Page 1

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

DF-331

SERVICE MANUAL

11563

Page 2

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

CONTENTS

GENERAL,

MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. COMPONENT IDENTIFICATION .................................. ........................... .......M-3

3. CROSS-SECTIONAL VIEW ............................................................................M-4

4. DRIVE SYSTEM ..............................................................................................M-5

5. ELECTRICAL COMPONENT LAYOUT ...........................................................M-6

6. DESCRIPTION OF MODES ............................................ .............. ..................M-7

6-1. Mixed Original Mode . ...............................................................................M-7

6-2. 1-Sided Mode ..........................................................................................M-7

6-3. 2-Sided Mode ..........................................................................................M-7

6-4. Single Feed Mode ....................................................................................M-7

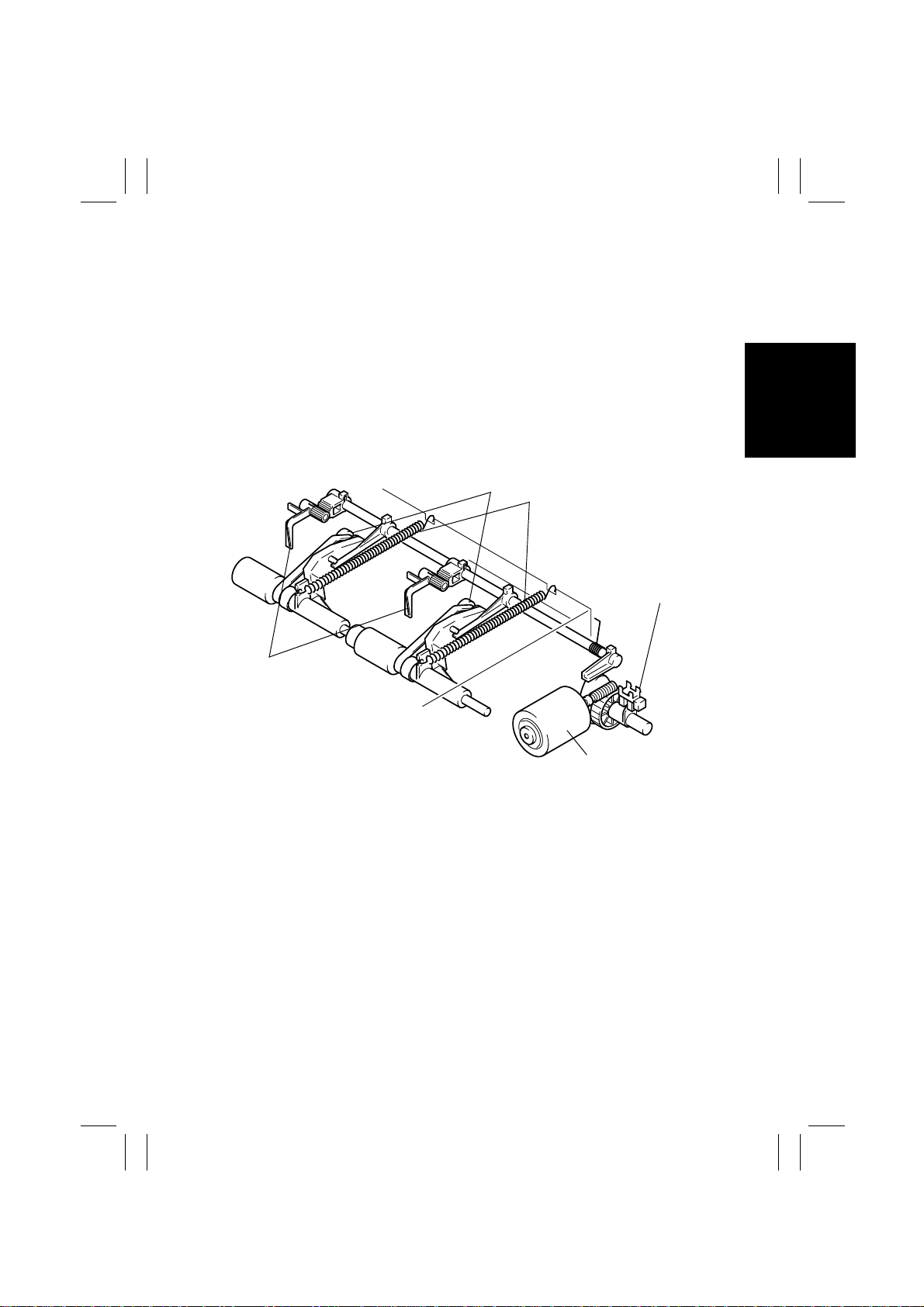

7. DOCUMENT TAKE-UP/FEEDING MECHANISM ............................................M-8

7-1. Parts Identification ...................................................................................M-8

7-2. Document Pick-Up Mechanism ...............................................................M-9

7-3. Document Take-Up Mechanism ..............................................................M-11

8. DOCUMENT TRANSPORT MECHANISM ......................................................M-13

8-1. Parts Identification ................................................................................... M-13

8-2. Document Transport Mechanism .............................................................M-13

9. TURNOVER/EXIT MECHANISM .....................................................................M-15

9-1. Parts Identification ................................................................................... M-15

9-2. Document Transport Mechanism .............................................................M-15

9-3. Turnover/Exit Switching Mechanism ........................................................M-17

10. SCALE DRIVE MECHANISM ..................... .....................................................M-18

10-1.Parts Identification ....................... ............. .... .... ............. .... ............. .... .... .M-18

10-2.Pressing of the Scale Drive Mechanism ..................................................M-18

10-3.Scale Drive Mechanism ...........................................................................M-19

10-4.Thin Paper Mode ....................................................... .... ...... ........... ...... ...M-19

11. MISCELLANEOUS ..........................................................................................M-20

11-1.Document Size Detection Mechanism .....................................................M-20

(1) Document Width Detection ..............................................................M-20

(2) Document Length Detection ............................................................ M-20

(3) Document Size Detection ................................................................M-21

11-2.15° Open Detection Mechanism ..............................................................M-22

11-3.Raised/Lowered Position Detection Mechanism .....................................M-22

TEST MODES

1. OUTLINE OF THE TEST MODES ...................................................................S-1

1-1. Test Mode Setting Procedure ..................................................................S-1

1-2. Types of Test Modes ...............................................................................S-1

2. PAPER PASSAGE CHECK ............................................................................. S-2

2-1. Paper Passage Modes ............................................................................S-2

2-2. Paper Passage Check Procedure ...........................................................S-2

2-3. Indication by LEDs in Paper Passage Check ..................................... .... .S-3

(1) Indication by LEDs in closure failure .......................................... .....S-3

i

Page 3

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

(2) Indication by LEDs in Misfeed, Trouble and Warning ......................S-3

3. UNIT CHECK ..................................... ............................ ........................... .......S-4

3-1. Unit Check Modes ...................................................................................S-4

3-2. Unit Check Procedure ..............................................................................S-4

(1) Pick-Up Motor check ...................... .................................................S-4

(2) Take-Up Motor check ....................... ........................... ....................S-5

(3) Main Motor check .............. ............................ ........................... .......S-5

(4) Turnover/Exit Motor che ck ................................... ............... .............S-5

(5) Scale Drive Motor check .................................................................. S-6

(6) Turnover Solenoid check .................................................................S-6

4. SENSOR CHECK ................................ ............................ ........................... .....S-7

4-1. Sensor Check Mode ............................................................................... .S-7

4-2. Sensor Check Proc edure ....................................... ........................... .......S-8

(1) Sensor Check 1 check .............. ........................... ............................S-8

(2) Sensor Check 2 check .............. ........................... ............................S-8

5. BOARD CHECK ..............................................................................................S-9

5-1. Board Check Mode .................................................................................. S-9

5-2. Board Check Procedure .......................................................................... S-9

DIS/REASSEMBLY, ADJUSTMENT

1. MAINTENANCE SCHEDULE ..........................................................................D-1

2. DISASSEMBLY ...............................................................................................D-2

2-1. Removal of the Transport Belt .................................................................D-2

2-2. Removal of the Pick-Up Rolls, Take-Up Rolls, and Separator Pads .......D-3

3. ADJUSTMENTS ..............................................................................................D-5

3-1. Adjustment of Ske w in the ADF ............................................. ..................D-5

3-2. Adjustment of the Document Feed Tray Reference Position ...................D-6

3-3. Adjustment of the Single Feed Tray Reference Position .........................D-7

3-4. Adjustment of the Document Stop Position in the 1-Sided and

1-Sided Mixed Original Mode ..................................................................D-8

3-5. Adjustment of the Document Stop Position in the 2-Sided Mode ............D-9

3-6. Adjustment of the Document Stop Position in the Single Feed Mode .....D-10

3-7. Adjustment of Turnover Solenoid ............................................................D-11

TROUBLESHOOTING

1. MISFEED DETECTION ................................ ............... ........................... .........T-1

2. MISFEED TROUBLESHOOTING PROCEDURES .........................................T-3

3. Closure Failure Detection ................................................................................T-7

4. Time chart .................................... ............... ........................... ..........................T-8

4-1. 1-Side Original Mode ...............................................................................T-8

4-2. Mixed Original Mode ................................................................................T-9

4-3. 2-Side Original Scanning Mode ...............................................................T-10

4-4. Single Feed Mode ....................................................................................T-11

ii

Page 4

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

GENERAL,

MECHANICAL/ELECTRICAL

Page 5

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

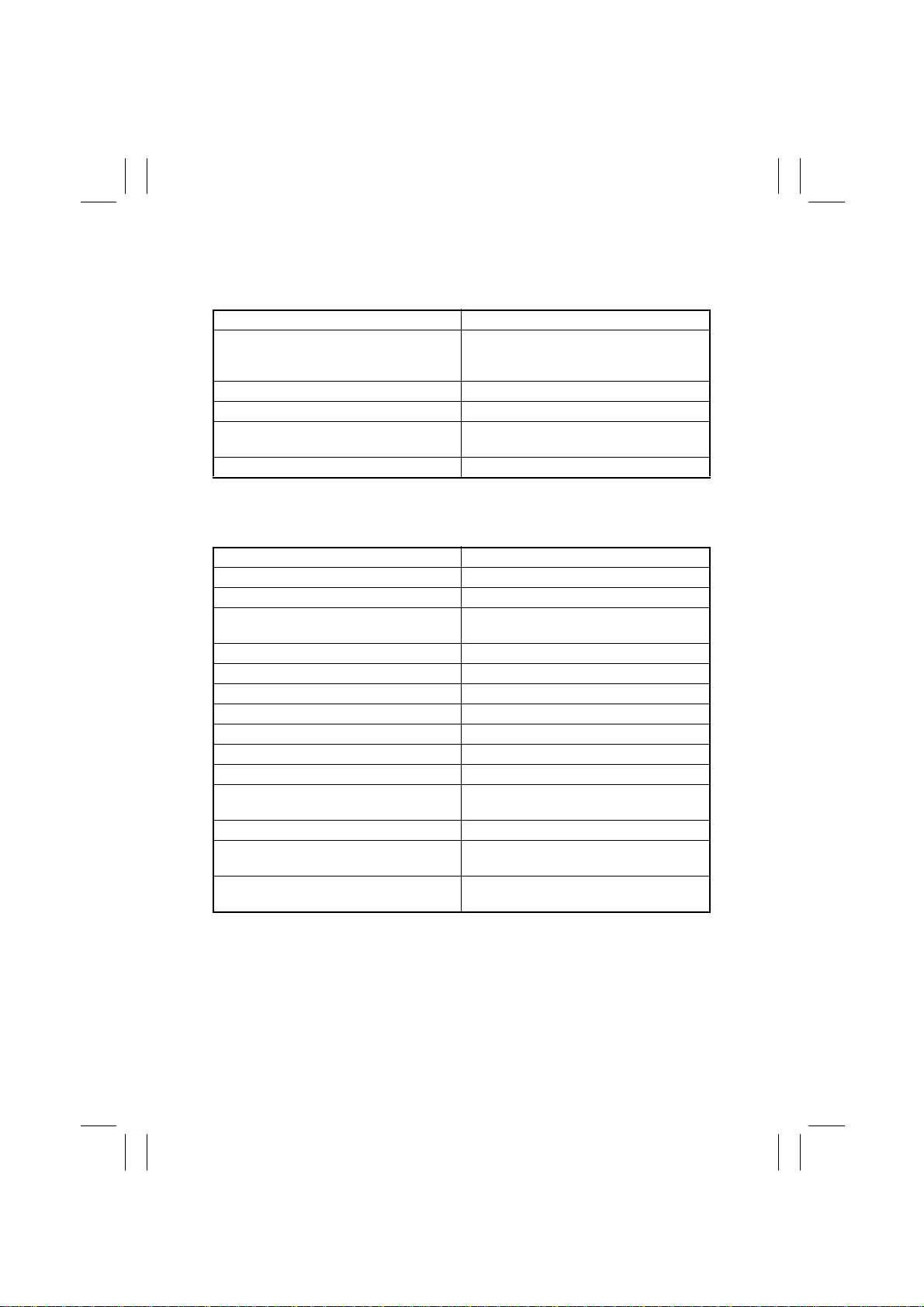

1. SPECIFICATIONS

Name : Duplexing Document Feeder

Type : Paper Take-Up : Take-up from top of stack, U-turn feeding

Installation : Mounted on the copier

Type of Document : Plain paper : 1-Sided mode - 50 g/m² to 110 g/m²

Detectable Document

Sizes

Capacity : Document Feed Tray: 50 sheets -- 80 g/m²

Alignment : Rear Document Edge Guide

Document Loading : Face up

Modes : Mixed Original

Power Source : DC 24 V -- supplied from the copier

Power Consumption : 60 W or less

Dimensions : Width 603 mm

Weight : 12.0 kg

Operating Environment : Same as copier

Transport : Single-belt transport

Turnover : Loop turnover

Ejection : Straight ejection

2-Sided mode - 60 g/m² to 90 g/m²

Single Feed mode - 35 g/m² to 200 g/m²

: Metric Area (Standard)

A5 C/L, B5 C/L, A4 C/L, B4 L, A3 L, 11 × 15 L,

8-1/2 × 11 L, 8 × 13 L

Inch Area (Standard)

A4 L, 5-1/2 × 8-1/2 C/L, 8-1/2 × 11 C/L, 8-1/2 × 14 L,

11 × 15 L, 11 × 17 L

Document Exit Tray: 50 sheets -- 80 g/m²

1-Sided

2-Sided

Single Feed

Height 110 mm

Depth 502 mm -- excluding Document Exit Tray

M-1

Page 6

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

Originals Which Should

Not be Used

Type of Original Possible Trouble

Sheets stapled or clipped together Take-up failure, damaged sheet, defective

Sheets glued together Take-up failure, damaged sheet

Sheets folded, torn, or wrinkled Take-up failure, damaged sheet

Sheets severely curled Sheets mis-fed due to being dog-eared or

Sheets weighing less than 40 g/m² Damaged sheet

Originals for Which Feeding is not Guaranteed

Type of Original Possible Trouble

Pieces of paper pasted up on a sheet Folded or torn pasted-up pieces

Slightly curled sheets: curl 10 to 15 mm Dog-eared pages, ejection failure

Heat-sensitive paper Folded leading edge, ejection failure, trans-

Coated sheets Take-up failure, transport failure

Translucent paper Take-up failure, transport failure

Sheets just fed out of the copier Take-up failure, transport failure

Perforated sheets: loose-leaf, etc. Multiple feed due to burrs in perforations

Sheets with two to four holes Transport failure

Sheets folded in half or Z-folded Transport failure, distorted image

Sheets weighing 40 g/m² to 50 g/m² Folded leading edge

Sheets with surface irregularities:

letterhead, etc.

Pencil-written sheets Dirty originals

Folded sheets Distorted image, multiple feed, take-up

Sheets of a size outside the range detectable by the ADF

: The following types of originals, if used with the ADF, are

very likely to cause trouble.

drive mechanism due to jammed staples or

clips.

fed in askew

: The following types of originals, if used with the ADF, may

or may not cause trouble.

port failure

Take-up failure

failure

Void image

M-2

Page 7

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2. COMPONENT IDENTIFICATION

1

8

9

10

2

3

4

7

11

5

4490M001AA

6

1. Hookup Cord

2. Rear Cover

3. Document Feed Tray

4. Upper Cover

5. Single Feed Tray

6. Take-Up Cover

7. Document Edge Guide

13

12

4652M501AA

8. Exit Cover

9. Document Exit Tray

10. Transport Belt

11. Magnet

12. Holder Touch Lever

13. Scale Drive Lever

M-3

Page 8

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3. CROSS-SECTIONAL VIEW

22

21

20

17

19

18

1. Pick-Up Roll

2. Empty Sensor PC1

3. Take-Up Roll

4. Separator Pad

5. Registration Sensor PC2

6. Registration Driven Roller

7. Registration Drive Roller

8. Single Feed Empty Sensor PC9

9. Single Feed Roller

10. Single Feed Roll

11. Width Sensor 1/2/3 PC5/6/7

12. Transport Belt Drive Roller

13. Transport Belt

16

15

2423

25

14

14. Transport Rolls

15. Transport Belt Driven Roller

16. Transport Roll

17. Turnover Roller

18. Exit Sensor PC3

19. Exit Roller

20. Exit Roll

21. Turnover/Exit Switching Plate

22. Turnover Roll

23. Turnover Sensor PC4

24. Turnover Roll

25. Transport Roller

123456

13

7

8

9

10

11

12

4652M502AA

M-4

Page 9

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

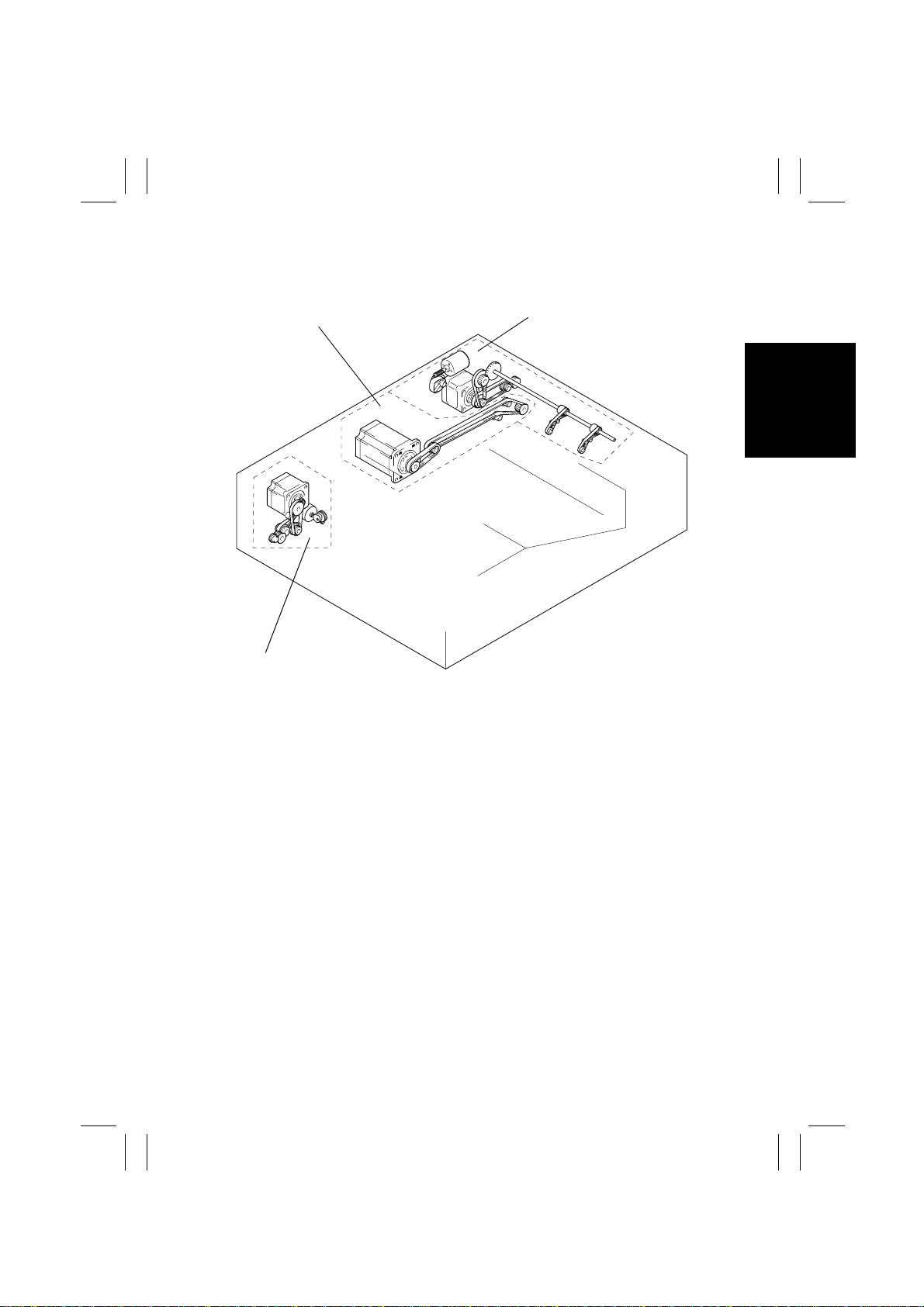

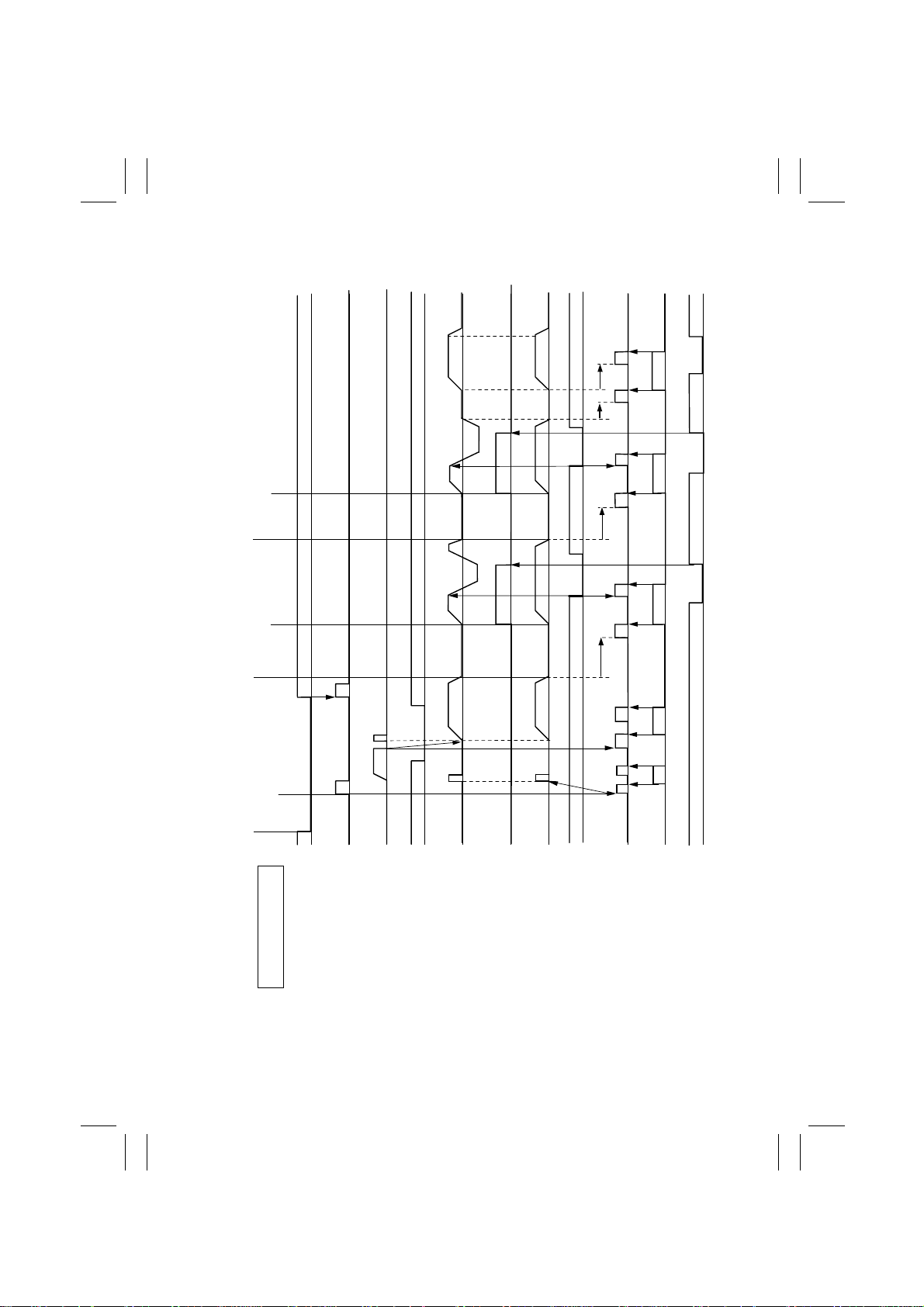

4. DRIVE SYSTEM

Document Transport

Turnover/Exit/Scale Drive

Document Take-Up/Feeding

4652M503AA

M-5

Page 10

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

5. ELECTRICAL COMPONENT LAYOUT

M2

SL1

PC11

M4

PC3

PWB-A

M5

PC8

M1

M3

PC4

PC12

PC1

PC9

PC2

PC10

PC5

PC6

PC7

4652M504AA

Code Name Code Name

PWB-A

M1

M2

M3

M4

M5

SL1

PC1

PC2

PC3

PC4

Main Control Board

Pick-Up Motor

Take-Up Motor

Main Motor

Turnover/Exit Motor

Scale Drive Motor

Turnover Solenoid

Empty Sensor

Registration Sensor

Exit Sensor

Turnover Sensor

PC5

PC6

PC7

PC8

PC9

PC10

PC11

PC12

Paper Width Sensor 1 (Option)

Paper Width Sensor 2

Paper Width Sensor 3 (Option)

Pick-Up Sensor

Single Feed Empty Sensor

Take-Up Cover Open/Close

Sensor

Exit Cover Open/Close Sensor

Scale Drive Sensor

M-6

Page 11

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

6. DESCRIPTION OF MODES

6-1. Mixed Original Mode

• The copier detects the size of each page of the document as it is taken up and fed in and,

according to the size detected, feeds the copy paper of the corresponding size selected

from among the available paper sources.

• The mode is mainly used when making copies from a document set consisting of pages

of different sizes.

6-2. 1-Sided Mode

• When a multi-page document is being copied, the copier detects the size of only the first

page of the document and copies the subsequent pages based on that size detection.

• This saves the copier the time required for detecting the sizes of the subsequent pages

of the document, making for a faster and more efficient paper feed timing.

NOTE

If a document of pages of varying sizes is used in this mode, image trouble could result

including missing copy image. (The system does not, however, force a misfeed condition.)

6-3. 2-Sided Mode

• The ADF automatically turns over 2-sided originals for a speedy copying operation (copies are made in the order of the first and second pages).

6-4. Single Feed Mode

• This mode may be used when the user wants to make copies from an original for which

feeding is not guaranteed (pasted-up sheet, translucent paper, heat-sensitive paper,

etc.).

• When a single original is inserted into the Single Feed Tray, the ADF automatically takes

it up and feeds it in to let the copier run a single copy cycle.

• Each original is transported at a low speed.

M-7

Page 12

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

7. DOCUMENT TAKE-UP/FEEDING MECHANISM

7-1. Parts Identification

1

16

15

14

13

12

1. Take-Up Motor M2

2. Empty Sensor PC1

3. Single Feed Roller

4. Single Feed Empty Sensor PC9

5. Registration Roller

6. Registration Sensor PC2

7. Paper Width Sensor 1 PC5: Option

8. Paper Width Sensor 2 PC6

9. Paper Width Sensor 3 PC7: Option

2

3

4

5

11

10

10. Take-Up Cover Open/Close Sensor

PC10

11. Take-Up Rolls

12. Separator Pads

13. Pick-Up Rolls

14. Document Stoppers

15. Pick-Up Sensor PC8

16. Pick-Up Motor M1

6

7

8

9

4652M505AB

M-8

Page 13

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

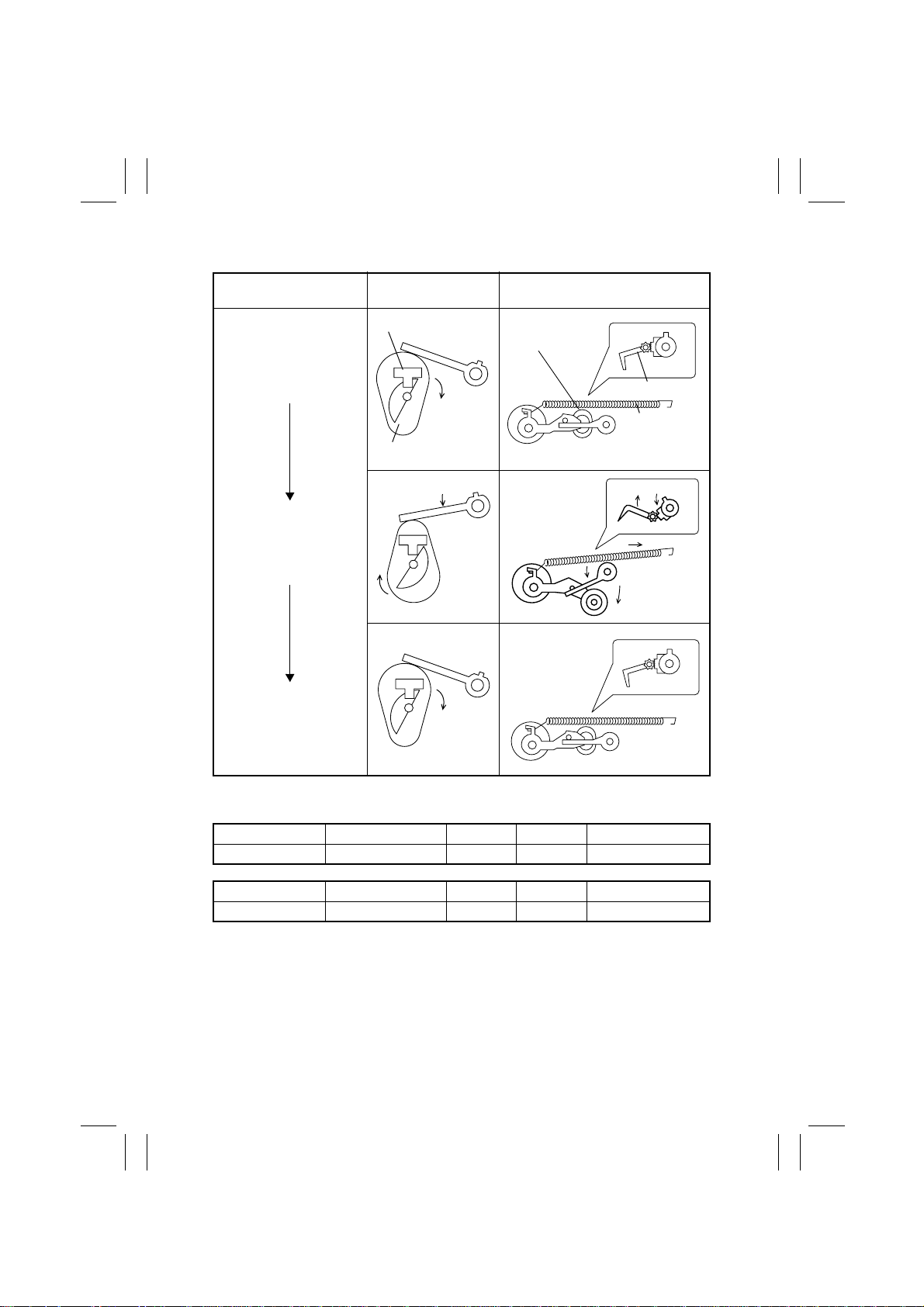

7-2. Document Pick-Up Mechanism

• The document pick-up mechanism consists of the Document Stoppers and Pick-Up

Rolls.

• The Document Stoppers determine the leading edge position of the document loaded in

the ADF.

• They are in the lowered position when in their standby position and raised when a document take-up sequence is started.

• The Pick-Up Rolls are in the raised position in their standby state and lowered when a

document take-up sequence is started, pressing the document set downward during the

sequence with the tension of the Document Pressure Springs.

• The operation of the Document Stoppers and Pick-Up Rolls is controlled by Pick-Up

Motor, Pick-Up Sensor, and a cam.

Pick-Up Rolls

Document Pressure Springs

Pick-Up Sensor PC8

Document Stoppers

Pick-Up Motor M1

4490M007AB

M-9

Page 14

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

✽

Control of Operation of the Document Stoppers and Pick-Up Rolls

Home position

Pick-Up Rolls press document; Document Stoppers

retract.

Home position

PC8 and Cam

Operation

Pick-Up Sensor PC8

Cam

4490M008AA

4652M506AA 4652M517AA

Document Stoppers/Pick-Up

Rolls Operation

Pick-Up Roll

Document Stopper

Document

Pressure Spring

4490M009AA

4490M008AA

✽

Pick-Up Motor Control

CONTROL SIGNAL ON OFF WIRING DIAGRAM

M1 PWB-A PJ8A-2 L H 7 - H

CONTROL SIGNAL Blocked Unblocked WIRING DIAGRAM

PC8 PWB-A PJ12A-2 L H 3 - I

M-10

4490M009AA

Page 15

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

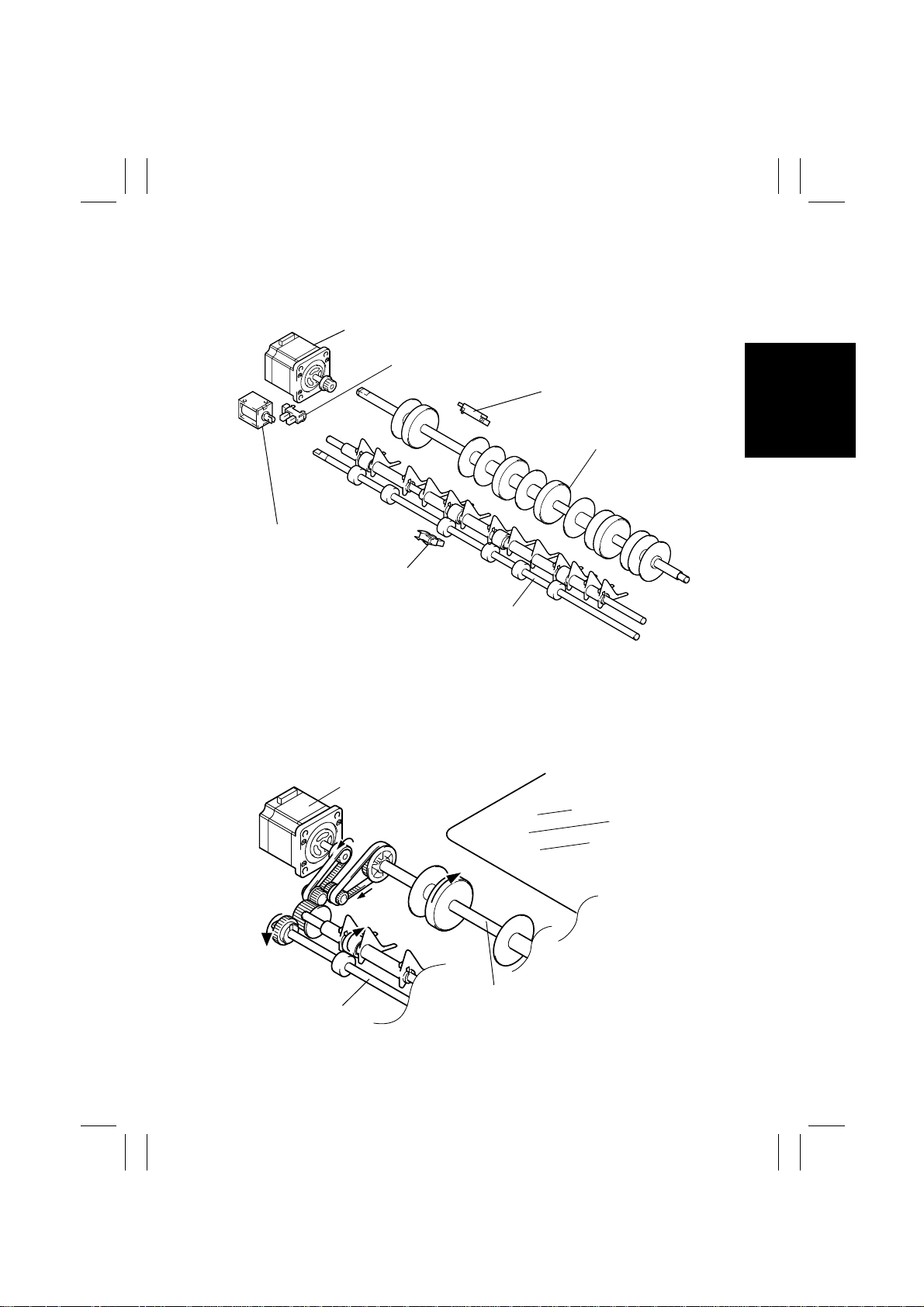

7-3. Document Take-Up Mechanism

• The Pick-Up Rolls and Take-Up Rolls turn to transport the document loaded in the Document Feed Tray up to the Registration Roller.

• The Single Feed Roller, on the other hand, turns to transport the document placed in the

Single Feed Tray.

• The Pick-Up Rolls, Take-Up Rolls, and Single Feed Roller are driven by Take-Up Motor.

• To drive the Single Feed Roller, Take-Up Motor is turned backward, at which time the

Take-Up Roll Shaft also turns backward. Because of the functioning of the one-way pulley, however, the backward rotation of the shaft is not transmitted to the Pick-Up Rolls or

Take-Up Rolls.

• The Front Separator Pads and Separator Pads together function to prevent double feed

when two or more pages of a document set are taken up.

One-Way Pulley

Take-Up Motor M2

Take-Up Roll Shaft

Pick-Up Rolls

Front Separator Pads

Separator Pads

Take-Up Rolls

Single Feed

Roller

Registration Roller

4490M012AD

M-11

Page 16

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

✽

Take-Up Motor Control

• The pulse signals output from PJ7A on PWB-A are supplied to the two coils inside TakeUp Motor and the combination and sequence of the pulse signals energized are varied to

turn Take-Up Motor forward or backward.

• The distance over which an original is transported is detected by counting the number of

pulses generated.

PWB-A

PJ7A-5 L H H L

PJ7A-4 L L H H

PJ7A-6 H L L H

PJ7A-3 H H L L

Forward

Rotation

Backward

Rotation

Sequence

1234

M2 PWB-A PJ7A-3~6 Pul se Output 7 - I

Pick-Up Rolls and Take-Up Rolls are turned to take up an

original.

The Single Feed Roller is turned to take up an original.

CONTROL SIGNAL ON OFF WIRING DIAGRAM

M-12

Page 17

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

8. DOCUMENT TRANSPORT MECHANISM

8-1. Parts Identification

1

4

2

3

4650M507AA

1. Main Drive Motor M3

2. Registration Driven Roller

3. Registration Drive Roller

4. Transport Belt

8-2. Document Transport Mechanism

• Rotation of the Registration Rollers and Transport Belt results in the original fed from the

Document Feed Tray or Single Feed Tray being transported up to the Original Width

Scale.

• The Registration Rollers and Transport Belt are driven by Main Drive Motor.

Main Drive Motor M3

Registration Rollers

Transport Belt

4490M014AA

M-13

Page 18

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

✽

Main Drive Motor Control

• The pulse signals output from PJ6A on PWB-A are supplied to the two coils inside Main

Drive Motor and the combination and sequence of the pulse signals energized are varied

to turn Main Drive Motor forward or backward.

• The distance over which an original is transported is detected by counting the number of

pulses generated.

• The motor speed is controlled by varying the cycle “A” of the pulse signal.

PWB-A

PJ6A-3 L H H L

PJ6A-5 L L H H

PJ6A-4 H L L H

PJ6A-6 H H L L

Forward

Rotation

Backward

Rotation

Sequence

1234

M3 PWB-A PJ6A-3~6 Pulse O utput 8 - G

A

Transports the original toward the Original Width Scale.

Transports the original, which has been turned over, towards

the take-up section.

CONTROL SIGNAL ON OFF WIRING DIAGRAM

M-14

Page 19

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

9. TURNOVER/EXIT MECHANISM

9-1. Parts Identification

Turnover/Exit Motor M4

Exit Cover Open/Close Sensor PC11

Turnover Solenoid SL1

Exit Sensor PC3

Turnover Sensor PC4

Turnover Roller

Exit Roller

4490M015AC

9-2. Document Transport Mechanism

• The Turnover Roller and Exit Roller turn over or feed out of the ADF the original transported from the transport mechanism.

• The Turnover Roller and Exit Roller are driven by Turnover/Exit Motor.

Turnover/Exit Motor M4

Transport Belt

Turnover Roller

Exit Roller

4490M016AC

M-15

Page 20

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

✽

Turnover/Exit Motor Control

• The pulse signals output from PJ4A on PWB-A are supplied to the two coils inside Turnover/Exit Motor to energize Turnover/Exit Motor.

• The distance over which an original is transported is detected by counting the number of

pulses generated.

• The motor speed is controlled by varying the cycle “A” of the pulse signal.

PWB-A

PJ4A-3 L H H L

PJ4A-5 L L H H

PJ4A-4 H L L H

PJ4A-6 H H L L

Energized

Sequence

1234

A

Transports the original towards the turnover or exit

mechanism.

CONTROL SIGNAL ON OFF WIRING DIAGRAM

M4 PWB-A PJ4A-3~6 Pulse O utput 8 - C

CONTROL SIGNAL Blocked Unblocked WIRING DIAGRAM

PC3 PWB-A PJ11A-2 L H 3 - C

PC4 PWB-A PJ3A-5 L H 3 - C

PC11 PWB-A PJ3A-2 L H 3 - B

M-16

Page 21

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

9-3. Turnover/Exit Switching Mechanism

• The turnover/exit switching mechanism uses the Turnover/Exit Switching Plate which is

swung downward or upward to change the document path, thereby allowing the original

to be turned over or ejected from the ADF.

• The switching plate is actuated as Turnover Solenoid is energized and deenergized.

✽

Arrow indicates the direction of motion when SL1 is energized.

Turnover/Exit Switching Plate

Exit Roller

Turnover/Exit Switching Shaft

Turnover Solenoid

SL1

<For Exit> SL1-Deenergized <For Turnover> SL1-Energized

Turnover Roller

Turnover/Exit Switching Plate

Exit Roller

SL1 PWB-A PJ5A-2 L H 8 - B

Original

CONTROL SIGNAL ON OFF WIRING DIAGRAM

4652M508AA 4652M509AA

Turnover/Exit Switching Lever

4652M510AA

M-17

Page 22

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

10. SCALE DRIVE MECHANISM

10-1. Parts Identification

Scale Drive Motor M5

Scale Drive Cam

Scale Drive Sensor

PC12

Actuator

Scale Drive Lever

Positioning Lever

4652M511AA

10-2. Pressing of the Scale Drive Mechanism

• The Scale Drive Mechanism is pressed against the Scale Holder to ensure positive

action of the Original Width Scale.

Positioning Lever

Scale Drive Lever

Fulcrum

Original Width Scale

Scale Holder

Tension Spring

Scale Drive Motor M5

4652M512AA

M-18

Page 23

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

10-3. Scale Drive Mechanism

• The Original Width Scale is installed on the left edge of the Original Glass. To allow the

originals to be turned over and ejected out of the ADF even in this configuration, a mechanism is provided that retracts the Original Width Scale and brings it back to the original

position.

✽

Control of Operation of the Scale Drive Lever

Scale Drive Sensor and Cam Operation

Home Position

Cam

Actuator

Scale Drive Sensor

PC12

Scale Drive Lever

Scale Drive Lever Down

Original Width Scale

is Retracting

Scale Drive Lever Up

Home Position

M5 PWB-A PJ14A -2 L H 7 - A

CONTROL SIGNAL Blocked Unblocked WIRING DIAGRAM

PC12 PWB-A PJ13A-2 H L 3 - D

Original Width Scale

Rotation

Down

Rotation

Up

CONTROL SIGNAL ON OFF WIRING DIAGRAM

Scale Holder

Stops rotating when

sensor is unblocked.

Stops rotating when

sensor is blocked.

4652M513AA

4652M514AA

4652M515AA

10-4. Thin Paper Mode

• A function is provided to prevent a thin original from being bent as it is brought to contact

with the Original Width Scale. It brings the original to a stop at an exact point without letting it hit against the Original Width Scale. In the Thin Orig. mode, the Original Width

Scale is in the retracted position.

✽

Set method: Utility Administrator mode Expert User’s Mode Thin Orig.

Functioning mode: 1-Side No Detect mode, 1-Side Mixed orig. mode, Single feeding mode

M-19

Page 24

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

11. MISCELLANEOUS

11-1. Document Size Detection Mechanism

• The document size is determined by means of two different systems of document width

detection and document length detection.

(1) Document Width Detection

• The width of an original is detected by the combination of the “L” and “H” states of Width

Sensors 1 PC5, 2 PC6, and 3 PC7, as detected while the original is being taken up.

• Each sensor is located as follows with reference to the Document Edge Guide in the

rear.

PC5: 236.5 mm; PC6: 268 mm; PC7: 288 mm

Paper Width Sensor 1 PC5 (Option)

Paper Width Sensor 2 PC6

Paper Width Sensor 3 PC7 (Option)

4652M518AA

(2) Doc ument Lengt h Detection

• The length of an original is detected by counting the number of pulses generated by Main

Motor for the period of time from when the Registration Roller starts turning to when the

trailing edge of the original moves past Registration Sensor.

• In the Single Feed mode, the period of time for counting the number of pulses is up to

when the trailing edge of the original moves past Single Feed Empty Sensor.

M-20

Page 25

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

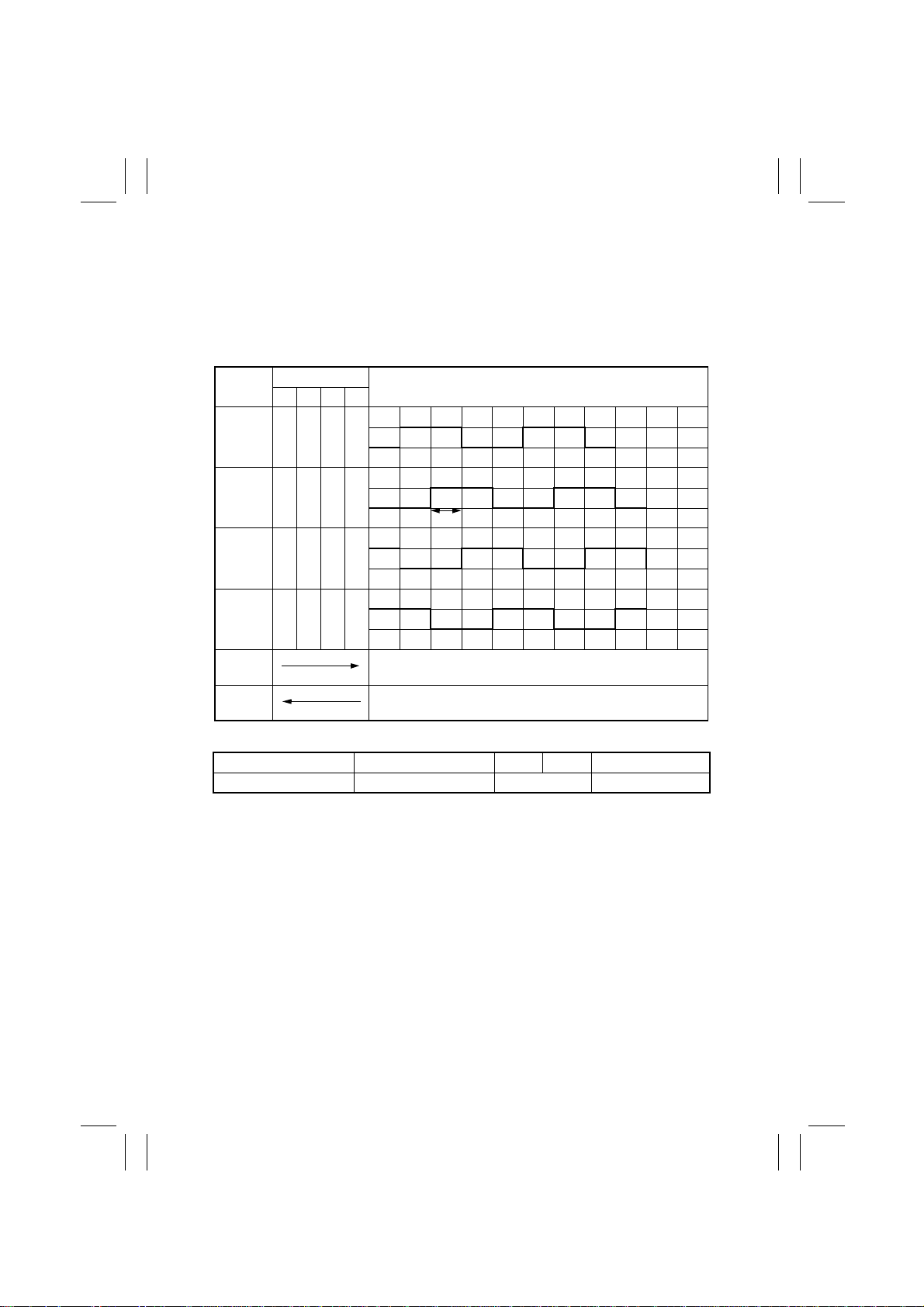

(3) Document Size Detection

• Details of Paper Width Sensor/Document Length and Detectable Document Sizes

Standard (PC6 only)

Metric Area Inch Area

Document Length

PC6

(mm)

Document Size PC6

~ 158.5 A5 C

158.6 ~ 192.0 B5 C 149.8 ~ 225.9 5-1/2

192.1 ~ 220.0 A5 L 226.0 ~ 289.4 8-1/2

Document Length

(mm)

~ 149.7 5-1/2

Document Size

×

8-1/2 C

×

8-1/2 L

×

220.1 ~ 267.0 B5 L 289.5 ~ 307.0 A4 L

H

267.1 ~ 289.4 8-1/2

289.5 ~ 307.0 A4 L 365.7 ~ 11

307.1 ~ 340.0 8

×

11 L 307.1 ~ 365.6 8-1/2 × 14 L

×

13 L

H

×

17 L

340.1 ~ 374.0 B4 L

374.1 ~ A3 L

~ 220.0 A4 C

220.1 ~ 391.0 11

L

×

15 L 226.0 ~ 391.0 11 × 15 L

L

~ 225.9 8-1/2

391.1 ~ A3 L 391.1 ~ 11

×

×

17 L

11 L

11 C

Standard with Options (PC5, 6, 7)

Paper Width sensor

PC5 PC6 PC7 Metric Area Inch Area

Document Length

(mm)

Document Size

~ 158.5 A5 C 5-1/2

158.6 ~ 225.9 A5 L 5-1/2

226.0 ~ 267.0 B5 L

×

×

13 L

×

14 L

11 L

HHH

267.1 ~ 289.4 8-1/2

289.5 ~ 307.0 A4 L

307.1 ~ 340.0 8

340.1 ~ 365.6 8

365.7 ~ A3 L

~ 192.0 B5 C

192.1 ~ 220.0 A4 C

×

HHL

220.1 ~ 225.9 8-1/2

226.0 ~ 289.4 8-1/2

11 C

×

11 L

289.5 ~ 374.0 B4 L

374.1 ~ A3 L

×

HLH or L

226.0 ~ 391.0 11

391.1 ~ 11

L H or L H or L

220.1 ~ A3 L

~ 225.9 8-1/2

~ 220.0 A4 C

×

15 L

×

17 L

11 C

×

8-1/2 C

×

8-1/2 L

M-21

Page 26

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

11-2. 15° Open Detection Mech anis m

• To enable the copier to detect the document size when the ADF is used as the Original

Cover of the copier, there is the Lever Actuator provided in the ADF body.

• The Lever Actuator moves the Original Cover Detecting Lever mounted on the copier.

11-3. Raised/Lowered Position Detection Mechanism

• There is a magnet installed in the ADF body to allow the copier to know that the ADF is

raised or lowered.

• This magnet actuates the Size Reset Switch on the copier.

Magnet

Lever Actuator

Original Cover Detecting Lever

Size Reset Switch SW10

4652M516AA

M-22

Page 27

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

TEST MODES

Page 28

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

1. OUTLINE OF THE TEST MODES

• The test modes for the ADF may be initiated from the “Tech. Rep. Mode” menu screen

provided for the copier or by changing the position of a DIP switch key on PWB-A of the

ADF.

• For the “Tech. Rep. Mode” menu screen, see “SWITCHES ON PWBs: Tech. Rep. Mode”

of the copier’s Service Manual.

1-1. Test Mode Setting Procedure

ON

DIP Switch S2

1

4

2

5

3

Test Mode Switch S1

LED

PWB-A

4490S001AB

• Flip S2-5 to the ON position and turn OFF and ON the Power Switch of the copier. This

sets the ADF into the Test mode.

• Various types of Test Mode operations are available, each being selected with a particular combination of ON and OFF settings of S2-1 to -5. To run a particular operation,

make the correct DIP switch key settings, raise and lower the ADF to validate the settings, and press S1 to start the operation.

1-2. Types of Test Modes

• The following four types of Test Modes are available:

Paper Passage Check

Unit Check

Sensor Check

Board Check

S-1

Page 29

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2. PAPER PASSAGE CHECK

2-1. Paper Passage Modes

• Each paper passage mode starts by setting the DIP switch of S2.

Paper Passage Mode

1-Sided Continuous ON

Intermittent ON ON

Mixed Original Continuous ON ON

Intermittent ON ON ON

2-Sided Continuous ON ON

Intermittent ON ON ON

Single Feed Intermittent ON ON ON

(Blank means OFF.)

✽

To adjust the stop position, flip S2-3 to ON. The adjustment procedure will be found in

DIS/REASSEMBLY , ADJUSTMENT to follow.

12345

Setting the DIP switch of S2

2-2. Paper Passage Check Procedure

1. Turn OFF the Power Switch of the copier and flip S2-5 to ON.

2. Turn ON the Power Switch of the copier. (This sets the ADF into the Test Mode.)

3. Make the necessary settings of S2-1 to -4 for the desired paper passage mode.

4. Raise and lower the ADF.

5. Load a document set in the Document Feed Tray.

6. Press S1 once.

7. This starts the paper passage check.

✽

To interrupt a continuous paper passage mode (S2-4: OFF), press S1 once. If S1 is then

pressed a second time, the ADF feeds all originals out of itself to terminate the paper

passage mode.

✽

In an intermittent paper passage mode (S2-4: ON), each press of S1 lets the ADF feed

an original through itself.

✽

To select either the continuous or intermittent mode, turn OFF the Power Switch of the

copier, flip S2-4 to OFF and then ON, and turn ON the Power Switch.

S-2

Page 30

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2-3. Indication by LEDs in Paper Passage Check

(1) Indication by LEDs in closure failure

LED Indication

12345

❍❍❍●

❍❍●❍

❍●❍❍

( : Blinking, ❍: OFF, ●: ON)

LED1 stays blinking at all times.

(2) Indication by LEDs in Misfeed, Trouble and Warning

LED Indication

12345

❍❍❍❍

❍❍❍

❍❍ ❍

❍❍

❍❍❍

❍❍

❍❍

❍

❍❍❍

❍❍

❍❍

●●●●

( : Blinking, ❍: OFF, ●: ON)

LED1 stays blinking at all times.

Displays the control internal data while paper is being fed through the ADF.

Take-Up Cover

ADF open

Exit Cover

Standby

Document not reaching Registration Sensor.

Document staying at Registration Sensor.

Document not reaching Exit Sensor.

Document staying at Exit Sensor.

Document left after operation is started.

Pick-Up Motor M1 malfunction.

Document staying at Single Feed Empty Sensor.

Document not reaching Turnover Sensor.

Document staying at Turnover Sensor.

Scale Drive Motor M5 malfunction.

Document staying at Document Feed Tray or Sin-

gle Feed Tray. -- Warning

Document left at before operation is started.

-- Warning

Description

Description

S-3

Page 31

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3. UNIT CHECK

3-1. Unit Check Modes

• Each unit check mode starts by setting the DIP switch of S2.

Unit Check Mode

Pick-Up Motor M1 ON

Take-Up Motor M2 ON ON

Main Drive Motor M3 ON

Turnover/Exit Motor M4 ON ON

Scale Drive Motor M5 ON ON

Turnover/Exit Switching

Solenoid

(Blank means OFF.)

✽

Flipping S2-4 to ON before the Power Switch is turned ON allows for setting the ADF into

the Durability mode which, once started, continues running until stopped.

SL1 ON ON ON

12345

Setting the DIP switch of S2

3-2. Unit Check Procedure

1. Turn OFF the Power Switch of the copier and flip S2-5 to ON. (Flip S2-4 to ON for the

Durability mode.)

2. Turn ON the Power Switch of the copier. (This sets the ADF into the Test Mode.)

3. Make the necessary settings of S2-1 to -5 for the desired unit check mode.

4. Raise and lower the ADF.

5. This completes the setting of the unit check mode.

(1) Pick-Up Motor check

• Each press of S1 repeats the operation shown below.

No. of Times S1

is Pressed

0

1

( : Blinking, ❍: OFF, ●: ON)

12345

LED Indication

❍❍❍❍

❍❍❍●

Standby

Rotation (Take-Up Rolls down)

Operation

S-4

Page 32

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

(2) Take-Up Motor check

• Each press of S1 repeats the operation shown below.

• The motor automatically stops turning in about 60 second.

No. of Times S1

is Pressed

0

1

2

3

( : Blinking, ❍: OFF, ●: ON)

(3) Main Motor check

• Each press of S1 repeats the operation shown below.

• The motor automatically stops turning in about 60 second.

No. of Times S1

is Pressed

0

1

2

3

4

5

( : Blinking, ❍: OFF, ●: ON)

(4) Turnover/Exit Motor check

• Each press of S1 repeats the operation shown below.

• The motor automatically stops turning in about 60 second.

12345

12345

LED Indication

❍❍❍❍

❍❍❍●

❍❍●❍

❍❍●●

LED Indication

❍❍❍❍

❍❍❍●

❍❍●❍

❍❍●●

❍●❍❍

❍●❍●

Operation

Standby

Forward rotation (150 mm/s)

Stop

Backward rotation (300 mm/s)

Operation

Standby

Forward rotation (660 mm/s)

Stop

Backward rotation (660 mm/s)

Stop

Forward rotation (300 mm/s)

No. of Times S1

is Pressed

0

1

2

3

( : Blinking, ❍: OFF, ●: ON)

12345

LED Indication

❍❍❍❍

❍❍❍●

❍❍●❍

❍❍●●

Standby

Rotation (660 mm/s)

Stop

Rotation (300 mm/s)

S-5

Operation

Page 33

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

(5) Scale Drive Motor check

• Each press of S1 repeats the operation shown below.

• The motor automatically stops turning in about 60 second.

No. of Times S1

is Pressed

0

1

( : Blinking, ❍: OFF, ●: ON)

(6) Turnover Solenoid check

• Each press of S1 repeats the operation shown below.

• The solenoid stops operating in about 60 second.

No. of Times S1

is Pressed

0

1

( : Blinking, ❍: OFF, ●: ON)

12345

12345

LED Indication

❍❍❍❍

❍❍❍●

LED Indication

❍❍❍❍

❍❍❍●

Operation

Standby

Rotation

(Original Width Scale is

Retracting)

Operation

Standby

ON/OFF is repeated at one

cycle of the second.

S-6

Page 34

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4. SENSOR CHECK

4-1. Sensor Check Mode

•“Tech. Rep. Mode” menu screen on the copier Touch Panel:

1. Select “ADF Check” on the “Tech. Rep. Mode” menu screen.

4652S501CA

2. Select “I/O Check”.

3. Using a sheet of paper or other device, activate the sensor to be checked and check

the data shown on the screen (paper present: 1; paper not present: 0).

4652S502CA

• DIP Switch S2 on PWB-A of this ADF:

Mode

Sensor Check 1

Sensor Check 2 ON

(Blank means OFF.)

Sensor Check 1:

• Empty Sensor PC1

• Registration Sensor PC2

• Exit Sensor PC3

• Turnover Sensor PC4

4652S503CA

Setting the DIP switch of S2

12345

Sensor Check 2:

• Single Feed Empty Sensor PC9

• Width Sensor 1 PC5 (option)

• Width Sensor 2 PC6

• Width Sensor 3 PC7 (option)

S-7

Page 35

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4-2. Sensor Check Procedure

1. Turn OFF the Power Switch of the copier and flip S2-5 to ON.

2. Turn ON the Power Switch of the copier. (This sets the ADF into the Test Mode.)

3. Make the necessary settings of S2-1 to -5 for the desired sensor check mode.

4. Raise and lower the ADF.

5. This completes the setting of the sensor check mode.

(1) Sensor Check 1 check

• Using a sheet of paper or other device, activate the sensor to be checked and check for

the LED condition.

Sensor

Empty Sensor PC1

Registration Sensor PC2

Exit Sensor PC3

Turnover Sensor PC4

( : Blinking, ❍: OFF, ●: ON)

(2) Sensor Check 2 check

• Using a sheet of paper or other device, activate the sensor to be checked and check for

the LED condition.

Sensor

Single Feed Empty Sensor PC9

Width Sensor 1 PC5 (option)

Width Sensor 2 PC6

Width Sensor 3 PC7 (option)

( : Blinking, ❍: OFF, ●: ON)

12345

12345

LED Indication

❍❍❍●

❍❍●❍

❍●❍❍

●❍❍❍

LED

❍❍❍●

❍❍●❍

❍●❍❍

●❍❍❍

Operation

Blocked

Blocked

Unblocked

Blocked

Operation

Blocked

Unblocked

Unblocked

Unblocked

S-8

Page 36

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

5. BOARD CHECK

5-1. Board Check Mode

• Each electrical component is energized sequentially to determine if the drive circuit of

PWB-A is fully operational.

1. Turn OFF the Power Switch of the copier and DIP switch to ON.

Mode

Board Check Mode ON

(Blank means OFF.)

2. Turn ON the Power Switch of the copier.

3. This completes the setting of the board check mode.

12345

Setting the DIP switch of S2

5-2. Board Check Procedure

• Each press of S1 energizes the following electrical components in that order, one at a

time.

• The motor automatically stops turning in about 60 second.

No. of Times S1

is Pressed

0

1

2

3

4

5

12345

LED Indication

❍❍❍❍

❍❍❍●

❍❍●❍

❍❍●●

❍●❍❍

❍●❍●

Standby

Scale Drive Motor turns.

Turnover Solenoid ON. (1 s)

Pick-Up Motor turns.

Take-Up Motor turns.

(150 mm/s)

Main Motor turns. (660 mm/s)

Turnover/Exit Motor turns.

(660 mm/s)

Operation

S-9

Page 37

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

DIS/REASSEMBLY,

ADJUSTMENT

Page 38

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

1. MAINTENANCE SCHEDULE

• To ensure good copies and an extended service life of the this Unit, it is recommended

that the maintenance jobs described in this schedule be carried out.

Maintenance

PM Parts

Pick-Up Roll

Take-Up Roll 111V51160 2

Separator Pad 111V-9310 2

Transport Belt

Registration Drive

Roller

Registration Driven

Roller

Turnover Roller – 1

Turnover Roll – 4

Exit Roller – 1

Exit Roll – 4

Reflector-type

sensor

K = 1,000 sheets

✽

Perform the service job based on the values of the PM Counter of the copier.

✽

The Pick-Up Roll, Take-Up Roll and Separator Pad should be replaced as a set.

✽

During regular maintenance visit, clean or replace parts an necessary.

• The above information is subject to change without notice.

Schedule Cycle

Clean Replace

120K

30K

120K

–

Tools

Used for

Cleaning

Cloth,

Alcohol

Blower

brush

Parts No. QTY

111V51150 2

– 1

– 1

– 1

– 2

PM

Counter

ADF

Feed

ADF

Rev.

ADF

Feed

Reference

Page

☞

D-3

☞

D-3

☞

D-3

D-1

Page 39

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2. DISASSEMBLY

2-1. Removal of the Transport Belt

1. Snap off the C-clip.

4652D520AA

2. Unlock the holder that holds the Transport Belt

Drive Roller.

4490D002AB

4490D003AA

4490D004AB

4490D005AA

3. Pull the Transport Belt Roller Assy toward you

and remove it from the ADF.

NOTE

• At reinstallation, make sure that the mylar on the

right-hand side does not sneak under the Transport Belt.

4. Remove two screws and bend the roller unit

inward.

5. Remove the Transport Belt.

D-2

Page 40

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2-2. Removal of the Pick-Up Rolls, Take-Up Rolls, and Separator

Pads

1. Open the Take-Up Cover and remove one screw

and the Upper Cover.

4490D006AB

2. Lift the Pick-Up Roll Arm.

3. Snap off the C-clip from the Pick-Up Roll Shaft

and remove the Pick-Up Roll.

4490D007AB

4. Unhook the two springs from the Pick-Up Roll

Arm.

5. Remove one screw and the Paper Empty Sensor.

4490D008AB

4490D009AB

4490D010AB

6. Snap off the C-clip.

7. Slide off the bushing and raise the shaft.

8. Snap off the C-clips and remove the Take-Up

Rolls from their shaft.

NOTE

When reinstalling the Take-Up Rolls, make sure that

the blue end of the one-way bearing is on the side

opposite the Take-Up Roll.

D-3

Page 41

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

9. Remove the Transport Belt Roller Assy.

☞

D-2

4490D003AA

10. Remove two screws and the Separator Pad

Assy.

4490D012AA

11. Remove the Separator Pads.

4652D521AA

D-4

Page 42

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3. ADJUSTMENTS

• NEVER attempt to adjust “Registration Loop” under “Tech. Rep. Choice” in the field. It is

only for factory adjustment.

• Before starting any of the adjustment procedures, take necessary steps to prevent the

Original Width Scale from interfering with the procedures.

1. Press down the Original Width Scale and insert a

piece of paper into the space in the Scale Holder

in the rear. Make sure that the Original Width

Scale remains lower than the surface of the Original Glass.

Bend Piece of Paper

toward the Rear

4652D501AA

3-1. Adjustment of Skew in the ADF

Requirement: Skew should be 0.35% or less with respect to the document length.

For A4 crosswise: 1.0 mm

Start Key

A4C original

NOTE

• Bend the piece of paper inserted toward the rear to

ensure that it will not be in the way through which

originals move.

1. Load an A4C original in the Document Feed Tray

and select 1-Sided mode.

2. Press the Start key.

3. Press the Stop key when the original is taken up

and then the scan motion stops.

4. Gently raise the ADF.

Stop key

4652D502AA

5. Check in which direction, A or B, the original positioned on the Original Glass tilts.

6. If the specifications are not met, perform the following steps 7 through 9.

Specifications: 1 mm or less

A4C

4652D503AA

1 mm or less

7. Loosen the three screws of the left hinge.

8. If the original tilts in the direction of A:

Move the ADF to the front.

If the original tilts in the direction of B:

Move the ADF to the rear.

9. Tighten the three screws.

Screws

4652D504AA

✽

After this adjustment has been made, perform the following steps: Adjustment of the

Document Feed Tray Reference Position and Adjustment of the Document Stop Position

in each mode.

D-5

Page 43

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-2. Adjustment of the Document Feed Tray Reference Po sitio n

Requirement: The deviation of the edge of the original with respect to the Original Length

Start Key

Scale should be 4 ± 1 mm.

1. Load an A4C original in the Document Feed Tray

2. Press the Start key.

3. Press the Stop key when the original is taken up

A4C original

4. Gently raise the ADF.

and select 1-Sided mode.

and then the scan motion stops.

Stop key

4652D502AA

4652D505AA

4490D017AB

5. Check in which direction, C or D, the original

positioned on the Original Glass deviates with

respect to the Original Length Scale.

6. If the specifications are not met, perform the following steps 7 through 9.

Specifications: 4 ± 1 mm

Original Length Scale

A4C

4 ± 1 mm

4652D506AA

7. Loosen the screw shown.

8. 3 mm or less:

Move the Document Edge Guide to the front.

5 mm or more:

Move the Document Edge Guide to the rear.

9. Tighten the screw.

D-6

Page 44

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-3. Adjustment of the Single Feed Tray Reference Position

Requirement: The deviation of the edge of the original with respect to the Original Length

Scale should be 4 ± 1 mm.

1. Insert an original into the Single Feed Tray.

2. Press the Stop key when the original is taken up

3. Gently raise the ADF.

4490D018AA

4. Check in which direction, C or D, the original

5. If the specifications are not met, perform the fol-

4652D505AA

and then the scan motion stops.

positioned on the Original Glass deviates with

respect to the Original Length Scale.

lowing steps 6 through 8.

Specifications: 4 ± 1 mm

Original Length Scale

4652D508AA

A4C

4 ± 1 mm

4652D506AA

6. Loosen the screw shown.

7. 3 mm or less:

Move the Document Edge Guide to the front.

5 mm or more:

Move the Document Edge Guide to the rear.

8. Tighten the screw.

D-7

Page 45

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-4. Adjustment of the Document Stop Position in the 1-Sided

and 1-Sided Mixed Original Mode

Requirement: The leading edge of the original should be located 1 to 3 mm toward the exit

Start Key

side away from the end face of the Original Width Scale.

1. Load an A4C original in the Document Feed Tray

and select 1-Sided mode.

2. Press the Start key.

3. Press the Stop key when the original is taken up

A4C original

and then the scan motion stops.

4. Gently raise the ADF.

Stop key

4652D502AA

5. Determine how much (in mm) the original posi-

6. If the specifications are not met, perform the fol-

4652D509AA

7. Select the functions in the following order: Tech.

8. That follows: adjust the document stop position.

4652D515CA

✽

Document Stop Position Setting Procedure:

9. Go back to the Basic screen.

1. Select the appropriate paper passage mode (the

10 key

2. Using the Clear key, clear the numeric value.

3. Enter the new value from the 10-Key Pad.

ID key

• Select + to move in the direction of F.

• Select - to move in the direction of E.

Clear key

4652D517AA

4. Touch [END].

5. Make the paper passage check.

tioned on the Original Glass is off in the direction

of E or F with respect to the Original Width Scale.

lowing steps 7 through 9.

Specifications: 1~3 mm

Exit Section

A4C

1~3 mm

4652D510AA

Rep. Mode ADF check Tech. Rep.

Choice Original Stop Position 1-Sided

Set

Referring to “Document Stop Position Setting

Procedure”

selected mode is highlighted).

(Use the ID key to change the sign.)

D-8

Page 46

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-5. Adjustment of the Document Stop Position in the 2-Sided

Mode

Requirement: The leading edge of the original should be located 1 to 3 mm toward the exit

Start Key

side away from the end face of the Original Width Scale.

1. Load an original in the Document Feed Tray and

select the 2-Sided 2-Sided mode.

2. Press the Start key.

3. When the second face of the original is posi-

A4L original

tioned on the Original Glass, press the Stop key.

Stop key

A4L

4652D511AA

4652D512AA

4652D514CA

4. Gently raise the ADF.

5. Determine how much (in mm) the original positioned on the Original Glass is off in the direction

of E or F with respect to the Original Width Scale.

6. If the specifications are not met, perform the following steps 7 through 9.

Specifications: 1~3 mm

Exit Section

A4L

1~3 mm

4652D513AA

7. Select the functions in the following order: Tech.

Rep. Mode ADF check Tech. Rep.

Choice Original Stop Position 2-Sided

Set

8. Adjust the document stop position.

☞

D-8

9. Go back to the Basic screen.

D-9

Page 47

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-6. Adjustment of the Document Stop Position in the Single

Feed Mode

Requirement: The leading edge of the original should be located 1 to 3 mm toward the exit

side away from the end face of the Original Width Scale.

1. Insert an original into the Single Feed Tray.

2. Press the Stop key when the original is taken up

and then the scan motion stops.

3. Gently raise the ADF.

4490D018AA

4. Check in which direction, C or D, the original

positioned on the Original Glass deviates with

respect to the Original Length Scale.

5. If the specifications are not met, perform the following steps 6 through 8.

Specifications: 1~ 3 mm

4652D509AA

4652D516CA

Exit Section

A4C

1~ 3 mm

4652D510AA

6. Select the functions in the following order: Tech.

Rep. Mode ADF check Tech. Rep.

Choice Original Stop Position SingleFeed Set

7. Adjust the document stop position.

☞

D-8

8. Go back to the Basic screen.

D-10

Page 48

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3-7. A d justment of Turnover Solenoid

Requirement: The Turnover/Exit Switching Plate should be positioned in contact with the

rib on the exit guide plate.

1. Remove two screws shown and the Rear Cover.

2. Unplug the seven connectors.

3. Remove one screw shown and the ground wire.

4652D518AA

4. Remove one screw shown and the Document

Exit Tray.

4490D023AA

4490D024AB

4490D026AA

4490D025AB

5. Remove the ADF from the copier.

6. Remove the Transport Belt Roller Assy.

☞

D-2

7. Open the Exit Cover.

8. Remove the four screws shown and the Turnover/Exit Assy.

D-11

Page 49

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

9. Loosen two screws that secure Turnover Solenoid.

4490D027AA

Rib

Contact

10. With Turnover Solenoid in the energized position,

move the Turnover Solenoid body to the right and

left to find a position at which the Turnover/Exit

Switching Plate is in contact with the rib on the

exit guide plate. Then, secure Turnover Solenoid.

4490D028AB

D-12

Page 50

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

TROUBLESHOOTING

Page 51

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

1. MISFEED DETECTION

• When a misfeed or malfunction is detected in the ADF, the corresponding code as

detailed below is shown on the copier Touch Panel.

• In addition, the LEDs on PWB-A of the ADF blink or remain OFF, as detailed below, to

indicate the type of misfeed or malfunction.

B

✽

Touch Panel Code, LED Indication, and Detection Timing of Each Misfeed/Malfunction.

• The following lists the types of misfeed detection and detection timings for different misfeed locations within the ADF.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the original page detected by the sensor.

A. Take-up section misfeed

Touch

LED Indication Description Detection Start Detection Timing

Panel

❍❍❍

A

❍❍

(Blinking: OFF: ❍)

Original not reaching

Registration Sensor

Pick-Up Motor

malfunction

AC

4652T501CA

When Main Motor is

energized

When Pick-Up Motor

is energized

Registration Sensor

(L)

Pick-Up Motor Pulse

Sensor

(Blocked) or

(Unblocked)

T-1

Page 52

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

B. Transport section misfeed

Touch

LED Indication Description Detection Start Detection Timing

Panel

❍❍ ❍

❍

❍❍

B

(Blinking: OFF: ❍)

C. Turnover/exit section misfeed

Touch

Panel

C

(Blinking: OFF: ❍)

❍❍❍

❍❍

❍❍

LED Indication Description Detection Start Detection Timing

❍❍❍

❍❍

Document staying at

Registration Sensor

Document staying at

Single Feed Empty

Sensor

Document not reaching Exit Sensor

Document not reaching Turnover Sensor

Scale Drive Motor

malfunction

Document left (after

operation is started)

Document staying at

Exit Sensor

Document staying at

Turnover Sensor

When Main Motor is

energized.

When Main Motor is

energized.

When Main Motor is

energized.

When Main Motor is

energized.

When Scale Drive

Motor is energized.

When original is

positioned after it

has been taken up.

When Main Motor is

energized

When Main Motor is

energized

Registration Sensor

(T)

Single Feed Empty

Sensor

(T)

Exit Sensor

(L)

Turnover Sensor

(L)

Scale Drive Sensor

(Blocked) or

(Unblocked)

Exit Sensor

(L)

Exit Sensor

(T)

Turnover Sensor

(T)

D. Warning for document left

Touch

LED Indication Description Detection Start Detection Timing

Panel

A ~ C

(Blinking: OFF: ❍)

Document left

(before operation is

started)

When an original is

loaded in the Document Feed Tray with

all closures in the

closed position

Registration Sensor

Exit Sensor

Turnover Sensor

(Blocked)

T-2

Page 53

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

2. MISFEED TROUBLESHOOTING PROCEDURES

1. Check the code shown on the Touch Panel.

2. Check the LED indication to identify the detail of the misfeed.

3. Determine the problem.

4. Perform the check procedures according to the problem.

A. Take-up section misfeed

• Original is not taken up at all.

• Original is stationary before Registration Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Document exceeds the tray capacity. YES Instruct User.

3 Take-Up Rolls, Pick-Up Rolls, or Separator Pads

deformed, worn, or dirty with paper dust.

4 P ick-Up Rolls pressing the original. NO Check the Pick-Up

5 Take-Up Motor rotation. YES Replace Main Control

YES Clean or Replace.

Mechanism.

Board.

NO Replace Take-Up

Motor.

• Two or more originals are taken up at once.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Take-Up Rolls, Pick-Up Rolls, or Separator Pads

deformed, worn, or dirty with paper dust.

YES Clean or Replace.

T-3

Page 54

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

B. Transport section misfeed

• The original has been transported to Registration Sensor.

Step Check Item Result Action

1 Registration Sensor check. YES Replace Main Control

Board.

2 Voltage acros s PJ9A-11 on Main Control Board

and GND change from DC5 V to DC0 V when

Registration Sensor is blocked with a sheet of

paper.

• The trailing edge of the original is yet to move past Registration Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Reg istration Roller deformed, worn, or dirty. YES Clean or Replace.

3 Reg istration Sensor chec k. YES Go to step 5.

4 Voltage acros s PJ9A-11 on Main Control Board

and GND change from DC5 V to DC0 V when

Registration Sensor is blocked with a sheet of

paper.

5 Trans port Belt worn or dirty. YE S Clean or Replace.

6 Original Glass dirty. YES Clean or Replace.

7 Main Motor rotation. YES Replace Main Control

YES Replace Main Control

Board.

NO Replace Registration

Sensor.

YES Replace Main Control

Board.

NO Replace Registration

Sensor.

Board.

NO Replace Main Motor.

• The original is not taken up at all.

• The trailing edge of the original is yet to move past Single Feed Empty Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 S ingle Feed Empty Sensor check. YES Go to step 4.

3 Voltage acros s PJ9A-14 on Main Control Board

and GND change from DC0 V to DC5 V when Single Feed Empty Sensor is blocked with a sheet of

paper.

4 Trans port Belt worn or dirty. YE S Clean or Replace.

5 Original Glass dirty. YES Clean or Replace.

6 Main Motor rotation. YES Replace Main Control

YES Replace Main Control

Board.

NO Replace Single Feed

Empty Sensor.

Board.

NO Replace Main Motor.

T-4

Page 55

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

• An ADF misfeed is displayed on the Touch Panel when a document is loaded in the Document Feed Tray.

• An ADF misfeed is displayed on the Touch Panel immediately after the Start key has

been pressed.

Step Check Item Result Action

1 Original left in the ADF. YES Remove the original.

2 Felt paper of Registration Sensor dirty or sepa-

rated.

3 Car ry out a unit check of each sensor placed

along the document path to determine if it is operational.

• The original is stationary before Exit Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Trans port Belt worn or dirty. YE S Clean or Replace.

3 Original Glass dirty. YES Clean or Replace.

4 E xit Sensor check . YES Go to step 6.

5 Voltage acros s PJ11A-2 on Main Control Board

and GND change from DC5 V to DC0 V when Exit

Sensor is blocked with a sheet of paper.

6 Main Motor rotation. YES Replace Main Control

YES Clean or replace the felt

paper.

YES Replace Main Control

Board.

NO Replace the defective

sensor.

YES Replace Main Control

Board.

NO Replace Exit Sensor.

Board.

NO Replace Main Motor.

• The original is stationary before Turnover Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Trans port Belt worn or dirty. YE S Clean or Replace.

3 Original Glass dirty. YES Clean or Replace.

4 Turnover Sensor check. YES Go to step 6.

5 Voltage across PJ3A-5 on Main Control Board and

GND change from DC5 V to DC0 V when Exit

Sensor is blocked with a sheet of paper.

6 Main Motor rotation. YES Replace Main Control

YES Replace Main Control

Board.

NO Replace Turnover Sen-

sor.

Board.

NO Replace Main Motor.

T-5

Page 56

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

• An original is caught by the Turnover/Exit Switching Plate.

Step Check Item Result Action

1 Turnover/Exit Switching Plate operates abnor-

mally.

2 Carry out a unit check of Turnover Solenoid. YES Replace Main Control

C. Turnover/exit section misfeed

• The trailing edge of the original is yet to move past Exit Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Trans port Belt worn or dirty. YE S Clean or Replace.

3 Original Glass dirty. YES Clean or Replace.

4 E xit Sensor check . YES Go to step 6.

5 Voltage acros s PJ11A-2 on Main Control Board

and GND change from DC5 V to DC0 V when Exit

Sensor is blocked with a sheet of paper.

6 Main Motor rotation. YES Replace Main Control

YES Replace the Turnover/

Exit Switching Plate.

Board.

NO Replace the Turnover

Solenoid.

YES Replace Main Control

Board.

NO Replace Exit Sensor

Board.

NO Replace Main Motor.

• The trailing edge of the original is yet to move past Turnover Sensor.

Step Check Item Result Action

1 Original meets specifications for reliable feeding. NO Instruct User.

2 Turnov er Ro ller deformed, worn, or dirty. YES Clean or Replace.

3 Trans port Belt worn or dirty. YE S Clean or Replace.

4 Original Glass dirty. YES Clean or Replace.

5 Turnover Sensor check. YES Go to step 7.

6 Voltage across PJ3A-5 on Main Control Board and

GND change from DC5 V to DC0 V when Exit

Sensor is blocked with a sheet of paper.

7 Turnover/Exit Motor rotation. NO Replace Turnover/Exit

8 Main Motor rotation. YES Replace Main Control

YES Replace Main Control

Board.

NO Replace Turnover Sen-

sor.

Motor.

Board.

NO Replace Main Motor.

T-6

Page 57

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

3. CLOSURE FAILURE DETECTION

• When a closure failure is detected in the ADF, the corresponding code as detailed below

is shown on the copier Touch Panel.

• In addition, the LEDs on Main Control Board of the ADF blink or remain OFF, as detailed

below, to indicate the type of closure failure.

BAC

4652T502CA

✽

Touch Panel Code, LED Indication, and Detection Timing of Each Closure Failure

Touch

LED Indication Description Detection Start Detection Timing

Panel

❍❍❍●

A

❍❍●❍

B

❍●❍❍

C

( : Blinking, ❍: OFF, ●: ON)

Take-Up Cover closure failure

ADF closure failure When Original is set Size Reset Switch on

Exit Cover closure

failure

When Original is set Take-Up Cover

Open/Close Sensor

(Blocked)

the copier (ON)

When Original is set Exit Cover Open/

Close Sensor

(Blocked)

T-7

Page 58

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4. TIME CHART

4-1. 1 -Side Or iginal Mode

2nd Copy End

2nd Copy Set

1st Copy End

1 1-Side Original Mode (When Two A4) Documents are Loaded Crosswise

1st Copy Set

Start Key"ON"

Documents Set

H

Empty Sensor

CW : Forward Rotation

CCW: Backward Rotaition

Ascent

Descent

L

PC1

ON

OFF

ON

Take-Up Motor

Pick-Up Motor

M1

OFF

M2

H

L

CW

Main MotorM3Turnover Solenoid

Registration Sensor

PC2

OFF

ON

OFF

SL1

ON

OFF

CW

Scale Drive Motor

Turnover/Exit Motor

M4

OFF

M5

H

L

Scale Drive Sensor

PC12

4652T503CB

H

L

Exit Sensor

PC3

T-8

Page 59

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4-2. Mixed Original Mode

2nd Copy End

2nd Copy Set

Ascent

1st Copy Set

2 Mixed Original Mode (When Two A4) Documents are Loaded Crosswise

1st Copy End

Start Key"ON"

Documents Set

H

Empty Sensor

CW : Forward Rotation

CCW: Backward Rotaition

L

PC1

Descent

ON

OFF

Pick-Up Motor

M1

H

ON

OFF

Take-Up Motor

M2

Registration Sensor

L

CW

OFF

Main MotorM3Turnover Solenoid

PC2

ON

OFF

SL1

ON

OFF

CW

Scale Drive Motor

Turnover/Exit Motor

M4

OFF

M5

H

L

Scale Drive Sensor

PC12

4652T504CB

H

L

Exit Sensor

PC3

T-9

Page 60

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4-3. 2-Side Original Scanning Mode

TurnoverTurnover

2nd Copy End

2nd Copy Set

1st Page Set

Documents Set

3 2-Side Original Mode (When Two A4) Documents are Loaded Crosswise

1st Copy End

Start Key"ON"

H

Empty Sensor

CW : Forward Rotation

CCW: Backward Rotaition

L

PC1

Ascent

Descent

ON

OFF

Pick-Up Motor

M1

H

ON

OFF

Registration Sensor

Take-Up Motor

M2

L

PC2

T-10

CW

OFF

CCW

Main Motor

M3

ON

ON

OFF

Turnover/Exit Motor

Turnover Solenoid

SL1

OFF

M4

H

L

Turnover Sensor

PC4

CW

OFF

Scale Drive Motor

M5

H

L

Scale Drive Sensor

PC12

4652T505CC

H

L

Exit Sensor

PC3

Page 61

FrameMaker Ver.5.5(PC) DF-331 OPTION FOR 7915/7920

01.02.09

4-4. Single Feed Mode

4 Single Feed Mode (When One A4) Documents are Loaded Crosswise

Copy Start

Documents Set

H

Empty Sensor

CW : Forward Rotation

CCW: Backward Rotaition

L

PC1

ON

OFF

CCW

Take-Up Motor

M2

ON

OFF

CW

M4

OFF

M5

CW

OFF

Main MotorM3Scale Drive Motor

Turnover/Exit Motor

T-11

H

L

Scale Drive Sensor

PC12

H

L

Exit Sensor

PC3

4652T506CB

Loading...

Loading...