Page 1

1

OUTLINE

1 OUTLINE

Page 2

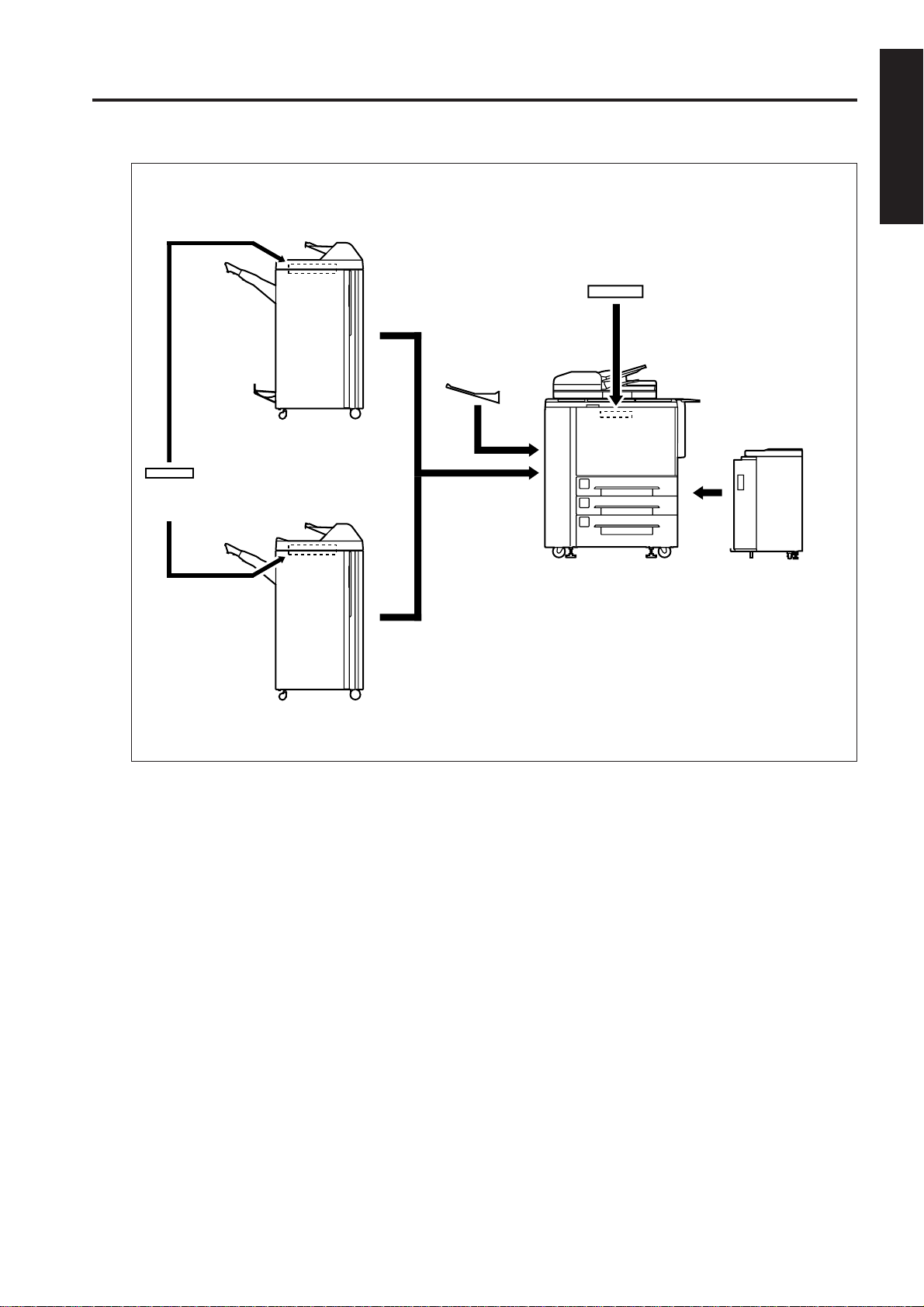

OUTLINE OF SYSTEM

Finisher

[FS-108BM]

Post Inserter

[PI-108]

MAIN BODY

1 OUTLINE

Expansion memory unit

[MU-401/402]

Paper exit tray

Finisher

[FS-108]

4000-sheet LCT

[LT-401]

1 - 1

Page 3

7075 PRODUCT SPECIFICATIONS

7075 PRODUCT SPECIFICATIONS

1. T ype

1 OUTLINE

Installation Type:

Copying method:

Document tray type:

Photosensitive material:

Sensitizing method:

Paper feed trays:

2. Functions

Applicable document types:

Document size:

Copy paper size:

Magnifications

Fixed magnifications:

Special ratio magnifications:

Vertical magnifications:

Horizontal magnifications:

Console type (floor-mounted type)

Indirect electrostatic method

Fixed

OPC

Laser writing

Three stacked trays (two for 500

sheets of 80 g/m2 paper; one for

1000 sheets of 80 g/m2 paper)

A by-pass tray for various paper

sizes (150 sheets of 80 g/m2 paper)

LCT (4000 sheets of 80 g/m

paper)*1

*1: Optional

Sheets, book, solid object

A3 max.

A3 to A5

11x17 to 8.5x11, F4

x1.00, x2.00, x1.41, x1.22, x1.15,

x0.86, x0.82, x0.71, x0.50

3 modes

x0.33 to x4.00 (400 dpi, in 1% steps)

x0.33 to x2.00 (600 dpi, in 1% steps)

x0.33 to x4.00 (400 dpi, in 1% steps)

x0.33 to x2.00 (600 dpi, in 1% steps)

First copy out time:

3.9 seconds or less (for A4, manual

copy density selection, straight

paper ejection with the copied image

facing up, platen mode, life size,

paper feed from tray 1)

Continuous copy speed (life size, copies/

min):

Size cpm

A4 75

Continuous copy count:

1 to 9999

Copy density selections:

AE, manual

Arbitrary density (2 modes)

2

E-RDH memory capacity:

standard 64MB

maximum 512MB

Special functions:

Interleaves, chapter , combination (2

in 1, 4 in 1, 8 in 1), booklet, OHP

interleave, image insertion, book

copy, automatic tray selection for

mixed sized document, special

document (text, photo, pencil),

reversed image, repeated copy,

frame/fold erase, auto layout, thin/

thick paper, shift/reduction shift, nonimage area erase, memory copy,

density monitoring, single step copy ,

density shift, printing function, copy

reservation, image rotation, weekly

timer, job memory, interrupts, auto

power sav e, auto reset, auto shutoff,

SDF function, EKC.

*2: 6 minutes is the machine for the

230VAC specification.

Warm-up time differs depending

on the Power source (voltage).

Warm-up time:

Less than 6 minutes*2

1 - 2

Page 4

MAIN BODY

3. Applicable Copy Paper

Plain paper:

High quality paper 60 g/m2 to 90 g/m

Special paper (bypass feed only):

Tabs

OHP film

Blueprint master paper

Recycled paper

High quality plain paper (50 g/m2 to

59 g/m2, 91g/m2 to 200 g/m2)

4. Options

Finisher: FS-108, FS-108BM

4000-sheets LCT: LT-401

Expantion memory unit:

MU-401: 64MB

MU-402: 128MB

Post inserter: PI-108

Paper exit tray

5. Particulars of Machine

Power supply:

230 VAC -14% to 10.6%

50 Hz/60 Hz

Power consumption:

2850W max.

(with LT-401)

Weight: Approx. 280 kg

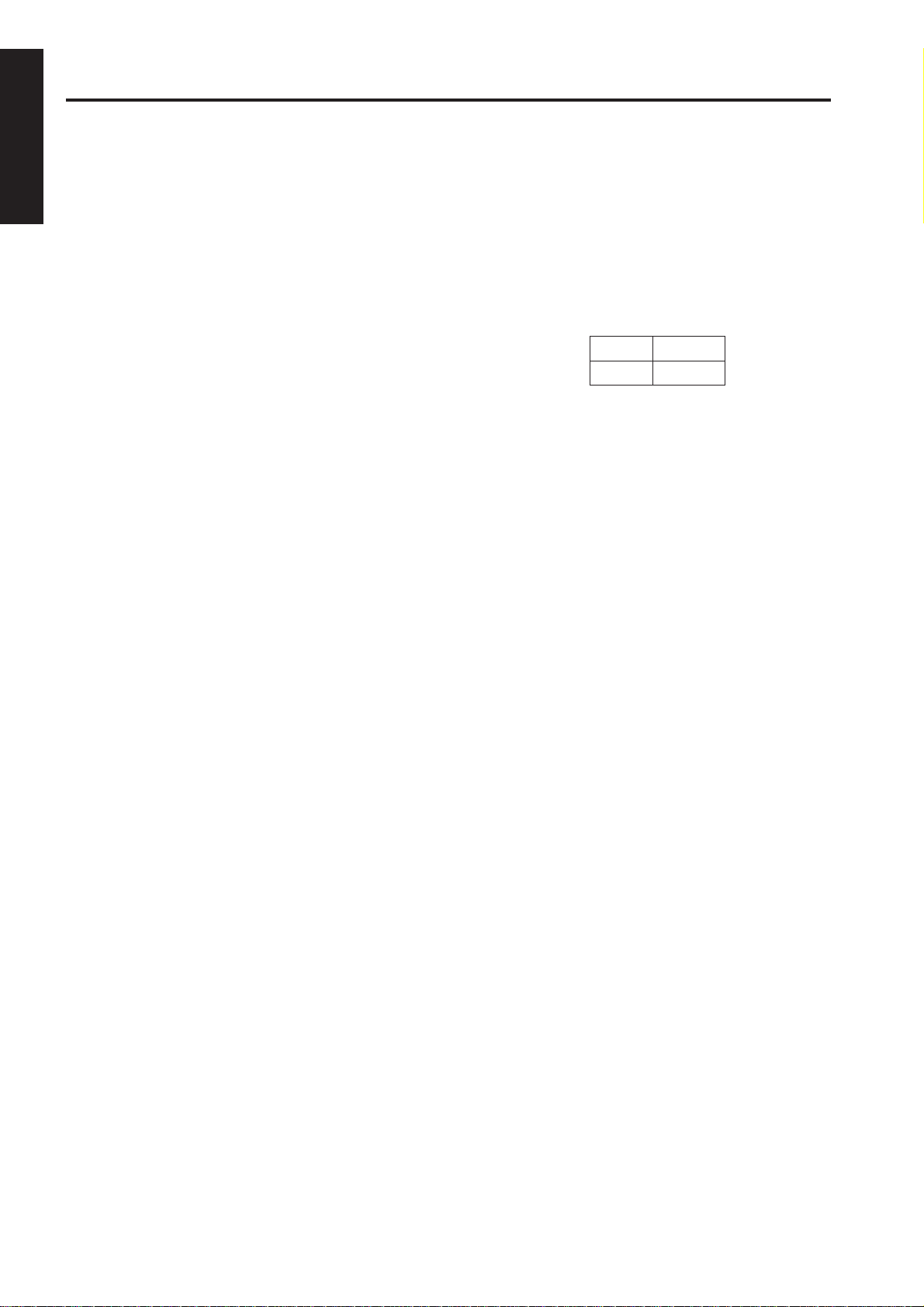

Machine dimensions:

6. Maintenance and Life

1 OUTLINE

Periodic maintenance:

2

Every 250,000 copies

Machine life:

30,000,000 copies or 5 years

7. Consumables

Developer: Exclusively for Konica 7075

Toner : Exclusively for Konica 7075

Drum: Exclusively for Konica 7075 (ø100)

8. Environmental Conditions

Temperature:

10°C to 30°C (50°F to 86°F)

Humidity: 10% to 80% RH

The information herein may subject

to change for improvement without

notice.

887 mm

1203 mm

775 mm

1 - 3

Page 5

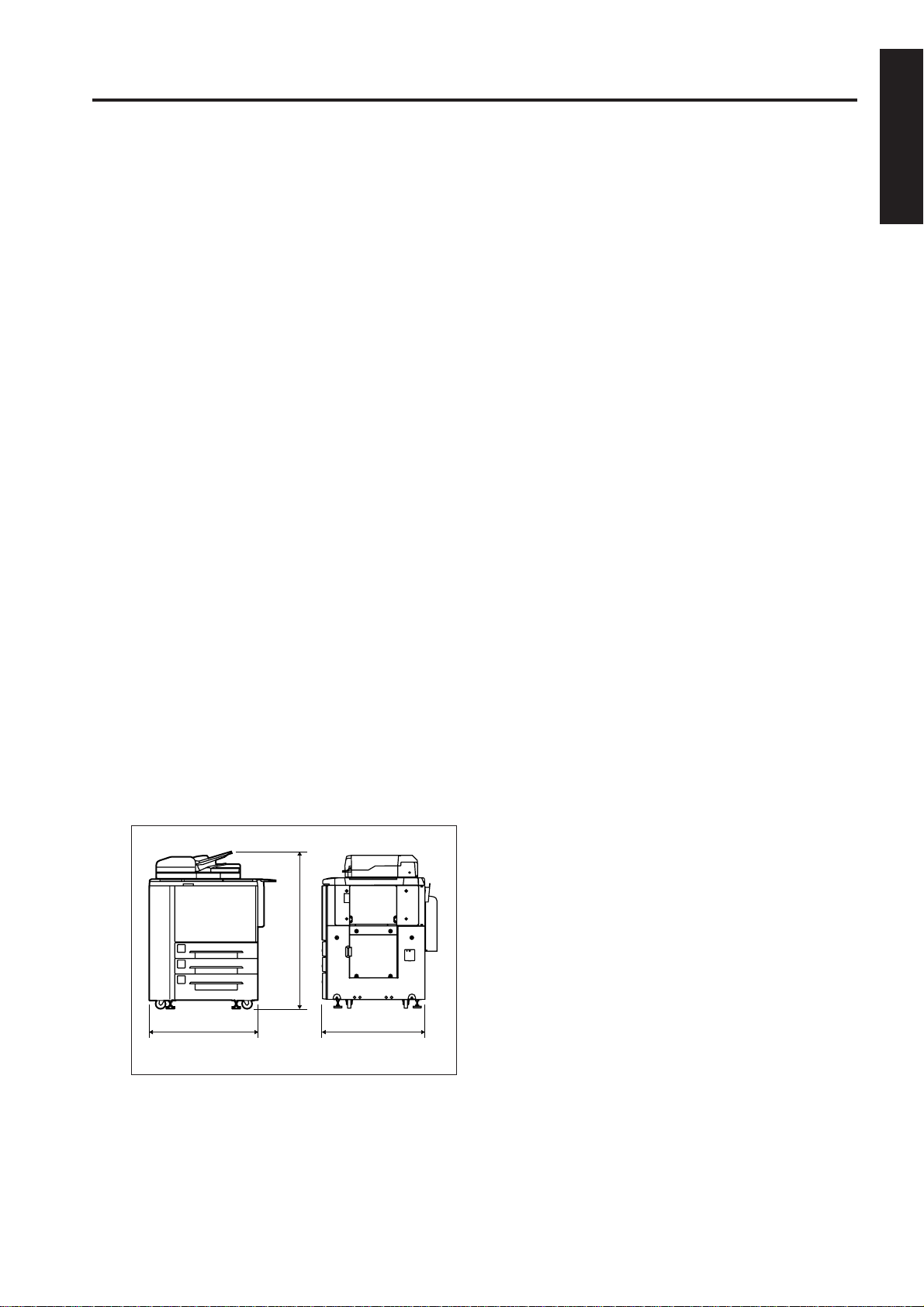

MAIN UNIT

CENTER CROSS-SECTIONAL VIEW

1 OUTLINE

Image processing

section

Exposure lamp

Fixing

section

Paper exit

section

Paper reverse/

exit section

Cleaning section

PCL

Charging corona

section

RADF

Image read

section

Image write

section

Developing

section

Second paper

feed

section

By-pass tray

Transfer corona

section

Vertical conveyance

section

TSL

Paper conveyance

section

1 - 4

Separation

corona section

Tr a y 1

Tr a y 2

Tr a y 3

ADU

Page 6

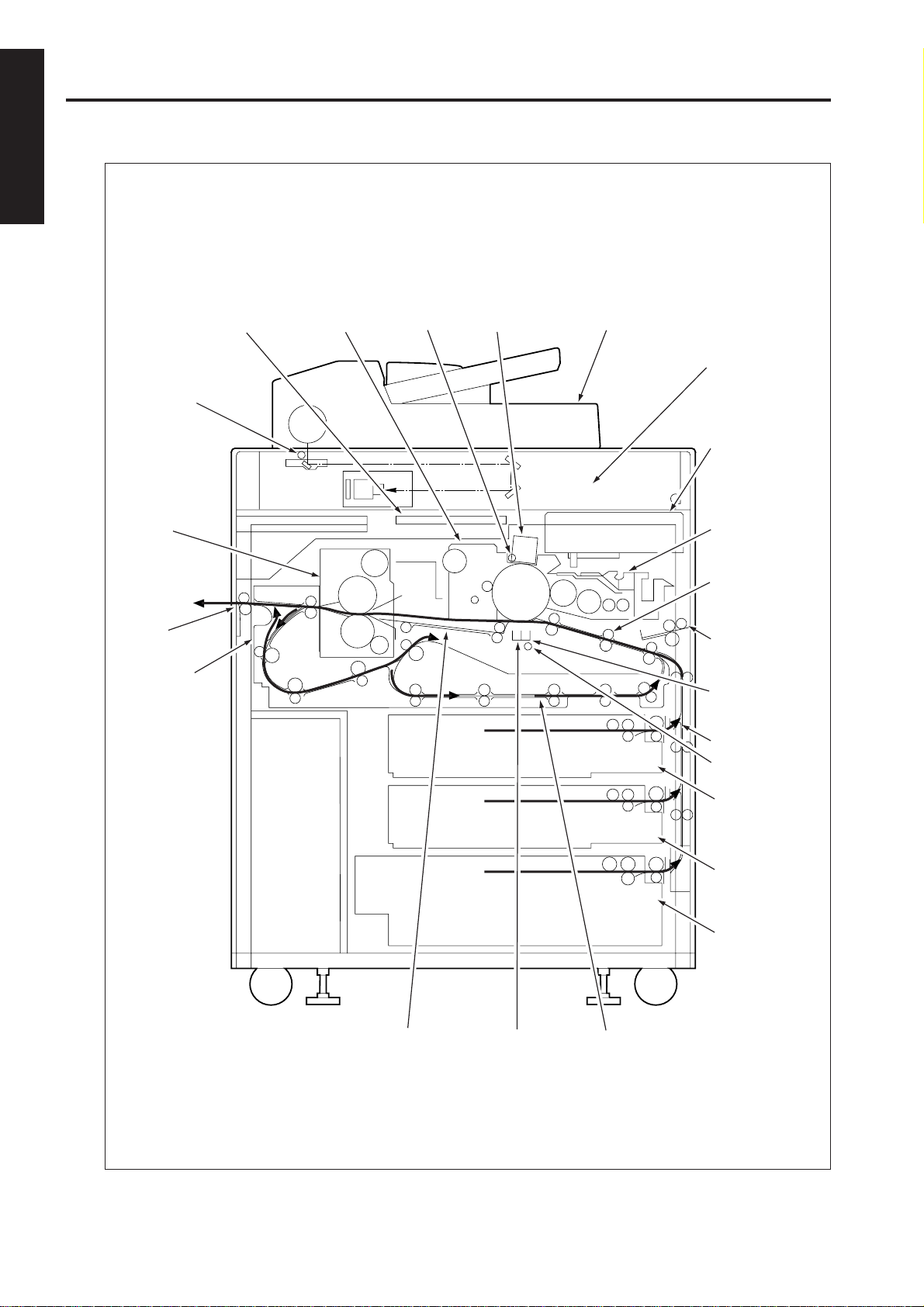

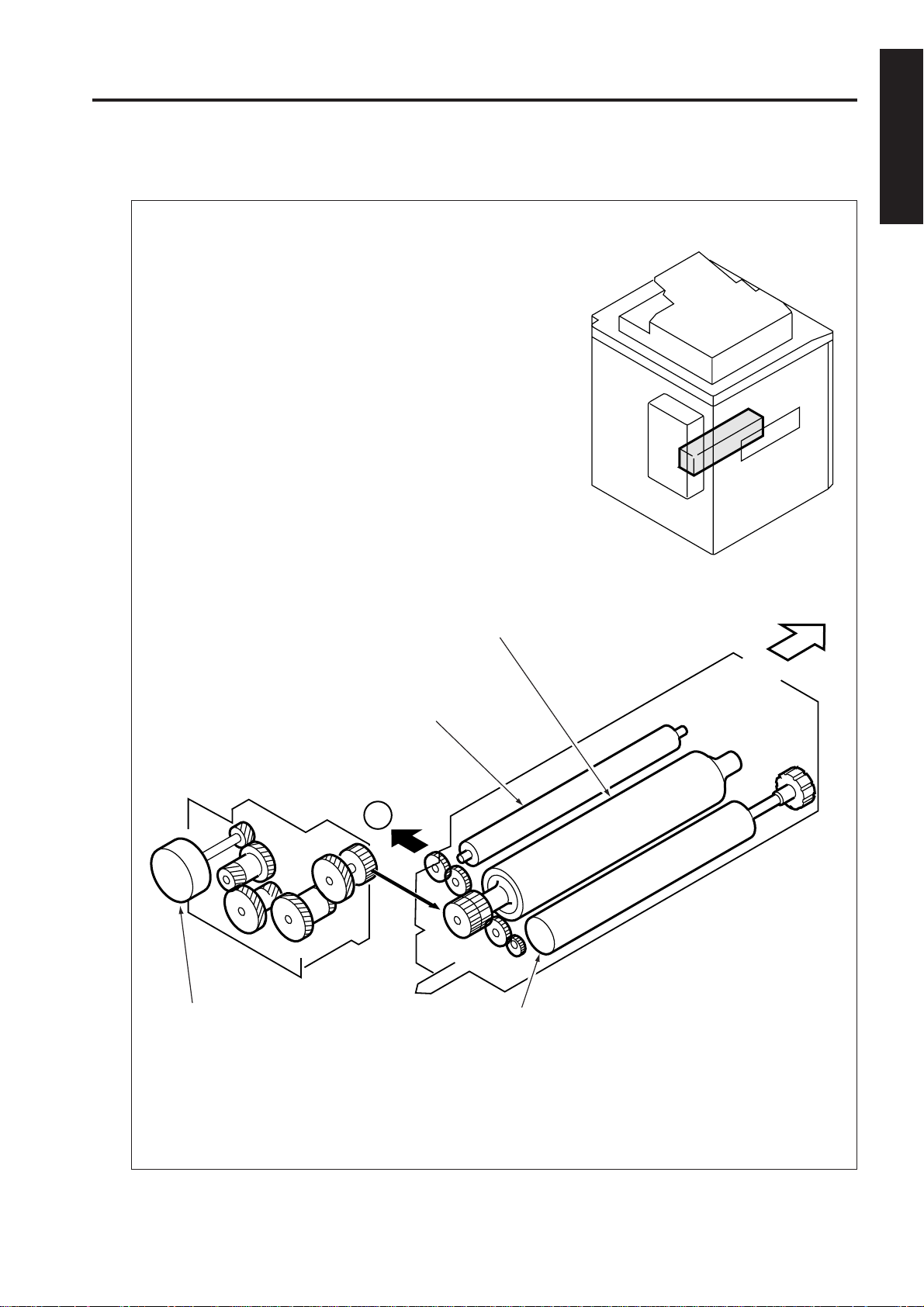

DRIVE SYSTEM DIAGRAM

MAIN BODY

[1] Main Drive Section

1 OUTLINE

FRONT

Fixing unit

upper roller

Main motor (M1)

Fixing unit

Heating roller

To paper conveyance and

transfer/separation corona

cleaning section

1

Fixing unit lower roller

1 - 5

Page 7

MAIN BODY

1 OUTLINE

[2] Drum Drive Section

FRONT

Drum

motor (M2)

Separation claw

solenoid (SD4)

Drum

Toner

guide

brush

Toner guide

shaft

Toner conveyance

screws

Separation claw unit

Separation claw swing cam

1 - 6

Page 8

MAIN BODY

[3] Developing Drive Section

1 OUTLINE

FRONT

Developing motor (M3)

Agitator screw

Agitator wheel

Developing sleeve

1 - 7

Page 9

MAIN BODY

1 OUTLINE

[4] Paper Feed Drive Section

5

6

To vertical conveyance section

To vertical conveyance section

To tray 1 paper feed/

2

tray up drive section

3

To tray 3 paper feed/

4

tray up drive section

FRONT

To tray 2 paper feed/

tray up drive section

Paper feed motor (M4)

1 - 8

Page 10

MAIN BODY

[5] Tray 1 and 2 Paper Feed Drive Section

1 OUTLINE

Tray up motor 1/2 (M19/M20)

Pre-registration MC1/2

(MC4/MC6)

2

3

From paper feed

drive section

Feed roller

Pre-feed registration roller

Feed MC1/2 (MC3/MC5)

FRONT

Paper feed roller

Double feed

prevention roller

1 - 9

Page 11

MAIN UNIT

1 OUTLINE

[6] Tray 3 Paper Feed Drive Section

Pre-feed registration roller

Pre-registration MC3

(MC8)

4

From paper feed drive

section

Feed roller

FRONT

Tray up motor 3 (M21)

Paper feed roller

Double feed

prevention roller

Feed MC3 (MC7)

1 - 10

Page 12

MAIN BODY

[7] Vertical Conveyance Drive Section

1 OUTLINE

FRONT

Vertical

conveyance

MC1 (MC9)

Vertical

conveyance

MC2 (MC10)

From bypass

paper feed drive

7

section

From paper

feed drive

5

section

From paper

feed drive

6

section

Vertical conveyance

roller (Upper)

Vertical conveyance

roller (Middle)

Vertical conveyance

roller (Lower)

1 - 11

Page 13

MAIN BODY

1 OUTLINE

[8] By-pass Paper Feed Drive Section

Tray up/down motor (by-pass tray: M22)

Paper feed roller

To ADU conveyance

8

drive section

FRONT

Feed roller

Loop roller motor (M6)

7

To vertical conveyance

1 - 12

Page 14

MAIN BODY

[9] Conveyance/Transfer and Separation Wire Cleaning Drive Section

1 OUTLINE

Transfer/separation cleaning motor (M18)

Thick paper conveyance rollers

1

From main drive section

FRONT

Conveyance belts

1 - 13

Page 15

MAIN BODY

1 OUTLINE

[10] ADU Conveyance Drive Section

Loop roller

Registration roller

Registration MC

(MC1)

Registration motor

(M12)

ADU exit roller

8

From by-pass

paper feed

drive section

Pre-registration roller

Pre-transfer roller

ADU horizontal

conveyance roller 2

ADU pre-registration

MC (MC2)

Transfer motor (M9)

From fixing

unit drive

FRONT

ADU conveyance motor (M8)

ADU reverse roller

ADU reverse motor (M7)

Paper reverse/exit

motor (M5)

Paper reverse/

exit roller 1

Pre-registration loop roller

ADU horizontal

conveyance roller 1

1 - 14

Paper reverse/exit

entrance roller

Paper reverse/

exit roller 2

Paper reverse/exit roller 3

Page 16

MAIN BODY

[11] Paper Exit Drive Section

1 OUTLINE

Paper exit motor (M10)

FRONT

Paper exit roller

1 - 15

Page 17

MAIN BODY

1 OUTLINE

[12] Toner Supply Drive

Toner supply motor 1 (M11)

Toner supply motor 2 (M15)

FRONT

Toner cartridge

1 - 16

Page 18

MAIN BODY

[13] Optics Drive Section

First mirror

1 OUTLINE

Slit-glass

FRONT

Scanner drive motor

(M13)

Second mirror

Third mirror

Optics wire (Rear)

Optics wire (Front)

1 - 17

Page 19

MAIN BODY

1 OUTLINE

[14] Web Drive Section

Web drive motor (M16)

FRONT

Cleaning web

1 - 18

Loading...

Loading...