size Detecting Board.

4004D184AB

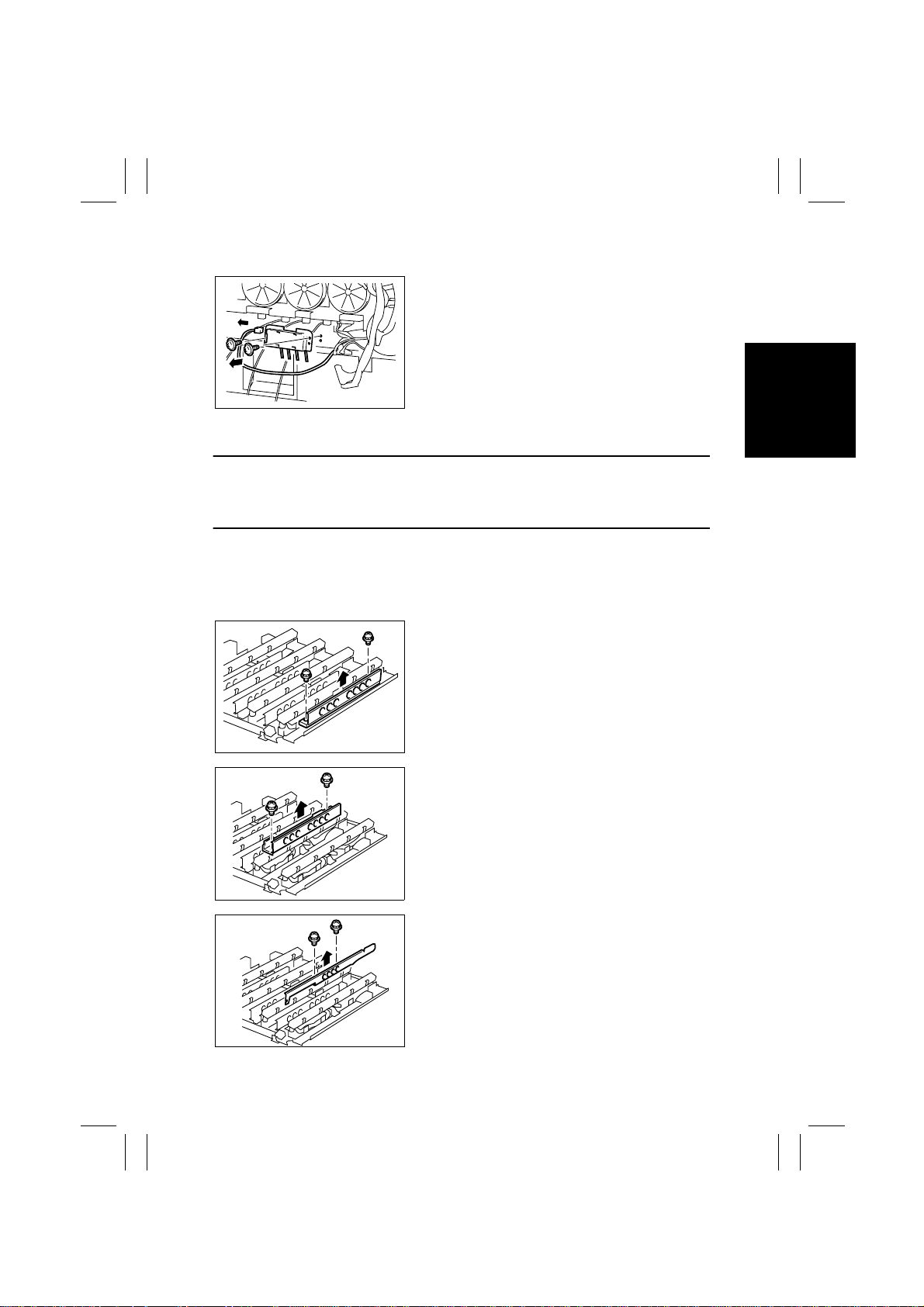

(8) Removal of the LED Board and ATDC Sensors Y, M, and C

NOTE

• Whenever the Imaging Unit has been slid out of the copier, be sure to cover it with the

light blocking bag (black) or light blocking cloth for packing purposes and place it in a

dark place. Avoid leaving it to stand for a long time.

1. Remove the LED Unit.

☞

D-22

✽

Removal of the LED Assy Bk

2. Remove two screws and the Right Guide.

4004D108AA

4004D110AA

4004D109AA

3. Remove two screws and the Right Guide for C.

4. Remove two screws and the Left Guide.

D-13

Page 18

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

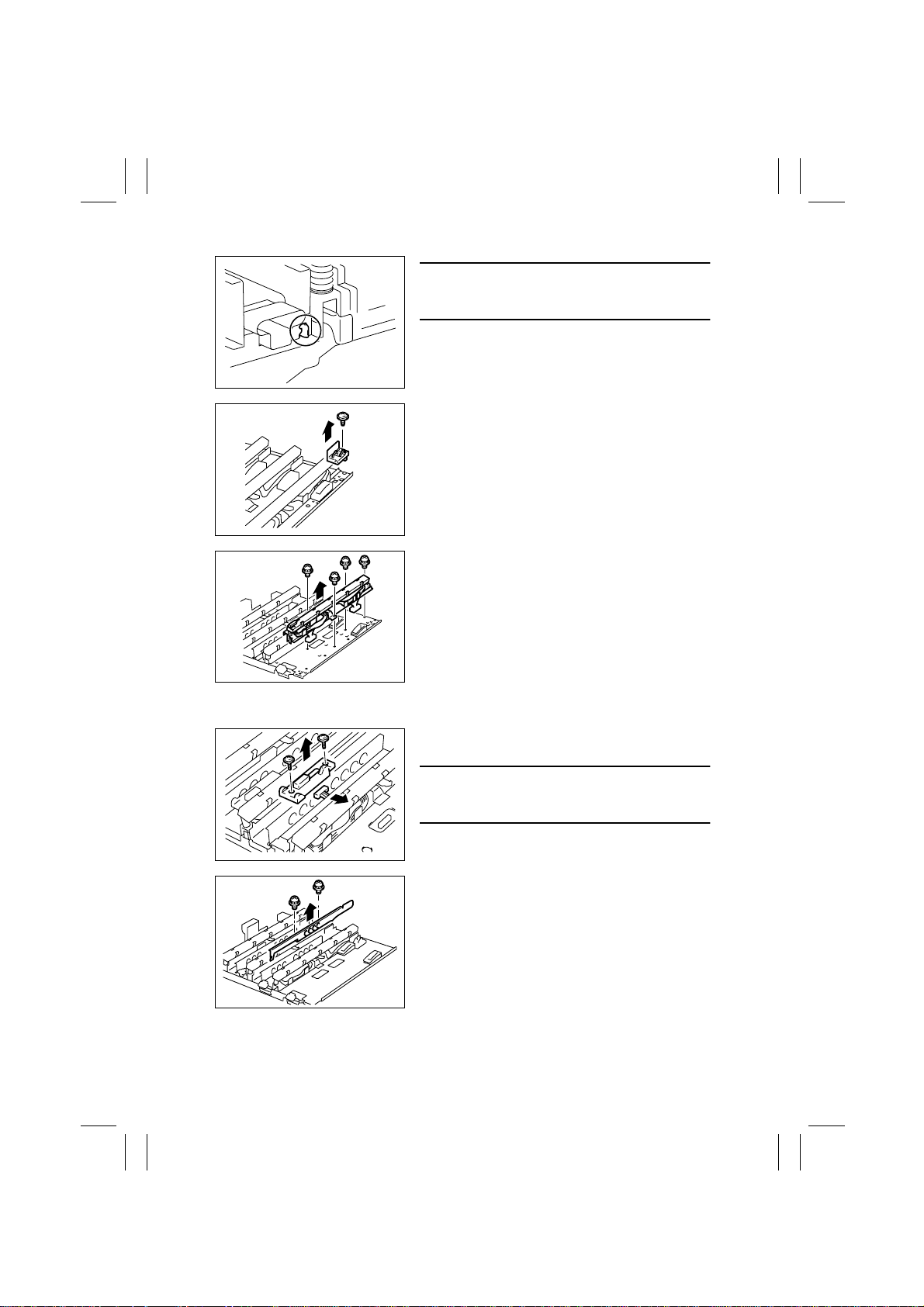

NOTE

• At reinstallation, ensure that the front hook makes

positive engagement.

4004D197AA

5. Remove one screw and the holder.

4004D113AA

6. Remove four screws, unplug two connectors, and

remove the LED Assy Bk.

✽

Removal of the LED Assy C

4004D114AB

7. Remove two screws, unplug one connector, and

remove the ATDC Sensor C.

NOTE

• When the ATDC Sensor is replaced, the Imaging

Unit should also be replaced.

4004D115AA

8. Remove two screws and the Left Guide.

4004D117AA

D-14

Page 19

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

NOTE

• At reinstallation, ensure that the front hook makes

positive engagement.

4004D197AA

9. Remove one screw and the holder.

4004D118AA

10. Remove four screws, unplug two connectors, and

remove LED Assy C.

11. Following the same procedure as when removing

LED Assy C, remove LED Assemblies M and Y.

4004D119AB

4004D120AB

4004D121AB

12. Remove 23 screws and the LED Board Cover.

NOTE

• The illustration shows only the representative

screw. Remove all (23 in total) LED Board Cover

mounting screws.

13. Unplug two connectors.

14. Remove nine screws and the LED Board.

D-15

Page 20

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

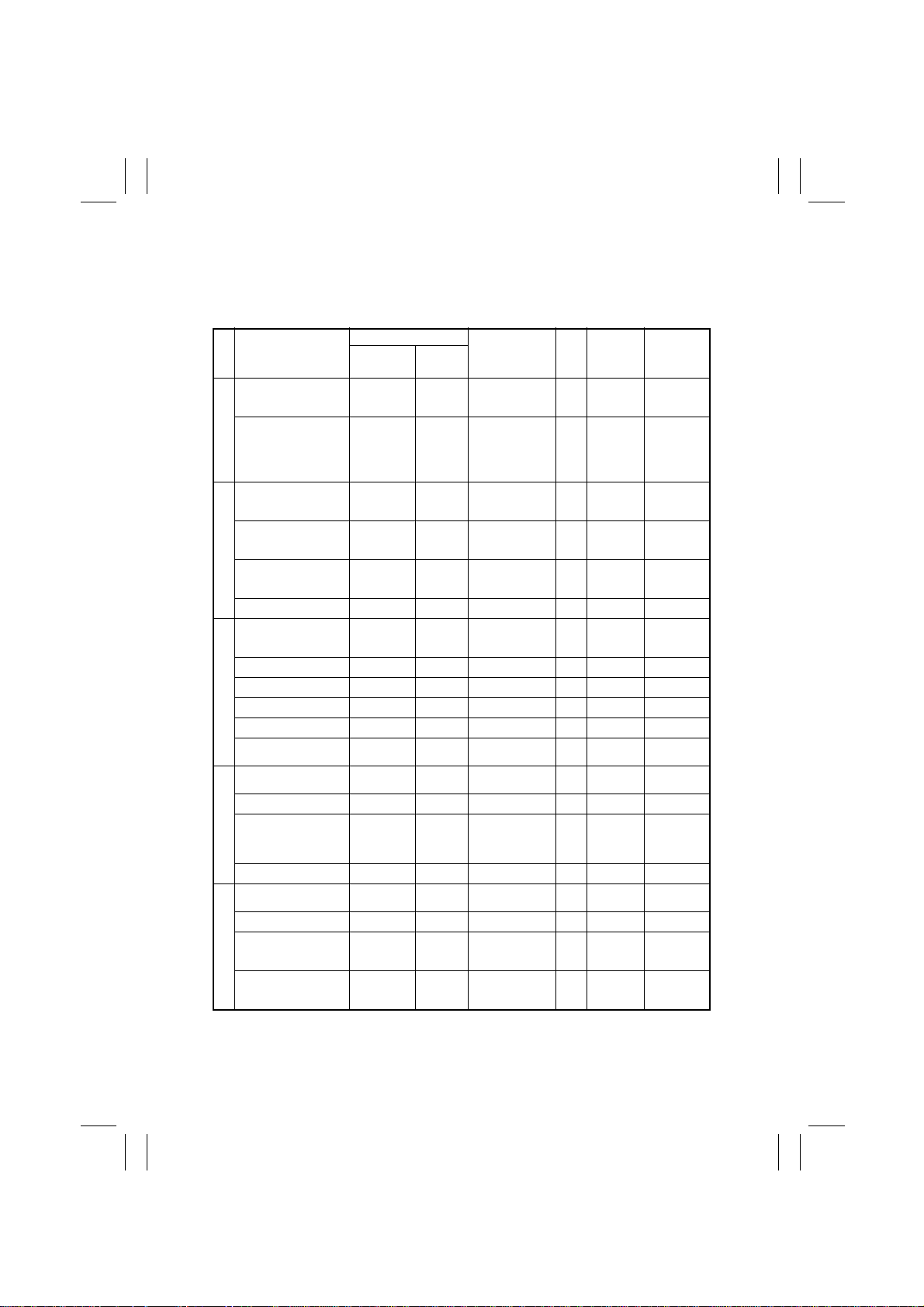

2-3. MAINTENANCE SCHEDULE

• To ensure that the copier produces good copies and to extend its service life, it is recommended that the maintenance jobs described in this schedule be carried out as

instructed.

Maintenance Cycle

PM Parts

Paper Take-Up Roll

Separator Roll Assy

Paper Take-Up Section

Scanner Rail

Mirrors (1st, 2nd, and 3rd)

IR Section

Lens

Original Glass Upon call ———

Transfer Belt Unit (✽1)

Transfer Roller Unit (✽1) — 121 K 111T44010 1 —

Synchronizing Roller 60 K ———

Paper Dust Remover (✽1) 60 K 121 K 111T-2010 1

Waste Toner Bottle — (✽2) 111T-3210 1 —

Image Transfer Section

Around waste toner

collecting port

Imaging Unit C/M/Y — 4562 M —

Imaging Unit Bk — 7204 M — 1 —

LED

Developing Section

Ozone Filter (✽1) — 121 K 111T32040 1 —

Fusing Unit — 102 (✽3)

Fusing Web Unit — (✽4) 111T53010 1 —

Oil Coating Unit —

Fusing Section

Fusing Entrance Guide

Plate

Clean Replace

When

malfunction

occurs

When

malfunction

occurs

When

malfunction

occurs

When

malfunction

occurs

When

malfunction

occurs

When

malfunction

occurs

Upon call ———

Each time

each Imaging

Unit is

replaced

When

malfunction

occurs

200 K

200 K 111T-5010 1

———

———

———

121 K 111T-4410 1 —

———

34 K or

325,000

sec

———

Parts No. Qty

111T51020

111T51010

110G-5300 (120 V)

110H-5300 (230 V)

111T53020 1 —

Ref. Page in

This Manual

1

1

each

1 —

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

D-38

D-60

D-38

D-61

D-25

D-25

D-25

D-26

D-38

D-39

D-40

—

D-40

D-41

Ref. Page

in Unit

Replacement

Manual

—

—

—

—

—

—

P-26

☞

P-26

☞

—

P-26

☞

P-19

☞

—

P-11

☞

P-21

☞

—

P-26

☞

P-22

☞

P-2

☞

P-6

☞

—

D-16

Page 21

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

✽

1: Replace the Transfer Belt Unit, Transfer Roller Unit, Paper Dust Remover, and Ozone

Filter at the same time.

✽

2: About 4.5 K after a waste toner near full condition has been detected.

✽

3: Forced to a stop when 110 K is reached.

✽

4: About 1 K after 17 K has been reached or a web near empty condition has been

detected.

NOTES

• K = 1,000 copies

• The contents of the above maintenance schedule are subject to change without notice.

D-17

Page 22

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

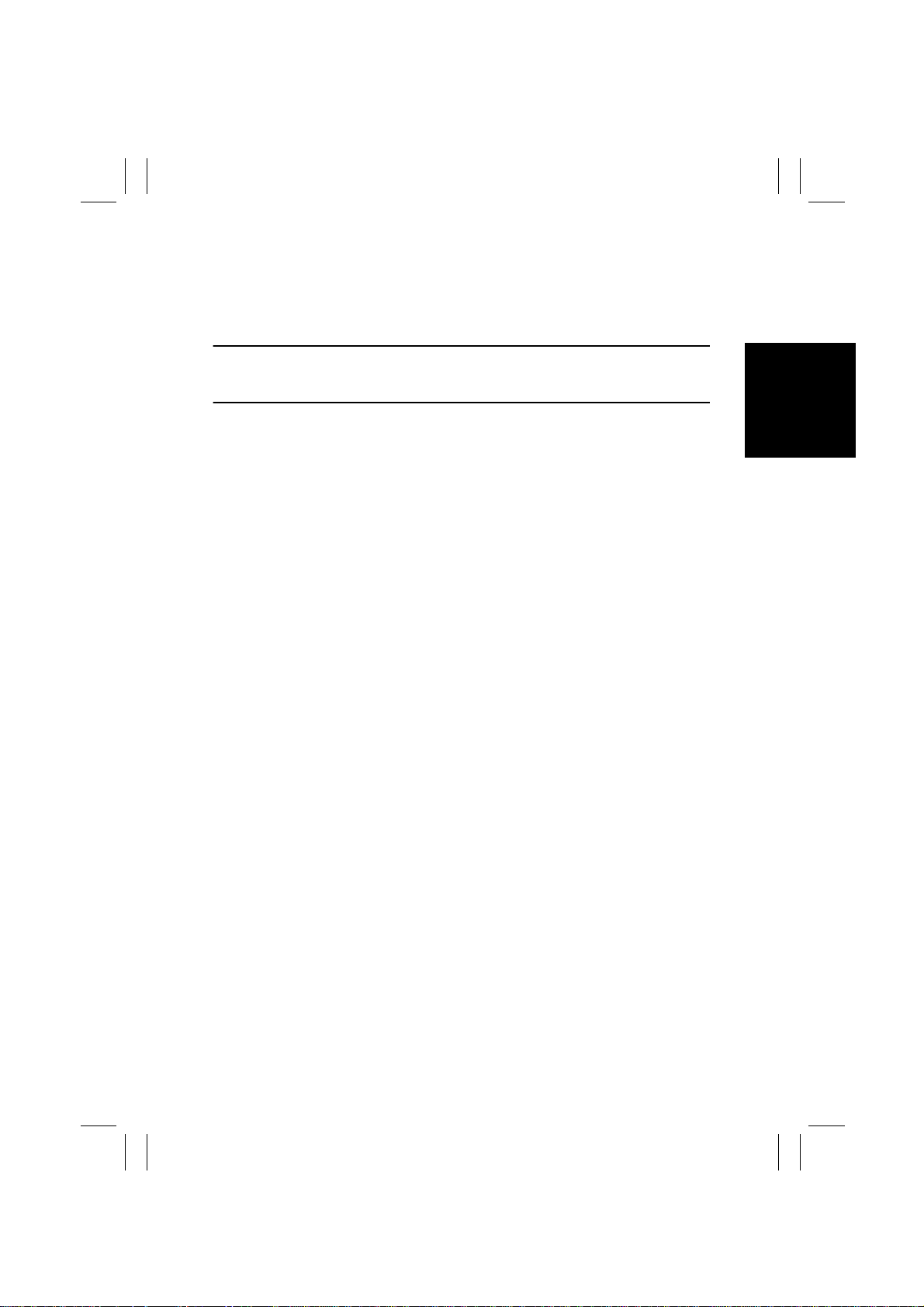

2-4. Guidelines for Life Specifications Values by Unit

NOTES

• The life specifications values represent the number of copies made or figures equivalent

to it when given conditions are met. They can be more or less depending on the copier

operating conditions of each individual user.

• The initiation of a new copy cycle is inhibited upon 1 K after a near life condition has

been detected for all units (except the Toner Bottle and Waste Toner Bottle).

Life

Unit

Toner Bottle — B/E

Waste Toner

Bottle

Fusing Web

Unit

20-cpm copier

Oil Coating

Unit

15-cpm copier

Oil Coating

Unit

Fusing Unit 101 K B/C/D/F

Transfer Belt

Unit

20-cpm copier

Imaging Unit

(C, M, and Y)

15-cpm copier

Imaging Unit

(C, M, and Y)

20-cpm copier

Imaging Unit

(Bk)

15-cpm copier

Imaging Unit

(Bk)

Spec.

Value

120 K A/B/C/D/F

Copying

Condition

40 K B/C/D/E/F

17 K B/C/D/F

33 K

A/B/C/D/F

26 K 26 K 27 K

30 K

27 K

A/B/C/D/F

50 K

47 K

Description

An approximate life value is 10 K

under the specified conditions.

A waste toner full condition is

detected when about 4.5 K copies

are made after a waste toner nearfull condition has been detected.

The life specifications value is

based on A4C or Letter C. A near

life condition is detected when a

web empty condition is detected or

a predetermined number of copies

are made, whichever arrives earlier.

The life specifications value is

based on A4C or Letter C. A near

life condition or a life condition is

detected when the Oil Coating

Roller has turned a pre determined

period of time or a predetermined

number of copies are made, whichever arrives earlier.

The life specifications value is

based on A4C or Letter C.

The life specifications value is

based on A4C or Letter C.

The near life and life time values

are detected when the PC Drum

has turned or the Developing Unit

has been energized for a predetermined period of time, whichever

arrives earlier.

Near Life

Value

— 10 K

— 40 K

16 K 17 K

33 K 34 K

101 K

2

✽

120 K

(17400 M)

3

✽

4415 M

(30 K)

3

✽

4415 M

(27 K)

3

✽

6972 M

(50 K)

3

✽

6972 M

(47 K)

Life Value

1 102 K

✽

2

✽

121 K

(17545 M)

3

✽

4562 M

(31 K)

3

✽

4562 M

(28 K)

3

✽

7122 M

(51 K)

3

✽

7122 M

(48 K)

M: minutes

D-18

Page 23

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

✽

1: As a rule, the Fusing Unit is to be replaced at the same time that the Fusing Web Unit

is replaced a sixth time (17 K × 6 = 102 K). If the Fusing Web Unit is replaced before

17 K is reached, there will be a discrepancy in the replacement cycle, resulting in a

near life and life value ranging between 90 K and 110 K.

✽

2: The life of the Transfer Belt Unit is controlled based on the number of copies made.

The life counter gives a time value display.

✽

3: The life of the Imaging Unit is controlled based on a time value. The life counter gives

a time value display.

• Conditions for Life Specifications Values

Copying Conditions 20-cpm Copier 15-cpm Copier

Job Type A Making two copies per job

Paper Size B A4 or Letter

Color Ratio C C (color) to Bk (black) = 5 to 1 C (color) to Bk (black ) = 2.5 to 1

CV/M D 6 K 3.5 K

Original Density E B/W = 5 % for each color

No. of Operating

Days per Month

F 20 days (Power Switch turned ON and OFF 20 times per month)

D-19

Page 24

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

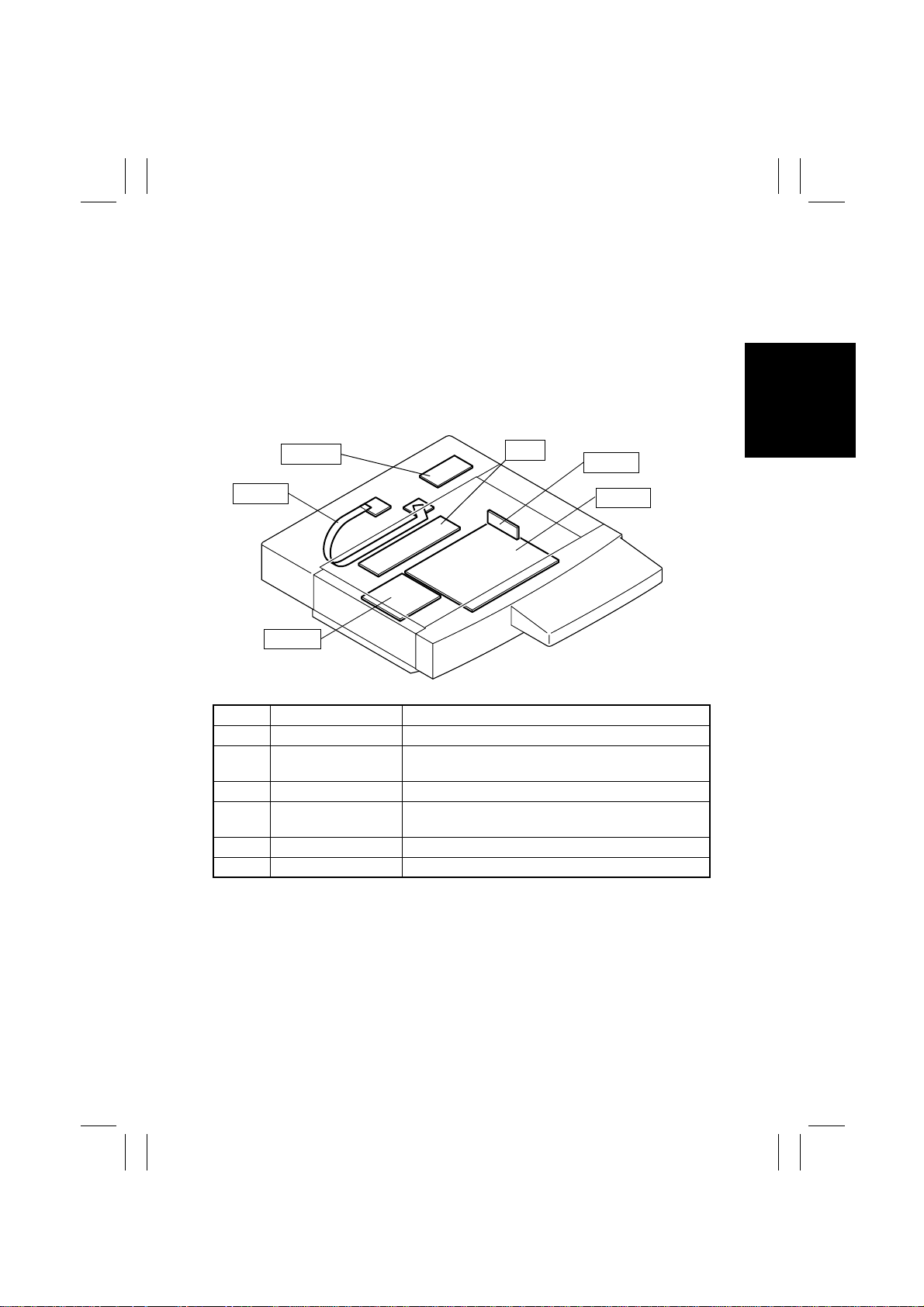

2-5. Removal of Units

• Note that replacement of a unit may call for recheck and readjustments of some items.

Transfer Belt Unit

LED Unit

Fusing Web Unit

Oil Cleaning Unit

Fusing Unit

Imaging Unit

Hopper Unit

4004D182AA

NOTE

• For the removal of the Imaging Unit, Transfer Belt Unit, Fusing Unit, Fusing Web Unit,

and Oil Coating Unit, see the Unit Replacement Manual.

D-20

Page 25

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

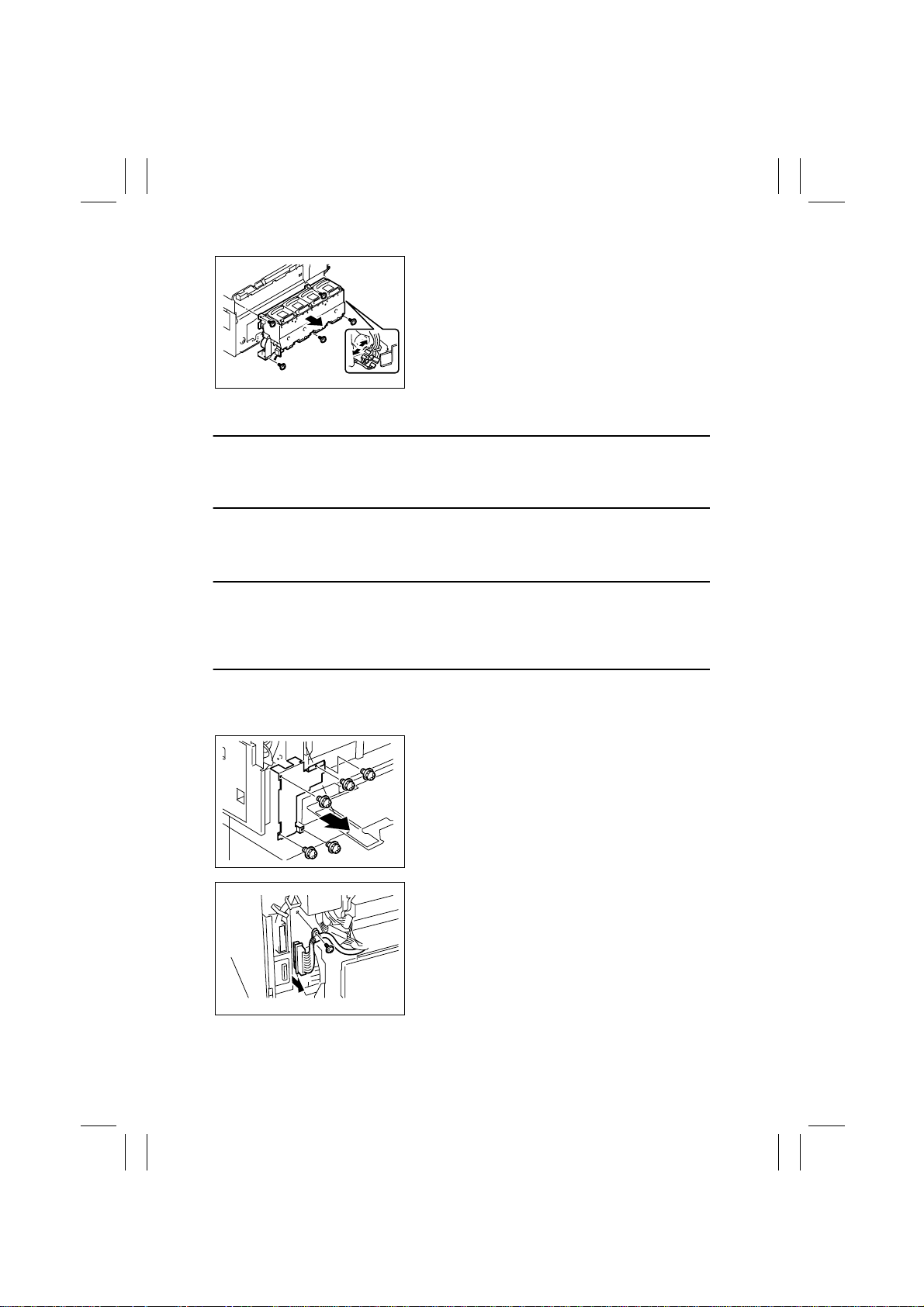

(1) Removal of the Toner Hopper Unit

NOTE

• Whenever the Imaging Unit has been slid out of the copier, be sure to cover it with the

light blocking bag (black) or light blocking cloth for packing purposes and place it in a

dark place. Avoid leaving it to stand for a long time.

1. Remove the Paper Output Cover.

2. Open the Front Door.

3. Remove the Toner Supply Door.

4. Remove the Hopper Left Cover.

5. Slide out the Imaging Unit (C/M/Y/Bk).

☞

Unit Replacement Manual

NOTES

• After the Imaging Unit has been pulled out, place the Imaging Unit lock lever back into

the locked position.

• When sliding the Imaging Unit back in, make sure that the shutter is opened if the Imaging Unit Lower Cover is not to be used.

6. Remove two screws and the Right Front Cover.

4004D043AA

4004D044AA

4004D045AA

7. Remove two screws and the Front Door Switch

Cover.

8. Disconnect three terminals.

✽

Terminals: Blue, white, and green from top down

D-21

Page 26

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

9. Unplug three connectors.

10. Remove five screws and the Toner Hopper Unit.

4004D046AB

(2) Removal of the LED Unit

NOTE

• Whenever the Imaging Unit has been slid out of the copier, be sure to cover it with the

light blocking bag (black) or light blocking cloth for packing purposes and place it in a

dark place. Avoid leaving it to stand for a long time.

1. Open the Front Door.

2. Slide out the Imaging Unit (C/M/Y/Bk).

☞

Unit Replacement Manual

NOTES

• After the Imaging Unit has been pulled out, place the Imaging Unit lock lever back into

the locked position.

• When sliding the Imaging Unit back in, make sure that the shutter is opened if the Imaging Unit Lower Cover is not to be used.

3. Open the Right Door and Rear Left Cover.

4. Remove the Ozone Filter, Waste Toner Bottle, and Transfer Belt Unit.

5. Remove the Rear Cover and Rear Left Cover.

6. Remove five screws and the cover.

4004D229AA

7. Remove one screw and unplug one connector on

the PIC Board.

4004D047AA

D-22

Page 27

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

8. Unplug five connectors.

4004D048AB

A

B

4004D232AA

4004D024AA

NOTE

• Make sure that all four hubs are locked in position.

NOTE

• When unplugging the connector, make sure that

connector A (on the copier side) is disconnected.

Connector B (on the LED Unit side) should not be

disconnected.

9. Lock the Imaging Unit (C/M/Y/Bk) drive hub.

NOTES

• During the locking procedure, use care not to

touch the LED surface.

• Should the LED surface be touched, clean it with

the LED Cleaning Jig.

☞

D-40

D-23

4004D049AA

Page 28

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

10. Remove two screws and slide out the LED Unit.

4004D050AA

Precaution for Reinstalling the LED Unit

• The lever of the LED Unit must be fit into the space between the metal bracket in the

rear of the copier and another lever as illustrated below.

LED Unit Lever

4004D051AA

Precaution for Replacement of the LED Unit

• When the LED Unit is to be replaced, remove the ATDC Sensor from the old LED Unit

and remount it on the new one.

This step is not, however, necessary if the Imaging Unit is replaced at the same time.

D-24

Page 29

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

2-6. Cleaning and Disassembly of the IR Unit

(1) Cleaning of the Scanner Rails

1. Remove the IR Right Cover and Original Glass.

2. Using a soft cloth dampened with alcohol, wipe

the Scanner Rails clean of dirt.

NOTE

• Apply lubricant after cleaning.

4004D198AA

(2) Cleaning of the Mirrors (1st/2nd/3rd)

1. Remove the IR Right Cover and Original Glass.

2. Using a soft cloth dampened with alcohol, wipe

mirrors clean of dirt.

4004D199AA

(3) Cleaning of the Lens

4004D001AC

4004D200AB

1. Remove the IR Right Cover and Original Glass.

2. Remove eight screws and the optical cover.

3. Using a soft cloth dampened with alcohol, wipe

the Lens clean of dirt.

D-25

Page 30

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(4) Cleaning of the Original Glass

1. Using a soft cloth dampened with alcohol, wipe

the Lens clean of dirt.

4004D201AA

(5) Removal of the Original Glass Cooling Fan Motor

1. Remove the IR Rear Upper Cover and IR Rear

Cover.

2. Unplug one connector and remove the harness

from one wiring saddle.

3. Remove two screws and the Original Glass Cooling Fan Motor.

4004D018AB

(6) Removal of the Scanner Motor

4004D015AA

4004D027AA

1. Remove the IR Rear Upper Cover, IR Rear

Cover, and IR Rear Right Cover.

2. Remove the Original Glass Cooling Fan Motor.

3. Remove two screws and the reinforcement

frame.

4. Remove four screws and the hinge support in the

rear of the IR.

D-26

Page 31

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

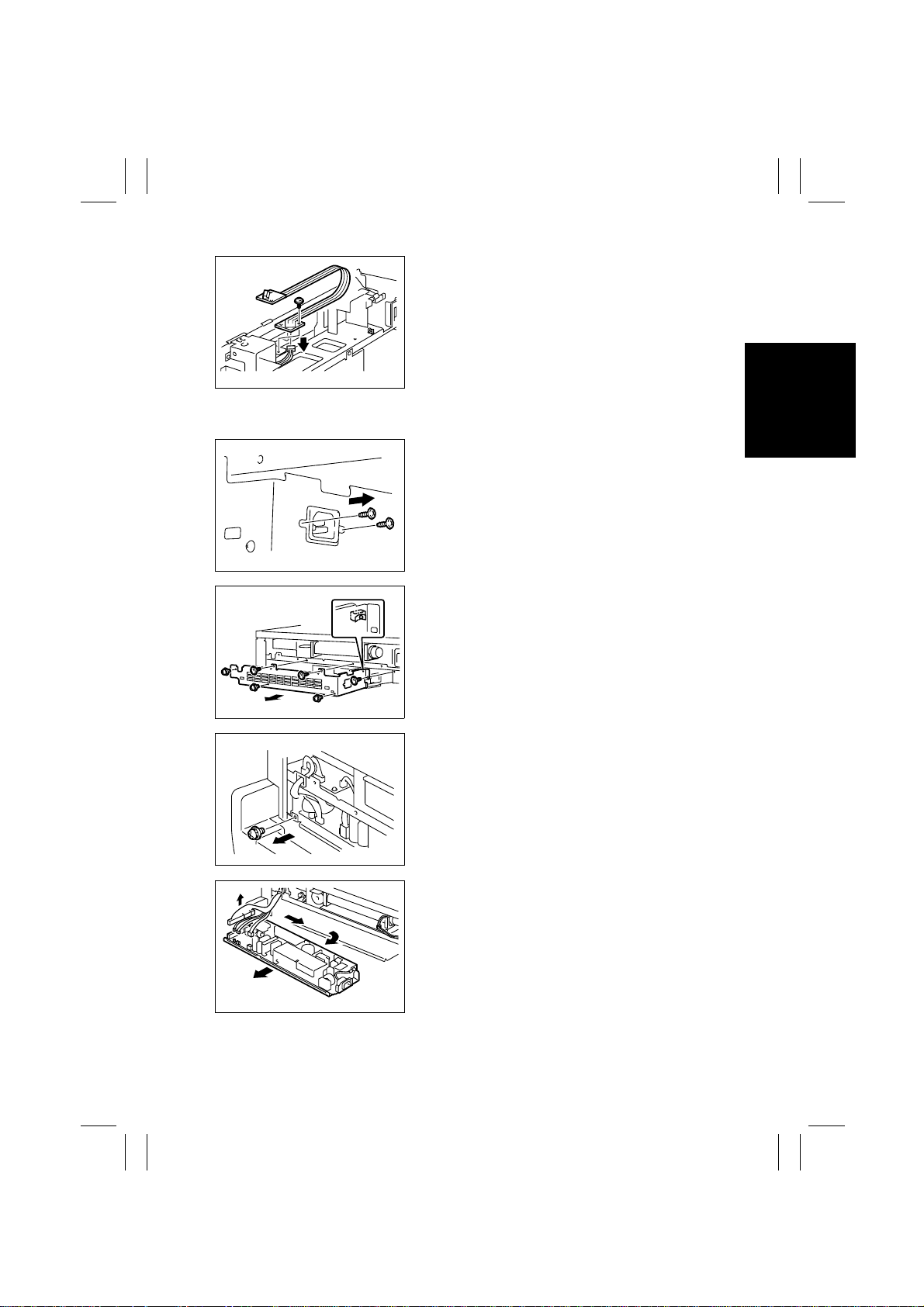

5. Remove the tension spring for the Scanner Motor

timing belt.

4004D028AA

6. Remove the harness from one cord clamp and

one edge cover.

7. Remove three screws and the Scanner Motor

Assy.

4004D029AD

8. Remove two screws and the Scanner Motor.

4004D030AA

(7) Removal of IR Cooling Fan Motor 2

1. Remove the IR Right Cover.

2. Remove the Original Glass.

3. Remove the Control Panel.

4. Remove the IR Lower Front Cover, IR Front Cover, and IR Rear Upper Cover.

5. Remove the optical cover.

6. Remove three screws and the Imaging Processing Lid on the right inside the IR.

4004D002AB

D-27

Page 32

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

7. Remove four screws and the IR upper right metal

bracket.

4004D004AA

8. Unplug one connector.

9. Remove two screws and IR Cooling Fan Motor 2.

4004D032AD

(8) Removal of IR Cooling Fan Motor 1

1. Remove the IR Right Cover and Original Glass.

2. Unplug one connector.

3. Remove two screws and IR Cooling Fan Motor 1.

4004D034AB

(9) Removal of the Scanner Home Sensor

1. Remove the Control Panel.

2. Unplug one connector.

3. Remove one screw and the Scanner Home Sensor Assy.

4004D035AB

4. Remove one screw and the Scanner Home Sensor.

4004D036AB

D-28

Page 33

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(10) Removal of the Original Cover Detecting Sensor

1. Remove the IR Rear Upper Cover and IR Rear

Cover.

2. Unplug one connector.

3. Remove one screw and the Original Cover

Detecting Sensor Assy.

4004D037AA

4. Remove the sensor fixing bracket and the Original Cover Detecting Sensor.

4004D038AA

(11) Removal of Original Size Detecting Sensors FD1 and FD2

4004D123AA

4004D122AA

1. Remove the IR Right Cover and Original Glass.

2. Unplug one connector.

3. Remove one screw and Original Size Detecting

Sensor FD1.

4. Unplug one connector.

5. Remove one screw and Original Size Detecting

Sensor FD2.

D-29

Page 34

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(12) Removal of Original Size Detecting Sensor CD1

1. Remove the IR Right Cover and Original Glass.

2. Unplug one connector.

3. Remove one screw and Original Size Detecting

Sensor CD1.

4004D124AA

(13) Removal of the Size Reset Switch

1. Remove the Control Panel and IR Front Cover.

2. Unplug one connector.

3. Remove one screw and Size Reset Switch.

4004D039AB

(14) Removal of the Scanner Assy

4004D202AA

Scanner mounting Screws

Scanner

positioning Screws

4004D203AA

1. Remove the IR Right Cover and Original Glass.

2. Move the Scanner Assy to the location shown

and remove one mounting screw each at the

front and rear end.

NOTE

• Do not remove the Scanner Positioning Screw.

D-30

Page 35

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. Take out the Scanner Assy by turning it in the

direction of the arrow shown.

NOTE

• The Scanner Assy cannot be completely taken off

the copier as a Flat Cable is still connected to it at

this time.

4004D017AB

4. Remove two screws, unplug one connector, and

remove the Scanner Assy Flat Cable.

5. Remove the Scanner Assy.

4004D025AA

(15) Removal of the Exposure Lamp

1. Remove the IR Right Cover and Original Glass.

2. Remove the Scanner Assy.

☞

D-30

3. Remove the Exposure Lamp from the Lamp Terminals.

4. Remove the Exposure Lamp.

4004D040AB

(16) Removal of the Temperature Fuse

1. Remove the IR Right Cover and Original Glass.

2. Remove the Scanner Assy.

☞

D-30

3. Remove one screw and the fuse cover.

4004D041AA

D-31

Page 36

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

4. Remove two screws and the Temperature Fuse.

4004D042AB

(17) Removal of the Scanner Drive Cables

1. Remove the Control Panel.

2. Remove the IR Right Cover, IR Lower Front Cover, IR Rear Upper Cover, and IR Rear

Cover.

3. Remove the Original Glass.

4. Remove the optical cover.

5. Remove the Scanner Assy and Flat Cable.

☞

D-30, D-10

6. Unhook the springs of the Scanner Drive Cables

on the hook side, one each at the front and in the

rear.

7. Remove the front and rear Scanner Drive Cables.

4002D110AB

4002D112AA

4002D113AA

8. Remove the Scanner Motor Assy.

☞

D-26 (steps 4 through 8)

9. Remove one screw and then slide the front pulley

and bushing toward the rear.

10. Remove one screw and then slide the rear pulley

and bushing toward the front.

D-32

Page 37

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

11. Remove the Scanner Drive Gear, pulleys and

bushings at the front and rear, and the shaft.

4002D114AD

(18) Winding of the Scanner Drive Cables

Pulley C

Pulley E

Pulley D

Pulley A

Pulley F

Pulley B

4002D001AA

Front

1. Position the round bead of the Scanner Drive

Cable in the pulley as shown.

NOTE

• Make sure that the bead snugly rests in the slit in

the pulley.

4002D002AA

2. Wind the fixed bead end of the cable around the

pulley five turns clockwise, from the rear toward

the front side.

4002D003AA

D-33

Page 38

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. Wind the hook end of the cable around the pulley

five turns counterclockwise, from the front toward

the rear side.

NOTE

• Make sure that no part of the cable rides on the

other.

4002D004AA

4. Slip the Cable Holding Jig onto the pulley to

secure the cable in position.

4002D501AA

Rear

5. Position the round bead of the Scanner Drive

Cable in the pulley as shown.

4002D002AA

4002D006AA

4002D004AA

NOTE

• Make sure that the bead snugly rests in the slit in

the pulley.

6. Wind the fixed bead end of the cable around the

pulley five turns clockwise, from the front toward

the rear side.

7. Wind the hook end of the cable around the pulley

five turns counterclockwise, from the rear toward

the front side.

NOTE

• Make sure that no part of the cable rides on the

other.

D-34

Page 39

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

8. Slip the Cable Holding Jig onto the pulley to

secure the cable in position.

4002D502AA

9. Mount the front and rear pulleys and bushings on

the shaft and install the shaft to the Scanner Unit.

10. Mount the Scanner Drive Gear on the shaft and

secure it in position with one screw.

4002D115AD

11. Install an Allen wrench into the holes in the shaft

and the IR Base Plate.

4002D116AD

4002D117AC

4002D118AD

12. Slide the front pulley and bushing to the front and

install one mounting screw.

13. Slide the rear pulley and bushing to the rear and

install one mounting screw.

D-35

Page 40

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

Front

14. Wind the bead end of the cable around pulley C

and pulley B, then hook the bead onto the Adjust-

Pulley C

able Anchor.

Pulley B

Pulley B

Pulley A

Pulley E

4002D008AA

4002D009AA

4002D119AB

Pulley F

4002D010AA

15. Wind the hook end of the cable around pulley A

and pulley B.

16. Fit the hook end of the cable into the groove in

the Cable Guide and hook the spring.

Rear

17. Wind the bead end of the cable around pulley F

and pulley E, then hook the bead onto the Adjustable Anchor.

Pulley E

Pulley D

18. Wind the hook end of the cable around pulley D

and pulley E.

4002D011AA

D-36

Page 41

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

19. Fit the hook end of the cable into the groove in

the Cable Guide and hook the spring.

4002D120AB

20. Mount the Scanner Motor Assy.

21. Remove the Cable Holding Jigs from the front and rear pulleys.

22. Remove the Allen wrench.

23. Mount the Scanner Assy and Flat Cable.

24. Reinstall the optical cover.

25. Reinstall the Original Glass.

26. Reinstall the IR Right Cover, IR Lower Front Cover, IR Front Cover, IR Rear Upper

Cover, and IR Rear Cover.

27. Reinstall the Control Panel.

28. Adjust the position of the Scanner and 2nd/3rd Mirrors Carriage.

☞

D-90

NOTE

• Whenever the Scanner Drive Cables have been removed, be sure to carry out the “FD-

Mag” adjustment procedure.

☞

D-85

D-37

Page 42

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

2-7. CLEANING AND DISASSEMBLY OF THE ENGINE PARTS

(1) Cleaning of the Paper Take-Up Roll

1. Slide out the drawer.

2. Using a soft cloth dampened with alcohol, wipe

the Paper Take-Up Roll clean of dirt.

4658D005AA

(2) Cleaning of the Paper Separator Roll

1. Remove the Paper Separator Roll Mounting

Assy.

☞

D-61

2. Using a soft cloth dampened with alcohol, wipe

the Paper Separator Roll clean of dirt.

4658D006AA

(3) Cleaning of the Synchroni zing Rollers

1. Open the Right Door.

2. Remove two screws and the guide.

4004D204AB

3. Using a soft cloth dampened with alcohol, wipe

the Synchronizing Rollers clean of dirt.

4004D205AC

D-38

Page 43

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(4) Cleaning of the Paper Dust Remover

1. Open the Right Door.

2. Remove the Paper Dust Remover.

4004D206AB

3. Using a brush, whisk dust off the Paper Dust

Remover.

4004D207AA

(5) Cleaning of the Transfer Belt Unit

NOTES

• If any solvent is to be used, select one from among the following:

IPA, ethyl alcohol, PPC Cleaner, and Solmix AP-7.

• When the solvent has been used for cleaning, make 28 or more copies using A3 blank

sheets of paper to remove image noise.

1. Remove the Transfer Belt Unit.

☞

Unit Replacement Manual

2. Wipe the surface of the Transfer Belt with a dry

cloth.

NOTES

• If the dry cloth is not effective in removing dirt,

4004D228AA

dampen it with alcohol.

• Do not use a cloth wet with water.

D-39

Page 44

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(6) Cleaning of the LED

NOTE

• Whenever the Imaging Unit has been slid out of the copier, be sure to cover it with the

light blocking bag (black) or light blocking cloth for packing purposes and place it in a

dark place. Avoid leaving it to stand for a long time.

1. Open the Front Door.

2. Remove the Imaging Unit (C/M/Y/Bk).

3. Wipe the LED of the LED Assy with the LED Cleaning Jig clean by moving the jig three

reciprocating cycles.

NOTE

• Use the specified LED Cleaning Jig only.

4004D223AB

(7) Cleaning of the Area around the Waste Toner Collecting Port

1. Open the Rear Left Cover.

2. Remove the Waste Toner Bottle.

4004D221AA

D-40

Page 45

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. Wipe the areas around the Waste Toner Collecting Port clean of spilled toner and dirt using a soft

cloth dampened with water or alcohol.

4004D222AB

(8) Cleaning of the Fusing Entrance Guide Plate

1. Remove the Fusing Unit.

☞

Unit Replacement Manual

2. Wipe the Fusing Entrance Guide Plate clean of

dirt using a waste cloth dampened with alcohol.

4004D208AA

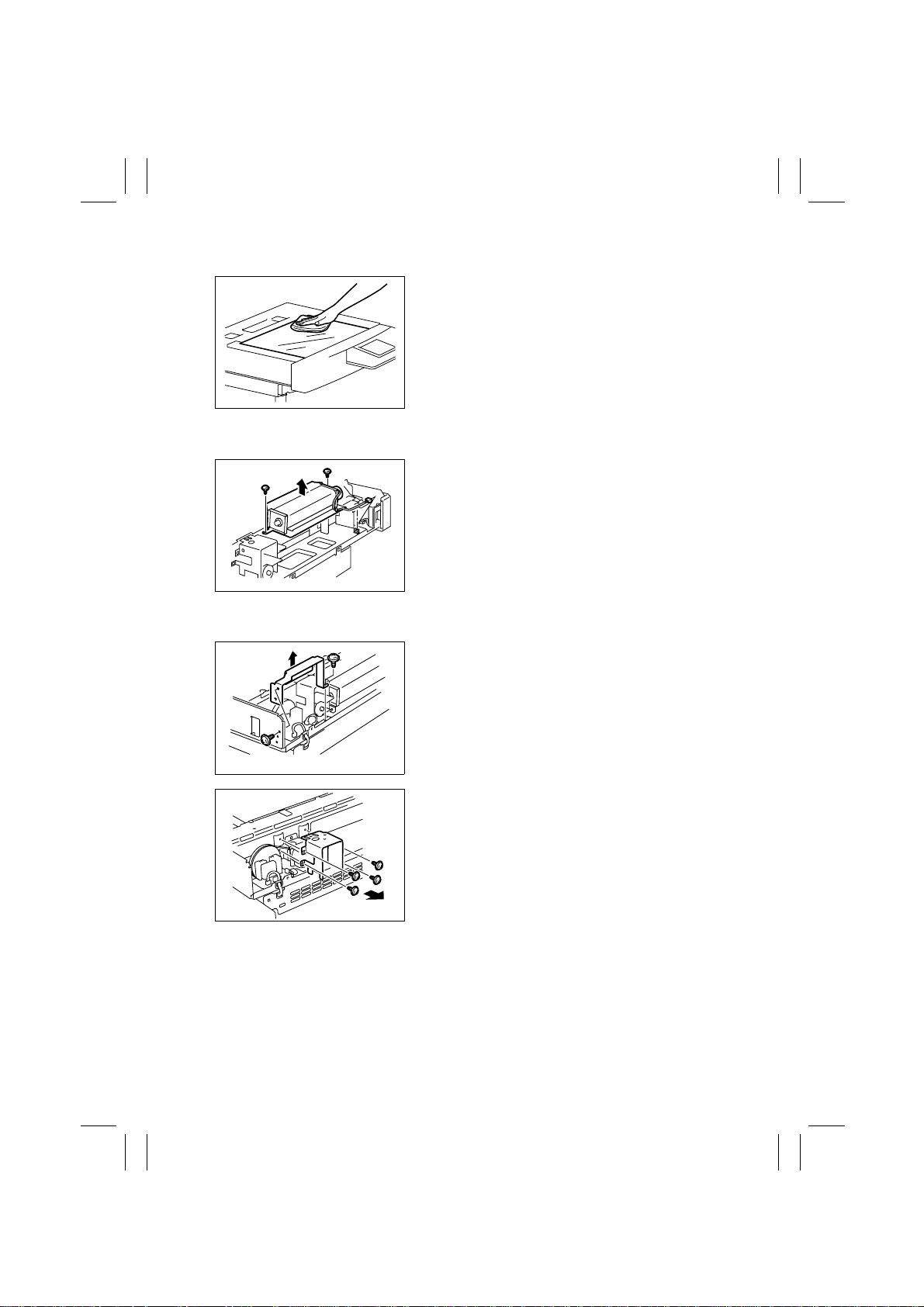

(9) Removal of the Imaging Unit Motor C/M/Y/Bk

NOTE

• Whenever the Imaging Unit has been slid out of the copier, be sure to cover it with the

light blocking bag (black) or light blocking cloth for packing purposes and place it in a

dark place. Avoid leaving it to stand for a long time.

1. Remove the Rear Cover.

2. Open the Upper Right Door.

3. Remove the Rear Upper Cover.

4. Open the Right Door.

5. Remove the Rear Right Cover.

6. Remove the Ozone Filter.

7. Open the Left Door.

8. Remove the Waste Toner Bottle.

9. Remove the Rear Left Cover.

10. Remove six screws and the MSC Cover.

4004D052AB

D-41

Page 46

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

11. Remove two screws and the mounting bracket.

4004D053AA

12. Unplug two connectors of the 2nd Drawer.

4004D054AA

13. Remove two screws and the power line mounting

bracket for the 2nd Drawer.

14. Remove the harness from two wiring saddles.

4004D055AA

4004D056AB

4004D057AB

15. Unplug eight connectors.

16. Remove 11 screws and the MSC/PIC Board Box.

17. Remove the LED Unit.

☞

D-22

18. Unplug two connectors.

19. Remove four screws and Imaging Unit Motor Y.

D-42

Page 47

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

20. Remove the harness from the wiring saddle.

✽

Wiring saddle: Two for M/C; one for Bk

21. Unplug two connectors each.

22. Remove four screws each and Imaging Unit

Motor M/C/Bk.

4004D058AB

(10) Removal of the Main Motor

1. Remove the MSC/PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Unplug one connector.

3. Remove four screws and the Main Motor.

4004D060AA

(11) Removal of the Ozone Ventilation Fan Motor

1. Remove the MSC/PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Unplug one connector.

3. Remove four screws and the Ozone Ventilation

4004D061AC

(12) Removal of the Fusing Drive Motor

1. Remove the MSC/PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Unplug one connector.

3. Remove four screws and the Fusing Drive Motor.

4004D062AB

Fan Motor.

D-43

Page 48

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(13) Removal of the Fusing Pressure/Retraction Motor

1. Remove the MSC /PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Remove the Fusing Drive Motor.

3. Remove two screws and the harness holder.

4004D063AA

4. Unplug two connectors.

5. Remove three screws and the Fusing Pressure/

Retraction Motor Assy.

4004D064AA

4004D125AA

4004D209AA

4004D126AB

6. Snap off one E-ring and remove the gear and pin.

NOTE

• Use care not to lose the pin.

7. Snap off one E-ring and remove the bushing.

8. Remove two screws and the Fusing Retraction

Position Sensor mounting bracket.

9. Remove the gear (black).

10. Remove two screws and the Fusing Pressure/

Retraction Motor.

D-44

Page 49

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

Precaution for Reinstallation

• When reinstalling the harness holder,

make sure that the protrusion on the

backside of the holder fits into the

hole in the metal bracket.

(14) Removal of the 1st Image Transfer Pressure/Retraction Motor

1. Remove the MSC/PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Unplug three connectors and remove two terminals.

3. Remove six screws and High Voltage Unit 2.

4004D065AB

4004D066AA

4004D067AB

4004D068AA

4004D069AA

4. Unplug one connector.

5. Remove three screws and the Fusing Cooling

Fan Motor 2 Unit.

6. Remove four screws and, sliding the board

holder to the left, take it off.

7. Unplug one connector.

8. Remove two screws and the 1st Image Transfer

Pressure/Retraction Motor.

D-45

Page 50

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(15) Removal of Toner Replenishing Motor C/Bk

1. Open the Front Door.

2. Remove the Right Front Cover.

3. Unplug one connector.

4. Remove four screws and the Toner Replenishing

Motor C/Bk As sy.

4004D071AB

(16) Removal of Toner Replenishing Motor Y/M

1. Remove the Toner Hopper.

☞

D-21

2. Remove two screws and the Front Door Switch

Assy.

4004D072AA

3. Unplug one connector.

4. Remove four screws and the Toner Replenishing

Motor Y/M Assy.

4004D073AE

(17) Removal of the Cleaning Web Drive Motor

1. Remove the Toner Hopper.

☞

D-21

2. Remove the Upper Right Front Cover.

3. Open the Right Door and Upper Right Door.

4. Slid out the Fusing Unit.

5. Remove three screws and the Upper Right Front

Cover Guide.

4004D127AA

D-46

Page 51

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

6. Unplug one connector.

7. Remove two screws and the Cleaning Web Drive

Motor Assy.

4004D128AB

8. Remove two screws and the Cleaning Web Drive

Motor.

4004D129AA

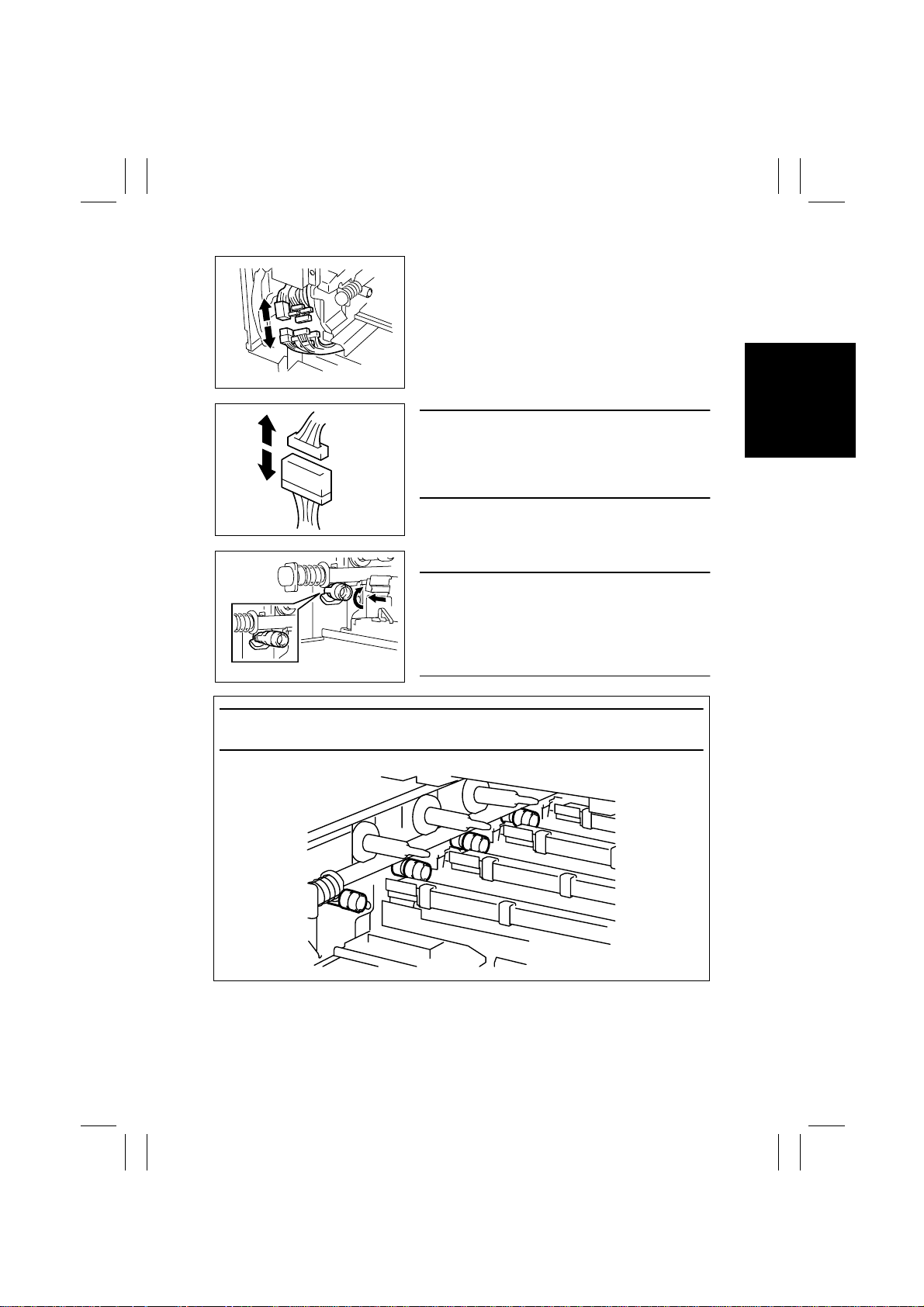

Gear Assy Construction

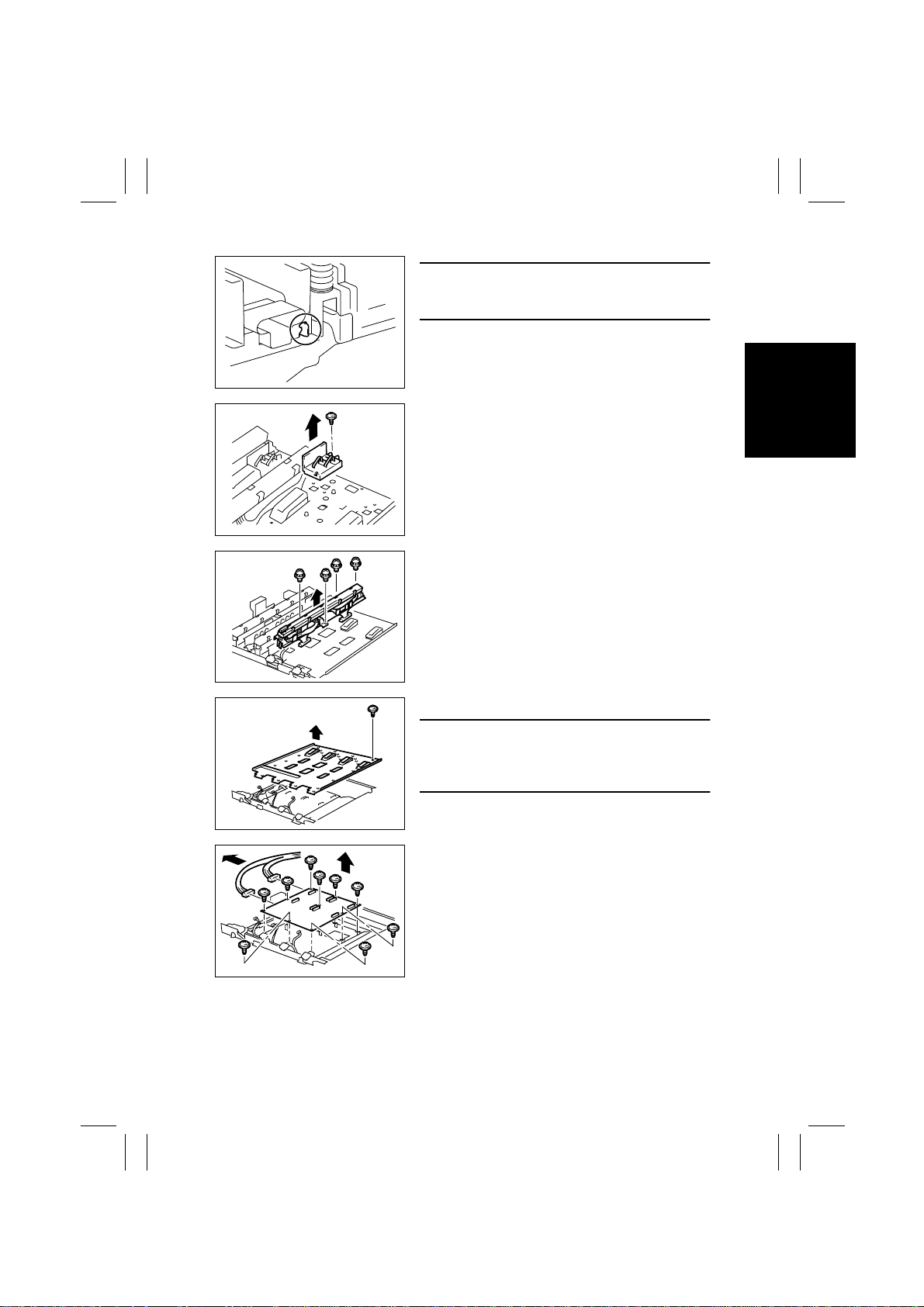

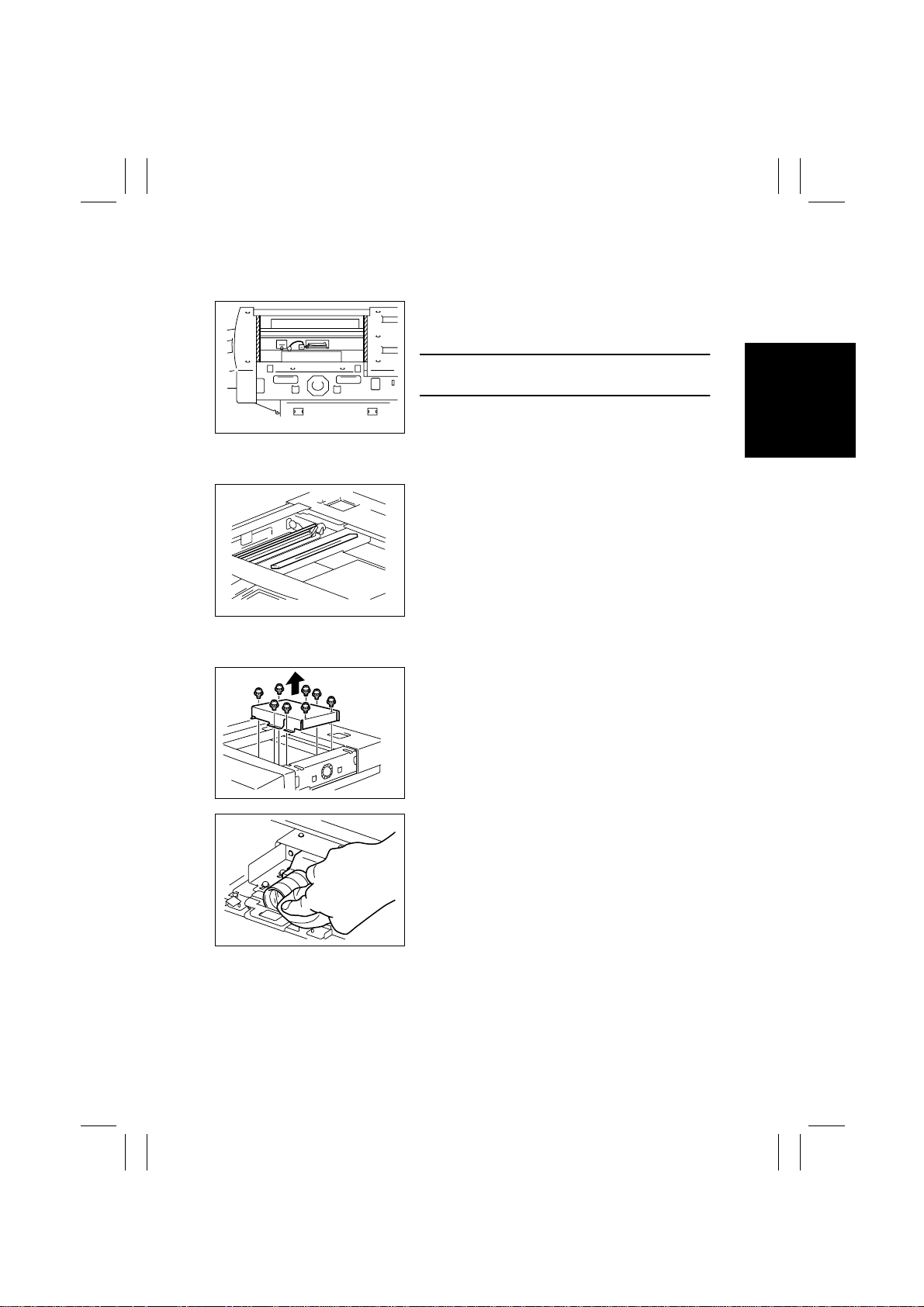

(18) Removal of the Power Supply Cooling Fan Motor

1. Remove the Paper Output Cover, Rear Cover,

and Rear Upper Cover.

2. Remove six screws and the DC Power Supply 1

Cover.

4004D074AA

D-47

4004D130AA

Page 52

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. Unplug 15 connectors and remove

the harness from 13 cord clamps

and five wiring saddles.

4. Remove nine screws and DC

Power Supply 1.

4004D075AB

5. Remove two screws and the Power Supply Cooling Fan Motor.

4004D076AA

(19) R emoval of Fusing Cooling Fan Motor 2

1. Remove the Paper Output Cover, Rear Cover,

and Rear Upper Cover.

2. Unplug one connector.

3. Remove two screws and Fusing Cooling Fan

Motor 2.

4004D077AC

(20) R emoval of Fusing Cooling Fan Motor 1

1. Open the Right Door.

2. Open the cover.

3. Unplug one connector.

4004D078AA

D-48

Page 53

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

Lock

4. Disengage the lock at the front.

4004D079AB

5. Disengage the lock in the rear and remove the

2nd Image Transfer Roller.

Lock

4004D080AB

6. Remove ten screws and the Right Door reinforcement frame.

4004D081AB

7. Remove two screws and the support.

8. Remove four screws and the fan motor duct.

4004D082AC

4004D083AA

9. Remove two screws and Fusing Cooling Fan

Motor 1.

D-49

Page 54

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(21) Removal of the 2nd Image Transfer Pressure/Retraction Clutch

1. Open the Right Door.

2. Unplug one connector.

3. Snap off one C-clip and remove the 2nd Image

Transfer Pressure/Retraction Clutch.

4004D084AA

NOTE

• When reinstalling the 2nd Image Transfer Pres-

sure/Retraction Clutch, make sure that it is

installed correctly as shown.

4004D210AA

(22) Removal of the Synchronizing Roller Clutch

1. Open the Right Door.

2. Remove the 2nd Image Transfer Pressure/Retra ction Clutch.

3. Remove the 2nd Image Transfer Roller.

4. Unplug one connector of the Synchronizing

Roller Clutch.

4004D085AA

4004D086AC

5. Snap off one C-clip and remove the Synchronizing Roller Clutch.

D-50

Page 55

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

NOTE

• When reinstalling the Synchronizing Roller Clutch,

make sure that it is installed correctly as shown.

4004D211AA

(23) Removal of the Manual Feed Paper Take-Up Clutch

1. Remove the Rear Right Cover.

2. Unplug one connector.

3. Remove four screws and the Manual Bypass

Unit.

4004D087AB

4. Remove one screw and the ground plate.

4004D088AB

4004D089AA

4004D212AB

5. Unplug one connector.

6. Snap off one C-clip and remove the Manual Feed

Paper Take-Up Clutch.

NOTE

• When reinstalling the Manual Feed Paper Take-Up

Clutch, make sure that it is installed correctly as

shown.

D-51

Page 56

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(24) Removal of the Paper Take-Up Clutch

1. Remove the Rear Cover and Rear Right Cover.

2. Remove the MSC /PIC Board Box.

☞

D-41 (steps 1 through 14)

3. Remove the Main Motor.

4. Unplug two connectors, disconnect three ground

connections, and remove the harness from the

wiring saddle.

5. Remove two screws and the hookup connector

metal bracket.

4004D090AC

6. Remove two screws and the harness guide.

7. Remove the harness from one edge cover.

4004D091AB

4004D092AB

4004D093AC

8. Remove one bearing.

9. Snap off three E-rings and remove three bushings.

10. Remove nine screws and the Gear Assy Guide.

11. Remove one gear.

12. Snap off one E-ring and remove the Paper TakeUp Clutch.

D-52

Page 57

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

NOTE

• When reinstalling the Paper Take-Up Clutch, make

sure that it is installed correctly as shown.

4004D213AA

(25) Removal of AIDC/Registration Sensor 1/2

1. Open the Right Door.

2. Remove four screws and the Synchronizing

Roller entrance guide.

4004D094AA

3. Remove four screws and the cover.

4004D230AA

4004D095AA

4004D096AA

4. Remove two screws, unplug one connector, and

remove AIDC/Registration Sensor 1.

5. Remove two screws, unplug one connector, and

remove AIDC/Registration Sensor 2.

D-53

Page 58

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(26) Removal of the Temperature/Humidity Sensor

1. Remove the Synchronizing Roller entrance

guide.

☞

D-53 (steps 1 and 2)

2. Remove one screw, two washers, and the cover.

4004D097AA

3. Remove one screw, unplug one connector, and

remove the Temperature/Humidity Sensor.

4004D098AB

(27) Removal of the Toner Supply Door Sensor

1. Remove the Toner Hopper.

☞

D-21

2. Unplug one connector.

3. Remove the sensor fixing bracket and Toner

Supply Door Sensor.

4004D131AB

(28) Removal of the Manual Feed Paper Take-Up Sensor

1. Remove the Rear Right Cover.

2. Remove the Manual Bypass Unit.

☞

D-51

3. Remove the ground plate.

☞

D-50

4. Unplug one connector.

5. Remove the sensor fixing bracket and Manual

Feed Paper Take-Up Sensor.

4004D132AA

D-54

Page 59

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(29) Removal of the 1st Image Transfer Retraction Position Sensor

1. Remove the 1st Image Transfer Pressure/Retraction Motor.

☞

D-43

2. Remove four screws and the 1st Image Transfer

Retraction Position Sensor Assy.

4004D133AA

3. Unplug one connector.

4. Remove the sensor fixing bracket and 1st Image

Transfer Retraction Position Sensor.

4004D134AA

(30) Removal of the Double Feed Sensor

4004D135AA

4004D136AA

4004D137AB

1. Pressing the tabs of the right and left rails, slide

out the drawer.

2. Unplug one connector.

3. Remove one screw and the Double Feed Sensor.

D-55

Page 60

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(31) Removal of the Drawer Set Sensor and Drawer Paper Near-Empty Sensor

1. Slide out the drawer.

2. Remove the Rear Upper Cover, Rear Right Cover, Rear Left Cover, and Rear Cover.

3. Remove the MSC /PIC Board Box.

☞

D-41 (steps 1 through 8)

4. Remove four terminals.

✽

Terminal colors: White, blue, red, and orange from

top down

5. Remove two screws and the terminal harness

guide.

4004D138AB

6. Remove two screws and High Voltage Unit 1.

7. Unplug two connectors.

8. Remove the harness from one cord clamp and

one edge cover.

4004D140AB

4004D139AA

4004D141AB

9. Unplug three connectors.

10. Remove the harness from one edge cover.

11. Remove two screws and High Voltage Unit 1.

12. Remove one screw and the sensor assy.

13. Remove the harness from one edge cover and

unplug two connectors.

D-56

Page 61

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

14. Remove the sensor fixing bracket and take off

the Drawer Set Sensor and Drawer Paper NearEmpty Sensor.

4004D142AA

(32) Removal of the Left Door Switch

1. Remove the power supply box.

☞

D-47 (steps 1 through 5)

2. Remove two terminals.

3. Remove one screw and the Left Door Switch.

4004D099AB

(33) Removal of the Right Door Switch

4004D143AB

4004D144AB

1. Remove the MSC/PIC Board Box.

☞

D-43 (steps 1 through 8)

2. Remove two terminals.

3. Remove one screw and the Right Door Switch

Assy.

4. Remove one screw and the Right Door Switch.

D-57

Page 62

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(34) Removal of the Front Door Switch

1. Open the Front Door.

2. Open the Toner Supply Door.

3. Remove the Hopper Left Cover.

4. Remove two terminals.

5. Remove two screws and the Front Door Switch.

4004D145AA

(35) Removal of the Fusing Roller Rotation Detecting Sensor

1. Open the Right Door and Upper Right Door.

2. Slide out the Fusing Unit.

3. Unplug one connector.

4. Remove two screws and the Fusing Roller Rotation Detecting Sensor.

4004D146AA

(36) Removal of the Fusing Retraction Position Sensor

1. Remove the Fusing Pressure/Retra ction Motor

Assy.

☞

D-44 (steps 1 through 5)

2. Remove the sensor fixing bracket and Fusing

Retraction Position Sensor.

4004D147AA

(37) Removal of the Exit Sensor

1. Open the Upper Right Door.

2. Unplug one connector.

3. Remove the sensor fixing bracket and Exit Sensor.

4004D148AB

D-58

Page 63

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(38) Removal of the 2nd Image Transfer Pressure Position Sensor

1. Open the Right Door.

2. Remove the 2nd Image Transfer Roller.

☞

D-48 (steps 1 through 3)

3. Unplug one connector.

4. Remove one screw and the 2nd Image Transfer

Pressure Position Sensor.

4004D151AA

(39) R emoval of the Synchronizing Roller Sensor

1. Open the Right Door.

2. Remove the 2nd Image Transfer Roller.

☞

D-48 (steps 1 through 3)

3. Unplug one connector.

4. Remove two screws and the Synchronizing

Roller Sensor.

4004D152AA

(40) Removal of the OHP Detecting Sensor

1. Open the Right Door.

2. Remove the Paper Dust Remover Unit.

4004D153AA

3. Remove the 2nd Image Transfer Roller.

☞

D-48 (steps 1 through 3)

4. Unplug one connector.

5. Remove the sensor fixing bracket and OHP

Detecting Sensor.

4004D154AA

D-59

Page 64

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(41) Removal of the CD Paper Size Detecting Sensor Assy

Where Sensor

Assy is Installed

Rear

Front

4004D156AA

1. Remove the LED Unit.

☞

D-22

2. Slide out the drawer.

☞

D-55 (step 1)

3. Pressing the portion indicated by the arrow of the

CD Paper Size Detecting Sensor Assy, slide the

assy to the right and take it off.

4004D506AB

4. Unplug two connectors.

4004D155AB

(42) Removal of the Paper Take-Up Roll

1. Slide out the drawer.

2. Lock the Paper Lifting Plate into position.

3. Snap off one C-clip from the Paper Take-Up Roll

4. Slide the Paper Take-Up Roll Assy to the rear

4658D008AA

D-60

Assy.

and take its shaft off the front bushing.

Page 65

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

5. Snap off one C-clip and remove the Paper TakeUp Roll.

4658D009AA

(43) Removal of the Paper Separator Roll

1. Slide out the drawer.

2. Remove two screws and the Paper Separator

Roll mounting bracket assy.

4658D002AA

3. Take off the rubber stopper, shaft, spring, and

guide plate to remove the Paper Separator Roll

fixing bracket assy.

NOTE

• At reinstallation, make sure that the rubber stopper

4658D003AA

4. Snap off one E-ring and the Paper Separator Roll

4658D004AA

(44) Removal of High Voltage Unit 1

☞

D-45 (steps 1 through 2)

(45) Removal of High Voltage Unit 2/3

☞

D-56 (steps 1 through 8)

(46) Removal of DC Power Supply 1

☞

D-47 (steps 1 through 5)

is on the rear side of the copier.

Assy.

D-61

Page 66

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(47) Removal of the Charge Neutralizing Relay

1. Remove the MSC/PIC Board Box.

☞

D-41 (steps 1 through 8)

2. Remove four terminals.

3. Remove one screw and the Charge Neutralizing

Relay.

4004D160AB

(48) R emoval of the Waste Toner Full Detecting Sensor

1. Remove the LED Unit.

☞

D-22

2. Remove one screw and the Waste Toner Full

Detecting Sensor Cover.

4004D161AA

3. Unplug one connector and remove the Waste

Toner Full Detecting Sensor.

4004D162AB

(49) R emoval of the Waste Toner Bottle Set Sensor

1. Remove the LED Unit.

☞

D-22

2. Disengage two locking tabs and remove the

Waste Toner Bottle Set Sensor Assy.

4004D163AA

D-62

Page 67

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. Unplug one connector.

4. Remove one screw and the Waste Toner Bottle

Set Sensor.

4004D164AA

(50) Removal of the Toner Empty Switch (Y/M/C/Bk)

1. Open the Front Door.

2. Remove six screws and the Toner Empty Switch

Cover.

4004D111AB

3. Unplug one connector each and remove the

Toner Empty Switch.

4004D112AB

D-63

Page 68

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3. ADJUSTMENTS

• The adjustment procedures must be carried out in the order of printer and IR.

3-1. ADJUSTMENT JIGS AND TOOLS USED (SPECIAL TOOLS)

Part No. 111T00110

Part No. 11ZT00040

111T00120

4004D510AA

Scanner Positioning Jigs

Scanner Drive Cable

4002D503AA

Holding Jig

3-2. OTHER TOOLS USED (ACCESSORY PARTS OF MACHINE)

4004D185AA

Imaging Unit Pull-out Jig LED Cleaning Jig

4004D186AA

4004D187AA

LED Cleaning Jig Pad

D-64

Page 69

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

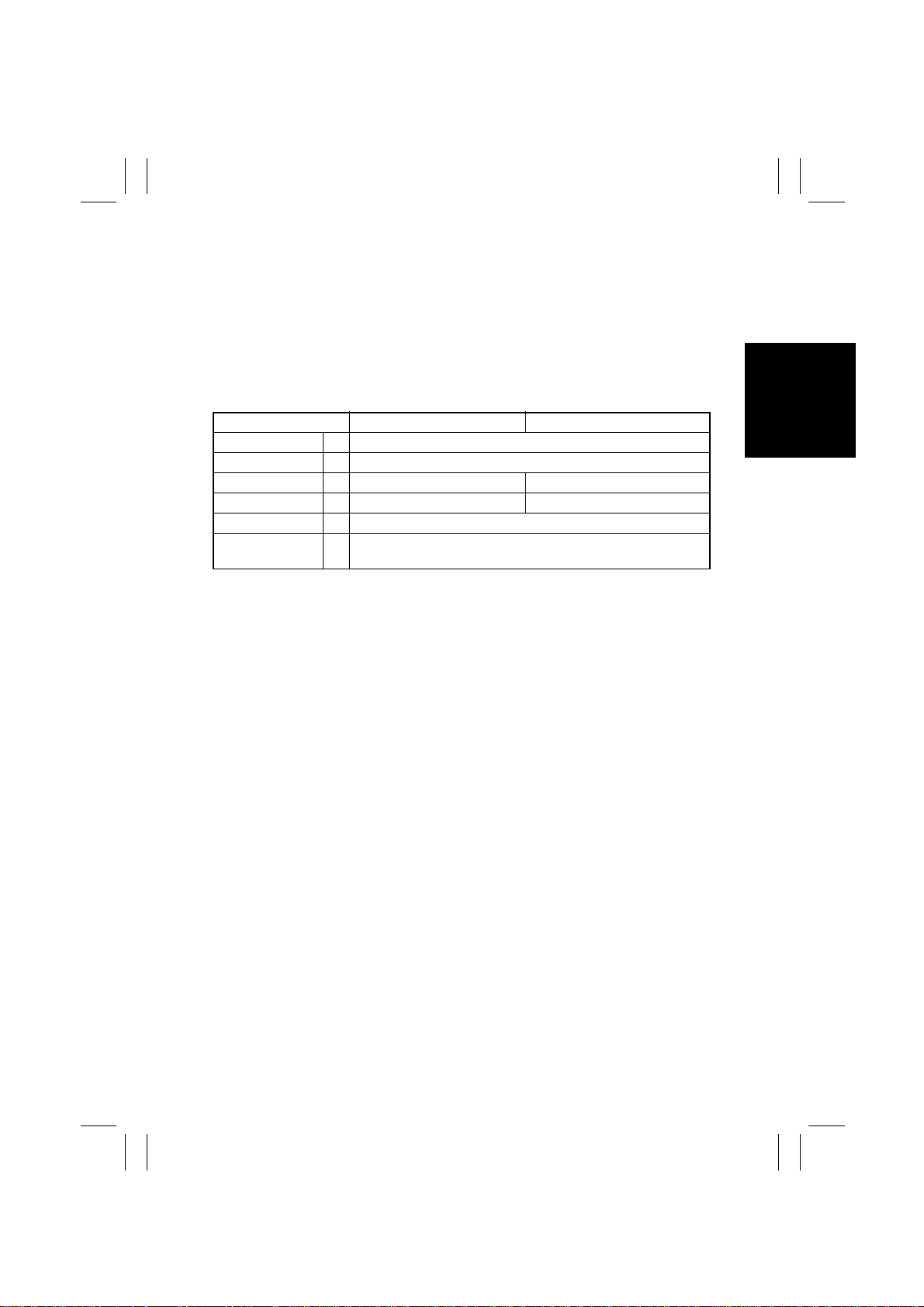

3-3. ADJUSTMENT REQUIREMENTS LIST

Adjustment Item Requirements Ref. Page

Touch Panel Adj. Automatically adjusted

Top Margin 5.0 ± 1.0 mm

Left Margin 3.0 ± 1.0 mm

Dup. Left Margin 3.0 ± 1.0 mm

Paper Loop Test print tilts ± 0.

Color Shift Correction

Fuser Nip 7 ± 0.5 mm

Printer

Fuser Temp. —

Fuser Speed —

Gradation Adjust —

PRT Max Density —

PRT Highlight —

Background Voltage Margin —

Left Image 0 ± 1.0 mm

Top Image 10 ± 1.0 mm

CD-Mag. 200 ± 1.0 mm

IR

FD-Mag. 300 ± 1.5 mm

Org. Detect Sensor Automatically adjusted

FD, CD, and tilt ± 0 with

reference to Bk.

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

D-69

D-70

D-72

D-73

D-74

D-75

D-78

D-80

D-81

D-87

D-88

D-88

D-89

D-82

D-83

D-84

D-85

D-86

D-65

Page 70

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

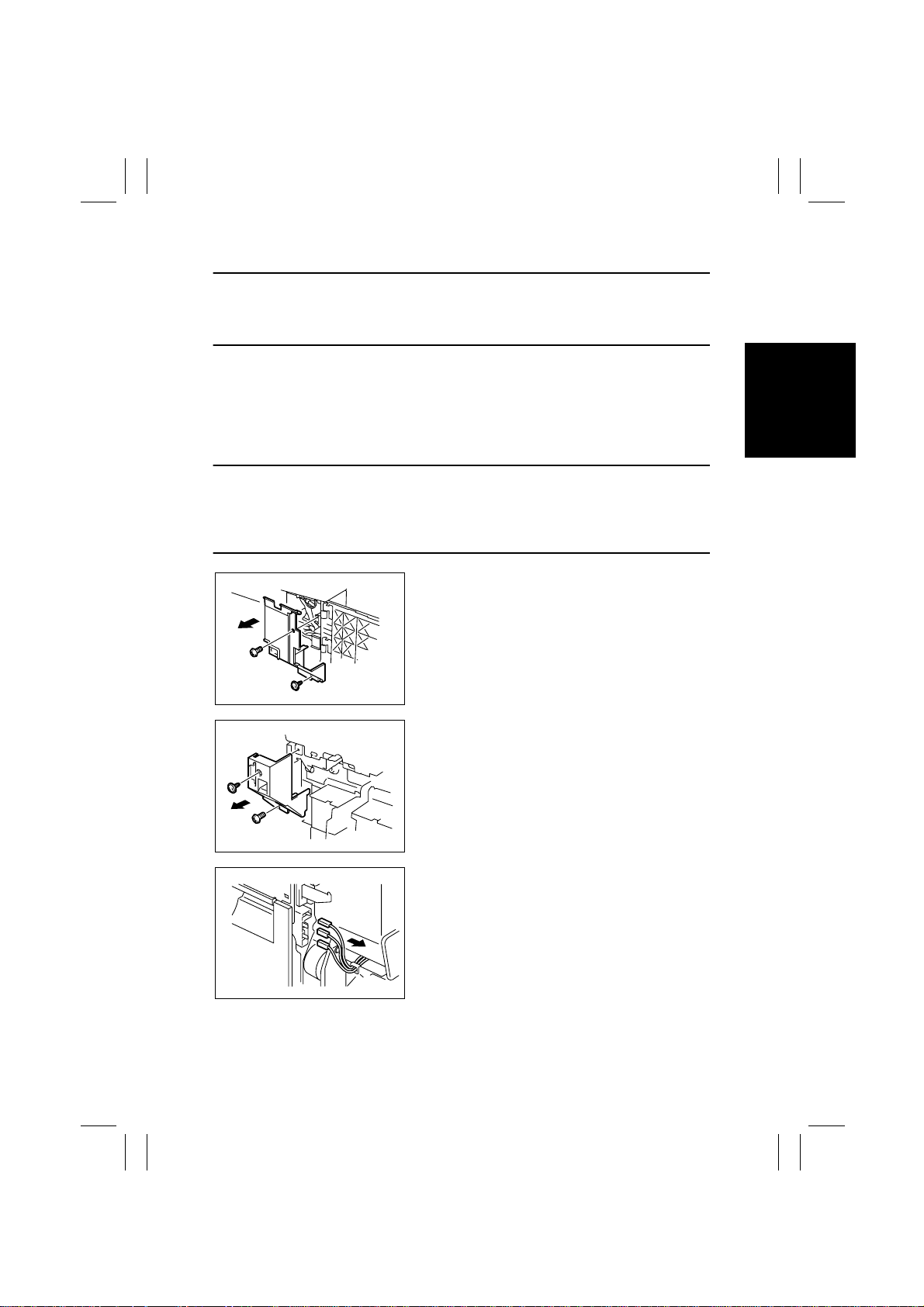

3-4. ADJUSTMENT OF SWITCHES

(1) Microswitches

The following microswitches are used in various parts of this copier.

Blue

(NC)

1136D008AA

Red

(COM)

Yellow

(NO)

Red

(COM)

1136D007AA

Wiring for the NO Type Wiring for the NC Type

NC (Normally-Closed) : Current flows between NC and COM when the actuator is open.

NO (Normally-Open) : Current flows between NO and COM when the actuator is

closed.

COM (Common) : Common contact for NC and NO.

Requirement

The gap between the switch and actuator should be

0.1 to 0.5 mm when the actuator is closed.

0.1 mm to

Actuator

COM

NC

NO

0.5 mm

1074D040AA

Out-of-Adjustment (When the actuator is closed)

• If the gap between the switch and actuator is too big, current dose not at times flow to NC

or NO.

• If there is no gap between the switch and actuator, the actuator is bent or the switch can

be broken.

D-66

Page 71

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3-5. ADJUSTMENT OF BELT TENSION

Checks after Adjustment

• Turn the timing belt and check that all the pulleys and grooves of the belt fit securely.

• Each belt should flex a little when the belt is lightly pressed with a finger.

Reference

• Since a given tension is applied by a tension spring to the Tension Lever that maintains

the tension of each timing belt, adjustment is completed by re-tightening the mounting

screw after it has been loosened.

(1) Adjustment of the Scanner Motor Timing Belt

1. Remove the Original Glass Cooling Fan Motor.

☞

D-26

2. Loosen the three screws that secure the Scanner

Motor mounting bracket.

4004D188AC

4004D231AB

3. With the Scanner Drive Gear mounting screw

positioned on the motor side, move the Scanner

Motor to the right and left three times.

4. Tighten the three screws that secure the Scanner

Motor mounting bracket.

D-67

Page 72

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

3-6. ELECTRICAL/IMAGE ADJUSTMENT

(1) Accessing the Tech. Rep. Mode

1. Press the Utility key.

2. Touch [Meter Count].

3. Press the following keys in this order:

Stop → 0 → 0 → Stop → 0 → 1

(2) Producing a Test Print

1. Call the Tech. Rep. Mode to the screen.

2. Touch [Test Print].

3. Select the desired test pattern type.

4. Make the necessary settings.

5. Press the Start key.

✽

Press the Stop key to terminate the Test Print function.

D-68

Page 73

FrameMaker Ver.5.5E(PC) 7915/7920 DIS/REASSEMBLY, ADJUSTMENT

01.02.09

(3) Touch Panel Adj.

NOTE

• Make this adjustment if the Touch Panel is slow to respond to a pressing action.

1. Press the following keys:

Stop → 0 → Stop → 3

2. Using the tip of a pen or similar object, touch the

four crosses (+) on the screen in sequence.

NOTES

• These crosses may be touched in any order; but

be sure to touch the center of each cross.

• Use care not to damage the screen surface with

the tip of the pen.

1155D191CA

3. The cross touched changes into a grid marker

that consists of a square with a cross superimposed.

4. Touch [END].

1155D192CA

D-69

Page 74