Page 1

3

SERVICE

3 SERVICE

Page 2

Main Precautions for Maintenance

1. Points to be confirmed before maintenance

Before starting maintenance, ask a user and

collect information about troubles occurred on

the machine before the maintenance and the

conditions of the machine to grasp key points

for the maintenance.

2. Copy sample

Be sure to make copy samples at the start and

the end of maintenance for checking images.

4. When replacing the drum and developer, must

perform neccessary adjustment by refering to

the 7075 List of Adjustment Items.

5. After having completed maintenance work, must

reset the PM counter (using the 25 mode).

6. When replacing the fixing unit cleaning web,

must reset the fixing unit cleaning web counter(

using the 36 mode).

3 SERVICE

3. Drum

1) Never expose the drum to the sunlight. Be

also careful not to expose a drum to indoor

light as far as possible.

When a drum unit or a drum is out of

the machine, nev er fail to cov er it with a drum

cover .

2) When replacing a drum or a cleaning blade ,

refer to Item of mounting/dismounting of a

cleaning blade for doing a replacement work.

7. When replacing a toner cartridge, wait until the

toner supply LED on the operation panel flashes

before the replacement.

caution: Turn the main switch off and pull out

the power pulg without fail before

the work of maintenance.

Page 3

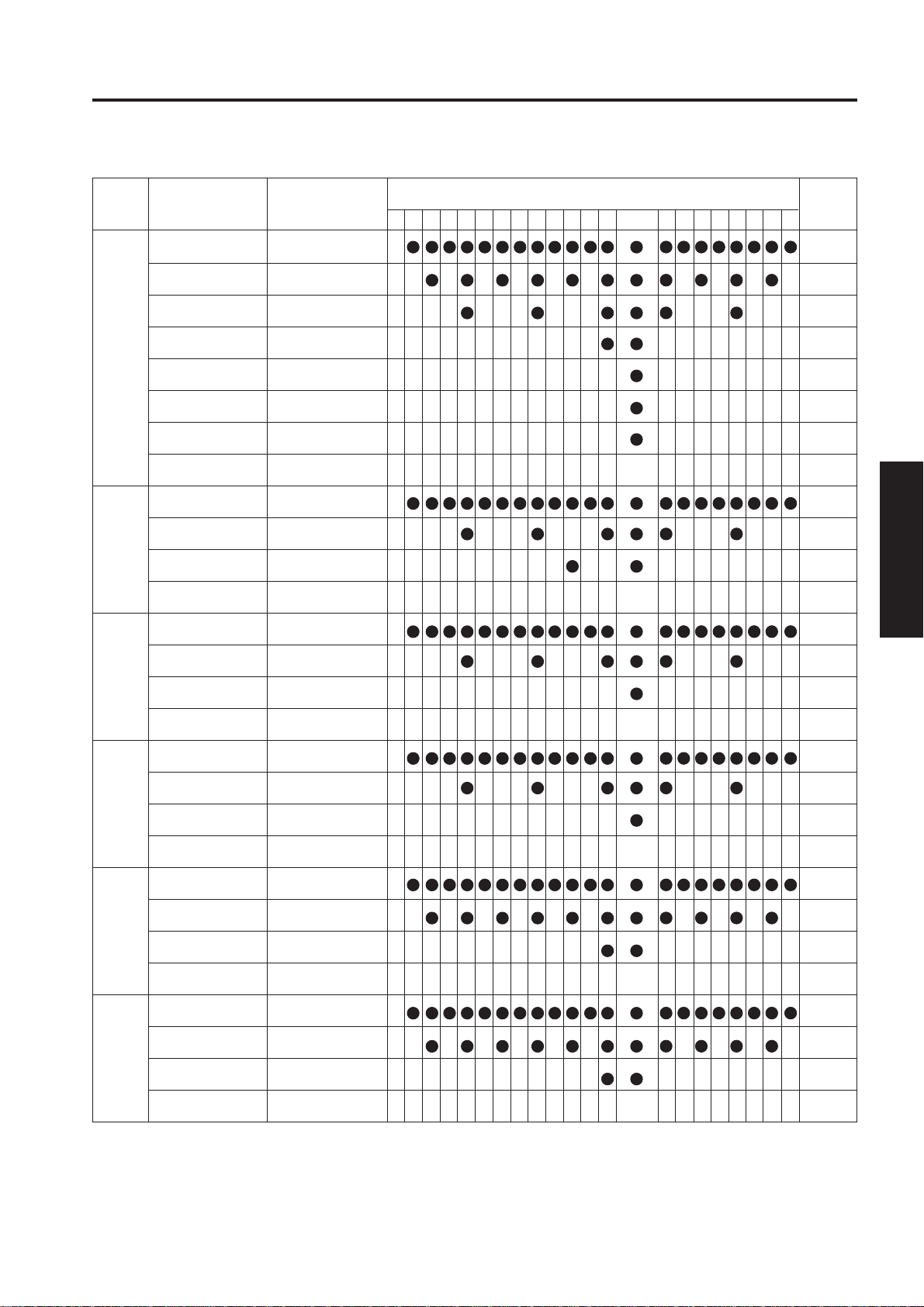

SERVICE SCHEDULE

[1] Service Schedule

SERVICE

Main body

RADF

DF-313

FNS

Service item

Maintenance

Periodic check (I)

Periodic check (II)

Periodic

check

(III)

Periodic

check

(IV)

Periodic

check

(V)

Periodic

check

(VI)

Maintenance

Periodic check (I)

Periodic check (II)

Maintenance

Numbe of

copies

Every 250,000 copies

Every 500,000 copies

Every 1,000,000 copies

Every 3,000,000 copies

Every 4,500,000 copies

Every 6,000,000 copies

Every 10,000,000 copies

Every 250,000 copies

Every 1,000,000 copies

Every 2,500,000 copies

Every 250,000 copies

0 25 50 75 100 125 150 175 200 225 250 275 300 2800 2825 2850 2875 2900 2925 2950 2975

Guarantee period (5 years or 30,000,000 copies)

× 10,000 copies

............

............

............

............

............

............

............

............

............

............

............

Service

count

119 times

59 times

29 times

9 times

6 times

4 times

2 times

119 times

29 times

11 times

3 SERVICE

119 times

FS-108

FNS

FS-108BM

LCT

LT-401

PI

PI-108

Periodic check (I)

Periodic check (II)

Maintenance

Periodic check (I)

Periodic check (II)

Maintenance

Periodic check (I)

Periodic check (II)

Maintenance

Periodic check (I)

Periodic check (II)

Every 1,000,000 copies

Every 6,000,000 copies

Every 250,000 copies

Every 1,000,000 copies

Every 6,000,000 copies

Every 250,000 copies

Every 500,000 copies

Every 3,000,000 copies

Every 250,000 copies

Every 500,000 copies

Every 1,000,000 copies

............

............

............

............

............

............

............

............

............

............

............

29 times

4 times

119 times

29 times

4 times

119 times

59 times

9 times

119 times

59 times

29 times

3 - 1

Page 4

SERVICE

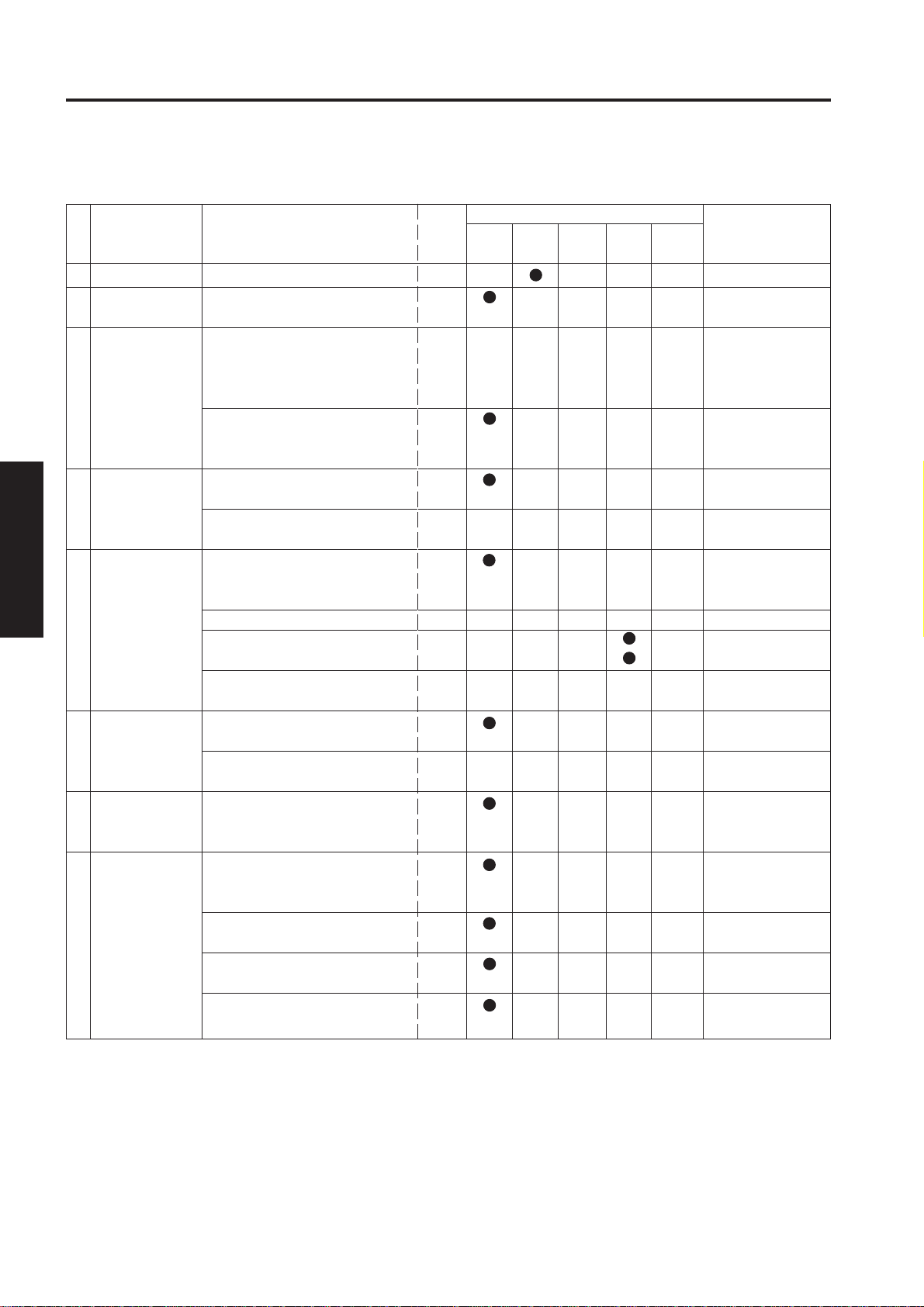

[2] Maintenance Items

1. Main body (Every 250,000 copies)

NO

1 Preparation

2 Fixing unit

3 Drum carriage

4 Cleaner

5 Charging corona

3 SERVICE

unit

6 Developing unit

7 Transfer/

separation

corona unit

8 Registration

Classification Service item

(1) Image check

(1) Fixing separation claws

(upper and lower) cleaning

(1) Charging corona unit,

cleaner, and developing

unit, sensor support stay

assembly, drum removal

(2) Drum carriage inside

cleaning (including drum

fixing coupling surface)

(1) Cleaner unit cleaning

(2) Installation on drum

carriage

(1) Charging corona unit/PCL

cleaning

(2) Charging wire 55VA2509*

(3) Charging wire unit vibration

proof rubber 25BA2501*

(4) Installation on drum

carriage

(1) Developing unit cleaning

(2) Installation on drum

carriage

(1) Transfer/separation corona

unit cleaning

(1) Paper dust removing brush/

registration roller/others

cleaning

(2) Registration sensor

cleaning

(3) Mis-centering detection

sensor cleaning

(4) Second paper feed sensor

cleaning

Number

of parts

replaced

2

2

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Supply

Materials/tools

used

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad/

blower brush

Cleaning pad/

blower brush

Drum cleaner/

cleaning pad/

blower brush

Cleaning pad/

blower brush

Drum cleaner/

cleaning pad/

blower brush

Cleaning pad/

blower brush

Blower brush

Drum cleaner/

cleaning pad

Blower brush

3 - 2

Page 5

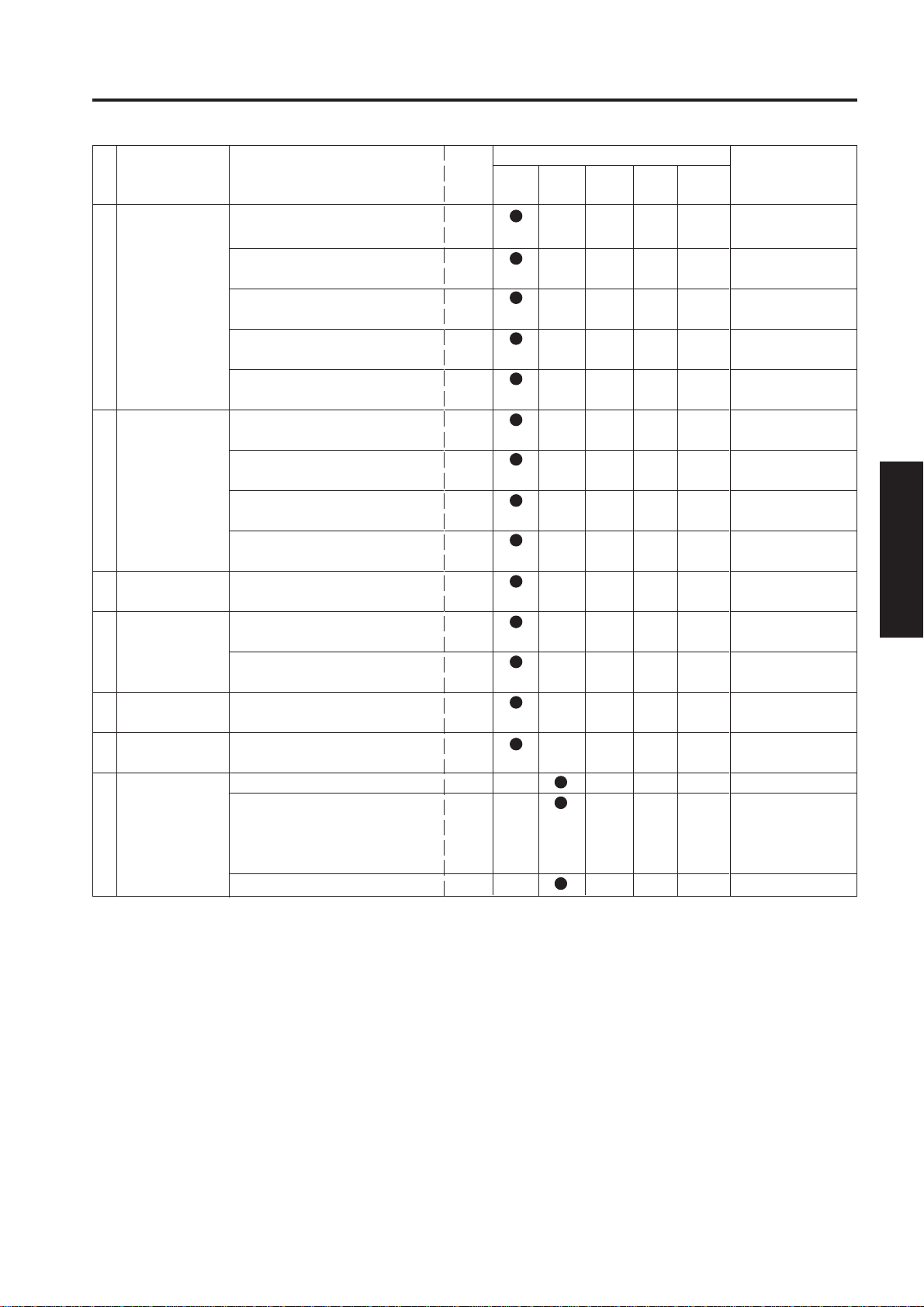

SERVICE

Classification Service item

NO

9 ADU

10 Tray

11 By-pass tray

12 Read

13 Main body

14 Toner supply

15 Final check

(1) Horizontal conveyance

roller/others cleaning

(2)

Paper reverse/exit entrance

guide plate cleaning

(3) Paper reverse/exit detection

sensor cleaning

(4) ADU deceleration detection

sensor cleaning

(5) ADU paper pre-registration

detection sensor cleaning

(1) Paper dust removing brush

(500-sheet tray)

(2) Paper dust removing brush

(1000-sheet tray)

(3) Paper feed detection sensor

cleaning

(4) Paper pre-registration

detection sensor cleaning

(1) Trailing edge size detection

sensor cleaning

(1) Platen glass cleaning

(2) Slit glass cleaning

(1) Exterior and interior

cleaning

(1) Cartridge insertion opening

cleaning

(1) W.U.T check

(2) Image and paper feeding

check (including vertical

magnification adjustment

and timing adjustment)

(3) PM counter resetting

Number

of parts

replaced

Implementation classification

Replace-

Inspection

Lubrication

Cleaning

ment

Supply

Materials/tools

used

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Blower brush

Blower brush

Cleaning pad/

blower brush

Cleaning pad/

blower brush

Blower brush

Blower brush

Cleaning pad/

blower brush

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Cleaning pad

3 SERVICE

3 - 3

Page 6

SERVICE

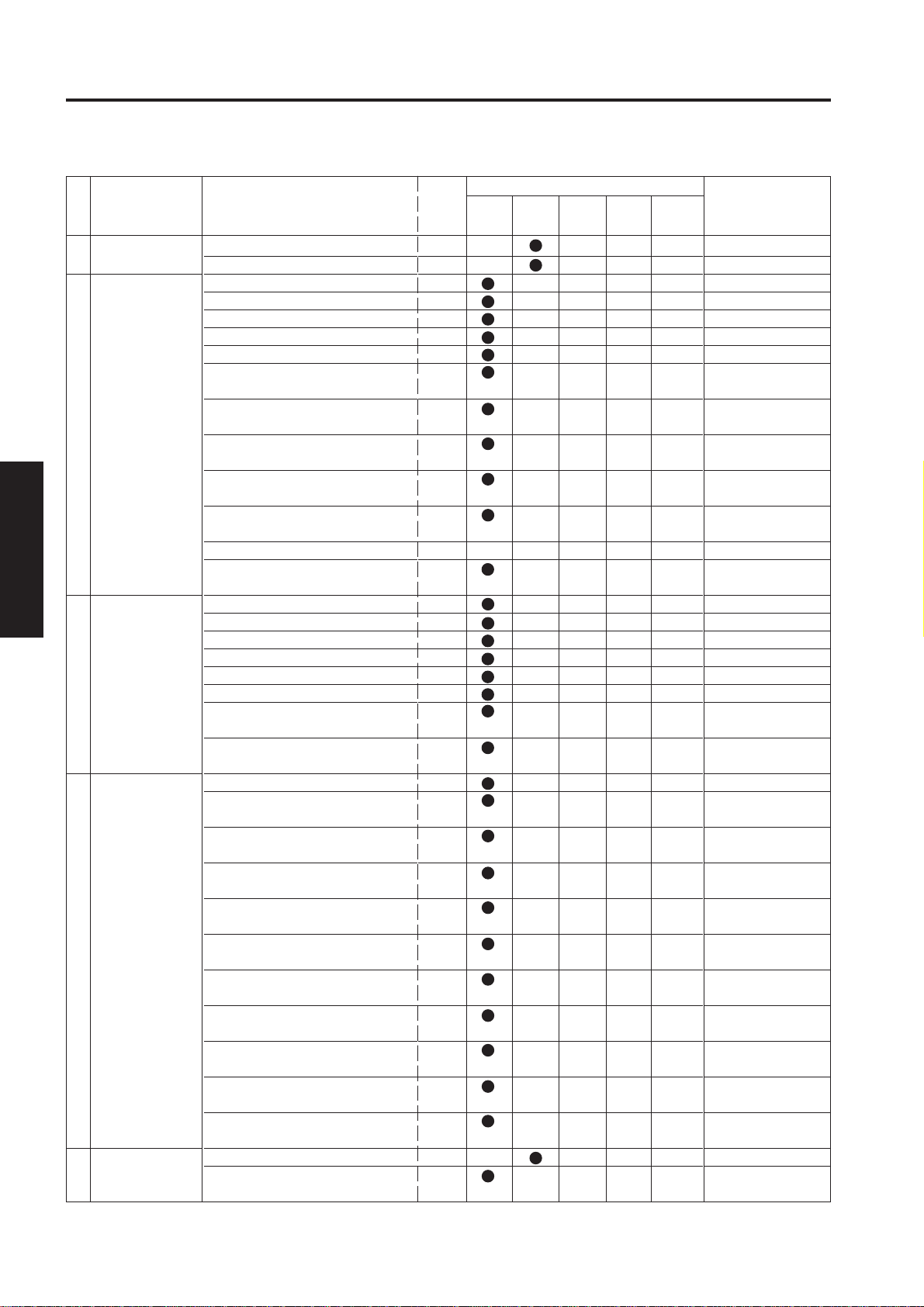

2. RADF [DF-313] (Every 250,000 copies)

NO

1 Preparation

2 Paper feed

section

3 SERVICE

3 Conveyance

section

4 Paper exit

section

5 Final check

Classification Service item

(1) Paper feeding check

(2) Exterior

(1) Size detection sensor 1

(2) Size detection sensor 2

(3) Size detection sensor 3

(4) Registration sensor

(5) Registration mirror

(6) Paper feed roller

(7) Separation roller

(8) Double feed prevention

roller

(9) Separation assist roller

(10) Double feed prevention

roller rubber

(11) Cleaning pad

(12) Registration roller

(1) Read sensor

(2) Read sensor mirror

(3) Skew sensor (F)

(4) Skew sensor (F) mirror

(5) Skew sensor (R)

(6) Skew sensor (R) mirror

(7) Read roller

(8) Paper exit roller 1

(1) Reversal sensor/left sensor

(2) Reversal sensor/left sensor

mirror

(3) Reversal sensor/middle

sensor

(4) Reversal sensor/middle

sensor mirror

(5) Reversal sensor/right

sensor

(6) Reversal sensor/right

sensor mirror

(7) Reversal roller

(8)

Reverse conveyance roller 1

(9)

Reverse conveyance roller 2

(10) Paper exit roller 2

(11) Reversal paper exit roller

(1) Paper feeding check

(2) Exterior cleaning

Number

of parts

replaced

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Supply

Materials/tools

used

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Drum cleaner/

cleaning pad

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

3 - 4

Page 7

3. FNS [FS-108] (Every 250,000 copies)

Classification Service item

NO

1 Preparation

2 Conveyance

section

3 Paper exit

section

4 Drive section

5 Stapler unit

6 Final check

(1) Paper feeding check

(1) Conveyance roller

(2) Intermediate conveyance

roller (sponge roller)

122H4825*

(1) Paper exit roller A (sponge

roller) 122H4825*

(2) Cleaning of area around

paper exit roller A

(1) Main drive unit *1

(2) Tray up unit *1

(3) Shift drive unit *1

(4) Paper exit drive unit *1

(5) Staple unit *1

(1) Staple cartridge12QRK001*

(1) Paper through check *2

Number

of parts

replaced

4

10

2

Implementation classification

Replace-

Inspection

Lubrication

( )

(

)

(

)

)

(

)

(

( )

Cleaning

ment

Supply

SERVICE

Materials/tools

used

Drum cleaner/

cleaning pad

Plus guard No.2

Plus guard No.2

Plus guard No.2

Plus guard No.2

Plus guard No.2

5,000 staples/

cartridge Replace

as necessary

Stapler PS jig

(2) Exterior cleaning

4. FNS [FS-108BM] (Every 250,000 copies)

Classification Service item

NO

1 Preparation

2 Conveyance

section

3 Paper exit

section

4 Drive section

5 Folding unit

6 Stapler unit

7 Final check

(1) Paper feeding check

(1) Conveyance roller

(2)

Intermediate conveyance roller

(sponge roller) 122H4825

Paper exit roller A (sponge

(1)

roller) 122H4825

(2) Cleaning of area around

paper exit roller A

(1) Main drive unit *1

(2) Tray up unit *1

(3) Shift drive unit *1

(4) Paper exit drive unit *1

(5) Staple unit *1

(6) Folding unit *1

(1) Flat belt

(2) Folding roller

(3) Pressure roller

(1) Staple cartridge

12QRK001*

(1) Paper through check

*2

(2) Exterior cleaning

*

*

Number

of parts

replaced

4

10

2

Implementation classification

Replace-

Inspection

Lubrication

( )

(

(

(

(

(

)

)

)

)

)

Cleaning

ment

( )

Supply

Drum cleaner

and cleaning pad

Materials/tools

used

Drum cleaner/

cleaning pad

Plus guard No.2

Plus guard No.2

Plus guard No.2

Plus guard No.2

Plus guard No.2

Plus guard No.2

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

5,000 staples/

cartridge Replace

as necessary

Stapler PS jig

Drum cleaner/

cleaning pad

3 SERVICE

*1: If abnormal sound is heard due to insufficient oil, apply oil (Plus guard No. 2).

*2: Check if the staple is clinched correctly.

3 - 5

Page 8

SERVICE

5. LCT [L T-401] (Every 250,000 copies)

Classification Service item

NO

1 Preparation

2 Inside of

machine

3 Final check

(1) Paper feeding check

(1) Paper dust removing brush

cleaning

(2) Feed sensor cleaning

(3) Pre-registration sensor

cleaning

(1) Paper feeding check

(2) Exterior cleaning

6. PI-108 (Every 250,000 copies)

Classification Service item

NO

1 Conveyance

3 SERVICE

section

2 Paper feed

section

3 Final check

(1) Conveyance roller

(1) Paper feed roller

(2) Feed roller

(3) Double feed prevention

roller *1

(1) Paper feeding check

(2) Exterior cleaning

*1

*1

Number

of parts

replaced

Number

of parts

replaced

Implementation classification

Replace-

Clea-

Inspe-

ning

ction

Implementation classification

Clea-

Inspe-

ning

ction

Lubrication

Lubrication

Replace-

ment

ment

Supply

Supply

Materials/tools

used

Cleaning pad/

blower brush

Blower brush

Blower brush

Drum cleaner/

cleaning pad

Materials/tools

used

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Plus guard No. 2

Drum cleaner/

cleaning pad

Plus guard No. 2

Drum cleaner/

cleaning pad

Plus guard No. 2

Drum cleaner/

cleaning pad

*1: If abnormal sound is heard due to insufficient oil, apply oil (Plus guard No. 2).

3 - 6

Page 9

[3] Main Unit Periodic Inspection Items

1. Periodic check (I) (Every 500,000 copies)

SERVICE

Classification Service item

NO

(1)

1 Fixing unit

2 Drum carriage

3 Cleaner

4 Charging corona

unit

5 Developing unit

6 Transfer/

separation

corona unit

Fixing cleaning web (counter

resetting)

(1) Separation claw replace-

ment 55VA2919*

(2) Drum replacement (counter

resetting)

(1) Cleaning blade 55VA5601*

(2) Fur brush 55VA-574*

(3) Scattering prevention felt

(1) Charging control plate

(2) Charging wire cleaning unit

(3) Resin ring (φ2) 45AA2040*

(1) Suction filter 55VA3108*

(2) Developer replacement

(counter resetting)

(1) Transfer/separation wire

(2) Transfer wire cleaning unit

(3) Separation wire cleaning

unit 55VA-277*

(4) Transfer/separation

vibration proof rubber

(5) Resin ring (φ2) 45AA2040*

55VA-524*

55VA5568*

55VA2508*

55VA-255*

55VA2613*

55VA-276*

55VA2615*

Number

of parts

replaced

1

3

1

2

1

1

1

1

2

1

1

3

1

1

3

2

Implementation classification

Replace-

Inspection

Lubrication

Cleaning

ment

Supply

Materials/tools

used

Setting powder

Setting powder

3 SERVICE

3 - 7

Page 10

SERVICE

2. Periodic check (II) (Every 1,000,000 copies)

NO

1 Tray

2 By-pass tray

3 SERVICE

3 Fixing unit

Classification Service item

(1) Paper feed roller (500-sheet

tray) 55VA-464*

(2) Feed roller (500-sheet tray)

(3) Double feed prevention roller

(500-sheet tray) 55VA-463*

(4) Paper feed roller (1000-

sheet tray) 55VA-484*

(5) Feed roller (1000-sheet

tray) 55VA-483*

(6) Double feed prevention roller

(1000-sheet tray) 55VA-483*

(1) Paper feed roller (bypass

tray) 55VA-464*

(2) Feed roller (bypass tray)

(3) Double feed prevention roller

(bypass tray) 55VA-463*

(1) Fixing upper roller

55VA-5304*

(2) Fixing lower roller assembly

(3) Fixing claw (upper)

55VA5321*

(4) Fixing claw (lower)

25AA5329*

(5) Insulating sleeve (upper)

(6) Upper roller bearing

(7) Cleaning roller 55VA5386*

(8) Heat roller cleaning

55VA-463*

55VA-463*

55VA-528*

45405339*

45407504*

Number

of parts

replaced

2

2

2

1

1

1

1

1

1

1

1

6

2

2

2

1

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Supply

Materials/tools

used

Actual

replacement

count: 300K feeds

Actual

replacement

count: 200K feeds

Roller cleaner

3 - 8

Page 11

3. Periodic check (III) (Every 3,000,000 copies)

SERVICE

Classification Service item

NO

1 Drum

2 Transfer/

separation

corona unit

3 Registration

4 ADU

5 Fixing

6 Main body

7 Toner supply

(1) Drum temperature sensor

(1) Transfer/separation corona

unit 55VA-270*

(1) Registration roller

(2) Registration bearing

(3) Registration loop roller

(4) Registration clutch

(1) Paper reverse/exit roller 1

(1) Insulating sleeve (heating

roller) 45405339*

(2) Heating roller bearing

(3) Temperature sensor (upper

roller fault) 55VA8804*

(4)

Temperature sensor (heating

roller fault) 55VA8806*

(5) Fixing heating roller

(6) Exit actuator 55VA5383*

(7) Heater lamp L2

(8) Heater lamp L3

(9) Heater lamp L4

(10)

Fixing web driving motor 1

(1) Ozone filter 1 55FA7301*

(2) Ozone filter 2 55VA1107*

(1) Toner supply sleeve 1

(2) Toner supply sleeve 2

55VA-952*

55VA4603*

55VA7552*

55VA-068*

55VA8201*

55VA4740*

26AA5316*

55VA5307*

55VF8302*

55VF8303*

55VF8304*

55VA8017*

55VA-334*

55VA-335*

Number

of parts

replaced

1

1

1

2

1

1

1

2

2

1

1

1

1

2

1

1

1

2

1

1

1

Implementation classification

Replace-

Inspection

Lubrication

Cleaning

ment

Supply

Materials/tools

used

3 SERVICE

4. Periodic check (IV) (Every 4,500,000 copies)

Number

Classification Service item

NO

1 Tray

(1) Feed clutch 55VA8201*

(2) 1st paper feed clutch

55VA8201*

of parts

replaced

3

3

3 - 9

Implementation classification

Replace-

Inspection

Lubrication

Cleaning

ment

Supply

Materials/tools

used

Actual replacement

count: 3,000K

feeds

Page 12

SERVICE

5. Periodic check (V) (Every 6,000,000 copies)

NO

1 Charging corona

unit

2 Developing unit

3 Transfer/separa-

tion corona unit

4 Vertical

conveyance

section

5 Fixing unit

6 ADU

3 SERVICE

7 Main body

Classification Service item

(1) Charging corona unit

(2) PCL 55VA-257*

(1) Developing unit 55VA-300*

(1) TSL 55VA8308*

(1) Vertical conveyance clutch

(2) Vertical conveyance roller

(upper) 55VA4410*

(3) Passage detection sensor

cleaning

(4) Exit sensor cleaning

(1) Fixing drive gear 2

(1) Pre-registration roller

(2)

ADU pre-registration bearing

(3) Pre-registration loop roller

(4) ADU exit roller 55VA4681*

(5) ADU reversal sensor

cleaning

(6) Reversal entrance section

roller 55VA4766*

(7) Paper reverse/exit roller 2

(8) Paper reverse/exit roller 3

(9) ADU reverse roller

(10)ADU horizontal conveyance

roller 1 55VA4681*

(11)ADU horizontal conveyance

roller 2 55VA4681*

(12)ADU pre-registration clutch

(1) Paper exit sensor cleaning

55VA-250*

55VA8202*

55VA7783*

55VA4682*

55VA7555*

55VA4681*

55VA4748*

55VA4741*

55VA4767*

55VA8201*

Number

of parts

replaced

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Supply

Materials/tools

used

Actual replacement

count: 4,500K

feeds

Blower brush

Blower brush

Blower brush

Blower brush

3 - 10

Page 13

6. Periodic check (VI) (Every 10,000,000 copies)

SERVICE

Number

Classification Service item

NO

1 Vertical convey-

ance section

2 ADU

3. Tray

(1) Vertical conveyance roller

(middle, lower) 55VA4411*

(1) Sensor actuator 25SA5046*

(2)

Guide part/Front

(3)

Guide part/Rear

(4) Guide part 55VA4757*

(1) Pre-registration roller (500-

sheet tray, 1000-sheet tray)

55VA4730*

55VA4731*

55VA4016*

of parts

replaced

[4] RADF [DF-313]

1. Periodic check (I) (Every 1,000,000 copies)

Number

Classification Service item

NO

1 Paper feed

section

(1)

Paper feed roller

(2) Separation roller

(3) Double feed prevention

roller 13GA4606*

(4) Separation assist roller

13GA4604*

13GA4605*

13GA4601*

of parts

replaced

Implementation classification

Replace-

Inspection

Lubrication

ment

Supply

Cleaning

2

3

1

1

4

3

Materials/tools

used

3 SERVICE

Implementation classification

Replace-

Inspection

Lubrication

ment

Supply

Cleaning

1

1

1

1

Materials/tools

used

Actual replacement

count: 200K feeds

2. Periodic check (II) (Every 2,500,000 copies)

Number

Classification Service item

NO

1 Paper feed

section

of parts

replaced

3 - 11

Implementation classification

Replace-

Inspection

Lubrication

ment

Supply

Cleaning

1(1) Torque limiter 13GA-135*

Materials/tools

used

Actual replacement

count: 500K feeds

Page 14

SERVICE

[5] FNS [FS-108]

1. Periodic check (I) (Every 1,000,000 copies)

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Classification Service item

NO

1 Stapler unit

Number

of parts

replaced

2(1) Stapler unit 129U4266*

2. Periodic check (II) (Every 6,000,000 copies)

Number

Classification Service item

NO

1 Drive unit

*1: When the motor is removed by CE, please remove it holding the up/down tray to paper exit with hand.

[6] FNS [FS-108BM]

3 SERVICE

1. Periodic check (I) (Every 1,000,000 copies)

Classification Service item

NO

1 Stapler unit

(1) Paper feed motor *1

(Tray up/down unit motor)

129U-108*

of parts

replaced

1

Number

of parts

replaced

2(1) Stapler unit 129U4266*

Implementation classification

Replace-

Clea-

Inspe-

ning

ction

Implementation classification

Clea-

Inspe-

ning

ction

Lubrication

Lubrication

Replace-

ment

ment

Supply

Supply

Supply

Materials/tools

used

Actual replacement

count: Each 200K

staples

Materials/tools

used

Actual replacement

count: 2,500K

feeds

Materials/tools

used

Actual replacement

count: Each 200K

staples

2. Periodic check (II) (Every 6,000,000 copies)

Number

Classification Service item

NO

1 Drive unit

down unit motor) *1

129U-108*

*1: When the motor is removed by CE, please remove it holding the up/down tray to paper exit with hand.

of parts

replaced

1(1) Paper feed motor (Tray up/

Implementation classification

Replace-

Cleaning

Inspection

Lubrication

ment

Supply

Materials/tools

used

Actual replacement

count: 2,500K

feeds

3 - 12

Page 15

[7] LCT [LT-401]

1. Periodic check (I) (Every 500,000 copies)

SERVICE

Number

Classification Service item

NO

1 Inside of

machine

(1) Paper feed roller 55VA-484*

(2) Feed roller 55VA-483*

(3) Double feed prevention

roller 55VA-483*

of parts

replaced

2. Periodic check (II) (Every 3,000,000 copies)

Number

Classification Service item

NO

1 Inside of

machine

(1) Feed clutch 55VA8201*

(2) Conveyance clutch

55VA8201*

of parts

replaced

[8] PI-108

1. Periodic check (I) (Every 500,000 copies)

Number

Classification Service item

NO

1 Paper feed

section

(1) Feed roller assembly B

(2) Double feed prevention

roller assembly 13FG-406*

50BA-575*

of parts

replaced

Implementation classification

Replace-

Inspection

Inspection

Lubrication

Lubrication

ment

Replace-

ment

Supply

Supply

Cleaning

1

1

1

Implementation classification

Cleaning

1

1

Materials/tools

used

Actual replacement

count: 500K feeds

Materials/tools

used

Actual replacement

count: 3,000K

feeds

3 SERVICE

Implementation classification

Replace-

Inspection

Lubrication

ment

Supply

Cleaning

1

1

Materials/tools

used

Actual replacement

count: 100K feeds

Actual replacement

count: 100K feeds

2. Periodic check (II) (Every 1,000,000 copies)

Number

Classification Service item

NO

1 Paper feed

section

50BA-574*

of parts

replaced

3 - 13

Implementation classification

Replace-

Inspection

Lubrication

ment

Supply

Cleaning

1(1) Feed roller assembly A

Materials/tools

used

Actual replacement

count: 200K feeds

Page 16

SERVICE

COPY MATERIALS

[1] Consumables (Single unit supply)

Name

Toner cartridge 50,000

Developer 500,000

Drum 500,000

3 SERVICE

Durability/copies

[2] PM parts kit (500,000 copies/kit)

Name Quantity

Charging wire 55VA2509* 2

Charging wire unit vibration 2

proof rubber 25BA2501*

Charging control plate 55VA2508 1

Charging wire cleaning unit 55VA-255* 1

Cleaning blade 55VA5601* 2

Cleaning web 55VA-524* 1

Toner guide brush 55VA-579* 1

Separation claw 55VA2914* 3

Scattering prevention felt 55VA5568* 1

Suction filter 55VA3108* 1

Resin ring (ø2) 45AA2040* 4

Transfer/separation wire 55VA2613* 3

Transfer wire cleaning unit 55VA-276* 1set

Separation wire cleaning unit 1set

55VA-277*

Transfer/separation vibration proof 3

rubber 55VA2615*

Cleaning pad (10 pcs) 9

Polyethylene gloves 1 pair

Dust bag (rubber band) 1

Deve. collection sheet (rubber band) 1

Hand case for collection 1

Cotton swabs (4 pcs) 2

[3] Maintenance kit

500,000 copies/kit

PM parts kit + Developer (1 pc)

3 - 14

Page 17

SERVICE MATERIAL LIST

Material No. Material Name Appearance Remarks

000V-16-0 Drum cleaner

200 ml

000V-17-0 Roller cleaner

200 ml

00GR00020 Plus guard No.2

25 g

SERVICE

000V-19-0 Setting powder

000V-18-0 Cleaning pad

25 g

10 pcs

1 pack

3 SERVICE

3 - 15

Page 18

SERVICE

CE TOOL LIST

Material No. Material Name Appearance Quantity Remarks

55VAJG011 Temp. sensor PS jig/A

(for upper fixing roller)

55VAJG021 Temp. sensor PS jig/B

(for heating roller)

55VAJG031 Thermostat PS jig/A

(for upper fixing roller)

55VAJG041 Thermostat PS jig/B

(for heating roller)

3 SERVICE

7050K0020 Optics position

adjusting jig

1

1

1

1

2

00M6-2-00 Door switch jig

00VD-5000 New pyramid chart

1

1

3 - 16

Page 19

SERVICE

Material No. Material Name Appearance Quantity Remarks

00VC-2-00 Drum cover

00VD-1000 Blower brush

00VE-1004 Tester

120A1052 * PS jig

120A9711 * ADJ chart

1

1

1

2pc/set

1

For DF-311/

312/313

3 SERVICE

For DF-311/

312/313

120A9712 * White chart

129XJG011 Stapler PS jig

1

1

For DF-311/

312/313

For FS-108/

108BM

3 - 17

Loading...

Loading...