Page 1

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

PF-231

SERVICE MANUAL

10794

Page 2

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

CONTENTS

GENERAL,

MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. PARTS IDENTIFICATION ................................ ...............................................M-2

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM ..............................................................................................M-3

5. ELECTRICAL COMPONENTS LAYOUT ........................................................M-3

6. MECHANISM AND CONTROL ............................... ............... ..........................M-4

6-1. Vertical Transport Drive Mechanism ........................................................M-4

6-2. Paper Take-Up Mechanism .....................................................................M-4

6-3. Paper Take-Up Control ............................................................................M-4

6-4. Edge Guides and Trailing Edge Stop ......................................................M-5

6-5. Paper Lifting Plate ...................................................................................M-5

6-6. Double Feed Prevention ..........................................................................M-6

6-7. Drawer-in-Position Detection ................................................................... M-6

6-8. Paper Near Empty Detection ...................................................................M-7

6-9. Paper Empty Detection . ...........................................................................M-7

6-10.Paper Level Indicator LED .......................................................................M-8

6-11.Paper Size Detection ...............................................................................M-9

6-12.Paper Dehumidifying Heater (Option) .....................................................M-10

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

1-1. Maintenance Schedule .......................................................... ......... .. .... .. .D-1

1-2. Removal of the Paper Take-Up Roll ........................................................D-2

1-3. Removal of the Separator Roller Assy .....................................................D-3

1-4. Cleaning of the Paper Take-Up Roll ............................................. .... .... .. .D-4

1-5. Cleaning of the Separator Roll .................................................................D-4

1-6. Cleaning of the Vertical Transport Roller/Ro lls ........................................D-4

2. ADJUSTMENT .................................................................................................D-5

2-1. Reference Position Adjustment .................................................. .............D-5

MISFEED DETECTION

1. MISFEED DETECTION ........................................................................ ...........T-1

1-1. Location of Misfeed Detecting Sensors ...................................................T-1

1-2. Misfeed Detection Timing ........................................................................T-2

i

Page 3

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

GENERAL,

MECHANICAL/ELECTRICAL

Page 4

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1. SPECIFICATIONS

Type : Add-on paper source unit

Installation : Mounted beneath Upper Drawer of copier

Type of Copy Paper : Plain paper

Paper Sizes : B5L/C to A3L or 8-1/2 × 11LC to 11 × 17L

Paper Weight :

Registration : Center

Capacity : 500 sheets

Power Requirements : DC24 V ± 10 %, DC5.1 V ± 5 % (supplied from copier)

Max. Power Consumption : 16.8 W

Dimensions : Width ... 535 mm or 21 in

Weight : 8.5 kg or 18-3/4 lbs.

64 to 90 g/m

Depth ... 568 mm or 22-1/4 in

Height ... 127 mm or 5 in

2

or 17 to 24 lbs.

M-1

Page 5

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

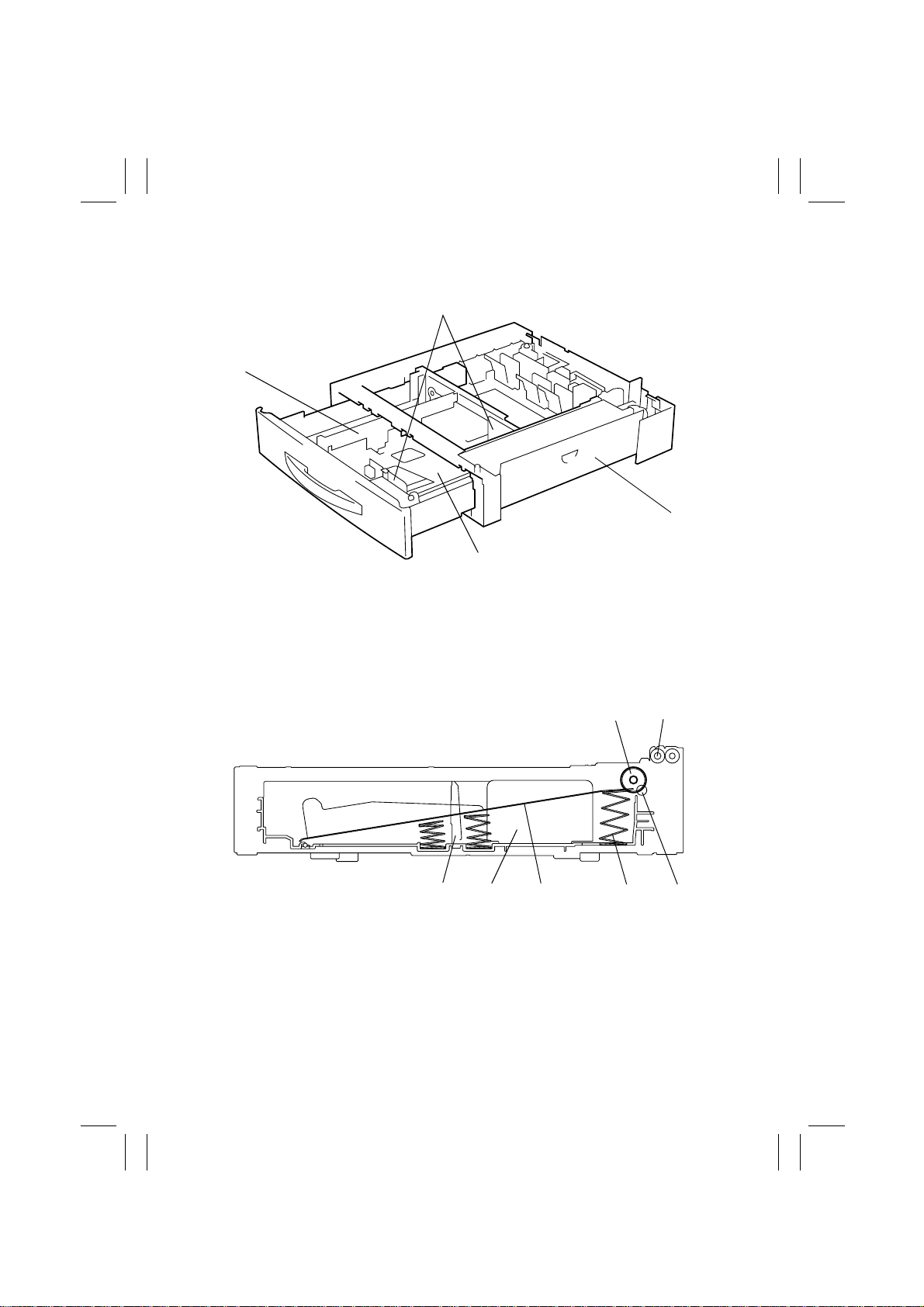

2. PARTS IDENTIFICATION

1

4

2

1. Edge Guides

2. Right Side Door

3. Paper Lifting Plate

4. Trailing Edge Stop

3. CROSS-SECTIONAL VIEW

1. Paper Take-Up Roll

2. Vertical Transport Roller

3. Separator Roll

4. Paper Lifting Spring

5. Paper Lifting Plate

6. Edge Guide

7. Trailing Edge Stop

3

4658M001AB

21

34567

4658M002AA

M-2

Page 6

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

4. DRIVE SYSTEM

Paper Take-Up

Drive Mechanism

5. ELECTRICAL COMPONENTS LAYOUT

4658M003AA

CL1

M1

PWB-A

PW A

Symbol Name Symbol Name

PWB-A

Control Board

M1

Paper Take-Up Motor

CL1

Paper Take-Up Clutch

UN1

Paper Near Empty Board

PC1

Paper Take-Up Sensor

PC2

Paper Empty Sensor

PC3

Paper Near Empty Sensor

PW C

PW B

PC4

PW D

PC4

PC5

SW A

SW B

SW C

SW D

PC3

PC5

PC2

PC1

4658M004AA

Door Set Sensor

Double Feed Sensor

Paper Size Detection Switch 1

Paper Size Detection Switch 2

Paper Size Detection Switch 3

Drawer Set Switch

UN1

M-3

Page 7

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6. MECHANISM AND CONTROL

6-1. Vertical Transport Drive Mechanism

• The Paper Take-Up Motor provides the drive for the Vertical Transport Roller.

Paper Take-Up Motor

M1

Vertical Transport Roller

4658M005AB

6-2. Paper Take-Up Mechanism

• Paper take-up drive is provided by the Paper Take-Up Motor via the Paper Take-Up

Clutch.

Paper Take-Up Clutch

CL1

Paper Take-Up Roll

Paper Take-Up Motor

M1

Separator Roll

4658M006AB

6-3. Paper Take-Up Control

• The Paper Take-Up Clutch is energized and deenergized by the signals output from pins

13 and 14 of PJ3A on the Control Board.

Start Key ON

Paper Tak e-Up Motor

M1

Paper Tak e-Up Clutch

CL1

Paper Tak e-Up Sensor

PC1

ON

OFF

ON

OFF

H

L

4658M502CA

M-4

Page 8

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-4. Edge Guides and Trailing Edge Stop

• The Trailing Edge Stop can be removed and reinstalled to the specified position corresponding to the size of the paper to be loaded.

• The Edge Guides can be slid to the exact size of the paper to be loaded.

Trailing Edge Stop

4658M007AA 4658M008AA

Edge Guides

6-5. Paper Lifting Plate

• The Paper Lifting Plate is locked into position when it is pressed down. It is unlocked

automatically when the drawer is slid into the unit.

• The Paper Lifting Plate is pushed upward by the Paper Lifting Springs at all times.

Paper Lifting Spring

Paper Lifting Plate

4658M009AB

M-5

Page 9

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-6. Double Feed Prevention

• If a sheet of paper reaches the Double Feed Sensor earlier than a predetermined period

of time after the paper take-up sequence has been started, the sequence is temporarily

halted. After an adequate period of time thereafter, the paper take-up sequence is

restarted again so that a given distance is provided between sheets of paper.

Paper Path

Vertical Transport Roller

Paper Take-Up Roll

Paper

Double Feed Sensor PC5

4658M503AA

6-7. Drawer-in-Position Detection

• When the drawer is slid into the unit, the Drawer Set Switch is actuated, allowing the

copier to determine that the drawer has been slid into position.

Drawer Set Switch SW D

4658M010AA

M-6

Page 10

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-8. Paper Near Empty Detection

• The Paper-Near-Empty Sensor detects a paper-near-empty condition in the drawer.

• A given number of sheets of paper has been determined as the basis for detection of a

paper-near-empty condition.

Predetermined No. of Sheets (Paper Level)

Paper-Near-Empty Detected 50 ± 30 sheets

Paper Near Empty Sensor PC3

Paper

4658M011AA

6-9. Paper Empty Detection

• The Paper Empty Sensor detects a paper-empty condition in the drawer.

Paper Empty Sensor PC2

4658M012AA

Paper Lifting Plate

4658M504AA

4658M505AA

M-7

Page 11

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-10. Paper Level Indicator LED

• An LED is used to indicate different levels of the paper loaded in the drawer.

Drawer Condition LED Indication

Open ON

Paper empty ON

Paper near empty Blinking

Paper loaded OFF

LED

M-8

4658M013AA

Page 12

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-11. Paper Size Detection

• When the drawer is slid into the unit, some of the contacts of the three Paper Size

Detecting Switches are closed according to the position of the Edge Guides and Trailing

Edge Stop. The combination of the open and closed states of these contacts of the

Paper Size Detecting Switches determines a specific paper size.

SW A SW B SW C

FD1 FD2 FD3 FD4 FD5 FD6 FD7 FD8 FD9 FD10 FD11 CD1

Leager L H H H H H H H H H H H L

A3L LHHHHHHHH H H L

B4L HLHHHHHHH H H H

11 × 14L HHL H HHHHH H H L

Legal L H H L H H H H H H H H H

FLS HHHLHHHHH H H H

A4L HHHHLHHHH H H H

Letter L H H H H H L H H H H H H

B5L HHHHHHLHH H H H

Letter C HHHHHHHLH H H L

A4C HHHHHHHHL H H L

G, Letter C HHHHHHHHH L H H

B5C HHHHHHHHH H L H

✽

ON: L, OFF: H

Trailing Edge Stop

Paper Size Detection Switch 1

SW A

Paper Size Detection Switch 2

SW B

Paper Size Detection Switch 3

SW C

4658M014AB

Edge Guides

M-9

Page 13

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

6-12. Paper Dehumidifying Heater (Option)

• The Paper Dehumidifying Heater prevents an image transfer failure from occurring,

caused by paper that gets damp under changing environmental conditions (temperature

and humidity).

Conditions

Power cord plugged in ON

Power Switch OFF ON

Sleep ON

Copy cycle OFF

Predrive (Imaging Unit Motor energized) OFF

Paper Dehumidifying Heater

(Heater Switch ON)

M-10

Page 14

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

DIS/REASSEMBLY,

ADJUSTMENT

Page 15

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1. DISASSEMBLY

1-1. Maintenance Schedule

• To ensure good copies and an extended service life of the this Unit, it is recommended

that the maintenance jobs described in this schedule be carried out.

Maintenance

PM Parts

Paper Take-Up

Roll

Separator Roll

Assy

Vertical

Transport

Roller

Vertical

Transport Rolls

K=1,000 sheets

✽

The above maintenance schedule is to be based on the value of Counter/Life.

✽

Cleaning (indicated by “❍” in the above schedule) should be performed when a paper

transport failure occurs.

✽

The Paper Take-Up Roll and Separator Roll Assy should be replaced at the same time.

✽

The above information is subject to change without notice.

Schedule Cycle (K)

Clean Replace

❍

❍

❍

❍

200

200 111T-5010 1

––1

––9

Tools

Used for

Cleaning

Cloth,

alcohol

Parts No. Q T Y

111T51010 1

Counter/

Life

2nd.

3rd.

4th.

Reference

Page

☞

☞

☞

☞

D-2

D-3

D-4

D-4

D-1

Page 16

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1-2. Removal of th e Paper Take-Up Roll

1. Slide out the drawer.

4658D001AA

2. Lock the Paper Lifting Plate.

3. Snap off one C-clip from the Paper Take-Up Roll

assy.

4. Move the Paper Take-Up Roll assy toward the rear

of the unit and lift it off the bushing at the front.

4658D008AA

5. Snap off one C-clip and remove the Paper TakeUp Roll.

4658D009AA

D-2

Page 17

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1-3. Removal of the Separator Roller Assy

1. Slide out the drawer.

4658D001AA

2. Remove two screws and the Separator Roll mounting bracket assy.

4658D002AA

3. Remove the rubber stopper, shaft, spring, and the

guide plate. Then, remove the Separator Roll fixing

bracket assy.

4658D003AA

4658D004AA

NOTE

• At reinstallation, make sure that the rubber stopper

is on the rear side of the unit.

4. Snap off one E-ring and remove the Separator Roll

assy.

D-3

Page 18

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1-4. Cleaning of the Paper Take-Up Roll

1. Slide out the drawer.

2. Dampen a soft cloth with alcohol and wipe the surface of the Paper Take-Up Roll clean of dirt.

4658D005AA

1-5. Cleaning of the Separator Roll

1. Slide out the drawer.

2. Remove two screws and the Separator Roll mounting bracket assy.

3. Dampen a soft cloth with alcohol and wipe the surface of the Separator Roll clean of dirt.

4658D006AA

1-6. Cleaning of the Vertical Transport Roller/Rolls

1. Slide out the drawer.

2. Open the Right Side Door.

3. Dampen a soft cloth with alcohol and, turning the

knob, wipe the surfaces of the Vertical Transport

Roller/Rolls clean of dirt.

4658D007AA

D-4

Page 19

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

2. ADJUSTMENT

2-1. Reference Position Adjustment

1. Press the Utility key and touch “Meter Count.”

2. Press the following keys in this order to show the

Tech. Rep. mode screen: Stop → 0 → 0 → Stop →

0 → 1.

3. Touch “Machine Adjust.”

4658D507CA

4. Touch “PRT Area.”

4658D508CA

Feeding

Direction

5. Touch “Left Margin.”

4658D509CA

6. Touch “2nd.”

NOTE

• Use the same procedures that follow for “3rd” and

“4th.”

4658D510CA

7. Press the Start key to produce a test print.

8. Measure dimension A to determine if it falls within

A

the specified range.

✽

Specifications: 3.0 ± 1.0 mm

9. Using or key, input the difference

between the measured value of dimension A and

the specifications.

4658D505AA

10. Produce another test print and make a check

again.

D-5

Page 20

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

11. If the specifications are not met, perform the following steps to make an adjustment.

12. Unload paper from the drawer and loosen the two

screws of the drawer.

C4658U024AA

13. Watching the scale on the adjusting plate inside

the drawer, move the Edge Guide as necessary.

14. Tighten the two screws. Then, produce a test print

to check again.

C4658U025AA

D-6

Page 21

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

MISFEED DETECTION

Page 22

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1. MISFEED DETECTION

1-1. Location of Misfeed Detecting Sensors

• The explanations given hereunder are based on a paper feed unit configuration of the

2nd Drawer (standard) + 3rd Drawer + 4th Drawer as illustrated below.

Synchronizing Roller Sensor PC17

Paper Take-Up Sensor of the 2nd Drawer PC101

Paper Take-Up Sensor of the 3rd Drawer PC1

Paper Take-Up Sensor of the 4th Drawer PC1

4658T501AA

T-1

Page 23

FrameMaker Ver.5.5(PC) PF-231 OPTION FOR 7915/7920

01.02.09

1-2. Misfeed Detection Timing

• The following lists the types of misfeed detection and detection timings for different misfeed locations.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the paper detected by the sensor.

Type Detection Start Detection

Paper left

Paper take-up failure in

the 2nd Drawer

Paper take-up failure in

the 3rd Drawer

Paper take-up failure in

the 4th Drawer

Misfeed in the 2nd

Drawer vertical transport

section

Misfeed in the 3rd Drawer

vertical transport section

Misfeed in the 4th Drawer

vertical transport section

Misfeed caused by a size

error

Power Switch ON

Misfeed reset

Paper Take-Up Motor of the

2nd Drawer energized

Paper Take-Up Motor of the

3rd Drawer energized

Paper Take-Up Motor of the

4th Drawer energized

Paper Take-Up Sensor of the

2nd Drawer (L)

Paper Take-Up Sensor of the

3rd Drawer (L)

Paper Take-Up Sensor of the

4th Drawer (L)

Paper Take-Up Sensor of the

2nd Drawer (L)

Paper Take-Up Sensor of the

3rd Drawer (L)

Paper Take-Up Sensor of the

4th Drawer (L)

Paper Take-Up Sensor of

each drawer ON

Paper Take-Up Sensor of the

2nd Drawer (L)

Paper Take-Up Sensor of the

3rd Drawer (L)

Paper Take-Up Sensor of the

4th Drawer (L)

Synchronizing Roller Sensor

(L)

Paper Take-Up Sensor of the

2nd Drawer (L)

Paper Take-Up Sensor of the

3rd Drawer (L)

Paper Take-Up Sensor of the

2nd Drawer (T)

Paper Take-Up Sensor of the

3rd Drawer (T)

Paper Take-Up Sensor of the

4th Drawer (T)

T-2

Loading...

Loading...