Page 1

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Page 2

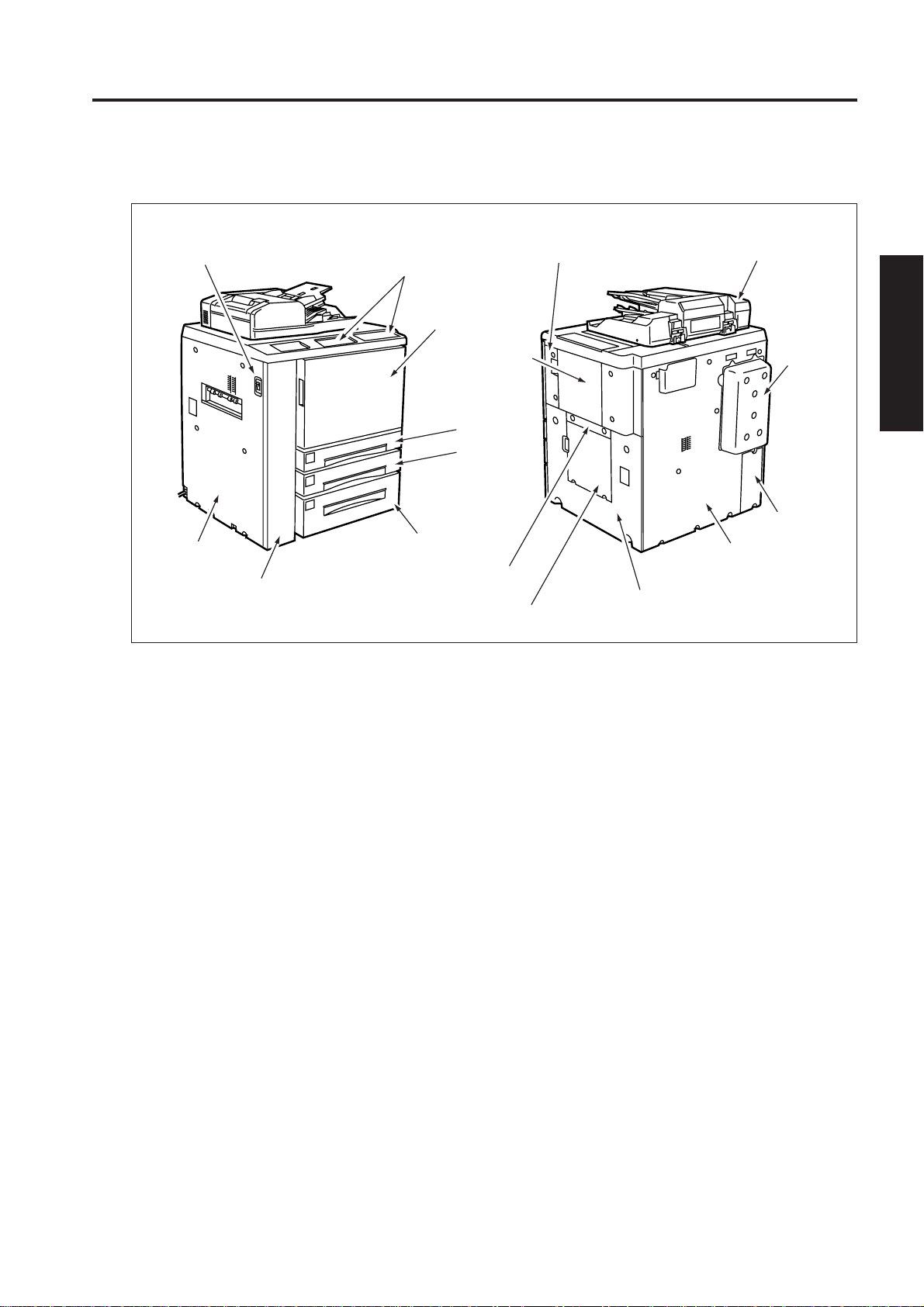

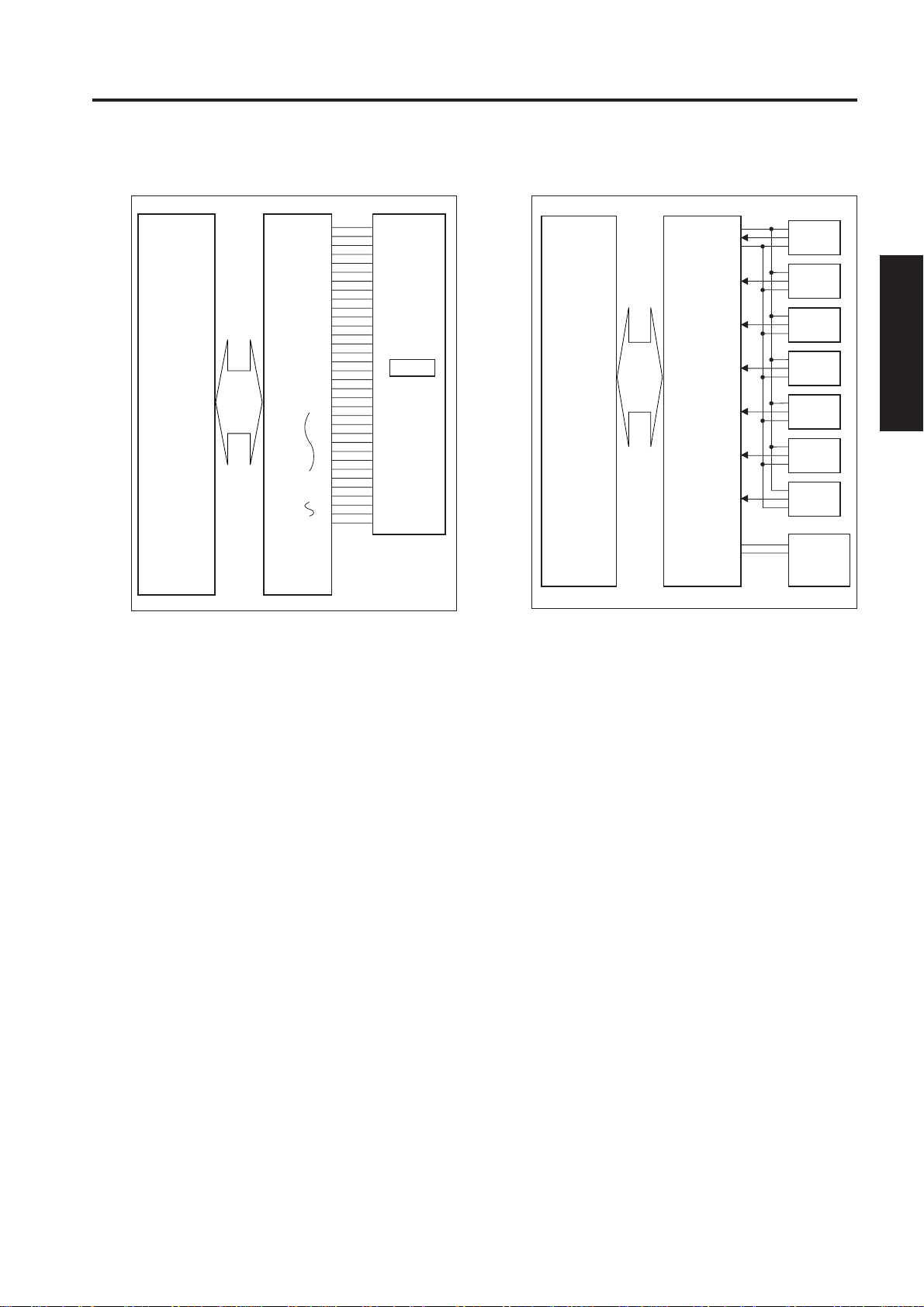

EXTERNAL SECTION

[1] Composition

Main switch

Operation panel

Front right door

Right side cover

(upper)

EXTERNAL SECTION

RADF

Left side cover

Left front door

Bypass tray

Tr a y 1

Tr ay 2

Tr a y 3

Right side cover

(middle)

Vertical

Conveyance

door

Cooling

cover

2 UNIT EXPLANATION

Optional cover

Rear cover

Right side cover

(lower)

2 - A - 1

Page 3

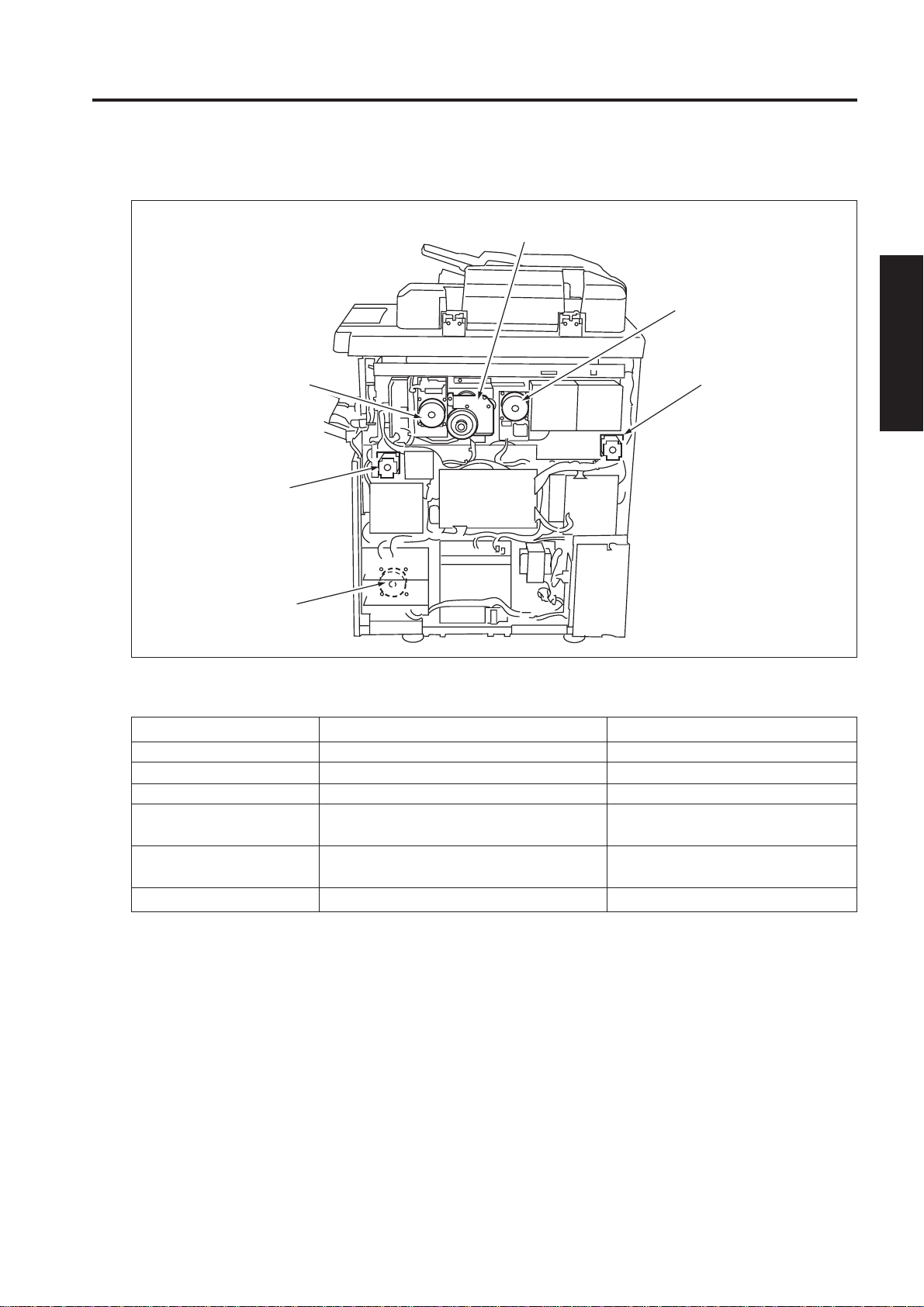

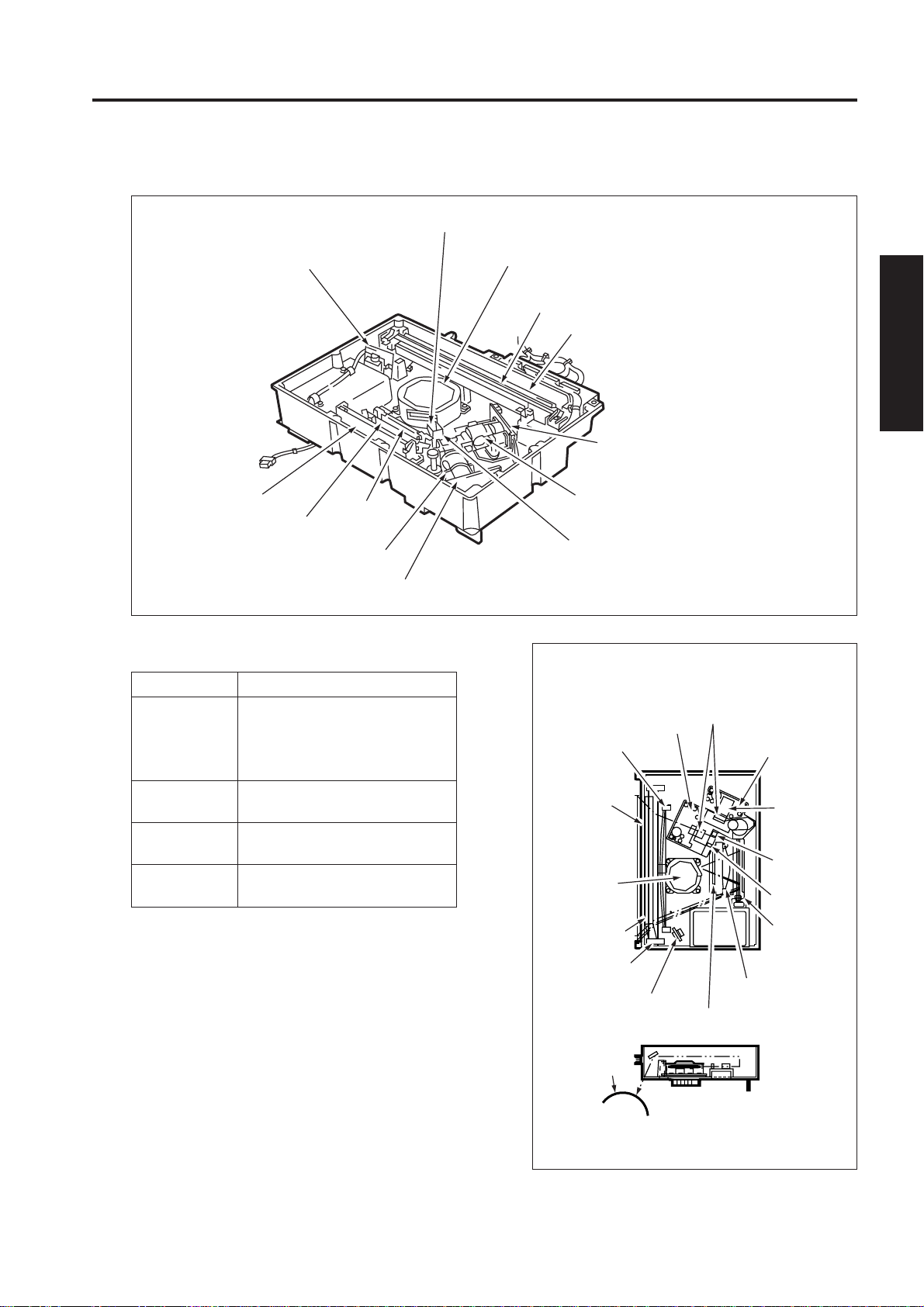

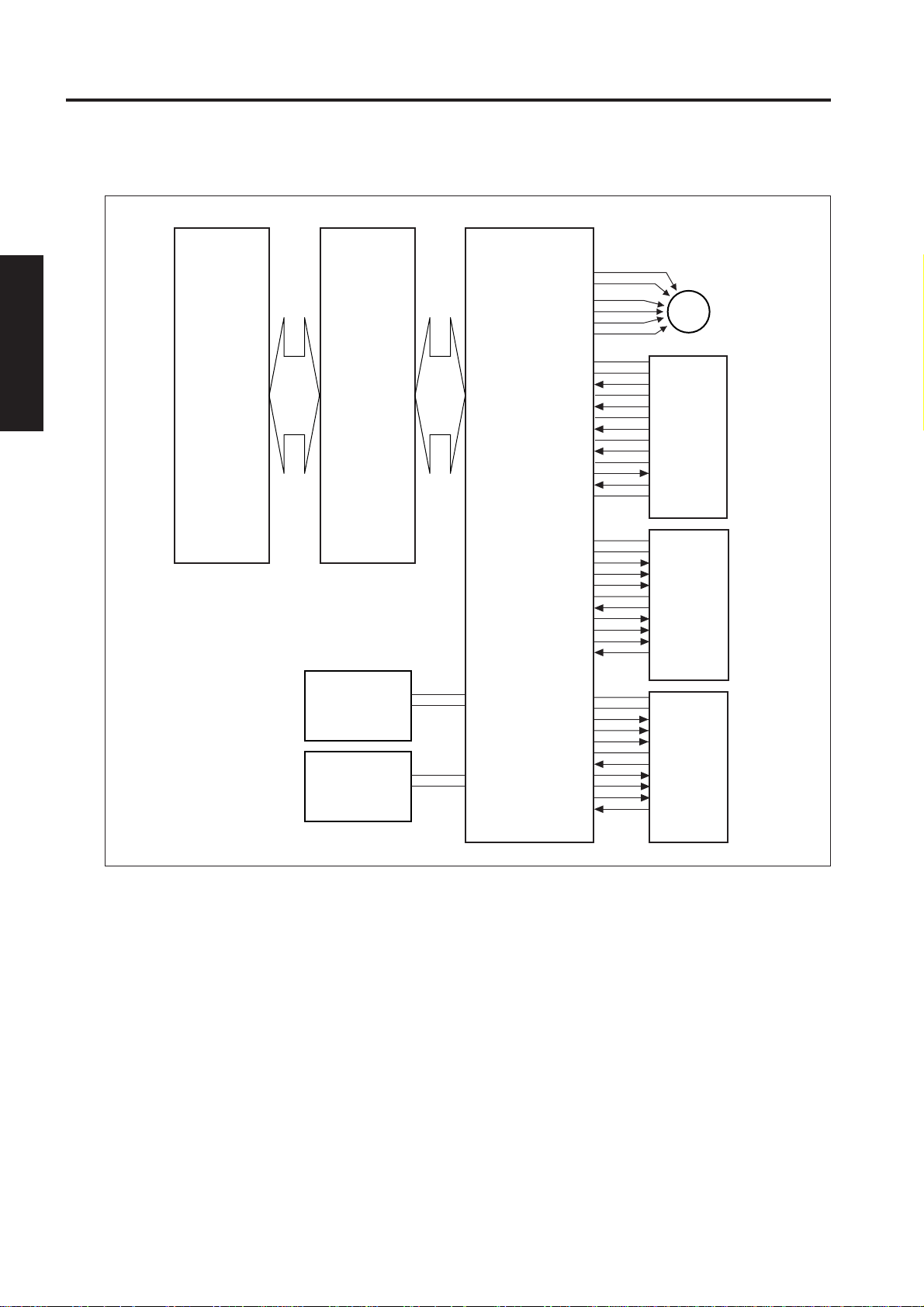

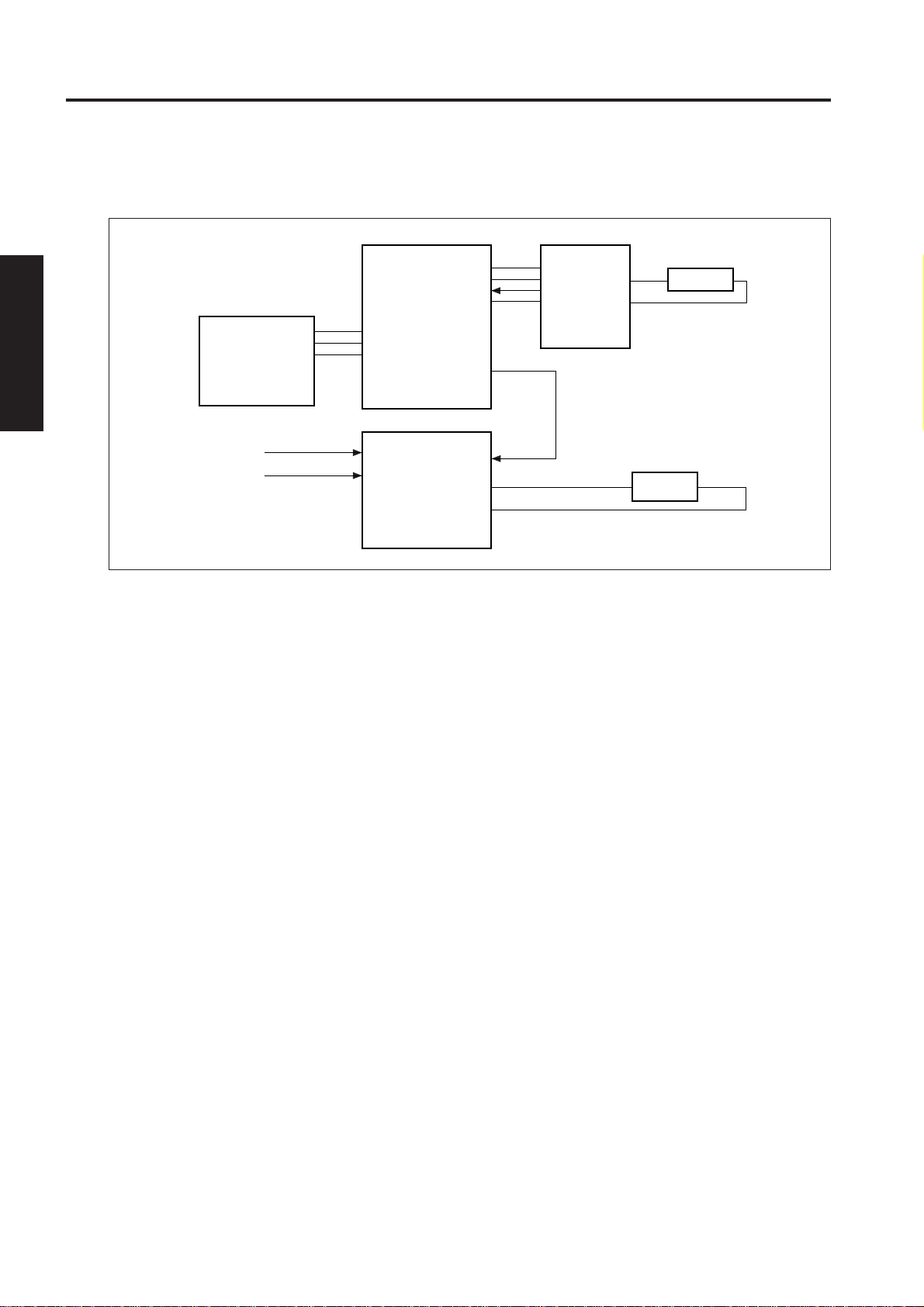

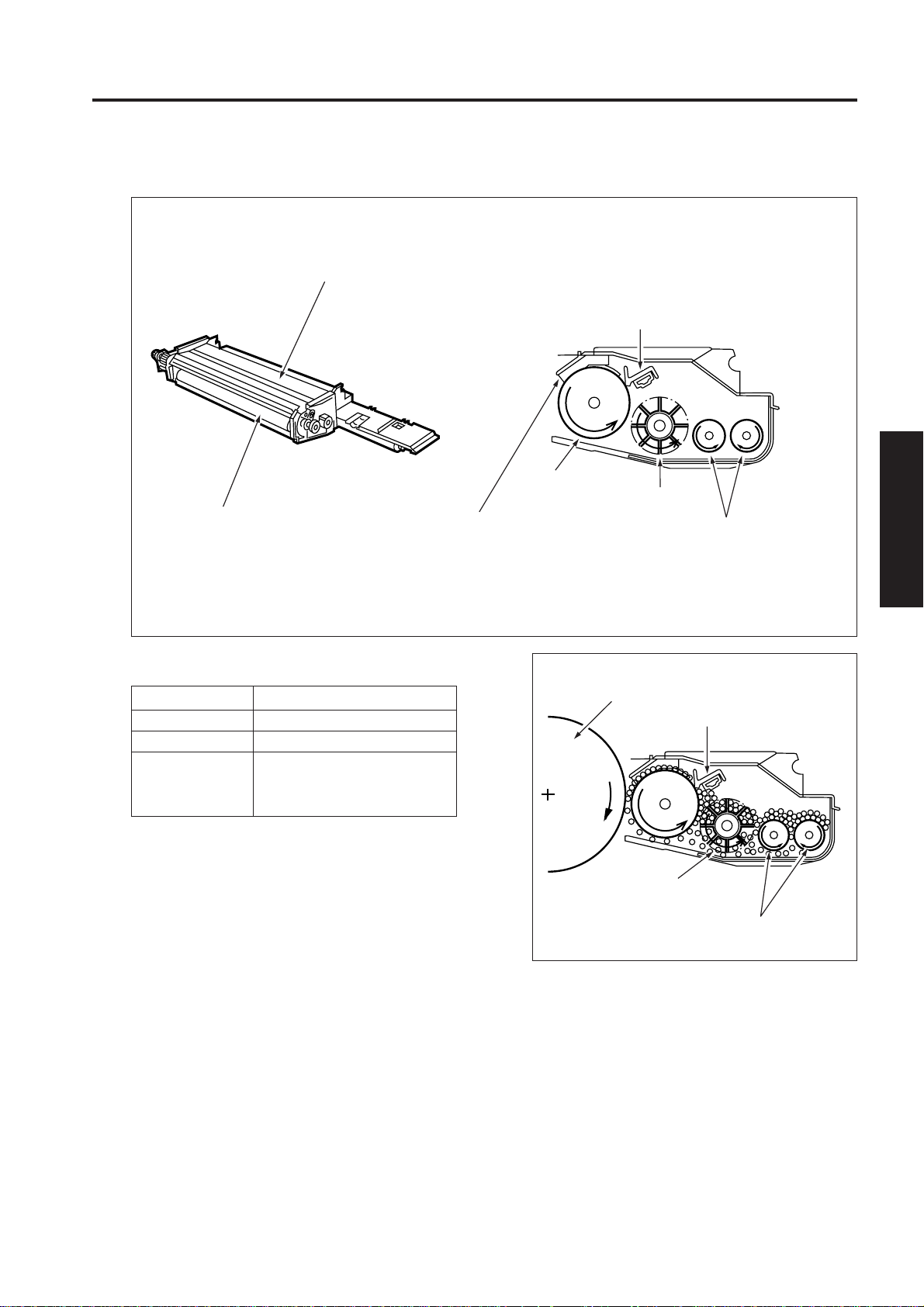

DRIVE SECTION

[1] Composition

DRIVE SECTION

Drum motor (M2)

Main motor (M1)

Developing motor (M3)

Loop roller motor (M6)

Paper feed motor (M4)

[2] Mechanisms

Mechanism

*1 Drum drive

*1 Developing drive

*1 Main drive

*1 Paper feed drive

*1 By-pass/loop drive

*1 Paper exit drive

Driven Parts

Drum, toner guide roller

Developing sleeve

Fixing upper roller

Tray 1/2/3, Vertical conveyance roller

(middle/lower)

By-pass feed roller, loop roller, vertical

conveyance roller (upper)

Paper exit roller

Paper exit motor

(M10)

2 UNIT EXPLANATION

Method

Gear drive (dedicated motor)

Gear drive (dedicated motor)

Gear drive (dedicated motor)

Gear drive (dedicated motor) + Belt

Gear drive (dedicated motor)

Gear drive (dedicated motor)

*1 Independent drive mechanisms

Drive mechanisms are driven by dedicated motors to ensure high-speed operation and to improve serviceability and developing performance.

2 - B - 1

Page 4

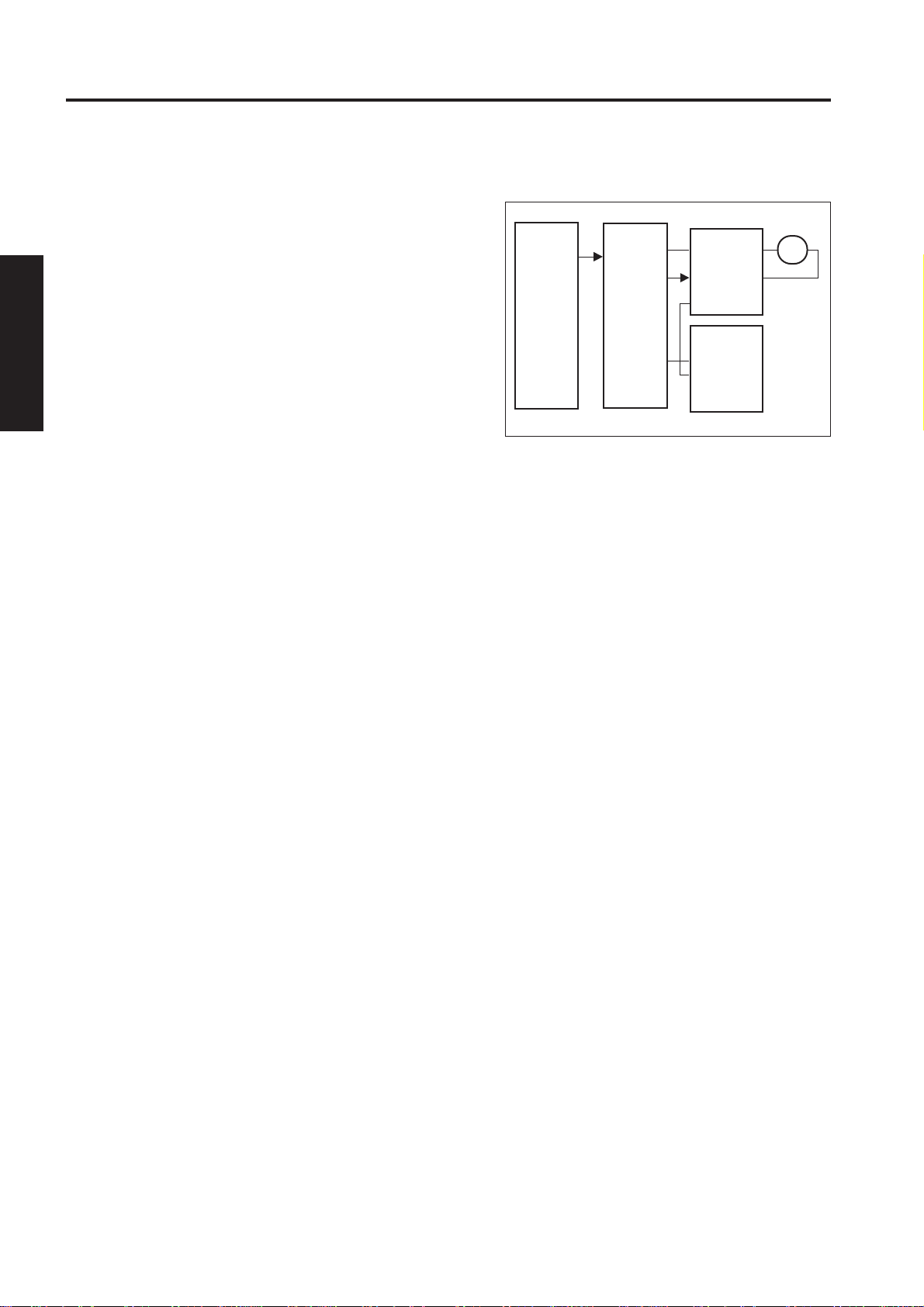

DRIVE SECTION

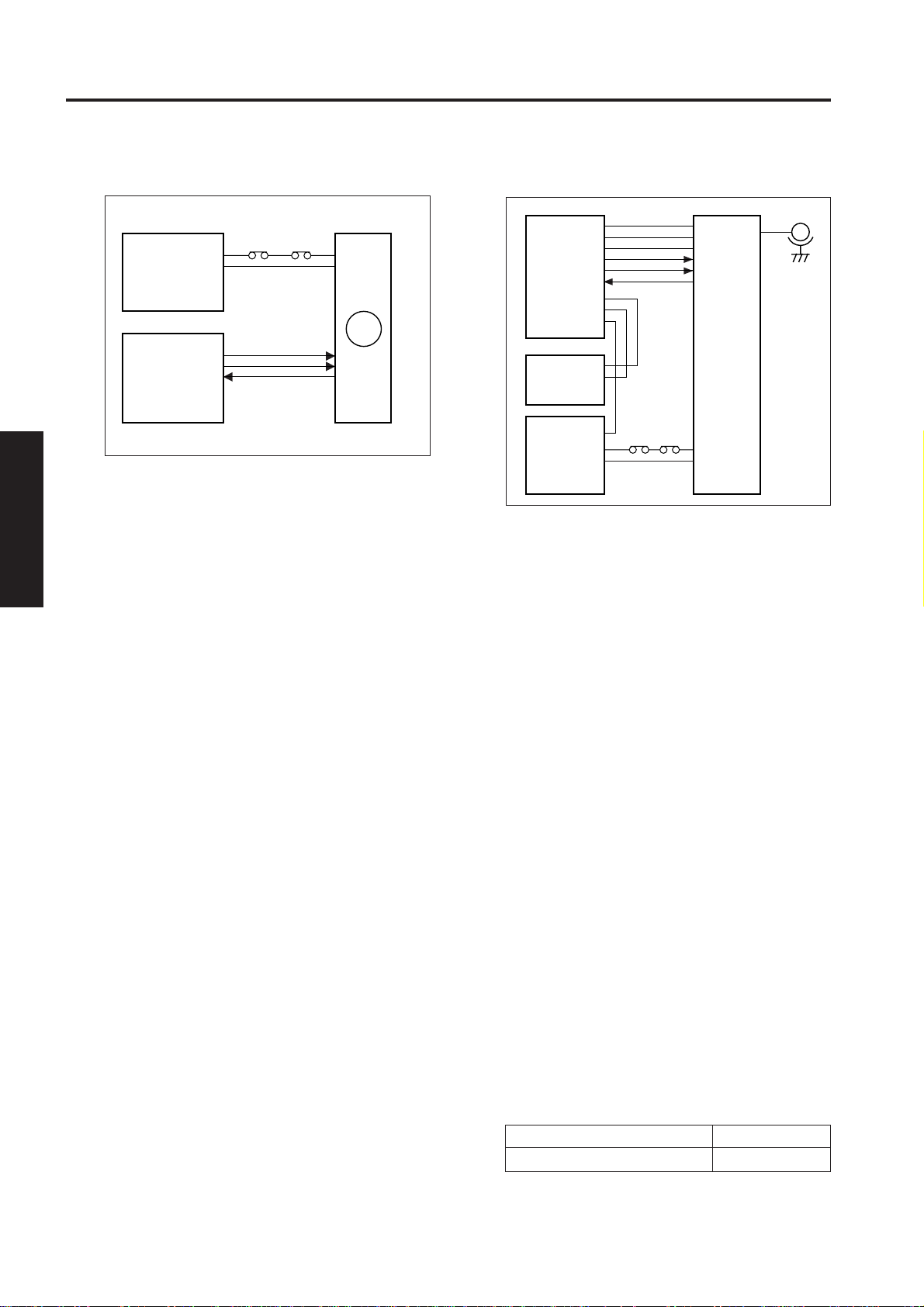

[3] M1 (Main) Control

MS2 MS1

24VDC

PGND

DCPS2

M1 CONT

M1 EM

2 UNIT EXPLANATION

M1 (main) is controlled by the PRCB (printer control

board) and the motor drive power is supplied from

DCPS2 (DC power supply unit 2).

1. Operation

M1 is a motor driven by 24V DC. It drives fixing

upper and lower rollers, paper conveyance belts,

and thick paper conveyance roller. M1 incorporates a speed controller circuit to send a signal

indicating abnormal rotation to PRCB when the

PLL lock has been released for longer than the

specified period of time.

M1 starts rotating when the START PRINT button is pressed and stops when the last copied

paper has been ejected. During the warm-up

operation, M1 rotates to rotate the fixing rollers.

When either one of the front doors of this machine

opens or closes, MS1 (interlock 1) or MS2

(interlock 2) actuates to stop supplying the DC

power to the motor, causing the M1 to stop.

PRCB

M1

[4] M2 (Drum) Control

MS2 MS1

24VDC

PGND

DCPS2

M2

M2CONT

M2 F/R

SGMD

M2 EN

PRCB

M2 (drum) is controlled by the PRCB (printer control

board) and the motor drive power is supplied from

DCPS2 (DC power supply unit 2).

1. Operation

M2 is a motor driven by 24V DC. It drives a drum,

toner guide brush, toner guide shaft, toner

conveyance screw, and separation claw swing

sections. M2 incorporates a speed sensor (encoder) to send a feedback signal to PRCB. Using

this signal, PRCB detects the rotational speed

and calculates the PWM duty to be given to the

motor, controlling the M2 speed. In addition to

the speed sensor, M2 also has a flywheel mechanism to ensure accurate and steady rotation.

M2 starts rotating when the ST ART PRINT button

is pressed and stops when the last copied paper

has been ejected.

When either one of the front doors of this machine

opens or closes, MS2 (interlock 1) or MS2

(interlock 2) actuates to stop supplying the DC

power to the motor, causing the M2 to stop.

2. Signals

a. Input signal

(1) M1 EM (M1 to PRCB)

M1 fault detection signal

[H]: Abnormal rotation (PLL lock has been

released for 2 to 3 seconds or longer.)

[L]: Normal rotation

b. Output signal

(1) M1 CONT (PRCB to M1)

M1 drive control signal.

[H]: M1 ON

[L]: M1 OFF

2. Signals

a. Input signal

(1) M2 EN (M2 to PRCB)

M2 motor encoder signal

b. Output signals

(1) M2 CONT (PRCB to M2)

M2 drive control signal (PCOM)

[L]: M2 ON

[H]: M2 OFF

(2) M2 F/R (PRCB to M4)

M2 rotational direction switchover signal

[H]: CCW (relative to motor shaft)

[L]: CW (relative to motor shaft)

2 - B - 2

Page 5

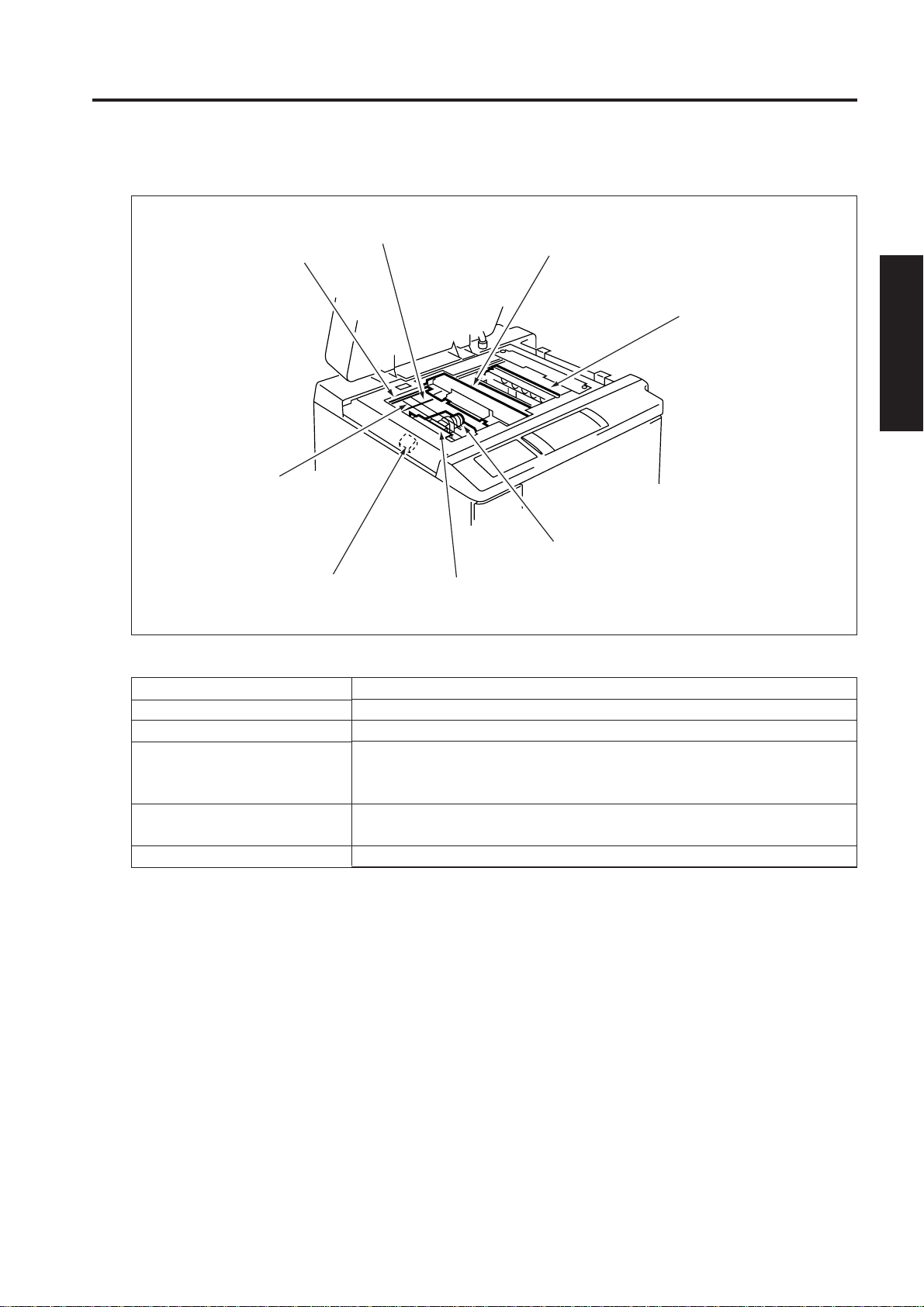

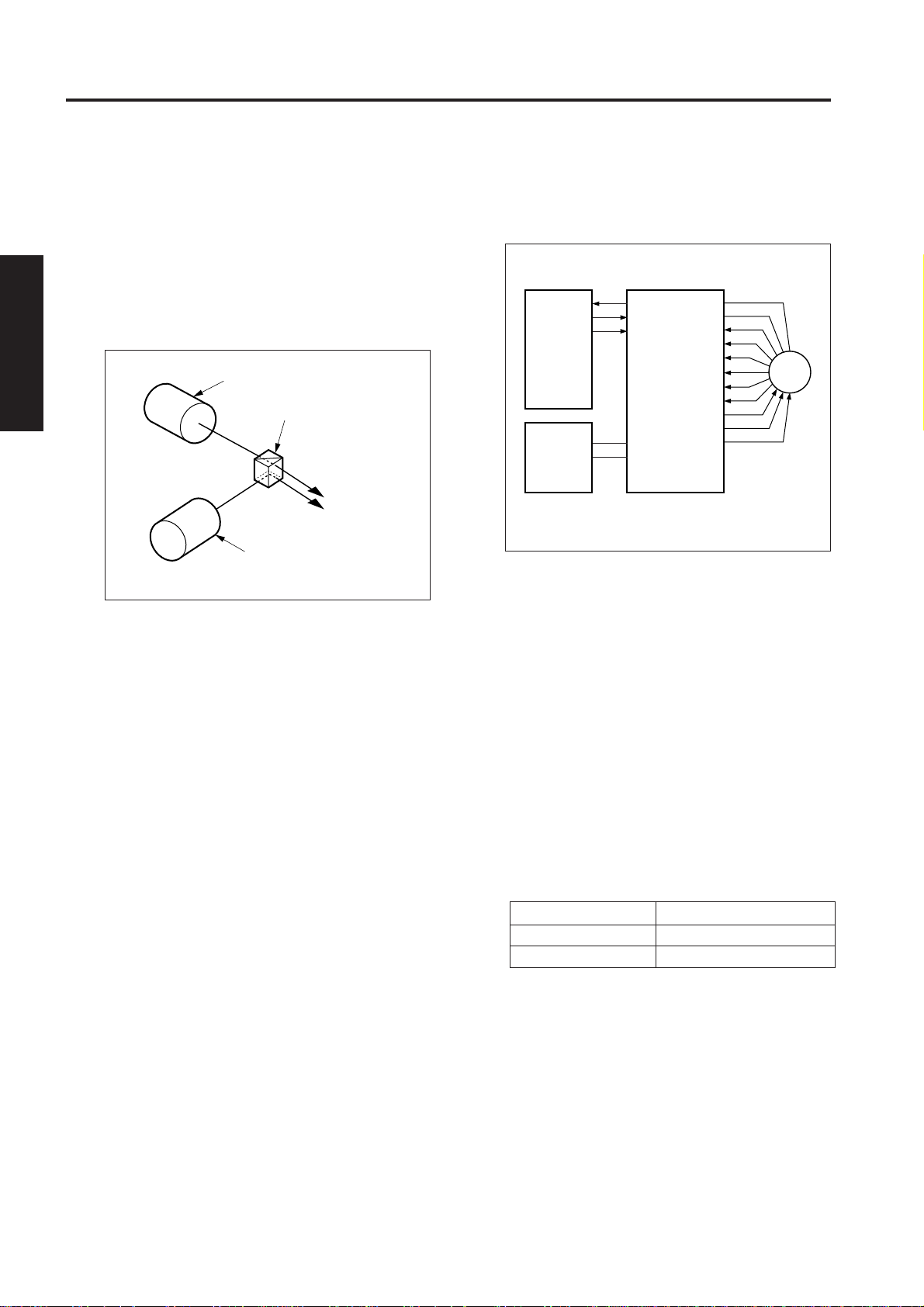

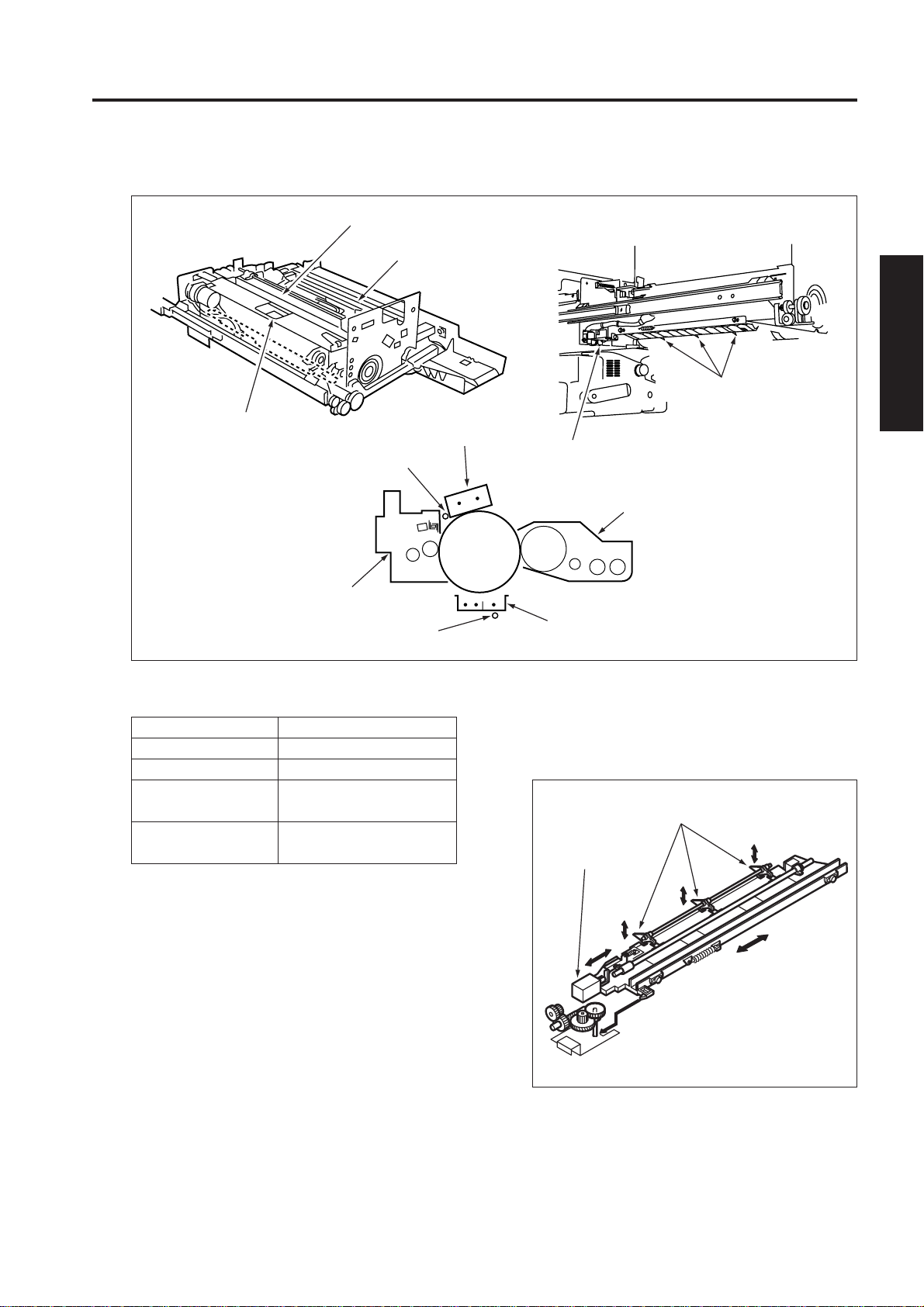

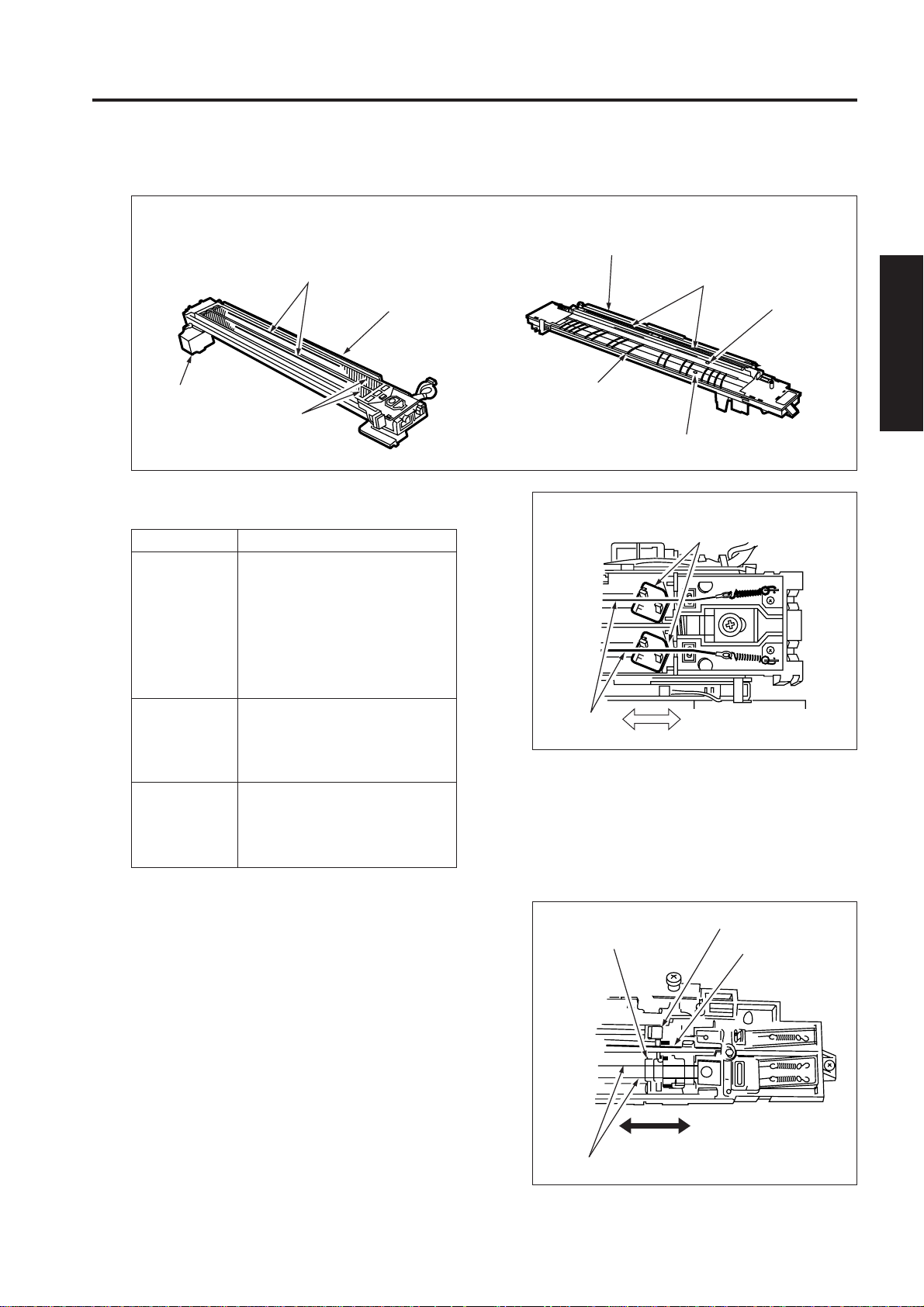

READ SECTION

[1] Composition

Optics rail (R)

Slit glass

READ SECTION

Scanner drive wire

Exposure unit

V-mirror unit

(2nd and 3rd mirrors)

2 UNIT EXPLANATION

Scanner cooling fan (FM7)

[2] Mechanisms

Mechanism

Light source

Exposure

Scanning

Lamp power supply

Optics cooling

CCD unit

A/D converter

board

Method

Xenon lamp

Light source shift slit exposure

Platen original scanning: 1st, 2nd, and 3rd mirrors are shifted.

RADF original scanning: Original is moved with light source held

stationary.

Lamp cord

Cooling fan

2 - C - 1

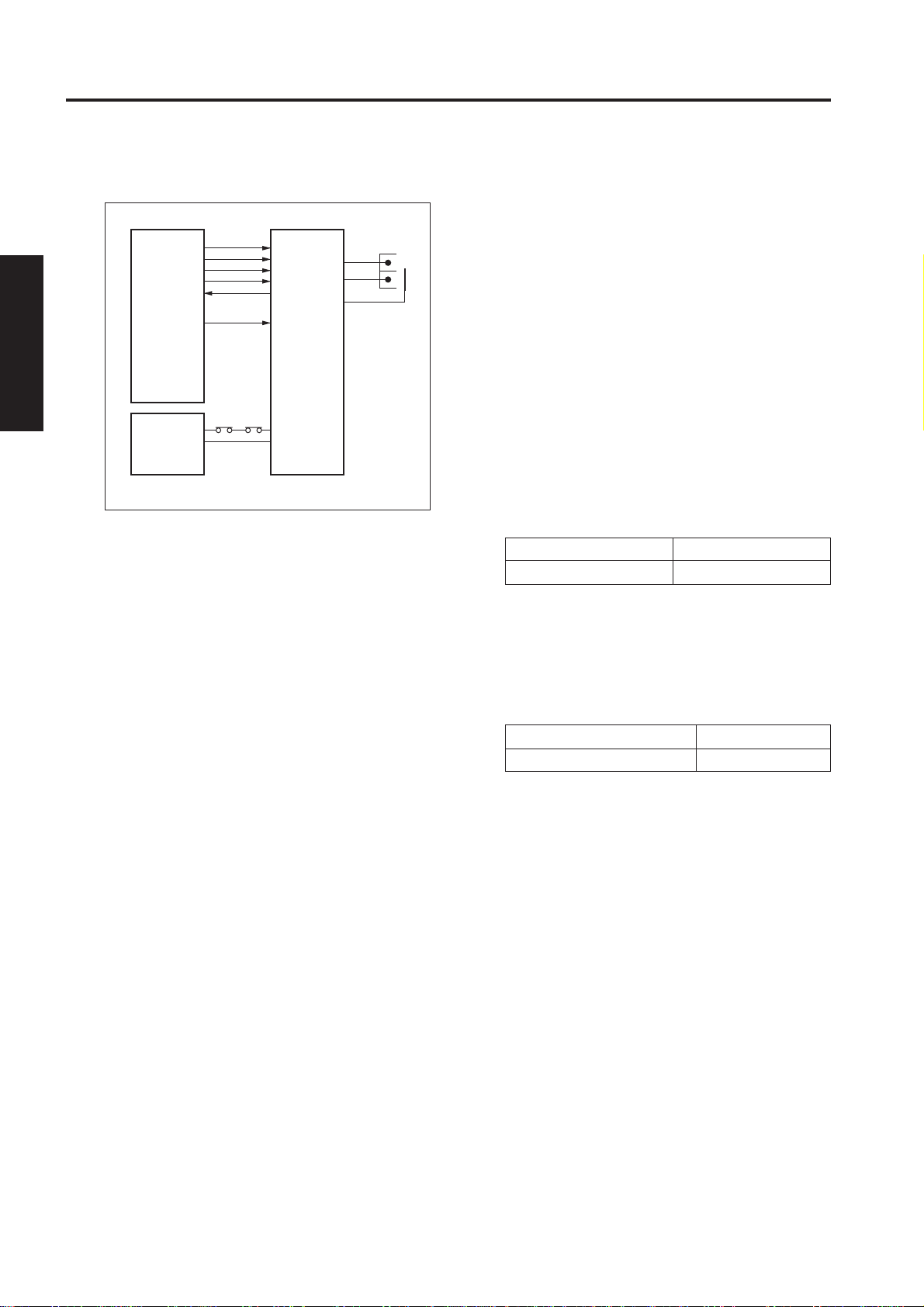

Page 6

READ SECTION

[3] M13 (Scanner Drive) Control

2 UNIT EXPLANATION

M13 CLK

M13 F/R

M13 CSEL

M13 V0

M13 V1

M13 V2

PS5

PS7

PS6

PS4

PRCB SCDB DCPS1

M13 DRIVE U

M13 DRIVE V

M13 DRIVE W

5VDC

PS5

SGND

PS7

5VDC

PS6

SGND

PS4

M13

PS5

PS7

PS6

PS4

24VDC

PGND

DCPS2

5VDC

SGND

M13 (scanner drive) is driven by the SCDB (scanner

drive board) and is controlled by the PRCB (printer

control board).

Related signals are PS4 (scanner reverse), PS5

(scanner HP), PS6 (original HP), and PS7 (ADF

brake).

1. Operation

a. Operation of M13

M13 is a 3-phase stepping motor driven using

the 3-phase bipolar constant-current drive

method. The motor is turned ON/OFF by

supplying/stopping clock pulses.

b. Movement speed of the exposure unit

Scanning speed

Operation mode

Scan

Movement speed

370 mm/sec (400 dpi, 1:1)

164.4 mm/sec (600 dpi,

1:1)

Forward

Home position

569.23 mm/sec

92.5 mm/sec

search

2 - C - 2

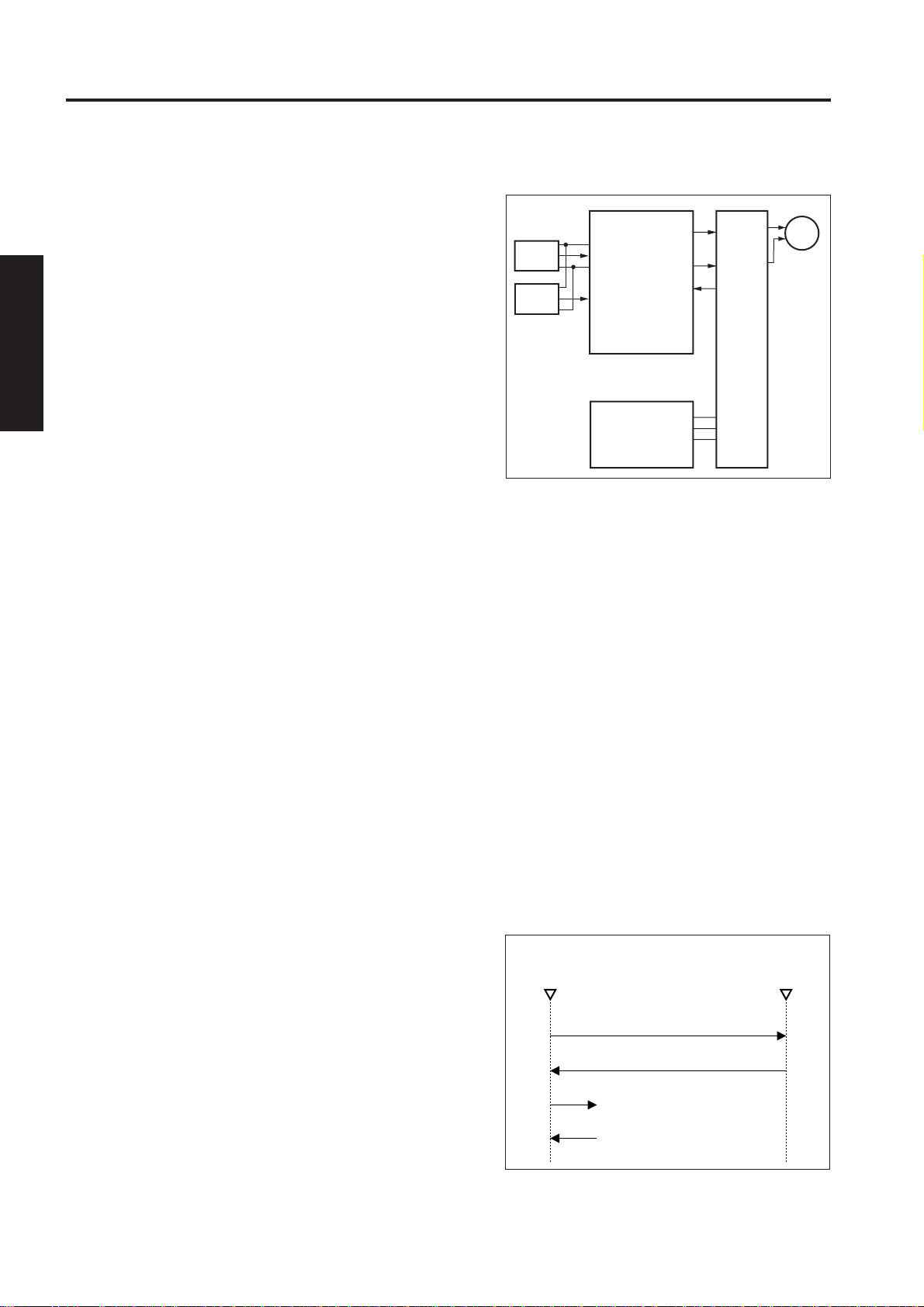

Page 7

c. Positions of sensors

Paper exit side Paper feed side

PS7 PS5 PS6 PS4

ADF break Scanner HP

PS7 PS5

READ SECTION

White correction

d. Exposure unit home position search

If the exposure unit is not at the home position

when the main switch is turned ON or when the

START PRINT button is pressed, the home

position is searched for in the follo wing manner:

(1) When the exposure unit is on the paper exit side

with respect to the home position

When the exposure unit is at PS7 (ADF brake)

(PS7 is ON), it moves forward at a low speed

until PS5 (scanner HP) turns ON and OFF again,

then it stops. Next the exposure unit moves

backward until PS5 turns ON again.

When the exposure unit is between PS7 and PS5,

it moves backward until PS7 turns ON before

moving forward as mentioned above.

(2) When the exposure unit is on the paper feed side

When the exposure unit is at PS5 (PS5 is ON), it

moves forward at a low speed until PS5 turns

OFF before moving as discussed in (1) above.

When the exposure unit is on the paper feed side

with respect to PS5, it stops after PS5 turns ON

and moves forward before moving as discussed

in (1) above.

400dpi shading correction

600dpi shading correction

2 UNIT EXPLANATION

f. ADF copy operation

PS7 PS5

Original read

position

e. Read with shading correction

When L1 (exposure lamp) is turned ON, the

exposure unit mov es toward the paper e xit side,

thus reading the light reflected by the white

reference plate installed underneath the glass

stopper plate and performing white correction.

Then, L1 is turned OFF for black correction,

returning to the home position. Shading correction

is performed at 400 dpi and 600dpi.

g. Platen copy operation

Scanner HP

PS5 PS6 PS4

AE scan

Original area judgment

Exposure scan

Home position search

Original HP

Scanner

return

2 - C - 3

Page 8

READ SECTION

2. Signals

a. PRCB input signals

(1) PS4 (PS4 to SCDB to PRCB)

Scanner reverse detection signal.

In the platen mode, the return position of the

exposure unit is detected on the original's leading

edge side.

[L]: The exposure unit is detected.

[H]: The exposure unit is not detected.

(2) PS5 (PS5 to SCDB to PRCB)

Scanner home position detection signal.

The reference position for the home position of

2 UNIT EXPLANATION

the exposure unit is detected.

[L]: The exposure unit is detected.

[H]: The exposure unit is not detected.

(3) PS6 (PS6 to SCDB to PRCB)

Original home position detection signal.

In the platen mode, the reference position for the

original's leading edge is detected.

[L]: The exposure unit is detected.

[H]: The exposure unit is not detected.

(4) PS7 (PS7 to SCDB to PRCB)

ADF brake detection signal.

In the DF mode, the exposure reference position

is detected.

[L]: The exposure unit is detected.

[H]: The exposure unit is not detected.

b. PRCB output signals

(1) M13 CLK (PRCB to SCDB)

Clock signal for M13

(2) M13 F/R (PRCB to SCDB)

M13 rotational direction switchover signal.

[L]: The exposure unit is moved toward the

paper exit side.

[H]: The exposure unit is moved toward the

paper feed side.

(3) M13 CSEL (PRCB to SCDB)

M13 excitation switchover signal.

[L]: 2-/3-phase excitation

[H]: 2-phase excitation

(4) M13 V0 to V2 (PRCB to SCDB)

M13 excitation current switchover signal.

c. OPDB output signals

(1) M13 DRIVE, U, V, W (SCDB to M13)

M13 drive control signals.

These signals are used to control rotation of M13.

By supplying and stopping clock pulses, the motor

is turned ON/OFF and the rotational direction is

switched.

[4] Exposure control

L1 CONT

PRCB SCDB

24VDC

L1 CONT

L1 (exposure lamp) is driven by the L1 INVB (L1

inverter) and is controlled by the PRCB (printer control

board) via the SCDB (scanner drive board).

1. Operation

L1 is a xenon lamp driven by the inverter circuit.

The xenon lamp can emit a constant quantity of

light and generates less heat than other lamps,

requiring neither light quantity controller circuit

nor thermal protector circuit that have been used

in the conventional machines. However, since

L1 is held lit when the exposure unit is

nonoperational in the DF mode, a FM7 (scanner

cooling) is installed in the read section.

2. Signals

a. Output signals

(1) L1 CONT (PRCB to SCDB to L1 INVB)

L1 ON/OFF control signal.

[L]: L1 ON

[H]: L1 OFF

L1 INVB

24VDC

PGND

DCPS2

LV

HV

L1

2 - C - 4

Page 9

READ SECTION

5VDC

PS62

SGND

PS63

PS64

PS65

PS66

PS67

PS68

PRCB ICB IFB

PS62

PS63

PS64

PS65

PS66

PS67

PS68

DCPS1

5VDC

SGND

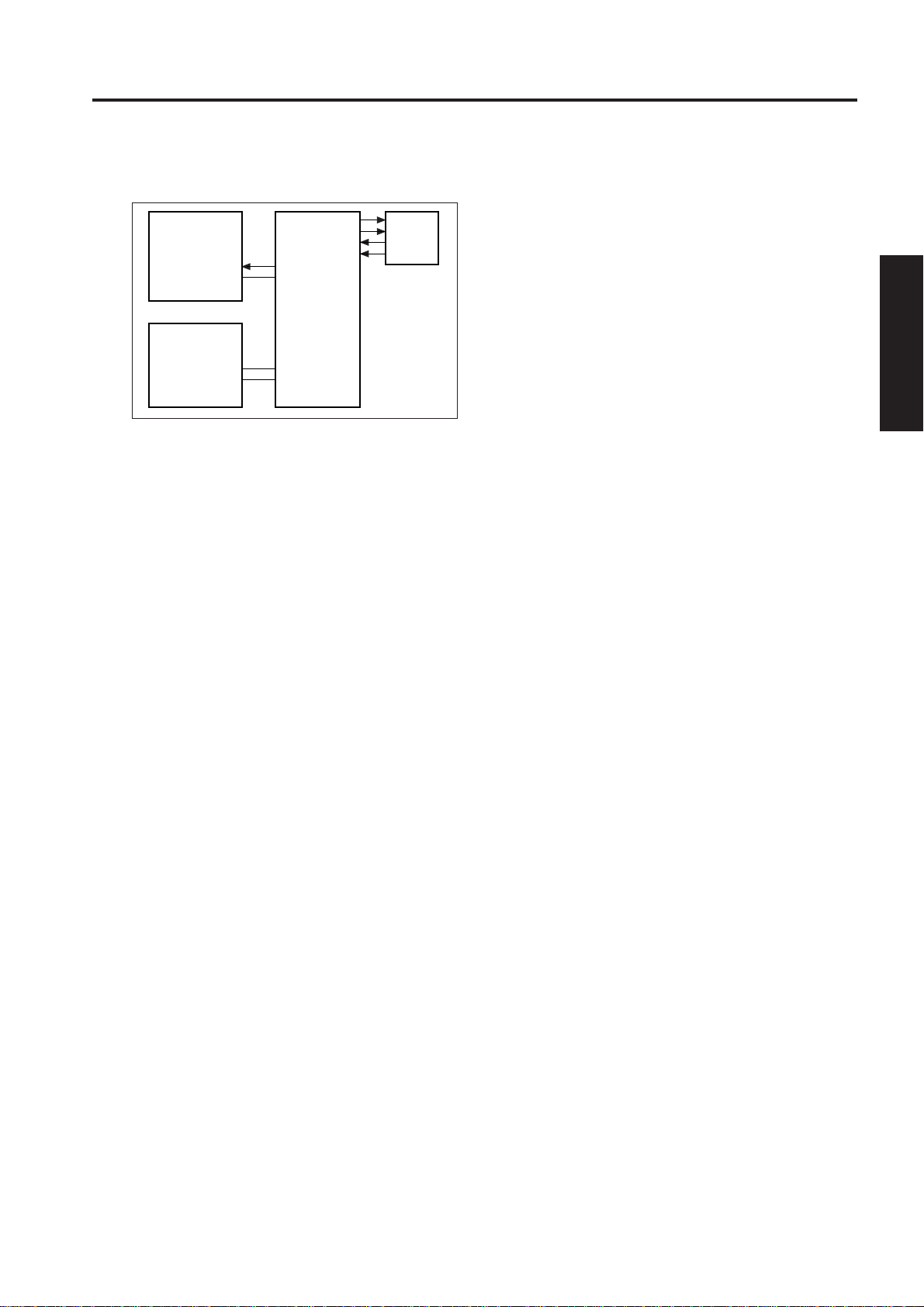

[5] Original Read Control

TCK1

SGND

TCK2

SGND

RCK1

SGND

RCK1

SGND

TG

CLMP

S CK

S IN

S LD

MD0

MD1

MD2

S LP

SGND

AD CK

APR

OD0

OD8

SGND

ED0

ED3

ICB IFB ICB

[6] APS Control

CCD

ADB

2 UNIT EXPLANATION

Original read control is performed by the ADB (A/D

converter board) and CCD sensor installed in the ADB.

1. Operation

The light reflected by the exposed original is input

to the CCD sensor through the lens. The analog

voltage corresponding to the quantity of input light

is A/D-converted in the ADB, being output to the

ICB (image control board).

a. Original read

The original read timing is as follows:

(1) Platen mode

Specified interval after exposure unit turns PS6

(original HP) ON.

(2) DF mode

After lapse of the specified time after the original's

leading edge turns ON PS308 (Original).

The APS method used in the platen mode is different

from that used in the DF mode.

The signal read by the APS sensor or the original size

detection sensor of the RADF is processed by the CB

(control board).

1. Operation

a. APS detection

(1) DF mode

The original size is detected according to the

combination of ON/OFF states of PS302 (original

size detection 1) and PS303 (original size

detection 2) and the resistance value of VR301

(original size detection).

2 - C - 5

Page 10

READ SECTION

(2) Platen mode

The paper size is detected according to the

combination of ON/OFF states of PS62 (APS 1),

PS63 (APS 2), PS64 (APS 3), PS65 (APS 4),

PS66 (APS 5), PS67 (APS 6), and PS68 (APS

7).

The APS sensor consists of LEDs and

photosensors. Lights emitted from the LEDs is

reflected by the original and received by

photosensors.

2 UNIT EXPLANATION

Paper exit side

Relationships between sensors and original sizes

are as follows:

Sensor

Paper

size

B5R

B5

B4

A4R

A4

A3

8.5 x 11R

8.5 x 11

8.5 x 14

11x 17

Min. size

PS63

PS62 PS68

PS66

PS64

PS67

PS65

Photo sensor

LED

PS62 PS63 PS64 PS65 PS66 PS67 PS68

ON

OFF

b. APS detection timing

The APS detection timing differs between the

platen mode and DF mode.

(1) DF mode

When the DF mode is selected or original is set

on the RADF original feed tray, APS detection

takes place using PS302 (original size detection

1), PS303 (original size detection 2), and VR301

(original size detection).

(2) Platen mode

When RADF is closed and PS315 (APS timing)

turns ON, APS detection takes place using PS62

to PS68.

2. Signals

a. Input signals

(1) PS62 (PS62 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(2) PS63(PS63 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(3) PS64 (PS64 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(4) PS65 (PS65 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(5) PS66 (PS66 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(6) PS67 (PS67 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(7) PS68 (PS68 to ICB IFB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

2 - C - 6

Page 11

READ SECTION

[7] AE Control

ICB IFB ICB

TCK1

SGND

TCK2

SGND

RCK1

SGND

RCK1

SGND

TG

CLMP

S CK

S IN

S LD

MD0

MD1

MD2

S LP

SGND

AD CK

APR

OD0

OD8

SGND

ED0

ED3

CCD

ADB

(2) DF mode

The image at the leading edge of the original is

read when the PRINT START button is pressed.

The read data is used to measure the image

density on the original.

<AE sampling area>

(1) Main scanning direction

• 10-mm area inside the original detected by

APS

(2) Sub scanning direction

Range between 2mm to 7.3mm from the leading

edge of the original.

2 UNIT EXPLANATION

The CCD sensor detects the image density on an

original during AE scanning to select the optimum copy

gamma correction curve.

AE processing is controlled by the ICB (image control

board).

1. Operation

a. AE detection

(1) Platen mode

The image density on an original is measured

while the exposure unit moves from the home

position to the leading edge of the original after

depression of the START PRINT button.

<AE sampling area>

(1) When ADF is closed

10mm inside perimeter of original size detected

by APS.

(2) When ADF is opened

Entire original area detected by forward scanning.

2 - C - 7

Page 12

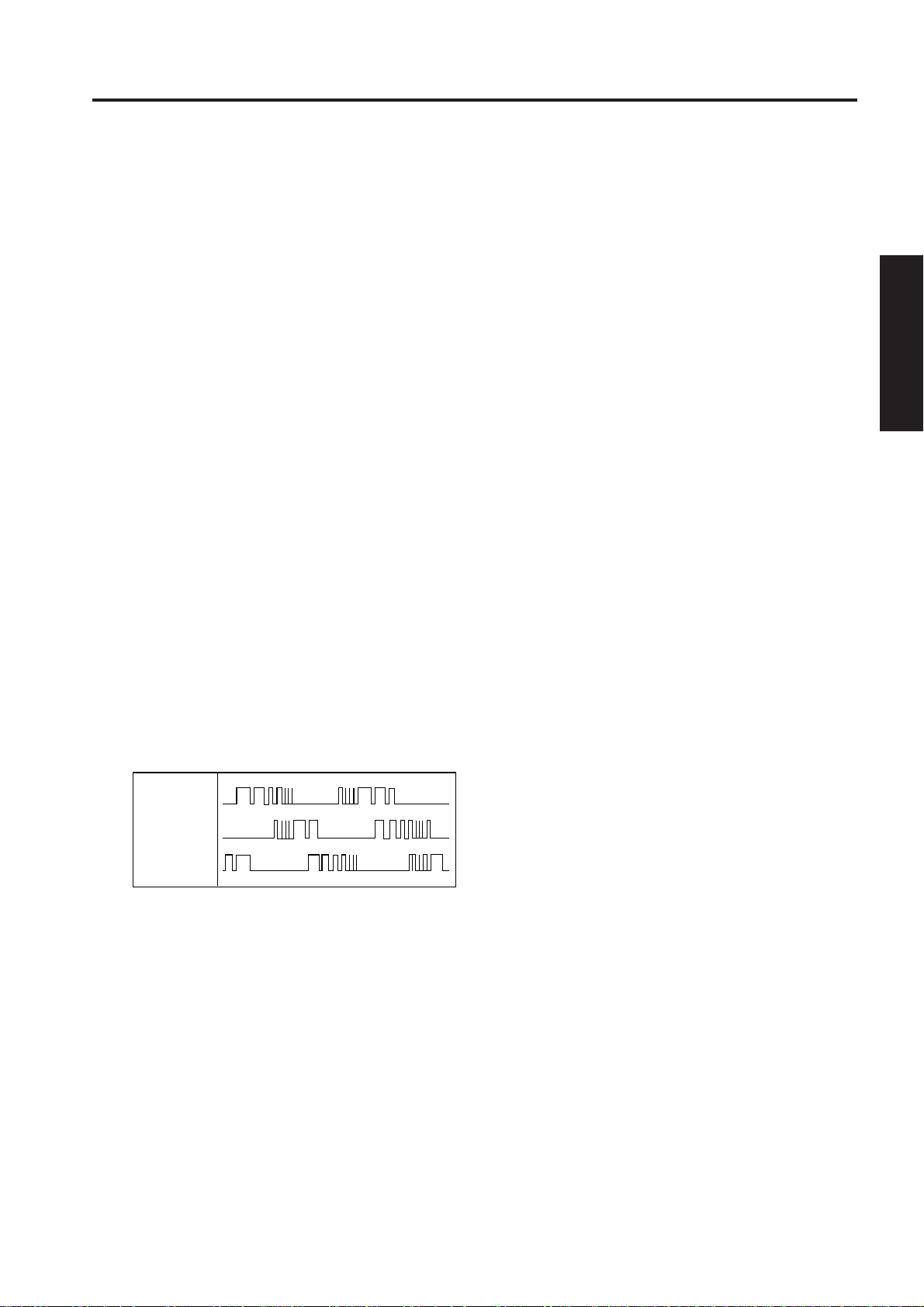

WRITE UNIT

[1] Composition

WRITE UNIT

Cylindrical lens 1

Index sensor board

2nd mirror

[2] Mechanisms

Mechanism

*1 Scan

Light source

*2 Positioning

*3 Laser beam

combining

fθ lens 2

fθ lens 1

Collimator lens unit 1

Laser driver board LD1

Method

Polygon mirror

Rotational speed:

21,850.4 rpm (400dpi)

32,775.6 rpm (600dpi)

Laser diodes (two)

(Output: Max. 20 mW)

Index sensor

Fine adjustment prism

Beam combining prism

Polygon mirror

Cylindrical lens 2

3rd mirror

Collimator lens unit 2

Beam combining prism

CY2 lens

3rd mirror

Polygon

mirror

Laser driver board LD2

Semiconductor

laser LD2

Compression prism

2 UNIT EXPLANATION

Semiconductor laser

LD1

Collimator

lens unit

Beam

combining

prism

CY1 lens

*1 Path of laser light

The light output from semiconductor laser is

radiated onto the OPC drum via the collimator

lens, compression prism, fine adjustment prism,

beam combining prism, cylindrical lens 1, polygon

mirror,fθ lens 1, fθ lens 2, second mirror,

cylindrical lens 2, and third mirror.

2 - D - 1

Glass cover

Index mirror

Index sensor

OPC drum

2nd mirror

fθ lens 2

fθ lens 1

Page 13

WRITE UNIT

*2 Positioning

Each laser beam is positioned by the

compression prism and fine adjustment prism.

*3 Laser beam combining

Two laser beams output at right angle to each

other are redirected in the same direction using

the beam combining prism.

2 UNIT EXPLANATION

Semiconductor laser 1

Laser 1 beam passes

Laser 2 beam

reflected

Beam combining

prism

Semiconductor

laser 2

[3] M17 (Polygon ) Control

M17 is driven by the PMDB (polygon driver board)

and is controlled by the PRCB (printer control board).

M17 EM

M17 CLK

M17 CONT

PRCB

24VDC

PGND

DCPS2 PMDB

1. Operation

a. Explanation of operation

M17 is a 3-phase brushless DC motor which is

driven by the 3-phase bipolar method. The

current flowing through the coil is switched

according to the position of the rotor detected by

the position sensor (magnetic sensor) in the

motor.

This motor rotates the polygon mirror to scan the

laser beams from LDB1 and 2 (laser driver boards

1 and 2) in the axial direction of the drum. Its

rotation is held constant by PLL control.

b. Rotational speed

M17 is powered by 24 VDC and its speed is as

follows:

SGND

24VDC

M17 MAG A’

M17 MAG A

M17 MAG B’

M17 MAG B

M17 MAG C’

M17 MAG C

M17 DRIVE C

M17 DRIVE B

M17 DRIVE A

M17

2 - D - 2

Machine state Rotational speed

400 dpi 21,850.4 rpm

600 dpi 32,775,6 rpm

2. Signals

a. PRCB input signals

(1) M17 EM (PMDB to PRCB)

This signal indicates the clock synchronization

state of M17.

[L]: Synchronous (normal)

[H]: Asynchronous (abnormal)

Page 14

b. PRCB output signals

(1) M17 CONT (PRCB to PMDB)

This signal turns ON/OFF M17.

[L]: M17 ON

[H]: M17 OFF

(2) M17 CLK (PRCB to PMDB)

This is a reference clock signal f or PLL-controlling

M17 in PMDB.

c. PMDB input signals

(1) M17 MAG A/A’ (M17 to PMDB)

(2) M17 MAG B/B’ (M17 to PMDB)

(3) M17 MAG C/C’ (M17 to PMDB)

Output signals from the position sensor (magnetic

sensor) incorporated in M17.

The PMDB detects the position of the motor

rotator using these signals, switching among

outputs, M17 DRIVE A to C.

d. PMDB output signals

(1) DRIVE A to C (PMDB to M17)

M17 drive signals.

M5 DRIVE A to C supplies the corresponding

voltages to M17. Pulses of the voltages

applied to M17 are shown below. The pulse

widths of the PMDB output signals change as

shown below depending on the state of M17

rotation, causing the effective values of the

voltages supplied to M17. Thus, the M17

speed can be controlled.

WRITE UNIT

2 UNIT EXPLANATION

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

2 - D - 3

Page 15

WRITE UNIT

[4] Image Write Control

2 UNIT EXPLANATION

M24 PWR A

M24 PWR B

M24 DRIVE A

M24 DRIVE A’

M24 DRIVE B

M24 DRIVE B’

5VDC

SGND

M INDEX 1

SGND

M INDEX 2

SGND

S INDEX1

SGND

S INDEX 2

SGND

HL VL

IPR

SGND

M24

INDEXSB

ADB

ICB

5VDC

SGND

DCPS1

24VDC

PGND

DCPS2

The analog image data from the CCD sensor is A/Dconverted by the ADB (A/D conv erter board), then sent

to the ICB (image control board) for data processing.

The processed image data is converted into a laser

beam according to the control signal received from

the ICB through the ICB IFB (ICB I/F board), then the

beam is radiated onto the drum surface. Two lasers

5VDC

SGND

LD1 SH

LD1 ENB

LD1 VIDEO

SGND

LD1 ALM

LD1DCLK

LD1 DI

LD1 LD

LD1 PR

LDB1

5VDC

SGND

LD2 SH

LD2 ENB

LD2 VIDEO

SGND

LD2 ALM

LD2 DCLK

LD2 LD

LD2 AD

LD2 PR

LDB2ICB IFB

are provided to write two lines of image data per scan.

The write start position is detected by the INDXSB

(index sensor board). The ICB has an E-RDH

(electronic RDH processing) function to store digitized

data. Various editing functions can be performed

based on this data.

2 - D - 4

Page 16

WRITE UNIT

1. Operation

a. Image processing

The following processing is performed by the ICB

(image control board):

(1) AOC (Auto Offset Control)

During shading correction, a read operation takes

place while L1 (exposure lamp) is OFF, and the

analog offset voltage of the output from the CCD

sensor is automatically adjusted so that the

resulting level is the lower limit of the A/D

converter.

(2) AGC (Auto Gain Control)

During shading correction, the white reference

plate is read, and the amplification of the analog

output from the CCD sensor is automatically

adjusted so that the resulting level is the upper

of the A/D converter.

(3) Shading correction

<Timing>

• When SW1 (main switch) is turned ON

(4) Brightness/density conversion

(5) EE processing

(6) Text/dot pattern judgment

(7) Filtering/magnification change processing

(8) Magnification change processing

(9) Copy gamma correction

(10)Skew correction

(11)Error diffusion processing

(12)Data compression

(13)Write density control

b. Write

The ICB (image control board) sends image data

on a pixel basis to LDB1 and LDB2 according to

the control signals from the PRCB (printer control

board).

LDB1 and LDB2 cause the lasers to emit for a

period corresponding to the image data. This laser light is radiated onto the drum surface.

(1) MPC (Maximum Power Control)

ICB informs LDB1 and LDB2 of the maximum

output value and sets that value for the laser

beam emission. LDB1 and LDB2 store this setting

value and maintain the quantity of the laser beam

emission using the APC (Auto Power Control).

<MPC timing>

a) When SW1 (main switch) is turned ON

(2) APC (Auto Power Control)

The ICB outputs an APC start instruction to the

LDB at the following timing, after MPC is set.

<APC timing>

a) The LDB1 and LDB2 automatically monitor the

laser drive current one line at a time, and

controls it so that the light intensity remains

the MPC value.

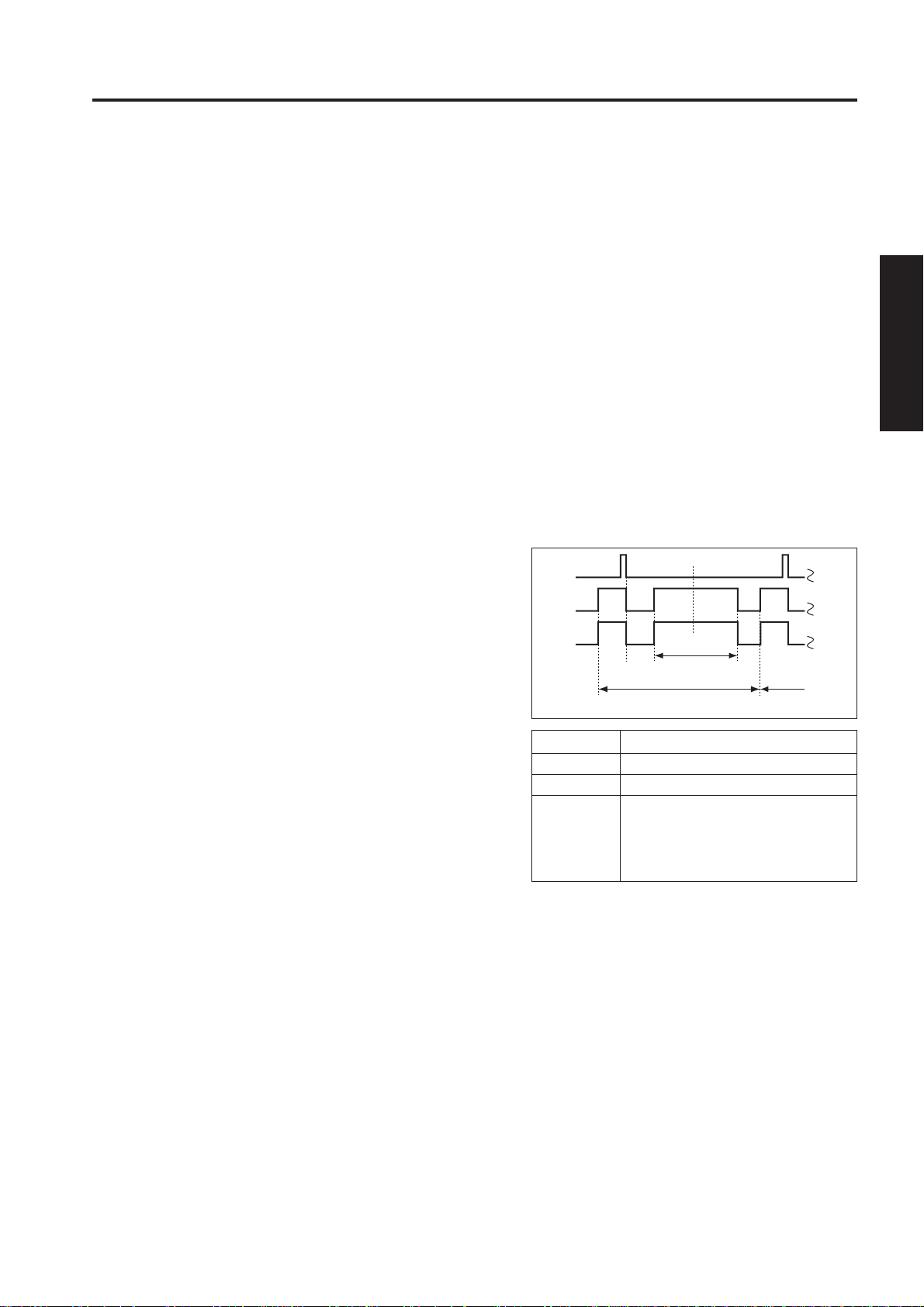

(3) Write timing

a) Main scanning direction

Using INDEX signal from INDXSB, determines

the laser write reference position for each scan

in the drum rotation direction, and writes the

image to copy paper using the paper position

information derived from the paper position

detection by PS1(paper mis-centering).

INDEX

Laser

output 1

Laser

output 2

ab c d e

Symbol

a

b

b-c

c-d

d-e

Image area

1st scanning 2nd scanning

Description

Laser goes ON for first scan

Index sensor goes ON.

The timing at the left is controlled

by counting the LD1 IRCLK and

LD2 IRCLK signals. It differs

depending on the document size.

b) Sub scanning direction

Specified interval after PS44 (registration)

detects the tip of the copy paper.

(4) Laser beam position correction

a) Main scanning direction

The index sensor detects the deviation of the

positions of the two beams. This error is

corrected by changing the timing of the light

emission from the laser.

b) Sub scanning direction

The index sensor detects the deviation of the

positions of two beams in order to change the

angle of the fine adjustment prism of the LD1

laser using M24 (laser correction), thus adjusting the vertical angle of the beam.

2 UNIT EXPLANATION

2 - D - 5

Page 17

WRITE UNIT

2. Signals

a. ICB IFB input signals

(1) M INDEX 1, 2 (INDEXSB to ICB IFB)

This is an index signal used to detect deviation

of vertical scanning.

(2) S INDEX 1, 2 (INDEXSB to ICB IFB)

This is an index signal used to detect deviation

of horizontal scanning.

(3) IPR (INDEXSB to ICB IFB)

This signal monitors the INDEXSB power supply .

[H]: Normal

[L]: Abnormal

2 UNIT EXPLANATION

(4) LD1 ALM (LDB1 to ICB IFB)

This signal indicates the state of the LD1 laser

drive current.

[H]: Normal

[L]: Abnormal

(5) LD1 PR (LDB1 to ICB IFB)

LD1 power supply monitor signal.

[H]: Normal

[L]: Abnormal

(6) LD2 ALM (LDB2 to ICB IFB)

This signal indicates the state of the LD2 laser

drive current.

[H]: Normal

[L]: Abnormal

(7) LD2 PR (LDB2 -> ICB IFB)

LD2 power supply monitor signal.

[H]: Normal

[L]: Abnormal

b. ICB IFB output signals

(1) M24 PWR A (ICB IFB to M24)

M24 A-phase drive signal.

(2) M24 PWR B (ICB IFB to M24)

M24 B-phase drive signal.

(3) M24 DRIVE A/A'(ICB IFB to M24)

M24 A-phase drive pulse signal.

(4) M24 DRIVE B/B' (ICB IFB to M24)

M24 B-phase drive pulse signal.

(5) LD1 SH (ICB IFB to LDB1)

One scan line equivalent APC sampling signal.

(6) LD1 ENB (ICB IFB to LDB1)

Laser APC function ON/OFF control signal.

Laser beam emission stops when it is OFF.

(7) LD2 SH (ICB IFB to LDB2)

One scan line equivalent APC sampling signal.

(8) LD2 ENB (ICB IFB to LDB2)

Laser APC function ON/OFF control signal.

Laser beam emission stops when it is OFF.

(9) LD1 VIDEO (ICB IFB to LDB1)

LD1 laser image signal.

(10)LD2 VIDEO (ICB IFB to LDB2)

LD2 laser image signal.

(11)LD1 DCLK (ICB IFB to LDB1)

LD1 clock signal for MPC value data transmission.

(12) LD1 DI (ICB IFB to LDB1)

LD1 data signal for MPC.

(13) LD1 AD (ICB IFB to LDB1)

LD1 MPC value storage command signal.

(14) LD2 DCLK (ICB IFB to LDB2)

LD2 clock signal for MPC value data transmission.

(15) LD2 DI (ICB IFB to LDB2)

LD2 data signal for MPC.

(16) LD2 AD (ICB IFB to LDB2)

LD2 MPC value storage command signal.

2 - D - 6

Page 18

DRUM UNIT

[1] Composition

DRUM UNIT

Charging corona unit

Developing unit

Separation claws

Cleaning/toner recycle unit

Cleaning/toner recycle unit

[2] Mechanisms

Mechanism

Carriage support

PCL/TSL

*1 Auxiliary separa-

tion

*2 Conveyance

assistance

PCL

Method

Fixed rail

LED

Separation claws

Ratchet wheel

Charging corona unit

TSL

2 UNIT EXPLANATION

Separation claw solenoid

Developing unit

Transfer and separation corona unit

mechanism slides the separation claws about

5 mm back and forth in parallel with the drum

surface.

Separation claw

Separation

claw

solenoid(SD4)

The drum unit is an integral assembly consisting of a

drum, charging corona unit, developing unit, cleaning

unit, toner recycle unit, PCL, and separation claws.

*1 Auxiliary separation

• To prevent paper jamming, three separation

claws are used to separate paper from the

drum forcibly. These separation claws are

pressed against the drum or detached from it

by turning ON/OFF the separation claw

solenoid (SD4).

• To prevent a specific part of image copied

paper from being stained and to prevent the

drum from being scratched, the swing

*2 Conveyance assistance

The thick paper conveyance ability has been

improved by the use of ratchets.

2 - E - 1

Page 19

DRUM UNIT

[3] Separation Claw Control

24VDC

SD4 DRIVE

DCDB

SD4 CONT

M2CONT

M2EM

24VDC

PGND

PRCB

24VDC

DCPS2

MS2 MS1

PGND

2 UNIT EXPLANATION

Separation claws are driven by SD4 (separation claw

drive solenoid). Separation claws are slid by M2 (main).

SD4 is controlled by the PRCB (printer control board)

via the DCDB (DC drive board).

1. Operation

a. Separation claw ON/OFF control

SD4 is a pull-type solenoid powered by 24 VDC .

It turns ON to press separation claws against the

drum to help image copied paper separate.

(1) SD4 operation timing

SD4 turns ON after a lapse of specified time from

turning ON of PS45 (leading edge detection). It

turns OFF after a lapse of the time set by the

PRCB timer.

b. Separation claw swing control

Separation claws are swung by M2 (main) via

the cam mechanism.

2. Signals

a. CB output signal

(1) SD4 CONT (CB to DCDB)

SD4 drive control signal.

[L]: SD4 ON

[H]: SD4 OFF

b. DCDB output signal

(1) SD4 DRIVE (DCDB to SD4)

SD4 drive control signal.

[L]: SD4 ON

[H]: SD4 OFF

SD4

M2

[4] Paper Guide Plate Control

GP CONT

PRCB

24VDC

PGND

DCPS2

ADUSDB

To prevent toner from adhering to the paper guide

plate, a constant voltage is applied to the paper guide

plate. This voltage is supplied from HV2 (high v oltage

unit 2) and is controlled by the serial data sent from

the PRCB (printer control board) via the ADUSDB

(ADU frame control board). When the front door of

this machine opens or closes, MS1 (interlock 1) or

MS2 (interlock 2) operates to interrupt the DC power

supply to HV2, stopping the voltage application to the

paper guide plate.

1. Operation

a. ON/OFF timing

Turning ON/OFF in sync with M2 (drum)

b. Applied voltage

-500 VDC

2. Signal

a. Output signal

(1) GP CONT (ADUSDB to HV2)

This signal controls turning ON/OFF the voltage

application to paper guide plate.

[L]: Voltage applied

[H]: Voltage not applied

GP

HV2

2 - E - 2

Page 20

DRUM UNIT

[5] Drum Potential Control

DPS DRIVE A

DPS DRIVE B

DPS ANG 1

DPS ANG 2

DPSB

PRCB

DCPS2

DPS ANG

SGND

24VDC

PGND

The drum potential is detected by the DPS (Drum

Potential Sensor) and send the PRCB (printer control

board) via the DPSB (drum potential sensor board).

1. Operation

Drum potential control is performed to keep the

drum surface potential constant and maintain

image quality regardless of the usage

environment or the number of copies.

(1) Method

The image is created on the drum surface by the

difference in the exposure potential and

developing bias. A patch is created with laser

PWM maximum.

The developing bias is corrected so that the

difference between the after exposure potential

(solid black area) and the developing bias is

always 500V and the charging current and the

grid voltage are corrected so that the difference

between the before exposure potential and

developing bias is 150V.

(2) Timing

a) When the fixing temperature is lower than 50°C

at power ON.

b) At the end of job after every 5,000 copies.

DPS

2. Signals

a. PRCB Input signals

(1) DPS ANG (DPSB to PRCB)

Analog signal corresponding to the drum

charging potential.

b. DPSB Input signals

(1) DPS ANG 1 and 2(DPS to DPSB)

Analog signal corresponding to the drum

charging potential.

c. DPSB output signals

(1) DPS DRIVE A and B(DPSB to DPS)

DPS(drum potential) drive signal.

2 UNIT EXPLANATION

2 - E - 3

Page 21

DRUM UNIT

[6] HTR1 (drum heater) Control

12VDC

5VDC

DRUM TEMP

AGND

TH5 ANG1

TH5 ANG2

TH5

12VDC

5VDC

SGND

DCPS1

2 UNIT EXPLANATION

AC(H)

AC(C)

The drum is heated by HTR1 (drum heater). The

PRCB (printer control board) detects the drum

temperature with TH5 (drum temperature sensor) and

controls HTR1 through ACDB (AC drive board). TH5

is a sensor that changes resistance according to the

detected temperature. Therefore, its value is

converted to voltage by DTSB (drum temperature

sensor board) and output to PRCB.

1. Operation

a. Temperature Control

HTR1 is normally maintained at 30°C and the

temperature is increased only when humidity is

high. When warming up under high humidity , the

drum is rotated after the drum temperature

reaches a specified value and then drum potential

control, Dmax control, and gradation correction

control are performed. When warm up completes,

HTR1 is turned ON/OFF to maintain the drum

temperature constant. Under high humidity, the

temperature is raised to 45°C every 30 minutes

and then returned to specified temperature to

prevent dew condensation.

b. Error detection

HTR1 is equipped with self recover type

thermostat to prevent abnormal increase in drum

temperature. The thermostat turns off at 70°C.

HTR1 CONT

PRCB

HTR1 CONT

HTR1 DRIVE

ACDB

DTSB

HTR1

2. Signals

a. PRCB input signal

(1) DRUM TEMP (TH5 to DTSB to PRCB)

Drum temperature signal. The relationship

between drum temperature and output voltage

is linear.

b. PRCB output signal

(1) HTR1 CONT (PRCB to ACDB to HTR1)

Drum heater ON/OFF control signal

c. ACDB output signal

(1) HTR1 CONT (DTSB to HTR1)

Drum heater ON/OFF control signal

(2) HTR1 DRIVE (DTSB to HTR1)

Drum heater drive power supply line

2 - E - 4

Page 22

CORONA UNIT SECTION

[1] Composition

CORONA UNIT SECTION

<Charging corona unit>

Charging corona unit

Charging

wire cleaning

motor (M23)

Charging

wire cleaning

material

[2] Mechanisms

Mechanism

*1 Charging

Scorotron (DC negative

corona discharge). Discharge

wire: Tungsten, 0.06 mm dia.

(gold-plated skin path: with

automatic wire cleaner). Grid

control: Gold-plated stainless

plate

*2 Toner

transfer

DC positive corona discharge.

Discharge wire: Oxide film

tungsten, 0.06 mm dia., with

automatic wire cleaner.

Toner

detach

AC/DC corona discharge.

Discharge wire: Oxide film

tungsten, 0.06 mm dia., with

automatic wire cleaner

*1 Cleaning the charging wire

The charging corona unit has wire cleaning pads.

The charging wire cleaning pad drive motor

moves the charging wire cleaning pad back and

forth, removing toner and dirt from the wires.

Method

PCL

<Transfer and separation corona unit>

Transfer entrance

guide plate

Plunging prevention plate

Charging

wire

Guide rollers

Transfer

corona unit

Separation corona unit

Charging wire

cleaning material

*2 Cleaning the transfer and separation wires

The transfer and separation wire unit has a wire

cleaner. The transfer and separation wire

cleaning pads drive motor moves the transfer and

separation wire cleaning pads back and forth,

removing toner and dirt from the wires.

Transfer wire

Separation wire cleaning

material

cleaning material

Transfer wire

2 UNIT EXPLANATION

2 - F - 1

Separation wire

Page 23

CORONA UNIT SECTION

[3] Charging Control

C CONT1

C CONT2

C SHIFT

SGND

G SHIFT

PRCB

2 UNIT EXPLANATION

24VDC

DCPS2 HV1

MS2 MS1

PGND

Charging control is performed using the serial data

sent from the PRCB (printer control board) via the

ADUSDB (ADU stand drive board). HV1 (high voltage

unit 1) is used to apply voltage to the charging wires.

1. Operation

a. Charging

A Scorotron charging method is used. 24 VDC

supplied from DCPS2 is raised to a negative DC

voltage which is then discharged after being

applied to the charging wire.

When the front door of this machine opens or

closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply to HV1,

stopping the voltage supply to the charging

corona unit and charging grid.

b. Grid voltage

The grid voltage is output from HV1 to the

charging plate.

C SIG

CHARGING

2. Signals

a. Input signal

(1) C SIG (HV1 to PRCB)

Leak or short detection signal.

[L]: Normal

[H]: Abnormal

b. Output signals

(1) C CONT1, 2 (PRCB to HV1)

Charging 1/2 output ON/OF control signal.

[L]: Charging voltage ON

[H]: Charging voltage OFF

(2) C SHIFT (PRCB to HV1)

Charging corona unit output level control signal.

The output to the charging corona unit is

controlled according to the duty ratio of the pulse

(PWM) signal sent from the PRCB.

C SHIFT duty 20% to 80%

Charging output range -500µA to -1900µA

(3) G SHIFT (PRCB to HV1)

Charging grid output level control signal.

The output to the charging grid is controlled

according to the duty ratio of the pulse (PWM)

signal sent from the PRCB.

G SHIFT duty 20% to 80%

Grid voltage output range -400 V to -1000 V

2 - F - 2

Page 24

CORONA UNIT SECTION

[4] Transfer/Separation Control

24VDC

PGND

DCPS2

MS2 MS1

24VDC

T CONT

S CONT

SEL

T SIG

S SIG

SGND

PGND

ADUSDB

S SHIFT(DC)

S FB(AC)

S FB(DC)

S SHIFT(AC)

T SHIFT

PRCB HV2

The transfer and separation corona unit is controlled

by the PRCB (printer control board) and ADUSDB

(ADU stand drive board) via the HV2 (high voltage

unit 2). Between the the PRCB and ADUSDB, signals

are exchanged using serial data. When the front door

of this machine opens or closes, MS1 (interlock 1) or

MS2 (interlock 2) operates to interrupt the DC power

supply to HV2, stopping the voltage supply to the

transfer and separation corona unit.

SEPARATION

TRANSFER

b. PRCB output signals

(1) T SHIFT (PRCB to HV2)

Transfer corona unit output level control signal.

This signal controls the level of the output to the

transfer corona unit according to the duty ratio of

the pulse (PWM) signal sent from the PRCB.

T SHIFT duty 20% to 80%

Transfer DC output range

70µA to -700µA

(2) S SHIFT (DC) (PRCB to HV2)

Separation corona unit output level control signal.

This signal controls the level of the output (DC

bias component) to the separation corona unit

according to the duty ratio of the pulse (PWM)

signal sent from the PRCB.

S SHIFT duty 20% to 80%

Separation DC output range

0µA to -300µA

(3) S SHIFT (AC) (PRCB to HV2)

Separation corona unit output level control signal.

This signal controls the level of the output (AC

component) to the separation corona unit according to the duty ratio of the pulse (PWM) signal

sent from the PRCB.

2 UNIT EXPLANATION

1. Operation

a. Transfer

Positiv e DC high voltage is used for toner transf er

to the drum surface.

b. Separation

AC high voltage is used for toner separation from

the drum surface.

2. Signals

a. PRCB input signals

(1) S FB (AC) (HV2 to PRCB)

Toner separation (AC) current feedback signal.

This signal monitors the toner separation (AC)

current. It is a 0 to 5V analog signal corresponding to the output level.

(2) S FB (DC) (HV2 to PRCB)

Transfer and separation (DC) current feedback

signal

This signal monitors the toner transfer and

separation (DC) current. It is a 0 to 5V analog

signal corresponding to the output level.

S SHIFT duty 20% to 80%

Separation AC output range

500µA to 1400µA

c. ADUSDB input signals

(1) T SIG (HV2 to ADUSDB)

Leak or short toner transfer abnormality detection signal

[L]: Normal

[H]: Abnor mal

(2) S SIG (HV2 to ADUSDB)

Leak or short toner separation abnormality detection signal

[L]: Normal

[H]: Abnormal

2 - F - 3

Page 25

CORONA UNIT SECTION

d. ADUSDB output signals

(1) T CONT (ADUSDB to HV2)

Transfer corona unit output ON/OFF control

signal.

[L]: Transfer corona unit ON

[H]: Transfer corona unit OFF

(2) S CONT (ADUSDB to HV2)

Separation corona unit output ON/OFF control

signal.

[L]: Separation corona unit ON

[H]: Separation corona unit OFF

(3) SEL (ADUSDB to HV2)

2 UNIT EXPLANATION

Feedback switchover signal.

This signal determines whether the feedback

signal of the transfer and separation (DC) current

is used for toner separation monitor or toner

transfer monitor.

[L]: Toner separation monitor

[H]: Toner transfer monitor

[5] M23 (Charger Cleaning ) Control

M23 CONT

5VDC

PS41

PS42

PS41

SGND

PS42

M23 F/R

M23 EM

PRCB

12VDC

5VDC

SGND

DCPS1

M23 (charger cleaning ) is a 12V DC motor which is

controlled by the PRCB (printer control board) via the

DCDB (DC drive board). Related signals are PS41

(charging wire cleaning pad HP ) and PS42 (charging

wire cleaning pad limit).

1. Operation

a. Purpose of driving

M23 is used to drive the charging wire cleaning

pad.

b. Operation timing

The charging corona wires are cleaned when the

main switch is turned ON, when the fixing

temperature is lower than 50°C (122°F). They

are also cleaned when the specified copy count

is reached.

* Changeable with 25 mode DIPSW

c. Cleaning operation

The home position of the charging wire cleaning

pad is on the rear side of machine. The charging

wire cleaning pad operates as follows:

M23

DRIVE1

M23

DRIVE2

DCDB

M23

2 - F - 4

Charging wire cleaning

pad HP PS

PS41 PS42

Cleaning (forward)

Cleaning (return)

Home search (forward)

Home search (return)

Charging wire cleaning

pad limit PS

Page 26

CORONA UNIT SECTION

2. Signals

a. PRCB input signals

(1) M23 EM (DCDB to PRCB)

M23 rotation state detection signal.

[L]: Normal rotation.

[H]: Abnormal rotation

(2) PS41 (PS41 to PRCB)

Charging wire cleaning pad home position

detection signal.

This signal detects the reference position (rear

side) of the charging wire cleaning pad home

position.

[L]: HP detected

[H]: HP not detected

(3) PS42 (PS42 to PRCB)

Charging wire cleaning pad limit detection signal.

This signal detects the front drive limit position

of charging wire cleaning pad.

[L]: Limit position detected

[H]: Limit position not detected

b. CB output signals

(1) M23 CONT (PRCB to DCDB)

M23 drive control signal.

[L]: M23 ON

[H]: M23 OFF

(2) M23 F/R (PRCB to DCDB)

M23 rotational direction signal.

[L]: CW (to the rear end from the home position)

[H]: CCW (to the home position from the rear

end)

c. DCDB output signal

(1) M23 DRIVE1, 2 (DCDB to M23)

M23 drive control signal.

The drive direction of M23 is controlled by

switching the drive current directions of two

signals.

Status

Forward stroke

of cleaning

Return stroke of

cleaning

Stop

M23 DRIVE1 M23 DRIVE2

HL

LH

LL

[6] M18 (Transfer/Separation Cleaning)

Control

M18

DRIVE1

DRIVE2

24VDC

PGND

DCPS2

PRCB

5VDC

SGND

DCPS1

MS2 MS1

5VDC

PS11

SGND

PS12

ADUSDB

M18 (transfer/separation cleaning) is a 24 VDC motor

which is controlled by the PRCB (printer control board)

via the ADUSDB (ADU stand drive board). Between

the PRCB and ADUSDB, signals are exchanged using

serial data. Related signals are PS11 (transfer/

separation wire cleaning pad HP) and PS12 (transfer/

separation wire cleaning pad limit). When the front right

or left door of this machine opens or closes, MS1

(interlock 1) or MS2 (interlock 2) operates to interrupt

the DC power supply to DCDB, stopping the voltage

supply to M18.

1. Operation

a. Purpose of driving

M8 is used to drive the transfer and separation

wire cleaning pads.

b. Operation timing

The transfer and separation wires are cleaned

when the main switch is turned ON, when the

fixing temperature is lower than 50°C, or when

the specified copy count is reached.

* Changeable with 25 mode DIPSW.

M18

M18

PS11

PS12

2 UNIT EXPLANATION

2 - F - 5

Page 27

CORONA UNIT SECTION

c. Cleaning operation

The home position of the transfer and separation

wire cleaning pads is on the front side of machine. The transfer and separation wire cleaning pads operate as follows:

Tansfer/Separation wire

cleaning pad HP

PS11 PS12

Cleaning (forward)

2 UNIT EXPLANATION

Cleaning (return)

Home search (forward)

Home search (return)

2. Signals

a. PRCB input signals

(1) PS11 (PS11 to PRCB)

T ransf er and separation wire cleaning pads home

position detection signal.

This signal detects the reference position of the

transfer and separation wire cleaning pads home

position (front side).

[L]: HP detected

[H]: HP not detected

(2) PS12 (PS12 to PRCB)

T ransf er and separation wire cleaning pads drive

limit detection signal.

This signal detects the rear limit position of the

transfer and separation wire cleaning pads.

[L]: Limit position detected

[H]: Limit position not detected

b. ADUSDB output signals

(1) M18 DRIVE1, 2 (ADUSDB to M18)

M18 drive control signal.

The drive direction of M18 is controlled by

switching the drive current directions of two

signals.

Tansfer/Separation wire

cleaning pad limit

[7] PCL/TSL Control

24VDC

PGND

DCPS2

PCL CONT

PRCB

LEDs are used for PCL (pre-charging lamp) and TSL

(transfer synchronization lamp). PCL is driven by the

DCDB (DC drive board). TSL is driven b y the ADUSDB

(ADU stand drive board). PCL and TSL are controlled

by the PRCB (printer control board).

1. Operation

PCL is turned ON/OFF in sync with M2 (drum

drive). TSL turns ON after a lapse of specified

time from turning ON of PS45 (leading edge

detection) of the second paper feed section. It

turns OFF after a lapse of specified time from

detection of the trailing edge of copy paper.

2. Signals

a. Output signals

(1) PCL CONT (PRCB to DCDB to PCL)

PCL ON/OFF control signal.

[L]: PCL ON

[H]: PCL OFF

(2) TSL CONT (ADUSDB to TLS)

TSL ON/OFF control signal.

[L]: TSL ON

[H]: TSL OFF

24VDC

PCL CONT

DCDB

24VDC

TSL CONT

ADUSDB

PCL

TSL

Status

Forward stroke

of cleaning

Return stroke of

cleaning

Stop

M18 DRIVE1 M18 DRIVE2

HL

LH

LL

2 - F - 6

Page 28

DEVELOPING UNIT

[1] Composition

Developing unit cover

Developing sleeve

Splash prevention

sheet (upper)

Developing regulation plate

Developing

sleeve

Agitator

wheel

DEVELOPING UNIT

Agitator screws

[2] Mechanisms

Mechanism Method

Developing 2-component developer

Developing bias DC bias

Developer Main agitator

agitation Auxiliary agitator

1. The developing unit drive motor (M3)

drives the following parts via the gear unit

at the back:

• Developing sleeve

• Agitator wheel

• Agitator screws

2. Flow of developer

The developer inside the developing unit is

supplied to the developing sleeve by the agitator

wheel, and maintained at a constant thickness

by the developing regulation plate (bristle height

regulation plate). The dev eloper remaining on the

developing sleeve is returned to the agitator

screws.

2 UNIT EXPLANATION

Drum

Developing regulation plate

Agitator wheel

Agitator screw

2 - G - 1

Page 29

DEVELOPING UNIT

[3] M3 (Developing Unit Drive) Control

24VDC

PGND

DCPS2

M3 CONT

M3 CLK

M3 EM

PRCB

M3 (developing) is controlled by the PRCB (printer

control board) and the motor drive power is supplied

by DCPS2 (DC power supply unit 2). When the front

left or right door of this machine opens or closes, MS1

(interlock 1) or MS2 (interlock 2) operates to interrupt

the DC power supply to M3, stopping the voltage

2 UNIT EXPLANATION

supply to the developing sleeve.

MS2 MS1

M3

[4] Developing Bias Control

24VDC

5VDC

SGND

B CONT

B SHIFT

B FB

PRCB

5VDC

SGND

DCPS1

24VDC

24VDC

PGND

DCPS2

MS2 MS1

HV1

The developing bias is controlled by PRCB (printer

control board) via the HV1(high voltage unit 1). When

the front left or right door of this machine opens or

closes, MS1 (interlock 1) or MS2 (interlock 2) operates

to interrupt the DC power supply to HV1, stopping the

voltage supply to the developing sleeve.

BIAS

1. Operation

M3 which is the 24V driven DC motor drives the

developing slee ve and agitator . M3 equipped with

speed control circuit send the rotation error signal

to PRCB when PLL lock is released longer than

the specified time period. M3 starts after the

specified time interval from the start switch is ON,

and stops after the specified time interval from

the charging wire unit stops charging.

2. Signals

a. Input signals

(1) M3 EM (M3 to PRCB)

M3 fault detection signal

[H] Abnormal rotation (when PLL is unlocked

for more than 1.5 seconds)

[L] Normal rotation

b. Output signals

(1) M3 CONT (PRCB to M3)

M3 drive control signal

[L] M3 ON

[H] M3 OFF

1. Operation

The developing bias voltage is applied to the

developing sleeve based on the M2 (drum)

rotation state signal.

2. Signals

a. Input signals

(1) B FB (HV1 to PRCB)

Developing bias voltage feedback signal.

This signal monitors the developing bias v oltage.

It is an 0V to 5V analog signal corresponding to

the output level.

b. Output signals

(1) B CONT (PRCB to HV1)

Developing bias output ON/OFF control signal.

[L]: Developing bias ON

[H]: Developing bias OFF

(2) B SHIFT (PRCB to HV1)

Developing bias output level control signal.

The developing bias output level is controlled

according to the duty ratio of the pulse (PWM)

signal sent from the PRCB.

B SHIFT duty 20% to 80%

Developing bias output range -300 V to-800 V

2 - G - 2

Page 30

DEVELOPING UNIT

[5] Toner Density Control

24VDC

24VDC

M11 CLK

M11 RES

M11 VREF

M11 FEM

PRCB DCDB

24VDC

PGND

DCPS2

Toner density is controlled by controlling M11 (toner

supply 1) by PRCB (printer control board) via DCDB

(DC drive board). When the front right or left door of

this machine opens or closes, MS1 (interlock 1) or MS2

(interlock 2) operates to interrupt the DC power supply

to the motor, stopping the M15.

24VDC

24VDC

M11 DRIVE A

M11 DRIVE A

M11 DRIVE B

M11 DRIVE B

MS2 MS1

M11

2. Signals

a. PRCB input signal

(1) M11 FEM (DCDB to PRCB)

Signal detecting whether the fuse for M11 is

blown.

[L]: Not detected

[H]: Detected

b. PRCB output signals

(1) M11 CLK (PRCB to DCDB)

Reference clock signal f or M11 rotational speed

control.

(2) M11 RES (PRCB to DCDB)

M11 reset signal.

(3) M11 VREF (PRCB to DCDB)

M11 current control signal.

c. DCDB output signals

(1) M11 DRIVE A, A (DCDB to M11)

M11 A-phase drive signal.

(2) M11 DRIVE B, B (DCDB to M11)

M11 B-phase drive signal.

2 UNIT EXPLANATION

1. Operation

a. Toner density detection

The toner density detection sensor detects the

density of toner concentration in the developing

unit using a patch detection method, and outputs the corresponding analog voltage signal to

the PRCB.

The PRCB compares the detected voltage with

the reference value to determine whether toner

must be added.

b. Toner supply operation

Upon read of the patch, M11 is turned on to supply toner. The time needed to add toner depends

on the paper size.

2 - G - 3

Page 31

DEVELOPING UNIT

[6] Dmax Control

2 UNIT EXPLANATION

24VDC

24VDC

DCPS2

12VDC

DCPS1

PGND

5VDC

SGND

MS2 MS1

DRUM TEMP

Dmax LED CONT

Dmax LED Vref

JAM LED CONT

PRCB

M2 CONT

M2 F/R

SGND

M2 EM

M3 CONT

M3 CLK

M3 EM

DPS ANG

AGND

12VDC

5VDC

AGND

5VDC

Dmax SIG

Dmax MONI

JAM SIG

M2

M3

DPS DRIVE A

DPS DRIVE B

DPS ANG 1

DPS ANG 2

DPSB

TH5 ANG1

TH5 ANG2

DTSB

TCSB

DPS

TH5

Dmax control is performed by the TCSB (toner control

sensor board), M2 (drum), M3 (developing), and so

on. These par ts are controlled by the PRCB (printer

control board). Related boards and sensors are a

DPSB (drum potential sensor board), DPS (drum

potential sensor), DTSB (drum temperature sensor

board), and TH5 (drum temperature sensor).

When the front right or left door of this machine opens

or closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply to the motor ,

stopping the M2 and M3.

1. Operation

The purpose of Dmax control is to adjust the

maximum density to the reference lev el for each

machine.

a. Dmax control

(1) Method

Latent images are created several times at the

maximum exposure lev el, images are dev eloped

with the rotational speed of the developing sleeve

varied, then each density is read by the Dmax

sensor (PD1) on the TSCB.

The developing sleeve speed detected when the

density has reached the reference level is

recorded as the optimum sleeve speed and the

developing is performed at this optimum sleeve

rotation speed.

(2) Timing

a) When the fixing temperature is lower than 50°C

at power ON

b) At the end of job after every 20,000 copies.

2 - G - 4

Page 32

2. Signals

a. PRCB input signals

(1) Dmax SIG (TCSB to PRCB)

Output voltage of the Dmax value detection

sensor (PD1) on the TCSB.

Reference voltage: 2.5V

(2) Dmax MONI (TCSB to PRCB)

This signal monitors the light reflected by the

drum surface (without toner).

The voltage applied to the Dmax detection LED

is corrected by γ/Dmax LED Vref so that the

output voltage becomes 4V (calibration).

Reference voltage: 4V

<Timing->

a) Before D max correction.

(3) JAM SIG (ITCSB to PRCB)

This signal detects a jam caused by paper

wrapping around the drum. A jam is detected

when the voltage becomes 4.0V or more.

[L]: LED ON

[H]: LED OFF

b. Output signals

(1) Dmax LED CONT (PRCB to TCSB)

This signal turns ON/OFF the D max LED.

(2) Dmax LED Vref (PRCB to TCSB)

Power supply line for PD1 LED on TSCB.

The voltage is adjusted so as the Dmax MONI

signal to be 4 V.

(3) JAM LED CONT (PRCB to TCSB)

This signal turns ON/OFF the JAM LED.

[L]: LED ON

[H]: LED OFF

DEVELOPING UNIT

2 UNIT EXPLANATION

2 - G - 5

Page 33

DEVELOPING UNIT

[7] Gradation Correction Control

2 UNIT EXPLANATION

24VDC

24VDC

DCPS2

12VDC

DCPS1

PGND

5VDC

SGND

MS2 MS1

/Dmax LED Vref

PRCB

M2 CONT

M2 F/R

SGND

M2 EM

M3 CONT

M3 CLK

M3 EM

DPS ANG

AGND

5VDC

LED CONT

SIG/MONI

M2

M3

DPS DRIVE A

DPS DRIVE B

DPS ANG 1

DPS ANG 2

DPSB

TCSB

DPS

Gradation correction control is performed by the TCSB

(toner control sensor board), M2 (drum), M3

(developing), and so on. These parts are controlled

by the PRCB (printer control board).

1. Operation

The gradation characteristics of the toner density

versus exposure amount at the image forming

section (drum area) are detected to obtain a linear

relation between the image density on a

document and the copying image density (toner

density).

(1) Method

Exposure is performed with the laser PWM varied

in several steps, and development is performed

at the toner transfer sleeve speed obtained by

Dmax correction.

Next, each density is read by γ sensor (PD2) on

the TCSB to detect the gradation char acteristics

of image density.

The gradation characteristics obtained here are

used as the values for correcting the laser

exposure amount.

(2) Timing

a) When the fixing temperature is lower than 50°C

at power ON

b) At the end of job after every 20,000 copies.

2. Signals

a. PRCB Input signals

(1) γ SIG/MONI (TCSB to PRCB)

Output voltage from the γ sensor (PD2) on the

TCSB. This signal monitors the light reflected

by the drum surface (without toner).

The voltage applied to the gradation detection

LED is corrected by γ/Dmax LED Vref so that the

output voltage becomes 4.5V (calibration).

Reference voltage: 4.5V

<Timing>

Before gradation correction.

2 - G - 6

Page 34

DEVELOPING UNIT

b. PRCB Output signals

(1) γ LED CONT (PRCB to TCSB)

ON/OFF control signal for gradation detection

LED.

[L]: LED ON

[H]: LED OFF

(2) γ Dmax LED Vref (PRCB to TCSB)

Power supply line to the γ LED on the TCSB.

The voltage applied to the γ LED is adjusted so

that the γ MONI signal becomes 4.5V

[8] Dot Diameter Correction Control

5VDC

/Dmax LED Vref

LED CONT

SIG/MONI

PRCB TCSB

Dot diameter is detected by TCSB and controlled by

PRCB.

1. Operation

Dot diameter correction is performed to prevent

the fluctuation of 1 dot laser beam in diameter

due to a soil in the writing unit or a change of

developing ability.

(1) Method

Creates several same condensation dot pattern

patches changing the laser power and reads

them with γ sensor (PD2). Uses the laser power

where the γ sensor output reaches reference

voltage as MPC.

(2) Timing

a) At the end of job after every 20,000 copies.

2 UNIT EXPLANATION

2 - G - 7

Page 35

DEVELOPING UNIT

[9] FM2 (Developing Suction) Control

FM2 CONT

FM2 EM

FM2 FEM

PRCB

24VDC

PGND

DCPS2 ACDB

FM2 (Developing suction) is controlled by the PRCB

2 UNIT EXPLANATION

(printer control board) via the ACDB (AC drive board).

When the front right or left door of this machine opens

or closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply, stopping

FM2.

1. Operation

a. ON timing

During idling: FM2 turns when M2 (drum) turns

ON.

During copying: FM2 turns when M1 (main) turns

ON.

b. OFF timing

During idling: FM2 turns OFF when M2 turns OFF

or in the specified interval after completion of

copying.

During copying: Always ON.

MS2 MS1

FM2 DRIVE

FM2 EM

PGND

FM2

b. PRCB output signals

(1) FM2 CONT (PRCB to ACDB)

FM2 control signal.

[L]: FM2 ON

[H]: FM2 OFF

c. ACDB output signal

(1) FM2 DRIVE (ACDB to FM2)

FM2 drive signal

[L]: FM2 OFF

[H]: FM2 ON

2. Signals

a. PRCB input signals (ACDB to PRCB)

(1) FM2 EM (FM2 to ACDB to PRCB)

FM2 fault detection signal.

[L]: FM2 is normal.

[H]: FM2 is abnormal.

(2) FM2 FEM (ACDB to PRCB)

Signal detecting whether the 24V fuse for FM2 is

blown.

[L]: Blown fuse is not detected.

[H]: Blown fuse is detected.

2 - G - 8

Page 36

TONER SUPPLY UNIT

[1] Composition

Toner supply

motor 1 (M11)

TONER SUPPLY UNIT

Toner cartridge

2 UNIT EXPLANATION

Push pressure lever

Toner supply

motor 2 (M15)

[2] Mechanisms

Mechanism Method

Toner supply Supply by screw

Toner level detection Piezoelectric method

130±30 g

*1 Toner agitation Agitator plates

*2 Toner cartridge Rotary cartridge

Capacity: 1700 g

Toner leakage Toner supply shutter

prevention

*1 Toner agitation

Toner agitator plates are driven by the following

two motors through the gear unit:

a. Toner supply motor 1 (M11): Drives the toner

supply screw.

b. Toner supply motor 2 (M15): Drives the toner

cartridge.

The agitator plates rotate faster when toner supply

motor 1 (M11) runs than when toner supply motor 2

(M15) runs. When the two motors are running

simultaneously, the one-way clutch installed on the

agitator shaft selects toner supply motor 2 (M15).

Shutter

The agitator plates prevent the toner from clumping

and accumulating on TLD (remaining toner detection

sensor).

Toner supply motor 1 (M11)

Toner supply motor 2 (M15)

Toner cartridge

Agitator plate

Toner supply screw

One way clutch

2 - H - 1

Page 37

TONER SUPPLY UNIT

*2 Toner cartridge

When the toner cartridge rotates, toner is fed to

the outlet of the cartridge through the spiral

groove on the surf ace of the toner cartridge. When

the outlet of the cartridge faces downward, toner

flows out of the outlet into the agitation/supply

section of the toner supply unit.

2 UNIT EXPLANATION

90° rotation

Outlet

A

C

C

To agitation/conveyance

block of toner supply unit

B

B

A

[3] Toner Level Detection Control

24VDC

PGND

DCPS2

M15 CONT

M15 EM

TLD CONT

TLD

SGND

PRCB DCPS1

Toner level detection is controlled by the TLD (toner

level detection sensor) and the PRCB (printer control

board).

12VDC

SGND

M15

TLD

1. Operation

a. Toner level detection

A piezoelectric device is used as the TLD.

When the level of toner in the cartridge becomes

low , the toner supply signal is output to the PRCB.

As a result, a message is displayed on the LCD

connected to the OB1 (operation board 1).

b. Detection timing

The detection timing is as follows:

• Power-on

• When the front door opens or closes

• During copying

c. Toner supply to toner supply unit

When the no toner state is detected by TLD, M15

(toner supply 2) is turned ON to supply toner from

the toner cartridge to the toner supply unit.

d. Detection of no toner state in toner cartridge

If the no toner state is detected by TLD after M15

has been held ON for a specified period of time,

the toner cartridge is assumed to be empty.

2 - H - 2

Page 38

2. Signals

a. Input signal

(1) TLD (TLD to PRCB)

When the level of toner in the cartridge becomes

low , this signal goes low [L], displaying a message

on the LCD connected to the OB1.

(2) M15 EM (M15 to PRCB)

M15 fault detection signal.

[L]: M15 normal

[H]: M15 Abnormal

a. Output signals

(1) TLD CONT (PRCB to TLD)

TLD power control signal.

The TLD is pow ered only when it is detecting the

toner level.

(2) M15 CONT (PRCB to M15)

M15 control signal

[L]: M15 ON

[H]: M15 OFF

TONER SUPPLY UNIT

2 UNIT EXPLANATION

2 - H - 3

Page 39

TONER SUPPLY UNIT

[4] M11 (Toner Supply 1) Control

/Dmax LED Vref

Dmax LED CONT

2 UNIT EXPLANATION

M11 (Toner Supply 1) is controlled by the PRCB

(printer control board) via the DCDB (DC drive board).

The toner density is detected by TCSB(toner control

sensor board).

When the front right or left door of this machine opens

or closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply to the motor ,

stopping M11.

5VDC

Dmax SIG

TCSB

24VDC

24VDC

M11 CLK

M11 RES

M11 VREF

M11 FEM

24VDC

24VDC

M11 DRIVE A

M11 DRIVE A

M11 DRIVE B

M11 DRIVE B

PRCB DCDB

24VDC

PGND

MS2 MS1

DCPS2

M11

Paper size Supply time (sec.)

A3 1.14

B4 0.86

F4 0.86

A4 0.57

A4R 0.57

B5 0.43

B5R 0.43

A5 0.29

A6 0.22

1. Operation

a. Detection of toner density

The Dmax sensor (PD1) mounted on the TCSB

detects the density of the toner control chart to

output the signal corresponding to the detected

density to the PRCB.

b. Toner supply

When the voltage detected by the TCSB is below

the specified value, the PRCB issues a control

signal to drive the M11. The relationship between

the paper size and toner supply time is

summarized in the following table:

2 - H - 4

Page 40

CLEANING/TONER RECYCLE UNIT

[1] Composition

Blade drive motor (M14)

Blade 2

CLEANING/TONER RECYCLE UNIT

[2] Mechanisms

Mechanism

*1 Drum cleaning

Toner collection

*2 Toner recycle

*1 Drum cleaning

T w o cleaning blades are installed in the cleaning

section. When the blade motor (M14) rotates, the

blade release arm is pressed down. At the same

time, the cleaning blade drive shaft with two

cleaning blades 1 and 2 is turned by the wire

wound around the shaft, thereby switching

between blades 1 and 2 automatically, increasing the usable life of the blades.

Cleaning blades

(switched automatically)

Toner guide brush

Toner conveyance by

screw

Method

Blade 1

Toner guide brush

Vibration sheet

Toner conveyance screw

Blade release arm

Blade 2

Toner guide shaft

Blade 1

2 UNIT EXPLANATION

*2 Toner collection

T oner remov ed by the cleaning blade is collected

by the toner guide brush to be reused.

2 - I - 1

Page 41

CLEANING/TONER RECYCLE UNIT

[3] M14 (Blade) Control

5VDC

PS30

SGND

PS30

PS31

M14 PL

M14 NL

2 UNIT EXPLANATION

M14 PR

M14 NR

M14 CEM

M14 24FEM

PRCB

24VDC

PGND

DCPS2

M14 (cleaning blade) is a 24V DC driven motor and

drives the cleaning blades. By M14, the cleaning blade

contacts on the drum surface slight pressing or

pressing to clean the drum surface. These two blades

are automatically switched by M14. M14 is controlled

by PRCB (printer control board) through DCDB (DC

drive board). Related signals are PS30 (blade 1) and

PS31 (blade 2).

1. Operation

M14 turns ON/OFF in synchronized with ON/OFF

of M2(drum).

The blade is controlled (pressing, slight pressing,

and switching) by PS30 and PS31 detecting the

blade position, and M14 rotaing forward and

backward.

The following table shows the relationship

between PS30/PS31 and blade position.

PS31

M14 DRIVE 1

M14 DRIVE 2

M14

DCDB

5VDC

SGND

DCPS1

MS2 MS1

Sensor Blade Position

Pressing CW/ Slight CW/ Switching

CCW pressing CCW

PS30 OFF OFF ON or OFF*ON ON

PS31 ON OFF OFF OFF ON

*Note: CW/CCW indicate the M14 rotating

direction for pressing, slight pressing, and

switching. The sensor logic for slight

pressing position is different between CW

and CCW rotation.

CCW: ON

CW: OFF

2 - I - 2

Page 42

a. Blade auto switching control

This unit uses two blades with M14 rotating to

automatically replace blades. During automatic

blade replacement, M2 (drum), M3 (developing),

developing bias, guide plate voltage, and PCL

are turned ON, toner is adhered to the drum, and

then the blade cleans it to prevent blade peeling.

<Timing>

a) At the end of job after every 20,000 copies.

b. Blade setting mode

Blade setting mode is available in 36 mode as a

task after blade replacement during maintenance.

Blade setting mode adheres toner on drum as in

blade auto replacement control and then the

blade cleans toner to prevent blade peeling.

c. Black stripe creation control

In order to improve durability of the b lade (stabilize load, prevent paper dust crushing), a black

stripe toner is adhered on drum once every ten

copies and then cleaned.

*Changeable with 25 mode DIPSW.

CLEANING/TONER RECYCLE UNIT

2 UNIT EXPLANATION

2. Signals

a. PRCB input signal

(1) PS30 (PS30 to PRCB)

Blade position detection signal 1

(2) PS31(PS31 to PRCB)

Blade position detection signal 2

(3) M14 CEM

M14 error detection signal

[L]: Normal

[H]: Error

(4) M14 24FEM

M14 blown fuse detection signal

[L]: Not detected

[H]: Detected

b. PRCB output signal

(1) M14 PL,NL,PR,NR(PRCB to DCDB)

M14 drive control signal

c. DCDB output signal

(1) M14 DRIVE 1,2 (DCDB to M14)

M14 drive control signal

2 - I - 3

Page 43

TRAY 1/2 PAPER FEED UNIT

[1] Composition

TRAY 1/2 PAPER FEED UNIT

Side guides

Trailing edge stopper

Wire B

Paper size detection VR1,2

Paper size detection PS1-1, 2-1(PS32, PS33)

Paper size detection PS1-2, 2-2(PS35, PS36)

Caution: Trays 1 and 2 have the same shape

and mechanisms.

Feed roller

Paper feed roller

Double feed prevention roller

Drive pulley

2 UNIT EXPLANATION

Wire A

Up drive motor1(M19), 2(M20)

[2] Mechanisms

Mechanism

*1 Paper lift-up

Tray loading

Double feed prevention

*2 1st paper feed

No paper detection

*3 Paper size detection (Universal)

*1 Paper lift-up

a. Hoisting of up/down plate

The up/down plate is lifted up by up/down wires. When the paper tray is loaded, the up drive motor

1(M19), 2(M20) rotates to wind the up/down wires around the drive pulleys and consequently the plate

moves up and push up papers set in the tray. When the tray upper limit PS1(PS20), 2(PS21) detects the

actuator of the plate that has moved up, the up drive motor 1(M19), 2(M20) stops.

Method

Up: Paper up/down plate driven by up/down wires

Down: Falls down by its own weight

Load from the front door side

Torque limiter

Paper feed roller

Pick up solenoid 1(SD8), 2(SD9)

Photosensor + Actuator

Width: VR

Length: Photosensor + Actuators (two)

2 - J - 1

Page 44

TRAY 1/2 PAPER FEED UNIT

b. Lowering of up/down plate

When the paper feed tray is pulled out, the

guide lever shown below is disengaged from

the rail, thus releasing the coupling gear that

transmits the drive force of the up drive motor

1(M19), 2(M20) to the drive pulleys. Then, the

up/down plate falls down naturally by the

weight of papers.

2 UNIT EXPLANATION

*2 1st paper feed

To keep a constant contact pressure on the paper by the paper feed roller at the time of paper

pick-up, the weight of the paper feed roller itself

is used. The pick up solenoid 1(SD8), 2(SD9)

moves the paper feed swivel plate down so that

the paper feed roller mounted on the plate falls

down to touch the paper as well. Then, the paper feed roller picks up a paper and feeds it

toward the paper conv eyance unit. The first paper

feed solenoid moves the paper feed swivel plate

down only when paper is to be fed. Otherwise, it

releases contact.

Coupling gear

Up drive motor

1(M19), 2(M20)

Guide lever

Paper feed swivel plate

Tray insertion

direction

*3 Paper size detection

Length: The rear guide of the tray moves,

causing the paper size detection