Page 1

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

TROUBLESHOOTING

18605

Page 2

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

CONTENTS

1. INTRODUCTION .............................................................................................T-1

1-1. Reading the Text .....................................................................................T-1

2. I/O CHECK ......................................................................................................T-1

2-1. Electrical Components Check Procedure ................................................T-1

2-2. I/O Check List ..........................................................................................T-3

2-3. How to Interpret “State Confirm” of “Tech. Rep. Mode” ........................... T-9

(1) Table # .............................................................................................T-9

(2) Level History 1 ............................................................................ .....T-10

(3) Level History 2 ............................................................................ .....T-10

2-4. Paper Misfeed ..........................................................................................T-11

2-5. Misfeed Detecting Sensor Layout ............................................................T-12

2-6. Types of Misfeed Detection and Detection Timing ..................................T-14

2-7. Misfeed Troubleshooting Procedures ......................................................T-17

(1) Copier Paper Take-Up Misfeed . ......................................................T-17

(2) Manual Bypass Take-Up Misfeed ....................................................T-19

(3) Copier Vertical Transport Misfeed ...................................................T-22

(4) 2nd Image Transfer Misfeed ............................................................T-25

(5) Exit Misfeed .......................................... ................... ................... .....T-27

(6) PF-231 Paper Take-Up Misfeed ......................................................T-29

(7) DB-431 Paper Take-Up Misfeed .....................................................T-32

(8) AD-231 Paper Take-Up Misfeed .....................................................T-35

3. MALFUNCTIONS ............................................................................................T-37

3-1. Detection Timing by Warning Code .........................................................T-38

3-2. Detection Timing by Malfunction Code ....................................................T-4 0

3-3. Troubleshooting Procedures by Malfunction Code ..................................T-48

(1) C0000: Main Motor’s failur e to tu rn

C0001: Main Motor turning at abnormal timing ...............................T-4 8

(2) C0010: Imaging Unit Motor C’s failure to turn

C0011: Imaging Unit Motor C turning at abnormal timing

C0012: Imaging Unit Motor M’s failure to turn

C0013: Imaging Unit Motor M turning at abnormal timing

C0014: Imaging Unit Motor Y’s failure to turn

C0015: Imaging Unit Motor Y turning at abnormal timing

C0016: Imaging Unit Motor Bk’s failu r e to tu r n

C0017: Imaging Unit Motor Bk turning at abnormal timing ..............T-49

(3) C0040: Fusing Cooling Fan Motor 1’s failure to tu r n

C0046: Fusing Cooling Fan Motor 2’s failure to tu rn

C004C: Ozone Ventilation Fan Motor’s failure to tur n

C004E: Power Supply Cooling Fan Motor’s failure to turn ..............T-51

(4) C0060: Fusing Drive Motor’s failure to turn

C0061: Fusing Drive Motor turning at abnormal timing ...................T-53

(5) C0094: 2nd Image Transfer Roller pressure/retraction failure ........T-54

(6) C0096: Image Transfer Belt pressure/retraction failure ...................T-55

(7) C0098: Fusing Roller pressure/retraction failure .............................T-56

(8) C0200: Cyan PC Drum Charge Corona malfunction

C0202: Magenta PC Drum Charge Corona malfunction

i

Page 3

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

C0204: Yellow PC Drum Charge Corona malfunction

C0206: Black PC Drum Charge Corona malfunction ......................T-58

(9) C0400: Exposure Lamp’s failure to turn ON

C0410: Exposure Lamp turning ON at abnormal timing ..................T-60

(10) C0500: Heating Roller warm-up failure

C0501: Lower Fusing Roller Heater Lamp warm-up failure

C0510: Heating Roller abnormally low temperature

C0511: Lower Fusing Roller Heater Lamp abnormally low temperature

C0520: Heating Roller abnormally high temperature

C0521: Lower Fusing Roller Heater Lamp abnormally high

temperature .....................................................................................T-61

(11) C0650: Scanner Home Sensor malfunction

C0660: Scanner overrun failure .......................................................T-63

(12) C0990: LCC Lift-Up Motor malfunction

C0991: LCC Lift 1 ascent motion failure

C0995: LCC Transport Motor malfunction

C0999: LCC Lift 2 ascent motion failure ..........................................T-65

(13) C0F30: Abnormally low toner density detected by Cyan ATDC Sensor/

C0F31: Abnormally high toner density detected by Cyan ATDC Sensor

C0F32: Abnormally low toner density detected by Magenta ATDC Sensor/

C0F33: Abnormally high toner density detected by Magenta ATDC Sensor

C0F34: Abnormally low toner density detected by Yellow ATDC Sensor/

C0F35: Abnormally high toner density detected by Yellow ATDC

Sensor .............................................................................................T-67

(14) C0F36: Abnormally low toner density detected by Black ATDC Sensor/

C0F37: Abnormally high toner density detected by Black ATDC

Sensor .............................................................................................T-69

(15) C0F3A: Cyan ATDC Sensor adjustment failure

C0F3B: Magenta ATDC Sensor adjustment failure

C0F3C: Yellow ATDC Sensor adjustment failure

C0F3D: Black ATDC Sensor adjustment failure .............................. T-70

(16) C13C8: New Transfer Belt Unit resetting failure

C13CA: New Fusing Unit resetting failure

C13CB: New Fusing Web Unit resetting failure

C13CC: New Oil Coating Unit resetting failure ................................T-71

(17) C13D1: Cyan IU EEPROM failure

C13D2: Magenta IU EEPROM failure

C13D3: Yellow IU EEPROM failure

C13D4: Black IU EEPROM failure ....................... ........................... .T-72

(18) C3310: CCD clamp/gain adjustment failure ....................................T-73

(19) C3700: IR Cooling Fan Motor 1 turning at abnormal timing

C3710: IR Cooling Fan Motor 2 turning at abnormal timing

C3720: Original Glass Cooling Fan Motor turning at abnormal

timing .............................................................................................T-74

(20) C3A00: PIC communication error

C3A01: PIC Board malfunction

C3FFF: ROM contents fault detected upon start .............................T-75

ii

Page 4

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

3-4. Power Supply-Related Malfunctions ........................................................T-76

(1) Copier Does not Turned ON. ................................. ..........................T-76

(2) No Control Panel Indicators Light up. ..............................................T-77

(3) No Power is Supplied to Options. ............................................. .... ...T-78

4. IMAGE QUALITY PROBLEMS ........................................................................T-79

4-1. Troubleshooting Image Quality Problems ................................................T-79

4-2. Initial Check Items ...................................................................................T-79

4-3. Troubleshooting Procedure by a Particular Image Quality Problem ........T-82

(1) IR Scanner System: white lines in FD, white bands in FD,

colored lines in FD, and colored bands in FD ..................................T-82

(2) IR Scanner System: white lines in CD, white bands in CD,

colored lines in CD, and colored bands in CD .................................T-83

(3) IR Scanner System: color spots ......................................................T-84

(4) IR Scanner System: fog ...................................................................T-85

(5) IR Scanner System: blurred image, blotchy image .........................T-87

(6) IR Scanner System: incorrect color image registration ...................T-88

(7) IR Scanner System: moire ............................................................... T-89

(8) IR Scanner System: skewed image .................................................T-90

(9) IR Scanner System: distorted image ...............................................T-91

(10) IR Scanner System: low image density, rough image .....................T-92

(11) IR Scanner System: defective ACS .................................................T-93

(12) IR Control System: blank copy, black copy .....................................T-94

(13) IR Control System: abnormal image ................................................ T-95

(14) Printer Monocolor: white lines in FD, white bands in FD,

colored lines in FD, colored bands in FD, white lines in CD,

white bands in CD, colored lines in CD, colored bands in CD .........T-96

(15) Printer Monocolor: uneven density in FD ........................................T-98

(16) Printer Monocolor: uneven density in CD ........................................T-100

(17) Printer Monocolor: low image density ..............................................T-101

(18) Printer Monocolor: gradation reproduction failure ...........................T-103

(19) Printer Monocolor: foggy background ..............................................T-105

(20) Printer Monocolor: void areas, white spots ......................................T-107

(21) Printer Monocolor: colored spots .....................................................T-108

(22) Printer Monocolor: blurred image ...................... .. .... .... ......... .. .... .... .T-109

(23) Printer Monocolor: blank copy, black copy .......... ...... .... ............. .....T-110

(24) Printer Monocolor: 0.5-mm-pitch uneven image ..............................T-111

(25) Printer Monocolor: 2-mm-pitch uneven image .................................T-112

(26) Printer Monocolor: 94-mm-pitch uneven image ...............................T-113

(27) Printer 4-Color: white lines in FD, white bands in FD,

colored lines in FD, and colored bands in FD ..................................T-114

(28) Printer 4-Color: white lines in CD, white bands in CD,

colored lines in CD, and colored bands in CD .................................T-116

(29) Printer 4-Color: uneven density in FD .............................................T-118

(30) Printer 4-Color: uneven density in CD .............................................T-119

(31) Printer 4-Color: low image density ...................................................T-120

(32) Printer 4-Color: poor color reproduction ..........................................T-122

(33) Printer 4-Color: incorrect color image registration ...........................T-124

iii

Page 5

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

(34) Pr in ter 4-Color: void areas, white spots ...........................................T-126

(35) Printer 4-Color: colored spots ..........................................................T-127

(36) Printer 4-Color: oil lines, oil on copy ................................................T-129

(37) Printer 4-Color: poor fusing performance, offset .............................T-130

(38) Printer 4-Color: brush effect, blurred image ....................................T-131

(39) Printer 4-Color: back marking ..........................................................T-132

(40) Printer 4-Color: 75-mm-pitch uneven image, 200-mm-pitch

uneven image .................................................................................. T-133

(41) Printer 4-Color: 94-mm-pitch uneven image ....................................T-134

4-4. Image Stabilizer Malfunction .............................................. ......................T-135

(1) P-5: AIDC Sensor Failure (AIDC Sensor 2)

P-28: AIDC Sensor Failure (AIDC Sensor 1) ...................................T-135

(2) P-6: Cyan Imaging Unit Failure

P-7: Magenta Imaging Unit Failure

P-8: Yellow Imaging Unit Failure

P-9: Black Imaging Unit Failur e .................................................. .....T-135

(3) P-21 : Co l o r Sh i ft Correction Fai l u re ( T e s t P a tt e rn Fa i l u r e ) .......... .. .. T-136

(4) P-22: Color Shift Correction Failure

(Correction Amount Failure) ............................................................T-136

(5) P-23: Cyan 1st Image Transfer ATVC Failure

P-24: Magenta 1st Image Transfer ATVC Failure

P-25: Yellow 1st Image Transfer ATVC Failure

P-26: Black 1st Image Transfer ATVC Failure

P-27: 2nd Image Transfer ATVC Failure .........................................T-136

(6) S-1: CCD Gain Adjustment Failure ....................................... ...........T-137

(7) S-2: Intensity Adjustment Failure .....................................................T-137

iv

Page 6

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

1. INTRODUCTION

1-1. Reading the Text

1. The paper transport failure troubleshooting procedures are given according to the

symptom. First identify the location where the paper is present and start the procedure

for that particular location. For malfunction troubleshooting, start with step 1 and

onward.

2. Make checks in the numerical order of steps and, if an item is checked okay, go to the

next step.

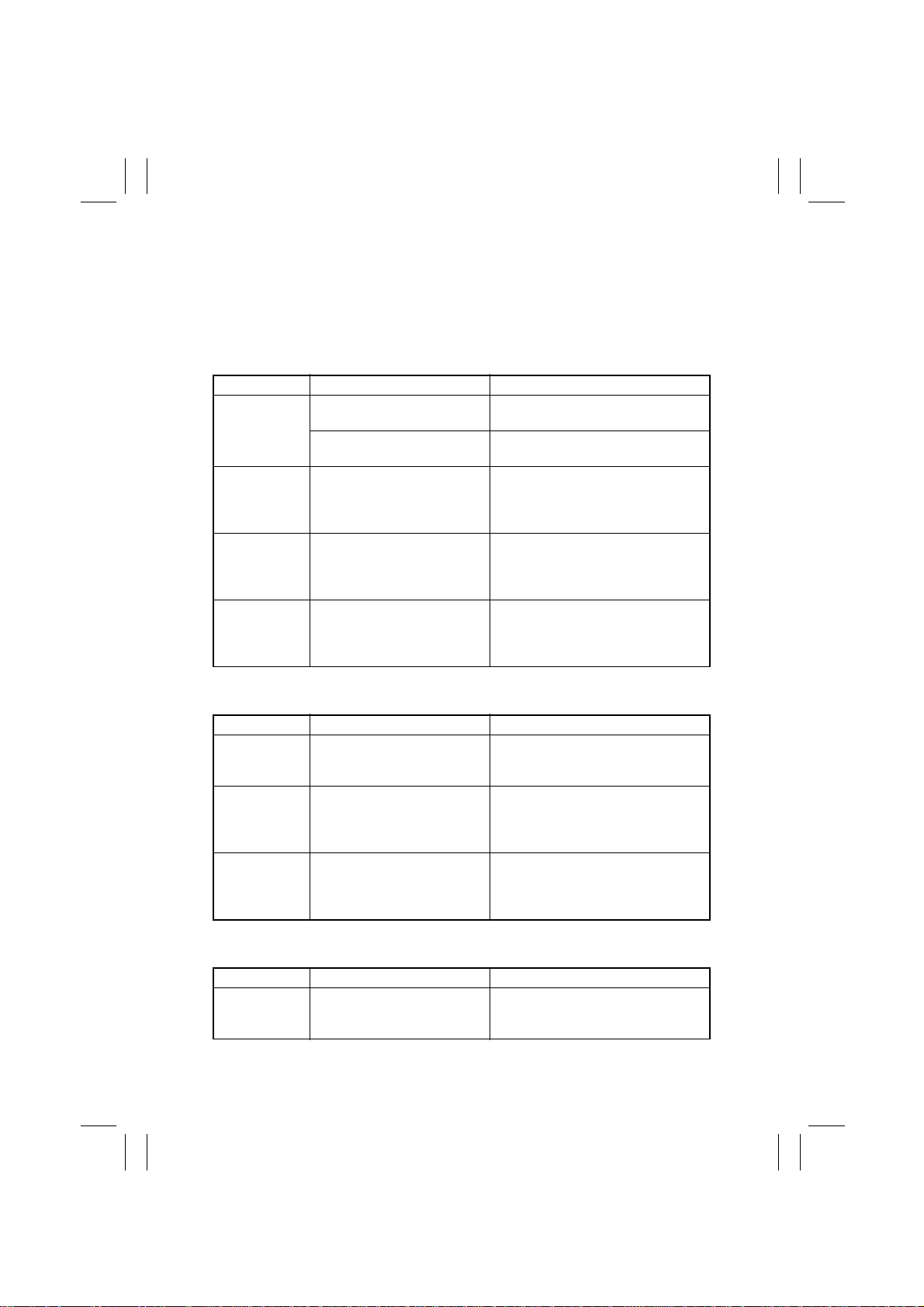

Pattern 1

Step Check Result Action

1 Is ..? YES Do this.

2

Go to step 2 if you answered No.

Pattern 2

Step Check Result Action

1 Is ..? YES Do this.

NO Check that.

2

Go to step 2 if it is checked okay.

2. I/O CHECK

2-1. Electrical Components Check Procedure

To allow the Tech. Rep. to easily and safely determine whether a particular electrical component is fully operational, this copier provides the following provision. Checking the data of

the input port of the board IC with the copier in the standby state (including a misfeed, malfunction, and closure failure condition) allows the Tech. Rep. to determine whether signals

are properly input to an electrical component.

<Procedure>

1. When a misfeed or malfunction occurs, identify on the circuit diagram accompanying

the text the electrical component that is probably responsible for the problem.

2. Select “State Confirm” from the “Tech. Rep. Mode” menu and then select “I/O Check.”

Then, from among the Sensors 1 to 7 screens, select the screen that contains the electrical component picked out in step 1 above. (See “Tech. Rep. Mode” contained in

SWITCHES ON PWBs.)

3. Check the input data to determine if the signal is correctly input.

T-1

Page 7

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

<Electrical Component Check Procedure Through Checking Input Data>

Example

When a paper misfeed occurs in the paper take-up section of the copier, the 2nd Drawer

Paper Take-Up Sensor is considered to be responsible for it.

<Procedure>

1. Remove the sheet of paper misfed.

2. From the I/O Check List that follows, it is known that the input signal of the 2nd Drawer

Paper Take-Up Sensor may be checked with the data of “Take-Up” of “2nd Drawer.”

3. From the “Tech. Rep. Mode” menu, select “State Confirm” and then “I/O Check.” Then,

select the screen that contains “Take-Up” under “2nd Drawer.”

4. Check that the data for “Take-Up” under “2nd Drawer” is “0” (sensor blocked).

5. Move the actuator to unblock the 2nd Drawer Paper Take-Up Sensor.

6. Check that the data for “Take-up” under “2nd Drawer” changes from “0” to “1” on the

screen.

1: Sensor is operational. 0: Sensor is faulty.

T-2

Page 8

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

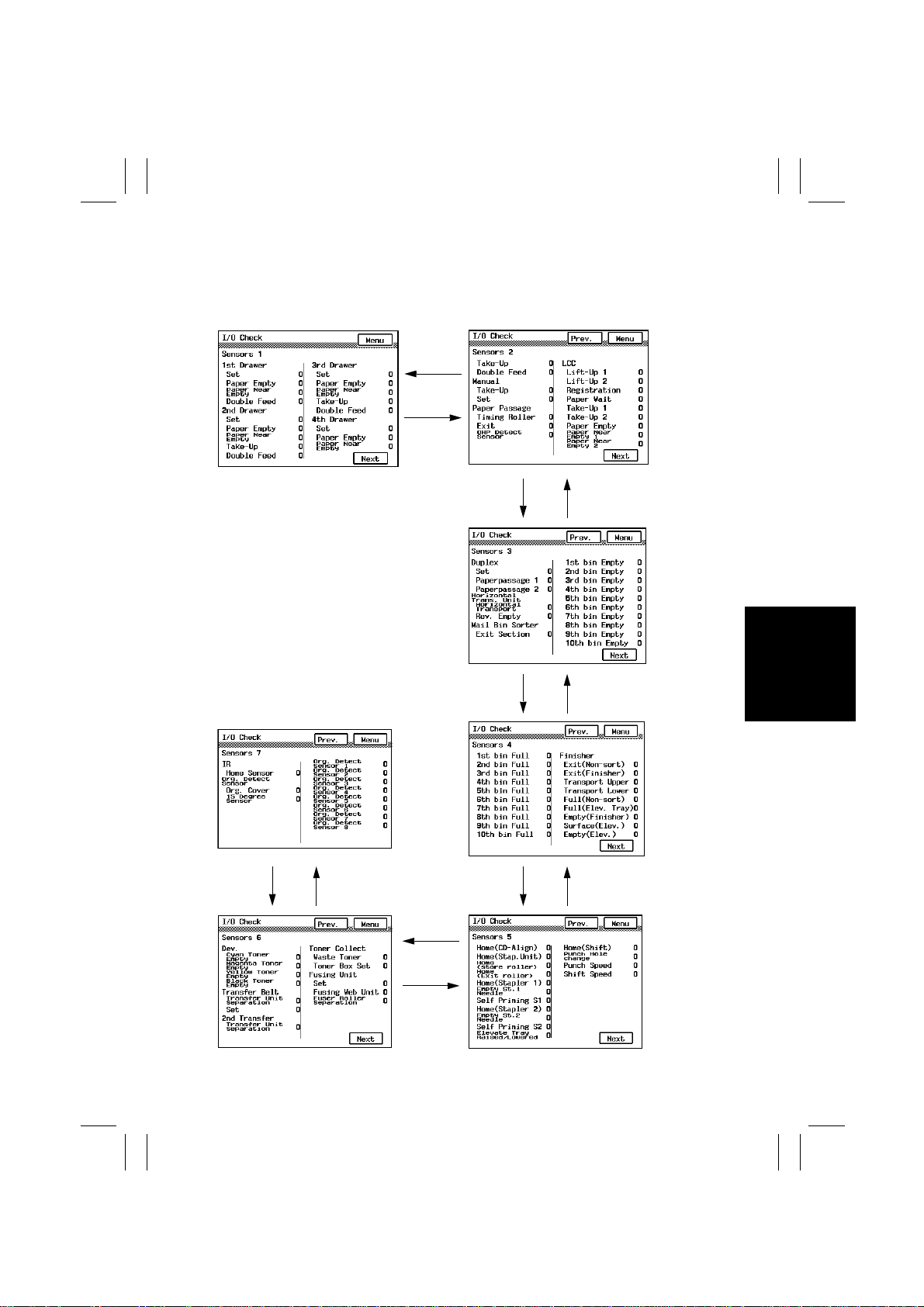

2-2. I/O Check List

<I/O Check Screens>

• These are only typical screens which may be different from what are shown on each indi-

vidual copier.

Previous

Screen

Next

Screen

4004P047CA 4004P048CA

Previous

Screen

Next

Screen

4004P053CA

Next

Screen

Next

Screen

Next

Screen

Next

Screen

Previous

Screen

4004P049CA

Previous

Screen

4004P050CA

Previous

Screen

Previous

Screen

T-3

4004P051CA4004P052CA

Page 9

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

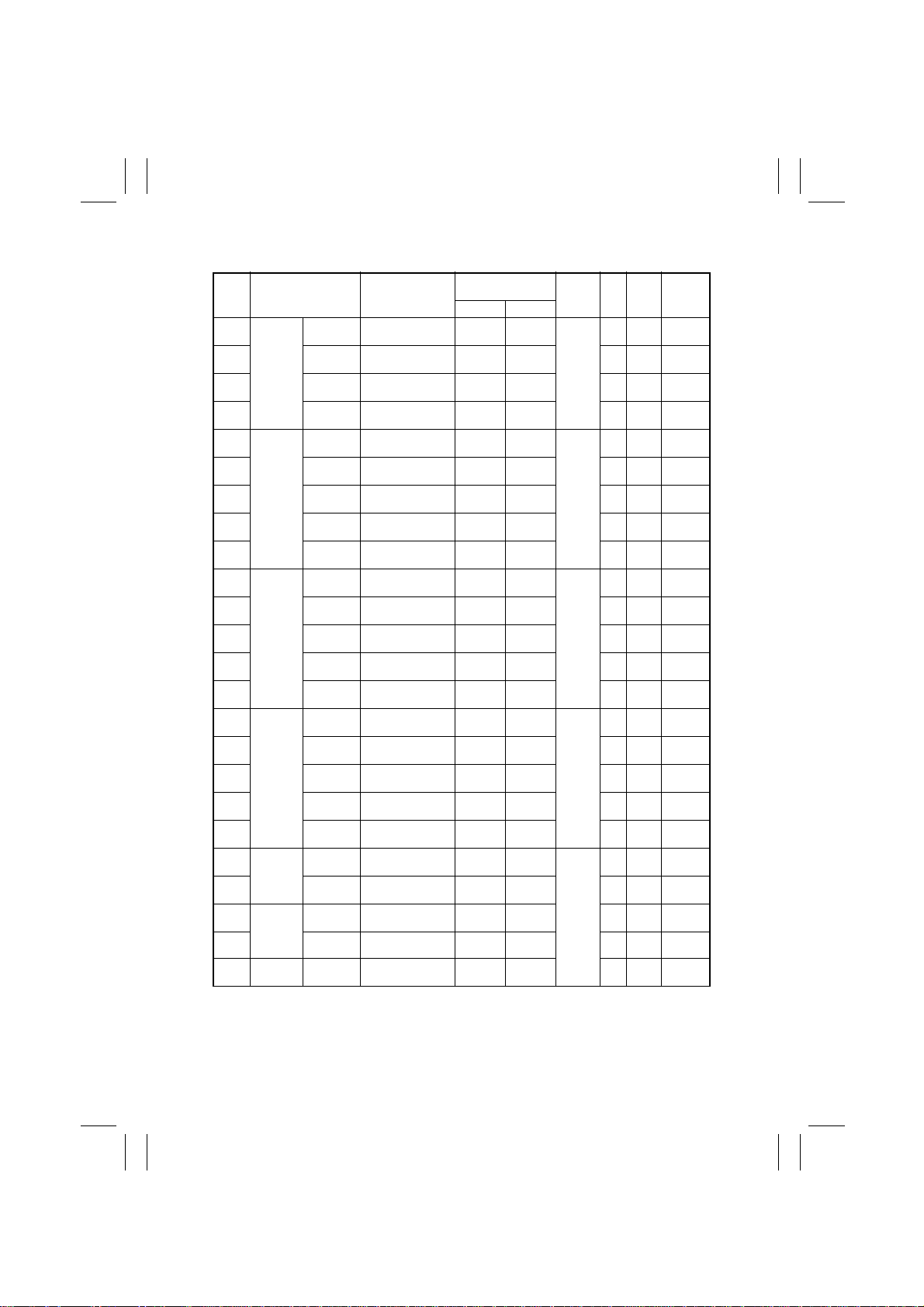

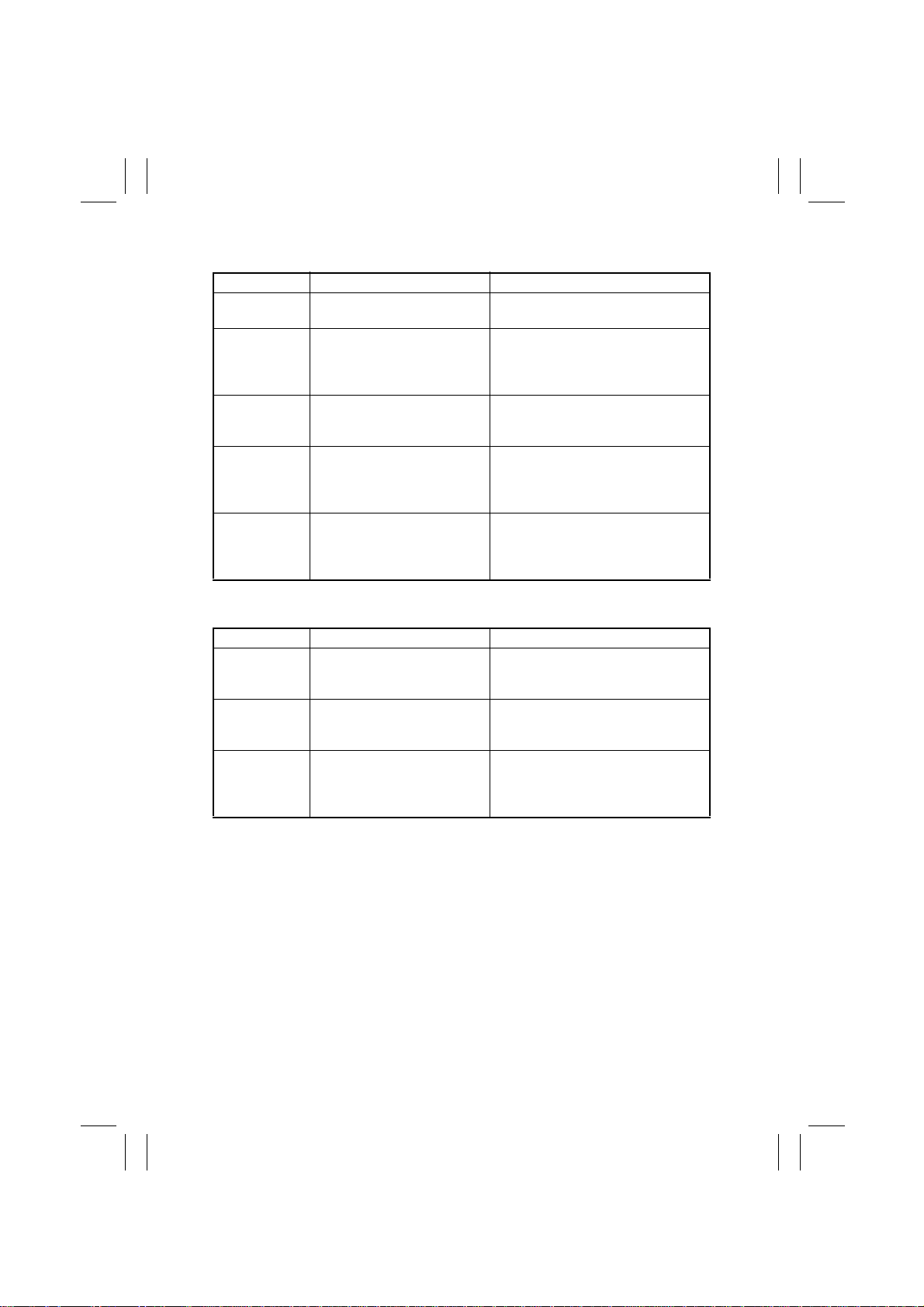

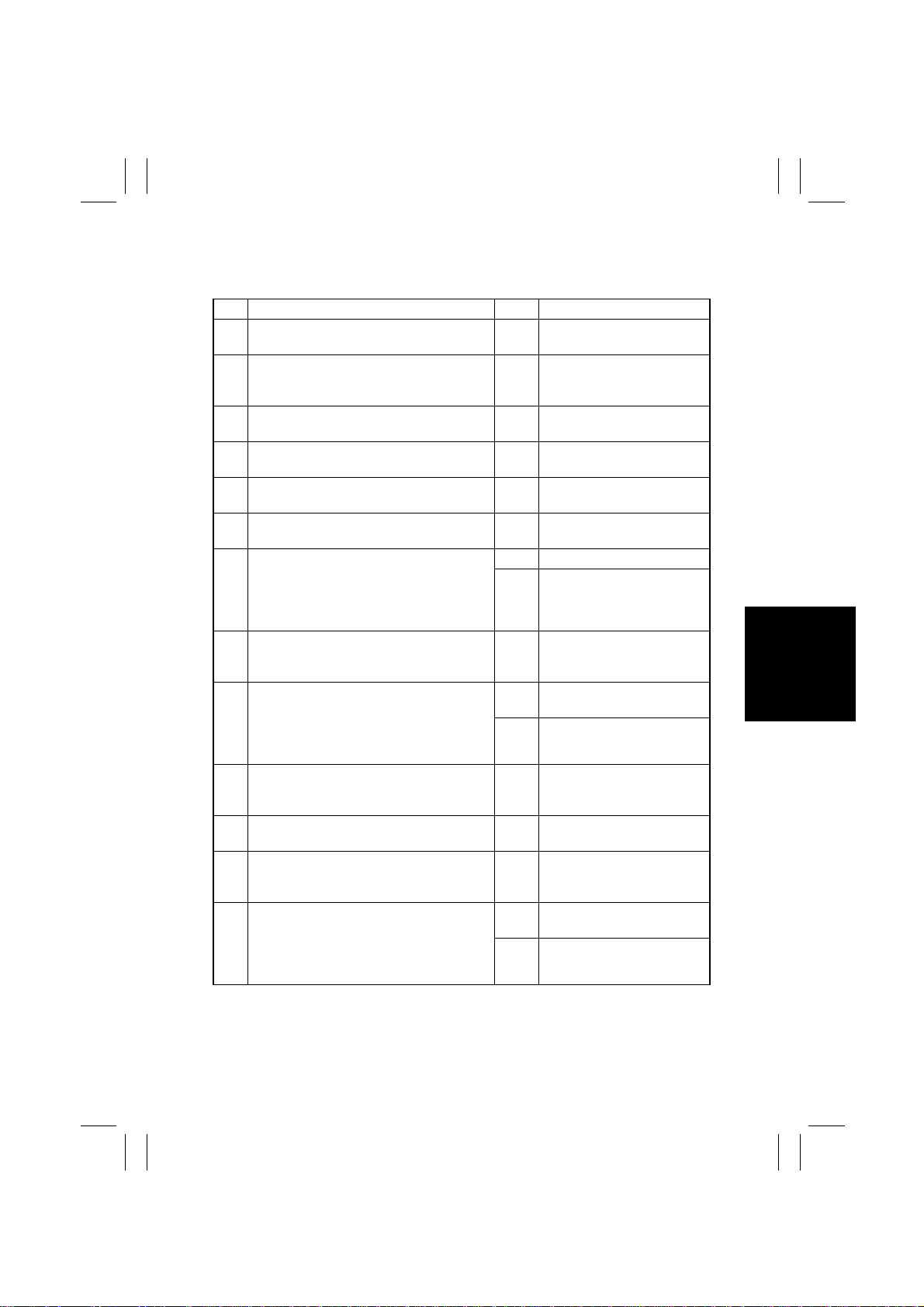

<I/O Check List>

Operation Characteris-

Symbol Panel Display Part/Signal Name

PC3 1st Drawer Set 1st Drawer Set

PC6 Paper

PC4 Paper Near

PC13 Double

SW D 2nd

Drawer

PC102 Paper

PC103 Paper Near

PC101 Take-Up 2nd Drawer Paper

PC105 Double

SW D 3rd Drawer Set Drawer Set Switch In position Out of

PC2 Paper

PC3 Paper Near

PC1 Take-Up Drawer Paper Take-

PC5 Double

SW D 4th Drawer Set Drawer Set Switch In position Out of

PC2 Paper

PC3 Paper Near

PC1 Take-Up Drawer Paper Take-

PC5 Double

PC15 Manual Take-Up Manual Feed Paper

PC15 Set Manual Feed Paper

PC17 Paper

Passage

PC10 Exit Exit Sensor Paper

PC19 Paper

Passage

OHP Detect

Sensor

1st Drawer Paper

Empty

Empty Sensor

1st Drawer Paper

Empty

Near-Empty Sensor

1st Drawer Double

Feed

Feed Sensor

Set 2nd Drawer Set

Switch

2nd Drawer Paper

Empty

Empty Sensor

2nd Drawer Paper

Empty

Near-Empty Sensor

Take-Up Sensor

2nd Drawer Double

Feed

Feed Sensor

Drawer Paper Empty

Empty

Sensor

Drawer Paper Near-

Empty

Empty Sensor

Up Sensor

Drawer Double Feed

Feed

Sensor

Drawer Paper Empty

Empty

Sensor

Drawer Paper Near-

Empty

Empty Sensor

Up Sensor

Drawer Double Feed

Feed

Sensor

Take-Up Sensor

Take-Up Sensor

Timing

Synchronizing Roller

Roller

Sensor

OHP Detecting

Sensor

Sensor

tics/Panel Display

10

In position Out of

Paper not

present

Blocked Unblocked IC6 PG0 PJ17I-6A

present

In position Out of

Paper not

present

Blocked Unblocked IC1 PB6 PJ3A-11A

present

present

Paper not

present

Blocked Unblocked IC1 PB6 PJ3A-11A

present

present

Paper not

present

Blocked Unblocked IC1 PB6 PJ3A-11A

present

present

present

In position Out of

present

present

present

Paper

Paper

Paper

Paper

Paper

Paper

Paper

Paper

Paper

OHP

position

Paper

present

Paper not

present

position

Paper

present

Paper not

present

Paper not

present

position

Paper

present

Paper not

present

Paper not

present

position

Paper

present

Paper not

present

Paper not

present

Paper not

present

position

Paper not

present

Paper not

present

OHP not

present

Input

Board

Master

Board

(PWB-I)

Control

Board

(PWB-A)

Control

Board

(PWB-A)

Control

Board

(PWB-A)

Master

Board

(PWB-I)

IC

Port

No.

CN/PJ

No.

10B

No.

IC6 PG1 PJ17I-9A

IC5 PI7 PJ3I-8A

IC6 PI0 PJ5I-8B

IC1 PC0 PJ3A-4B

IC1 PB5 PJ3A-14A

IC1 PB7 PJ3A-5A

IC1 PC3 PJ3A-8A

IC1 PC0 PJ3A-4B

IC1 PB5 PJ3A-14A

IC1 PB7 PJ3A-5A

IC1 PC3 PJ3A-8A

IC1 PC0 PJ3A-4B

IC1 PB5 PJ3A-14A

IC1 PB7 PJ3A-5A

IC1 PC3 PJ3A-8A

IC6 PI5 PJ15I-7B

IC5 PH4 PJ15I-

IC1 P77 PJ14I-9B

IC6 PI4 PJ3I-14A

IC1 AN5 PJ14-2B

T-4

Page 10

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

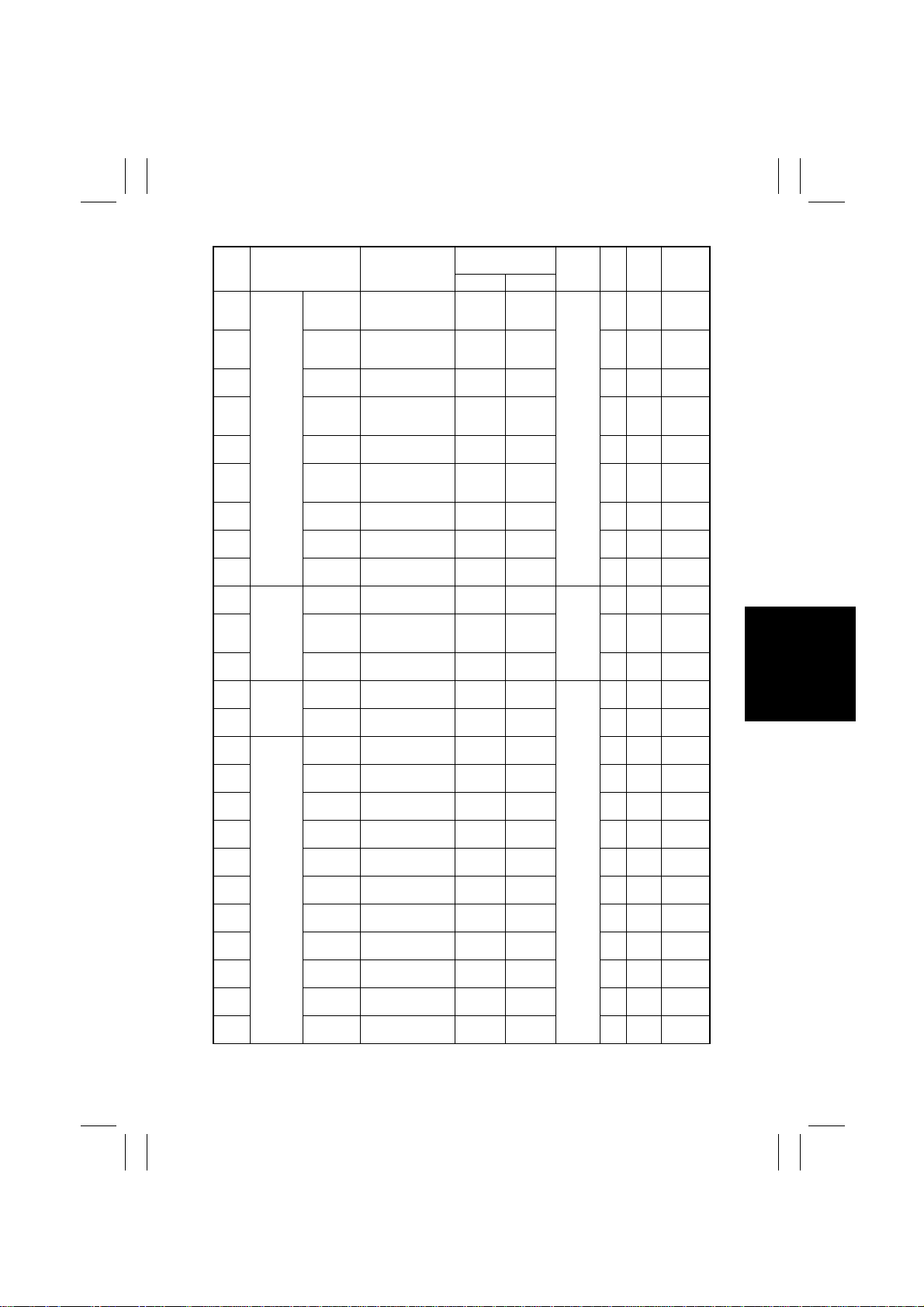

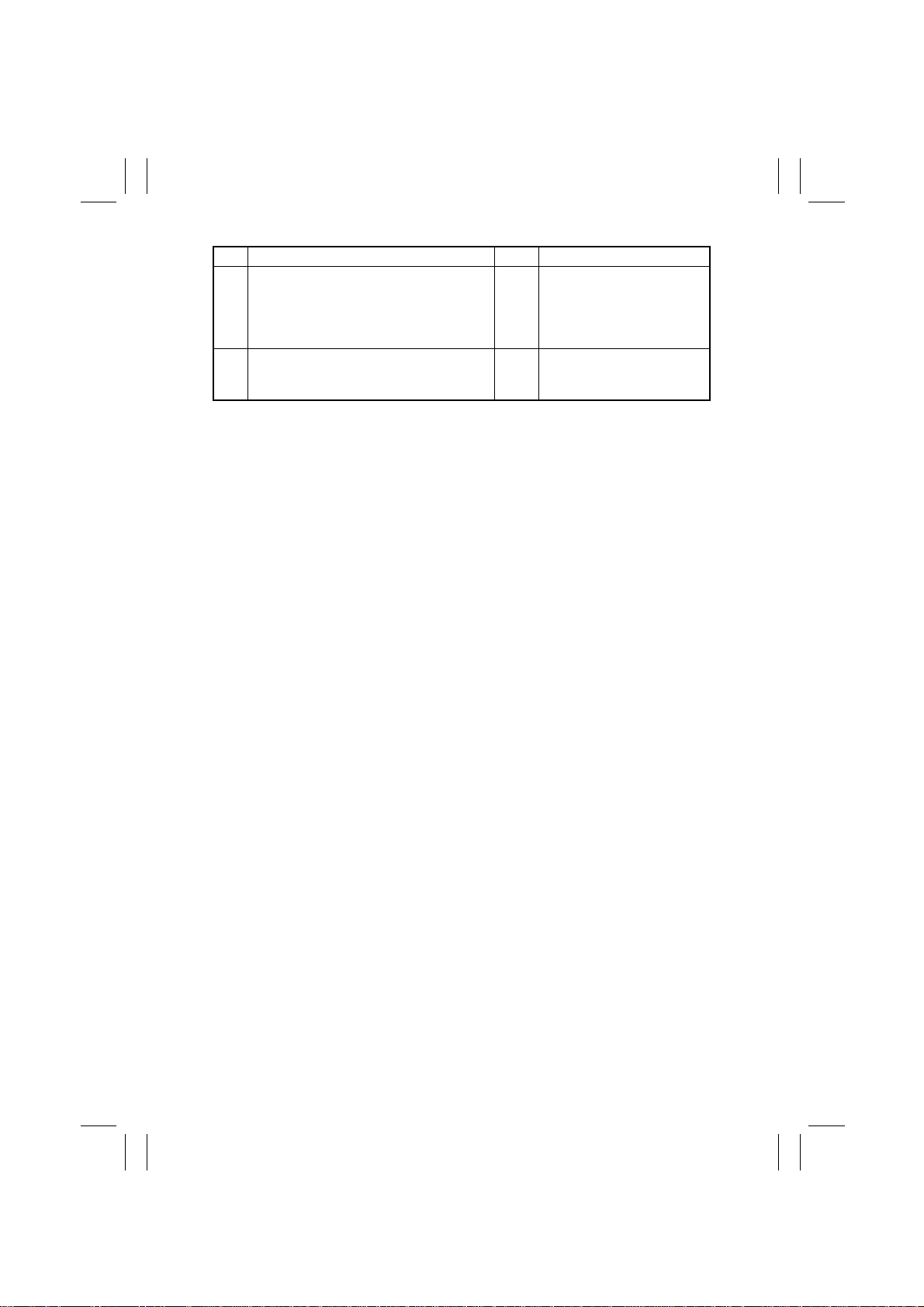

Operation Characteris-

Symbol Panel Display Part/Signal Name

LS1 LCC Lift-Up 1 Lift-Up Sensor 1 At raised

LS2 Lift-Up 2 Lift-Up Sensor 2 At raised

RSEN Registration Registration Sensor Paper

S1 Paper Wait Paper Standby

PPS0 Take-Up 1 LCC Paper Take-Up

PPS1 Take-Up 2 Paper Empty Sensor 1Paper

EMP Paper

RS1 Paper Near

RS2 Paper Near

PWB-A

Duplex Set Duplex Unit Door Set

PI2

PWB-A

PI1

PC1 Paper

PC1 Horizontal

Trans. Unit

PC6 Rev. Empty Turnover Empty

PWB-B Mail Bin

PWB-B 1st bin

PWB-D 2nd bin

PWB-D 3rd bin

PWB-D 4th bin

PWB-D 5th bin

PWB-D 6th bin

PWB-D 7th bin

PWB-D 8th bin

PWB-D 9th bin

PWB-D 10th bin

Sorter

Empty 1

Empty 2

passage 1

passage 2

Horizontal

Transport

Position Sensor

Sensor

Paper Empty Sensor 2Paper not

Empty

Paper Near Empty

Sensor 1

Paper Near Empty

Sensor 2

Sensor (in PWB-A)

Paper

Duplex Unit

Transport Sensor 1

(in PWB-A)

Duplex Unit

Transport Sensor 2

Paper Sensor Paper not

Detecting Sensor

Exit

Exit Sensor Board Paper

Section

Non-Sort Bin Empty

Empty

Sensor

2nd Bin Empty

Empty

Sensor

3rd Bin Empty

Empty

Sensor

4th Bin Empty

Empty

Sensor

5th Bin Empty

Empty

Sensor

6th Bin Empty

Empty

Sensor

7th Bin Empty

Empty

Sensor

8th Bin Empty

Empty

Sensor

9th Bin Empty

Empty

Sensor

10th Bin Empty

Empty

Sensor

tics/Panel Display

position

position

present

At standby

position

Paper

present

present

present

Unblocked Blocked IC4 P75/

Unblocked Blocked IC4 P76/

Paper

present

Paper

present

present

Paper

present

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

Paper

present

10

Not at

raised

position

Not at

raised

position

Paper not

present

Not at

standby

position

Paper not

present

Paper not

present

Paper

present

Paper not

present

Paper not

present

Paper

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Paper not

present

Board

Control

Board

(PWB-A)

Duplex

Control

Board

Control

Board

(PWB-A)

Input

IC

No.

LCC

IC4 P74/

IC4 P73/

IC4 P22/

IC4 P23/

INTP2/

IC4 P24/

IC4 P25/

INTP4/

IC4 P72/

--PJ1A-3

--PJ1A-12

--PJ4A-3

IC1

IC1

IC26

IC1

IC1 P25 PJ6A-7

IC1 P40 PJ6A-5

IC1 P41 P J7A-4A

IC1 P42 PJ7A-11A

IC1 P43 P J7A-4B

IC1 P44 PJ7A-11B

IC1 P45 P J8A-4A

IC1 P46 PJ8A-11A

IC1 P47 P J8A-4B

IC1 P23 PJ8A-11B

P21 PJ9A-4PWB-D

Port

No.

ANI4

ANI3

INTP1

CI

INTP3

ASCK

ANI2

ANI5

ANI6

P26

P27

PE3

P22

CN/PJ

No.

CN4A-6

CN4A-9

CN4A-2

CN3A-5

CN4A-11

CN3A-2

CN3A-8

CN6A-12

CN5A-5

PJ15A-4

PJ12-2

PJ15A-12

PJ13-2

T-5

Page 11

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

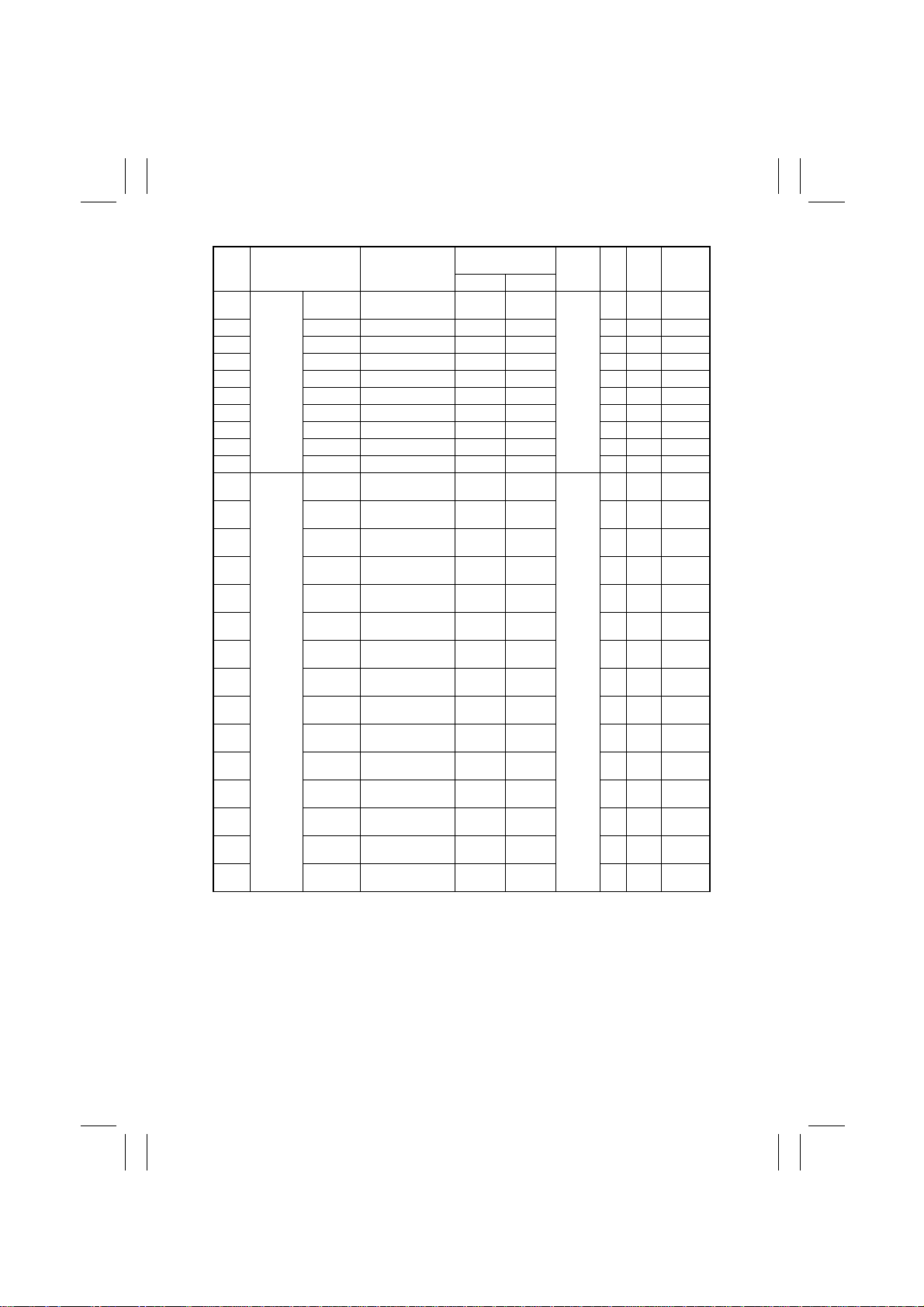

Operation Characteris-

Symbol Panel Display Part/Signal Name

PWB-B Mail Bin

PWB-D 2nd bin Full 2nd Bin Full Sensor Blocked Unblocked IC1 P71 PJ7A-1A

PWB-D 3rd bin Full 3rd Bin Full Sensor Blocked Unblocked IC1 P72 PJ7A-8A

PWB-D 4th bin Full 4th Bin Full Sensor Blocked Unblocked IC1 P73 PJ7A-1B

PWB-D 5th bin Full 5th Bin Full Sensor Blocked Unblocked IC1 P74 PJ7A-8B

PWB-D 6th bin Full 6th Bin Full Sensor Blocked Unblocked IC1 P75 PJ8A-1A

PWB-D 7th bin Full 7th Bin Full Sensor Blocked Unblocked IC1 P76 PJ8A-8A

PWB-D 8th bin Full 8th Bin Full Sensor Blocked Unblocked IC1 P77 PJ8A-1B

PWB-D 9th bin Full 9th Bin Full Sensor Blocked Unblocked IC1 P66 PJ8A-8B

PWB-C 10th bin Full 10th Bin Full Sensor Blocked Unblocked IC1 P67 PJ9A-1

PC1 Finisher Exit

PC3 Exit

PC4 Transport

PC2 Transport

PC6 Full

PC7 Full

PC5 Empty Finisher Tray Paper

PWB-D Finisher Elevator Tray Upper

PC8 Surface

PC9 Empty

PC14 Home

PC12 Home

PC13 Hole

- Home

- Empty St. 1

1st bin Full Non-Sort Bin Full

Sorter

(Non-sort)

(Finisher)

Upper

Lower

(Non-sort)

(Elev. Tray)

(Elev.)

(Elev.)

(CD-Align)

(Stap. Unit)

(store roller)

(Stapler 1)

Needle

Sensor

1st Tray Exit Sensor Paper

Storage Sensor Paper

Upper Entrance

Sensor

Lower Entrance

Sensor

1st Tray Full

Detecting Sensor

Elevator Tray Full

Detecting Sensor

Detecting Sensor

Limit Sensor PQ

Elevator Tray Paper

Detecting Sensor

CD Aligning Home

Position Sensor

Staple Home

Position Sensor

Storage Roller Home

Position Sensor

Exit Rolls Home

Position Sensor

Stapler Home 1 Blocked Unblocked IC1 P71,

Stapler Empty 1 Blocked Unblocked IC1 P72,

tics/Panel Display

10

Blocked Unblocked Control

present

present

present

present

Blocked Unblocked IC26 PC5 PJ19A-3

Blocked Unblocked IC26 P A7 PJ19A-12

position

present

Blocked Unblocked IC26 PA5 PJ25A-9

Blocked Unblocked IC26 PD2 PJ25A-6

Blocked Unblocked IC26 PD3 PJ22A-3

Blocked Unblocked IC26 PC6 PJ20A-6

Blocked Unblocked IC26 PC7 PJ19A-15

Paper not

present

Paper not

present

Paper

Paper not

present

Paper

Paper not

present

Out of

In position IC26 PD1 PJ25A-2

Paper

Paper not

present

Input

Board

Board

(PWB-A)

Control

IC26 PC4 PJ19A-6

Board

(PWB-A)

IC26 PD0 PJ20A-3

IC26 PE6 PJ20A-9

IC26 PE7 PJ19A-8

IC26 PA6 PJ21A-2

IC

Port

No.

ANI1

ANI2

CN/PJ

No.

PJ23A-2

PJ23A-4

No.

IC1 P70 PJ6A-4

T-6

Page 12

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

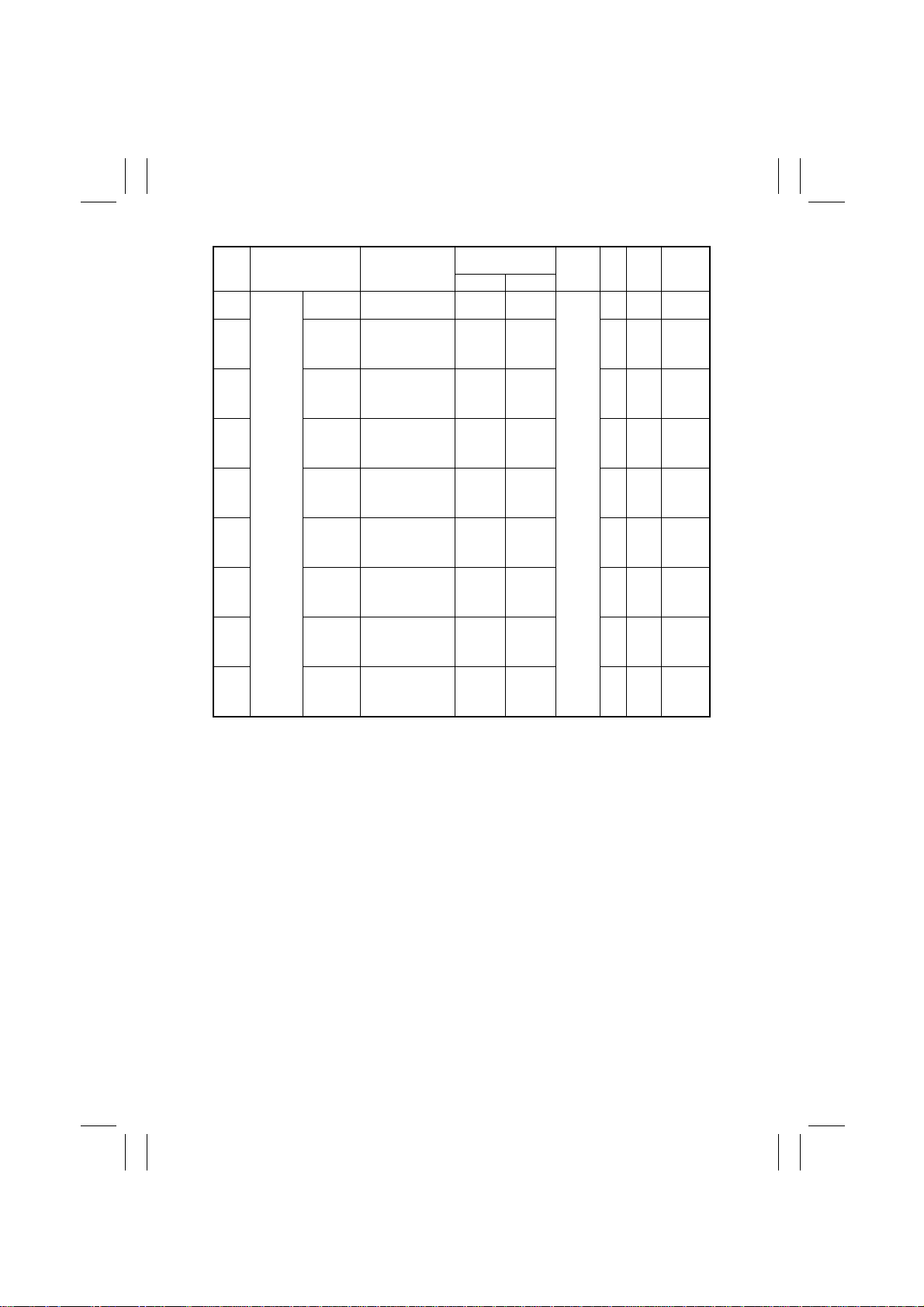

Operation Characteris-

Symbol Panel Display Part/Signal Name

- Finisher Self

- Home

- Empty St. 2

-Self

S2

S3

PC10 Home

S4 Punch Hole

PC15 Punch

PC11 Shift Speed Shift Motor Pulse

SW6 Dev. Cyan Toner

SW7 Magenta

SW8 Yellow

SW5 Black Toner

PC28 Transfer

- Set - In position Out of

PC23 2nd

Transfer

PC29 Toner

Collect

PC18 Toner Box

- Fusing

- Fusing Web

PC7 Fuser Roller

PC24 IR Home

SW10 Scanner

Sensor

Priming S1

(Stapler 2)

Priming S2

Raised/

Lowered

Change

Transfer

Belt

Separation

Transfer

Separation

Unit

Separation

Org. Cover Size Reset Switch Lowered Raised - - PJ7D-2

Home

Stapler Self-Priming 1Blocked Unblocked Control

Stapler Home 2 Blocked Unblocked IC1 P75,

Staple Empty 2 Blocked Unblocked IC1 P76,

Needle

Stapler Self-Priming 2Blocked Unblocked IC1 P77,

Elevate

Elevate Tray Raised/

Tray

Lowered

Shift Home Position

(Shift)

Sensor

Hole Punch Position

Switch

Punch Motor Pulse

Speed

Sensor

Sensor

Toner Empty Switch CON OFF Master

Empty

Toner Empty Switch MON OFF IC6 PH5 PJ5I-3A

Toner

Empty

Toner Empty Switch YON OFF IC6 PH4 PJ5I-1A

Toner

Empty

Toner Empty Switch BkON OFF IC6 PH7 PJ5I-5B

Empty

1st Image Transfer

Unit

Retraction Position

Sensor

2nd Image Transfer

Unit

Pressure Position

Sensor

Waste

Waste Toner Full

Toner

Detecting Sensor

Waste Toner Bottle

Set

Set Sensor

Set Fusing Unit In position Out of

Not used Not used Not used - - -

Unit

Fusing Pressure

Position Sensor

Org. Detect Sensor At home Out of

Sensor

tics/Panel Display

10

ON OFF - - PJ4A-4

Blocked Unblocked IC26 PD4 PJ25A-12

ON OFF IC28 PE2 PJ12A-3

Blocked Unblocked IC1 P21

Blocked Unblocked IC1 P24

Not

Retracted

Not

Retracted

Unblocked Blocked IC8 3Y PJ7I-7B

In position Out of

Pressed State

Input

IC

Port

Board

No.

IC1 P73,

Board

(PWB-A)

IC6 PH6 PJ5I-5A

Board

(PWB-I)

Retracted IC5 PI1 PJ17I-1A

Image

Process-

ing

Board

(PWB-C)

IC5 PE7 PJ4I-8

IC5 PI4 PJ7I-5B

IC5 PH5 PJ6I-7A

IC5 PI6 PJ17I-3B

--PJ6C-2

position

Retracted IC5 PI2 PJ14I-6B

position

position

other than

pressed

home

No.

ANI3

ANI5

ANI6

ANI7

INPO

INPO

CN/PJ

No.

PJ23A-3

PJ24A-2

PJ24A-4

PJ24A-3

PJ13A-8

PJ25A-14

T-7

Page 13

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Symbol Panel Display Part/Signal Name

PC25 Org.

Sensor

PC30 Org. Detect

PC31 Org. Detect

PC31 Org. Detect

PC33 Org. Detect

PC33 Org. Detect

PC32 Org. Detect

PC32 Org. Detect

PC34 Org. Detect

Detect

15 Degree

Sensor

Sensor 1

Sensor 2

Sensor 3

Sensor 4

Sensor 5

Sensor 6

Sensor 7

Sensor 8

Original Cover

Detecting Sensor

Original Size

Detecting Sensor

FD1

Original Size

Detecting Sensor

FD2

Original Size

Detecting Sensor

FD2

Original Size

Detecting Sensor

FD3

Original Size

Detecting Sensor

FD3

Original Size

Detecting Sensor

CD1

Original Size

Detecting Sensor

CD1

Original Size

Detecting Sensor

CD2

Operation Characteris-

tics/Panel Display

10

Less than

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

Original

loaded,

mounted

15°

not

not

not

not

not

not

not

not

15° or

more

Original

not loaded

Original

not loaded

Original

not loaded

Original

not loaded

Original

not loaded

Original

not loaded

Original

not loaded

Original

not loaded

Input

Board

Image

Process-

ing

Board

(PWB-C)

IC

Port

No.

CN/PJ

No.

No.

--PJ2C-2B

--PJ7C-1

--PJ7C-7

--PJ7C-9

--PJ9C-3

--PJ9C-5

--PJ7C-12

--PJ7C-14

--PJ9C-10

T-8

Page 14

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

2-3. How to Interpret “State Confirm” of “Tech. Rep. Mode”

Study the following to interpret data provided by “State Confirm” of “Tech. Rep. Mode.”

Note, however, that the specific data given hereunder is only for reference.

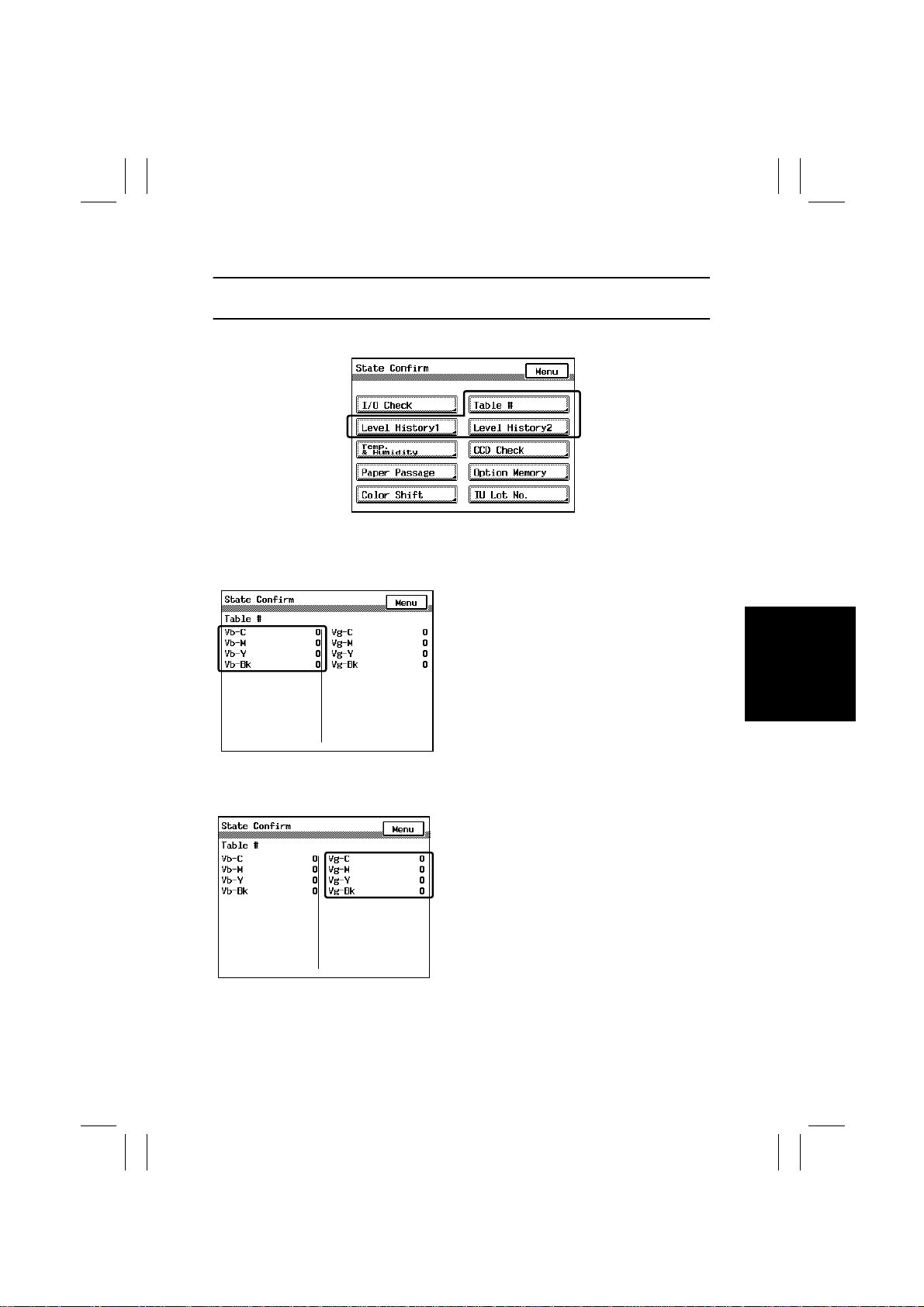

4004P054CA

(1) Table #

Vb-C/-M/-Y/-Bk

Output table value of each developing bias,

representing data applicable during making

copies.

Though the minus sign is not displayed, all

are negative values.

4004P055CA

4004P056CA

Standard: Color (C , M, and Y) : Arou nd -400 V

If the image is light, the value becomes

great.

If the image is dark, the value becomes

small.

Used as a means of correcting image quality

problems.

Vg-C/-M/-Y/-Bk

Output table value of each PC Drum Charge

Corona grid mesh, representing data applicable during making copies.

Though the minus sign is not displayed, all

are negative values.

Standard: Color (C , M, and Y) : Arou nd -500 V

If the image is light, the value becomes

great.

If the image is dark, the value becomes

small.

Used as a means of correcting image quality

problems.

Black (Bk): Around -800 V

Black (Bk): Around -900 V

T-9

Page 15

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

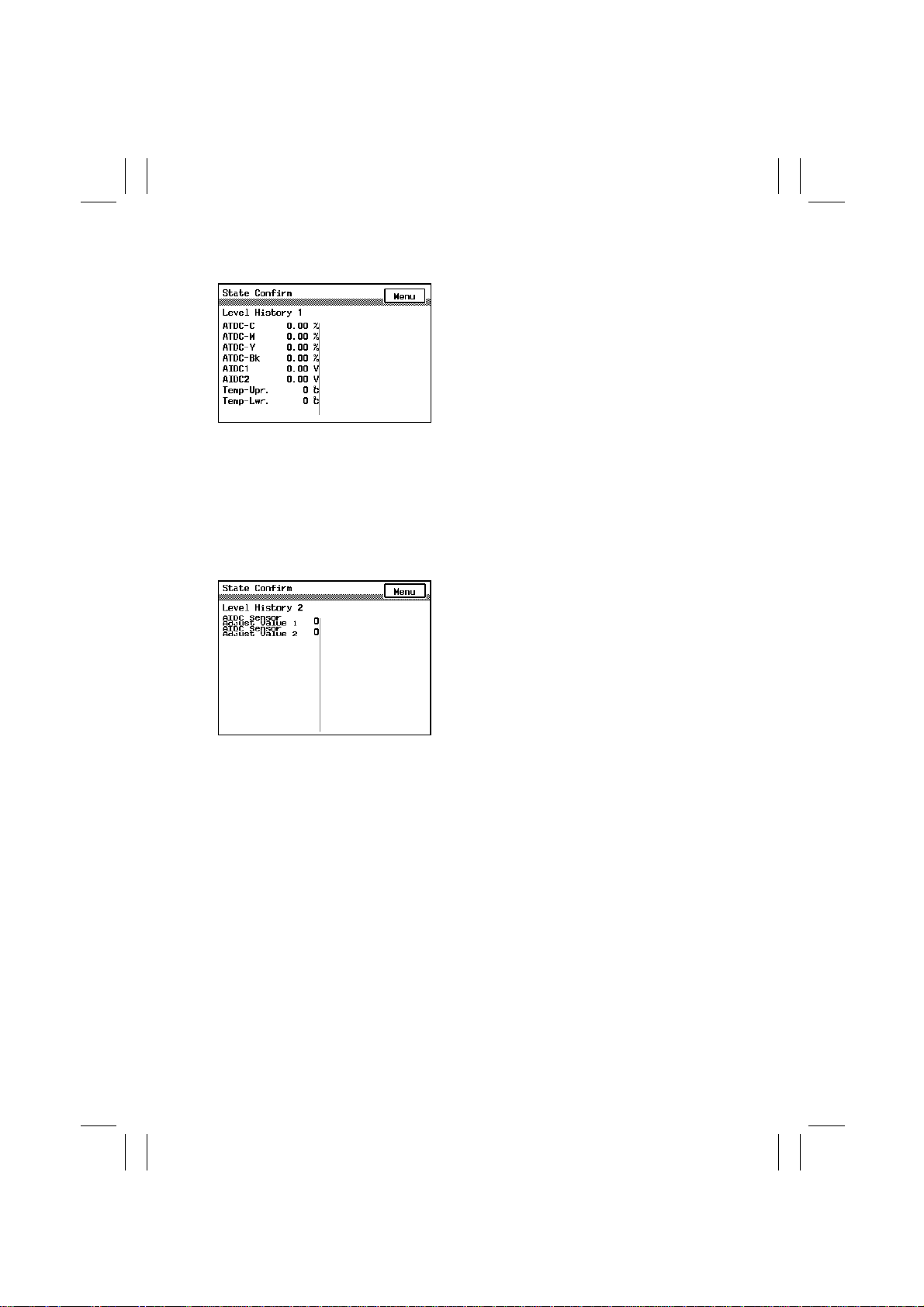

(2) Level History 1

ATDC-C/-M/-Y/-Bk

Displays T/C ratios.

The value is displayed in units of 0.01 %.

Target value:

Color (C, M, and Y) T/C: 5 ±1 %

Black (Bk) T/C: 4.5 ±1 %

AIDC1/2

Displays the AIDC Sensor output values.

The value is displayed in units of 0.01 V.

Normally, the value should be around 4.5 V

4004P057CA

and the output can range from 0 V to 5 V.

Temp Upr./Lwr.

Displays the temperatures of the Upper and

Lower Fusing Rollers.

The value is displayed in units of 5 °C.

(3) Level History 2

AIDC Sensor Adjust Value 1/2

Displays the AIDC intensity adjustment values.

The values represent the intensity determined through AIDC intensity control.

The value is displayed in units of 1 step.

Intensity range: 0 to 255

4004P058CA

T-10

Page 16

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

2-4. Paper Misfeed

When a paper misfeed occurs in the copier, the misfeed message, misfeed location, and

paper location are displayed on the Touch Panel.

3

2

4

6

5

1

7

8

9

10

11

12

11

13

11

14

11

15

Display Misfeed/Paper Location Ref. Item No.

1ADF take-up

2 ADF transport

3 ADF turnover/exit

4 Horizontal Unit

5

Mailbin/Finishing option transport/

Finishing option exit

See relevant

Option Service Manual.

6 Mailbins

7 Duplex Unit transport (8)

8 Fusing/Exit (5)

9 2nd Image Transfer (4)

10 Manual Bypass take-up (2)

11 Vertical Transport/Duplex Unit take-up (3)

12 1st Drawer take-up (1)

13 2nd Drawer take-up (1)

14

3rd Drawer take-up/LCC take-up/

LCC Lift 2 to 1 paper transport

(6) (7)

15 4th Drawer take-up (6) (7)

4004P059CA

<Misfeed Display Resetting Procedure>

Misfeed in copier Open the relevant door, clear the misfeed and

Misfeed in option

remove paper left, and then close the door. (For

the option, clear the misfeed and then install the

option back up against the copier.)

T-11

Page 17

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

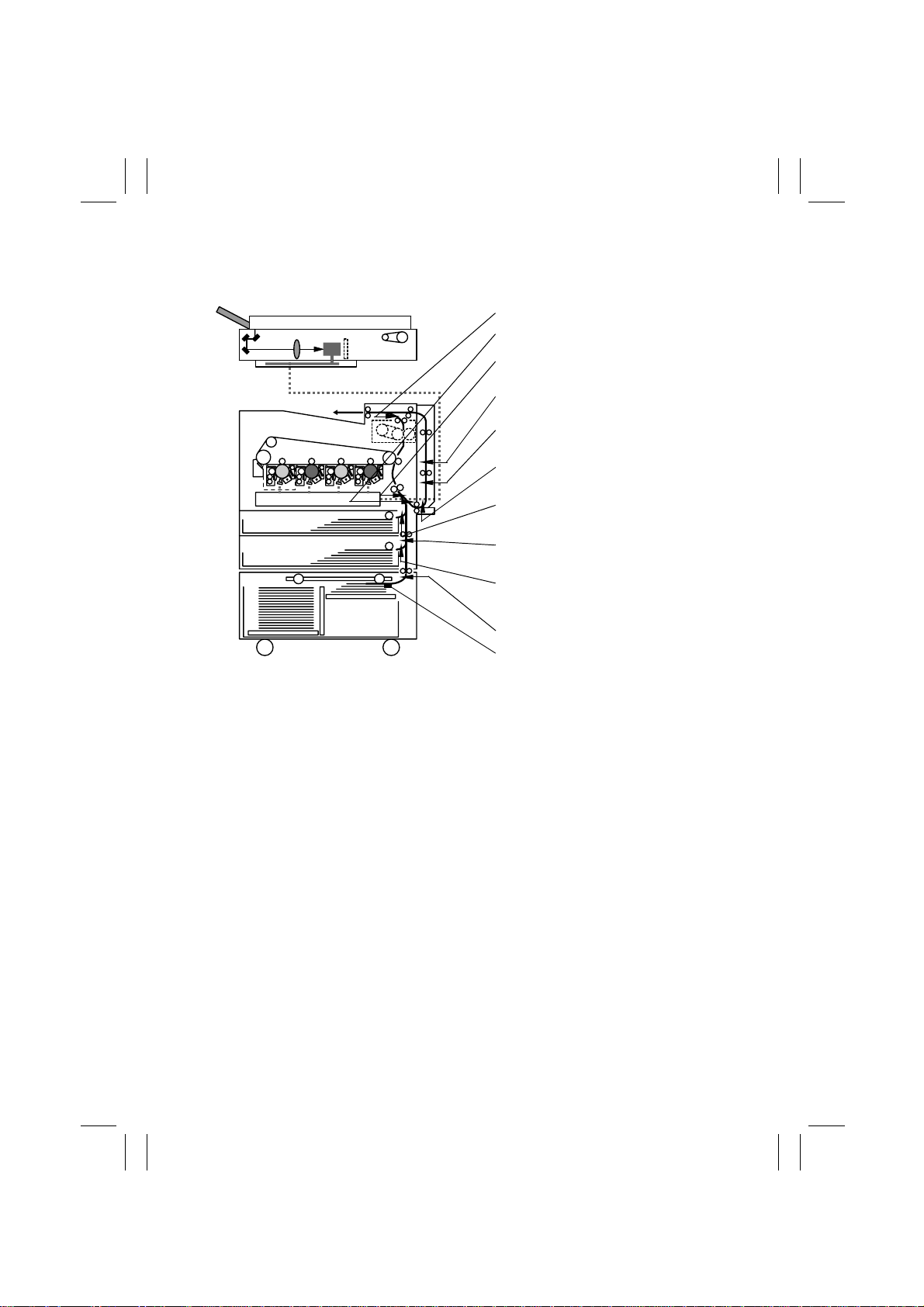

2-5. Misfeed Detecting Sensor Layout

• System Mounted with AD-231 and DB-431

Exit Sensor (PC10)

2/ OHP Detecting Sensor (PC19)

Synchronizing Roller Sensor (PC17)

Duplex Unit Transport Sensor 1 (PI1)

Duplex Unit Transport Sensor 2

(PC1)

Manual Feed Paper Take-Up Sensor

(PC15)

1st Drawer Double Feed Sensor

(PC13)

2nd Drawer Paper Take-Up Sensor

(PC101)

2nd Drawer Double Feed Sensor

(PC105)

4011T055AA

LCC Registration Sensor (RSEN)

LCC Paper Take-Up Sensor (PPS0)

T-12

Page 18

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

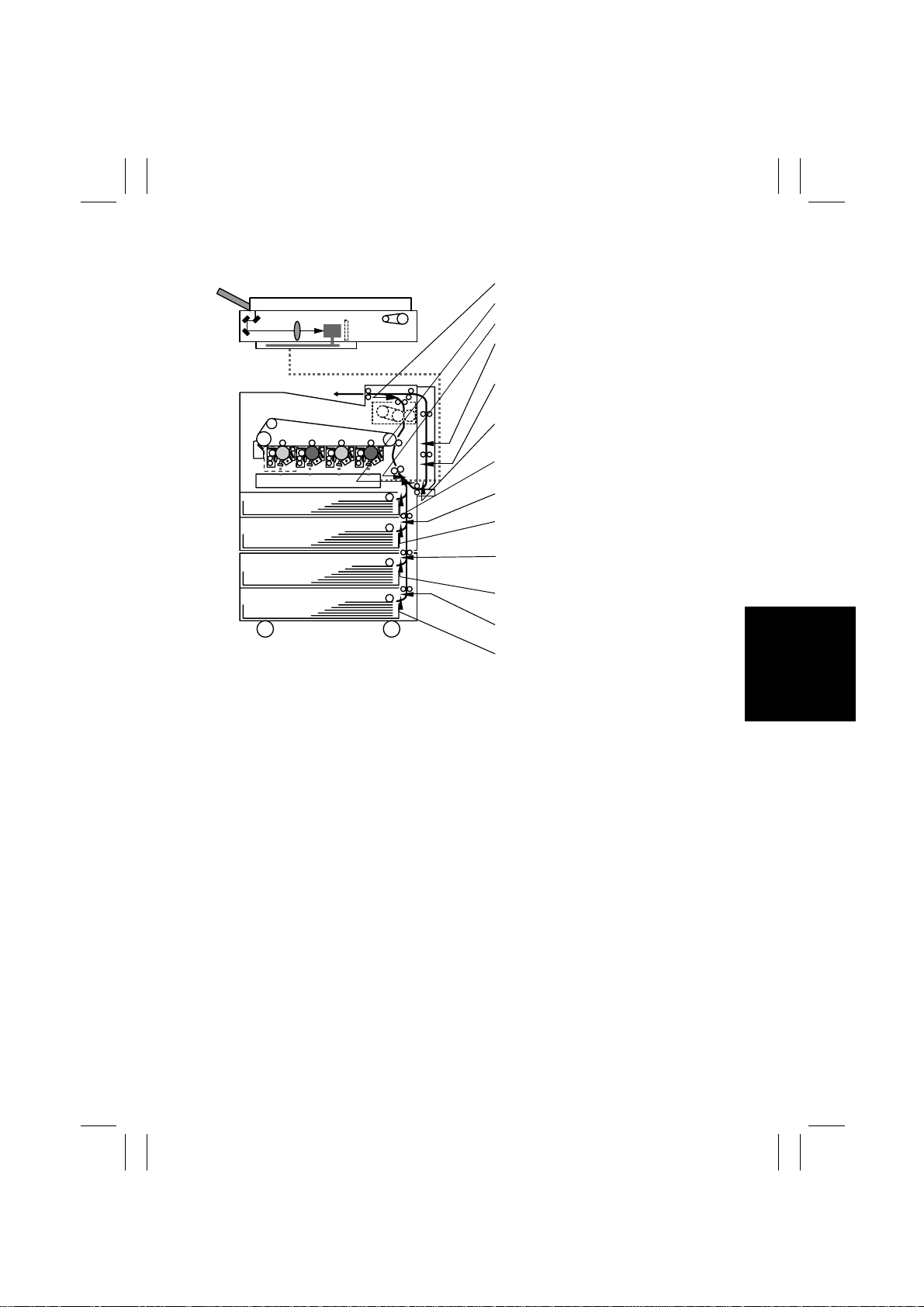

• System Mounted with AD-231 and PF-231

4011T056AA

Exit Sensor (PC10)

OHP Detecting Sensor (PC19)

Synchronizing Roller Sensor (PC17)

Duplex Unit Transport Sensor 1 (PI1)

Duplex Unit Transport Sensor 2

(PC1)

Manual Feed Paper Take-Up Sensor

(PC15)

1st Drawer Double Feed Sensor

(PC13)

2nd Drawer Paper Take-Up Sensor

(PC101)

2nd Drawer Double Feed Sensor

(PC105)

3rd Drawer Paper Take-Up Sensor

(PC1)

3rd Drawer Double Feed Sensor

(PC5)

4th Drawer Paper Take-Up Sensor

(PC1)

4th Drawer Double Feed Sensor

(PC5)

T-13

Page 19

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

2-6. Types of Misfeed Detection and Detection Timing

• The following lists the types of misfeed detection and detection timings for different misfeed locations.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the paper detected by the sensor.

<Copier Paper Take-Up Misfeed>

Type Detection Start Detection

Paper take-up

failure detection

1st Drawer size

error detection

2nd Drawer size

error detection

Detection of

paper left in 2nd

Drawer

1st Drawer Paper Take-Up

Clutch energized

2nd Drawer Paper Take-Up

Clutch energized

Synchronizing Roller Sensor (L) Synchronizing Roller Sensor (T)

2nd Drawer Paper Take-Up

Sensor (L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

Synchronizing Roller Sensor (L)

2nd Drawer Paper Take-Up Sensor (L)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

2nd Drawer Paper Take-Up Sensor (T)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

2nd Drawer Paper Take-Up Sensor

activated

<Manual Bypass Take-Up Misfeed>

Type Detection Start Detection

Bypass paper

take-up failure

detection

Manual bypass

size error detection

Detection of

paper left in

Manual Bypass

Table

<Copier Vertical Transport Misfeed>

Type Detection Start Detection

2nd Drawer

paper take-up

failure

Manual Feed Paper Take-Up

Sensor (L)

Synchronizing Roller Sensor (L) Synchronizing Roller Sensor (T)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

2nd Drawer Paper Take-Up

Sensor (L)

Synchronizing Roller Sensor (L)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

Manual Feed Paper Take-Up Sensor

activated

Synchronizing Roller Sensor (L)

T-14

Page 20

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

<2nd Image Transfer Misfeed>

Type Detection Start Detection

2nd Image

Transfer misfeed detection

Detection of

paper left at 2nd

Image Transfer

<Exit Misfeed>

Type Detection Start Detection

Exit misfeed Exit Sensor activated (L) Exit Sensor deactivated (T)

Detection of

paper left at exit

Synchronizing Roller Sensor (L) Synchronizing Roller Sensor (T)

Exit Sensor (L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

Exit Sensor deactivated (T) Duplex Unit Transport Sensor 1 (L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

Synchronizing Roller Sensor activated,

OHP Detecting Sensor activated

Exit Sensor activated

<PF-231 Paper Take-Up Misfeed>

Type Detection Start Detection

3rd Drawer size

error detection

4th Drawer size

error detection

Detection of

paper left in 3rd

Drawer

Detection of

paper left in 4th

Drawer

3rd Drawer Paper Take-Up

Sensor (L)

4th Drawer Paper Take-Up

Sensor (L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

3rd Drawer Paper Take-Up Sensor (T)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

4th Drawer Paper Take-Up Sensor (T)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

3rd Drawer Paper Take-Up Sensor

activated

4th Drawer Paper Take-Up Sensor

activated

T-15

Page 21

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

<DB-431 Paper Take-Up Misfeed>

Type Detection Start Detection

LCC misfeed

detection

Lift 2 to 1 misfeed detection

LCC vertical

transport misfeed detection

LCC size error

detection

Detection of

paper left in

LCC

LCC paper take-up request LCC Exit signal ON

LCC Paper Take-Up Request LCC Paper Take-Up Sensor activated,

LCC Exit signal ON 2nd Drawer Paper Take-Up Sensor (L)

2nd Drawer Paper Take-Up

Sensor (L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

LCC Paper Empty Sensor 1 activated,

Paper Standby Position Sensor activated

2nd Drawer Paper Take-Up Sensor (T)

[When the paper size detected is ±20

mm or more of the size data fed from

the controller]

LCC Registration Sensor Paper-Left

Misfeed signal ON

<Duplex Paper Take-Up Misfeed>

Type Detection Start Detection

Duplex paper

take-up misfeed detection

Duplex transport misfeed

detection

Detection of

paper left in

Duplex

Duplex paper take-up start Synchronizing Roller Sensor (L), Man-

Duplex Unit Transport Sensor 1

(L)

Power Switch is turned ON,

door or cover is opened and

closed, misfeed or malfunction

is reset

ual Feed Paper Take-Up Sensor (L)

Duplex Unit Transport Sensor 2 (L)

Duplex Unit Transport Sensor 1 activated, Duplex Unit Transport Sensor 2

activated

T-16

Page 22

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

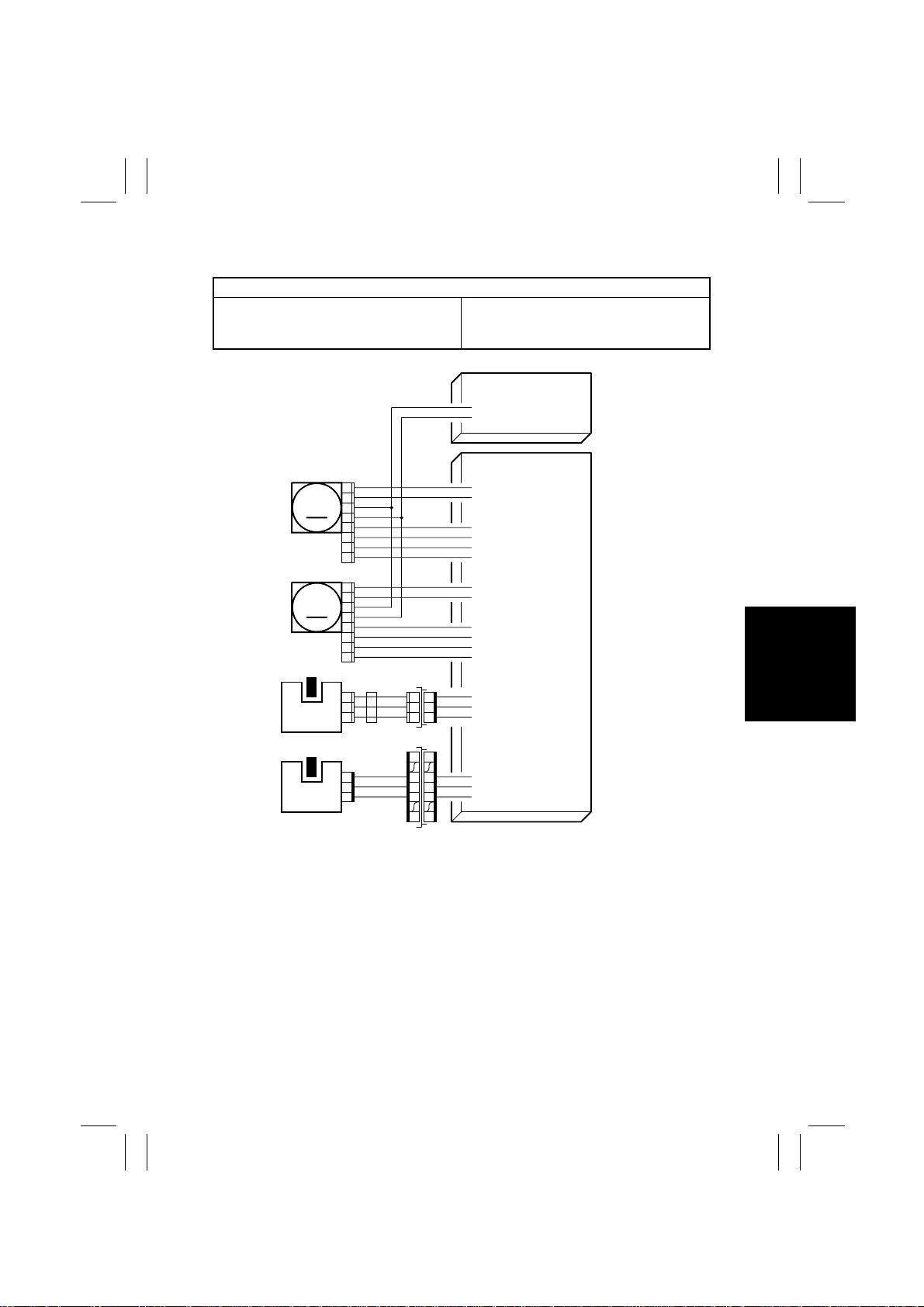

2-7. Misfeed Troubleshooting Procedures

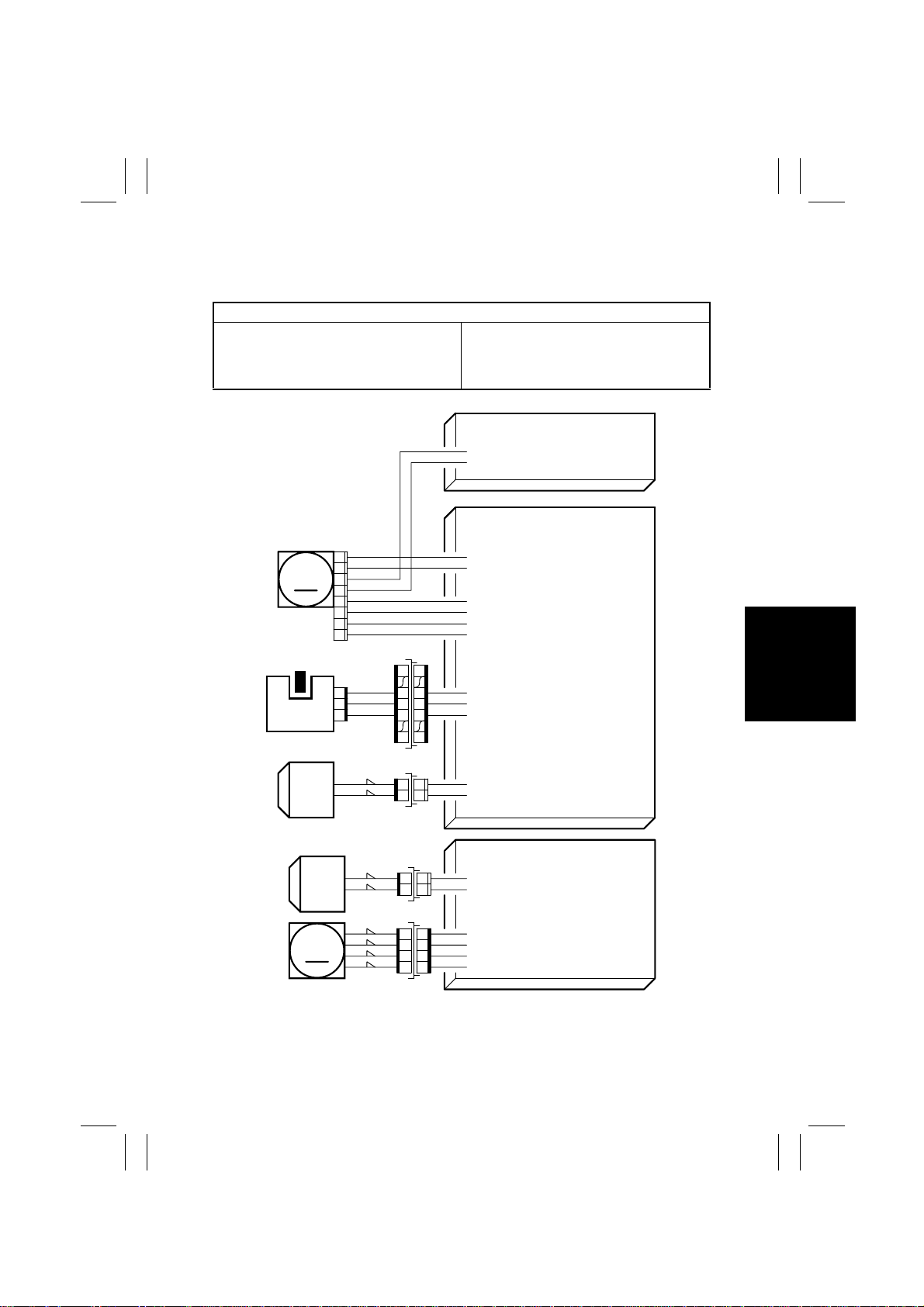

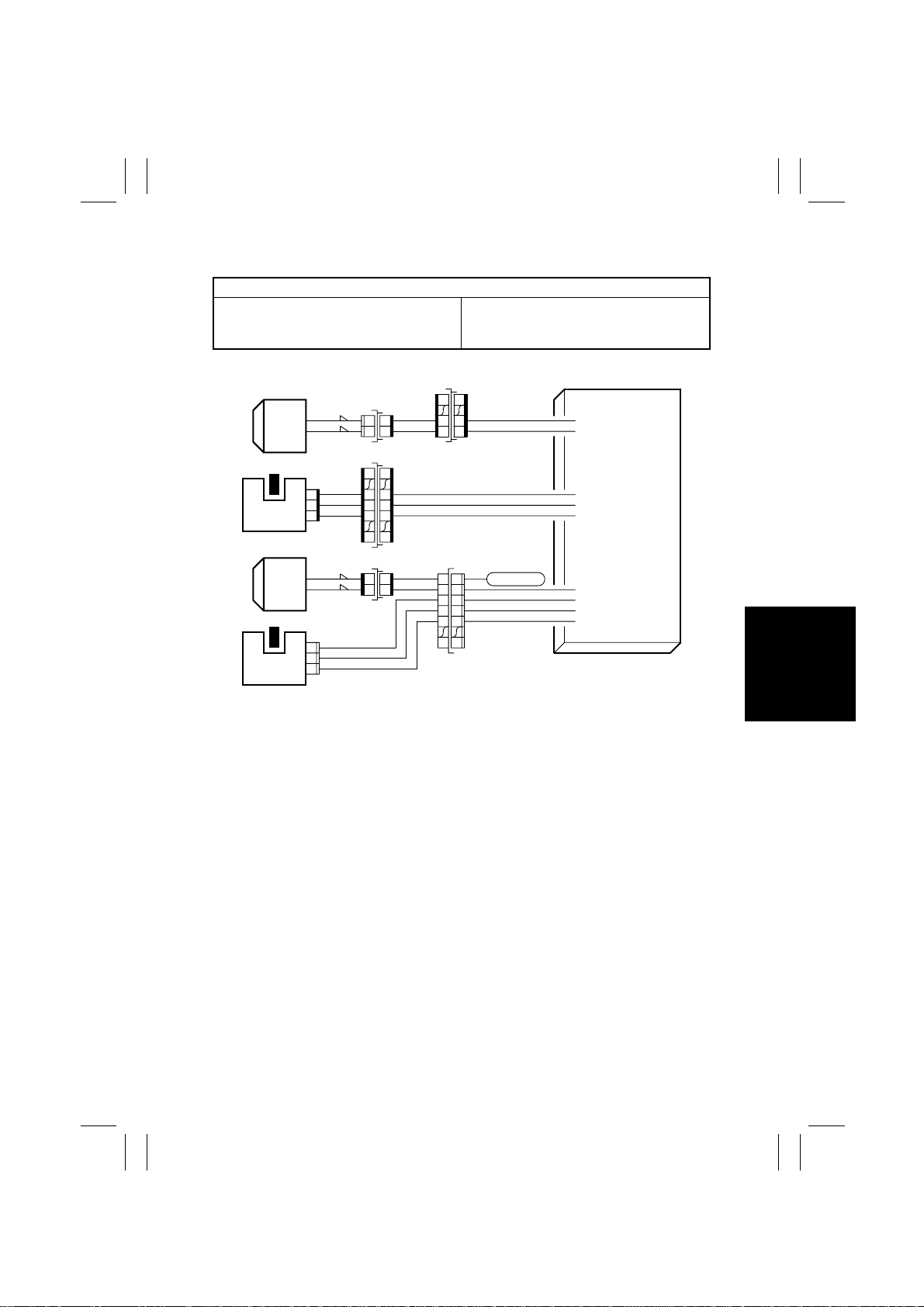

(1) Copi e r Pa pe r Ta ke-Up Misfeed

Relevant Electrical Parts

1st Drawer Paper Take-Up Clutch (CL1)

2nd Drawer Paper Take-Up Clutch (CL101)

Synchronizing Roller Sensor (PC17)

Main Motor (M13)

2nd Drawer Paper Take-Up Motor (M101)

Master Board (PWB-I)

DC Power Supply 1 (PU1)

2nd Drawer Control Board (PWB-A)

PU1

PJ7PU1-4(DC24 V)

PJ7PU1-5(GND)

M13

PC17

CL1

CL101

M101

PJ105

1

2

3

4

5

6

7

8

PJ116

3

2

1

CN63

121

8

94

12 1

CN55

CN1

CN61

1

PWB-I

PJ13I-7A(M13 LOCK)

PJ13I-8A(M13 REM)

PJ13I-9A(M13 CLK)

PJ13I-10A(DC5 V)

PJ13I-11A(GND)

PJ13I-12A(M13 CW/CCW)

67

5

21

12

21

12

14

23

32

4

PJ14I-7A(DC5 V)

PJ14I-8A(GND)

PJ14I-9A(PC17 ON)

PJ15I-10A(DC24 V)

PJ15I-11A(CL1 REM)

PWB-A(2nd Tray)

PJ3A-13B(DC24 V)

PJ3A-14B(CL101 REM)

–

PJ5A-4(

)

B

PJ5A-3(B)

–

PJ5A-2(

)

A

PJ5A-1(A)

–

4004C16TAD

T-17

Page 23

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Copier Paper Take-Up Misfeed Troubleshooting Procedures

• Paper is not taken up at all.

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Paper is curled, wavy, or damp. YES Change paper. Instruct user

in correct paper storage.

Install Paper Dehumidifying

Heater.

3 Edge Guide and Trailing Edge Stop are at

correct position to accommodate paper.

4 Paper Take-Up Roll is deformed, worn, or

dirty with paper dust or other foreign matter.

5 Paper Lifting Plate is dirty, deformed, or

scratched.

6 Separator Pad is deformed, worn, or dirty

with paper dust or other foreign matter.

7 Separator Roll is deformed, worn, or dirty

with paper dust or other foreign matter.

8 Paper take-up guide plate is dirty,

deformed, or scratched.

9 Paper take-up guide plate is installed prop-

erly.

10 Paper Take-Up Roll turns when the Start

key is pressed with the 1st Drawer selected.

11 1st Drawer Paper Take-Up Clutch operation

when the Start key is pressed with the 1st

Drawer selected: the voltage across PJ15I11A on Master Board and GND is DC 24 V

when the clutch is deenergized and DC 0 V

when the clutch is energized.

12 Paper Take-Up Roll turns when the Start

key is pressed with the 2nd Drawer

selected.

13 2nd Drawer Paper Take-Up Clutch opera-

tion when the Start key is pressed with the

2nd Drawer selected: the voltage across

PJ3A-14B on Master Board and GND is DC

24 V when the clutch is deenergized and

DC 0 V when the clutch is energized.

NO Set as necessa ry.

YES Clean or change.

YES Clean or change.

YES Clean or change.

YES Clean or change.

YES Clean or change.

NO Reinstall.

NO Correct drive coupling (cou-

pling engagement, position of

drive transmitting pin).

YES Check for overload. Change

clutch.

NO Change Master Board.

NO Correct drive coupling (cou-

pling engagement, position of

drive transmitting pin).

YES Check for overload. Change

clutch.

NO Change Control Board.

T-18

Page 24

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

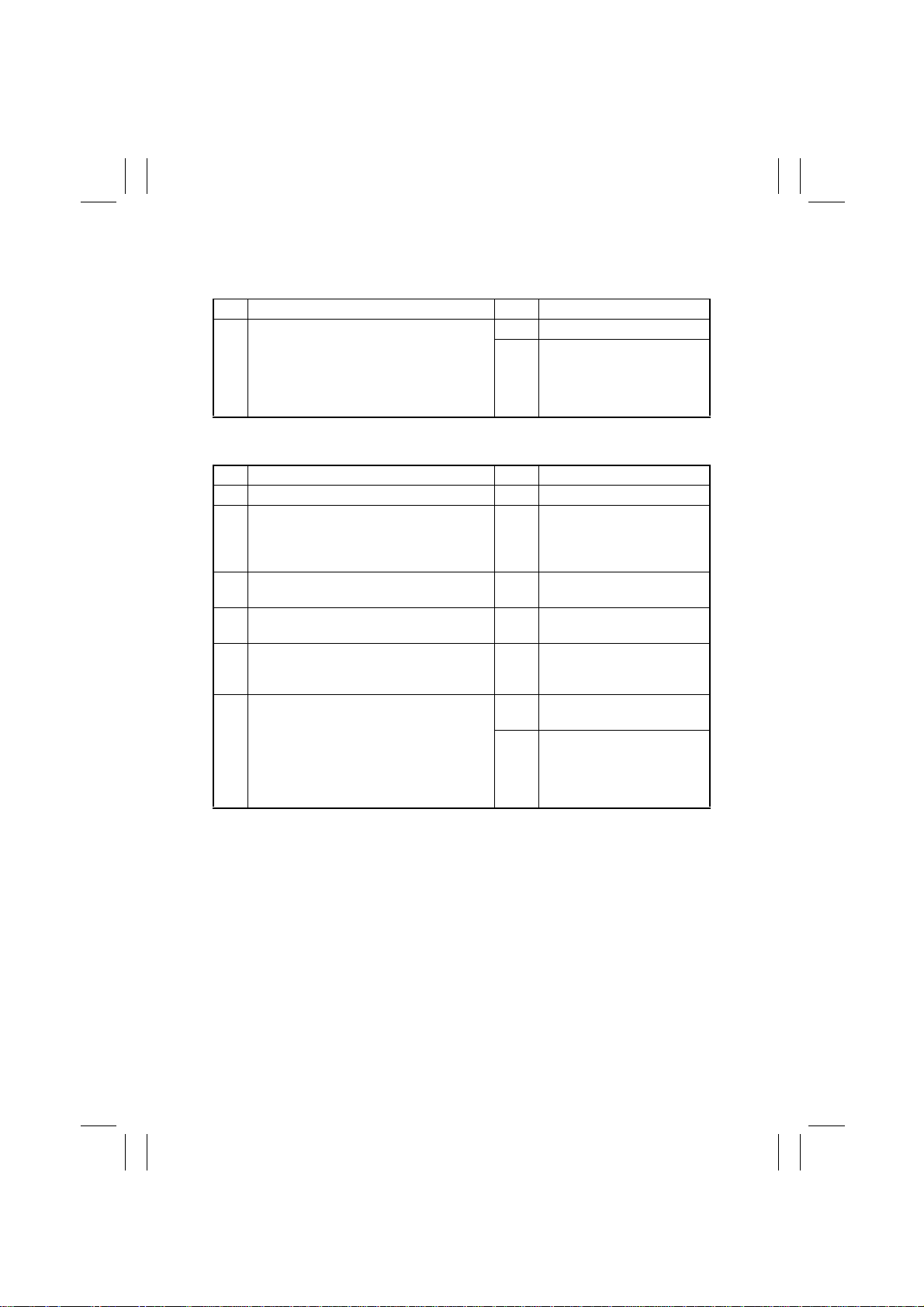

(2) Manual Bypass Take-Up Misfeed

Relevant Electrical Parts

Manual Feed Paper Take-Up Sensor

(PC15)

Manual Feed Paper Take-Up Clutch (CL13)

Synchronizing Roller Sensor (PC17)

Synchronizing Roller Clutch (CL21)

Master Board (PWB-I)

CN65

71

26

7

1

CL21

CN30

21

12

CN63

121

8

94

12 1

CN41

67

5

CN33

21

12

11

22

3

3

4

4

5

5

8

8

PC17

CL3

PC15

PJ116

3

2

1

PJ40

1

2

3

DC24 V

PWB-I

PJ14I-14A(DC24 V)

PJ14I-15A(CL21 REM)

PJ14I-7B(DC5 V)

PJ14I-8B(GND)

PJ14I-9B(PC17 ON)

PJ15I-9A(CL3 REM)

PJ15I-7B(PC15 ON)

PJ15I-8B(GND)

PJ15I-9B(DC5 V)

4004C17AD

T-19

Page 25

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Manual Bypass Take-Up Misfeed Troubleshooting Procedures

• Paper is not detected.

Step Check Item Result Action

1 I/O check for Manual Feed Paper Take-Up

Sensor operation when the Manual Bypass

Table is used: the voltage across PJ15I-7B

on Master Board and GND is DC 0 V when

the sensor is unblocked and DC 5 V when

the sensor is blocked (paper present).

• Paper is not taken up at all.

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Paper is curled, wavy, or damp. YES Change paper. Instruct user

3 Guide plate is dirty with paper dust,

deformed, or scratched.

4 Manual Bypass Take-Up Roll is dirty with

paper dust, deformed, or worn.

5 Manual Bypass Take-Up Roll turns when

the Start key is pressed with the Manual

Bypass Table used.

6 Manual Feed Paper Take-Up Clutch opera-

tion when the Manual Feed Paper Take-Up

Sensor is blocked with the Manual Bypass

Table used: the voltage across PJ15I-9A on

Master Board and GND is DC 24 V when

the clutch is deenergized and DC 0 V when

the clutch is energized.

YES Change Master Board.

NO Correct actuator. Check sen-

sor connector connection.

Change sensor.

in correct paper storage.

Install Paper Dehumidifying

Heater.

YES Clean or change.

YES Clean or change.

NO Correct drive coupling (drive

transmitting gear engagement).

YES Check for overload. Change

clutch.

NO Change Master Board.

T-20

Page 26

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

• Paper is at a stop at the vertical transport section.

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Synchronizing Rollers are dirty with paper

dust, deformed, or worn.

3 Paper Dust Remover is deformed or worn. NO Change Paper Dust Remover

4 Paper Dust Remover is installed properly. NO Reinstall Paper Dust

5 An adequate length of loop is formed before

the Synchronizing Rollers.

6 I/O check for Synchronizing Roller Sensor

operation when the Manual Bypass Table is

used: the voltage across PJ14I-9B on Master Board and GND is DC 0 V when the sensor is unblocked (paper present) and DC 5

V when the sensor is blocked.

7 Synchronizing Rollers turn when the Start

key is pressed with the Manual Bypass

Table used.

8 Synchronizing Roller Clutch operation when

the Manual Bypass Table is used: the voltage across PJ15I-9A on Master Board and

GND after the Manual Feed Paper Take-Up

Clutch has been energized is DC 24 V

when the clutch is deenergized and DC 0 V

when the clutch is energized.

9 Size error display after the misfeed display

has been reset.

YES Clean or change.

Unit.

Remover Unit.

NO Adjust “Paper Loop.” (See

ADJUSTMENT.)

YES Change Master Board.

NO Correct actuator. Check sen-

sor connector connection.

Change sensor.

NO Correct drive coupling (drive

transmitting gear engagement).

YES Check for overload. Change

clutch.

NO Change Master Board.

YES Check paper size.

T-21

Page 27

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

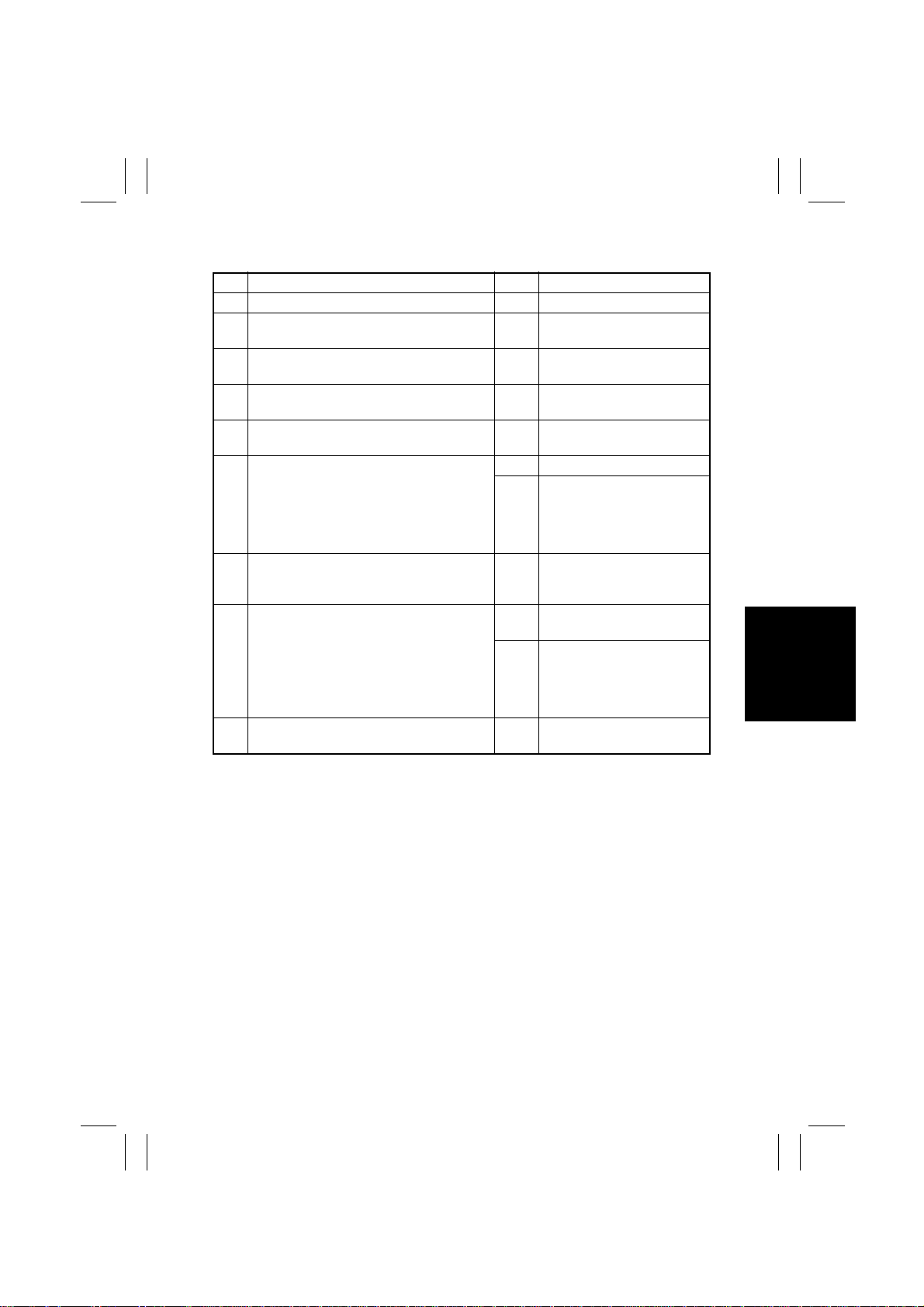

(3) Copier Vertical Transport Misfeed

Relevant Electrical Parts

Synchronizing Roller Sensor (PC17)

2nd Drawer Paper Take-Up Sensor

(PC101)

Synchronizing Roller Clutch (CL21)

1st Drawer Paper Take-Up Clutch (CL1)

Main Motor (M13)

2nd Drawer Paper Take-Up Motor (M101)

Master Board (PWB-I)

DC Power Supply 1 (PU1)

2nd Drawer Control Board (PWB-A)

2nd Drawer Paper Take-Up Clutch (CL101)

PJ7PU1-4(DC24 V)

PJ7PU1-5(GND)

PU1

M13

CL21

PC17

CL1

PC101

CL101

M101

PJ105

1

2

3

4

5

6

7

8

PJ116

3

2

1

PJ12

3

2

1

CN30

CN63

8

94

12 1

CN55

PWB-I

PJ13I-7A(M13 LOCK)

PJ13I-8A(M13 REM)

PJ13I-9A(M13 CLK)

PJ13I-10A(DC5 V)

PJ13I-11A(GND)

71

26

1

21

12

14

23

32

4

PJ13I-12A(M13 CW/CCW)

PJ14I-14A(DC24 V)

PJ14I-15A(CL21 REM)

PJ14I-7A(DC5 V)

PJ14I-8A(GND)

PJ14I-9A(PC17 ON)

PJ15I-10A(DC24 V)

PJ15I-11A(CL1 REM)

PWB-A(2nd Tray)

PJ3A-3A(DC5 V)

PJ3A-4A(GND)

PJ3A-5A(PC101 ON)

PJ3A-13B(DC24 V)

PJ3A-14B(CL101 REM)

–

PJ5A-4(

)

B

PJ5A-3(B)

–

PJ5A-2(

)

A

PJ5A-1(A)

–

4004C18TAD

CN65

21

12

7

121

67

5

21

12

CN1

CN61

1

T-22

Page 28

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Copier Vertical Transport Misfeed Troubleshooting Procedures

• Paper is at a stop at the vertical transport section.

Step Check Item Result Action

1 Synchronizing Rollers are deformed or

worn.

2 Paper dust deposits on Synchronizing Roll-

ers.

3 Paper Dust Remover is deformed or worn. YES Change Paper Dust Remover

4 Paper Dust Remover is installed properly. NO Reinstall Paper Dust

5 An adequate length of loop is formed before

the Synchronizing Rollers.

6 Vertical transport guide plate is dirty,

deformed, or scratched.

7 I/O check for Synchronizing Roller Sensor

operation: the voltage across PJ14I-9B on

Master Board and GND is DC 0 V (paper

present) when the sensor is unblocked and

DC 5 V when the sensor is blocked.

8 Synchronizing Rollers turn when the Start

key is pressed with the 1st Drawer selected.

9 Synchronizing Roller Clutch operation when

the 1st Drawer is used: the voltage across

PJ14I-14A on Master Board and GND is DC

24 V when the clutch is deenergized and

DC 0 V when the clutch is energized.

10 2nd Drawer Vertical Transport Roller 1 is

dirty with paper dust, deformed, or

scratched.

11 2nd Drawer vertical transport guide plate is

dirty, deformed, or scratched.

12 Synchronizing Rollers turn when the Start

key is pressed with the 2nd Drawer

selected.

13 Synchronizing Roller Clutch operation when

the 2nd Drawer is used: the voltage across

PJ14I-14A on Master Board and GND is DC

24 V when the clutch is deenergized and

DC 0 V when the clutch is energized.

YES Check type of paper being

used.

YES Clean Synchronizing Rollers.

Check Paper Dust Remover

for proper function.

Unit.

Remover Unit.

NO Adjust “Paper Loop.” (See

ADJUSTMENT.)

YES Clean or change.

YES Change Master Board.

NO Correct actuator. Check sen-

sor connector for connection.

Change sensor.

NO Correct drive coupling (drive

transmitting gear engagement).

YES Check for overload. Change

clutch.

NO Change Master Board.

YES Clean or change.

YES Clean or change.

NO Correct drive coupling (drive

transmitting gear engagement).

YES Check for overload. Change

clutch.

NO Change Master Board.

T-23

Page 29

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Step Check Item Result Action

14 2nd Drawer Paper Take-Up Motor turns

when the Start key is pressed with the 2nd

Drawer selected.

15 Size error display after the misfeed display

has been reset.

NO Correct drive coupling (cou-

pling engagement, position of

drive transmitting pin).

Change motor. Change 2nd

Drawer Control Board.

YES Check paper size. Check

positioning of the Edge Guide

and Trailing Edge Stop.

T-24

Page 30

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

(4) 2nd Image Transfer Misfeed

Relevant Electrical Parts

Exit Sensor (PC10)

Synchronizing Roller Sensor (PC17)

Main Motor (M13)

Fusing Drive Motor (M14)

Master Board (PWB-I)

DC Power Supply 1 (PU1)

PJ7PU1-4(DC24 V)

PJ7PU1-5(GND)

PU1

M14

M13

PC10

PC17

PJ106

1

2

3

4

5

6

7

8

PJ105

1

2

3

4

5

6

7

8

PJ133

3

2

1

PJ116

3

2

1

CN17

CN63

121

8

94

12 1

PWB-I

PJ13I-1A(M14 LOCK)

PJ13I-2A(M14 REM)

PJ13I-3A(M14 CLK)

PJ13I-4A(DC5 V)

PJ13I-5A(GND)

PJ13I-6A(M14 CCM/CM)

PJ13I-7A(M13 LOCK)

PJ13I-8A(M13 REM)

PJ13I-9A(M13 CLK)

PJ13I-10A(DC5 V)

PJ13I-11A(GND)

PJ13I-12A(M13 CCM/CM)

31

22

13

67

5

PJ3I-12A(DC5 V)

PJ3I-13A(GND)

PJ3I-14A(PC10 ON)

PJ14I-7B(DC5 V)

PJ14I-8B(GND)

PJ14I-9B(PC17 ON)

4004C20TAB

T-25

Page 31

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

2nd Image Transfer Misfeed Troubleshooting Procedures

• Paper is at a stop at the 2nd Image Transfer section.

Step Check Item Result Action

1 Vertical transport guide plate is dirty,

deformed, or scratched.

2 Image Transfer Roller Unit is not installed

properly.

3 Pre-Image Transfer Guide Plate is dirty,

deformed, or scratched.

Seal is separated.

4 Transfer Belt is driven when the Start key is

pressed.

5 Transfer Belt is deformed or damaged. YES Change Transfer Belt Unit.

6 Transfer Roller turns when the Start key is

pressed.

7 Transfer Roller is dirty with paper dust or

other foreign matter, deformed, or worn.

8 Fusing Rollers turn when the Start key is

pressed.

9 Paper winds around Transfer Belt. YES Readjust Paper Separator

10 Paper winds around Transfer Roller. YES Change Transfer Roller Unit.

11 I/O check for Exit Sensor operation: the

voltage across PJ3I-14A on Master Board

and GND is DC 0 V (paper present) when

the sensor is unblocked and DC 5 V when

the sensor is blocked.

YES Clean or change.

YES Reinstall.

YES Clean or change Image

Transfer Roller Unit.

NO Correct drive coupling (drive

transmitting gear engagement). Reinstall Transfer Belt

Unit.

NO Correct drive coupling (drive

transmitting gear engagement). Reinstall Transfer

Roller Unit.

YES Clean or change Image

Transfer Roller Unit.

NO Correct drive coupling (drive

transmitting gear engagement). Correct the installed

position of Fusing Unit.

Fingers. Readjust “Top Margin.”

YES Change Master Board.

NO Correct actuator. Check sen-

sor connector for connection.

Change sensor.

T-26

Page 32

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

(5) Exit Misfeed

Relevant Electrical Parts

Exit Sensor (PC10)

Fusing Drive Motor (M14)

Master Board (PWB-I)

DC Power Supply 1 (PU1)

PJ7PU1-4(DC24 V)

PJ7PU1-5(GND)

PU1

M14

PC10

PJ106

1

2

3

4

5

6

7

8

PJ133

3

2

113

CN17

PWB-I

PJ13I-1A(M14 LOCK)

PJ13I-2A(M14 REM)

PJ13I-3A(M14 CLK)

PJ13I-4A(DC5 V)

PJ13I-5A(GND)

PJ13I-6A(M14 CCM/CM)

31

22

PJ3I-12A(DC5 V)

PJ3I-13A(GND)

PJ3I-14A(PC10 ON)

4004C21TAA

T-27

Page 33

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Exit Misfeed Troubleshooting Procedures

• Paper is at a stop at the 2nd Image Transfer section.

Step Check Item Result Action

1 Fusing guide plate is dirty, deformed, or

damaged.

2 Fusing Rollers are dirty, deformed, or

scratched.

3 Fusing Paper Separator Fingers are dirty,

deformed, or worn.

4 Fusing Exit Roller is dirty, deformed, or

scratched.

5 Fusing Rollers turn when the Start key is

pressed.

6 I/O check for Exit Sensor operation: the

voltage across PJ3I-14A on Master Board

and GND is DC 0 V (paper present) when

the sensor is unblocked and DC 5 V when

the sensor is blocked.

7 Exit Turnover Roller is dirty, deformed, or

scratched.

8 Exit Turnover Roller turns when the Start

key is pressed.

YES Clean or change.

YES Clean or change Fusing Unit.

YES Clean, correct, or change.

YES Clean or change.

NO Correct drive coupling (drive

transmitting gear engagement). Correct installed position of Fusing Unit. Change

Fusing Unit.

YES Change Master Board.

NO Correct actuator. Check sen-

sor connector for connection.

Change sensor.

YES Clean or change.

NO Correct drive coupling (roller

position).

T-28

Page 34

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

(6) PF-231 Paper Take-Up Misfeed

Relevant Electrical Parts

3rd Drawer Paper Take-Up Sensor (PC1)

4th Drawer Paper Take-Up Sensor (PC1)

3rd Drawer Paper Take-Up Clutch (CL1)

4th Drawer Paper Take-Up Clutch (CL1)

3rd Drawer Paper Take-Up Motor (M1)

4th Drawer Paper Take-Up Motor (M1)

3rd Drawer Control Board (PWB-A)

4th Drawer Control Board (PWB-A)

PC1

CL1

M1

PC1

CL1

M1

PJ12

3

2

1

PJ12

3

2

1

CN73

21

12

CN61

14

23

32

4

1

CN73

21

12

CN61

14

23

32

1

4

PWB-A(3rd Tray)

PJ3A-3A(DC5 V)

PJ3A-4A(GND)

PJ3A-5A(PC1 ON)

PJ3A-13B(DC24 V)

PJ3A-14B(CL1 REM)

–

PJ5A-4(

B

PJ5A-3(B)

–

PJ5A-2(

A

PJ5A-1(A)

PWB-A(4th Tray)

PJ3A-3A(DC5 V)

PJ3A-4A(GND)

PJ3A-5A(PC1 ON)

PJ3A-13B(DC24 V)

PJ3A-14B(CL1 REM)

–

PJ5A-4(

B

PJ5A-3(B)

–

PJ5A-2(

A

PJ5A-1(A)

)

)

)

)

–

–

T-29

4004C22TAB

Page 35

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

PF-231 Paper Take-Up Misfeed Troubleshooting Procedures

• Paper is not taken up at all.

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Paper is curled, wavy, or damp. YES Change paper. Instruct user

in correct paper storage.

Install Paper Dehumidifying

Heater.

3 Edge Guide and Trailing Edge Stop are at

correct position to accommodate paper.

4 Paper Take-Up Roll is deformed, worn, or

dirty with paper dust or other foreign matter.

5 Paper Lifting Plate is dirty, deformed, or

scratched.

6 Separator Roll is deformed, worn, or dirty

with paper dust or other foreign matter.

7 Paper take-up guide plate is dirty,

deformed, or scratched.

8 Paper take-up guide plate is installed prop-

erly.

9 Paper Take-Up Roll turns when the Start

key is pressed with the 3rd Drawer

selected.

10 3rd Drawer Paper Take-Up Clutch opera-

tion when the Start key is pressed with the

3rd Drawer selected: the voltage across

PJ3A-14B on Control Board and GND is DC

24 V when the clutch is deenergized and

DC 0 V when the clutch is energized.

11 3rd Drawer Paper Take-Up Motor turns

when the Start key is pressed with the 3rd

Drawer selected.

12 Paper Take-Up Roll turns when the Start

key is pressed with the 4th Drawer

selected.

13 4th Drawer Paper Take-Up Clutch opera-

tion when the Start key is pressed with the

4th Drawer selected: the voltage across

PJ3A-14B on Control Board and GND is DC

24 V when the clutch is deenergized and

DC 0 V when the clutch is energized.

NO Set as necessa ry.

YES Clean or change.

YES Clean or change.

YES Clean or change.

YES Clean or change.

NO Reinstall.

NO Correct drive coupling (cou-

pling engagement, position of

drive transmitting pin).

YES Check for overload. Change

clutch.

NO Change 3rd Drawer Control

Board.

NO Correct drive coupling (drive

transmitting gear engagement). Change motor.

Change 3rd Drawer Control

Board.

NO Correct drive coupling (cou-

pling engagement, position of

drive transmitting pin).

YES Check for overload. Change

clutch.

NO Change 4th Drawer Control

Board.

T-30

Page 36

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

Step Check Item Result Action

14 4th Drawer Paper Take-Up Motor turns

when the Start key is pressed with the 4th

Drawer selected.

• Paper is at a stop at the Vertical Transport Rollers.

Step Check Item Result Action

1 Paper take-up guide plate or vertical trans-

port guide plate is dirty or deformed.

2 Vertical Transport Rollers are dirty with

paper dust, deformed, or worn.

3 I/O check for 3rd Drawer Paper Take-Up

Sensor operation when the 3rd Drawer is

used: the voltage across PJ3A-5A on Control Board and GND is DC 0 V when the

sensor is unblocked and DC 5 V (paper

present) when the sensor is blocked.

4 Vertical Transport Roller 3 turns when the

Start key is pressed with 3rd Drawer

selected.

5 I/O check for 4th Drawer Paper Take-Up

Sensor operation when the 4th Drawer is

used: the voltage across PJ3A-5A on Control Board and GND is DC 0 V when the

sensor is unblocked and DC 5 V (paper

present) when the sensor is blocked.

6 Vertical Transport Roller 4 turns when the

Start key is pressed with 4th Drawer

selected.

7 Size error display after the misfeed display

has been reset.

NO Correct drive coupling (drive

transmitting gear engagement). Change motor.

Change 4th Drawer Control

Board.

YES Clean, correct, or change.

YES Clean or change.

YES Change 3rd Drawer Control

Board.

NO Correct actuator. Check sen-

sor connector for connection.

Change sensor.

NO Correct drive coupling (drive

transmitting gear engagement, clutch spring operation).

YES Change 4th Drawer Control

Board.

NO Correct actuator. Check sen-

sor connector for connection.

Change sensor.

NO Correct drive coupling (drive

transmitting gear engagement, clutch spring operation).

YES Check paper size.

T-31

Page 37

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

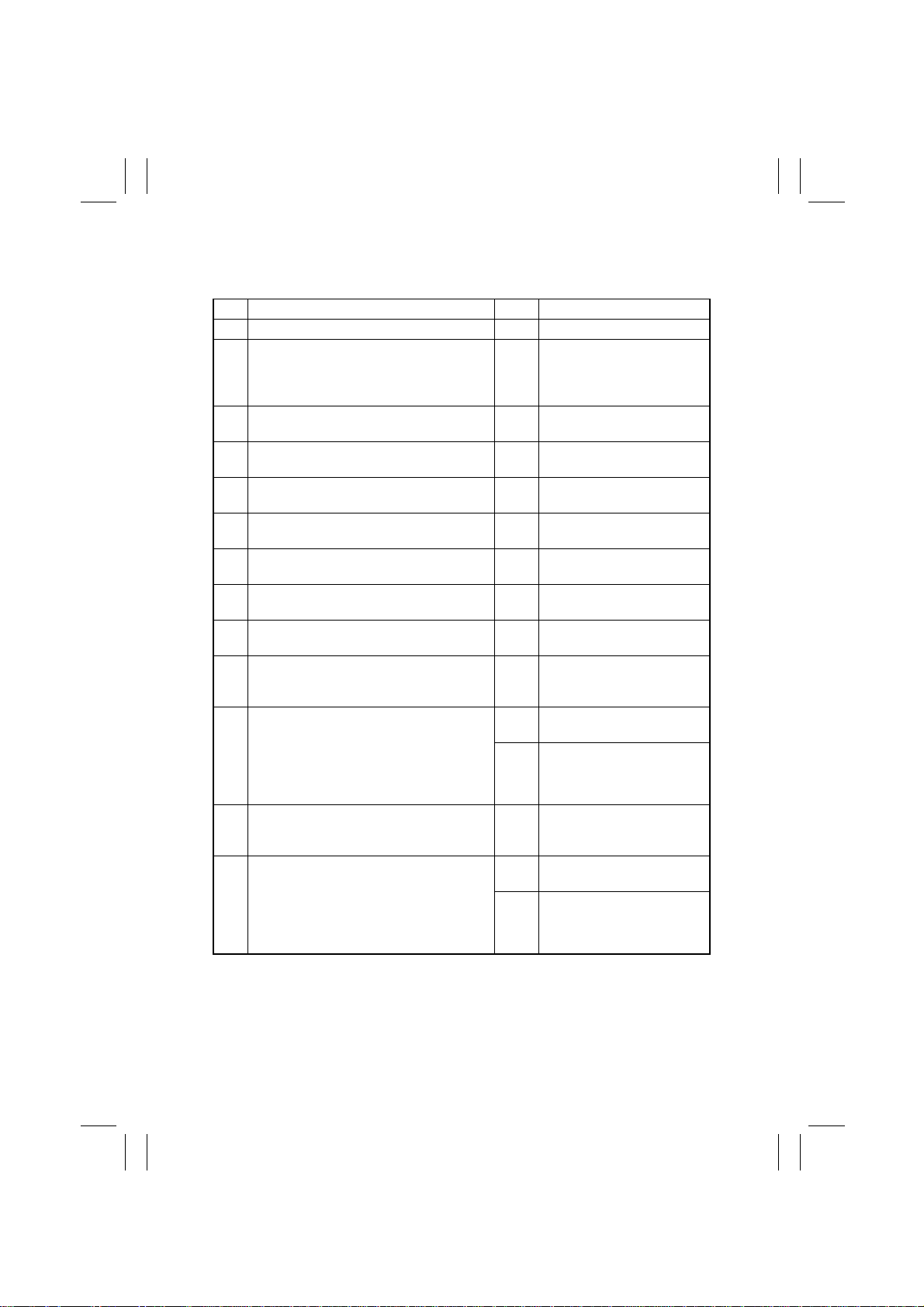

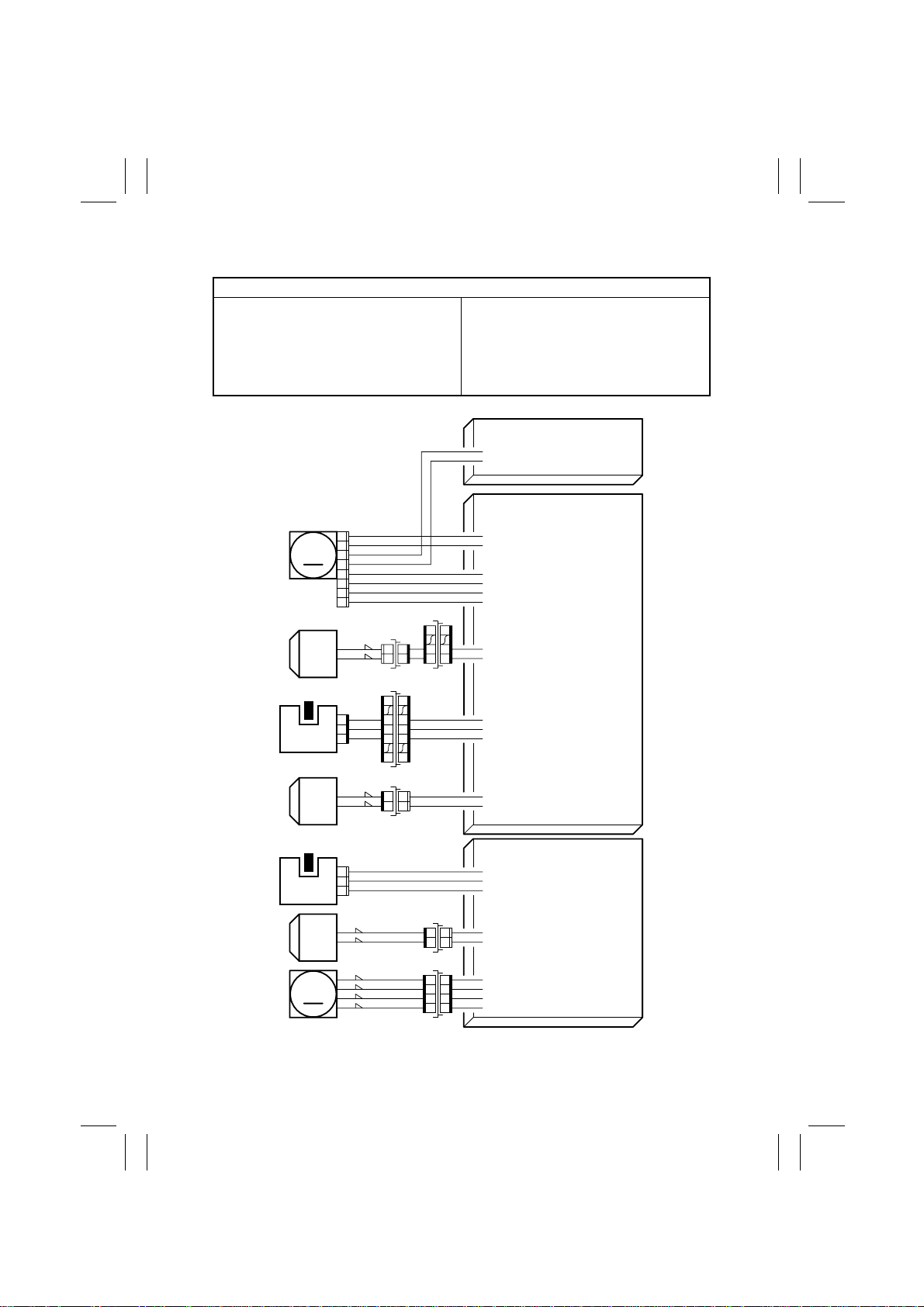

(7) DB-431 Paper Take-Up Misfeed

Relevant Electrical Parts

LCC Paper Take-Up Sensor (PPS0)

Paper Standby Position Sensor (S1)

LCC Registration Sensor (RSEN)

LCC Paper Take-Up Clutch 1 (P1CL)

LCC Separator Clutch (BCL)

LCC Registration Clutch (RCL)

LCC Transport Motor (HMOT)

LCC Control Board (PWB-A)

LCC Paper Take-Up Clutch 2 (P2CL)

S1

RSEN

PPSO

HMOT

BCL

RCL

P2CL

PJ10

1

2

3

PJ7

1

2

3

PJ4

1

2

3

PJ4

1

2

3

4

5

6

CN14

12

21

CN13

12

21

CN12

12

21

PWB-A(LCC Tray)

CN3A-6(S1 LED)

CN3A-5(S1 ON)

CN3A-4(DC5 V)

CN4A-3(RSEN LED)

CN4A-2(RSEN ON)

CN4A-1(DC5 V)

CN4A-12(PPSO LED)

CN4A-11(PPSO ON)

CN4A-10(DC5 V)

CN6A-6(HMOT CLK)

CN6A-5(DC5 V)

CN6A-4(HMOT SIG)

CN6A-3(CTND)

CN6A-1(DC24 V)

CN7A-2(BCL ON)

CN7A-1(DC24 V)

CN7A-4(RCL ON)

CN7A-3(DC24 V)

CN7A-6(P2CL ON)

CN7A-5(DC24 V)

P1CL

CN11

12

21

T-32

CN7A-8(P1CL ON)

CN7A-7(DC24 V)

4004C23TAB

Page 38

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

DB-431 Paper Take-Up Misfeed Troubleshooting Procedures

• Paper is not taken up at all. (Lift 1)

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Paper is curled, wavy, or damp. YES Change paper. Instruct user

in correct paper storage.

Install Paper Dehumidifying

Heater.

3 Lift is dirty, deformed, or damaged. YES Clean or change.

4 Paper Take-Up Roll 1 is dirty, deformed, or

scratched.

5 Paper Take-Up Roll 1 turns when the Start

key is pressed with Lift 1 used.

6 LCC Paper Take-Up Clutch 1 operation

when the Start key is pressed with Lift 1

used: the voltage across CN7A-8 on LCC

Control Board and GND is DC 24 V when

the clutch is deenergized and DC 0 V when

the clutch is energized.

YES Clean or change.

NO Correct drive coupling (drive

transmitting gear engage-

ment, spring operation, belt

tension).

YES Check for overload. Change

clutch.

NO Change LCC Control Board.

• Paper is not taken up at all. (Lift 2)

Step Check Item Result Action

1 Paper meets product specifications. NO Change paper.

2 Paper is curled, wavy, or damp. YES Change paper. Instruct user

3 Lift is dirty, deformed, or damaged. YES Clean or change.

4 Paper Take-Up Roll 2 is dirty, deformed, or

scratched.

5 Paper Take-Up Roll 2 turns when the Start

key is pressed with Lift 2 used.

6 LCC Paper Take-Up Clutch 2 operation

when the Start key is pressed with Lift 2

used: the voltage across PJ7A-6 on LCC

Control Board and GND is DC 24 V when

the clutch is deenergized and DC 0 V when

the clutch is energized.

in correct paper storage.

Install Paper Dehumidifying

Heater.

YES Clean or change.

NO Correct drive coupling (drive

transmitting gear engage-

ment, spring operation, belt

tension).

YES Check for overload. Change

clutch.

NO Change LCC Control Board.

T-33

Page 39

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

• Paper is stationary at the Vertical Transport Roller.

Step Check Item Result Action

1 Feed Roll is deformed, worn, or dirty with

paper dust or other foreign matter.

2 Separator Roll is deformed, worn, or dirty

with paper dust or other foreign matter.

3 Paper take-up guide plate is dirty,

deformed, or damaged.

4 Vertical Transport Roller is dirty with paper

dust, deformed, or worn.

5 Vertical transport guide plate is dirty or

deformed.

6 I/O check for Paper Standby Position Sen-

sor operation when the LCC Drawer is

used: the voltage across PJ3A-5 on LCC

Control Board and GND is DC 5 V when

there is reflected light and DC 0 V when

there is no reflected light.

7 Feed Roll turns when the Start key is

pressed with the LCC Drawer selected.

8 Separator Roll turns when the Start key is

pressed with the LCC Drawer selected.

9 LCC Separator Clutch operation when the

Start key is pressed with the LCC Drawer

selected: the voltage across CN7A-2 on

LCC Control Board and GND is DC 24 V

when the clutch is deenergized and DC 0 V

when the clutch is energized.

10 I/O check for LCC Registration Sensor

operation when the LCC Drawer is used:

the voltage across CN4A-2 on LCC Control

Board and GND is DC 5 V when there is

reflected light and DC 0 V when there is no

reflected light.

11 Vertical Transport Rollers turn when the

Start key is pressed with the LCC Drawer

selected.

12 LCC Registration Clutch operation when

the Start key is pressed with the LCC

Drawer selected: the voltage across CN7A4 on LCC Control Board and GND is DC 24

V when the clutch is deenergized and DC 0

V when the clutch is energized.

YES Clean or change.

YES Clean or change.

YES Clean or change.

YES Clean or change.

YES Clean, correct, or change.

YES Change LCC Control Board.

NO Check sensor connector for

connection. Change sensor.

NO Correct drive coupling (drive

transmitting gear engage-

ment, belt tension).

NO Correct drive coupling (spring

operation).

YES Check for overload. Change

clutch.

NO Change LCC Control Board.

YES Change LCC Control Board.

NO Check sensor connector for

connection. Change sensor.

NO Correct drive coupling (drive

transmitting gear engage-

ment).

YES Check for overload. Change

clutch.

NO Change LCC Control Board.

T-34

Page 40

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

(8) AD-231 Paper Take-Up Misfeed

Relevant Electrical Parts

Duplex Unit Transport Sensor 1 (PI1)

Duplex Unit Transport Sensor 2 (PC1)

Manual Feed Paper Take-Up Sensor

(PC15)

Duplex Unit Transport Motor (M2)

Switchback Motor (M1)

Duplex Control Board (PWB-A)

Master Board (PWB-I)

Manual Feed Paper Take-Up Clutch (CL3)

CL3

PC15

PJ40

1

2

3

CN41

21

12

CN33

11

22

3

3

4

4

5

5

8

8

M1

M2

DC24 V

PWB-I

PJ15A-9A(CL3 REM)

PJ15A-7B(PC15 ON)

PJ15A-8B(GND)

PJ15A-9B(DC5 V)

PWB-A

–

PJ3A-1(

)

B

PJ3A-2(B)

–

PJ3A-3(

)

A

PJ3A-4(A)

–

PJ2A-1(

)

B

PJ2A-2(B)

–

PJ2A-3(

)

A

PJ2A-4(A)

PC1

PJ10

3

2

1

T-35

PJ4A-1(DC5 V)

PJ4A-2(GND)

PJ4A-3(PC1 ON)

PI1

4004C24TAD

4004C24TAD

Page 41

FrameMaker Ver.5.5E(PC) 7915/7920 TROUBLESHOOT ING

01.02.09

AD-231 Paper Take-Up Misfeed Troubleshooting Procedures

• Paper is at a stop in the Duplex Unit transport section.

Step Check Item Result Action

1 Transport Roller is dirty, deformed, or worn. YE S Clean or change.

2 Transport Roll is dirty, deformed, or worn. YES Clean or change.

3 Transport guide is dirty, deformed, or dam-

aged.

4 Torn piece of paper left at the transport sec-

tion.

5 Duplex Unit Transport Roller 1 turns when

the Start key is pressed with the Duplex

Unit used.

6 Switchback Motor turns when the Start key

is pressed with the Duplex Unit used.

7 Duplex Unit Transport Roller 2 turns when

the Start key is pressed with the Duplex

Unit used.

8 Duplex Unit Transport Roller 3 turns when

the Start key is pressed with the Duplex

Unit used.

9 Duplex Unit Transport Motor turns when the

Start key is pressed with the Duplex Unit

used.

YES Clean, correct, or change.

YES Clean.

NO Correct drive coupling (drive

transmitting gear engage-

ment).

NO Correct drive coupling.

Change motor. Change

Duplex Control Board.

NO Correct drive coupling (drive

transmitting gear engage-

ment).

NO Correct drive coupling (drive

transmitting gear engage-

ment).

NO Correct drive coupling.

Change motor. Change