Page 1

3

DISASSEMBLY/ASSEMBLY

3 DIS./ASSEMBLY

Page 2

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the

precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

2. The disassembled parts must be reassembled following the

disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely .

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 3

EXTERNAL SECTION

EXTERNAL SECTION

[1] Replacing Ozone Filters

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution: When replacing ozone filters, insert

them in the openings in the main body

as far as they will go.

a. Procedure

(1) Loosen the two screws to remove the cooling fan

cover.

(2) Replace two ozone filters 1 (upper/2) and one

ozone filter 2 (lower/1).

Ozone filter 1

Screws

(loosen 2)

[2] Removing and Reinstalling the

External Cover

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the two screws to detach the option

cover.

(2) Remove the nine screws to detach the rear cover.

Rear cover 1

Screws (9)

3 DIS./ASSEMBLY

Ozone filter 2

(3) Reinstall the above parts following the removal

steps in reverse.

Cooling cover

Option cover 1

(3) Remove the six screws to detach the left side

cover.

Screws (6)

Left side cover

Screws (2)

3 - A - 1

Page 4

EXTERNAL SECTION

(4) Remove the four screws to detach the right side

cover (upper).

Right side cover (upper)

Screws (4)

(5) Open the vertical paper transport jam access

door.

(6) Remove the four screws to detach the right side

3 DIS./ASSEMBLY

cover (lower).

[3] Removing and Reinstalling the Front

Right Door

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the front right door.

(2) Remove the screw to disconnect the ground

cable.

Ground

cable

Right side cover (lower)

Screws (4)

Vertical paper

transport access

door

(7) Reinstall the above parts following the removal

steps in reverse.

Caution: Covers can be detached separately.

Screw

(3) Loosen the two screws securing the hinge.

(4) While holding the top of the front right door by

hand so that it does not fall down, remove the

door with the hinge pin held up.

Front

right door

Screws

(loosen)

3 - A - 2

(5) Reinstall the above parts following the re-

moval steps in reverse.

Page 5

EXTERNAL SECTION

[4] Removing and Reinstalling the Front

Left Door

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the front left door.

(2) Remove the screw to disconnect the ground

cable.

Ground cable

[5] Removing and Reinstalling the

Operation Panel

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the RADF.

(2) Remove the two shoulder screws to remove

the original stopper plate (right).

(3) Remove the three shoulder screws to remove

the original stopper plate (rear).

(4) Remove the two shoulder screws to remove

the original stopper plate (left).

(5) Remove the platen glass.

Shoulder

screws

(2)

Shoulder

screws (3)

Original

stopper

plate (rear)

Shoulder

screws (2)

3 DIS./ASSEMBLY

Screw

(3) Loosen the two screws securing the hinge.

Caution: When loosening the screws, hold the

top of the door by hand so that it does

not fall down.

(4) Remove the door with the hinge pin held up.

Front left door

Screws

(loosen)

Original

stopper

plate (left)

Platen glass

Original

stopper plate

(right)

(5) Reinstall the above parts following the removal

steps in reverse.

3 - A - 3

Page 6

EXTERNAL SECTION

(6) Remove the six screws to detach the top

cover (middle).

(7) Open the front right door and the front left door.

Screws (6)

Top cover (middle)

(8) Draw out the toner supply unit. (See “TONER

3 DIS./ASSEMBLY

SUPPLY UNIT.”)

(9) Remove the seven screws (three at the top and

four on the bottom).

(10)Draw out the operation panel forward.

Caution: When removing the operation panel,

pay attention to the following points:

• The operation panel and main

body are connected with a wiring

harness. Moving the operation

panel too far away from the main

body could break the wiring

harness.

• Care should be taken not to

damage the display section.

(11) Disconnect the two relay connectors (CN475,

CN157) and remove the operation panel.

Connector (CN475)

Connector (CN157)

Screws (3 at the top)

Screws (4 on the buttom)

(12)Reinstall the above parts following the removal

steps in reverse.

3 - A - 4

Page 7

DRIVE SECTION

DRIVE SECTION

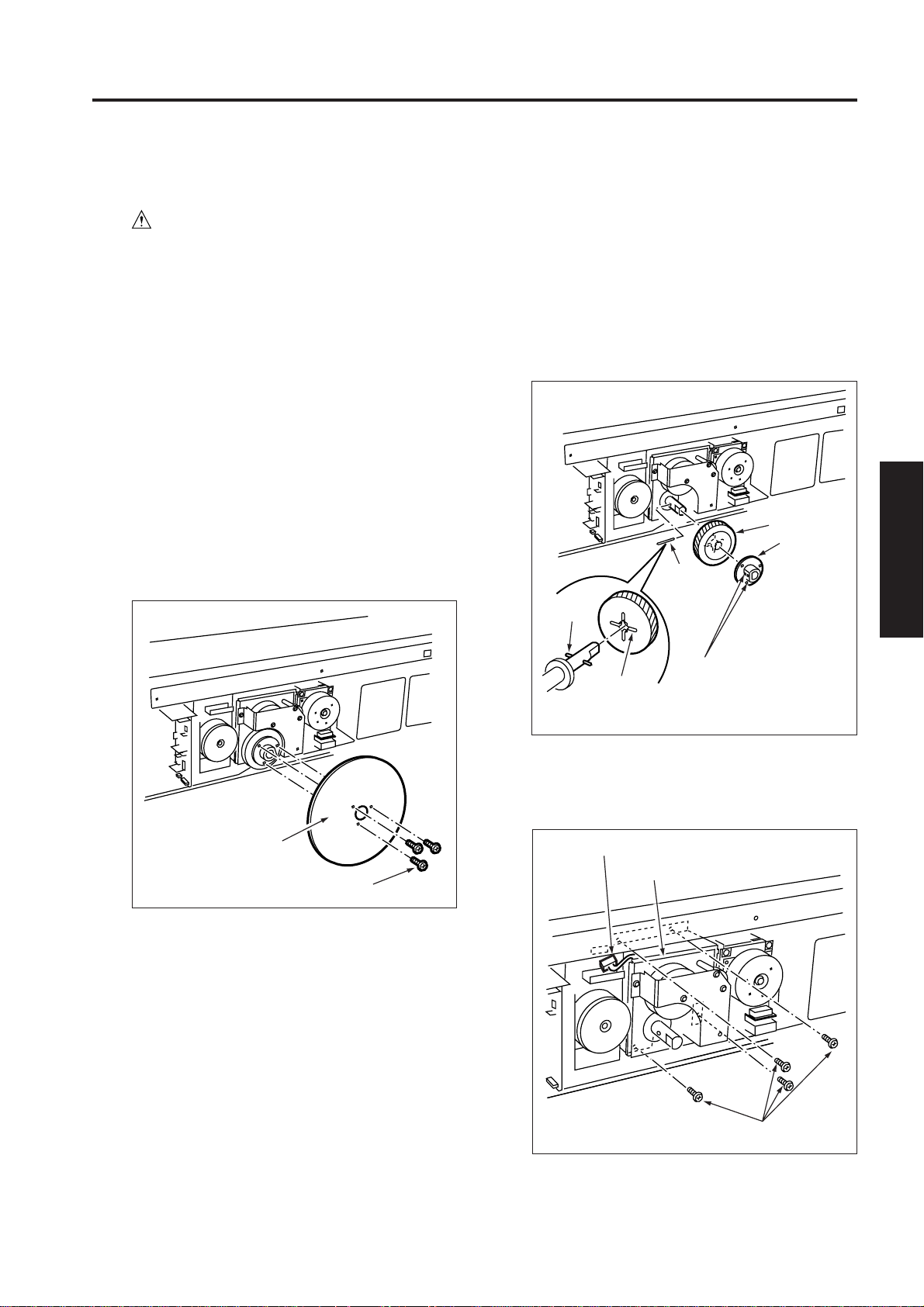

[1] Removing and Reinstalling the

Drum Motor

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution: Be sure to draw the drum unit out of

the main body before removing or

reinstalling the drum drive motor.

If you fail to draw out the drum unit,

the cleaning blade may be damaged

because the drum rotates when

installing or removing the flywheel

or gear.

a. Procedure

(1) Draw the drum unit out of the main body. (See

“DRUM UNIT.”)

(2) Remove the rear cover. (See “EXTERNAL SEC-

TION.”)

(3) Remove the three screws to remove the three

flywheels.

(4) Loose the two setscrews to remove the gear

holder, gear, and pin from the shaft.

Caution 1: Install the gear with the shaft pin fit

into the groove at the back of the

gear. As the pin inserted in the shaft

moves freely, take care not to drop

or lose it.

Caution 2: Secure the gear holder with the

setscrews while pressing the gear

holder against the gear.

Gear

Gear

holder

Pin

Pin

3 DIS./ASSEMBLY

Flywheels (3)

Setscrews (loosen 2)

Groove (at

the back of

gear)

(5) Disconnect the connector (CN58) and remove

the four screws to detach the drum motor unit.

Connector (CN58)

Drum motor unit

Screws (3)

3 - B - 1

Screws (4)

Page 8

DRIVE SECTION

(6) Disconnect the connector (CN180) and remove

the four screws and two locking supports to

remove the drum motor from the drum motor unit.

Screw (4)

Drum motor

(M2)

Connector (CN180)

Locking supports

(7) Reinstall the above parts following the removal

3 DIS./ASSEMBLY

steps in reverse.

Caution: When installing the gear holder, set it

to fit to the gear, then secure it b y the

set screw .

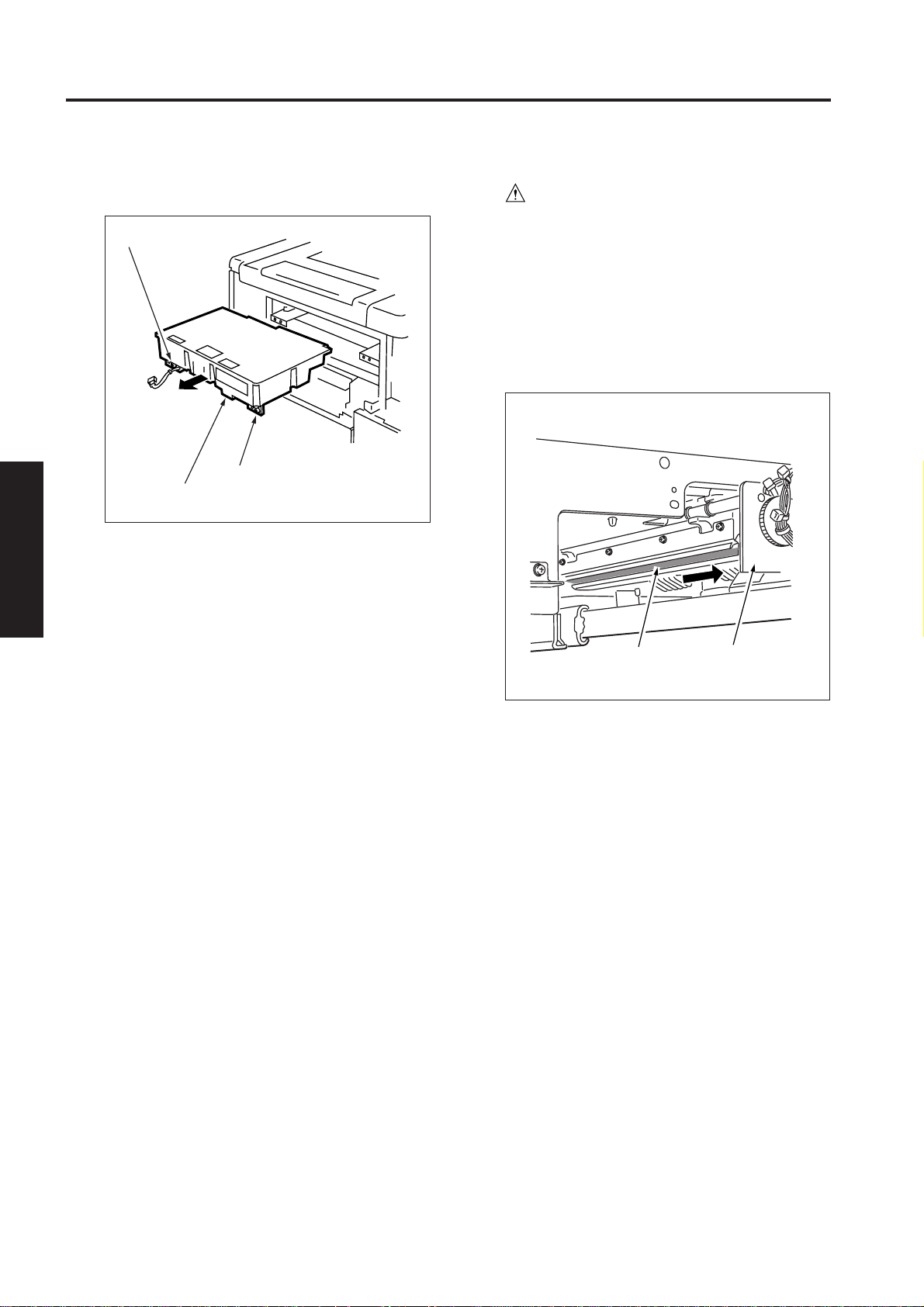

[2] Removing and Reinstalling the Main

Motor

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

(1) Remove the rear cover. (See “EXTERNAL SEC-

TION.”)

(2) Disconnect the connector (CN181).

(3) Remove the four screws to release the motor

board locking supports.

(4) Remove the main motor from the main body.

Main motor

Locking

supports

Screws

Connector (CN181)

3 - B - 2

Page 9

READ SECTION

READ SECTION

[1] Screw that Must not be Removed/

Loosened

a. 14 screws securing the CCD unit

Screws that

Screws that

must not be

removed

Screws that must not be removed

Screws that

must not be

removed

b. One screw securing the read position

adjusting plate and two screws securing the

glass stopper plate (right)

must not be

removed

[2] Removing and Reinstalling the CCD

Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution: Be sure to perform image adjustment

after installing the CCD unit. (See

“ADJUSTMENT.”)

a. Procedure

(1) Remove the original stopper plates (right, rear,

and left), platen glass, and top cover (middle).

(See “EXTERNAL SECTION.”)

(2) Remove the two screws to detach the white color

reference plate assembly.

Screws (2)

3 DIS./ASSEMBLY

Read position

adjusting plate

Screws that must

not be removed

White color reference

plate assembly

(3) Remove the two screws to detach the lens light

blocking cover 2.

Screws (2)

Glass stopper plate (right)

Lens light blocking cover

3 - C - 1

Page 10

READ SECTION

(4) Remove the eight screws to detach the lens light

blocking cover 1.

Screws (8)

Lens light blocking cover 1

(5) Remove the left side cover. (See “EXTERNAL

SECTION.”)

(6) Remove the seven screws to detach the fan

3 DIS./ASSEMBLY

mounting plate.

(7) Disconnect the connector (CN110) from the im-

age control board.

Image control board

Connector (CN110)

(8) Disconnect the connector (CN197) from the CCD

unit.

Screws (7)

Connector (CN197)

Fan mounting bracket

3 - C - 2

Page 11

READ SECTION

(9) Remove the two screws to detach the CCD unit.

Screws (2)

CCD unit

(10)Reinstall the above parts following the removal

steps in reverse.

[3] Replacing the Exposure Lamp

Caution 1. Be sure the power cord has

been unplugged from the wall

outlet.

Caution 2. Do not touch the exposure

lamp with bare hands.

Caution: Be sure to perform image adjustment

after installing the exposure lamp.

(See “ADJUSTMENT.”)

a. Procedure

(1) Remove the original stopper plates (right, rear,

and left), platen glass, and top cover (middle).

(See “EXTERNAL SECTION.”)

(2) Move the exposure unit to the notch in the main

body frame on the paper exit side.

(3) Remove the connector and two screws to detach

the exposure unit.

Screws (2)

Exposure lamp

Connector

3 DIS./ASSEMBLY

3 - C - 3

(4) Reinstall the above parts following the removal

steps in reverse.

Page 12

READ SECTION

[4] Replacing and Reinstalling the

Exposure Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution 1: When installing the exposure unit,

use the optical unit positioning jig.

Caution 2: Be sure to perform image adjust-

ment after installing the exposure

lamp. (See “ADJUSTMENT.”)

a. Removal procedure

(1) Remove the original stopper plates (right, rear,

and left), platen glass, and top cover (middle).

(See “EXTERNAL SECTION.”)

(2) Remove the operation panel. (See “EXTERNAL

SECTION.”)

(3) Move the exposure unit to the notch in the main

body frame on the paper exit side.

(4) Remove the two screws to detach the cord clamp

(B).

(5) Remove the screw to remove the ground termi-

3 DIS./ASSEMBLY

nal.

(6) Disconnect the connector (CN632).

(7) Remove the four screws to detach the exposure

unit.

Exposure unit fixing screw

b. Installation procedure

(1) Insert the optics unit positioning jig in the hole at

the exposure unit mounting position from the

front.

(2) Slide the exposure unit to the paper feed side

until it touches the optical unit positioning jig.

Exposure unit

Optics unit positioning jigs

(3) Secure the four screws to attach the exposure

unit to the optics wire mounting bracket.

(4) Remove the optics unit positioning jig.

(5) After the procedure (4), reinstall the parts re-

moved in "a. Removal procedure" following the

removal steps in reverse.

Screws (2)

Screws (2)

Connector

(CN632)

Screw (ground) Exposure unit fixing screw

Cord clamp/B

Screws

3 - C - 4

Page 13

READ SECTION

[5] Installing the Optics Wire

Caution: Be sure the power cord has been

unplugged from the wall outlet.

Caution 1: When winding the optics wire

around the pulley, be sure to run

the wire tightly so that it does not

ride on the side of the pulley.

Caution 2: When re-tensioning or replacing

the optics wire, be sure to use the

optics positioning jig.

Caution 3: Be sure to perform image adjus-

tment after replacing or re-installing the wire. (See “ADJUSTMENT.”)

a. Procedure

(1) Remove the exposure unit.

(2) Remove the two screws to detach the white color

reference plate.

Screws

(4) Insert the optics positioning jigs in the holes at the

exposure unit mounting position from the front.

Exposure unit

V-mirror unit

Optics positioning jigs

Exposure unit fixing hole

V-mirror fixing hole

3 DIS./ASSEMBLY

White color reference

plate

(3) Move the V-mirror unit toward the paper feed

side, then insert the optics positioning jigs from

the front to secure the V-mirror unit. Ensure that

the optics positioning jigs pass through the Vmirror unit.

Optics positioning jig insertion holes

3 - C - 5

Page 14

READ SECTION

(5) The exposure unit mounting plate is installed on

each optics wire. The position of mounting plate

differs depending on whether it is installed on the

front or rear wire. Use the wire on which the

mounting plate is installed nearer to the metal

bead at the end, at the rear.

(6) Place the metal bead at the midpoint of each

optics wire in the mounting hole in the drive

pulley. Starting at this point, wind the optics wire

five turns to the outside and four times to the

inside on the drive pulley.

Caution 1: Ensure that there is a metal bead

at the end of the outer wire, and a

wire terminal at the end of the inner

wire.

Caution 2: Pull out the outer wire from above

the drive pulley in the paper exit

direction, and the inner wire from

under the drive pulley in the paper

feed direction.

(7) After winding the outer wire, secure it to the wire

3 DIS./ASSEMBLY

stopper via the outside of pulley 1 and V-mirror

pulley.

3 - C - 6

Page 15

READ SECTION

Five turns

Front

Metal bead

Optics wire

(front)

11

Four

Drive

pulley

Wire stopper

Metal bead

Wire

stopper

10

Pulley 1

Four

10

Wire stopper

Metal bead

Metal bead

Five turns

Rear

Metal bead

Exposure unit

mounting piece

Optics wire

(rear)

V-mirror

unit

Wire stopper

V-mirror unit

Metal

bead

Spring

Screws

Spring fixing plate

Exposure unit

mounting piece

Metal bead

Rear

Pulley 3

Spring fixing plate

13

12

Lug terminal

11

Pulley 1

Pulley 2

3 DIS./ASSEMBLY

9

Pulley 1

V-mirror

unit

Caution: There are two grooves in the wire

stopper. Ensure that the outer groo ve

is at the rear and the inner groove is

at the front.

(8) Pass the inner wire through the notch in the wire

stopper, reverse it at pulley 2, pass it along the

inside of the V-mirror pulley and pulley 3, then

attach the wire terminal to the spring fixing plate.

At this time, secure the spring fixing plate temporarily with one screw.

Metal bead

Optics wire (rear)

Optics wire (front)

(9) Install the other wire following the same proce-

dure.

(10)Loosen each screw that was tightened tempo-

rarily, install the spring on the spring fixing plate,

and tighten each screw.

3 - C - 7

Page 16

READ SECTION

[6] Cleaning the Slit Glass and White

Color Reference Plate Glass

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

(1) Open the RADF.

(2) Remove the original stopper plates (right, rear,

and left) and platen glass. (See “EXTERNAL

SECTION.”)

(3) Remove the two screws to detach the white color

reference plate subassembly.

(4) Clean the slit glass portions of the removed white

color reference plate subassembly and the glass

surface of the white color reference plate, using

drum cleaner and cleaning pad.

White color reference

plate subassembly

3 DIS./ASSEMBLY

Slit glass

[7] Cleaning the Platen Glass

Caution: Be sure the power cord has been

unplugged from the wall outlet.

(1) Open the RADF.

(2) Remove the original stopper plates (right, rear,

and left) and platen glass. (See “EXTERNAL

SECTION.”)

(3) Place the removed platen glass on the towel or

rags and clean it using drum cleaner and cleaning

pad.

Shoulder

screws (2)

Original stopper plate (rear)

Shoulder

screws (3)

Shoulder

screws (2)

White color reference

plate glass

(5) Reinstall the above parts following the removal

steps in reverse.

Platen glass

Original stopper plate (left)

Original

stopper plate

(right)

(4) Reinstall the above parts following the removal

steps in reverse.

3 - C - 8

Page 17

WRITE SECTION

WRITE UNIT

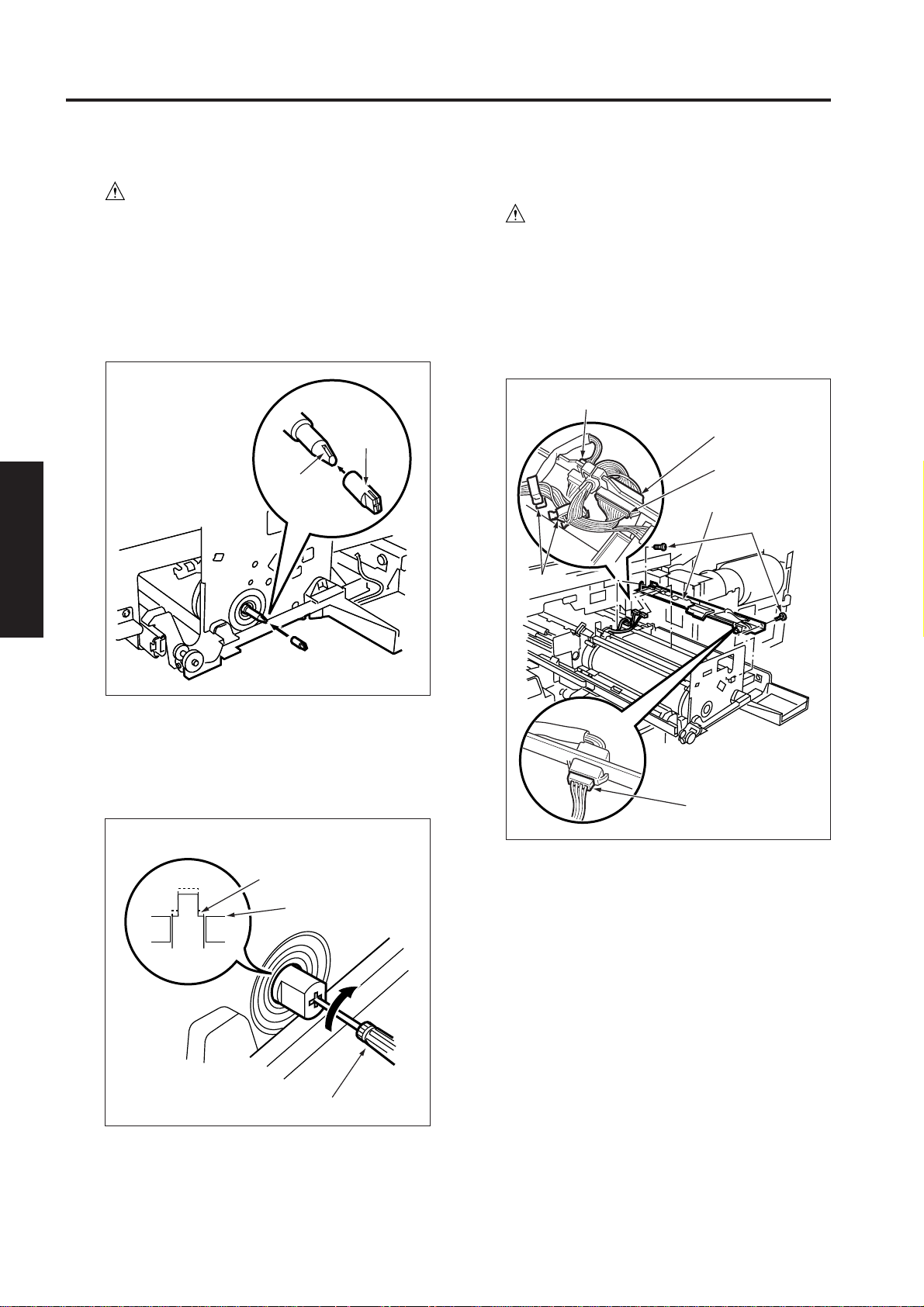

[1] Removing and Reinstalling the Write

Unit

Warning:

(1) Do not energize the write unit when it is

not in the correct position.

(2) Never remove the write unit cover and the

polygon unit cover.

If the laser beam gets into your eyes, y ou

may lose your sight.

(3) Never remove the write unit for at least

two minutes after turning OFF the main

switch.

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the original stopper plates (right/rear/

left) and platen glass. (See “EXTERNAL SECTION.”)

(2) Remove the six screws to detach the board

protection cover.

Screws (6)

(3) Disconnect the four connectors (CN190, 191,

192, and 193) from the write unit.

CN190

CN191

Write unit

(4) Remove the right side cover (upper) (by remov-

ing the four screws).

(5) Disconnect the three connectors (CN76, 474 and

583).

(6) Remove the four screws to detach the write unit

cover.

CN193

CN192

3 DIS./ASSEMBLY

Board protection cover

Screws (4)

Connector (CN76,

CN583)

Write unit cover

Connector (CN474)

3 - D - 1

Page 18

WRITE UNIT

(7) Loosen the two screws to draw out and remove

the write unit.

Screw (loosen)

Screw (loosen)

Write unit

(8) Reinstall the above parts following the removal

steps in reverse.

3 DIS./ASSEMBLY

[2] Cleaning the Dust-proof Glass

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw out the drm unit. (See “Drum Unit.”)

(2) Remove the dust-proof glass assembly by draw-

ing it out forward.

(3) Using a cleaning pad and blower brush, clean the

dust-proof glass portions.

Dust-proof glass

Drum unit

(4) Reinstall the above parts following the removal

steps in reverse.

3 - D - 2

Page 19

[3] Removing and Reinstalling the

Image Control Board

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the left side cover. (See “EXTERNAL

SECTION.”)

(2) Remove the seven screws to detach the fan

mounting plate.

Fan mounting plate

WRITE UNIT

(5) Reinstall the above parts following the removal

steps in reverse.

Caution 1: Insert the board along the guides

in the main body.

Caution 2: Be sure the connector of the board

is inserted securely.

Image control board

Screw (7)

(3) Remove the CCD flat cable connector (CN110)

and ethernet cable connector (CN111).

(4) Remove the two screws and the image control

board.

Connector (CN 110)

Connector

(CN111)

Guide

3 DIS./ASSEMBLY

Screws (2)

Image control board

3 - D - 3

Page 20

DRUM UNIT

DRUM UNIT

[1] Removing and Reinstalling the

Drum Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution 1: Be sure to put a drum cover over

the removed drum unit and store

the drum unit in a dark place.

Caution 2: When installing or removing the

drum unit, do not rotate it in the

direction opposite to the specified

one. Rotating the drum unit in the

opposite direction during copy

operation could damage the

cleaning blade.

Caution 3: When installing or removing the

drum unit, take care not to touch

the separation claw.

a. Procedure

(1) Open the front right door to draw out the toner

supply unit completely. (See “TONER SUPPLY

UNIT”)

(2) Remove the three screws to detach the drum

cover.

(3) With the solenoid release lever under the ADU

frame held down to the left, turn down the ADU

frame drawing lever.

(4) Remove the two screws securing the drum unit.

(5) Remove the screw securing the coupling to de-

tach the coupling.

(6) Supporting the drum unit by hand at the two

positions shown below, draw out the drum unit.

Caution: When drawing out the drum unit, do

not grip the pipe in the toner recycle

section.

Hold here.

3 DIS./ASSEMBLY

Handle

Coupling

Screw

Drum cover

Screws (2)

Handle release lever

(7) Reinstall the above parts following the removal

steps in reverse.

Caution: For how to install the coupling, see “[2]

Installing the Coupling.”

Screw (3)

3 - E - 1

Page 21

DRUM UNIT

[2] Cleaning and Installing the Coupling

Caution: Be sure the power cor d has been

unplugged from the wall outlet.

a. Procedure

(1) Clean the outer surface of the coupling with drum

cleaner.

(2) Aligning the line marked on the coupling with the

key way in the drum shaft, push in the coupling by

hand.

Markedoff line

Key way

3 DIS./ASSEMBLY

[3] Removing and Reinstalling the

Drum Temperature Sensor Board

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw the drum unit out of the main body.

(2) Disconnect the three connectors (350, 351, and

353) and remove two screws to detach the sensor support stay assembly.

Connector (CN350)

Connector (CN353)

Connector (CN353)

Sensor support stay

assembly

Screws (2)

Cord tie

(3) While pressing the standard screwdriver tip

against the coupling, turn the coupling clockwise

until the cut face of the coupling is flush with the

bearing face.

Cut face

Bearing face

Driver

(4) Tighten the screws.

Connector (CN351)

3 - E - 2

Page 22

DRUM UNIT

(3) Disconnect the connector (CN455) and remove

three screws to detach the drum temperature

sensor.

Connector (CN455)

Drum temperature sensor

Screws (three)

(4) Reinstall the above parts following the removal

steps in reverse.

Caution: After reinstalling the drum temperature

sensor board, visually check that the

drum temperature sensor is in good

contact with the drum.

[4] Cleaning the Toner Control Sensor

Board

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw the drum unit out of the main body.

(2) Remove the drum cleaning unit. (See “CLEAN-

ING/TONER RECYCLE UNIT.”)

(3) Remove the screw at the back of the sensor

guide and loosen the screw at the front to move

the sensor guide.

Screw

3 DIS./ASSEMBLY

Sensor guide

Screw (loosen)

(4) Clean the sensors on the toner control sensor

board (the Dmax/jam detection sensor at the

front and the γ sensor at the back) using a blower

brush.

γ sensor

Dmax/jam detection sensor

3 - E - 3

Page 23

DRUM UNIT

[5] Removing, Cleaning and

Reinstalling the Drum

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution1: Be careful not to touch the drum

or the cleaning blade with bare

hands, or damage these parts.

Caution2: When leaving the drum to stand,

be sure to put a drum cover over

the drum and store it in a dark

place.

Caution3: When reinstalling the drum,

cleaning blade and toner guide

brush, apply setting powder to the

entire surface of the drum and also

to the cleaning blade regardless of

whether the parts are new or old.

Caution4: After applying setting powder to the

drum, carry out the following work

before installing the drum unit in

3 DIS./ASSEMBLY

a. Procedure

(1) Draw the drum unit out of the main body.

(2) Remove the charging corona unit, developing

unit, developing suction assembly drum temperature sensor board, and cleaning unit. (See

“CORONA UNIT SECTION,” “DEVELOPING

UNIT,” and “CLEANING/TONER RECYCLE

UNIT.”)

the main body.

1) With the charging corona unit

and developing unit removed,

turn the drum once (to prevent

setting powder from scattering

onto the charging corona unit,

and to prevent image defects).

2) When installing a new drum, be

sure to enter the 25 mode and

select “Copy Count by Parts to

be Replaced” to reset drum

counter. (See “ADJUSTMENT. ”)

(3) Remove the screw at the back of the sensor

guide and loosen the screw at the front to move

the sensor guide (to prevent the drum from being

damaged during reinstallation).

Screw

Sensor guide

Screw (loosen)

(4) Supporting the drum at both ends with your

fingers so that the drum surface is not damaged,

slowly remove it upward (front side first).

(5) Clean the hole (that engages with the bearing on

the rear end of the drum shaft) on the rear side of

the drum cartridge with drum cleaner.

(6) Clean toner scattered around the drum installation

area using a blower brush.

Engaging hole

Drum

3 - E - 4

Need to clean

toner

(7) Reinstall the above parts following the removal

steps in reverse.

Page 24

DRUM UNIT

[6] Removing and Reinstalling the

Separation Claws

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution 1: T ake care not to damage the drum

when removing the separation

claws.

Caution 2: Pa y attention to the orientation and

position of the separation claws

when reinstalling them.

Caution 3: Do not touch the cleaning blade

and drum with bare hands.

a. Procedure

(1) Draw the drum unit out of the main body.

(2) Remove the cleaning/toner recycle unit. (See

“CLEANING/TONER RECYCLE UNIT.”)

(3) To protect the drum surface, set A3 paper as

shown below.

Caution: After installing the separation claw,

remove the A3 paper by pulling it do wn

as shown below.

(4) Disconnect the connector (CN354), and remove

the spring and two screws to detach the separation claw unit.

(5) Remove the retaining ring and slide the shaft to

remove the three separation claws.

Caution 1: Clean the separation claw drive

shaft with alcohol when installing

it.

Caution 2: Must insert the retaining ring

between the ribs.

Caution 3: After reinstalling the separation

claws, make sure they move

smoothly.

Separation

claws

Retaining

ring

3 DIS./ASSEMBLY

Screws

Spring

Connector (CN354)

A3 paper

Ribs

3 - E - 5

Page 25

DRUM UNIT

(6) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing the separation claw

unit, be sure to fit the pin in the guide

hole as shown below.

Pin

Guide hole

Drum unit

3 DIS./ASSEMBLY

Separation

claw unit

[Reference]

When you removed the separation claw unit (you

need not remove it usually but you need to remove

it only when replacing the solenoid), install it in

the following manner:

(1) Install the separation claw unit in the drum car-

tridge.

(2) Tighten the solenoid screw when one of the

separation claws, which is closest to the drum,

contacts the drum. (Hex. nut, M3)

Separation

claw

solenoid

(SD4)

Screws (2)

(Hex. nut)

Drum

Separation

claw unit

(3) Set the drum cartridge in the main body and

check the tips of the separation claws are off the

drum surface.

Standard value of clearance: More than 0 mm up

to 1 mm inclusive

3 - E - 6

Page 26

CORONA UNIT SECTION

CORONA UNIT SECTION

[1] Screws that Must not be Removed/

Loosened

a. Five screws securing the transfer entrance

guide plate

Screws that must not be removed

Transfer entrance guide

plate

Caution 1: Do not strain the transf er entrance

guide plate and guide rollers, for

example, pressing down on them

strongly, when removing the

charging corona unit.

Caution 2: T ak e care not to damage the edge

of the transfer entrance guide plate

since it is deformed easily.

[2] Removing and Reinstalling the

Charging Corona Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution: When removing the charging

corona unit, do not touch the mesh

of the charge control plate.

a. Procedure

(1) Remove the drum unit from the main unit. (See

“DRUM UNIT.”)

(2) Disconnect the connector (CN353). Holding the

charging corona unit at the positions shown below with both hands, remove it.

Connector (CN353)

Charging corona

unit

3 DIS./ASSEMBLY

3 - F - 1

(3) Reinstall the above parts following the removal

steps in reverse.

Page 27

CORONA UNIT SECTION

[3] Removing and Reinstalling the

Charge Control Plate

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the charging corona unit.

(2) Press the lever in the direction of the arrow to

release the lock, then remove the charge control

plate.

Caution: Do not loosen or tighten the screws

securing the lever.

Charge control plate

3 DIS./ASSEMBLY

(4) Remove the springs of wires (one each) to re-

move the wires.

Caution 1: Do not drop or lose the support

rubbers when removing wires.

Caution 2: Reinstall wires so that their hooks

are inside.

Spark arrester plate

Lever

(3) Reinstall the above parts following the removal

steps in reverse.

[4] Replacing the Charging Wires

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the charging corona unit.

(2) Remove the charge control plate.

(3) Remove the spark arrester plates (front and

rear).

Support rubber

Wire

Spring

Hook (inward)

3 - F - 2

(5) Reinstall the above parts following the removal

steps in reverse.

Page 28

CORONA UNIT SECTION

1

2

3

[5] Removing and Reinstalling the

Charging Wire Cleaning Pad

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the two charging wires.

(2) Remove the two retaining rings to remove the

charging wire cleaning pads.

Caution 1: Take care not to drop or lose the

lower collars when removing the

charging wire cleaning pads.

Caution 2: When reinstalling the charging wire

cleaning pads, pay attention to the

orientation shown below. Do not

forget to attach the collars.

Charging wire cleaning pad

[6] Removing and Reinstalling the PCL

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the charging corona unit.

(2) Disconnect the connector (CN356) of the PCL

and release the lock to remove the PCL.

Connector

(CN356)

3 DIS./ASSEMBLY

Collar

Retaining ring

Charging wire

cleaning pad

(3) Reinstall the above parts following the removal

steps in reverse.

(3) Reinstall the above parts following the removal

steps in reverse.

3 - F - 3

Page 29

CORONA UNIT SECTION

[7] Cleaning the Charging Corona Unit/

PCL

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the charging corona unit.

(2) Remove the charge control plate and PCL.

(3) Place the charge control plate on a flat place and

clean its surface with light taps of the cleaning

pad moistened with drum cleaner. Next, remove

any remaining dirt with a blower brush.

Caution: Take care not to damage the mesh of

the charge control plate during

cleaning.

(4) Clean the PCL with a cleaning pad moistened

with drum cleaner.

3 DIS./ASSEMBLY

Charge control plate

[8] Removing and Reinstalling the

Transfer/Separation Corona Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the toner supply unit. (See “TONER SUP-

PLY UNIT.”)

(2) Detach the ADU cover. (See “ADU UNIT.”)

(3) Loosen the two screws to remove the transfer/

separation corona unit.

Transfer/separation corona unit

Screw

PCL

Screw

Lever

(4) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing the transfer/

separation corona unit, make sure the

cleaning gear coupling is engaged

properly.

3 - F - 4

Page 30

CORONA UNIT SECTION

[9] Removing and Reinstalling the

Plunger Prevention Plate

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the toner supply unit. (See “TONER SUP-

PLY UNIT.”)

(2) Draw the ADU frame out of the main body. (See

“ADU UNIT.”)

(3) Remove the transfer/separation corona unit.

(4) Release the twelve locks to remove the plunger

prevention plate.

Plunging prevention plate

[10] Replacing the Transfer/Separation

Wires, Transfer/Separation Wire

Cleaning Block and Support

Rubbers

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the toner supply unit. (See “TONER SUP-

PLY UNIT.”)

(2) Draw the ADU frame out of the main body. (See

“ADU UNIT.”)

(3) Remove the transfer/separation corona unit.

(4) Remove the plunger prevention plate.

(5) Remove the spark arrester plates (front and

rear).

Spark arrester plate (rear)

Spark arrester plate (front)

3 DIS./ASSEMBLY

Locks

(the same number of locks

on the opposite side)

(5) Reinstall the above parts following the removal

steps in reverse.

(6) Remove the springs of wires (one each) to re-

move the wires.

Caution: When installing the springs, bend the

edge of each spring in side.

3 - F - 5

Page 31

CORONA UNIT SECTION

(7) Remove the three wires from cleaning blocks

along with support rubbers.

Transfer/cleaning

block

Separation wire cleaning block

Transfer wire

Separation wire

Support rubber

3 DIS./ASSEMBLY

(8) Turn the transfer/separation corona unit upside

down, remove the retaining rings, and remove

the transfer wire cleaning block and separation

wire cleaning block from the front side.

Spring

Coupling

Retaining rings

(9) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing the transfer/

separation wires, check the coupling

of the cleaning pad drive gear is

engaged correctly.

3 - F - 6

Page 32

CORONA UNIT SECTION

[11] Removing and Reinstalling the TSL

Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the toner supply unit. (See “TONER SUP-

PLY UNIT.”)

(2) Draw the ADU frame out of the main body. (See

“ADU UNIT.”)

(3) Remove the transfer/separation corona unit.

(4) Remove the four screws to remove the transfer

exposure cover.

Transfer and exposure cover

Screws

Screw

(5) Disconnect the relay connector (CN567) to re-

move the TSL unit.

Caution: Each relay connector consists of a

male side and a female side. Be sure

to remove only the male side (shown

below) of the CN567 connector.

Relay connector (CN567)

TSL unit

3 DIS./ASSEMBLY

(6) Reinstall the above parts following the removal

steps in reverse.

3 - F - 7

Page 33

DEVELOPING UNIT

DEVELOPING UNIT

[1] Screws that must not be Removed/

Loosened

a. Procedure

(1) Two screws securing the toner transfer regulation

plate.

(2) One screw securing the magnet angle adjusting

knob.

Screws that must not be removed

Screws that must not be removed

[2] Removing and Reinstalling the

Developing Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw out the drum unit from the main body. (See

“DRUM UNIT.”)

(2) Remove the screw to remove the toner suction

filter case.

Toner suction filter case

Screw

3 DIS./ASSEMBLY

(3) Release the developing unit push pressure lever.

Caution: When releasing the push pressure

lever, do not touch the front and rear

panels of the drum unit.

Developing unit push

Rear panel

pressure lever

Front panel

3 - G - 1

Page 34

DEVELOPING UNIT

(4) Supporting the developing unit at the positions

shown below with both hands, remove it from the

drum unit.

Developing unit

(5) Reinstall the above parts following the removal

steps in reverse.

3 DIS./ASSEMBLY

Caution 1: When installing the developing unit,

assure that the toner transfer sleeve

does not contact with the front panel

of the drum unit.

Caution 2: Never rotate the developing gear

clockwise.

[3] Replacing the Developer

Caution 1: When replacing the developer in

the developing unit, take care not

to allow dirt to get into it.

Caution 2: To rotate the developing sleeve,

rotate the developing gear counterclockwise using a standard screwdriver.

Caution 3: Never rotate the developing gear

clockwise.

Developing gear

a. Procedure

(1) Draw out the drum unit from the main body. (See

“DRUM UNIT.”)

(2) Remove the developing unit from the drum unit.

(3) Release the hooks of the developing unit cover

and remove it upward.

3 - G - 2

Developing unit cover

Page 35

DEVELOPING UNIT

(4) Tilt the developing unit about 45° and rotate the

developing gear counterclockwise using a

standard screwdriver to discharge all of the

developing adhering to the inside of the developing

unit and magnet roller.

Developing gear

45°

(5) Supply fresh developer evenly from the top of the

agitator screws.

(6) Rotate the developing gear until the developer

enters the developing unit.

(7) Perform steps (5) and (6) repeatedly to supply all

of the developer.

(8) Rotate the developing gear counterclockwise to

check that the developer bristles along the entire

length of the toner transfer sleeve.

Developing sleeve

Developing gear

Developing unit

stopper roller

(9) Install the developing unit cover, then install the

developing unit in the drum unit.

Caution: After installing the developing unit in

the drum unit, make sure the

developing unit stopper roller is in

contact with the developing unit

stopper plate (allocation of DSD).

3 DIS./ASSEMBLY

Developer

Developing unit

stopper roller

3 - G - 3

Page 36

DEVELOPING UNIT

[4] Removing and Reinstalling the

Developing Suction Filter

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw out the drum unit from the main body. (See

“DRUM UNIT.”)

(2) Open the lid of the developing suction filter case

and remove the suction filter.

Suction filter case

Suction filter

Lid

3 DIS./ASSEMBLY

(3) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing the developing suction

filter, assure that the lid of de v eloping

suction filter is closed completely.

3 - G - 4

Page 37

TONER SUPPLY UNIT

TONER SUPPLY UNIT

[1] Replacing and Cleaning the Toner

Cartridge

a. Procedure

(1) Open the front left and right doors to pull forward

the toner supply unit.

(2) Pull out the toner cartridge locking lever to re-

move the toner cartridge.

Toner cartridge

Push pressure lever

[2] Drawing out the Toner Supply Unit

Warning: The hinge used in the toner

supply unit mounting section

moves in two steps. Take care

not to get your finger caught in

the hinge when drawing out the

toner supply unit.

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the front left and right doors.

(2) Remove the three screws.

Caution: The upper left (rear) screw is not

removed because it is f astened with a

clip. Loosen it completely.

Screw fastened with clip

3 DIS./ASSEMBLY

(3) After removing the toner cartridge, clean the area

around the toner cartridge insertion hole with a

cleaning pad.

(4) Reinstall the above parts following the removal

steps in reverse.

Screws (3)

3 - H - 1

Page 38

TONER SUPPLY UNIT

(3) Pull forward the toner supply unit. Gripping the

portion shown below, pull out the unit completely.

Toner supply unit

3 DIS./ASSEMBLY

[3] Removing and Reinstalling the

Toner Supply Sleeves 1 and 2

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Pull out the toner supply unit completely.

(2) Remove the toner cartridge.

(3) Remove the four screws to detach the top cover.

Screws (4)

Top cover

(4) Reinstall the above parts following the removal

steps in reverse.

3 - H - 2

Page 39

TONER SUPPLY UNIT

(4) Remove toner supply sleeves 1 and 2.

Caution: T oner supply slee ves 1 and 2 must be

installed observing the correct

orientation shown below.

Toner supply sleeve 2

Correct orientation

Toner supply sleeve 1

[4] Removing and Reinstalling the

Toner Supply Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Pull out the toner supply unit completely.

(2) Remove the toner cartridge.

(3) Disconnect the connector (CN473) and remove

the wiring harness from the four wiring harness

clamps.

Caution: Route the wiring harness carefully

when reinstalling the toner supply unit,

because it is a movable component.

Connector (CN473)

3 DIS./ASSEMBLY

Toner supply sleeve 2

Toner supply sleeve 1

(5) Reinstall the above parts following the removal

steps in reverse.

Wiring harness

clamps (2)

(4) Loosen the two screws to remove the toner

supply unit.

Screws

(2)

(5) Reinstall the above parts following the removal

steps in reverse.

3 - H - 3

Page 40

CLEANING/TONER RECYCLE UNIT

CLEANING/TONER RECYCLE UNIT

[1] Removing and Reinstalling the

Cleaning/Toner Recycle Unit

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution 1: Do not touch the edges of the

cleaning blade with bare hands.

Caution 2: Before reinstalling the cleaning

unit, clean the cleaning/toner

recycle unit with a blower brush

and cleaning pad.

Caution 3: When reinstalling the cleaning unit,

apply setting powder to the entire

surface of the drum and cleaning

blade regardless of whether the

drum and cleaning blade are new

or old.

Caution 4: When you have applied setting

powder to the drum, carry out the

following work bef ore installing the

drum unit on the main body:

1) To ensure accurate toner

concentration, wipe scattered

setting powder off the γ and

Dmax sensors on the toner

control sensor board with a rag

moistened with alcohol.

2) With the charging corona unit

and developing unit removed,

turn the drum once (to prevent

setting powder from scattering

onto the charging corona unit,

and to prevent image defects).

a. Procedure

(1) Manually turn the drum once.

Caution: Must turn the drum once to prevent

toner on the brush falling.

(2) Draw out the drum unit from the main body. (See

"DRUM UNIT.")

(3) Release cleaning unit release levers (on both

sides).

(4) Disconnect one connector (CN355) and remove

the cleaning unit.

Caution 1: Remove the cleaning unit with its

rear surface alingned with the ribs

of the drum cartridge. (Tilt the

cleaning unit approximately 15

degree.)

Caution 2: Remove the cleaning unit with

drum cartridge reference pin in line

with the notch of the cleaning unit.

Notch

3 DIS./ASSEMBLY

Reference pin

Connector (CN355)

3 - I - 1

Cleaning unit

Cleaning unit mounting levers

(5) Reinstall the above parts following the removal

steps in reverse.

Page 41

CLEANING/TONER RECYCLE UNIT

[2] Cleaning the Cleaning/Toner

Recycle Unit

a. Procedure

(1) Remove the cleaning unit.

(2) Clean the areas shown below with a blower brush

and cleaning pad.

3 DIS./ASSEMBLY

[3] Removing and Reinstalling the

Cleaning Blade

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

Caution 1: Be sure to replace the following

parts at the same time:

• Toner cleaning blades 1 and 2

• Toner guide brush/plunging

prevention felt

Caution 2: Do not touch the edges of the

cleaning blade with bare hands.

Caution 3: When reinstalling the cleaning

bade, apply setting powder to the

entire surface of the drum and

cleaning blade regardless of

whether the drum and cleaning

blade are new or old.

Caution 4: When you have applied setting

powder to the drum, carry out the

following work bef ore installing the

drum unit on the main body:

1) To ensure accurate toner

concentration, wipe scattered

setting powder off the γ and

Dmax sensors on the toner

control board with a rag

moistened with alcohol.

2) With the charging corona unit

and developing unit removed,

turn the drum once (to prevent

setting powder from scattering

onto the charging corona unit,

and to prevent image defects).

3 - I - 2

Page 42

CLEANING/TONER RECYCLE UNIT

a. Procedure

(1) Remove the cleaning unit.

(2) Remove one screw to detach cleaning blade 2.

Screw (1)

Cleaning blade 2

(3) Clean the inside of the cleaning unit with a clean-

ing pad and blower brush.

(4) Install two new cleaning blades.

(5) Pull the blade release arm in the direction as

indicated by arrow in the following figure.

(6) Rotate the blade replacement lever all the way in

the direction as indicated by arrow in the following

figure, and then rotate the blade twice.

Caution: Do not release the blade release arm.

Must keep pulling it.

Blade replacement lever

(7) Pull down the blade release arm.

Caution: Must keep the blade replacement

lever being rotated in the arrow

direction by hand.

(8) Release the blade replacement lever.

(9) Remove one screw to detach cleaning blade 1.

Blade replacement lever

Screw (1)

Cleaning blade 1

(10)Clean the inside of the cleaning unit with a clean-

ing pad and blower brush.

(11)Install new cleaning blade 1.

(12)Reinstall other parts following the removal steps

in reverse.

Caution 1: After replacing cleaning blades 1

and 2, make sure that the blade

replacement lever has been pulled

to stretch the wire.

Caution 2: After replacing cleaning blades,

make sure to perform Blade Setting

Mode Adjustment in the 36 mode to

prevent the blades from peeling.

3 DIS./ASSEMBLY

Blade release

arm

3 - I - 3

Page 43

CLEANING/TONER RECYCLE UNIT

[4] Removing and Reinstalling the Toner

Guide Brush and Plunger

Prevention Felt

Caution 1: Be sure to replace the following

parts at the same time:

• Toner cleaning blades 1 and 2

• Toner guide brush/plunging

prevention felt

Caution 2: Do not touch the edges of the

cleaning blade with bare hands.

Caution 3: When reinstalling the cleaning

blade, apply setting powder to the

cleaning blade regardless of

whether the parts are new or old.

Caution 4: When you have applied setting

powder to the drum, carry out the

following work before installing the

drum unit on the main body:

1)To ensure accurate toner

concentration, wipe scattered

setting powder off the γ and

3 DIS./ASSEMBLY

Caution 5: When installing the toner guide

Caution 6: Do not touch the toner guide brush

Dmax sensors on the toner

control sensor board with a rag

moistened with alcohol.

2) With the charging corona unit

and developing unit removed,

turn the drum once (to prevent

setting powder from scattering

onto the charging corona unit,

and to prevent image defects).

brush, apply an even coat of setting

powder to the toner guide brush with

it removed from the cleaner unit.

with bare hands. Do not allow the

brush to come into direct contact

with other objects.

a. Procedure

(1) Remove the cleaning unit.

(2) Remove the two screws to detach the toner seal

plate.

Caution: When installing the toner seal plate,

must start securing the front screw

first.

Toner seal board

Caution: If the toner collection sheet on both

ends of cleaner unit are bent over to

the toner guide brush side, toner may

be spilled from the toner collection

unit.

If this happens, correct bent sheet as

follows.

Correct bent toner collection sheet as

it is in parallel with the toner guide

brush or is slightly bent toward the

front (less than 1 mm).

Toner guide br ush

Screws (2)

3 - I - 4

Toner collection

sheet

Page 44

CLEANING/TONER RECYCLE UNIT

(3) Remove the two screws to detach the two side

seals (front/rear).

Screw

Side seal (front)

(5) Remove one retaining ring and one bearing, then

the plunging prevention felt from the toner guide

brush shaft.

Toner guide brush

Toner prevention collar

(Do not lose.)

Splash

prevention felt

(replace)

Retaining ring

Bearing

(6) Reinstall the above parts following the removal

steps in reverse.

3 DIS./ASSEMBLY

Side seal (rear)

Screw

(4) Remove one retaining ring to detach the toner

guide brush.

Caution: Pull the toner guide brush leftward,

then remove it forward with the gap

between the brush and the bearing

aligned with the side plate.

Tone guide brush

3 - I - 5

Page 45

CLEANING/TONER RECYCLE UNIT

[5] Replacing Guide Plate Assembly

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the toner guide brush.

(2) Remove one E-ring, and one cleaning unit

mounting lever collar.

(3) Remove two screws to detach the drive shafts

support palte.

(4) Remove the cleaner drive gear A assembly.

(5) Remove the cleaner drive bearing and the

plunging prevention felt.

Caution: Once the plunging prevention felt is

removed, replace it.

(6) Remove one E-ring from the toner guide shaft,

then the cleaner drive gear B.

(7) Remove one E-ring from the toner guide shaft,

then the paper feed bearing.

3 DIS./ASSEMBLY

Paper feed

bearing

Toner guide

shaft

Cleaner

bearing

E-ring

Cleaner drive

gear B

E-ring

Cleaning unit

mounting lever

collar

E-ring

Plunging

prevention

felt

Cleaner drive

gear A

assembly

Drive shaft

support plate

Screw

(TP M3x6)

Screw

(B tight M3x8)

3 - I - 6

Page 46

(8) Remove one retaining ring from the toner guide

shaft, then the cleaner bearing.

(9) Remove the toner guide shaft.

Caution: When removing the toner guide shaft,

remove it from the side plate R first,

then from the side plate F.

(10)Remove two screws to detach the guide plate

assembly.

Caution: When installing the guide plate

assembly, secure it as it touches the

bottom.

Side plate F

Retaining

ring

Cleaner

bearing

CLEANING/TONER RECYCLE UNIT

Guide plate

assembly

Screws

(TP M4 x 4)

Toner guide

shaft

(11)Reinstall the above parts following the removal

steps in reverse.

Caution: When installing the drive reinforcing

plate, do not confuse the B tight screw

with the TP screw. After securing the

cleaning lever collar with the E-ring,

secure the drive reinforcing plate by

tightening the B tight screw first and

the TP screw next.

3 DIS./ASSEMBLY

Side plate R

3 - I - 7

Page 47

PAPER FEED UNITS OF TRAYS1 AND 2

PAPER FEED UNITS OF TRAYS 1 AND 2

Caution: The shape and mechanism of tray 1

is the same as those of tray2. The

procedure for removing and reinstalling tray 1 is explained below.

[1] Removing and Reinstalling Paper

Feed Trays 1 and 2

Warning: When removing the tray, stand

in a proper position so that you

do not hurt your back and waist.

If the tray contains paper,

remove all paper before

removing the tray.

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Open the front left and right doors.

(2) While pressing the tray release lever (at the left)

inward, draw out the tray.

(3) Remove the four screws and remove tray 1 with

it lifted.

[2] Removing and Reinstalling the Front

Covers of Trays 1 and 2

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw out paper feed tray 1.

(2) Remove the five screws to remove the front cover

of tray.

Caution: The front cover and main body of the

tray are connected with a wiring

harness of the handle release PS1

(PS14), handle release PS2 (PS15).

Remove the front cov er from the main

body carefully so as not to break the

wiring harness.

(3) Disconnect the handle detection PS connector

(CN265).

Caution: When reinstall the front cover, connect

the handle detection PS connector

without fail. If you f orget to connect it,

you cannot draw out any tray.

3 DIS./ASSEMBLY

Release lever

Screws (4)

Tray 1

Connector

(CN265)

Screws (2)

(4) Reinstall the above parts following the removal

steps in reverse.

Screws (2)

Tray 1 front cover

Screw (1)

Handle releae

PS1 (PS14)

Handle release

PS2 (PS15)

(4) Reinstall the above parts following the removal

steps in reverse.

3 - J - 1

Page 48

PAPER FEED UNITS OF TRAYS 1 AND 2

[3] Cleaning the Paper Dust Removing

Brush

a. Procedure

(1) Draw out paper feed tray 1.

(2) Release the two latches to detach the paper dust

removing brush.

(3) Clean the paper dust removing brush with a

cleaning pad and blower brush.

Paper dust removing brush

3 DIS./ASSEMBLY

Latches

[4] Cleaning the Paper Pre-registration

PS/Paper Feed PS

a. Procedure

(1) Draw out paper feed tray 1.

(2) Clean the paper pre-registration PS1 (PS48) / the

paper pre-registration PS2 (PS50) and the paper

feed PS1 (PS47) / the paper feed PS2 (PS49)

with a blower brush.

Paper pre-registration PS1

(PS48)

Paper pre-registration PS2

(PS50)

Paper feed PS1

(PS47)

Paper feed PS2

(PS49)

Clean these sensors.

(View from below)

3 - J - 2

Page 49

PAPER FEED UNITS OF TRAYS1 AND 2

[5] Removing and Reinstalling the

Paper Feed Roller and the Feed

Roller

a. Procedure

(1) Draw out paper feed tray 1.

(2) Remove the two retaining rings and slide the two

bearings outward to detach the paper feed roller

unit.

Retaining

ring

Bearing

Paper feed roller

unit

Bearing

Retaining

ring

(3) Remove the following parts from the paper pick-

up roller unit to remove individual rollers:

• Retaining rings (three)

• Bearing (one)

• Paper feed reference actuator

• Shafts (two)

• Fixing plate

Painting mark

Feed roller

Fixing

plate

Retaining ring

Paper pickup

reference

actuator

Paper feed

roller

Retaining

Bearing

ring

3 DIS./ASSEMBLY

(4) Reinstall the above parts following the removal

steps in reverse.

Caution 1: When reinstalling rollers, pay

attention to their orientation.

Caution 2: Check whether grease or the like

remains on each roller. If it does,

wipe it.

3 - J - 3

Page 50

PAPER FEED UNITS OF TRAYS 1 AND 2

[6] Removing and Reinstalling the

Double Feed Prevention Roller

a. Procedure

(1) Draw out paper feed tray 1.

(2) Raise the paper feed roller unit straight up.

(3) Remove the two screws to detach the inner

cover.

Inner cover

Screws (2)

3 DIS./ASSEMBLY

(4) Remove the two screws to detach the double

feed prevention roller.

(5) Remove the retaining ring to detach the double

feed prevention shaft with roller.

(6) Slide the double feed prevention roller out of the

shaft.

Painting mark

Double feed prevention

roller rubber

Paper feed

roller unit

Retaining ring

(7) Reinstall the above parts following the removal

steps in reverse.

Caution 1: When reinstalling the double feed

prevention roller, pay attention to

their orientation.

Caution 2: Check whether grease or like

remains on the double feed

prevention roller. If it does, wipe it.

Double feed

prevention

roller

Screws (2)

3 - J - 4

Page 51

PAPER FEED UNITS OF TRAYS1 AND 2

[7] Replacing the Pre-registration and

the Feed Clutches (MCs)

a. Procedure

(1) Draw out paper tray 1.

(2) Remove four screws to detach the paper convey-

ance cover.

Screw

(3) Disconnect the two connectors (CN261, CN260).

(4) Remove the retaining ring to detach the pre-

registration MC1 (MC4) / the pre-registration MC2

(MC6) and the feed MC1 (MC3) / the feed MC2

(MC5).

Paper conveyance

cover

Screw

[8] Removing and Reinstalling the Up/

Down Unit

a. Procedure

(1) Draw out paper feed tray 1.

(2) Remove the front cover of the tray.

(3) Disconnect the connector (CN264).

(4) Remove the two screws to detach the up/down

unit.

Connector (CN264)

Screws (2)

Up/down unit

(5) Reinstall the above parts following the removal

steps in reverse.

3 DIS./ASSEMBLY

Detent

Feed MC1

(MC3)

Feed MC2

(MC5)

Retaining

ring

Connector

(CN260)

Pre-registration

MC1 (MC4)

Pre-registration

MC2 (MC6)

Connector

(CN261)

Retaining ring

Detent

(5) Reinstall the above parts following the removal

steps in reverse.

Caution: When reinstalling each MC, fit the

detent in the slit in the MC.

3 - J - 5

Page 52

PAPER FEED UNITS OF TRAYS 1 AND 2

[9] Replacing the Up/Down Plate Wires

Caution 1: This section explains how to replace the rear wires. To replace the front wires, remove the

front cover of tray and paper up/down unit. The replacement procedure is the same as that

for the rear wires.

Caution 2: When replacement or reinstallation of the wires is complete, check whether the up/down

plate moves up and down smoothly by rotating the up/down plate drive pulley by hand.

Caution 3: Be sure to install wires so that they do not cross nor ride over each other.

Caution 4: After installing the wires, adjust inclination of the up/down plate.

<Removing Wires>

(1) Remove the up/down unit.

(2) Draw out paper feed tray 1/2.

(2)(4) Remove the retaining

ring to detach the wire

regulation cover and pulley.

Wire

regulation

cover

3 DIS./ASSEMBLY

Wire A

(Black)

(1) Remove the E-ring to slide

out the drive pulley.

Wire D

Wire C

Drive pulley

E-ring

Wire C

Wire B

(Black)

(3) Remove

wire C.

Pulley

Retaining ring

Wire D

(5) Remove wire D.

Wire D

Wire C

3 - J - 6

Page 53

<Wire Lengths>

PAPER FEED UNITS OF TRAYS1 AND 2

Wire A, C

Wire B, D

<Installing Wires>

207.5 mm (trays 1, 2)

497.5 mm (trays 1, 2)

Wire

regulation

cover

Wire A, C: 207.5±1 mm

Wire B, D: 497.5±1 mm

(2) Install the pulley, pass wire D through the

pulley, and install the wire restraining cover

and retaining ring.

(4) Install the pulley, pass wires D and C, and

install the wire restraining cover and retaining ring. Wire D must be inside. Wires

should not cross nor ride over each other.

Wire regulation

cover

3 DIS./ASSEMBLY

Pulley

Retaining ring

Wire A

(Black)

(5) Install wires D and C

from inside the drive

shaft hole and push in

the drive pulley.

Wire D

Wire C

Drive pully

E-ring

Wire B (Black)

(3) Pass wire C

Wire C

Fixing plate A

through the

wire fixing

plate A.

Pully

Wire D

Retaining ring

Fixing plate B

(1) Pass wire D through the wire fixing

plate B.

Wire D

Wire C

3 - J - 7

Page 54

TRAY 3 PAPER FEED UNIT

TRAY 3 PAPER FEED UNIT

[1] Removing and Reinstalling the

Paper Feed Tray 3

Warning: When removing the tray, stand

in a proper position so that you

do not hurt your back and waist.

If the tray contains paper,

remove all paper before

removing the tray.

Caution: Be sure the power cor d has been

unplugged from the wall outlet.

a. Procedure

(1) Open the front left and right doors.

(2) While pressing the tray release lever (at the left)

inward, draw out the tray.

(3) Remove the four screws and remove the tray with

it lifted.

Release lever

[2] Removing and Reinstalling the Front

Cover of Paper Tray 3

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Draw out paper feed tray 3.

(2) Remove the five screws to remove the front cover

of tray.

Caution: The front cover and main body of the

tray are connected with a wiring

harness of the handle release PS3

(PS16). Remove the tray front cover

from the main body carefully so as not

to break the wiring harness.

(3) Disconnect the handle detection PS connector

(CN282).

Caution: When reinstalling the front cover,

connect the handle detection PS

connector without fail. If y ou f orget to

connect it, you cannot draw out any

tray.

3 DIS./ASSEMBLY

steps in reverse.

Screws (4)

Tray 3

Connector (CN282)

Screws (2)

(4) Reinstall the above parts following the removal

steps in reverse.(4) Reinstall the above parts following the removal

Tray front cover

Screws (2)

Screw (1)

Handle release PS3

(PS16)

3 - K - 1

Page 55

TRAY 3 PAPER FEED UNIT

[3] Cleaning the Paper Dust Removing

Brush

a. Procedure

(1) Draw out paper feed tray 3.

(2) Release the two latches to detach the paper dust

removing brush.

(3) Clean the paper dust removing brush with the

cleaning pad and blower brush.

Paper dust removing brush

3 DIS./ASSEMBLY

Latches

[4] Cleaning the Paper Pre-registration

PS/the Paper Feed PS

a. Procedure

(1) Draw out paper feed tray 3.

(2) Clean the paper pre-registration PS3 (PS52)/ the

paper feed PS3 (PS51) with a blower brush.

Paper pre-registration PS3

(PS 52)

Paper feed PS3

(PS51)

Clean these

sensors.

(View from below)

3 - K - 2

Page 56

TRAY 3 PAPER FEED UNIT

[5] Removing and Reinstalling the

Paper Feed Roller and the Feed

Roller

a. Procedure

(1) Draw out tray 3.

(2) Remove the two retaining rings and slide the two

bearings outward to detach the paper feed roller

unit.

Retaining

ring

Bearing

Paper pick-up

roller unit

Bearing

Retaining

ring

(3) Remove the following parts from the paper feed

roller unit to remove individual rollers:

• Retaining rings (3)

• Bearing (1)

• Paper feed reference actuator

• Shafts (2)

• Fixing plate

Painting mark

Feed roller

Fixing

plate

Retaining ring

Paper pickup

reference

actuator

Paper pickup roller

Bearing

Retaining

ring

3 DIS./ASSEMBLY

(4) Reinstall the above parts following the removal

steps in reverse.

Caution 1: When reinstalling rollers, pay

attention to their orientation.

Caution 2: Check whether grease or like

remains on each roller. If it does,

wipe it.

3 - K - 3

Page 57

TRAY 3 PAPER FEED UNIT

[6] Removing and Reinstalling the

Double Feed Prevention Roller

a. Procedure

(1) Draw out paper feed tray 3.

(2) Raise the paper feed roller unit straight up.

(3) Remove the three screws to detach the inner

cover.

Inner cover

Screws (3)

3 DIS./ASSEMBLY

(4) Remove the two screws to detach the double

feed prevention roller unit.

(5) Remove the retaining ring to detach the double

feed prevention roller shaft with roller.

(6) Slide the double feed prevention roller out of the

shaft.

Painting mark

Double feed

prevention

roller

Paper feed

roller unit

Retaining ring

(7) Reinstall the above parts following the removal

steps in reverse.

Caution 1. When reinstalling the roller, pay

attention to its orientation.

Caution 2. Check whether grease or the like

remains on double feed pre vention

roller. If it does wipe it.

Double feed

prevention

roller

Screws (2)

3 - K - 4

Page 58

TRAY 3 PAPER FEED UNIT

[7] Replacing the Pre-registration MC3

(MC8) and the Feed MC3 (MC7)

a. Procedure

(1) Draw out paper tray 3.

(2) Remove the four screws to detach the paper

conveyance cover.

Screw

(3) Disconnect the two connectors (CN278, CN277).

(4) Remove the retaining ring to detach the pre-

registration MC3 (MC8) and the feed MC3 (MC7).

Paper conveyance

cover

Screw

Detent

[8] Removing and Reinstalling the Up/

Down Unit

a. Procedure

(1) Draw out paper feed tray 3.

(2) Remove the front cover of the tray.

(3) Disconnect the connector (CN281).

(4) Remove the two screws to detach the up/down

unit.

Connector (CN281)

Screws (2)

Up/down unit

(5) Reinstall the above parts following the removal

steps in reverse.

3 DIS./ASSEMBLY

Feed MC3

(MC7)

Retaining

ring

Connector

(CN277)

Pre-registration

MC3 (MC8)

Connector

(CN278)

Retaining ring

Detent

(5) Reinstall the above parts following the removal

steps in reverse.

Caution: When reinstalling each MC, fit the

detent in the slit in the MC.

3 - K - 5

Page 59

TRAY 3 PAPER FEED UNIT

[9] Replacing the Up/Down Plate Wires

Caution 1: This section explains how to replace the rear wires. To replace the front wires, remove the

front cover of tra y and paper up/down unit. The replacement procedure is the same as that f or

the rear wires.

Caution 2: When replacement or reinstallation of the wires is complete, check whether the up/down

plate moves up and down smoothly by rotating the up/down plate drive pulley by hand.

Caution 3: Be sure to install wires so that they do not cross nor ride over each other.

Caution 4: After installing the wires, adjust inclination of the up/down plate.

<Wire Lengths>

<Removing wires>

(1) Remove the up/down unit.

(2) Draw out paper feed tray 3.

(2)(4) Remove the

retaining ring to detach the

wire regulation cover and

pulley.

Wire regulation

cover

3 DIS./ASSEMBLY

Wire A

(Black)

(1) Remove the E-ring to slide

out the drive pulley.

Wire D

Wire C

Drive pulley

E-ring

Wire C

Wire B

(Black)

(3) Remove

wire C.

Pulley

Retaining ring

Wire D

(5) Remove wire D.

Wire D

Wire C

3 - K - 6

Page 60

Wire A, C: 309±1 mm

309 mm (tray 3)

Wire A, C

Wire B, D

Wire

regulation

cover

Pulley

Retaining ring

599 mm (tray 3)

Wire B (Black)

TRAY 3 PAPER FEED UNIT

Wire B, D: 599±1 mm

<Installing Wires>

(2) Install the pulley, pass wire D through the

pulley, and install the wire restraining cover

and retaining ring.

(4) Install the pulley, pass wires D and C, and

install the wire restraining cover and retaining ring. Wire D must be inside. Wires

should not cross nor ride over each other.

Wire regulation cover

3 DIS./ASSEMBLY

Wire A

(Black)

Wire C

(5) Install wires D and C

from inside the drive

shaft hole and push in

the drive pulley.

Wire D

Wire C

Drive pully

E-ring

(3) Pass wire C

Fixing plate A

(1) Pass wire D through the wire fixing

through the

wire fixing

plate A.

Pully

Wire D

Fixing plate B

plate B.

Wire D

Retaining ring

Wire C

3 - K - 7

Page 61

BY-PASS TRAY

BY-PASS TRAY

[1] Removing and Reinstalling the By-

pass Tray

Caution: Be sure the power cord has

been unplugged from the wall

outlet.

a. Procedure

(1) Remove the right side cover (upper). (See "EX-

TERNAL SECTION.")

(2) Disconnect the connector (CN254).

(3) Remove the four screws to remove the by-pass

tray.

Connector (CN254)

[2] Cleaning the Paper Size Detection

Sensors

a. Procedure

(1) Open the bypass tray.

(2) Clean the two paper size sensors (PS55, PS56)

with a blower brush.

Paper size sensor 1

(PS55)

Paper size sensor 2

(PS56)

3 DIS./ASSEMBLY

Screws (4)

By-pass tray

(4) Reinstall the above parts following the removal

steps in reverse.

3 - L - 1

Page 62

BY-PASS TRAY

[3] Replacing the Paper Feed Roller/the

Feed Roller Rubbers

a. Procedure

(1) Remove the by-pass tray.

(2) Remove the two retaining rings and slide the two

bearings outward to remove the roller assembly.

Roller

assembly

Bearings

3 DIS./ASSEMBLY

Retaining rings

[4] Replacing the Double Feed

Prevention Roller Rubber

a. Procedure

(1) Remove the by-pass tray and place the tray

upside down.

(2) Remove the spring and retaining ring to remove

the double feed prevention roller together with

the shaft.

Caution: There are three spring mounting

holes. Engage the spring with the hole

at the center.

Spring mounting

hole

Spring

Retaining

ring

(3) Remove the three retaining rings from the roller

subassembly to remove rollers.

Painting mark

Retaining ring

Paper feed

roller

Feed roller

Feed roller rubber

Paper feed

roller rubber

Retaining ring

(4) Reinstall the above parts following the removal

steps in reverse.

Caution: When reinstalling the rollers, pay

attention to their orientation and

position.

Double feed

prevention roller

shaft

(3) Remove the retaining ring to pull the double feed

prevention roller from the shaft.

<Installation>

Painting mark

shaft

Double feed prevention roller

Retaining ring

Double feed prevention

roller rubber