Page 1

4

ELECTRIC PARTS LIST

ELECTRIC PARTS LIST

4

Page 2

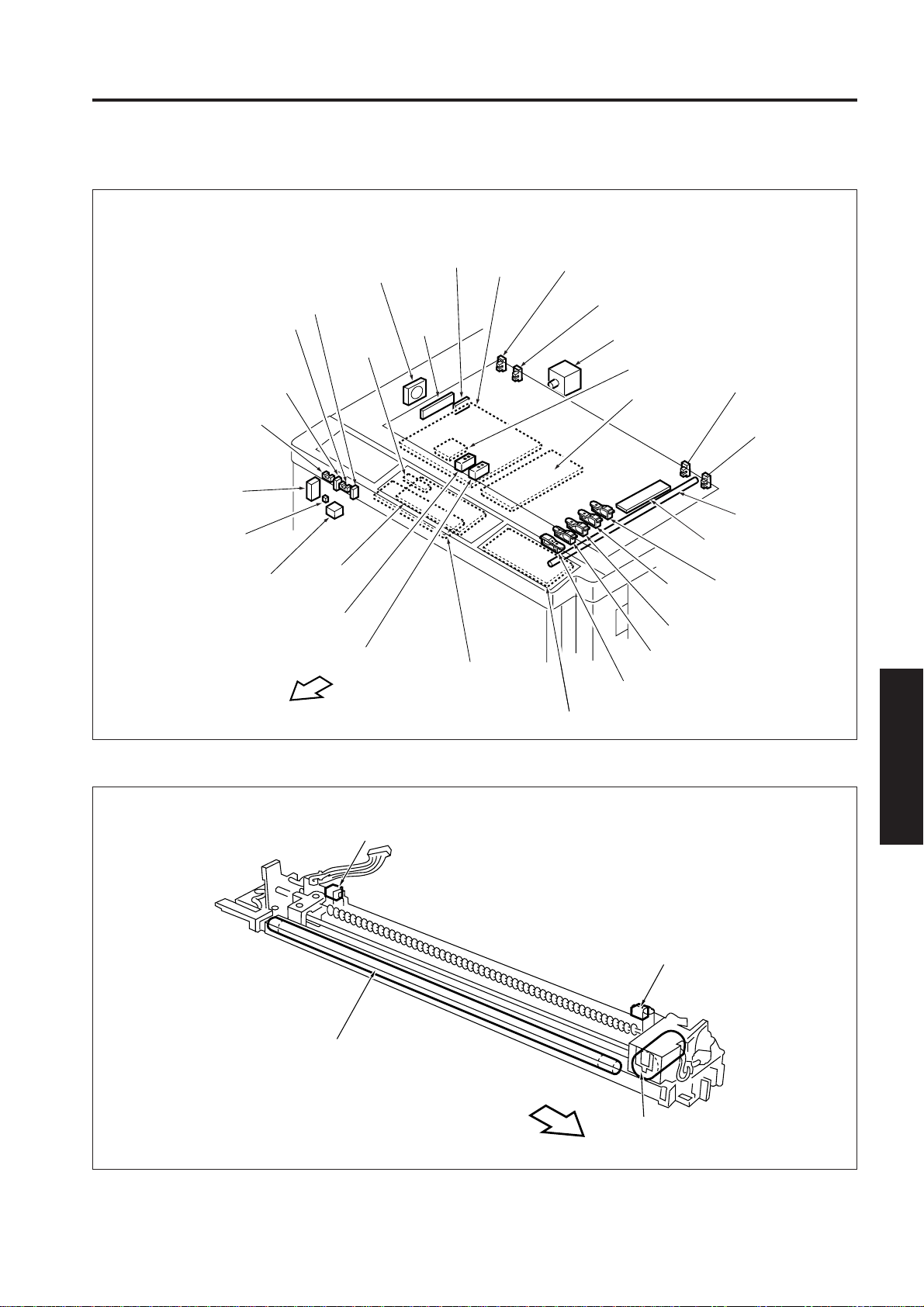

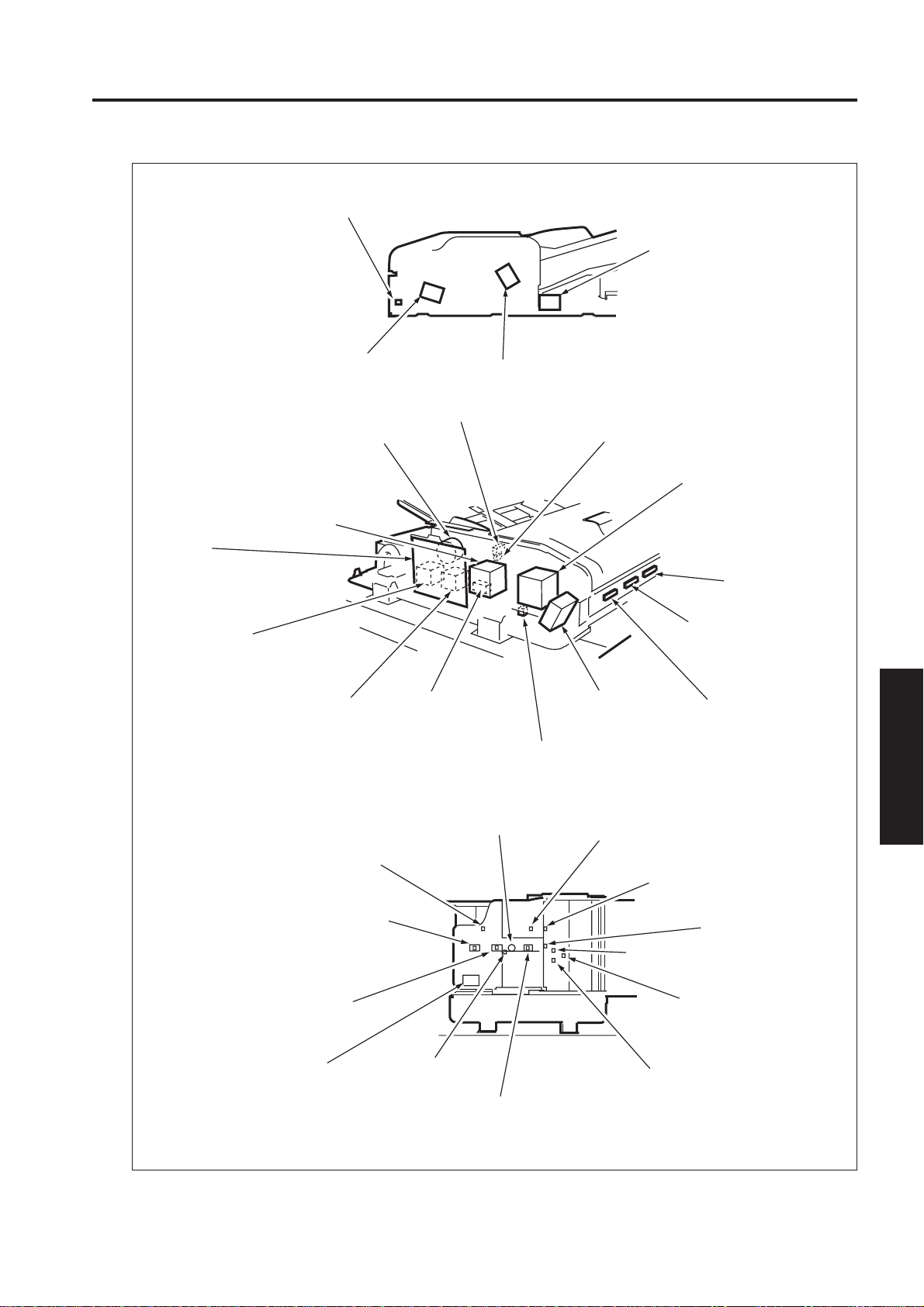

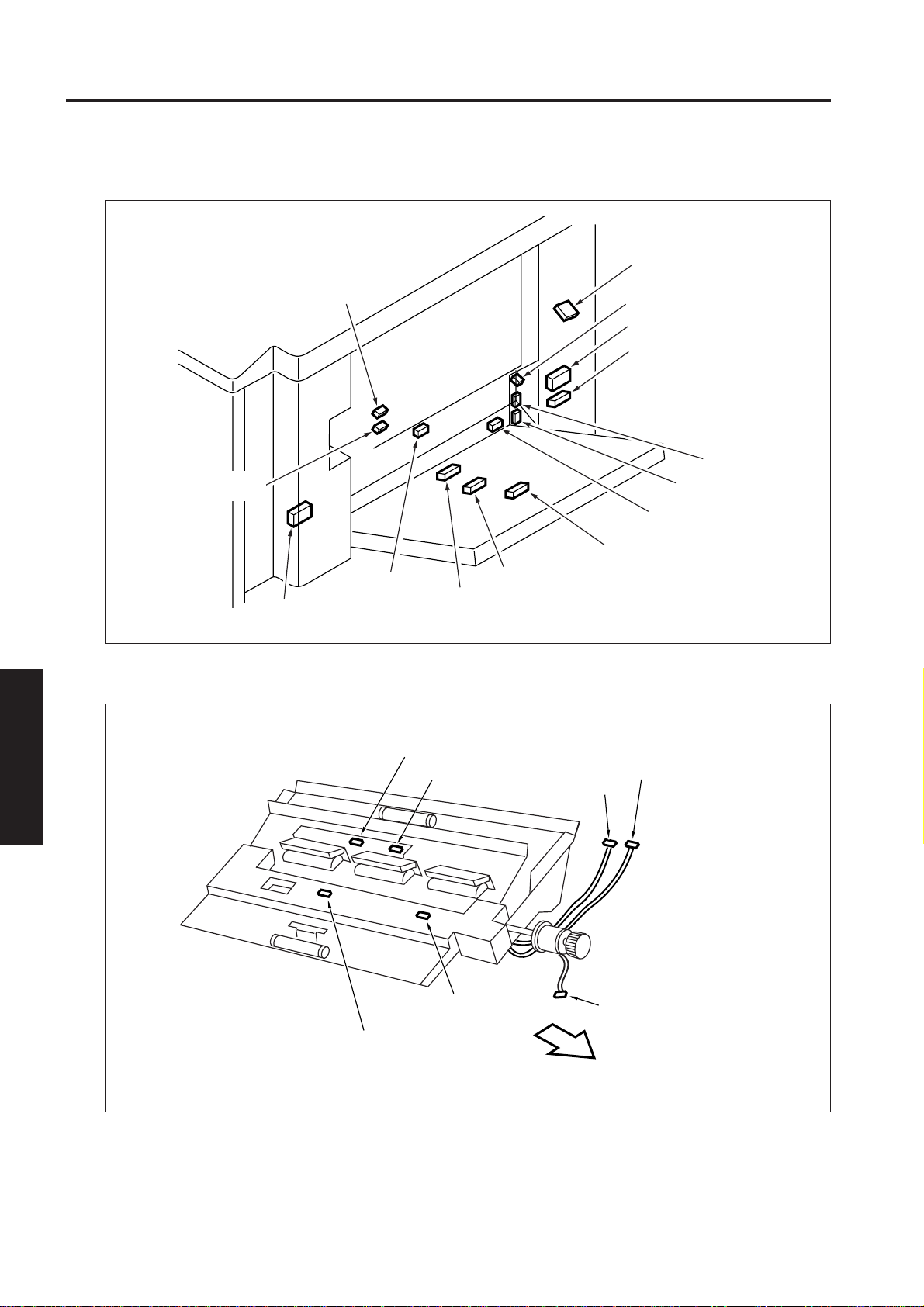

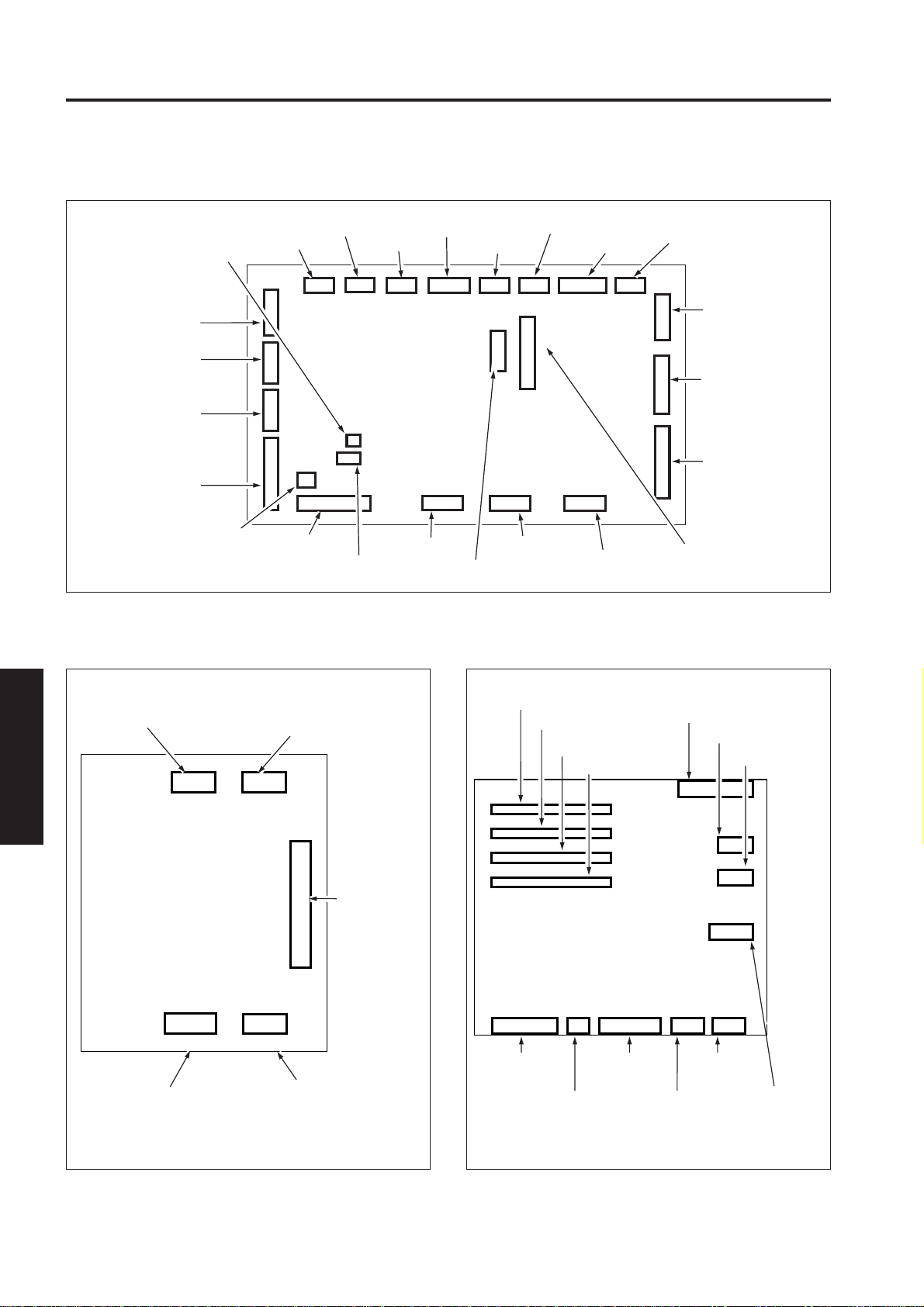

7075 PARTS LAYOUT DRAWING

7075 ELECTRICAL PARTS LAYOUT DRAWING

[1] Read Section/Operational Section

ICB

PS24

Front door open/close

detection PS1

MS2

Interlock 2

PS25

Front door open/close

detection PS2

SW1

Main switch

SW2

Reset switch

C(T)

Total counter

FM7

Scanner cooling fan

MS1

Interlock 1

OB INVB

OB Inverter

board

LCD

Indicator

board

PS63

APS sensor 2

PS62

APS sensor 1

FRONT

Image

control

board

ADB

A/D

converter

board

OB1

Operation board 1

OP IFB

Optional I/F

board

PS7

ADF brake PS

PS5

Scanner HP PS

M13

Scanner drive motor

MB

Memory board

ICB IFB

ICB I/F board

PS67

APS sensor 6

PS65

APS sensor 4

OB2

Operation board 2

PS6

Original HP PS

L1

Exposure lamp

L1 INVB

L1 Inverter

PS68

PS66

APS sensor 5

PS64

APS sensor 3

APS sensor 7

Scanner

reverse PS

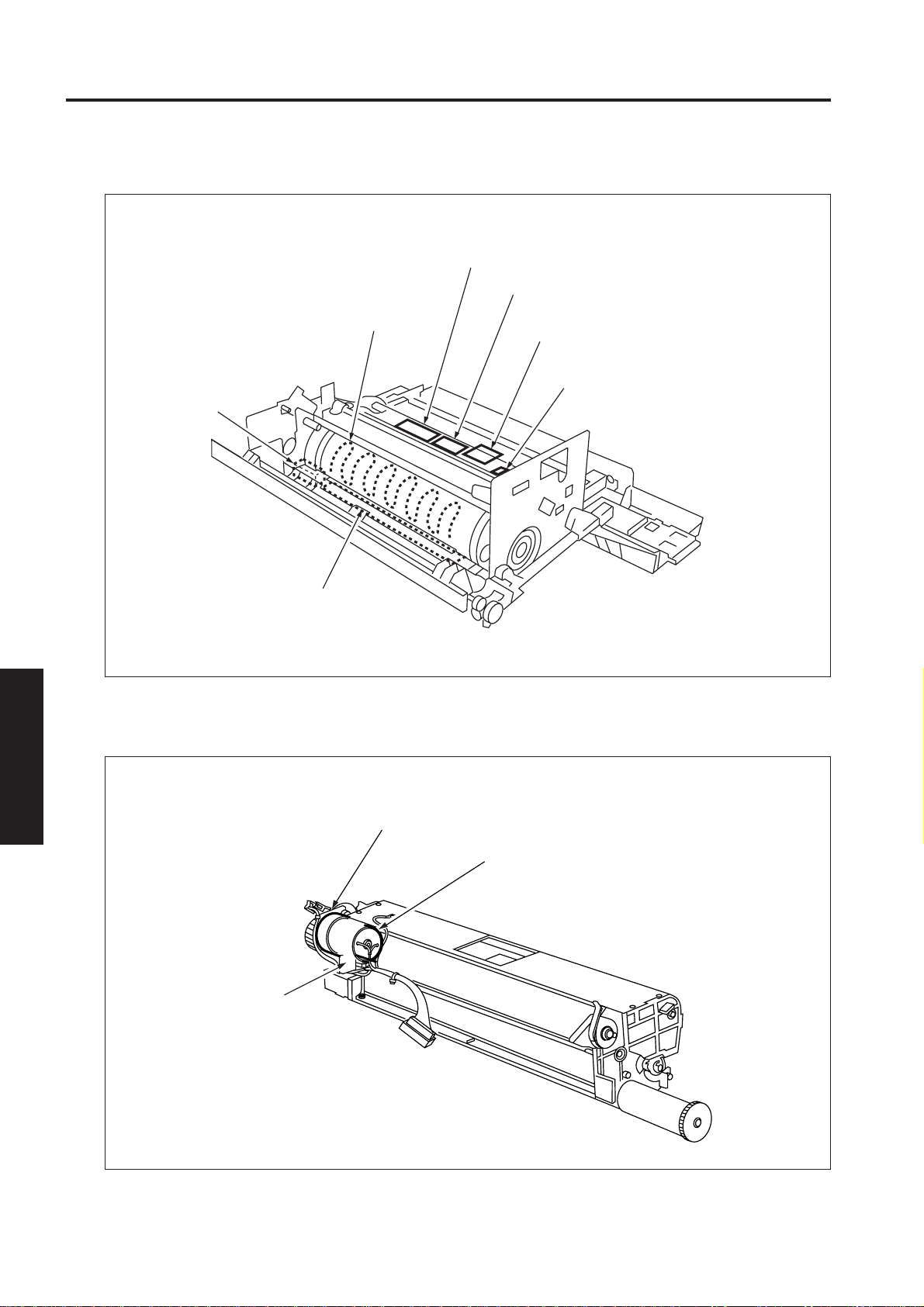

[2] Charging Corona Wire Unit

PS41

Charging wire cleaning pad HP PS

PCL

Pre-charging exposure lamp

FRONT

ELECTRIC PARTS LIST

4

PS42

Charging wire cleaning pad limit PS

M23

Charger cleaning motor

4 - 1

Page 3

7075 PARTS LAYOUT DRAWING

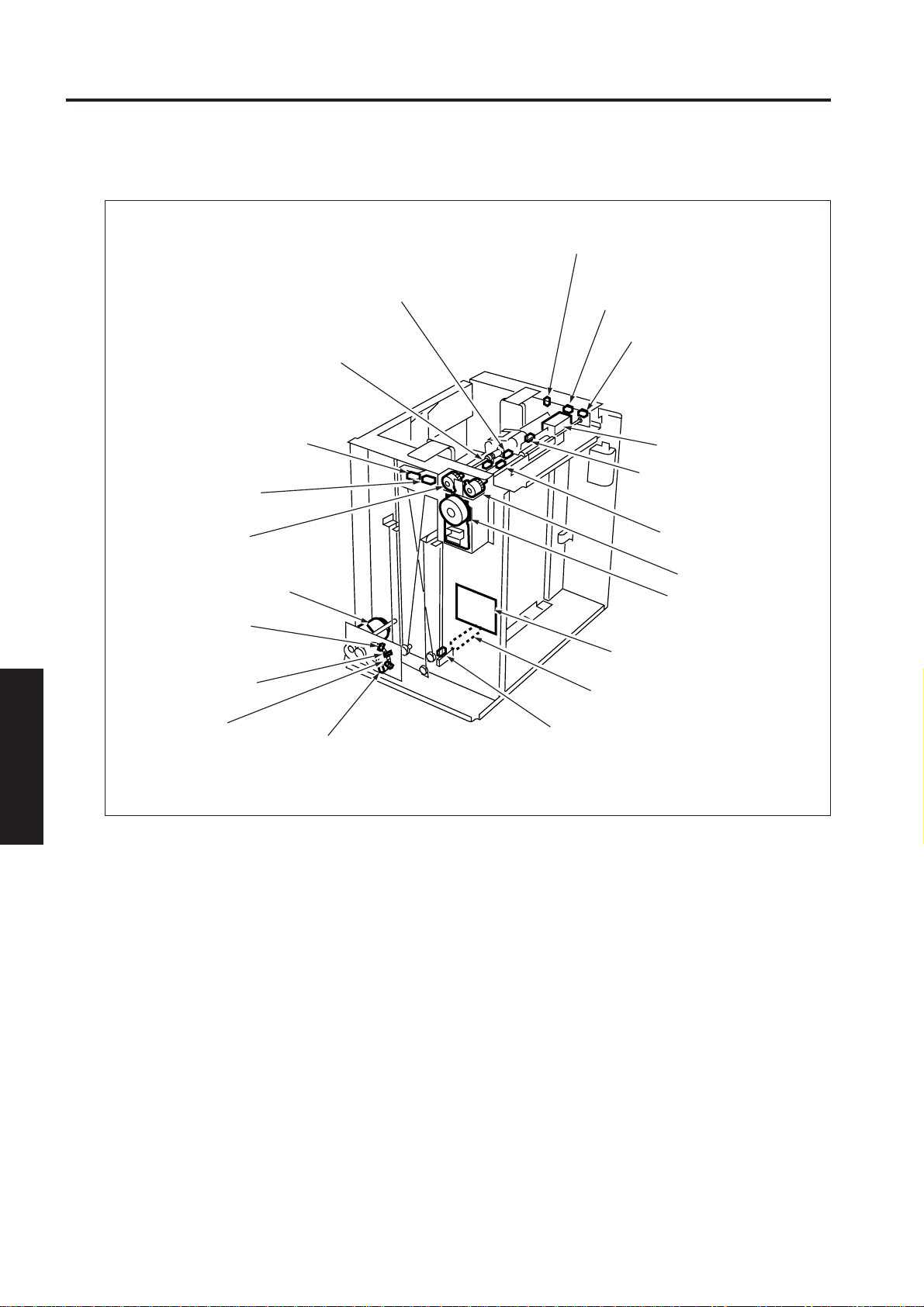

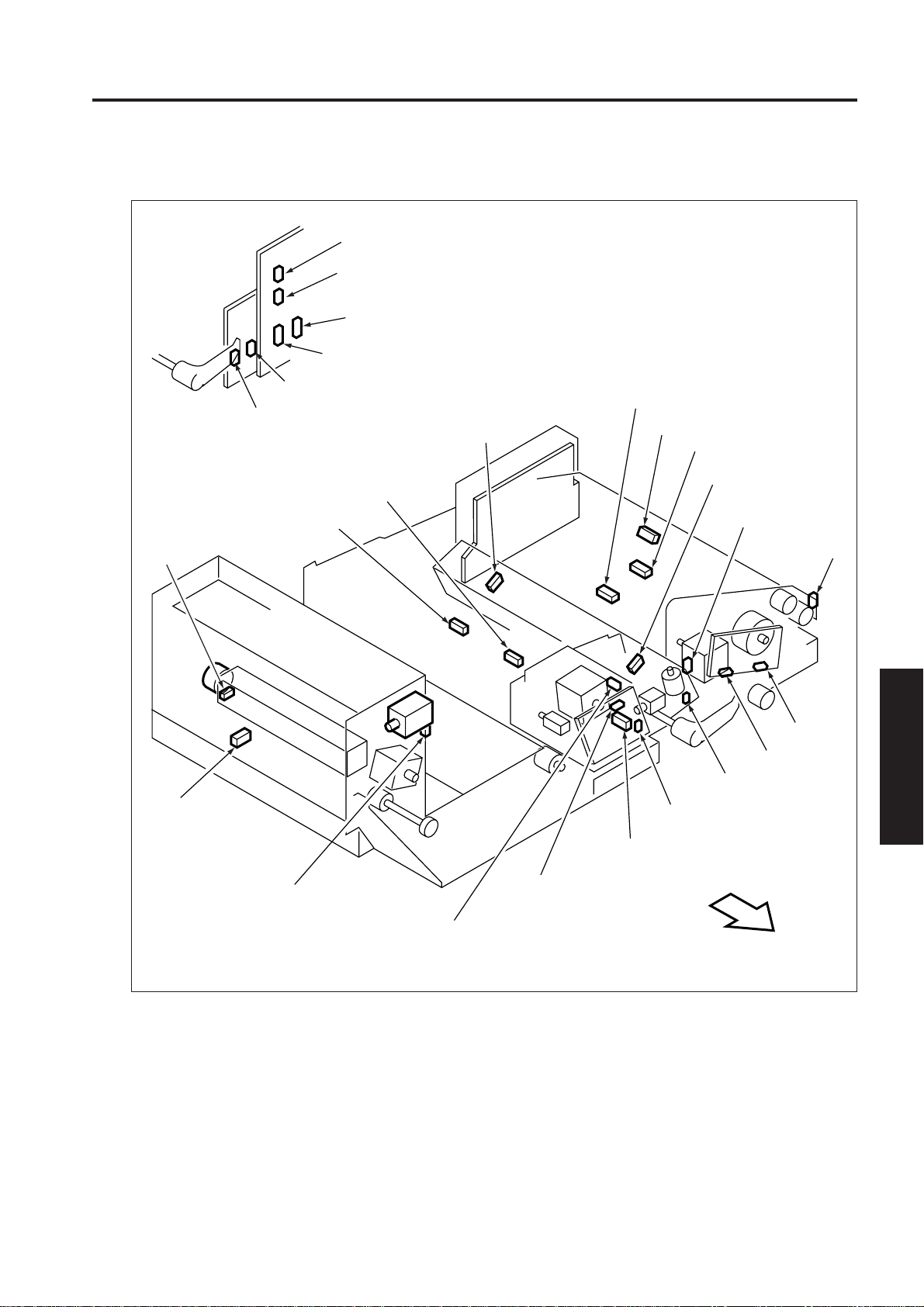

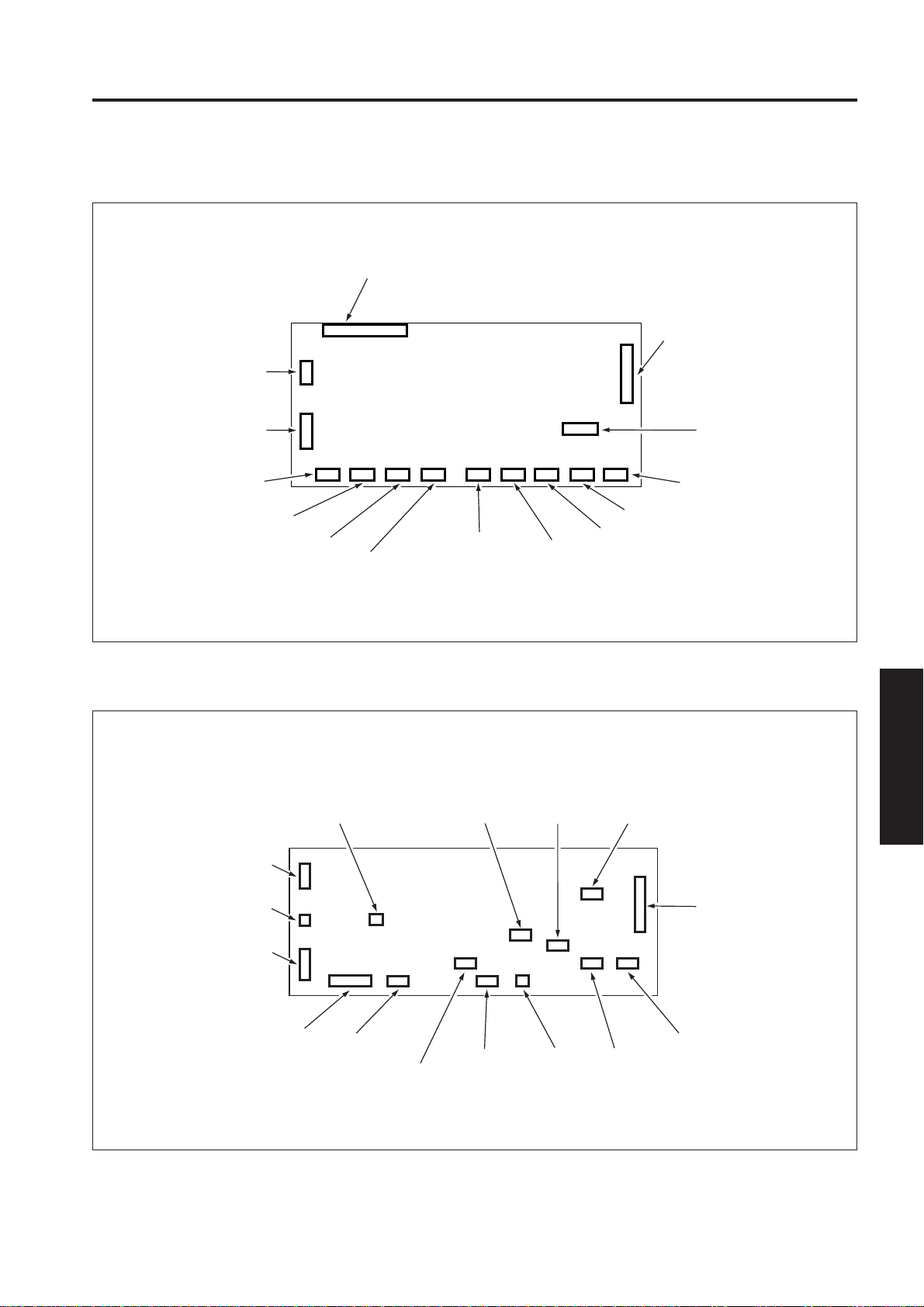

[3] Drum Unit

HTR1

Drum heater

DPSB

Drum potential sensor board

DPS

Drum potential sensor

DTSB

Drum temperature sensor board

SD4

Separation claw SD

[4] Cleaning Unit

ELECTRIC PARTS LIST

4

TH5

Drum temperature sensor

TCSB

Toner control sensor board

PS30

Blade PS1

M14

Blade motor

PS31

Blade PS2

4 - 2

Page 4

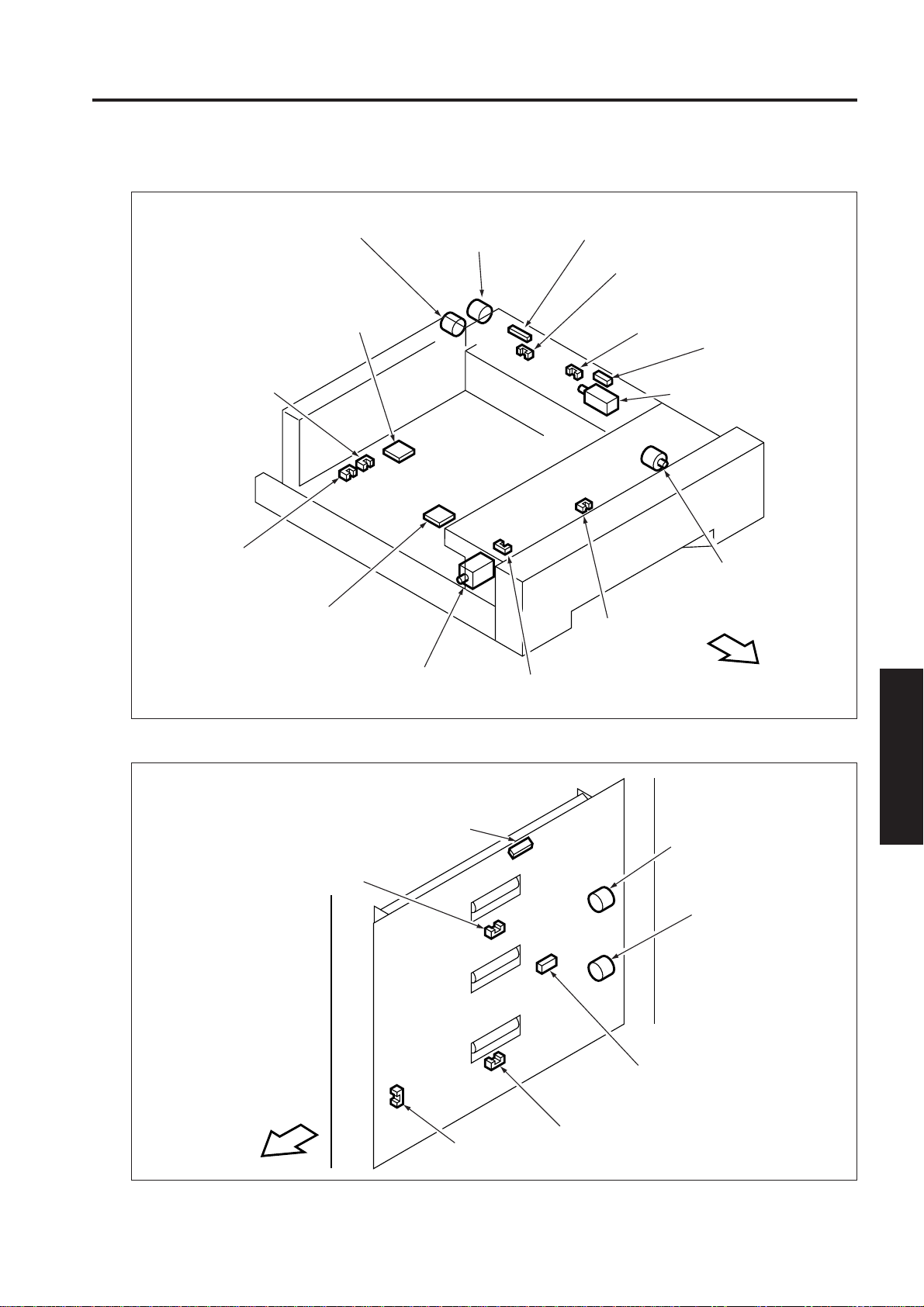

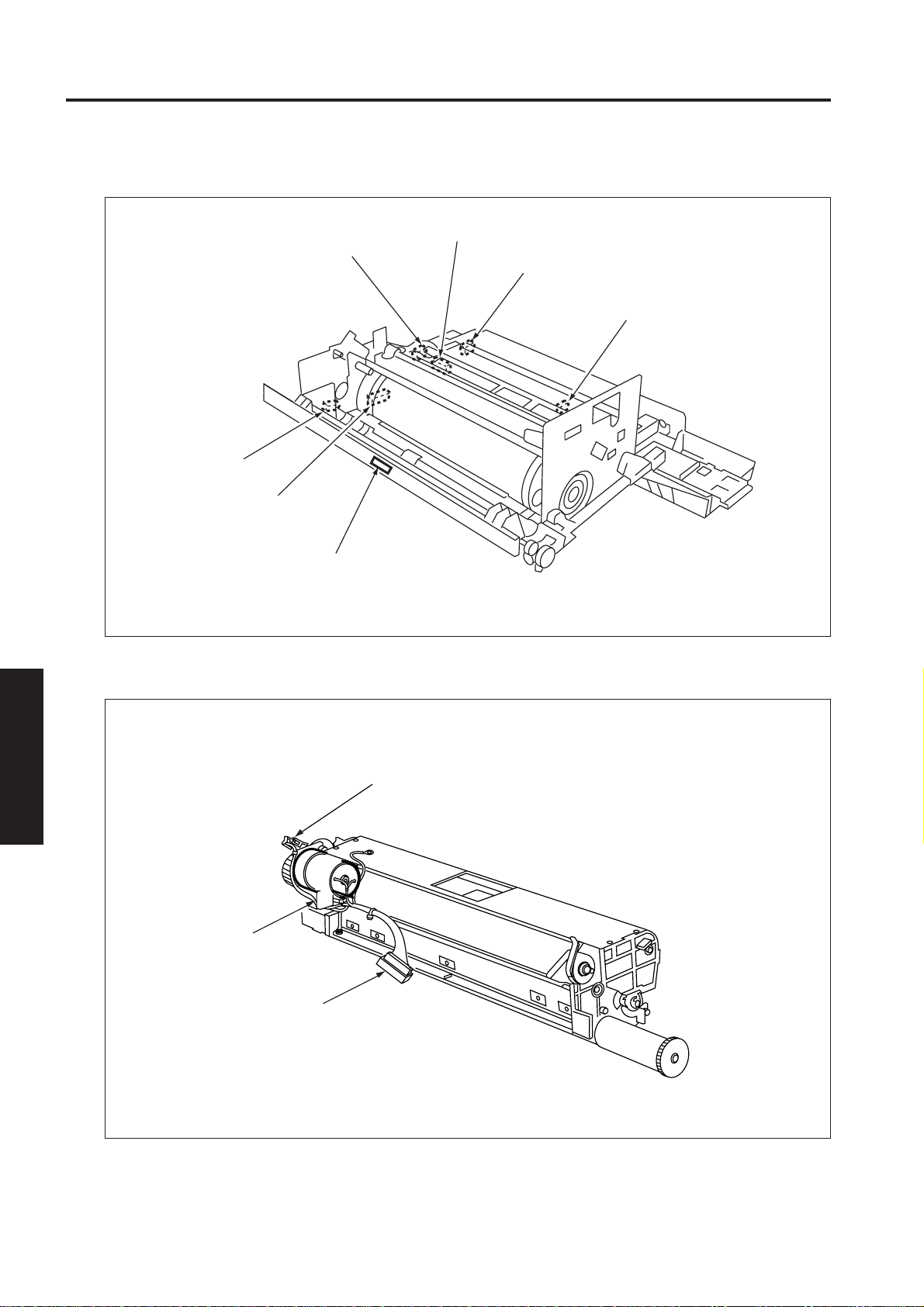

[5] Tray 1,2,3

7075 PARTS LAYOUT DRAWING

PS33/36/39

Paper size detection

PS2-1/2/3

PS32/35/38

Paper size detection

PS1-1/2/3

VR1/2/3

Paper size detection VR 1/2/3

MC3/5/7

Feed clutch 1/2/3

HTR2/3/4

Tray heater 1/2/3

MC4/6/8

Pre-registration clutch 1/2/3

SD5/6/7

Lock Solenoid 1/2/3

PS48/50/52

Paper pre-registration PS 1/2/3

PS26/27/28

No paper PS 1/2/3

PS20/21/22

Tray upper limit PS 1/2/3

PS47/49/51

Paper feed PS 1/2/3

SD8/9/10

Pick up SD 1/2/3

M19/20/21

Up drive motor 1/2/3

PS14/15/16

Handle release PS

1/2/3

PS34/37/40

Remaining paper detection PS 1/2/3

FRONT

[6] Vertical Conveyance Section

PS18

Vertical conveyance PS1

FRONT

PS54

Loop PS

PS19

PS17

Open/close detection PS

Vertical conveyance PS3

MC9

Vertical conveyance

clutch1

MC10

Vertical conveyance

clutch 2

PS53

Vertical conveyance PS2

ELECTRIC PARTS LIST

4

4 - 3

Page 5

7075 PARTS LAYOUT DRAWING

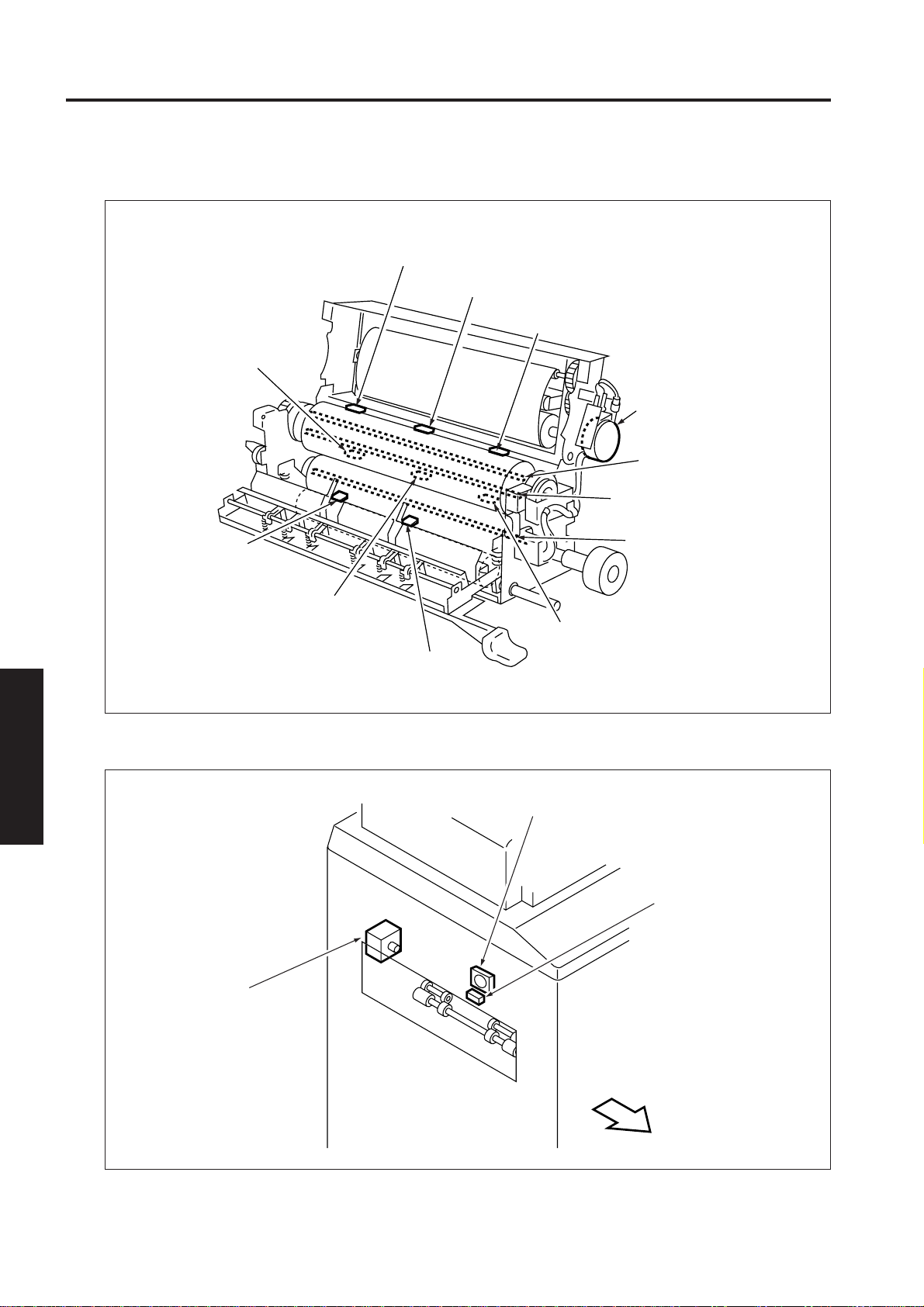

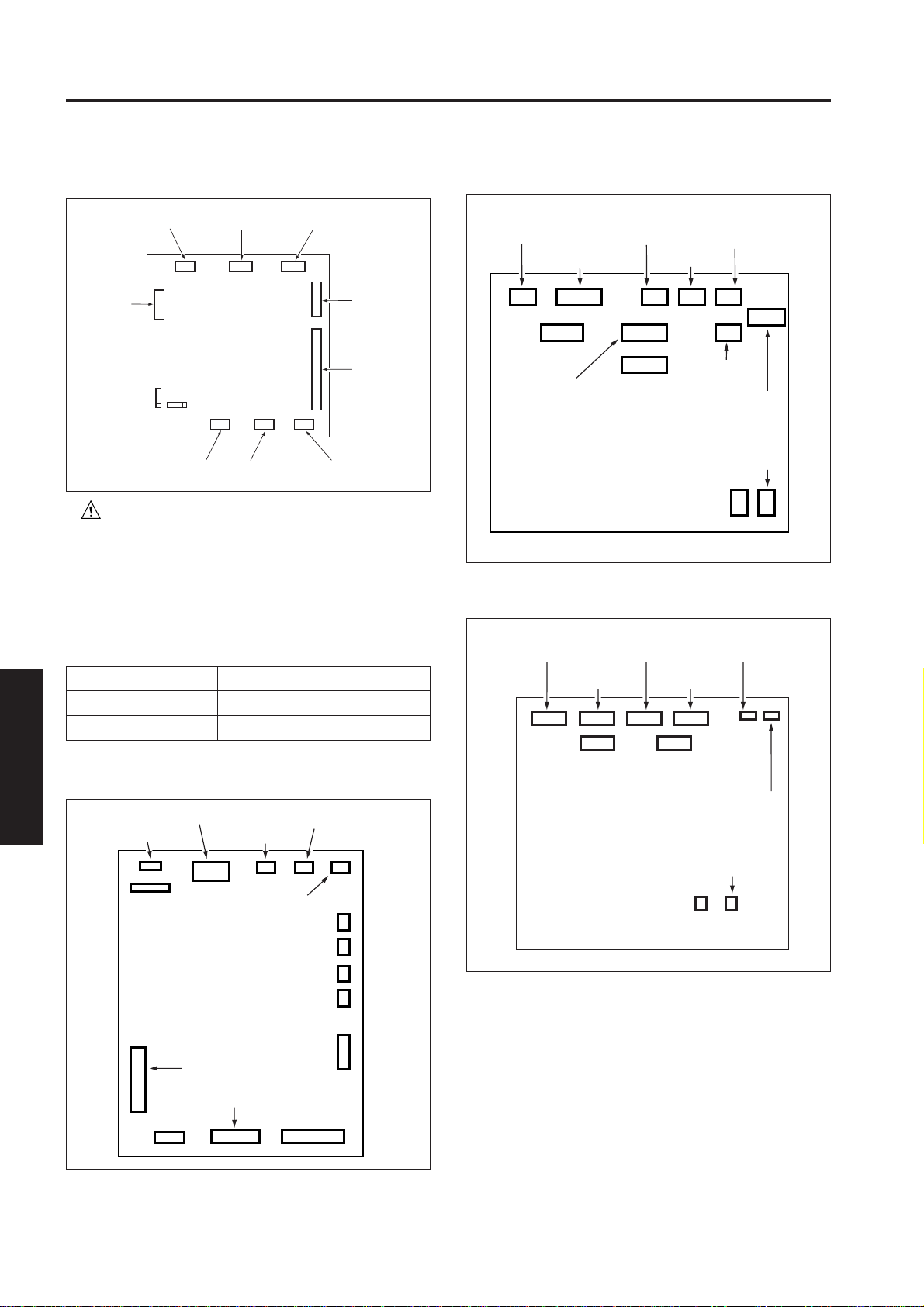

[7] By-pass Feed Section

PS23

Tray upper limit PS (by-pass)

FM5

Write section

cooling fan 1

FM8

Write section

cooling fan 2

SD11

Pick up SD (by-pass)

M22

Up/down motor (by-pass)

PS43

Tray lower limit PS

(by-pass)

PS29

No paper PS (by-pass)

[8] Second Paper Feed Section

ELECTRIC PARTS LIST

4

PS45

Leading edge detection PS

PS55

VR4

Paper size detection VR (by-pass)

Paper size PS1 (by-pass)

PS44

Registration PS

PS1

Paper mis-centering PS

PS56

Paper size PS2 (by-pass)

MC1

Registration MC

4 - 4

FRONT

Page 6

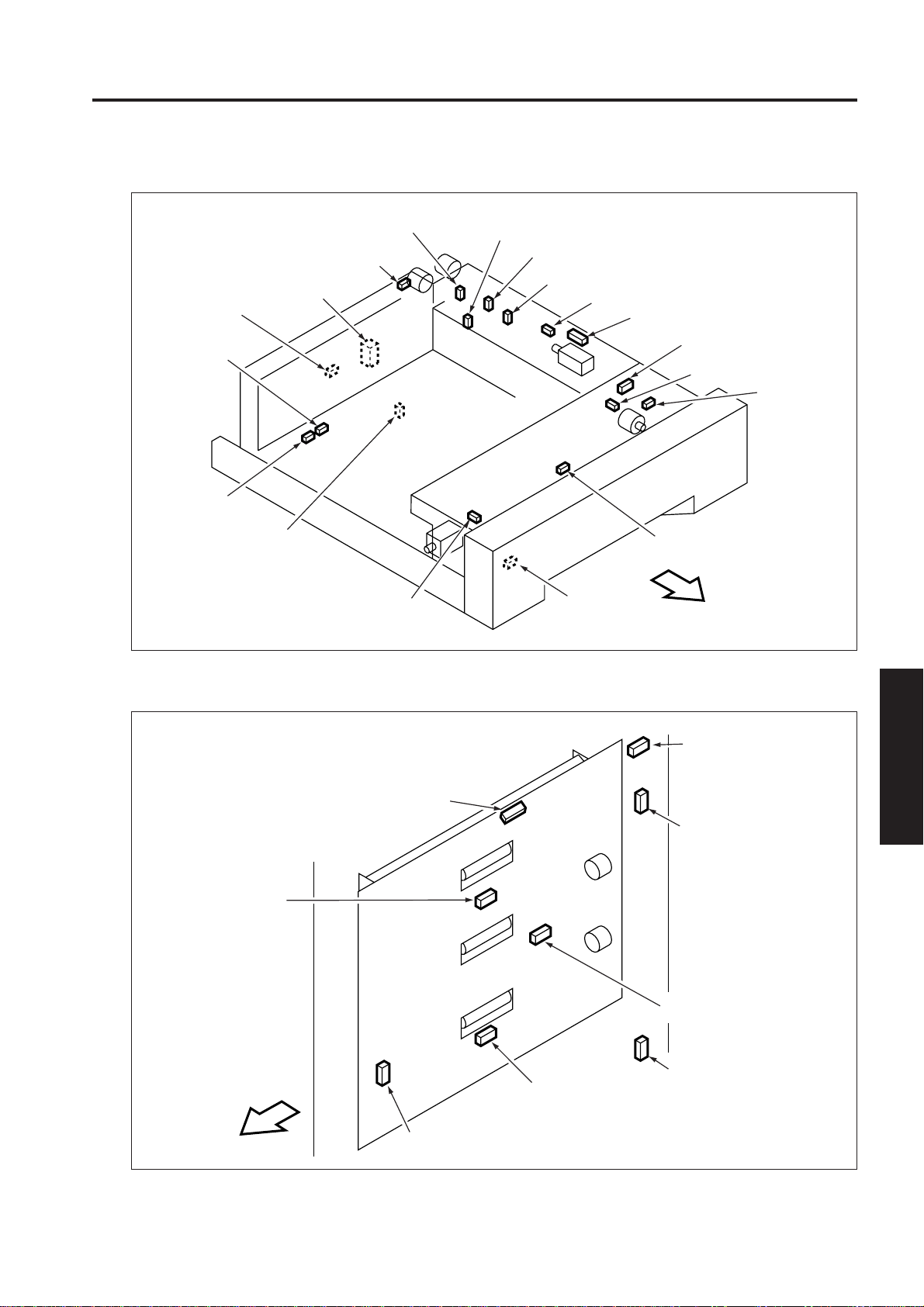

[9] ADU Unit

PS13

ADU No paper detection PS

PS58

ADU paper reverse PS

FM1

Paper exit

fan

PS57

paper reverse/

PS

PS8

Paper reverse/

conveyance PS

PS12

Transfer/separation wire

cleaning pad limit PS

M7

ADU reverse motor

M5

SD2

Paper reverse

gate SD

Paper reverse/

exit motor

HV2

High voltage unit 2

TSL

Transfer

synchronization lamp

ADUSDB

ADU stand drive

board

7075 PARTS LAYOUT DRAWING

PS59

ADU deceleration PS

PS60

ADU Pre-registration PS

PS46

ADU exit PS

PS11

Transfer/Separation wire cleaning

pad HP PS

SD1

ADU lock SD

JAMIB

Jam indicator

board

SD3

Fixing guide SD

M8

ADU conveyance motor

PS9

ADU paper conveyance PS

M9

Transfer motor

M12

Registration motor

MC2

ADU Pre-registration

M18

Transfer/Separation cleaning

motor

PS10

ADU handle release PS

MC

FRONT

PS61

Paper exit PS

PS57

Paper

reverse PS

PS58

ADU paper

reverse PS

PS9

ADU paper

PS8

Paper reverse/conveyance PS

conveyance PS

PS13

ADU No paper

detection PS

PS45

Copy paper leading

edge detection PS

PS59

ADU deceleration PS

4 - 5

ELECTRIC PARTS LIST

4

PS44

Registration PS

PS46

ADU exit PS

PS60

ADU pre-registration PS

Page 7

7075 PARTS LAYOUT DRAWING

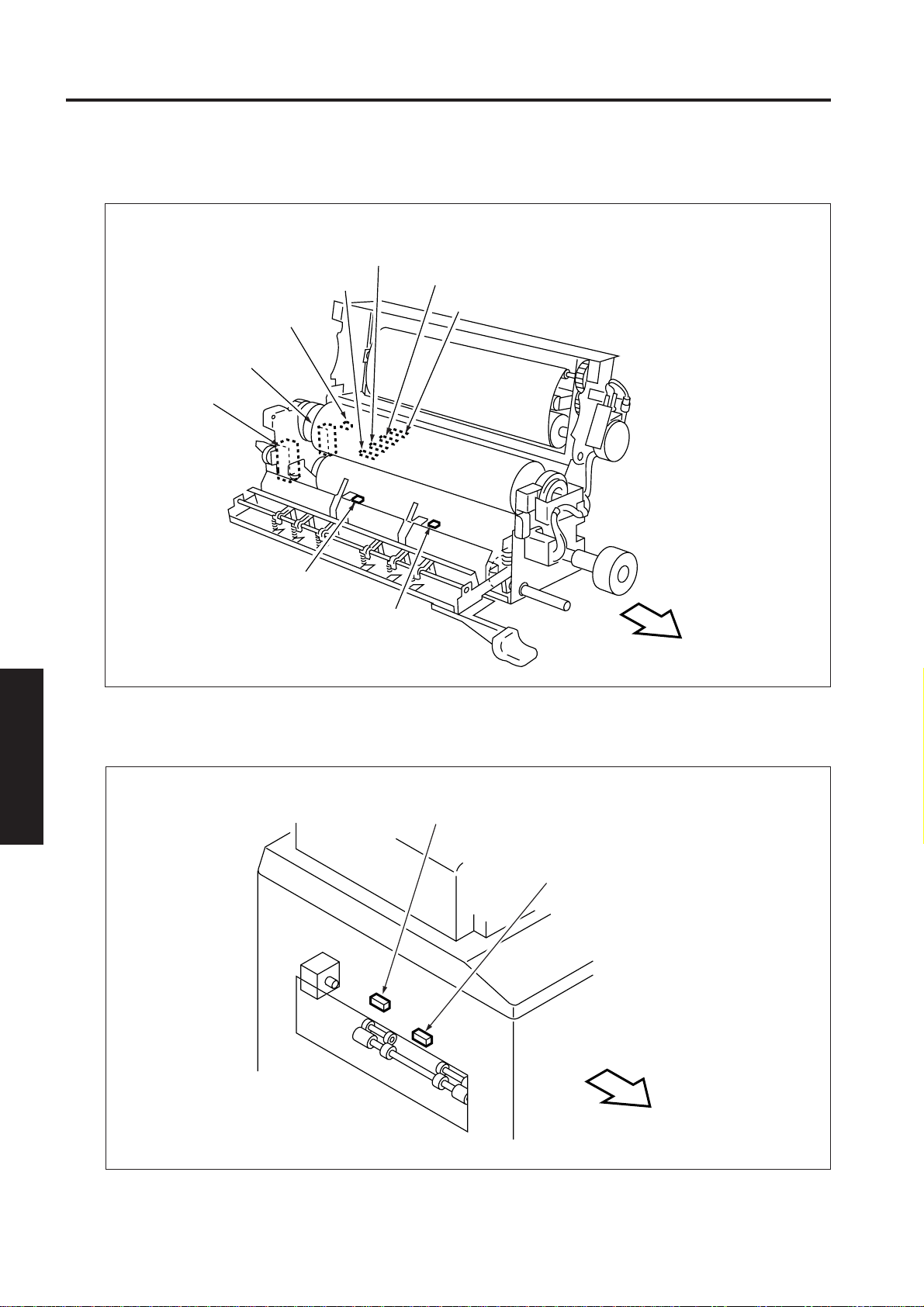

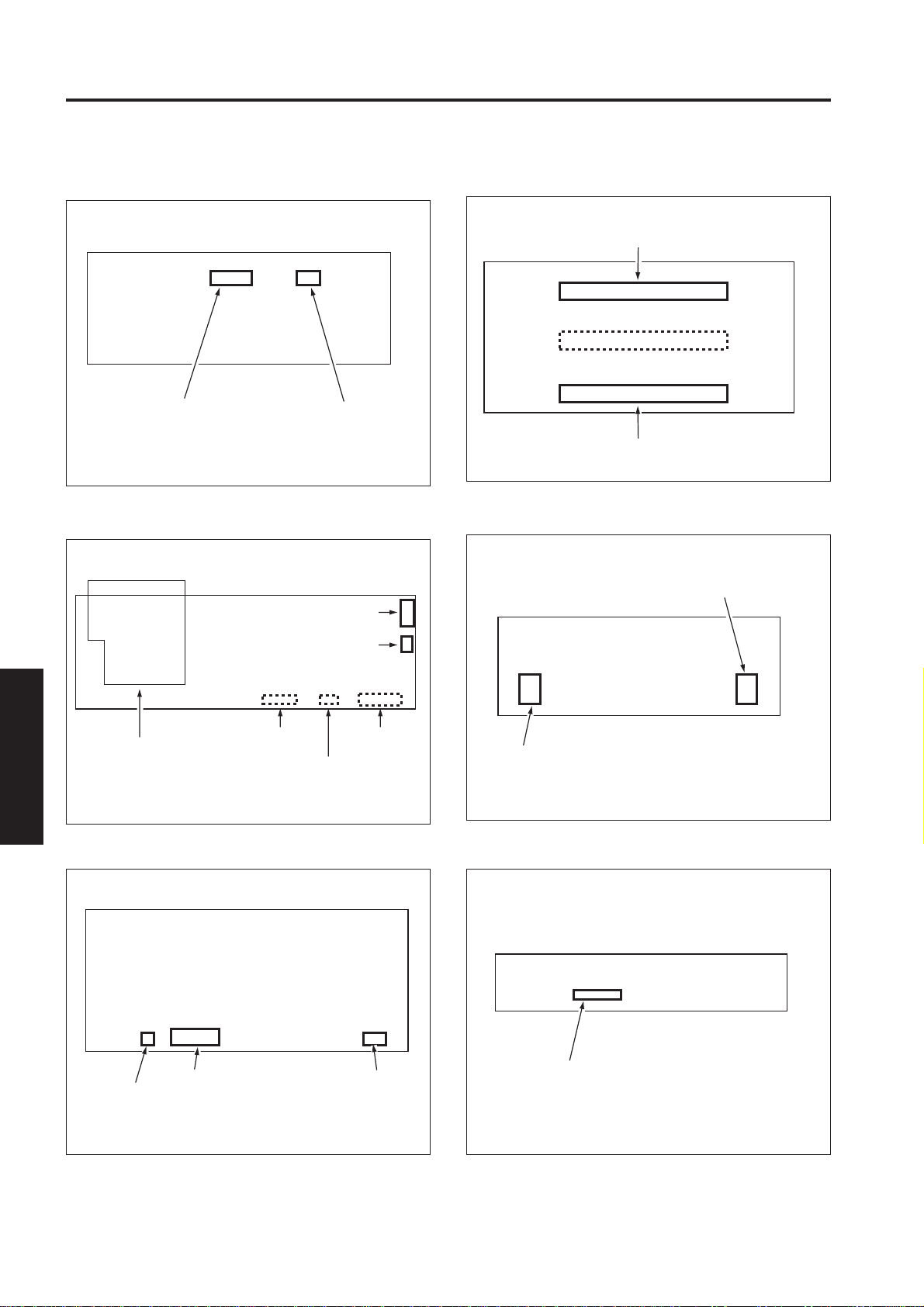

[10] Fixing Unit

TH4

Fixing temperature

sensor 4

PS3

Fixing jam PS

TH2

Fixing temperature sensor 2

TH1

Fixing temperature sensor 1

TS1

Thermostat (upper)

M16

Web drive motor

L2

Fixing heater lamp 1

L3

Fixing heater lamp 2

L4

Fixing heater lamp 3

[11] Paper Exit Section

ELECTRIC PARTS LIST

4

M10

Paper exit motor

TH3

Fixing temperature

sensor 3

TS2

Thermostat 2 (lower)

PS2

Fixing exit PS

FM6

Main body cooling fan 3

PS61

Paper exit PS

4 - 6

FRONT

Page 8

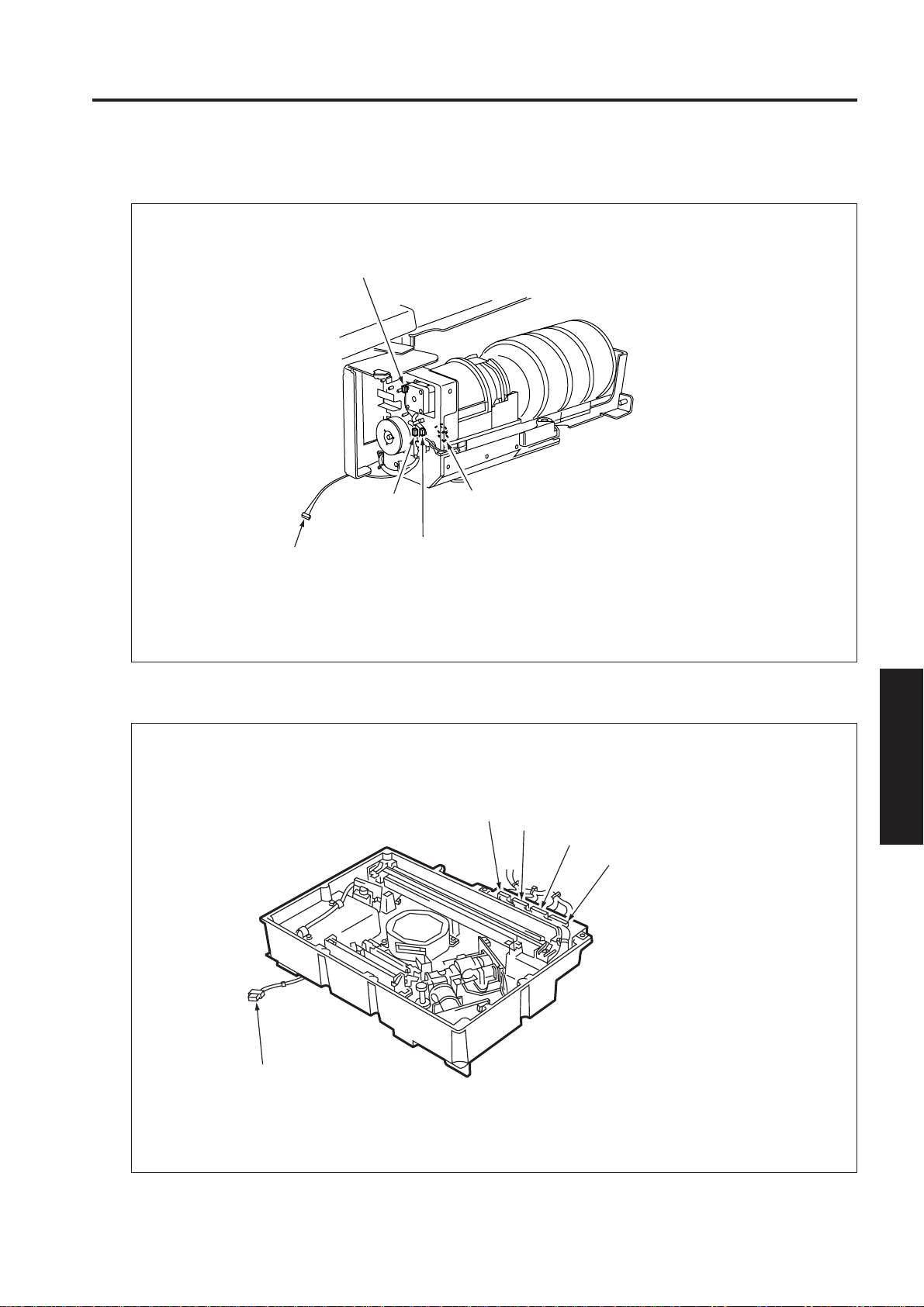

[12] Toner Supply Unit

M11

Toner supply motor 1

7075 PARTS LAYOUT DRAWING

[13] Write Section

PMDB

Polygon motor drive board

M15

Toner supply motor 2

INDXSB

Index sensor board

TLD

Toner level detection sensor

M17

Polygon motor

M24

Laser correction motor

ELECTRIC PARTS LIST

4

LDB1

Laser driver board 1

4 - 7

LDB2

Laser driver board 2

Page 9

7075 PARTS LAYOUT DRAWING

[14] Control/Drive Unit in Rear Section

SCDB

Scanner drive board

M2

Drum motor

M3

Developing motor

HV1

High voltage unit 1

FM2

Developing section fan

M1

Main motor

KRDS

KRDS board

M13

Scanner drive motor

KRDS

LAN IFB

LAN I/F board

FM4

Main unit cooling

fan 2

FM3

Main unit cooling

fan 1

M6

Loop roller

motor

PSMB

Power

supply

management

ELECTRIC PARTS LIST

board

4

DCDB

DC drive board

DCPS1

DC power

supply unit 1

M4

Paper feed

motor

PRCB

Printer control

board

DCPS2

DC power

supply unit 2

RL1

Main relay

RL3

AC input relay for IP

CBR1

Circuit

breaker 1

M10

Paper exit motor

CBR2

Circuit breaker 2

TRC1

Triac 1

TRC2

Triac 2

ACDB

AC drive board

Transformer

NF

Noise filter

RL2

AC input relay for DCPS2

4 - 8

Page 10

OPTIONAL PARTS LAYOUT DRAWING

DF-313 ELECTRICAL PARTS LAYOUT DRAWING

PS301

RADF open/close detection PS

SD303

Original exit gate SD

SD301

Flapper drive SD

M303

Tray up/down drive motor

M302

DFCB

RADF

control board

M305

Original exit motor 2

Original feed motor

M304

Original exit motor 1

PS313

Original exit reverse detection PS

PS302

Original size detection PS1

PS303

Original size detection PS2

PTBD

Tray board

MS301

Cover open/close MS

SD304

SDF switching SD

VR301

Original size

detection VR

PS314

Original exit PS2

PS310

Original count detection PS

SD302

Pressure roller release SD

PS316

Tray lower limit detection PS

FM301

ADF fan

PS317

APS timing PS

PS304

Reverse jam detection PS

PS309

Original reversal detection PS

PS315

Tray upper limit detection PS

PS305

No original detection PS

M301

Original conveyance motor

PS311

Original skew

detection PS 1

PS308

Original conveyance

detection PS

PS312

Original skew

detection PS2

ELECTRIC PARTS LIST

4

PS307

Original exit PS1

PS306

Original registration

detection PS

4 - 9

Page 11

OPTIONAL PARTS LAYOUT DRAWING

LT-401 ELECTRICAL PARTS LAYOUT DRAWING

SW100

LT tray down drive switch

PS108

LT No paper detection PS

PS107

LT pre-registration PS

MS102

LT top cover interlock MS2

PS100

LT top cover open/

close detection PS

MC101

LT feed drive MC

M100

LT up/down motor

PS102

LT remaining

paper detection PS1

PS103

LT remaining

paper detection PS2

PS104

LT remaining

paper detection PS3

PS105

LT remaining paper detection PS4

MS101

LT top cover interlock MS1

PS110

LT jam access door

open/close detection PS

SD100

LT 1st paper feed SD

PS109

LT upper limit detection PS

PS106

LT feed PS

MC102

LT 1st paper feed MC

M101

LT paper feed motor

LTDB

LT drive board

HTR101

LT internal heater

PS101

LT lower limit detection PS

ELECTRIC PARTS LIST

4

4 - 10

Page 12

7075 CONNECTOR LAYOUT DRAWING

7075 CONNECTOR LAYOUT DRAWING

[1] Read Section

651 (W: 3pin)

640 (BK:4pin)

665 (W: 3pin)

666 (W: 3pin)

650 (W: 3pin)

652 (W: 3pin)

653 (W: 3pin)

660 (W: 3pin)

661 (W: 3pin)

662 (W: 3pin)

663 (W: 3pin)

664 (W: 3pin)

FRONT

[2] Charging Corona Wire Unit

356 (W: 2pin)

631 (BK:4pin)

353 (W: 11pin)

ELECTRIC PARTS LIST

4

357 (W: 3pin)

358 (W: 3pin)

359 (W: 3pin)

4 - 11

FRONT

Page 13

7075 CONNECTOR LAYOUT DRAWING

[3] Drum Unit

342 (W: 2pin)

341 (BK: 26pin)

[4] Cleaning Unit

350 (W: 4pin)

353 (W: 7pin)

340 (B: 12pin)

351 (W: 4pin)

341 (BK: 10pin)

ELECTRIC PARTS LIST

4

361 (W: 3pin)

360 (W: 3pin)

355 (BK: 9pin)

4 - 12

Page 14

[5] Tray 1,2,3

7075 CONNECTOR LAYOUT DRAWING

250, 252 (BK: 24pin)

269, 307 (W: 2pin)

271, 288 (W: 3pin)

270, 287 (W: 3pin)

268, 252 (W: 3pin)

261, 278 (W: 2pin)

260, 277 (W: 2pin)

255, 283 (W: 3pin)

262, 279 (W: 6pin)

275 (W: 3pin)

276 (W: 3pin)

274 (W: 3pin)

273 (W: 3pin)

263, 280 (W:6pin)

264 (W: 2pin)

277, 289

(W:2pin)

265, 282 (W: 3pin)

FRONT

267, 285 (BK: 2pin)

[6] Vertical Conveyance Section

292 (W: 3pin)

293 (W: 3pin)

295 (W: 3pin)

254 (W: 12pin)

253 (W: 10pin)

294 (W: 3pin)

750 (W: 10pin)

ELECTRIC PARTS LIST

4

FRONT

296 (W: 3pin)

4 - 13

Page 15

7075 CONNECTOR LAYOUT DRAWING

[7] By-pass Feed Section

471 (BK:9pin)

77 (BK:4pin)

76 (BK:4pin)

473 (W:13pin)

[8] Second Paper Feed Section

246 (W:3pin)

247 (W:2pin)

470 (W:13pin)

254 (W:12pin)

248 (W:2pin)

254 (W:7pin)

244 (W:3pin)

243 (W:3pin)

242 (W:3pin)

241 (W:3pin)

ELECTRIC PARTS LIST

4

599 (W: 3pin)

570 (W: 3pin)

598 (W: 3pin)

591 (W: 10pin)

569 (W: 7pin)

568 (W: 8pin)

565 (W: 2pin)

FRONT

4 - 14

Page 16

[9] ADU Unit

7075 CONNECTOR LAYOUT DRAWING

557 (W: 6pin)

565 (W: 3pin)

569 (W: 7pin)

568 (W: 8pin)

592 (W: 3pin)

578 (W: 3pin)

678 (W: 6pin)

593 (W: 2pin)

581 (W: 3pin)

580 (W: 3pin)

586 (W: 3pin)

583 (W: 3pin)

588 (W: 3pin)

584 (W: 3pin)

531 (W: 7pin)

587 (W: 3pin)

585 (W: 3pin)

557 (W: 6pin)

577 (W: 3pin)

564 (W: 2pin)

580 (W: 5pin)

561 (W: 2pin)

ELECTRIC PARTS LIST

4

525 (W: 2pin)

562 (W: 2pin)

569 (W: 6pin)

FRONT

4 - 15

Page 17

7075 CONNECTOR LAYOUT DRAWING

[10] Fixing Unit

489 (W: 5pin)

462 (W: 2pin)

451 (BK: 20pin)

450 (B: 8pin)

488 (W: 4pin)

487 (W: 3pin)

486 (W: 2pin)

[11] Paper Exit Section

ELECTRIC PARTS LIST

4

465 (W: 3pin)

464 (W: 3pin)

FRONT

177 (W: 3pin)

480 (W: 3pin)

4 - 16

FRONT

Page 18

[12] Toner Supply Unit

7075 CONNECTOR LAYOUT DRAWING

482 (W: 6pin)

[13] Write Section

184 (W: 4pin)

473 (W: 13pin)

483 (W: 3pin)

193 (W: 6pin)

484 (W: 3pin)

192 (W: 13pin)

190 (W: 12pin)

191 (W: 14pin)

ELECTRIC PARTS LIST

4

583 (W: 5pin)

4 - 17

Page 19

7075 CONNECTOR LAYOUT DRAWING

[14] Printer Control Board

224 (W: 7pin)

291 (N.C.)

230 (W: 3pin)

222 (W: 15pin)

228 (W: 8pin)

227 (W: 9pin)

211 (GY: 60pin)

271 (GY:16pin)

220 (GY: 50pin)

292 (N.C.)

295 (N.C.) 200 (W: 5pin)

290 (N.C.)

[15] Power Supply Management Board

225 (GY: 20pin)

37 (N.C.)

298 (N.C.)

[16] Image Control Board

229 (W: 5pin)

216 (W: 15pin)

218 (W: 12pin)

223 (GY: 20pin)

215 (GY: 18pin)

210 (GY: 30pin)

213 (GY: 60pin)

299 (N.C.)

904 (W: 5pin)

ELECTRIC PARTS LIST

4

900 (W: 8pin)

902 (W: 3pin)

901

(W: 18pin)

903 (W: 4pin)

117 (BK: 168pin)

116 (BK: 168pin)

115 (BK: 168pin)

113 (BK: 120pin)

111 (GY: 8pin)

114 (BK: 168pin)

110 (GY: 34pin)

118 (W: 20pin)

112 (BK: 120pin)

128 (BN: 20pin)

129 (BN: 40pin)

119 (W: 3pin)

120 (BK: 60pin)

4 - 18

Page 20

[17] ICB I/F Board

101 (W: 3pin)

7075 CONNECTOR LAYOUT DRAWING

127 (BK: 120pin)

100 (W: 10pin)

134 (BK: 20pin)

133 (W: 8pin)

132 (W: 13pin)

131 (W: 14pin)

130 (W: 12pin)

[18] ADU Stand Drive Board

500 (W: 8pin)

140 (W: 9pin)

139 (W: 8pin)

135 (GY: 22pin)

137 (GY: 20pin)

138 (W: 13pin)

523 (W: 6pin)527 (W: 7pin)528 (W: 8pin)524 (W: 6pin)

145 (N.C.)

ELECTRIC PARTS LIST

4

501 (W: 2pin)

510 (W: 11pin)

525 (W: 12pin)

526 (W: 10pin)

591 (N.C.)

593 (N.C.)

4 - 19

594 (N.C.)

520 (GY: 28pin)

521 (GY: 16pin)

522 (W: 12pin)

Page 21

7075 CONNECTOR LAYOUT DRAWING

[19] DC Drive Board

301 (W: 2pin)

325

(W: 6pin)

F2

300 (W: 6pin)

Caution: Must use fuses specified by Konica

324 (W: 6pin)

F1

321 (W: 7pin)

323 (W: 7pin)

320 (W: 14pin)

when replacing F1 and F2. If fuses

are not specified by Konica, the

safety feature may not work,

resulting in burn damage to the

board or personal injury.

322

(W: 12pin)

310

(GY: 60pin)

[21] DC Power Supply Unit 1

60 (W: 6pin)

57 (W: 8pin)

58 (W: 8pin)

55 (W: 10pin)

59 (W: 4pin)

54 (W: 5pin)

52 (W: 5pin)

56 (W: 10pin)

53 (W: 7pin)

1 (W: 2pin)

[22] DC Power Supply Unit 2

51 (W: 4pin)

2 (W: 2pin)

Parts specified by Konica

Part Part number

F1 963003200

F2 963003000

[20] AC Drive Board

ELECTRIC PARTS LIST

4

35 (W: 5pin)

420 (GY: 18pin)

36 (N.C.)

410 (GY: 60pin)

400 (W: 8pin)

424 (W: 2pin)

401 (W: 2pin)

FT1 (W: 1pin)

FT3 (W: 1pin)

FT2 (W: 1pin)

FT4 (W: 1pin)

430 (W: 4pin)

440 (W: 5pin)

422 (W: 6pin)

442 (W: 5pin)

71 (W: 7pin)

72 (W: 8pin)

73 (W: 8pin)

74 (W: 10pin)

76 (W: 9pin)

75 (W: 4pin)

FT4 (W: 1pin)

FT1 (W: 1pin)

FT2 (W: 1pin)

FT3 (W: 1pin)

4 - 20

Page 22

7075 CONNECTOR LAYOUT DRAWING

[23] Scanner Drive Board

620 (W: 3pin)

623 (W: 7pin)

622 (W: 4pin)

621 (W: 4pin)

610 (W: 15pin)

600 (W: 6pin)

[24] High Voltage Unit 1

[26] Jam Indicator Board

531 (W:7pin)

[27] L1 Inverter

251 (W:9pin)

[25] High Voltage Unit 2

551 (W:11pin)

250 (W:3pin)

550 (W:4pin)

632 (W: 3pin) 2 (W: 2pin)

[28] Drum Potential Sensor Board

457 (W: 5pin)

458 (W: 4pin)

ELECTRIC PARTS LIST

4

4 - 21

Page 23

7075 CONNECTOR LAYOUT DRAWING

[29] Drum Temperature Sensor Board

455 (W: 4pin)

456 (BK: 2pin)

[30] Operation Board 1

161 (BK: 14pin)

[32] Optional I/F Board

123 (W: 120pin)

122 (BK: 60pin)

124 (W: 120pin)

[33] OB Inverter

165 (W: 3pin)

152

ELECTRIC PARTS LIST

4

[31] Operation Board 2

163 (W: 3pin)

164 (BK: 24pin) 151 (W: 7pin)

162 (W: 4pin)

150 (W: 10pin)

153 (W: 3pin)

160 (BK: 24pin)

166 (W: 4pin)

[34] Toner Control Sensor Board

454 (W: 9pin)

4 - 22

Page 24

7075 CONNECTOR LAYOUT DRAWING

[35] KRDS

219 (W: 11pin)

217 (BK: 25pin)

[36] Index Sensor Board

[39] Polygon Motor Drive Board

130 (W: 5pin)

422 (W: 12pin)

[40] Memory Board

141 (W: 20pin)

442 (W: 11pin)

[37] A/D Converter Board

410 (W: 5pin)

411 (W: 34pin)

[38] Laser Driver Board 1/2

142 (W: 20pin)

[41] LAN I/F Board

144

(W: 8pin)

ELECTRIC PARTS LIST

4

145 (W: 8pin)

440 (W: 12pin)

4 - 23

Page 25

OPTION CONNECTOR LAYOUT DRAWING

DF-313 CONNECTOR LAYOUT DRAWING

4 (W: 7pin)

3 (W: 8pin)

1 (W: 4pin)

16 (W: 3pin)

15 (W: 6pin)

ELECTRIC PARTS LIST

4

49 (W: 3pin)

6 (W: 6pin)

5 (W: 3pin)

14 (W: 6pin)

13 (W: 6pin)

57 (W: 2pin)

7 (W: 9pin)

12 (W: 7pin)

59 (W: 2pin)

8 (GY: 24pin)

64/65 (W: 3pin)

54 (W: 6pin)

61 (W: 2pin)

66 (W: 2pin)

41 (W: 3pin)

10 (W: 6pin)

11 (W: 6pin)

11 (W: 6pin)

51 (W: 3pin)

50 (W: 3pin)

52 (W: 3pin)

53 (W: 3pin)

54/55 (W: 6pin)

35 (W: 3pin)

22 (W: 9pin)

21 (W: 6pin)

34 (W: 3pin)

23 (W: 3pin)

4 - 24

44 (W: 3pin)

45 (W: 3pin)

48 (W: 3pin)

38 (W: 3pin)

39 (W: 3pin)

37 (W: 3pin)

41 (W: 3pin)

Page 26

OPTION CONNECTOR LAYOUT DRAWING

LT-401 CONNECTOR LAYOUT DRAWING

744 (W: 3pin)

742 (W: 3pin)

741 (W: 3pin)

766 (W: 2pin)

784 (W: 2pin)

747 (W: 3pin)

746 (W: 3pin)

765 (W: 2pin)

774 (W: 2pin)

762 (W: 3pin)

749 (W: 3pin)

780 (B: 3pin)

781 (W: 3pin)

783 (W: 3pin)

782 (B: 3pin)

Caution: Must use fuses specified by

Konica when replacing F1. If

fuse is not specified by Konica,

the safety feature may not work,

resulting in burn damage to the

board or personal injury.

745 (W: 3pin)

761 (W: 2pin)

767 (W: 2pin)

773 (W: 3pin)

740 (W: 3pin)

773 (W: 2pin)

771 (W: 2pin)

751 (W: 6pin)

750 (W: 10pin)

720 (W: 5pin)

F1

723 (W: 8pin)

721

(W: 8pin)

722

(GY: 20pin)

ELECTRIC PARTS LIST

4

Parts specified by Konica

Part Part number

F1 963003200

700 (W: 4pin) 710 (GY: 18pin)

4 - 25

Page 27

7075 OVERALL WIRING DIAGRAM (1/5)

CBR1

BK BK

NF

FORMER

751-5

GY

18

305-5

GY

17

305-3

GY

16

305-1

GY

15

TRANS

BK

12-1

90-1

10 11

BK

BK

BK BK

MAIN RELAY

W

4

W

506

12-4

90-2

1

MAIN SWITCH

13-1

RL1

SW1

20-1

BK BK

13-3

2

W

TRC1

504

TRC2

505

100V SYSTEM

BK

501

503

OUTLET

13-2

20-3

BK

RESET SWITCH

SW2

21-1

INLET

W

11-1

10-1

BK BK

21-2

13-4

BK

10-2

W

10-4

W

1

RL3

)

2-1 AC(H

10-3

BK

W

WW W

1

1-1 AC(H

2-2 AC(C

1-2 AC(C

)

)

)

53-1 5VDC

53-2 5VDC

53-3 5VDC

RBR

R

R

172-1

172-2

R

R

20

21

22

53-4 SGND

53-5 SGND

53-6 SGND

B

B

172-3

172-4

177-7

B

B

23

24

25

59-1 12VDC

BN

172-5

BN

27

ICB

59-2 5VDC

59-3 SGND

59-4 SGND

BBB

172-7

172-8

172-9

BBB

R

29

30

31

58-7 SGND

57-2 12VDC

BN

172-10

33

32

54-2 5VDC

54-4 SGND

B

B

R

34

35

36

PRCB

BK

W

W

BVYGYBRB

R

DCPS 1 DCPS 2

57-6 SGND

54-5 V DES

57-1 12VDC

54-1 5VDC

54-3 SGND

57-5 SGND

57-3 12VDC

55-1 5VDC

55-6 SGND

57-7 SGND

58-1 12VDC

56-1 5VDC

60-2 -5VDC

60-4 SGND

56-6 SGND

58-5 SGND

56-3 5VDC

56-8 SGND

55-2 5VDC

55-7 SGND

57-4 12VDC

55-3 5VDC

55-8 SGND

55-4 5VDC

57-8 SGND

60-1 -5VDC

56-7 SGND

B

B

B

B

45

46

ACDB

BN

258-2

47

48

BBBRBRB

R

GY

258-3

258-4

258-5

258-6

258-7

49

50

51

52

ADUSDB

R

R

278-3

278-3

278-4

55

53

54

28

HDD

SCDB

R

GY

26

R

BN

BN

37

41

38

42

39

40

DCDB

BGYBRB

RBR

BN

472-4-5

472-3-6

472-2-7

472-1-8

472-5-4

177-5

177-4

177-3

B

RBR

BN

57

56

LT-401

61

58

62

60

63

72

74

OB

56-2 5VDC

58-5 SGND

58-2 12VDC

BN

177-2

177-1

755-2

66

64

65

ADB

5VDC 52-1

56-5 5VDC

56-10 SGND

60-5 SGND

B

BRB

R

755-3

755-6

89

67

77

FNS

SGND 52-2

56-4 5VDC

56-8 SGND

758-3

758-4

70

DF-313

REM/2 52-3

REM/1 52-4

SW SIG 52-5

SGND 51-1

F GND BT1

58-3 12VDC

BN

342-3

68

PRCB

Y

5VDC 51-2

SGND 51-3

REM/2 51-4

RL2

10-5

PT-3 AC(H

)

SGND 71-1

10-6

PT-4 AC(C

)

72-1 24VDC

O

78 79 80

DCDB

O

5VDC 71-2

SGND 71-3

REM/2 71-4

REM/3 71-5

CUR EM 71-6

NC 71-7

72-5 PGND

72-2 24VDC

72-6 PGND

73-1 24VDC

73-5 PGND

72-4 24VDC

72-8 PGND

73-2 24VDC

73-6 PGND

72-3 24VDC

73-6 PGND

73-3 24VDC

OBKOBKOBKOBKOBKOBKOBKOBKO

BK

258-1

258-8

342-1

342-2

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97

M4

ACDB

ADUSDB

LT-401

PMDB

DPSB

72-7 PGND

73-4 24VDC

73-8 PGND

HDD

74-1 24VDC

74-7 PGND

278-1

278-5

278-2

74-2 24V2

74-8 PGND

74-10 PGND

75-1 24VDC

75-3 PGND

74-9 PGND

75-2 24VDC

75-4 PGND

BK

BKOBK

BKOBK

278-6

278-7

755-1

755-4

755-5

758-1

758-2

100

112 102 103 104 105 106 107 108 109 110 111

98 99

FNS

SCANNER

DF-313

24VDC FT1

24VDC FT2

F GND BT1

76-1 PGND

76-2 PGND

76-3 PGND

76-4 PGND

76-5 PGND

76-6 PGND

BKBKBKBKBKBKBK

M3M2M1

HV1

M15

DCDB

76-8 PGND

76-7 PGND

BK

ACDB

ADUSDB

MS2 MS1

80-1

BK

80-2

BK

81-1

81-2

81-3

81-4

81-5

OOOOOOO

113 114 115 116 117 118 119 120

M3M2M1

HV1

M15

650

651

652

653

654

655

656

80-3

BK

80-4

BK

82-1

82-3

82-2

O

ACDB

DCDB

ADUSDB

4

5

657

658

659

200V SYSTEM

510

509

BN

R

B

B

B

R

R

B

B

TRC1

TRC2

CBR2

100-5 12VDC

100-7 5VDC

100-8 SGND

100-9 SGND

100-10 SGND

100-1 5VDC

100-2 5VDC

100-3 SGND

100-4 SGND

504

505

501

503

503

502

508

APS

SENSOR

PS62

665-3

R

163-9-1

174-1-12

RBNB

5VDC 137-A1

RL3

1

OUTLET

W

3

5

SCANNER

APS

APS

APS

SENSOR

SENSOR

1

2

SENSOR

3

APS

SENSOR

4

5

PS63 PS64 PS65 PS66 PS67 PS68

665-2

665-1

666-3

666-2

666-1

662-3

662-2

662-1

664-3

664-2

664-1

661-3

661-2

661-1

R

R

R

B

B

163-7-3

163-8-2

163-6-4

174-3-10

174-2-11

174-4-9

Y

H

H

PS62 137-A3

PS63 137-A4

137-A2

B

163-5-5

174-5-8

V

H

PS64 137-A5

B

163-4-6

174-6-7

GY

H

PS65 137-A6

R

B

163-3-7

174-7-6

w

H

PS66 137-A7

APS

SENSOR

6

663-3

663-2

R

163-2-8

174-8-5

BK

PS67 137-A8

166-1

166-2

166-3

166-4

OB INVB

165-1

165-2

164-1

164-24

163-1

163-2

OB2

165-3

163-3

L

475-1

GY

475-5

BN

BN

57

475-6

R

R

475-4

B

58

B

60

475-3

Y

475-2

V

LCD

APS

SENSOR

7

161-1

161-14

162-1

161-4

P

160-24

157-5-5

157-4-6

157-3-7

157-2-8

157-1-9

GY

GY

GY

GY

P

CARD TXD 140-9

OB1 RXD ACK 140-4

OB1 TXD REQ 140-5

140-6

140-7

140-8

160-1

442-6

442-7

442-8

442-9

442-10

442-11

442-12

WRITING

442-1

442-13

442-2

442-3

442-4

442-5

442-6

442-7

442-8

442-9

442-10

OB1

442-1

442-2

442-3

442-4

442-5

442-6

442-7

442-8

442-9

442-10

442-11

442-11

442-12

442-12

663-1

660-3

660-2

660-1

R

B

B

LASER

CORRECTION

MOTOR

M24

INDEXSB LDB1 LDB2

442-1

442-2

442-3

442-4

442-5

RCRCRC

136-1-9

195-1

195-2

O

BN

H

PS68 137-A9

O

193-6-1

193-5-2

BN

PPPPP

NC 137-A10

M24 PWR A 133-1

M24 PWR B 133-2

174-9-4

H

195-3

193-4-3

BN

M24 DRIVE A 133-3

195-4

Y

193-3-4

Y

M24 DRIVE A’ 133-4

195-5

193-2-5

V

BOR

M24 DRIVE B 133-5

195-6

GY

193-1-6

GY

w

P

H

H

HLVL 133-7

SMPR 133-8

M24 DRIVE B’ 133-6

194-1

194-2

194-3

194-4

194-5

Y

O

R

BN

192-13-1

192-12-2

192-11-3

192-10-4

192-9-5

GY

GY

GY

GY

P

5VDC 132-1

SGND 132-2

SGND 132-4

M INDEX 1 132-3

194-6

194-7

194-8

194-9

B

V

W

GY

192-8-6

192-7-7

192-6-8

192-5-9

GYGYGY

GY

SGND 132-6

SGND 132-8

S INDEX 1 132-7

M INDEX 2 132-5

194-10

194-11

194-12

194-13

R

O

BK

BN

192-4-10

192-3-11

192-2-12

192-1-13

GY

GY

GY

GY

PPP

H

1PR 132-12

SGND 132-10

HL VL 132-11

S INDEX 2 132-9

Y

191-14-1

191-12-3

191-13-2

GY

GY

GY

5VDC 131-1

SGND 132-13

SGND 131-2

GY

LD1 APC CONT 1 131-3

191-11-4

191-10-5

GY

LD1 APC CONT 2 131-4

191-9-6

191-8-7

191-7-8

191-6-9

GYGYGY

GY

P

H

H

SGND 131-6

LD1 ALM 131-7

LD1 ICLK 131-8

LD1 VIDEO 131-5

GY

LD1 DCLK 131-9

191-5-10

GY

LD1 DI 131-10

191-4-11

191-3-12

GY

GY

LD1 AO 131-11

LD1 PR 131-12

190-12-1

190-11-2

GY

GY

NC 131-13

NC 131-14

5VDC 130-1

SGND 130-2

190-10-3

GY

LD1 APC CONT 1 130-3

190-9-4

GY

LD1 APC CONT 2 130-4

190-8-5

190-7-6

190-6-7

190-5-8

GYGYGY

GY

PHH

SGND 130-6

LD1 ALM 130-7

LD1 ICLK 130-8

LD1 VIDEO 130-5

190-4-9

GY

LD1 DCLK 130-9

190-3-10

GY

LD1 DI 130-10

190-2-11

190-1-12

GY

GY

LD1 AO 130-11

LD1 PR 130-12

ICB IFB - 1 / 2

72

60

475-8

RBR

475-7

B

153-1 5VDC

153-2 NC

154-3 CGND

PPP

157-9-1

157-8-2

157-7-3

157-6-4

GYGYGY

GY

GY

PPP

OB1 TXD 140-1

140-2

140-3

506

507

27

29

30

31

32

21

22

23

24

4 - 27

Page 28

7075 OVERALL WIRING DIAGRAM (2/5)

650

651

652

653

654

655

656

657

658

659

64

65

900-1 5VDC

900-2 SGND

900-6 REM/2

900-3 REM/1

R

20

900-5 5VDC

900-4 SW SIG

900-7 REM/3

900-8 CUREM

901-A1 WT LED

901-A2 ST LED

901-A3 ST SIG

901-A4 ALARM

901-A5 CPU OF

901-A6 IPRL CNT

VWY

R

O

GY

BN

472-3

472-2

472-1

197-5

350-5

GY

61

350-4

B

62

63

350-3

R

350-2

B

350-1

BN

197-4

197-3

197-2

197-1

410-5 -5VDC

410-4 SGND

410-3 5VDC

410-2 SGND

410-1 12VDC

901-A7 WT LON

Y

901-A8 ST LON

B

901-A9 SET CLK

901-B1 ST SIG

901-B2 RING

901-B3 SW SIG

V

GY

RC

411-1 TCK1

411-2 SGND

411-3 TCK2

411-4 SGND

PSMB

901-B4 24R CNT

901-B5 REM/2

901-B6 REM/3

R

O

BK

BN

411-5 RCK1

411-6 SGND

411-7 RCK2

901-B7 CUR EM

901-B8 N/C

901-B9 N/C

Y

411-8 SGND

411-9 TG

411-10 CLMP

411-11 S CK

411-12 S IN

411-13 S LD

176-4-4

140

ADB

411-14 MD 0

411-15 MD 1

411-16 MD 2

904-1 SGND

904-2 VDE REM

904-3 SGND

904-4 IP WEK

BYB

V

176-3-5

176-2-6

176-7-1

141

142

143

411-17 S LP

411-18 SGND

411-19 AD CK

411-20 APR

904-5 N/C

411-21 OD 0

5VDC 903-1

RL3 DRIVE 903-2

5VDC 903-3

RL2 DRIVE 903-4

411-22 OD 1

411-23 OD 2

411-24 OD 3

411-25 OD 4

176-1-7

411-26 OD 5

176-2-6

176-3-5

B

R

BN

5VDC 902-1

SGND 902-2

RING 902-3

L

L

411-27 OD 6

411-28 OD 7

411-29 OD 8

BK

BK

W

W

411-30 SGND

411-31 ED 0

411-32 ED 1

411-33 ED 2

RL3

RL2

KRDS

411-34 ED 3

LAN RB

175-1-13

175-2-12

175-3-11

175-4-10

175-5-9

175-6-8

175-7-7

175-8-6

175-9-5

175-10-4

175-11-3

GYGYGYGYGYGYGYGYGYGYGYGYGY

RING 138-8

ALARM 138-1

ST LON 138-5

CPU OF 138-2

WT LON 138-4

IPRL CNT 138-3

SET CLK 138-6

ST SIG 138-7

REM/2 138-11

SW SIG 138-9

24R CNT 138-10

ICB IFB - 2 / 2

175-12-2

175-13-1

REM/3 138-12

CUR EM 139-13

600

135-A1

B

BN

601

CN 112

CN 112

135-A2

135-A3

R

O

603

602

135-A4

PPPPPPPPP

135-A5

135-A6

135-A7 IPB IFB RXD

135-A8 SGND

135-A9 IPB IFB RXD REQ

135-A10 IPB IFB RXD ACK

135-A11 SGND

135-B1 IPB IFB RXD ERR

Y

BGNBVB

607

606

605

604

W

GY

611

610

609

608

135-B3 PVV

135-B4

135-B5 B VV

R

O

BN

614

613

612

135-B6 S VV

YGNV

615

616

110-1

110-2

110-3

135-B7 BYPAS SIZE

135-B8 EE VV

135-B9

GY

618

617

110-4

110-5

110-6

110-7

110-8

110-9

110-10

110-11

110-12

110-13

110-14

ICB

PPPPPPPPPPPPPPPPP

134-A1 HCLK

134-A2 DFD0

134-A3 DFD1

134-A4 DFD2

134-A5 DFD3

134-A6 DFD4

134-A7 DFD5

135-B10

W

619

134-A8 DFD6

ISW INTERFACE CONNECTER

RC

110-15

110-16

110-17

110-18

134-A9 DFD7

134-A10 PCLK

134-B1 PBUSY

110-19

110-20

110-21

110-22

110-23

134-B2 ADREQ

134-B3 XFLAG

134-B4 HBUSY

134-B5 DAVIL

134-B6 INT

110-24

110-25

110-26

110-27

110-28

134-B7 AC1284

134-B8 SGND

134-B9 SGND

134-B10 SGND

(FOR ISW TOOL)

110-29

110-30

110-31

110-32

101-1 5VDC

101-2 SGND

POWER

CONNECTER

110-33

110-34

DF TXD REQ 137-B2

DF TXD ACK 137-B3

DF RXD REQ 137-B5

DF RXD ACK 137-B6

PPPPPPP

139-1 5VDC

139-2 KRDS TXD

176-8-1

176-7-2

RC

OP IFB

CN 113 CN 113 CN 124

173-8-1

DF TXD 137-B1

P

P

P

DF RXD 137-B4

P

P

P

DF VALID 137-B7

P

PS315 137-B8

L

139-3 KRDS RTS

139-4 KDRS DTR

139-5 KDRS RXD

139-6 KDRS CRS

139-7 KDRS DSD

176-6-3

176-5-4

176-4-5

176-3-6

176-2-7

176-1-8

139-8 KDRS DSR

BN

173-7-2

R

173-6-3

O

173-5-4

Y

173-4-5

B

173-3-6

V

173-2-7

GY

173-1-8

W

CN 123

DF - 313

69

70

102

103

HDD IFB

IP IFB

SGND

140

141

4 - 28

VDB RBM

SGND

IP WEK

142

143

HDD

92

93

IP

28

25

Page 29

7075 OVERALL WIRING DIAGRAM (3/5)

SCANNER

EXPOSURE

LAMP

L1

LV

HV

M13 DRIVE W 620-3

610-5

610-6

INVB

832-1

832-2

BK

BK

831-1

831-2

O

830-1

830-2

O

H

24VDC 623-1

L1 CONT 623-2

610-7

610-8

610-9 FM7 EM

832-3

BK

831-3

831-4

830-3

NC 623-3

L

HHH

610-10 PS5

610-11 PS7

SCANNER

DRIVE

MOTOR

M13

100

96

53

54

95

97

601-7

601-1

O

94

601-2

601-3

601-4

601-5

601-6

O

R

B

B

B

600-3 24VDC

600-4 24VDC

600-1 5VDC

600-2 SGND

600-5 PGND

600-6 PGND

M13 DRIVE U 620-1

610-1

610-2

M13 DRIVE V 620-2

610-3

610-4

SCANNER

COOLING

FAN

FM7

640-1

640-2

640-4

B

L

PGND 621-3

FM7 EM 621-2

FM7 DRIVE 621-1

610-12 PS6

610-13 PS4

610-14 SCAN24V FEM

SCANNER

ADF

BRAKE

ORIGINAL

HP

HP

SENSOR

PS5 PS7 PS6 PS4

650-3

650-2

650-1

651-3

651-2

651-1

652-3

652-2

R

BRB

454-1

454-5

R

L

PS5 622-2

5VDC 622-1

B

SGND 622-3

H

PS7 622-4

R

5VDC 623-4

PS6 623-5

SCDB

610-15 SGND

H

652-1

454-7

SCANNER

B

SGND 623-6

RETURN

SENSOR

653-3

653-2

454-5

653-1

H

PS4 623-7

PAPER SIZE

SENSOR

1-1

PS32 PS33 PS26 PS48 PS20 PS47 PS14 PS34 VR1

270-1

270-2

270-3

R

BN

PAPER SIZE

B

SENSOR

2-1

271-1

271-2

RBY

271-3

NO PAPER

SENSOR 1

275-1

275-2

262-6-1

262-5-2

R

Y

REGISTRATION

SENSOR 1

275-3

262-4-3

B

PAPER

PRE-

276-3

262-3-4

R

276-2

262-2-5

BN

TRAY 1

276-1

262-1-6

B

TRAY

UPPER

LIMIT

SENSOR 1

274-1

274-2

263-3-4

263-2-5

R

TRAY 2 TRAY 3

PAPER

FEED

SENSOR 1

HANDLE

RELEASE

SENSOR 1

PAPER

DETECTION

SENSOR 1

PAPER

SIZE

DETECTION

VR 1

PAPER SIZE

SENSOR

1-2

PAPER SIZE

SENSOR

2-2

NO PAPER

SENSOR 2

PAPER

PRE-

REGISTRATION

SENSOR 2

TRAY

UPPER

LIMIT

SENSOR 2

PAPER

FEED

SENSOR 2

REMAINING

PS35 PS36 PS27 PS50 PS21 PS49 PS15 PS37 VR2

274-3

273-3

273-2

273-1

265-3

265-2

265-1

266-1

266-2

266-3

268-3

268-2

268-1

270-1

270-2

270-3

271-1

271-2

271-3

275-1

275-2

275-3

276-3

276-2

276-1

274-1

274-2

274-3

273-3

273-2

B

R

RBY

B

B

R

R

V

263-1-6

263-6-1

263-5-2

263-4-3

B

B

R

Y

BN

B

R

V

V

B

BN

R

262-6-1

R

262-5-2

Y

Y

262-4-3

B

R

262-3-4

R

BN

262-2-5

BN

B

262-1-6

B

R

263-3-4

R

BN

263-2-5

BN

B

263-1-6

B

R

263-6-1

R

Y

263-5-2

Y

273-1

B

263-4-3

B

HANDLE

RELEASE

SENSOR 2

265-3

265-2

R

V

265-1

B

REMAINING

PAPER

DETECTION

SENSOR 2

266-1

266-2

R

266-3

V

PAPER

DETECTION

268-3

B

SIZE

VR 2

R

PAPER SIZE

SENSOR

1-3

PAPER SIZE

SENSOR

2-3

NO PAPER

SENSOR 3

PAPER

PRE-

REGISTRATION

SENSOR 3

TRAY

UPPER

LIMIT

SENSOR 3

PAPER

FEED

SENSOR 3

PS38 PS39 PS28 PS52 PS22 PS51 PS16 PS40 VR3

268-2

268-1

287-1

287-2

287-3

288-1

288-2

288-3

275-1

275-2

275-3

276-3

276-2

276-1

274-1

274-2

274-3

273-3

273-2

280-2-5

BN

280-1-6

B

280-6-1

R

280-5-2

Y

273-1

280-4-3

B

R

RBY

B

V

B

BN

279-6-1

279-5-2

279-4-3

279-3-4

279-2-5

279-1-6

B

R

Y

280-3-4

B

R

R

BN

HANDLE

RELEASE

SENSOR 3

282-3

282-2

R

V

282-1

B

REMAINING

PAPER

DETECTION

SENSOR 3

283-1

283-2

R

V

DETECTION

283-3

B

PAPER

SIZE

VR 3

268-3

R

268-2

268-1

B

V

GY

GYGYGYGYGYGYGYGYGYGYGYGYGY

M13 V1 216-5

M13 V0 216-6

H

L1 CONT 216-7

L

FM7 CONT 216-8

216-9

216-10

216-11

P

M13 V2 216-4

M13 F/R 216-2

33

BN

CN200-1 12VDC

R

34

26

35

36

CN200-2 5VDC

GY

CN200-3 V_DES

B

CN200-4 SGND

B

CN200-5 SGND

M13 CLK 216-1

M13 CSEL 216-3

216-12

216-13

SCAN24V FEM 216-14

GY

SGND 216-15

250-12

250-14

250-11

250-23

Y

R

W

B

H

PS32 220-A3

5VDC 220-A2

SGND 220-A4

TRAY 1 SET 220-A1

250-15

Y

PS33 220-A6

250-19

Y

H

PS26 220-A10

250-21

GY

H

PS48 220-A13

250-17

GY

H

PS20 220-A8

250-22

BK

H

PS47 220-A14

250-16

V

H

PS14 220-A7

250-18

250-10

250-20

R

V

BK

L

PS34 220-A9

5VDC 220-A11

251-12

251-14

W

H

VR1 220-A12

TRAY 2 SET 220-A17

251-11

251-23

251-15

Y

R

B

PS35 220-A19

5VDC 220-A18

SGND 220-A20

251-19

Y

Y

H

PS36 220-A22

PS27 220-B1

251-21

GY

H

PS50 220-B4

251-17

GY

H

PS21 220-A24

251-22

BK

H

PS49 220-B5

251-16

V

H

PS15 220-A23

251-18

251-10

251-20

R

V

BK

L

VR2 220-B3

PS37 220-A25

5VDC 220-B2

252-12

252-14

252-11

252-23

Y

R

W

B

H

PS38 220-B13

5VDC 220-B12

SGND 220-B14

TRAY 3 SET 220-B11

252-15

Y

NC 220-B15

PS39 220-B16

252-19

Y

H

PS28 220-B20

252-21

GY

H

PS52 220-B23

252-17

GY

H

PS22 220-B18

252-22

BK

H

PS51 220-B24

252-16

252-18

V

H

PS16 220-B17

252-10

252-20

R

V

BK

L

VR3 220-B22

PS40 220-B19

5VDC 220-B21

PRCB - 1 / 3

H

228-4 M15 CONT

228-5 M15 EM

108

BNVBK

470-9-5

470-8-6

470-7-7

GY

473-5-9

473-6-8

473-7-7

Y

W

BK

184-2

184-3

184-4

H

228-6 M3 CONT

114

Y

O

182-1

182-2

DEVELOPING

MOTOR

H

HHHHH

211-A1

211-A2 M19 CONT

211-A3

211-A4

211-A5 MC4 CONT

211-A6 SD5 CONT

211-A7 MC3 CONT

211-A8 SD8 CONT

78

O

300-1 24VDC

BN

37

38

39

40

79

118

109

R

B

B

BK

O

BK

300-2 12VDC

300-3 5VDC

300-4 SGND

300-5 SGND

300-6 PGND

301-1 24VDC

301-2 PGND

H

320-1 24VDC

320-2 M19 CONT

OBKOYV

250-3

250-4

250-5

O

O

BK

O

264-1

264-2

260-1-2

M19

MC3 MC4 SD8 SD5

UP

FEED

DRIVE

CLUTCH 1

MOTOR 1

H

H

320-3 24VDC

320-4 MC3 CONT

320-5 MC4 CONT

250-6

250-7

V

Y

O

260-2-1

261-1-2

261-2-1

SOLENOID 1

PRE-

REGISTRATION

CLUTCH 1

O

272-1-2

PICK-

UP

250-8

272-2-1

H

320-6 SD8 CONT

GY

BN

H

310-A2

12V_F 310-A1

H

320-7 SD5 CONT

Y

250-9

Y

O

267-1

267-2

LOCK

SOLENOID 1

M19 EM 310-A3

L

M19 FEM 310-A4

310-A5

310-A6

310-A7

H

320-8 24VDC

320-9 M20 CONT

OBKOYV

251-3

251-4

O

BK

264-1

264-2

M20

UP

DRIVE

CLUTCH 2

MOTOR 2

310-A8

TRAY 1 TRAY 2 TRAY 3 BY-PASS DRUMVERTICAL

HHHHH

211-A9 M20 CONT

211-A10

211-A11

211-A12 MC6 CONT

211-A13 SD6 CONT

211-A14 MC5 CONT

L

310-A9

310-A12

310-A13

310-A14

M20 EM 310-A10

M20 FEM 310-A11

H

H

H

320-10 24VDC

320-11 MC5 CONT

320-12 MC6 CONT

320-13 SD9 CONT

GY

251-5

251-6

251-7

251-8

V

O

260-1-2

Y

260-2-1

O

261-1-2

261-2-1

O

272-1-2

BN

272-2-1

MC5 MC6 SD9 SD6

FEED

PRE-

REGISTRATION

CLUTCH 2

PICK-

UP

SOLENOID 2

SOLENOID 2

211-A15 SD9 CONT

211-A16 M21 CONT

310-A15

310-A16

H

320-14 SD6 CONT

Y

251-9

Y

O

267-1

267-2

LOCK

211-A17

M21 EM 310-A17

211-A18

L

M21 FEM 310-A18

HHH

H

211-A19 MC8 CONT

211-A20 SD7 CONT

211-A21 MC7 CONT

211-A22 SD10 CONT

310-A19

310-A20

310-A21

310-A22

H

321-1 24VDC

321-2 M21 CONT

OBKOYV

252-3

252-4

252-5

281-1

281-2

277-1-2

M21

MC7 MC8 SD10 SD7

UP

FEED

DRIVE

CLUTCH 3

MOTOR 3

211-A23 M22 TR1

211-A24 M22 TR2

211-A25 M22 TR3

310-A23

310-A24

310-A25

H

H

321-3 24VDC

321-4 MC7 CONT

321-5 MC8 CONT

252-6

252-7

277-2-1

278-1-2

278-2-1

SOLENOID 3

PRE-

REGISTRATION

CLUTCH 3

211-A26 M22 TR4

211-A27

L

310-A26

M22 FEM 310-A27

H

321-6 SD10 CONT

GY

252-8

289-1-2

289-2-1

PICK-

UP

SOLENOID 3

HHH

211-A28 SD11 CONT

211-A29 MC9/10 CONT

310-A28

310-A29

H

321-7 SD7 CONT

Y

252-9

285-1

285-2

LOCK

211-A30 M23 CONT

211-B1 M23 F/R

310-A30

311-B1

211-B2

M23 EM 311-B2

211-B3 M14 PL

211-B4 M14 NL

311-B3

322-1 M22 DRIVE 1

BN

254-1-12

247-1

M22

UP/DOWN

MOTOR

(BY-PASS)

211-B5 M14 PR

211-B6 M14 NR

211-B7

211-B8

311-B5

311-B6

M14 CEM 311-B7

L

M14 24FEM 311-B8

311-B4

H

322-2 M22 DRIVE 2

322-3 24VDC

322-4 SD11 CONT

322-5

V

O

BN

254-2-11

254-3-10

254-4-9

247-2

248-2-1

248-1-2

SD11 MC9 MC10

PICK-

UP

SOLENOID

(BY-PASS)

H

H

211-B9 SD4 CONT

211-B10 PCL CONT

311-B9

311-B10

H

322-6 24VDC

322-7 MC9 CONT

Y

O

253-1-10

253-2-9

YOV

OO

290-1-2

290-2-1

VERTICAL

CONVEYANCE

CLUTCH 1

PAPER

FEED

211-B11

211-B12

24VDC 311-B11

24VDC 311-B12

H

322-8 M10 CONT

BN

253-3-8

291-1-2

291-2-1

VERTICAL

CONVEYANCE

CLUTCH 2

211-B13

5VDC 311-B13

P

211-B14 M11 CLK

211-B15

311-B14

SGND 311-B15

323-1 M14 DRIVE 1

O

341-15

O

355-1

M14

CLEANING

BLADE

MOTOR

P

211-B16 M11 VREF

211-B17

211-B18 M6 CLK

L

311-B16

M11 FEM 311-B17

323-2 M14 DRIVE 2

323-6 M23 DRIVE 1

R

BK

341-17

341-18

341-16

341-24

B

R

BK

353-3-9

353-2-10

355-2

B

R

359-1

359-3

M23

CHARGER

CLEANING

MOTOR

211-B19 SGND

211-B20 M6 F/R

311-B18

311-B19

311-B20

323-7 M23 DRIVE 2

B

B

BK

353-1-11

BK

359-2

L

211-B21 M11 RES

211-B22 M6 OFF

311-B21

311-B22

323-3 24VDC

O

341-12

341-13

O

354-1

354-2

SD4

SEPARATION

CLAW

SOLENOID

211-B23 M6 VREF

211-B24

L

311-B23

M6 24FEM 311-B24

H

323-4 SD4 CONT

V

O

V

353-11-1

356-1-2

PCL

PCL

H

323-5 PCL CONT

BK

341-14

BKBKOBK

353-10-2

356-2-1

211-B25

FM5 EM 311-B25

12

340-2

352-1

355-9

L

L

211-B26 FM5 CONT

211-B27 FM5 H/L

311-B26

311-B27

13

340-3

W

352-2

HTR1

211-B28

211-B29

211-B30

L

SGND 311-B30

24VDC 311-B29

FM5 FEM 311-B28

PPPPPPP

324-1 24VDC

324-2 24VDC

324-3 M11 DRIVE A

OOV

470-6-8

470-5-9

470-4-10

GYGYGYGYGY

473-8-6

473-9-5

473-10-4

OOYBNV

482-1-6

482-2-5

482-3-4

M11 M6

TONER

SUPPLY

MOTOR 1

324-4 M11 DRIVE A

324-5 M11 DRIVE B

YBNV

470-3-11

470-2-12

473-11-3

473-12-2

W

482-4-3

482-5-2

324-6 M11 DRIVE B

325-1 24VDC

325-2 24VDC

470-1-13

GY

473-13-1

482-6-1

LOOP

ROLLER

MOTOR

DCDB

P

325-3 M6 DRIVE A

325-4 M6 DRIVE A

325-5 M6 DRIVE B

325-6 M6 DRIVE B

L

L

322-9 FM5/FM8 DRIVE

322-10 FM5/FM8 H/L

322-11 FM5 EM

322-12 PGND

O

Y

BN

BK

471-6

471-8

471-7

471-9

76-1

76-3

76-2

76-4

FM5

WRITE

SECTION

COOLING

FAN 1

77-1

77-2

FM8

WRITE

SECTION

COOLING

FAN 2

77-3

L

228-1 TLD CONT

228-2 TLD

228-3 SGND

V

R

B

117

O

470-13-1

470-12-2

470-11-3

470-10-4

GYGYGY

GYGYGY

473-1-13

473-2-12

473-3-11

V

R

B

473-4-10

O

483-3-1

483-2-2

483-1-3

GYGYGY

184-1

484-1

484-2

484-3

M15

TLD

TONER

TONER

SUPPLY

LEVEL

MOTOR 2

DETECTION

SENSOR

77-4

P

228-7 M3 CLK

228-8 M3 EM

116 107

105

BNVBKOBNVBK

182-3

182-4

182-5

181-1

181-2

M3

MAIN

MOTOR

H

229-1 M1 CONT

229-2 M1 EM

181-3

181-4

M1

2-1 SGND

2-2 24VDC

P

230-1

230-2 M17 CLK

86

Y

O

BN

474-1

474-2

474-3

474-4

583-5

583-1

583-2

583-3

O

Y

BK

130-5

130-2

M17 EM 130-1

2-3 M17 MAG A’

2-4 M17 MAG A

2-5 M17 MAG B’

2-6 M17 MAG B

M17

POLYGON

MOTOR

H

230-3 M17 CONT

87

V

BK

474-5

583-4

V

BN

130-3

130-4

PMDB

PPP

2-7 M17 MAG C’

2-8 M17 MAG C

2-9 M17 DRIVE C

H

220-A15 FEEDM_CONT

88

O

Y

306-1

183-1

183-2

183-3

M4

PAPER

FEED

MOTOR

2-10 M17 DRIVE B

2-11 M17 DRIVE A

H

220-A16 FEEDM_EM

229-3 M2 CONT

229-4 M2 F/R

229-5 SGND

229-6 M2 EN

115 106

89

W

306-2

183-4

V

Y

Y

O

BN

BK

158-1

158-2

158-3

158-4

158-5

Y

V

O

W

BN

180-1

180-2

180-3

180-4

180-5

M2

DRUM

MOTOR

BK

158-6

BK

180-6

4 - 29

Page 30

7075 OVERALL WIRING DIAGRAM (4/5)

BY-PASS VERTICAL PAPER FEED FIXING

PAPER SIZE

SENSOR

1

PAPER SIZE

SENSOR

PAPER SIZE

DETECTION

VR

(BY-PASS) (BY-PASS) (BY-PASS) (BY-PASS)

NO

PAPER

SENSOR

2

TRAY

LOWER

LIMIT

SENSOR

(BY-PASS) (BY-PASS)

VR4 PS29 PS55 PS56 PS43 PS23

241-3

241-2

241-1

244-1

244-2

244-3

242-3

242-2

242-1

243-3

243-2

243-1

245-1

245-2

245-3

R

B

W

254-4-4

254-6-7

Y

L

PS43 222-6

254-1-12

254-8-5

254-3-10

V

B

R

VR4 222-8

5VDC 222-1

SGND 222-3

R

Y

B

254-1-7

254-2-6

254-3-5

254-2-11

Y

L

PS29 222-2

254-4-9

BN

PS55 222-4

254-5-8

V

PS56 222-5

H

213-A1 RL1 DRIVE

213-A2 RL1 SIG

213-A3 C(T) DRIVE

213-A4

213-A5 ACV EM1

213-A6 ZERO CROSS

213-A7 HTR CONT

213-A8 L2 CONT

TRAY

UPPER

LIMIT

SENSOR

246-3

R

HHH

213-A9 L3 CONT

213-A10 L2/L3 CONT

246-2

246-1

B

Y

254-5-3

254-7-6

BN

H

PS23 222-7

P

213-A11 L4 CONT

213-A12 AC5V FEM

213-A13 AC12V FEM

213-A14 M16 CLK

LOOP

SENSOR

VERTICAL

CONVEYANCE

SENSOR

1

VERTICAL

CONVEYANCE

SENSOR

2

VERTICAL

CONVEYANCE

SENSOR

3

PS54 PS18 PS53 PS19 PS17

292-3

292-2

292-1

293-3

293-2

293-1

294-3

294-2

294-1

295-3

295-2

R

B

Y

253-7-4

253-6-5

253-5-6

B

R

BN

H

PS54 222-10

5VDC 222-9

SGND 222-11

H

213-A15 SGND

213-A16 M16 CONT

213-A17

213-A18 HTR1 DRIVE

213-A19 DH OPEN

R

B

BN

253-4-7

Y

H

PS18 222-12

P

213-A20 M10 CLK

213-A21 SGND

213-A22 M10 VREF

213-A23 M10 RES

213-A24 M10 OFF

R

Y

253-3-8

BN

H

PS53 222-13

213-A25

213-A26

B

213-A27

213-A28

295-1

R

V

253-2-9

V

H

PS19 222-14

L

213-A29

213-A30

213-B1 FM3 CONT

B

OPEN/CLOSE

DETECTION

L

213-B2 FM3 H/L

213-B3

296-3

296-2

296-1

R

B

GY

253-1-10

Y

H

PS17 222-15

L

L

213-B4

213-B5 FM4 CONT

213-B6 FM4 H/L

213-B7

L

213-B8

213-B9 FM6 CONT

451-1

FIXING

EXIT

SENSOR

PS2 PS3

464-1

464-2

464-3

B

R

W

BK

451-12

451-13

451-15

451-17

RYO

W

GY

H

H

PS2 223-A9

5VDC 223-A2

5VDC 223-A3

SGND 223-B2

FIX SET 1 223-A1

L

213-B10 FM6 H/L

213-B11

213-B12

SENSOR

H

213-B13 FM2 CONT

213-B14 NC

213-B15

FIXING

JAM

465-1

465-2

465-3

R

W

451-14

451-16

451-18

B

V

H

PS3 223-A10

5VDC 223-A4

213-B16

FIXING

1

TH1

466-1-2

R

451-2

W

466-2-1

R

451-3

BN

FIXING

TEMPARATURE

SENSOR

2

TH2

467-1-3

467-3-1

W

451-4

451-5

BN

TEMPARATURE

B

BK

451-19

451-10

V

O

GY

SENSOR

L

FIX SET 2 223-B1

TH1 ANG 1 223-A5

TH1 ANG 2 223-A6

TH2 ANG 1 223-A7

223-B3

223-B4

213-B17 AC ENB

213-B18

213-B19 C(K) SIG

213-B20 C(K) CONT

213-B21

213-B22

213-B23

213-B24

W

O

TH2 ANG 2 223-A8

213-B25

FIXING

TEMPARATURE

SENSOR

3

TH3

468-1-4

BK

451-6

O

TH3 ANG 1 223-B5

213-B26

213-B27

213-B28

468-3-2

BK

451-7

V

TH3 ANG 2 223-B6

213-B29

FIXING

TEMPARATURE

SENSOR

213-B30

4

TH4

469-2-4

B

451-8

R

TH4 ANG 1 223-B7

BLADE

BLADE

SENSOR

SENSOR

1

2

PS30 PS31 PS41 PS42

360-1

360-2

360-3

361-1

361-2

355-3

355-4

355-5

355-6

469-4-2

B

451-9

R

R

341-19

341-20

R

5VDC 225-A1

V

R

B

341-21

V

B

PS30 225-A2

SGND 225-A3

355-7

Y

341-22

Y

PS31 225-A4

TH4 ANG 2 223-B8

CHARGING

WIRE

CLEANING

PAD HP

SENSOR

361-3

357-1

357-2

357-3

355-8

353-3-9

353-4-8

353-5-7

B

B B

Y Y

R R

341-11

Y

L

NC 225-A5

PS41 225-A6

SGND 225-A7

PRCB - 2 / 3

CHARGING

WIRE

CLEANING

PAD LIMIT

SENSOR

358-1

358-2

358-3

353-6-6

353-7-5

353-8-4

R R

W W

341-23

W

H

PS42 225-A8

DRUM

DPS

DPS ANG 1 457-3

DPS ANG 2 457-4

DPS DRIVE A 457-1

DPS DRIVE B 457-2

DPSB

458-1

458-2 DPS ANG

458-3

458-4

Y

B

B

O

350-4-1

350-3-2

350-2-1

340-1

340-4

90 91

350-1-4

340-5

340-6

340-12

340-11

68

B B

224-6

H

AGND 224-7

DRUM SET 224-1

TEMPARATURE

TH5

TH5 ANG 1 456-1

TH5 ANG 2 456-2

DTSB

455-1

455-2

455-3 DRUM TEMP

455-4

Y

B

R

O

351-4-1

351-3-2

351-2-3

351-1-4

340-7

340-8

340-9

340-10

224-4

5VDC 224-3

AGND 224-5

12VDC 224-2

DRUM

SENSOR

TONER CONTROL SENSOR

454-1

R

341-1

R

5VDC 225-B1

BOARD

TCSB

454-2

454-3

454-4

454-5

454-6 Dmax SIG

454-7 Dmax MONI

Y

Y

V

V

W

W

341-2

341-3

341-4

341-5

341-6

341-7

V

Y

Y

W

BK

GY

LLL

γ LED CONT 225-B4

JAM LED CONT 225-B5

γ /Dmax LED Vref 225-B3

Dmax LED CONT 225-B2

225-B6

225-B7

454-9 JAM SIG

454-8 γ SIG/MONI

Y

W

341-8

341-9

VGYB

225-B8

225-B9

454-10

BN

341-10

AGND 225-B10

400-1 24VDC

400-2 12VDC

400-3 5VDC

400-4 SGND

400-5 SGND

R

O

B

B

BN

80

41

42

45

46

BN

410-A1

400-6 SGND

401-1 24VDC

401-2 PGND

BK

BK

81

119

110

Y

R

O

H

410-A2

410-A3

(C)T FEM 410-A4

PPP

422-1 24VDC

422-2 24VDC

422-3 M10 DRIVE A

422-4 M10 DRIVE A

422-5 M10 DRIVE B

GYGYGYGYGY

431-1-6

431-2-5

431-3-4

431-4-3

431-5-2

M10

PAPER

EXIT

MOTOR

V

B

GN

410-A7

ACV EM1 410-A5

ZERO CROSS 410-A6

L

L

P

422-6 M10 DRIVE B

420-A1 FM3 DRIVE

O

GY

431-6-1

85-1

85-3

W

GY

410-A8

410-A9

420-A2 FM3 H/L

420-A3 FM3 EM

420-A4 PGND

Y

W

BK

85-2

85-4

R

BK

BN

410-A10

410-A11

AC5V FEM 410-A12

L

L

420-A5 FM4 DRIVE

420-A6 FM4 H/L

V

O

86-1

86-3

86-2

Y

O

410-A14

AC12V FEM 410-A13

420-A7 FM4 EM

420-A8 PGND

88-1

W

BK

86-4

179-1

GN

410-A15

L

FM3 FM4 FM6 FM2

MAIN BODY

MAIN BODY

COOLING

FAN

2

MAIN BODY

COOLING

COOLING

FAN

1

V

B

L

410-A16

M16 VEM 410-A17

L

420-B2 FM6 DRIVE

420-B3 FM6 H/L

420-B4 FM6 EM

420-B5 PGND

Y

O

W

BK

88-3

88-2

88-4

179-3

179-2

179-4

FAN

3

W

GY

BK

410-A18

410-A20

DH OPEN 410-A19

L

420-B6 FM2 DRIVE

420-B7 NC

87-1

DEVELOPING

SUCTION

FAN

R

BN

410-A21

410-A22

420-B8 FM2 EM

420-B9 PGND

W

BK

87-2

87-3

Y

O

GN

410-A23

410-A24

M10 24FEM 410-A25

H

420-A9 24VDC

420-B1 C(T) CONT

O

BK

88-5

88-6

170-2-7

170-1-8

85-1

85-2

)

C(T

TOTAL

COUNTER

V

B

W

GY

BK

BN

NC 410-A26

15

250-1

269-1

410-B1

NC 410-A27

NC 410-A28

NC 410-A29

NC 410-A30

430-1 HTR2 CONT

430-2 HTR3 CONT

BK

BK

305-2

305-4

BK

BK

GY

GY

GY

250-13

251-1

251-13

252-1

GY

GY

269-2

269-1

269-2

307-1

HTR216HTR317HTR418HTR101

Y

R

O

L

FM3 EM 410-B3

FM3 FEM 410-B4

HFAN1 HL 410-B2

430-3 HTR4 CONT

BK

305-6

BK

GY

252-13

751-5

751-6

307-2

361-1

361-2

LT-401

B

GNVGY

410-B5

410-B6

FM4 EM 410-B7

430-4 HTR101 CONT

FT3 HTR1 CONT

343-1

BK

12 13 10 11

W

BK

410-B10

L

410-B9

FM4 FEM 410-B8

H

FT4 HTR1 DRIVE

343-2

Y

R

O

BN

L

410-B13

FM6 EM 410-B11

SFAN HL 410-B14

FM6 FEM 410-B12

FT2 AC30V(H)

FT1 AC30V(C)

BK

551-7

551-17

V

B

GN

L

AC ENB 410-B17

FM2 EM 410-B15

FM2 FEM 410-B16

L

400-7 24VDC

400-8 RL1 CONT

90-5

90-6

RL1

MAIN

RELAY

W

GY

410-B19

C(K) FEM 410-B18

R

BK

BN

410-B20

VENDER FEED 410-B22

VENDER CPOY 410-B21

Y

O

PAPER SIZE 0 410-B23

PAPER SIZE 1 410-B24

424-1 M16 DRIVE 1

424-2 M16 DRIVE 2

R

B

451-11

451-20

W

BK

M16

WEB

DRIVE

MOTOR

B

GN

PAPER SIZE 2 410-B25

PAPER SIZE 3 410-B26

442-4 L4 DRIVE

440-1 L2 DRIVE

500 502

501 503

500 502

450-3

450-1

462-1CN450-8

L4L2L3

W

TS1

CN450-5

BK

BK

CN14-1

BK

2

V

W

GY

NC 410-B28

NC 410-B29

VENDER double slded 410-B27

442-1 L3 DRIVE

504

W

BK

450-2

W

BK

TS2

BK

SGND 410-B30

440-2 L2 TRIG

442-2 L3 TRIG

440-4 AC(C)

442-5 AC(C)

442-3 AC(C)

505

4

506

ACDB

440-3 T3 DRVG

507

100V SYSTEM

35-1 24VDC

35-2 C(K)

35-3 SGND

35-4 C(K) CONT

35-5 PGND

953-1

953-2

953-5

935-6

)

C(K

VENDOR

PAPER SIZE 0 36-3

VENDER FEED 36-2

VENDER CPOY 36-1

COIN

PAPER SIZE 1 36-3

PAPER SIZE 2 36-3

NC 36-8

PAPER SIZE 3 36-3

VENDER double slded 36-7

NC 36-9

PGND 36-10

451-11

BK

M16

WEB

DRIVE

MOTOR

451-20

W

501

W

W

450-3

450-1

462-1

L4L2L3

R

R

TS1

TS2

CN450-8

CN450-5

BKBKBK

CN14-1

BK

2

502

CN450-6

509 508

504

W

450-2

BK

CN450-7

505

507

510

4

506

BK

200V SYSTEM

4 - 30

Page 31

7075 OVERALL WIRING DIAGRAM (5/5)

HV1

255-1 24VDC

255-2 12VDC

256-1 SGND

256-2

256-3

256-4

256-5

256-6

256-7

256-8 C SIG

256-9 B FB

R

O

GYGYGYGYGYGYGYGYGY

113

68

255-3 PGND

BK

104

600

601

B

BN

604

603

602

R

O

609

608

607

606

605

Y

BGNBVB

619

618

PAPER

617

EXIT

616

SENSOR

615

614

613

612

611

610

PS61

480-3

R

480-2

480-1

B

Y

FRONT

DOOR

OPEN/CLOSE

SENSOR

1

PS24 PS25

85-3

85-2

85-1

B

Y

R

81-1-6

81-2-5

81-3-4

FRONT

DOOR

OPEN/CLOSE

SENSOR

2

87-3

87-2

V

R

81-4-3

81-5-2

87-1

B

81-6-1

FS - 108

FS - 108BM

177-1-3

170-3-6

170-6-3

177-2-2

170-2-7

170-5-4

177-3-1

170-1-8

170-4-5

Y

BBB

GY

BN

GY

GN

Y

V

R

O

W

O

RRR

W

BN

PPP

215-B2 S SHIFT(DC)

215-B3

215-B4

215-B5 S SHIFT(AC)

Y

R

O

BN

540-11

540-12

540-13

540-14

Y

R

O

BN

P

215-B6 T SHIFT

215-B9 SGND

215-B7 ADU MCLK

P

B

W

540-15

540-18

540-16

540-17

P

B

W

P

215-B8

215-A8 ADU REQ

V

GY

540-8

540-7

V

GY

P

215-A7 ADU ACK

215-A6

215-A5

P

B

V

540-6

540-5

P

B

V

PPP

215-A4

215-A3 ADU LATCH

Y

OBNR

540-4

540-3

Y

OBNR

540-2

215-A2 ADU TXD CLK

215-A1 ADU TXD

540-1

510-1

510-2

510-3

510-4 ADU RXD CLK

510-8 ADU ERR

510-6 ADU RXD

510-7

510-5

510-9 RESIST

510-10

510-11

PRCB - 3 / 3

TRANSFER

MOTOR

557-6-1

557-5-2

GYGYGYGYGY

24VDC 527-1

24VDC 527-2

P

P

P

REVERSE

M9 M7 M8

557-4-3

557-3-4

557-2-5

557-1-6

GY

PPP

P

24VDC 523-1

M9 DRIVE A 527-3

M9 DRIVE A 527-4

M9 DRIVE B 527-5

M9 DRIVE B 527-6

PAPER

REVERSE

SENSOR

ADU

CONVEYANCE

PPP

M7 DRIVE A 523-3

M7 DRIVE A 523-4

M7 DRIVE B 523-5

MOTOR

559-6-1

559-5-2

GYGYGYGYGY

P

24VDC 528-1

24VDC 528-2

M7 DRIVE B 523-6

MOTOR

24VDC 523-2

ADU

559-4-3

M8 DRIVE A 528-3

559-3-4

REGISTRATION

560-1

559-2-5

559-1-6

GY

P

24VDC 521-A1

M8 DRIVE A 528-4

M8 DRIVE B 528-5

M8 DRIVE B 528-6

MOTOR

M12

560-2

560-3

HPPPP

M12 CONT 521-A5

560-4

M12 EM 521-A7

M12 CLK 521-A6

227-1

HHH

C SHIFT 227-4

G SHIFT 227-5

C CONT 1 227-2

C CONT 2 227-3

PAPER

REVERSE

/EXIT

MOTOR

M5

560-5

PPP

PGND 521-B12

24VDC 524-1

24VDC 524-2

M5 DRIVE A 524-3

M5 DRIVE A 524-4

M5 DRIVE B 524-5

227-9

B CONT 227-6

B SHIFT 227-7

227-8

PAPER

TRANSFER

/SEPARATION

CLEANING

MOTOR

EXIT

FAN

M18 FM1

561-1

561-2

592-1

592-2

592-3

O

Y

W

BK

BK

M18 DRIVE 1 520-B7

M18 DRIVE 2 520-B8

LLL

PGND 525-5

FM1 EM 525-4

FM1 DRIVE 525-3

P

M5 DRIVE B 524-6

P

IPB IFB TXD 210-A1

FIXING

GUIDE

SOLENOID

SD3 SD1 SD2 MC2 MC1 PS46 PS44 PS45

562-2-1

210-A7

210-A8

PPP

SGND 210-A2

SGND 210-A5

IPB IFB TXD ACK 210-A4

IPB IFB TXD REQ 210-A3

IPB IFB TXD ERR 210-A6

ADU

LOCK

SOLENOID

593-2-1

593-1-2

562-1-2

O

O

VBNO

Y

H

H

24VDC 520-B13

24VDC 522-1

SD3 CONT 520-B10

SD1 CONT 522-3

210-A9

210-A10

210-A11

210-A12

210-A13

PAPER

REVERSE

GATE

-REGISTRATION

SOLENOID

CLUTCH

525-2-1

525-1-2

H

24VDC 525-1

SD2 CONT 525-2

210-A15

210-B1

210-B2

210-B3

RESET 210-B4

TONER 210-A14

RESET CONT 210-B5

ADU

REGISTRATION

PRE

CLUTCH

565-2-1

O

24VDC 521-B11

564-1-2

Y

H

MC2 CONT 521-A8

565-1-2

O

GY

H

24VDC 520-B14

MC1 CONT 520-B11

564-2-1

5VDC 210-B6

5VDC 210-B7

ADUSDB

L

520-B5 PS11

520-B3 SGND

520-B2 5VDC

R

B

BN

576-3-4

576-4-3

B

R

BN

585-1

586-3

TRANSFER

/SEPARATION

WIRE

CLEANING

PAD LIMIT

SENSOR

H

520-B6 PS12

520-B4 SGND

Y

B

576-5-2

576-6-1

Y

B

586-2

586-1

587-3

HANDLE

RELEASE

SENSOR

522-2 5VDC

522-4 PS10

522-5 SGND

520-A1 24VDC

O

568-1-8

Y

R

B

O

587-2

587-1

591-10

ADU

PAPER MIS-CENTERING

520-A3 -5VDC

GY

568-2-7

GY

591-4

568-3-6

591-3

H

H

H

H

H

H

H

525-7 5VDC

525-9 PS57

525-11 SGND

525-6 5VDC

525-8 PS8

525-10 SGND

521-A2 5VDC

521-B3 PS58

521-B8 SGND

521-A13 5VDC

521-B6 PS9

521-B10 SGND

521-B1 5VDC

521-B7 PS13

521-B11 SGND

521-A12 5VDC

521-B5 PS59

521-B9 SGND

521-A4 5VDC

521-B4 PS60

521-A10 SGND

521-B1 5VDC

V

Y

R

571-3-1

B

578-3

571-2-2

Y

578-2

B

571-1-3

R

578-1

R

554-3-1

579-3

554-2-2

579-2

B

554-1-3

579-1

R

553-3-1

580-3

V

553-2-2

580-2

B

553-1-3

580-1

R

572-3-1

581-3

572-2-2

581-2

Y

R

R

R

B

B

B

573-1-3

582-1

574-3-1

583-3

W

574-2-2

583-2

574-1-3

583-1

575-3-1

584-3

BN

572-1-3

573-3-1

573-2-2

581-1

582-3

582-2

R

B

GY

575-2-2

575-1-3

576-1-6

576-2-5

B

R

Y

R

584-2

584-1

585-3

585-2

PS57 PS8 PS58 PS9 PS13 PS59 PS60 PS11 PS12 PS10 PS1

PAPER

REVERSE

/CONVEYANCE

SENSOR

ADU

PAPER

REVERSE

SENSOR

PAPER

CONVEYANCE

SENSOR

ADU

ADU

NO PAPER

DECELERATION

SENSOR

ADU

SENSOR

ADU PRE-

REGISTRATION

SENSOR

TRANSFER/

SEPARATION

WIRE

CLEANING

PAD HP

SENSOR

PS61 210-B9

PS24 210-B10

PS25 210-B11

5VDC 210-B8

SGND 210-B12

ADU

REGISTRATION

EXIT

SENSOR

SENSOR

588-3

588-2

588-1

577-1-3

577-2-2

577-3-1

Y

B

R

H

PS46 521-B2

5VDC 521-A3

SGND 521-A9

520-A2 5VDC

520-A4 PS1 VIDEO

520-A5 PS1 SI

520-A6 PS1 CLK

520-A7 PS1 LED

520-A8 SGND

Y

R

V

B

BN

GY

568-4-5

568-5-4

568-6-3

568-7-2

568-8-1

Y

R

V

B

BN

GY

591-1

591-6

591-8

591-9