Page 1

7832

SERVICE HANDBOOK

Dec. 2000

Ver. 1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

KCS783210

Page 2

INDEX (GENERAL)

GENERAL

MECHANICAL/ELECTRICAL

Page 3

Blank page

Page 4

GENERAL

Page 5

Blank page

Page 6

CONTENTS

1. SAFETY INFORMATION .................................................................................G-1

1-1. Laser Safety .............................................................................................G-1

1-2. Internal Laser Radiation ...........................................................................G-1

1-3. CDRH Regulations ..................................................................................G-2

1-4. Laser Safety Label ...................................................................................G-4

1-5. Location of Laser Warning Labels ...........................................................G-4

2. SPECIFICATIONS ...........................................................................................G-7

3. PRECAUTIONS FOR INSTALLATION ............................................................G-10

4. PRECAUTIONS FOR USE ..............................................................................G-11

5. HANDLING OF THE CONSUMABLES ...........................................................G-12

6. OTHER PRECAUTIONS .................................................................................G-12

7. SYSTEM OPTIONS .........................................................................................G-13

8. HIGHLIGHTS ...................................................................................................G-14

i

Page 7

Blank page

Page 8

1. SAFETY INFORMATION

1-1. Laser Safety

This is a digital copier which operates by means of a laser. There is no possibility of danger

from the laser, provided the copier is operated according to the instructions in this manual.

Since radiation emitted by the laser is completely confined within protective housing, the

laser beam cannot escape from the copier during any phase of user operation.

This copier is certified as a Class 1 laser product. This means the copier does not produce

hazardous laser radiation.

1-2. Internal Laser Radiation

Maximum Average Radiat Power: 78.1 µW at the laser aperture of the upper print head

assy.

Wavelength: 675-695 nm

This product employs a Class

The Laser Diode and the Scanning Polygon Mirror are Incorporated in the print head assy.

The print head assy is NOT A FIELD SERVICE ITEM.

Therefore, the print head assy should not be opened under any circumstances.

III

b Laser Diode that emits a laser beam.

Upper Print Head Assy

G-1

Lower Print Head Assy

1179O070AA

Page 9

1-3. CDRH Regulations

For the United States

This copier is certified as a Class I Laser product under Radiation Performance Standard

according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory for Laser

products marketed in the United States and is reported to the Center for Devices and

Radiological Health (CDRH) of the U.S. Food and Drug Administration of the U.S. Department of Health and Human Services (DHHS). This means that the device does not produce

hazardous laser radiation.

The label shown to page G-4 indicates compliance with the CDRH regulations and must be

attached to laser products marketed in the United States.

CAUTION:

Use of controls, adjustments or performance of procedures other than those specified in

this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 35 mW and the

wavelength is 675-695 nm.

For European Users

CAUTION:

Use of controls, adjustments or performance of procedures other than those specified in

this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 35 mW and the

wavelength is 675-695 nm.

For Denmark Users

ADVARSEL

Laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion. Undgå udsættelse

for stråling. Klasse 1 laser produkt der opfylder IEC60825 sikkerheds kravene.

Dansk: Dette er en halvlederlaser. Laserdiodens højeste styrke er 35 mW og

bølgelængden er 675-695 nm.

G-2

Page 10

For Finland, Sweden Users

LOUKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VAROITUS!

Laitteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle lasersäteilylle.

Tämä on puolijohdelaser. Laserdiodin suurin teho on 35 mW ja aallonpituus on 675-695

nm.

VARNING!

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan användaren utsättas för laserstrålning, som överskrider gränsen för laserklass 1.

Det här är en halvledarlaser. Den maximala effekten för laserdioden är 35 mW och

våglängden är 675-695 nm.

VARO!

Avattaessa ja suojalukitus ohitettaessa olet alttiina lasersäteilylle. Älä katso säteeseen.

VARNING!

Laserstrålning när denna del är öppnad och spärren är urkopplad. Betrakta ej strålen.

For Norway Users

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan

brukeren utsettes for laserstråling som overskrider grensen for laser klass 1.

Dette en halvleder laser. Maksimal effekt till laserdiode er 35 mW og bølgelengde er 675695 nm.

G-3

Page 11

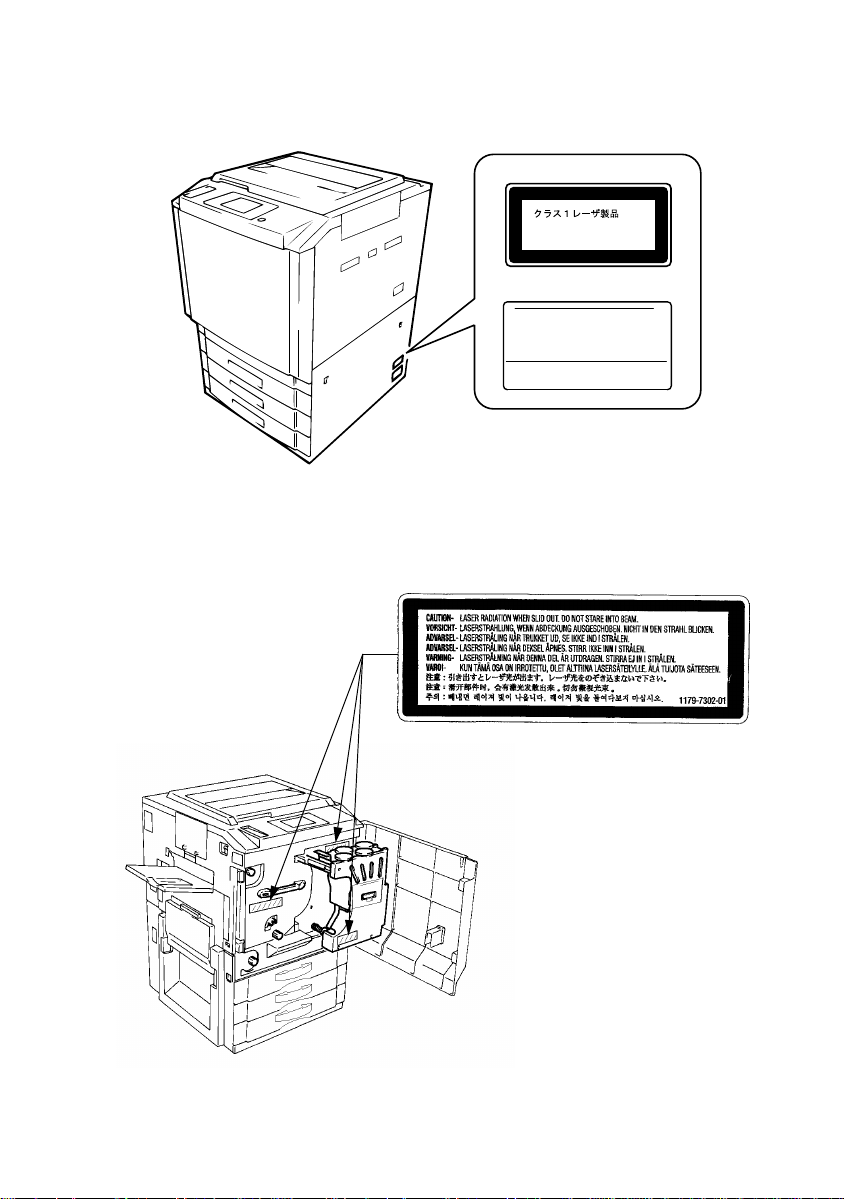

1-4. Laser Safety Label

A laser safety labels is attached to the outside of the copier shown below.

For Europe

CLASS 1 LASER PRODUCT

LASER KLASSE 1 PRODUKT

For United States

KONICA CORPORATION

1-26-2, Shinjuku Nomura Building No.26-2,

Nishishinjuku 1-chome, Shinjuku-ku, Tokyo 163-0512, Japan

MANUFACTURED :

THIS PRODUCT COMPLIES WITH 21 CFR

CHAPTER I , SUBCHAPTER J .

1-5. Location of Laser Warning Labels

Inside the Copier (Front)

1154-7411-01

1179M037CA

1179O075AA

G-4

1179O077AA

Page 12

Internal Right Side View

1179O080AA

1179O079AA

Rear Side View

1179O069AB

1179O076AA

G-5

1179O078AA

1179O078AA

Page 13

ALL Areas

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according

to the manufacturer’s instructions.

Denmark only

Norway only

Sweden only

Finland only

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende

type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

VAROlTUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä Käytetty paristo valmistajan ohjeiden

mukaisesti.

G-6

Page 14

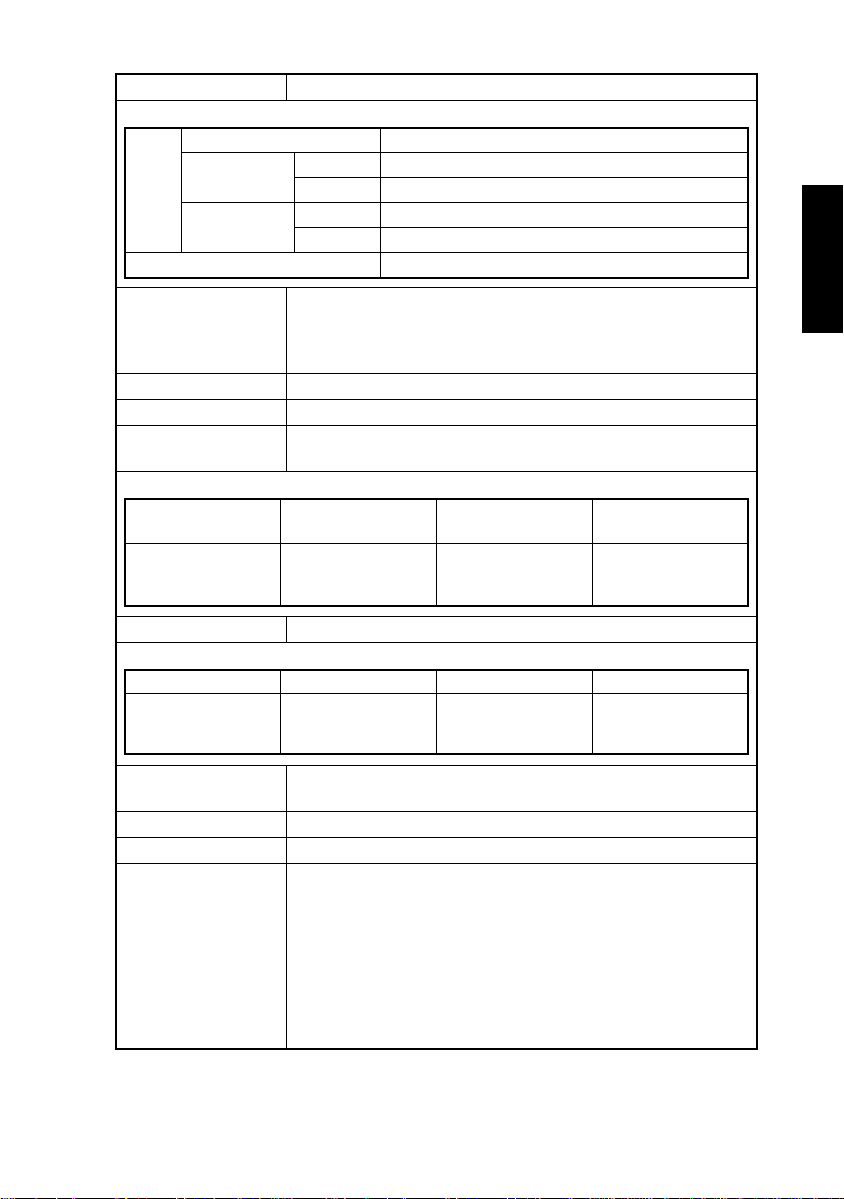

2. SPECIFICATIONS

Type Freestanding

Platen Type Stationary

Original Scanning Sequential scanning of different colors with a reduction-type color

CCD (RGB 3 lines each comprising 7,500 pixels)

Scanning Density 600 dpi × 600 dpi

Print Density 1800 dpi equivalent × 600 dpi

Copying System Electrostatic dry-powdered image transfer to plain paper

Paper Feeding System Four-way system

• Multi Bypass Table: 90 sheets of paper

• Middle Drawer (universal type): 250 sheets of paper

• Upper and Lower Drawer (fixed-size type): Each holding up to

500 sheets of paper

Exposure System Laser Diode 1 + Polygon Mirror

Developing System Micro-Toning System

Charging System Scorotron system (single-wire DC (–) + grid mesh)

Paper Attraction

System

Image Transfer

System

Paper Separating

System

Transfer Film Cleaning

System

PC Drum Cleaning

System

Ozone Removal

System

Fusing System Two lamp-heated rollers

Transfer Film Charge

Neutralizing

PC Drum OPC-MLII (Organic Photoconductor)

Types of Originals Sheet, book, and three-dimensional objects weighing up to 2 kg.

Maximum Size of

Original

Copy Paper Size Multi Bypass Table: Metric - A3 wide L (305 mm × 457 mm) to

Static charge attraction system (corotron charger + attraction

roller + backup mechanism)

Static image transfer system (corotron charger + backup mecha-

nism)

Static charge separating system (corotron charger + separator

fingers + film pressure mechanism)

Fur Brush (bias 0 or 360 V) + Oil Roller (900 V)

Cleaning Blade + PC Drum Charge Neutralizing Corona

Ozone Filters

Static charge neutralizing (corotron charger)

Metric - A3L

Inch - 11 × 17L

A5L, A6 thick paper

Inch - 12 × 18 to 5-1/2 × 8-1/2L,

4 × 6 thick paper

Upper/Middle/Lower Drawer: Metric - A3L to A5L

Inch - 11 × 17L to 5-1/2 × 8-1/2L

G-7

Page 15

Copy Paper Type:

1st to 3rd Drawers

(automatic feeding)

Plain paper (64 to 90 g/m2)

Translucent paper ——

OHP transparencies (dedicated) —

Thick paper 1 (91 to 128 g/m

Thick paper 2 (129 to 209 g/m

Copy paper

A6 thick paper (Metric)

4 × 6 thick paper (Inch)

Recycled paper ——

Max. (width × length mm) 297 × 432 mm 305 × 457 mm

Min. (width × length mm) 140 × 182 mm

Dimensions

❍

: Reliably fed —: Unreliably fed

✽

1: Reliably fed if 90 sheets or less.

✽

2: Reliably fed if 40 sheets or less.

✽

3: Reliably fed if 30 sheets or less.

2

)

2

)

❍❍ ✽

—

—

—

Multi Bypass Table

1

2

❍ ✽

2

❍ ✽

2

❍ ✽

3

❍ ✽

140 × 182 mm

[A6 thick paper

105 × 148 mm (Metric)

4 × 6 thick paper

102 × 152 mm (Inch)]

Warming-up Time Approx. 9 min. at ambient temperature of 20 °C and rated source

voltage

Warming-up Time

60 sec. or less

After Energy Saver

Mode

First Copy Time (Upper Drawer, ×1.000, manual color selection)

Area Paper Size Full Color Mono Color

Inch 8-1/2 × 11C

Metric A4C

21 sec. 10 sec.

Copying Speed for Multi-Copy Cycle (Upper Drawer, ×1.000) (copies/min.)

Area Paper Size Full Color Mono Color

A3L

Metric

Inch

B4L

A4L

B5L

A4C

A5L

11 × 17L

8-1/2 × 11L

8-1/2 × 11C

5-1/2 × 8-1/2L

416

832B5C

416

832

G-8

Page 16

Multiple Copies 1 to 99 copies (count-down system)

Zoom Ratios

Full size

Fixed

Enlargement

Reduction

Variable

Inch

Metric

Inch

Metric

×

1.214, ×1.294, ×2.000

×

1.154, ×1.224, ×1.414

×

0.647, ×0.733, ×0.785

×

0.707, ×0.816, ×0.866

×

0.250 to ×6.000 (in 0.001 increments)

1.000

×

Void Image Width Leading edge: 5 mm

Trailing edge: 4 mm

Front/rear edge: 3 mm [4 × 6 thick paper (Inch), A6 thick paper

(Metric); 5 mm]

Lens Through lens (F = 5, f = 79 mm)

Light Source Halogen frost tube lamp

Fusing Temperature Upper Fusing Roller surface temperature: 160 °C

Lower Fusing Roller surface temperature: 170 °C

Power/Current Consumption

Exposure Lamp

(Rating)

70 V

150 W

Fusing Roller Heater

Lamp (Rating)

120 V, 220-240 V

Upper: 650 W

Lower: 400 W

Max. Power

Consumption

1500 W 13 A/7 A

Max. Current

Consumption

Power Requirements 120 V, 220-240 V; 50 Hz/60 Hz

Environmental Conditions

Temperature Humidity Ambient Illumination Levelness

10 to 32 °C with a

fluctuation of 10 °C or

less per hour

15 to 85 % with a fluctuation of 10 % or less

per hour

3000 lx or less 1° or less

Dimensions 640 (W) × 765 (D) × 994 (H) mm (H: Up to Original Glass surface)

640 (W) × 765 (D) × 1024 (H’) mm (H’: Up to Original Cover)

Weight 215 kg

Standard Accessories Exit Tray, Operator’s Manual Holder

Options • Duplexing Document Feeder

DF-724

• ADF Kit 7823

• 10 Bin Staple Sorter ST-724

• 10 Bin Sorter ST-723

• Printer Controller Fiery Z4

08C-M

• VI Kit VI-631

• Large Capacity Cassette

LT-723

• Duplex Unit AD-723

• Printer Controller Fiery X3e

08C-M

• VI Kit VI-632

G-9

Page 17

3. PRECAUTIONS FOR INSTALLATION

Installation Site

To ensure safety and utmost performance of the copier, the copier should NOT be used in

a place:

• Where it will be subjected to extremely high or low temperature or humidity.

• Which is exposed to direct sunlight.

• Which is in the direct air stream of an air conditioner, heater or ventilator.

• Which puts the operator in the direct stream of exhaust from the copier.

• Which has poor ventilation.

• Where ammonia gas might be generated.

• Which does not have a stable, level floor.

• Where it will be subjected to sudden fluctuations in either temperature or humidity. If a

cold room is quickly heated, condensation forms inside the copier, resulting in blank

spots in the copy.

• Which is near any kind of heating device.

• Where it may be splashed with water.

• Which is dirty or where it will receive undue vibration.

• Which is near volatile flammables or curtains.

Power Source

Use an outlet with a capacity of 120 V/13 A, or 220-240 V/7 A or more.

• If any other electrical equipment is sourced from the same power outlet, make sure that

the capacity of the outlet is not exceeded.

• Use a power source with little voltage fluctuation.

• Never connect by means of a multiple socket any other appliances or machines to the

outlet being used for the copier.

• Make the following checks at frequent intervals:

✽

Is the power plug abnormally hot?

✽

Are there any cracks or scrapes in the cord?

✽

Has the power plug been inserted fully into the outlet?

✽

Does something, including the copier itself, ride on the power cord?

• Ensure that the copier does not ride on the power cord or communications cable of other

electrical equipment, and that it does not become wedged into or underneath the mechanism.

Grounding

To prevent receiving electrical shocks in the case of electrical leakage, always ground the

copier.

• Connect the grounding wire to:

✽

The ground terminal of the outlet.

✽

A grounding contact which complies with the local electrical standards.

• Never connect the grounding wire to a gas pipe, the grounding wire for a telephone, or a

water pipe.

G-10

Page 18

4. PRECAUTIONS FOR USE

To ensure that the copier is used in an optimum condition, observe the following precautions.

• Never place a heavy object on the copier or subject the copier to shocks.

• Insert the power plug all the way into the outlet.

• Do not attempt to remove any panel or cover which is secured while the copier is making

copies.

• Do not turn OFF the Power Switch while the copier is making copies.

• Provide good ventilation when making a large number of copies continuously.

• Never use flammable sprays near the copier.

• If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

• Do not turn ON the Power Switch at the same time when you plug the power cord into

the outlet.

• When unplugging the power cord, do not pull on the cord; hold the plug and pull it out.

• Do not bring any magnetized object near the copier.

• Do not place a vase or vessel containing water on the copier.

• Be sure to turn OFF the Power Switch at the end of the workday or upon power failure.

• Use care not to drop paper clips, staples, or other small pieces of metal into the copier.

Operating Environment

The operating environmental requirements of the copier are as follows.

• Temperature: 10 °C to 32 °C with a fluctuation of 10 °C per hour

• Humidity: 15 % to 85 % RH with a fluctuation of 10 % per hour

Power Requirements

The power source voltage requirements are as follows.

• Voltage Fluctuation: AC120 V, 220-240 V

• Frequency Fluctuation: 50/60 Hz ±0.3 %

±10 % (Copying performance assured)

–15 % (Paper feeding performance assured)

G-11

Page 19

5. HANDLING OF THE CONSUMABLES

Before using any consumables, always read the label on its container carefully.

• Use the right toner. The applicable copier model name is indicated on the Toner Bottle.

• Paper is apt to be easily damaged by dampness. To prevent absorption of moisture,

store paper, which has been removed from its wrapper but not loaded into the Drawer, in

a sealed plastic bag in a cool, dark place.

• Keep consumables out of the reach of children.

• Do not touch the PC Drum with bare hands.

• Store the paper, toner, and other consumables in a place free from direct sunlight and

away from any heating apparatus.

• The same sized paper is of two kinds, short grain and long grain. Short grain paper

should only be fed through the copier crosswise, long grain paper should only be fed

lengthwise.

• If your hands become soiled with toner, wash them with soap and water immediately.

• Do not throw away any used consumables (PC Drum, starter, toner, etc.). They are to be

collected.

NOTE

Do not burn, bury in the ground, or throw into the water any consumables (PC Drum,

starter, toner, etc.).

6. OTHER PRECAUTIONS

The Printerhead of this copier uses a laser diode that emits a laser beam. Use the following

precautions when performing service jobs at the users’ premises.

• When a service job needs to be performed in the laser beam path, such as when working

around the printerhead and PC Drum, be sure first to turn the copier OFF.

• If the job requires that the power cord be left plugged in, observe the following precautions

1. Take off your watch, ring, and any other reflective object and wear laser protective gog-

gles.

2. At the job site, select a place that is as far as possible away from the users and that is

enclosed by walls.

3. Do not bring a highly reflective tool into the laser beam path during the service job.

G-12

Page 20

7. SYSTEM OPTIONS

1

1151O007AA

6

1144O184AA

5

1139O0020A

1. Duplexing Document Feeder DF-724

2. Large Capacity Cassette LT-723

3. Printer Controller Fiery X3e 08C-M

4. Printer Controller Fiery Z4 08C-M

1154O028AA

1179O014AA

1179M558AA

1179O046AA

5. 10 Bin Staple Sorter ST-724

10 Bin Sorter ST-723

6. Duplex Unit AD-723

2

3

4

G-13

Page 21

8. HIGHLIGHTS

1. High-quality image reproduction

• HYPER DASH LIMOS & FEET processing.

2. Greater ease of operation

• Employs a touch panel display.

• Equipped with two image quality adjustment modes, “Color Adjust Mode (Basic)” and

“Color Adjust Mode (Professional).”

• Photo mode and Postcard

• ACS mode

• Capable of automatically determine the type of the original, whether it is a photo, text, or

a map, to set the most appropriate copy function.

• Color Auto Exposure function

• Copy track function by means of specific access codes that can be entered from the 10-

Key Pad.

3. Higher productivity

• Efficient, high-speed 2-sided printing with four sheets of paper being resident along the

paper path inside the copier.

4. Environmental consciousness

• Fuser oil recycling system

• Two-sheet attraction for a lower system speed and lower operating noise without sacrific-

ing productivity.

• The reduced number of drive-transmitting parts means a reduced number of noise

sources.

• Lower concentration of ozone by means of the Ozone Filter.

• Uses recyclable plastic materials.

• No harmful substances are used.

5. Better serviceability

• Unitized construction for greater serviceability

• Version upgraded by a flash memory card

G-14

Page 22

MECHANICAL/

ELECTRICAL

Page 23

CONTENTS

1. CROSS-SECTIONAL VIEW AND PAPER PATH ............................................M-1

2. COPY PROCESS ............................................................................................M-2

3. DRIVE SYSTEM ..............................................................................................M-5

4. OPERATING SEQUENCE ..............................................................................M-6

5. CONTROL BLOCK DIAGRAM ........................................................................M-13

6. IMAGE STABILIZATION SYSTEM ..................................................................M-14

6-1. Image Stabilization System Overview .....................................................M-14

6-2. Image Stabilization System Control .........................................................M-15

(1) V detection during multi-copy cycles ...............................................M-16

(2) AIDC detection during multi-copy cycles .........................................M-16

(3) Evaluation of whether or not to run image stabilization ...................M-16

(4) AIDC background adjustment ..........................................................M-16

(5) LDC detection ..................................................................................M-17

(6) Image formation Vg/Vb setting ........................................................M-17

(7) Series gradation detection ...............................................................M-17

(8) Density conversion by density table ................................................M-18

7. PC DRUM SECTION .......................................................................................M-19

7-1. Grounding of the PC Drum ......................................................................M-19

7-2. PC Drum Drive Mechanism .....................................................................M-20

7-3. PC Drum Temperature Control ................................................................M-21

8. PC DRUM CHARGING SECTION ...................................................................M-22

8-1. PC Drum Charge Corona ON/OFF Control .............................................M-22

8-2. PC Drum Charge Corona Wire Cleaning Mechanism .............................M-23

8-3. PC Drum Charge Section Ozone Filter ....................................................M-24

9. IMAGE READER (IR) SECTION .....................................................................M-25

9-1. IR Image Processing ...............................................................................M-26

9-2. CCD Sensor .............................................................................................M-35

9-3. Exposure Components Section ...............................................................M-36

9-4. Exposure Lamp Control ...........................................................................M-37

9-5. Scanner and 2nd/3rd Mirrors Carriage Movement Mechanism ...............M-38

9-6. Scanner Motor Drive Control ...................................................................M-39

9-7. IR Section Cooling Fan Motor Mechanism ..............................................M-41

9-8. Original Size Detecting Section ...............................................................M-42

(1) Original Size Detecting Sensors ......................................................M-42

(2) Original Size Detection Timing ........................................................M-43

(3) Determining Original Size ................................................................M-44

10. PRINTERHEAD (PH) SECTION ......................................................................M-46

10-1.Image Processing Block Diagram ...........................................................M-47

10-2.Laser Exposure Process .........................................................................M-50

10-3.Laser Emission Timing (SOS Signal) ......................................................M-51

10-4.Laser Emission Area ...............................................................................M-52

10-5.HYPER DASH LIMOS and FEET ............................................................ M-53

11. DEVELOPING UNIT SECTION .......................................................................M-54

11-1.Developing Unit Drive Mechanism ..........................................................M-55

11-2.Developer Flow ........................................................................................M-57

11-3.Developing Bias and ATDC Bias .............................................................M-59

i

Page 24

11-4.ATDC Sensor ..........................................................................................M-60

11-5.AIDC Sensor ............................................................................................M-62

11-6.Black Toner Replenishing Control ...........................................................M-63

11-7.Auxiliary Toner Replenishing Mechanism ...............................................M-64

11-8.Toner Suction Fan Motor ......................................................................... M-65

11-9.Pre-Image Transfer Corona .....................................................................M-66

11-10.Pre-Image Transfer Corona Output Control ..........................................M-67

11-11.Pre-Image Transfer Corona ON/OFF Control .......................................M-67

11-12.Pre-Image Transfer Corona Output Stabilization Control ......................M-67

12. TONER HOPPER SECTION ...........................................................................M-68

12-1.Toner Replenishing Mechanism ..............................................................M-69

12-2.Toner Empty Detection Control ...............................................................M-71

13. PAPER TAKE-UP/FEED SECTION ................................................................M-72

13-1.Universal Tray Paper Size Detection Mechanism ...................................M-73

13-2.Drawer-in-Position Detection Mechanism ...............................................M-75

13-3.Drawer Paper Lifting/Lowering Mechanism .............................................M-76

13-4.Paper Empty Detection Mechanism ........................................................M-78

13-5.Paper Take-Up Mechanism ..................................................................... M-79

13-6.Paper Dehumidifying Heaters and Humidity Sensor ...............................M-82

13-7.Vertical Transport Drive Mechanism .......................................................M-83

13-8.Paper Take-Up Control ............................................................................M-84

14. MANUAL FEED TABLE SECTION ..................................................................M-86

14-1.Manual Feed Paper Take-Up Mechanism ............................................... M-86

14-2.Manual Feed Take-Up Control ................................................................M-87

14-3.Manual Take-Up Roll Pressure Mechanism ............................................M-88

14-4.Manual Feed Paper Separating Mechanism ...........................................M-89

14-5.Manual Feed Paper Empty Detection Mechanism ..................................M-90

14-6.Manual Feed Paper Width Detection Mechanism ................................... M-91

14-7.Manual Feed Paper Length Detection Mechanism .................................M-92

15. SYNCHRONIZING ROLLERS SECTION ........................................................M-93

15-1.Synchronizing Roller Drive Mechanism ................................................... M-93

15-2.Synchronizing Roller Drive Control ..........................................................M-94

16. TRANSFER DRUM SECTION .........................................................................M-95

16-1.Transfer Drum Drive Mechanism ............................................................. M-96

16-2.Paper Attraction .......................................................................................M-97

(1) Static Charge Roller ........................................................................M-99

(2) Backup Blade 2 ...............................................................................M-100

(3) Static Charge Corona ......................................................................M-100

(4) Charge Neutralizing Cloth 1 ............................................................M-100

(5) Charge Neutralizing Cloth 2 ............................................................M-101

(6) Paper Attraction Detection (before image transfer) .........................M-101

(7) Control .............................................................................................M-102

16-3.Image Transfer Section ...........................................................................M-103

(1) Backup Blade 1 ...............................................................................M-104

(2) Image Transfer Corona ................................................................... M-105

(3) Charge Neutralizing Cloth 3 ............................................................M-105

(4) Paper Attraction Detection (after image transfer) ............................M-105

ii

Page 25

(5) Image Transfer Control ....................................................................M-106

16-4.Paper Separation Section ........................................................................M-107

(1) Paper Separation Lifting Finger .......................................................M-108

(2) Paper Separator Corona .................................................................M-108

(3) Paper Separator Finger ...................................................................M-108

(4) Paper Separating Failure Detection Mechanism .............................M-109

(5) Paper Holding Mechanism ..............................................................M-109

(6) Paper Separation Control ................................................................M-110

16-5.Transfer Film Cleaning mechanism .........................................................M-111

16-6.Oil Cleaning .............................................................................................M-113

(1) Oil Cleaning Backup Brush ..............................................................M-114

(2) Oil Roller ..........................................................................................M-114

(3) Oil Cleaning Control ........................................................................M-115

16-7.Toner Cleaning ........................................................................................M-116

(1) Toner Cleaning Backup Brush .........................................................M-117

(2) Fur Brush Unit .................................................................................M-117

(3) Fur Brush Roller/Toner Collecting Roller .........................................M-118

(4) Fur Brush Control ............................................................................M-119

16-8.Charge Neutralizing .................................................................................M-120

16-9.Transfer Drum Retraction Mechanism .....................................................M-121

17. PC DRUM CLEANING SECTION ....................................................................M-122

17-1.Pre-Cleaning Charge Corona ..................................................................M-122

17-2.PC Drum Cleaning ...................................................................................M-123

17-3.Ozone Exhaust from Pre-Cleaning Charge Corona and Transfer Drum .M-125

18. MAIN ERASE SECTION ..................................................................................M-126

19. FUSING UNIT SECTION .................................................................................M-127

19-1.Fusing Unit Drive Mechanism ..................................................................M-128

(1) Upper Fusing Roller .........................................................................M-128

(2) Lower Fusing Roller .........................................................................M-128

(3) Fusing Rollers Drive Mechanism .....................................................M-129

(4) Fusing Rollers Drive Control ............................................................M-130

(5) Fusing Speed Switching Control .....................................................M-131

(6) Fusing Motor Small-Amount Rotation Control .................................M-131

19-2.Fusing Roller Pressure Mechanism .........................................................M-132

19-3.Fusing Temperature Control ....................................................................M-133

19-4.Fusing Oil Application/Collection Mechanism .......................................... M-136

20. EXIT UNIT SECTION ......................................................................................M-138

21. HORIZONTAL TRANSPORT UNIT SECTION ................................................M-139

22. 2-Sided Copy Control with Several Sheets of Paper Resident along Paper

Path .................................................................................................................M-141

23. POWER SUPPLY ............................................................................................M-142

23-1.Power Lines When the Power Cord is Plugged in ...................................M-142

23-2.Power Lines When the Power Switch is Turned ON ...............................M-144

23-3.Power Supply Boards ON/OFF Control ...................................................M-146

23-4.CPU Reset Function ................................................................................M-146

23-5.Power Supply Cooling Mechanism ..........................................................M-147

24. MEMORY BACKUP .........................................................................................M-147

iii

Page 26

Blank page

Page 27

1. CROSS-SECTIONAL VIEW AND PAPER PATH

• The illustration below shows where different parts of the copier are placed and how the

copy paper moves through the copier.

• Each of the mechanical and electrical parts is identified and located in the relevant section that appears later in this manual.

Fusing Unit

IR

Sorter

Upper PH

Assy

Transfer

Unit

Duplex

Unit

PC Unit

Lower PH

Assy

Developing

Unit

Upper

Drawer

M-1

Middle

Drawer

Lower

Drawer

1179M014AA

Page 28

2. COPY PROCESS

20. Paper Exit 19. Fusing

13. Paper

Separation

14. Oil Cleaning

15. Toner Cleaning

16. Charge

Neutralizing

10. Manual

Feed

Transfer Drum

9. Paper

Feeding

11. Attraction

3. Photoelectric

Conversion

5. PH Image

Processing

17. Cleaning

12. Image

Transfer

8. Pre-Image

Transfer Corona

Charging

6. Laser

Exposure

1. PC Drum

4. IR Image

Processing

18. Main Erase

2. PC Drum

Charging

7. Developing

Upper Drawer

Middle Drawer

Lower Drawer

M-2

1179M038CA

Page 29

1. PC Drum

• An electrostatic latent image is formed on the surface of a photoconductive material that

coats an aluminum cylinder.

• An OPC type photoconductor is used.

2. PC Drum Charging

• A single-wire PC Drum Charge Corona employing the Scorotron system deposits a negative DC charge across the entire surface of the PC Drum.

3. Photoelectric Conversion

• The light from Exposure Lamp is directed onto the original and reflected to strike the

CCD Sensor through mirrors and lens, thereby forming a reduced image of the original.

• The CCD Sensor separates the light striking it into different colors using its color filters

(R, G, and B), then converts it into a corresponding electrical signal and outputs the signal to the IR Image Processing Unit.

4. IR Image Processing

• The electrical signal output from the Photoelectric Converter is converted to 8-bit digital

image signals (R, G, and B). After making some corrections, the IR Image Processing

Unit outputs video signals (C, M, Y, and Bk) to the PH Image Processing Unit.

5. PH Image Processing

• The video signals (C, M, Y, and Bk) output from the IR Image Processing Unit go through

some corrections. Following digital-to-analog conversion, these signals are then used for

the control of the intensity level of the laser diode.

6. Laser Exposure

• The laser beam emitted by the laser diode strikes the surface of the PC Drum to form an

electrostatic latent image.

7. Developing

• The toner, agitated and negatively charged in the developing unit of each color, is

attracted onto the electrostatic latent image formed on the surface of the PC Drum,

changing it to a visible, developed image.

• AC and DC negative bias voltages are applied to the Sleeve/Magnet Roller to ensure

toner transfer to the PC Drum.

8. Pre-Image Transfer Corona Charging

• A Scorotron system is used to even out the charge of toner, thereby stabilizing image

transfer.

9. Paper Feeding

• Paper is fed from each drawer.

10. Manual Paper Feeding

• The paper loaded in the Multi Bypass Table is fed.

M-3

Page 30

11. Attraction

• The Static Charge Corona applies a positive DC corona emission to the Transfer Film,

while the Static Charge Roller presses the paper against the surface of the Transfer Film

so that the paper is attracted to the film by static charge.

12. Image Transfer

• The Image Transfer Corona applies a DC positive corona emission to the Transfer Film to

attract the negatively charged toner on the surface of the PC Drum onto the surface of

the paper.

13. Paper Separation

• The Paper Separator Corona applies an AC corona emission to the paper to weaken the

attraction of the paper to the Transfer Film.

• The Lifting Finger pushes up the Transfer Film, while the Paper Separator Finger pushes

down the Transfer Film so that the paper can be effectively separated from the surface of

the Transfer Drum.

14. Oil Cleaning

• The Oil Roller collects fusing oil from the surface of the Transfer Film during 2-sided

copying.

15. Toner Cleaning

• The Fur Brush Unit collects toner particles sticking to the surface of the Transfer Film.

16. Charge Neutralizing

• The Charge Neutralizing Corona showers both sides of the Transfer Film with AC and DC

overlapped corona charges so that the film is neutralized.

17. Cleaning

• The Pre-Cleaning Corona applies either a DC negative or AC corona emission to the surface of the PC Drum to neutralize it.

• The residual toner left on the surface of the PC Drum is scraped off by the Cleaning

Blade and is then conveyed by the Toner Conveying Coil to the Toner Collecting Box.

18. Main Erase

• Light from Main Erase Lamp neutralizes any surface potential remaining on the surface

of the PC Drum.

19. Fusing

• The Upper and Lower Fusing Rollers apply heat and pressure to the paper so that the

four different color layers of toner lying on the surface of the paper are mixed and fused

together, as well as being fixed collectively to the paper.

• Fusing oil is applied to the Fusing Rollers to secure the release of the paper and to help

toner be cleaned from the surfaces of the two fusing rollers.

• The Oil Collecting Blade scrapes residual oil from the Lower Fusing Roller. The recovered oil is then filtered for recycling.

20. Exit

• The Paper Exit Roller is turned to feed the paper out of the copier.

M-4

Page 31

3. DRIVE SYSTEM

• The illustration below outlines the drive system of the copier.

• The directions of rotation of the motors, gears, pulleys, and belts will be found in the rele-

vant section that appears later in this manual.

Scanner Drive Motor

PC Drum

Drive Motor

PC Drum/

Transfer

Drum

Developing

Unit Drive

Developing Drive Motor

Hopper

Drive

Drive for Synchronizing Roller, Static

Charge Roller, and Fur Brush Unit

Cleaning Unit Drive

Flywheel

Paper Take-Up

Motor

Toner Replenishing Motor (Bk)

Toner Replenishing Motor (C)

Toner Replenishing Motor (M)

Toner Replenishing Motor (Y)

Fusing Motor

Drive for Paper

Take-Up,

Vertical

Transport,

Multi Bypass,

and Horizontal

Transport

Toner Transport Motor (C, M, Y)

Toner Transport Motor (Bk)

1179M549AA

M-5

Page 32

4. OPERATING SEQUENCE

Transfer Drum cleaning control

M-67

☞

Pre-Image Transfer Corona

output stabilization control

M-15

☞

Image stabilization control

rotation

Decelerated-speed

wire cleaning control

PC Drum Charge Corona

rotation

Full-speed

Power Switch ON

Power Switch ON

Power Supply Cooling Fan Motor

M20

Mxe Cooling Fan Motor M26

Ozone Ventilation Fan Motor M5

Toner Suction Fan Motor M4

M-6

rotation

Backward

rotation

Forward

Fusing Unit Cooling Fan Motor

M14

Charge Cleaner Return Position

Sensor PC17

PC Drum Charge Wire Cleaning

Motor M3

Charge Cleaner Home Position

Sensor PC16

Paper Take-Up Motor M15

ABC DEF

PC Drum Charge Corona output

PC Drum Drive Motor M18

ATDC bias

1179M039CA

Page 33

BC DEF

Fusing Roller Heater Lamp

temperature control completed

(warm-up cycle completed)

temperature: 110 C or more

Upper Fusing Roller surface

A

Main Erase Lamp LA2

Pre-Cleaning Charge Corona

output (AC)

Pre-Image Transfer Corona output

Fusing Motor M17

Transfer Drum Reference Position

Sensor 1 PC20

Static Charge Roller Solenoid

SL13

Backup Blade 2 Solenoid

SL19

M-7

Static Charge Corona output

Charge Neutralizing Corona

output (AC)

Fur Brush Pressure Solenoid

SL11

Internal Fur Brush Solenoid

SL15

Fur Brush Drive Clutch CL20

AG

Fur Brush HV

Paper Dehumidifying Heaters

1 to 4 H4 to H7

Scanner Motor M1

1179M040CB

Page 34

AG

Exposure Lamp LA1

Original Glass Cooling Fan Motor

M2

IR Cooling Fan Motor 1 M24

IR Cooling Fan Motor 2 M25

1179M041CA

M-8

Page 35

Image stabilization control

End of job

M-15

☞

Transfer Drum

cleaning control

ABC D E F G H I J K L M N O PQ R ST U

Start key ON

Start key ON (Full color, A4C, paper fed from Upper Drawer, single copy)

Transfer Drum Reference Position

Sensor 1 PC20

Transfer Drum Reference Position

Sensor 2 PC28

Paper Take-Up Motor M15

PC Drum Drive Motor M18

Upper Drawer Paper Take-Up

Clutch CL11

Upper Drawer Paper Take-Up

Transport Roller Clutch CL15

Transport Roller Sensor PC19

Paper Leading Edge Detecting

Sensor PC12

Sensor PC18

Synchronizing Roller Clutch CL21

Static Charge Roller Solenoid

SL13

Backup Blade 2 Solenoid SL19

1179M042CA

M-9

Page 36

ABC D E F G H I J K L M N O P Q R ST U

Static Charge Corona output

PC Drum Charge Corona output

ATDC bias

Main Erase Lamp LA2

Transfer Drum Retract Solenoid

SL12

Pre-Image Transfer Corona output

Pre-Cleaning Charge Corona

output (AC)

Developing Drive Motor M16

Developing bias output (DC)

M-10

C developing bias output (AC)

Developer Supply Clutch (C)

CL17

M developing bias output (AC)

Developer Supply Clutch (M)

CL18

Y developing bias output (AC)

1179M043CA

ABC D V F GWHXIJ K LMN PQRTU

Developer Supply Clutch (Y)

CL19

Page 37

ABC D V F GWHXIJ K LMN PQRTU

Bk developing bias output (AC)

Developer Supply Clutch (BK)

CL16

Toner Transport Motor (C, M, Y)

M23

Toner Transport Motor (BK) M22

Image Transfer Corona output

Backup Blade 1 Solenoid SL18

Paper Separator Finger Solenoid

SL14

Lifting Finger Solenoid SL16

M-11

Paper Separator Corona output

Charge Neutralizing Corona output

(DC)

Charge Neutralizing Corona output

(AC)

Fur Brush Pressure Solenoid

SL11

Internal Fur Brush Solenoid SL15

ABC D F G H J K L M N P Q R T U

Fur Brush HV

Fur Brush Drive Clutch CL20

1179M044CA

Page 38

ABC D F G H J K L M N PPQ R T U

Fusing Motor M17

Scanner Motor M1

Exposure Lamp LA1

Original Glass Cooling Fan Motor

M2

IR Cooling Fan Motor 1 M24

IR Cooling Fan Motor 2 M25

Power Supply Cooling Fan Motor

M20

Mxe Cooling Fan Motor M26

M-12

Ozone Ventilation Fan Motor M5

Toner Suction Fan Motor M4

Fusing Unit Cooling Fan Motor

M14

Paper Dehumidifying Heaters

1 to 4 H4 to H7

1179M045CB

Page 39

5. CONTROL BLOCK DIAGRAM

IR

Control Panel

UN27

Master Board

PWB-IM

PH

PH Control Board

SOS Board

PWB-S

IR Image

Processing Unit

IR Control Board

PWB-C

(Digital)

PWB-JD

Photo Diode Board

PWB-JM

Photoelectric

Converter

CCD Sensor Board

PWB-A

SCP Board

PWB-G

PHC Power Supply Board

PWB-LP

PH Image Processing Unit

LD Drive Board

PWB-JL

Laser Diode

LD1

Paper Take-Up

Board

PWB-K

Paper Source

PC Drum

Drive Board

PWB-ID

Transfer Drum

Engine Power Supply Board

PWB-LE

Developing Unit

Fusing Unit

Control Signal

Image Signal

M-13

Page 40

6. IMAGE STABILIZATION SYSTEM

6-1. Image Stabilization System Overview

Purpose Means Control (Sensor)

✽ γ

• To stabilize

image density

• To stabilize gradation

correction control

• V detection during multi-copy cycles

• AIDC detection during multi-copy

cycles

• AIDC background adjustment

• LDC detection

• Image formation Vg/Vb setting

• Series gradation detection

• To stabilize the

amount of toner

✽

ATDC control (C, M, Y)

✽

Black toner replenishment control (Bk)

attracted

• To stabilize PC

✽

PC Drum temperature control • PC Drum Heater Control

Drum sensitivity

• To stabilize

paper attration,

image transfer,

✽

Static Charge, Image Transfer, Paper

Separator, and Charge Neutralizing

Corona output control

paper separation, and charge

neutralization

✽

An explanation is given of each control other than γ correction control in the relevant section that follows the current one.

• AIDC Sensor UN20

• Surface Potential Detec-

tion Sensor UN22

• Humidity Sensor UN23

• ATDC Sensors UN33,

34, 35

• AIDC Sensor UN20

Board PWB-W

• Humidity Sensor UN23

Paper

Separator

Transfor mer

Fur Brush

Bias

Transformer

Image

Transfer

Transfor mer

Charge

Neutralizing

Transformer

Static

Charge

Transfor mer

Image Transfer,

Paper Separation,

Charge Neutralizing

Fur Brush

Toner

Replenishing

Motor

Humidity

Sensor

Charge

Neutralizing

Corona

ATDC Control

Black Toner

Replenishing

Control

Paper Separator

Corona

Image Transfer

Corona

Static

Charge

Corona

AIDC

Sensor

Pre-Image

Transfer

Corona

PC Drum

Heater Control

System

PC Drum Heater

Control Board

Developing Bias

ATDC Sensor

M-14

Pre-Cleaning Charge Corona

PC Drum

Heater

PC Drum Charge Corona

Pre-Image Transfer

Corona Transformer

LD1

Surface Potential

Detection Sensor

Developing

Bias

Transformer

PC Drum

Charge Corona

Grid and PreCleaning

Charge Corona

Transformer

LD1 Driver

Correction Control

γ

1179M046CA

Page 41

6-2. Image Stabilization System Control

• The copier uses the data obtained through AIDC detection and PC Drum surface potential detection to perform various operations, thereby finding the optimum γ correction

exposure curve for image stabilization control.

Sensitometry

Reversal

Developing

Characteristics

ID (Image Density)

VB

Image Density

Characteristics

=1

PC Drum

Surface

Potential

PC Drum Light

Decay Curve

Operation Flow

Start key ON

Copy cycle run

(1)

V detection during multi-copy cycles

(2)

AIDC detection during multi-copy cycles

End of copy cycle

(3)

Whether to run image stabilization or not evaluated.

Not run Run

Short

(5)

(6)

Image formation Vg/Vb setting

(7)

Series gradation detection

Misfeed or malfunction reset Power Switch ON

Long

LDC detection

Laser Radiation

Characteristics

Laser Light Intensity

Image

Input

Data

curve

1144M161CA

(4)

AIDC background adjustment

✽ Carried out twice when the Power

Switch is turned ON.

γ

set in PH Control Board (Digital).

Long

Pmax, Vg, and Vb updated.

End

M-15

Short

Page 42

(1) V detection during multi-copy cycles

• For correction of the intensity of light that can be varied due to variations in the PC Drum

sensitivity during multi-copy cycles, a potential pattern is produced between sheets of

paper to detect the surface potential.

Control Details

1. The potential pattern is produced before the Bk image is formed during a single-sheet

attraction and in areas between the Bk odd-numbered and even-numbered sheets

during two-sheet attraction. The Surface Potential Detection Sensor then detects the

surface potential.

2. The maximum intensity of the light of LD1 (Pmax) is corrected based on the detected

value.

(2) AIDC detection during multi-copy cycles

• To calculate developing efficiency during multi-copy cycles, a toner image is formed on

the potential pattern produced for the detection of V during multi-copy cycles and the

AIDC Sensor is used to detect the amount of toner sticking to the pattern on the PC

Drum.

Control Details

1. A toner image is formed on the potential pattern produced for the detection of V during

multi-copy cycles and the AIDC Sensor detects the amount of toner sticking to the pattern.

2. Developing efficiency is then calculated based on the detected value.

3. The amount of Bk toner supply is calculated based on the value found through the calculation.

☞

M-63

(3) Evaluation of whether or not to run image stabilization

• Whether to run image stabilization or not is evaluated based on the amount of process

fluctuation from the preceding sequence of image stabilization.

• If it is determined to run one, the specific type of image stabilization is then determined,

either Long or Short.

Long image stabilization

• Consists of AIDC background adjustment (only when power is turned ON), LDC detection, image formation Vg/Vb setting, and series gradation detection.

Short image stabilization

• Only series gradation detection is performed.

(4) AIDC background adjustment

• The AIDC Sensor detects the background level and the data is stored in memory.

Control Details

1. A toner image is formed with exposure data 0 level and the amount of toner sticking is

detected using the AIDC Sensor.

2. The detected results are used to calculate the background level and that data is stored

in memory.

M-16

Page 43

(5) LDC detection

• To prepare a formula approximating LDC (light decay curve) of the PC Drum, electrostatic latent image patterns with ten different exposure levels are formed at three varied

steps of Vg, thereby letting the Surface Potential Detection Sensor detect each surface

potential.

Control Details

1. Electrostatic latent image patterns are formed with ten different exposure levels at

three varied steps of Vg and the Surface Potential Detection Sensor detects the surface potential of each pattern.

2. The pattern is further exposed with a bias intensity for Vg = 0 V to detect surface

potential, thereby finding the residual potential.

3. The values of α and β concerning LDC (light decay curve) at each point of development and charging efficiency are calculated from 1 and 2.

4. The maximum intensity (Pmax) is calculated from LDC at each point of development.

(6) Image formation Vg/Vb setting

• Actual values are assigned for Vg and Vb of each color and, based on the values of the

amount of toner sticking to the PC Drum as detected by the AIDC Sensor, Vg and Vb are

set to obtain the target amount of toner sticking.

Control Details

1. Vb of three patterns is selected.

2. The value of Vg for producing each pattern is calculated based on the values of α and

β

calculated through LDC detection and the value of Vb for producing each pattern.

3. Each pattern is produced by using Pmax calculated through LDC detection.

4. The amount of toner sticking to each pattern is detected by the AIDC Sensor.

5. From the detection results, the value of Vb for each color that ensures the target

amount of toner sticking is calculated.

6. The optimum Vg value is calculated form the values of α, β, and Vb calculated.

(7) Series gradation detection

• A series gradation pattern is produced and gradation reproduction at that time is

detected using the AIDC Sensor to create a γ curve.

Control Details

1. A series gradation pattern is produced and the AIDC Sensor detects the amount of

toner sticking to it.

2. The density of the pattern is calculated based on the detected value (in which density

conversion by density table is used).

3. A table is calculated for conversion of exposure data to image density.

4. The value of γ is calculated based on the data obtained in step 3.

5. Developing efficiency is then calculated from the value detected by the AIDC Sensor

and exposure data.

M-17

Page 44

(8) Density conversion by density table

• The AIDC Sensor output value is converted to the corresponding image density value.

Corrections are also made at that time for environmental factor, IR scanning factor, and

image choice setting (Service mode) as detailed below.

Control Details

1. The value detected by the AIDC Sensor is converted to the corresponding image density value by using the density table.

2. A correction is made based on absolute temperature.

3. A correction is made based on the results of γ automatic adjustment.

4. A correction is made based on the adjustment value of “PRT Highlight” available from

the Service mode.

M-18

Page 45

7. PC DRUM SECTION

• The photoconductive drum used in this copier is the organic photoconductor (OPC) type.

• The drum consists of two distinct, light-sensitive, organic semiconductor materials on an

aluminum alloy base. The outer of the two layers is called the Charge Transport Layer

(CTL), while the inner layer is called the Charge Generating Layer (CGL).

• It is a type that is sensitive to the near infrared wavelength.

• Size = φ100 × 350 mm

φ

100

PC Drum

Handling Precaution

The PC Drum exhibits light fatigue after being exposed to light for a long time, which results

in its sensitivity being changed. Therefore, always wrap the drum in the PC Drum Cloth or a

soft cloth immediately after it has been removed from the copier.

350 mm

1074M017

CTL

Aluminum Cylinder

CGL

1076M043

7-1. Grounding of the PC Drum

• The potential on the surface of the PC Drum exposed to the laser beam is grounded

through the Ground Plate which is in contact with the drum shaft.

Flywheel

Ground Plate

Drum Shaft

PC Drum Drive Motor M18

PC Drum

M-19

1154M024AC

Page 46

7-2. PC Drum Drive Mechanism

• The PC Drum is driven by PC Drum Drive Motor.

• A flywheel is mounted on the PC Drum shaft to prevent image noise from occurring due

to uneven rotation of the drum.

• The PC Drum is turned backward for a very small period of time after the copy cycle has

been completed to remove any foreign objects that might have been trapped in the

Cleaning Blade.

☞

M-123

Flywheel

Ground Plate

Drum Shaft

PC Drum Drive Motor M18

<PC Drum Drive Control>

Control Signal Energized Deenergized Wiring Diagram

M18

PWB-ID PJ8ID-7 H H

PWB-ID PJ8ID-8 L H

Control Signal Blocked Unblocked Wiring Diagram

Transfer Drum

Reference

Position Sensor

PWB-ID PJ4ID-5B L H 17-E

PC20

Start Key ON

M18

ON

OFF

ON

OFF

H

L

PC20

Paper Take-Up

Motor M15

PC Drum

1154M024AC

16-C

1179M047CA

M-20

Page 47

7-3. PC Drum Temperature Control

• PC Drum Heater is installed inside the PC Drum to maintain drum sensitivity and prevent

condensation from forming on the drum surface.

• PC Drum Heater is turned ON or OFF by a temperature-sensitive reed switch installed

inside the PC Drum, keeping the drum surface temperature at 35±5 °C.

• PC Drum Heater is a 40 W heater.

• Power to PC Drum Heater is supplied through the electrodes on the front flange face.

<Temperature-Sensitive Reed Switch>

• The temperature-sensitive reed switch turns OFF when the temperature reaches 37 °C

and turns ON when the temperature becomes lower than 33 °C.

<PC Drum Heater ON Conditions>

• Power Switch is turned ON.

• The temperature-sensitive reed switch is turned ON.

<PC Drum Heater OFF Conditions>

• The temperature-sensitive reed switch is turned OFF.

• Power Switch is turned OFF.

• A misfeed or malfunction is reset or a door is opened.

PC Drum

Heater H3

TemperatureSensitive

Reed Switch

PC Drum

Internal

Temperature

ON

OFF

ON

OFF

( C)

37

33

0

PC Drum Heater H3

PC Drum

Front Flange

Temperature-Sensitive

Reed Switch

Electrodes

1144M025AA

Time

1179M048CA

M-21

Page 48

8. PC DRUM CHARGING SECTION

• The PC Drum Charge Corona has a Scorotron grid to deposit a negative DC charge

evenly across the surface of the PC Drum.

• The grid voltage (Vg) applied to the grid mesh is kept in the range between -300 and

-1000 V by the Constant-Voltage Circuit in High Voltage Unit 1. The constant voltage of

High Voltage Unit 1 is determined through image stabilization control.

Grid Mesh

Corona Wire

High Voltage Unit 1 HV1

PC Drum

Constant-Voltage

Circuit

1144M026AA

8-1. PC Drum Charge Corona ON/OFF Control

Control Signal Energized Deenergized Wiring Diagram

High Voltage

Unit 1 HV1

(PC Drum

Charge Corona)

PWB-ID PJ11ID-9 L H 13-E

Transfer Drum

Reference

Position Sensor

PC20

PC Drum Drive

Motor M18

HV1

PC20

Control Signal Blocked Unblocked Wiring Diagram

PWB-ID PJ4ID-5B L H 17-E

Start Key ON

ON

OFF

ON

OFF

H

L

End of Copy Cycle

1144M10TCC

M-22

Page 49

8-2. PC Drum Charge Corona Wire Cleaning Mechanism

• Rotation of PC Drum Charge Wire Cleaning Motor turns the screw shaft, which moves

the cleaner mounted on the screw shaft to clean the corona wire.

• Charge Cleaner Home Position Sensor and Charge Cleaner Return Position Sensor

detect the point at which the direction of PC Drum Charge Wire Cleaning Motor rotation

is switched from forward to backward, or vice versa, and at which PC Drum Charge Wire

Cleaning Motor is stationary, thereby moving or stopping the cleaner.

Cleaning Conditions

• Power Switch S1 is turned ON.

• The Front Door is opened and closed.

• At the end of a multi-copy cycle making 100 copies

Charge Cleaner Return

Position Sensor PC17

Charge Cleaner Home

Position Sensor PC16

Cleaner

Charge Corona Wire

Screw Shaft

Cleaner

PC Drum Charge

Wire Cleaning

Motor M3

Screw Shaft

1179M017AA

<Control>

Control Signal

PWB-ID PJ17ID-5A L H H

M3

PWB-ID PJ17ID-4A H L H

Forward

Rotation

Backward

Rotation

Stop Wiring Diagram

16-E

Control Signal Home Position Return Position Wiring Diagram

PC16 PWB-ID PJ8ID-12 L H 16-C

PC17 PWB-ID PJ8ID-11 H L 16-C

If PC16 is in the activated state when cleaning is started

Cleaning Conditions Met

H

PC16

L

1179M568AA

PC17

M3

(Forward Rotation)

M3

(Backward Rotation)

ON

OFF

OFF

ON

H

L

1179M049CA

M-23

Page 50

8-3. PC Drum Charge Section Ozone Filter

• Ozone produced by the PC Drum Charge Corona is absorbed by the Ozone Filter from

the air blown against the back of the PC Drum Charge Corona by Ozone Ventilation Fan

Motor.

PC Drum Charge Corona

1154M093AA

<Control>

Control Signal Energized Deenergized Wiring Diagram

M5 PWB-ID PJ17ID-6A L H 16-E

S1 ON

ON

M5

OFF

Ozone Ventilation

Fan Motor M5

Ozone Filter

Power OFF

1144M12TCA

M-24

Page 51

9. IMAGE READER (IR) SECTION

5 6

4

3

2

1

22

1. DC Power Supply 2 PU2

2. Original Glass Cooling Fan Motor M2

3. Original Cover Angle Detection Sensor

PC2

4. Actuator

5. SCP Board PWB-G

6. Scanner Motor M1

7. Original Size Detecting Sensor 1 SE1

8. Original Size Detecting Sensor 2 SE2

9. IR Section Thermostat TS3

10. IR Cooling Fan Motor 1 M24

11. CCD Sensor

8

7

9

10

11

18

19

20

21

12. IR Cooling Fan Motor 2 M25

13. Scanner Home Position Sensor PC1

14. Cable Pulley

15. Cable

16. IR Control Board PWB-C

17. CCD Sensor Board PWB-A

18. Exposure Lamp LA1

19. Scanner

20. 2nd/3rd Mirror

21. Size Reset Switch S12

22. Original Size Detecting Sensor 4 SE4

12

17

13

14

1179M019AA

15

16

M-25

Page 52

9-1. IR Image Processing

1. Photoelectric Conversion

2. Analog-to-Digital Conversion

3. Shading Correction

4. Line-to-Line Variation Correction

5. Zoom/Movement Processing

7. Image Data Editing

8. AE Processing

10. Color Correction (Reflection/Density

Conversion, Masking, UCR/BP)

11. Miscellaneous Processing (Improved Reproduction of Black Characters, Smoothing, Color Bal-

ance, Gamma (

To Printer Head (PH)

) Correction)

γ

6. Histogram Making

(ACS/AE Processing)

9. Image Area Discrimination

M-26

Page 53

1. Photoelectric Conversion

• A reduction-type color CCD Sensor is used.

• The R, G, and B chips of the CCD Sensor read the light reflected off the original and con-

vert the optical data into a corresponding analog electric signal.

• To make data processing faster, data transfer and output are done through two channels,

one for even-numbered pixels and the other for odd-numbered pixels.

2. Analog-to-Digital Conversion

The odd and even analog signals output from the CCD Sensor chips are synthesized to

form a single string of signal data which is in turn converted to 8-bit digital signals.

3. Shading Correction

An error is corrected that occurs due to variations in sensitivity of each CCD chip and the

light distribution varying along the length of Exposure Lamp.

Operation:

A. Before the start of each copy cycle, light from Exposure Lamp strikes the shading sheet

and the CCD Sensor reads the light reflected off this sheet.

B. This reading is compared with the shading sheet reading reference value (white refer-

ence value = max. value of image data) to determine the correction value for each pixel.

C. When the image is scanned, each pixel data is corrected with the above correction

value.

To prevent adverse effects on the image due to dust on the white plate (shading sheet), a

correction is made based on the readings taken of multiple lines.

4. Line-to-Line Variation Correction

• The R, G, and B chips of the CCD Sensor are placed so that there is a gap of 4 lines in

the sub-scanning direction between the two adjacent chips (R → G → B). This results in a

deviation in the scanning position of the original. (The slower the scanning speed, the

greater the amount of deviation.)

• A memory called FIFO

timing for R and G data to match it with that for B data.

✽

is used to compensate for this deviation. It retards the output

R data FIFO FIFO Output

G data FIFO Output

B data Output

✽

FIFO (first-in-first-out): Data is output in the same order as it is input.

M-27

Page 54

5. Zoom/Movement Processing

• The image is edited according to the editing features selected on the control panel

(enlargement/reduction, image moving, image repeat)

• Two memories (FIFOs) are used to edit the image as required.

• While one of the memories is reading, data is being written to the other one.

Input

(Write)

FIFO

Output

(Read)

Input

(Write)

Zoom

• The synchronous timing of the input data (read) and output data (read) is varied to

decrease (reduction) or increase (enlargement) the number of data readings, thereby

reducing or enlarging the image in the main scanning direction.

• The image is reduced or enlarged in the sub-scanning direction by varying the speed at

which the Scanner moves.

Movement

• The start position of the output data (read) with respect to the input data (read) is varied

to move the image in the main scanning direction.

• The image is moved in the sub-scanning direction by varying the scan start timing of the

Scanner.

Image Repeat

• The input data (read) stored in the memory is output (read) several times.

FIFO

Output

(Read)

M-28

Page 55

6. Histogram Making

• The scanning area is divided into multiple blocks.

• The image data of the original (excluding the edges) is sampled during the prescan after

the shading correction.

• A histogram is then generated of lightness by saturation.

• The number of color dots in each block is counted.

• The results of the counting are then used to determine whether each block on the original

(excluding the edges) is colored or monochrome.

• Based on the results of the color/monochrome evaluation made of each block, the copier

determines whether the entire original is colored or monochrome (ACS, or Auto Color

Selection).

Block Division

Edge

Edge

Original

Edge

7. Image Data Editing

• R, G, and B data are converted to V (value), Cr, and Cb (color component) for color

adjustments (saturation, lightness, and hue).

Edge

CD

FD

1154M076AA

Histogram

Frequency

Dark

Colored

Lightness

Monochrome

Light

1154M078AA

M-29

Page 56

8. AE Processing

Histogram Making

• Lightness data readings are tallied up for each four gradation levels using the image data

sampled through “Histogram Making.”

• The lightness data readings tallied up for each four gradation levels are totaled to generate one lightness histogram (for AE processing).

AE Level Evaluation

• From the histogram with lightness blocked into four gradation levels, the local maximum

value of each block (the gradation level with the greatest frequency in each block) is

extracted.

• Calculation is made to determine if there is any gradation level extracted, the sum of frequency of ±8 gradation levels of which accounts for a given level or more of the sum of

frequency of the entire original. (Processing is done in the order of the gradation level of

higher lightness).

• If there is, the AE level (local minimum value) is determined according to the lightness

frequency at that local maximum value.

• If not, the AE level is determined according to the original mode.

• The AE processing table is determined based on the AE level.

• Background processing (AE processing) is performed as the AE processing table is

determined.

Lightness Histogram

Frequency

Monochrome

Color

4 gradation levels

Local maximum value

Low Lightness High

1154M080AB

M-30

Page 57

9. Image Area Discrimination

• The image areas (color edge area, black edge area, dot area, continuous gradation area)

are discriminated to optimize edge emphasis, smoothing and other processing just right

for the image.

• Either HYPER DASH LIMOS or FEET is selected according to the result of this discrimination.

Original Mode Original Area

Text & Photo

mode

Photo Image

mode

Printed Image

mode

Map mode Edge area FEET Strong edge emphasis

Text mode Dot area HYPER DASH

Dot area HYPER DASH

Black edge area FEET BP amount 100 % (Printed

Color edge area FEET Edge emphasis

Continuous gradation area HYPER DASH

Edge area HYPER DASH

Continuous gradation area HYPER DASH

Dot area HYPER DASH

Continuous gradation area FEET

Black edge area FEET BP amount 100 % (printed

Color edge area FEET Edge emphasis

Continuous gradation area HYPER DASH

HYPER DASH

LIMOS/FEET

LIMOS

LIMOS

LIMOS

LIMOS

LIMOS

LIMOS

LIMOS

Smoothing/Edge Emphasis

Smoothing processing

with Bk toner only)

Weak edge emphasis

Smoothing processing

with Bk toner only)

M-31

Page 58

10. Color Correction

Reflection/Density Conversion

• Color reproduction faithful to the original is not possible if the original reflection data (R,

G, B) obtained through the CCD Sensor is converted to the complementary color data for

developing.

Example: White

Reflection

Factor

255

RGB

0

Becoming Black

255

CMY

0

1144M178CA

• The R, G, and B data are therefore input to the LOG table shown below to convert to the

density data (DR, DG, and DB).

Example : White

Reflection

Factor

RGB

255

0

225

DR

DG

DB

255

LOG Table

DR DG DB

0

RGB

225

0

Becoming WhiteDensity

255

CMY

0

1179M051CA

M-32

Page 59

Masking

Considering the spectral transmission characteristics of the R, G, and B filters of the CCD

Sensor and the spectral reflection characteristics of the toner, the image data is corrected

and the DR, DG, and DB data are replaced with C, M, and Y data, thereby enabling color

reproduction faithful to the original.

UCR and BP

• In UCR, or Under Color Removal, the C, M, and Y data required for color reproduction

areas are retained, while the C, M, and Y data of gray areas are removed.

• With BP, or Black Paint, a certain ratio of the gray area is replaced with Bk data, the ratio

varying depending on the saturation of the color.

255

M

Y

C

UCR

0

255

M

Y

C

0

Bk

1154M086AA

• Because of the spectral reflection characteristics of the toner, simply placing C, M, and Y

toner one on top of the other does not make a pure black.

• If C, M, and Y toner are put together to create a color close to black, it results in an

increased amount of toner sticking, meaning that more toner scatters and is consumed.

M-33

Page 60

11. Miscellaneous Processing

<Improved reproduction of black characters>

The Bk data for black characters is replaced with MAX (DR, DG, DB) data, which improves

reproduction of black fine lines, realizing reproduction of black characters that do not

depend on line width very much.

DR DG DB

1154M020AA

Edge Emphasis

• The number of data readings on the edges of the image is increased to make the outline

of the image sharper as it appears on the copy.

1144G04MBA

• The amount of edge emphasis is obtained in directions of 0°, 90°, 45°, and -45° and is

determined using the greatest value obtained.

Smoothing

The noise components contained in the image data are removed to smooth the data.

1144G05MBA

Density Adjustment and Color Balance

• Density adjustment is made by changing the angle of the γ curve that represents the rela-

tion between the input and output of the image data.

• Color balance is adjusted by changing the angle of the γ curve for each color.

255

Higher

Output

Density

128

0

Lower

Density

128 255

Input

curve

1179M052CB

Gamma (γ) Correction

The type of γ curve is changed to make the image brighter or darker, or sharper or softer.

Output

255

128

0

Darker

Brighter

128 255

Input

1179M053CB 1179M054CB

Output

255

128

0

Sharper

128 255

Input

Softer

M-34

Page 61

9-2. CCD Sensor

• A reduction-type color CCD sensor is used.